Patents

Literature

400 results about "Polypropylene carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene carbonate (PPC), a copolymer of carbon dioxide and propylene oxide, is a thermoplastic material. Catalysts like zinc glutarate are used in polymerization.

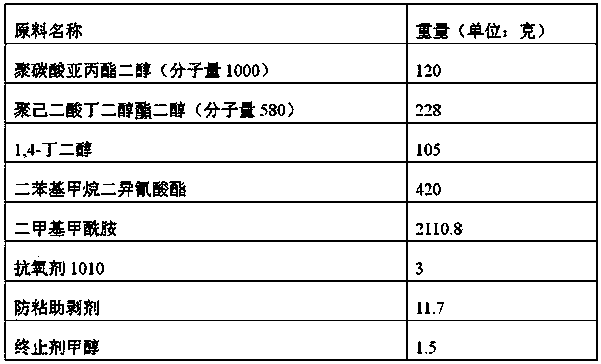

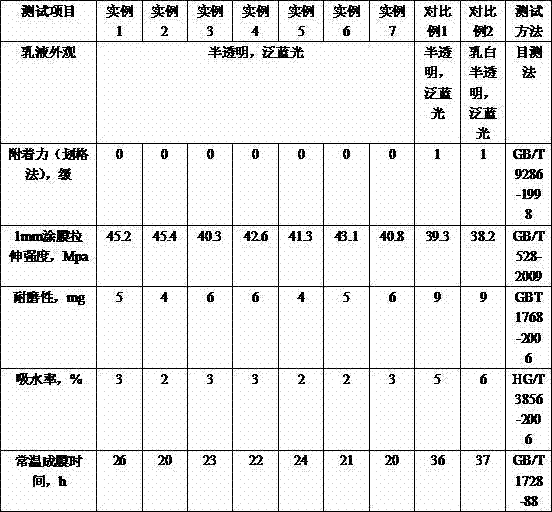

Preparation method of environment-friendly aqueous polyurethane coating of polypropylene carbonate type

InactiveCN103755911AHigh strengthStrong adhesionPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a preparation method of an environment-friendly aqueous polyurethane coating of a polypropylene carbonate type. The aqueous polyurethane coating is synthesized by using a two-step method. The method comprises the following steps: performing a reaction on a polypropylene carbonate polyalcohol, an isocyanate and an organic bismuth catalyst at 50 DEG C to 100 DEG C; then cooling and performing chain extension by adding a hydrophilic chain extender; neutralizing; crosslinking; and emulsifying. Compared with a polyether-type aqueous polyurethane coating, the aqueous polyurethane coating provided by the invention has the advantages of high strength, good adhesive force and good abrasion resistance; compared with a polyester-type aqueous polyurethane coating, the aqueous polyurethane coating provided by the invention has the advantages of high storage stability, hydrolysis resistance and the like; and meanwhile, the environment-friendly organic bismuth catalyst is used for replacing an organic tin catalyst which is harmful to the environment, so that the aqueous polyurethane coating provided by the invention is an environment-friendly product. The polypropylene carbonate polyalcohol is prepared from carbon dioxide taken as a raw material, so that the aqueous polyurethane coating provided by the invention is low in cost and good in market prospect.

Owner:GUANGDONG UNIV OF TECH

Polymer blends

ActiveUS20130209775A1High elongationSynthetic resin layered productsThin material handlingPolyolefinPolymer science

The present invention provides, among other things, extruded blends of aliphatic polycarbonates and polyolefins. In one aspect, provided blends comprise aliphatic polycarbonates such as poly(propylene carbonate) and a lesser amount of a crystalline or semicrystalline polymer. In certain embodiments, provided blends are characterized in that they exhibit unexpected improvements in their elongation properties. In another aspect, the invention provides methods of making such materials and applications of the materials in applications such as the manufacture of consumer packaging materials.

