Patents

Literature

131results about How to "Reduce leakage flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

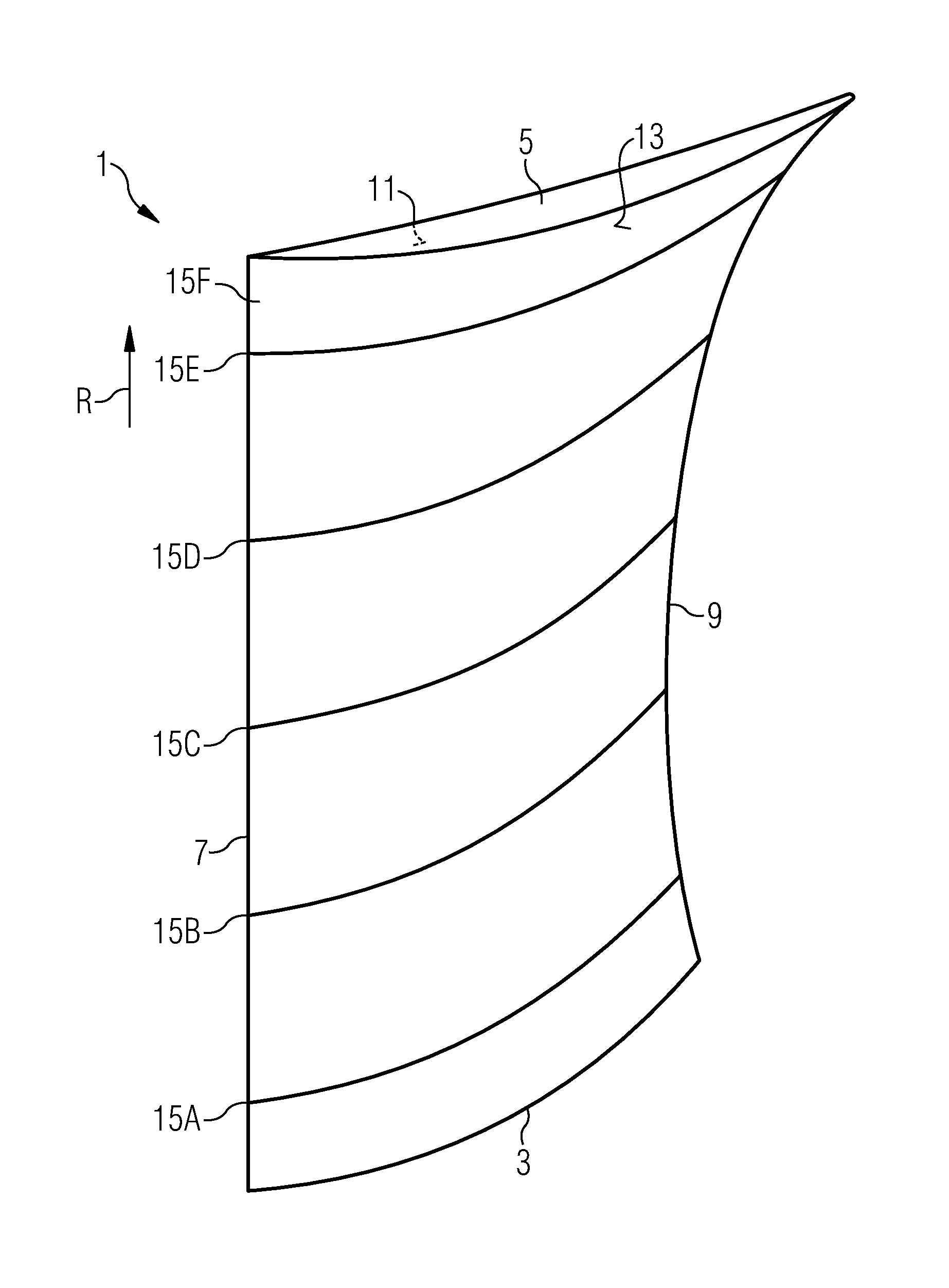

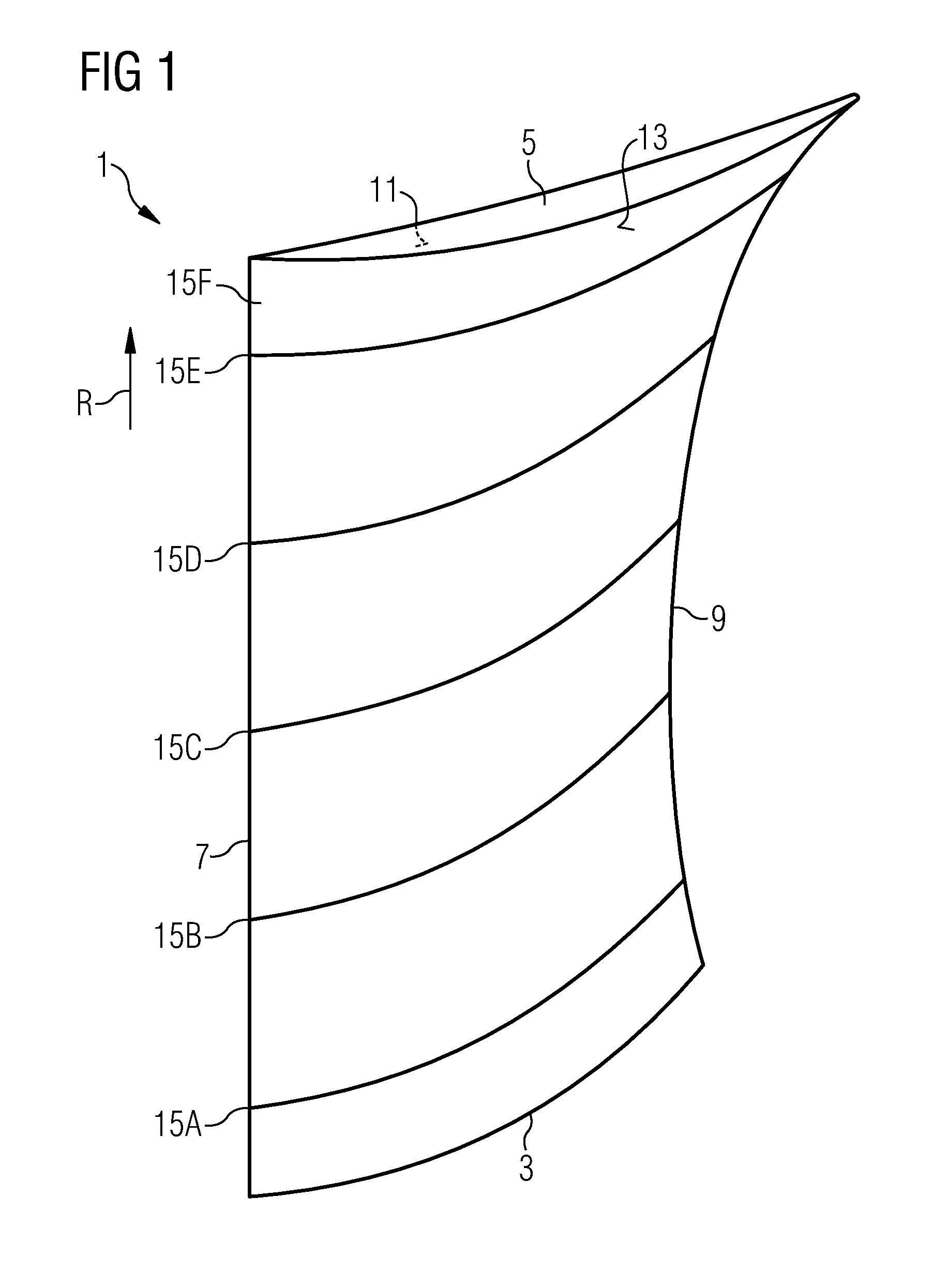

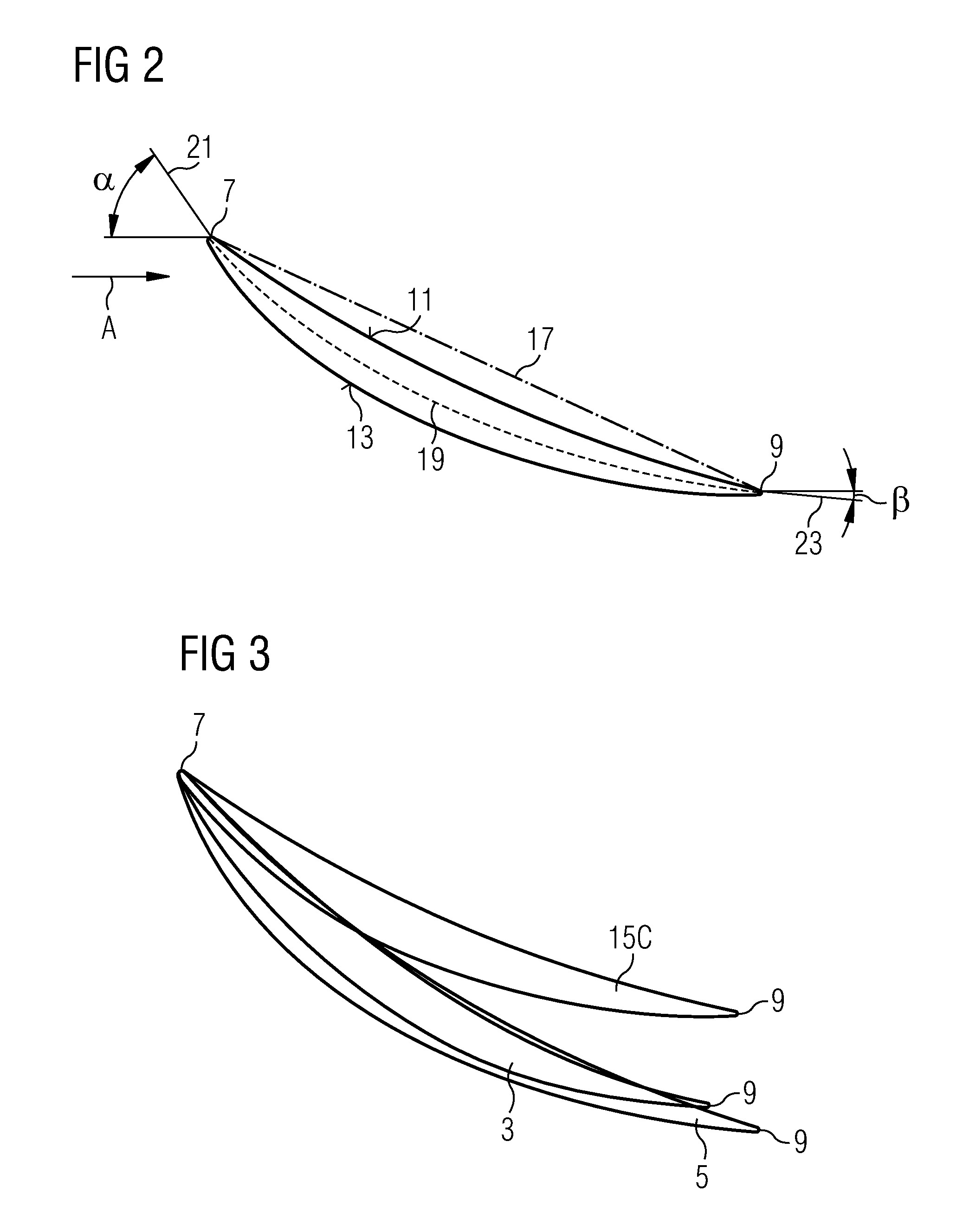

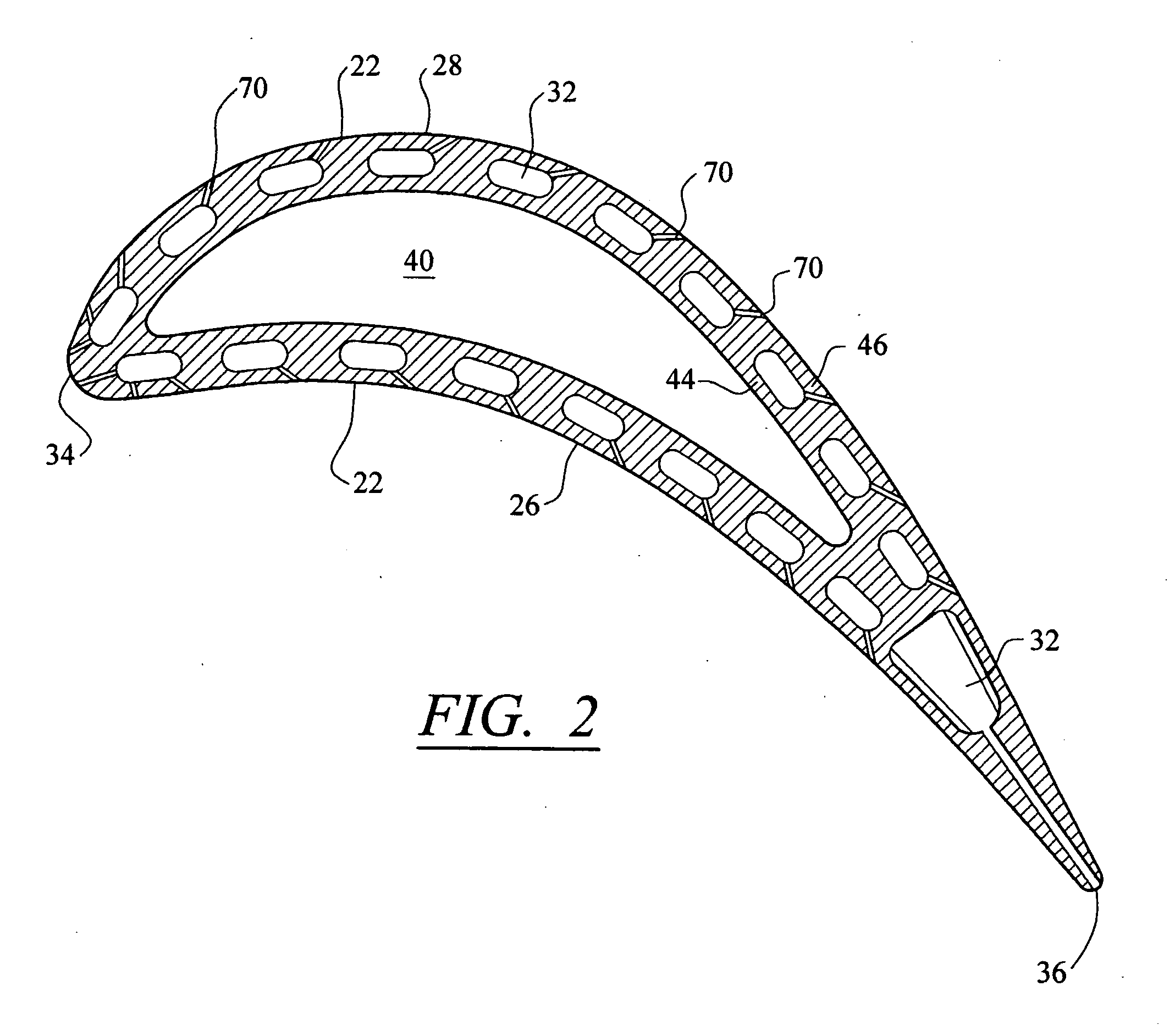

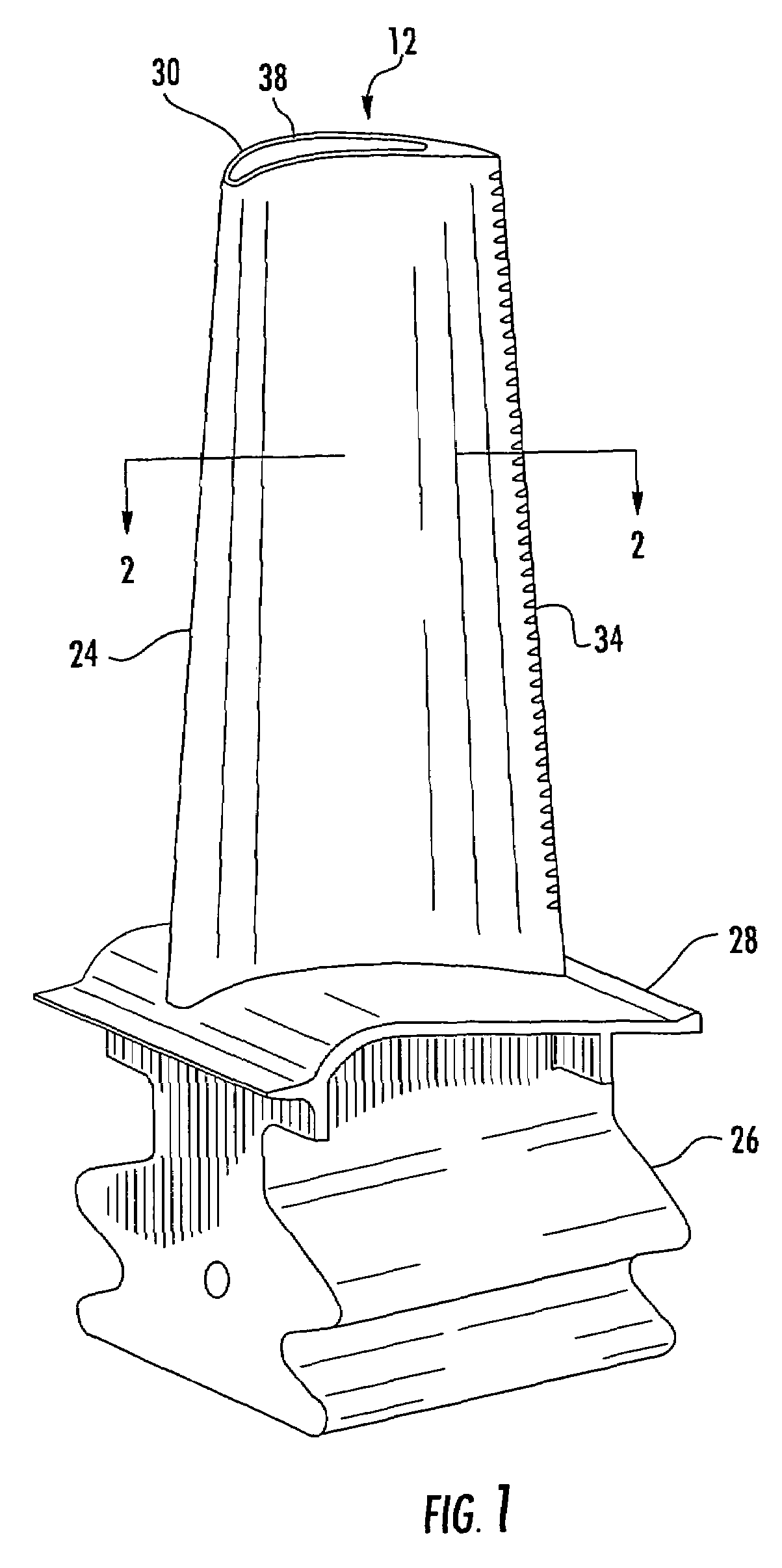

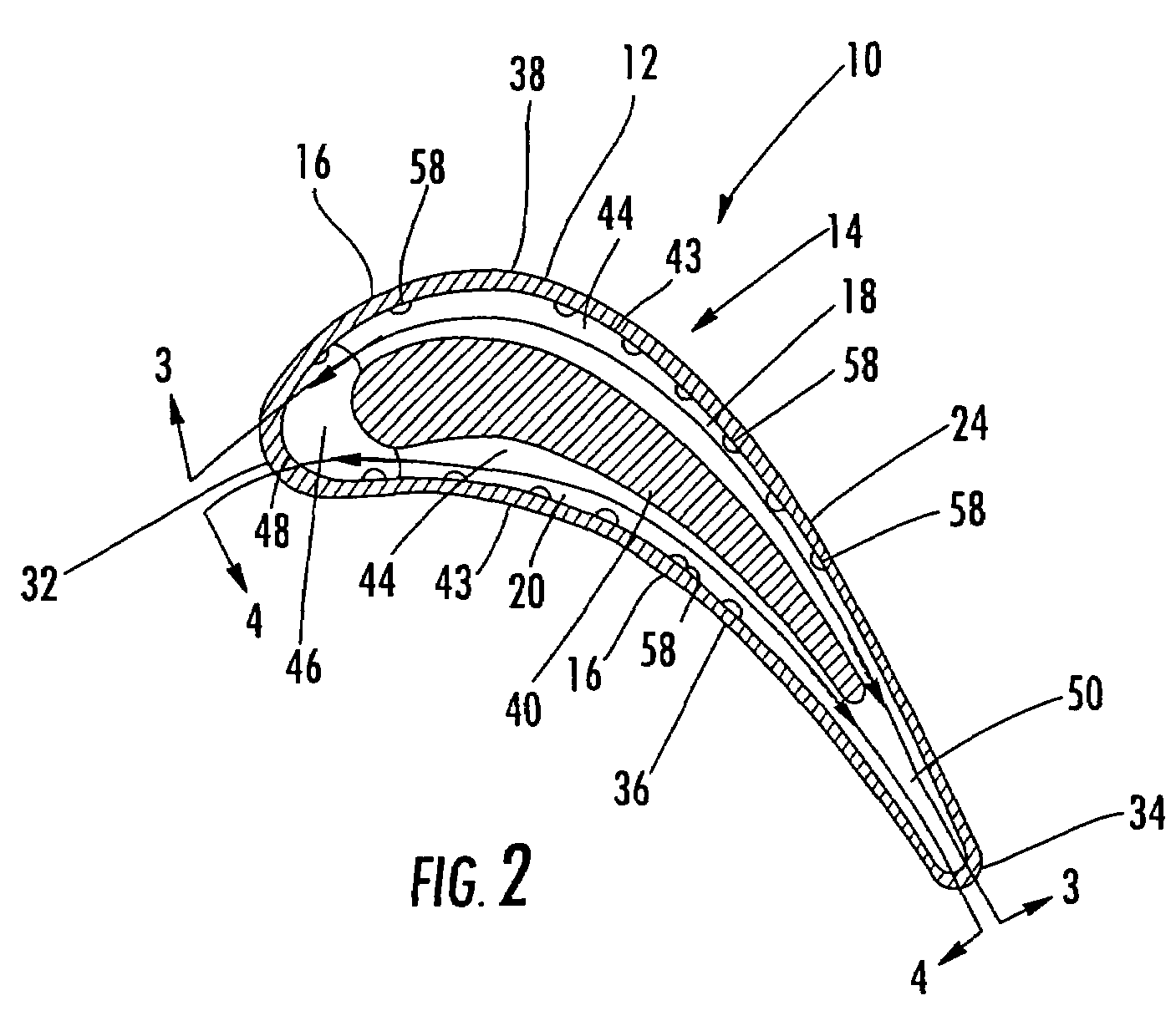

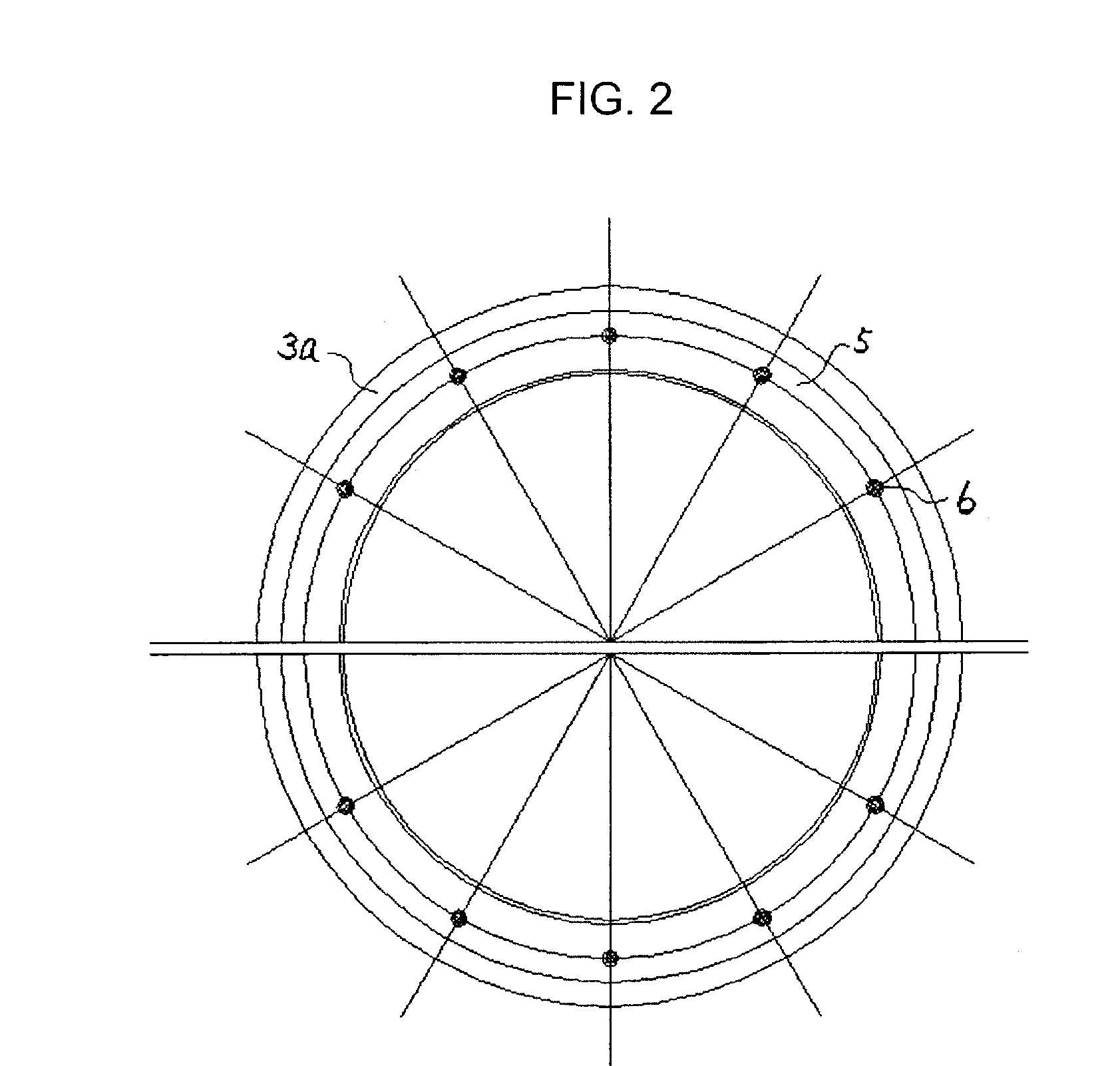

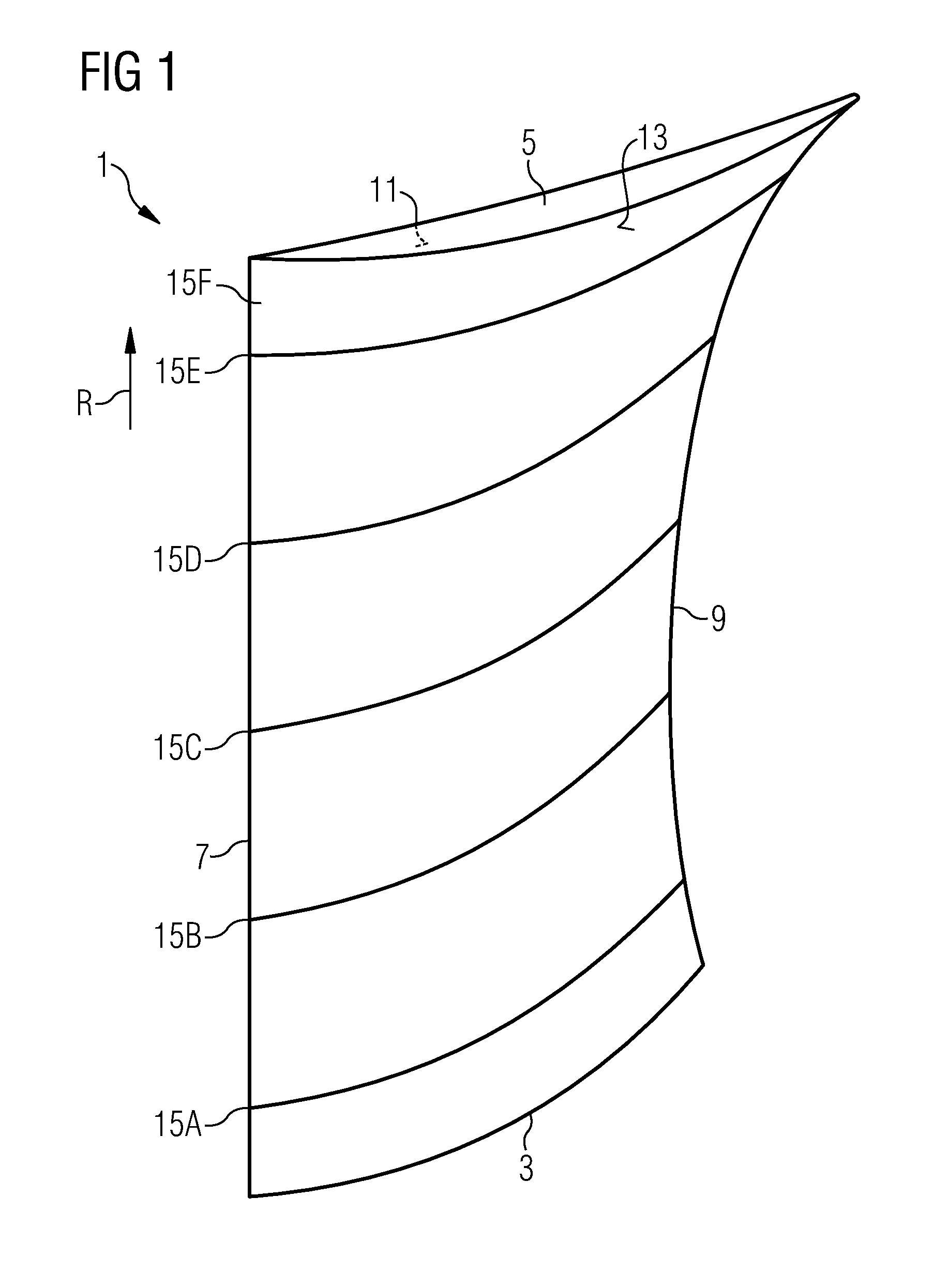

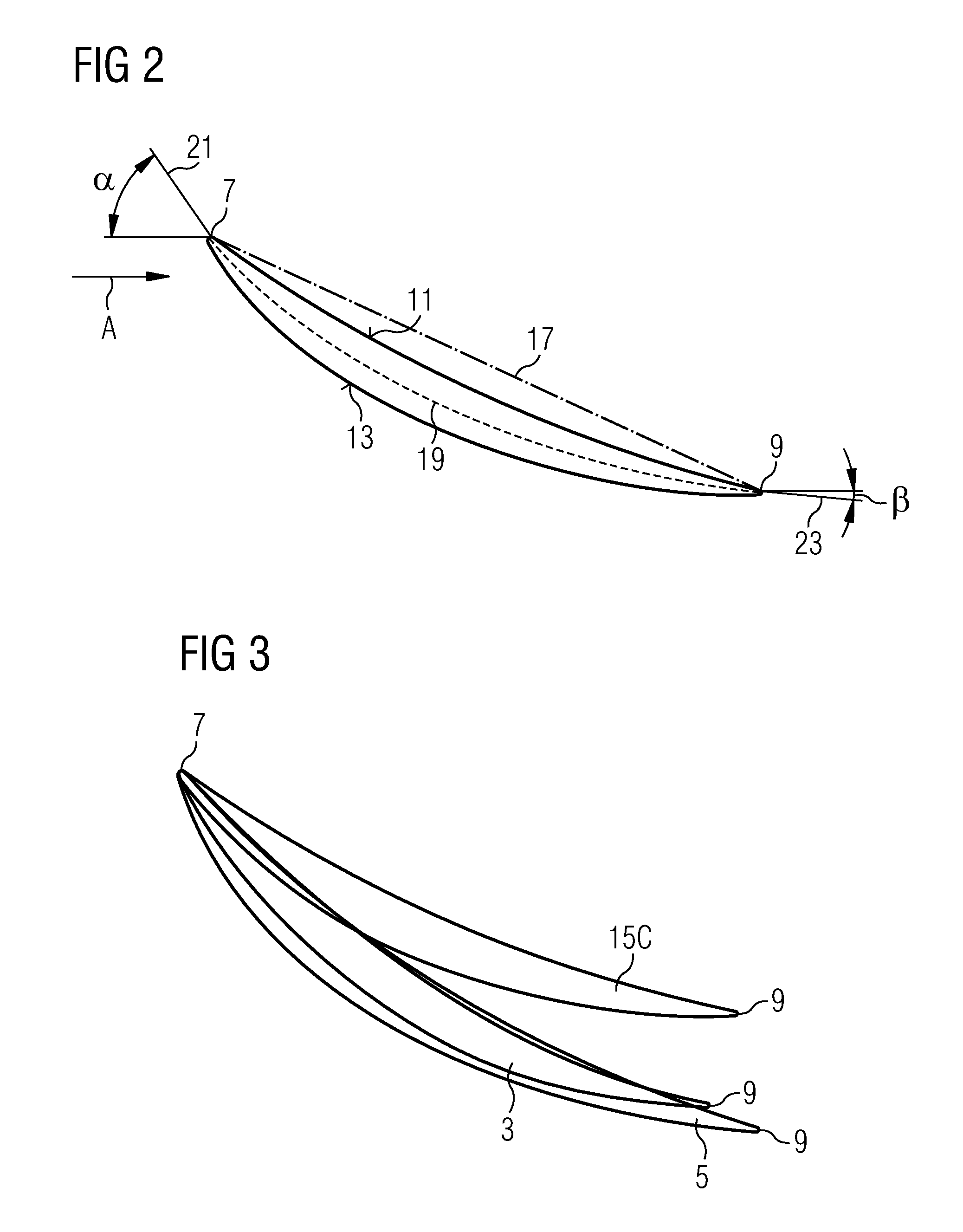

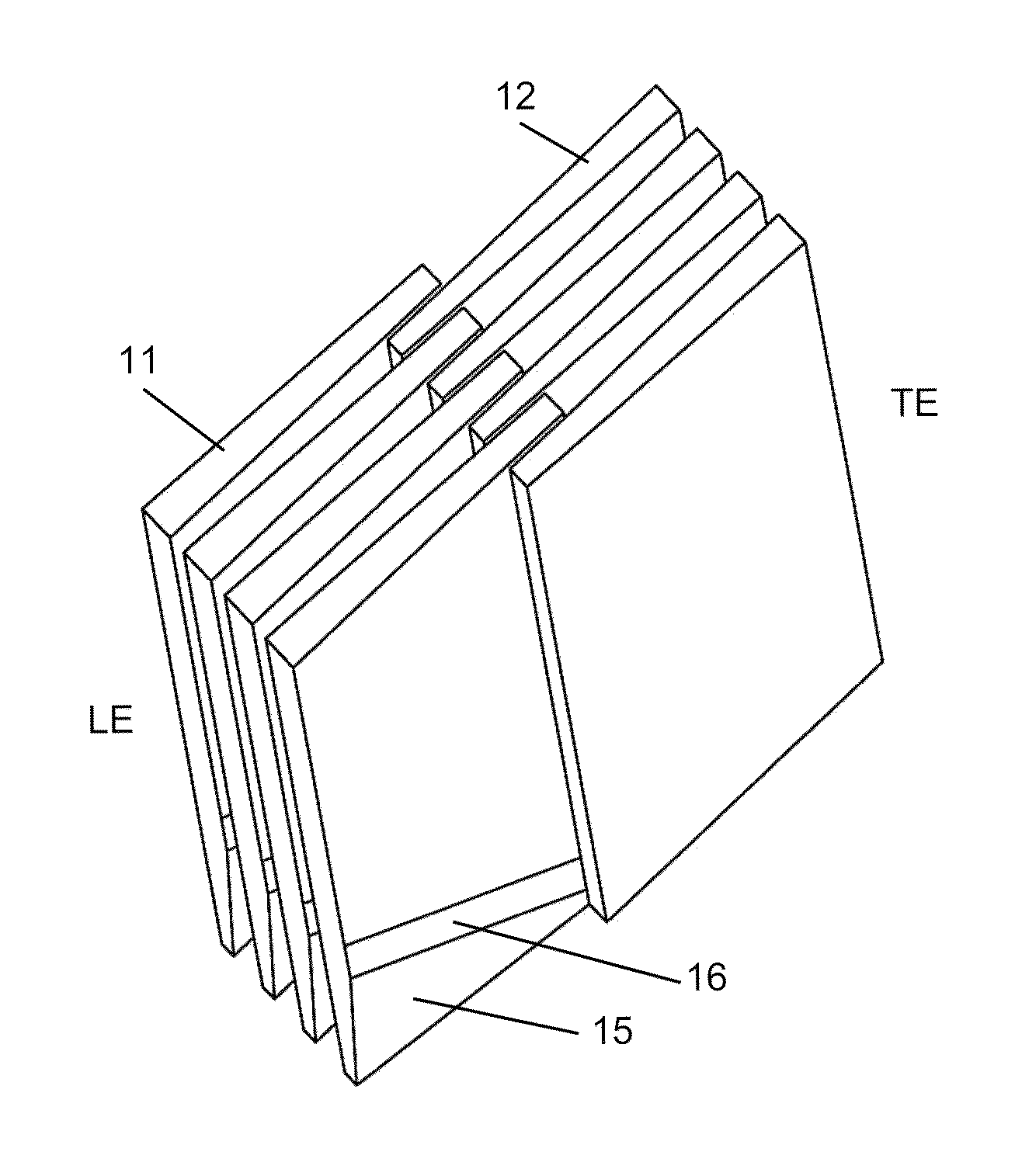

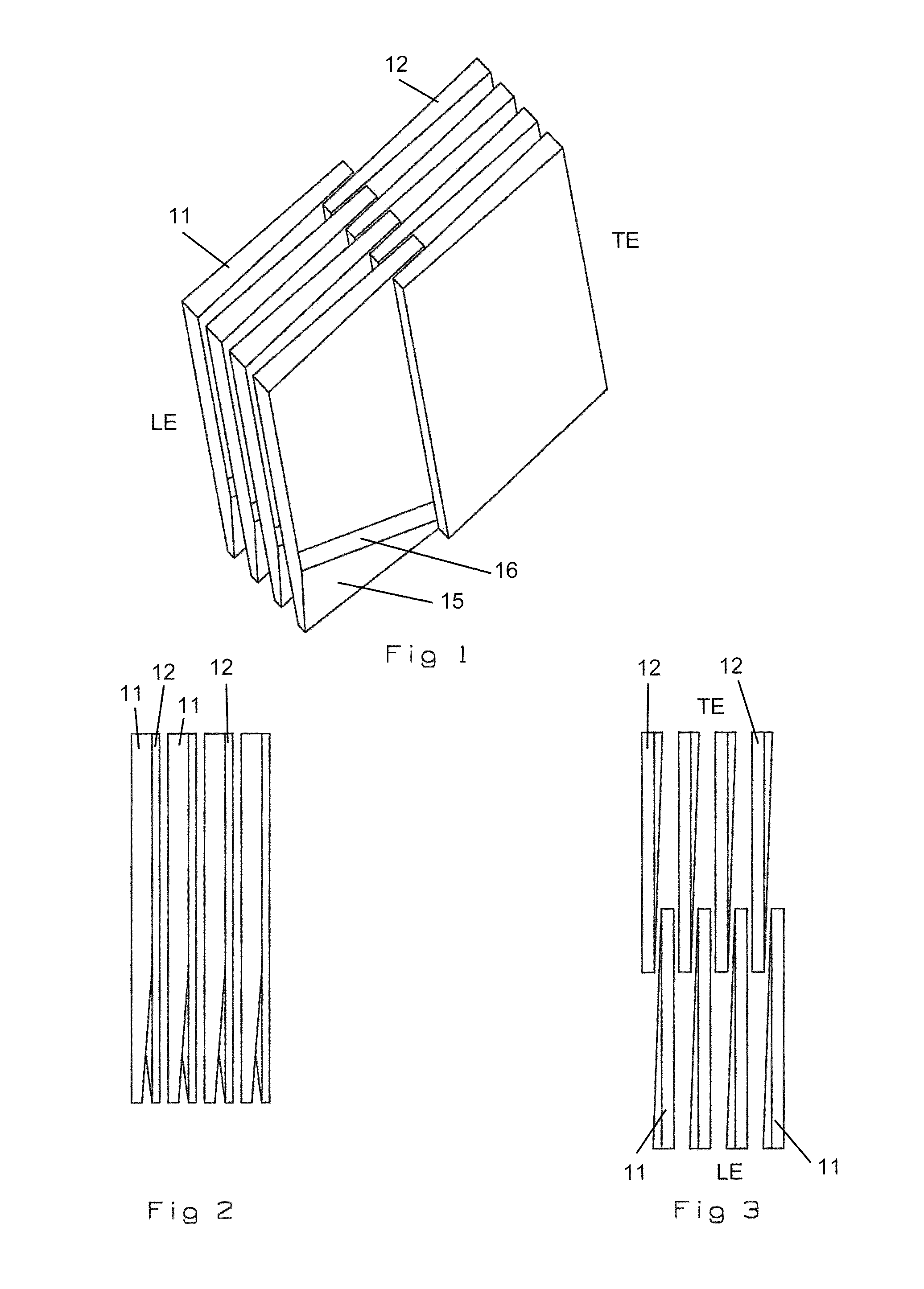

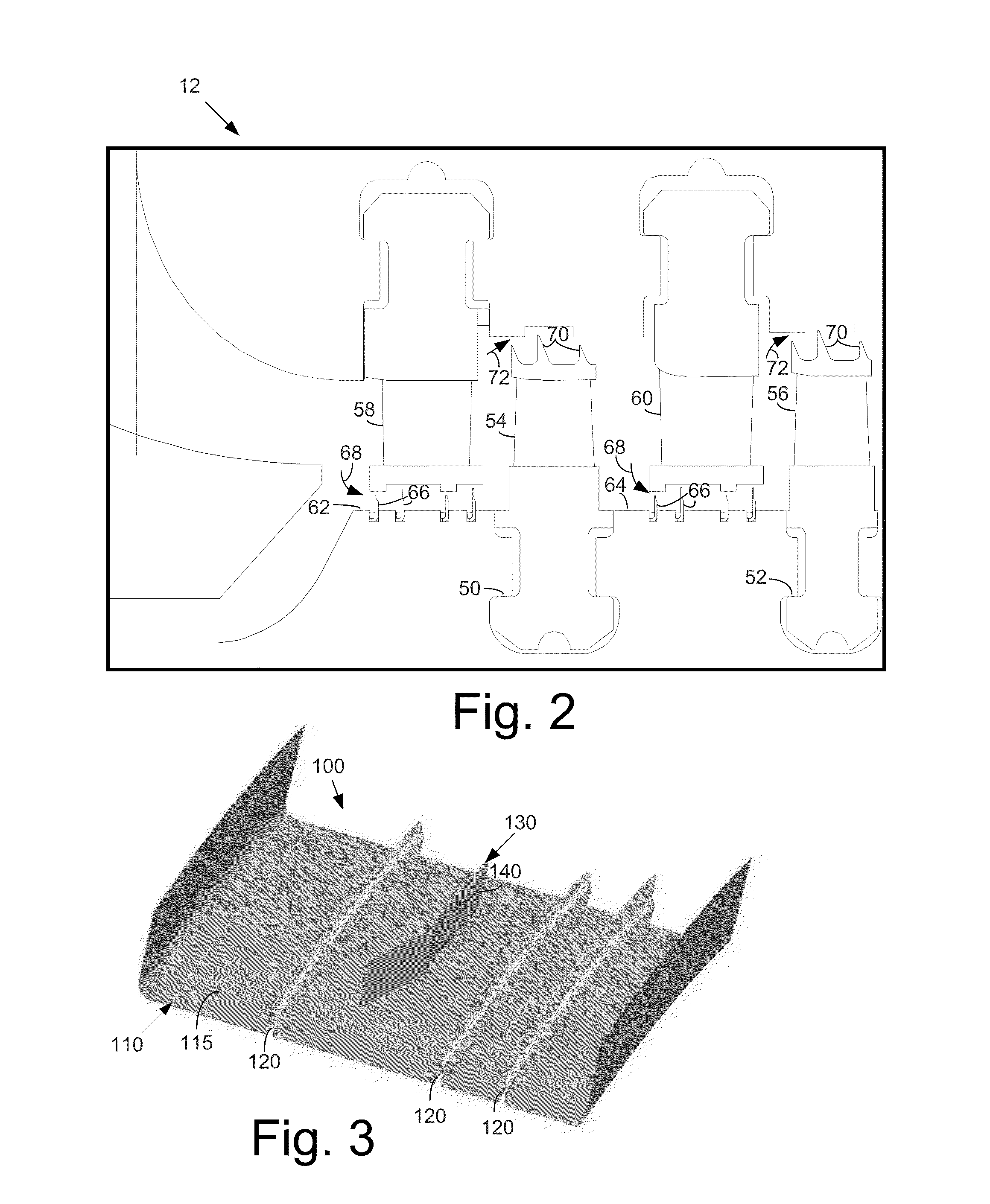

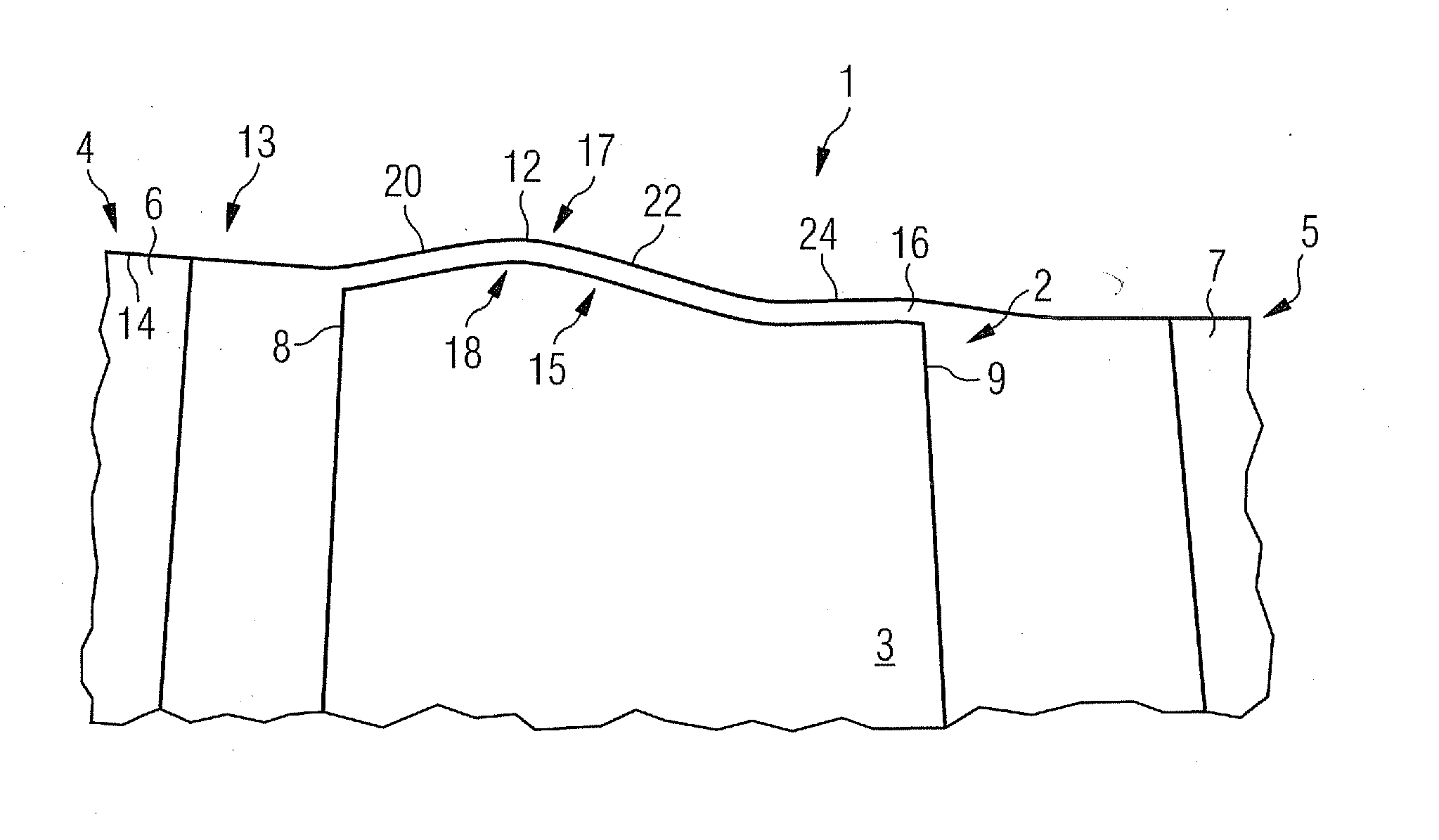

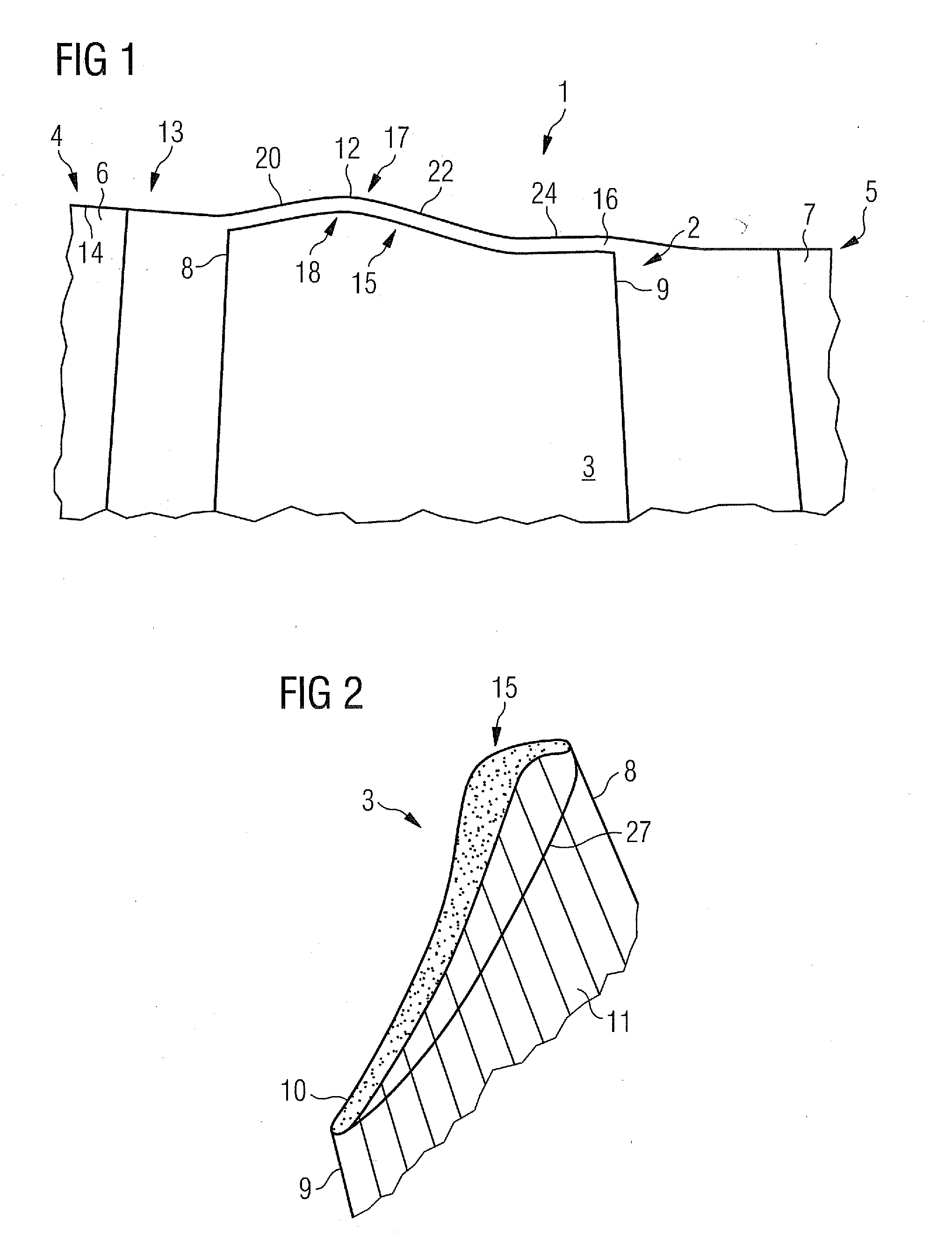

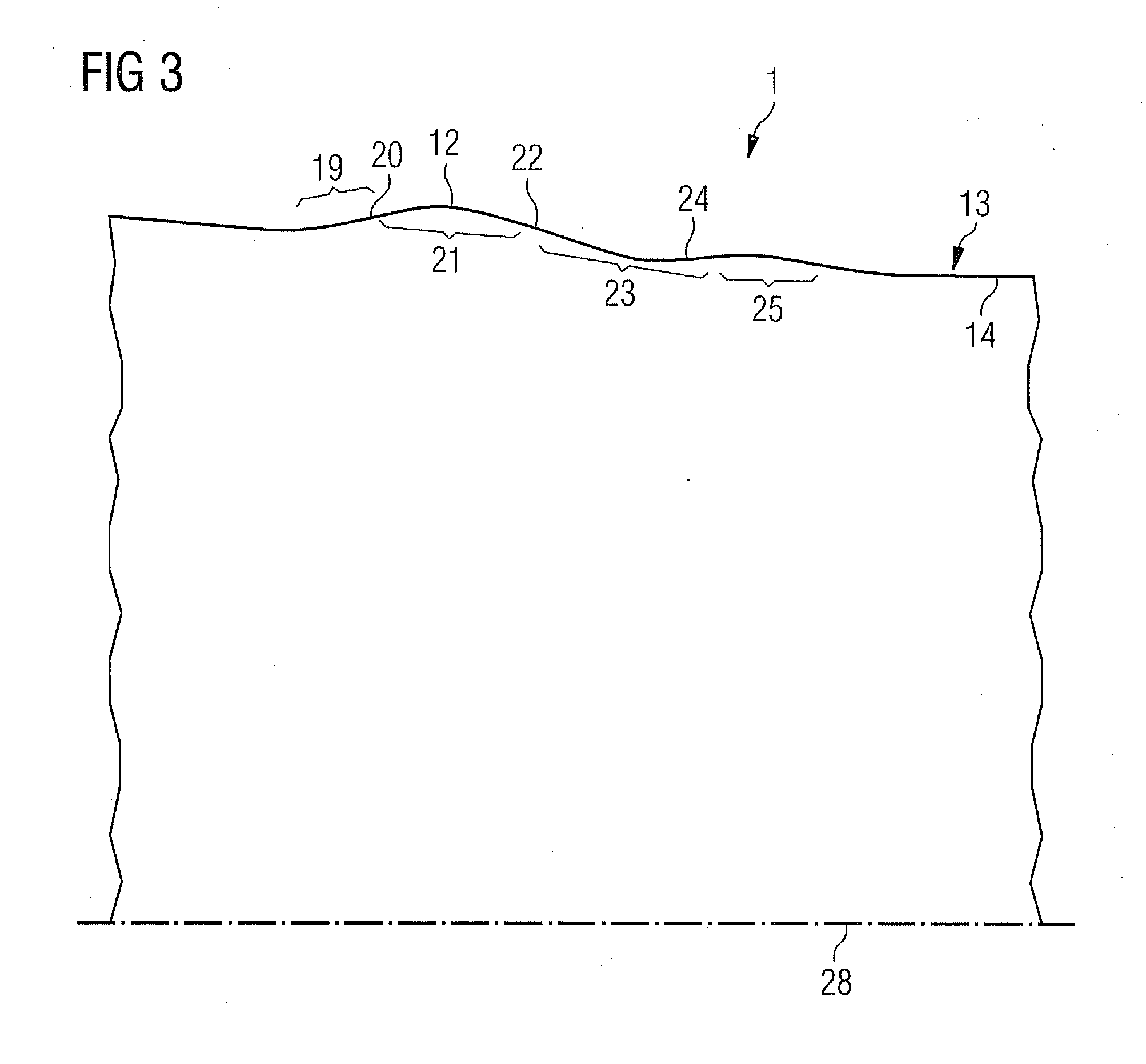

Vane or blade for an axial flow compressor

ActiveUS20110081252A1Losses have been minimisedExpand flow rangePropellersEngine manufactureLeading edgeTrailing edge

A compressor vane or compressor blade is provided. The axial flow compressor includes an axial direction, a radial direction, a compressor hub and a compressor casing. The vane or blade includes an airfoil with airfoil sections having a span, a chamber line and a leading edge at which the chamber line includes a leading edge blade angle with the axial direction of the compressor and a trailing edge at which the chamber line includes a trailing edge blade angle with the axial direction of the compressor. The airfoil sections are stacked at the leading edge on a straight line extending along a radial direction of the compressor from the compressor hub towards a compressor casing and in that the leading edge angles of the airfoil sections vary along the span and are larger for airfoil sections close to the hub and close to the wall than for mid-span airfoil sections.