Patents

Literature

616results about How to "Arc stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

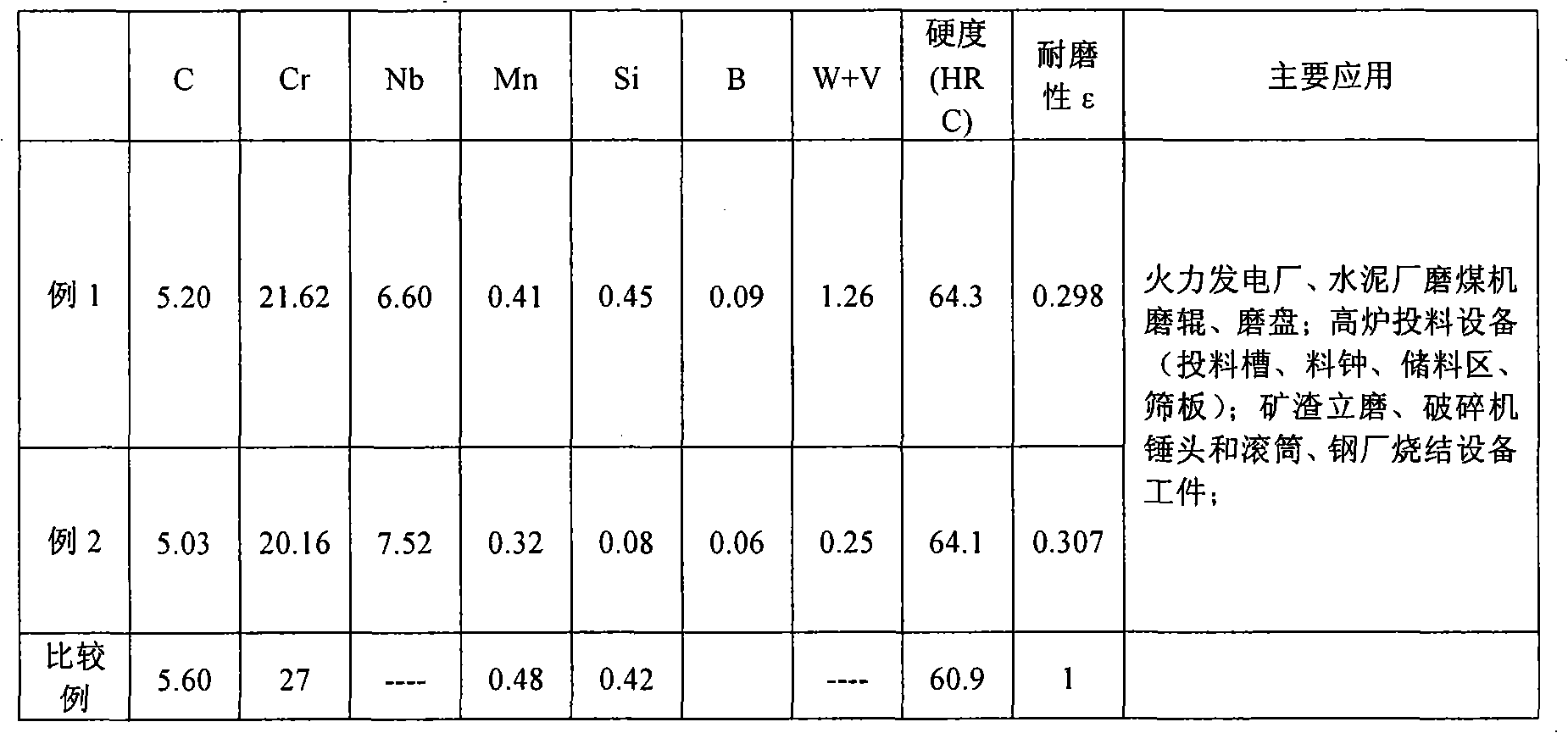

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

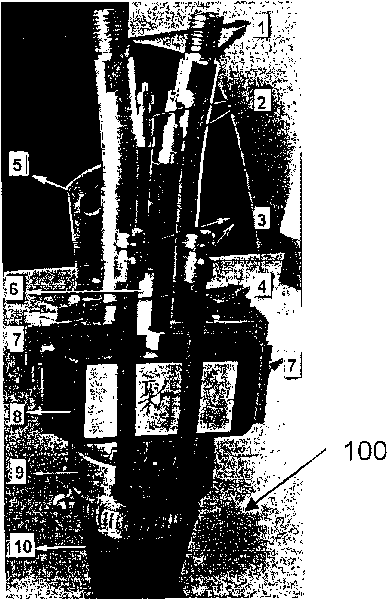

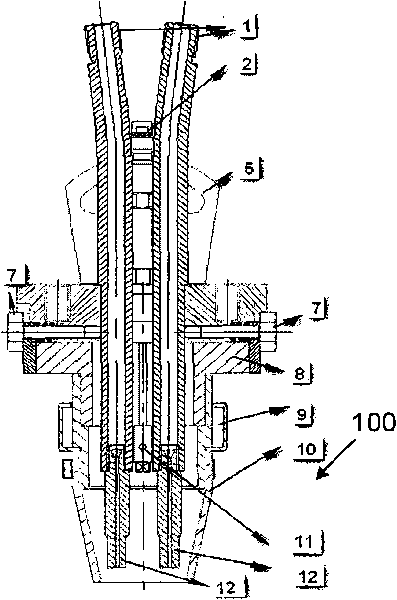

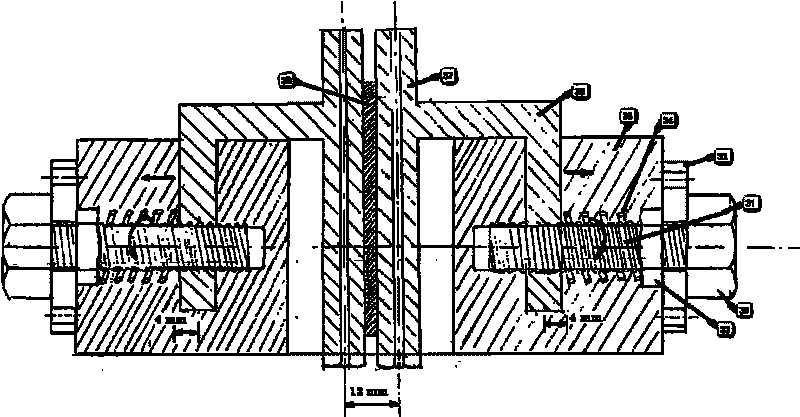

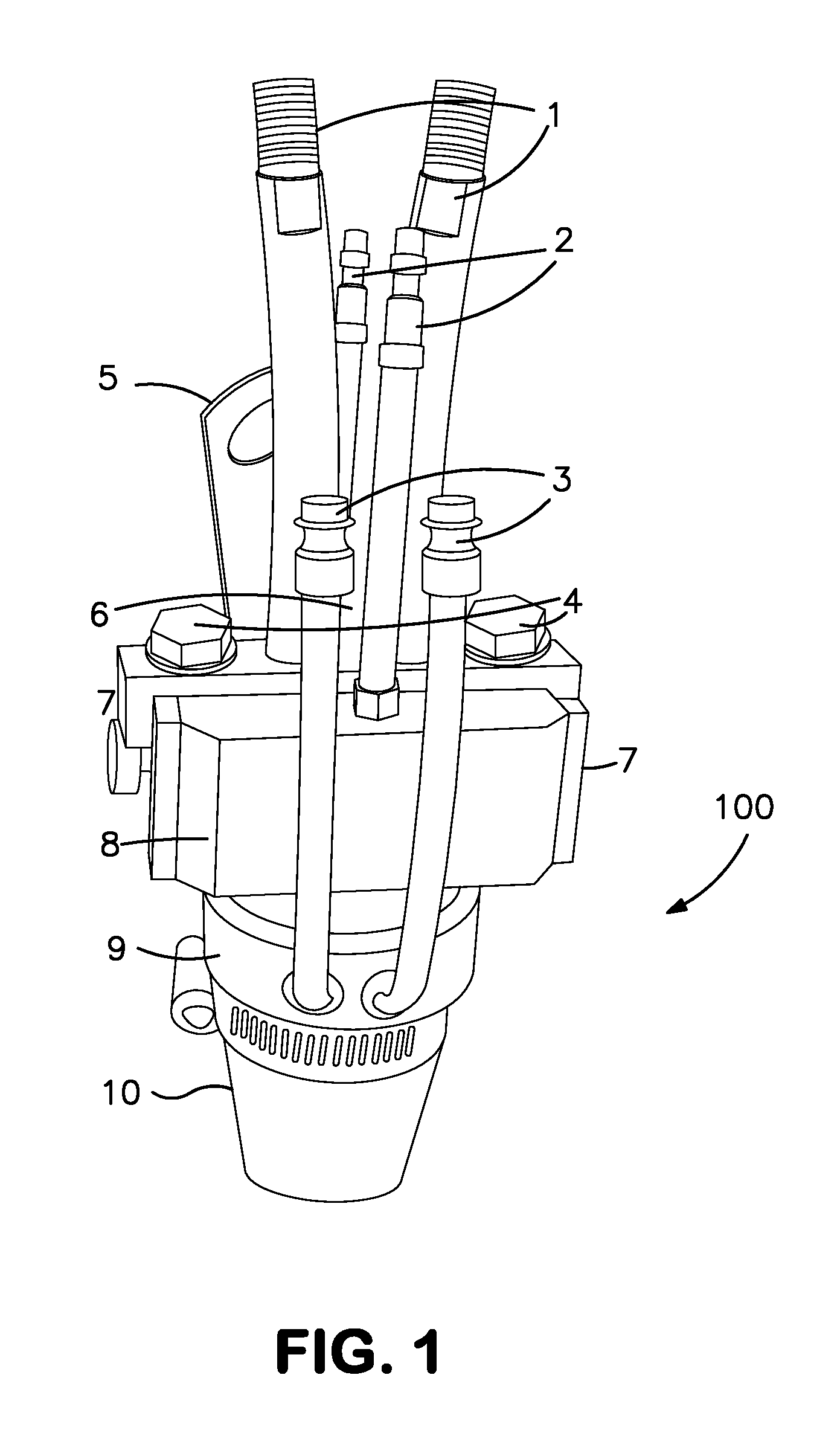

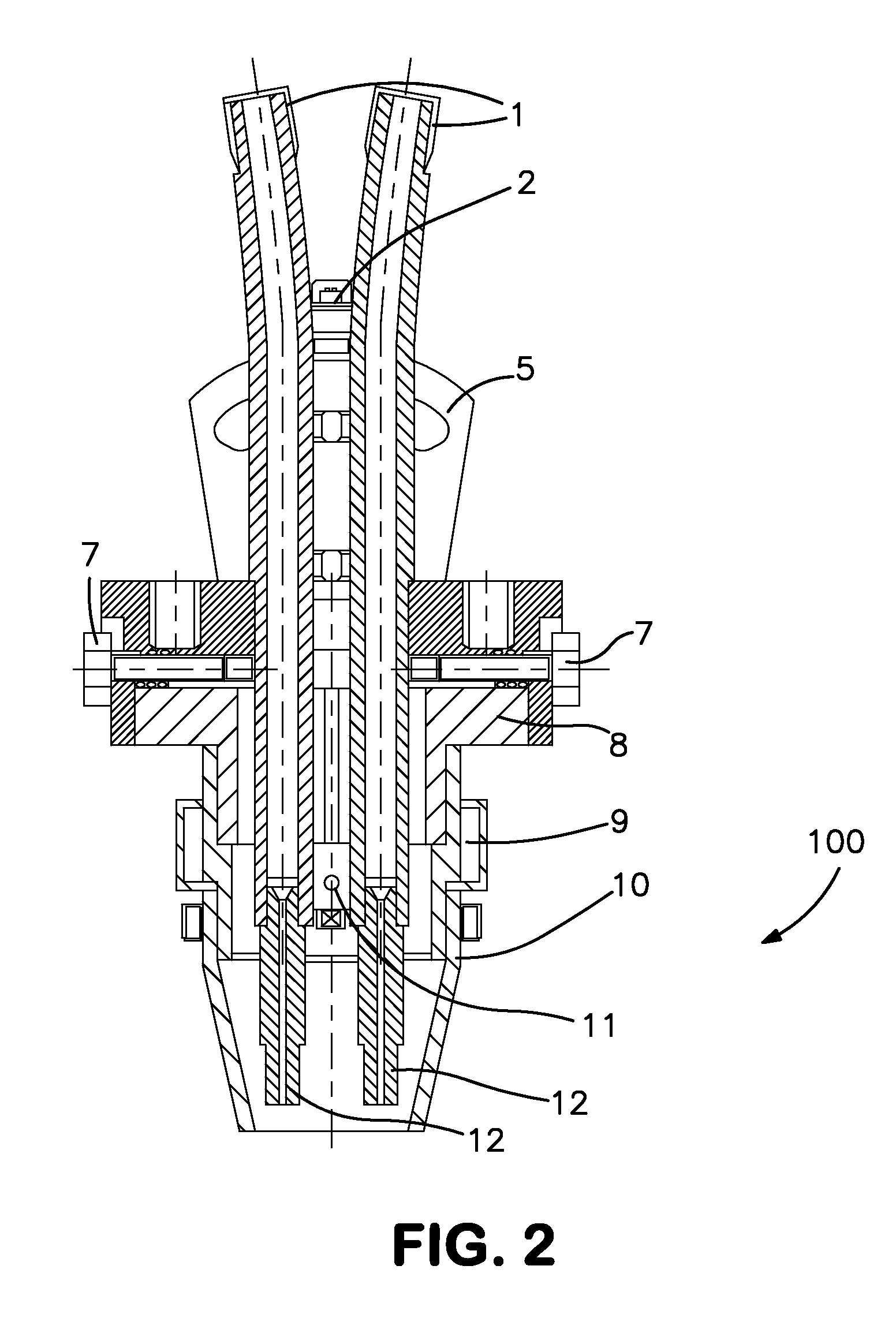

Twin-wire melting pole gas shielded welding torch and welding method

InactiveCN101745726AEliminate arc interferenceArc stabilizationElectrode supporting devicesWelding torchWelding

The invention relates to a twin-wire melting pole gas shielded welding device comprising a welding wire gap adjustable welding torch assembly. The twin-wire welding torch assembly is provided with a twin-wire gap adjusting mechanism. The welding torch assembly can be used for the nonsynchronous control droplet transfer welding technique by means of welding wire gap adjustment. The welding wires keep parallel before, during and after the welding wire space adjustment.

