Patents

Literature

109results about How to "Strong conveying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

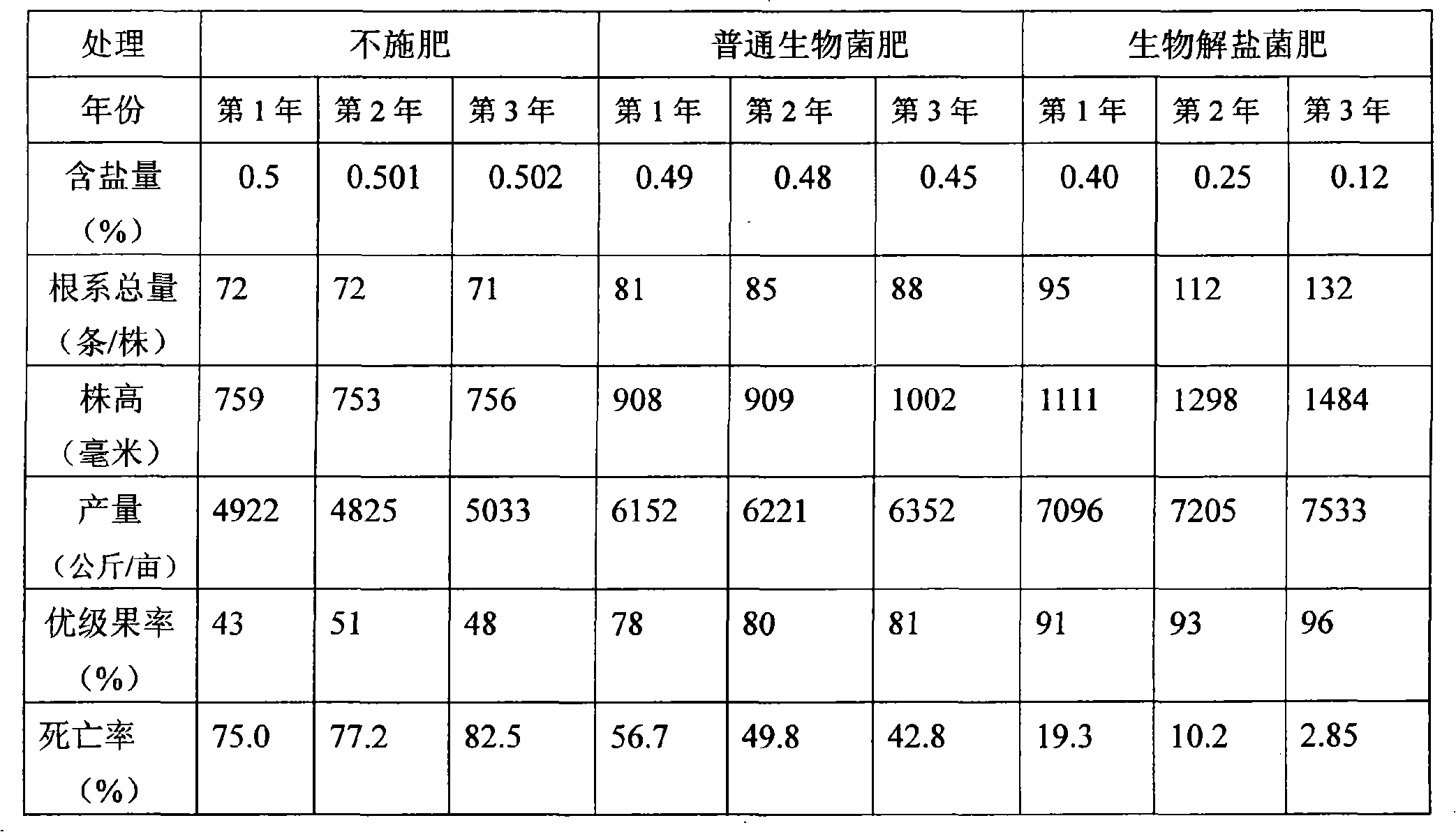

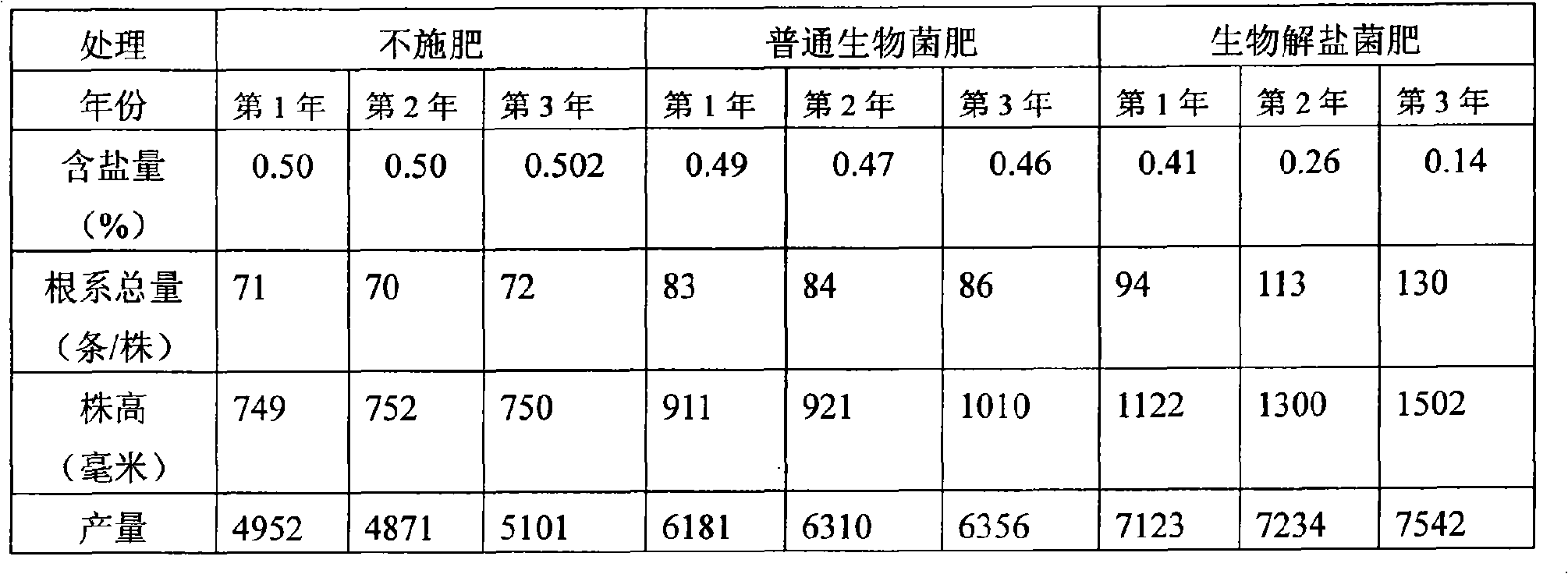

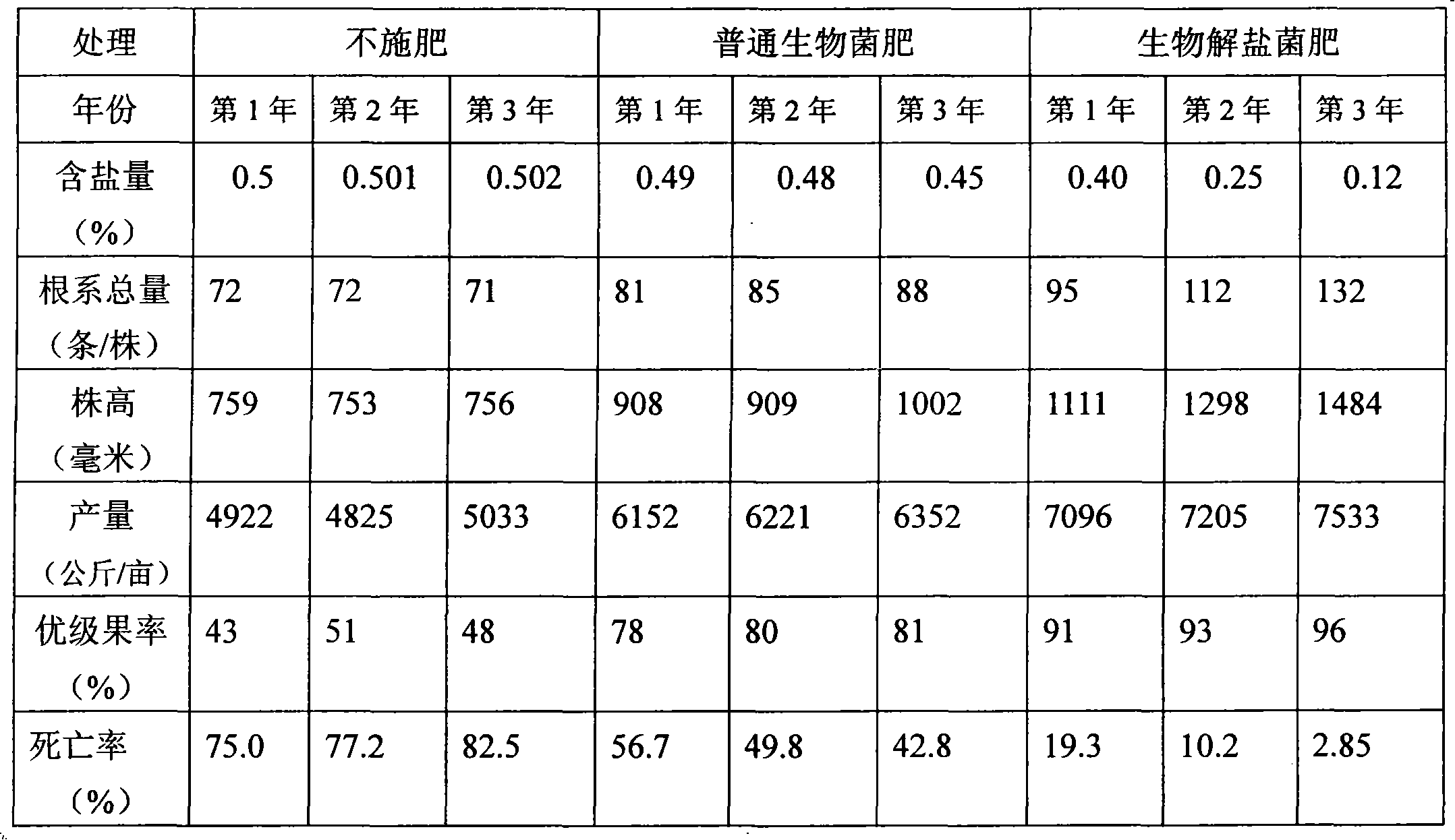

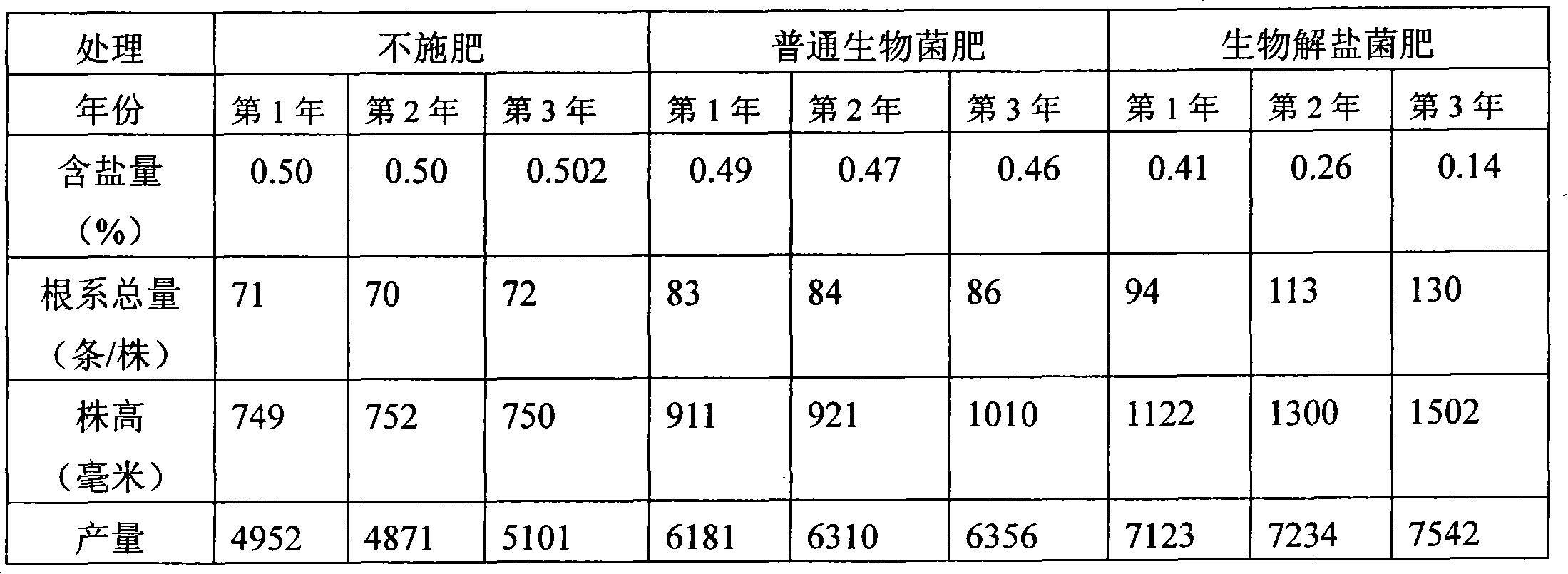

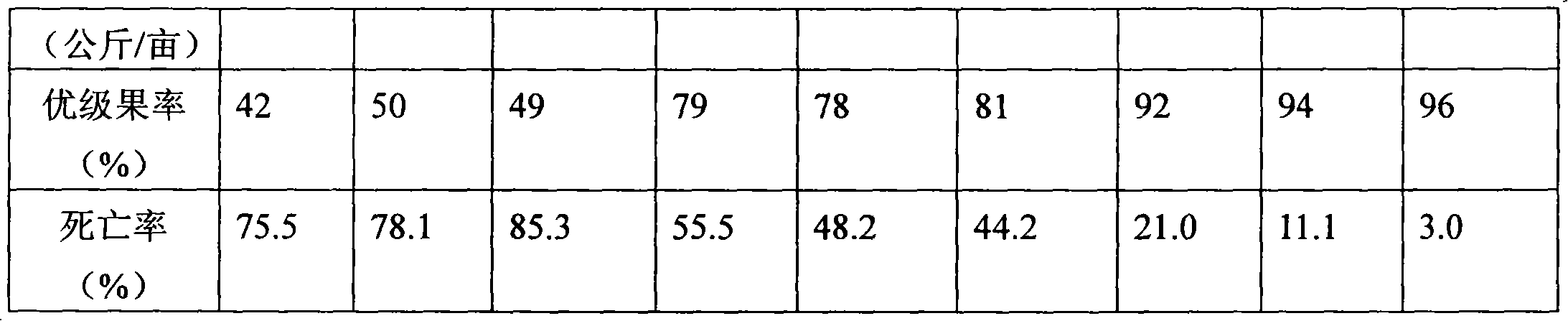

Biological salt-decomposition bacterial manure and method for preparing same

ActiveCN101289338AHigh viable countHigh content of effective viable bacteriaBio-organic fraction processingOrganic fertilisersBacillus megateriumDecomposition

The invention discloses a biological salt-degrading bacterial fertilizer consisting of the following components by weight proportion: 0.0013 to 0.0045 portions of gibberellin, 0.00002 to 0.0002 portions of cytokinins, 15 to 35 portions of bacillus megaterium, 50 to 80 portions of salt-degrading flora, 5 to 15 portions of amino acid and 2 to 10 portions of humic acid. The materials are evenly mixed and air dried. The bacterial fertilizer is formed by being extracted from marine microorganisms, rejuvenation, expanding propagation and being remixed with a plurality of trace elements. The bacterial fertilizer is scientific in formulation and very strong in activity, can be widely applied to salt lick improvement and a secondary salinization treatment, improves and optimizes soil environment and improves the deteriorated soil environment caused by the long-term use of chemical fertilizers and salt containing organic fertilizers (dungs). The bacterial fertilizer can facilitate the development of the roots of crops and can improve the ability of absorbing night soil. By applying the biological salt-degrading bacterial fertilizer, the fertilizer can facilitate the even seedling, uniform seedling and strong seedling at the earlier stage of crops, the strong nutrient transmission capacity at the middle stage and no premature senescence at the later stage.

