Patents

Literature

95results about How to "Good low temperature impact properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

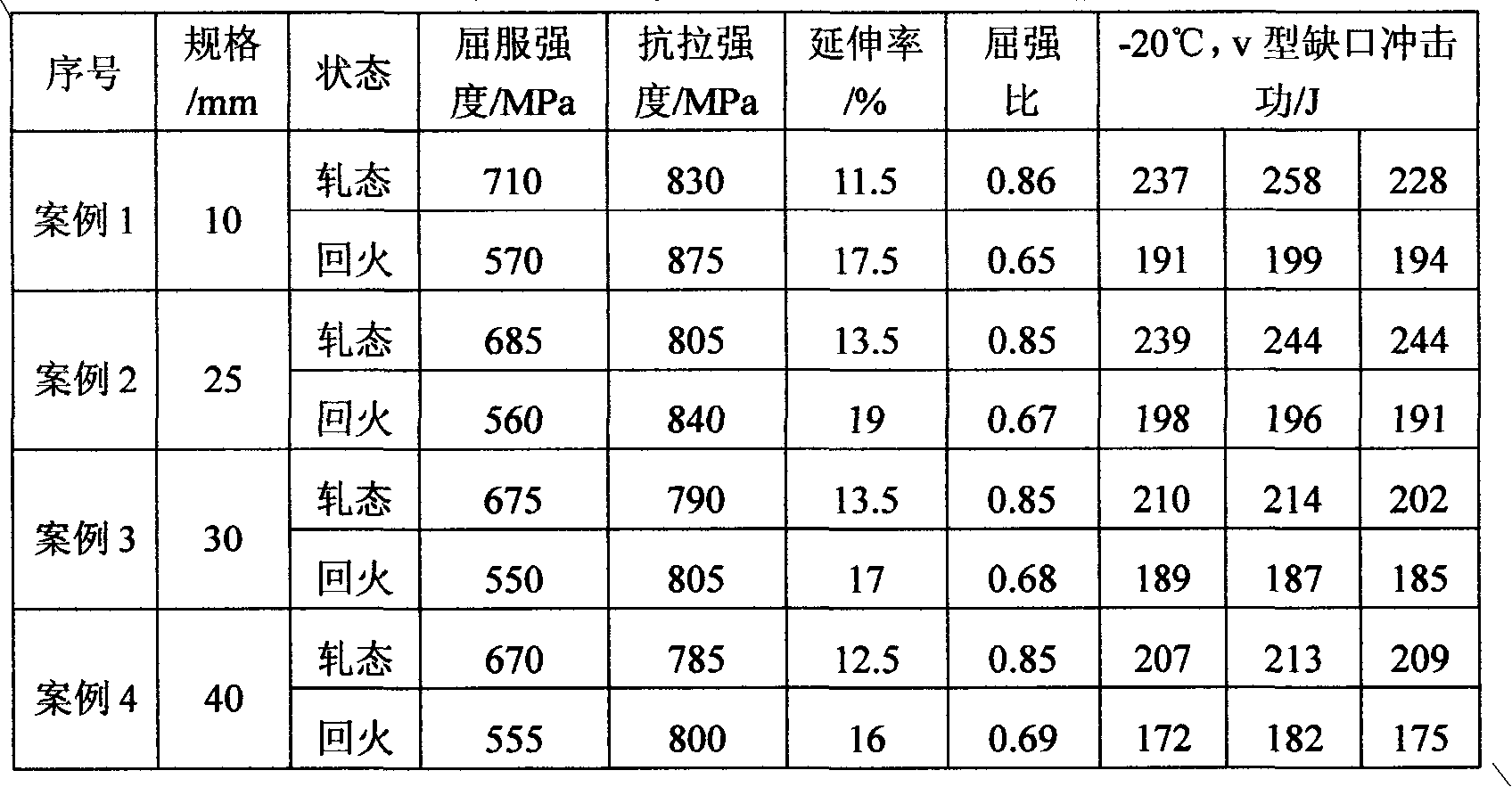

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

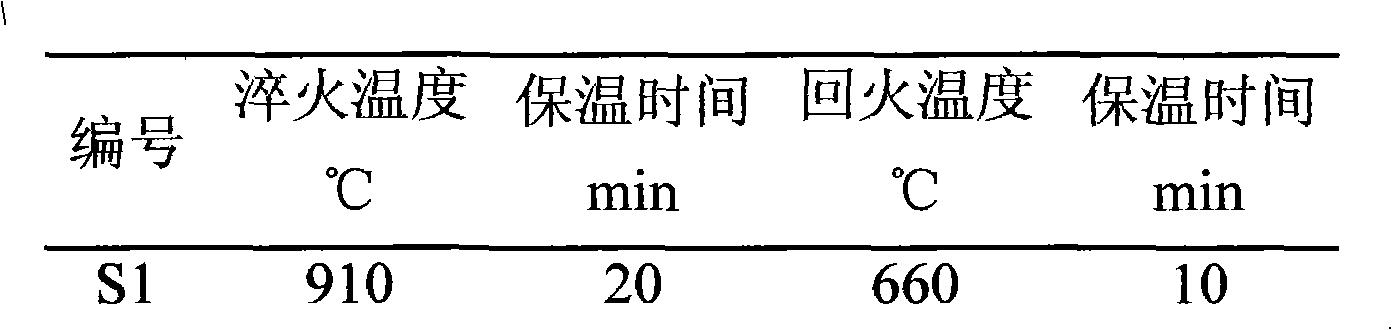

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

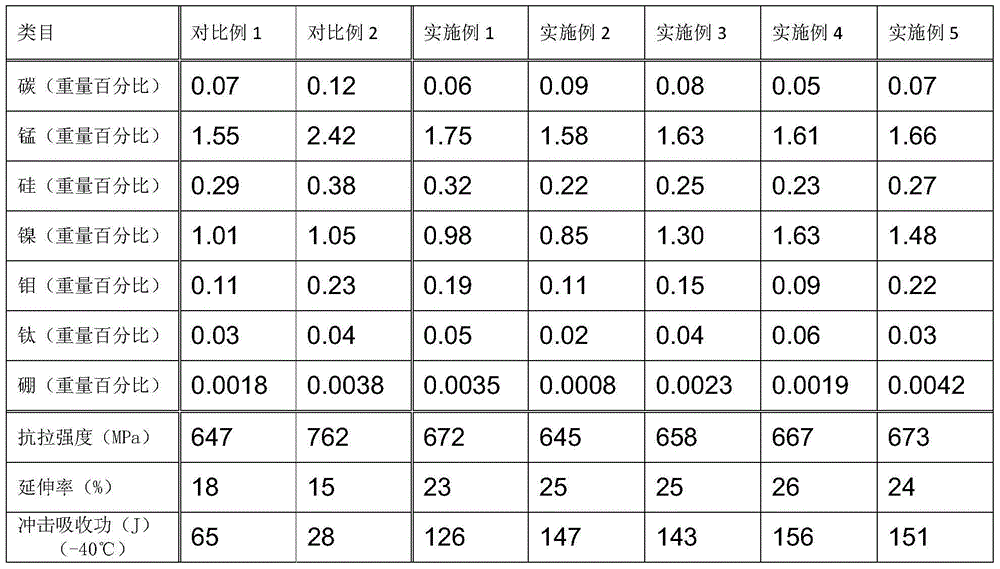

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

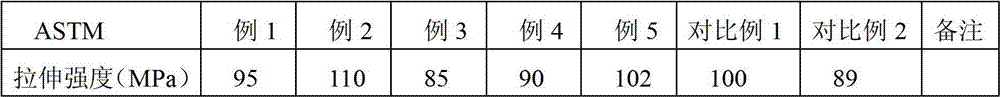

Long glass fiber reinforced composite polypropylene material, and preparation method and application thereof

The invention belongs to the technical field of high-molecular materials, and discloses a long glass fiber reinforced composite polypropylene material, and a preparation method and an application thereof The material is prepared by using the following components, by weight, 55-75 parts of polypropylene, 20-40 parts of a continuous glass fiber, 0.1-0.5 parts of a coupling agent, 0.01-0.1 parts of a primary antioxidant, 0.01-0.1 parts of an auxiliary antioxidant, 0.5-1 part of a lubricant and 3.5-4.2 parts of compatilizer. The invention also provides a preparation method of the long glass fiber reinforced composite polypropylene material, and a use of the long glass fiber reinforced composite polypropylene material in automobile components. The long glass fiber reinforced composite polypropylene material can be widely used in automobile components comprising header boards, automobile door panels, inner casings and the like, and has the characteristics of low cost, short injection molding period, low residual stress and small warpage of products, and low fraction defective of the products.

Owner:HEFEI GENIUS NEW MATERIALS

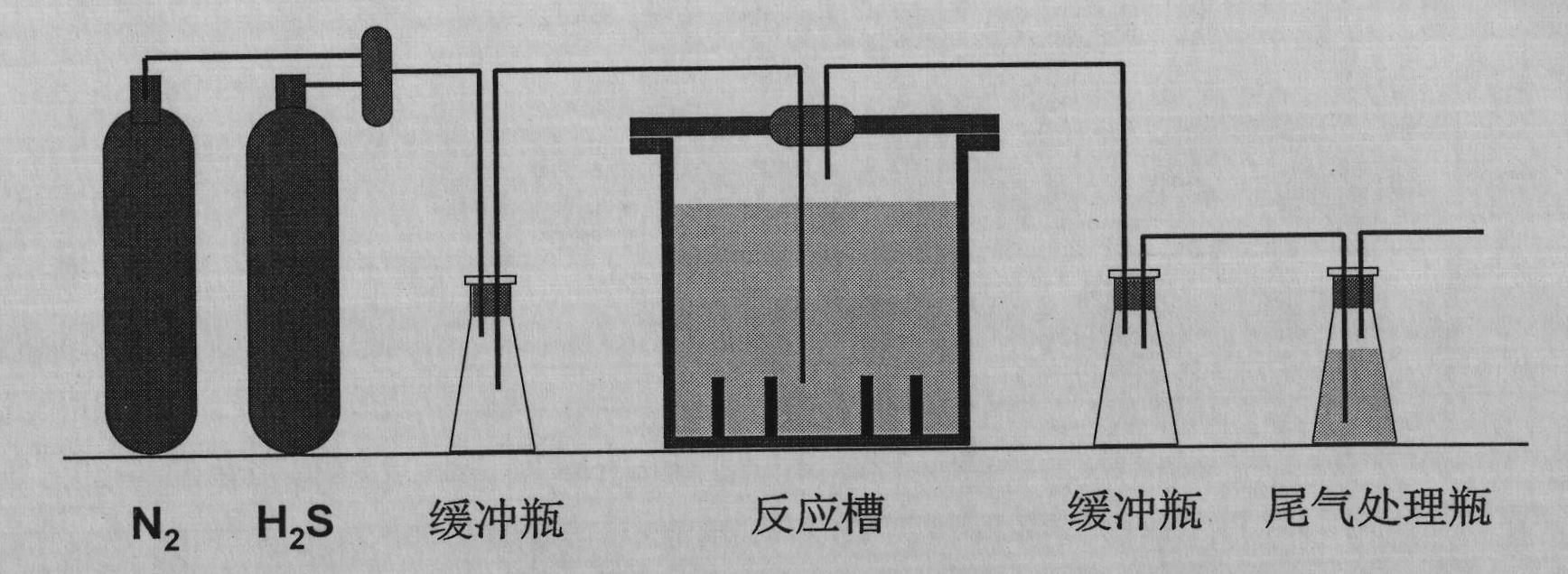

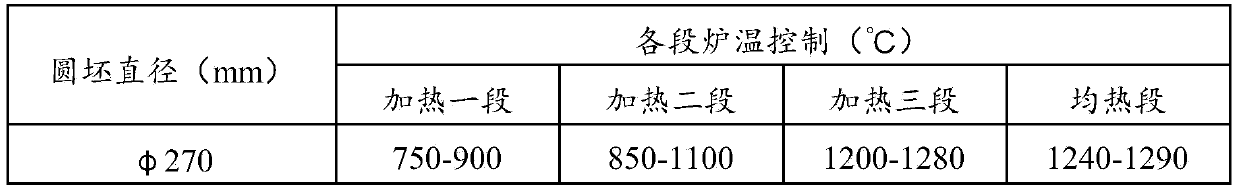

High low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and production method thereof

ActiveCN102605297AImprove strength and toughnessMeet manufacturing requirementsFurnace typesHeat treatment furnacesHydrogenWater flow