Owner:PRAXAIR TECH INC

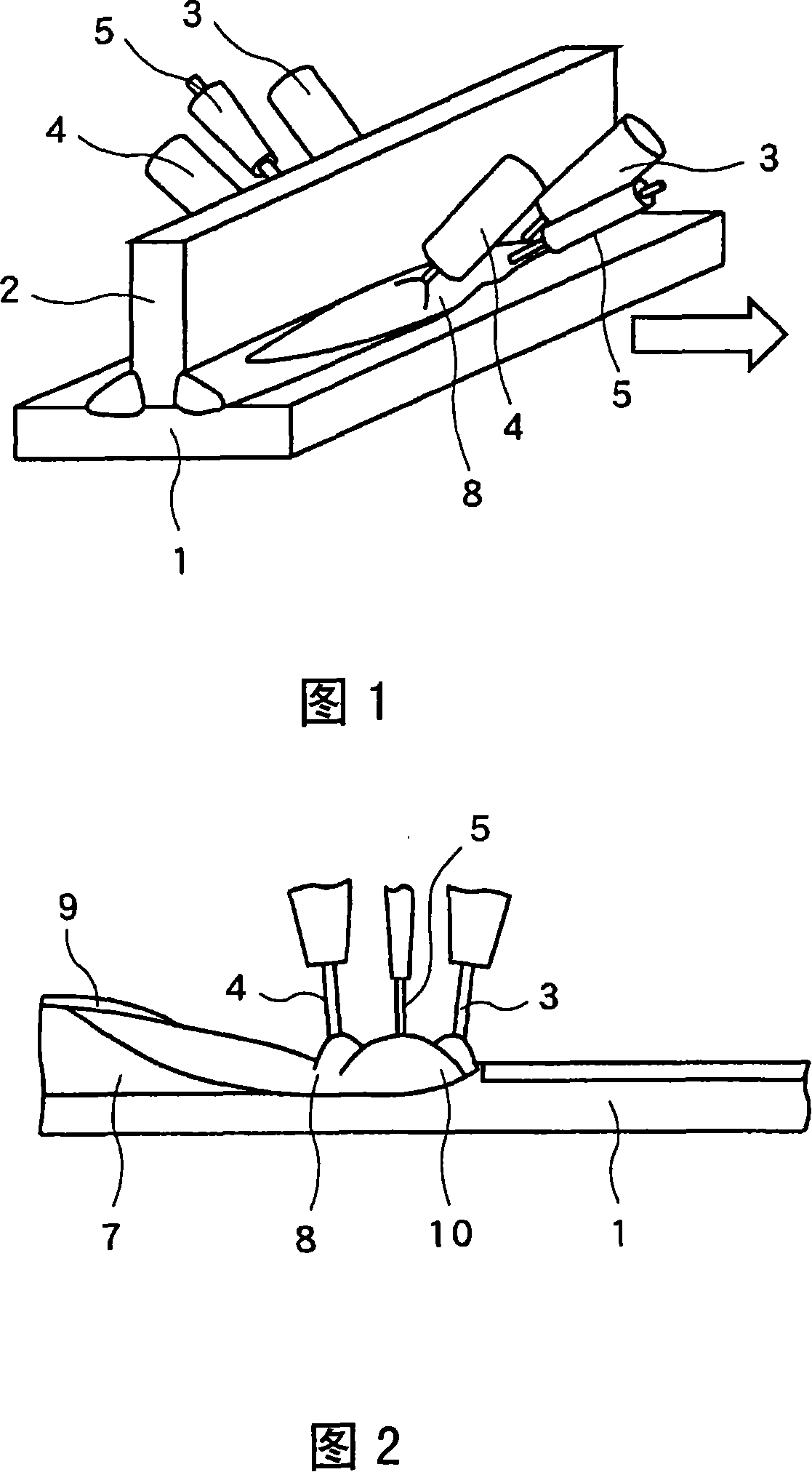

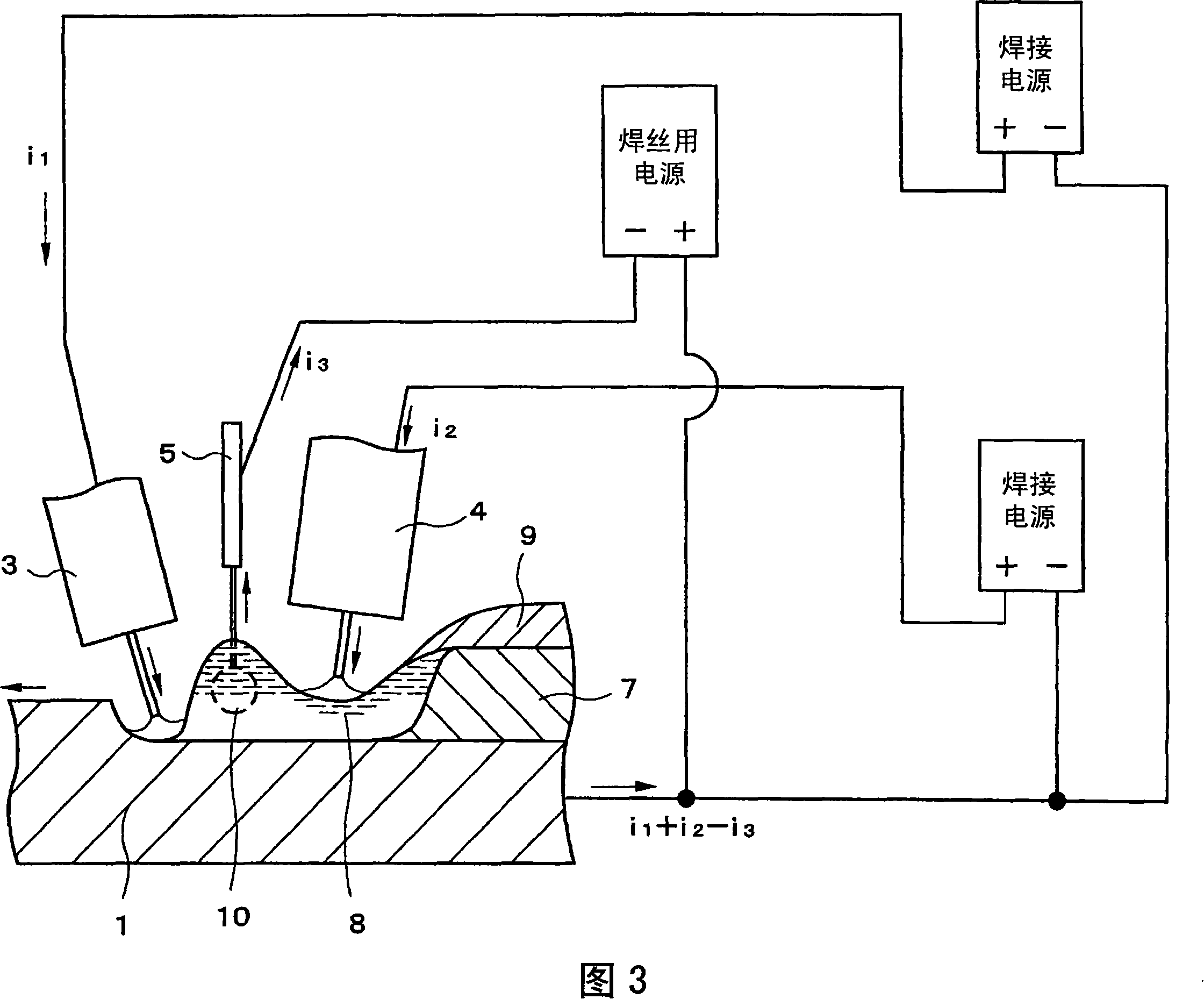

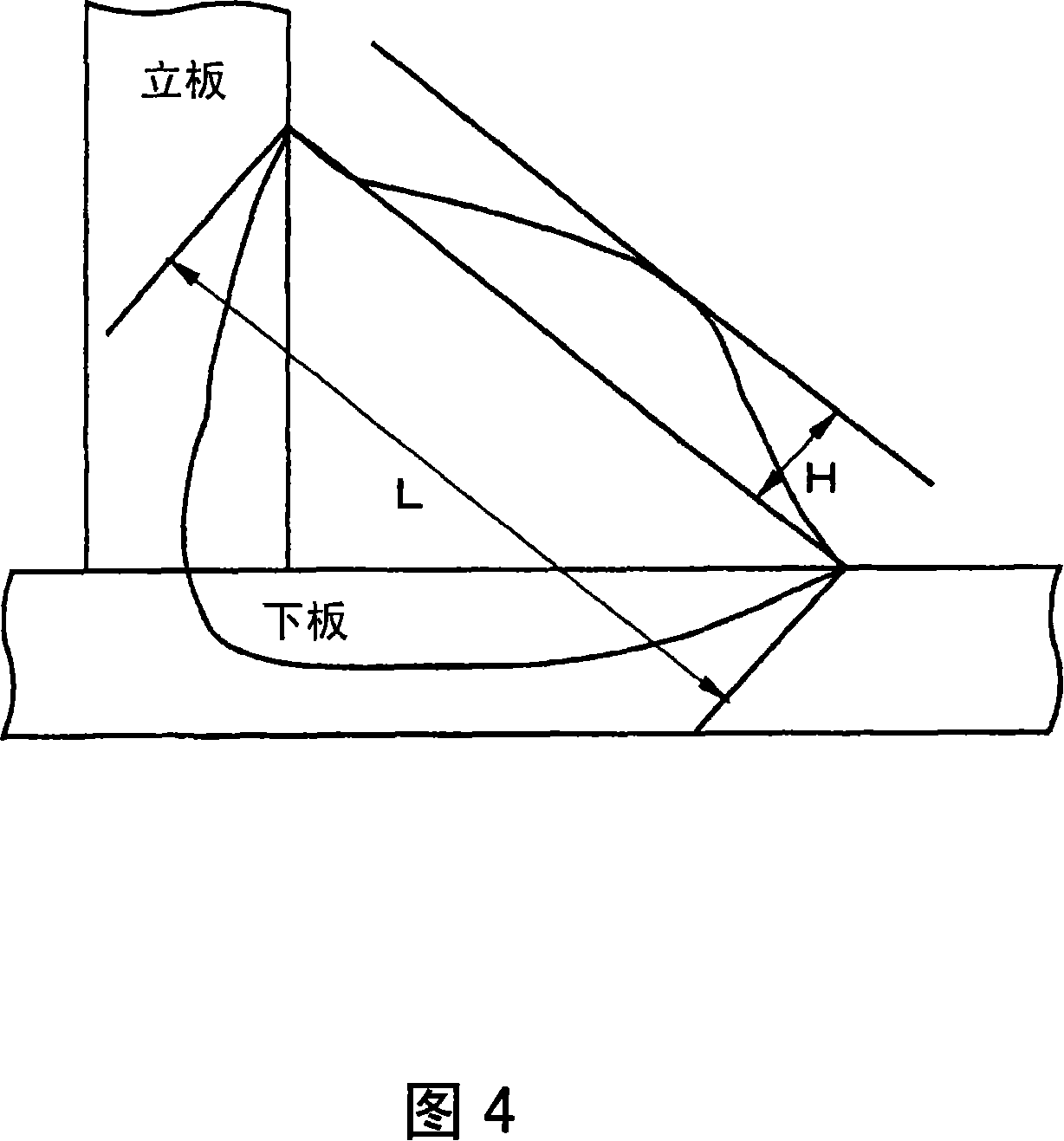

Multiple electrode gas protection arc welding method

ActiveCN101116926AImprove stabilityExcellent weld bead appearanceArc welding apparatusElectricityPositive current

The invention provides a method of multi-electrode gas shield arc welding, which comprises: taking an agent core for the gas shield arc welding as a beforeahead electrode and an afterahead electrode, setting the distance between the beforeahead electrode and the afterahead electrode of 15-50mm, inserting the stuffing welding wire in a melting bath disposed between the beforeahead electrode and the afterahead electrode, circulating an antipole current on the beforeahead electrode and the afterahead electrode, welding when circulating an positive current(welding wire cathode). At the time, the sum L+T of the beforeahead electrode melting speed L(g / min) and the afterahead electrode melting speed F(g / min) is 100-500g / min. The welding speed F(g / min) of the stuffing welding wire is 0.03(L+T) to 0.3(L+T). The method can provide a welding bead with a good appearance, prevent the deformed shape of the welding bead and increase the welding bath stability and prevent the deterioration of the pore resistance.