Owner:NOVOMER INC

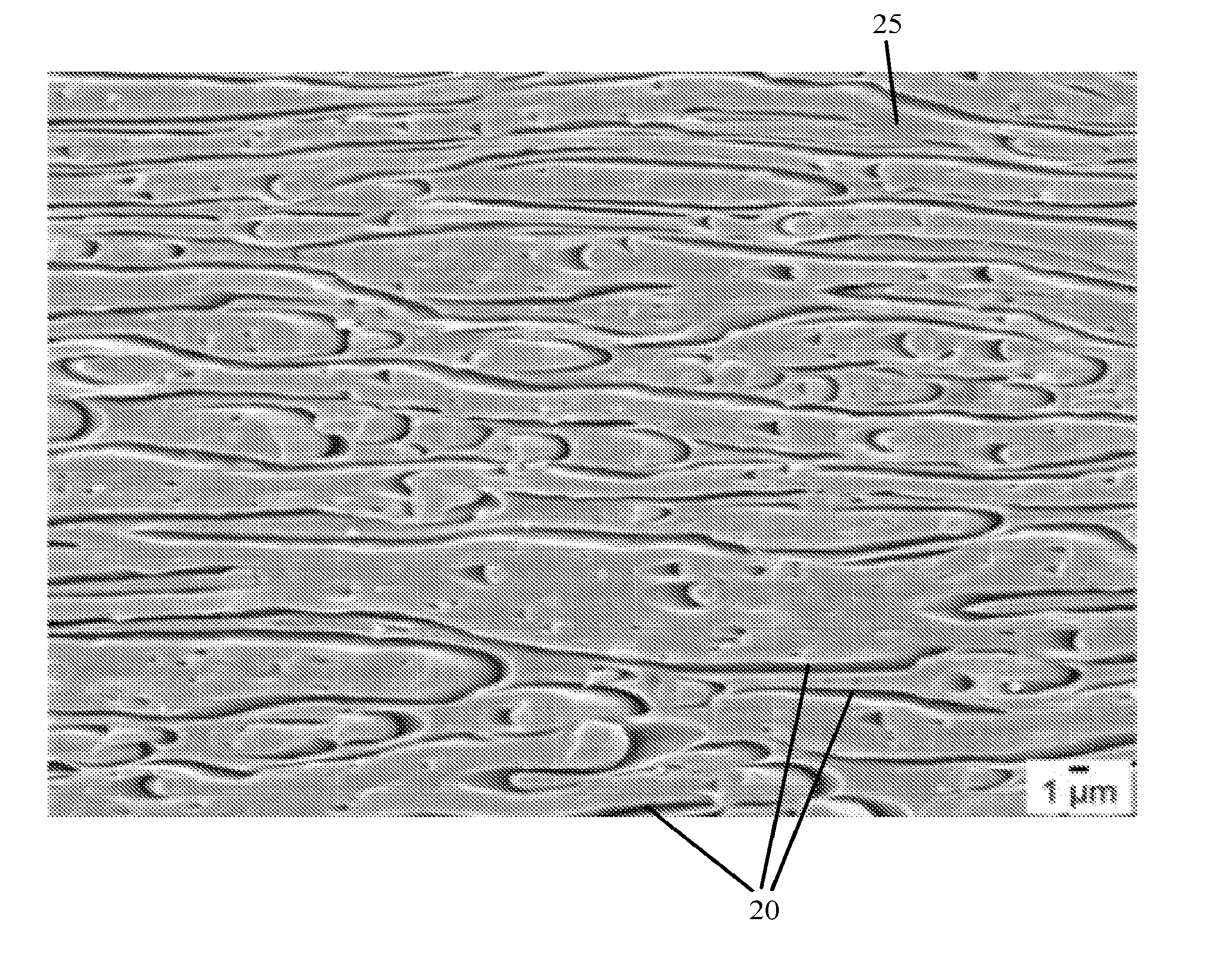

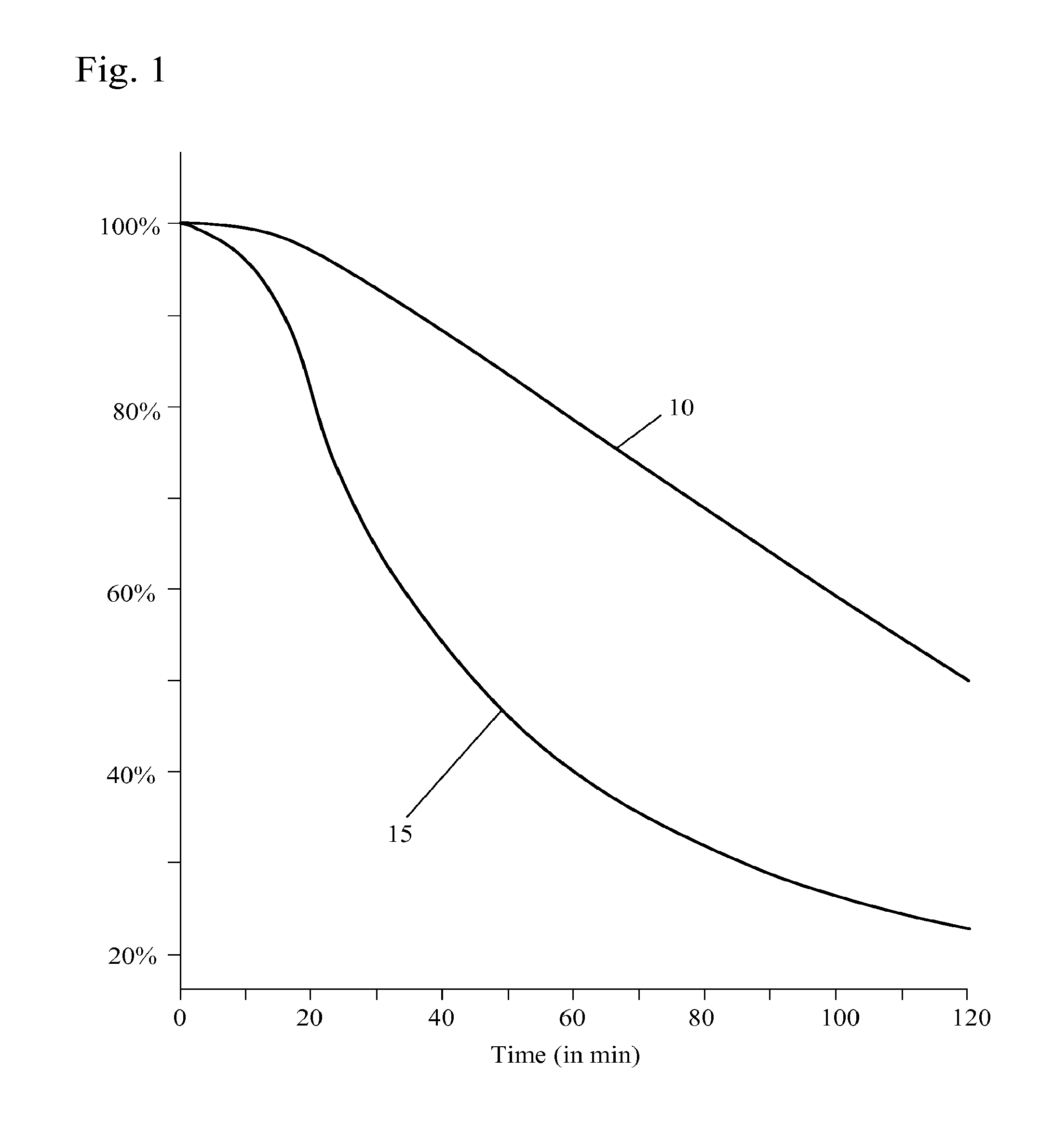

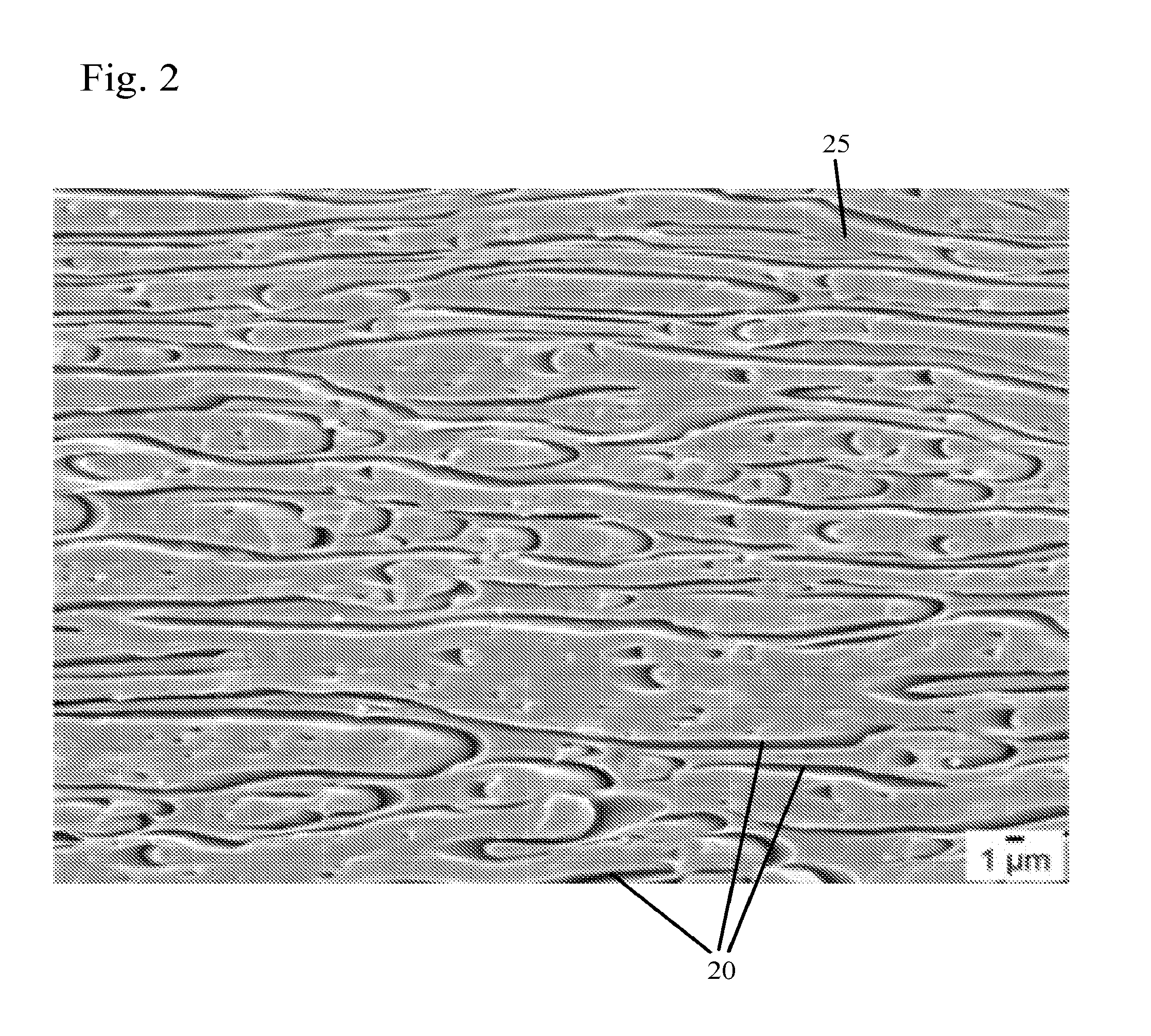

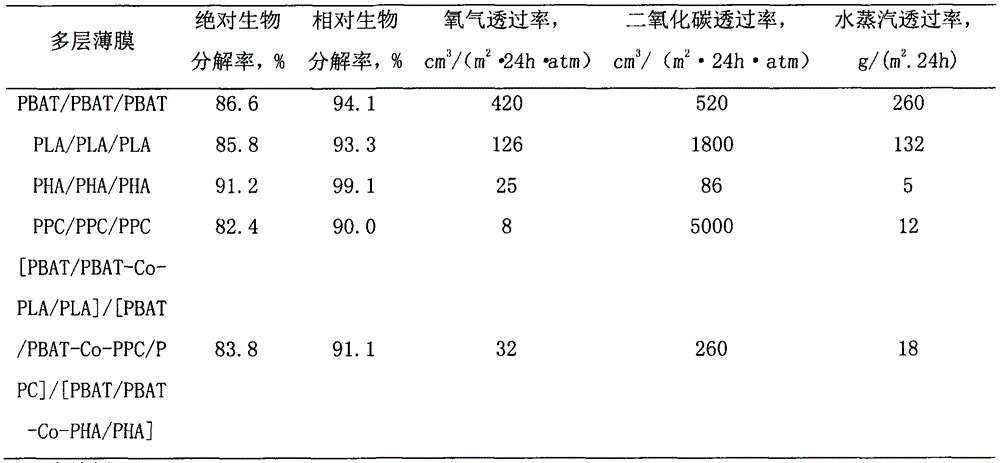

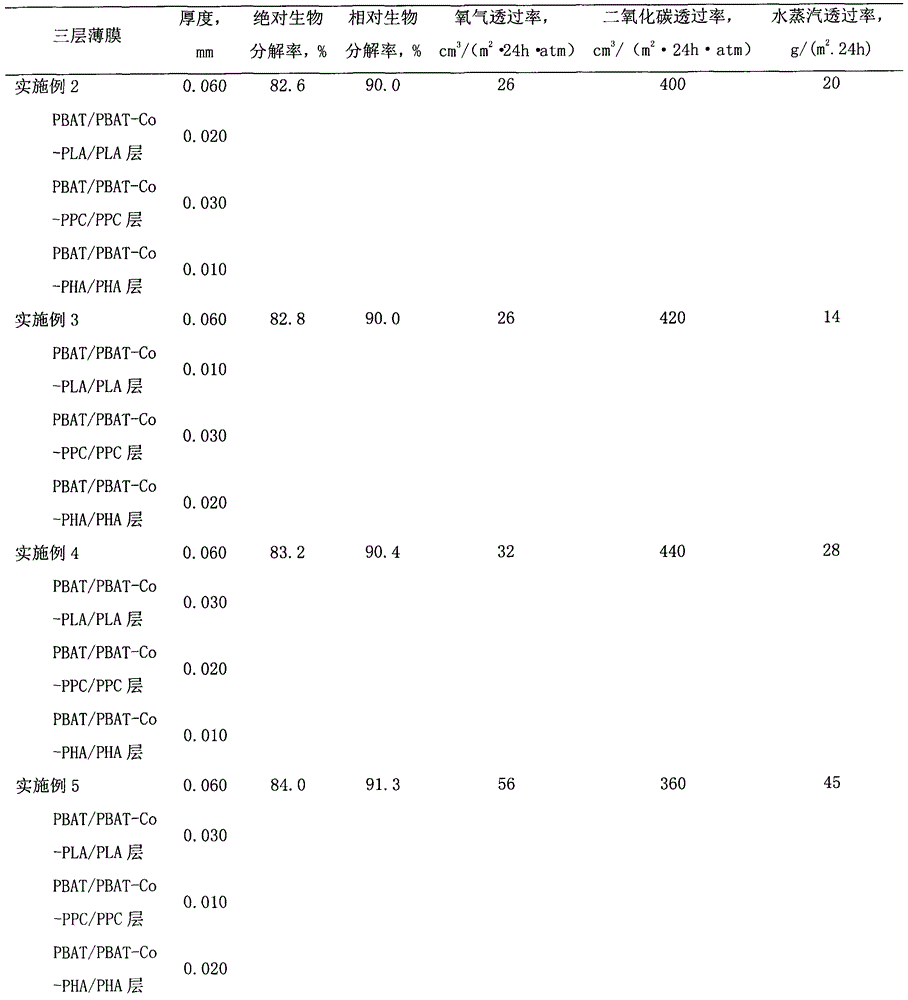

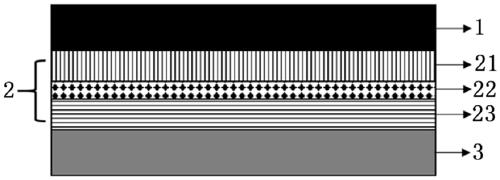

Biodegradable multilayer material with adjustable gas transmission rate and preparation method and applications thereof

ActiveCN104691067AStable physical propertiesNot easy to layerFlexible coversWrappersWater vaporOxygen

The invention relates to a biodegradable multilayer material, which can be a thin film material or a sheet material. The biodegradable multilayer material at least comprises one of an adipic butanediol terephthalate copolymer (PBAT) / PBAT-chain extender-polypropylene carbonate (PBAT-Co-PPC) / PPC blend layer, a PBAT / PBAT-chain extender-polylactic acid (PBAT-Co-PLA) / PLA blend layer and a PBAT / PBAT-chain extender-polyhydroxyalkanoate (PBAT-Co-PHA) / PHA blend layer, and blend resins are respectively prepared through twin-screw reactive extrusion. The multilayer material is produced by using extrusion and coextrusion methods, has a function that the transmission rates of oxygen, carbon dioxide and water vapor can be adjusted, and can be applied to the packaging field and the agriculture field, and especially applied to food packaging, pharmaceutical packaging, and ground film mulching.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Wholly-degradable poly(propylene carbonate) compound film material and preparation thereof

The invention discloses a completely-degradable poly (propylene carbonate) composite film material and a preparation method thereof. The composite film material is formed by blending and compounding poly (propylene carbonate) with polylactic acid, wherein the content of the polylactic acid is between 10 and 50 weight percent, and the content of the poly (propylene carbonate) is between 50 and 90 weight percent. The preparation method comprises the following steps that: the poly (propylene carbonate) and the polylactic acid are respectively dissolved in organic solvents and made into solutions; the two solutions are well mixed pro rata and volatilized at room temperature so as to eliminate most of the solvents, and then mixed liquid is cast in a plate glass mold; and after the mixed liquid is vacuum-dried to constant mass, a PPC-PLA composite film material can be obtained. The composite film material provided by the invention obviously improves the properties of the poly (propylene carbonate), effectively solves the increasingly serious white pollution problem, and has important significance for ecological environment protection. The preparation method is simple in process, convenient to operate, easy to realize, low in equipment dependence and little in material consumption.

Owner:HAINAN UNIVERSITY

Poly(propylene carbonate)-based water-borne polyurethane adhesive and preparation method thereof

InactiveCN102241956AImprove hydrolysis resistanceImprove adhesionPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to a poly(propylene carbonate)-based water-borne polyurethane adhesive and a preparation method thereof. The water-borne polyurethane adhesive is prepared from a polymer of carbon dioxide and propylene epoxide, namely poly(propylene carbonate)polyols, chain extender and polyisocyanate; and the water resistance of the water-borne polyurethane adhesive is improved by modifying or mixing a silane coupling agent. The water-borne polyurethane adhesive is obtained by pre-polymerizing (a) and (b), extending the chain through (c) and (d) and modifying and mixing through (e) as follows: (a) 10-30 parts of aromatic diisocyanate, (b) 100 parts of poly(propylene carbonate)polyols, (c) 1-5 parts of chain extender capable of forming hydrophilic groups and having active hydrogen, (d) 0-2 parts of chain extender having active hydrogen and (e) 1-8 parts of silane coupling agent. The poly(propylene carbonate)-based water-borne polyurethane adhesive prepared by the invention has the advantages of good adhesion property to wood, glass and fabric and good hydrolysis resistance.

Owner:JIANGSU ZHONGKE JINLONG CHEM

Textile anti-pilling polyurethane finishing agent and preparation method thereof

The invention discloses textile anti-pilling polyurethane finishing agent. The textile anti-pilling polyurethane finishing agent is made by the reaction of the following raw materials on a mass percent basis: 11.74-21.3% of polypropylene carbonate polyhydric alcohol, 3.81-10.2% of diisocyanate, 0.014-0.036% of catalyst, 0.9-1.864% of chain extender, 2.1-2.78% of organic solvent, 3.7-8.2% of amino silicon oil, 0.7-1.19% of neutralizer and 59.6-70.5% of deionized water, and the total content of the components is 100%. The invention further relates to a preparation method of the finishing agent, and the preparation method includes the steps of weighing the raw materials, preparing polyurethane prepolymers, preparing amino silicon oil grafting modification polyurethane, and finally adding the deionized water and the neutralizer into the amino silicon oil grafting modification polyurethane to obtain the finishing agent. The finishing agent can improve the anti-pilling property of textile and enable the textile to be soft.

Owner:库尔勒汇同泰印染科技有限公司

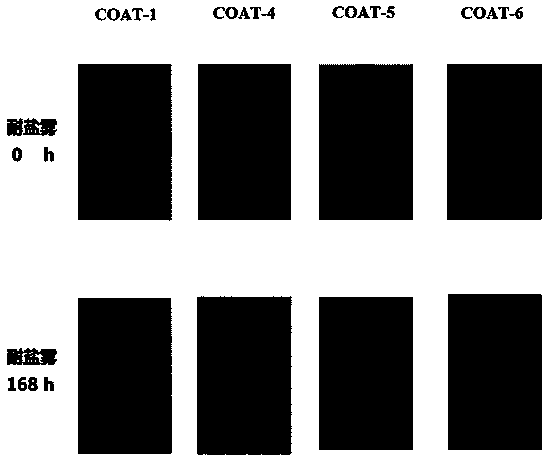

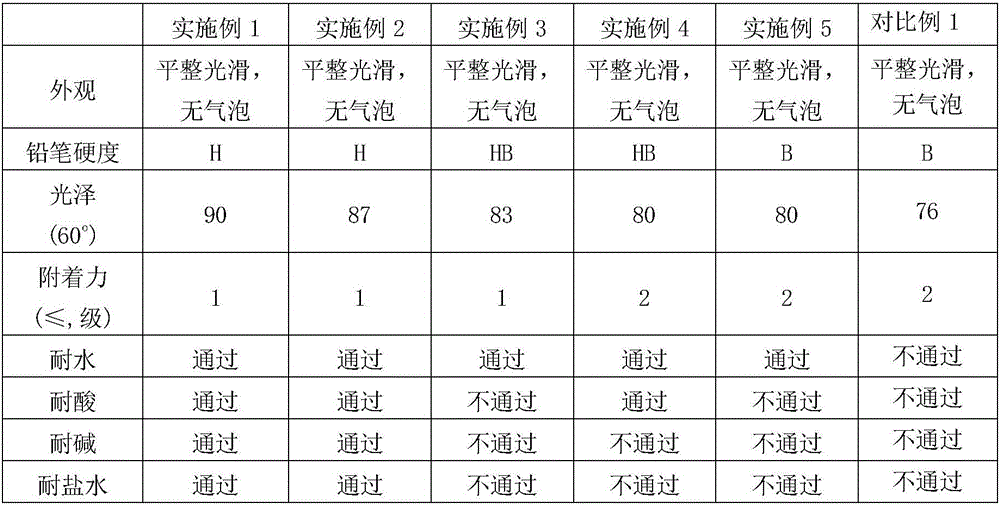

Preparation method of paint aqueous polyurethane/amino resin composite emulsion

ActiveCN104212330AEmission reductionIncrease the degree of cross-linkingPolyurea/polyurethane coatingsCross-linkEnvironmental resistance

The invention discloses a preparation method of an aqueous polyurethane / amino resin composite emulsion base on amino resin for manufacturing aqueous paint. The method is characterized by comprising, firstly, combining polypropylene carbonate dihydric alcohol with common macromolecular dihydric alcohol to partially or totally substitute the common macromolecular dihydric alcohol; performing reactions with diisocyanate, dimethylolpropionic acid, micromolecular chain extender and cross-linking agent; performing end capping with end-capping reagent; performing neutralization and emulsification to obtain a polyhydric end-capped aqueous polyurethane preformed polymer emulsion; compounding the polyhydric end-capped aqueous polyurethane preformed polymer emulsion with amino resin, catalyst, coating additive and deionized water to obtain the aqueous polyurethane / amino resin composite emulation. The preparation method of the paint aqueous polyurethane / amino resin composite emulation does not need organic cosolvent, and meanwhile, due to the fact of taking the polypropylene carbonate as one of the raw materials and performing end capping through the end-capping reagent containing secondary amino and hydroxyl, achieves high hydroxyl functionality and hydroxyl value; solidified paint molecular chains are high in crosslinking degree; the water-resistant and corrosion-resistant performance of coating can be improved, and obvious cost and environmental advantages can be obtained.

