Patents

Literature

166 results about "Furniture industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignin-epoxy resin composite material and preparation method thereof

The invention discloses a lignin-epoxy resin composite material and a preparation method thereof, relates to a lignin-polymer composite material and a preparation method thereof, and aims to solve the conventional problem of low effective utilization rate of lignin. The lignin-epoxy resin composite material uses the lignin as a substrate; epoxy resin, a curing agent, a toughening agent, and the like are evenly blended with the lignin; and through the processes of pre-pressing, hot-pressing and curing molding, the lignin-based composite material is obtained. The lignin-epoxy resin composite material disclosed by the invention has the advantages of little water absorption, good mechanical performance, degradability, and the like, is suitable for manufacturing floor boards, wall protection boards, construction formworks, door-window profiles, fences, guardrails, louvers, roof boards, and the like in the construction industry, can be used for manufacturing inner decorative boards of automobile doors, seat backing boards, automobile roof lining, and the like in the automobile industry, and can also be used in the fields of the packaging and transportation industry, the furniture industry, office articles, sports facilities, and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

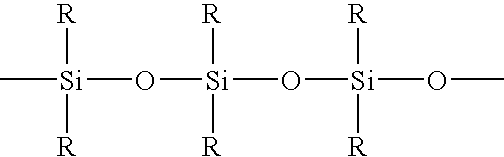

High resilient silicone foam and process for preparing same

A method for producing a novel silicone foam by reaction of a polyisocyanate with a silicone oligomer having a plurality of functional end groups with active hydrogens, optionally in the presence of fire-retardants, under foam forming conditions which creates a new silicone foam for use in items such as residential upholstered furniture industry, seat cushions and bedding etc., and specifically for use in applications that require, high resilience and fire-retardant properties such as aircraft and surface transportation seat cushioning, military and shipboard mattresses etc.

Owner:CHESTNUT RIDGE FOAM

High strength low density board for furniture industry

InactiveUS6268042B1Decreasing mineral wool contentIncreasing cellulosic fiber contentConstruction materialSolid waste managementCellulose fiberHigh intensity

A high strength, low density fiber board panel for use in the furniture industry is provided, including mineral wool, a lightweight aggregate material, cellulosic fiber, a binding agent and gypsum. The mineral wool makes up approximately 0% to 33%, the lightweight aggregate material approximately 25% to 41%, the cellulosic fiber approximately 20% to 35%, the binding agent approximately 5% to 9%, and the gypsum approximately 0% to 23%, of the dry solids weight of the panel.

Owner:UNITED STATES GYPSUM CO

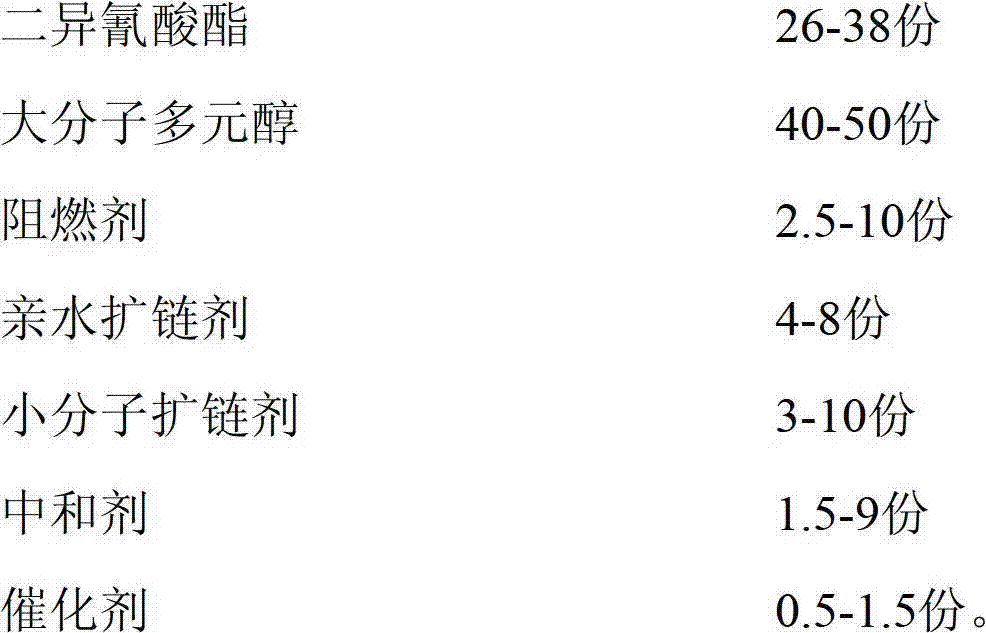

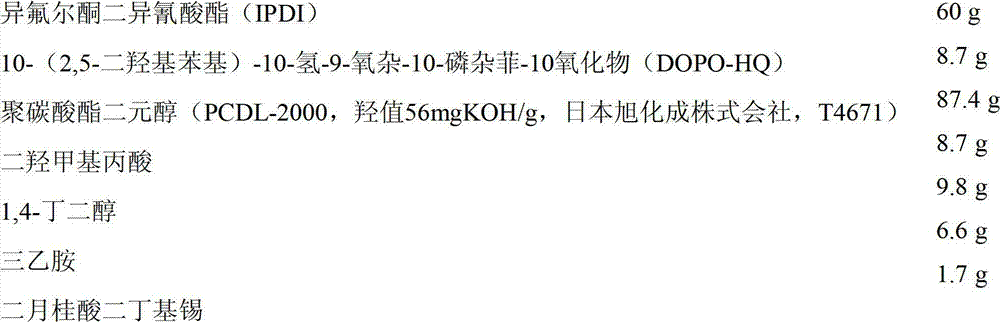

Environment-friendly flame-retardant polyurethane emulsion and preparation method thereof

ActiveCN103030770AGood internal flame retardant effectImprove water resistanceChemical structureEmulsion

The invention discloses an environment-friendly flame-retardant polyurethane emulsion and a preparation method thereof, wherein the environment-friendly flame-retardant polyurethane emulsion is composed of the following raw materials in parts by weight: 26-38 parts of diisocyanate, 40-50 parts of macromolecular polyatomic alcohol, 2.5-10 parts of a flame retardant, 4-8 parts of an hydrophilic chain extender, 3-10 parts of a micromolecular chain extender, 1.5-9 parts of a neutralizer, and 0.5-1.5 parts of a catalyst. According to the invention, a chemical structure with a flame-retardant function is introduced onto a main chain of polyurethane, so aqueous polyurethane has the flame-retardant performance and the application range of the aqueous polyurethane is enlarged; and in addition, gradually increased requirements on the flame-retardant performance in the furniture industry and the construction industry are satisfied.

Owner:HEFEI UNIV OF TECH

Nonreactive Thermoplastic Hot Melt Adhesives Based on Metallocene-Catalytically Manufactured Polyolefins

ActiveUS20080190541A1Different indexReduce the temperatureLaminationLamination apparatusWaxPolymer science

The invention relates to an adhesive system which is based on a non-reactive thermoplastic adhesive melt. The adhesive melt (A) contains a mixture of at least two metallocene-catalytically produced copolymers which are different from each other, and which are based on at least two a-olefins, whereby the copolymers of the mixture, which are different from each other, have different melt indices (MFIs); (B) optionally, at least one additional polymer; and (C) optionally, at least one resin and / or at least one wax. The inventive adhesive system is particularly suitable for use in the wood and furniture industry, e.g. for covering profiles or for gluing edges, in particular, by comparing copolymer adhesives to EVA melt adhesives which are used in a traditional manner, and the system enables considerably lower application temperatures to be used, and at the same time exhibiting improved adhesion capacity.

Owner:JOWAT

Method for laminating plastic films with wood-base substrates, in particular for producing high-gloss surfaces

The invention relates to a method for laminating a plastic film with a wood-base substrate, in particular for producing a high-gloss surface on a wood-base substrate, in which a plastic film is laminated by means of a laminating agent, preferably an adhesive, with a wood-base substrate and permanently bonded to the wood-base substrate, the plastic film being formed so as to be transparent on its top, and the products obtainable in this manner and their use, in particular in the area of the wood and furniture industry, for example for the production of pieces of furniture and fitments of all kinds.

Owner:JOWAT

High-hardness and wear-resistance aqueous wood lacquer and preparation method thereof

The invention discloses high-hardness and wear-resistance aqueous wood lacquer and a preparation method thereof. The wood lacquer is prepared from the following raw material in part by weight: 500 to 850 parts of aqueous polyurethane dispersion, 0 to 350 parts of acrylic acid emulsion, 90 to 110 parts of nano aluminum oxide slurry, 2 to 5 parts of defoaming agent, 4 to 6 parts of wetting agent, 1 to 2 parts of pH regulator, 13 to 15 parts of film-forming assistant, 3 to 5 parts of leveling agent, 3 to 5 parts of thickener, 2 to 4 parts of slipping agent and 15 to 25 parts of deionized water. Because the nano aluminum oxide additive is added into the aqueous wood lacquer system, the hardness and wear resistance of the aqueous wood lacquer are improved; and the aqueous wood lacquer is environmentally-friendly, stable in performance and suitable for home decoration and furniture industry.

Owner:王奇

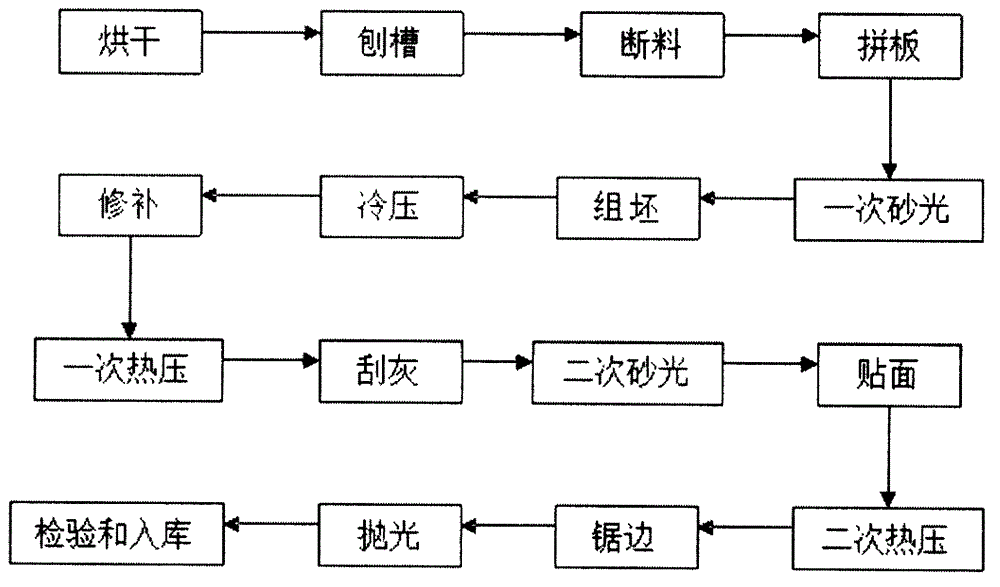

Manufacture process for eucalyptus core plate

InactiveCN102975269AImprove textureBeautiful border patternWood working apparatusEngineeringFurniture industry

The invention discloses a manufacture process for a eucalyptus core plate. The manufacture process comprises the following steps of: drying, groove planing, material cutting, plate joining, primary sanding, assembly, cold pressing, repairing, primary heat pressing, ash scraping, secondary sanding, surfacing, secondary heat pressing, edge sawing, polishing, inspecting, putting in storage and the like. The manufactured eucalyptus core plate has the advantages of good quality, attractive patterns on an edge, a smooth plate surface, large density, heavy weight, sensibility of thickness, easiness in processing, excellent nail holding force, non-deformation and the like. According to the manufacture process, core bars inside the eucalyptus are recycled and processed to form a eucalyptus core plate, thus the energy is saved, the cost is lowered, and the manufactured eucalyptus core plate can be applied in various fields of furniture industry.

