Patents

Literature

834results about How to "Light material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

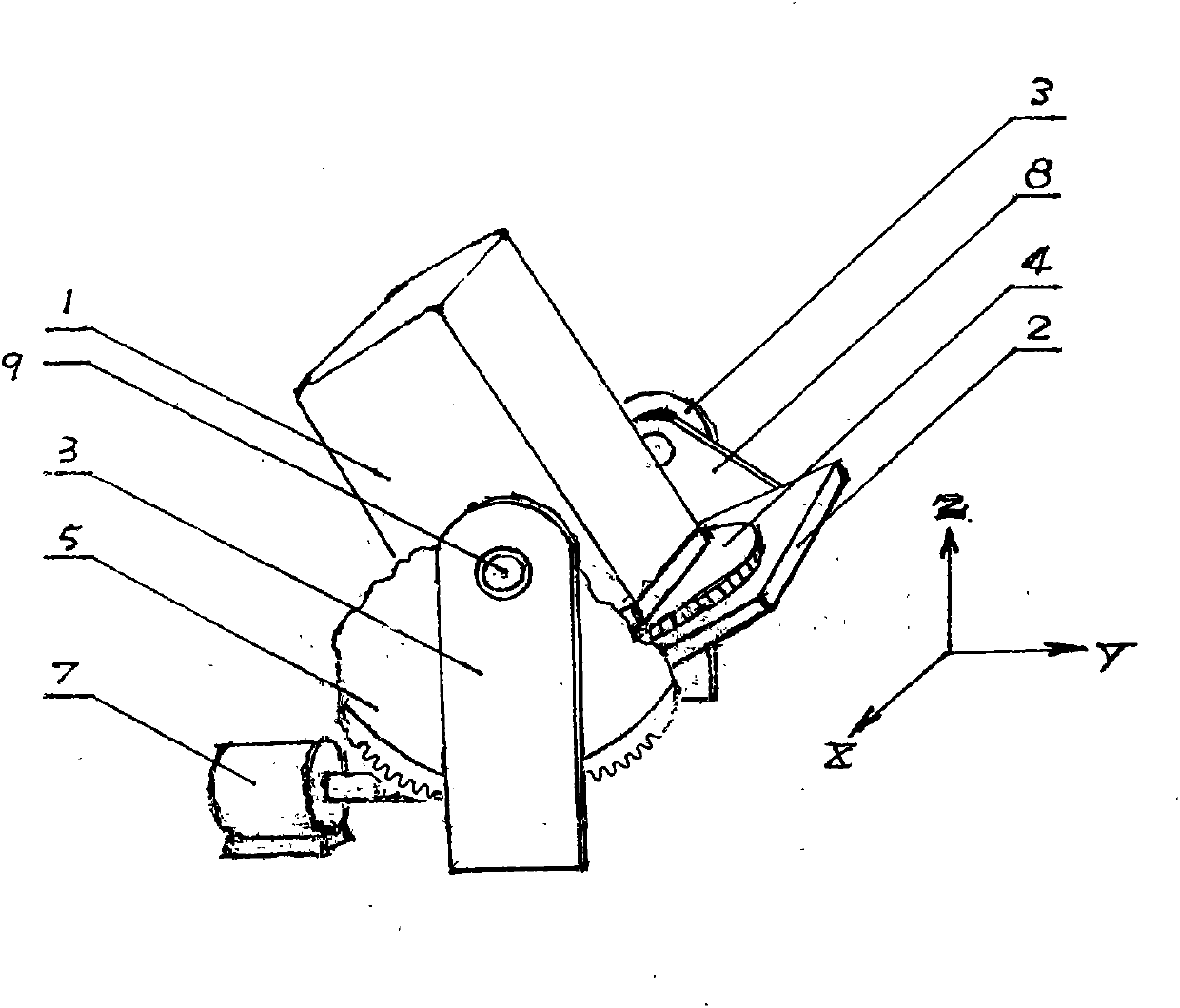

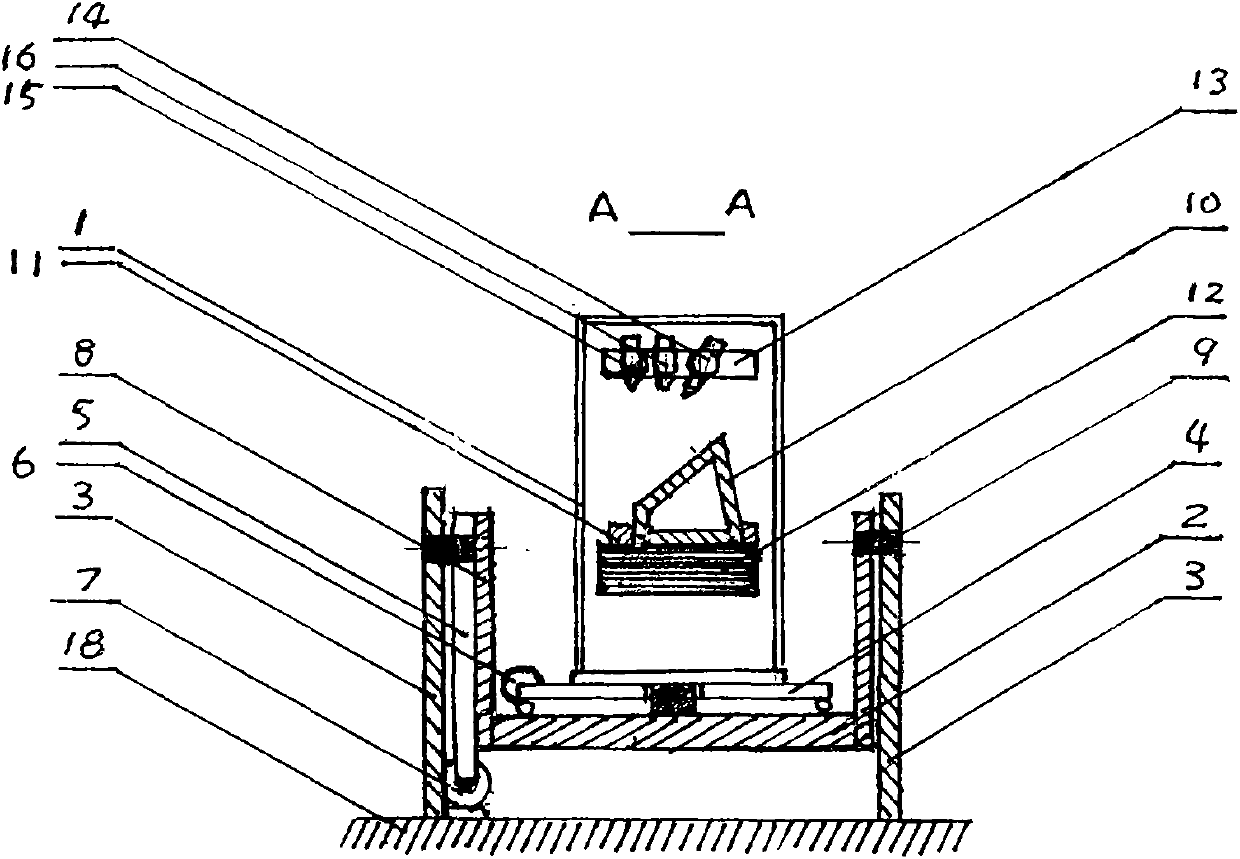

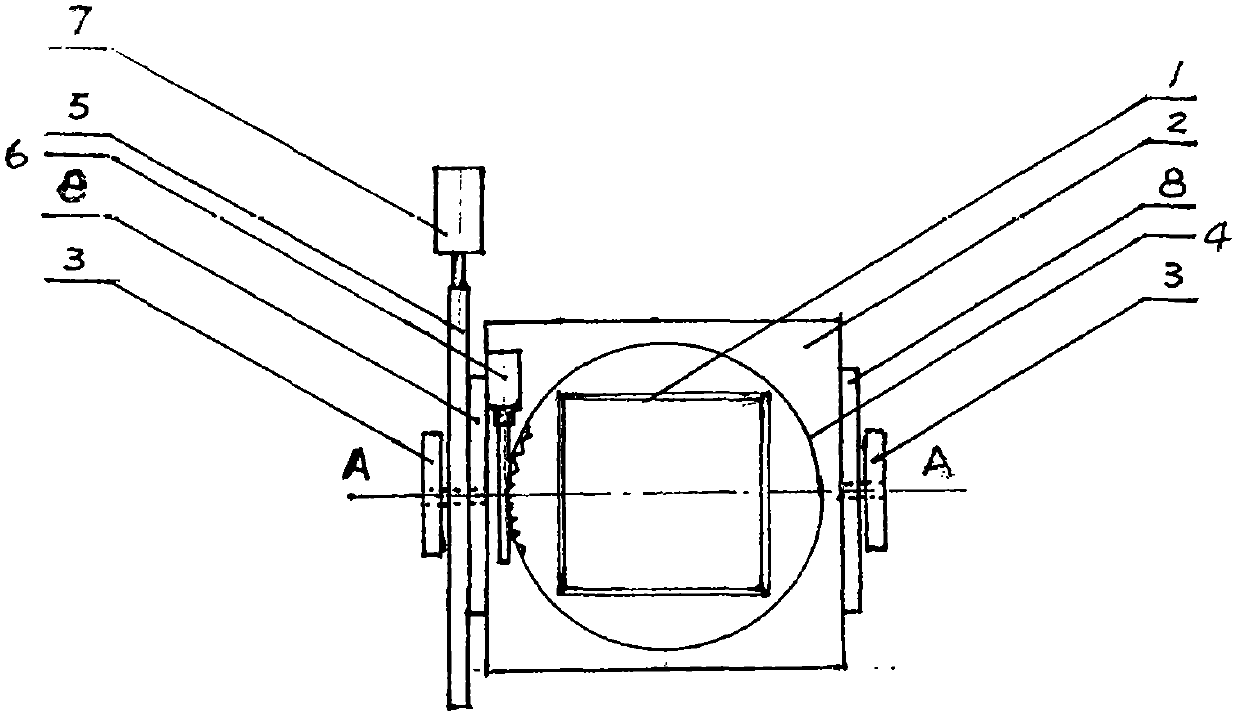

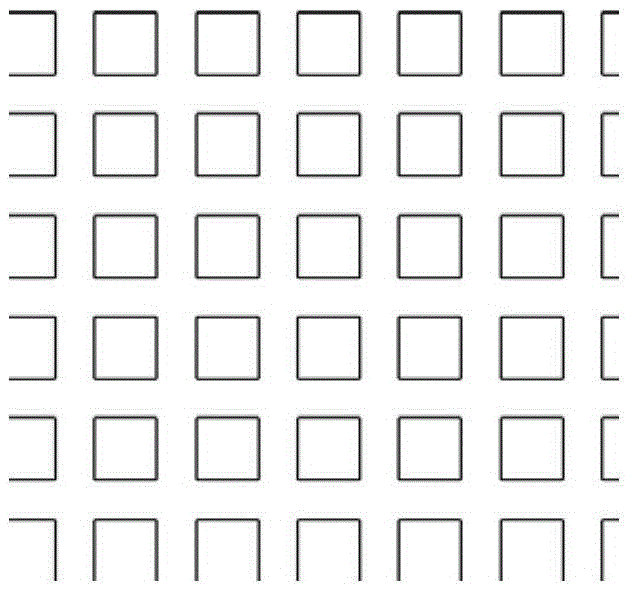

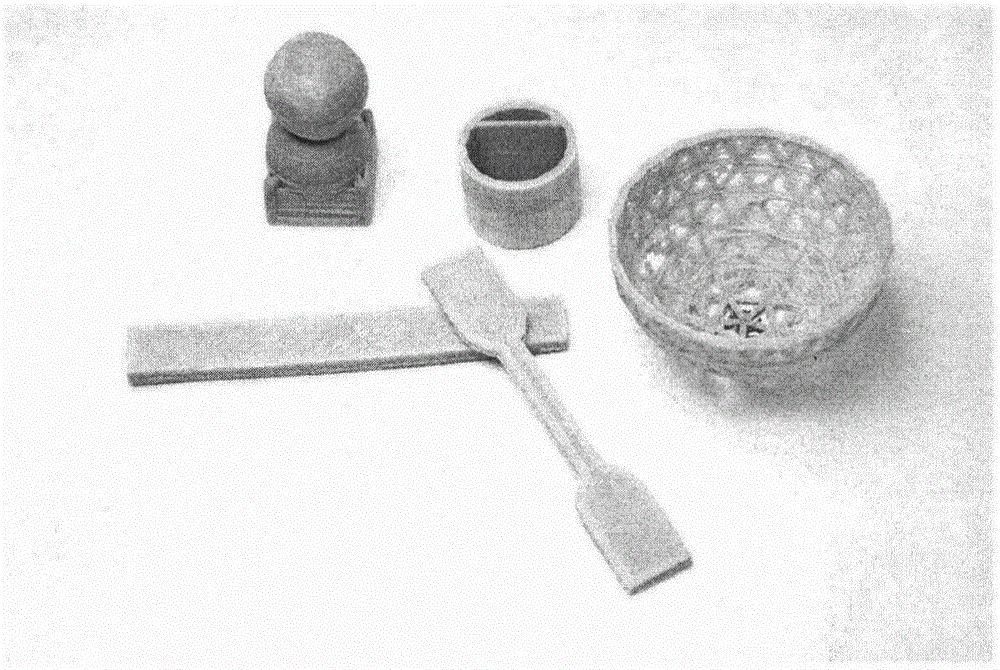

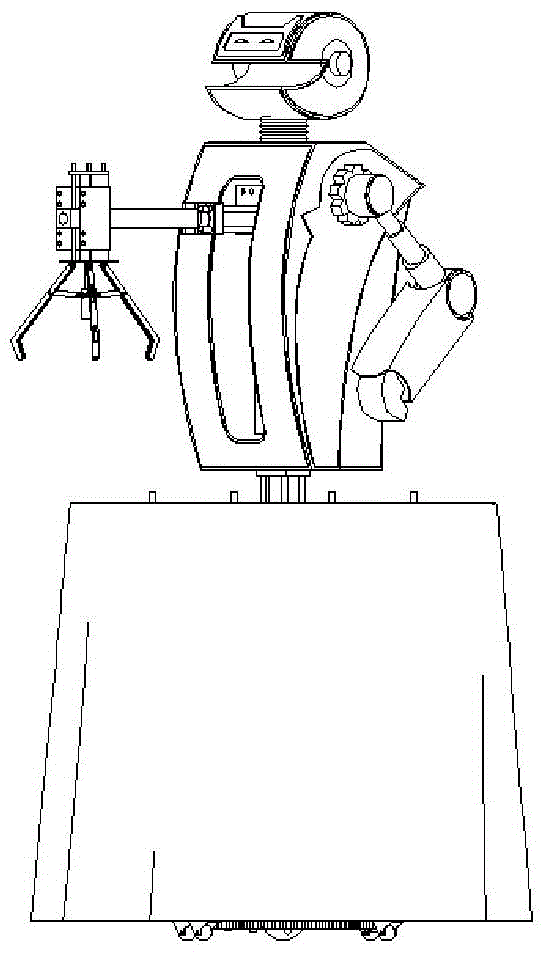

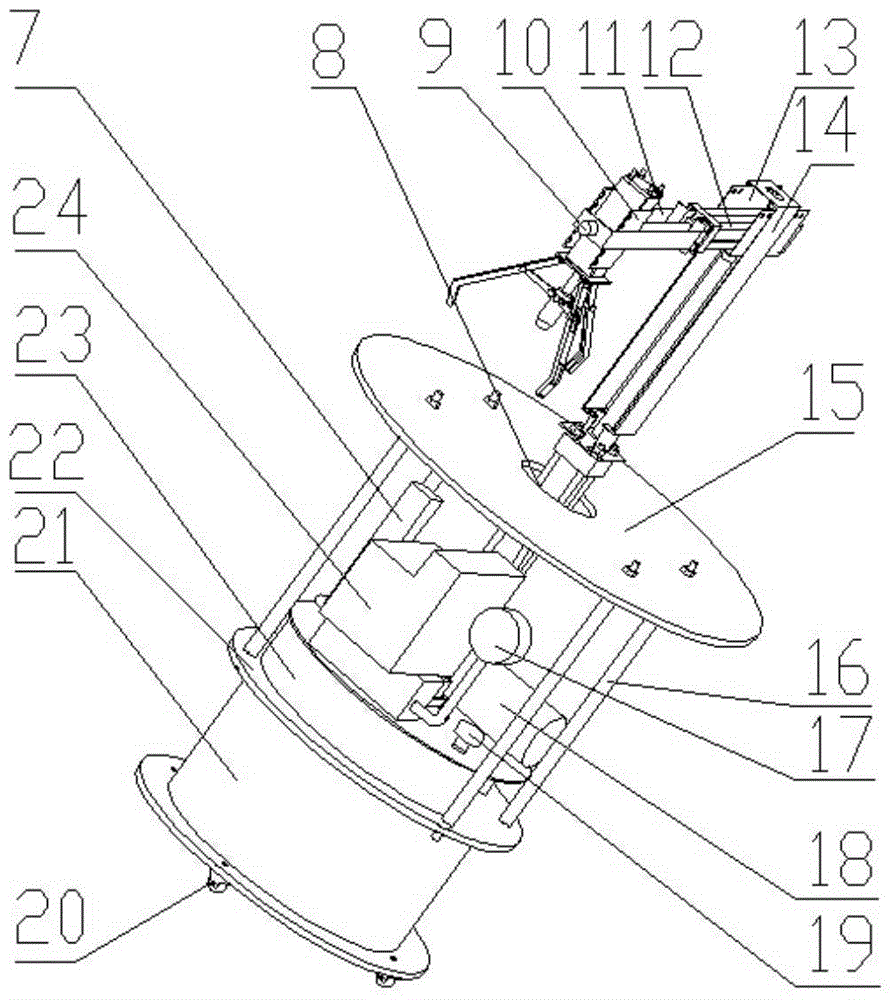

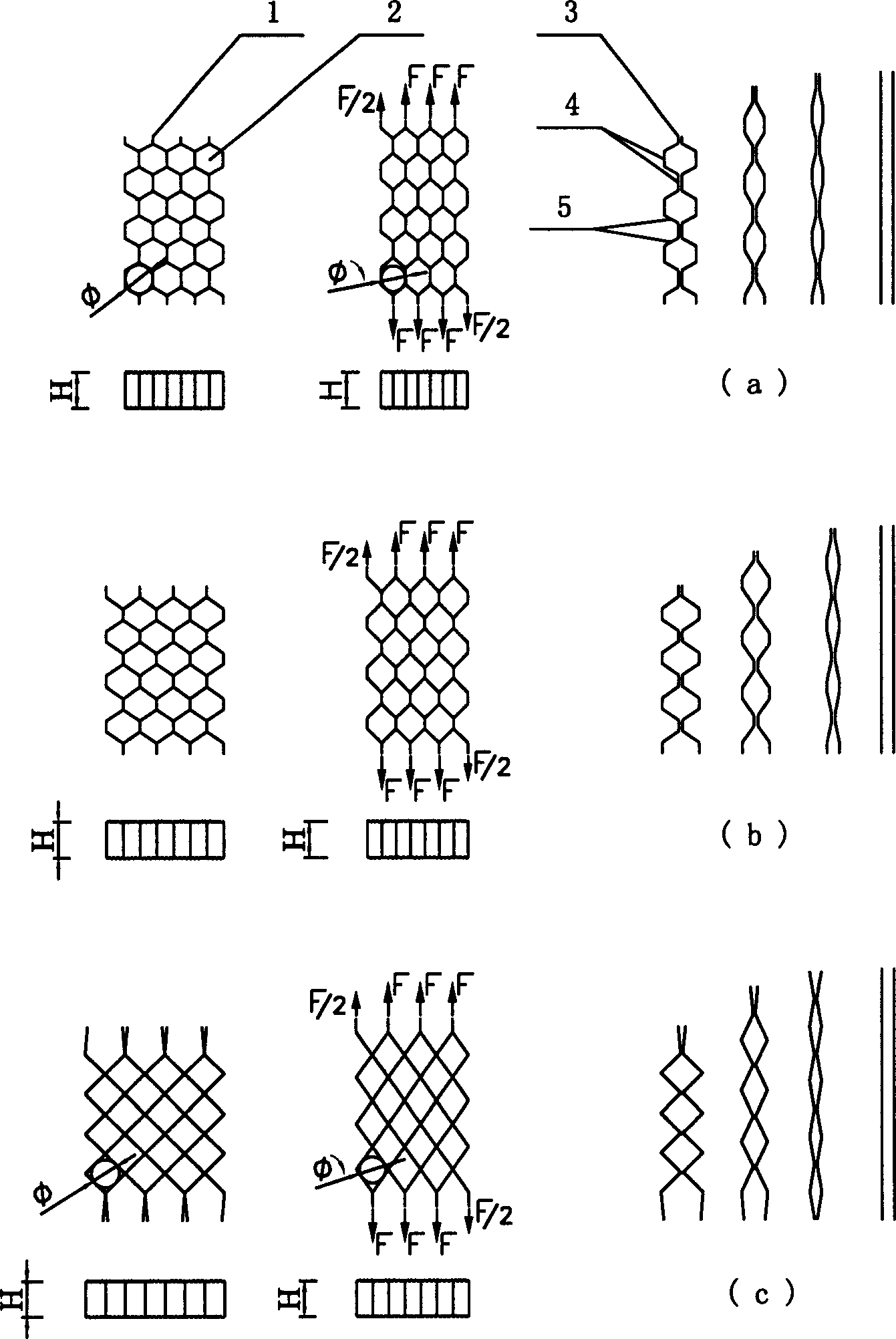

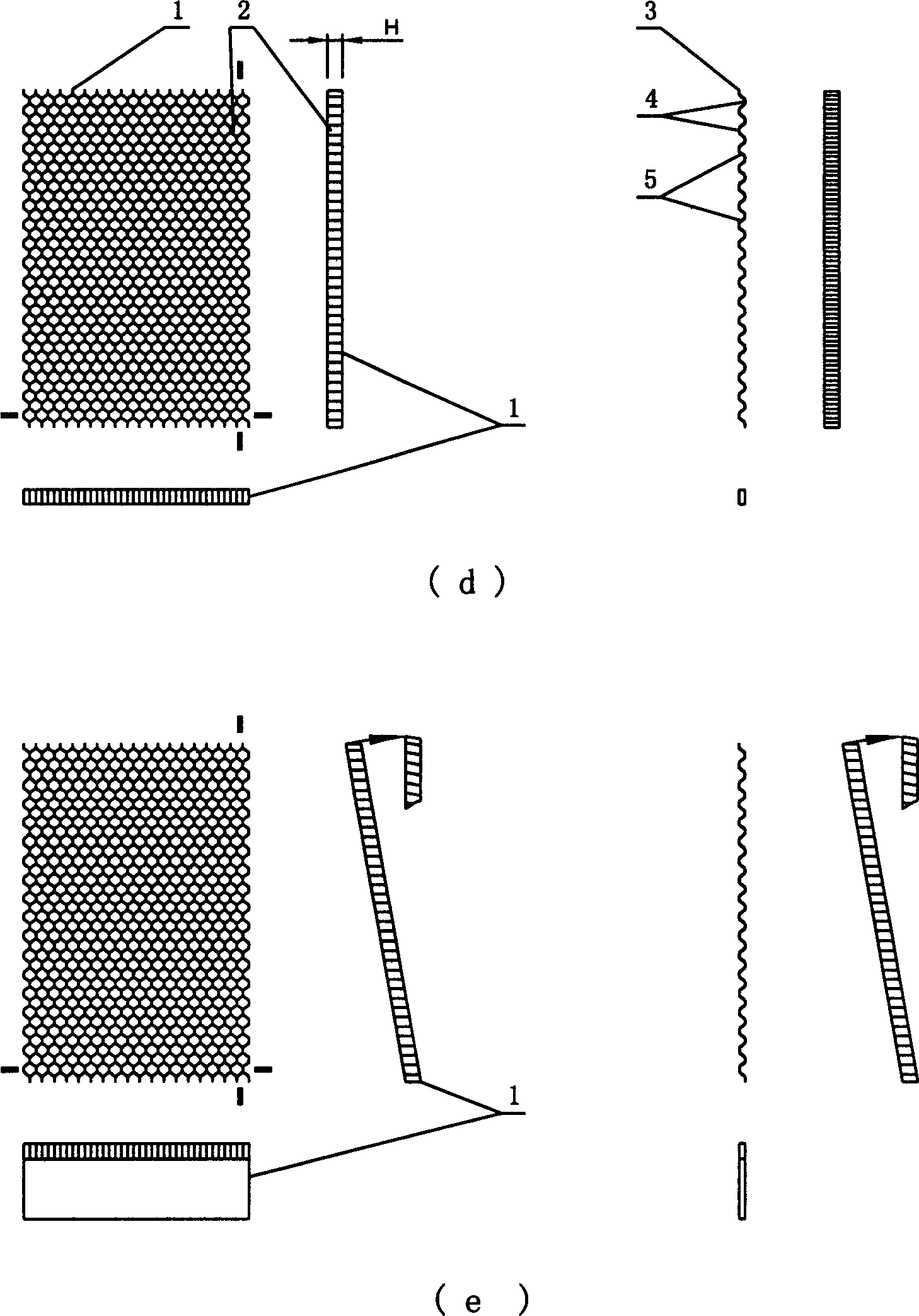

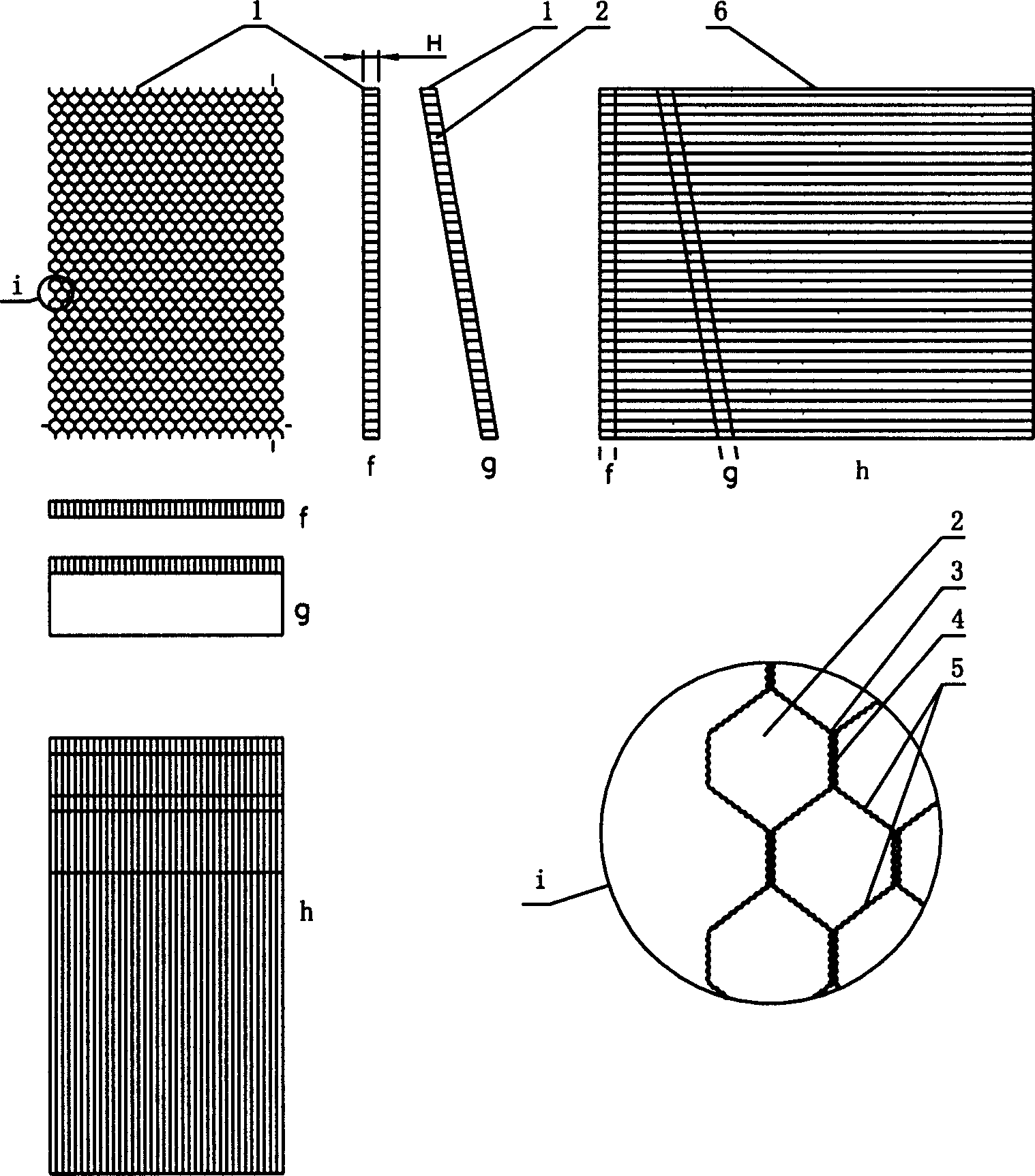

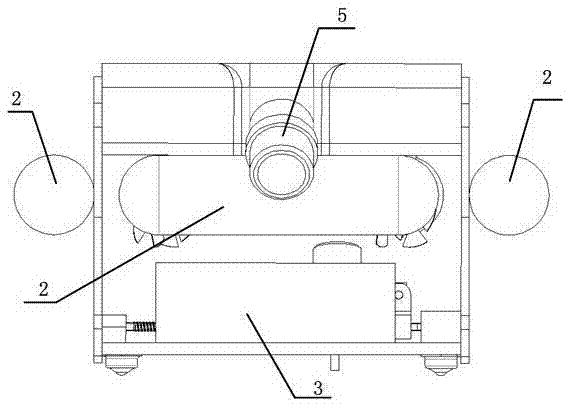

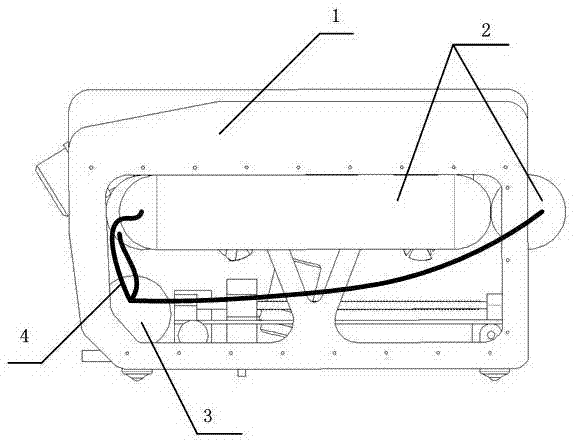

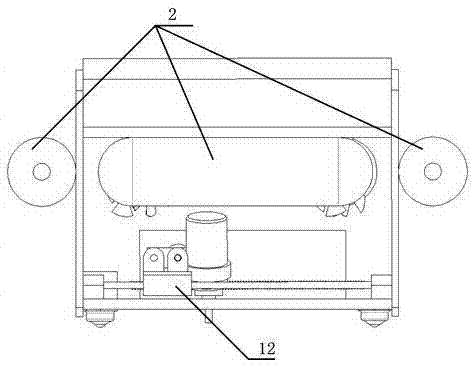

3D (three-dimensional) printer with inclinable machine body

The invention provides a 3D (three-dimensional) printer with an inclinable machine body. The 3D printer comprises a machine seat part and a 3D printer main body part, wherein the machine seat part is provided with a machine seat platform, a rotary platform, and worm wheel and worm motor devices which are used for respectively driving the machine seat platform to deflect and driving the rotary platform to rotate; the 3D printer main body part comprises a 3D printer main body, a deflectable nozzle, a fixed nozzle, a servo mechanism and an elevated working platform, wherein the 3D printer main body is arranged on the rotary platform of the machine seat, the deflectable nozzle and the fixed nozzle are arranged on a y-axis plate, and the servo mechanism is used for driving the deflectable nozzle. According to the inclination conditions of a cantilever and a cavity curved surface of a machined workpiece, the 3D printer performs no-support printing on the cantilever and the cavity curved surface of the machined workpiece through the rotation of the rotary platform of the machine seat and the deflection of a deflection surface of the machine seat as well as the deflection of the deflectable nozzle on the 3D printer main body part, thus hollow polyhedral, spherical and multilayer honeycomb structure workpieces can be machined, and the compatibility of two categories of 3D printing technologies is realized on the 3D printer. The machined multilayer honeycomb structure workpieces can be importantly applied to the fields of spaceflight, national defense and civil use.

Owner:康子纯

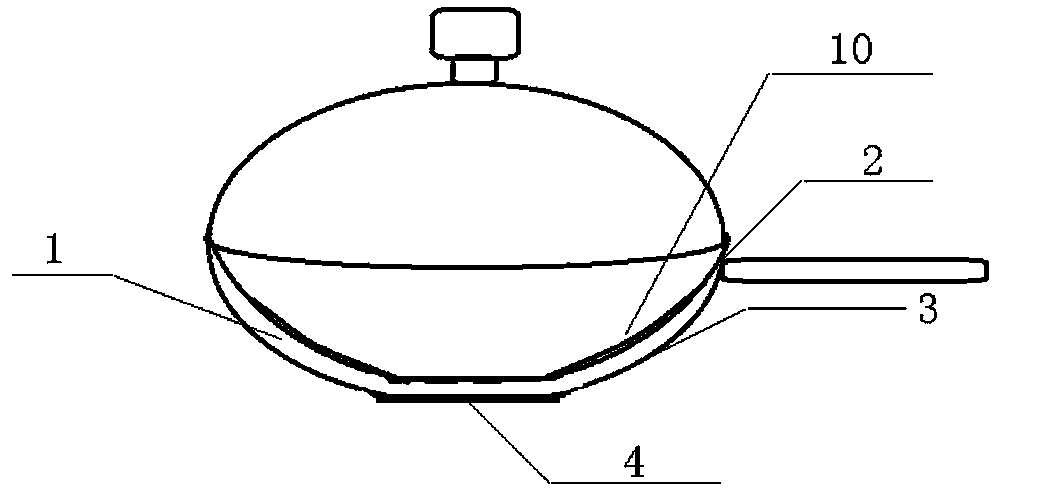

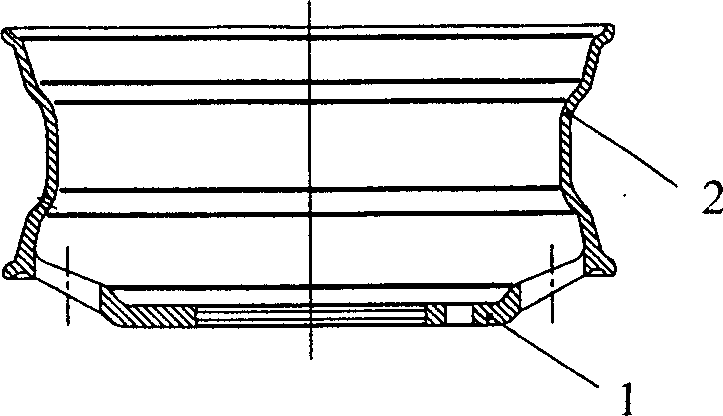

Novel composite cooker and manufacturing method thereof

The invention provides a novel composite cooker which comprises a cooker body with the thickness of 1.5 mm-5.0 mm. The thickness of the cooker wall is successively and progressively decreased by the 2 mm-3 mm space from the upper portion of the plane of a cooker bottom to the edge of the cooker wall. The cooker body comprises an inner layer cooker body and an outer layer cooker body, the inner layer cooker body is made of one of iron, iron-base alloy, stainless steel, titanium and titanium alloy, the outer layer cooker body is made of aluminum alloy or pure aluminum or AZ31B magnesium alloy or magnesium alloy, and a magnetic conduction energy storage layer is pressed on the outer surface of the outer layer cooker body. The materials of the inner surface of the cooker is healthful and sanitary, the heat conduction performance of the outer surface of the cooker is good, the outer surface is light in material, the magnetic conduction energy storage layer is arranged on the outer portion of the cooker bottom, the heat collection effect of the cooker bottom is increased, cooking energy consumption is reduced, and the application range of the cooker is expanded. The invention further provides a manufacturing method of the novel composite cooker. The method is easy to operate, saves materials, reduces cost, and is convenient to implement and beneficial to industrialization of the novel composite cooker.