Owner:莘县鑫海缘生物科技有限公司

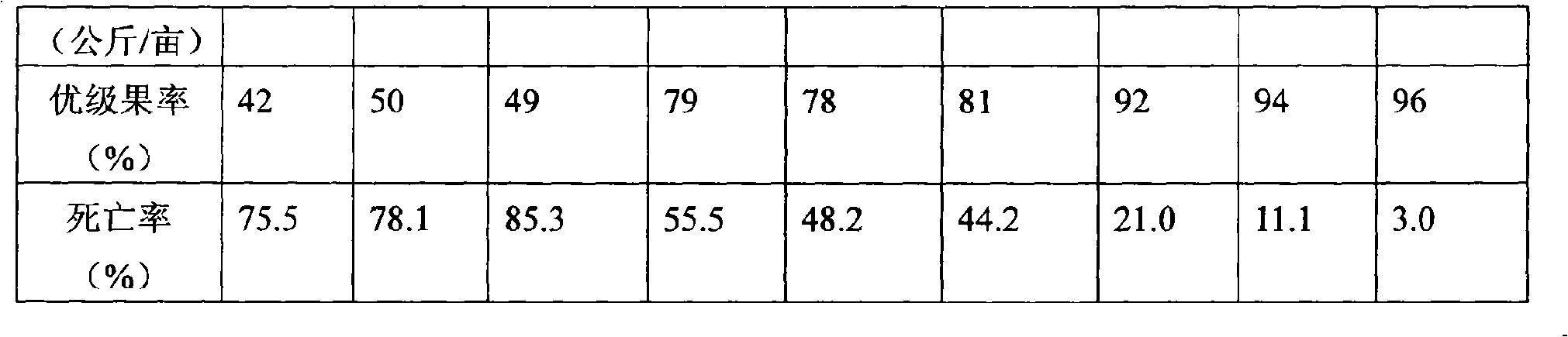

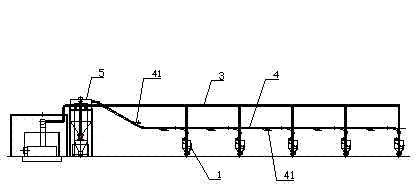

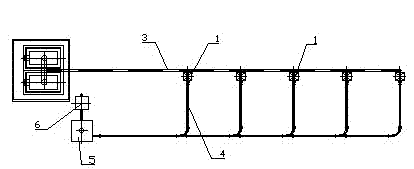

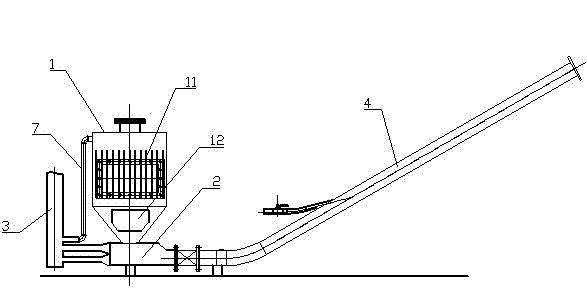

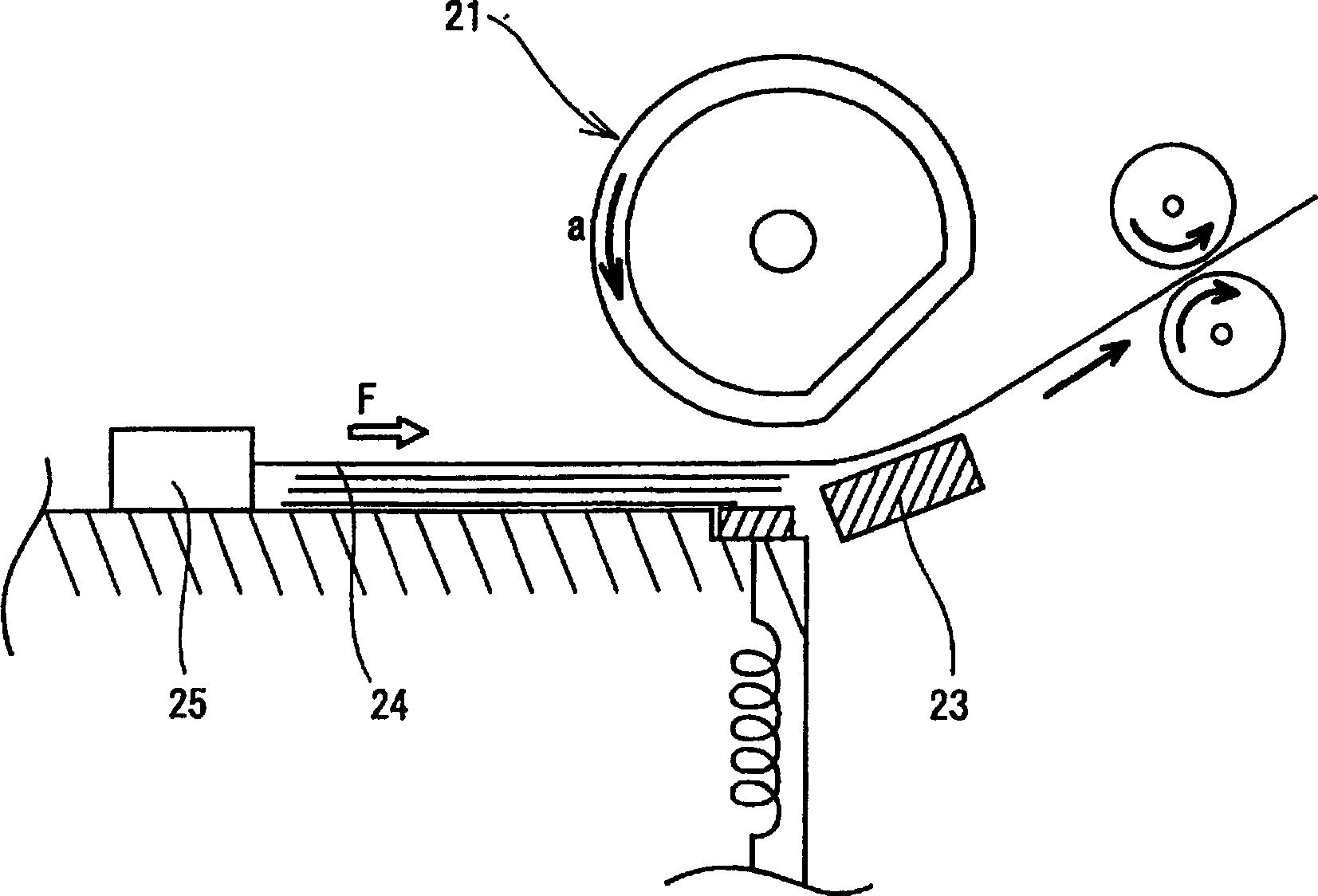

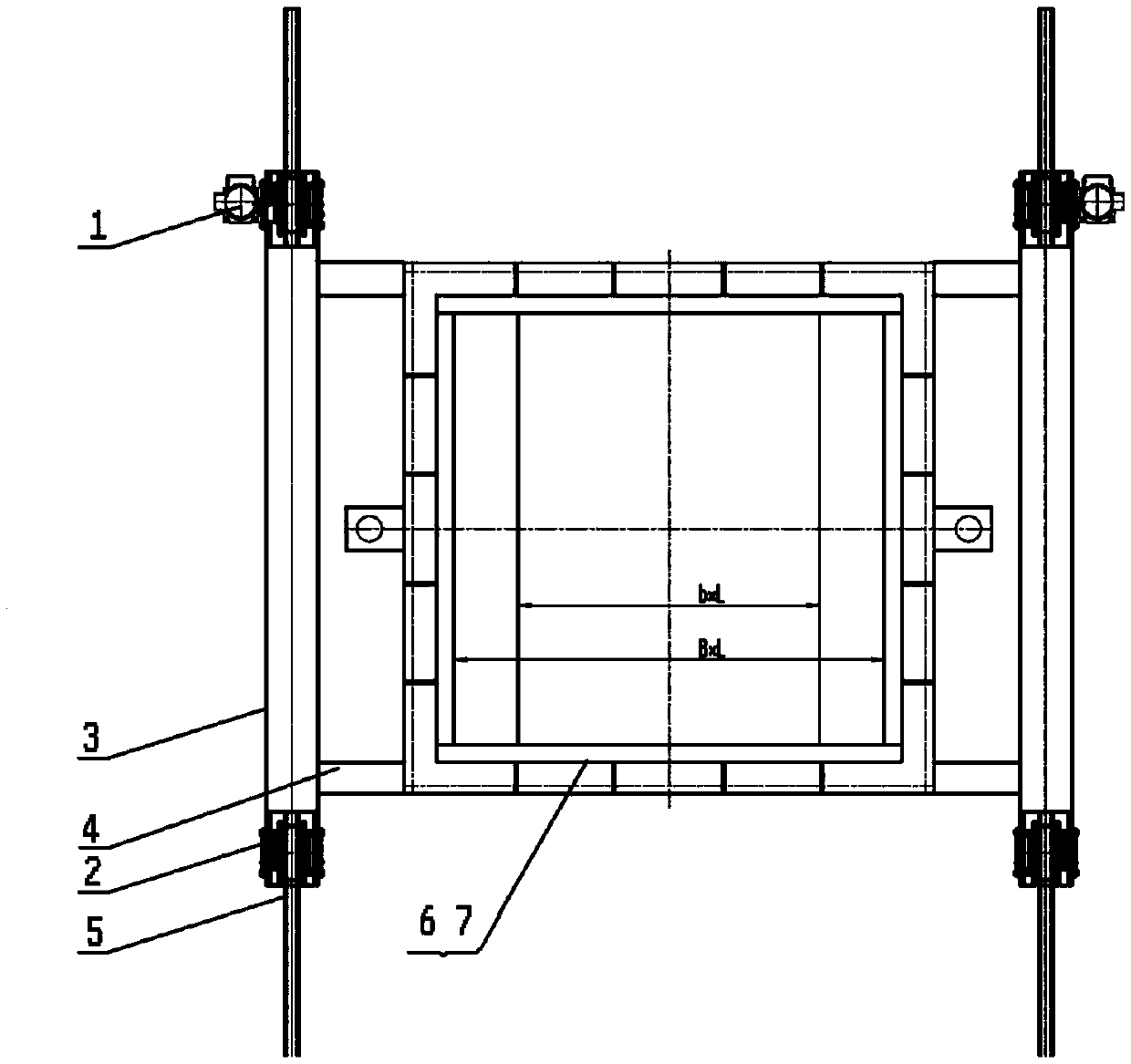

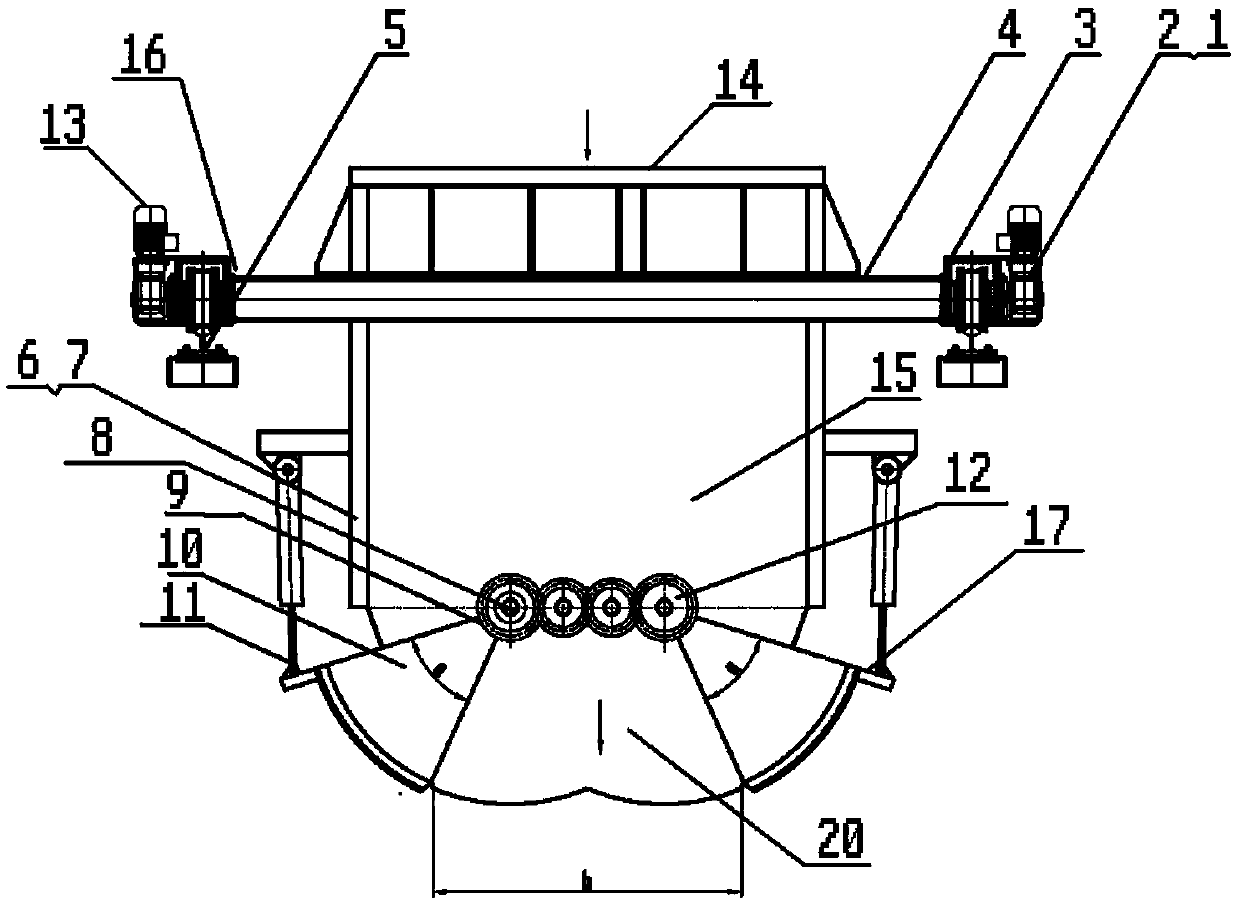

Method and system for transporting and loading bulk materials in storage yard

ActiveCN101786553ANo splashHigh measurement accuracyWeighing apparatus for continuous material flowLoading/unloadingTransport systemUnderground tunnel

The invention particularly relates to a method and a system for transporting and loading bulk materials in a storage yard, which are suitable for bulk material accurate loading of railways, public roads and ships. The invention comprises a storage yard transporting system, a belt transport system and an accurate and rapid quantitative loading system. The invention provides an economical and effective transporting and loading system for bulk materials in a storage yard, which has the following advantages: 1) the storage yard transport system combing a disc vibrating feeder with a low clearance flow control gate is adopted, thus greatly lowering the upper height of an underground tunnel and improving the capability of transporting the materials in the storage yard; 2) the accurate and rapid quantitative loading system is adopted, thus having the characteristics of rapid loading speed, high loading precision and high automation degree; and 3) a four-roller belt weigher is adopted, thus realizing the linkage of the storage yard transport system, the belt transport system and the accurate and rapid quantitative loading system effectively and greatly improving the operation efficiency of the system.

Owner:BIRTLEY TIANJIN IND EQUIP

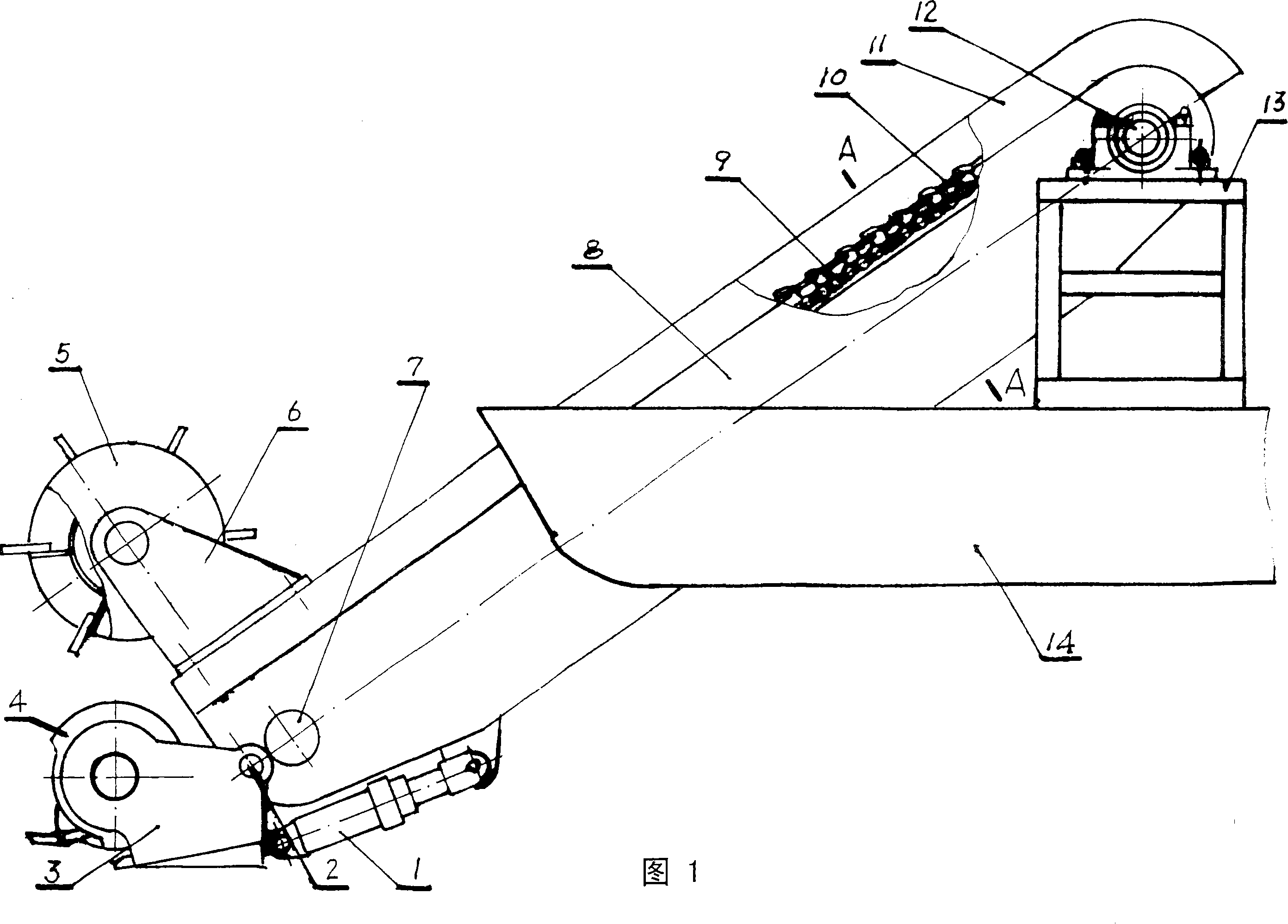

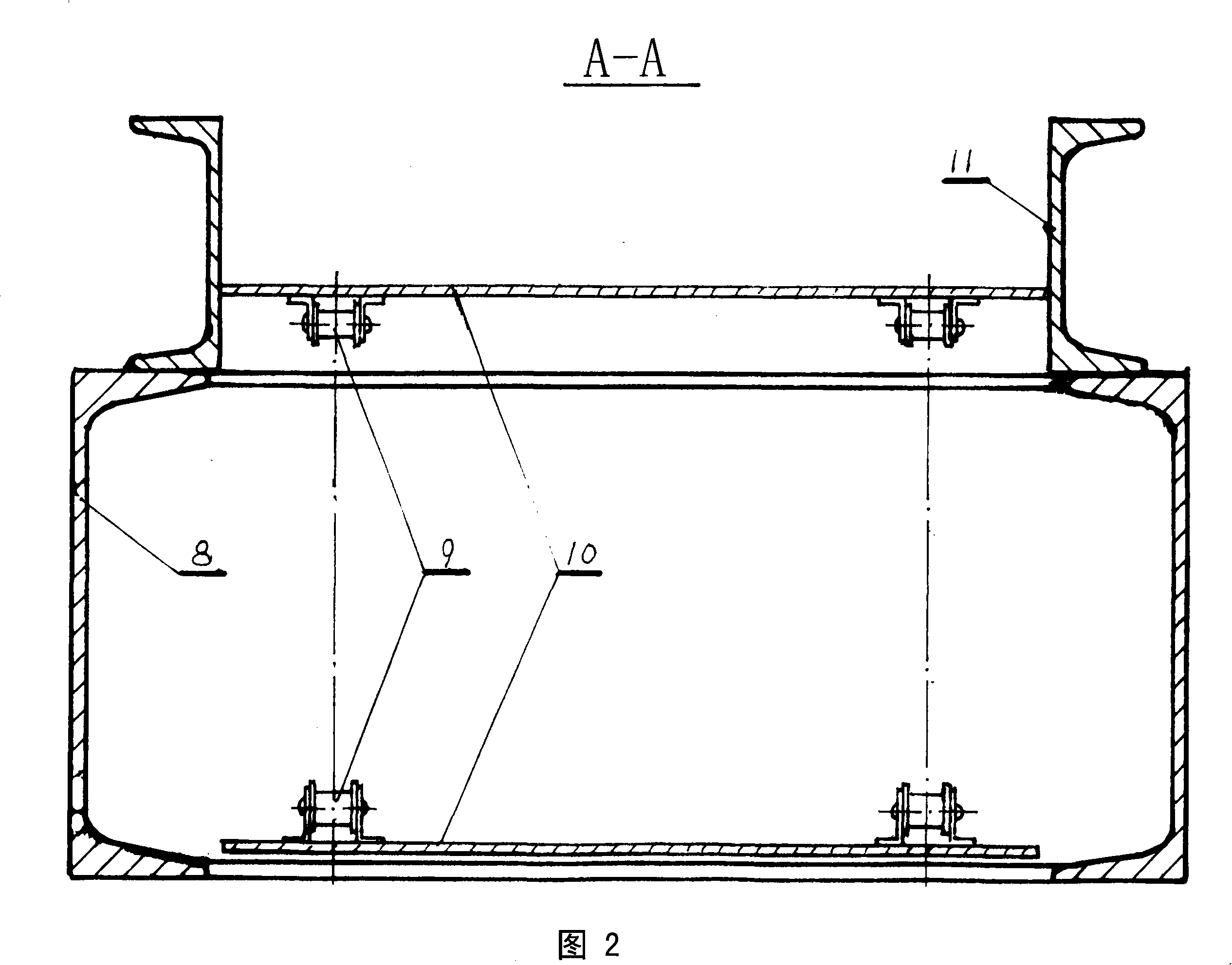

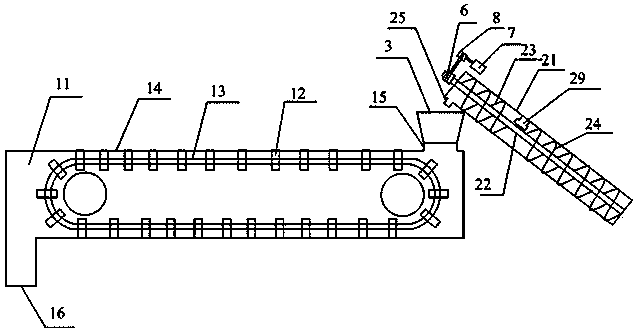

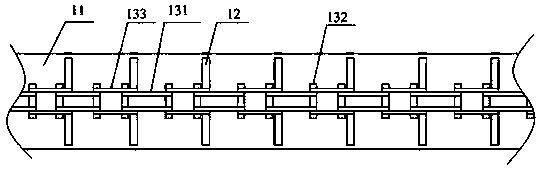

Excavator and sand dredger

InactiveCN101130995AEnhance sand dredging powerImprove delivery capacitySoil-shifting machines/dredgersHydraulic cylinderDrive shaft

The present invention is one kind of excavator and one kind of sand dredging boat, and relates to underwater sand excavation. The excavator is one sand dredging balance wheel with oscillating hydraulic cylinder to drive one balance wheel and the sand dredging board on the balance wheel to rotate reciprocally and periodically for cutting sand. The sand dredging boat includes one mechanical and hydraulic driving system and one conveying chain belt on the boat, and one sand dredging balance wheel in water. The present invention is superior to available chain-bucket sand dredging boat, and has separated excavating assembly and conveying assembly, hydraulic driving, 5-10 times raised production efficiency and easy control.

Owner:熊梓光

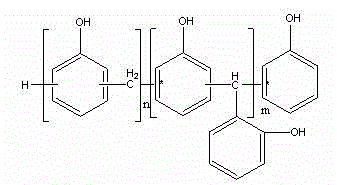

High heat conduction epoxy resin composition applicable to fully wrapped devices and preparation method

ActiveCN102911479ASolve the back air holeSolve defects such as filling dissatisfactionEpoxyEpoxy resin composite

An epoxy resin composition applicable to fully wrapped devices is composed of an epoxy resin, a phenolic resin, an inorganic filling agent, a heat conduction filler and an additive. The epoxy resin is represented as a formula (1) and / or a formula (2), and the mass content of the epoxy resin is 2-7% of the total mass of the composition; the phenolic resin is represented as a formula (3) and / or a formula (4), and the mass content of the phenolic resin is 2-7% of the total mass of the composition; and the heat conduction filler is a crystallized silicon dioxide powder, an aluminum oxide powder or a silicon nitride powder. The invention further discloses a preparation method of the epoxy resin composition. The epoxy resin composition has the advantages of being wide in applicability, high in filling, few in pores and high in reliability. According to the preparation method, open mixing rollers are added between an extruder and a fluted roller in traditional epoxy resin composition production processes for open milling and mixing, and a thread groove is added onto a grooved roller with low temperatures, so that the preparation method has the advantages of being high in conveying capacity and large in shear cutting force.

