Patents

Literature

1595 results about "Epoxy resin composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy is a thermosetting matrix resin and among the most commonly used resin systems in the composites industry. It's frequently used with continuous carbon fiber in aerospace, race car, marine and other high-performance applications.

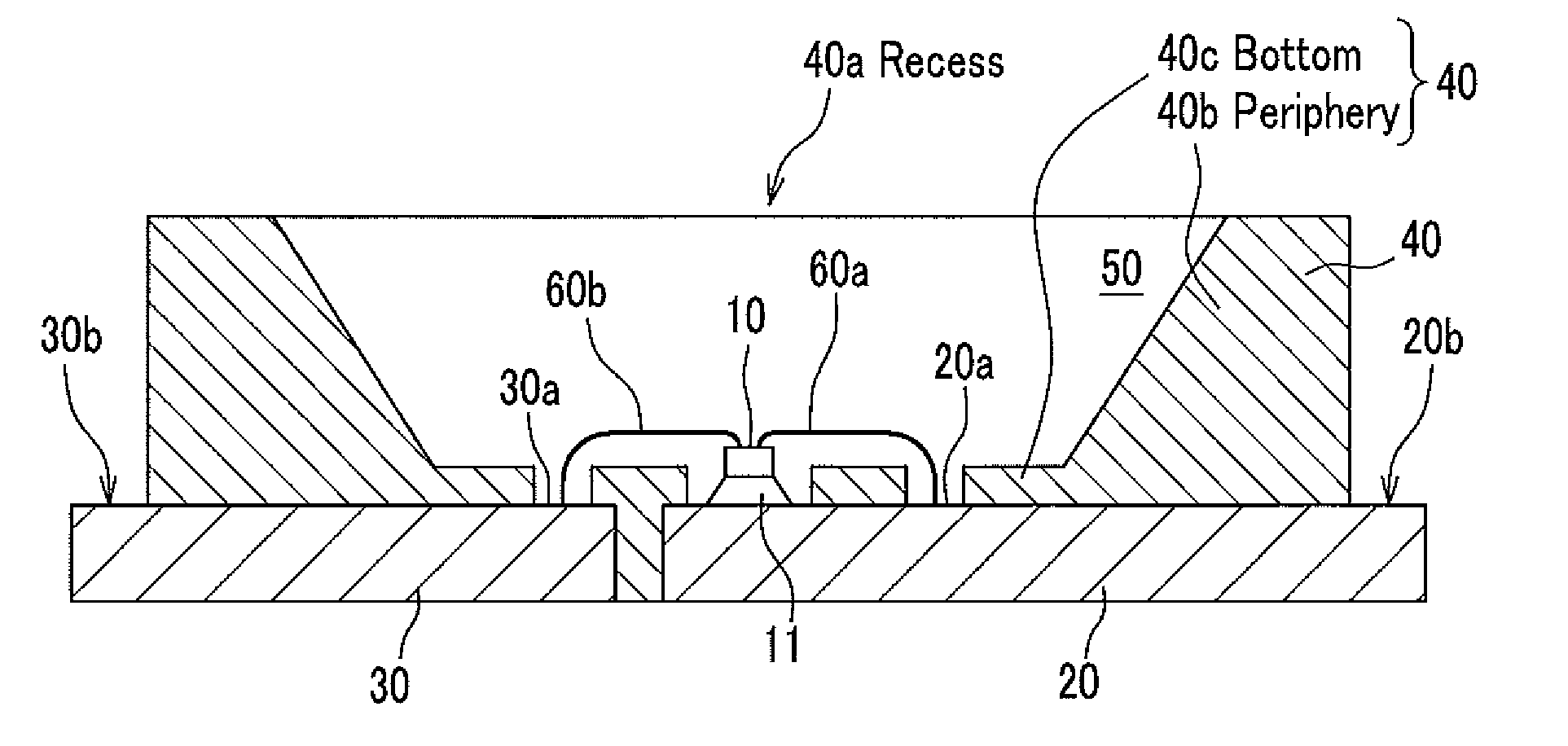

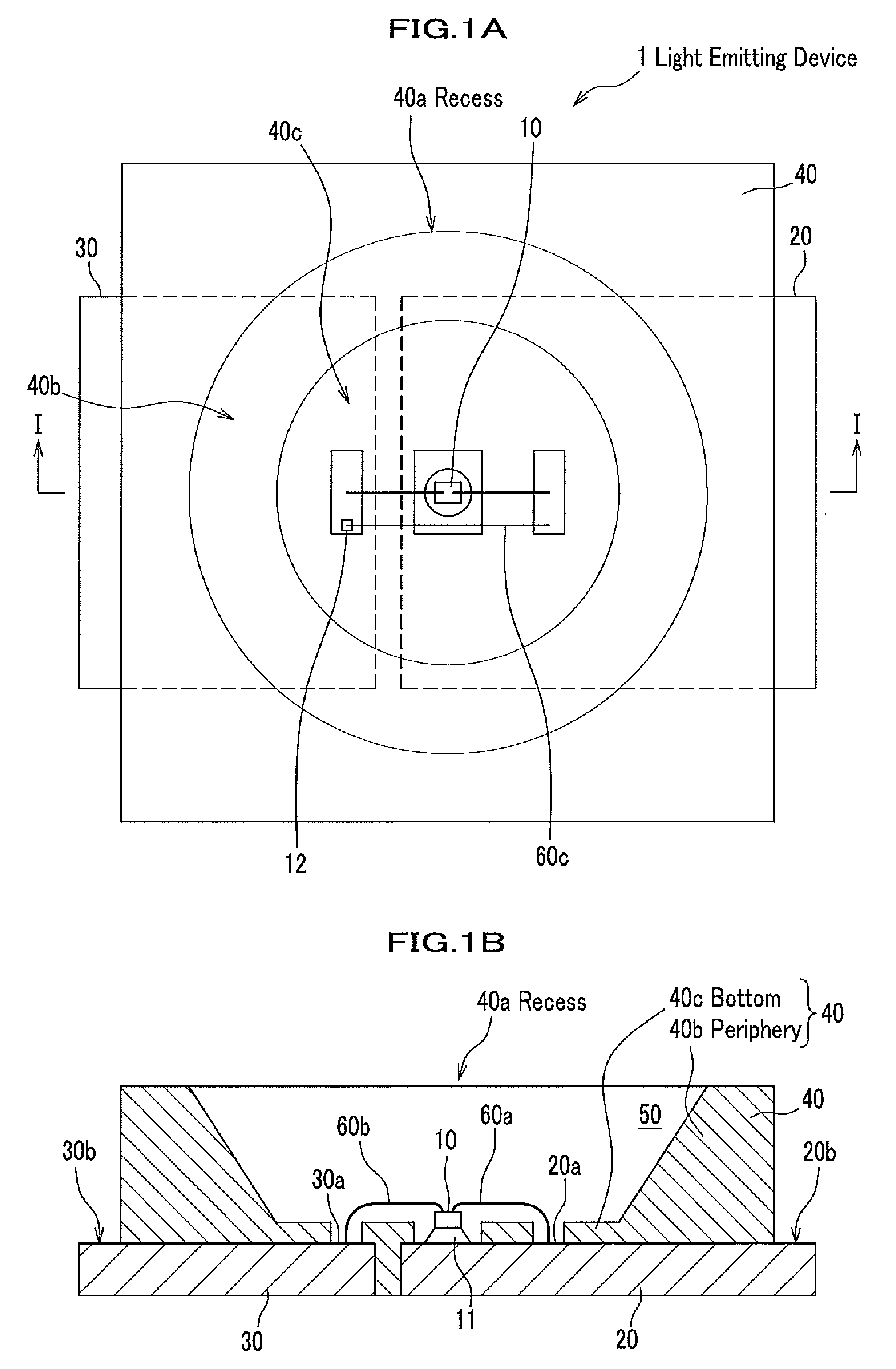

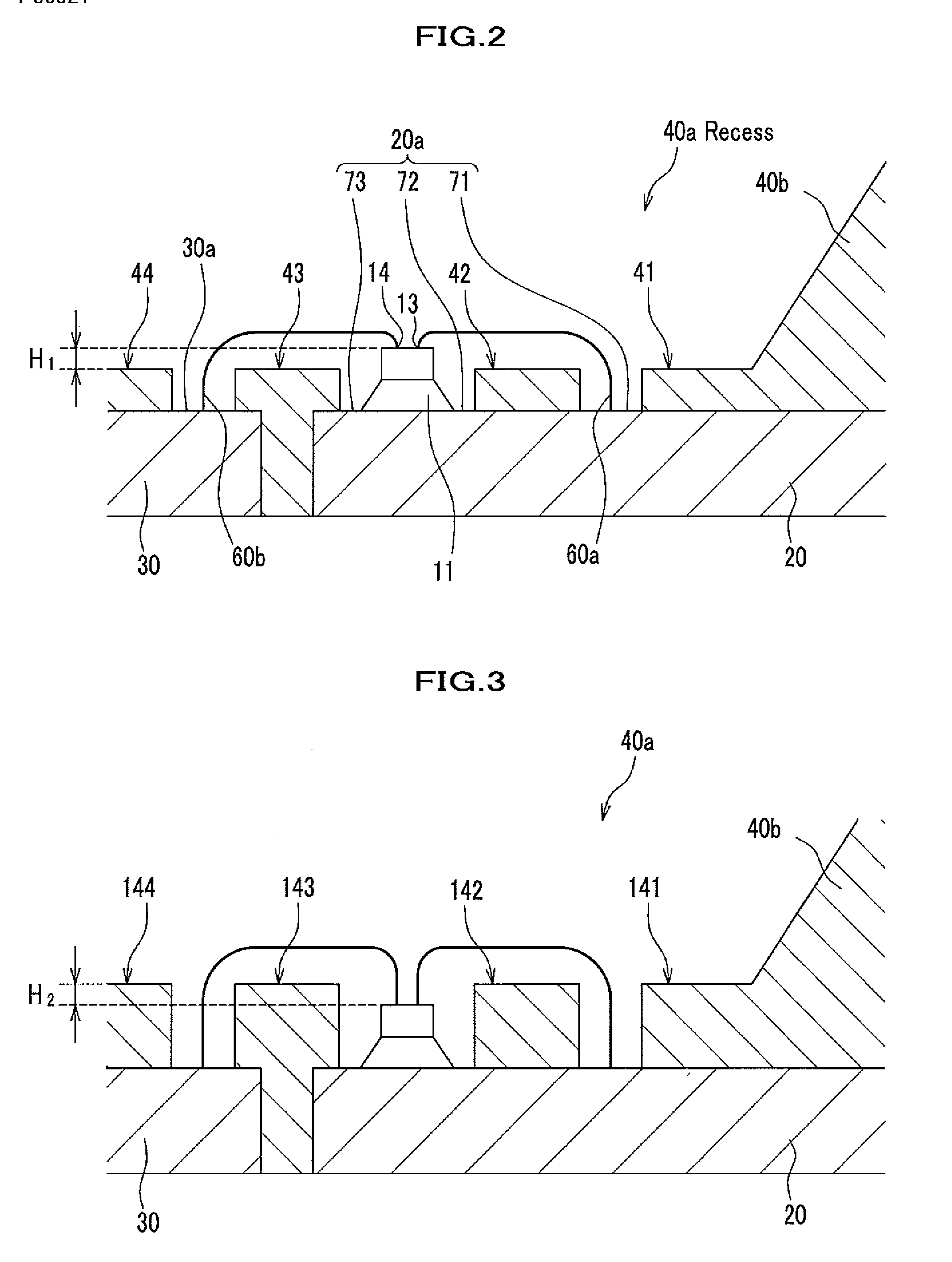

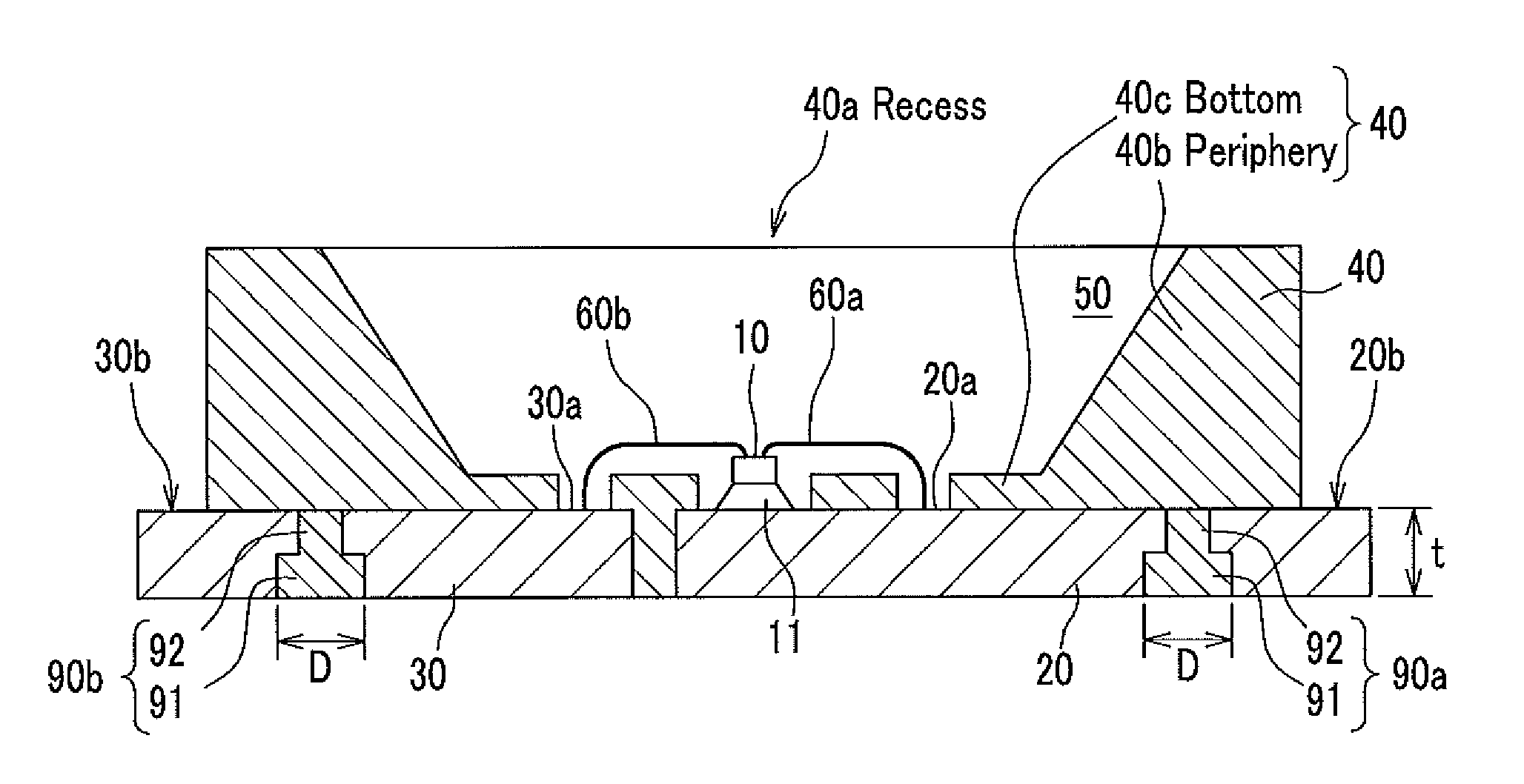

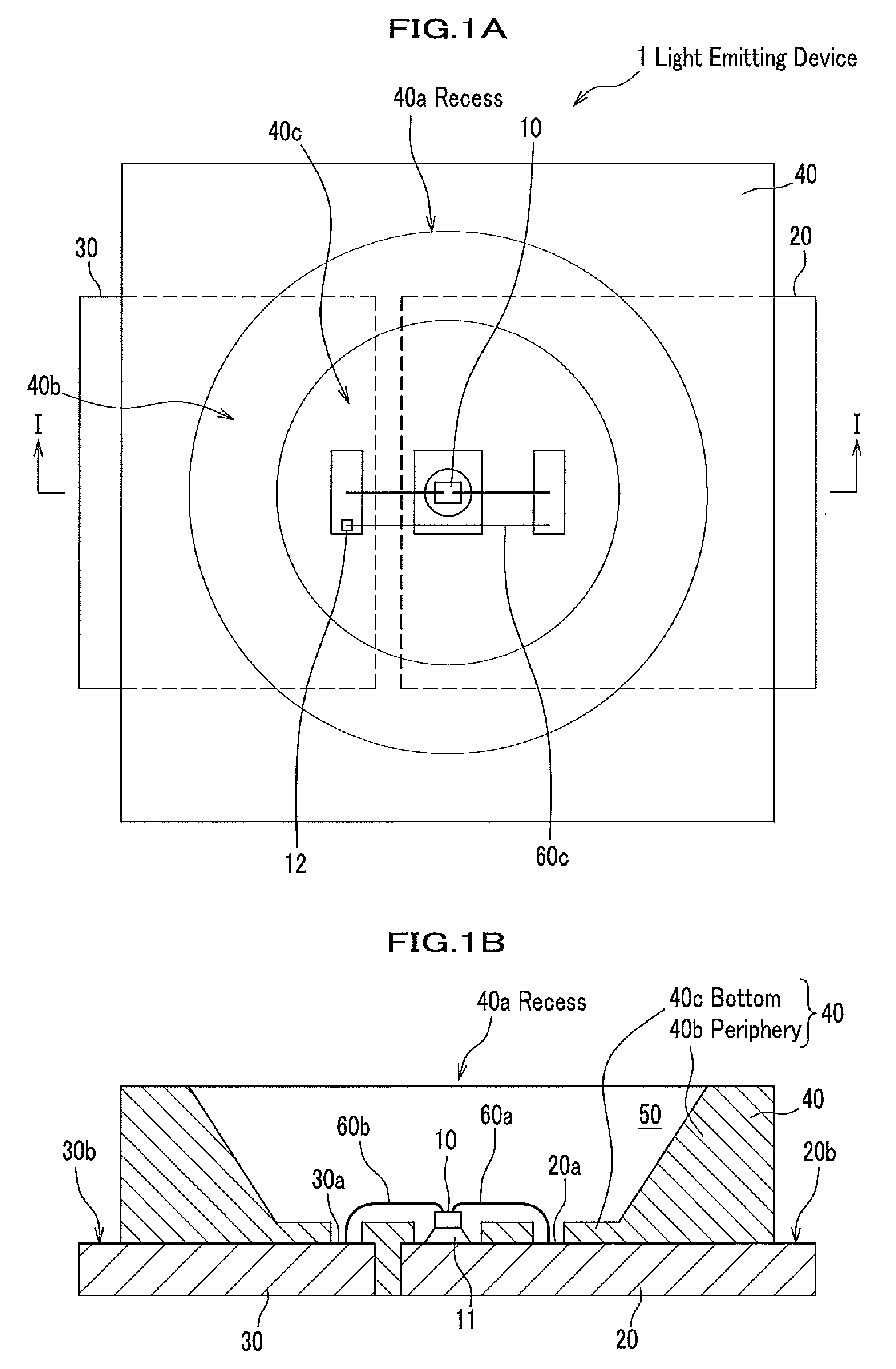

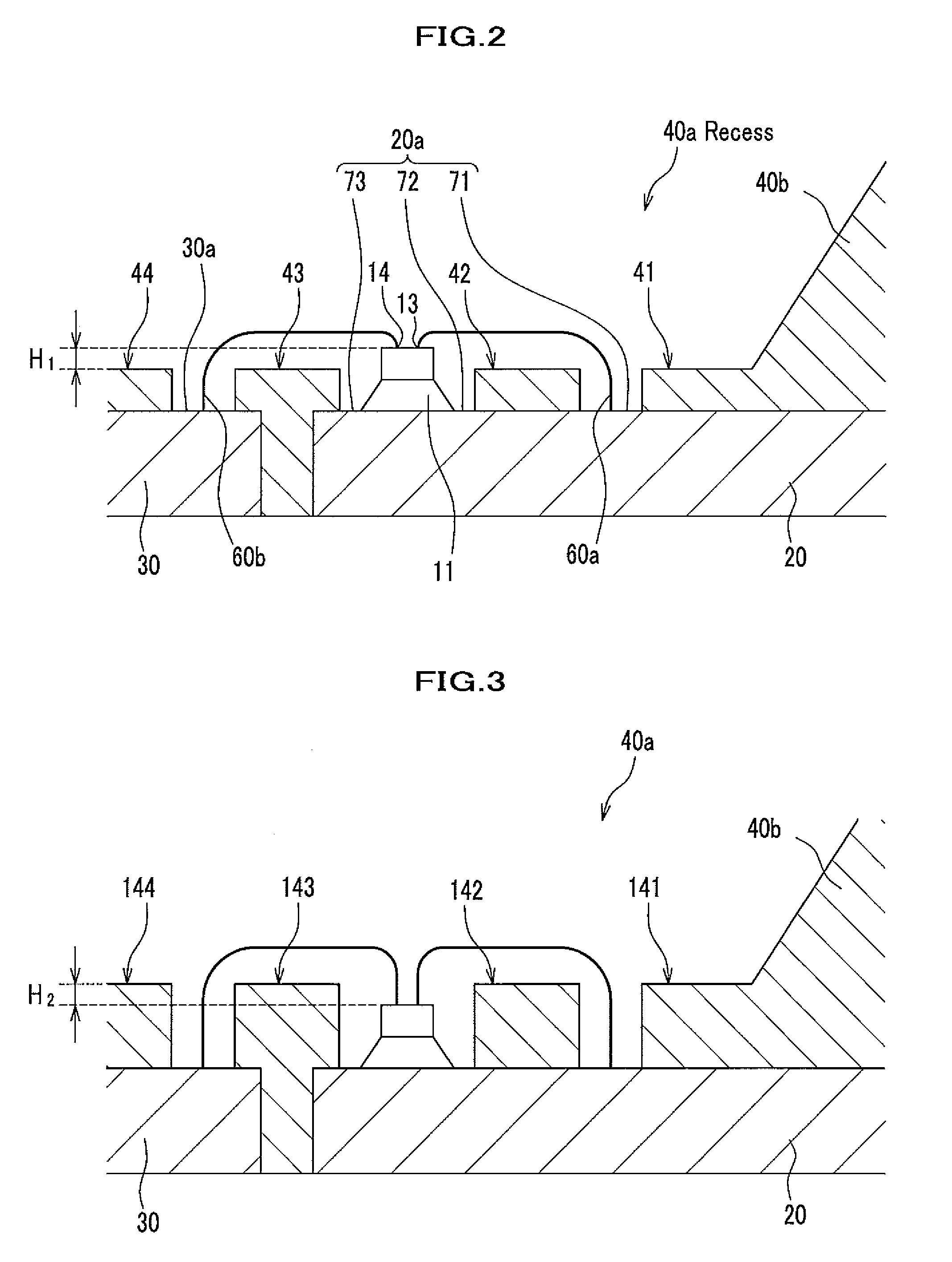

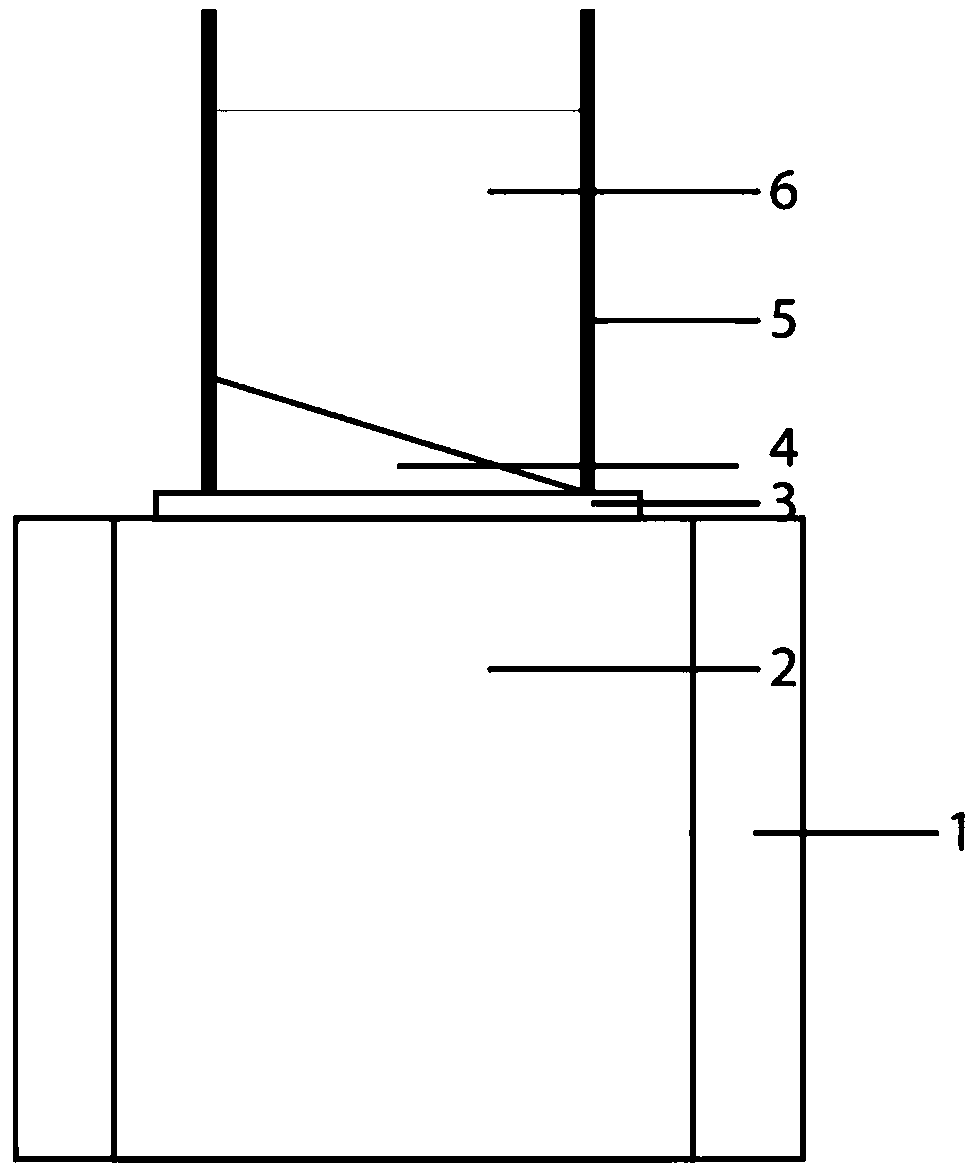

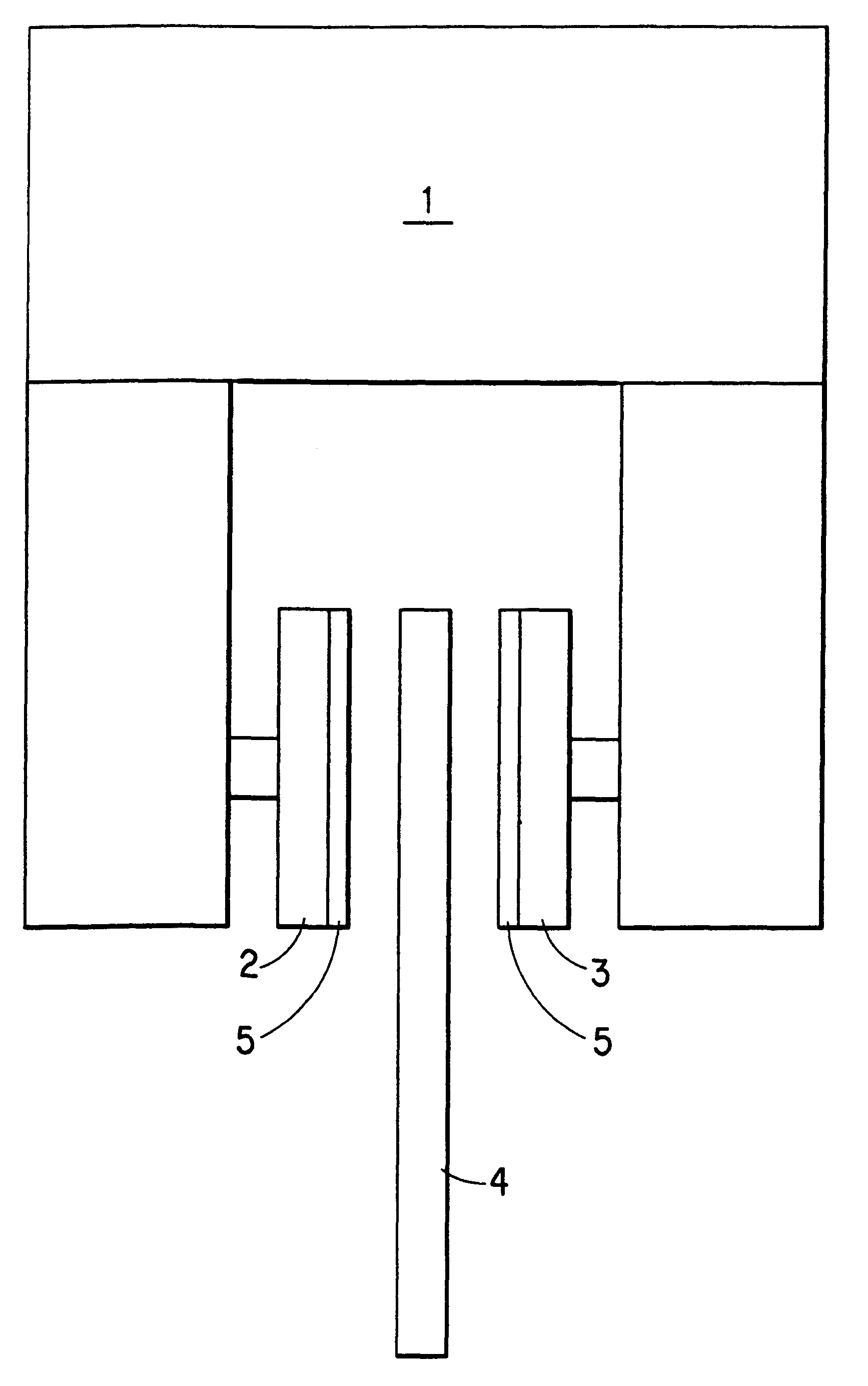

