Patents

Literature

84results about How to "High gel content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamable Composition, Process for Producing the Same and Foam

The present invention provides a foam which maintains high hardness while being lightweight and has excellent peel strength and permanent compression set, and a foamable composition used to obtain the aforementioned foam. A foamable composition comprising (A) an olefin-based copolymer; (B) a copolymer that is (B-I) and / or (B-II) described below, (B-I) a vinyl aromatic-based copolymer comprising a vinyl aromatic compound and a conjugated diene, and / or a vinyl aromatic-based copolymer comprising a vinyl aromatic compound and alkylene,(B-II) an ethylene-based copolymer having an unsaturated group; (C) an inorganic filler; (D) an organic silane coupling agent; and (E) a foaming agent; wherein a mass ratio of the component (A) to the component (B), (A / B), is from 5 / 95 to 100 / 0; an amount of the component (C) is from 0.5 to 35 mass parts, and an amount of the component (E) is from 0.1 to 20 mass parts, based on 100 mass parts of a total amount of the components (A) and (B); and an amount of the component (D) is from 0.1 to 50 mass parts, based on 100 mass parts of the component (C).

Owner:ASAHI KASEI CHEM CORP

Flame-resistant polyester fiber and preparation method thereof

ActiveCN105463610ASmall coefficient of thermal degradationReduce generationElectrolysis componentsFlame-proof filament manufacturePolyesterFiber

The invention relates to a flame-resistant polyester fiber and a preparation method thereof. The flame-resistant polyester fiber is prepared by spinning flame-resistant polyester and then carrying out ultraviolet irradiation. The limit oxygen index value of the flame-resistant polyester fiber is larger than 30, and the fiber has good molten drop resistance on the basis of flame resistance. Flame retardant 2-carboxyethyl(phenyl)phosphinicacid is used for improving the flame resistance of polyester, and unsaturated double bonds contained in polyester are opened to form crosslinking points under ultraviolet irradiation to form a certain quantity of network structures, so that the heat resistance temperature of the polyester fiber is increased, and the molten drop resistance of the polyester fiber is improved. The unsaturated double bonds are introduced into polyester and are effectively and safely controlled to be crosslinked after preparation of the polyester fiber is completed, the gel content of the fiber obtained after crosslinking is greatly increased, and therefore the mechanical performance, heat resistance, chemical resistance and flame resistance of the polyester fiber can be greatly improved.

Owner:JIANGSU HENGLI CHEM FIBER

Cross-linked polypropylene composite material and preparation method thereof

InactiveCN102070837AOvercome warm waterOvercoming craftPlastic/resin/waxes insulatorsPolypropylene compositesPolymer science

The invention discloses a cross-linked polypropylene composite material. The cross-linked polypropylene composite material is prepared by mixing polypropylene, an initiator, a cross-linking agent, a self-cross-linking promoter, a catalyst, a primary antioxidant, an auxiliary antioxidant and other processing aids according to a certain proportion. A preparation method of the cross-linked polypropylene composite material comprises the following steps of: weighing other components except the self-cross-linking promoter and the cross-linking catalyst according to the proportion first, fully mixing in a mixing kettle, and then adding into a twin-screw extruder from a feeding port; and adding the self-cross-linking promoter and the cross-linking catalyst into the twin-screw extruder from a side port of a screw, and then extruding and pelleting to obtain the cross-linked polypropylene composite material, wherein the adding of the self-cross-linking promoter from the side port of the screw is delayed, so that silane is grafted on polypropylene first and then reacts with the self-cross-linking promoter to form preliminary cross-linked polypropylene. The invention has the advantages of overcoming a warm water or steam cross-linking process in the conventional silane cross-linked polypropylene, realizing one-step continuous production, meeting the requirement of injection molding, and solving the problem that the subsequent processing cannot be performed by a radiation cross-linking method, along with excellent mechanical property.

Owner:KINGFA SCI & TECH CO LTD +2

High transparence MBS resin composition with excellent impact property

The invention relates to a high transparent MBS resin compound with excellent impact property, which is obtained through the methods: (1) synthesis of butadiene-styrene latex: butadiene, styrene, emulsifier, molecular weight regulator and initiator adopt seed emulsion polymerization under 65-75 DEG C to synthesize the butadiene-styrene latex with120nm of particle size; (2) grafting: polymeric monomer is methyl methacrylate, styrene and a third functional monomer (acrylonitrile, ethyl methacrylate, acrylic acid-2-hydroxyethyl or ethyl acrylate); the butadiene-styrene latex firstly is emulsion polymerized with the styrene and then is emulsion polymerized with other monomers continuously. The invention adopts seed emulsion polymerization to synthesize the latex, thus improving the transparency of the products. The third functional monomer is led in the grafting polymerization, thus causing the MBS resin to have excellent transparency and impact resistance. The complex initiation system and the grafting polymerization are adopted, thus greatly improving the grafting rate of the MBS, improving the gel content of the MBS and guaranteeing relatively high impact strength.

Owner:SHANDONG RUIFENG CHEM

Preparation method of cross-linkable acetal copolymer

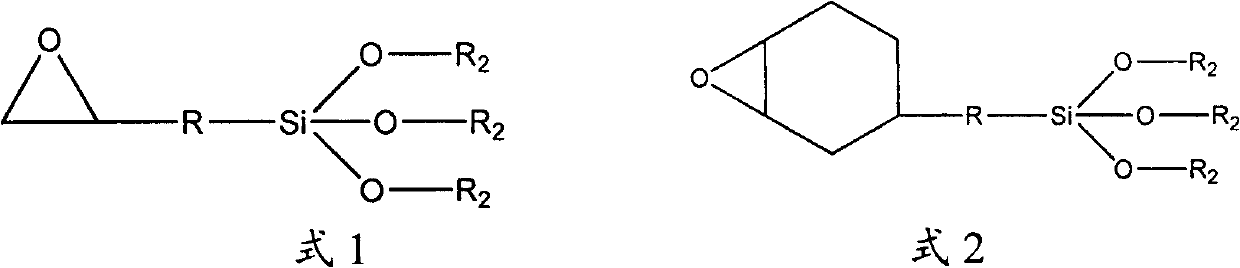

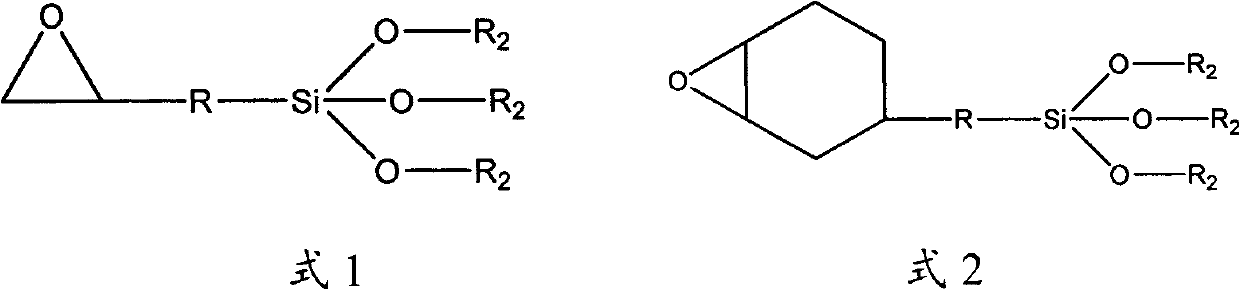

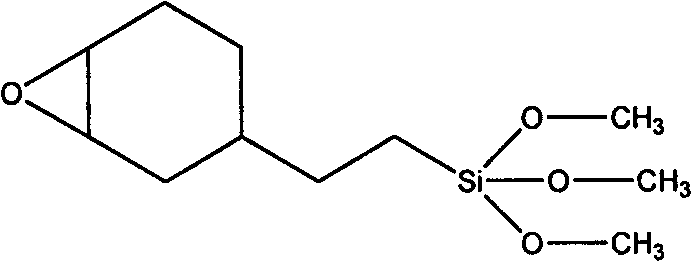

The invention discloses a preparation method of cross-linkable acetal copolymer. The preparation method is characterized in that: ternary polymerization of (a) trioxymethylene (TOX), (b) dioxolane (DXL) or cyclohexene oxide (CHO) and (c) a triethoxysilane compound with an epoxy group is catalyzed under a water-free and oxygen-free condition in the presence of an initiator BF3 complex or HClO4, wherein the triethoxysilane compound is shown as a formula 1 or 2; R is an alkyl group or aryl group containing 1-18 carbon atoms or a halogen-substituted group containing heteroatoms N, O, S and P, containing no active hydrogen and containing 1-18 carbon atoms; and R2 is an alkyl group containing 1-8 carbon atoms.