Owner:KOBE STEEL LTD

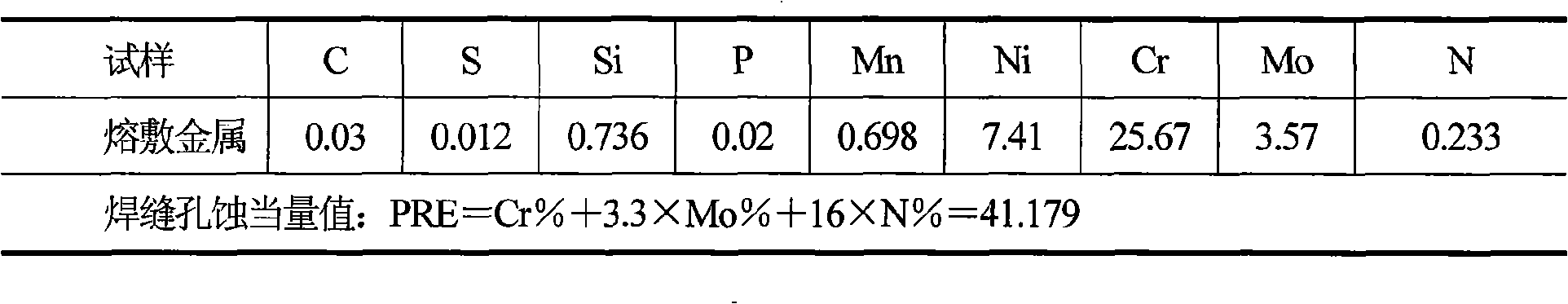

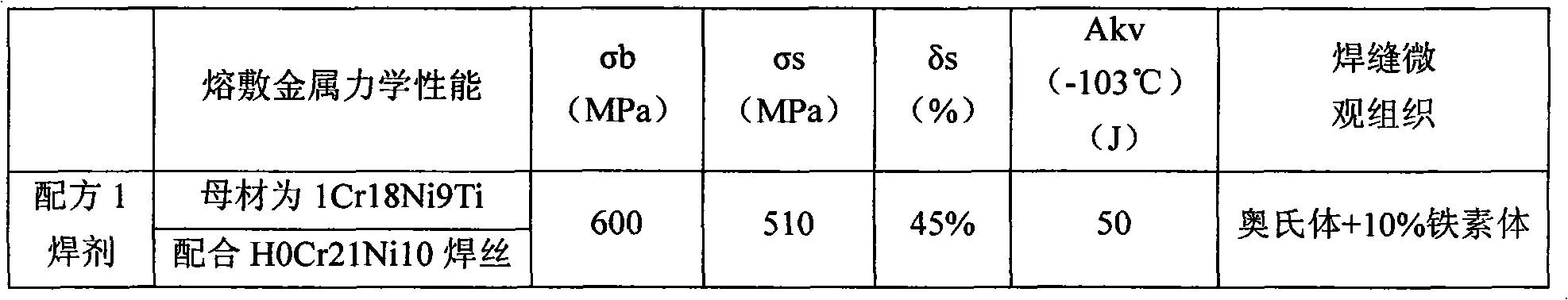

Acidic coating super two-phase stainless steel electrode

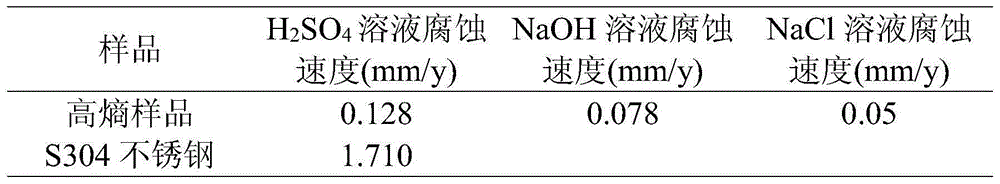

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

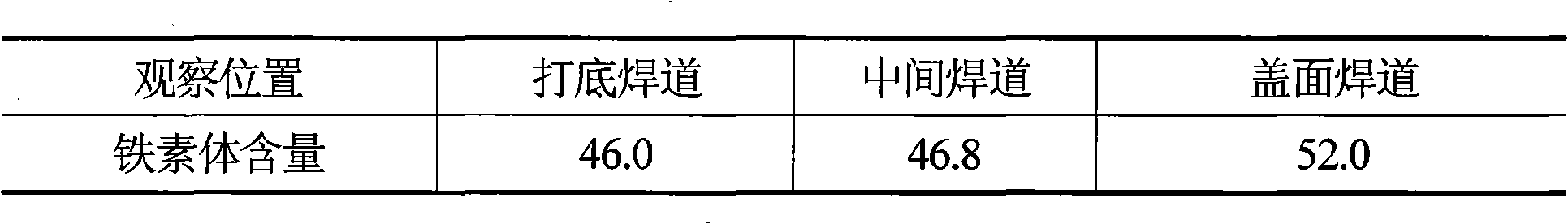

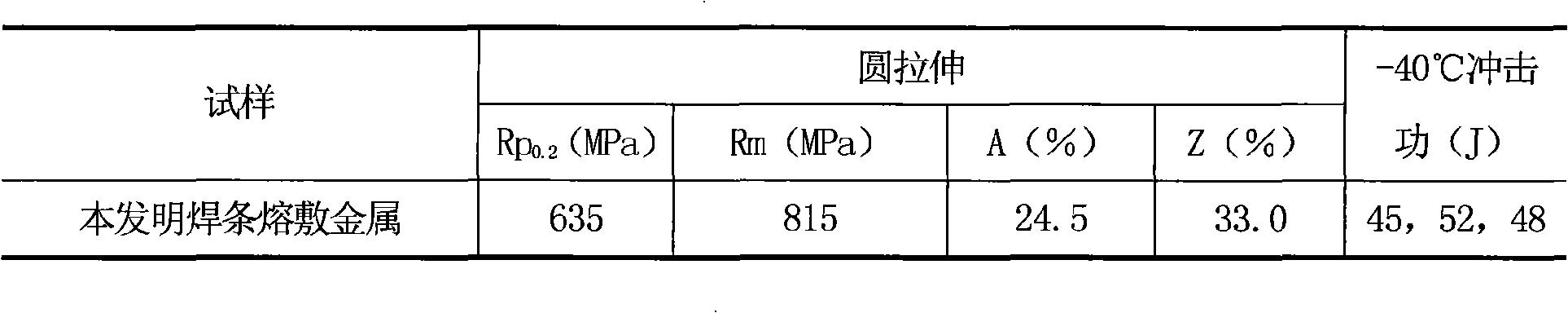

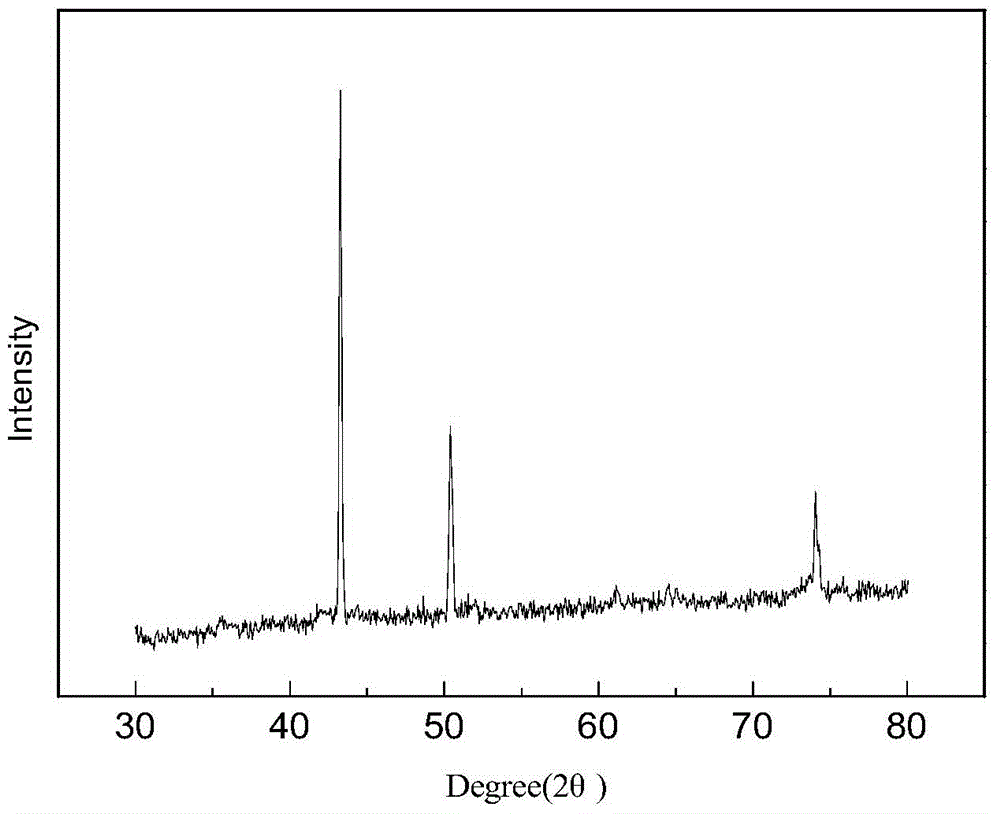

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Method for preparing high-entropy alloy coating

InactiveCN103556146AHigh hardnessImprove wear resistanceArc welding apparatusMetallic material coating processesHigh entropy alloysGas tungsten arc welding

The invention relates to the field of multi-principal element high-entropy alloy materials and in particular relates to a method for preparing a high-entropy alloy coating, belonging to the field of coating preparation. The method for preparing the high-entropy alloy coating comprises the following steps: pretreating a substrate, so that the surface of the substrate is clean and flat; preparing high-entropy alloy powder, uniformly mixing, and adding 3-6wt% of organic solution in the alloy powder; uniformly mixing the organic solution and the high-entropy alloy powder, and preparing into paste; uniformly coating the pasty alloy powder on the treated substrate, wherein the thickness of the coating layer is 0.3-6mm; baking the treated coating layer and substrate in an oven at the temperature of 55-80 DEG C for 20-30 hours; cladding the coating layer on the surface of the substrate through gas tungsten arc welding. According to the method for preparing the high-entropy alloy coating, the high-entropy alloy coating with the thickness of 0.3-6mm can be prepared, a heat affected zone to the substrate in the preparation process is small, and the coating is uniform in distribution and firmly bound to the base material.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

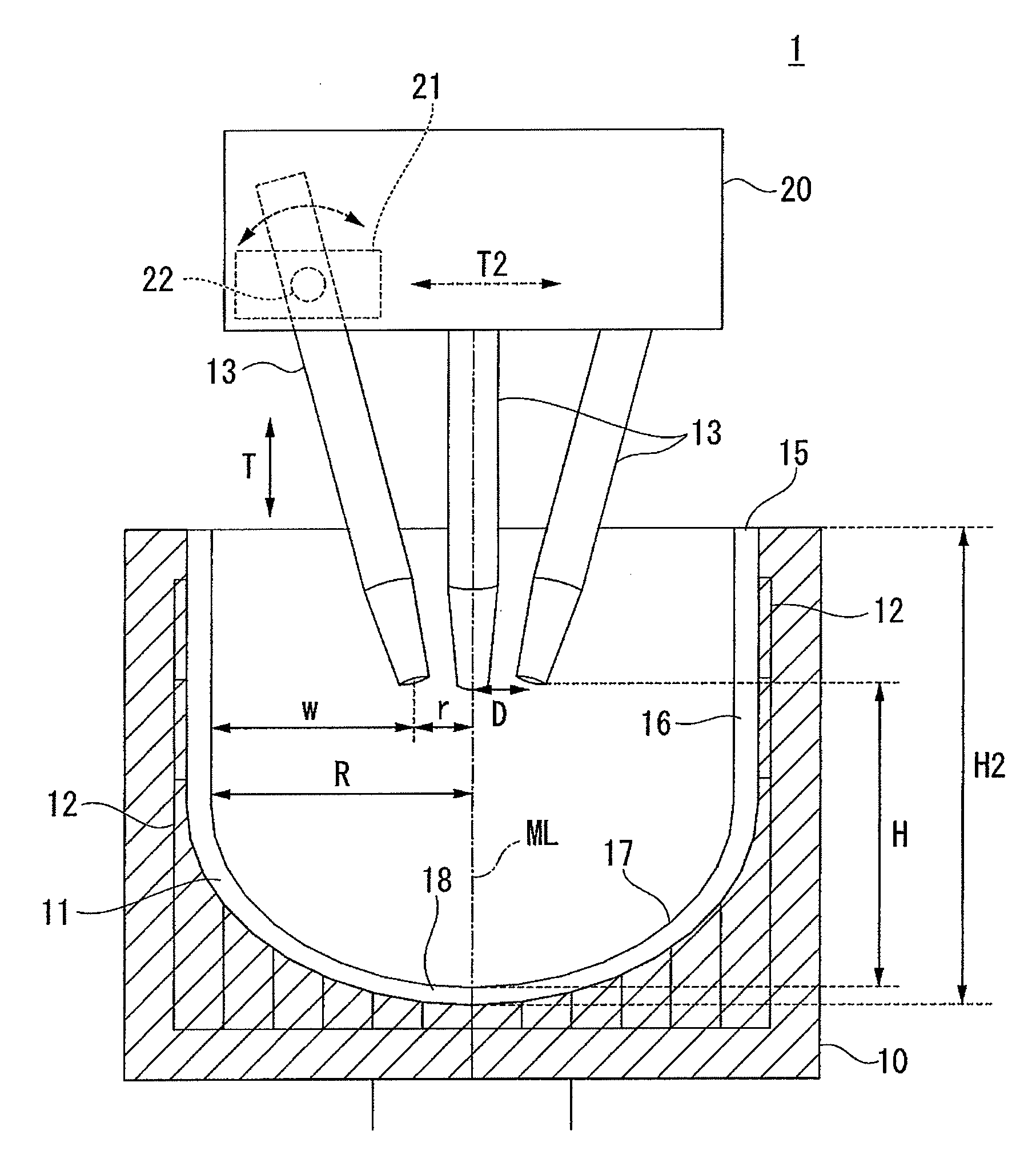

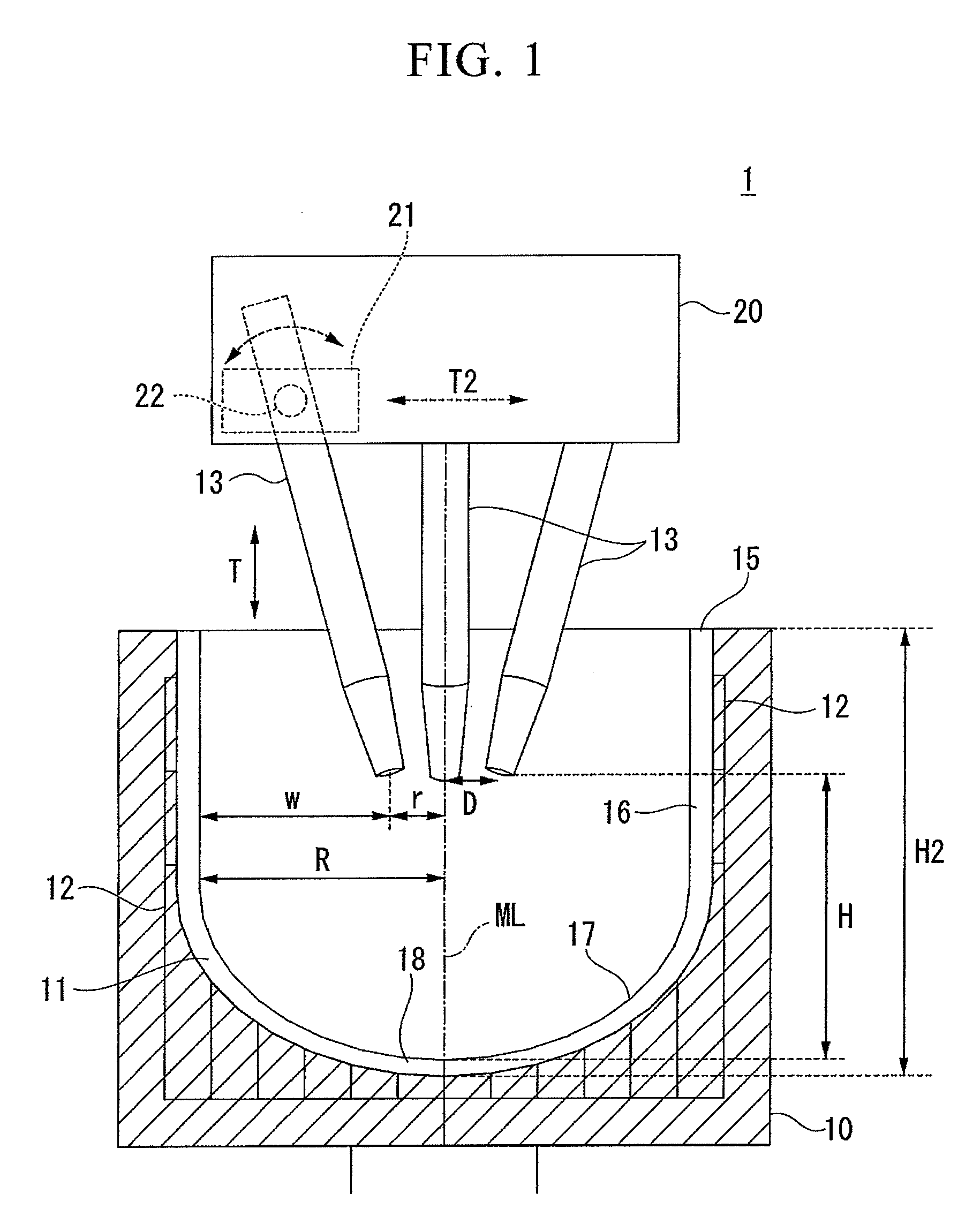

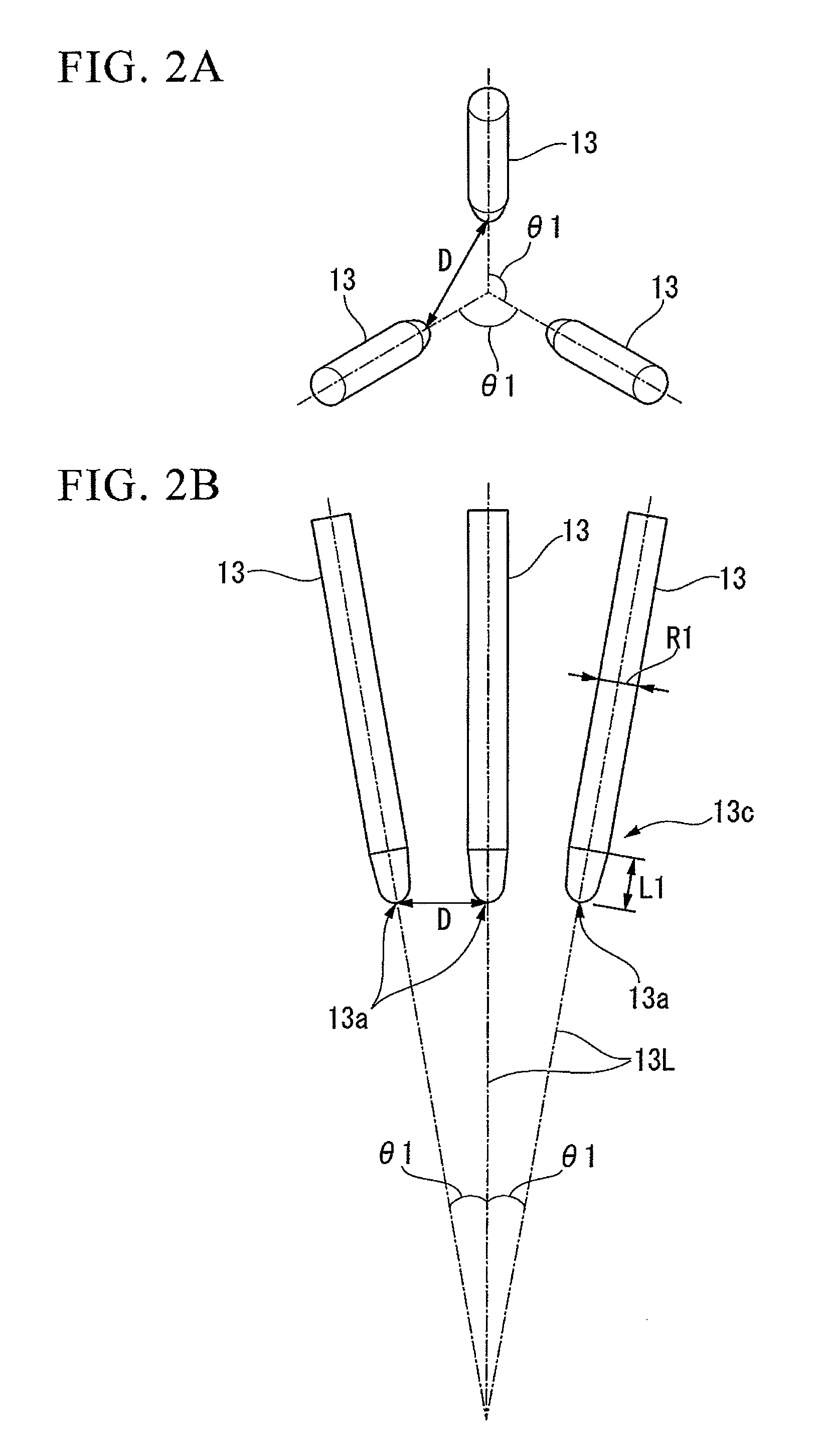

Method and apparatus for manufacturing fused silica crucible, and the fused silica crucible

ActiveUS20100071613A1Good transparent glass layerAvoid overall overheatingAfter-treatment apparatusPolycrystalline material growthCrucibleMaterials science

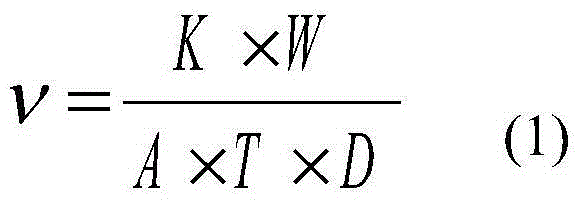

A method of manufacturing a fused silica crucible by heating and melting a vitreous silica powder compact shaped into a mold using arc discharge of electrodes arranged around a rotation shaft of the mold, includes the steps of: arranging the electrodes in a ring shape, and setting a ratio W / R of a horizontal distance W between the electrode front end and the surface of the vitreous silica powder compact to a vitreous silica powder compact opening radius R, for at least a predetermined time during arc heating, to be in the range of 0.002 to 0.98.

