Biodegradable melt-blown non-woven fabric sliced sheet and preparation method thereof

A melt-blown non-woven fabric, biodegradable technology, applied in the field of non-woven fabric manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

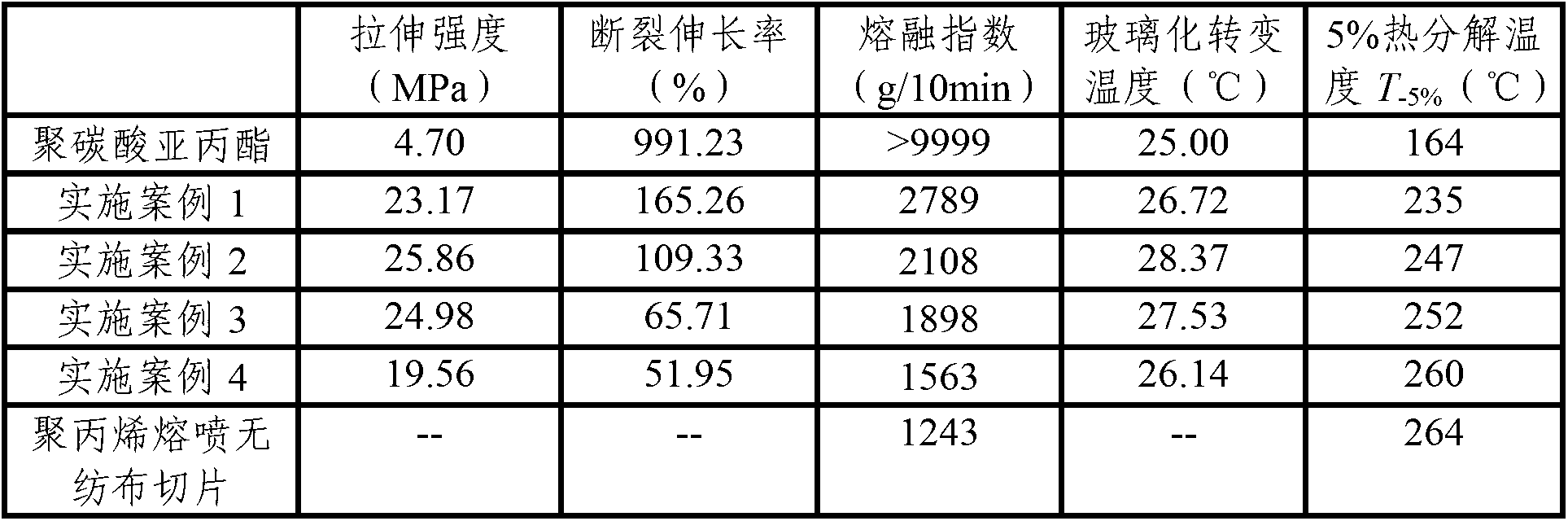

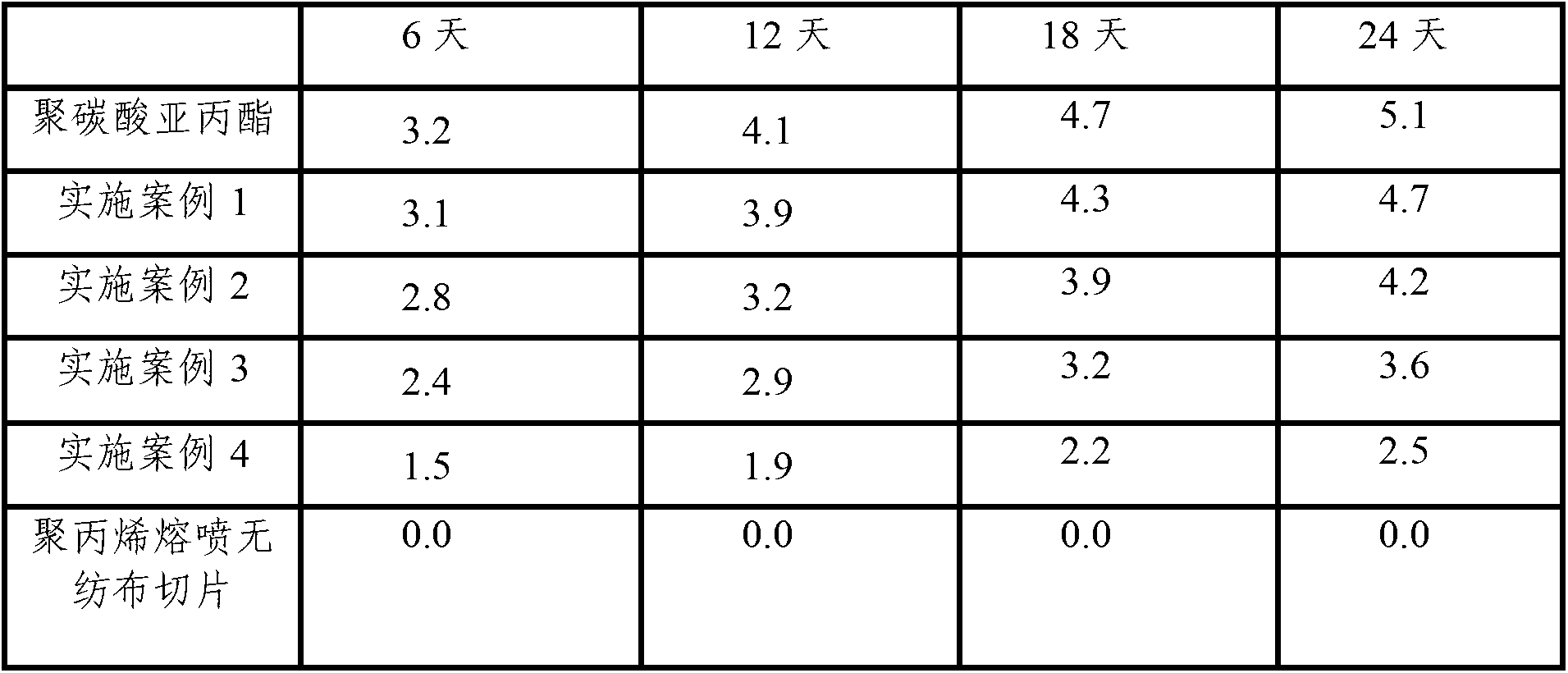

Examples

Embodiment 1

[0035] Weigh each component according to the following parts by mass:

[0036] 90 parts of polypropylene carbonate; 10 parts of polypropylene melt-blown non-woven fabric slices; 20 parts of nano calcium carbonate; 2 parts of maleic anhydride grafted polypropylene; 0.5 parts of maleic anhydride; 0.01 part of dicumyl peroxide; 1 part of nano silicon dioxide; 1 part of erucamide; 0.5 part of citric acid; 0.2 part of benzoin monoalkyl ether.

[0037] The preparation process is as follows:

[0038] Dry the above-mentioned components in an oven at 50°C for 6 hours (because polypropylene carbonate is easy to absorb water, in order to prevent it from absorbing water again during the drying process, some potassium hydroxide can be added as a water-absorbing agent). The dried components are mixed in a high-speed pulverizer in proportion for 0.5 min, and then melted and blended in an internal mixer. The blending temperature is 175 ° C, the blending time is 5 min, and the speed is 35 r / m...

Embodiment 2

[0048] Weigh each component according to the following parts by mass:

[0049] 80 parts of polypropylene carbonate; 20 parts of polypropylene meltblown non-woven fabric slices; 25 parts of nano calcium carbonate; 2 parts of maleic anhydride grafted polypropylene; 1 part of maleic anhydride; 0.01 part of dicumyl peroxide; 1 part of nano silicon dioxide; 1 part of erucamide; 0.5 part of oxalic acid; 0.2 part of benzoin monoalkyl ether.

