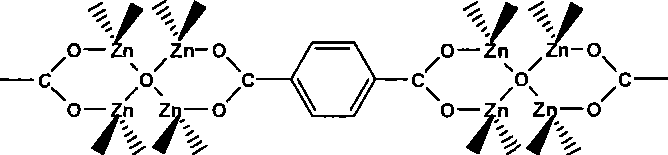

Catalytic system for synthesizing annular carbonic acid ester

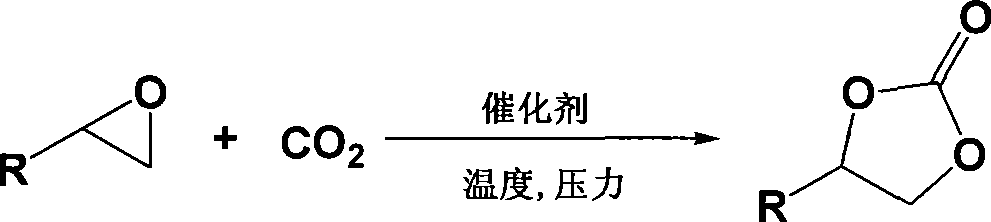

A technology of cyclic carbonates and catalytic systems, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve catalyst synthesis difficulties, low catalytic activity, and reaction requirements Problems such as high temperature and high pressure, to achieve the effect of strong industrial application value, high catalytic activity, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

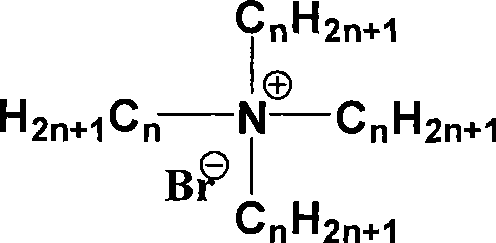

[0021] In a 25 ml autoclave, add 0.1 g of MOF-5, 0.161 g of tetrabutylammonium bromide and 1.16 g of propylene oxide in sequence, seal the autoclave and place it in a heating furnace at 50°C until the temperature is balanced Charge carbon dioxide to 6MPa in the reaction kettle afterwards, after stirring and reacting for 4 hours, cooling, deflation, with n-butanol as internal standard, detect by gas chromatography, utilize conventional internal standard method to calculate, obtain the yield of propylene carbonate The rate is 98%.

Embodiment 2

[0023] Using exactly the same reaction conditions and detection methods as in Example 1, only changing the catalytic system to 0.1 g of MOF-5 and 0.133 g of tetrapropylammonium bromide, the yield of propylene carbonate was 60%.

Embodiment 3

[0025] Adopting the same reaction conditions and detection method as in Example 1, only changing the catalytic system to 0.1 gram of MOF-5 and 0.12 gram of tetrabutylammonium bromide, all the other are the same as in Example 1, and the yield of propylene carbonate is 94 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com