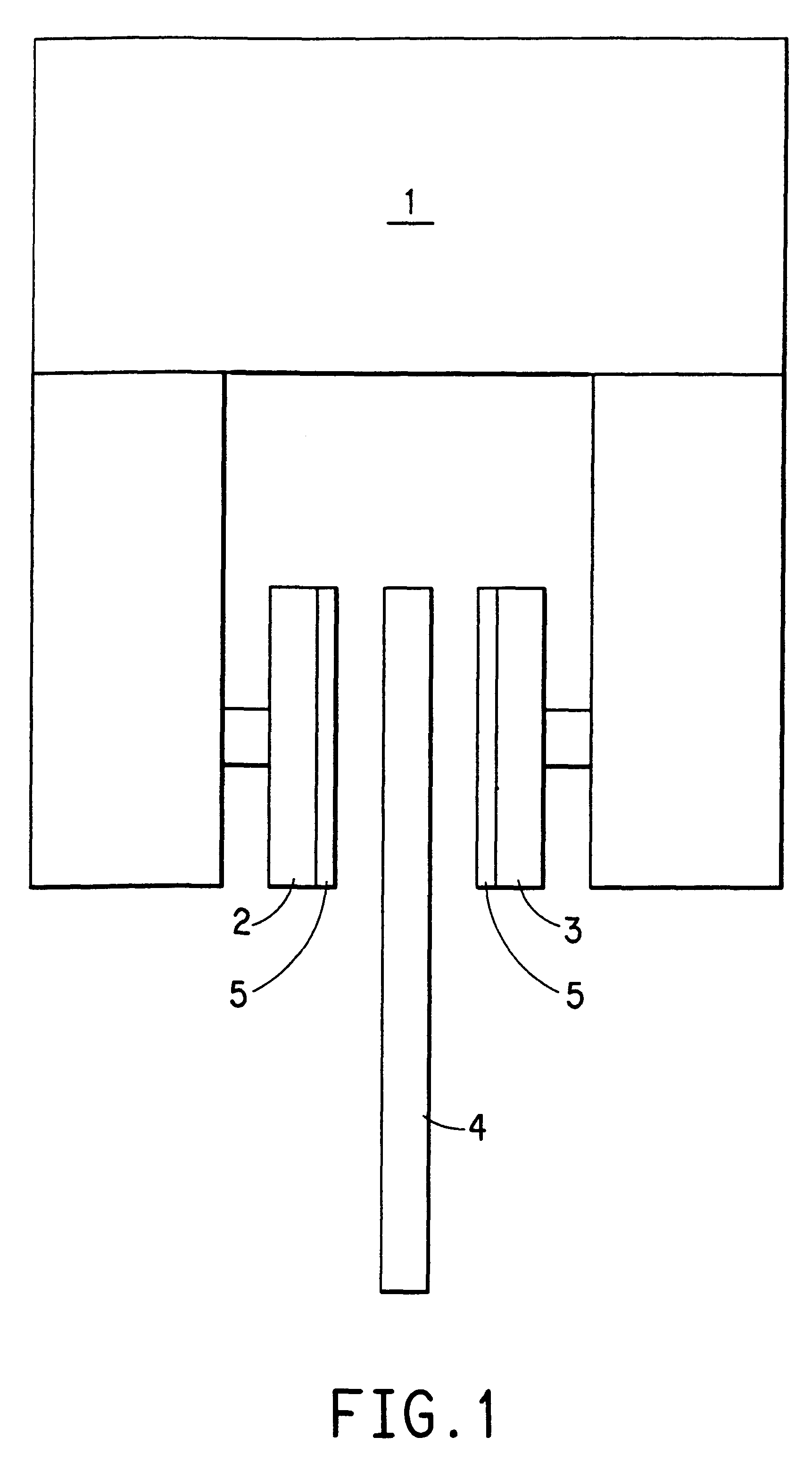

Light emitting device and method for manufacturing the same

ActiveUS20100314654A1Improve luminous performanceEfficient productionSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyEpoxy resin composite

A light emitting device, which can be efficiently manufactured and maintain a stable light emitting property for a long period, is provided. The light emitting device comprises a first resin forming body including a periphery that forms a recess to house a light emitting element and a bottom that forms a bottom portion of the recess, and a second resin forming body which covers the light