Owner:WUYI RUIPU KITCHENWARE CO LTD

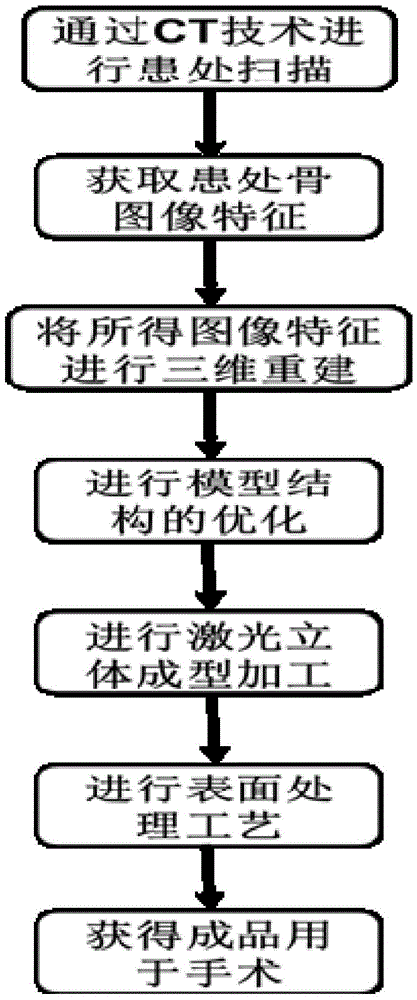

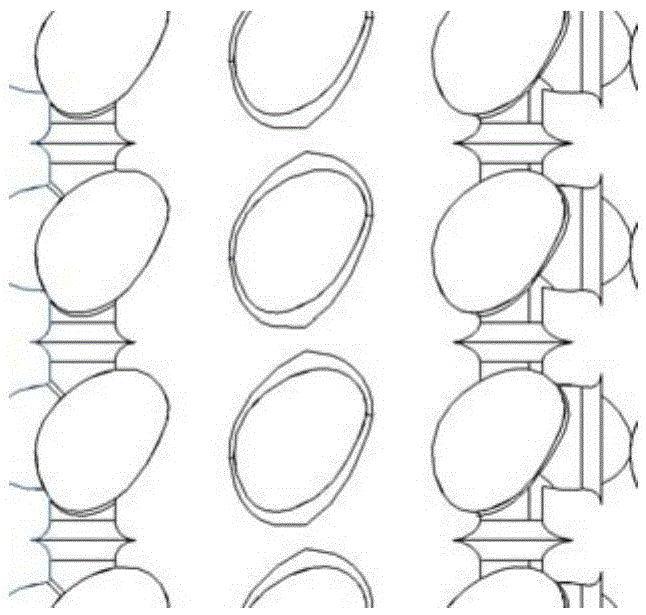

Method for preparing bone repair implant on basis of selective laser melting technology

InactiveCN105455925ASimplify the surgical processShorten operation timeAdditive manufacturing apparatusBone implantSelective laser meltingOriginal data

The invention provides a method for preparing a bone repair implant on the basis of the selective laser melting technology. The method includes the steps that original data is scanned on the basis of standard medical images of bones of a patient, and a digital three-dimensional model of a primary skeleton of the patient is extracted through image segmentation, editing and three-dimensional computation; according to individual conditions of the patient, osteotomy is directly conducted on the digital three-dimensional model of the primary skeleton to obtain a three-dimensional model of the bone repair implant; a porous structure capable of preventing stress shielding is designed in the three-dimensional model of the bone repair implant; an embedded structure capable of enhancing fixed connection with the primary skeleton is designed on the surface of the three-dimensional model of the bone repair implant; on the basis of the modified and designed three-dimensional model of the bone repair implant, the model is imported into quick forming auxiliary software for processing such as placement positioning, support adding, parameter setting and slicing and layering, a multi-layer slicing two-dimensional data model of the bone repair implant is obtained, metal 3D printing is conducted through the selective laser melting technology, and the bone repair implant is obtained.

Owner:广东中科安齿生物科技有限公司

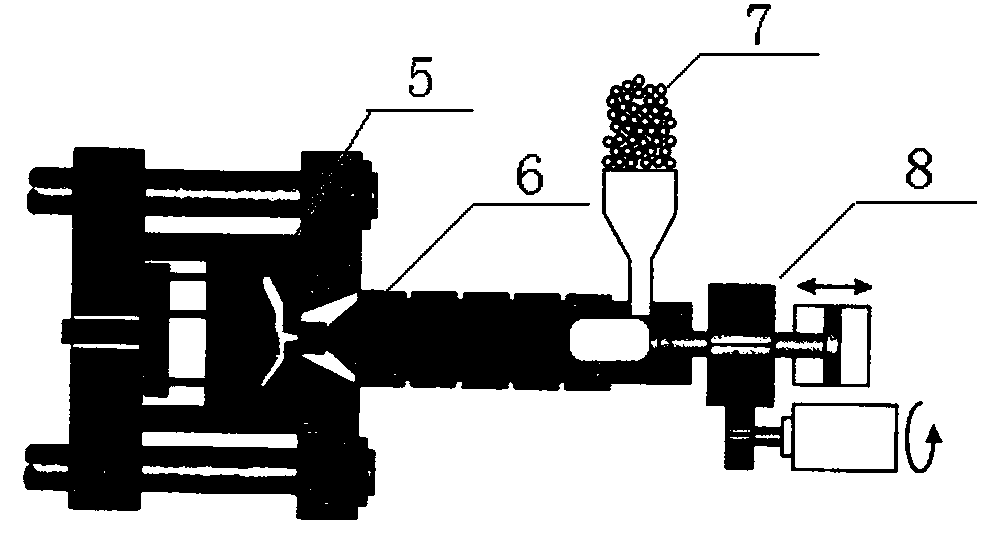

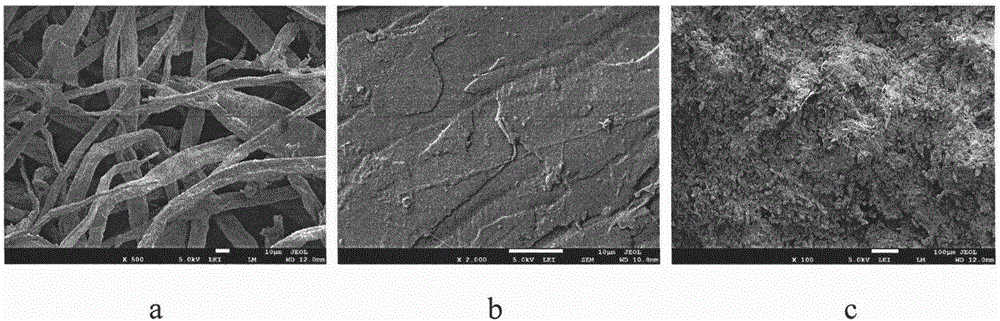

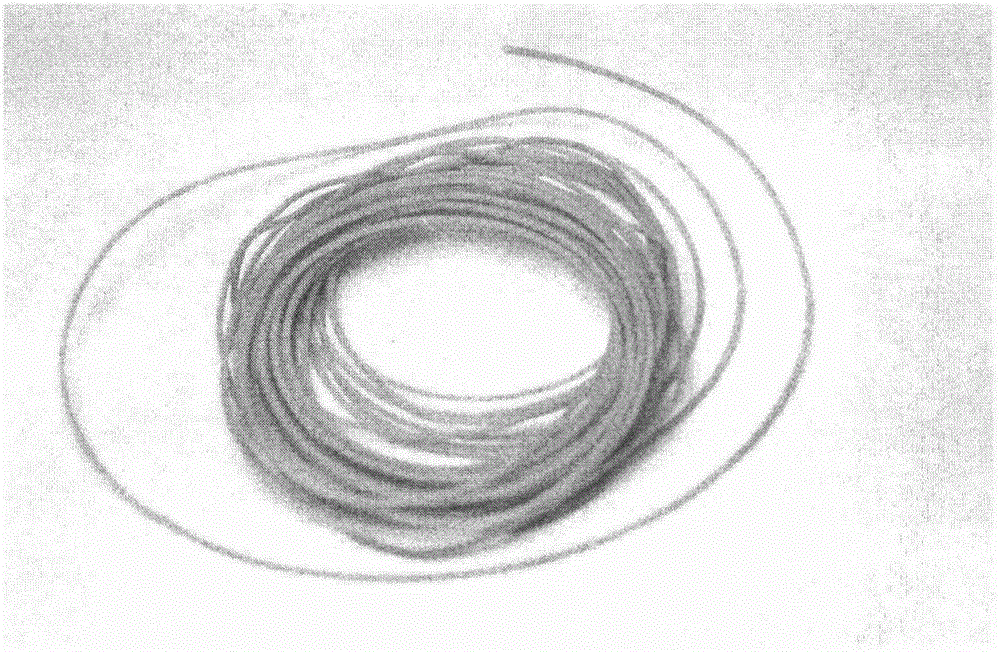

Preparation method of cellulose based 3D printing wire

The invention relates to a preparation method of a cellulose based 3D printing wire, and belongs to the field of biomass based 3D printing materials. The invention aims to provide a preparation method of a biomass based 3D printing material, which is low in production cost and can implement industrialization easily. The preparation method comprises the following steps: processing a cellulose raw material by virtue of polyethylene glycol (PEG:MW=400) in combination with a machine to prepare a cellulose polyethylene glycol dispersed solution smaller than 10 microns; flushing away polyethylene glycol by using dichloromethane to obtain a dichloromethane suspension of cellulose; adding a certain amount of silane coupling agent to perform surface silanization modification; adding modified cellulose, plasticizer polyethylene glycol and toughening agent solution into a dichloromethane solution of polylactic acid with certain concentration, mixing uniformly, and then recovering to remove a dichloromethane solvent by virtue of a condensing unit; and finally, performing extrusion molding at a certain temperature by virtue of a linear extrusion molding machine to prepare the cellulose based 3D printing wire.

