Patents

Literature

495 results about "Leakage flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

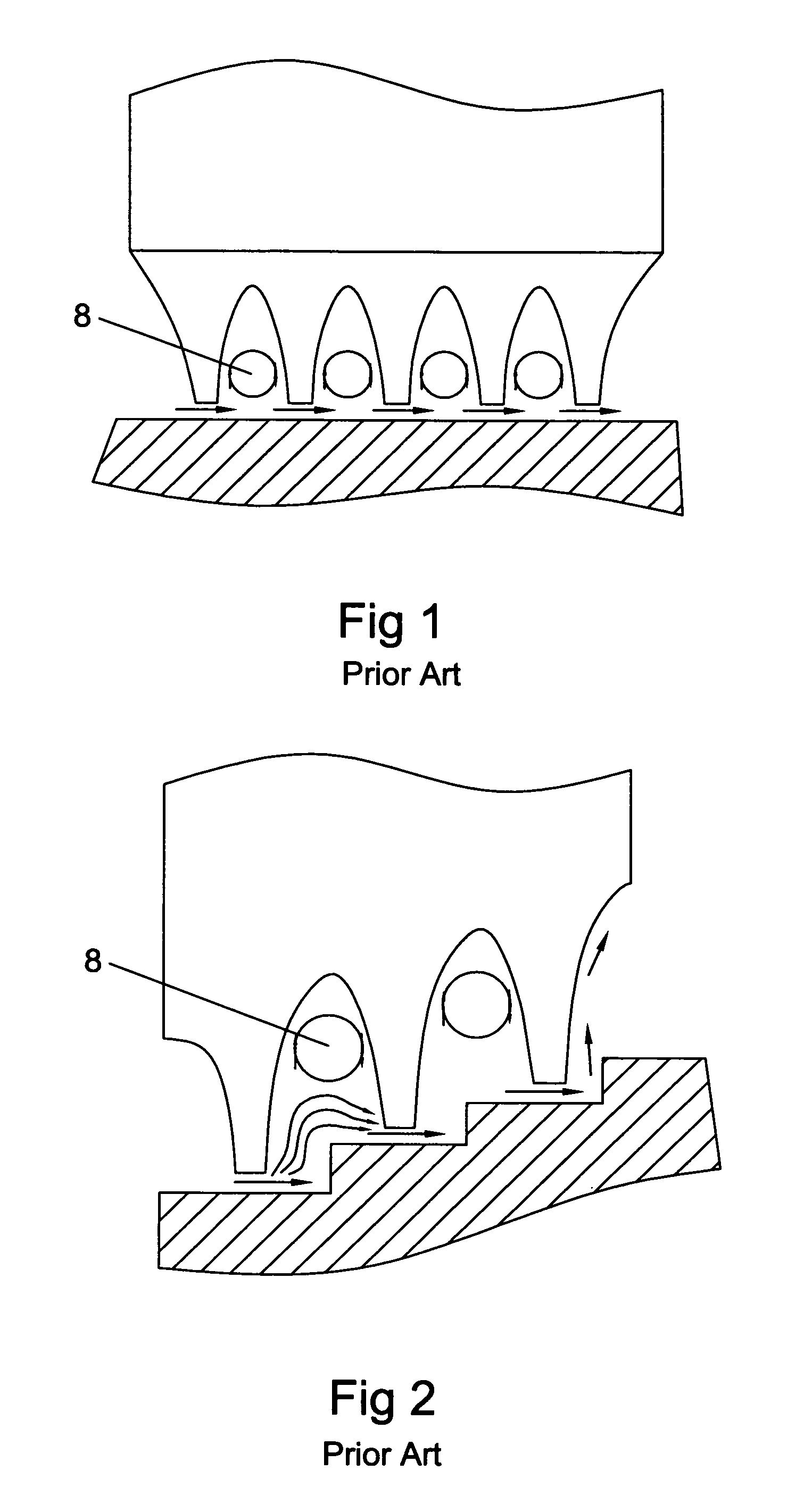

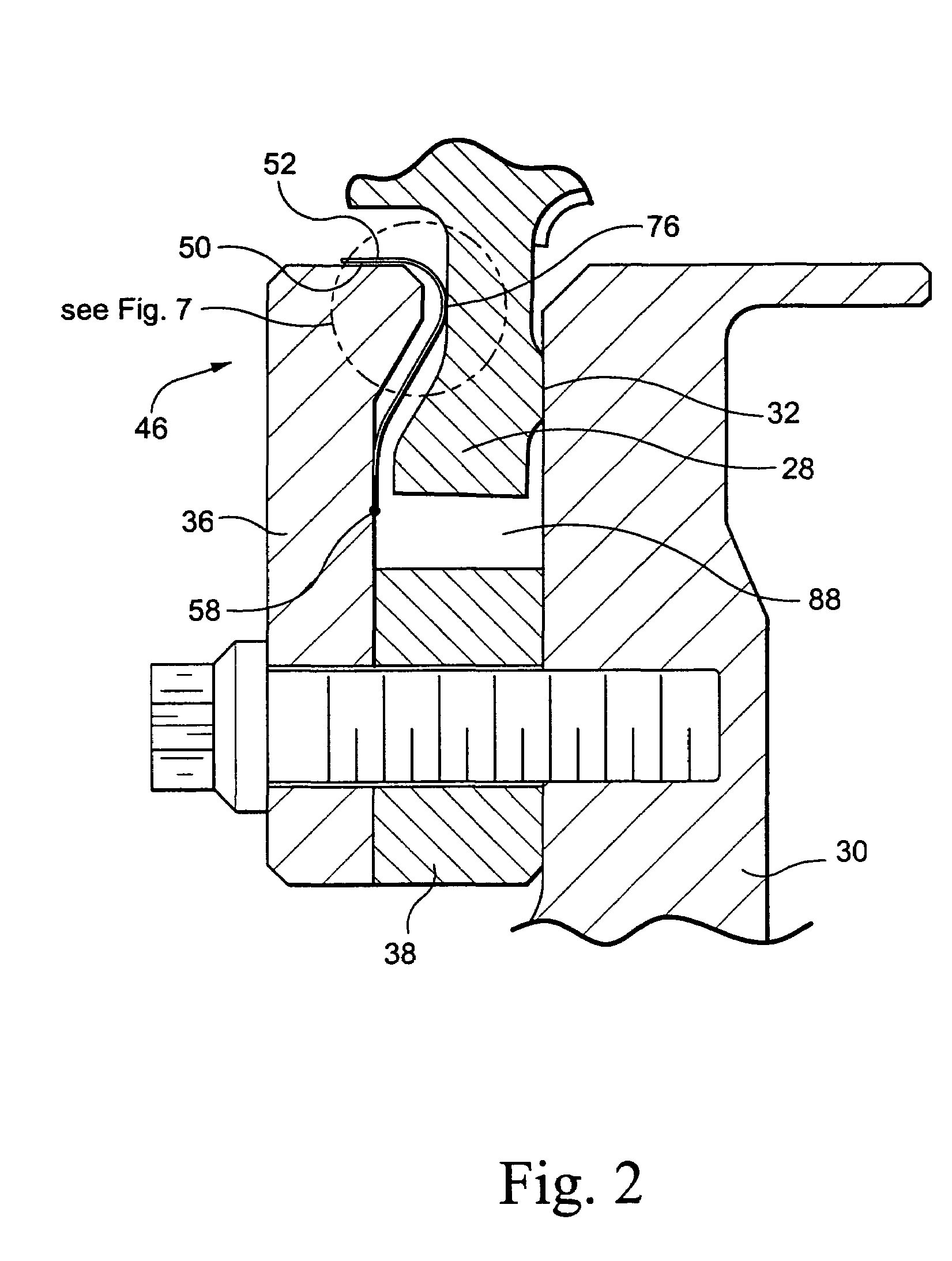

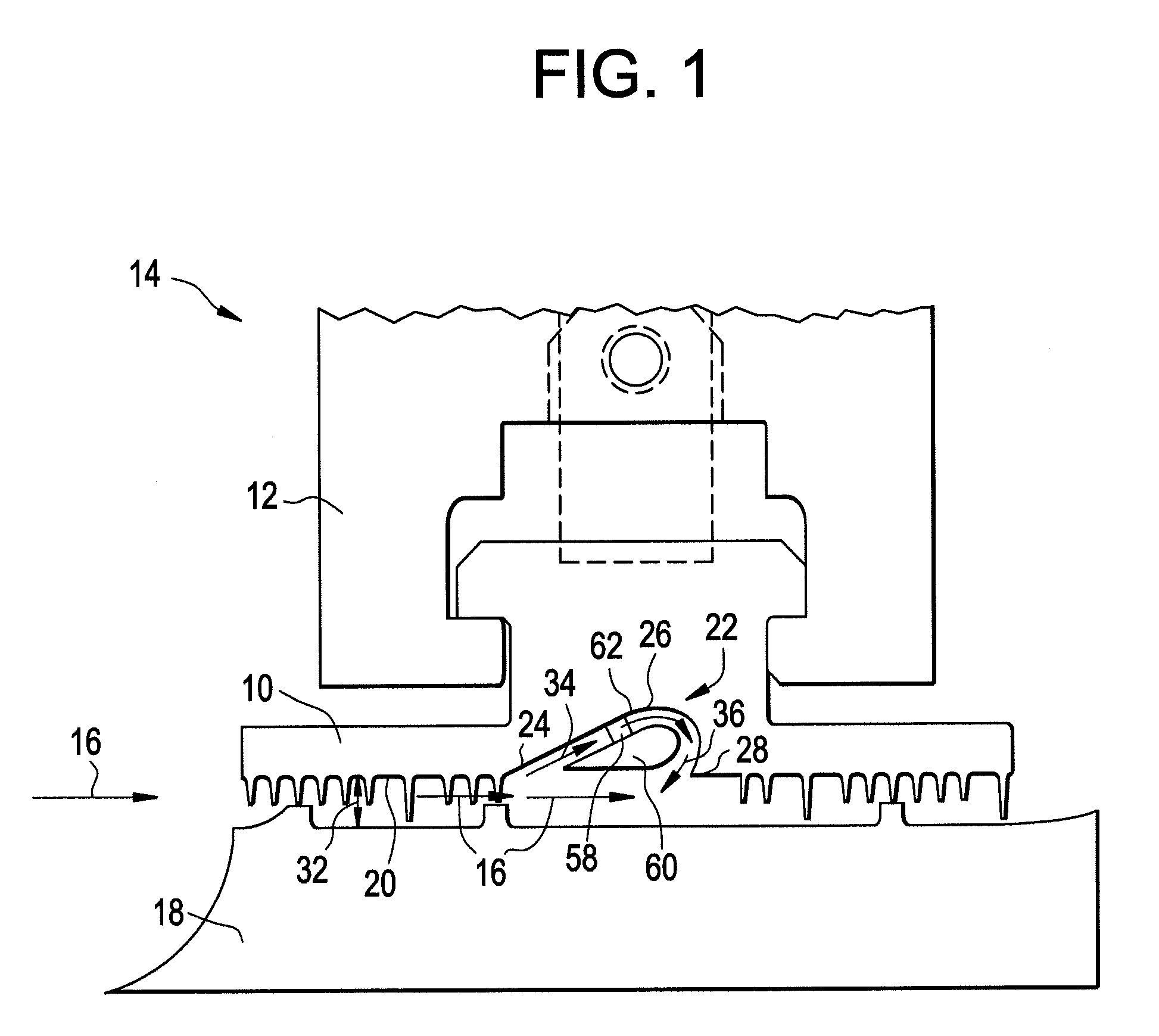

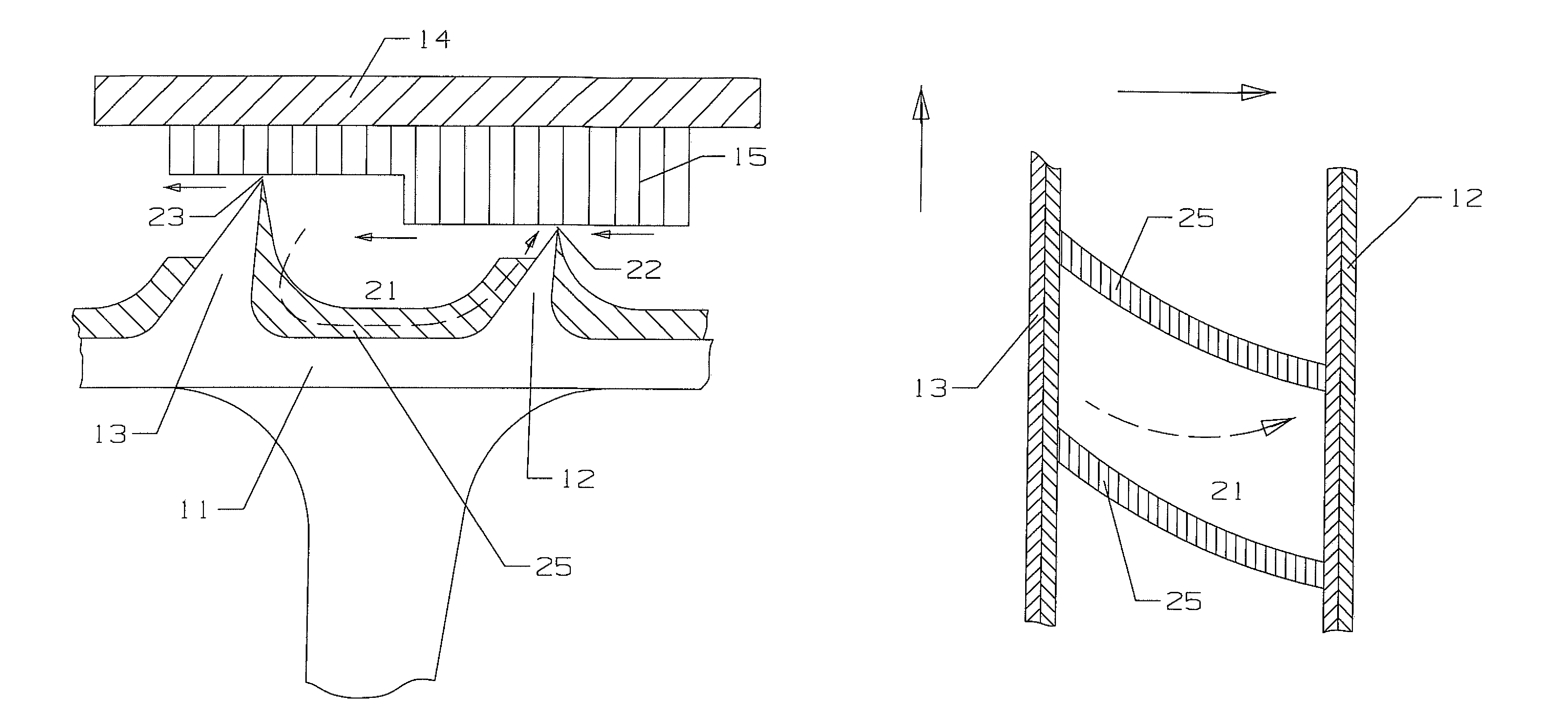

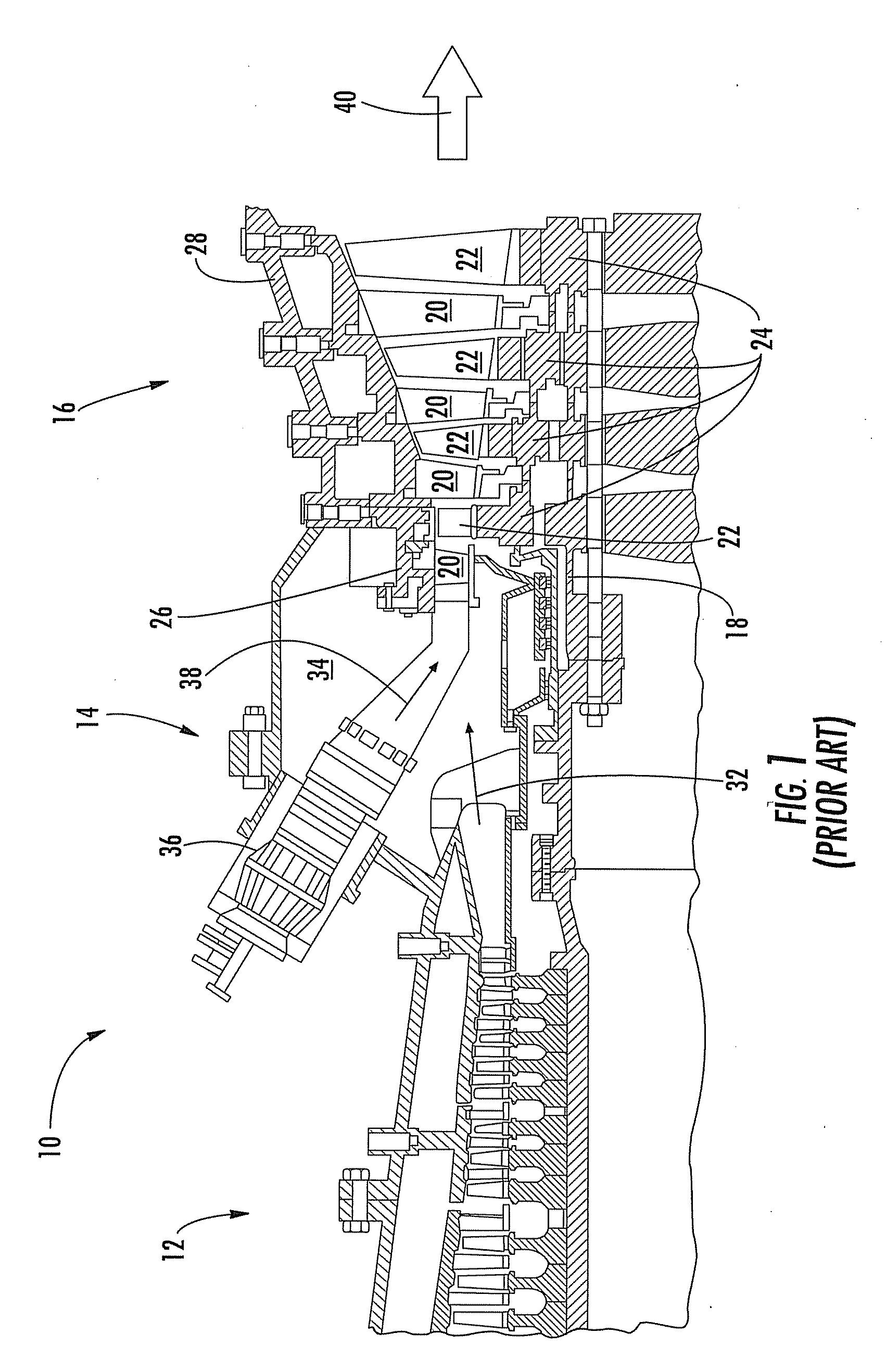

Stepped labyrinth seal

InactiveUS7445213B1Without slowing leakage flowReduce the impactEngine sealsEngine manufactureEngineeringLeakage flow

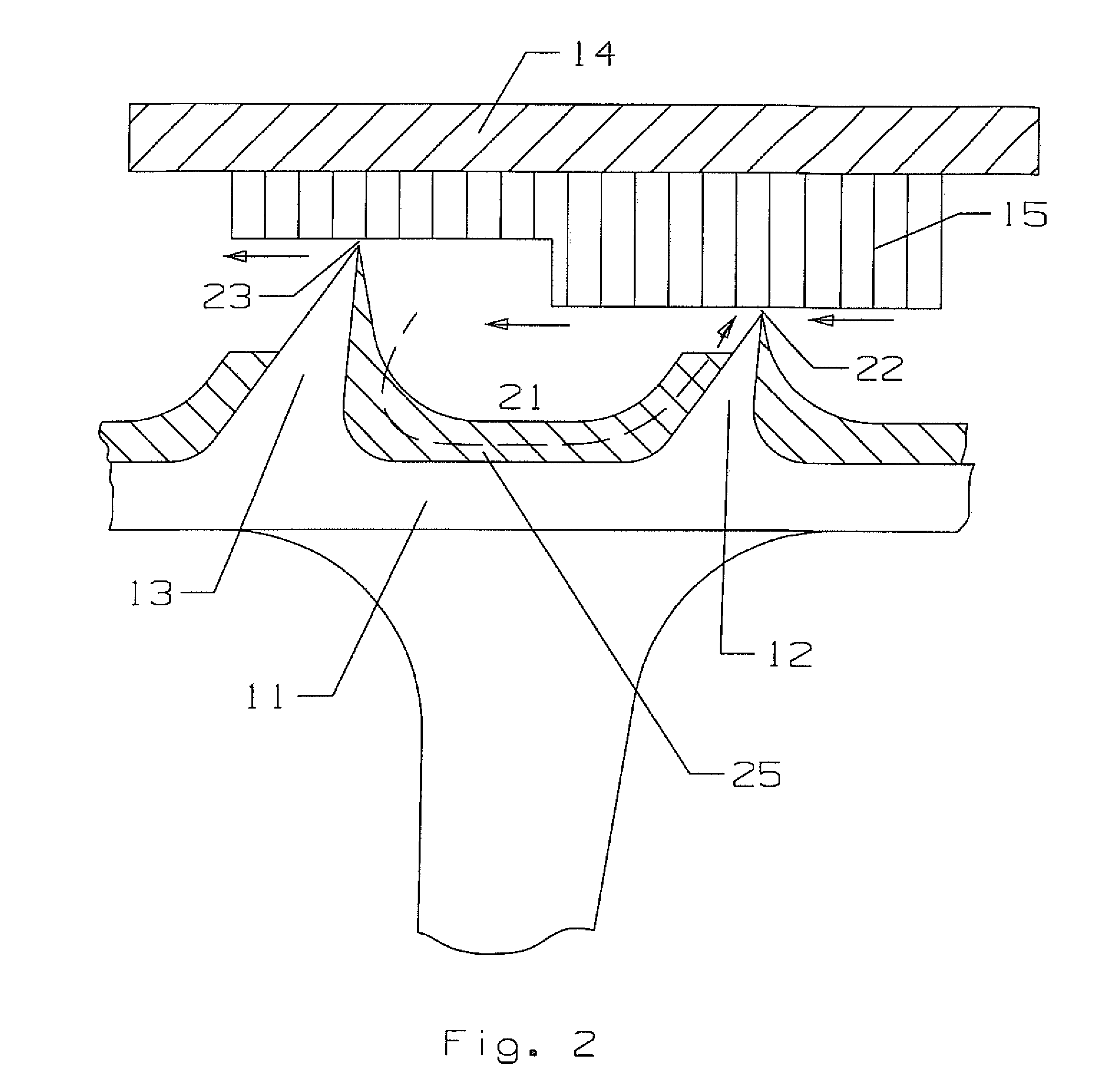

A stepped labyrinth seal for a turbomachine, the seal having a stepped portion with a redirecting groove formed thereon to redirect a leakage flow through the gap in substantially a reverse direction and onto a surface of the finger such that the dynamic pressure of the leakage flow is not substantially reduced and the static pressure increased. The cavity formed between adjacent fingers has a flow guiding surface that maintains the dynamic pressure of the flow, thereby keeping the flow at high velocity and low static pressure.

Owner:FLORIDA TURBINE TECH

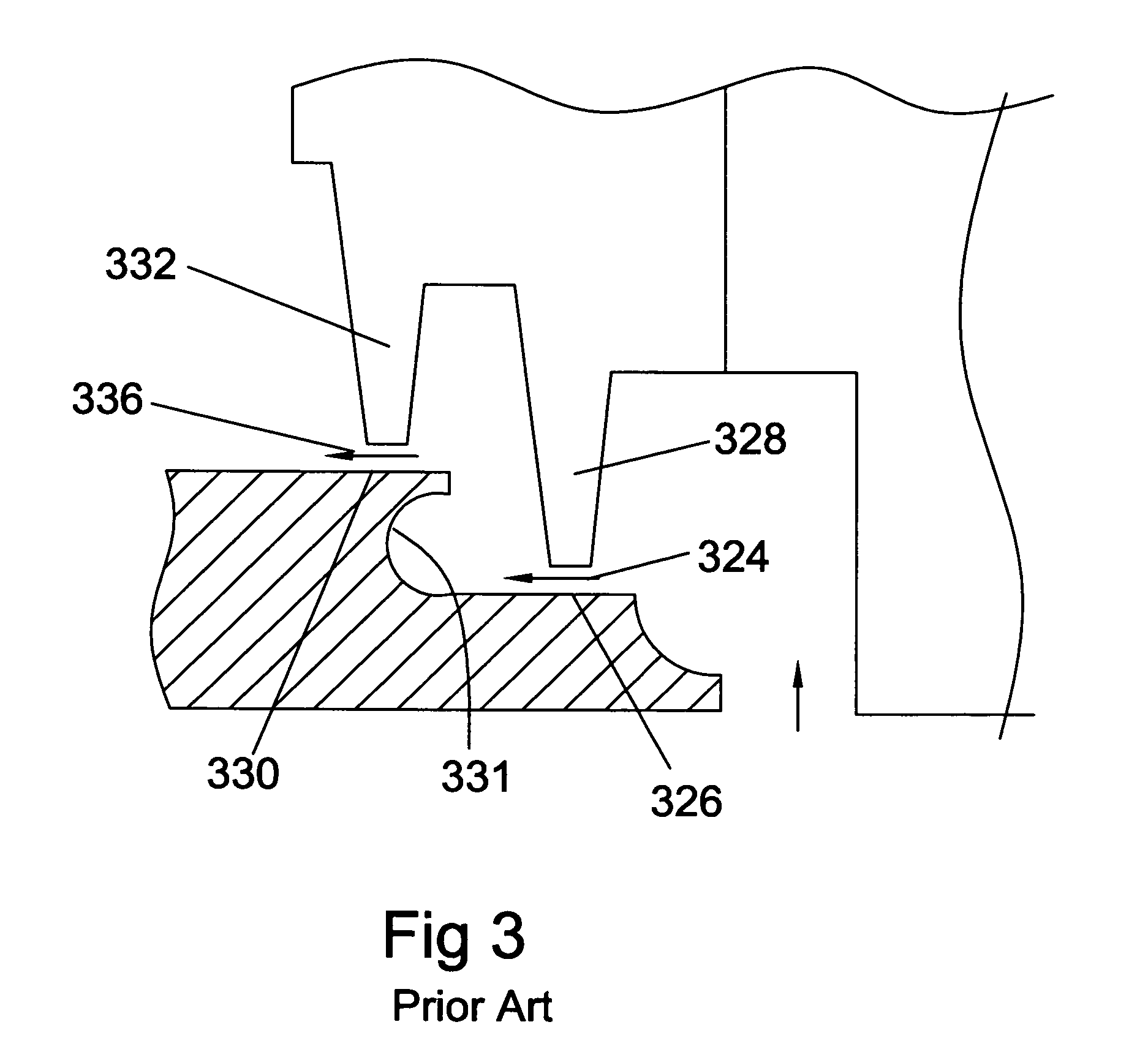

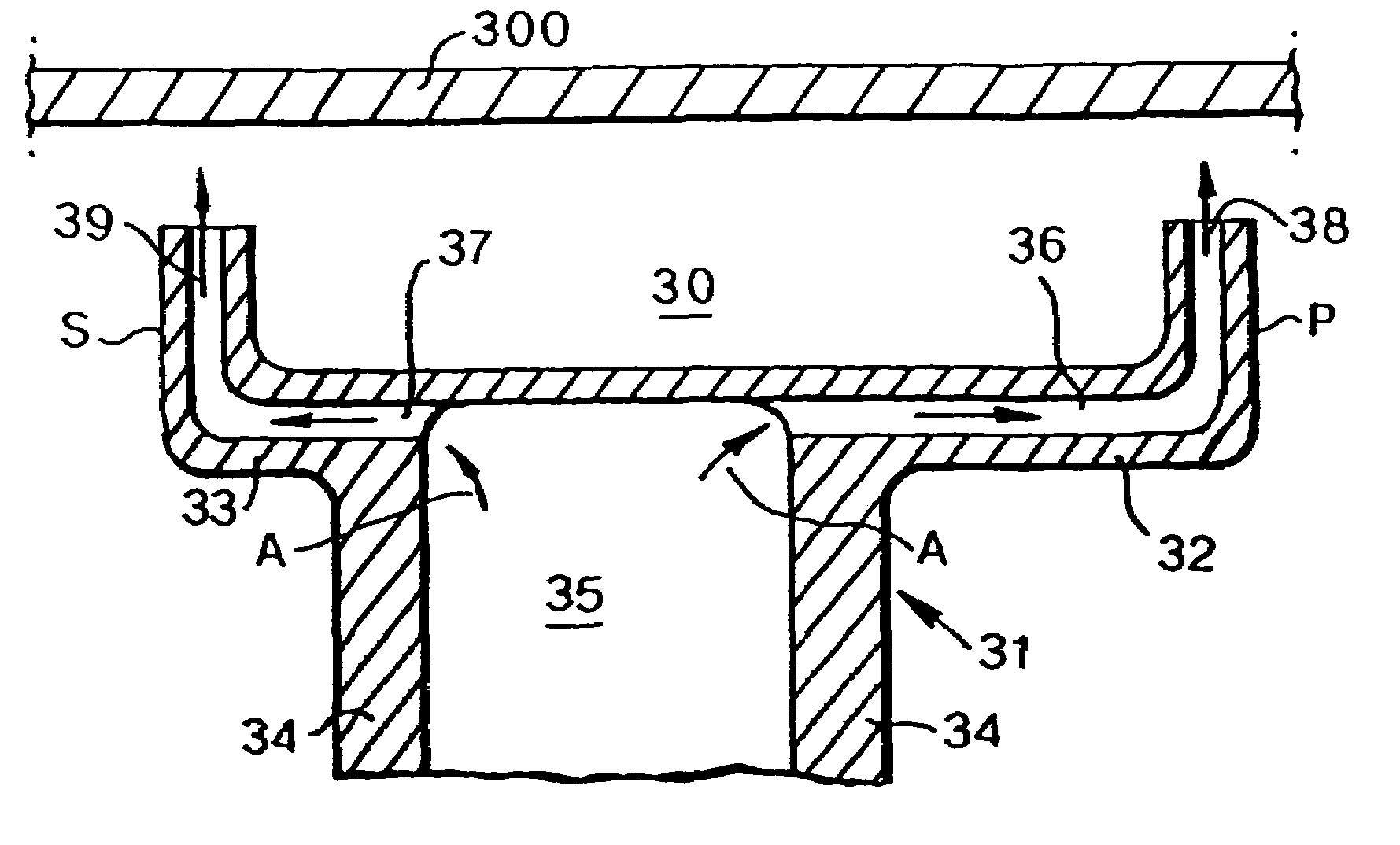

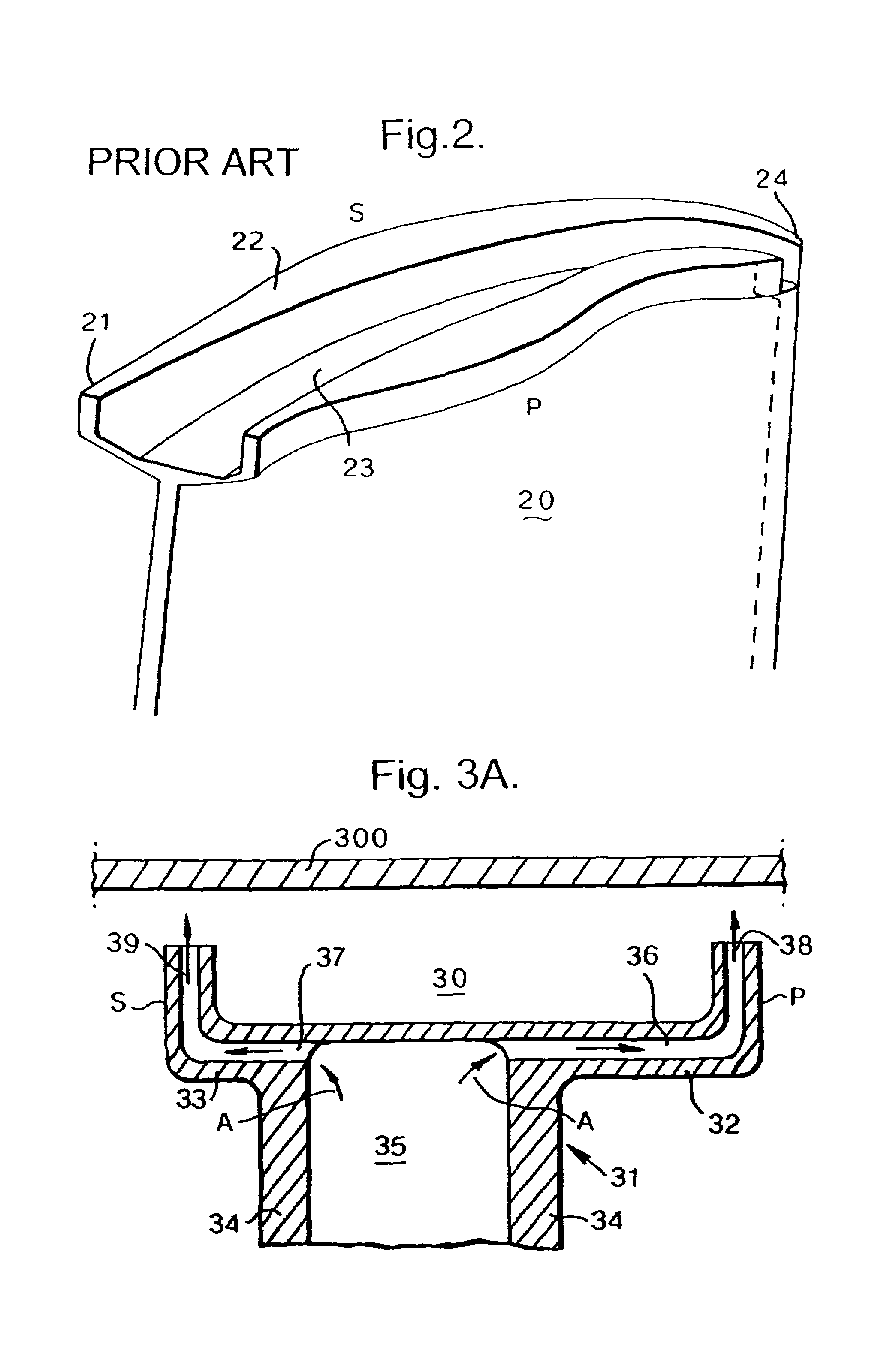

Turbine rotor blades

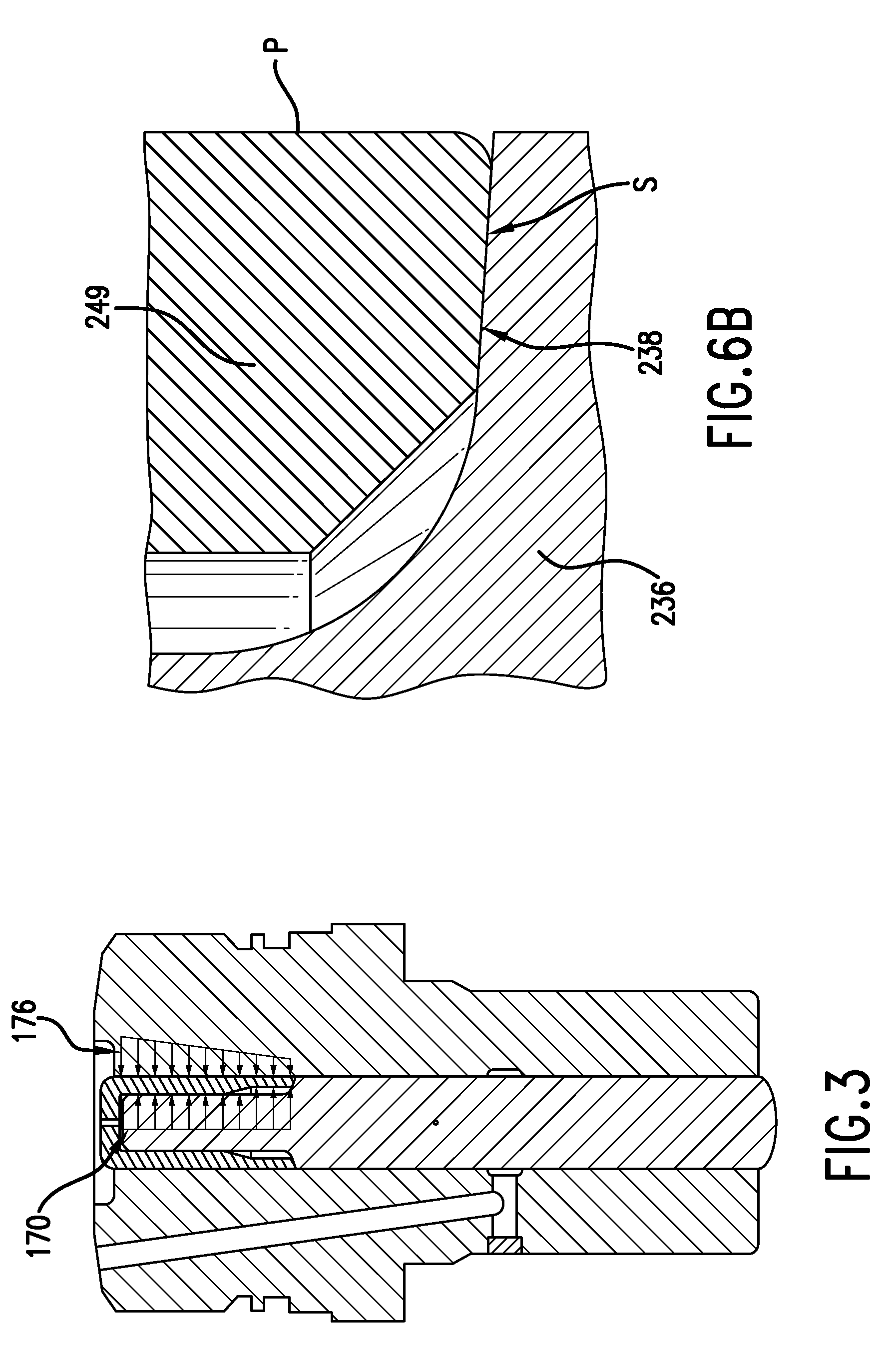

A rotor blade tip arrangement is provided in which winglets extend from the end of rotor blade aerofoil walls. These winglets incorporate passages which extend to coolant apertures or holes in order to present a coolant flow about the tip of the turbine rotor blade. The winglets define at least an open ended gutter channel in order to inhibit leakage flow across the tip arrangement from a pressure side P to a suction side S. The coolant flow facilitates cooling of the arrangement despite any heating caused by leakage flow across the arrangement.