Owner:UNIV OF SCI & TECH OF CHINA +1

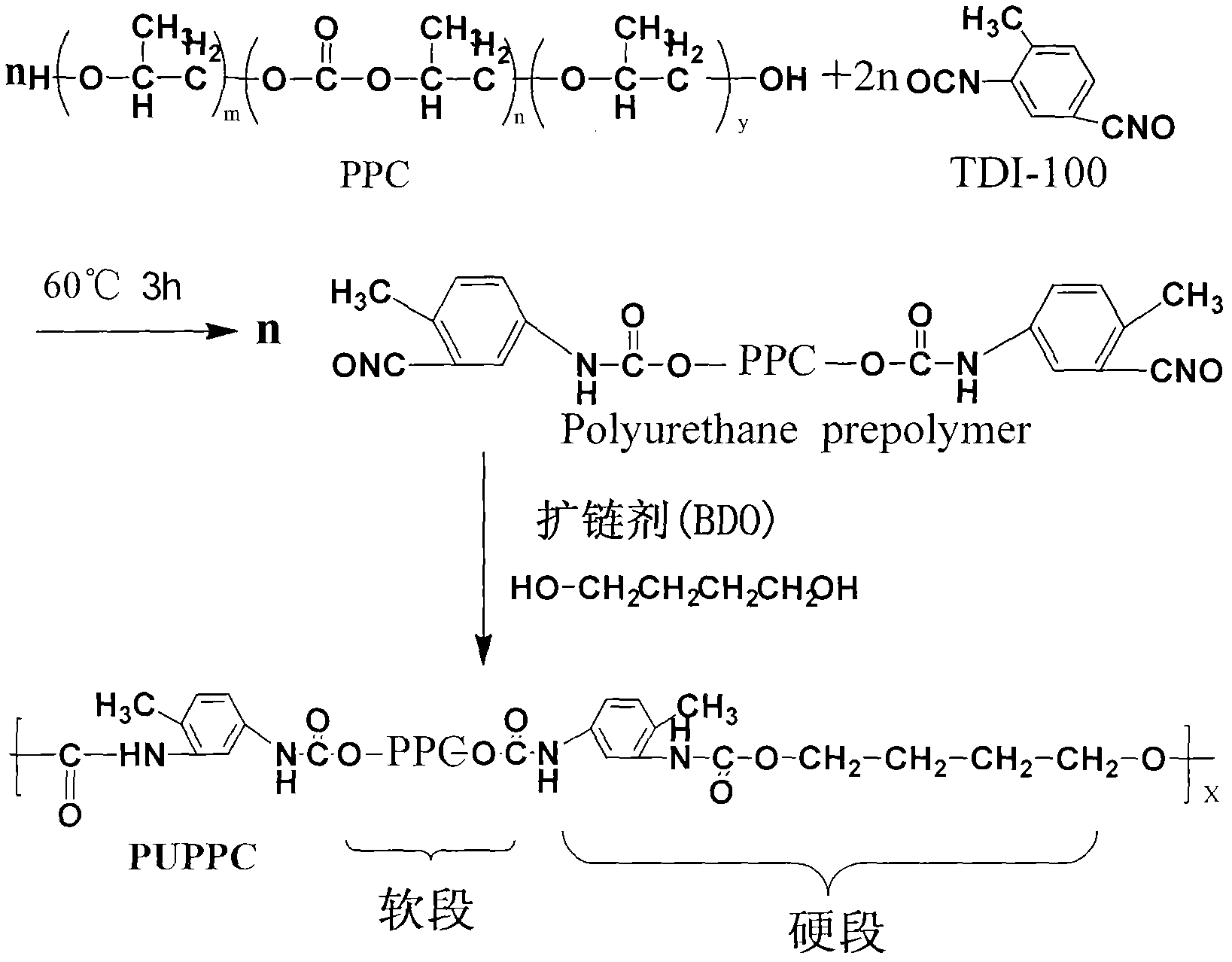

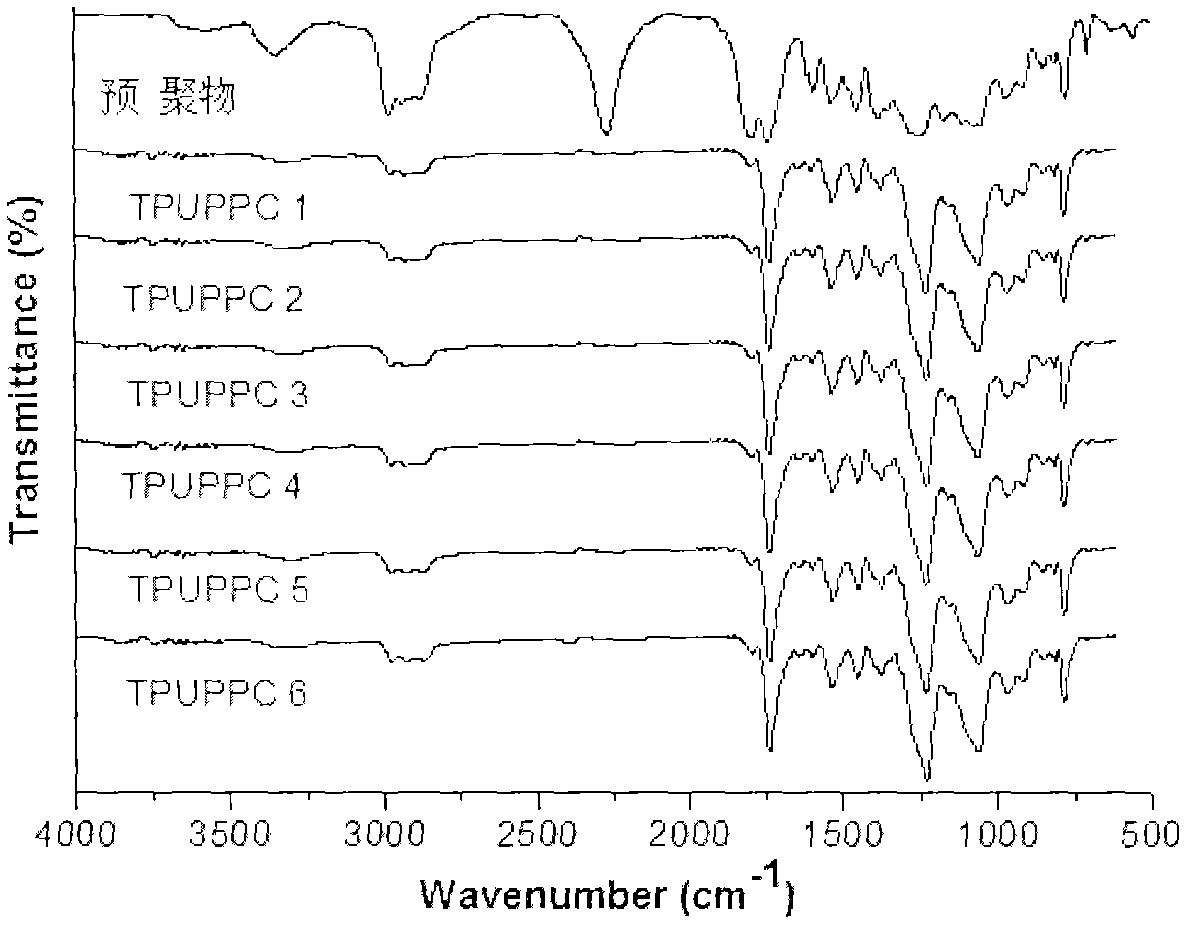

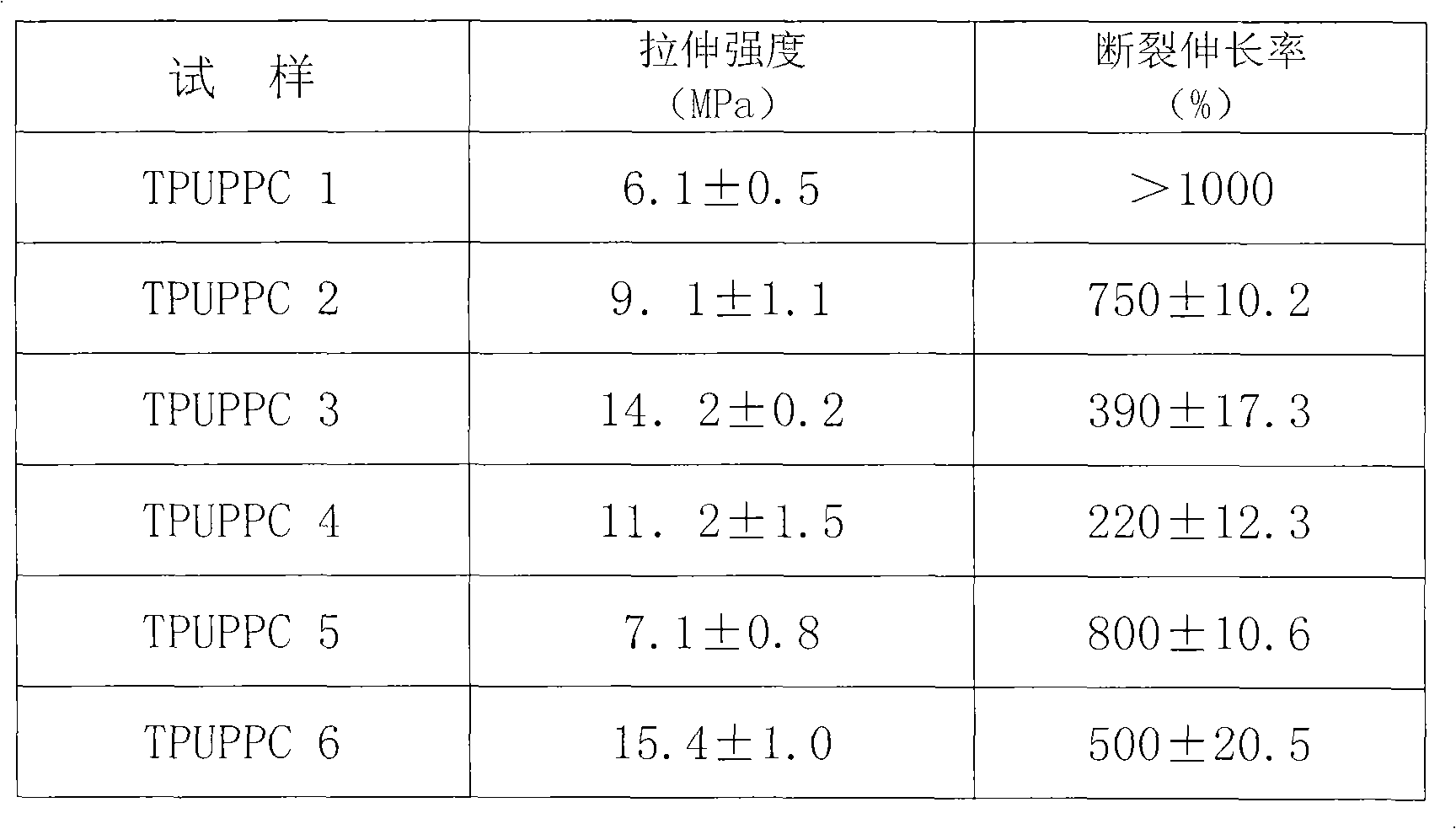

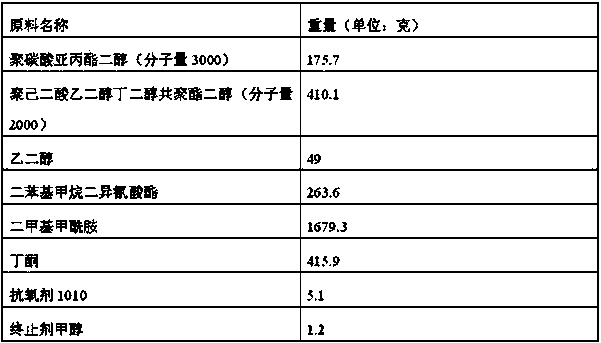

Preparation of thermoplastic polyurethane elastomer with polypropylene carbonate as soft segment

InactiveCN102838717ARich sourcesStretchability can be adjusted at willPolyolThermoplastic polyurethane

The invention relates to a method for preparation of a thermoplastic polyurethane elastomer with polypropylene carbonate as a soft segment. The method consists of: first adding diisocyanate and a catalyst into polypropylene carbonate polyol to undergo a reaction, then adding a chain extender to carry out a chain extension reaction, and conducting drying and curing to obtain the thermoplastic polyurethane elastomer. The invention has the characteristics of simple process, abundant raw material sources, land ow production cost. By employing a prepolymerization method for preparation of the thermoplastic polyurethane elastomer, the prepared product does not turn yellow, has strong plasticity and excellent performance, and the tensile property of the elastomer can be adjusted at will.

Owner:HAINAN UNIVERSITY

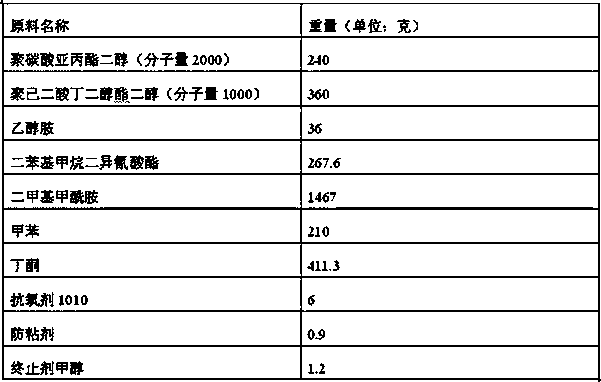

Polypropylene carbonate type polyurethane resin as well as preparation method and application thereof

ActiveCN103724579AImprove heat resistanceImprove hydrolysis resistanceTextiles and paperAlcoholPetrochemical

The invention discloses polypropylene carbonate type polyurethane resin. The polypropylene carbonate type polyurethane resin is composed of the following components in parts by weight: 4-10 parts of polypropylene carbonate glycol, 7-14 parts of polyhydric alcohol, 0.5-3.5 parts of a chain extender with the molecular weight of less than 150, 6-14 parts of diisocyanate, 0.04-0.06 part of a terminating agent, 0-2 parts of an additive, 0.1-1 part of an antioxidant and 64-71 parts of a solvent. The invention further provides a preparation method of the resin and an application of the resin in a synthetic leather dry-method process field. With the adoption of the formula composition of the polypropylene carbonate type polyurethane resin, the polyurethane resin and synthetic leather prepared from the polyurethane resin have an excellent heat-resisting performance, but also have an excellent hydrolysis resistance effect. Furthermore, not only can the requirements on petrochemical raw materials be reduced, but also the effective utilization of carbon dioxide is also realized.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

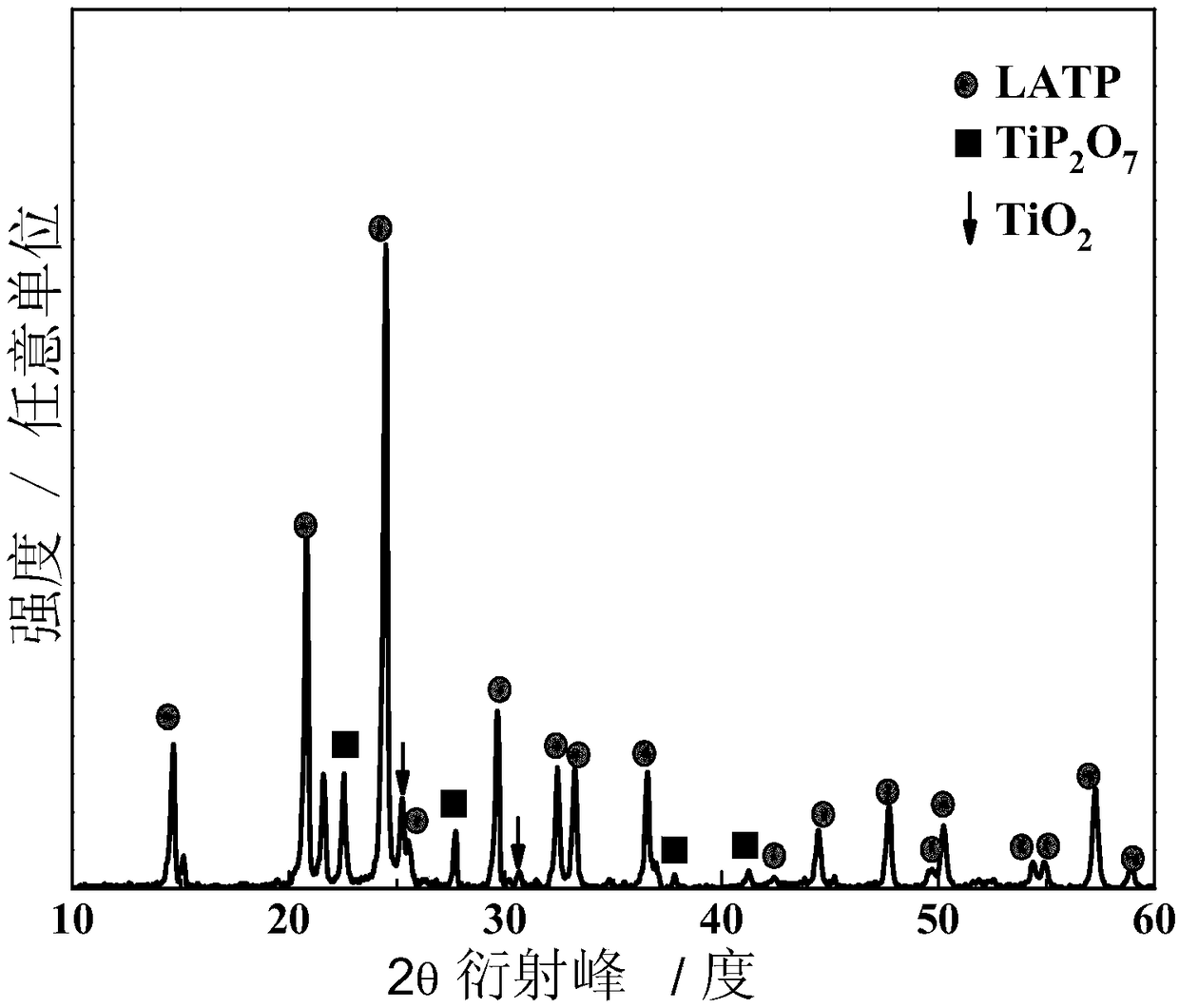

Quasi-solid electrolyte as well as preparation method and application thereof

ActiveCN108365260AImprove mechanical propertiesGood chemistrySolid electrolytesSecondary cellsSolid state electrolyteHexafluoropropylene

The invention discloses a quasi-solid electrolyte which is prepared from the following raw materials including a polymer, a ceramic electrolyte, lithium salt and ionic liquid; the polymer is preparedfrom polyvinylidene fluoride-hexafluoropropylene and polypropylene carbonate; the ceramic electrolyte is prepared from a principal-phase lithium titanium aluminum phosphate and impurity-phase TiP2O7 / TiO2; and the ionic liquid is fluorine-containing imidazolium ionic liquid. The invention also discloses the quasi-solid electrolyte which has high mechanical strength and toughness, high room-temperature lithium ion conductivity and high chemical / electrochemical stability with a metal lithium negative electrode and an oxide positive electrode, is used for a metal lithium cell, a lithium air cell and a lithium-sulfur battery and can realize good electrochemical performance.

