Patents

Literature

1123 results about "Phenyl Ethers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous suspension of agrochemical

InactiveUS6306414B1Low viscosityEffective dispersionOrganic active ingredientsBiocideSuspended particlesPhenyl Ethers

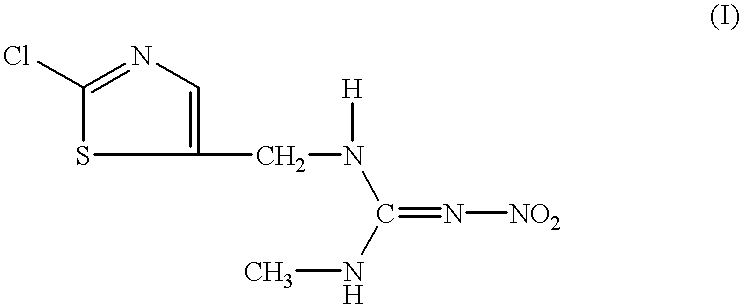

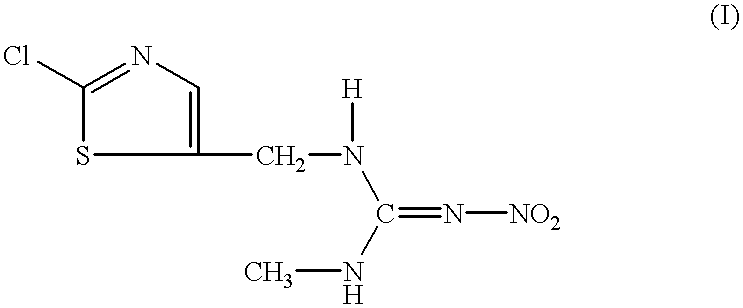

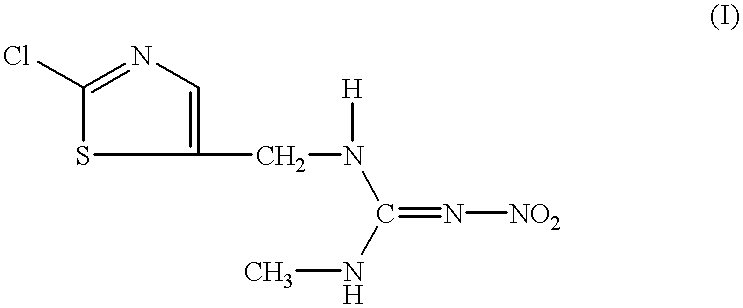

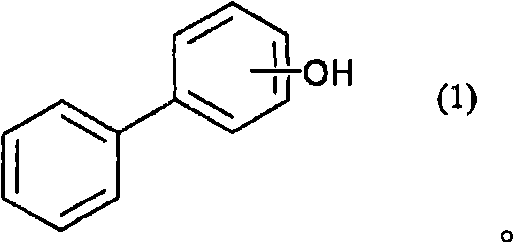

The present invention relates to an aqueous suspension comprising (i) a compound of the formula:or a salt thereof, (ii) a condensate of formaldehyde with an aromatic sulfonic acid or a salt thereof or a polyoxyalkylene allyl phenyl ether sulfate, and (iii) an absorptive water-soluble polymer. The aqueous suspension of the invention can be used with advantage as a stable aqueous suspension of low viscosity providing for excellent delivery from a container, with excellent dispersibility in diluent water and excellent long-term fluidity free from caking due to precipitation of the suspended particles.

Owner:SUMITOMO CHEM CO LTD

Mitigation of Biomolecular Adsorption with Hydrophilic Polymer Additives

ActiveUS20090280251A1Reduce surface tensionInhibit bindingSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

Surfactants

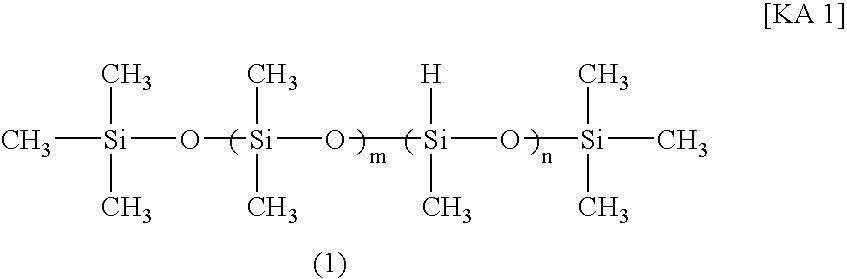

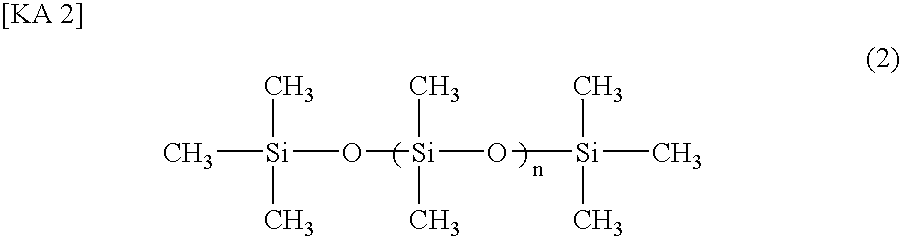

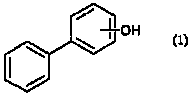

InactiveUS6841655B1No adverse effectsHigh strengthTransportation and packagingMixingPhenyl EthersEmulsion polymerization

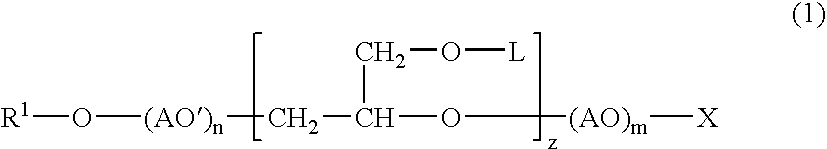

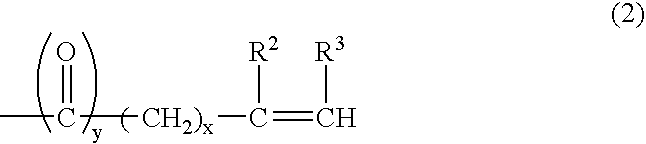

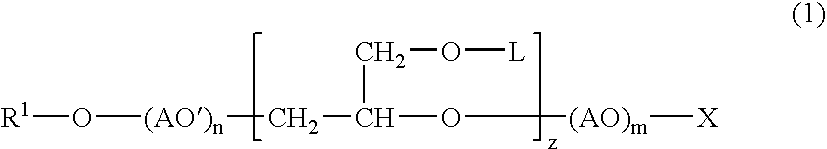

Disclosed are surfactants represented by the following formula (1): wherein R1 represents a branched aliphatic hydrocarbon group, a secondary aliphatic hydrocarbon group or a branched aliphatic acyl group, AO and AO′ each independently represents an oxyalkylene group having 2 to 4 carbon atoms, L represents a group represented by formula (2) to be described below, z stands for a number of from 1 to 10, X represents a hydrogen atom or an ionic hydrophilic group, m stands for a number of from 0 to 1,000, and n stands for a number of from 0 to 1,000. wherein R2 and R3 each independently represents a hydrogen atom or a methyl group, x stands for a number of from 0 to 12, and y stands for a number of 0 or 1. These surfactants do not contain any phenyl ether group considered to have significant effects on the environment, such as a nonylphenyl group, and have performance comparable with reactive surfactants containing one or more phenyl ether groups. Emulsifiers for emulsion polymerization, dispersants for dispersion polymerization and resin modifiers, all of which contain the surfactants, are also disclosed.

Owner:ADEKA CORP

Mitigation of biomolecular adsorption with hydrophilic polymer additives

ActiveUS8481125B2Inhibit bindingReduce surface tensionSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

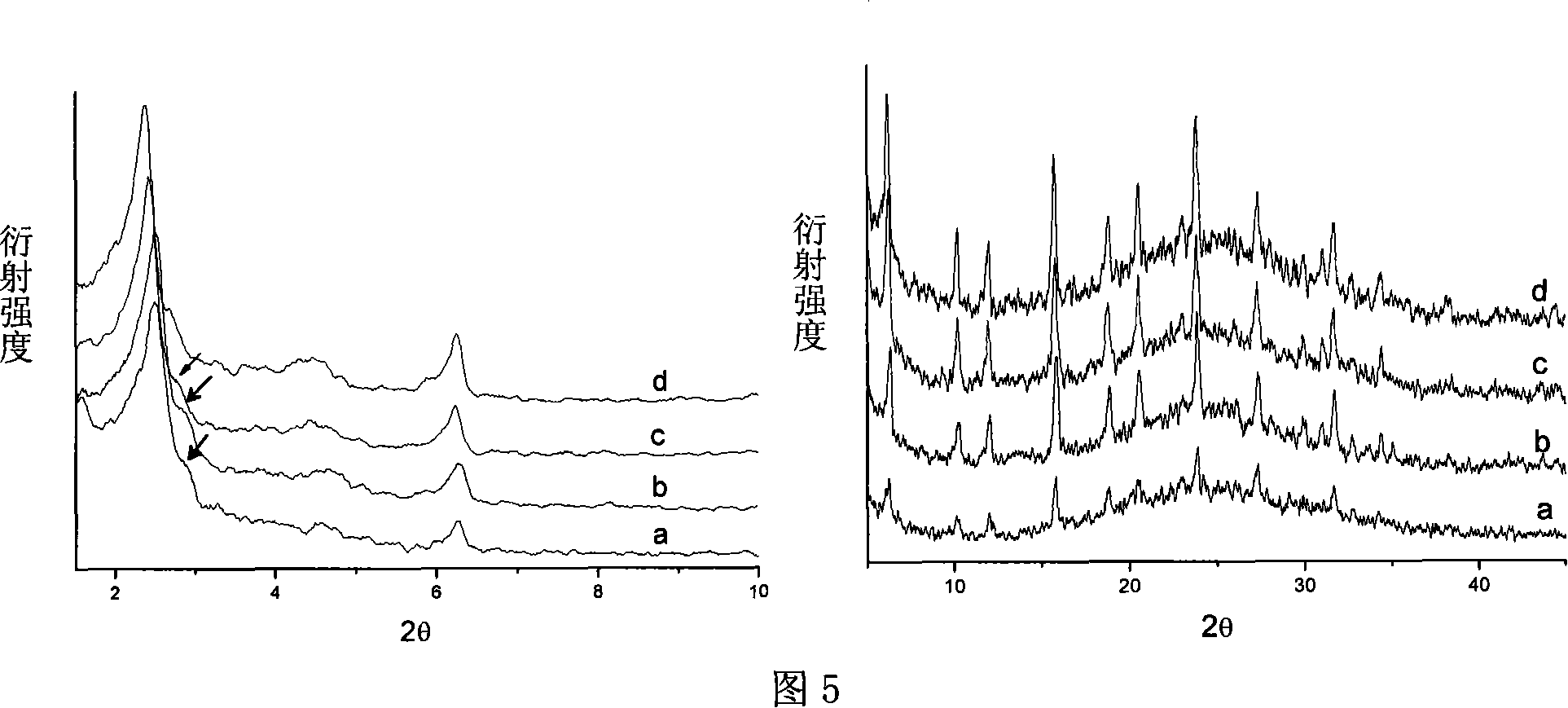

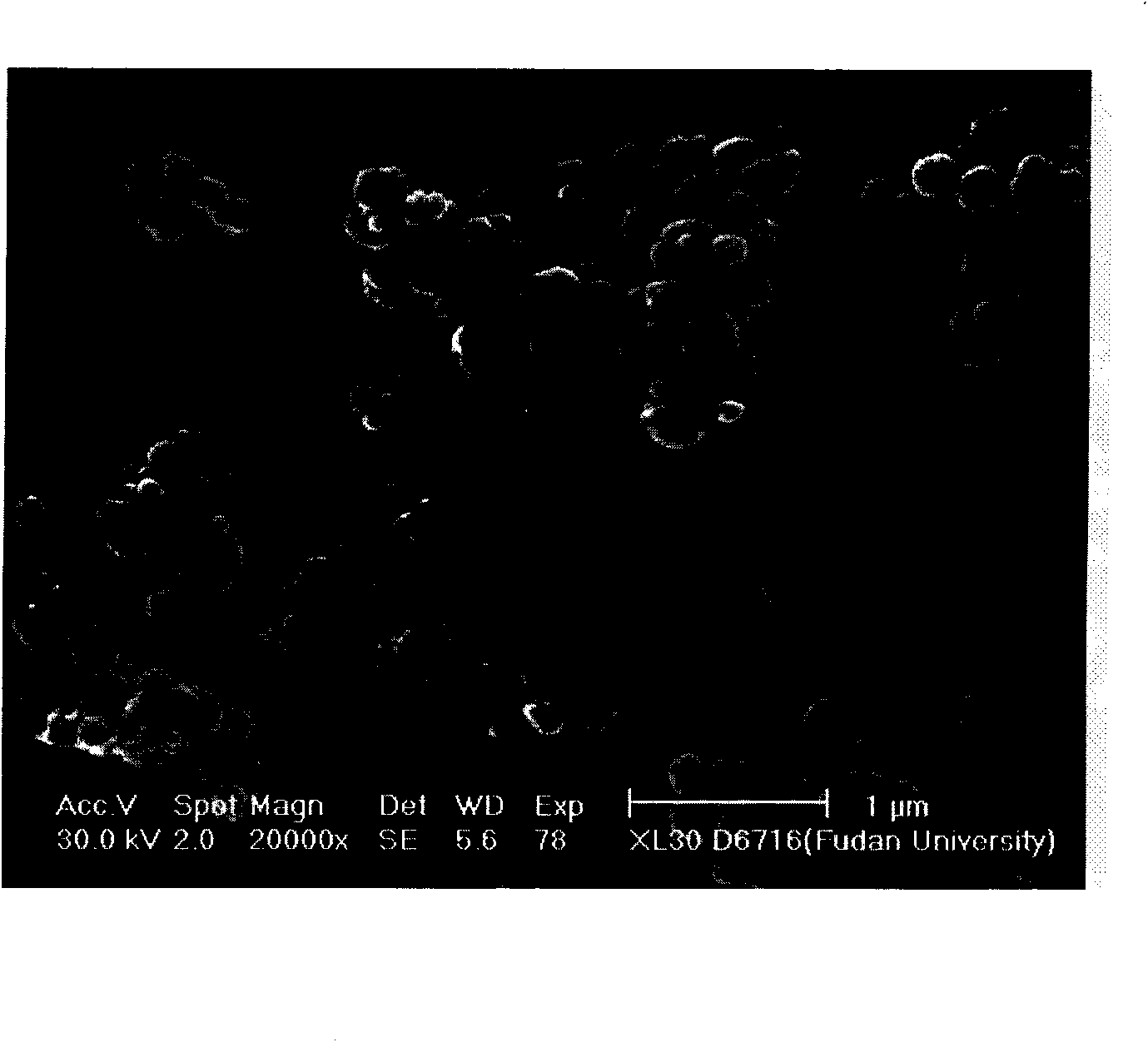

Y/MCM-48 composite molecular screen and preparation method thereof

InactiveCN101186311AReduce manufacturing costMeet the needs of different catalytic reactionsFaujasite aluminosilicate zeoliteMolecular sievePhenyl Ethers