Owner:GUANGXI AUS SINO WOODY IND

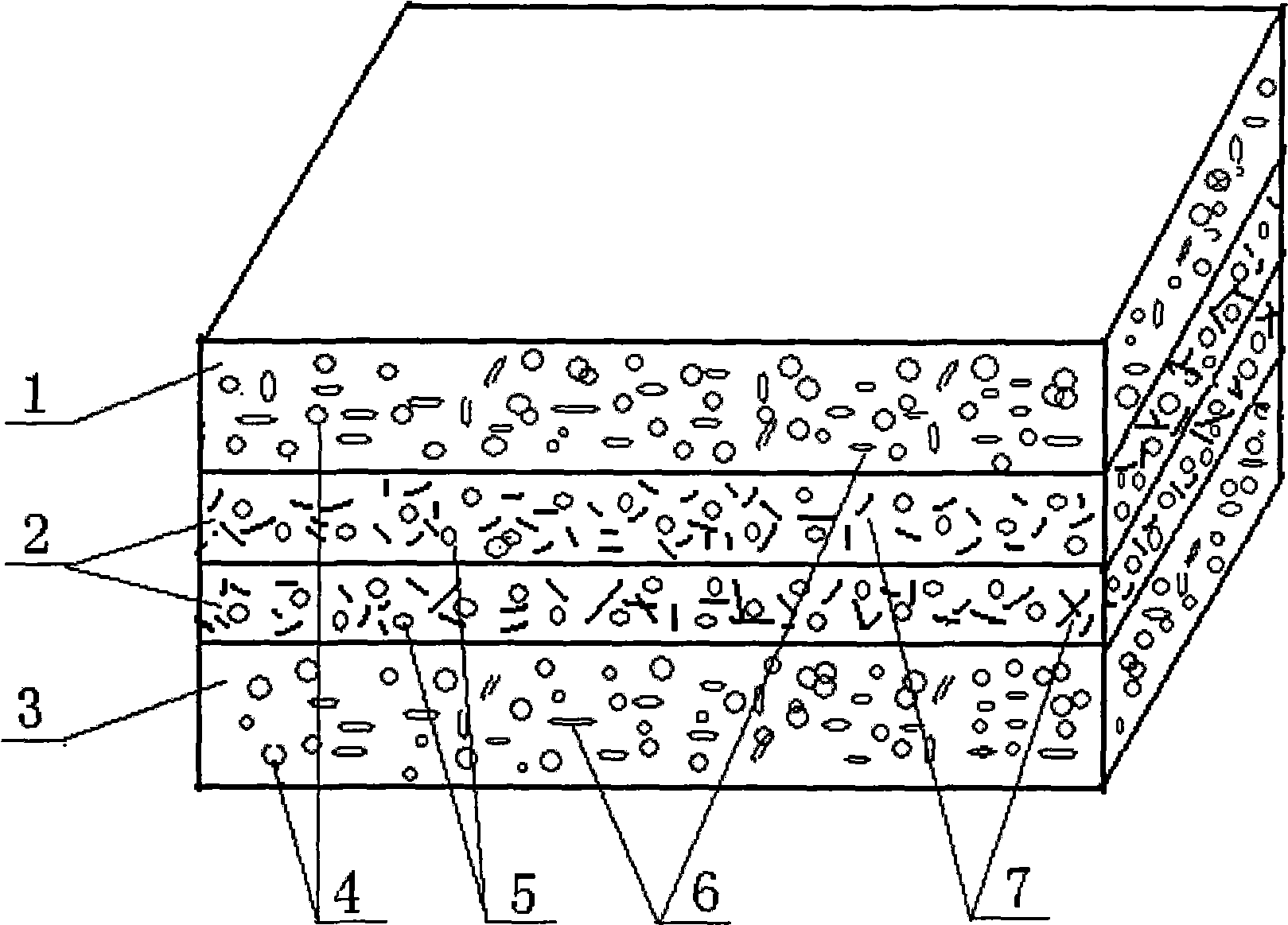

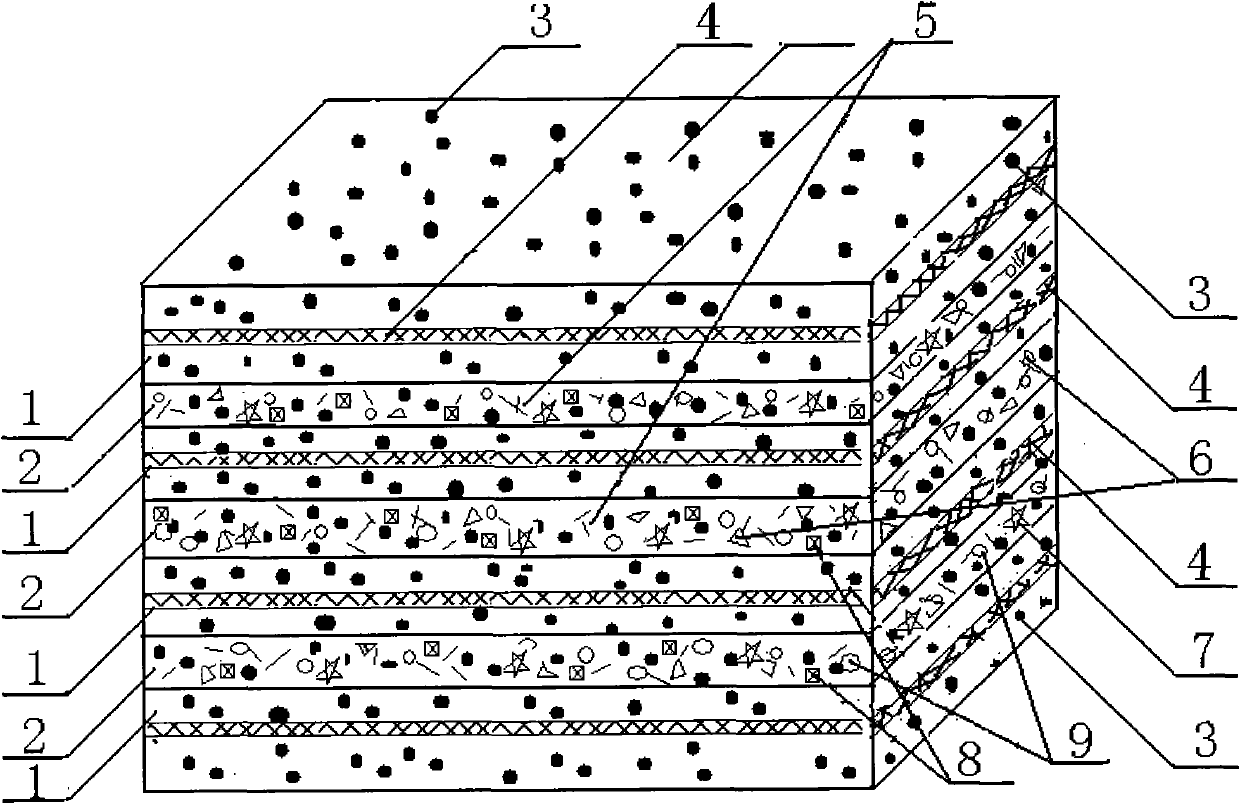

Surface flame-retardant wood-plastic composite material plate and preparation thereof

InactiveCN101486267AReasonable designSimple structureSynthetic resin layered productsFiberMagnesium Sulfate whiskers

The invention relates to a surface flame retarded wood plastic composite plate and a method for preparing the same, which relates to a composite material, an environment-friendly material and a method for preparing the same. The composite material is applicable to making the following products: floor boards, shelf boards, and the like for means of transportation such as automobiles, planes, and the like in the field of transportation; road slabs, fences, wallboards, aisle guard bars, and the like in the field of construction; and outdoor desks and chairs, office partition boards, storage boxes, flower boxes, adjustable shelves, beach chairs, and the like in the furniture industry. The surface flame retarded wood plastic composite plate consists of two layers of crystal whisker modified plastic layers and plant fiber reinforced plastic layers, wherein the plant fiber reinforced plastic layers are arranged between the two layers of the crystal whisker modified plastic layers through die stamping. The crystal whisker modified plastic layers are made from modified basic magnesium sulfate whiskers, plastic particles, and the like through mixed calendering. The plant fiber reinforced plastic layers are made from plastic particles and plant fibers through mixed calendering.

Owner:NANJING FORESTRY UNIV

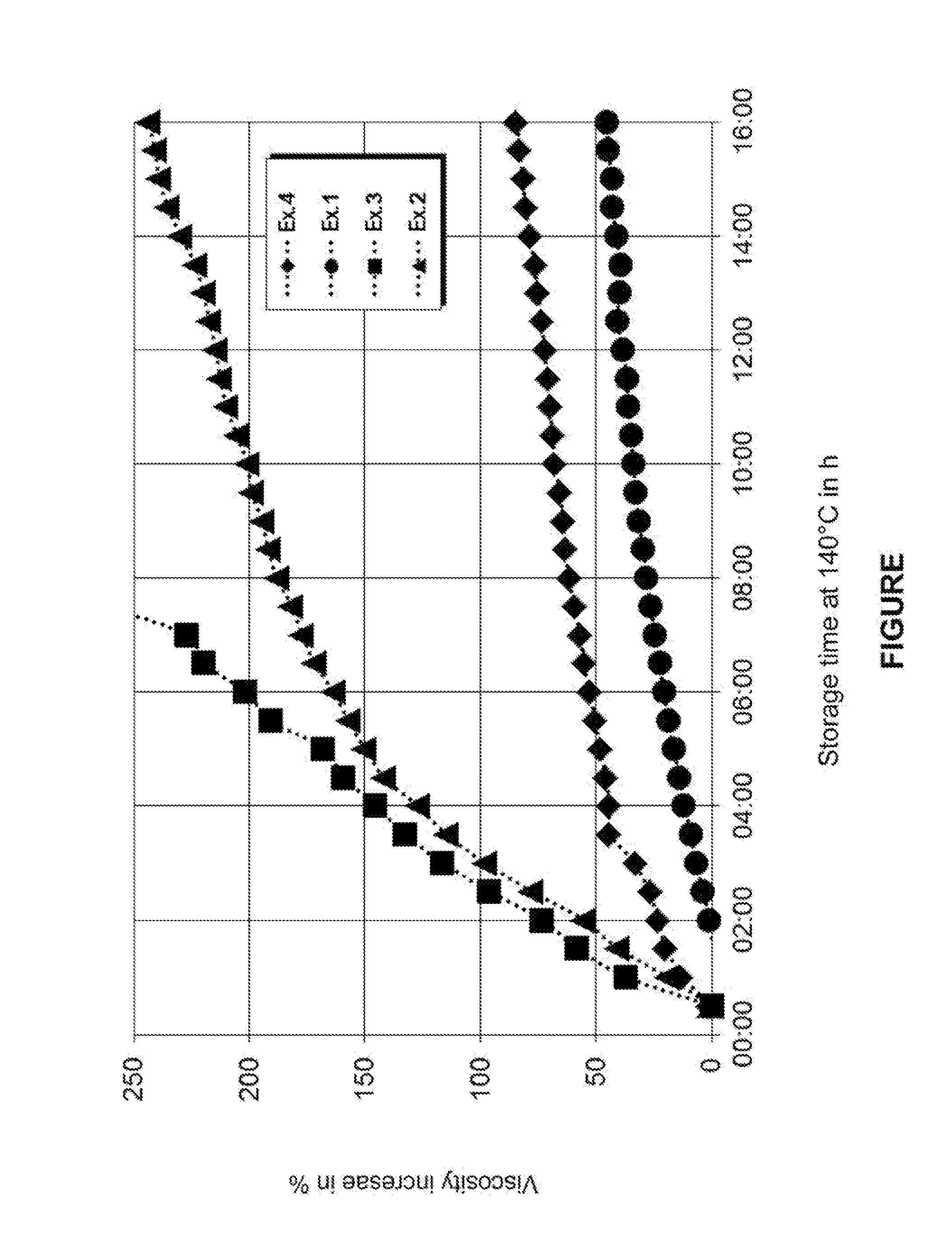

Nonreactive thermoplastic hot melt adhesives based on metallocene-catalytically manufactured polyolefins

ActiveUS8366865B2Different indexReduce the temperatureLaminationLamination apparatusWaxPolymer science

The invention relates to an adhesive system which is based on a non-reactive thermoplastic adhesive melt. The adhesive melt (A) contains a mixture of at least two metallocene-catalytically produced copolymers which are different from each other, and which are based on at least two a-olefins, whereby the copolymers of the mixture, which are different from each other, have different melt indices (MFIs); (B) optionally, at least one additional polymer; and (C) optionally, at least one resin and / or at least one wax. The inventive adhesive system is particularly suitable for use in the wood and furniture industry, e.g. for covering profiles or for gluing edges, in particular, by comparing copolymer adhesives to EVA melt adhesives which are used in a traditional manner, and the system enables considerably lower application temperatures to be used, and at the same time exhibiting improved adhesion capacity.

Owner:JOWAT

Steel-based multifunctional ceramic composite coating and preparation method thereof

InactiveCN101579958AImproved thermal shock stabilityIntegrity guaranteedMolten spray coatingCeramic layered productsChemical industryCeramic composite

The invention discloses a steel-based multifunctional ceramic composite coating and a preparation method thereof, comprising an iron and aluminum alloy layer, an alumina coating, a silicon dioxide coating and a silicon carbide coating which are adhered on the surface of alloy steel. The invention provides a method which takes iron and aluminium powder, alumina powder, silicon dioxide (quartz) powder, and silicon carbide powder as raw materials, utilizes the vacuum plasma spraying technology to prepare the composite coating on the surface of the base material of the alloy steel, and finally utilizes the hot isostatic pressing technology to carry out densification treatment to the composite coating so as to ultimately obtain the novel alumina / silicon dioxide / silicon carbide multi-functionalceramic composite coating. The method has concise procedures, is convenient for large-scale production, is not only applicable to fusion reactor with rigorous requirement and other nuclear industry fields, but also applicable to the fields of chemical industry, daily furniture industry, electrical appliance industry, manufacturing industry, boiler and high temperature resistant material and the like.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Anti-cracking technology of solid wood

InactiveCN102189578AAvoid crackingAvoid deformationWood treatment detailsWood impregnation detailsSolid woodPulp and paper industry

The invention relates to a processing method of wood of the furniture industry, in particular to an anti-cracking technology of solid wood. The anti-cracking technology of the solid wood sequentially comprises the following steps of: (1) soaking a raw wood in a water tank for 60 to 90 days; (2) cutting the soaked raw wood into boards according to the required size; (3) steaming the boards in a steam box for 2 to 4 days; and (4) drying the steamed boards to a required moisture content. The raw wood is soaked for long time so as to lead the raw wood to die really; the boards are steamed for days; the wood is plasticized so that the boards are more tougher; the boards and the wood are combined so as to lead the wood to be tough, tensile and firm and is not easy to crack; and a special drying technology of first natural drying and then alternating temperature drying prevents the wood from cracking and deforming in the drying process.

Owner:ZHEJIANG MOXIA IND

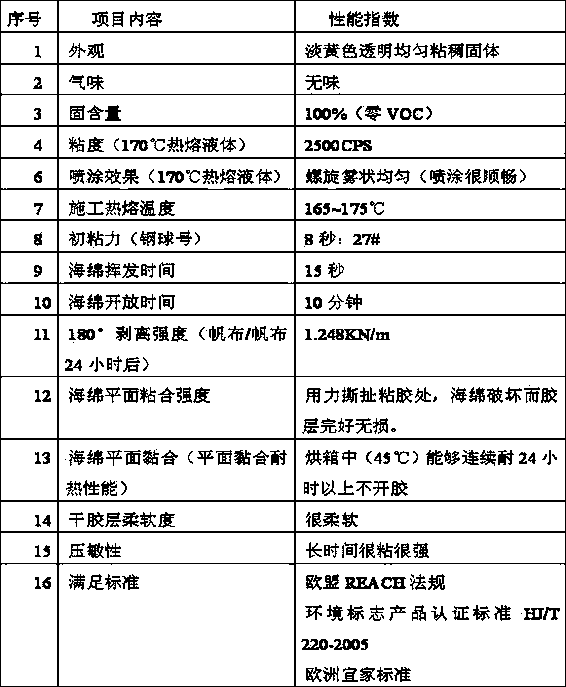

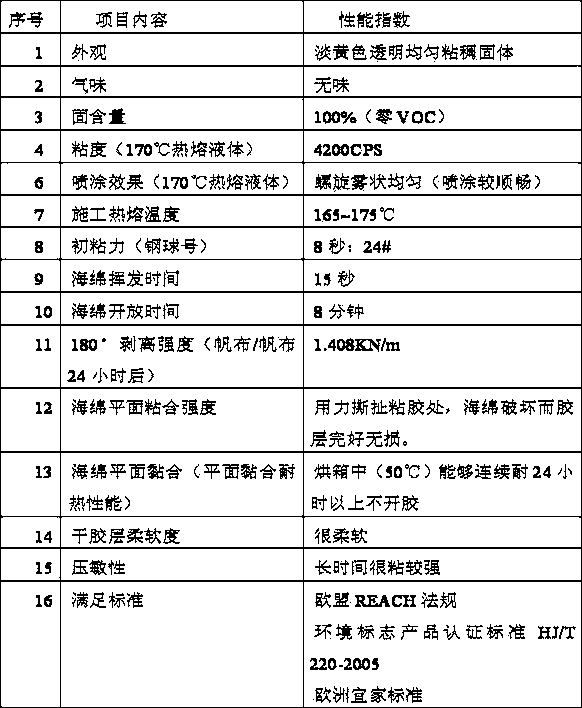

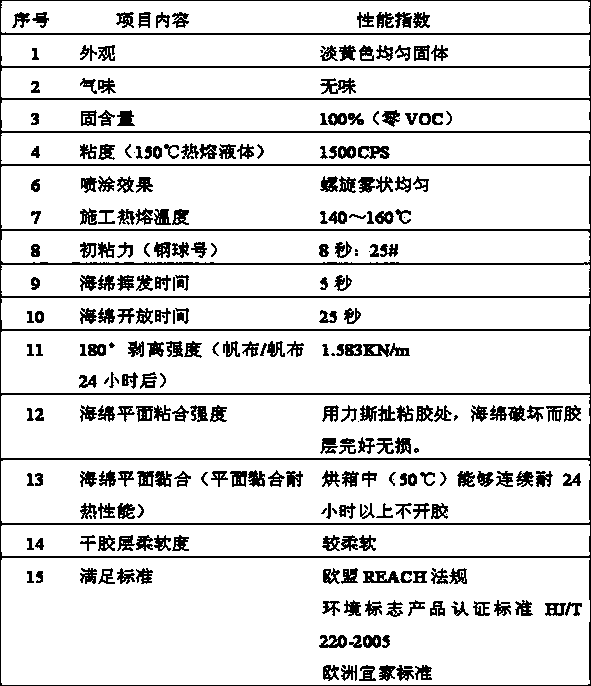

Environment-friendly hot-melt pressure-sensitive adhesive capable of being sprayed and preparation method thereof