Owner:ZHEJIANG UNIV

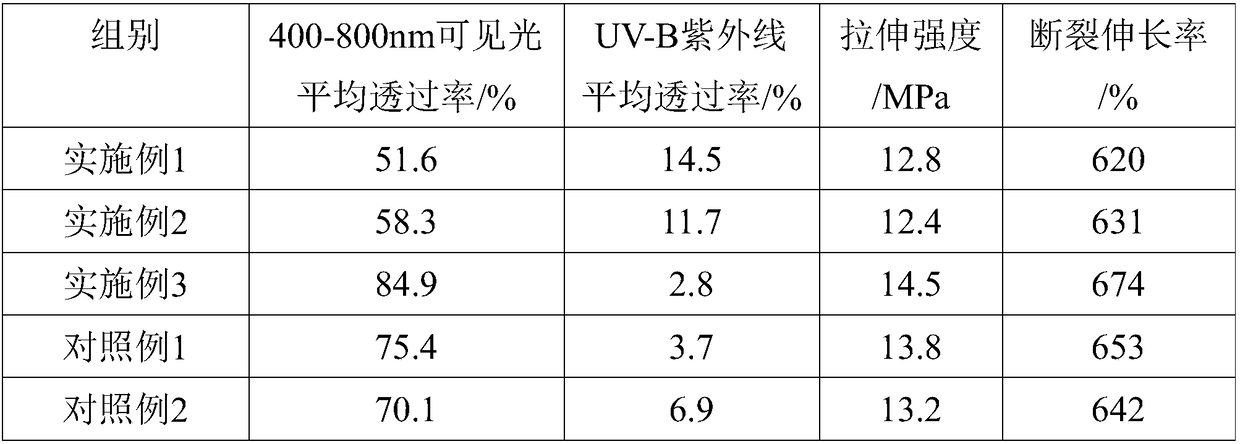

Preparation method of high-thermal-insulation/soil-moisture-preservation degradable agricultural mulching film material

ActiveCN105860459AMeet the needs of mulchBlown film process is stableThermal insulationFilm material

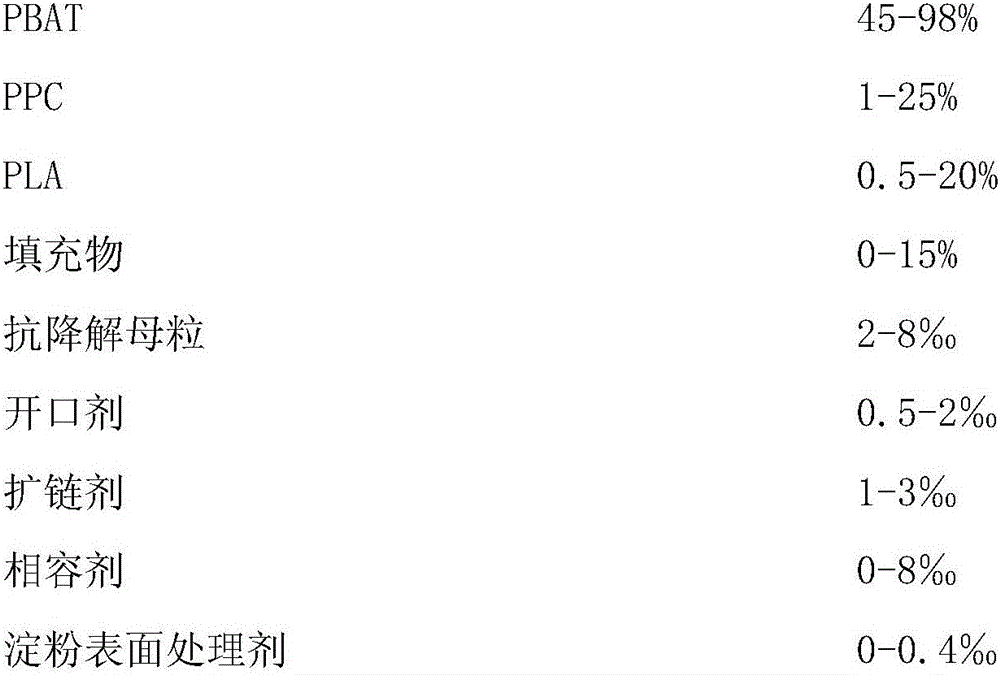

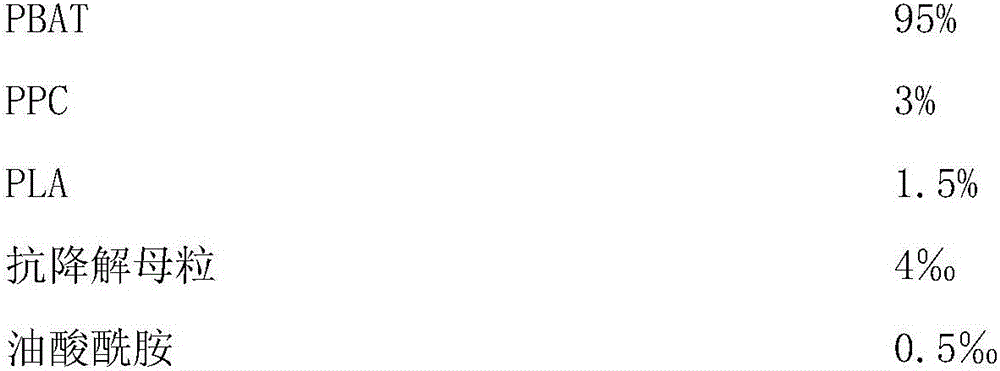

The invention relates to a preparation method of a high-thermal-insulation / soil-moisture-preservation degradable agricultural mulching film material. The agricultural mulching film is prepared from PBAT (poly(butyleneadipate-co-terephthalate)), PPC (polypropylene carbonate), PLA (polylactic acid), an anti-degradation master batch, an opening agent, a compatilizer, a chain extender and a starch surface treating agent. The preparation method comprises the following steps: proportionally weighing all the raw materials, carrying out drying pretreatment on the PBAT, PPC, PLA and anti-degradation master batch, carrying out batch mixing, sending the mixture into a double screw extruder through different agravic weighers, melting by heating, carrying out extrusion, drawing, cooling, granulation and drying to obtain granules, and sealing and storing in an aluminum-plastic packaging bag. The film blowing experiment proves that the degradable plastic can completely satisfy the mulching film demands. The minimum thickness of the film can reach 6 mu m. The preparation method has the advantages of stable film blowing technique and controllable size of the blown film. The mulching film material has the characteristics of favorable mechanical properties, high thermal insulation property, high soil moisture preservation property, high light transmittance, lower price and the like, can be completely degraded into water and carbon dioxide after being buried underground after use, and thus, satisfies the environmental requirements.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

Internal crosslinking polypropylene carbonate waterborne polyurethane emulsion and preparation method and application thereof

InactiveCN103408715AEasy to prepareEasy to operatePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention belongs to the field of waterborne polyurethane and discloses an internal crosslinking polypropylene carbonate waterborne polyurethane emulsion and a preparation method and application thereof. The preparation steps are as follows: mixing polypropylene carbonate polyols and diisocyanate, increasing the temperature to 60 DEG C, adding a catalyst, increasing the temperature to 80-90 DEG C gradually, and performing thermal reaction for 2-3 h; adding a hydrophilic chain extender and performing thermal reaction; cooling to 60 DEG C, adding a crosslinking agent and performing reaction for 1-2 h; adding a proper amount of acetone to adjust viscosity; when the temperature is reduced to 35-45 DEG C, adding a neutralizer for reaction for 0.5-1 h; adding deionized water for emulsification, stirring for 0.5-1 h at a high speed; evaporating acetone to obtain the internal crosslinking polypropylene carbonate waterborne polyurethane emulsion. The internal crosslinking polypropylene carbonate waterborne polyurethane emulsion has superior cohesiveness and can be used as water paint and adhesive, an emulsion membrane prepared from the internal crosslinking polypropylene carbonate waterborne polyurethane emulsion has good transparency and high tearing strength.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

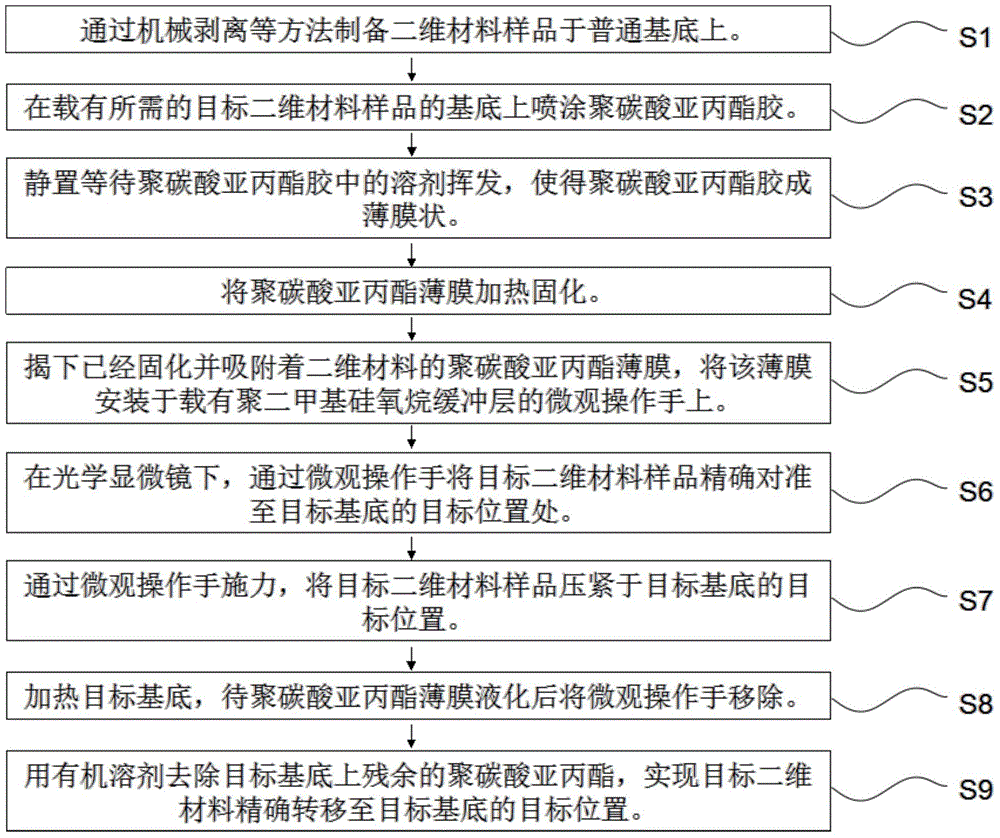

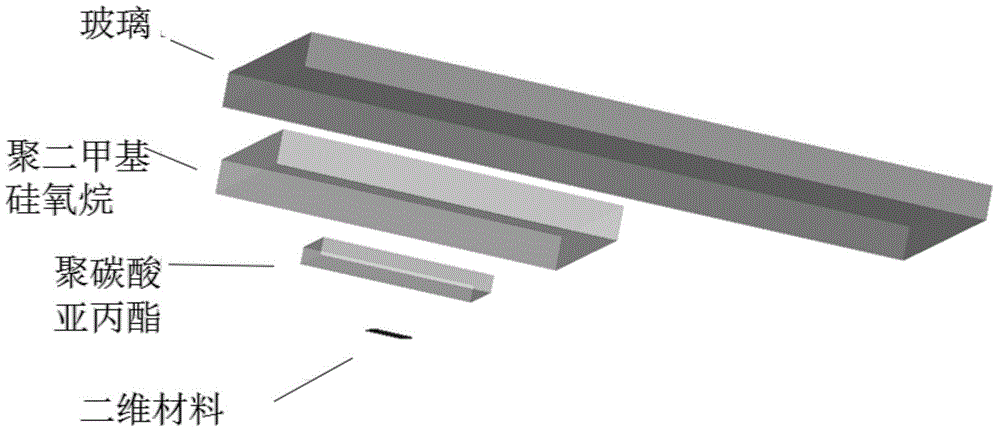

Controllable flexible transfer method of two-dimensional materials

InactiveCN104960286AControlled Flexible Transfer MethodLoose size requirementsCeramic layered productsOrganic solventEngineering

The invention discloses a controllable flexible transfer method of two-dimensional materials. The controllable flexible transfer method includes the steps: adopting a mechanical striping method or other methods to obtain a target two-dimensional material to be transferred; spraying polypropylene carbonate glue on the surface of the two-dimensional material; standing and heating to solidify the polypropylene carbonate glue to enable the two-dimensional material to be adhered below a formed polypropylene carbonate thin film; mounting the thin film on a micro manipulator carrying a polydimethylsiloxane buffering layer, and accurately aligning the thin film to a target position of a target substrate with the help of an optical microscope; heating to melt the polypropylene carbonate thin film, and using organic solvent to remove residual polypropylene carbonate. By the controllable flexible transfer method, accurate and controllable transfer of the two-dimensional material is realized. The method is simple in process, high in efficiency, wide in application range and high in expandability and has wide using prospect in the fields of microelectronics, biological detection and batteries.

Owner:SOUTHEAST UNIV

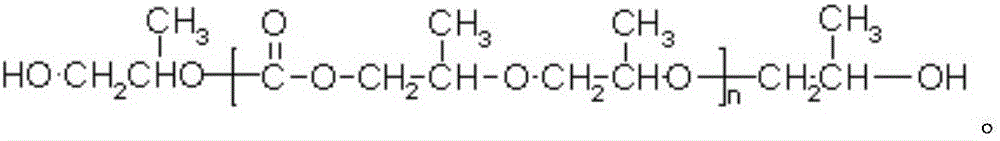

Water-based polypropylene carbonate polyurethane emulsion and preparation method thereof

The invention provides a water-based polypropylene carbonate polyurethane emulsion which is prepared from the following components in parts by weight: 100 parts of polypropylene carbonate polylol containing unsaturated double bond on the side chain, 3-10 parts of hydrophilic chain extender, 0.1-10 parts of polymerization inhibitor, 20-100 parts of polyisocyanate, 1-10 parts of chain extension crosslinking agent, 2-10 parts of salifying agent and 100-300 parts of deionized water. The invention also provides a preparation method of the water-based polypropylene carbonate polyurethane emulsion. The side chain of the water-based polypropylene carbonate polyurethane emulsion contains the unsaturated double bond, so that the water-based polypropylene carbonate polyurethane emulsion can be further crosslinked to obtain the crosslinked polyurethane product with higher hardness, higher strength and favorable solvent resistance.

