Patents

Literature

246 results about "Underwater welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

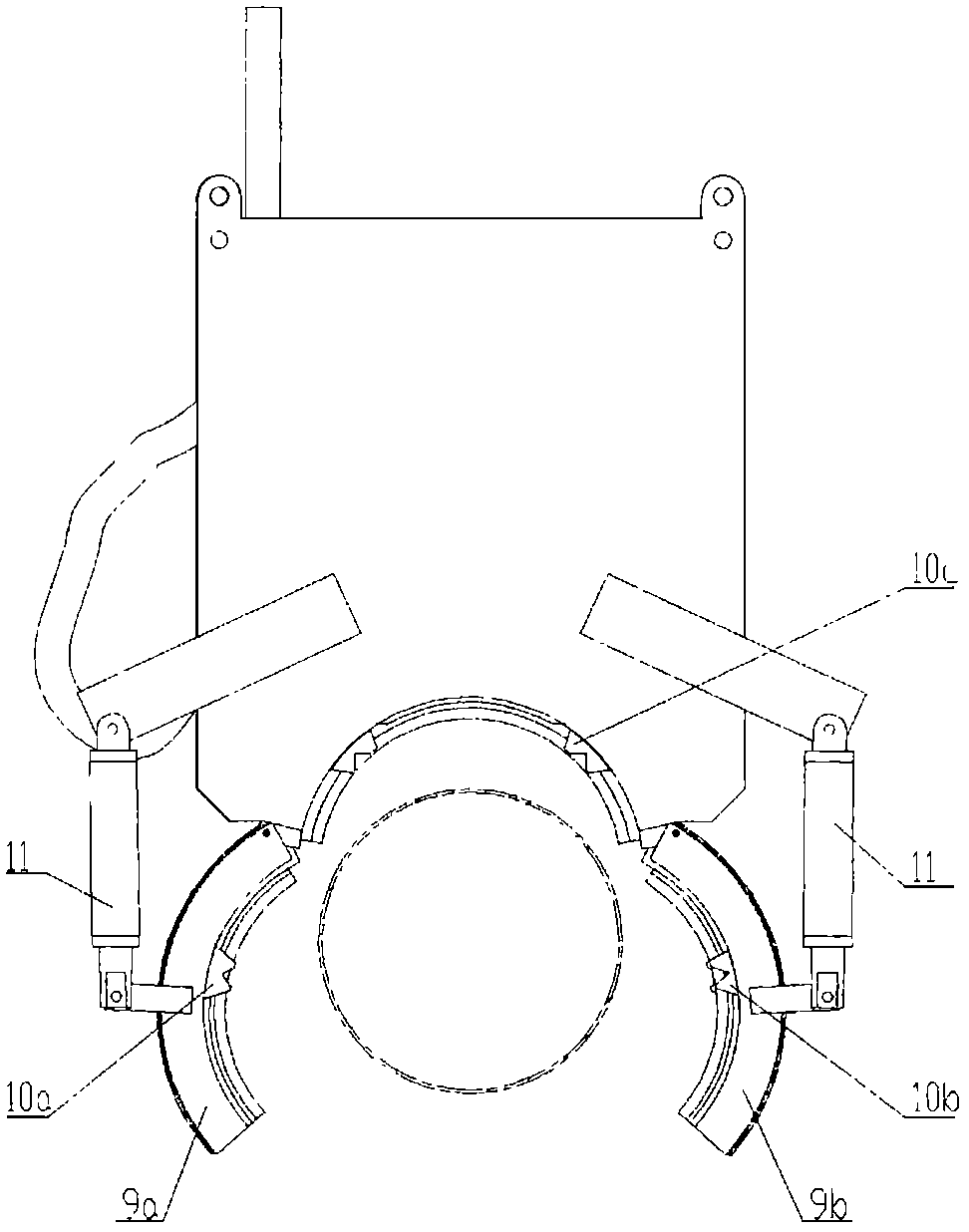

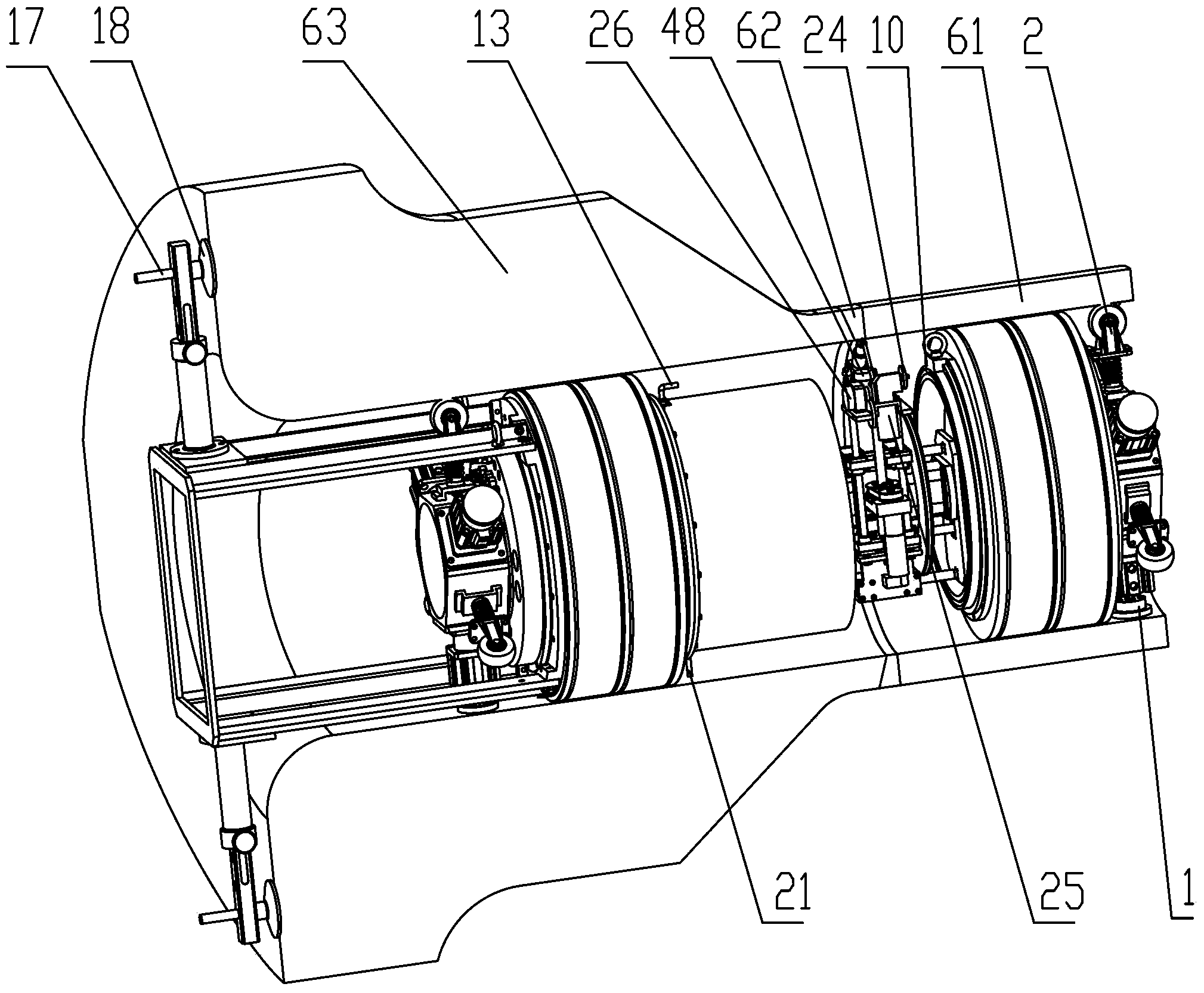

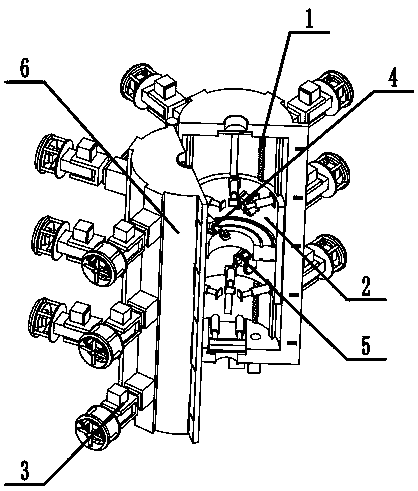

Local dry-method underwater welding robot based on ROV

InactiveCN103785923AImprove welding efficiencyImprove welding qualityArc welding apparatusUnderwater equipmentHydraulic pumpElectric cables

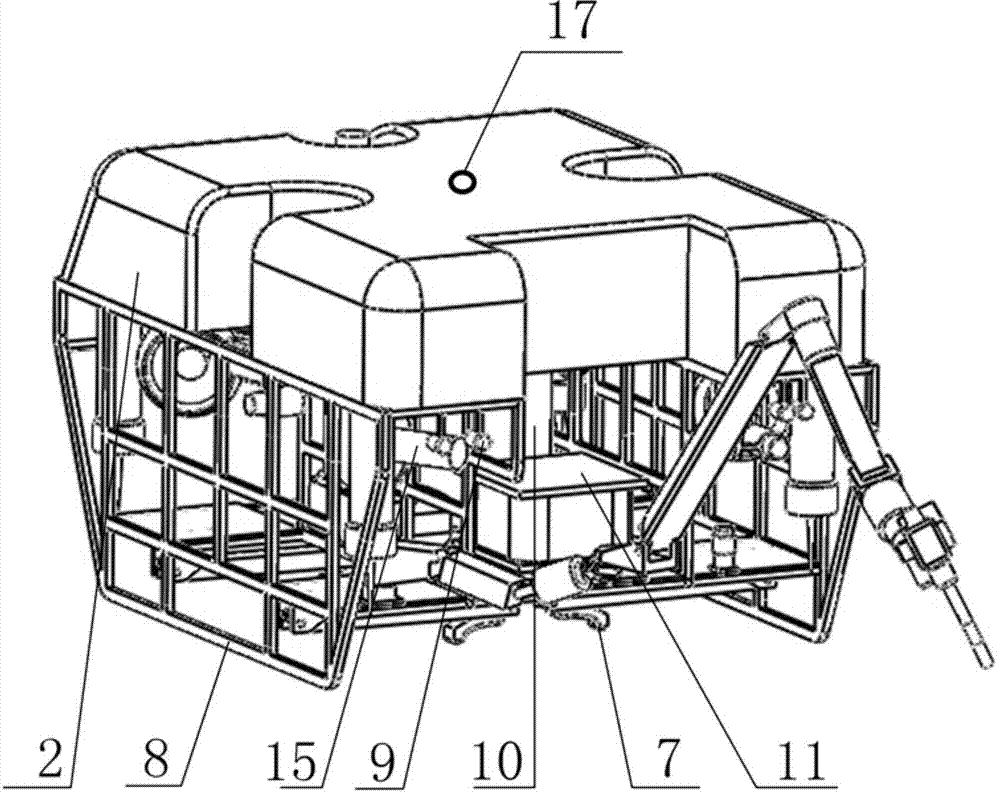

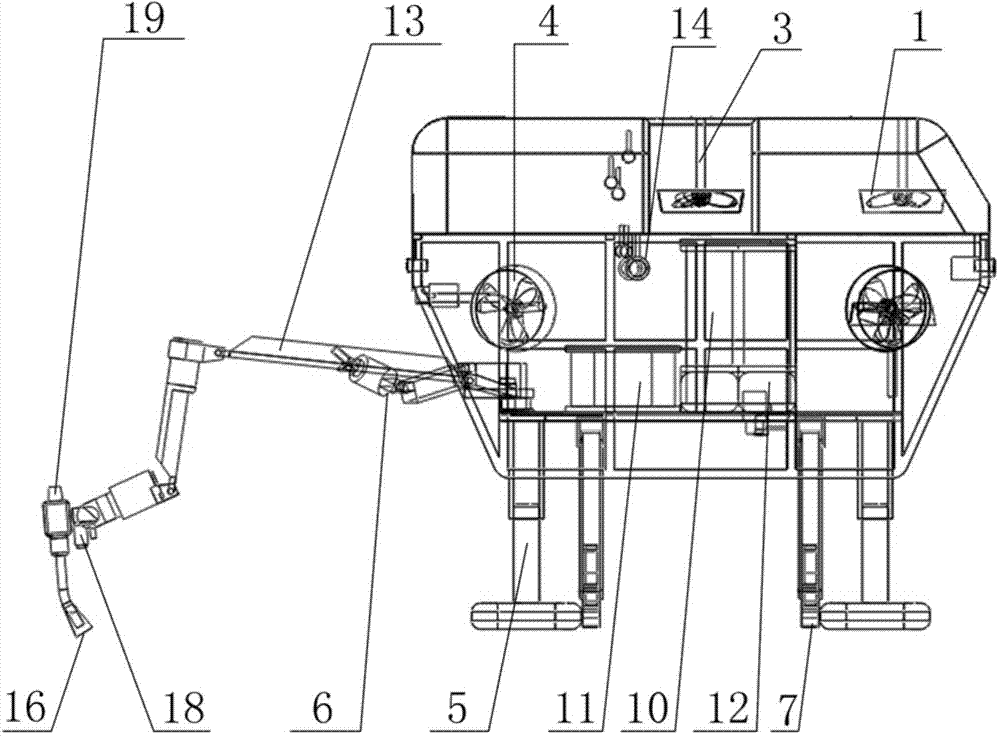

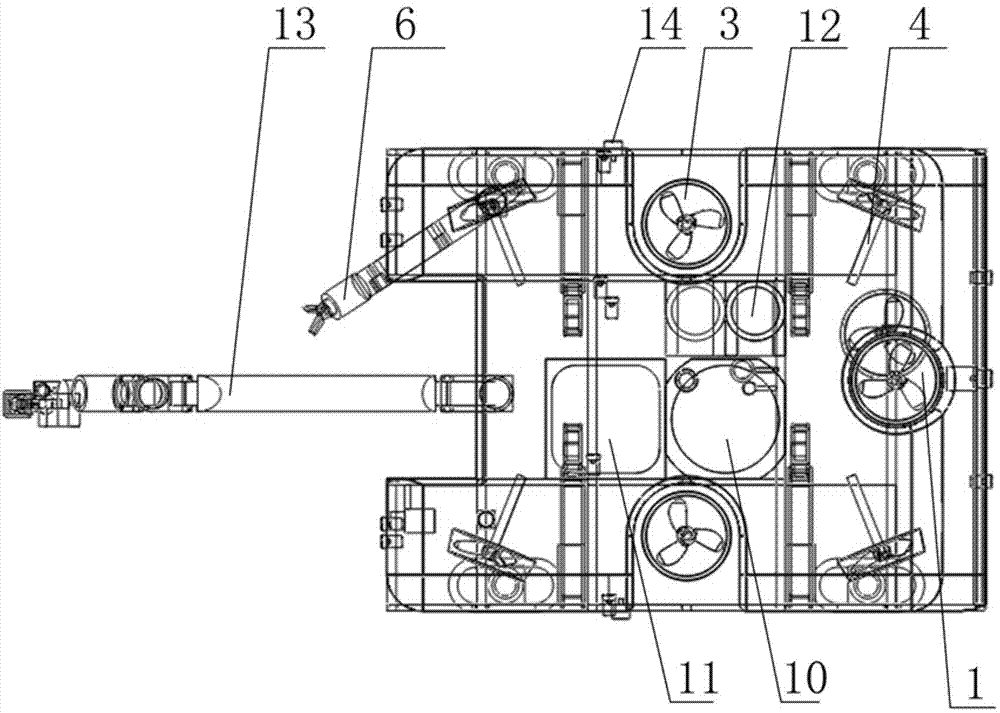

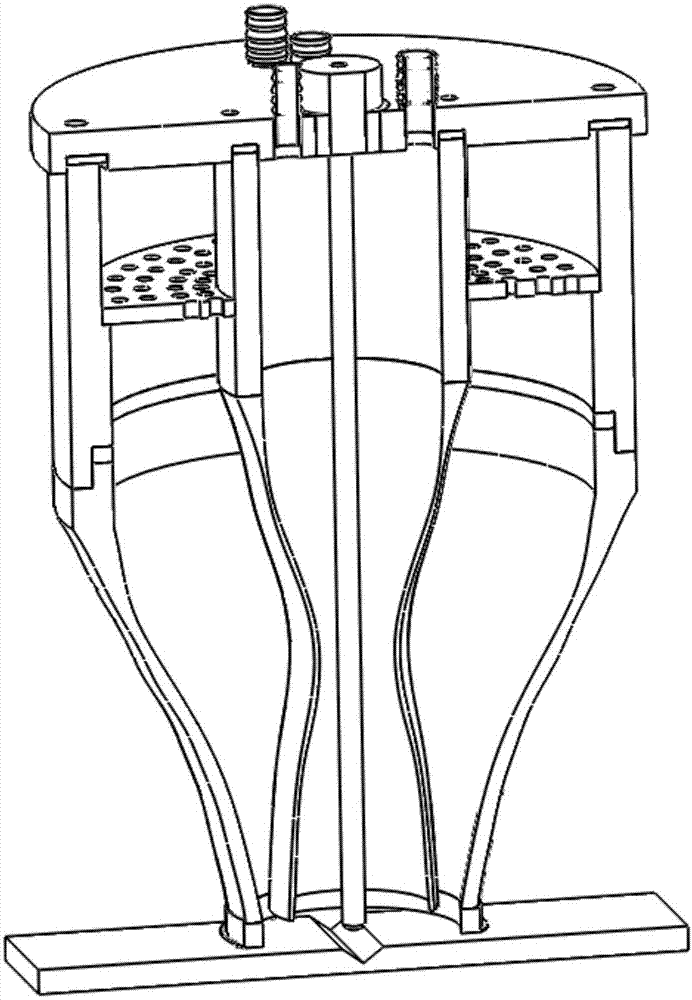

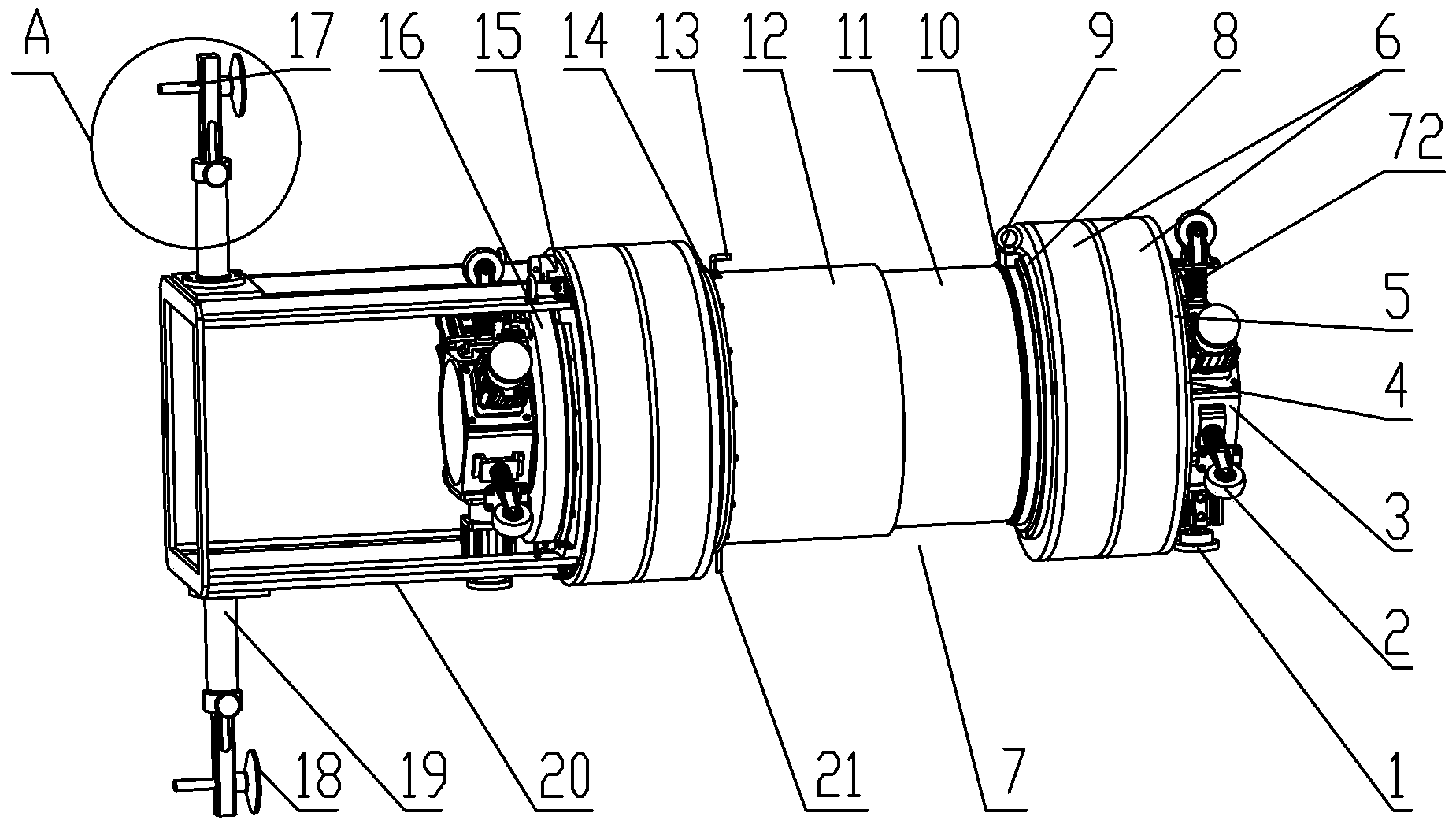

The invention provides a local dry-method underwater welding robot based on an ROV. The local dry-method underwater welding robot comprises the ROV and a welding mechanical arm installed on the ROV. The ROV comprises a frame, a vertical auxiliary thruster, a vertical main thruster and a horizontal thruster, wherein the vertical auxiliary thruster, the vertical main thruster and the horizontal thruster are installed on the frame, the upper portion of the frame is provided with buoyancy materials, the middle portion of the frame is provided with an electronic device sealed cabin and a welding device sealed cabin, the front of the frame is provided with an imaging sonar and an underwater lighting device, the two sides of the frame are provided with camera systems, and the bottom of the frame is provided with a pipeline fixing claw, a hydraulic pile leg and an underground hydraulic pump. The ROV is connected with a water surface control system on a mother ship through a funicle cable. The front portion of the welding mechanical arm is provided with a local dry-method arc welding gun and a weld tracker. The local dry-method underwater welding robot is high in working efficiency, large in working depth, good in underground welding flexibility and especially suitable for being used in the nuclear radiation or poisonous and harmful underwater, the atmospheric environment or in the site where workers cannot arrive at.