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

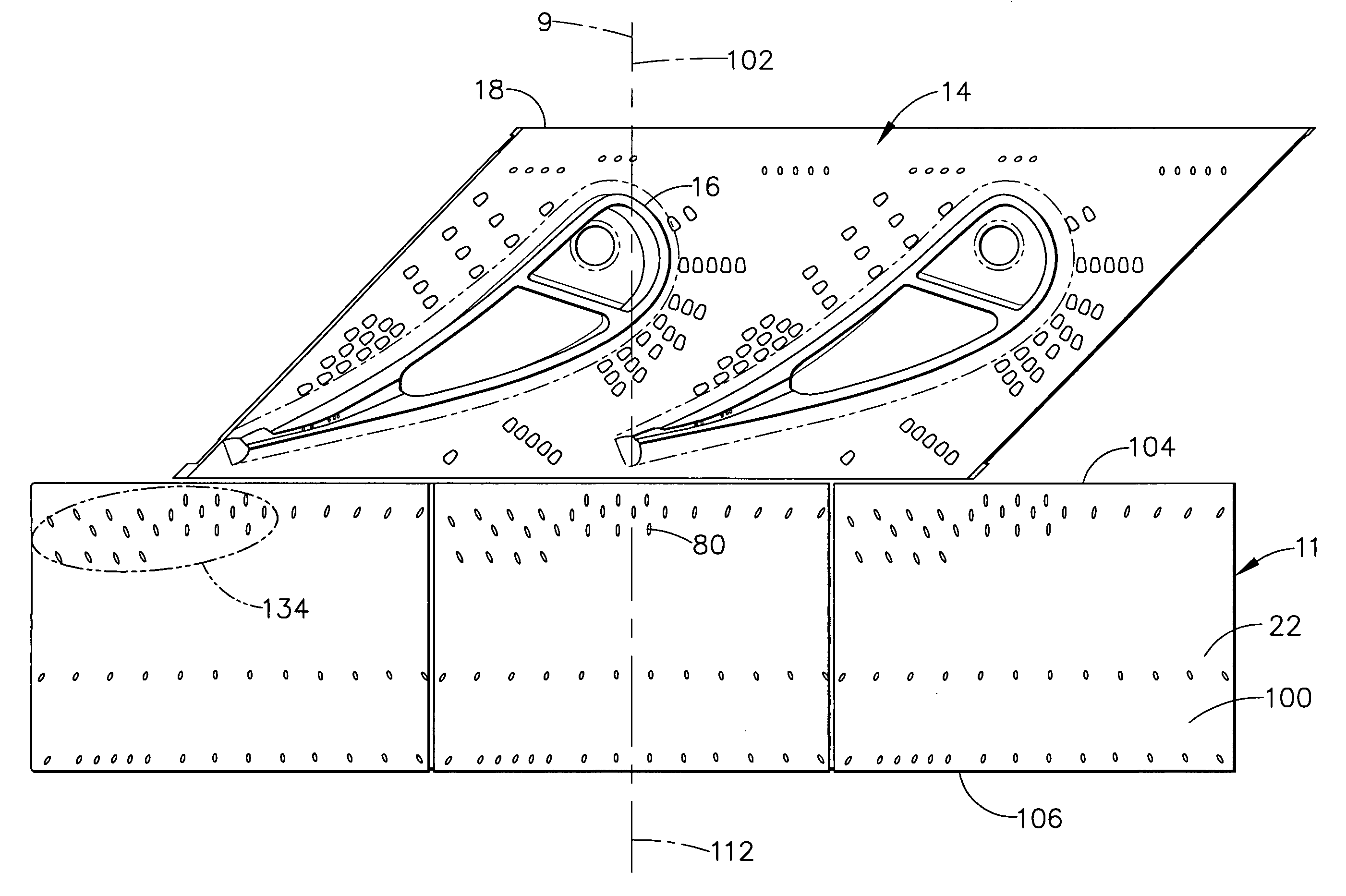

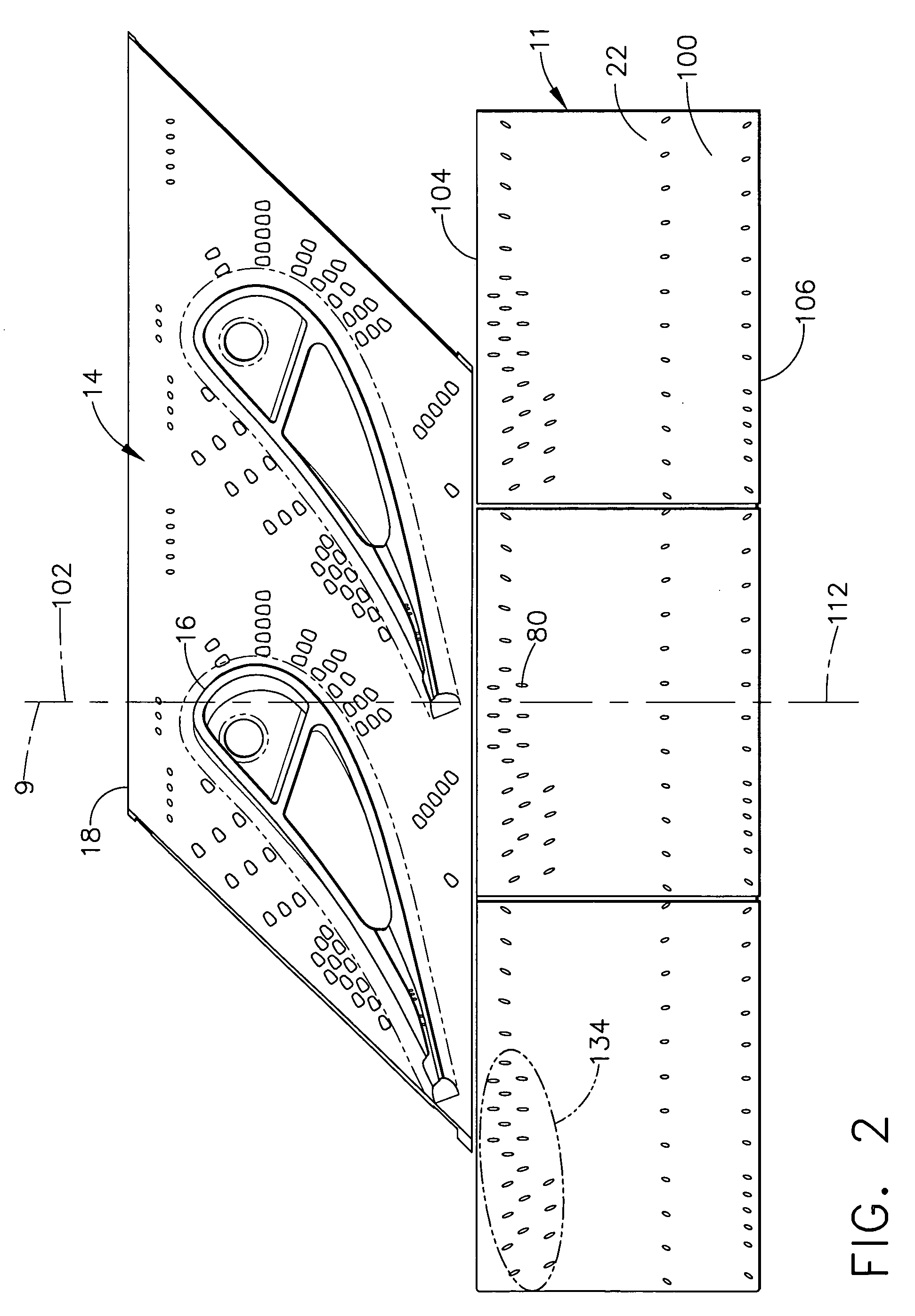

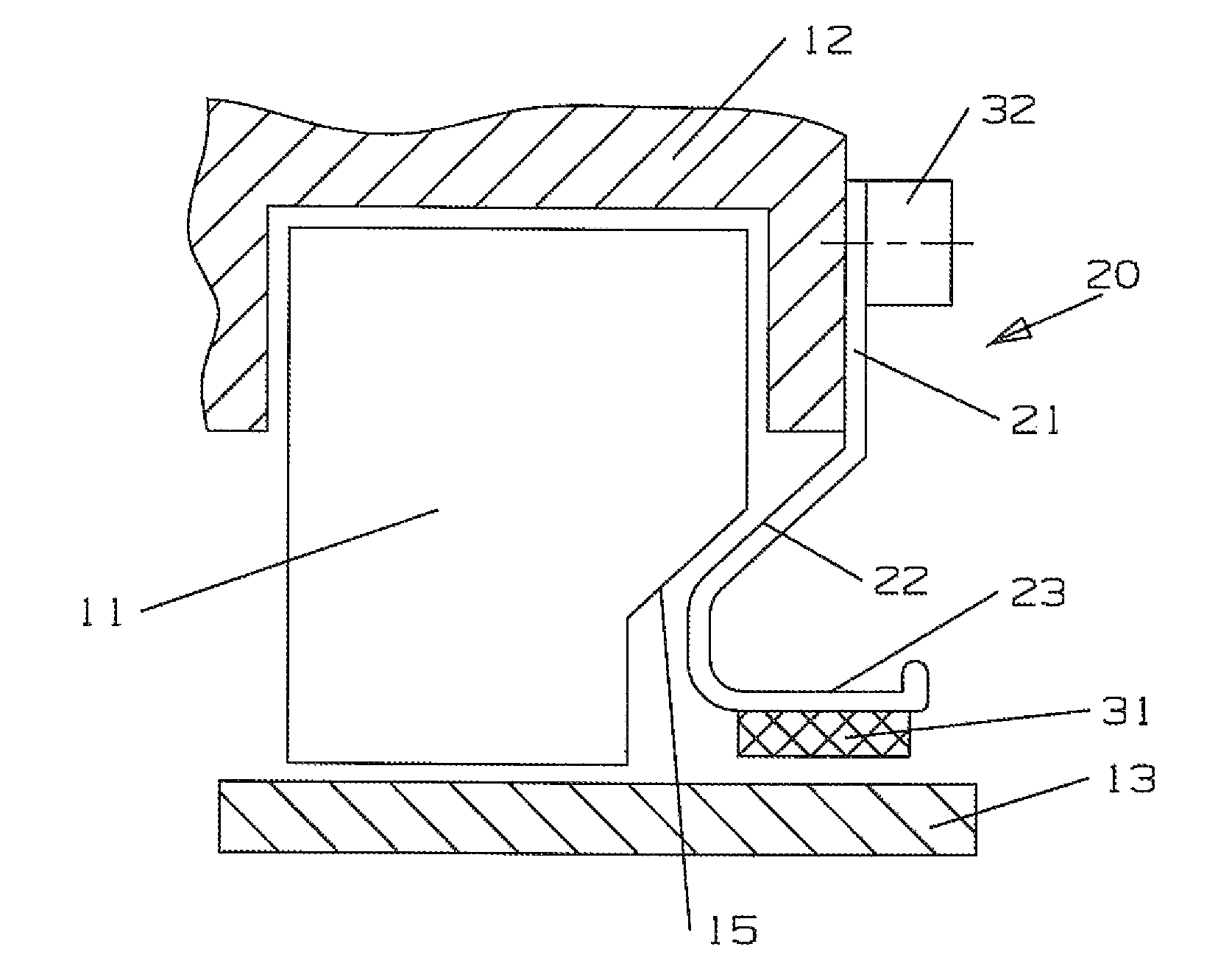

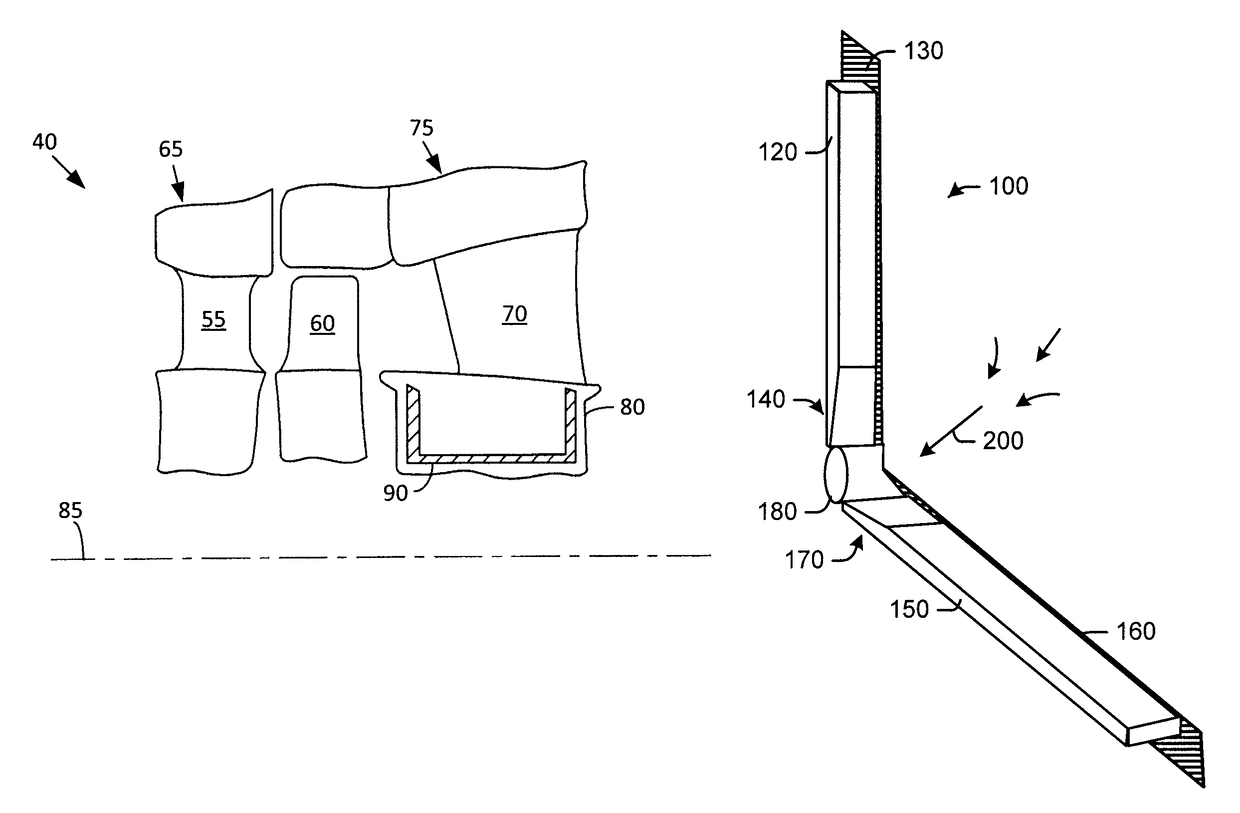

Turbine shroud asymmetrical cooling elements

ActiveUS7147432B2Degree of reductionReduce gradientPump componentsEngine fuctionsHigh densityEngineering

A turbine shroud assembly asymmetrical cooling element such as a shroud segment or a baffle includes an arcuate panel. The panel has a plurality of cooling apertures extending through the panel and an axially extending midline of the panel parallel to an axis of rotation of the arcuate panel. A symmetric portion of the cooling apertures have a symmetrical density of aperture inlets that is symmetric with respect to the axially extending midline. An asymmetric portion of the cooling apertures have an asymmetrical density of aperture inlets that is asymmetric with respect to the axially extending midline. One exemplary cooling element includes a high density area of the cooling apertures in the asymmetric portion having a higher density of aperture inlets than in the symmetric portion. A low density area of the cooling apertures in the asymmetric portion has a lower density of aperture inlets than in the symmetric portion of the cooling apertures.