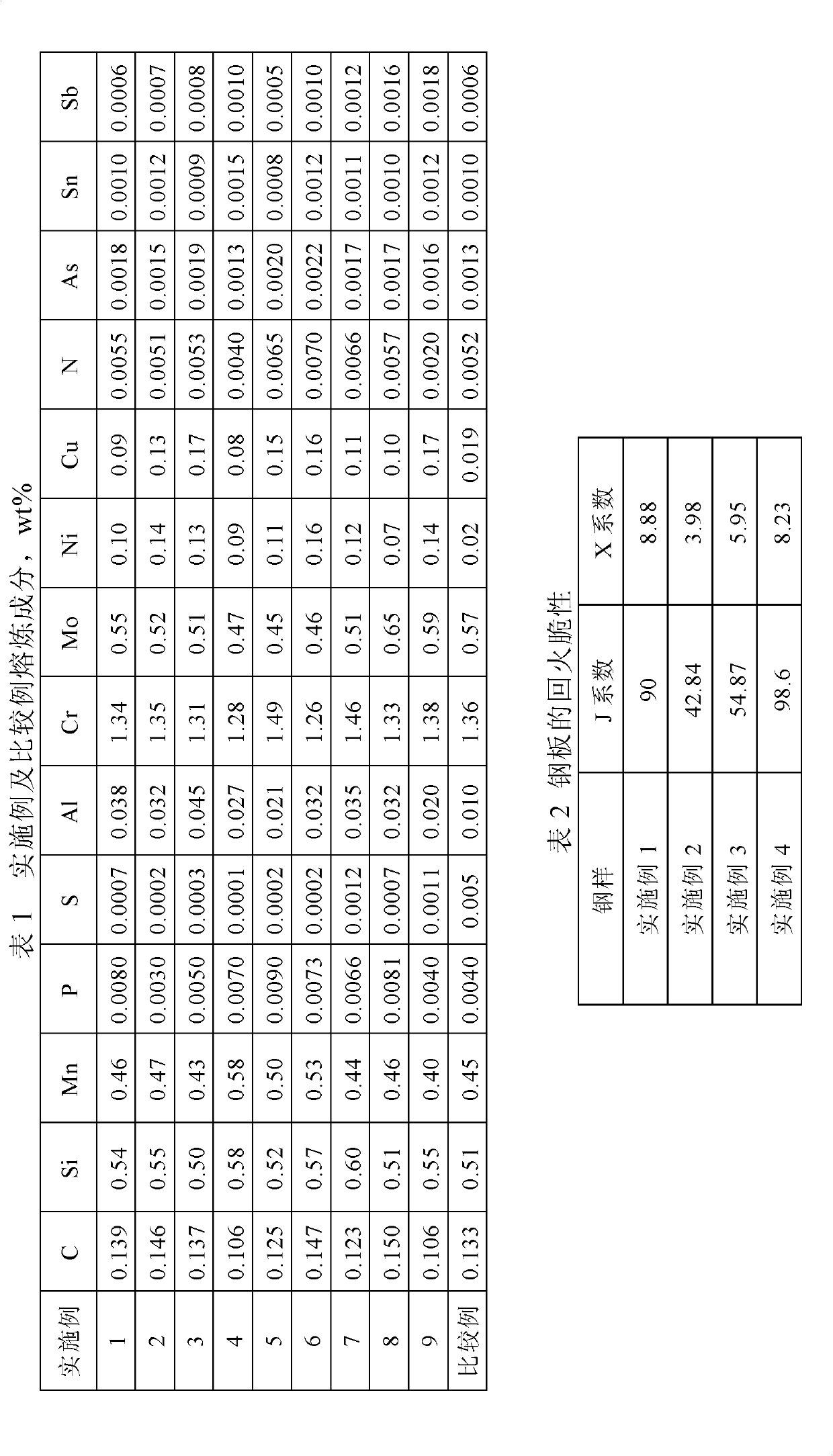

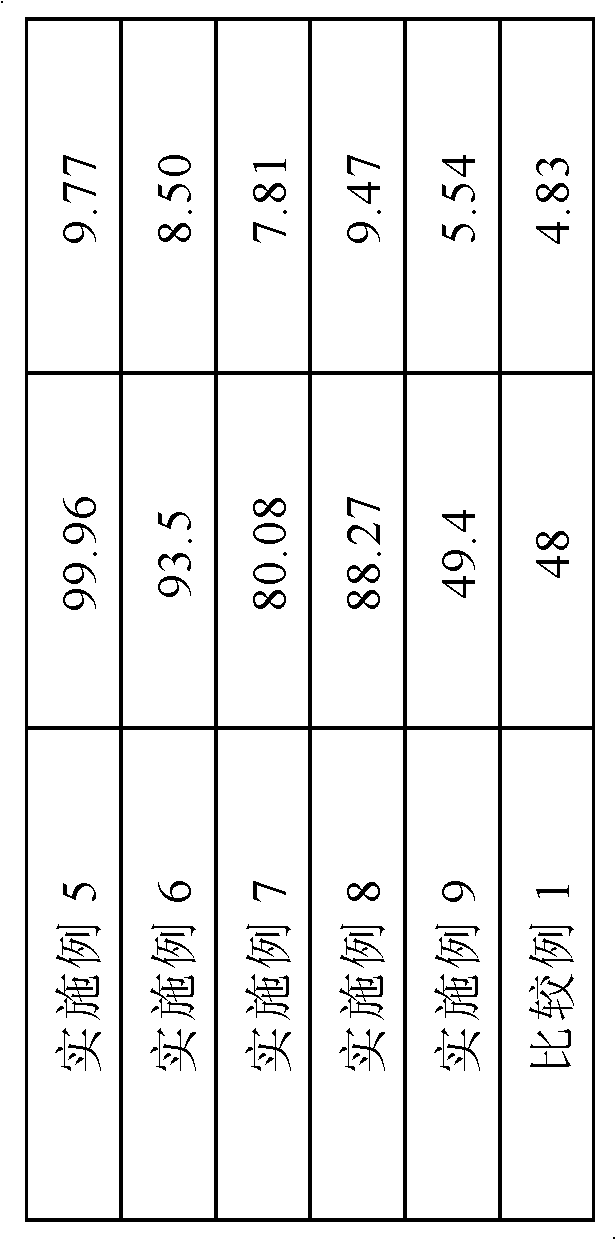

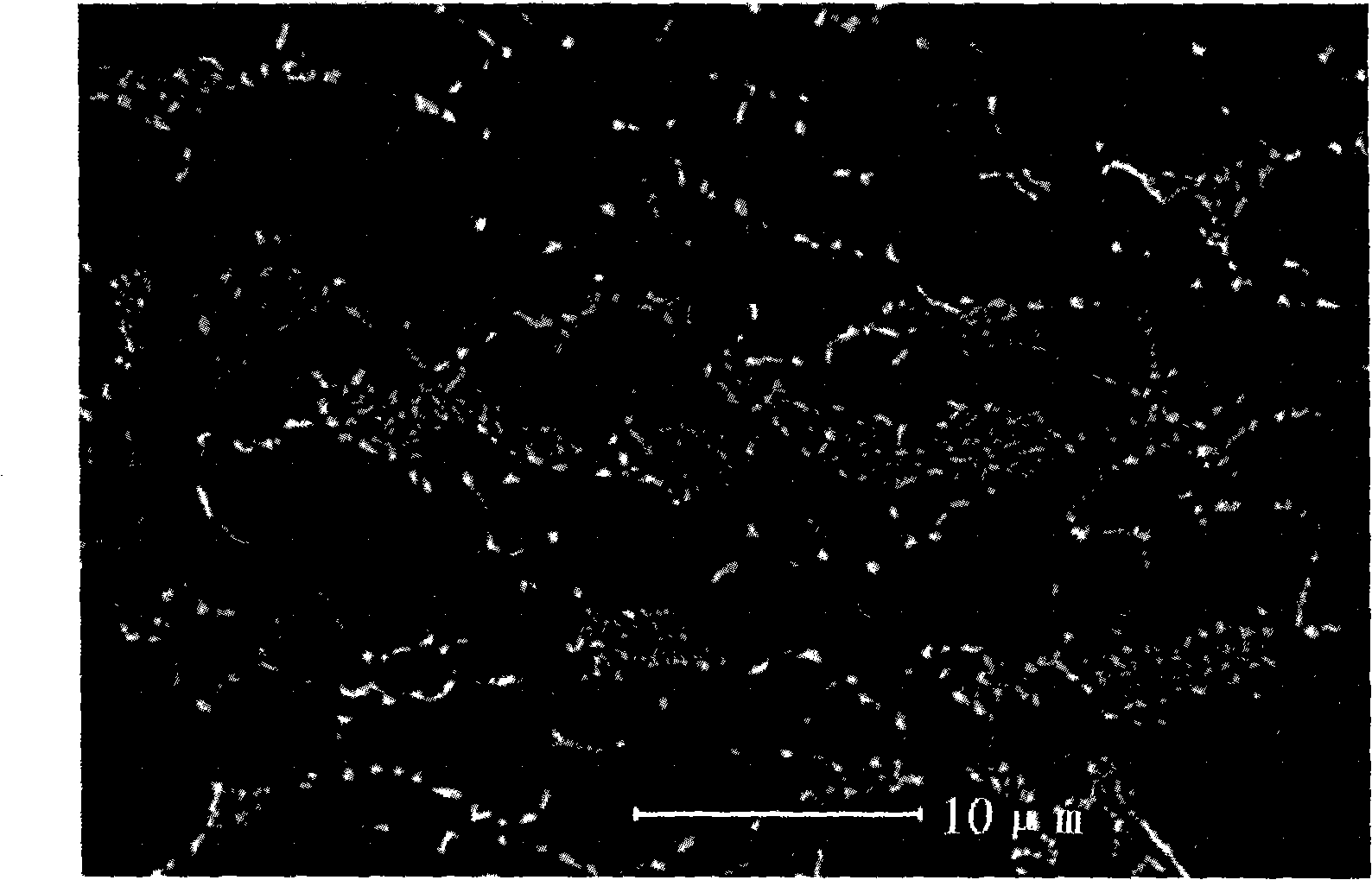

Disclosed are high low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and a production method thereof. The production method includes the steps: firstly, smelting and casting; secondly, heating plate blanks at 1070-1210 DEG C and rolling the plate blanks according to a compression ratio of 2.7-6.4; thirdly, normalizing within an austenitization temperature range; fourthly, accelerated cooling with water for 4-15 minutes; and fifthly, tempering at 700-750 DEG C; and sixthly cooling, wherein the steel plates comprise, in weight percentage, 0.10-0.15% of C, 0.50-0.60% of Si, 0.40-0.60% of Mn, not more than 0.010% of P, not more than 0.003% of S, 1.25-1.50% of Cr, 0.45-0.65% of Mo, 0.08-0.18% of Cu, 0.07-0.17% of Ni, 0.020-0.045% of Al, not more than 0.003% of Sn, not more than 0.003% of Sb, not more than 0.003% of As, 0.0020-0.0070% of N, the balance of Fe and unavoidable impurities, low-pressure section water flow of a pressure quenching machine is 18-38m<3> / min, top-to-bottom water volume ratio of each steel plate is 1:1.0-1.3, and the surface temperature of the steel palate at an outlet of the pressure quenching machine is not more than 120 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength hot rolled steel plate and manufacturing method thereof

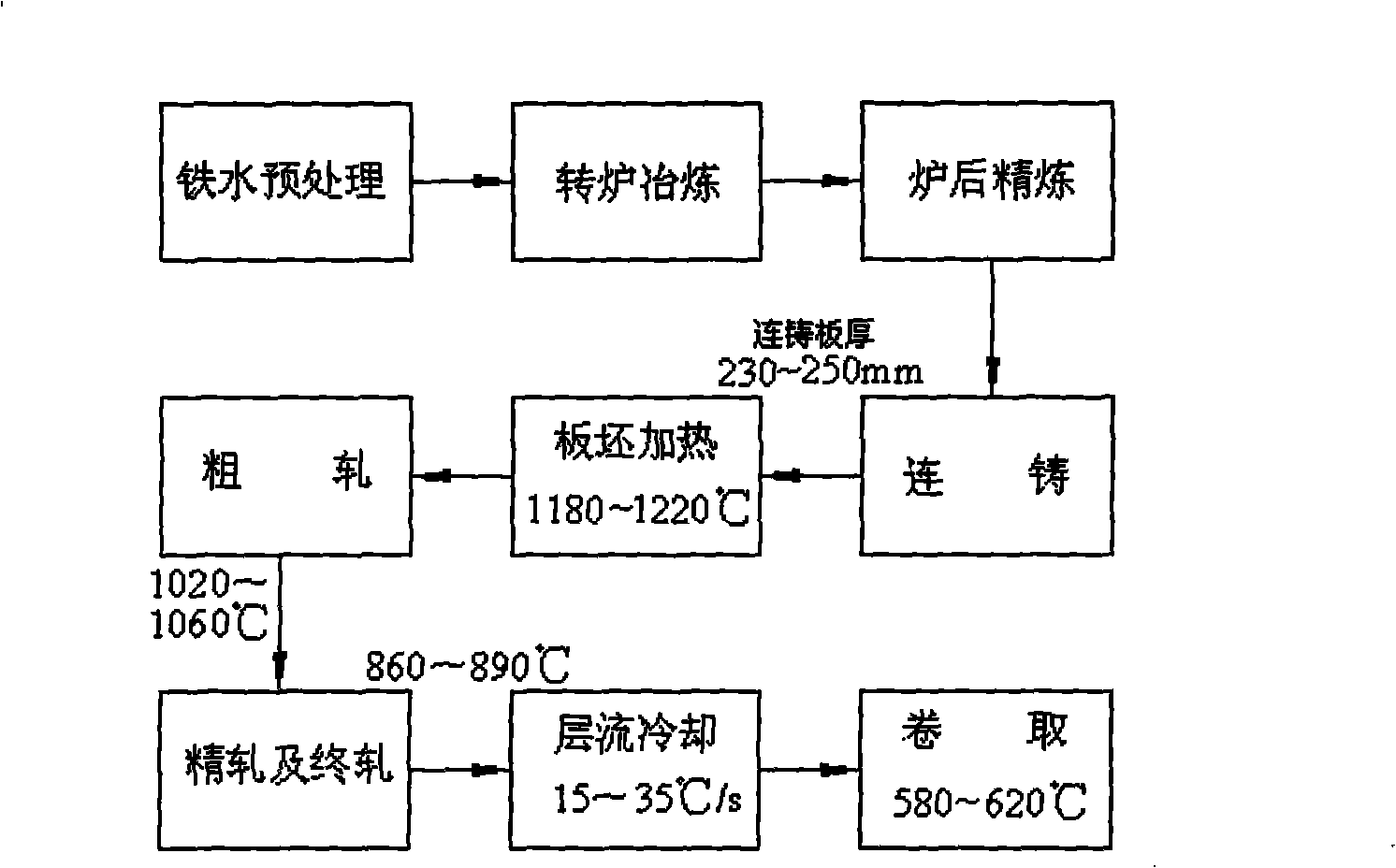

ActiveCN101280390APure steelImprove performanceTemperature control deviceManufacturing convertersManganeseUltimate tensile strength

The invention discloses a high strength hot rolled structure steel plate, which belongs to the technical field of the metal structure material. In the invention, an Nb microalloying element is added into low carbon and high manganese clean steel, and also Ca in minute quantities is added. Simultaneously, the invention also discloses the manufacturing method of the steel plate, the manufacturing method comprises the steps that the converter smelting and refining, continuous caster protecting casting, and rolling control and cooling control process is adopted, through the thinning strengthening and precipitation strengthening of the crystal grain, the hot tandem rolled coiled sheet with pure steel quality, good combined property and uniform and fine grain size can be obtained, the steel plate not only has high strength, but also has very high toughness and superior cold forming performance, and the structure requirement of the vehicle can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

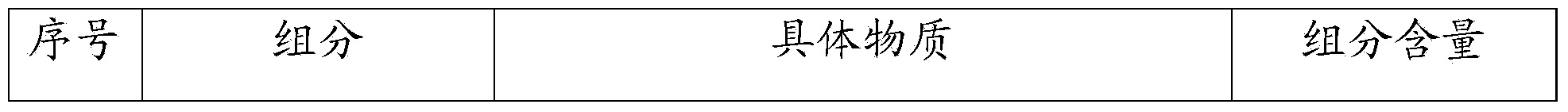

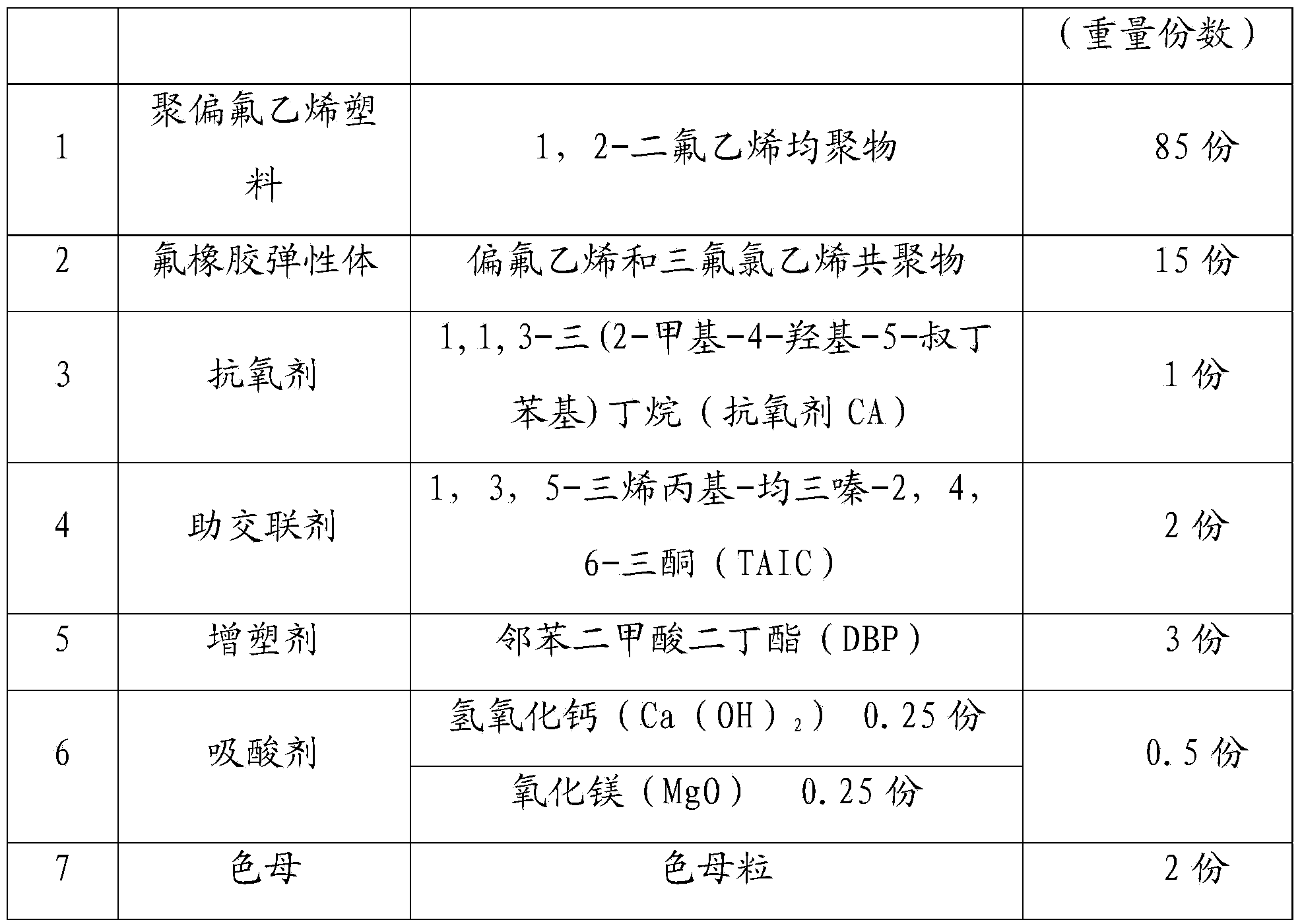

Elastic polyvinylidene fluoride heat-shrinkable sleeve and preparation method thereof

