Patents

Literature

2920 results about "Dicumyl peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is a member of a class of chemicals called organic peroxides. USE: Dicumyl peroxide is an important commercial chemical. It is used in the vulcanization of rubber, to make other chemicals and in the production of resins. EXPOSURE: Workers that use dicumyl peroxide may breathe in vapors or have direct skin contact.

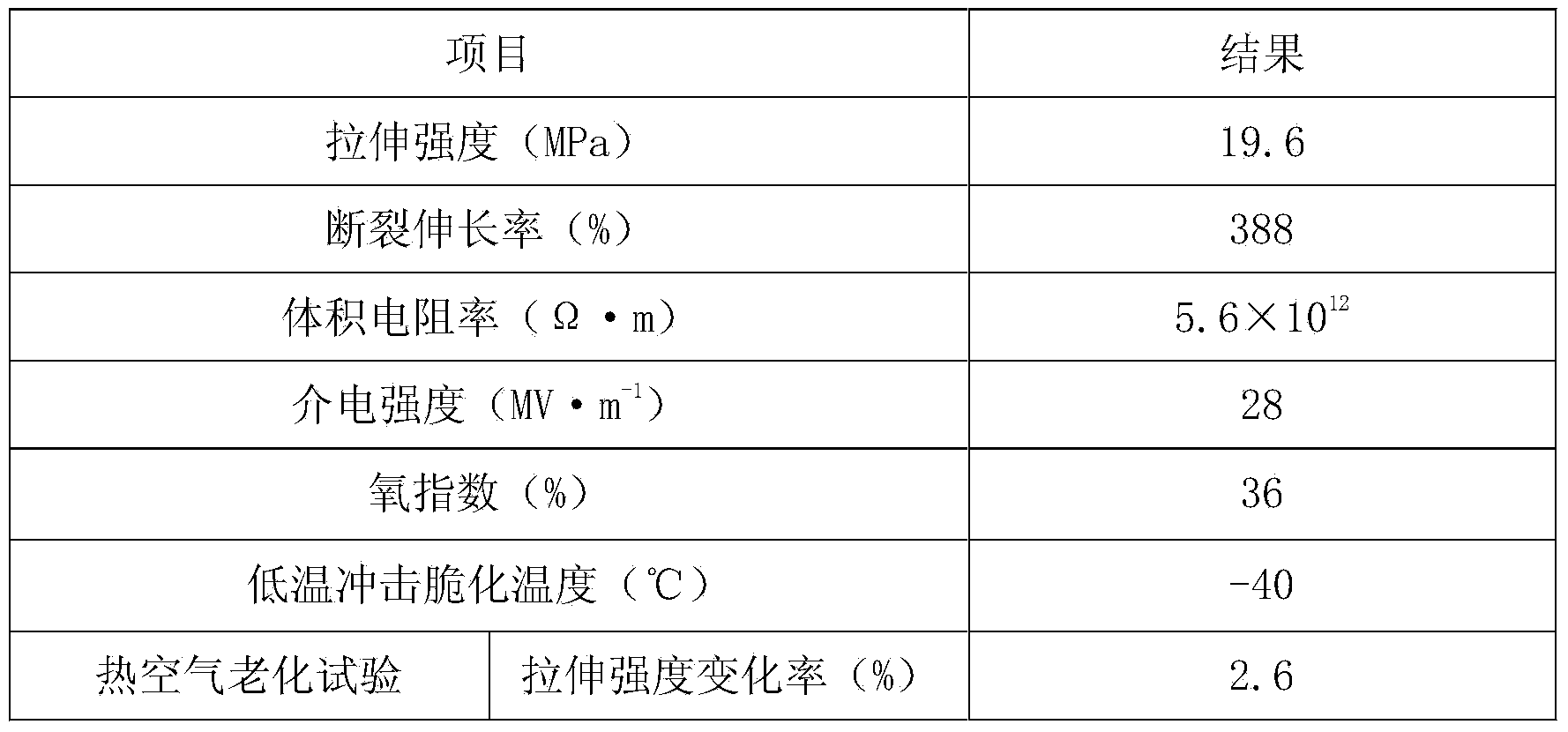

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

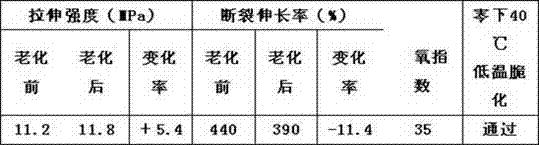

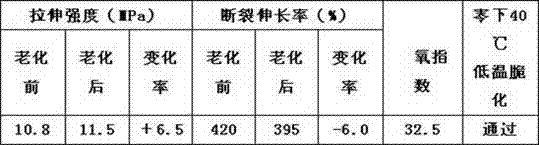

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Method for preparing ethylene vinyl acetate (EVA)/ thermoplastic urethane (TPU)/ polyolefin elastomer (POE) composite foaming material

Disclosed is a method for preparing an ethylene vinyl acetate (EVA) / thermoplastic urethane (TPU) / polyolefin elastomer (POE) composite foaming material. The method includes fully and evenly mixing EVA, POE, EVA grafted maleic anhydride and TPU in an internal mixer, adding azodicarbonamide serving as a foaming agent, dicumyl peroxide serving as a cross-linking agent, an auxiliary foaming agent and talcum powders to the internal mixer for mixing to obtain a mixture, pressing the mixture on an open dual-roller mixing mill into sheets, feeding the sheets to a vulcanizing machine, and performing mould pressing, crosslinking and foaming forming to discharge the sheets to obtain the EVA / TPU / POE composite foaming material. By means of EVA-maleic anhydride (MA), the EVA / TPU composite material with good compatibility can be obtained, usage of 4, 4-diaminodiphenylmethane is avoided, the process is simple, costs are saved, and better performances are achieved; and simultaneously, a POE material is introduced to a system, so that important performance indexes of the prepared foaming material are well improved.

Owner:SHAANXI UNIV OF SCI & TECH

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

Rubber packing ring and manufacturing technology thereof

InactiveCN101315144AMedium resistantHigh tensile strengthFluid pressure sealed jointsPolymer scienceManufacturing technology

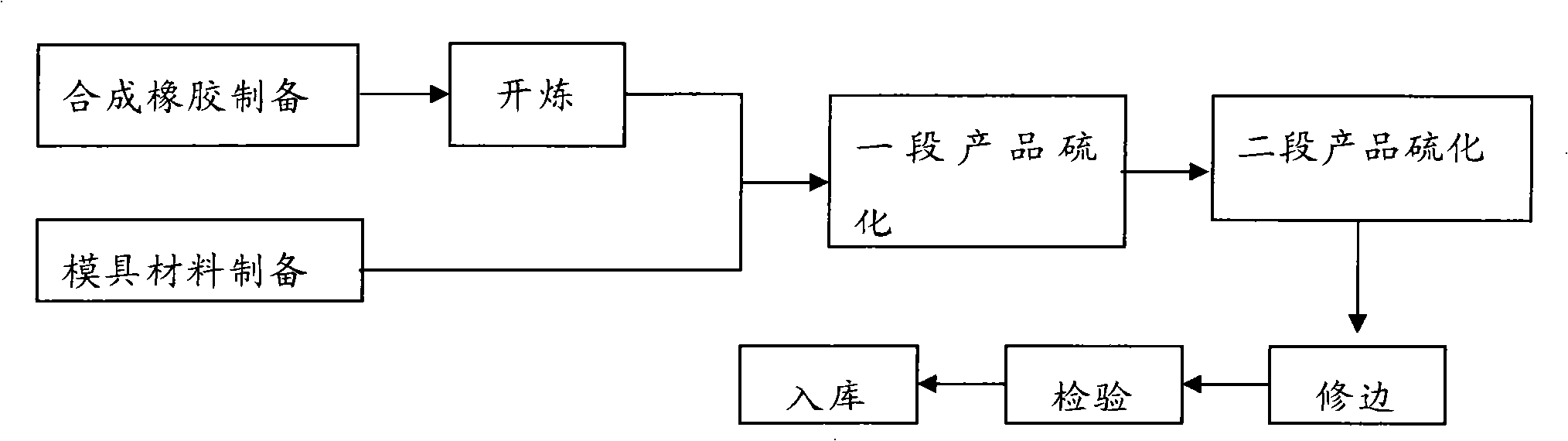

The invention provides a rubber sealing ring and a production method thereof. The rubber sealing ring is prepared from the following components of (by weight parts): ethylene propylene diene monomer (EPDM) 80-120, carbon black 55-75, paraffin oil 15-25, indirect process zinc oxide 4-6, stearic acid 0.2-1, anti-aging agent 2-4, sulfur S-80 0.1-0.35, vulcanizing agent dicumyl peroxide (DCP) 3-5, and lubricating agent 1-3. The production method comprises the steps of: synthesizing rubber with a Banbury mixer, forming the synthetic rubber with a mixing mill, first-stage vulcanizing in a mold of a vulcanizing device, second-stage the product from the first-stage vulcanization in an oven, trimming, testing, and storing. The inventive rubber sealing ring has improved tensile strength, extensibility, tear strength, self-lubrication effect, compression and deformation resistance, heat resistance and aging resistance, good medium resistance, and prolonged service life. The inventive production method is simple and reasonable.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Valve sealing gasket sizing material and preparation method thereof

ActiveCN103012891AImprove performanceGood high and low temperature resistanceDiphenylsilanediolSolvent

The invention discloses a valve sealing gasket sizing material, which is prepared from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile-butadiene rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (TOSOH, Japan), 2-3 parts of gamma-methacryloxypropyltrimethoxysilane, 1-2 parts of diphenyl silandiol, 14-16 parts of modified tree ash, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high-abrasion resistant carbon black N330, 20-25 parts of precipitated white carbon black, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminium oxide, 5-8 parts of dolomite, 13-15 parts of modified iron tailing powder, 0.1-0.3 part of accelerating agent MBTS, 1-2 parts of sulphur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of benzimidazole-2-thiol, 1-3 parts of methyltrimethoxy silane, and 2-3 parts of paraffin. The sizing material of the rubber has excellent high and low temperature-resistant, oil-proof, solvent-resistant and chemical-resistant performance, and at the same time is good in mechanical property and low in cost.

