Patents

Literature

232 results about "Cyclohexene oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclohexene oxide is a cycloaliphatic epoxide. It can react in cationic polymerization to poly(cyclohexene oxide). As cyclohexene is monovalent, poly(cyclohexene oxide) is a thermoplastic.

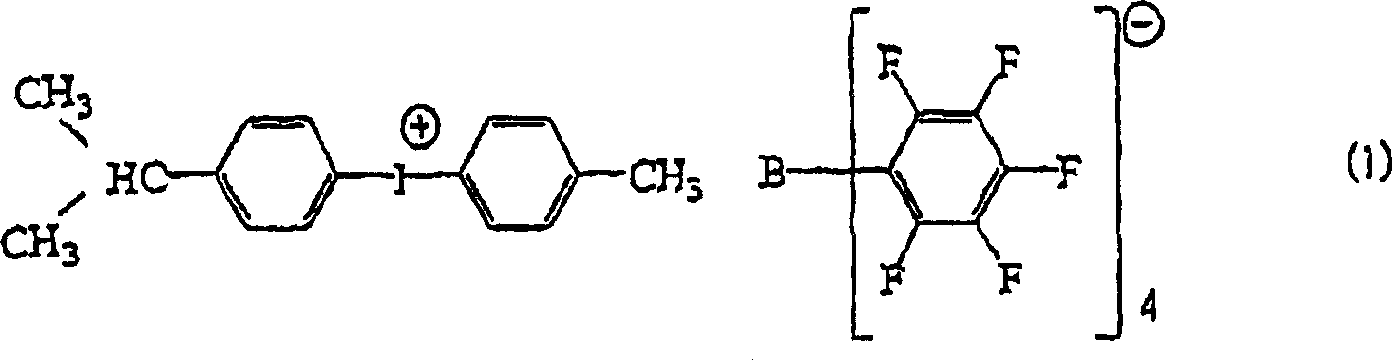

Photo-curable resin composition

A photo-curable resin composition capable of providing a three-dimensional object having excellent mechanical strength and high dimensional accuracy when used in a photo-fabrication process. The resin composition is also capable of providing a three-dimensional object with excellent stability in shape and properties in a photo-fabrication process. The photo-curable composition includes: (A) a compound represented by the formula (1) wherein R1 and R2 independently represent a hydrogen atom or a methyl group; (B) a compound having a cyclohexene oxide structure; (C) a cationic photo-initiator; (D) an ethylenically unsaturated monomer; (E) a radical photo-initiator; and (F) a polyol having three or more hydroxyl groups.

Owner:DSM IP ASSETS BV +2

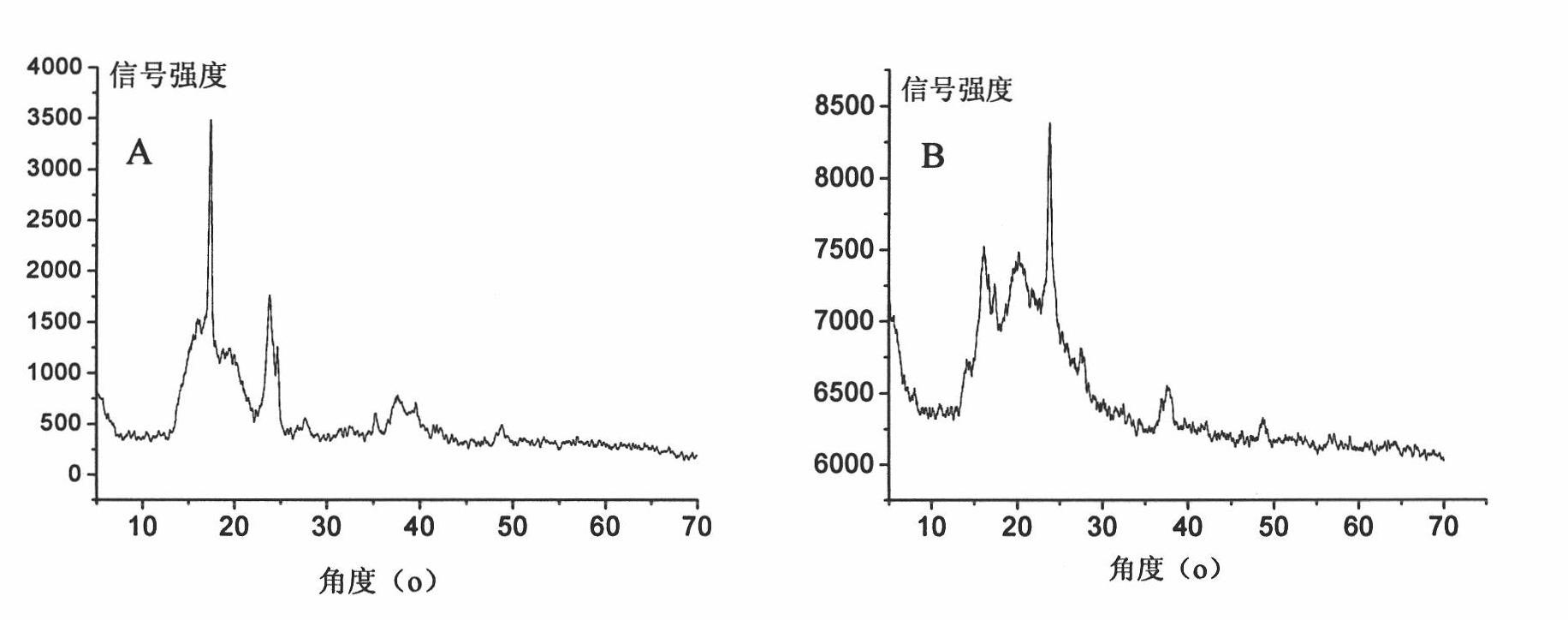

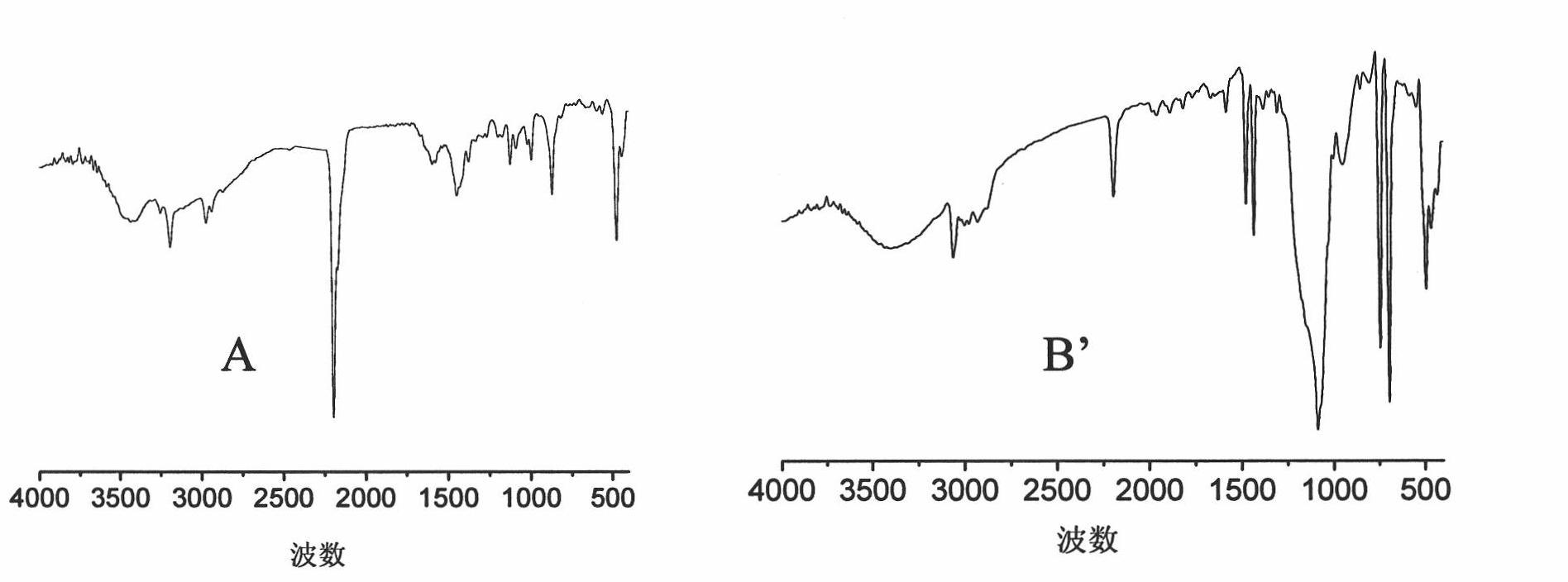

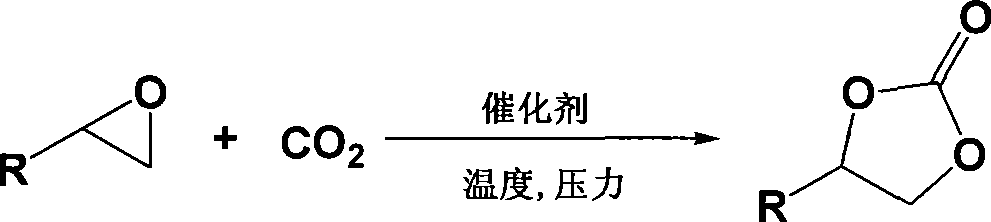

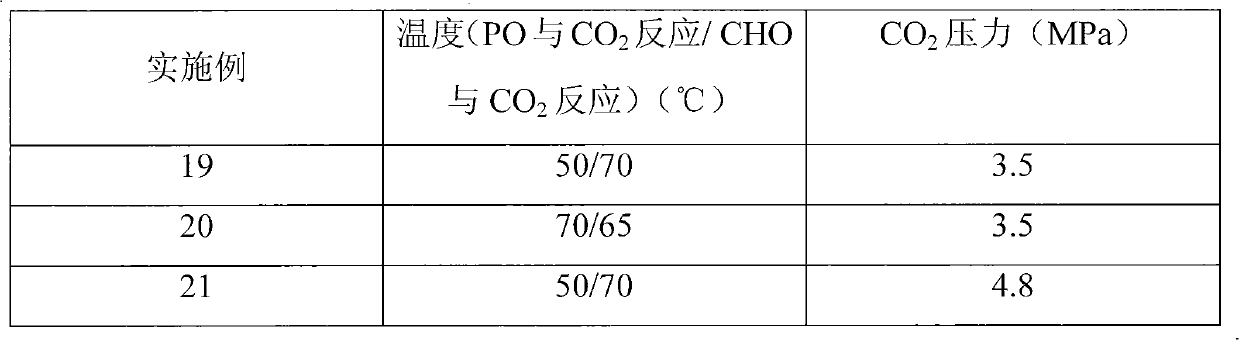

Method for preparing aliphatic polycarbonates by catalyzing by metal cyanide coordination catalyst

The invention discloses a method for preparing aliphatic polycarbonates by catalyzing by the metal cyanide coordination catalyst. In a high pressure reactor, the metal cyanide coordination catalyst is utilized to catalyze epoxide and carbon dioxide body or solution copolymerization, wherein, the copolymerization temperature is 20-150 DEG C; the carbon dioxide pressure is 0.5-10MPa; the reaction time is 1-48h; the catalyst concentration is 1-100kg epoxide / g catalyst; the polymerization activity is more than 1.0kg of polymer / g catalyst; the weight-average molecular weight of the copolymer is more than 80 thousand; the molecular weight distribution is 1.5-4; the alternation degree of the copolymer is more than 90%; the cyclic carbonate by-product is less than 5wt%; the CO2 fixed rate of CO2 / epoxypropane copolymer is more than 40wt%; and the CO2 fixed rate of CO2 / cyclohexene oxide copolymer is more than 30wt%.