ActiveCN103805112AReduce usageGet rid of severe constraintsMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention discloses an environment-friendly hot-melt pressure-sensitive adhesive capable of being sprayed and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following main components in percentage by weight: 20 percent of SIS (Styrene Isoprene Styrene) thermoplastic styrene isoprene copolymer rubber of which the melt index is 6, 8 percent of SBS (Styrene Butadiene Styrene) thermoplastic butadiene styrene rubber of which the melt index is 8, 7 percent of water-white hydrogenated rosin, 10 percent of white disproportionated hydrogenated rosin glycerol ester, 8 percent of pale yellow modified terpene resin, 5 percent of C5 petroleum resin, 7.5 percent of white tackifying resin, 3 percent of polyisobutene and 4 percent of sasol wax. The environment-friendly hot-melt pressure-sensitive adhesive disclosed by the invention contains no organic solvent, zero VOC (volatile organic compounds), no heavy metals and no smell, is totally green, environment-friendly and nontoxic, has the advantages of being excellent in adhesive property, large in peel strength, high in drying speed, long in opening time, glue-saving, convenient for construction, low in cost, fireproof, safe and the like, and is widely applied to upholstered furniture industries such as mattresses, sofas, swivel chairs, pillows, screens and the like as well as sanitation product industries such as diapers, sanitary towels and the like, especially suitable for application in Europe and America environment-friendly high-grade export products and products for children.

Owner:深圳市顾康力化工有限公司

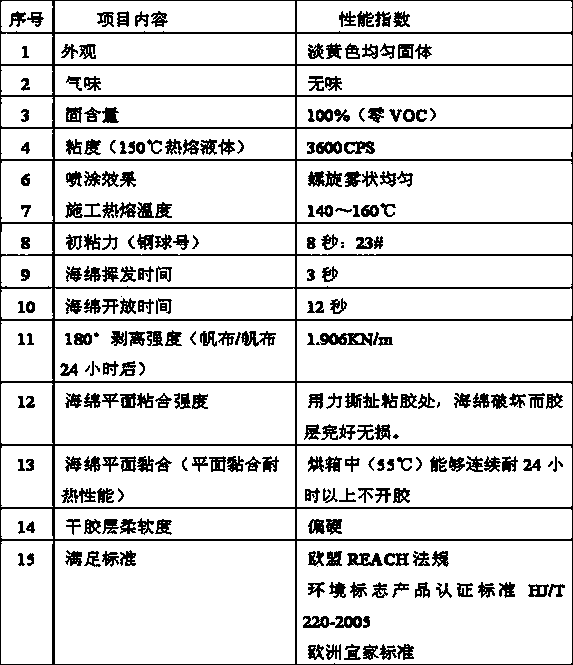

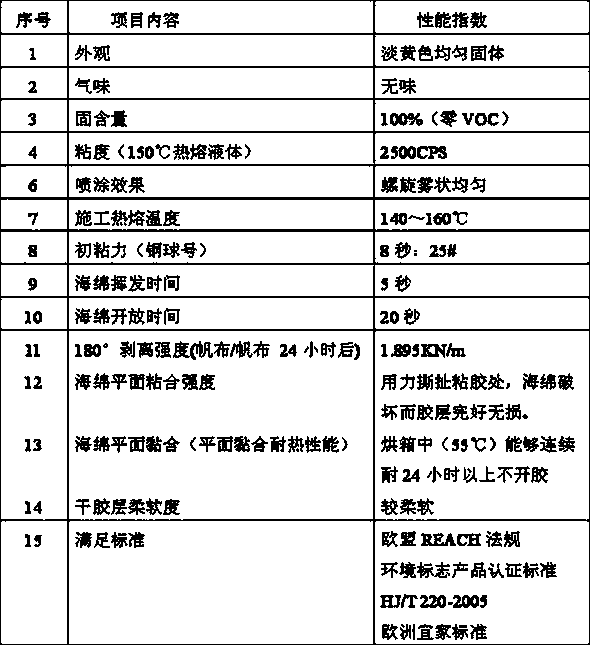

Sprayable environment-friendly hot melt glue and preparation method thereof

ActiveCN103805098AReduce usageGet rid of severe constraintsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMicrocrystalline waxEngineering

The invention discloses sprayable environment-friendly hot melt glue and a preparation method thereof. The spray glue mainly comprises the following components in percentage by weight: 12% of EVA thermoplastic resin with melting index 30, 18% of EVA thermoplastic resin with melting index 65, 10% of water-white rosin, 12% of water-white hydrogenated rosin, 8% of C9 petroleum resin, 14.5% of white tackifying resin, 5% of polyisobutene and 8% of microcrystalline wax. The sprayable environment-friendly hot melt glue disclosed by the invention has comprehensive advantages in multiple aspects such as environmental friendliness and no toxin, no organic solvent, zero VOC, no heavy metal or odor, good initial viscous force, high bonding strength, high permanent adhesion, heat and aging resistance, high drying speed, large spray area of unit weight (saving glue) and efficient and quick spraying construction, and has the advantages of complete environmental friendliness, improvement of the operation and construction environment, low cost, no odor, fire safety and the like, and is widely applied to the upholstered furniture industries such as sofa, swivel chairs, mattress, pillows and screens and especially applicable to the European and American environment-friendly high-grade exported products and children products.

Owner:深圳市顾康力化工有限公司

One-component, high-solid-content and low-crystallinity polyurethane resin and preparation method thereof

The invention relates to a one-component, high-solid-content and low-crystallinity polyurethane resin and a preparation method thereof. The polyurethane resin comprises the following components by mass: 1 to 11% of isophorone diisocyanate, 9 to 34% of diphenylmethane-4, 4'-diisocyanate, 11 to 50% of polyadipate type polyester polyol, 1 to 31% of castor oil, 0.5 to 8% of chain extender, and 20 to 50% of solvent, wherein the solvent is the mixture of N, N-dimethylformamide and butanone or the mixture of the N, N-dimethylformamide and acetic ether. The polyurethane resin provided by the invention is high in solid content and low in crystallinity, and can be applied to the synthetic leather industry, such as the bags industry, the clothing industry and the furniture industry.

Owner:SHANGHAI HUIDE TECH CO LTD

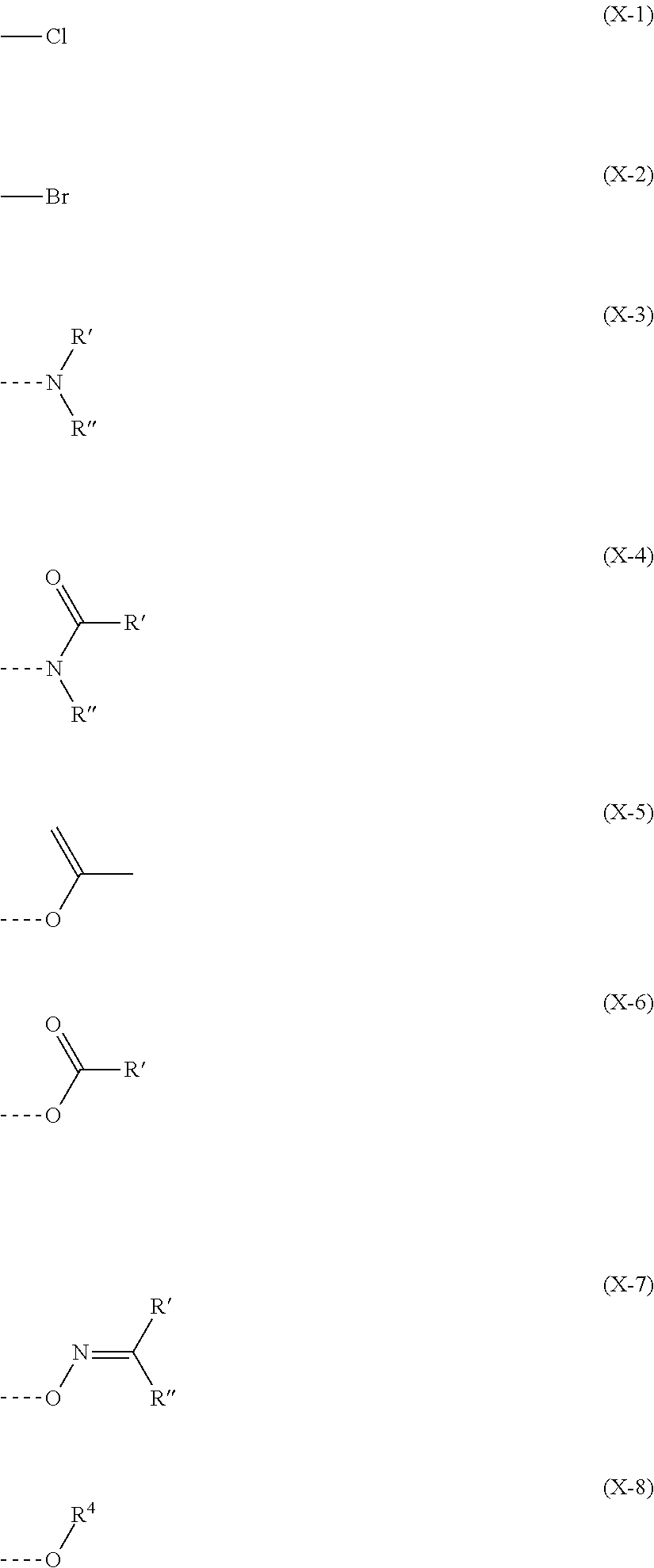

Polyurethane hot-melt adhesive having a low content of diisocyanate monomers and good cross-linking speed

ActiveUS20170002239A1Reduce contentStable storageAdhesive processesPolyureas/polyurethane adhesivesPolymer scienceHot melt

A moisture-cured hot-melt adhesive can be formulated as a PUR-HM that is R-40 classification-free and stable during storage and processing, having a residual monomer content of less than 1 wt. % and having good cross-linking density and full-curing speed. The hot-melt adhesive is particularly suitable for vehicle construction in industrial manufacture, in particular of automobiles, in the textile or furniture industry or in the packaging industry.