Owner:JIANGSU HHCK NEW MATERIAL CO LTD

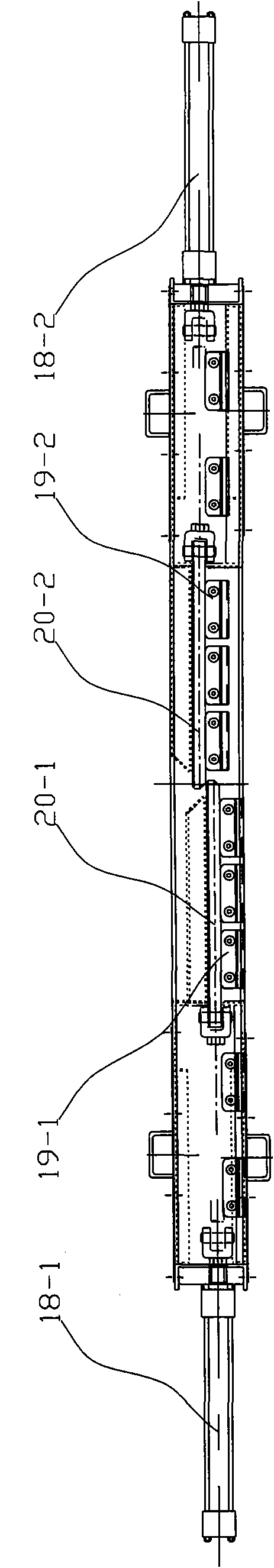

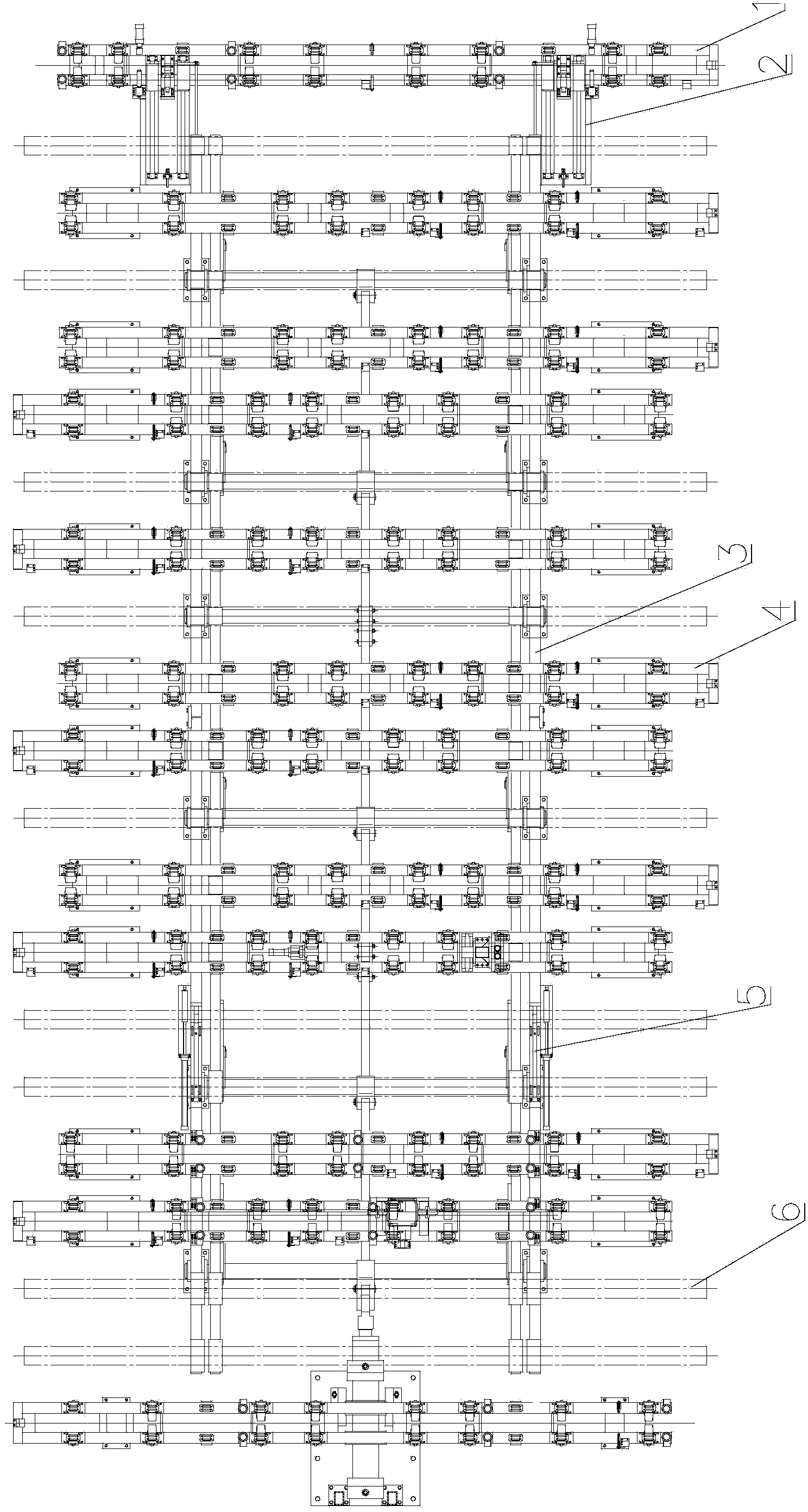

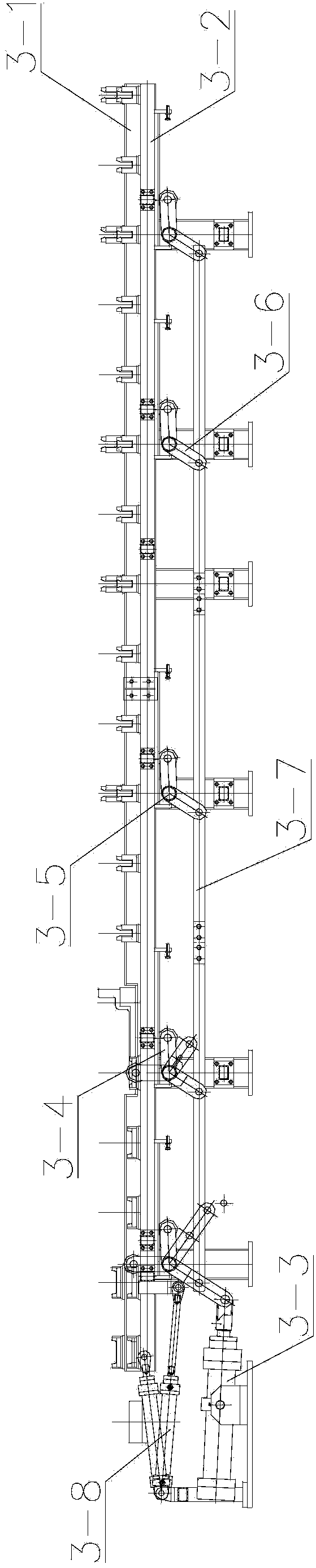

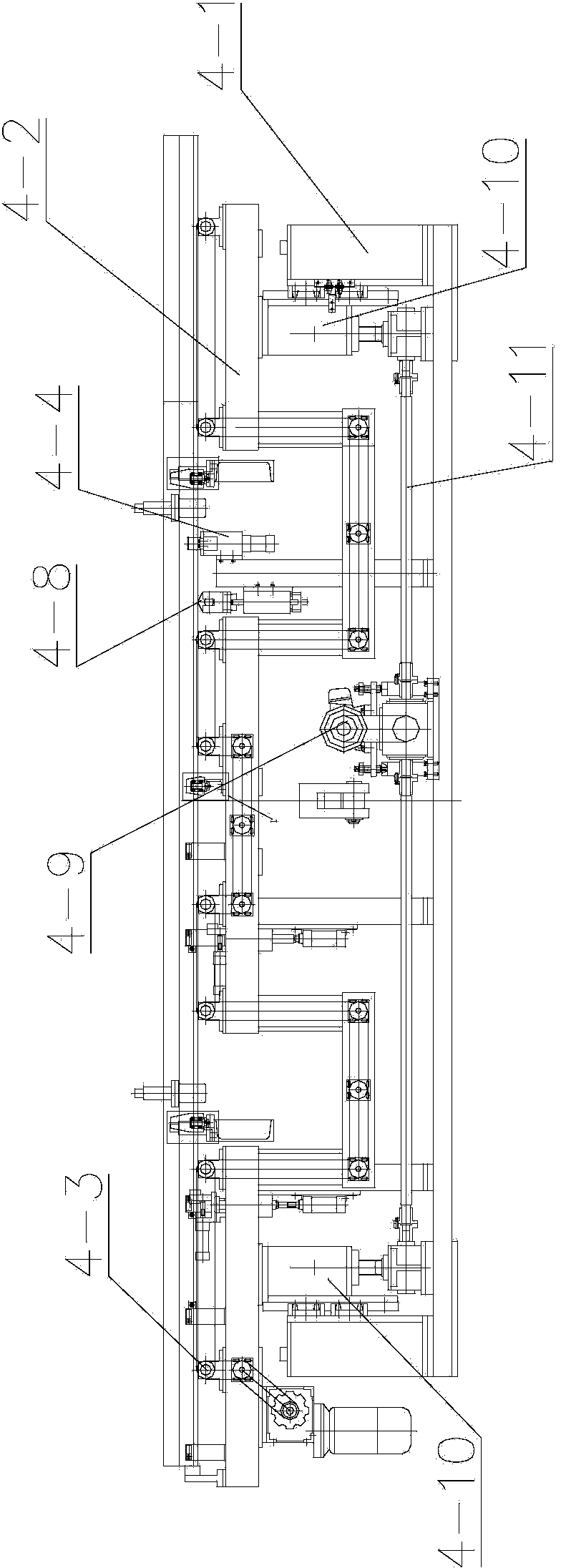

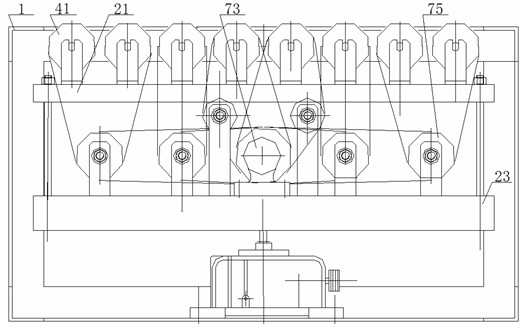

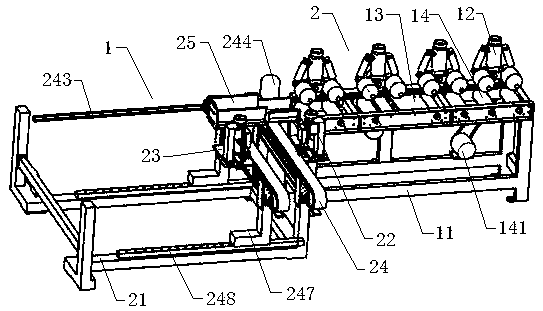

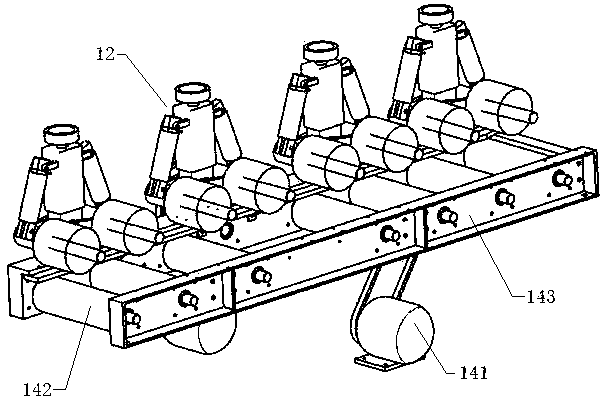

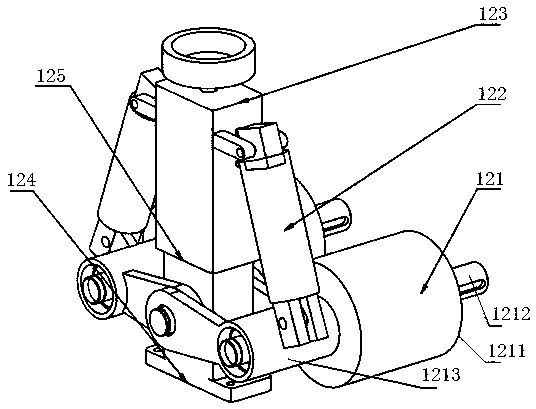

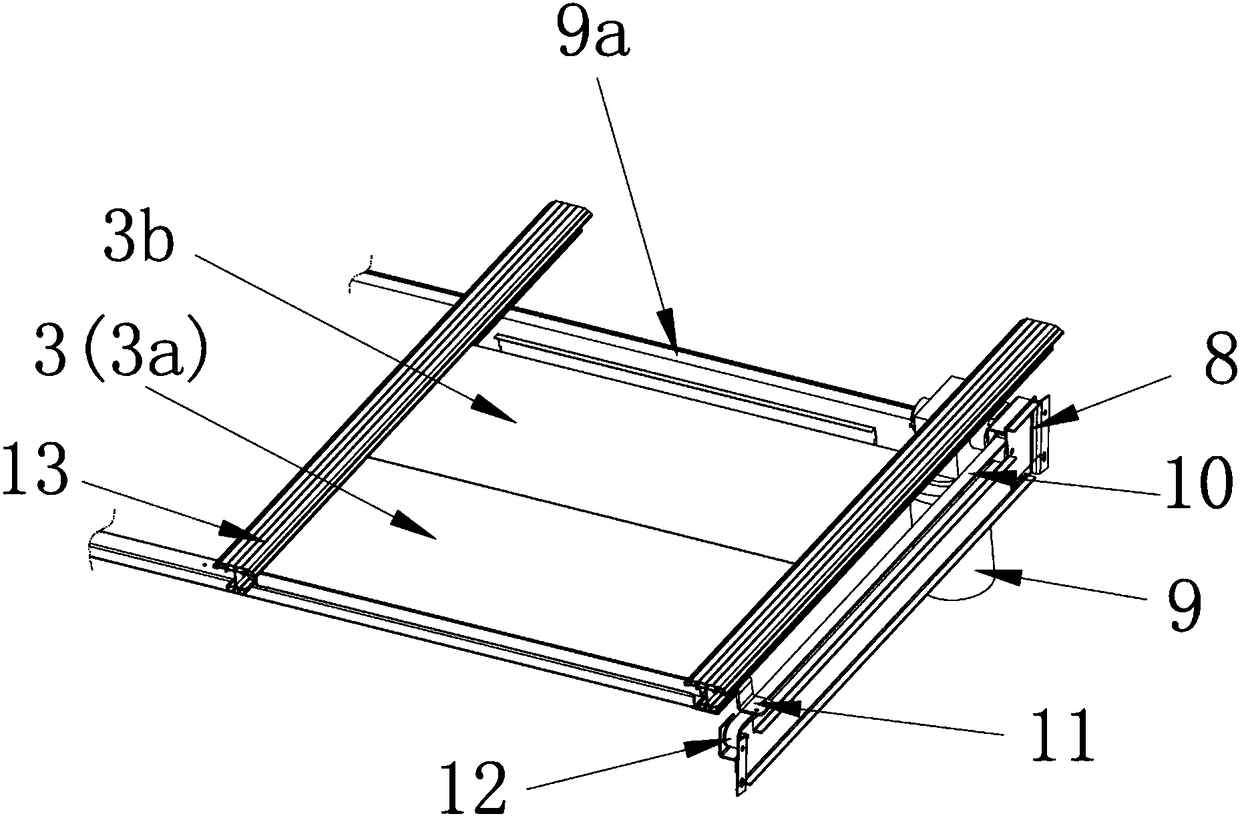

Blank conveying system for automatic elevator guide rail machining production line

ActiveCN103962844ACompact structureWide adaptabilityOther manufacturing equipments/toolsElevatorsProduction lineEngineering

The invention relates to a blank conveying system for an automatic elevator guide rail machining production line. The blank conveying system comprises feeding frames, feeding turnover devices, transverse conveying devices for conveying elevator guide rails transversely, longitudinal feeding devices and guide rail turnover devices. The feeding turnover devices are arranged between the feeding frames and the transverse conveying devices, the longitudinal feeding devices are arranged in the transverse conveying devices respectively so as to conduct feeding on all elevator guide rail machining units longitudinally, and the guide rail turnover devices are located between the longitudinal feeding devices of elevator guide rail installation hole machining units and the longitudinal feeding devices of elevator guide rail countersinking machining units. The blank conveying system has the advantages that due to the fact that the blank conveying system is compact in structure, an installation site is saved, and the adaptability is wider; furthermore, the blank conveying system is high in conveying capacity and reliable in motion and increases the production efficiency.

Owner:常州市三利精机有限公司

Thermosensitive recording material and method of producing the same

ActiveCN101011897AGood time stabilityStrong conveying capacityThermographyOther printing apparatusPolyvinyl alcoholLeuco dye

A thermosensitive recording material and the method of producing the same are provided, in which the protective layer-coating liquid represents superior temporal stability, transporting ability at printing is superior even under higher temperatures and humidities and even by use of printers with lower motor torque, and also coloring property and storage property at image and background portions are excellent. The thermosensitive recording material comprises comprises at least a support, a thermosensitive recording layer and a protective layer in order, wherein the thermosensitive recording layer comprises at least a leuco dye and a color developer, and the protective layer is formed from a protective layer-coating liquid comprising at least a diacetone-modified polyvinyl alcohol, a carbodihydrazide compound and an aqueous ammonia solution.

Owner:RICOH KK

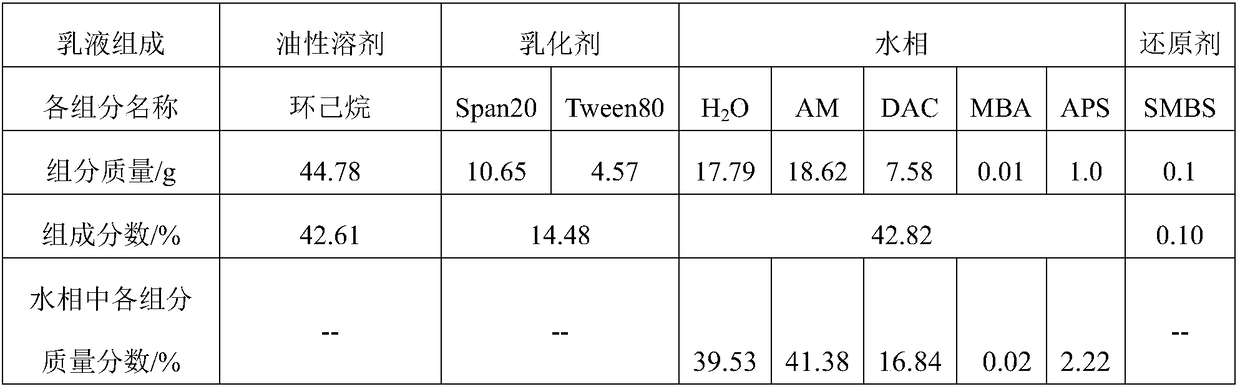

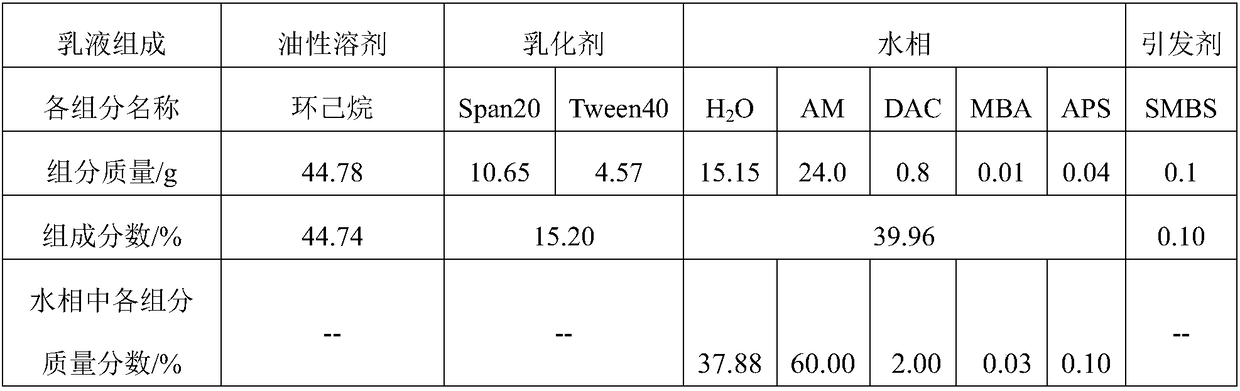

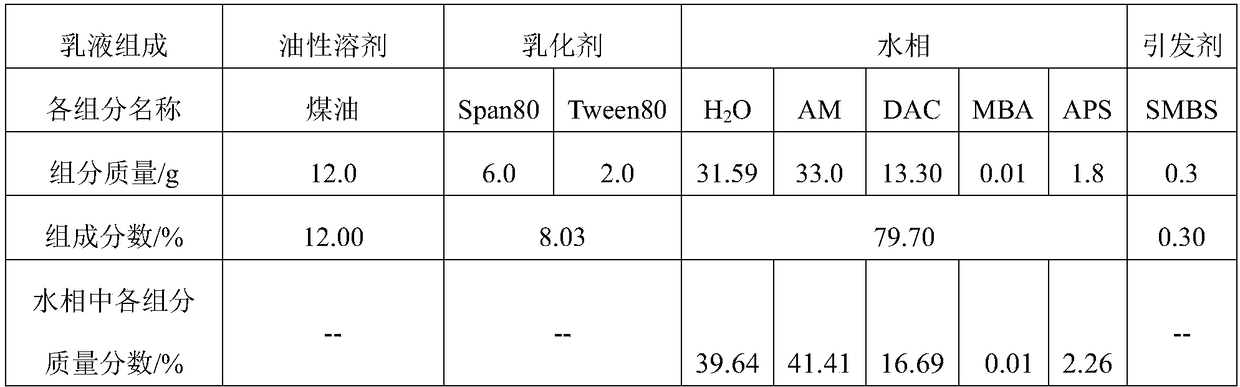

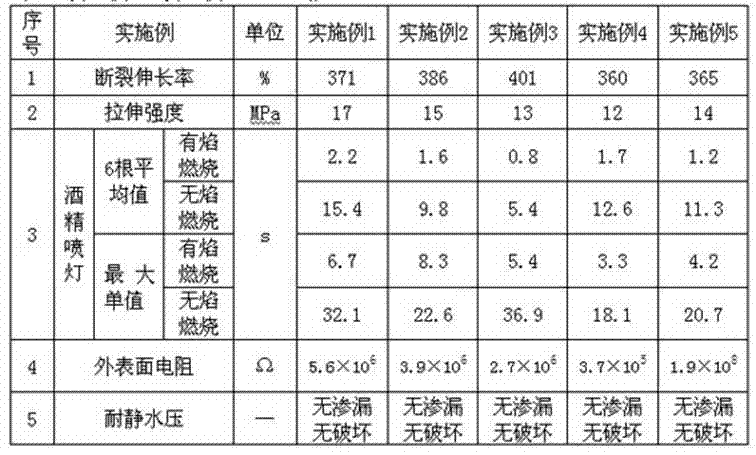

Method for preparing fracturing fluid thickener with self-destruction effect

The invention discloses a fracturing fluid thickener with a self-destruction effect. The fracturing fluid thickener comprises, by weight, 5-80% of monomer aqueous phase, 12-70% of oil-based solvents and 8-25% of emulsifiers. The usage of reducing agent solution in oxidation-reduction initiators accounts for 0.1-0.5% of the mass of emulsion. A method for preparing the fracturing fluid thickener mainly includes dissolving the emulsifiers in the oil-based solvents; adding the monomer aqueous phase with excessive oxidizing destruction agents into the oil-based solvents; carrying out stirring and deoxidizing, adding the reducing agent solution at the temperatures of 10-40 DEG C and initiating reaction for 0.5-4 hours to obtain inverse emulsion with the oxidizing destruction agents partially coated by micro-spheres; directly diluting the emulsion by the aid of water to prepare the fracturing fluid thickener with the self-destruction effect, or separating out the micro-spheres by sedimentation and then preparing the fracturing fluid thickener with the self-destruction effect. The fracturing fluid thickener and the method have the advantages that the fracturing fluid thickener and destruction agents can be produced by the aid of the method in an integrated manner, the destruction agents can be uniformly placed and can be released in a delayed manner, and accordingly the problems of difficulty in controlling the destruction time of directly mixed destruction agents for use in conventional processes or high cost and uneven destruction of capsule destruction agents can be solved.

Owner:YANSHAN UNIV

Special material for water supply pipe used in mine

The invention relates to a special material for a water supply pipe used in a mine. The special material is prepared from raw materials consisting of 50 to 70 parts of a polyethylene resin, 10 to 30 parts of a reinforcing agent, 5 parts of a coloring agent, 10 to 30 parts of a fire retardant, 0.1 to 1 part of an antistatic agent, 0.01 to 1 part of a processing aid, etc. A preparation method for the special material comprises the following steps: adding the polyethylene resin, the reinforcing agent, the coloring agent, the fire retardant, the antistatic agent and the processing aid in proportion into a high speed mixer for mixing for 10 to 30 min; and subjecting an obtained mixed material to plasticizing and extrusion by a double screw extruder, cooling and granulation so as to prepare the special material for the water supply pipe used in the mine. The special material prepared by the invention has the advantages of good flame retardation, excellent antistatic performance, high rigidity, light weight, corrosion resistance, no fouling, convenience in installation, etc., can be used for conveying high-sulfur water containing calcium ions, magnesium ions, etc. under the mine and has wide market prospects.

Owner:吉林喜丰节水科技股份有限公司

Efficient positive-pressure pneumatic conveying system of pebble coal

InactiveCN102923485AStable deliveryFully adapted to emission requirementsBulk conveyorsPositive pressureEngineering

The invention relates to an efficient positive-pressure pneumatic conveying system of pebble coal for pebble coal discharge of a medium-speed coal pulverizer in a heat-engine plant. The efficient positive-pressure pneumatic conveying system of the pebble coal comprises a pebble coal bunker of which the upper end is connected with a pebble coal outlet of the medium-speed coal pulverizer, wherein the outlet at the lower end of the pebble coal bunker is connected with a feeding device; the inlet at the front end of the feeding device is connected with a compressed air pipeline; the outlet at the rear end of the feeding device is connected with the pebble coal bunker via a transfer pipeline; and a gas outlet of the pebble coal bunker exhausts through a dust remover. According to the efficient positive-pressure pneumatic conveying system, the defects of an original negative-pressure pneumatic conveying system are solved; the entire system is low in energy consumption, small in noise, high in reliability and strong in delivery capacity, and the delivery capacity of the system can be reinforced by a loose duct. Meanwhile, the situation that a solving method is provided when the system is broken down is ensured, and a vibrating screen of the pebble coal bunker can effectively remove the material which is not suitable for pneumatic conveying, and ensures that the system is not blocked.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Cross turning roller conveyor

InactiveCN102275710AGood direction changeHigh precisionConveyor partsRoller-waysGear wheelDrive shaft

The invention discloses a cross turning raceway conveyor which comprises a rack and a turntable, wherein a conveying device is arranged on one surface of a top disc in the turntable, and the other surface of the top disc is connected with a chassis through a side beam; the other surface of the chassis is in rotary fit with a rotary bracket; the two ends of the rotary bracket are connected with the rack through a support seat; a rotary device comprises a rotary motor, a rotary driving gear and a rotary driven gear, wherein the rotary motor is connected with the chassis sequentially through the rotary driving gear, the rotary driven gear and a hollow rotary shaft; a transmission device arranged on the chassis comprises a driving bevel gear, a driven bevel gear and a main transmission shaft; a transmission motor is in transmission fit with the conveying device sequentially through the hollow rotary shaft, the driving bevel gear, the driven bevel gear, the main transmission shaft, a master belt wheel and a slave belt wheel; and the conveying device comprises a transmission roller and a roller support leg corresponding to each other. The cross turning raceway conveyor disclosed by the invention has the advantages of good reversing effect, high conveying efficiency, good transmission effect, stronger controllability, less noise and lower production cost.

Owner:金国华

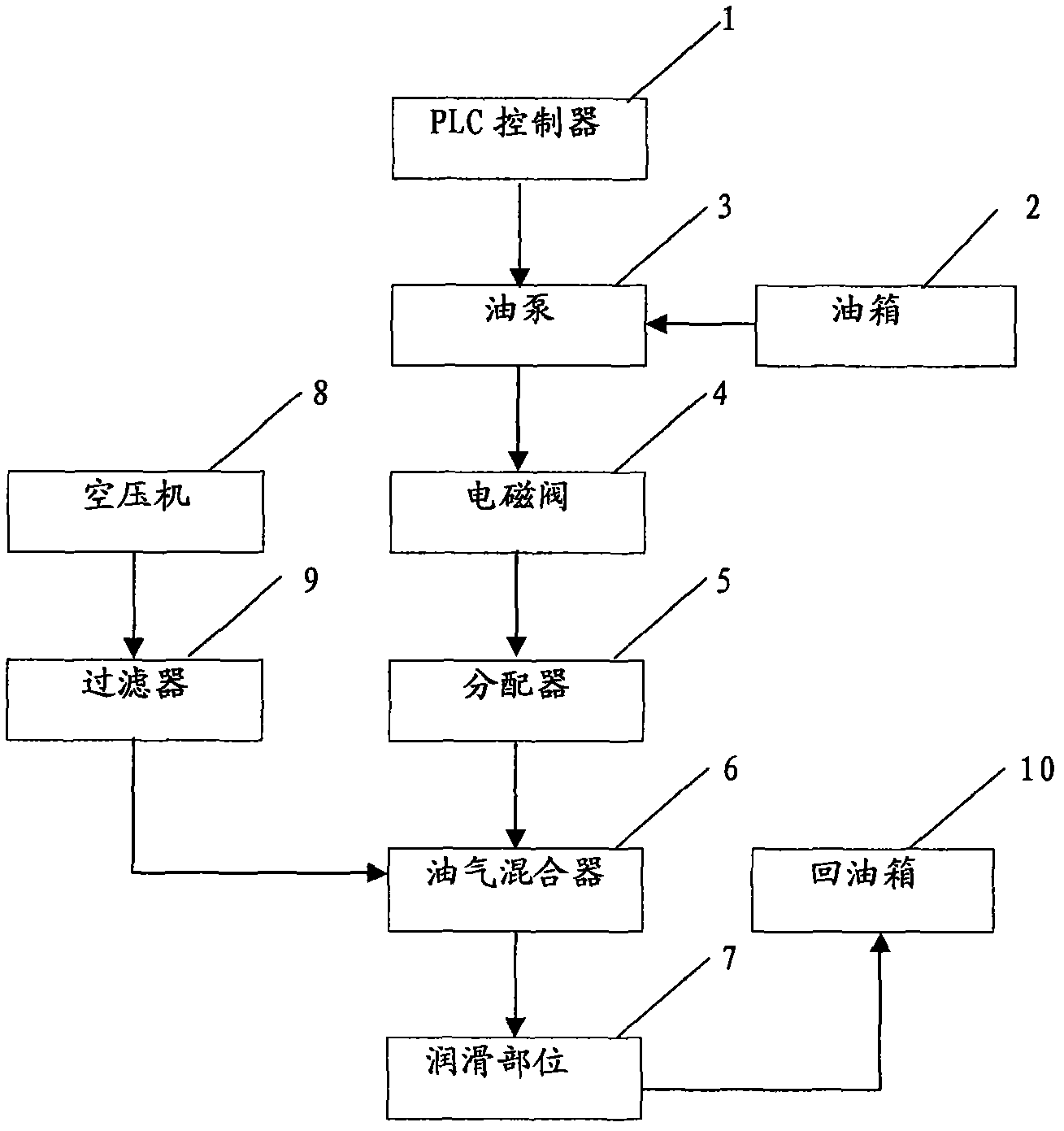

Oil-gas lubrication method

InactiveCN103836319AReduce fuel consumptionStrong conveying capacityEngine lubricationGas lubricationPositive pressure

The invention discloses an oil-gas lubrication method. The method comprises the steps that first, a PLC control system controls an entire oil-gas lubrication process and is sequentially connected with an oil pump, an electromagnetic valve, a distributor, an oil and gas mixer, a lubrication part and an oil return box; second, an oil box is connected with the oil pump; third, an air compressor is connected with the oil and gas mixer through a filter. The oil-gas lubrication method has the advantages that oil consumption (1 / 8-1 / 10 of that of oil-mist lubrication) is low, the adaptability (150-680 cst / 40 DEG C) to lubricating oil viscosity is wide, oil mist conveying capacity (conveying air pressure is 2-10 bar, and air flow speed is 30-80 m / s) is high, conveying distance (capable of achieving 100m) is long, the sealing effect on a bearing is good (the positive pressure in the bearing is 0.3-0.8 bar), the service life of the bearing is long (the service life is prolonged by 2-4 times), emission of oil mist is avoided, and the environment is not polluted, thereby having high popularization value.