Owner:INST OF CHEM CHINESE ACAD OF SCI

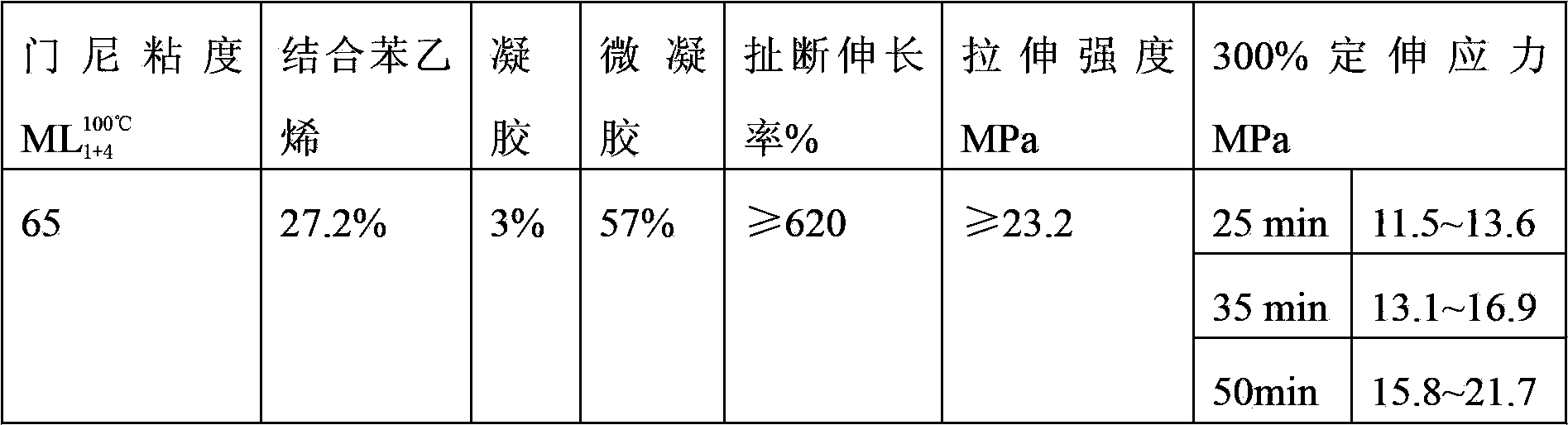

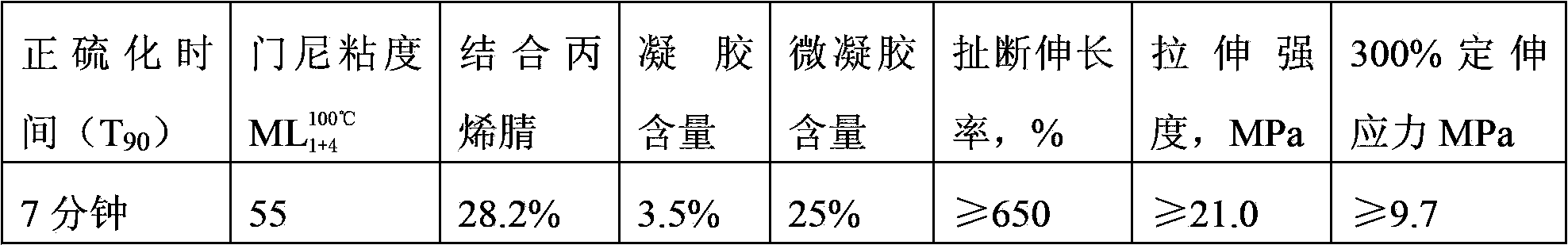

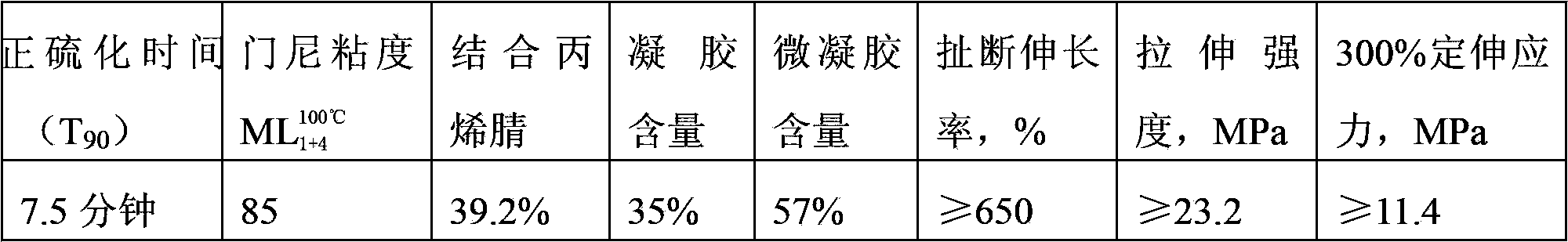

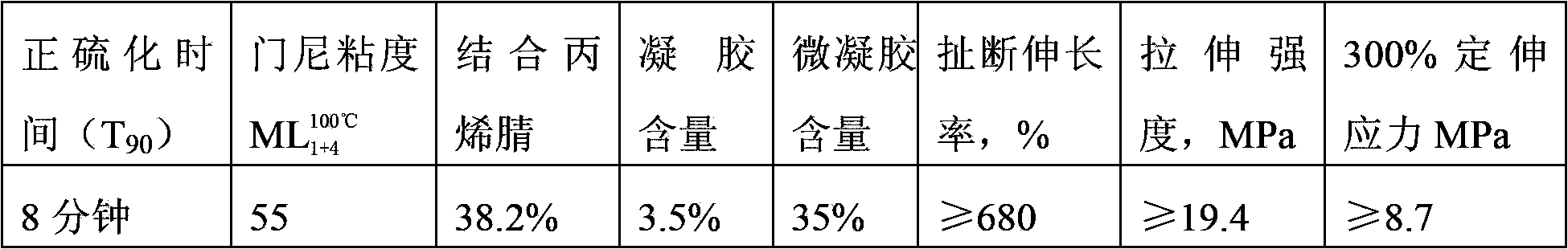

Emulsion polymerization method for preparing tractable butadiene styrene rubber

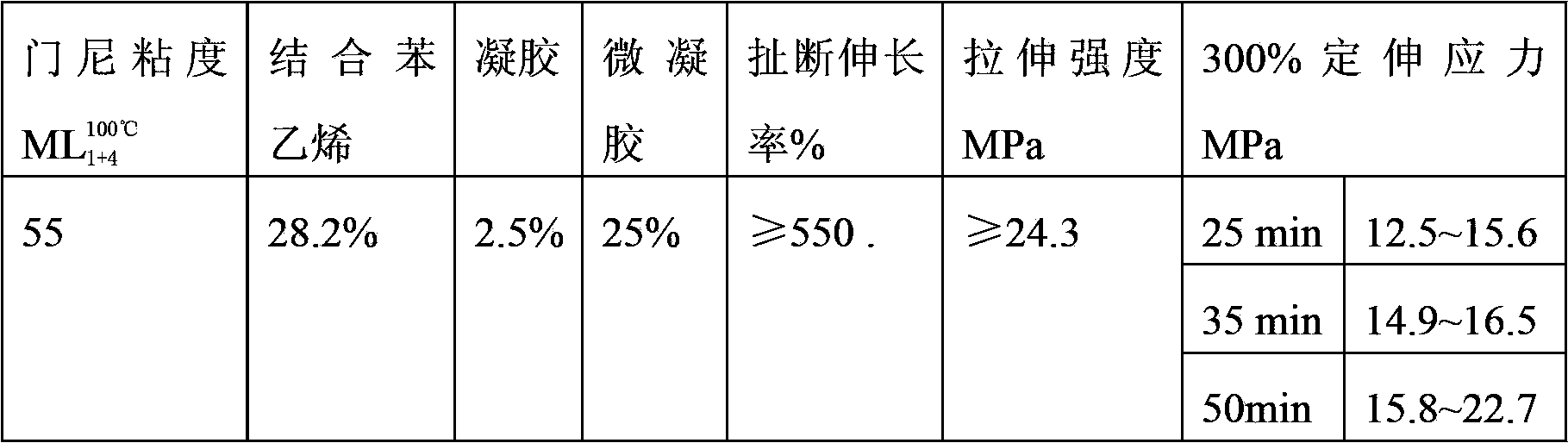

The invention relates to an emulsion polymerization method for preparing a tractable butadiene styrene rubber. The polymerization method comprises at least the following steps: adding part of styrene (an oil phase) and part of an emulsifier (an aqueous phase), a regulator and an initiator into a polymerization kettle; adding butadiene; carrying out emulsion polymerization with stirring; and when conversion rate of the polymerization reaction in the middle stage reaches 30-60%, refilling the emulsifier, the crosslinking agent, styrene and the regulator by one or more times. The styrene butadiene rubber prepared by the method provided by the invention has high micro gel content and low gel content; coupled with the electron cloud effect of the pi bonds in the benzene ring of the molecular chain, a three-dimensional net shape structure is easy to form in the processing process; and the rubber product has good physical and mechanical properties, increased Mooney viscosity, and correspondingly increased tensile strength and 300% stretching strength.

Owner:PETROCHINA CO LTD

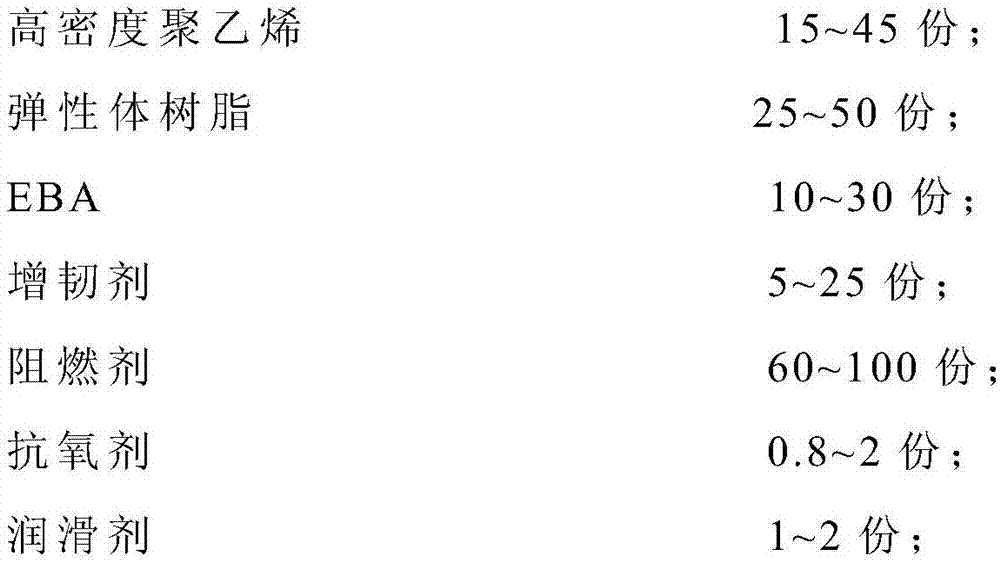

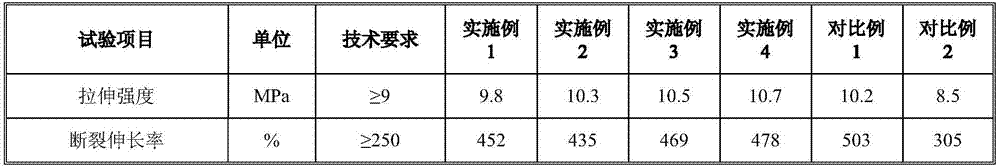

High pressure resistance irradiation crosslinking environment-friendly and flame-retardant rubber and plastic composite material and preparation method thereof

The invention relates to a high pressure resistance irradiation crosslinking environment-friendly and flame-retardant rubber and plastic composite material and a preparation method thereof. A formula of the composite material comprises raw materials in parts by weight: 15 to 45 parts of high-density polyethylene, 25 to 50 parts of elastomer resin, 10 to 30 parts of EBA, 5 to 25 parts of flexibilizer, 60 to 100 parts of flame retardant, 0.8 to 2 parts of antioxidant, 1 to 2 parts of lubricant, 0.03 to 0.1 part of crosslinking agent and 1 to 2.5 parts of crosslinking sensitizer, wherein the elastomer resin is prepared from polyurethane elastomer and ethylene propylene diene monomer elastomer, and a mass ratio of the polyurethane elastomer to the ethylene propylene diene monomer elastomer is 1 to (1 to 3). According to the composite material disclosed by the invention, the formula is improved; for example, the polyurethane elastomer and the ethylene propylene diene monomer elastomer are utilized as the elasomer resin, the high-density polyethylene and the EBA are added, meanwhile the matters of the flexibilizer, the flame retardant, the antioxidant and the like are added in an auxiliary mode; thus, the composite material disclosed by the invention has excellent wear resistance, flame resistance and heat resistance, a higher gel content can be obtained, and a pressure-resistant requirement of the material in a high-temperature welding process is met.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Polyvinyl chloride plastic pipe and preparation method thereof

The invention discloses a polyvinyl chloride plastic pipe which is prepared from the following raw materials in parts by weight: 4-6 parts of carbon nanotube, 40-60 parts of 90-93% sulfuric acid, 60-70 parts of 95-97% nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of 2-hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of liquid ethylene propylene diene monomer rubber, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride, 17-20 parts of wollastonite powder and 5-6 parts of tributyl citrate. The high-dispersity liquid ethylene-propylene rubber is added into the polyvinyl chloride matrix and effectively combined with the modified carbon nanotubes through double bonds, and thus, the matrix can transfer loading stress to the carbon nanotubes through chemical bonds, thereby enhancing the mechanical strength.

Owner:安徽玉发塑业有限公司

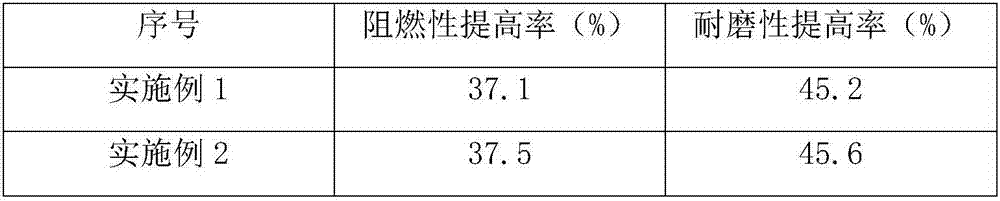

Cable insulation material of wearproof modified phenolic resin

InactiveCN108003501AHigh mechanical strengthHigh gel contentPlastic/resin/waxes insulatorsSodium stearatePolyvinyl chloride

The invention discloses a cable insulation material of wearproof modified phenolic resin. The cable insulation material is prepared from, by weight, 32-36 parts of polyvinyl chloride, 30-34 parts of modified phenolic resin, 11-15 parts of silicone rubber, 4-8 parts of an ethylene-vinyl acetate copolymer, 2-6 parts of ethylene acrylic grafted maleic anhydride, 3-7 parts of an ethylene-vinylacetategrafting maleic anhydride copolymer, 1-5 parts of sodium stearate, 5-9 parts of aramid short fiber, 6-10 parts of montmorillonite, 2-6 parts of paraffin, 4-8 parts of nano-polyacrylate modified magnesium hydrate, 2-6 parts of nano calcium carbonate, 3-7 parts of nano boron nitride, 1-5 parts of microcrystalline cellulose, 2-6 parts of silane coupling agent, 4-8 parts of wearproof powder, 5-9 partsof talcum powder, 2-6 parts of zinc oxide whiskers, 1-5 parts of graphene, 1-5 parts of fullerene, 3-7 parts of antioxygen, 5-9 parts of fire retardant and 6-10 parts of filling fine materials. The wearproof performance and the fire resistance of the cable insulation material are improved, and the service life of a cable can be guaranteed.