Owner:ZHEJIANG UNIV

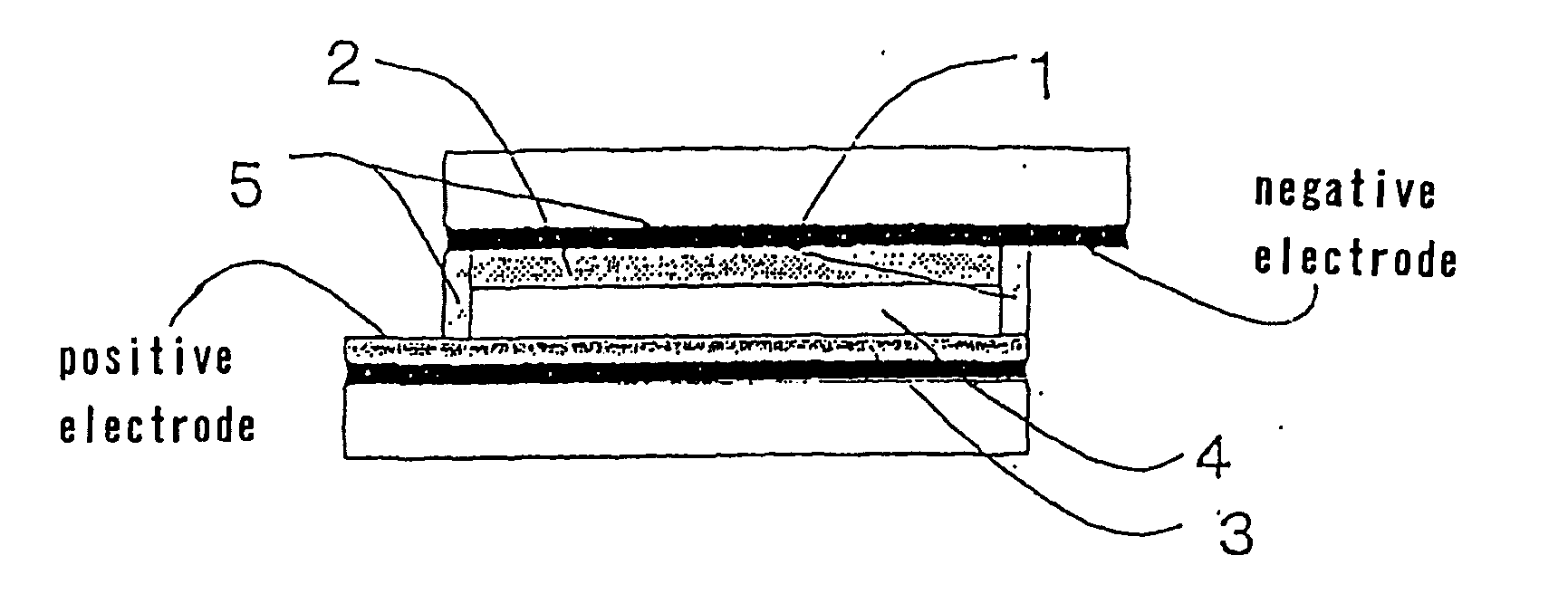

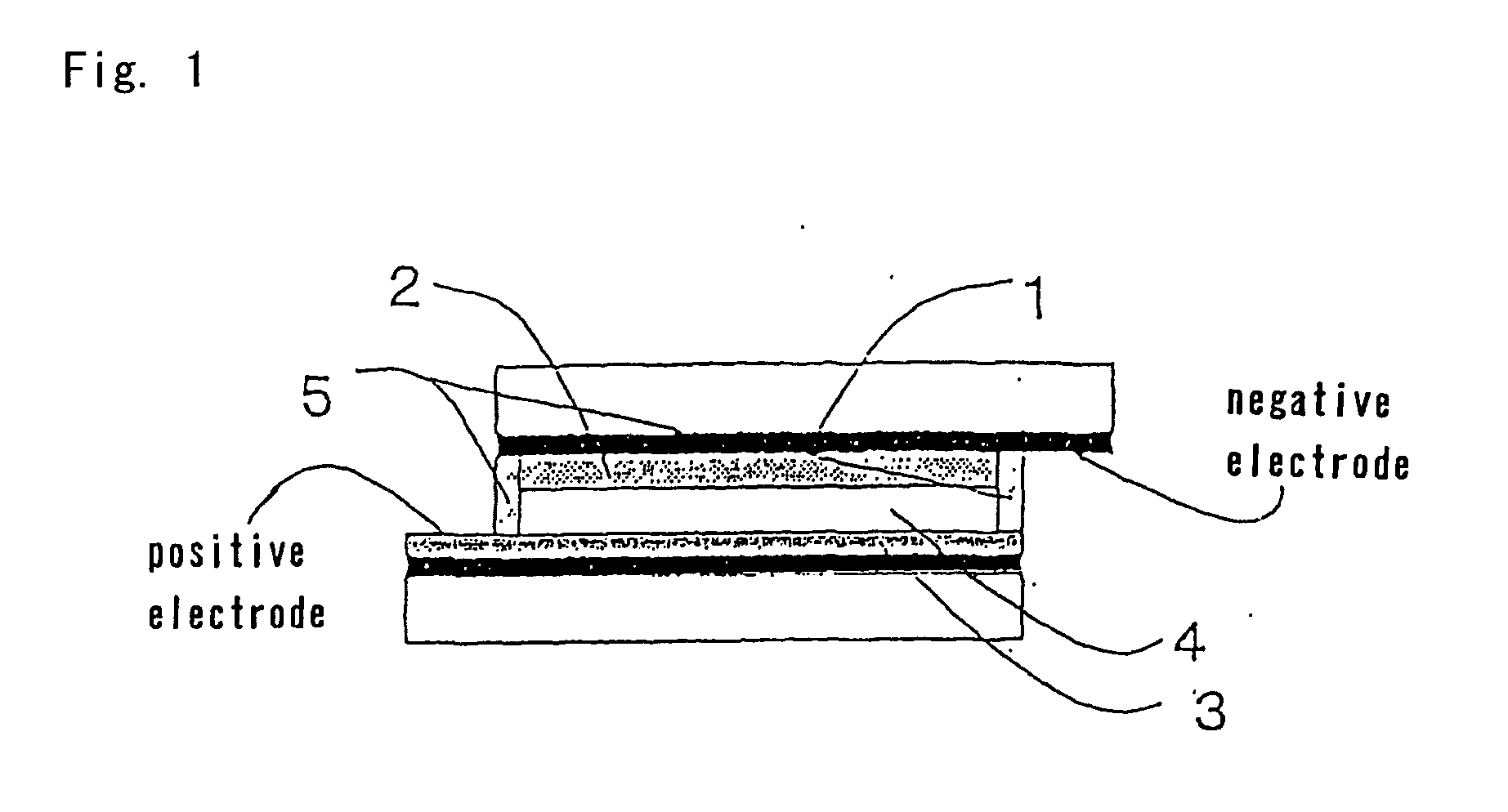

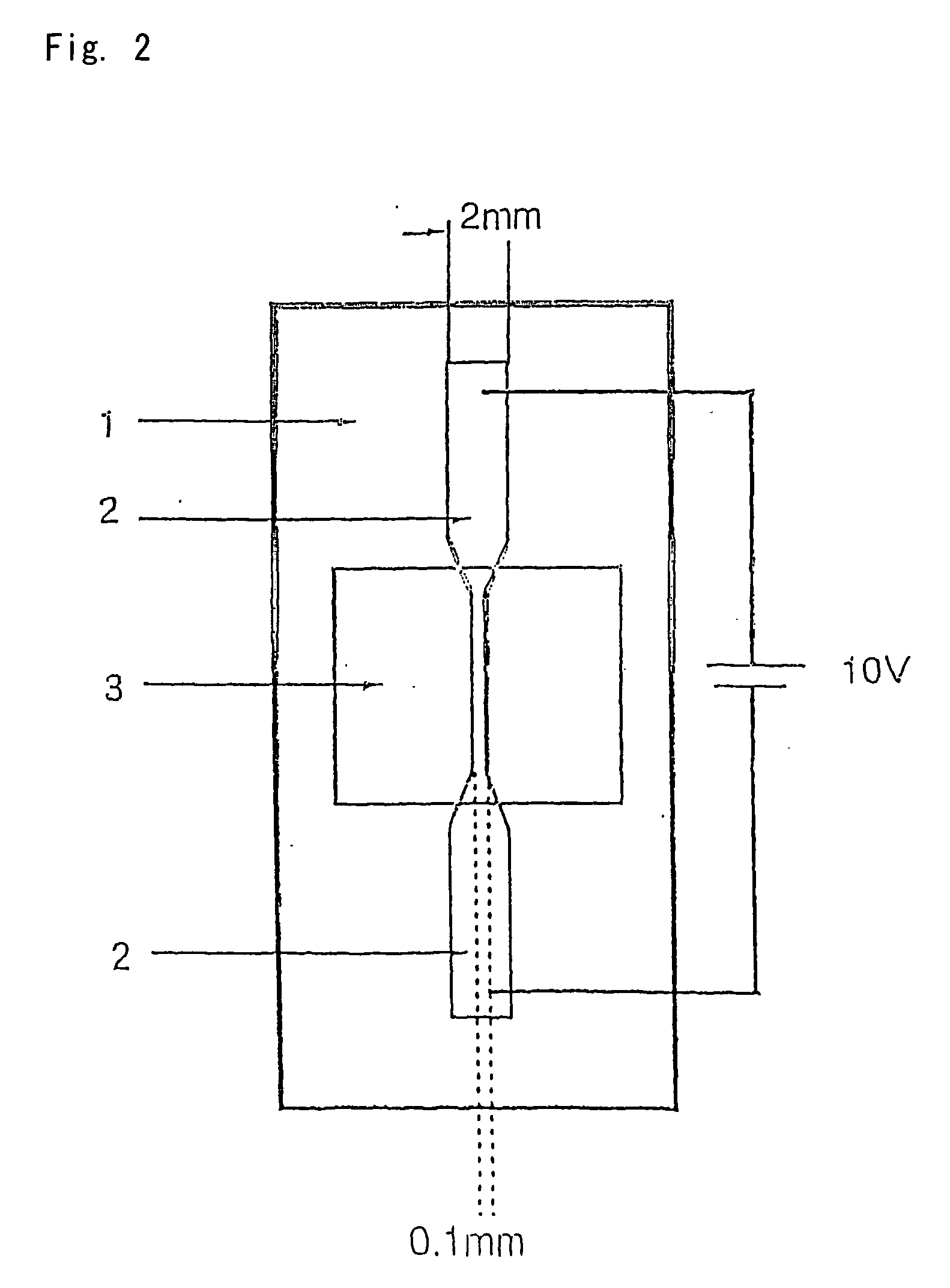

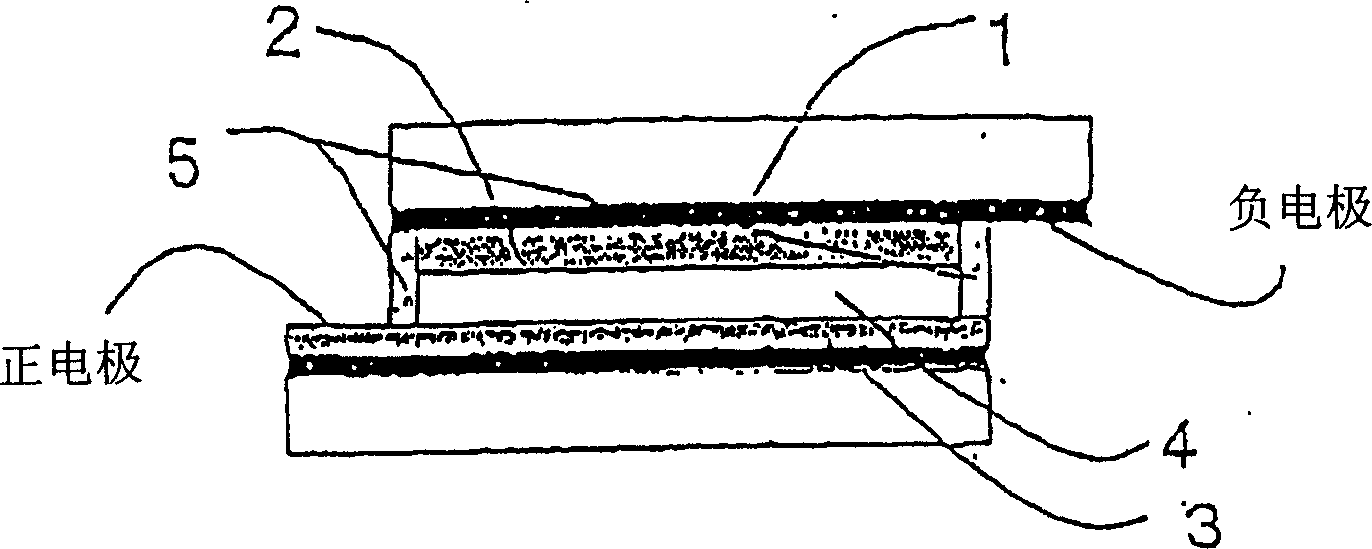

Sealing agent for photoelectric conversion element and photoelectric conversion device element using the same

InactiveUS20060162771A1Improve adhesion strengthReliable moisture resistanceLight-sensitive devicesFinal product manufactureVinyl etherCationic polymerization

A sealing agent for a photoelectric conversion device which comprises one or more of a compound having a glycidyl structure, a compound having a cyclohexene oxide structure, a compound having an oxetane structure and a compound having a vinyl ether structure, and a cationic polymerization initiator; a photoelectric conversion device using the sealing agent; and a solar cell comprising the photoelectric conversion device. The sealing agent for a photoelectric conversion device can be used for pasting together upper and lower electroconductive glass substrates at an ordinary temperature in the manufacture of a photoelectric conversion device, and is excellent with respect to adhesion strength and the reliability in moisture resistance.

Owner:NIPPON KAYAKU CO LTD

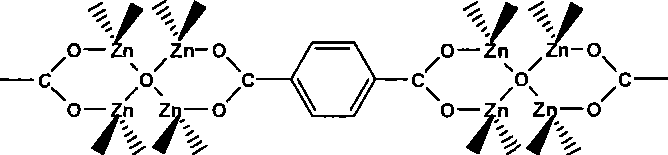

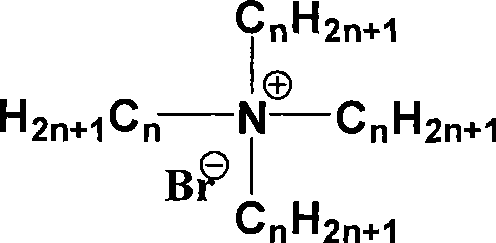

Catalytic system for synthesizing annular carbonic acid ester

InactiveCN101474576AHigh catalytic activityWide applicabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyStyrene oxide

The invention discloses a catalytic system used for synthesizing cyclic carbonate ester. The catalytic system comprises a catalyst with structural unit shown in formula I and quaternary ammonium salt shown in a general structure of formula II, wherein n is equal to 1-4 in the general structure of formula II. The catalytic system is suitable for catalyzing the reaction system in which carbon dioxide reacts with epoxy compound to synthesize the cyclic carbonate ester, in the reaction system, all the various epoxy compounds are applicable to the method, such as propylene oxide, epoxy chloropropane, styrene oxide, 2,3-glycidyl phenyl ether or cyclohexene oxide; the reaction temperature is 30-80 DEG C; the pressure of carbon dioxide is 2-12 MPa; and reaction time is 1-24 h. Compared with the conventional method, the catalytic system has the advantages of mild reaction condition, high recovery rate and high selectivity, and reuse of the major catalyst metal-organic coordination polymer (MOF-5) by simple filtration. Therefore, the catalytic system has strong industrial application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Full-biological degradation nonwoven cloth material

InactiveCN101220534AConjugated synthetic polymer artificial filamentsNon-woven fabricsEpoxyCyclohexene oxide

The invention relates to a total biodegradable non-woven fabric material which is produced by adding 10 to 40 percent of low molecular weight carbon dioxide-cyclohexene oxide copolymer or 10 to 40 percent of high molecular weight poly L-polylactic acid or 10 to 40 percent of poly-hydroxylic butyrate to biodegradable carbon dioxide-propylene oxide or carbon dioxide-epoxy ethane copolymer materials, thus improving the dimensional stability of the carbon dioxide copolymer under high temperature. The number average molecular weight of the carbon dioxide-cyclohexene oxide copolymer is between 4000 and 8000 and the number average molecular weight of the poly L-polylactic acid is above 100,000. By using the carbon dioxide copolymer material of the invention, manufacture can be carried out by adopting a spun-bond method which is commonly used in non-woven fabric manufacturing technique. The obtained non-woven fabrics can maintain dimensional stability at the temperature between 70 DEG C and 75 DEG C, have biodegradation characteristics under the situation of composts or landfill with carbon dioxide and water as degradation end products, and cannot pollute environment when being burnt.