Owner:SUMCO CORP

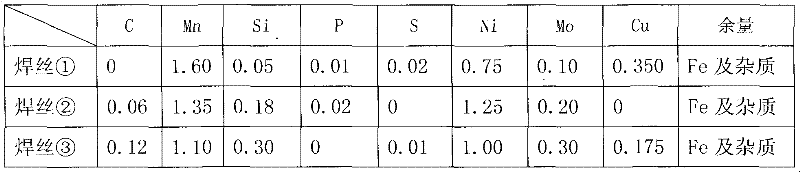

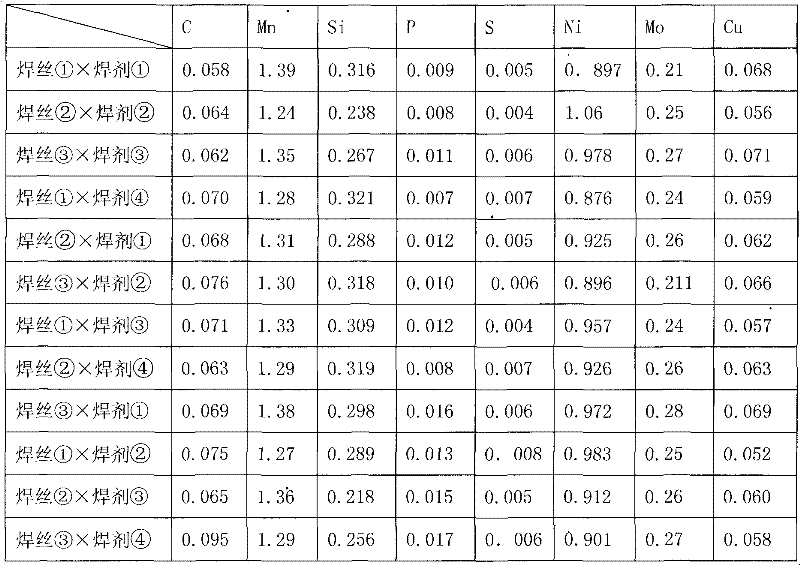

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

E309L stainless steel lengthened welding electrode capable of being used for large-current welding

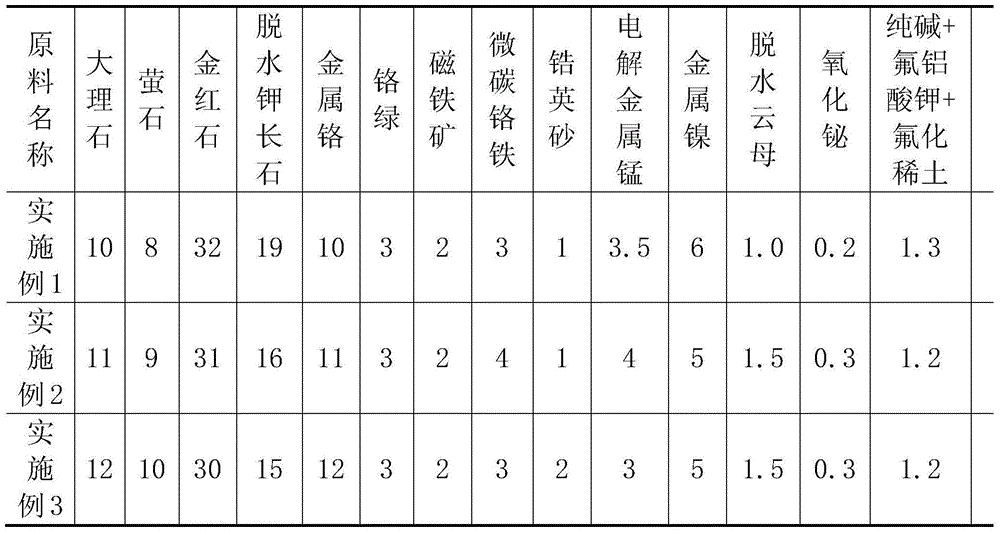

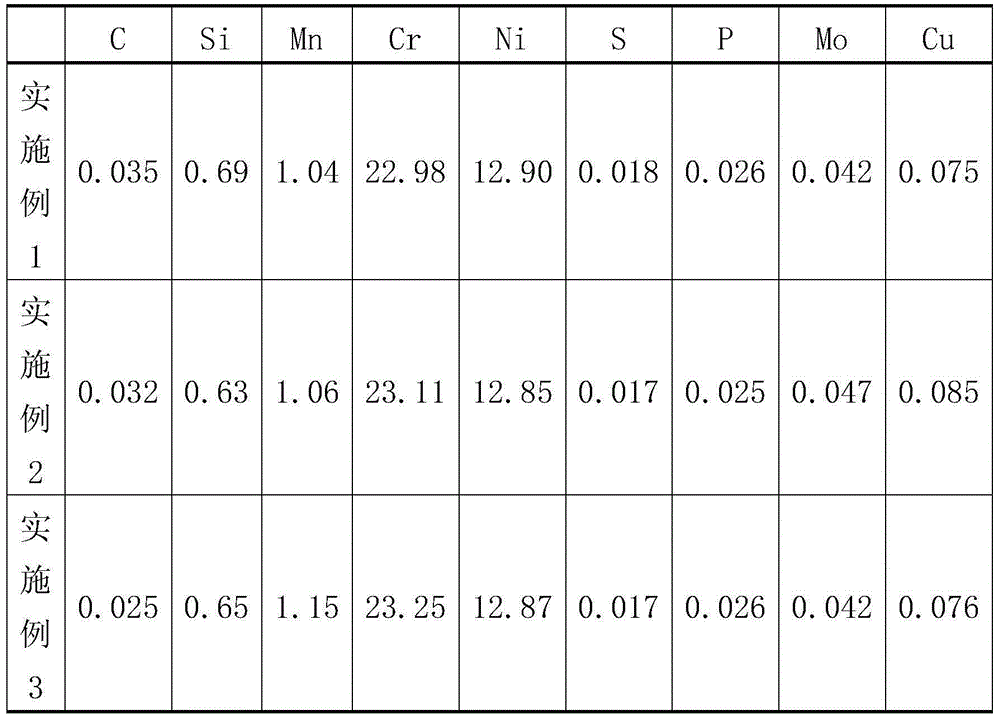

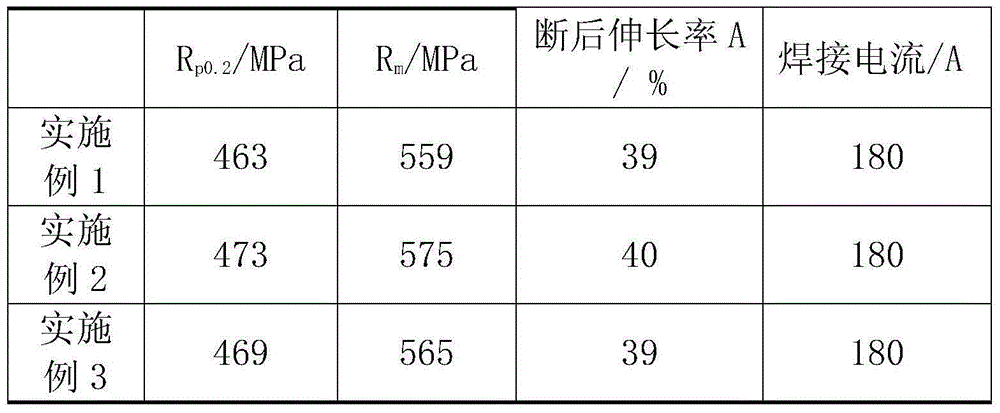

ActiveCN105215580ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPotassiumRare earth

Provided is an E309L stainless steel lengthened welding electrode capable of being used for large-current welding. A coating contains marble, fluorite, rutile, dehydrated potassium feldspar, dehydrated mica, bismuth oxide, chrome green, magnetite, sodium carbonate, micro-carbon ferro chrome, electrolytic manganese metal, zircon sand, potassium fluoroaluminate, rare earth fluoride, chromium metal and metallic nickel, blending and even stirring are conducted according to the ratio of the coating, 15-20% of sodapotash water glass is added and evenly stirred according to the total weight of the coating, the coating and an ER308L welding wire are put in an oil pressure type welding electrode extrusion press to produce and prepare the lengthened welding electrode, and no coating cracks or flushing can happen when the large current is 170-180 A and the welding core length is 450 mm; though an ER308L welding core is adopted, the cladding metal chemical components meet the requirement of E309L chemical components through the coating transition alloy method, and therefore the welding electrode has good welding process performance and is stable in electric arc, convenient to operate, good in weld appearance during welding, and sediments are easily separated.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Sintered flux for stainless steel

InactiveCN101585123AEasy to remove slagArc stabilizationWelding/cutting media/materialsSoldering mediaSlagPotassium silicate

The present invention provides a sintered flux for stainless steel. The slag system of the flux is CaF2-Al2O3. The invention is characterized in that the oxidability and the sensibility of the gas hole are small. The stainless steel structure and the stainless steel overlaying welding can be welded when the sintered flux is matched with the corresponding welding stick. The invention is characterized in that the sintered flux comprises the following components: more than 40% by weight of calcium fluoride (CaF2), and furthermore the summation of the calcium fluoride and aluminum oxide (CaF2+Al2O3) is larger than or equal to 70% by weight; other components as follows: smaller than or equal to 5% by weight of CaCO3, 1-3% by weight of CrO3, smaller than 4% by weight of NaAlF6, 1-3% by weight of rare earth fluoride, 3-10% by weight of SiO2, 3-10% by weight of MnO, 1-3% by weight of TiO2, 5-10% by weight of MgO, and 1-3% of iron alloy; and bonding agent of sodium potassium silicate.

Owner:THE LINCOLN ELECTRIC HELI ZHENGZHOU WELDING MATERIALS

Gas-shielded overlaying flux cored soldering wire for repairing hot-forging mould

ActiveCN102029482ASimple welding processGood welding wire crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceFerrosilicon

The invention discloses a gas-shielded overlaying flux cored soldering wire for repairing a hot-forging mould, which is manufactured by taking SPCC-SD cold-rolling low-carbon steel belts as raw materials of a soldering wire and utilizing a conventional flux cored transient alloy way, a universal flux cored standard and a flux cored soldering wire manufacturing technique. The soldering wire flux core contains fluoride, calcium carbonate, feldspar, magnesia and alloy powder according to a proportion, wherein the fluoride comprises calcium fluoride, sodium fluoride and barium fluoride, and the alloy powder contains iron powder, high-carbon ferrochrome, electrolytic manganese, ferrosilicon, ferromolybdenum, ferrovanadium, nickel powder, tungsten powder and cobalt powder. The invention has the following beneficial effects: because the gas-shielded overlaying flux cored soldering wire takes CO2 or a gas mixture with volume percentage ratio of 80% Ar and 20% CO2 as the protective gas, the gas-shielded overlaying flux cored soldering wire has the advantages of great soldering technique, stable electric arc, less splash, easy deslagging, good crack resistance, great high-temperature hardness and thermal fatigue resistance, continuous soldering and improvement on production efficiency.