Owner:NANJING FORESTRY UNIV

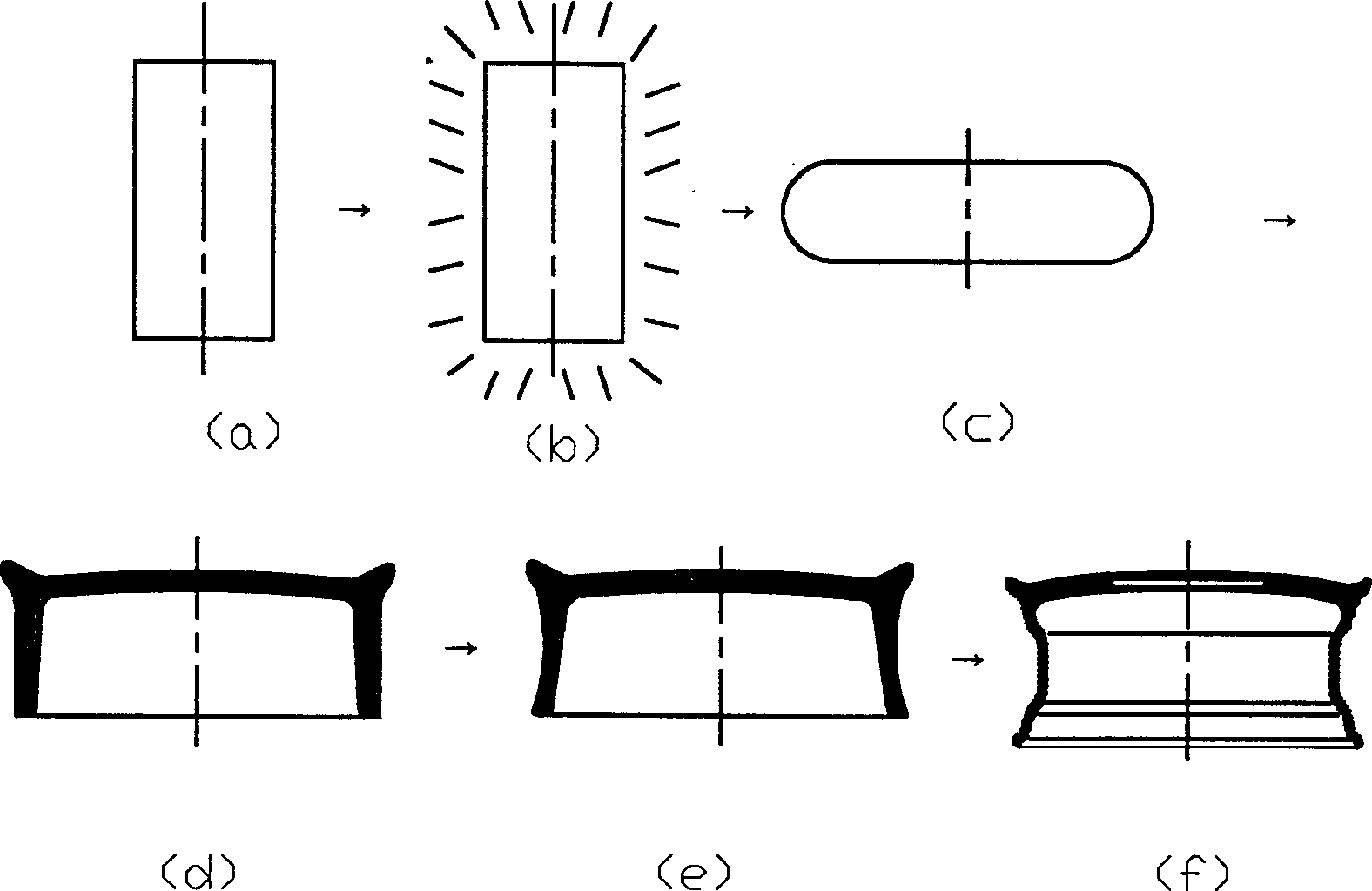

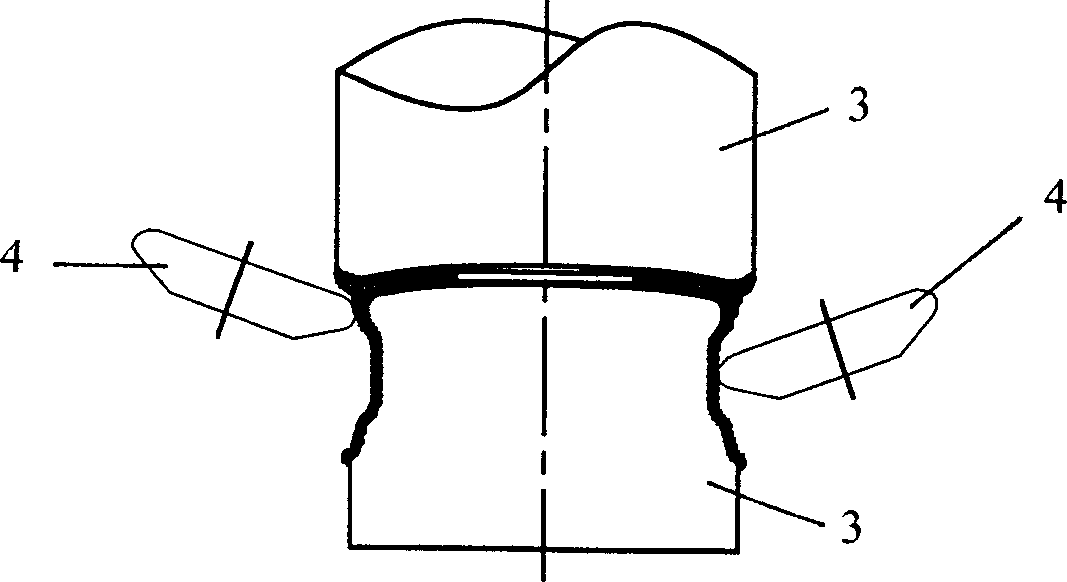

Forging and rotary extrusion forming process for aluminium alloy wheel

InactiveCN1827289AQuality improvementLight in massMetal-working apparatusMaterial consumptionRotational molding

The invention relates to a forging aluminum alloy wheel forging-rotational molding method, which combines the forging and rotational compressing techniques. In forging, molding part of spoke of wheel, and pre-molding the rim; then in rotational compressing, rotationally compressing the rim to complete the molding. Wherein, the rim is molded by forging, and the rim is mainly molded by rotational compression. The invention can combine the forging and rotational compression to express their advantages. And the inventive aluminum alloy wheel has better quality, high accuracy, less finish allowance, higher strength, and reduced material consumption.

Owner:JIAXING STONE WHEEL

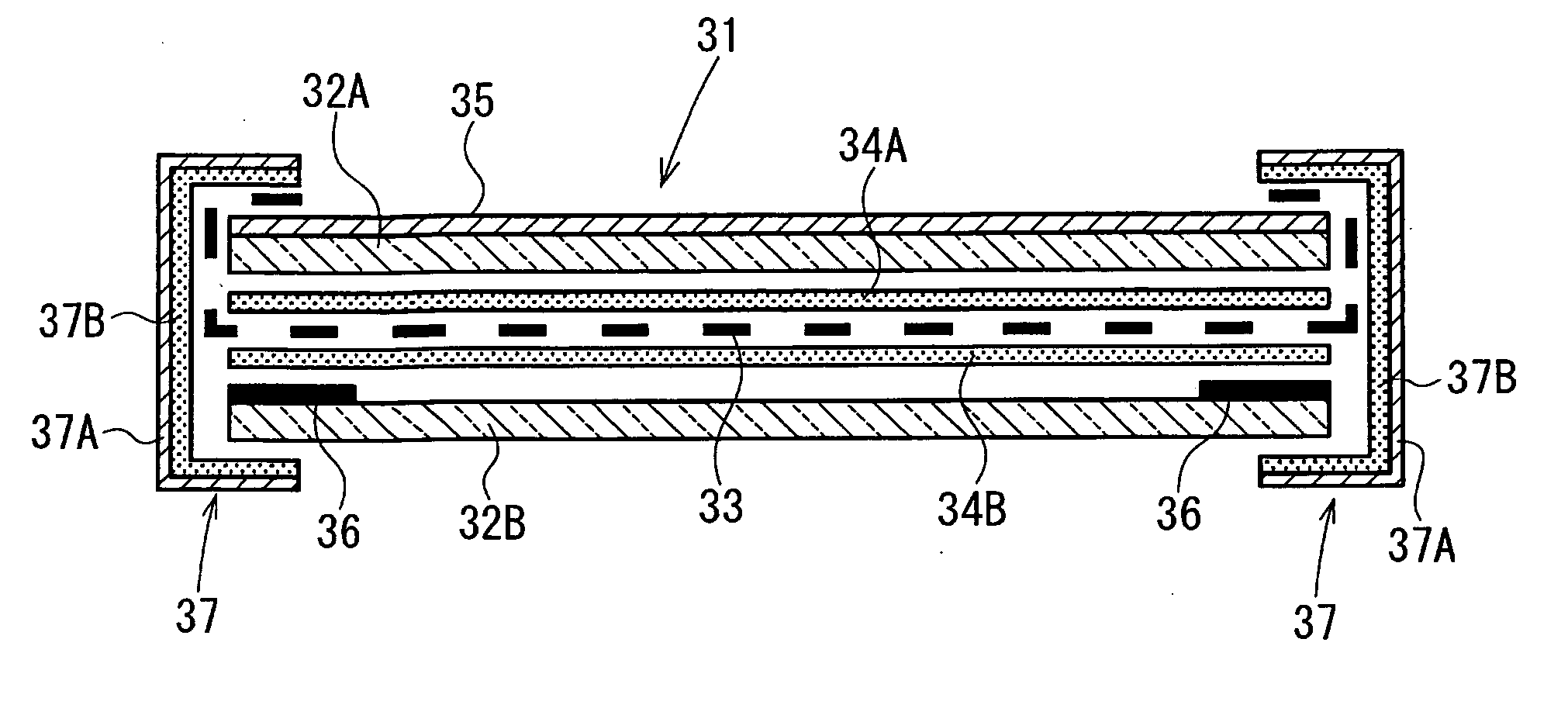

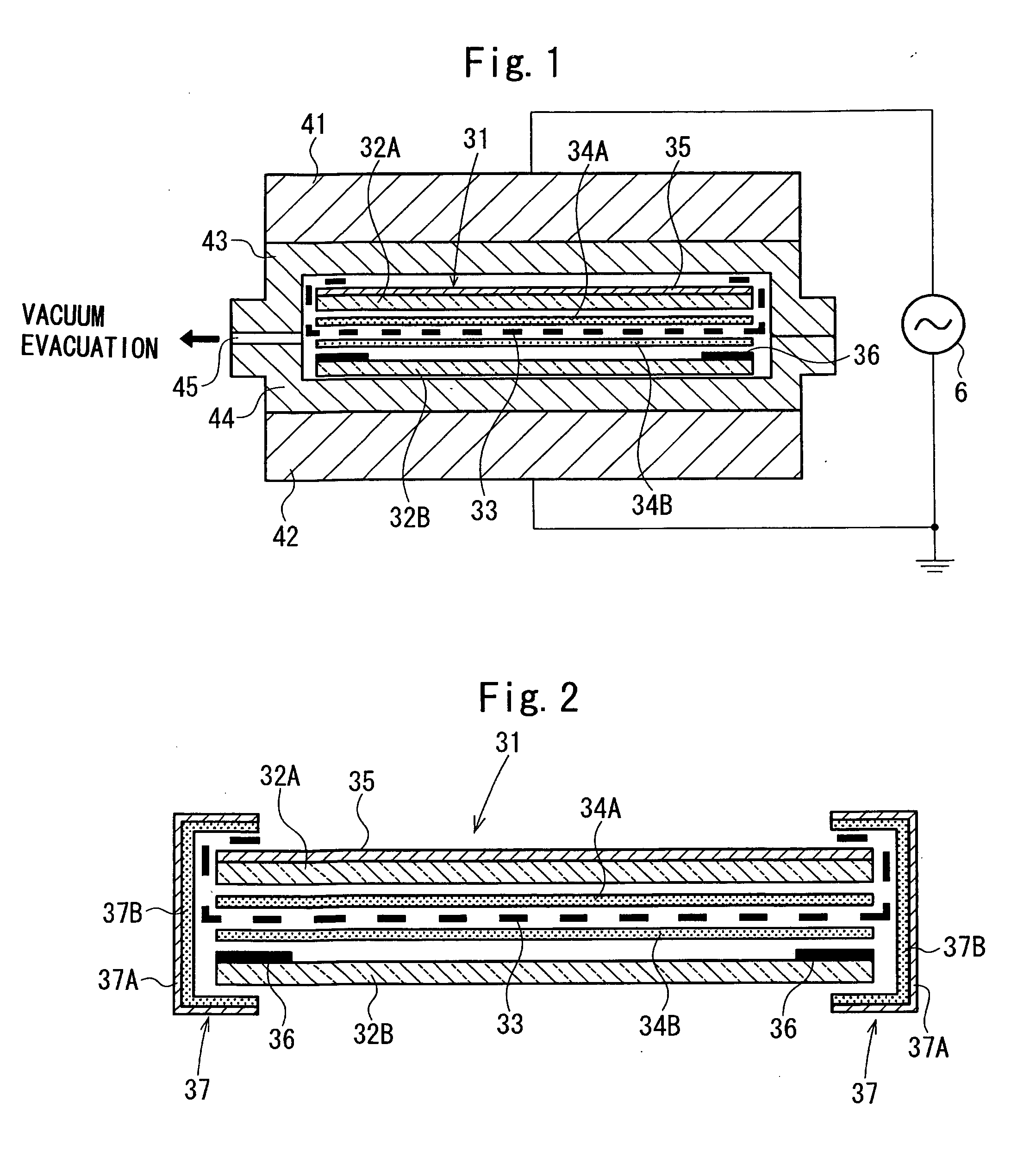

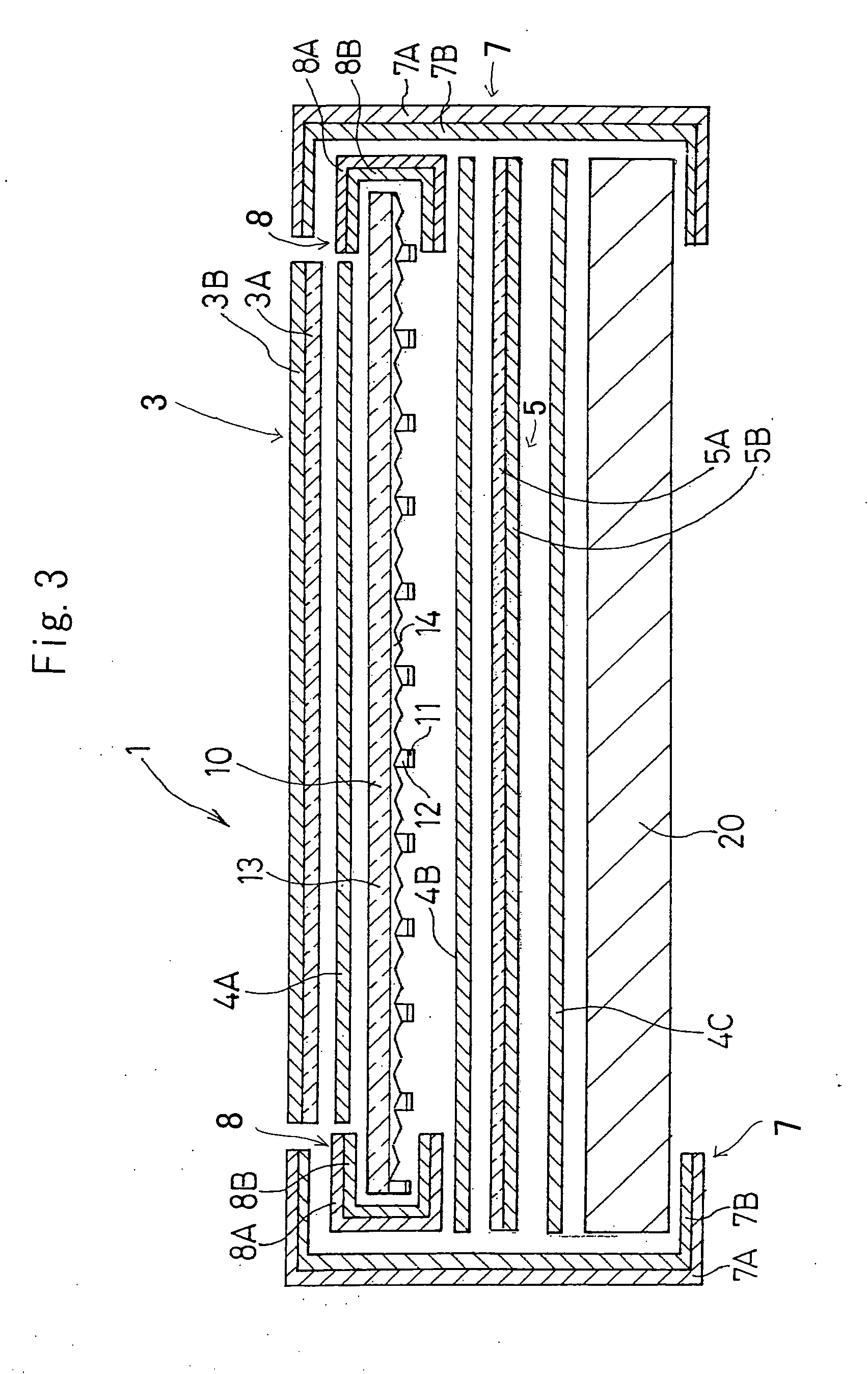

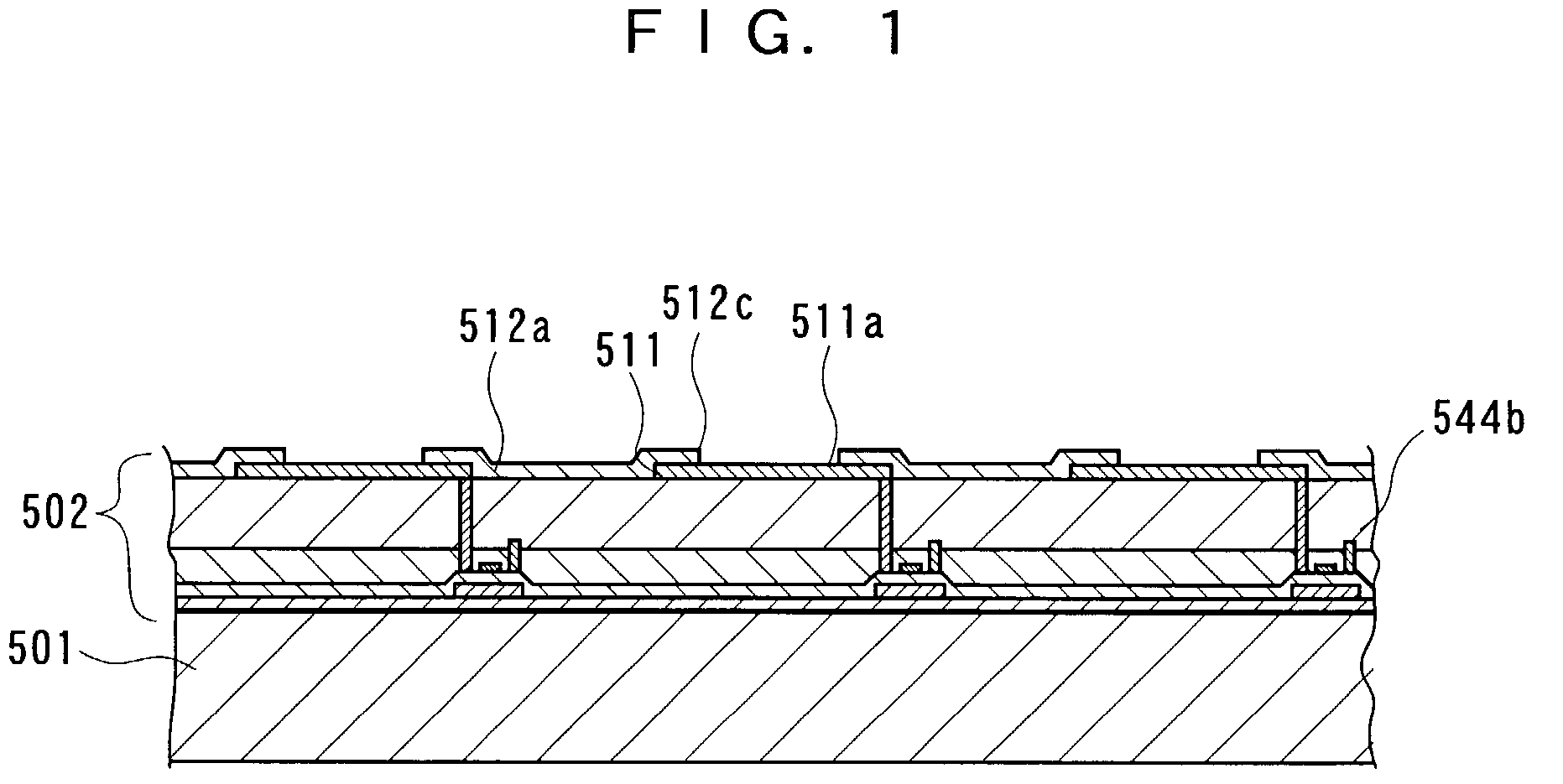

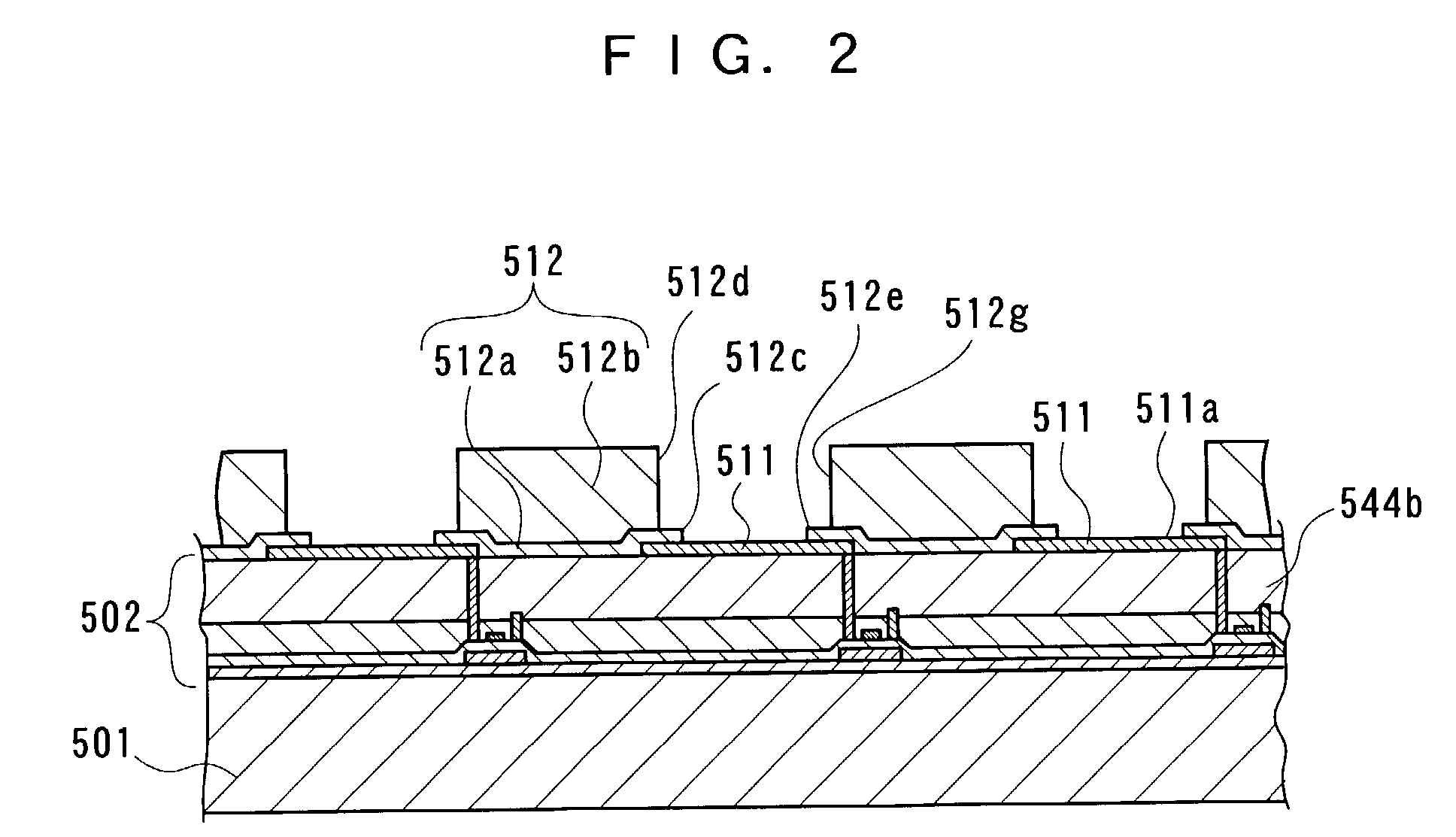

Manufacturing methods of electromagnetic-wave shielding and light transmitting window material, display panel, and solar battery module

InactiveUS20070011863A1Improve production efficiencyAddressing slow performanceGas-filled discharge tubesWave amplification devicesHigh frequency powerEngineering

In order to decrease the time (adhesion time in an adhesion step) for manufacturing an electromagnetic-wave shielding and light transmitting window material and a display panel, a top mold 43 and a bottom mold 44, which are made of a synthetic resin having high heat resistance, are disposed between a top and a bottom pressing plate 41 and 42, and a laminate is disposed between the molds 43 and 44. This laminate is formed of a transparent substrate 32A provided with an anti-reflection film 35, an adhesive interlayer film 34A used as an adhesive resin, an electrical conductive mesh 33, an adhesive interlayer film 34B, and a transparent substrate 32B provided with a black frame paint 36. While air in a molding space between the molds 43 and 44 is vacuum-evacuated via an exhaust port 45, a high-frequency voltage is simultaneously applied to the pressing plates 41 and 42 from a high-frequency power source 46, and in addition, the above laminate is pressed by the pressing plats 41 and 42 for a predetermined time. Accordingly, the interlayer films 34A and 34B is heated by induction heating and is cured, and as a result, the laminate is integrated.