Owner:GUANGDONG UNIV OF TECH

Polypropylene carbonate moisture-curable polyurethane hot-melt adhesive and preparation method thereof

The invention relates to a polypropylene carbonate moisture-curable polyurethane hot-melt adhesive and a preparation method thereof. The polypropylene carbonate moisture-curable polyurethane hot-melt adhesive is composed of, by weight part, 10-30 parts of polyisocyanates, 20-75 parts of polypropylene carbonate, 0-60 parts of polyether polyol, 0-60 parts of polyester polyol and 0-0.5 part of catalyst. The preparation method comprises adding the polypropylene carbonate, the polyether polyol and the polyester polyol into a reactor, performing dehydration during vacuum melting to obtain a dried polyol mixture; cooling down to 60-80 DEG C, filling nitrogen in for protection, slowly adding the polyisocyanates into the mixture for reaction at 60-120 DEG C for 1-4 hours, then adding in the catalyst, performing vacuumization until no bubbles exist, and then performing discharging and sealed packaging to obtain the polypropylene carbonate moisture-curable polyurethane hot-melt adhesive.

Owner:DONGHUA UNIV

Preparation method and application of high-solid-content water-based polyurethane resin and coating thereof

ActiveCN106750130AHigh hardnessImprove performancePolyurea/polyurethane coatingsWater basedPolymer science

The invention discloses a preparation method and application of high-solid-content water-based polyurethane resin and coating thereof. The preparation method comprises the following steps: reacting poly (propylene carbonate) polyols or a mixture of poly (propylene carbonate) polyols and other conventional polypolyols with isocyanate, a chain extender, a crosslinking agent, a catalyst and a sulfonic acid type hydrophilic chain extender, adding water to perform emulsification, and removing a solvent to obtain the high-solid-content water-based polyurethane resin; adding aids such as a leveling agent, a thickening agent, color paste, an environment-friendly cosolvent and a defoaming agent to obtain high-solid-content water-based polyurethane resin coating prepared from the poly(propylene carbonate)polyols. Film-forming and drying speed is high, plumpness is high, and high adhesive force, hardness, water resistance and solvent resistance are achieved.

Owner:JIANGSU ZHONGKE JINLONG CHEM

Composite solid-state electrolyte membrane, preparation method and solid-state lithium battery

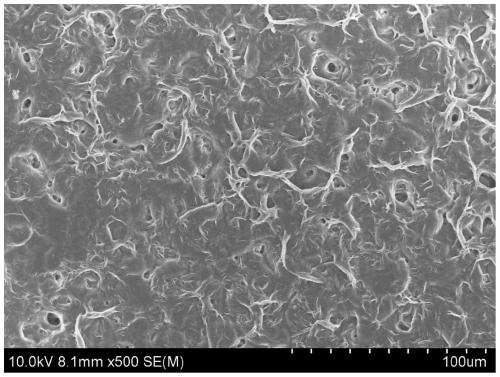

InactiveCN111430788AImprove cycle stabilityImprove capacity playMaterial nanotechnologySolid electrolytesSolid state electrolytePolyvinyl chloride

The invention discloses a composite solid-state electrolyte membrane, a preparation method and a solid-state lithium battery. The composite solid-state electrolyte membrane comprises a support membrane, an organic-inorganic composite coating A coated on the surface of the positive electrode side of the support membrane, and an organic-inorganic composite coating B coated on the surface of the negative electrode side of the support membrane, wherein the coating A comprises an organic polymer A, a lithium salt and a nano inorganic solid electrolyte, and the organic polymer A is one or more thantwo of polyvinylidene fluoride, a polyvinylidene fluoride copolymer, polyacrylonitrile and polyvinyl chloride; the coating B comprises an organic polymer B, a lithium salt and a nano inorganic solid electrolyte; and the organic polymer B is one or more than two of polyoxyethylene, polypropylene carbonate, polycarbonate and poly trimethylene carbonate. Aiming at different requirements of positive and negative electrode layers in the solid-state lithium battery on the electrolyte membranes, the graphene oxide membrane is used as a support, and the electrolyte membranes containing different polymer groups are designed on the two sides of the graphene oxide membrane respectively so that the comprehensive performance of the battery is further improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

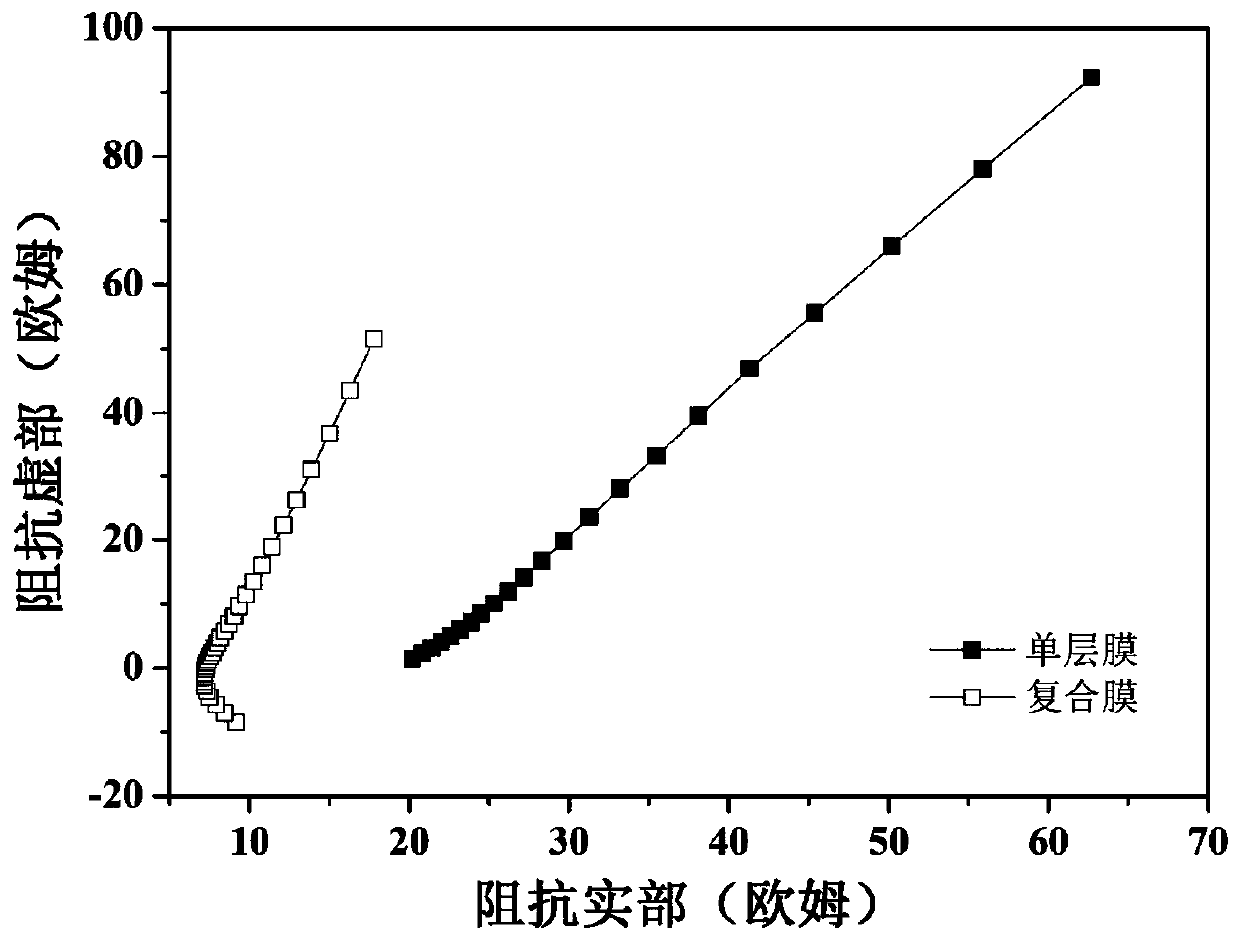

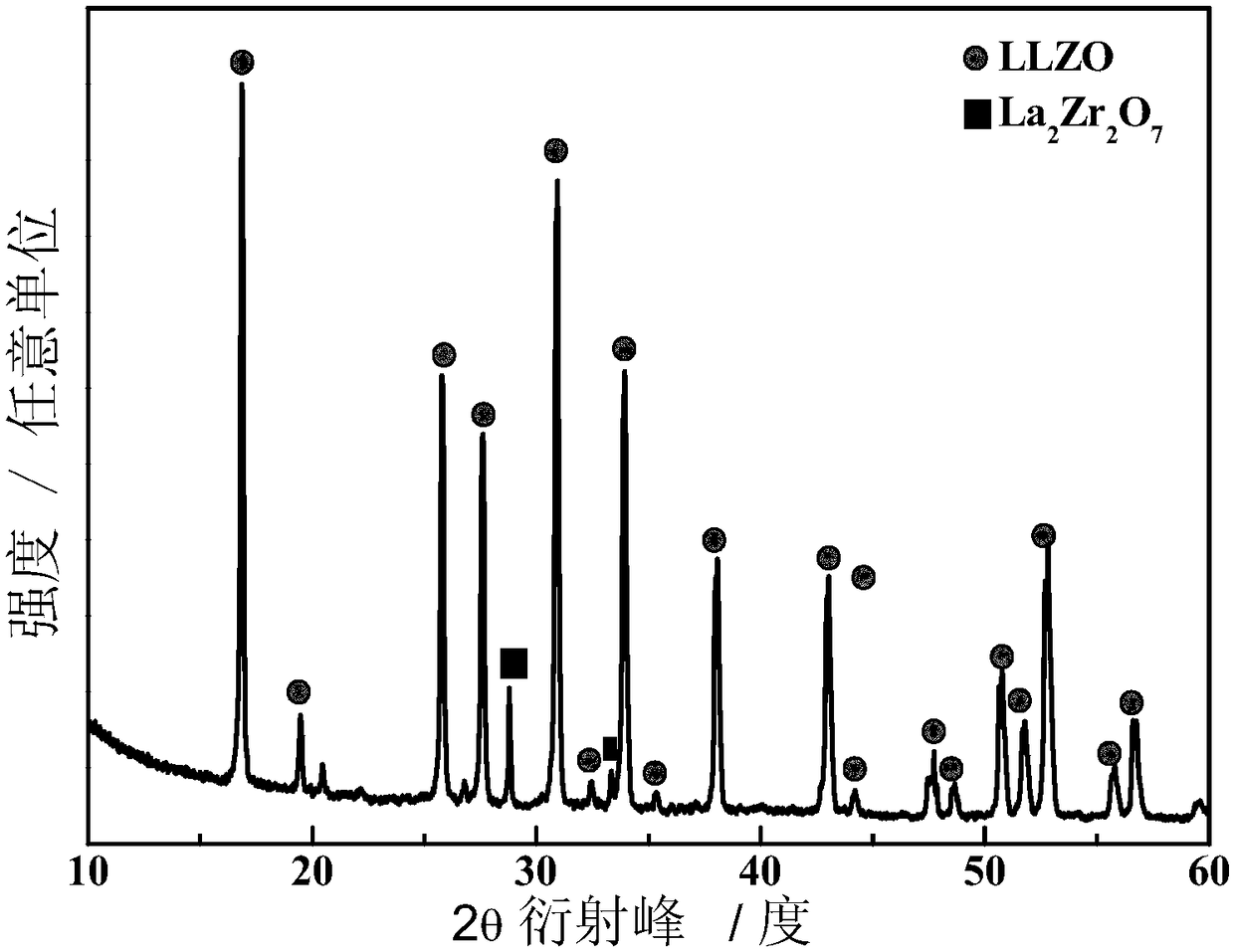

Quasi-solid state lithium ion conductive electrolyte and preparation method and application thereof

ActiveCN108598561AImprove mechanical propertiesGood chemistrySecondary cellsElectrolytesHexafluoropropyleneLanthanum

The invention discloses a quasi-solid state lithium ion conductive electrolyte. The raw material comprises a polymer, a ceramic electrolyte, a lithium salt and an ionic liquid, wherein the polymer comprises polyvinylidene fluoride-hexafluoropropylene and polypropylene carbonate, the ceramic electrolyte comprises a main phase lanthanum-lithium-zirconium-oxygen and an impurity phase La2Zr2O7, and the ionic liquid is a fluorine-containing imidazolium ionic liquid. The invention discloses the quasi-solid state lithium ion conductive electrolyte. The quasi-solid state lithium ion conductive electrolyte has high mechanical strength, is compatible with flexibility, has high room-temperature lithium ion conductivity and high chemical / electrochemical stability with a metal lithium negative electrode and an oxide positive electrode, and favorable electrochemical performance can be achieved when the quasi-solid state lithium ion conductive electrolyte is used for a metal lithium battery, a lithium-air battery and a lithium-sulfur battery.

Owner:ZHEJIANG UNIV

Solder resist for high-temperature co-fired multilayer ceramic and preparation method of solder resist

The invention relates to a solder resist for high-temperature co-fired multilayer ceramic. The solder resist for the high-temperature co-fired multilayer ceramic consists of organic powder and organic carriers. The organic powder consists of main body solder resisting materials and firing aids. The main body solder resisting materials consist of one or more of aluminum oxide, magnesium oxide and zirconium oxide. The firing aids consist of a plurality of compounds which at least contain one element of calcium, magnesium, aluminum and silicon and are mixed according to certain proportions. The organic carriers consist of mixed solvent, binder, dispersing agent, thixotropic agent and coloring agent, wherein the mixed solvent is made of ethanol and terpineol according to certain proportions; and the binder is made of at least one of polyvinyl butyral, polypropylene carbonate and ethyl cellulose. The invention additionally discloses a preparation method of the solder resist. The solder resist disclosed by the invention has the advantages that the cost of raw materials is low, the preparation process is simple, a multilayer ceramic processing technology and a high-temperature co-firing technology are compatible with each other, the solder resisting effect is good, the strength of bonding between a solder resisting coating layer and a ceramic substrate is high, the thermal expansion matching performance is good and the salt mist is resisted.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Biodegradable melt-blown non-woven fabric sliced sheet and preparation method thereof