Owner:TIANJIN YONGCHANG WELDING WIRES

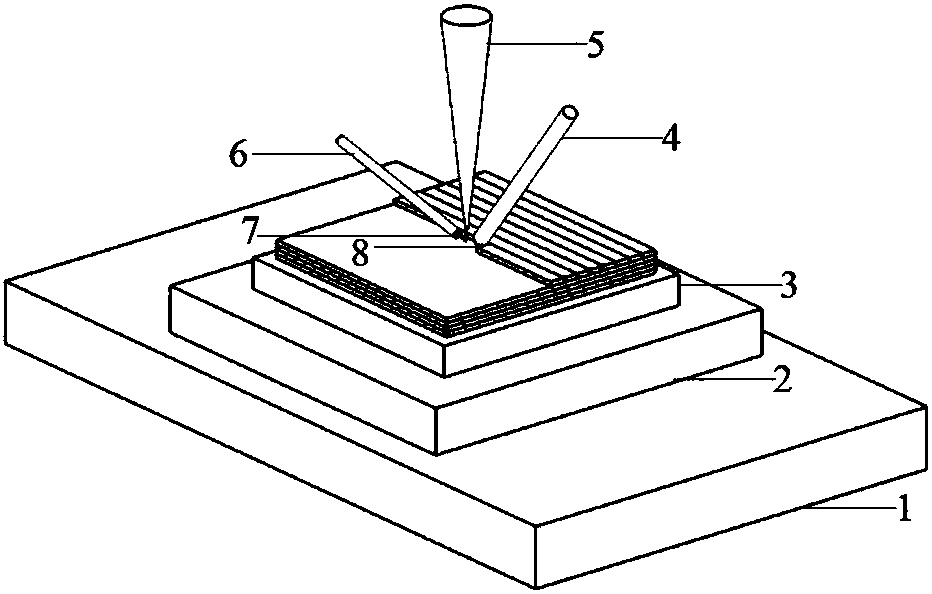

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

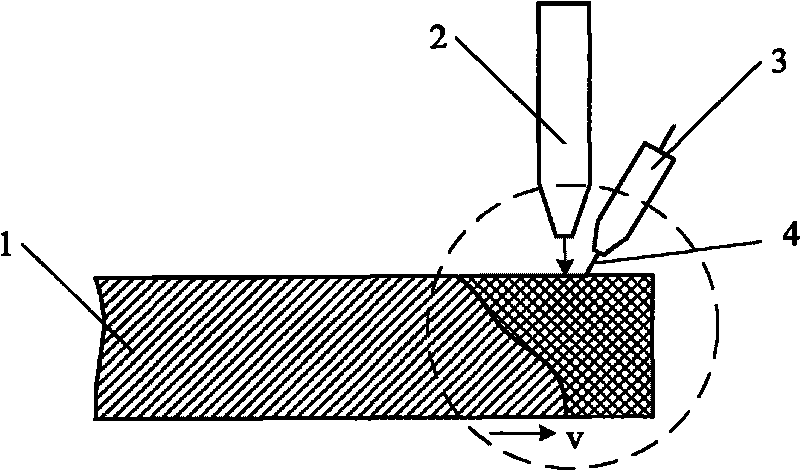

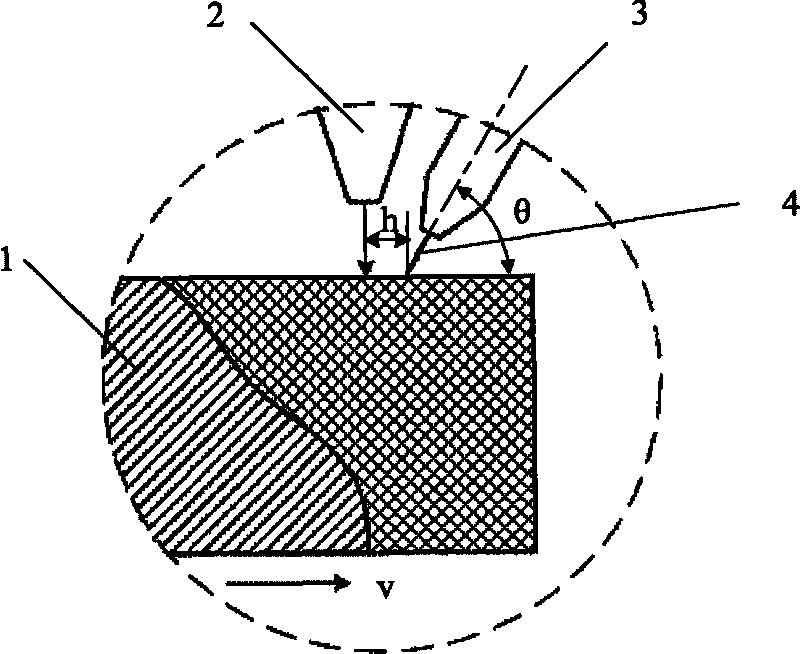

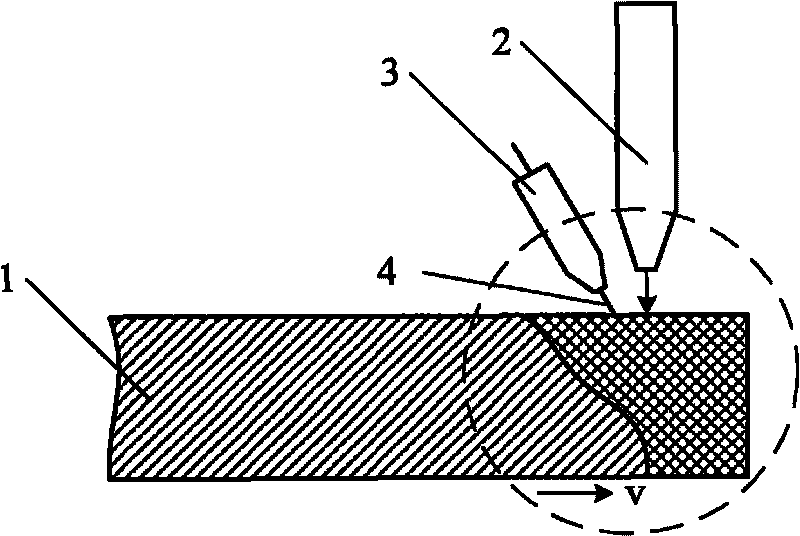

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

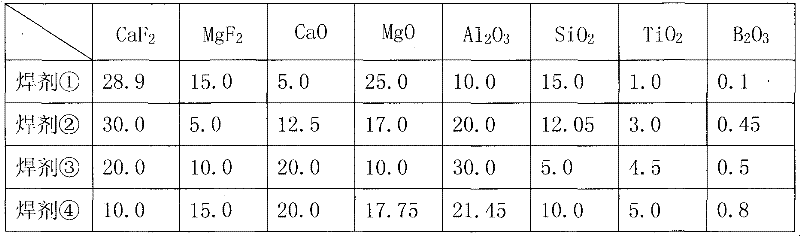

Sintered flux utilized in automatic submerged arc welding with multiple wires in high speed

InactiveCN1415454AGood composition uniformityImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaWeld seamSoldering process

A sintering welding wire for the multi-wire high-speed autoamtic hidden arc welding contains MgO (19-28 mass%), CaF2 (12-18%), ZrO2 (8-15%), Al2O3 (18-24%), SiO2 (17-25%), CaO (7-13%), RE (0-7%), MnO (0-5%), TiO2 (0-5%), Na2O+K2O (2-5%), S (0-0.05%), and P (0-0.06%). Its advantages are stable arc, beautiful welded seam, and high welding speed (1.5-2 m / m).

Owner:YANSHAN UNIV

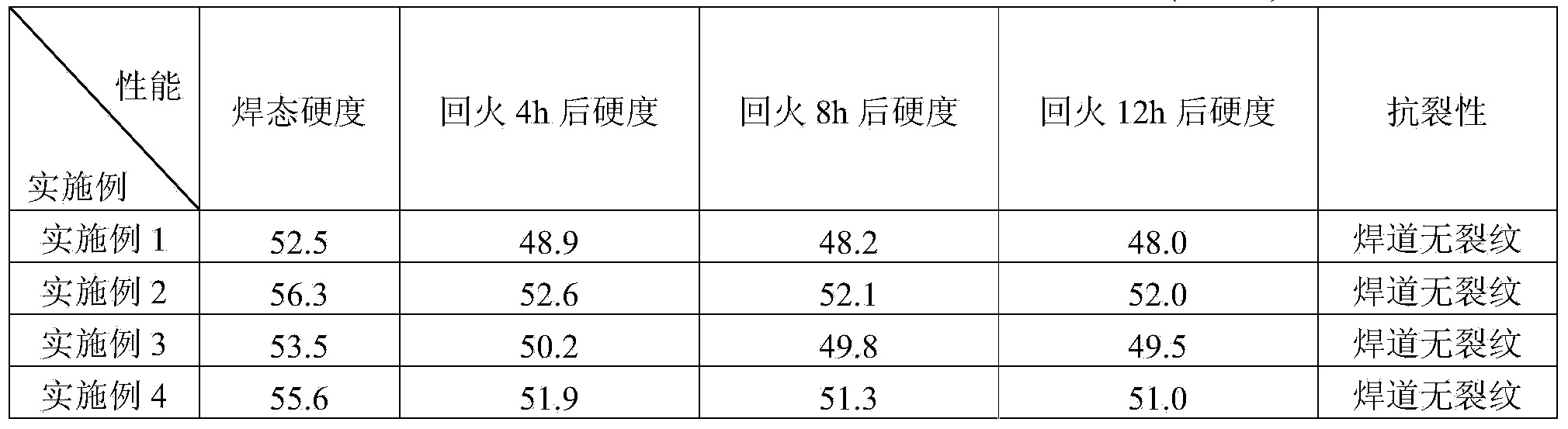

Surfacing flux-cored wire used for repairing hot-forging die

InactiveCN103862194AImprove crack resistanceNo crackArc welding apparatusWelding/cutting media/materialsCrack resistanceElectrolysis

The invention discloses a surfacing flux-cored wire used for repairing a hot-forging die and belongs to the technical field of welding materials. Flux-cored powder is wrapped by adopting a carbon steel belt, and comprises the following substances in mass percentage content: 2-6 percent of sodium fluoride, 5-8 percent of calcium fluoride, 3-5.5 percent of rutile, 1-5 percent of quartz, 4.3-13.2 percent of high-carbon ferrochrome, 24.8-38.3 percent of pure chromium powder, 6-11.3 percent of nickel powder, 1.5-3.5 percent of Fe-W powder, 2.5-5.1 percent of electrolytic manganese, 14.7-27.3 percent of Fe-Mo powder, 3.6-6.1 percent of ferrosilicon powder, 0.2-1.4 percent of ferrovanadium powder and the balance of reduced iron powder. The filling rate of the flux-cored wire is 20-35 percent. Compared with traditional materials, the surfacing flux-cored wire disclosed by the invention has the advantages that (1) the thermal stability and the thermal fatigue resistance are very good, and the hardness range is 48-52HRC; (2) surfacing metal is high in crack resistance, so that preheating before welding or immediate heat treatment after welding is not needed; (3) the surfacing manufacturability is good, and the appearance of a weld is attractive.

Owner:BEIJING UNIV OF TECH

Welding rod for welding of martensite heat-resistant steel

ActiveCN106346167AImprove mechanical propertiesHigh strengthWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a welding rod for welding of martensite heat-resistant steel and belongs to the technical field of welding materials. The welding rod consists of a core wire and a coating, wherein the core wire is prepared from components in percentage by weight as follows: 0.07%-0.10% of C, less than or equal to 0.3% of Si, 0.3%-0.7% of Mn, less than or equal to 0.004% of P, less than or equal to 0.002% of S, 8.5%-9.5% of Cr, 2.8%-3.3% of W, 2.8%-3.5% of Co, 0.04%-0.08% of Nb, 0.15%-0.25% of V, 0.8%-1.0% of Cu, 0.007%-0.011% of N, 0.011%-0.020% of B and the balance of Fe; the coating is prepared from components as follows: 30%-45% of marble, 18%-25% of fluorite, 5%-10% of rutile, 10%-16% of barium carbonate, 5%-10% of ferrotitanium, 1.5%-3% of electrolytic manganese, 5%-10% of iron powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxymethyl cellulose and 0.8%-3% of chromium metal powder. The welding rod has the advantages that the arc is stable during welding, few splashes are caused, the all-position operability is good, the slag detachability is good, formed welds are attractive in appearance, and deposited metal after welding has high strength and high toughness close to that of a parent metal, higher endurance strength and excellent crack sensitivity.