Owner:BRIDGESTONE CORP

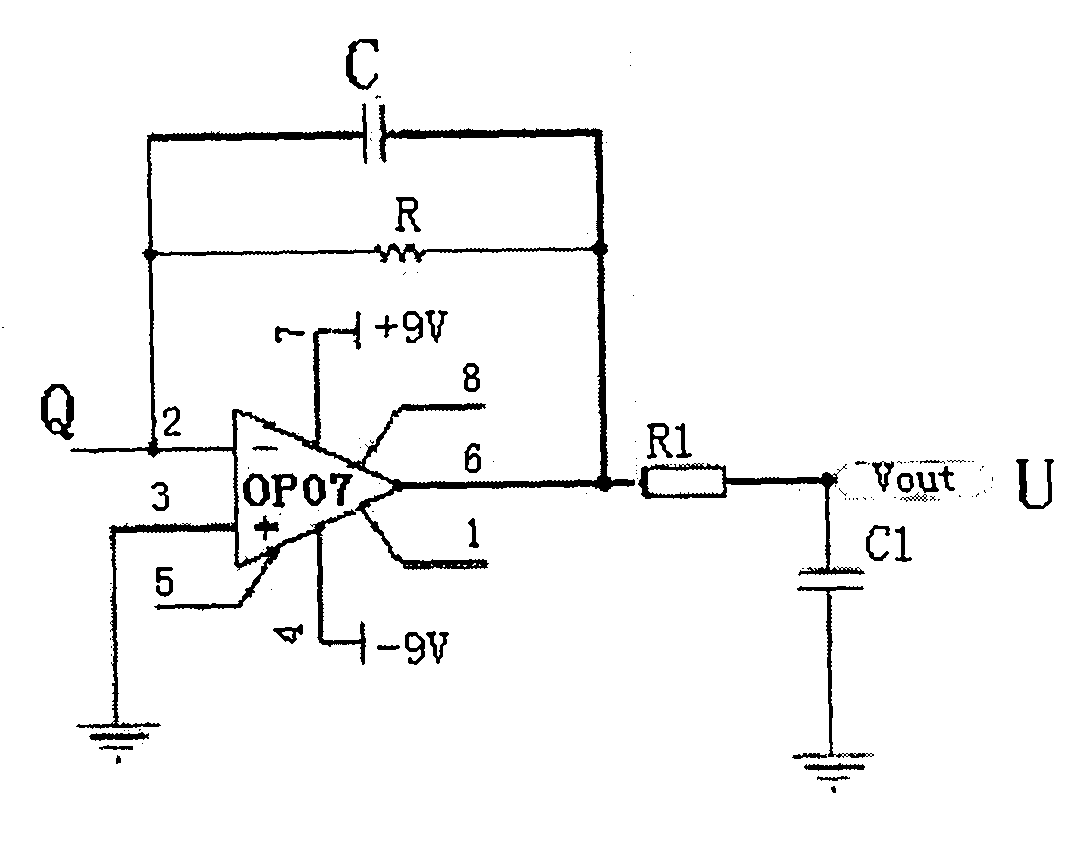

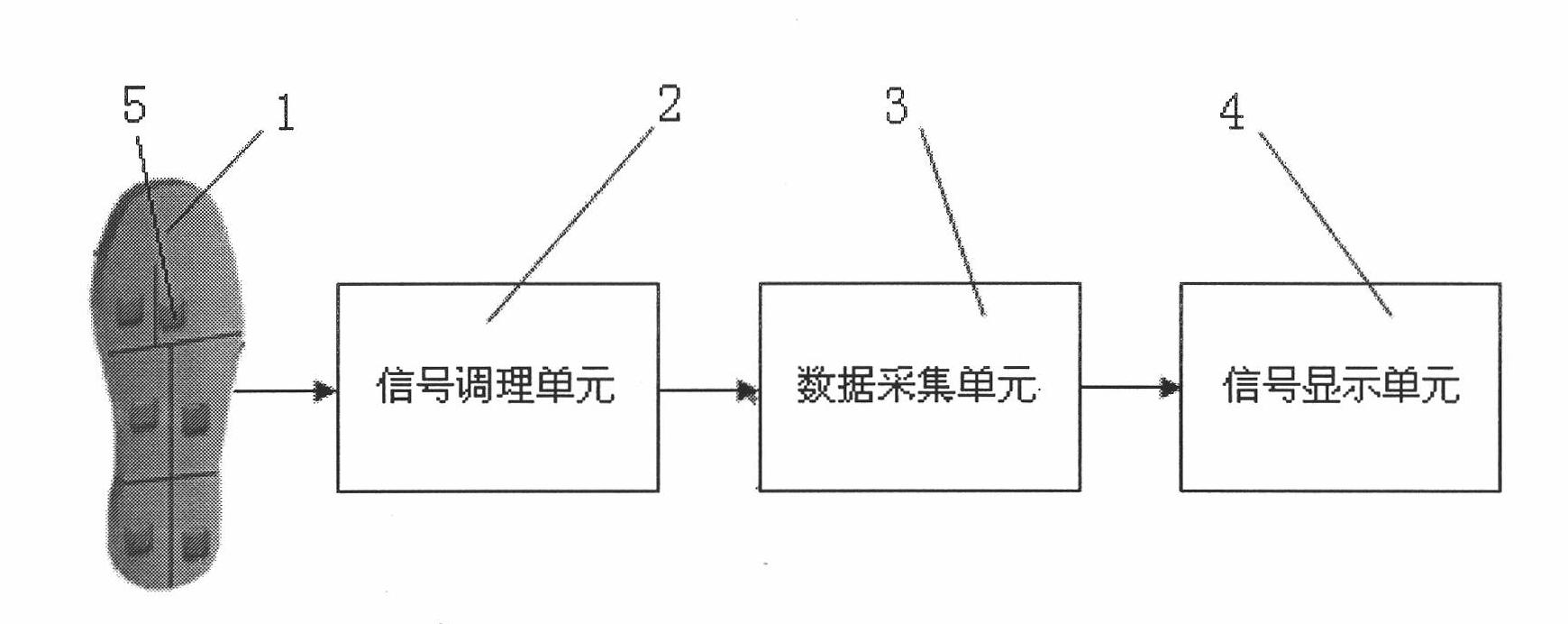

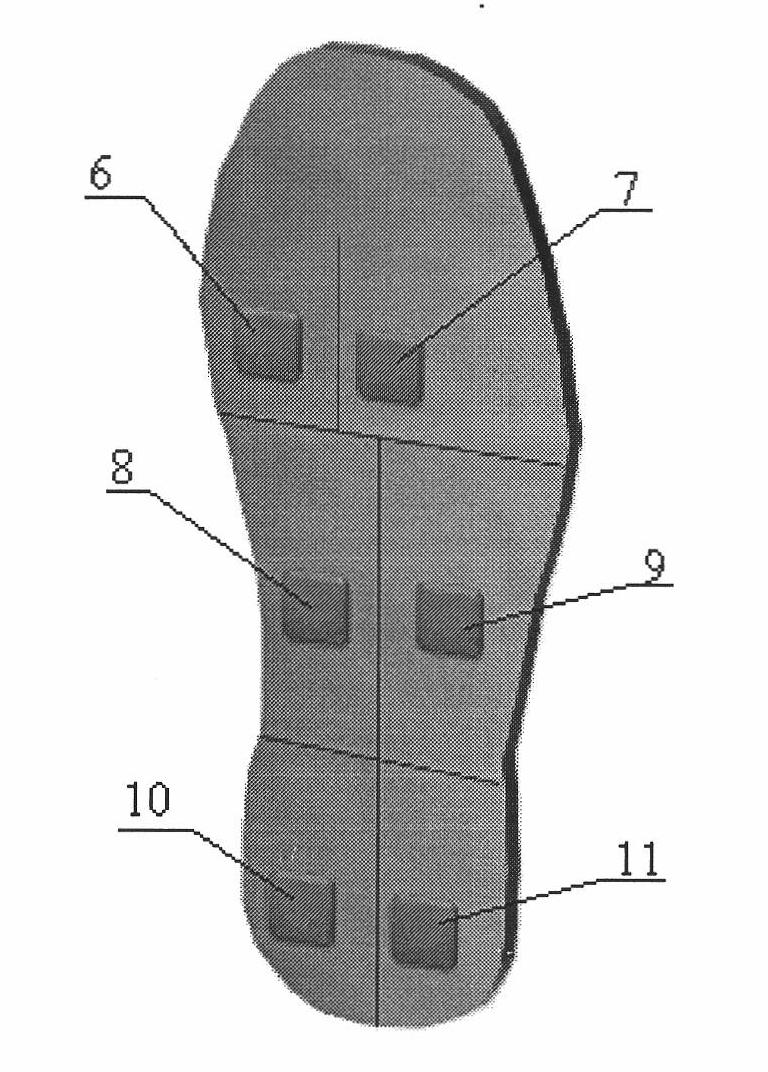

Dynamic sole pressure test insole with multilayer sensing core structure

InactiveCN101828794AReduce the effective areaHigh strengthInsolesForce measurement using piezo-electric devicesElectricitySignal-to-noise ratio (imaging)

The invention relates to a dynamic sole pressure test insole with a multilayer sensing core structure, which comprises an insole, a signal conditioning unit, a data acquisition unit and a signal display unit, wherein a sensing core structural film sensor unit is embedded into the insole; the sensing core structural film sensor unit is formed by vertically overlapping at least two layers of polyvinylidene fluoride films, and a hard synthetic material film is embedded between contact faces of the sensing core structural film sensor unit and the insole; and the sensing core structural film sensor unit in the insole is connected with the signal conditioning unit, the data acquisition unit and the signal display unit which are sequentially connected in series. The signal-to-noise ratio of a PVDF piezoelectric film sensor and the corresponding lag quality of the test insole on dynamic signals are improved by adopting the multilayer sensing core structure and the design of the spaced material films; and the test insole can be put into various daily worn shoes to perform test, and can provide the basis for biomechanical analysis of human gait and comfort evaluation of shoes.

Owner:DONGHUA UNIV

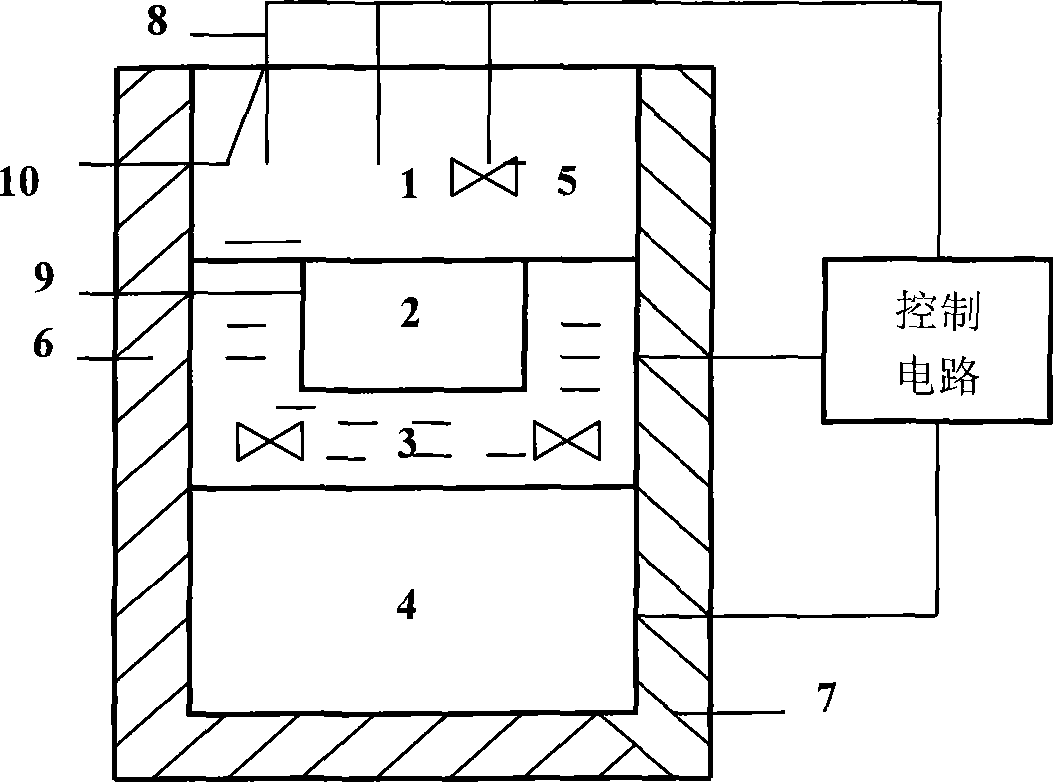

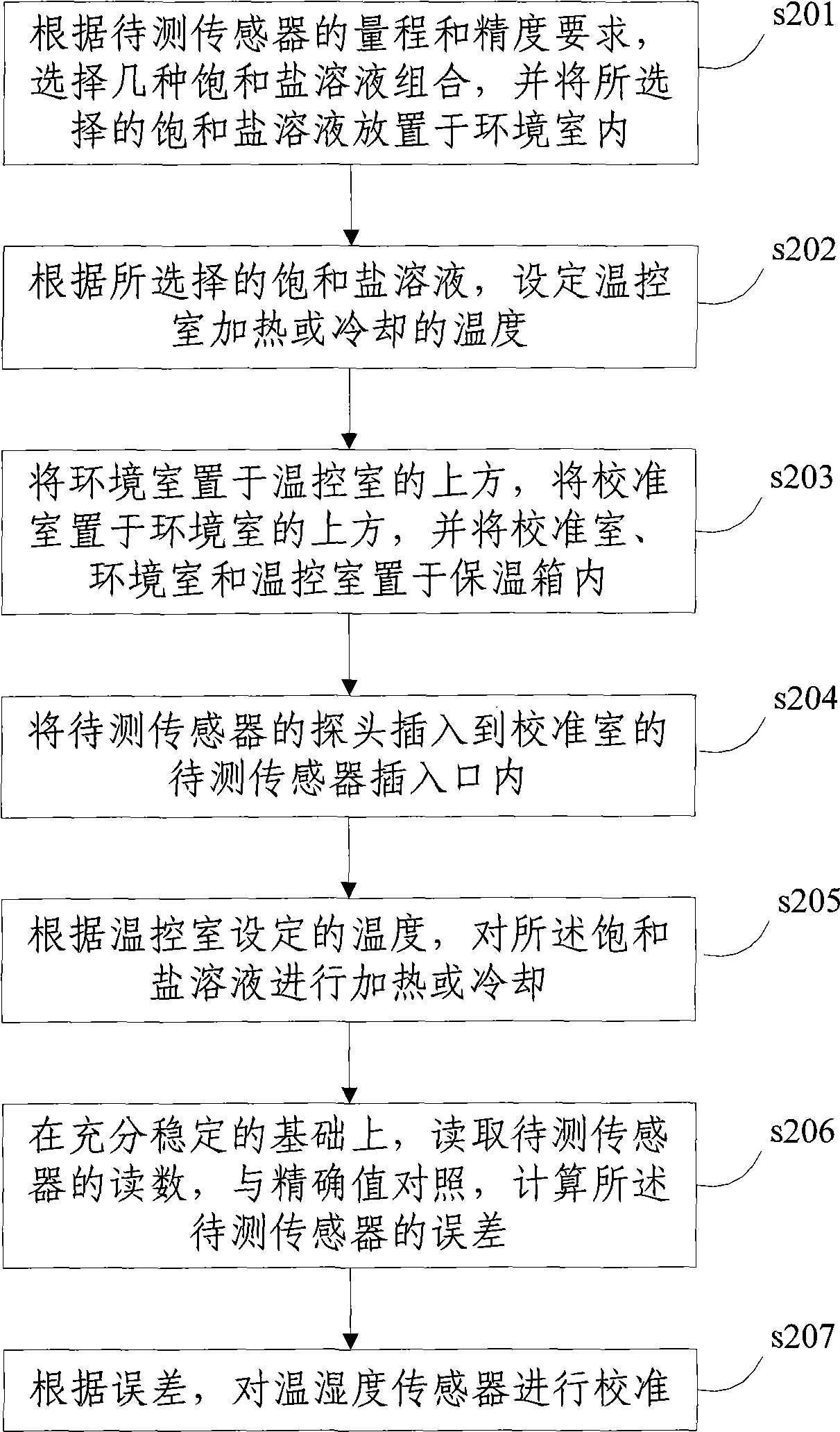

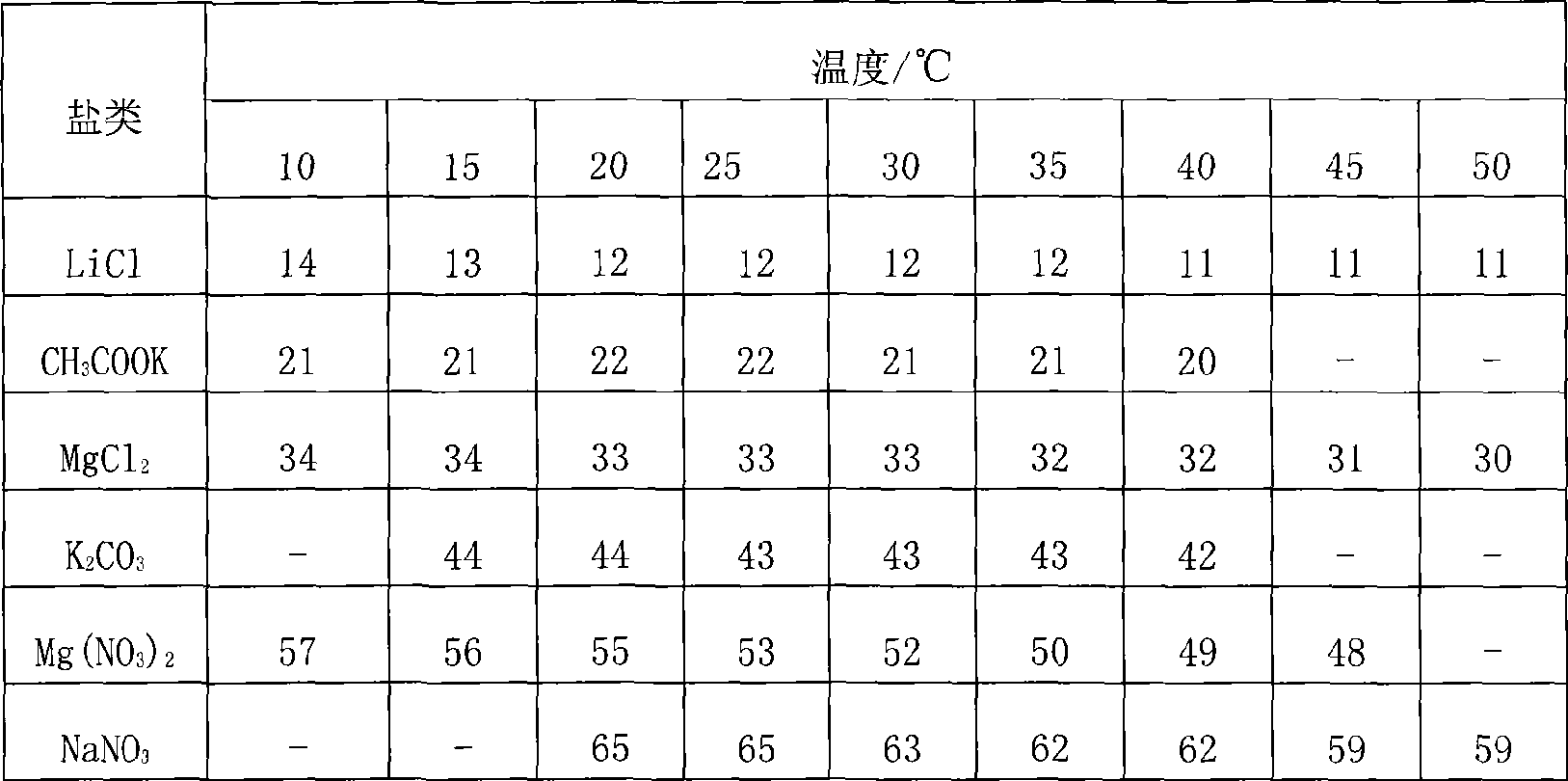

Calibration system and calibration method of humidity-temperature sensor

InactiveCN101532888AAchieve calibrationCompact structureThermometer testing/calibrationTemperature controlWater baths

The invention discloses a calibration system of humidity-temperature sensor, comprising a calibration chamber of which the top is provided with multiple to-be-measured sensor sockets for mounting to-be-measured sensors; an environmental chamber arranged below the calibration chamber and comprising a saturated salt solution container that is used for holding saturated salt solution and arranged in the heat transferring medium of a water bath tank, and the water bath tank; a temperature control chamber arranged below the environmental chamber and used for fast heating or cooling the water bath tank; a thermal container which is used for keeping the measurement environment stable and in which the calibration chamber, the environmental chamber and the temperature control chamber are arranged; and a control circuit for controlling the heating or cooling of the temperature control chamber. The invention also discloses a calibration method of humidity-temperature sensor. The invention realizes the calibration of humidity-temperature sensor by the same system, and is compactly structured, simple and practical. The calibration has small time consumption and is convenient for practical operation. The calibrating device of the invention is simple, has small volume, can realize portable measurement, has cheap material and low cost, and can be popularised and applied in large scale.

Owner:CHINA AGRI UNIV

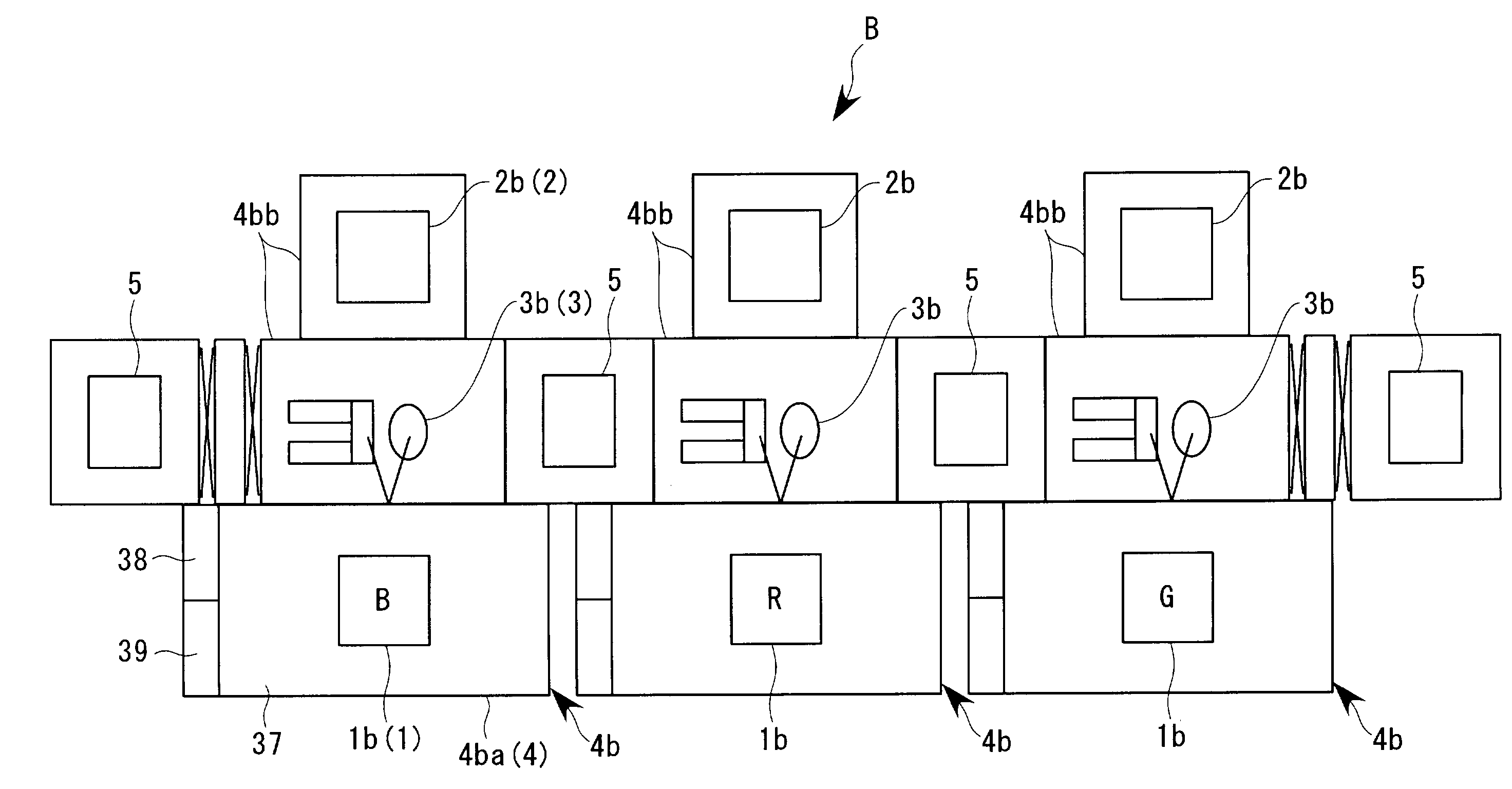

Method of, and apparatus for, manufacturing organic EL device; organic EL device; electronic device; and liquid droplet ejection apparatus

InactiveUS7517549B2Eliminate contactDamage in qualityInking apparatusVacuum evaporation coatingEngineeringElectron

An organic EL function layer is formed in the following manner. Namely, relative scanning is carried out between a substrate and a function liquid droplet ejection head having introduced therein a light function material is selectively ejected toward the emitting function material. The light emitting substrate such that an organic EL function layer is formed on a multiplicity of pixel regions on the substrate. The work of ejecting the light emitting function material is carried out in an atmosphere of an inert gas.