Owner:平湖市博宏塑料制品厂

Environment-friendly rubber plastic heat-insulating material and its preparation method

The invention relates to an environment-friendly rubber plastic heat-insulating material and its preparation method, and the rubber plastic heat-insulating material is prepared from butyronitrile rubber (NBR), antimonous oxide (Sb2O3), zinc oxide, sulfur, dioctyl-phthalate (DOP), epoxidized soybean oil (ADDA), mercaptobenzothiazole (M), anti-aging agent (4020), antioxidant (AST-500), protective wax (HGB-3), ethylene-vinyl acetate copolymer (EVA), dicumyl peroxide (DCP crosslinking agent), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, foaming agent-dinitrosopentamethylene tetraamine (H), diphenylguanidine (D), pigment, anti-aging agent (RD), anti scorching agent (PVI), and the like. By limited use of raw materials containing chlorine ion components and cooperation of a new vulcanization foaming technology, environment-friendly and heat-insulating performances of the product can be stabilized, the prepared environment-friendly rubber plastic heat-insulating material has no corrosion performance in use, the material life is prolonged, metal pipes in refrigeration equipment can be effectively protected, and maximized performance of the product can be performed.

Owner:周良文

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Enhanced toughening recycled polyethylene material and preparation method thereof

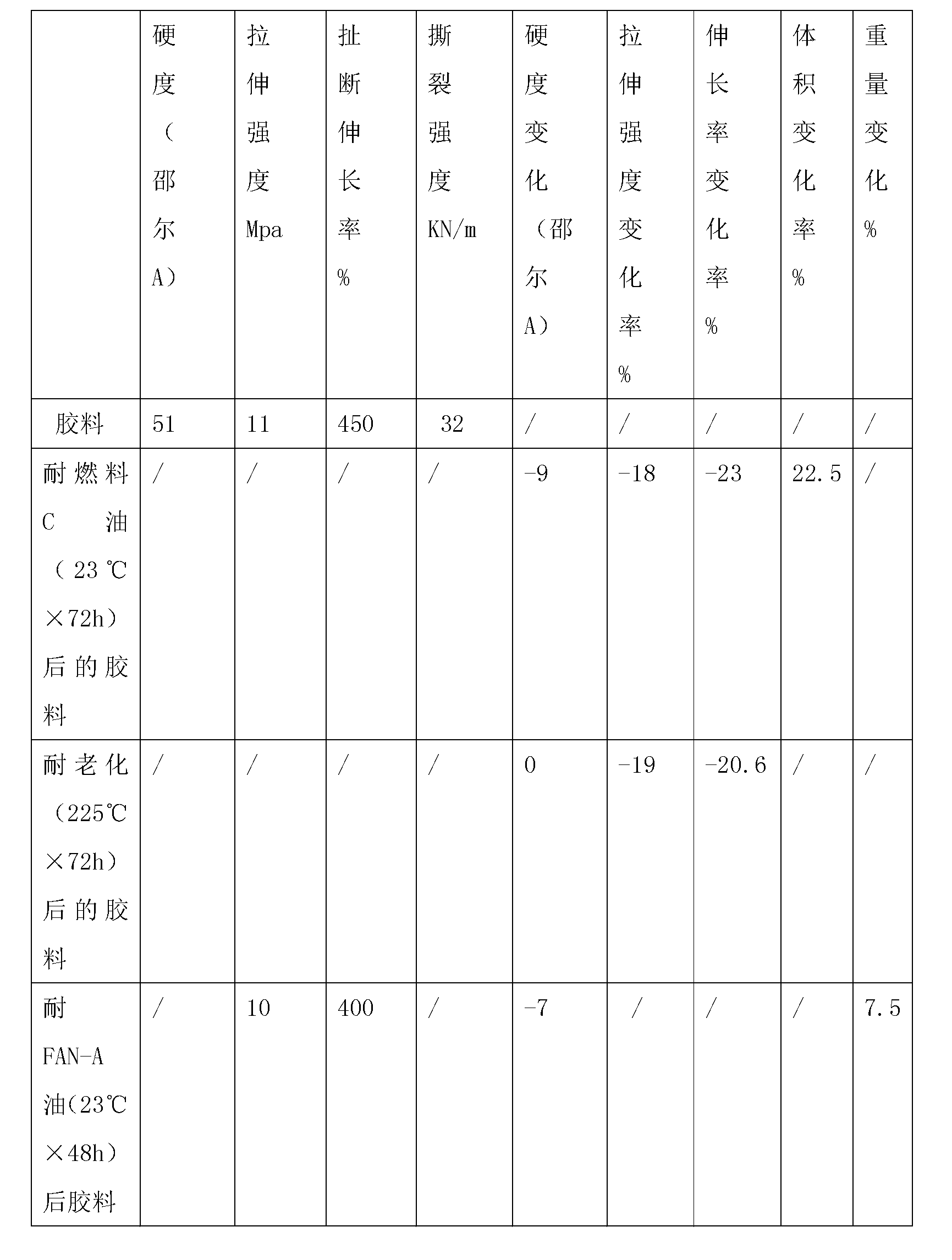

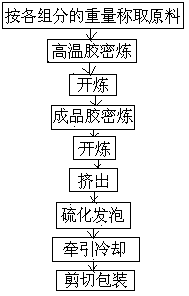

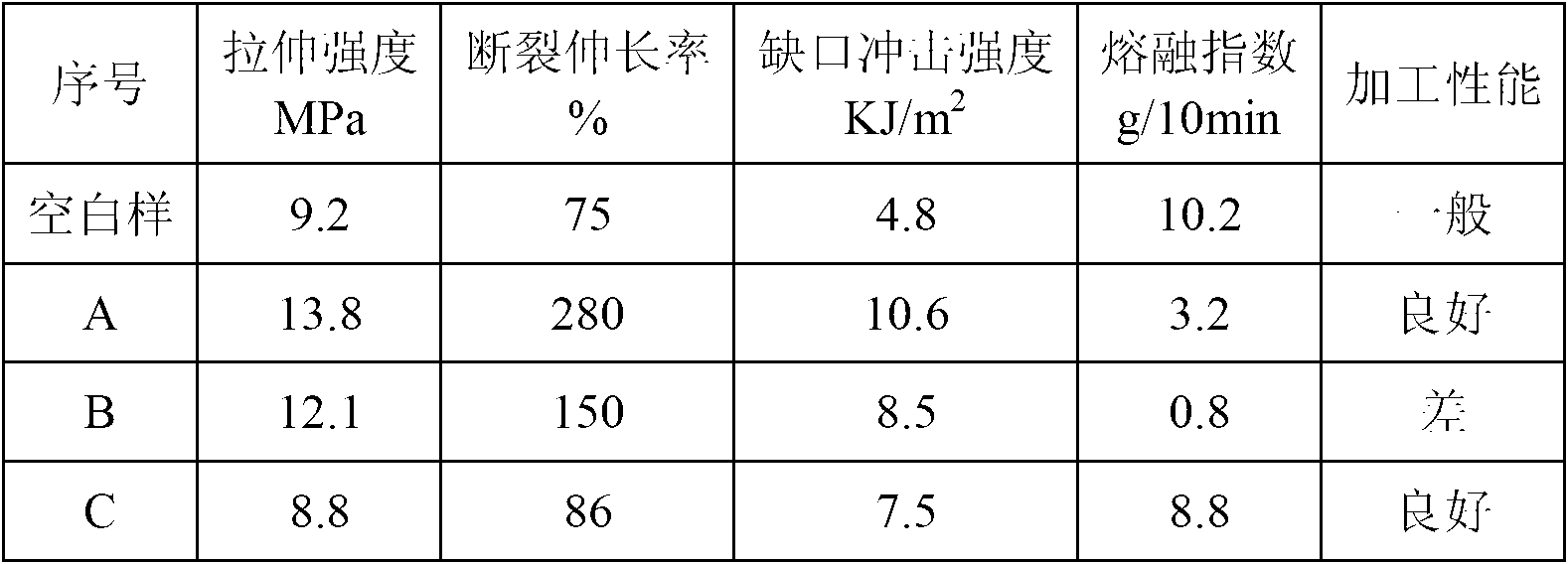

The invention relates to an enhanced toughening recycled polyethylene material. The enhanced toughening recycled polyethylene material is characterized by comprising, by mass, recycled polyethylene 100 parts, crosslinking masterbatch 1part to 5 parts, flexibilizer 0part to 3 parts, antioxygen 0.2 part to 1.5 parts, and processing agent 0.1 part to 0.5 part, wherein the crosslinking masterbatch is ethylene-vinyl acetate copolymer with a substrate as ethylene, a cross-linking agent is dicumyl peroxide and the like, an assistant cross-linking agent is melamine three allyl ester and the like, on the basis of total mass of the crosslinking masterbatch, by mass, a base body is 95%-98%, the cross-linking agent is 2%-5%, and the assistant cross-linking agent is 0%-2%. The tensile strength of the enhanced toughening recycled polyethylene material is 11.3-15.3MPa, the rupture elongation ratio is 220%-380%, the notch impact strength is 10.9-14.5KJ / m2, the melt index is 1.6g-2.9g / 10min, and the processability is good. The invention further discloses and a preparation method of the enhanced toughening recycled polyethylene material.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

