Flux-cored wire for underwater welding and preparation method

A technology of flux-cored welding wire and underwater welding, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc. It can solve the problems of weld cracks, welding spatter and slag peeling performance, etc., and achieve slag Good peeling performance, beautiful weld shape, and less welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

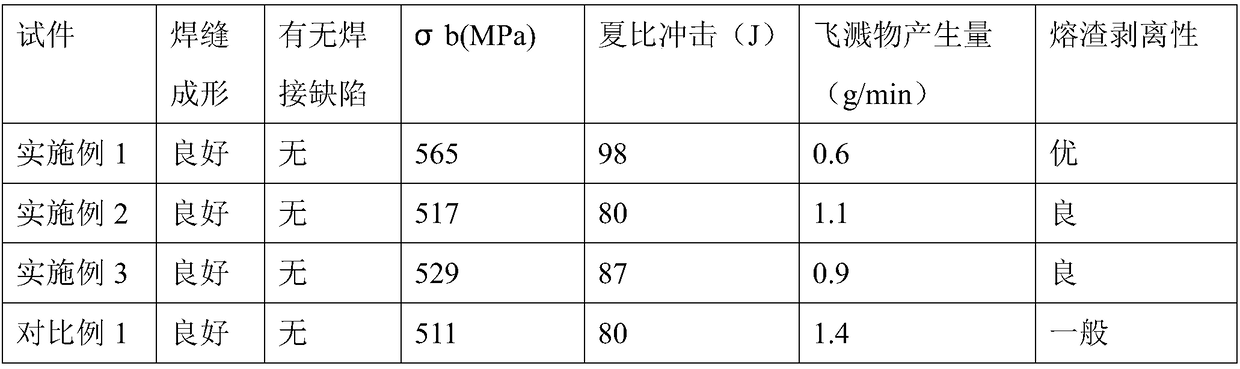

Embodiment 1

[0048]A flux-cored welding wire for underwater wet welding, the core composition of the flux-cored welding wire is as follows: 1.0% calcium oxide, 1.0% magnesium oxide, 7.5% titanium oxide, 4.0% iron oxide, silicon oxide 0.4%, calcium fluoride 0.5%, lithium fluoride 0.2%, barium fluoride 1.5%, calcium carbonate 1.8%, magnesium carbonate 0.8%, barium carbonate 0.8%, manganese 1.0%, nickel 0.7%, aluminum 0.4%, iron 4.0 %, silicon 0.4%, titanium 0.6%, magnesium 0.4%, boron 0.2%.

Embodiment 2

[0050] A flux-cored welding wire for underwater wet welding, the core composition of the flux-cored welding wire is as follows: 1.0% calcium oxide, 1.0% magnesium oxide, 7.0% titanium oxide, 5.2% iron oxide, silicon oxide 0.4%, Calcium Fluoride 1.5%, Lithium Fluoride 0.6%, Calcium Carbonate 1.8%, Magnesium Carbonate 0.8%, Manganese 1.8%, Nickel 1.2%, Aluminum 0.4%, Iron 4.0%, Silicon 0.4%, Titanium 0.6%, Magnesium 0.4%, Boron 0.2%.

Embodiment 3

[0052] A flux-cored welding wire used for underwater wet welding. The core composition of the flux-cored welding wire is as follows: 1.0% calcium oxide, 1.0% magnesium oxide, 8.0% titanium oxide, 4.2% iron oxide, silicon oxide 0.4%, calcium fluoride 0.7%, lithium fluoride 0.3%, barium fluoride 1.1%, calcium carbonate 1.8%, magnesium carbonate 0.8%, barium carbonate 0.8%, manganese 1.0%, nickel 0.8%, iron 5.0%, silicon 0.4 %, titanium 0.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com