Owner:吉林金源北方科技发展有限公司

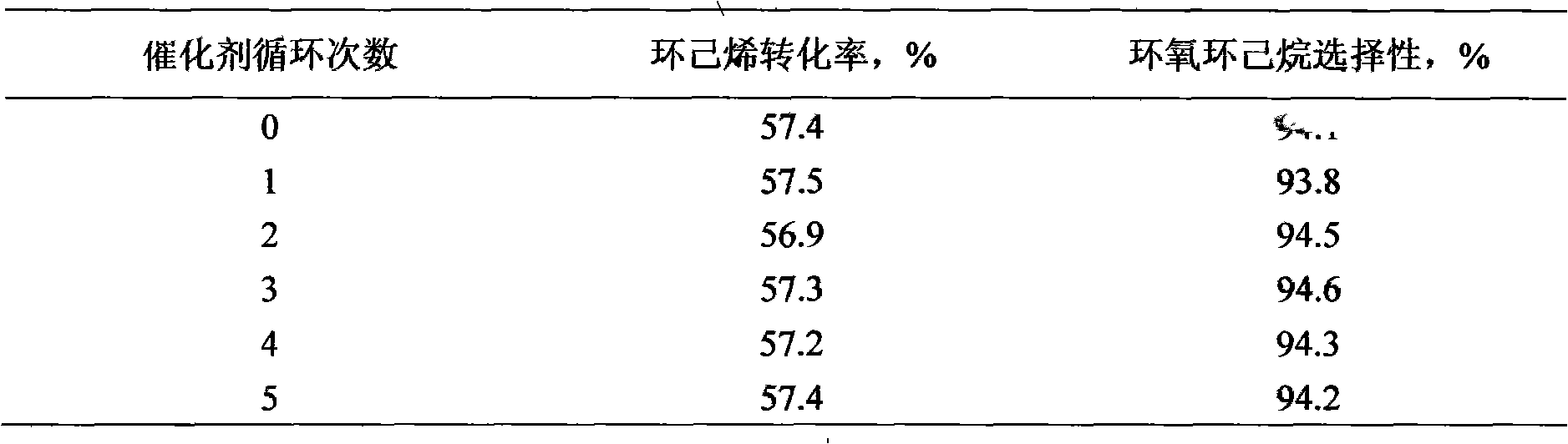

Method for synthesis epoxy cyclohexane with titanium molecular sieve catalysis

InactiveCN101343260AHigh catalytic activityHigh selectivityOrganic chemistryChemical recyclingEpoxyMolecular sieve

The invention relates to a method for using a titanium silicate molecular sieve to catalytically synthesize cyclohexene oxide, which is characterized in that: cyclohexene and peroxide are taken as raw materials, the titanium silicate molecular sieve serves as a catalyst for catalysis and epoxidation, and the cyclohexene oxide is generated through the reaction with high selectivity; and the catalyst and a solvent used in the reaction can be recycled. The method has advantages of low production cost, environmental friendship and reasonable preparing route, and is suitable for the industrialized production of cyclohexene oxide.

Owner:YUEYANG CHANGDE CHEM IND

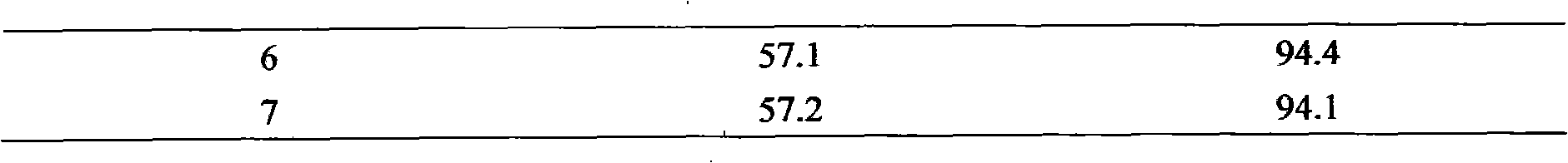

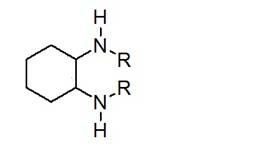

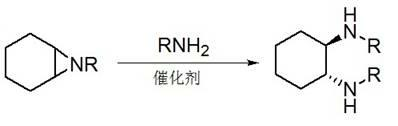

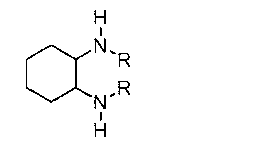

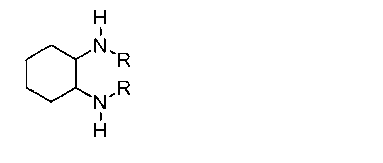

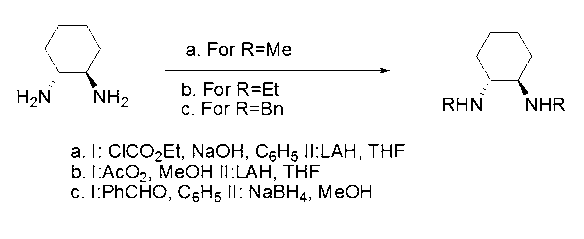

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

InactiveCN102531918ASimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

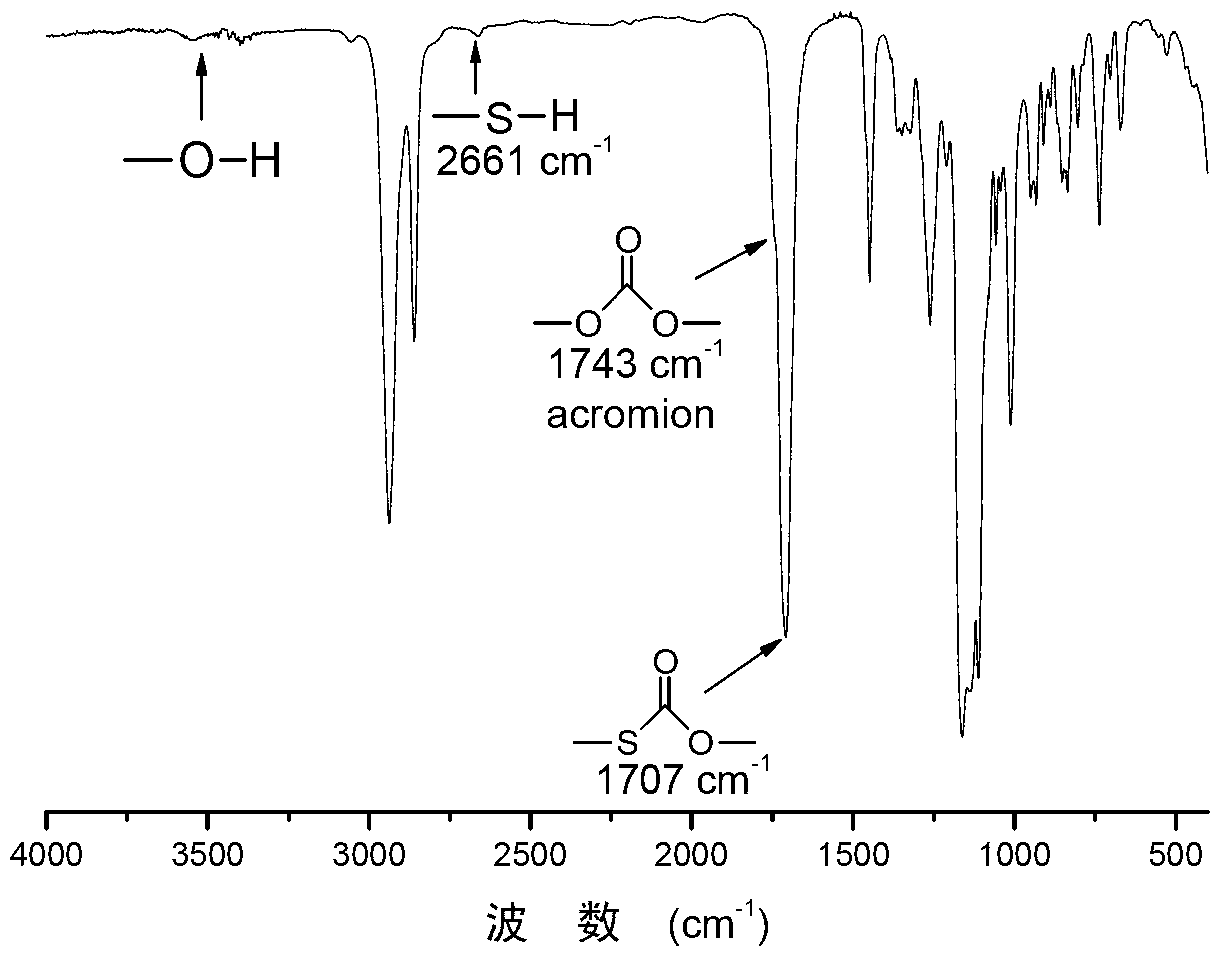

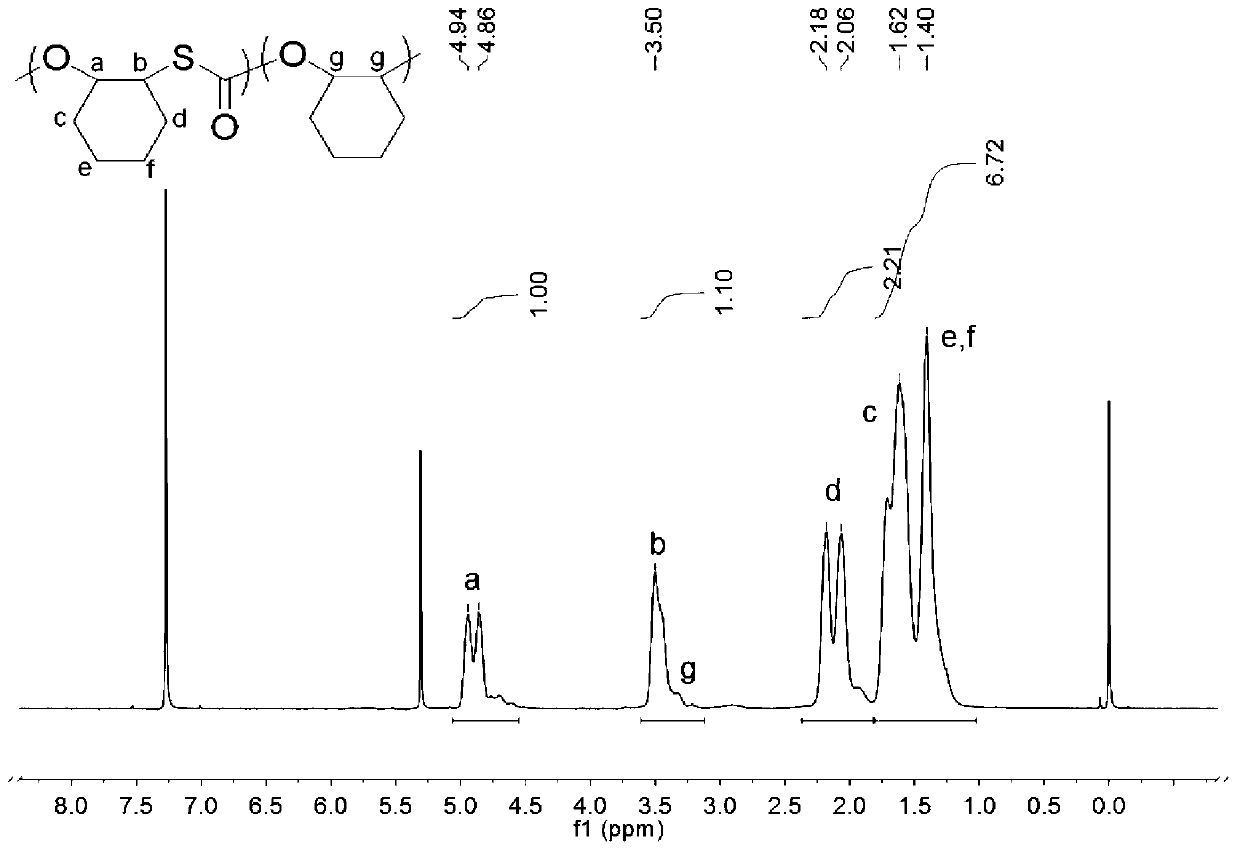

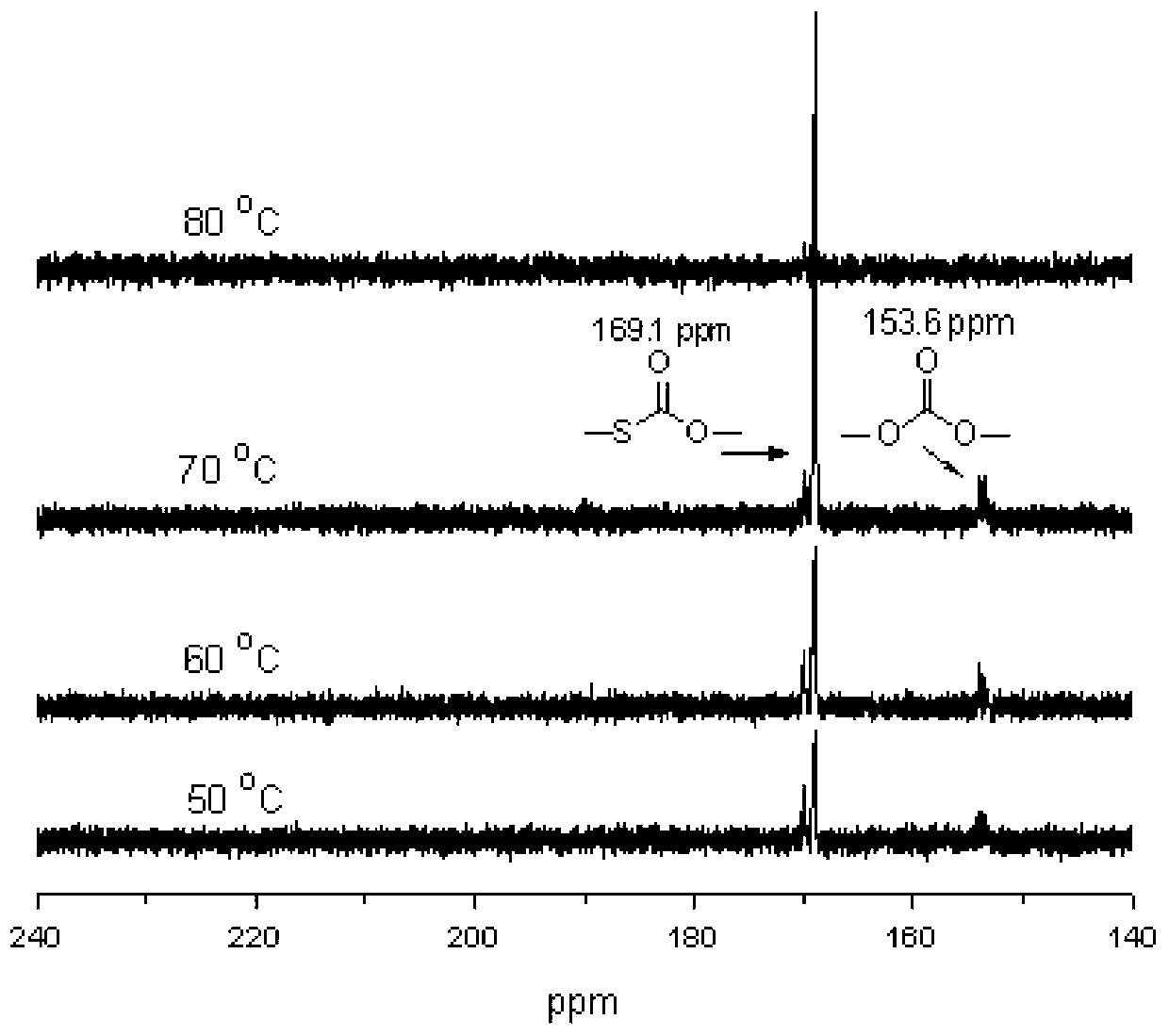

Polythiocarbonate and preparation method thereof

The invention relates to the field of high molecular material synthesis and aims at providing polythiocarbonate and a preparation method thereof. The preparation method comprises the following steps of: adding an epoxide, carbon oxysulfide and a catalyst into a dry high-pressure reaction kettle, carrying out reaction for 1-12 hours at 20-150 DEG C and self-generated pressure, purifying the generated product and drying the generated product to obtain a polythiocarbonate product, wherein the catalyst is a zinc-cobalt double-metal cyanide complex or a silicon dioxide loaded zinc-cobalt double-metal cyanide complex. The polythiocarbonate provided by the invention has wide purposes, the refractive index of the polymerized product is obviously higher than that of a general polymer, such as a COS (Carbon Oxysulfide)-cyclohexene oxide copolymer, and is 1.66, and therefore the polythiocarbonate has potential use in the aspect of a light-guide fiber.