Owner:ROLLS ROYCE PLC

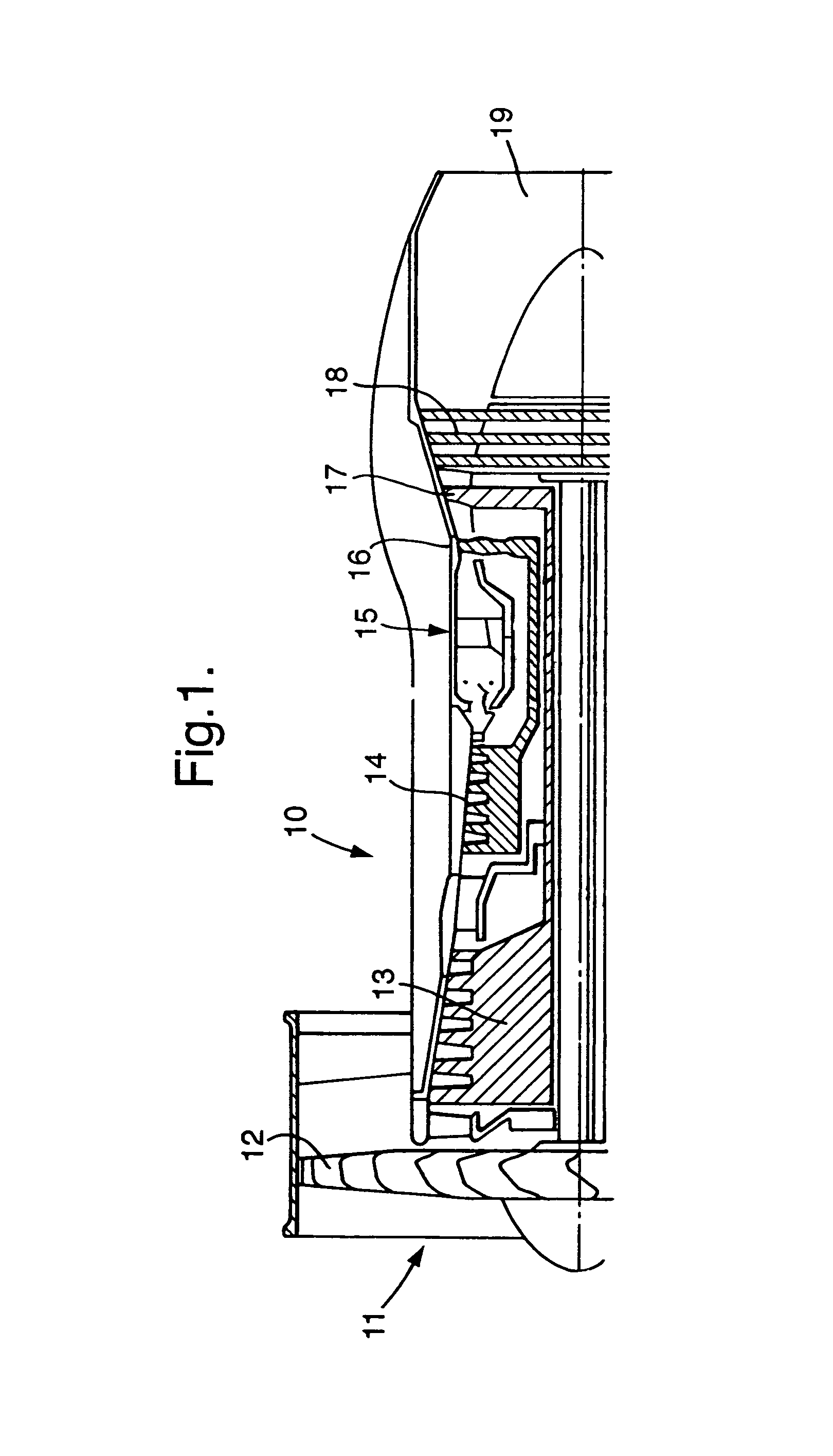

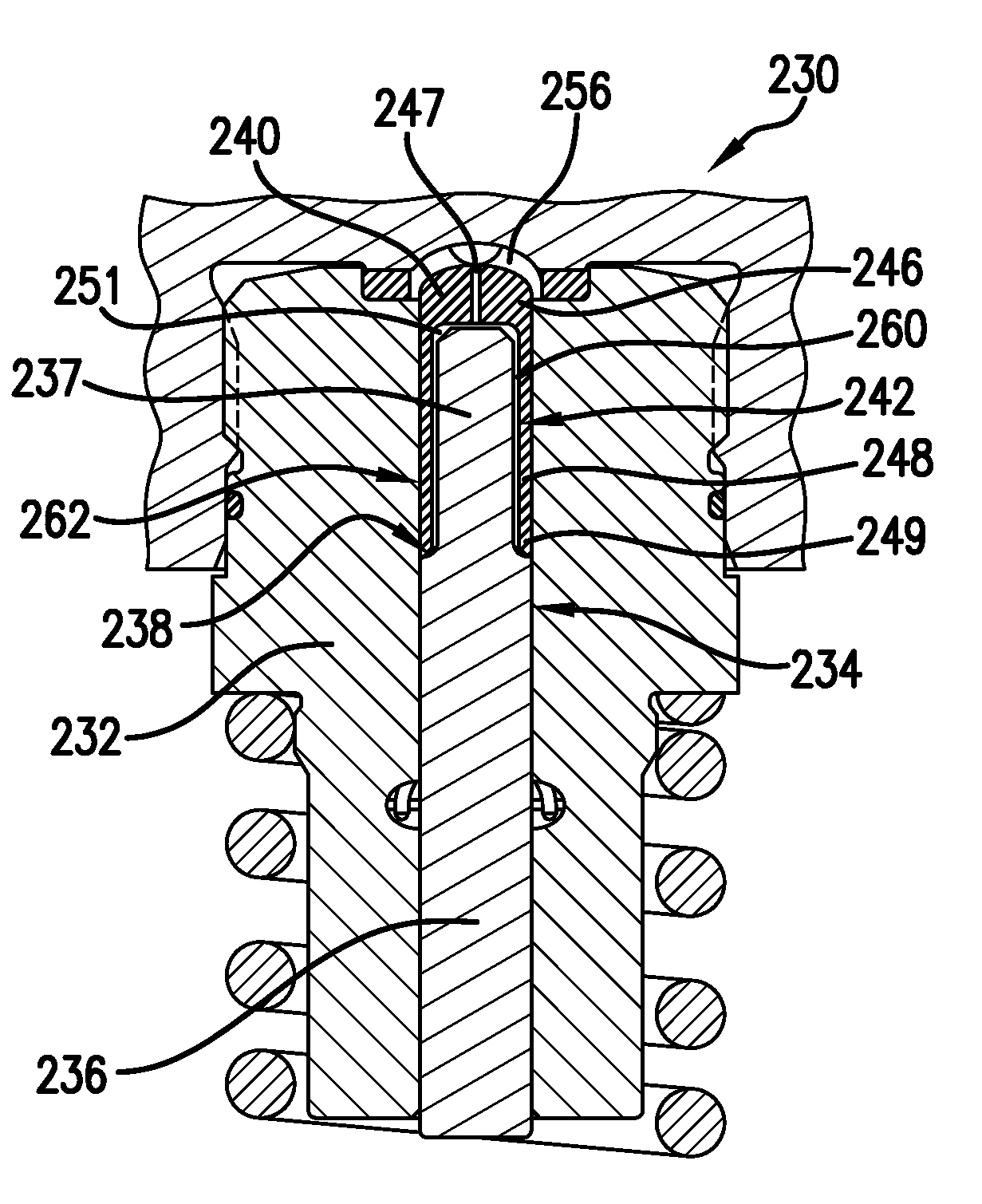

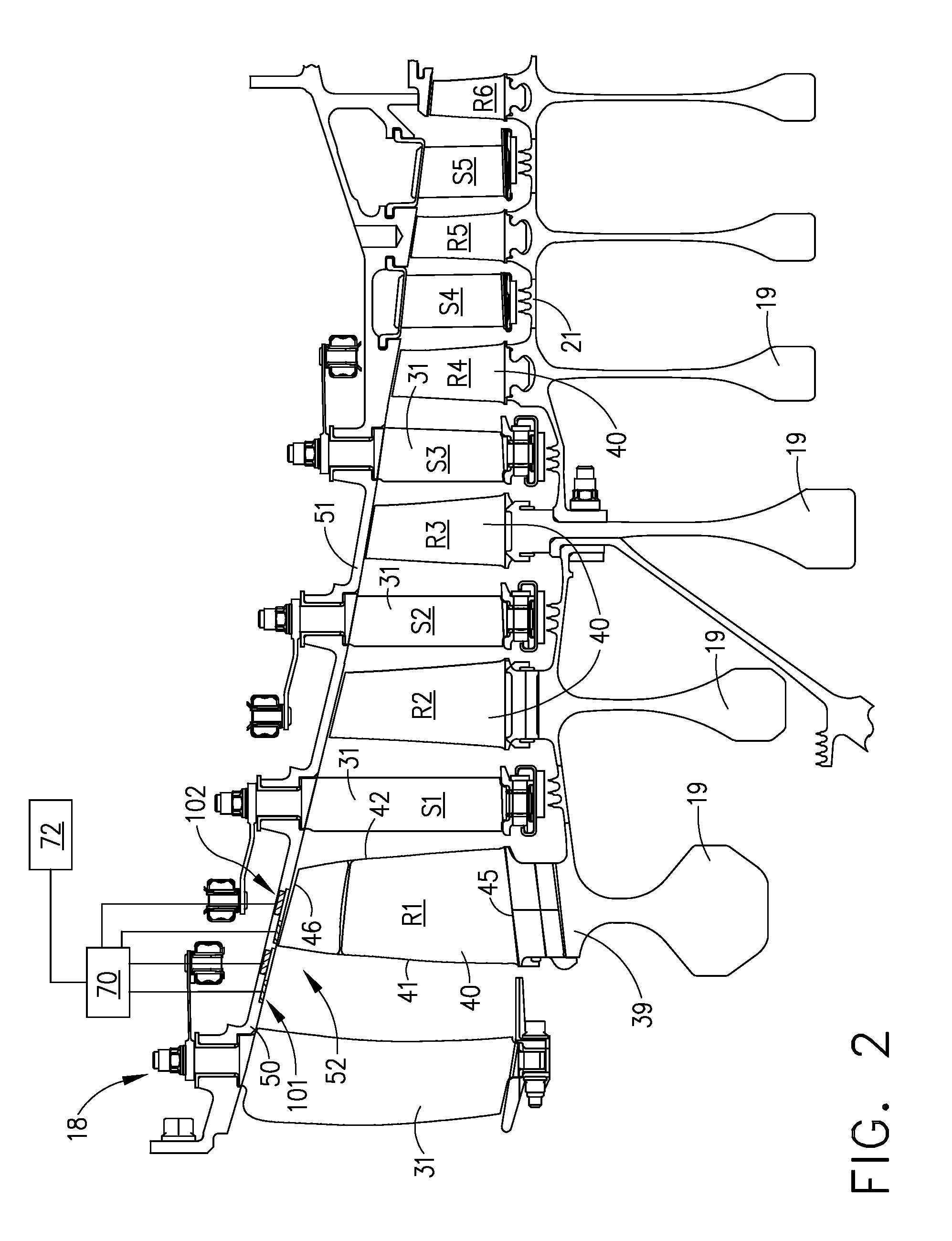

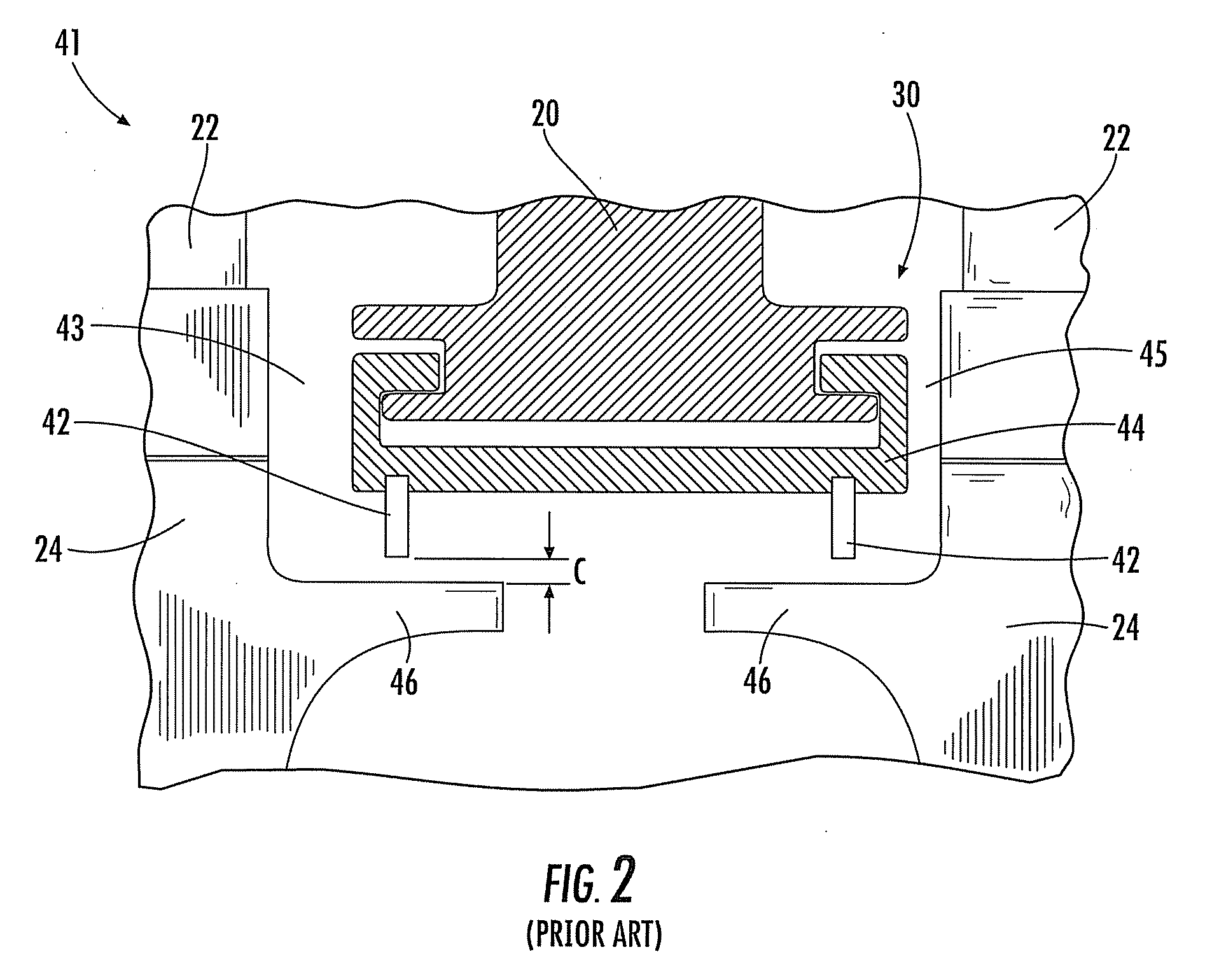

System for sealing an inner retainer segment and support ring in a gas turbine and methods therefor

InactiveUS7094026B2Improve engine efficiencyReduce leakagePump componentsStatorsLeakage flowGas turbines

Arcuate seal layers conforming with one another are disposed between inner retainer segments and inner rails of nozzle segments of a gas turbine. The layers are secured to the aft axial face of the segments and project radially outwardly to seal against the forward axial faces of the rails. The rear axial faces of the rails have chordal seals for sealing against the forward axial faces of the support rings. The seal layers have radial cuts misaligned with one another in an axial direction to preclude leakage flows through gaps formed by the cuts. Arcuate spacers are staggered circumferentially with the arcuate retainer segments whereby an intermediate pressure plenum is formed between the finger seals and chordal seals.

Owner:GENERAL ELECTRIC CO

Method and device for reducing axial thrust in rotary machines and a centrifugal pump using same

InactiveUS6129507AReducing axial thrustReduce and even eliminate effectPump componentsReaction enginesRotation velocityAxial thrust

A method and device for reducing or eliminating axial thrust in a rotary machine such as a centrifugal pump or compressor by altering the fluid pressure in a cavity formed between a rotor and a housing. The device contains a disk placed along the rotor for subdividing the fluid in the cavity in such a way that all annular gap leakage flow is channeled and pumped through the space between that disk and the rotor from the center of the pump towards the periphery. As a result, the pressure in the cavity is altered to reduce and control the axial thrust on the rotor which becomes independent of the wear state of the shaft seals. In another embodiment, the step of flow subdividing is achieved by providing a set of braking vanes along the periphery of the cavity for reducing the rotational speed of the fluid coming from the cavity as well as from the annular gap and a stationary disk placed along the interior wall of the housing for directing the radial flow of that fluid towards the center of the pump.

Owner:TECH COMMLIZATION

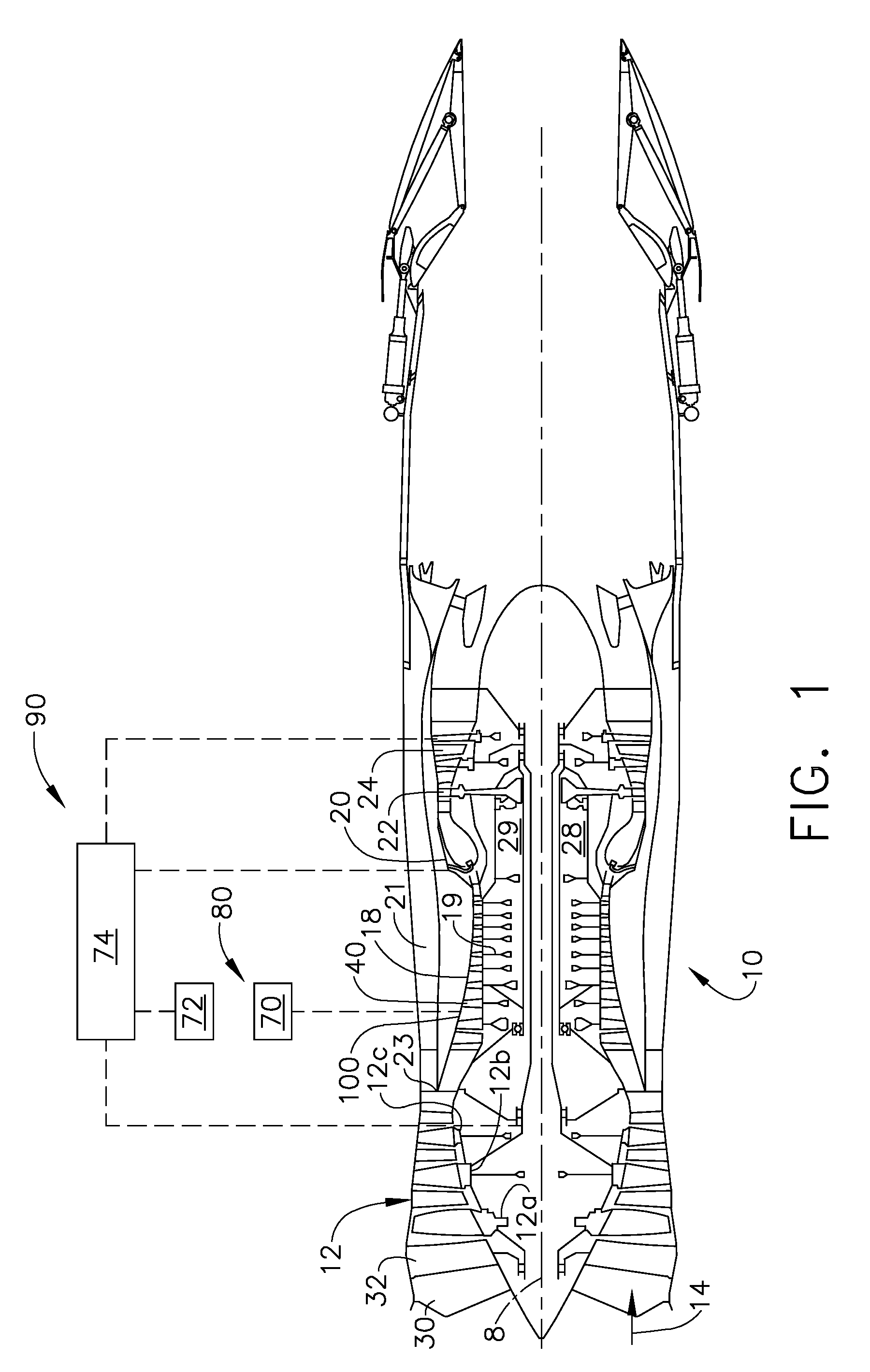

Electrodynamic Control of Blade Clearance Leakage Loss in Turbomachinery Applications

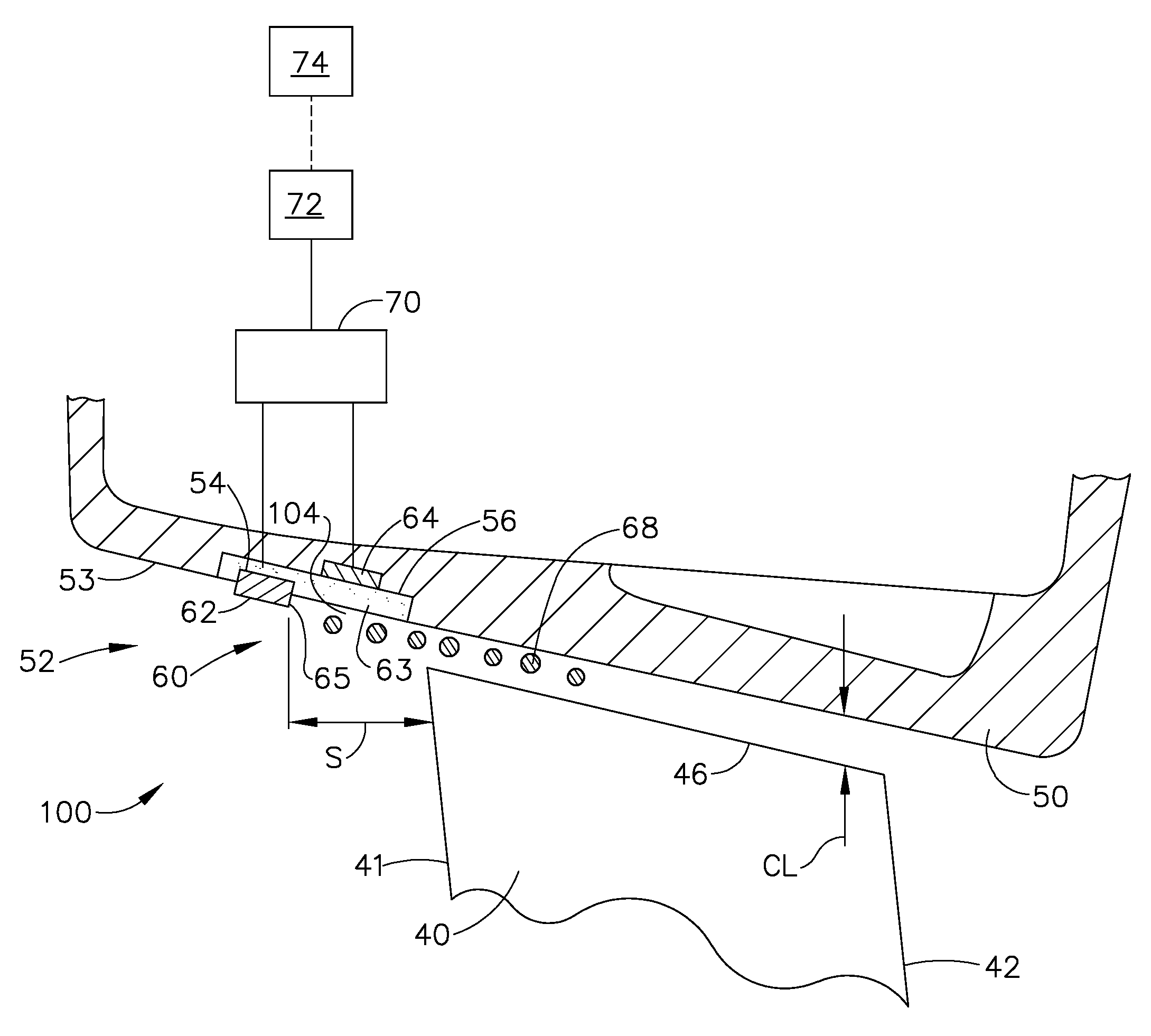

Electrodynamic control of fluid leakage loss is provided. Embodiments utilize electrohydrodynamic (EHD) principles to control and / or reduce leakage flow in turbomachinery. Electrodes can be used to provide a flow actuation mechanism inside the clearance gap for generating discharge. The electrodes can be positioned to have geometric asymmetry. Embodiments provide the electrodes on a turbine blade. The blade can have a DC power that can function as a square pulsed DC wave with the duty cycle equal to the blade passing frequency and the stator can be grounded. In an embodiment, the stator can have the actuator of the electrode-insulator assembly attached to the inside. In one embodiment, the actuators can be arranged just on the stator or casing. The phase and power supply to individual electrodes can be adapted as needed. In one embodiment, the phase can be lagged for accurate control of leakage flow. The control of the power supply to the electrodes can involve a closed control loop that monitors tip gap size.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

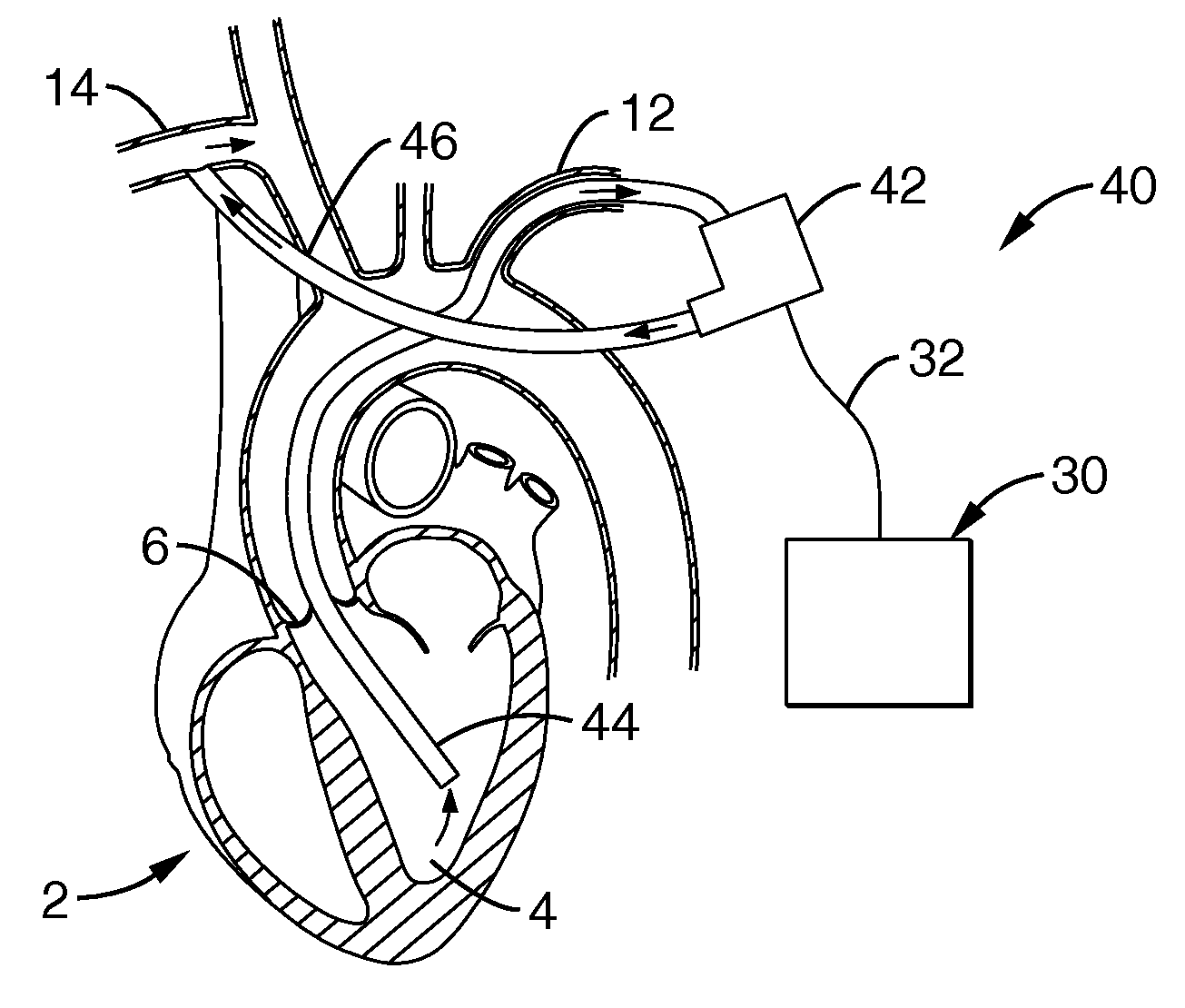

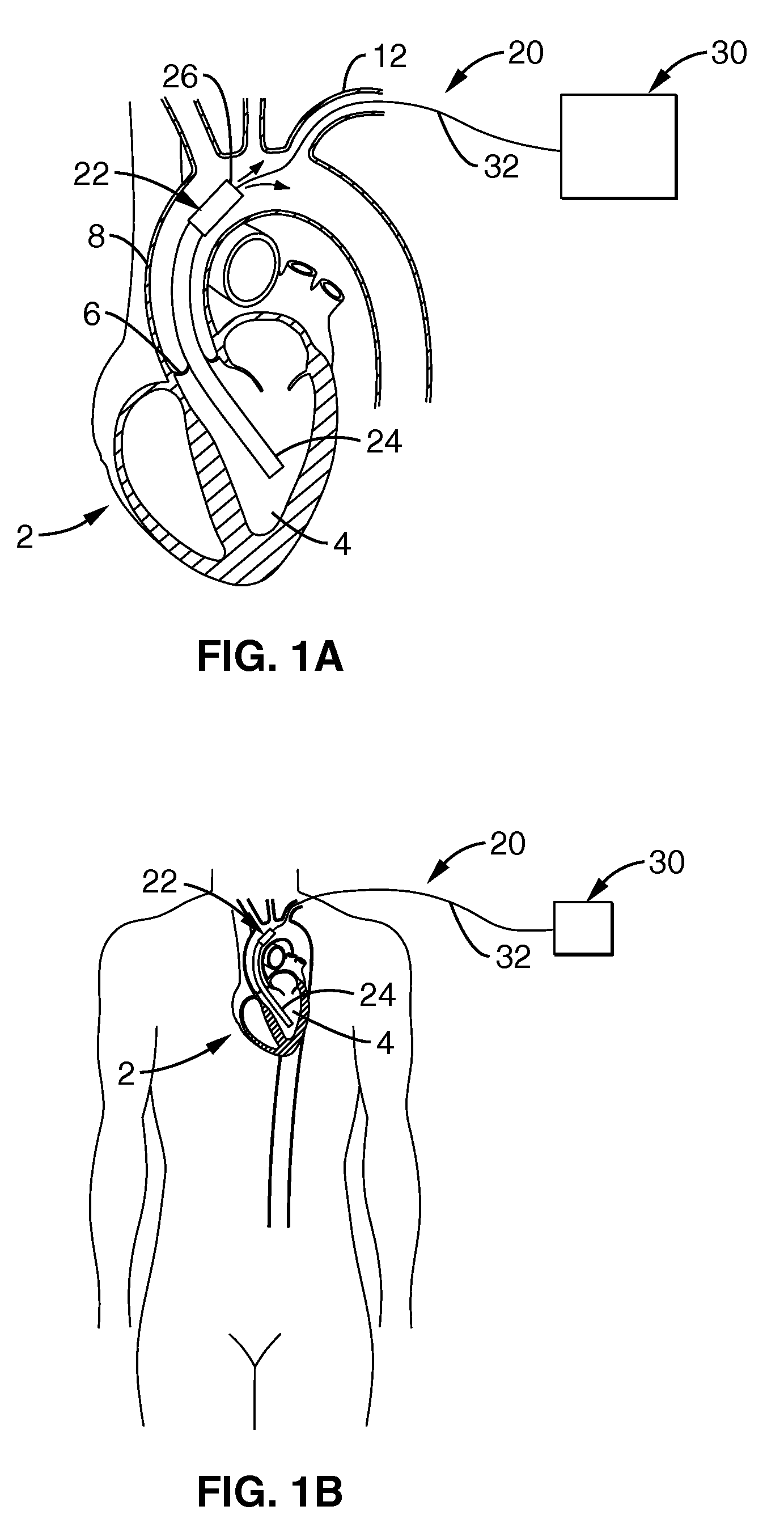

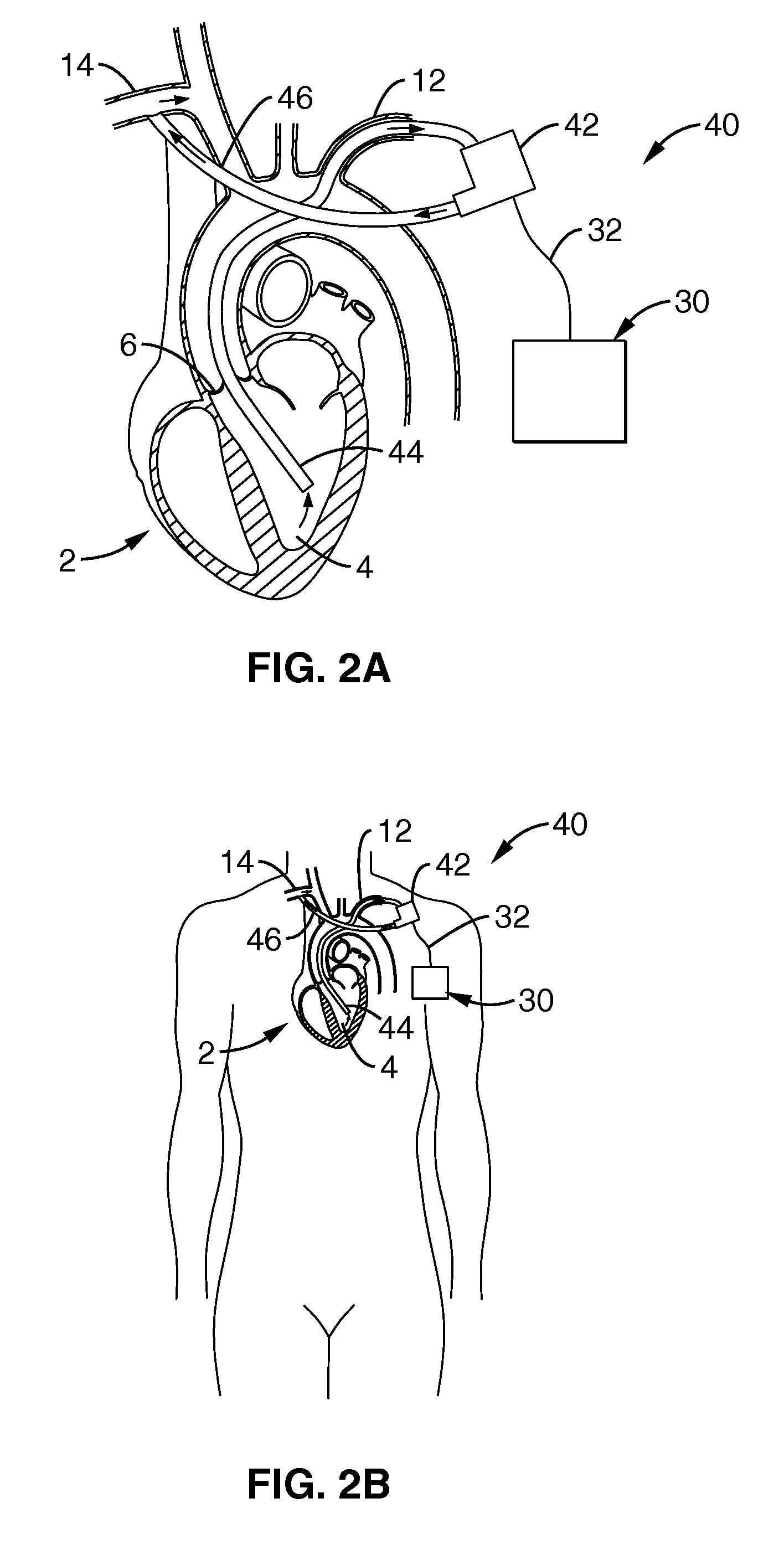

Heart assist device

A heart assist device comprising a rotary pump housing having a cylindrical bore, a pumping chamber and a motor stator including an electrically conductive coil located within the housing and surrounding a portion of the cylindrical bore. A rotor has a cylindrical shaft, at least one impeller appended to one end of the shaft, and a plurality of magnets located within the shaft. The rotor shaft is positioned within the housing bore with the magnets opposite the motor stator, and the impeller is positioned within the pumping chamber. The housing bore is closely fitted to the outer surface of the shaft forming a hydrodynamic journal bearing, with the pumping chamber and journal bearing connected by a leak path of blood flow between the pumping chamber and the journal bearing. A backiron of the motor stator attracts the rotor magnets to resist longitudinal displacement of the rotor within the housing during operation. The relative orientation of positions of the inflow, outflow, and leakage flow paths may be varied within the pump, such as to accommodate different intended methods for implantation and / or use.

Owner:VADOVATIONS INC

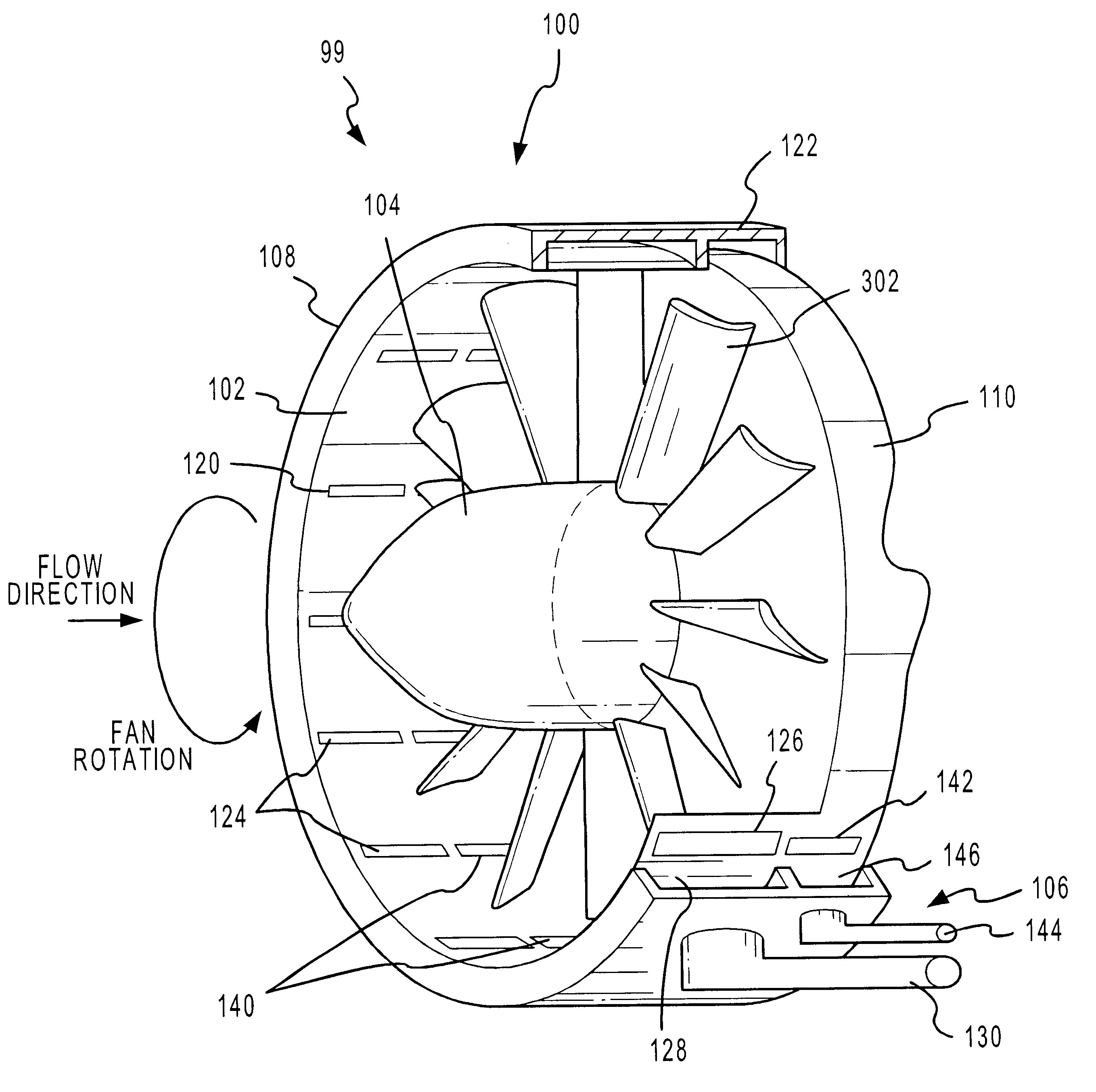

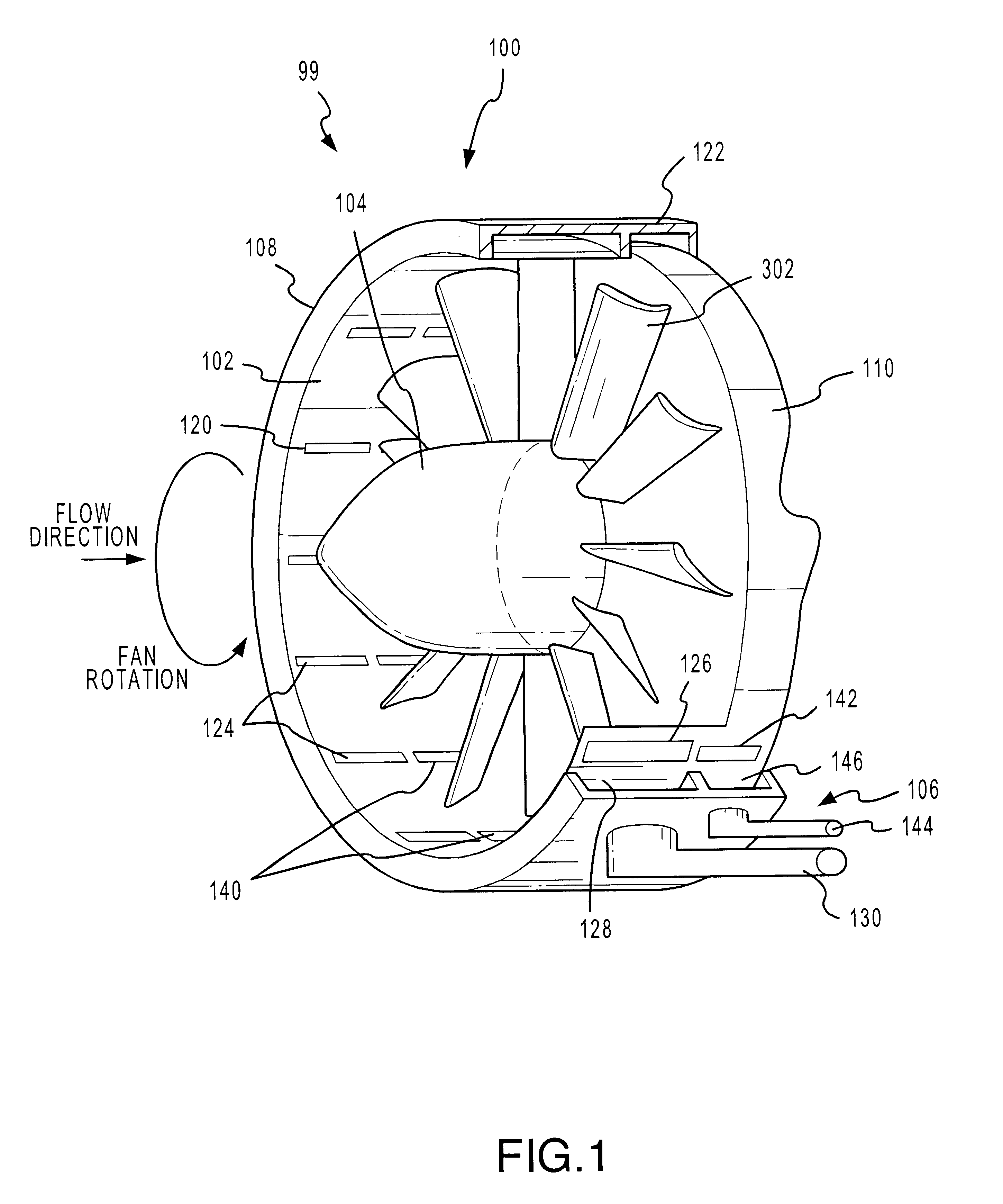

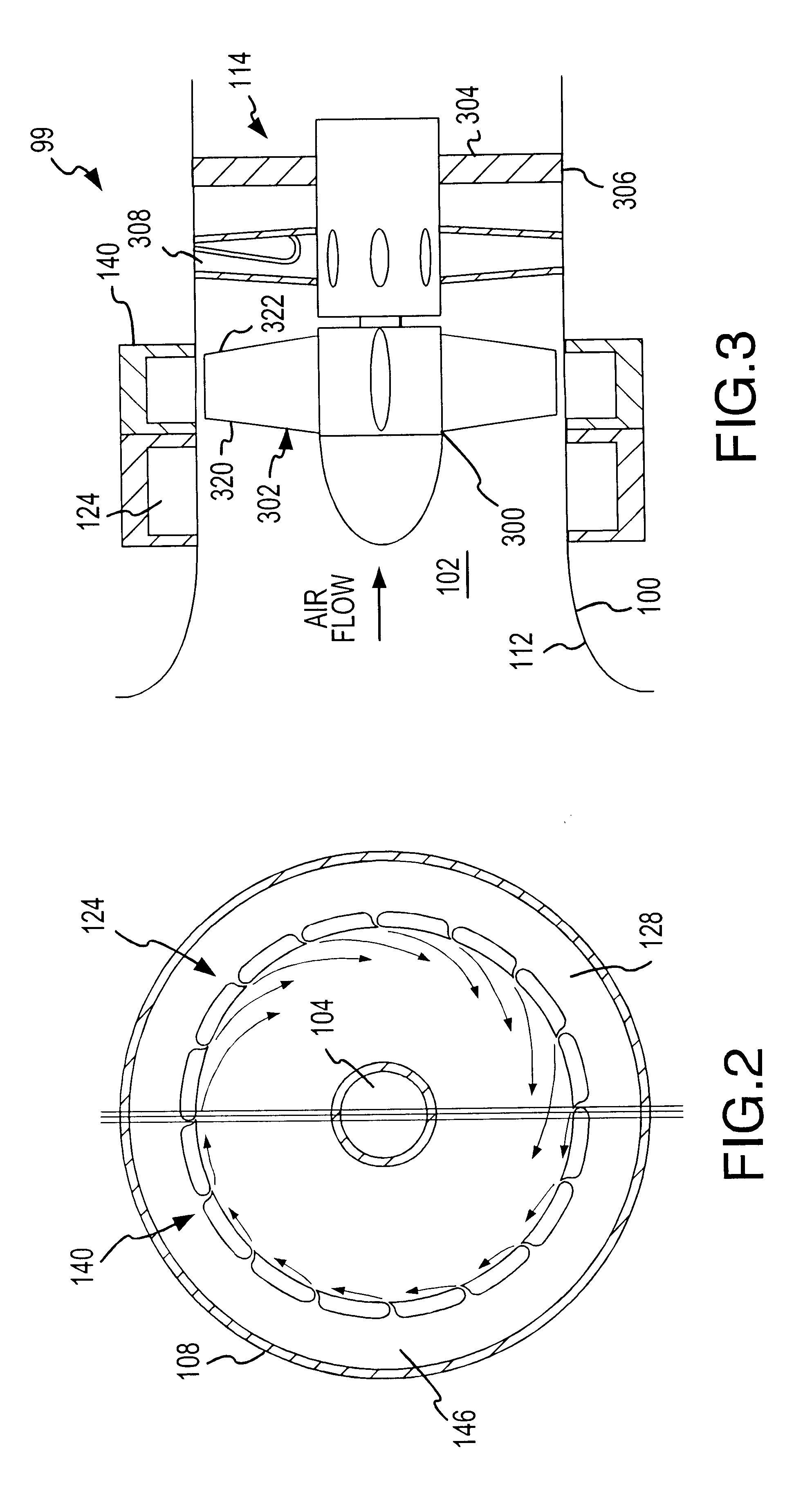

Method and apparatus for a fan noise controller

A fan system, such as a turbofan, marine propeller, or a cooling fan, includes a fan noise control system for reducing noise generated by the fan system. The noise control system may be configured to reduce either broadband noise, blade-passage noise, or both. In particular, the fan noise control system suitably includes a pre-swirl generator configured to provide a layer of fluid upstream from the fan blades. The layer swirls in the direction of the fan's rotation, reducing the angular velocity differential between the fan blades and the incident fluid. In addition, the fan noise control system may also include a fluid seal generator configured to create a fluid barrier between the fan blade tips and the interior surface of the fluid flow channel. The fluid seal inhibits leakage flow between the fan blade tips and the interior surface as well as the formation of blade vortices. By minimizing the blade wake and the blade tip vortices without adding solid surfaces, noise tends to diminish.