[0050] The preparation process is as follows:

[0051] Dry the above-mentioned components in an oven at 50°C for 6 hours (because polypropylene carbonate is easy to absorb water, in order to prevent it from absorbing water again during the drying process, some potassium hydroxide can be put in as a water-absorbing agent). The dried components were mixed in a high-speed pulverizer in proportion for 0.5 min, and then melted and blended in an internal mixer. The blending temperature was 175 ° C, the blending time was 5 min, and the rotation speed ...

Embodiment 3

[0061] Weigh each component according to the following parts by mass:

[0062] 70 parts of polypropylene carbonate; 30 parts of polypropylene melt-blown non-woven fabric slices; 28 parts of nano calcium carbonate; 3 parts of maleic anhydride grafted polypropylene; 1 part of di-n-butylamine; 0.01 part of benzoyl peroxide; 1 part of zinc oxide; 1 part of phthalimide oleate; 0.3 part of oxalic acid; 0.2 part of benzophenone.

[0063] The preparation process is as follows:

[0064] Dry the above-mentioned components in an oven at 50°C for 6 hours (because polypropylene carbonate is easy to absorb water, in order to prevent it from absorbing water again during the drying process, some potassium hydroxide can be put in as a water-absorbing agent). The dried components are mixed in proportion in a high-speed mixing pulverizer for 0.5 min, and then melted and blended in an internal mixer. The blending temperature is 175 ° C, the blending time is 5 min, and the rotation speed is 35 r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com