Owner:ZHEJIANG UNIV

Method for oxidation synthesis of adipic acid by epoxy cyclohexane

InactiveCN101177390AOrganic compound preparationCarboxylic compound preparationEpoxyCyclohexene oxide

The invention relates to a method for synthesizing adipate using cyclohexene oxide through oxidation, which uses the tungsten and molybdenum polyoxometalates as the catalyst, and the hydrogen peroxide solution as the oxidant to catalyze the oxidation of the cyclohexene oxide to synthesize the adipate. The invention is characterized in that the organic solvent is no longer used as the reacting medium, so as to avoid the environment pollution caused by using the nitric acid as the oxidant. The reacting temperature is 60 to 105 DEG C; the reacting time is 6 to 20 hours and the adipate yield can reach 46.9% to 83.2%.

Owner:JIANGSU UNIV

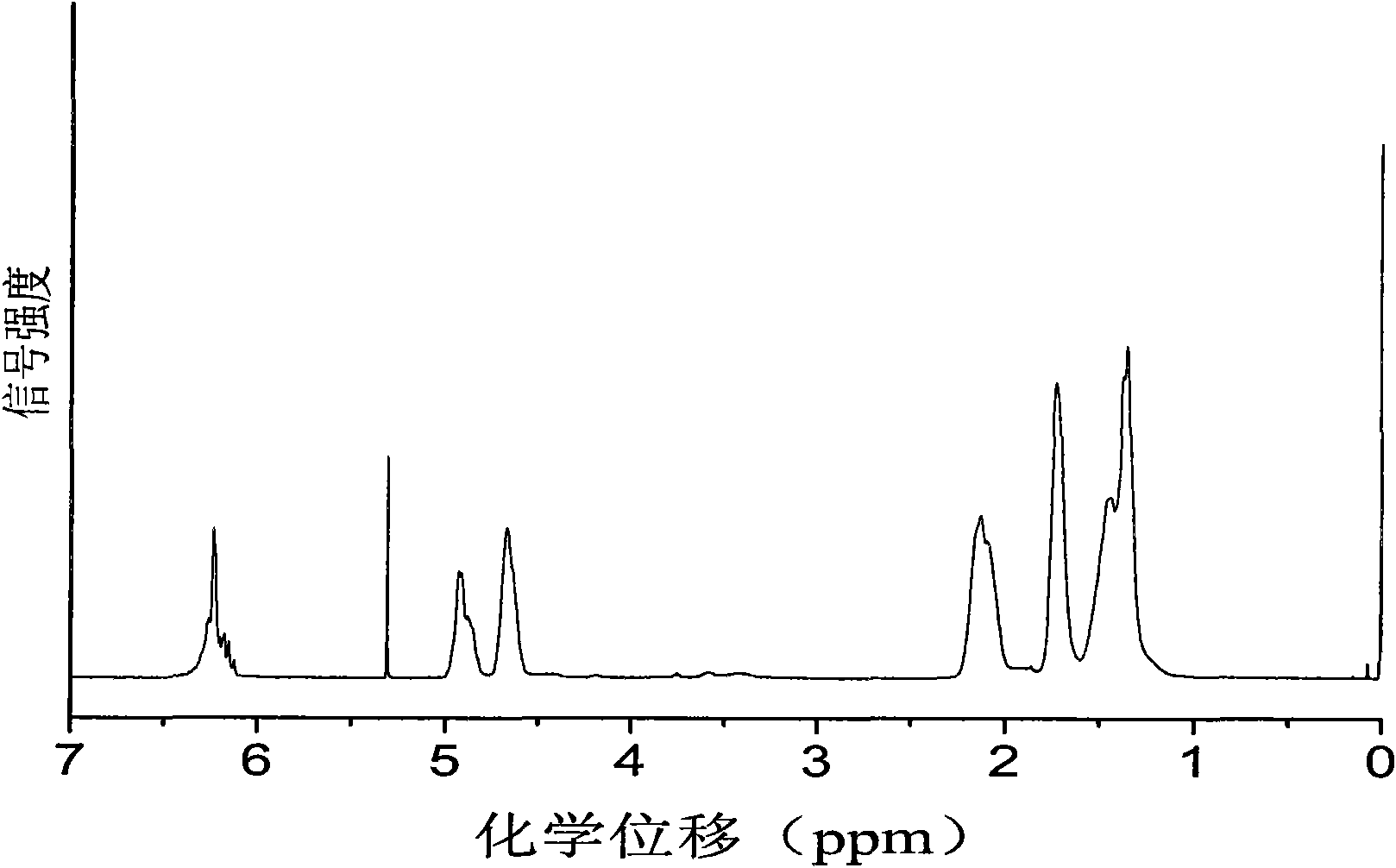

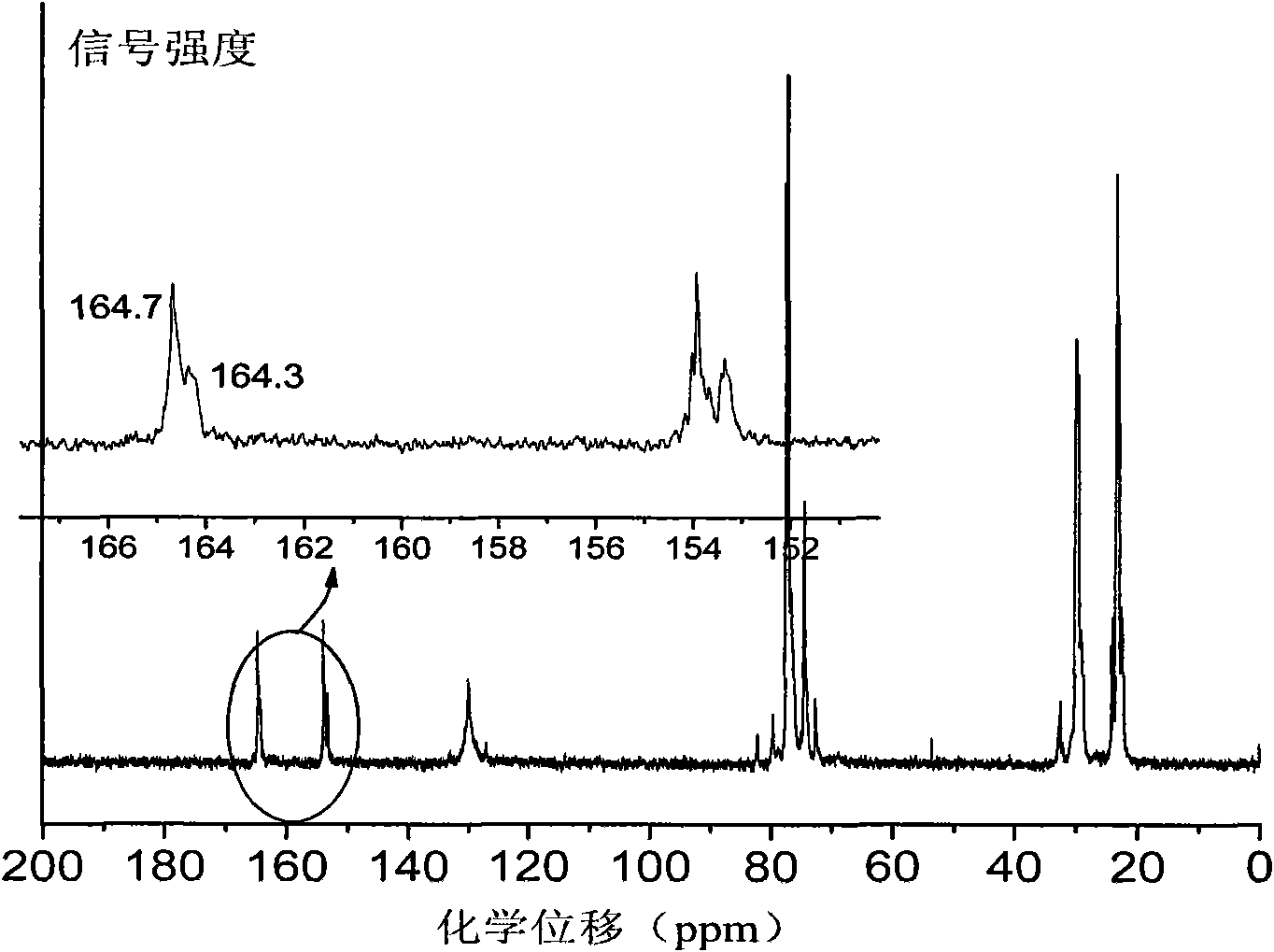

Terpolymer containing polyester chain links and polycarbonate chain links and synthetic method thereof

The invention discloses a terpolymer containing polyester chain links and polycarbonate chain links and a synthetic method thereof. The synthetic method comprises the following steps: mixing zinc-cobalt double metal cyanide complex catalyst, cyclohexene oxide and dicarboxylic anhydride in a solvent, introducing CO2 under the temperature of 30 to 150 DEG C till the pressure of CO2 is 0.5 to 10.0MPa, carrying out copolyreaction for 0.5 to 48 hours so as to obtain a crude product, and preparing the terpolymer which contains polyester chain links and polycarbonate chain links and has excellent thermal property and easy decomposition after purification. The molar percentage content of the polyester chain links, the polycarbonate chain links and polyether chain links of the terpolymer containing polyester chain links and polycarbonate chain links in the main chain are respectively 5 to 70 percent, 23 to 90 percent and 0.5 to 7 percent.