Owner:MCDONNELL DOUGLAS

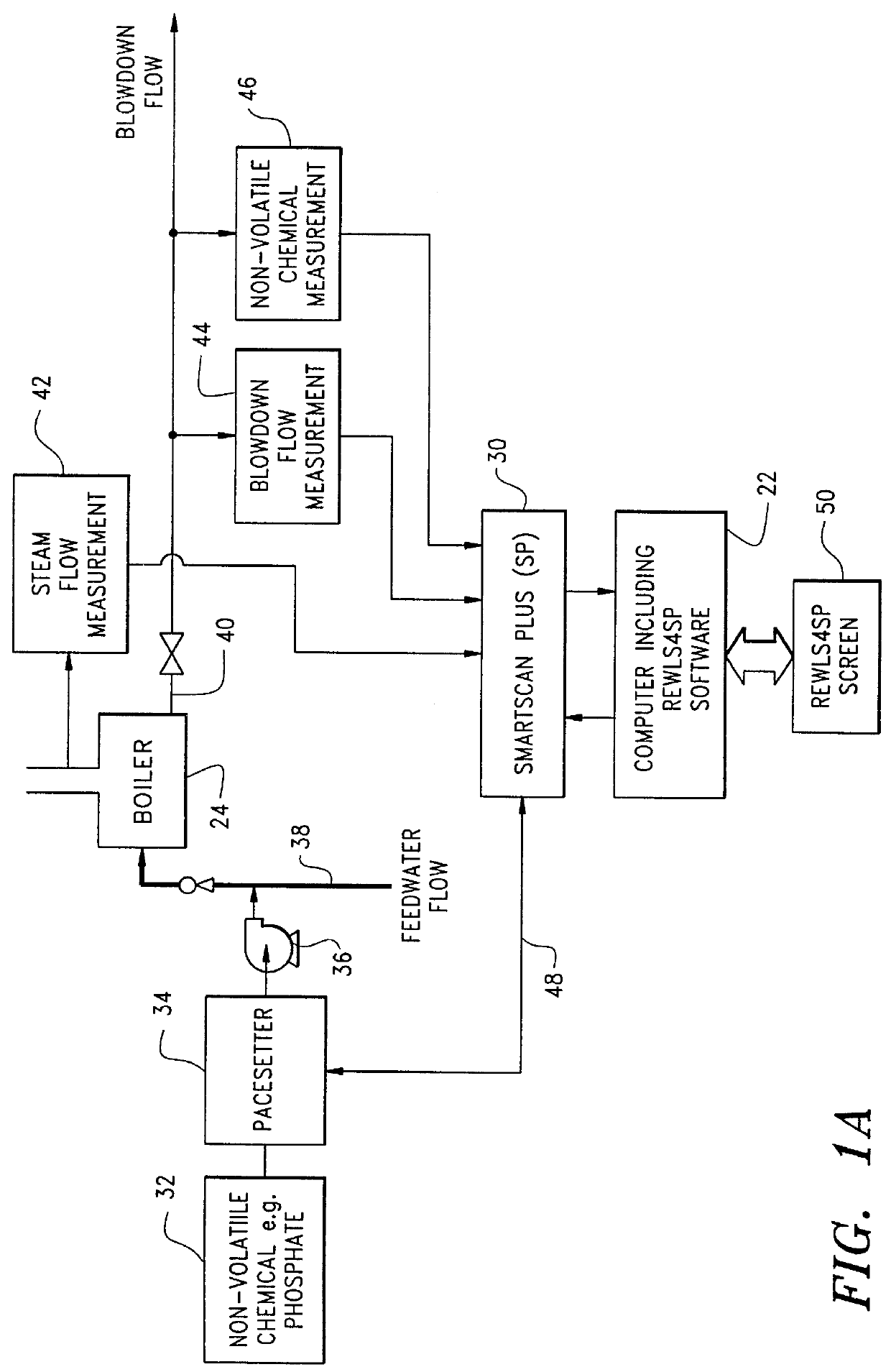

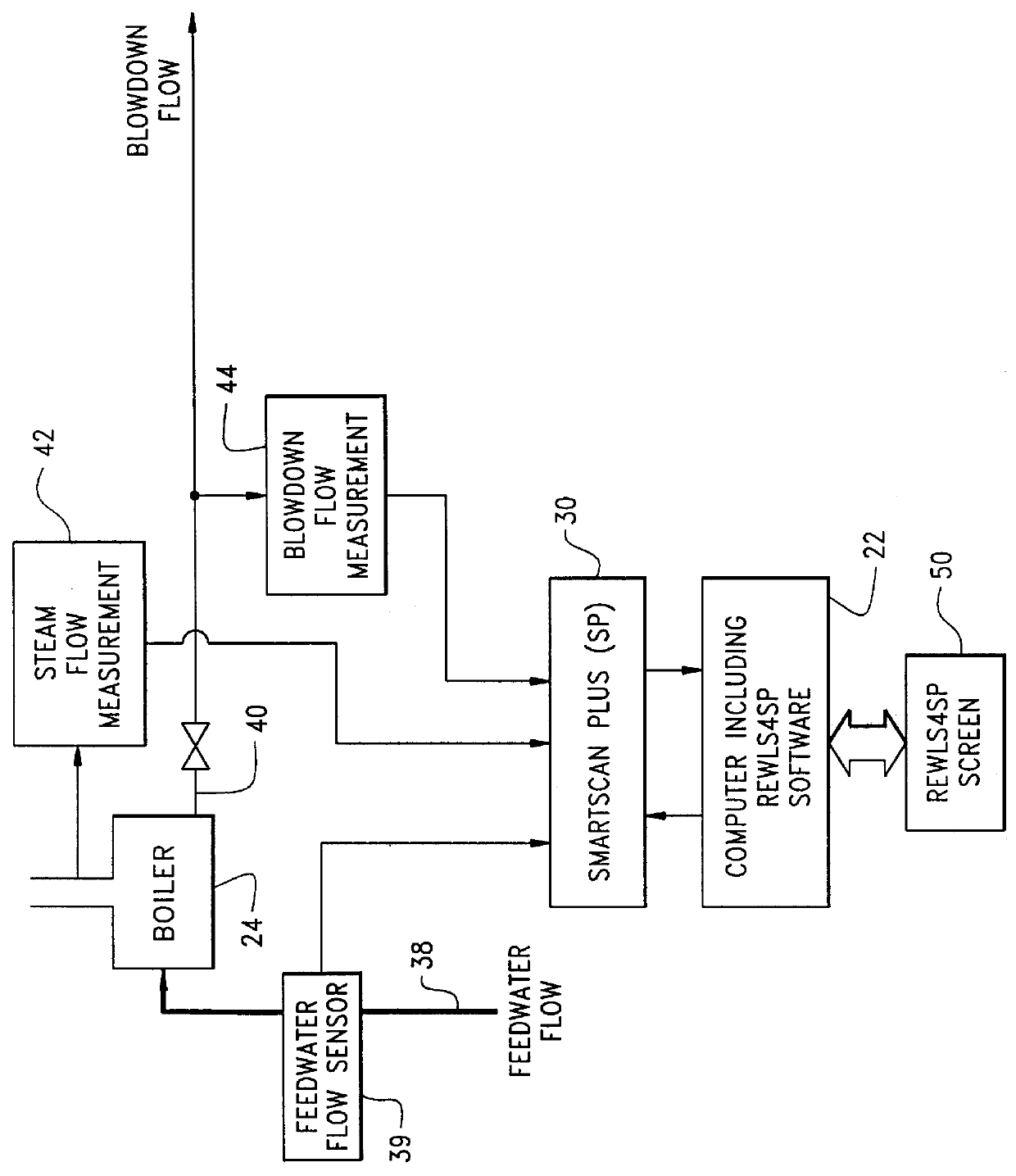

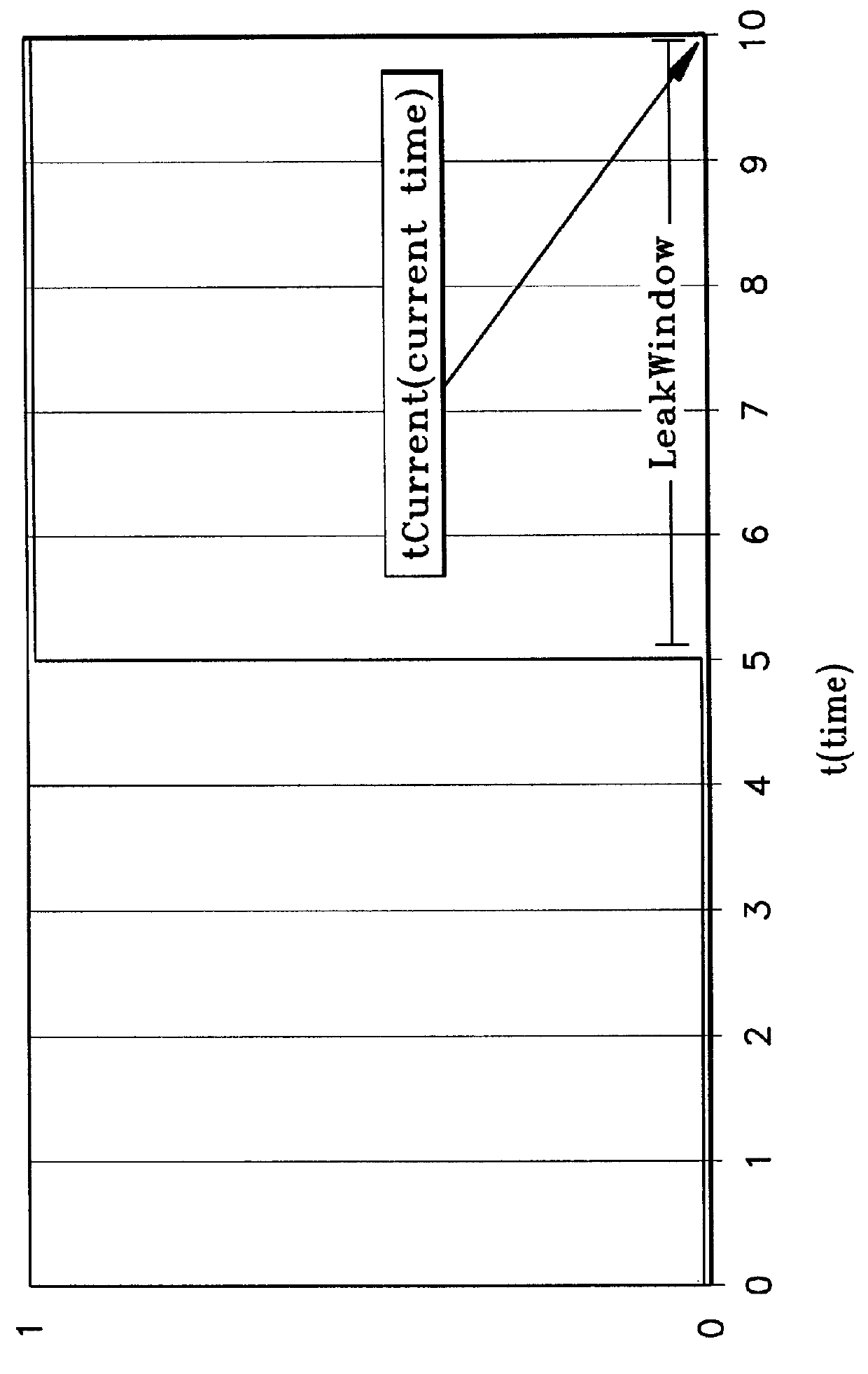

System and method for least squares filtering based leak flow estimation/detection using exponentially shaped leak profiles

InactiveUS6076048AMinimum loss of sensitivityOptimally efficient statisticDetection of fluid at leakage pointFlow propertiesEngineeringLeakage flow

A method and system for detecting and estimating leaks in an industrial boiler whereby the method and system formulate the leak detection problem as a least squares fitting problem, where one or more of the fitted parameters estimate leak flows. The method and system create a representation that incorporates a leak model component, a process model component and a noise model component into the representation. This invention provides a variety of leak flow estimates and associated significance tests that have a much higher statistical efficiency and are sensitive to leaks with a wider range of leak growth rates than prior approaches.

Owner:ULTRAK +1

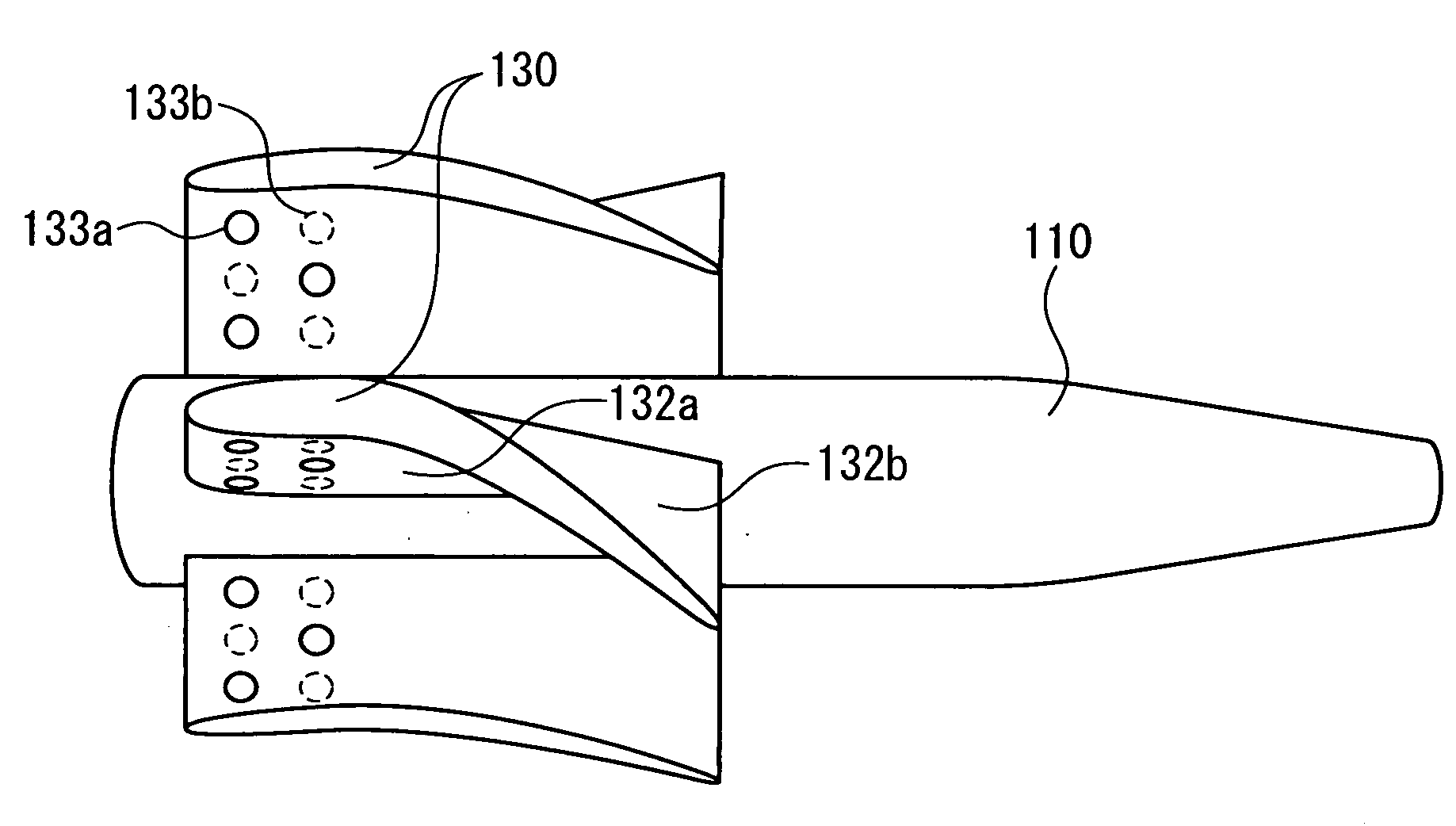

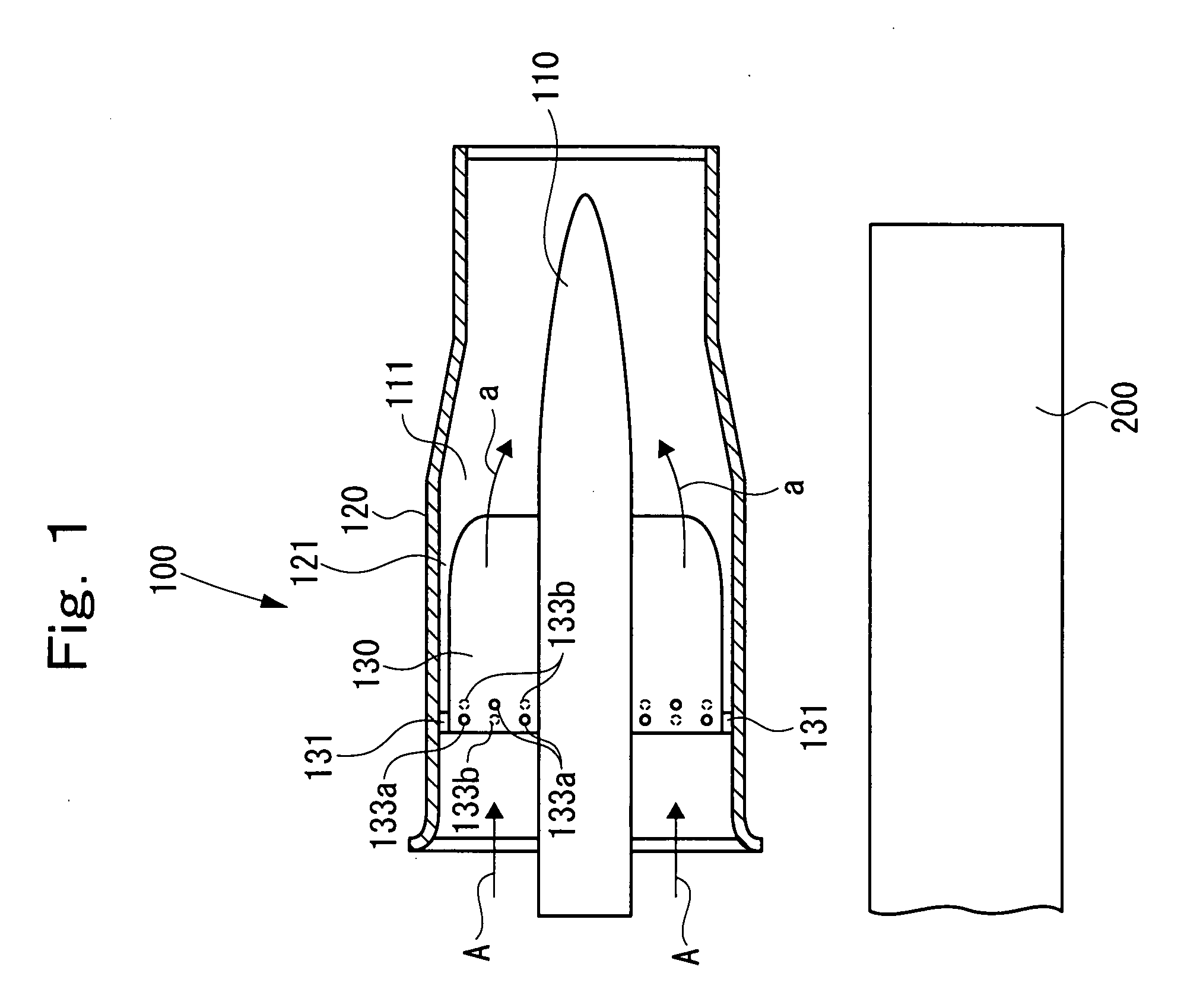

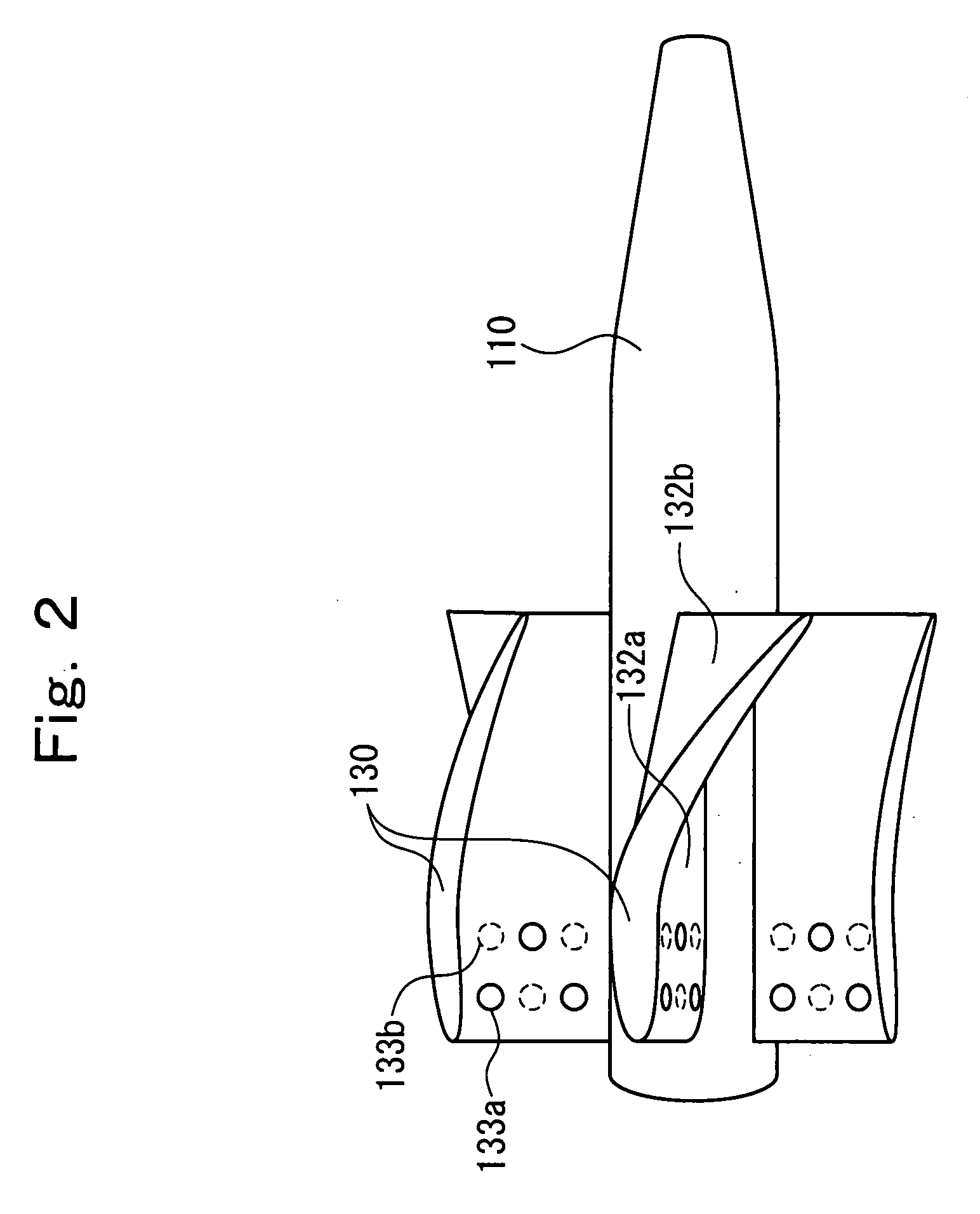

Premixed Combustion Burner of Gas Turbine Technical Field

ActiveUS20080148736A1Avoid it happening againFuel concentration becomes uniformContinuous combustion chamberGas turbine plantsCombustorEngineering

A fuel nozzle 110 having a plurality of swirl vane 130 on an outer peripheral surface thereof is installed within a burner tube 120, with a clearance 121 being provided. Each swirl vane 130 progressively curves from an upstream side toward a downstream side (inclines along a circumferential direction) in order to swirl compressed air A flowing through an air passage 111 to form a swirl air flow a. Here, curvature of each swirl vane 130 is greater on its outer peripheral side than on its inner peripheral side. By suppressing occurrence of an air streamline heading from the inner peripheral side toward the outer peripheral side, therefore, flow velocity on the inner peripheral side and flow velocity on the outer peripheral side become equal, thus preventing flashback on the inner peripheral side. Moreover, a swirl imparting force in the circumferential direction per unit length on the inner peripheral side and that on the outer peripheral side become equal, equalizing the fuel concentration on the inner peripheral side and the fuel concentration on the outer peripheral side. Furthermore, a leakage flow, which passes from the vane dorsal surface side through the clearance 121 and leaks to the vane ventral surface side, generates a vortex air flow, promoting mixing of fuel and air.

