Patents

Literature

1113 results about "Load force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

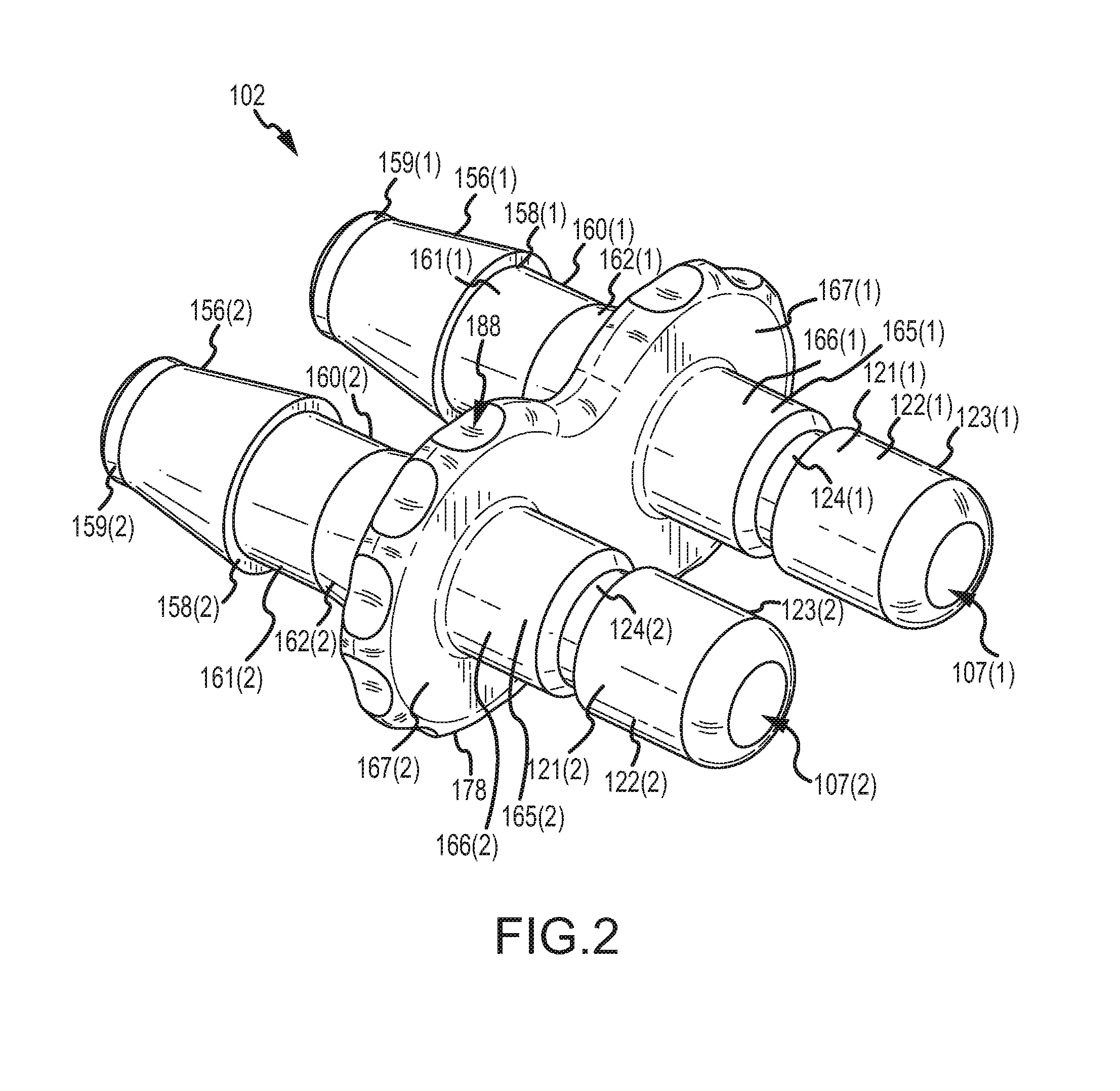

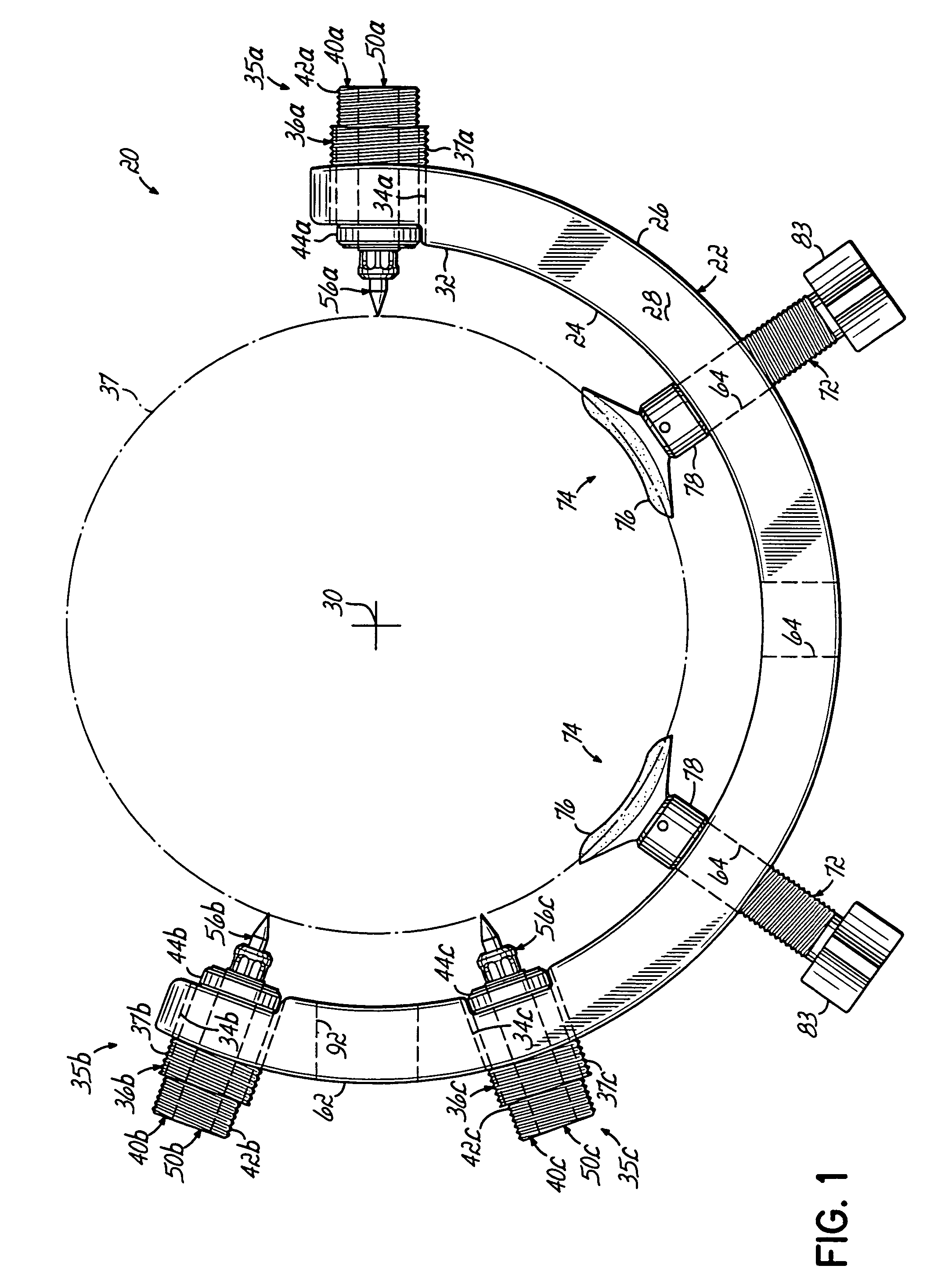

Non-pneumatic tire

InactiveUS7201194B2Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsElastomerShear modulus