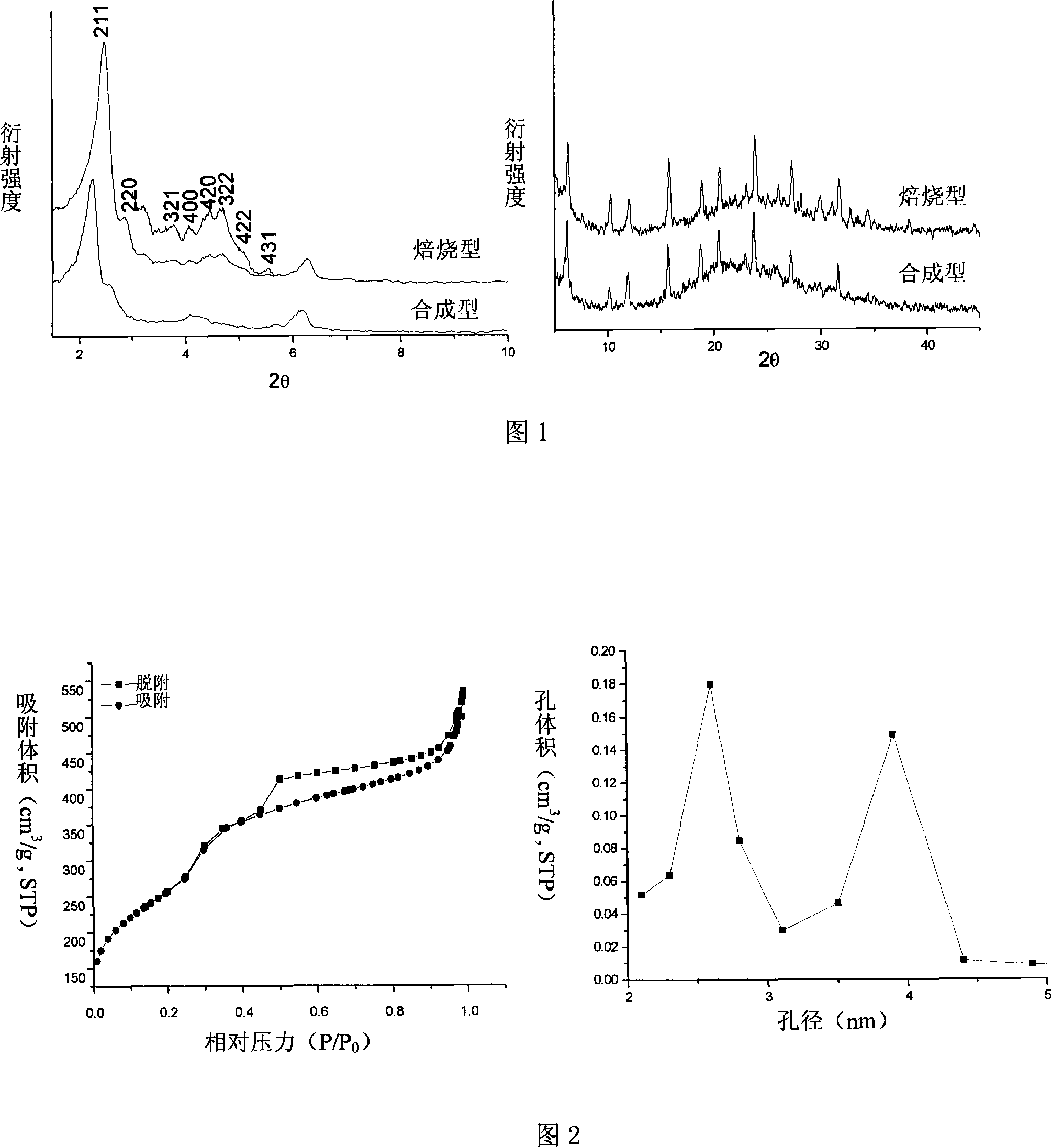

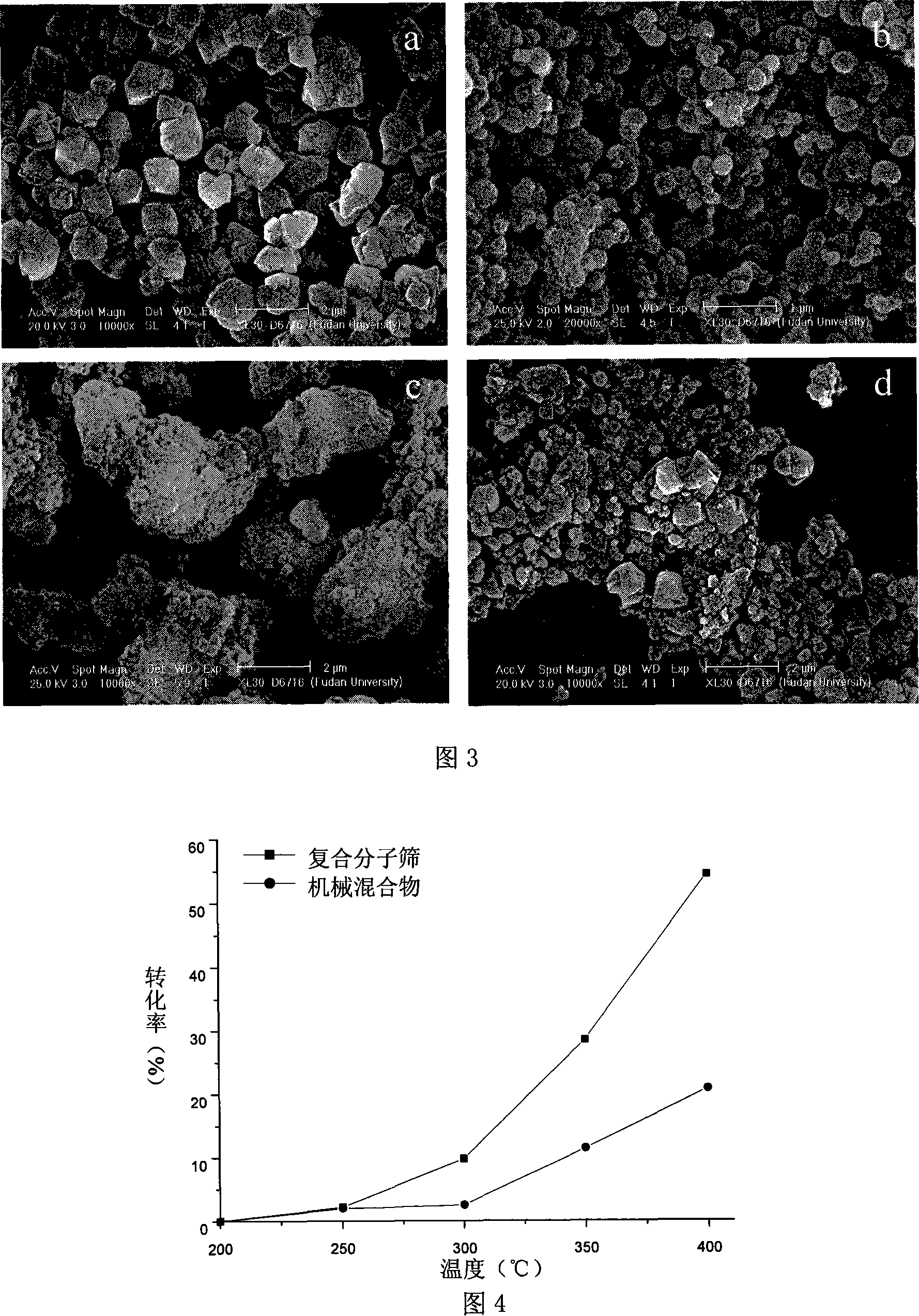

The invention relates to a catalytic material of a composite molecular sieve containing micropore Y-zeolite phase and mediated hole MCM- 48 phase, which is produced by taking mixed cationic and non-ion surfactant as template; the invention also relates to a preparation method of the catalytic material. By adopting a method of overgrowth and employing mixed aqueous solution of cationic surfactant: cetylíítrimethyl ammonium bromide(CTAB) and nonionic surfactant: p -octyl polyethylene phenyl ether OP-10 as template, under the alkaline hydrothermal condition the invention synthesizes composite molecular sieve which is provided with Y / MCM-48 with micropore and two-mode mediated holes. The framework ratio Si / Al of microporous phase Y-zeolite of the composite molecular sieve is higher than traditional Y-zeolite, and the ratio Si / Al and the content of the framework of microporous phase can be adjusted by changing synthesis conditions. The method of the invention has simple operation and good repeatability, which provides with optional materials for developing novel catalyst with industrial application prospect, and the synthesis has practical application value.