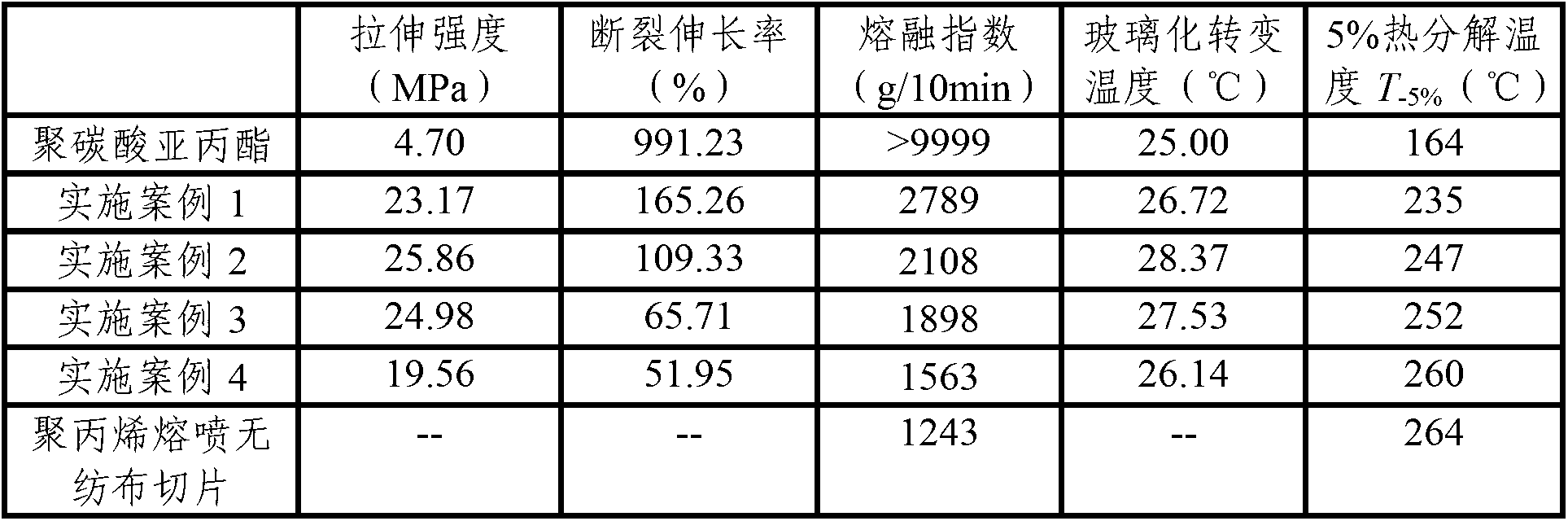

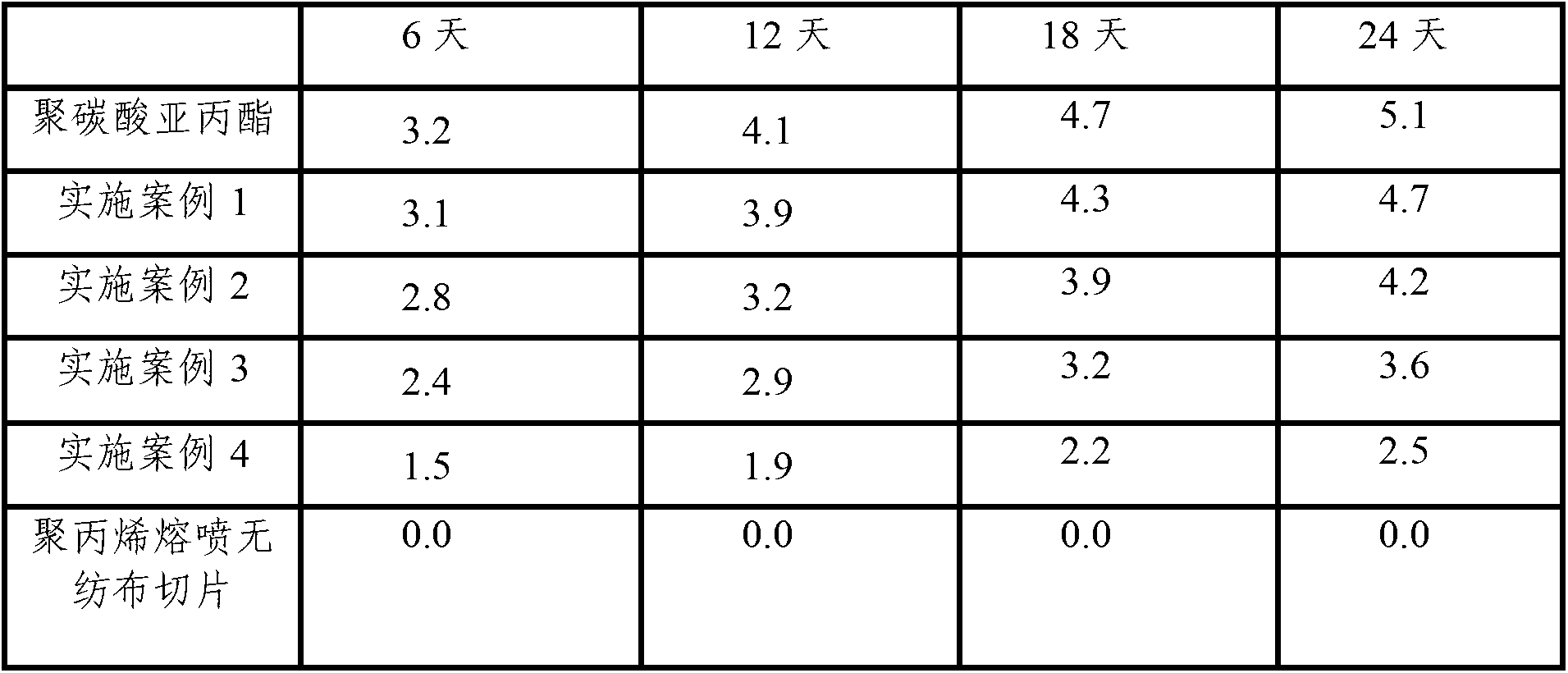

The invention discloses a biodegradable melt-blown non-woven fabric sliced sheet and a preparation method thereof. The biodegradable melt-blown non-woven fabric sliced sheet comprises the following components in part by mass: 50-90 parts of polypropylene carbonate, 10-50 parts of polypropylene melt-blown non-woven fabric sliced sheets, 0-40 parts of nano-particles, 0-10 parts of bulking agent, 0-8 parts of end-capping reagent, 0-0.1 part of initiating agent, 0-2 parts of heat-resisting stabilizing agent, 0-2 parts of slipping agent, 0-2 parts of biodegradation accelerant and 0-1 part of photolysis agent; and the preparation method comprises the following steps: drying the components for 6-12 h at the temperature of 45-55 DEG C; performing melt blending in proportion in mixing equipment, wherein the blending temperature is 100-210 DEG C, the blending time is 3-8 min, and the rotating speed is 15-50 r / min; and then performing extrusion and granulation on the blend through a single-screw or double-screw extruder, wherein the temperature of the extruder is 100-210 DEG C, and the rotating speed is 15-50 r / min. According to the biodegradable melt-blown non-woven fabric sliced sheet provided by the invention, the tensile strength can reach 25.86 MPa to the maximum, the melt flow rate is 800-3000 g / 10min, the glass-transition temperature Tg can reach 28.37 DEG C to the maximum, and the thermal decomposition temperature T(-5%) can reach 260 DEG C to the maximum.

Owner:XINLONG HLDG GROUP +1

Full-biodegradable plastic mulching film, preparation method and application thereof

InactiveCN112980153AAffect mechanical strengthIncrease the range that can be addedClimate change adaptationPlant protective coveringsButanedioic acidPlastic mulch

The invention provides a full-biodegradable plastic mulching film, a preparation method and application thereof. The full-biodegradable plastic mulching film comprises the following components in parts by weight: 100 parts of a full-biodegradable resin, 10-30 parts of an auxiliary agent, 10-60 parts of modified starch and 10-100 parts of modified calcium carbonate, wherein the full-biodegradable resin is prepared from one or more of poly (butylene succinate) (PBS), polylactic acid (PLA), polyhydroxyalkanoate (PHA), poly (butylene adipate-butylene terephthalate) (PBAT) and polypropylene carbonate (PPC). According to the biodegradable mulching film, the contradiction that crops need longer service life of the mulching film and lower thickness of the mulching film and the requirement on the lowest thickness of a polyethylene plastic mulching film can be solved, and the technical scheme of the biodegradable mulching film also has the effects of slow degradation in the early stage, strong protection capability and accelerated degradation in the later stage, so that the influence of the biodegradable mulching film on the planting of succeeding crops is reduced.

Owner:北京惠林苑生物科技有限公司 +1

Fully-biodegradable heat shrinkage film and preparation method thereof

InactiveCN102924890AGood heat sealing performanceImprove breathabilityPolymer scienceMixed materials

The invention discloses a fully-biodegradable heat shrinkage film. A substrate resin material is any one or a mixed material of polyhydroxyalkanoate, poly-butylenes succinate, polylactic acid, polycaprolactone, polyesteramide and polypropylene carbonate. The heat shrinkage film is prepared from a fully-biodegradable material, has superior physical and mechanical properties, can be used for replacing the conventional heat shrinkage film, can be biodegraded fully after being discarded, and is environment-friendly.