Owner:SIKA TECH AG

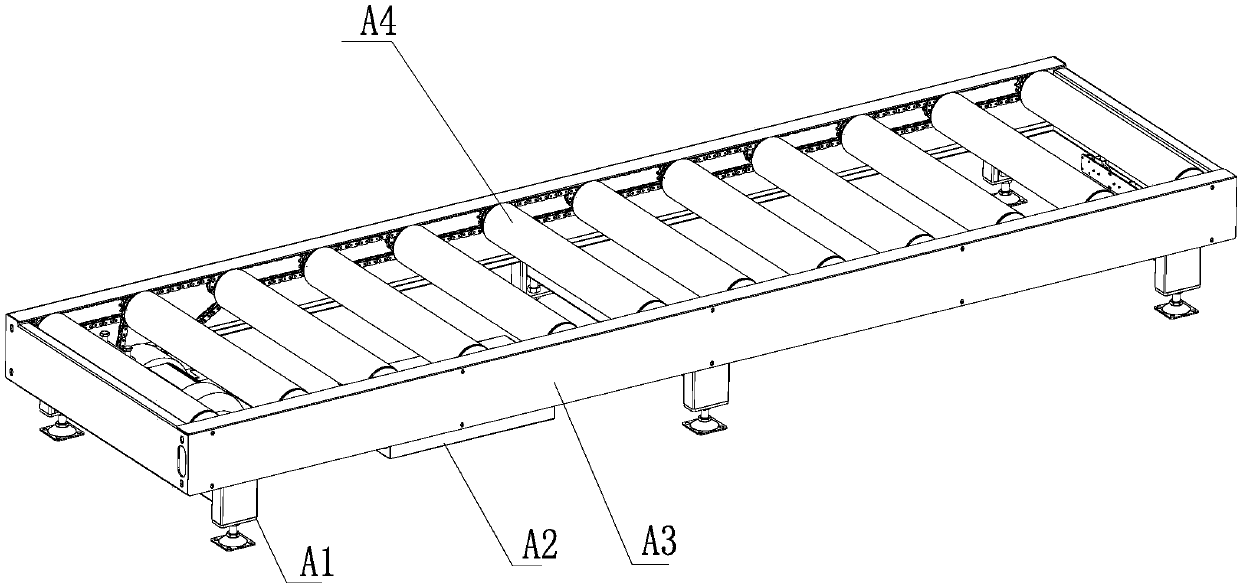

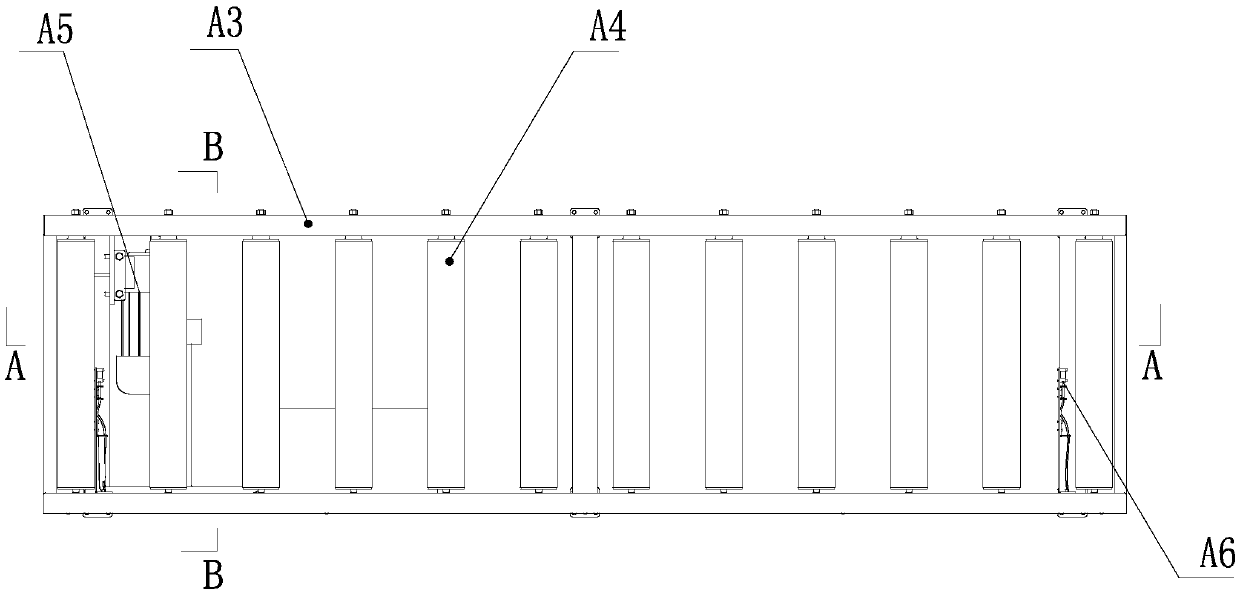

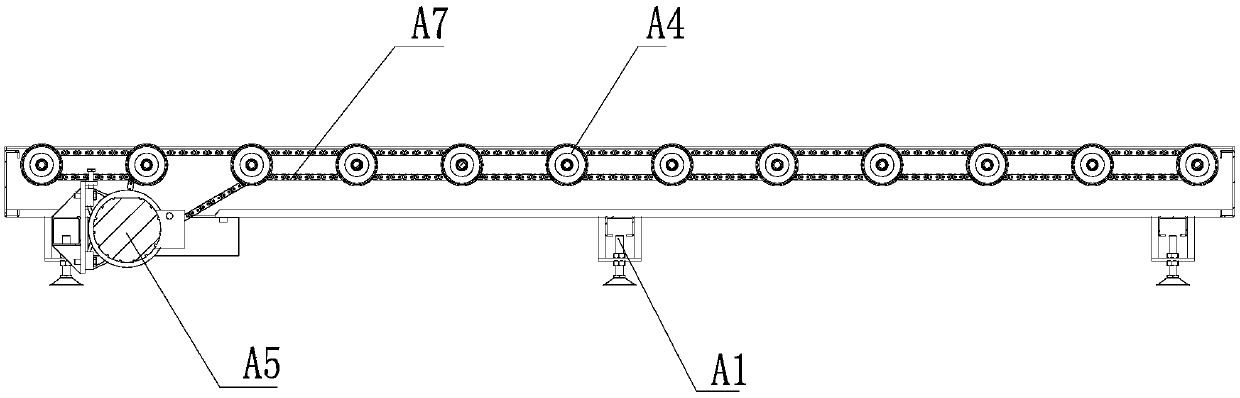

Panel furniture flexible production line

PendingCN109531757AFully automatedRealize intelligent productionOther plywood/veneer working apparatusConveyorsProduction lineStack machine

The invention discloses a panel furniture flexible production line. The panel furniture flexible production line comprises a panel storage mechanism, a rail trolley for conveying and a plate banding mechanism, and further comprises a power roller conveying line used for conveying panels, an electronic saw discharging machine used for discharging materials, a rotary lifting table used for transferring the panels, a vertical rotary sorting machine used for sorting the panels, a box sealing machine used for sealing and casing finished-products of panel furniture and a roadway stacking machine used for stereoscopic storage and automatic warehouse outlet of the finished-products of the panel furniture. By adopting the panel furniture flexible production line, customized production in the furniture industry is realized; the panel furniture flexible production line is applicable to both large-scale standard product production and small-scale customized production; labor cost is reduced; and automatic and intelligent production of the furniture is realized.

Owner:广东友力智能科技有限公司

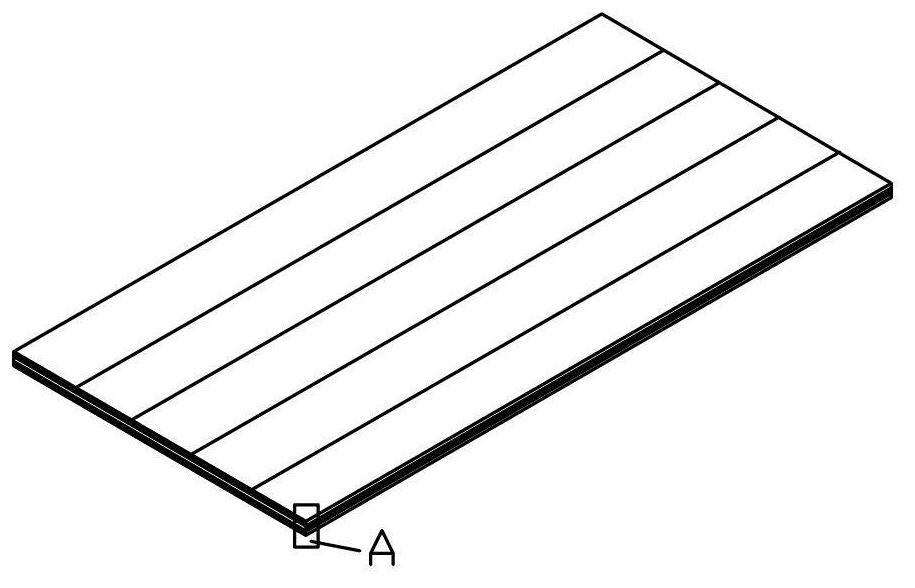

Solid wood sawed composite board and machining process

InactiveCN102689338AAvoid crackingDoes not disrupt stress balanceWood veneer joiningWood layered productsSolid woodAdhesive

The invention discloses a solid wood sawed composite board and a machining process, and relates to the solid wood sawed composite board which is used in industry, agriculture, building material industry and furniture industry. The solid wood sawed composite board is characterized by consisting of a plurality of layers of dried and sawed solid wood veneers and an adhesive, wherein the solid wood veneers are trimmed and then aligned and tiled; the trimmed edges of the solid wood veneers are adhered into a veneer solid wood board through the adhesive; two to nine veneer solid wood boards are adhered through the adhesive and are compacted into a multi-layer solid wood sawed composite board; and fibers of two adjacent veneer solid wood boards of the solid wood sawed composite board are laminated in vertical direction or laminated and adhered in a parallel or staggered way. The process flow of the machining process comprises the following steps of: drying the board; sawing the veneer; performing secondary balancing on the veneer; trimming; placing in a balanced staggered way, placing in a cross vertical mode and coating the adhesive; performing cold pressing or hot pressing adhesion; sanding and trimming; and finishing. The solid wood sawed composite board has the characteristics of novel structure, easiness and convenience in machining, non-deformation, less using amount of the adhesive, environmental friendliness, health and the like.

Owner:周连群

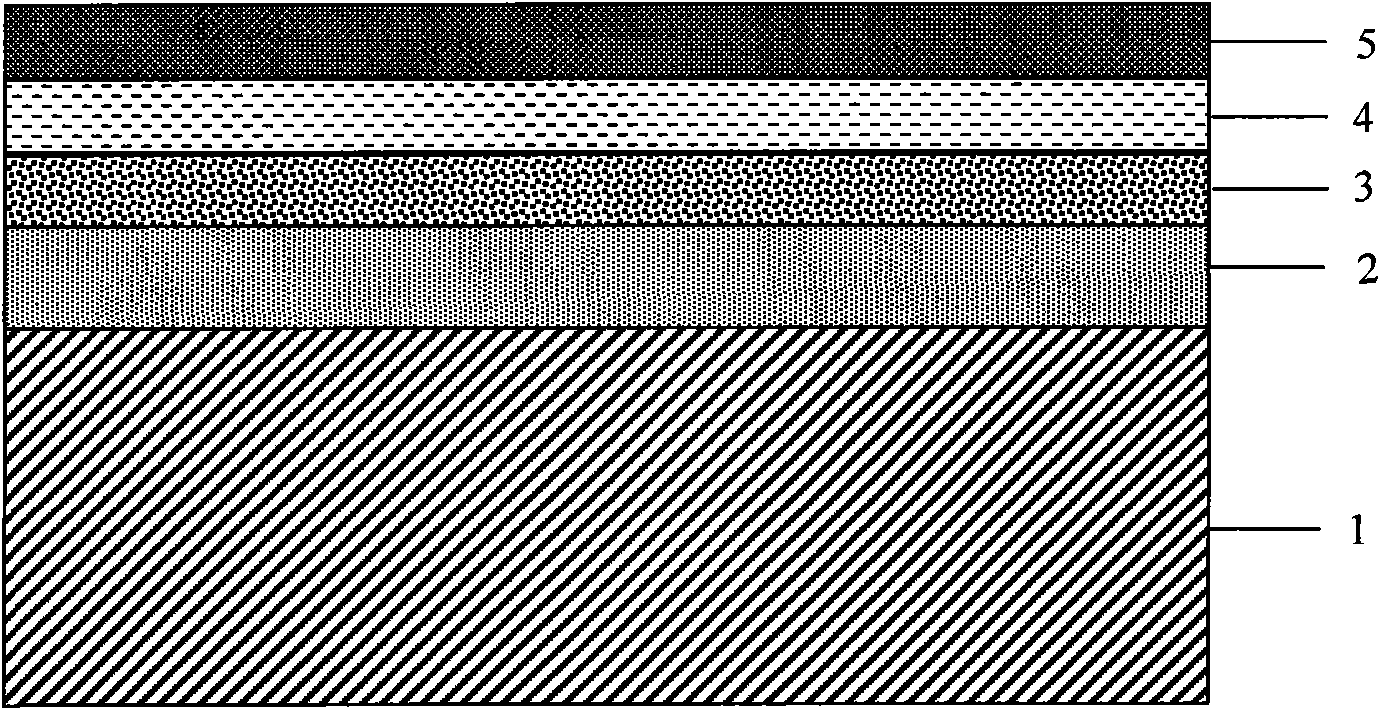

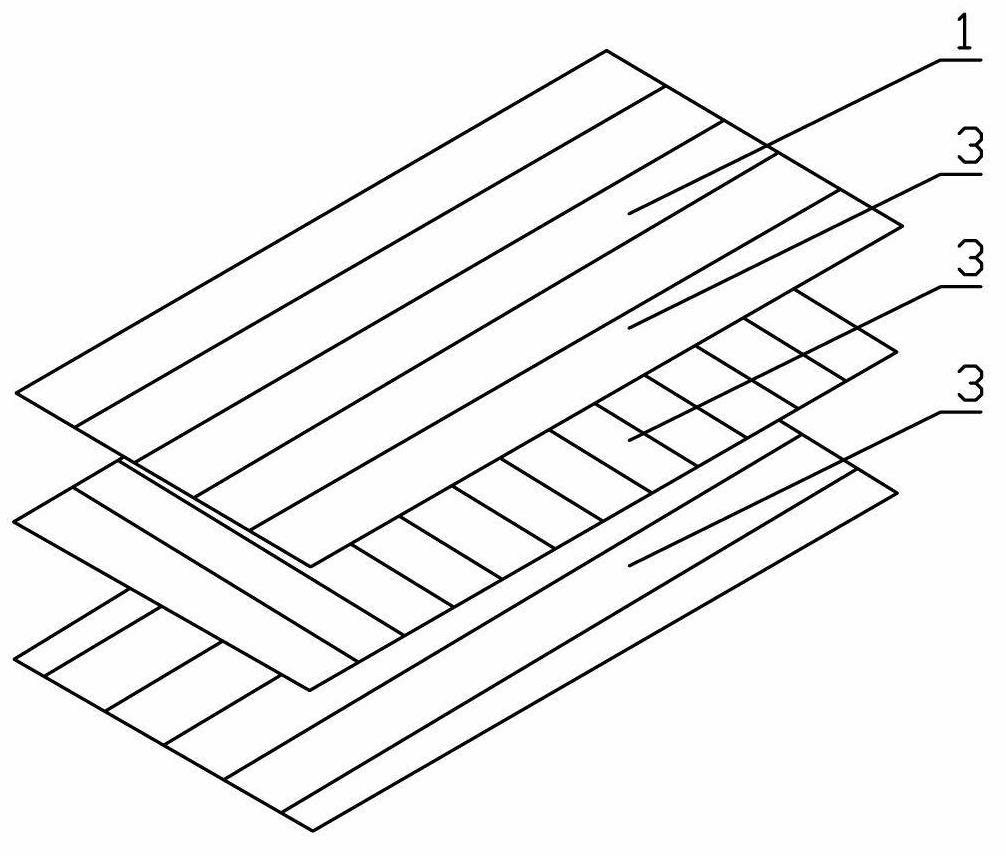

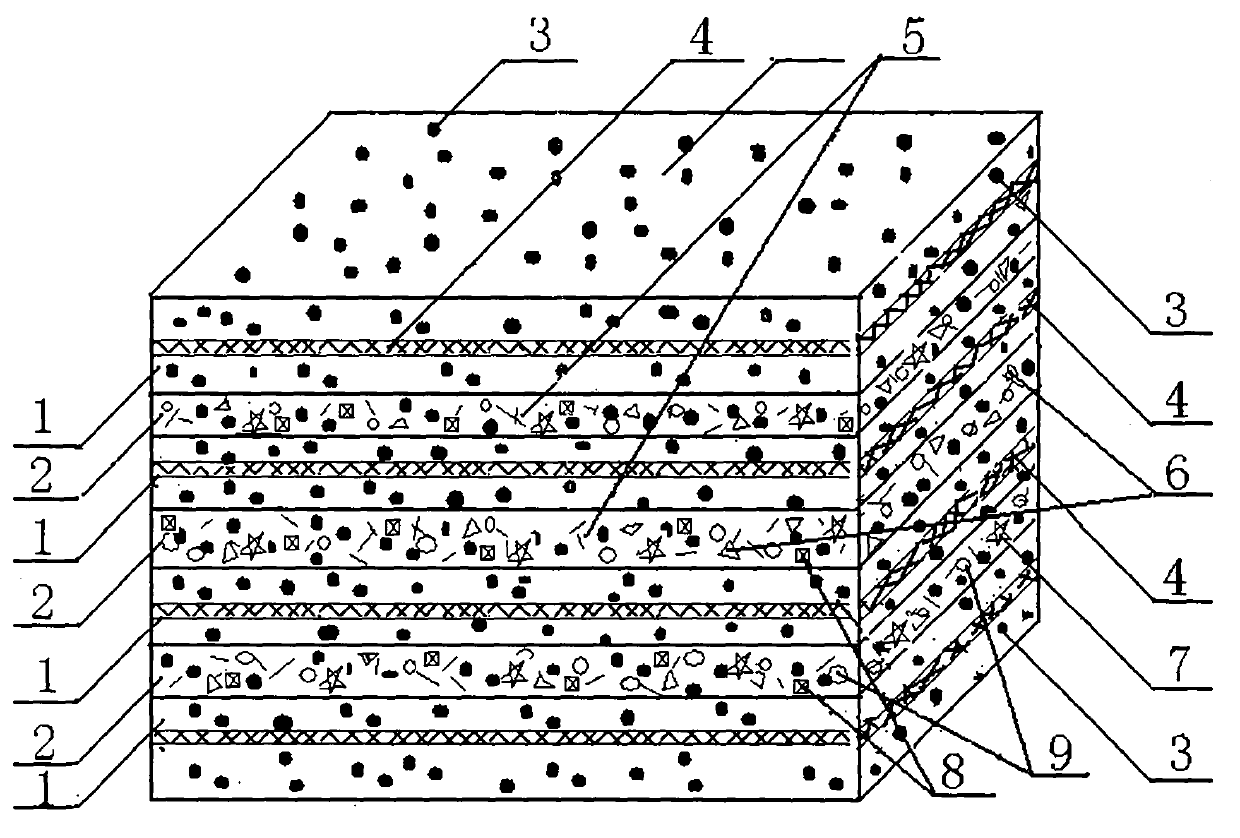

Sandwich material plate and preparation method thereof

InactiveCN102001200ASimple structureReasonable designSynthetic resin layered productsLaminationFiberPlasticizer