Owner:FUDAN UNIV

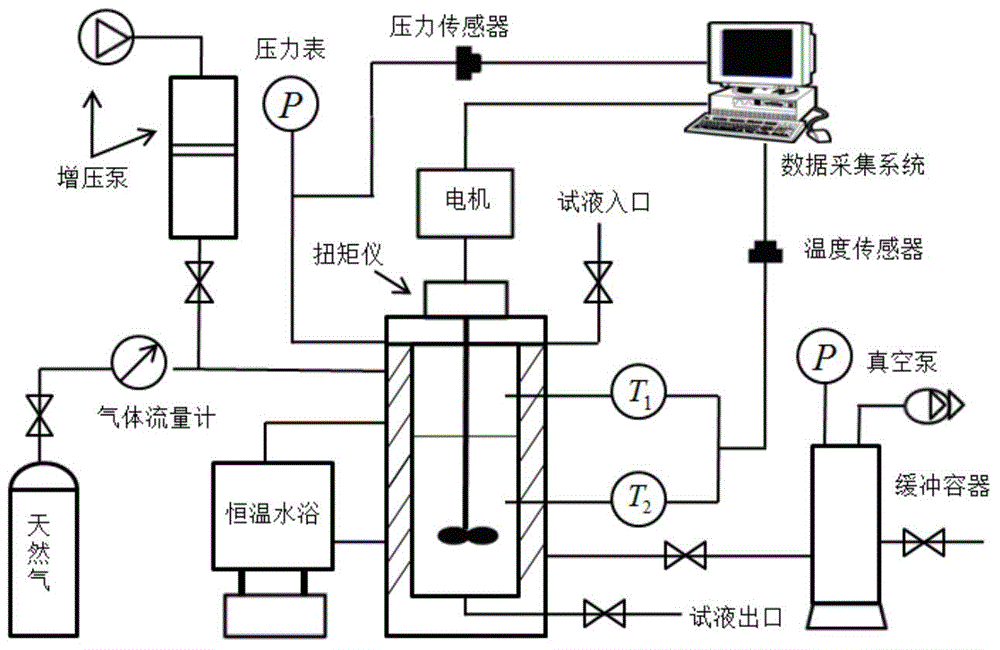

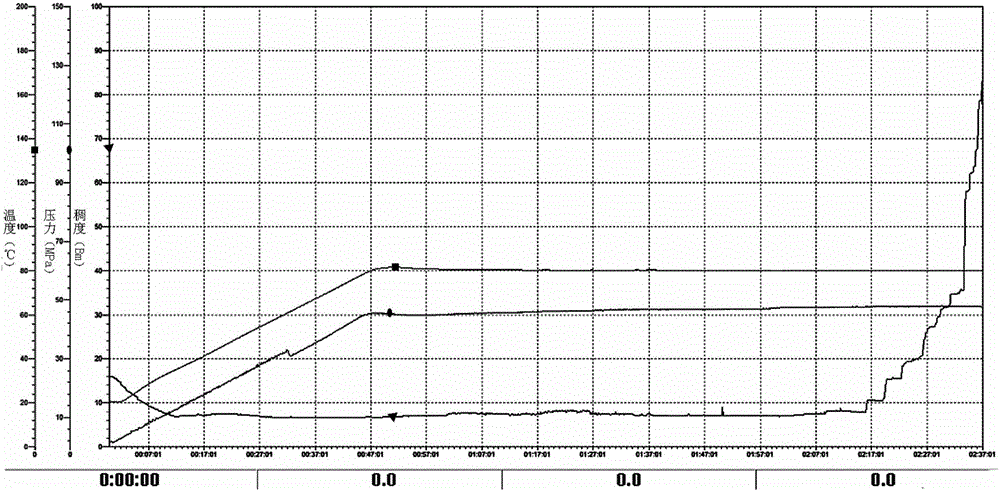

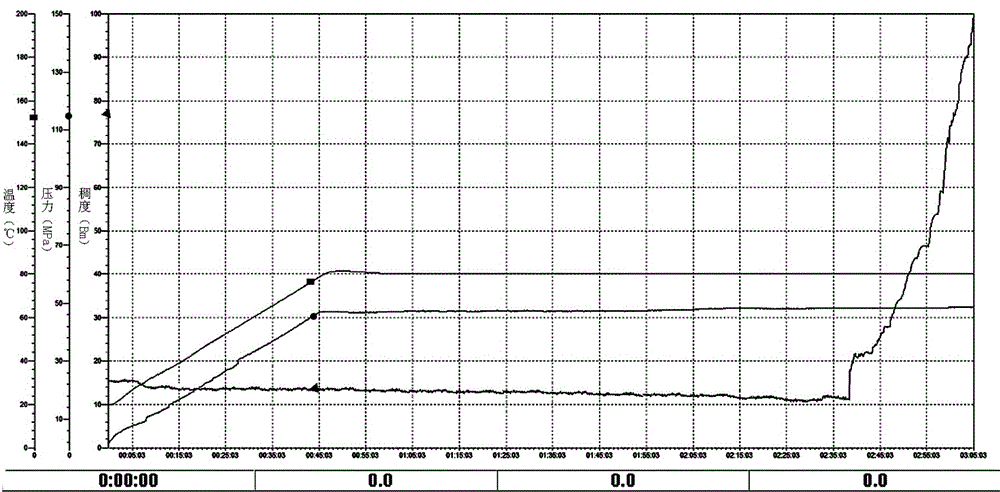

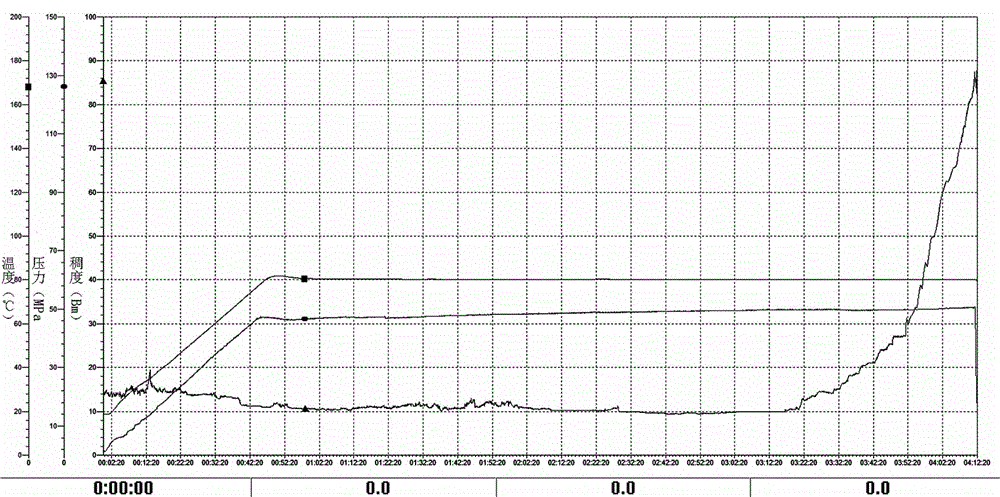

Compound low dosage natural gas hydrate inhibitor

The invention discloses a compound low dosage natural gas hydrate inhibitor. The hydrate inhibitor benchmarked against the mass of water in a deepwater drilling fluid completion fluid comprises, by mass, 0.1-2% of a hydrate kinetic inhibitor, 0.1-2% of a kinetic inhibitor synergist and 0-10% of a hydrate thermodynamic inhibitor. The hydrate kinetic inhibitor is at least one of polyvinyl pyrrolidone, polyvinyl caprolactam, and a copolymer generated through a reaction of vinyl pyrrolidone, vinyl caprolactam, alkenyl sulfonic acid and isopropylmethacrylamide. The kinetic inhibitor synergist is at least one of benzyltributylammonium chloride, tetraheptylammonium bromide, ethylene glycol phenyl ether, propylene glycol phenyl ether, polyoxyethylene and polyoxypropylene. The hydrate inhibitor can effectively inhibit generation of hydrates under a low dosage (0.2-10%), is suitable for deepwater and ultra-deep water drilling and completion, greatly reduces the cost and the logistical support burden, and has small harms to environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

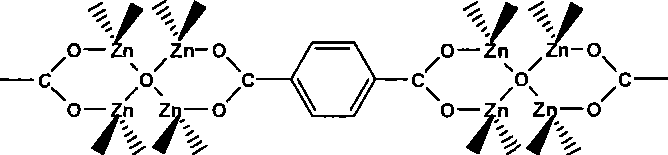

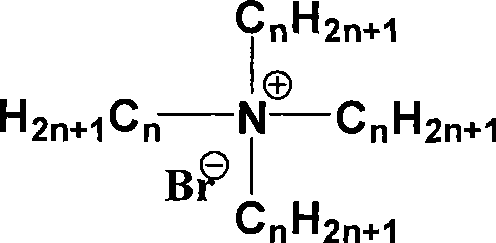

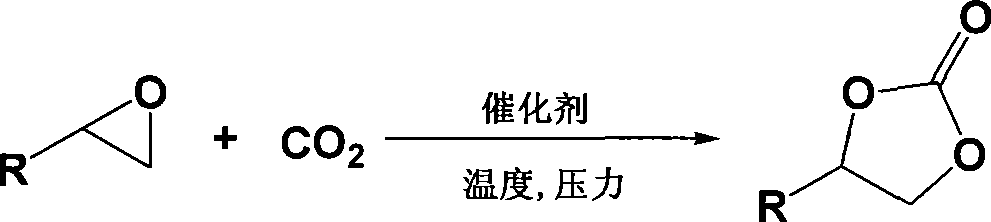

Catalytic system for synthesizing annular carbonic acid ester

InactiveCN101474576AHigh catalytic activityWide applicabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyStyrene oxide

The invention discloses a catalytic system used for synthesizing cyclic carbonate ester. The catalytic system comprises a catalyst with structural unit shown in formula I and quaternary ammonium salt shown in a general structure of formula II, wherein n is equal to 1-4 in the general structure of formula II. The catalytic system is suitable for catalyzing the reaction system in which carbon dioxide reacts with epoxy compound to synthesize the cyclic carbonate ester, in the reaction system, all the various epoxy compounds are applicable to the method, such as propylene oxide, epoxy chloropropane, styrene oxide, 2,3-glycidyl phenyl ether or cyclohexene oxide; the reaction temperature is 30-80 DEG C; the pressure of carbon dioxide is 2-12 MPa; and reaction time is 1-24 h. Compared with the conventional method, the catalytic system has the advantages of mild reaction condition, high recovery rate and high selectivity, and reuse of the major catalyst metal-organic coordination polymer (MOF-5) by simple filtration. Therefore, the catalytic system has strong industrial application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

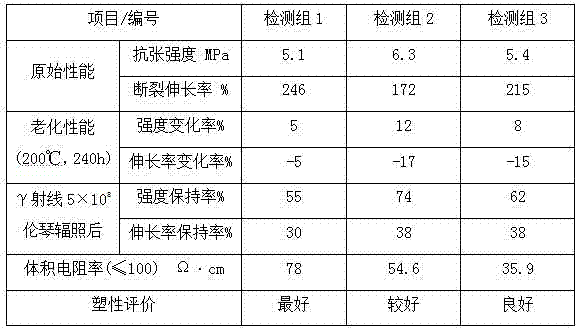

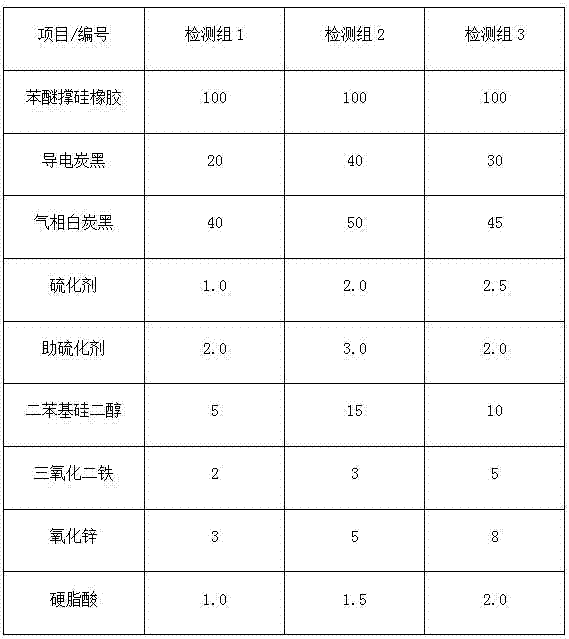

Semiconductive silicon rubber shielding material for radiation-resistant cable, and preparation method thereof

InactiveCN102964841AImprove radiation resistanceImprove plasticityInsulated cablesInsulated conductorsPolymer sciencePhenyl Ethers

The invention relates to a semiconductive silicon rubber shielding material for a radiation-resistant cable, and a preparation method of the material, belonging to the technical field of cable shielding material. The semiconductive silicon rubber shielding material comprises the raw material components in parts by weight: 100 parts of silicon rubber, 20-40 parts of conductive carbon black, 40-50 parts of white carbon black, 1.0-2.5 parts of dicumyl peroxide, 2.0-3.0 parts of auxiliary vulcanizing agent, 5-15 parts of diphenyl silanediol, 1.0-2.0 parts of stearic acid, 4-6 parts of zinc oxide and 2-5 parts of ferric oxide, wherein the silicon rubber is phenyl ether supporting silicone rubber or phenylene silicone rubber; and the auxiliary vulcanizing agent is triene propyl cyanurate. The silicon rubber shielding material is good in radiation-resistant performance, and can give play to the specified function for a long time on radiation occasion when being used as a shielding layer of an electric wire and the cable.

Owner:SICHUAN MINGXING CABLE

PE (polyurethane) protective film glue and preparation method thereof

InactiveCN102206476AStrong adhesionHigh bonding strengthFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateWater based

The invention discloses PE (polyurethane) protective film glue and a preparation method thereof. The PE protective film glue consists of the following components in parts by weight: monomers: 20-60 parts of butyl acrylate, 25-45 parts of methyl methacrylate, 12-32 parts of methyl acrylate, 5-15 parts of acrylic acid, 10-24 parts of hydroxyethyl acrylate, 120-140 parts of enthyl hexyl acrylate; emulsifying agents: 0.5-1.5 parts of polyoxyethylene octyl phenyl ether, 0.5-1.5 parts of sodium dodecyl sulphate, 0.5-1.5 parts of sodium dodecyl benzene sulfonate; a solvent: 280-350 parts of deionized water; and an initiating agent: 0.6-1.5 parts of ammonium persulfate. The PE protective film glue provided by the invention is the water-based adhesive and has the advantages of environment friendliness, no pollution, strong adhesive force and adhesive strength, and short drying time. A PE protective film coated with the PE protective film glue provided by the invention can be used for a vehicleprotective film, the protective films of all home appliances and so on. The effects of non-degumming and no residue glue can be realized.

Owner:BOLEX SHENZHEN ADHESIVE PROD

Pesticidal emulsifiable concentrate composition

InactiveUS6878674B2Improve emulsion stabilityGood low temperature stabilityBiocideDead animal preservationPolyoxyethylene castor oilPhenyl Ethers

There is provided a novel pesticidal emulsifiable concentrate composition that contains a phenoxypropionate herbicide (e.g., quizalofop-p-ethyl), a polar solvent (e.g., N-methyl-2-pyrrolidone), non-polar solvent (e.g., aromatic or aliphatic hydrocarbon) and a surfactant (e.g., polyoxyethylene castor oil ether, polyoxyethylene styryl phenyl ether), and that is improved in low-temperature stability and emulsion stability.

Owner:NISSAN CHEM IND LTD

Method for preparing ethylene glycol phenyl ether, propylene glycol phenyl ether and butylene glycol phenyl ether

InactiveCN101712600AAvoid many problems caused by distillation processLess investmentEther preparation from oxiranesPolymer sciencePhenyl Ethers

The invention discloses a method for preparing ethylene glycol phenyl ether, propylene glycol phenyl ether and butylene glycol phenyl ether, comprising the following steps: 1) firstly, adding phenyl into a reaction kettle, introducing inert gas and adding catalyst, then adding ethylene oxide or propylene oxide or butylene oxide, reacting under the conditions that the temperature is at 70-140 DEG C and the pressure is less than 1 MPa, thereby generating the crude product of ethylene glycol phenyl ether or propylene glycol phenyl ether or butylene glycol phenyl ether, wherein the mol ratio of the added phenyl to the added ethylene oxide or propylene oxide or butylene oxide is 1:0.6-1; and 2) reducing pressure and distilling the prepared crude benzene under the conditions that the vacuum degree is not less than 0.07MPa and the temperature is at 80-110 DEG C, thereby obtaining the product of ethylene glycol phenyl ether or propylene glycol phenyl ether or butylene glycol phenyl ether. The product of ethylene glycol phenyl ether or propylene glycol phenyl ether or butylene glycol phenyl ether prepared by the invention has a purity more than 99%, and does not need to be rectified and purified; and the method has the advantages of low equipment investment, convenient maintenance, simple operation control, low comprehensive cost and the like, and has considerable economic benefit.