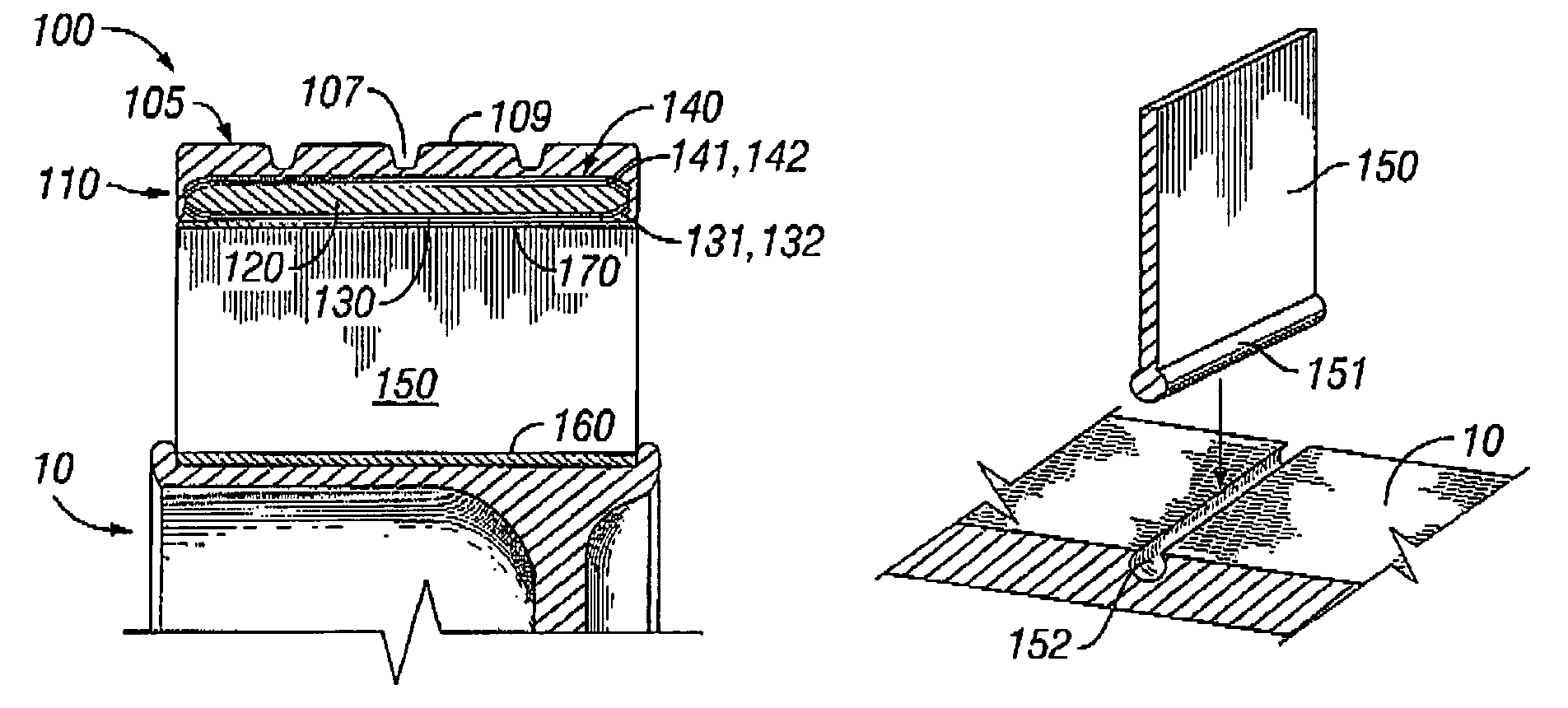

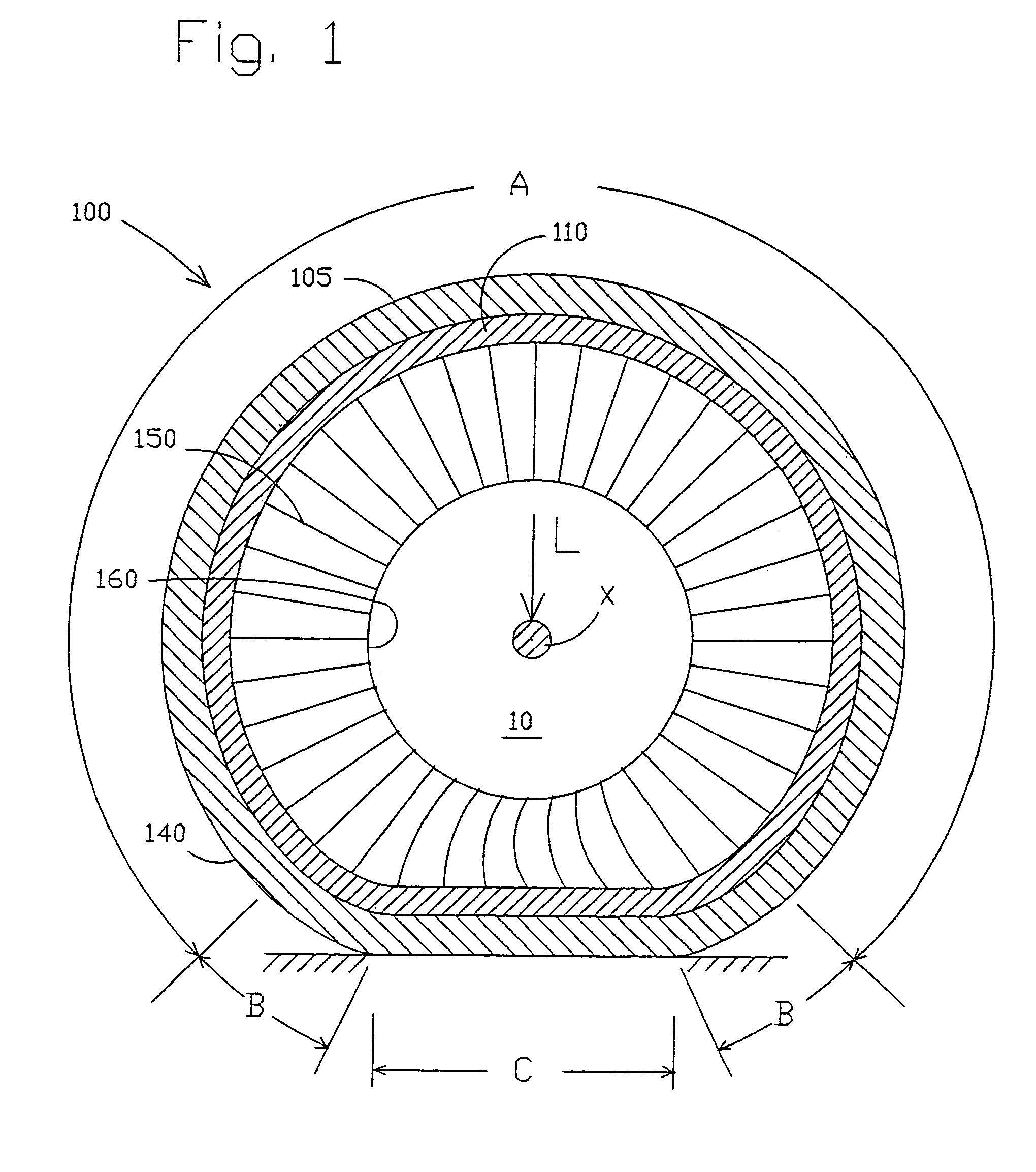

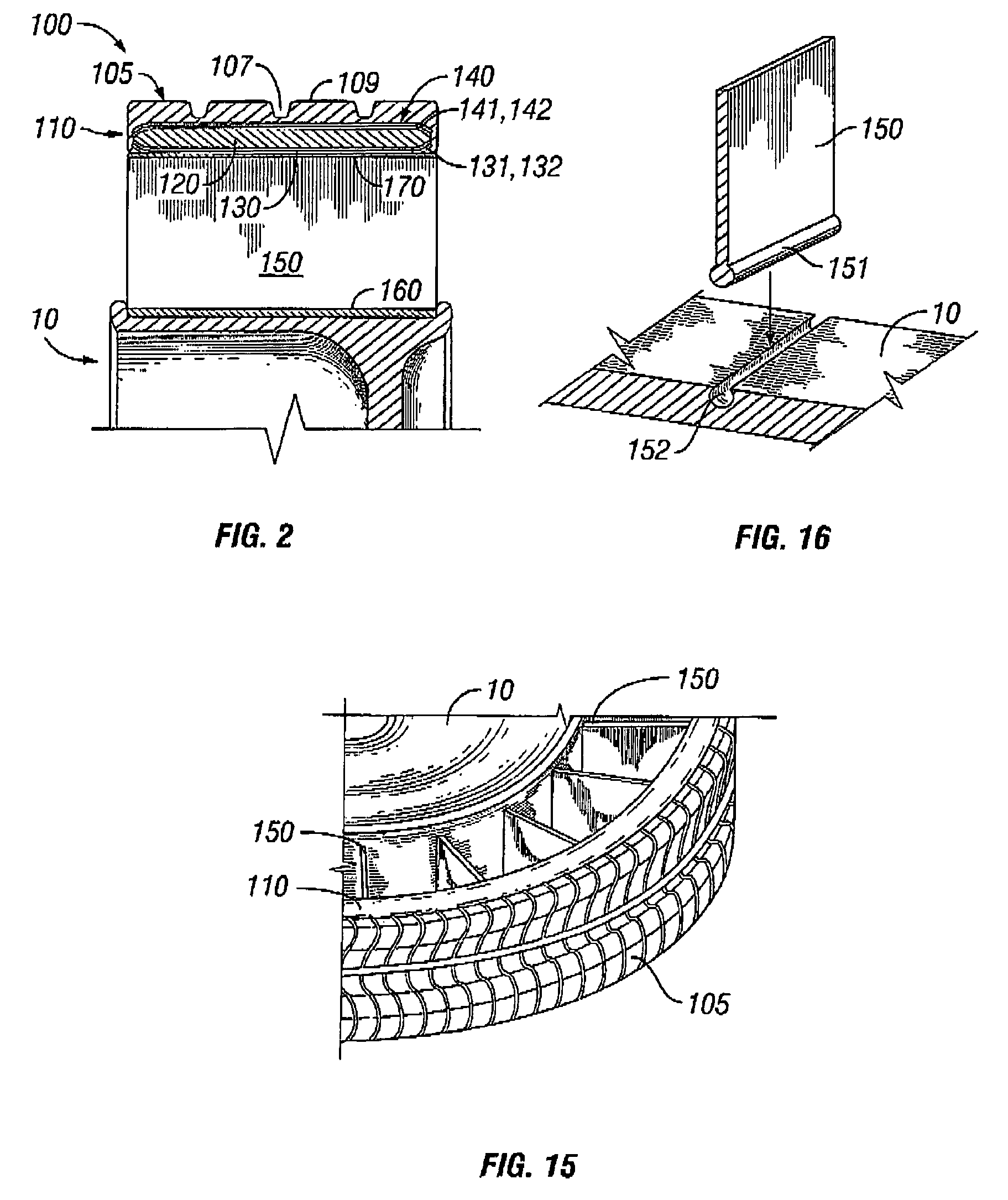

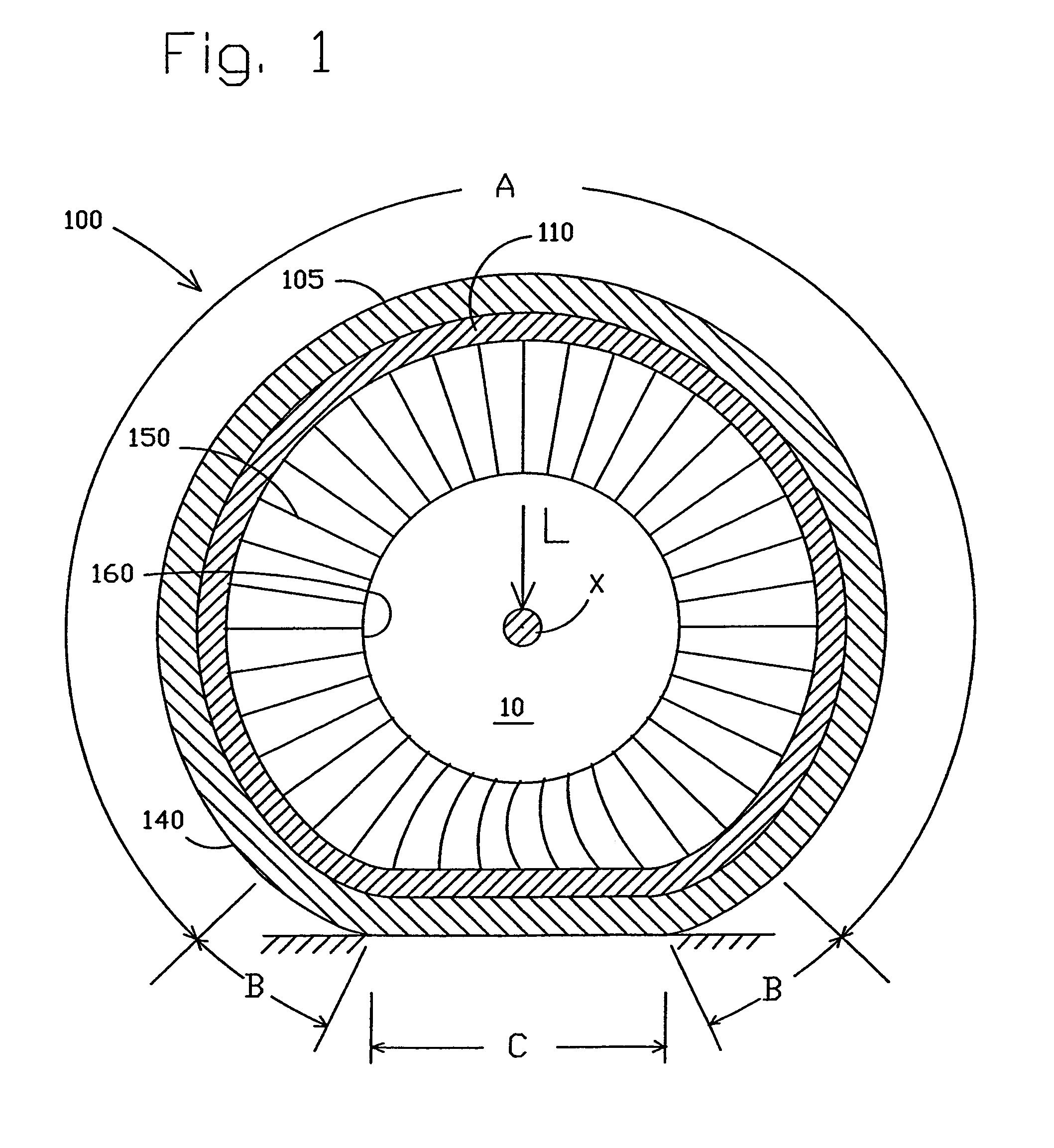

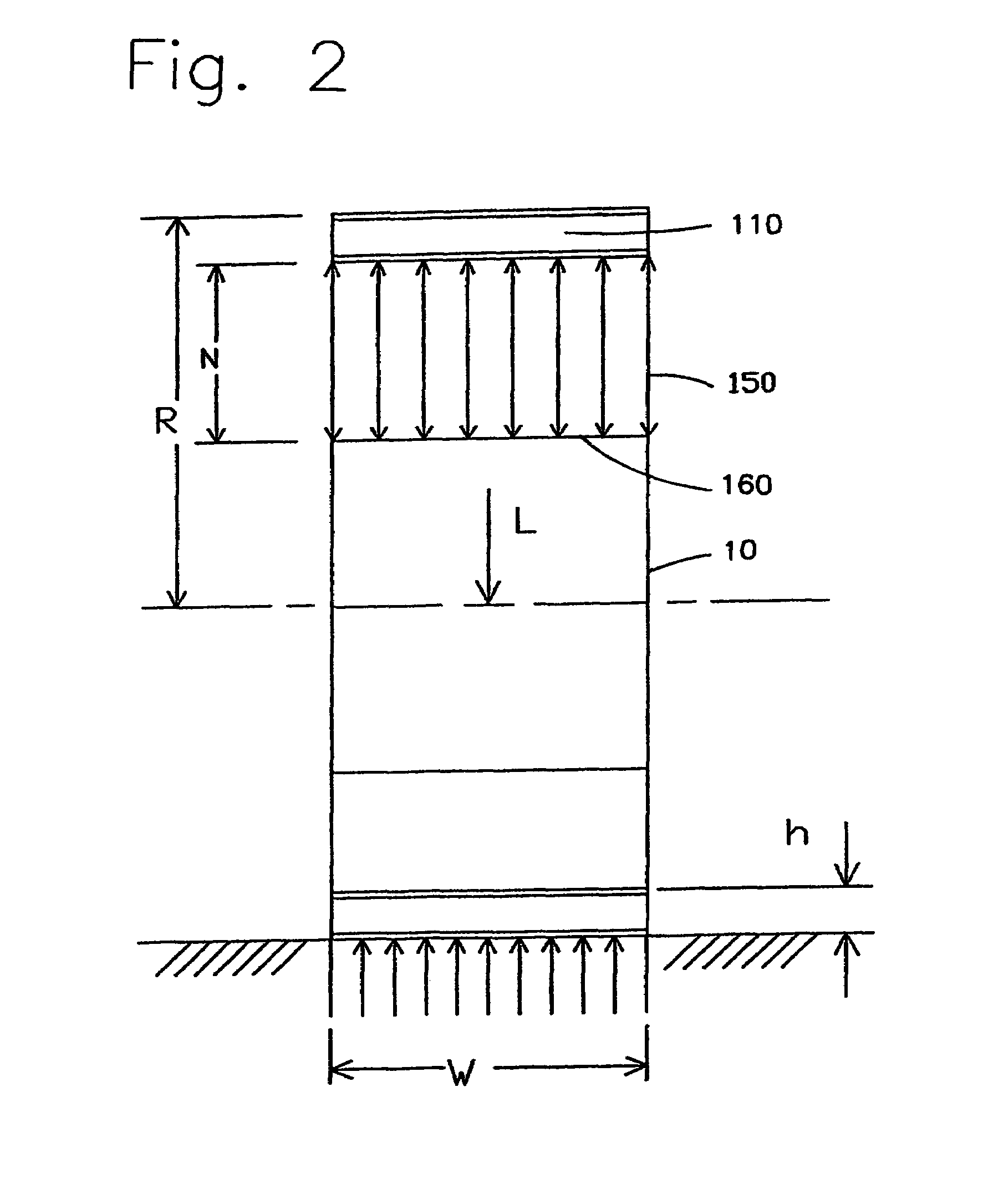

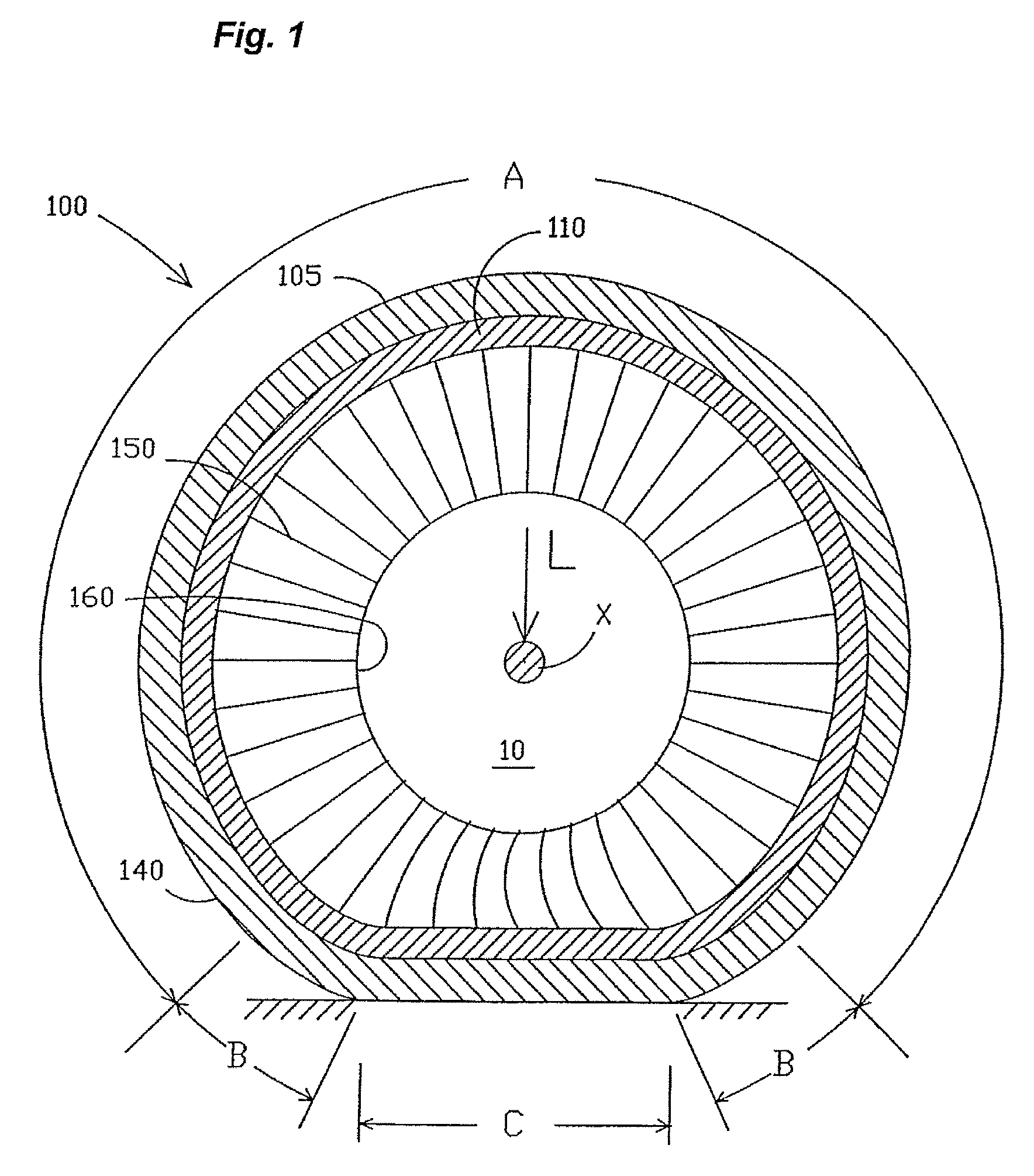

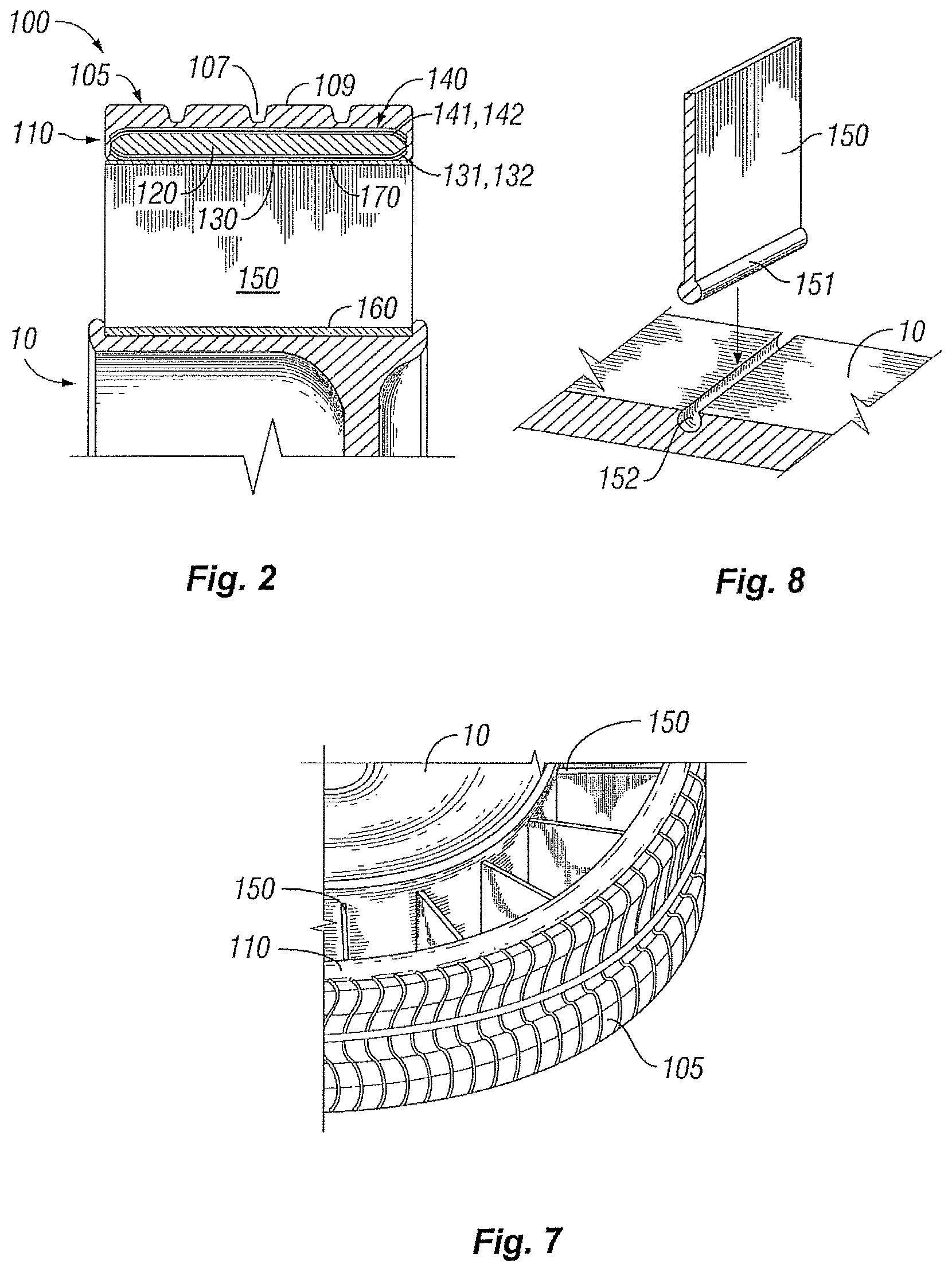

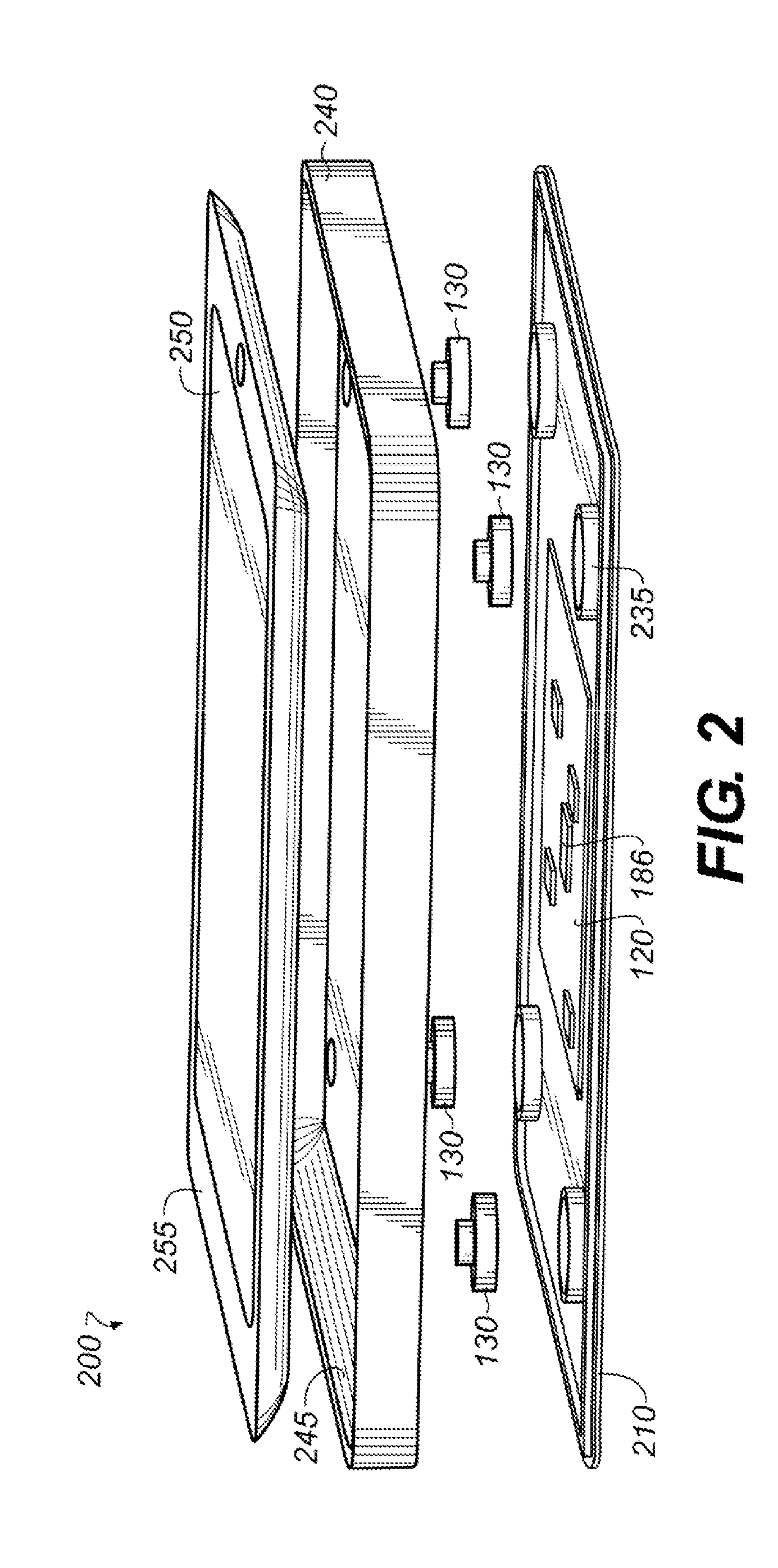

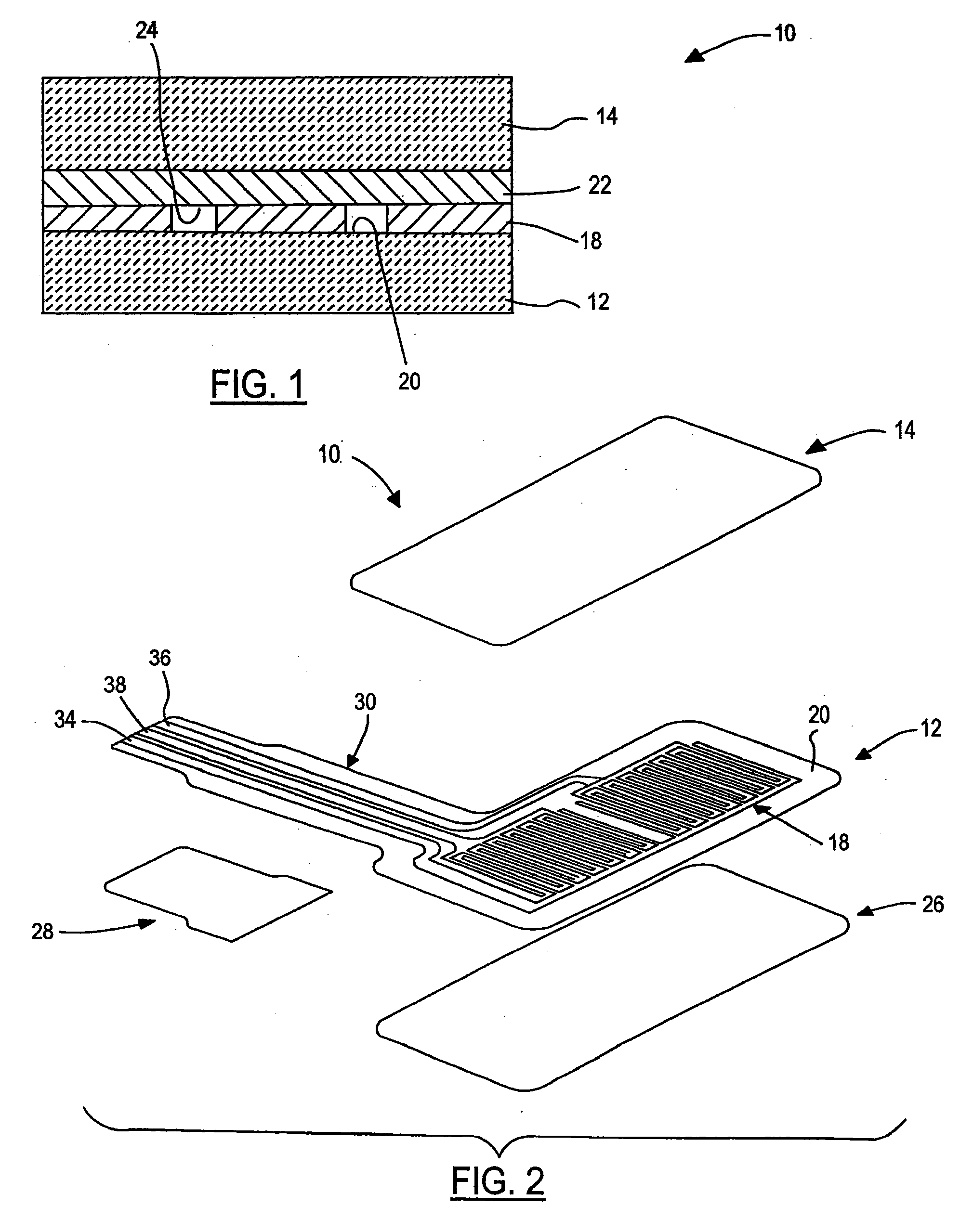

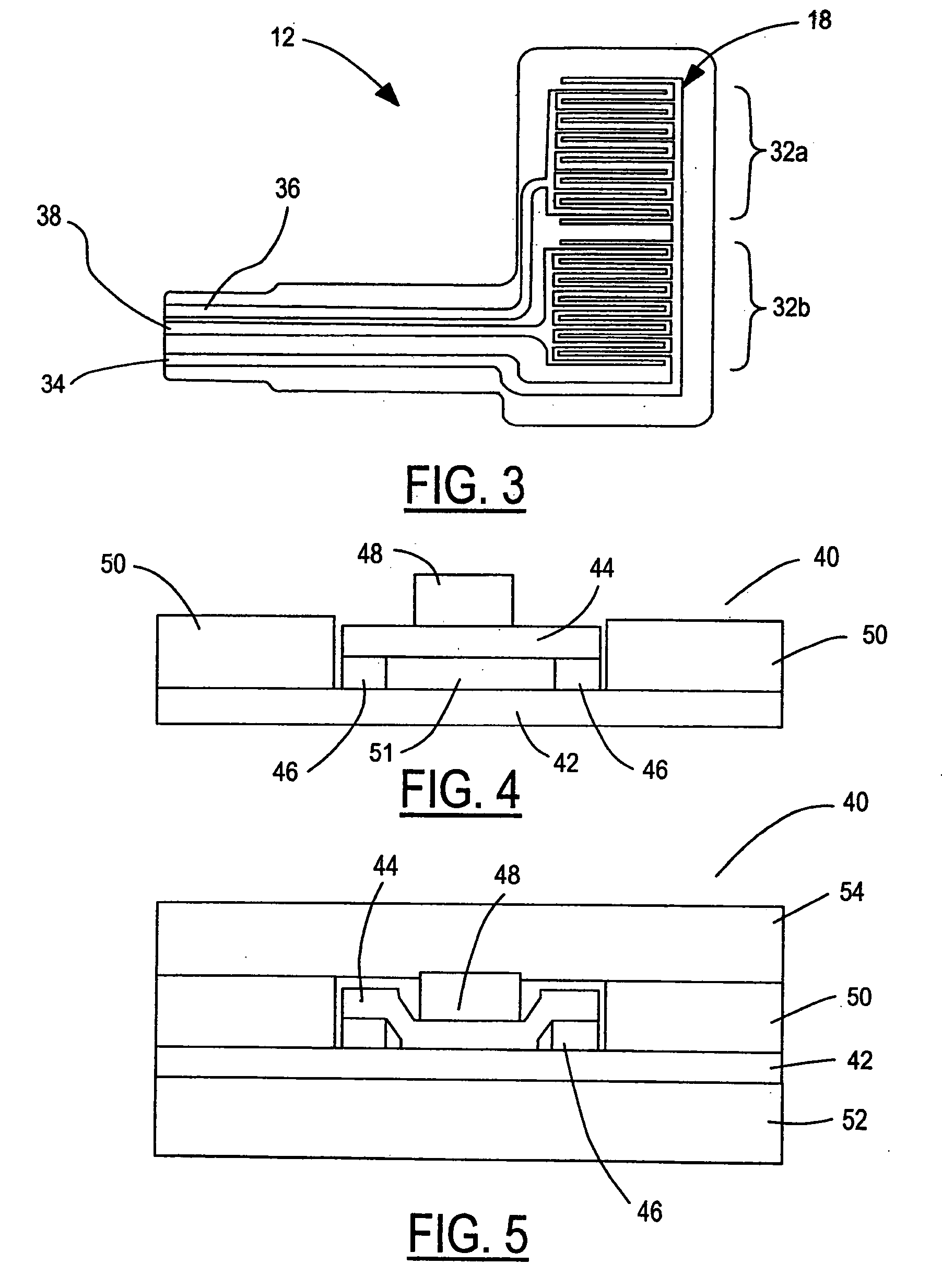

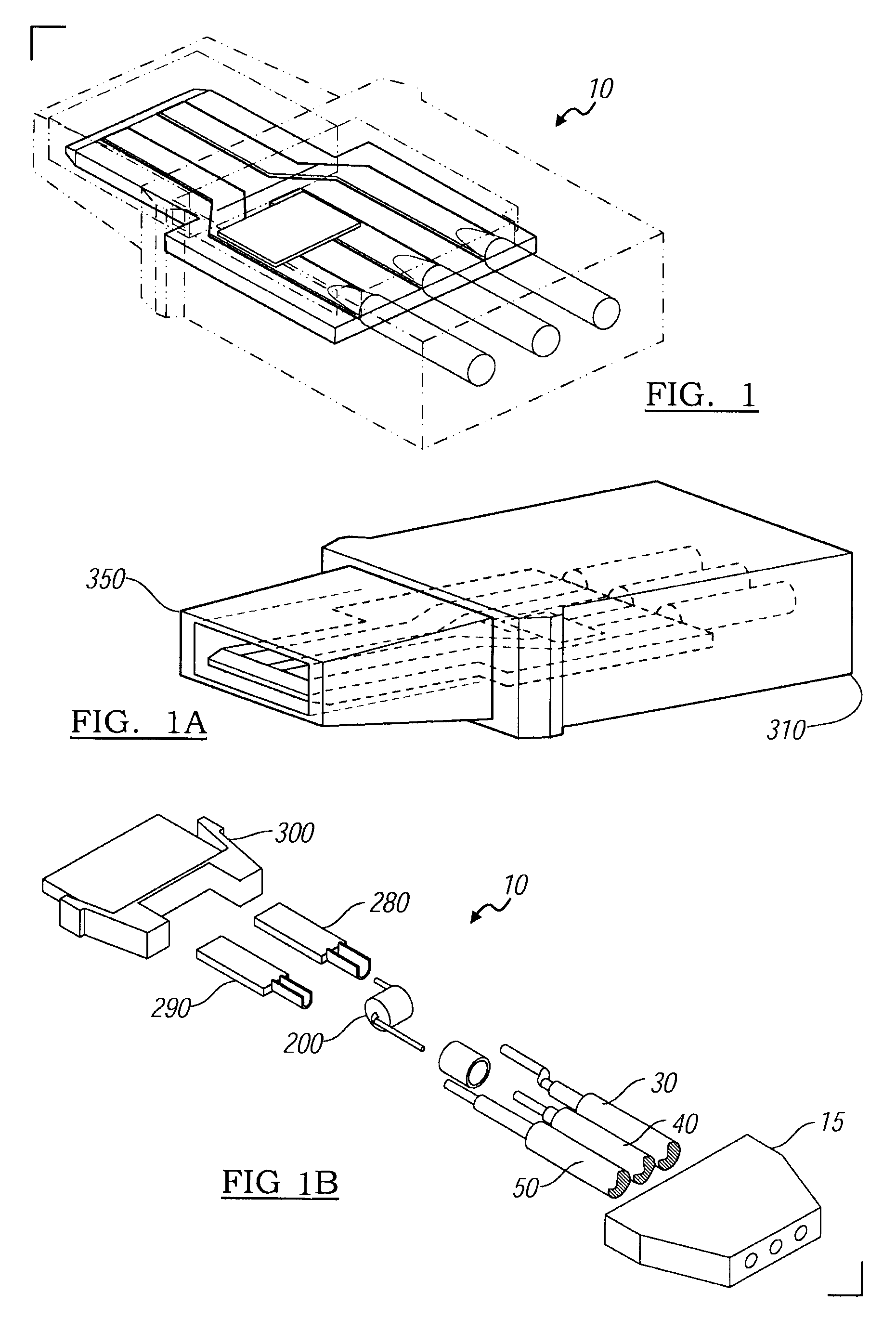

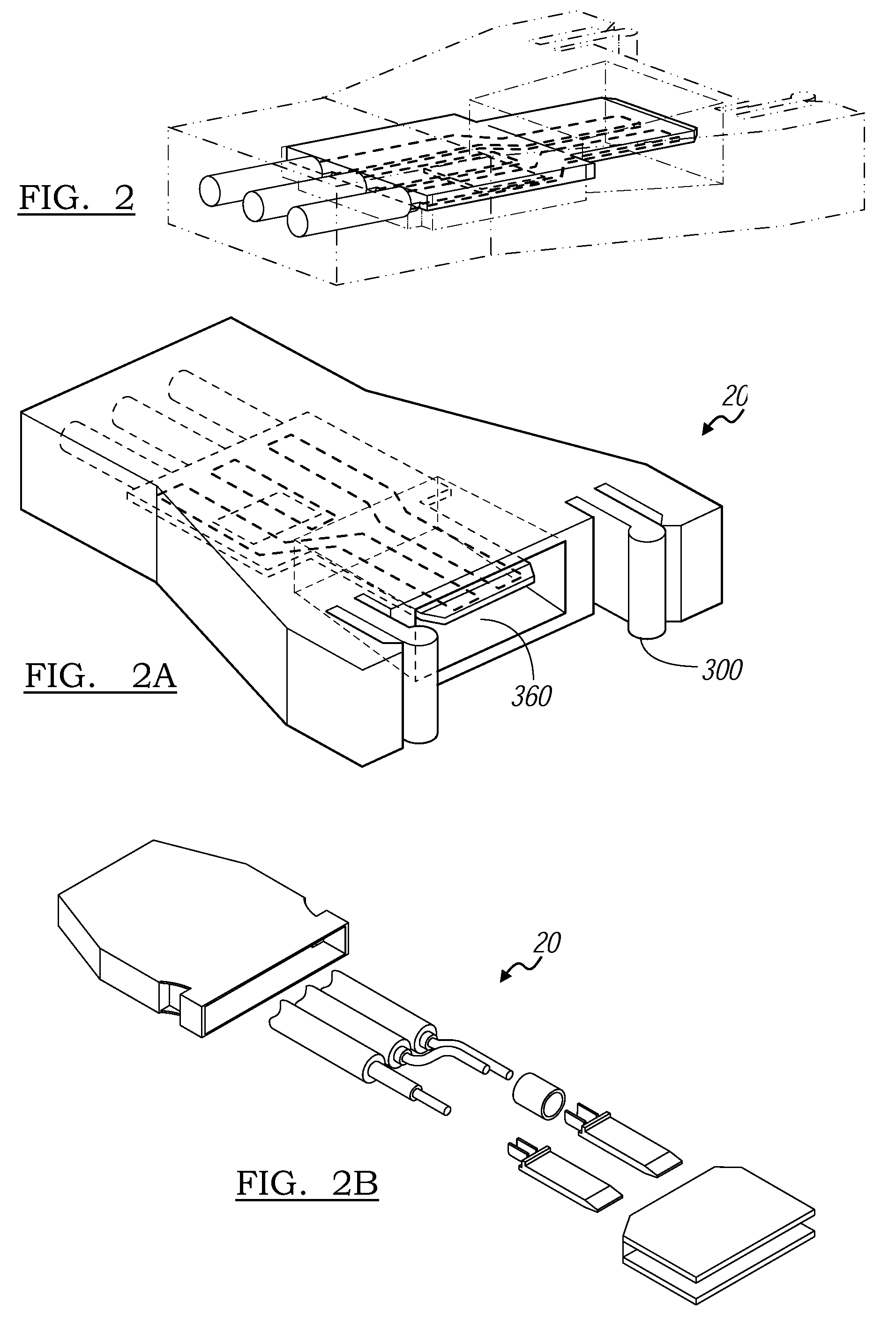

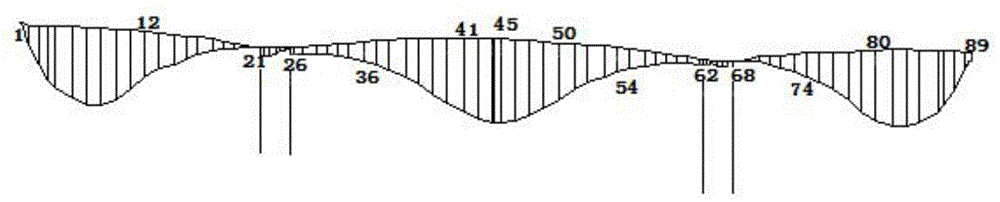

A structurally supported tire includes a ground contacting tread portion, a reinforced annular band disposed radially inward of the tread portion, and a plurality of web spokes extending transversely across and radially inward from the reinforced annular band and anchored in a wheel or hub. The reinforced annular band comprises an elastomeric shear layer, at least a first membrane adhered to the radially inward extent of the elastomeric shear layer and at least a second membrane adhered to the radially outward extent of the elastomeric shear layer. Each of the membranes has a longitudinal tensile modulus sufficiently greater than the shear modulus of the shear layer so that when under load the ground contacting portion of the tire deforms to a flat contact region through shear strain in the shear layer while maintaining constant the length of the membranes, the web spokes transmitting load forces between the annular band and the hub through tension in the web spokes not connected to the ground contacting portion of the tire.

Owner:MICHELIN RECH & TECH SA

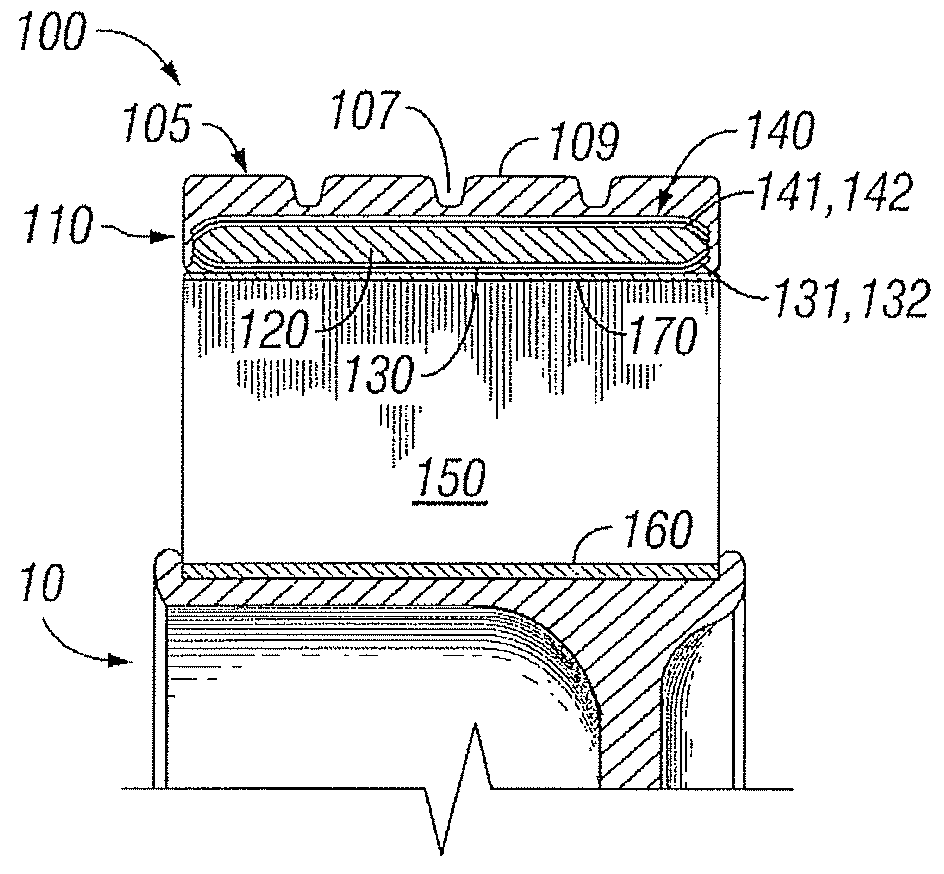

Compliant wheel

InactiveUS7013939B2High effective stiffness in tensionLow effective stiffness in compressionNon-inflatable tyresWheel manufactureBand bendingGround contact

A compliant wheel includes a compliant band and a plurality of web spokes extending transversely across and inward from the reinforced compliant band for attachment to a hub. The compliant band bends to comply with a contact surface and to envelope obstacles. The web spokes transmit load forces between the compliant band and the hub through tension in the web spokes not connected to the ground contacting portion of the wheel. The outer surface of the compliant band may be formed to include a tread, or a separate tread band may be attached.