Owner:韩丽娟

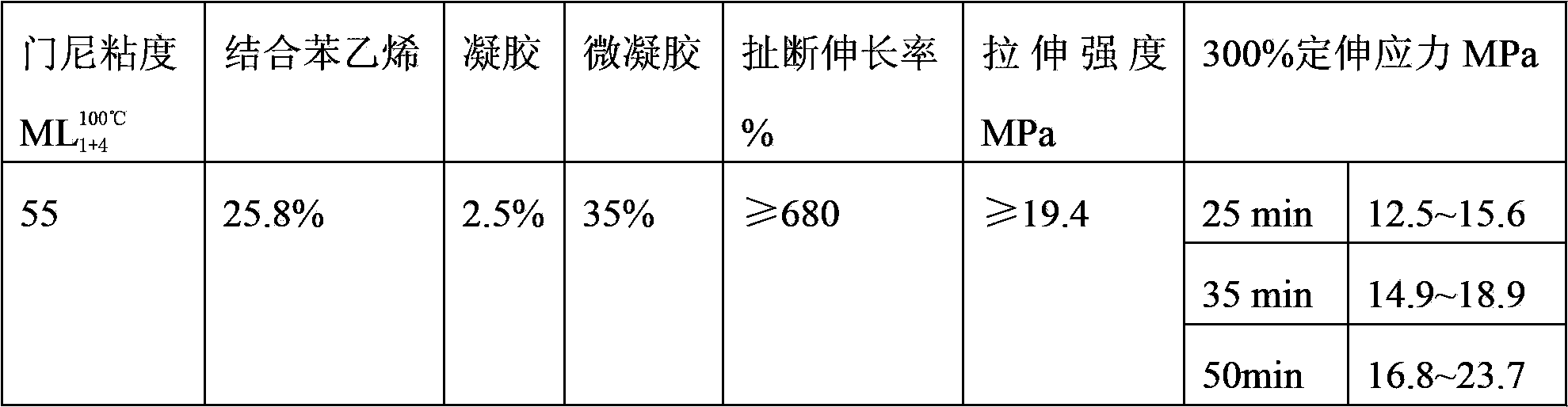

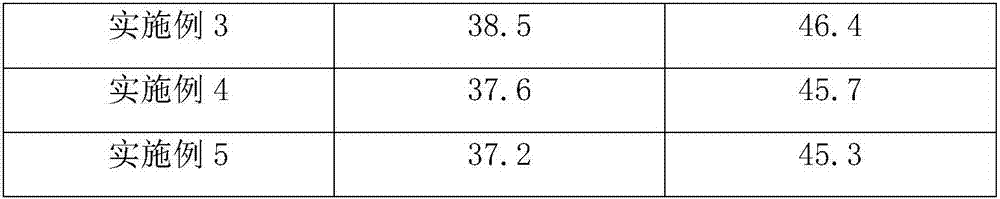

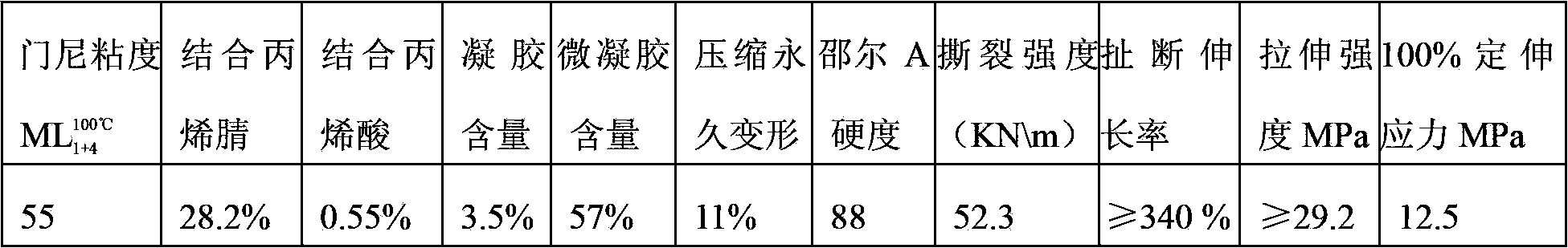

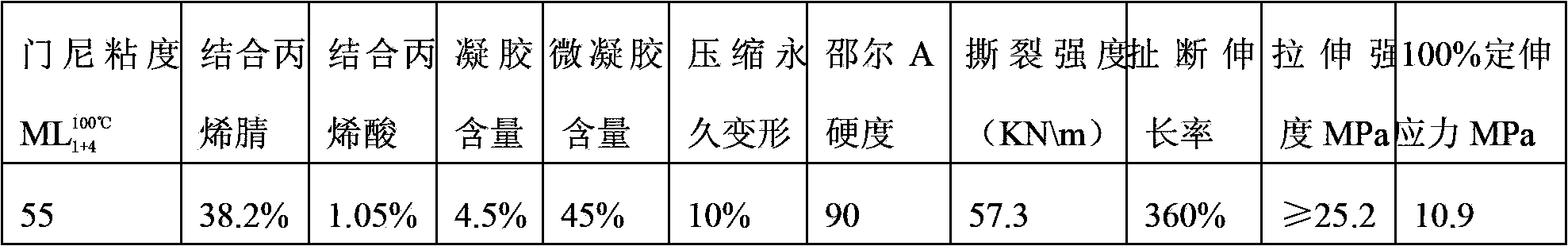

Process for preparing carboxylic acrylonitrile butadiene rubber through emulsion polymerization method

The invention relates to a process for preparing carboxylic acrylonitrile butadiene rubber through an emulsion polymerization method. An emulsifier and an adjusting agent are added in batch, and a crosslinking agent and a pre-crosslinking agent titanate are added at different times, so the carboxylic acrylonitrile butadiene rubber has the characteristics of high content of a microgel, low content of a gel, controllable combined acid index, easy formation of a stereo netted structure in the processing process, uniform distribution of carboxylic groups on a molecular chain, uniform structure formed in the vulcanizing and product processing processes, slight stress relax phenomenon, and good dimension stability. The rubber obtained through adopting the method has good physical and mechanical properties and an improved Mooney viscosity, and has corresponding better compression set, Shore A hardness, tearing strength, tensile strength, elongation at break and 100% stress at definite elongation than common carboxylic rubber.

Owner:PETROCHINA CO LTD

Rubber composition for tires and pneumatic tire

ActiveUS20160102193A1Excellent abrasion resistanceImprove breaking performanceSpecial tyresBiological water/sewage treatmentPolymer scienceLatex particle

The present invention aims to provide rubber compositions for tires that contain a natural rubber achieving a balanced improvement in abrasion resistance, breaking performance, and processability to achieve a balanced improvement in abrasion resistance, breaking performance, and processability, and also provide pneumatic tires containing such rubber compositions for tires. Included is a rubber composition for tires comprising a modified natural rubber prepared by treating natural rubber latex with a proteolytic enzyme, and then treating the treated natural rubber latex with a lipolytic enzyme and / or a phospholipid degrading enzyme. Also included is a rubber composition for tires, comprising a modified natural rubber prepared by centrifuging natural rubber latex to recover a latex fraction comprising latex particles having an average particle size of 0.25 μm or less.