Owner:GENERAL ELECTRIC CO

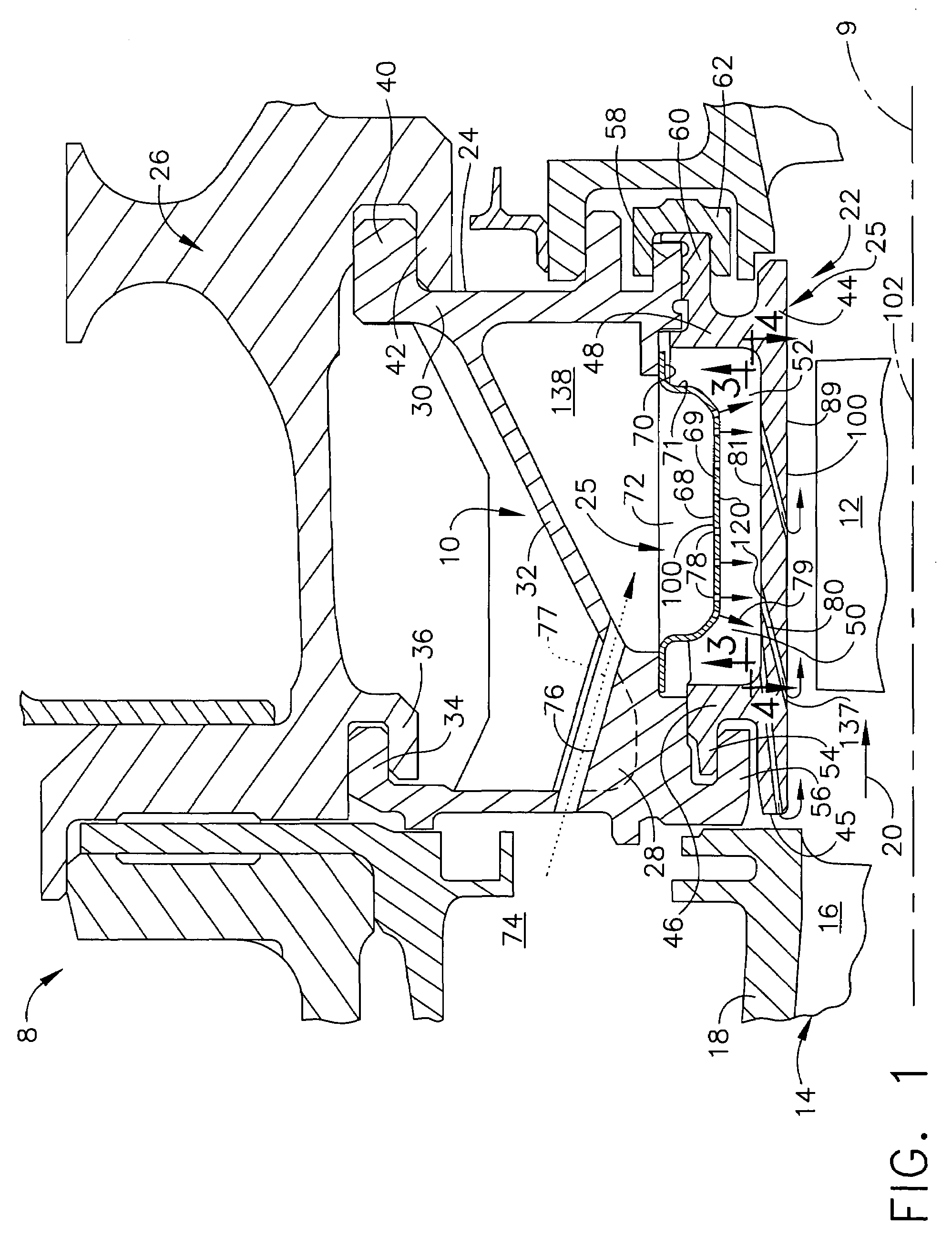

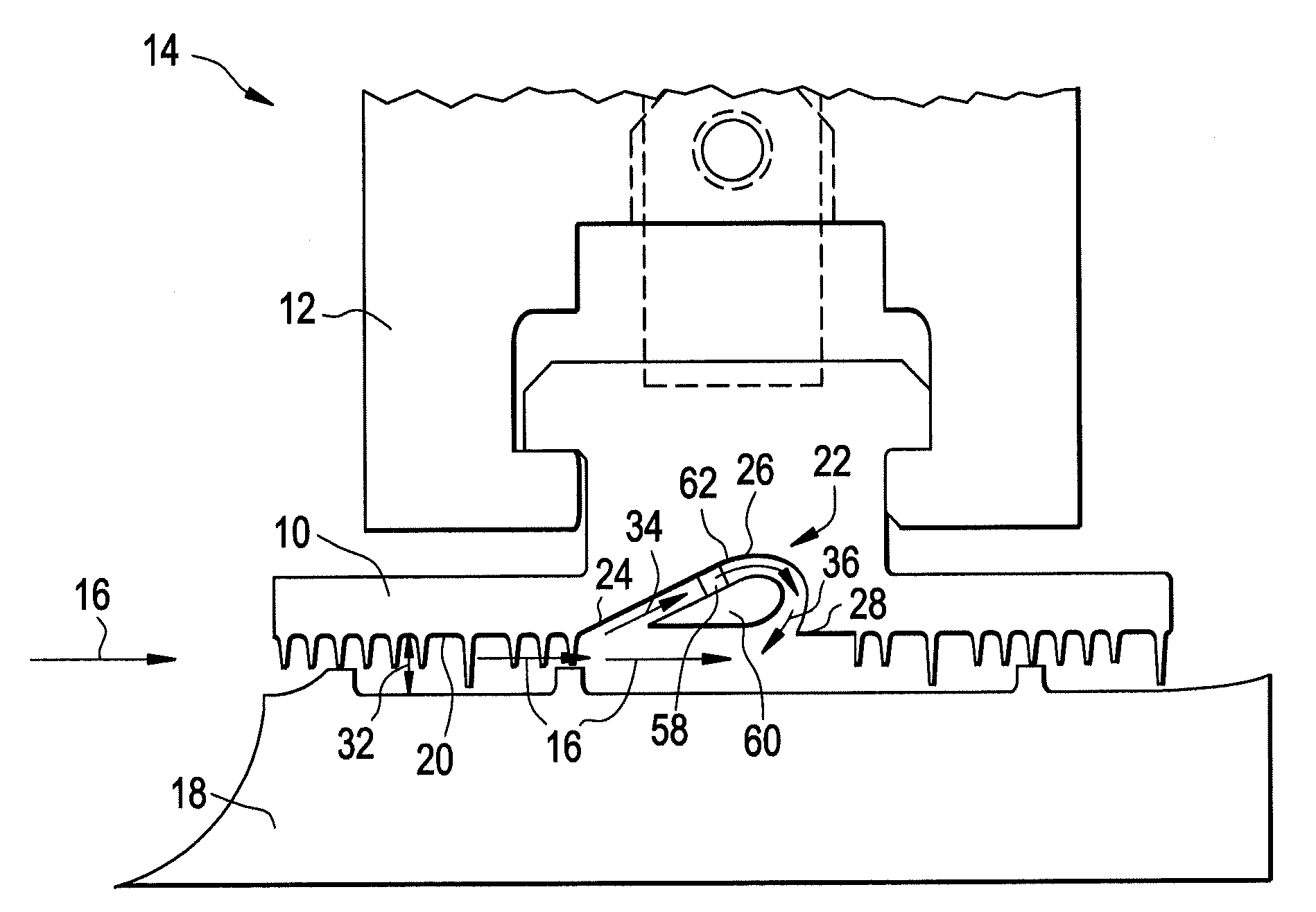

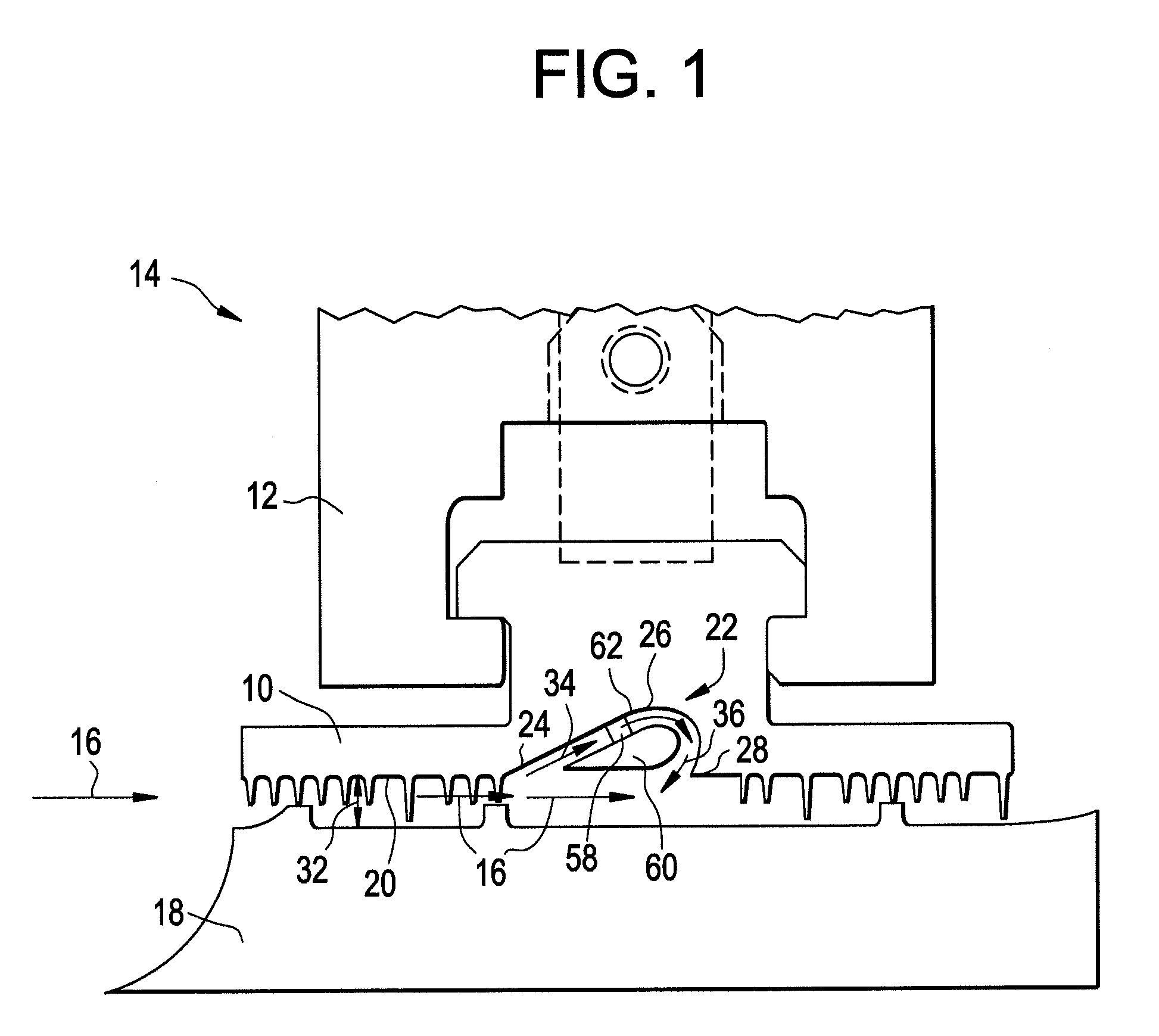

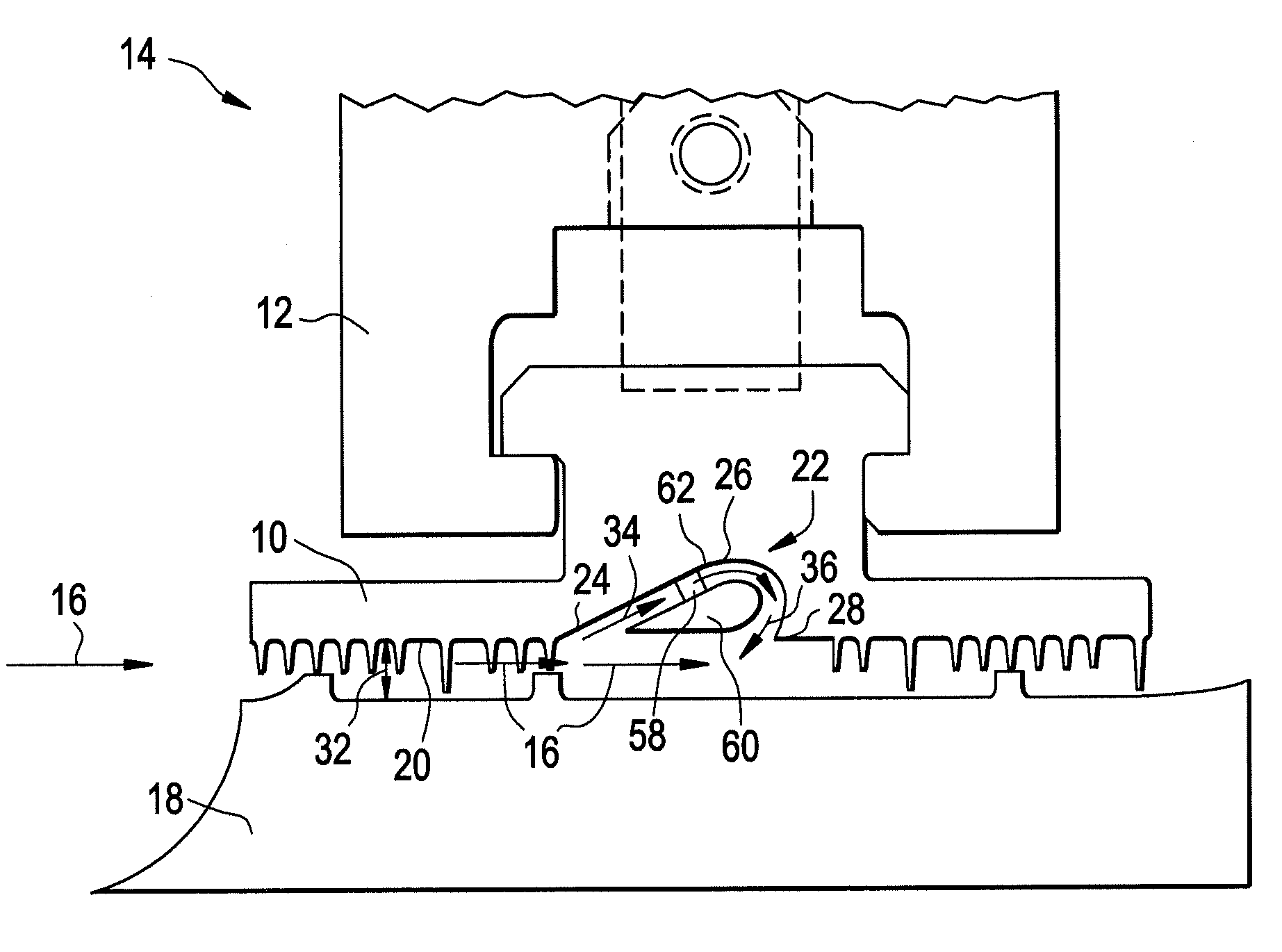

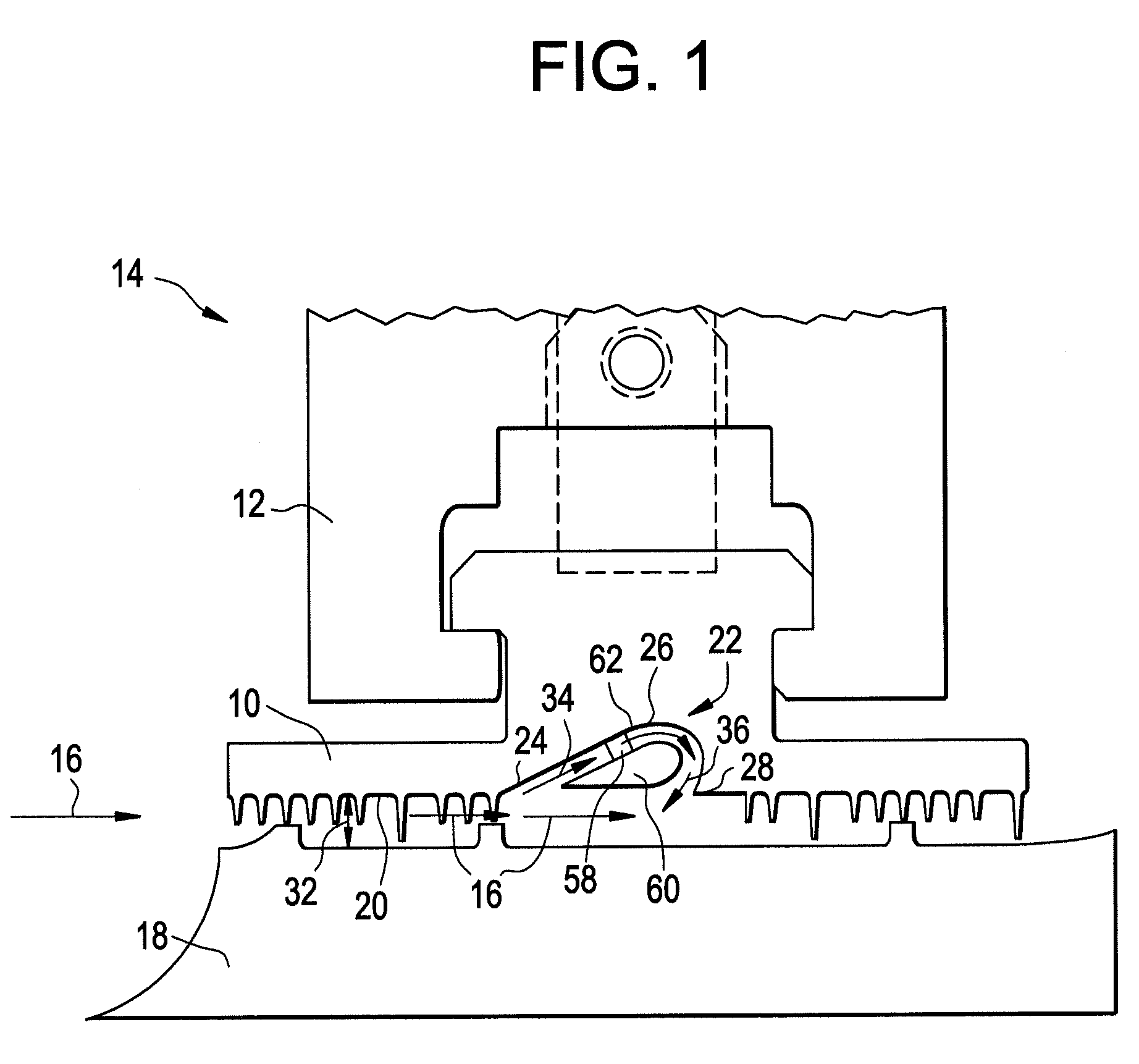

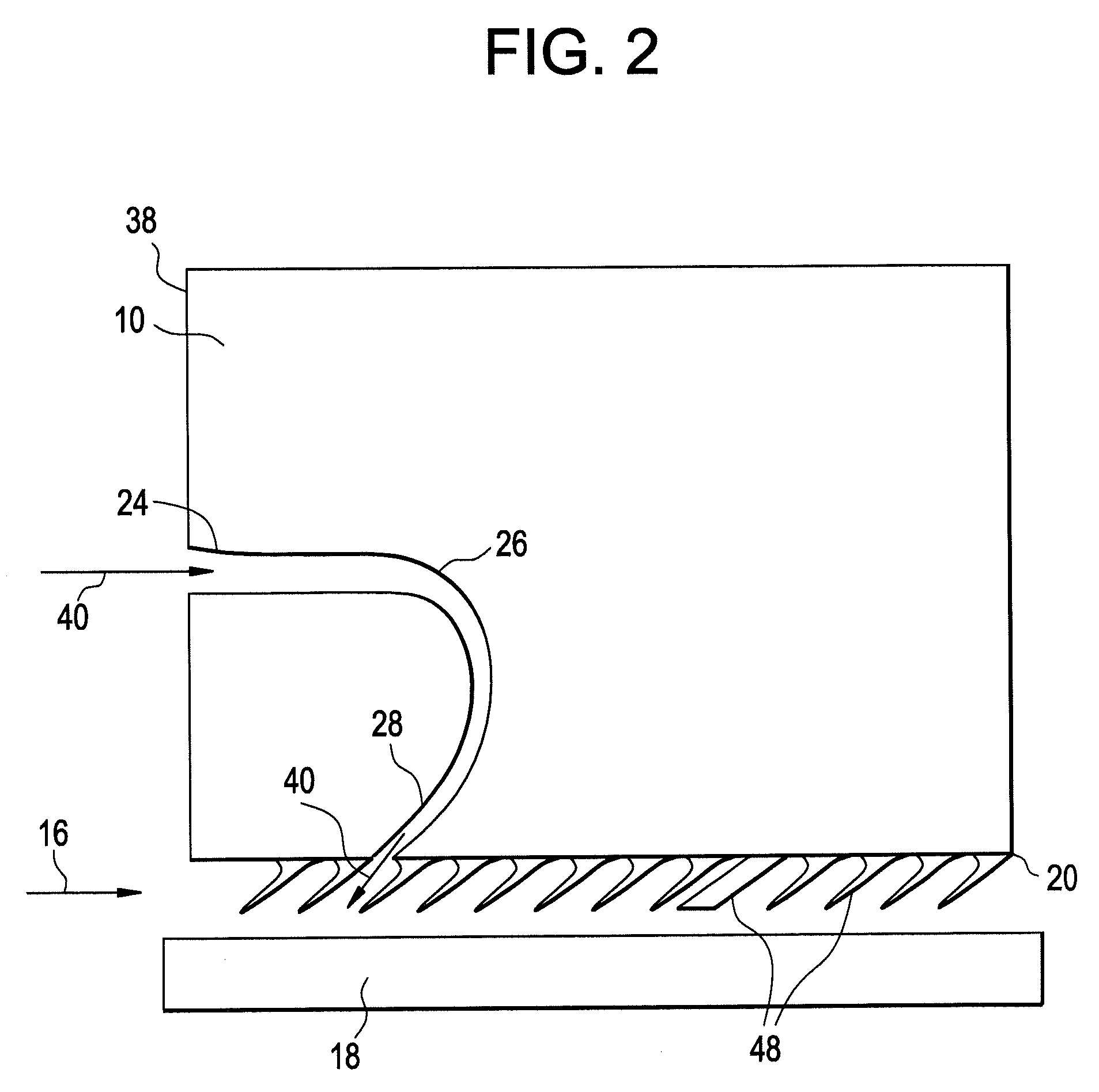

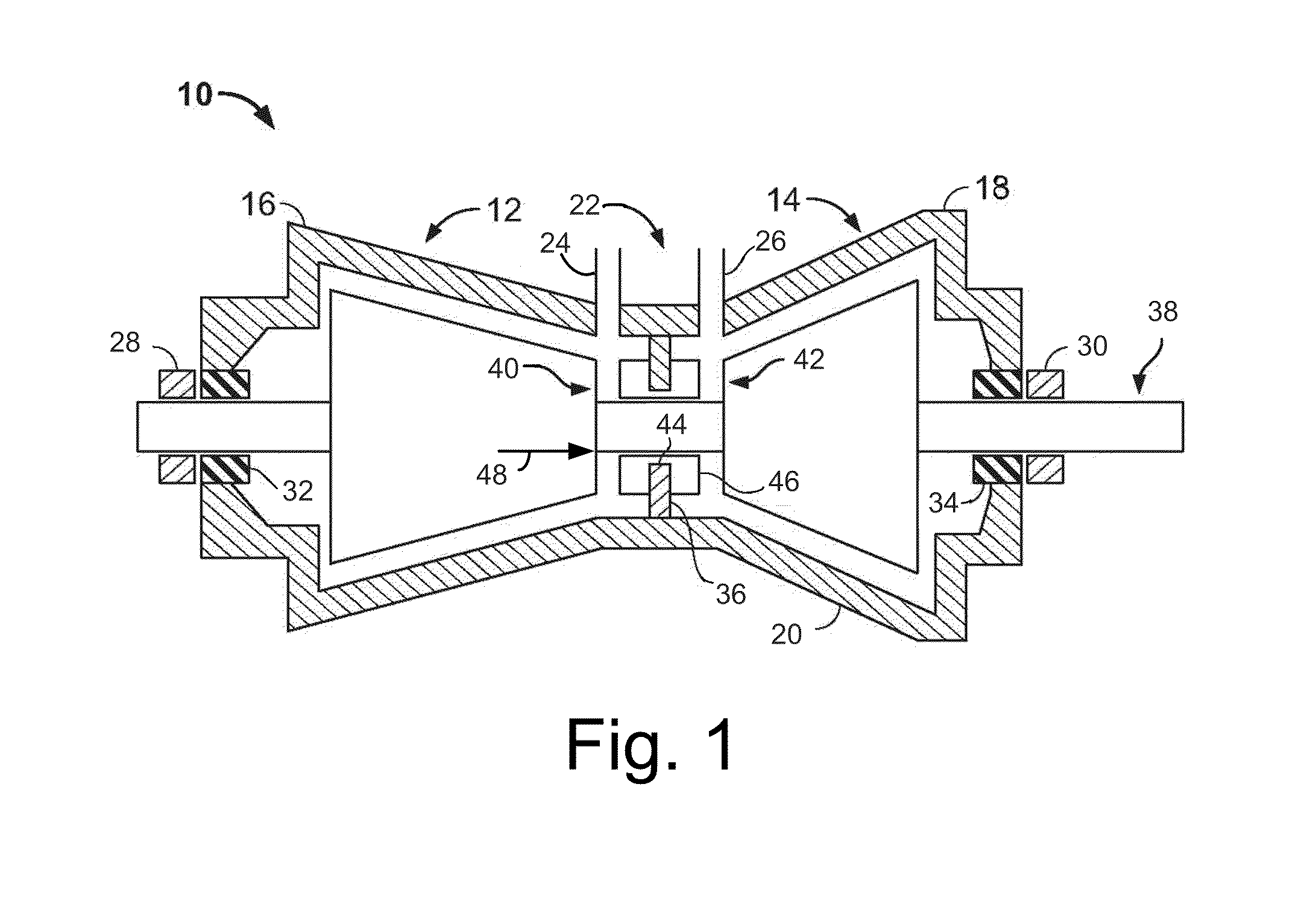

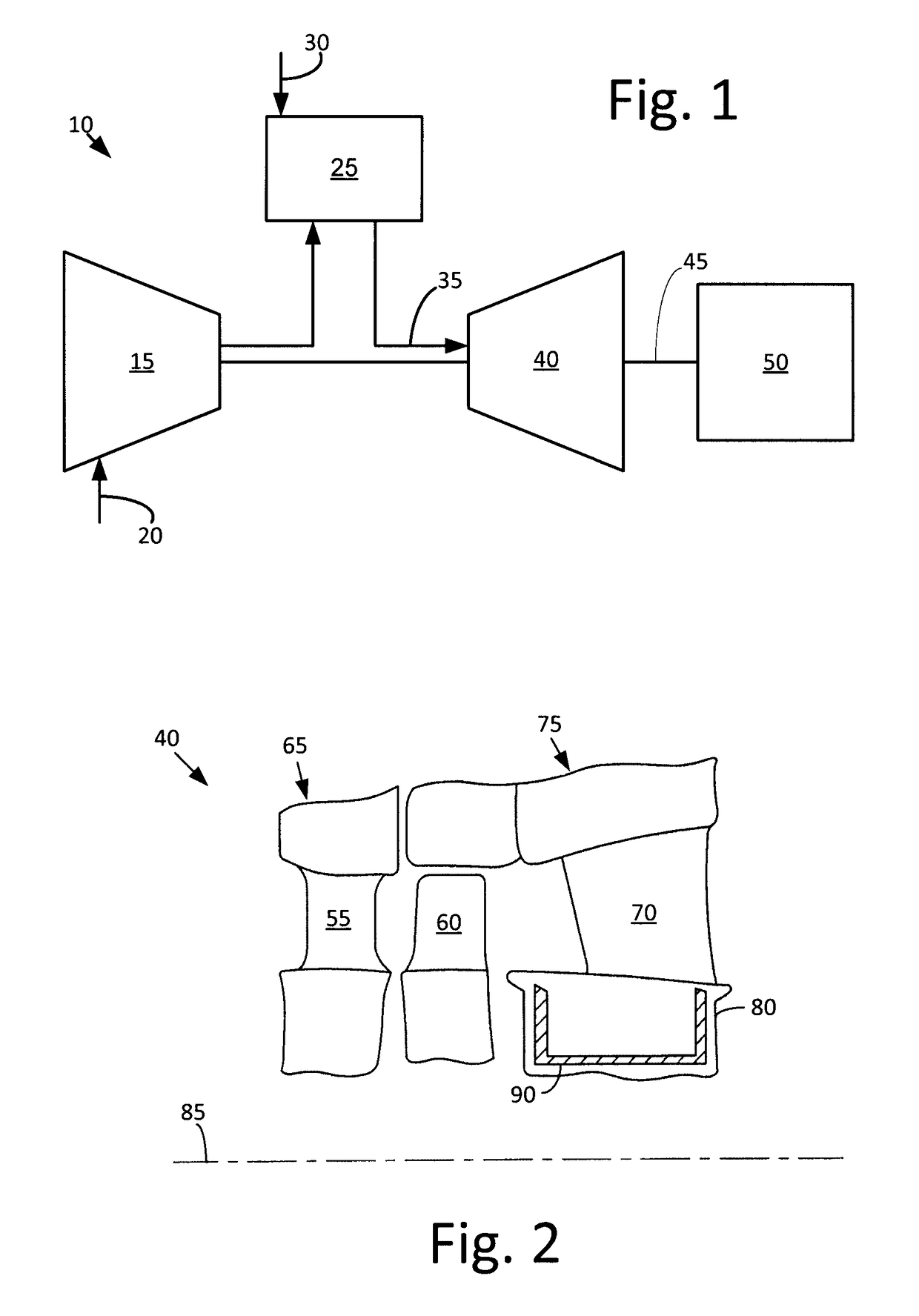

Fluidic sealing for turbomachinery

Disclosed is a seal for turbomachinery including a seal face locatable between a first turbomachinery component and a second turbomachinery component. At least one fluid channel extends through the seal. The at least one fluid channel is capable of injecting fluid flow between the first turbomachinery component and the second turbomachinery component at the seal face thereby disrupting a leakage flow between the first turbomachinery component and the second turbomachinery component. Further disclosed is a turbomachine utilizing the seal.

Owner:GENERAL ELECTRIC CO

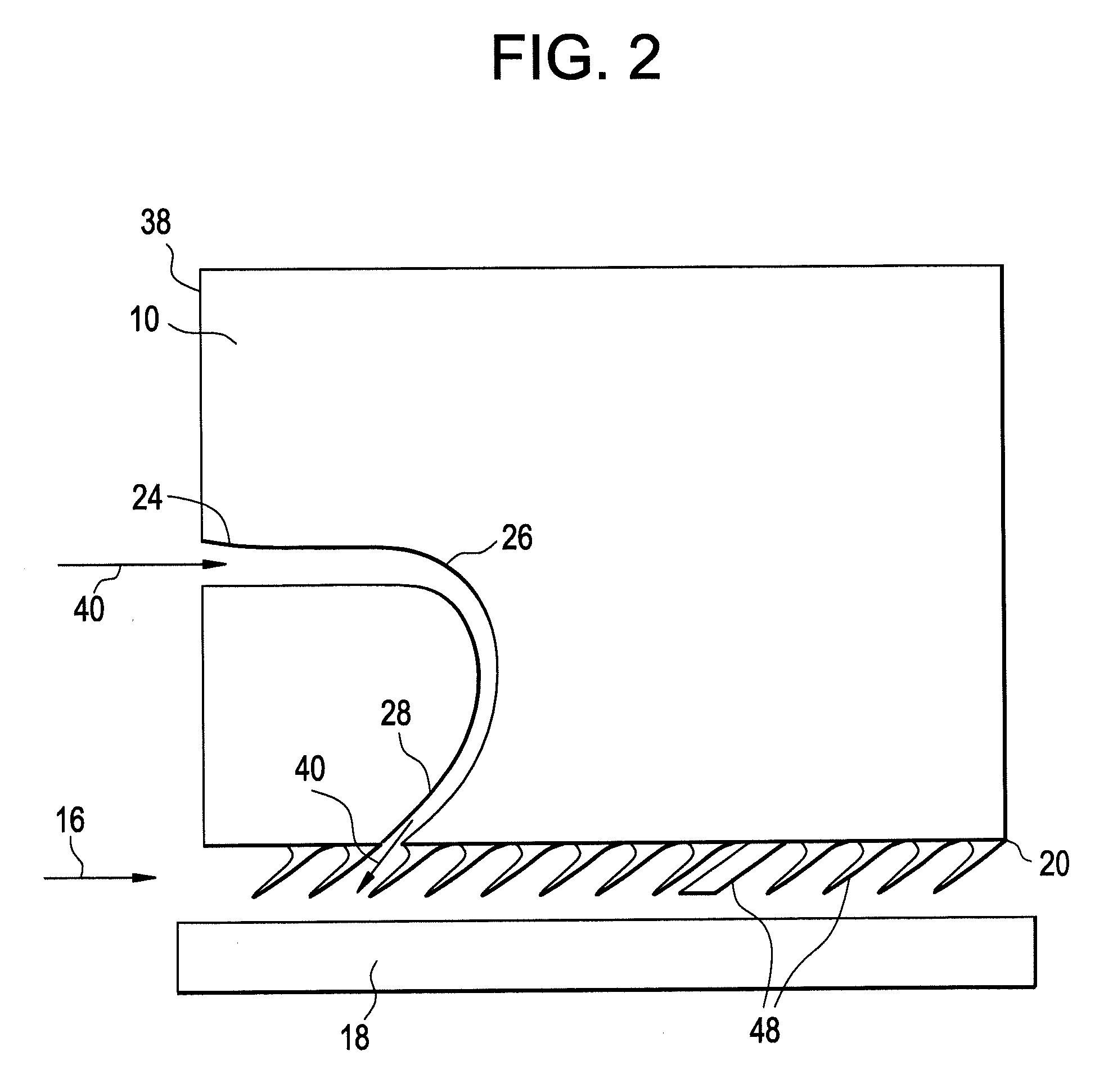

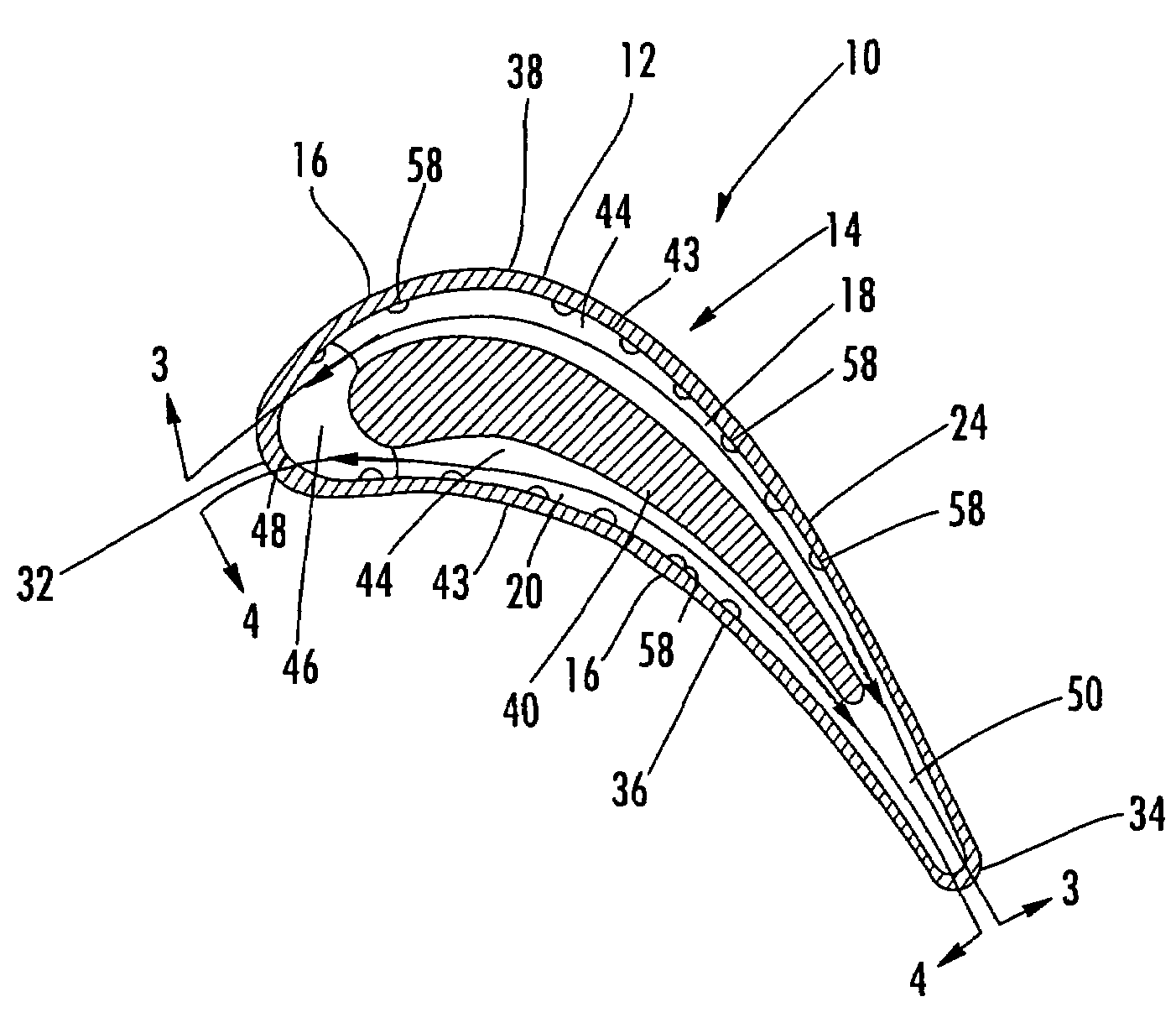

Cooling system for a tip of a turbine blade

InactiveUS20050244270A1Reduce effective sizeReduce effective leakage flow pathPropellersPump componentsTurbine blade

A turbine blade for a turbine engine having at least one secondary flow deflector proximate to a blade tip for reducing the effective flow path between the blade tip and an adjacent outer seal. The turbine blade may be a superblade having a central opening forming a hollow turbine blade. The turbine blade may include a secondary flow deflector on upstream sides of the pressure side wall and the suction side wall. The downstream sides of the pressure and suction side walls may include chamfered corners. The secondary flow deflector reduces the effective flow path between the blade tip and an outer seal in numerous ways.

