Iron clud head

a technology of iron club head and clud head, which is applied in the field of iron club head, can solve the problems of ineffective expansion of the elastic deformation area of the striking plate b>2/b>, adverse affect the coefficient of restitution of the body, etc., and achieve the effect of improving the overall elastic deformation capacity of the iron club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

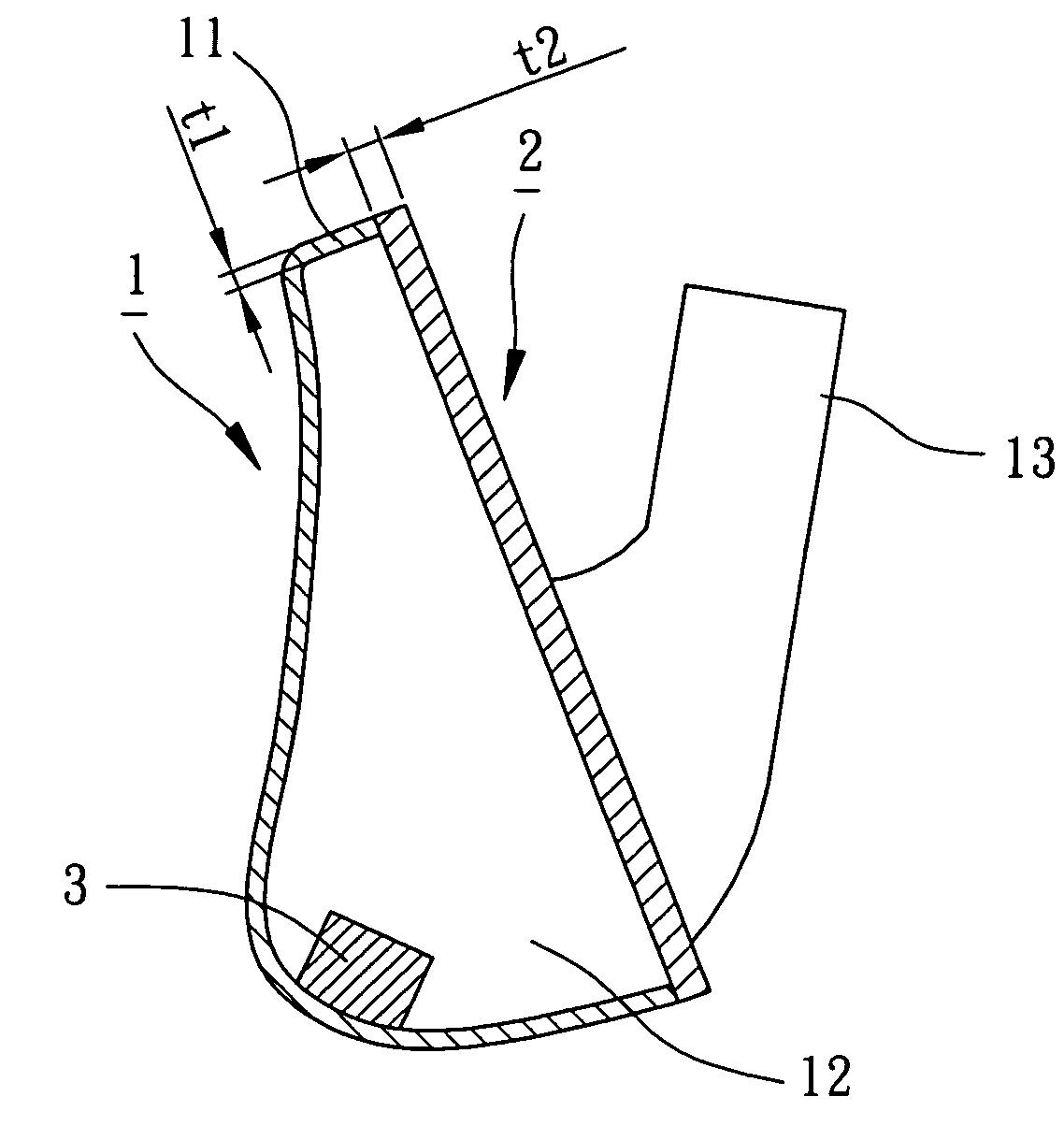

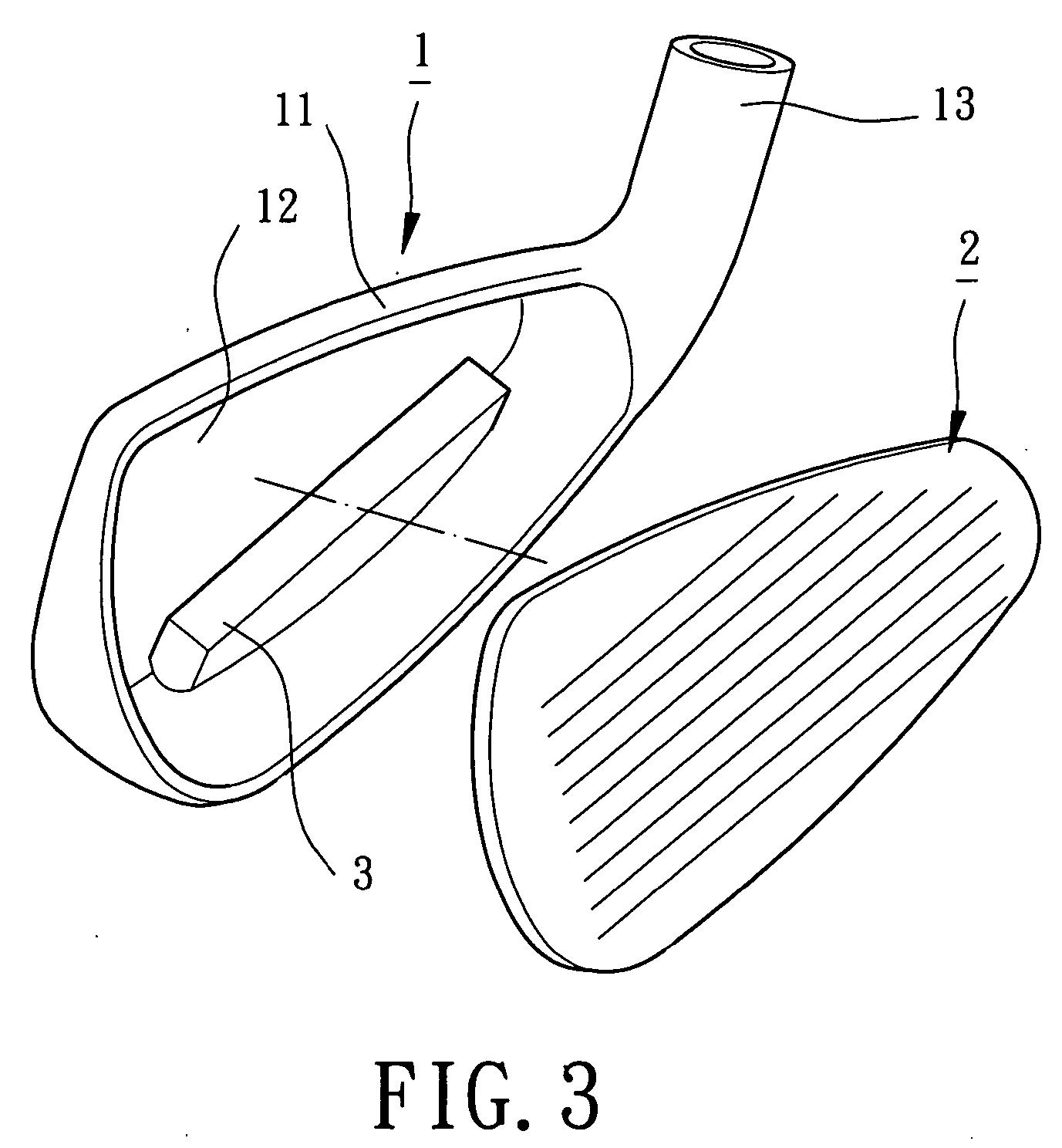

[0022] Referring to FIGS. 3 and 4, an iron club head in accordance with the present invention comprises a body 1, a striking plate 2, and a weight member 3. The body 1 includes an elastically deformable thin wall 11 and an opening 12 in a front side of the body 1. The thin wall 11 includes an open front side and a closed rear side and surrounds the opening 12 in the front side of the body 1. A hosel 13 extends from a side of the body 1 for engaging with a shaft (not shown). The thin wall 11 has a thickness t1 preferably between 0.5 mm and 2.0 mm, most preferably 0.7 mm and 1.5 mm. The thickness t1 of the thin wall 11 may be uniform throughout the thin wall 11 or varied within a range. The coefficient of restitution (COR) of the thin wall 11 can be increased by means of reducing the thickness t1 of the thin wall 11. Thus, adverse affection to the elastic deformation and momentum resulting from the damping effect of the material of the thin wall 1 is eliminated and / or obviated. In a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com