Owner:TIANJIN YIBO STEEL MAKING

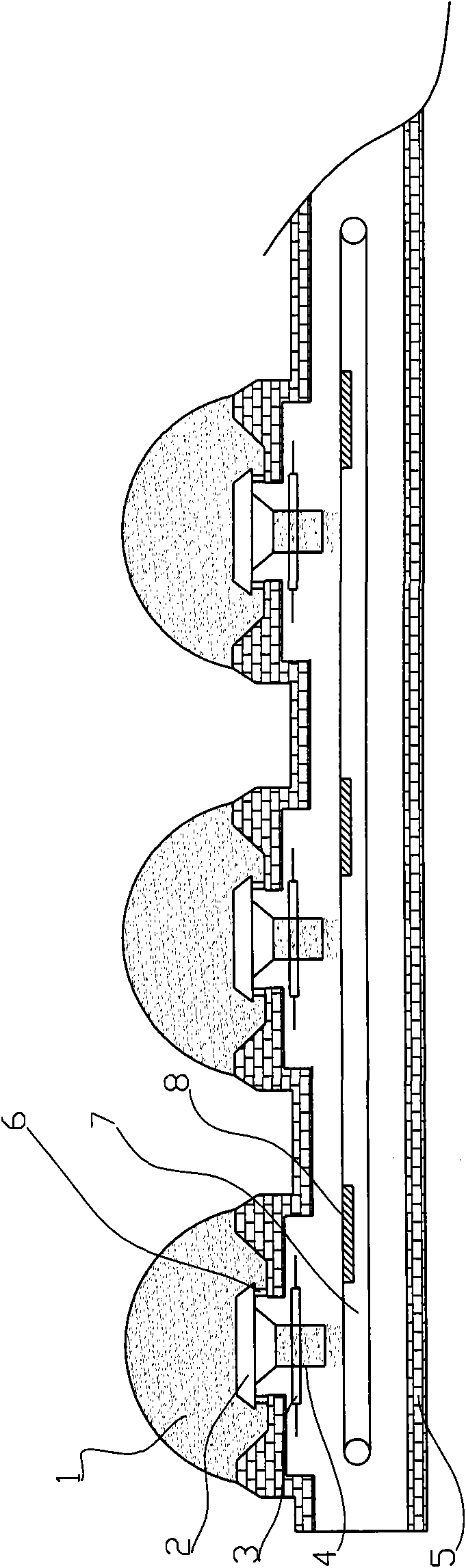

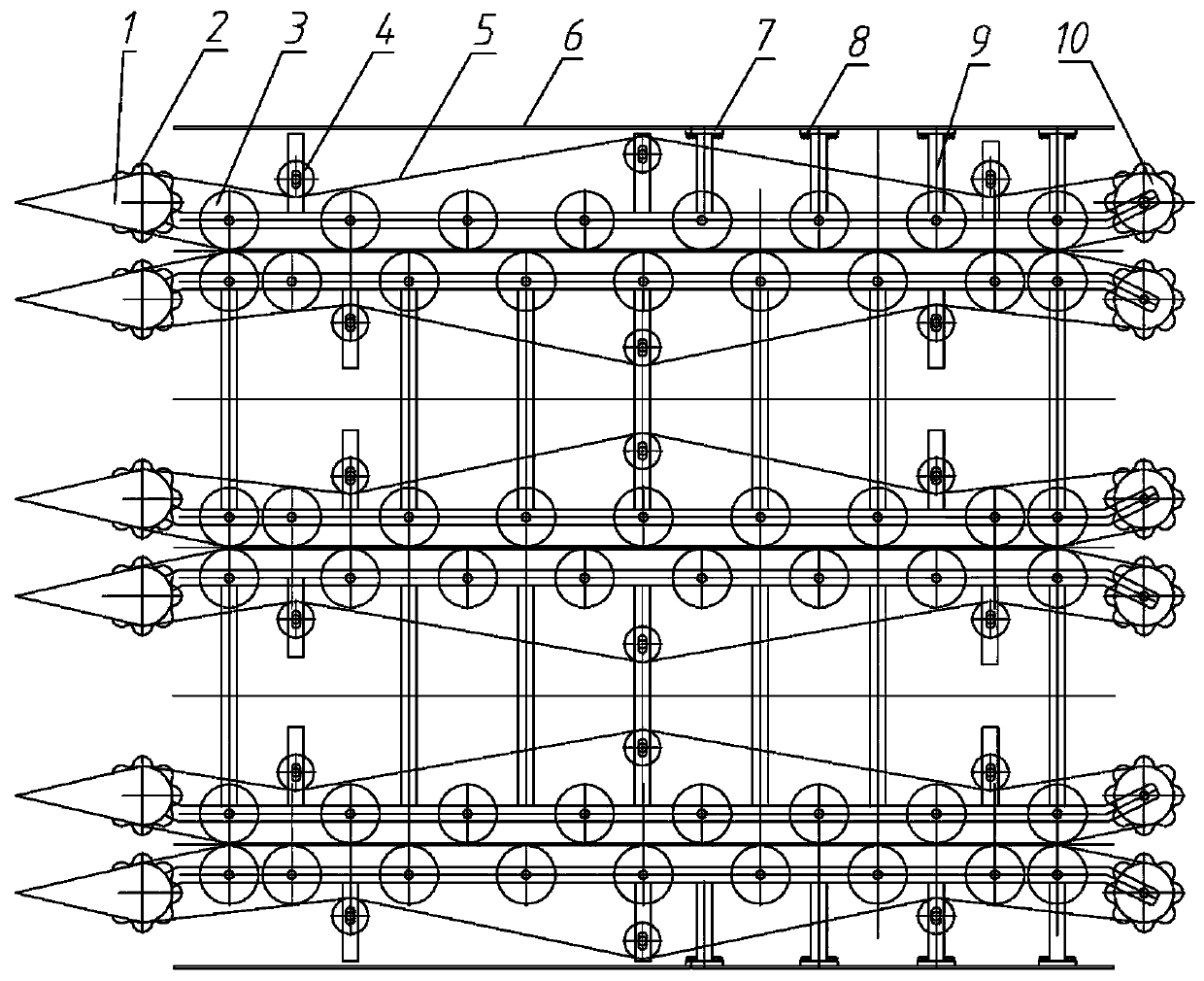

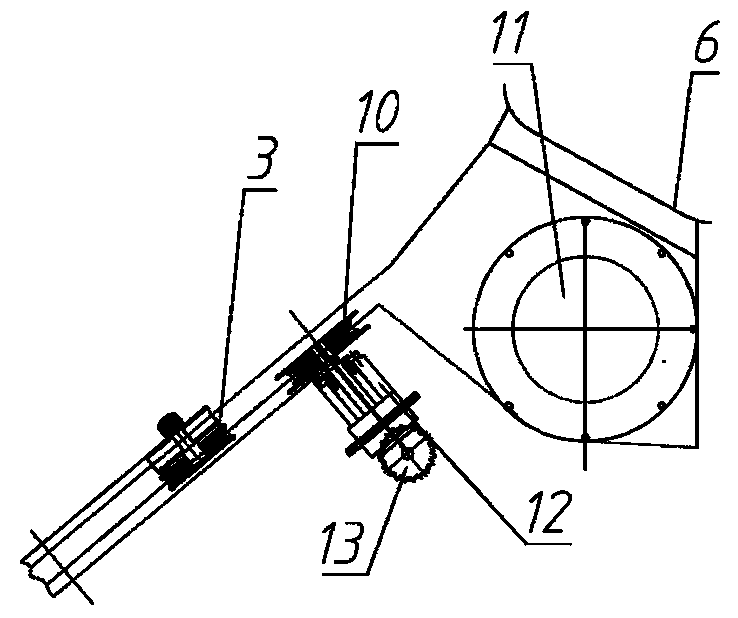

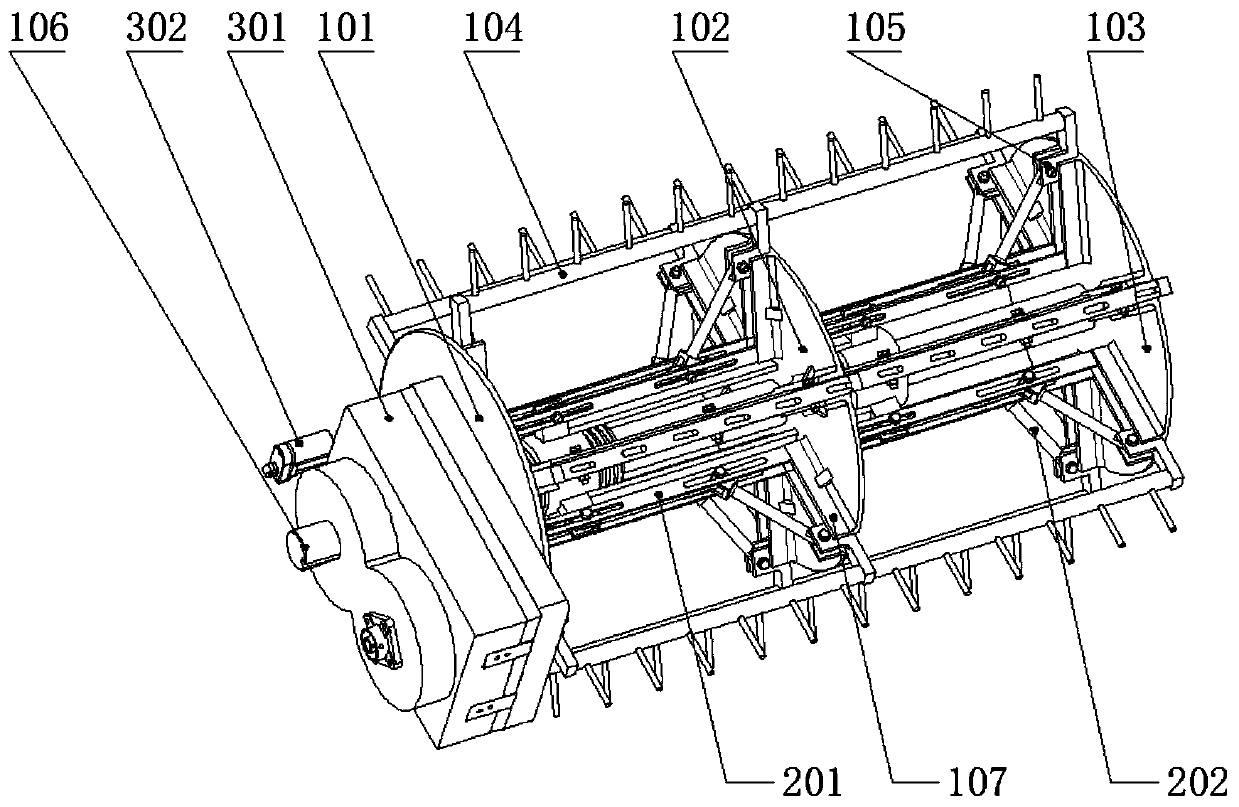

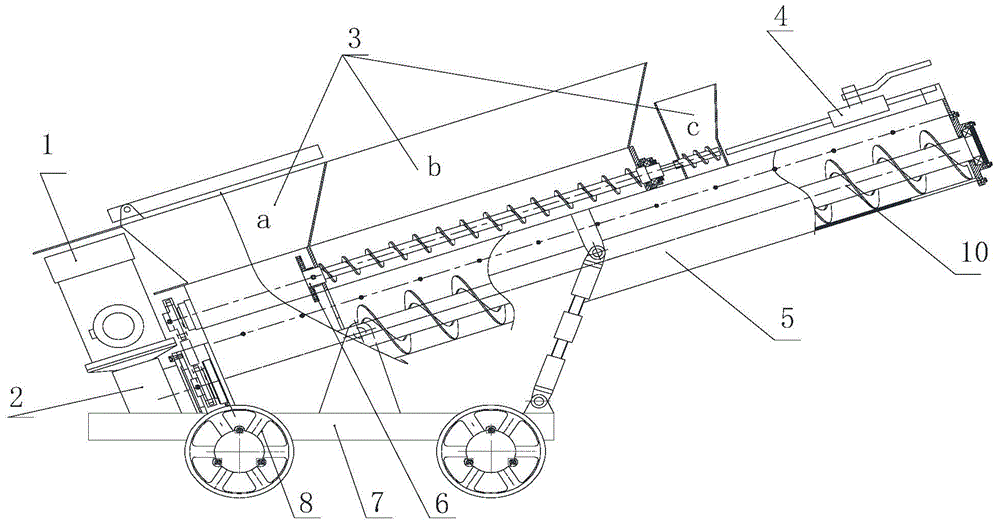

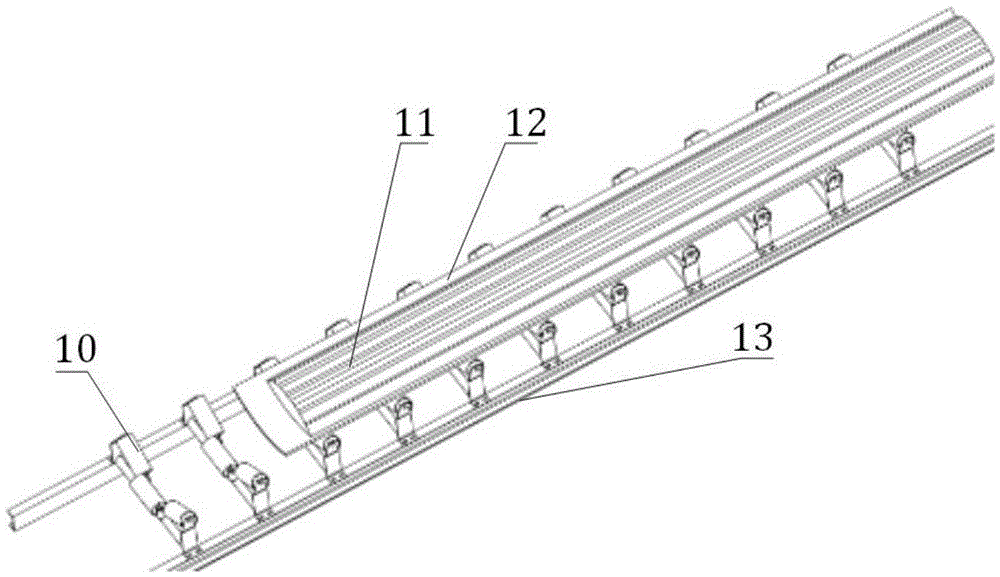

Stalk pulling and clamping conveying device of cotton stalk pulling crusher

The invention discloses a stalk pulling and clamping conveying device of a cotton stalk pulling crusher. The device comprises a rack which is obliquely arranged, wherein a film lifting shovel is arranged at the lower end of the rack, front clamping and conveying mechanisms are arranged on the rack at intervals side by side, and each clamping and conveying mechanism comprises seedling dividers, bottom guiding wheels, belt wheels, tensioning wheels, V-shaped belts and top guiding wheels positioned at the upper part of the rack; the top of the rack is provided with auger conveying rollers, a transmission box and a transmission chain wheel are arranged below rotating shafts of the top guiding wheels respectively, the transmission chain wheel is connected with an external power input mechanism,and the bottom guiding wheels, the belt wheels and the top guiding wheels are all driven to rotate by the transmission box and the V-shaped belts; the belt wheels are mounted on a belt wheel bracketthrough connecting shafts, the tension wheels are mounted on the belt wheel bracket through connecting shafts, the belt wheel bracket is fixed to the rack through connecting bolts used for connectingplates, and the connecting plates are welded to the rack. The device has the advantages of reliable work and excellent conveying capacity, and the capacity of grabbing stems can be improved.

Owner:XINJIANG AGRI UNIV

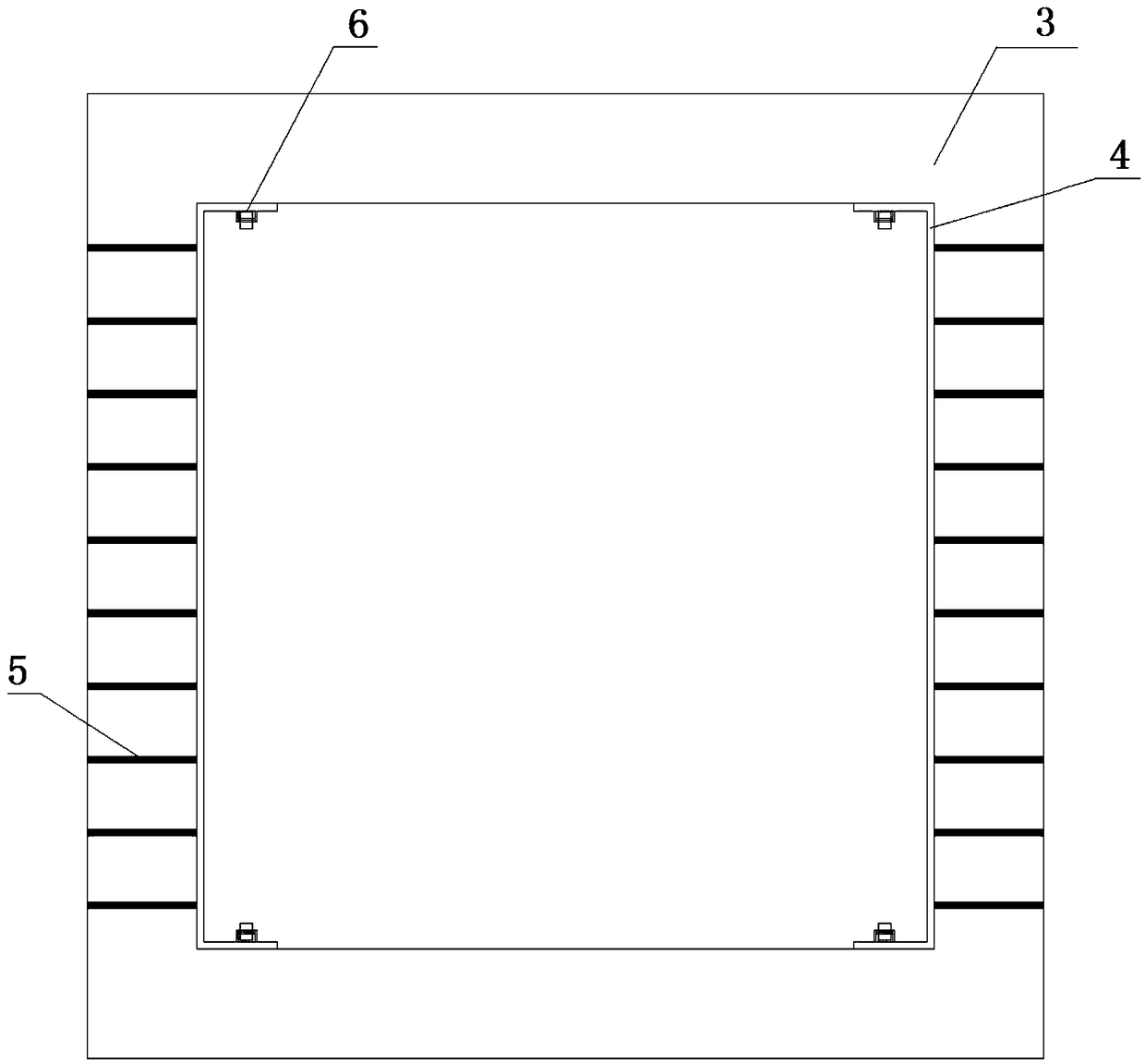

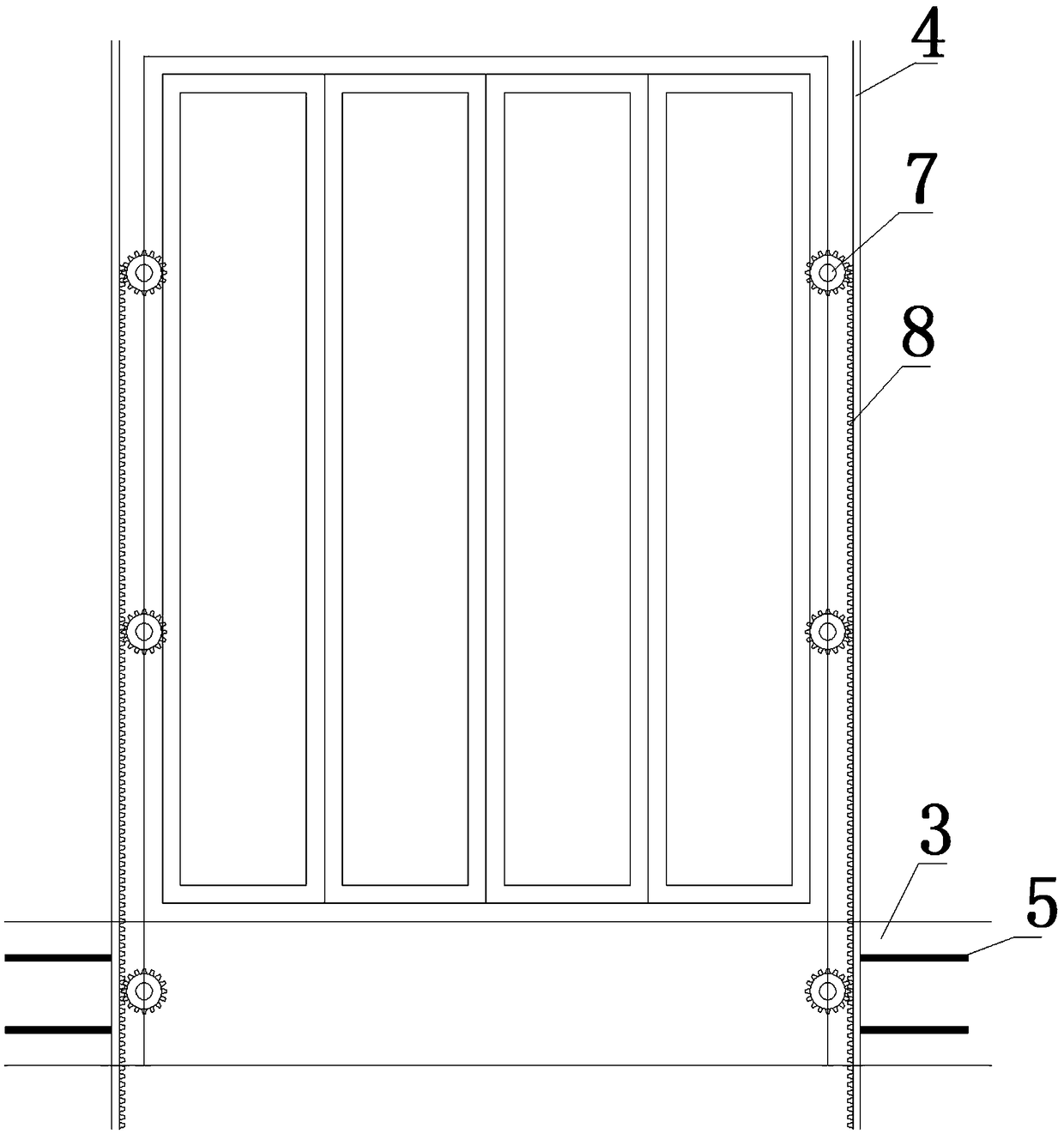

Panel surface edge scraping machine

PendingCN109352754AEasy to adjust scraping depthVarious scraping effectsProfiling/shaping machinesEngineering

The invention discloses a panel surface edge scraping machine. The panel surface edge scraping machine comprises a longitudinal edge scraping device (1) and a transverse edge scraping device (2) perpendicular to the discharging direction of the longitudinal edge scraping device (1), wherein a feeding port of the transverse edge scraping device (2) is arranged below the end side of a discharging port of the longitudinal edge scraping device (1). The longitudinal edge scraping device (1) is provided with a scraping mechanism (3) capable of performing edge scraping on the long edge side wall of aplate. The transverse edge scraping device (2) is provided with a scraping mechanism (3) capable of performing edge scraping on the short edge side wall of the plate. When the panel surface edge scraping machine is used to perform edge scraping processing on the panel, the panel enters the feeding port of the longitudinal edge scraping device first to be subject to edge scraping processing in thelength direction and then enters the transverse edge scraping device from the discharging port of the longitudinal scraping device to be subject to edge scraping processing in the width direction, sothat panels with different thicknesses and lengths can be adapted to, the edge scraping depths of the panels can be adjusted conveniently, and the edge scraping effects are diversified.

Owner:盐城鼎恒机械有限公司

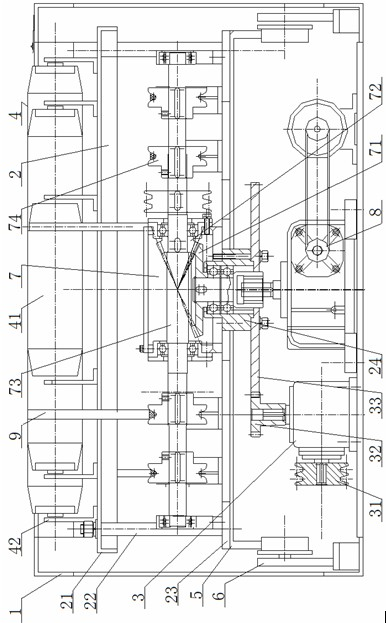

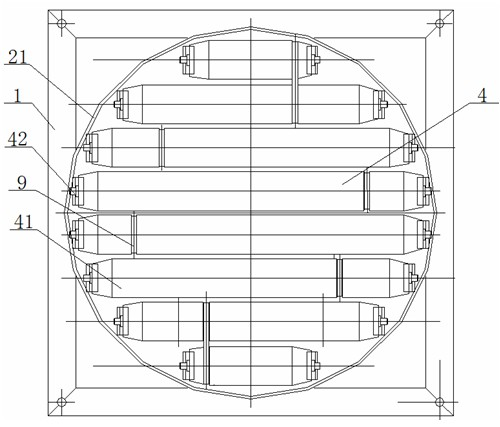

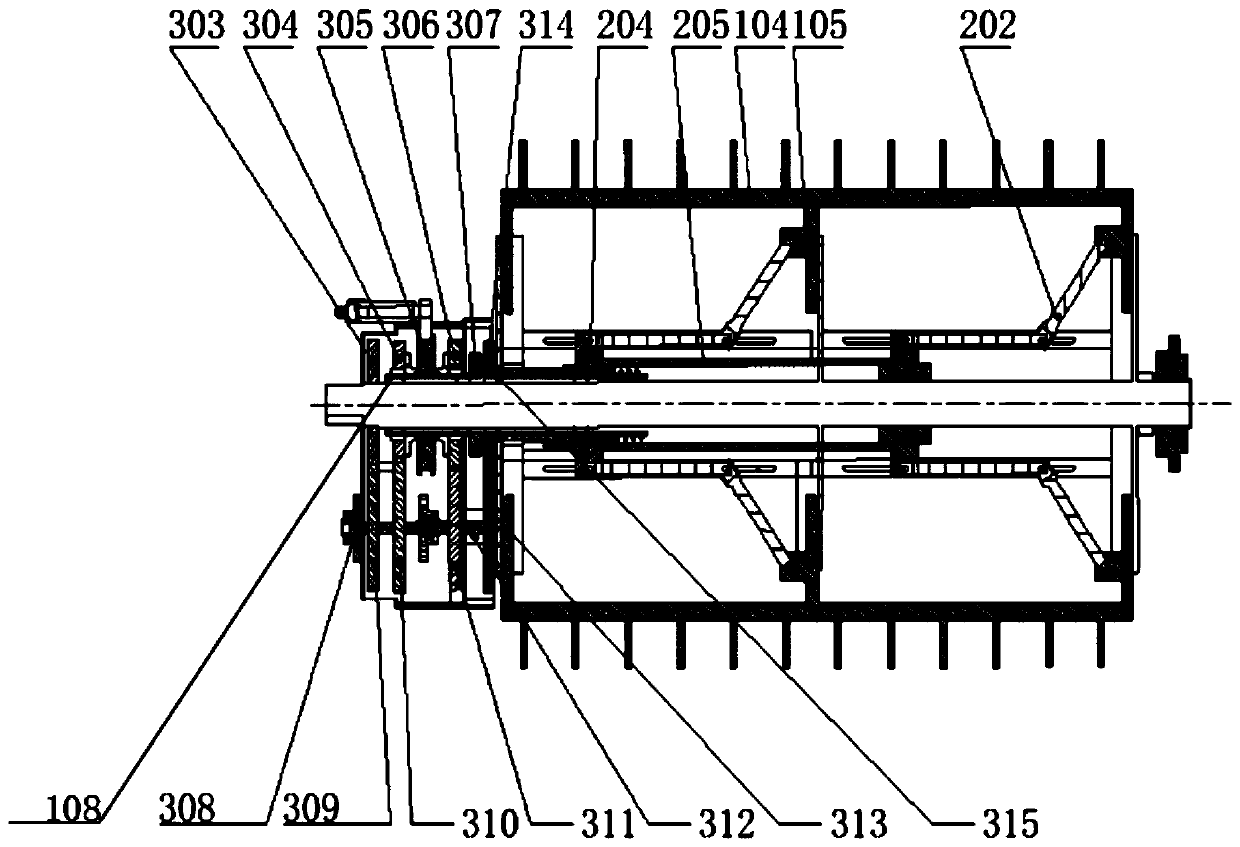

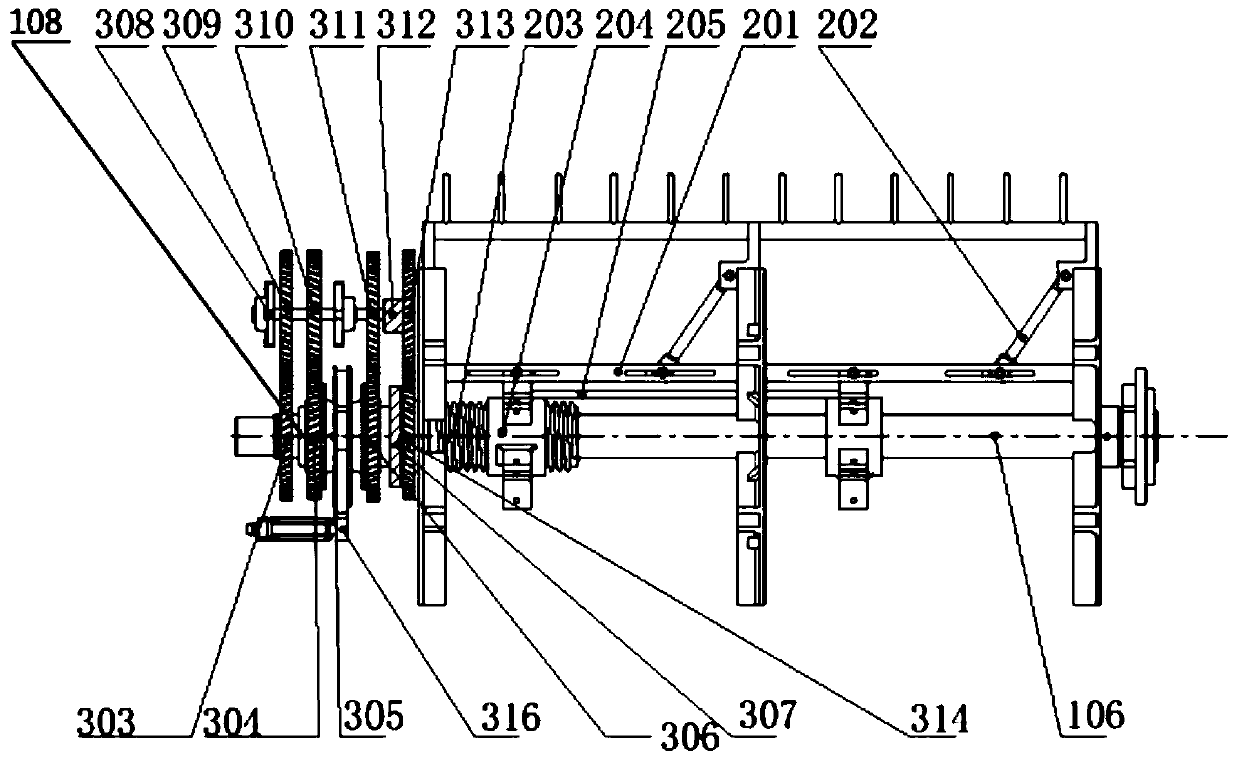

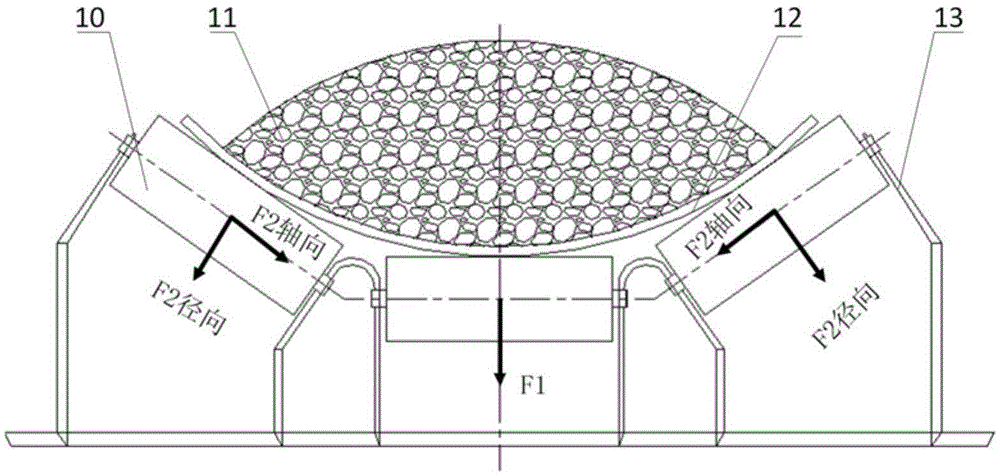

Threshing cylinder with adjustable threshing diameter, adjusting method and combine harvester