Owner:HARBIN ENG UNIV

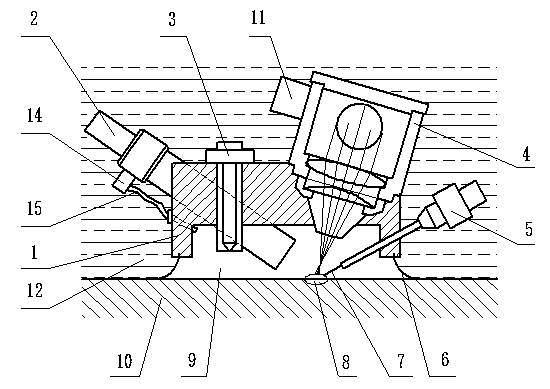

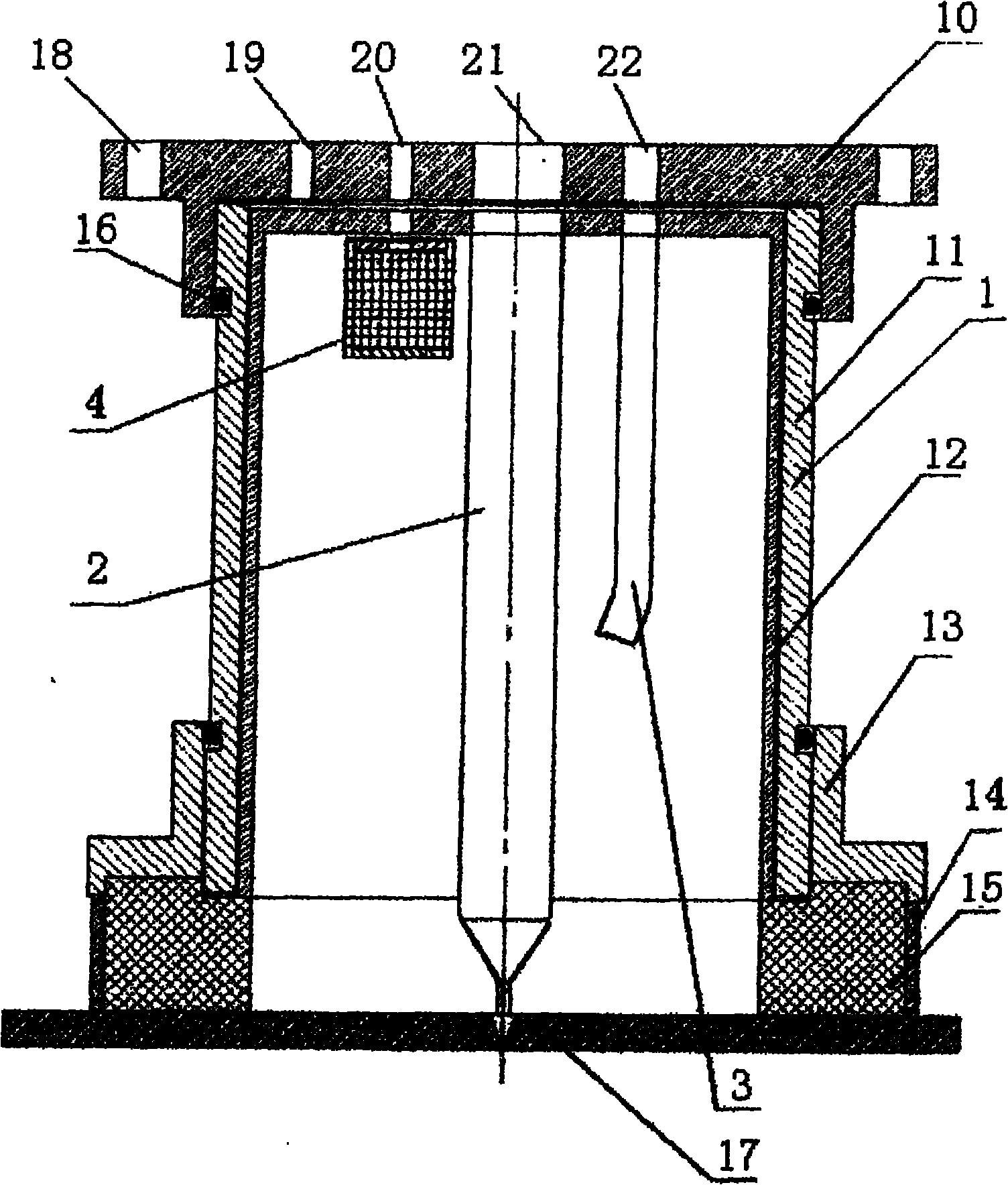

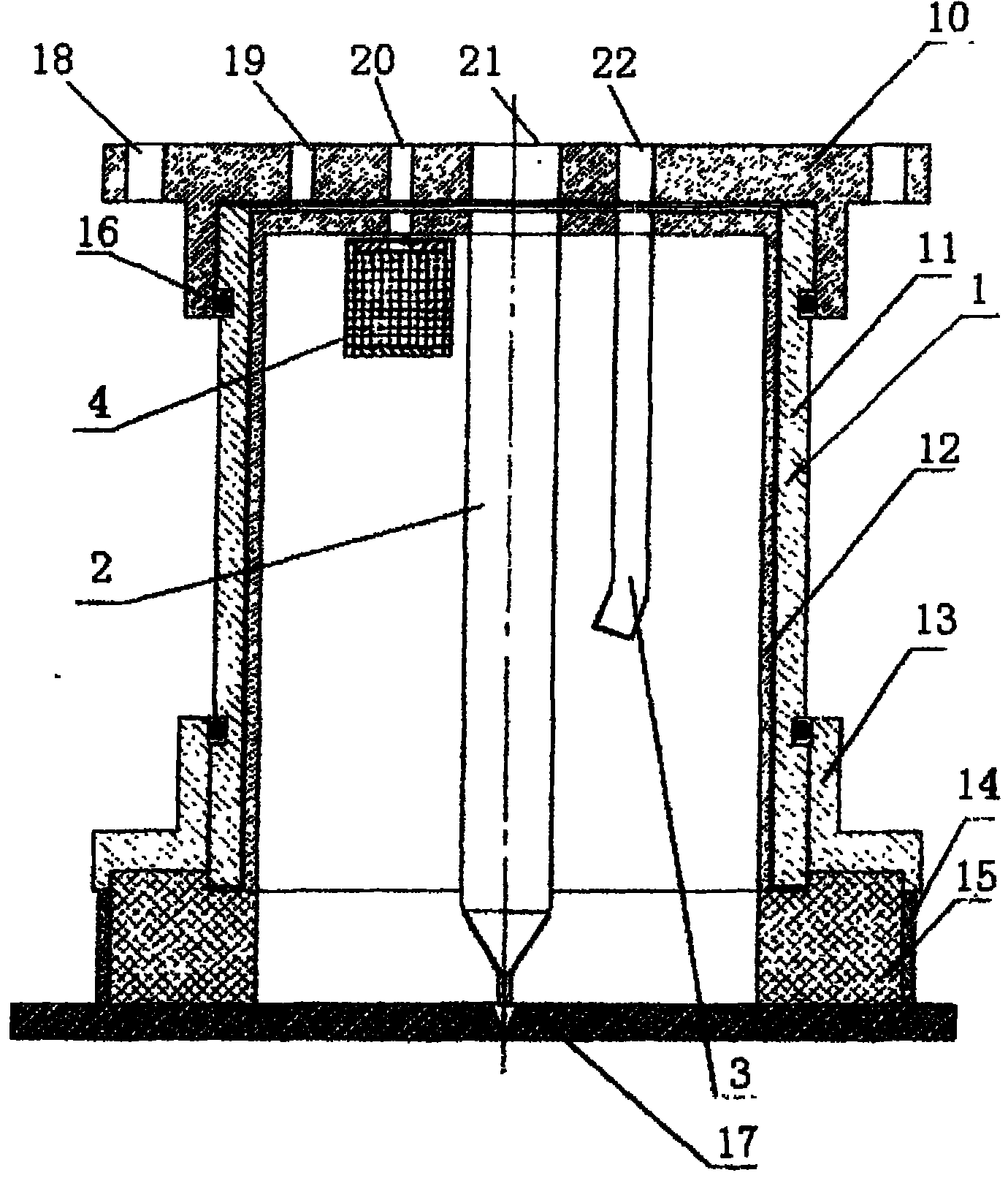

Partial dry type automatic welding drainage arrangement

InactiveCN101244498AReliable weldingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesAdhesiveEngineering

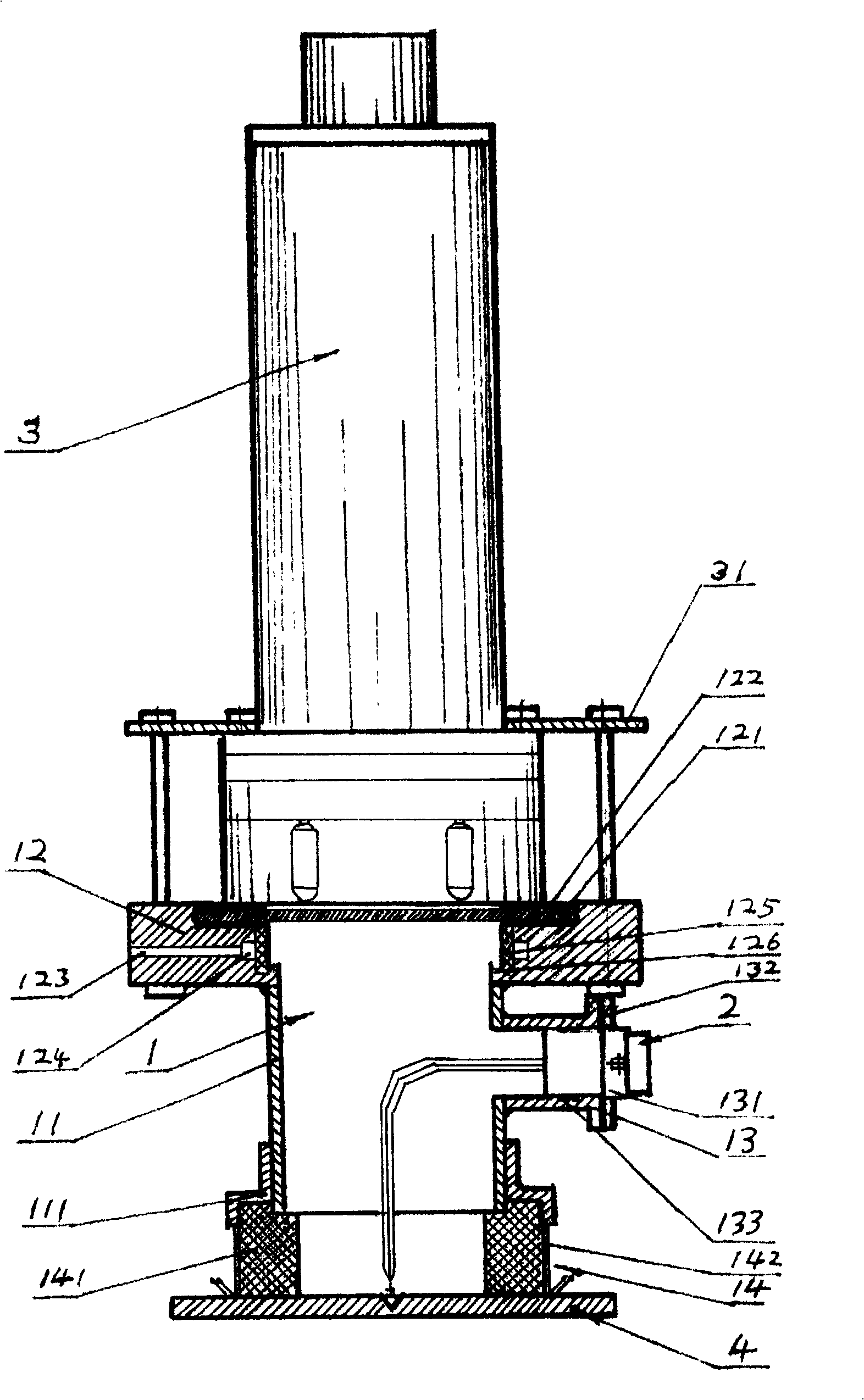

The invention discloses a local dry automatic welding drainage device, which is mainly composed of a drainage hood frame (1), a flexible welding torch (2) and an underwater welding camera (3), wherein the camera-connected end cover (12) of the drainage hood frame (1) is provided with a lens (121), a sealing ring (122), a intake blowhole (123), a buffering gas chamber (124) and an annular metal screen (125). The camera-connected end cover (12) is connected with the underwater welding camera (3) via a coupling flange (31). A welding torch input port is arranged at a side of the invention, which is fixed with the flexible welding torch (2) via snap ring (131). The bottom of the tube of the drainage hood frame (1) is the external screw thread which is reelingly connected with the internal screw thread of the screwed flange (111). A sealed body (14) is stuck to the tube (11) and the screwed flange (111) via adhesive, and impacts a workpiece (4). The underwater welding camera enables the remote supervision and control of the welding in the drainage hood frame (1). The automatic welding drainage device has an advantage of higher welding quality and efficiency, simple structure, easy use, maintenance and repair.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Combination device capable of achieving underwater laser welding and laser shot blasting

InactiveCN103521919AReduce volumeAdaptableLaser beam welding apparatusLasing wavelengthLaser peening

The invention discloses a combination device capable of achieving underwater laser welding and laser shot blasting. A laser welding-shot blasting component, an ultrasound detecting device, a water-argon inlet and a welding strip filling device are mounted on the same sealing cover which is placed underwater. Two functions of laser welding and laser shot blasting are achieved, and laser ultrasound detecting can be directly carried out on a workpiece after processing. By setting different laser wavelengths and sealing cover cavity inner environments, different functions can be used. During laser welding, a sealing cover cavity is filled with argon through the water-argon inlet. During laser shot blasting, the sealing cover cavity is filled with water through the water-argon inlet. The combination device is ingenious in structure, easy to operate, strong in adaptability, high in machining efficiency, capable of being used for alternating or continuous working of underwater welding and laser shot blasting and especially suitable for working under a special environment and defect repairing under the situation that the face where a defect exists is small in area.

Owner:JIANGSU UNIV

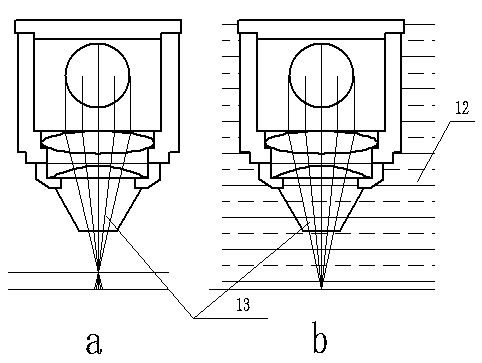

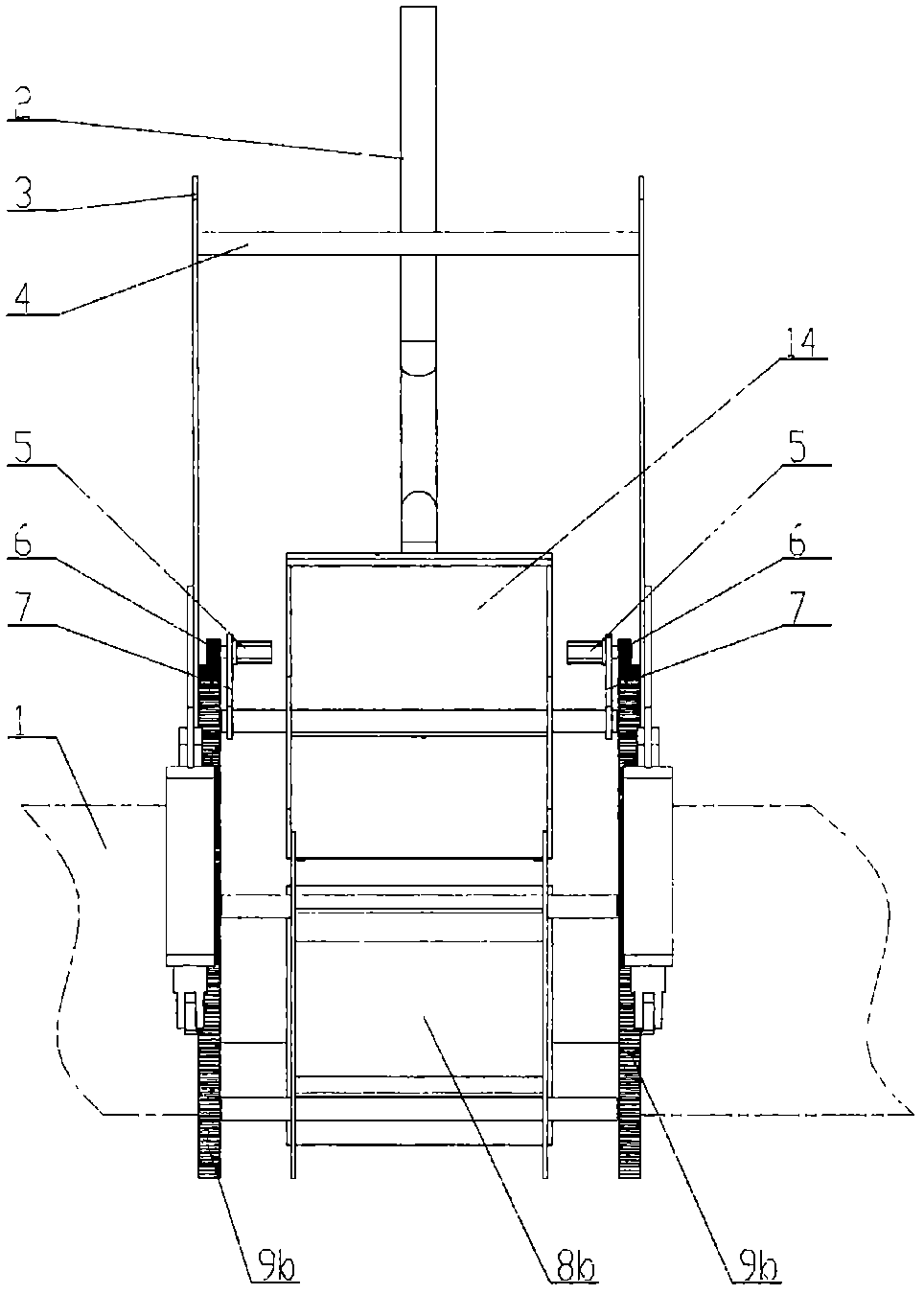

Underwater pipeline dry type automatic welding method and welding device

PendingCN108296598AGuarantee welding qualityGuaranteed reliabilityWelding accessoriesWorking environmentHigh pressure

The invention discloses an underwater pipeline dry type automatic welding method and a welding device. The welding device comprises opening and closing ring gears, opening and closing claws, an opening and closing enclasping working cabin and a sealed working cabin; the sealed working cabin is filled with high-pressure air and is provided with one or more sliding tables which can move in an axialdirection and a radial direction of a pipeline; and the sliding tables are provided with a welding gun and other functional components. When the welding device works, the enclasping working cabin andthe sealed working cabin are both filled with high-pressure gas to form a dry type working environment, various works including online measurement, welding process monitoring, pre-welding groove milling, pre-welding and post-welding ultrasonic flaw detection, post-welding welding seam corrosion prevention treatment and the like can be realized under the dry type working environment, so that the feasibility, the reliability and the welding quality of underwater welding construction and underwater repair as well as the construction efficiency are greatly improved.

Owner:北京隆源自动成型系统有限公司

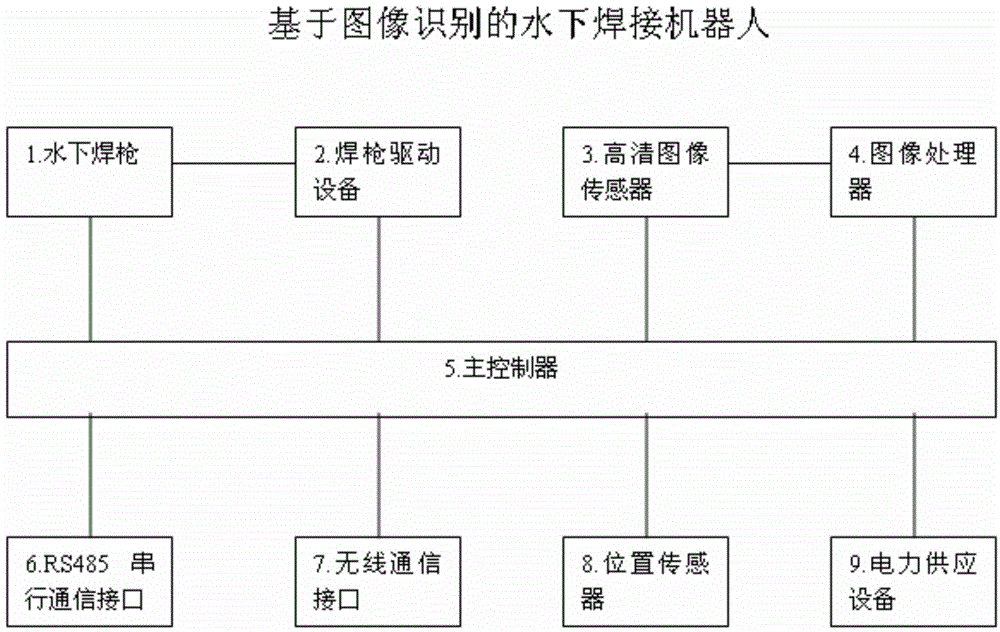

Underwater welding method

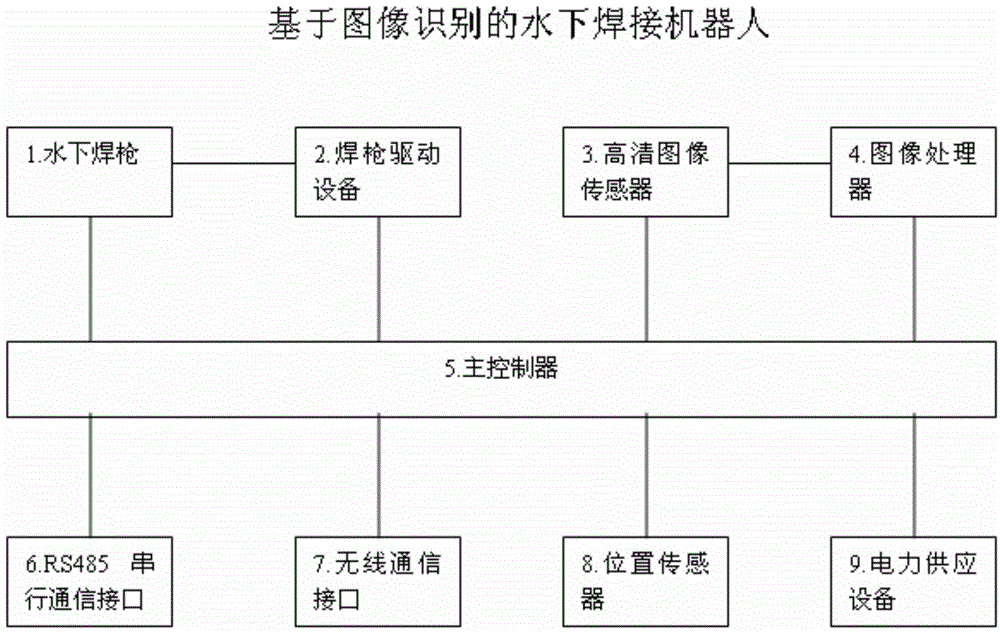

InactiveCN104625320AImprove the efficiency of underwater weldingWelding accessoriesEngineeringMaster controller

The invention relates to an underwater welding method. The underwater welding method includes the following steps: (1) providing an underwater welding robot based on image identification, wherein the underwater welding robot comprises a welding gun driving device, a high-definition image sensor, an image processor and a master controller; the high-definition image sensor is used for collecting welding images of welding workpieces; the image processor is connected with the high-definition image sensor and executes image identification processing on the welding images so as to detect welding line positions in the welding images; the master controller is connected with the welding gun driving device and the image processor, and the welding gun driving device is controlled based on the welding line positions to drive an underwater welding gun to reach the welding line positions; (2) the underwater welding robot is used for welding.

Owner:泰州市江洲数控机床制造有限公司

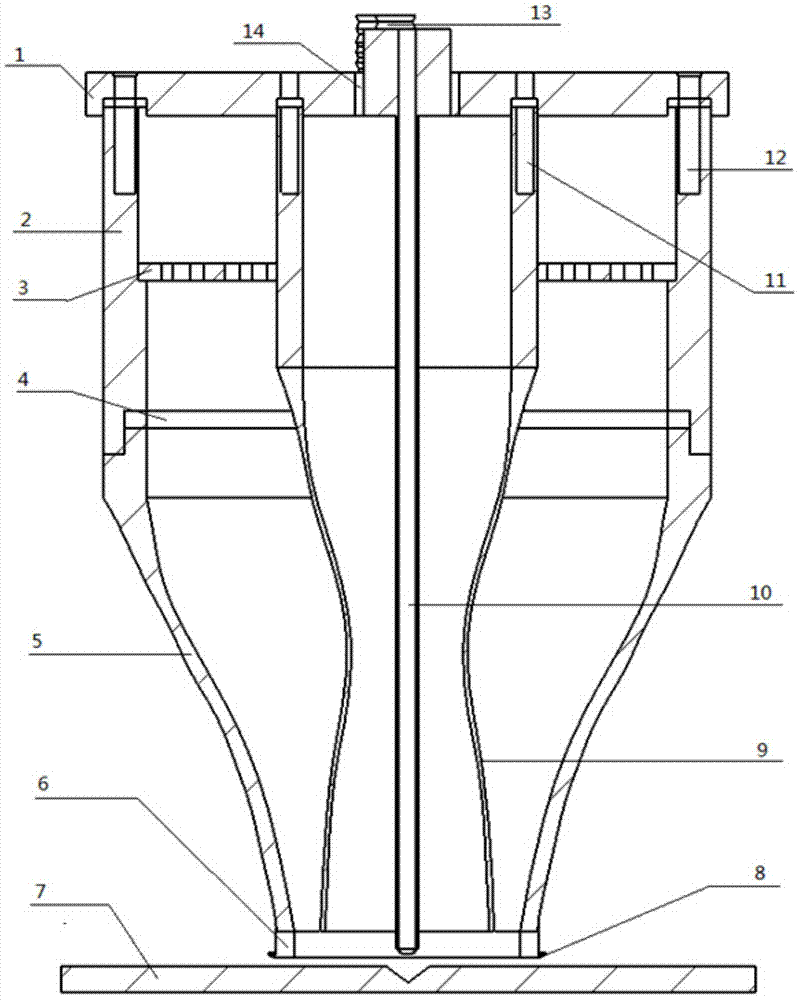

Local dry type drainage device for underwater welding robot and drainage method thereof

InactiveCN104722973APrevent pressingIncrease speedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh pressure

The invention discloses a local dry type drainage device for an underwater welding robot and a drainage method thereof. The local dry type drainage device for the underwater welding robot comprises an upper end cover, an outer drainage cover body, an inner drainage cover body and a spoiler, wherein the inner drainage cover body is arranged in the outer drainage cover body, the lower end of the outer drainage cover body and the lower end of the inner drainage cover body are open, and the upper end of the outer drainage cover body and the upper end of the inner drainage cover body are sealed and fixed through the upper end cover; an installation hole for a welding gun and a high-pressure gas inlet are formed in the upper portion of the upper end cover, and high-pressure gas is introduced into an inner cavity of the outer drainage cover body and an inner cavity of the inner drainage cover body. The local dry type drainage device for the underwater welding robot is reasonable in design, reliable in performance, simple in structure and convenient to use, the problem that the underwater welding robot is affected by the water environment factor when used for welding can be effectively solved, welding can be conducted by the underwater welding robot smoothly by the adoption of the drainage device, and the welding efficiency and the welding quality of the underwater welding robot are improved.

Owner:SOUTH CHINA UNIV OF TECH

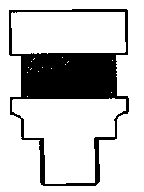

Underwater welding local mask with welding line tracking function

ActiveCN102179599AEasy to replace and maintainReduce volumeWelding/cutting auxillary devicesArc welding apparatusControl systemEngineering

The invention relates to an underwater welding local mask with welding line tracking function, which is characterized by comprising a mask body, wherein the top of the mask body is provided with a mask cover; a spoiler with a plurality of through holes is arranged below the mask cover; the mask cover is provided with a drain gas connector; a welding gun passes through the mask cover and the spoiler and is arranged in the mask body; a connected part of the welding gun and the mask cover is provided with a sealing element; a tracking camera assembly is arranged in the mask body; the side wall of the mask body corresponding to the tracking camera assembly is provided with a window; the window is circumferentially in sealed connection with a sensor assembly arranged outside the mask body through a sensor fixing seat; the sensor assembly and the tacking camera assembly are electrically connected with a control system outside the mask body; and the bottom of the mask body is circumferentially provided with a flexible ring element. The underwater welding local mask is simple and skillful in structure and convenient to operate, and can provide a local waterless environment for the welding, so the underwater welding local mask can be widely applied to the local dry automatic underwater welding process.

Owner:TSINGHUA UNIV

Self-protection flux-cored wire for underwater wet-method welding

ActiveCN104057214AEasy arc startGood mechanical propertiesWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

Underwater welding robot based on image identification

InactiveCN104588833AImprove the efficiency of underwater weldingWelding accessoriesWeld seamControl theory

The invention relates to an underwater welding robot based on image identification. The underwater welding robot comprises a welding gun driving device, a high-definition image sensor, an image processor and a main controller, wherein the high-definition image sensor is used for collecting a welding image of welding work; the image processor is connected with the high-definition image sensor and is used for carrying out image identification processing on the welding image to detect the position of a welding seam in the welding image; the main controller is connected with the welding gun driving device and the image processor and is used for controlling the welding gun driving device to drive an underwater welding gun to reach the position of the welding seam based on the position of the welding seam. Through the underwater welding robot disclosed by the invention, the intelligent degree of the underwater welding robot can be increased, and the locating and the welding on an underwater welding seam can be completed without manual operation.