Owner:MITSUBISHI POWER LTD

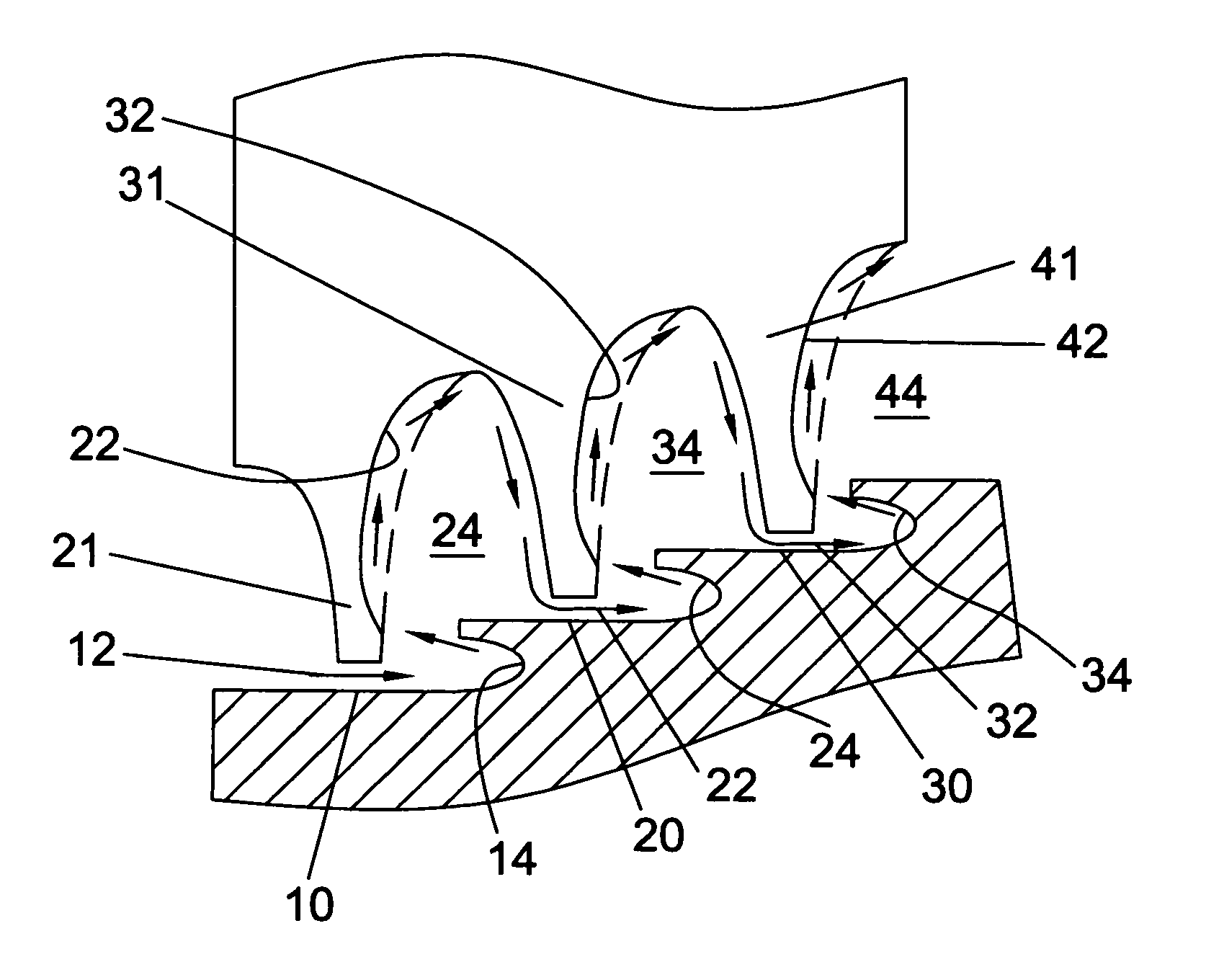

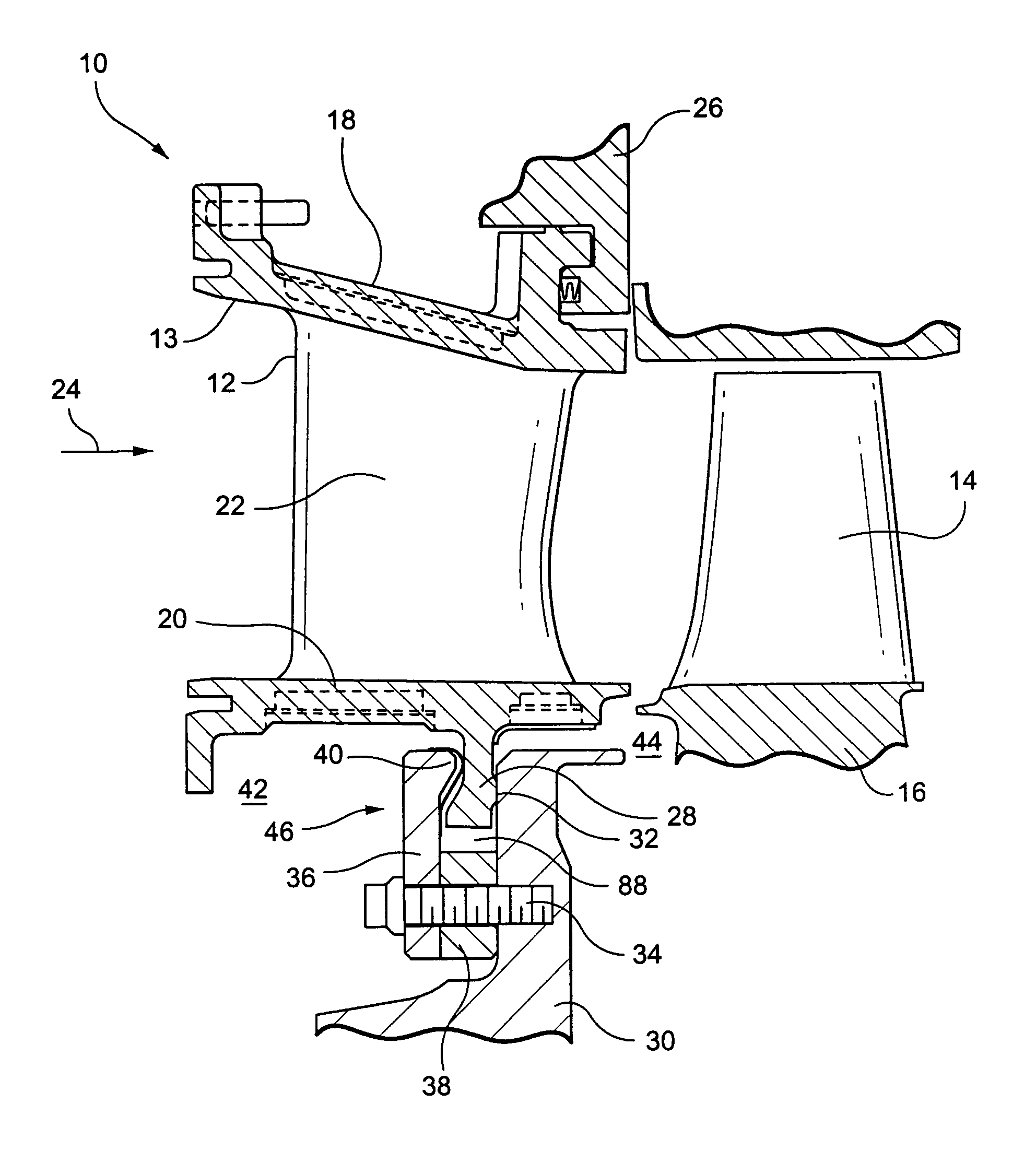

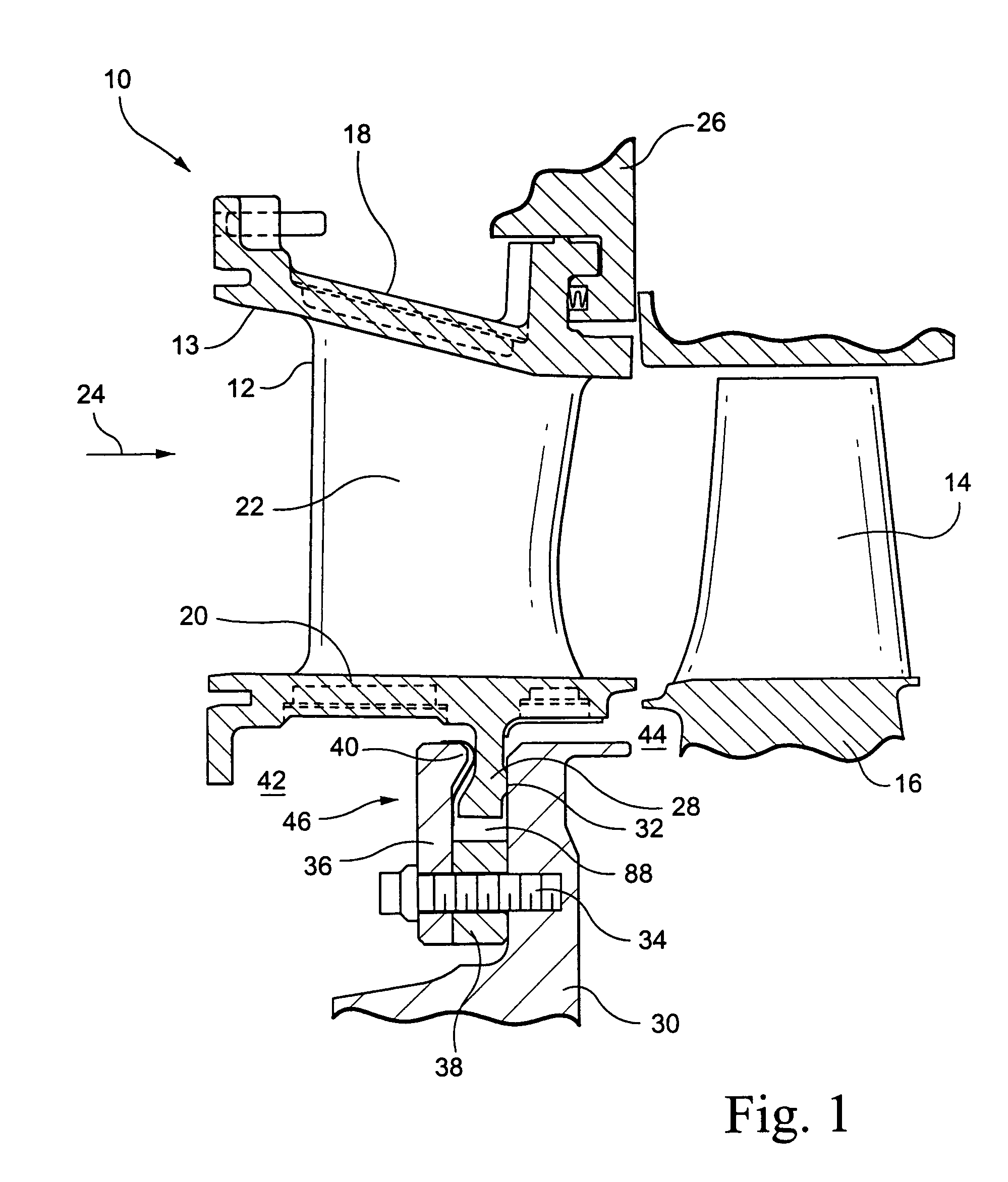

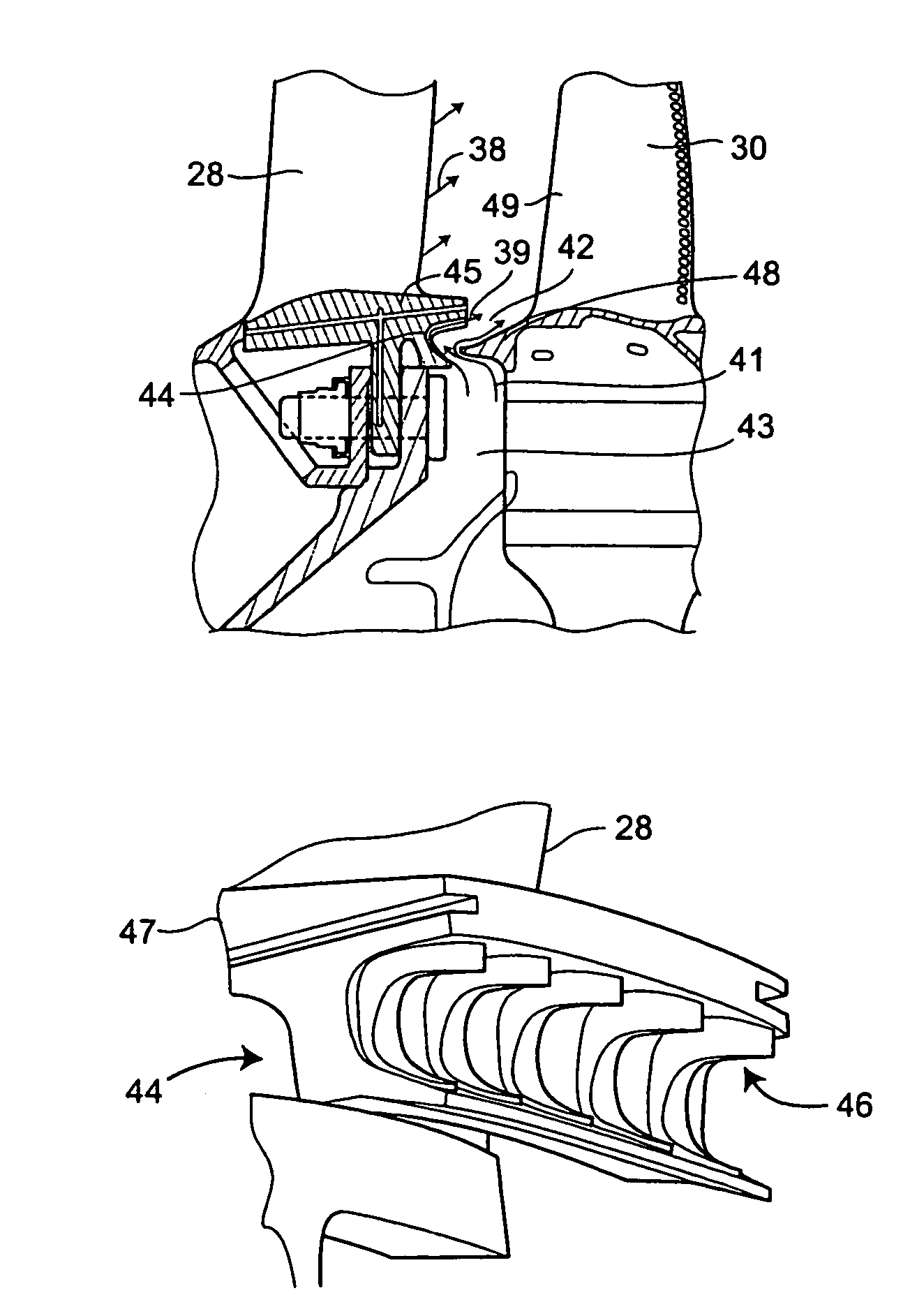

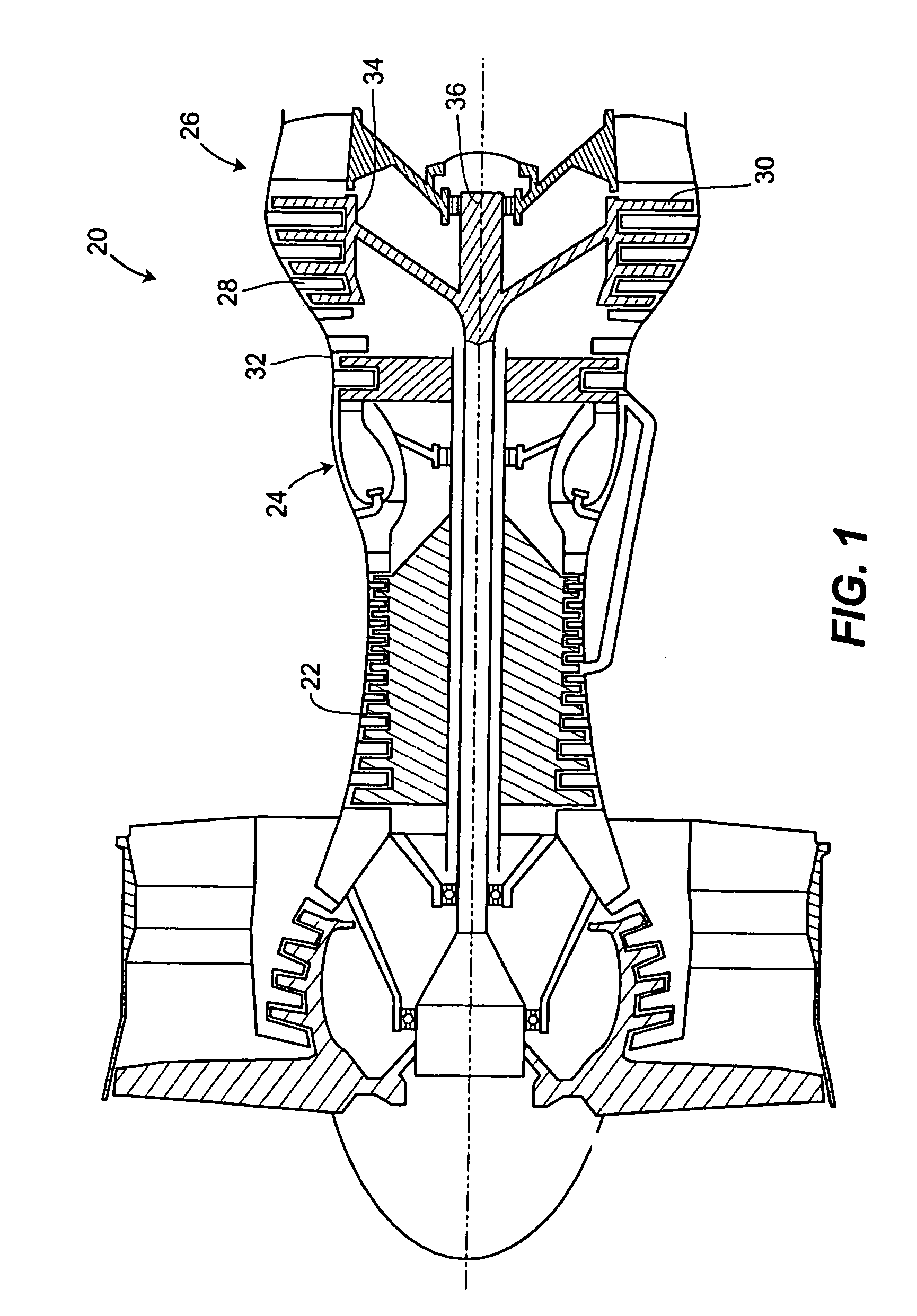

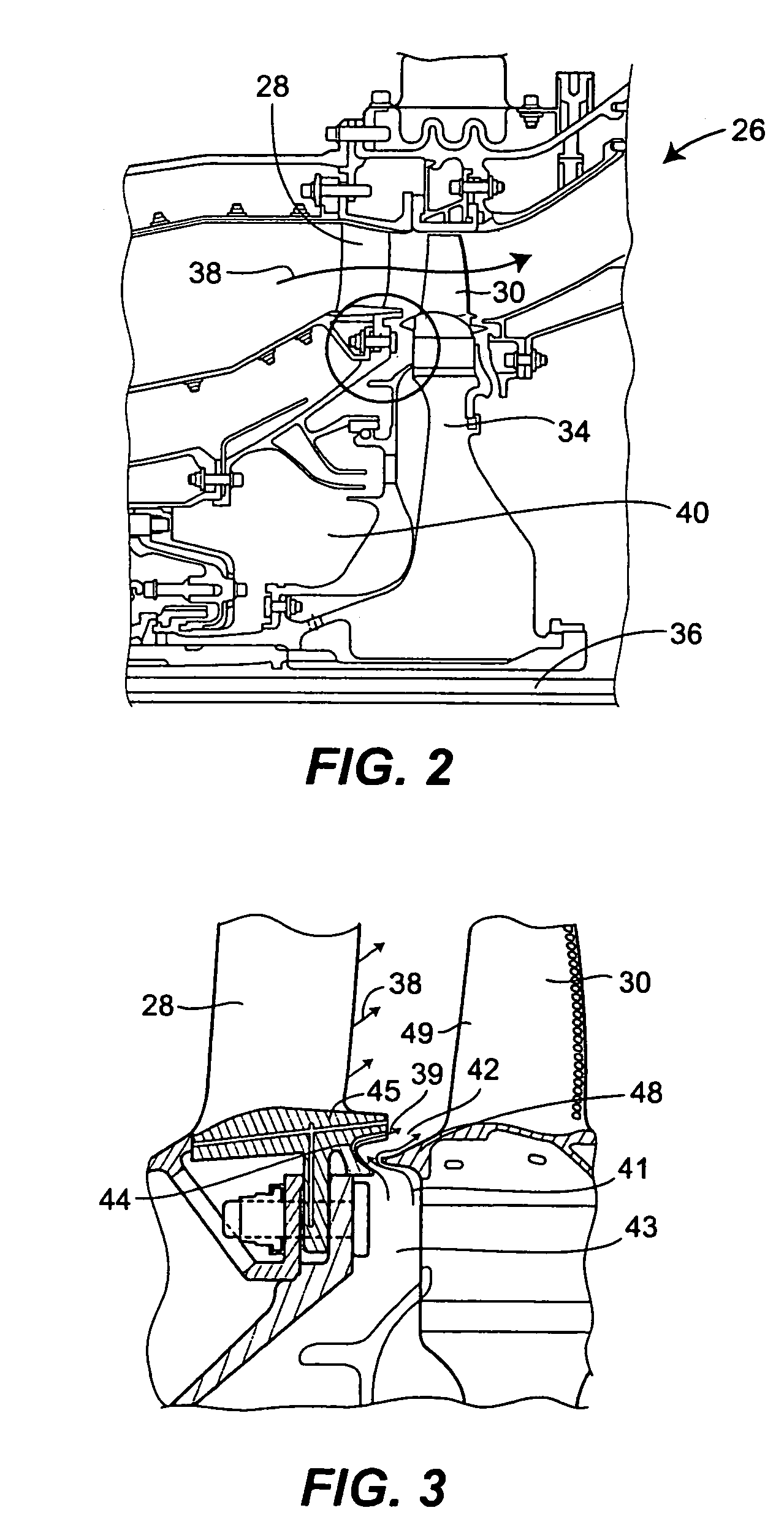

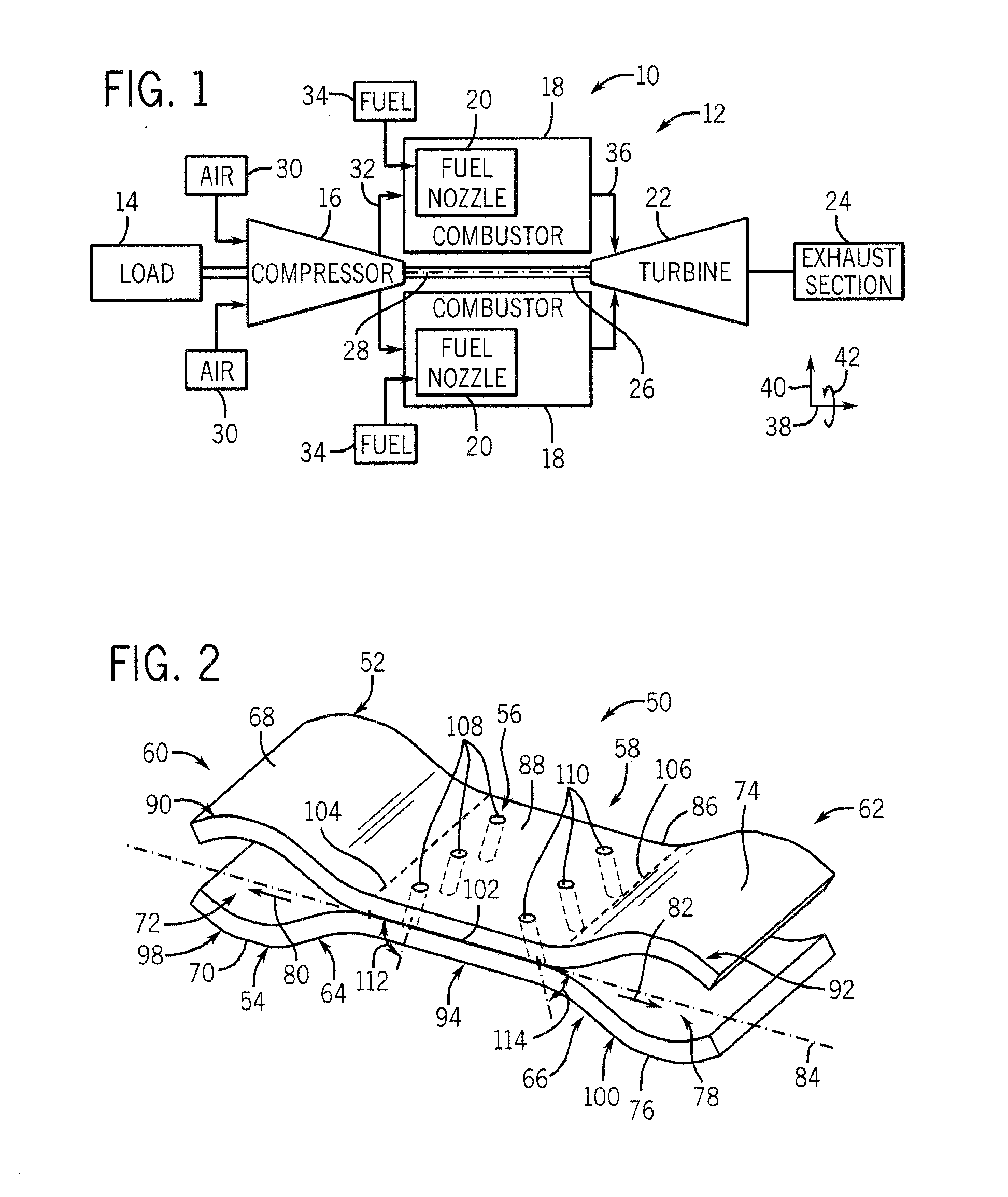

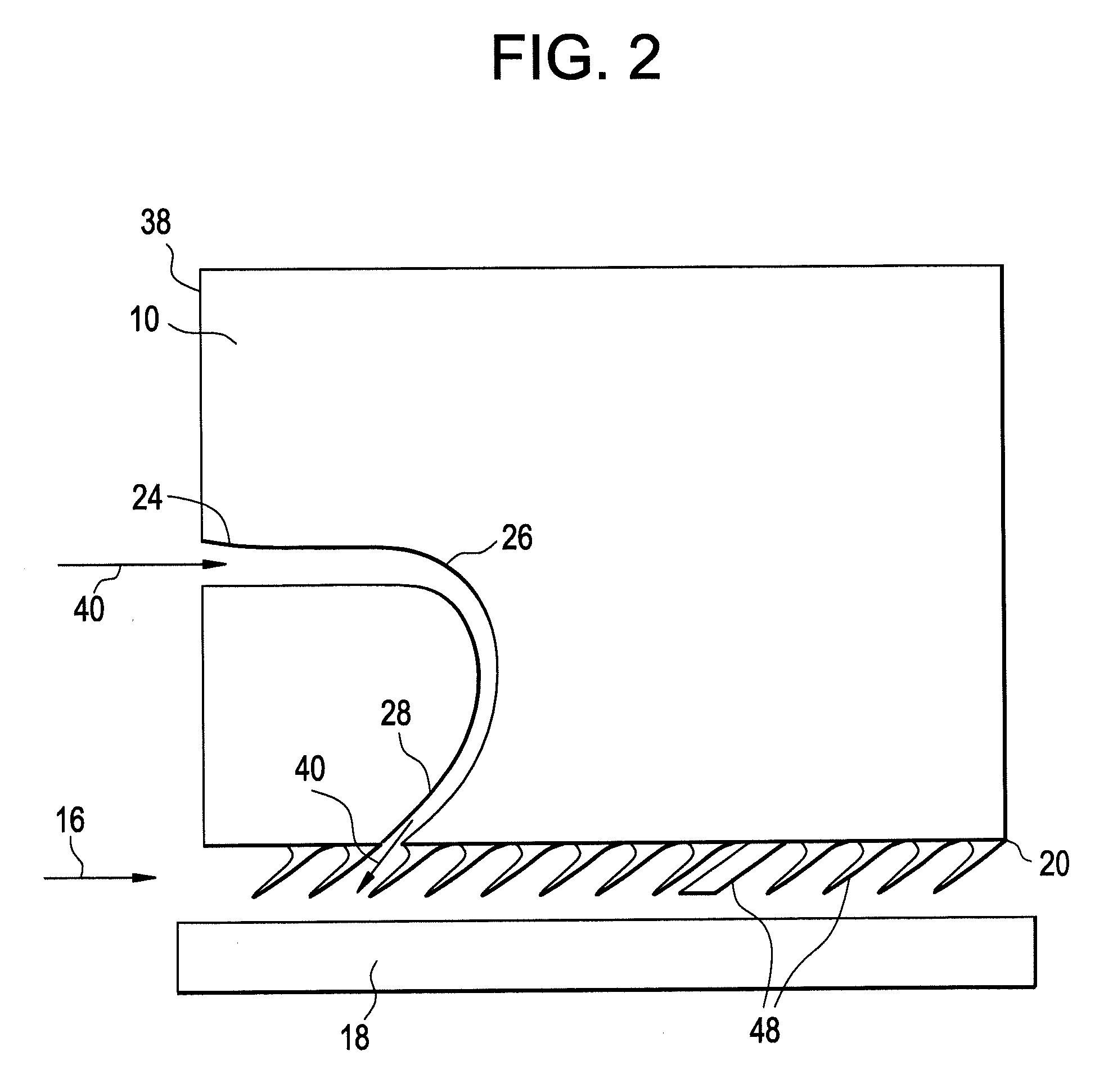

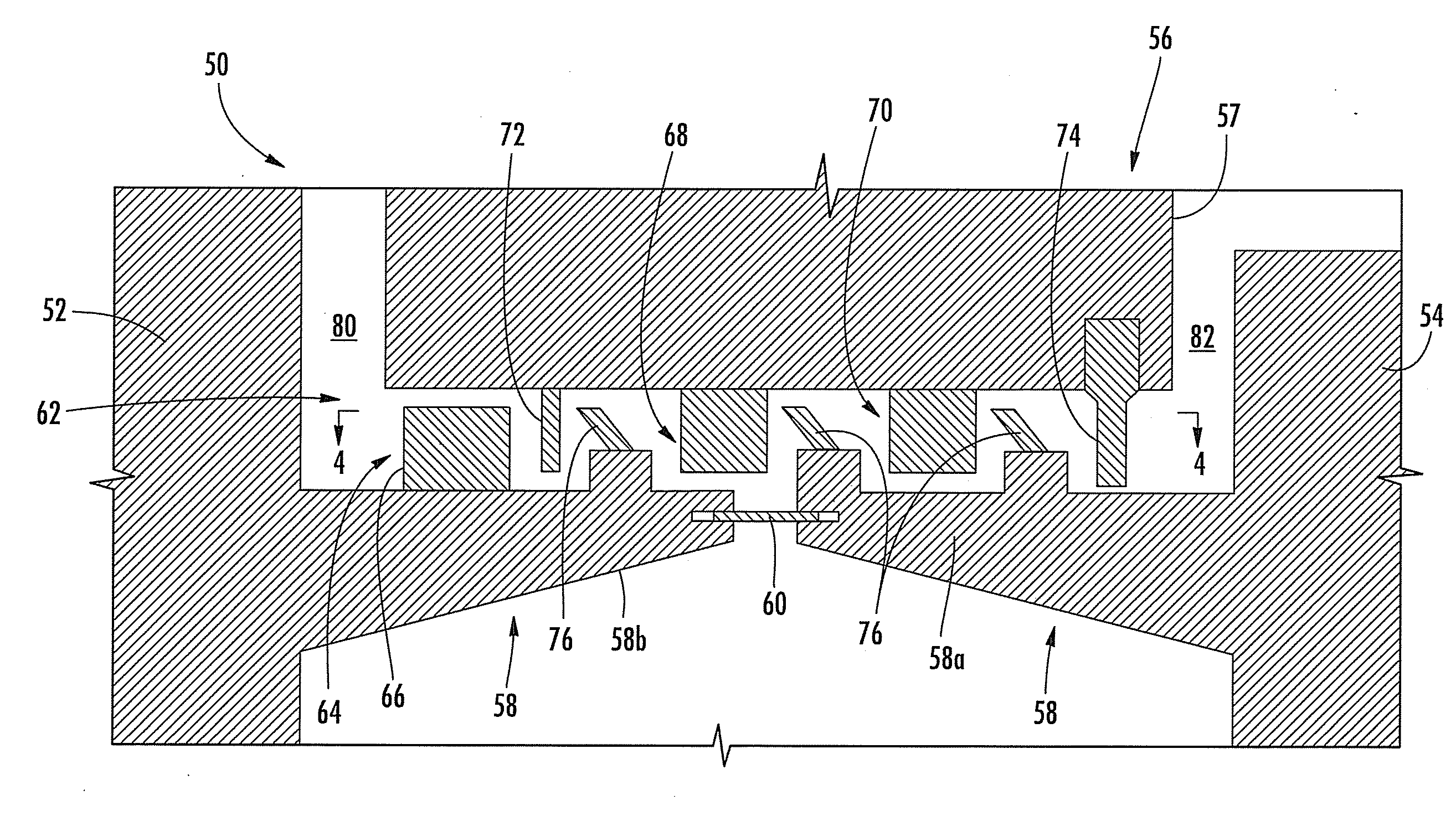

Cavity on-board injection for leakage flows

A gas turbine engine having a turbine section cooling system is disclosed which is able to cool the turbine section of the gas turbine engine to an optimal operating temperature range, while at the same time not substantially degrading engine performance. The disclosure provides a number of different structures for doing so including the provision of turning foils, turning holes, and turning grooves within a secondary air flow cavity which turns or directs cooling and parasitic leakage air into the turbine section in a direction in substantial alignment with a gas flow path through the turbine section.

Owner:RTX CORP

Seal for turbomachine segments

In one embodiment, a system includes a seal having a first sealing end portion, a second sealing end portion, and an intermediate portion between the first and second sealing end portions, wherein the seal has at least one metering hole configured to control a leakage flow across the seal.

Owner:GENERAL ELECTRIC CO

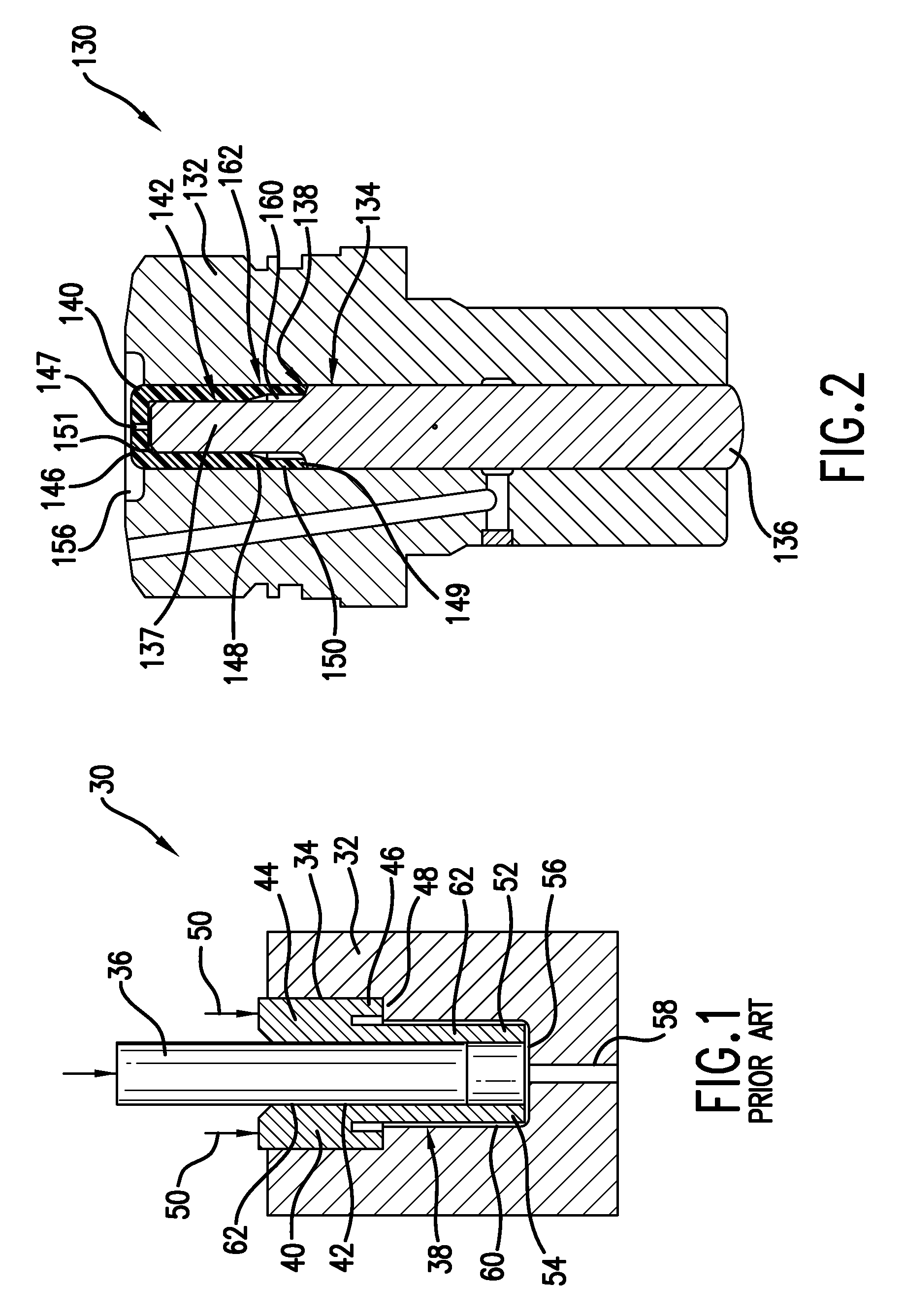

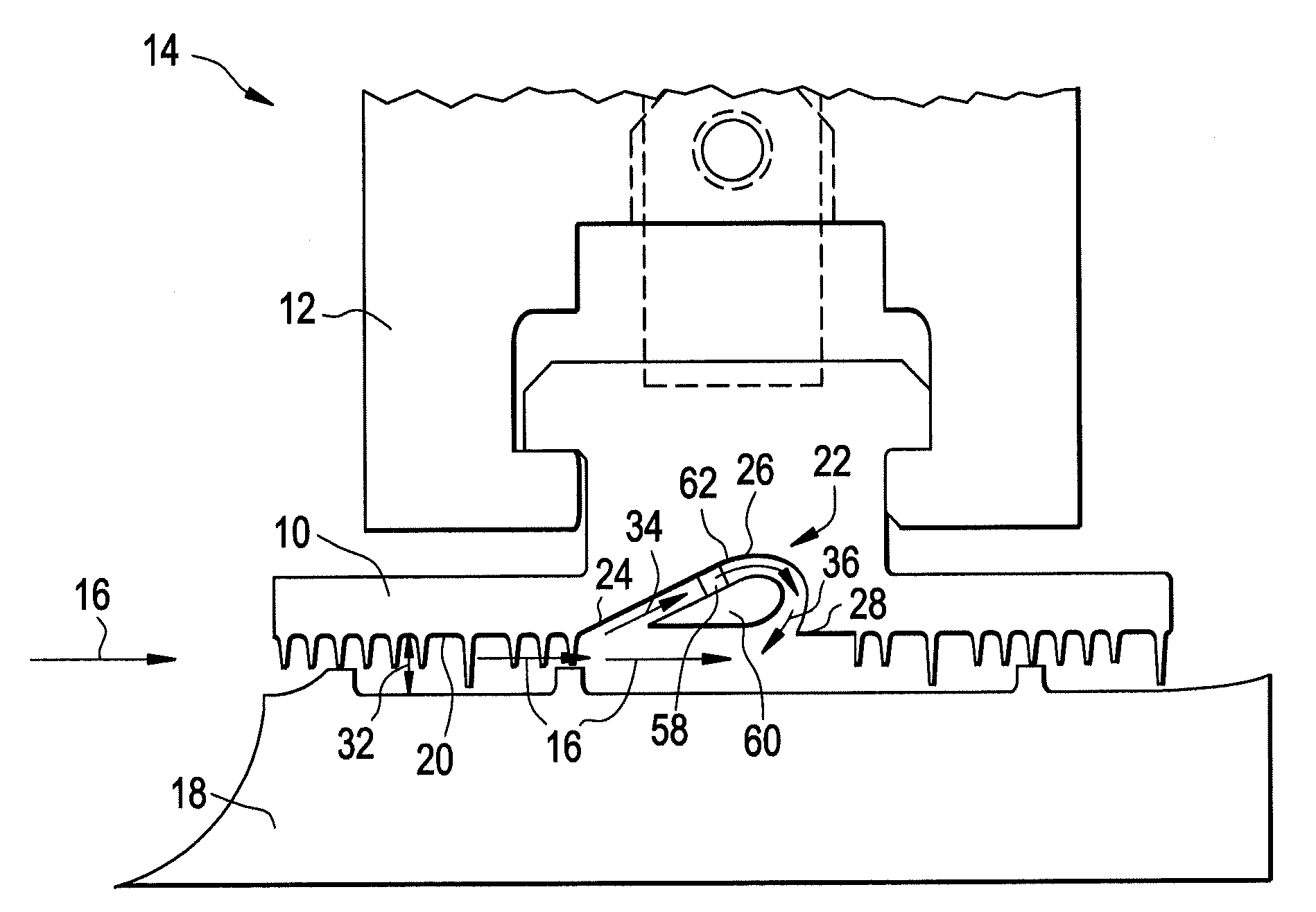

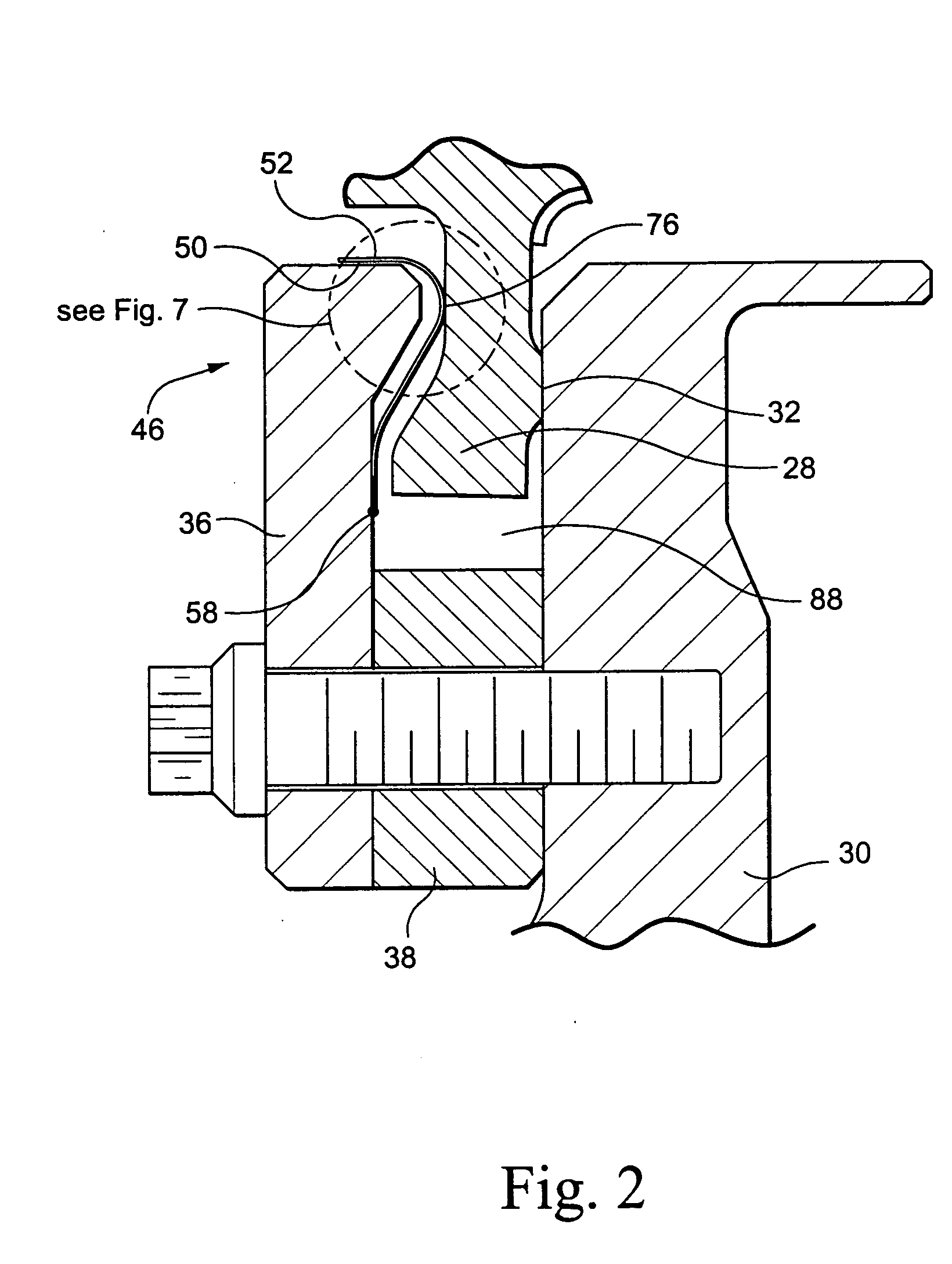

Low leakage plunger assembly for a high pressure fluid system

InactiveUS20080224417A1Minimize fuel leakageImprove efficiencyEngine sealsLeakage preventionFluid controlReciprocating motion

A fluid control device for use in a high pressure fluid system, the device including a device body with a cavity and a high pressure circuit, a plunger positioned for reciprocal movement in the cavity, and a leakage reduction cap mounted to the plunger for reducing fluid leakage flow. In one implementation, the leakage reduction cap includes a flexible portion positioned between the device body and the plunger, and defining an annular clearance gap between the leakage reduction cap and the device body. The flexible portion of the leakage reduction cap resiliently flexes radially outwardly in response to fluid pressure forces to reduce the annular clearance gap so as to minimize fluid leakage flow through the annular clearance gap.

Owner:CUMMINS INC

Fluidic sealing for turbomachinery

Disclosed is a seal for turbomachinery including a seal face locatable between a first turbomachinery component and a second turbomachinery component. At least one fluid channel extends through the seal. The at least one fluid channel is capable of injecting fluid flow between the first turbomachinery component and the second turbomachinery component at the seal face thereby disrupting a leakage flow between the first turbomachinery component and the second turbomachinery component. Further disclosed is a turbomachine utilizing the seal.

Owner:GENERAL ELECTRIC CO

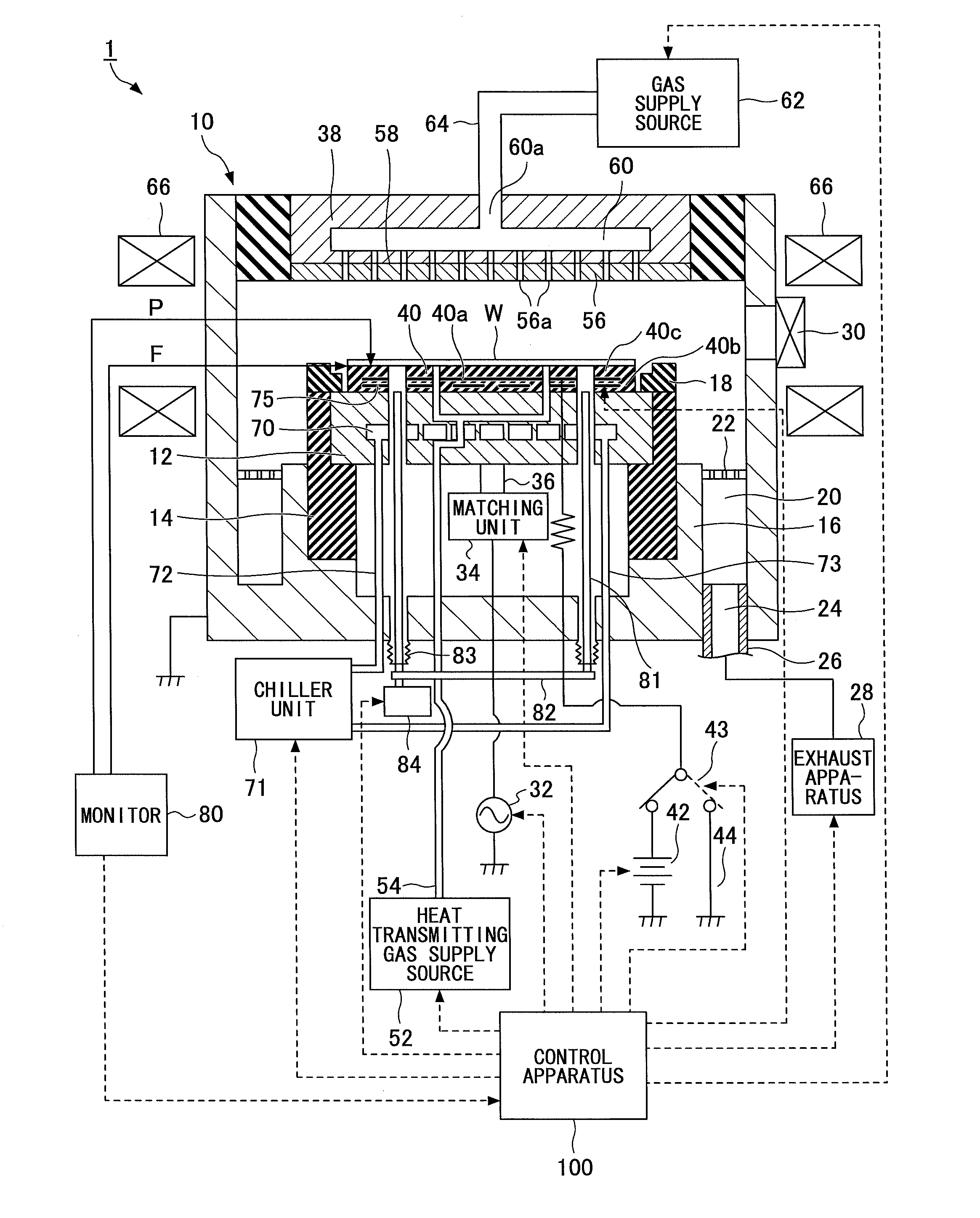

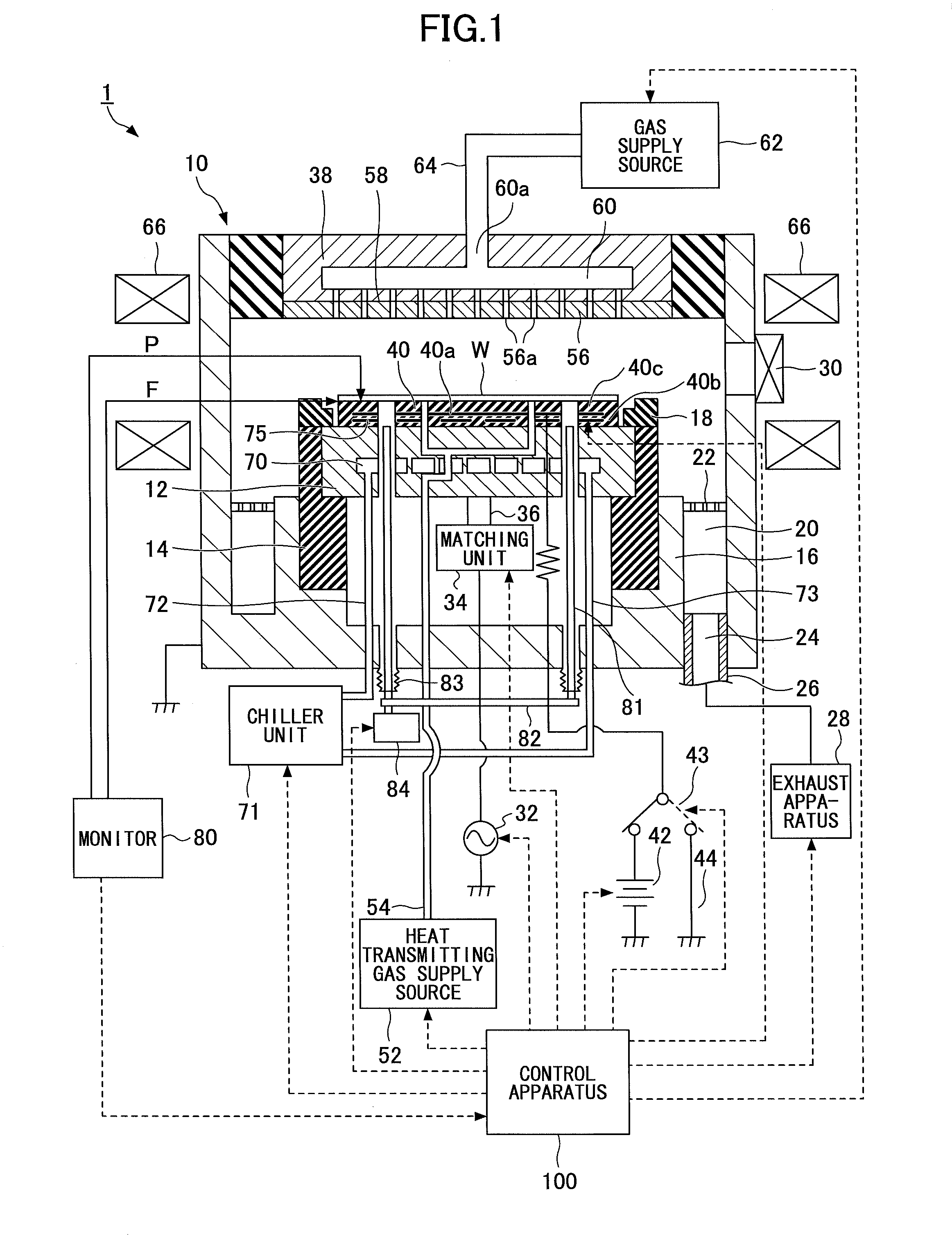

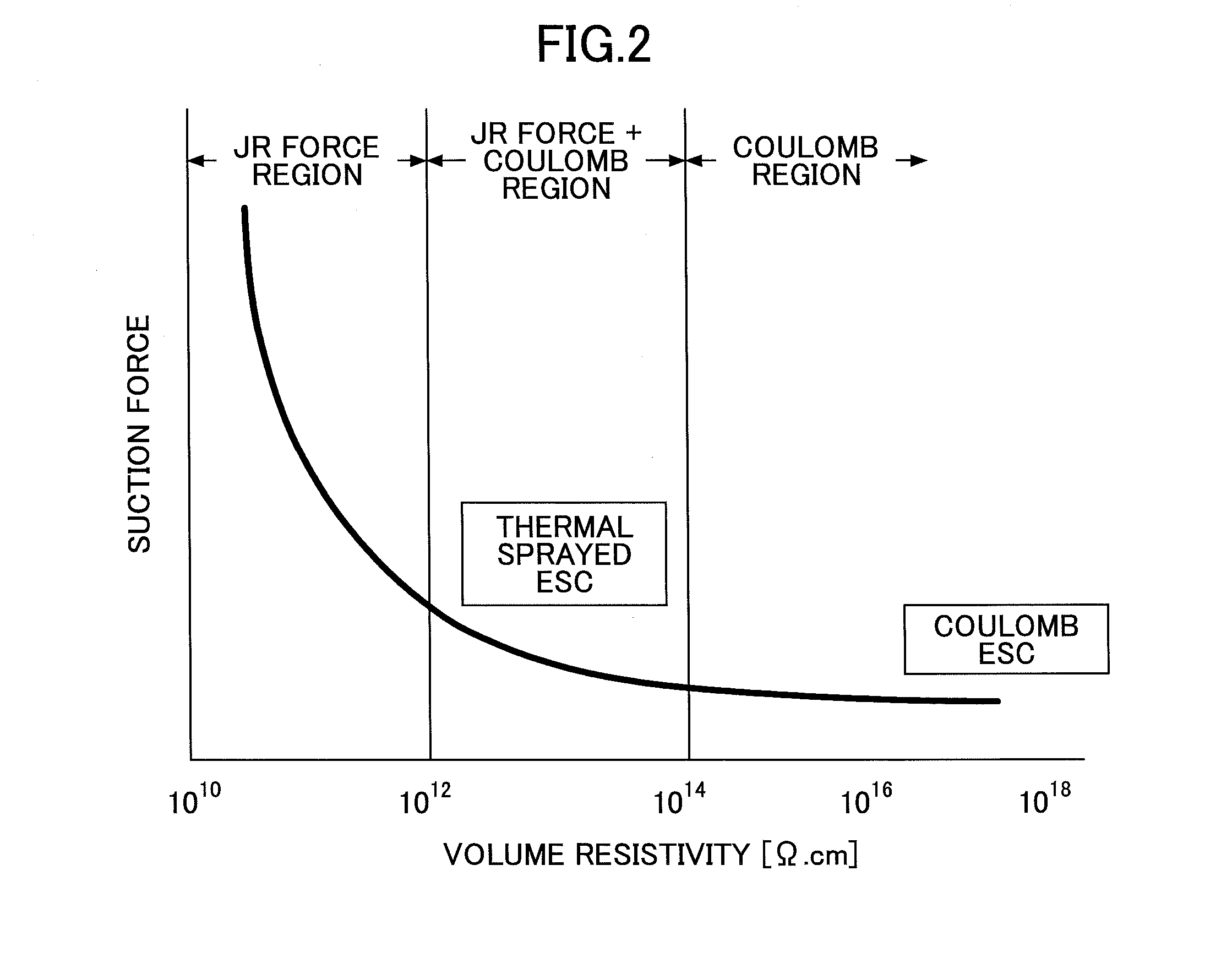

Dechuck control method and plasma processing apparatus

ActiveUS20130153147A1Reduce pressureElectric discharge tubesSemiconductor/solid-state device manufacturingDecreased pressureElectrical polarity

A dechuck control method includes performing a discharge process by introducing an inert gas into a processing chamber and maintaining the pressure within the processing chamber at a first pressure; monitoring the pressure of a heat transmitting gas supplied to the processing object rear face and / or the leakage flow rate of the heat transmitting gas; obtaining the amount and polarity of the residual electric charge of the electrostatic chuck surface and applying a voltage for supplying an electric charge that is of the same amount as the residual electric charge but of the opposite polarity to a chuck electrode; evacuating the inert gas from the processing chamber while applying the voltage to the chuck electrode and reducing the pressure within the processing chamber to a second pressure; and turning off the voltage applied to the electrostatic chuck and dechucking the processing object from the electrostatic chuck.