The invention relates to an elastic polyvinylidene fluoride heat-shrinkable sleeve which is composed of the following components in parts by weight: 85-95 parts of polyvinylidene fluoride plastic, 5-15 parts of fluororubber elastomer, 1-3 parts of antioxygen, 2-5 parts of assistant crosslinker, 3-8 parts of plasticizer, 0.5-2 parts of acid accepter and 2-5 parts of color master. The polyvinylidene fluoride plastic is one or two of the following matters: 1,2-difluoroethene homopolymer and 1,2-difluoroethene- hexafluoropropylene homopolymer. The fluororubber elastomer is one, two or more than two of the following matters: vinylidene fluoride and chlorotrifluor ethylene copolymer, vinylidene fluoride and hexafluoropropylene copolymer, vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene terpolymer. According to the elastic polyvinylidene fluoride heat-shrinkable sleeve, such performances of fluoroplastic as wear resistance, mechanical damage resistance and the like are kept simultaneously, elasticity of the heat-shrinkable sleeve is improved, the elastic polyvinylidene fluoride heat-shrinkable sleeve has such specific performances of fluororubber as oil resistance simultaneously, application scope of the fluoride heat-shrinkable sleeve is broadened and risk in the process of use is reduced.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and preparation method thereof

The invention discloses a lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and a preparation method thereof. The lithium battery case flame-retardant material is prepared from the following components in parts by weight: polypropylene, continuous glass fiber, coupling agent, main antioxidant, auxiliary antioxidant, lubricant, compatilizer, composite flame retardant and black master batch. The preparation method comprises the following steps: adding all the components expect the continuous glass fiber into a high-speed mixer, uniformly mixing, sending into an extruding machine, carrying out melt extrusion on the material into an impregnator, and meanwhile, sending the continuous glass fiber into the impregnator to carry out disperse impregnation with the molten material; and finally, carrying out die drawing at a setting port of the impregnator, cooling, carrying out blow-dry, and granulating to obtain the finished product. The lithium battery case flame-retardant material disclosed by the invention has higher strength and toughness, can not be easily combusted in naked fire, can effectively lower the possibility of battery combustion accidents, and ensures the case to have high plasticity and compressive strength.

Owner:HEFEI GENIUS NEW MATERIALS

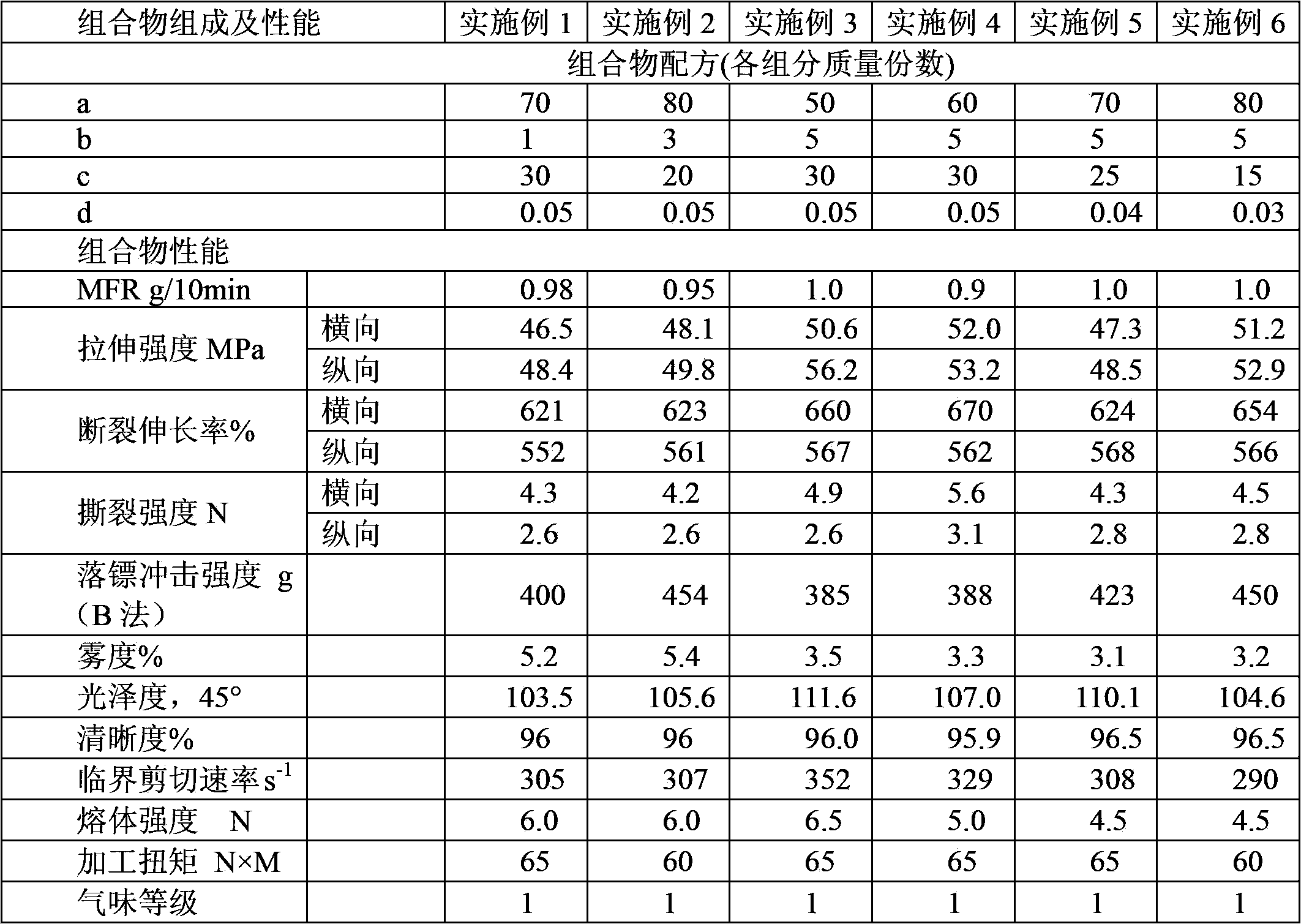

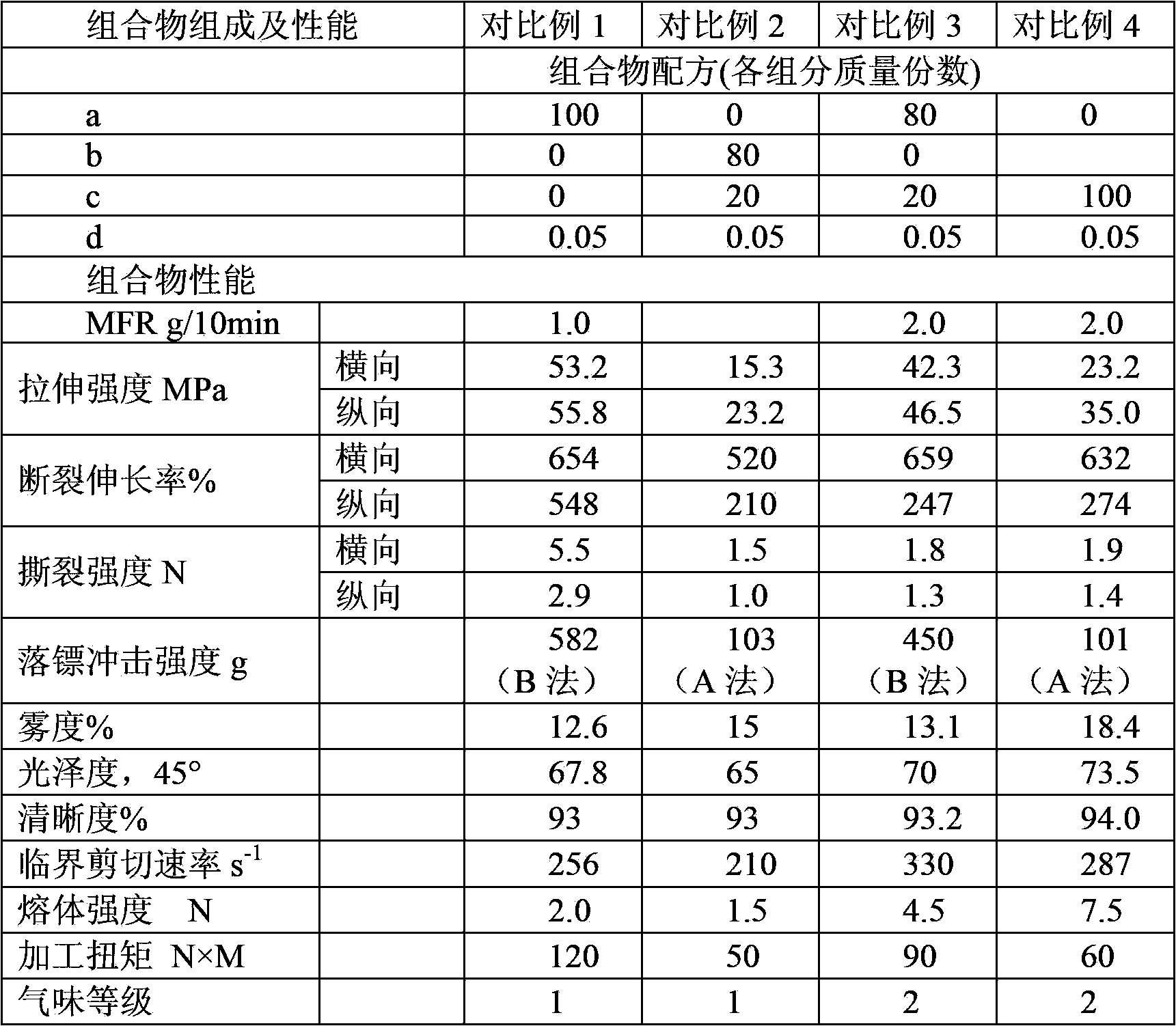

Highly-transparent polyethylene composition and preparation method thereof

The invention relates to a polyethylene composition, specifically to a highly-transparent polyethylene composition and a preparation method thereof. The highly-transparent polyethylene composition comprises a matrix resin and a processing auxiliary agent, wherein the matrix resin is prepared by co-mixing first mLLDPE, second mLLDPE and high pressure LDPE. The composition has characteristics of good strength, good flexibility, good processability, good aging resistance, low odor, excellent gloss, excellent impact strength, excellent tensile strength and excellent tear strength, can be used for preparing composite package films with excellent comprehensive performances, and can be provided for avoiding phenomena such as scratch, puncture and breaking by external force due to insufficient performances such as tear resistance and the like during the use process. In addition, after the mLLDPE resin and the normal resin are blended, the thickness of the film is reduced, the comprehensive performance is excellent, the product cost is reduced, and the processability of the composition is improved.

Owner:CHINA PETROLEUM & CHEM CORP

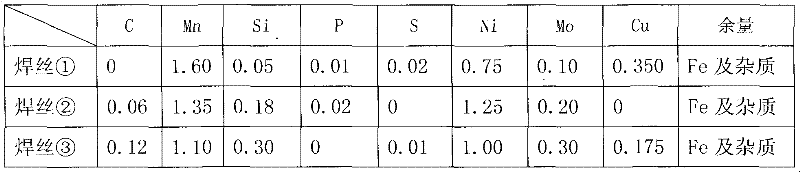

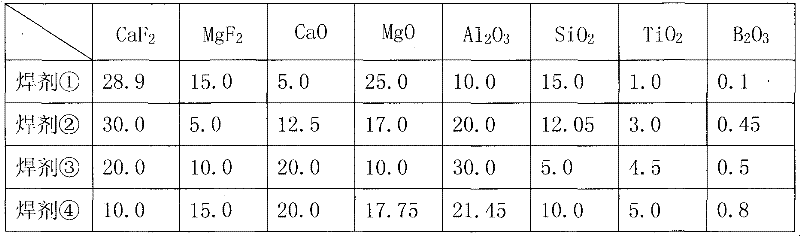

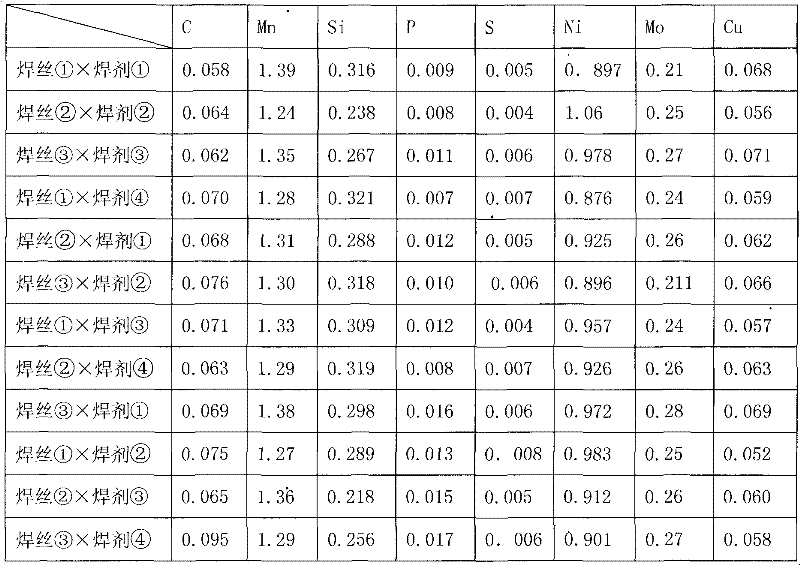

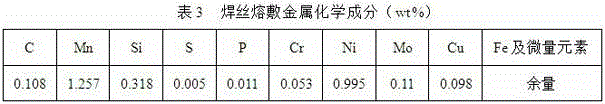

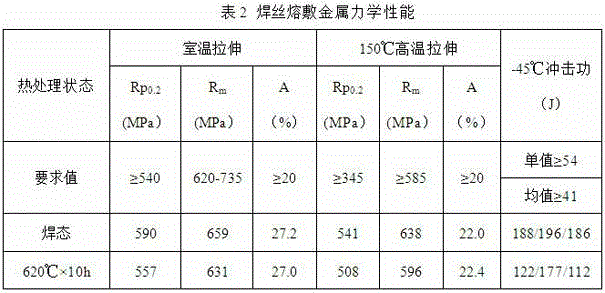

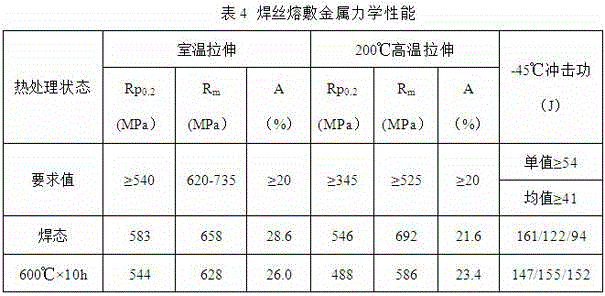

Submerged-arc welding wire and welding flux for high-intensity low-temperature steel

ActiveCN102233493AGood performance with welding operationArc stabilizationWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a submerged-arc welding wire and a submerged-arc welding flux for high-intensity low-temperature steel. After being matched with each other, the welding wire and the welding flux have extremely high welding operation performance that: an electric arc is stable, a welding seam is aesthetically molded, slag is easy to remove, and high crack resistance and high low-temperature impact properties are realized; and the welding seam (after being subjected to post-weld heat treatment at the temperature of 620 DEG C for 1 hour) has metal mechanical properties that: tensile strength is 480 to 660MPa, yield strength is 400 to 550MPa, elongation rate is 22 to 35 percent, and Charpy impact work is AKv(-51 DEG C) which is more than or equal to 160J.