Owner:JIAHUA CHEM

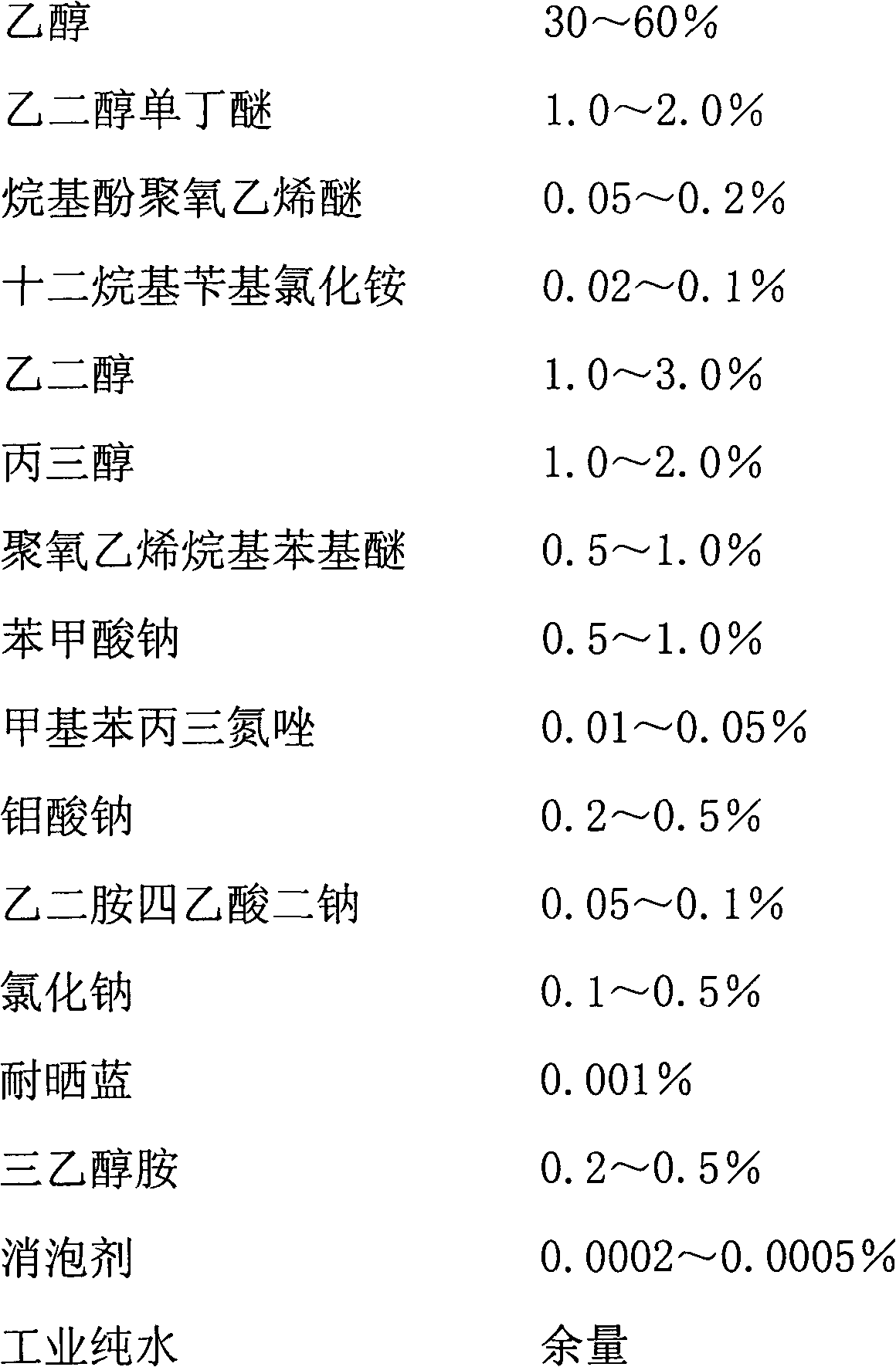

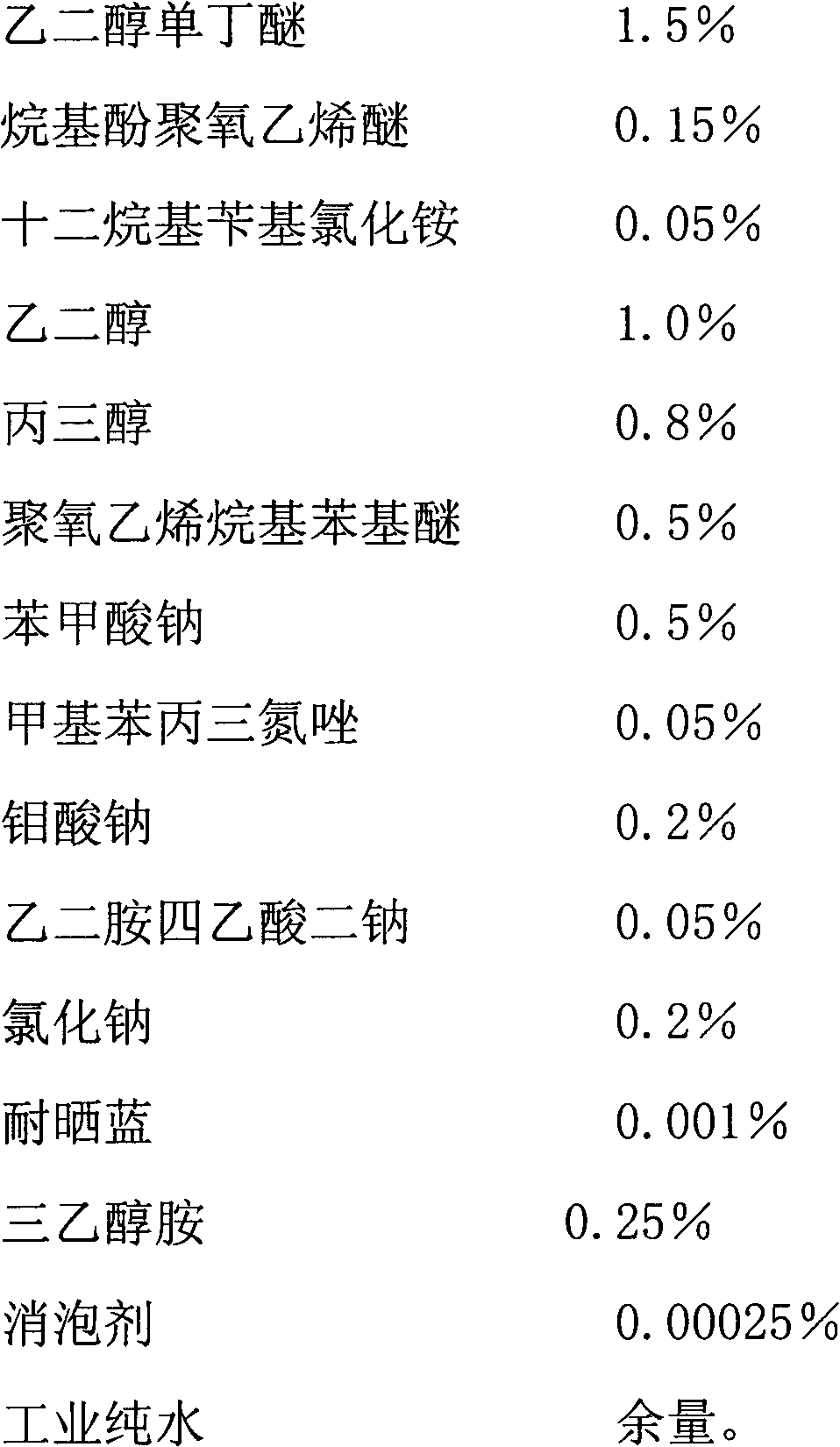

Long-acting environment-friendly automobile air window glass washing liquid

ActiveCN102492582ASolubilizeHigh speedSurface-active non-soap compounds and soap mixture detergentsPhenyl EthersGlycerol

The invention relates to a long-acting environment-friendly automobile air window glass washing liquid which is a non-toxic environment-friendly automobile air window glass washing liquid which can prevent freezing, prevent fog and remove ice and snow. The washing liquid is formed by stirring and reacting the following components by mass weight: ethanol, ethylene glycol monobutyl ether, alkylphenol polyoxyethylene ether, dodecyl benzyl ammonium chlorine, glycol, glycerol, polyoxyethylene alkyl phenyl ether, sodium benzoate, methyl benzotriazole, sodium molybdate, disodium ethylene diamine tetraacetate, sodium chloride, sunlight-resisting blue, triethanolamine, a defoaming agent and industrial pure water. By using the washing liquid, industrial methanol is prevented from being used as a solvent in the traditional formula; and simultaneously, the washing liquid and ethylene glycol monobutyl ether are matched and used, thereby greatly improving the dissolution effect of a single solvent on blots. The washing liquid disclosed by the invention is prepared by using non-toxic and easily biodegradable raw materials and is environment-friendly, can not pollute environment if being used for a long term, and prevents toxic gases from volatilization to harm a driver in the use process. The washing liquid has the characteristics of preventing fog, removing ice and snow, maintaining no icing on the surface of the glass for a long term, is not burnt and does not corrode.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Super-high extreme pressure type micro-emulsification cutting fluid and preparation method thereof

ActiveCN102766510AHigh extreme pressureExcellent anti-rustLubricant compositionPhenyl EthersChlorinated paraffins

The invention relates to a metal processing cutting fluid and specifically relates to a super-high extreme pressure type micro-emulsification cutting fluid and a preparation method thereof. According to the super-high extreme pressure type micro-emulsification cutting fluid, 5# white oil is used as basic oil and is easy to emulsify; emulsification lubricating agents comprise tall oil, oleic diethanolamide, polyoxyethylene(10)nonyl phenyl ether, isononanoicacid, synthetic petroleum sodium sulfonate and zinc naphthenate, and the emulsifying capacity is stronger when the emulsification lubricating agents are matched for using; and more chlorine containing extreme-pressure agent chlorinated paraffin S52 and sulfur containing extreme-pressure agents TPS32 can be emulsified into the basic oil to obtain the super-high extreme pressure type micro-emulsification cutting fluid. According to the super-high extreme pressure type micro-emulsification cutting fluid, emulsification particles are small, and the cutting fluid is stable; simultaneously, a synthetic ester of a fatty acid methyl ester which serves as a lubrication reinforcing agent is added, extreme pressure lubrication requirements of medium-high temperature processing are met, and the super-high extreme pressure type micro-emulsification cutting fluid is suitable for mechanical processing with wider ranges of processing temperatures; and triazine amino-acid esters are used for reinforcing rust protection so that the rust-protecting effects can reach to the best.

Owner:温州宝罗润滑材料有限公司

Halogen-free flame-proof highly anti-flush polyphenylacetylene composition and method of making the same

The invention discloses a non-bittern flame-proof high-impact polystyrene composition and preparing method in resin flame-proof modified domain, which is characterized by the following: comprising 100 wt high-impact polystyrene resin, 35-80 wt non-bittern combustion inhibitor and 10-30 wt forming carbon agent; setting the non-bitter flame-proof as poly ammonium phosphate pentaerythritol ester; setting the forming carbon agent as poly 2, 6-dimethyl-1, 4 phenyl ether or mixture with mass ratio at 3:1-6:1 poly 2, 6-dimethyl-1, 4 phenyl ester and nanometer caoline; comprising flexibilizer with 10-40 wt; choosing the flexibilizer from at least one of grafts of styrene-butene-styrene terpolymer and maleic anhydride, grafts of octane-ethene binary multipolymer and maleic anhydride and silicon rubber; mixing each component; melting; blending; getting the product. This invention possesses high flame-proof efficiency, which does not generate droplet.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

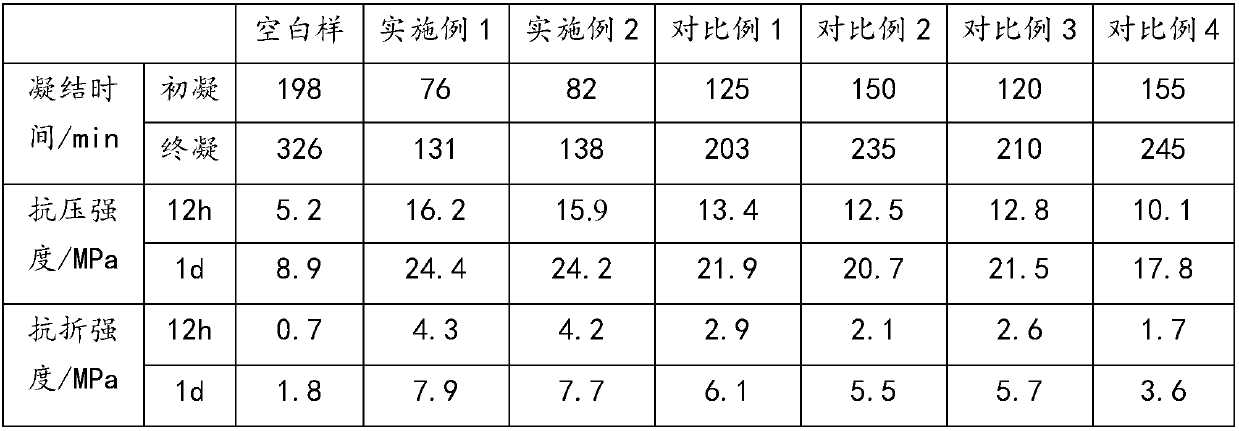

Hydrated calcium silicate early strength agent and preparation method thereof

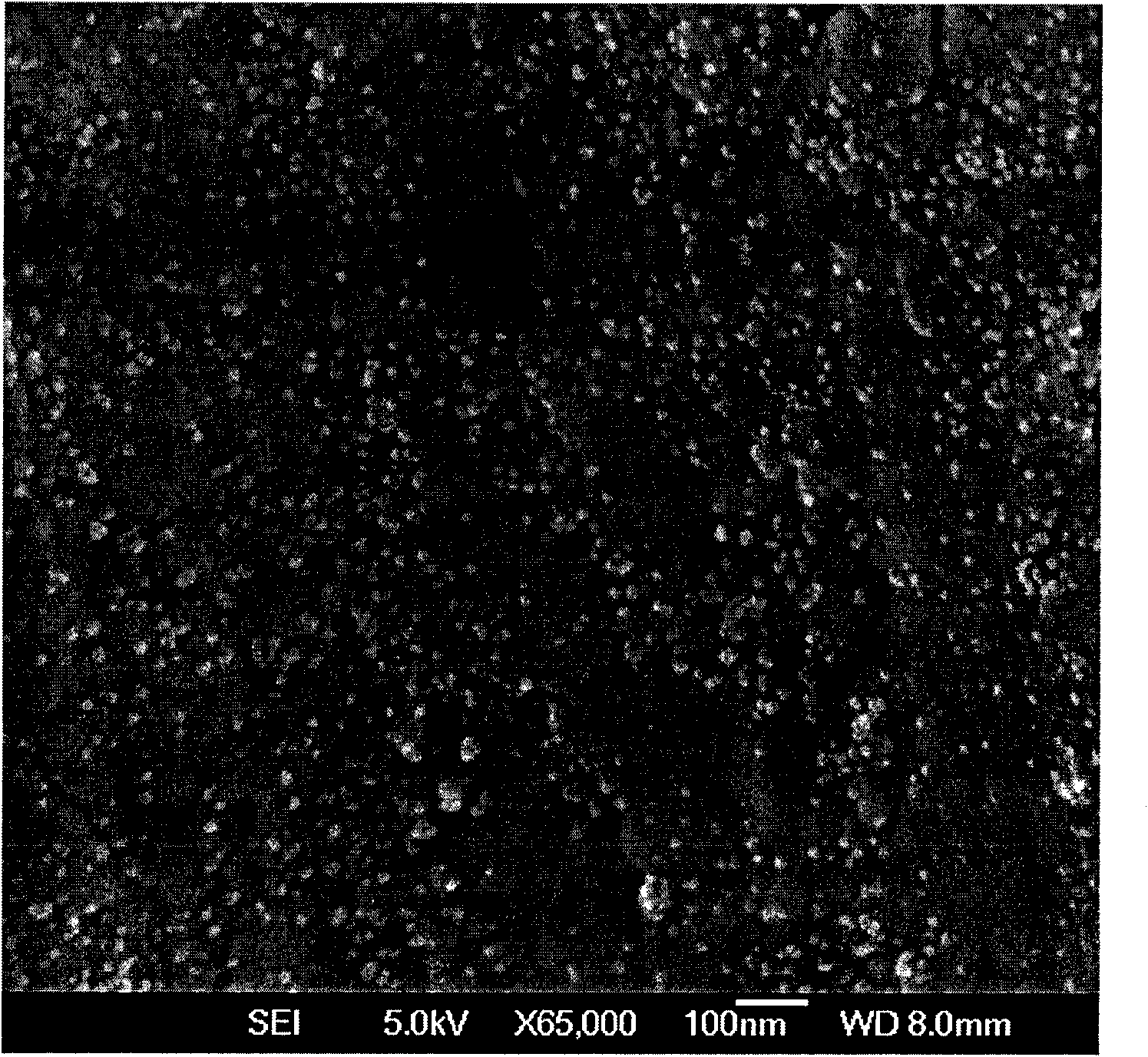

ActiveCN109650398ASmall particle sizeGood dispersionAlkaline-earth metal silicatesCalcium silicatePhenyl Ethers