Owner:TOKYO ELECTRON LTD

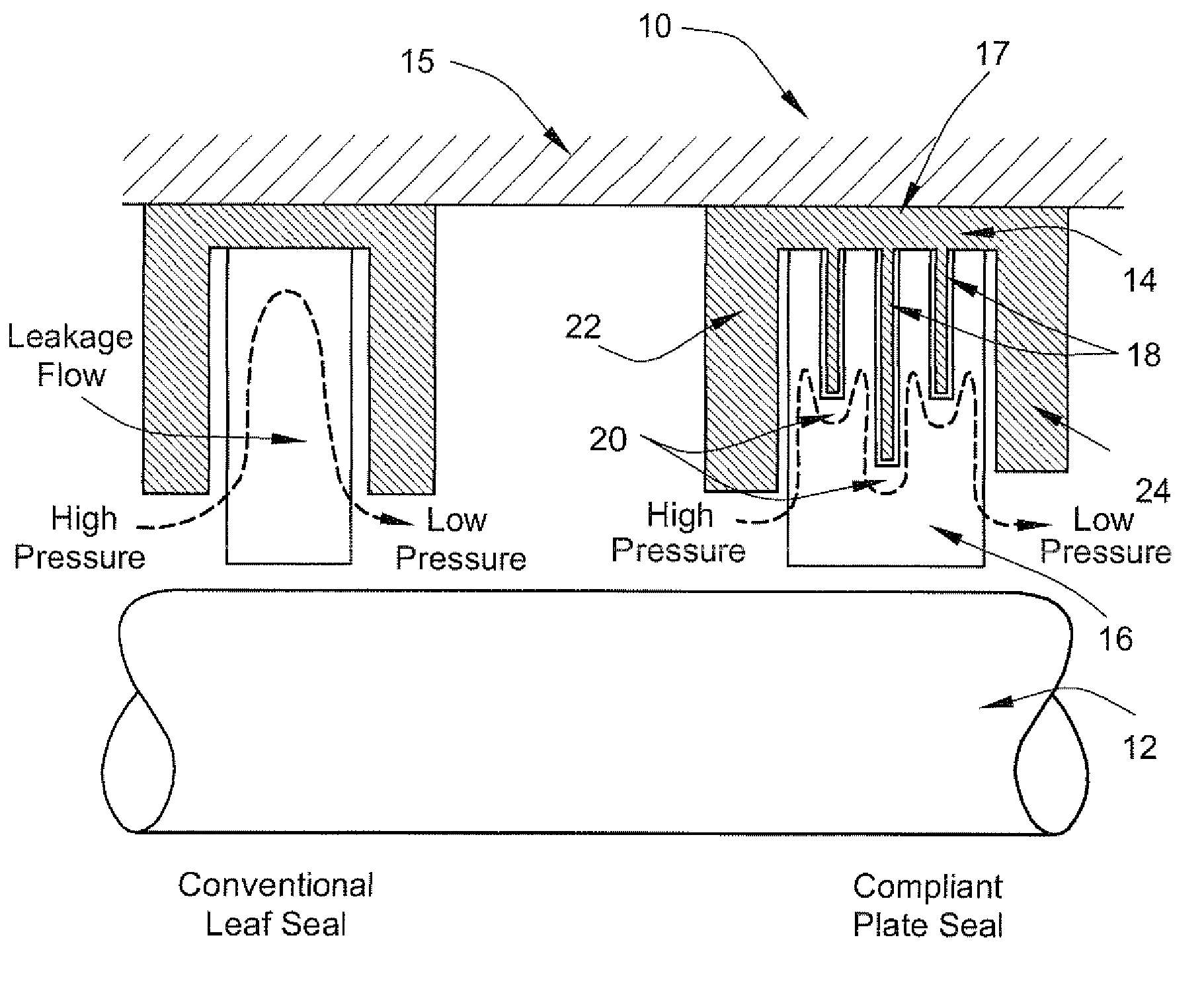

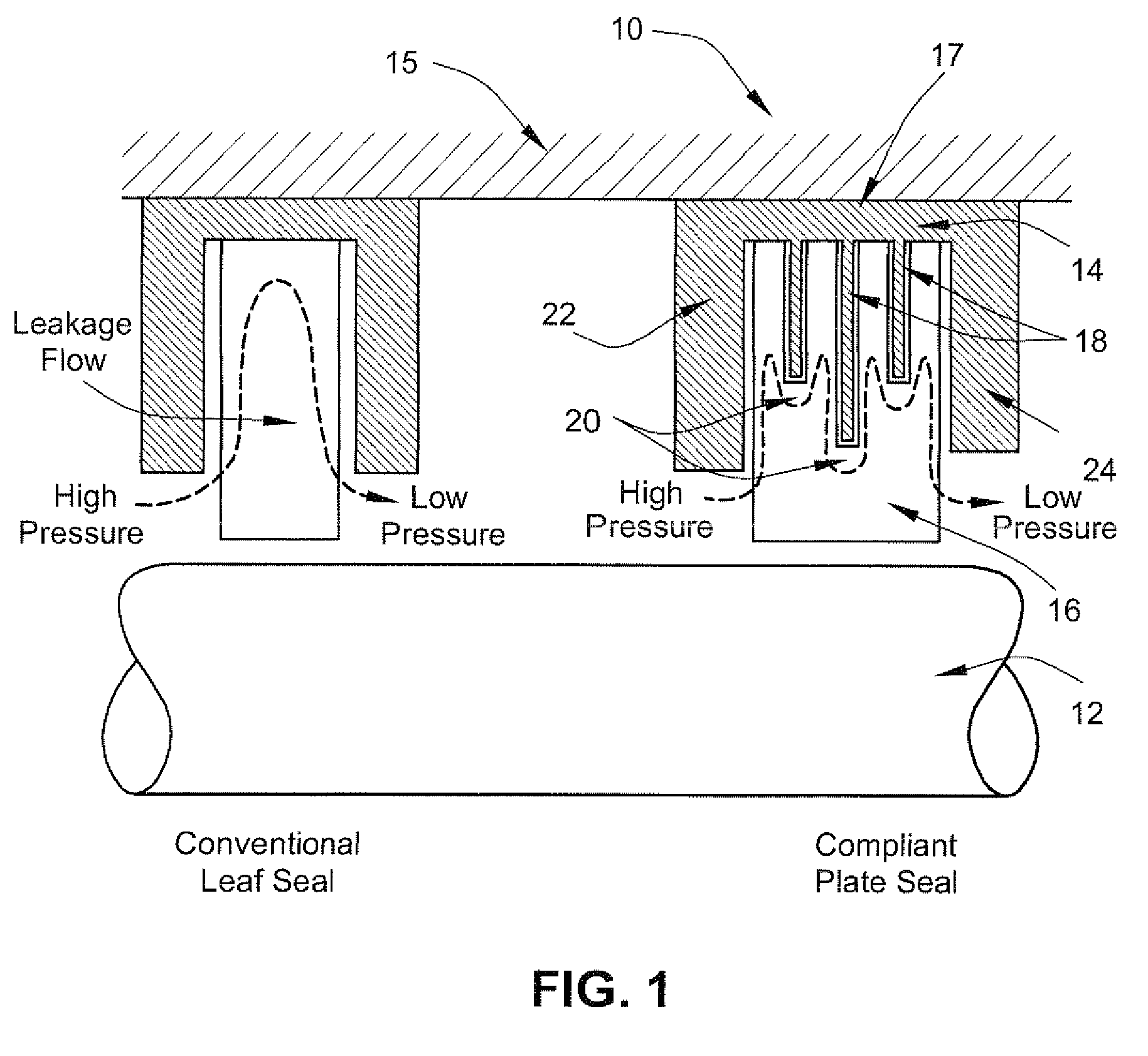

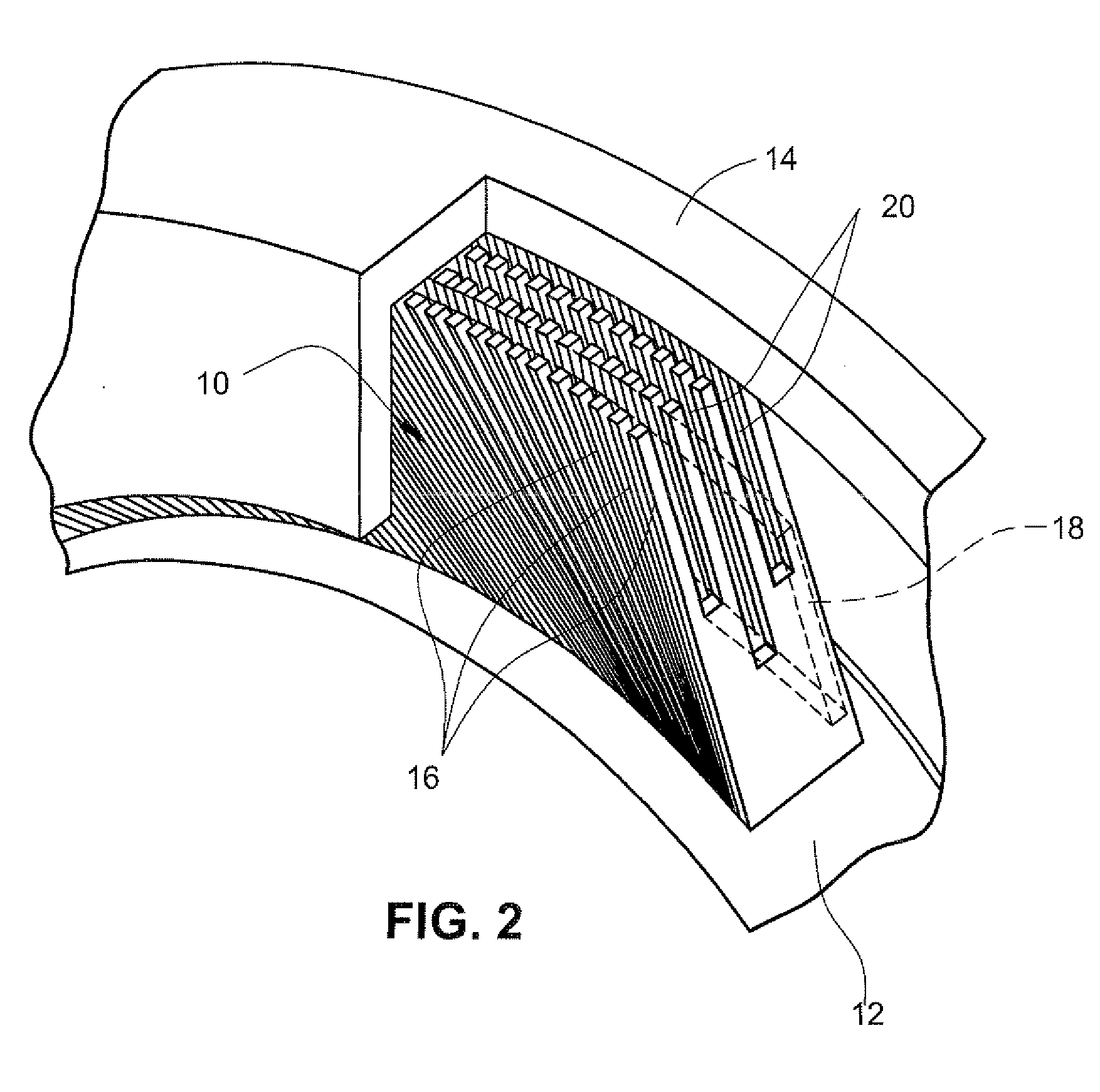

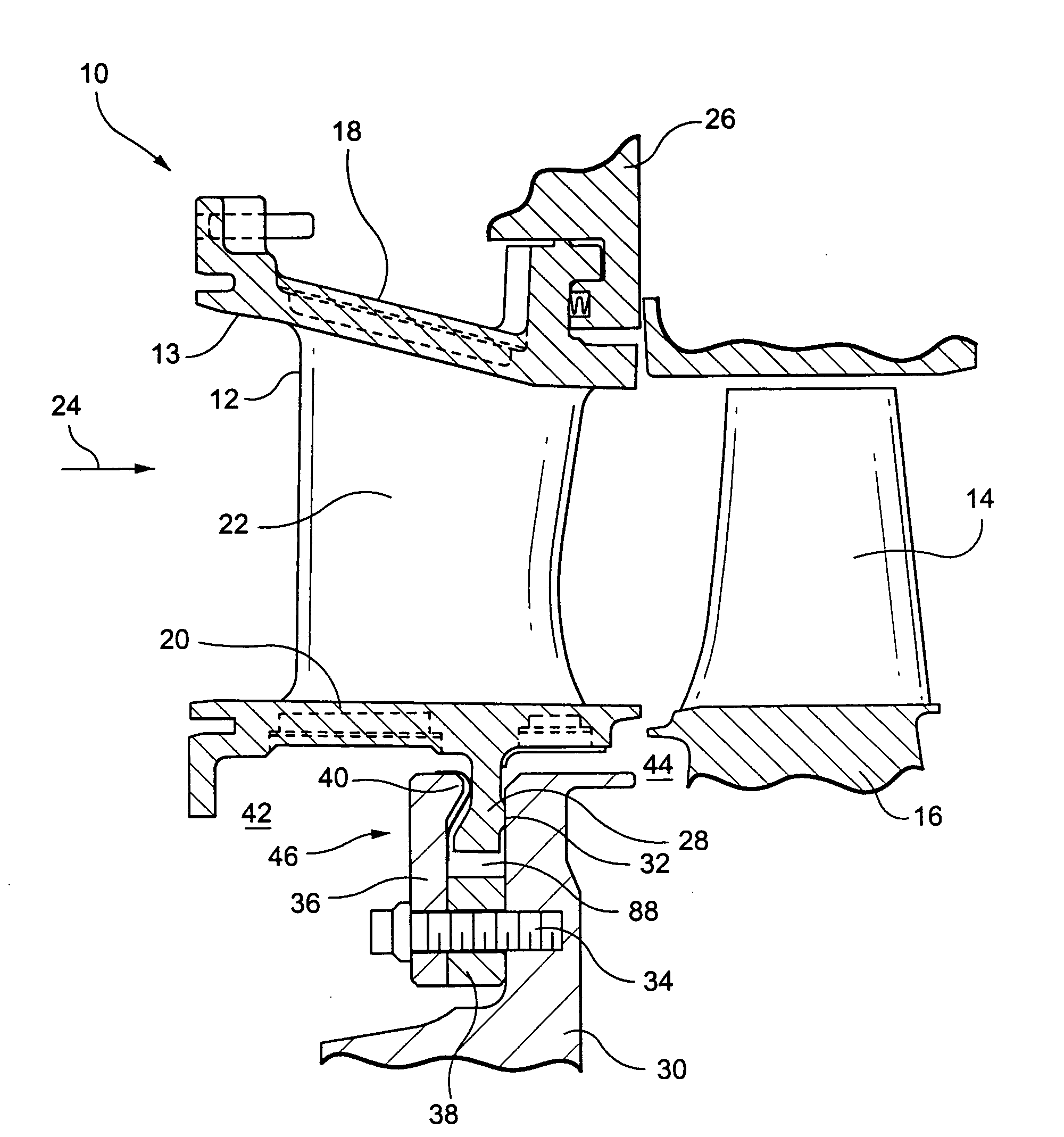

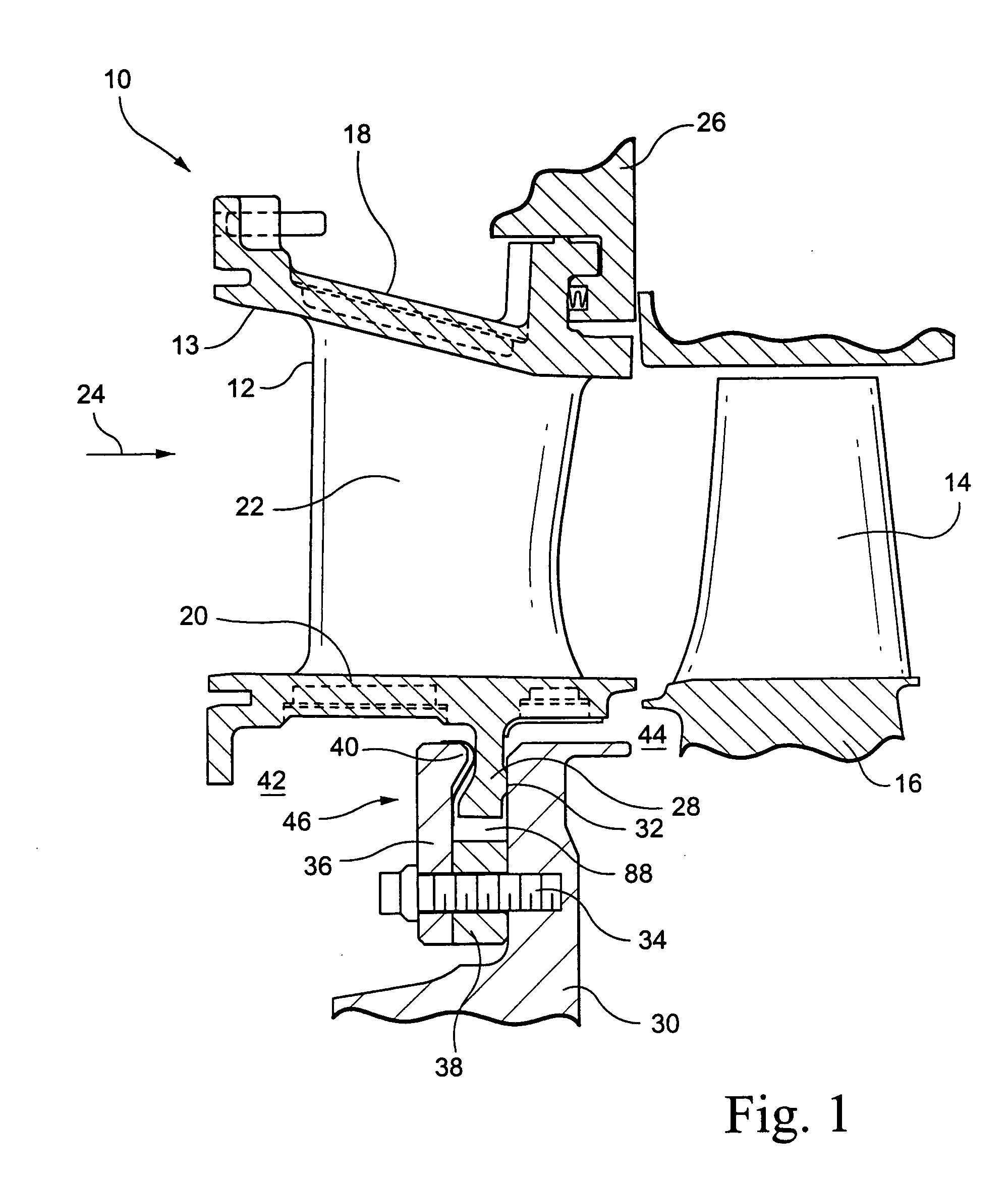

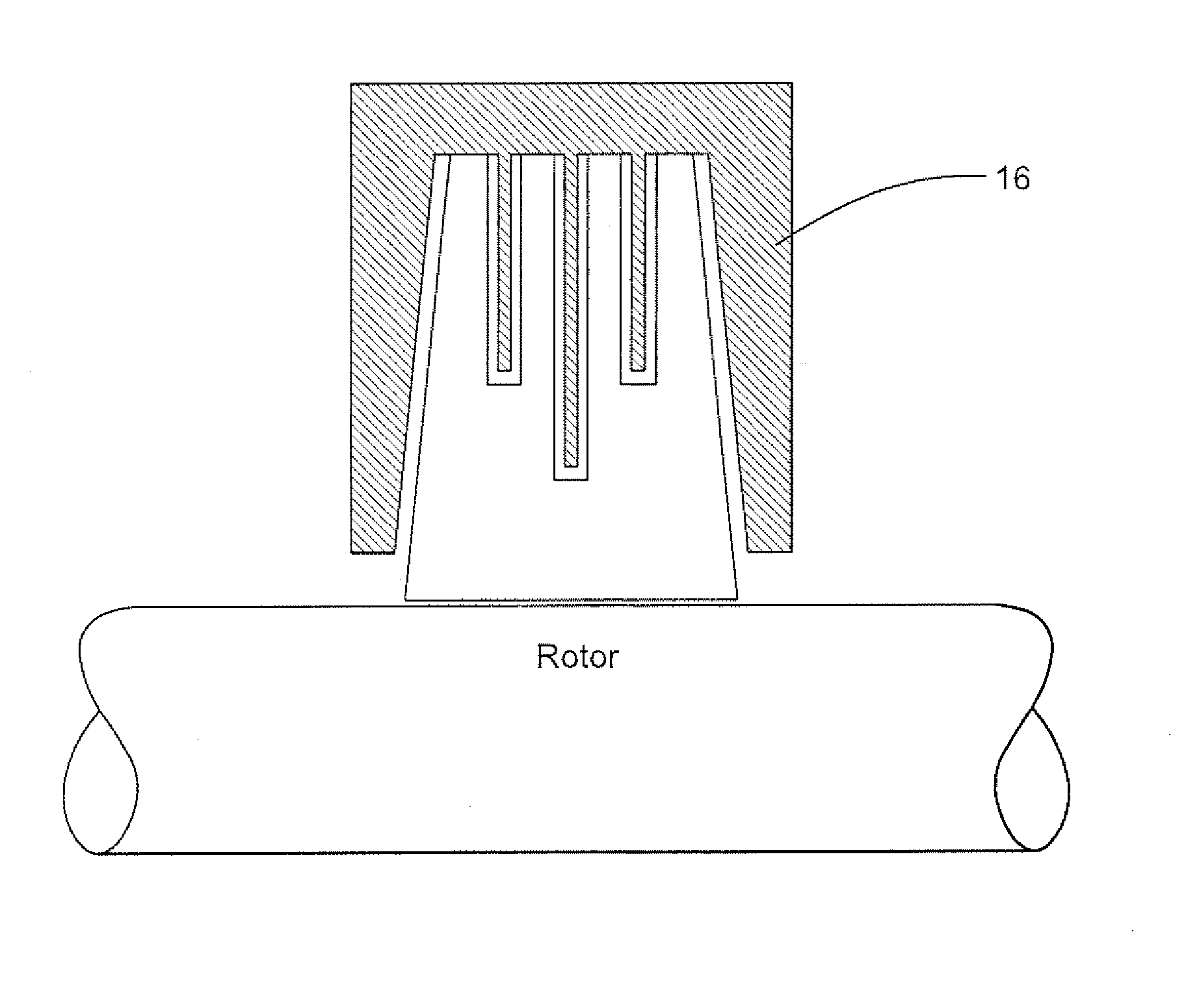

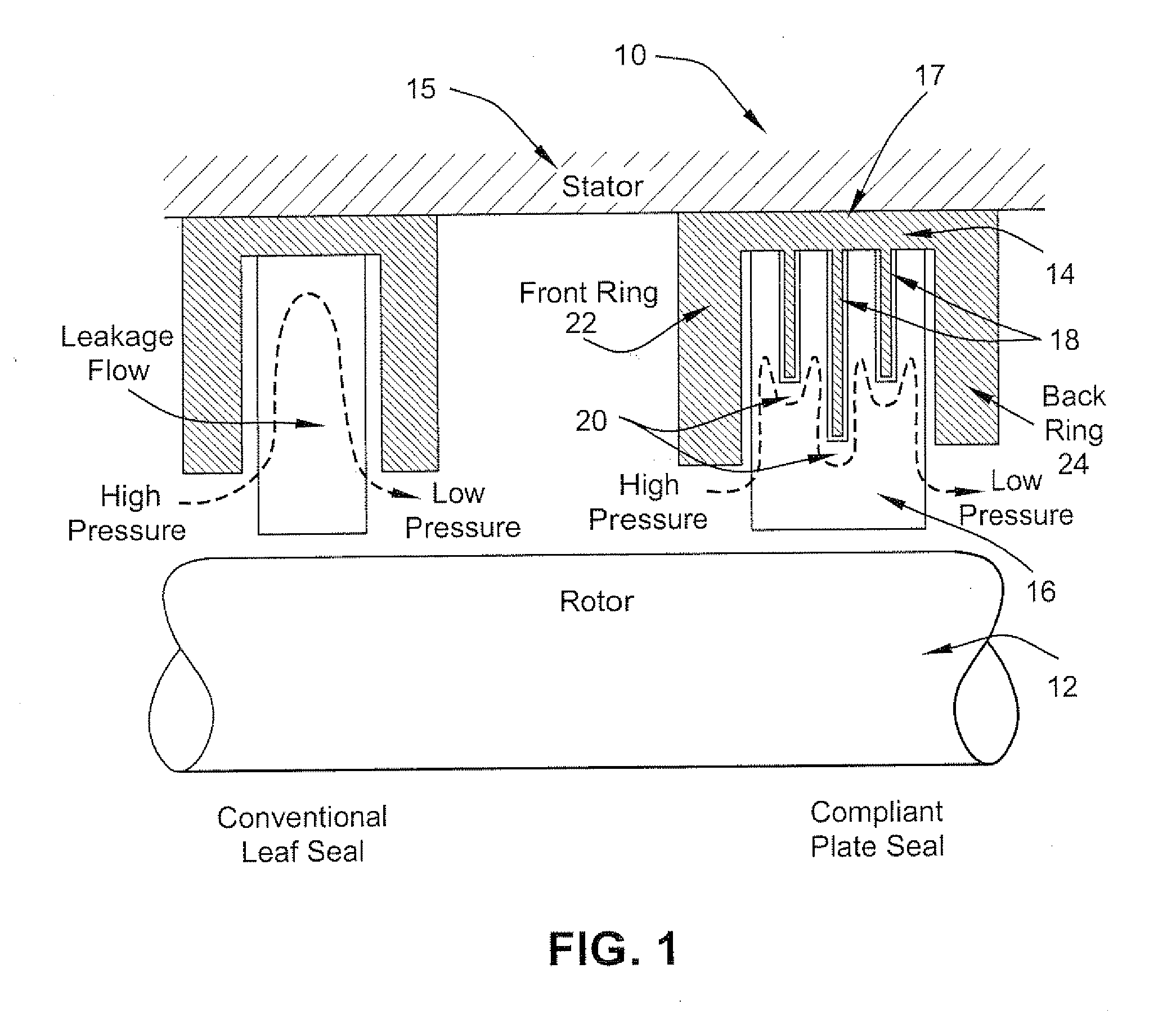

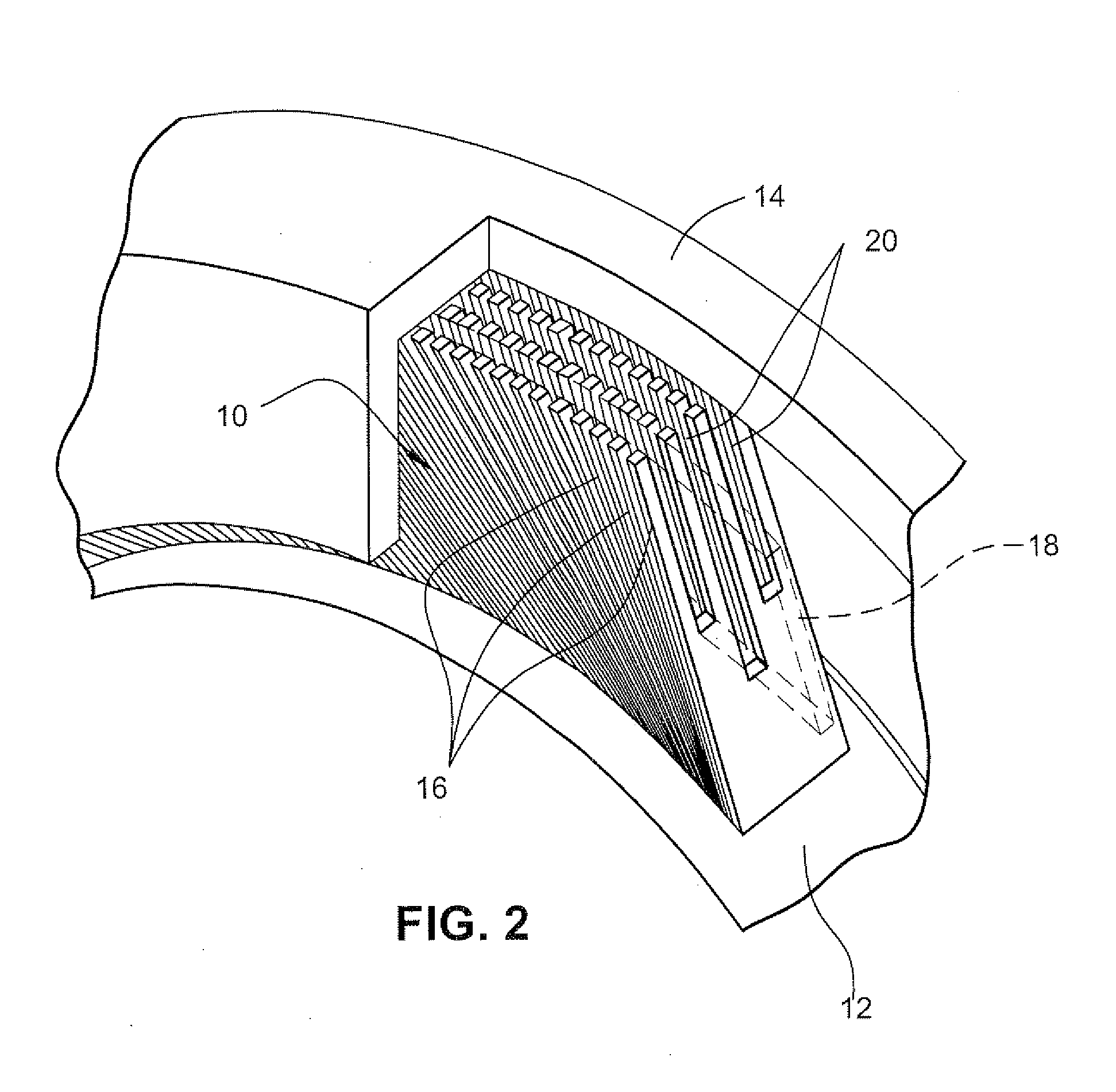

Compliant Plate Seals for Turbomachinery

A shaft seal serves to reduce leakage between a rotating shaft and a static shell. The shaft seal includes a plurality of compliant plate members, each having a root and a tip. The compliant plate members are secured to one of the static shell and the rotating shaft at their root in facing relation. The tips of the compliant plate members define a sealing ring between the static shell and the rotating shaft. An axial flow resistance member is disposed within the compliant plate members and serves as a harrier to axial leakage flow between the compliant plate members.

Owner:GENERAL ELECTRIC CO

System for sealing an inner retainer segment and support ring in a gas turbine and methods therefor

InactiveUS20050244267A1Improve sealingIncreasing turbine engine efficiencyPump componentsStatorsLeakage flowGas turbines

Arcuate seal layers conforming with one another are disposed between inner retainer segments and inner rails of nozzle segments of a gas turbine. The layers are secured to the aft axial face of the segments and project radially outwardly to seal against the forward axial faces of the rails. The rear axial faces of the rails have chordal seals for sealing against the forward axial faces of the support rings. The seal layers have radial cuts misaligned with one another in an axial direction to preclude leakage flows through gaps formed by the cuts. Arcuate spacers are staggered circumferentially with the arcuate retainer segments whereby an intermediate pressure plenum is formed between the finger seals and chordal seals.