The invention discloses a sandwich material plate and a preparation method thereof, relates to a composite material, an environment-friendly material and a preparation method thereof, and is applied to manufacturing door plates, instrument panel frames, trunk liners, rear shelf panels for vehicles and the like of automobiles, airplanes and other means of transportation, building templates, clapboards, seaside floors, industrial floors and the like in the field of buildings, outdoor open tables and chairs, storage tanks, movable shelves and the like in the furniture industry, and pavement plates, flower boxes and the like in municipal landscape engineering. The sandwich material plate consists of 2 to 4 layers of flax fabric reinforced plastic layers and wood plastic composite material layers, wherein 3 to 5 wood plastic composite material layers are pressed between two adjacent flax fabric reinforced plastic layers; the flax fabric reinforced plastic layers are formed by pressing flaxfabrics treated by plastic particles and silane coupling agents; and the wood plastic composite material layers are prepared by drying, mixing and rolling the plastic particles, wood powder, interface solubilizers, calcium carbonate, lubricating agents and plasticizers.

Owner:NANJING FORESTRY UNIV

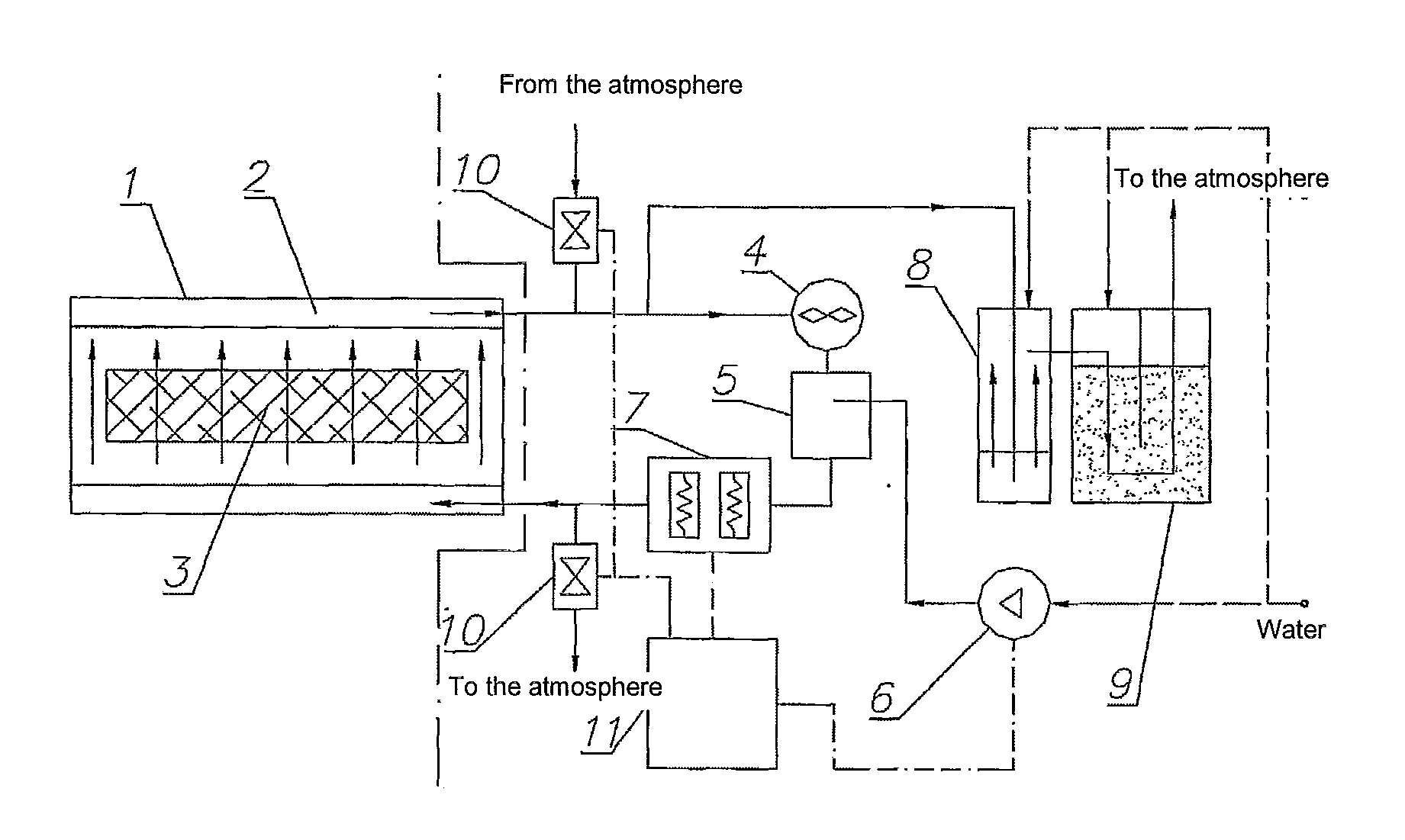

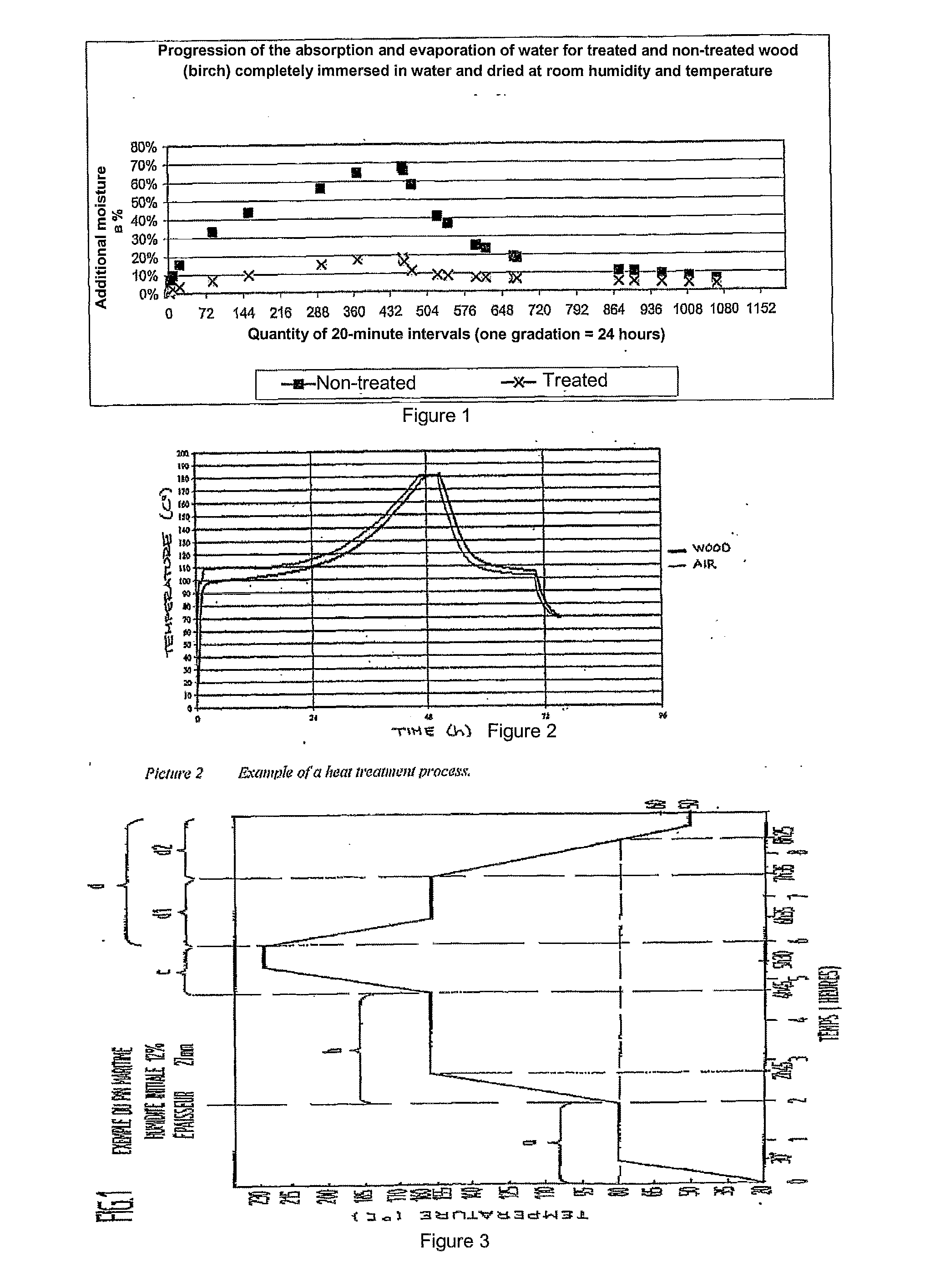

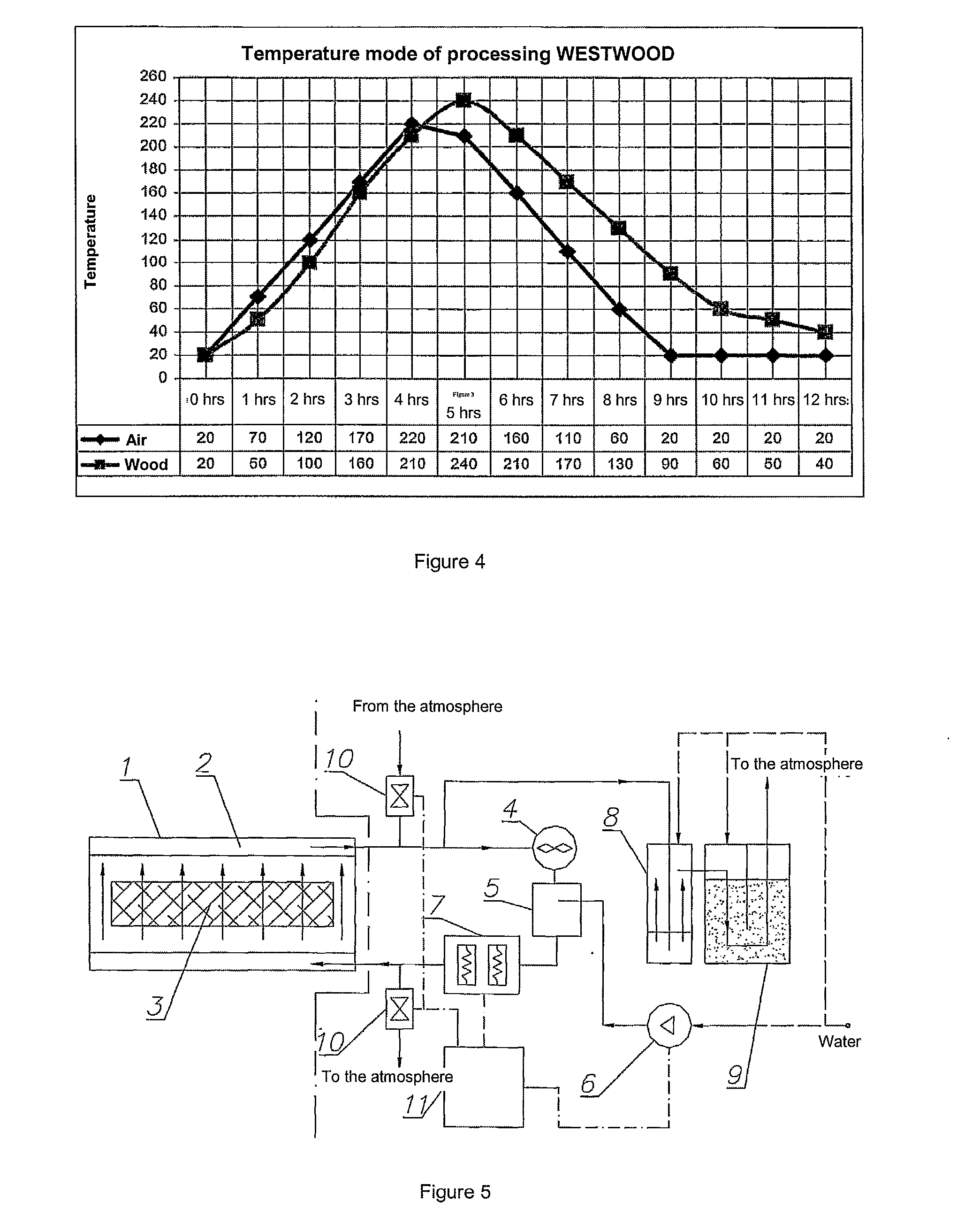

Method for wood heat treatment and a device for carrying out said method

InactiveUS20110020568A1Improve stabilityImprove the immunityDrying using combination processesDead plant preservationElectricityControl signal

The group of inventions relates to a method and a device for wood heat treatment and can be used for building and in the wood work and timber and furniture industries. The inventive method consists in controlling a heat-treatment process by forming control actions corresponding to parameters of current information inputted in the form of control signals into a computer system for determining the optimal values of the process parameters. The inventive device comprises a control cabinet which is provided with a computer system for controlling and programming a process and is connected to electrically driven shutters. Said invention makes it possible to improve the quality of treatable wood.