PendingCN111226610AImprove adaptabilityImprove harvesting efficiencyMowersThreshersStructural engineeringThreshing

The invention provides a threshing cylinder with an adjustable threshing diameter, an adjusting method and a combine harvester. The threshing cylinder comprises a threshing cylinder, a diameter adjusting device and a driving device, wherein the diameter adjusting device is positioned on inner sides of a front support amplitude disc and a rear support amplitude disc of the threshing cylinder; and the driving device is used for conducting power to the diameter adjusting device. The threshing diameter of the threshing cylinder can be steplessly adjusted through the diameter adjusting device, meanwhile, the adjusted diameter of the threshing cylinder can be locked by the driving device, and thus operation stability of the threshing cylinder can be ensured. By adopting the threshing cylinder, the cylinder threshing diameter of the combine harvester can be conveniently and rapidly adjusted in real time, the threshing linear velocity and the threshing interval of the threshing cylinder can beadjusted according to harvesting situations, and the threshing adaptability of the combine harvester can be improved.

Owner:JIANGSU UNIV

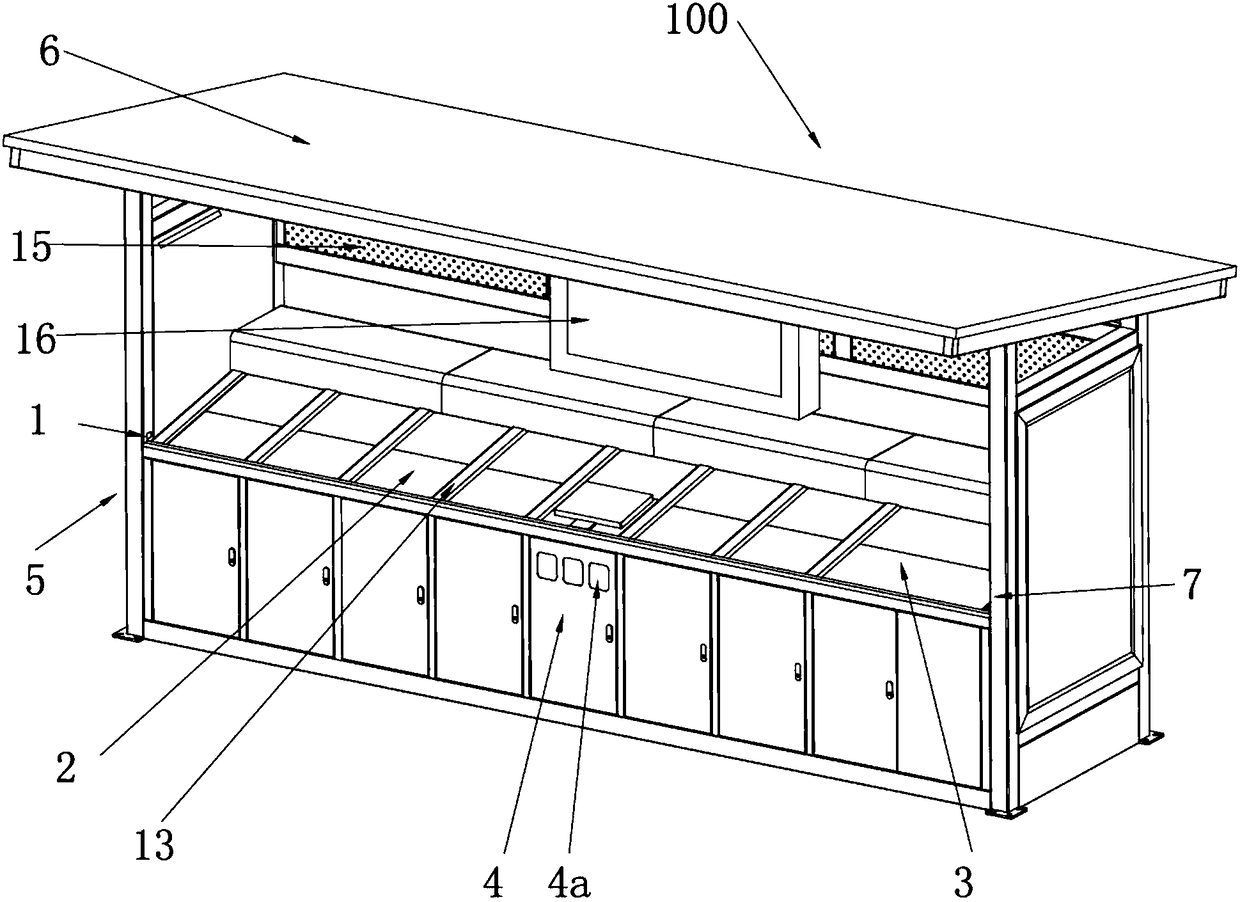

Intelligent waste recovery device provided with temporary storage cabinet

InactiveCN108516237AImprove operating experienceEasy to take outRefuse receptaclesRefuse cleaningElectricityEngineering

The invention provides an intelligent waste recovery device provided with a temporary storage cabinet. The intelligent waste recovery device provided with the temporary storage cabinet comprises a support body, a conveying device and the temporary storage cabinet. The support body is provided with a control unit, a human-computer interaction unit and a plurality of waste recovery units which are sequentially distributed. Each waste recovery unit comprises a cloth waste bag detachably mounted on the support body. The conveying device and the human-computer interaction unit are electrically connected with the control unit. The temporary storage cabinet is located on the back side of the support body. One end of the conveying device communicates with the temporary storage cabinet. A noxious substance recovery box is arranged on the front side of the support body. A plurality of noxious substance recovery units are arranged in the noxious substance recovery box. By adoption of the technical scheme, the intelligent waste recovery device provided with the temporary storage cabinet is high in intelligent degree, the use experience of users is effectively improved, transferring and temporary storage of waste are easy and convenient, and the workload of sanitation workers is reduced; and fine classification is achieved through the noxious substance recovery units, so that it is ensuredthat recovery and classification of noxious substances are more reasonable.

Owner:广东沫益清环保科技有限公司

Mining spiral feeder

ActiveCN104819001AGood transportabilityExcellent fill factorUnderground chambersTunnel liningEngineeringCam

The invention discloses a mining spiral feeder. The mining spiral feeder is composed of a body, a frame and wheels; the body is hinged to the frame; the wheels for moving back and forth are symmetrically mounted at the bottom of the frame. The body comprises an explosion-proof motor, a burdening mechanism and a water spraying device, all of which are located on the same inclined surface; the explosion-proof motor is mounted at the bottom end of the body and used for driving a cam vibrating screen mechanism and a stirring conveying trough. The cam vibrating screen mechanism is arranged under the burdening mechanism; the stirring conveying trough is arranged under the cam vibrating screen mechanism; the burdening mechanism is communicated with the stirring conveying trough by use of the cam vibrating screen mechanism. The mining spiral feeder has the advantages of reducing the underground operating personnel, saving the material cost, reducing the labor intensity of workers and improving the field operating environment; meanwhile, the guniting feeding is also even and the guniting quality is improved certainly.

Owner:SHANDONG UNIV OF SCI & TECH

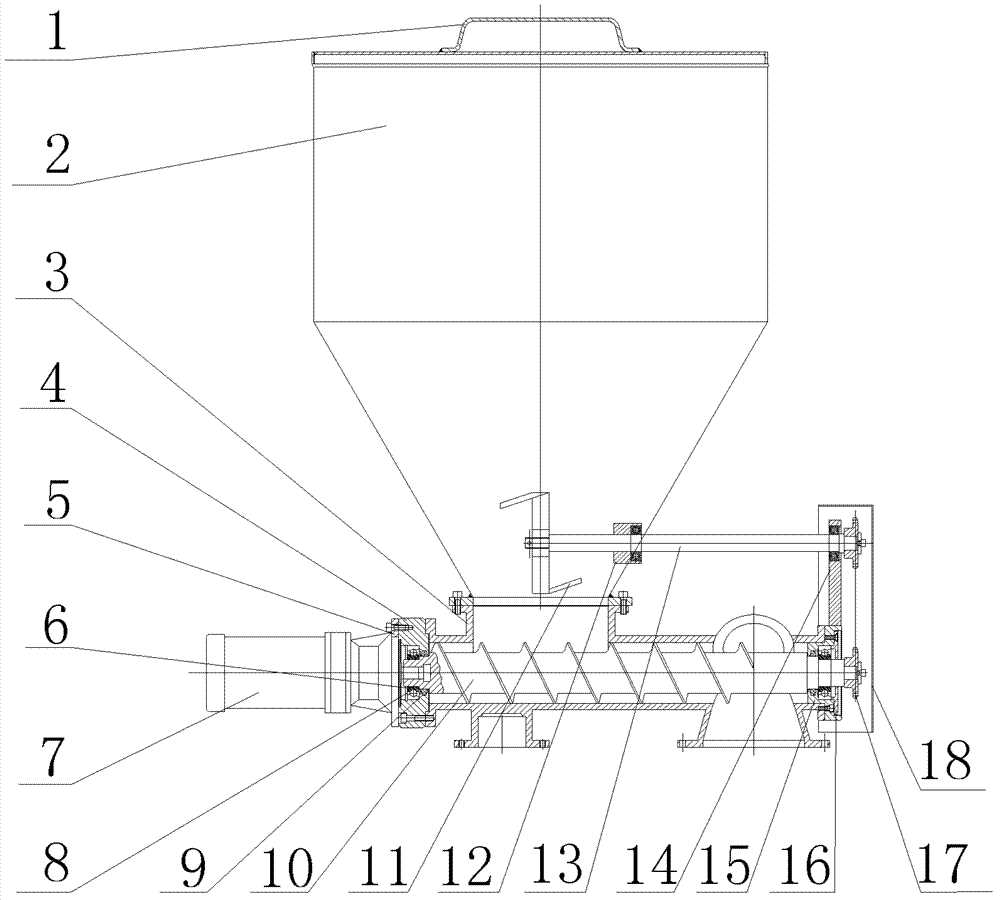

Precise polyvinyl chloride (PVC) high-calcium fill metering and feeding device of conical twin-screw extruder

The invention relates to a precise polyvinyl chloride (PVC) high-calcium fill metering and feeding device of a conical twin-screw extruder. The device comprises a storage device, a feeding device and a stirring device, wherein the storage device consists of a feeding hopper and a hopper cover arranged at the upper part of the feeding hopper; the feeding device comprises a feeding barrel, a driving motor, a motor connecting plate, a motor connecting body, a feeding screw rod, a first bearing seat, a deep groove ball bearing, a bearing check ring, a felt ring and a bearing cover; the stirring device comprises a stirring body, a stirring shaft, a second bearing seat, a shaft sleeve, a sprocket chain and a sprocket cover. Compared with the prior art, the precise PVC high-calcium fill metering and feeding device has the advantages of easiness in blanking, accuracy in feeding, simple and attractive structure, high conveying capacity, no fluctuation, good self-cleaning performance, high metering precision, wide application scope, etc.

Owner:SHANGHAI JINHU EXTRUSION EQUIP

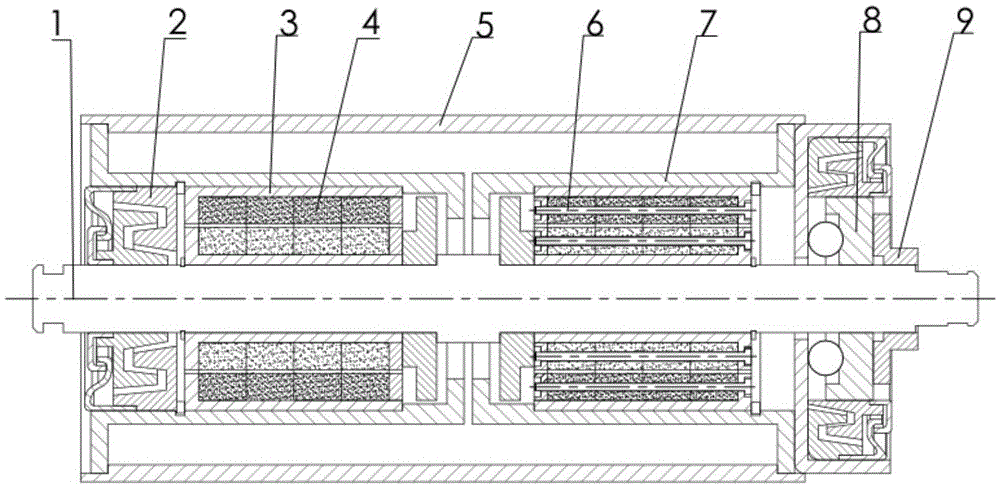

Permanent magnet carrier roller belt conveyor

The invention discloses a permanent magnet carrier roller belt conveyor. The belt conveyor is provided with a barrel (5), a bearing pedestal (7) and radial and axial supporting components installed on a center shaft (1) from outside to inside, wherein the barrel (5), the bearing pedestal (7) and the radial and axial supporting components are connected in sequence, and the radial and axial supporting components are sealed in a labyrinth seal (2) mode. As the permanent magnet supporting structure is adopted, a series of health and environment hazarding problems such as friction, noise, heat emission and lubrication contamination caused by a traditional mechanical bearing can be weakened or solved, the service life of the belt conveyor is prolonged, and the conveying capacity of the belt conveyor is improved.

Owner:WUHAN UNIV OF TECH

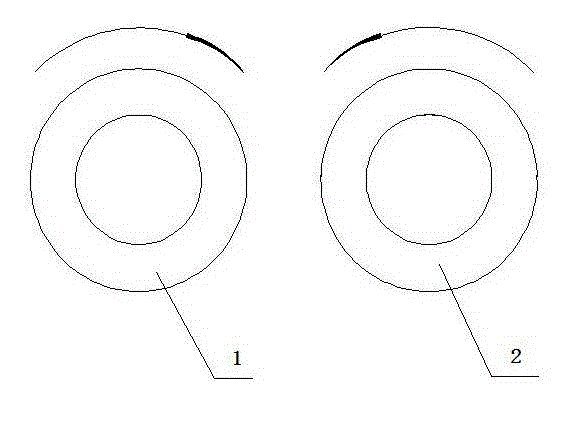

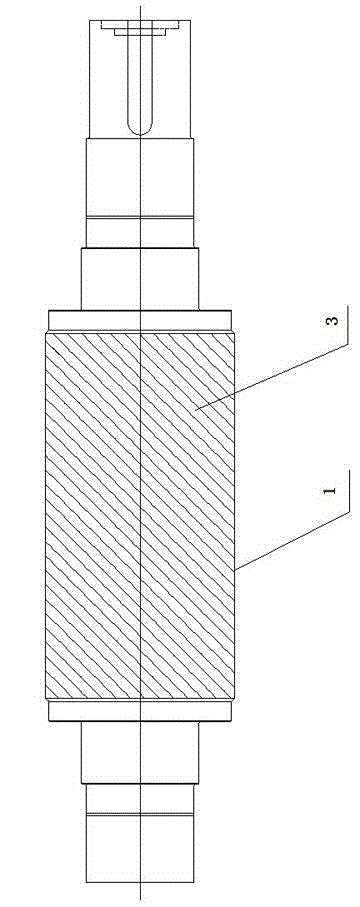

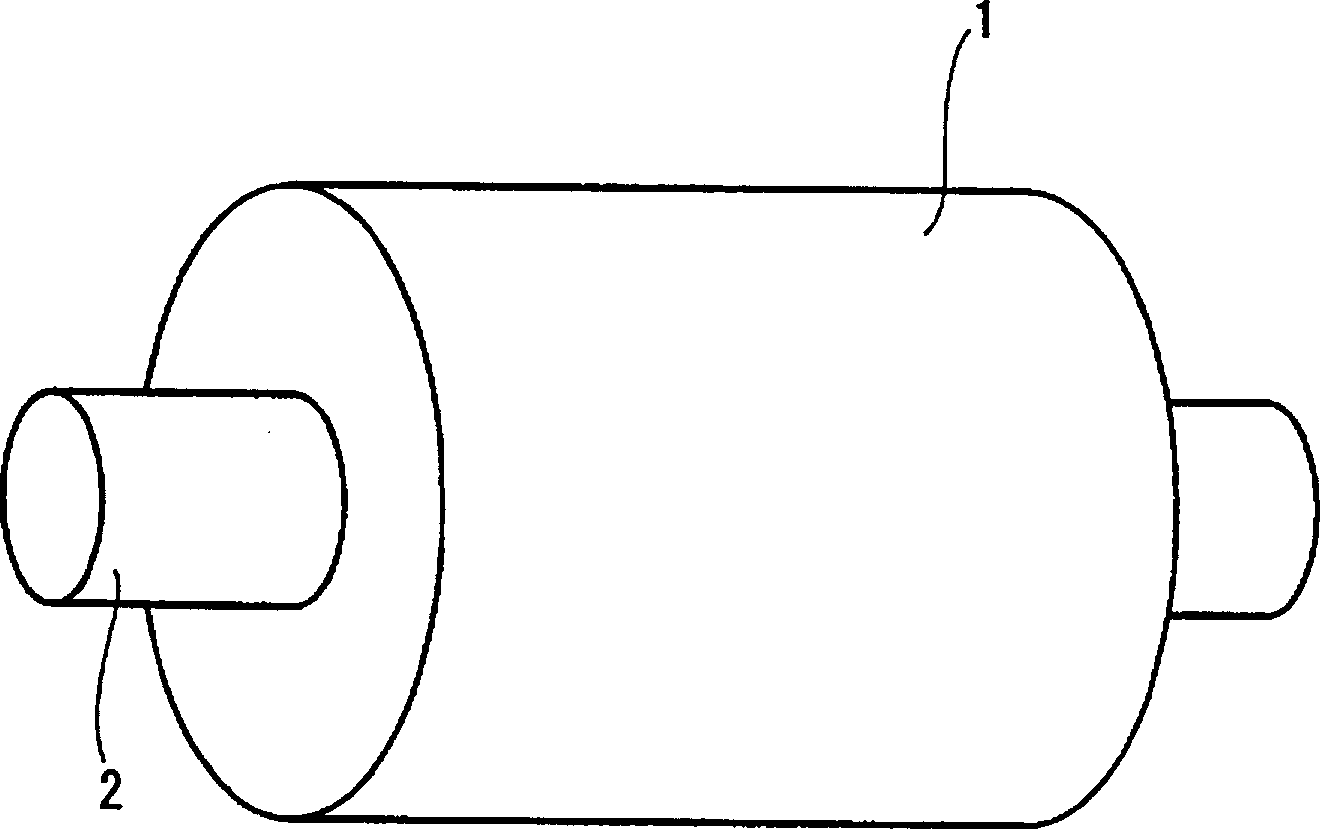

Paper feed roller and method for producing paper feed roller

InactiveCN1421369ADurableElasticOther chemical processesElectrographic process apparatusSurface layerThermoplastic elastomer

The invention provides a paper feed roller having durability, elasticity, and flexibility like rubber and also having moldability like resin, having a superior abrasion resistance, and having a sufficient carrying force relative to, especially, a silica sheet. This paper feed roller 1 is formed by molding thermoplastic elastomer composition, in which crosslinkable rubber or thermoplastic elastomer is dispersed by dynamic crosslinking, in thermoplastic resin or the thermoplastic elastomer into a roller state. At least, the surface layer of the roller includes titanium oxide at the ratio of not less than 1.5% but not more than 50% in a volume percentage.