emitting element. The first resin forming body is composed of a thermosetting epoxy resin composite whose essential component is an epoxy resin. The bottom covers surfaces of lead frames excluding mounting regions of the light emitting element and wires. A thickness of the bottom is formed thinner than a thickness from the surface of the lead frames to a leading end of the light emitting element.

Owner:NICHIA CORP

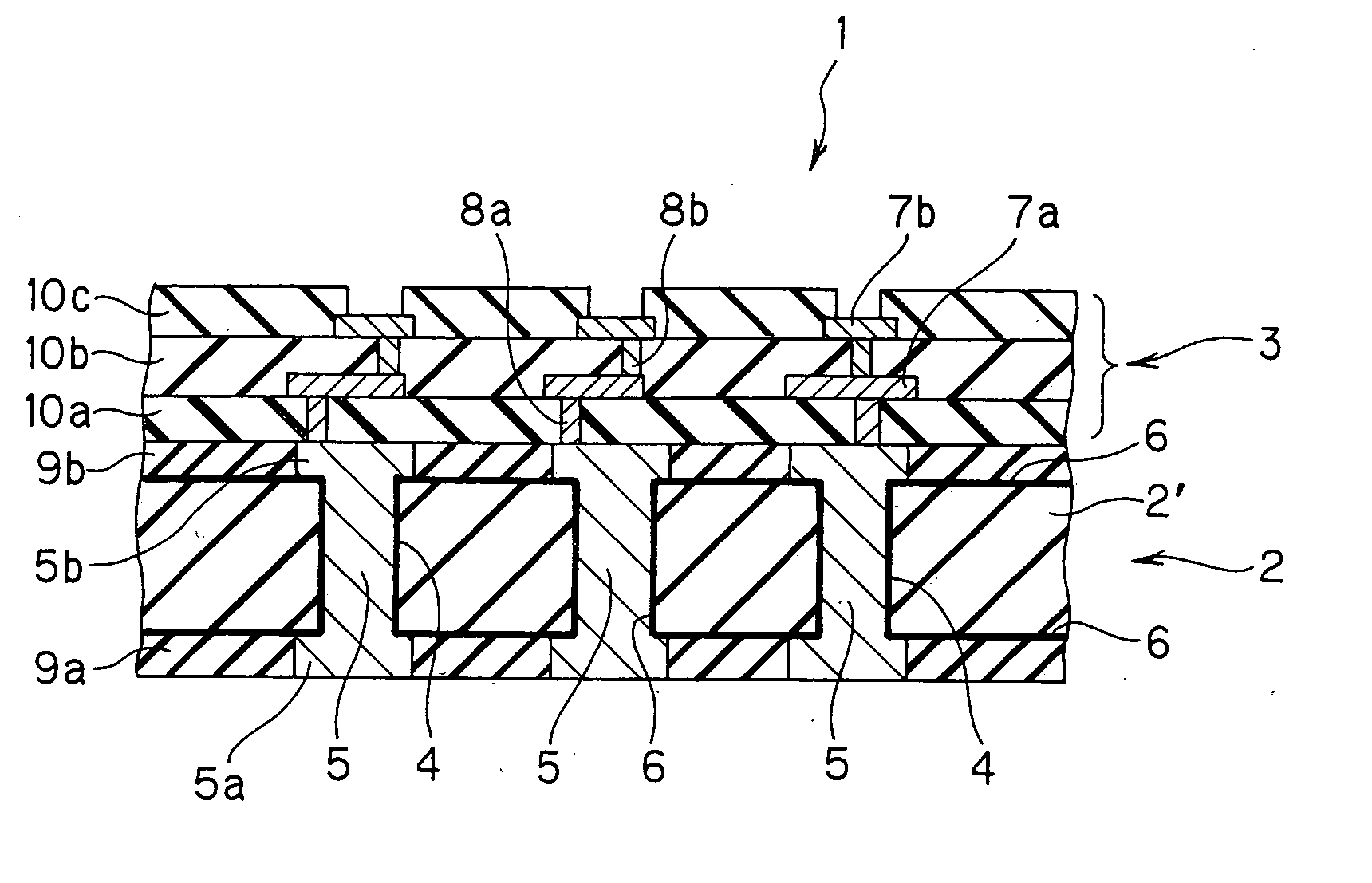

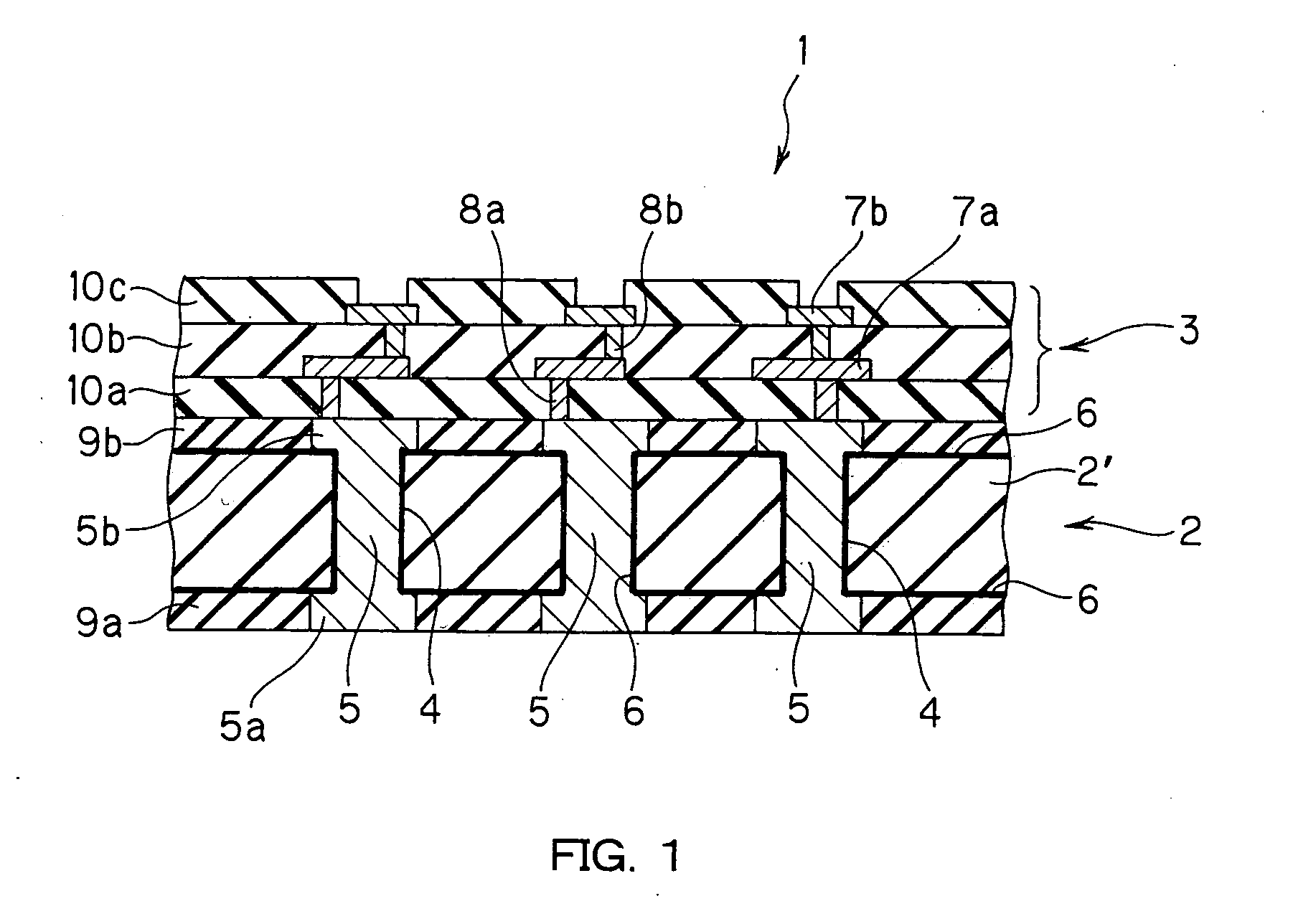

Multilayer wiring board and manufacture method thereof

ActiveUS20050012217A1Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringThermal expansion