Owner:WUXI SANGNIAN TECH

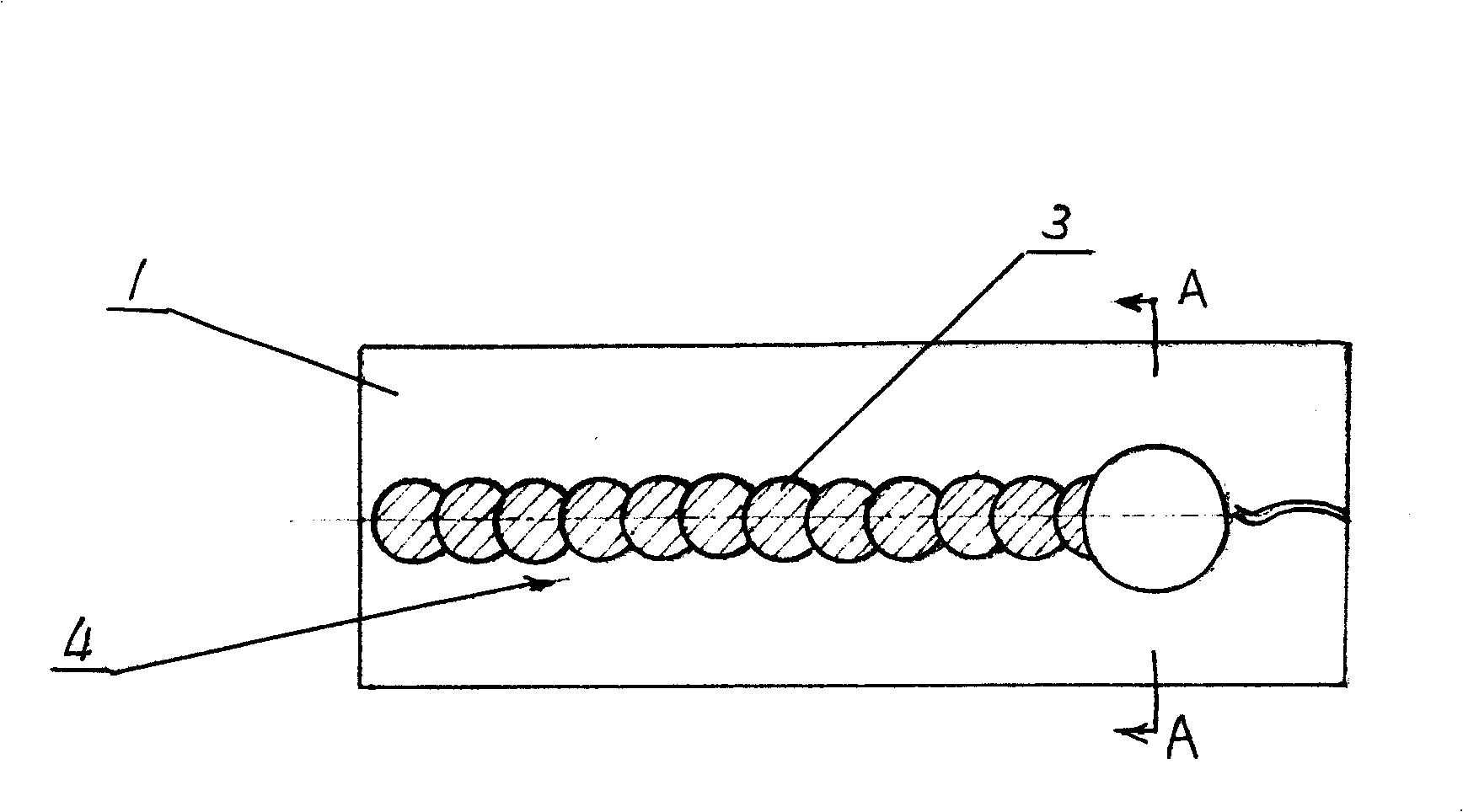

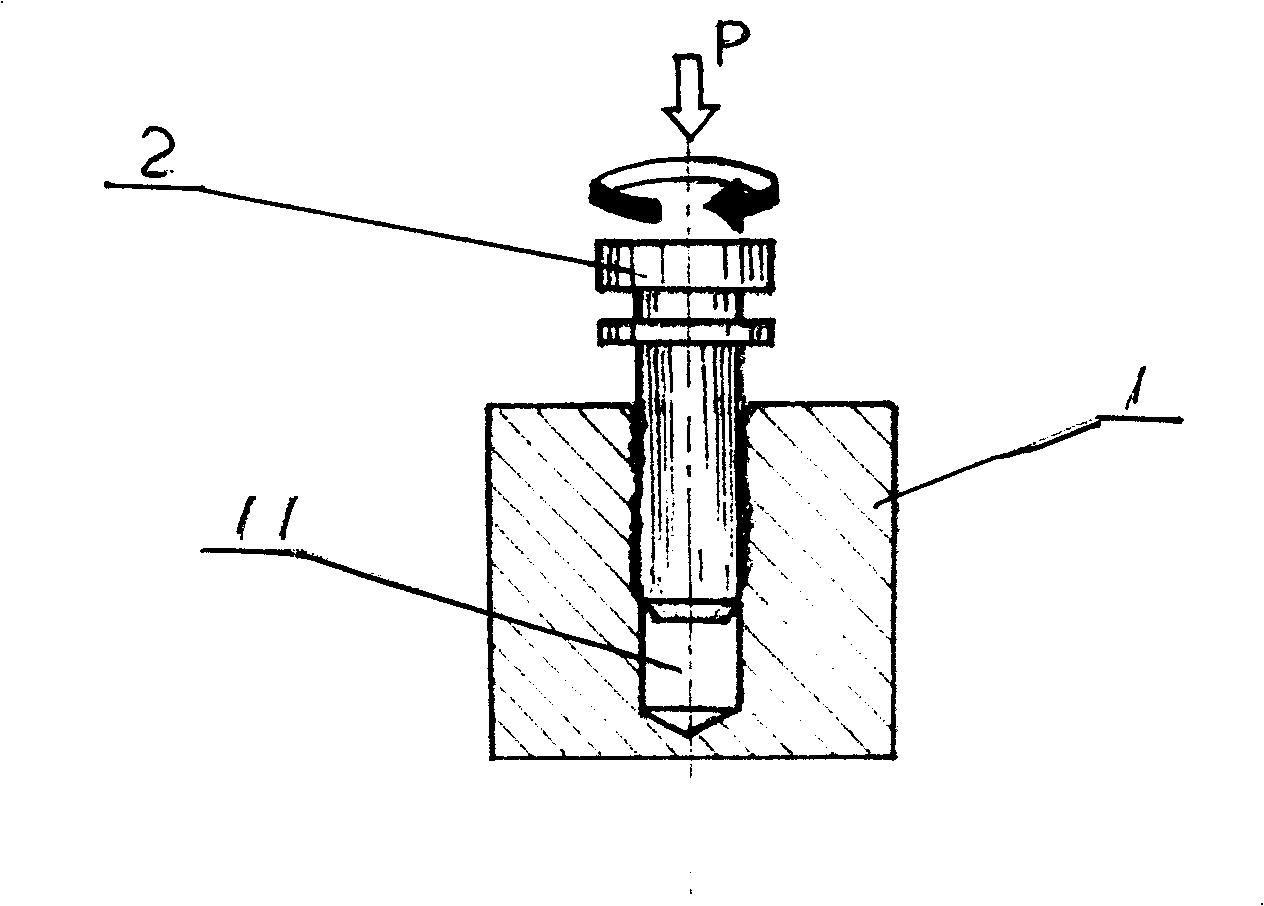

Friction stitch welding experimental device

InactiveCN101244484ABreak through the depth limit of saturation divingImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesHot meltEngineering

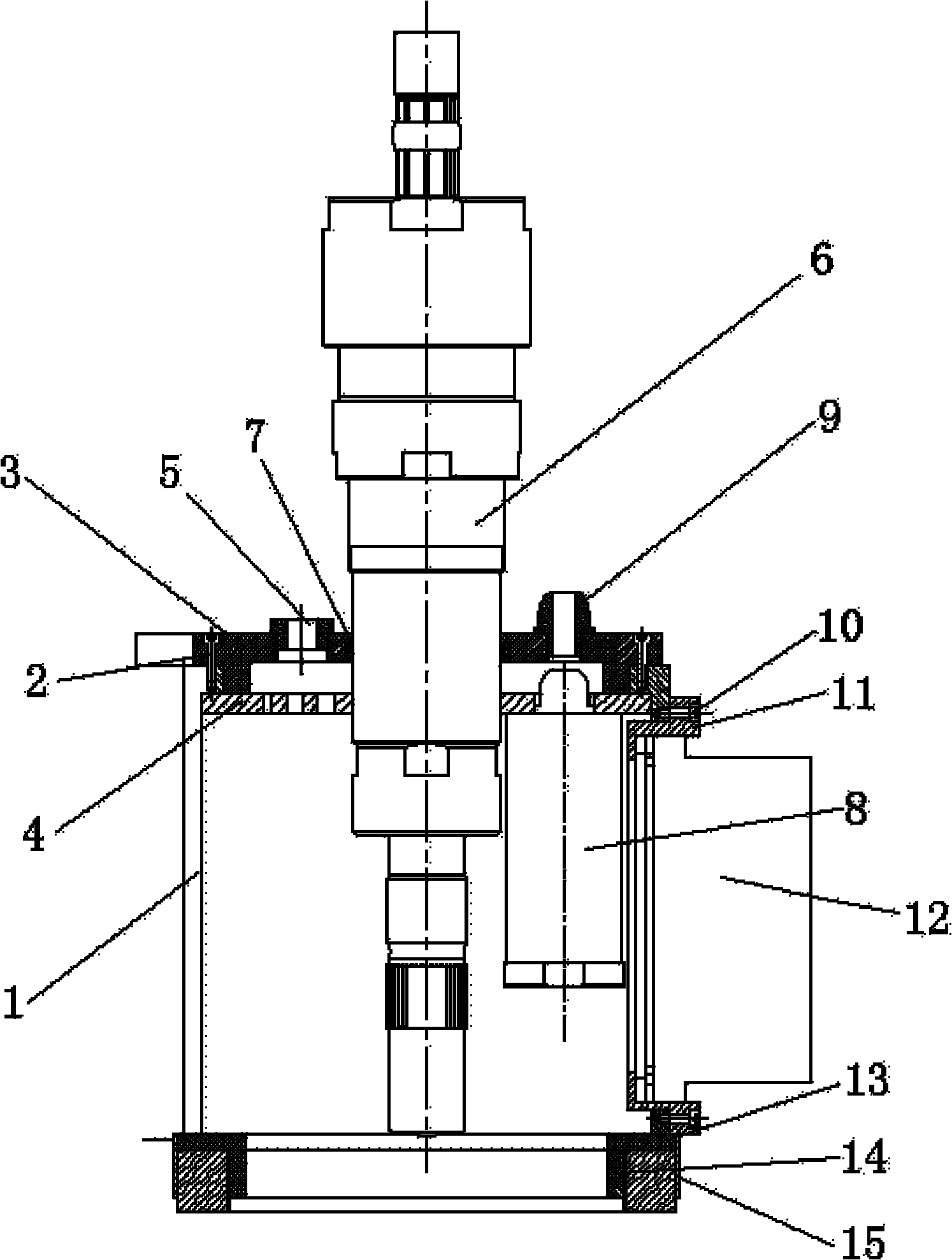

The invention discloses a friction stitch welding method and the experimental device. The friction stitch welding method is as follow: a stopper (2), which rotates at high speed and applies pressure in axial direction, is inserted into a pre-boring welding hole (11) of a body (1) to be welded; the contact interface of the welding hole (11) and the stopper (2) is hot-melted, and a welding unit is formed after the crystallization and metallurgy reaction of the interface; a series of welding units (3) are overlapped to form a complete weld joint. The friction stitch welding experimental device comprises a base (5), a shift slipway (6) arranged on the base, a workpiece fixture (7), a beam (8), and a friction main shaft head (9), and is controlled by a console (10). The experimental device can not only be used in plate welding and pipeline welding, but also used in underwater welding experiments after assembled with a matching flume (71). The friction stitch welding method and the experimental device have the advantages of simple method, easy operation, high reliability, excellent quality; simple equipment, low cost, simple use, maintenance and repair.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

High-strength underwater welding electrodes

InactiveCN1939649AEasy arc startStable arc burningWelding/cutting media/materialsSoldering mediaUnderwater weldingHigh intensity

A high-strength wet welding electrode for underwater welding is composed of the core made of H08E steel wire a coated surficial water-proof layer, and a coated sandwich layer containing rutile (42-54 Wt%), potash feldspar (12-20), talc (6-14), cellulose (4-12), ferromanganese (6-14), Ni powder (0-4), Fe powder (3-12) and Al-Mg alloy (0-4).

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

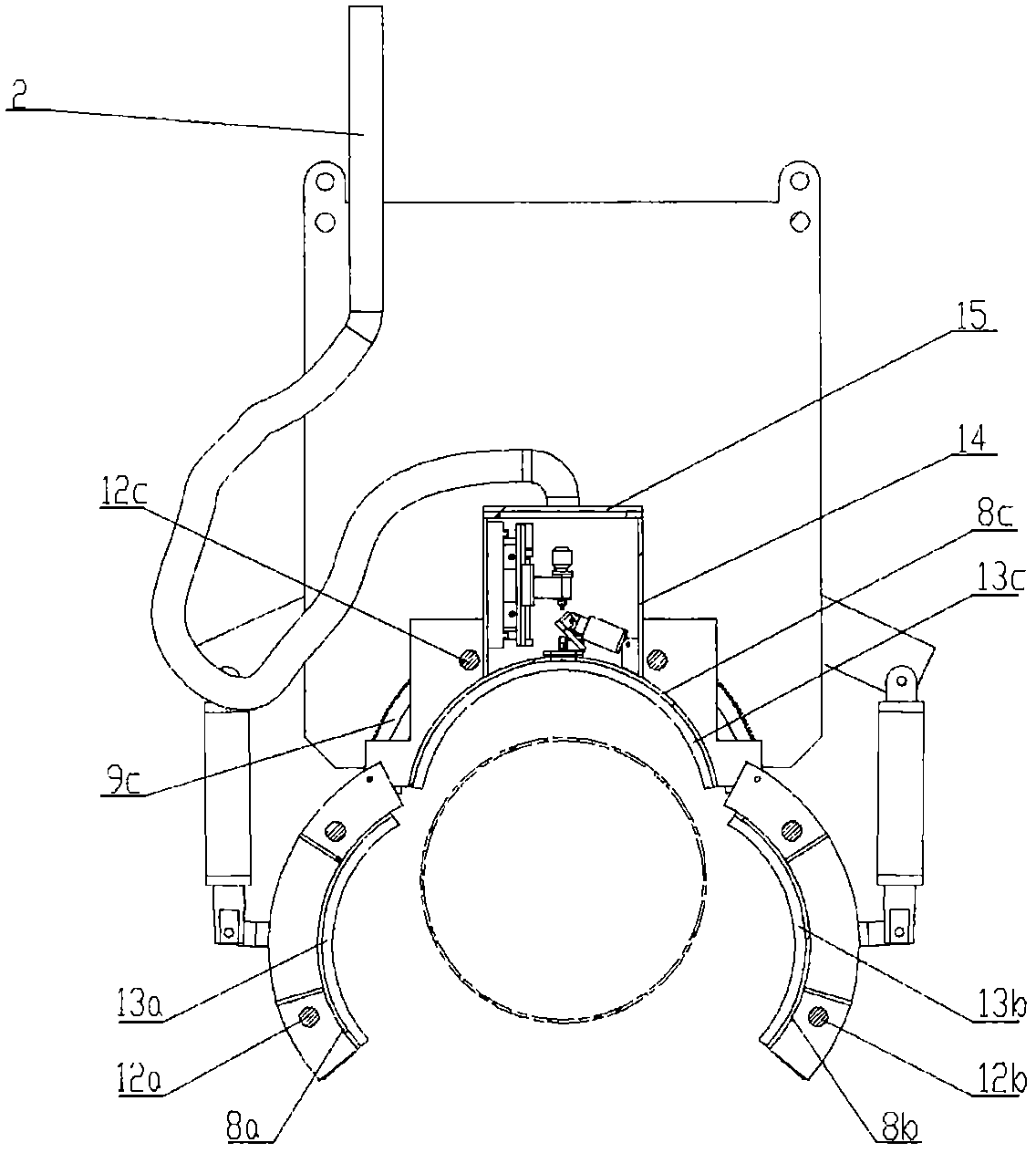

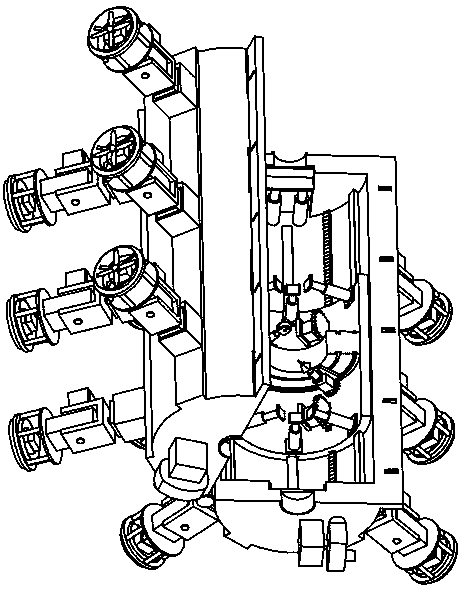

Robot for underwater welding, robot system and operation method

PendingCN107718046APrecision weldingEnsure welding reliabilityNuclear energy generationWelding/cutting auxillary devicesRobotic systemsMarine engineering

The invention discloses a robot for underwater welding, which can identify and weld welding lines under control of an external control monitoring module. The robot for underwater welding comprises a mobile carrier, a panorama camera module, a multi-degree-of-freedom mechanical arm, a welding gun, a visual detecting module and a communication module; the panorama camera module searches the weldinglines; the visual detecting module comprises a first camera, a second camera and a laser; the laser projects lasers on the welding lines, and scans the welding lines; the first and second cameras acquire laser images, and send the laser images to the control monitoring module for processing and welding monitoring; and the multi-degree-of-freedom mechanical arm controls the welding gun to move to acorresponding position according to coordinate information of the welding lines obtained by processing. The invention further discloses a robot system for underwater welding, which comprises the robot for underwater welding and the control monitoring module. In addition, the invention further discloses an operation method of the robot system for underwater welding.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