Owner:DANCHENKO IGOR ALEKSANDROVICH

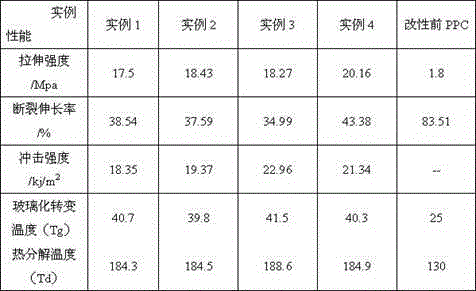

Polypropylene carbonate modified composite material and preparation method thereof

InactiveCN104017348AImprove thermal stabilityWide processing temperature rangeAntioxidantUv absorber

The invention discloses a polypropylene carbonate modified composite material. The composite material is prepared by blending the following components in parts by weight: 60-75 parts of polypropylene carbonate, 15-30 parts of polypropylene, 5-10 parts of a compatilizer, 0.1-0.2 part of a primary antioxidant, 0.1-0.2 part of an auxiliary antioxidant, 0.15-0.3 part of an ultraviolet absorbent and 0.3-0.8 part of an auxiliary agent. The invention also discloses a preparation method of the polypropylene carbonate modified composite material. PPC subjected to PP modification has good thermal stability, so that the processing temperature range of PPC can be expanded, and the application of a PPC material in occasions requiring high performances can be met; thermal performance test results show that the glass-transition temperature and thermal decomposition temperature of a PPC / PP blending material are higher than that of PPC before modification; therefore, the composite material disclosed by the invention can be widely applied to the fields of automobile industry, daily necessities, furniture industry, packaging industry, biological medicines and the like.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

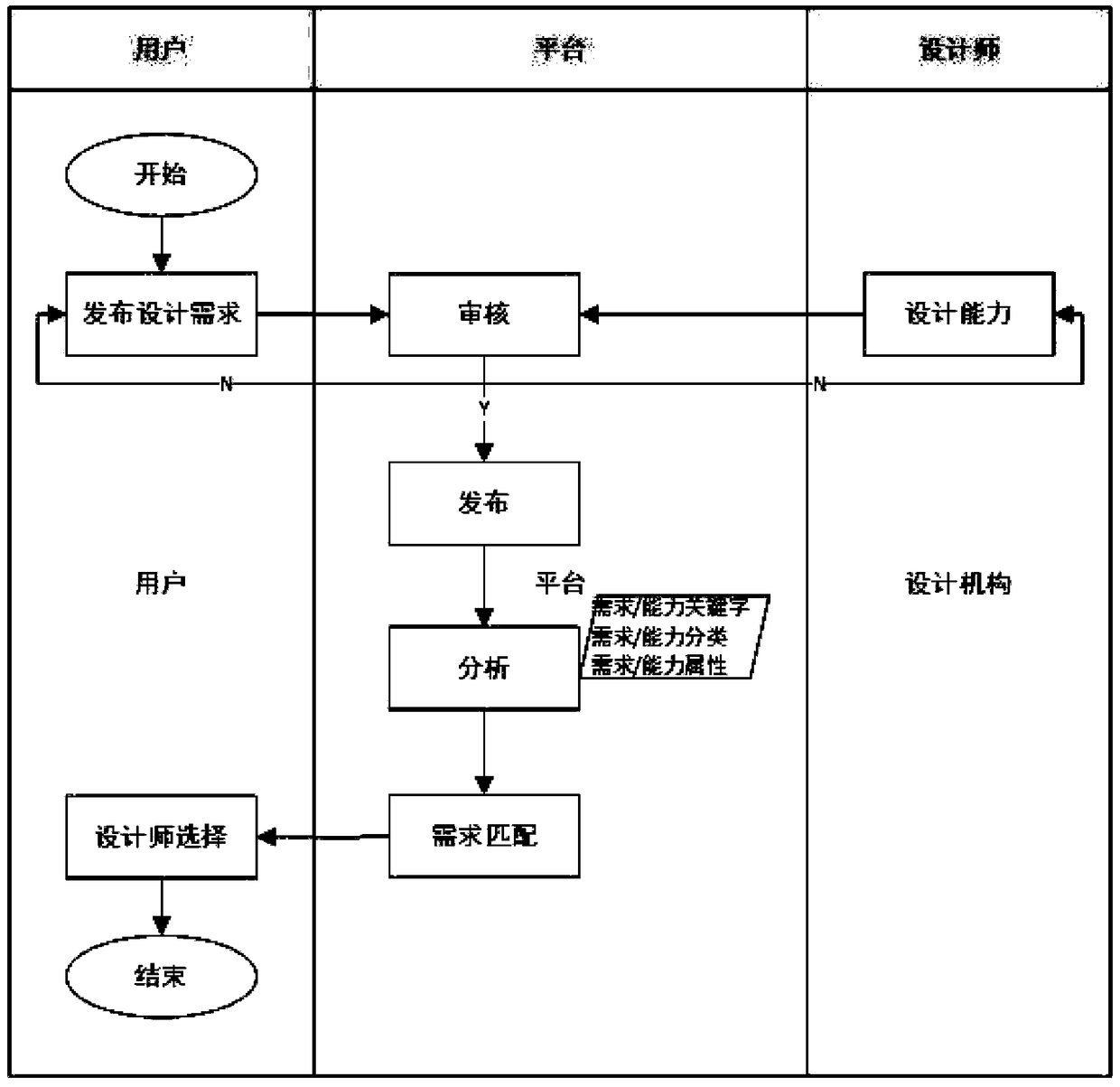

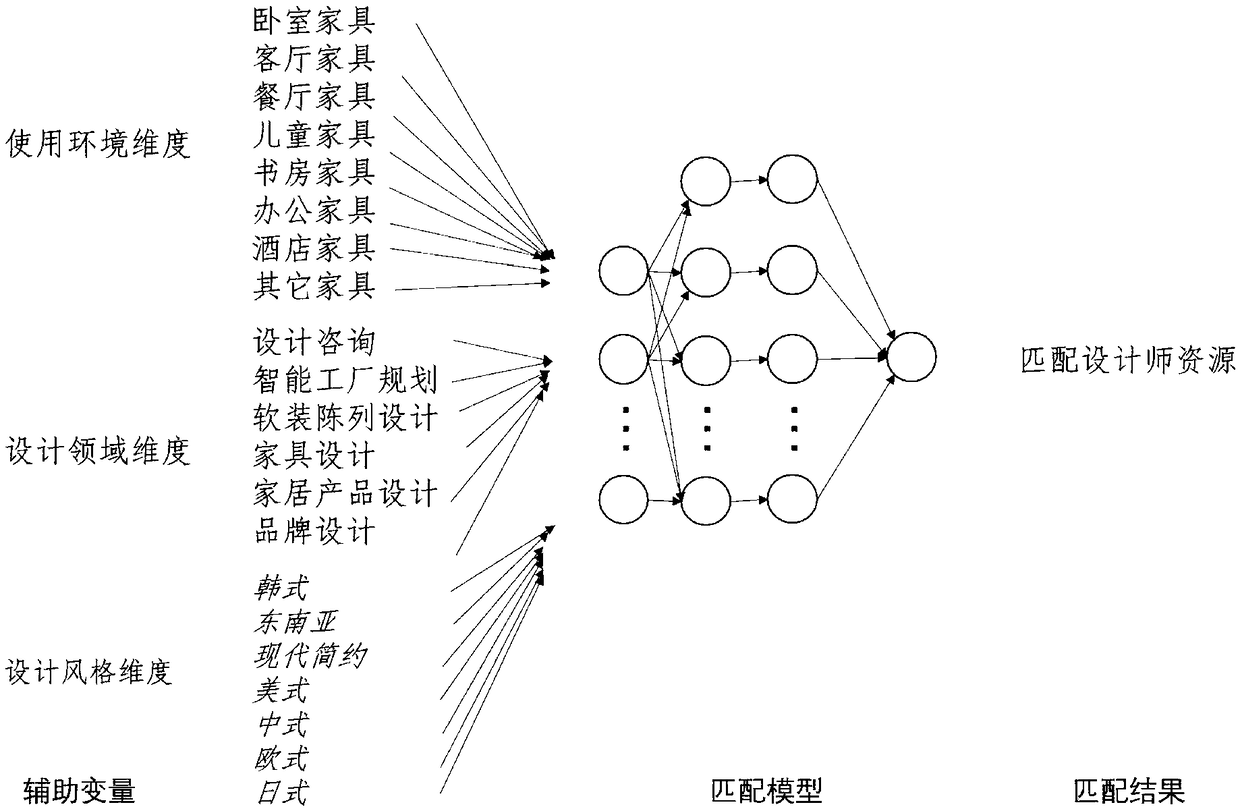

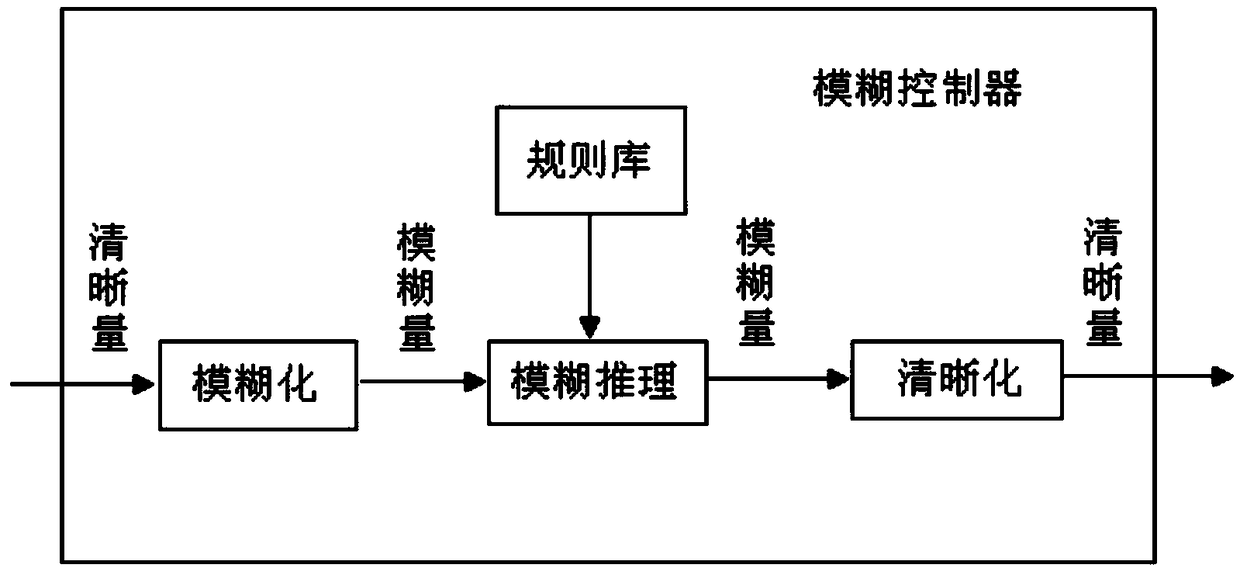

A method and system for intelligently retrieve and matching designer resource in furniture industry

PendingCN109299386AImprove matchImprove efficiency in designing transactional servicesDigital data information retrievalBuying/selling/leasing transactionsFurniture industryComputer science

The invention relates to a furniture industry designer resource intelligent retrieval matching method and system. The method comprises the following steps: a user, a designer and a design institutionpublish design demand information or design capability information through a furniture design service platform; The furniture design service platform audits the information, determines the informationformat, and the content conforms to the platform rules to ensure the retrieval matching according to the platform rules; The design requirement information and the design capability information are stored in the database of the cloud server, and the storage mode is based on the keywords, classification and attributes. In the cloud server, the design requirement information and the design capability information are automatically retrieved and matched based on the fuzzy neural network, and the matching results are arranged in descending order from high to low according to the matching degree, and the matching results are intelligently fed back to the users. The invention can improve the retrieval efficiency of furniture design resources, improve the matching precision of furniture design supply and demand docking, and realize intelligent retrieval and optimization matching of design demand description and design resources.