Owner:MICHELIN RECH & TECH SA

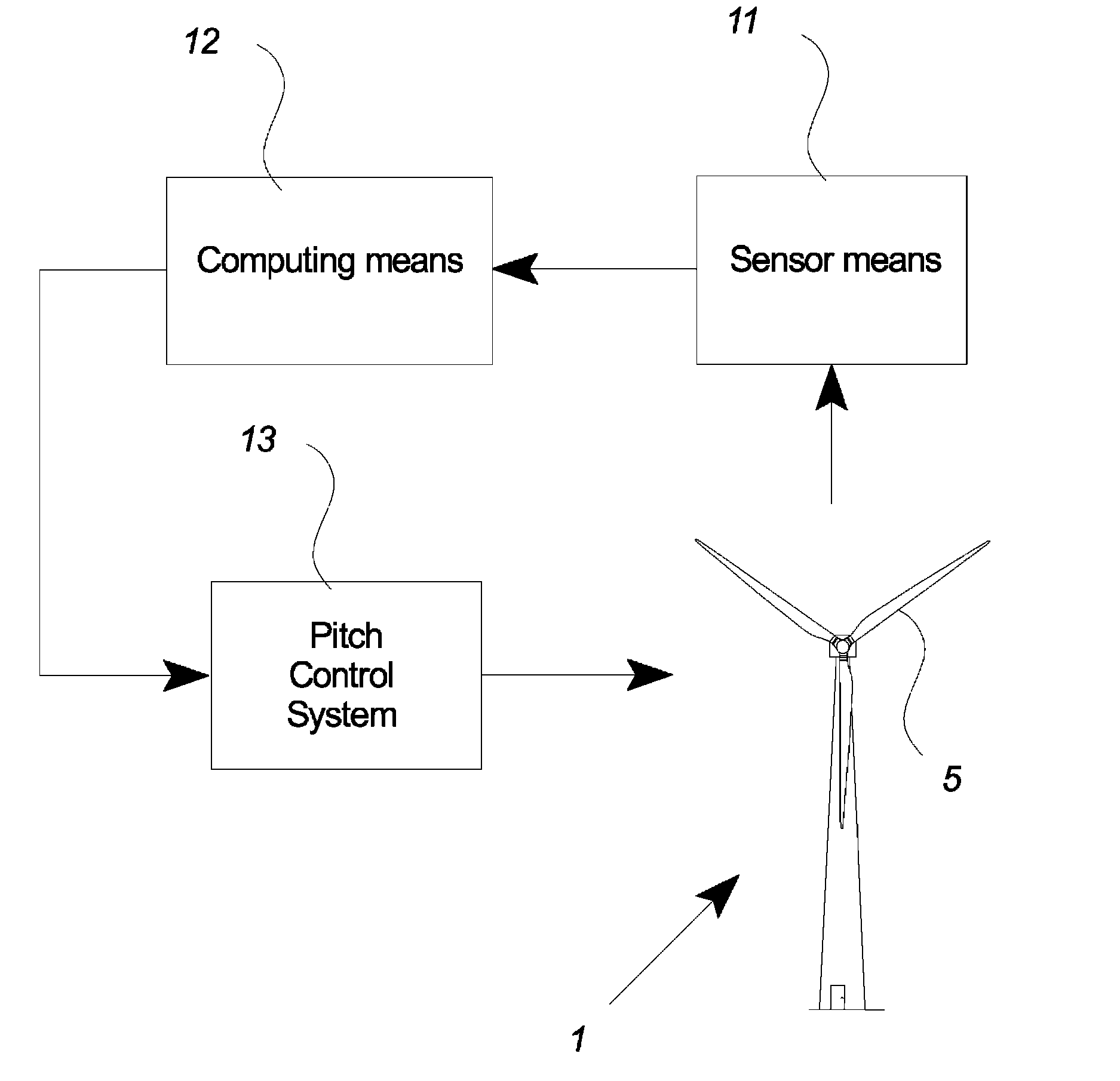

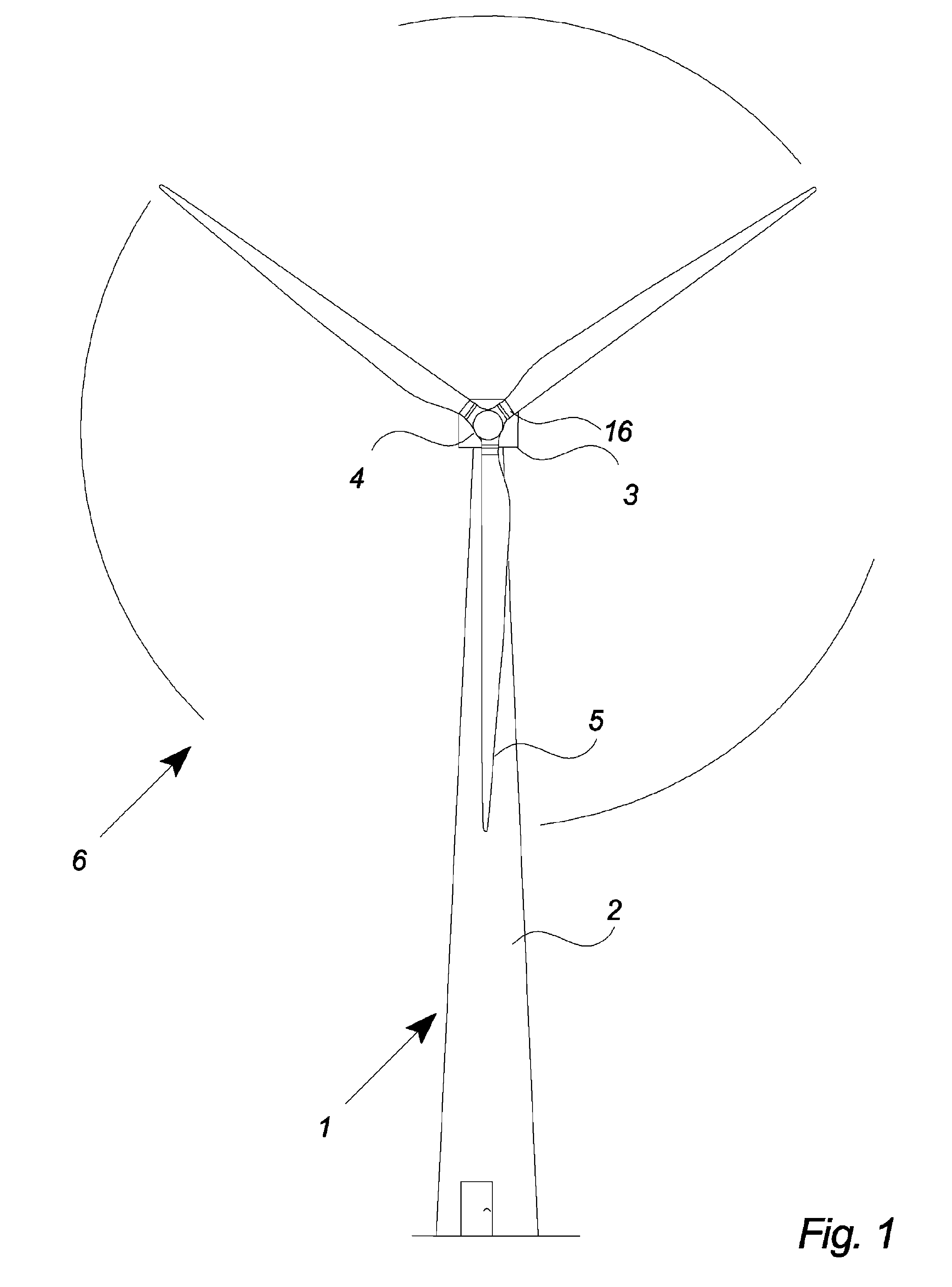

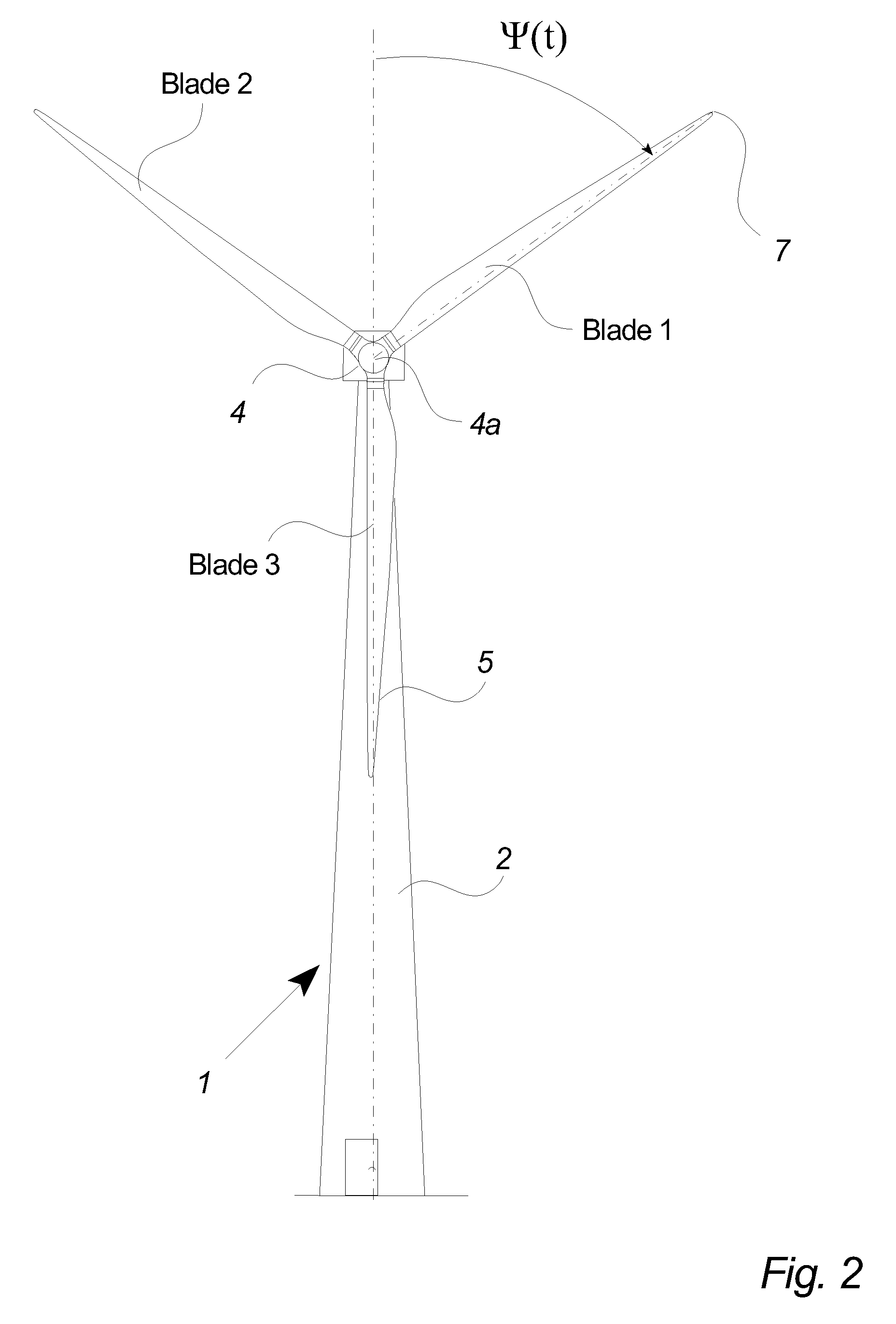

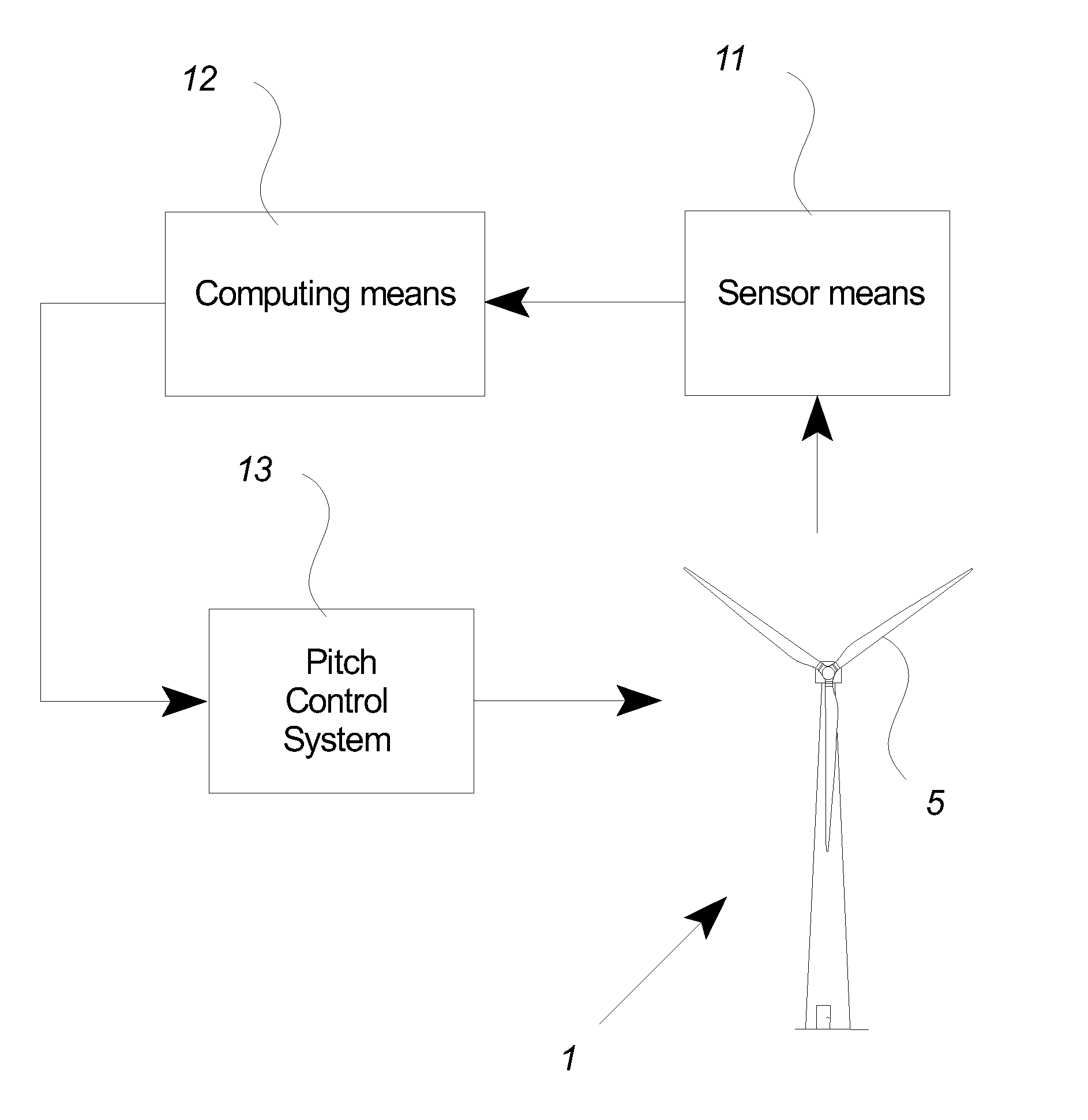

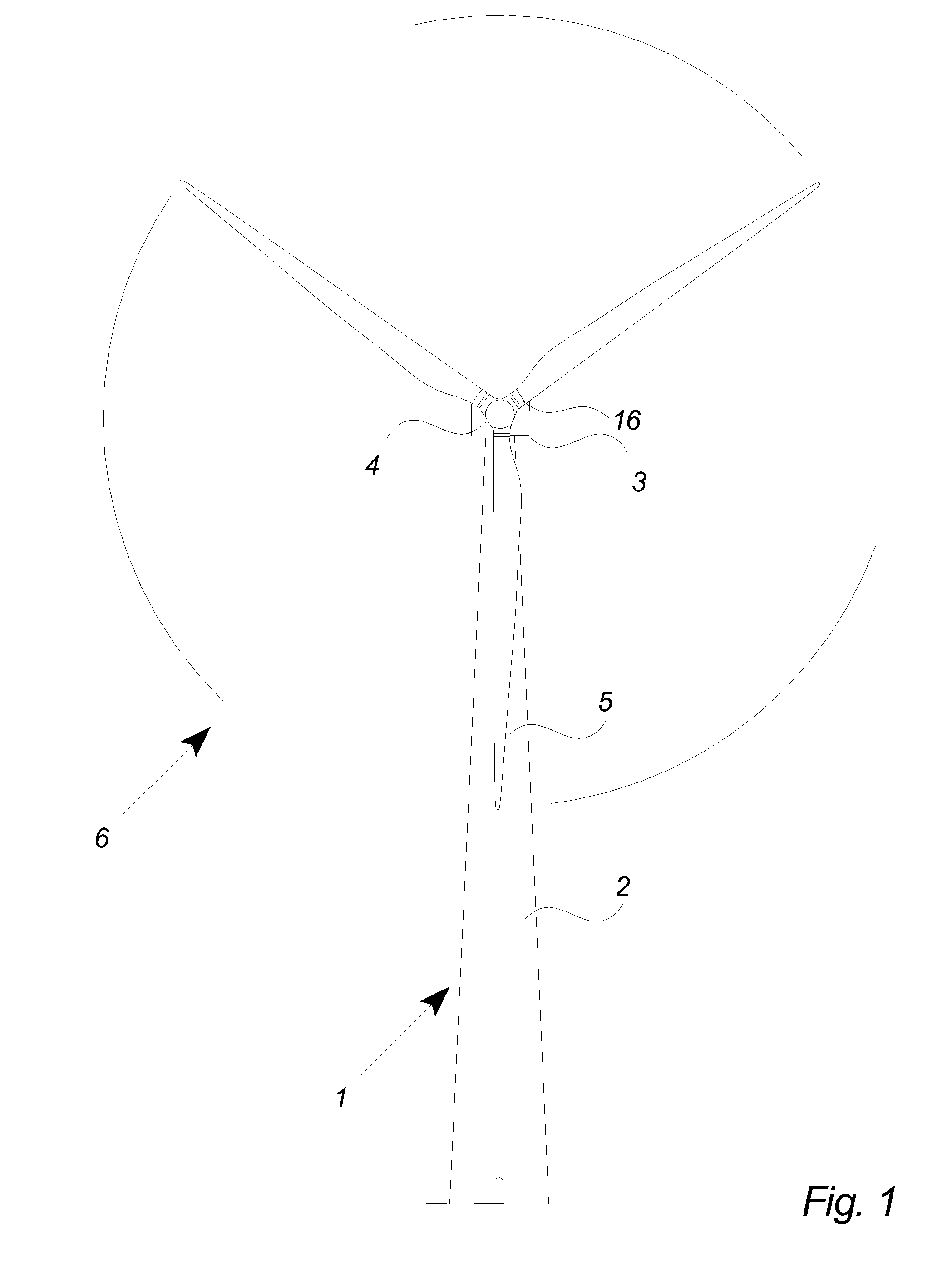

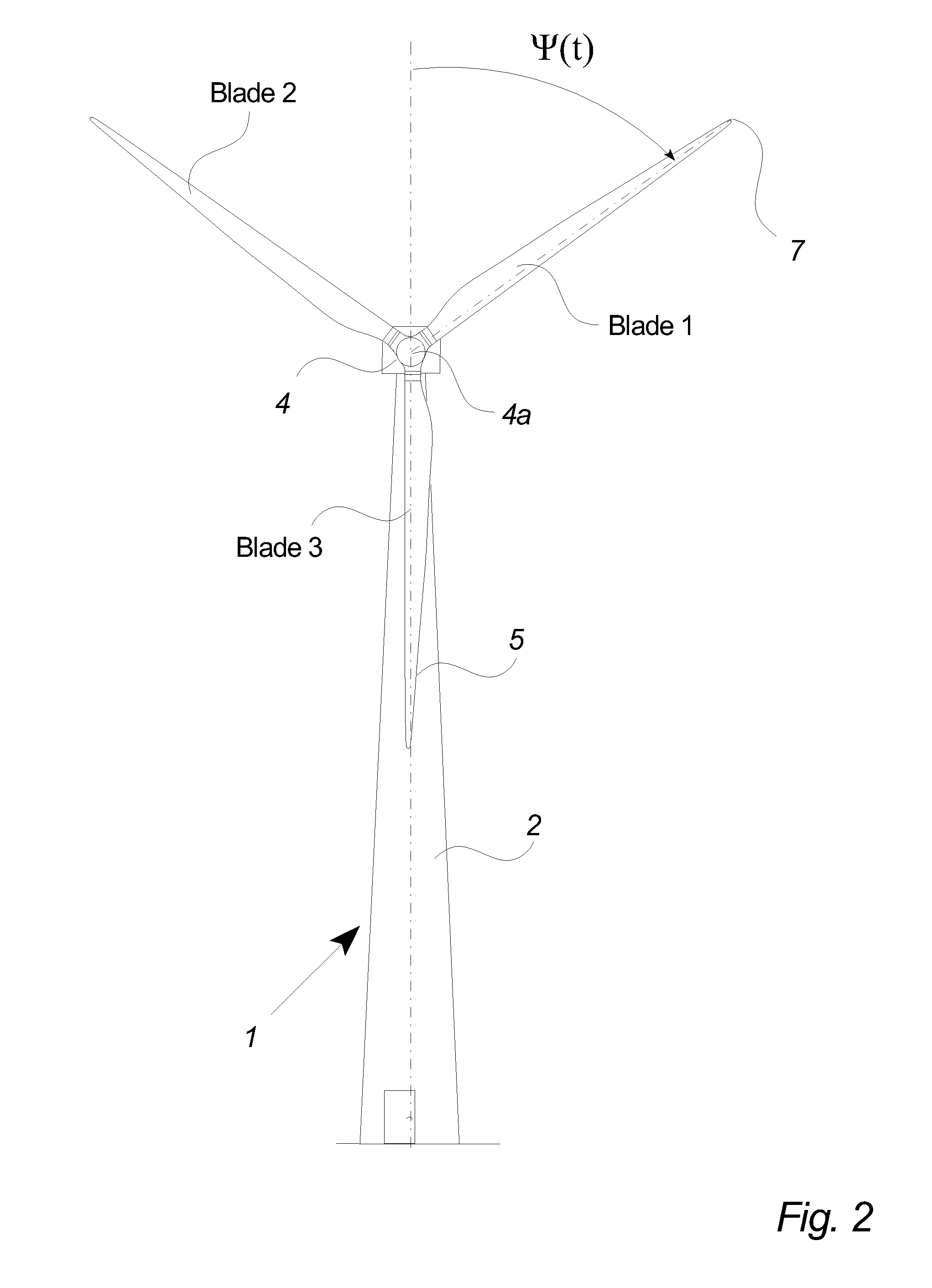

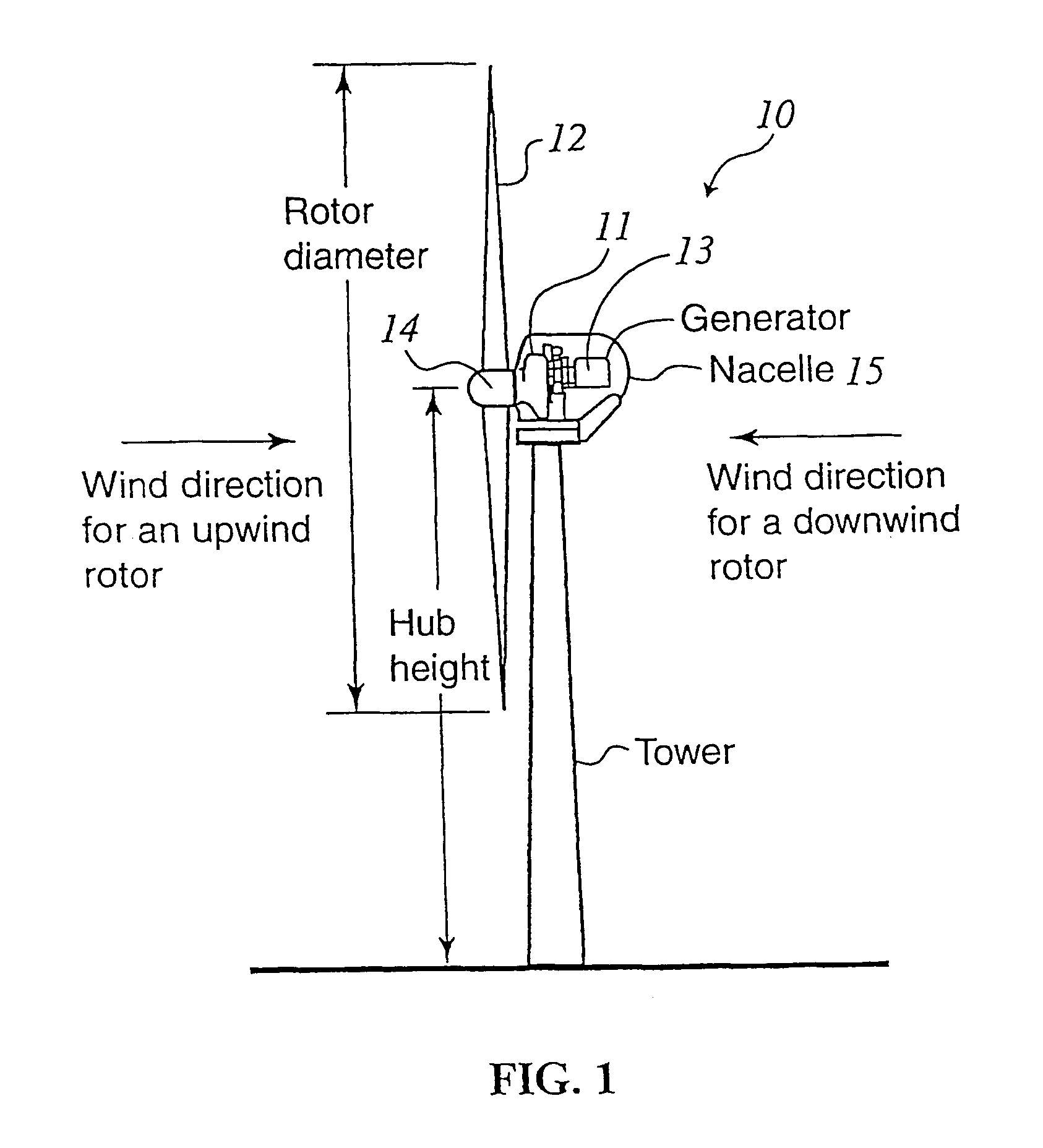

Wind turbine with pitch control arranged to reduce life shortening loads on components thereof

ActiveUS8096762B2Easy to operateReducing the mean bending momentPropellersPump componentsPull forceGravitational force

A wind turbine is presented where the operation lifetime of the main bearing is extended by relieving the main bearing by reducing the mean bending moment on the bearing by means of individual pitch control of the blades of the rotor so as to create an aerodynamic mean tilt moment on the rotor by means of aerodynamic forces on the blades, the tilt moment at least partly counteracting the bending moment caused by the overhang load forces on the main bearing from the gravitational pull on the rotor mass.