Owner:SUMITOMO RUBBER IND LTD

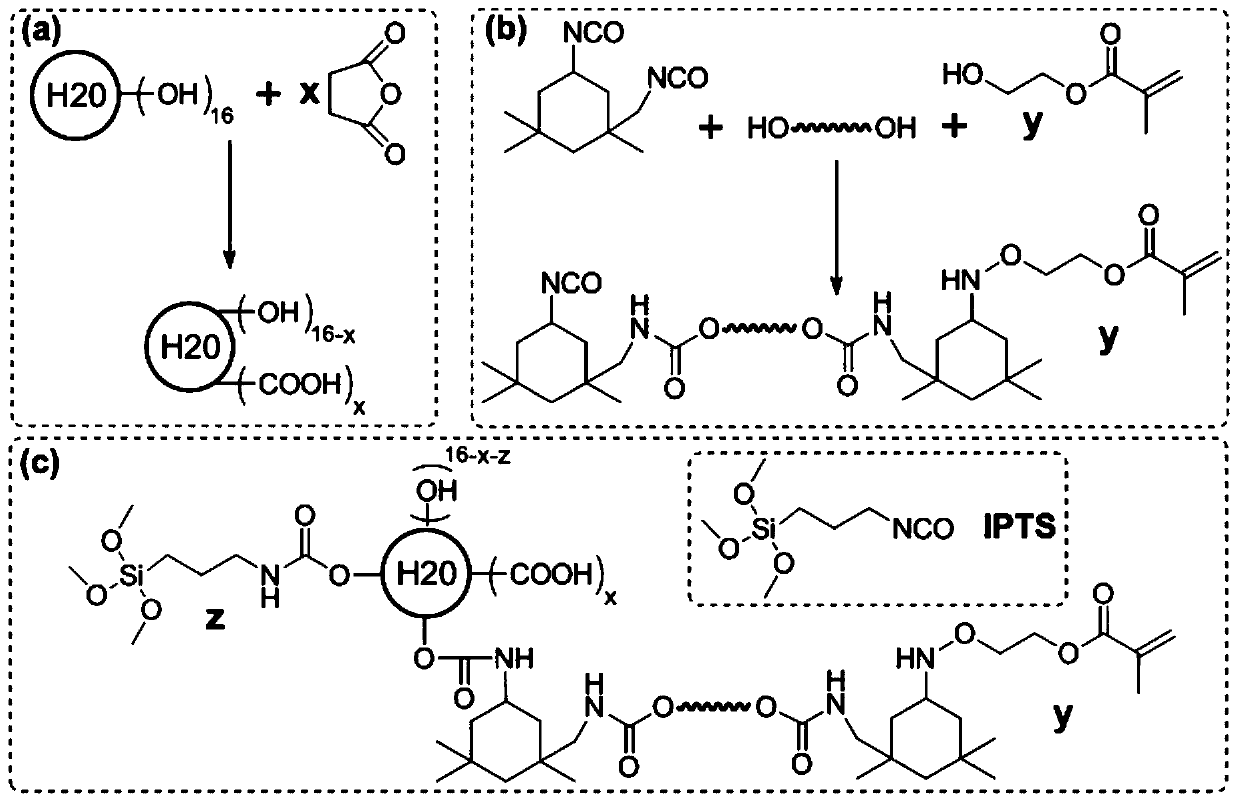

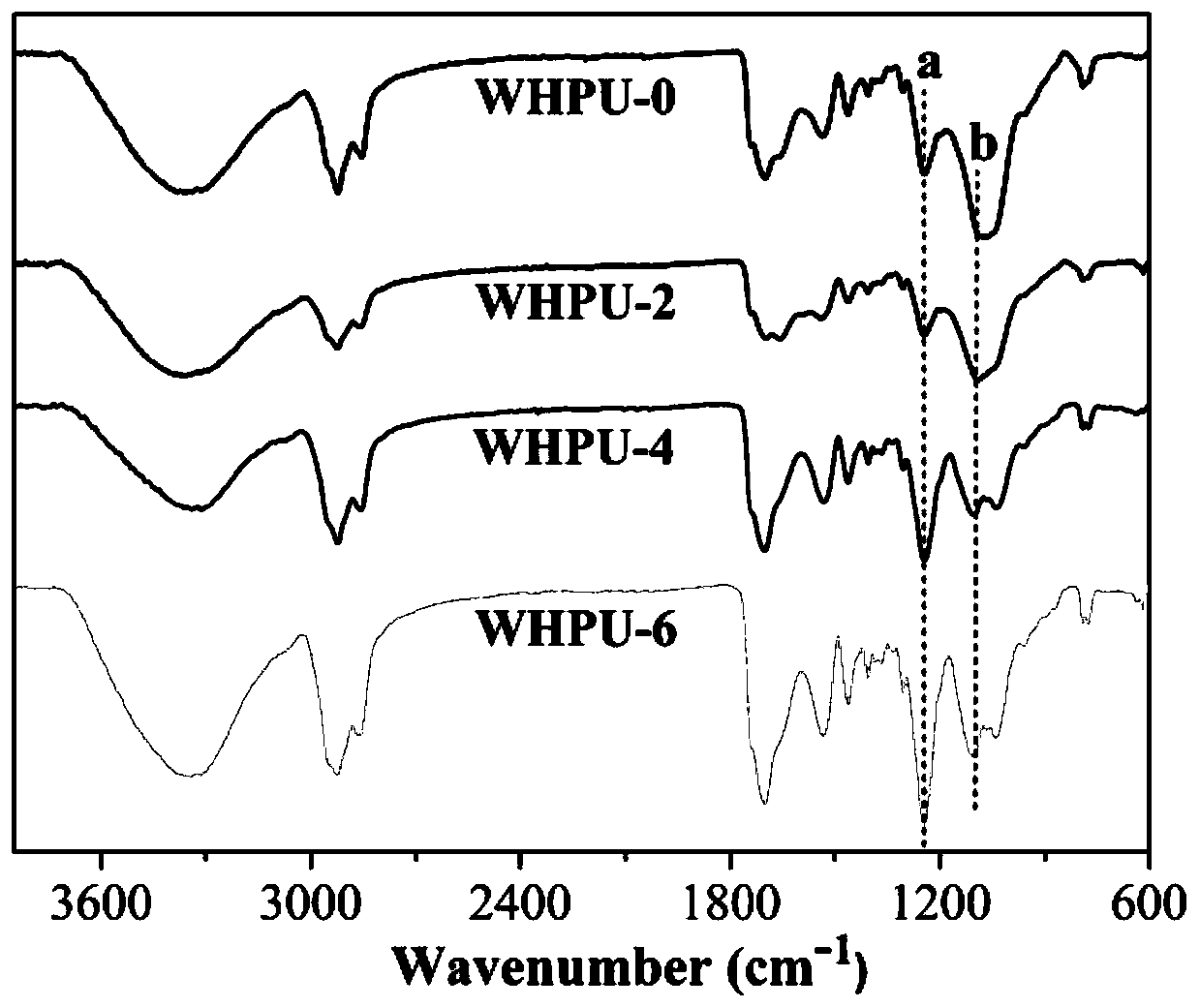

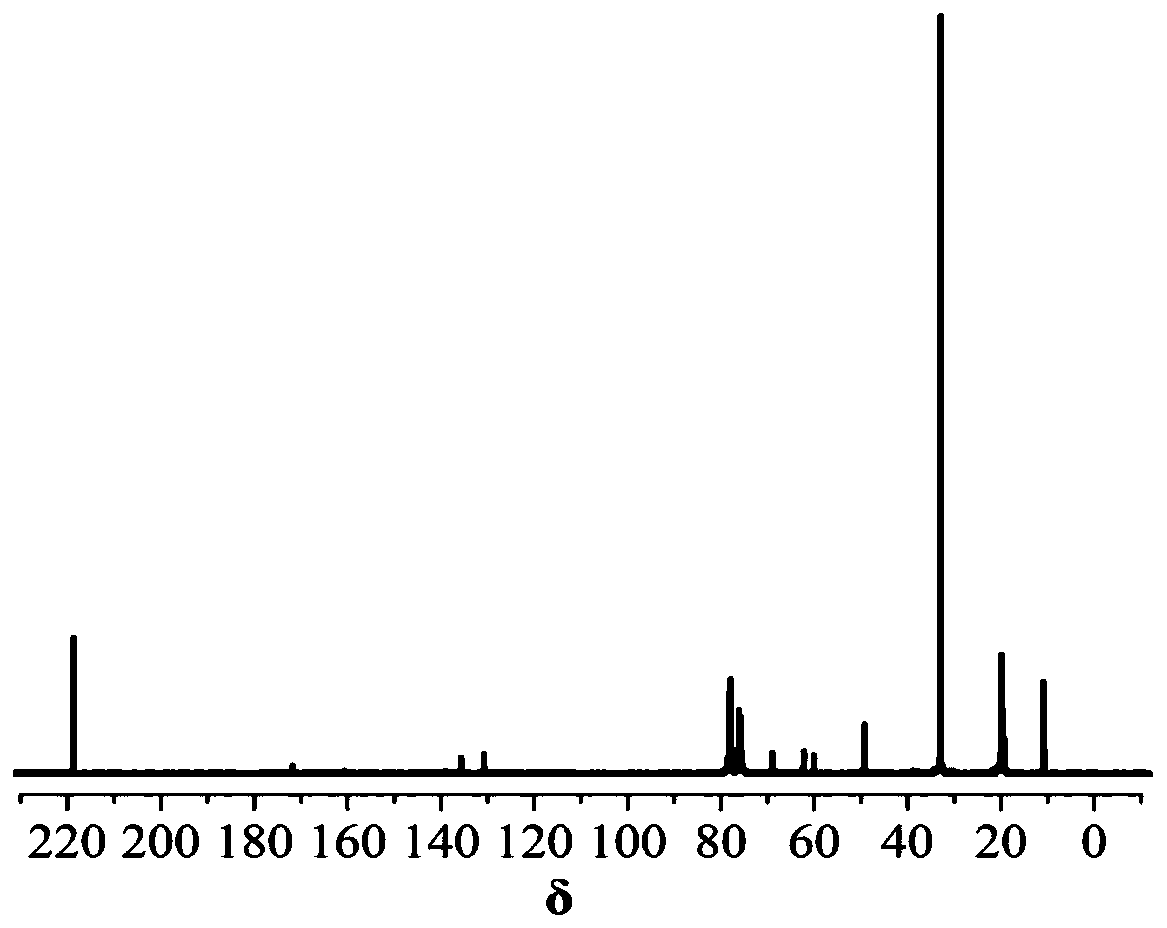

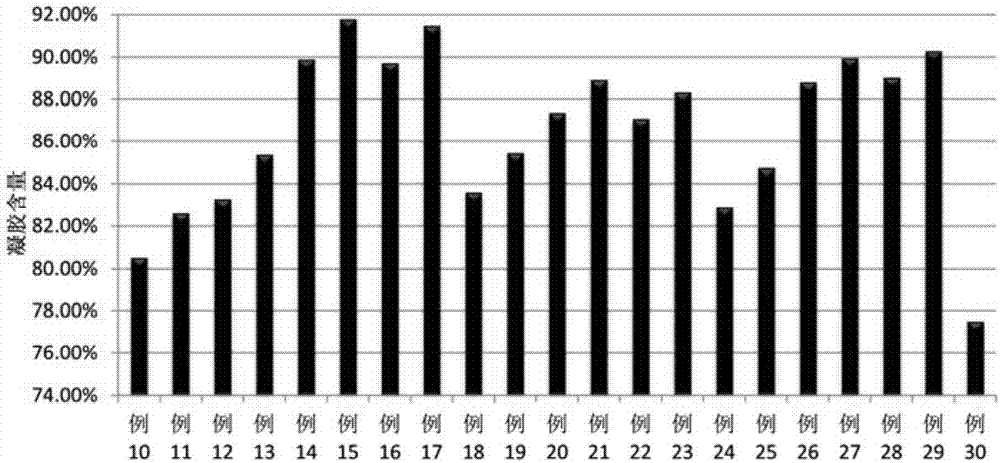

Organosilane coupling agent modified ultraviolet curing material

Belonging to the technical field of materials, the invention discloses an organosilane coupling agent modified ultraviolet curing material. The preparation method includes: reacting hyperbranched polyester Boltorn H20 with succinic anhydride to prepare a hydrophilic hyperbranched polyester, and then carrying out reaction with a methacrylate group modified polyether based polyurethane prepolymer and 3-isocyanatopropyltriethoxysilane (IPTS) sequentially to synthesize organosilane coupling agent modified ultraviolet-cured polyether hyperbranched waterborne polyurethane (WHPU). A film formed by curing of the prepared organosilane coupling agent modified ultraviolet curing material has a gel content up to 92%, and the adhesive force on a surface of glass reaches grade 0; and compared with WHPUwithout an organosilane coupling agent, the WHPU has remarkably improved thermal stability and water contact angle performance, significantly reduced water absorption rate, and provides certain theoretical basis for modification and research of WHPU.

Owner:临沂中科芯华新材料科技有限公司

Antibacterial polyvinyl chloride plastic tube and preparation method thereof

InactiveCN105778351AHigh mechanical strengthImprove antibacterial and antiseptic effectPolyvinyl chlorideCarbon nanotube

The invention discloses an antibacterial polyvinyl chloride plastic tube and a preparation method thereof. The antibacterial polyvinyl chloride plastic tube consists of the following raw materials in parts by weight: 0.1-0.2 part of isothiazolinone, 0.7-1 part of polybenzimidazole, 2-3 parts of calcium propionate, 0.1-0.3 part of alkanolamide, 1-3 parts of palm wax, 3-5 parts of dibutyl maleate, 0.2-0.4 part of polypropylene oxide glyceryl ether, 1-2 parts of sodium diacetate, 3-4 parts of carbon nanotubes, 40-60 parts of 90-93% sulfuric acid, 60-70 parts of 95-97% nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of a liquid ethylene propylene diene monomer, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride and 10-15 parts of attapulgite. By adopting the antibacterial polyvinyl chloride plastic tube, the antibacterial and anti-corrosion properties of a finished tube product are effectively improved, the adaptability of the tube to the environment is improved, and the service life of the tube is prolonged.

Owner:安徽玉发塑业有限公司

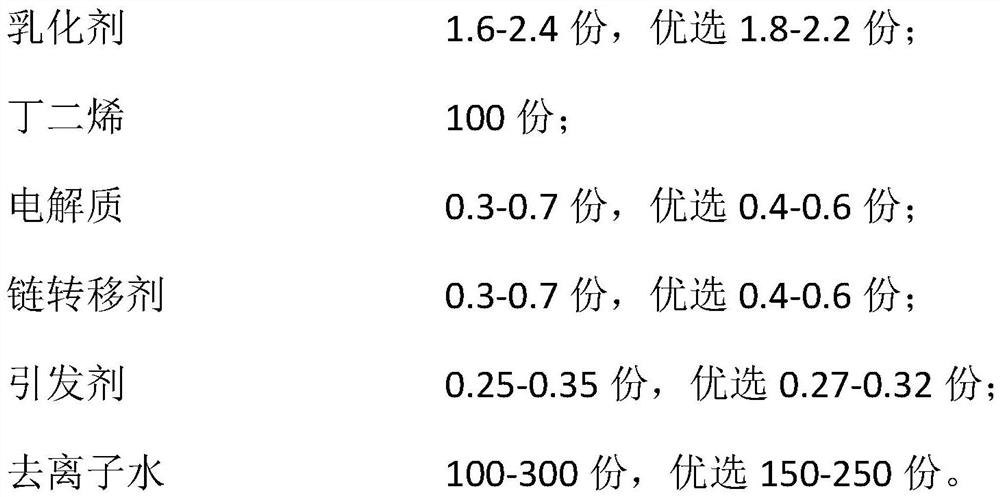

Emulsion polymerization method for preparing rapid vulcanization butadiene-acrylonitrile rubber

The invention provides an emulsion polymerization method for preparing a rapid vulcanization butadiene-acrylonitrile rubber. Addition of a pre-crosslinking agent increases degree of branching of a microgel in molecular structure, so as to realize low gel and high microgel content; and a vulcanization cross-linking agent added in the mid-term of a reaction, and the formed molecular structure accelerates vulcanization process in the processing of the rubber, so as to reach good vulcanization effect. As microstructure of rubber molecules is controlled and adjusted, the butadiene-acrylonitrile rubber prepared by the method provided by the invention has high microgel content and low gel content, and can easily form a stereochemical structure during a processing process; and the rubber product has good physical and mechanical properties, increased Mooney viscosity, and correspondingly enhanced tensile strength, elongation at rupture and 300% stress at definite elongation.

Owner:PETROCHINA CO LTD +1

Water-based paint composition and preparation method thereof

ActiveCN106883716AEvenly dispersedGood compatibilityAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses a water-based paint composition, which comprises branchlike or hyperbranched polyamine of which at least one part of amino end group is cationized, clay and a film-forming matter, wherein the film-forming matter comprises at least one emulsion polymer, wherein at least one part of the branchlike or hyperbranched polyamine of which at least one part of amino end group is cationized is intercalated into a clay layer. The water-based paint composition is good in compatibility among various components, and the formed paint film has higher gel content and improved mechanical property, barrier property, scrub resistance and the decay resistance. The invention further discloses a preparation method of the water-based paint composition.

Owner:NIPPON PAINT GUANGZHOU

Polyolefin alloy in kettle, and preparation method thereof

The invention relates to the field of olefin polymerization, and discloses a polyolefin alloy in a kettle and a preparation method thereof. The preparation method of the polyolefin alloyin the kettlecomprises the following steps: 1) carrying out a first polymerization reaction on a first olefin monomer in the presence of a catalyst, and introducing a second olefin monomer into the polymerizationreaction system for a second polymerization reaction, wherein the first olefin monomer is different from the second olefin monomer, and the first polymerization reaction and / or the second polymerization reaction is carried out in the presence of organosilane; and 2) contacting water and / or alcohol with a product obtained in the step 1). The general formula of the organosilane is R1<m>SiX<n>R2<k>;and in the formula, R1 is a C2-C6 1-alkylene group, R2 is a C2-C20 1-alkylene group, X is halogen, m, n and k are respectively 1 or 2, and m+n+k = 4. The polyolefin alloy disclosed by the invention ishigh in cross-linking degree of rubber, and has higher impact toughness and flexural modulus.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heat-resistant polyester activated industrial yarn and preparation method thereof

ActiveCN105506772ASmall coefficient of thermal degradationReduce generationFibre typesMelt spinning methodsPolyesterFiber

The invention relates to heat-resistant polyester activated industrial yarn and a preparation method thereof. The heat-resistant polyester activated industrial yarn is polyester industrial yarn with a surface clad with an activating agent coating, and is obtained by carrying out solid phase viscosity increment on polyester including an unsaturated double bond, and then spinning the polyester subjected to the solid phase viscosity increment, and carrying out ultraviolet irradiation on the spun polyester; the heat-resistant polyester activated industrial yarn has gel content which is more than 10 percent and a fusion temperature which is more than 275 DEG C; when the heat-resistant polyester activated industrial yarn is in the test conditions of 0.05cN / dtex of fiber in 10min at temperature of 177 DEG C, the fiber has a dry heat shrinkage rate which is 2.5(+ / -)0.5 percent and a wicking height which is not more than 5mm. The unsaturated double bond is introduced into the polyester; a cross linking reaction is completed in the spinning process of the fiber, so that the fiber is improved to a larger extent at the aspect of heat resistance; meanwhile, by forming the resinous activating agent coating on the surface of the polyester industrial yarn, the polarity of the polyester is enhanced; the reactivity with RFL (Resorcinol Formaldehyde Latex) is improved.

Owner:JIANGSU HENGLI CHEM FIBER

High-flame-retardant modified phenolic resin cable material

InactiveCN105602075AHigh mechanical strengthHigh gel contentPlastic/resin/waxes insulatorsAmmonium polyphosphateMaleic anhydride

The invention discloses a high-flame-retardant modified phenolic resin cable material. The high-flame-retardant modified phenolic resin cable material is prepared from the following raw materials: HDPE, LDPE, EVA, hydrogenated styrene, modified phenolic resin, nitrile rubber, ethylene-vinyl acetate copolymer, ethylene acrylic acid grafted maleic anhydride, maleic anhydride grafted ethylene-vinyl acetate copolymer, ethylene-propylene-diene-terpolymer rubber, a silane coupling agent WD-21, fullerene, ammonium polyphosphate, nano polyacrylate modified magnesium hydroxide, nano aluminum hydroxide, nano calcium carbonate powder, nano boron nitride, talcum powder, an antioxidant and calcium stearate. The high-flame-retardant modified phenolic resin cable material has excellent flame-retardant performance.