Owner:山东省意可曼科技有限公司

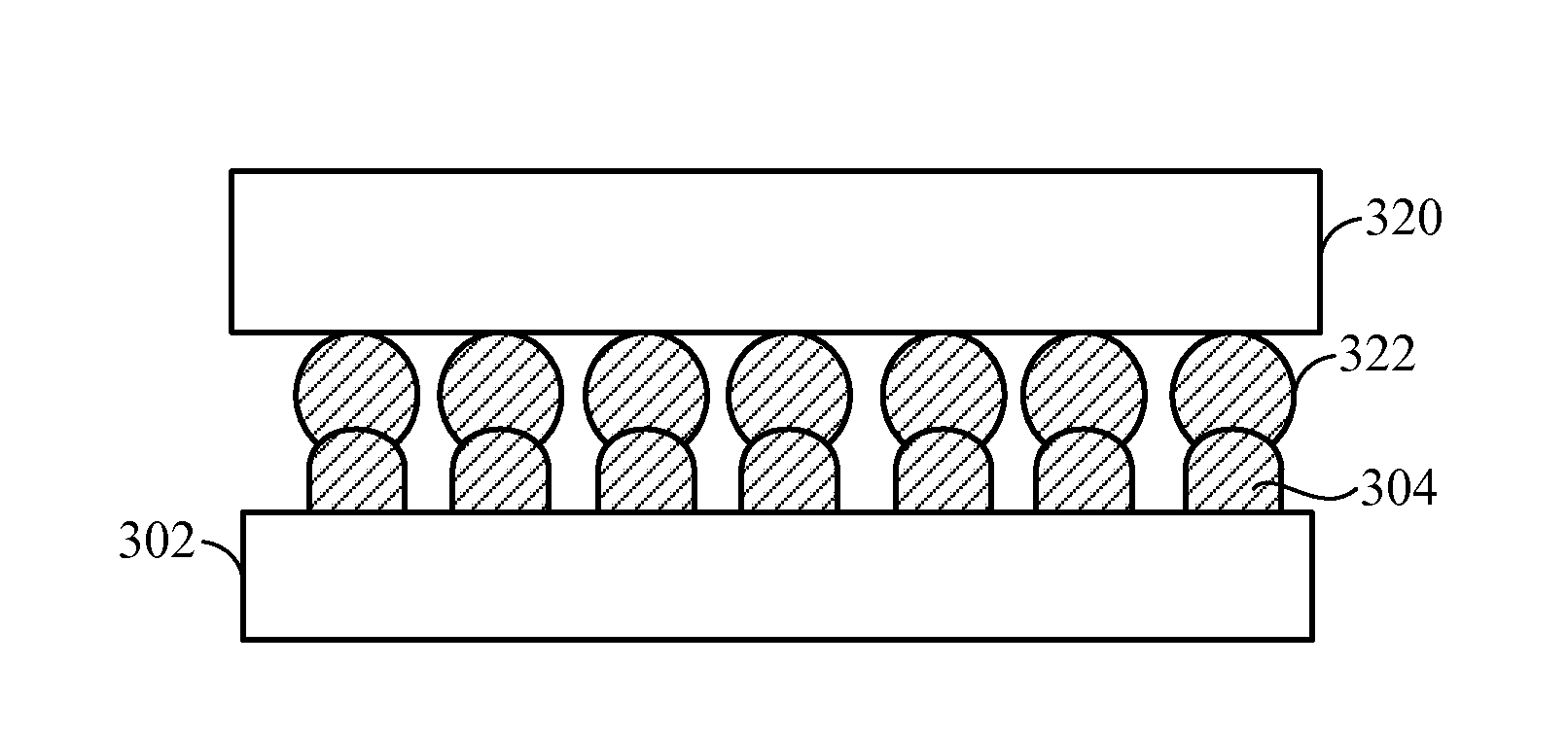

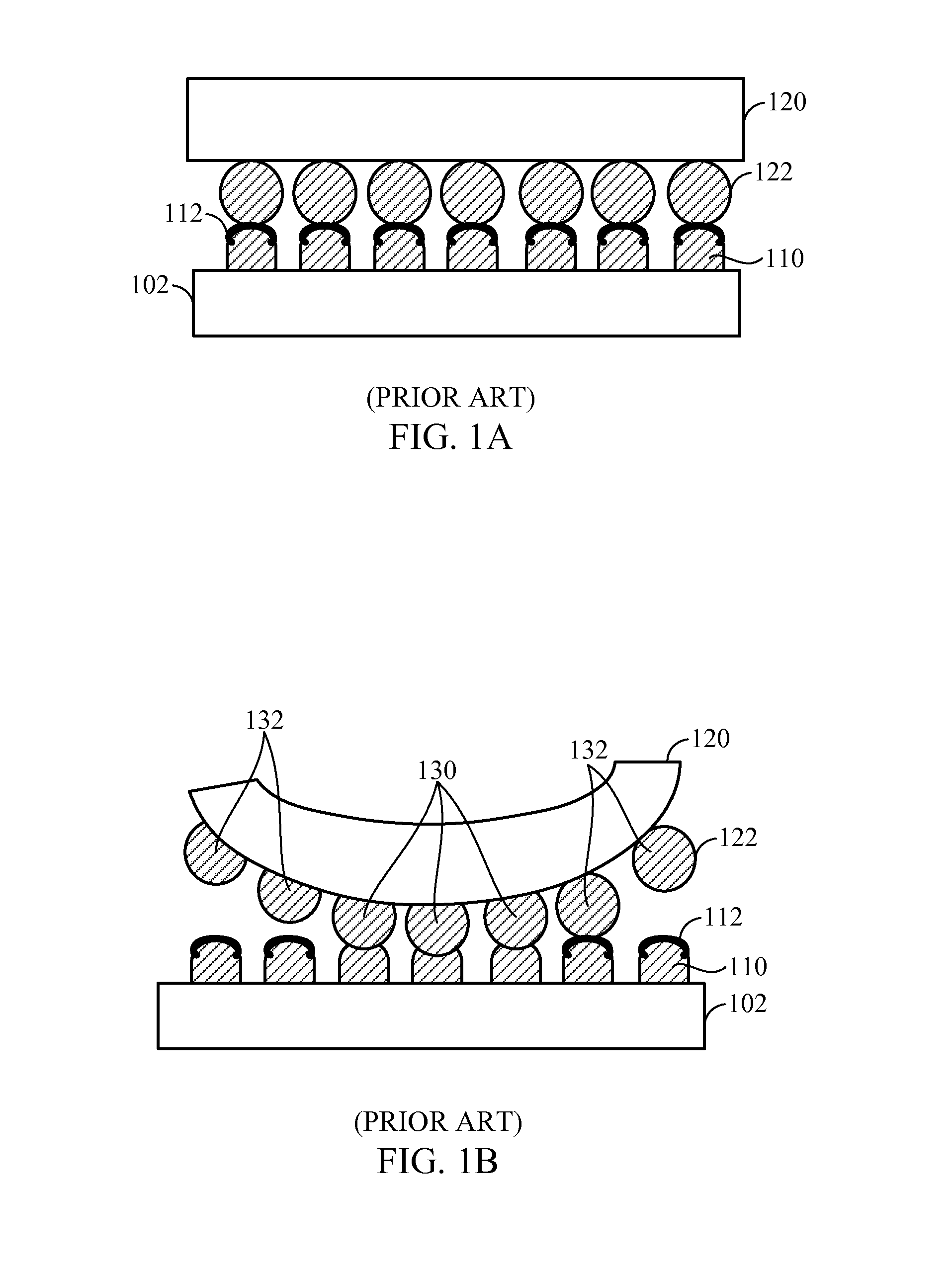

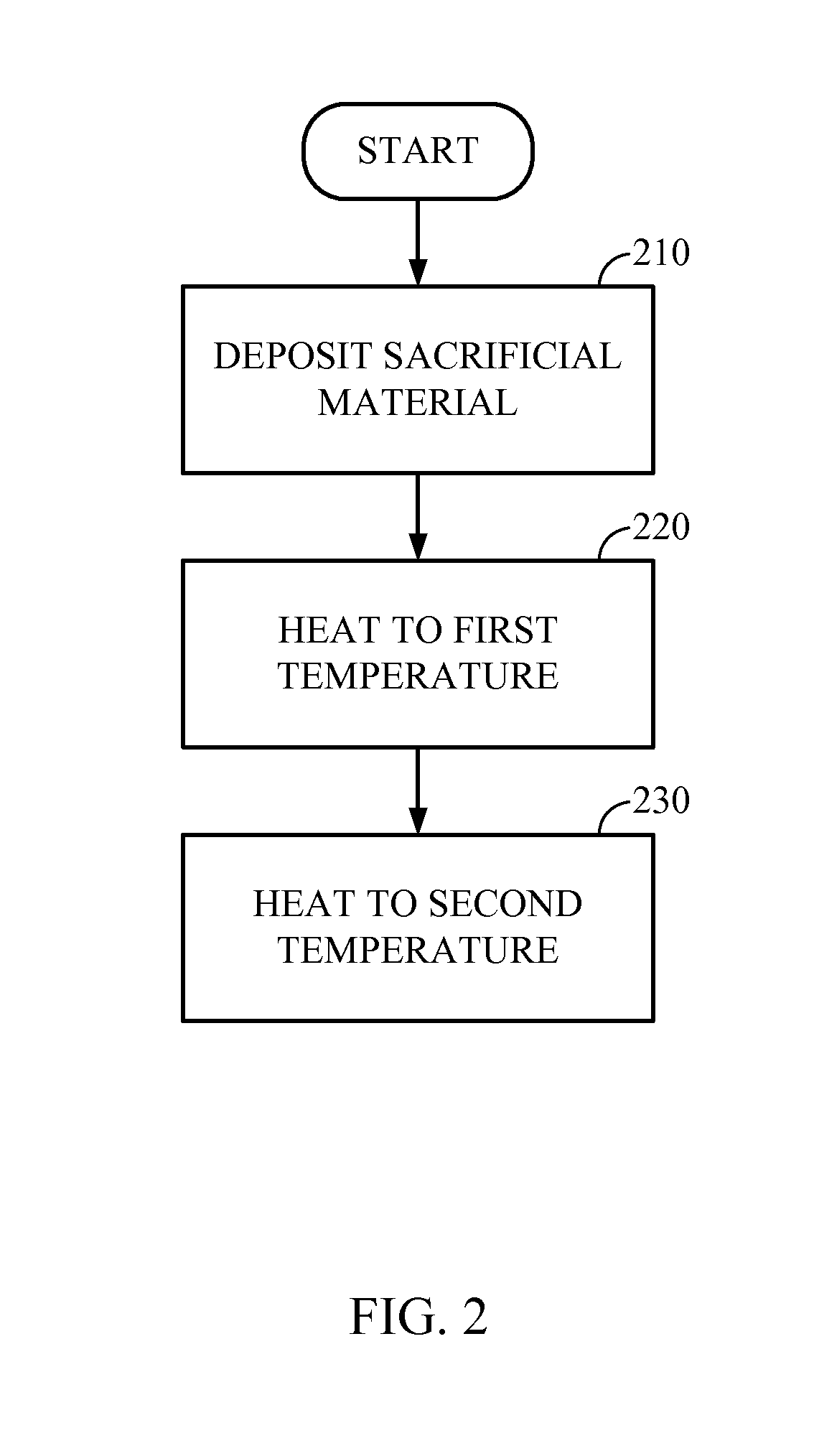

Sacrificial Material to Facilitate Thin Die Attach

ActiveUS20110233790A1Reduce warpageSemiconductor/solid-state device detailsSolid-state devicesSacrificial metalPolypropylene carbonate

A sacrificial material applied to a thin die prior to die attach provides stability to the thin die and inhibits warpage of the thin die as heat is applied to the die and substrate during die attach. The sacrificial material may be a material that sublimates at a temperature near the reflow temperature of interconnects on the thin die. A die attach process deposits the sacrificial material on the die, attaches the die to a substrate, and applies a first temperature to reflow the interconnects. At the first temperature, the sacrificial material maintains substantially the same thickness. A second temperature is applied to sublimate the sacrificial material leaving a clean surface for the later packaging processes. Examples of the sacrificial material include polypropylene carbonate and polyethylene carbonate.

Owner:QUALCOMM INC

Modified polypropylene carbonate based polyurethane water-based coating agent applied to leather and preparation method of water-based coating agent

ActiveCN104278530AImprove adhesionImprove water resistanceFibre treatmentLeather surface finishingEpoxyPolymer science

The invention relates to the technical field of high polymer materials of leather coating agents and provides a modified polypropylene carbonate based polyurethane water-based coating agent applied to leather and a preparation method of the water-based coating agent. The modified polypropylene carbonate based polyurethane water-based coating agent applied to the leather comprises the following components in parts by mass: 100 parts of polypropylene carbonate polyhydric alcohol, 35-65 parts of diisocyanate, 0.05-5 parts of an organic tin catalyst, 5-20 parts of a hydrophilic chain extender, 1-15 parts of epoxy resin, 0.5-50 parts of a neutralizer and 1-5 parts of a chain extender, wherein the epoxy resin is selected from one or more of E-44 epoxy resin, E-51 epoxy resin and E-20 epoxy resin; the chain extender is isophorone diamine. The coating agent is prepared by copolymerization reaction of the polypropylene carbonate polyhydric alcohol, the diisocyanate and the epoxy resin. The coating agent prepared by the method has the characteristics of being high in underlying adhesive property, excellent in stability, low in cost, green and environment-friendly.

Owner:HUIZHOU DAYAWAN DAZHI FINE CHEM

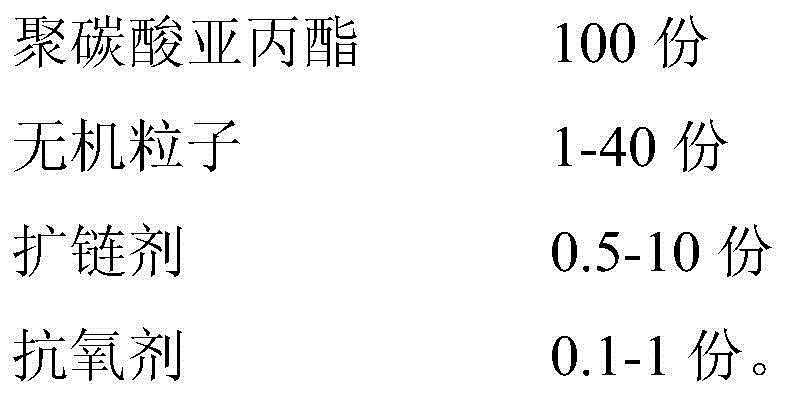

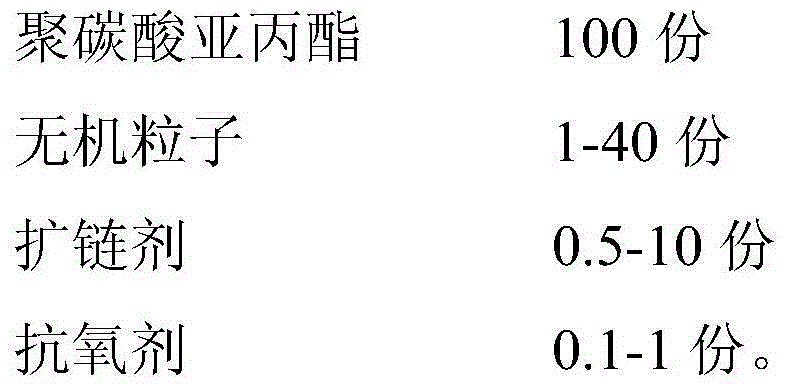

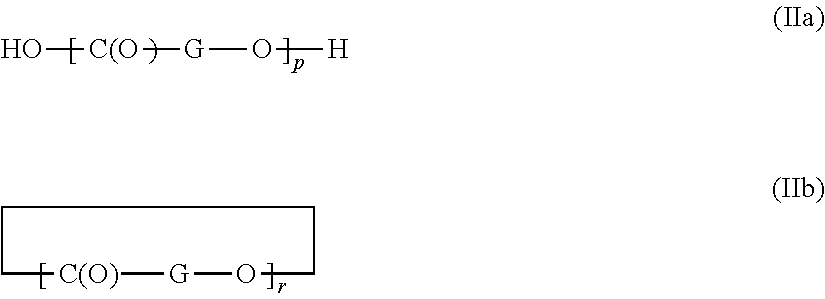

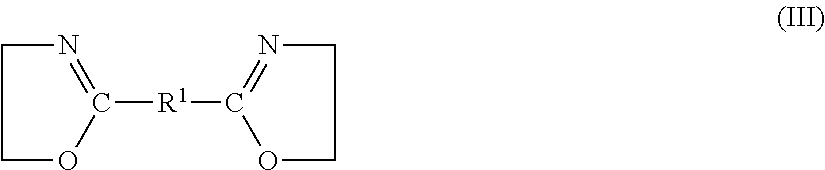

Polypropylene carbonate composite material for 3D printing and preparation method thereof

InactiveCN104693773AGood dispersionImprove mechanical propertiesAdditive manufacturing apparatusPolymer scienceInorganic particle

The invention belongs to the technical field of a macromolecular material and discloses a polypropylene carbonate composite material for 3D printing and a preparation method thereof. The polypropylene carbonate composite material is prepared from the following raw materials in parts by weight: 100 parts of polypropylene carbonate, 1-40 parts of inorganic particles, 0.5-10 parts of chain extender and 0.1-1 part of antioxidant. The polypropylene carbonate composite material is obtained by means of blending, extrusion and modification; the prepared composite material is high in mechanical property, better in heat-resistant property, biodegradable and better in forming and processing property of 3D printing; meanwhile, the technological process is simple and the production cost is low; printed products have good size stability and high printing precision.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Biodegradable polymer mixture

The present invention relates to biodegradable polymer mixtures comprisingi) 40% to 95% by weight, based on the total weight of components i to ii, of at least one polyester based on aliphatic or aliphatic and aromatic dicarboxylic acids and aliphatic dihydroxy compounds;ii) 5% to 60% by weight, based on the total weight of said components i to ii, of polyalkylene carbonate, particularly polypropylene carbonate;iii) 0% to 60% by weight, based on the total weight of said components i to iii, of at least one biodegradable homo- or copolyester selected from the group consisting of polylactic acid, polycaprolactone and polyhydroxyalkanoate, and / or of an inorganic or organic filler;iv) 0% to 10% by weight, based on the total weight of said components i to ii, of an epoxy-containing copolymer based on styrene, acrylic ester and / or methacrylic ester, andv) 0% to 15% by weight of an additive selected from the group consisting of lubricant, antiblocking agent, antistat, UV absorber, UV stabilizer, thermal stabilizer, dye, pigment, colorant, plasticizer, fertilizer and active crop protection ingredient.The present invention further relates to processes for producing biodegradable polymer mixtures, to the use of biodegradable polymer mixtures in the production of moldings, films or fibers and also moldings, films or fibers comprising biodegradable polymer mixtures.