Owner:KUSN GINTUNE WELDING

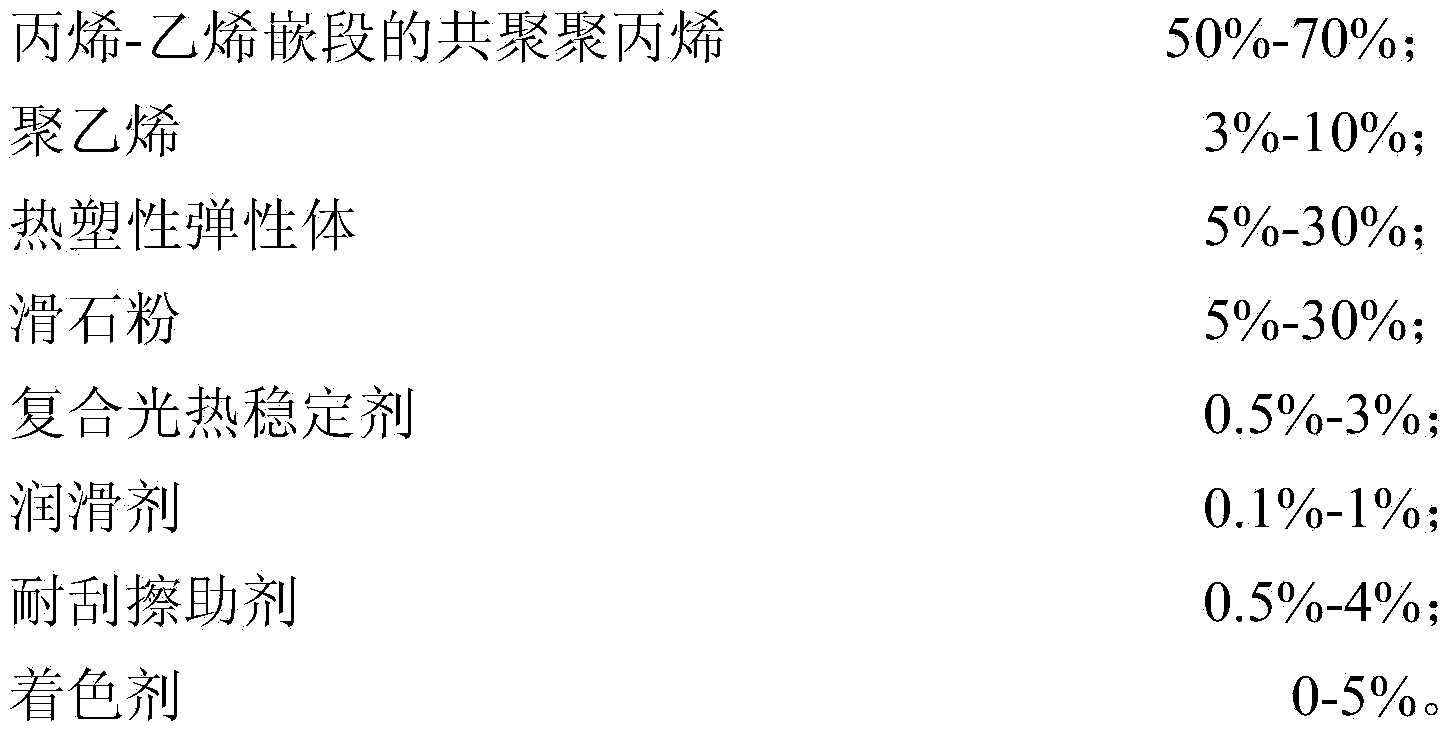

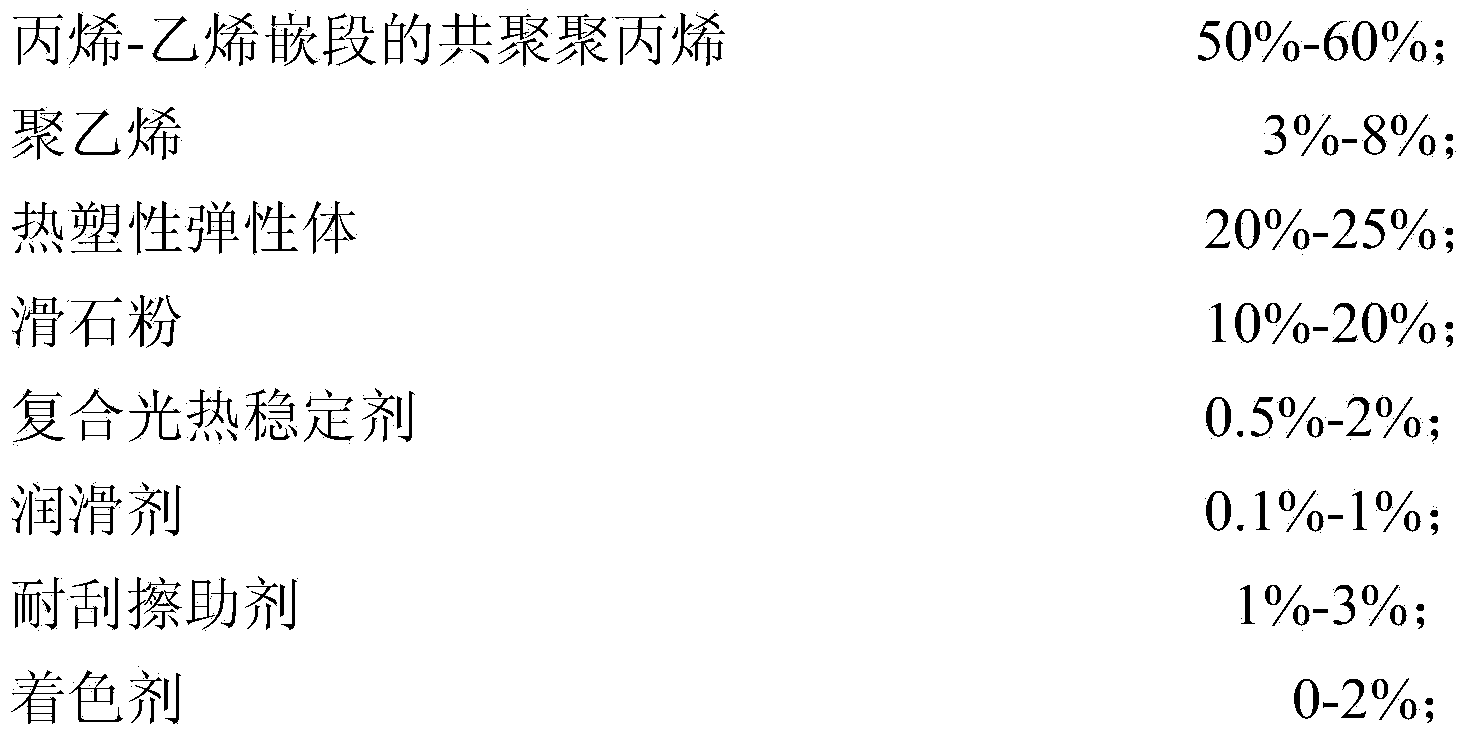

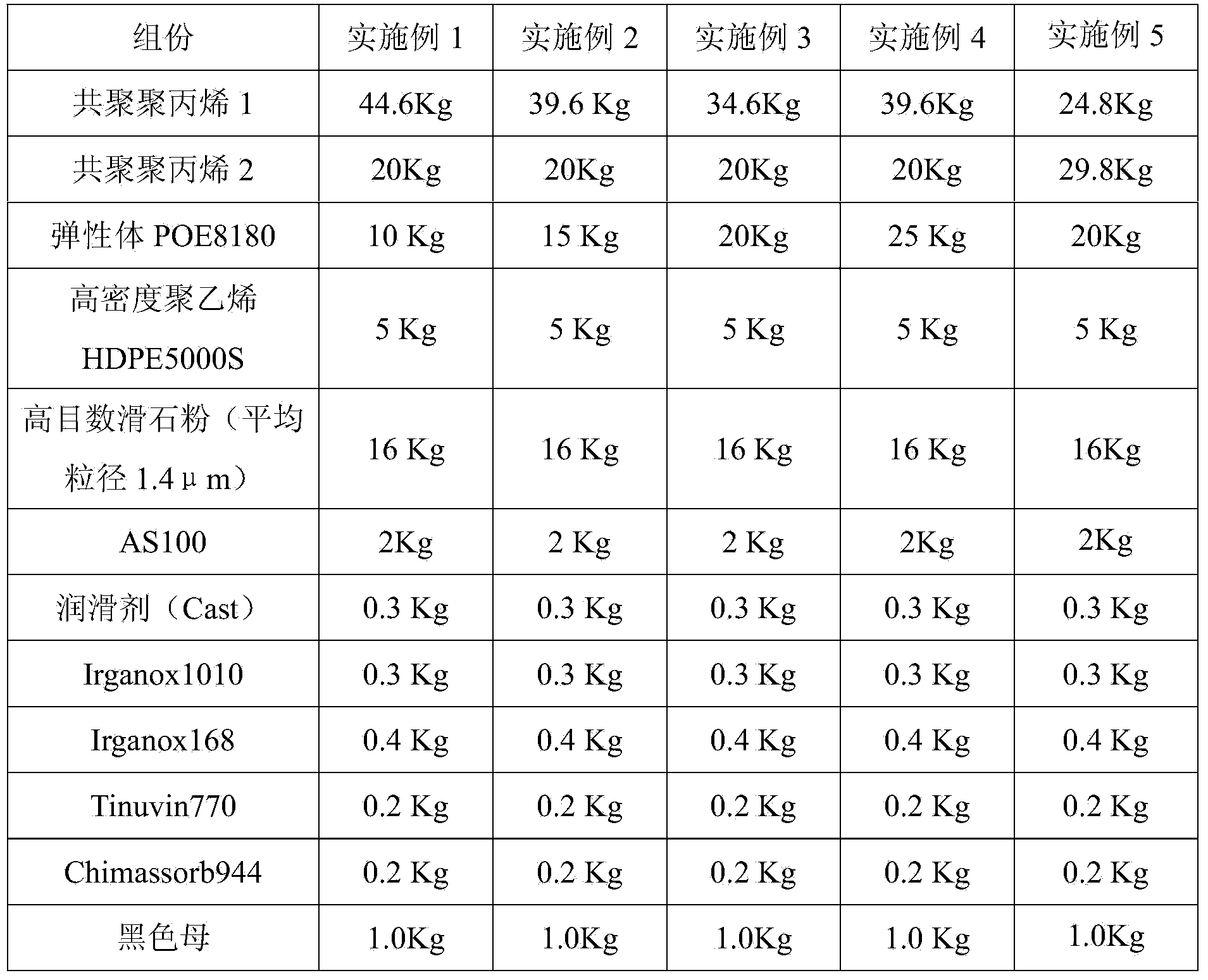

Polypropylene composite material as well as preparation method and application thereof

InactiveCN104109330AGood low temperature impact propertiesGood weather and scratch resistanceWeather resistanceStabilizing Agents

The invention discloses a polypropylene composite material for a car seamless dashboard. The polypropylene composite material consists of the following raw materials in percentage by weight: 50-70% of propylene-ethylene block co-polypropylene, 3-10% of polyethylene, 5-30% of a thermoplastic elastomer, 5-30% of talcum powder, 0.5-3% of a composite photo-thermal stabilizing agent, 0.1-1% of a lubricating agent, 0.5-4% of anti-scratch additives and 0-5% of a coloring agent. The polypropylene composite material for the car seamless dashboard can show excellent low-temperature impact resistance, particularly, can be used for meeting the multi-axial low temperature impact performance of fracture toughness at -35 DEG C, also has the characteristics such as scratch resistance, weather resistance and low total carbon, and can be used for meeting the requirements of a high-grade car seamless blasting dashboard. The invention also discloses a preparation method of the polypropylene composite material. The preparation method is simple to operate, does not need special equipment, is low in cost, and is suitable for industrial production.

Owner:CGN JUNER NEW MATERIALS +1

Metallocene polyolefin tenacity-increased profax resin composition

The invention relates to a metallocene polyolefin tenacity-increased profax resin composition comprising raw materials of the following constituents (by weight proportion): polypropylene 60-85%, metallocene polyolefine 5-30%, compatibilzer 5-10%, anti-oxidant 0.1-1% and lubricating agent 0.1-0.5%.

Owner:SHANGHAI SUNNY

High-strength high-tenacity electro-gas welding agent core welding wire and preparation method

ActiveCN104139250ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaFluorideMetal powder

The invention provides a high-strength high-tenacity electro-gas welding agent core welding wire and a preparation method. The strength of the welding wire is in 600 MPa class. An SPCC-SD cold-rolled low-carbon steel strip is used as a welding wire raw material, a welding wire core is composed of fluoride, carbonate, oxide, ferroalloy and metal powder. The preparation method comprises the steps of baking, powder blending, strip cutting, filling forming, drawing, layering winding, packaging and the like. The 600MPa-class high-strength high-tenacity electro-gas welding agent core welding wire has the advantages that the welding process is good, electric arcs are stable, splashing is small, slag is easy to remove, formation of weld is attractive, and the minus 40 DEG C impact property is excellent. The 600MPa-class high-strength high-tenacity electro-gas welding agent core welding wire is mainly used for welding longitudinal joints of a 100000-stere oil storage tank.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Preparation method of ultraviolet cured adhesive for flat panel display

The invention relates the method for preparation of ultra-violet light curing adhesive, which is made by main body rubber, reinforced rubber, deflocculating agent, organosilicon coupling agent, stabilizing agent and photo-initiation agent. The ultra-violet light curing adhesive comprises following characteristics: 1 not needing mix; 2 rapid curing at indoor temperature, and controlling the curing speed; 3 suiting for supermatic flow operation; 4 excellent moisture-proof, low and high temperature impact property resistance, and long life; 5 100% solid coating, no environmental contamination. The UV curing adhesive possesses the advantages of short curing adhesive, strong adhesive force, heat resistance and moisture-proof, so it is used in LCD rim.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