Owner:ANHUI DUJIANG CABLE GROUP

Flame-retardant polyvinyl chloride plastic pipe and preparation method thereof

The invention discloses a flame-retardant polyvinyl chloride plastic pipe which consists of the following raw materials in parts by weight: 0.6-1 part of 2-thiol benzimidazole, 3-5 parts of triethylene glycol di-2-ethylhexoate, 1-2 parts of molybdenum disulfide, 3-4 parts of a carbon nano tube, 40-60 parts of 90-93 percent of sulfuric acid, 60-70 parts of 95-97 percent of nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of liquid ethylene-propylene-diene monomer rubber, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride, 2-3 parts of decabromodiphenyl ether, 0.1-0.2 part of butylmercaptooxo stannane, 1-2 parts of calcium aluminate, 0.1-0.2 part of polysorbate 80, 2-4 parts of ammonium polyphosphate, 10-15 parts of talcum powder and 2-3 parts of hydrated zinc borate. According to the invention, the fire resistance and the flame resistance of the finished plastic pipe are improved, and the service safety of finished products is improved.

Owner:安徽玉发塑业有限公司

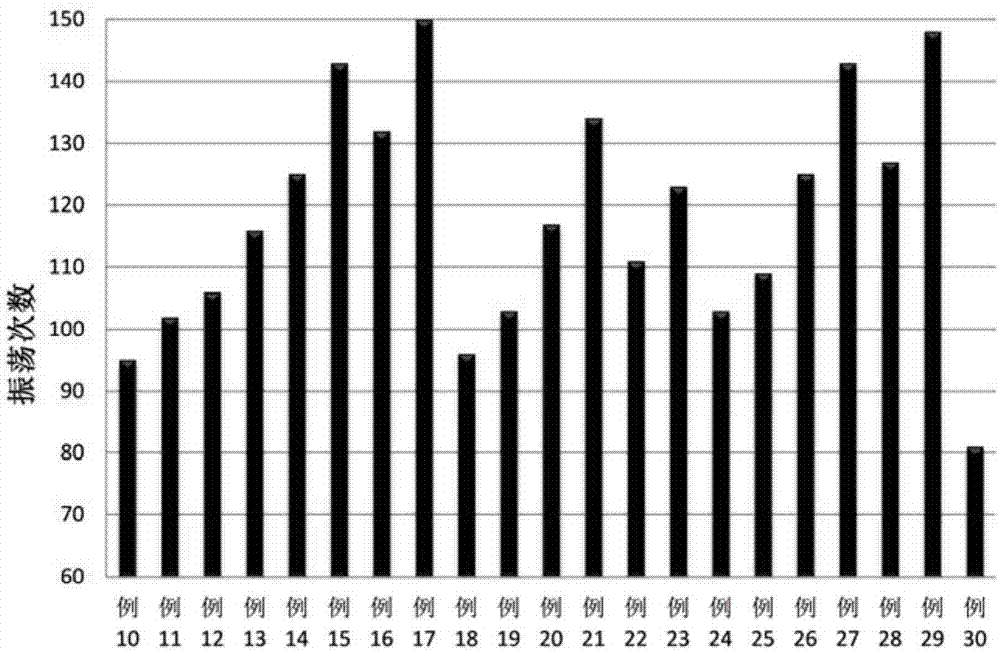

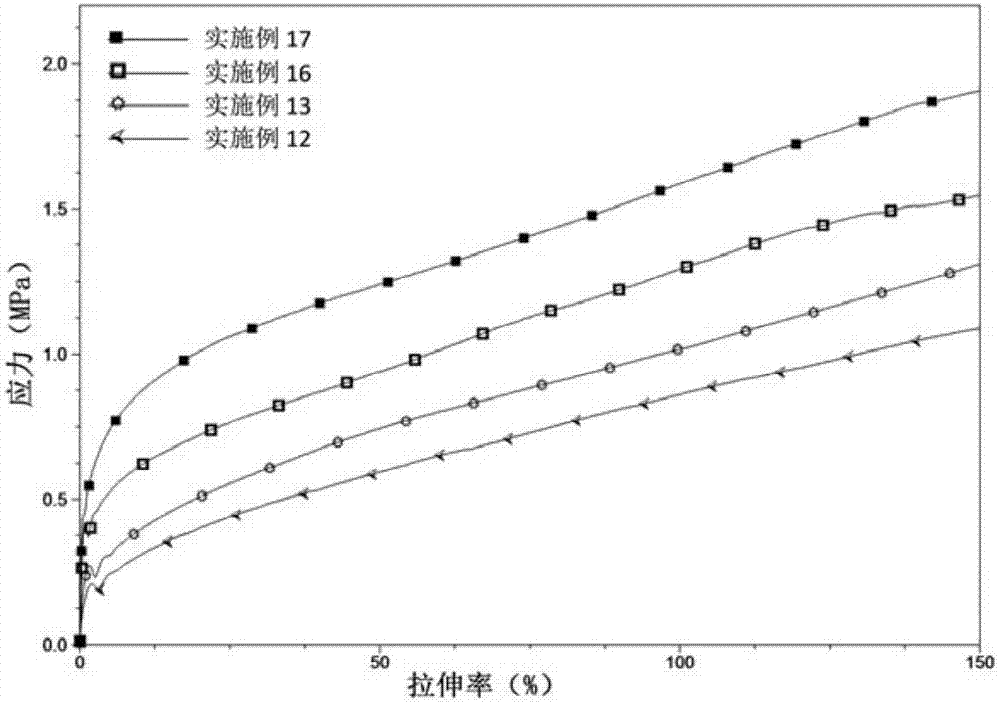

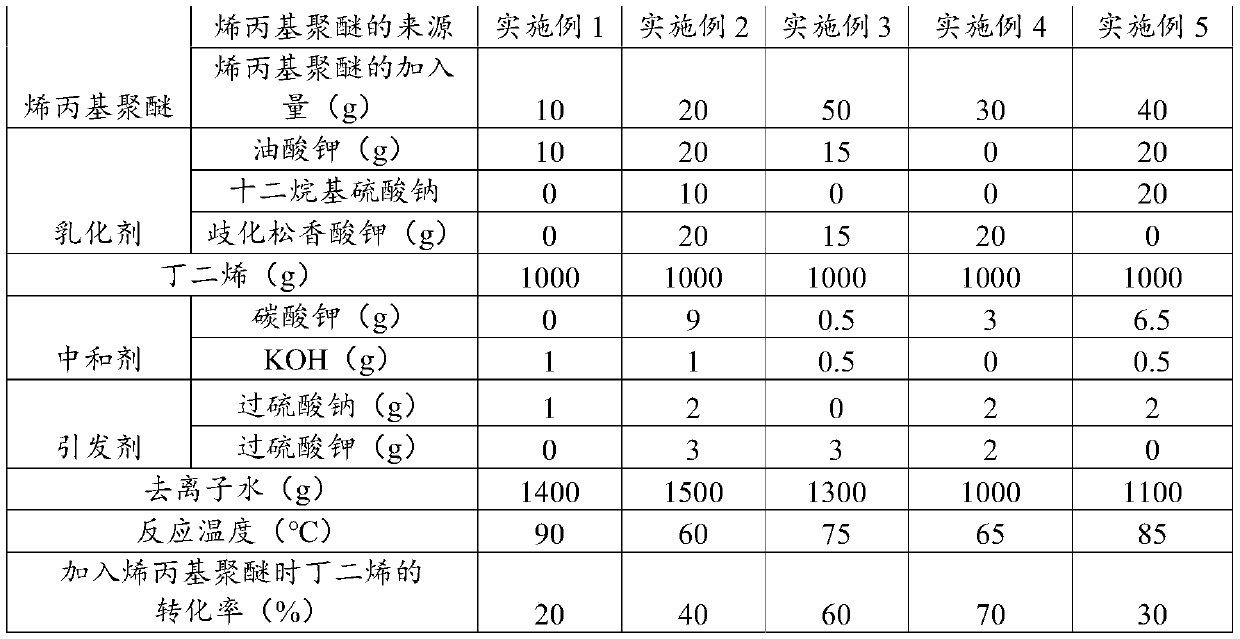

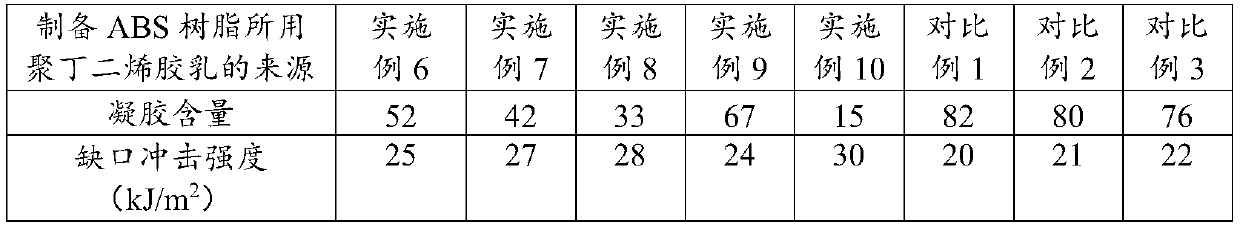

Preparation method of polybutadiene latex with low gel content, and prepared polybutadiene latex

The invention provides a preparation method of polybutadiene latex with a low gel content, and the prepared polybutadiene latex. The method comprises the following steps: respectively adding 1-5 partsby weight of an emulsifier, 100 parts by weight of butadiene, 0.1-1 part by weight of a neutralizer, 0.1-0.5 part by weight of an initiator and 100-150 parts by weight of water into a reaction container, raising the temperature to 60-90 DEG C, and carrying out a polymerization reaction; and adding allyl polyether when the butadiene conversion rate is greater than or equal to 20% and less than orequal to 70%, carrying out a copolymerization reaction, and obtaining the polybutadiene latex when the butadiene conversion rate is greater than or equal to 90%. An allyl polyether monomer containingn EO chain segments and m PO chain segments is added when the conversion rate of butadiene is 20-70%, and is copolymerized with butadiene, so that the prepared polybutadiene latex has low gel content,and the impact resistance of ABS resin can be effectively improved.

Owner:WANHUA CHEM GRP CO LTD

Water-based metal rust-proof white paint and preparation method thereof

ActiveCN103666163AIncrease coverageImprove adhesionAnti-corrosive paintsPolymer scienceFunctional monomer

The invention discloses water-based metal rust-proof white paint and a preparation method thereof, and belongs to the field of coating. According to the invention, water serves as a diluent; water-soluble resin which is formed by copolymerizing an acrylate monomer and a self-crosslinking functional monomer is selected; high-covering-power titanium dioxide imported from Japan, and high-performance corrosion-resistant fillers, a salt-mist-resistant agent, a flash-rust-resistant agent and a silane coupling agent are provided; the gel content is increased by a crosslinking molecular chain; the coating is subjected to complex reaction on the surface of metal to form a corrosion-resistant complex; the resin has an ultraviolet-stable monomer structure and a group with a special function, high adhesive force and waterproofness, so that the coating has excellent weather resistance and water resistance, good covering powder, no yellowing phenomenon, good adhesive force and high hardness, does not add any toxic corrosion-resistant fillers and aids, and is safe, environment-friendly and convenient to construct.