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

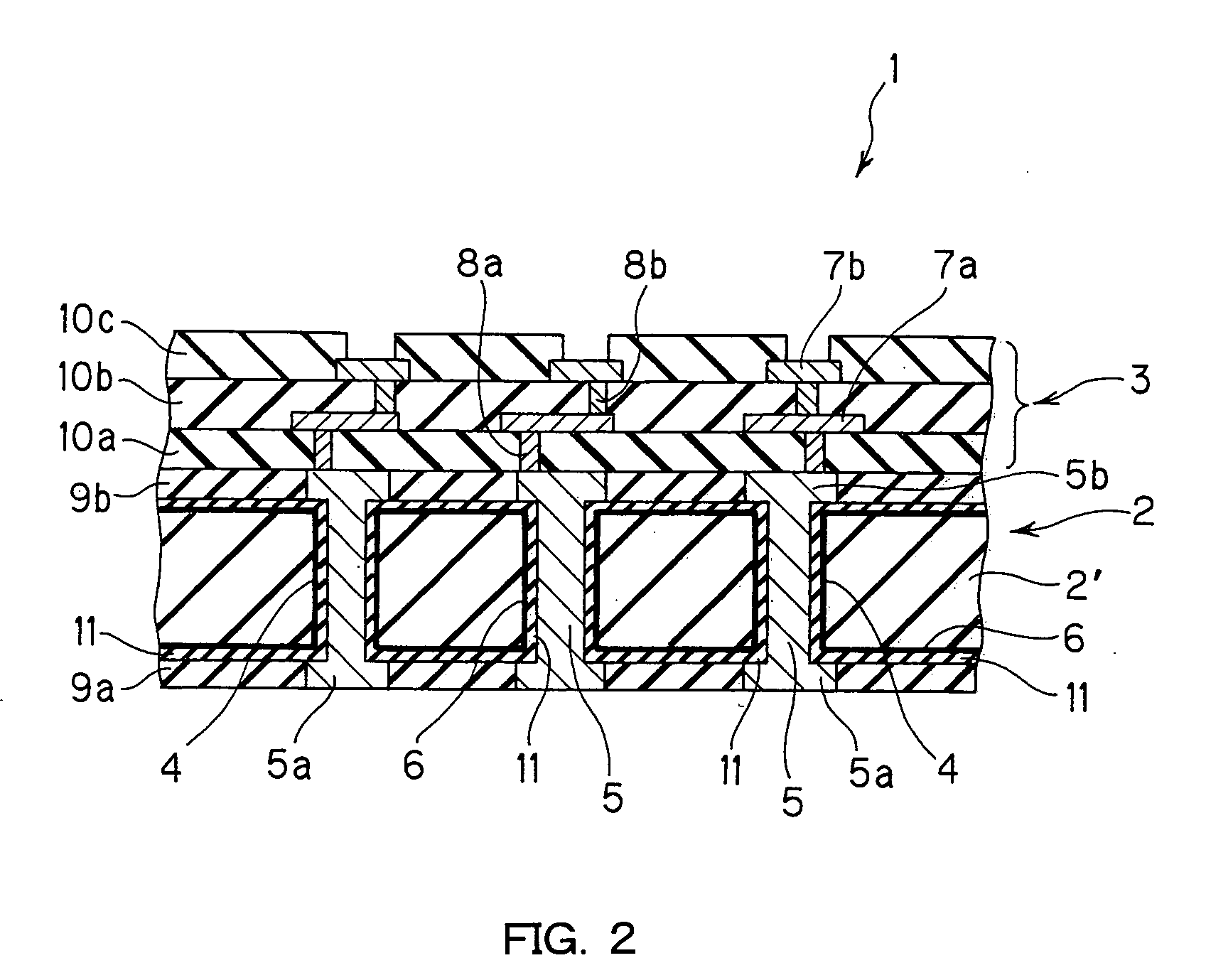

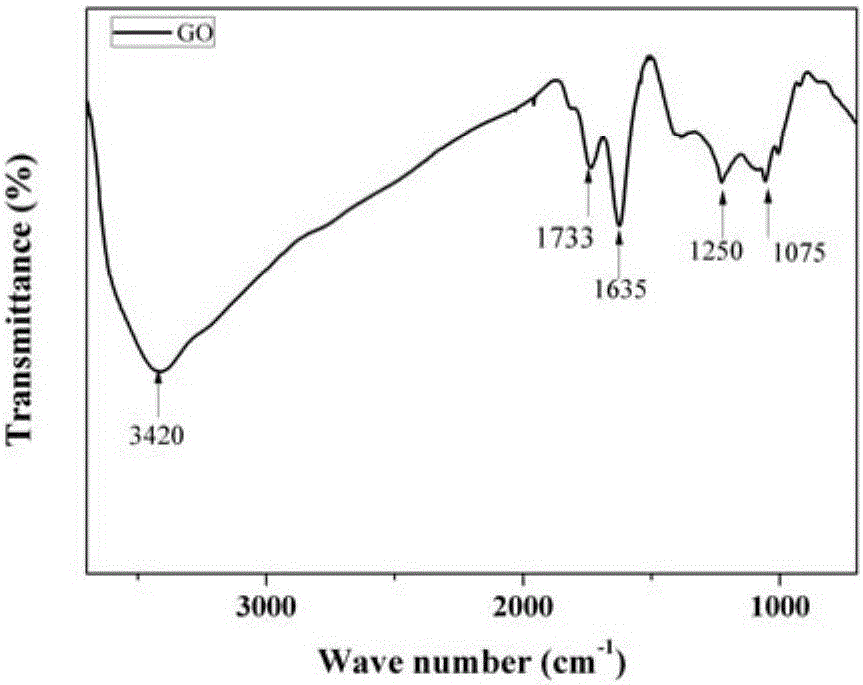

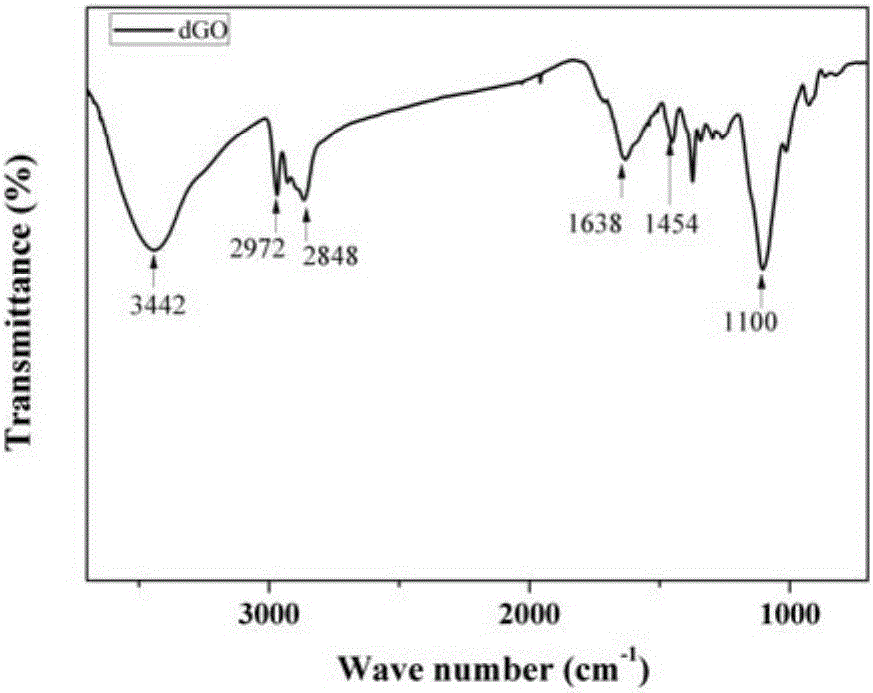

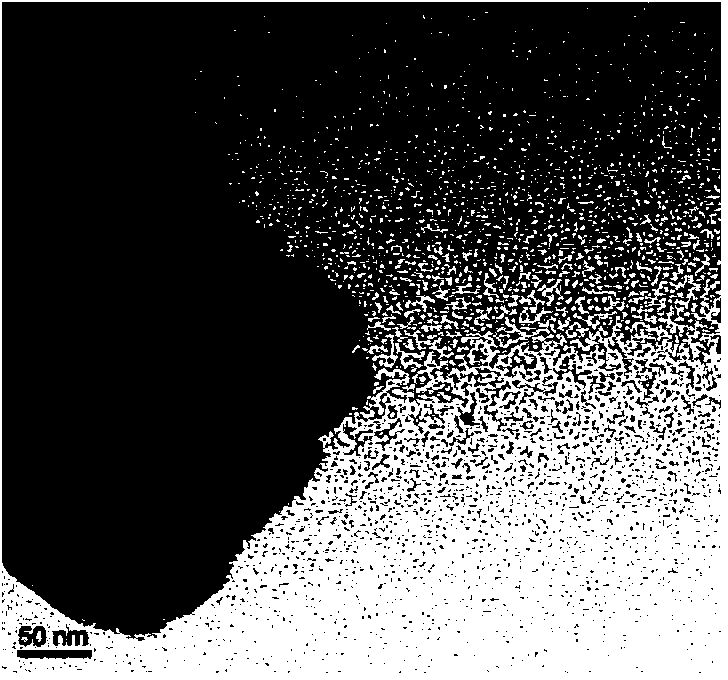

Method for chemically modifying inorganic filler with graphene oxide, product and application

InactiveCN103788413AImprove adhesionHigh mechanical strengthPigment treatment with organosilicon compoundsPigment physical treatmentEpoxySilanes

The invention discloses a method for chemically modifying inorganic filler with graphene oxide and a product. The method comprises the following steps: performing surface hydroxylation treatment and silane coupling agent treatment on the inorganic filler; maintaining the pH of a graphene oxide solution at 5.8-6.0 with an MES buffer solution; sequentially adding EDC and NHS, and performing ultrasonic treatment for 1-3 hours; adding the treated inorganic filler, and performing an amidation reaction at room temperature; and after the reaction, filtering, washing and drying to obtain the graphene oxide modified inorganic filler. The invention also discloses a method for preparing an inorganic filler / epoxy resin composite by use of the product. The process flow of the method disclosed by the invention is simple and environmentally friendly; the GO is connected to the surface of the inorganic filler by a chemical modification process, and the firm covalent bond combination between the GO and inorganic particles is generated, so that the interface adhesiveness and mechanical strength between the inorganic filler and the polymer are enhanced, and a new idea is provided to the modification of an inorganic filler surface and the preparation of a high-performance composite.

Owner:UNIV OF JINAN

Epoxy resin composite, and preparation method thereof and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Microencapsulation expansion type flame retardant and application in epoxy resin composite material thereof

The invention discloses a microencapsulation expansion type flame retardant and application in an epoxy resin composite material thereof. The microencapsulation expansion type flame retardant uses ammonium polyphosphate as a capsule core and uses a thermosetting resin melamine-formaldehyde resin as a capsule material. The microencapsulation expansion type flame retardant epoxy resin composite material consists of the epoxy resin, a curing agent, a curing accelerator, the microencapsulation expansion type flame retardant and a flame-retardant carbon-forming accelerator. The microencapsulation expansion type flame retardant and the application are economic, simple and convenient; the flame retardant has good flame-retardant synergistic effects; and under the condition of little flame retardant addition, the composite material can pass V-0 level of UL-94 test, and the oxygen index reaches over 30.0 percent.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for recovering carbon-fiber enhanced epoxy resin composite material

The invention relates to a method for recovering a carbon-fiber enhanced epoxy resin composite material. In the existing method, the requirement for equipment is high and the recovery cost is large. The method comprises the following steps of: cutting materials needing to be decomposed into blocks with the volume being 5cm<3>, putting the blocks in a backflow device containing acid liquor, heating for 5-20 minutes at the temperature of boiling point, cleaning and carrying out vacuum drying; then putting the obtained mixture into a reaction kettle, adding an organic solvent and an oxidizing agent, firstly heating, then cooling to normal temperature, and obtaining a primary product; and after cleaning, putting a solid product in the primary product into industrial acetone solution for dipping, obtaining recovered carbon fiber and carrying out pressure-reduced distillation on a liquid product to obtain phenol and derivatives thereof. In the method, reaction under low temperature and low pressure is realized and has the advantages of moderate reaction condition, easy control of reaction, fewer side products, no pollution basically and no corrosion to equipment and the like, so that the method is a green recovering method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for reclaiming carbon fiber reinforced epoxy resin composite material

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Prepreg with moderate-temperature cured epoxy resin as substrate material and preparation method thereof

The invention relates to a prepreg with moderate-temperature cured epoxy resin as a substrate material and a preparation method of the prepreg, relates to a prepreg and a preparation method of the prepreg, and is used for solving the problems that the prepreg is prepared at the curing temperature higher than 120 DEG C, so that the product is high in energy consumption and the dimensional accuracy of the product is difficult to control. The prepreg with moderate-temperature cured epoxy resin as the substrate material is composed of an epoxy resin mixture, a curing agent system mixture and a moderate-temperature cured epoxy resin infiltration reinforcing material prepared by a toughening agent, wherein the epoxy resin mixture is composed of solid or semisolid epoxy resin and liquid epoxy resin, and the curing agent system mixture is composed of a curing agent and a promoter. The preparation method comprises the steps of: (1) preparing the epoxy resin mixture; (2) preparing the curing agent system mixture; (3) preparing the moderate-temperature cured epoxy resin; and (4) preparing the prepreg. The prepared product can be used for preparing planes, spacecrafts, yachts, golf rods and the like, and has important commercial value.

Owner:HARBIN FRP INST

Lignin-epoxy resin composite material and preparation method thereof

The invention discloses a lignin-epoxy resin composite material and a preparation method thereof, relates to a lignin-polymer composite material and a preparation method thereof, and aims to solve the conventional problem of low effective utilization rate of lignin. The lignin-epoxy resin composite material uses the lignin as a substrate; epoxy resin, a curing agent, a toughening agent, and the like are evenly blended with the lignin; and through the processes of pre-pressing, hot-pressing and curing molding, the lignin-based composite material is obtained. The lignin-epoxy resin composite material disclosed by the invention has the advantages of little water absorption, good mechanical performance, degradability, and the like, is suitable for manufacturing floor boards, wall protection boards, construction formworks, door-window profiles, fences, guardrails, louvers, roof boards, and the like in the construction industry, can be used for manufacturing inner decorative boards of automobile doors, seat backing boards, automobile roof lining, and the like in the automobile industry, and can also be used in the fields of the packaging and transportation industry, the furniture industry, office articles, sports facilities, and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Epoxy resin composition as well as prepreg and copper-foil-clad laminated board prepared by using same

InactiveCN102443138AHigh glass transition temperatureHigh functionalitySynthetic resin layered productsMetal layered productsEpoxyDielectric loss

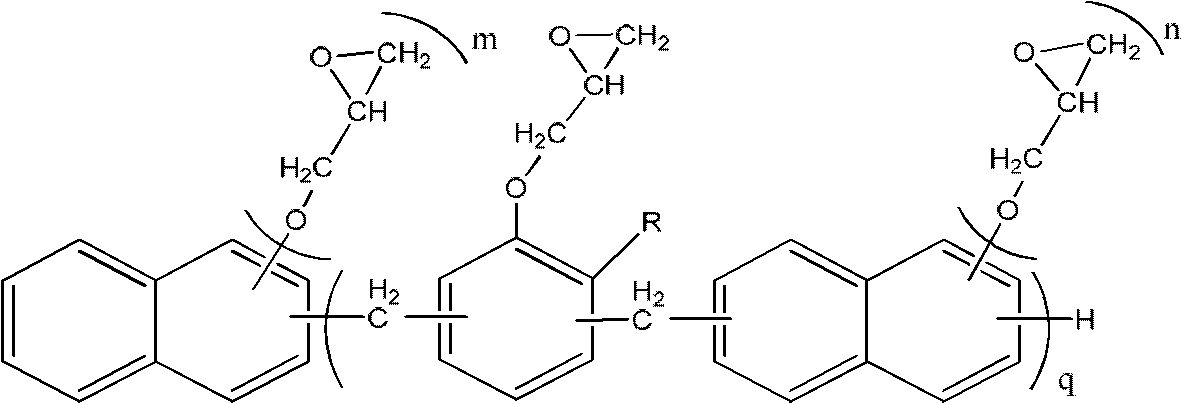

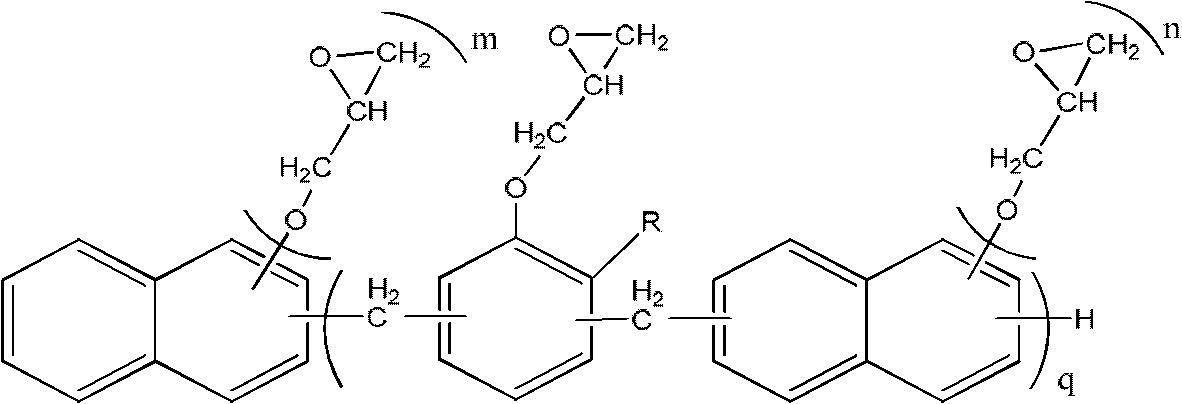

The invention relates to an epoxy resin composition as well as a prepreg and a copper-foil-clad laminated board prepared by using the same. The epoxy resin composition comprises the following essential components: (A) epoxy resin containing a naphthol structure, (B) an active ester serving as a curing agent, and (C) a curing accelerant. Because epoxy resin at least contains the naphthol structure in the molecular structure, the epoxy resin composition provided by the invention has higher functionality degree and high glass transition temperature; at the same time, the naphthol group structure is introduced to the molecular structure, thus the cured product has low water absorptivity and low expansion coefficient; due to the active ester serving as the curing agent, the advantages that the a polar group is not generated during the reaction between the active ester and epoxy, thus the dielectric properties are excellent and moisture and heat resistance are good are fully exerted; and in addition, because of the epoxy resin containing the special naphthol structure, the hydroscopicity of the resin cured product is further reduced and the dielectric loss value of the cured product is lowered. The prepreg and the copper-foil-clad laminated board provided by the invention have excellent dielectric properties, moisture and heat resistance and high glass transition temperature.