Owner:VESTAS WIND SYST AS

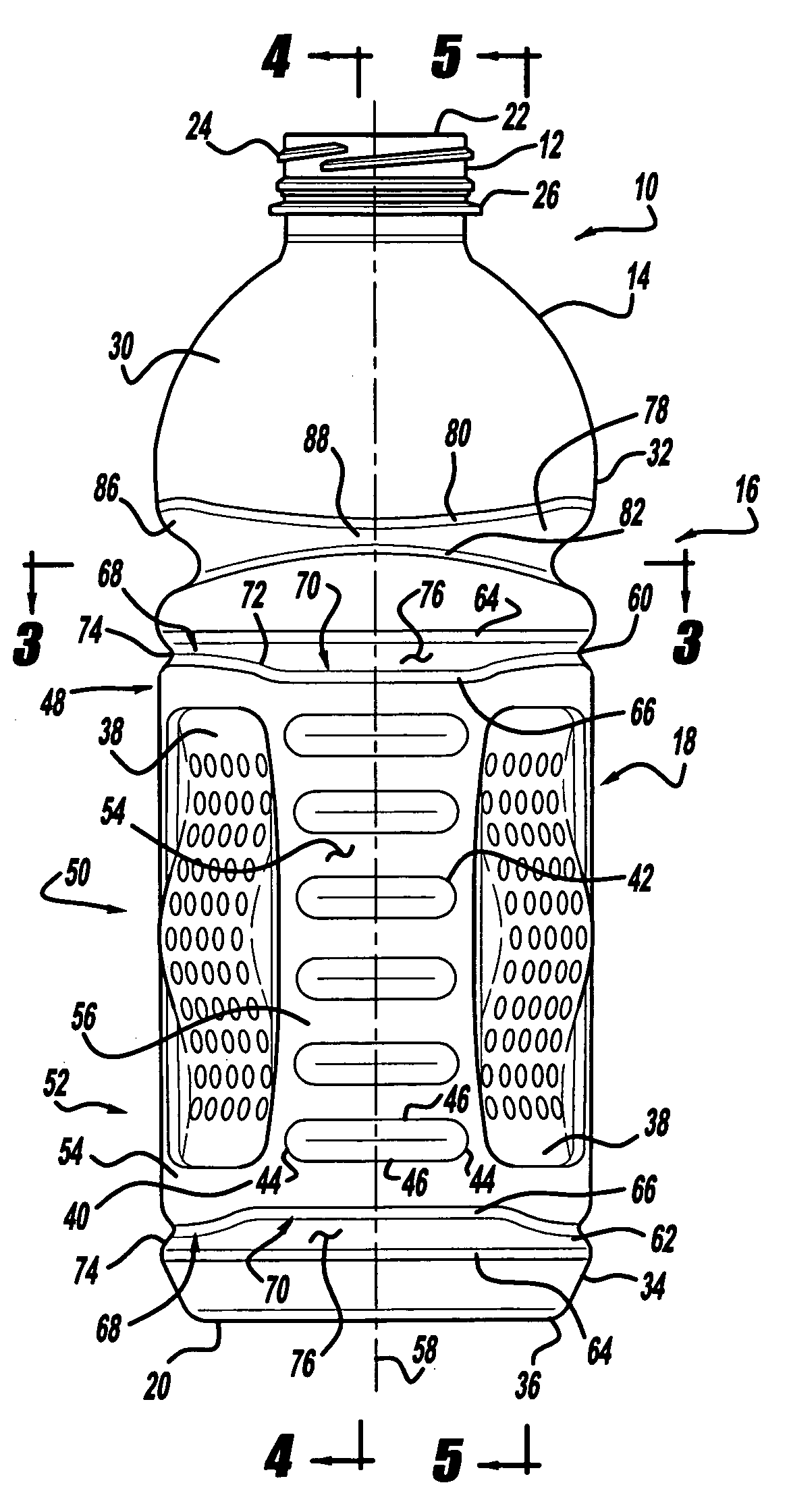

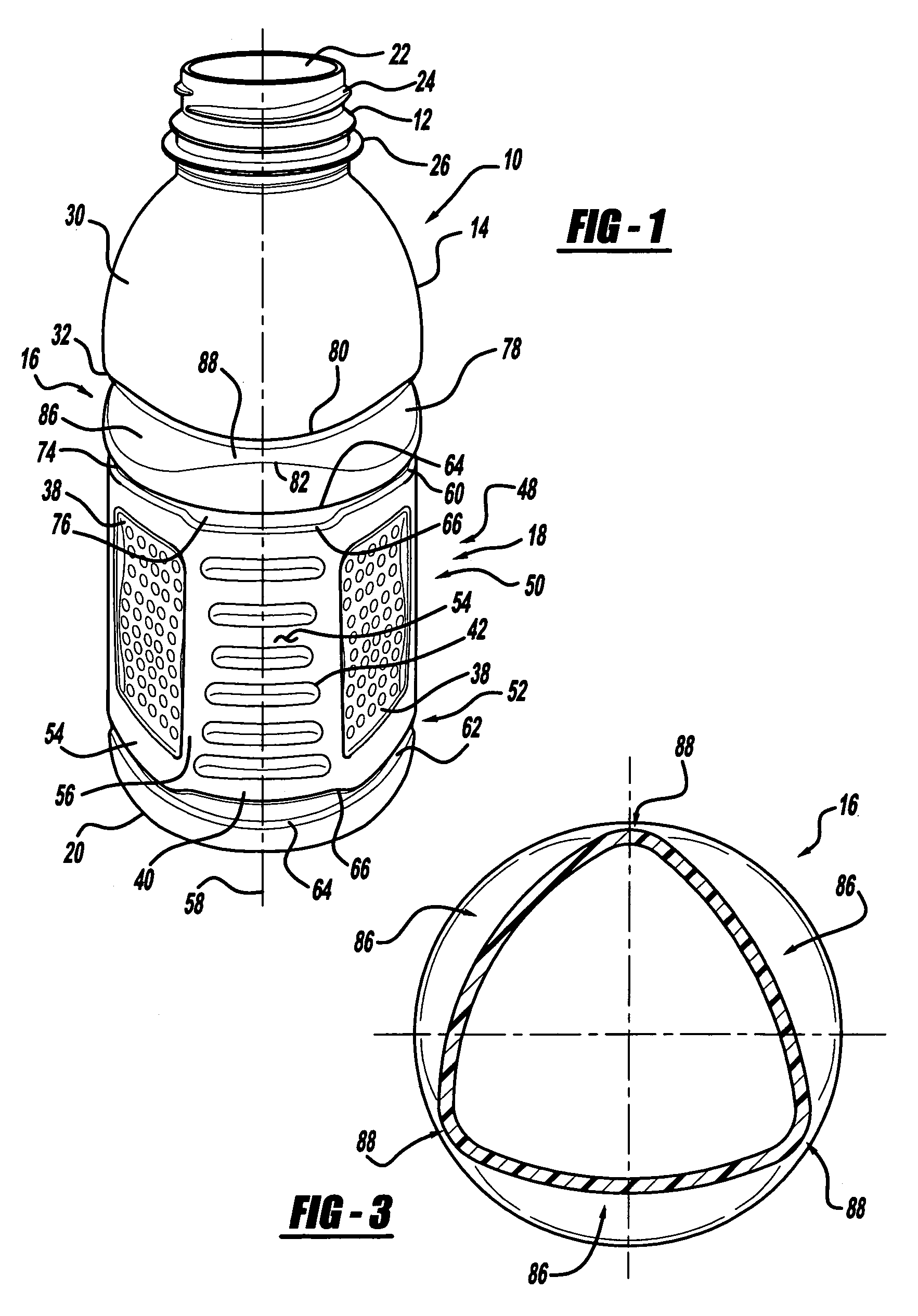

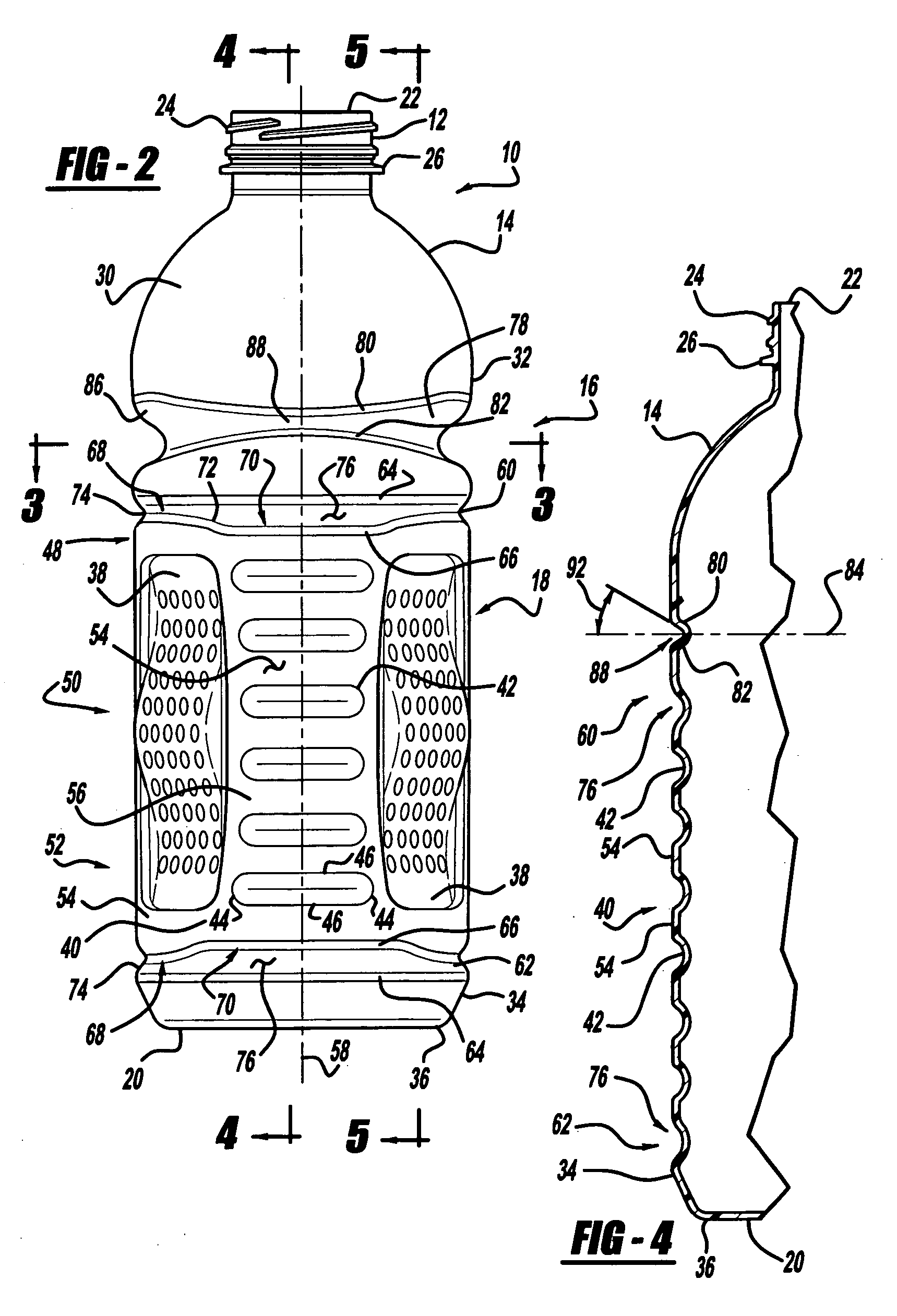

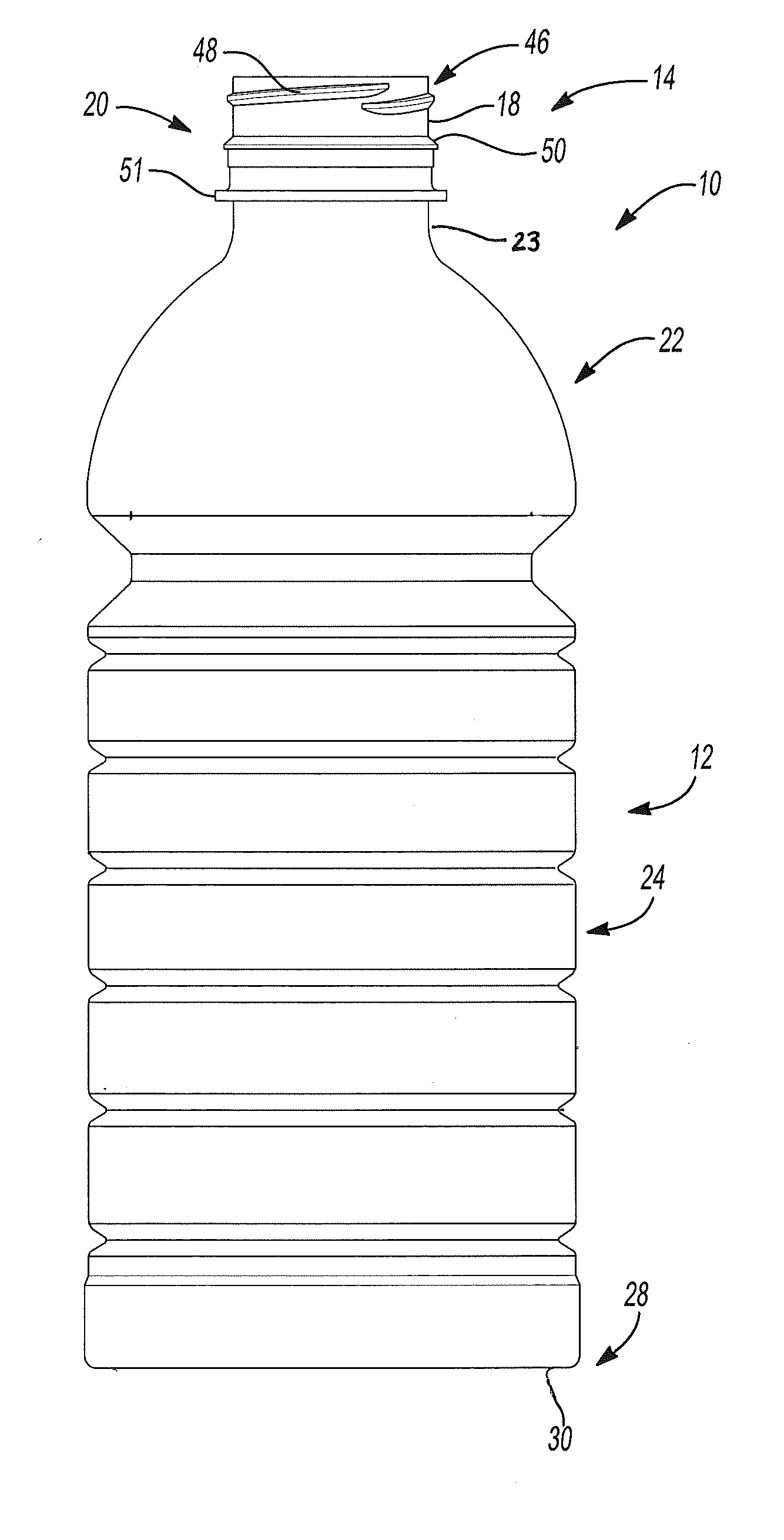

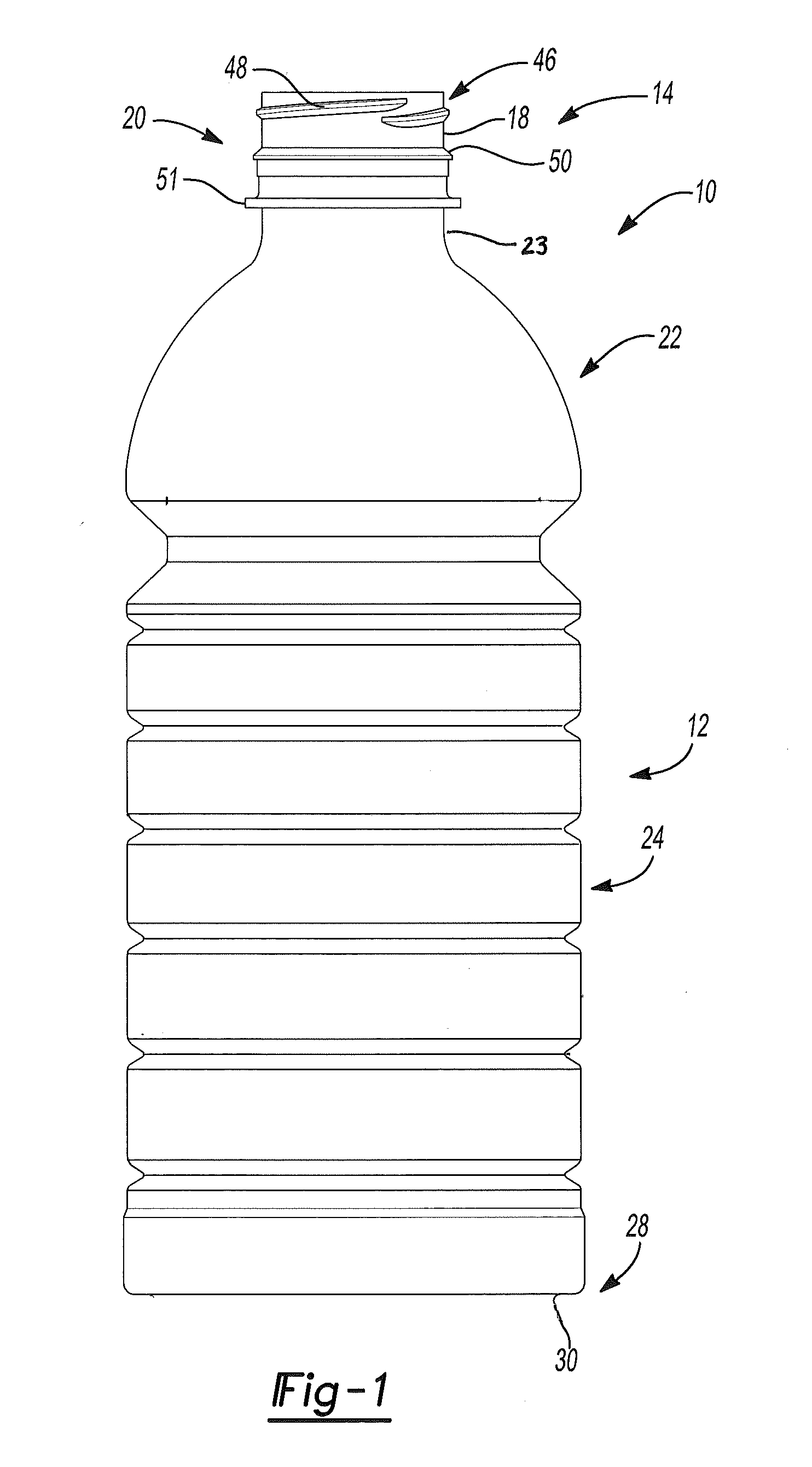

Lightweight container

ActiveUS7080747B2Improve abilitiesMaintain mechanical integrityBottlesLarge containersVacuum pressureEngineering

A hot fill, blow molded plastic container adapted for vacuum pressure absorption and top load force enhancement having a waist region, and generally rectangular shaped vacuum panels and columns equidistantly spaced about the container. The waist region being movable to accommodate top load forces. The vacuum panels being movable to accommodate internal thermally induced volumetric and pressure variations in the container resulting from heating and cooling of its contents.

Owner:AMCOR RIGID PLASICS USA LLC

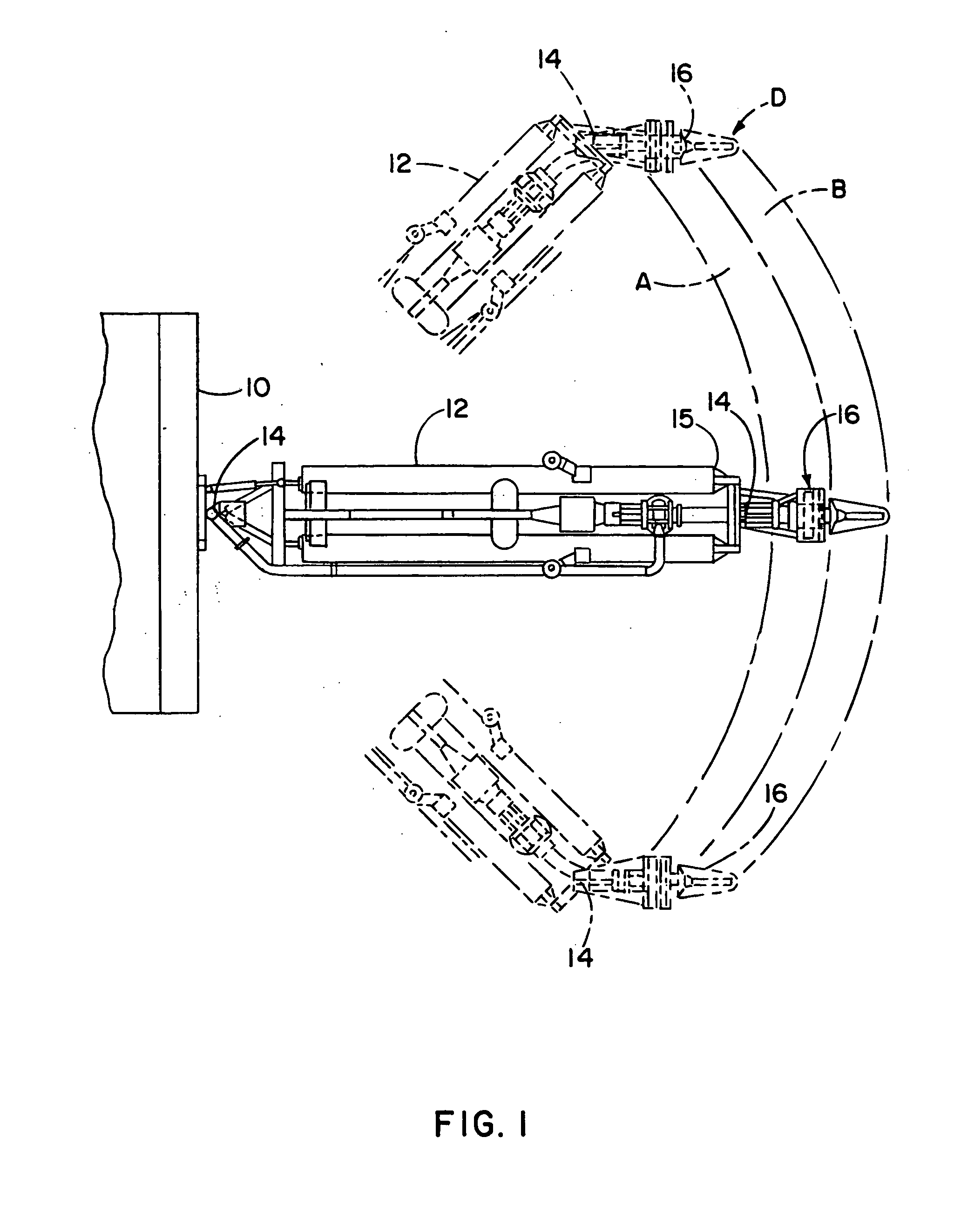

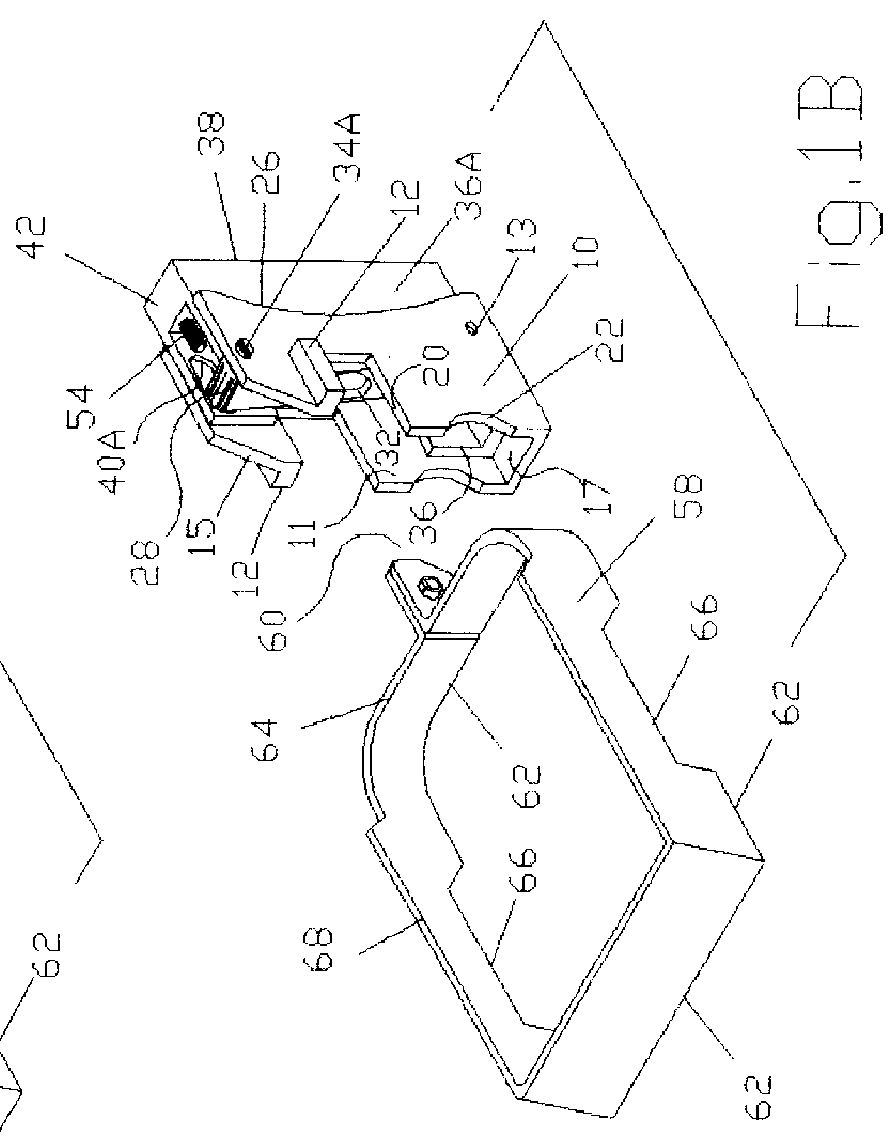

Power tong

InactiveUS6082224AEffectively grip a tubularPrevent slippingDrilling rodsWrenchesMechanical engineeringLoad force

A new power tong for rotating tubular members for make-up (connection) and break-out (disconnection) operations. In one aspect such a tong has at least one movable jaw with a smooth surface gripping element thereon and pre-load apparatus for applying a pre-load force to a movable jaw so that the jaw does not slip on a tubular to be rotated and so it does not mark or damage the tubular. In one aspect the pre-load apparatus includes a first pre-load device at one end of a movable jaw for breakout operations and a second pre-load device at another end of the jaw for make-up operations. In one aspect a power tong which has unique smooth surfaced jaw inserts made, e.g., of aluminum. In one aspect a single pivotable pre-load cylinder, fixed to rotary, pivots for pivotable connection to one jaw or the other. This can be done manually or a powered smaller piston / cylinder may be used to pivot the pre-load cylinder. In one aspect a jaw unit which comprises a jaw holder and a jaw movable with respect to said jaw holder, characterized in that said jaw is slidably mounted on said jaw holder.

Owner:WEATHERFORD TECH HLDG LLC

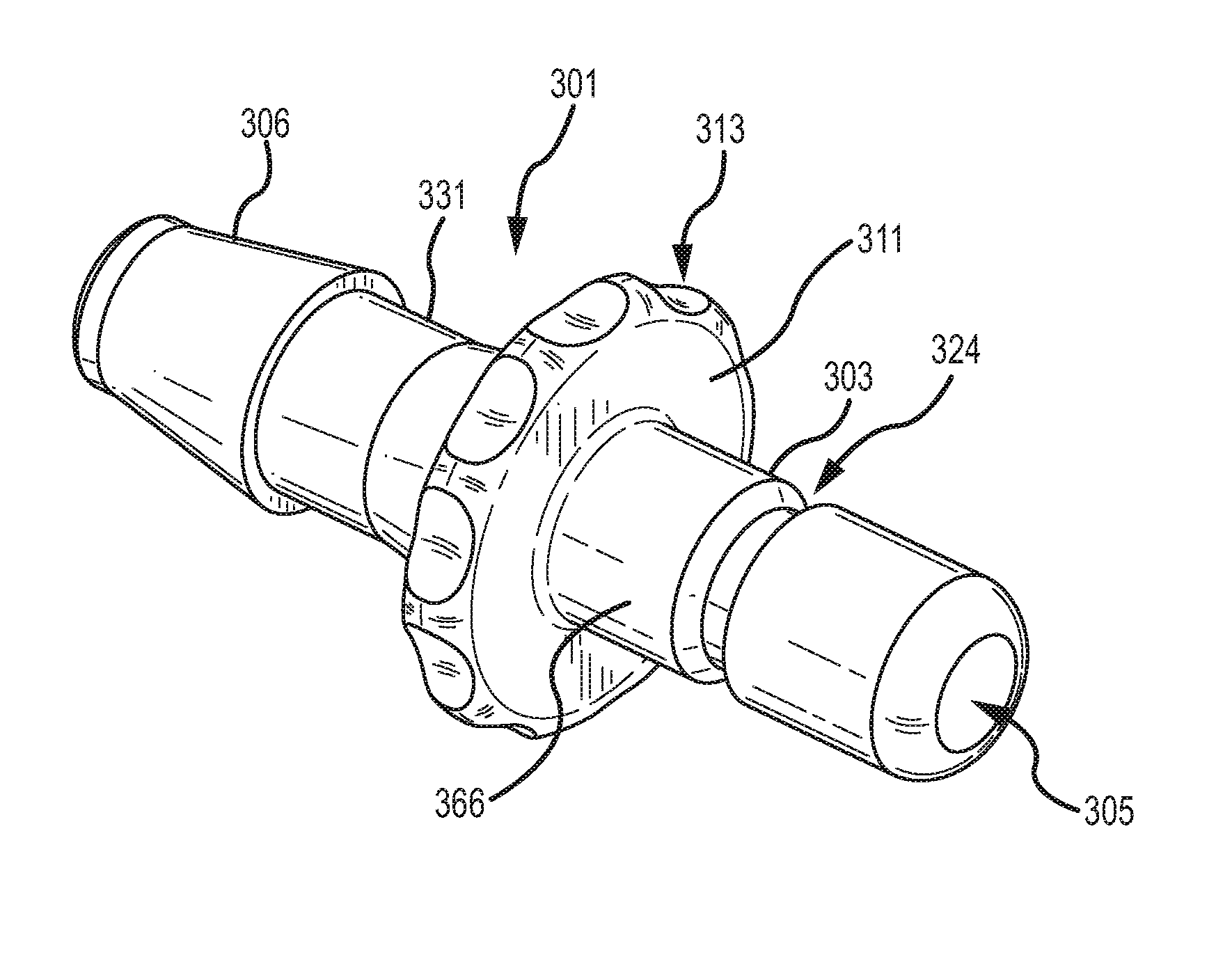

Male bayonet connector

A male bayonet connector connects a section of tubing to a female latch connector. The male bayonet connector includes a shaft defining a lumen, a distal end portion, and a proximal end portion. The distal end portion of the shaft has a sealing surface configured to engage a seal member within the female latch connector to create a fluid-tight seal. The shaft defines an annular recess proximal to and adjacent the distal end portion. The annular recess has a proximal chamfered sidewall and a distal sidewall perpendicular to the axis of the lumen, which are separated by a band of smaller diameter than the sealing surface. A grip is formed on the make bayonet connector between the proximal end portion and the annular recess. A ratio of a length of the first sealing surface to a distance between the grip and the distal sidewall is such that a side-load force, as imparted on the male bayonet connector, will not break a fluid-tight seal between the sealing surface and the seal member.

