Submerged-arc welding wire and welding flux for high-intensity low-temperature steel

A submerged arc welding wire and low-temperature steel technology, which is applied in the field of welding wire and flux, can solve limited problems and achieve the effects of easy slag removal, beautiful weld shape, and stable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]Embodiment 1: smelt three kinds of welding wires (specification 4.0mm) with the welding wire composition designed in the present invention, denote as welding wire ①, welding wire ②, welding wire ③, its chemical composition is shown in Table 1; Produce four kinds with the flux designed in the present invention Flux, recorded as flux ①, flux ②, flux ③, flux ④, its chemical composition is shown in Table 2; welding with welding wire of the present invention and flux, welding process specification is: current 550A, voltage 32V, welding speed 420mm / min, welding Afterwards (620℃×1 hour) heat treatment, the workability is good during the welding process, and there is no air hole in the test plate after welding. The physical and chemical properties of the deposited metal after welding are shown in Table 3 and Table 4:

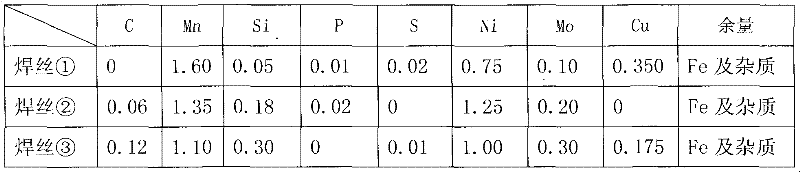

[0047] Table 1 Chemical composition of welding wire (weight%)

[0048]

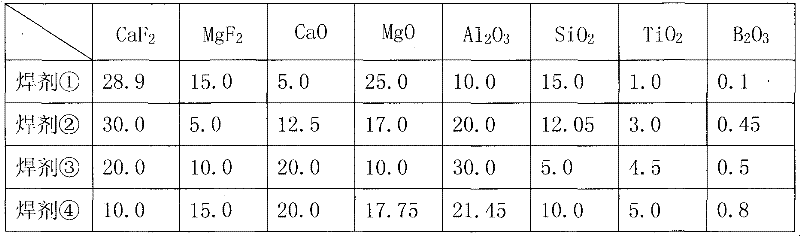

[0049] Table 2 Soldering flux composition (weight %)

[0050]

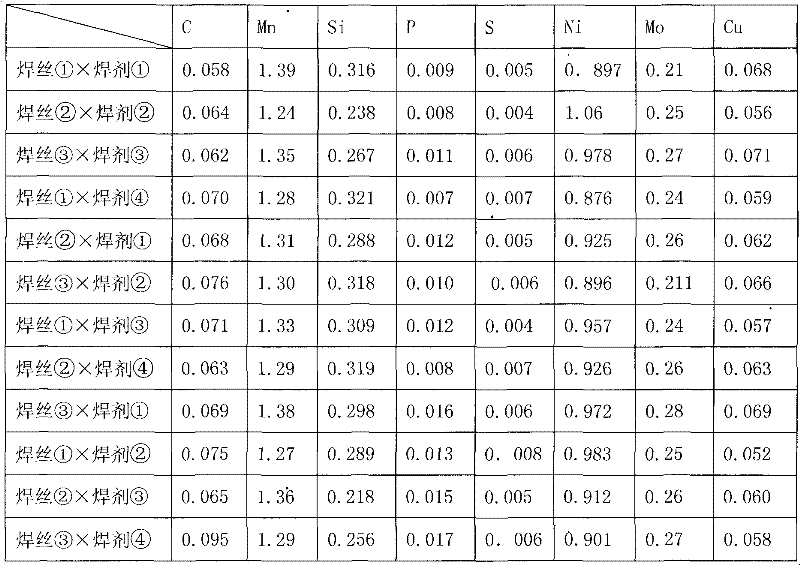

[0051] Table 3 Ch...

Embodiment 2

[0055] Embodiment 2: Cooperate welding with welding wire of the present invention and a kind of SJ101 flux that buys on the market (recorded as flux ⑤, and flux composition sees the following table five), and welding process specification is: electric current 550A, voltage 32V, welding speed 420mm / min, Heat treatment at 620°C for 1 hour after welding. The workability is good during the welding process, and the test plate after welding is qualified. The physical and chemical properties of the deposited metal after welding are shown in Table 6 and Table 7:

[0056] Table 5 Composition of flux ⑤

[0057]

[0058] Table 6 welding wire combination flux of the present invention ⑤ welding gained deposited metal chemical composition

[0059]

[0060] Table 7 welding wire combined flux of the present invention ⑥ welded deposited metal mechanical properties

[0061]

[0062] The above examples show that the welding wire of the present invention has excellent welding operabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com