Owner:GENERAL ELECTRIC CO

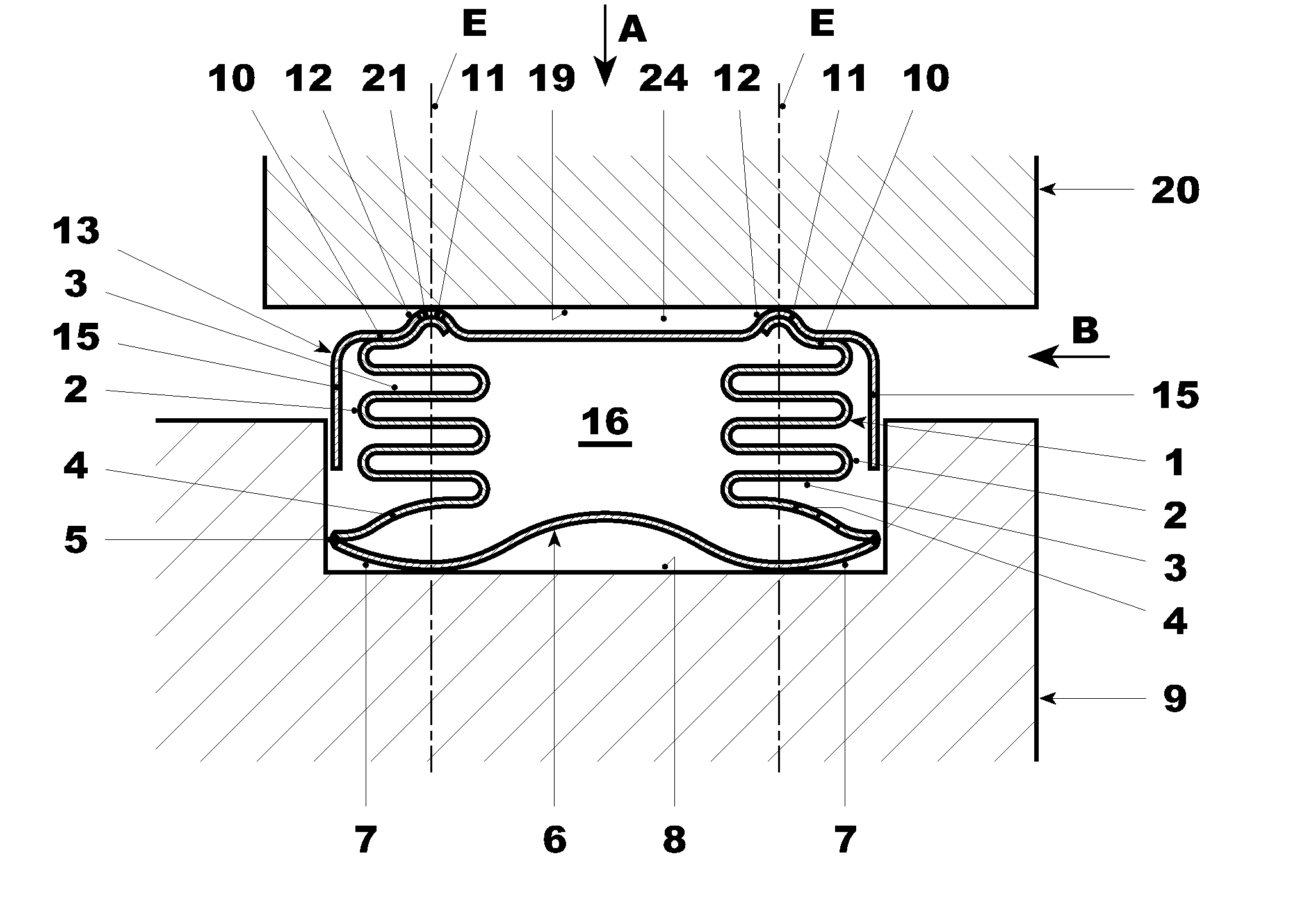

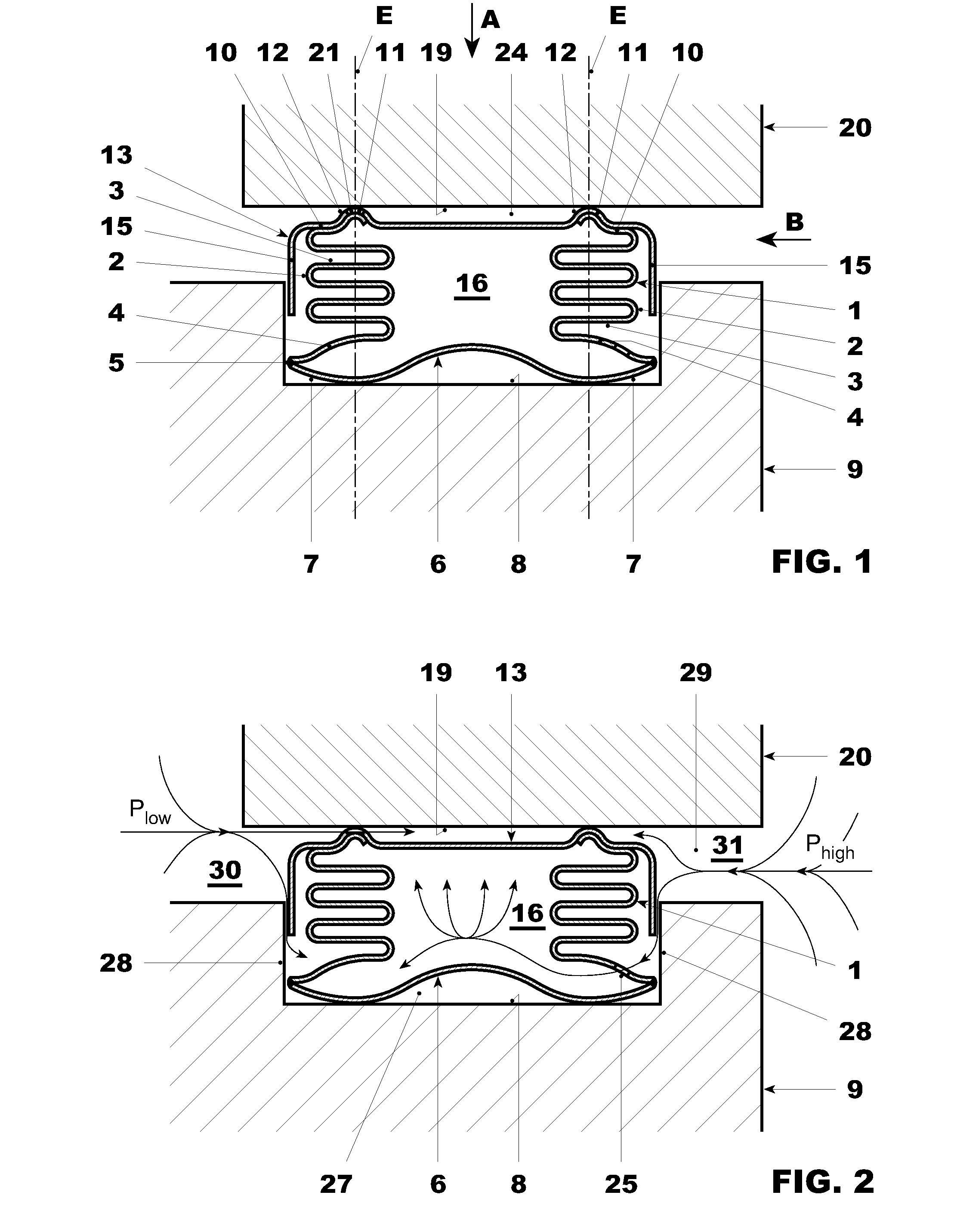

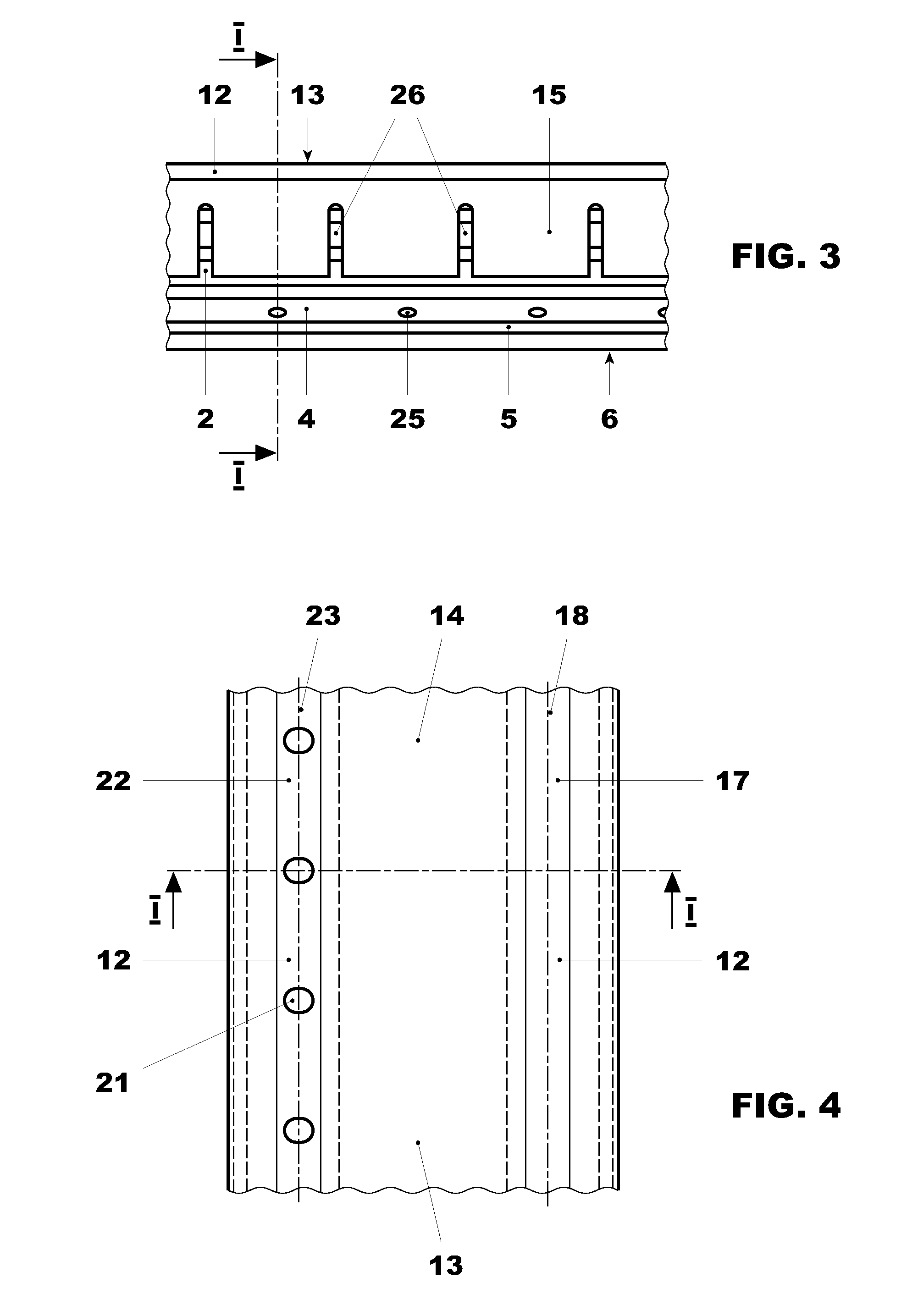

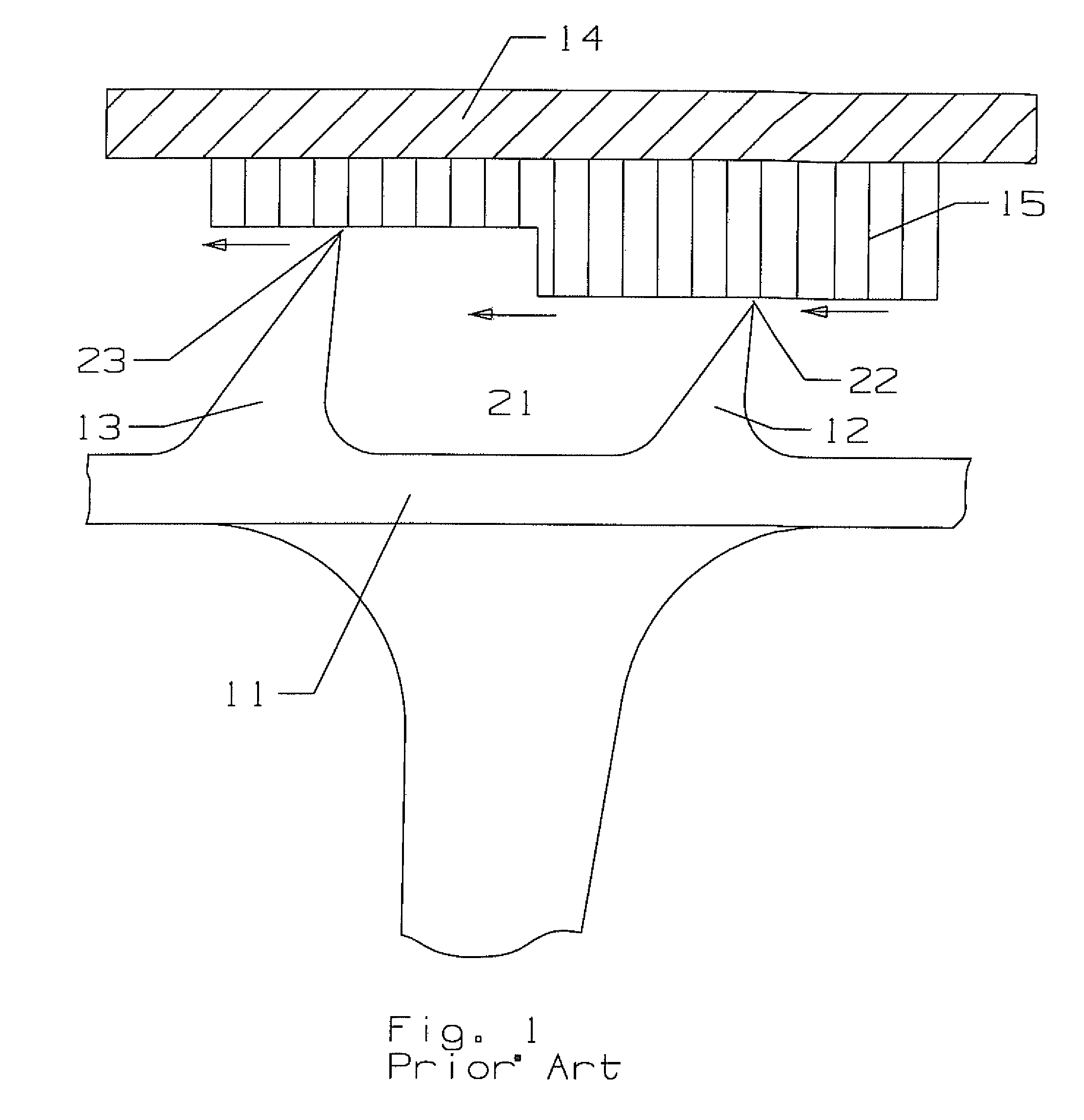

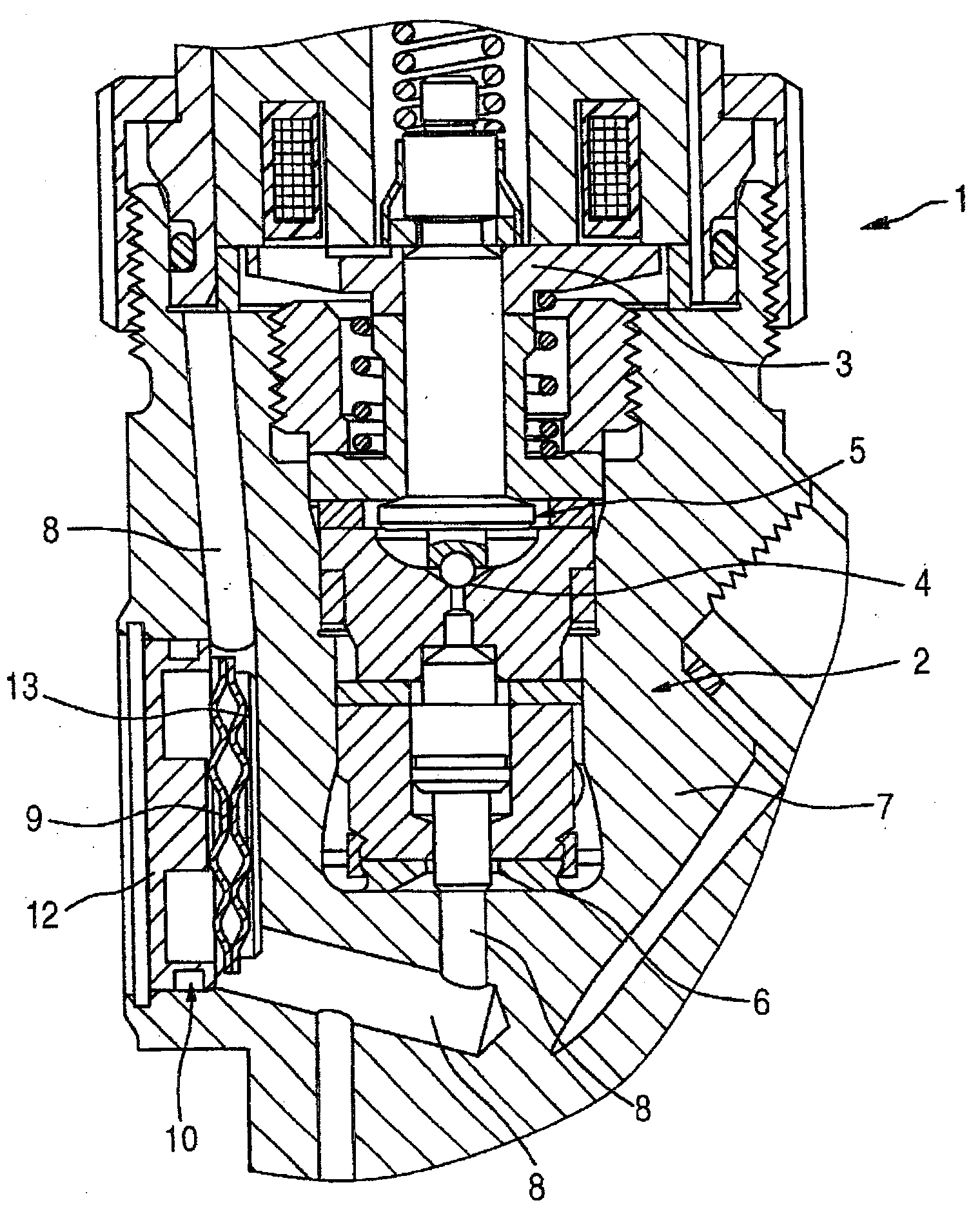

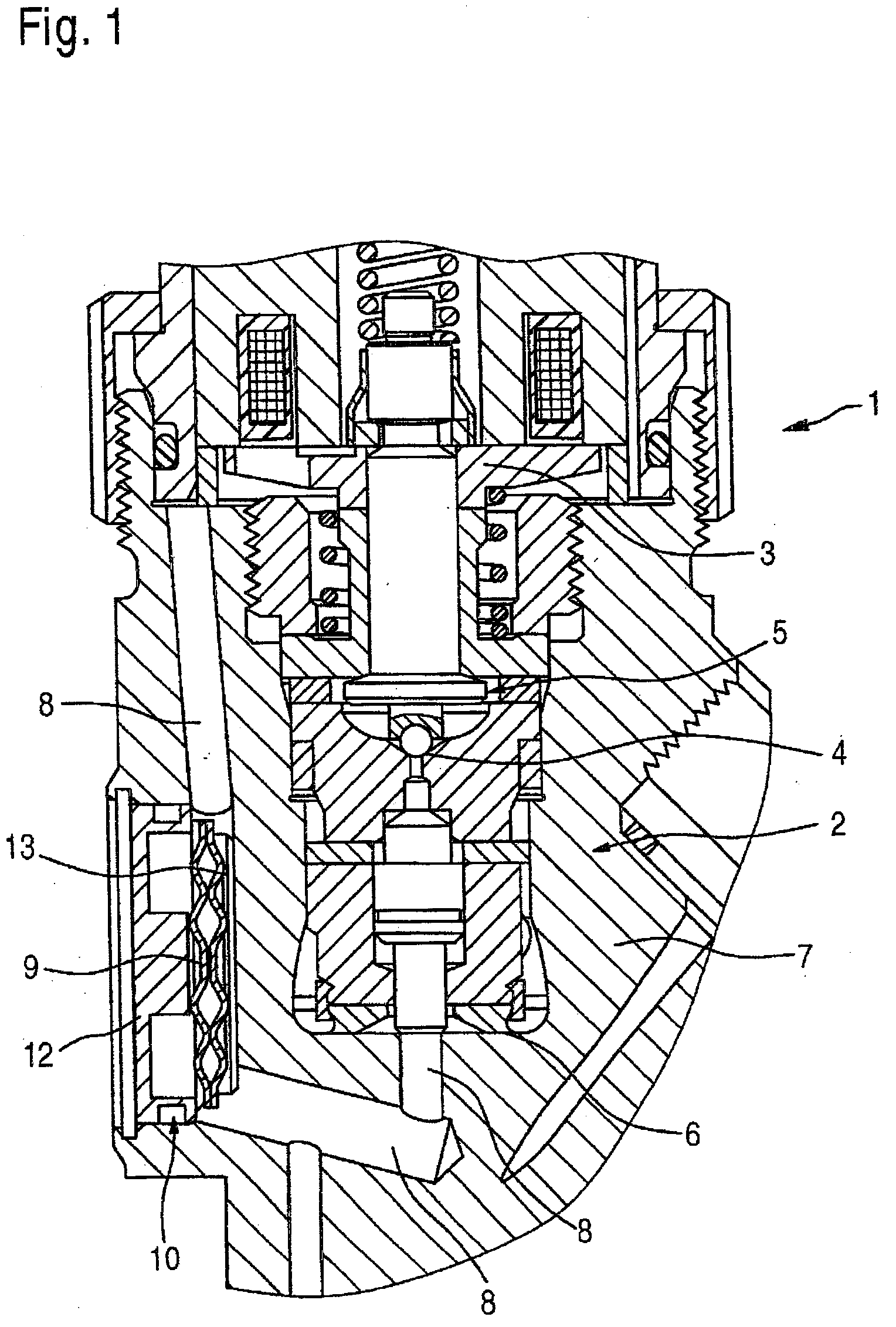

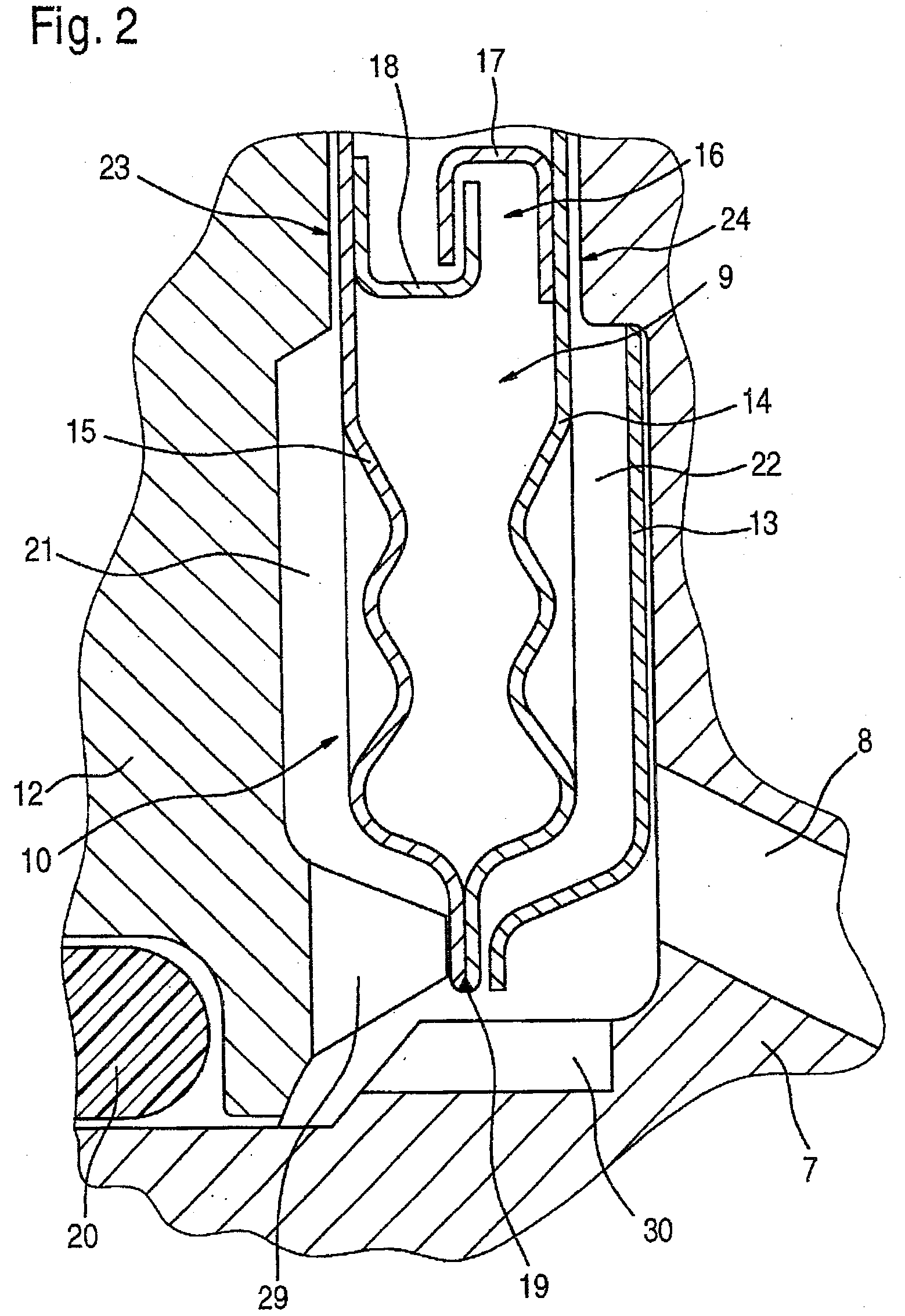

Seal and seal arrangement for confining leakage flows between adjacent components of turbo-machines and gas turbines

InactiveUS20110150635A1Improve rigidityIncrease flexibilityEngine sealsContinuous combustion chamberEngineeringLeakage flow

A seal for stemming leakage flows between adjacent components (9, 20), especially of a gas turbine, has an elastically deformable, thin-walled sealing element (1) and a thin-walled cover element (13) which is U-shaped in cross section and between its legs (15) and its base (14) partially accommodates the sealing element (1). The legs (15) of the cover element (13) are arranged in the sealing arrangement, which features the seal, between two oppositely disposed walls (28) of the other component (9) in a movable manner relative to these walls (28) which, together with the sealing surface (8) of the other component (9), form a groove (27) which is U-shaped in cross section. Forces, which act laterally upon the seal, are absorbed by the cover element (13) and via the legs (15) are diverted into the other component (9) so that the integrity of the seal is maintained even in the case of lateral forces.

Owner:ANSALDO ENERGIA IP UK LTD

Compliant Plate Seals for Turbomachinery

A shaft seal serves to reduce leakage between a rotating shaft and a static shell. The shaft seal includes a plurality of compliant plate members, each having a root and a tip. The compliant plate members are secured to the static shell at their root in facing relation. The tips of the compliant plate members define a sealing ring between the static shell and the rotating shaft. An axial flow resistance member is disposed within the compliant plate members and serves as a barrier to axial leakage flow between the compliant plate members.

Owner:GENERAL ELECTRIC CO

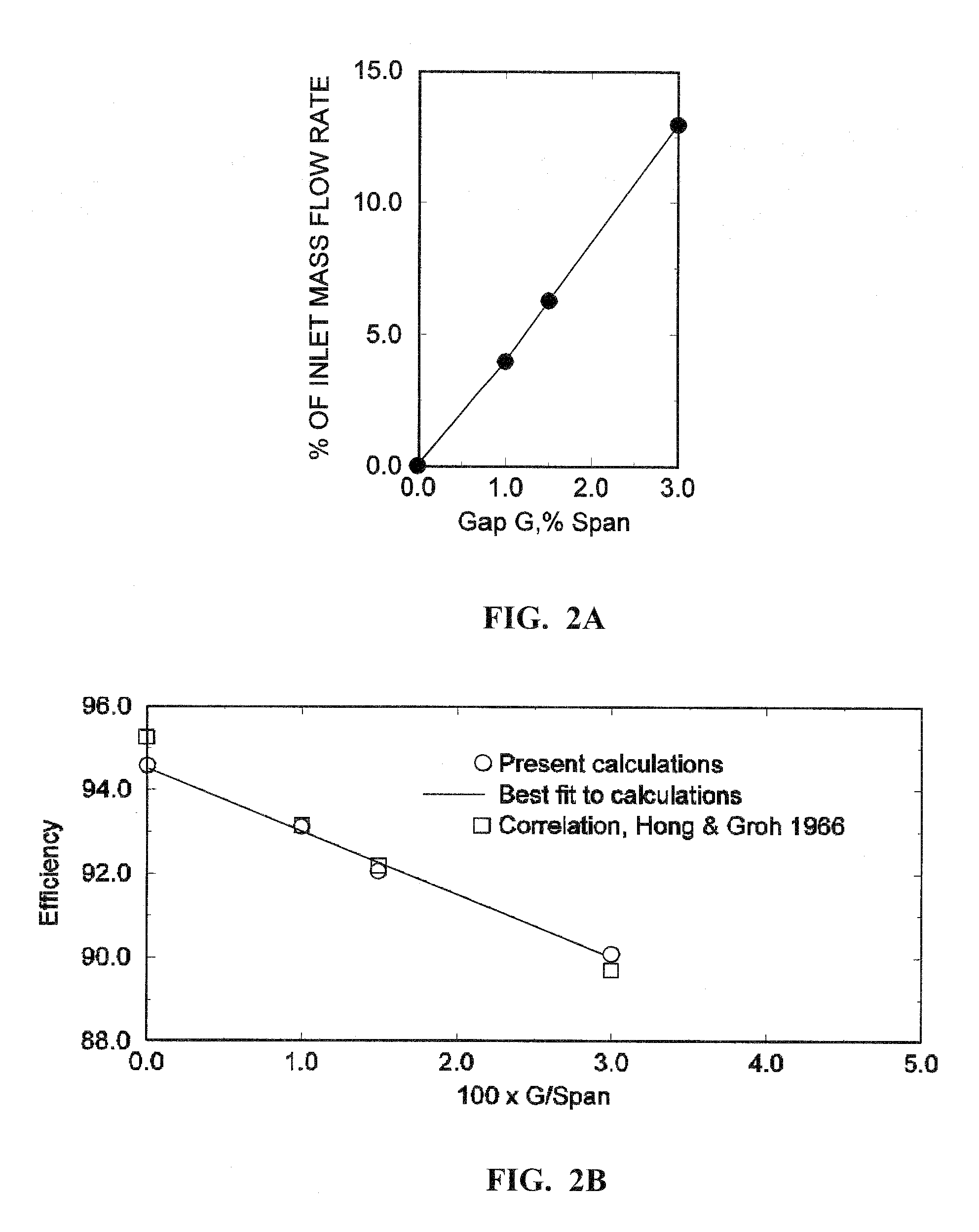

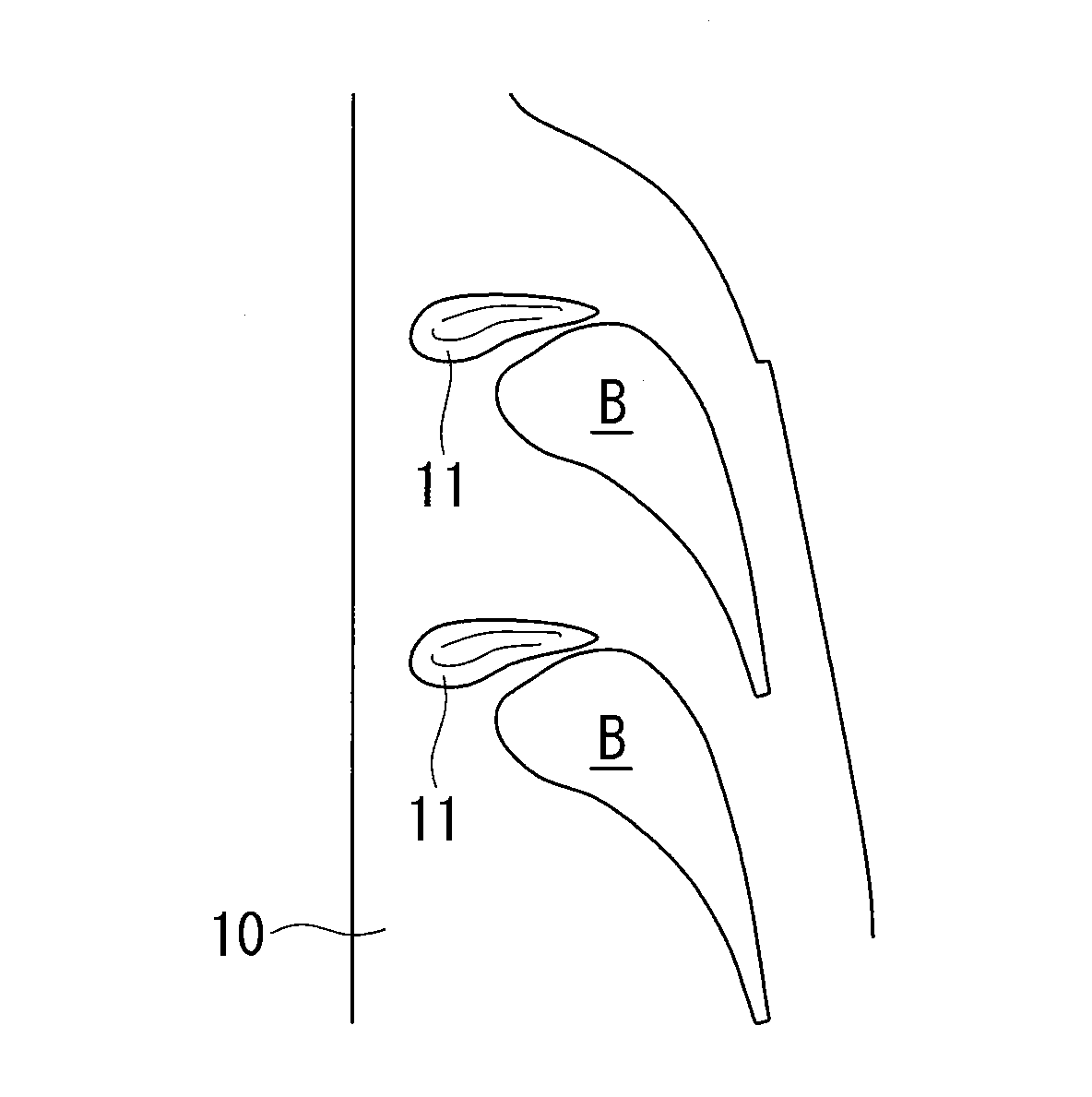

Turbine blade cascade endwall

ActiveUS20100196154A1Improve performanceReduce secondary flow lossEngine manufacturePump componentsSuction stressTurbine blade

Provided is a turbine blade cascade endwall that is capable of suppressing a vortex generated on a suction surface of a turbine stator blade and that is capable of reducing secondary-flow loss due to this vortex. A turbine blade cascade endwall that is positioned on a tip side of a plurality of turbine stator blades arranged in a ring form is provided with a pressure gradient alleviating part that alleviates a pressure gradient generated in the blade height direction at a suction surface of the turbine stator blades due to a clearance leakage flow, leaking out of a gap between a tip of a turbine rotor blade located on the upstream side of the turbine stator blades and a tip endwall disposed facing the tip of this turbine rotor blade.

Owner:MITSUBISHI POWER LTD

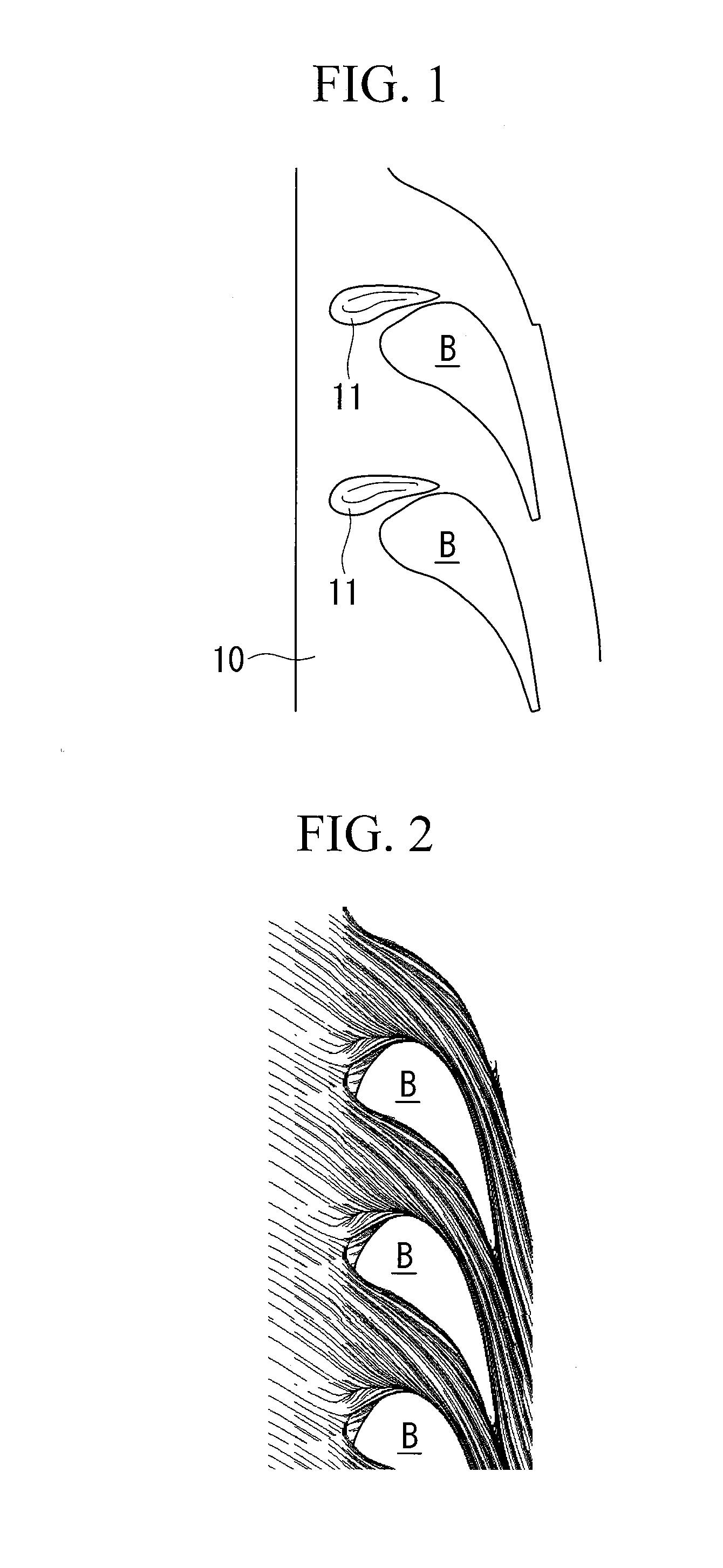

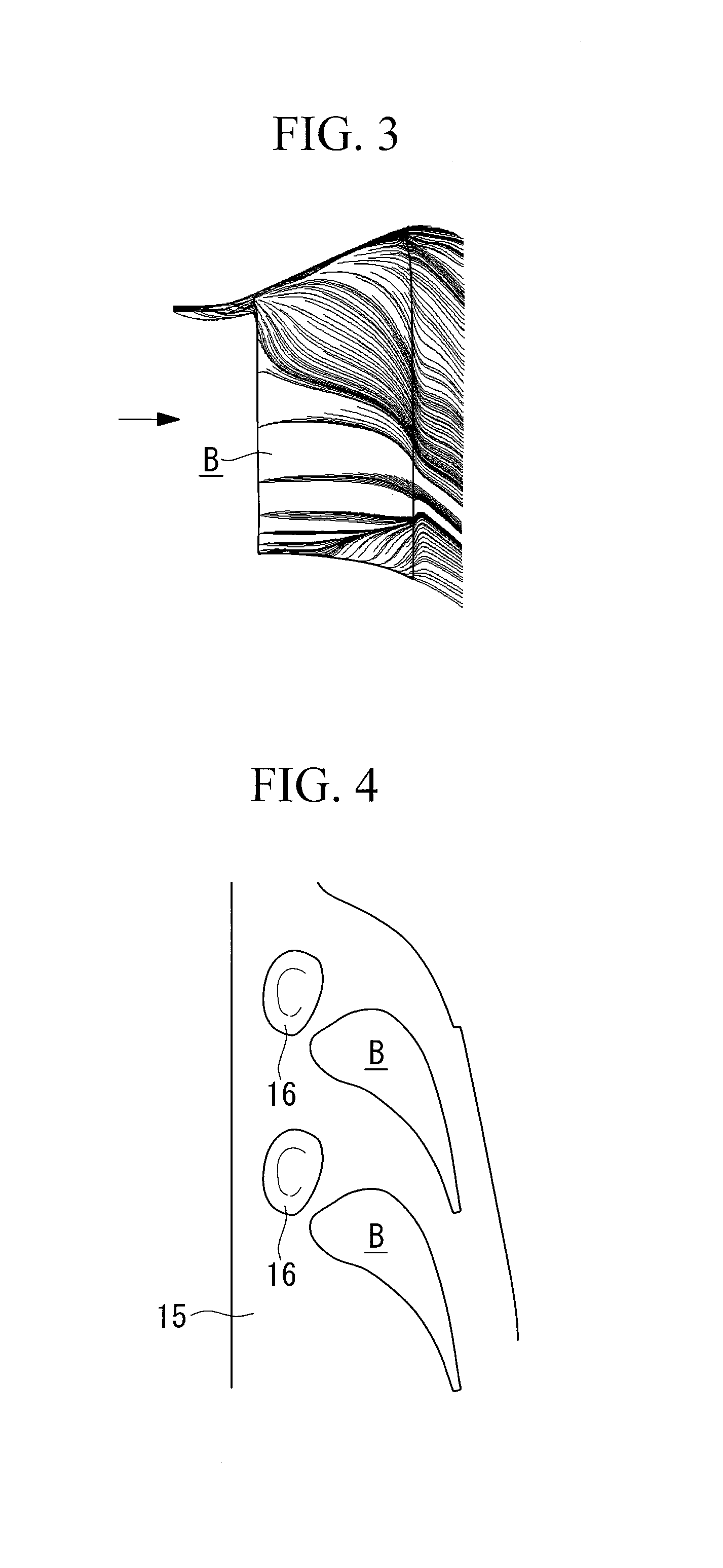

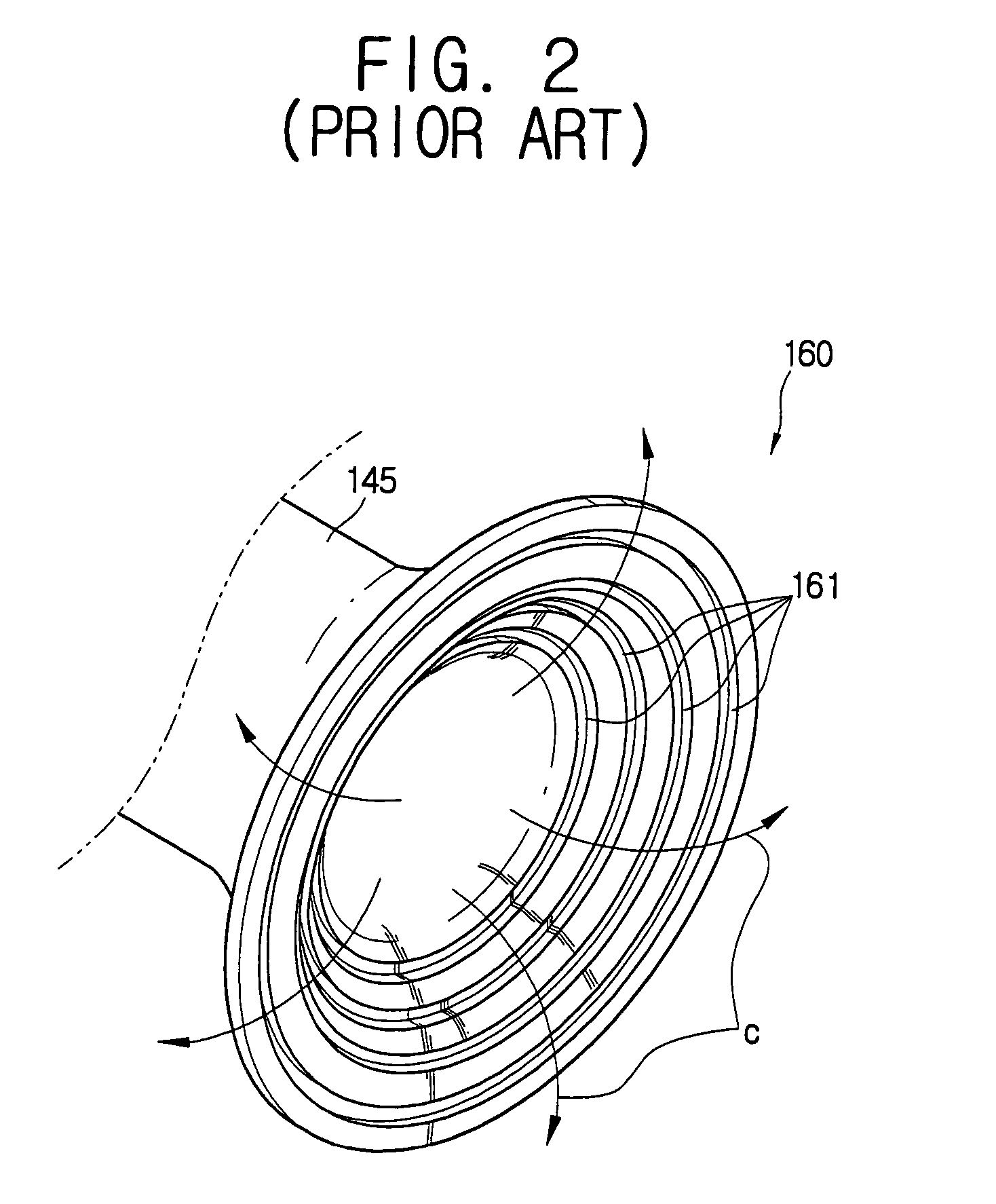

Labyrinth seal

A stepped labyrinth seal having a plurality of teeth forming gaps between a stationary honeycomb member, where the cavities formed between adjacent teeth include a plurality of vortex flow generating strips on the wall of the cavity that redirect the leakage flow from a gap back toward the gap and in a direction toward the gap in order to limit the leakage flow through the gap. The vortex generating strips extend along the cavity floor and up the sides of the teeth forming the cavity. The strips slope downward from the downstream tooth toward the upstream tooth in the direction of rotation, and with a curvature in the direction of rotation. The stepped labyrinth seal is intended for use in a gas turbine engine having a plurality of stages in the turbine, with the labyrinth seal being used to seal the gap between rotating blades and the honeycomb surface on the stationary casing.

Owner:FLORIDA TURBINE TECH

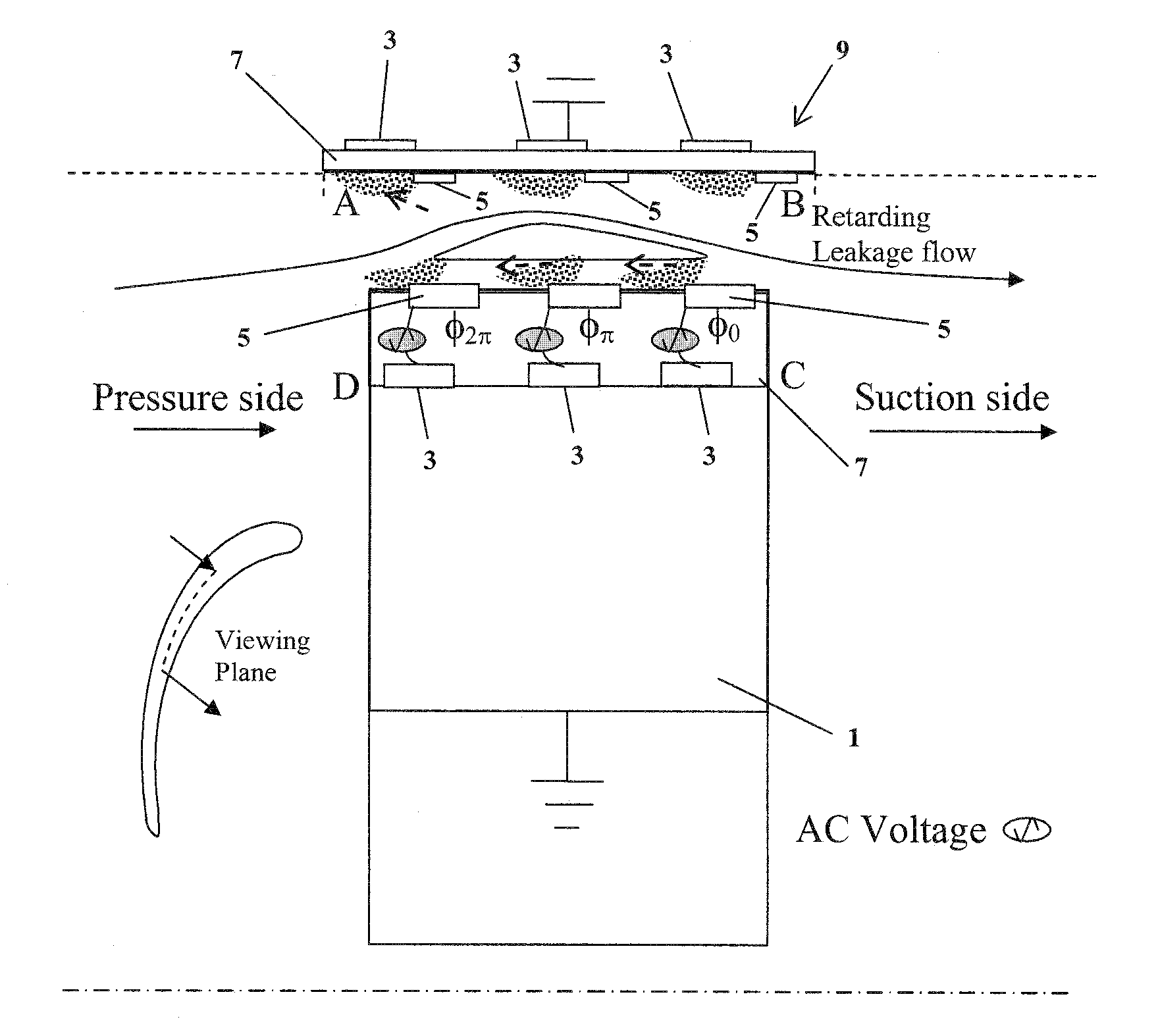

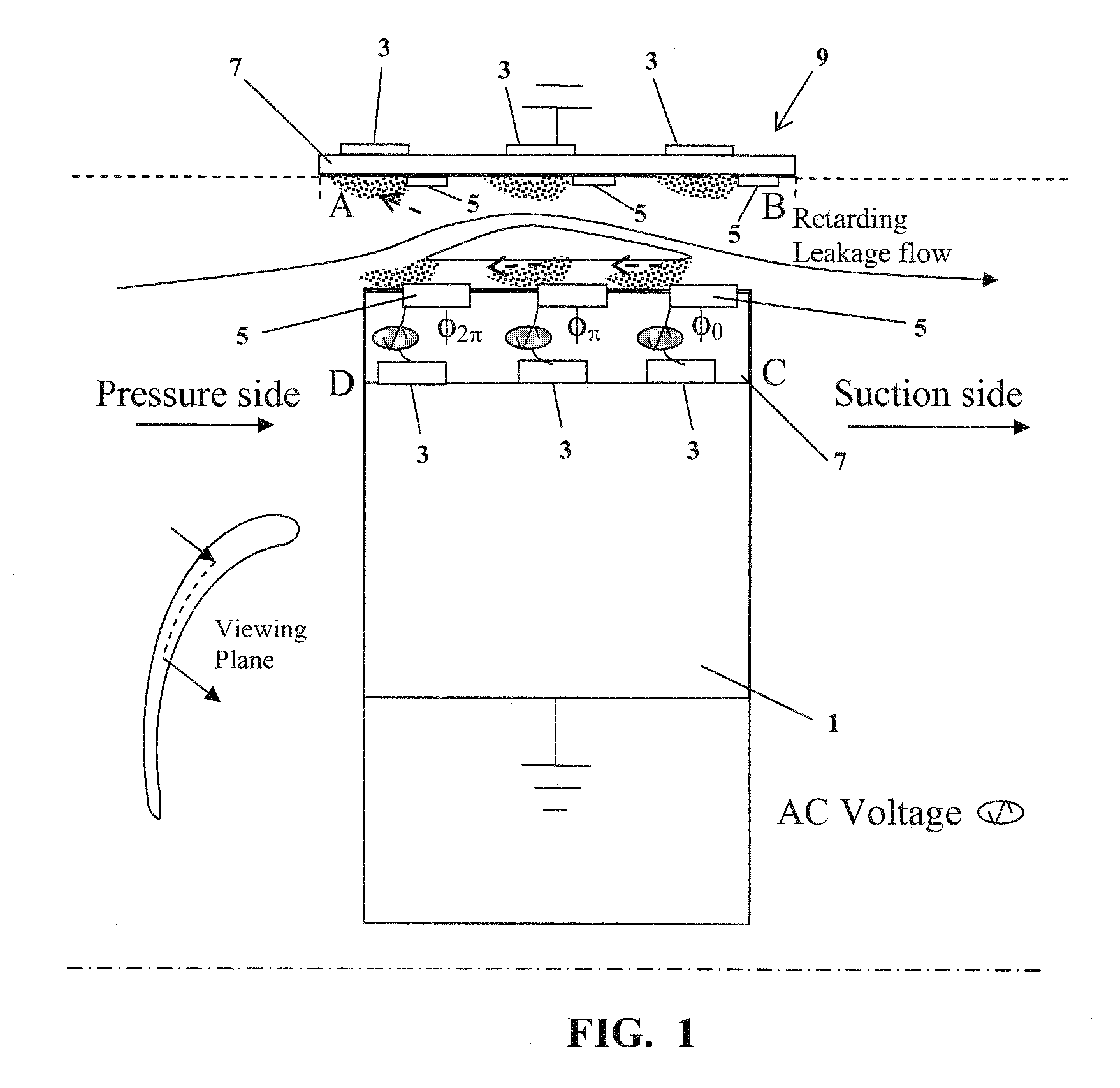

Plasma Clearance Controlled Compressor

InactiveUS20100284795A1Improving stable flow rangeReduce leakage flowPump componentsBlade accessoriesElectricityControl system

A plasma leakage flow control system for a compressor is disclosed, comprising a circumferential row of compressor blades, an annular casing surrounding the tips of the blades, located radially apart from the tips of the blades and at least one annular plasma generator located on the annular casing. The annular plasma generator comprises an inner electrode and an outer electrode separated by a dielectric material. A gas turbine engine having a plasma leakage flow control system further comprises an engine control system which controls the operation of the annular plasma generator such that the blade tip leakage flow can be changed.