Owner:ZHEJIANG UNIV

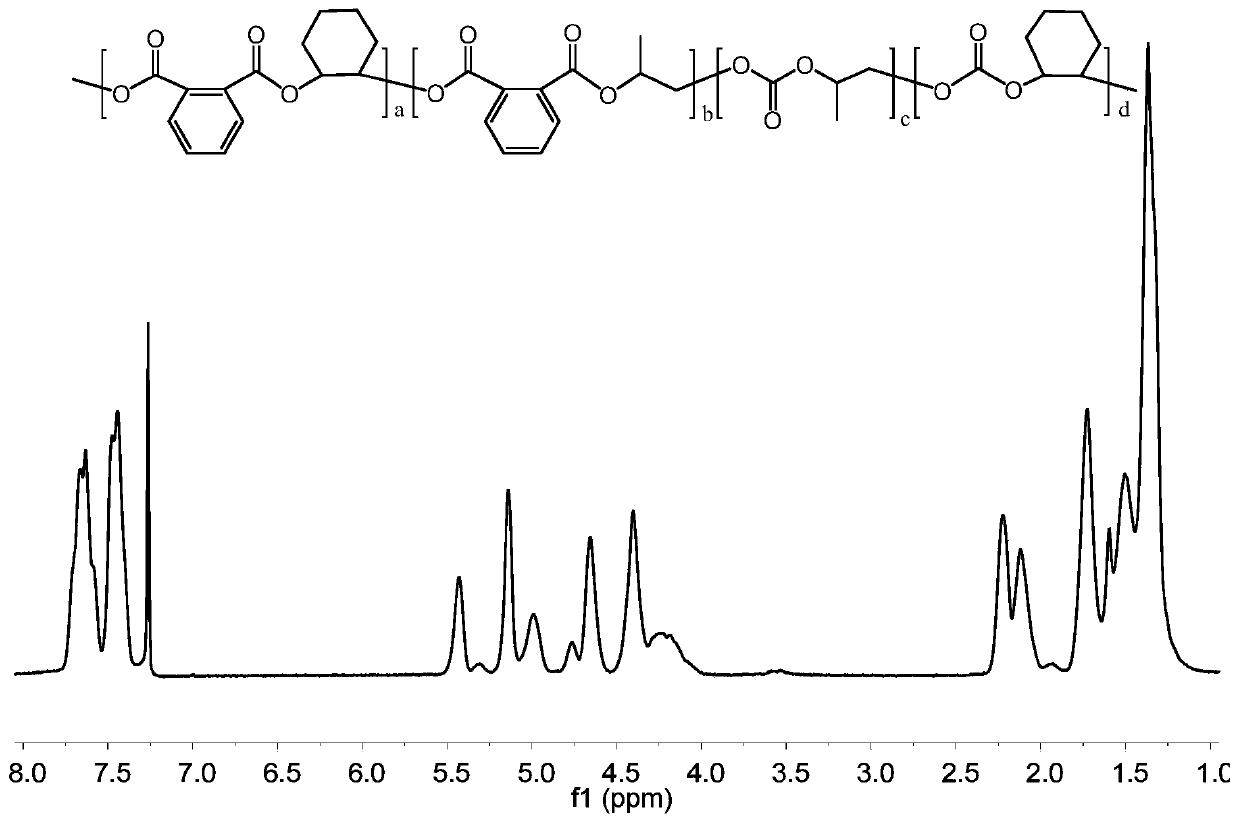

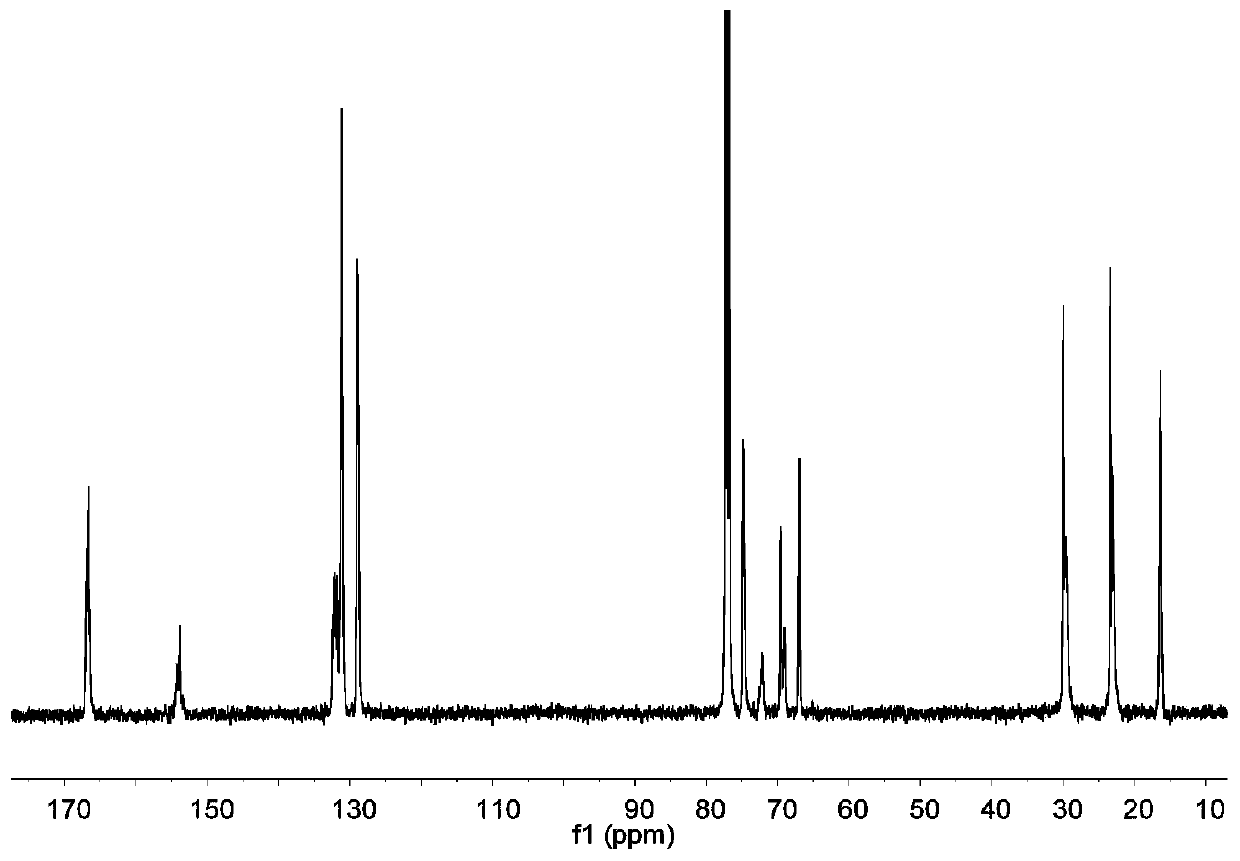

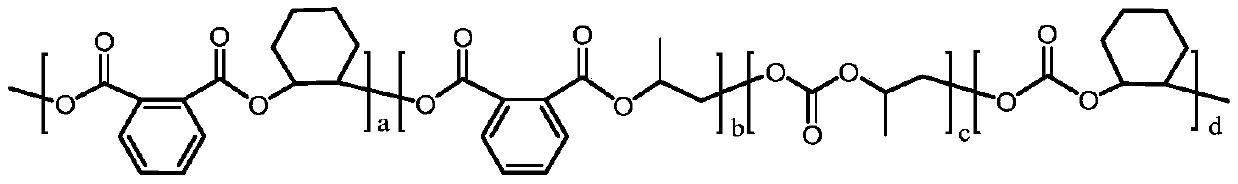

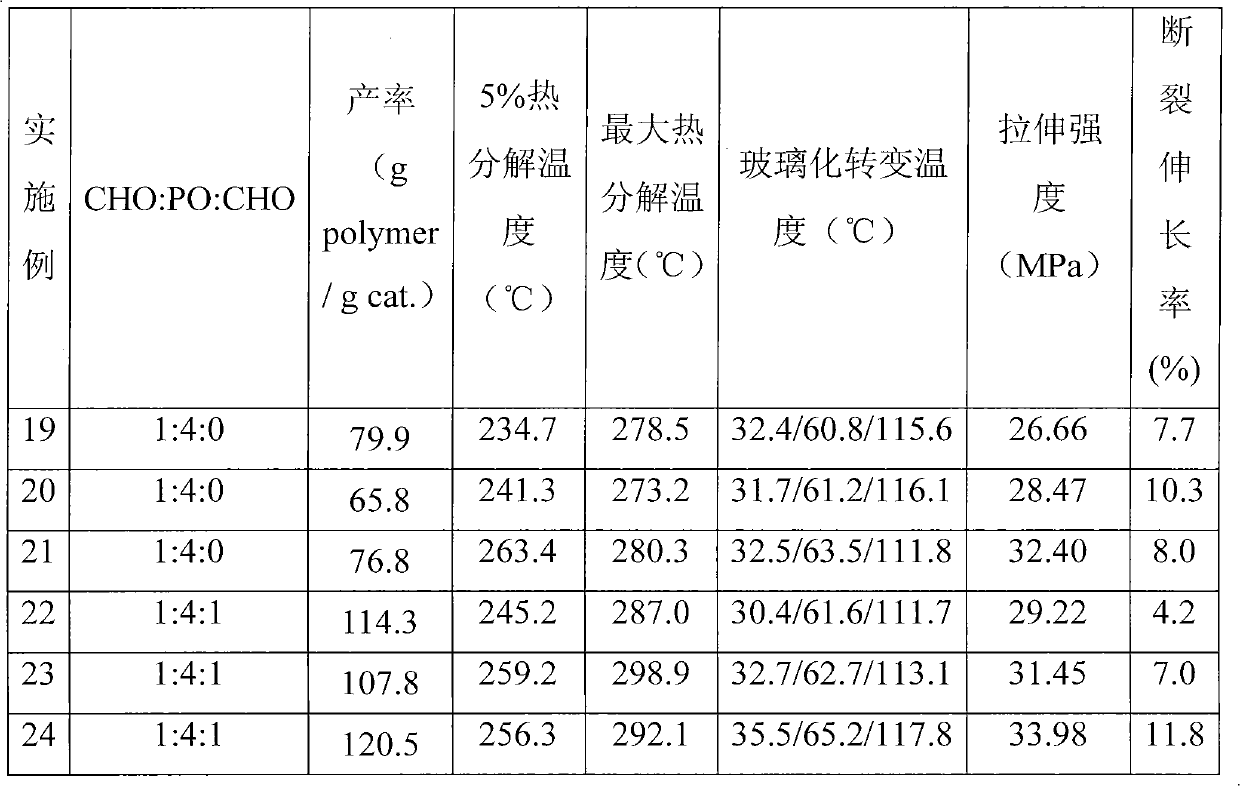

Preparation method of carbon-dioxide-based polyester-polycarbonate quadriblock copolymer

PendingCN111333825ASolve residual problemsHigh glass transition temperaturePolymer sciencePtru catalyst

The invention relates to the technical field of polymer material synthesis, particularly to a preparation method of a carbon-dioxide-based biodegradable polyester-polycarbonate quadriblock copolymer.The block copolymer comprises a diblock copolymer (A-B type); the chain segment A is polycarbonate obtained by ring-opening polymerization of epoxypropane, cyclohexene oxide and CO2, and the chain segment B is aromatic polyester obtained by ring-opening polymerization of epoxypropane, cyclohexene oxide and phthalic anhydride. Commercialized Lewis acid-base pairs are used as catalysts; phthalic anhydride and cyclohexene oxide are successfully introduced into a main chain of polymethyl ethylene carbonate (PPC) through a one-pot one-step method, so that the glass-transition temperature, the thermal stability and the tensile strength of the PPC are greatly improved; and a problem of metal catalyst residues in the prior art is solved, and the application range of the PPC material is expanded.

Owner:SUN YAT SEN UNIV

Sealing agent for photoelectric conversion element and photoelectric conversion element using the same

InactiveCN1751410AReduce pollutionImprove adhesion strengthLight-sensitive devicesOther chemical processesVinyl etherCationic polymerization

A sealing agent for a photoelectric conversion element which comprises one or more of a compound having a glycidyl structure, a compound having a cyclohexene oxide structure, a compound having an oxetane structure and a compound having a vinyl ether structure, and a cationic polymerization initiator; a photoelectric conversion element using the sealing agent; and a solar cell comprising the photoelectric conversion element. The sealing agent for a photoelectric conversion element can be used for pasting together upper and lower electroconductive glass substrates at an ordinary temperature in the manufacture of a photoelectric conversion element, and is excellent with respect to adhesion strength and the reliability in moisture resistance.

Owner:NIPPON KAYAKU CO LTD

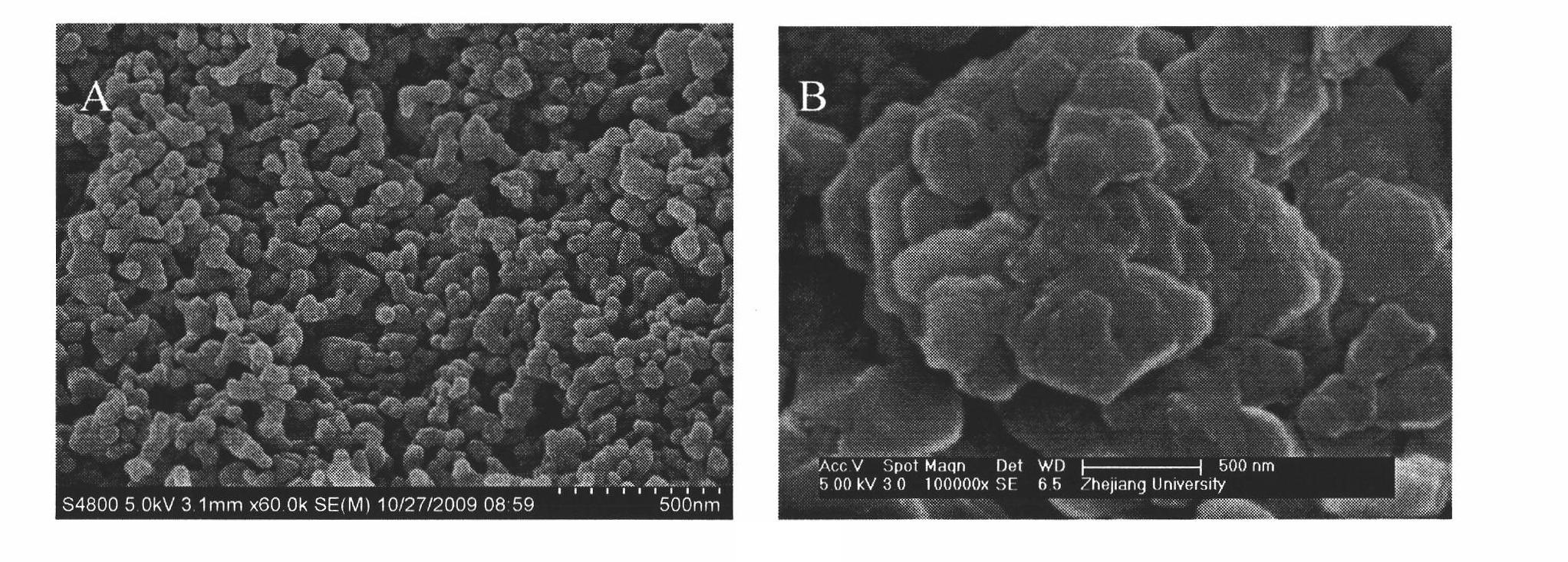

Hierarchical-pore titanium silicon molecular sieve catalyst synthesized with assistance of aerosol and preparation method of hierarchical-pore titanium silicon molecular sieve catalyst

InactiveCN103418432AThe preparation process is simple and continuousShort synthesis cycleMolecular sieve catalystsOxygen compounds preparation by hydrocarbon oxidationMolecular sieveCyclohexenone

The invention discloses a hierarchical-pore titanium silicon molecular sieve catalyst synthesized with the assistance of an aerosol and a preparation method of titanium silicon molecular sieve catalyst, and the titanium silicon molecular sieve catalyst is applied to the catalytic oxidation reaction of cyclohexene. The silicon molecular sieve catalyst is a hierarchical-pore titanium silicon molecular sieve synthesized through an aerosol method, is spherical, contains TS-1 nanometer crystals with MFI micropore structures, and is covered with a porous titanium silicon material. The catalyst can adopt hydrogen peroxide as an oxidant to perform catalytic oxidation on the cyclohexene to synthesize cyclohexene oxide, cyclohexanediol, cyclohexenone and cyclohexanol. The titanium silicon molecular sieve catalyst has the advantages that the preparation process is simple and continuous, the synthesis period is short, the atom utilization ratio is high, the titanium distribution is uniform, and the reaction can be magnified according to a certain ratio. The titanium silicon molecular sieve catalyst provided by the invention has the characteristics of mild reaction conditions, high activity and selectivity, small using amount, and easy recycling.

Owner:DALIAN UNIV OF TECH

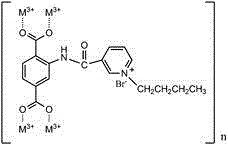

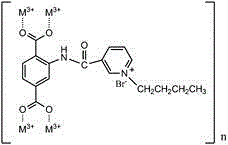

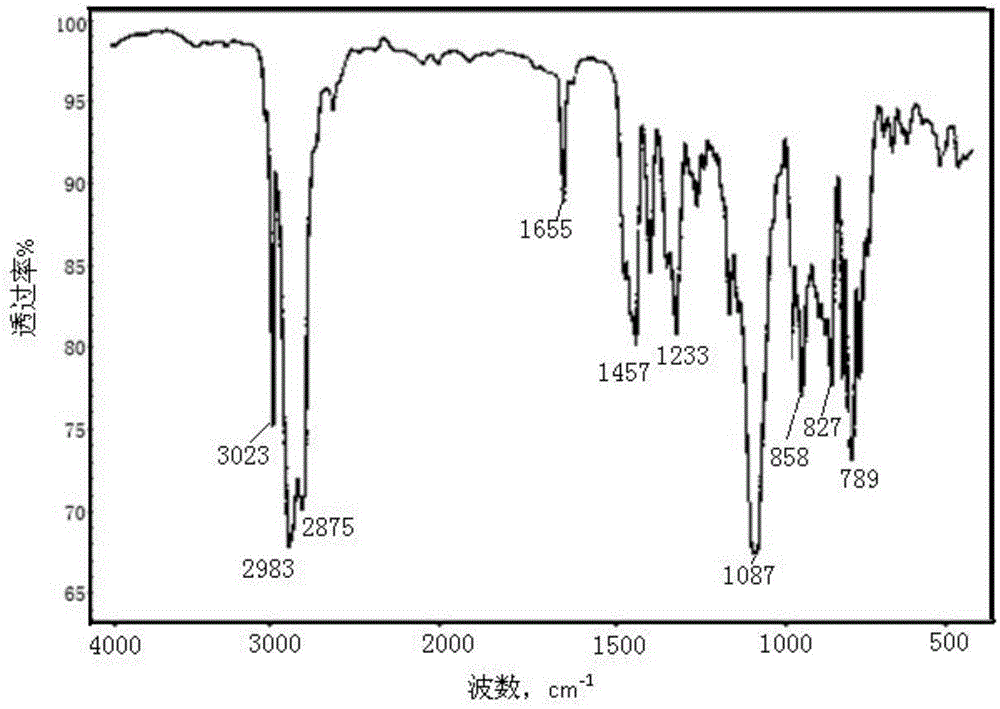

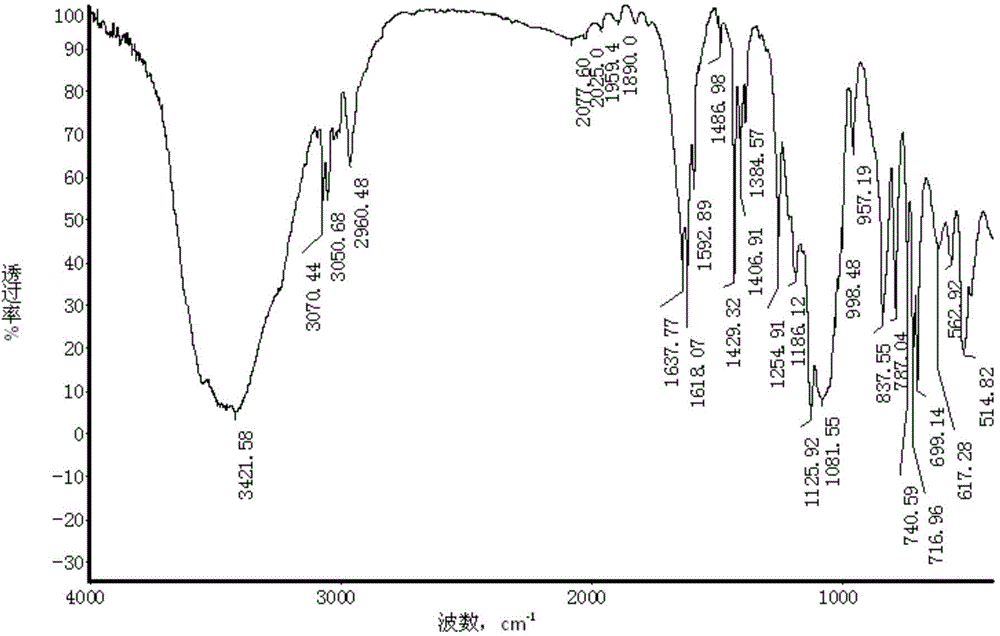

Method for catalyzed synthesis of cyclic carbonate through functional metal organic frame material