Owner:CENT IRON & STEEL RES INST

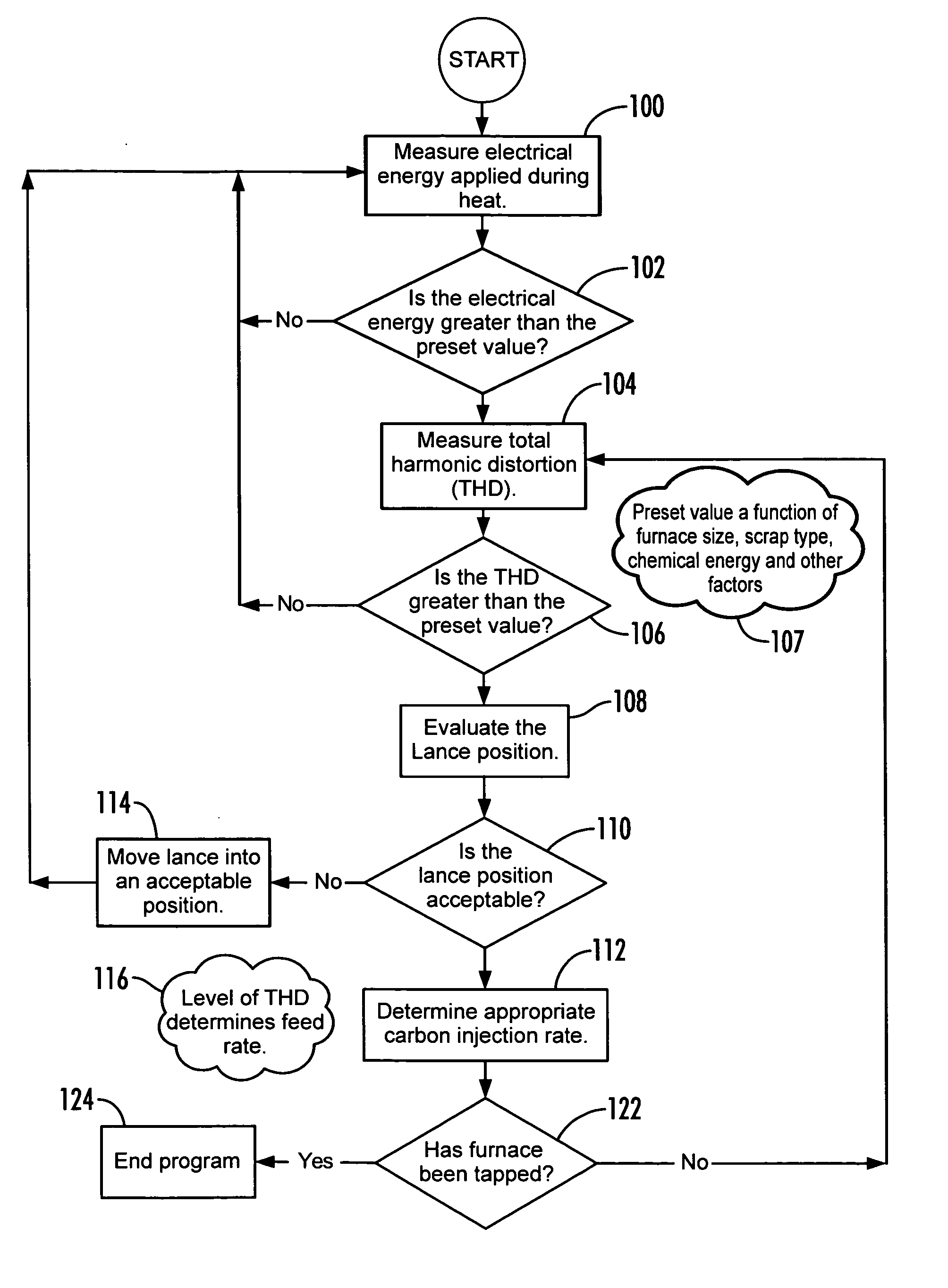

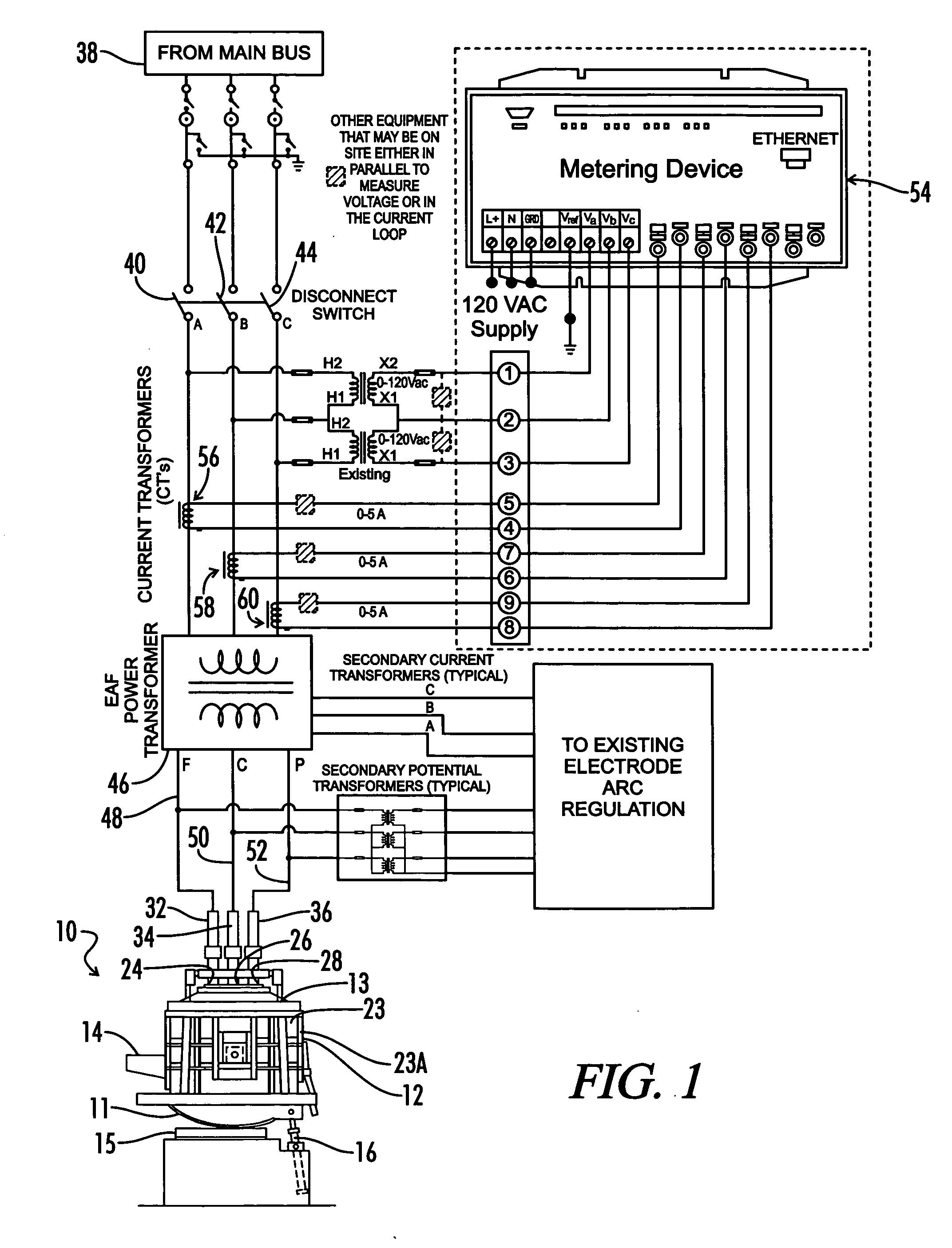

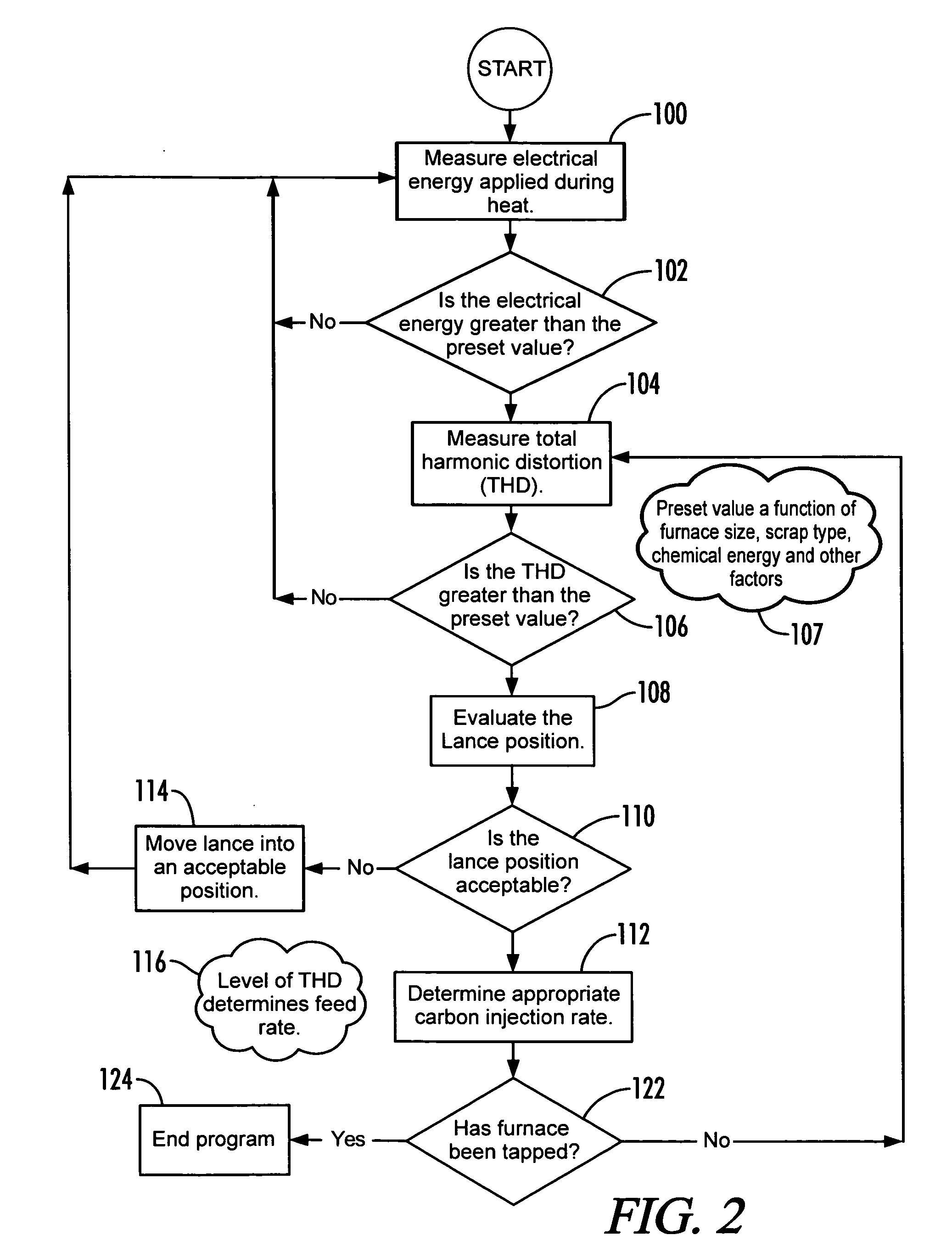

Method for controlling foaming of slag in an electric arc furnace

InactiveUS20070133651A1Arc stabilizationSimple methodSteel manufacturing process aspectsIncreasing energy efficiencyElectric arc furnaceFoaming agent

A method for controlling the foaming of slag in an electric arc furnace is disclosed. The furnace comprises at least one electrode column. Current is applied to the electrode column, causing an arc to form between the tip of the electrode column and the scrap, melting the scrap. Impurities in the molten scrap metal rise to the surface forming slag. A meter determines the total harmonic distortion associated with the system. If the total harmonic distortion is greater than a predetermined set point, and the scrap metal is sufficiently molten, then a foaming agent is added thereto.

Owner:GRAFTECH INT HLDG INC

Supercritical ferrite and heat-resistant steel matched electrode and production method thereof

ActiveCN103071946AReasonable tensile strengthReasonable shock valueWelding/cutting media/materialsSoldering mediaElectrolysisNiobium

The invention discloses a supercritical ferrite and heat-resistant steel matched electrode, which consists of a core wire and coating. The coating comprises the following components by mass percentage: 28-40 percent of marble, 18-28 percent of fluorite, 1.5-4 percent electrolytic manganese, 2-5 percent of ferrosilicon, 4-10 percent of silica powder, 20-26 percent of chromium metal, 1-1.8 percent of nickel powder, 4-5 percent of ferromolybdenum, 0.4-0.8 percent of ferrocolumbium, 0.2-0.6 percent of amorphous graphite, 3-8 percent of ferrotitanium, 0.4-0.8 percent of soda ash, 0.4-0.8 percent of CMC, 1-1.8 percent of ferrovanadium and 0.6-1.5 percent of ferrochrome nitride. The matched electrode provided by the invention is used for welding supercritical steam turbine ZG1Cr10MoVNbN steel with T91 / P91 pipe heat-resistant steel. Welds after welding have excellent performances such as higher strength, high toughness and better 100-thousand-hour endurance strength similar to the performance of bodies.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Self-protecting flux-cored wire for overlaying welding and use thereof

ActiveCN101081467AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaChromium carbideFerrosilicon

The present invention belongs to the field of composite material producing technology, and is especially one kind of self-protecting flux cored welding wire for build-up welding and its use. The flux core of the welding wire is mixture of alloy powder and mineral powder, and consists of chromium carbide 50-80 wt%, Mn 4-10 wt%, 75# ferrosilicon 2-6 wt%, Zr-Si-Fe 1-3 wt%, graphite 3-6 wt%, dolomite 1-3 wt%, natural rutile 0.1-3 wt%, Mo 1-6 wt%, Nb 3-6 wt%, V 2-8 wt%, W 0.1-2 wt%, Na2SiF6 0.1-3 wt%, ZrO2 1-3 wt%, and NaF0.1-2 wt%. The self-protecting flux cored welding wire for build-up welding has no need of adding protecting gas and flux, stable arc, fewer spattering and other advantages. It is applied mainly for build-up welding of grinding roll, grinding disc, antiwear plate, etc.

Owner:李淑华 +1

Metal powder type flux-cored wire used for welding high-impact-toughness steel

ActiveCN102489902AImprove impact toughnessImprove performanceWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention relates to a metal powder type gas shield flux-cored wire used for welding high-impact-toughness steel. The metal powder type gas shield flux-cored wire comprises 0.01-0.1wt% of C, 0.1-0.4wt% of Mn, 0.01-0.03wt% of Si, 0.005-0.015wt% of S, 0.005-0.015wt% of P and balance of ferric low carbon steel skin as well as flux accounting for 14-25% of the total weight of the metal powder type gas shield flux-cored wire, wherein the flux comprises the following components in percent by the total weight of the metal powder type gas shield flux-cored wire: 1.2-4.0% of middle-carbon ferromanganese, 0.20-2.0% of ferrosilicon powder, 0.05-0.5% of magnesium powder, 0.1-2.0% of molybdenum ferrous powder, 1-2% of nickel powder, 0.05-0.2% of fused magnesia, 0.01-0.3% of fluoride and 7-14% of ferrous powder; and all the components are blended and then are placed on a low-carbon steel thin steel strip to be rolled into strips and be drawn into wires. The metal powder type gas shield flux-cored wire provided by the invention has the characteristics that almost no slag is left on a deposited metal after welding, continuous multi-layer welding without removing slag can be carried out, welding speed is fast and efficiency is high, welding technological property is good, electric arc is stable, splashing is less and moulding is beautiful, welding low temperature toughness is high and vertical down welding can be realized by virtue of short circuit transition.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