Owner:徐州市三为水性漆科技有限公司

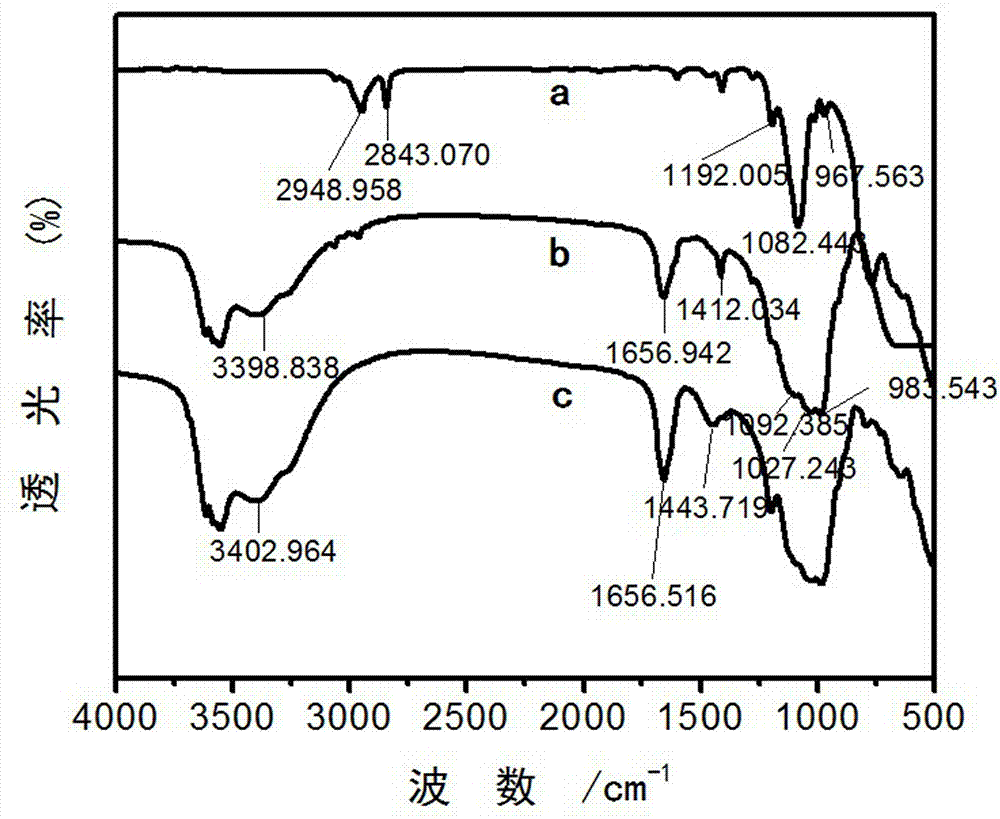

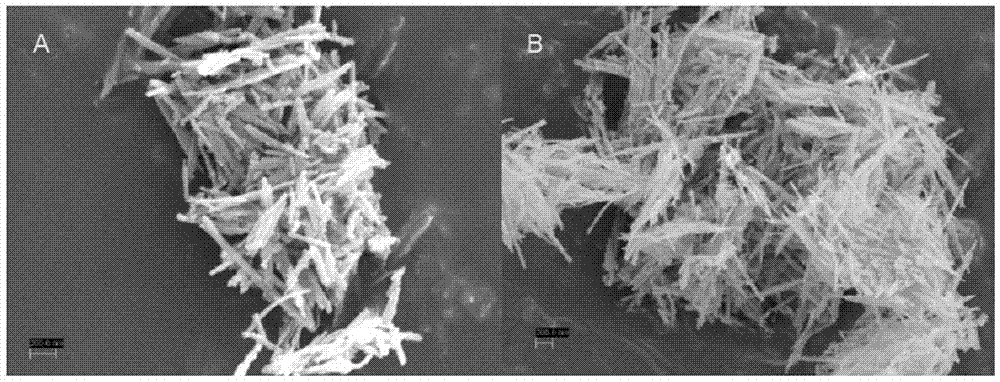

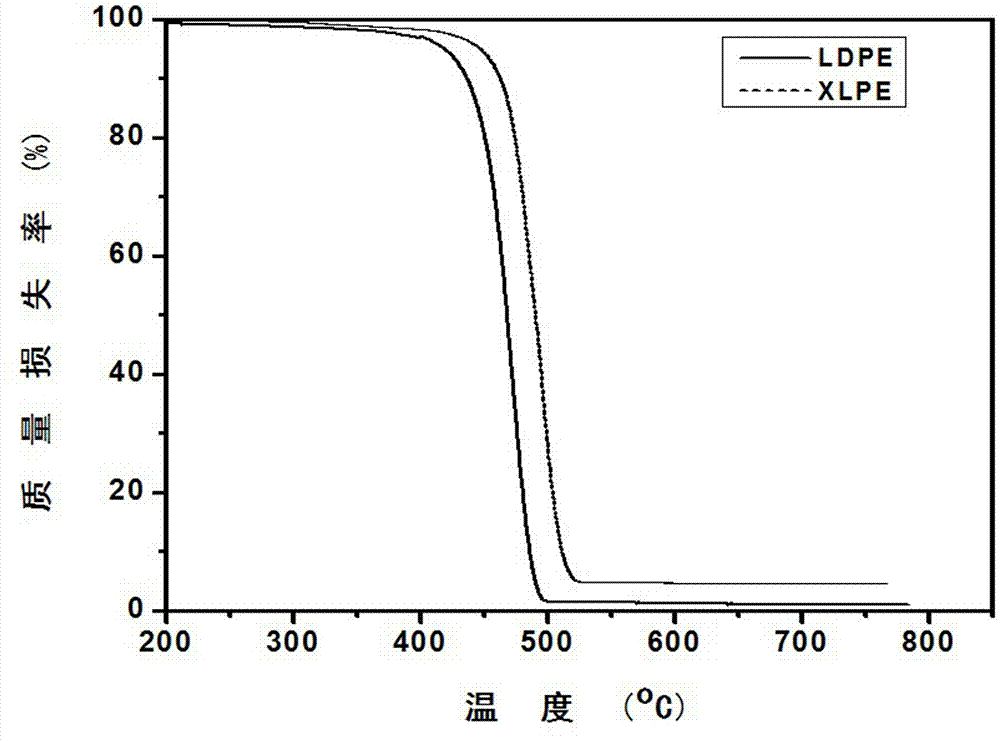

Palygorskite silane crosslinking agent preparation method and application of palygorskite silane crosslinking agent in low-density polyethylene crosslinking

The invention provides a palygorskite silane crosslinking agent preparation method and belongs to the field of high polymer materials. The method includes: dispersing activated palygorskite in an ethyl alcohol-water mixed solution, ultrasonic dispersing, adding an acidulated silane crosslinking agent, stirring, centrifuging, drying, conducting soxhlet extraction in a xylene solution, drying and grinding to obtain the palygorskite stem grafting silane crosslinking agent. Infrared absorption spectrum and scanning electron microscope analysis shows that the silane crosslinking agent is grafted on the surface of palygorskite clay, and a part of activated crosslinking group is reserved. Compared with vinyl trimethoxy silane of a common crosslinking agent of density polyethylene, under the condition of the same adding quantity and same processing technology, the palygorskite silane crosslinking agent is applied to crosslinking of the low-density polyethylene, and the mechanical property and gel content of the low-density polyethylene are improved. Meanwhile, combustion performance and thermal stability of a low-density polyethylene material are improved, the cost of the low-density polyethylene material is reduced, and the palygorskite silane crosslinking agent preparation method and the application have good application prospects.

Owner:兰州众邦电线电缆集团有限公司

Preparation method of polybutadiene latex

The invention discloses a preparation method of polybutadiene latex. According to the invention, unreacted butadiene is removed under a butadiene conversion rate of 60-80%, such that small-particle-size polybutadiene latex is prepared; liquid polybutadiene with a certain molecular weight is added into the system to increase the particle size of the latex to a target value; the latex prepared by the method has lower cross-linking degree, and the ABS resin prepared from the latex has lower VOC content, yellow index and impact resistance.

Owner:WANHUA CHEM GRP CO LTD

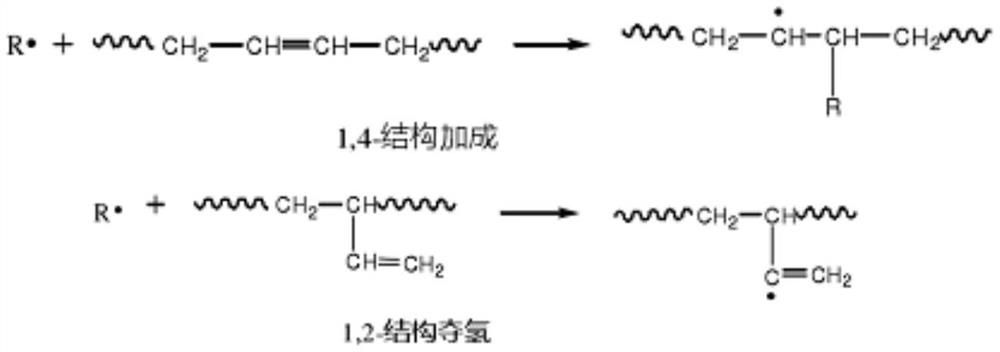

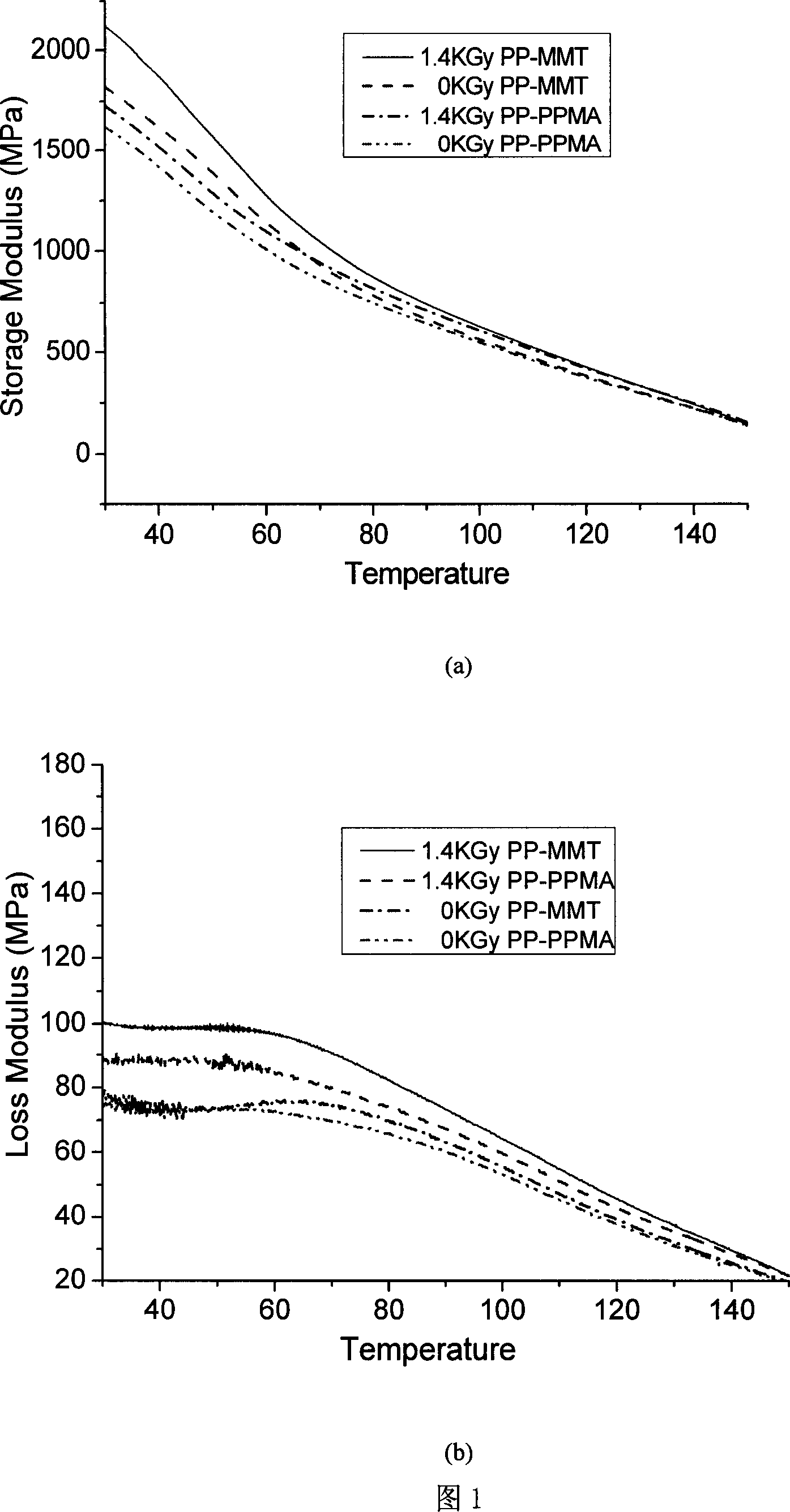

Radiation crosslinked polypropylene/montmorillonite composite material preparation method

InactiveCN1962750APrevent infiltrationImprove high temperature mechanical propertiesMaterials preparationMontmorillonite

The invention discloses a preparing method of polypropylene / montmorillonite composite material through irradiating and crosslinking, which comprises the following steps: 1) putting polypropylene grafted by maleic anhydride and organic montmorillonite with weight rate at 1:1 in the squeezer to grain; preparing the mother material of polypropylene / montmorillonite; 2) blending 60-100g mother material, 50g crosslinking agent and 1000g polypropylene evenly; producing irradiated material of polypropylene / montmorillonite; 3) irradiating the irradiated material of polypropylene / montmorillonite in the air with irradiating dose at 0.1-2Kgy.