Owner:GUANGDONG SHENGYI SCI TECH

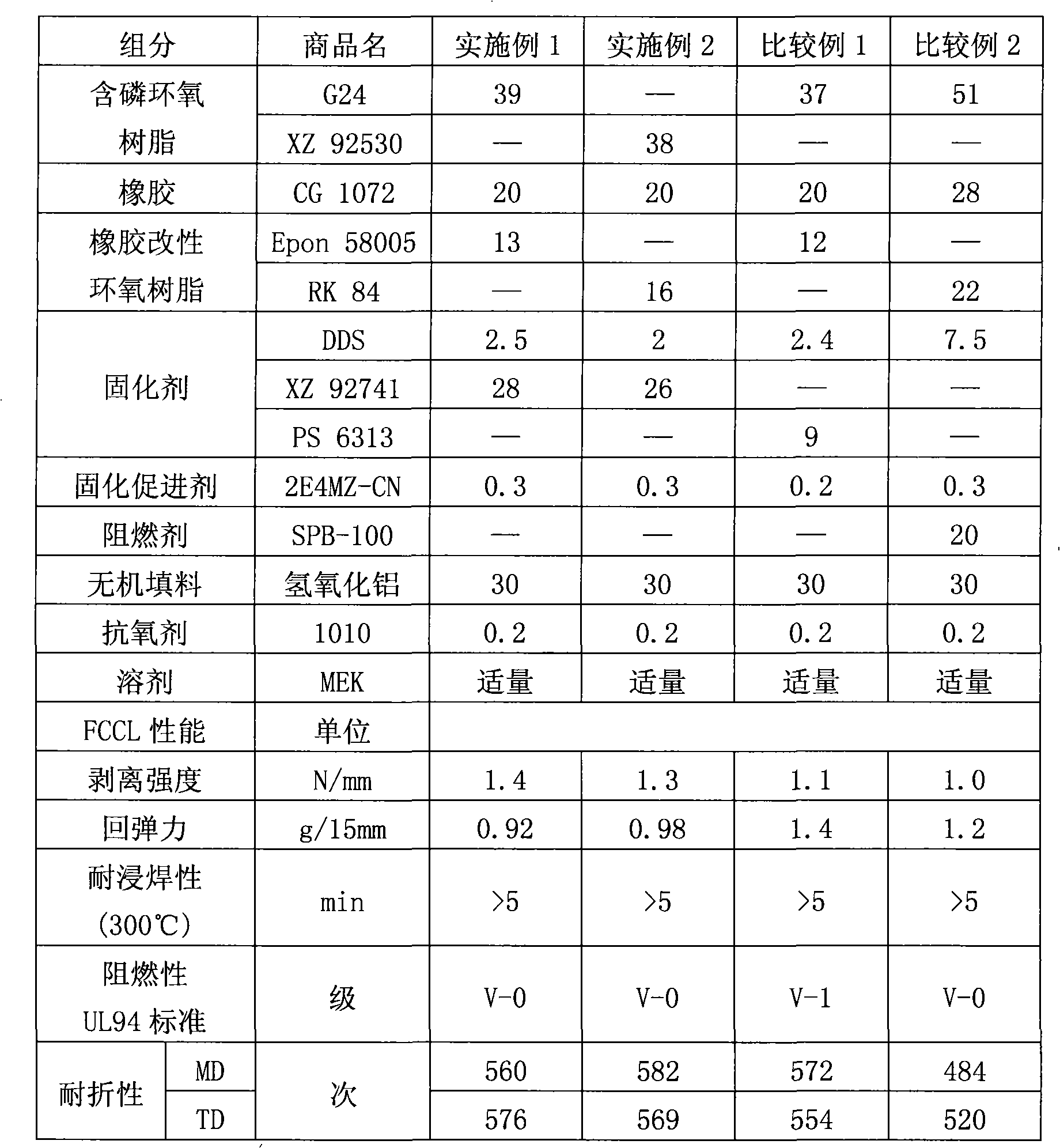

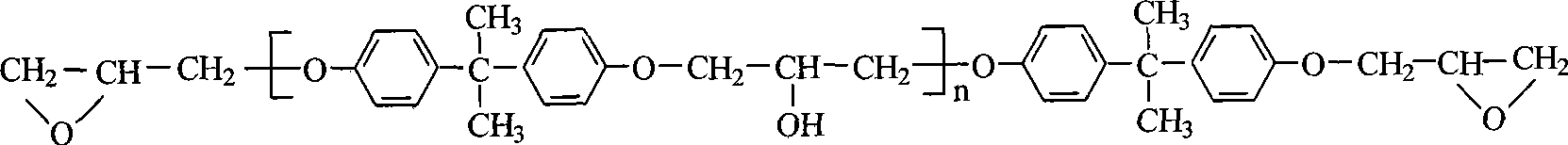

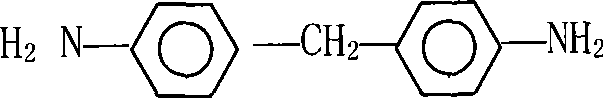

Halogen-free flame-retardant epoxy resin composition, flexible copper clad laminate made therefrom and preparation of the flexible copper clad laminate

InactiveCN101280093AGood compatibilityImprove mechanical propertiesCircuit susbtrate materialsSolid componentEpoxy

The invention relates to a halogen-free flame-retardant epoxy resin composite, the flexible copper clad laminate made from the epoxy resin composite and the production method. The halogen-free flame-retardant epoxy resin composite is composed of solid components and organic solvents, wherein, the solid components include: phosphorus epoxy resin, synthetic rubber, rubber-modified epoxy resin and composite curing agent. The flexible copper clad laminate made from the halogen-free flame-retardant epoxy resin composite is a three-layer flexible copper clad laminate, including a polyimide insulation film, a coating of halogen-free flame-retardant epoxy resin composite coated on the polyimide insulation film, and a copper foil pressed on the coating of halogen-free flame-retardant epoxy resin composite. The resin composite of the invention is halogen-free and dispenses with other organic phosphorus flame retardants; the flexible copper clad laminate made from the composite has the flame retardancy up to UL94 V-0-level and has the advantages of high peeling strength, excellent dimensional stability, softness, good ion migration resistance and processing performance.

Owner:GUANGDONG SHENGYI SCI TECH

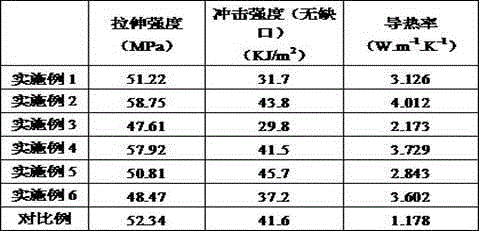

Heat-conduction epoxy resin composite material and preparation method thereof

The invention relates to the field of high-molecular composite materials, and concretely relates to a heat-conduction epoxy resin composite material and a preparation method thereof. The heat-conduction epoxy resin composite material comprises the following compositions in parts by mass: 0.5-3.0 parts of carbon nanotubes, 0.5-10.0 parts of nanometer aluminium nitride, 0.1-1.0 part of a silane coupling agent, 0.1-0.5 part of stearic acid, 60-80 parts of epoxy resin and 8-30 parts of a curing agent. According to the preparation method, amino-functionalized carbon nanotubes and nanometer aluminium nitride subjected to surface modification by employing a coupling agent are dispersed in epoxy resin, so that the epoxy resin material with heat-conduction function is prepared, the operation technology is simple, on the one hand, the heat conduction performance of the material is guaranteed, and on the other hand, the cost is reduced. The addition amount of functional materials employed by the composite material is less, the stability of the product is good, and the composite material is applicable to electric appliances, electron heat radiation and other aspects.

Owner:东莞市福佑电子科技有限公司

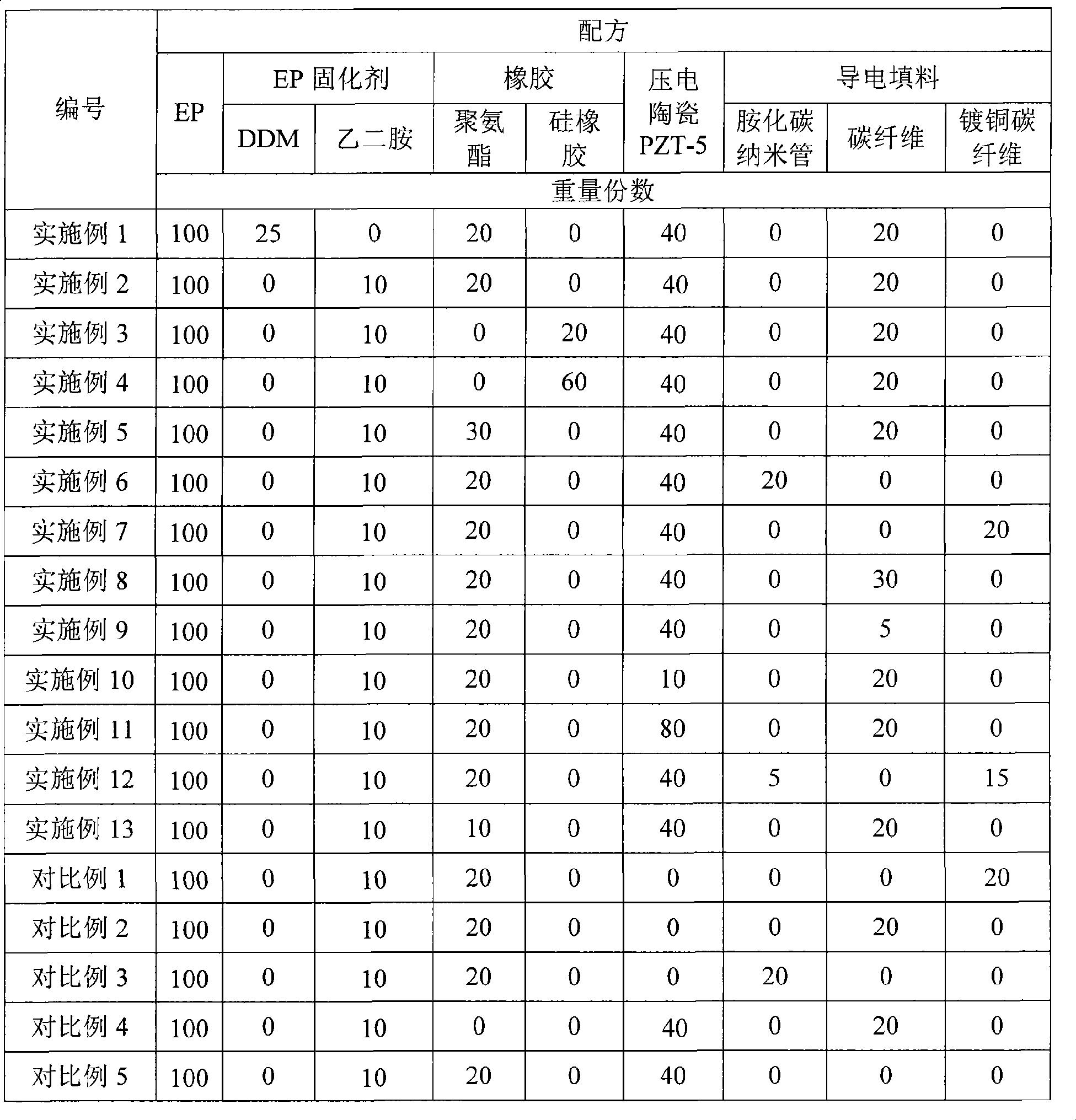

Piezoelectric conductive epoxy resin composite damping material and preparation method thereof

InactiveCN101392090ANon-conductive material with dispersed conductive materialEpoxy resin adhesivesLiquid stateConductive materials

The invention provides epoxy resin composite damping slurry for preparing a damping material, and a preparation method and the composite damping material thereof. The epoxy resin composite damping slurry contains components as follows: 100pbw (part by weight) of epoxy resin, 3pbw to 60pbw of rubber, 5pbw to 80pbw of piezoelectric filler and 3pbw to 30pbw of conductive filler; wherein, epoxy resin prepolymer is bisphenol A type epoxy resin; the rubber is the one which is in liquid state at normal temperature; the piezoelectric filler is piezoelectric ceramics with an average grain size of 2 Mum to 8 Mum; the conductive filler is a carbon series conductive material. The components are evenly and fully mixed according to the parts by weight and cured by adding a curing agent so as to obtain the epoxy resin composite damping material of the invention. The piezoelectric and conductive epoxy resin composite damping material of the invention has good damping effects such as eliminating noise and vibration, preventing electrostatic and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method for high-performance epoxy resin composite material

InactiveCN101104725AReduce clumpingGood dispersionPigment treatment with non-polymer organic compoundsEpoxyCross-link

The invention relates to a preparation method of a high performance epoxy resin composite. First, carbon nano tubes are modified on the surface by acidification, acyl chlorination and amination to prepare carbon nano tubes with amino. The dispersion of the carbon nano tubes in the epoxy resin is improved; the high performance epoxy resin composite is obtained through proper ultrasonic oscillation and strong stirring dispersion and through the amino on the carbon nano tubes having chemical cross-linking with epoxy groups in the epoxy resin.