Owner:SIEMENS ENERGY INC

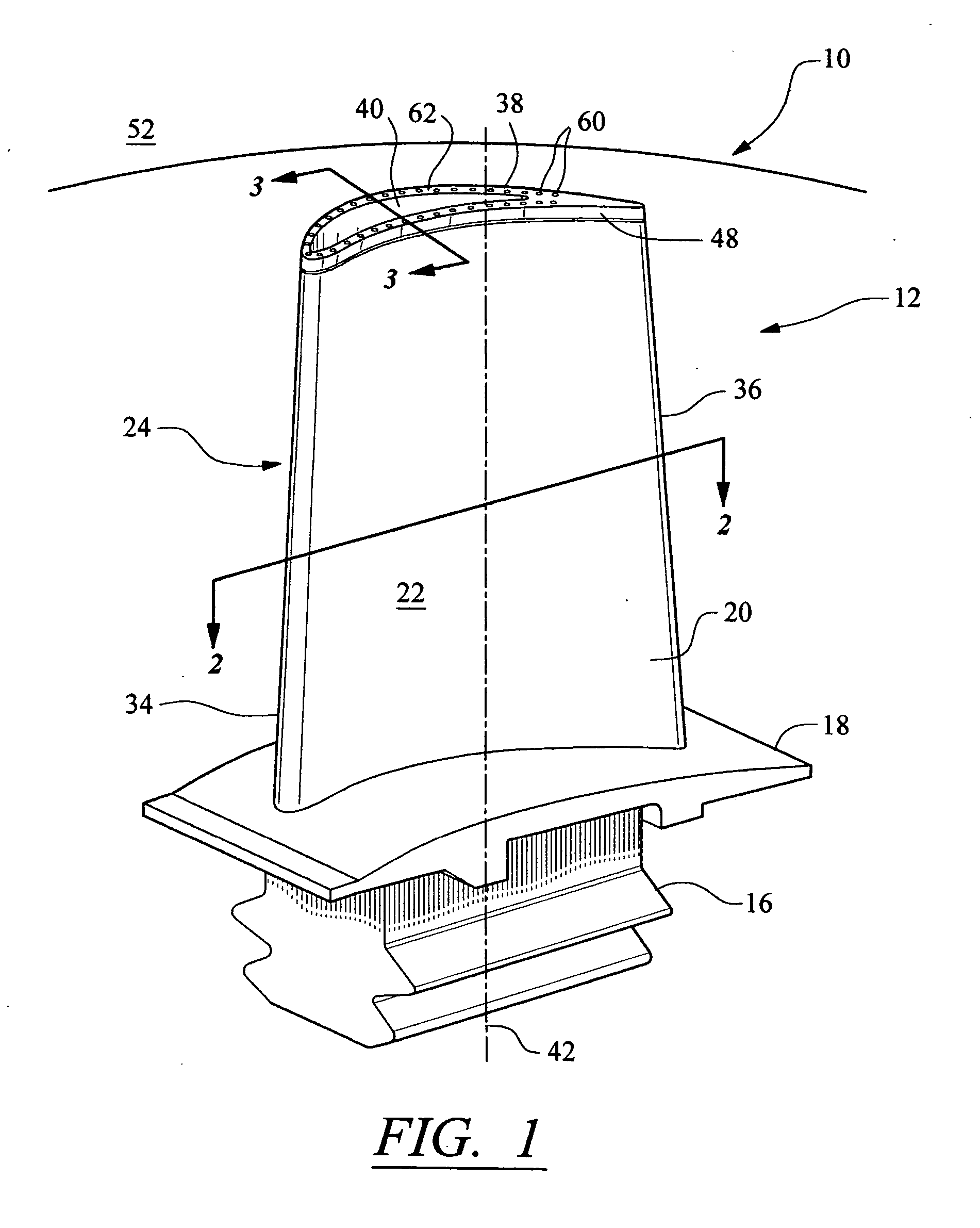

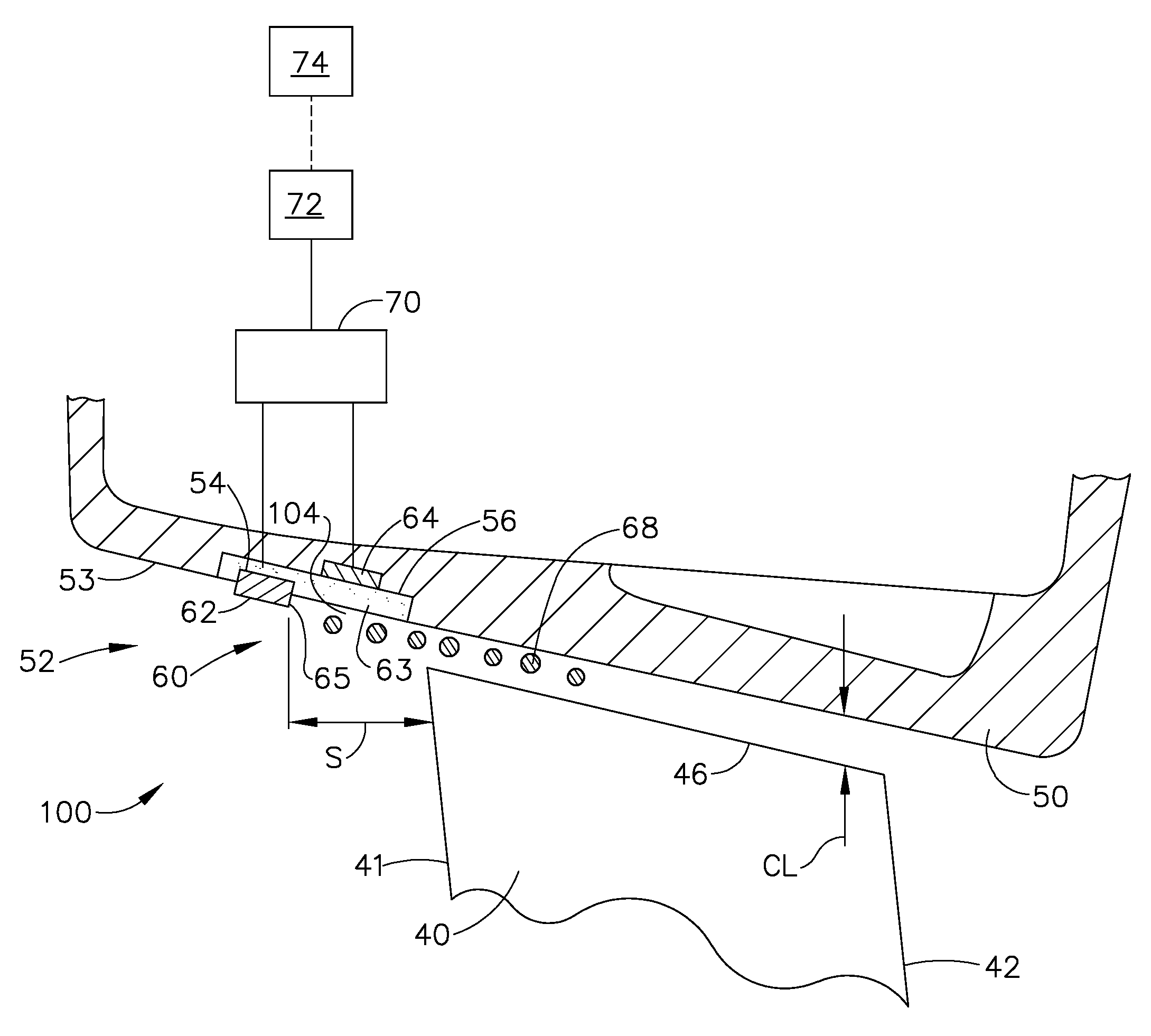

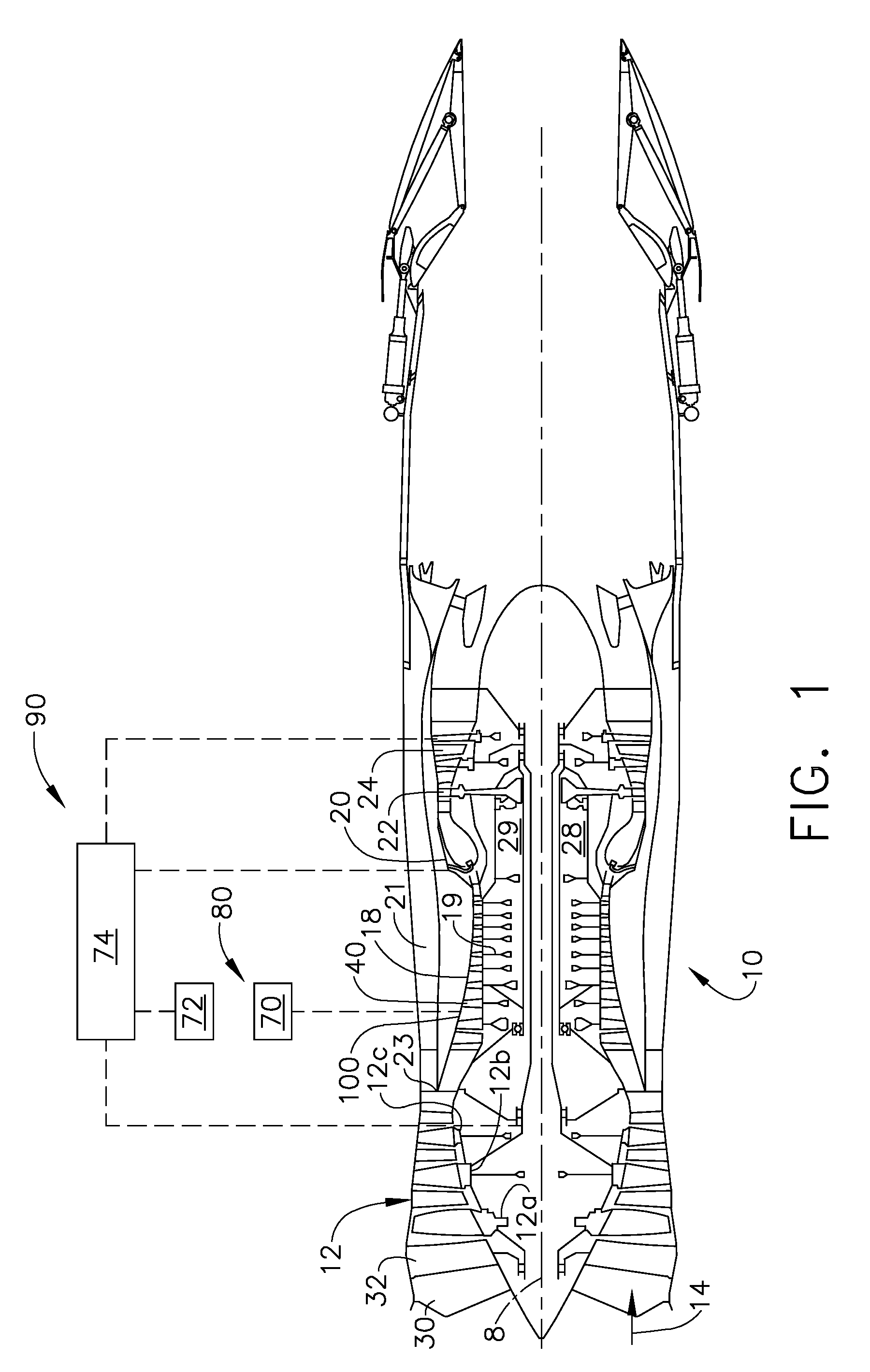

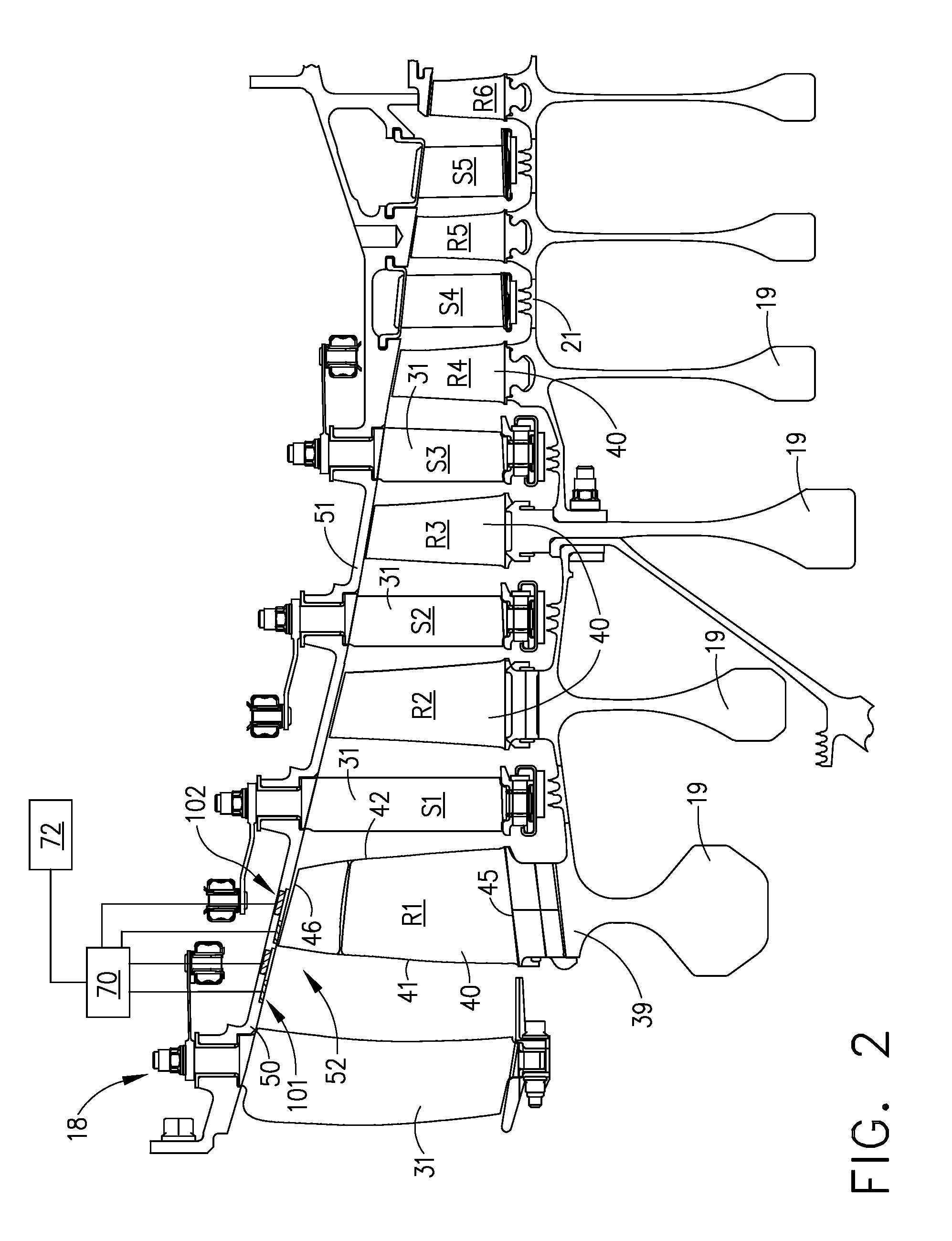

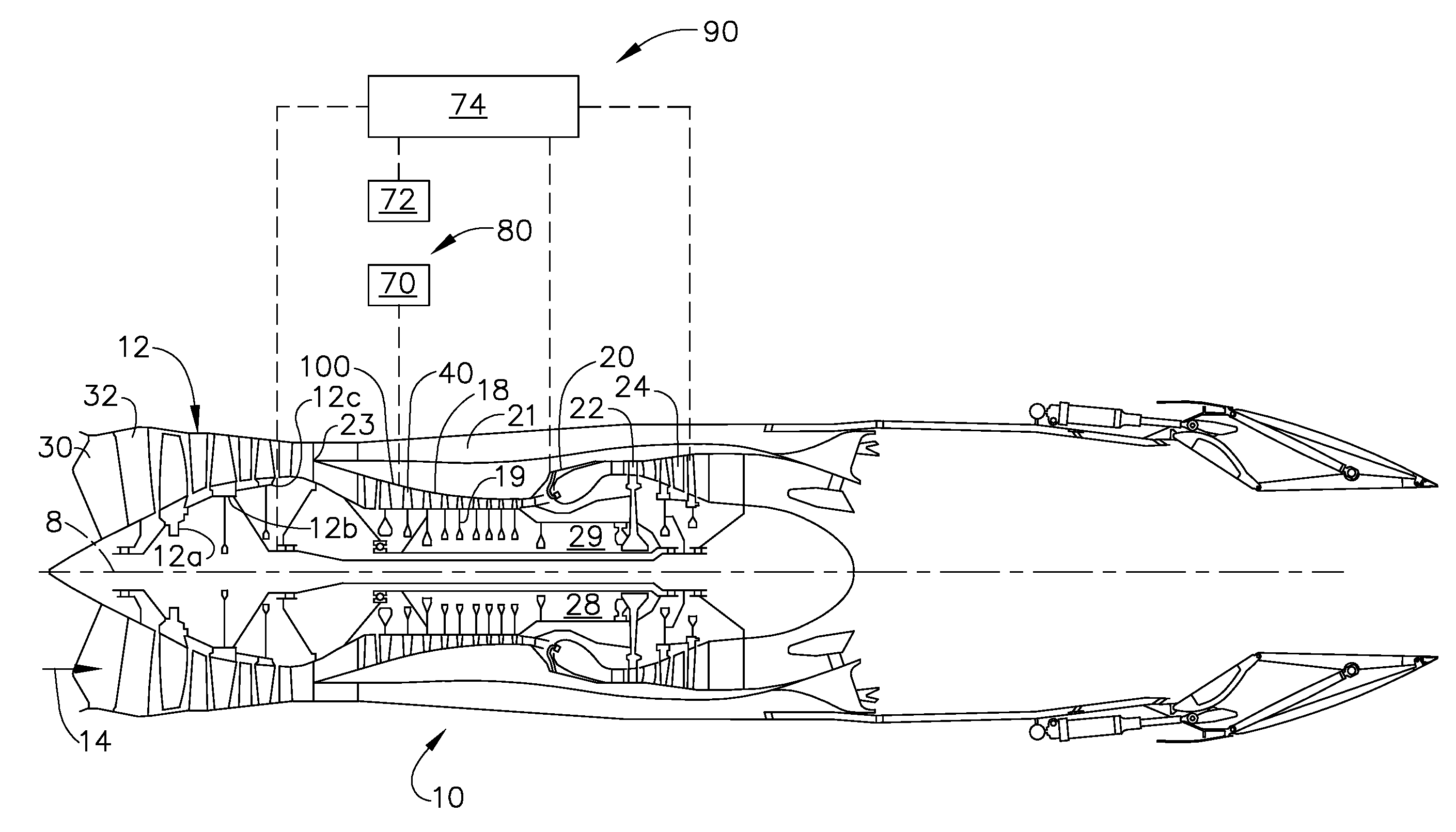

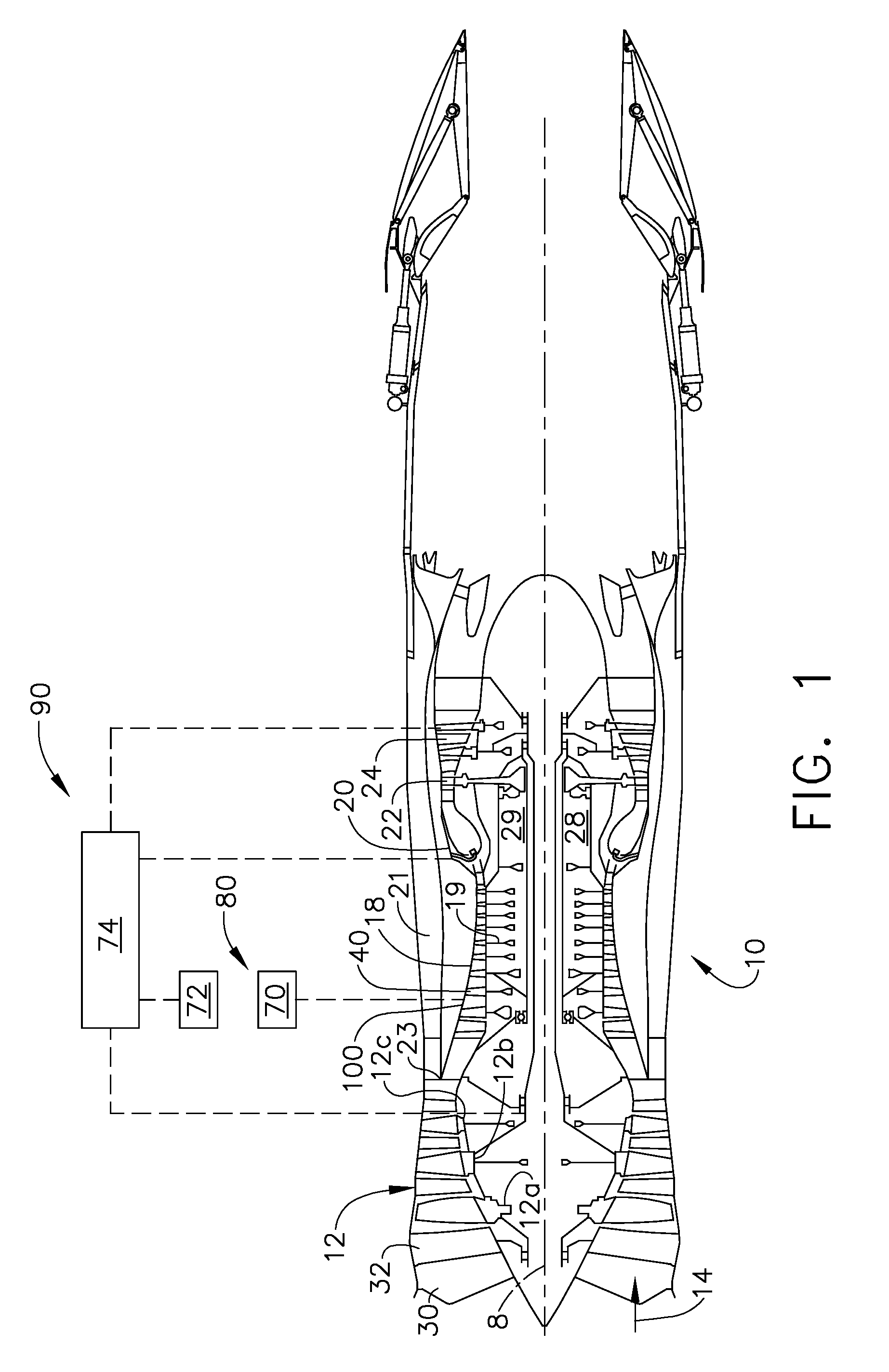

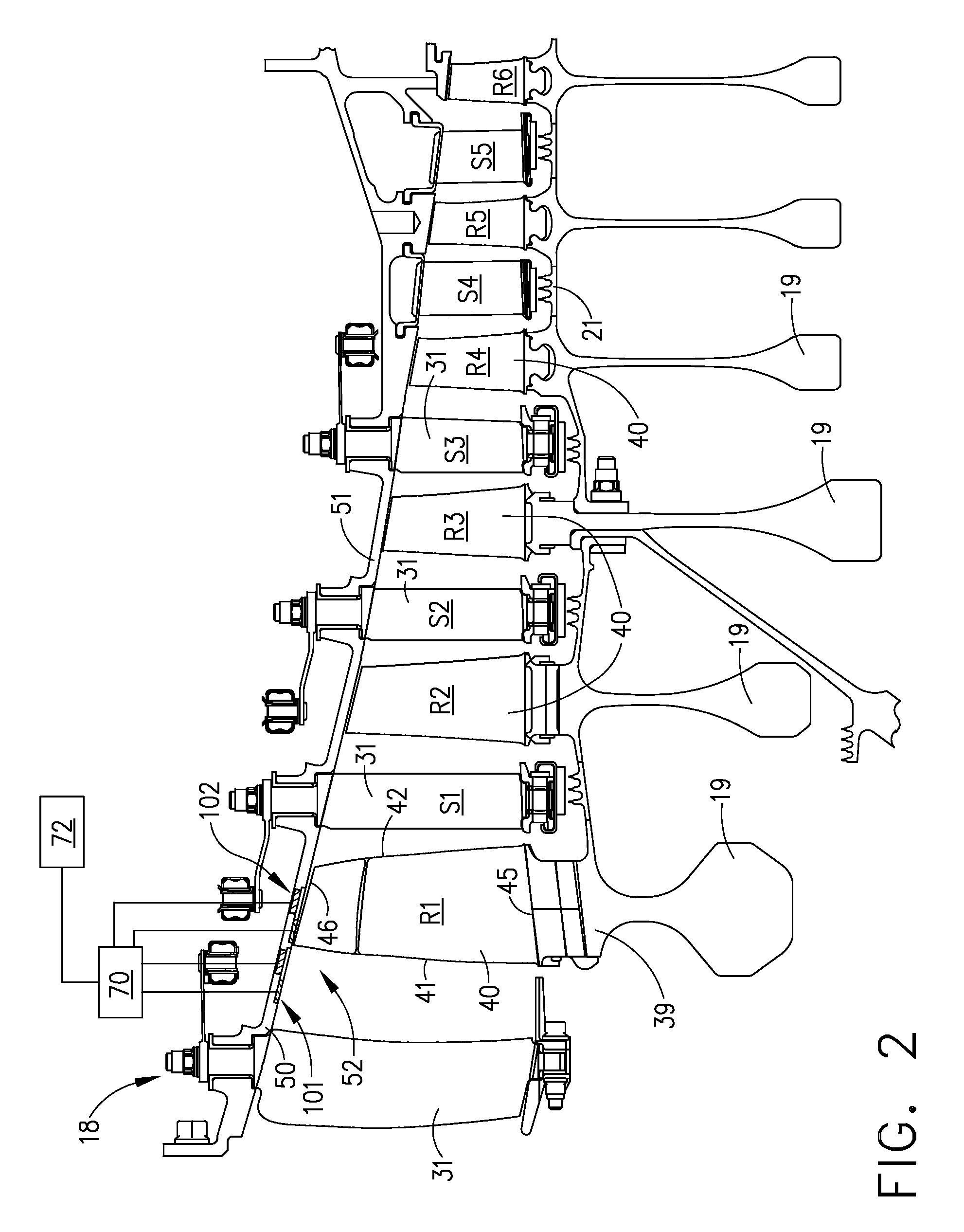

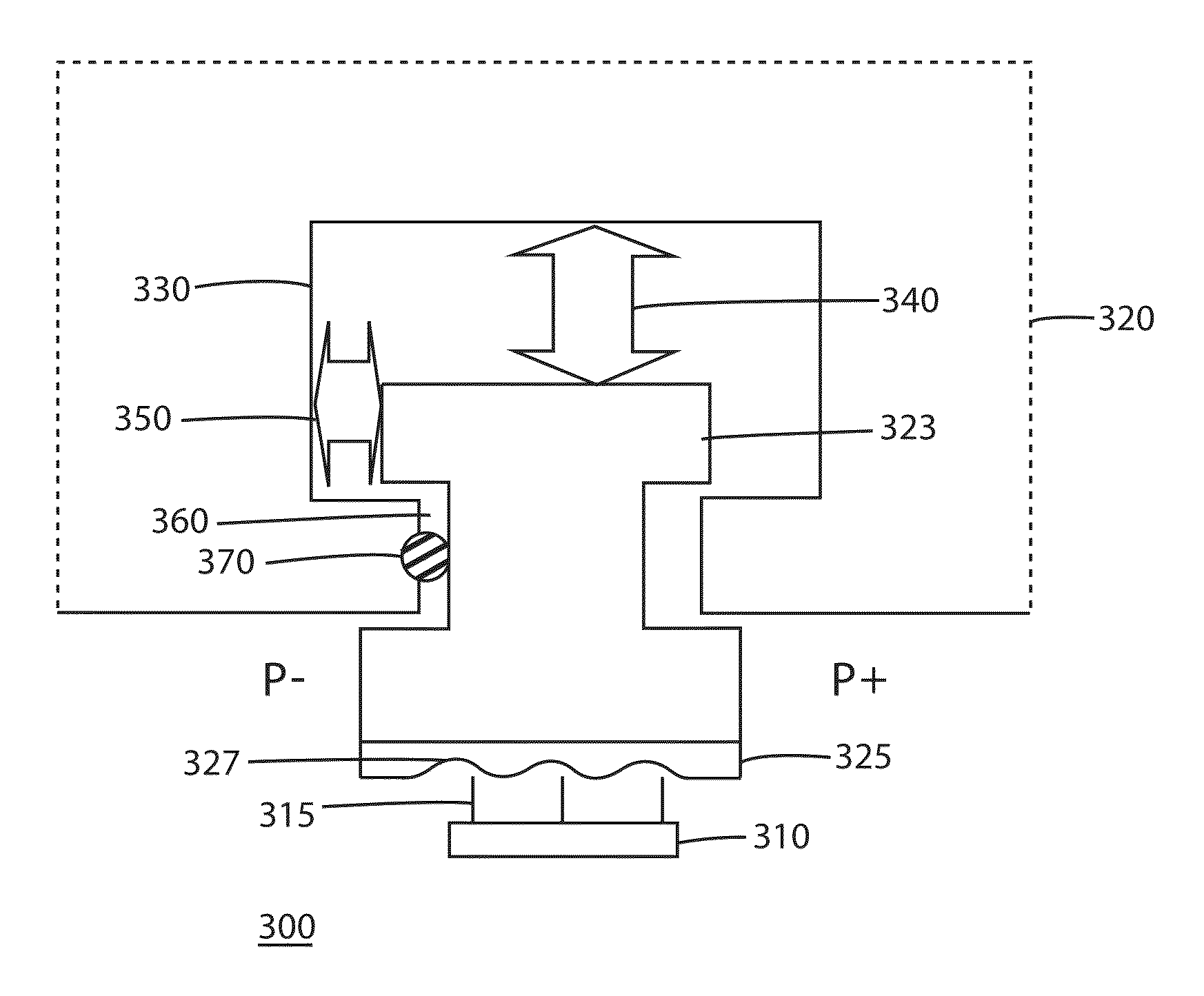

Plasma Clearance Controlled Compressor

InactiveUS20100284795A1Improving stable flow rangeReduce leakage flowPump componentsBlade accessoriesElectricityControl system

A plasma leakage flow control system for a compressor is disclosed, comprising a circumferential row of compressor blades, an annular casing surrounding the tips of the blades, located radially apart from the tips of the blades and at least one annular plasma generator located on the annular casing. The annular plasma generator comprises an inner electrode and an outer electrode separated by a dielectric material. A gas turbine engine having a plasma leakage flow control system further comprises an engine control system which controls the operation of the annular plasma generator such that the blade tip leakage flow can be changed.

Owner:GENERAL ELECTRIC CO

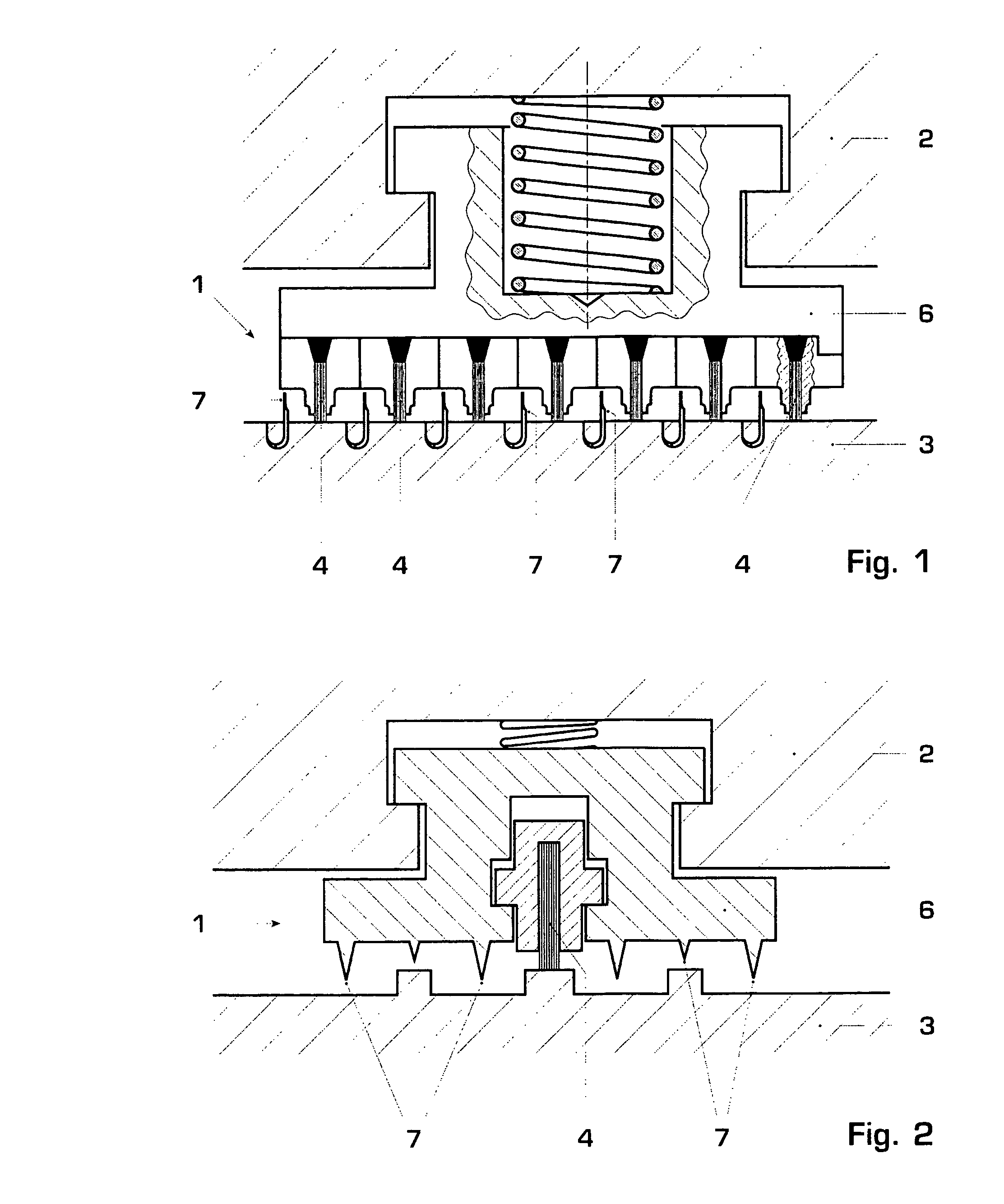

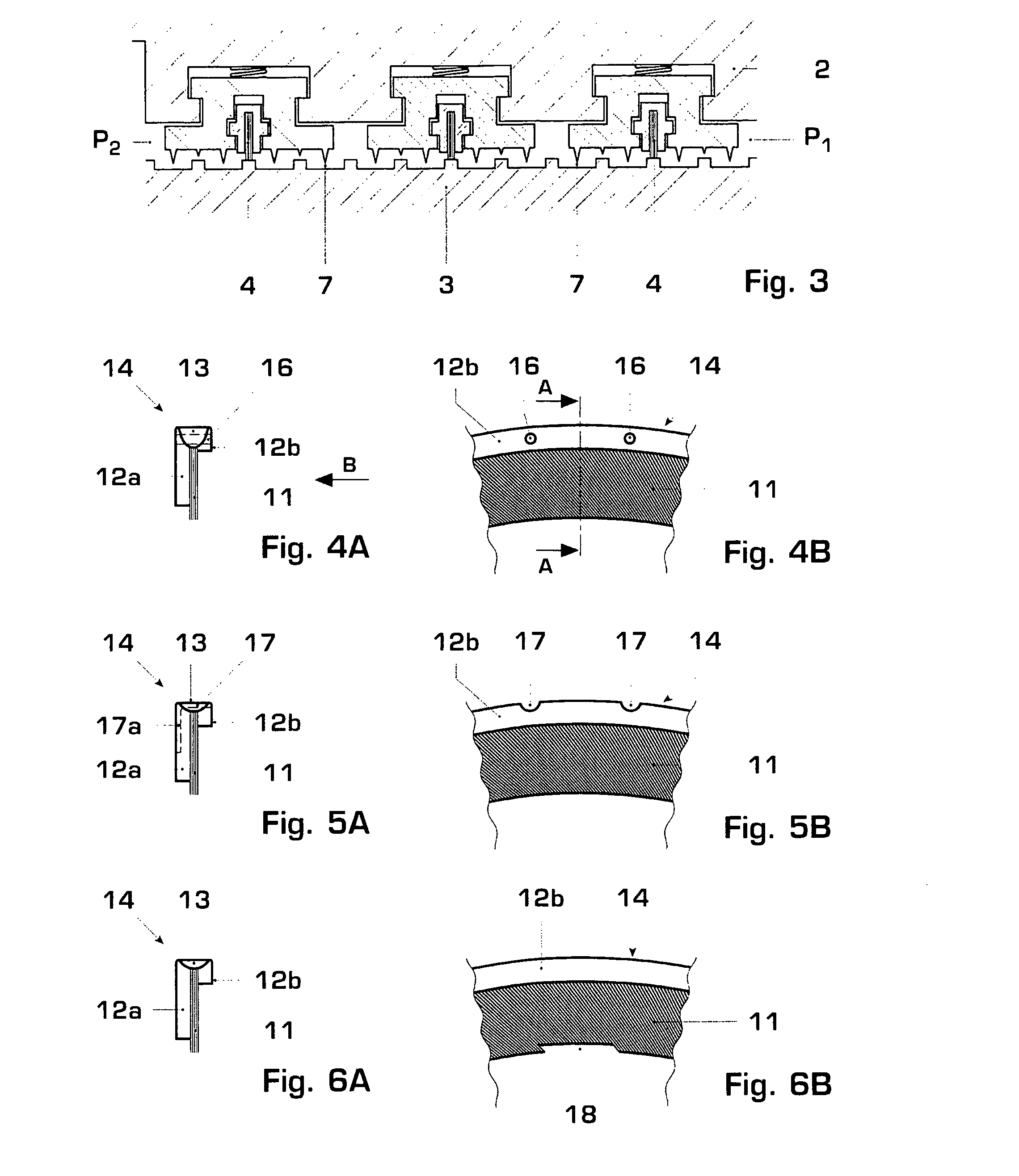

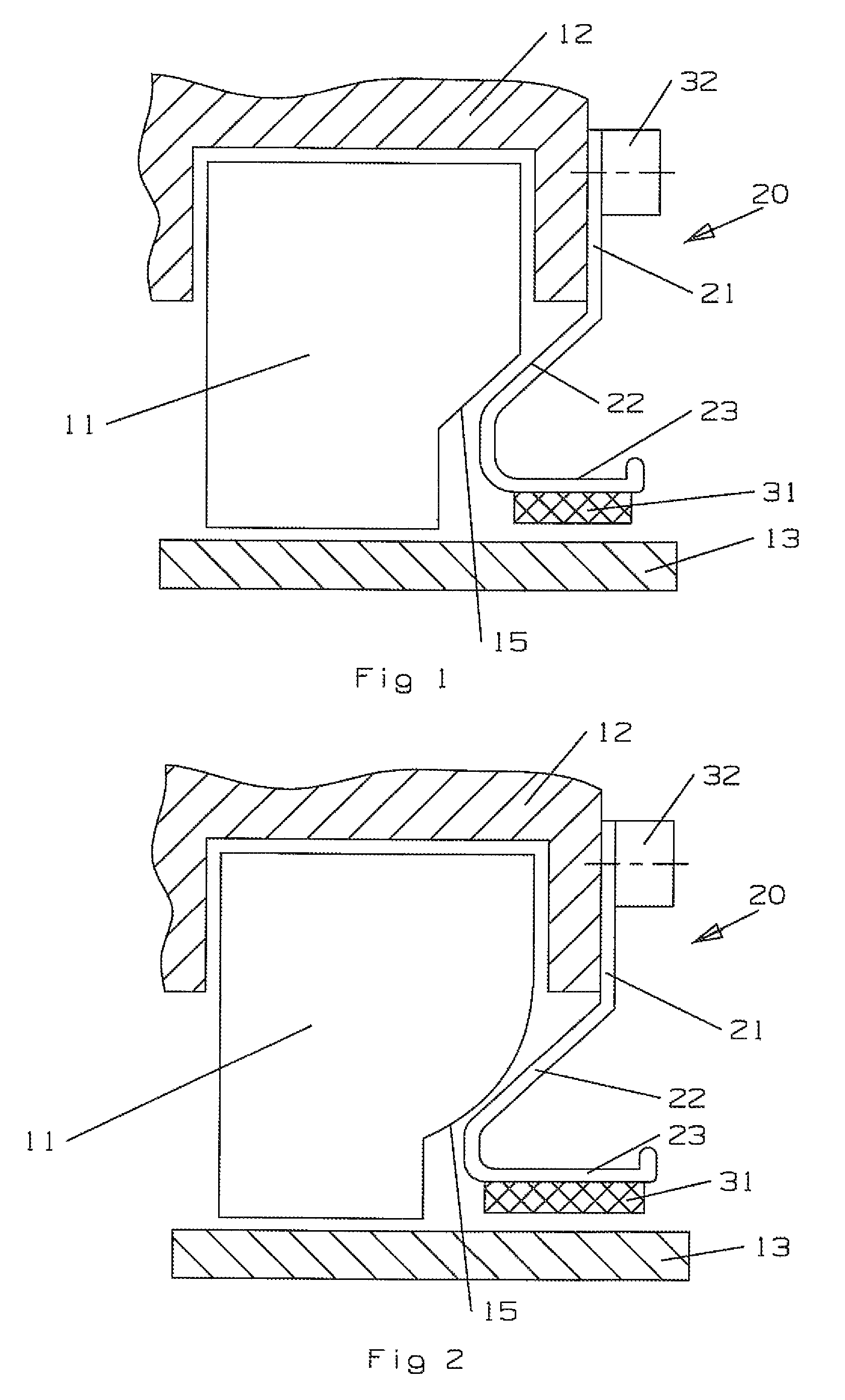

Sealing arrangement using flexible seals

InactiveUS20050104300A1Increase radial clearancePerformance of flexible is reducedEngine sealsLeakage preventionNormal levelEngineering

A sealing arrangement is provided between relatively rotatable bodies of a machine in which, in operation, a relatively high pressure (P1) exists on one side of the sealing arrangement and a relatively low pressure (P2) exists on the other side, the pressure difference (P1-P2) being up to a predetermined maximum pressure difference (ΔPmax). The sealing arrangement includes a series of seals, the pressure dropping across each successive seal from the high pressure side of the sealing arrangement to the low pressure side. At least two of the seals are flexible seals, e.g. brush or leaf seals. Each flexible seal 14 is designed to function under a pressure drop (Δp) up to a predetermined maximum pressure drop (Δpmax) across the flexible seal 14 and to provide a given resistance to fluid flow. Each flexible seal 14 is capable of recovering from an abnormal condition, due to normal operation of the machine, in which the resistance of the flexible seal to fluid flow decreases from a normal level to a substantially lower level. The series of seals are arranged in such a manner that the pressure drop across each flexible seal is less than the predetermined maximum pressure drop (Δpmax) when the pressure difference (P1-P2) between the high pressure side of the sealing arrangement and the low pressure side is equal to the said predetermined maximum pressure difference (ΔPmax) and another one of the flexible seals has suffered a recoverable decrease in its resistance to fluid flow. In one embodiment the flexible seal 14 is provided with a permanent by-pass path 16 communicating between its upstream and downstream sides.