Owner:GENERAL ELECTRIC CO

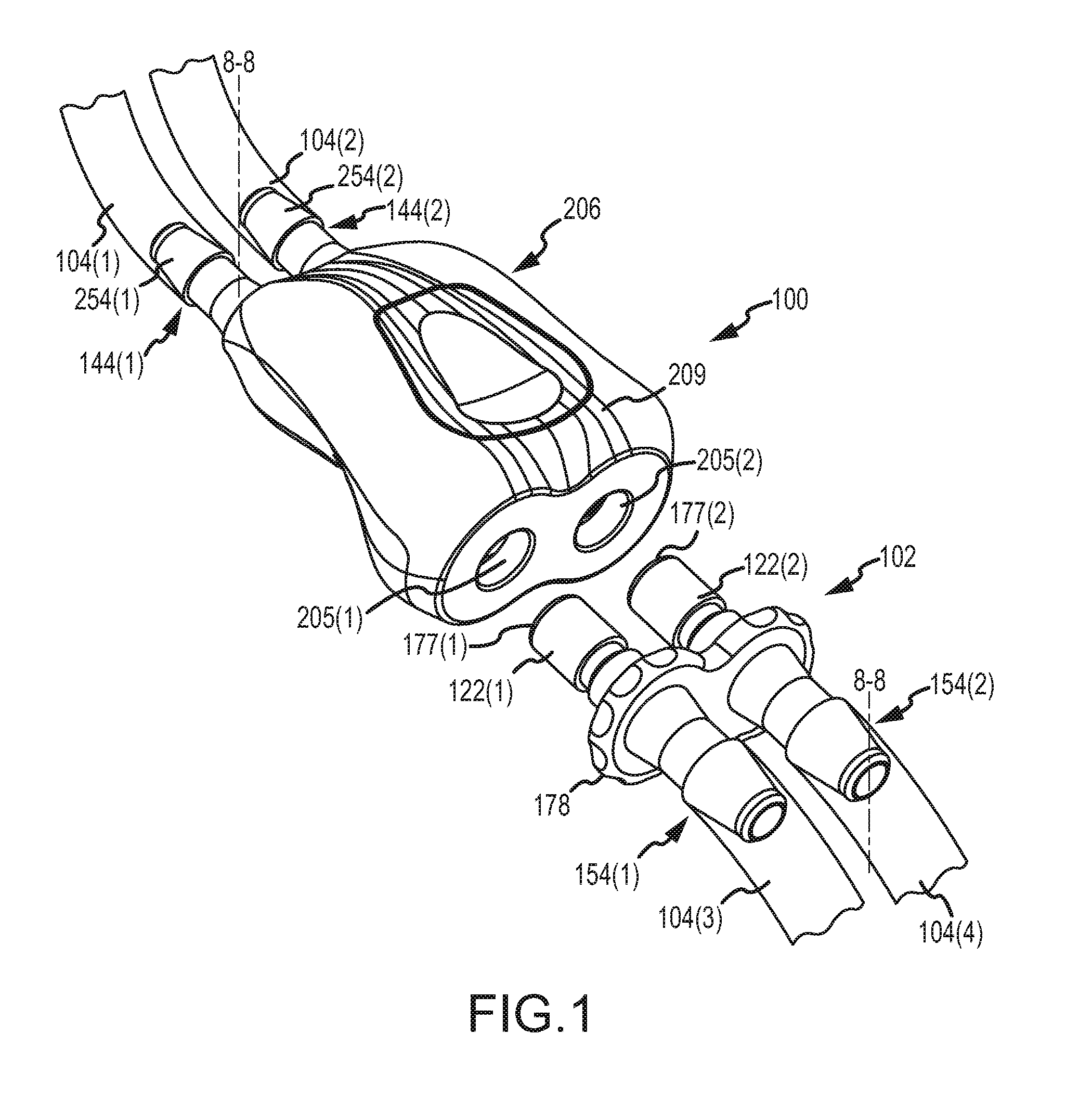

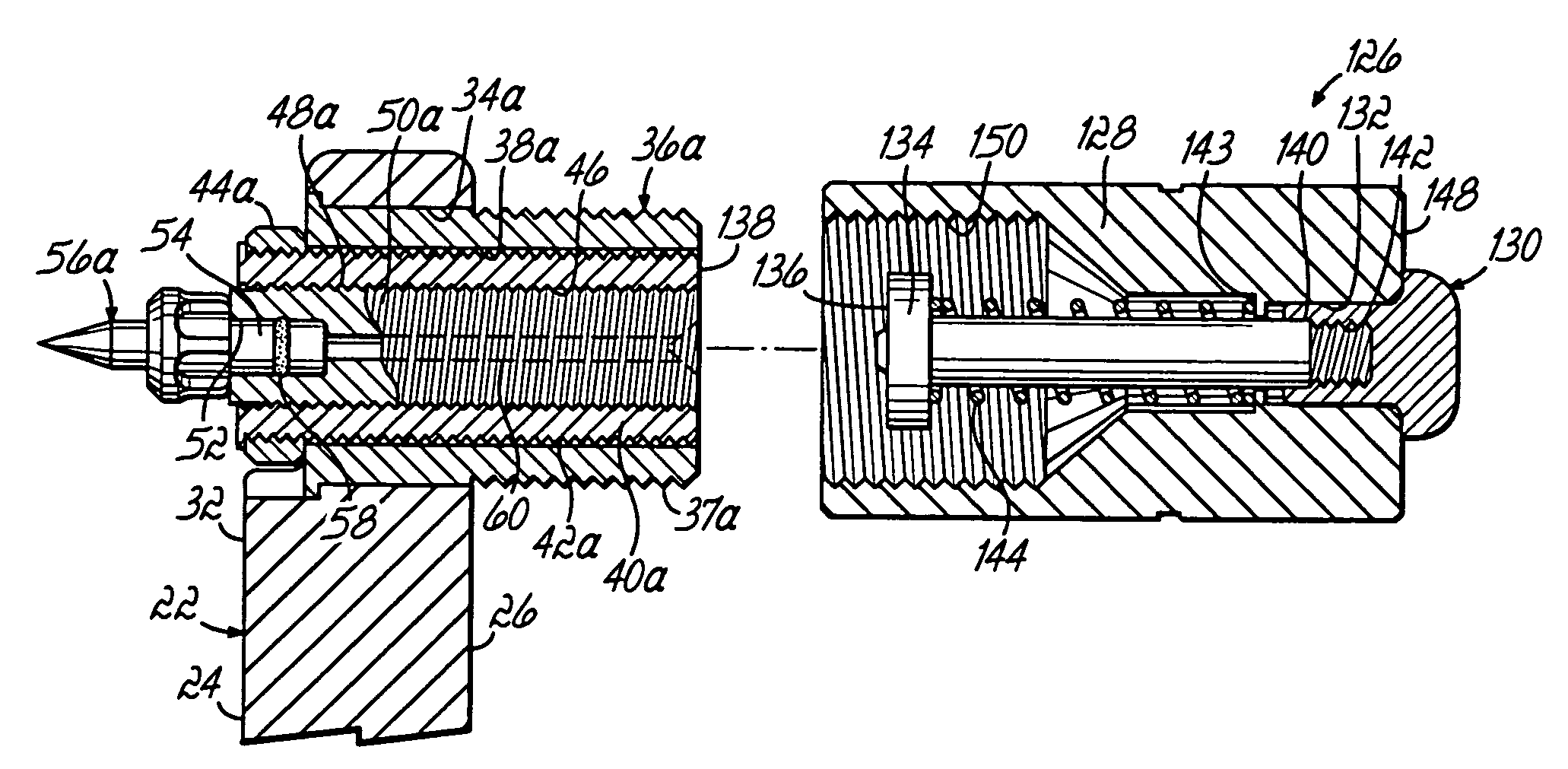

Non-pneumatic tire having web spokes

InactiveUS7650919B2High effective radial stiffness in tensionLow effective radial stiffnessNon-inflatable tyresPneumatic tyre reinforcementsGround contactElastomer

Owner:MICHELIN RECH & TECH SA

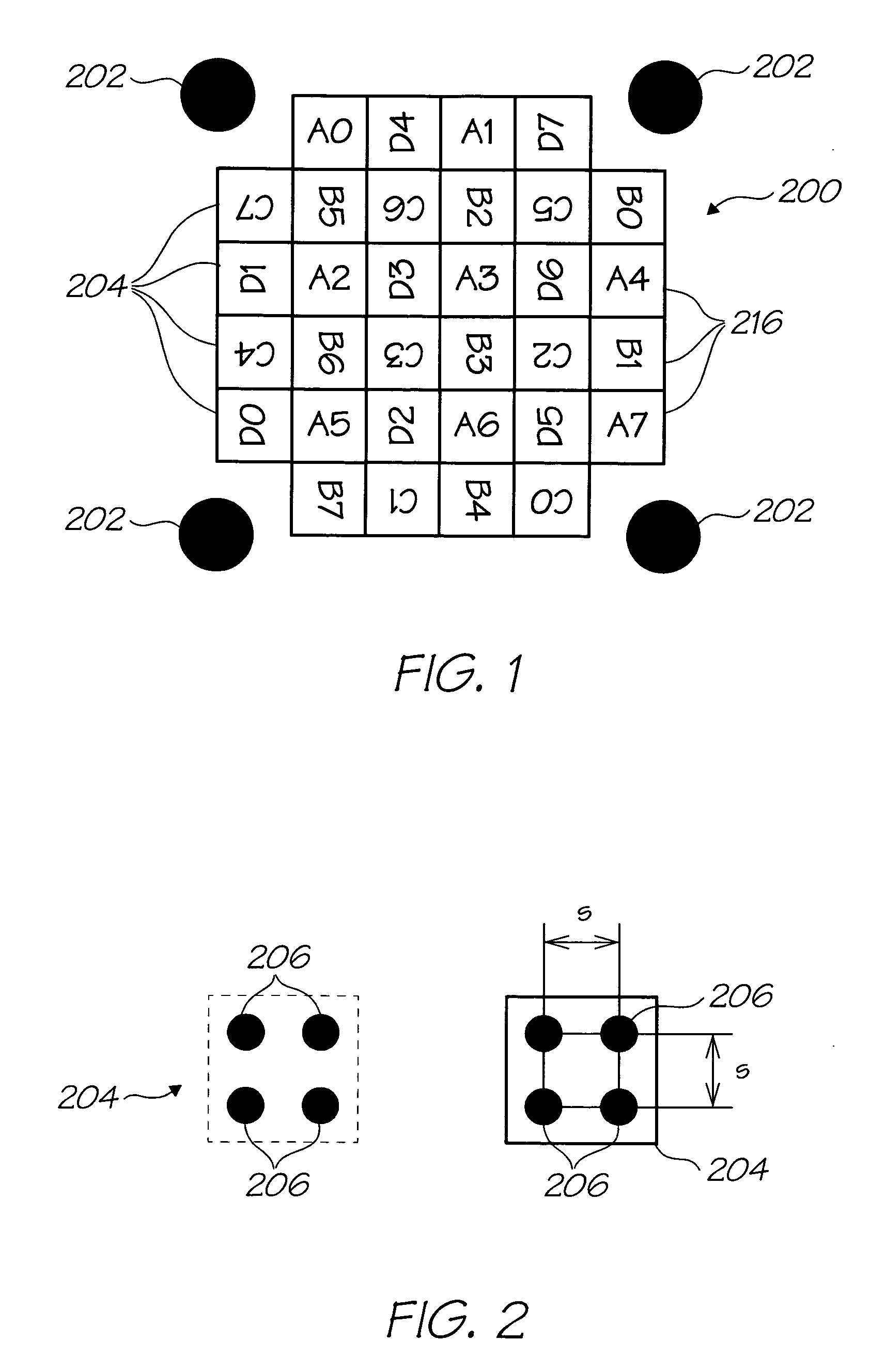

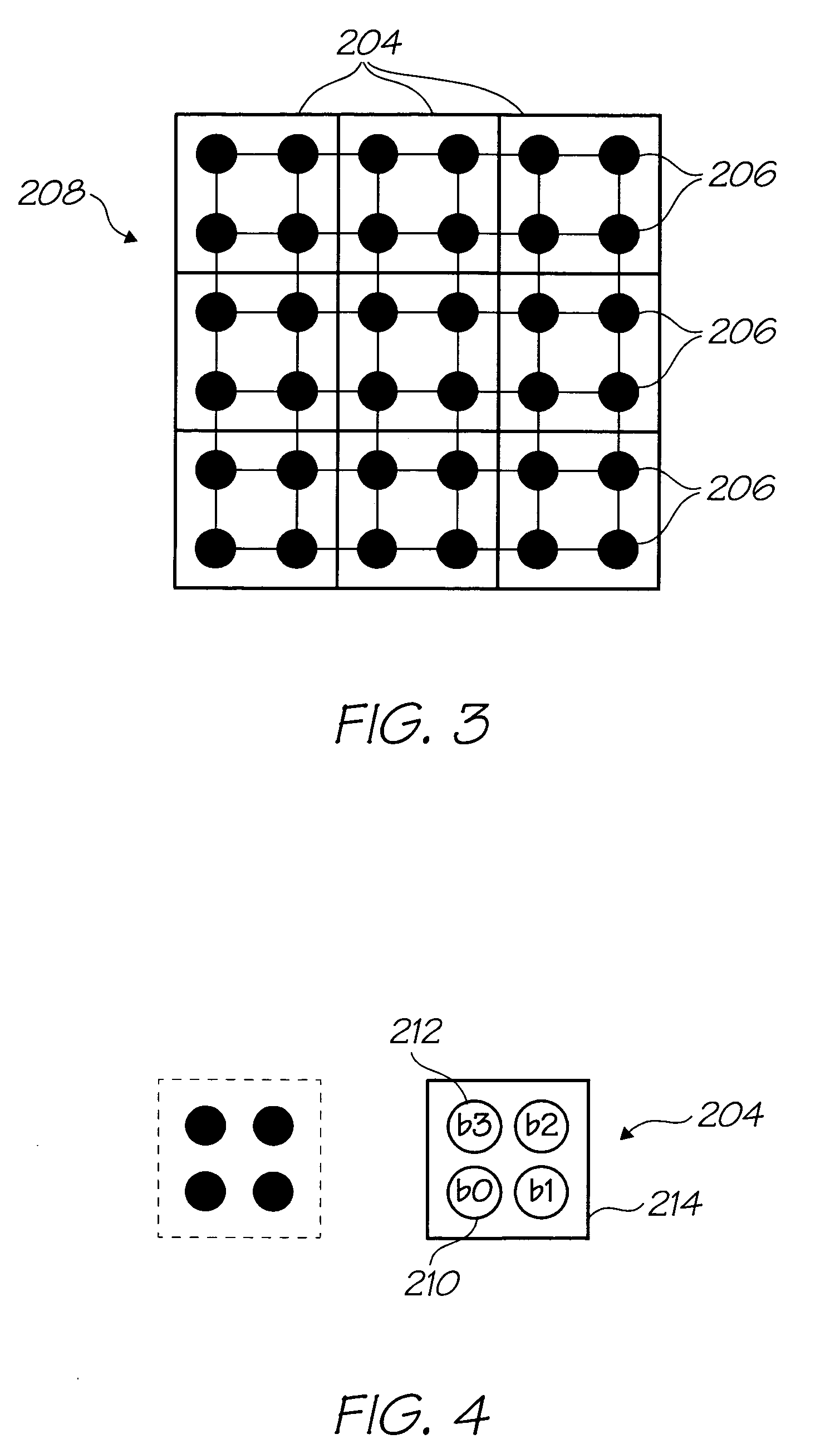

Devices, systems and methods to determine area sensor

ActiveUS20150168205A1Improve accuracyWeighing apparatus using elastically-deformable membersForce measurementTransducerEngineering

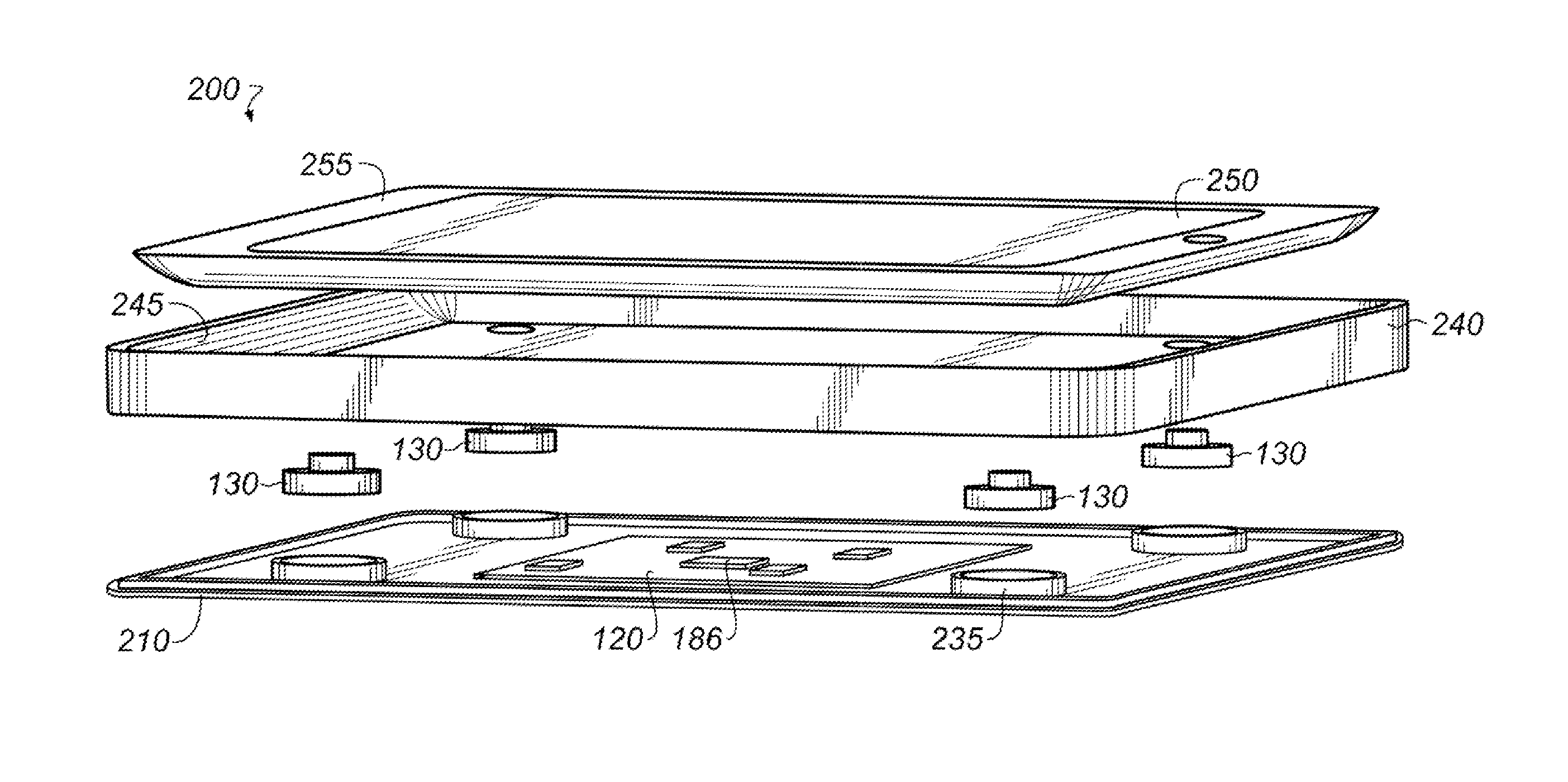

A weighing scale includes a platform supporting a load. Force transducers beneath the platform output respective transducer force signals of the load. An area sensor above the platform outputs area force signals of load forces applied to respective spatial areas of the platform. A processor is configured to determine the load's weight and location on the platform based on the transducer force signals and the area force signals. A method of weighing the load is also described. A method of monitoring the load includes measuring first transducer force signal(s) and first area force signal(s) of the load, and then repeatedly measuring second force signal(s) of the load using the transducer(s) or area sensor until the first and second signal(s) indicate a change in a weight or location of the load. A changed weight or changed location of the load is then determined using the measured second force signal(s).

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

System and method for towing a trailer

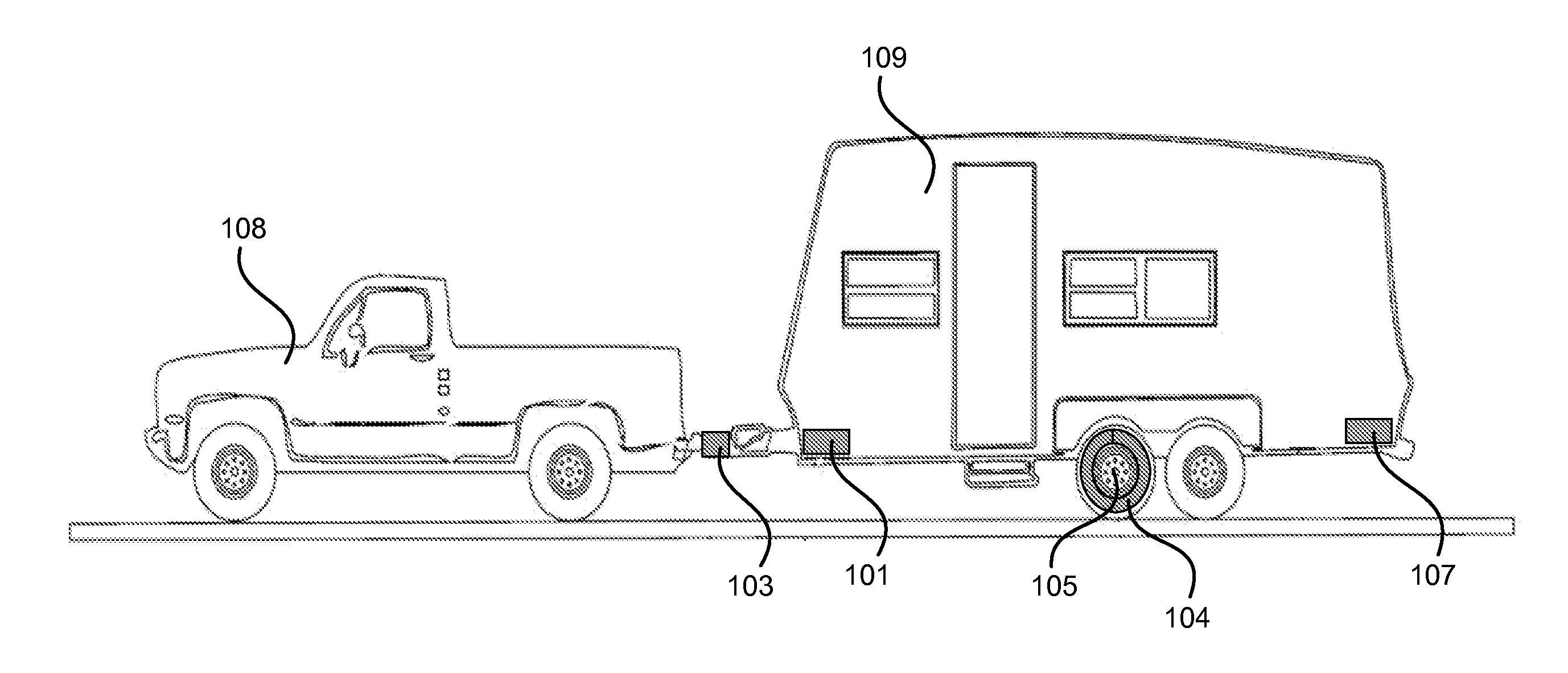

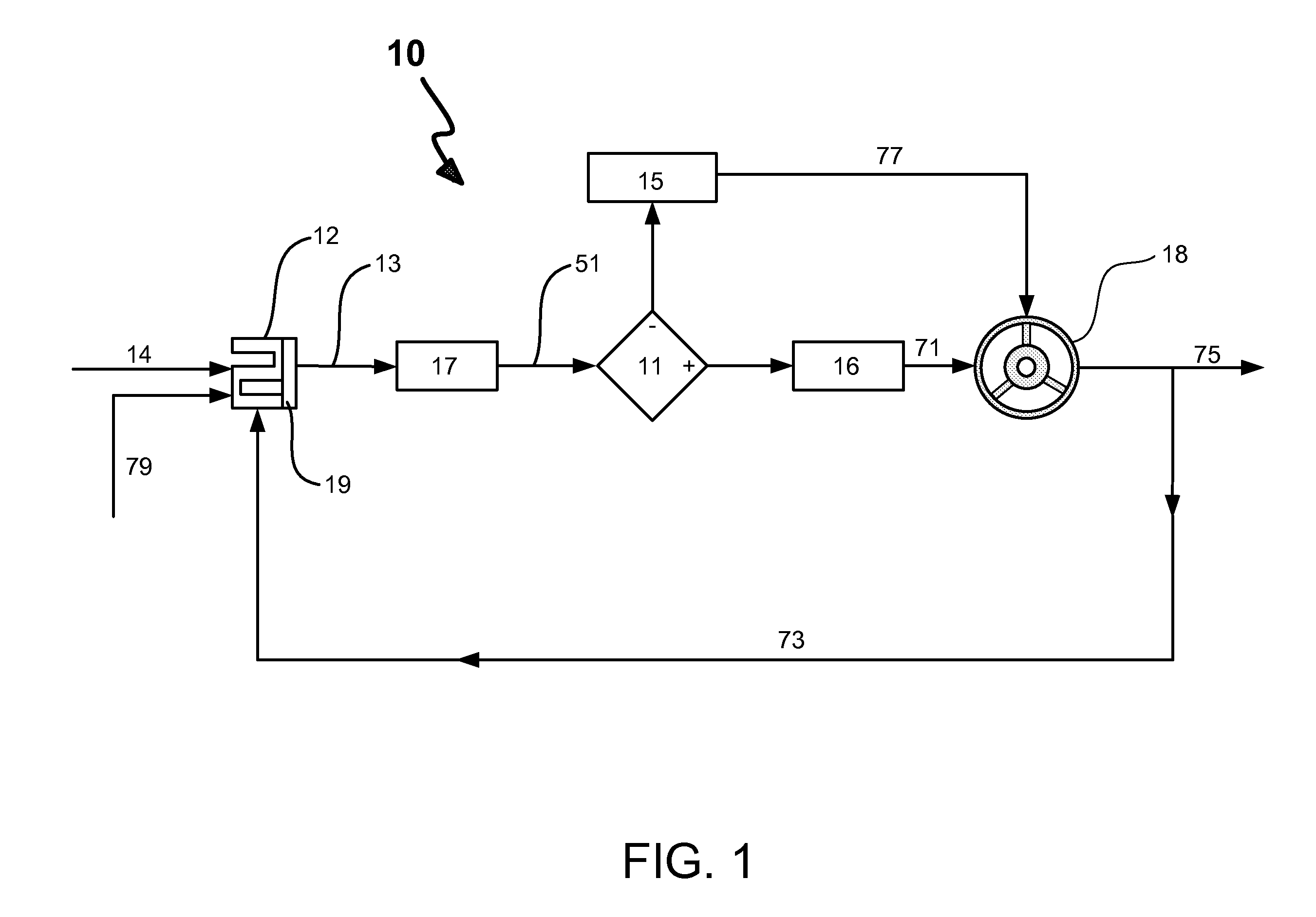

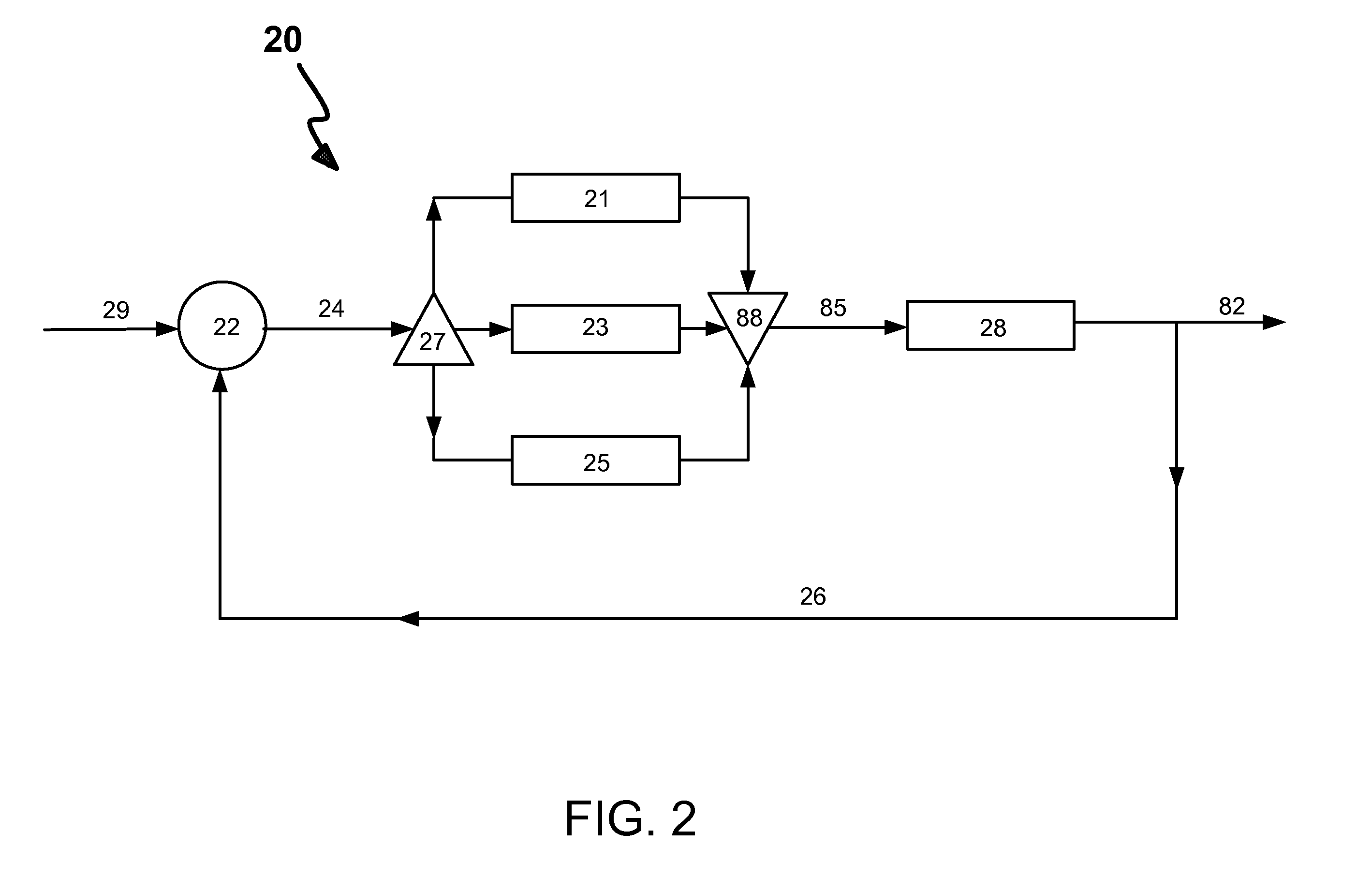

ActiveUS20110042154A1Maximize fuel efficiencyImprove performanceAnalogue computers for trafficComputations using stochastic pulse trainsClosed loopFuel efficiency

Systems for towing a trailer by a towing vehicle and a method for controlling such a system are disclosed. The systems and method are configured to maintain a constant towing load on the towing vehicle as well as optimizing other performance criteria such as fuel efficiency. The system comprises a closed loop controller, a towing arm assembly, a load measuring device, an electric hub motor, brakes, a motor controller and a brake controller disposed on the trailer. In another embodiment, two separate systems are installed, one on each side of the trailer. A load force feeds into a PID controller programmed with preset proportional, differential and integral parameters. The PID controller generates a command signal to either modulate the brakes or motor up or down depending on the sign of the command signal. A process output updates the system which continuously adjusts based on driving conditions.