InactiveCN105481821ALarge specific surface areaHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureCyclohexene oxide

The invention provides a method for catalyzed synthesis of cyclic carbonate through a functional metal organic frame material. According to the method, carbon dioxide and epoxide are taken as raw materials, cyclic carbonate is obtained through synthesis under the catalytic action of the functional metal organic frame material, and the functional metal organic frame material is pyridine type ionic liquid modified NH2-mil-101; the epoxide is epoxypropane, epichlorohydrin, phenylethylene oxide or cyclohexene oxide, preferably, the mass ratio of the functional metal organic frame material to the epoxide is (1:20)-(1:200), the pressure of carbon dioxide is 0.5-5 MPa, the reaction temperature is 50-150 DEG C, and the reaction time is 0.5-5 h. According to the method, the reaction conditions are mild, soluble aids or organic solvents are not required to be added, the product yield is high, a product and a catalyst can be separated in a centrifugal or filtering manner, the process is simple, the energy consumption is low, and the reusability of the catalyst is good.

Owner:SHAOYANG UNIV

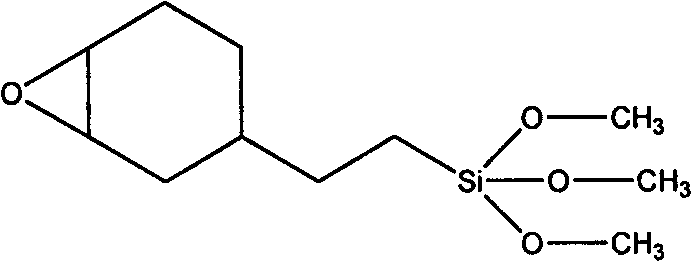

Organic silicon hydrogen-containing tackifying crosslinking agent for addition type silicon rubber and preparation method thereof

InactiveCN108384014ASimple preparation processMild reaction conditionsCyclohexene oxideRefractive index

The invention belongs to the technical field of a tackifying crosslinking agent, and particularly relates to an organic silicon hydrogen-containing tackifying crosslinking agent for addition type silicon rubber and a preparation method thereof. The tackifying crosslinking agent is prepared by performing addition reaction on high-hydrogen-content silicon oil or D4H and vinyl cyclohexene oxide or allyl glycidyl ether and then adding inhibitors. The process is simple; the reaction conditions are mild; the therepeatability and the controllability are good; the impurities in the reaction process are few; organic solvents are not used; the environment is protected; no pollution is caused. The obtained tackifying crosslinking agent has the stable performance; the tackifying and crosslinking effects can be achieved at the same time. The compatibility with silicon rubber is good; no catalyst poisoning phenomenon exists; the bonding performance of the addition type silicon rubber with metal suchas copper foil can be obviously improved; in addition, the refractive index of the organic silicon hydrogen-containing tackifying crosslinking agent is adjustable and controllable in a range of 1.40to 1.55, so that the tackifying crosslinking agent is applicable to the silicon rubber with (high and low) different refractive indexes.

Owner:SOUTH CHINA UNIV OF TECH

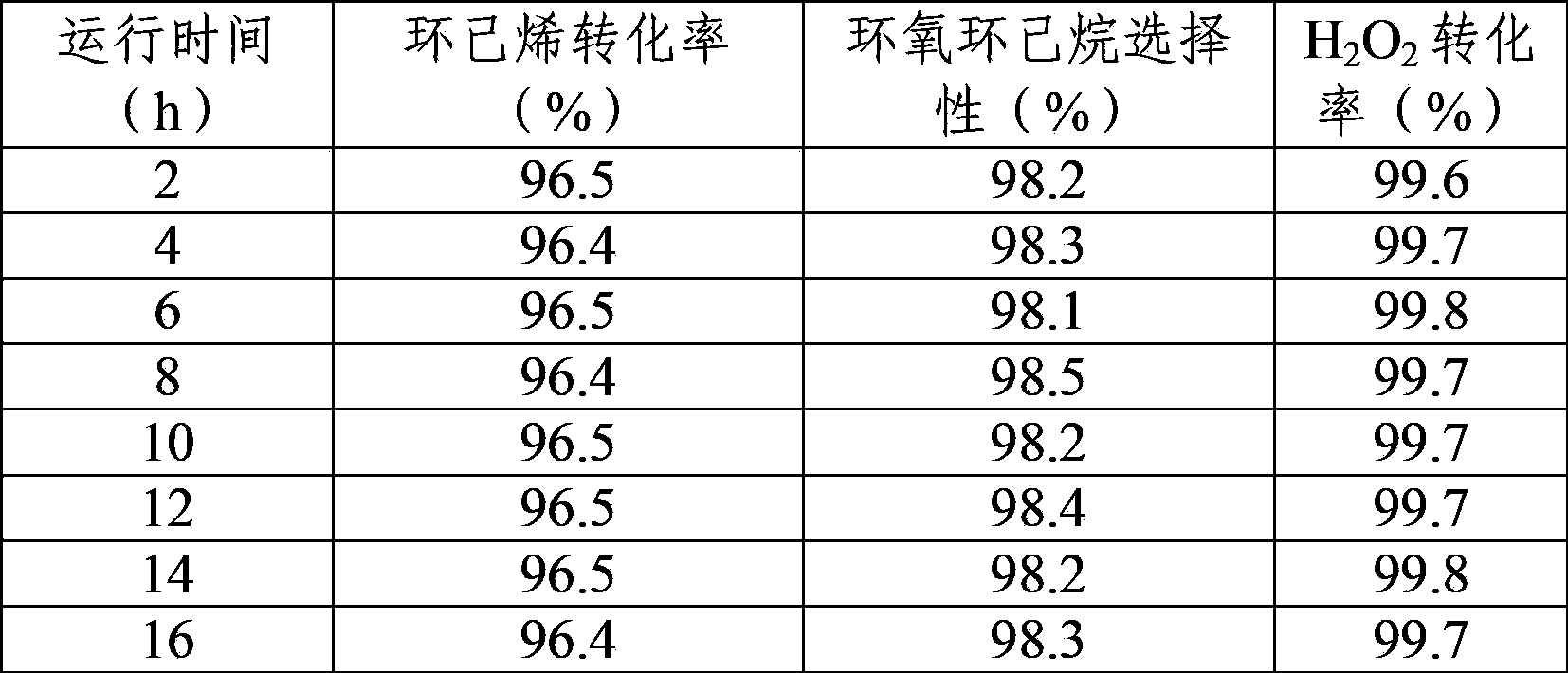

Method for preparing cyclohexene oxide through hydrogen peroxide epoxidation

InactiveCN101613330AReduce hydrolysisHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDistillationCyclohexene oxide

The invention relates to a method for preparing cyclohexene oxide by directly taking hydrogen peroxide as an oxygen source and adopting the heteropolyacid salt mixture with reaction-controlled phase transfer catalysis property to catalyze cyclohexene epoxidation. Cyclohexene reacts with hydrogen peroxide under the action of a reaction-controlled phase transfer catalyst; through the regulation of additives, the conversion rate of cyclohexene is greater than 96 percent; the selectivity of hydrogen peroxide to cyclohexene is greater than 98 percent; after reaction ends, the hydrogen peroxide is separated and purified through atmospheric distillation; and the catalyst can be separated and recycled after the reaction ends.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ring-opening reaction new method of process for reclaiming epoxy cyclohexane from light oil

ActiveCN101225077ASolve problems such as hydrolysis side reactionsOrganic chemistryBoiling pointReaction temperature

The invention relates to a new method of ring-opening reaction for recovering cyclohexene oxide from light oil, which mainly comprises the following steps: a. mixing cyclohexene oxide in light oil and hydrogen chloride for ring-opening reaction, enabling the cyclohexene oxide to be converted into 2-chlorocyclohexanol with high boiling point; b. adopting method of vacuum distillation or atmospheric distillation to separate the 2-chlorocyclohexanol with high boiling point from other components in light oil; c. mixing alkali and the collected 2-chlorocyclohexanol for ring-closing reaction after separation, and cyclohexene oxide is obtained through distillation. The new method of ring-opening reaction for recovering cyclohexene oxide from light oil is characterized in that in step a, the hydrogen chloride can either be liquid or gaseous; the molar ration of the cyclohexene oxide in light oil to the hydrogen chloride is 1:0.80 to 1.30; the reaction temperature is -20 to 130 DEG C.

Owner:昌德新材科技股份有限公司

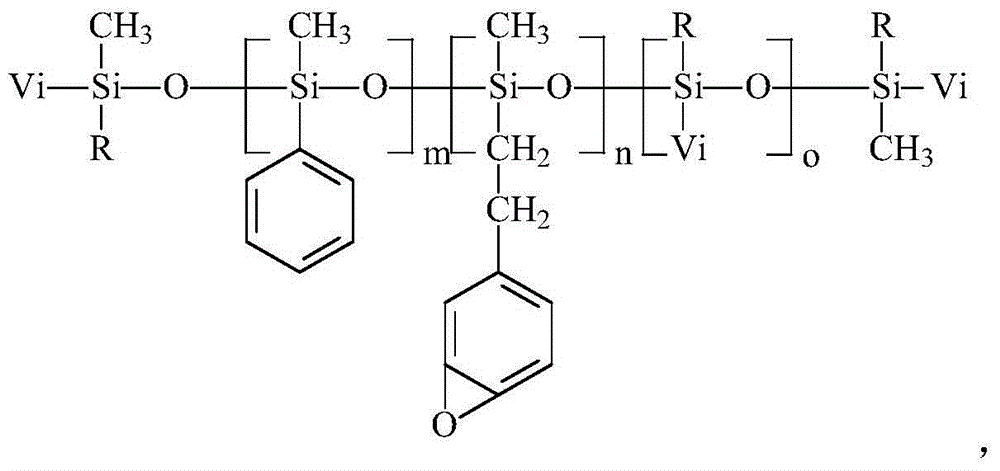

Vinyl phenyl silicon resin with side chain containing epoxy group and preparation method of vinyl phenyl silicon resin

The invention relates to vinyl phenyl silicon resin with a side chain containing an epoxy group, and the structural formula is as shown in the specification. The invention also discloses a preparation method of the vinyl phenyl silicon resin. The preparation method comprises the following steps: under nitrogen condition, adding 1,3,5,7-tetramethyl cyclotetrasiloxane and 4-vinyl cyclohexene oxide to a reaction container according to a proportion, adding a solvent, a catalyst and a polymerization inhibitor in parts by weight, increasing temperature to react, carrying out reduced pressure distillation to obtain a cyclotetrasiloxane containing cyclohexene oxide group, then adding cyclotetrasiloxane containing cyclohexene oxide group, vinyl cyclosiloxane, methyl phenyl cyclosiloxane and an end-capping reagent to the other reaction container according to a proportion, increasing temperature to react, and carrying out reduced pressure distillation to obtain vinyl phenyl silicon resin with a side chain containing an epoxy group. The preparation method is simple, flexible, moderate in reaction condition and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

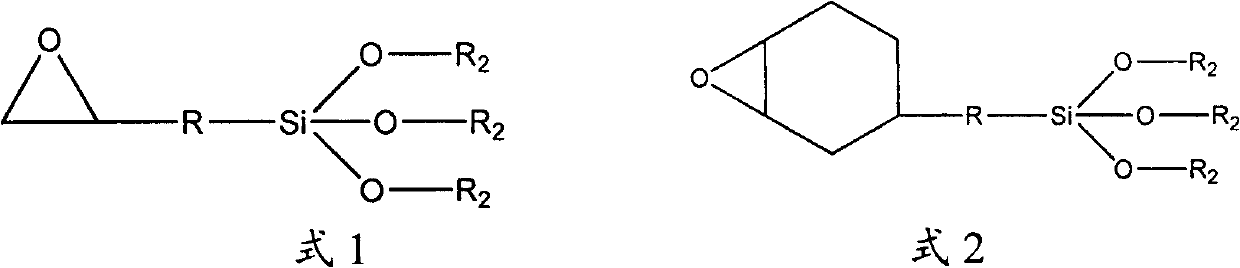

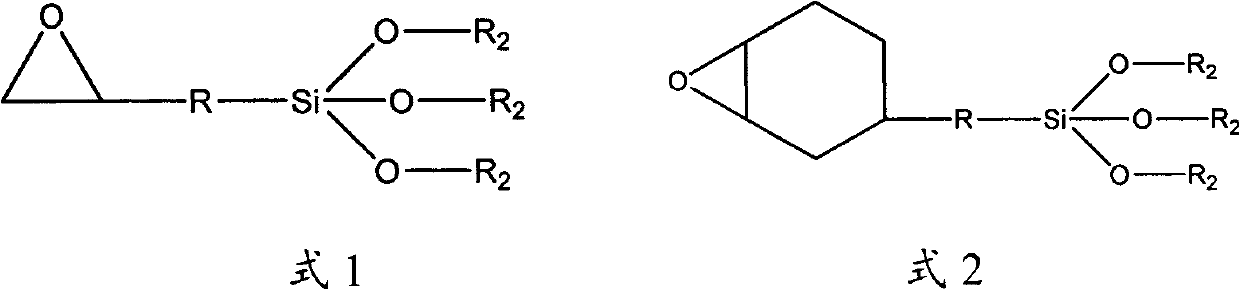

Preparation method of cross-linkable acetal copolymer

The invention discloses a preparation method of cross-linkable acetal copolymer. The preparation method is characterized in that: ternary polymerization of (a) trioxymethylene (TOX), (b) dioxolane (DXL) or cyclohexene oxide (CHO) and (c) a triethoxysilane compound with an epoxy group is catalyzed under a water-free and oxygen-free condition in the presence of an initiator BF3 complex or HClO4, wherein the triethoxysilane compound is shown as a formula 1 or 2; R is an alkyl group or aryl group containing 1-18 carbon atoms or a halogen-substituted group containing heteroatoms N, O, S and P, containing no active hydrogen and containing 1-18 carbon atoms; and R2 is an alkyl group containing 1-8 carbon atoms.