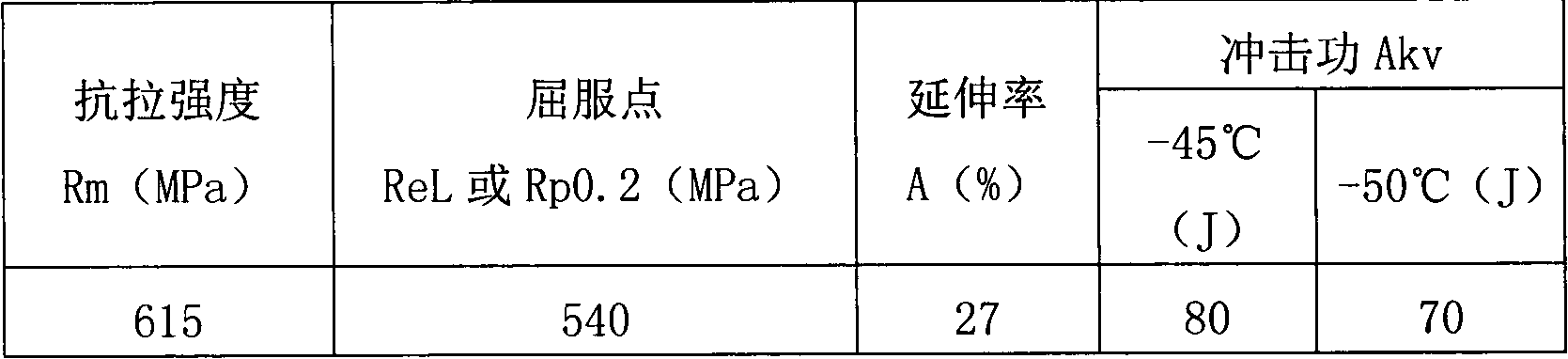

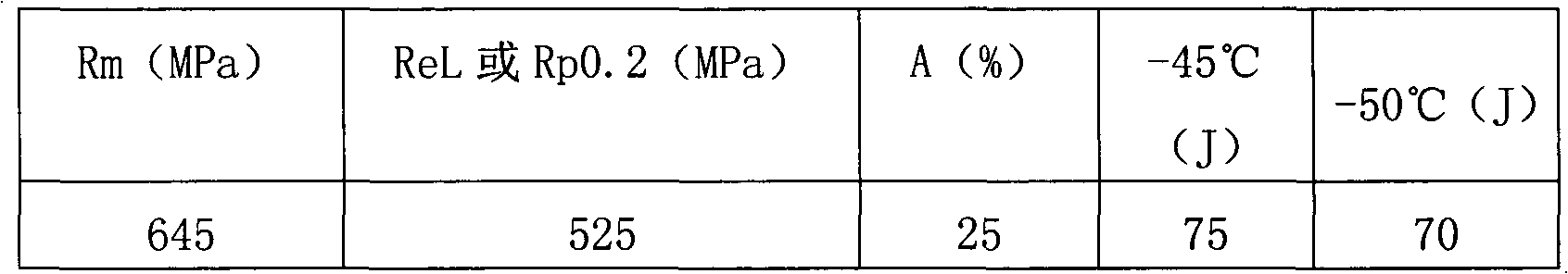

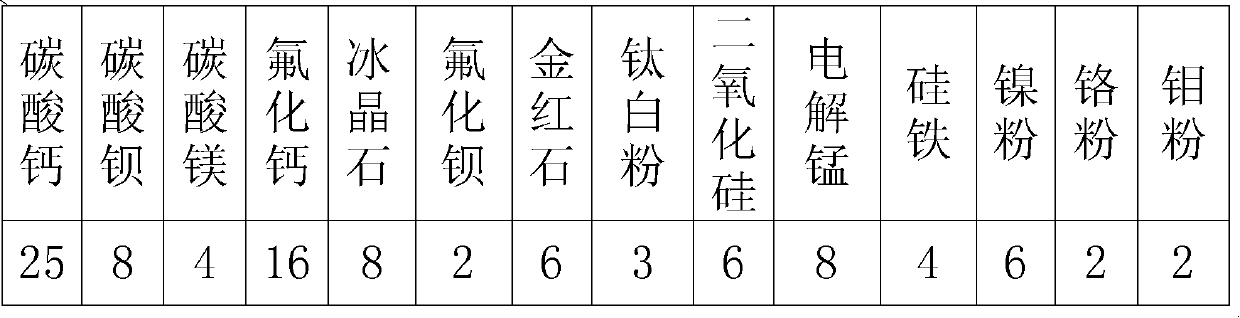

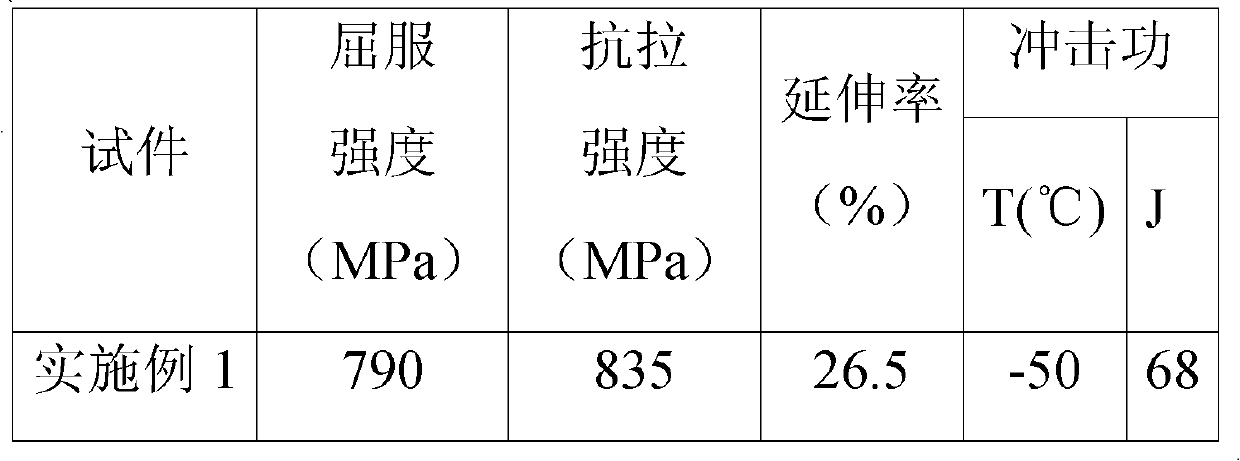

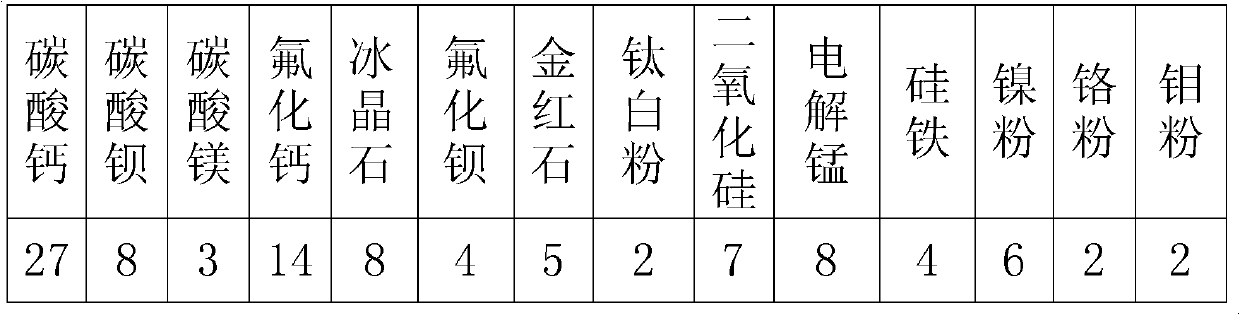

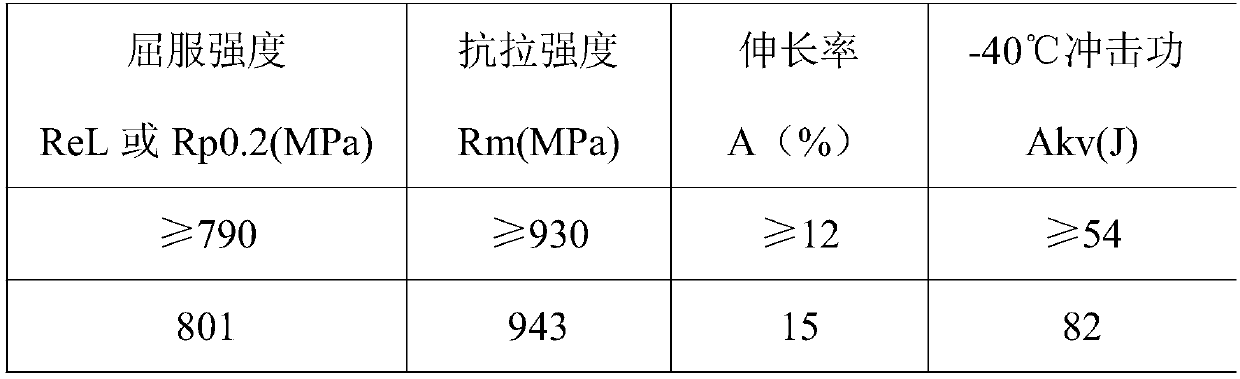

High-strength and high-toughness low alloy steel electric welding rod

ActiveCN102554500AExcellent welding performance in all positionsArc stabilizationWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention publishes a high-strength and high-toughness low alloy steel electric welding rod, which consists of a core and a covering, wherein the covering is coated on the outer wall of the core, and the weight factor of the covering in the total weight of the welding rod is 0.4-0.5; the core comprises the following components in percentage by weight: 0.01-0.08 percent of C, 0.10-0.25 percent of Si, 0.30-0.55 percent of Mn, 0.005-0.20 percent of Cr, 0.005-0.30 percent of Ni, 0.007-0.012 percent of P, 0.007-0.012 percent of S and the balance of Fe; and the covering is of a basic slag system and comprises the following components in percentage by weight: 20-30 percent of calcium carbonate, 1-5 percent of magnesium carbonate, 5-10 percent of barium carbonate, 10-20 percent of calcium fluoride, 1-8 percent of cryolite, 1-5 percent of barium fluoride, 3-8 percent of rutile, 1-5 percent of titanium white, 2-10 percent of silicon dioxide, 5-10 percent of electrolytic manganese, 2-5 percent of ferrosilicon, 4-8 percent of nickel powder, 1-3 percent of chromium powder and 1-3 percent of molybdenum powder. The welding rod is adopted for welding; the strength of a welded joint is 800 MPa; the impact energy at -50 DEG C is greater than 60 J; the diffusible hydrogen content is 2-3 ml / 100 g; and the electric welding rod is mainly applied to welding of 80 kg of low alloy steel structure.

Owner:KUSN GINTUNE WELDING

Method for manufacturing a solid aluminum alloy structure through wire filling type additive

ActiveCN108161229AImprove organizationRefined dimensionsArc welding apparatusLaser beam welding apparatusInter layerLap joint

The invention provides a method for manufacturing a solid aluminum alloy structure through a wire filling type additive, and belongs to the field of additive manufacturing. The method aims to solve the problems in the existing aluminum alloy laser filler wire additive manufacturing and electric arc additive manufacturing that the reflectivity of the aluminum alloy to the laser is high, the formingquality is poor caused by unstable electric arc, and the structure of a forming part is large caused by large heat input and the like. A laser-TIG composite heat source is adopted, and the laser andthe electric arc interact, so that on one hand, the heat input can be reduced, the structure of the forming part is refined, and the strength is improved; and on the other hand, the laser can stabilize the electric arc, so that the electric arc is more stable in the multi-layer multi-channel forming process, and the lap joint effect is optimized. According to the method, arc currents and inter-layer arc currents between adjacent welding beads are adjusted, so that the heat input in the continuous forming process is reduced, the appearance size of the obtained forming part is stable, crystal grains are refined, and the forming efficiency is remarkably improved compared with the control interlayer temperature and the interlayer residence time.

Owner:DALIAN UNIV OF TECH

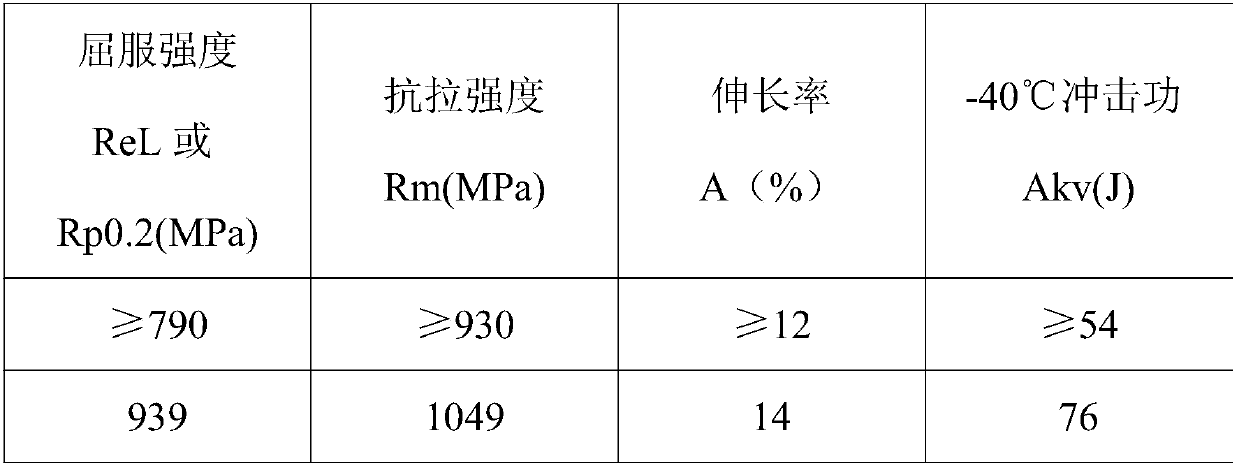

High-strength steel welding rod for hydroelectric engineering and preparation method for high-strength steel welding rod

ActiveCN107931888AIncrease temperatureImprove deformationWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a high-strength steel welding rod for hydroelectric engineering and a preparation method for the high-strength steel welding rod. The high-strength steel welding rod comprisesa welding core and a coating coated on the surface of the welding core, the coating comprises the following ingredients of, by weight, 9.5-10.5 parts of marble, 4.25-5 parts of fluorite, 1.5-2 parts of rutile, 1.5-2 parts of silica powder, 1-1.5 parts of manganese metal, 0.8-1.05 parts of silicon iron, 0.6-0.675 part of ferromolybdenum, 0.025-0.05 part of graphite, 0.05-0.50 part of chromium metal, 0.625-0.675 part of iron powder, 0.1-0.15 part of sodium carbonate, 0.1-0.15 part of sodium alga acid, 0.1-0.15 part of CMC, 0.05-0.075 part of ferroboron and 1.7-1.9 parts of nickel powder. By means of the high-strength steel welding rod for hydroelectric engineering and the preparation method for the high-strength steel welding rod, when welding is performed, an electric arc is stable, spatteris small, slag-removal is well performed, molding is good, whole position operation performance is good, vertical welding position strength in welding deposited metal reaches standard requirements, and the impact toughness of the deposited metal is larger than or equal to 47 J at the temperature of -40 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Low-hydrogen super diphasic stainless steel electrode

InactiveCN101367161AArc stabilizationWell formed weldWelding/cutting media/materialsSoldering mediaPotassium feldsparFerrosilicon

The invention discloses a low-hydrogen type super duplex stainless steel welding rod. The prior duplex stainless steel wire is adopted as a welding core. The coating of the welding rod comprises the compositions in percentage by weight: 35 to 45 percent of marble, 20 to 33 percent of fluorite, 0 to 5 percent of titanium pigment, 2 to 5 percent of potassium feldspar, 0 to 2 percent of sodium carbonate, 5 to 15 percent of iron alloy, 10 to 20 percent of metal powder, and 0 to 2 percent of CrN iron, wherein the iron alloy consists of ferrosilicon and ferromolybdenum under the condition of constant total content, and the metal powder consists of manganese metal, chromium metal, and nickel powder under the condition of the constant total content. After raw materials of the compositions of the coating are mixed evenly, pure sodium water glass with certain Baume concentration is added, and the pressing of the welding rod is performed on welding rod production equipment. The use of the welding rod can satisfy the welding need of super duplex stainless steel in the national engineering construction, the welded welding seam has excellent mechanical property and good corrosion resistance, the tensile strength can reach 800MPa, and the welding rod has good low-temperature toughness.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

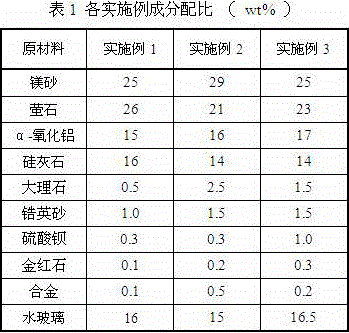

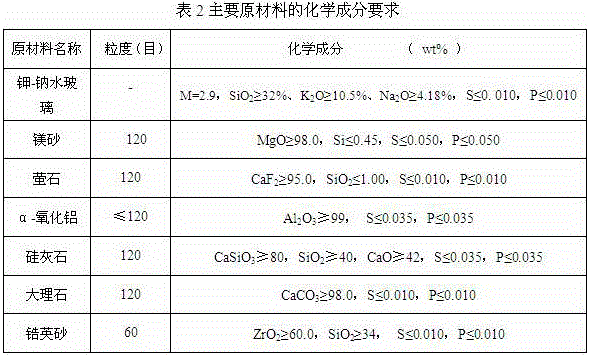

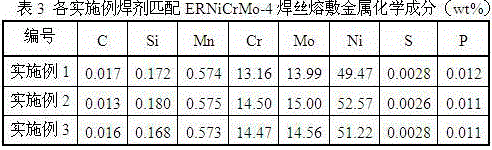

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

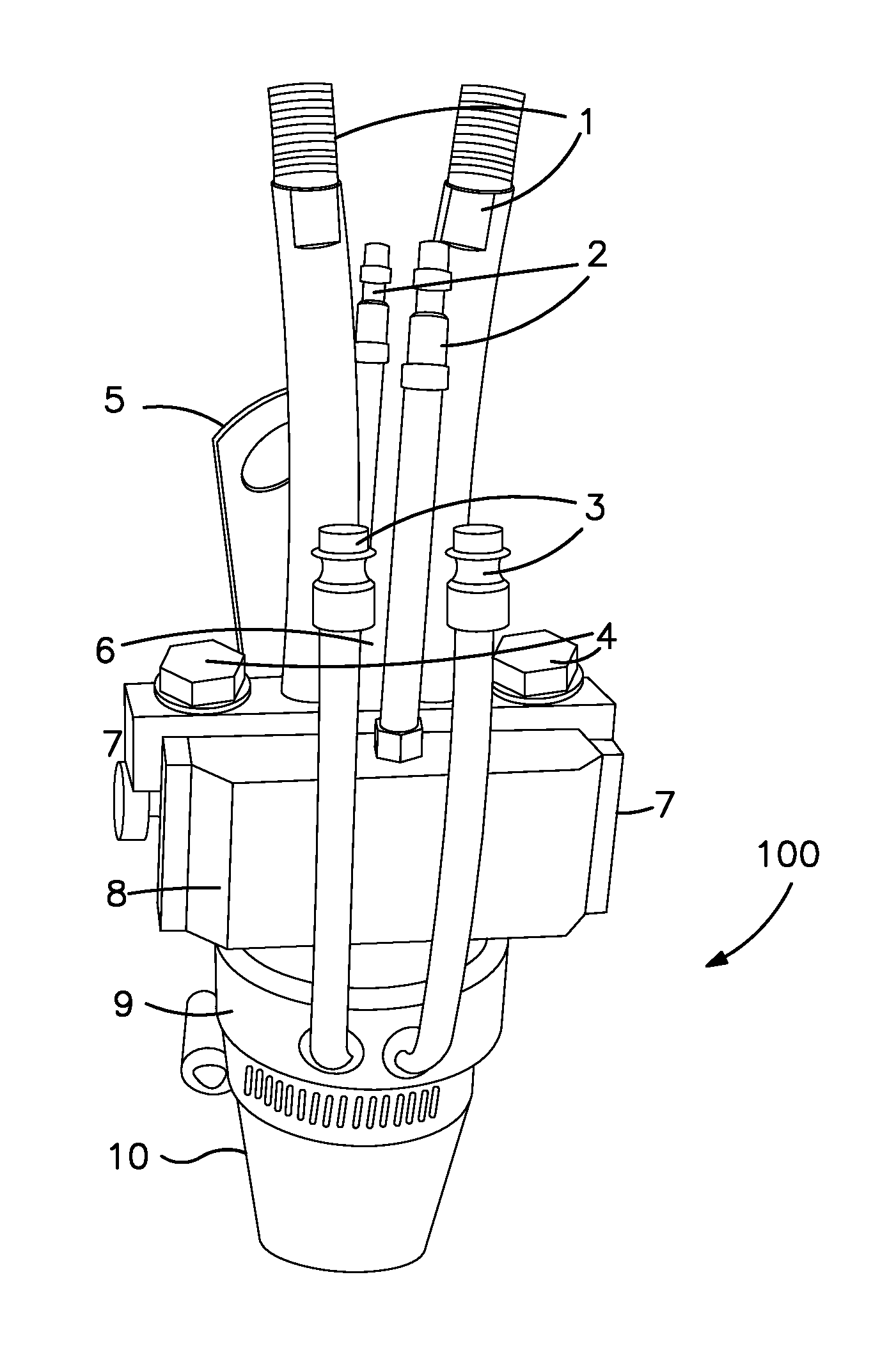

Double wire gmaw welding torch assembly and process

ActiveUS20120055911A1Arc interactionImprove processing stabilityElectrode supporting devicesMechanical engineeringWelding process

A double wire GMAW welding apparatus having a wire spacing adjustable torch assembly is disclosed. The double wire torch assembly has a wire spacing adjusting mechanism, by means of wire spacing adjustment the torch assembly can be used for a non-synchronized metal transfer weld process. The wires remain parallel before, during, after wire spacing adjustment.