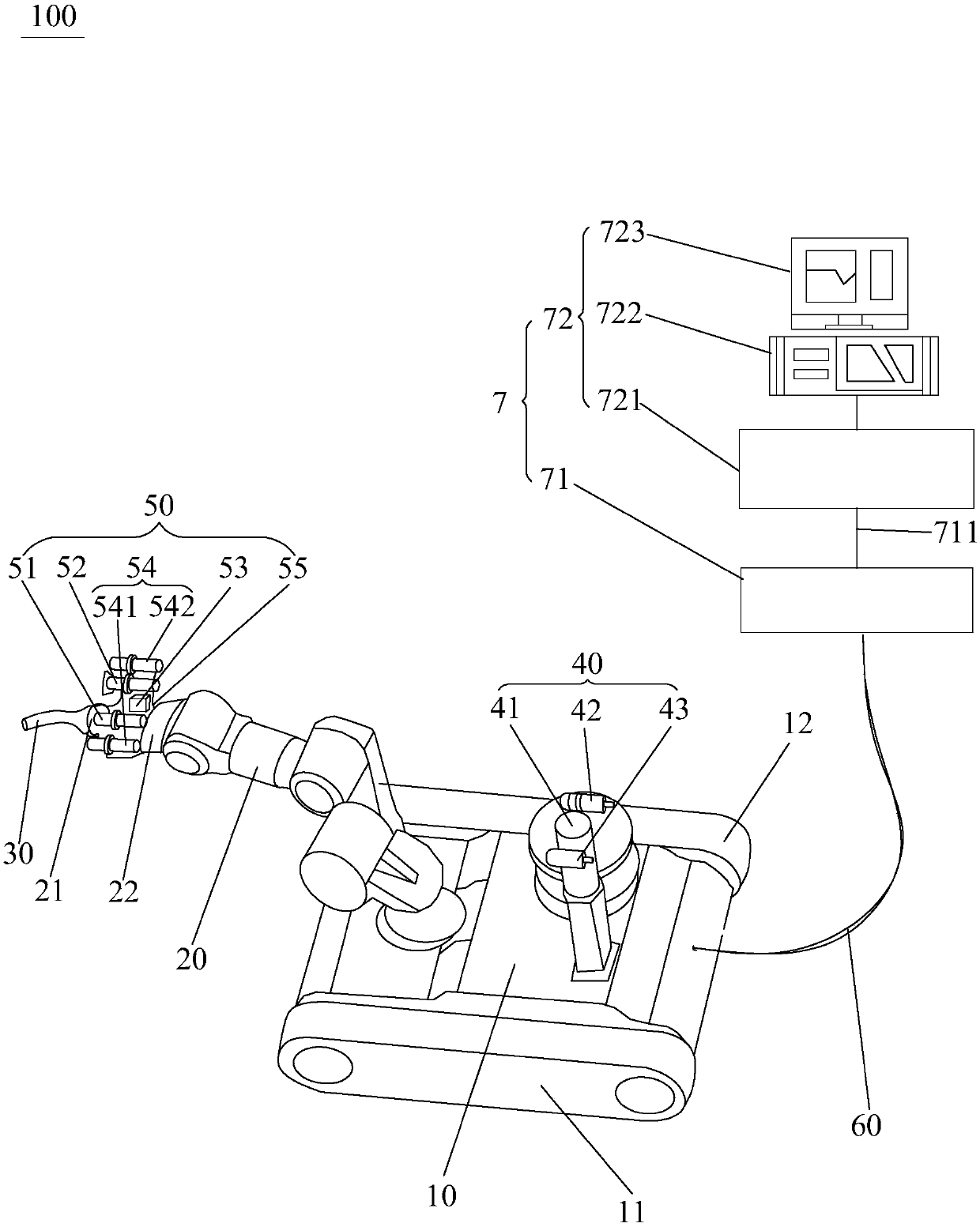

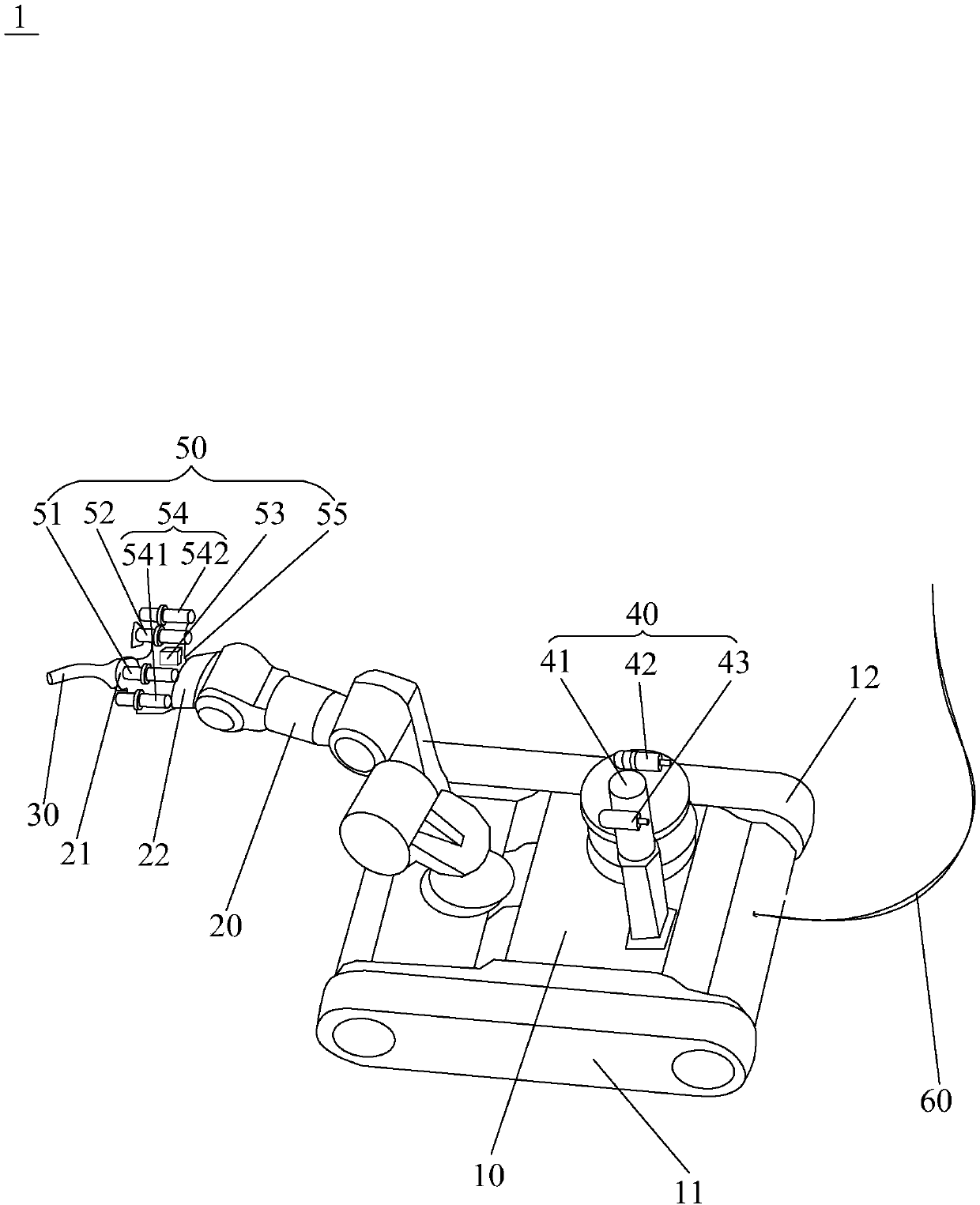

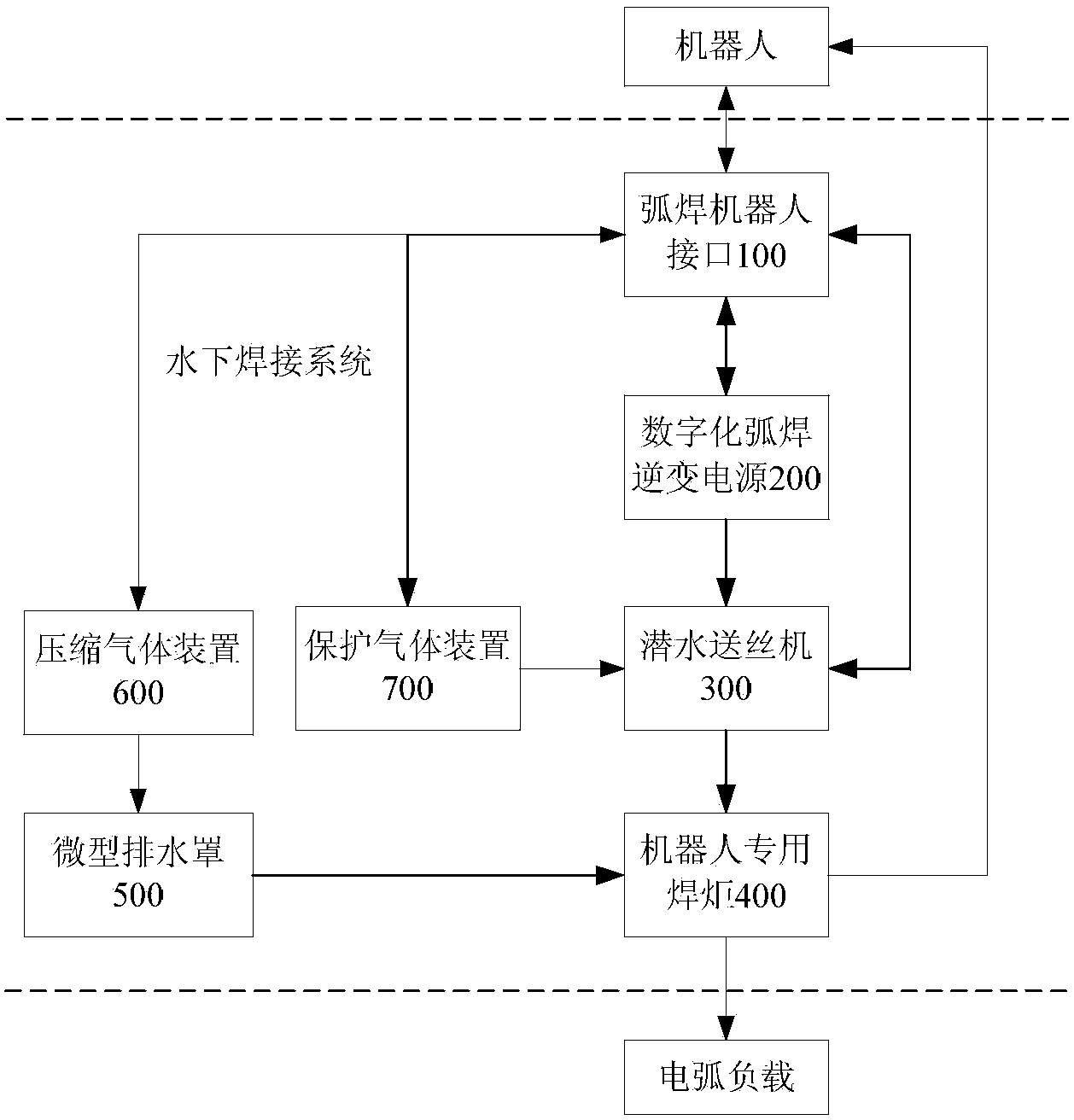

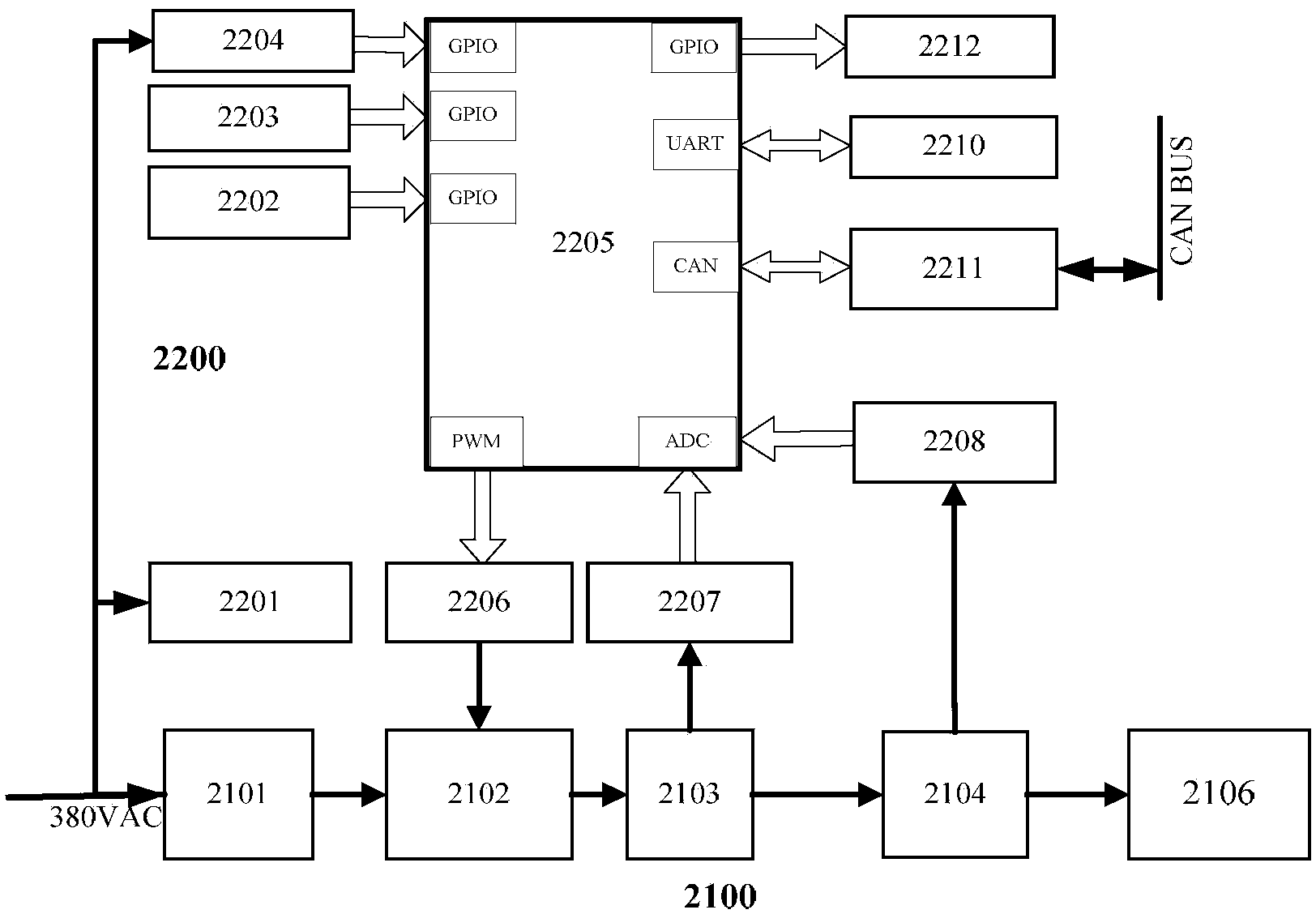

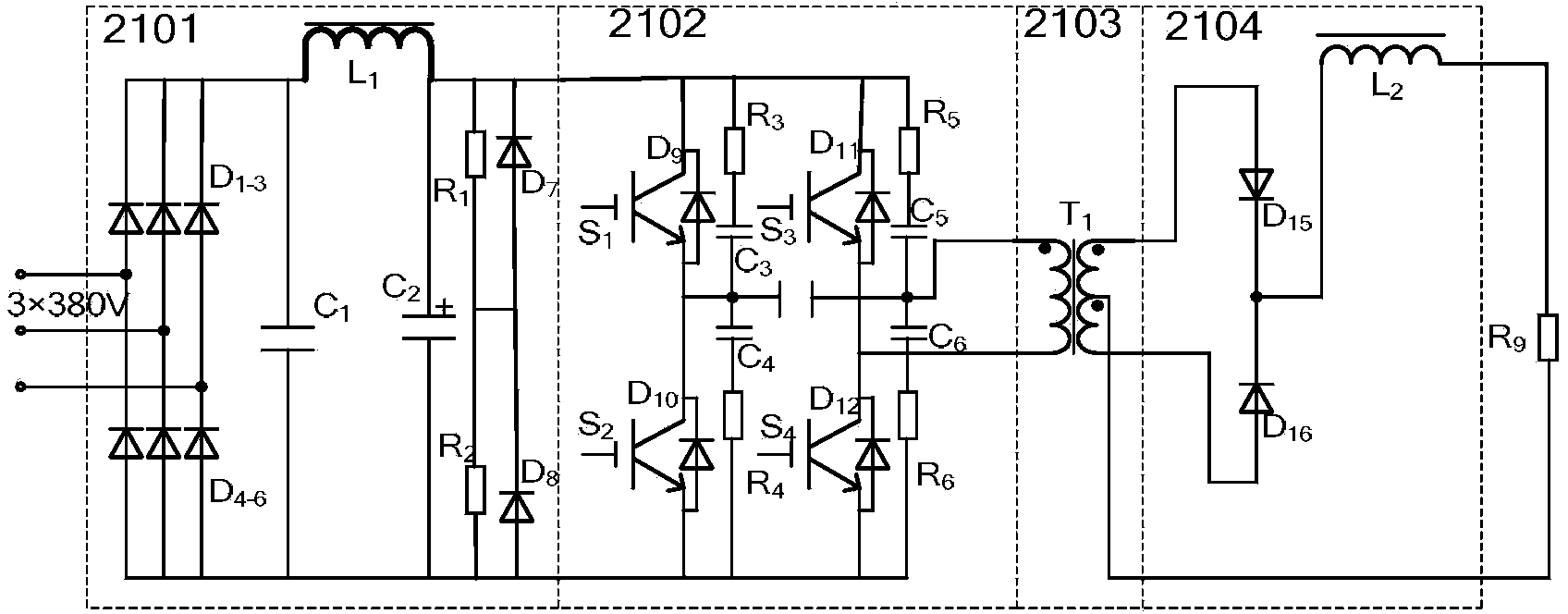

Multifunctional welding system of underwater welding robot

ActiveCN103706927ARealize full digital controlFlexible structureWelding/cutting auxillary devicesAuxillary welding devicesUnderwater weldingElectric arc

The invention provides a multifunctional welding system of an underwater welding robot. The system comprises an arc welding robot interface, a digital arc welding inverter power supply, a diving wire feeder, a special welding torch for the robot, a miniature drainage cover, a compressed gas device and a protection gas device. The arc welding robot interface, the digital arc welding inverter power supply, the diving wire feeder and the special welding torch for the robot are sequentially connected; the arc welding robot interface with one end connected with the robot is connected with the diving wire feeder and respectively connected with the compressed gas device and the protection gas device; the special welding torch for the robot is installed on the robot and connected with the miniature drainage cover, and one end of the special welding torch for the robot is connected with an arc load; the compressed gas device is connected with the miniature drainage cover, and the protection gas device is connected with the diving wire feeder. The welding system can automatically adapt to the characteristics of an underwater welding arc in the welding process, a stable welding power supply-underwater arc system can be established, and then high-quality underwater robot welding can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

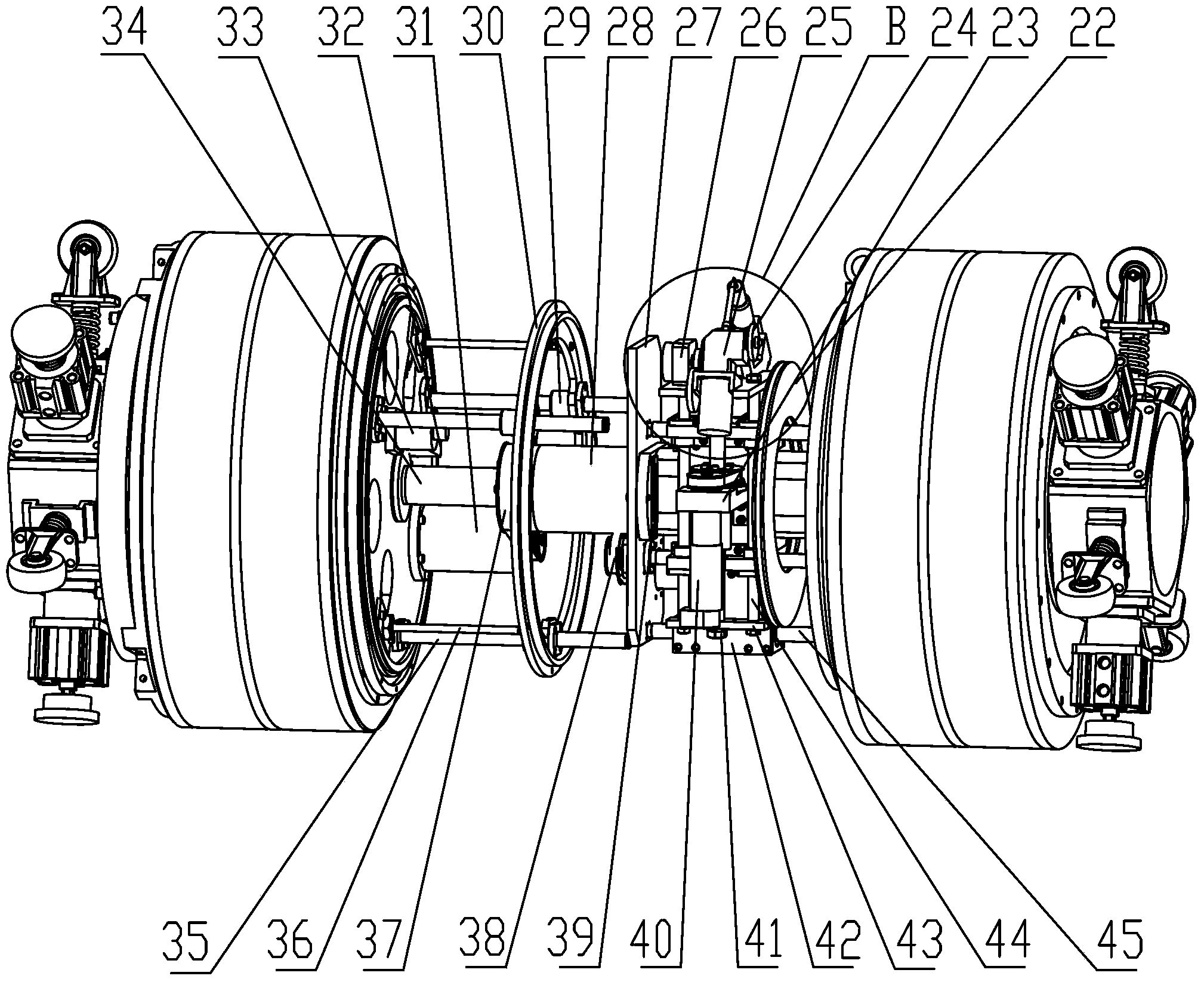

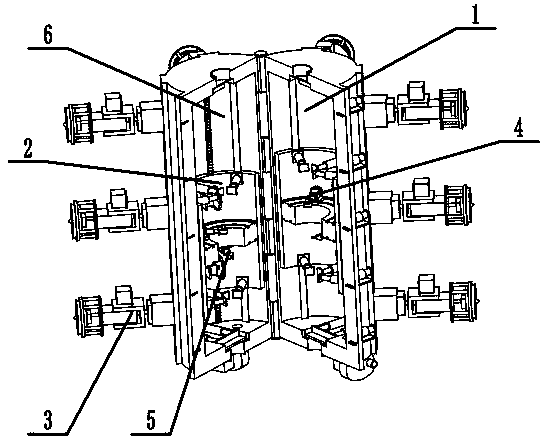

Automatic underwater welding maintenance equipment

ActiveCN103480940AAvoid the impact of normal workReduce the risk of radioactive contaminationWelding accessoriesUnderwater equipmentWorking environmentRadioactive contamination

The invention provides automatic underwater welding maintenance equipment comprising a spindle. Two air-bag supports are symmetrically arranged at two ends of the spindle and respectively provided with an air bag, a welding space is formed between the air-bag supports, a barrel capable of axially moving is arranged in the welding space, an air inlet pipe and a drainage pipe are arranged on the barrel, the drainage pipe is communicated with the welding space and a drainage space on the outer side of the air-bag supports, and a welding device is arranged in the barrel. Due to the fact that the welding space is isolated through the air bags, and water in the welding space is discharged under the action of the air inlet pipe and the drainage pipe, a partially-dried type working environment is established; welding seams are repaired through the welding device by which affect of a water environment upon operation of parts is effectively avoided, risk of the parts being subjected to radioactive contamination is lowered, and stability of a welding process and repairing quality of the welding seams are guaranteed.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Underwater welding globular transfer real-time monitoring device and method

ActiveCN104002069AReduce the impactRealize visualizationWelding/cutting auxillary devicesArc welding apparatusImaging qualityX-ray

The invention relates to an underwater welding globular transfer real-time monitoring device and method. The device comprises an X-ray source, an X-ray image receiver, a welding electric signal collecting unit and a remote control mechanism. The X-ray source emits an X-ray which penetrates through an electric arc area above a welding workpiece, a globular transfer X-ray image is formed and is projected to the X-ray image receiver, and the X-ray image receiver converts the globular transfer X-ray image into a visual image which is sent to a computer in the remote control mechanism. The welding electric signal collecting unit synchronously collects welding voltage and welding current in the welding process. Collected image signals and welding electric signals are transmitted to the computer in the remote control mechanism in real time, and the welding globular transfer process is monitored in real time through the computer. The underwater welding globular transfer real-time monitoring device and method have the advantages of being slightly affected by the welding environment, and being high in applicability, high in image quality, capable of conducting microarea observation, high in image collection frequency, capable of achieving remote control and convenient to operate, and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

Sealed type underwater welding robot

InactiveCN107598425AEasy to weldImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

A sealed type underwater welding robot comprises a first shell portion, two fixed portions, twelve turbine portions, two polishing portions, two welding portions and a second shell portion. The sealedtype underwater welding robot is characterized in that two second arc sliding blocks of the two welding portions are installed in arc dovetail grooves on the lower sides of the two fixed portions ina sliding manner correspondingly, two third gears are meshed with arc racks on the lower sides of the two fixed portions, a welded part is clamped through the first shell portion and the second shellportion, six second hydraulic cylinders shrink to drive six clamping plates to tightly lock the two shell portions, a first water pump and a seventh stepping motor are driven by a first stepping motorto drive a second water pump to completely pump out water in the shell portions, the water at the welded part is pumped out by the machine, a good environment is provided for welding, the welding quality and welding efficiency are improved, and welding of some precise pipelines is facilitated.

Owner:孟庆仕

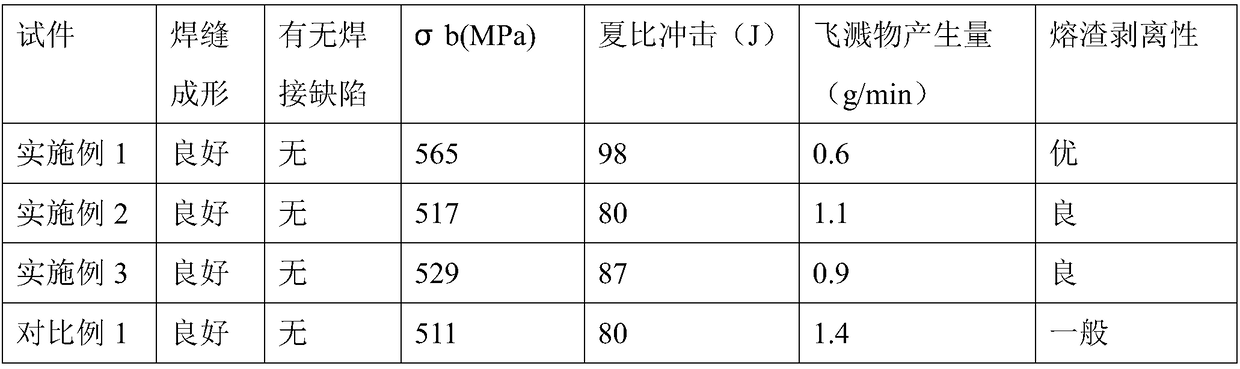

Flux-cored wire for underwater welding and preparation method

ActiveCN108296667AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaUnderwater weldingBrown iron oxide

The invention discloses a flux-cored wire for underwater welding and a preparation method. The flux-cored wire is composed of outer skin and a flux core. The flux-cored wire is characterized in that the outer skin is made from low-carbon steel, the flux core is prepared from oxide, carbonate, fluoride and metal powder, the oxide is the mixture of calcium oxide, magnesium oxide, titanium oxide, iron oxide and silicon oxide, the fluoride is the mixture of calcium fluoride, lithium fluoride and barium fluoride, the carbonate is the mixture of calcium carbonate, magnesium carbonate and barium carbonate, and the metal powder is the mixture of silicon, aluminum, titanium, magnesium, nickel, iron, manganese and boron. The flux-cored wire enables underground wet welding to have the advantages thatelectric arc is stable, less splash is produced, molten slag stripping performance is excellent, welding seam forming performance is good, and welding seam structure performance is excellent.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

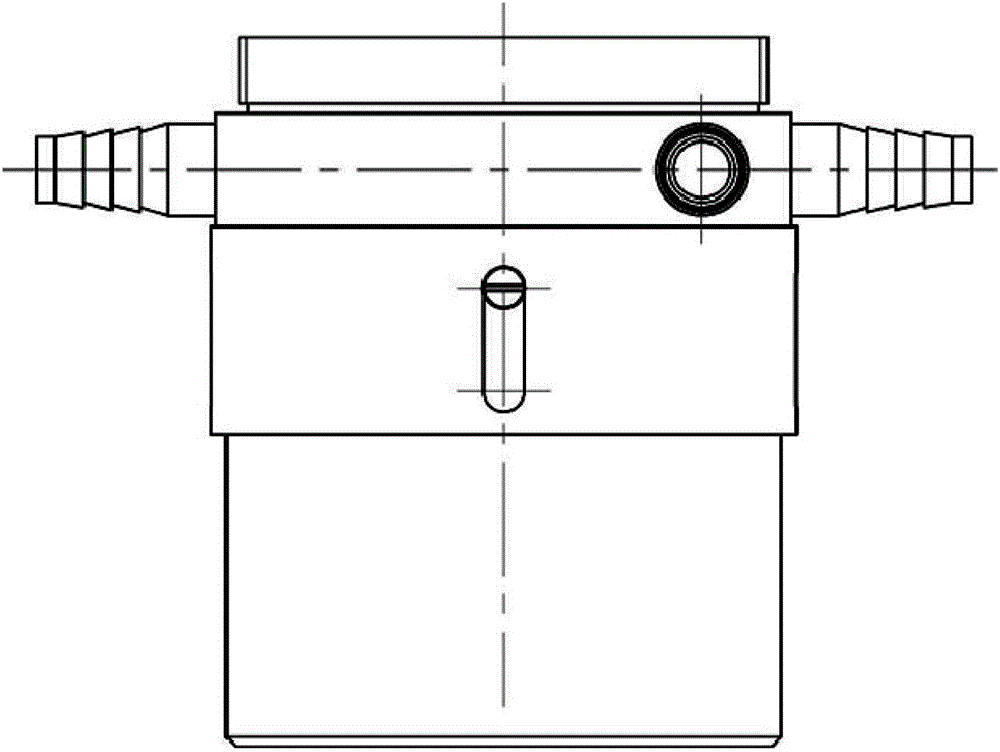

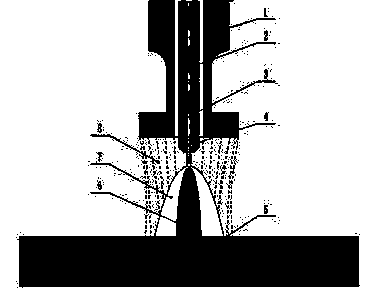

Local dry-type welding small-sized drainage device

ActiveCN102039477ASimple structureLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh pressure water

The invention relates to a local dry-type welding small-sized drainage device which mainly comprises a drainage hood body (1), a small-sized soldering gun (2) and a miniature underwater welding optical fiber sight glass (3), wherein the drainage hood body (1) mainly comprises a hood body upper end cover (10), a locking sleeve (11), a water seepage sleeve (12) and a lower end cover (13), the mall-sized soldering gun (2), and the miniature underwater welding optical fiber sight glass (3) and a high-pressure gas filter (4) are arranged in the drainage hood body (1). In the invention, sponge can always keep moist in the welding process by high-pressure water column poured into the water seepage sleeve to fulfill the function of protecting the sponge; the drainage hood body (1) is arranged underwater above drainage sponge (15) and is sleeved with a sealing sleeve (14), high-pressure gas is led into the body, water is drained through the drainage sponge (15), and then, underwater local dry-type welding can be carried out. The invention has the advantages of simple structure, stable and reliable work, low cost, easy popularization and simple use, maintenance and repair.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

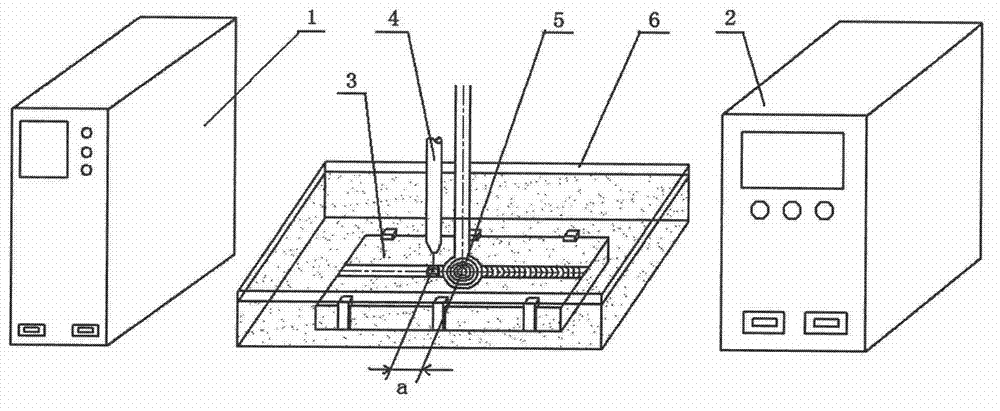

Method and device for improving underwater wet welding joint structure property

InactiveCN103111734AReduce cooling rateReduce hardened structureWelding accessoriesHeat-affected zoneStructure property

The invention relates to the technical field of welding, and particularly relates to a method and a device for improving an underwater wet welded joint structure property. The method comprises the step that a welded sample is welded underwater through a welding torch and the step that weld preheating before welding and / or heat treatment after welding is conducted on the welded surface of the welded sample. Corresponding devices comprise an underwater welding power supply, the welding torch connected with the underwater welding power supply, the welded sample and a welding water groove arranged outside the welded sample. An induction heating coil is arranged on the upper surface of the welded sample and is controlled by an induction heating power supply. By adopting the method and the device for improving the underwater wet welded joint structure property, when heat treatment is effectively conducted on the welded sample, weld joint cooling speeds can meanwhile be slowed down, and accordingly the effects of reducing wet welding defects such as the number of weld joints, quenched structures of heat affected zones and cold crack inclination. Therefore, the method and the device for improving the underwater wet welded joint structure property are convenient to operate.