Owner:ZHEJIANG UNIV +1

Formulation for coating material

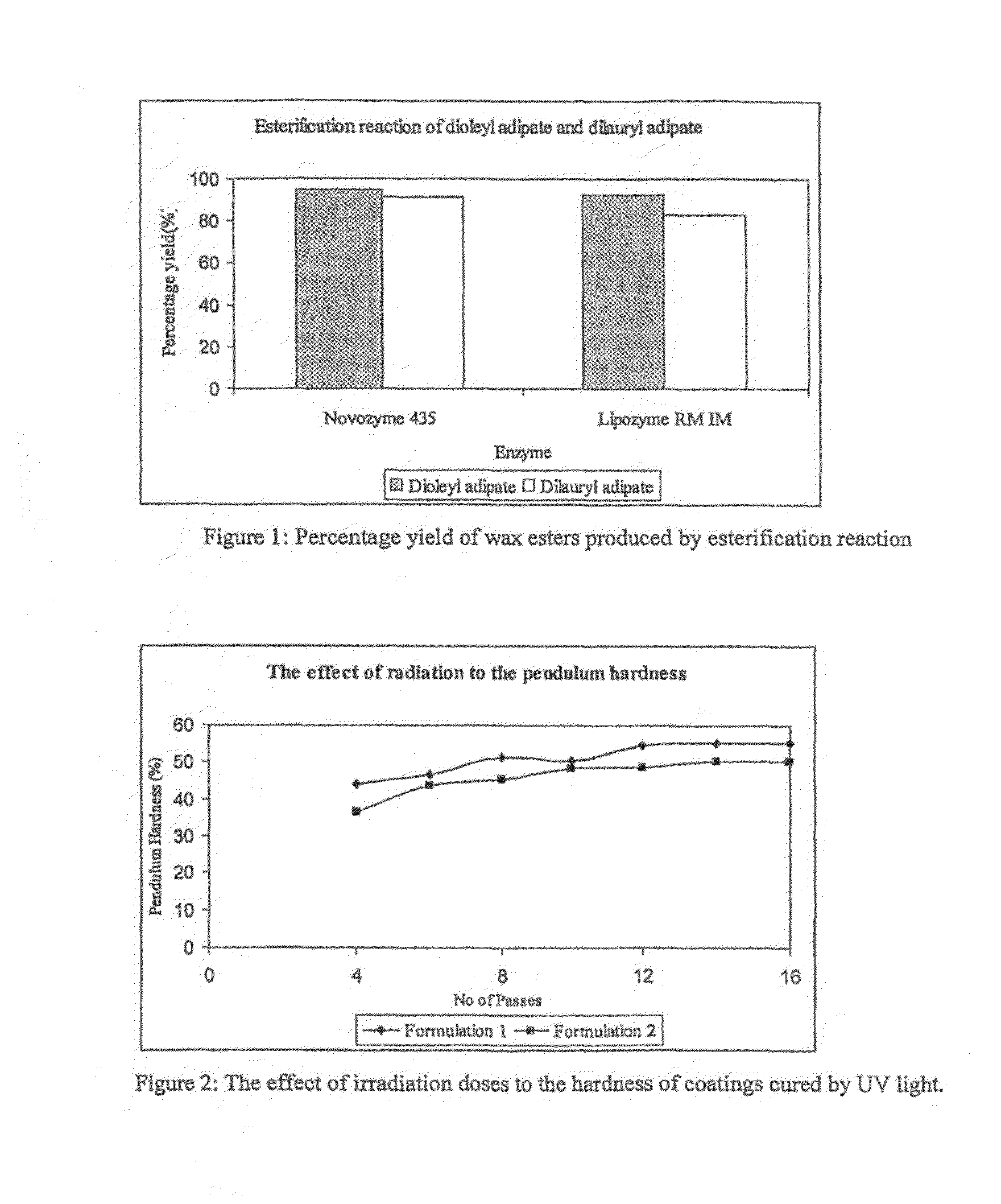

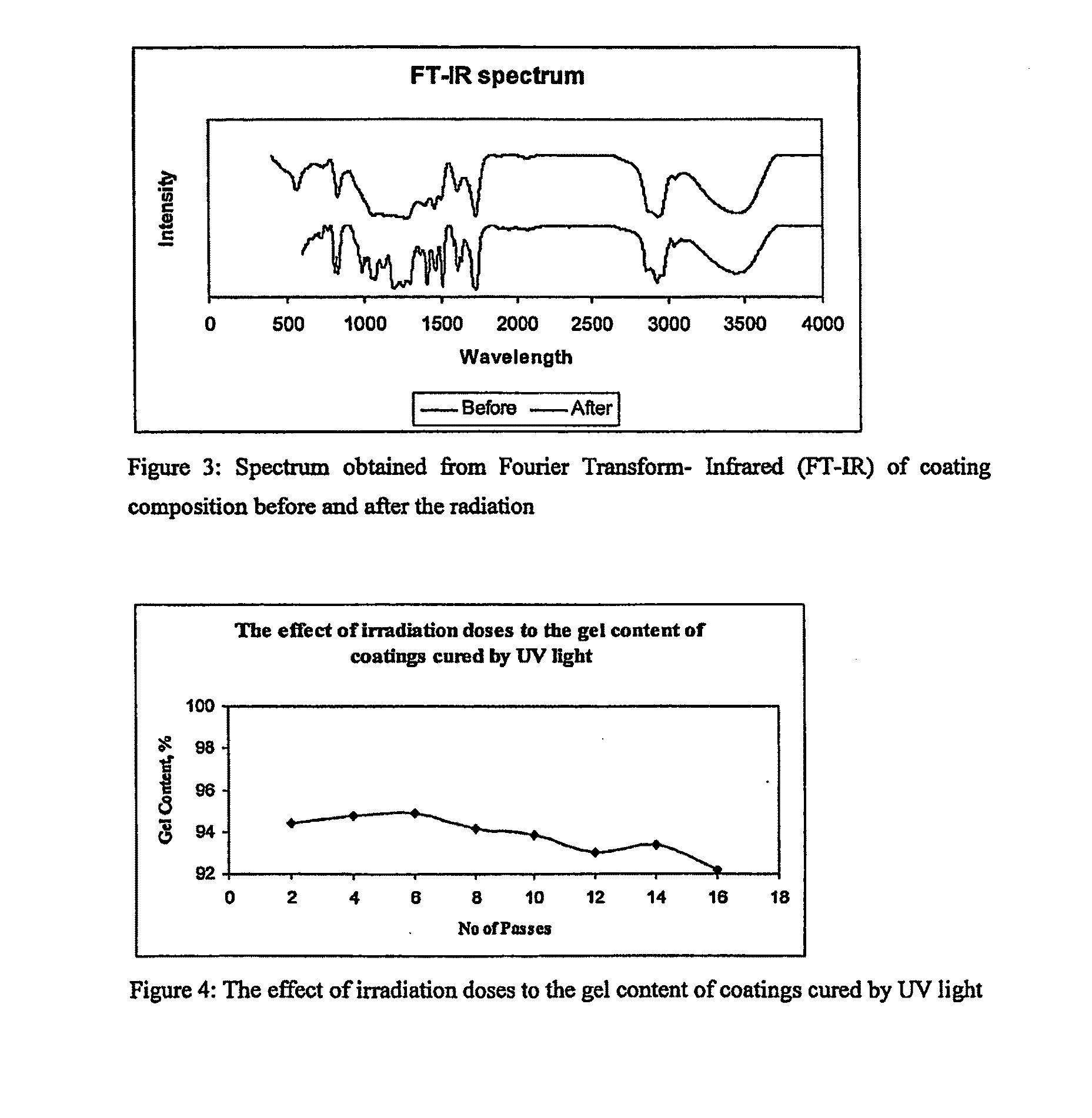

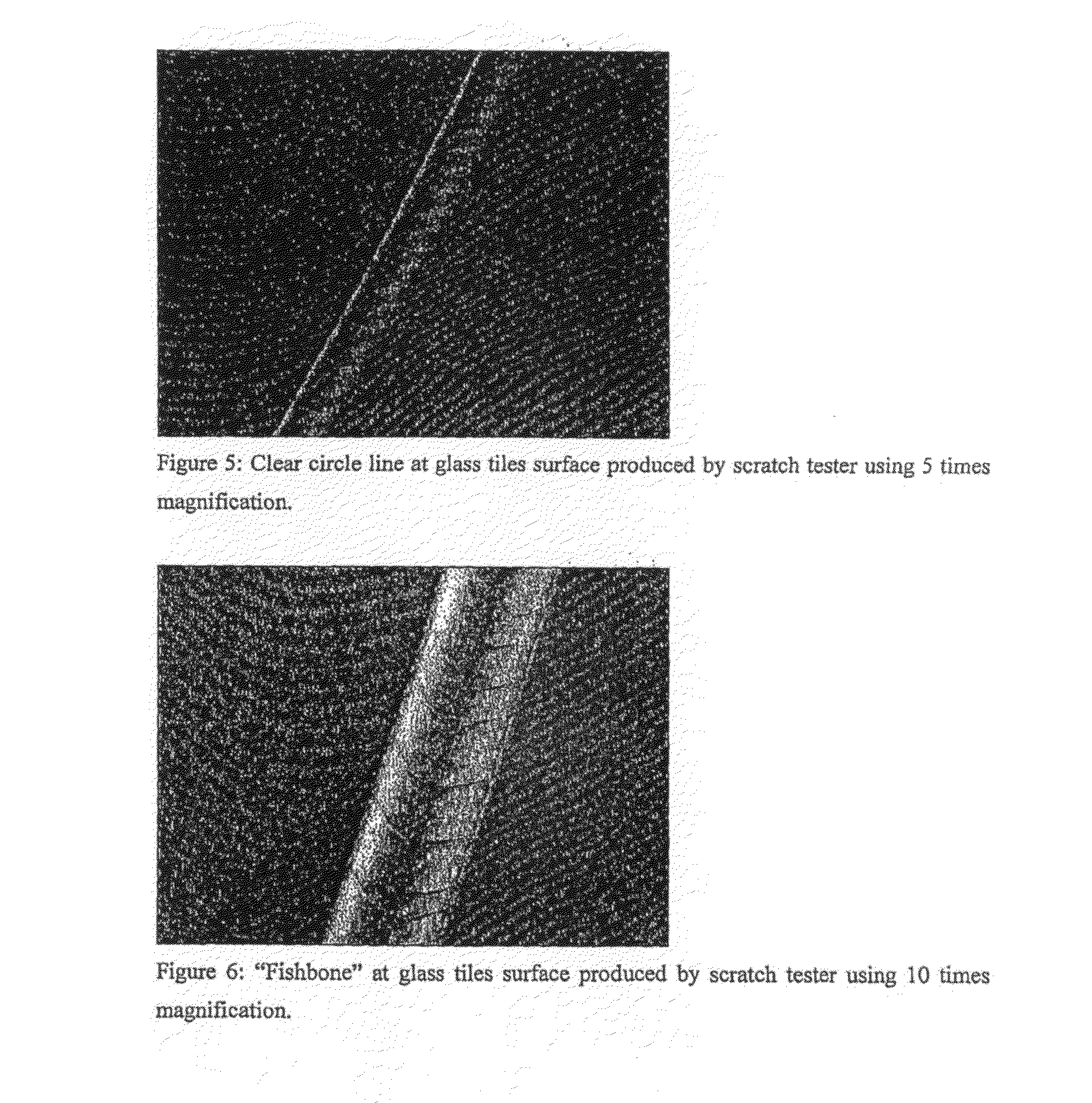

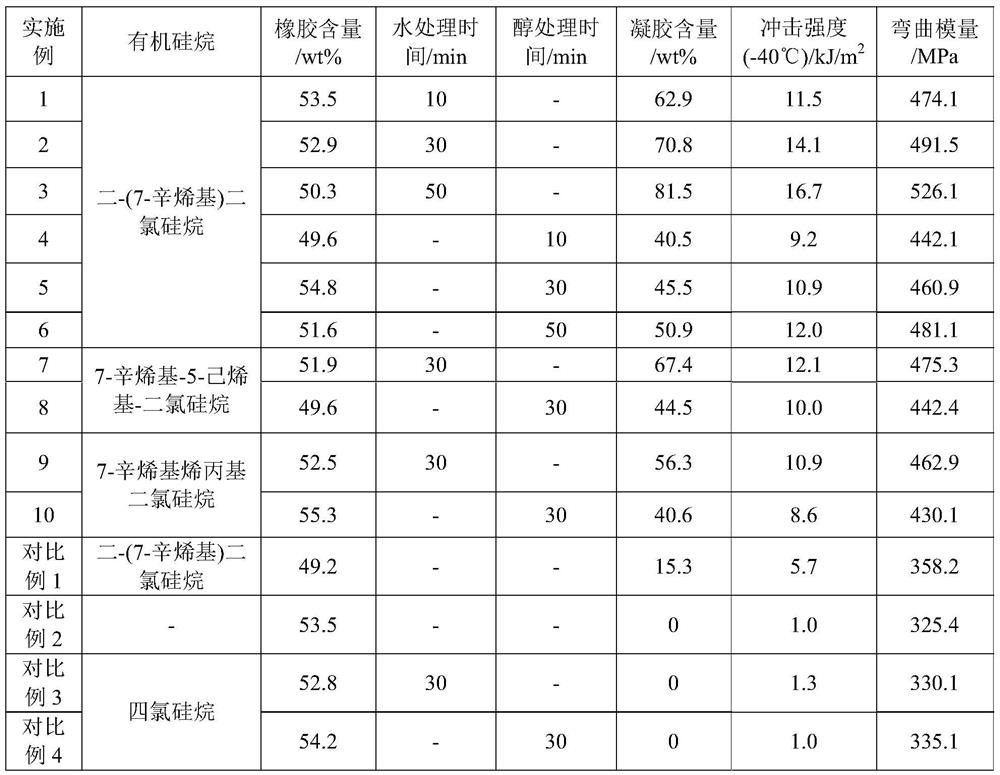

InactiveUS20100186628A1High gel contentImprove scratch resistanceFireproof paintsBiocideSolvent freeUltraviolet

The present invention relates to a Solvent-free coating material and treating agents used as wood coating material as a protective agent. The wood coating material is used to provide a short period of time ultra-violet (UV) radiation curing. Furthermore the coating material relates to an anticorrosion formulation and a method for forming a coated panel. This invention also provides a low volatility and high scratch resistance of coating for wooden surfaces.