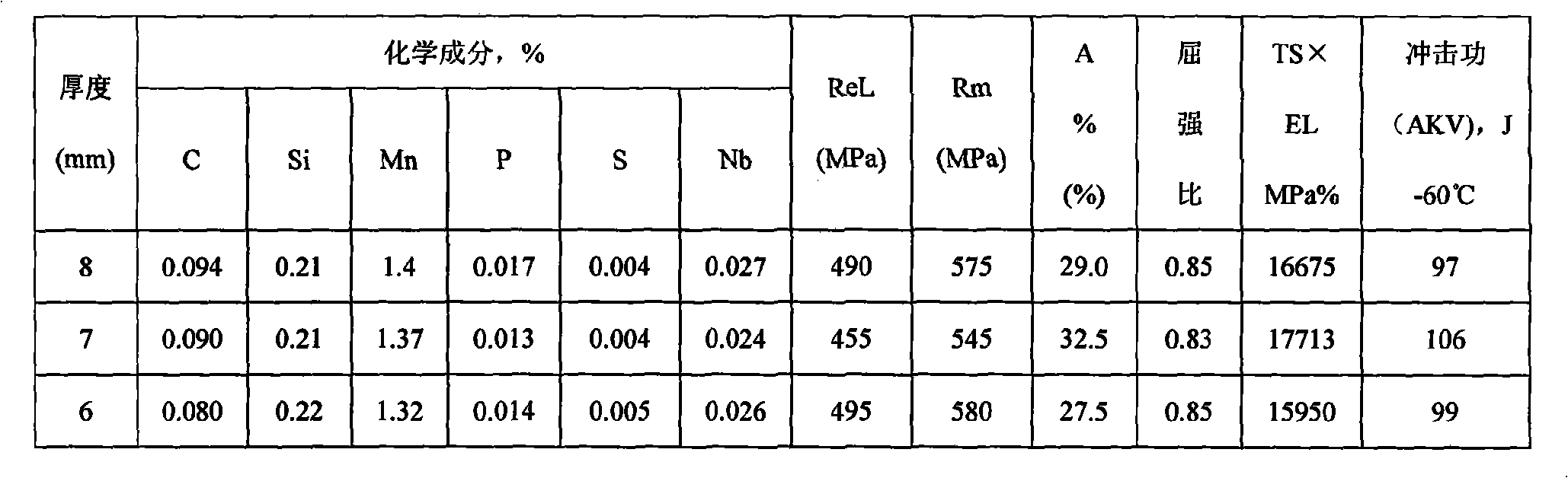

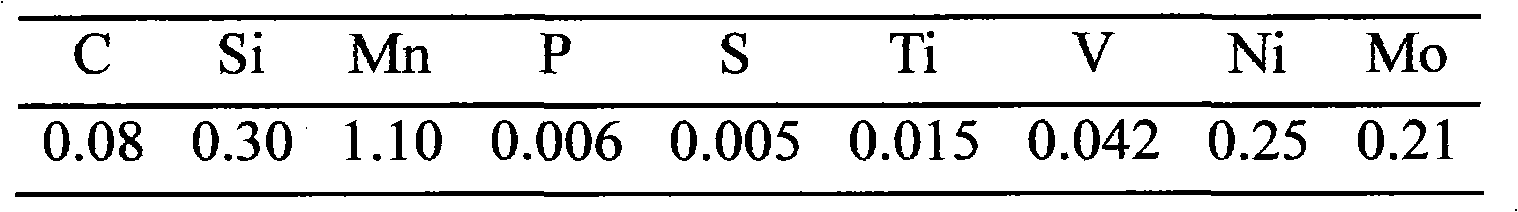

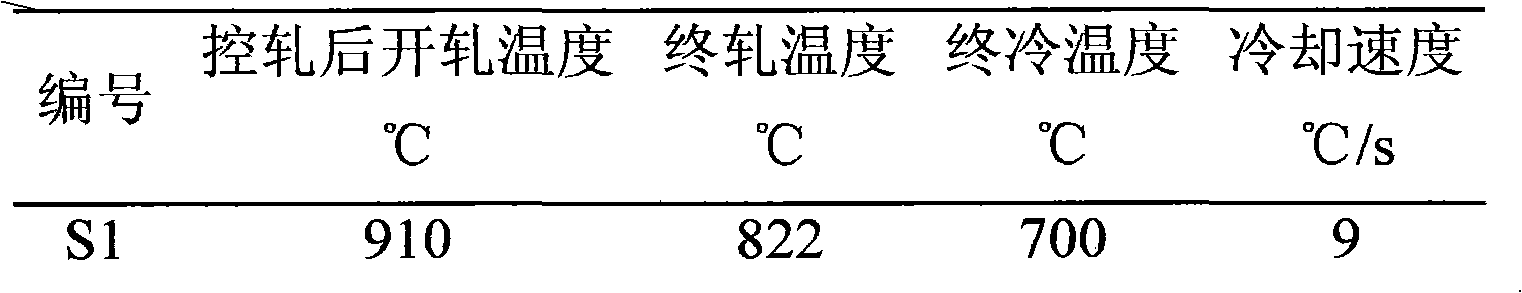

Method for manufacturing high-strength steel plate used in low-temperature environment

ActiveCN101831594AGood welding adaptabilityImprove impact toughnessTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

The invention relates to a method for manufacturing a high-strength steel plate used in low-temperature environment. The steel plate comprises the following chemical components in percentage by weight: 0.06-0.10 percent of C, 0.10-0.40 percent of Si, 0.9-1.40 percent of Mn, 0.010-0.030 percent of Ti, 0.01-0.06 percent of V, 0.0-0.40 percent of Cr, 0.10-0.30 percent of Ni, 0.10-0.30 percent of Mo and the balance of Fe; the equivalent weight of the component carbon is required to be smaller than or equal to 0.45 percent, and the thickness specification of the produced steel plate ranges from 10mm to 60mm. The performance control is carried out by adopting a rolling and cooling control and heat treatment technology; the method has the advantage that the comprehensive mechanical performance of the produced steel plate is greatly improved than that of a steel plate in the same grade; the thickness is between 10mm and 60mm, the yield strength can stably reach not smaller than 490MPa, the tensile strength can stably reach 60kg grade, a low-temperature impact power average value at minus 60 DEG C stably reaches not smaller than 100J, and the high-performance requirement on the steel plate in the low-temperature environment of minus 60 DEG C can be fully met.

Owner:SHOUGANG CORPORATION

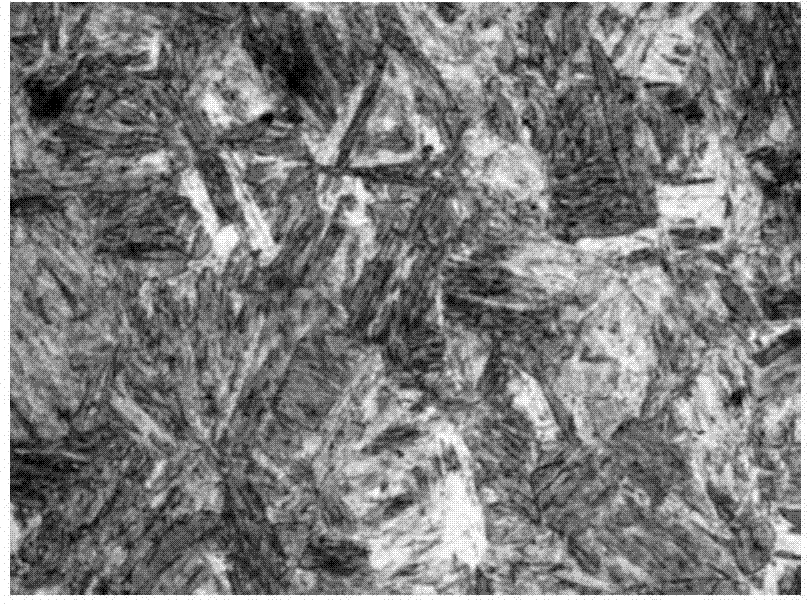

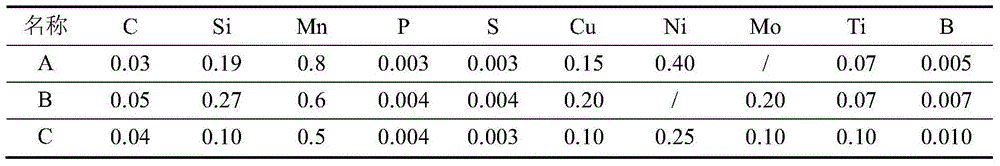

Method for manufacturing seamless pipeline pipe from low-carbon martensite pulp conveying wear-resistant seamless pipeline steel

ActiveCN104726790AImprove hardenabilityGuarantee product qualityFurnace typesHeat treatment furnacesSteelmakingSludge

The invention provides a method for manufacturing a seamless pipeline pipe from low-carbon martensite pulp conveying wear-resistant seamless pipeline steel. The method comprises the following steps: performing steelmaking, namely preparing the low-carbon martensite pulp conveying wear-resistant seamless pipeline steel according to a weight ratio; smelting by adopting an electric furnace or a converter together with an LF (ladle furnace) and a VD (vacuum degasser), wherein before tapping of the electric furnace or the converter, P is required to be less than or equal to 0.010%, then refining with the LF and VD is performed, S is ensured to be less than or equal to 0.005%, [N] is ensured to be less than or equal to 0.0080%, and [O] is ensured to be less than or equal to 0.0020% after refining, an appropriate amount of Al wires are fed at the last stage of the LF, then Fe-Ti wires and Si-Ca wires are fed, and B wires or Fe-B wires are fed before VD vacuum treatment; performing continuous casting; rolling; and processing and performing heat treatment to obtain a seamless pipeline pipe. The method provided by the invention has the effects that a low-carbon boron-containing micro-alloy steel type is adopted, the steel pipe is high in hardenability, a pipe body structure is a martensitic structure, the hardness is 360-440HBW, the wear resistance is good, the welding performance is good, and the low-temperature impact performance is good, so that the pipe is suitable for transportation and treatment of mining tailings. The seamless pipeline pipe can also be used for transmitting semi-fluid and can meet requirements of a concrete pumping system, sludge waste transportation and the like for seamless wear-resistant steel pipes.

Owner:TIANJIN STEEL PIPE MFG CO LTD

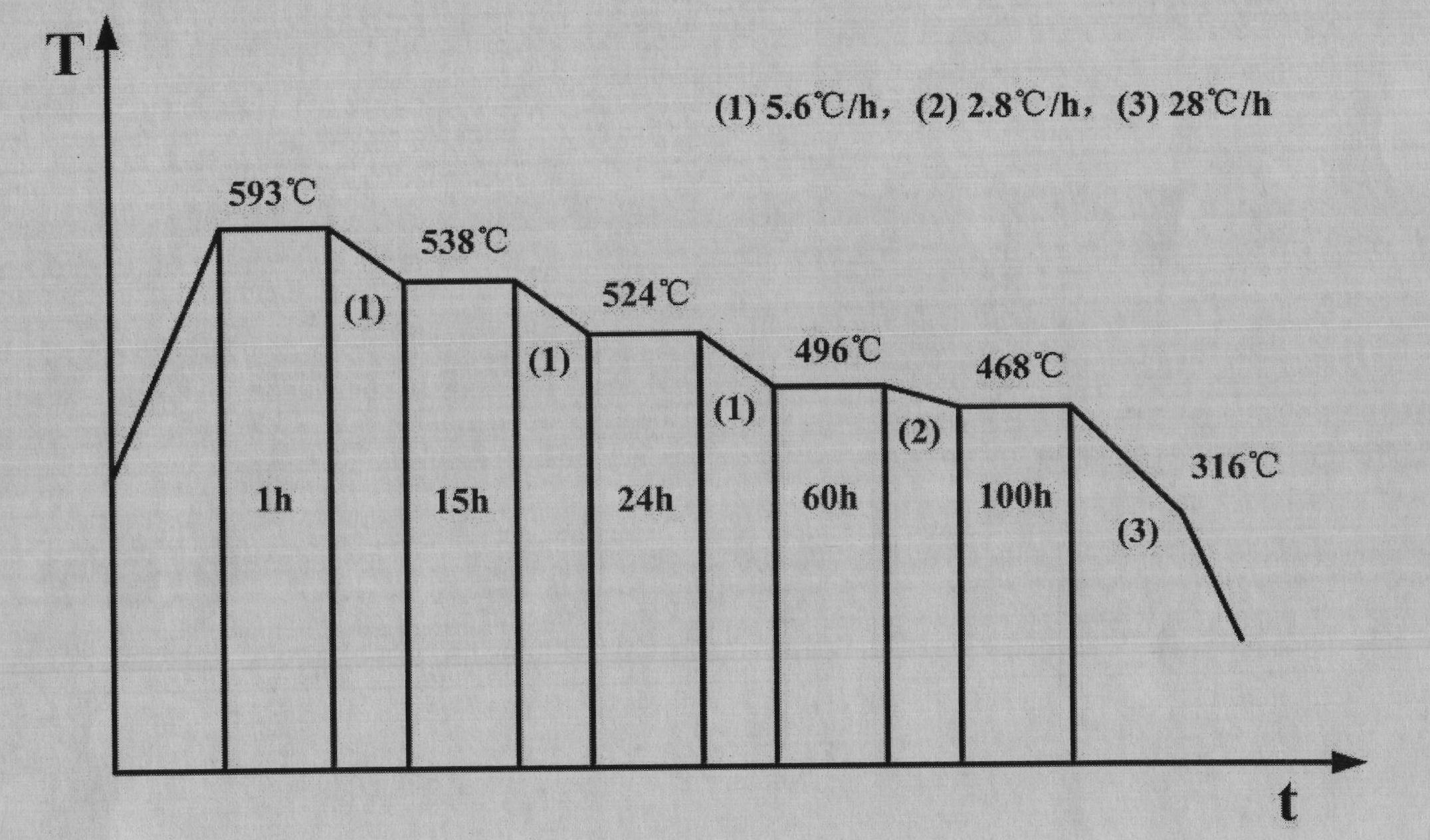

HIC-resistant heat resistant steel in iron element system and preparation process thereof

The invention relates to hydrogen induced cracking (HIC)-resistant heat resistant steel in an iron element system and a preparation process thereof. The steel comprises the following components in percentage by weight: 0.1 to 0.15 percent of C, 0.2 to 0.5 percent of Si, 0.3 to 0.6 percent of Mn, 2.0 to 2.5 percent of Cr, 0.9 to 1.1 percent of Mo, less than or equal to 0.003 percent of S, less than or equal to 0.010 percent of P and the balance of iron and impurities. The preparation process comprises a heating process, a hot rolling process and a heat treatment process sequentially, wherein the heat treatment process comprises a normalizing process and a tempering process. The steel has a high comprehensive mechanical property, a high low-temperature impact property, high HIC resistance and relatively low tempering tendering sensitivity; and the preparation process is simple, easy to operate, low in cost, high in yield and wide in thickness specification ranges, and a small number of alloys with a few varieties are added.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Austenitic stainless steel for low temperature, casting of austenitic stainless steel and manufacturing method of casting

ActiveCN106893945AGood low temperature impact toughnessGood welding performanceFoundry mouldsFoundry coresAustenitic stainless steelNickel

The invention provides austenitic stainless steel for low temperature, a casting of austenitic stainless steel and a manufacturing method of the casting. The austenitic stainless steel comprises lower than 0.08% of C, 1.0%-1.6% of Mn, 0.6%-1.2% of Si, 17.0%-20.0% of Cr, 10.0%-13.0% of Ni, 2.0%-3.0% of Mo, 0.04%-0.12% of N and the balance Fe and impurities; in the impurities, P is smaller than or equal to 0.04%, S is smaller than or equal to 0.02%, Sn is smaller than or equal to 0.015%, As is smaller than or equal to 0.01%, Pb is smaller than or equal to 0.01%, Sb is smaller than or equal to 0.01%, and the sum of the Sn, the As, the Pb and the Sb is smaller than or equal to 0.035%. Chemical components are adjusted, the temperature points of Ms and Md (30 / 50) are controlled, the casting process is reasonably controlled, high-nickel welding rod selection, heat treatment temperature control and the like are achieved, the stability of a cast structure is guaranteed, and the good mechanical performance and size stability are achieved.