Owner:SUMITOMO RUBBER IND LTD

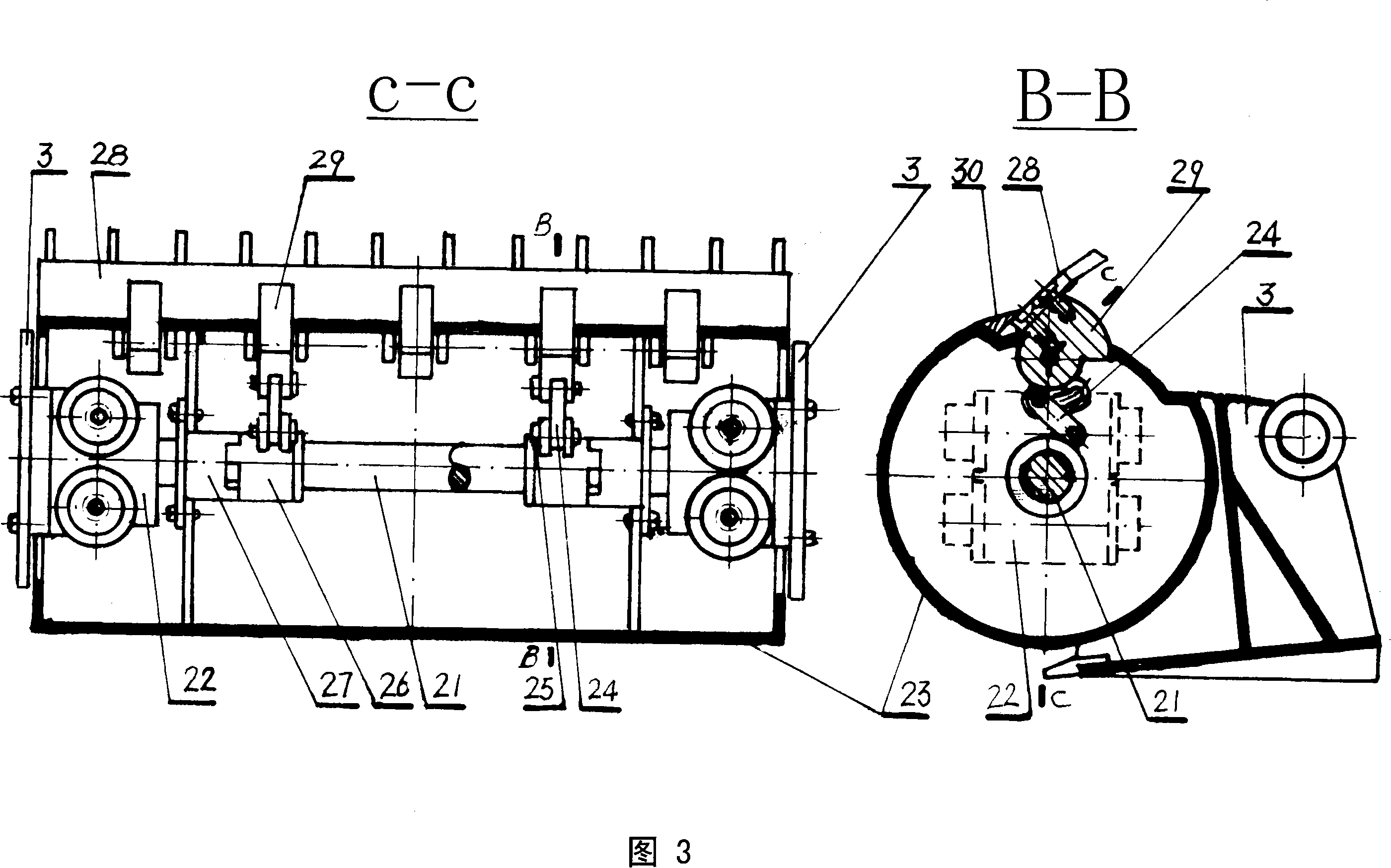

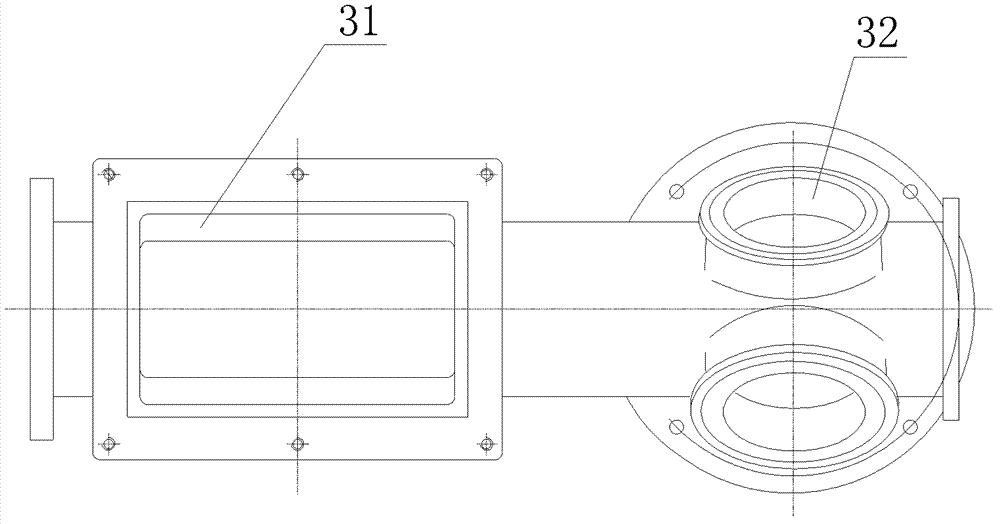

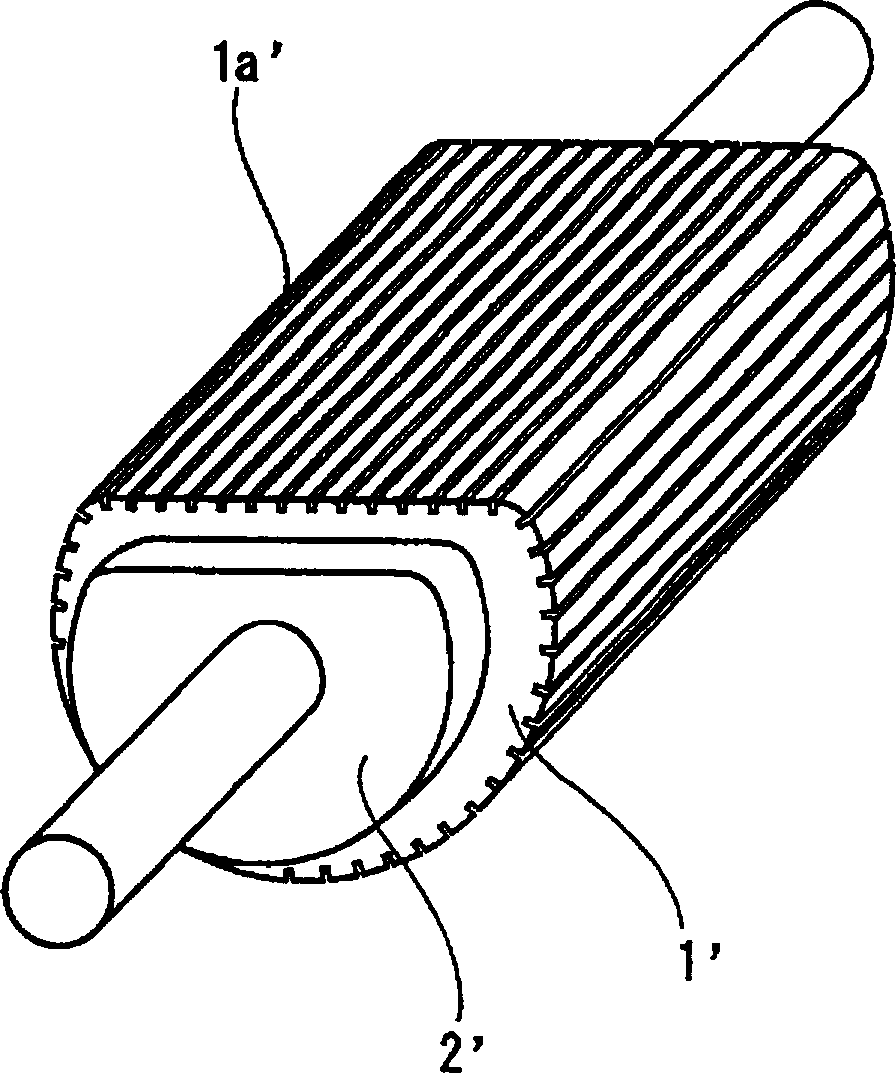

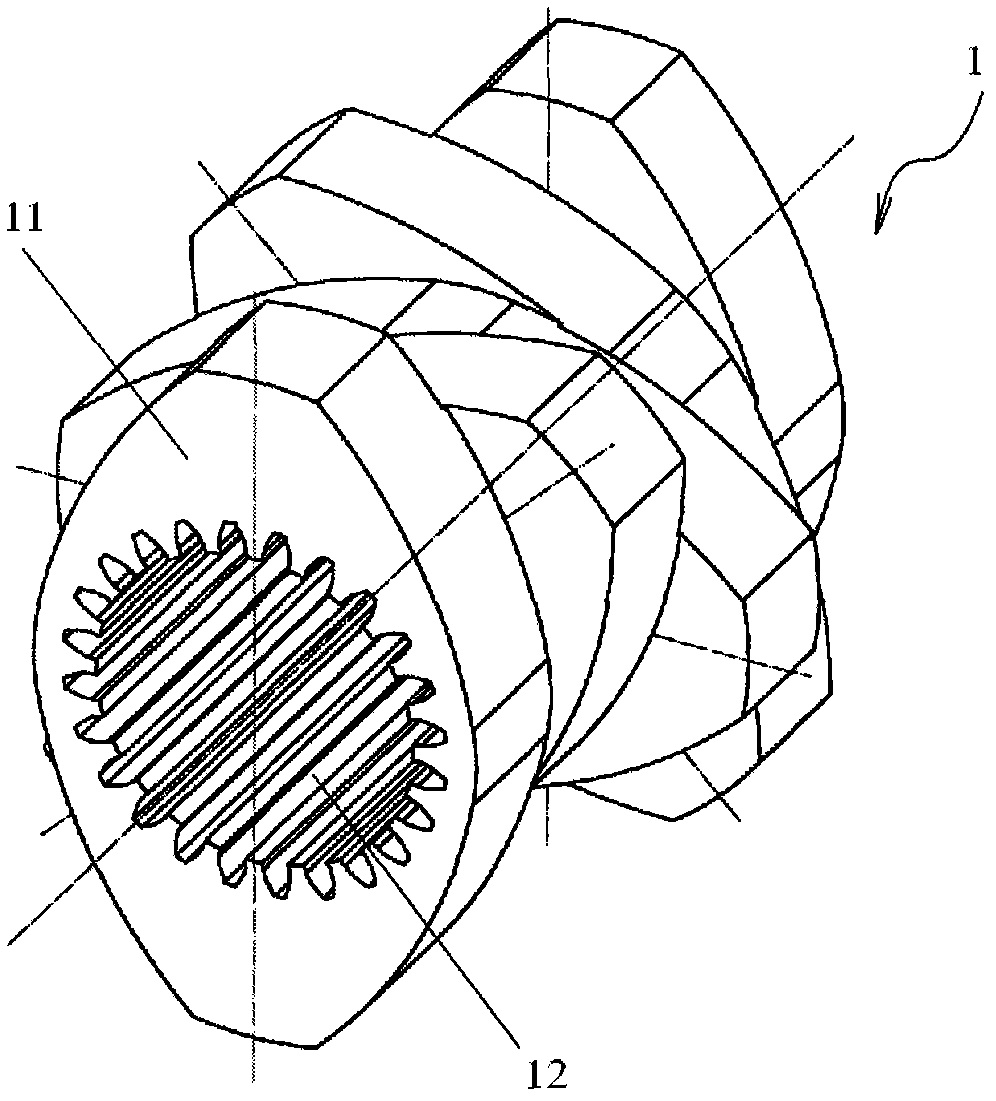

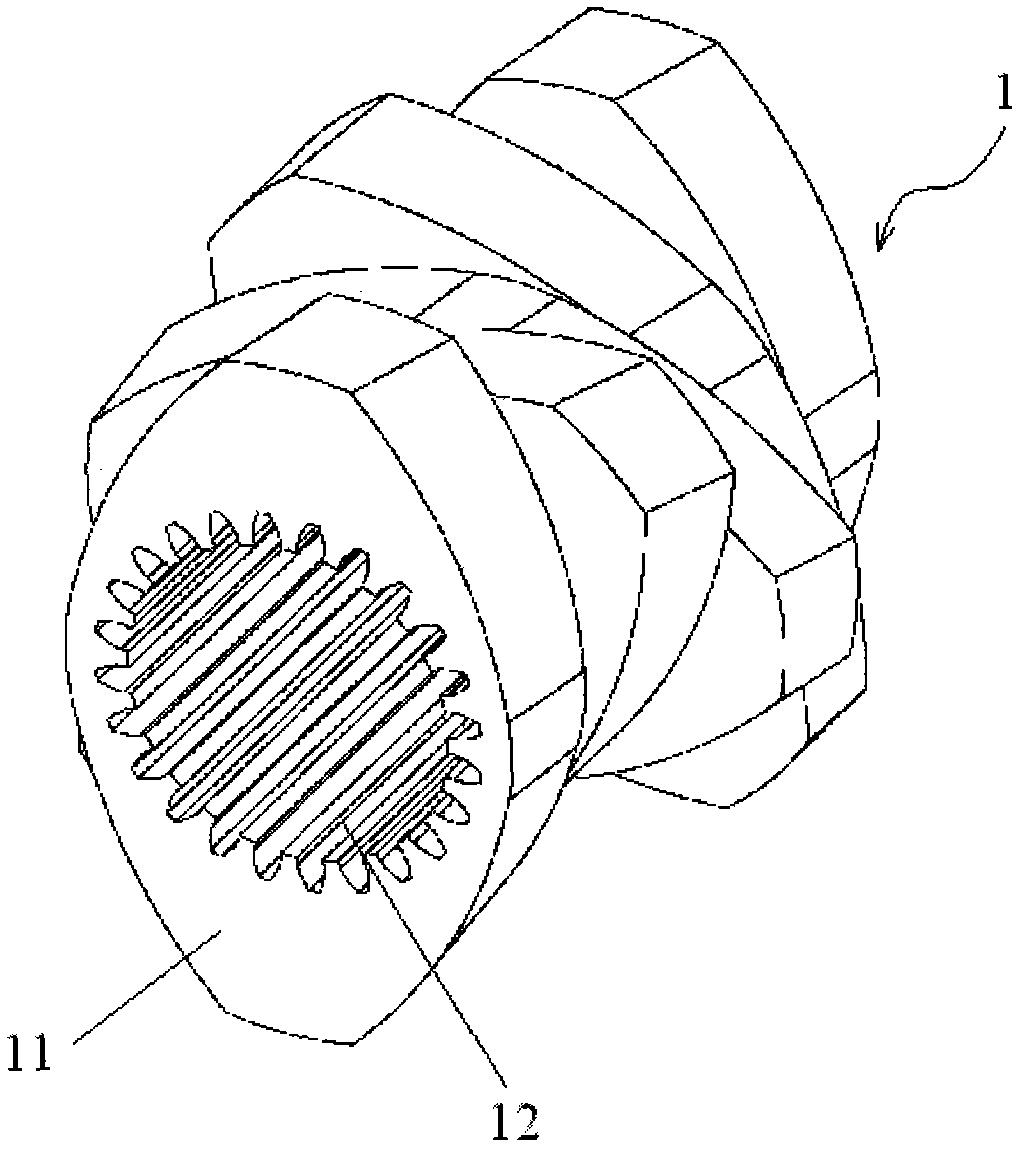

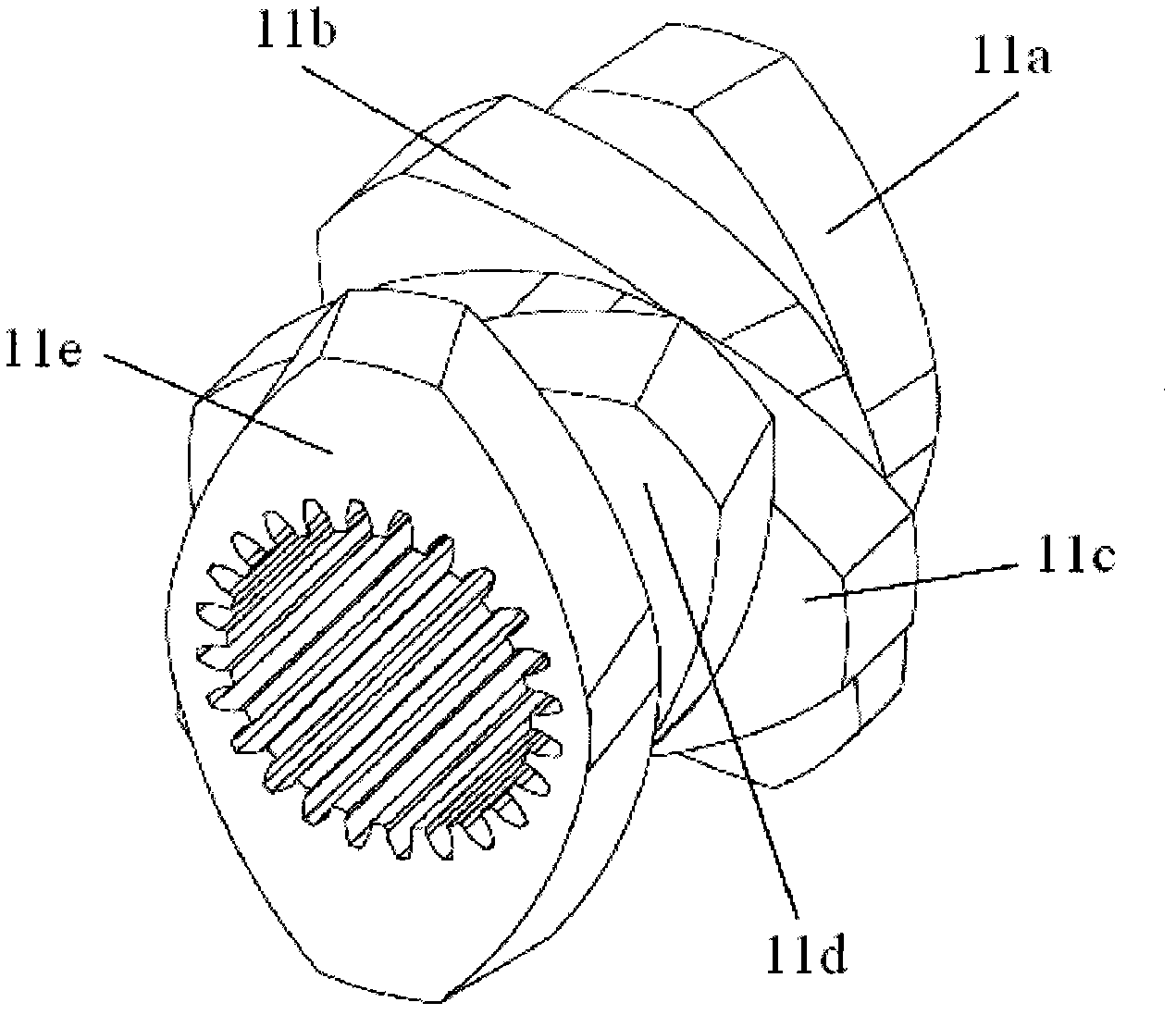

Twin-screw extruder and meshing disk element therefor

ActiveCN102463666AImprove delivery capacityImprove the ability to build pressureEngineeringMechanical engineering

Owner:BEIJING UNIV OF CHEM TECH

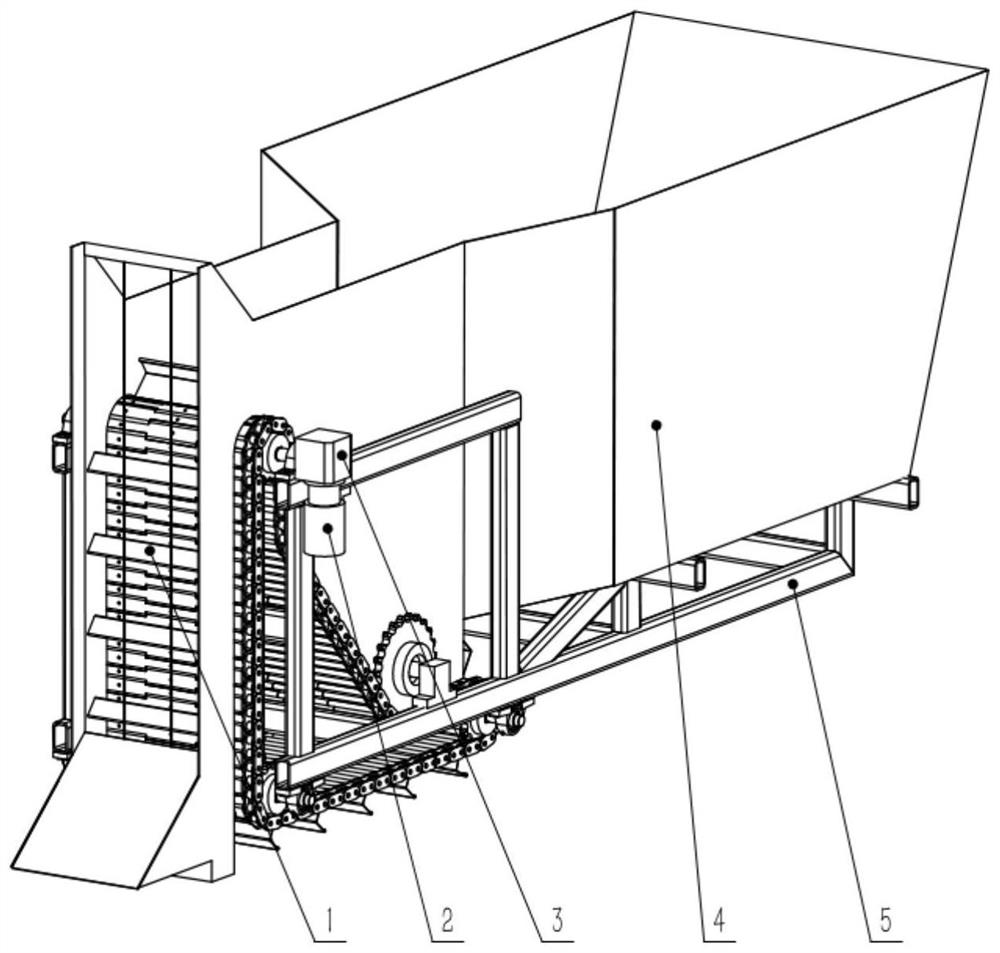

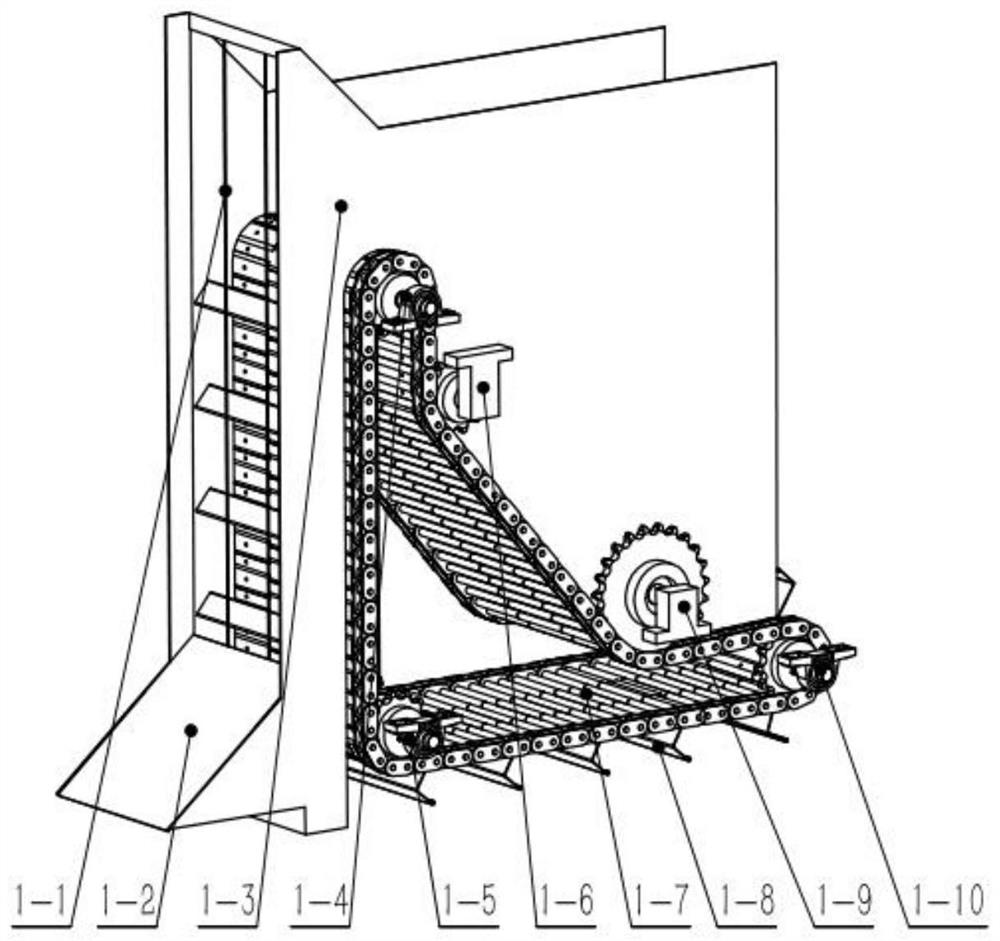

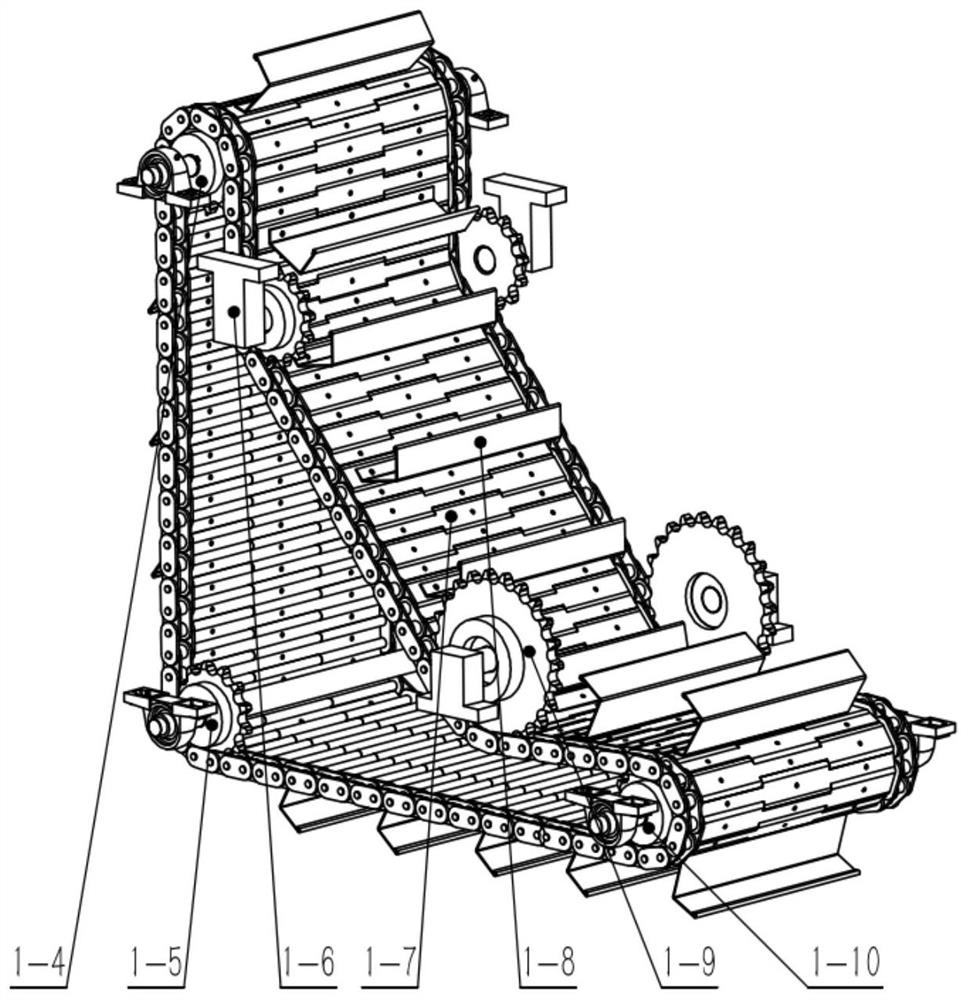

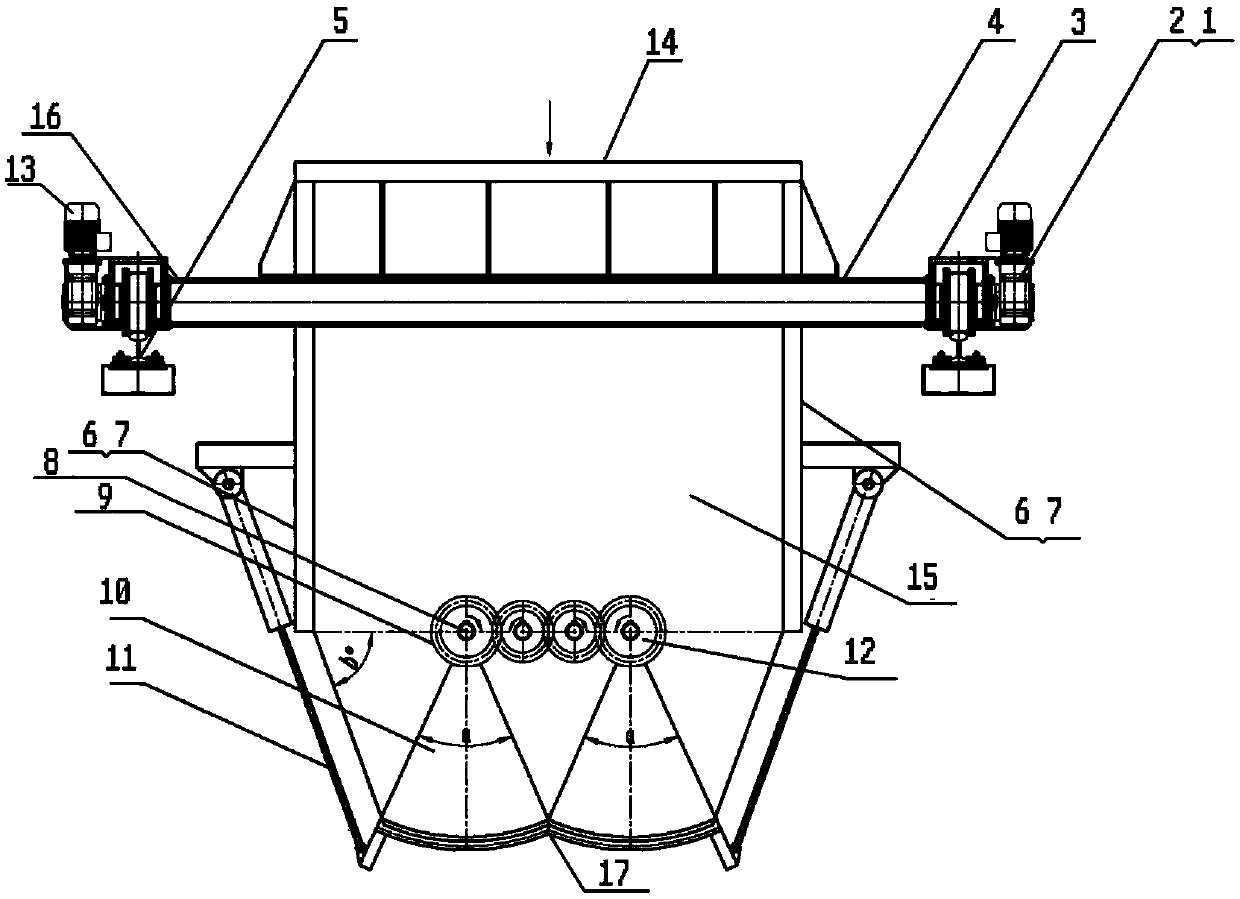

Double-bud section sugarcane seed continuous supply device

PendingCN112772073AEfficient deliveryAvoid overheadPlantingAgricultural scienceAgricultural engineering