Owner:GENERAL ELECTRIC CO

Fuel injector

InactiveUS20090127356A1Increase external pressureSafe and reliable functionOperating means/releasing devices for valvesSpray nozzlesCombustion chamberLine tubing

The invention relates to a fuel injector for injecting fuel into a combustion chamber, having a solenoid valve for controlling a mini-servo valve. A movable armature can be placed in a sealing fashion on a valve seat in a lower armature chamber, wherein in addition the mini-servo valve is held in an injector body and seals a control line against a flat seat. By means of the flat seat, during an actuation of the solenoid valve, the control line can be relieved of pressure from a high fuel pressure to a return pressure into at least one return line. A mechanism for reducing pressure oscillations are provided in the at least one return line, which includes at least one diaphragm cell which is held in a recess and which is placed in fluidic connection with the at least one return bore. A fuel injector with the mechanism for reducing pressure oscillations is therefore created in the at least one return line which operates without a leakage flow and has a simple and effective function.

Owner:ROBERT BOSCH GMBH

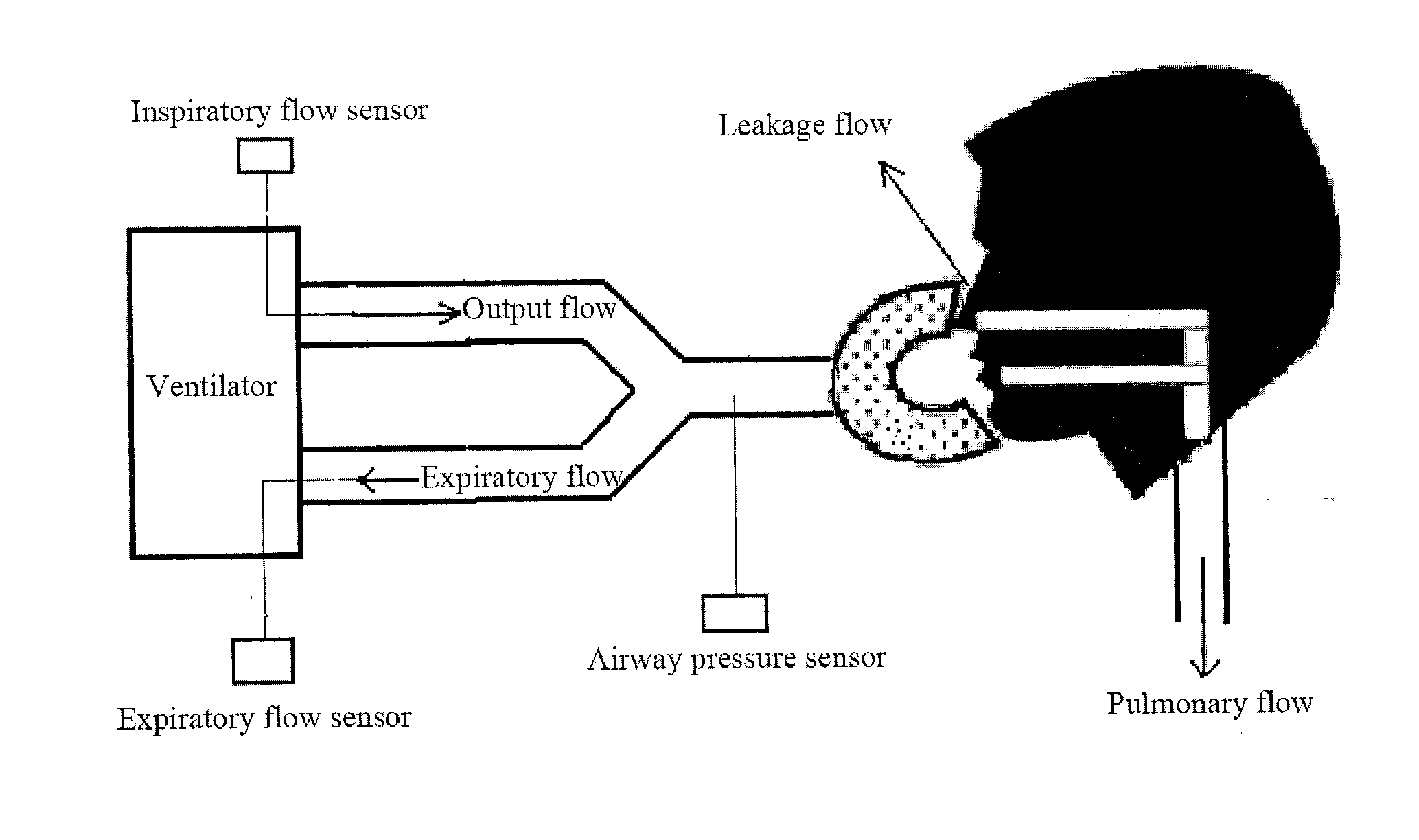

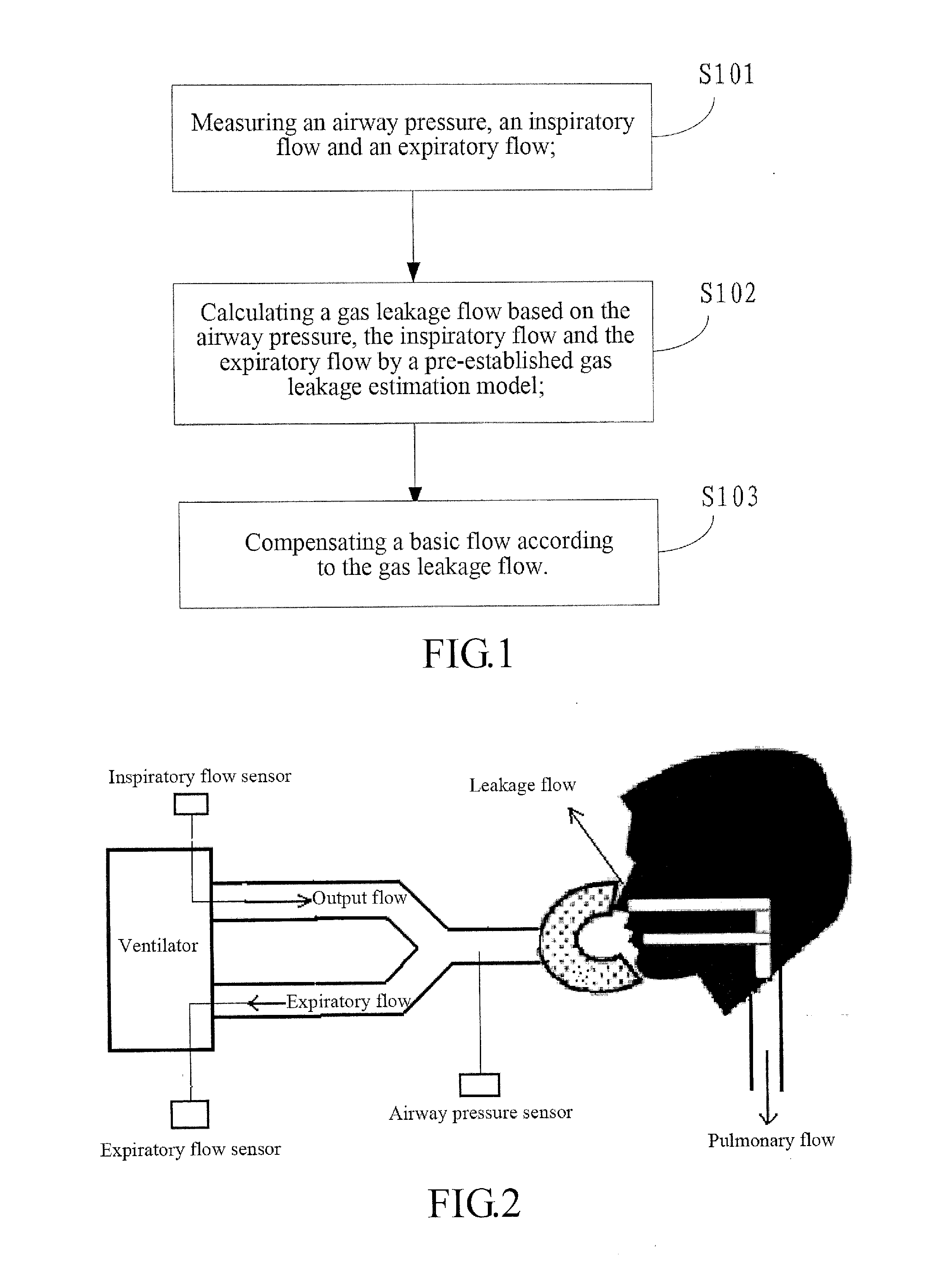

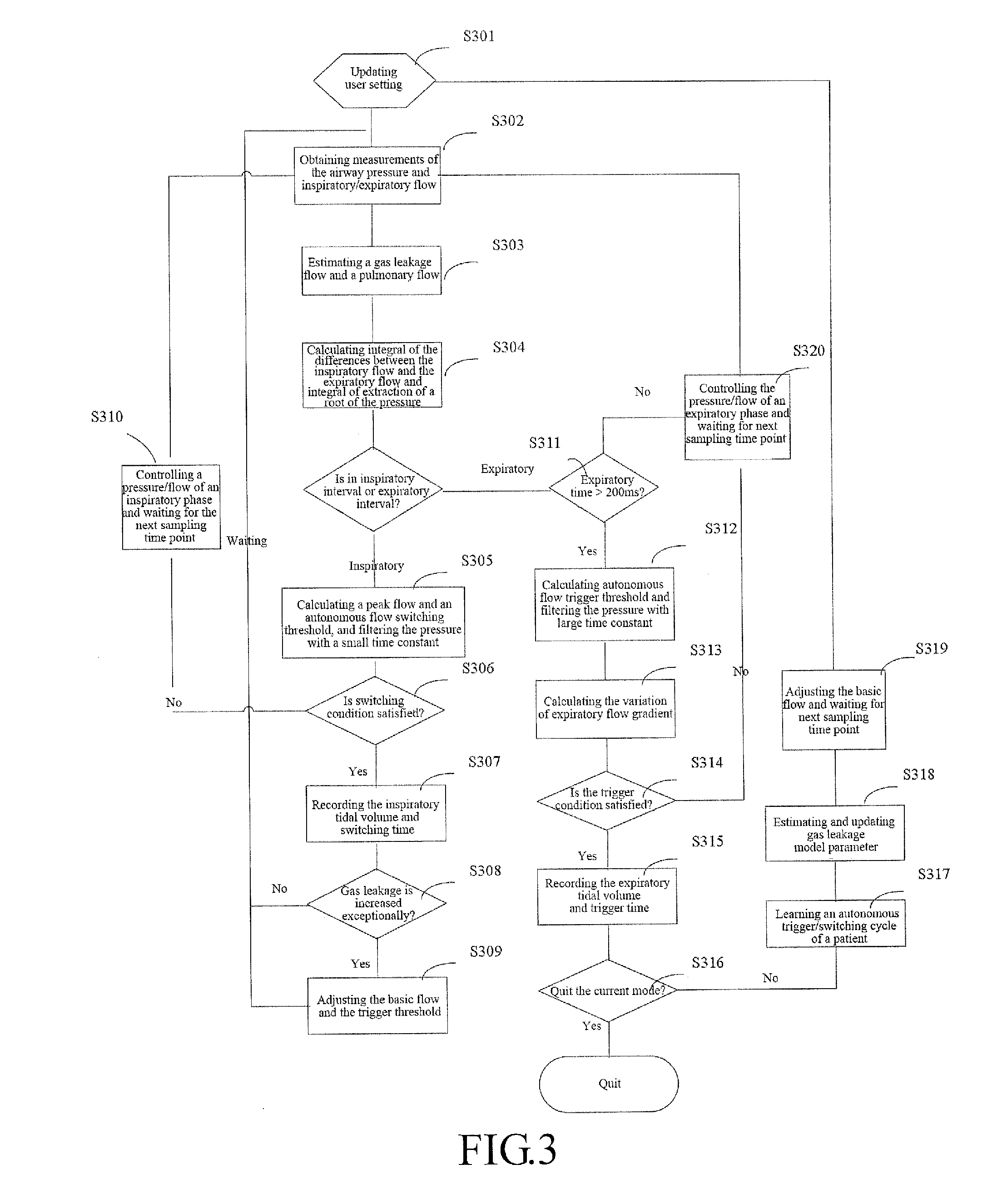

Human-Machine Synchronization Method And Device Of Invasive Ventilator Operating In Noninvasive Ventilation Mode

InactiveUS20140053840A1Improve ventilationAccurate gas leakage estimationRespiratorsOperating means/releasing devices for valvesNoninvasive ventilationInspiratory flow

A human-machine synchronization method and device of an invasive ventilator operating in a noninvasive ventilation mode. The method includes steps of: measuring an airway pressure, an inspiratory flow, and an expiratory flow; calculating a gas leakage flow according to a pre-established gas leakage estimation model and by using the airway pressure, the inspiratory flow and the expiratory flow; and compensating a basic flow according to the gas leakage flow. In the above method, the gas leakage flow is estimated by means of the gas leakage estimation model, to compensate the gas leakage, thereby facilitating the noninvasive ventilation of the invasive ventilator and improving the human-machine synchronization.

Owner:BEIJING AEONMED

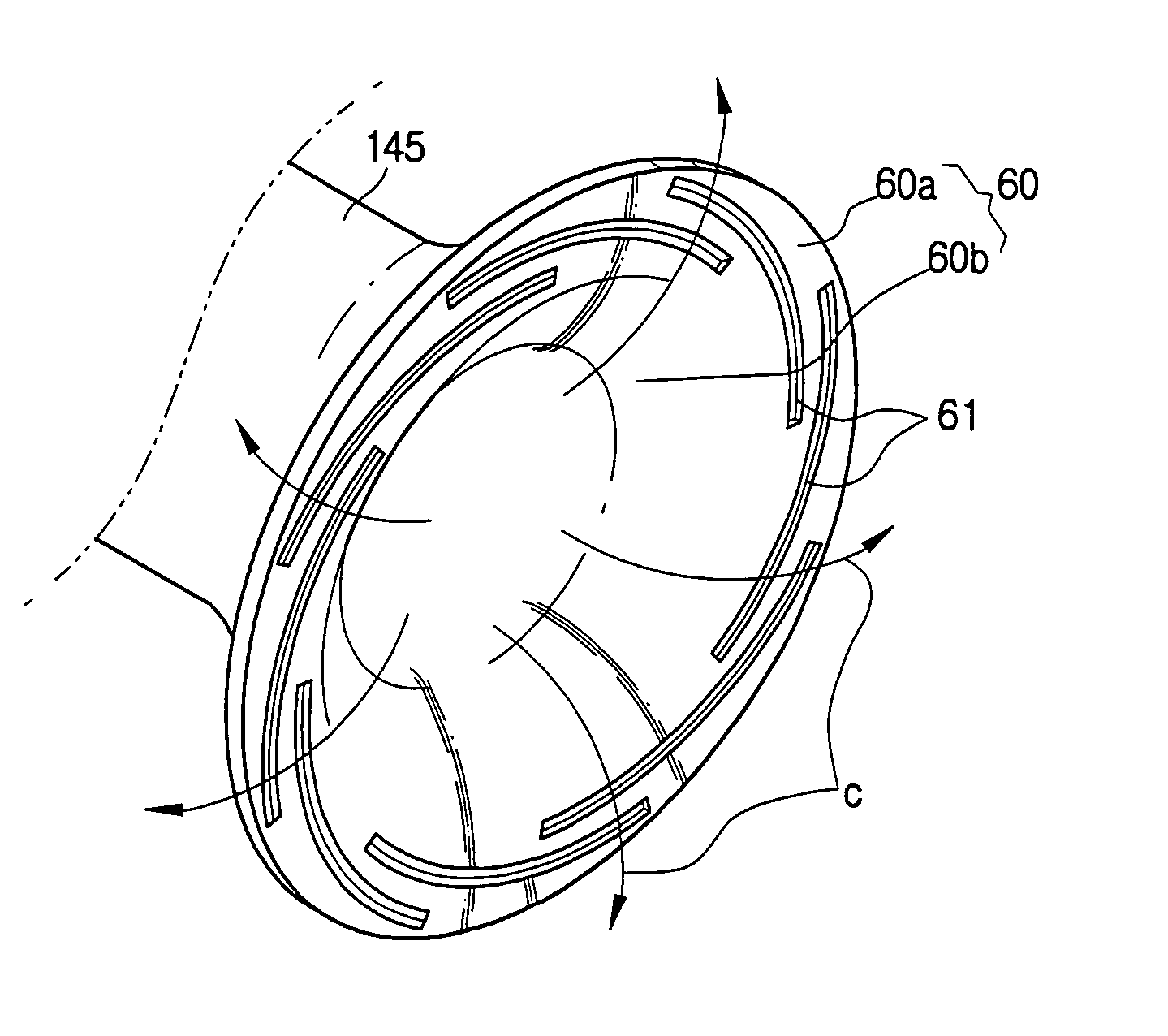

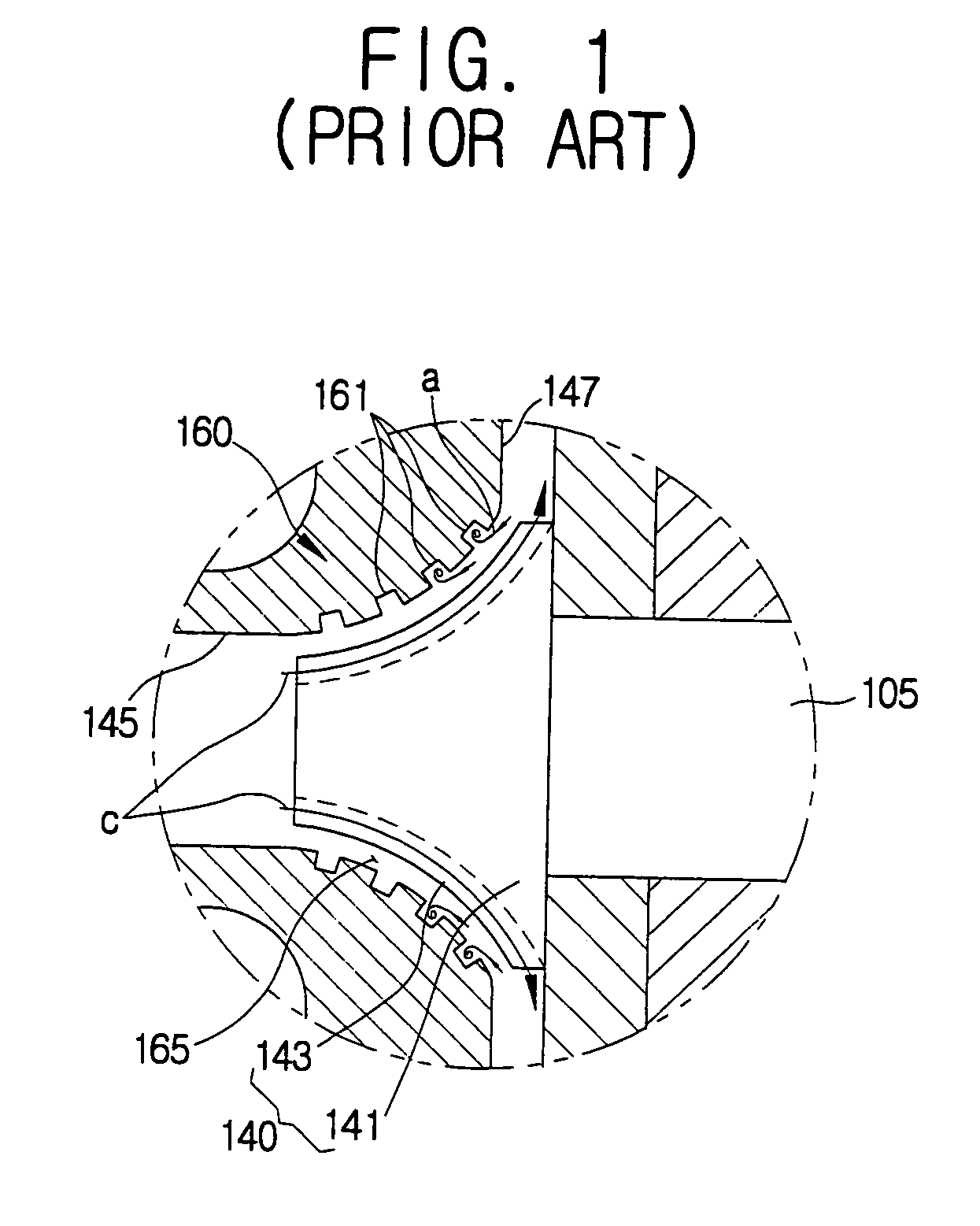

Turbo compressor

A turbo compressor comprising a driving motor, an impeller to be rotated by the driving motor, a second gas suction part through which gas is introduced into the impeller, and a discharger through which the gas is discharged from the impeller, the turbo compressor comprises a shroud provided between the gas suction part and the gas discharger and spaced from a blade of the impeller; and a plurality of channels provided on the shroud and inclined toward the gas discharger along a rotating direction of the impeller. With this configuration, the present invention provides a turbo compressor in which compression efficiency is increased by eliminating a backflow and a leakage flow.

Owner:SAMSUNG ELECTRONICS CO LTD

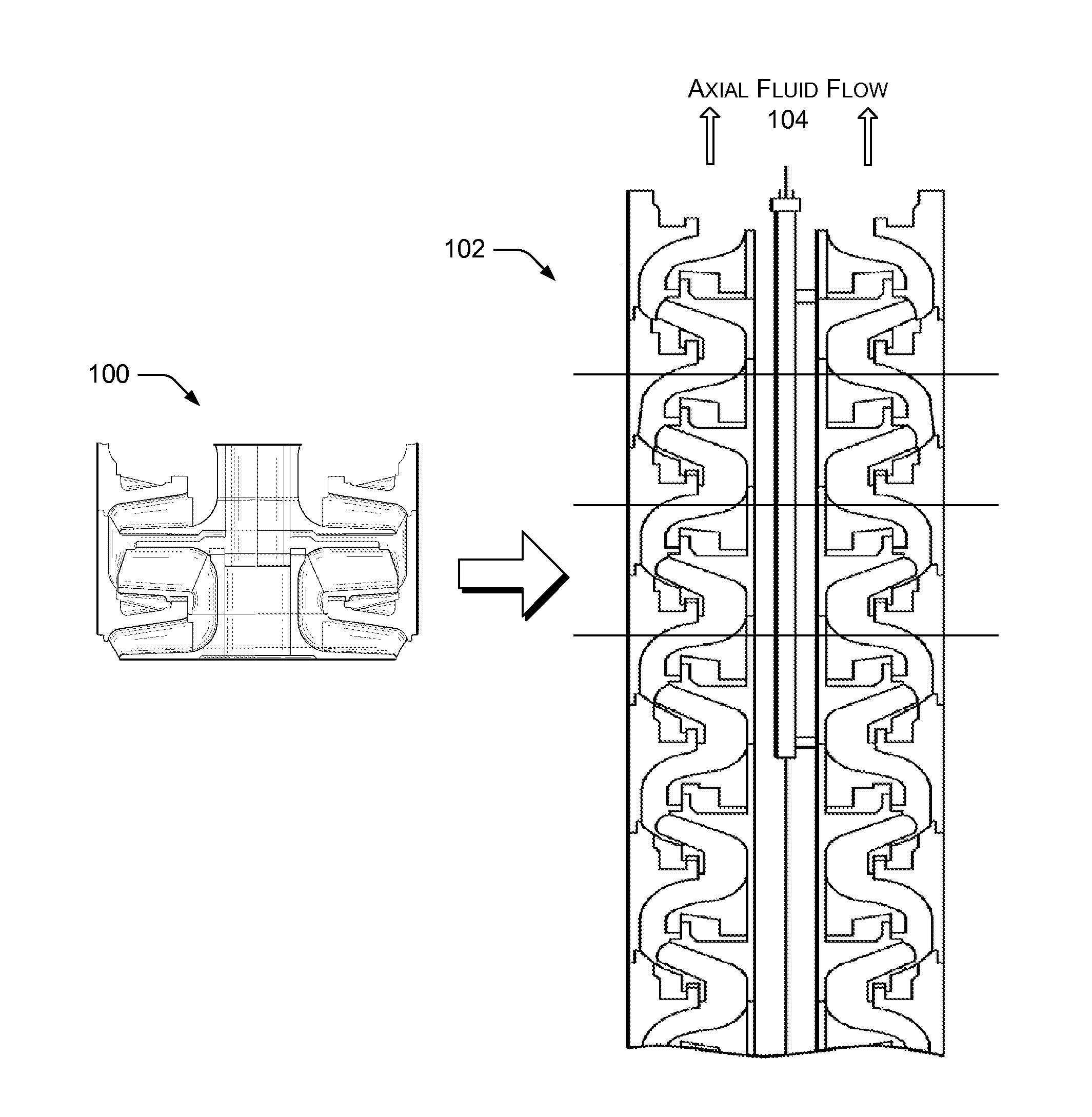

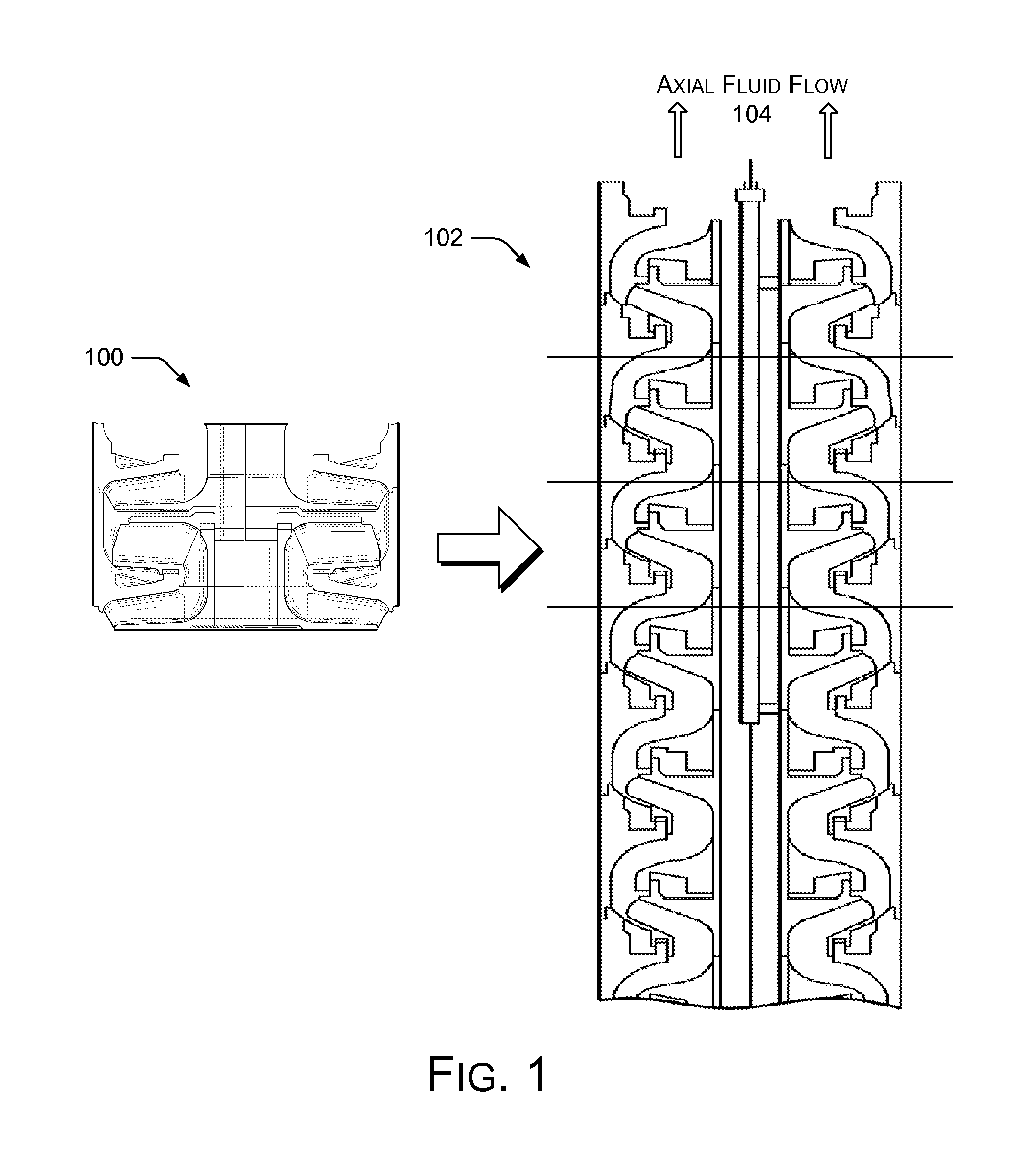

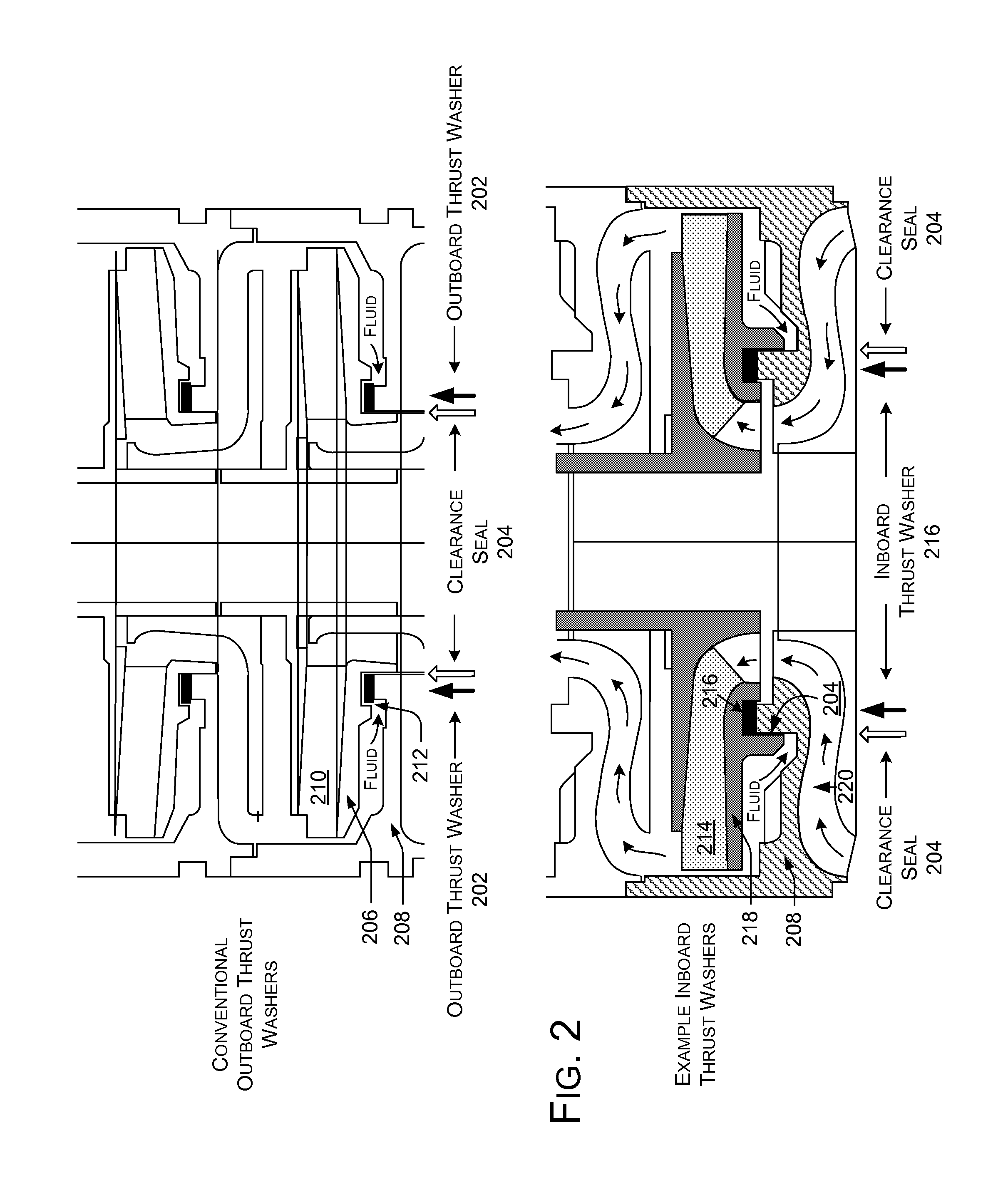

Durable pumps for abrasives

InactiveUS20130209225A1Inhibit wearEasy to rinseSpecific fluid pumpsPump componentsImpellerLeakage flow

Durable pumps for abrasives are provided. An example centrifugal pump stage for subsurface operation has a thrust washer located inside the circumference of an outboard clearance seal between an impeller shroud and the diffuser. Relocation of the thrust washer allows the clearance seal to protect the thrust washer from abrasives. A centrifugal action of an outboard seal lip effects a separation of the particles from the fluid nearest the gap of the outboard seal and drives the particles away from the gap of the outboard seal. When an abrasive particle in the leakage flow does clear the outboard seal, the particle is readily flushed across the thrust washer by the leakage flow to the central fluid inlet to prevent wear of the thrust washer. In an implementation, the inside diameter of the thrust washer is approximately flush with the bore of a central fluid inlet of the pump stage.

Owner:SCHLUMBERGER TECH CORP

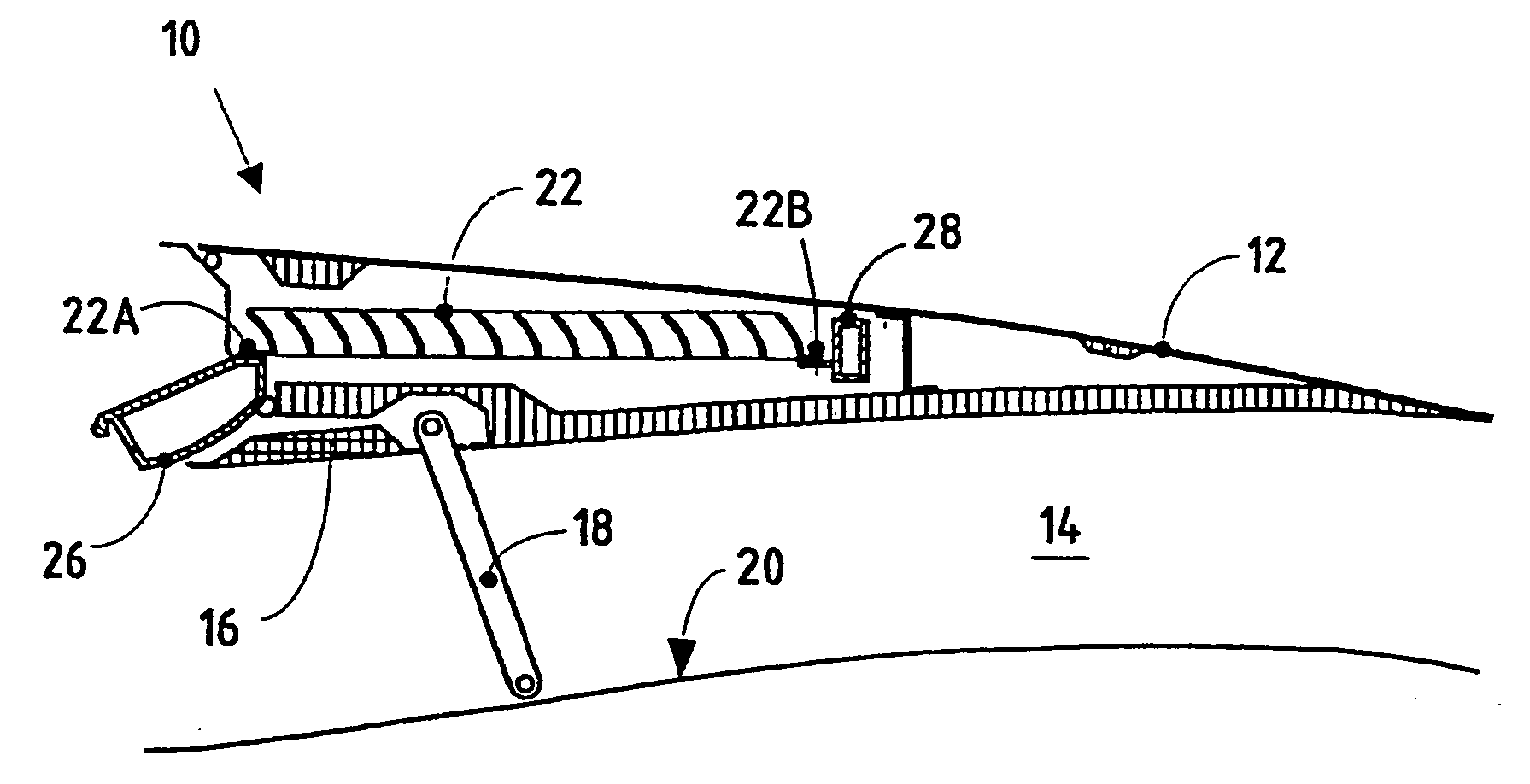

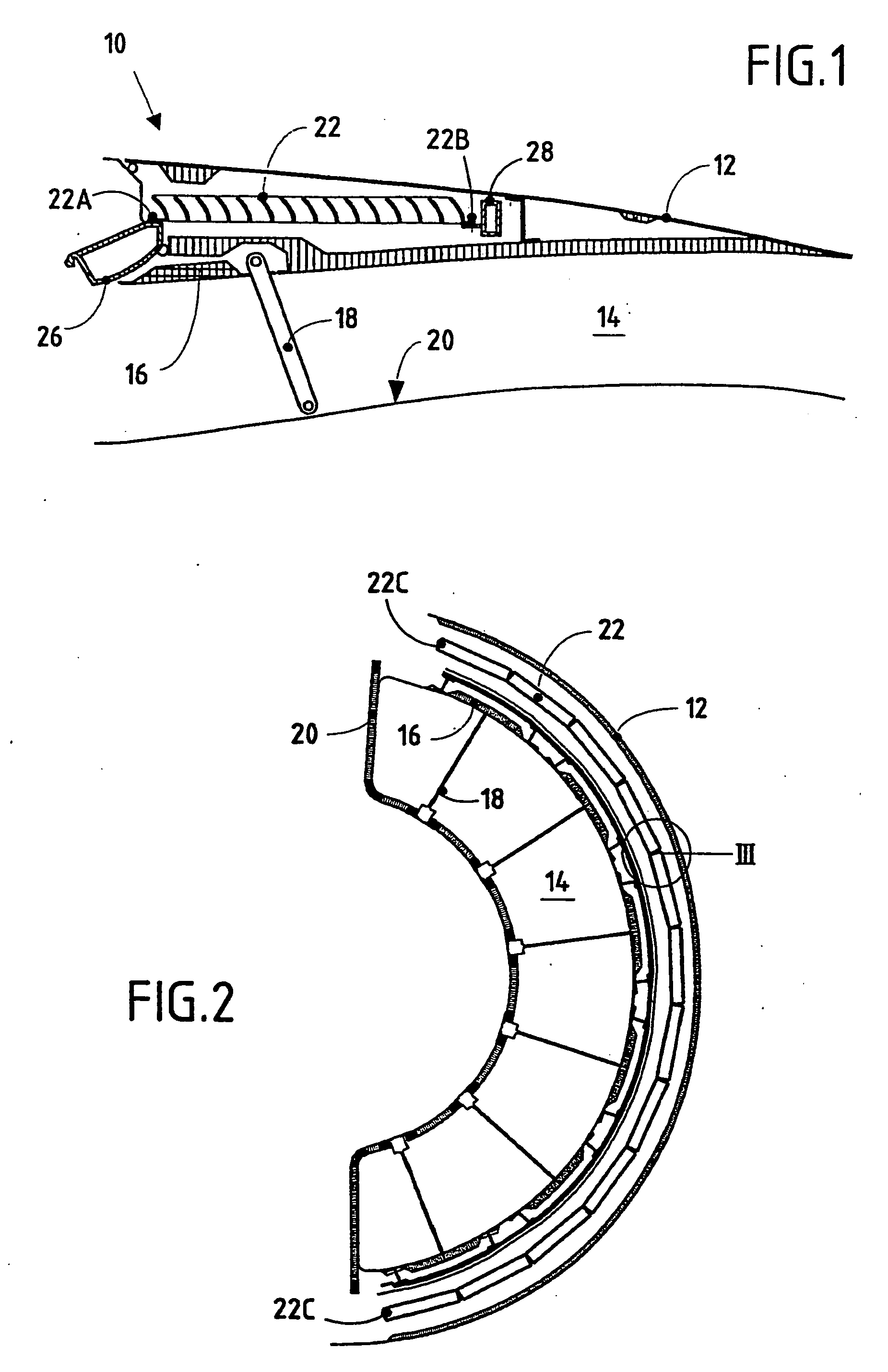

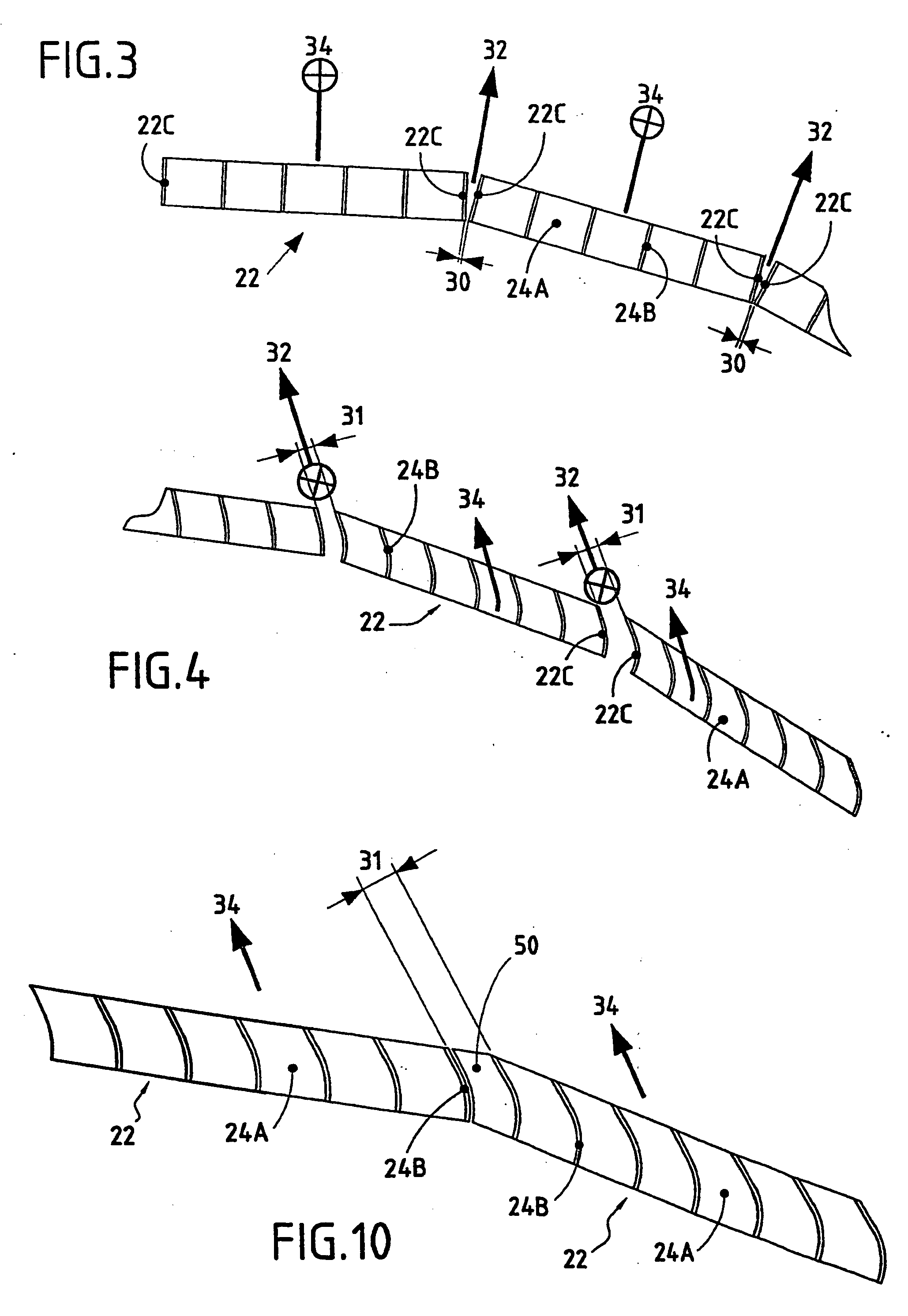

Thrust reverser comprising optimised deflector gratings

InactiveUS20060005530A1Improve efficiencyMitigate such drawbackEfficient propulsion technologiesJet propulsion plantsGratingJet engine

The invention relates to a device comprising gratings, which are used to form a reverse flow from a jet engine thrust flow. The inventive device comprises a plurality of flow diverter gratings which are disposed side-by-side at the outer edge of an annular thrust flow circulation channel. Each of the gratings comprises a plurality of intersecting inner transverse blades and inner longitudinal blades, two adjacent gratings being separated by a side clearance which generates a leakage flow. The device also comprises means of re-directing the aforementioned leakage flow in a direction such as to increase the effectiveness of the reverse flow, said re-direction means comprising aerodynamic appendages which are mounted to at least one outer longitudinal edge of each grating.