Owner:FUJIAN PROVINCE DATONG RECIPROCITY VALVE CO LTD

Gas protection welding wire for nuclear power steel containment vessel

ActiveCN104128715AImprove toughnessReduce manufacturing costWelding/cutting media/materialsSoldering mediaNuclear powerWeld seam

The invention provides a gas protection welding wire for a nuclear power steel containment vessel and belongs to the field of welding materials. The gas protection welding wire comprises, by mass, 0.07%-0.12% of C, 1.10%-1.60% of Mn, 0.25%-0.55% of Si, 0.80%-1.40% of Ni, at most 0.025% of S, at most 0.025% of P, at most 0.20% of Cr, 0.10%-0.30% of Mo, at most 0.50% of Cu, and the balance iron and inevitable impurities. The gas protection welding wire is low in cost, welding arcs are stable, welding spatter is slight, welding seams are formed neatly, obtained deposited metal and welded joints are high in comprehensive mechanical performance in the welded condition, low-temperature impact performance is high, and tenacity is extremely high. The gas protection welding wire can be widely applied to steel structure welding in nuclear power engineering.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +2

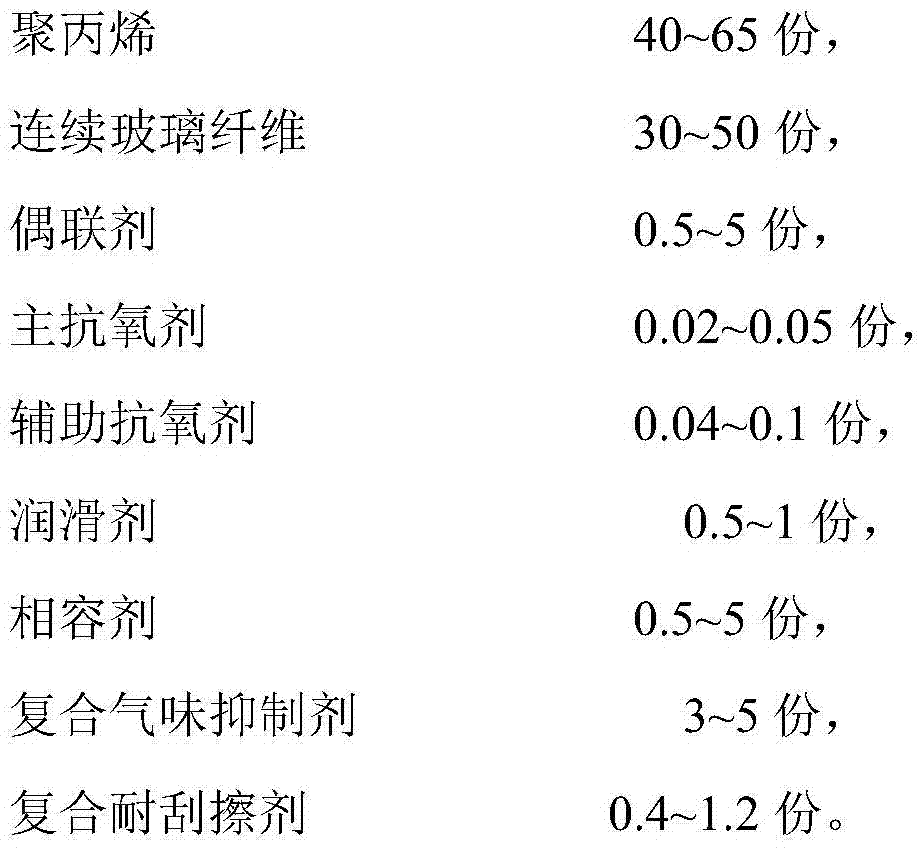

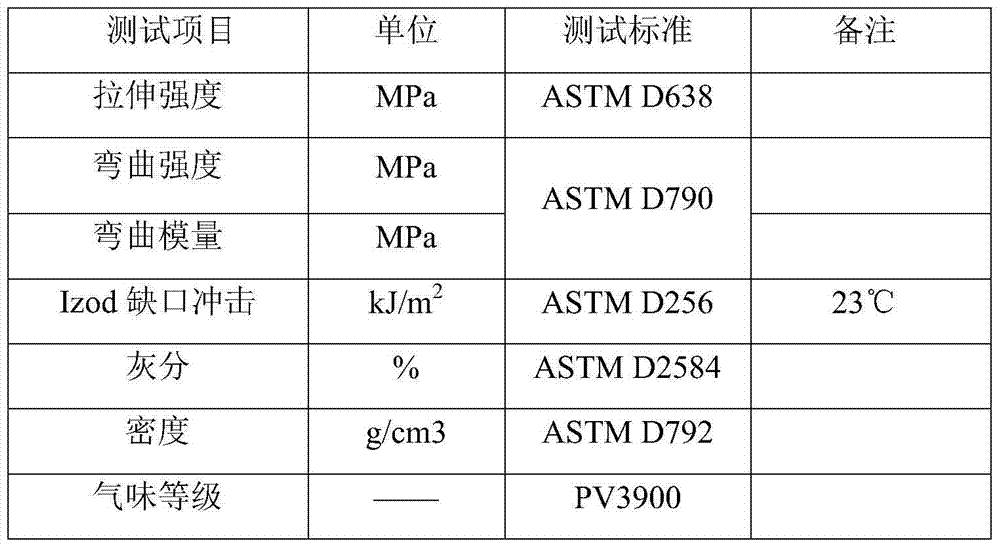

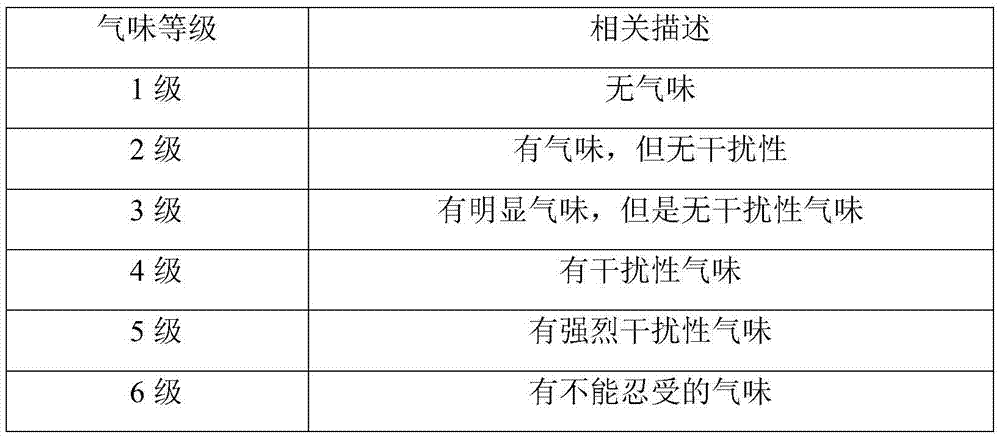

Low-odor and scratch-resistant continuous fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN106995553AMeet the use requirementsOvercome irritating odorGlass fiberPolypropylene composites

The invention belongs to the technical field of high polymer materials, and relates to a low-odor and scratch-resistant continuous fiber reinforced polypropylene composite material and a preparation method thereof. The composite material is prepared from the following ingredients in parts by weight: 40 to 65 parts of polypropylene, 30 to 50 parts of continuous glass fiber, 0.5 to 5 parts of coupling agent, 0.02 to 0.05 part of primary antioxidant, 0.04 to 0.1 part of auxiliary antioxidant, 0.5 to 1 part of lubricant, 0.5 to 5 parts of compatilizer, 3 to 5 parts of compound odor inhibitor and 0.4 to 1.2 parts of compound scratch-resistant agent. By means of adding the compound odor inhibitor and the compound scratch-resistant agent, an odor level of the continuous glass fiber reinforced polypropylene composite material provided by the invention can be 3-level or higher, and a scratch-resistant effect can reach a five-finger scratch color difference value delta L smaller than 1.0; furthermore, original excellent mechanical strength of the continuous glass fiber reinforced polypropylene composite material is not affected after the odor inhibitor and the scratch-resistant agent are added, and application of the continuous glass fiber reinforced polypropylene composite material in automotive upholstery, electric tool casings and parts of home appliance workpieces is widened.

Owner:HEFEI GENIUS NEW MATERIALS

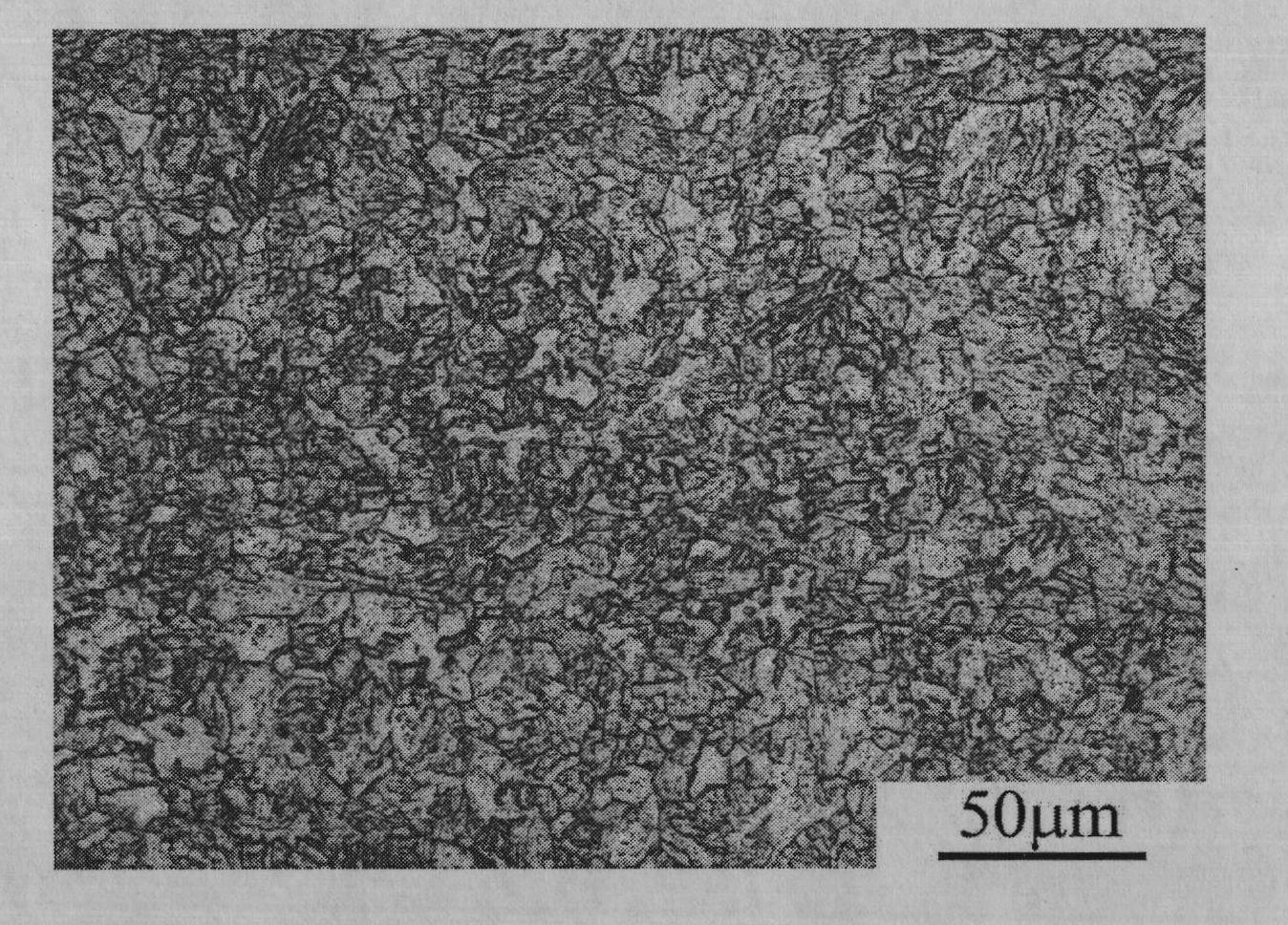

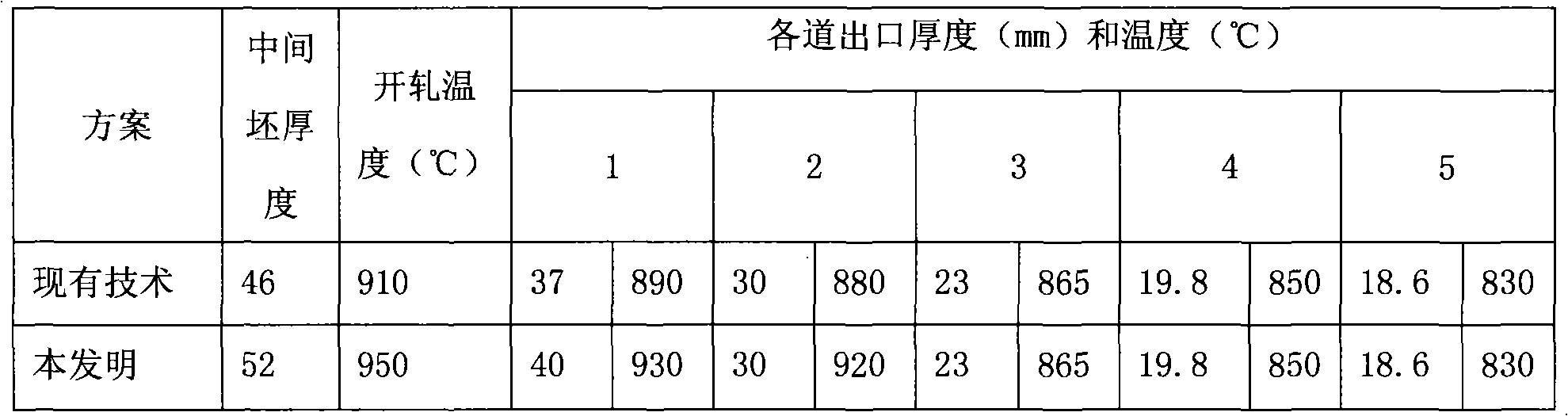

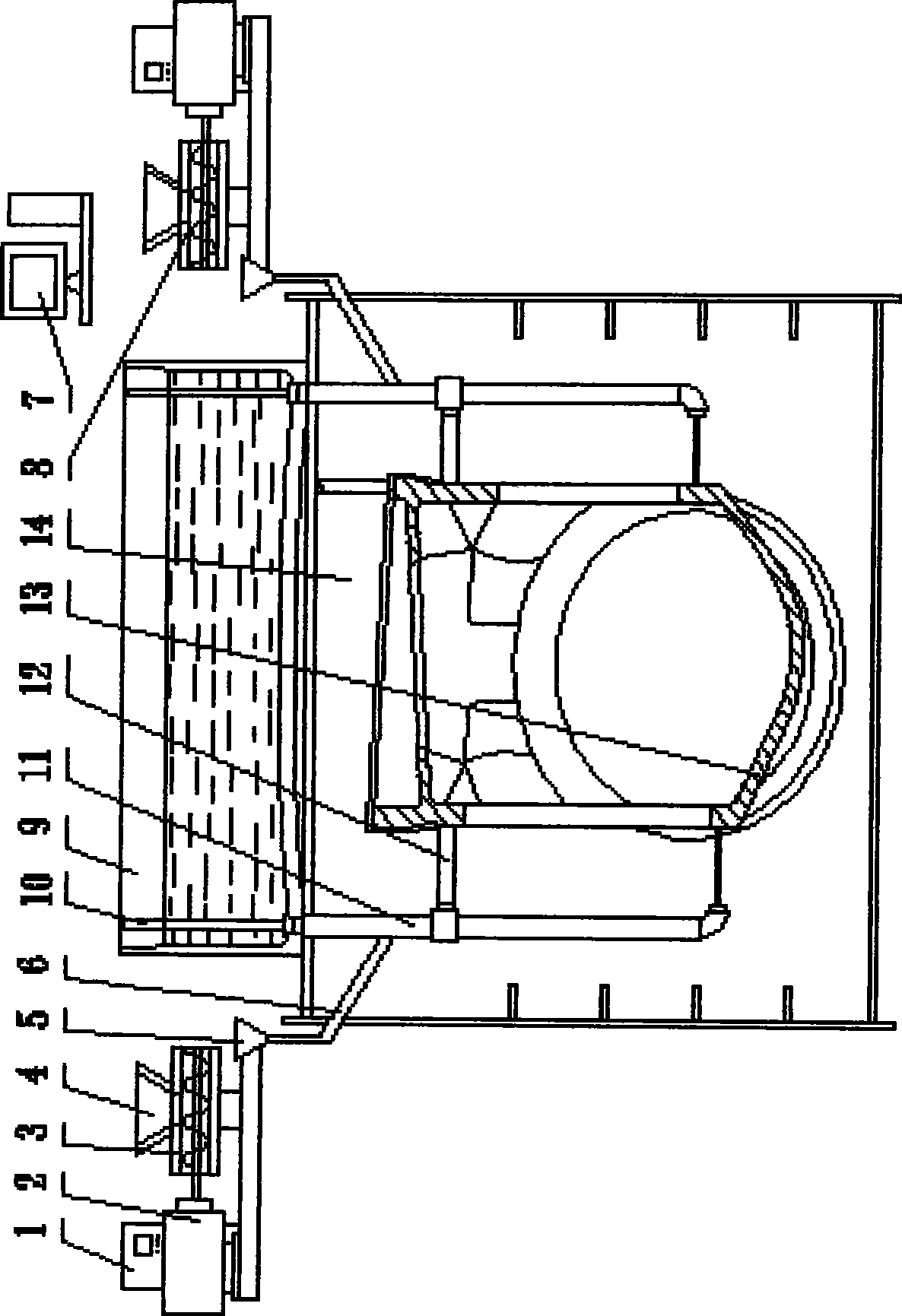

Method for medium plate of controlled rolling at two stages in non-recrystallization region

InactiveCN101954376AImprove deformationReduce generationTemperature control deviceMetal rolling arrangementsSheet steelHigh pressure water

The invention discloses a method for a medium plate of controlled rolling at two stages in a non-recrystallization region. The method is to perform two-stage rolling in a temperature range of the non-recrystallization region so as to improve the initial rolling temperature of rolling in the non-recrystallization region, and reduce the soaking time of an intermediate billet at high-temperature stage. The method comprises the following steps: the intermediate billet is immediately subject to first high pressure water descaling operation, when the intermediate billet is cooled to the temperature of the non-recrystallization temperature region, and then is subject to the first-stage rolling in the non-recrystallization region; the intermediate billet is subject to swing holding on the front or rear roller bed of a rolling mill; and the intermediate billet is subject to second high pressure water descaling operation after the billet is held to the set temperature, and then is subject to second-stage rolling in the non-recrystallization region to obtain the medium plate in accordance with the requirement. The method has few rolling passes and large total deformation of rolling in the non-recrystallization region, improves the output per hour, can stabilize the low-temperature impact performance of the steel plate, and improves the performance qualification rate.