The invention relates to the technical field of building materials, in particular to a hydrated calcium silicate early strength agent and a preparation method thereof. The preparation method of the hydrated calcium silicate early strength agent comprises the following preparation steps of: 1) preparing calcium solution; 2) preparing silicon liquid by taking silicate ester as a silicon source; 3) synthesis of hydrated calcium silicate: placing dispersant solution prepared by compounding polyoxyethylene (5) nonyl phenyl ether and cyclohexane into a shearing and stirring mixing device, keeping stirring at room temperature, adding prepared calcium solution and silicon solution, adjusting the pH value of mixed solution by using alkaline solution, stirring at constant temperature to obtain whitehydrated calcium silicate gel; centrifugally washing obtained white hydrated calcium silicate gel, and drying in a vacuum drying box to obtain the hydrated calcium silicate early strength agent. After the hydrated calcium silicate early strength agent prepared by the preparation method is mixed with cement, the hydration of cement can be promoted, the setting time of cement is obviously shortened, the early strength of cement is improved, and the hydrated calcium silicate early strength agent has important practical application value in the building field.

Owner:KZJ NEW MATERIALS GROUP CO LTD

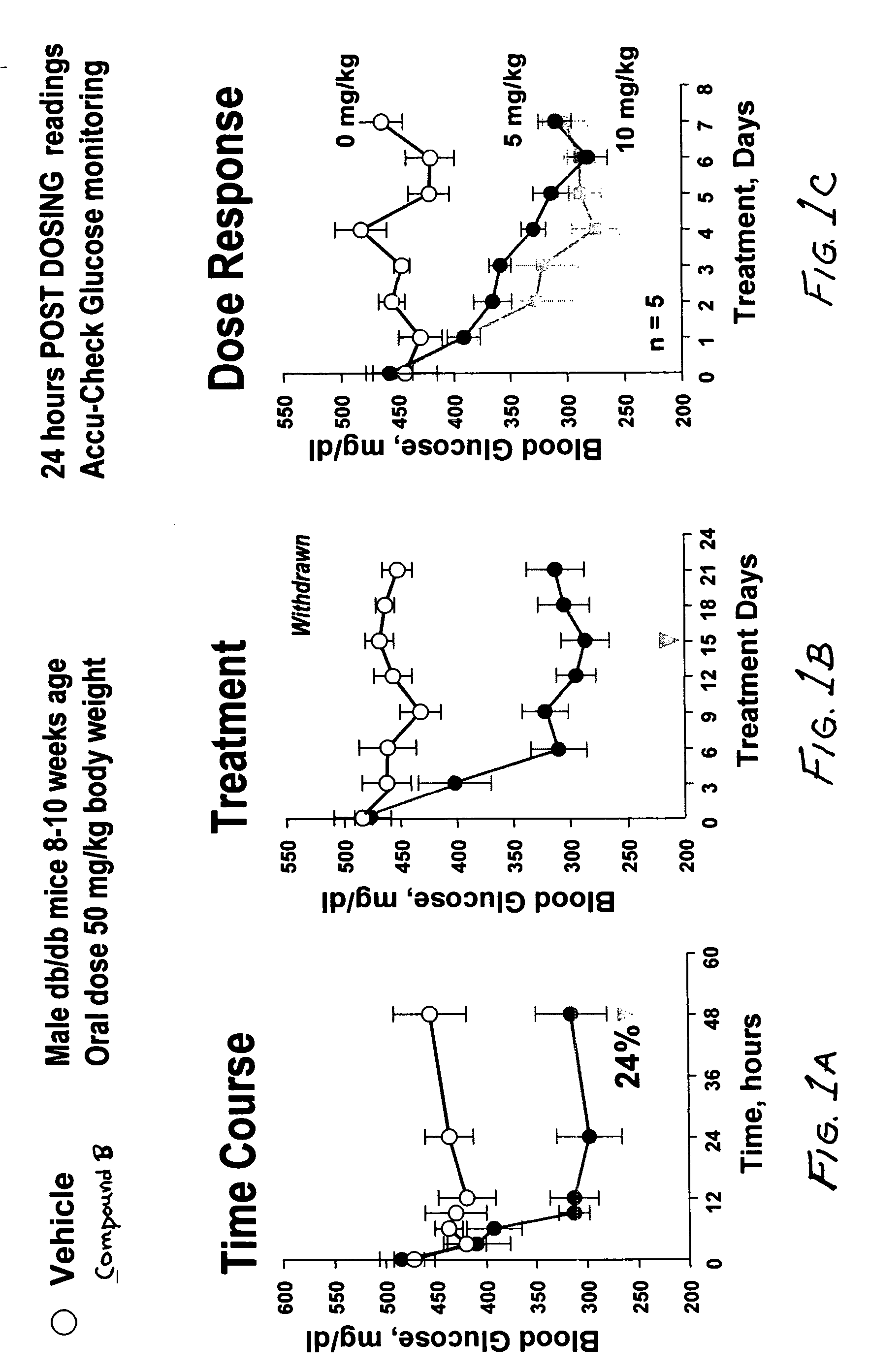

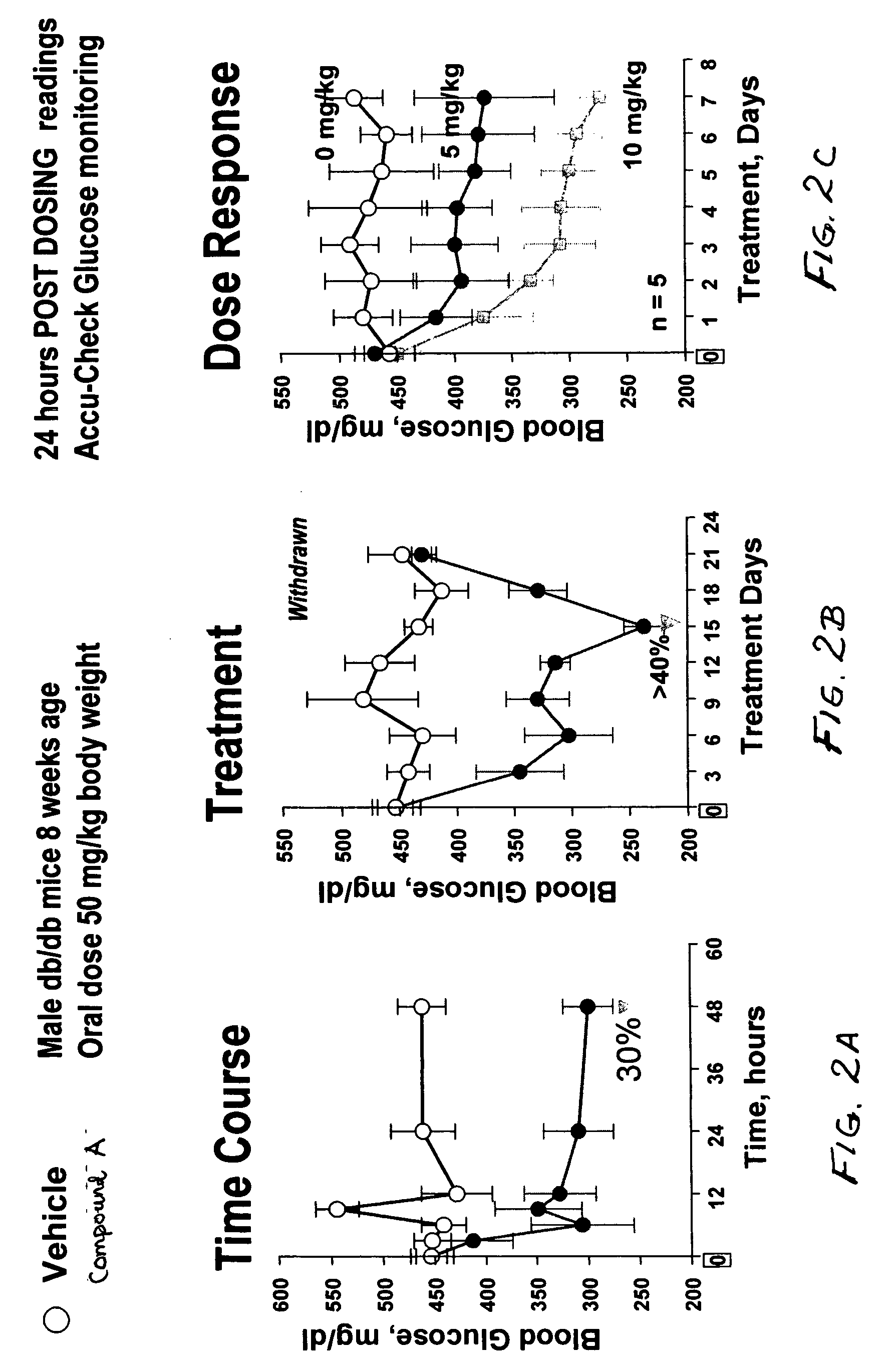

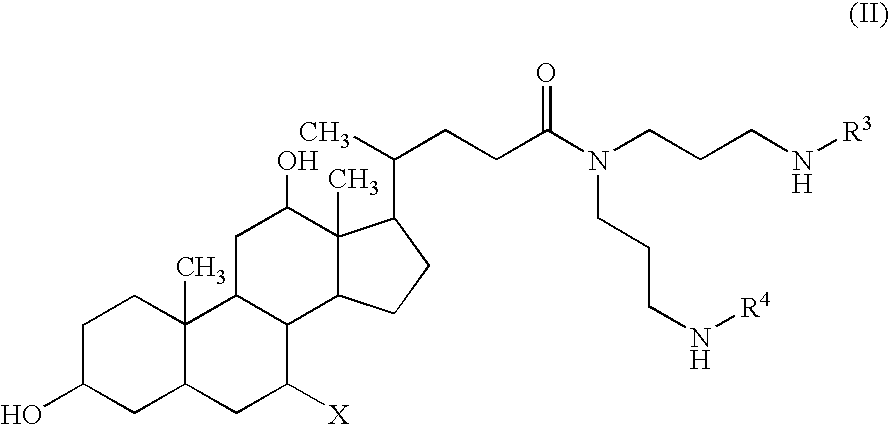

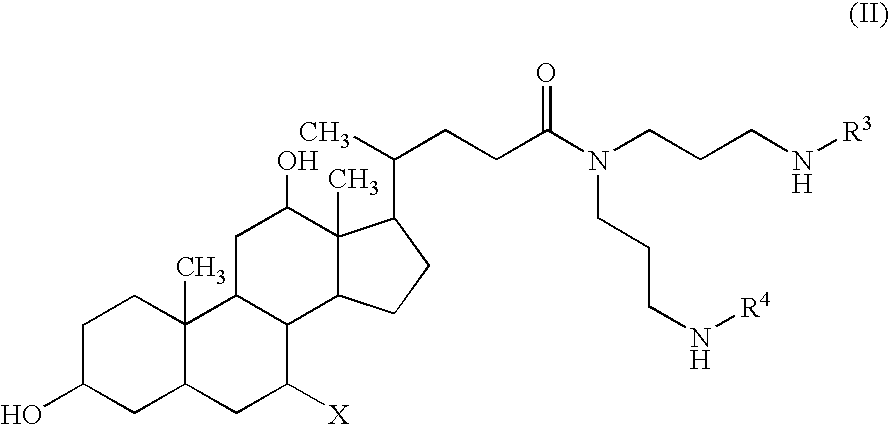

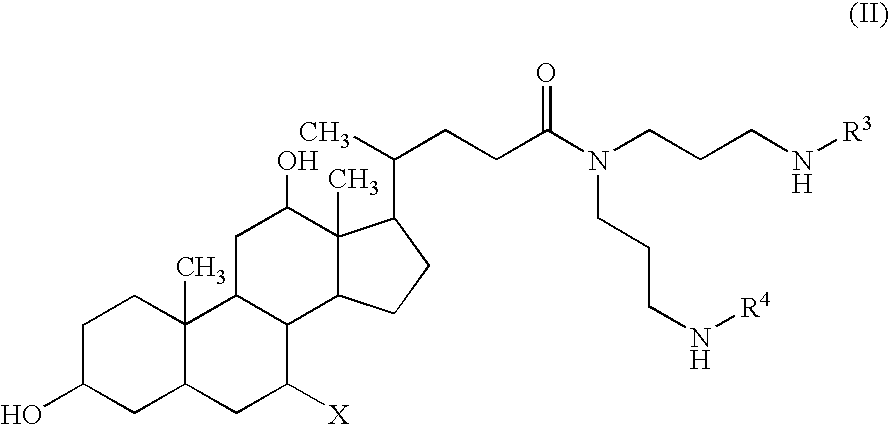

Dipeptide phenyl ethers

Novel dipeptide ethers are effective for lowering blood glucose, serum insulin, free fatty acids, cholesterol and triglyceride levels. The dipeptide ethers are also useful for the treatment and / or prophylaxis of diabetes, obesity, inflammation and autoimmune diseases such as multiple sclerosis and rheumatoid arthritis.