Owner:HISPANO HUREL

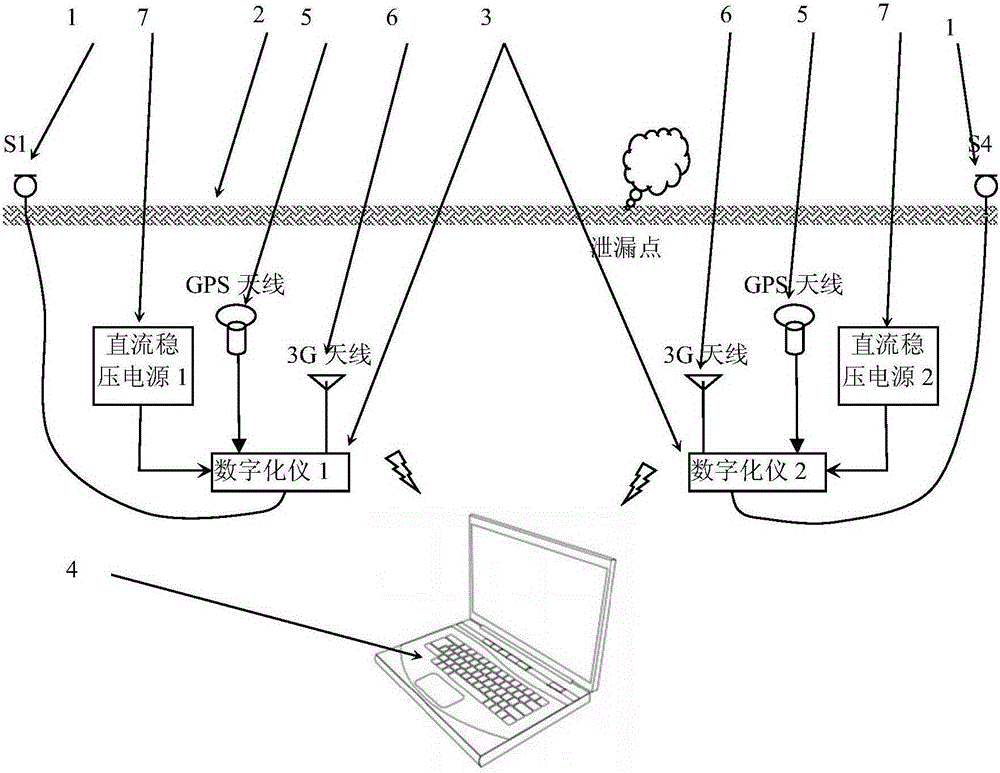

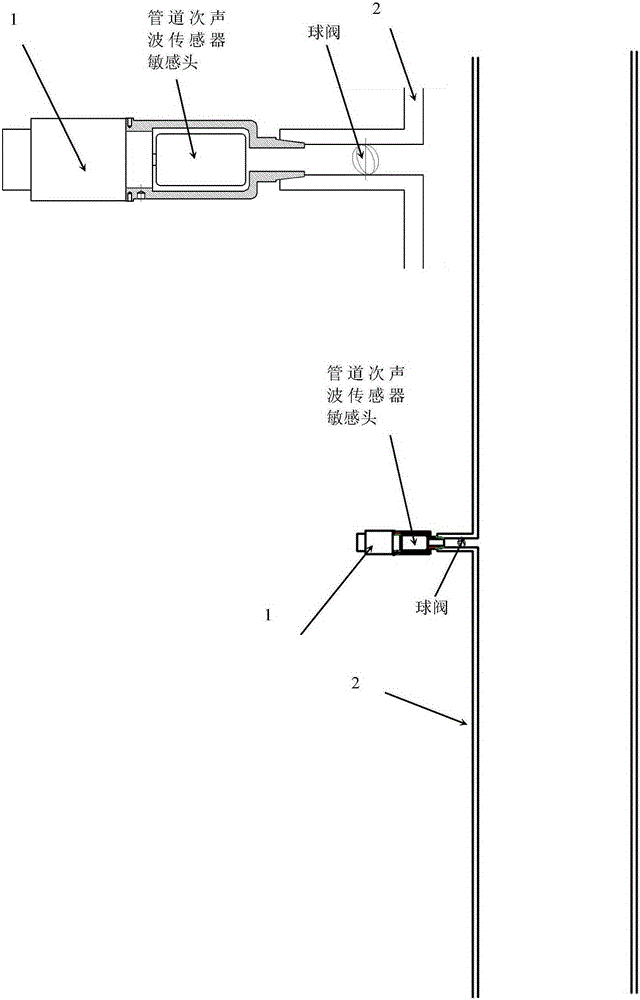

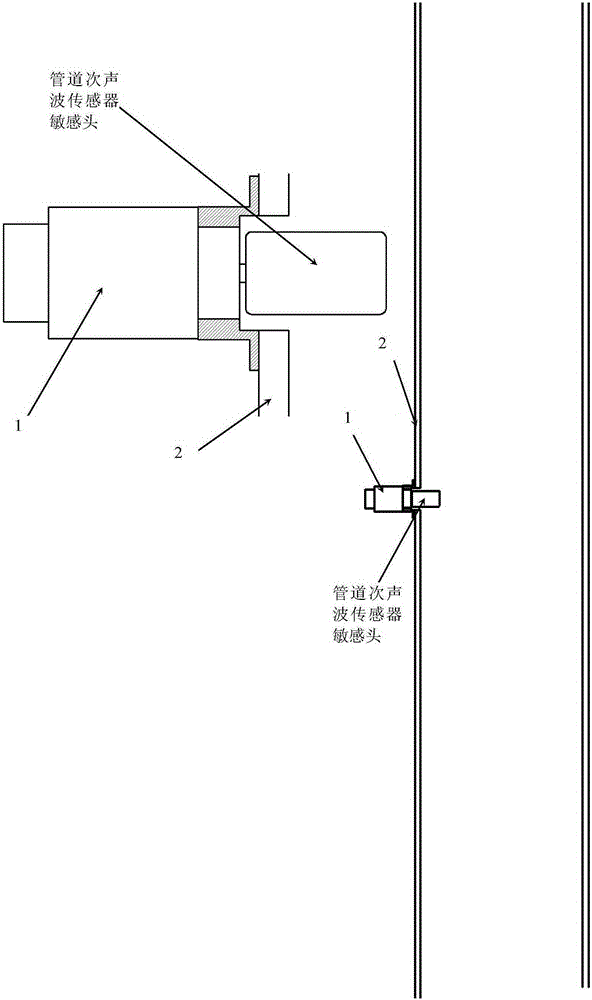

Pipeline leakage recognizing and positioning system and method based on sound wave imaging

The invention relates to a pipeline leakage recognizing and positioning system and method based on sound wave imaging. The pipeline leakage recognizing and positioning system and method are mainly characterized in that the system comprises pipeline infrasonic wave sensors, digitalizers, direct-current voltage stabilizing power sources and a monitoring server; the pipeline infrasonic wave sensors are arranged at the two ends of a measured pipeline respectively, and sensing heads of the pipeline infrasonic wave sensors are in complete contact with a medium in the pipeline and immersed in the medium in the pipeline through open holes in the measured pipeline; the pipeline infrasonic wave sensors upload measured signals to the monitoring server through the digitalizers; and the monitoring server calculates a sound and image graph for sound pressure distribution in the part, between the two pipeline infrasonic wave sensors, of the pipeline according to the measured signals uploaded by the two digitalizers, and the position and strength of a leakage sound source are recognized on the sound and image graph. According to the pipeline leakage recognizing and positioning system and method based on sound wave imaging, leakage is recognized based on the stability of the sound and image graph according to the wideband characteristic of leaking sounds, the accuracy of leakage recognition is improved and reaches more than 95%, the rate of false alarms is lower than 5%, the leakage process can be reflected, and the leakage flow is estimated.

Owner:NANJING QIAOSHENG FLUCTUATION TECH

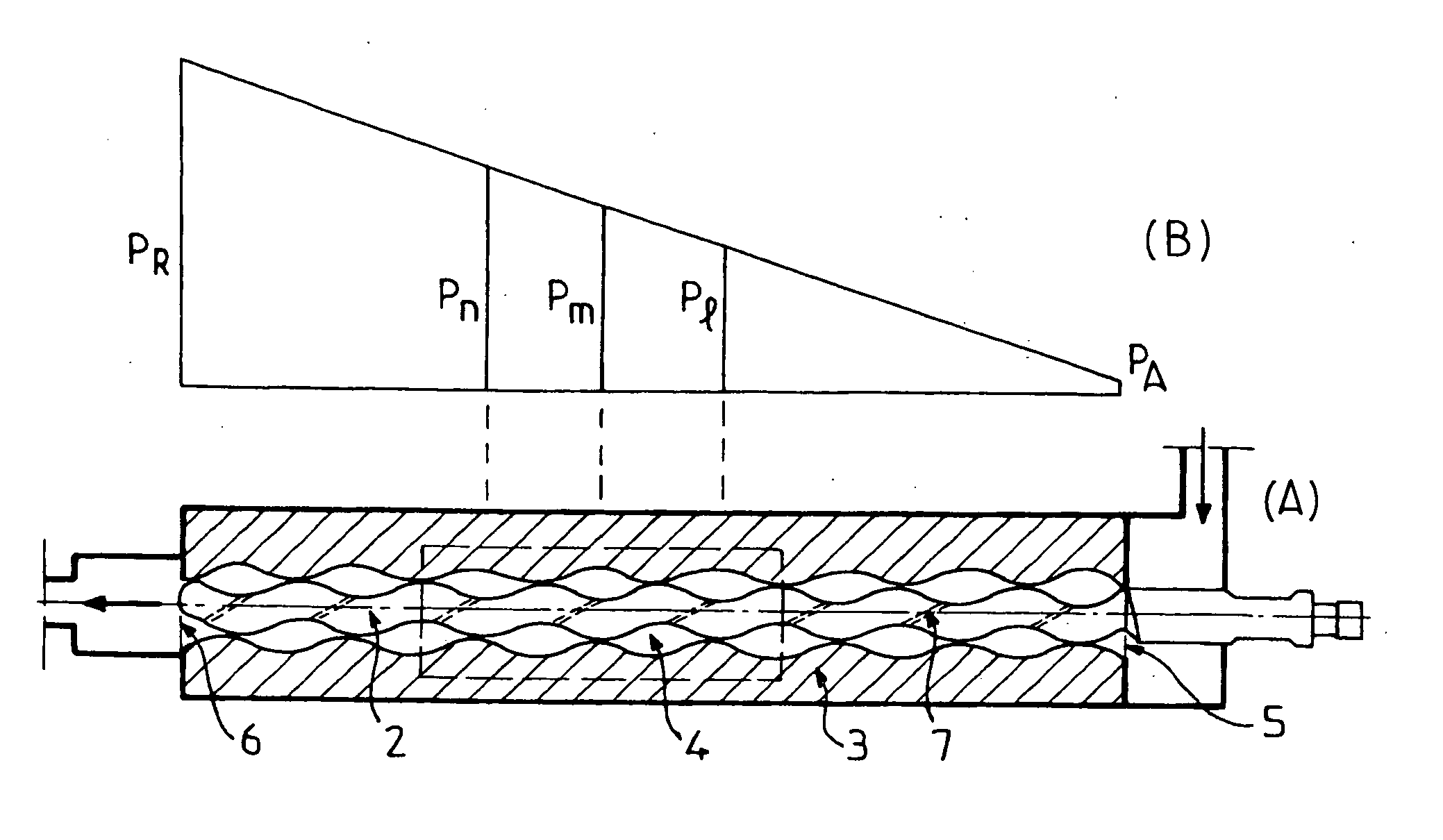

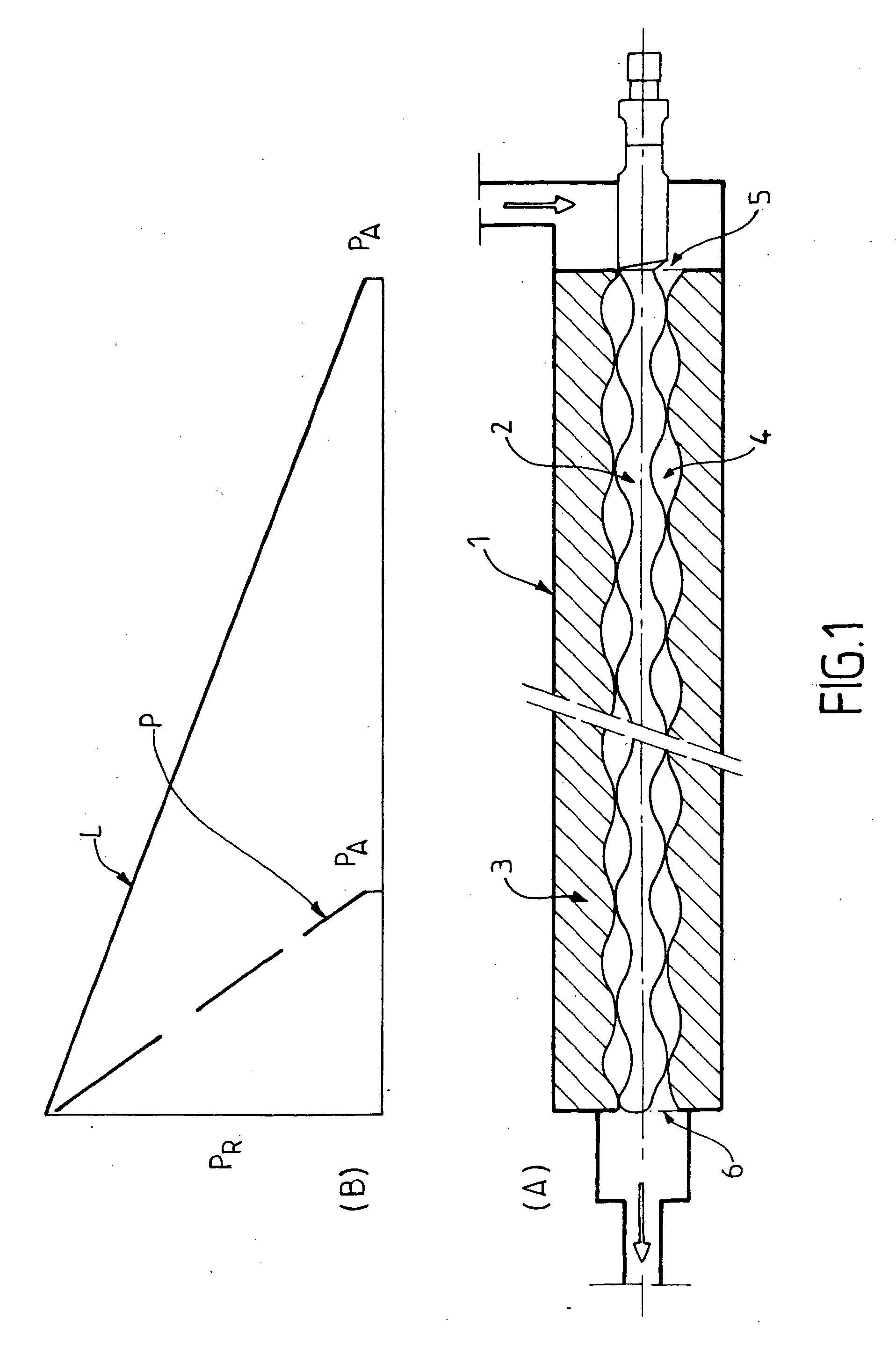

Progressing cavity pump

ActiveUS20050169779A1Improve system reliabilityImprove reliabilityPump componentsOscillating piston enginesTemperature controlEngineering

This progressing cavity pump including a helical rotor (2) mounted to turn inside a helical stator (3), said stator (3) and said rotor (2) being disposed such that the cavities (4) formed between said rotor (2) and said stator (3) move from the inlet (5) towards the outlet (6), is characterized by the fact that hydraulic regulation (HR) means are provided for obtaining internal recirculation of the pumped fluid between at least two of said cavities (4) under conditions capable of performing at least one function selected from: achieving the desired pressure distribution along the pump, stabilizing the temperatures, controlling the leakage flow rates, and compensating for the volumes of compressed gas.

Owner:PC MALL INC

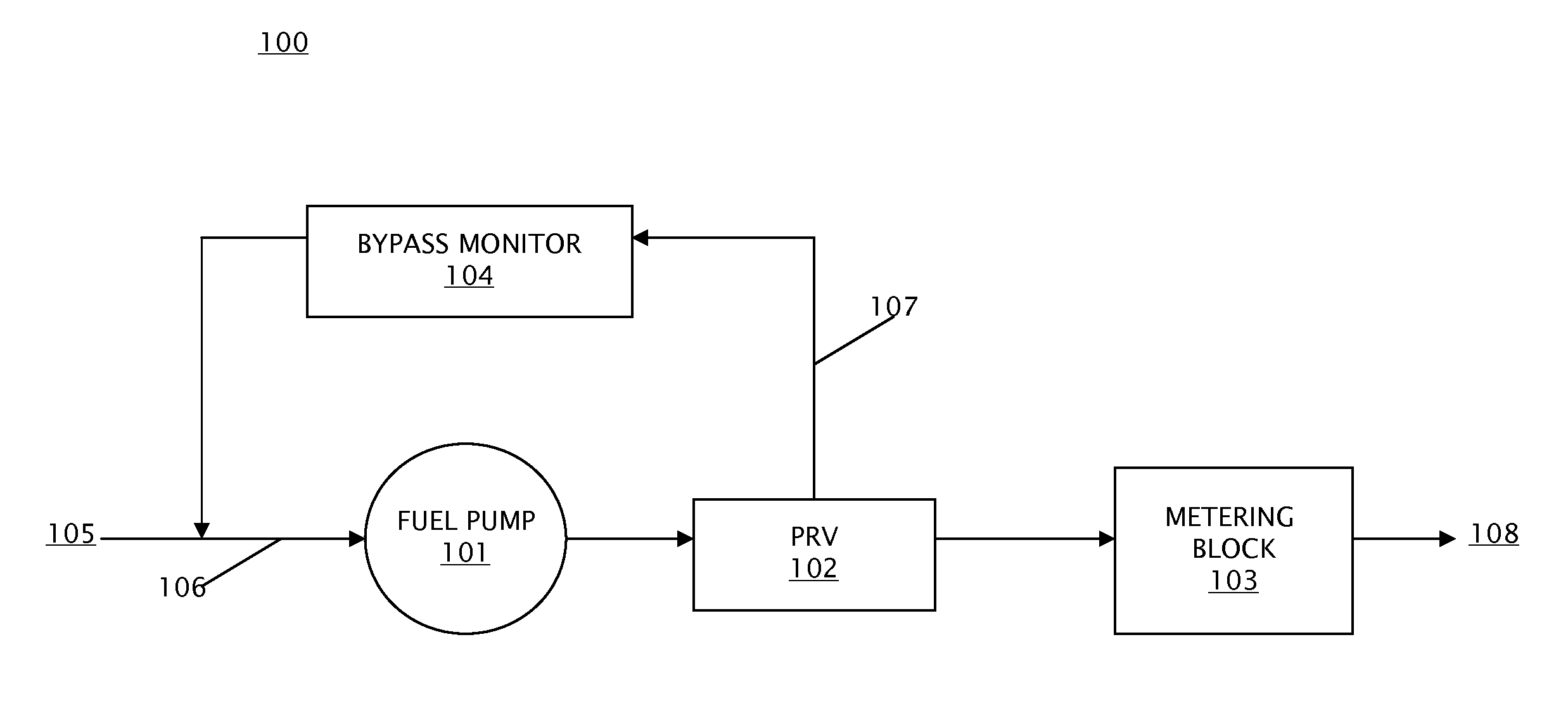

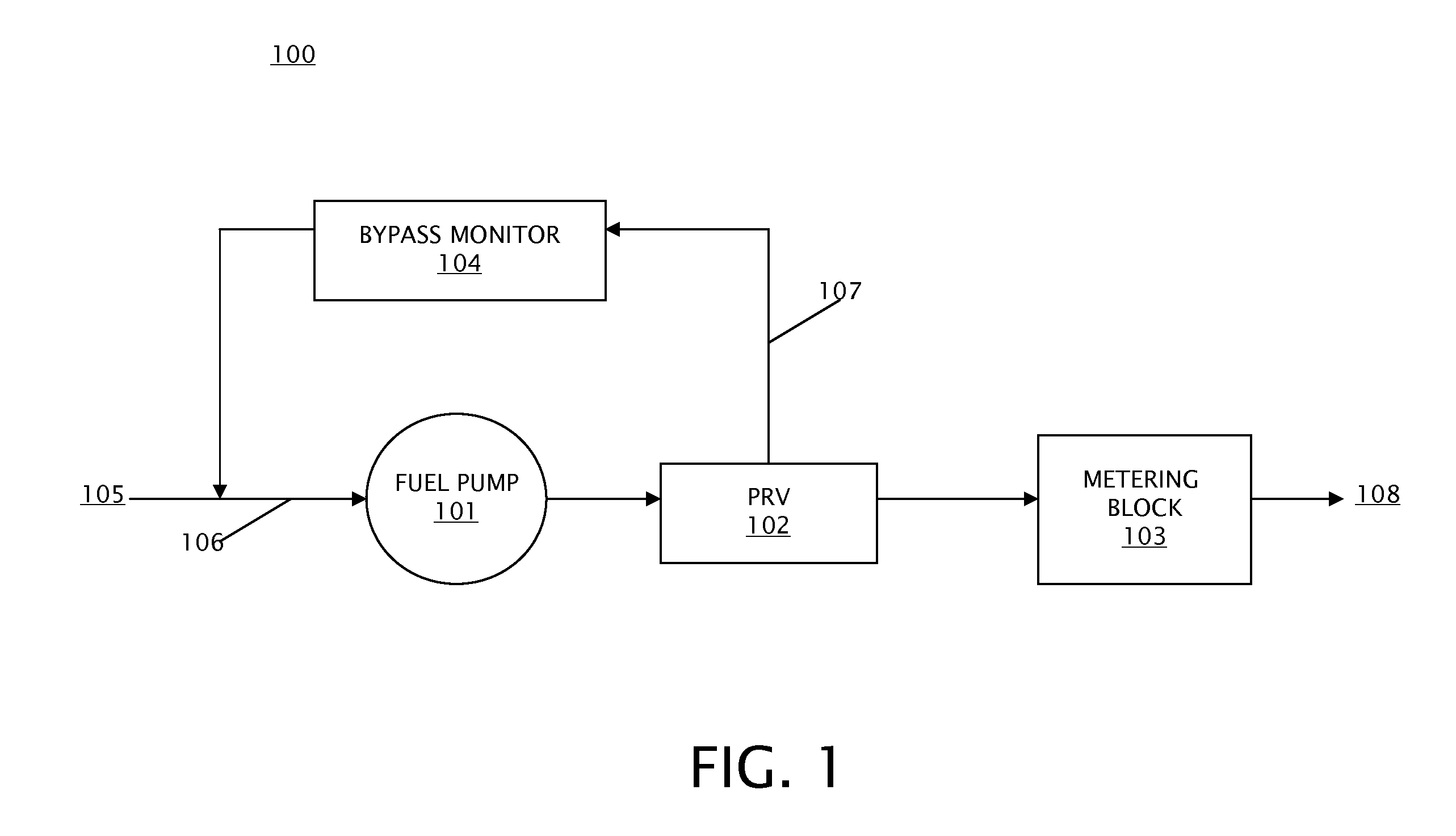

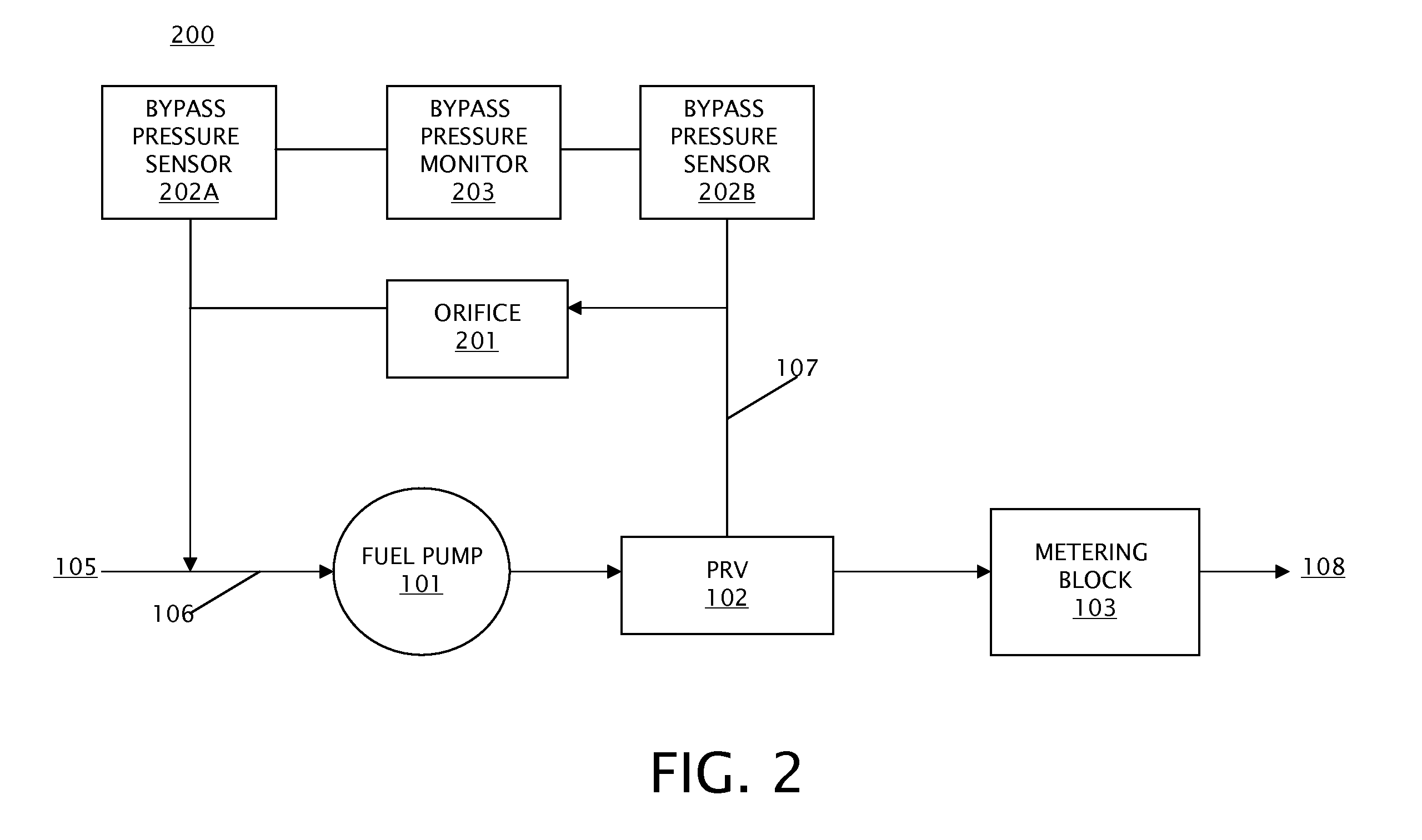

Bypass Monitor for Fuel Supply System

A method for monitoring a fuel supply system for a turbine engine, the fuel supply system comprising a fuel pump and a pressure regulation valve configured to receive fuel from an outlet of the fuel pump includes determining by a bypass monitor an amount of bypass flow in a bypass path located between the pressure regulation valve and an inlet of the fuel pump; determining an amount of leakage flow in the fuel supply system by the bypass monitor based on the bypass flow; and determining whether the leakage flow exceeds a predetermined threshold by the bypass monitor, and in the event the leakage flow exceeds the predetermined threshold, indicating a need for maintenance of the fuel supply system.

Owner:HAMILTON SUNDSTRAND CORP

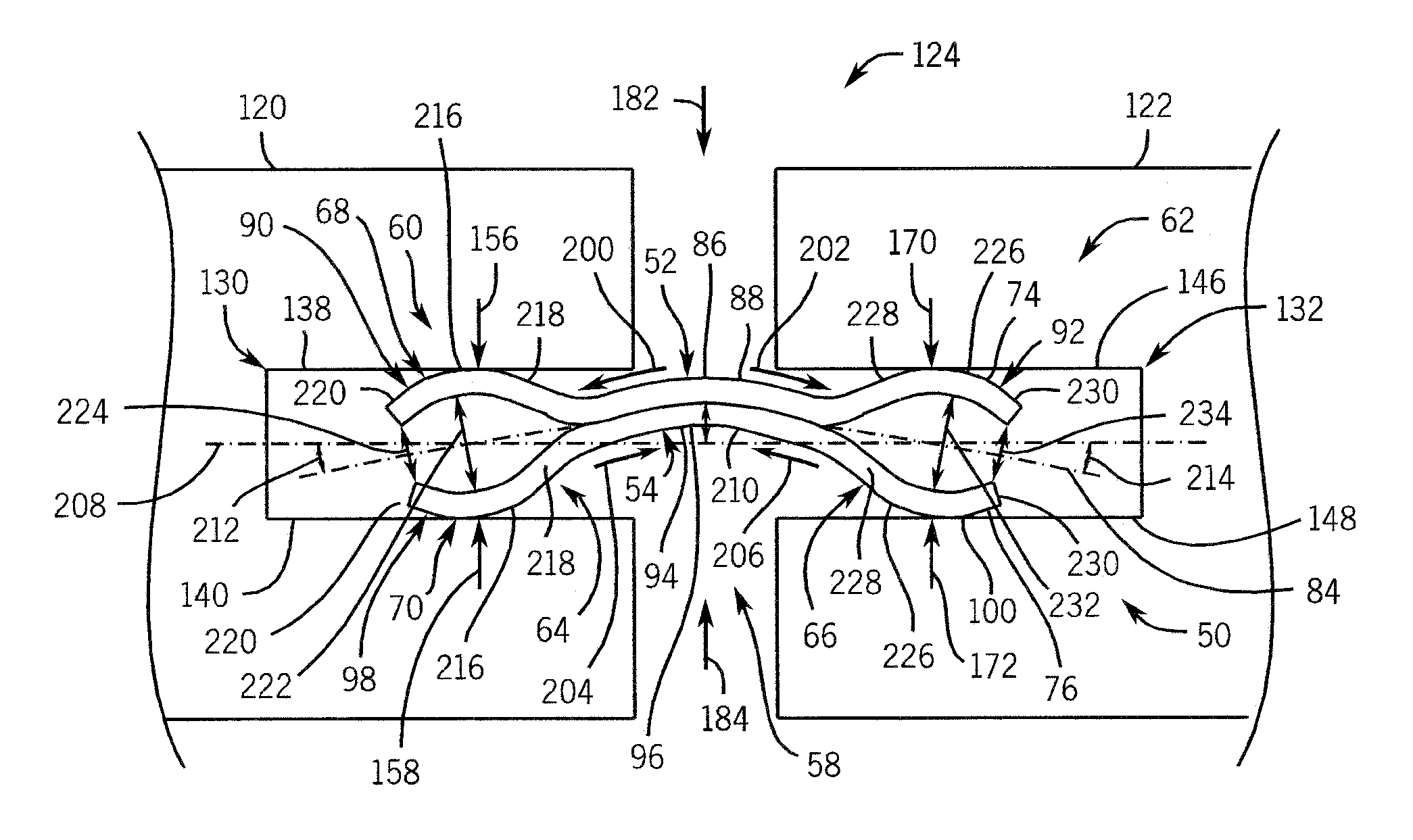

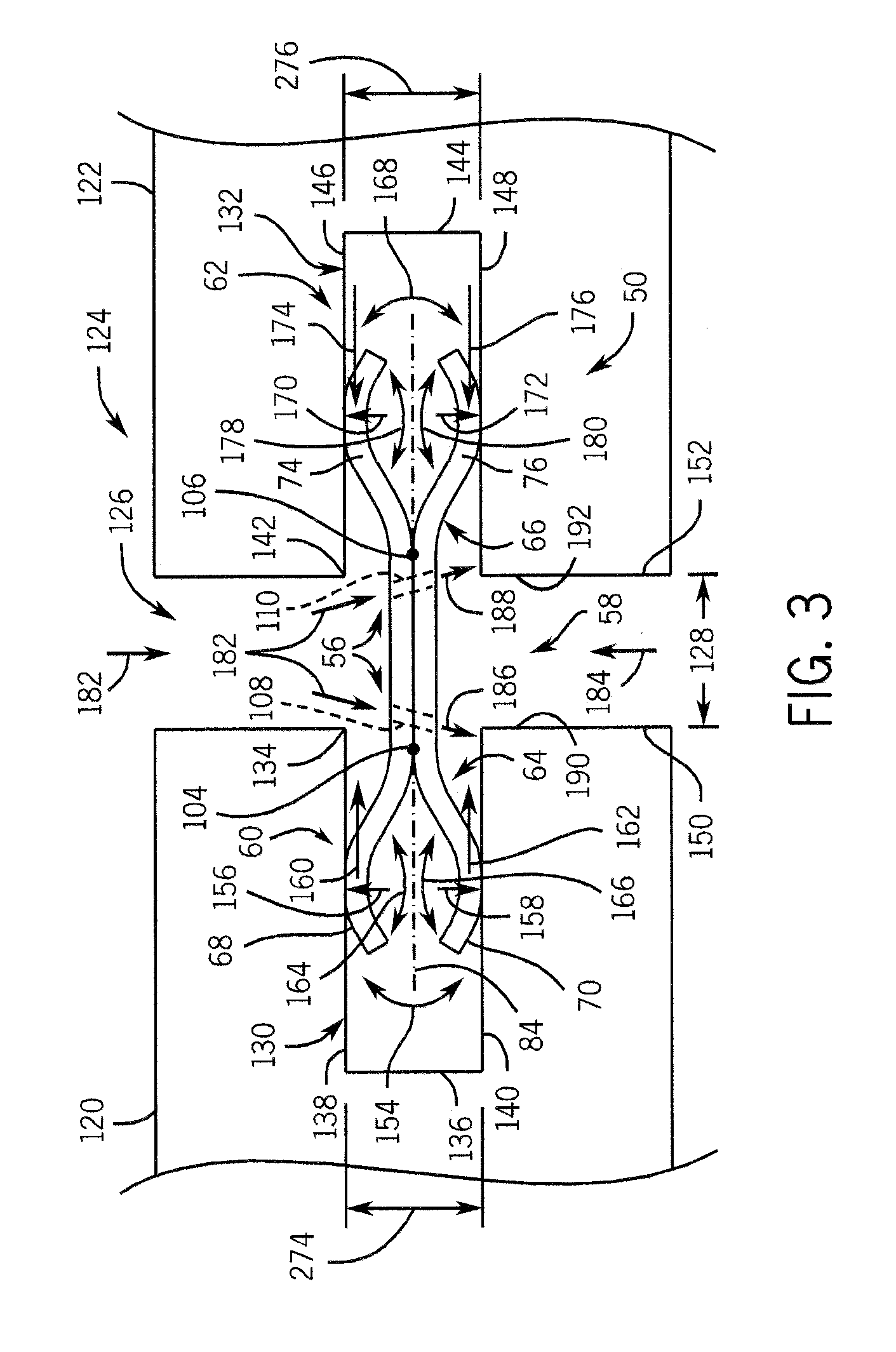

Leakage flow minimization system for a turbine engine

InactiveUS20100196139A1Reduce interface areaReduce the cross-sectional areaEngine sealsPump componentsInstabilityEngineering

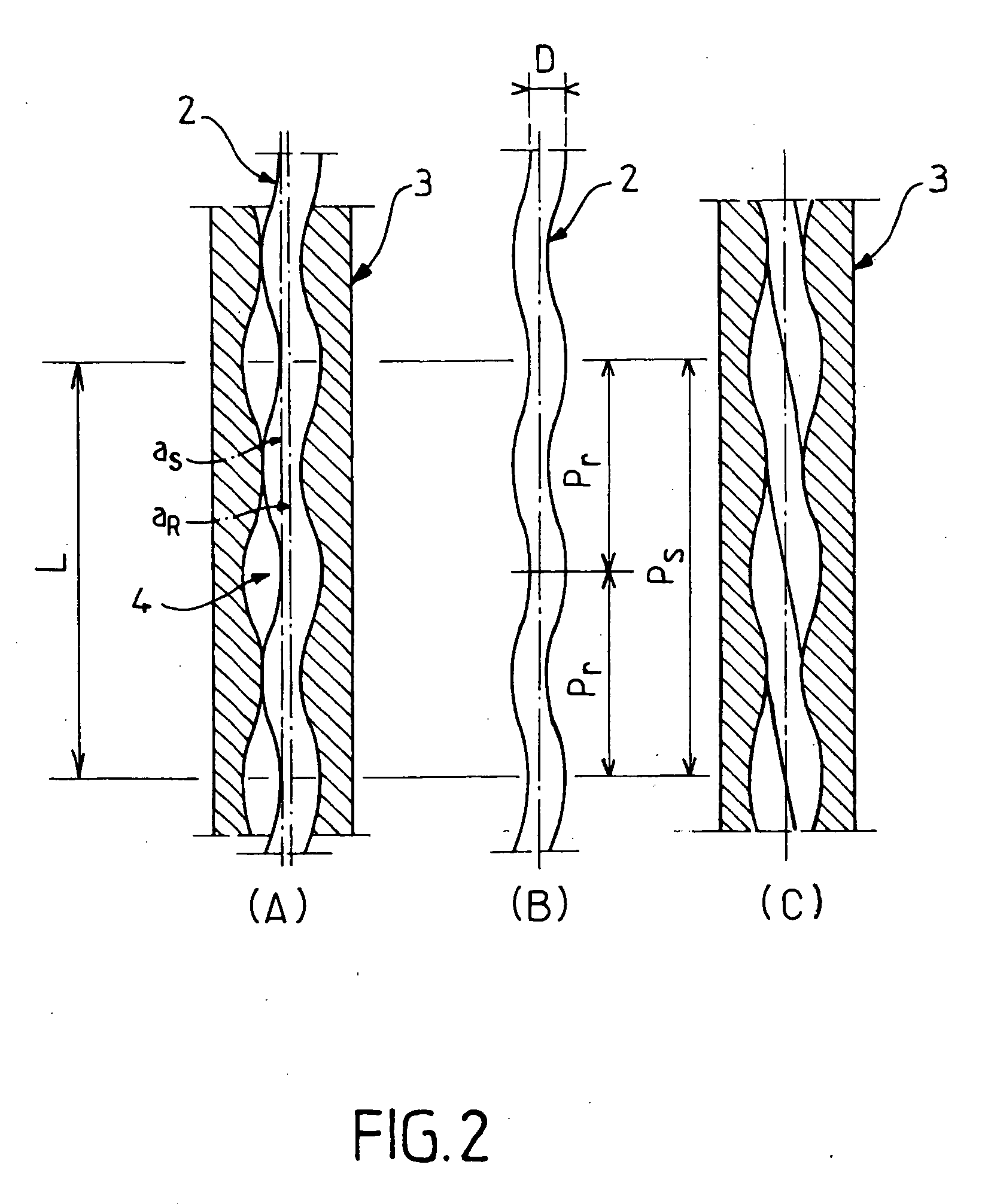

A sealing system is applied to the interface between a stator and a rotor in a turbine engine to minimize fluid leakage across the interface. One interface can be defined between portions of neighboring rotor disks and a stator. The sealing system includes one or more rows of flow guides, such as airfoils, provided on the rotor disk near the upstream end of the interface. These flow guides can impart tangential velocity on the leakage flow. One or more undulating seal structures can be connected to the stator downstream of the flow guides. These undulating seals can have a periodic waveform conformation. The undulating seals can create unsteadiness in the flow and recirculation of the leakage flow, which causes losses. The sealing system can also include other types of seals, such as labyrinth seals and brush seals, to further create a tortuous path for any leakage flow.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com