Owner:TONGJI UNIV

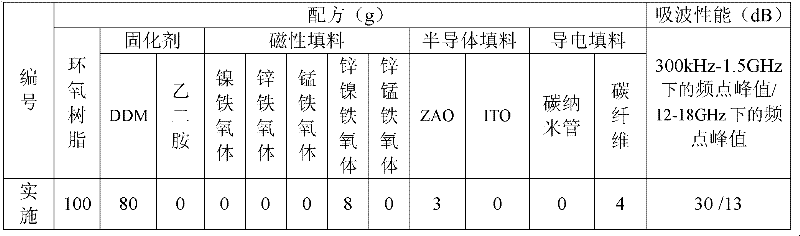

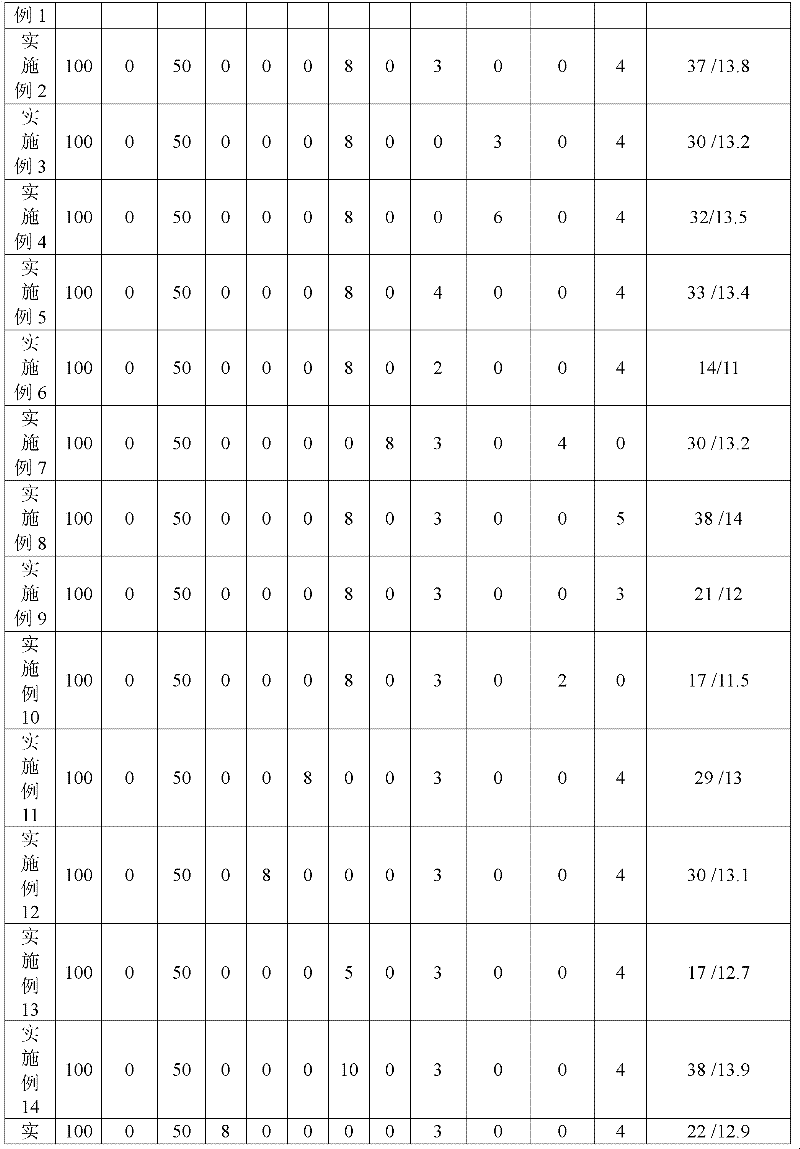

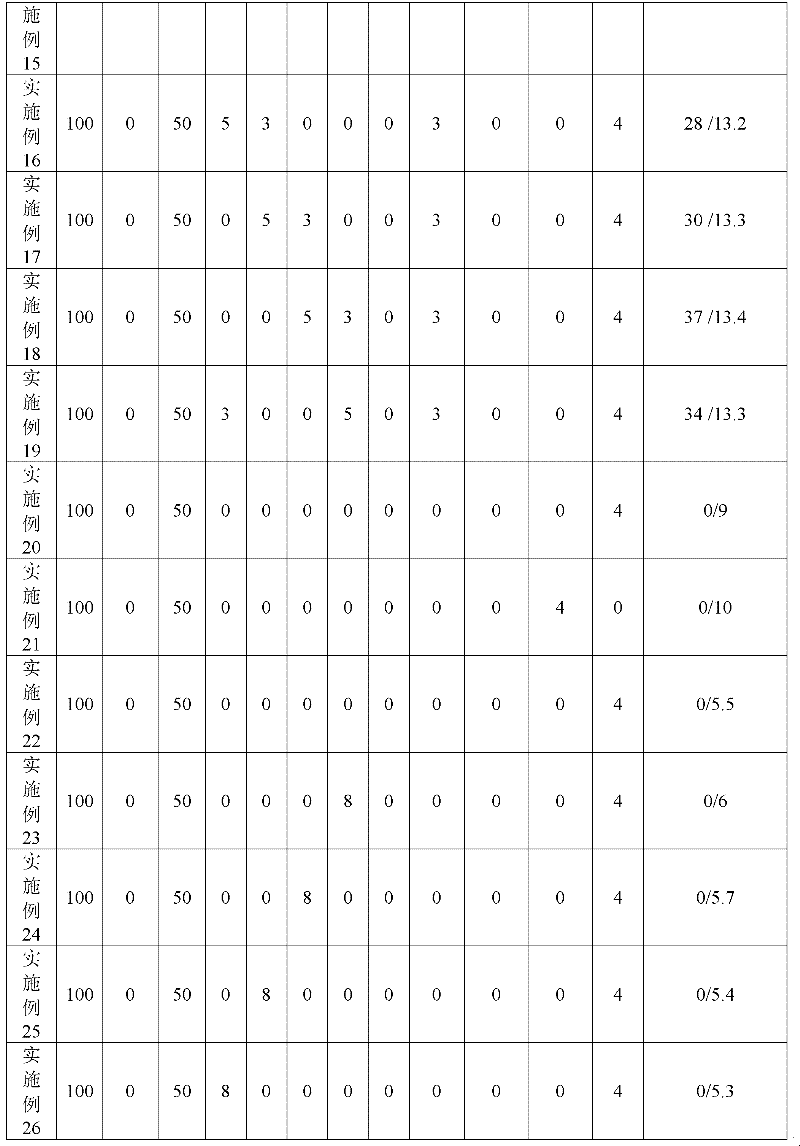

Epoxy resin composite wave-absorbing material and preparation method thereof

InactiveCN102504495AImprove absorbing performanceIncreased maximum absorptionEpoxyEpoxy resin composite

The invention discloses an epoxy resin composite wave-absorbing material and a preparation method thereof, belonging to the field of electromagnetic wave-absorbing materials. The wave-absorbing material comprises 100 parts by weight of epoxy resin, 50-100 parts by weight of a curing agent, 3-10 parts by weight of a magnetic filling material, 2-6 parts by weight of a semiconductor filling materialand 2-5 parts by weight of a conductive filling material. The preparation method comprises the following steps of: after adding the magnetic filling material, the semiconductor filling material and the conductive filling material into the heated and thinned epoxy resin, uniformly mixing, and curing by adding the curing agent. According to the invention, the semiconductor filling material is composited with the magnetic filling material and the conductive filling material to form the electromagnetic wave-absorbing material to be used, so that the wave-absorbing efficiency of the electromagnetic wave-absorbing material is increased, furthermore, the wave-absorbing frequency band can be effectively broadened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

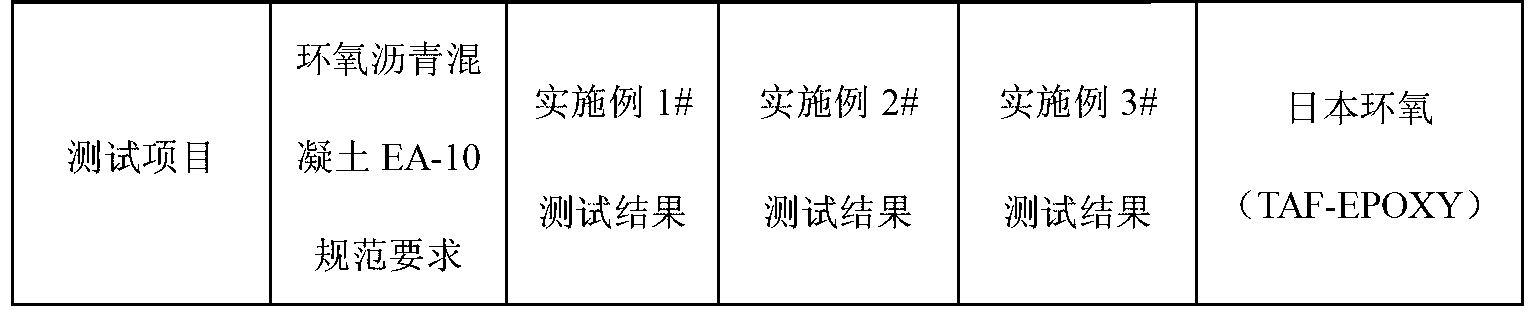

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

Light emitting device

ActiveUS8093619B2Improve extraction efficiencyImprove luminous performanceSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyEpoxy resin composite

A light emitting device, which can be efficiently manufactured and maintain a stable light emitting property for a long period, is provided. The light emitting device comprises a first resin forming body including a periphery that forms a recess to house a light emitting element and a bottom that forms a bottom portion of the recess, and a second resin forming body which covers the light emitting element. The first resin forming body is composed of a thermosetting epoxy resin composite whose essential component is an epoxy resin. The bottom covers surfaces of lead frames excluding mounting regions of the light emitting element and wires. A thickness of the bottom is formed thinner than a thickness from the surface of the lead frames to a leading end of the light emitting element.

Owner:NICHIA CORP

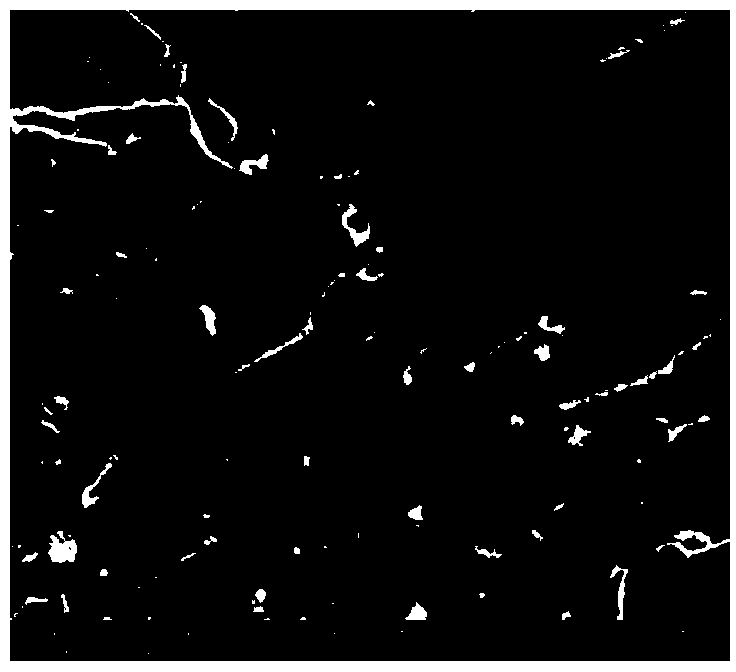

Graphene-toughened epoxy resin composite material and preparation method thereof

InactiveCN104927302AImprove toughnessAvoid harmPigment treatment with macromolecular organic compoundsEpoxyProviding material

The invention provides a graphene-toughened epoxy resin composite material and a preparation method thereof. The provided material is prepared by the following steps: taking epoxy resin as the base material, then adding a graphene toughening agent and a curing agent, and finally heating and curing to obtain the graphene-toughened epoxy resin composite material. The graphene toughening agent is polydopamine modified graphene, polydopamine can well adhere on the graphene surface, the molecular chain of polydopamine comprises a great amount of hydroxy groups and amino groups, thus the interface binding performance between graphene and epoxy resin is enhanced, and the dispersion of the graphene toughening agent in epoxy resin is promoted. The weight ratio of epoxy resin, curing agent, and graphene toughening agent is 100:(15-50):(0.1-8). The preparation method has the advantages that no toxic solvent is used during the preparation process, thus the harm to human and environment is avoided; the raw materials are cheap and easily available; the operation is convenient, and massive production can be easily achieved. Compared with the epoxy resin, the toughness of the prepared epoxy resin composite material is greatly improved, and moreover, due to the excellent thermal conductivity of graphene, the conductivity of epoxy resin is improved.

Owner:JIANGNAN UNIV

Method for catalytically decomposing carbon fiber-reinforced thermosetting epoxy resin composite material

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

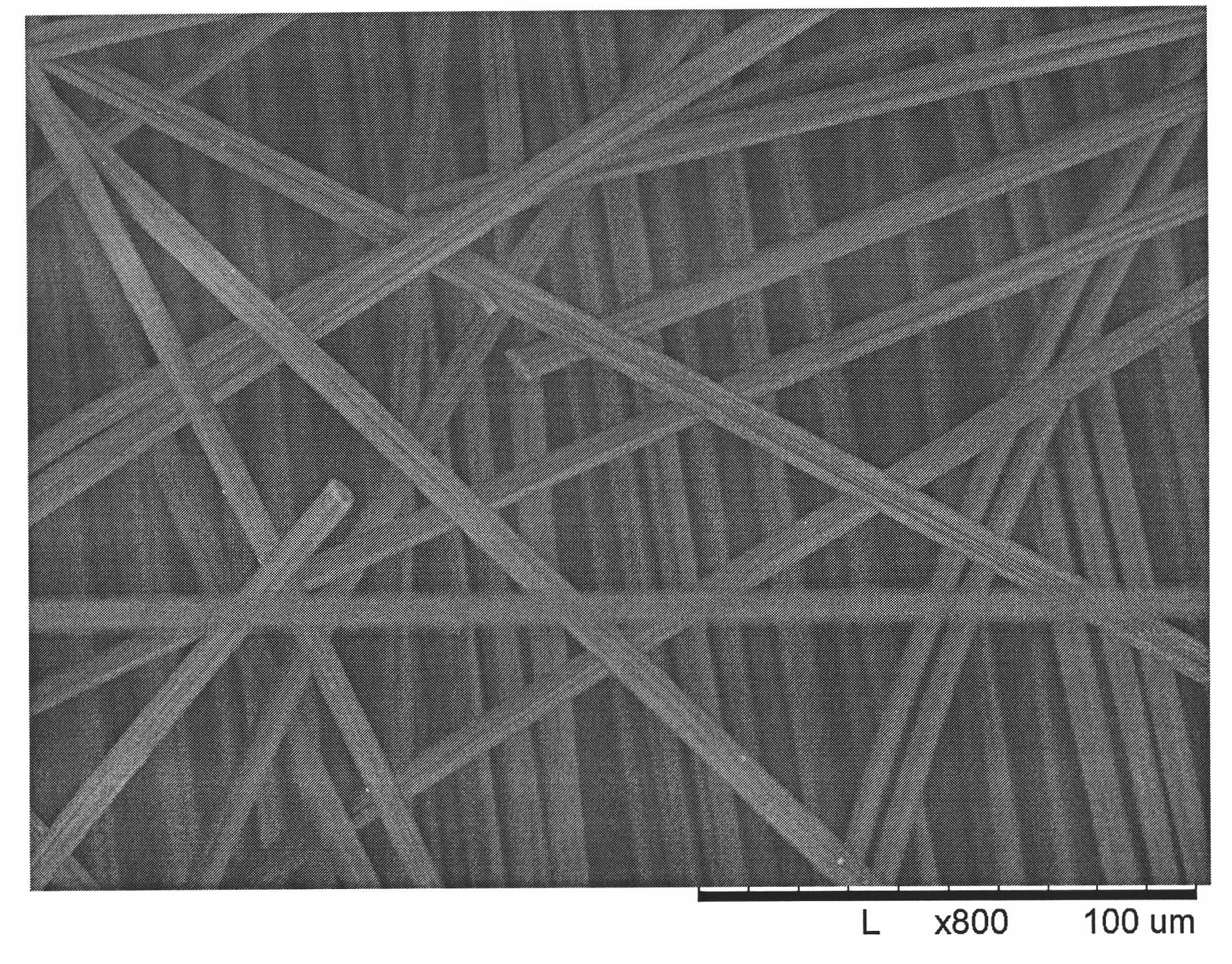

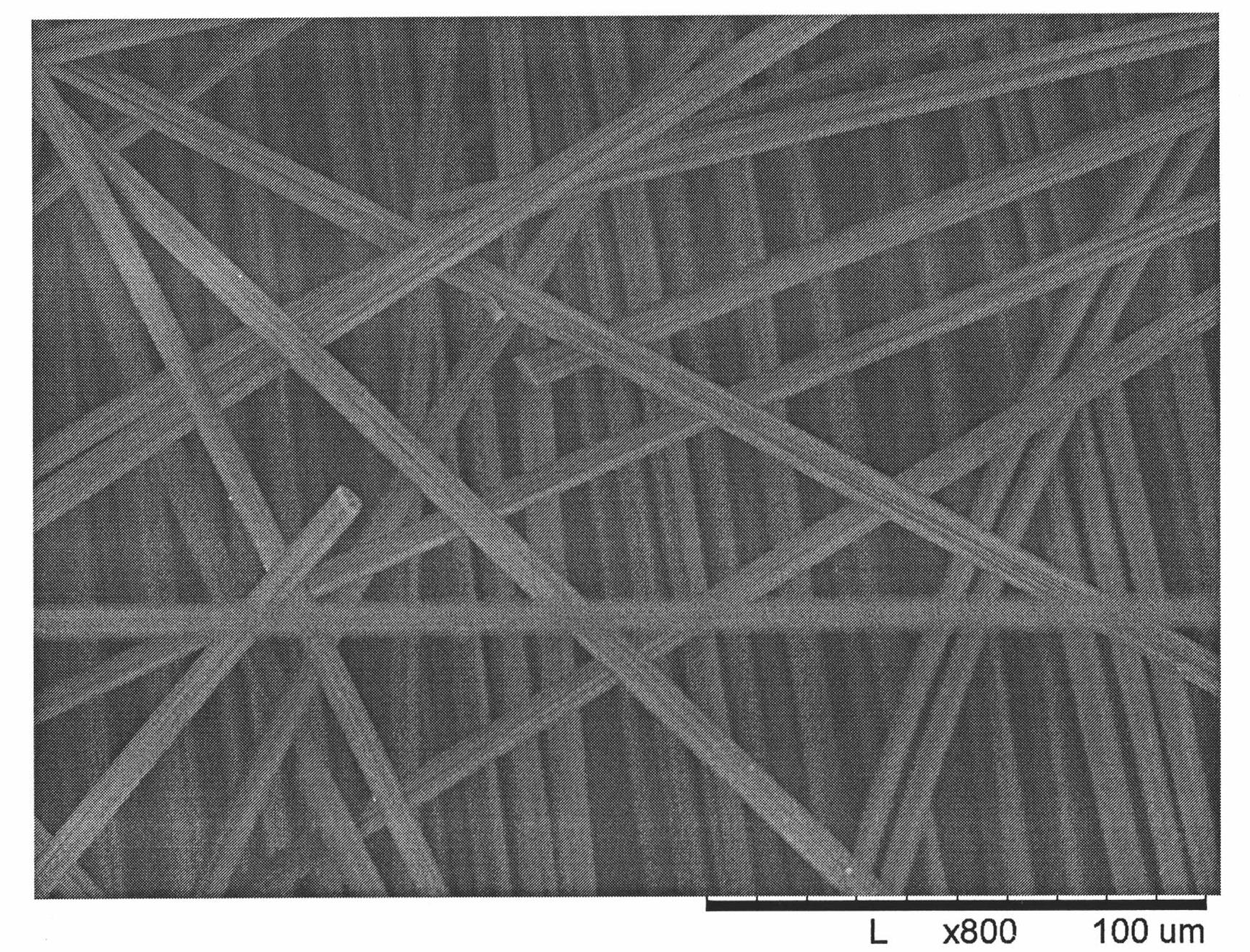

Preparation method of carbon fiber/graphene/epoxy resin prepreg and carbon fiber composite material