Owner:ALSTOM TECH LTD

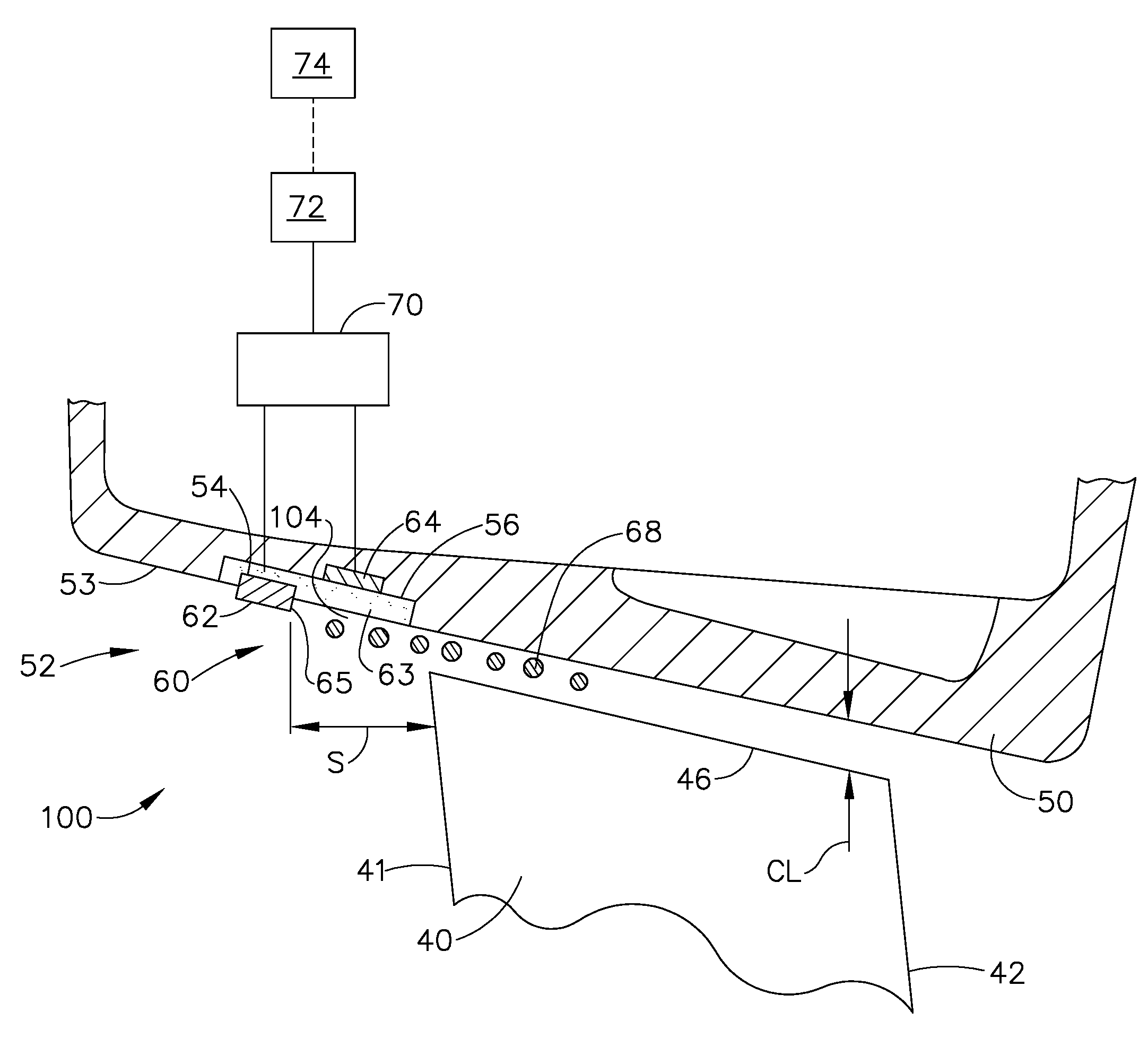

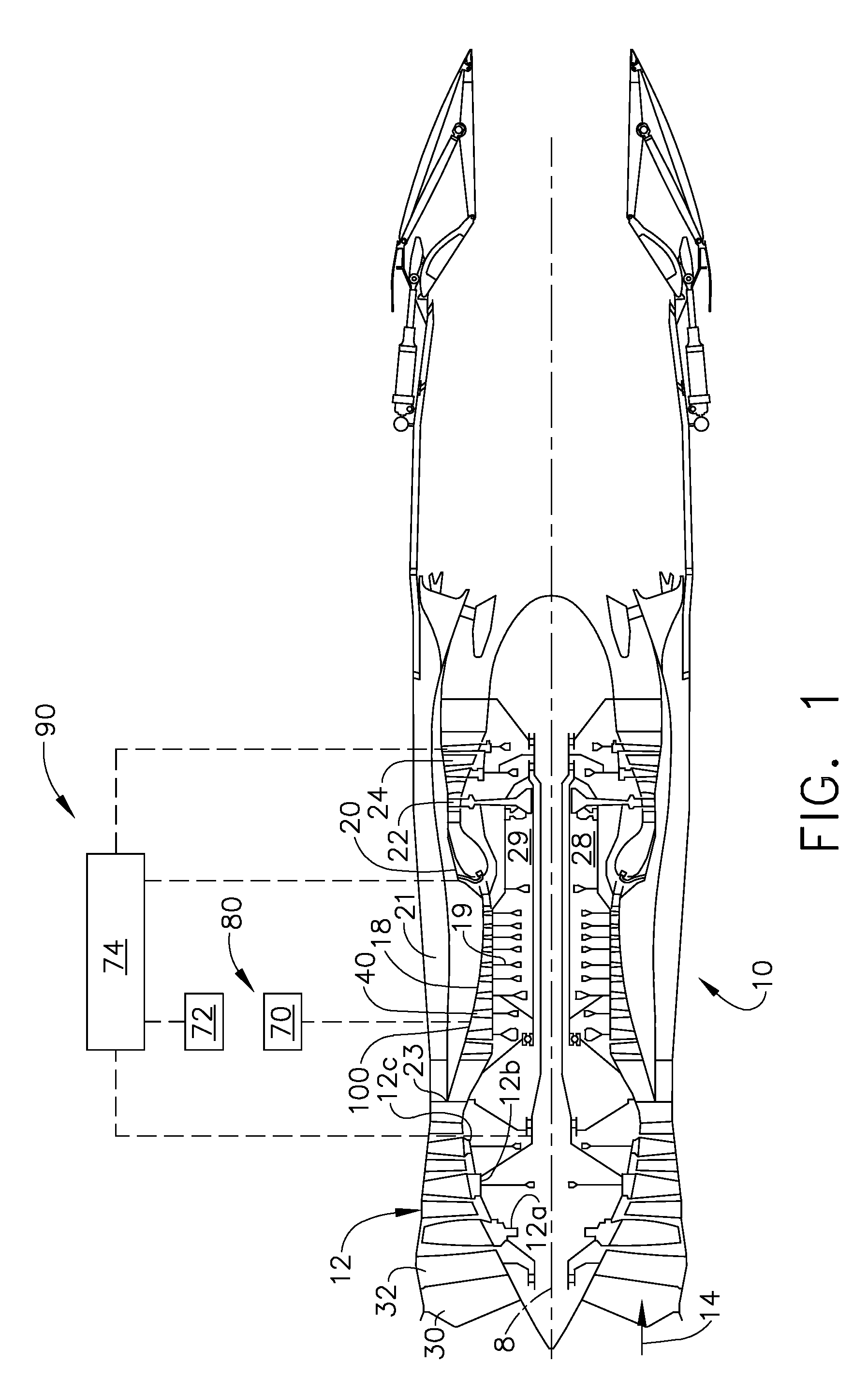

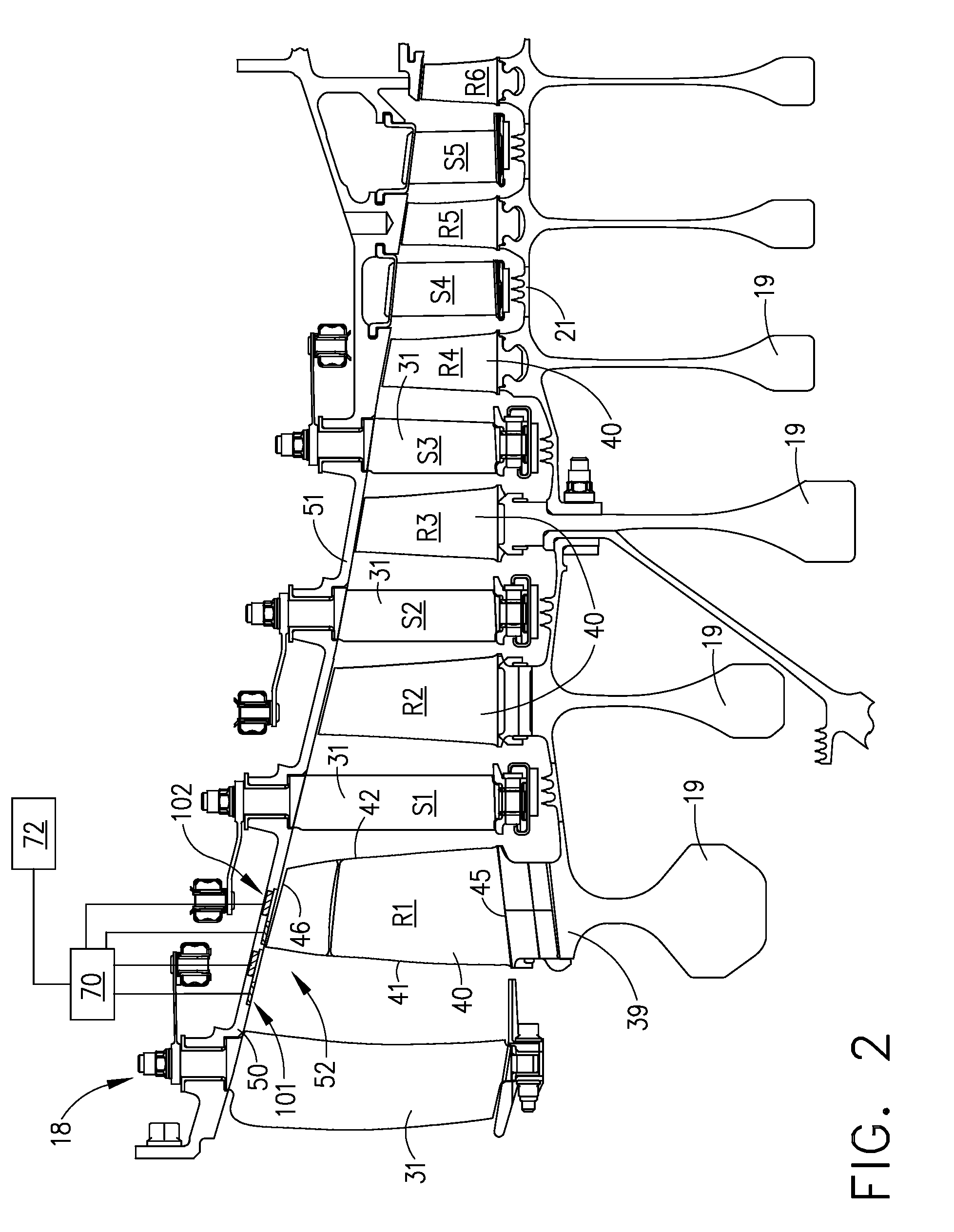

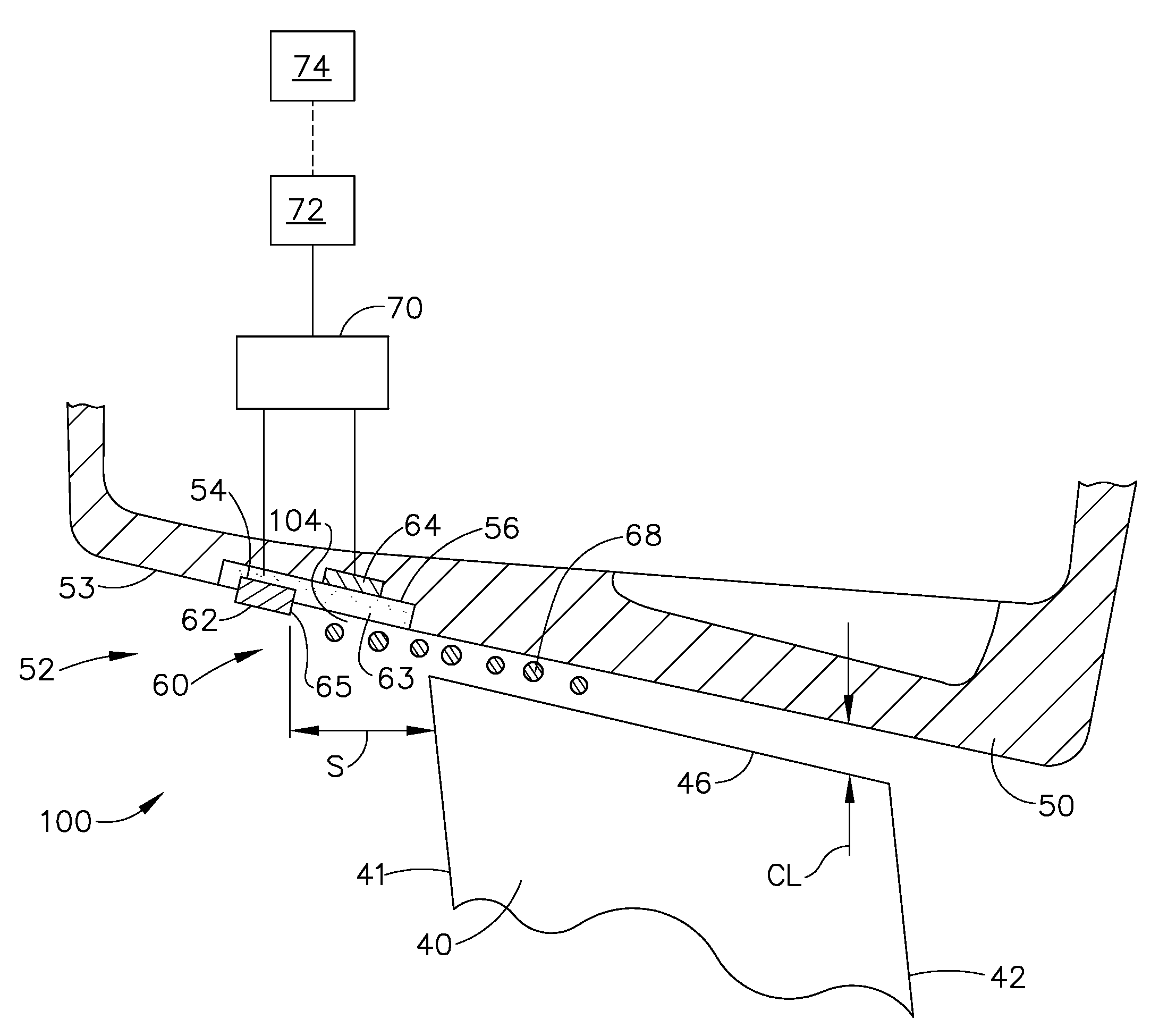

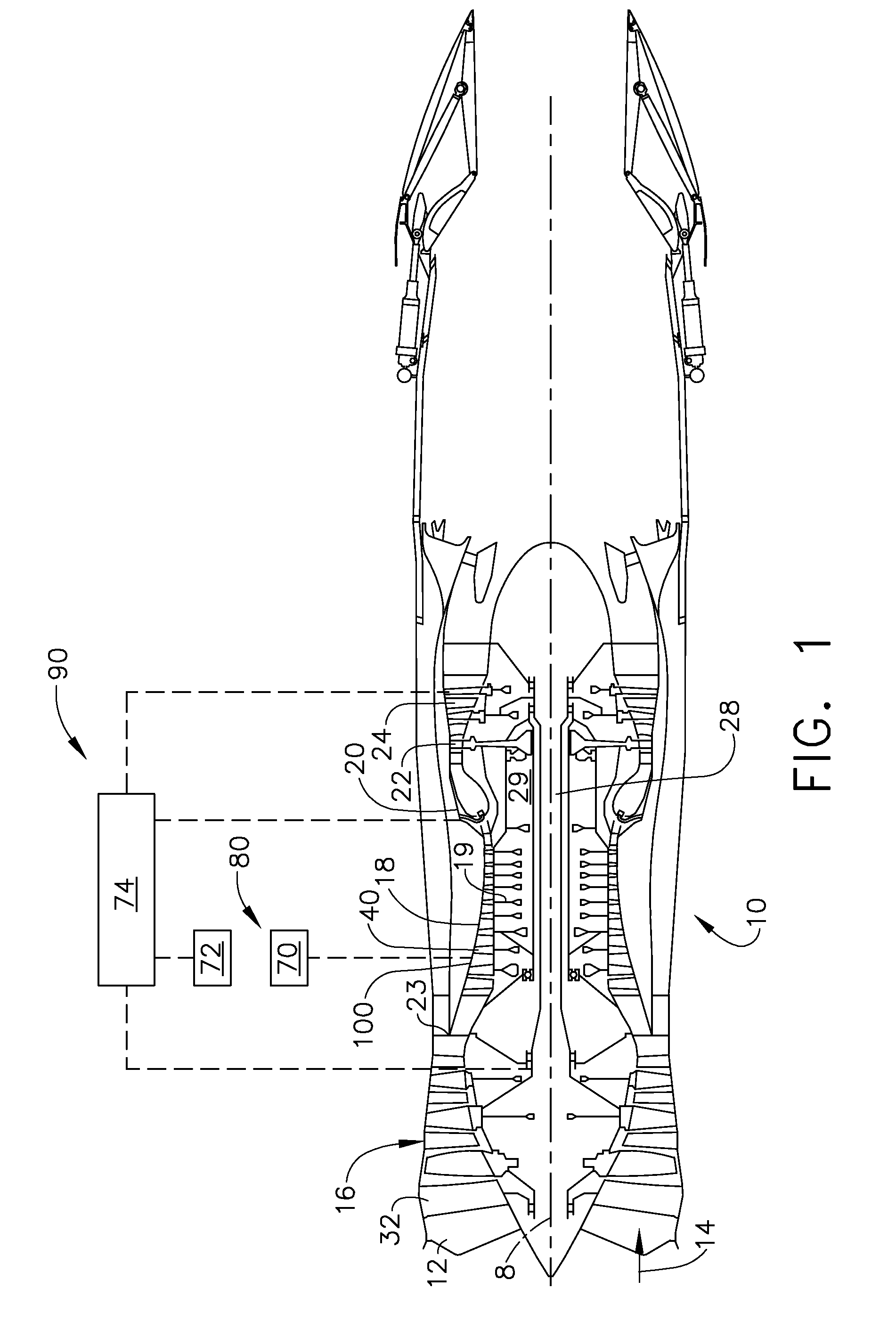

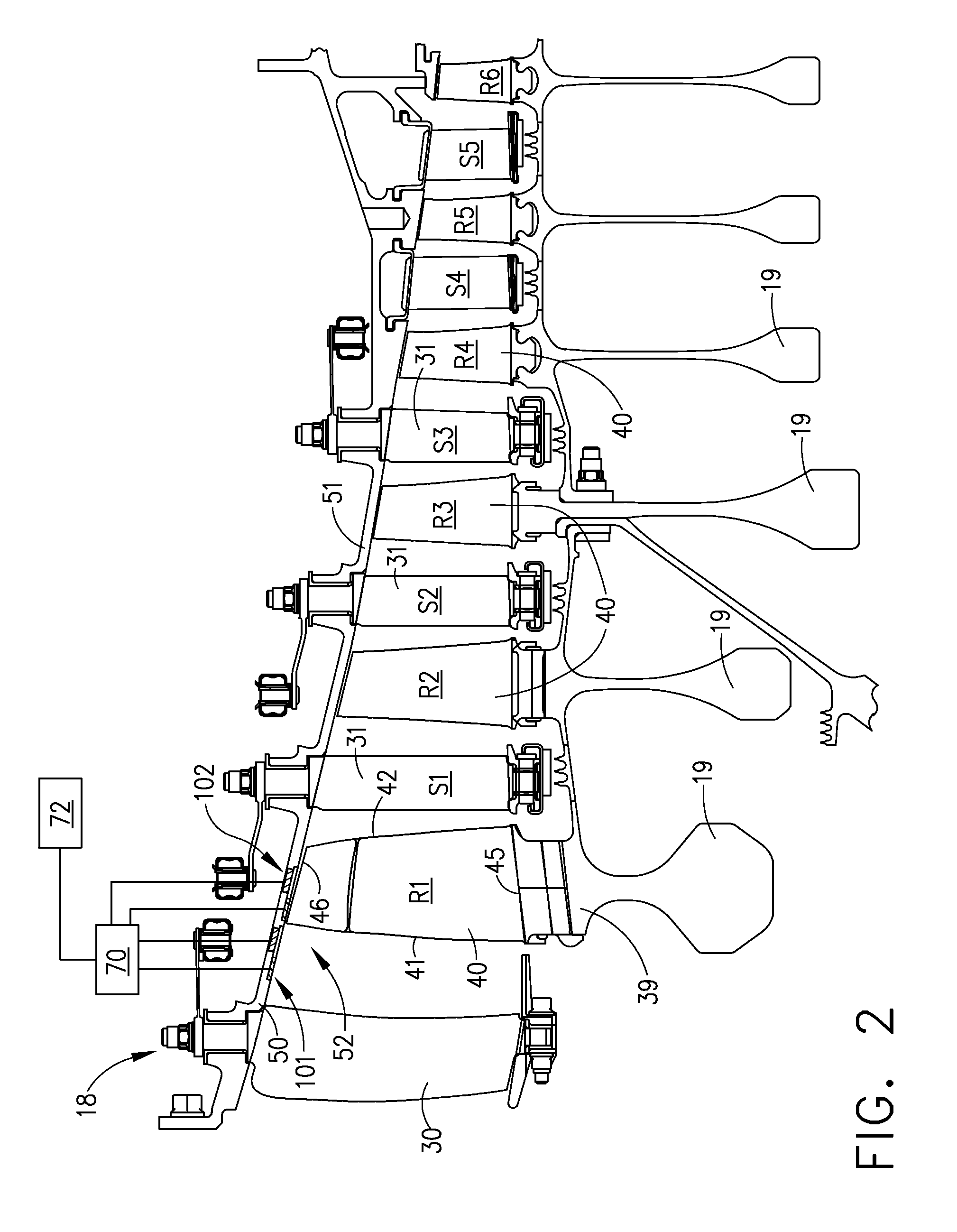

Plasma Enhanced Compressor

InactiveUS20100047060A1Broaden the stable operating rangeImprove compressor efficiencyPump componentsBlade accessoriesControl systemPlasma generator

A gas turbine engine is disclosed, comprising a compressor having a circumferential row of blades, a casing surrounding the tips of the blades, located radially apart from the tips of the blades and at least one plasma generator located on the casing. The plasma generator comprises a first electrode and a second electrode separated by a dielectric material. The gas turbine engine further comprises an engine control system which controls the operation of the plasma generator such that the stable operating range of the compressor is increased.

Owner:WADIA ASPI RUSTOM +4

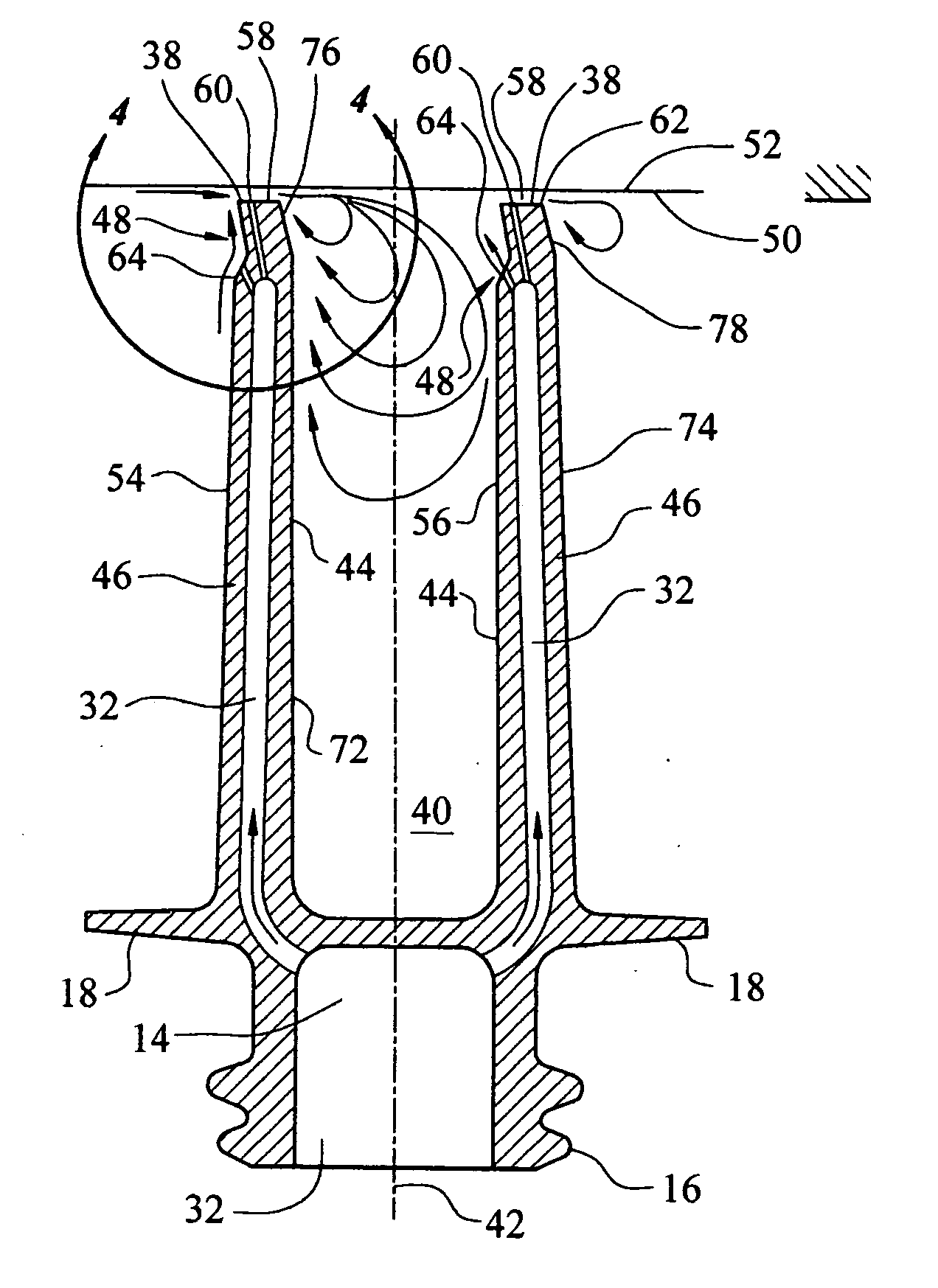

Turbine airfoil cooling system with axial flowing serpentine cooling chambers

InactiveUS20080050241A1Enhancing blade HCF capabilityIncrease cooling fluid air pressureEngine manufacturePump componentsLeading edgeCooling chamber

A cooling system for a turbine airfoil of a turbine engine having suction and pressure side serpentine cooling channels formed between an internal support core and an outer wall of the turbine airfoil. The suction and pressure side serpentine cooling channels may be formed from legs extending in a general chordwise direction between leading and trailing edges of the airfoil. The suction and pressure side serpentine cooling channels may receive cooling fluids from a cooling fluid supply source through a cooling fluid inlet, pass the cooling fluids through the cooling system and exhaust the cooling fluids through a cooling fluid exhaust orifice proximate to the tip section. The cooling system is particularly suitable for use with low cooling fluid flow.

Owner:SIEMENS ENERGY INC

Method of Operating a Compressor

InactiveUS20100284780A1Improving stable flow rangeReduce leakage flowPump componentsBlade accessoriesCompressor stallEngineering

A method of operating a compressor having a row of blades for preventing a compressor stall is disclosed, the method comprising the steps of mounting a plasma generator in a casing or a shroud radially outwardly and apart from the blade tips wherein the plasma generator comprises a radially inner electrode and a radially outer electrode separated by a dielectric material; and supplying an AC potential to the radially inner electrode and the radially outer electrode.

Owner:GENERAL ELECTRIC CO

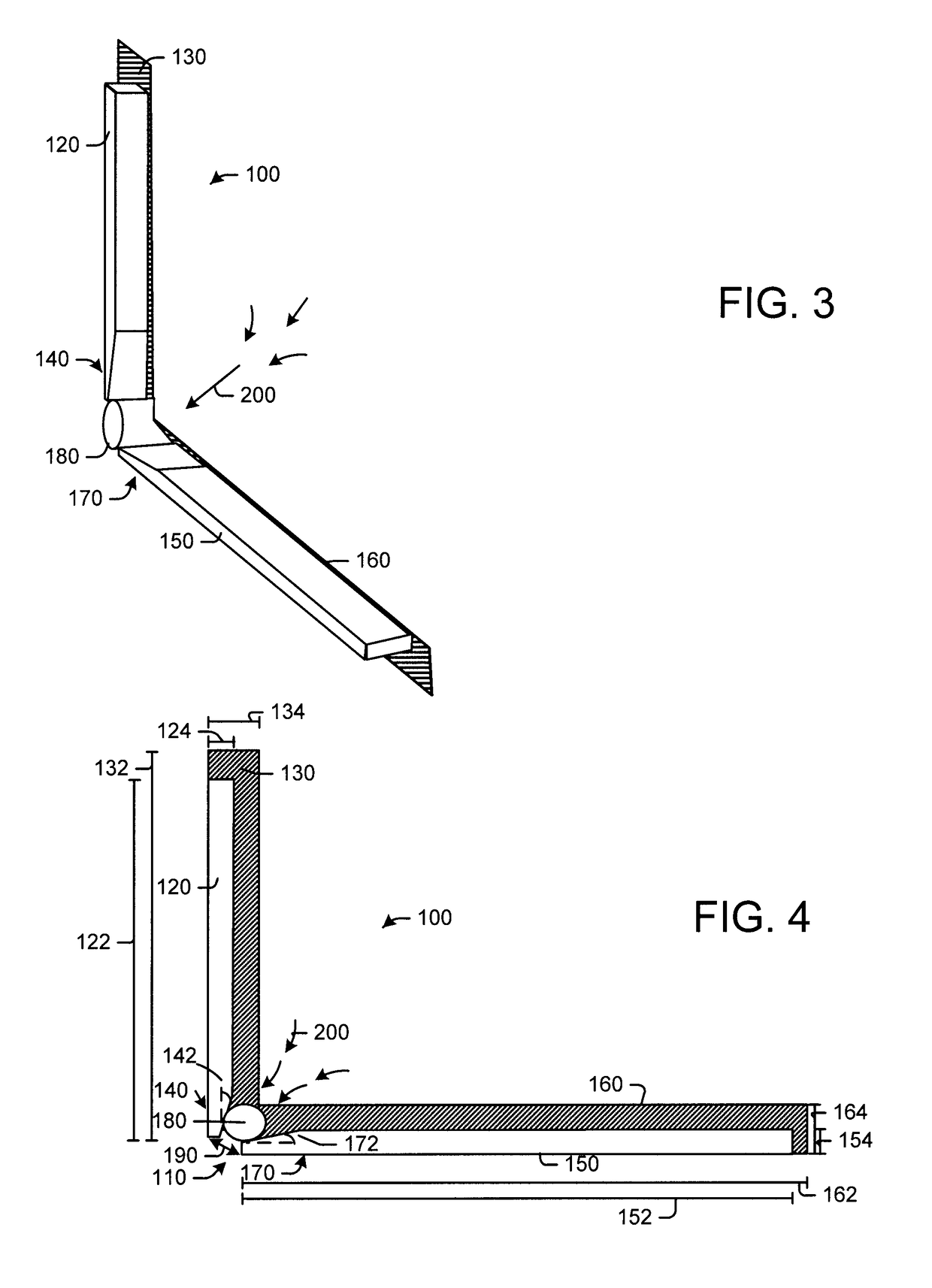

Card seal with conical flexible seal

InactiveUS8152462B1Avoid passingReduce leakage flowEngine sealsPump componentsEngineeringMechanical engineering

A card seal with an annular arrangement of cards that are positioned within an annular groove of a casing, and a conical flexible seal is secured to the casing on the low pressure side of the cards. The cards and the flexible seal both includes slanted surfaces that interact during operation such that the flexible seal gap decreases with the rotor shaft and the cards are secured within the annular groove during assembly and installation of the card seal. The flexible seal blocks leakage through the cards and includes an axial extending inner end that can include an abradable material to allow for rub with the shaft while decreasing the gap to prevent leakage across the cards.

Owner:FLORIDA TURBINE TECH

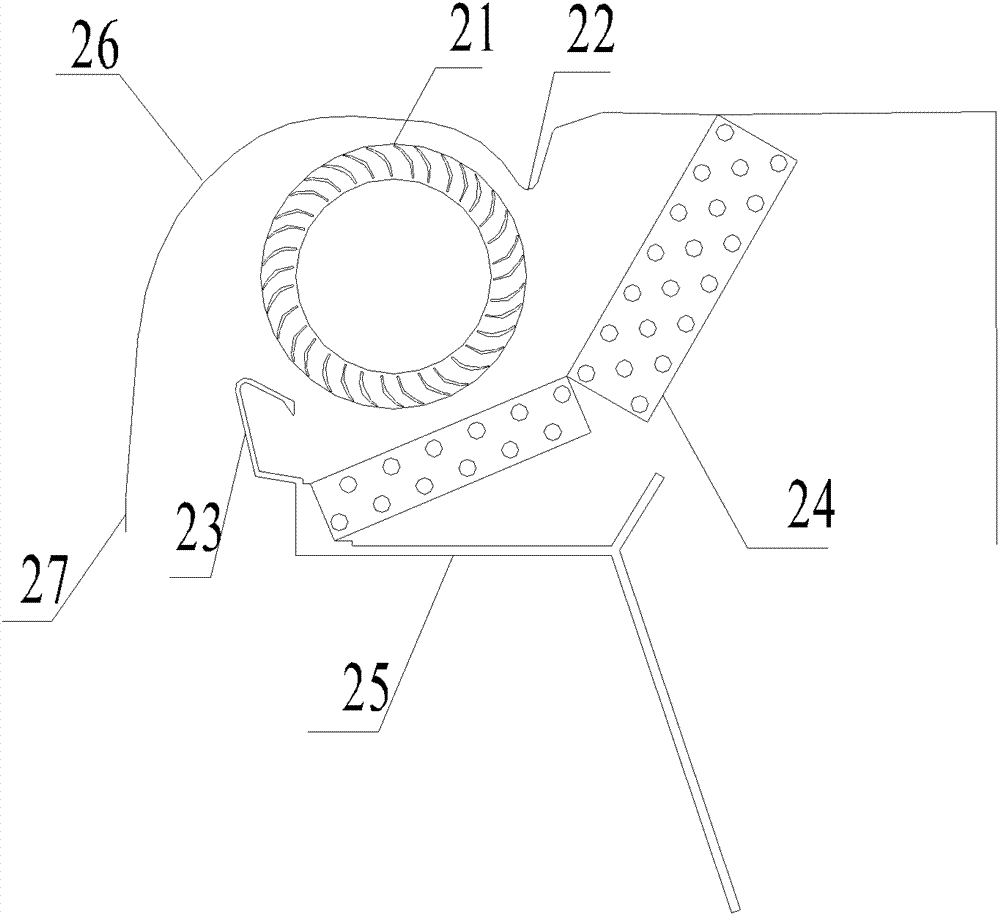

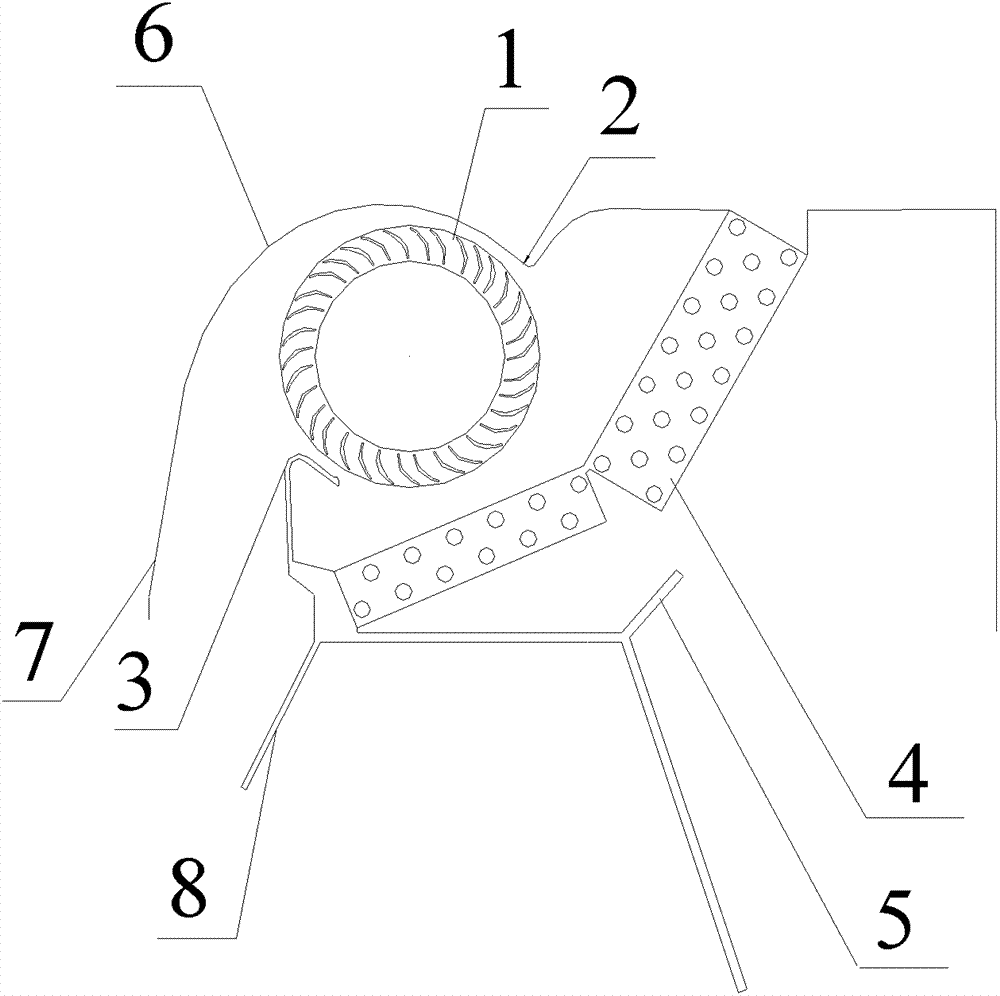

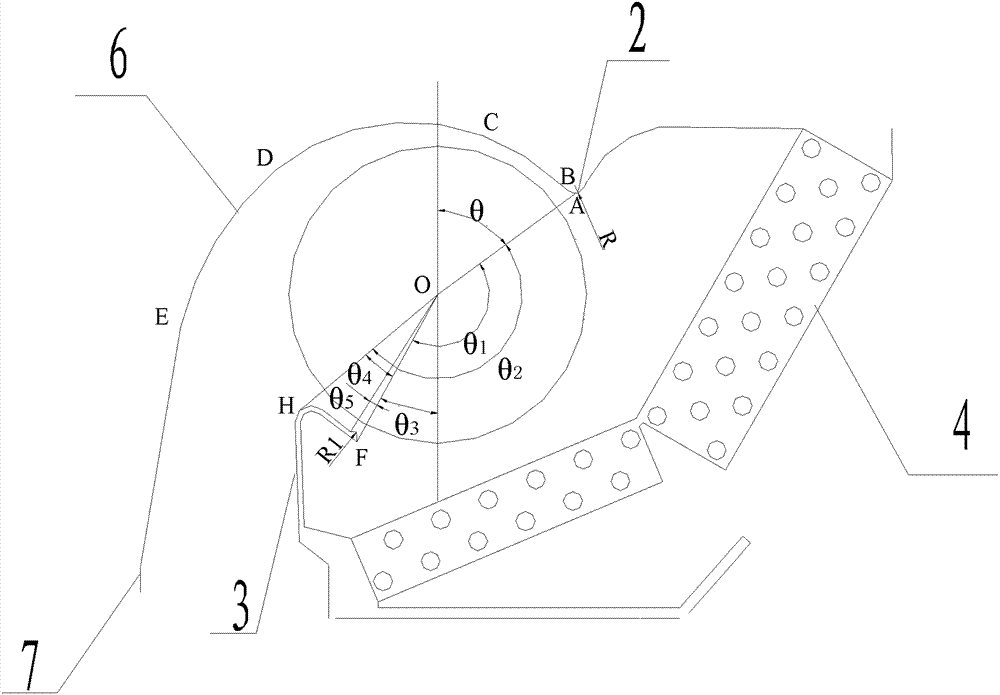

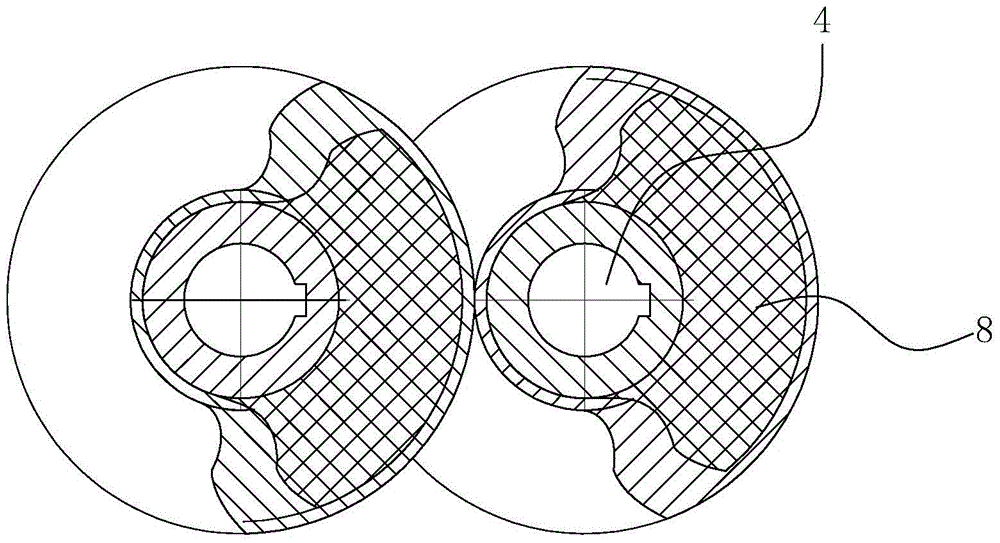

Cross-flow fan

ActiveCN102900676AReduce leakage flowSmall scalePump componentsRadial flow pumpsEvaporatorEngineering

The invention provides a cross-flow fan which comprises a cross-flow wind wheel, a chassis volute, an evaporator, a front volute tongue and a water receiving disc, wherein the chassis volute is provided with a curved inner surface, is covered on the outer side of the cross-flow wind wheel, and comprises a wind outlet section, a wind inlet section and a rear volute tongue; the wind inlet and the wind outlet both extend downward; the wind outlet side of the water receiving disc is also provided with a wind outlet guide plate extending downward from the lower direction of the front volute tongue; the wind outlet guide plate and the longitudinal wall of the front volute form a wind guide angle; and the tangential point of the cross section curve of the rear volute tongue and the water level is a point A, and an included angle formed between the connecting line of the point A and the central point of the cross-flow wind wheel and a vertical line passing through the central point O of the cross-flow wind wheel is theta, and theta is greater than or equal to 45 degrees and less than or equal to 55 degrees. The cross-flow fan provided by the invention has an optimized air channel structure, is high in wind rate, and is low in noise.