Owner:HARBIN INST OF TECH AT WEIHAI

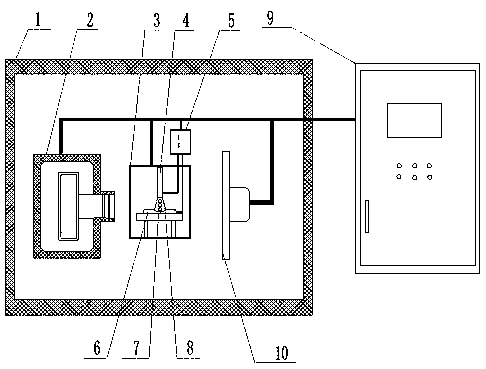

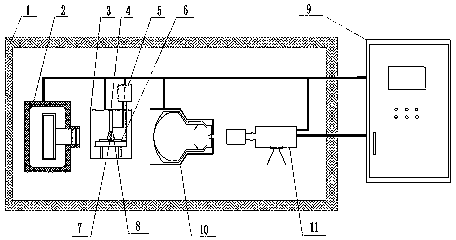

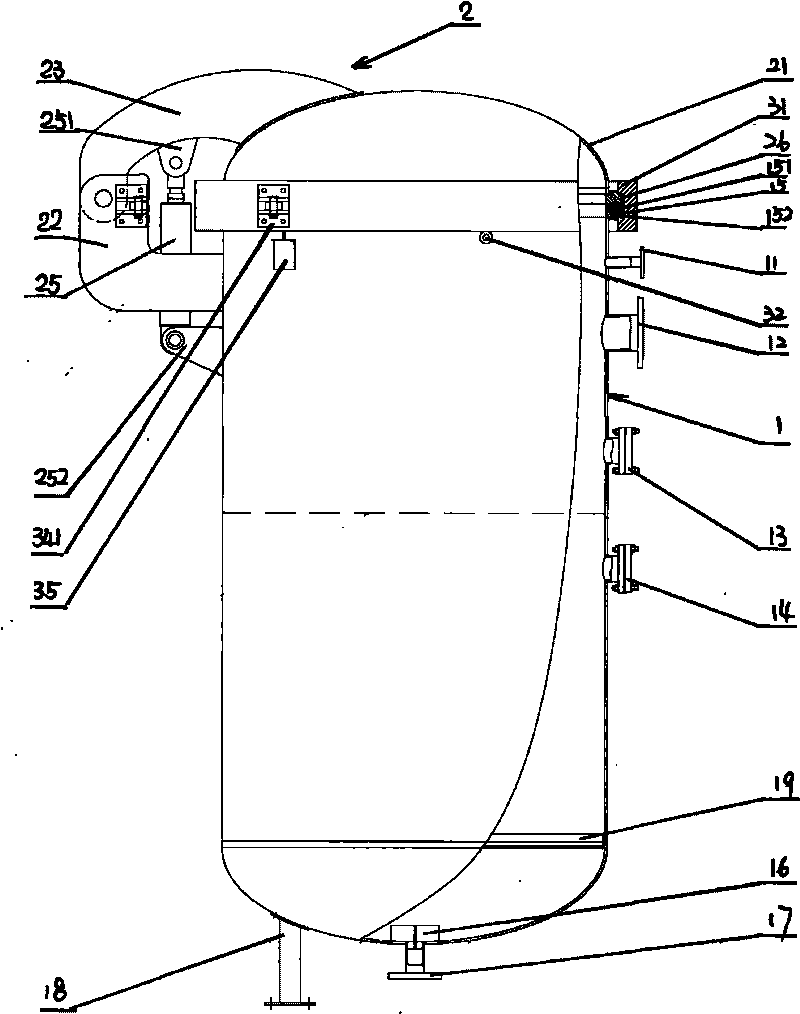

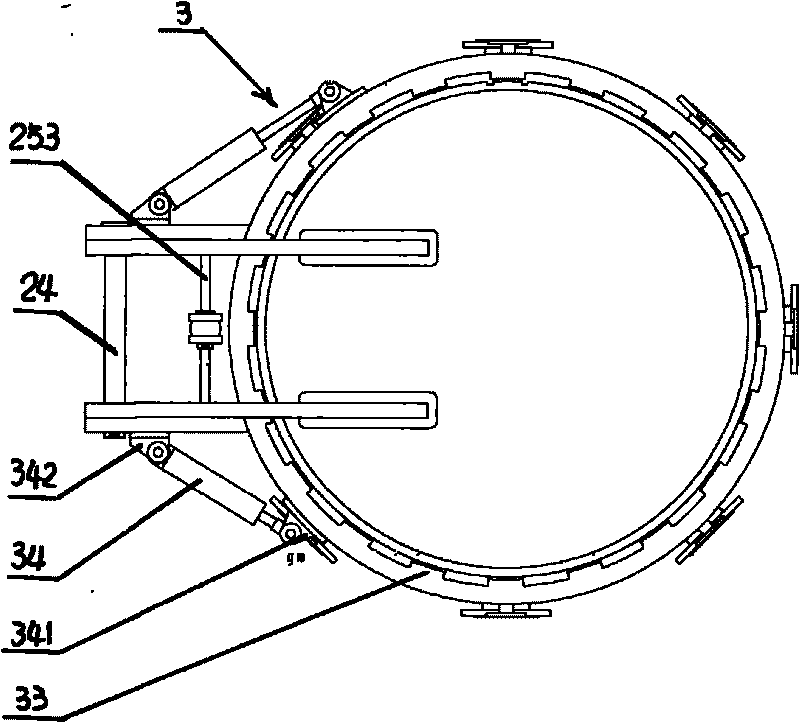

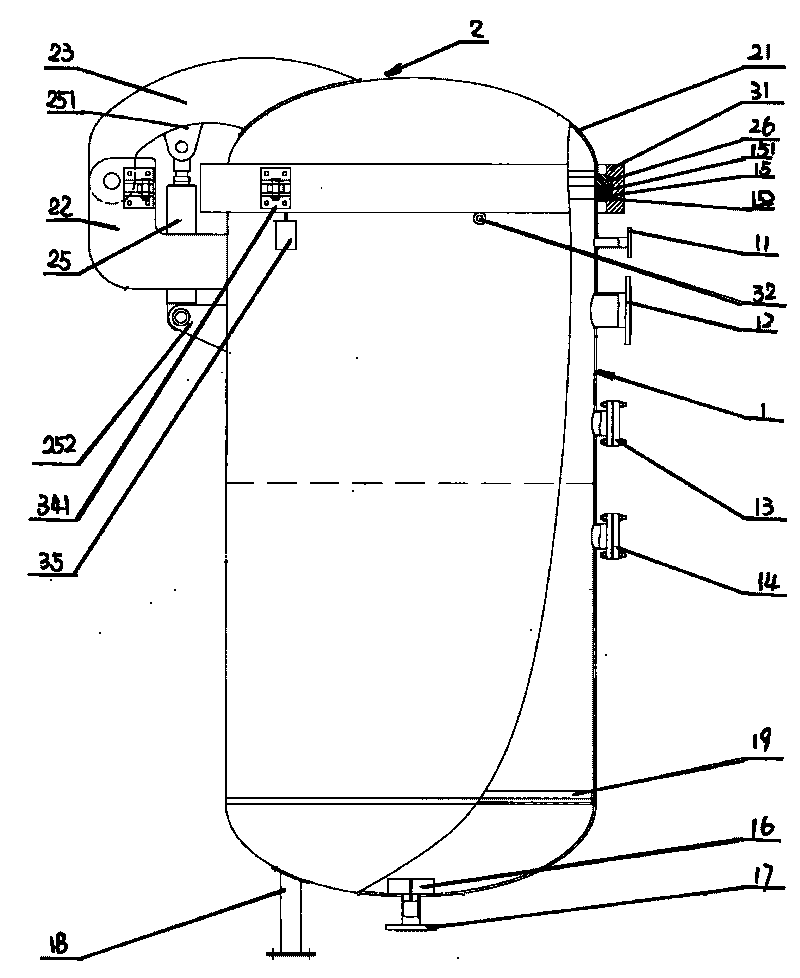

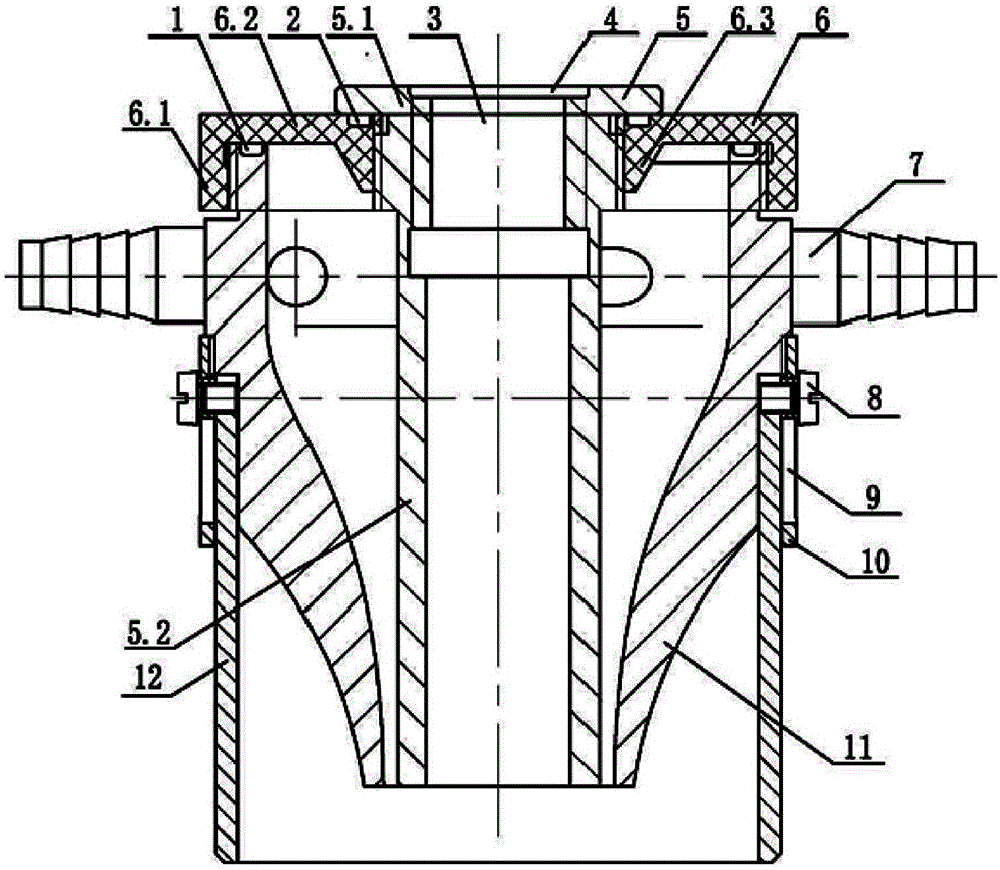

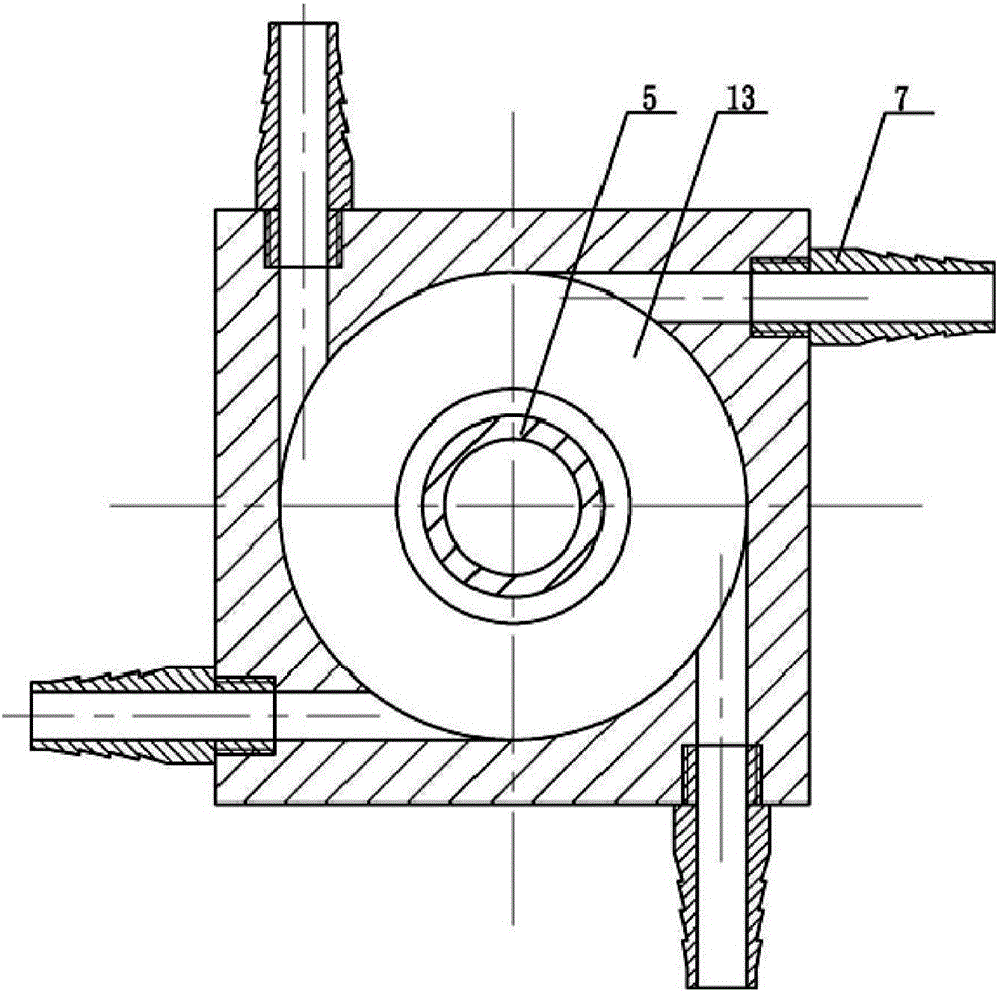

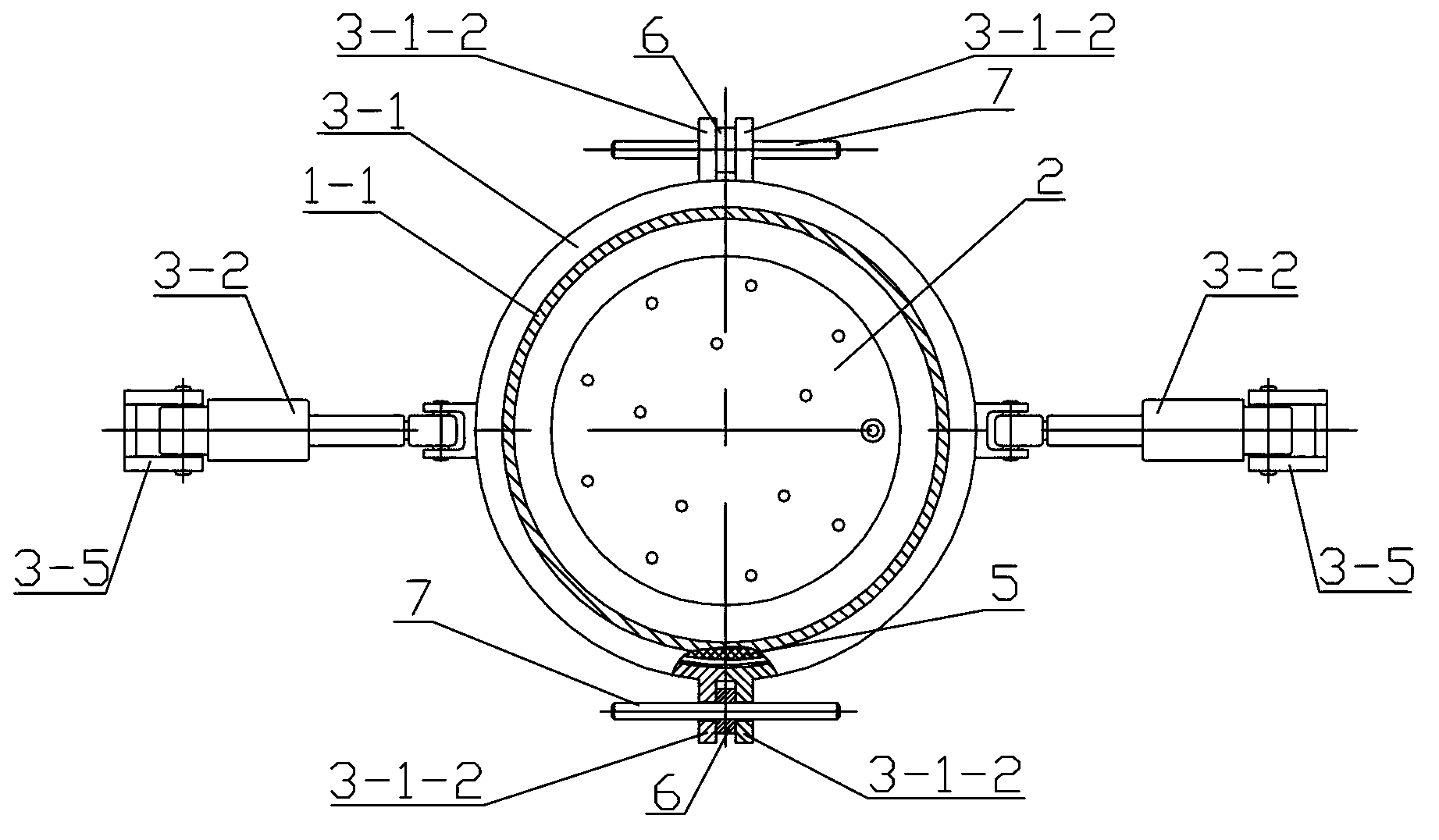

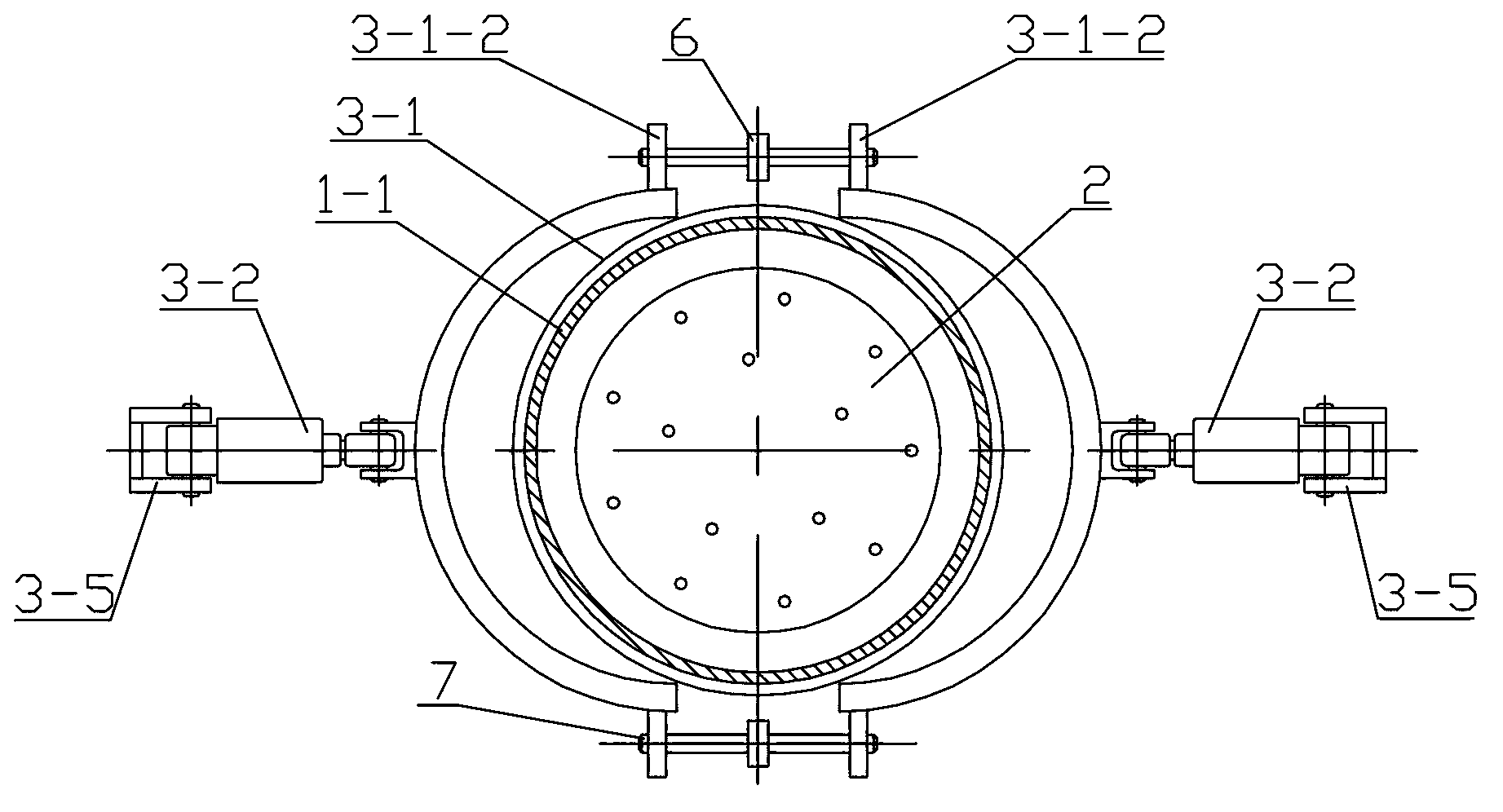

Underwater welding test chamber

InactiveCN101758334AImprove test simulationSimple and Reliable ConnectivityWelding/cutting auxillary devicesAuxillary welding devicesTest efficiencyTest chamber

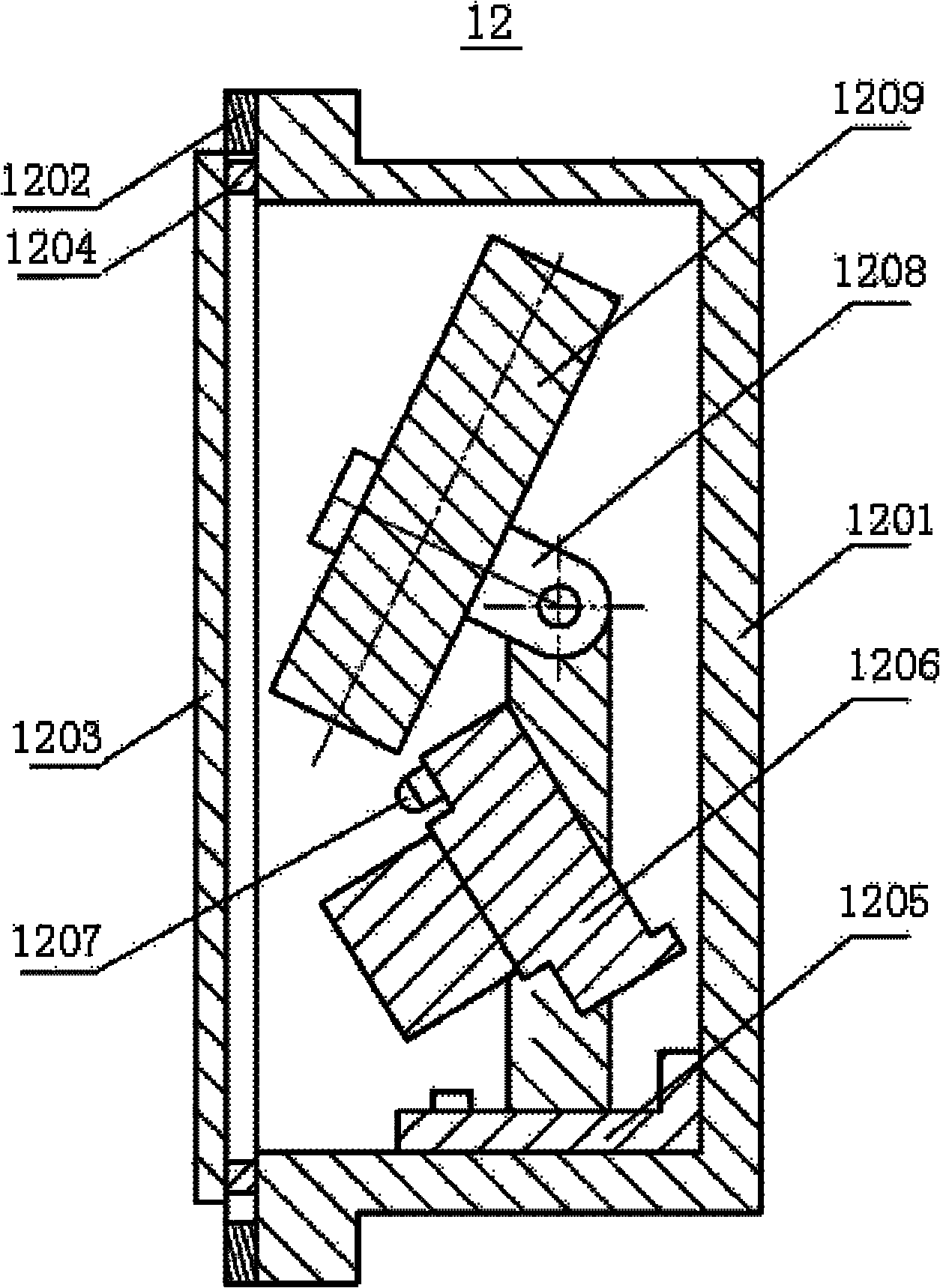

The invention discloses an underwater welding test chamber, which comprises a cylinder (1), a fast opening door device (2) and a clamping rotation locking device (3); wherein a cylinder flange (15) is arranged on the upper edge of the cylinder (1); a plurality of small-diameter nozzles (11), large-diameter nozzles (12), higher viewing lens (13) and lower viewing lens (14) are provided along the circumferential direction of the cylinder (1); a filter net (16), a water in-and-out nozzle (17) and a supporting seat (18) are arranged at the bottom end of the cylinder (1); a clamping rotation oil tank (34) drives a clamper (31) to rotate corresponding to the cylinder (1) so as to fasten an external block button (33) with an internal block button tightly; only when underwater welding test is finished, the clamper (31) can release a fast opening door (21), and an opening door oil tank (25) opens the fast opening door (21). The invention is used for the underwater welding test, and can achieve a simple and reliable connection and sealing of tubes and cables between internal equipments and external equipments; the test pressure can be preset, and the test operation is safe and convenient and the test efficiency is high.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