Owner:NANJING IRON & STEEL CO LTD

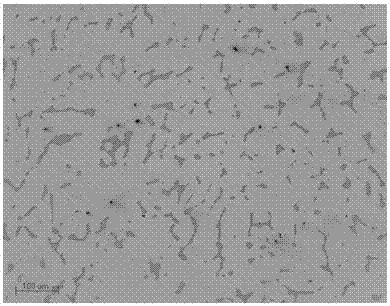

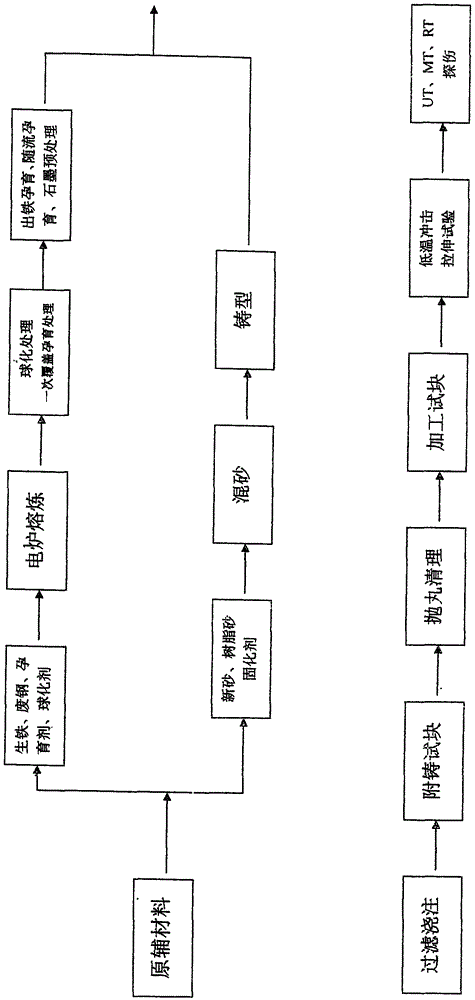

Technology for producing spheroidal graphite cast iron

InactiveCN104451020AInnovativeAdvanced technologyFoundry mouldsFoundry coresChemical compositionCasting mold

The invention discloses a technology for producing spheroidal graphite cast iron, which is characterized in that by optimizing a casting mold technology, a proper filtering cast system is employed, a reasonable chemical component is selected, spheroidising and inoculating treatment can be controlled, high-quality ductile iron pig iron is selected, and the qualified castings of the spheroidal graphite cast iron with -40 DEG C low-temperature impact can be produced by a graphite pretreatment technology and the filtering cast technology. The technology comprises the steps of selecting the raw auxiliary materials of pig iron, waste steel, an inoculants and a nodulizer, melting in an electric furnace, spheroidising, tapping and inoculating, performing stream inoculation, pretreating graphite, filtering and casting, casting test block, performing shot blast cleaning, processing test block, performing a low-temperature impact tensile test, and performing UT, MT and RT flaw detection. The technology is suitable for producing the spheroidal graphite cast iron with -40 DEG C low-temperature impact.

Owner:杨长国

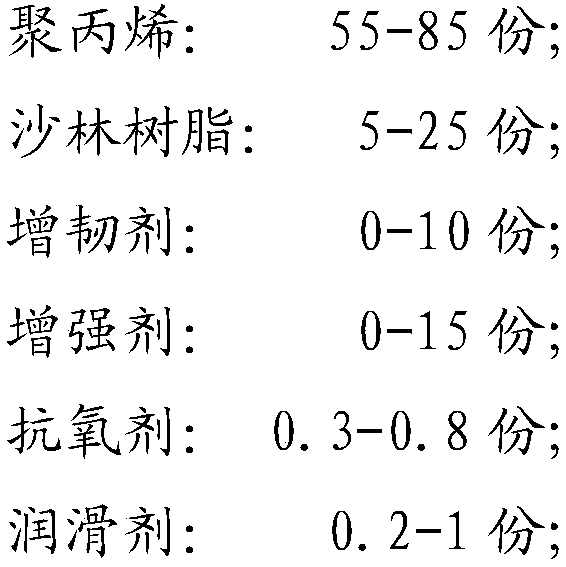

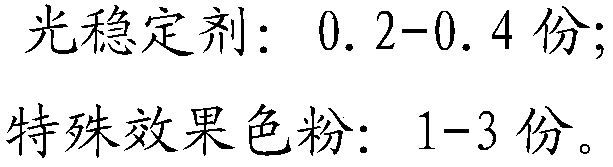

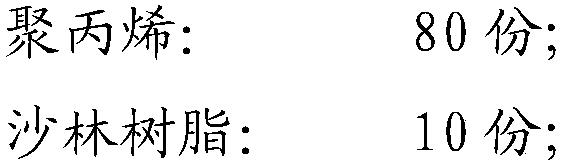

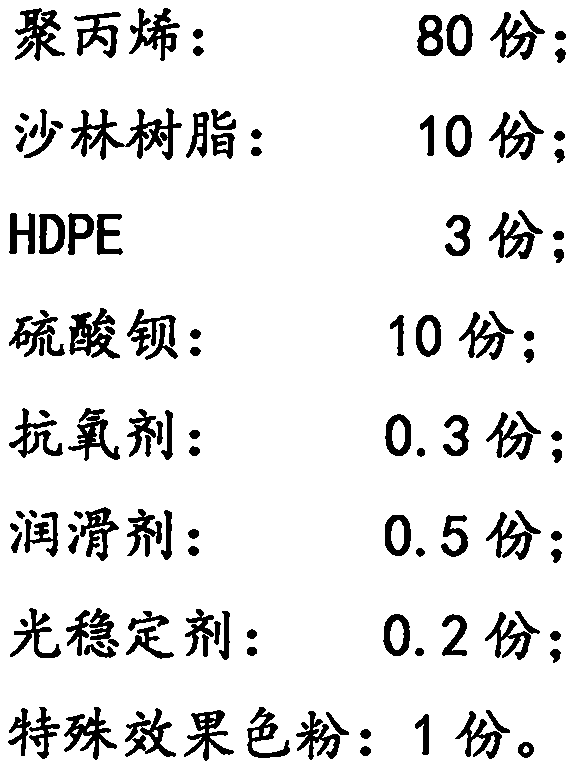

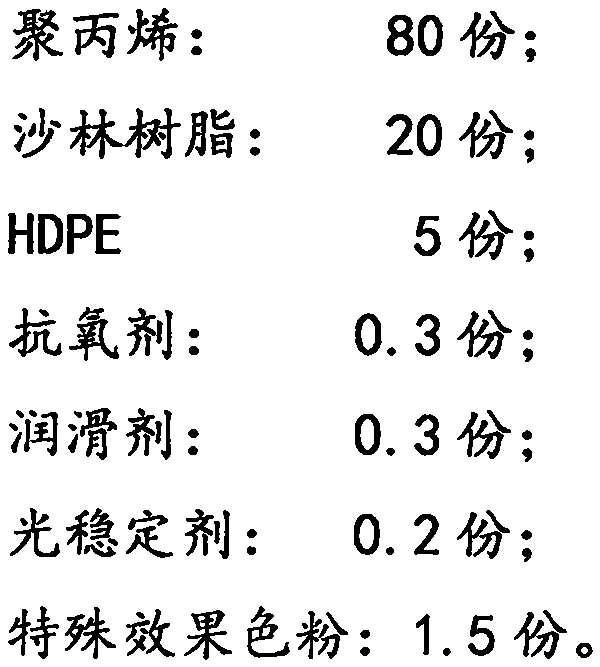

Metal appearance-imitated polypropylene-surlyn composite material and preparation method thereof

InactiveCN108342015AGood low temperature impact propertiesImprove low temperature brittlenessPolypropyleneSpecial effects

The invention relates to a metal appearance-imitated polypropylene-surlyn composite material and a preparation method thereof. The metal appearance-imitated polypropylene-surlyn composite material isprepared from the following components in parts by weight: 55-85 parts of polypropylene, 5-25 parts of surlyn, 0-10 parts of flexibilizer, 0-15 parts of enhancer, 0.3-0.8 part of antioxidant, 0.2-1 part of lubricant, 0.2-0.4 part of light stabilizer, and 1-3 parts of special effect toners. The surlyn has high low temperature impact resistance, and can remarkably improve the low temperature brittleness of a PP material after being added, the composite material has transparency and high gloss, and can remarkably improve the surface gloss of the composite material, so that the visual effect of metal is more outstanding; and the composite material has high scratch resistance, and can be remarkably improved in scratch resistance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

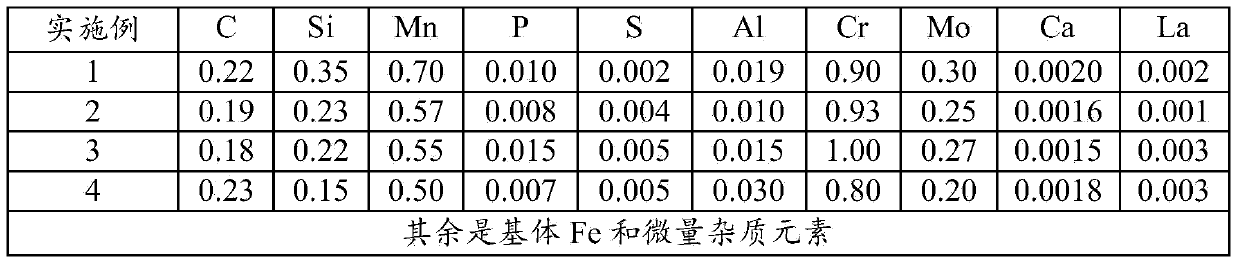

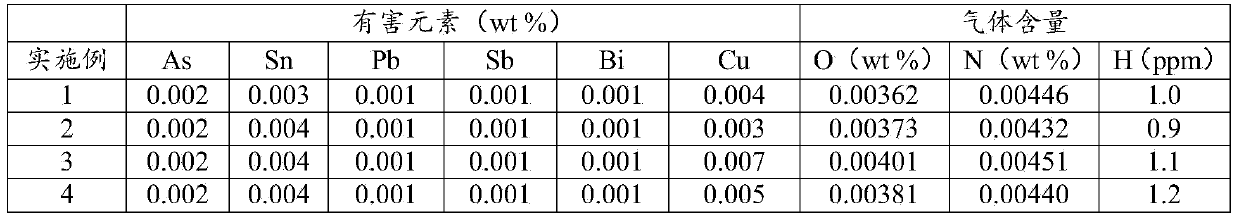

Low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material and production method thereof

InactiveCN103436787AStrong enoughImprove resistance to H

<sub>2</sub>

S corrosion performanceChemical compositionRare earth

The invention discloses a low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material. The low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material comprises the following chemical components in percentage by mass: 0.18-0.23% of C, 0.15-0.23% of Si, 0.50-0.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.05% of S, 0.010-0.030% of Al, 0.80-1.00% of Cr, 0.20-0.30% of Mn, 0.0015-0.0020% of Ca, less than or equal to 0.03% of La and the balance of matrix Fe and impurity elements. The invention also discloses a production method of the low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material. The low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material has the advantages of relatively low cost, good plasticity, low crack sensitivity, low residual stress, good hardenability, stable performance and relatively high percentage of elongation.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

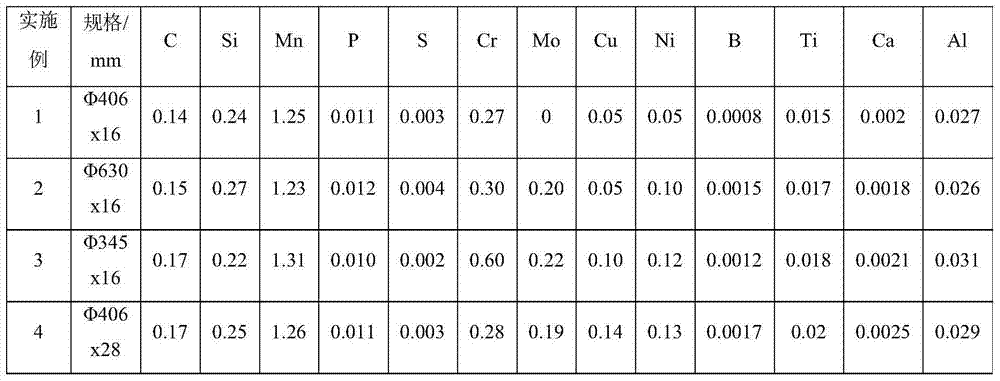

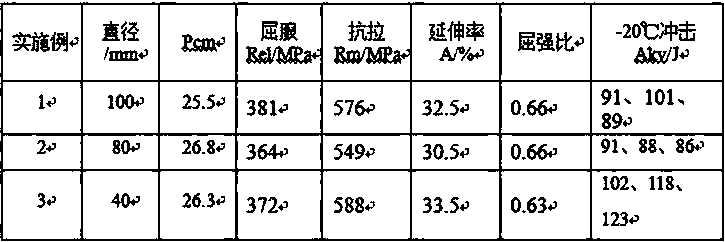

Producing method of hot rolled round steel used for high-rise building structure

The invention discloses a producing method of hot rolled round steel used for a high-rise building structure. The composition weight percentage of the steel is 0.12-0.18 % of C, 0.25-0.50% of Si, 1.20-1.70% of Mn, no more than 0.025% of P, no more than 0.015% of S, no less than 0.020% of Al, 0.41-0.45% of carbon equivalent, and the balance Fe and unavoidable impurities; the key process steps include smelting, LF furnace forging, VD furnace forging, continuous casting, heating, rolling, and cooling; the tensile strength of the produced steel is at 470-630 Mpa, the yield strength is at 315-455 Mpa, the yield ratio is below 0.80, the elongation rate is above 22%, and the welding crack sensitivity coefficient is below 0.28%, the impact Akv at minus 20 DEG C is above 47 J. The hot rolled roundsteel used for the high-rise building structure has high strength, high yield ratio, elongating performance, low temperature impact performance, welding performance, seismic performance and the like and can well meet the using demands of the seismic, refractory, welding performances of the hot rolled round steel of various high-rise building structures.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

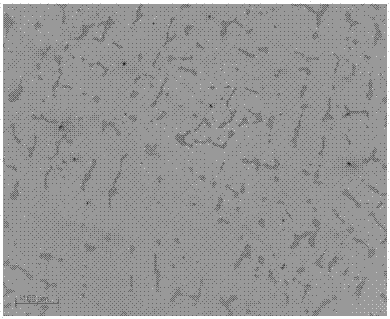

Instant inoculation method of large-section magnesium iron

The invention relates to an inoculation method for large-section ductile iron, which can accurately change the adding speed of inoculant according to different flow rates of molten iron during pouring. The method can be used for producing the large-section ductile iron with high performance requirement and capable of resisting low-temperature shock. The inoculation method for the large-section ductile iron is characterized in that the molten iron is poured into a straight pouring channel from a runner box, an automatic feeding device adds the inoculant into the straight pouring channel through a pipeline at the same time of pouring, the inoculant and the molten iron are in a half filling state in the straight pouring channel, mixed and then poured into a die cavity, and the automatic feeding device automatically adjusts the adding speed of the inoculant according to the flow change of the molten iron.

