High heat conduction epoxy resin composition applicable to fully wrapped devices and preparation method

A technology of epoxy resin and composition, which is applied in the preparation of epoxy resin composition and the field of high thermal conductivity epoxy resin composition, which can solve the problems of poor mixing effect and more insoluble matter, and achieve strong conveying force and less pores , Wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

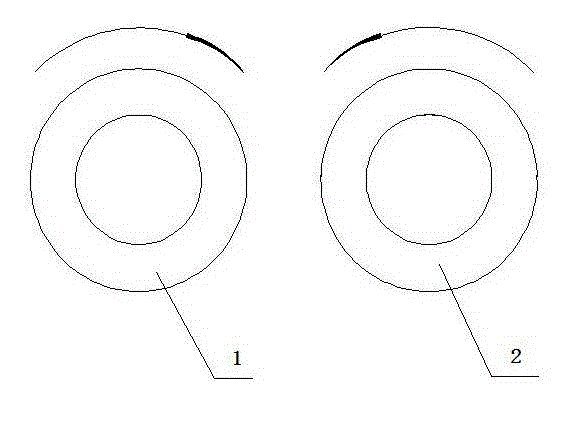

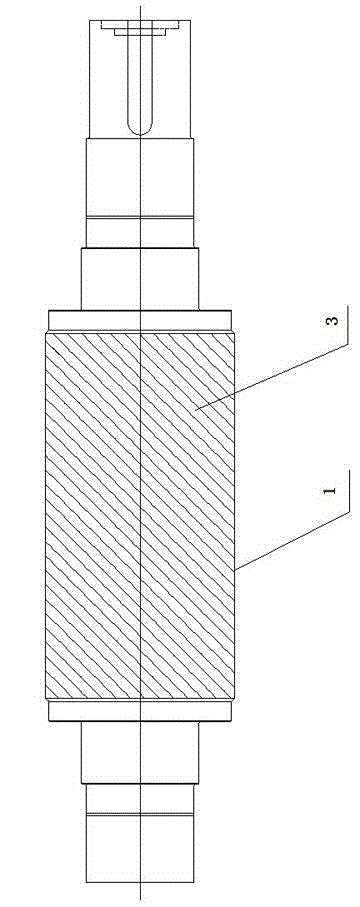

[0038] Embodiment 1, an epoxy resin composition suitable for fully encapsulating devices, the composition is composed of epoxy resin, phenolic resin, inorganic filler, thermally conductive filler and additive;

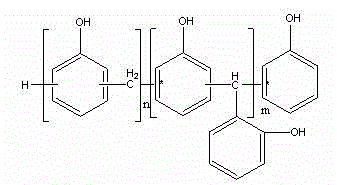

[0039] The epoxy resin is the epoxy resin shown in the general formula [1] and the general formula [2]; the ratio of the two is not less than 30% of the epoxy resin amount, and the content of the epoxy resin accounts for the total amount of the composition. 4% for quality;

[0040] The phenolic resin is the phenolic resin shown in the general formula [3] and the general formula [4], the ratio of the two is not less than 10% of the amount of the phenolic resin, and the content of the phenolic resin accounts for 4% of the total mass of the composition ;

[0041] In various formulas: n=0-5; m=1-5;

[0042] The thermally conductive filler is one or more of crystalline silica powder, alumina powder or silicon nitride powder; the content of the thermally conductive filler ...

Embodiment 2

[0045] Embodiment 2, an epoxy resin composition suitable for fully encapsulating devices, the composition is composed of epoxy resin, phenolic resin, inorganic filler, thermally conductive filler and additive;

[0046] The epoxy resin is the epoxy resin shown in the general formula [1] or the general formula [2]; the content of the epoxy resin accounts for 3% of the total mass of the composition;

[0047] The phenolic resin is the phenolic resin represented by the general formula [3] or the general formula [4], and the content of the phenolic resin accounts for 2% of the total mass of the composition;

[0048] In various formulas: n=0-5; m=1-5;

[0049] The thermally conductive filler is one or more of crystalline silica powder, alumina powder or silicon nitride powder; the content of the thermally conductive filler is 20% of the total mass of the composition;

[0050] The content of described inorganic filler is 70% of total composition quality;

[0051] The additives are c...

Embodiment 3

[0052] Embodiment 3, an epoxy resin composition suitable for fully encapsulating devices, the composition is composed of epoxy resin, phenolic resin, inorganic filler, thermally conductive filler and additive;

[0053] The epoxy resin is the epoxy resin shown in the general formula [1] and the general formula [2]; the ratio of the two is not less than 10% of the epoxy resin amount, and the content of the epoxy resin accounts for the total amount of the composition. 7% for quality;

[0054] The phenolic resin is the phenolic resin shown in the general formula [3] and the general formula [4], the ratio of the two is not less than 30% of the amount of the phenolic resin, and the content of the phenolic resin accounts for 6% of the total mass of the composition ;

[0055] In various formulas: n=0-5; m=1-5;

[0056] The thermally conductive filler is one or more of crystalline silica powder, alumina powder or silicon nitride powder; the content of the thermally conductive filler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com