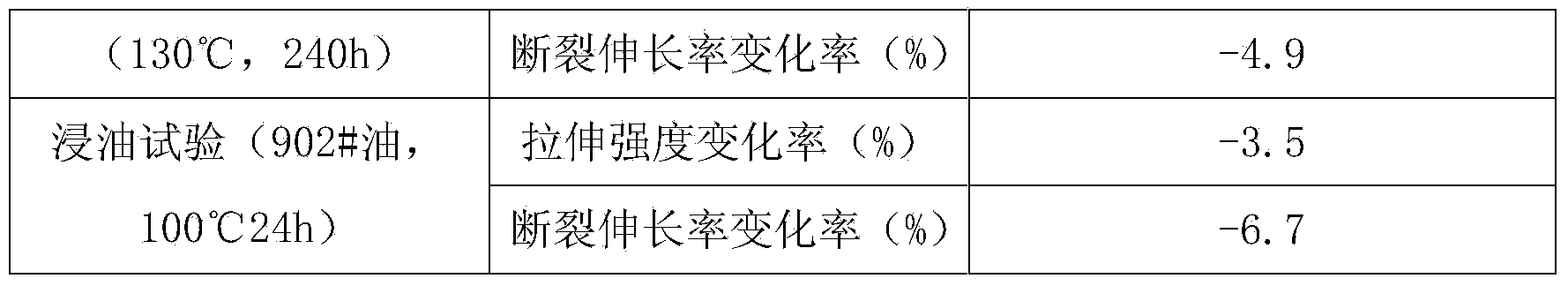

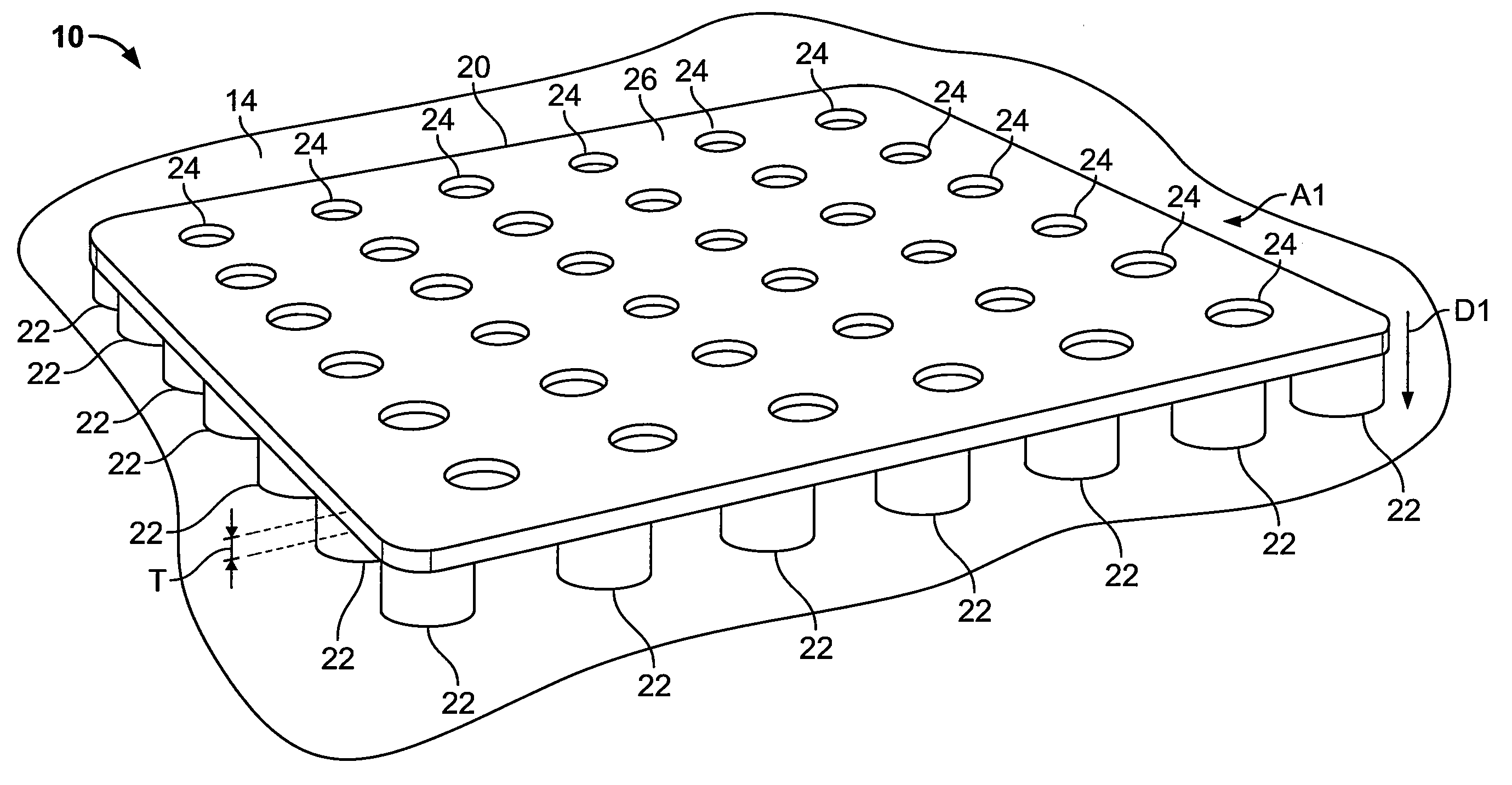

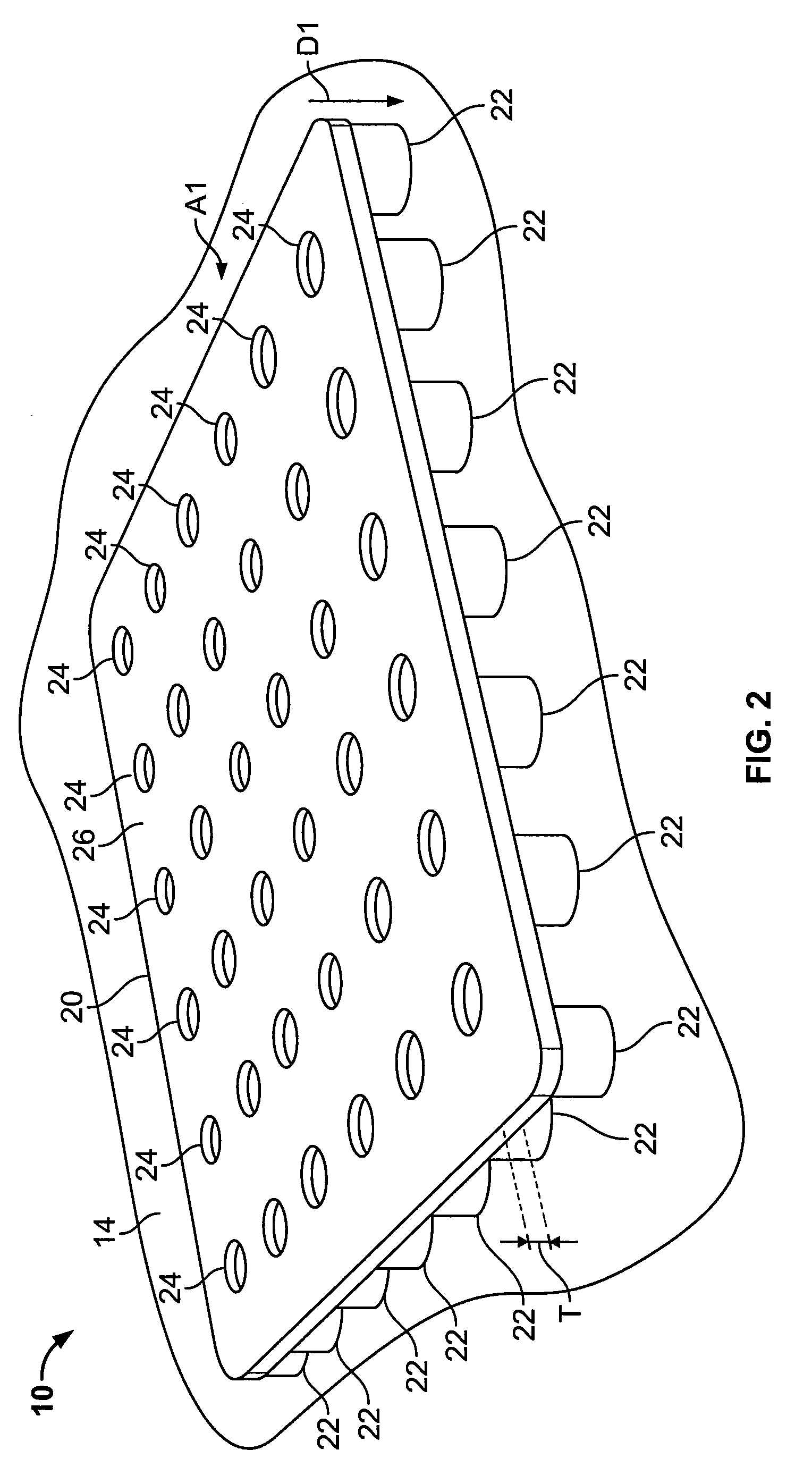

Seat cushion

A seat cushion having a flexible and semi-rigid body is provided. The body has a seating surface, having a first area, and a support surface, having a second area, spaced apart from the seating surface forming a body thickness. The body has a body composition with a first percentage by volume of EVA (Ethyl Vinyl Acetate), substantially evenly mixed with additional materials, such as polyethylene, color pigment, polycarbonate, and / or dicumyl peroxide, in various percentages of the body composition. The seat cushion also has a plurality of spacing members spaced apart and substantially evenly distributed across the second area. The plurality of spacing members each have a spacing member composition with a second percentage by volume of EVA and with a third percentage by volume of rubber. The seat cushion further has a plurality of ventilation holes extending through the body from the seating surface to the support surface.