Owner:INST OF CHEM CHINESE ACAD OF SCI

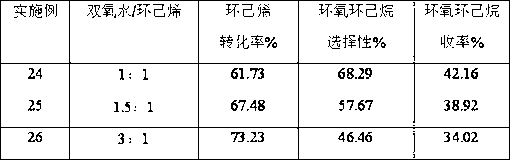

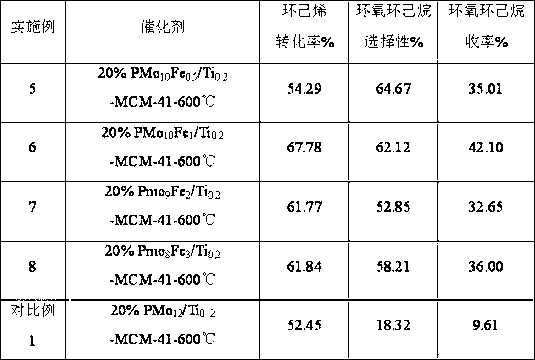

Method for preparing cyclohexene oxide

ActiveCN102786499AEasy to makeLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexene oxideOxygen

The invention discloses a method for preparing cyclohexene oxide, belonging to the technical field of a fine chemical product. The method comprises the steps of: taking cyclohexene as a substrate and acetonitrile as a reaction solvent, taking 30wt% of hydrogen peroxide as an oxidizing agent, carrying out olefin epoxidation under the action of a catalyst taking a Ti-MCM-41 mesoporous molecular sieve as a carrier to load phosphorus molybdenum iron composite oxide, rectifying the reaction liquid, and taking fraction at 130-135 DEG C to obtain cyclohexene oxide. The load type composite oxide disclosed by the invention has good catalytic activity, and can be repeatedly used; the hydrogen peroxide is used as an oxygen source in the reaction; a byproduct is water and accords with green chemical requirements; the condition is mild at constant pressure; reactant and the byproducts are easily separated; the reaction selectivity is good; the reaction energy consumption is low; and the demand on the reaction device is low; the obtained product cyclohexene oxide is easily separated, and the yield of the cyclohexene oxide is high.

Owner:平邑仁安中医药产业发展有限公司

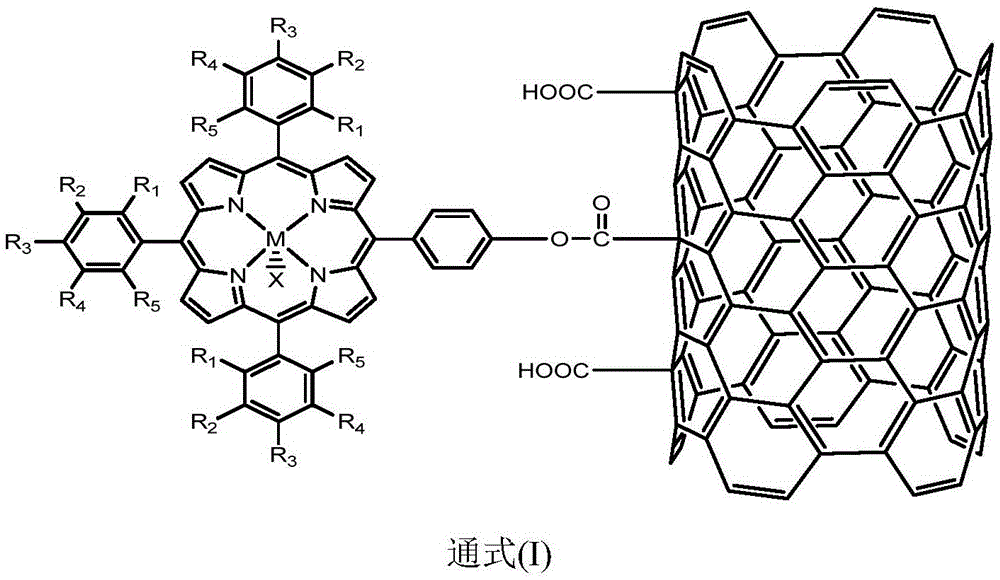

Preparation method of cyclohexene oxide

The invention discloses a preparation method of cyclohexene oxide. According to the preparation method, with cyclohexene as a raw material, carbon nanotube-supported unidirectional metal porphyrin as a catalyst and oxygen as an oxygen source, a catalytic reaction is carried out under the conditions that the reaction temperature is controlled to be 20-60 DEG C and the reaction pressure is controlled to be 0.1-1 MPa, and then cyclohexene oxide is obtained. The preparation method has the advantages that the reaction conditions are mild, operation is convenient, catalytic efficiency is high, and the catalyst can be reused.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

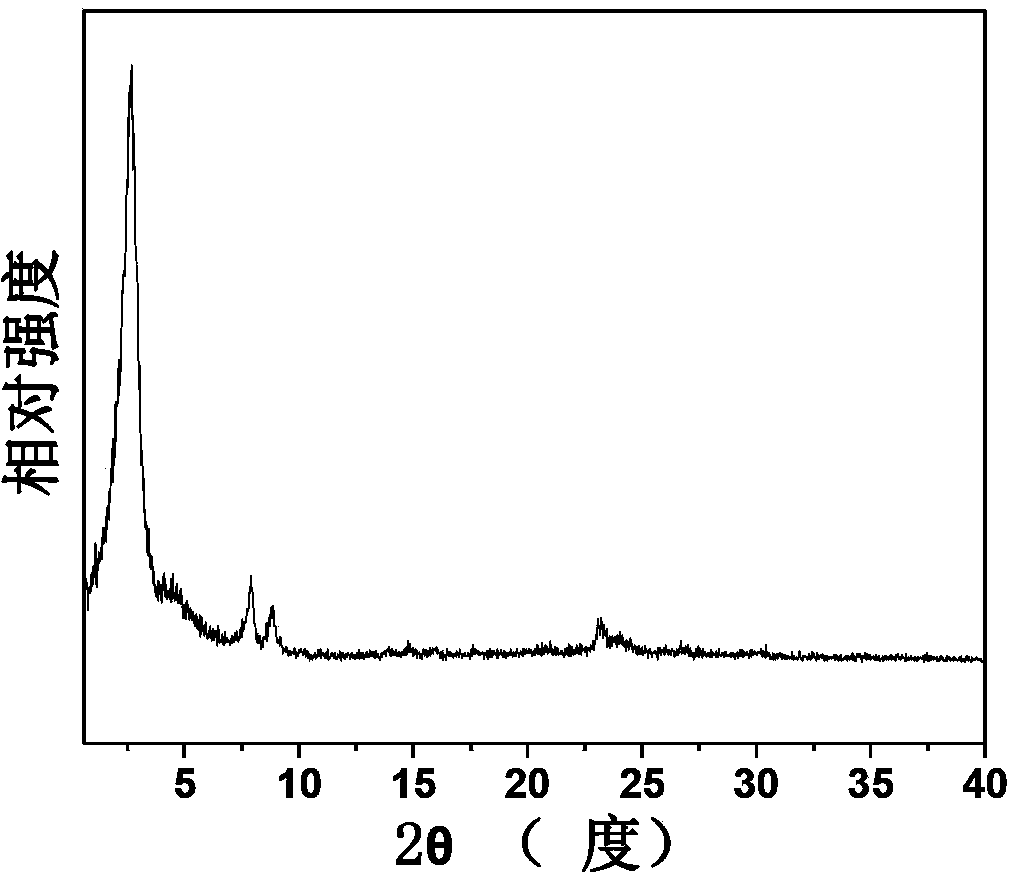

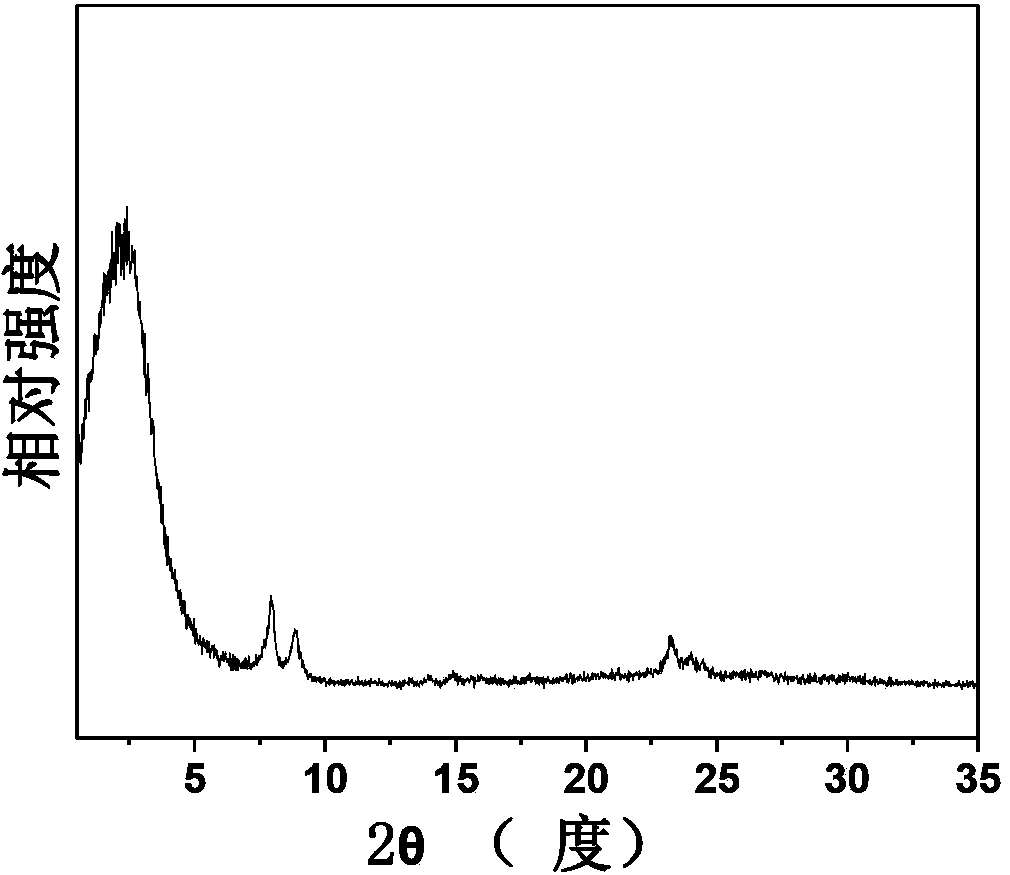

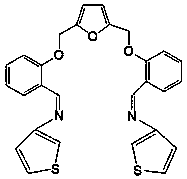

Catalyst for catalyzing copolymerization reaction of carbon dioxide and cyclohexene oxide to prepare poly(cyclohexene carbonate)

ActiveCN107778473ARaw materials are cheap and easy to getEasy to makeOrganic chemistryFuranCyclohexene oxide

The invention discloses a catalyst for catalyzing a copolymerization reaction of carbon dioxide and cyclohexene oxide to prepare poly(cyclohexene carbonate). The catalyst is a 2,5-bis(2-formylphenyloxymethyl)furan 3-aminothiophene zinc complex. Poly(cyclohexene carbonate) with different molecular weights can be prepared under the condition that the catalyst catalyzes the copolymerization of carbondioxide and cyclohexene oxide at the temperature of 60-200 DEG C and the carbon dioxide pressure of 0.5-5MPa. The catalyst disclosed by the invention is high in catalytic activity and simple in preparation process. Poly(cyclohexene carbonate) with different molecular weights can be obtained under a reaction condition that the catalyst catalyzes the copolymerization of carbon dioxide and cyclohexene oxide to prepare poly(cyclohexene carbonate), the highest catalytic efficiency reaches up to 216g polymers / g catalyst, and the content of polycarbonate in poly(cyclohexene carbonate) exceeds 95%.

Owner:天长市润源催化剂有限公司

Method for preparing aliphatic polycarbonate by catalytic copolymerization of carbon dioxide and cyclohexene oxide by utilizing 2-furan formic acid zinc complex

The invention discloses a method for preparing aliphatic polycarbonate by catalytic copolymerization of carbon dioxide and cyclohexene oxide by utilizing 2-furan formic acid zinc complex. The method is characterized by comprising the step of catalyzing carbon dioxide and cyclohexene oxide to copolymerize by utilizing the catalyst at 60-150 DEG C under the carbon dioxide pressure of 1-6MPa, so as to prepare different molecular weights of aliphatic polycarbonate, wherein the catalytic efficiency can be up to 910g polymer / g zinc; and the mol content of the polycarbonate in the polymer exceeds 95%. The catalyst prepared by the method disclosed by the invention is cheap in used material, simple in preparation method, high in catalytic efficiency and good in reaction selectivity.

Owner:HENAN POLYTECHNIC UNIV

Macromolecular supported catalyst, and preparation method and application thereof

The invention discloses a macromolecular supported catalyst, and a preparation method and application thereof. The catalyst is prepared from macromolecular polyaniline and a SalenMx catalyst, wherein the molecular chain of the macromolecular polyaniline contains an imine group. The catalyst prepared by the method can be used for catalyzing copolymerization of carbon dioxide and cyclohexene oxide, has high catalytic efficiency, and still has activity after being reused for three times. The preparation method is simple in step, low in cost and convenient to operate.