Owner:BARTEL BRIAN DANIEL

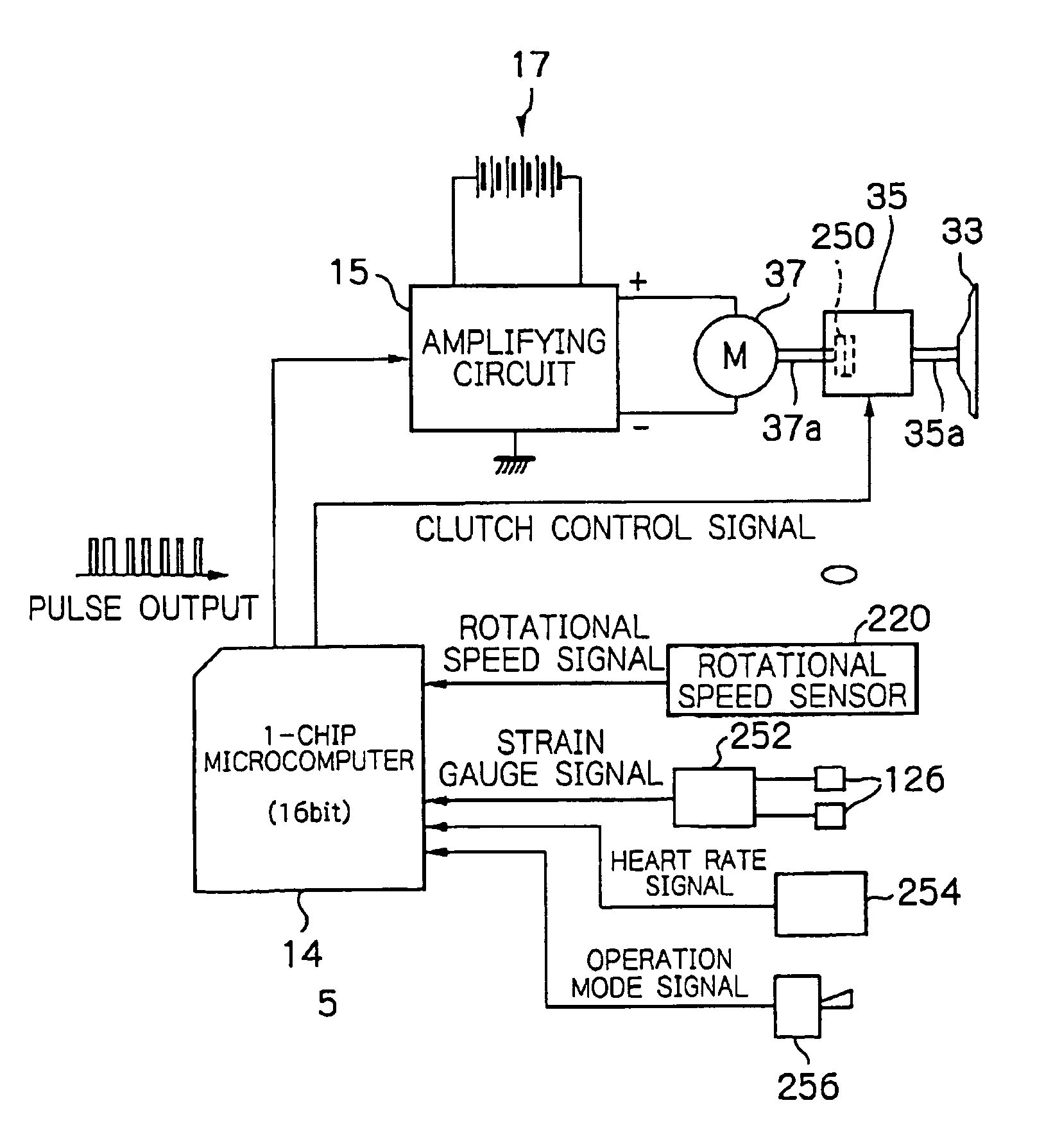

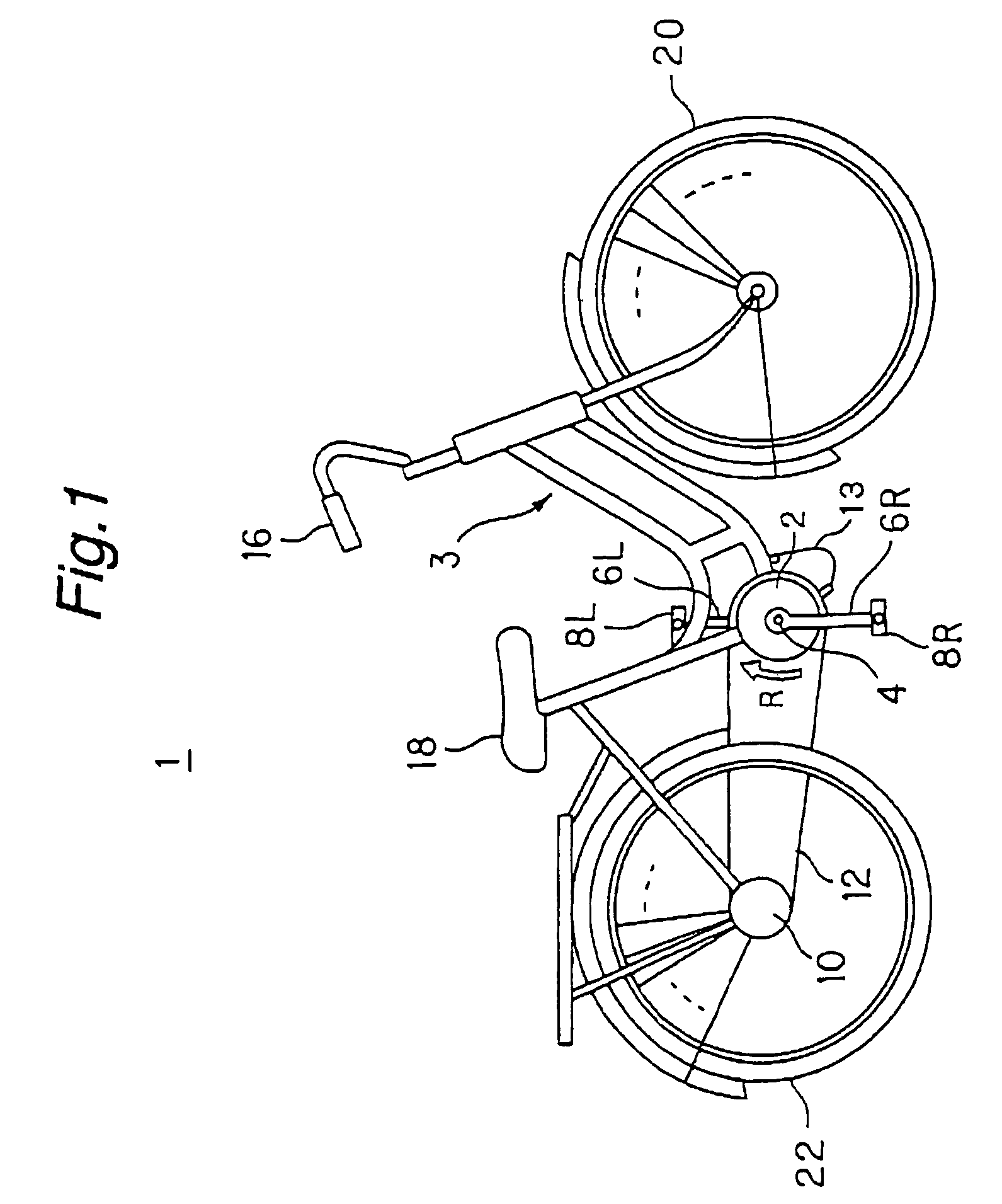

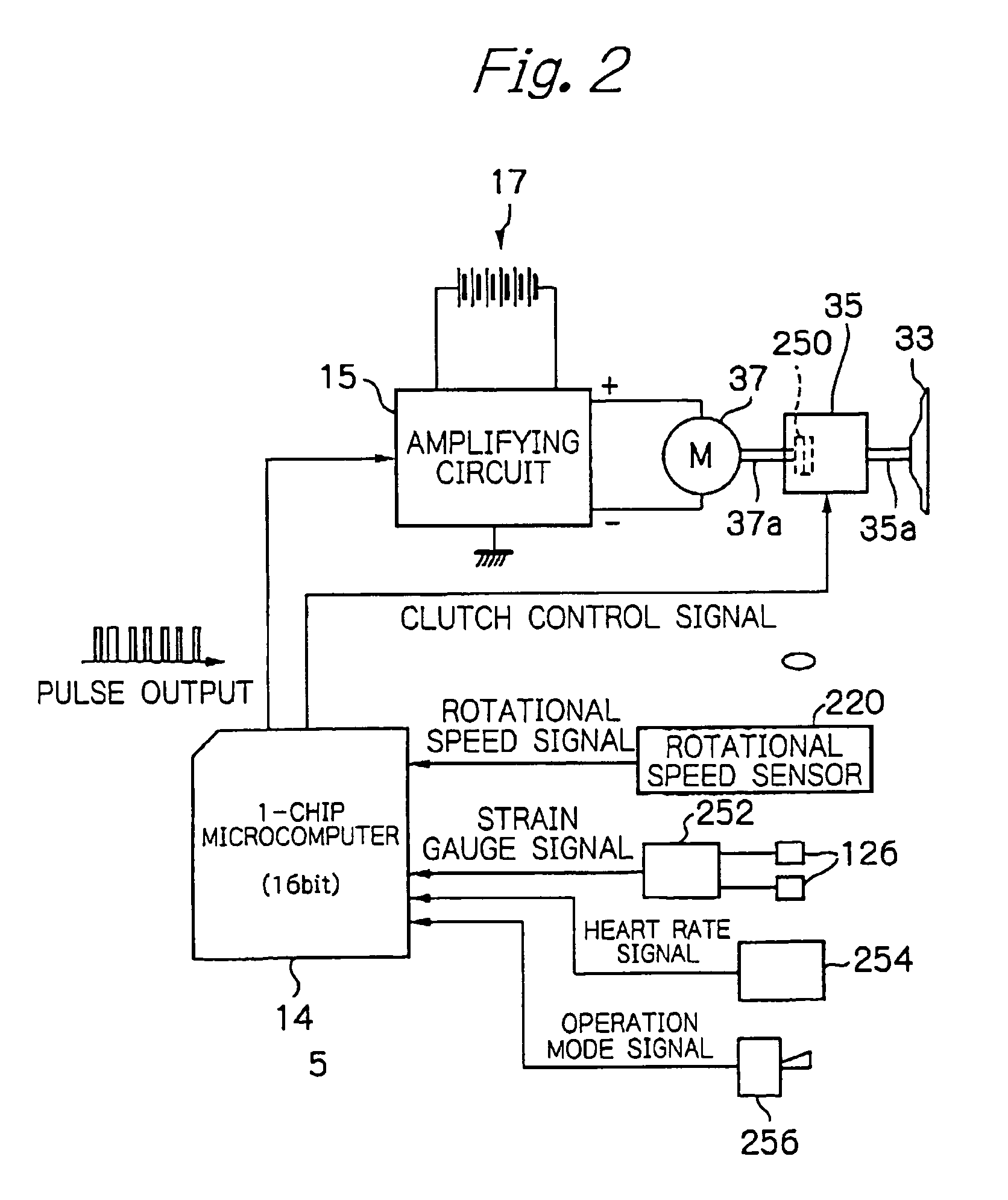

Electrically assisted bicycle which enables aerobic exercise

Owner:SUNSTAR GIKEN KK +1

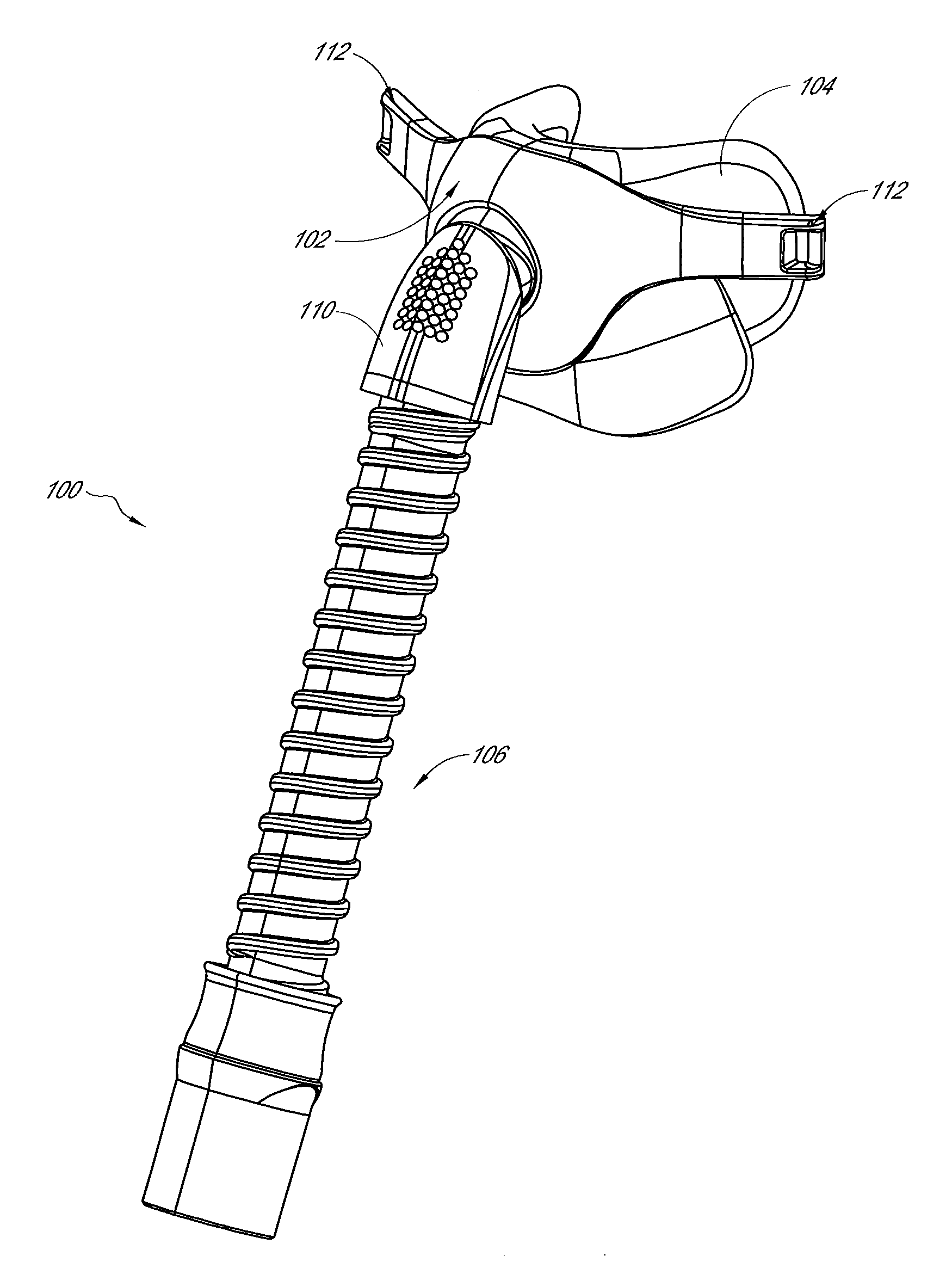

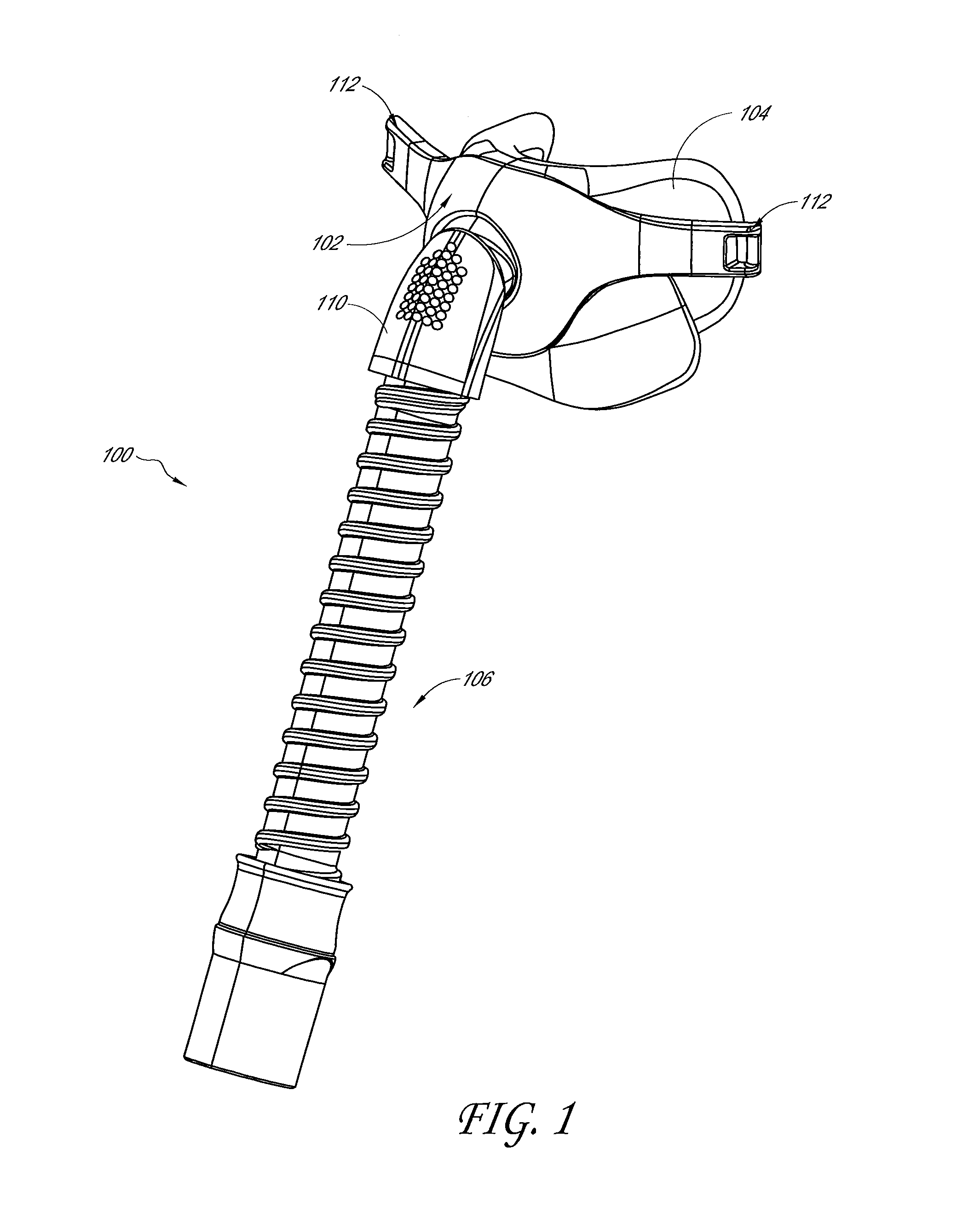

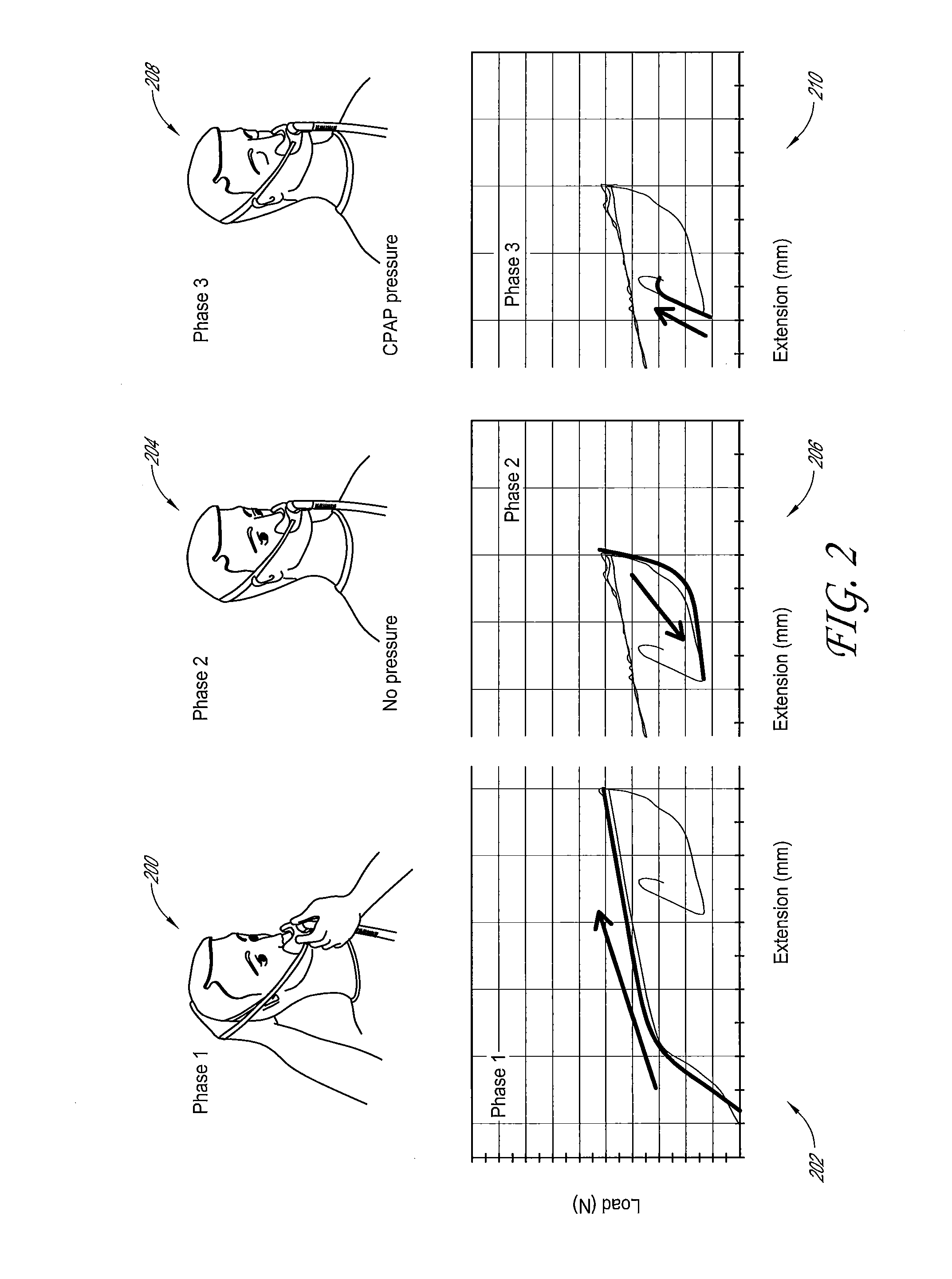

Automatically adjusting headgear for patient interface

ActiveUS20160082217A1Eliminate needEasy to installRespiratory masksBreathing masksEngineeringElastance

A headgear for securing a mask to a user's face is described. The headgear requires a first load force to elongate the headgear and, when fitted to a user, applies a balanced fit force that substantially equals a load force applied to the headgear during respiratory therapy. In some embodiments, the headgear includes an elastic portion configured to provide a retraction force, a non-elastic portion configured to be inelastic in comparison to the elastic portion, and a restriction mechanism connected to the non-elastic portion and to the elastic portion. The restriction mechanism is configured to apply a first resistance force to the user's head on elongation of the headgear and a second resistance force to the user's head on retraction of the headgear.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Wind Turbine With Pitch Control Arranged To Reduce Life Shortening Loads On Components Thereof

ActiveUS20100014971A1Maximize power outputMinimizing variation of loadPropellersWind motor controlGravitational forceBlade pitch

A wind turbine is presented where the operation lifetime of the main bearing is extended by relieving the main bearing by reducing the mean bending moment on the bearing by means of individual pitch control of the blades of the rotor so as to create an aerodynamic mean tilt moment on the rotor by means of aerodynamic forces on the blades, the tilt moment at least partly counteracting the bending moment caused by the overhang load forces on the main bearing from the gravitational pull on the rotor mass.