Owner:BACKJOY ORTHOTICS

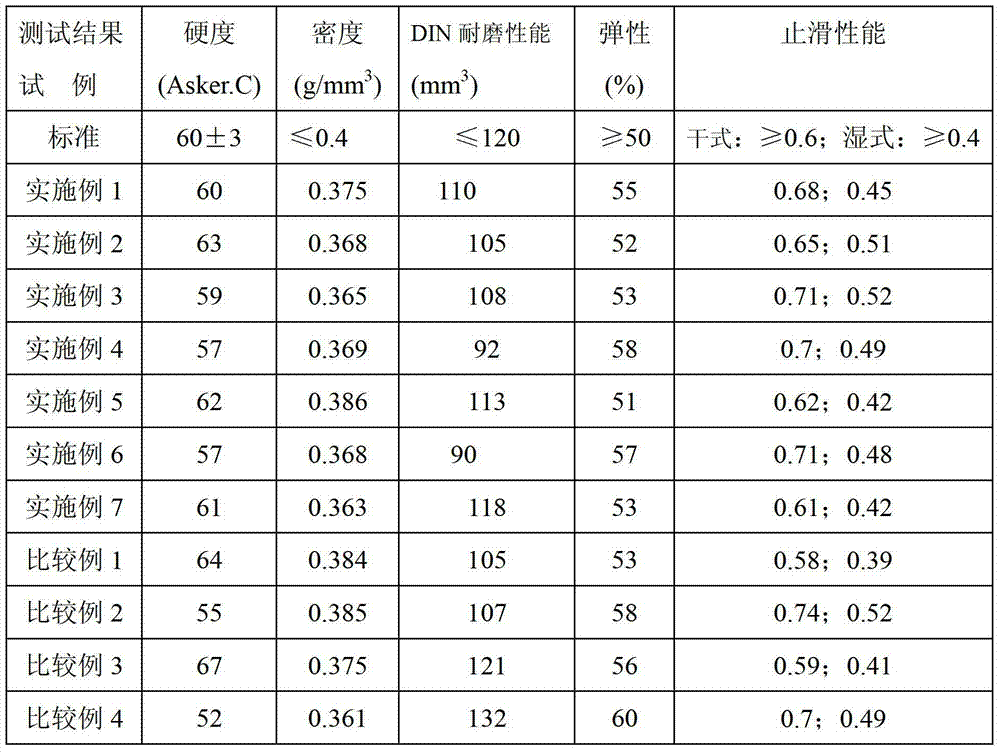

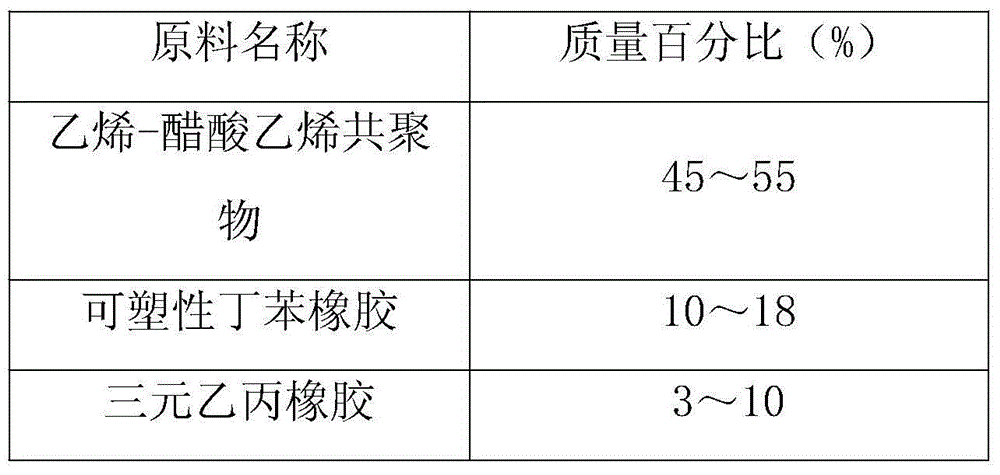

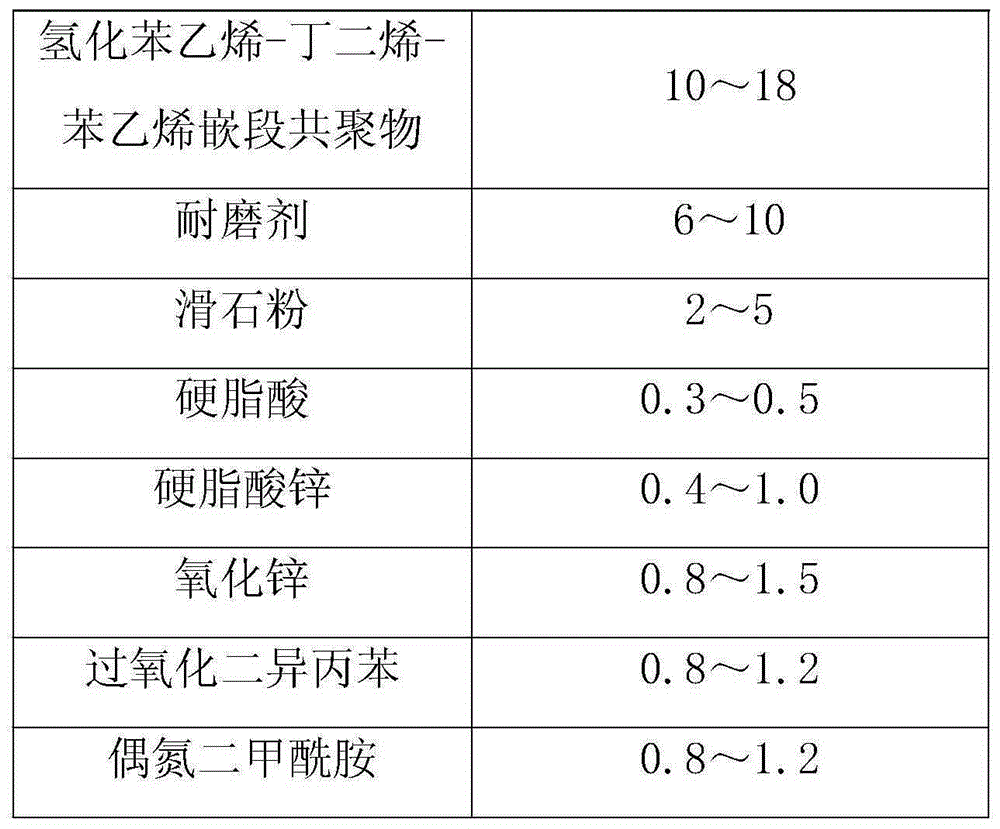

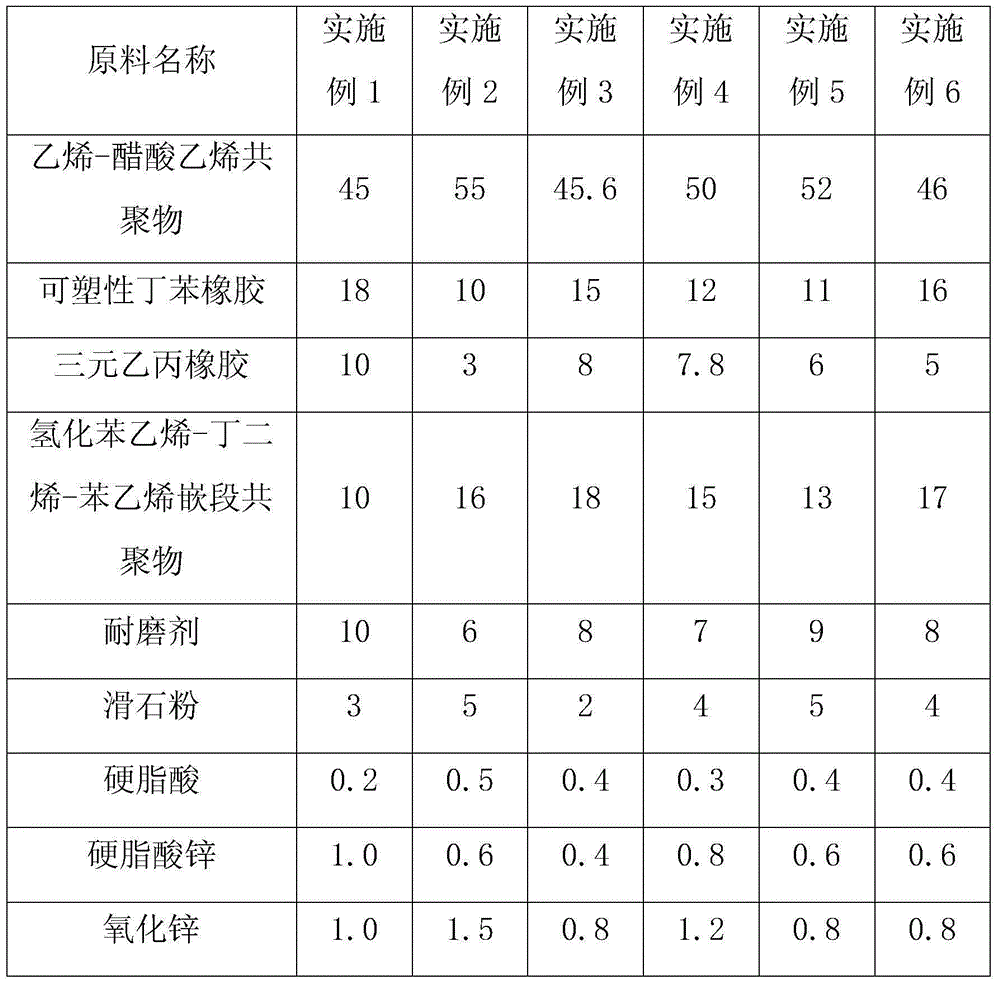

Super wear-resistant rubber foamed sport shoe material and preparation method thereof

InactiveCN104910507AImprove slip resistanceStrong slip resistanceSolesDomestic footwearPolymer scienceWear resistant

The invention discloses a super wear-resistant rubber foamed sport shoe material comprising the components of ethylene-vinyl acetate copolymer, plastic styrene-butadiene rubber (TVA), ethylene propylene diene monomer (EPDM), hydrogenated styrene-butadiene-styrene block copolymer (SEBS), a wear-resistant agent, talc powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide (DCP) and azodicarbonamide. The invention also discloses a preparation method of the super wear-resistant rubber foamed sport shoe material. The super wear-resistant rubber foamed sport shoe material disclosed by the invention is good in slip resistance, the wear resistance of the sport shoe material is superior to that of common hard rubber, and the sport shoe material can be directly molded by ejecting. The invention also discloses a preparation method of the super wear-resistant rubber foamed sport shoe material, wherein physical parameters are strictly controlled during preparation to ensure that the prepared super wear-resistant rubber foamed sport shoe material has more excellent wear resistance and slip resistance.