A method for preparing carbon fiber / graphene / epoxy resin prepreg and carbon fiber composite materials, belonging to the field of carbon fiber composite material preparation. In this invention, graphene prepared by the modified Hummers method is surface modified, and -NH is grafted on the surface or edge of the graphene. 2 , improve its dispersion in the resin matrix, and at the same time, it can effectively increase the interfacial adhesion between micron-sized carbon fiber and epoxy resin matrix, reduce the existence of void defects, and thereby improve the mechanical properties of epoxy resin-based composite materials. The carbon fiber / graphene / epoxy resin composite material provided by the invention has optimal mechanical properties when the addition amount of graphene is 0.5wt%, with a bending strength of 1525.4MPa and an interlayer shear strength of 91.14MPa. Compared with carbon fiber reinforced rings, Oxygen resin composites improved by 15.41% and 14.14% respectively. The invention has the characteristics of simple process, low solvent toxicity, and is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

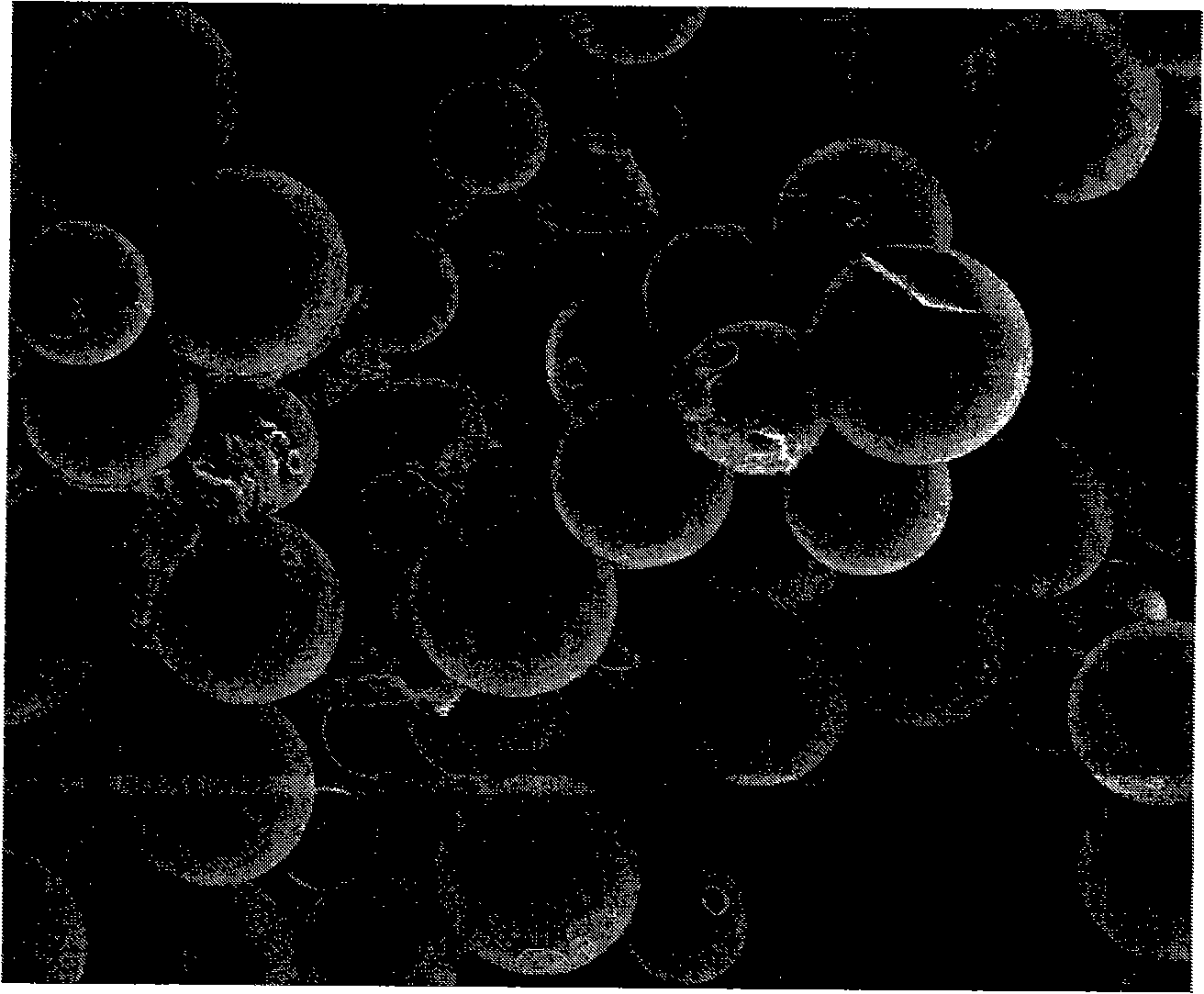

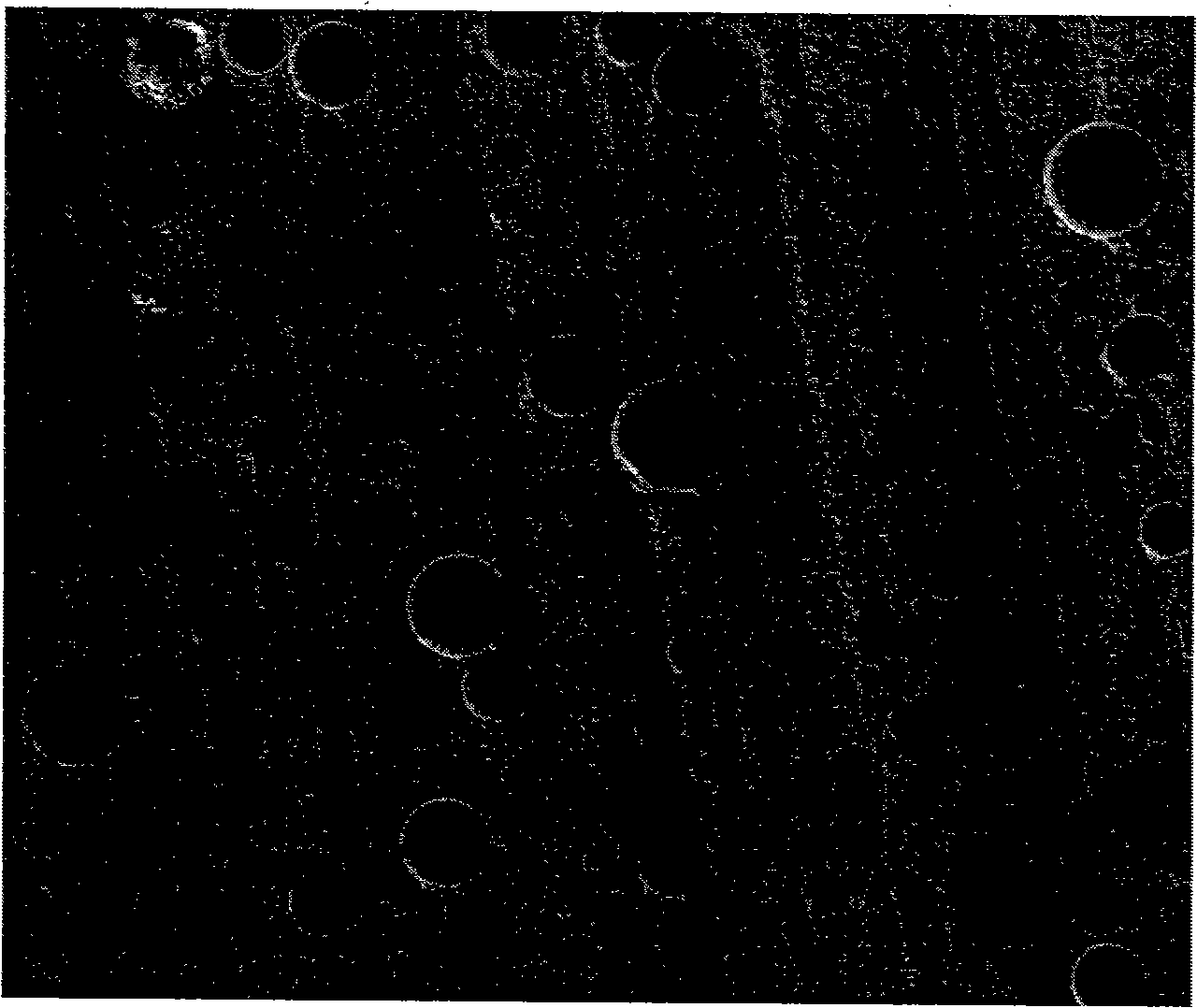

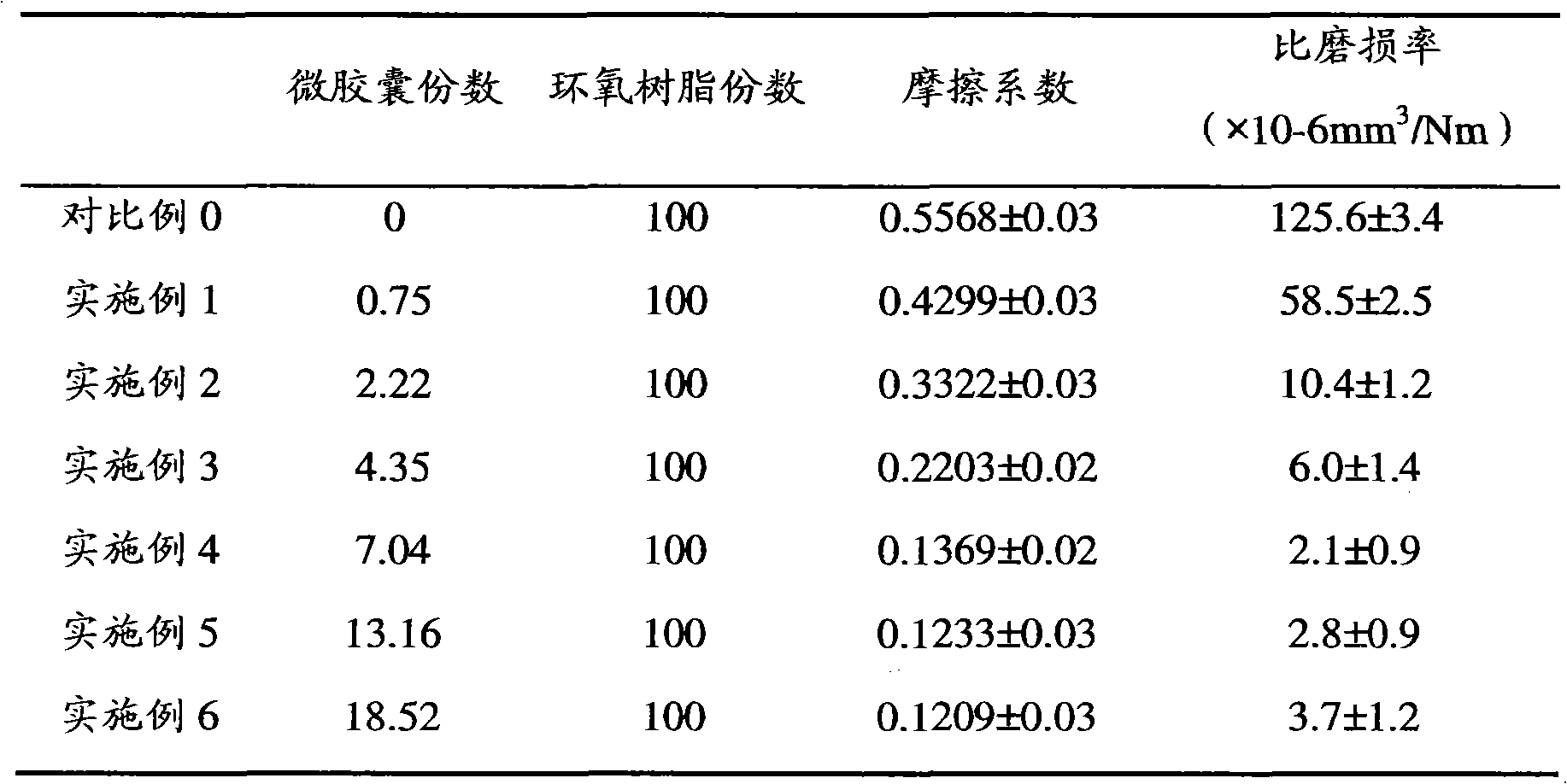

Self-lubricating type epoxide resin material and preparation thereof

InactiveCN101348600AImprove stabilityReduce pollutionMicroballoon preparationLubricant compositionFirming agentEpoxy resin composite

The invention discloses a self-lubricating type epoxy resin material and a preparation method thereof, belonging to the polymer material field. The self-lubricating type epoxy resin material comprises the following components in weight percentage: 60 to 80 percent of epoxy resin, 0.5 to 25 percent of lubricating oil microcapsules and 15 to 35 percent of curing agents. The preparation method for the self-lubricating type epoxy resin material comprises the following steps of well mixing the lubricating oil microcapsules, the epoxy resin with the curing agents and casting rapidly when to-be-mixed matter has gel phenomena, so as to obtain the self-lubricating type epoxy resin material. The invention also provides a lubricating oil microcapsule needed in the preparation of the epoxy resin material and a preparation method for the lubricating oil microcapsule. A technical proposal provided by the invention adds the lubricating oil microcapsules to the epoxy resin so as to prepare the epoxy resin compound material, which can remarkably improve the wear reducing-resisting performance of the epoxy resin material and has broad application prospects.

