Method for medium plate of controlled rolling at two stages in non-recrystallization region

A non-recrystallized zone and stage control technology, applied in the field of medium plate rolling, can solve the problems of large deformation resistance, difficulty, and increase of rolling passes, and achieve stable low-temperature impact performance, improved performance qualification rate, and increased overall Deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

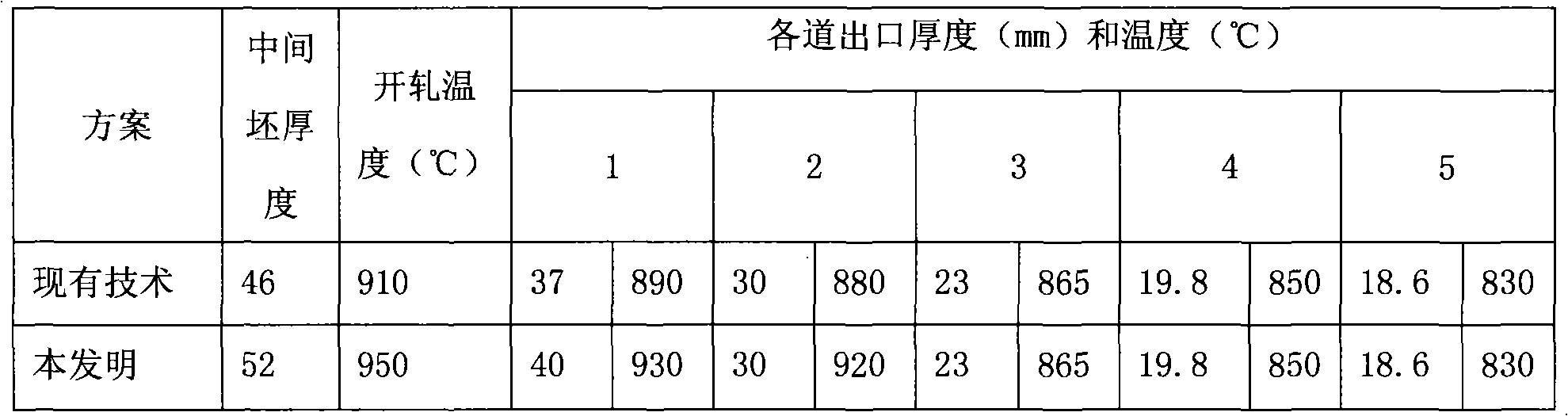

[0018] A 2800 double-stand four-high rolling mill medium plate factory adopts the invention to adjust and roll the 18.6×2000 X60 pipeline for rolling a 220mm billet.

[0019] A method for two-stage controlled rolling of a middle plate in a non-recrystallization zone, the method is two-stage rolling within the temperature range of the non-recrystallization zone, increases the rolling start temperature of the non-recrystallization zone, and reduces the waiting time for the high-temperature stage of the intermediate billet Warming time, the specific steps are as follows:

[0020] Once the intermediate billet is cooled to the non-recrystallization temperature zone, the first high-pressure water descaling operation is performed immediately, and the first-stage rolling is carried out in the non-recrystallization zone; the rolling passes of the first stage can be 2-4 passes , if there is a high-pressure water descaling system behind the rolling mill, it can be rolled for 3 passes, ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com