Calibration system and calibration method of humidity-temperature sensor

A temperature and humidity sensor and calibration system technology, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as limited space for adjustment, inability to meet user requirements, and easy formation of dead ends in the test box. Time-consuming, compact results for tuning and approval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

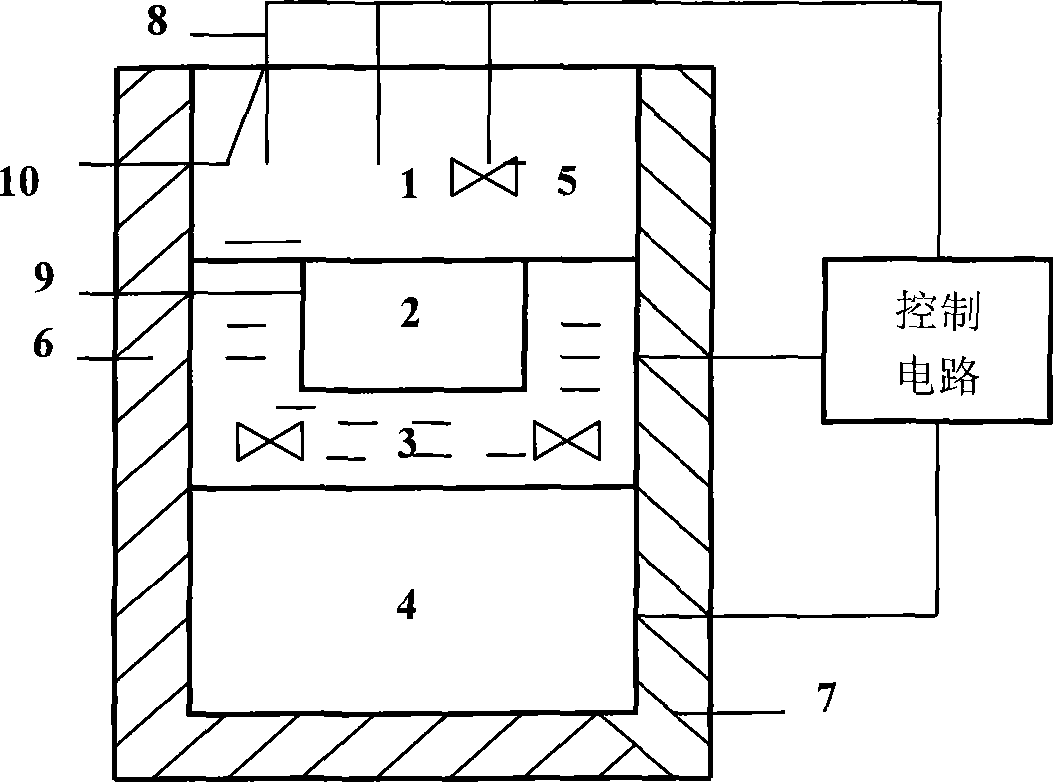

Image

Examples

Embodiment 1

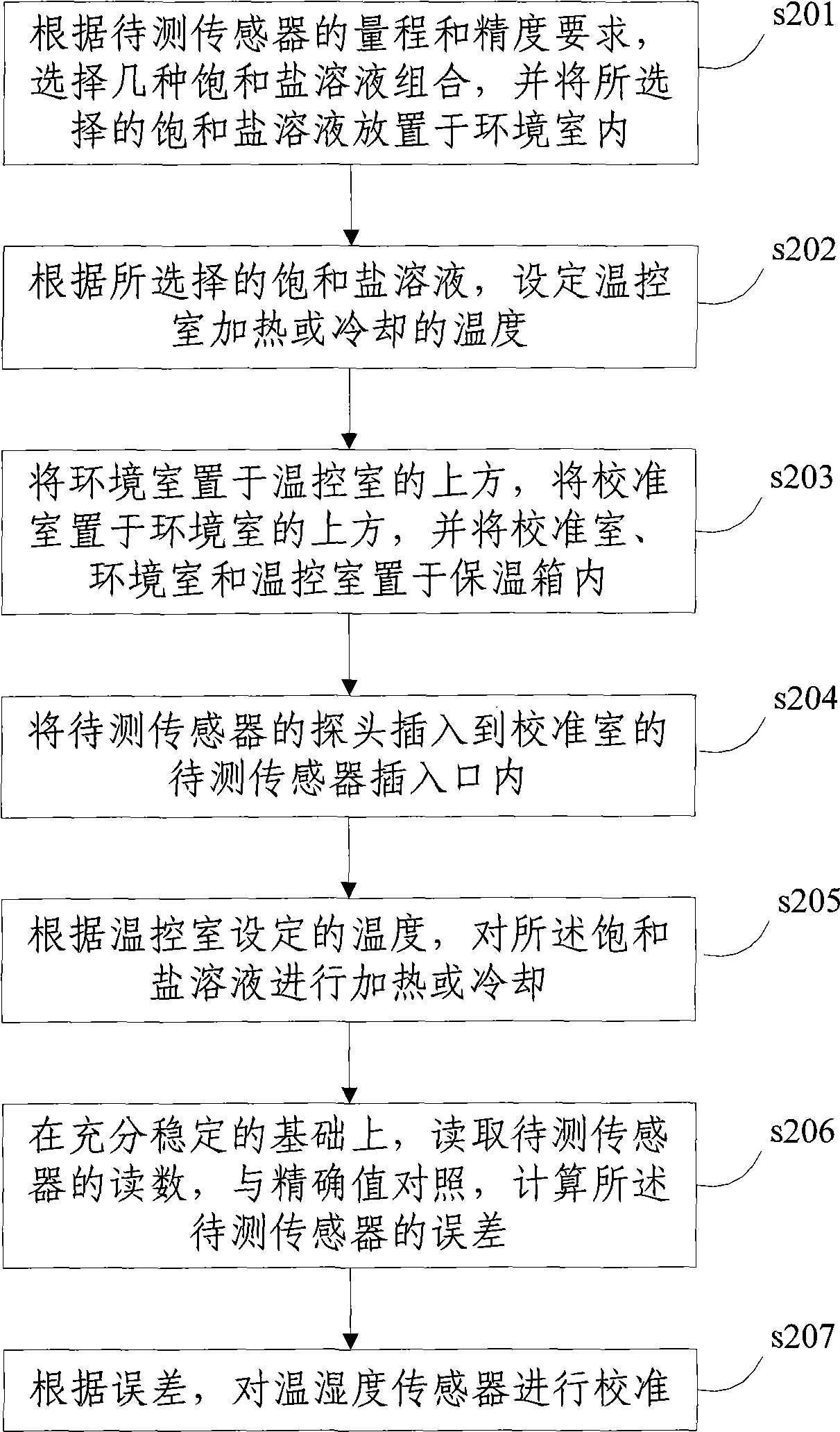

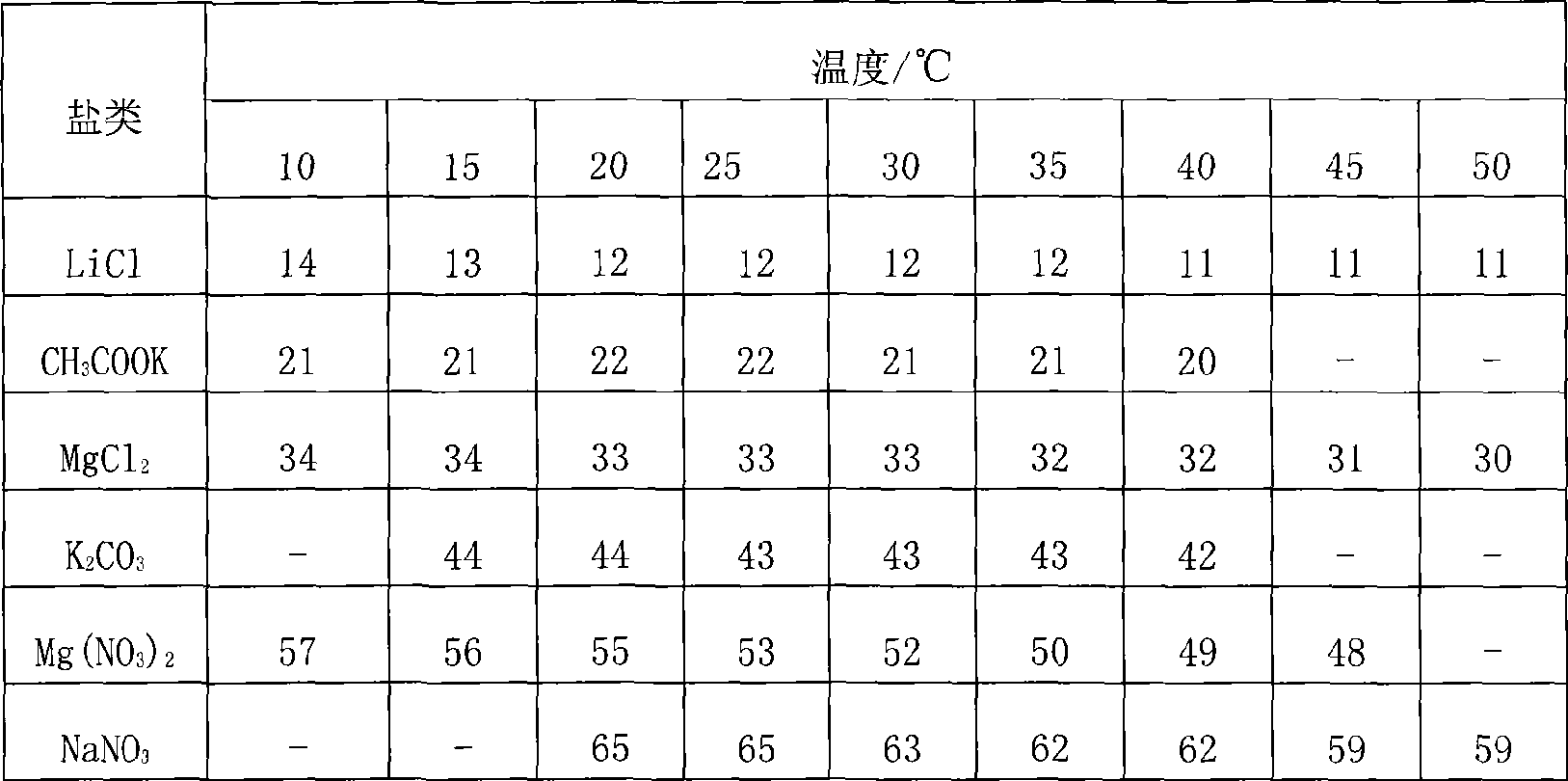

[0041] Example 1: Calibration of low-precision mercury thermometers

[0042] Select a certain type of mercury thermometer (range: 0-100°C, accuracy: 0.01°C) to be tested, and install it in the insertion port of the sensor to be tested in the calibration room; check the table to select a suitable saturated salt solution, which is used in this embodiment NaCl saturated solution, put it into the corresponding saturated saline solution container; set the temperature of the temperature control room according to the needs, complete the assembly of the temperature control room, the environment room and the calibration room, and place them in the incubator, turn on the control circuit switch, wait for After automatic stop, read the reading of the mercury thermometer to be tested, compare it with the accurate value, calculate its error, and complete the calibration of the mercury thermometer.

example 2

[0043] Example 2: Adjustment of the two-wire integrated temperature and humidity sensor

[0044] Take the JWS type temperature and humidity integrated sensor commonly used in industrial and agricultural production as an example. %RH, put the probe into the calibration room after packaging, use the two-core signal line to connect the signal output of the temperature and humidity sensor to a certain type of data acquisition board, the data acquisition board has the ability to convert analog signals into digital signals and Packaged into a network signal function, the computer uses a network cable to connect to the data acquisition board through a network hub or a switch, so as to check the temperature and humidity values in real time; look up Table 1 to select a suitable saturated salt solution, and select K in this embodiment. 2 CO 3Put the saturated solution into the corresponding saturated saline solution container; set the temperature of the temperature control room accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com