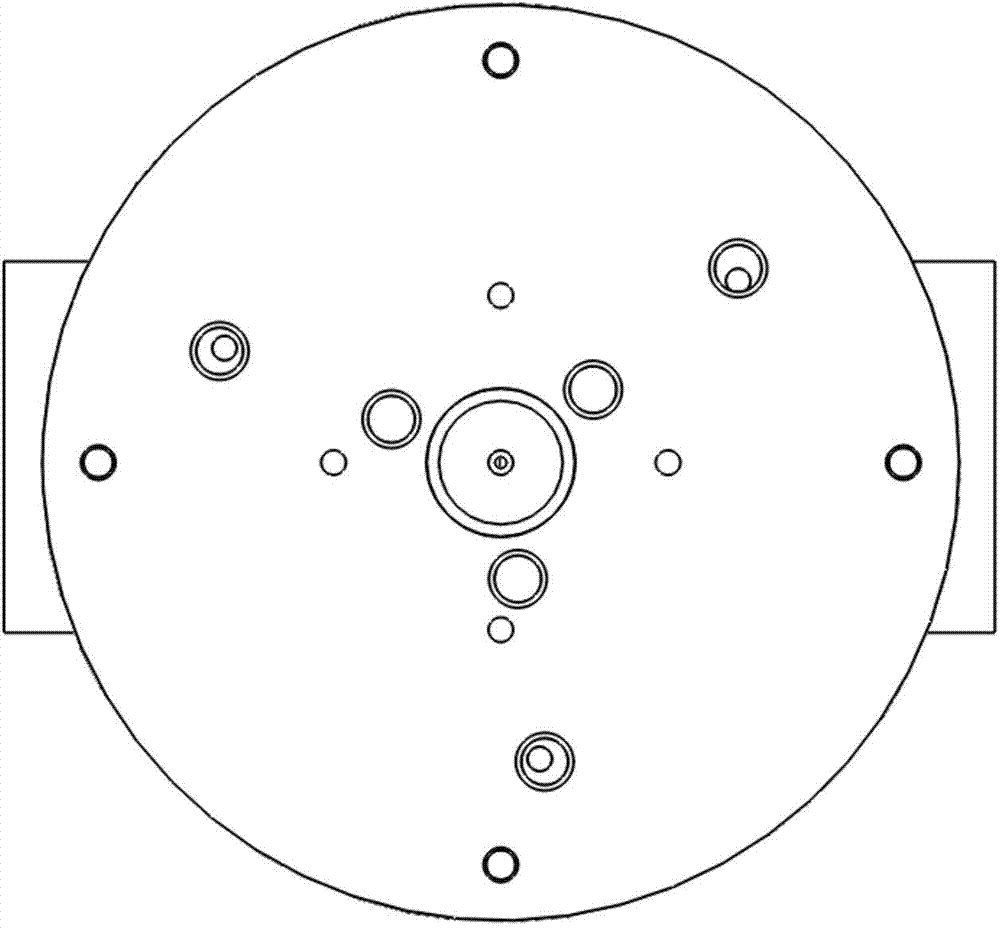

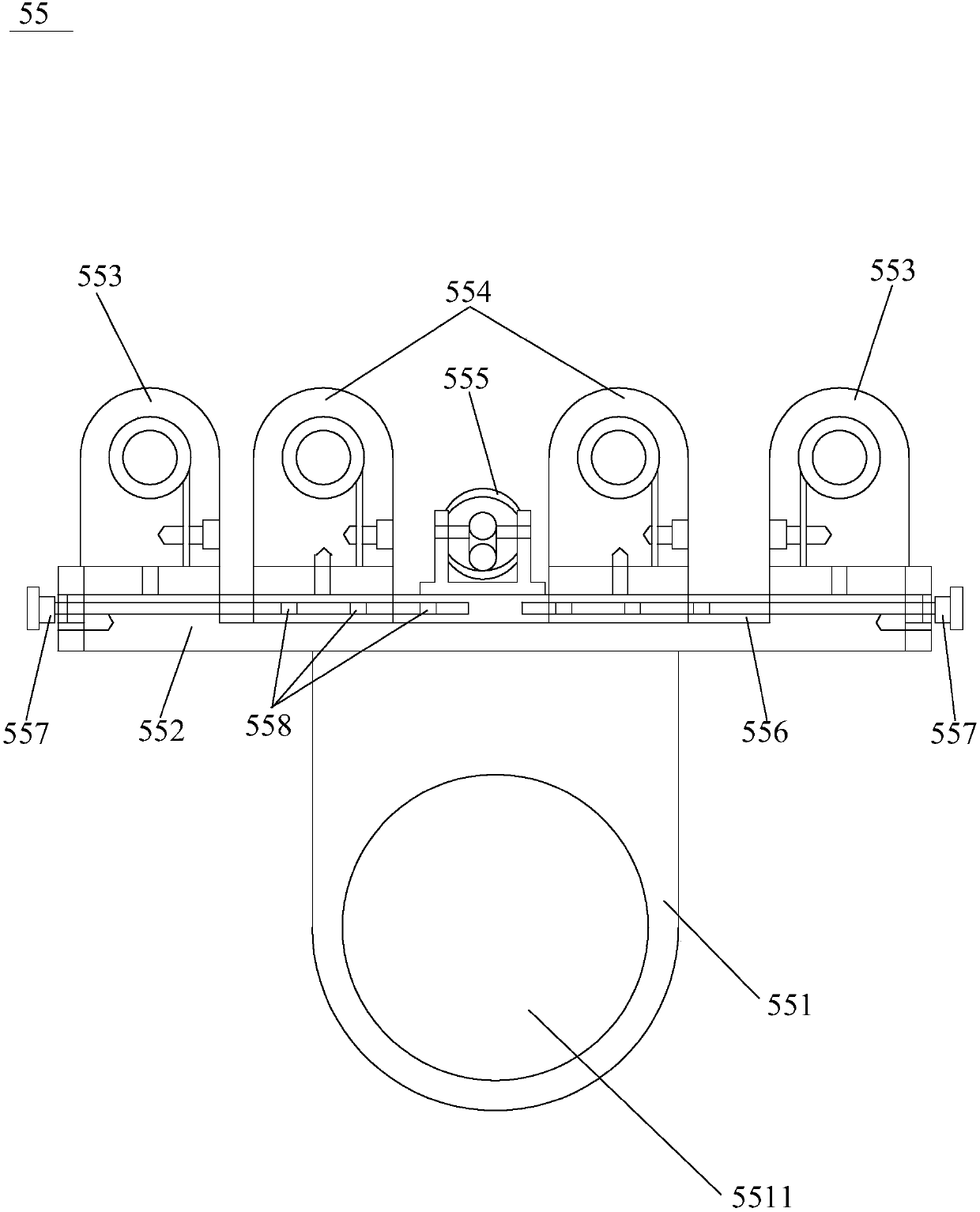

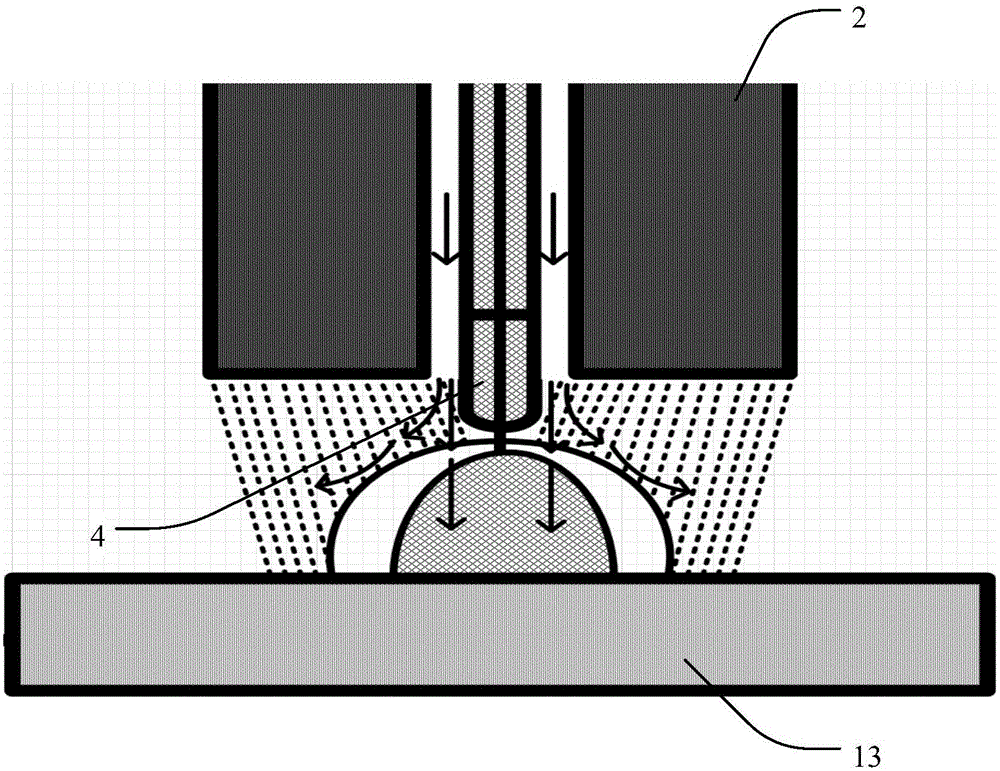

Miniature drainage cover for local dry welding underwater robot of double-airflow structure

ActiveCN106624258AReasonable structureImprove drainage capacityGas flame welding apparatusSlagEngineering

The invention provides a miniature drainage cover for a local dry welding underwater robot of a double-airflow structure. The miniature drainage cover is characterized by comprising an inner air cover, an outer air cover and a water retaining sleeve, wherein the inner air cover, the outer air cover and the water retaining sleeve are arranged in sequence from inside to outside; a welding torch mounting hole which is used for arranging a welding torch is formed in the inner air cover; a convergent nozzle cavity is formed between the outer air cover and the inner air cover; a sealing cover covers the top of the convergent nozzle cavity; at least one air inlet pipe is connected with the outer air cover; a pipe cavity of the at least one air inlet pipe communicates with the convergent nozzle cavity so as to input compressed gas; the water retaining sleeve is connected with the outer air cover so as to form a slag discharge cavity; and the lower part of the welding torch mounting hole and the lower part of the convergent nozzle cavity respectively communicate with the slag discharge cavity. The drainage cover has the advantages of reasonable structure, small size and flexibility in use and has a good drainage effect and a preventive effect on a welding area, and the underwater welding quality can be increased.