Owner:BASF SE

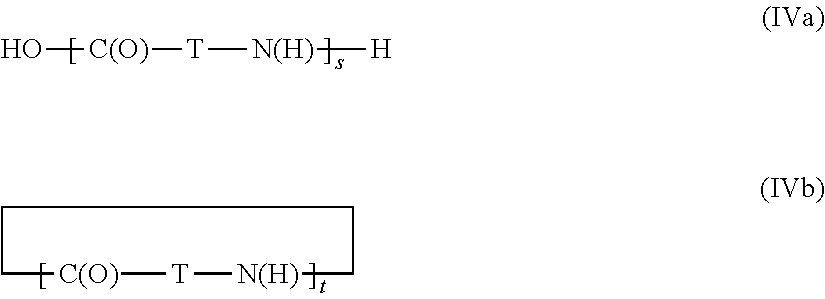

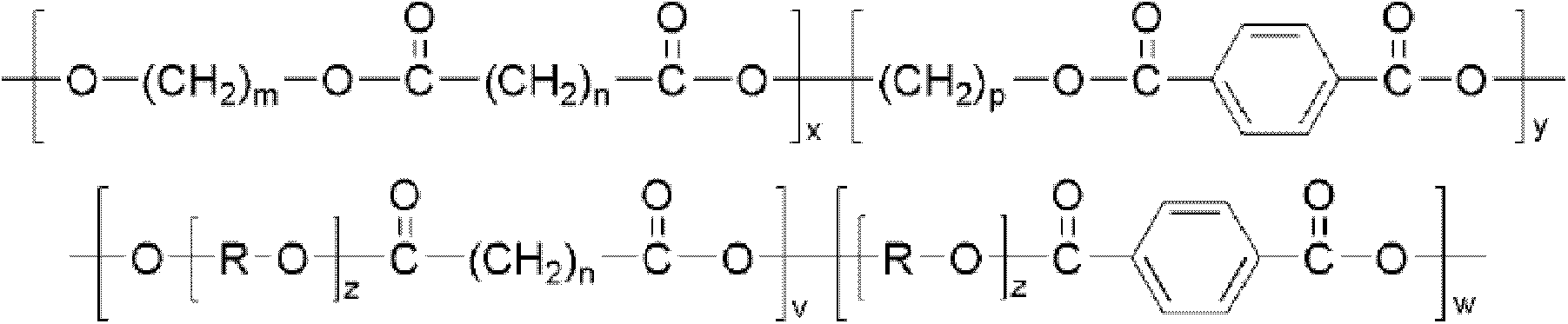

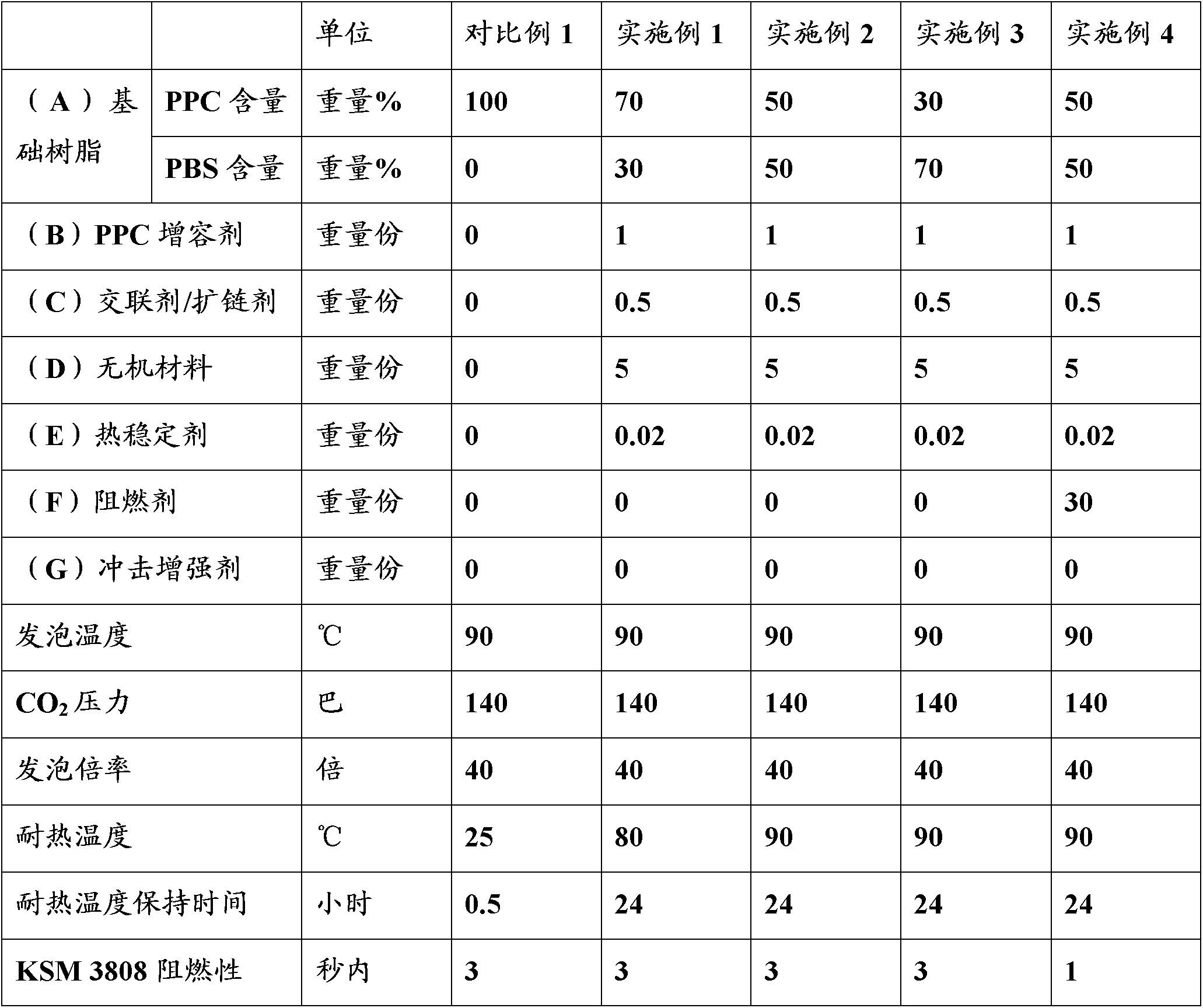

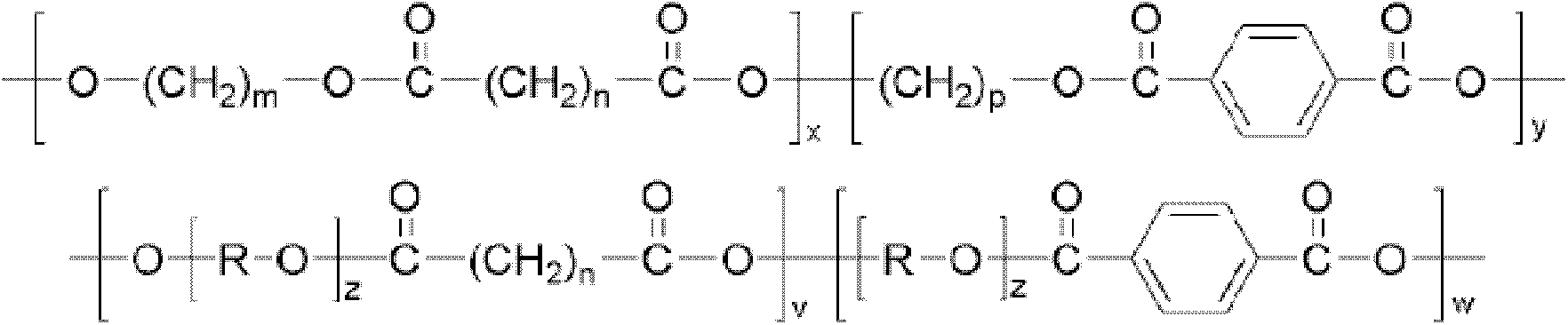

Composition for preparing expandable polypropylene carbonate and expandable polypropylene carbonate prepared therefrom

Provided are a composition for preparing expandable polypropylene carbonate and an expandable polypropylene carbonate prepared therefrom, and more particularly, to a composition for preparing expandable polypropylene carbonate capable of using supercritical carbon dioxide as a foaming agent and producing a foam having excellent moldability by using an appropriate foaming method. By using the composition according to the present invention, highly magnificated expandable polypropylene carbonate capable of having excellent thermal stability and dimensional stability can be prepared.

Owner:SK INNOVATION CO LTD

Biodegradable polylactic acid agricultural mulching film and processing technology thereof

ActiveCN108690336AStrong environmental protectionEasy to useClimate change adaptationPlant protective coveringsCyclodextrinBiology

The invention discloses a biodegradable polylactic acid agricultural mulching film and a processing technology thereof, and relates to the technical field of agricultural mulching films. The biodegradable polylactic acid agricultural mulching film is prepared from the following raw materials in parts by weight: 100-120 parts of polylactic resin, 15-30 parts of light calcium carbonate, 5-10 parts of polypropylene carbonate, 5-10 parts of carboxymethyl-beta-cyclodextrin, 1-5 parts of PEG-60 hydrogenated castor oil, 1-5 parts of hexakis(methoxymethyl)melamine, 1-5 parts of ultraviolet screening agent and 0.5-2 parts of antioxidant. According to the biodegradable polylactic acid agricultural mulching film and the processing technology thereof, the polylactic acid film is prepared by taking thepolylactic resin as a main material and co-taking a plurality of auxiliary materials, and the prepared polylactic acid film belongs to the biodegradable film and is non-toxic, harmless and strong inuse environmental protection property; and in addition, the usability is excellent, and the use requirement of the agricultural mulching film is met.

Owner:湖北嘉鑫环保新材料科技有限公司

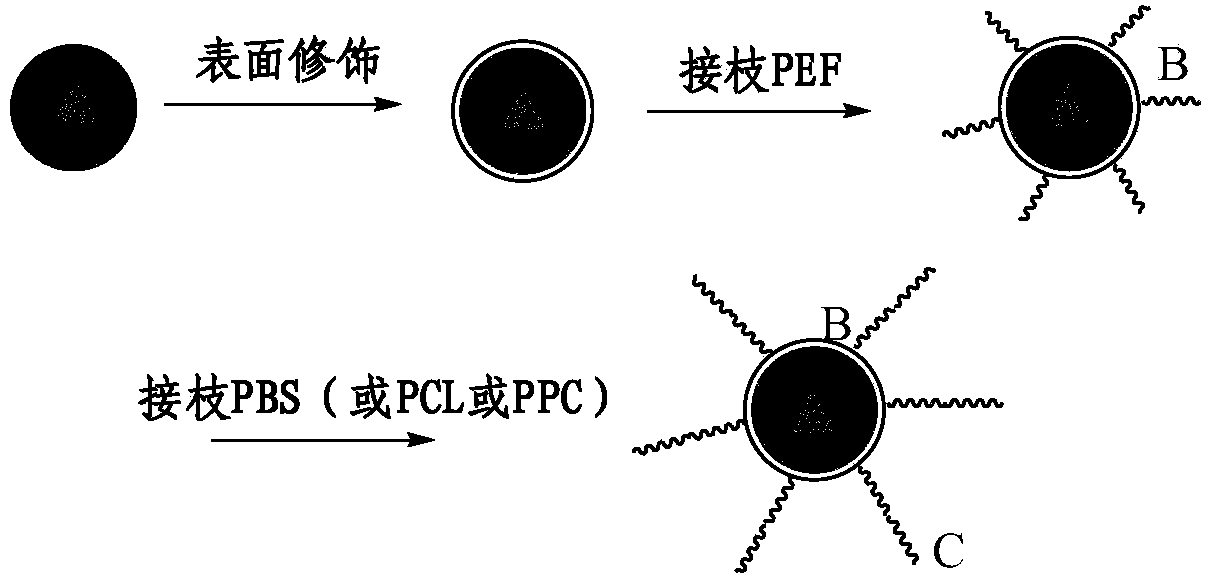

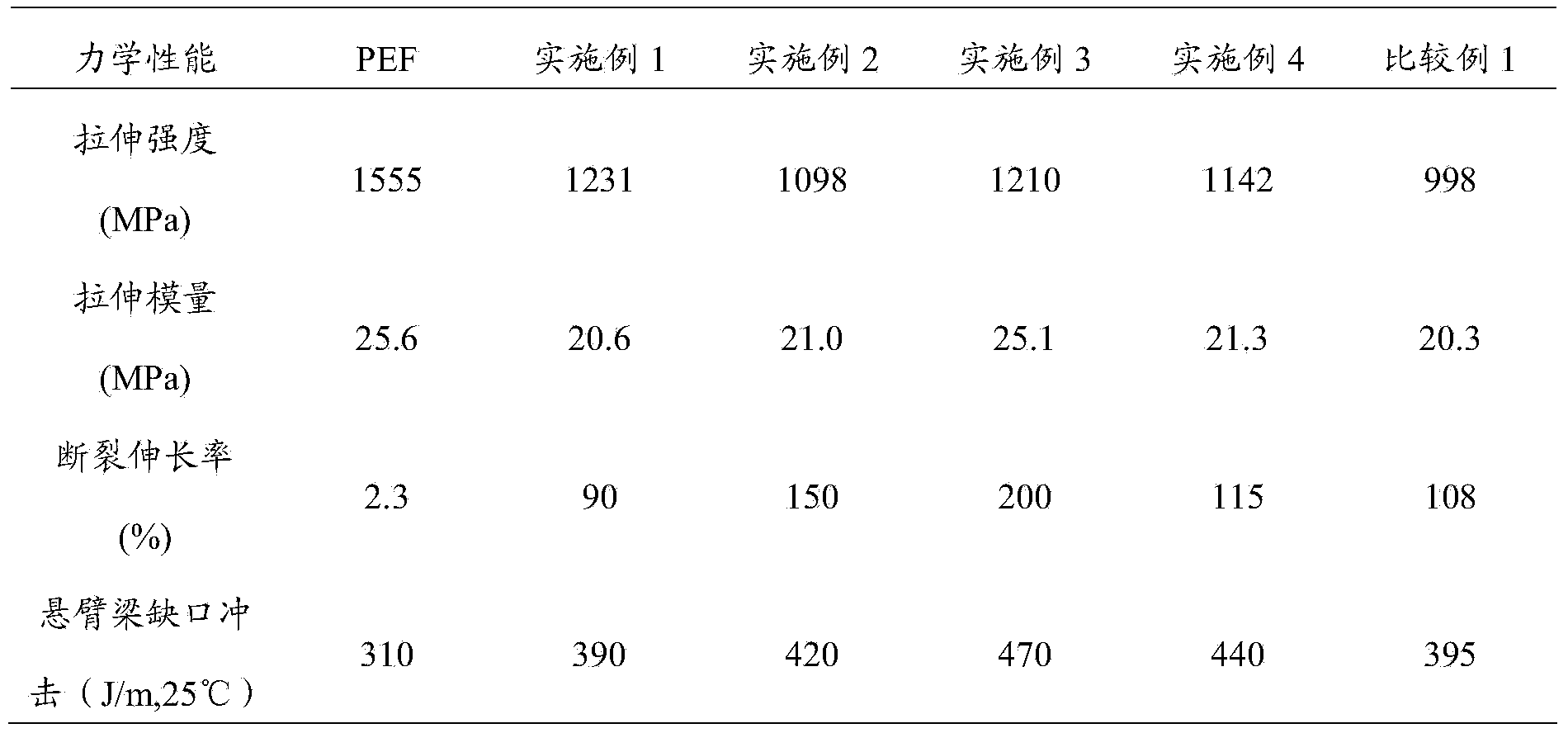

Poly-2,5-furandicarboxylic acid glycol ester composite material and preparation method thereof

The application provides a poly-2,5-furandicarboxylic acid glycol ester composite material and a preparation method thereof. The poly-2,5-furandicarboxylic acid glycol ester composite material is prepared by mixing first poly-2,5-furandicarboxylic acid glycol ester, a first polymer and an additive; the additive is formed through the step that cellulose beads or cellulose whiskers are sequentially grafted onto a second poly-2, 5-furandicarboxylic acid glycol ester and a second polymer after being modified by a silane coupling agent with amino at the tail end. When poly-2,5-furandicarboxylic acid glycol ester composite material is compared with the prior art, the mixing for modification is adopted, poly(butylene succinate), polycaprolactone and polypropylene carbonate are fatty group linear polymers with flexible chains, and have excellent flexibility and relatively high elongation at break, so that the tenacity of the poly-2,5-furandicarboxylic acid glycol ester can be increased, and the impact strength can be improved; by adding the additive, the interfacial compatibility of the composite can be improved, and the cellulose beads or the cellulose whiskers in the additive have the function of strengthening the composite.

Owner:芜湖万隆新材料有限公司

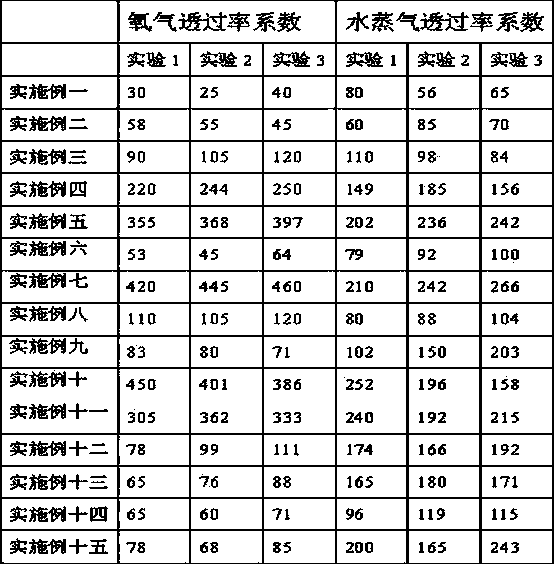

High-resistance polypropylene carbonate based composite film material and preparation method thereof

InactiveCN103804879ANo problems with inorganic metal residuesEasy to prepareComposite filmPolymer science

The invention discloses a high-resistance polypropylene carbonate based composite film material and a preparation method thereof. The high-resistance polypropylene carbonate based composite film material comprises the following raw materials in parts by weight: 60-95 parts of polypropylene carbonate, 5-20 parts of polyvinyl alcohol, 0.5-10 parts of layered silicate and 5-20 parts of plasticizer. With the polypropylene carbonate as a base material, the degradable high-resistance polypropylene carbonate based composite film material is prepared through modification, wherein the oxygen permeability coefficient is low to 25cm<3>.mu m / (m<2>.24h.atm), and the water vapor permeability coefficient is low to 56g / (m<2>.24h). The high-resistance polypropylene carbonate based composite film material is improved in barrier property, thermal property and mechanical property when the original characteristic of the base material raw material is kept, especially improved in barrier performance, is capable of completely replacing high-resistance materials such as polyethylene-vinyl alcohol, and is used in the production of various packaging products requiring high resistance.

Owner:HENAN TIANGUAN GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com