Owner:GREE ELECTRIC APPLIANCES INC

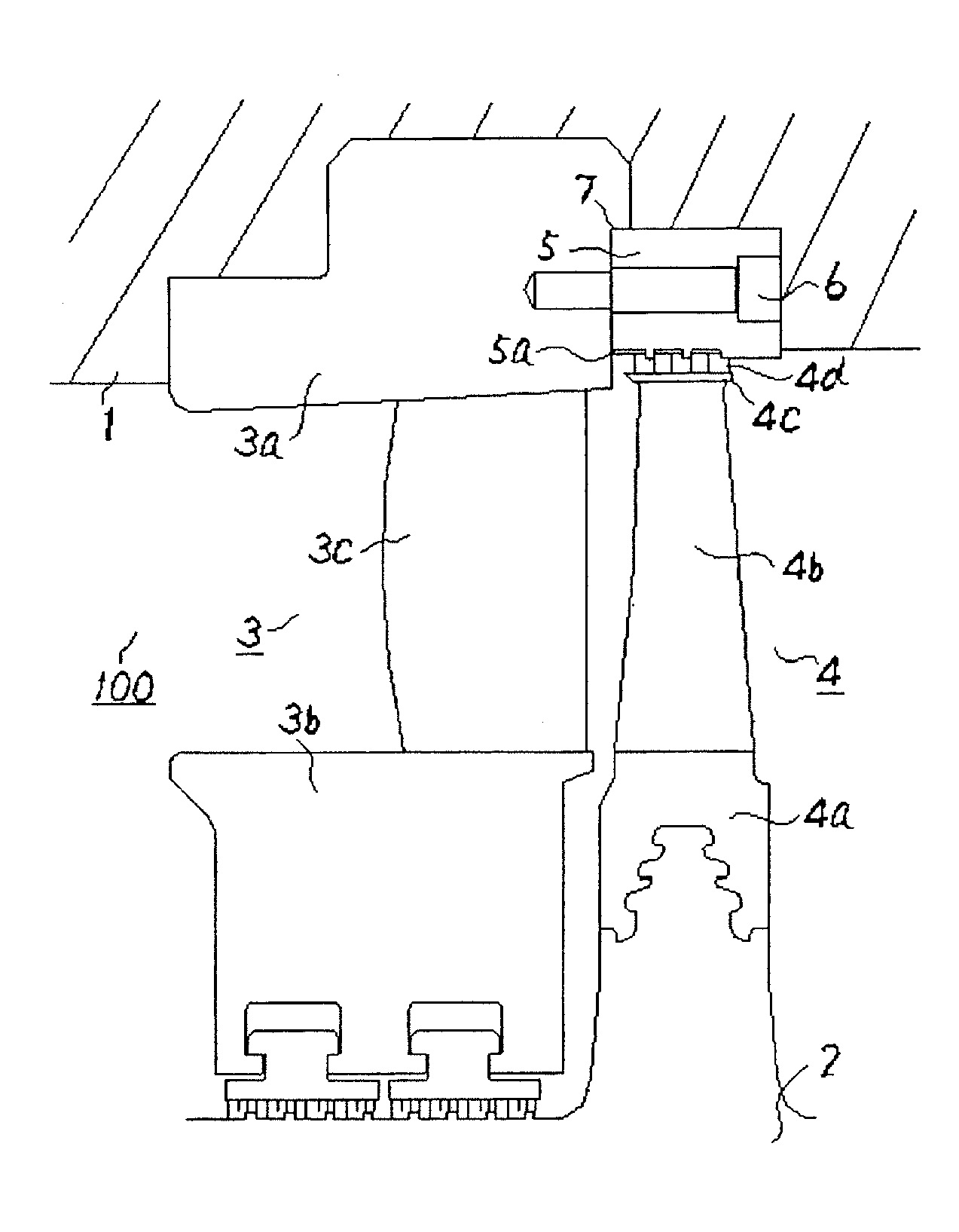

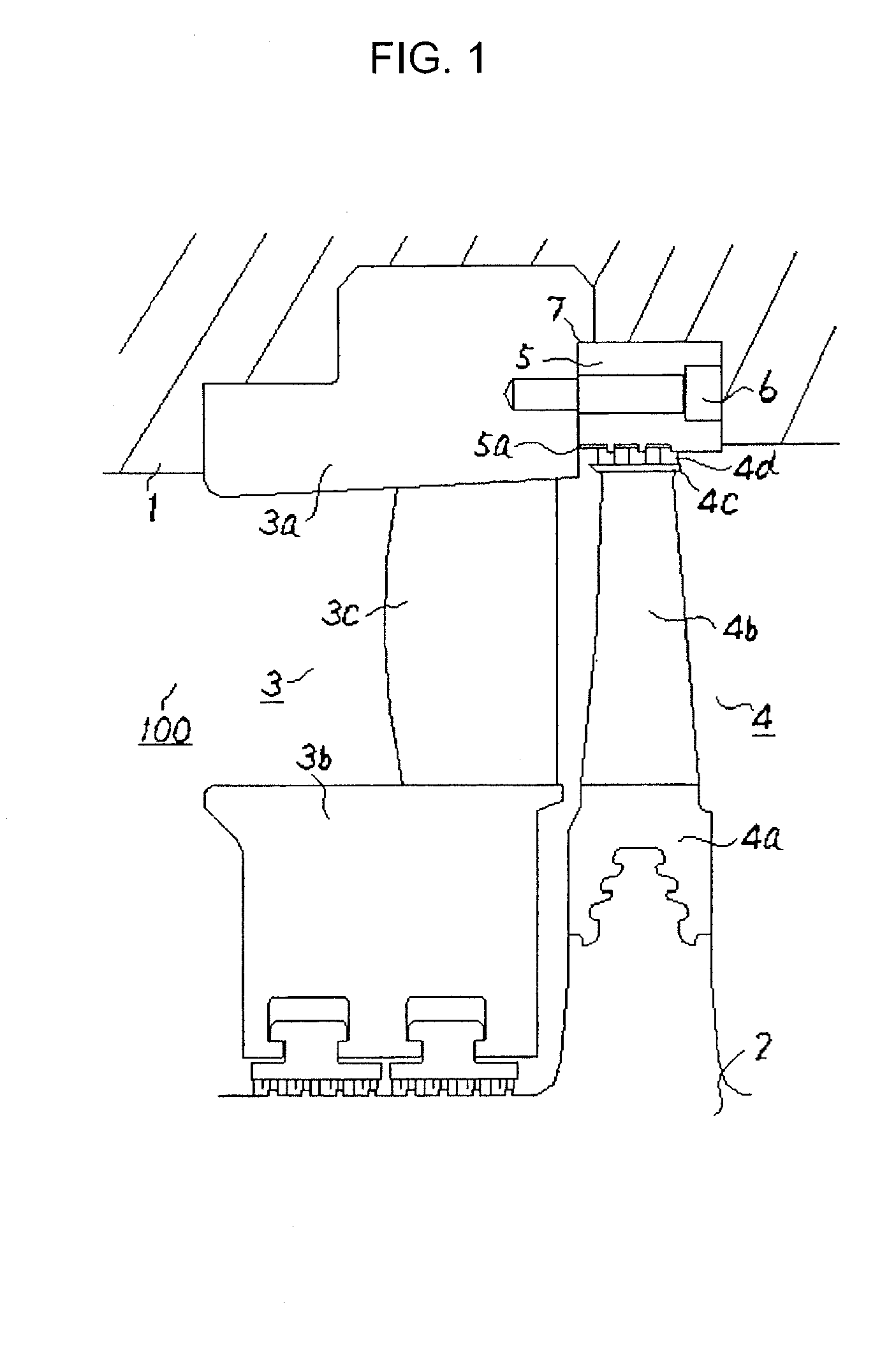

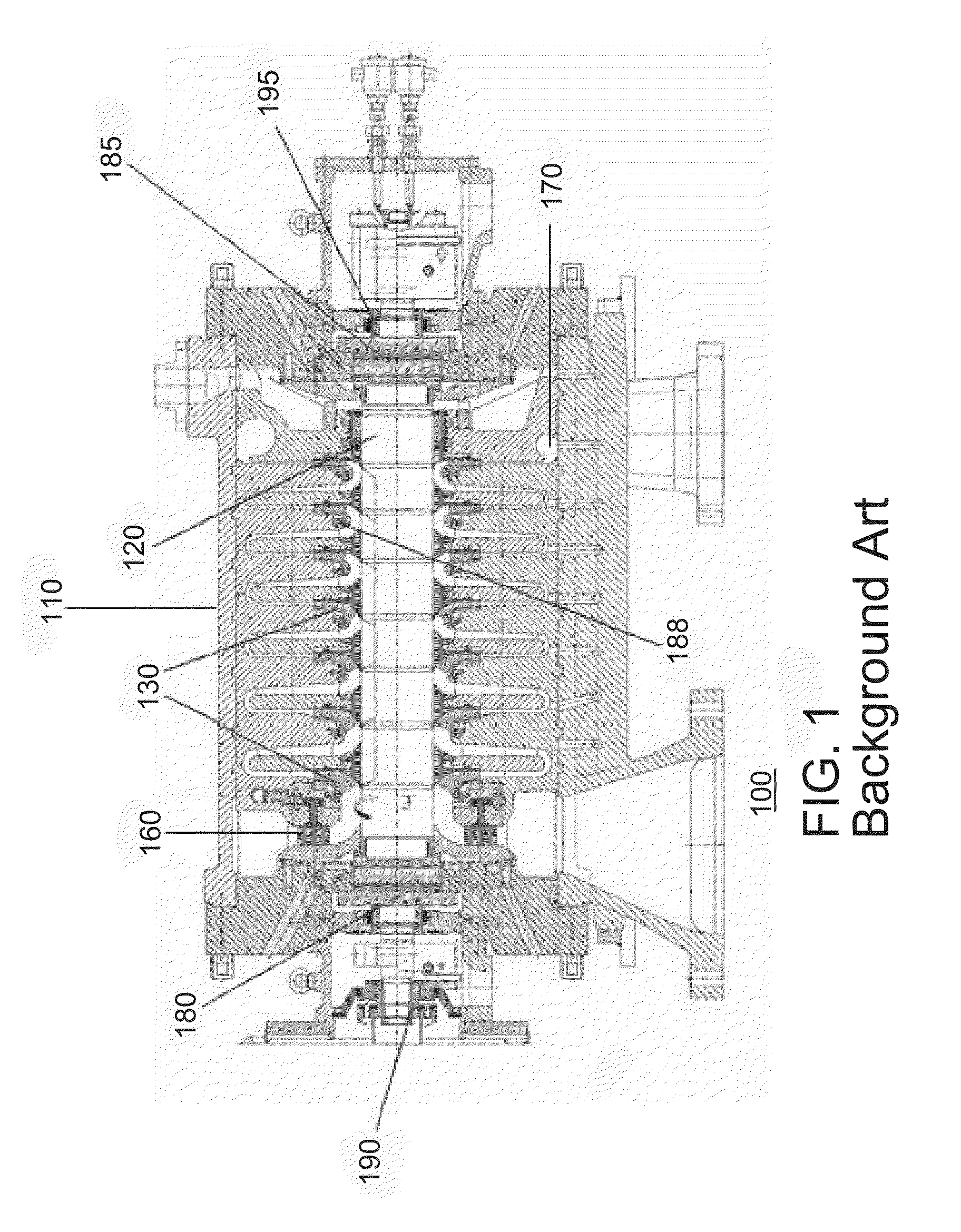

Steam turbine

ActiveUS20080175706A1Improve efficiencyImprove maintainabilityPump componentsBlade accessoriesSteam turbineNozzle

A steam turbine has: a casing; a rotor rotatably arranged in the casing; a nozzle diaphragm concentrically arranged with respect to the rotor, the nozzle diaphragm being engaged with the casing; moving blades arranged in circumferential direction on outer circumference of the rotor at positions adjacent to the nozzle diaphragm; seal strips circumferentially extending on tips of the moving blades, the seal strips protruding in radial outward direction; and an abradable structure rigidly connected to the nozzle diaphragm. The abradable structure faces the seal strips in radial direction at a facing surface, and has an abradable part made of an abradable material arranged at the facing surface.

Owner:KK TOSHIBA

Vane or blade for an axial flow compressor

ActiveUS8678757B2Losses have been minimisedExpand flow rangePropellersEngine manufactureLeading edgeTrailing edge

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Abradable seal with axial offset

ActiveUS20130142628A1Improve sealing propertiesReduce leakage flowEngine sealsPump componentsEngineeringMechanical engineering

A sealing system for a centrifugal compressor includes a stator having a seal, a seal disposed in the seal housing and having an abradable portion along an inner circumference, a rotor having a plurality of rotor teeth configured to rotate within the inner circumference of the seal and configured to create rub grooves within the abradable portion, and a first spring disposed between the stator and the seal and configured to facilitate axial movement of the seal relative to the seal housing.

Owner:NUOVO PIGNONE TECH SRL

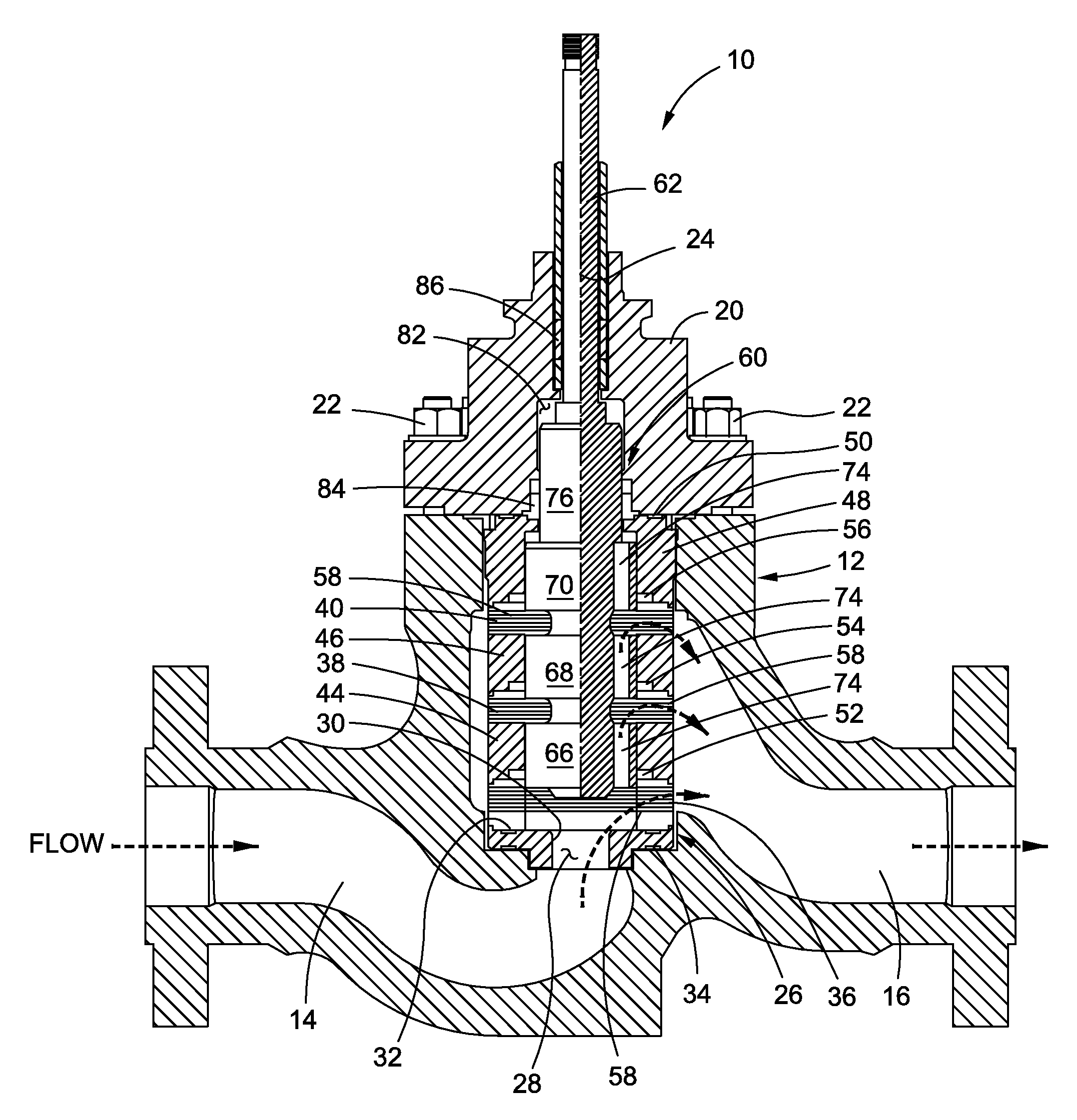

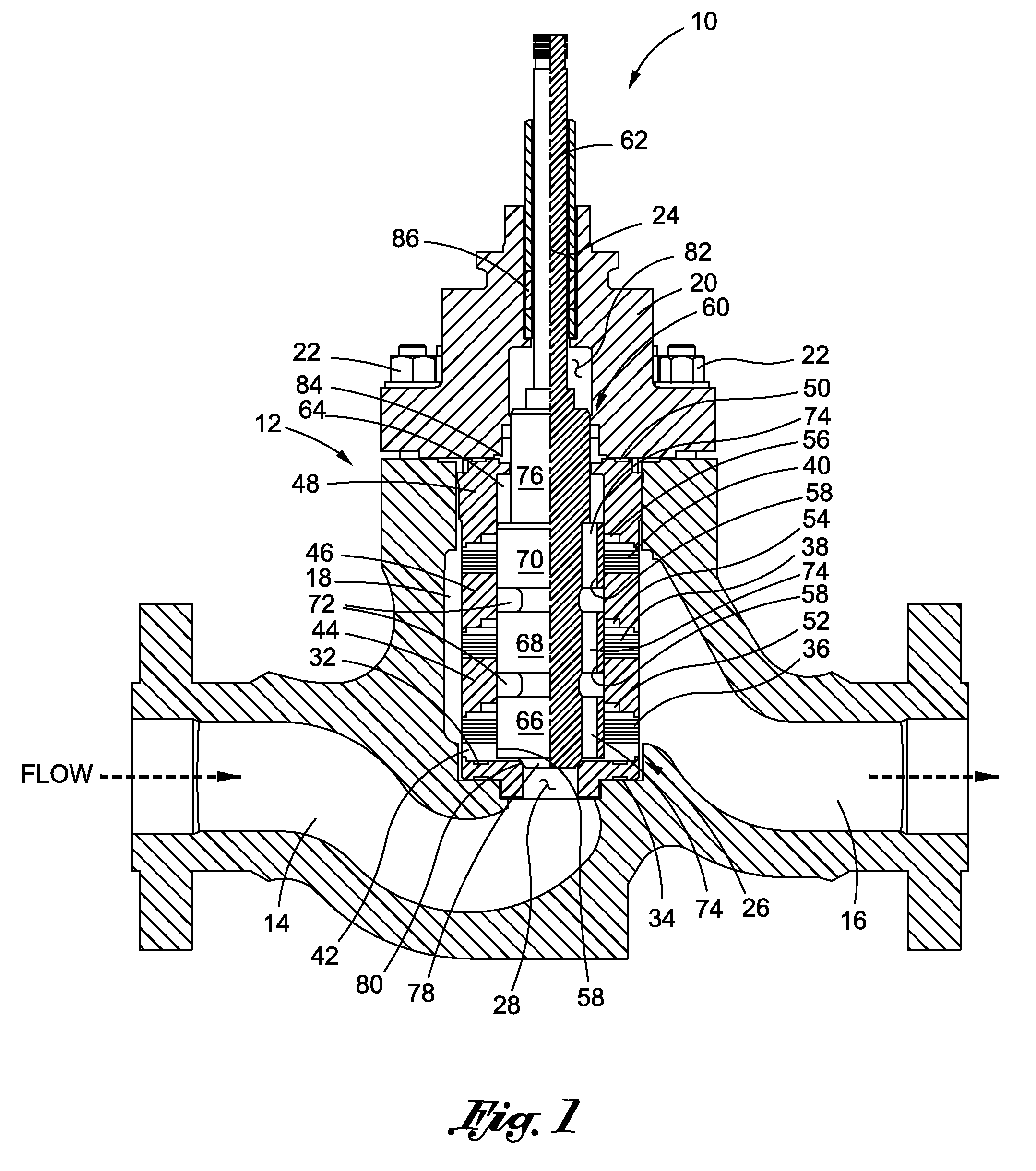

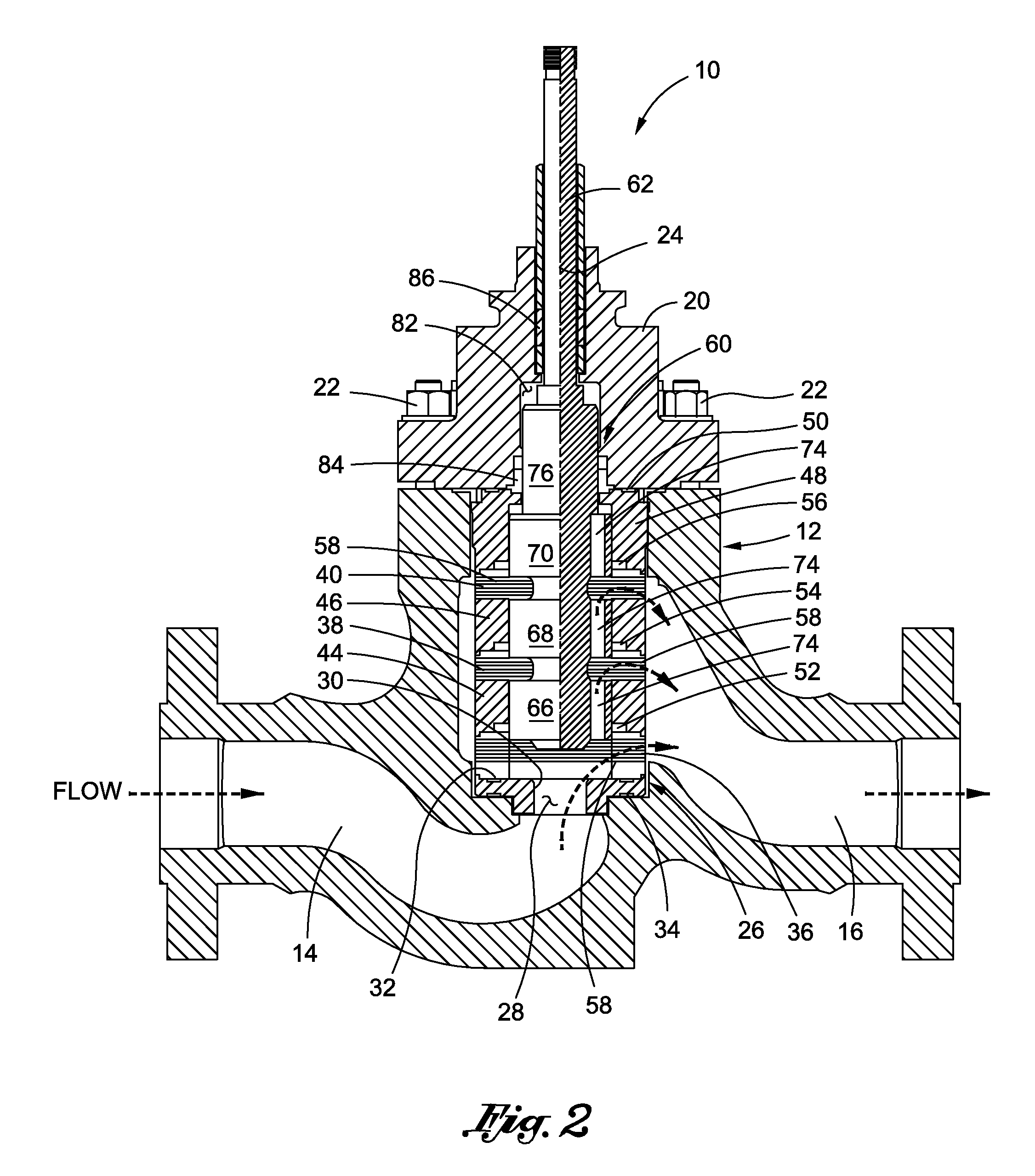

Short stroke control valve

ActiveUS20100300565A1Reduce leakage flowReduce effectOperating means/releasing devices for valvesPressure relieving devices on sealing facesTraffic volumeEngineering

A short stroke flow control device or valve which is adapted to provide velocity control trim in a short stroke. The valve constructed in accordance with the present invention comprises multiple disk stacks or cages which are separated from each other by intervening spacers, and are placed axially in a valve gallery clamped between a seat ring and bonnet of the valve. The fluid passageways in the cages are throttled in a controlled manner by a plug which defines multiple throttling elements or plug lobes, the number of plug lobes defined by the plug preferably being equal to the number of cages included in the valve. The plug lobes of the plug control the flow of fluid through the disk stacks or cages in tandem. All of the throttling elements or plug lobes of the plug, with the possible exception of the plug lobe which contacts the seat ring for closure, is larger in diameter than the remainder of the plug and has at least one kidney bean shaped flow passage extending therethrough. The flow area of such flow passages in the plug lobes is designed to satisfy prescribed seat bore velocity criteria.

Owner:CONTROL COMPONENTS INC

Card seal for a turbine

InactiveUS8393859B1Reduces leakage flow pathIncrease to overall card stiffnessEngine sealsPump componentsTrailing edgeEngineering

A card seal with an annular arrangement of cards that form the card seal, where the cards are interweaved and staggered to increase a sealing capability of the cards. The card seal is formed from leading edge cards staggered with trailing edge cards, and the cards have a thicker outer end and a thinner inner end where the interweaving occurs. Because of the varying thickness of the staggered cards, each card has a taper on the lower outer end that decreases from a high to a low on the inner side in order that a foot print for the card is constant across the bottom surface that floats on the rotating part.

Owner:FLORIDA TURBINE TECH

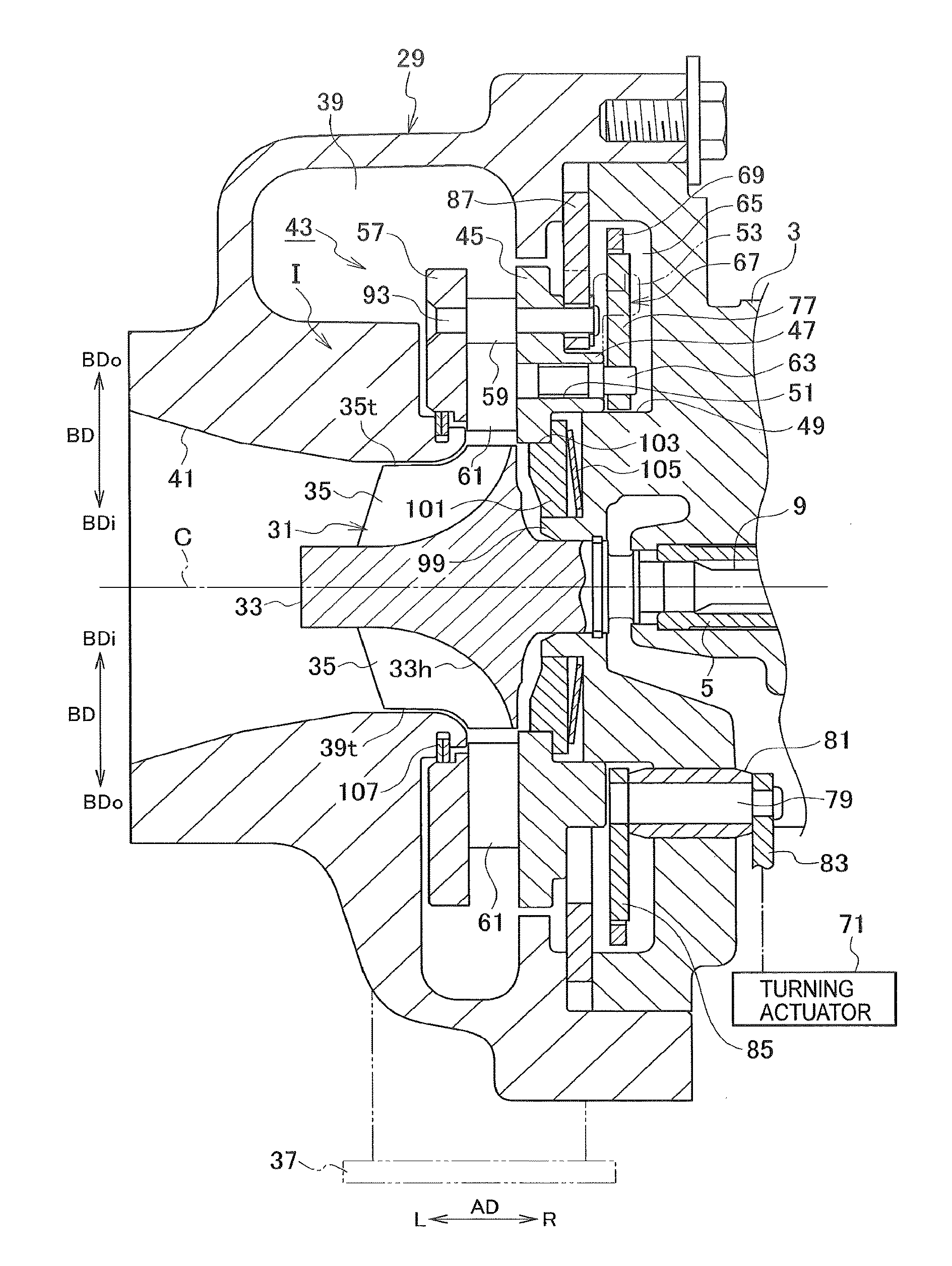

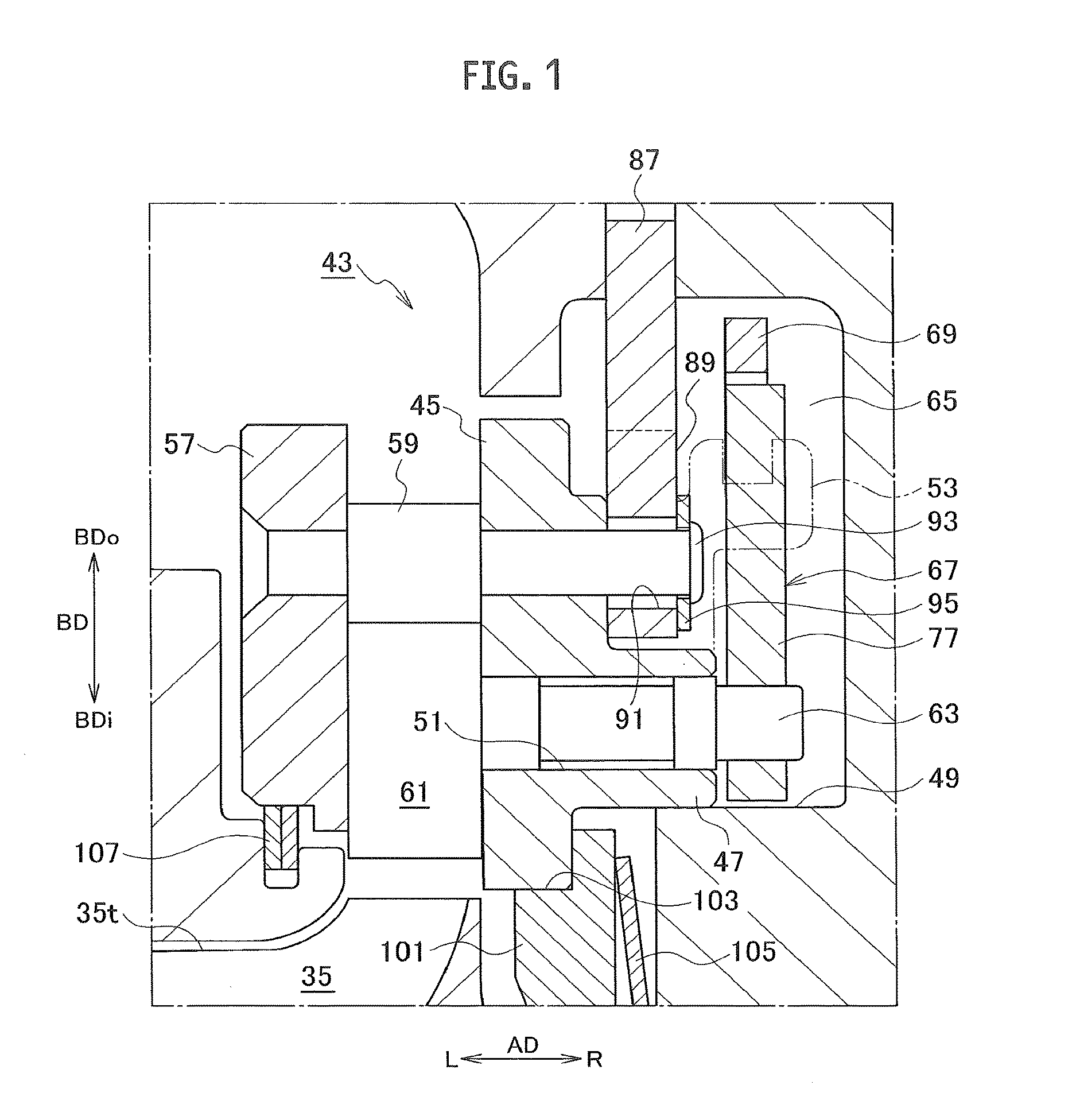

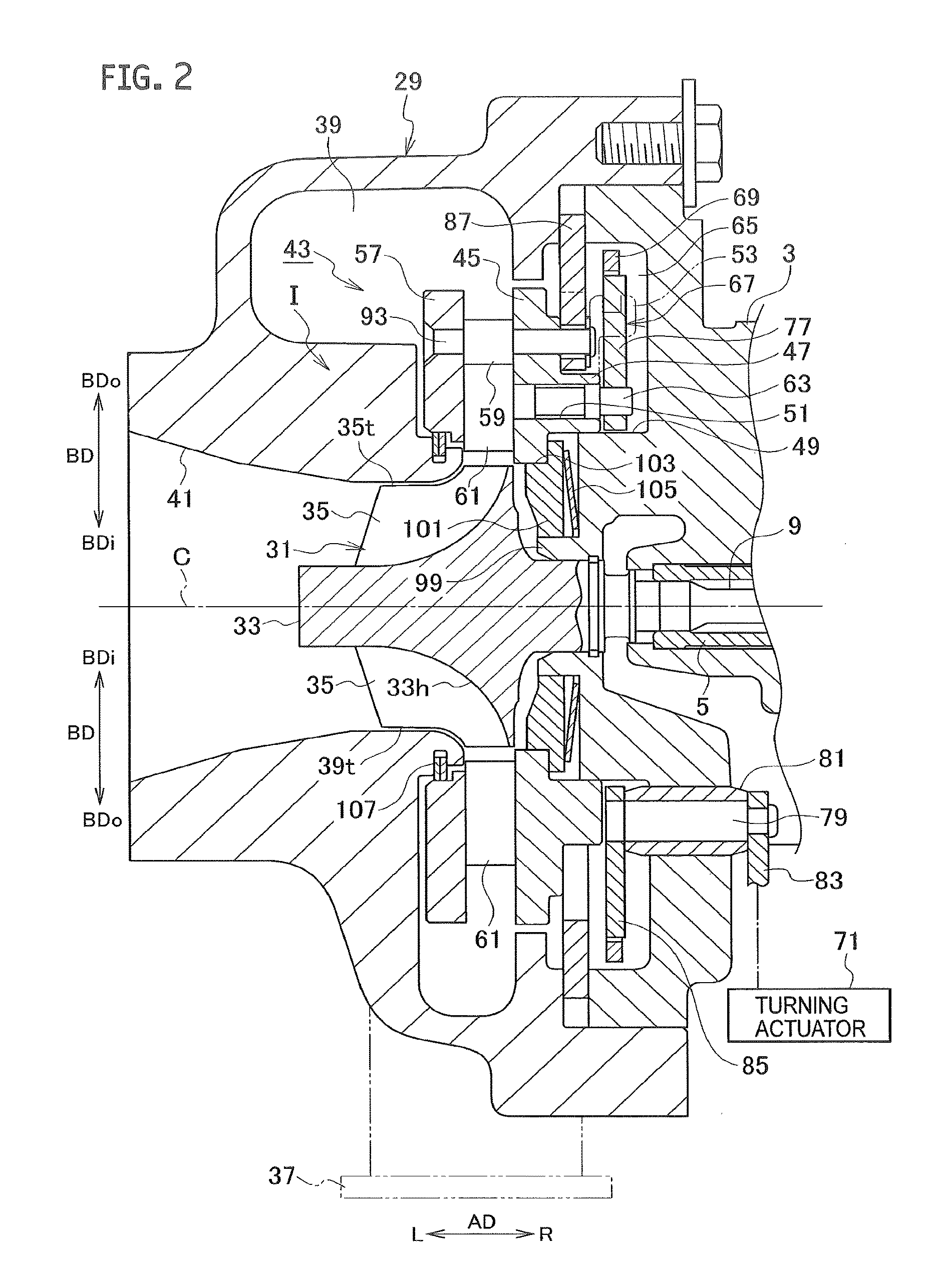

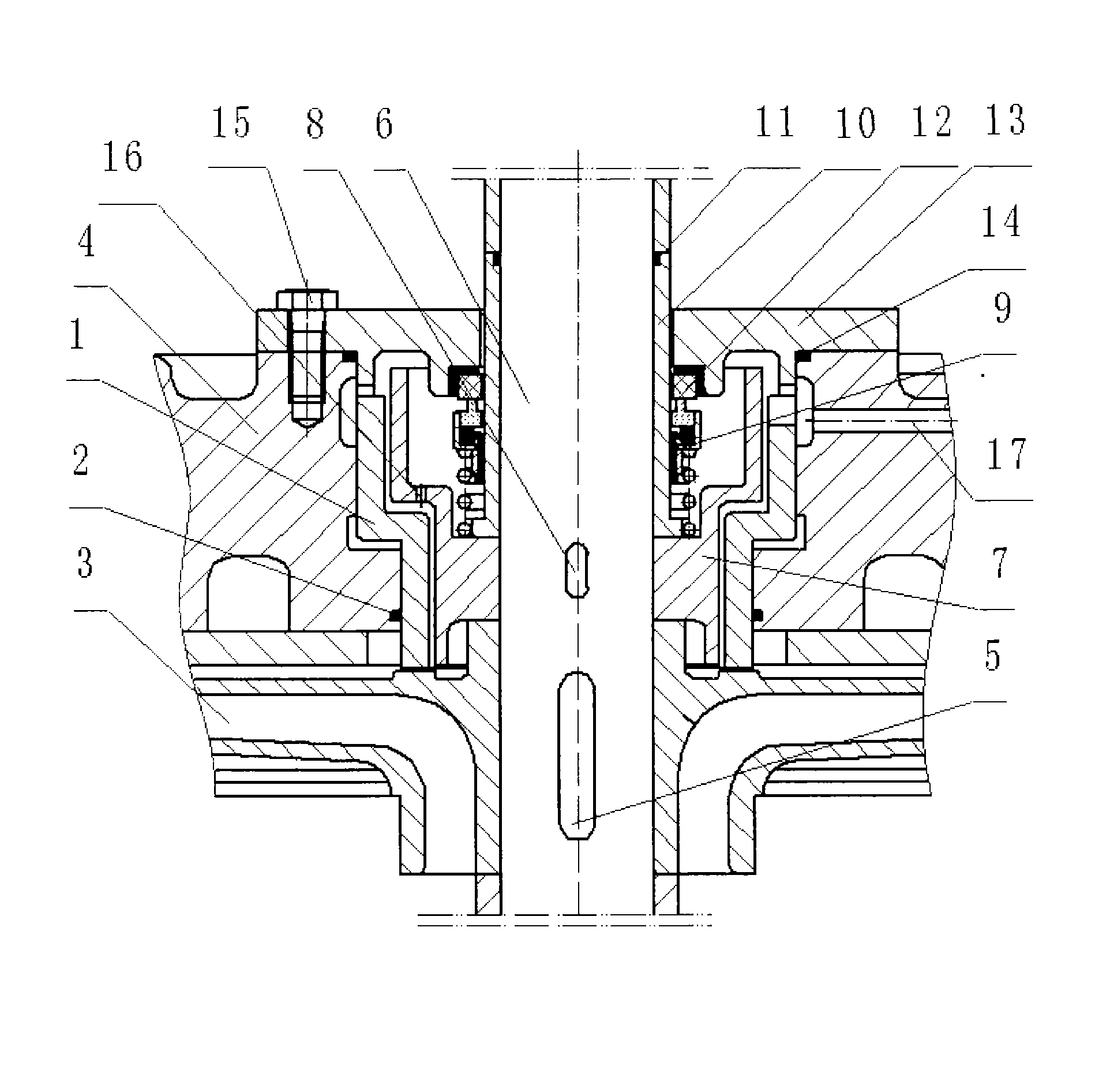

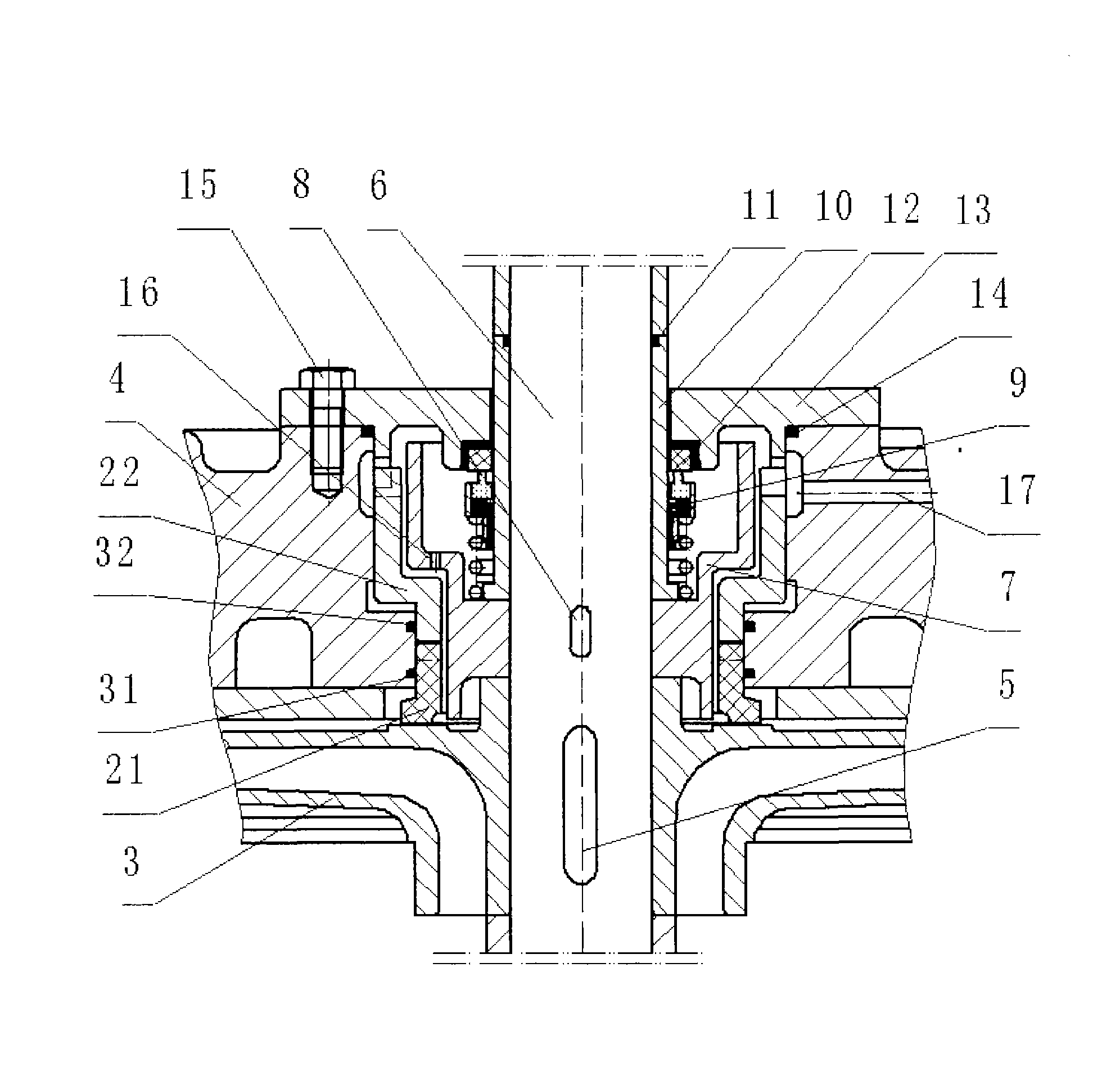

Variable nozzle unit and variable geometry turbocharger

ActiveUS20170058764A1Ensure reliableIncrease channel areaEngine manufactureInternal combustion piston enginesLeft directionRivet

In a variable nozzle unit, at a position located away from and opposed to a first nozzle ring in a right-left direction, a second nozzle ring is provided integrally with the first nozzle ring through multiple connecting pins arranged in a circumferential direction. An inner edge portion of a support ring is connected to the first nozzle ring by riveting of one end portions of the multiple connecting pins. Each pin hole in the support ring is formed into such a shape extending in a radial direction of the support ring. A washer is provided between a rim of each pin hole in the support ring and a rivet head brought about by joining of the end portion of the corresponding connecting pin.