Owner:北京航天智造科技发展有限公司

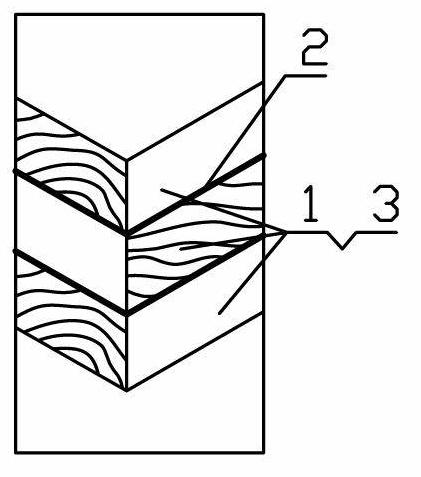

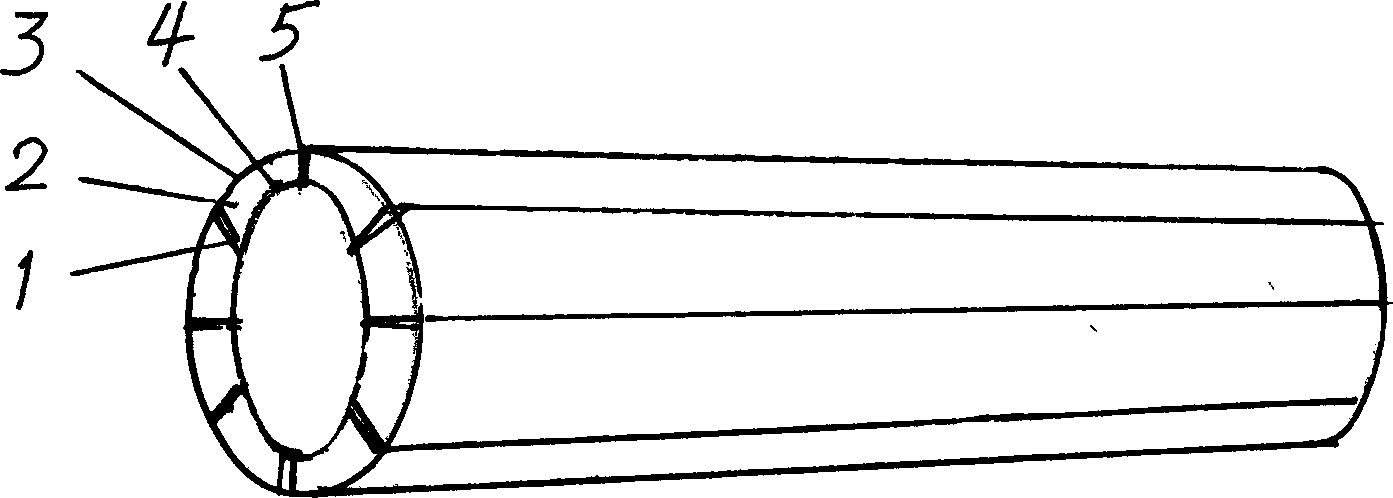

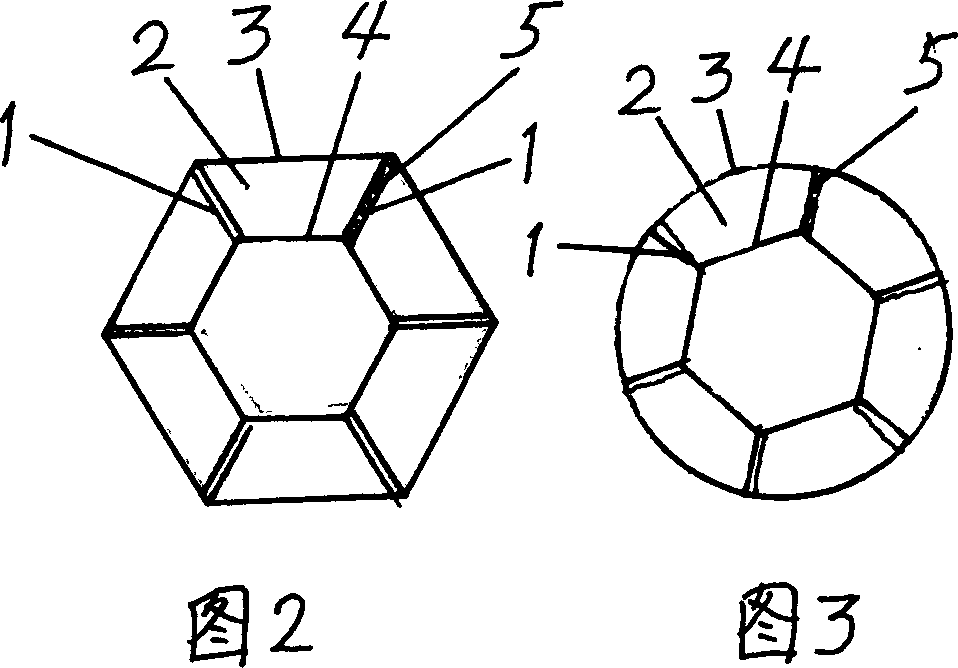

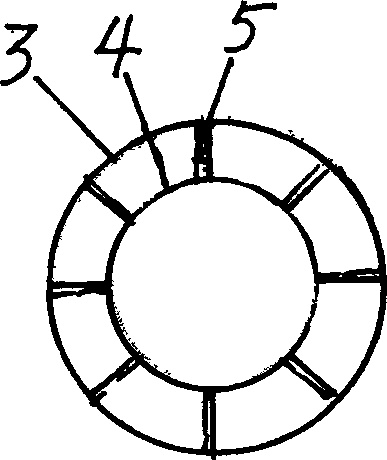

Hollow wooden integration column

The invention discloses a hollow wood integrated column, which is characterized by the following: the basic composition unit is trapezoidal wood bar with ring-shaped cross section, which is covered by three trapezoids or similar trapezoids (2); the bottom (3) of trapezoid or similar trapezoid (2) constitutes the periphery of ring, whose roof (4) constitutes the internal surface of ring; the adhesive layer (5) is coated among waists (1) of two adjacent trapezoids or similar trapezoids. The invention can be applied in architecture industry and furniture industry, which saves the raw material and time.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for locking water in wood and wood processed with same

InactiveCN102357926ARealize blockingSolve the problem of dry shrinkage and wet expansionWood treatment detailsEnvironmental resistanceParaffin oils

The invention provides a method for locking water in wood and wood processed with same. The method comprises the following steps of: under a vacuum condition, controlling a gas content and a water content in wood in which water needing to be locked; under the vacuum condition, putting paraffin in a container and heating to fully melt the paraffin; putting the wood obtained in the first step in the container of the second step, fully immersing the wood in the melted paraffin, keeping a certain time and keeping the container in a vacuum state; under the vacuum condition, lowering temperature in the container to a normal temperature, solidifying the melted paraffin and blocking gaps in the wood; and taking out the wood, and removing the paraffin attached to the surface. The problem that the wood shrinks when dry and expands when wet is thoroughly solved, and the emission of smell in the wood is avoided. The method can be used for wood engineering and furniture industry and is environment-friendly and energy-saving. The wood cannot crack or deform and has good mothproof and corrosion-proof effect. The method can particularly produce great economic benefit for the production, transport and use of red wood furniture.

Owner:于仁杰

Wooden article shading process

InactiveCN102553792AImprove adhesionImprove mechanical propertiesPretreated surfacesCoatingsAir velocityEngineering

The invention relates to a processing method for wood working of furniture industry. A wooden article shading process sequentially comprises the following steps of: a, sanding primer; b, checking whether a spray gun has an air leakage phenomenon; c, adjusting the amount of a paint; d, controlling air velocity in a spray room; e, preparing before spraying; f, spraying base color; g, shading and polishing; and h, performing secondary shading according to the step g. According to the wooden article shading process, the main means of increasing air pressure of an air gun, spraying air pressure, air velocity in the spray room, spraying pressure and distance of a spray gunpoint is adopted; and a paint film on the surface of a wooden article is rich, smooth and attractive by adopting the secondary shading method.

Owner:LANGFANG HUARI FURNITURE CO LTD

Method for pressing fire-proof material from bamboo wood filament and strip or shavings

InactiveCN101209567AEnsure safetyImprove the ecological environmentFlat articlesDomestic articlesWood shavingsFire control

The invention provides a method which presses fireproof material by taking bamboo wood strips or wood shavings as raw material. The bamboo wood strips or wood shavings are prepared, collected, dried to meet the requirement of water-content, dipped by fireproof liquid, drained after gluing, and dried again to provide the water content less than or equal to 4% to 4-12%; die-entering pavement or pad plate upper pavement of a multilayer hot press is carried out; under the pressure of 1-10Mpa, the die is hotly solidified for 5-48h under the environment of 50-100 DEG C; after being heated to 100-180 DEG C in the hot press and solidified for 0.6-2.0min / mm of unit thickness, the material is released for standby after being cooled. The fireproof material is especially suitable for application in building industry and furniture industry, is taken as building material, furniture material and facility material in the buildings of housing, schools, conference halls and ballrooms, meets fire-control safety requirement, and is beneficial for ensuring possession and personal safety. Nowadays almost overall forest banning is carried out all over the world, and thinnings, leftover materials, lap wood and fruticose stalks are taken as raw material, thus effectively solving the source problem of bamboo wood material and having active ecological conservation meaning at the same time.