Owner:TOKYO ELECTRON LTD

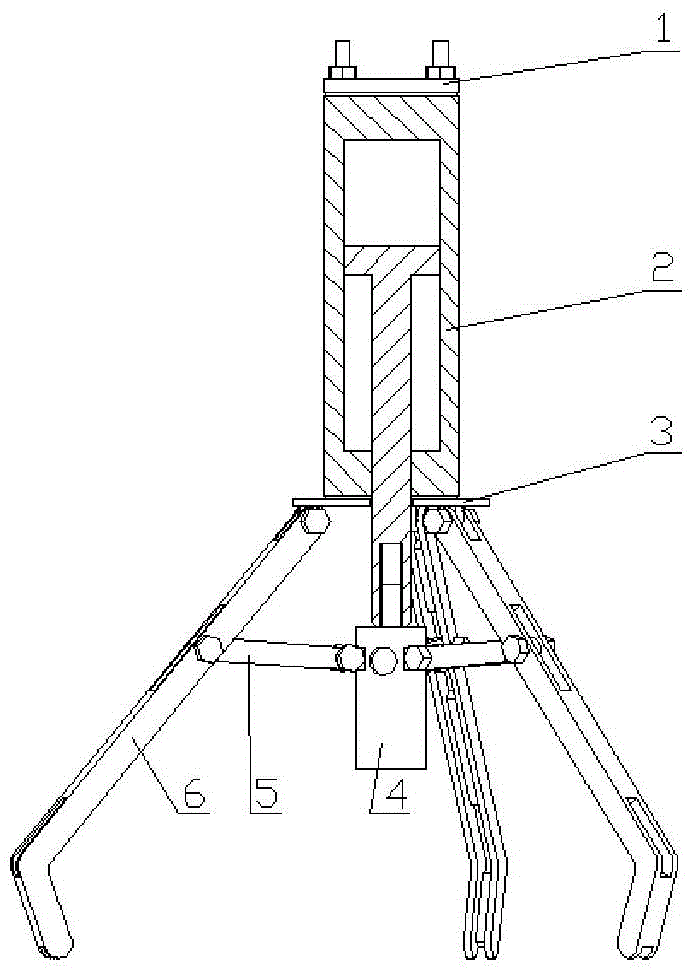

Tracking meal delivering robot

The invention discloses a tracking meal delivering robot which is a mechanical, electrical and hydraulic combinational integrated product. The tracking meal delivering robot is composed of a mechanical system, a hydraulic system and a control system; the mechanical system comprises a driving wheel, a direct-current walking motor, a step-by-step steering motor and a sensor; the robot achieves the functions such as walking and turning through the mechanical system; the hydraulic system comprises an oil tank, a gear pump, a direct-current motor, a vertical cylinder, a horizontal cylinder and a grabbing cylinder; the functions of looking for plates, grabbing the plates and sending the plates to a guest dinner table are achieved through the hydraulic system; the analysis and detection on the movement track in the robot walking process and positioning on the plates in the robot dish serving process are achieved through the control system, and the control system has the advantages that the feedback precision is high and the system operation is stable. The tracking meal delivering robot is simple in structure, steady in system operation and low in manufacturing cost, and capable of saving labor force for foodservice industry and solving the problem of human resource shortage.

Owner:郅伦臣

Method for producing degradable material with manioc waste and wine stillage

InactiveCN101302734AWith foldableCompressive and folding resistantNatural cellulose pulp/paperReinforcing agents additionCartonPaperboard

The invention discloses a method for producing a novel degradable material by manioc dreg and pot ale and comprises the following steps: the manioc dreg or the pot ale is purified, ground, cleaned, drained and mixed with dry paper pulp according to the weight proportion of a to b; wherein, the a lies between 2 and 5, and the b lies between 5 and 8; a papermaking addition agent is added, and the mixture is molded and parched, thus obtaining the degradable material product. Paper pulps of vegetable fiber such as waste newspapers, carton paper, paperboards and other paper pulps of vegetable fiber materials can be taken as the dry paper pulp. The method for producing the novel degradable material by the manioc dreg and the pot ale adequately utilizes wastes of manioc resources such as the manioc dreg, the pot ale to produce the novel industrial degradable material with good quality and low cost, replaces degradable materials of cellular plastics, and not only solves the difficult processing problem of wastes and changes wastes into valuable, but also effectively generates the actions of controlling and eliminating the white pollution; furthermore, the method for producing the novel degradable material by the manioc waste and the pot ale has uncomplicated technique, short production period, low cost, low energy consumption, simple and convenient operation, high product stability and good economic, social and environment-protective benefits.

Owner:广西农垦明阳生化有限公司

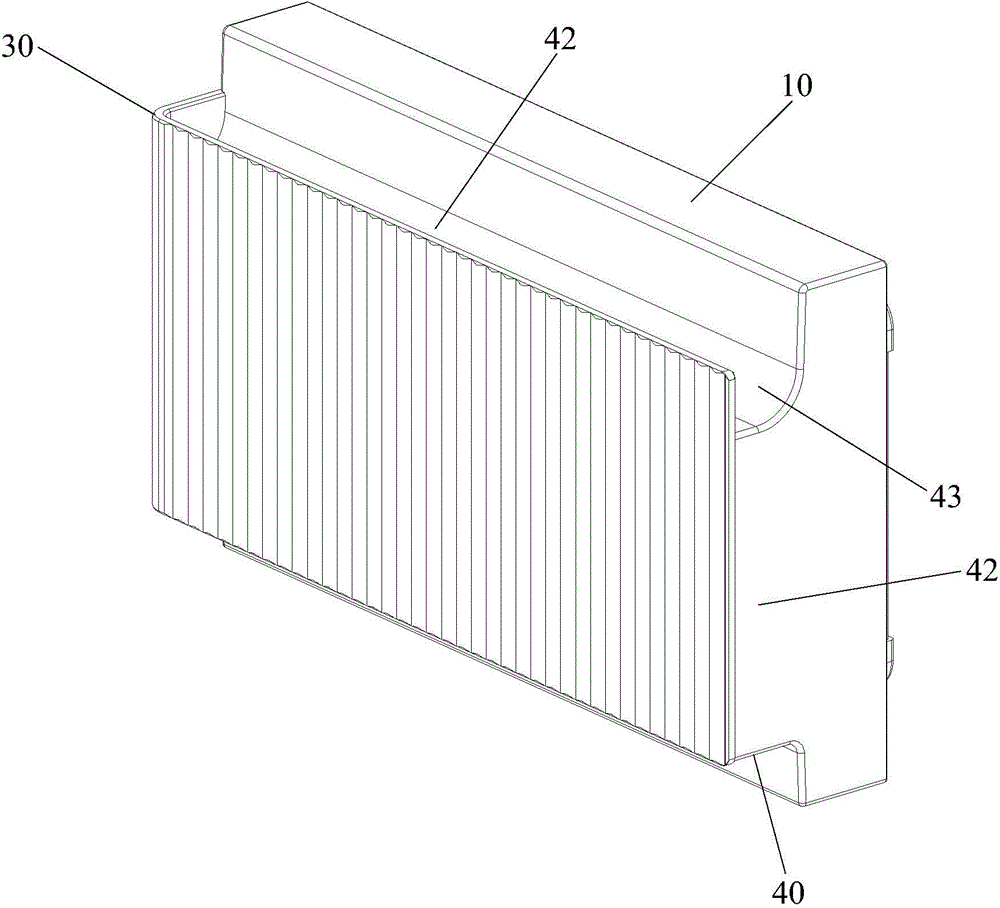

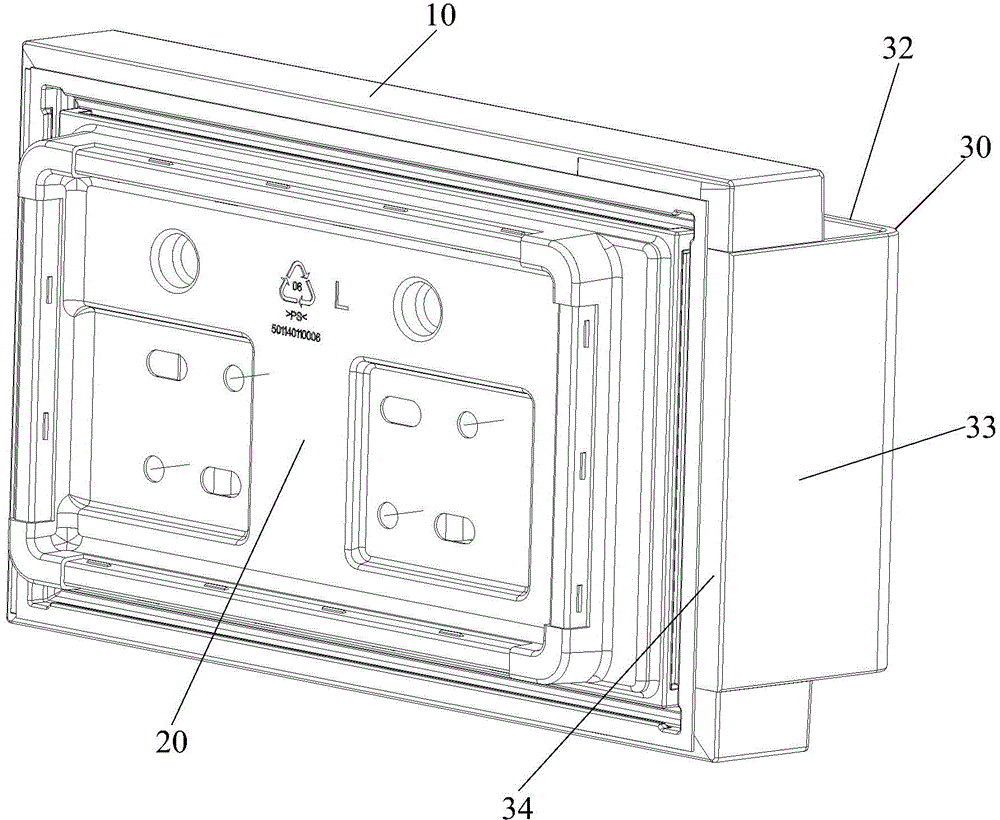

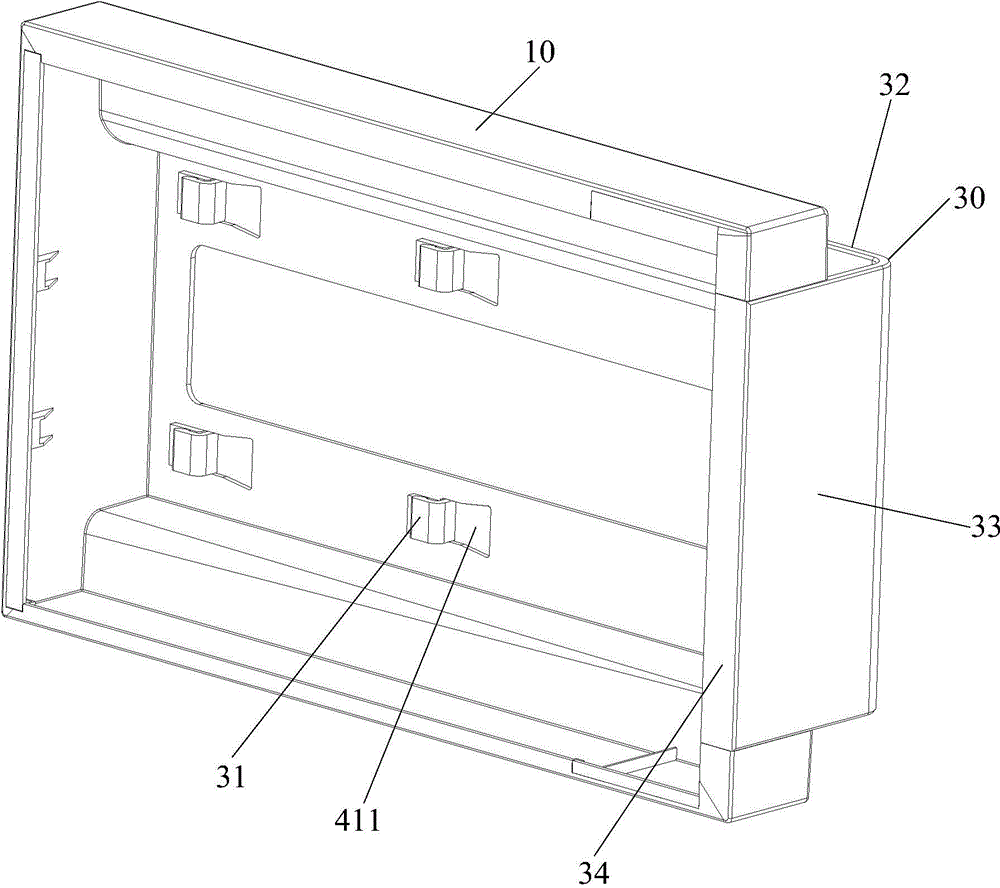

Refrigerator door body and refrigerator

ActiveCN104457115AHigh strengthReduce weightDomestic cooling apparatusLighting and heating apparatusAlloyEngineering

The invention discloses a refrigerator door body which comprises a door frame, a door liner and an aluminum alloy panel, wherein the door liner and the aluminum alloy panel are fixedly connected with the door frame, a fixed seat is arranged on one side, deviated from the door liner, of the door framework in a protrusion manner, one side, deviated from the door frame, of the fixed seat is arranged to be a top wall, and the aluminum alloy panel is fixed on the top wall of the fixed seat. The invention further discloses a refrigerator. According to the refrigerator door body, the aluminum alloy panel is fixedly connected to the door frame, the fixed seat is arranged on the door frame in the protrusion manner, the aluminum alloy panel is fixed to the top wall of the fixed seat, and the aluminum alloy material is light, and the strength is large, so that the weight of the refrigerator door body is effectively reduced, and the strength of the refrigerator door body is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Banana fiber and its production and its blending wires and fabrics

InactiveCN1472372ALight materialGood hygroscopicityVegetable fibres from other vegetable matterYarnYarnFiber bundle

Provided is a banana fiber using a banana stem which is an industrial waste as a raw material, a method for producing the banana fiber, a union yarn composed of a staple fiber of the banana fiber and other fiber and a fiber structure prepared from the union yarn. The banana fiber is obtained by drying peeled temporary stem of banana and opening the fiber so as to have 10-50 mm average fiber length and 0.5-80 dtex average fineness. The method for producing the banana fiber comprises a step (a) for cutting stems of banana, a step (b) for peeling and removing colored epidermis of stems, a step (c) for peeling much bark constituting stems to provide a unit bark, a step (d) for taking out a fiber bundle by pressing the unit bark by a press, a step (e) for drying the fiber bundle, a step (f) for obtaining a monofilament from the dried fiber bundle and a step (g) cutting the monofilament into a definite length and obtaining the staple fiber.

Owner:NISSHINBO IND INC

High-strength aluminum alloy welding wire and preparation method thereof

ActiveCN102114579ALight materialImprove performanceWelding/cutting media/materialsSoldering mediaSlagHeating temperature

The invention discloses a high-strength aluminum alloy welding wire which comprises the following chemical compositions in percentage by weight: 2.5-3.5 percent of Cu, 2.2-3.2 percent of Si, 0.1-0.25 percent of Ti, 0.1-0.25 percent of Zr, 0.1-0.2 percent of Mn and the balance of Al. The preparation method comprises the following steps: melting and ingot-casting raw materials so as to prepare intermediate alloy of Al-Cu50, Al-Mn10, Al-Si30, Al-Ti10 and Al-Zr10; pouring the pure aluminum ingot into a crucible according to composition proportion, raising temperature, adding and melting the intermediate alloy of Al-Mn10, Al-Cu50, Al-Ti10 and Al-Zr10 in sequence according to composition proportion after the aluminum ingot is entirely molten; after melting is finished, raising the temperature to 800 DEG C for heat preservation for 15 minutes, pressing hexachloroethane into the bottom of the alloy liquid with a graphite hood, stirring to conduct degassing and slagging, wherein the using amount of the hexachloroethane is 0.3-0.4 percent of the amount of a furnace, scattering a little amount of scouring agent to remove surface float slag after finishing slagging-off; continuing to raise the temperature to 820-850 DEG C, fully stirring, and discharging; conducting pull-casting to prepare high-strength aluminum alloy cast ingot; then taking out and sawing the cast ingot into segments and peeling; putting the cast ingot into an extruder at the heating temperature of 330-380 DEG C for extrusion; and conducting wiredrawing in a wiredrawer, and annealing in the drawing process, thus obtaining high-strength aluminum alloy welding wires when achieving the standard diameter.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

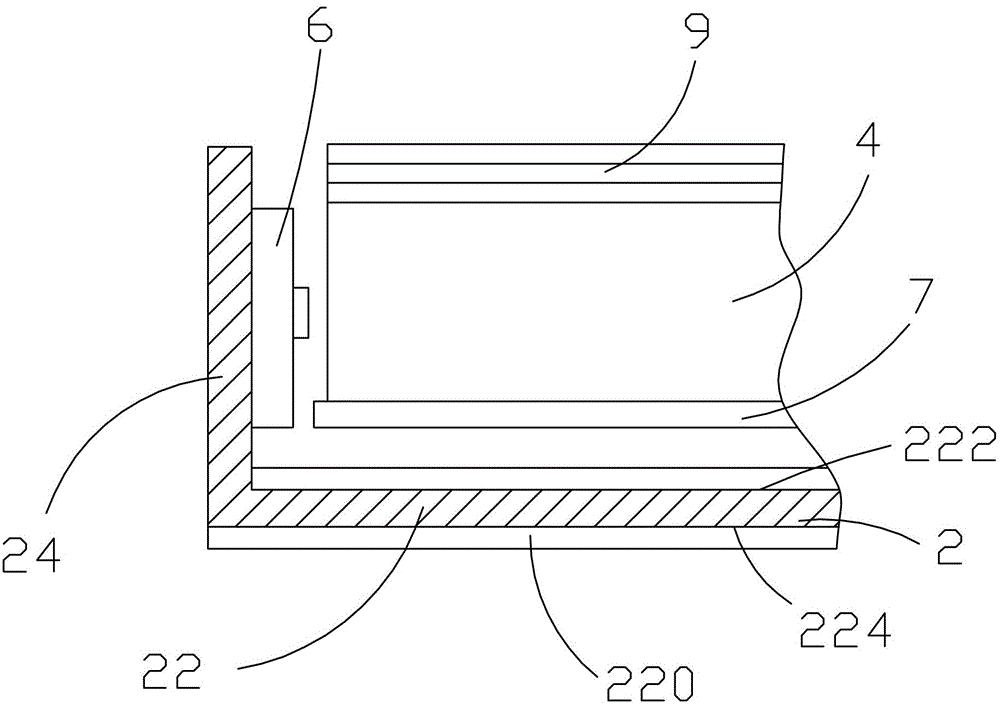

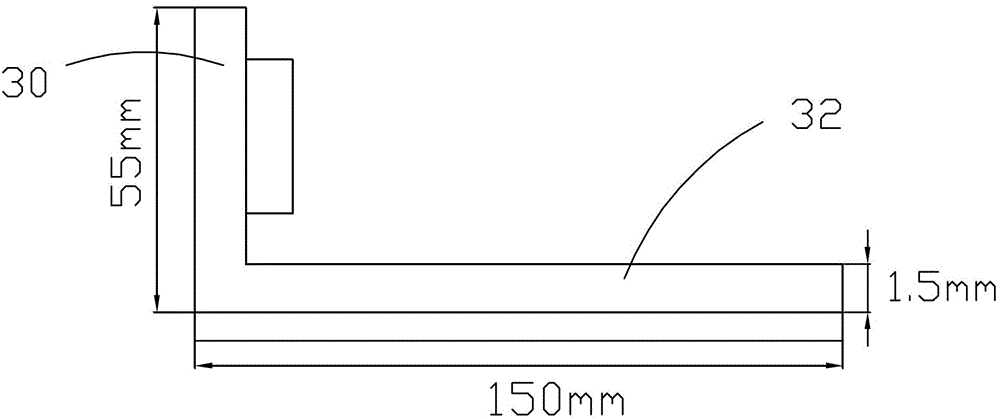

Backlight unit

InactiveCN103336388AImprove cooling effectEven heat distributionPoint-like light sourceLighting heating/cooling arrangementsBackplaneEngineering

The invention provides a backlight unit which comprises a back plate (2), a light guide plate (4) arranged in the back plate (2), a back light source (6) arranged on the back plate (2), and a heat dissipating film (220) arranged on the back plate (2). The heat dissipating film (220) is made of grapheme and is 0.01-0.05 thick. The backlight unit is effectively improved in heat dissipating effect through the arrangement of the heat dissipating film made of the grapheme on the back plate, enables heat to be evenly distributed on the whole surface in the plane direction of the heat dissipating film, and removes local heat points. Moreover, grapheme materials are light, so that the further-arranged heat dissipating film made of the grapheme can not obviously increase the weight of the backlight unit.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