Owner:UNIVERSITI PUTRA MALAYSIA

Method for preparing polyolefin in-kettle alloy and polyolefin in-kettle alloy prepared by method

The invention relates to the field of olefin polymerization, and discloses a method for preparing polyolefin in-kettle alloy and the polyolefin in-kettle alloy prepared by the method. The preparationmethod comprises the following steps: 1) carrying out a first polymerization reaction on a first olefin monomer in the presence of a catalyst, and introducing a second olefin monomer into the polymerization reaction system to carry out a second polymerization reaction, the first olefin monomer being different from the second olefin monomer, and the first polymerization reaction and / or the second polymerization reaction being carried out in the presence of organosilane; and 2) bringing water and / or alcohol into contact with the product obtained in the step 1), with the organosilane having a general formula of R1mSiXnR2k, wherein R1 is a 1-alkylene group of C7-C20, R2 is a 1-alkylene group of C2-C20, X is halogen, m, n and k are respectively 1 or 2, and m + n + k = 4. The polyolefin in-kettle alloy rubber disclosed by the invention is high in cross-linking degree, and has higher impact toughness and bending modulus.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Light-weight polyvinyl chloride plastic tube and preparation method thereof

The invention discloses a light-weight polyvinyl chloride plastic tube. The light-weight polyvinyl chloride plastic tube is prepared from the following raw materials in parts by weight: 0.1-0.2 part of nonylphenol, 1-2 parts of triallyl isocyanurate, 0.2-0.3 part of linoleic acid, 3-4 parts of carbon nanotubes, 40-60 parts of 90-93% sulfuric acid, 60-70 parts of 95-97% nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of 2-hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of liquid ethylene propylene diene monomer, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride, 10-14 parts of light-weight calcium carbonate, 3-5 parts of N-methylpyrrolidinone, 0.2-0.3 part of coconut diethanolamide, 3-4 parts of allyl polyethylene glycol, 0.8-1 part of zinc dialkyl dithiophosphate and 0.03-0.1 part of sp80. The light-weight polyvinyl chloride plastic tube disclosed by the invention is low in processing cost, and high in weather resistance and impact resistance.

Owner:安徽玉发塑业有限公司

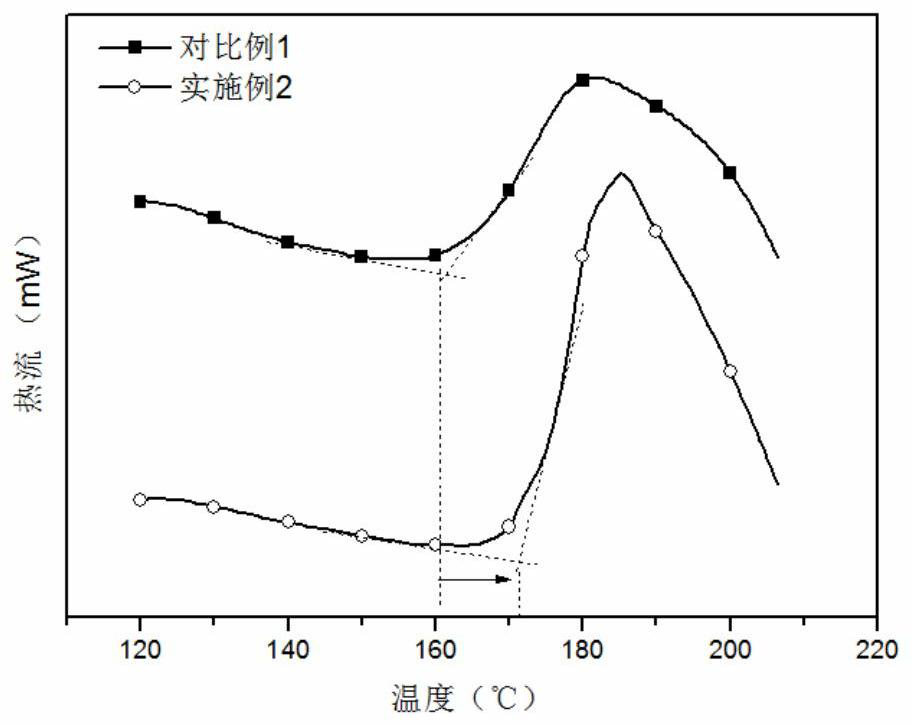

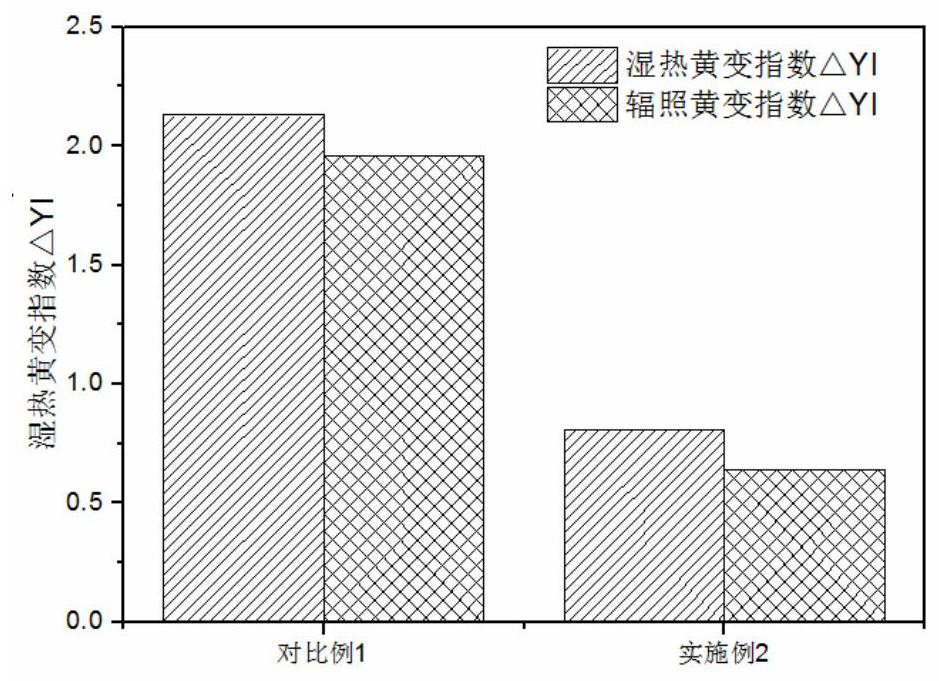

Crosslinkable POE composition and application thereof, crosslinked POE membrane and preparation method and application thereof

PendingCN114350281AImprove processabilityExtended service lifeNon-macromolecular adhesive additivesFilm/foil adhesives without carriersCross linked membranePolyolefin

The invention relates to the field of cross-linked POE products, and discloses a cross-linkable POE composition and application thereof, a cross-linked POE film and a preparation method and application thereof. The crosslinkable POE composition comprises a POE polyolefin elastomer, a peroxide cross-linking agent, an assistant cross-linking agent, a nitroxide free radical inhibitor and an antioxidant, wherein relative to 100 parts by weight of the POE polyolefin elastomer, the dosage of the peroxide cross-linking agent is 0.05 to 2 parts by weight, the dosage of the assistant cross-linking agent is 0.05 to 2 parts by weight, the dosage of the nitroxide free radical inhibitor is 0.05 to 1 part by weight, and the dosage of the antioxidant is 0.05 to 1 part by weight. The crosslinked POE composition is not prone to early crosslinking in the processing process and has excellent processing stability in the extrusion / casting process of the composition, and the long-term stability of a crosslinked POE film prepared from the crosslinked POE composition under the conditions of high temperature, high humidity and high ultraviolet radiation can be remarkably improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

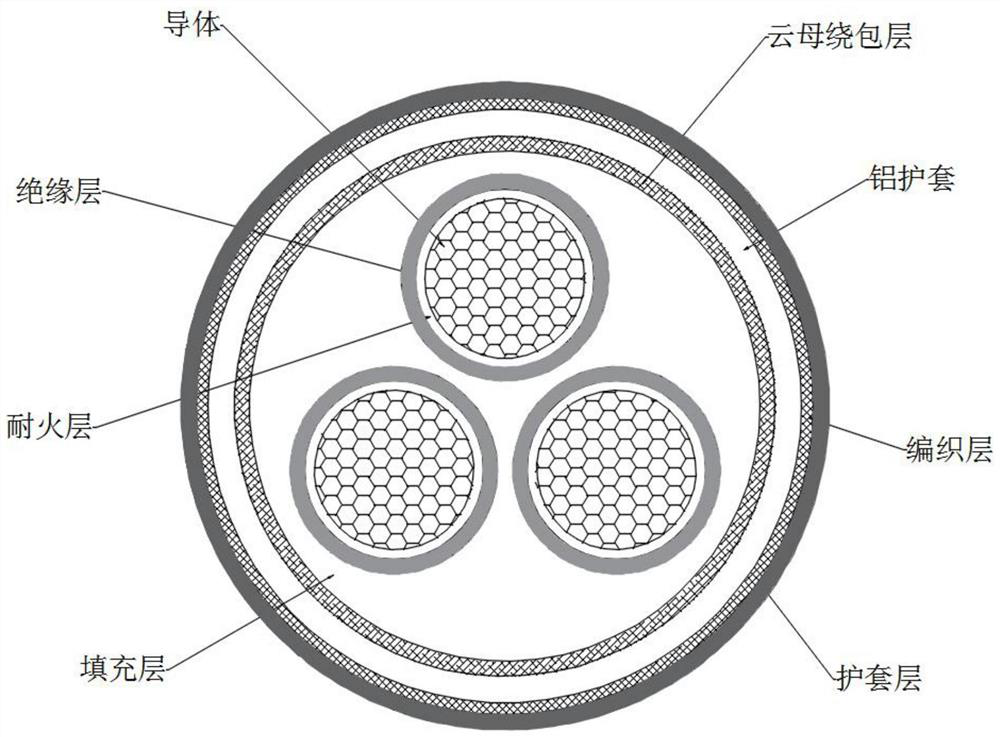

Flexible fireproof cable production process

PendingCN113539585AGood heat insulationReduced hazards to personnel and electrical equipmentPlastic/resin/waxes insulatorsClimate change adaptationCopper wireEthylene propylene rubber

The invention discloses a flexible fireproof cable production process which comprises the following steps: S1, drawing a copper bar into copper wires, and twisting the copper wires to form a copper conductor; S2, wrapping a flame-retardant composite belt outside the conductor to form a fireproof layer, and then extruding ethylene propylene rubber outside the fireproof layer to form an insulating layer; S3, bundling at least two conductive cable cores, and then filling the periphery of the bundled conductive cable cores with high-flame-retardant inorganic matters to obtain a filling layer; S4, wrapping a mica tape outside the filling layer to obtain a mica wrapping layer, and then extruding ceramic silicone rubber outside the mica wrapping layer to form a lining layer; S5, wrapping the outside of the lining layer with an aluminum alloy metal belt to form an aluminum sheath; and S6, braiding outside the aluminum sheath to form a braided layer, and finally extruding crosslinking modified low-density polyethylene outside the braided layer to form a sheath layer, thereby obtaining the flexible fireproof cable. The flexible fireproof cable produced by the process disclosed by the invention has good heat insulation property, insulating property and aging resistance.

Owner:安徽正豪电缆有限公司

Anti-aging polyvinyl chloride plastic tube and preparation method thereof

InactiveCN105820469AHigh mechanical strengthImprove anti-aging propertiesCarbon nanotubePolyvinyl chloride

The invention discloses an anti-aging polyvinyl chloride plastic tube which consists of the following raw materials in parts by weight: 0.3-0.5 part of N-phenyl-2-naphthylamine, 1-2 parts of stearamide, 3-4 parts of carbon nanotubes, 40-60 parts of 90-93% sulfuric acid, 60-70 parts of 95-97% nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of a liquid ethylene propylene diene monomer, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride, 0.2-0.5 part of trimethylolpropane, 10-14 parts of attapulgite, 0.1-0.3 part of 1,2-dimethyl imidazole, 2-3 parts of pentaerythritol, 3-5 parts of isopropyl palmitate, 1-2 parts of dipotassium glycyrrhizinate and 2-3 parts of sodium silicate. The anti-aging property of a finished product of the anti-aging polyvinyl chloride plastic tube is improved, and the service life of the finished product is prolonged.

Owner:安徽玉发塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com