The invention discloses a double-bud section sugarcane seed continuous supply device which comprises a rack, a sugarcane box and a conveying mechanism. The sugarcane box is installed on the rack and used for providing sugarcane seeds for the conveying mechanism, and the conveying mechanism is installed on the rack and located at the front side of the sugarcane box; the conveying mechanism comprises a conveying belt rotatably mounted on the rack and a plurality of sugarcane grooves; the conveying belt is triangular, the front side section of the conveying belt is a seed falling section, and the rear side section of the conveying belt is a seed arrangement section, wherein the seed arrangement section is divided into an inlet section, a lifting section and a redundancy discharging section in sequence from back to front, wherein the inlet section is horizontally arranged or inclines downwards from front to back; the lifting section inclines downwards from front to back, and the included angle between the lifting section and the horizontal plane is larger than that between the inlet section and the horizontal plane, and the redundancy discharging section is vertically arranged; and the sugarcane grooves are formed in the outer side face of the conveying belt at intervals. According to the double-bud section sugarcane seed continuous supply device, the seeds can be continuously, uniformly and orderly fed into a sugarcane collecting box of a seed-metering device, the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:GUANGXI UNIV FOR NATITIES +2

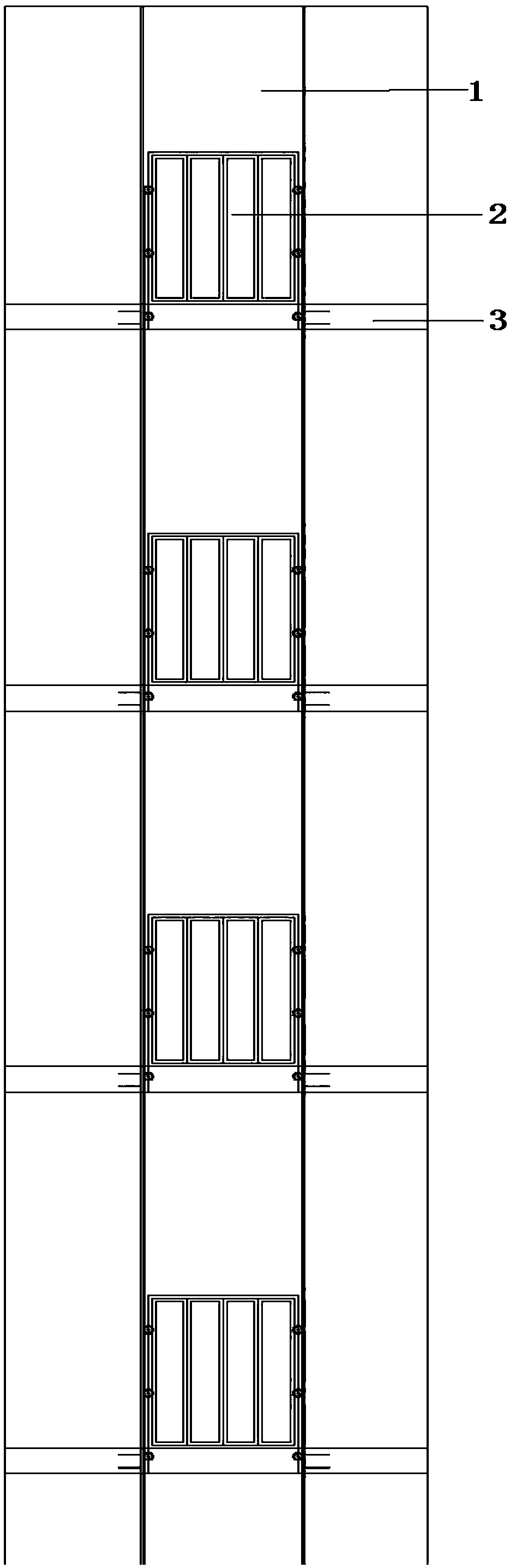

Multi-elevator-car vertical elevator

PendingCN109436993ASave effective spaceRealize deliveryElevatorsBuilding liftsFloor slabControl system

The invention relates to the technical field of elevators, in particular to a multi-elevator-car vertical elevator. The multi-elevator-car vertical elevator specifically comprises guide rails arrangedin a shaft and a plurality of elevator cars, wherein the number of the elevator cars is smaller than the number of floors of a building where the elevator is located by one. The elevator cars are arranged on various continuous floor slabs, and the elevator cars only run up and down on the guide rails corresponding to the floor height of single adjacent floors. The elevator is further provided with a control system for controlling the elevator cars to synchronously run and a drive device for driving the elevator cars to run up and down. According to the multi-elevator-car vertical elevator, the multiple elevator cars are arranged, are in linkage and synchronously run, the multi-elevator-car vertical elevator has the characteristics that the usage space is small, the transportation amount is large, and the waiting time is short, and good popularization prospects are achieved.

Owner:GUANGZHOU METRO DESIGN & RES INST

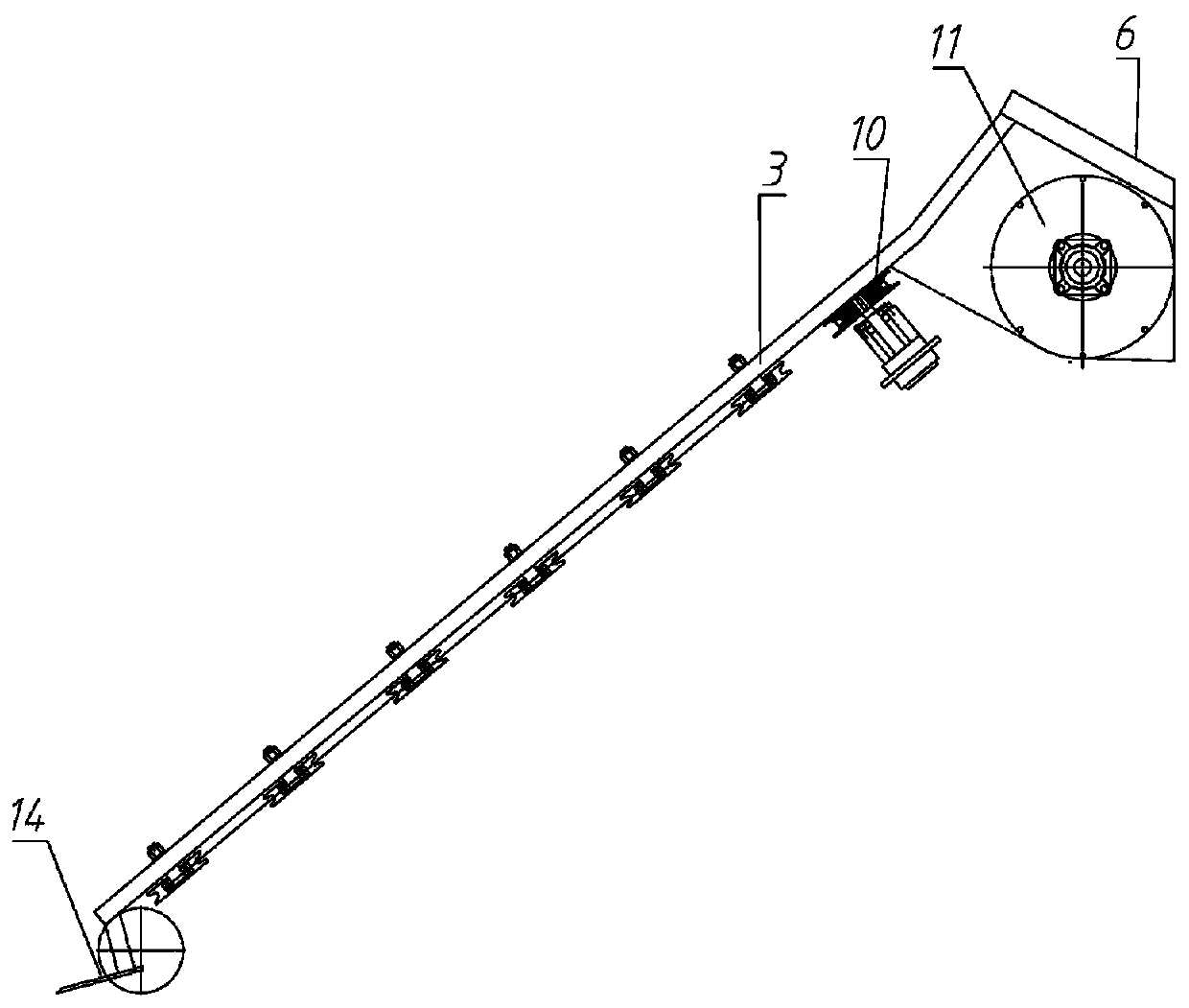

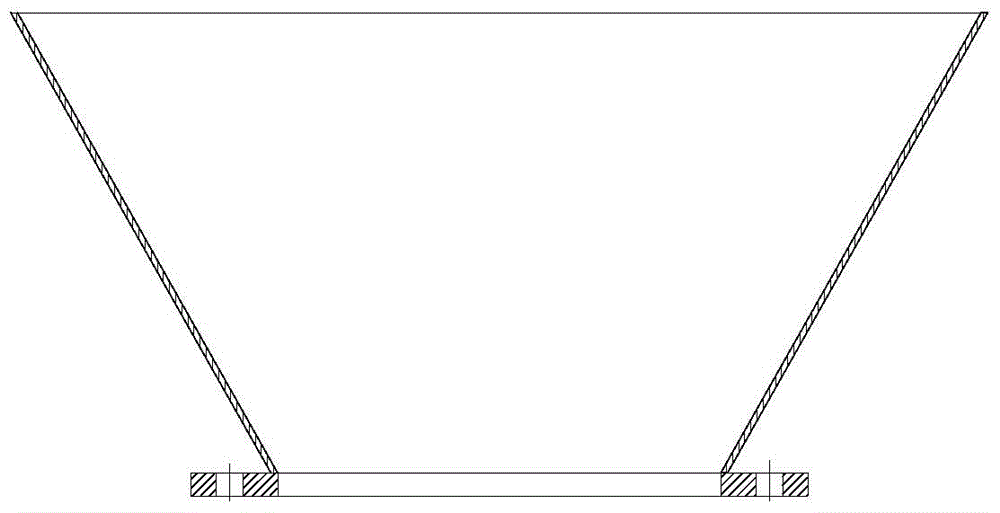

Rapeseed conveying equipment easy to observe

InactiveCN104386439ANo manual handling requiredLabor savingPackagingMechanical conveyorsRapeseedChain link

The invention discloses rapeseed conveying equipment easy to observe. The rapeseed conveying equipment easy to observe comprises a rapeseed lifting device and a rapeseed conveying device, wherein the rapeseed conveying device comprises a feeding trough, a cover plate arranged above the feeding trough and a conveying chain arranged in the feeding trough; a plurality of scraping plates are arranged on the two sides of the conveying chain; a conical hopper is arranged above the rapeseed inlet of the feeding trough; the inlet of the conical hopper directly faces the outlet of the rapeseed lifting device; the outlet of the conical hopper directly faces the rapeseed inlet; the rapeseed lifting device comprises a lifting trough, a packing auger arranged in the lifting trough, and a limiting mechanism for preventing the packing auger from up-warping; the packing auger consists of a hinge shaft, and a first blade and a second blade which wrap the hinge shaft spirally; the limiting mechanism is positioned between the first blade and the second blade. According to the rapeseed conveying equipment easy to observe, rapeseeds are not required to be transported manually during the overall rapeseed conveying process, so that labor is saved; the rapeseed lifting device is simple in structure and low in cost; moreover, the limiting mechanism which has a stabilizing effect is arranged in the lifting trough so as to limit the packing auger from up-warping or moving, and therefore, the stability is high.

Owner:SICHUAN DEYANG NIANFENG FOOD

Biological salt-decomposition bacterial manure and method for preparing same

ActiveCN101289338BStrong conveying capacityFormulation ScienceBio-organic fraction processingOrganic fertilisersBacillus megateriumDecomposition

Owner:莘县鑫海缘生物科技有限公司

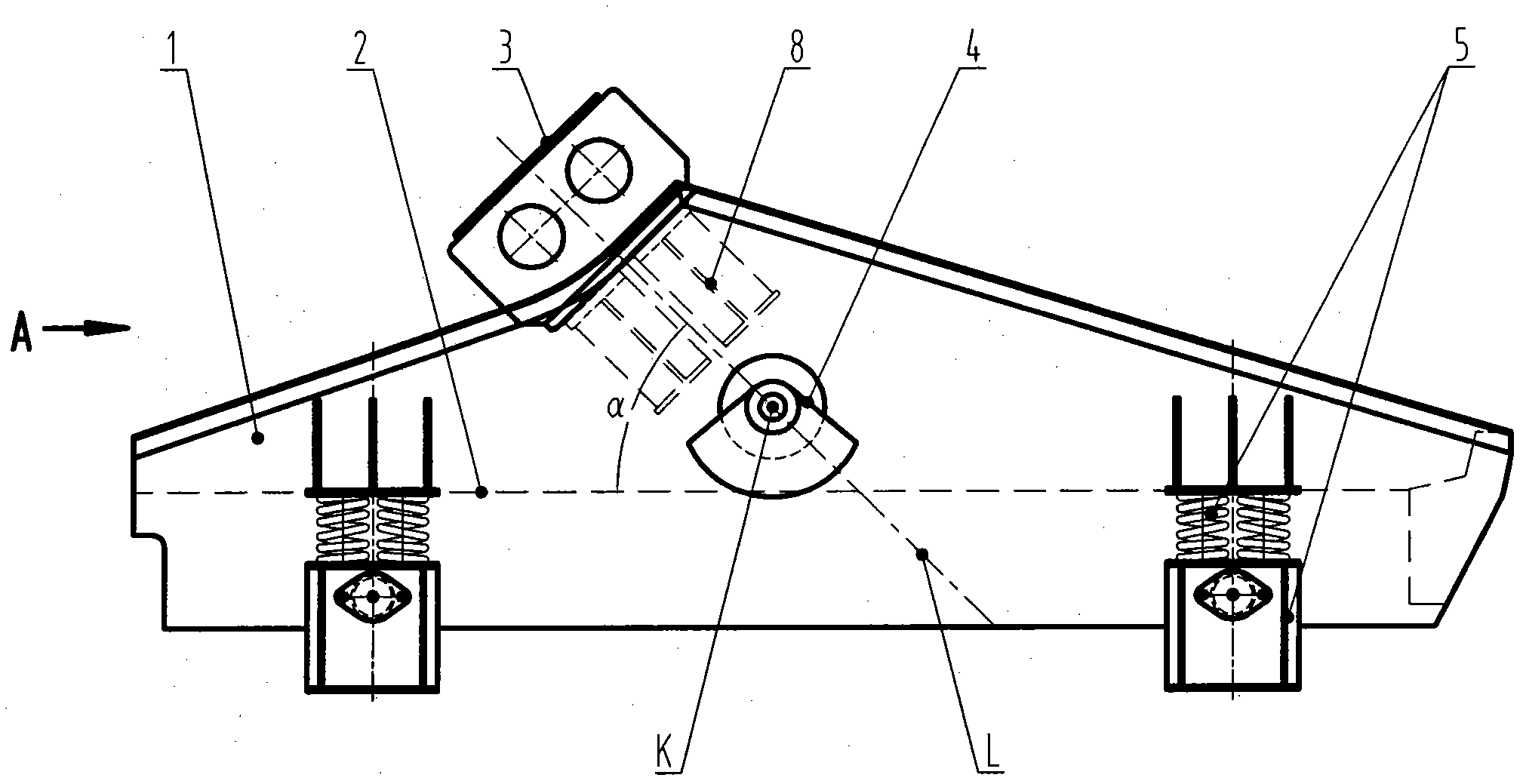

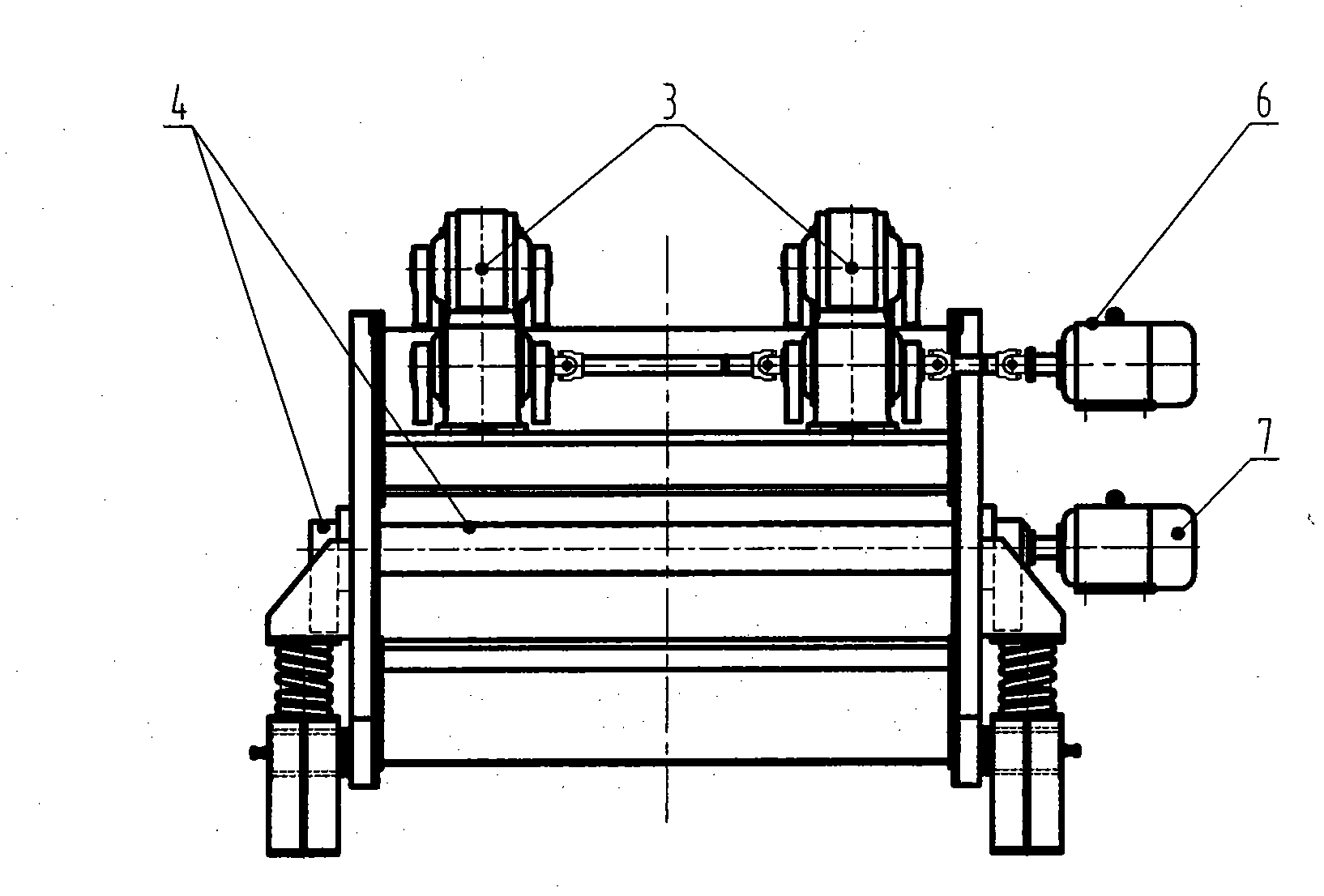

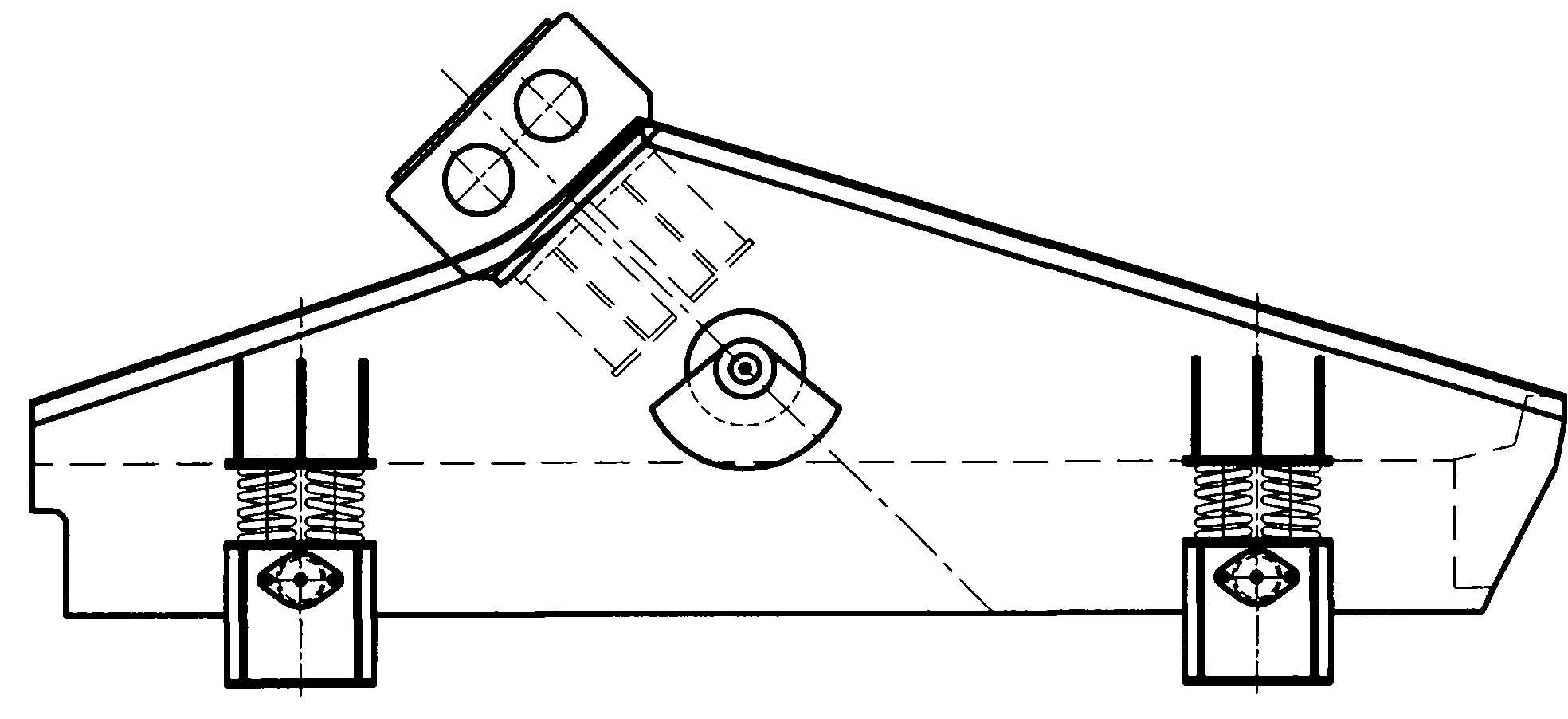

Elliptical track vibrating screen

InactiveCN101972742AStrong without blocking the sieve holeStrong conveying capacitySievingScreeningLongitudinal planeGear wheel

The invention relates to an elliptical track vibrating screen, which belongs to the field of vibratory screening machines, can ensure that material particles move in an elliptical track on a screen surface, solve the problem of mesh blockage caused by materials which are difficult to screen or critical particle materials, and improve the sieving rate of the vibrating screen. The vibrating screen mainly comprises a screen frame, the screen surface, a double-shaft gear forced-synchronization exciter, a single-shaft exciter, a vibration reduction support device and a motor transmission device, wherein the double-shaft gear forced-synchronization exciter is arranged on a driving girder of the screen frame to ensure that a screen box vibrates in a linear track according to a 30 to 60 DEG vibration direction angle; an axis of the single-shaft exciter traverses the screen frame and is arranged under two lateral plates of the screen frame or the driving girder to ensure that the screen box vibrates in a circular track; and combination of vibration of the double-shaft gear forced-synchronization exciter and the single-shaft exciter drives the screen box to vibrate in the elliptical track in a longitudinal plane. The elliptical track vibrating screen has the characteristics of compact structure, steady operation, high sieving efficiency and the like, is convenient to adjust, and is suitable for screening the materials which are difficult to screen in various industries.