Owner:KUNMING UNIV OF SCI & TECH

Method for separation recovery of cyclohexene oxide from cyclohexanone by-product light oil

Belonging to the technical field of organic chemistry, the invention relates to a method for separation recovery of cyclohexene oxide from light oil which is a by-product of cyclohexane oxidation for preparing cyclohexanone and cyclohexanol. The method is characterized by: subjecting the light oil to pre-rectification, conducting chemical treatment on a separated cyclohexene oxide crude product to remove aldehyde ketone and alcohol impurities contained therein, and finally carrying out purification rectification. Thus, the purpose of recovering cyclohexene oxide from the light oil can be reached, and the cyclohexene oxide with purity up to more than 99% can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

InactiveCN102531918BSimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

Method for preparing 1,2-epoxycyclohexane and dicumyl peroxide

ActiveCN102295627AHigh activityGood choiceOrganic compound preparationPeroxy compound preparationEpoxyCyclohexene oxide

The invention relates to a method for preparing 1,2-cyclohexene oxide and dicumyl peroxide, and mainly solves the problems that when the 1,2-cyclohexene oxide is independently produced and an essential raw material of the dicumyl peroxide, namely alpha, alpha-dimethyl benzyl alcohol is independently produced, the production processes pollute environment seriously, the quality of products is low, and production cost is high in the prior art. The method comprises the following steps of: a) performing contact reaction of cyclohexene serving as a raw material, dimethylbenzyl hydroperoxide dissolved in a solvent, and a catalyst in an oxidation-reduction reaction device to obtain a material flow I; b) allowing the material flow I to enter a separating column and rectifying and separating to obtain a material flow II on a column top and a material flow III containing alpha, alpha-dimethyl benzyl and dimethylbenzyl hydroperoxide; c) refining the material flow II to obtain a product 1,2-cyclohexene oxide; and d) allowing the material III to enter a condensation reactor, and performing condensation reaction of alpha, alpha-dimethyl benzyl and dimethylbenzyl hydroperoxide at the presence of a condensation agent to obtain a product dicumyl peroxide. The technical scheme solves the problem well and can be used for the industrial production of 1,2-cyclohexene oxide and dicumyl peroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

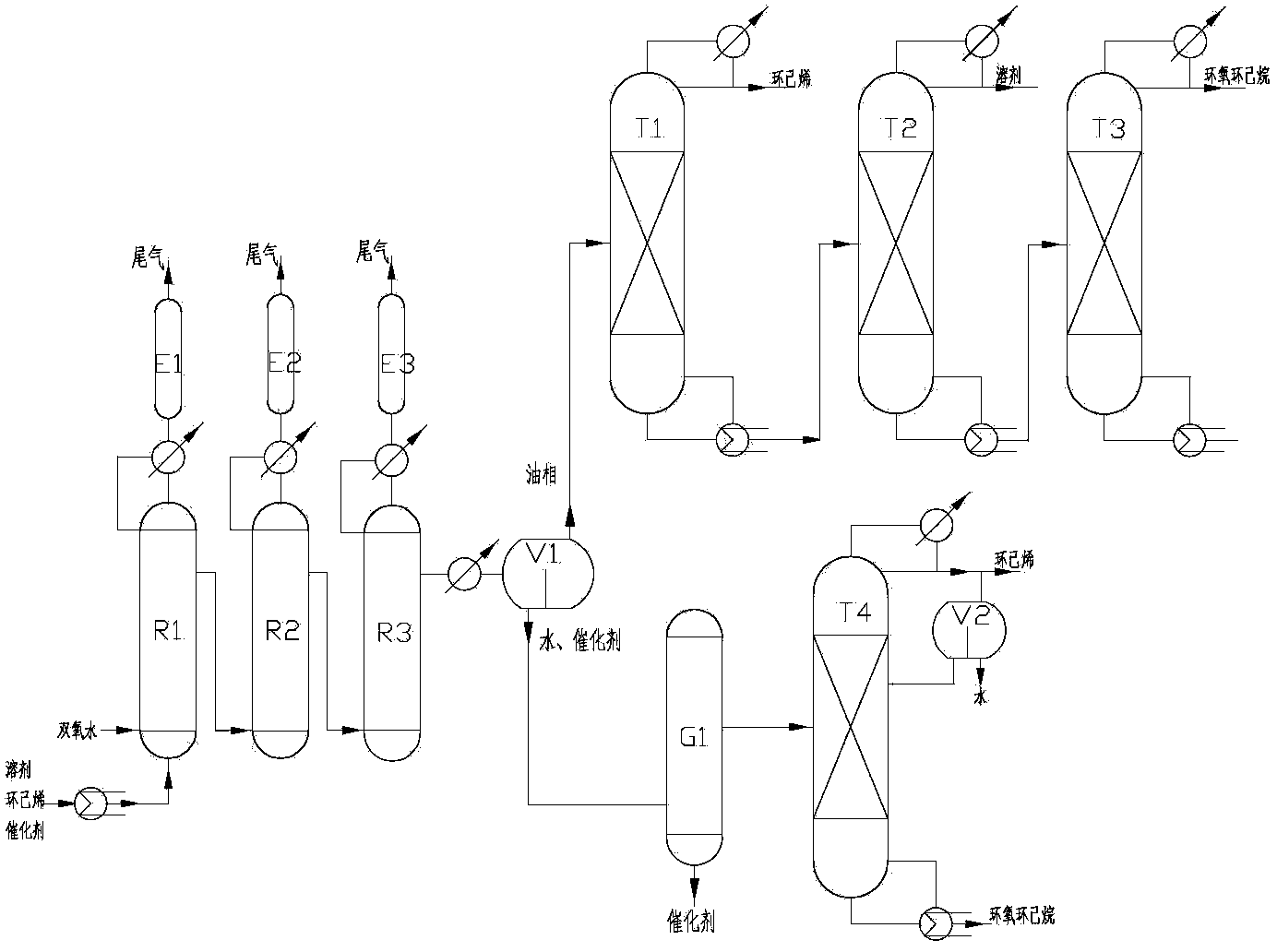

Continuous production method for preparing cyclohexene oxide through cyclohexene oxidation with hydrogen peroxide under normal pressure

InactiveCN103880781ASimple processEasy to operateOrganic chemistryContinuous reactorCyclohexene oxide

The present invention discloses a continuous production method for preparing cyclohexene oxide through cyclohexene oxidation with hydrogen peroxide under a normal pressure. According to the continuous production method, a reaction part and a separation part are provided, wherein the reaction part reactor comprises two continuous reactors connected in series and two switchable batch reactors connected in parallel, a quaternary ammonium heteropolyphosphatotungstate is adopted as a catalyst, hydrogen peroxide is adopted as an oxidant, preparation of cyclohexene oxide through cyclohexene oxidation is performed under a normal pressure condition, and the separation part is separating an oil phase and a water catalyst mixture through a separator after completing the reaction, wherein the oil phase is subjected to rectification so as to respectively separate the solvent, cyclohexene and cyclohexene oxide, the water catalyst mixture is filtered through a filter to obtain the catalyst, and the water phase is subjected to rectification to separate cyclohexene and cyclohexene oxide contained in the water phase. With the process, the continuous production of cyclohexene oxide through cyclohexene oxidation with phase transfer catalyst catalysis is achieved, and the whole process has characteristics of simpleness, easy operation and mild reaction condition.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

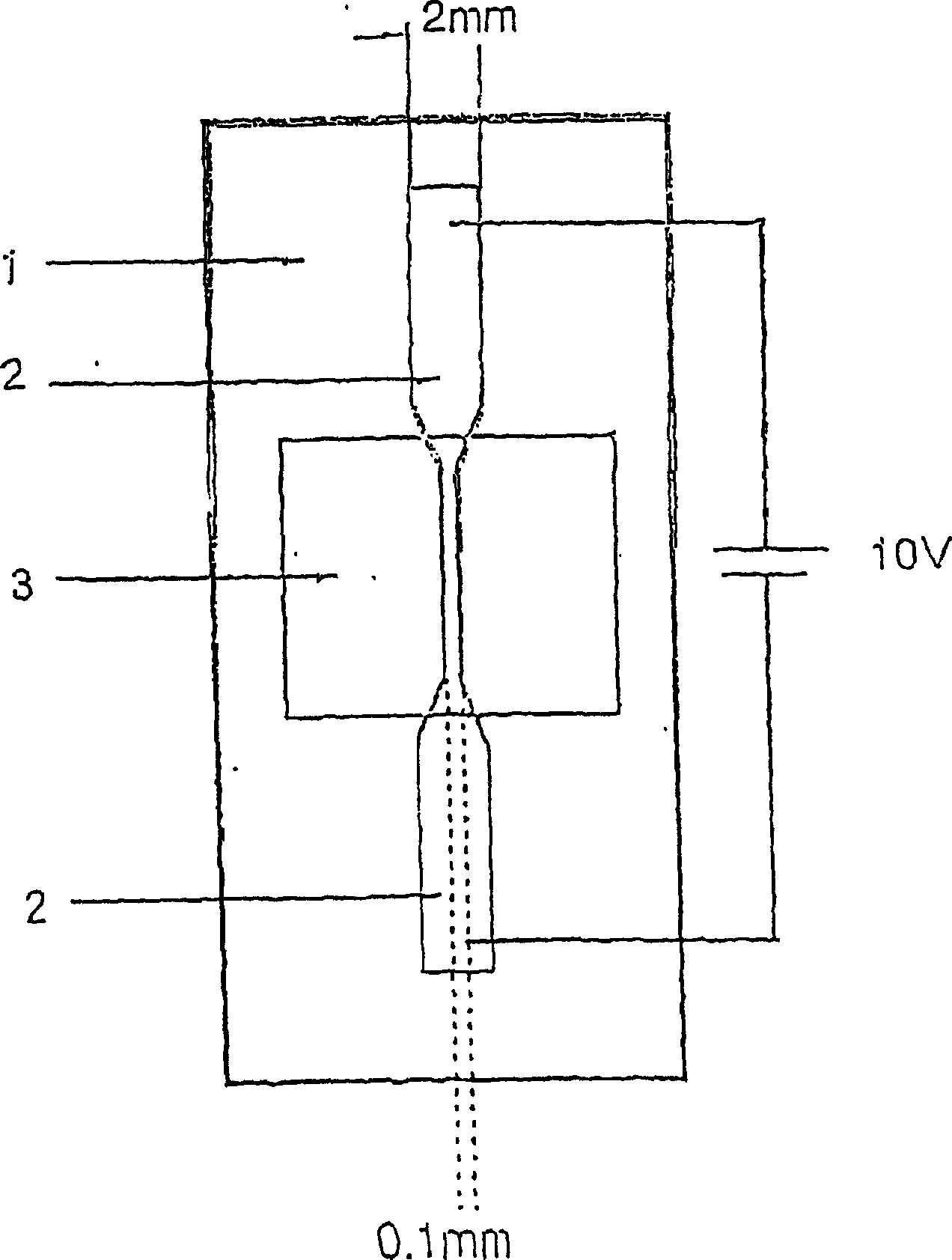

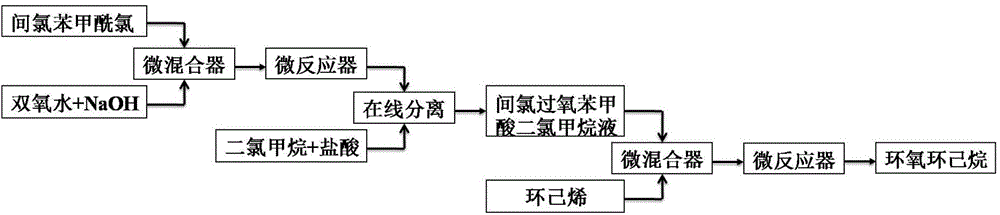

Method for preparing cyclohexene oxide by using micro flow field reaction technique

The invention discloses a method for preparing cyclohexene oxide by using a micro flow field reaction technique. According to the method, cyclohexene oxide is prepared from raw materials such as m-chlorobenzoyl chloride, an aqueous hydrogen peroxide solution and inorganic base in a microchannel modular reaction device. Compared with the prior art, the method is simple and easy to control, adopts easily available and cheap raw materials, is high in yield and percent conversion and can be put into industrial production favorably.

Owner:NANJING UNIV OF TECH

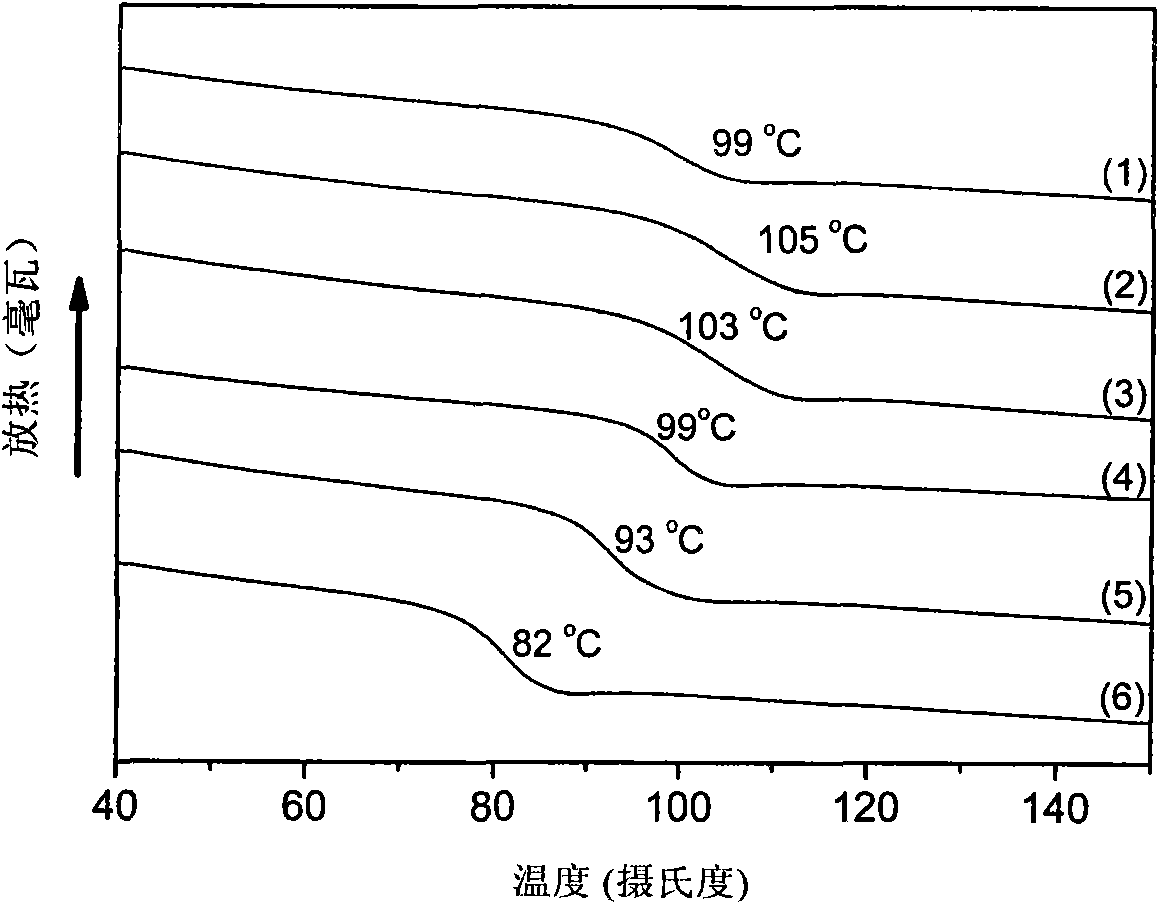

Methyl ethylene carbonic ester block copolymer and preparation method thereof

The invention discloses a methyl ethylene carbonic ester block copolymer and a preparation method thereof. The structure of the block copolymer is shown as (I) or (II). In the invention, a segmented polymerization method is adopted to ensure that carbon dioxide sequentially reacts with propylene oxide or cyclohexene oxide monomers in the presence of the catalysis of loaded binary carboxylic zinc to synthesize a di-block or tri-block polymer containing soft block polymethyl ethylene carbonic ester and hard block polyethylene carbonic ester. Due to the introduction of a hard polyethylene carbonic ester block, the prepared block copolymer has a chemical structure similar to an SBS (Styrene-Butadiene-Styrene) thermoplastic elastomer, and the thermal property and the mechanical property of the block copolymer are obviously superior to that of the traditional polymethyl ethylene carbonic ester as a binary copolymer and a methyl ethylene carbonic ester-cycloethylene carbonic ester random copolymer, thereby the application scope of the polymethyl ethylene carbonic ester is expanded, and the industrialization of carbon dioxide based plastics is promoted.

Owner:SUN YAT SEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com