Owner:SUN YAT SEN UNIV

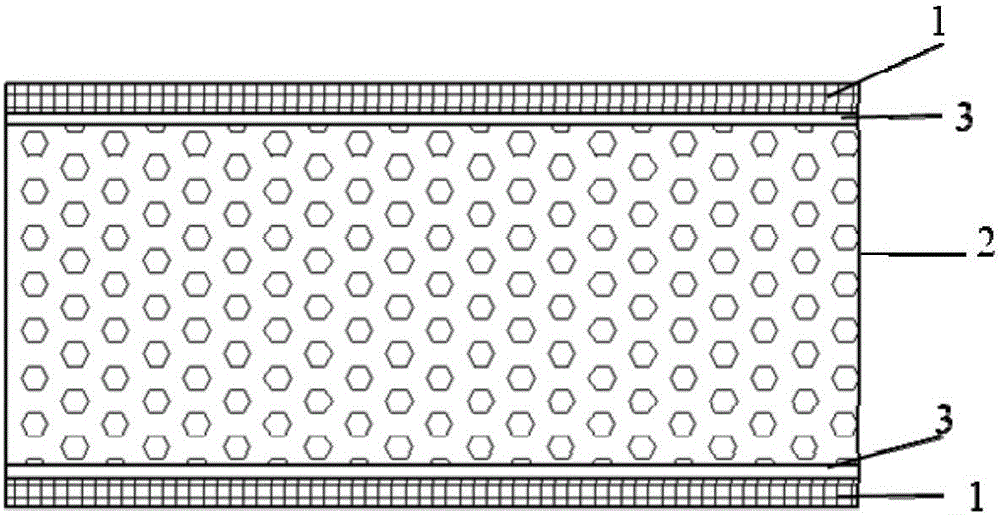

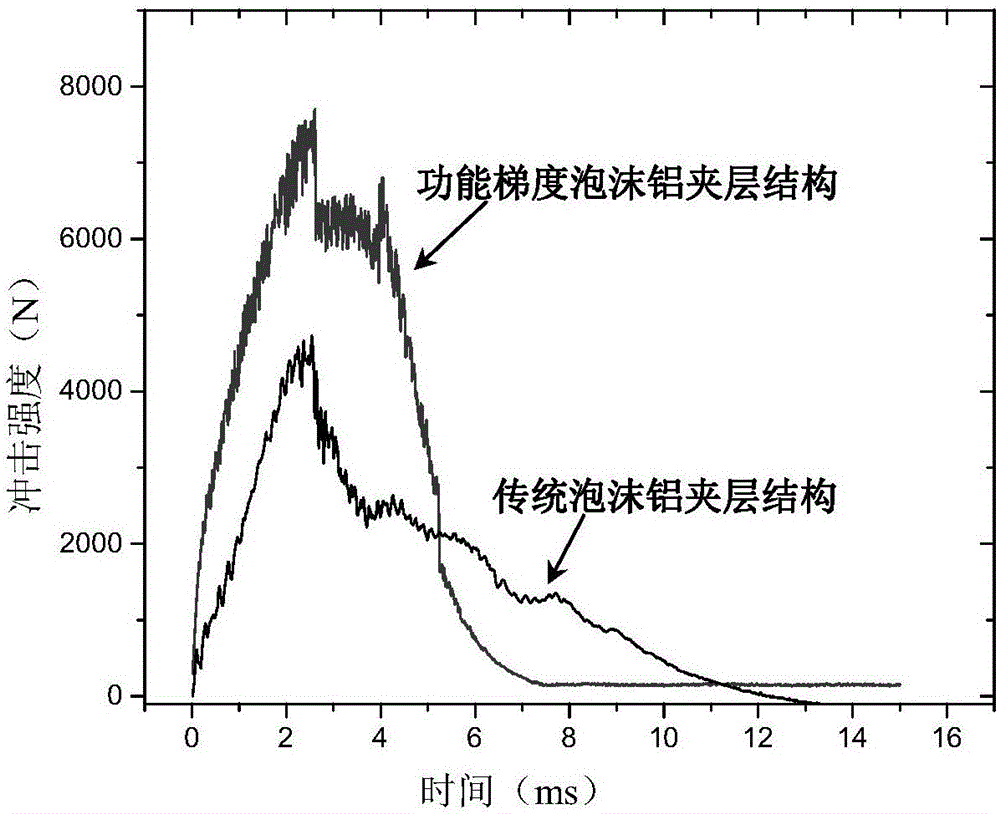

Foamed aluminum sandwich structure composite material and preparing method thereof

ActiveCN106273902AImprove the interface bonding strengthSmall difference in coefficient of thermal expansionSynthetic resin layered productsVehicle componentsFiberEpoxy

The invention provides a foamed aluminum sandwich structure composite material and a preparing method thereof. The foamed aluminum sandwich structure composite material comprises a foamed aluminum core material, a toughening interface layer and skin, wherein the toughening interface layer is located between the foamed aluminum core material and the skin, the toughening interface layer is made of an epoxy resin composite material, and the epoxy resin composite material is composed of an epoxy resin matrix, a toughening agent, a diluent, hollow microspheres, chopped fiber, a curing agent and an accelerant; pores in the surface of the foamed aluminum core material is filled with the epoxy resin composite material to form the toughening interface layer. According to the technical scheme, the toughening interface layer is formed between the composite material skin and the foamed aluminum core material by means of multi-component low-density epoxy filling adhesive, and interface bonding strength can be effectively improved; by means of the skin designed based on functional gradient, the interface bonding property of the foamed aluminum sandwich structure in a humid and hot environment is improved, and the impact resistance of the foamed aluminum sandwich structure is improved.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

Modified graphene oxide and epoxy resin composite material and method for preparing same

ActiveCN105906842AFix compatibility issuesTo overcome the disadvantage of lower performanceEpoxyEpoxy resin composite

The invention discloses a modified graphene oxide and epoxy resin composite material and a method for preparing the same. The modified graphene oxide and epoxy resin composite material and the method have the advantages that graphene oxide is modified by the aid of polyether amine to obtain novel polyether amine modified graphene oxide materials, and accordingly the problems in the aspect of dispersibility of graphene in polymer matrixes can be effectively solved; as proved by test results, the tensile mechanical strength, the toughness and the bending strength of epoxy resin materials can be simultaneously greatly improved by the added polyether amine modified graphene oxide while the glass transition temperatures of the epoxy resin materials is increased by the added polyether amine modified graphene oxide, enhancement effects of the epoxy resin materials are superior to enhancement effects of epoxy resin materials with unmodified graphene oxide, and accordingly the modified graphene oxide and epoxy resin composite material and the method have broad market application prospects.

Owner:SICHUAN UNIV

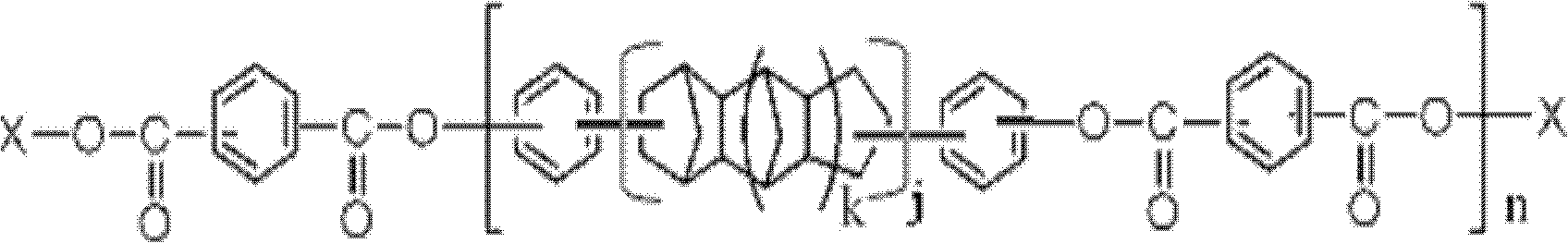

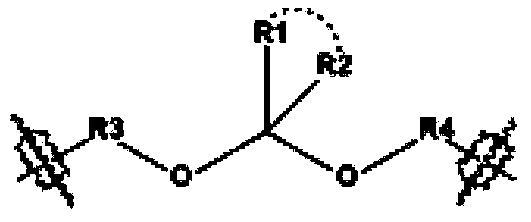

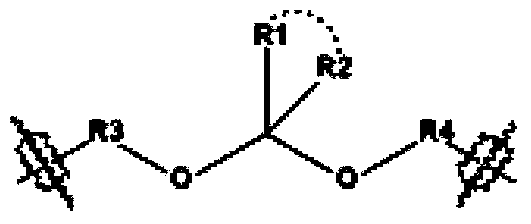

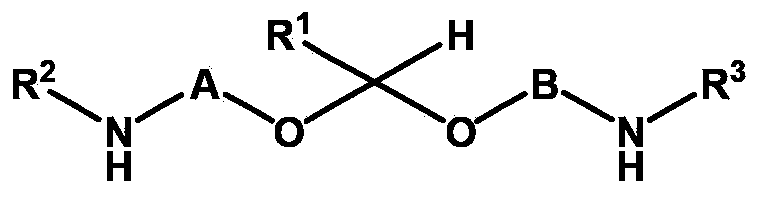

Degrading and recovering method of epoxy resin composite material

ActiveCN103524784ADegradation reachesEffective Recycling MethodsPlastic recyclingChemical recyclingEpoxyOligomer

The invention provides a novel degradable oligomer (polymer) mixed polyamine epoxy resin curing agent and a synthesis method thereof. The curing agent can react with an epoxy resin system to generate a polymerized substance which can be recovered through degradation; the curing agent, the epoxy resin system, reinforcing materials and auxiliary materials can be prepared into a reinforced composite material; and the material can be recovered through degradation. The synthesis method of the degradable oligomer (polymer) mixed polyamine curing agent provided by the invention is mild in reaction conditions, short in production cycle and suitable for industrial mass production; and the cured substance and the reinforced composite material generated by the reaction of the degradable oligomer (polymer) mixed polyamine curing agent and the epoxy resin can be degraded under normal-pressure mild but specific conditions, the degradation process is simple to operate, and industrial mass recovery can be easily realized.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

Method for preparing functionalized graphene and composite material of functionalized graphene

InactiveCN102862976AGood dispersionImprove interface performanceMaterial nanotechnologyCarbon compoundsEpoxyOrganic solvent

The invention discloses a method for preparing functionalized graphene and a composite material of the functionalized graphene. The method for preparing the functionalized graphene comprises the following steps of: performing Friedel-Crafts reaction on natural graphite which is taken as a raw material to obtain modified graphite, extracting, purifying, and uniformly dispersing in an organic solvent with ultrasonic to form stable graphene suspension liquid. The method for preparing the composite material comprises the following steps of: adding epoxy resin into the graphene suspension liquid, stirring for dissolving, uniformly mixing with ultrasonic, distilling under reduced pressure to remove the organic solvent to obtain a graphene / epoxy resin composite; and adding an epoxy resin curing agent, an accelerant and micrometer silver sheets sequentially, and heating for curing to obtain the composite material of a graphene polymer, namely a graphene / epoxy resin conducting composite material. The edge functionalized graphene has a high interaction between functional groups at the edge and a polymer matrix, so that the dispersion of the graphene in the polymer matrix can be promoted, the agglomeration degree can be reduced, and the interface performance of the composite material can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Epoxy resin composite coating solution, and preparation method and application method thereof

InactiveCN103965745AImprove anti-corrosion performanceImprove adhesionLiquid surface applicatorsEpoxy resin coatingsEpoxyEpoxy resin composite

The invention provides an epoxy resin composite coating solution. The composite coating solution comprises a solvent, epoxy resin and graphene, wherein the graphene is evenly dispersed into the solution, and the graphene accounts for 0.1-10% of the mass of the epoxy resin. In order to avoid agglomerating and improve the dispersion uniformity of the graphene, the graphene preferably is silane coupling agent-modified graphene and simultaneously is supplemented by the physical ultrasonic dispersing technology. The composite coating solution integrates the advantages of the epoxy resin and the graphene, and the obtained coating has low friction coefficient and excellent wear-resisting property when the composite coating solution is used for preparing a coating on the surface of a substrate. Therefore, the epoxy resin composite coating solution is a good anti-wear and anti-friction coating material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

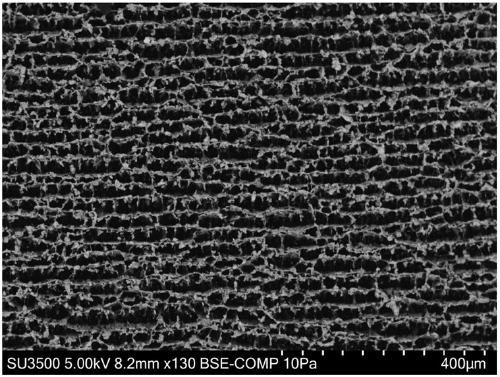

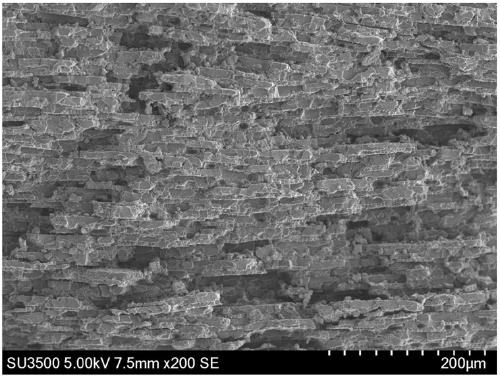

Boron nitride/epoxy resin composite and preparation method and application thereof

ActiveCN109666263AImprove thermal conductivityIncreased anisotropyHeat-exchange elementsEpoxyBoron nitride

The invention relates to boron nitride / epoxy resin composite and a preparation method and application thereof. The preparation method includes: 1) dispersing boron nitride nanosheet and a binder in water to form a mixed solution; 2) subjecting the mixed solution to bidirectional freezing, and removing ice crystal by lyophilization to obtain boron nitride aerogel with lamellar oriented structure; 3) filling the lamellar oriented structure of the boron nitride aerogel with cured epoxy resin to obtain the boron nitride / epoxy resin composite. The preparation method is simple to perform, is available to large-scale preparation and is suitable for industrial scaled application.

Owner:ZHEJIANG UNIV

Method of decomposing thermoset epoxy resin and its composite material

InactiveCN1974641ASolve recycling difficultiesLow monofilament tensile forcePlastic recyclingEpoxyFiber

The method of decomposing thermoset epoxy resin and its composite material is for recovering and reusing thermoset epoxy resin and its composite material. The method of decomposing thermoset epoxy resin includes the steps of adding thermoset epoxy resin and decomposing liquid into reaction kettle; and decomposing. The method of decomposing thermoset epoxy resin composite material includes the steps of adding thermoset epoxy resin composite material and decomposing liquid into reaction kettle; decomposing; solid-liquid separating; and washing and stoving solid matter to obtain decomposed thermoset epoxy resin and reinforcing fiber. The present invention has thermoset epoxy resin decomposing rate of 90-100 % and reinforcing fiber recovering rate of 100 %, and the decomposed product is separated and reused as chemical material.

Owner:HARBIN INST OF TECH

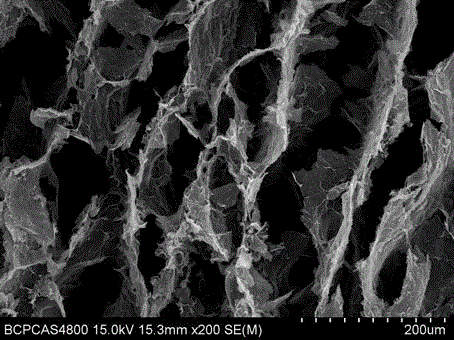

Method for preparing graphene aerogel and application thereof

The invention discloses a method for preparing graphene aerogel and application thereof, and relates to the technical field of graphene materials. The method includes steps of uniformly mixing graphene oxide dispersion liquid and amine curing agents with one another to obtain graphene oxide mixed liquid; hermetically heating the obtained graphene oxide mixed liquid to obtain the graphene aerogel. The amine curing agents are one type of or a plurality of types of diaminodiphenyl-methane, diamino diphenyl sulfone, diethylenetriamine, triethylenetetramine, diethylaminopropylamine and m-phenylenediamine. The graphene aerogel prepared by the aid of the method can be applied to epoxy resin, so that graphene aerogel / epoxy resin composite materials with high conductivity and excellent mechanical properties can be obtained. The method and the application have the advantages that the graphene aerogel prepared by the aid of the method is internally of a uniform macroporous structure and is high in porosity; the amine curing agents are adopted in preparation procedures, accordingly, the epoxy resin interface bonding can be improved, and the conductivity and the mechanical properties of the epoxy resin can be enhanced.

Owner:BEIJING UNIV OF CHEM TECH

Composite coated jaw faces

Clamp or grip faces used in fiber / fabric tensile testing instruments are coated with an aramid-epoxy composite, thus allowing high-strength fiber / fabric samples to be tested with greater reproducibility at lower applied pressure and without clamp or grip face scarring.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com