Owner:IHI CORP

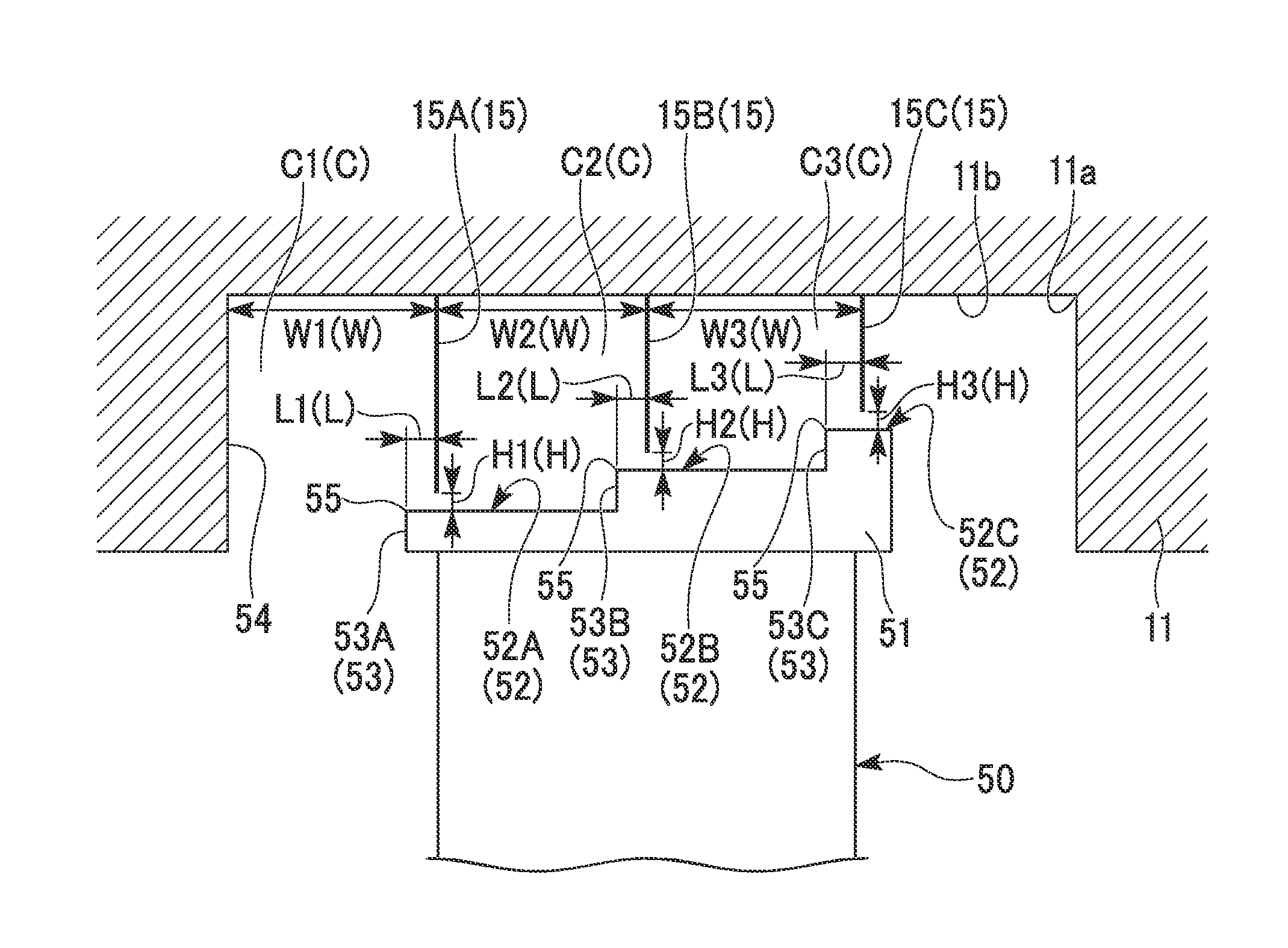

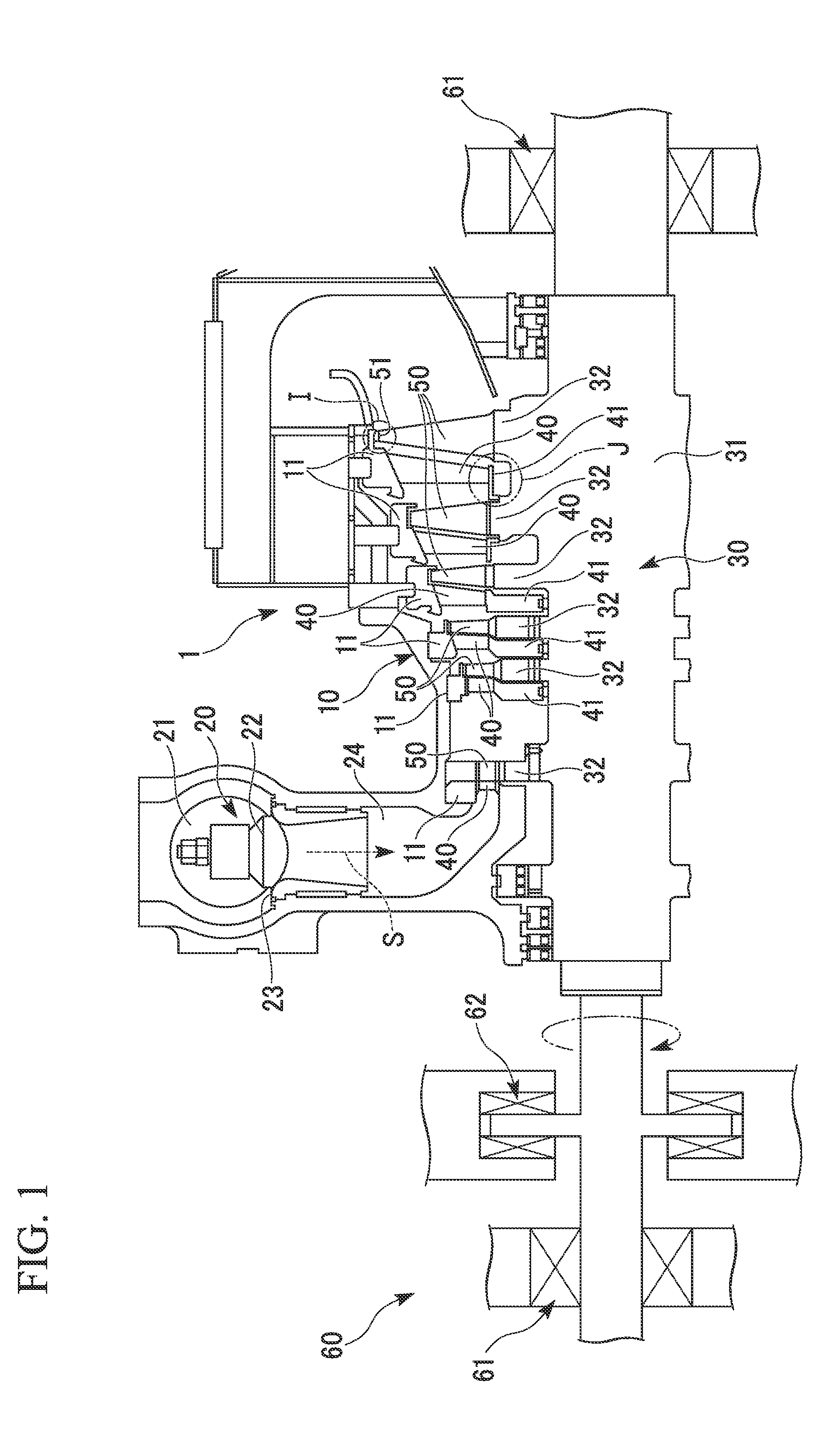

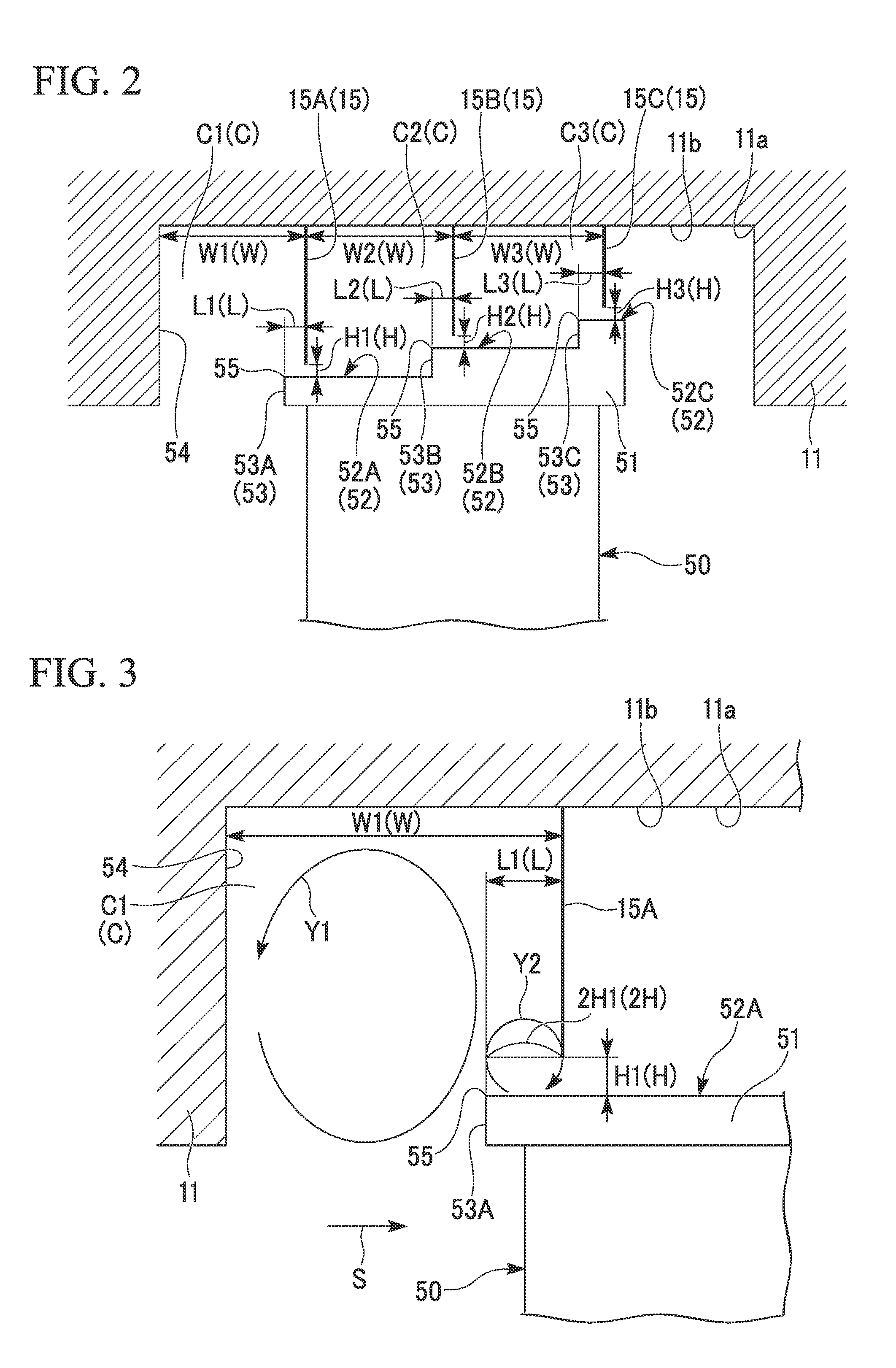

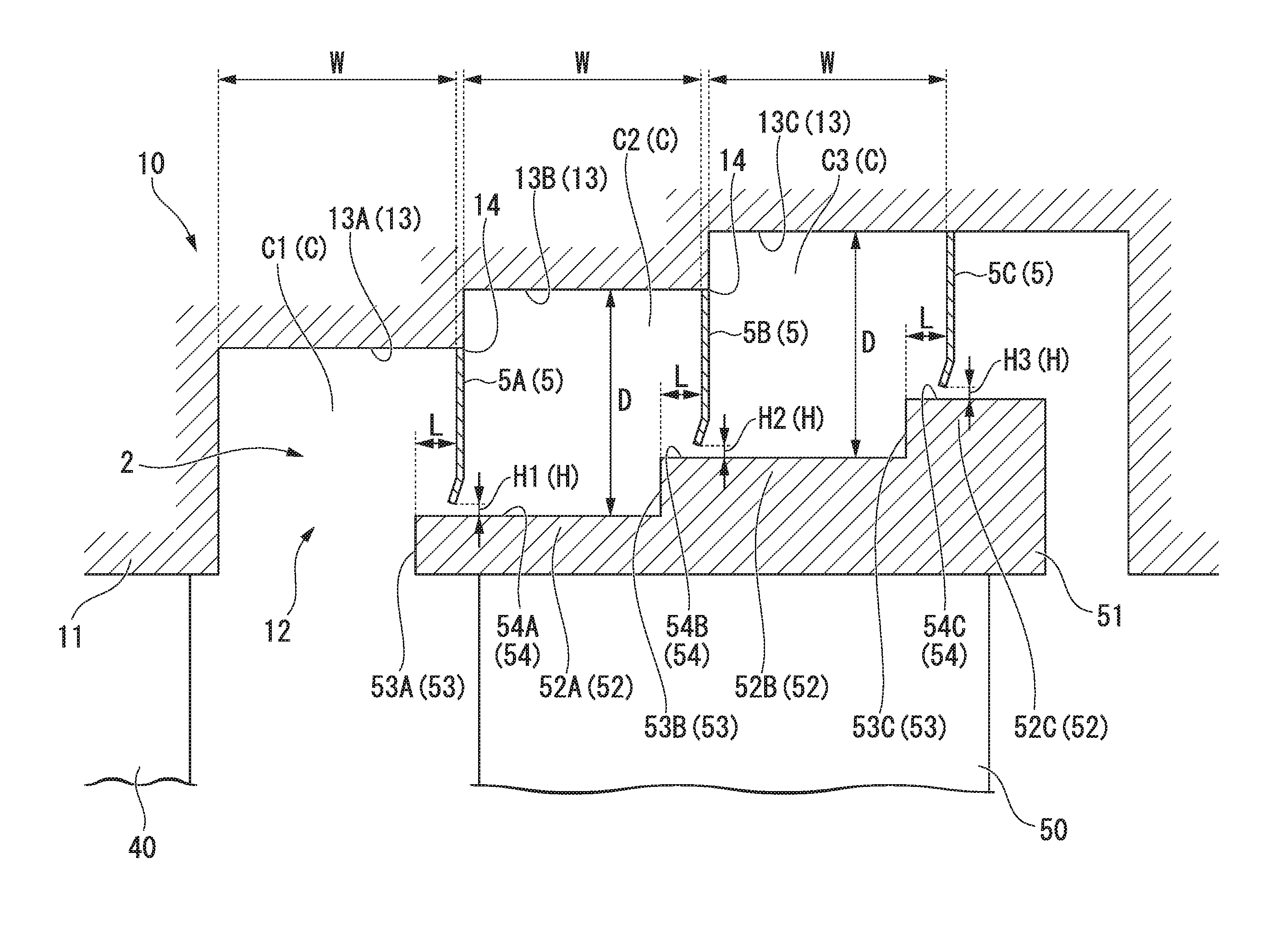

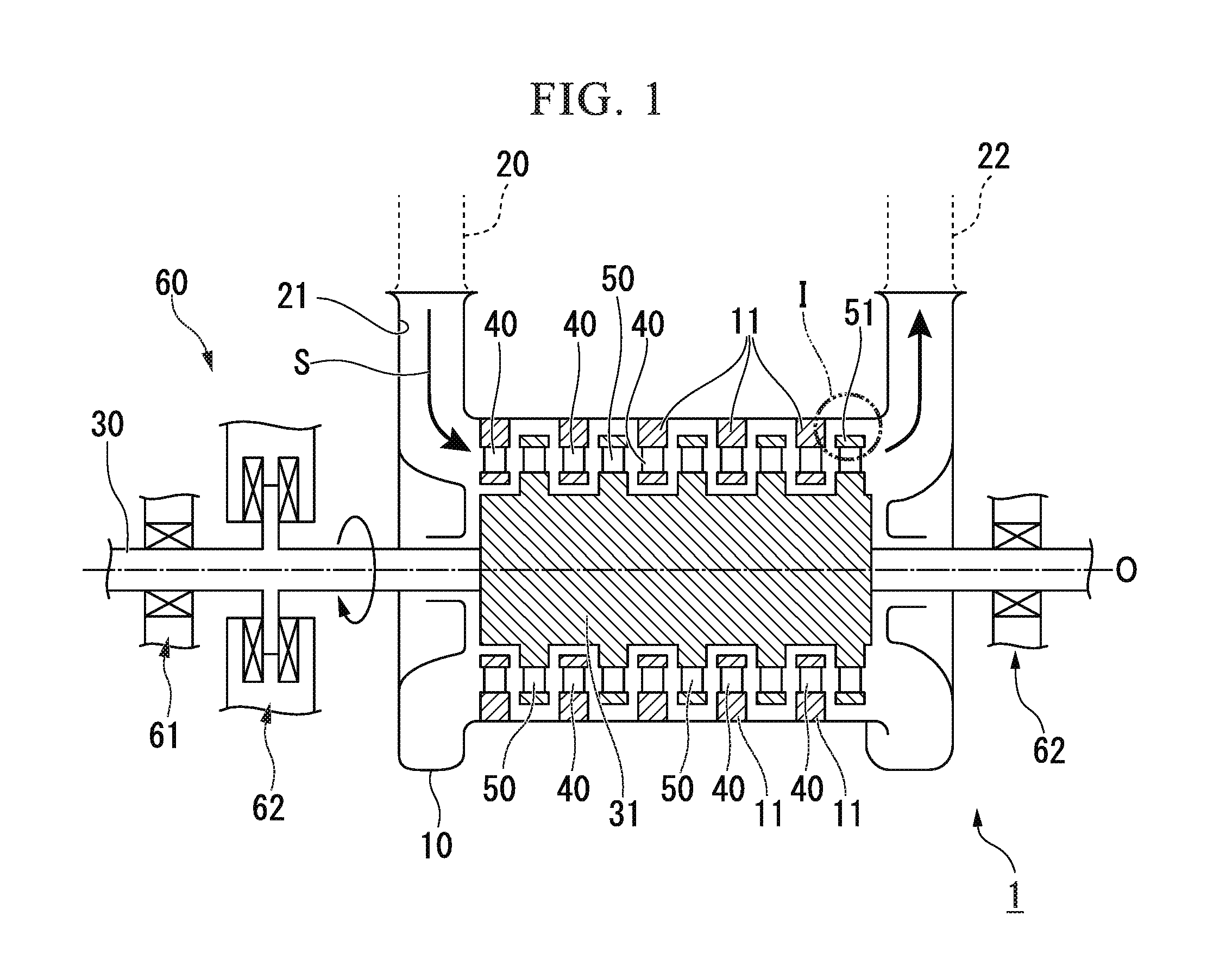

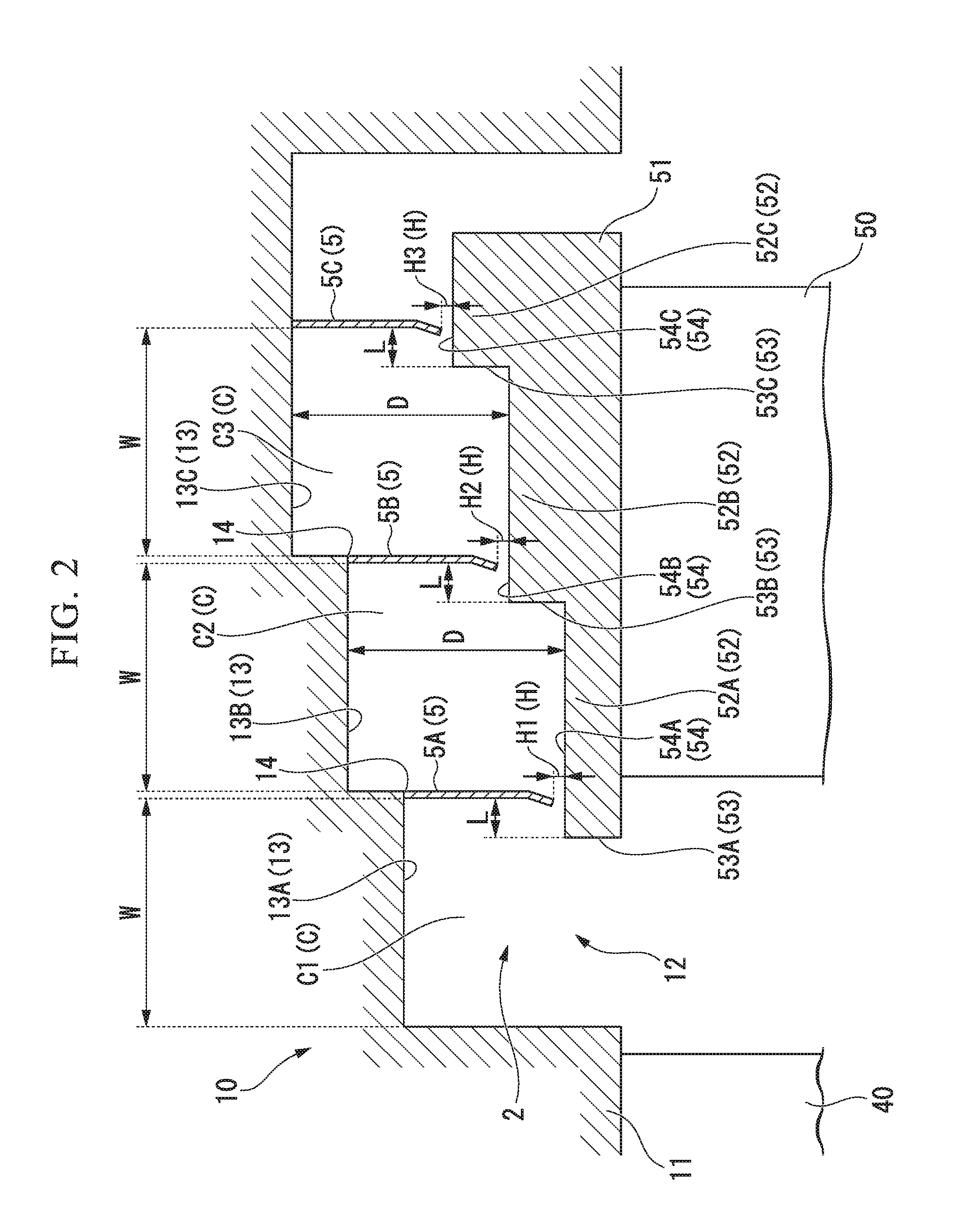

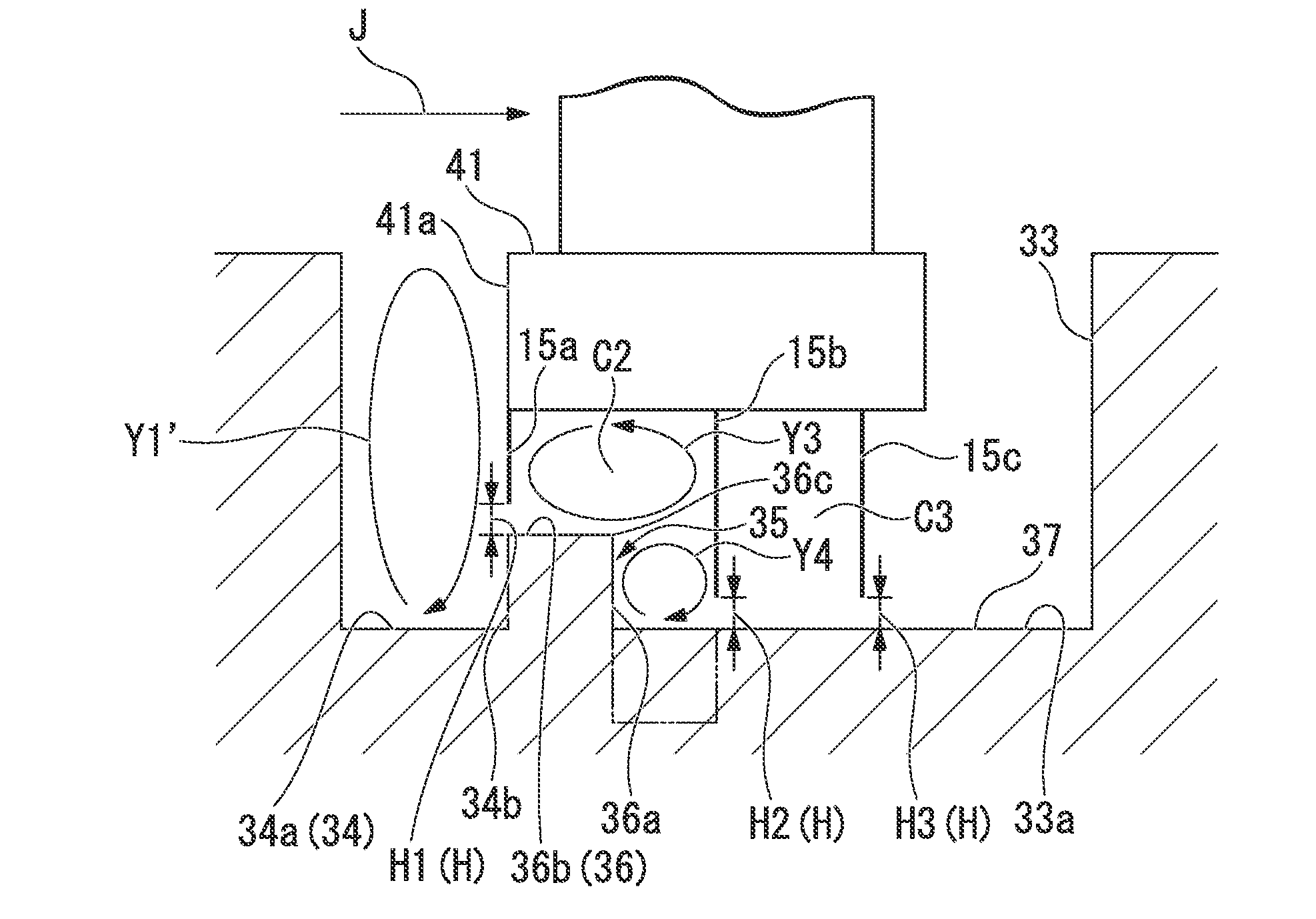

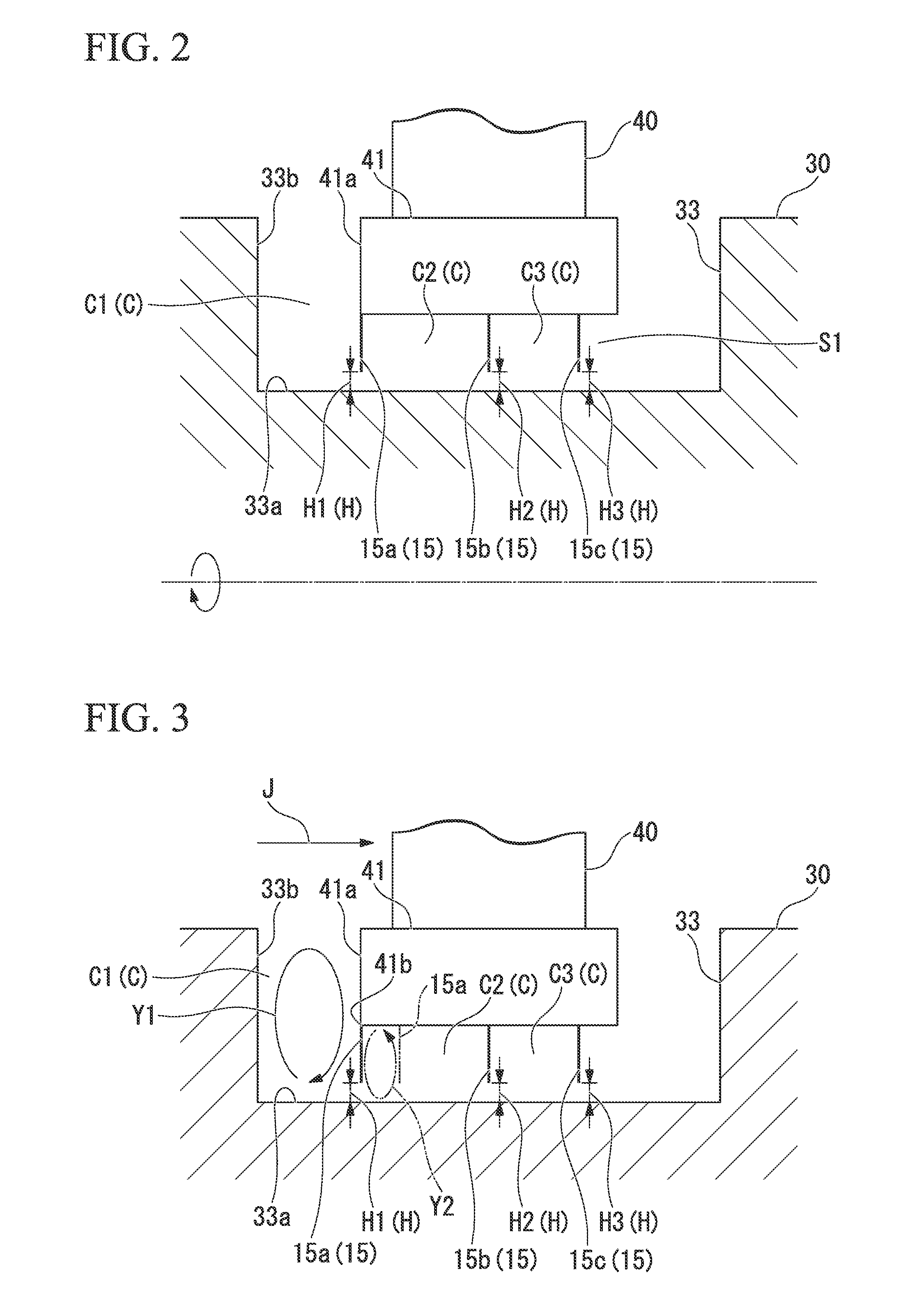

Turbine

ActiveUS20120121393A1Reduce leakage flow rateHigh performanceEngine sealsPump componentsEngineeringTurbine

The turbine is provided with a blade (50) and a structure body (11) which rotates relatively with respect to the blade (50). A stepped part (52A) having a step surface (53A) is installed at one of the leading end of the blade (50) and the structure body (11) corresponding to the leading end thereof, while a seal fin (15A) which extends toward the stepped part (52A) to form a small space (H) is installed at the other of them. A cavity (C1) is formed between the blade (50) and the structure body (11) and also between the seal fin (15A) and the partition wall which faces thereto in the rotating shaft direction of the structure body (11) on the upstream side. When a distance of the cavity (C1) between the partition wall and the seal fin (15A) is given as a cavity width (W), and a distance between the seal fin (15A) and the end edge (55) of the stepped part (52A) in the rotating shaft direction on the upstream side is given as (L), at least one of the distances (L) satisfies the following formula (1).0.7H≦L≦0.3W (1)

Owner:MITSUBISHI HEAVY IND LTD

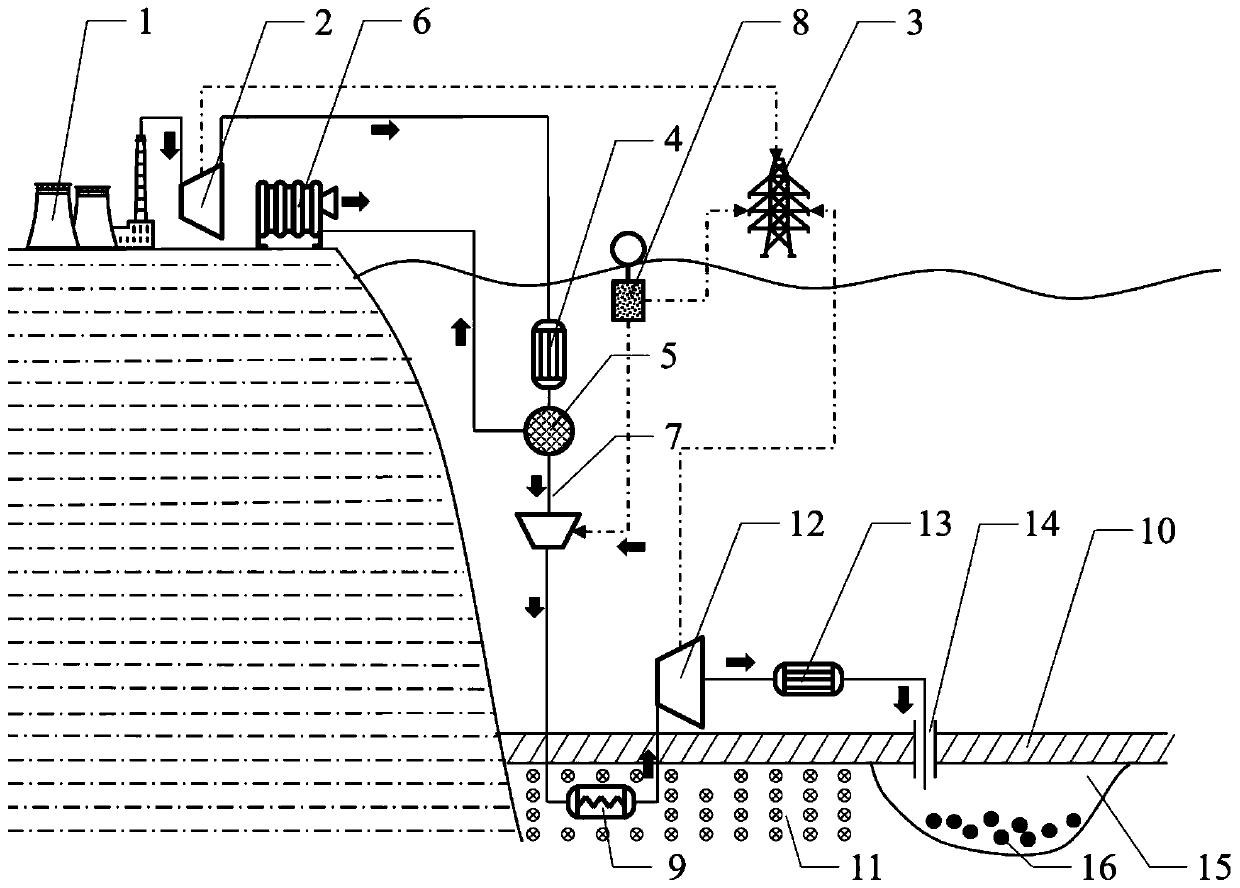

Deep-sea carbon storage and power generation system

The invention discloses a deep-sea carbon storage and power generation system. The deep-sea carbon storage and power generation system comprises a waste heat turbine, a waste gas heat exchanger, a gasstripping device, a waste gas treatment device, a supercritical carbon dioxide compressor, wave energy power generation equipment, a geothermal heat exchanger, a supercritical carbon dioxide turbineand a seabed cooler. According to the deep-sea carbon storage and power generation system disclosed by the invention, waste heat power generation and carbon dioxide stripping are performed on power plant waste gas, and the stripped carbon dioxide is applied to a seabed geothermal Brayton cycle, and is finally stored in deep-sea storage holes. The system is compact in structure, is small in size and is high in efficiency. Rich seabed geothermal energy is used as a heat source, is free of pollution and is low in cost; carbon dioxide is stored in the form of carbon dioxide hydrate, is relativelylow in cost, is environmentally-friendly and is good in leakproofness; and a dried oilfield, gas field or natural hole with a good storage cover in a seabed geologic body is utilized as a carbon storage site, so that the storage effect is good, and later-period maintaining and monitoring cost is reduced, and therefore, the system has a wide application prospect.

Owner:XI AN JIAOTONG UNIV

Method of operating a compressor

InactiveUS8317457B2Improving stable flow rangeReduce leakage flowPump componentsBlade accessoriesPlasma generatorEngineering

A method of operating a compressor having a row of blades for preventing a compressor stall is disclosed, the method comprising the steps of mounting a plasma generator in a casing or a shroud radially outwardly and apart from the blade tips wherein the plasma generator comprises a radially inner electrode and a radially outer electrode separated by a dielectric material; and supplying an AC potential to the radially inner electrode and the radially outer electrode.

Owner:GENERAL ELECTRIC CO

Fluidic sealing for turbomachinery

Disclosed is a seal for turbomachinery including a seal face locatable between a first turbomachinery component and a second turbomachinery component. At least one fluid channel extends through the seal. The at least one fluid channel is capable of injecting fluid flow between the first turbomachinery component and the second turbomachinery component at the seal face thereby disrupting a leakage flow between the first turbomachinery component and the second turbomachinery component. Further disclosed is a turbomachine utilizing the seal.