Owner:厦门联合信诺新材料有限公司

Novel low-smoke zero-halogen flame-retardant cable sheath material

InactiveCN102532649AReduce dosageDosage reachedInsulated cablesInsulated conductorsLow-density polyethyleneHigh carbon

The invention relates to a novel low-smoke zero-halogen flame-retardant cable sheath material, which comprises the following components in percentage by weight: 15-35 percent of low-density polyethylene, 15-35 percent of ethylene-vinylacetate copolymer, 8-30 percent of modified nano magnesium hydroxide, 2-6 percent of microencapsulated red phosphorus, 8-19 percent of thermoplastic phenolic resin, 1.8-3 percent of dicumyl peroxide as a crosslinking agent, 0.1-0.25 percent of antioxidant 1010, 1-3.5 percent of lead sulfate tribasic as a lead compound and 0.1-1 percent of N-salicyl aminophthalimide as a copper inhibitor. According to the novel low-smoke zero-halogen flame-retardant cable sheath material, the consumption of the modified nano magnesium hydroxide is reduced by adding the thermoplastic phenolic resin and the microencapsulated red phosphorus on the basis of ensuring the performance of mechanical energy, and the purpose of synergically retarding flame is achieved. When the cable sheath material burns, the microencapsulated red phosphorus absorbs a great deal of water decomposed and released when the modified nano magnesium hydroxide burns, to generate phosphoric acid, metaphosphoric acid, polymetaphosphoric acid and the like which cover the surface of the thermoplastic phenolic resin with higher carbon content, so that the surface of the thermoplastic phenolic resin can be dehydrated and carbonized in an accelerating way to form a thick liquid film layer for isolating oxygen and heat from the inside sheath material, and thus burning can be weakened or interrupted, and the flame-retardant effect of the cable sheath material is enhanced; meanwhile, the novel low-smoke zero-halogen flame-retardant cable sheath material disclosed by the invention has the advantages of zero halogen, low smoke formation amount during burning and little pollution to environment.

Owner:JIANGSU HENGTONG POWER CABLE

Composite flame-retardant expandable polystyrene particles and preparation technology thereof

Disclosed are composite flame-retardant expandable polystyrene particles and a preparation technology thereof. The particles are prepared from the following components of: by weight, 100 parts of styrene monomer, 100-150 parts of water, 1-10 parts of expandable graphite, 1-12 parts of a phosphorus compound, 0.1-0.5 part of white oil, 0.1-0.5 part of polyethylene wax, 0.05-0.2 part of dicumyl peroxide, 0.2-0.8 part of benzoyl peroxide, 0.1-0.4 part of polyvinyl alcohol, 1.1-2.1 parts of tricalcium phosphate and 8-12 parts of pentane. By the addition of a composite fire retardant of expandable graphite and the phosphorus compound before polymerization of styrene, adverse influence of the fire retardant on performance of the product is reduced; expandable graphite and the phosphorus compound are halogen-free fire retardants, the particles have good environmental protection performance; by the addition of white oil, the particles have plasticising and internal lubricant functions as well as good stability and low volatility, and fluidity during the forming of polystyrene particles can be greatly improved; polyvinyl alcohol and tricalcium phosphate are dispersion stabilizers and by timely adding a proper amount of the dispersion stabilizers, the product appearance can be improved, the production efficiency can be raised, and cost can be reduced; and the addition of all the components guarantees the performance of the product.

Owner:BEIJING HUACHEN DECHUANG CHEM TECH

Anti-tear EVA (ethylene-vinyl acetate copolymer) foaming shoe material and preparation method thereof

ActiveCN103194019AOvercoming poor tear resistanceOvercoming the Innate Deficiency of FragilitySolesButadiene-styrene rubberDicumyl peroxide

The invention provides an anti-tear EVA (ethylene-vinyl acetate copolymer) foaming shoe material and a preparation method thereof, belonging to a casual shoe sole. The anti-tear EVA foaming shoe material comprises the following raw materials: EVA, ethylene-octene copolymer, hydrogenated styrene-butadiene-styrene block copolymer, ethylene-acrylic acid copolymer, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and color masterbatch. The preparation method comprises the following steps of: mixing dicumyl peroxide with the azo foaming agent for later use, mixing the rest raw materials, then pouring the mixture into an internal mixer to carry out first-stage internal mixing and then adding the mixture of dicumyl peroxide and the azo foaming agent to carry out second-stage internal mixing to obtain an internally mixed mixture; thinning the obtained internally mixed mixture on a roller machine; transferring the material uniformly mixed by the roller machine to a granulator to be granulated; mixing the granules after granulation according to a set multiplying power and injecting the mixture into a shoe mold via an injection molding machine to be molded; and sizing the molded sole into a foaming profile finished product via a thermostat.

Owner:泉州泰亚鞋业有限公司

Halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method

The invention discloses a halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method. The cable material comprises the following raw materials, by weight, 90-110 parts of a polyolefin elastomer (POE) 8450 / American DuPont, 50-60 parts of PVC resin powder, 40-60 parts of wollastonite powder, 60-80 parts of nanometer attapulgite, 50-80 parts of ethylene-propylene-diene terpolymer rubber, 40-50 parts of nitrile butadiene rubber, 20-30 parts of nanometer pottery clay, 30-40 parts of aluminum hydroxide, 1-4 parts of precipitated white carbon black, 60-80 parts of light calcium carbonate, 3-5 parts of insoluble sulfur, 1-4 parts of triallyl isocyanurate, 3-5 parts of an antiager TPPD, 4-6 parts of dicumyl peroxide (DCP), 3-8 parts of dibasic lead phosphite, 5-7 parts of an antioxidant 1010, 2-5 parts of monoglycerin stearate and 50-70 parts of antimony trioxide. The cable material has the advantages of simple preparation method, excellent electrical property, good heat, ageing and wear resistances, small swelling deformation at a high temperature, secondary vulcanizing processing benefiting, low smoke and fire resistance, and environmental protection and safety.

Owner:苏州益普敦新材料科技有限公司

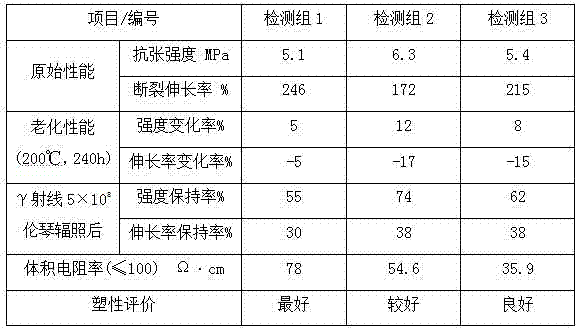

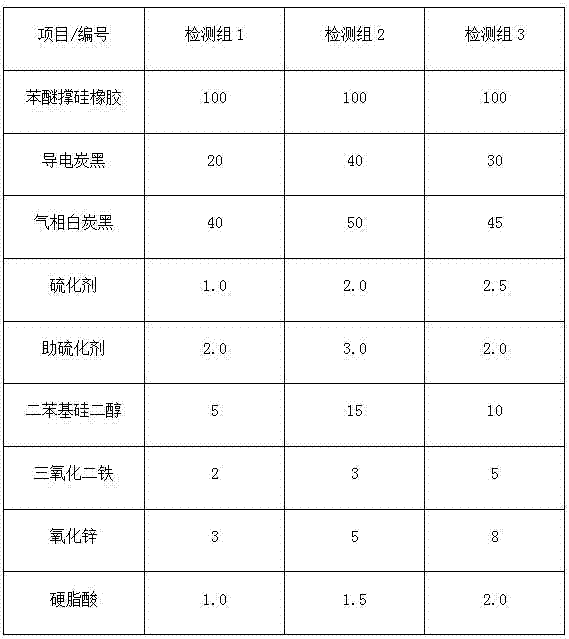

Semiconductive silicon rubber shielding material for radiation-resistant cable, and preparation method thereof

InactiveCN102964841AImprove radiation resistanceImprove plasticityInsulated cablesInsulated conductorsPolymer sciencePhenyl Ethers

The invention relates to a semiconductive silicon rubber shielding material for a radiation-resistant cable, and a preparation method of the material, belonging to the technical field of cable shielding material. The semiconductive silicon rubber shielding material comprises the raw material components in parts by weight: 100 parts of silicon rubber, 20-40 parts of conductive carbon black, 40-50 parts of white carbon black, 1.0-2.5 parts of dicumyl peroxide, 2.0-3.0 parts of auxiliary vulcanizing agent, 5-15 parts of diphenyl silanediol, 1.0-2.0 parts of stearic acid, 4-6 parts of zinc oxide and 2-5 parts of ferric oxide, wherein the silicon rubber is phenyl ether supporting silicone rubber or phenylene silicone rubber; and the auxiliary vulcanizing agent is triene propyl cyanurate. The silicon rubber shielding material is good in radiation-resistant performance, and can give play to the specified function for a long time on radiation occasion when being used as a shielding layer of an electric wire and the cable.