Owner:BEXEL PHARMA INC

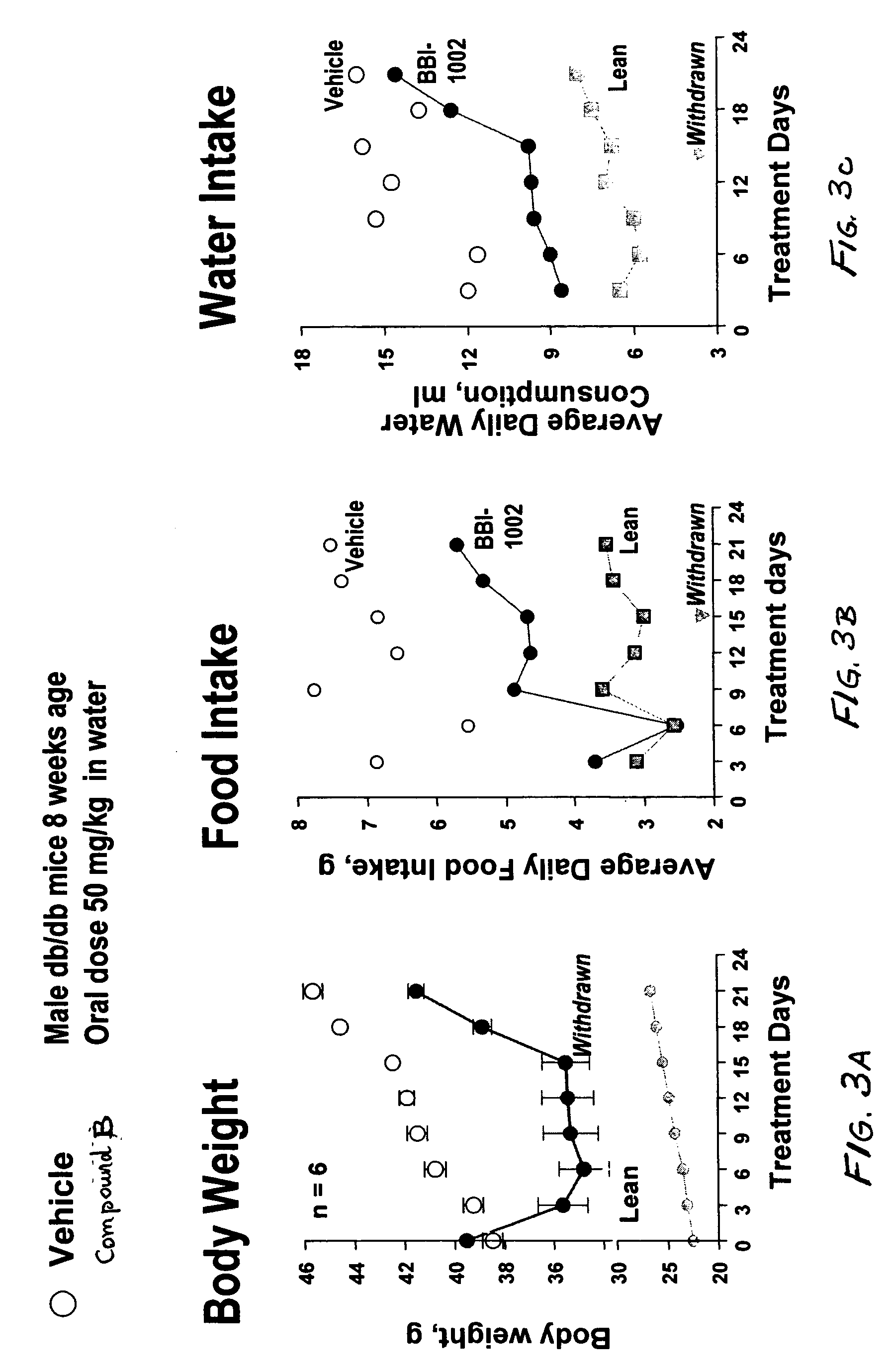

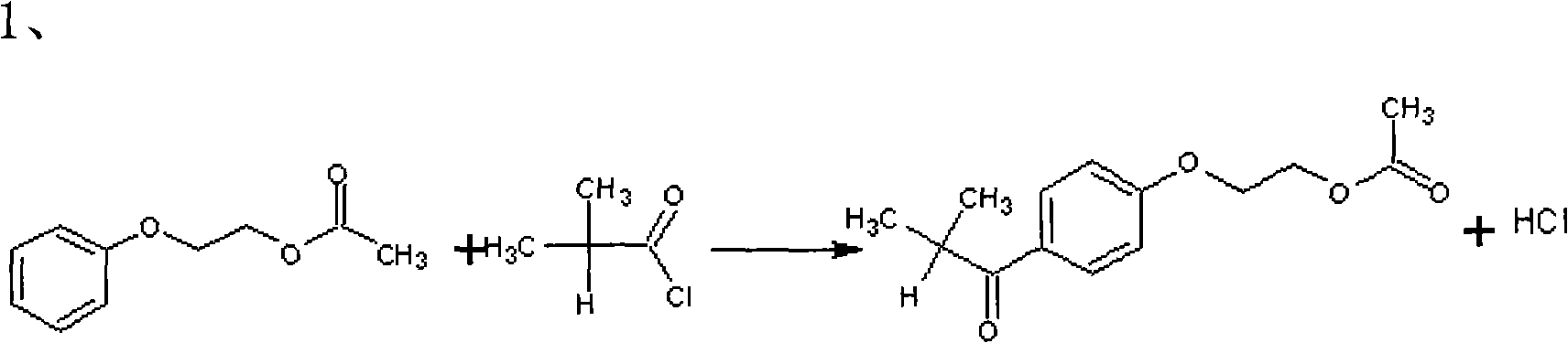

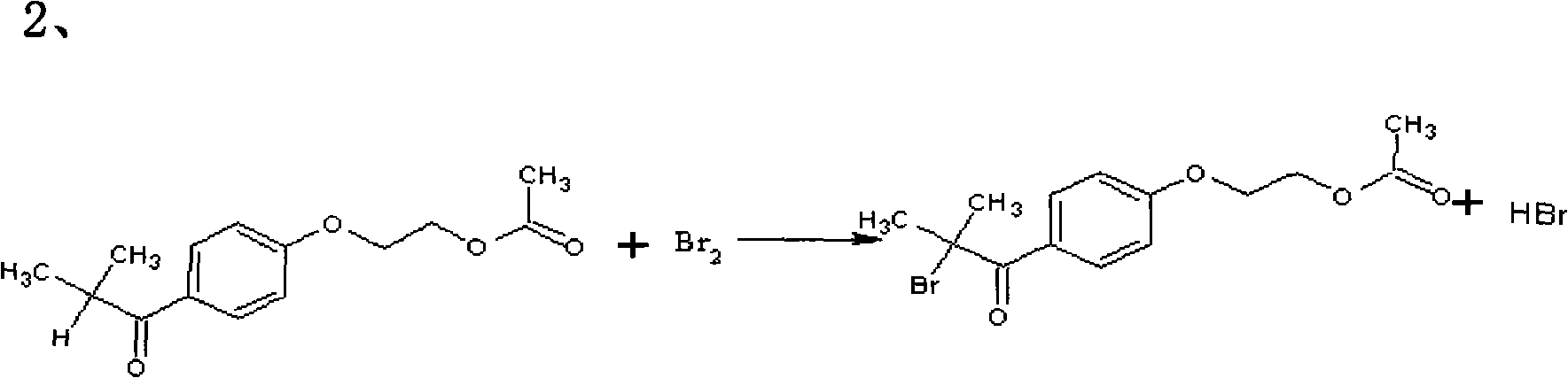

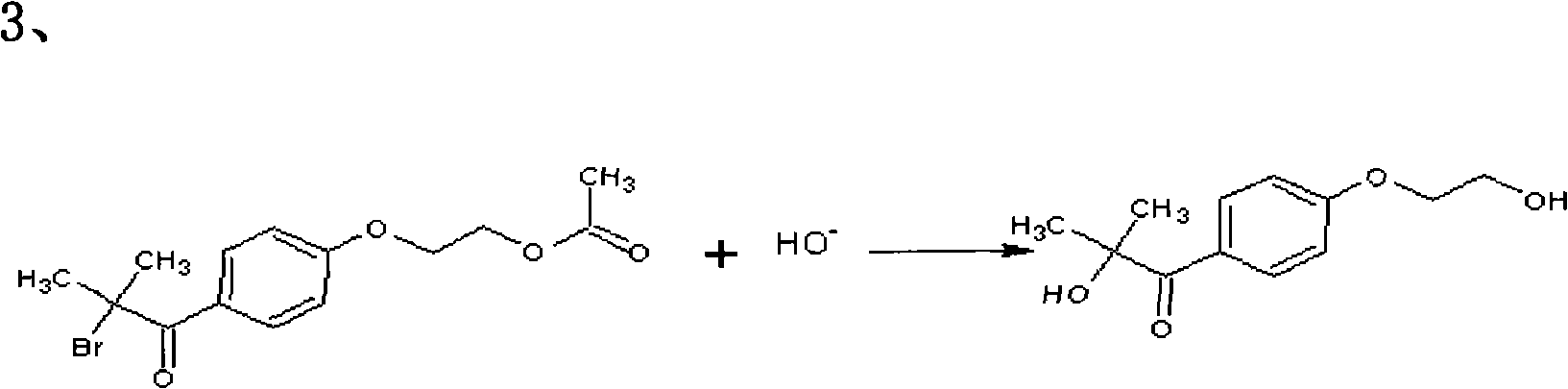

Preparation method of 2-hydroxyl-1-{4-(2-hydroxyethyl) phenyl}-2-methyl-1-acetone

InactiveCN101811951AShorten the timeSimple processOrganic compound preparationCarbonyl compound preparationN dimethylformamidePhenyl Ethers

The invention relates to a preparation method of 2-hydroxyl-1-{4-(2-hydroxyethyl) phenyl}-2-methyl-1-acetone, which comprises the following steps that: ethylene glycol phenyl ether acetate serves as the raw material and carries out friedel-crafts reaction with isobutyl chloride with the molar ratio of 1 to 1.2 times of equivalent under the catalysis of lewis acid, the reaction temperature is -5 to 5DEG C, and the reaction time is 3 to 6h; bromination is carried out under the catalysis of N, N-dimethylformamide or iodine; at room temperature, phase transfer catalyst is used for carrying out catalysis and hydrolysis to a brominated product; and finally the product is prepared through purification and crystallization. The preparation method of 2-hydroxyl-1-{4-(2-hydroxyethyl) phenyl}-2-methyl-1-acetone adopts dichloromethane or dichloroethane as the solvent during the bromination process, does not use acetic acid any more, carries out reaction under the catalysis of DMF or I2, so that the reaction time is greatly shortened. The phase transfer catalyst is introduced during the hydrolysis process, so that the intermediate brominated product directly has reaction with alkali in water, thereby preventing using a large amount of ethanol as the solvent, simplifying the process, reducing the production cost and improving the yield.

Owner:GANSU JINDUN CHEM

Mesoporous molecular sieve supported solid acid catalyst used for santene essential-oil isomerous esterification reaction

InactiveCN102274750AIncrease contentHigh yieldOxygen-containing compound preparationMolecular sieve catalystsPhenyl EthersSolid acid

The invention discloses a mesoporous molecular sieve supported solid acid catalyst used for santene essential-oil isomerous esterification reaction. Lauryl amine and polyoxyethylene octyl phenyl ether are taken as a mixed template; a sodium silicate solution is added, stirred, heated, aged, washed and filter-pressed, thereby acquiring a silicon raw material; the silicon raw material is mixed withbutyl titanate and solvent and then is thermally stirred and aged, thereby acquiring a solid powder mesoporous molecular sieve; the solid powder mesoporous molecular sieve is mixed and stirred with phosphotungstic acid, metatitanic acid and water; and after the mixture reacts, attapulgite is added and is uniformly stirred, dried and shaped after being pelleted, thereby acquiring the mesoporous molecular sieve supported solid acid catalyst. The mesoporous molecular sieve supported solid acid catalyst has the advantages that the uniformity of a cellular structure is high, the specific surface activity is high, the selectivity is excellent, the catalyst is easily separated from a product, the catalyst can be recycled and regenerated, the environment is protected, and the like. With the help of the mesoporous molecular sieve supported solid acid catalyst, the content and the yield of the product from the santene essential-oil isomerous esterification reaction are greatly promoted.

Owner:ANHUI JIMIN MEDICAL TECH

Foamless low temperature degreasing agent

The invention provides a non-foaming low-temperature degreasant which belongs to the chemical technique field. The non-foaming low-temperature degreasant is prepared from components by weight percentage as follows: water 77.4-96.35%, sodium hydroxide 3-20%, polyoxyethylene nonyl phenyl ether 0.1-0.5%, fatty alcohd-polyoxyethlene ether 0.1-0.5%, carmowax 0.05-0.1%, disodium EDTA 0.2-0.5%, silicone antifoam agent 0.1-0.5%, fatty alcohol polyethenoxy ether type osmotic agent 0.1-0.5%. The non-foaming low-temperature degreasant has advantages of better oil removing effect, low use temperature, and simple preparing method. The non-foaming low-temperature degreasant has better application prospect.

Owner:NORTHEASTERN UNIV

Environmentally friendly willow woven product water-based paint

The present invention discloses an environmentally friendly willow woven product water-based paint, and relates to the technical field of willow woven product water-based paints. The willow woven product water-based paint is made from the following materials by mass: 15-20% of methyl methacrylate, 3-5% of acrylic acid, 12- 16% of styrene, 10-15% of butyl acrylate, 0.5-1% of dibenzoyl peroxide, 0.2-0.5% of beta-thionaphthol, 4 -8% of 1-isopropoxy-2-propanol, 5-9% of diisopropanolamine, 0.5-1% of dioctyl phthalate, 3-5% of propylene glycol phenyl ether, 0.2-0.5% of Agitan 315, 0.1-0.2% of 2,4,5,6 -tetrachloro phthalonitrile, 0.8-1.2% of a polyurethane thickener, 1-3% of polyvinyl alcohol, 0.1-0 .3% of naphthenate, 0.5-1.5% of a dispersant, 0.2-0.5% of a leveling agent, 0.5-1% of an adhesion promoter, and 40-45% of water. The environmentally friendly willow woven product water-based paint may be applied to different willow woven product surfaces, and is delicate and fine in paint appearance, anti-mildew, anti-algae, strong in hiding power, and free of environment pollution.