Owner:ALEXANDER BINZEL SCHWEISSTECHN GMBH & CO

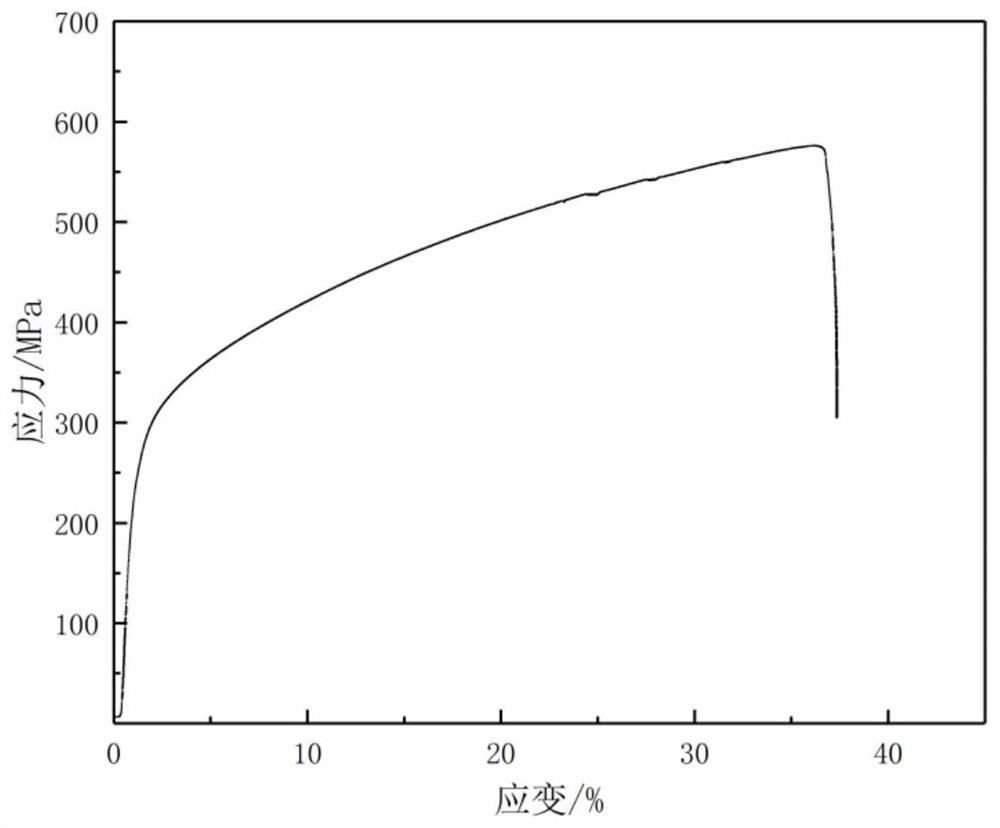

Submerged-arc welding wire and welding flux for high-intensity low-temperature steel

ActiveCN102233493AGood performance with welding operationArc stabilizationWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a submerged-arc welding wire and a submerged-arc welding flux for high-intensity low-temperature steel. After being matched with each other, the welding wire and the welding flux have extremely high welding operation performance that: an electric arc is stable, a welding seam is aesthetically molded, slag is easy to remove, and high crack resistance and high low-temperature impact properties are realized; and the welding seam (after being subjected to post-weld heat treatment at the temperature of 620 DEG C for 1 hour) has metal mechanical properties that: tensile strength is 480 to 660MPa, yield strength is 400 to 550MPa, elongation rate is 22 to 35 percent, and Charpy impact work is AKv(-51 DEG C) which is more than or equal to 160J.

Owner:KUSN GINTUNE WELDING

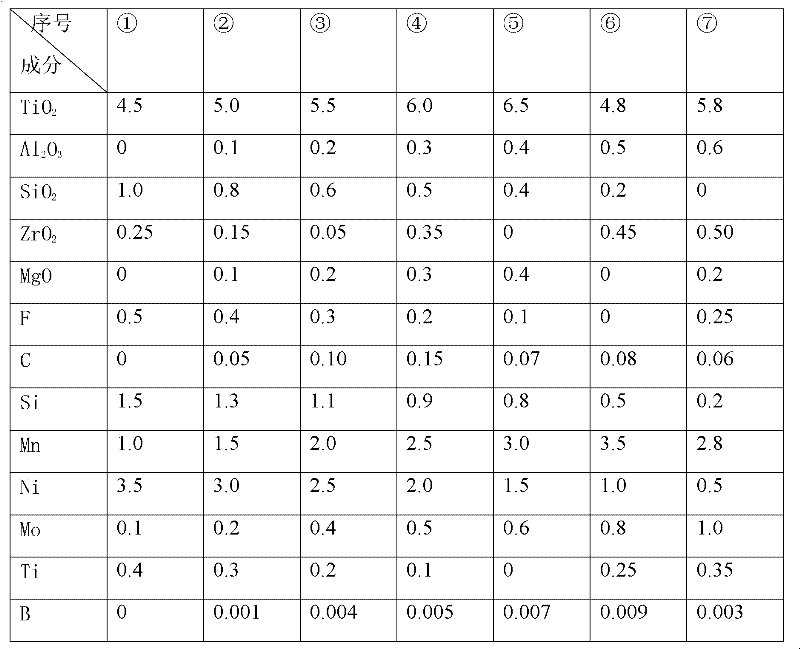

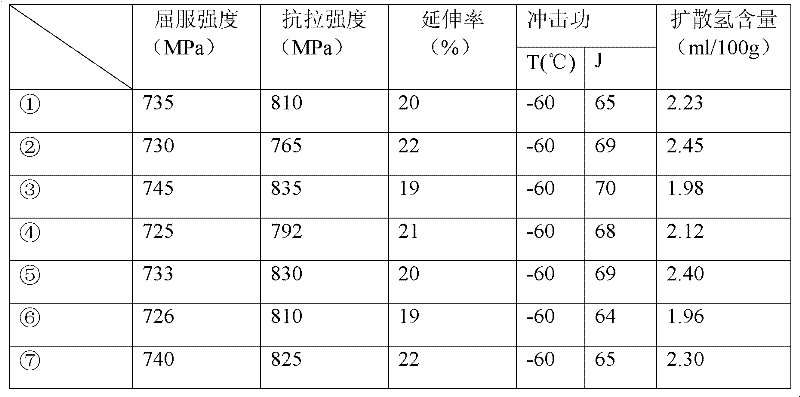

High-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire

ActiveCN102528332AIncrease coverageArc stabilizationWelding/cutting media/materialsSoldering mediaHydrogen contentMetal

The invention discloses a high-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire, which comprises the following components in percentage by mass (based on total mass): 4.5-6.5% of TiO2, 0-0.6% of Al2O3, 0-1% of SiO2, 0-0.5% of ZrO2, 0-0.4% of MgO, 0-0.5% of F, 0-0.15% of C, 0.2-1.5% of Si, 1.0-3.5% of Mn, 0.5-3.5% of Ni, 0.1-1.0% of Mo, 0-0.4% of Ti and 0-0.009% of B. The cold-rolled steel strip for preparing the flux-cored wire comprises the following chemical ingredients by weight content: not more than 0.02% of C, not more than 0.010% of P, and not more than 0.008% of S. The tensile strength of the deposited metal can reach more than 760MPa, the low-temperature impact at -60 DEG C achieves more than 47J, and the diffusible hydrogen content is smaller than 4mL / 100g ( mercury method); and the flux-cored wire has excellent welding operational performance, and is suitable for port machines, ocean platforms, bridges and the like.

Owner:KUSN GINTUNE WELDING

Nitrogen and boron alloying high tenacity hardfacing flux-cored wire

ActiveCN102886620AImprove impact toughnessImprove plasticityWelding/cutting media/materialsSoldering mediaNiobiumRare earth

The invention relates to a nitrogen and boron alloying high tenacity hardfacing flux-cored wire. The skin of the nitrogen and boron alloying high tenacity hardfacing flux-cored wire adopts a mild-carbon steel strip, and the core part is filled with alloy or mineral powder, and is pulled into a wire. The nitrogen and boron alloying high tenacity hardfacing flux-cored wire is characterized in that nitrogen and boron compounds, such as NaN3, BN and the like and a rear earth oxide are added into flux-cored powder to realize the surfacing metal nitrogen and boron alloying. The flux-cored wire comprises chemical components (weight percentage) including 1.0-3.0 % of carbon, 35-40% of chromium, 1.0-2.0% of niobium, 3.0-8.0% of boron, 2.0-5.0% of nitrogen, 1.0-2.0% of molybdenum, 1.0-2.5% of rare earth oxide, and the balance of iron or other impurities. Because the flux-cored wire adopts nitrogen and boron to replace part of carbon alloying surfacing metal, the hardness of a surfacing layer is high, and the highest hardness can reach HRC 66-69. The nitrogen and boron alloying high tenacity hardfacing flux-cored wire has the advantages of favorable toughness and outstanding wear resistance. The nitrogen and boron alloying high tenacity hardfacing flux-cored wire can be mainly used for the surfacing repair and the composite manufacturing of easily-damaged parts of ferrous metallurgy equipment, building machinery and the like.

Owner:HUNAN UNIV OF TECH

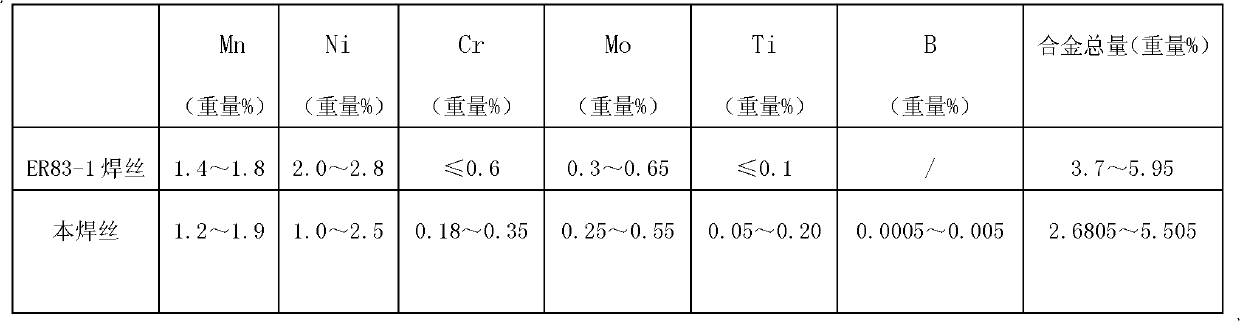

High-toughness low-alloy solid welding wire

ActiveCN101905392AQuality improvementReduced crack susceptibilityWelding/cutting media/materialsSoldering mediaSheet steelChemical composition

The invention relates to a high-toughness low-alloy solid welding wire which comprises the following chemical components in percentage by weight: not more than 0.10 percent of C, 0.4 to 0.8 percent of Si, 1.2 to 1.9 percent of Mn, 1.0 to 2.5 percent of Ni, 0.25 to 0.55 percent of Mo, 0.18 to 0.35 percent of Cr, 0.05 to 0.20 percent of Ti, 0.0005 to 0.005 percent of B, not more than 0.015 percent of S, not more than 0.015 percent of P and the balance of Fe and other inevitable impurities. The high-toughness low-alloy solid welding wire has the tensile strength of deposited metal more than 830MPa, the yield strength of the deposited metal more than 730MPa, and the reduced alloy content by near 50 percent compared with the welding wire ER83-1 on the premises of ensuring the strength and the impact toughness, can satisfy the welding of 830MPa-grade and 900MPa-grade steel plates and greatly reduce the cost and is suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

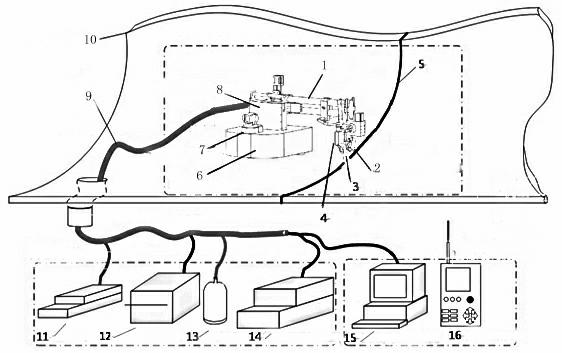

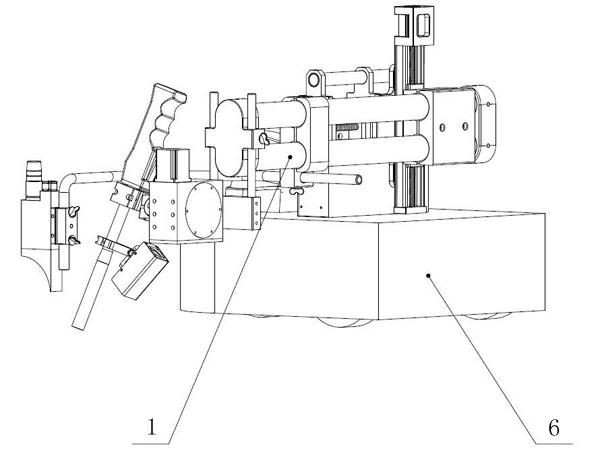

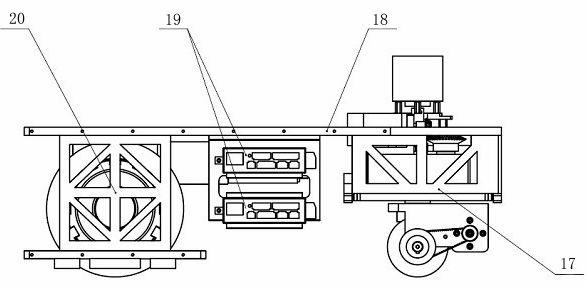

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

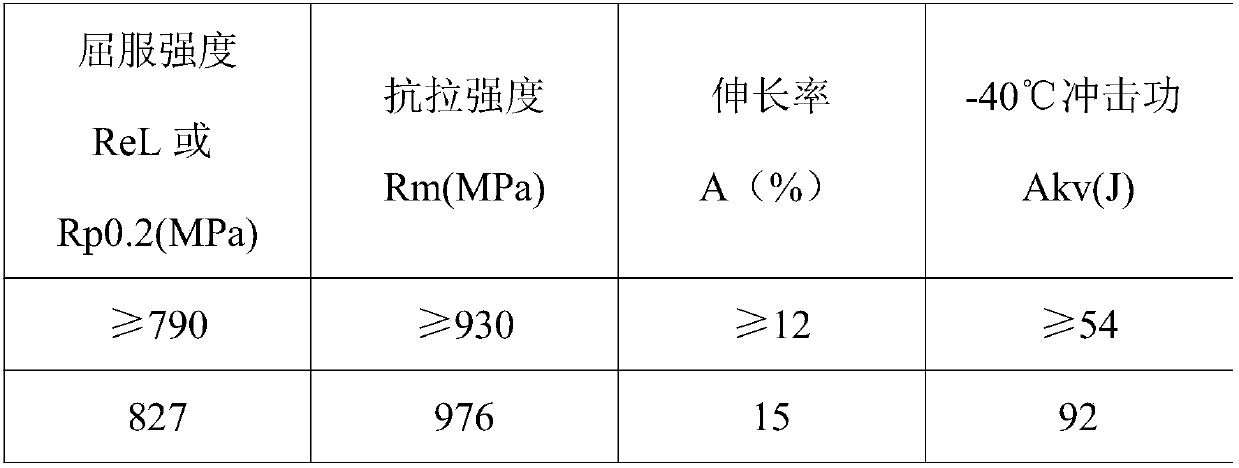

Metal type flux-cored wire and method of manufacturing austenitic stainless steel structural part

ActiveCN111992923AShort preparation cycleIncrease productivityWelding/cutting media/materialsSoldering mediaManufacturing technologyFerrosilicon

The invention discloses a metal type flux-cored wire. The metal type flux-cored wire is adopted as a raw material, an austenitic stainless steel structural part is manufactured on the basis of an electric arc additive manufacturing technology, and the formed thin-wall structural part has excellent mechanical properties. Flux-cored alloy of the metal type flux-cored wire comprises, by mass percentage, 8% of silicon iron, 18%-22% of manganese powder, 27% of nickel powder, 26% of chromium powder, 4%-8% of molybdenum powder, 1%-3% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder,0.5% of lanthanum oxide, 1% of niobium carbide and the balance iron powder. The sum of the mass percentages of the components is 100%. The austenitic stainless steel thin-wall structural part obtained through additive manufacturing is attractive in appearance and has the excellent mechanical properties. The austenitic stainless steel metal type flux-cored wire for additive manufacturing can be used for additive manufacturing of complex parts in the fields of national defense, energy, petroleum, chemical engineering, aerospace and bioengineering.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com