Owner:SOUTH CHINA UNIV OF TECH

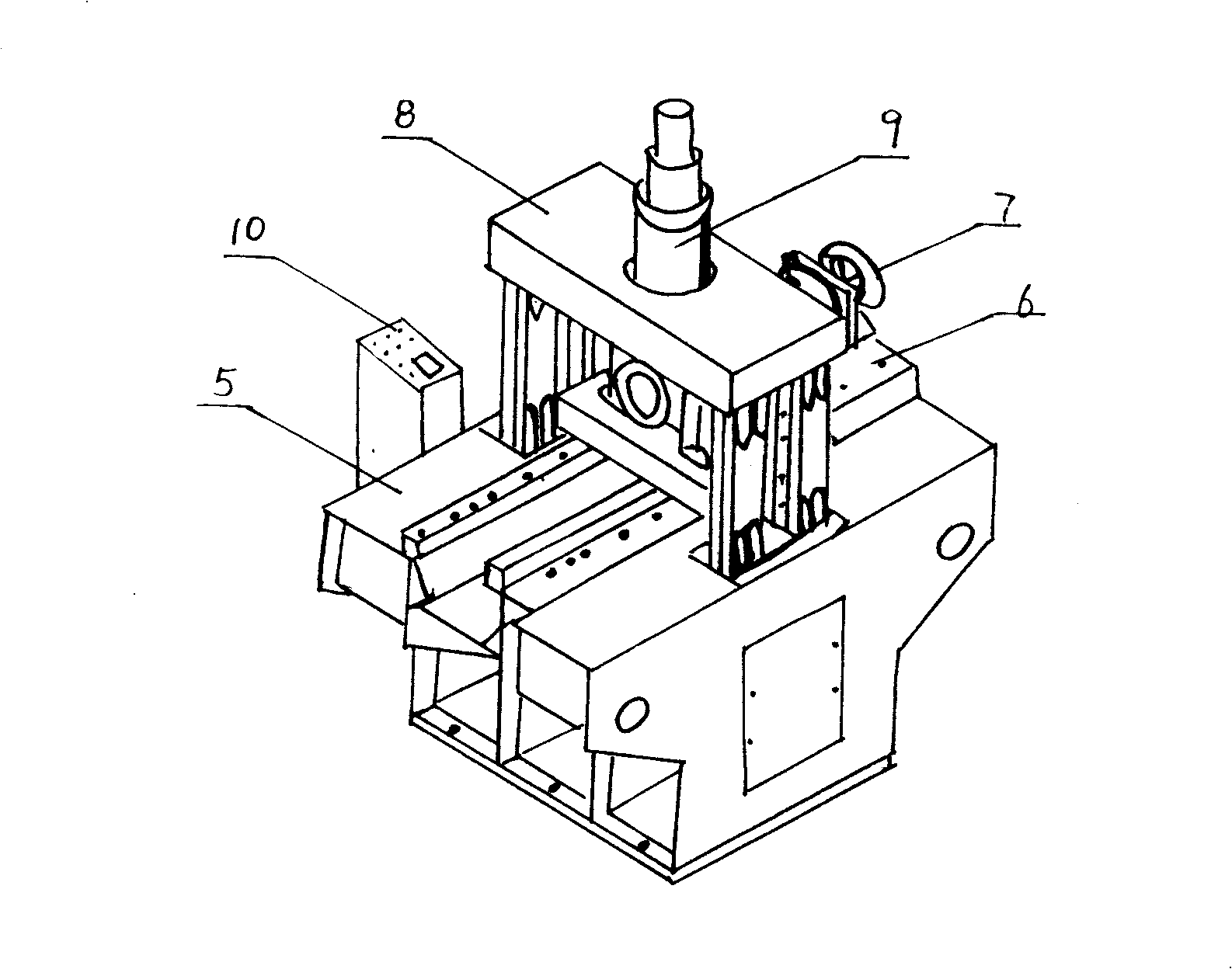

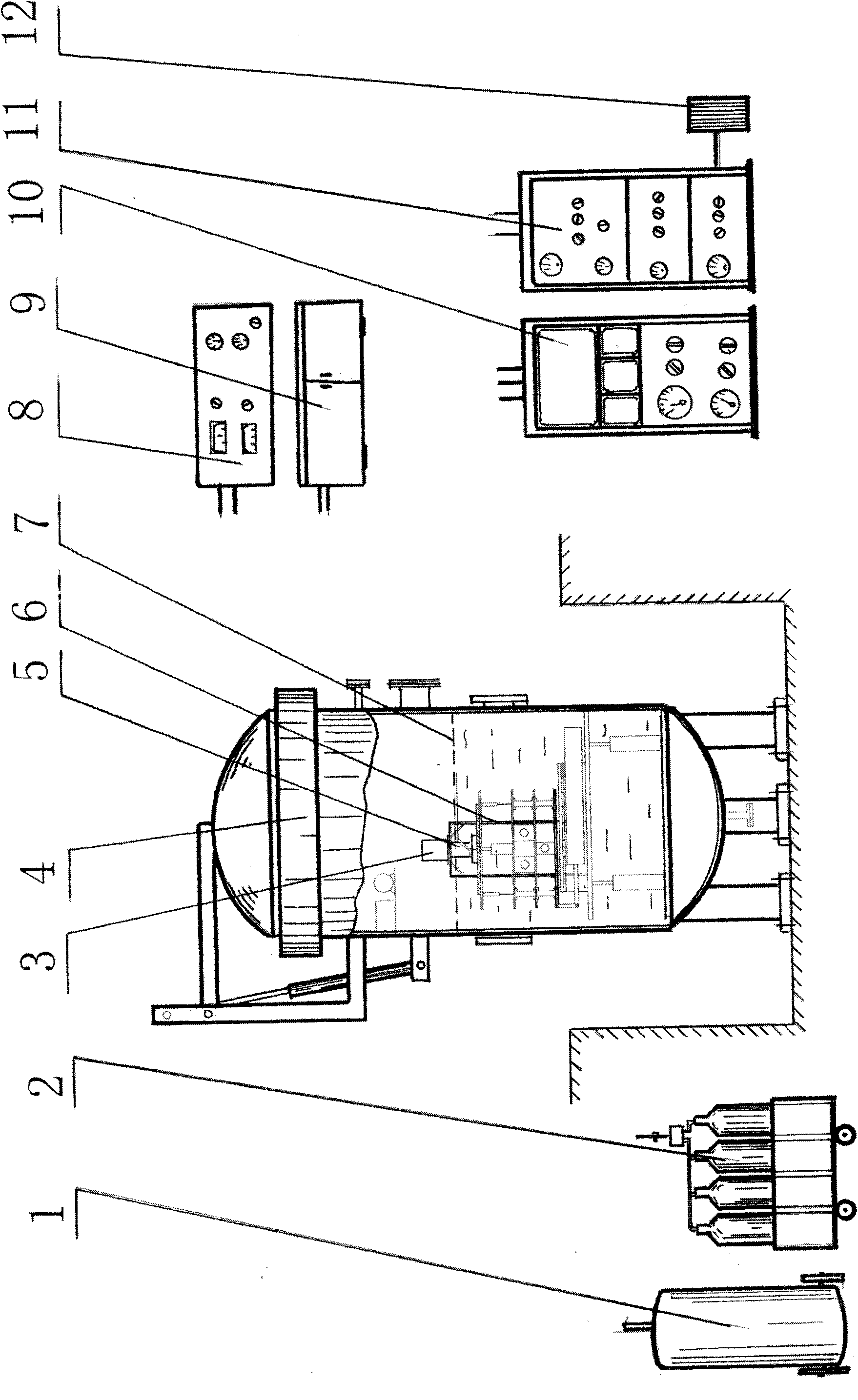

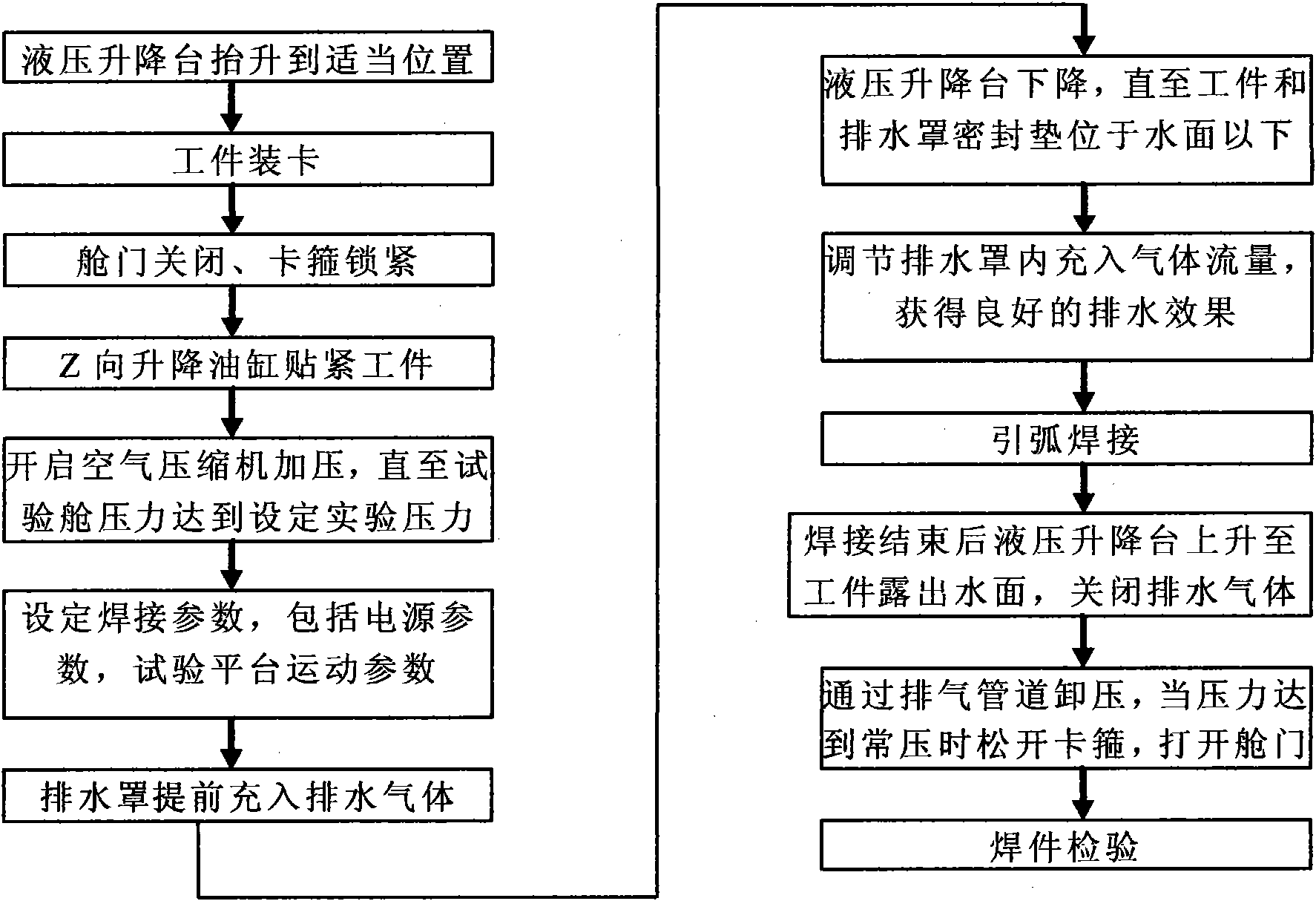

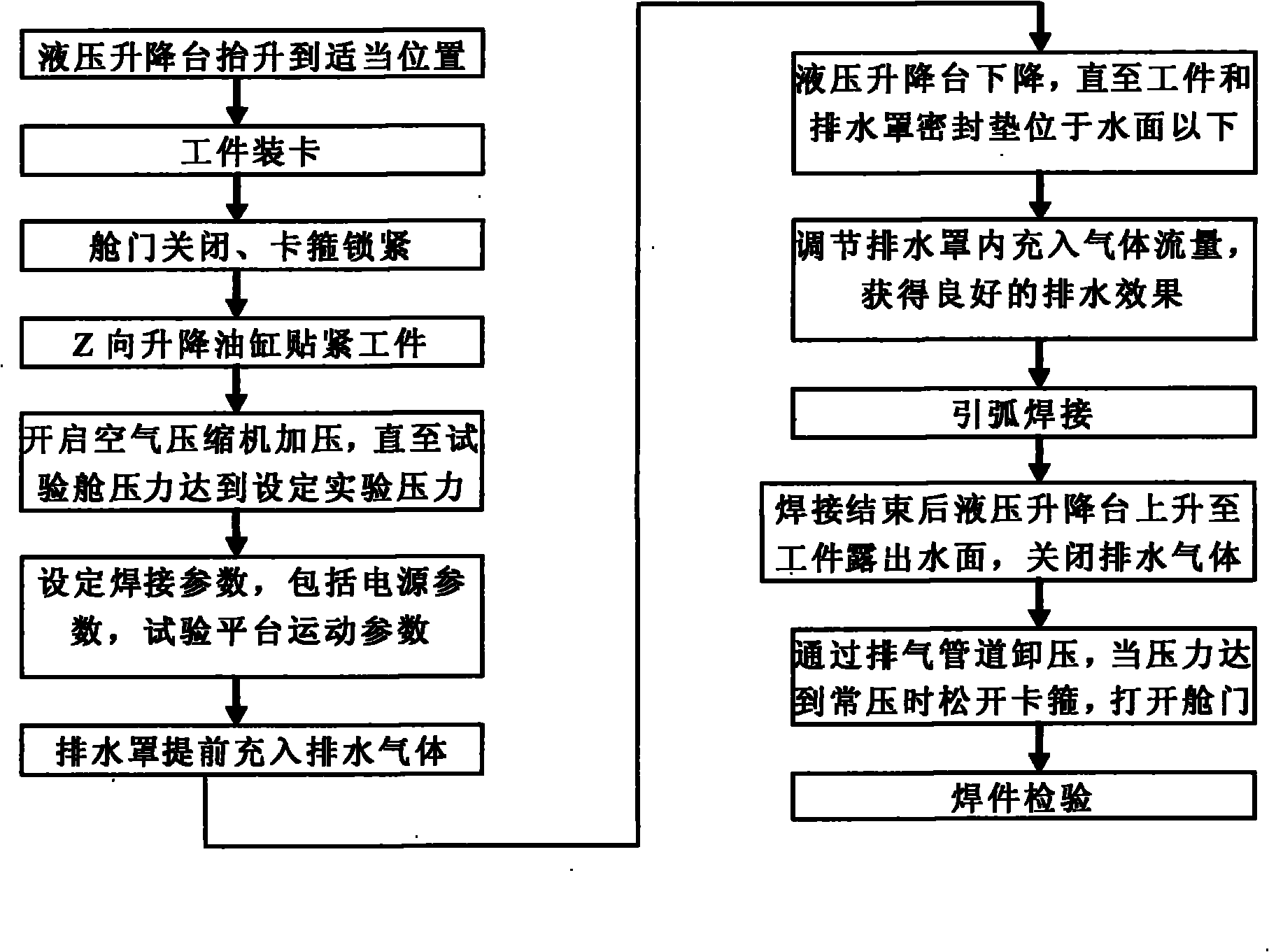

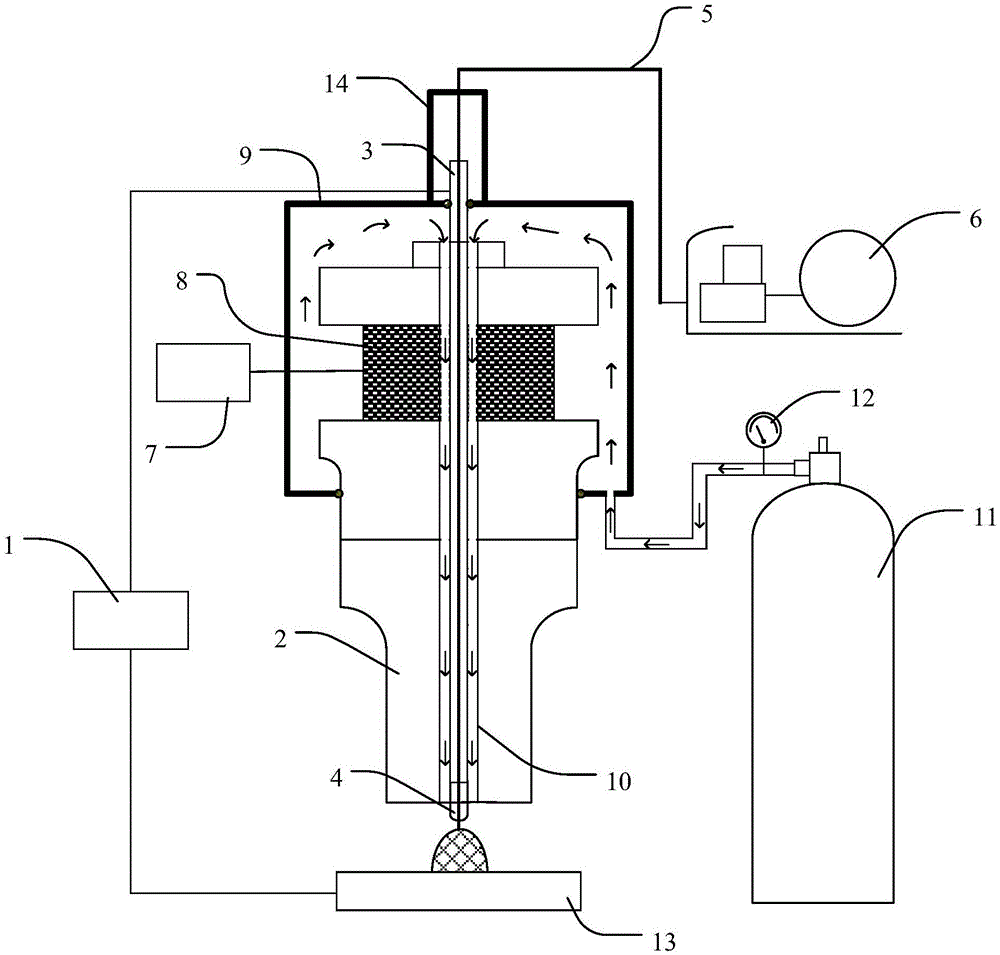

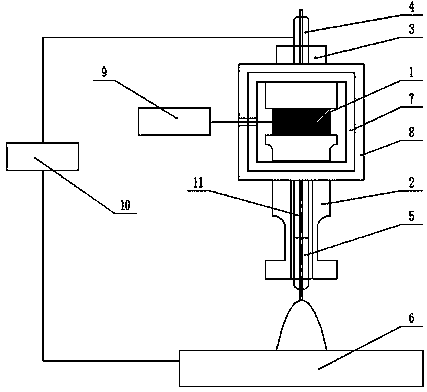

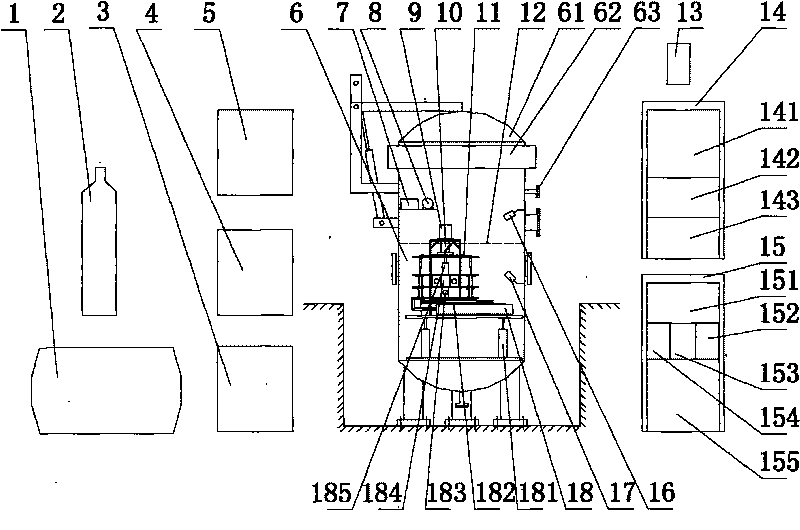

Full-automatic underwater welding method

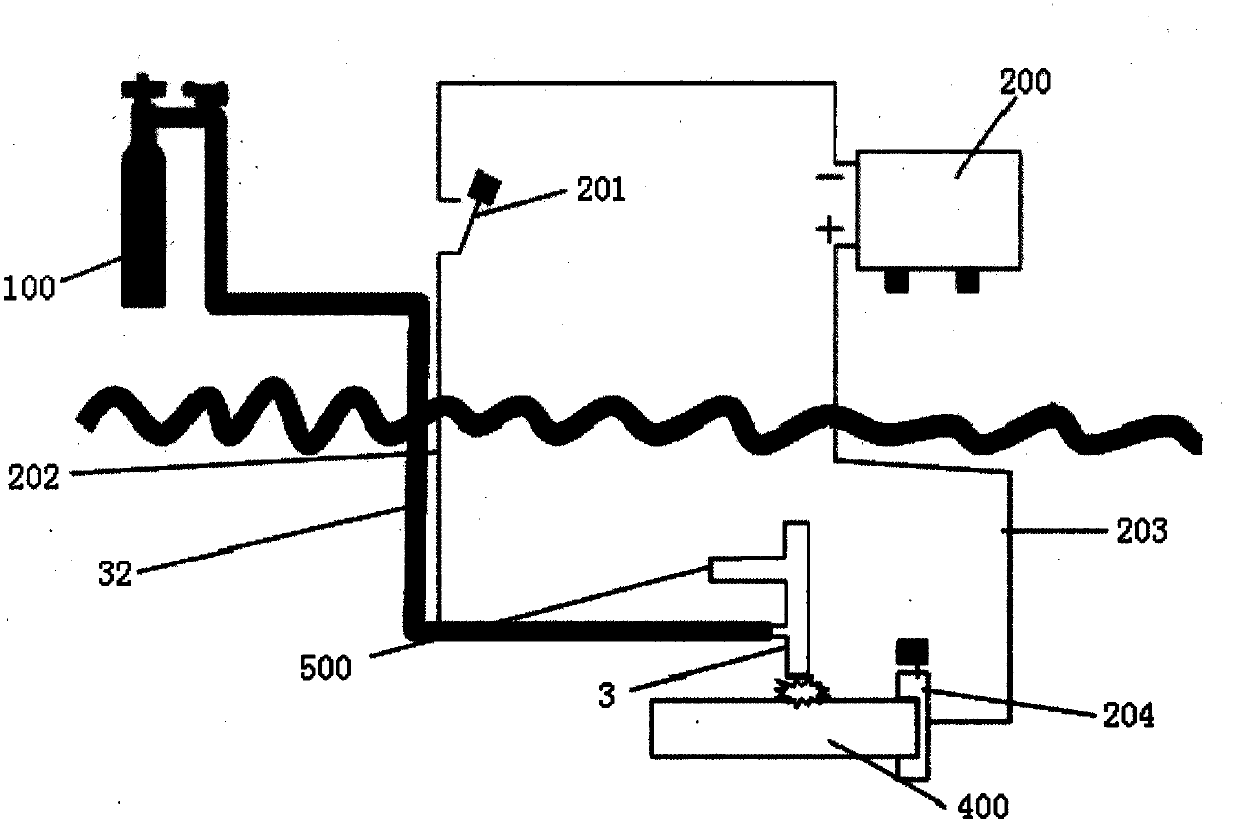

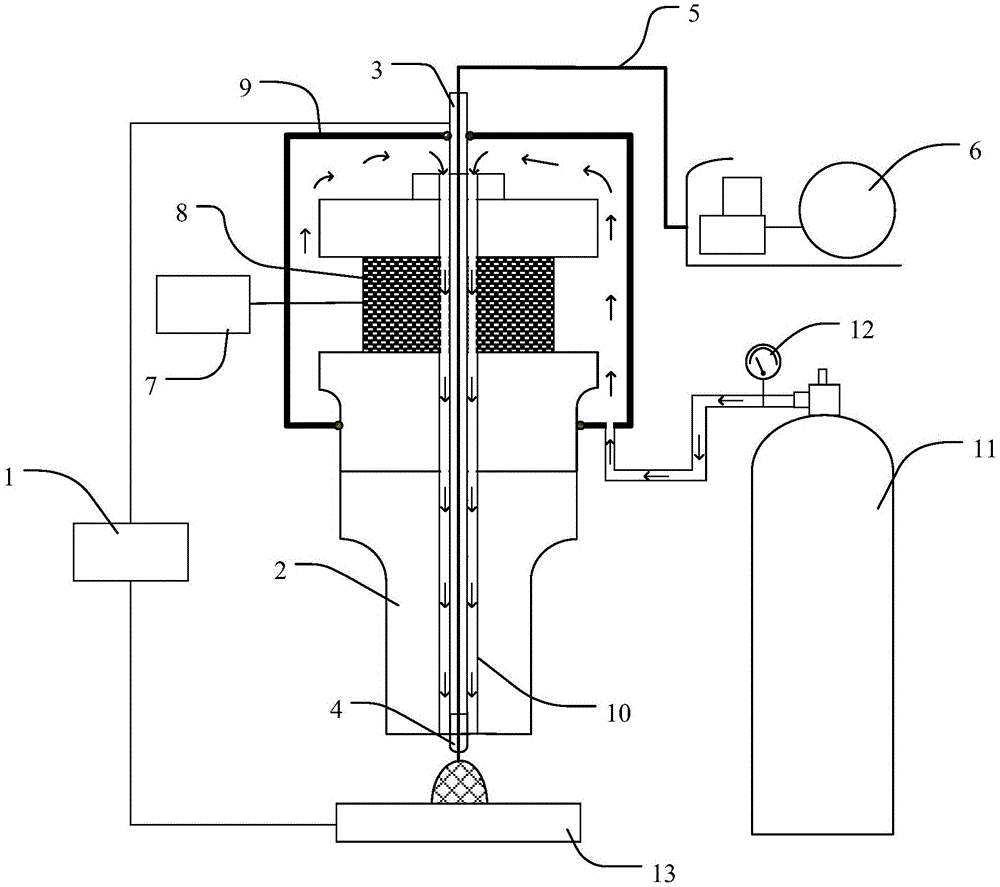

InactiveCN101767244ARealize remote control of fully automatic partial dry underwater welding operationLarge protected areaArc welding apparatusButt weldingGas cylinder

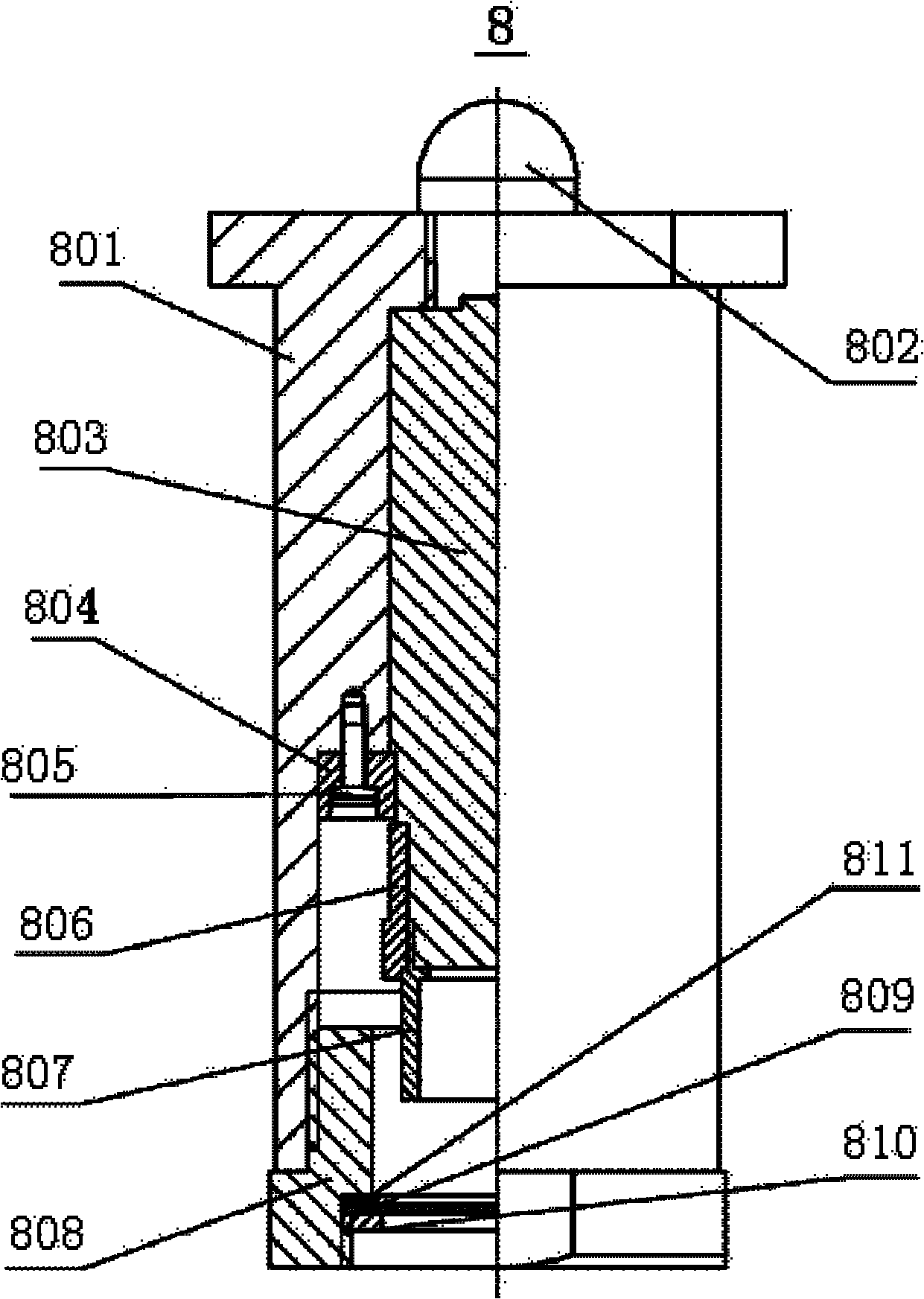

The invention provides a full-automatic underwater welding method and equipment. The equipment comprises an air compressor (1), a gas cylinder (2), a welding camera (3), a welding test chamber (4), a water drain device (5), a hydraulically-driven automatic welding platform (6), a water surface (7), a welding analyzer (8), a welding power supply (9), a monitoring television cabinet (10), a control system cabinet (11), and a manual control box (12). A local dry underwater welding method is used for underwater surfacing and groove butt welding; during welding, the unitary pulse metal inert gas arc welding is adopted; the gas used for water drainage during the welding is also used as the welding shielding gas; before welding, the welding parameters including welding method, welding speed, swinging speed, swinging amplitude, left-right standstill time and the like are set through the manual control box (12) as required, wherein the parameters can be regulated in real time according to the actual condition; the camera system is used for performing omnibearing remote monitoring on the inside of the welding test chamber (4); and the welding analyzer (8) is used for acquiring welding electric parameters and performing statistical analysis in real time. The equipment can be used in the places where the personnel cannot reach, such as deep water area, radiant environment and the like, thereby not only realizing remote control of fully-automatic underwater welding operation, but also ensuring good formation of seams to further ensure the obtaining of high-quality underwater welding joint.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

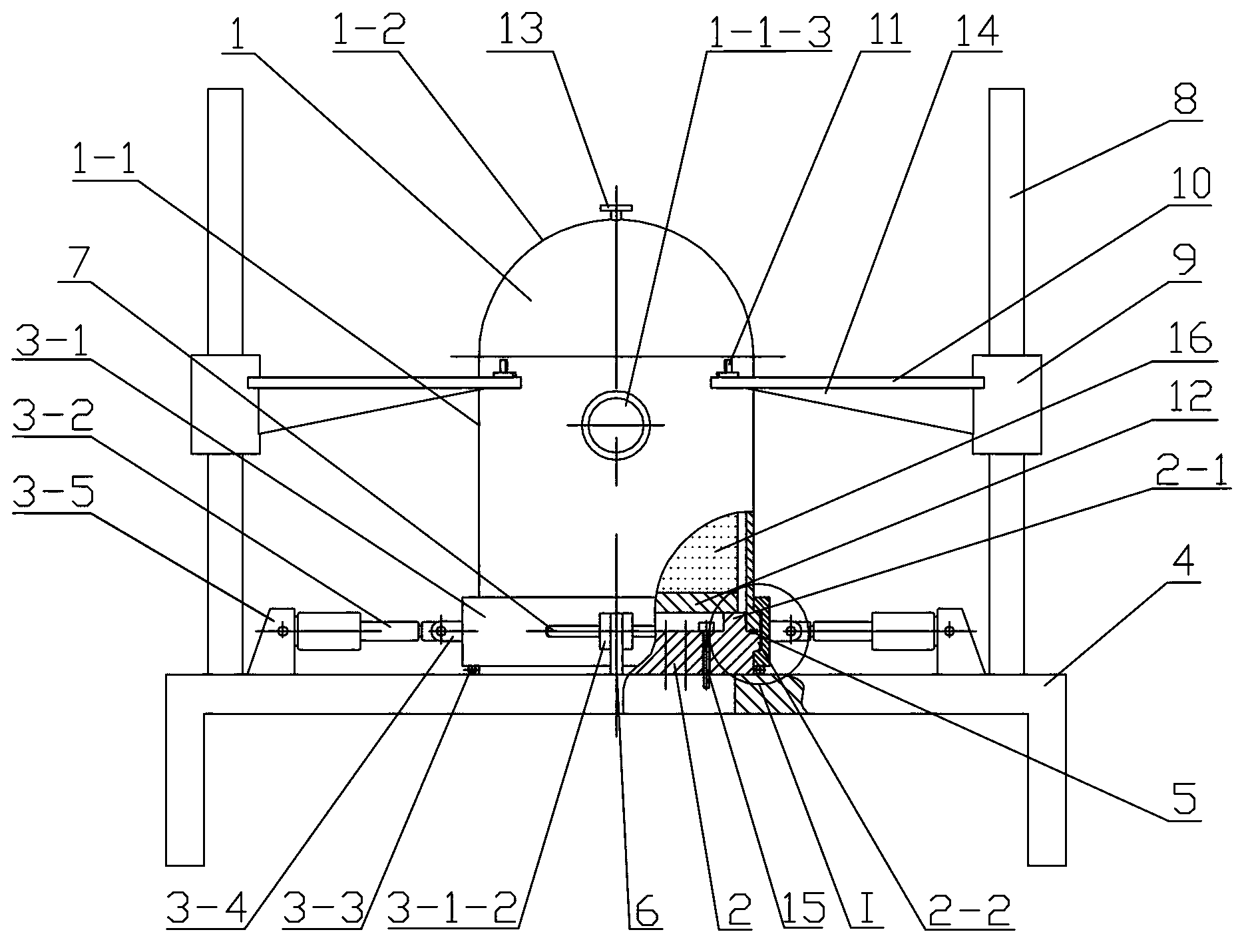

Welding experiment chamber for simulating medium-pressure liquid or gas environment

The invention disclose a welding experiment chamber for simulating a medium-pressure liquid or gas environment, and relates to an underwater welding experiment chamber. The welding experiment chamber aims to solve the problems that for the existing experimental equipment for simulating underwater welding, components in a chamber are not easy to replace, the applicability is poor, the simulated pressure for simulating a welding experiment is low, and only a single pressure medium is available. A chamber bottom is arranged on the upper end face of a platform support; a plurality of chamber penetrating connectors are uniformly arranged in the chamber bottom; a chamber body is arranged above the chamber bottom; two semicircular hoops are buckled to form a ring; two side walls of a trapezoidal groove are tightly matched with an upper inclined plane and a lower inclined plane; an oil cylinder support is fixedly connected with the upper end face of the platform support; two lifting guide rails are symmetrically arranged on the outer side of the oil cylinder support by adopting the vertical center line of the chamber body as a reference; each lifting guide rail is provided with a lifting oil cylinder; four lugs are uniformly distributed on the external wall at the upper end of a barrel; one end of each lifting support is connected with one of the lifting oil cylinders; the other end of each lifting support is connected with two of the four lugs; and a welding platform is arranged on an annular boss. The experiment chamber is used for simulating the underwater welding.

Owner:HARBIN INST OF TECH

Underwater multifunctional stud welding device and welding method thereof

ActiveCN104259637AQuick repairShort welding timeShielding gas supply/evacuation devicesWelding/cutting media/materialsWelding power supplyStud welding

The invention belongs to underwater welding cutting equipment, in particular relates to a underwater multifunctional stud welding device and a welding method thereof. The underwater multifunctional stud welding device mainly consists of a high-power welding power supply, a welding cutting set, an air supply system, a welding cable and a control system, wherein the air supply system comprises an air storage bottle, a pressure reducer and a corresponding air supply pipeline; and the welding cable comprises a welding ground, a cable fixing clamp, a welding gun welding cable and a welding gun control cable. The underwater multifunctional stud welding device has such characteristics as short welding time, good underwater welding quality, no need of operation by special underwater welders, reduction of fastening pieces and all-position welding, can realize such multiple functions as underwater stud welding, underwater manual arc welding and underwater electricity-oxygen cutting, and provides a whole set of solutions for such underwater emergency repair as damaged part repairing, repair plate stud fixation and reinforcement seal welding of damaged ships. The underwater multifunctional stud welding device can perform quick underwater repair without needing the ships to dock for drainage, so that the repair resource and cost are largely reduced, and the repair efficiency is improved.