Owner:SICHUAN MINGXING CABLE

Hydrophilic carrier for microbial biofilm formation

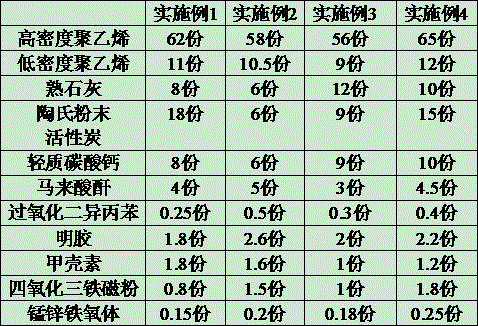

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

Low-thermal-shrinkage low-smoke halogen-free flame retardant sheath material for optical cable and preparation method

The invention provides a low-thermal-shrinkage low-smoke halogen-free flame retardant sheath material for an optical cable. The sheath material comprises the following components in parts by weight: 100 parts of basic resin, 100-120 parts of flame retardant A, 20-30 pats of flame retardant B, 1.0-2.5 parts of coupling agent, 0.1-0.5 parts of cross-linking initiator, 0.5-1 part of antioxidant and 0.5-3 parts of lubricant, wherein the cross-linking initiator is dicumyl peroxide. The invention provides the low-smoke halogen-free flame retardant sheath material for with low thermal shrinkage and good flame retardant property and a reparation method thereof.

Owner:上海至正新材料有限公司

High-strength and shock-resistance type metal ceramic composite lining plate and preparation method thereof

InactiveCN105081327AImprove wear resistanceStrong impact resistanceCeramic compositeShock resistance

The invention discloses a high-strength and shock-resistance type metal ceramic composite lining plate and a preparation method thereof. The composite lining plate comprises, by mass, 20-80 parts of ceramic particles, 30-80 parts of metal powder, 30-50 parts of ultra-high molecular weight polyethylene, 5-10 parts of medium density polyethylene, 6-8 parts of low density polyethylene, 1-3 parts of magnesium hydroxide, 1-2 parts of diatomite, 10-15 parts of glass fibers, 0.5-1 part of dicumyl peroxide, 1-5 parts of coupling agent, 1-3 parts of antistatic agent, 1-3 parts of curing agent and 1-2 parts of addition agent. The preparation method includes the steps that the ceramic particles, the metal powder and the addition agent are mixed first so that a mixture A can be obtained; then the other components are mixed so that a mixture B can be obtained; afterwards, the mixture A and the mixture B are mixed, formed, sintered, quenched and tempered, and accordingly the composite lining plate is obtained. The metal ceramic composite lining plate has the characteristics of excellent abrasion resistance, impact resistance, chemical corrosion resistance and low-temperature toughness, and meanwhile has the characteristics of being good in processability and low in material cost.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Method for increasing EVA/PE blending foaming material performance by ozone oxidization

InactiveCN101121792AImprove two-phase compatibilityImprove performanceDomestic articlesChemistryDicumyl peroxide

The invention discloses a method using the ozone oxidation to improve the performance of the EVA / PE blend foam material. (a) the ozone oxidation is done for the polyethylene (PE) powder at the temperature between 20 and 90 Celsius system; the concentration of the ozone gas is between 10 and 75 mg per liter; the time of the ozone oxidation is between 10 and 180 minutes; (b) the ethylene-acetate ethylene ester copolymer (EVA) and the polyethylene treated by the ozone oxidation are mixed well according to the proportion from 90 to 10 to form 60 to 40; 100 weight shares of the mixture, 0.5 to 0.8 weight shares of the dicumyl peroxide (DCP), 2.0 to 4.0 weight shares of the vesicant, 0.4 to 1.2 weight shares of the zinc oxide (ZnO), 0 to 0.6 weight shares of the stearic acid (HSt), 0 to 0.6 weight shares of the zinc stearate (ZnSt) and 0 to 10 weight shares of the inorganic mineral powder are taken; the dual-roller mixer is added into to be melted and mixed; the mixing temperature is between 105 and 130 Celsius system; the mixing time is between 10 and 15 minutes; then the EVA / PE blend complex can be made; (c) the blended complex is arranged on the flat vulcanization machine to mold and foam; the foaming temperature is between 160 and 170 Celsius system; the mold compression pressure is between 10 and 15 MPa; the foaming time of the mold compression is between 15 and 35 minutes; then the EVA / PE blend foam material can be made.

Owner:SICHUAN UNIV

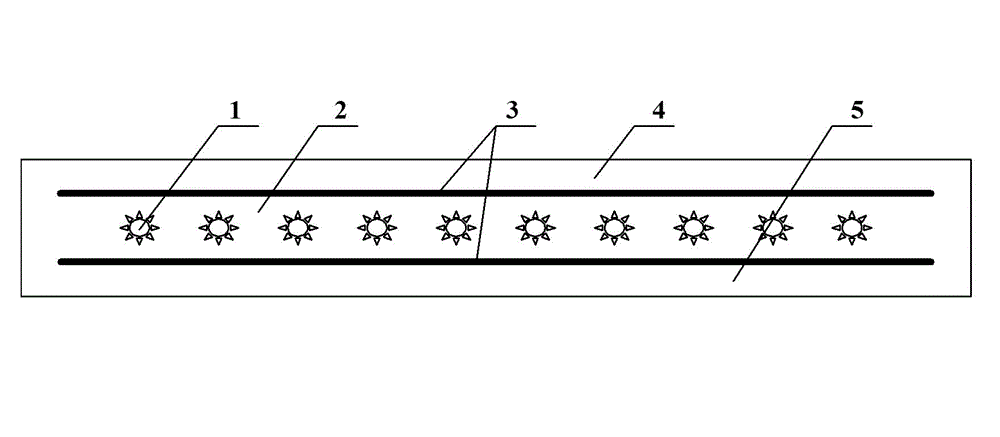

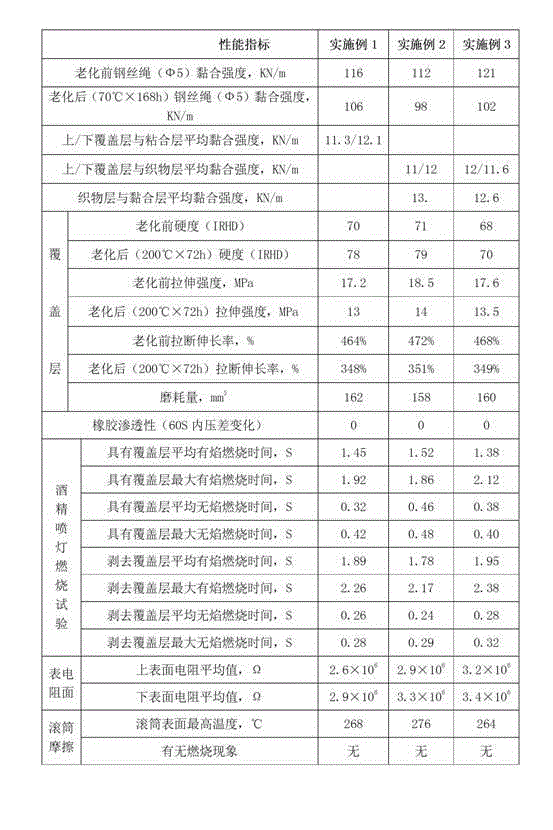

High temperature resistant wire rope core flame-retardant conveying belt

ActiveCN102718016AImprove high temperature resistanceHigh high temperature resistanceConveyorsEpoxyPolymer science

The invention discloses a high temperature resistant wire rope core flame-retardant conveying belt, and solves the problem that the conventional wire rope core flame-retardant conveying belt is not high temperature resistant. According to the invention, the sizing material of an upper covering bond layer as well as that of a lower covering bond layer comprise the following ingredients in part by weight: 30 to 50 parts of ethylene-propylene-diene rubber, 25 to 35 parts of chlorinated butyl rubber, chlorosulfonated polyethylene rubber or neoprene, 25 to 35 parts of chlorinated polyethylene rubber, 4 to 6 parts of dicumyl peroxide, 0.5 to 1.5 parts of sulfur, 0.5 to 1 part of tert-octylphenol-formaldehyde resin, 1 to 3 parts of epoxy resin, 8 to 12 parts of zinc oxide and / or magnesium oxide, 1 to 2 parts of stearic acid, 2 to 8 parts of accelerating agent, 2 to 4 parts of antiager, 8 to 15 parts of conductive carbon black, 25 to 45 parts of high abrasion resistant carbon black, 10 to 15 parts of active glass fiber powder, 20 to 50 parts of solid flame retardant, 10 to 20 parts of liquid flame retardant, and 3 to 8 parts of flame-retardant lubricant MB-202. Two glass fiber canvas thermal insulating layers are arranged between a middle bond layer and the upper covering bond layer and between the middle bond layer and the lower covering bond layer respectively. The high temperature resistant wire rope core flame-retardant conveying belt can be used for a long time at the temperature of 250 DEG C, and meets the conveying requirements of special high-temperature materials.