Owner:GENERAL ELECTRIC CO

Adverse Pressure Gradient Seal Mechanism

InactiveUS20110163505A1Reduce leakage flowEngine sealsLeakage preventionEngineeringMechanical engineering

Owner:GENERAL ELECTRIC CO

Axial force balancing device of pump

The invention relates to an axial force balancing device of a pump, which is characterized in that an engine body at the rear end of an impeller is provided with one or a set of step type floating sealing sleeve(s). When in work, under the condition of changeable pressure at the two ends, the step type floating sealing sleeve(s) can automatically regulate the axial clearance with the impeller, thereby having the effects of reducing leakage flow rate and automatically balancing axial force; a rotating main shaft at the rear end of the impeller is provided with a step type balancing drum matched with the step type floating sealing sleeve(s); the step type balancing drum is not only matched with the function that the step type floating sealing sleeve(s) can automatically regulate the axial clearance with the impeller, but also preserves the function of the traditional balancing drum, and has the effect of labyrinth clearance seal. The axial force balancing device of the pump has compact structure and small axial dimension, is high in the generalized degree with the existing products and parts, can greatly reduce the volume loss and disk friction loss, improves the efficiency of the pump, and has the characteristics of simple structure, low manufacturing cost as well as safe and reliable use.

Owner:杨丽萍

Sealing structure and rotary machine

ActiveUS20160333714A1Improve shrinkageReduce leakage flowEngine sealsEngine manufactureRotary machineStator

A sealing structure that seals a clearance between an outer peripheral surface of a rotor and an inner peripheral surface of a stator. The sealing structure includes: a plurality of step portions that are provided on a first surface which is one of the outer peripheral surface of the rotor and the inner peripheral surface of the stator so as to be arranged in the axial direction, and that protrude from the first surface toward a second surface which is the other of the outer peripheral surface of the rotor and the inner peripheral surface of the stator; and a seal fin that is provided on the second surface, and that forms a small clearance between a corresponding peripheral surface of the step portions. A portion in the vicinity of a tip of the seal fin in the radial direction is inclined toward the upstream side.

Owner:MITSUBISHI POWER LTD

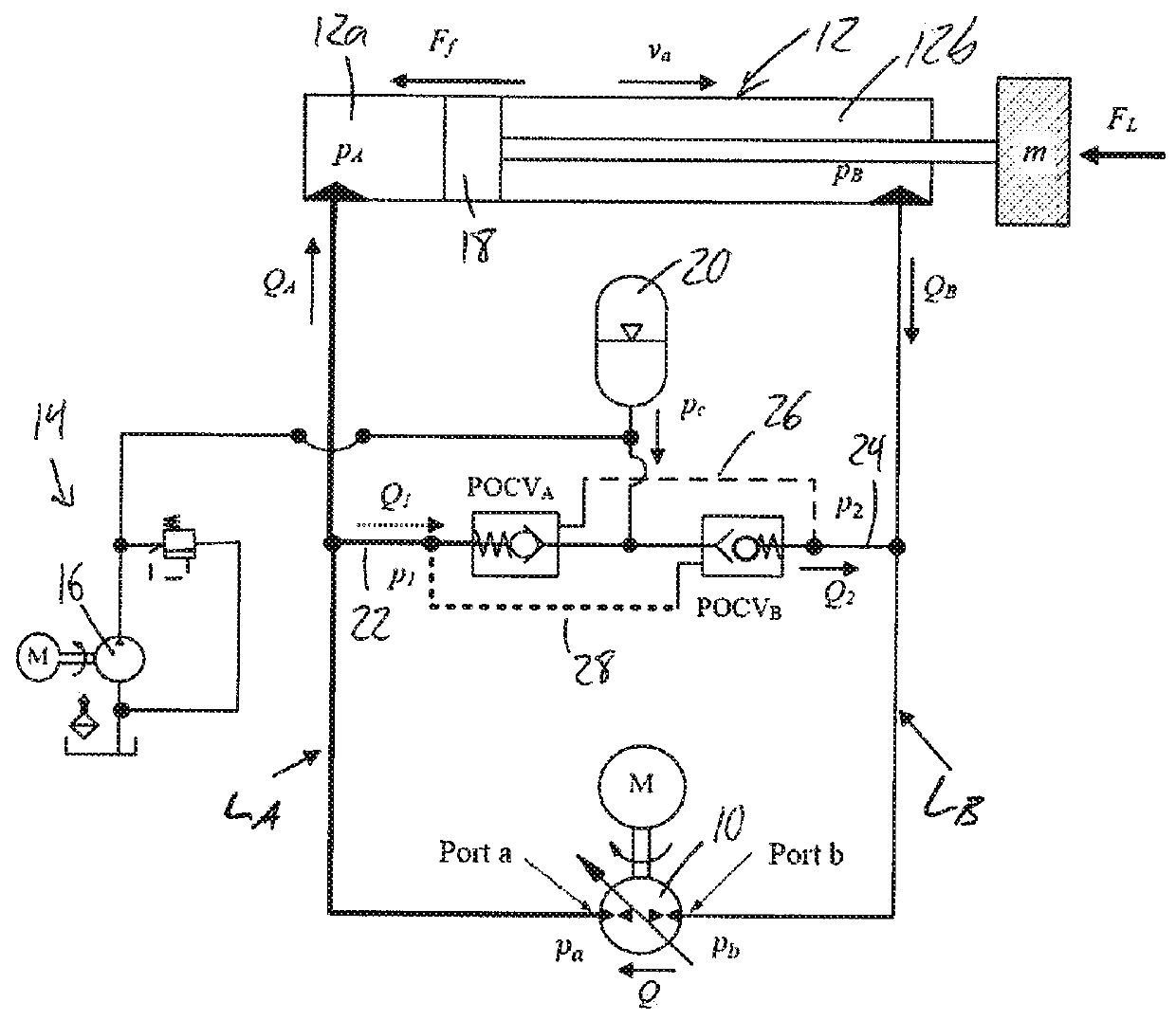

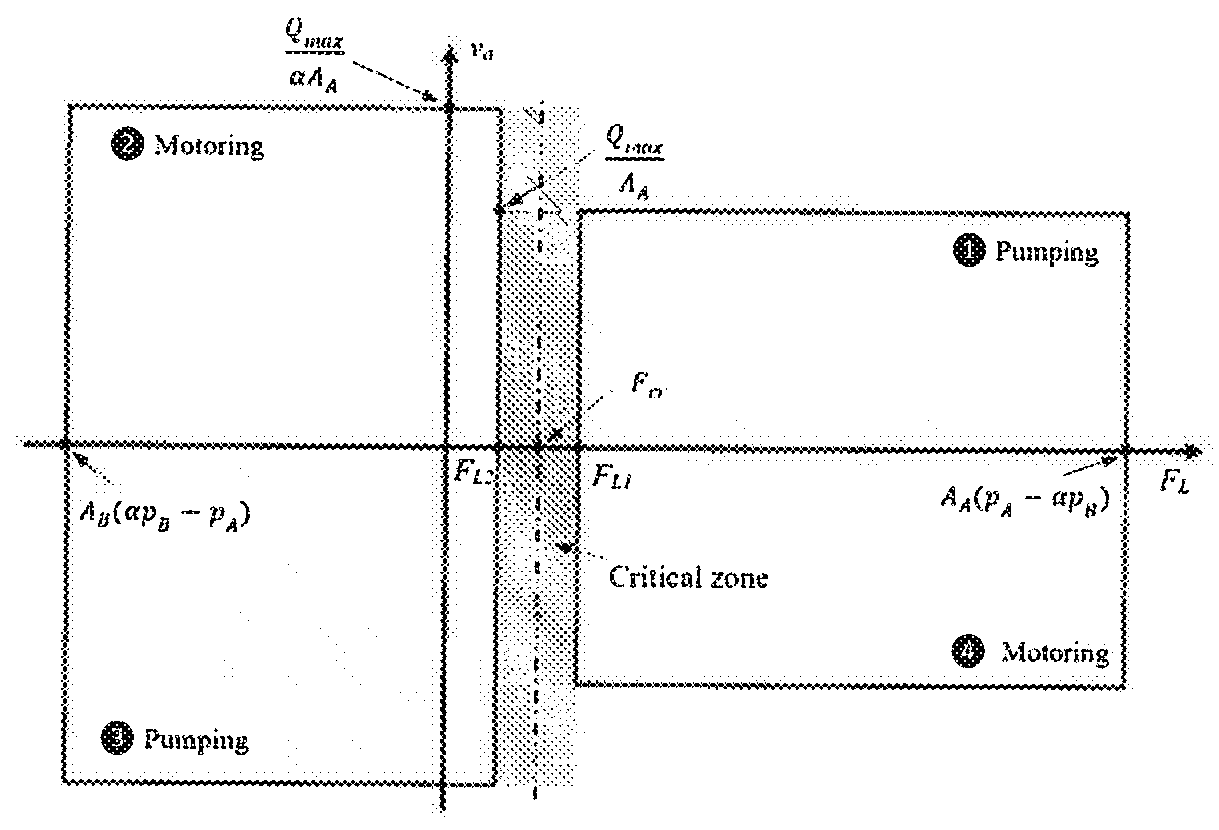

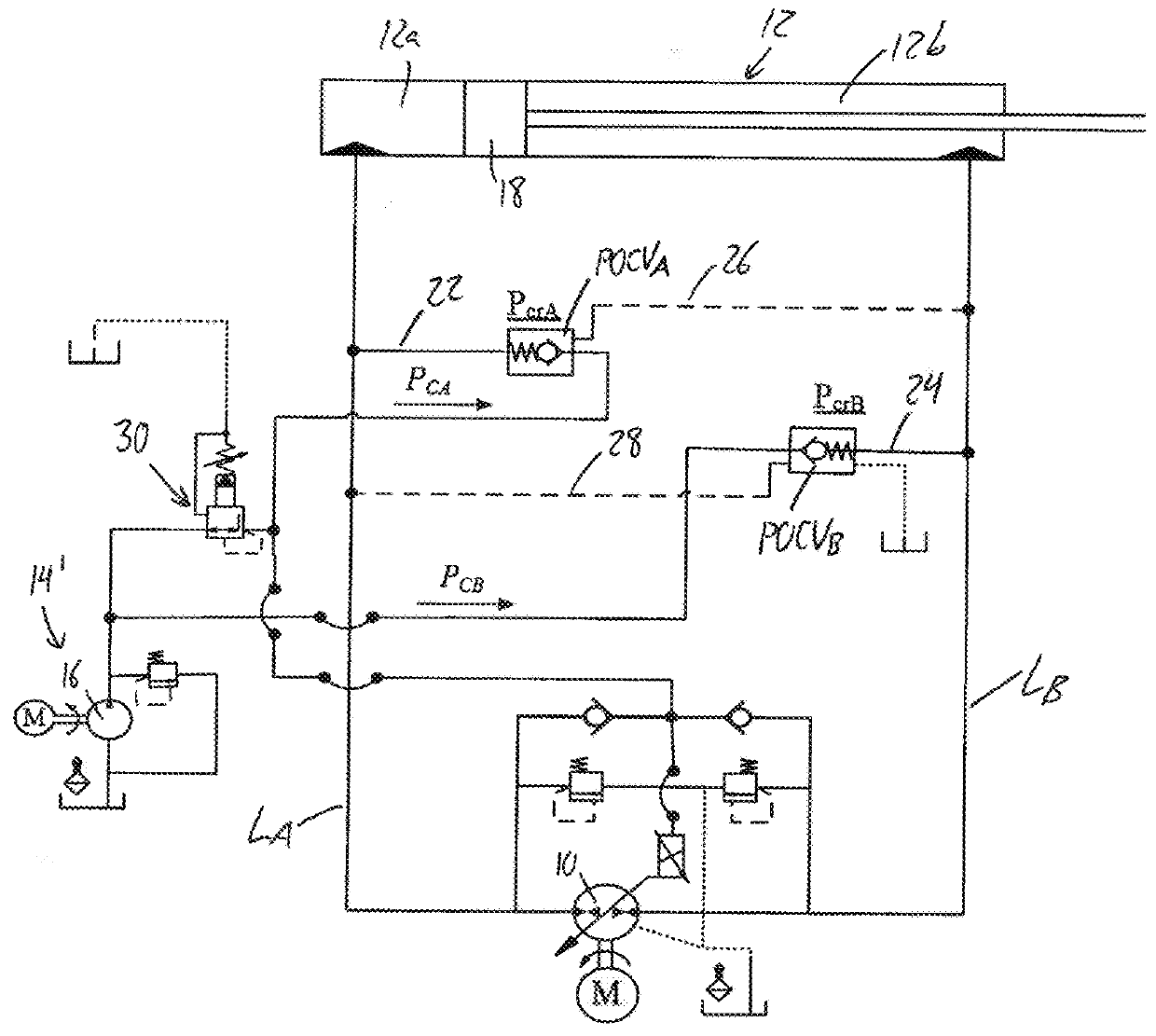

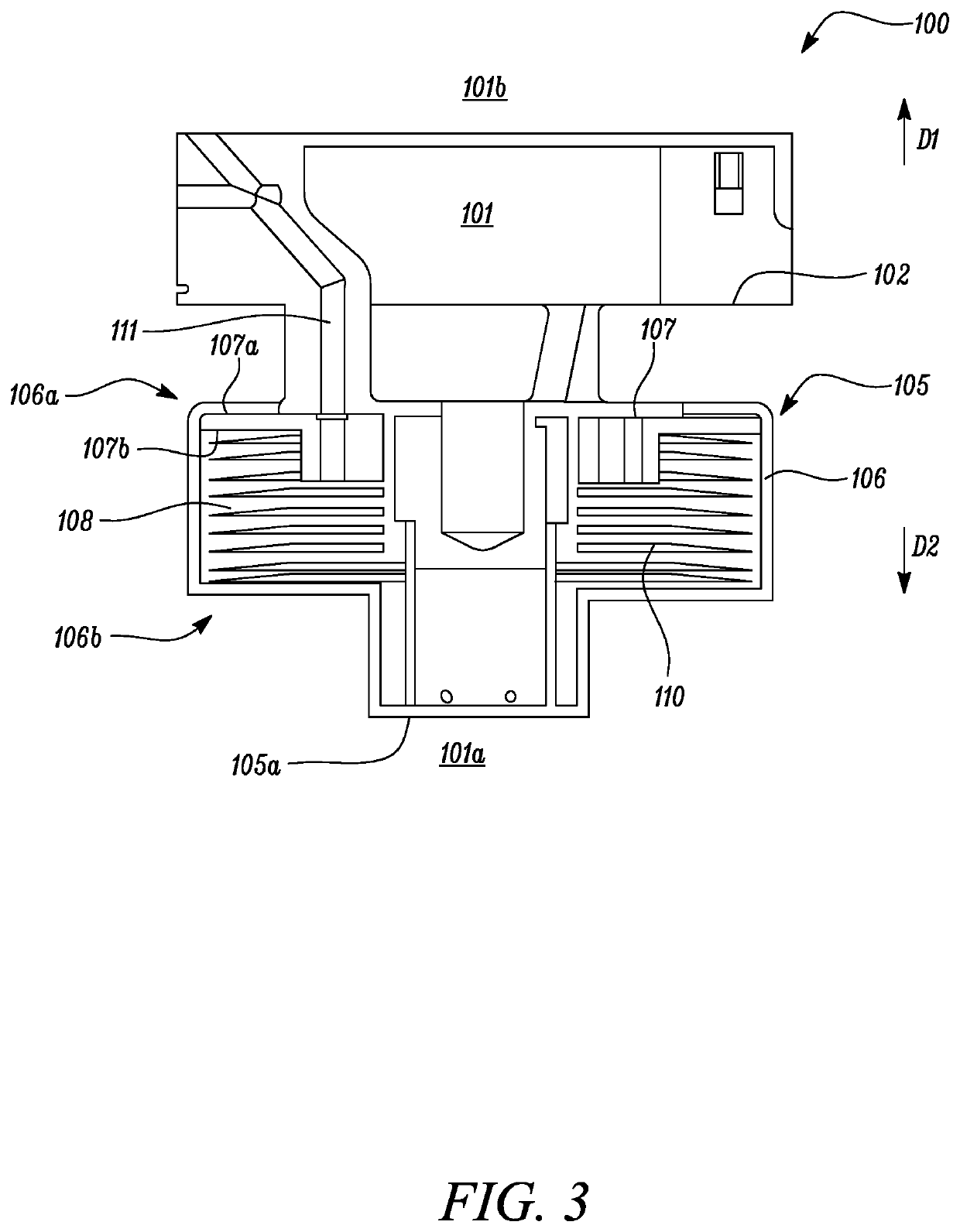

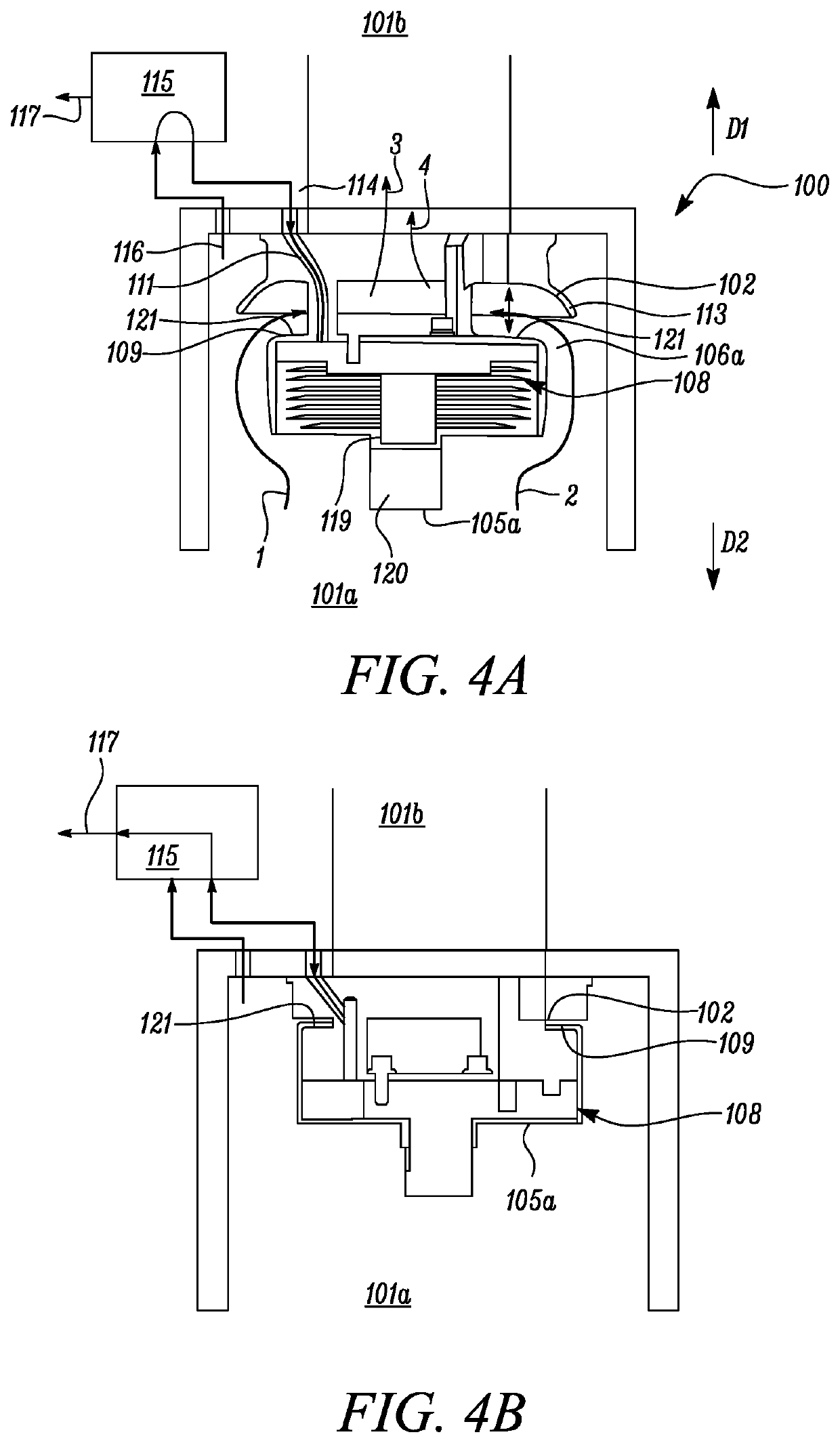

Pump-Controlled Hydraulic Circuits for Operating a Differential Hydraulic Actuator

ActiveUS20180266447A1Avoid energy lossReduce the amplitudeServomotorsTelemotorsLow loadHydraulic circuit

Pump-controlled hydraulic circuits are more efficient than valve-controlled circuits, as they eliminate the energy losses due to flow throttling in valves and require less cooling effort. Presently existing pump-controlled solutions for single rod cylinders encounter an undesirable performance during certain operating conditions. Novel circuit designs employ use of different charge pressures on a pair of pilot-operated charging-control valves or different piston areas and / or spring constants on a shuttle-type charging control valve to shift a critical loading region in a load-force / actuator-velocity plane to a lower load force range, thereby reducing the undesired oscillations experienced in the response of the typical critical loading region. One or more specialized valves are controlled by fluid pressures to provide throttling in the circuit only within the critical loading region, thereby reducing the oscillatory amplitude while avoiding throttling-based energy losses outside the critical region over the majority of the circuit's operational overall operating area.

Owner:UNIVERSITY OF MANITOBA

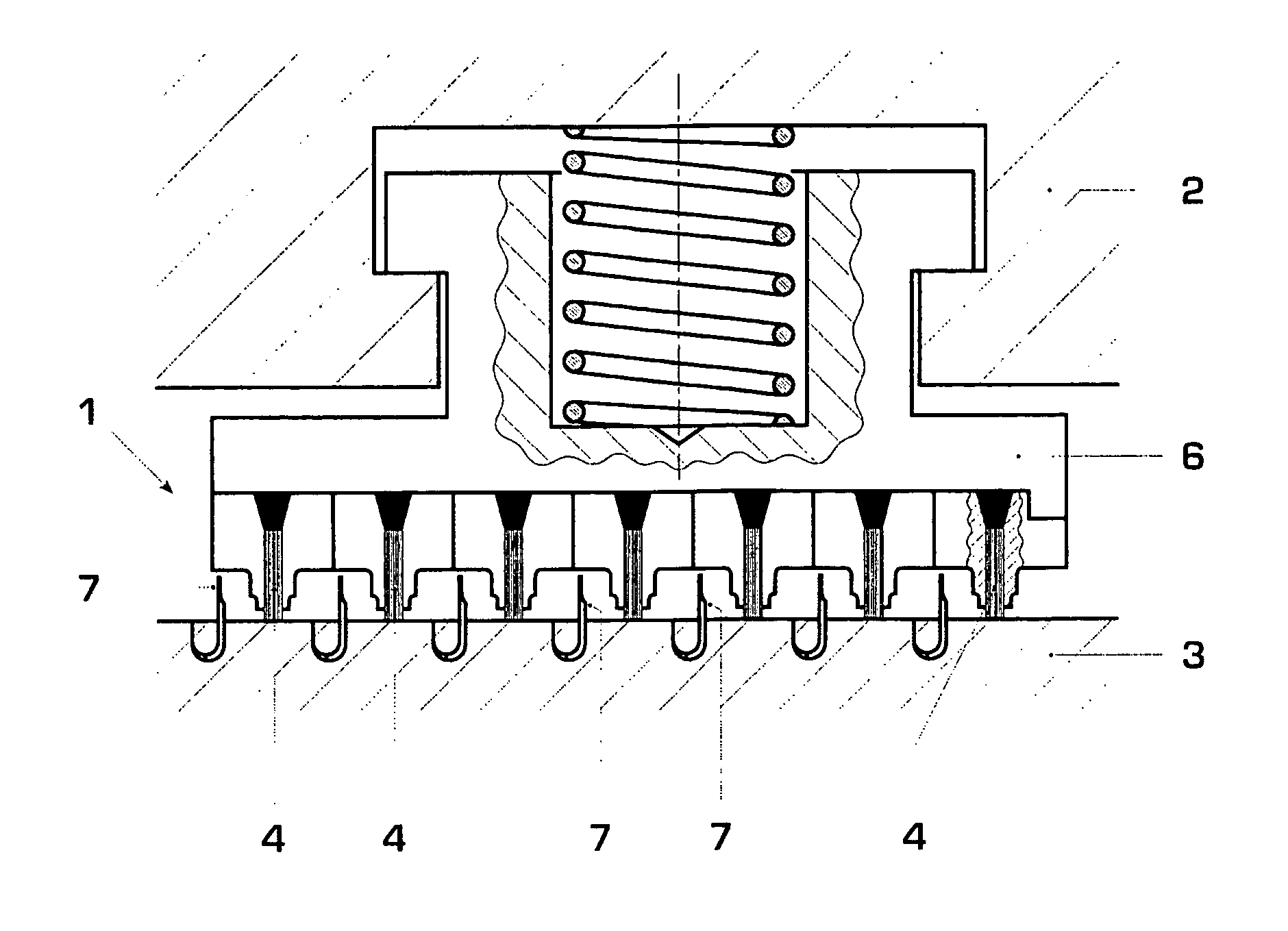

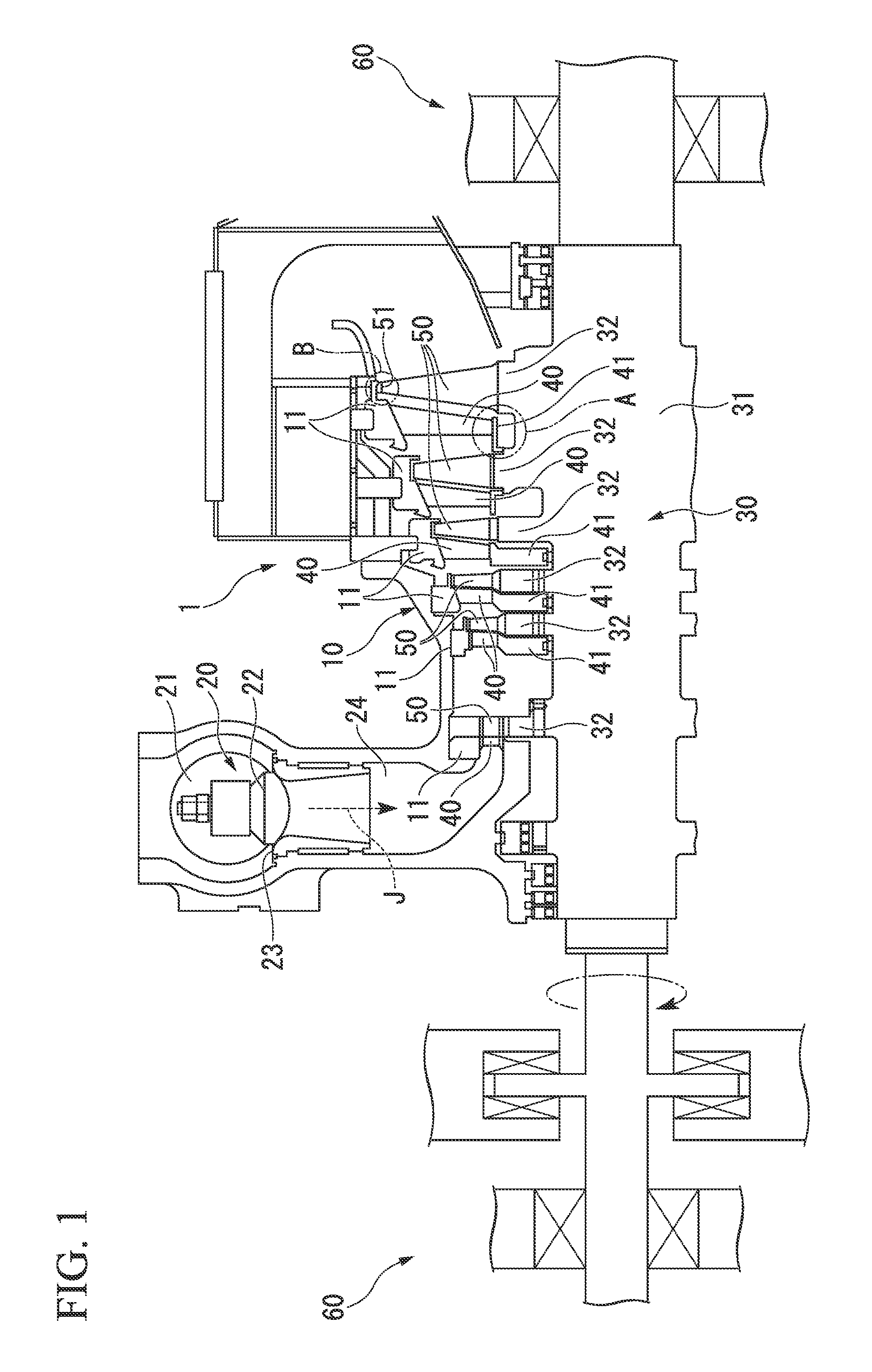

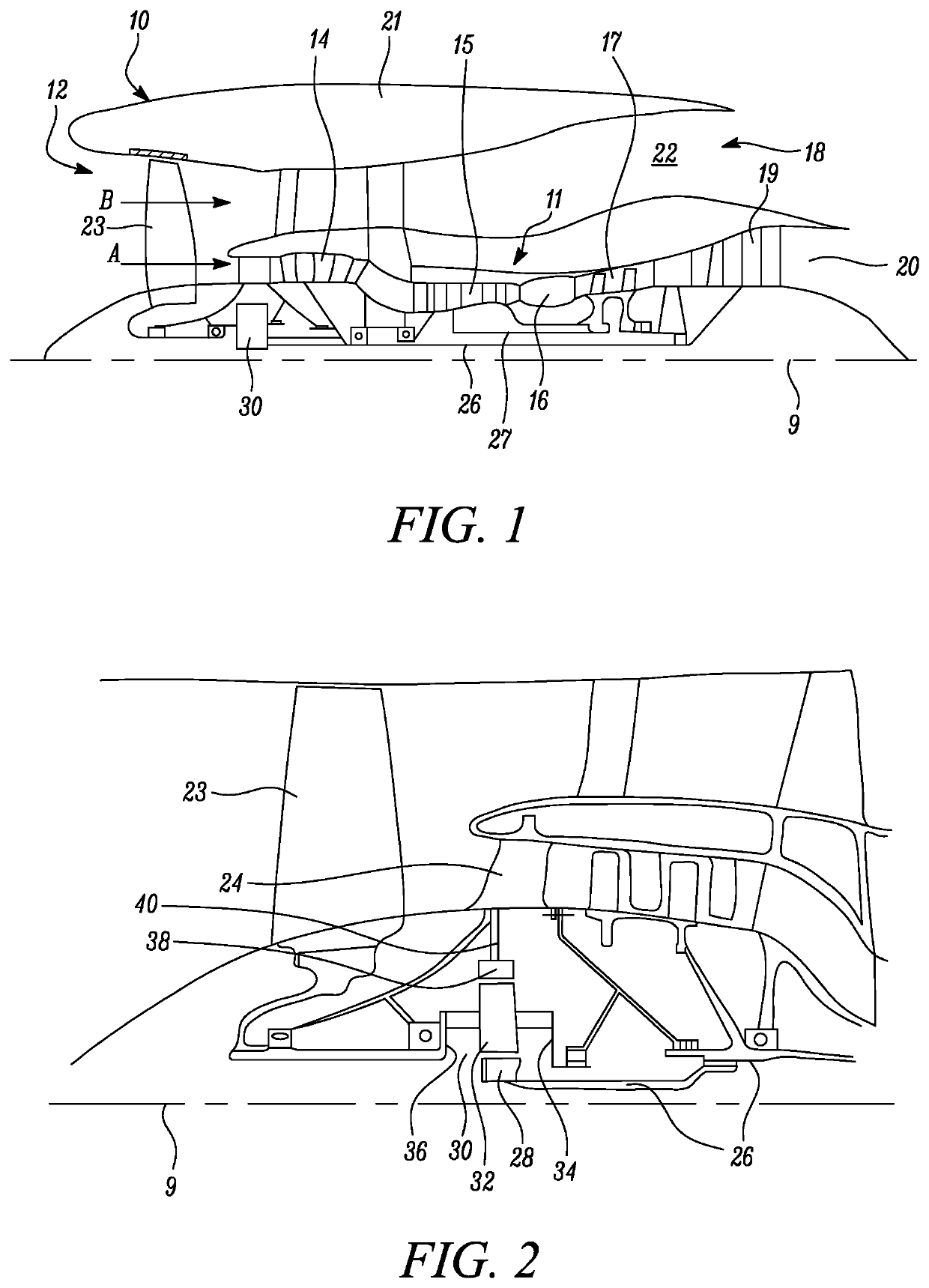

Axial turbo engine with low gap losses

InactiveUS20110189020A1Reduce radial clearanceReduce leakage flowPropellersEngine manufactureEngineeringFront edge

An axial turbomachine including a rotor blade cascade is provided. The rotor blade cascade includes rotor blades each including front edge, a radially outer free blade tip and an annular enclosure enclosing the rotor blade cascade with an annulus inner side by means of which the annular enclosure is arranged directly adjacent to the blade tips to give a radial gap between the enveloping ends of the blade tips and the annulus inner side. The rotor blades include a radial projection in the region of the front edge on the blade tip and the annular enclosure has an annular radial recess in the annulus inner side, arranged at a radial distance from the ends of the blade tips, such that in the main flow direction of the axial turbomachine the line of the radial projections on the side facing the radial gap matches the line of the radial recess.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Turbine

Provided is a turbine in which seal fins (15) are provided to a hub shroud (41) to protrude toward a bottom surface (33a) of an annular groove (33), small gaps (H) are formed between the tip ends of the seal fins and the bottom surface of the annular groove, and assuming that the axial distance between a first seal fin (15a) disposed on the front edge side of the hub shroud among the seal fins and a front edge (41a) of the hub shroud is (L) and the axial distance between the front edge of the hub shroud and an inside surface (33b) of the annular groove is (Bu), the first seal fin is disposed to satisfy L / Bu<0.3.

Owner:MITSUBISHI HEAVY IND LTD

Tapered gas turbine segment seals

The present application and the resultant patent provide improved gas turbine component sealing. In one example embodiment, a gas turbine segment seal assembly may include a first tapered segment seal with a first tapered portion having a first tapered surface and a first taper angle. The gas turbine segment seal assembly may include a second tapered segment seal with a second tapered portion having a second tapered surface and a second taper angle. The gas turbine segment seal assembly may include a seal pin positioned in between the first tapered segment seal and the second segment seal and adjacent to the first tapered surface and the second tapered surface.

Owner:GE INFRASTRUCTURE TECH INT LLC

Valve assembly

InactiveUS20200109795A1Susceptible to leakageSusceptible to wearSpindle sealingsOperating means/releasing devices for valvesEngineeringActuator

A valve assembly comprising: a fluid flow passage to permit the flow of a fluid through the valve assembly; a valve seat; and an actuator assembly. The actuator assembly comprises: a valve member moveable relative to the valve seat between a first position in which the valve member is at least partially engaged with the valve seat to at least partially block the fluid flow passage, and a second position in which the valve member is remote from the valve seat; an actuator body in a fixed position relative to the valve seat; and a metal bellows that is attached to the valve member and to the actuator body and is disposed within the fluid flow passage. The valve member of the actuator assembly is moveable relative to the actuator body and extends around the actuator body such that the actuator body is disposed within the valve member.

Owner:ROLLS ROYCE PLC

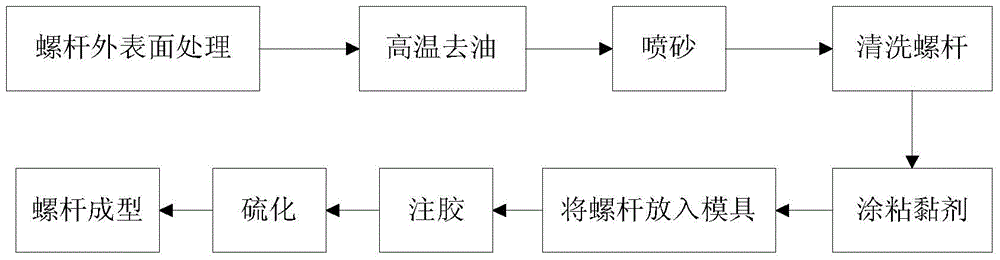

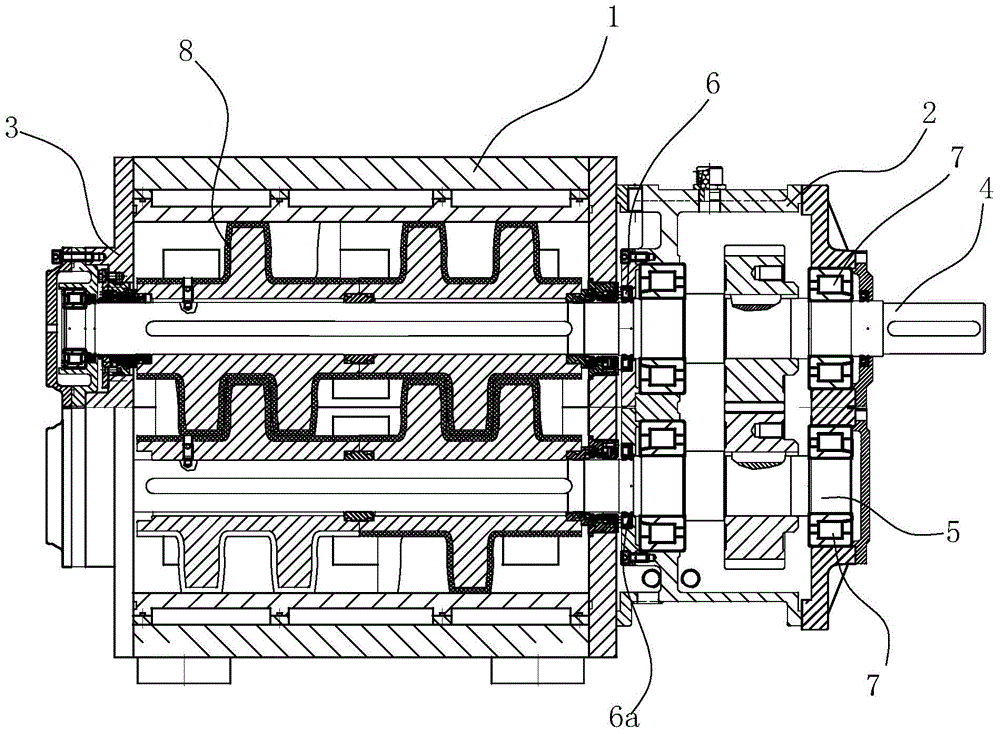

Two-screw pump and preparation method of corresponding rubber lined screw rods of two-screw pump

InactiveCN104791242AReduce wearReduce leakage flowRotary piston pumpsRotary piston liquid enginesVulcanizationAdhesive

The invention discloses a two-screw pump and a preparation method of rubber lined screw rods of the two-screw pump. The two-screw pump comprises a pump body, a pump front cover, a pump rear cover, a driving screw rod and a driven screw rod, wherein the driving screw rod and the driven screw rod are arranged in the pump body and meshed with each other; the pump body adopts such a transmission manner that liquid inlets are formed in two ends of the pump body and a liquid outlet is formed in the middle of the pump body; the surface of the driving screw rod as well as that of the driven screw rod is lined with a layer of rubber. The preparation method comprises the following steps: conducting de-oiling and sand-blast treatment on the outer surfaces of the screw rods; coating the outer surfaces of the screw rods with a layer of an adhesive after cleaning and drying; placing the screw rods coated with the adhesive into a screw rod mold for rubber injection; performing vulcanization molding in a large-scale rubber vulcanization tank; opening the screw rod mold after cooling, so that the required rubber lined screw rods are obtained. The surfaces of the driving screw rod and the driven screw rod are lined with the layers of rubber in such a manner of local rubber injection and local air discharge, so that the preparation method is simple and easy to operate, the rubber injection difficulty is reduced, and the quality of a rubber body is also guaranteed; the two-screw pump is resistant to abrasion, high in sealing performance and long in service life, and the medium through capability can be effectively improved.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com