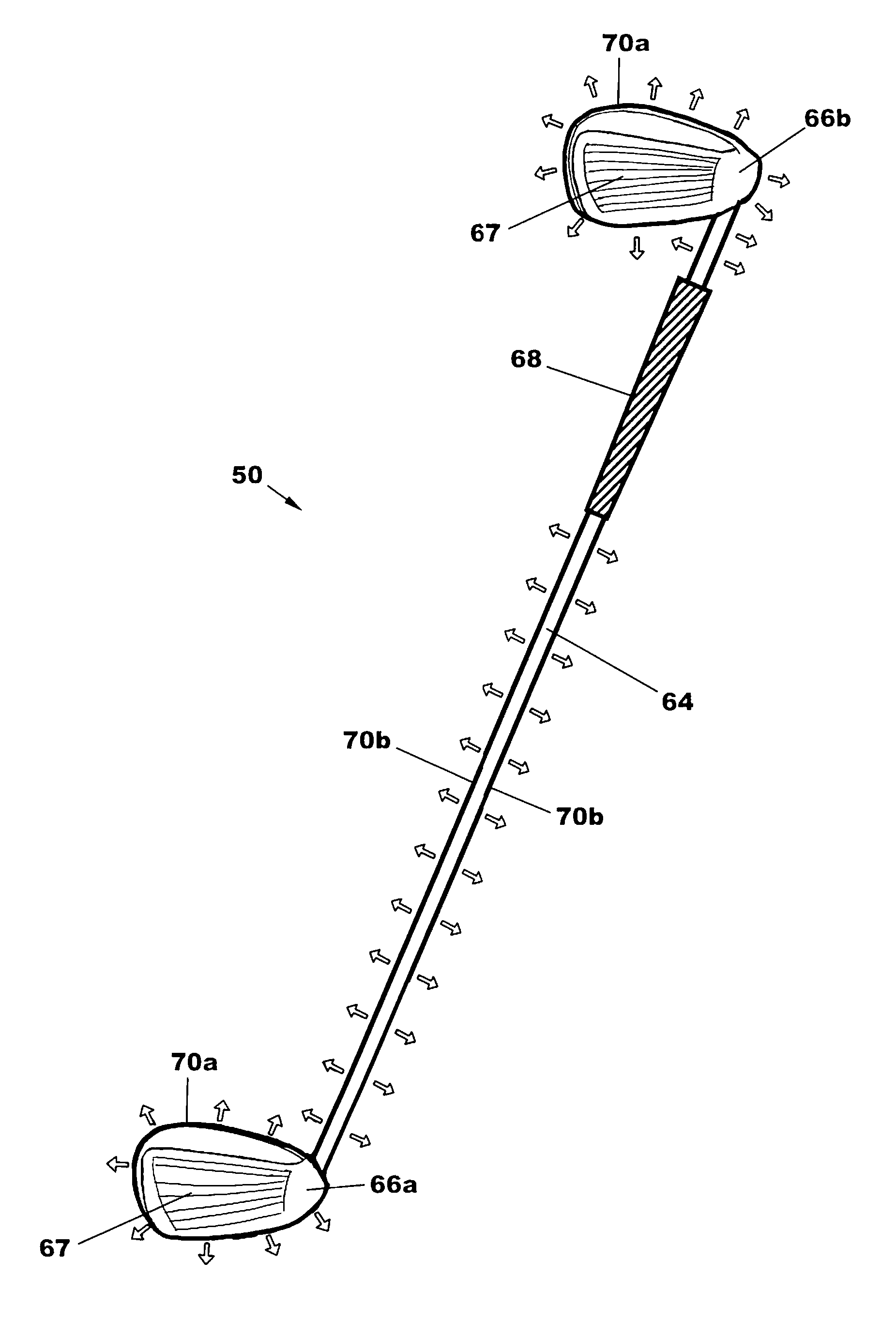

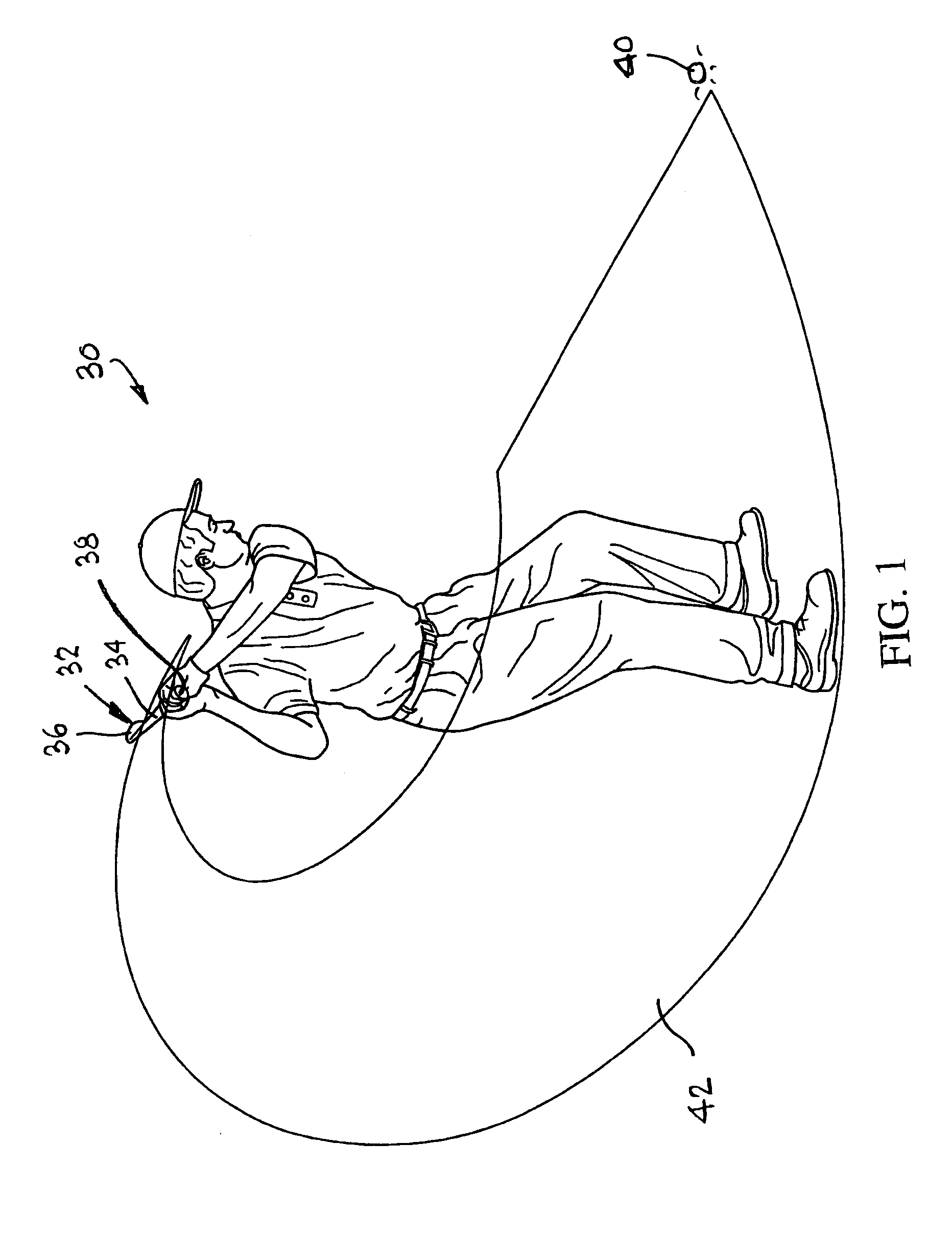

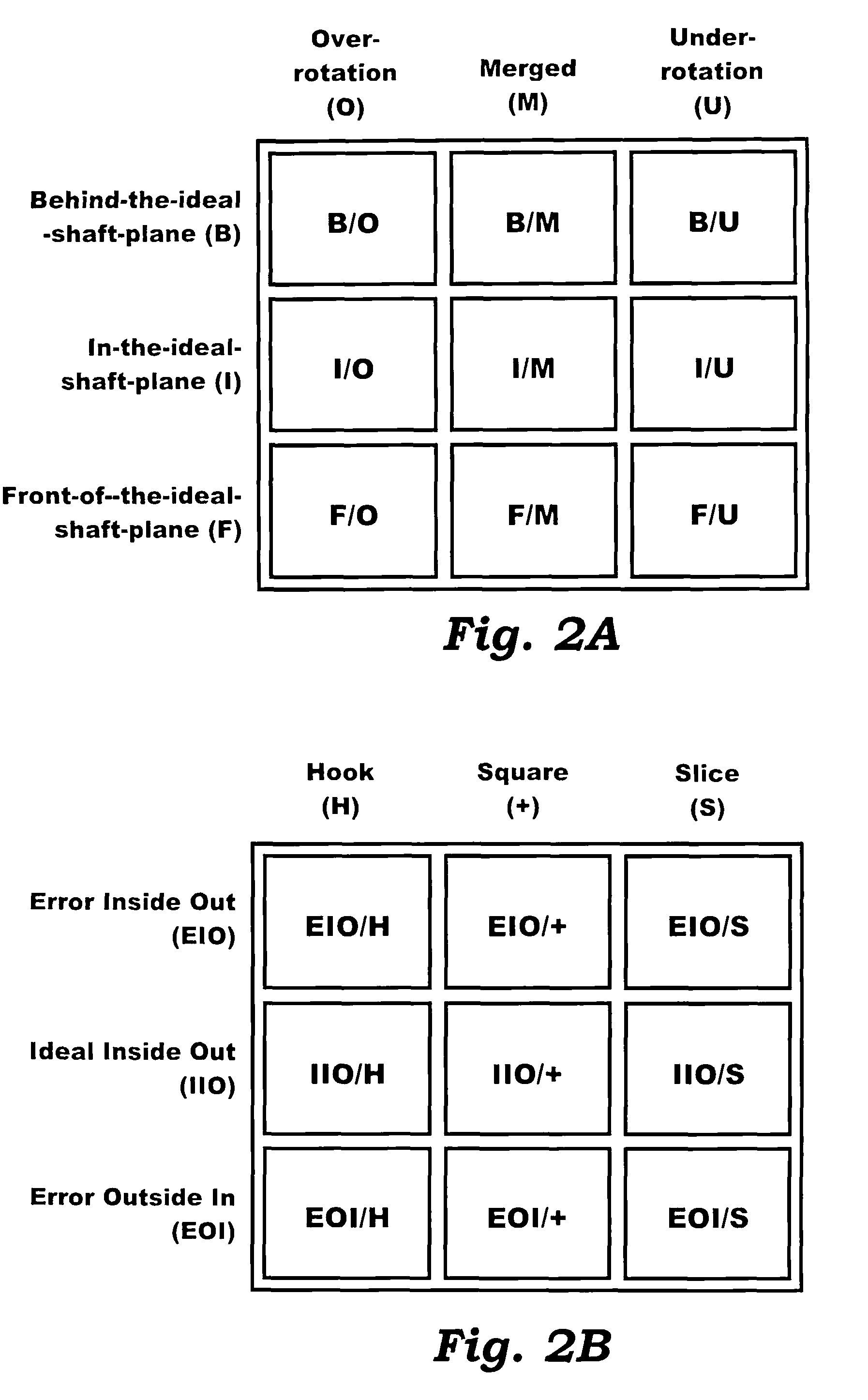

Motion training apparatus and method

InactiveUS8597133B2Effectively realistically visualizeProvide real-timeGymnastic exercisingVideo gamesEngineeringBiofeedback

The invention is directed to a motion trainer for improving a person's movement of an implement by allowing the person to visualize the path of the implement during the movement. The motion trainer comprises an implement having a plurality of motion characteristic sensors located thereon for determining, among other things, the direction of the movement and the orientation of the implement during the movement. Biofeedback devices provide the person information regarding the positioning of the implement during the movement.

Owner:PRIESTER WILLIAM B

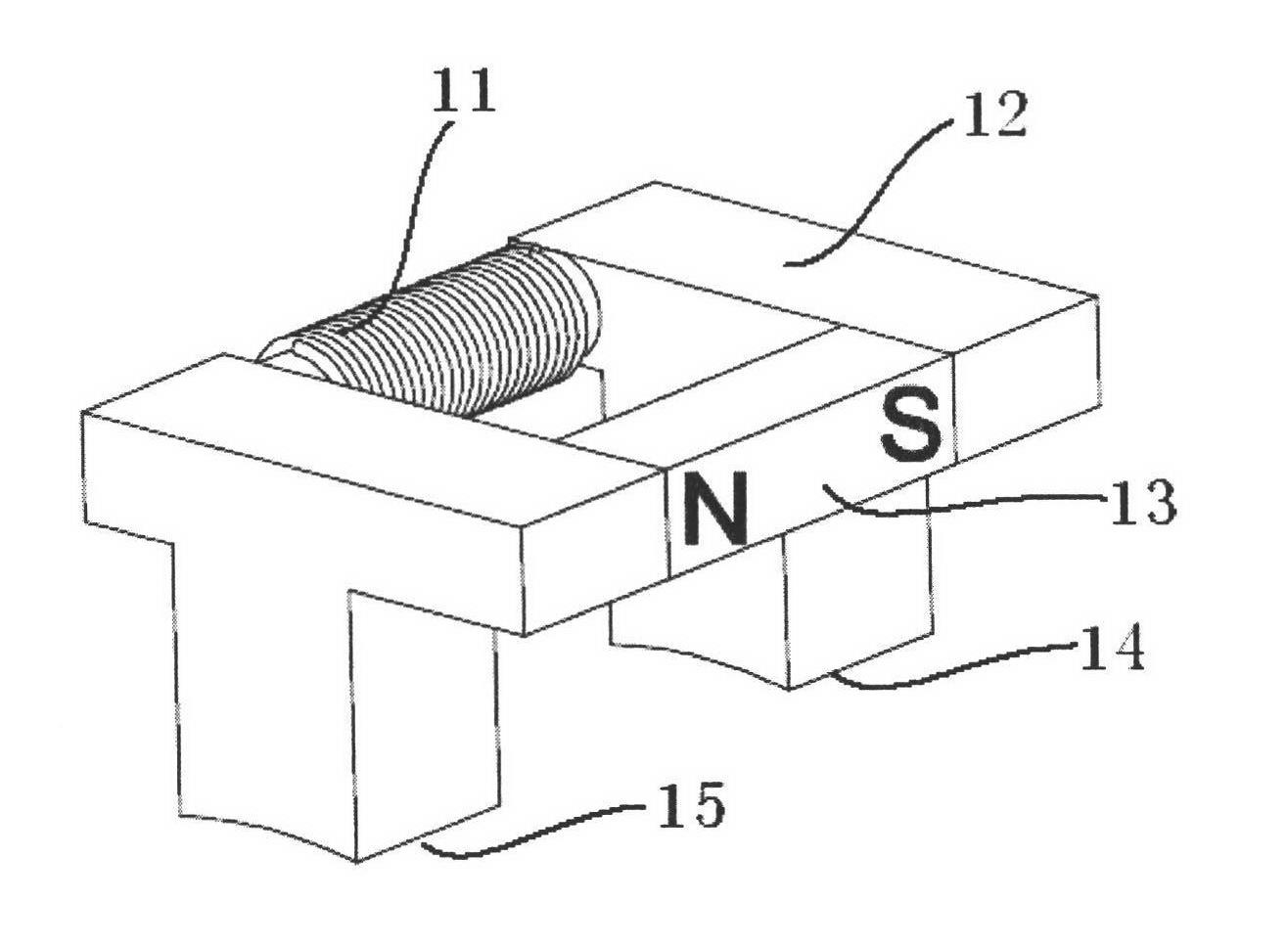

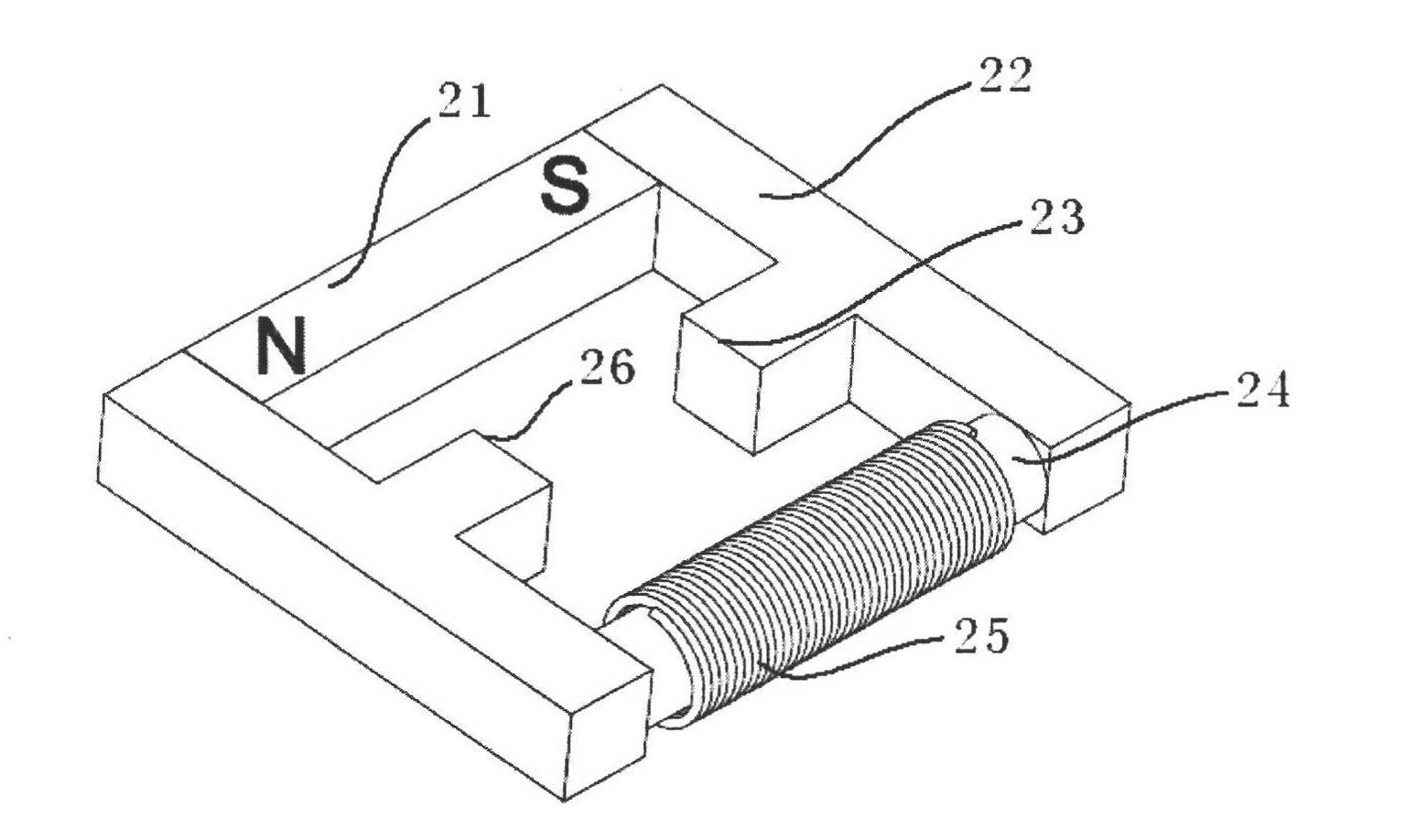

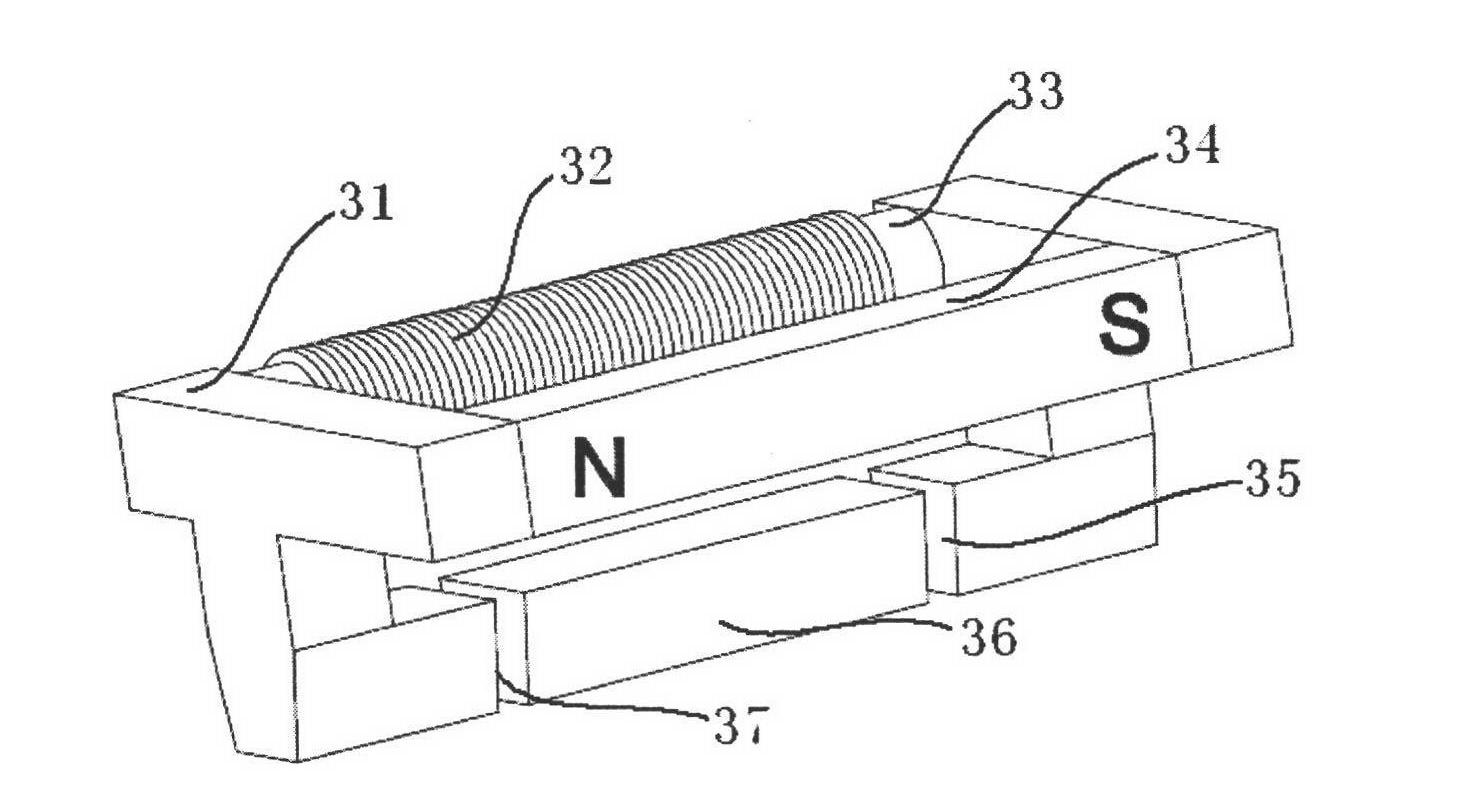

Electric excitation permanent magnet switch, reluctance motor for electric excitation permanent magnet switch and electric excitation method

InactiveCN102184809AWith energy saving effectShorten the reluctance ratioMagnetic circuitSynchronous machinesElectricityControl power

The invention relates to an electric excitation permanent magnet switch, a reluctance motor for the electric excitation permanent magnet switch and an electric excitation method. In the electric excitation permanent magnet switch, two magnetic poles of a permanent magnet are respectively connected with both ends of an iron core on which magnet exciting coils are wound by two soft magnets; and salient poles are arranged on the soft magnets. In the reluctance motor, the switch is used as basic components of a stator and a rotor, and the two magnetic salient poles of each component are arranged in an axial direction; the salient poles of the stator component and the rotor component are arranged oppositely, and air gaps are reserved between the salient poles; and the magnet exciting coils of the stator component and the rotor component at the axial symmetrical position are connected in series or in parallel and then are used as a phase line respectively to be connected to an excitation control power supply. The invention also provides a combination motor formed by connecting motor monomers by using a shaft in a rotary and dislocation mode and a method for the simultaneous diphase electric excitation of the stator component. The switch and the motor save energy, and have low magnetic loss and high magnetic efficiency; and the combination motor with the diphase electric excitation realizes the subdivision of stepper angles, and improves running stability, control accuracy and output power.

Owner:戴珊珊

Soft hand feel coating and preparation method thereof

The invention discloses a soft hand feel coating which comprises expandable microsphere pulp, styrene-acrylate emulsion, dispersant, wetting agent, film-forming additive, anti-freezing agent, defoaming agent, thickener, anti-mildew agent, preservative, titanium dioxide, kaolin, triple(concentrated) superphosphate and water, wherein, the expandable microsphere pulp consists of 10%-15% of expandable microspheres and 85%-90% of water by weight percent. The process comprises the steps of pre-mixing, grinding, dispersing, adding the emulsion, adding the additives and adding the expandable microsphere pulp. The expandable microspheres added in the coating change the structure and the texture of the surface of a paint film and soften the touch; additionally, the expandable microspheres in the paint film improve the porosity of the paint film and reduce the spread-ability of heat and sound in the paint film, pores of the paint film can play the regulating role on water in the air, the water is absorbed when the humidity is high, and the water is released when the humidity is low.

Owner:GUANGDONG NATURAL COATING CHEM CO LTD

Bamboo chopstick processing method

InactiveCN105291238ASave energyGuaranteed anti-corrosion performanceWood treatment detailsReed/straw treatmentSulfurMildew

The invention discloses a bamboo chopstick processing method. The bamboo chopstick processing method comprises the following steps: a bamboo is sawn to a bamboo cylinder; the bamboo cylinder is processed to a bamboo piece, and is processed to a bamboo chopstick blank; one end of the bamboo chopstick blank is sharpened; the wet disinfection and the blenching are performed; the preservative treatment is performed; the carbonizing treatment is performed; the drying and the disinfection are performed; the polishing is performed; and the sorting and the packing are performed. Compared with the mildew prevention and the disinfection of chopsticks smoked by sulfur and boiled by hydrogen peroxide, the bamboo chopstick processing method is safer and more reliable; as ozone cannot leave any poisonous substances on the chopsticks, and an ozone disinfection method saves more energy, the excellent mould preventing, bleaching and disinfecting effects can be obtained only by consuming less electric energy without needing heating; bamboo chopsticks are dip in paraffin liquid or tung oil under high temperature, so that the corrosion preventing effect of the chopsticks in later use is effectively guaranteed; the bamboo chopsticks prepared by the method has such performances as corrosion prevention, insect prevention, mildew prevention and damp prevention, and such natural colors as faint yellow and brown are given to the bamboo chopsticks; and the bamboo chopstick processing method increases the mechanical degree, quickens the production speed, and improves the production efficiency.