Owner:ANHUI ZHONGYI RUBBER BELTS

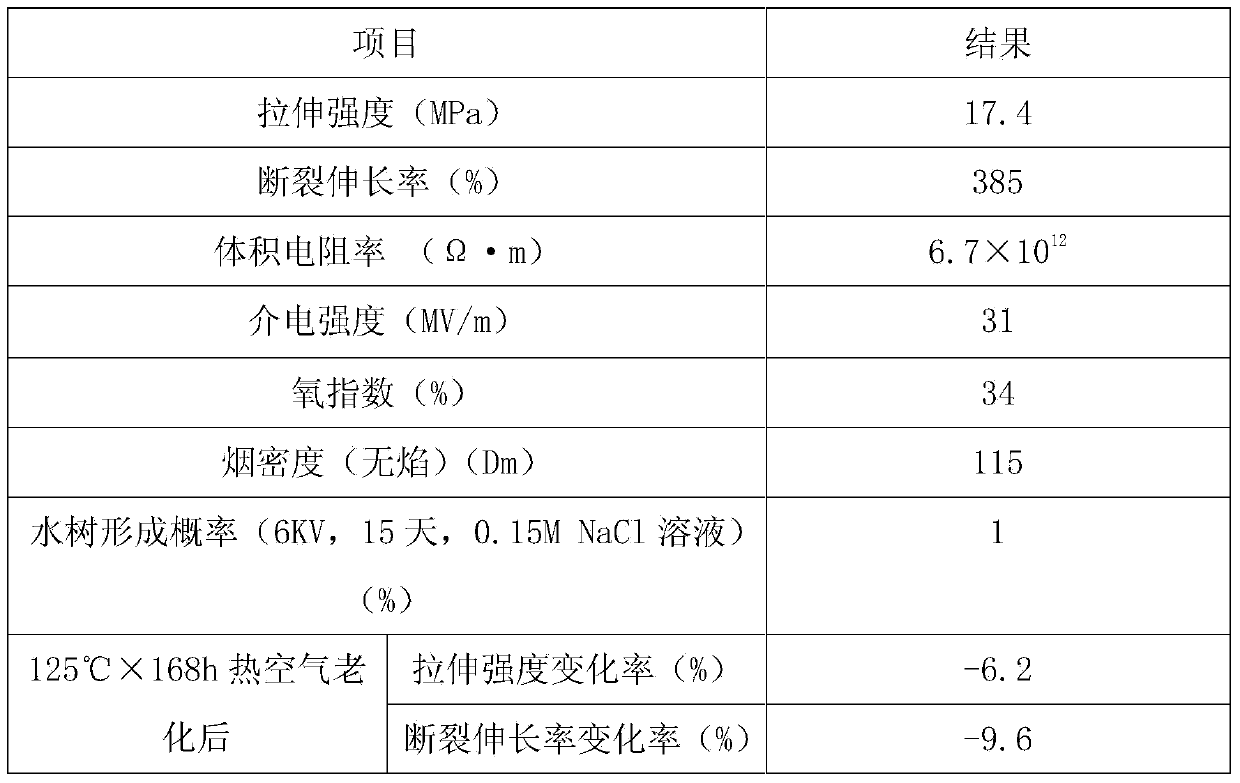

Water tree-resistant polyethylene insulated cable material and preparation method thereof

InactiveCN103467818ASimple structureImprove anti-water tree agingPlastic/resin/waxes insulatorsLow-density polyethyleneElastomer

The invention discloses a water tree-resistant polyethylene insulated cable material and a preparation method thereof. The cable material is prepared by the following raw materials in parts by weight: 70-80 parts of low-density polyethylene, 10-15 parts of maleic anhydride grafted EVA (ethylene vinyl acetute), 5-10 parts of maleic anhydride grafted POE (polyolefin elastomer), 0.5-1.5 parts of sorbitol, 2-3 parts of polyethylene glycol, 2-3 parts of dicumyl peroxide, 0.4-0.6 parts of antioxidant DLTP (dilauryl thiodipropionate), 3-4 parts of triallyl isocyanurate, 2-3 parts of polydimethylsiloxane and the like. According to the cable material and the method, maleic anhydride grafted EVA and maleic anhydride grafted POE with good compatibility with low-density polyethylene are added to improve a polyethene structure, and sorbitol, polyethylene glycol, polydimethylsiloxane and the like are added to inhibit water tree formation, so that the water tree aging resistance and physical and mechanical properties of the polyethylene cable material are improved obviously; a technical bottle neck of water tree growth of the cable insulation layer is solved; the service life of a cable is prolonged; and the cable safety during use is improved.

Owner:JING FENG GRP

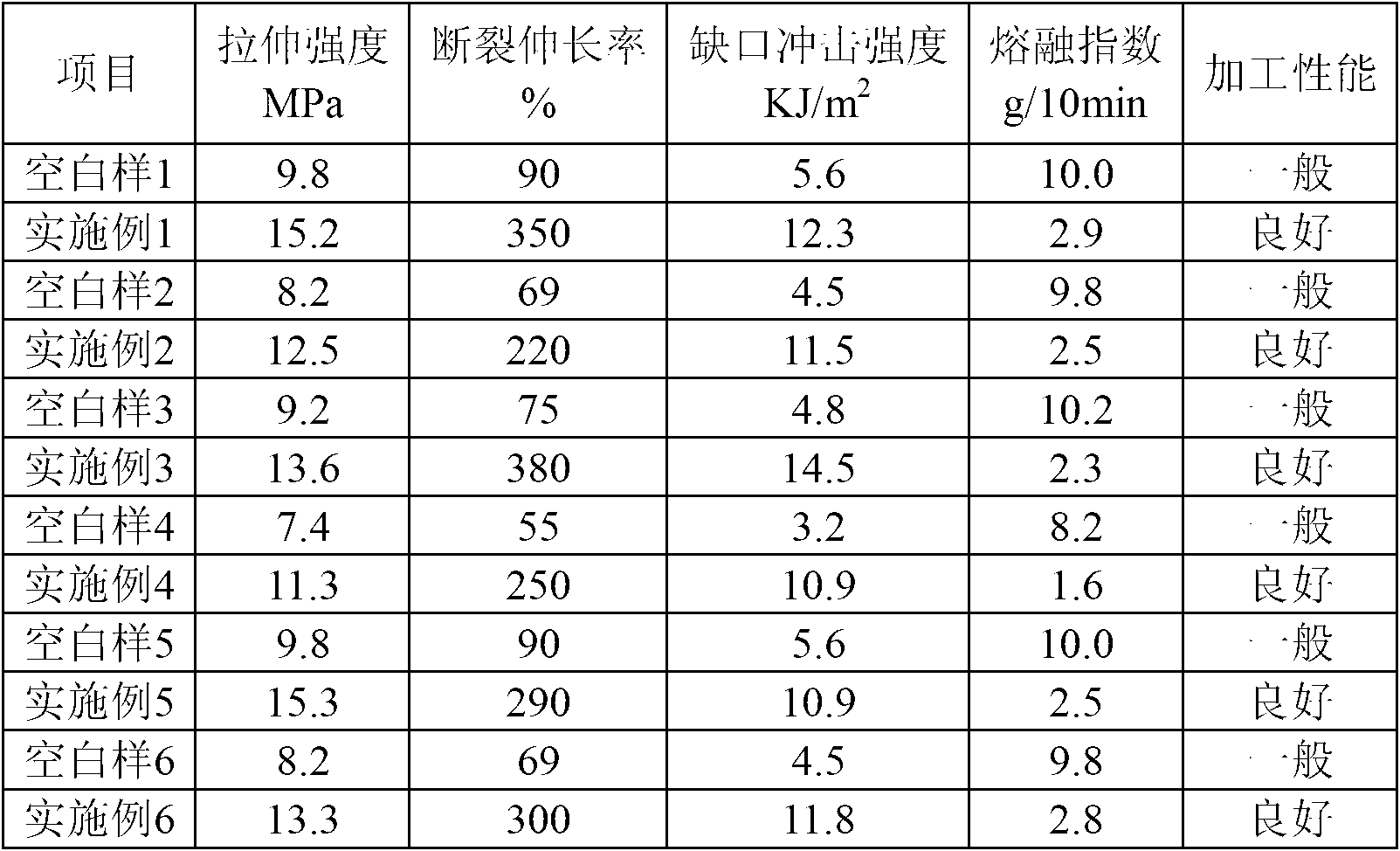

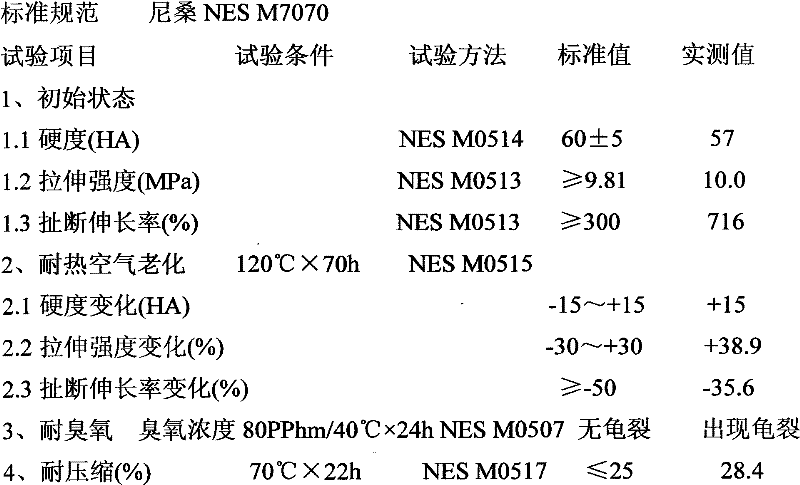

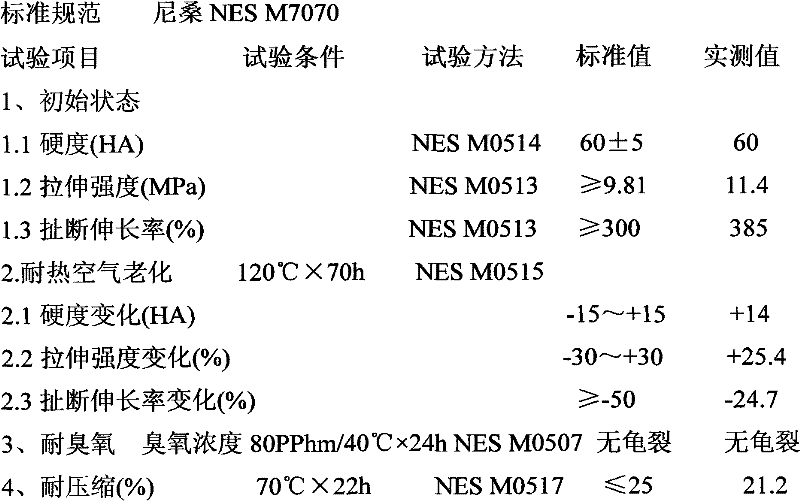

Preparation method of heat/ozone/compressive deformation resistant rubber material for automobile sealing element

The invention discloses a preparation method of a heat / ozone / compressive deformation resistant rubber material for an automobile sealing element, and the method comprises a formula and a preparation process. In the invention, nitrile rubber / polyvinyl chloride resin and rubber are adopted; in the formula, a vulcanizing system of dicumyl peroxide and N,N'-m-phenylene dimaleimide is adopted, the anti-aging agents of 2,2,4-trimethyl-1,2-dihyaroquinoline polymer and 2-mercaptobenzimidazole are added, the anti-aging agent of N-isopropyl-N'-phenyl-p-phenylenediamine and a paraffin lubricating agent with ozone resistance are added, and the technical scheme of the corresponding preparation process is provided, thus the problems and defects of low temperature / ozone / permanent compressive deformation resistances in the prior art are overcome, and through the heat / ozone / compressive deformation resistant rubber material prepared by the method, the manufactured rubber article of an automobile oil tank pumping hole sealing element achieves the purpose of improving the heat / ozone / compressive deformation resistances to conform to the Nissan NES M707 standard.