Owner:威领新能源股份有限公司

Movable sludge material conveying box

PendingCN109516114AGuaranteed uptimeStrong conveying capacityLoading/unloadingMechanical conveyorsElectronic controllerDrive wheel

The invention provides a movable sludge material conveying box. The movable sludge material conveying box comprises rails, a material trolley, a sludge self-discharging material box and an electroniccontroller, wherein the rails are two parallel suspended steel rails; the material trolley comprises a driving device, a driven wheel set and a driving wheel set; the sludge self-discharging materialbox is fixed on the material trolley, an open feeding port is arranged at the top, discharging doors which are opened oppositely are arranged at the bottom, and a box body is symmetrically distributedwith respect to the rails on the two sides; a discharging door unit comprises a pair of the symmetrically distributed discharging doors and a reciprocating mechanism connected with the discharging doors, and the discharging doors synchronously move to two sides to be opened or synchronously move oppositely to be closed; and the electronic controller is connected with the driving device and the reciprocating mechanism, controls the material trolley to walk or stand still on the rails and controls opening and closing of the discharging doors. The movable sludge material conveying box has a large-volume conveying function, achieves material reciprocating conveying according to the line distance between the conveying starting point and the final point and achieves automatic running and operation. The discharging doors are closed and opened automatically, and discharging is thorough.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

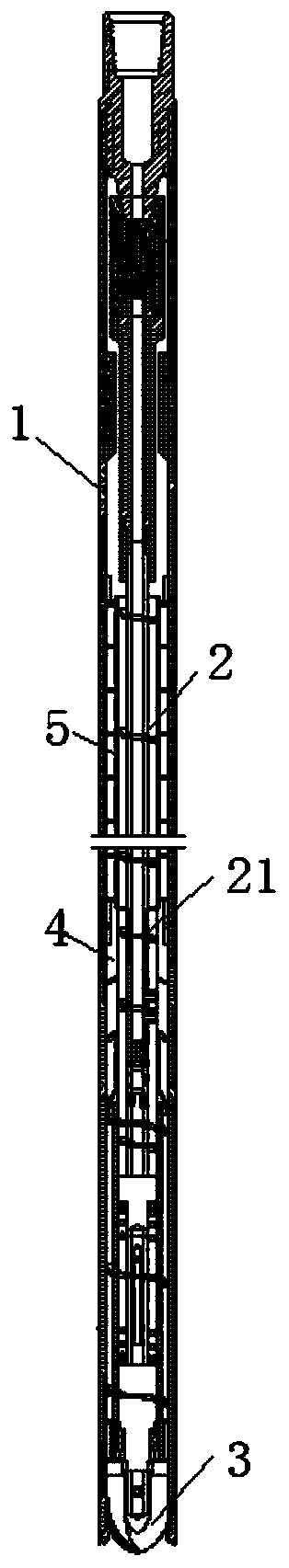

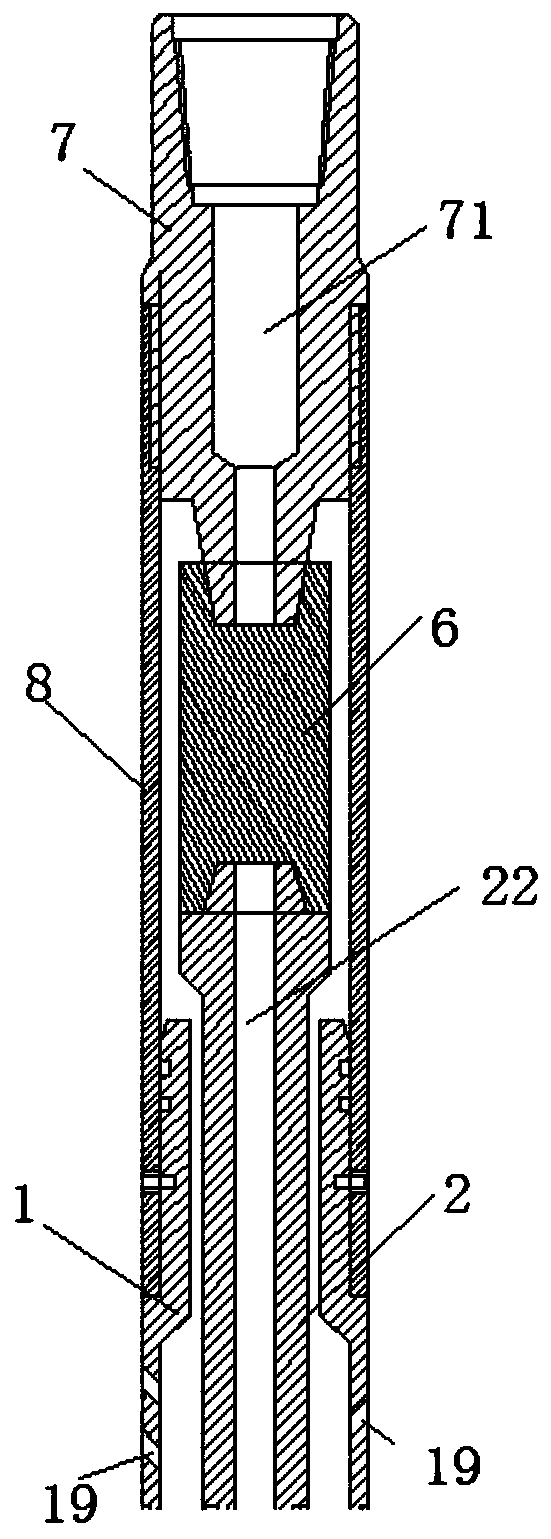

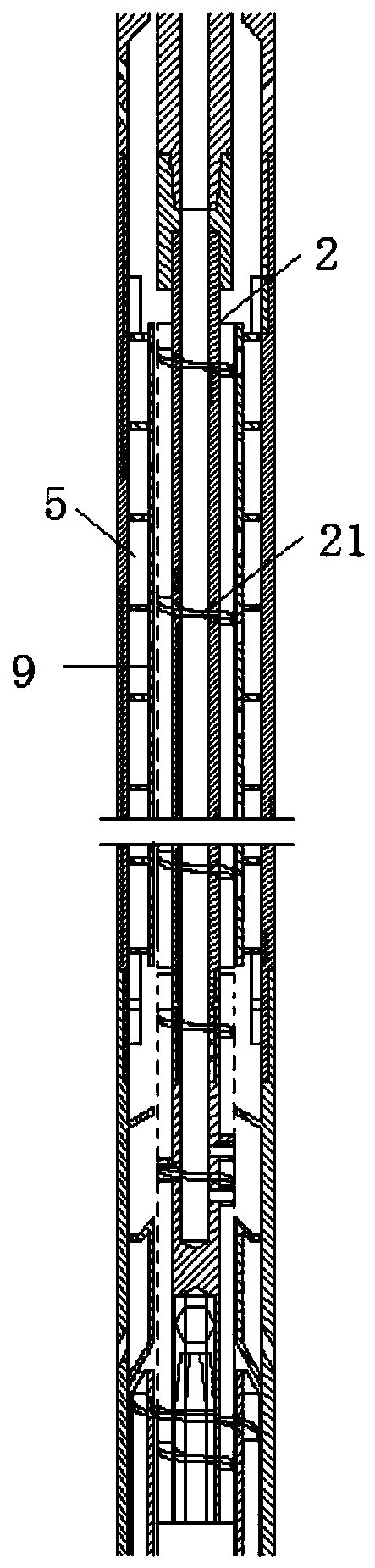

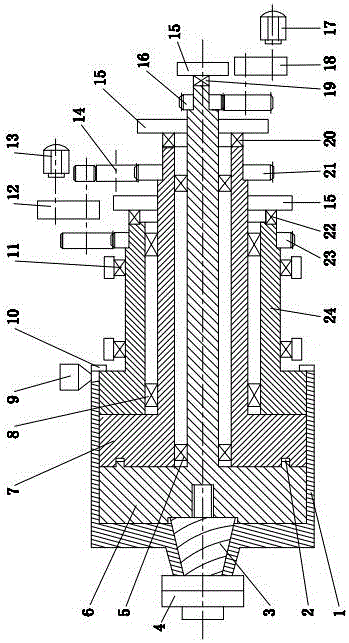

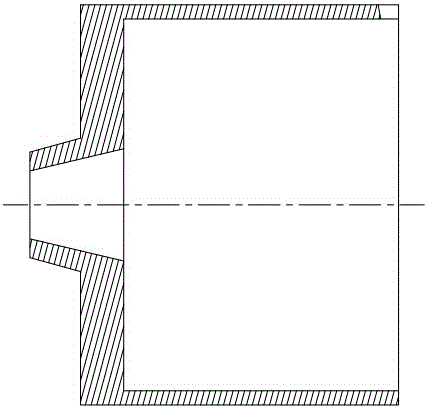

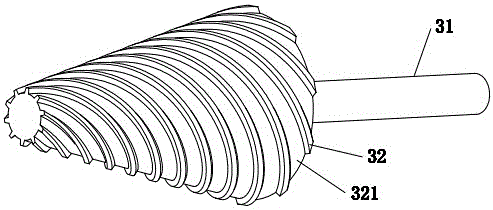

Set milling integrated sand bailing device and application method thereof

The invention discloses a set milling integrated sand bailing device and an application method thereof. The set milling integrated sand bailing device comprises an outer sleeve and a central rotatingshaft, the central rotating shaft is sleeved in the outer sleeve, a rock debris lifting channel is formed between the inner wall of the outer sleeve and the central rotating shaft, and spiral blades are arranged on the outer surface of the central rotating shaft; and the inner side of the outer sleeve is provided with a debris storage cavity. According to the set milling integrated sand bailing device, the bottom rock debris is transported into the debris storage cavity through the rock debris lifting channel through the spiral blades; and compared with other conveying modes, the mode that thespiral blades 21 are used to convey the rock debris is strong in rock debris carrying capacity, and the carried rock debris is more, so that the sand bailing efficiency of the device is improved, andthe rock debris at the bottom inside an oil well can be cleaned in time.

Owner:北京三叶西蒙科技有限公司

Multi-stage series coaxial wheel type mixing and extrusion device

The invention relates to a multi-segment series connection coaxial wheel type mixing extrusion device. The multi-segment series connection coaxial wheel type mixing extrusion device comprises a special-shaped machine barrel, a heat-resisting sealing ring, a conical threaded rod, an extrusion machine head, a first radial bearing set, a second radial bearing set, a third radial bearing set, a hopper, a baffle, a first transmission mechanism, a second transmission mechanism, a first motor, a second motor, a transition gear, a base, a first gear, a second gear, a third gear, a first thrust bearing, a second thrust bearing and a third thrust bearing. The mixing extrusion device is characterized by further comprising a first rotary wheel, a second rotary wheel and a third rotary wheel; a center screw channel set is arranged on a conical wheel of the conical threaded rod, an end face screw channel set is arranged on the left end face of the first rotary wheel, and a first outer circumference screw channel set, a second outer circumference screw channel set and a third outer circumference screw channel set are arranged on screw wheels of the first rotary wheel, the second rotary wheel and the third rotary wheel respectively; the first outer circumference screw channel set, the second outer circumference screw channel set and the third outer circumference screw channel set are sequentially in series connection; the right end of the third outer circumference screw channel set is communicated with the hopper, and the left end of the first outer circumference screw channel set is communicated with the end face screw groove set; the end face screw groove set is communicated with the center screw groove set, and the left end of the center screw groove set is communicated with a through hole of the extrusion machine head; and thus, smashing, grinding, extruding, mixing and conveying passageways for materials are formed. The plastifying performance, the mixing capacity and the grinding and pressing capacity of the device are high, and the plastifying and mixing quality and the yield of the materials are improved.

Owner:安徽原上草节能环保科技有限公司

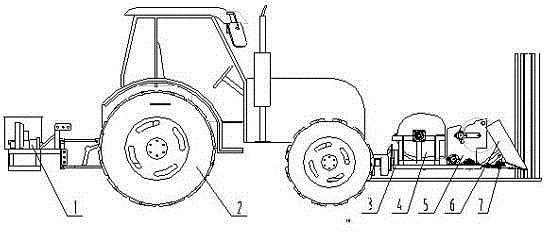

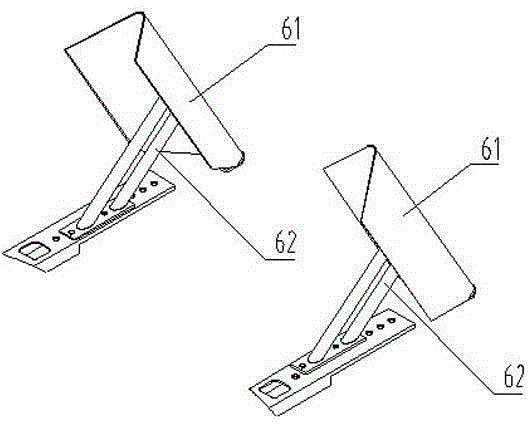

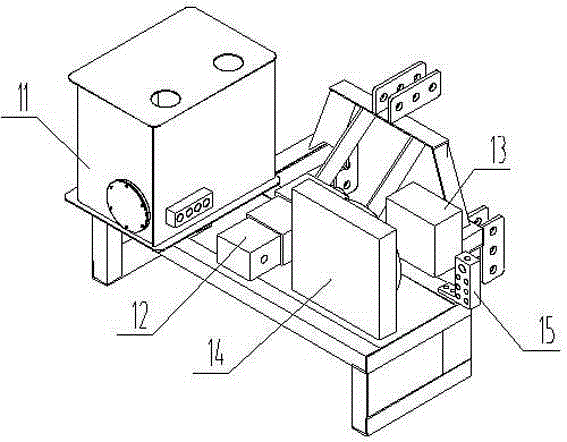

Cassava straw smashing and returning machine

ActiveCN104012250ACapable of cuttingStrong conveying capacityCrop conditionersMowersCassava (food)Tractor

The invention provides a cassava straw smashing and returning machine. The cassava straw smashing and returning machine comprises a tractor, a hydraulic system, a machine frame, a cutting system, a conveying system, a smashing system and straightening systems. The machine frame is installed at the front end of the tractor. The straightening systems, the cutting system, the conveying system and the smashing system are sequentially arranged on the machine frame from front to back. The hydraulic system is arranged at the rear end of the tractor and connected with a power output shaft on the tractor and provides hydraulic power for the smashing system, the conveying system and the cutting system. The straightening systems are symmetrically arranged on the two sides of the front end of the machine frame. Each straightening system comprises a straightening separation board inclining to the upper rear portion and the upper end of each straightening separation board corresponds to an inlet of the conveying system. The cassava straw smashing and returning machine has the advantages of having the cutting capacity and the conveying capacity, being high in smashing capacity, stable in operation and high in operation efficiency and the like.

Owner:GUANGXI INST OF HYDRAULIC MACHINERY

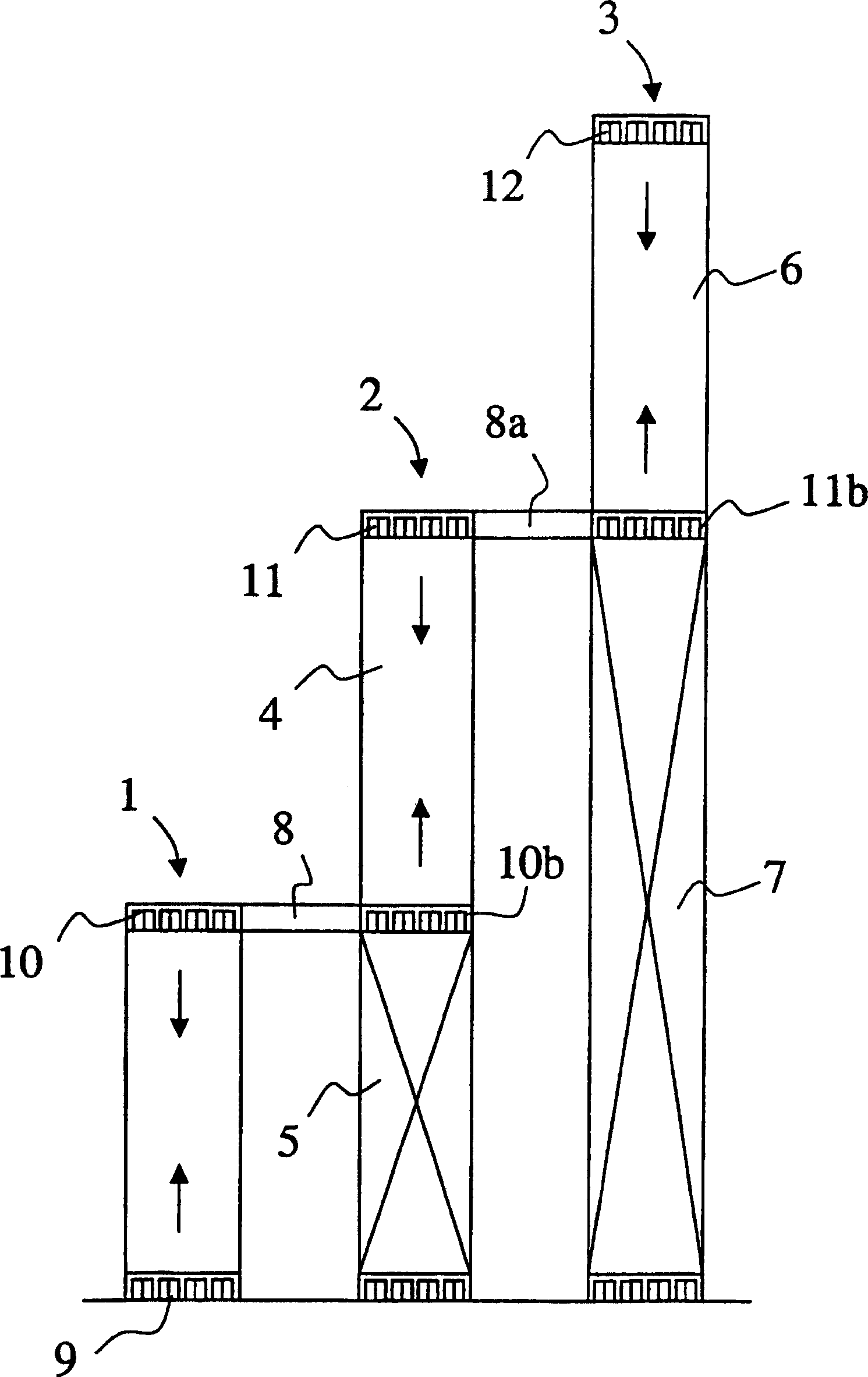

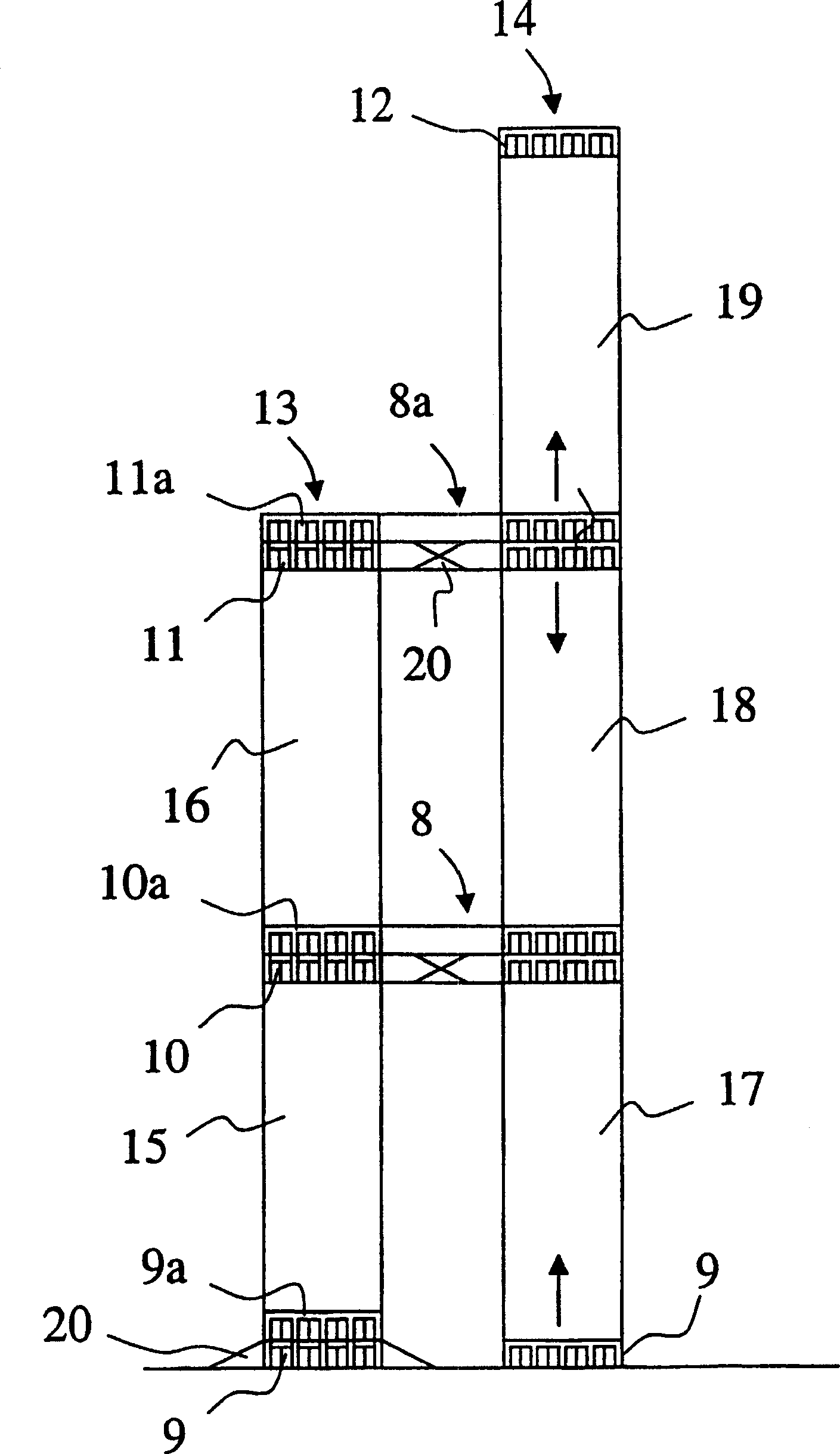

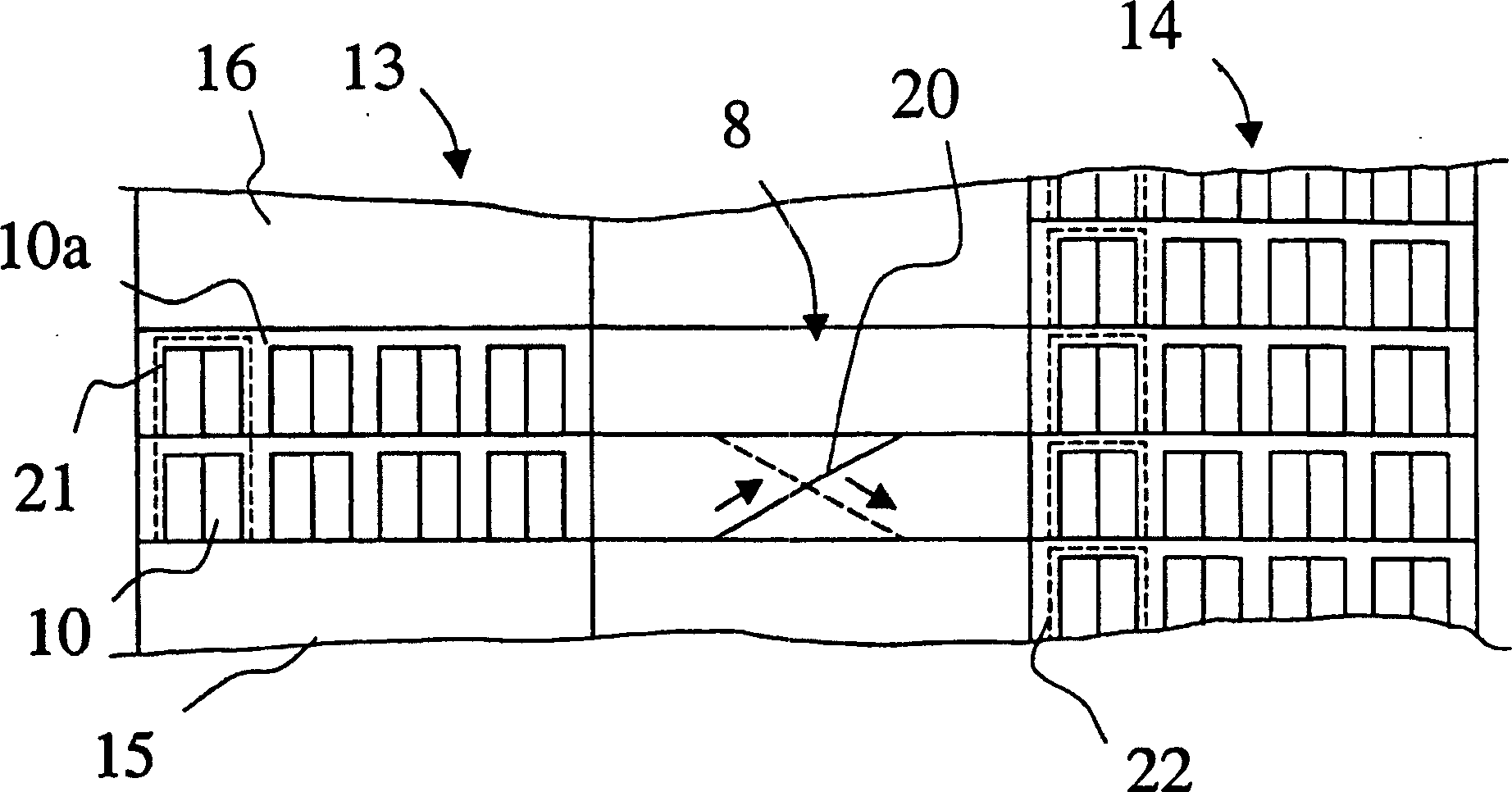

Elevator system

The invention relates to an elevator system in tall buildings, said system comprising at least one first elevator shaft (13), which houses an elevator arranged to stop at floors called transfer levels (8, 8a), and at least one second elevator shaft (14), which houses elevators whose elevator cars (22) are disposed one above the other in the elevator shaft, which elevator cars are designed to stop during their travel at any floor to which or from which a call has been issued. The second elevator shaft (14) is divided vertically into local shafts (17, 18, 19) situated one above the other, the number of which is at least one for each zone between transfer levels (8, 8a).

Owner:KONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com