A six-degree-of-freedom underwater moving platform

A technology with a mobile platform and a degree of freedom, which is applied in the direction of auxiliary devices, devices supporting electrode clamps, arc welding equipment, etc., can solve the problems of automatic welding seam tracking and other problems, and achieve improved welding quality, simplified attitude control, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

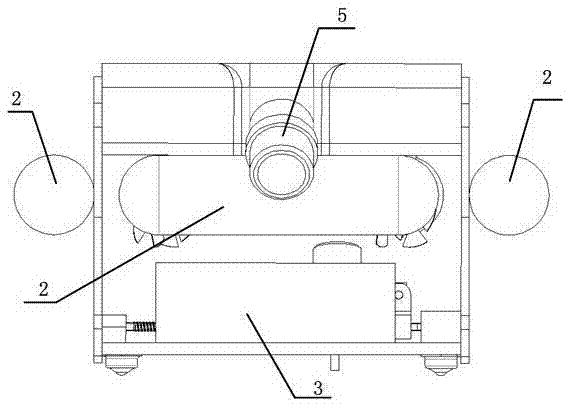

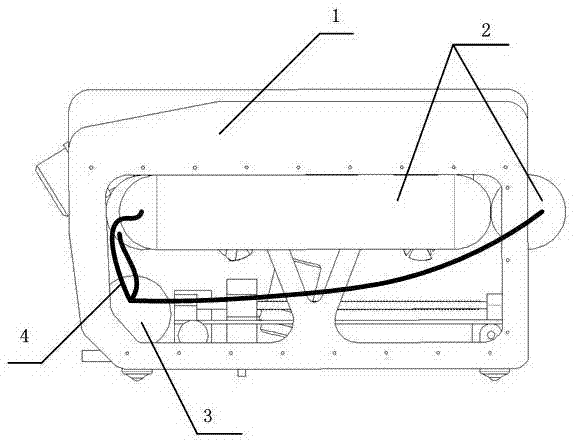

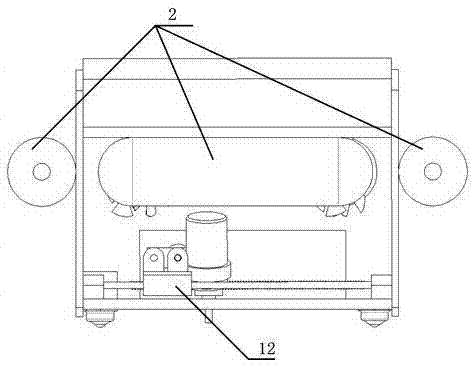

[0032] A six-degree-of-freedom underwater mobile platform, which consists of: an open-frame underwater robot (1); four cylindrical airbags (2) are installed around the open-frame underwater robot (1), and then pass through a hose ( 4) Connected to the solenoid valve in the glass cylinder (3) at the front of the platform, the front-view camera (5) and the down-view camera (6), a horizontal screw (7) and a horizontal screw ( 7) Install a horizontal groove (8) on the other side of the parallel, install a vertical screw (9) on the horizontal screw (7), and fix one end of the vertical screw (9) to drive the waterproof motor (10) On the horizontal screw (7), the other end of the outer cover is embedded in the horizontal groove (8), the vertical groove (11) that moves with the vertical screw (9), and the vertical groove (11) is embedded Welding control box (12), welding torch (13) extends through the hollow area at the bottom of the platform, and by controlling the movement posture of...

Embodiment 2

[0034] According to the movement mechanism of the six-degree-of-freedom underwater mobile platform described in Embodiment 1, the platform is equipped with two vertical thrusters (14) and four horizontal thrusters (15), and the four horizontal thrusters ( 15) The four corners are arranged oppositely; the said propeller uses a DC brushless inner rotor motor and is equipped with a reduction box. The tail end and the front end are sealed with a sealing ring, and the shaft is sealed with a skeleton oil seal.

Embodiment 3

[0036] According to the movement mechanism of the six-degree-of-freedom underwater mobile platform described in embodiment 1, the glass cylinder (3) at the front end of the platform is connected to the image processing equipment and the air pump of the shore control system; the solenoid valve is connected to the shore air pump With the cylindrical airbag (2) around the platform, the platform can be turned in any direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com