Owner:VESTAS WIND SYST AS

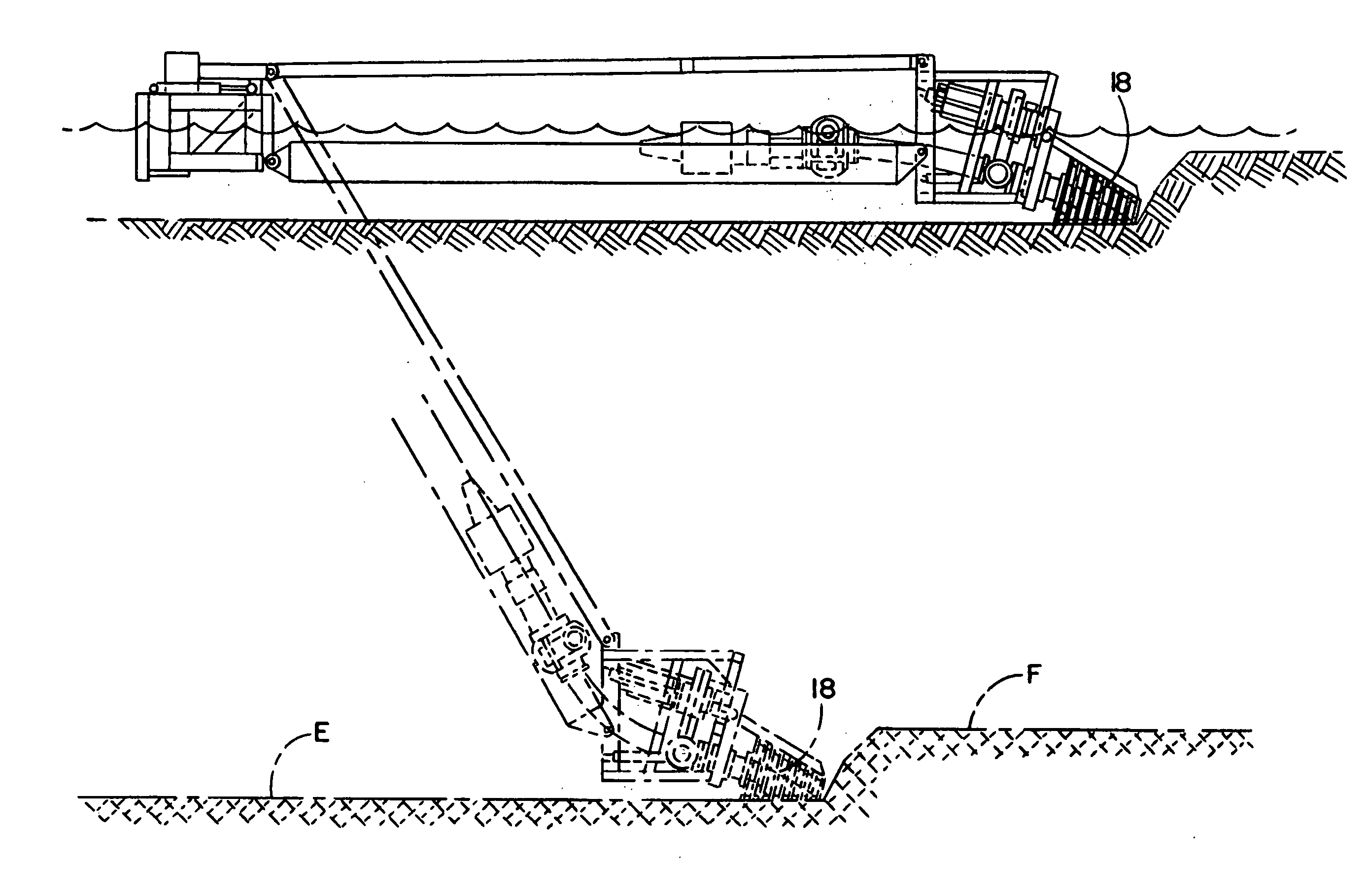

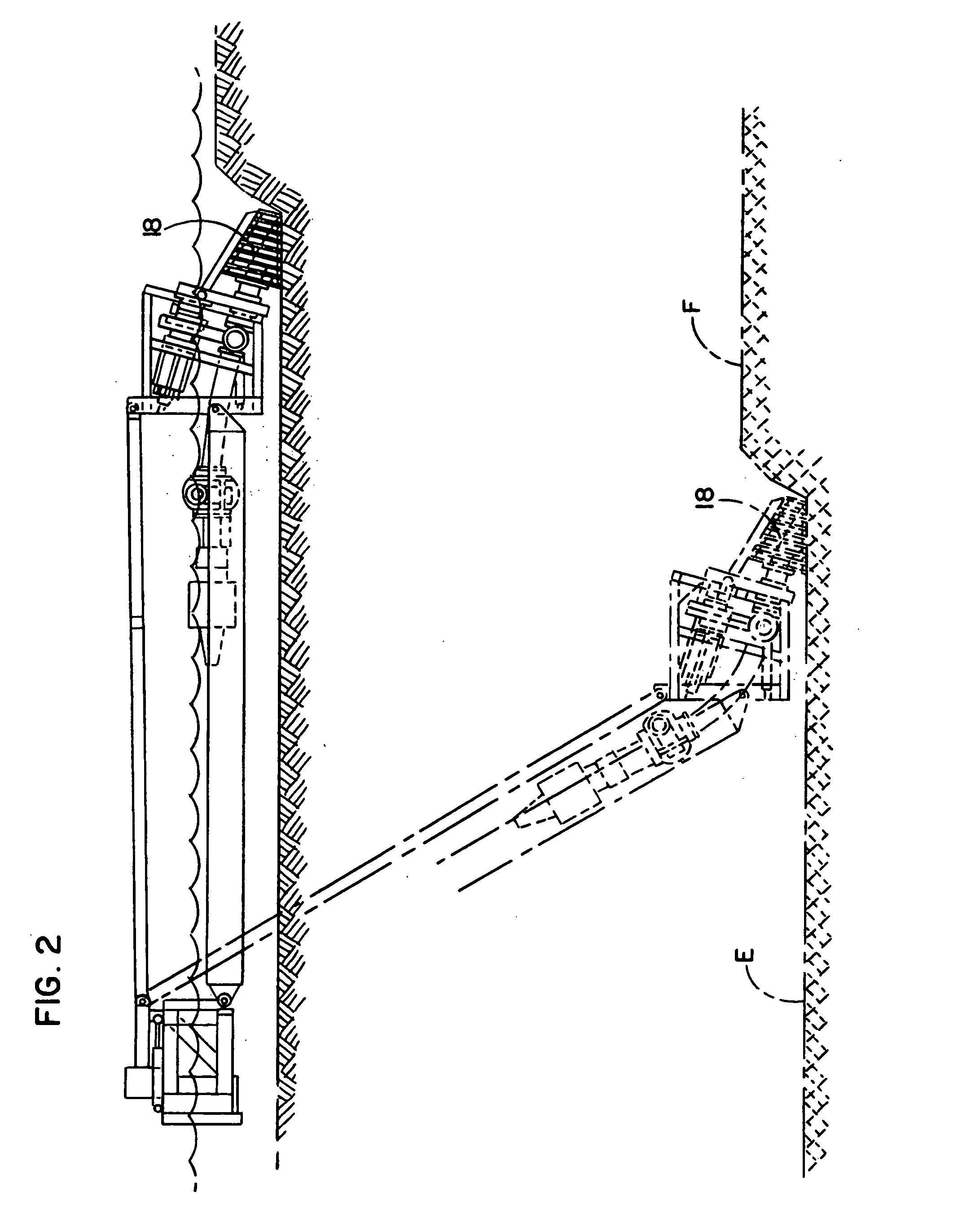

Method and apparatus for pumping with a dredge

InactiveUS20050268499A1Reduce turbidityGreat tractionSpecific fluid pumpsAgricultural machinesFlow transducerTurbidity

A system usable for dredging may include a suction bypass system for automatically maintaining a sufficiently high, liquid flow velocity. Preferably, a flow sensor monitors flow velocity and when the monitor flow decreases to an extent that plugging may occur, a liquid bypass valve is opened and an intake line valve is closed until the flow velocity increases whereupon the valves are returned to their original positions. An automatic level cut removes a relatively constant layer of material from a contoured bottom. The illustrated automatic level cut process comprises adjusting the force with which the suction head engages the bottom, moving the suction head in a direction opposite to the direction of the swing of the boom to keep the suction head pointing straight ahead, and maintaining the suction head to stay substantially level with the bottom even though the angle of the boom increases to the surface of the water body. A leveling device comprising a parallelogram linkage may be used to maintain the suction head substantially level with the bottom. A predetermined amount of load force may be applied by the head against the bottom. Herein, a winch and cable and the controller are operated to lift some of the head weight until the desired predetermined head force is applied to the bottom. A walking system moves the pipe intake for taking a sideways cut without the use of a spud pole, anchors and anchor lines. Large blade members or feet travels in an endless path with the feet entering the bottom while vertically disposed and remained disposed vertically while entering and leaving the bottom so as not to dig or stir the bottom that will cause large liquid turbidity. A low turbidity head cleaning system prevents the head from being plugged and debris or sticky material. Preferably, a rotatable cone-shaped head is provided with spaced rings and bars that define sized openings that limit the size of debris entering into the intake. A fixed comb removes material stuck on the rotating head. A shroud has an open bottom side thereby preventing bottom material from escaping and increasing with turbidity. A suction head articulation system keeps the head pointed in the forward direction of dredge advancement to create a smooth finish grade.

Owner:EDDY PUMP CORP

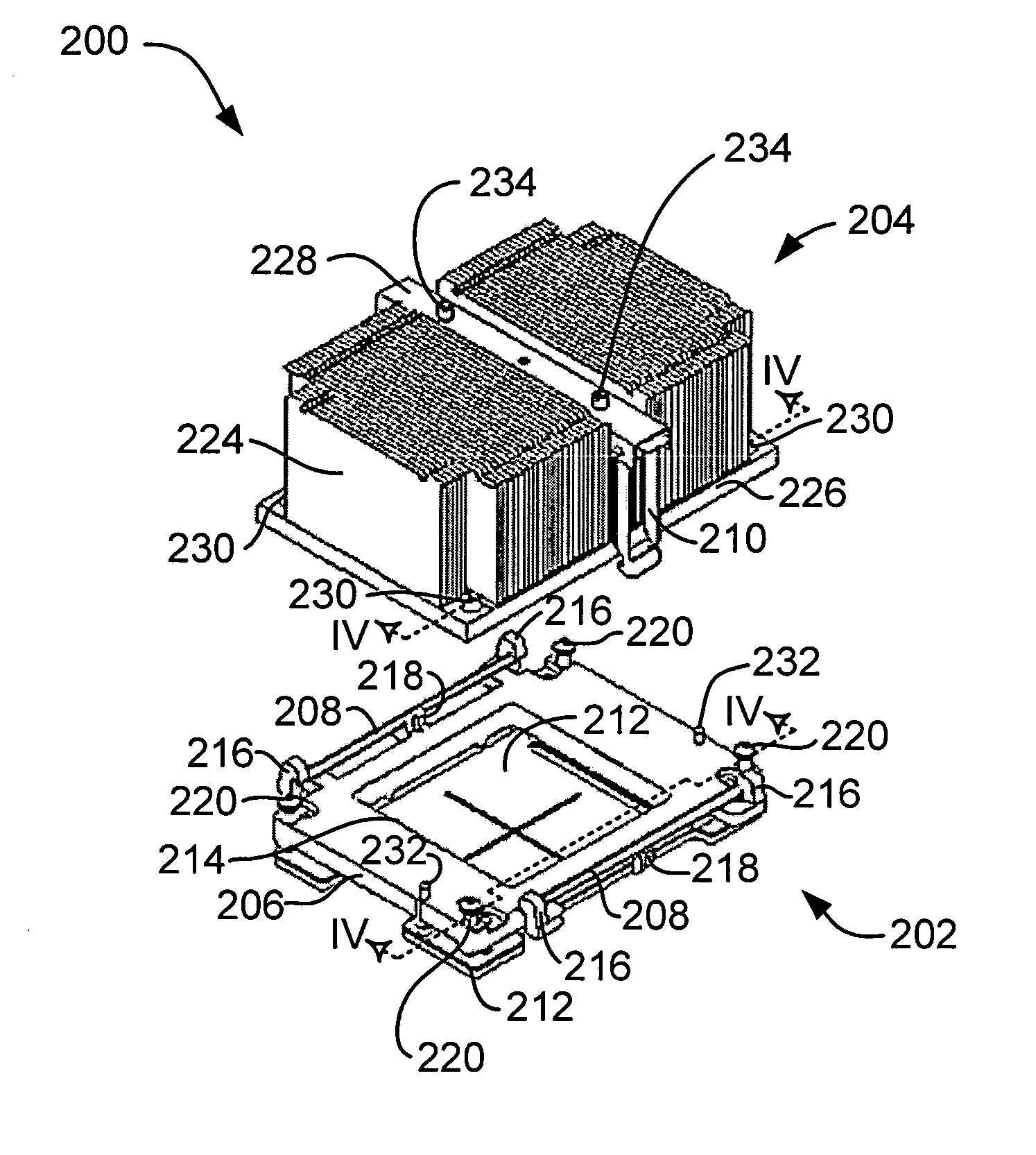

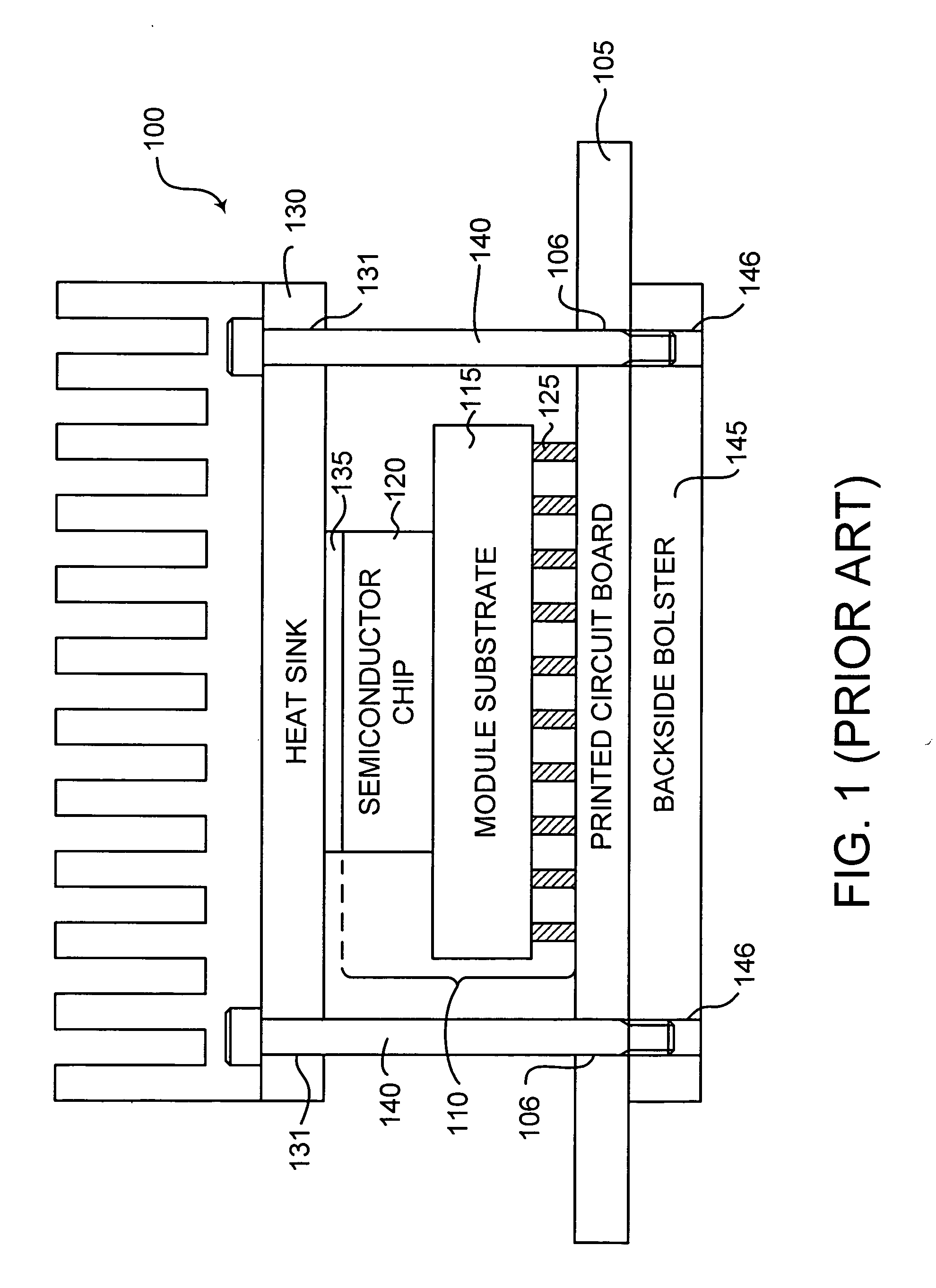

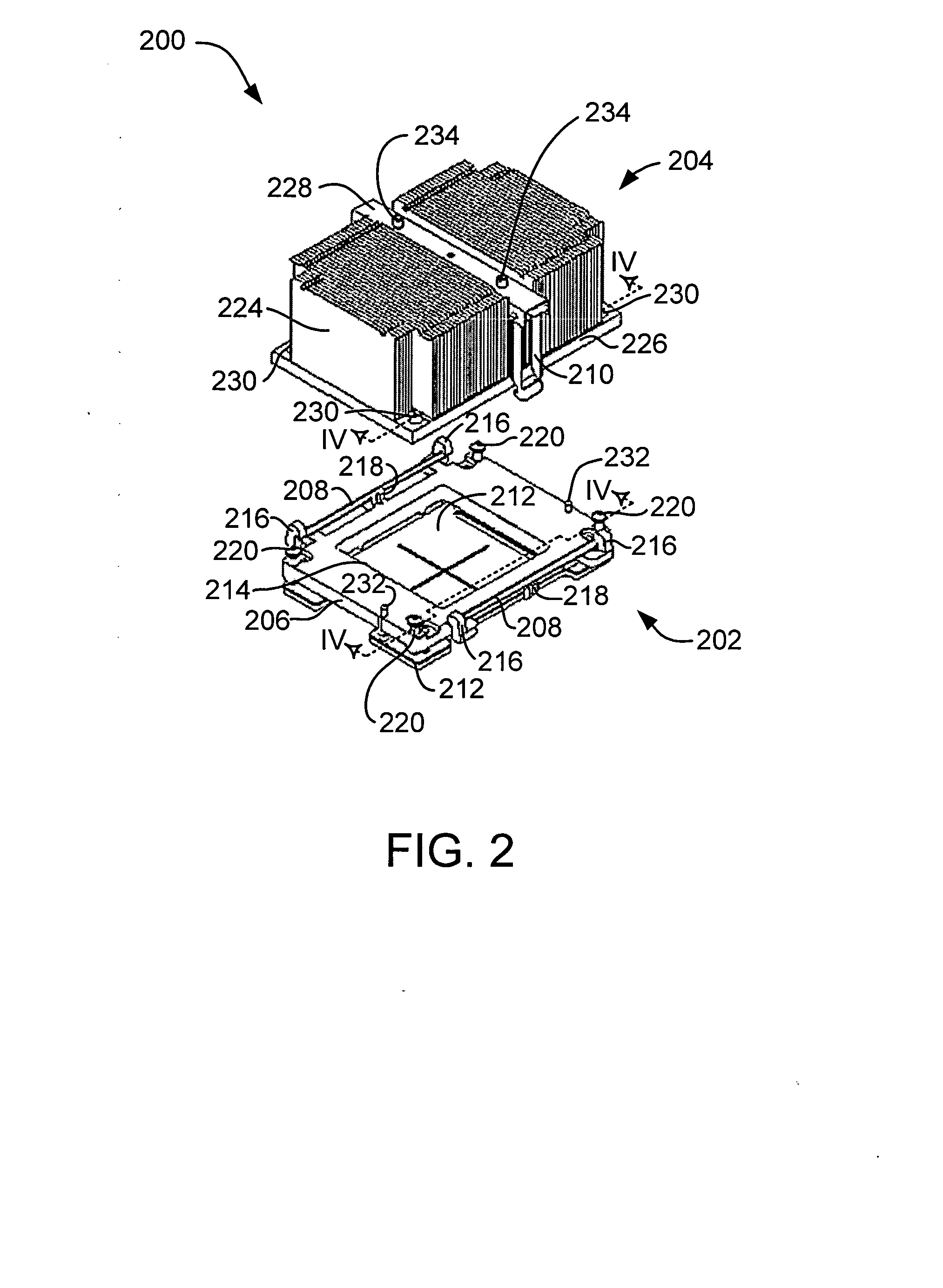

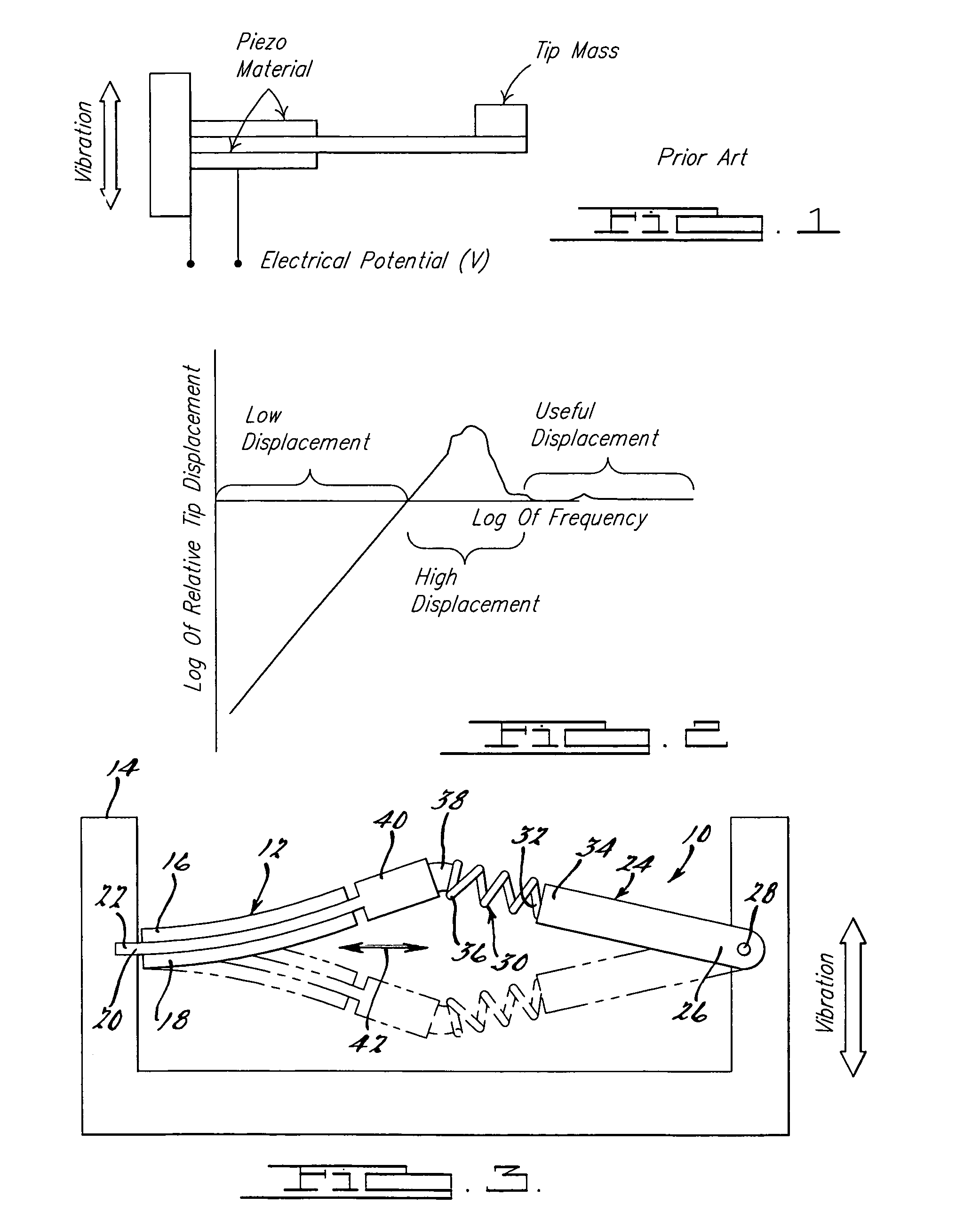

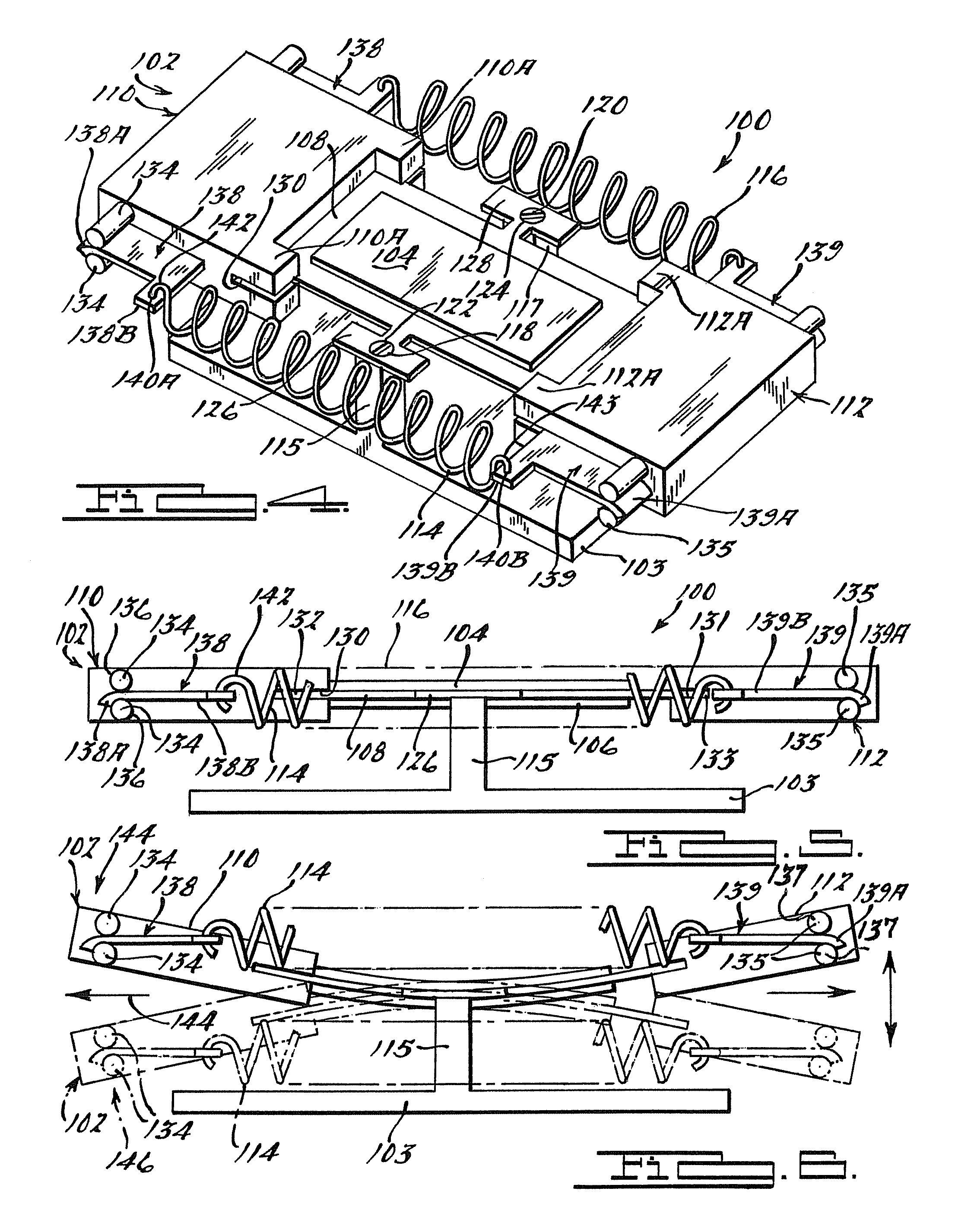

Method and apparatus for mounting a heat sink in thermal contact with an electronic component

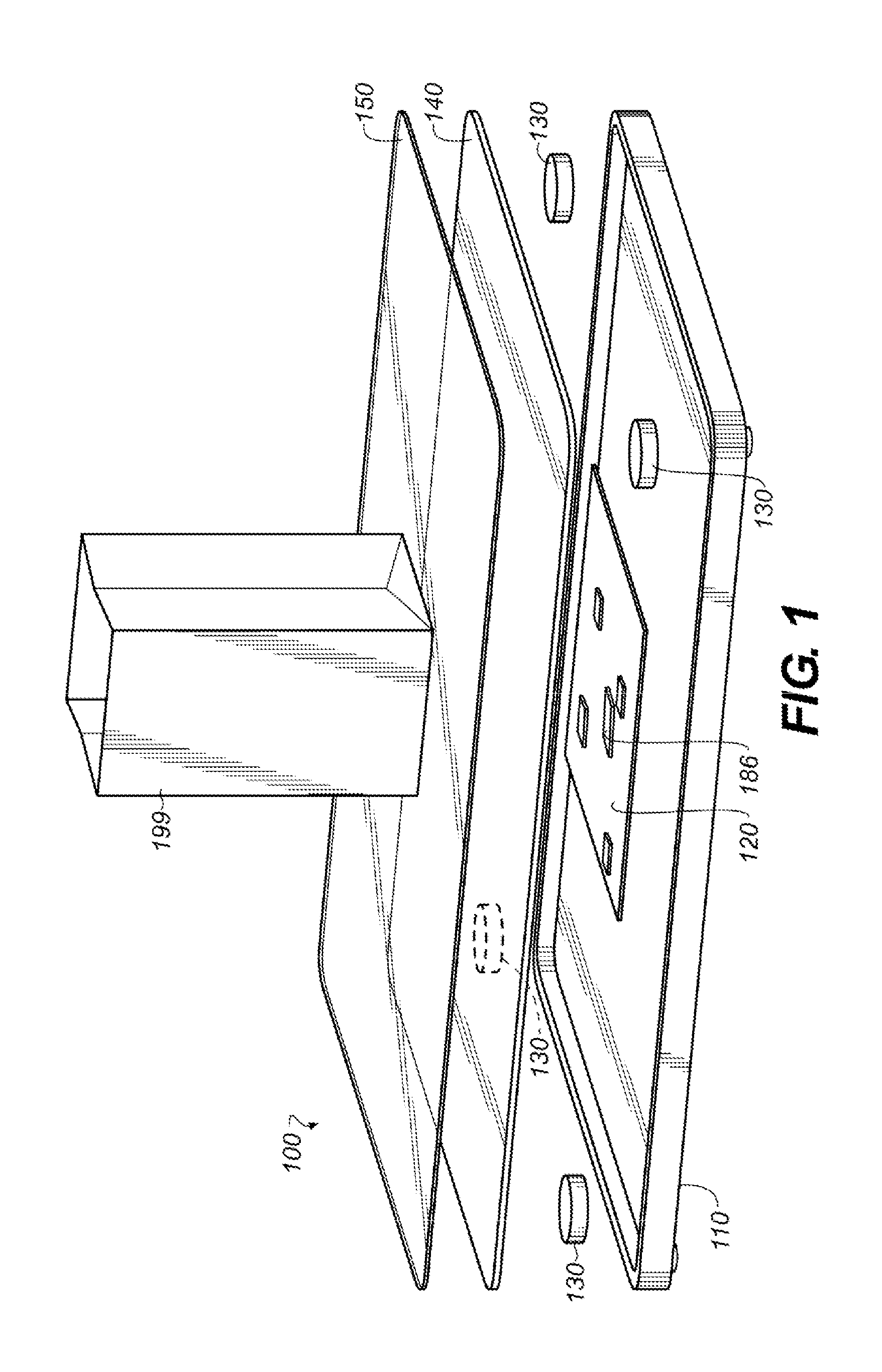

ActiveUS20070035937A1Overcome disadvantagesSemiconductor/solid-state device detailsSolid-state devicesConductive materialsElectronic component

A heat transfer apparatus comprises a load frame having load springs and an open region that exposes an electronic component. The load frame is mounted to a printed circuit board on which the electronic component is mounted. A heat sink assembly is disposed on the load frame and has a main body in thermal contact with the electronic component through a thermally conductive material. The heat sink assembly has load arms for engaging the load springs. A load plate extends between the load arms and has an actuation element operative to displace the main body relative to the load plate and thereby resiliently deform the load springs and produce a load force that compresses the thermally conductive material to achieve a desired thermal interface gap between the main body and the electronic component. Non-influencing fasteners secure the heat sink to the load frame and maintain the desired thermal interface gap.