Owner:ZHEJIANG FORESTRY UNIVERSITY

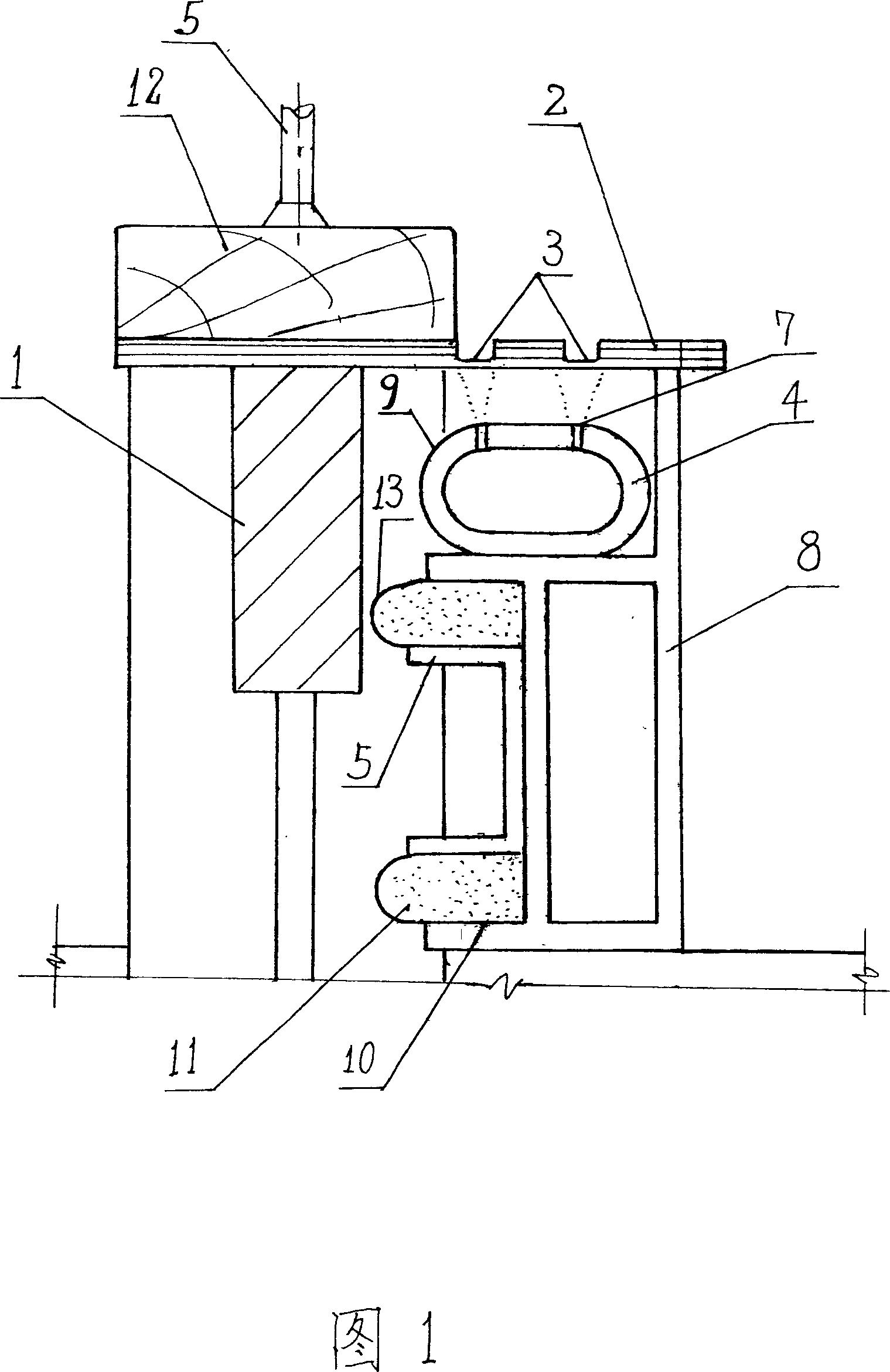

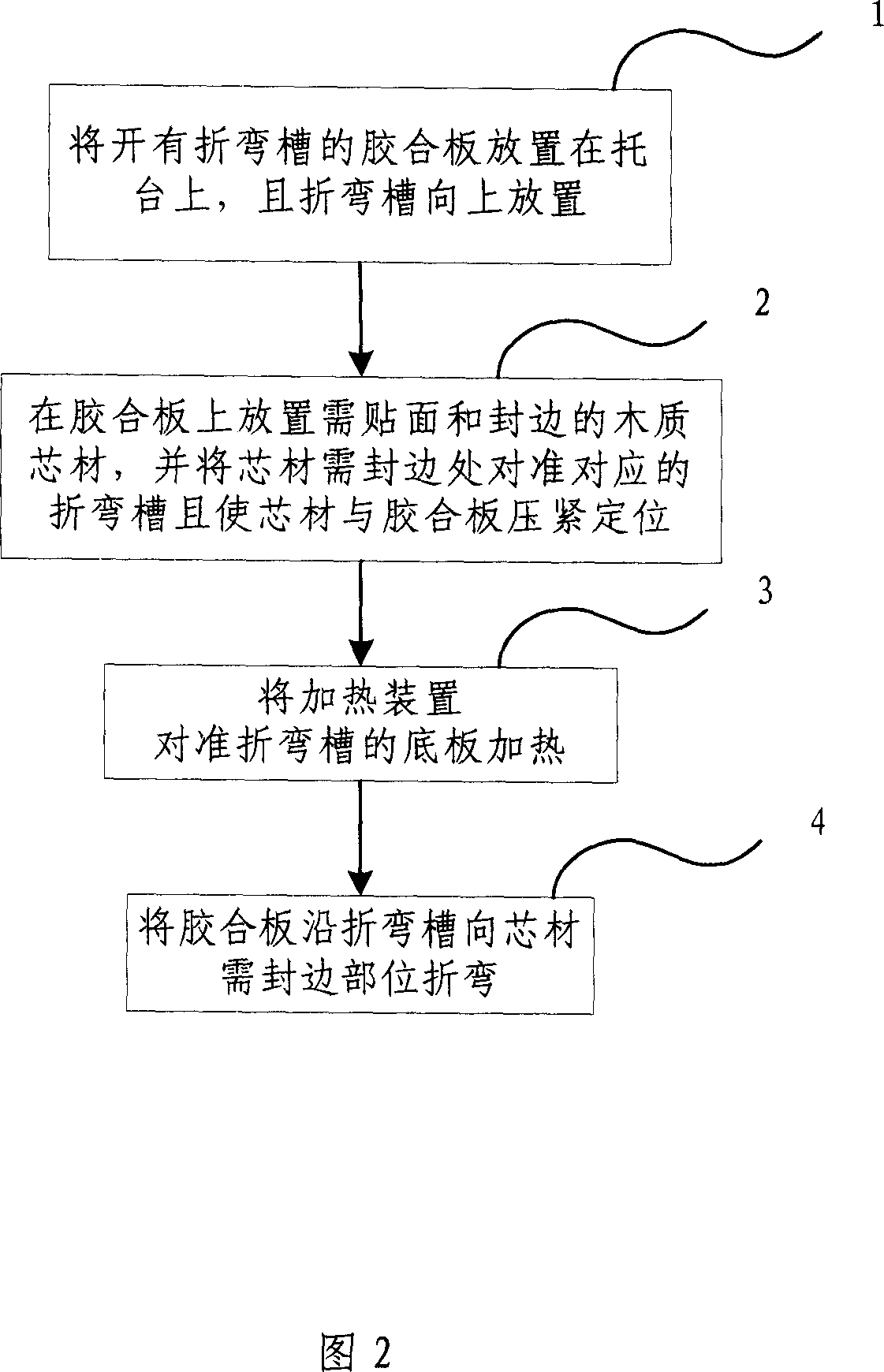

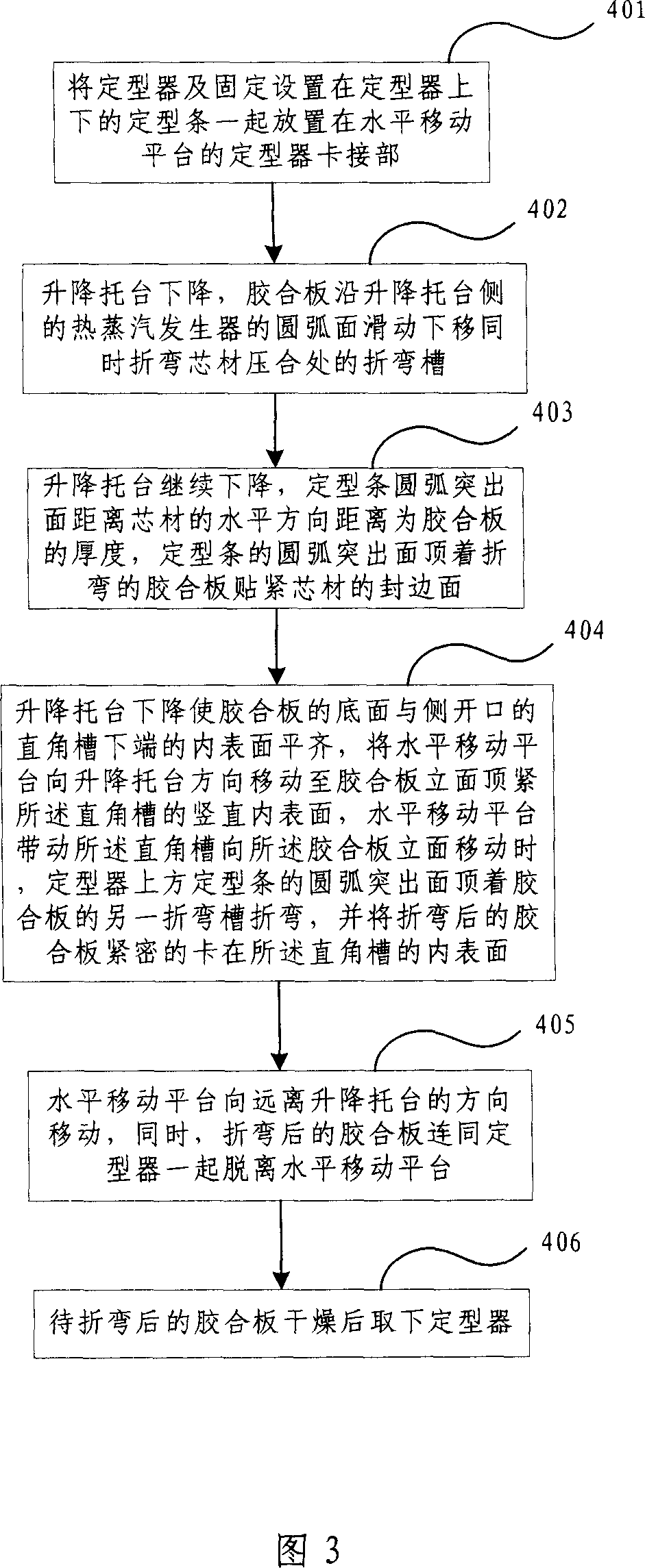

Painted veneered plywood bending device and use thereof

InactiveCN101015923AIncrease productivityIncrease color varietiesWood veneer joiningFurniture industryEdge banding

The invention relates to a device for bending paint decorate adhesive plate, comprising a support for arranging the object paint decorate adhesive plate, and a heating device for heating the target bended groove paint decorate adhesive face. The invention also provides a relative bending method. The invention can realize seamless seal the edge of wood corn via adhesive plate, to avoid crack and worse color at the seal part.

Owner:郭建生

Method for manufacturing anti-cracking solid wood blue-white porcelain floor

ActiveCN101886456AImprove water absorptionLow water absorptionFlooringSolid woodPulp and paper industry

The invention discloses a method for manufacturing an anti-cracking solid wood blue-white porcelain floor. The method is characterized by comprising the following steps of: drying solid wood to prepare a blank, processing the blank into the floor, performing surface glue injection and drying for one or more times, and finally sanding or polishing and coating the floor to obtain a finished product. Glue, chemical or coating is injected twice on the surface of the solid wood floor by using a negative pressure vacuum tank, and the solid wood floor is dried so that pits or holes of the wood can be fully closed or plugged and the solid wood floor has low water absorption and is not easy to crack or deform after long-term use; and the service life can be prolonged, the using effect is good, and the product produced by the method has the blue-white porcelain-like visual effect. The solid wood floor can reduce water absorption and prevent cracking, and has the characteristics of long service life, good using effect and blue-white porcelain-like visual effect. The method also can be used in the field of solid wood products such as furniture industry and the like.

Owner:ZHEJIANG BIYORK WOODEN

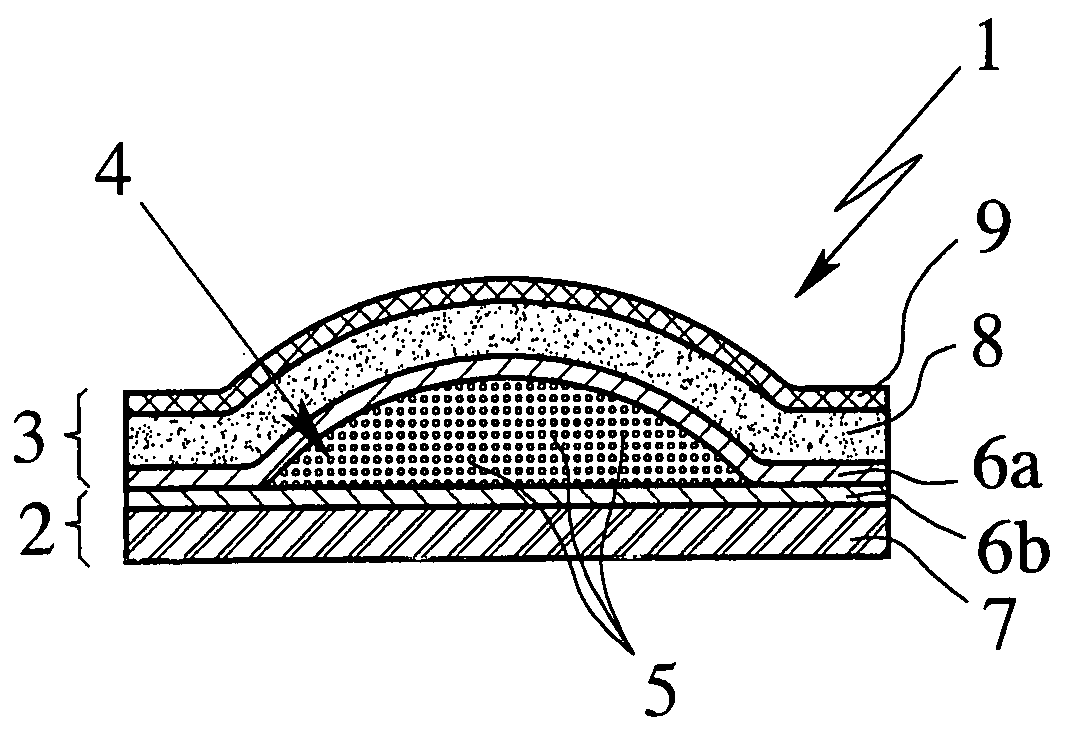

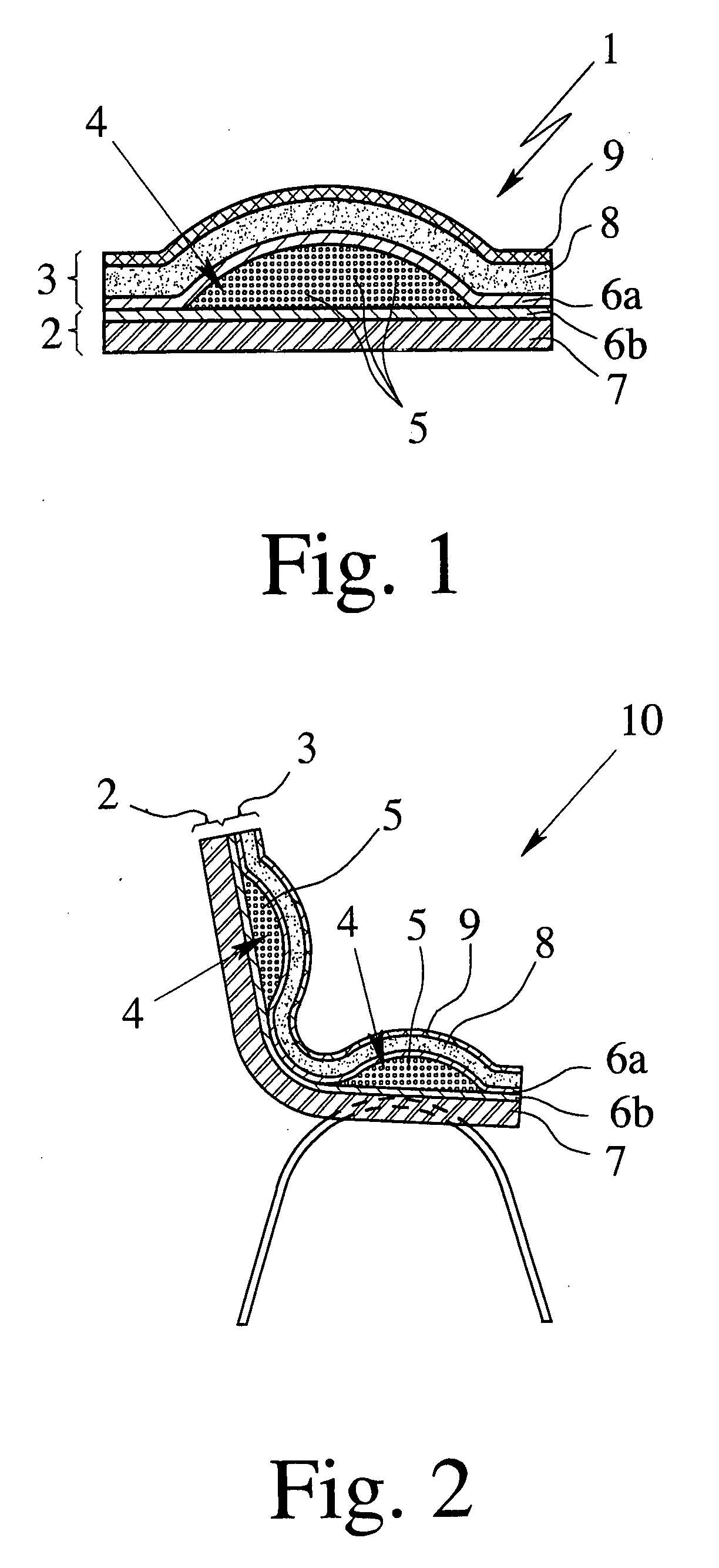

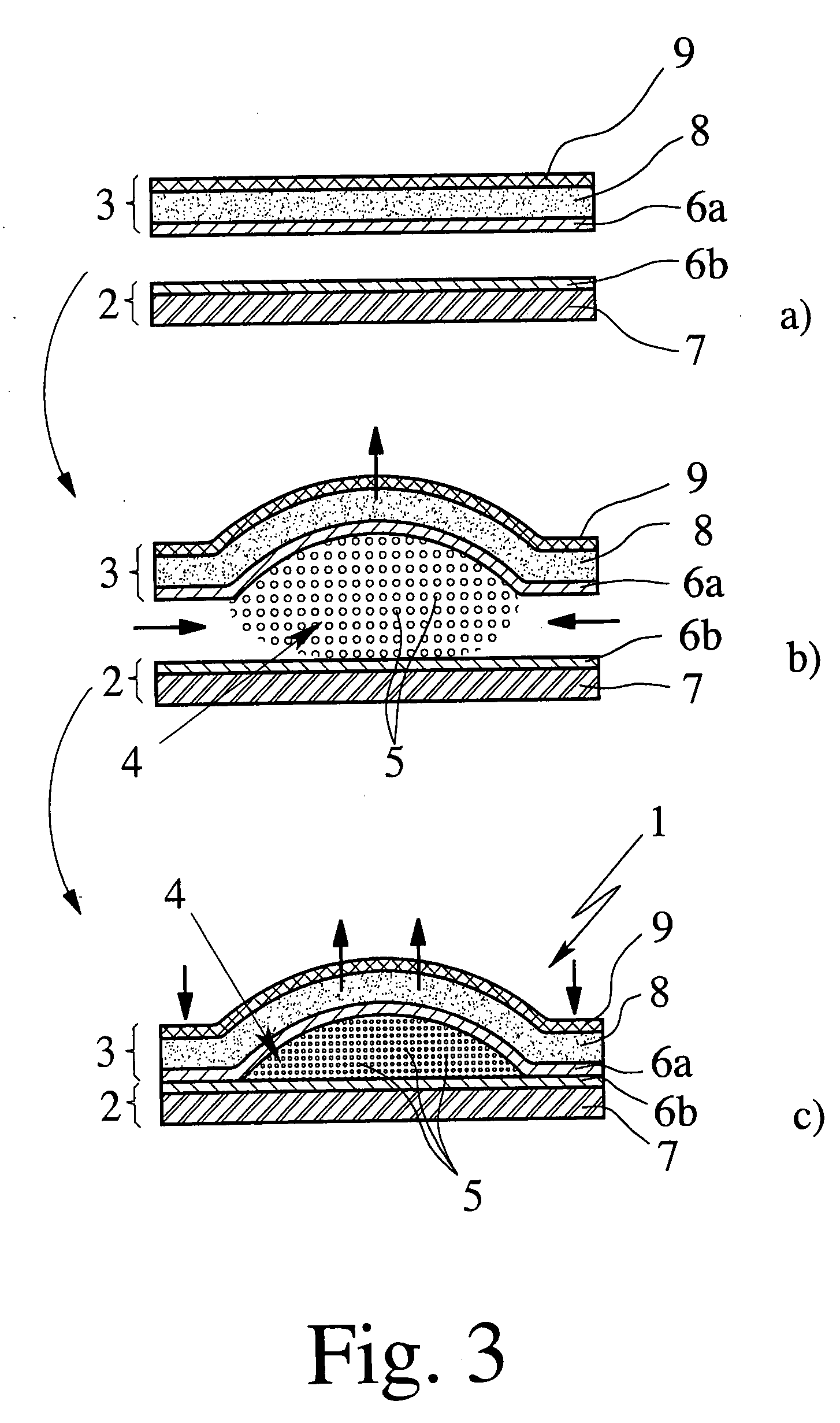

Three-dimensional cavity-formed part having a multilayered structure and process of its manufacture

The invention concerns a three-dimensional hollow molded piece having a multilayered construction, with a cavity formed by a substrate material and a cover material. The cavity is arranged between the substrate material and the cover material and filled with a filling medium. The hollow molded piece has in relation to the substrate material and the cover material a filmlike layer at least essentially impermeable to the filling medium, which is especially suitable for use in the furniture industry, especially for the manufacture of seating furniture.

Owner:SKS SITZKOMPONENTEN

Method for laminating plastic films with wood-base substrates, in particular for producing high-gloss surfaces

The invention relates to a method for laminating a plastic film with a wood-base substrate, in particular for producing a high-gloss surface on a wood-base substrate, in which a plastic film is laminated by means of a laminating agent, preferably an adhesive, with a wood-base substrate and permanently bonded to the wood-base substrate, the plastic film being formed so as to be transparent on its top, and the products obtainable in this manner and their use, in particular in the area of the wood and furniture industry, for example for the production of pieces of furniture and fitments of all kinds.

Owner:JOWAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com