Owner:安徽泓浩竹科技股份有限公司

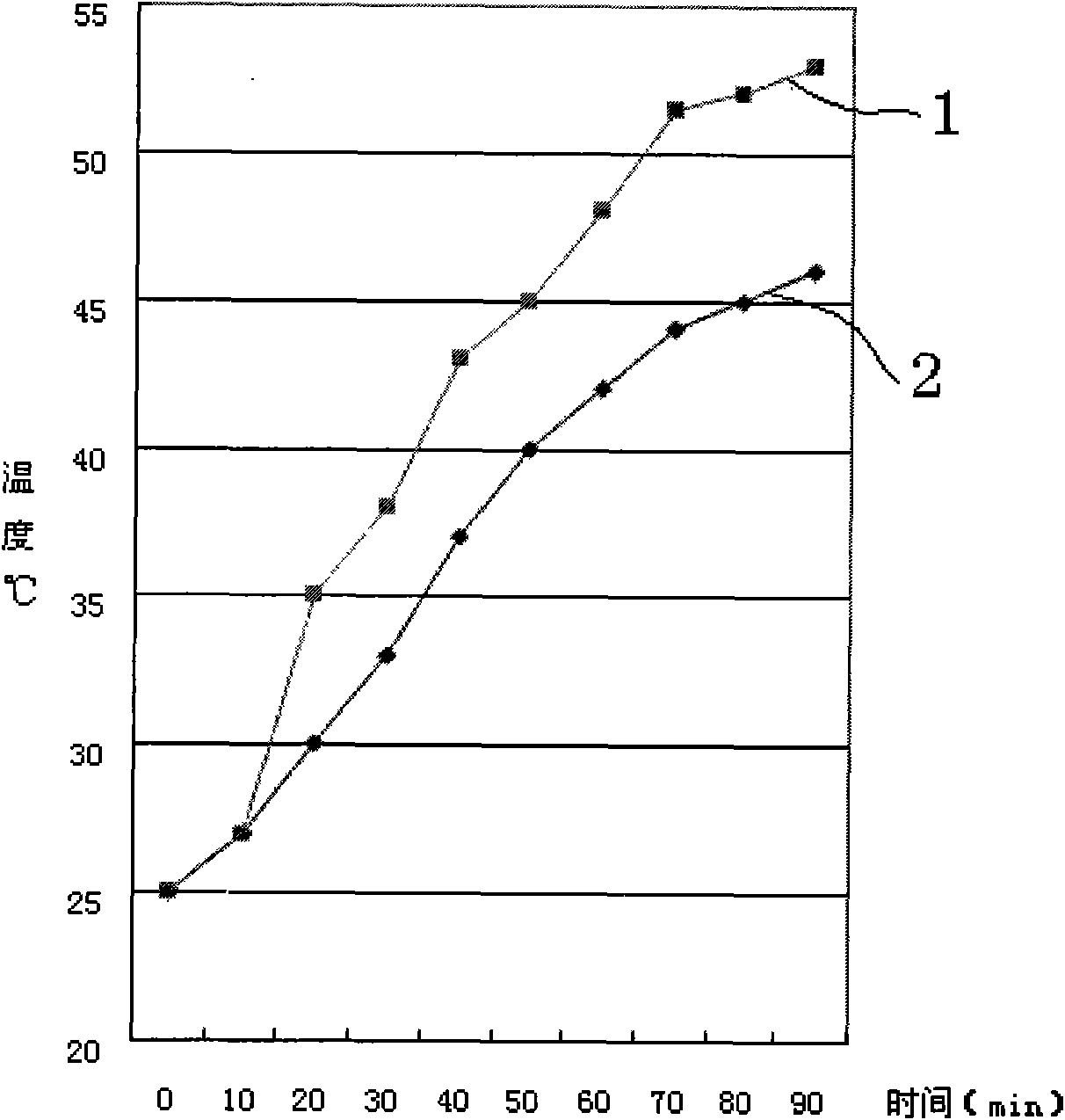

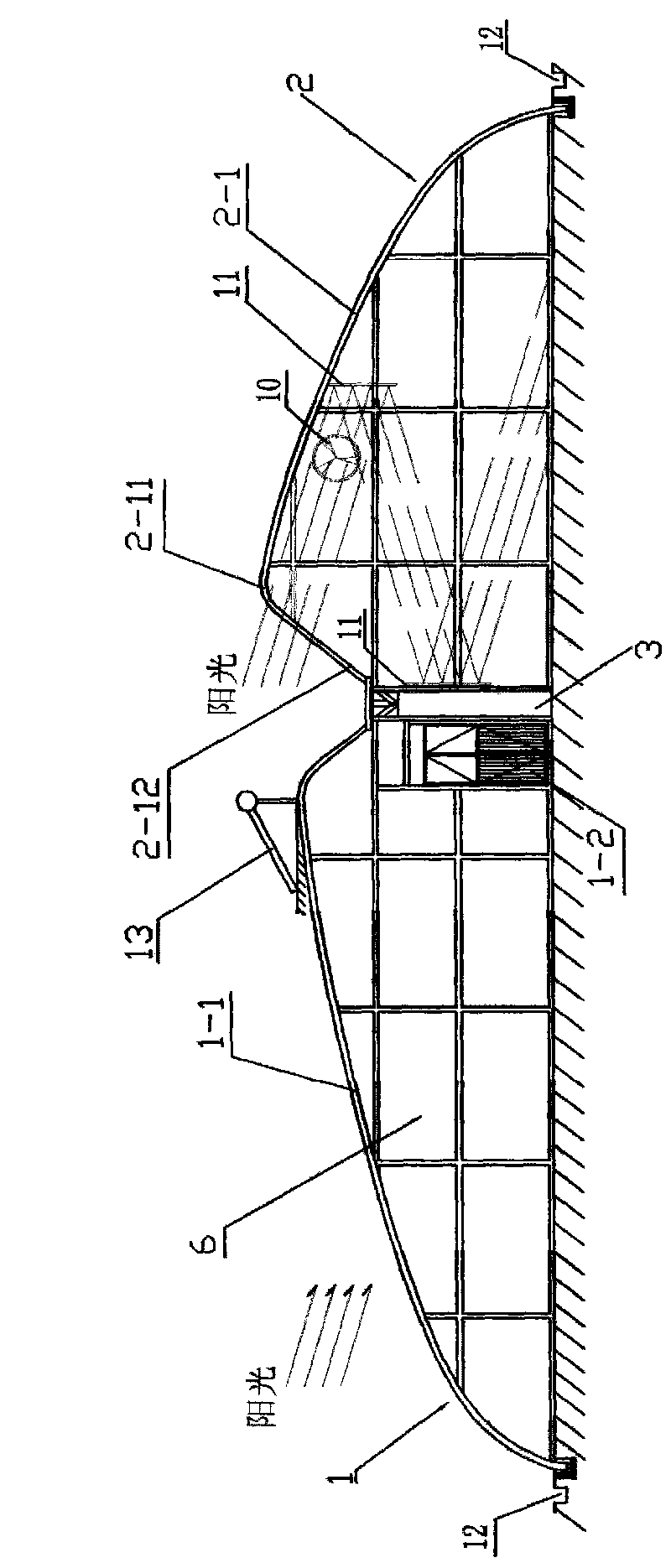

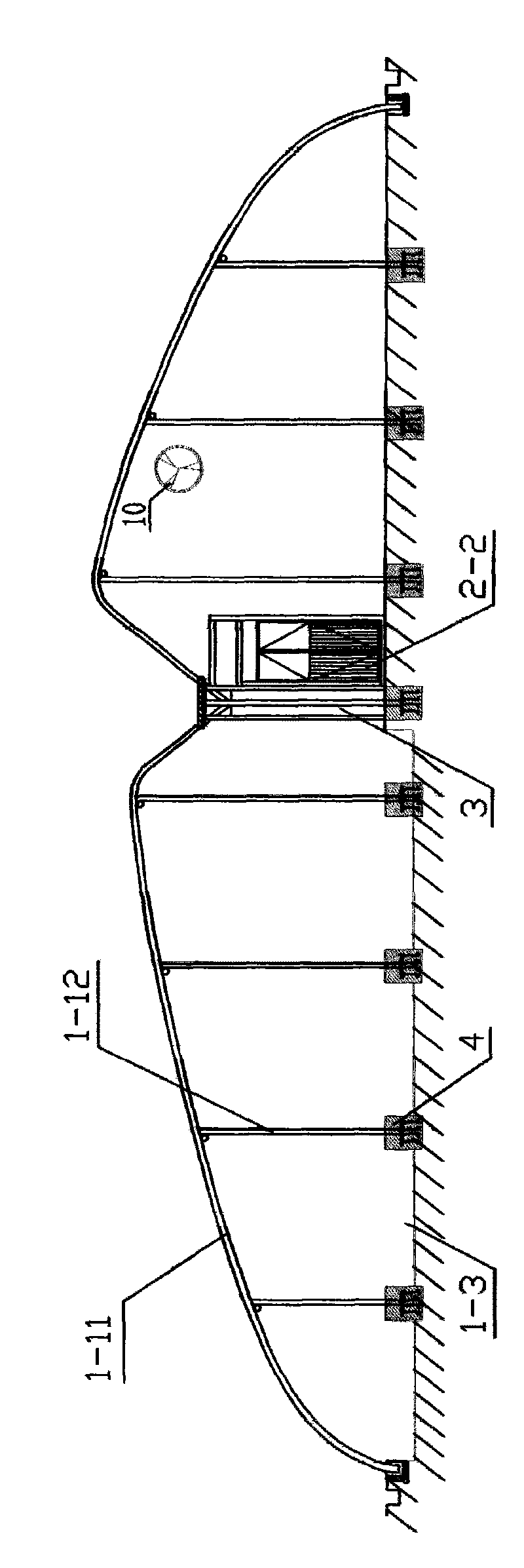

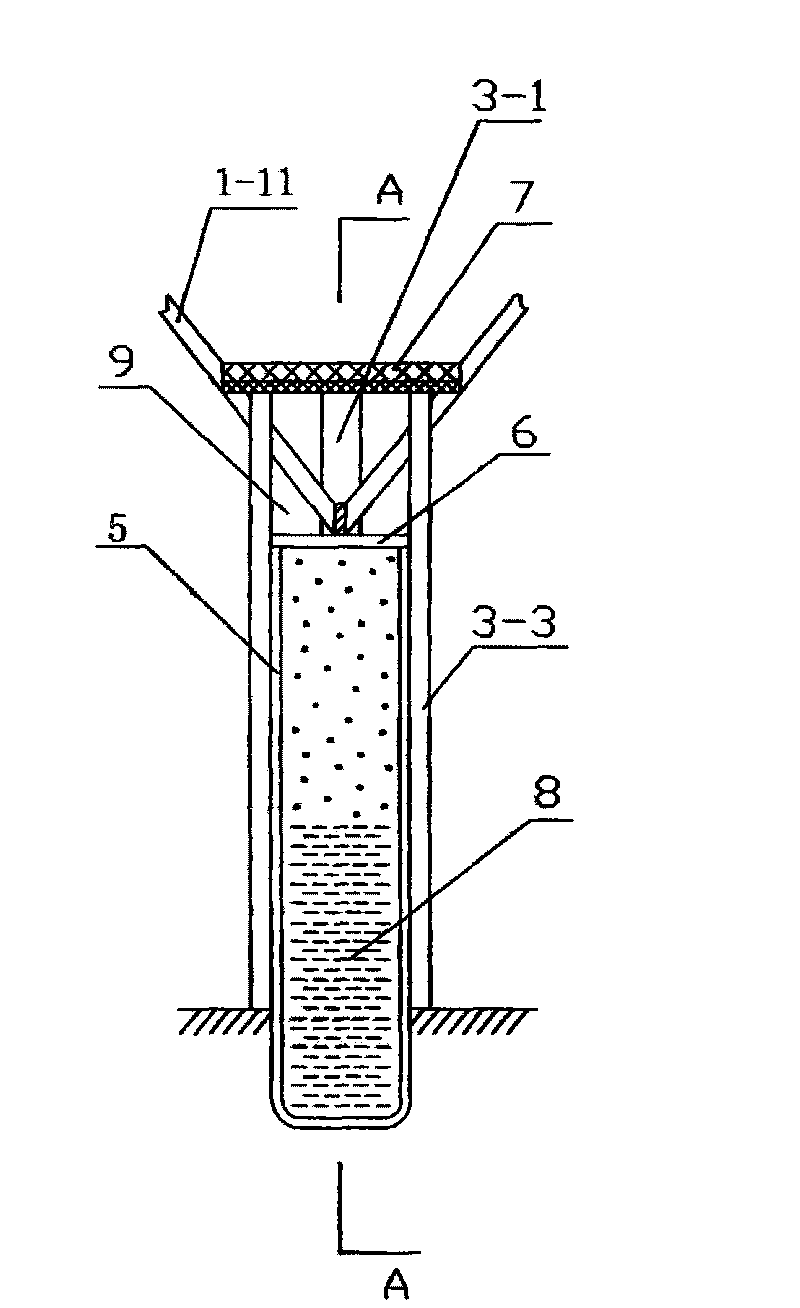

Planting breeding circular economy sunlight greenhouse

InactiveCN101691822AExcellent natural insulation effectAvoid insufficient heatingAgricultural buildingsClimate change adaptationThermal insulationDaylight

The invention relates to a planting breeding circular economy sunlight greenhouse. The greenhouse comprises a shed body facing the sun and a shed body in the shade, wherein the shed facing the sun is used for planting, the shed in the shade is used for breeding, the two shed bodies are arranged back to back and share the same cavity wall, and the cavity wall is a biomass pool for converting the straws of planted crops and excrements of bred animals; the work shops of the two shed bodies are arranged inside the sheds; the shed cover of the shed in the shade is higher than that of the shed facing the sun, and the shed in the shade has one lighting surface facing the sun. As the two shed bodies are arranged back to back, namely the planting shed is arranged on the back of a thermal effect greenhouse for breeding poultry and livestock on a large scale, the breeding shed becomes the natural thermal insulation facility for the planting shed and the natural thermal insulation effect is much better than that of the common sunlight greenhouse. The invention converts wastes of the planting and breeding to methane used for heating the shed bodies without outsourcing energy; the greenhouse of the invention can also save land and protect arable land farthest, when building the greenhouse, the top soil in the planting shed is stacked up in the breeding shed and the top soil can become more fertile after being cured by the breeding organic feed for several years.

Owner:吴宗声

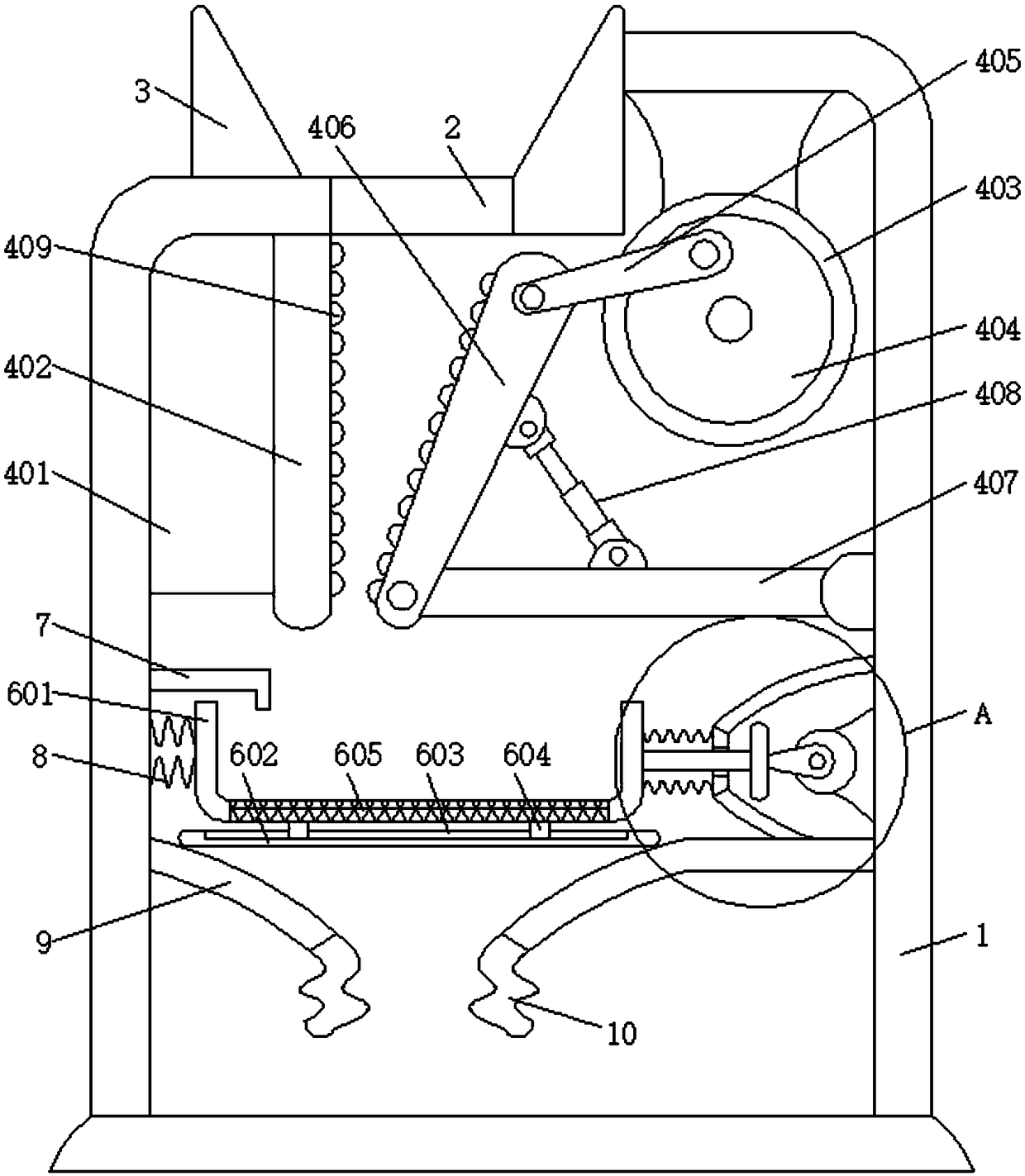

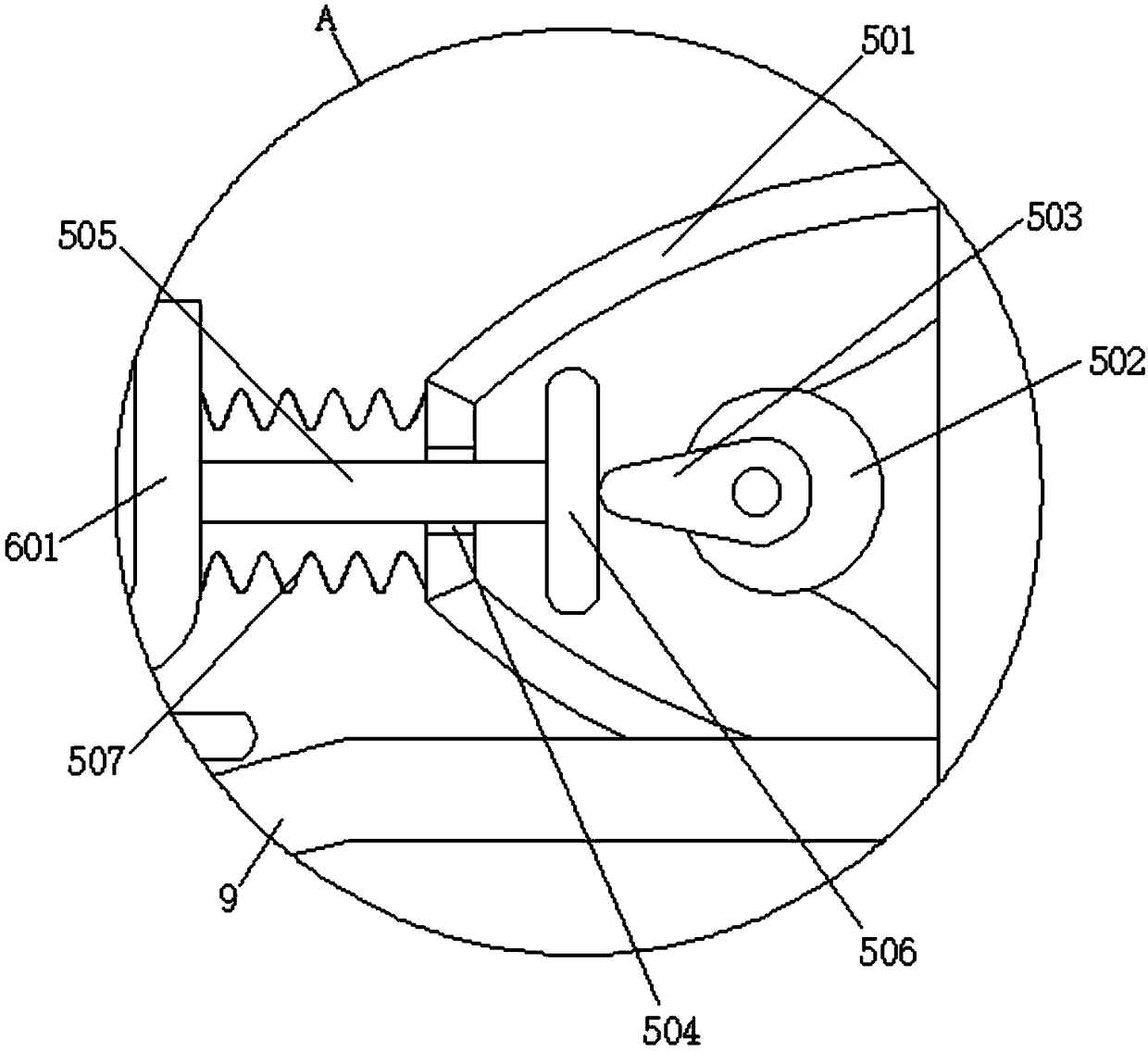

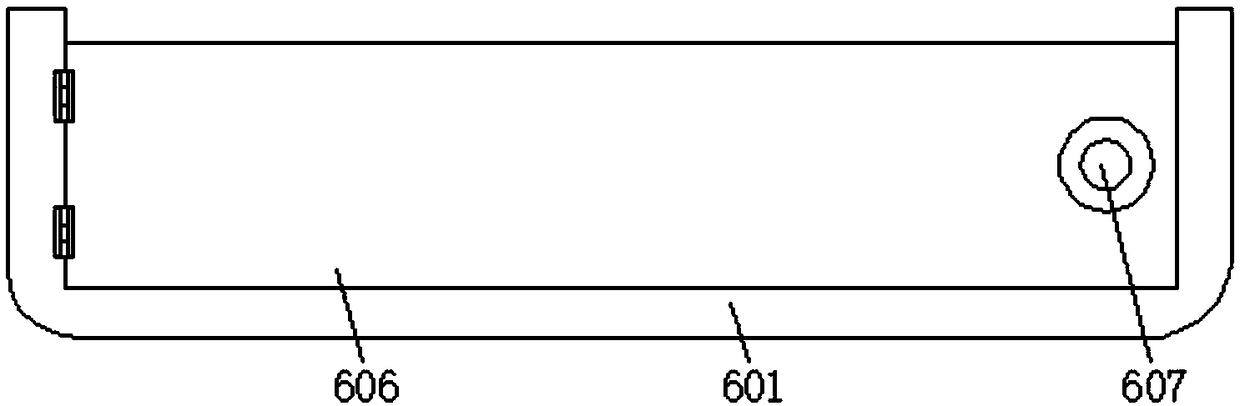

Waste heat preservation concrete block recovery processor for building construction

InactiveCN109012814ALight materialQuick breakSievingScreeningEnvironmental resistanceArchitectural engineering

The invention relates to the technical field of environmental protection, in particular to a waste heat preservation concrete block recovery processor for building construction to solve the technicalproblems that most building construction organizations treat heat preservation concrete blocks as building rubbish, environmental pollution is caused, and energy saving and environment protection arenot facilitated. To solve the technical problems, the waste heat preservation concrete block recovery processor for building construction comprises a machine body, one side of the top of the machine body is provided with a through charging port, the top in the machine body is provided with a material crushing mechanism, one side of the middle in the machine body is provided with a position movingmechanism, and the middle in the machine body is provided with a material filtering mechanism. The waste heat preservation concrete block recovery processor for building construction rapidly crushes and screens waste heat preservation concrete blocks to retain fine heat preservation concrete materials, the fine heat preservation concrete materials can be reused after being stirred by a stirring machine, pollution of the waste heat preservation concrete to the environment is avoided, and the environment friendliness effect is achieved.