Owner:赛诺(浙江)聚氨酯新材料有限公司

Oil-Based White Ink for Ink Jet Recording

ActiveUS20080194754A1Improve anti-settling performanceEasy to demouldMeasurement apparatus componentsDuplicating/marking methodsOrganic solventPhenyl Ethers

The present invention relates to an ink jet ink which is an oil-based white ink for ink jet recording containing (a) titanium oxide having an average particle size of 0.15 to 0.25 μm, (b) a resin, (c) an organic solvent and (d) a nonionic surfactant, wherein the nonionic surfactant comprises at least one member selected from polyoxyethylene alkyl ethers and polyoxyethylene phenyl ethers. According to the invention, there can be provided an oil-based white ink for ink jet recording which is excellent in ejection stability and in recovery properties after standing for a long period of time.

Owner:SEIKO EPSON CORP +1

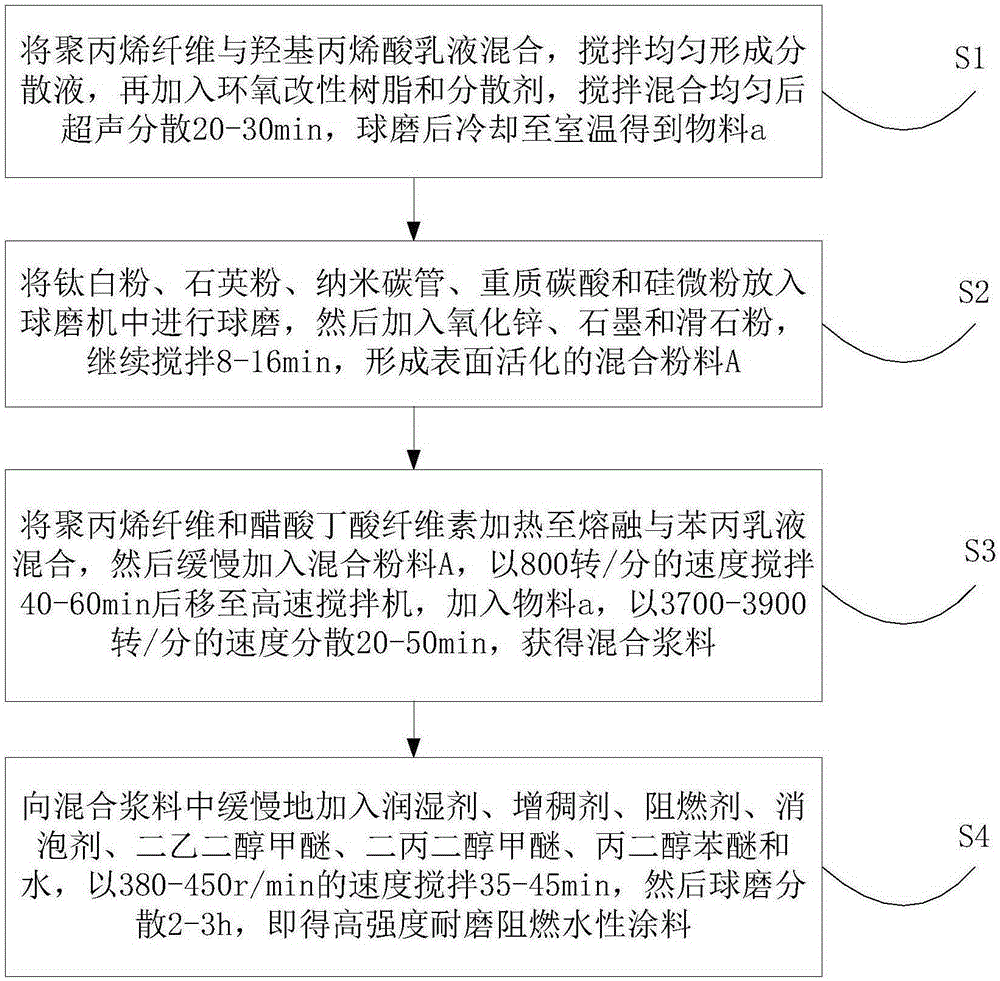

High-strength wear-resistant flame-retardant water-based paint and preparation method thereof

InactiveCN105199510AGood color retentionGood flexibilityFireproof paintsPolyurea/polyurethane coatingsWater basedWear resistant

The invention discloses high-strength wear-resistant flame-retardant water-based paint. The paint is prepared from, by weight, 100 parts of hydroxy acrylic acid emulsion, 75 parts of epoxy modified resin, 50 parts of water-based polyurethane emulsion, 40 parts of silicon-acrylic emulsion, 10 parts of styrene-acrylic emulsion, 5 parts of titanium dioxide, 3.5 parts of quartz powder, 3.5 parts of polypropylene fibers, 5.5 parts of cellulose acetate butyrate, 3 parts of silica powder, 4.5 parts of zinc oxide, 3.5 parts of carbon nano-tubes, 3.5 parts of graphite, 5 parts of coarse whiting, 5 parts of talcum powder, 3.5 parts of wetting agents, 6 parts of thickener, 2.5 parts of dispersant, 3.5 parts of flame retardant, 2 parts of antifoaming agents, 3 parts of diethylene glycol monomethyl ether, 4 parts of dipropylene glycol monomethyl ether, 5 parts of propylene glycol phenyl ether and 20 parts of water. The invention further provides a preparation method of the high-strength wear-resistant flame-retardant water-based paint. The water-based paint is high in strength, good in wear resistance and great in flame retardancy.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Tannin extract/polycarboxylate concrete water reducer and preparation method thereof

The invention discloses a tannin extract / polycarboxylate concrete water reducer. The tannin extract / polycarboxylate concrete water reducer is prepared from the following raw materials by weight: 2 to 4 parts of polyvinyl alcohol, 3 to 5 parts of tannin extract, 4 to 6 parts of hydrogen peroxide with a concentration of 20 to 30%, 0.1 to 0.2 part of polysorbate-80, 40 to 50 parts of modified polycarboxylate mother liquor, 1 to 2 parts of sodium humate, 1 to 2 parts of sorbitol, 0.2 to 0.4 part of polyoxyethylene nonyl phenyl ether and 40 to 50 parts of water. The water reducer has good compatibility with cement, is small in doping amount and high in a water reducing rate, can improve the bonding strength of cement, strengthen the compression resistance and fracture resistance of concrete and enhance the strength of concrete, effectively prevents corrosion of steel bars in concrete, prolongs the service life of the steel bars, and has a high practical value.