Owner:辽宁隆达集团百星达铸造有限责任公司

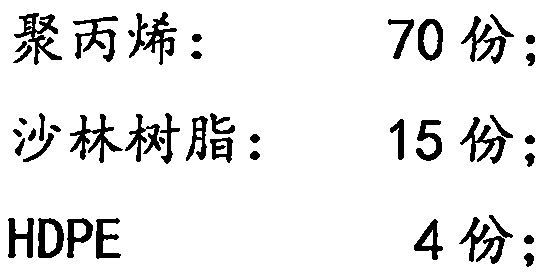

Polypropylene-surlyn resin composite material

The invention relates to a polypropylene-surlyn resin composite material. The composite material comprises, by weight, 55-85 parts of polypropylene, 5-25 parts of surlyn resin, 3-5 parts of HDPE, 0-10parts of a toughening agent, 0-15 parts of an enhancer, 0.3-0.8 part of an antioxidant, 0.2-1 part of a lubricant, 0.2-0.4 part of a light stabilizer and 1-3 parts of special effect color powder. Thesurlyn resin has excellent low-temperature impacting performance, the low temperature brittleness of a PP material can be significantly improved, the surlyn resin is transparent and has high glossiness, the surface gloss level of the composite material can be significantly improved after the surlyn resin is added, a metal imitation visual effect is more outstanding, the surlyn resin has higher scratching resistance, and therefore the scratching resistance of the material can be significantly improved.

Owner:严静儿

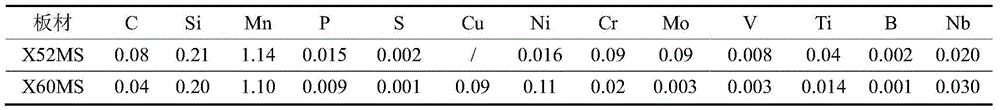

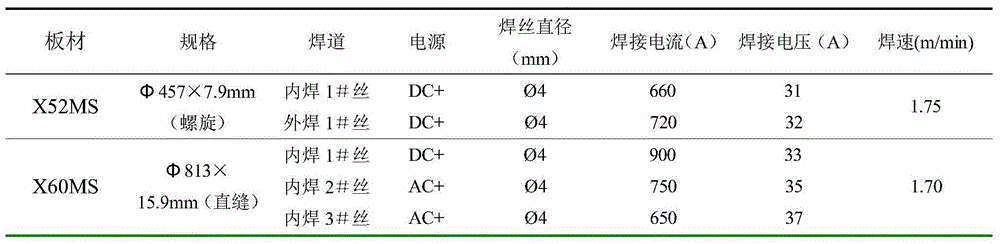

Welding wire suitable for welding low-strength H2S-corrosion-resistant pipeline steel in submerged arc mode

InactiveCN104942469AModerate intensity controlLow Hardness ControlArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthMechanical property

The invention discloses a welding wire suitable for welding low-strength H2S-corrosion-resistant pipeline steel in a submerged arc mode. The welding wire is composed of, by weight, 0.03-0.05% of C, 0.5-0.8% of Mn, 0.1-0.22% of Si, smaller than or equal to 0.005% of P, smaller than or equal to 0.004% of S, 0.1-0.2% of Cu, 0.06-0.15% of Ti and 0.005-0.012% of B and is further composed of, by weight, one or two of 0.2-0.5% of Ni and 0.1-0.2% of Mo and the balance Fe, wherein the sum of C%, Si% / 30, Mn% / 20, Cu% / 20, Mo% / 15 and Ni% / 60 is smaller than or equal to 0.15. The welding wire is mainly developed for welding the low-strength H2S-corrosion-resistant pipeline steel in the submerged arc mode, and the low strength of 360 Mpa to 420 Mpa corresponds to the steel grade of X52MS to X60MS of the acid-resistant pipeline steel; according to the welding wire, on the basis of adding a small amount of Ni and Mo, the contents of impurities of P and S are controlled as mush as possible, it is ensured that a welding joint meets the mechanical properties of an H2S-corrosion-resistant welding pipe with low strength of 360 Mpa to 420 Mpa, and the quite excellent H2S corrosion resistance is achieved as well.

Owner:BAOJI PETROLEUM STEEL PIPE

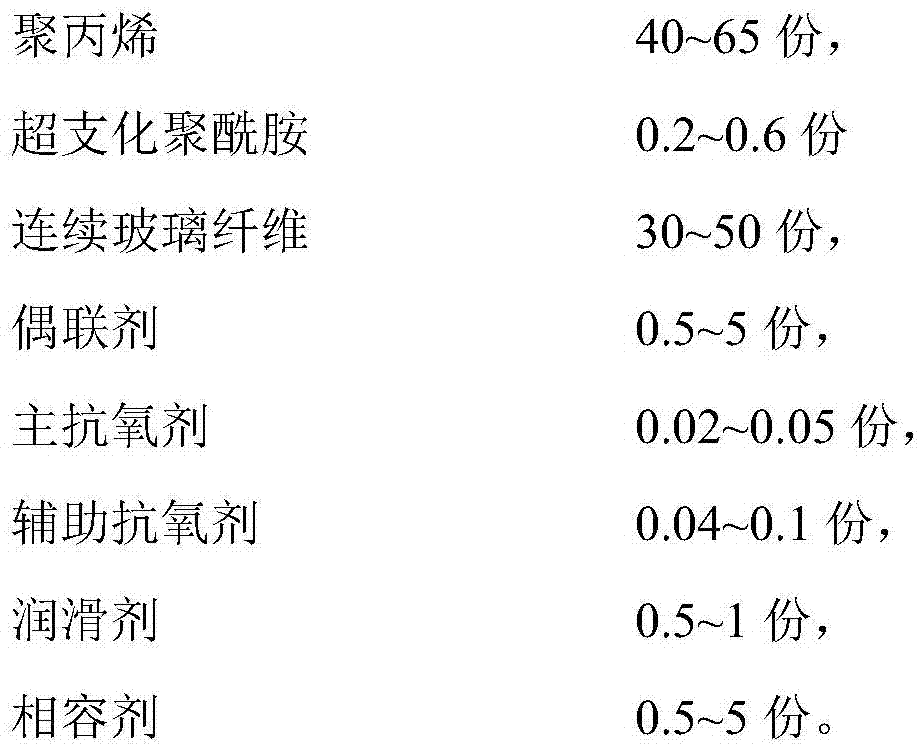

Hyperbranched polyamide modified polypropylene composite material and preparation method thereof

The invention provides a hyperbranched polyamide modified polypropylene composite material and a preparation method thereof. The hyperbranched polyamide modified polypropylene composite material is prepared from 40 to 65 parts of polypropylene, 0.2 to 0.6 part of hyperbranched polyamide, 30 to 50 parts of continuous glass fiber, 0.5 to 5 parts of coupling agent, 0.02 to 0.05 part of primary antioxidant, 0.04 to 0.1 part of auxiliary antioxidant, 0.5 to 1 part of lubricant and 0.5 to 5 parts of compatilizer. The raw materials are mixed, molten, dipped, pulled and extruded to be prepared into the hyperbranched polyamide modified polypropylene composite material. According to the hyperbranched polyamide modified polypropylene composite material disclosed by the invention, alkyl terminated hyperbranched polyamide is utilized as a flow accelerant to be mixed and modified with the low melt index polypropylene to reduce system viscosity, and a melting, pulling and extruding technology is utilized to prepare the continuous glass fiber reinforced polypropylene composite material; thus, material cost is obviously reduced, mechanical property of the material is remarkably improved, and the problems of high raw material cost, difficult processing and shaping and poor product odor in existing continuous glass fiber reinforced polypropylene production are solved.

Owner:HEFEI GENIUS NEW MATERIALS

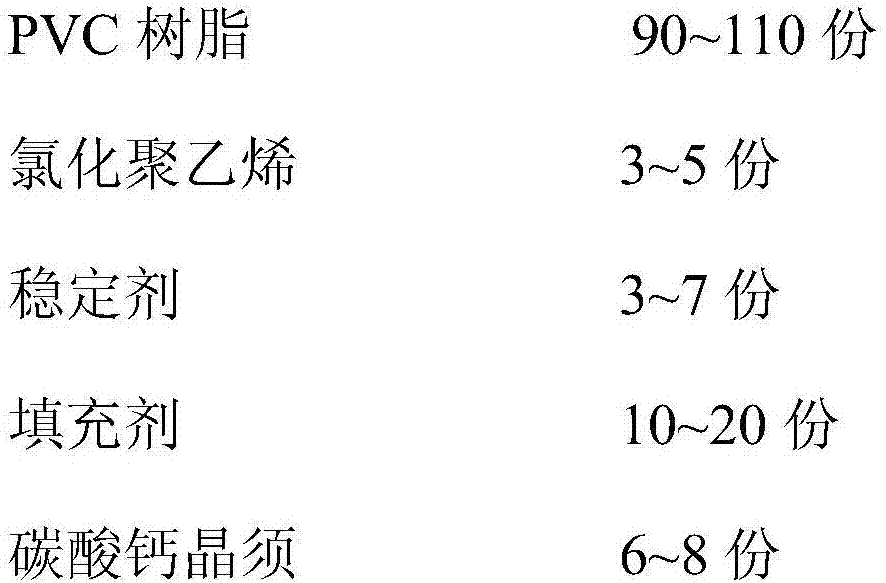

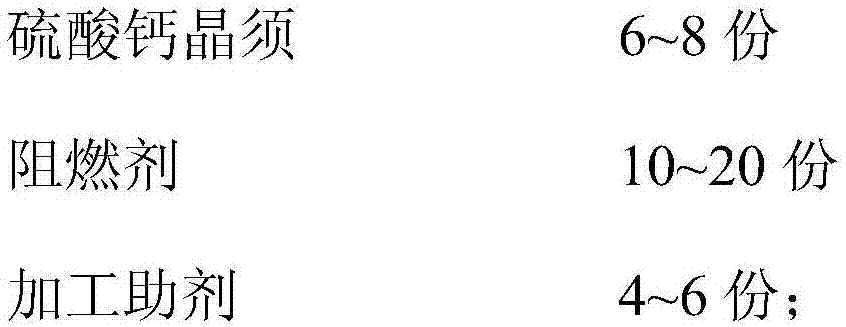

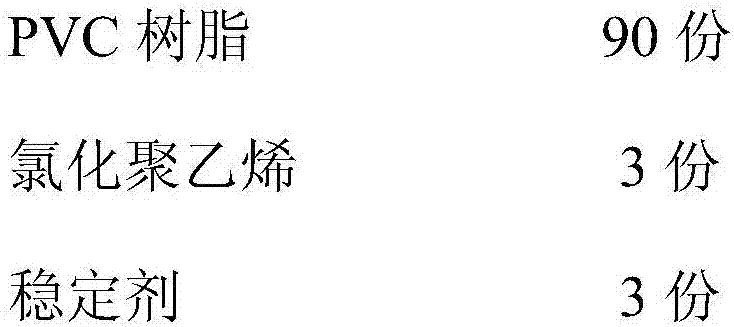

PVC (polyvinyl chloride) electrical conduit with low smoke and high flame retardancy

ActiveCN107987412AReduce surface temperatureReduce pollutionEnvironmental resistanceMelamine phosphate

The invention relates to the field of electrical conduits and discloses a PVC (polyvinyl chloride) electrical conduit with low smoke and high flame retardancy. The PVC electrical conduit is prepared from the following components in parts by weight: 90-110 parts of PVC resin, 3-5 parts of chlorinated polyethylene, 3-5 parts of a stabilizer, 10-20 parts of filler, 6-8 parts of calcium carbonate whiskers, 6-8 parts of calcium sulfate whiskers, 10-20 parts of a flame retardant and 4-6 parts of a processing aid, wherein the flame retardant is composition containing 3-6 parts of zinc borate, 1.5-3 parts of zinc stannate, 2-3 parts of ammonium octamolybdate, 1-2 parts of nano-clay, 1.5-3 parts of melamine phosphate and 1-3 parts of ammonium polyphosphate. The PVC electrical conduit with low smokeand high flame retardancy has the advantages of good environment-friendliness, excellent flame retardancy, proper smoke amount, good tensile strength and tensile rate, high oxygen index, good low-temperature impact performance and the like.

Owner:浙江高峰控股集团有限公司

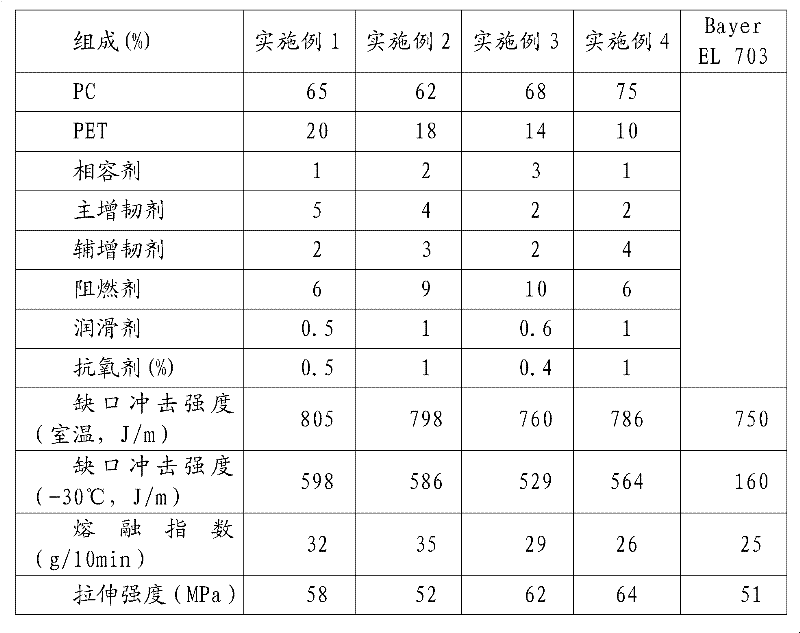

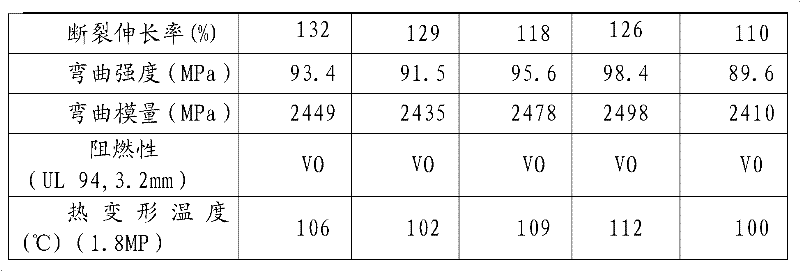

Flame-retardant PC (polycarboante)/PET (polyethylene terephthalate) composite material and preparation method thereof

InactiveCN102329492AGood mold filling fluidityGood low temperature impact propertiesPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a flame-retardant PC (polycarboante) / PET (polyethylene terephthalate) composite material and a preparation method thereof. The flame-retardant PC / PET composite material is prepared from the following components in percentage by weight: 65-75% of PC, 15-25% of PET, 1-2% of antioxidant, 4-8% of main toughener, 2-4% of auxiliary toughener, 0.5-2% of lubricant, 6-15% of flame retardant and 1-3% of compatibilizer. The flame-retardant PC / PET composite material disclosed by the invention has good mold filling fluidity, has excellent low-temperature impact resistance compared with the prior art, is an environment-friendly alloy material with excellent comprehensive performance, and can substitute for low-temperature-resistant flame-retardant polycarbonate or high-impact-resistant flame-retardant polycarbonate / acrylonitrile-butadiene-styrene alloy to be applied in electric products, traffic and transportation, communication devices and other industries.

Owner:SHENZHEN KEJU NEW MATERIAL

Rolled steel for wind-power flange and preparation method thereof

The invention relates to rolled steel for a wind-power flange. The rolled steel mainly comprises the following components in percentage by weight: 0.15-0.19 percent of C, 0.17-0.35 percent of Si, 1.45-1.55 percent of Mn, 0.060-0.090 percent of V, 0.02-0.04 percent of Nb, 0.015-0.040 percent of Al, less than or equal to 0.005 percent of Ti, less than or equal to 0.0015 percent of [O], less than or equal to 0.0120 percent of [N], less than or equal to 0.005 percent of S, less than or equal to 0.012 percent of P, less than or equal to 0.04 percent of As, less than or equal to 0.00015 percent of [H] and the balance of Fe. In the invention, the yield strength of the rolled steel is more than 465 MPa, and the tensile strength is more than 580 MPa; and the rolled steel has the characteristics of low-temperature resistance, high welding performance, high strength, high crack sensitivity resistance, high welding performance and high low-temperature impact performance, and can better adapt to the requirement of rolled steel for the wind-power flange in the wind-power industry.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com