Owner:雷细英

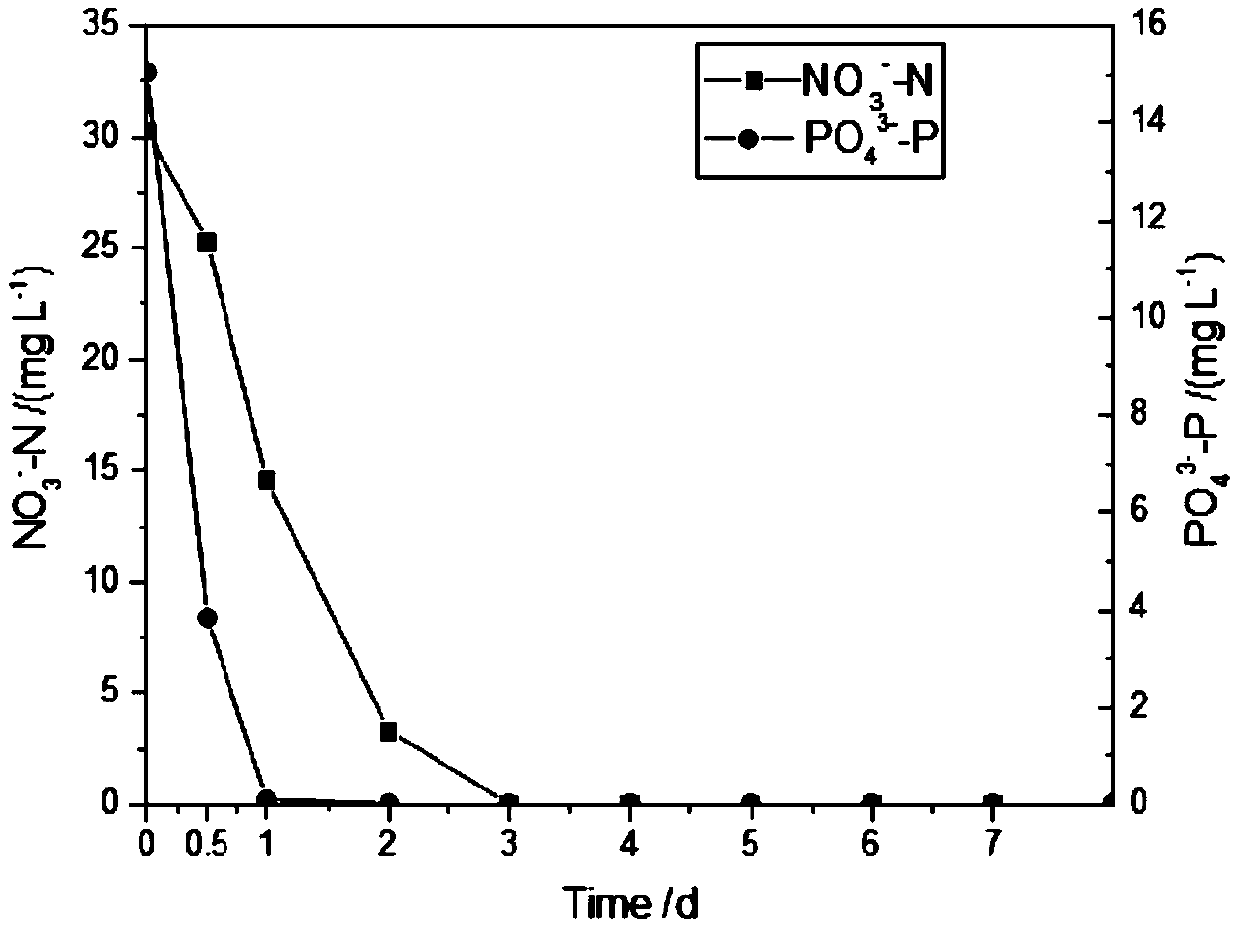

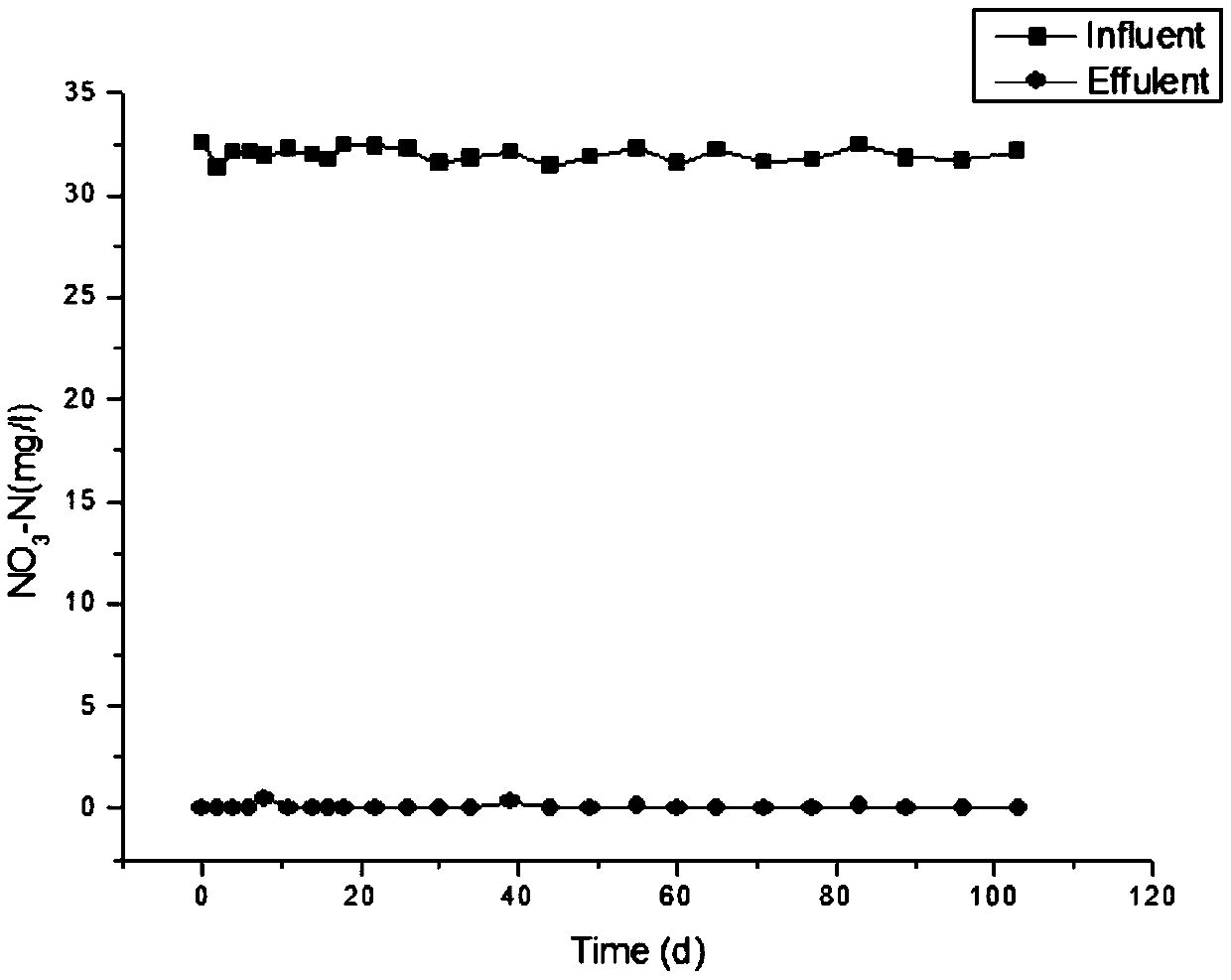

Simultaneous phosphorus and nitrogen removal light material, preparation method and application thereof

PendingCN110078221ALarge specific surface areaQuality improvementWater treatment parameter controlGas treatmentPorosityElectron donor

The invention discloses a simultaneous phosphorus and nitrogen removal light material, a preparation method and the application thereof, and belongs to the technical field of environment function materials and sewage disposal. A fusion mixture is obtained by sufficiently fusing and dispersing sulfur and an iron-based component, wherein the iron-based component is a pyrite and calcium magnesium carbonate mixture; and foaming treatment is carried out on the fusion mixture to form the simultaneous phosphorus and nitrogen removal light material. The simultaneous phosphorus and nitrogen removal light material disclosed by the invention has the characteristics of high porosity, large specific surface area, light weight and high reaction activity. The obtained light material, as a microbial carrier and an electron donor of biochemical reactions, is applied to the reactors, such as fixed beds and fluidized beds, for sewage disposal, and has the advantages of good microorganism adhesion property, high denitrification speed and good phosphorous removal effect.

Owner:NANJING UNIV +1

Method for manufacturing extruded bar from magnesium alloy

ActiveCN1695885AImprove mechanical propertiesMeet quality requirementsOther manufacturing equipments/toolsFree coolingIngot

Owner:NORTHEAST LIGHT ALLOY CO LTD

Preparation method of glass fibre fabric conductive material

InactiveCN1444234AImprove shielding effectReduce surface resistanceBraided wire conductorsGlass making apparatusGlass fiberMilitary installation

A method for preparing glass fiber fabric conduction material includes vacuum coating with Ni or Cu, then continuously coated with Ni, Cu, Ag or Mu metal layer on glass fiber cloth, net and felt matrix. This invented material can be retardant, fire resistant, suitable for screening materials of space and military installations or screening materials of electronic and precision instruments.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Light-weight, heat-insulating and environment-friendly composite wall building material

InactiveCN105801063AImprove flexural strengthHigh compressive strengthCeramicwareLow-density polyethyleneCellulose

The invention discloses a light-weight, heat-insulating and environment-friendly composite wall building material.The building coating is prepared from cellulose, carbon fiber particles, rubber particles, plant particles, low-density polyethylene resin, organosilicon-modified epoxy resin, calcium carbonate, magnesium oxide, magnesium silicate, magnesium calcium carbonate, calcium borate, nanosized silica, light-weight ceramic, EVA redispersable rubber powder and the like.The building wall coating has the advantages of being high in breaking strength and compressive strength, has the effects of heat preservation and sound insulation, is low in heat conductivity coefficient and good in energy-saving effect, and has the good waterproof effect.The obtained wall material is portable, low in cost, free of pollution and environmentally friendly, energy consumption and the production cost are greatly reduced, and the material can be widely applied to building construction.

Owner:韩旭霞

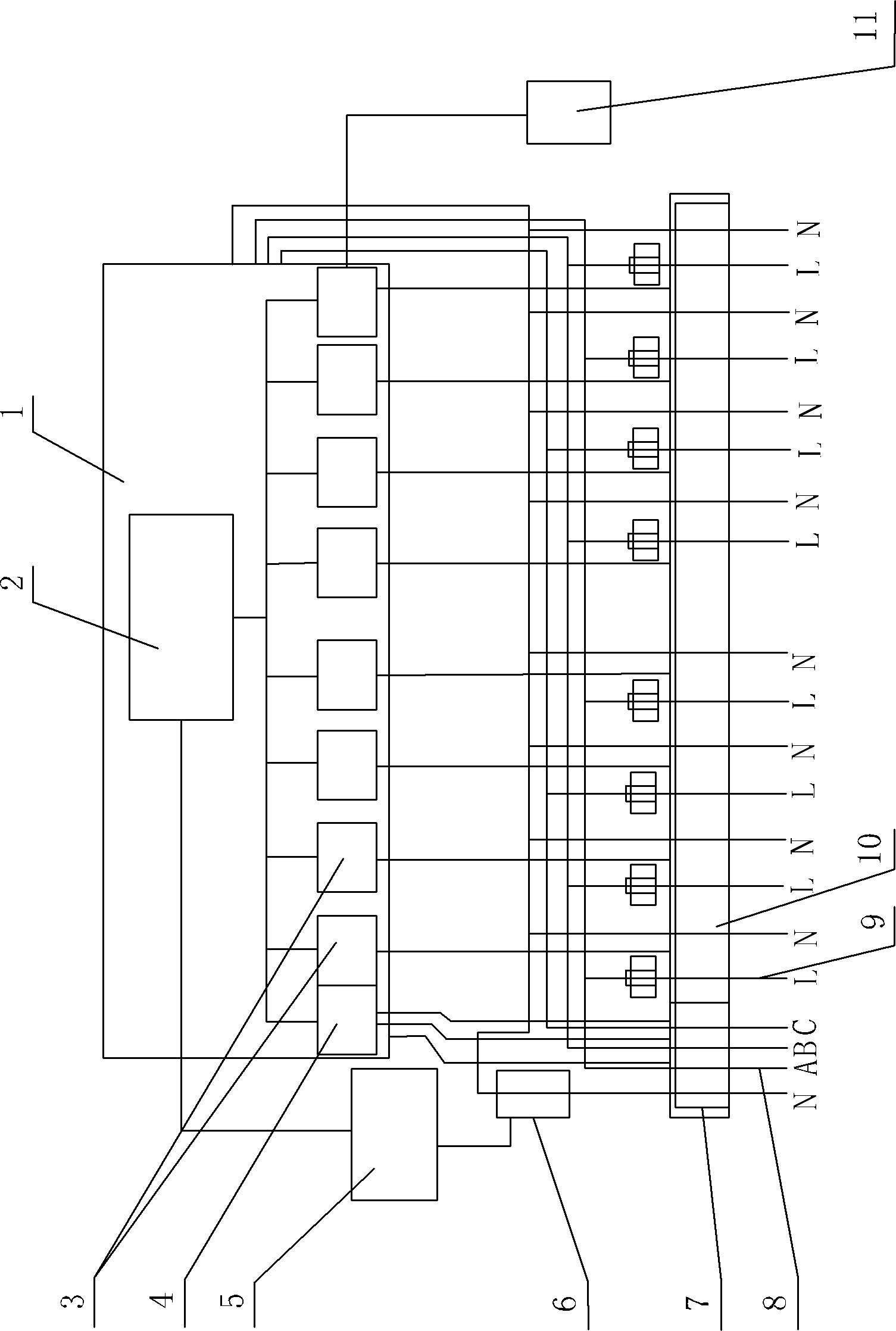

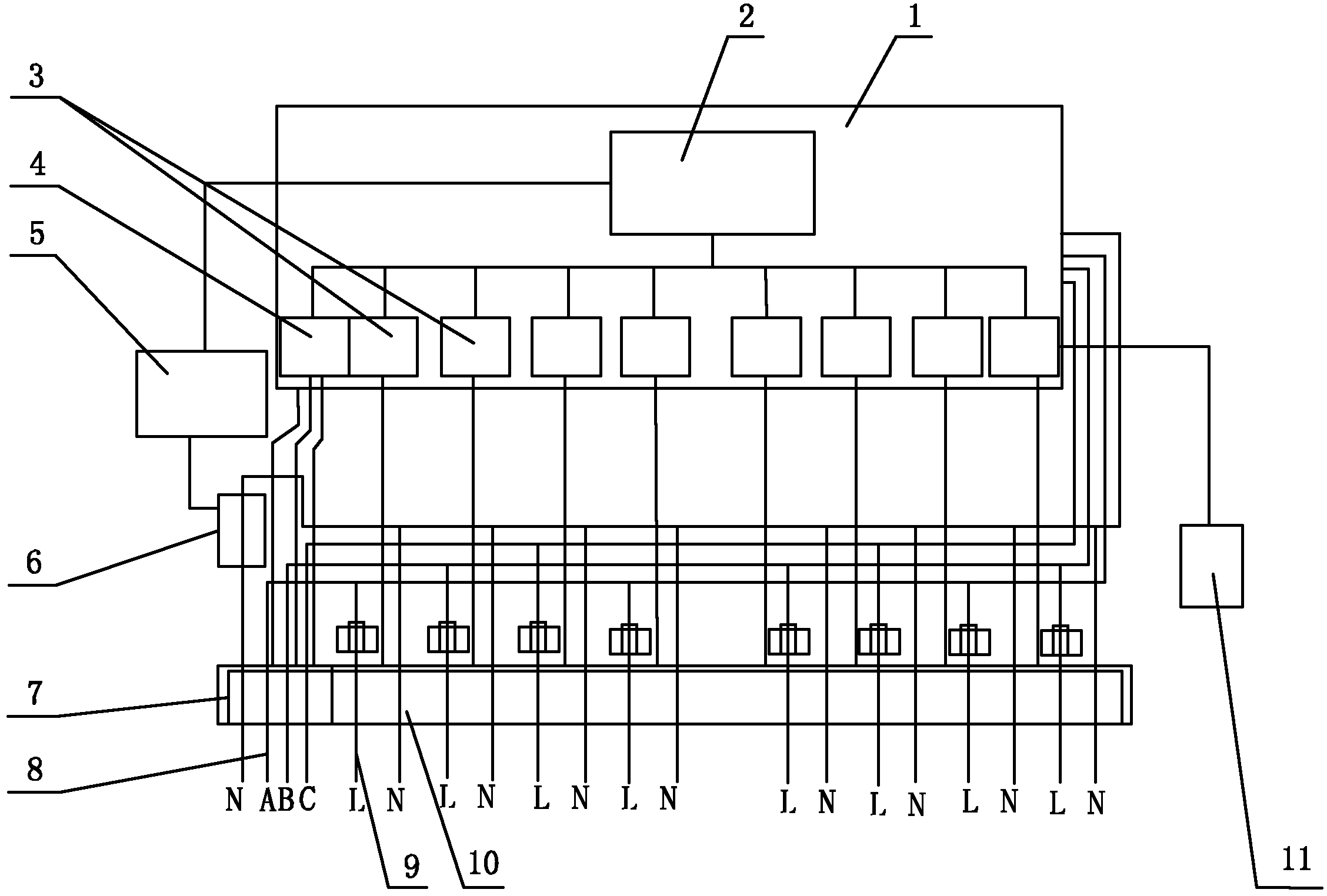

Unit multi-user intelligent electric energy meter box

InactiveCN102323461AConvenient for centralized meter readingEasy to manageTime integral measurementCommunication unitEngineering

The invention discloses a unit multi-user intelligent electric energy meter box, which belongs to devices for power utilization centralized metering, management and control of multi-user units of communities. The box comprises a box body, and is characterized in that: a master control display unit is arranged in the box body and is provided with connected communication unit and multi-user metering device; power consumption of each user is acquired by the multi-user metering device and information is transmitted into the master control display unit; a signal is calculated by the master control display unit and a result is displayed, so that centralized meter reading, management and control are facilitated; and uploading of data in the master control display unit and state detection signal transmission of a unit master incoming line can be finished by the communication unit. The meter box has the advantages of wide information acquisition, large capacity, reduced loss, energy conservation, material saving, and capabilities of improving measuring accuracy and meter efficiency, simplifying operation, independently checking meters of users, checking meters in turn and continuously and electrically checking meters on line.

Owner:山东计保电气有限公司

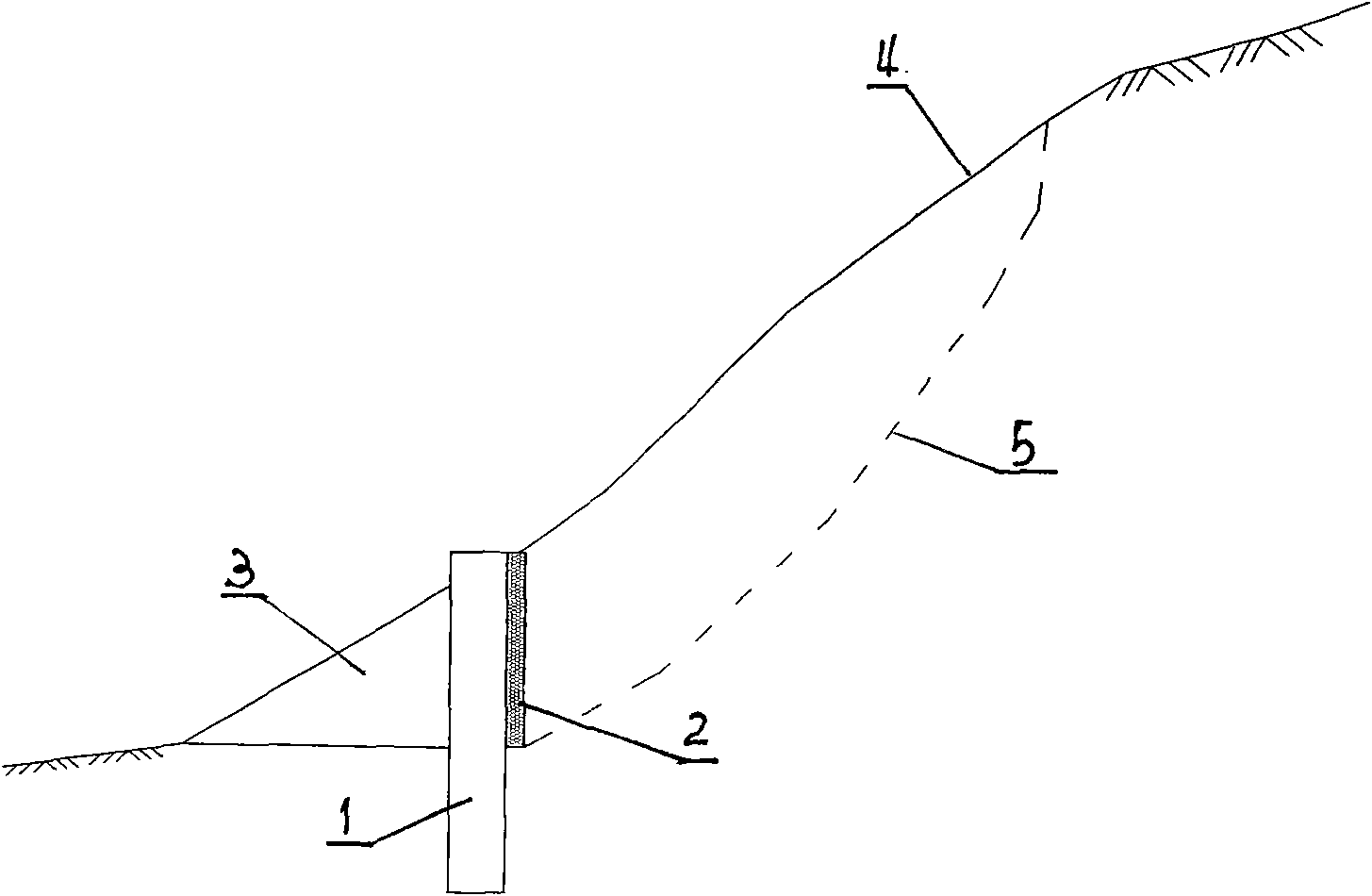

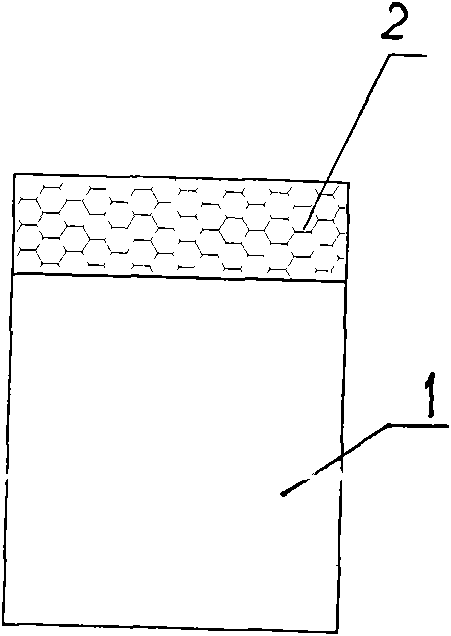

High cutting slope advanced supporting construction method

InactiveCN101624829ASimple structural designSimple designExcavationsBulkheads/pilesPolystyreneUltimate tensile strength

The invention relates to a high cutting slope advanced supporting construction method which is characterized in that: before digging a high cutting slope, an advanced supporting pile is dug and constructed firstly, polystyrene foam carpet material with a certain thickness is arranged above the digging surface of the backing side of the advanced supporting pile, and then a pile body concrete is poured, so as to form a novel structure of the advanced supporting pile with the polystyrene foam material, after the advanced supporting structure has 70 percent of intensity, the high cutting slope is dug; by adopting the self deformation of the polystyrene foam material (EPS), the soil pressure on the advanced supporting pile is reduced and the section size and reinforcing bars of the advanced supporting pile are optimized, thereby greatly reducing the construction investment of the high cutting slope advanced supporting structure and ensuring the whole stability and construction safety of the high cutting slope.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Multipurpose plastic honeycomb bundle

InactiveCN1596634ASignificant comprehensive benefitsRemarkable effectAnimal husbandryAquatic animalAquatic product

A multi-purpose plastic cellular bundle for raising silkworms, storage of grains, culture of aquatic animals, etc is made up of non-toxic plastics or composite material.

Owner:黄海芳

A six-degree-of-freedom underwater moving platform

ActiveCN106891073AReduce weightReduce volumeWelding/cutting auxillary devicesElectrode holder supportersMarine engineeringUnderwater

The invention relates to a six-degree-of-freedom underwater moving platform. An open frame type structure is employed, so that the weight and the size of the platform are reduced and the platform is suitable for more kinds of working areas; various structure of the platform are controlled via cables and the bottom of the platform is provided with a welding control box, so that the function of real-time welding tracking of the platform is guaranteed and the welding quality is improved; the platform can be turned simply via air bags, so that the cost is reduced and the posture control of the platform is simplified; via two vertical propelling devices and four horizontal propelling devices, six-degree-of-freedom movement can be realized; by combining the platform movement posture control mode and universal wheels, a wall climbing function is fulfilled, and the platform can move freely on any working planes. With the platform structure and with the functions of wall climbing and real-time welding tracking, an open frame type underwater working robot which is novel and stable and is low in cost is realized.

Owner:智真海洋科技(威海)有限公司

High-strength foam cement insulation board and preparation method thereof

ActiveCN103241997AImprove fire performanceExtended service lifeMould separation apparatusMouldsFiberPolymer science

The invention discloses a high-strength foam cement insulation board. The board is prepared from raw materials including cement, coal ash, water, emulsion, calcium stearate, fiber hair, a foam stabilizer, a water repellent, calcium chloride, aluminium sulfate and a foaming agent which are added in a ratio. The preparation method comprises steps of: first-level stirring: mixing the cement, the coal ash, the water, the emulsion, and calcium stearate according to a ratio, and stirring uniformly; second-level stirring: sequentially adding the fiber hair, the foam stabilizer, the water repellent, the calcium stearate and hydrogen peroxide into the size according to the ratio after first-level stirring, and stirring uniformly; carrying out injection molding, foaming and initial curing; demolding; cutting; and maintaining a finished product. The insulation board is short in production period, high in production efficiency, high in performance index and low in cost.

Owner:HUAIAN RUNCHENG BUILDING ENERGY SAVING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com