Owner:ANHUI FUNAN LVYUAN CHEM

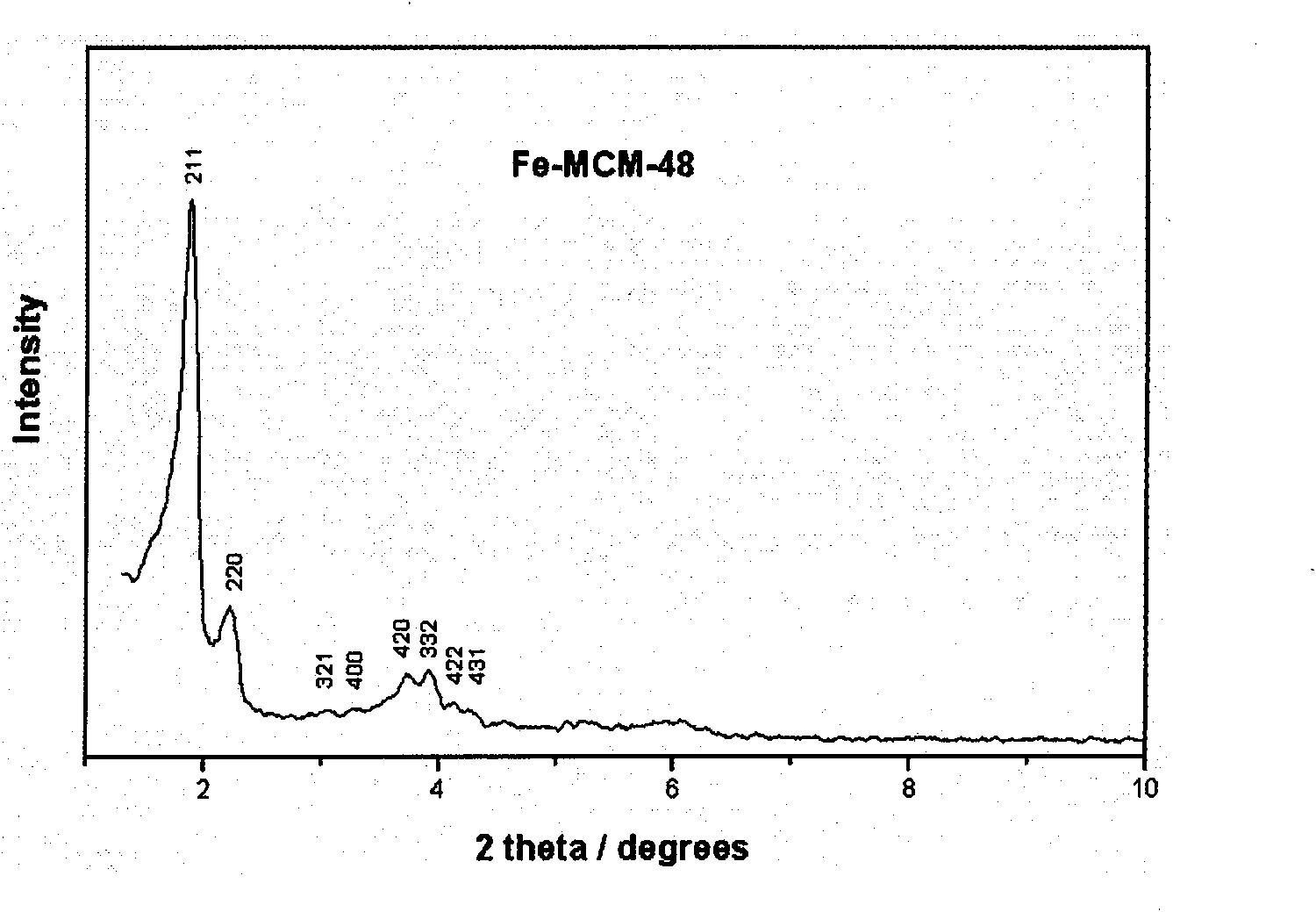

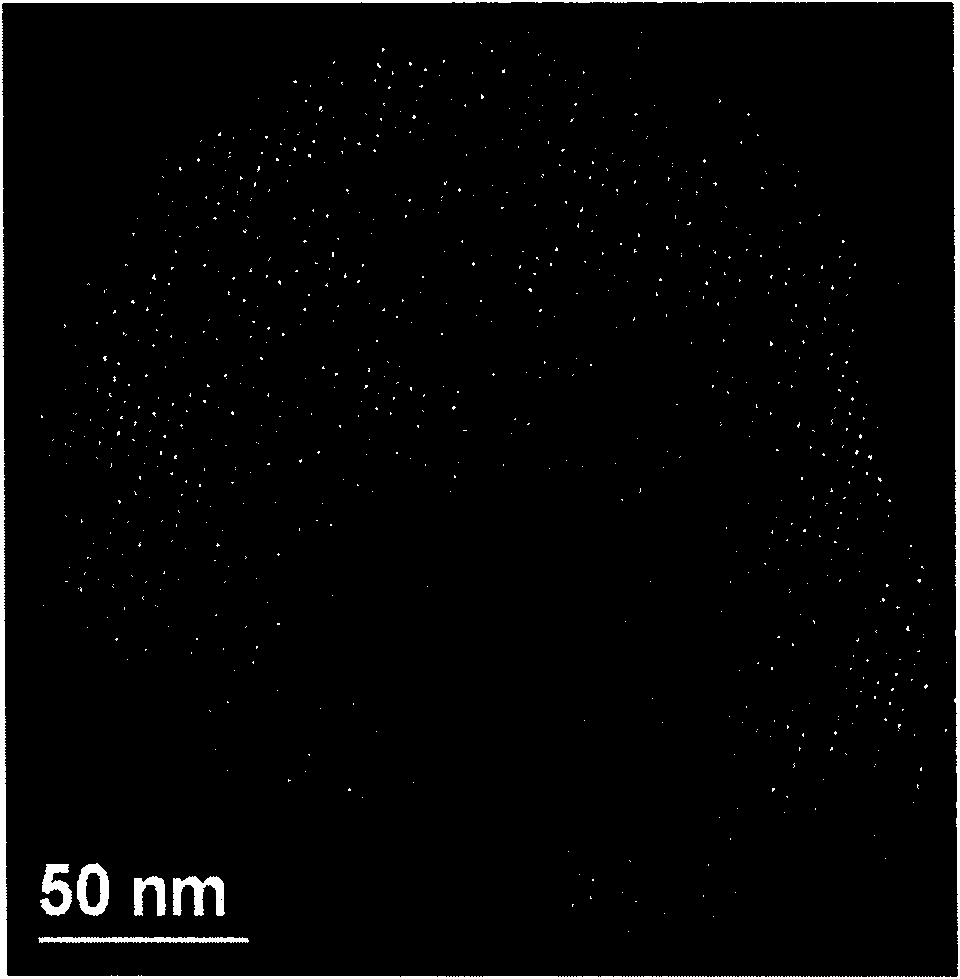

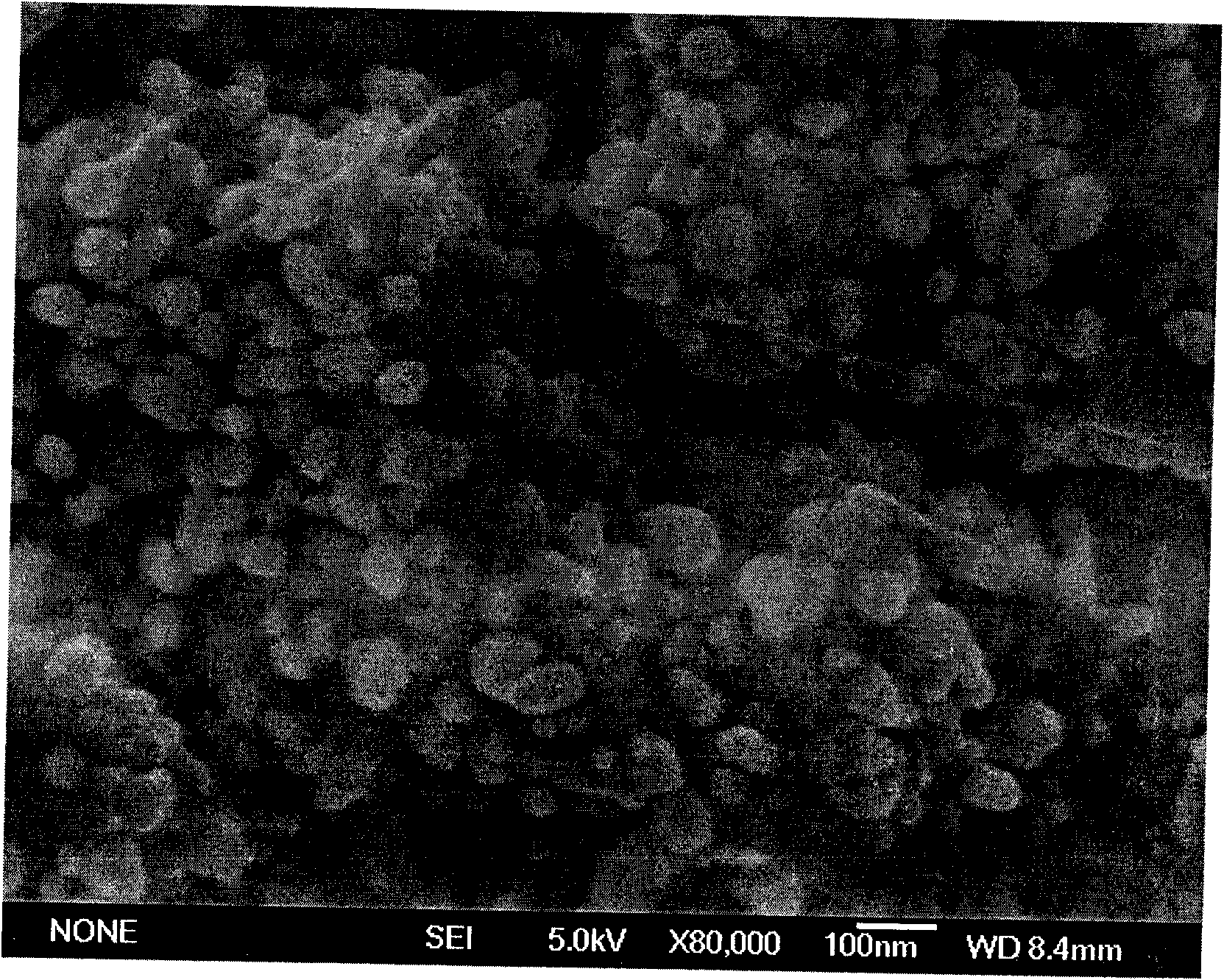

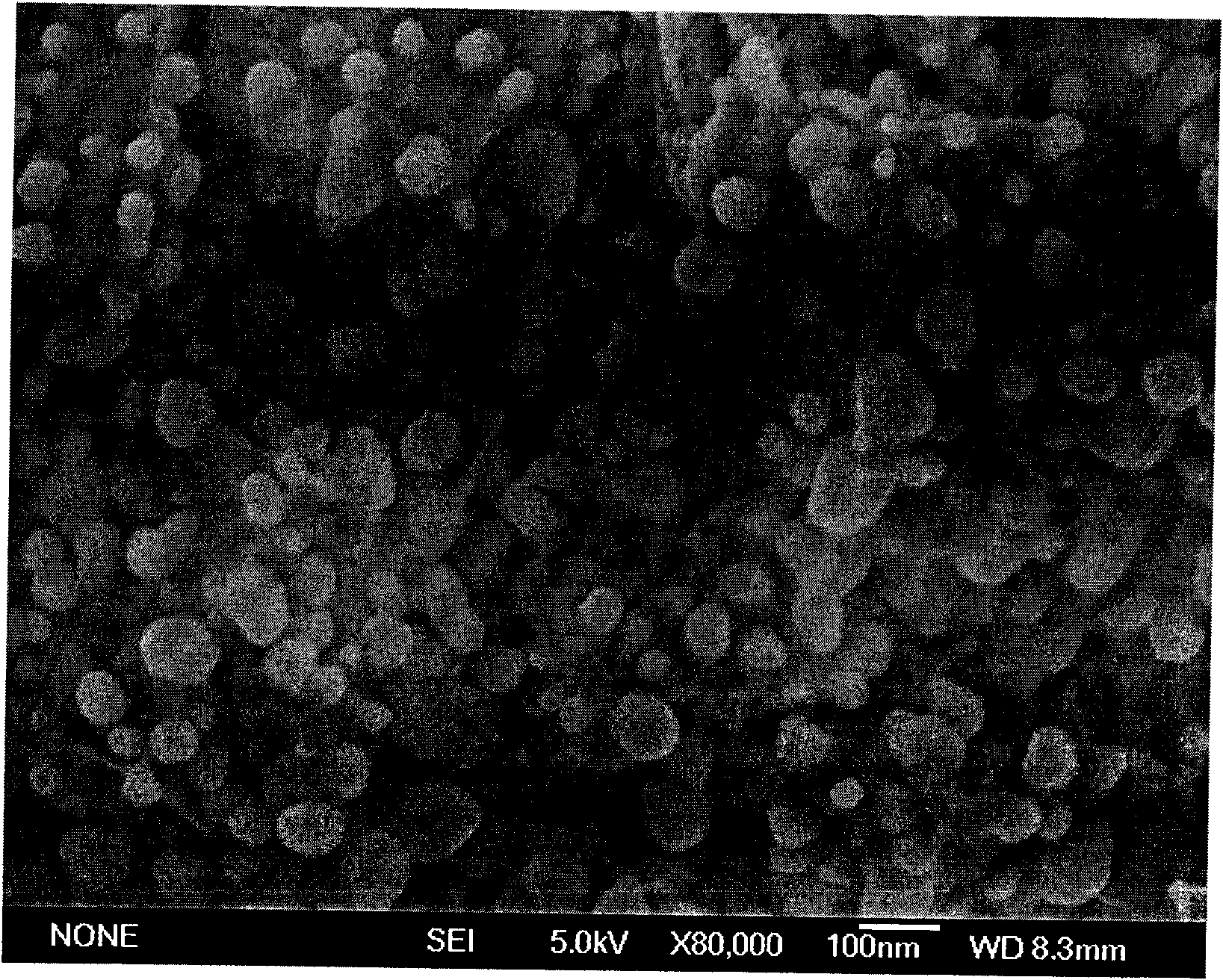

Synthesis of spherical Fe-MCM-48 mesoporous material and preparation of catalytic combustion catalyst loaded with Ag of spherical Fe-MCM-48 mesoporous material

In the invention, cheap sodium silicate which is sold in the market is used as the silicon source, common inorganic iron salt is used as the iron source and cationic surfactant cetyl trimethyl ammonium bromide (CTAB) and nonionic surfactant p-octyl polyethylene phenyl ether (Tx-100) are used as the co-template agent in a hydrothermal system to prepare Fe-MCM-48 mesoporous molecular sieve of a regular spherical structure. The prepared material is used as the carrier to load a catalyst prepared from precious metal silver which is relatively cheap, thus the obtained catalyst has better catalytic activity in the catalytic combustion reaction of benzene. The preparation method in the invention has advantages of simple operation, low cost, high activity.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Special cleaning agent for insulators and preparation method thereof

ActiveCN101629129ANo environmental pollutionLess corrosiveNon-ionic surface-active compoundsDetergent compounding agentsPhenyl EthersDecomposition

The invention provides a special cleaning agent for insulators, which comprises the following components in percentage by mass: 1 to 20 percent of polyethyleneglycol octyl phenyl ether, 1 to 20 percent of nonylphenol polyoxyethylene ether, 1 to 3 percent of dichloromethane, 5 to 20 percent of C5H2F10, 10 to 30 percent of C3HCl2F5, and 5 to 15 percent of C2Cl3H3. The invention also provides a preparation method for the special cleaning agent for the insulators, which comprises the following steps: filling the components into a closed container according to the proportion, and reacting the mixture for 1 hour under normal pressure at the temperature of between 20 and 30 DEG C. The cleaning agent has the advantages of non environment pollution, low erosion, strong physical decomposition capacity and safe and reliable use, and can quickly and thoroughly clean various insulators, deep dust, oil stain, impregnated carbon, salinity, moisture and metal dust and various charged particles, effectively eliminate 'flexible fault', ensure the optimal working state of equipment and reduce the maintenance cost.

Owner:SHANGHAI SHENJIE ENVIRONMENTAL PROTECTION TECH DEV

Method for measuring triglyceride in low-density lipoprotein and kit for measurement

InactiveUS20090226944A1Material analysis by observing effect on chemical indicatorMicrobiological testing/measurementA lipoproteinPhenyl Ethers

The present invention provides a method for a simple and accurate measurement of triglycerides in low-density lipoprotein in a sample comprising performing the following steps sequentially:(i) a step of generating free glycerol by allowing lipoprotein lipase to act on a sample, in an aqueous medium comprising the sample and a specific surfactant such as polyoxyethylene polyoxyalkylene polycyclic phenyl ether; (ii) a step of removing free glycerol present in the reaction solution of the above step (i); (iii) a step of generating free glycerol by allowing lipoprotein lipase to act on the reaction solution from which free glycerol has been removed in step (ii), in the presence of a specific surfactant such as polyoxyethylene polyoxyalkylene alkyl ether; and (iv) a step of measuring free glycerol generated in step (iii),and a kit used for the method.

Owner:KYOWA MEDEX CO LTD

Energy ray-curable resin composition and cured product thereof, and optical lens sheet

The invention provides an energy ray-curable resin composition having excellent demoulding character, mold reproducibility, bond strength with the substrate and light resistance; high refractivity; high glass-transition temperature and low viscosity. A energy ray-curable resin composition for optical lens sheets includes: a carbamate compound (A) obtained by reacting the epoxy resin (a), monocarboxylic acid compound (b) having ethylenically unsaturated group and aromatic polyisocyanic acid ester compound (c); a (meth) acrylate (B) having fluorene framework; a single acrylate monomer (C) with phenyl ether group; and a photopolymerization initiator (D), wherein the epoxy resin (a) is a reaction product of epihalohydrins and compound represented by the general formula (1).

Owner:NIPPON KAYAKU CO LTD

Method for preparing nano materials by direct electrodeposit in ionic liquid microemulsion

The invention relates to a method for preparing nano materials by direct electrodeposit in ionic liquid microemulsion, a new technology for preparing nano materials, which combines an electrochemical method and a microemulsion method. Under the effect of surface active agent polyoxyethylene octyl phenyl ether, 1-butyl-3-methylimidazole hexaflourophosphate salt ionic liquid and aqueous solution form water drum ionic liquid microemulsion with relatively high electroconductibility; an electroconductive electrode and the water drum ionic liquid microemulsion form an electrode system. A nano metal plating featuring controllable size and even distribution is prepared in a 'nano pool' in ionic liquid microemulsion by a current control method or an electric potential control method; wherein, size of the nano particles can be controlled by the mol ratio between water and the surface active agent; the technology for preparing novel nano materials has the advantages of low equipment cost, easy operation and easy control.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Anionic-nonionic composite efficient flushing fluid and preparation method thereof

ActiveCN104910885AImprove flushing efficiencyGood compatibilityDrilling compositionInorganic saltsPhenyl Ethers

The invention discloses an anionic-nonionic composite efficient flushing fluid and a preparation method thereof. The flushing fluid comprises, by mass, 6-10% of polyoxyethylene sorbitan fatty acid ester, 10-15% of fatty alcohol polyoxyethylene ether sodium sulfate, 6-10% of polyoxyethylene nonyl phenyl ether, 3-6% of sodium tripolyphosphate, 0.5-1.0% of an antifoaming agent, and the balance of water. The preparation method of the flushing fluid comprises the following steps: preheating water; adding sodium tripolyphosphate, and stirring for 20-30min to fully dissolve sodium tripolyphosphate; and adding polyoxyethylene sorbitan fatty acid ester, fatty alcohol polyoxyethylene ether sodium sulfate and polyoxyethylene nonyl phenyl ether, stirring under 800-1200rmp for 80-100min, and adding the polysiloxane antifoaming agent. The polysiloxane antifoaming agent can resist acids, alkali and inorganic salts, and can promote the flushing effect of the flushing fluid; the flushing fluid can be used in a temperature range of 25-160DEG C, and has a good flushing effect; the flushing fluid has good compatibility with oil base mud and water mud; and the flushing fluid has good stability, and can adapt to high temperature, high salinity and other environments.

Owner:成都欧美克石油科技股份有限公司

Emulsion paraffin removing and inhibiting agent and preparation method thereof

InactiveCN104109517AImprove wax removal effectIt has the function of washing oil, reducing viscosity and preventing waxDrilling compositionPhenyl EthersSodium phosphates

The invention discloses an emulsion paraffin removing and inhibiting agent and a preparation method thereof, belonging to the technical field of oil exploitation. The emulsion paraffin removing and inhibiting agent comprises, by weight, 20 to 25 parts of polyoxyethylene nonyl phenyl ether, 8 to 13 parts of monoglycerol linoleate, 3 to 5 parts of Bacillus licheniformis, 6 to 9 parts of a methacrylic resin, 10 to 15 parts of triisopropanolamine, 30 to 40 parts of isopropanol, 20 to 40 parts of tert-butyl alcohol, 3 to 8 parts of sodium hexametaphosphate, 6 to 12 parts of lignin quaternary ammonium salt surfactant, 8 to 15 parts of 2,4-di(brominated-3-alkylimidazole)-1,3-propylene glycol, 0.5 to 1 part of a soda effervescent tablet, 5 to 10 parts of agarose and 150 to 200 parts of water. The preparation method is simple; and the prepared emulsion paraffin removing and preventing agent has a good paraffin removing effect, exerts certain oil washing, viscosity reducing and paraffin inhibiting effects and has the characteristics of less combustion and explosion proneness, low toxicity, high efficiency, low cost, etc.

Owner:青岛蓬勃石油技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com