Owner:THE PLA NAVY SUBMARINE INST

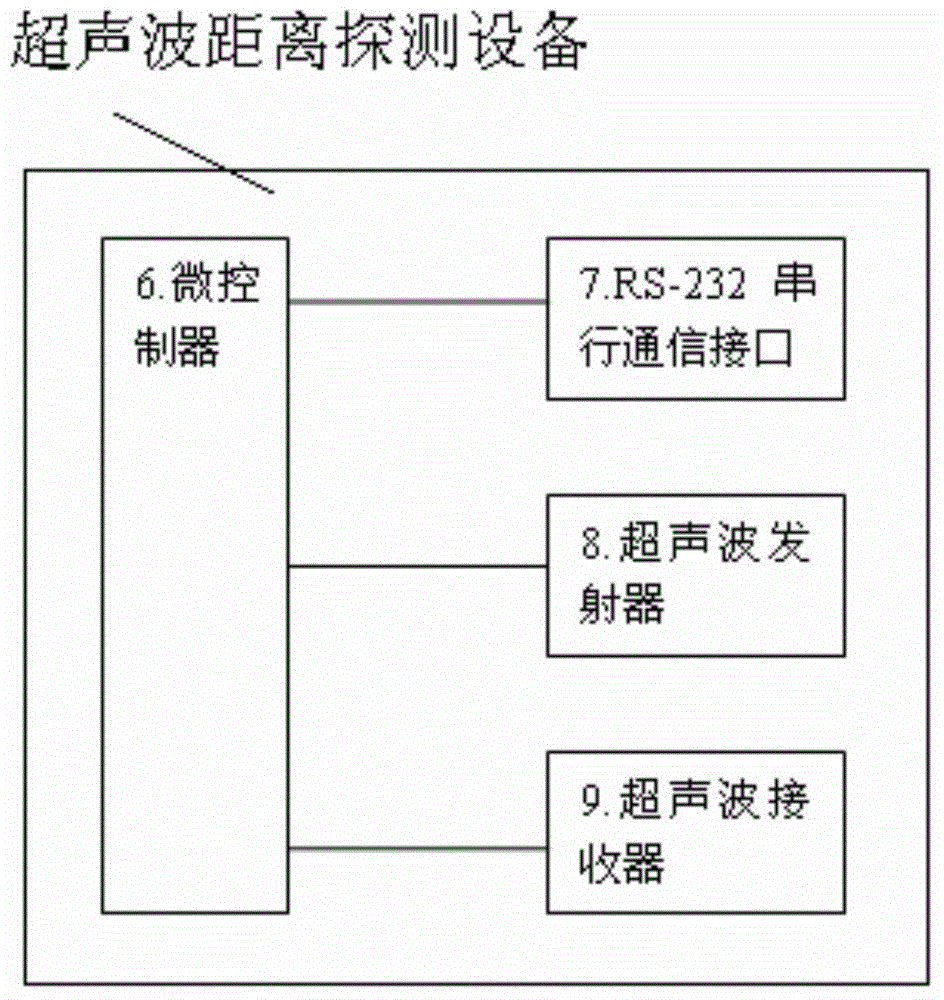

Ultrasonic-assisted and gas-shielded welding device and method adopting underwater wet method

ActiveCN105149747AFacilitated ionizationImprove stabilityWelding accessoriesUltrasonic assistedShielding gas

Owner:HARBIN INST OF TECH AT WEIHAI

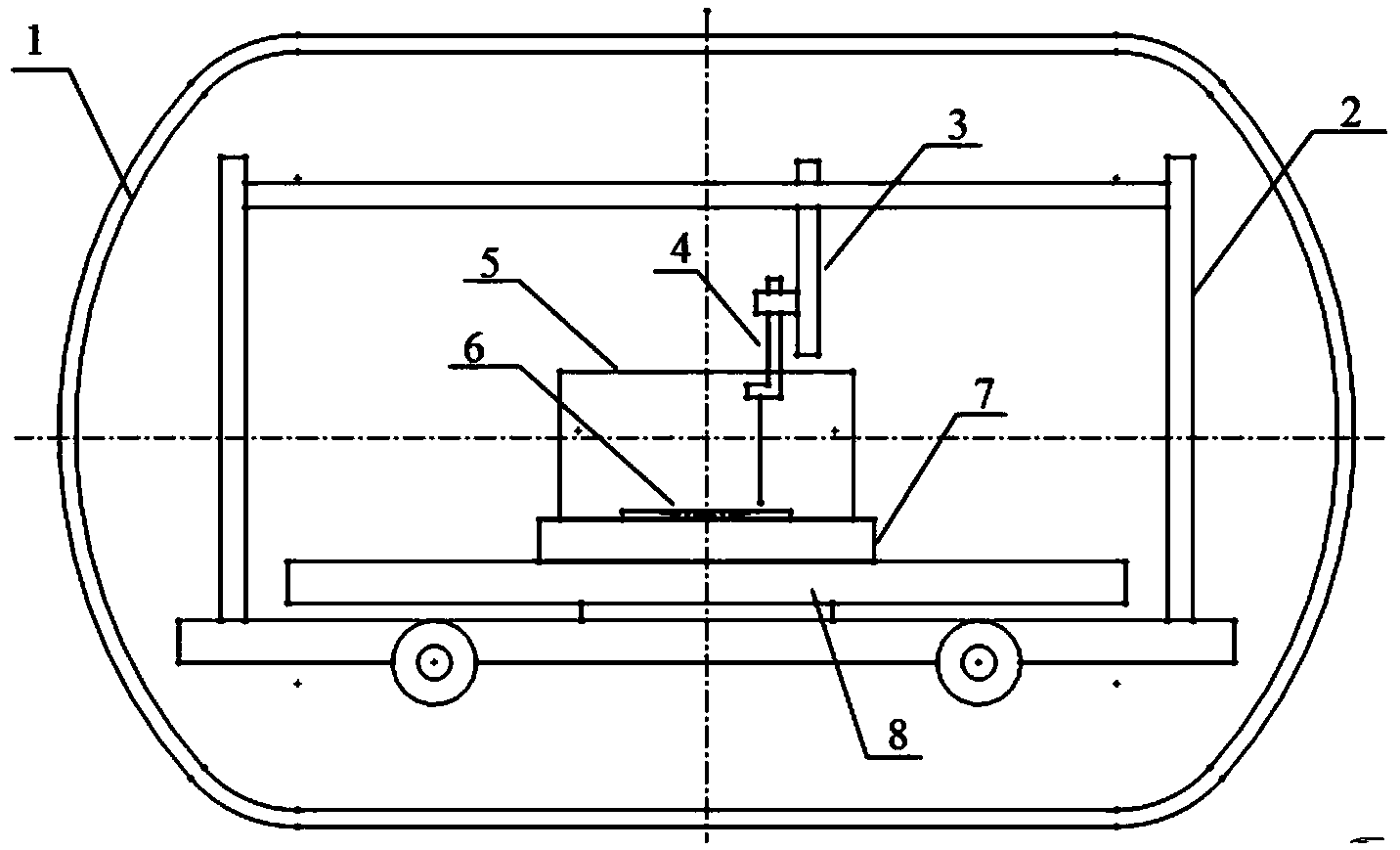

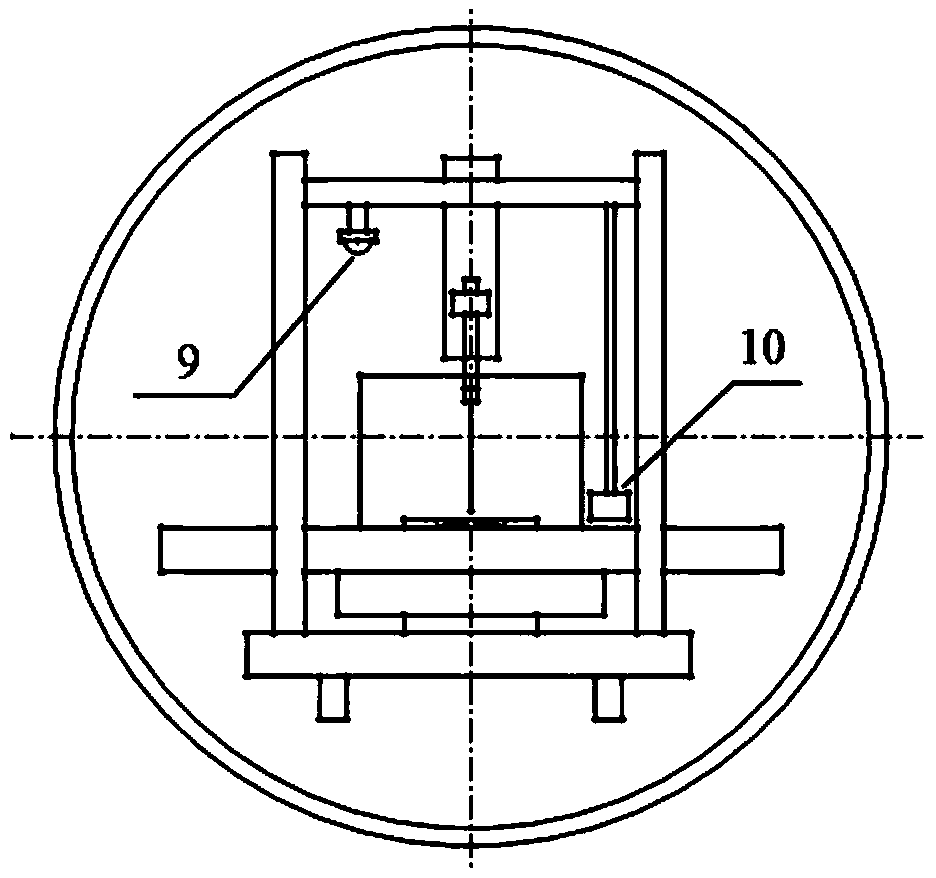

Automatic flat welding device capable of shooting underwater arc and simulating different water depths

InactiveCN103447659AHigh speed cameraHigh precisionWelding accessoriesUnderwater equipmentEngineeringSoldering gun

The invention provides an automatic flat welding device capable of shooting underwater arc and simulating different water depths. The rack of the device is arranged in a welding pressure cabin, and a sliding track and a sliding guide wheel which are meshed with each other are arranged on the rack and allow the rack to go in or out of the welding pressure cabin in parallel; a vertical welding rod / welding gun feeding mechanism is fixedly arranged at the top of the rack through a bolt, and a welding rod / welding gun clamp is fixedly arranged on a movement sliding block of the vertical welding rod / welding gun feeding mechanism; a horizontal two-dimensional motion x-direction platform and a horizontal two-dimensional motion y-direction platform are sequentially arranged at the bottom of the rack, and a water tank is arranged on the horizontal two-dimensional motion x-direction platform. The automatic flat welding device has the beneficial effects that the droplet transfer, arc states and the melting bath behavior in the underwater welding process are shot at high speed, the underwater wet welding and local dry welding can be simulated, and the hyperbaric dry welding can also be simulated. The maximum design pressure of the welding pressure cabin is 3Mpa, and the 300m-water-depth underwater wet welding, local dry welding and hyperbaric dry welding is realized.

Owner:TIANJIN UNIV

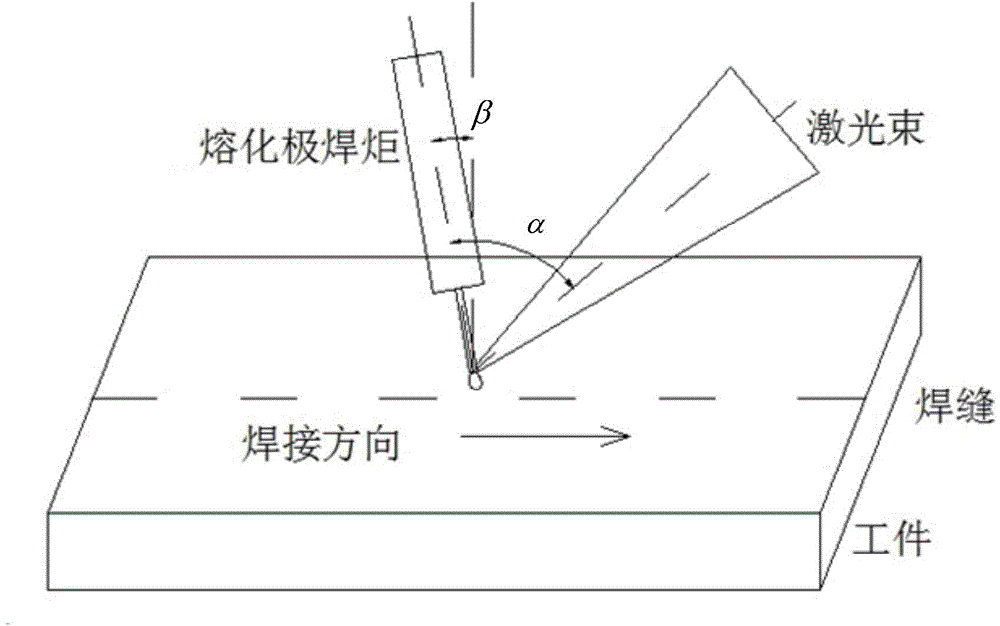

Laser-enhanced underwater GMAW droplet transfer control method

ActiveCN104551391AArc stabilizationImprove stabilityLaser beam welding apparatusMarine engineeringWeld seam

The invention discloses a laser-enhanced underwater GMAW droplet transfer control method. The method comprises the steps: placing a fusion electrode welding torch inside an underwater welding device, and placing a laser outside or inside the underwater welding device; leading a laser beam emitted by the laser into a GMAW welding droplet transfer necking position inside the underwater welding device, ensuring the laser beam and the fusion electrode welding torch to form an angle and to be arranged on the same straight line along the welding direction. By adopting the method, the orientated jet transfer state with stable arc and uniform droplet under the low welding current condition can be realized, the underwater welding droplet transfer time can be precisely controlled, the fusion penetration of a weld seam and the appearance shape of a weld pool can be controlled by freely selecting current under a wider condition, and the good weld seam formation can be realized on the premise of not obviously increasing the additional heat input.

Owner:北京三帝科技股份有限公司

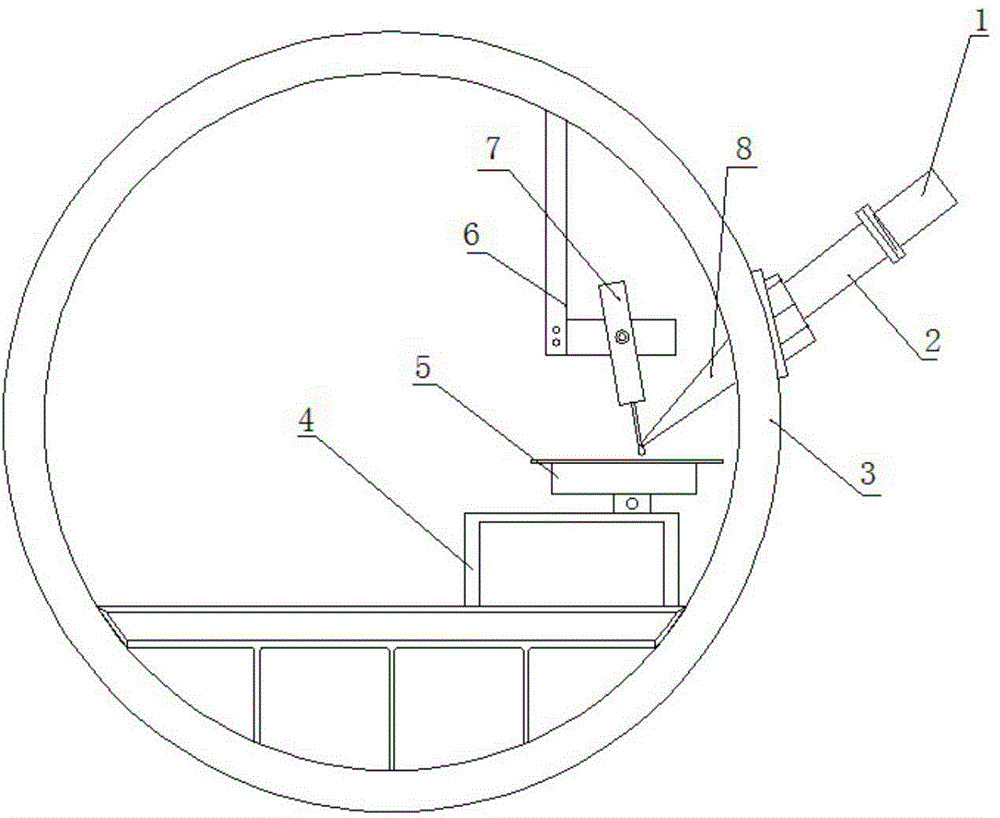

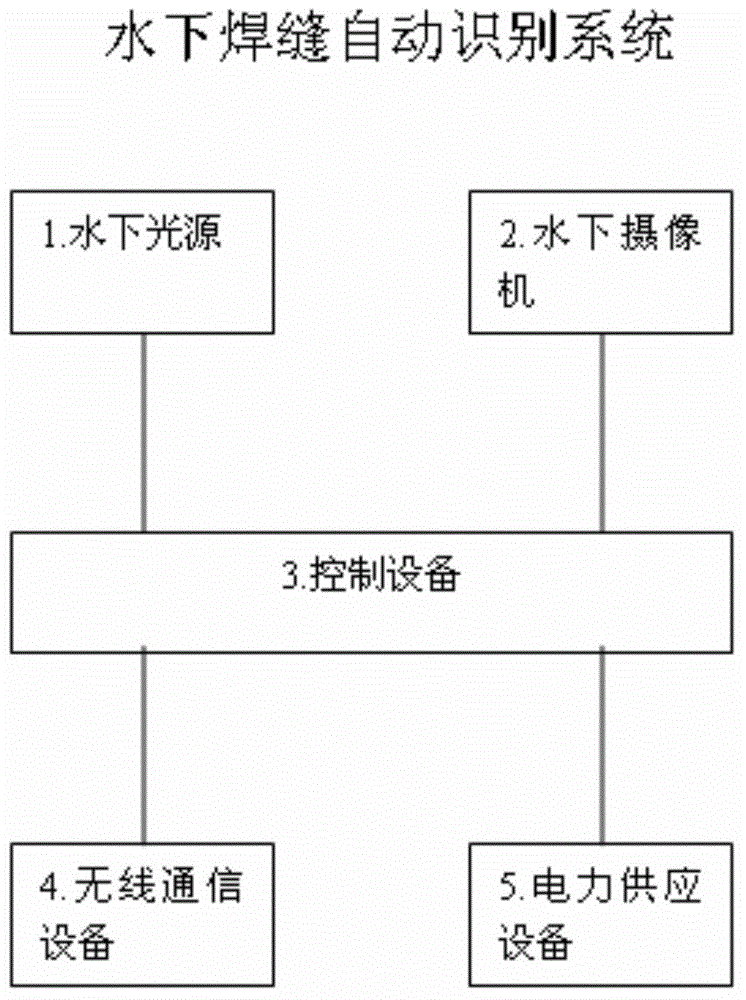

Underwater welding seam automatic identification system

InactiveCN104568970AImprove the level of intelligenceSave electricity underwaterWelding/cutting auxillary devicesOptically investigating flaws/contaminationImaging processingMarine engineering

The invention relates to an underwater welding seam automatic identification system. The underwater welding seam automatic identification system comprises an underwater light source, an underwater camera, control equipment and wireless communication equipment, wherein the underwater light source is used for providing a light source for underwater shooting of the underwater camera, the underwater camera is used for shooting a welding image of an underwater workpiece when the workpiece is welded, the control equipment is connected with the underwater camera for carrying out image processing on the welding image and recognizing a welding seam of the welding image of the workpiece, the wireless communication equipment is arranged on water, is connected with the control equipment by an underwater cable and is used for receiving the welding seam of the workpiece and sending the welding seam of the workpiece to a water computer wireless. According to the underwater welding seam automatic identification system, the welding seam can be automatically detected in a severe underwater environment, and the automatic identification system can provide reliable reference data for the water computer to realize underwater welding operation control.

Owner:YANTAI DAYOU INFINITY DATA SYST CO LTD

Ultrasonic-assisted underwater wet welding method

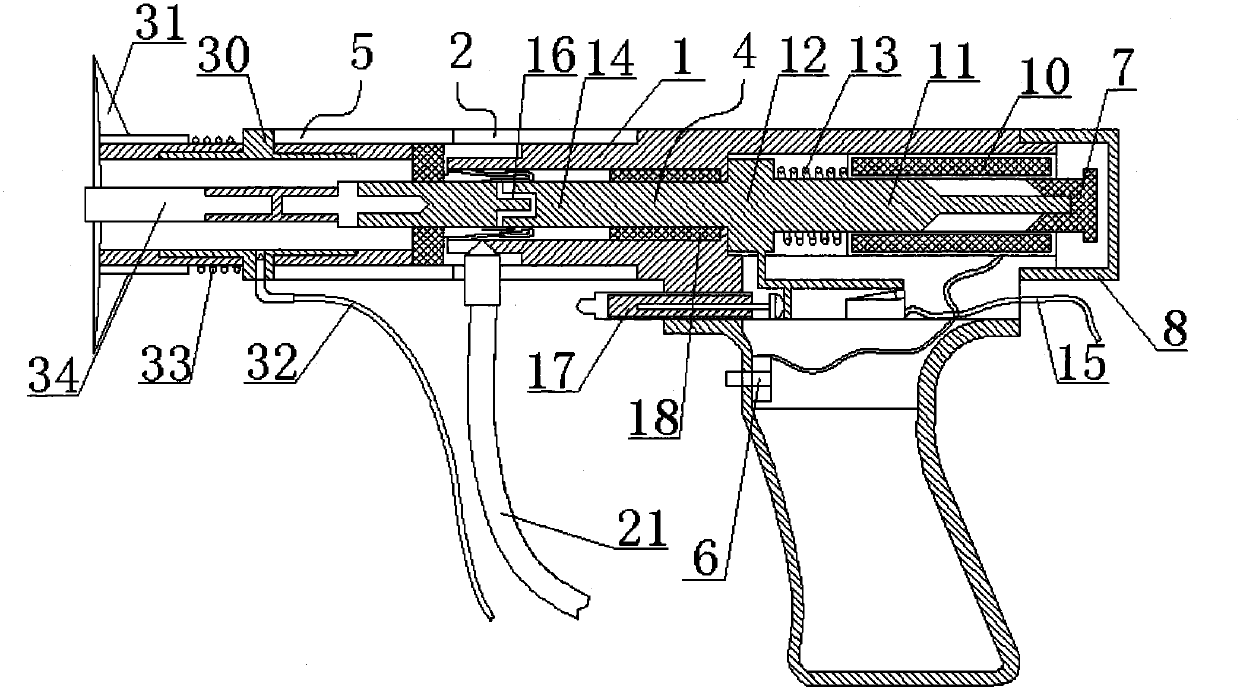

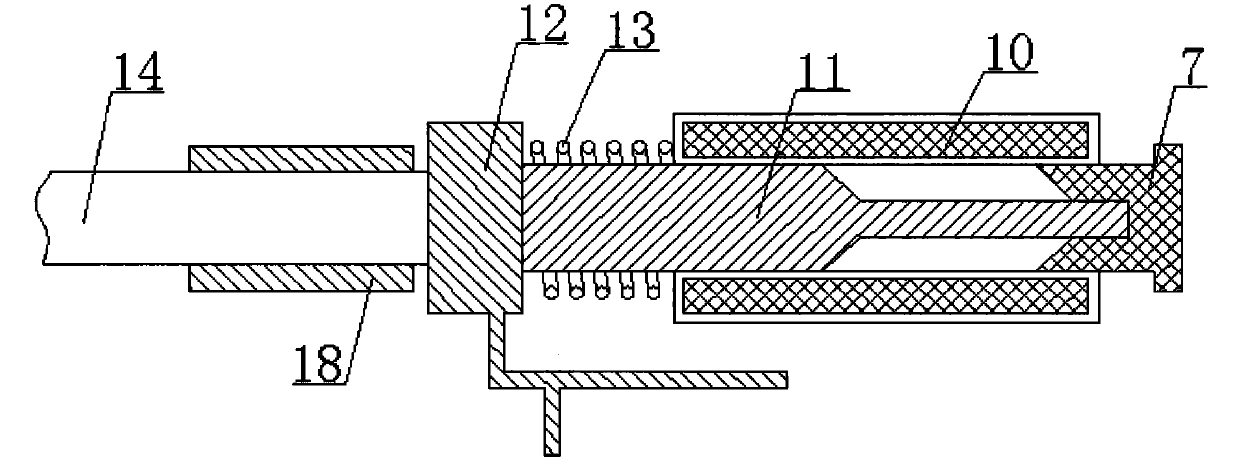

ActiveCN103769756AReduce the impactReduce extinction rateWelding apparatusUltrasonic assistedTransformer

The invention discloses an ultrasonic-assisted underwater wet welding method which is characterized in that an ultrasonic transducer is sealed in a waterproof shell, the shell is filled with aviation kerosene, the upper end of an ultrasonic amplitude transformer penetrates the waterproof shell and is connected with the lower end of the ultrasonic transducer in a threaded manner, an insulating sleeve penetrates the waterproof shell, is inserted into the waterproof shell from the upper end of the ultrasonic transducer and penetrates the ultrasonic amplitude transformer to reach the lower end face of the amplitude transformer, a conducting rod and a conducting nozzle are mounted in the insulating sleeve, the conducting nozzle is mounted at the lower end of the insulating sleeve and partially extends out of the ultrasonic amplitude transformer, the upper end of the conducting rod extends out of the shell and the insulating sleeve, the lower end of the conducting rod is connected with the conducting nozzle in a threaded manner, the conducting rod and the conducting nozzle are axially provided with welding wire feeding pipes, an ultrasonic power wire penetrates the waterproof shell and is connected with the ultrasonic transducer, a lifting adjustment mechanism is arranged on the conducting rod, and the conducting rod is connected with an underwater welding power supply. Arc blow and arc extinguishing rate is decreased, welding joints are uniformly formed, welding defects are decreased, and the ultrasonic-assisted underwater wet welding method has a quite large application space in the field of underwater welding.

Owner:HARBIN INST OF TECH AT WEIHAI

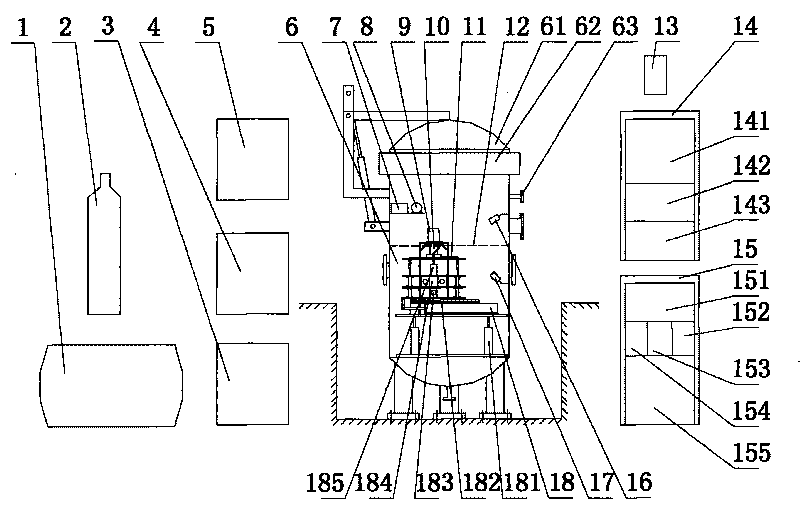

Underwater remote-control welding system

InactiveCN101758322AReduce labor intensityIncrease productivityWelding accessoriesGas cylinderWelding power supply

The invention discloses an underwater remote-control welding system, which is composed of an air compressor (1), an Ar gas bottle (2), a test chamber hydraulic station (3), a welding power supply (4), a welding platform hydraulic station (5), an underwater welding test chamber (6), a welding platform valve group (7), a wire feeder (8), an underwater welding camera (9), a drainage gas mask (10), a test steel plate (11), a water surface (12), a welding manual box (13), a control system cabinet (14), a monitor TV cabinet (15), a water surface camera (16), an underwater video camera (17) and a welding platform (18); wherein the underwater welding test chamber (6), the welding platform valve group (7), the wire feeder (8), the underwater welding camera (9), the drainage gas mask (10), the test steel plate (11), the water surface camera (16), the underwater video camera (17) and the welding platform (18) are arranged in the underwater welding test chamber (6); the air compressor (1), the Ar gas bottle (2), the test chamber hydraulic station (3), the welding power supply (4), the welding platform hydraulic station (5), the welding manual box (13), the control system cabinet (14) and the monitor TV cabinet (15) are positioned outside the underwater welding test chamber (6) and connected to the internal equipment of the underwater welding test chamber (6) through cables and air tubes. The invention can be used for the situation which staff cannot enter into such as deep water and the radiation environment, has compact equipment composition and high overall reliability, reduces operational risk, reduces labor intensity and improves production efficiency.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com