Owner:宁波市天普橡胶科技股份有限公司

Cross-linking agent modified polyethylene geogrid and manufacturing method thereof

InactiveCN103131071ASingle Rib Tensile Length IncreaseImprove single rib strengthSoil preservationCross-linkLinear low-density polyethylene

Disclosed is cross-linking agent modified polyethylene geogrid. Components with percentage content of the cross-linking agent modified polyethylene geogrid are 65% to 70% of high-density polyethylene (HDPE), 21% to 26% linear low density polyethylene (LLDPE), 0.5 % to 1% of dicumyl peroxide (DCP), 0.5% to 2% A-151, 0.5% to 1% dibutyltion dilautate (DBTDL) and 4.5% to 5% color master with carbon black content more than 45 %. The manufacturing method of the cross-linking agent modified polyethylene geogrid comprises steps as below: 1) master batch manufacturing: mixing part of HDPE, LLDPE, DCP, A-151 and DBTDL together, enabling the blend to pass through a screw extruder to be fused at the temperature of 160 DEG C to 200 DEG C to manufacture the master batch in a melting mode; 2) mixing of the master batch, the color master and remaining HDPE; 3) molding of sheet materials; 4) punching; 5) stretching. The cross-linking agent modified polyethylene geogrid improves toughness, significantly relieves the phenomenon of rib portion brittle fractures, and effectively lowers cost. Stretching length of a single rib is increased by 10 % to 20 %, strength is improved by 5 % to 10 %, and gram weight of a product is reduced by 20 % to 30 %.

Owner:NANCHANG TIANGAO ENVIRONMENTAL PROTECTION TECH CO LTD

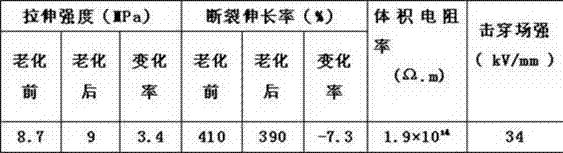

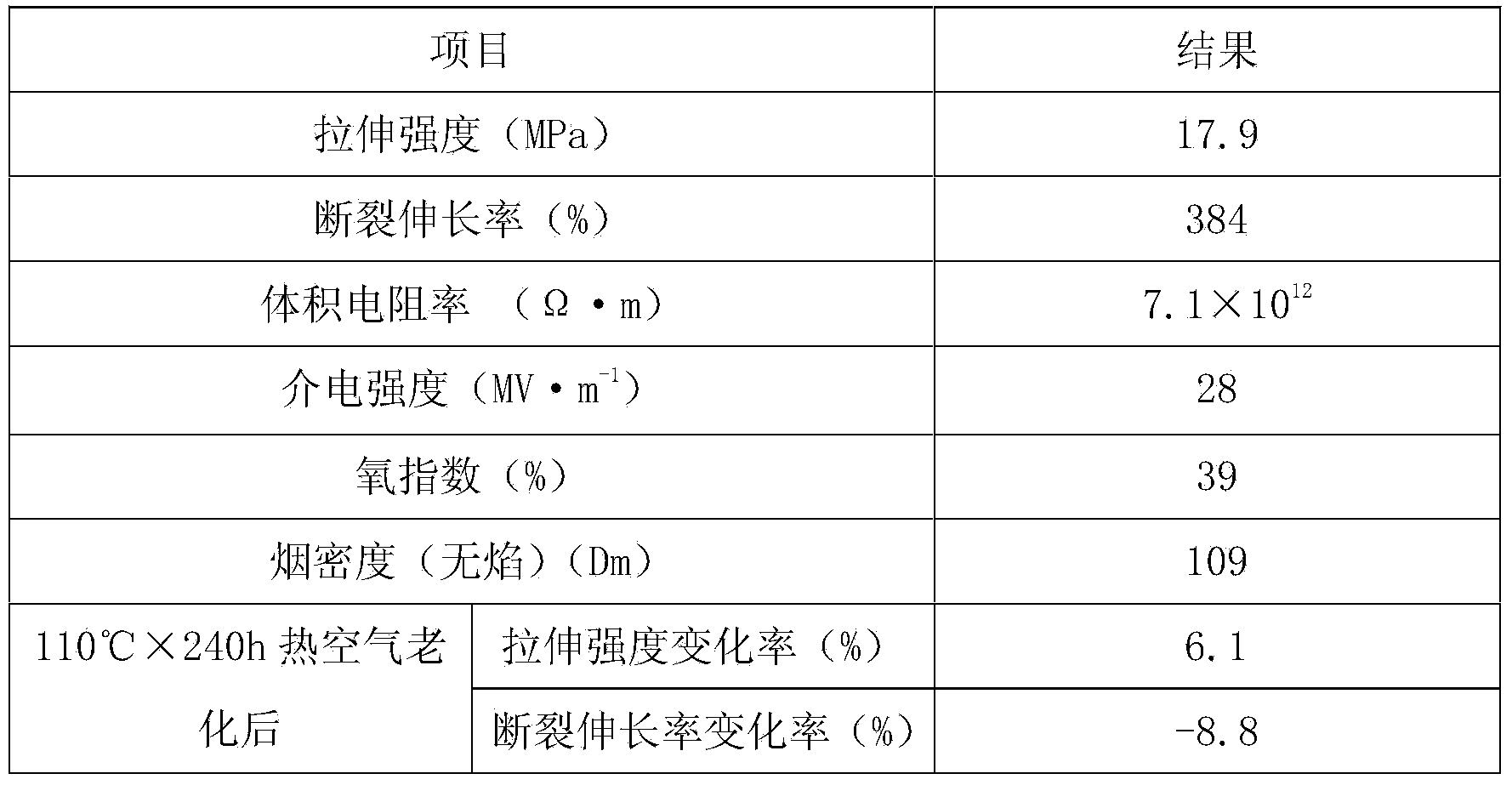

Medium-voltage ethylene propylene rubber insulating material and preparation method thereof

The invention discloses a medium-voltage ethylene propylene rubber insulating material and a preparation method thereof. The medium-voltage ethylene propylene rubber insulating material comprises the following components in percentage by weight: 15-30 percent of ethylene-propylene-diene rubber, 9-20 percent of ethylene-propylene rubber, 4-10 percent of linear low-density polyethylene, 4-7 percentof zinc oxide, 0.1-0.4 percent of stearic acid, 5-35 percent of superfine talc powder, 4-7 percent of paraffin hydrocarbon oil, 0.5-3 percent of paraffin, 10-30 percent of calcining clay, 0.1-0.9 percent of surface active agent gamma-aminopropyltriethoxysilane, 0.4-1.8 percent of antiager 4,4'di(alpha,alpha dimethylbenzyl)diphenylamine, 0.5-1.5 percent of vulcanizer dicumyl peroxide and 0.3-1.4 percent of vulcanizing agent triallyl cyanurate. By synthesizing the performance of various materials and learning from strengths to offset their weaknesses, the aims of reducing the cost and improvingthe electric performance are achieved. Tests prove that the medium-voltage ethylene propylene rubber insulating material disclosed by the invention has the volume resistivity of 1014 ohm.m and the breaking-down field strength of larger than 30KV / mm and has the advantages of excellent electric performance, higher thermal ageing performance and physical and mechanical performance, simple preparation process and strong operability.

Owner:JIANGSU HENGTONG POWER CABLE +1

Weather-proof polyolefin wire cable material and preparation method thereof

InactiveCN104109276AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsEpoxyPolyolefin

The invention discloses a weather-proof polyolefin wire cable material and a preparation method thereof, the cable material comprises the raw material by weight: 60-80 parts of LDPE, 15-25 parts of EVA, 10-15 parts of SEBS, 14-18 parts of magnesium hydroxide, 2-4 parts of stearic acid, 1-2 parts of zinc oxide, 5-10 parts of zinc borate, 1-2 parts of lead sulfate tribasic, 1-2 parts of vinyltriethoxysilane, 4-8 parts of octyl epoxy stearate, 0.5-1 part of light stabilizing agent GW-4800.5, 1-1.5 parts of anti-oxidant 215, 0.5-1 part of dibutyltin dilaurate, 0.5-1 part of dicumyl peroxide, 20-25 part of aluminum silicon black, 10-15 parts of nano barite, 5-10 parts of nano diatomite and 4-8 parts of composite filling material. The polyolefin cable material has excellent flame retardation performance, physical and mechanical properties and weatherability, can be widely used in electric power cable, communication cable, control cable, optical cable , subway cable, insulation or sheath, electronic wire, automobile and the like, and has the advantages of environmental protection and durable performance.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

Method for raising fluidity of thermoplastic cross-linked rubber

Owner:SHANDONG DAWN POLYMER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com