Owner:IBM CORP

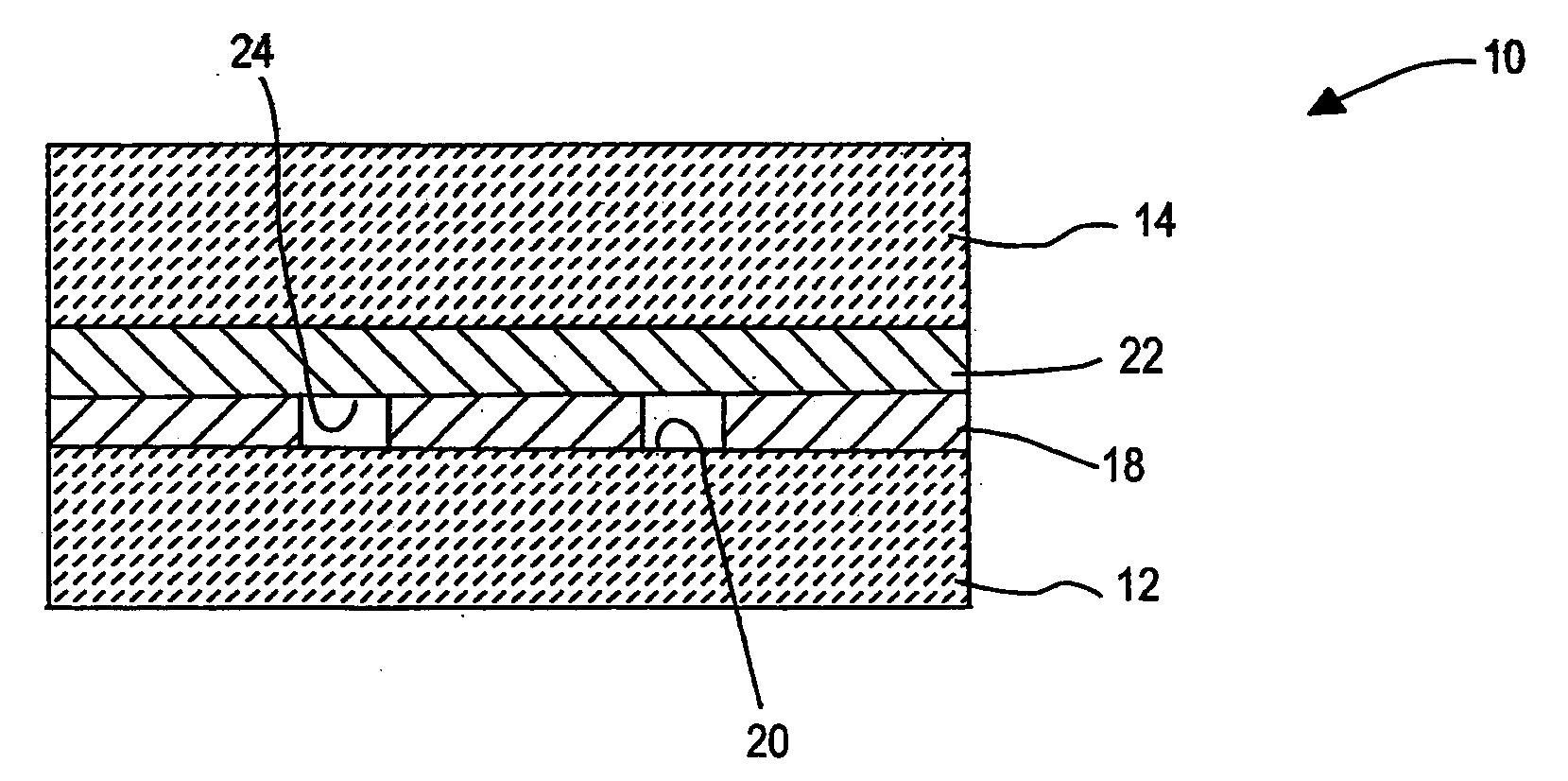

Pre-loaded force sensing resistor and method

ActiveUS20090134966A1Easy to useForce measurementCathode-ray tube indicatorsElectrical resistance and conductanceForce-sensing resistor

A force sensing resistor (FSR) includes a substrate having separated electrically conductive traces and another substrate having a resistive layer in which the substrates are subjected to a biasing force such that the substrates contact one another with the resistive layer electrically connecting the traces with a resistance inversely dependent on the biasing force. Upon an external force applied towards a substrate, the substrates contact one another with a total force which is the sum of the forces with the resistive layer electrically connecting the traces with a resistance inversely dependent on the total force. An FSR output which is a function of the resistance is measured. Whether a change in magnitude of the FSR output during a time interval is greater than a threshold is determined. A touch applied on the FSR is detected during the time interval if the change is greater than the threshold.

Owner:INTERLINK ELECTRONICS

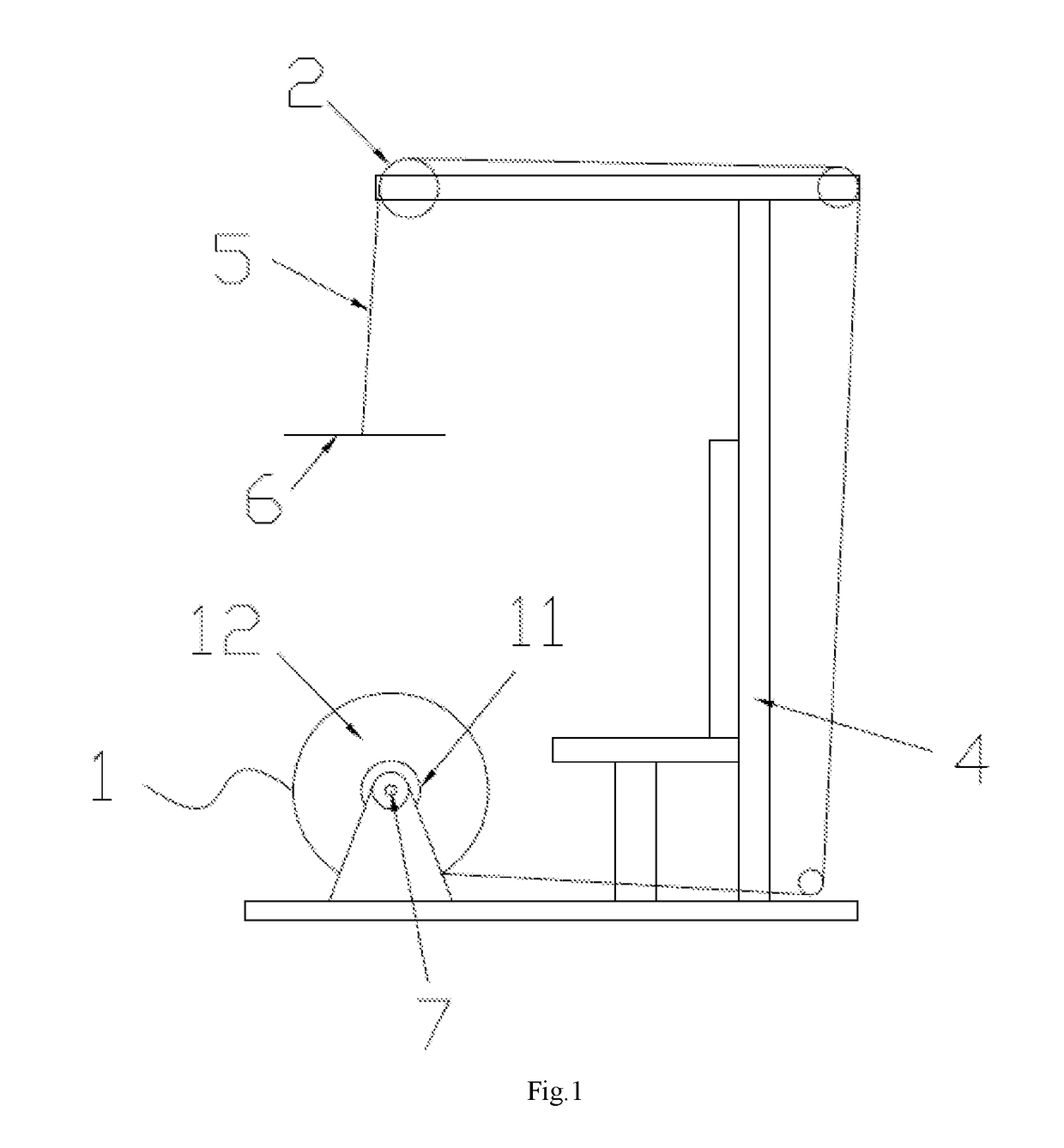

Calibrating and loading bench of large multi-dimensional force transducer

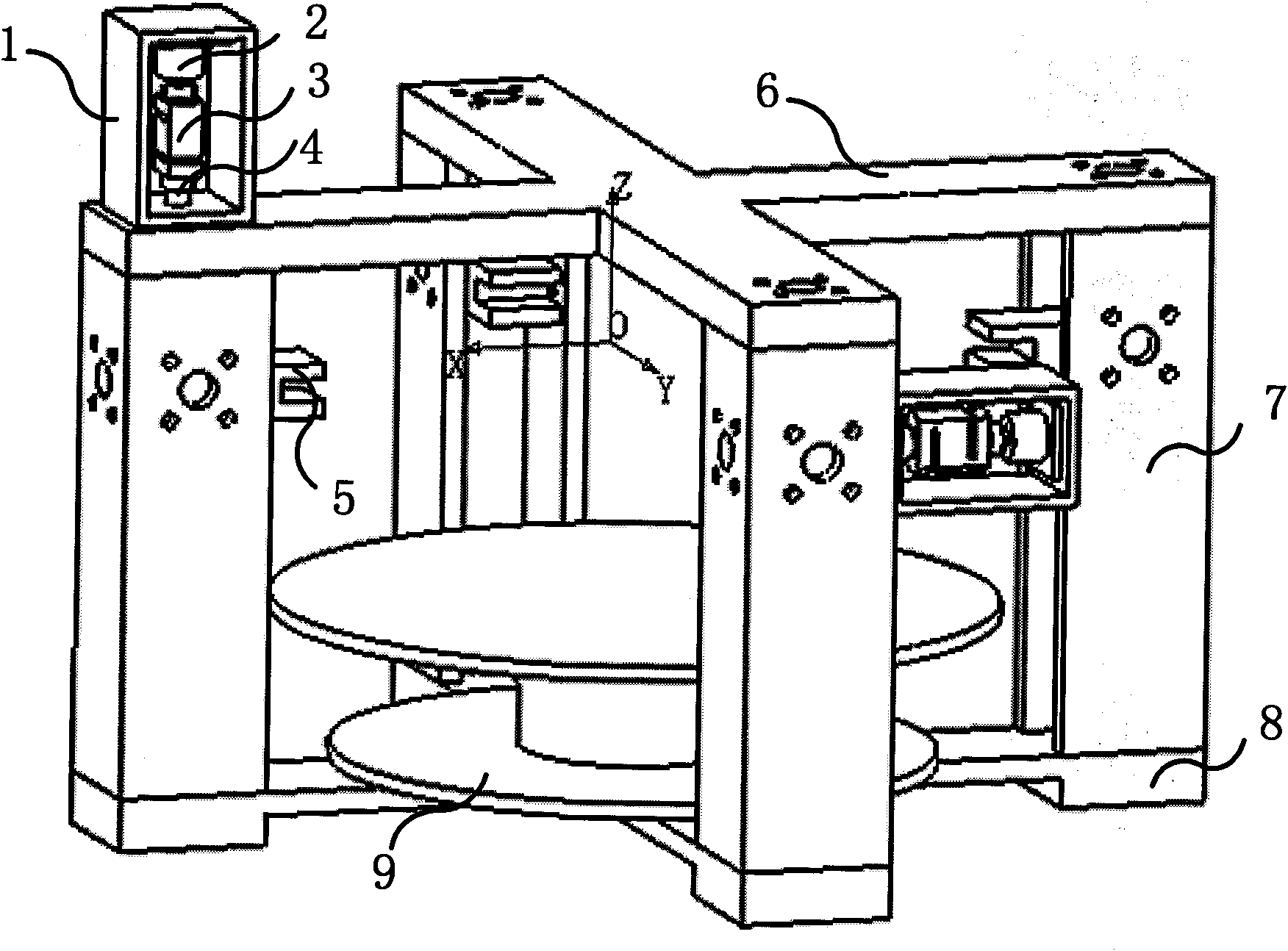

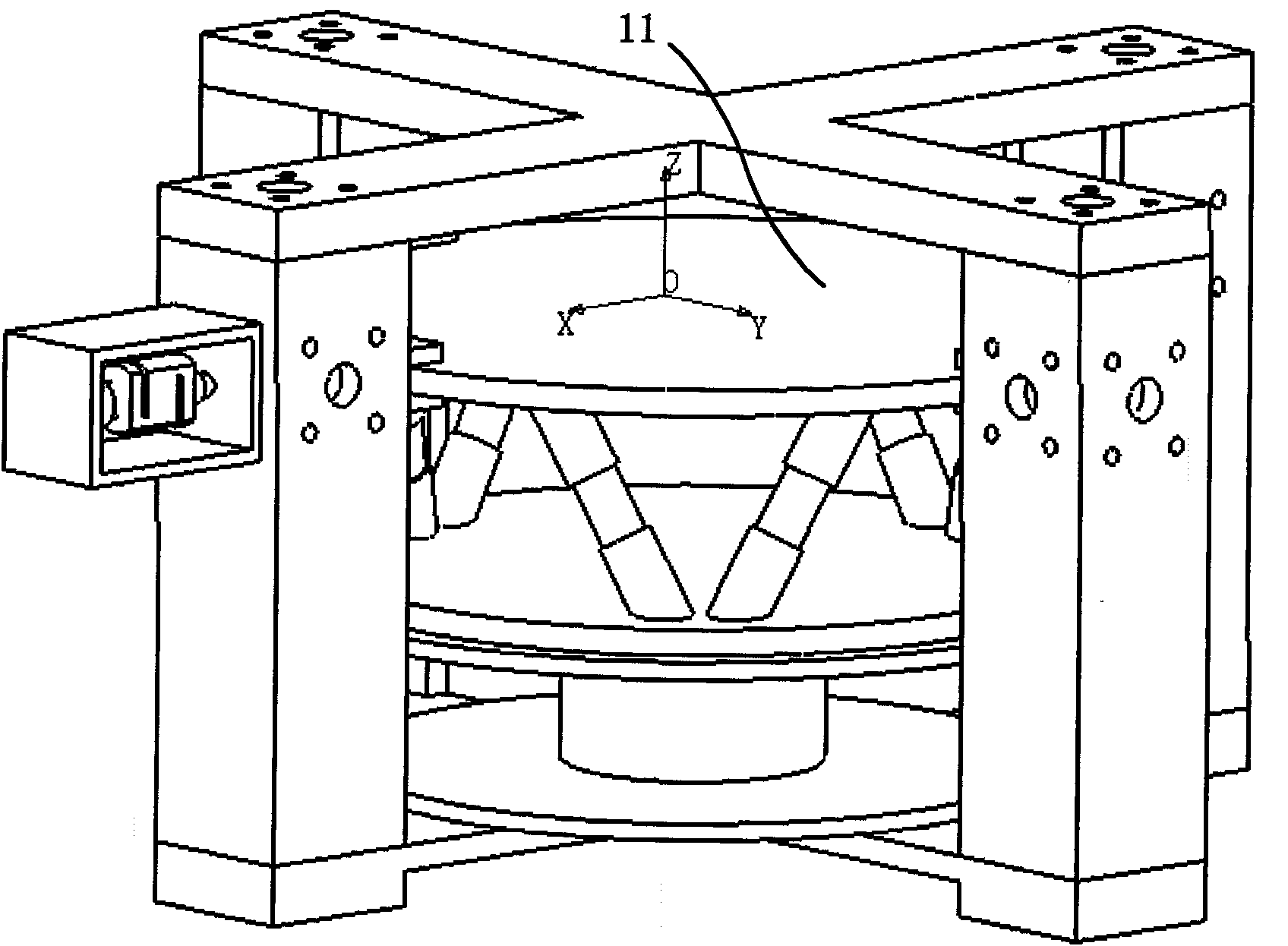

InactiveCN101776506ASimple structureCompact structureForce/torque/work measurement apparatus calibration/testingHydraulic cylinderTransducer

The invention discloses a calibrating and loading bench of a large multi-dimensional force transducer. The loading bench comprises an upper cross frame (6), a loading bench column (7), a lower cross frame (8), a multi-dimensional force transducer fixed support (9), loading units and loading blocks (5), wherein each loading unit comprises a loading frame (1), a loading hydraulic cylinder (2), a one-dimensional tension-pressure transducer (3) and a tension bar (4). By combining the different installation positions of the two loading units and the connection position of the tension bars (4) and the loading blocks (5), the calibration and the loading of the multi-dimensional force transducer can be realized. Compared with the prior art, the invention has the advantages of simple and compact structure, large range for calibrating and loading the force and high loading accuracy. Besides, by regulating the pressure of a hydraulic system, the invention can easily realize the continuous adjustment of the loaded force and the automatic and dynamic loading of the calibrated force, thereby being especially applicable to the static and dynamic calibration and loading of the large multi-dimensional force transducer.

Owner:YANSHAN UNIV

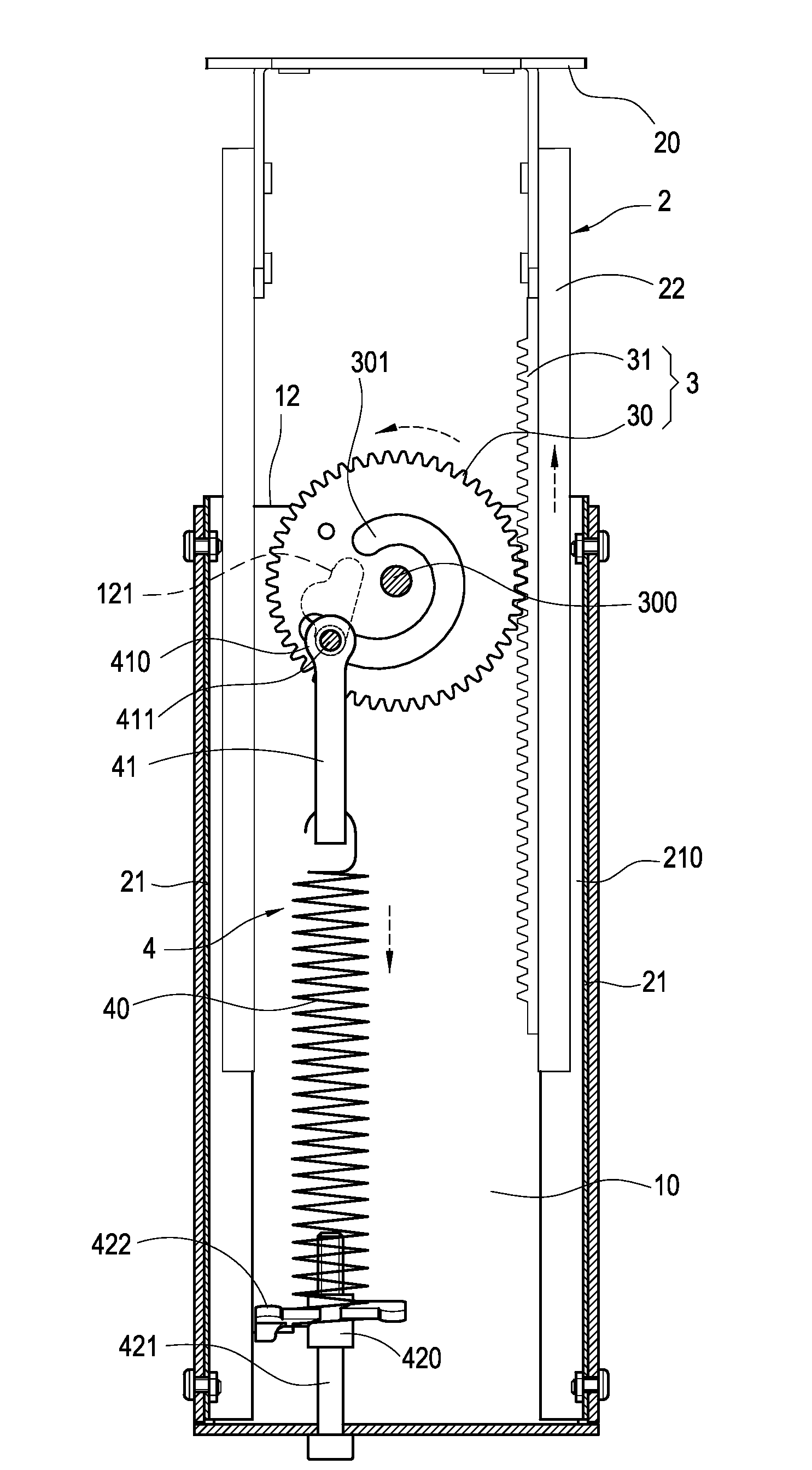

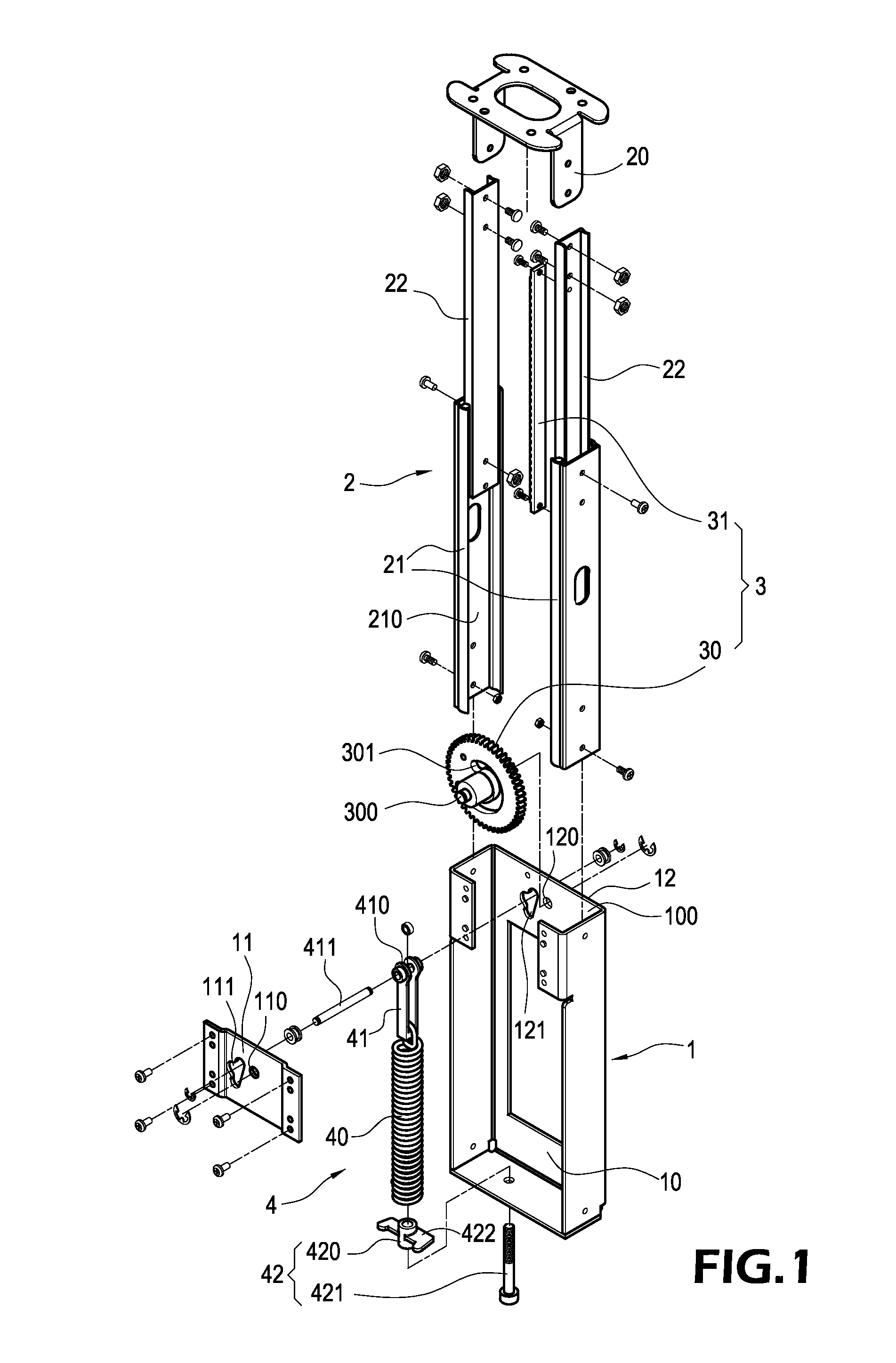

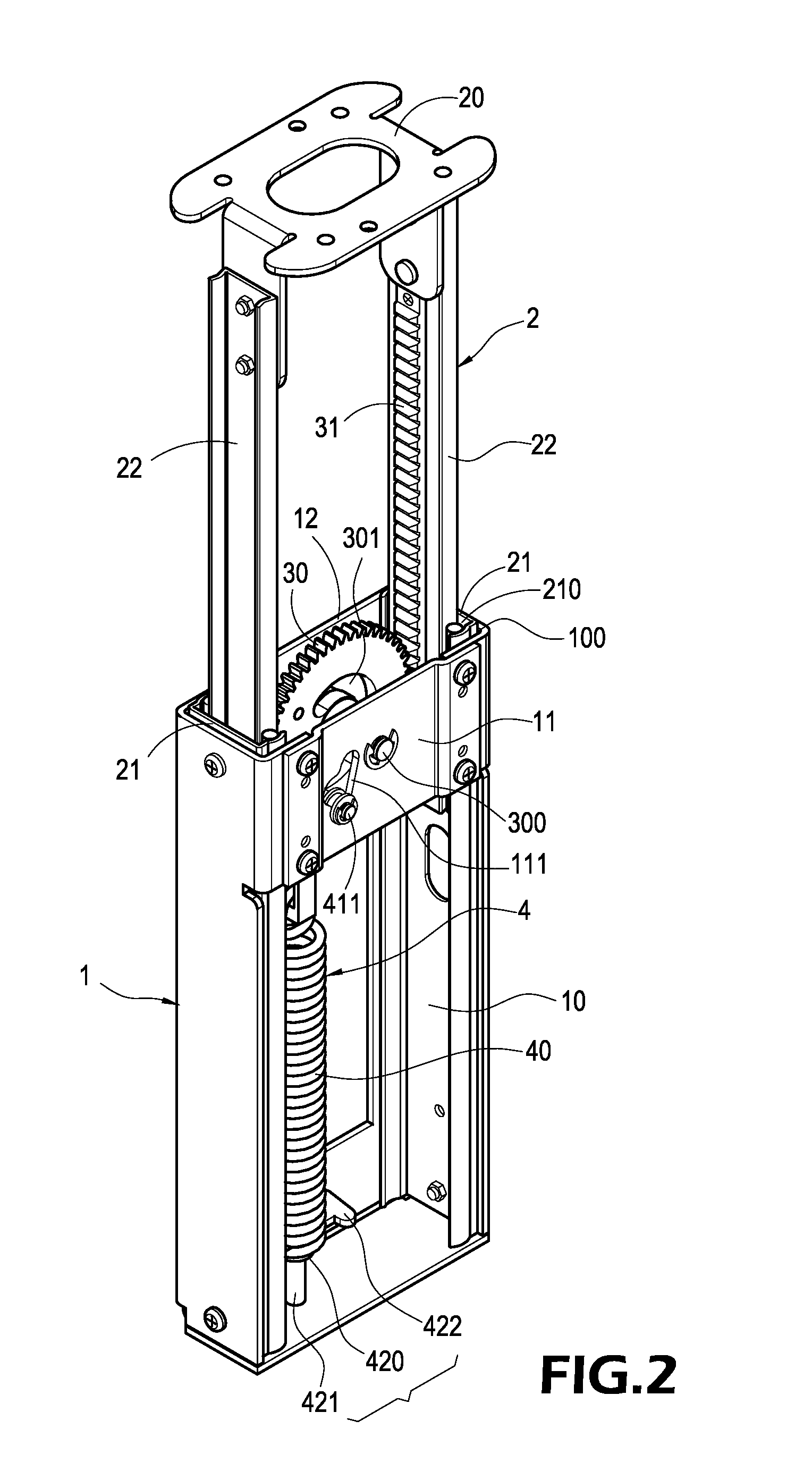

Stepless Adjustable Supporting Device

A stepless adjustable supporting device includes a base, a lifting arm, a transmission wheel assembly and an elastic module. The present invention employs the lever principle that the product of the load force and the load force arm is equal to the product of the applied force and the applied force arm. Further, with the structure in which a transmission wheel of the transmission wheel assembly is configured to have an eccentric groove, the applied torque generated by the supported article such as displayer with respect to the supporting device is kept to be equal to the load torque generated by the supporting device. In this way, the supporting device can perform a stepless adjustment of various heights while exhibit a supporting effect.

Owner:PAI CHIH TANG

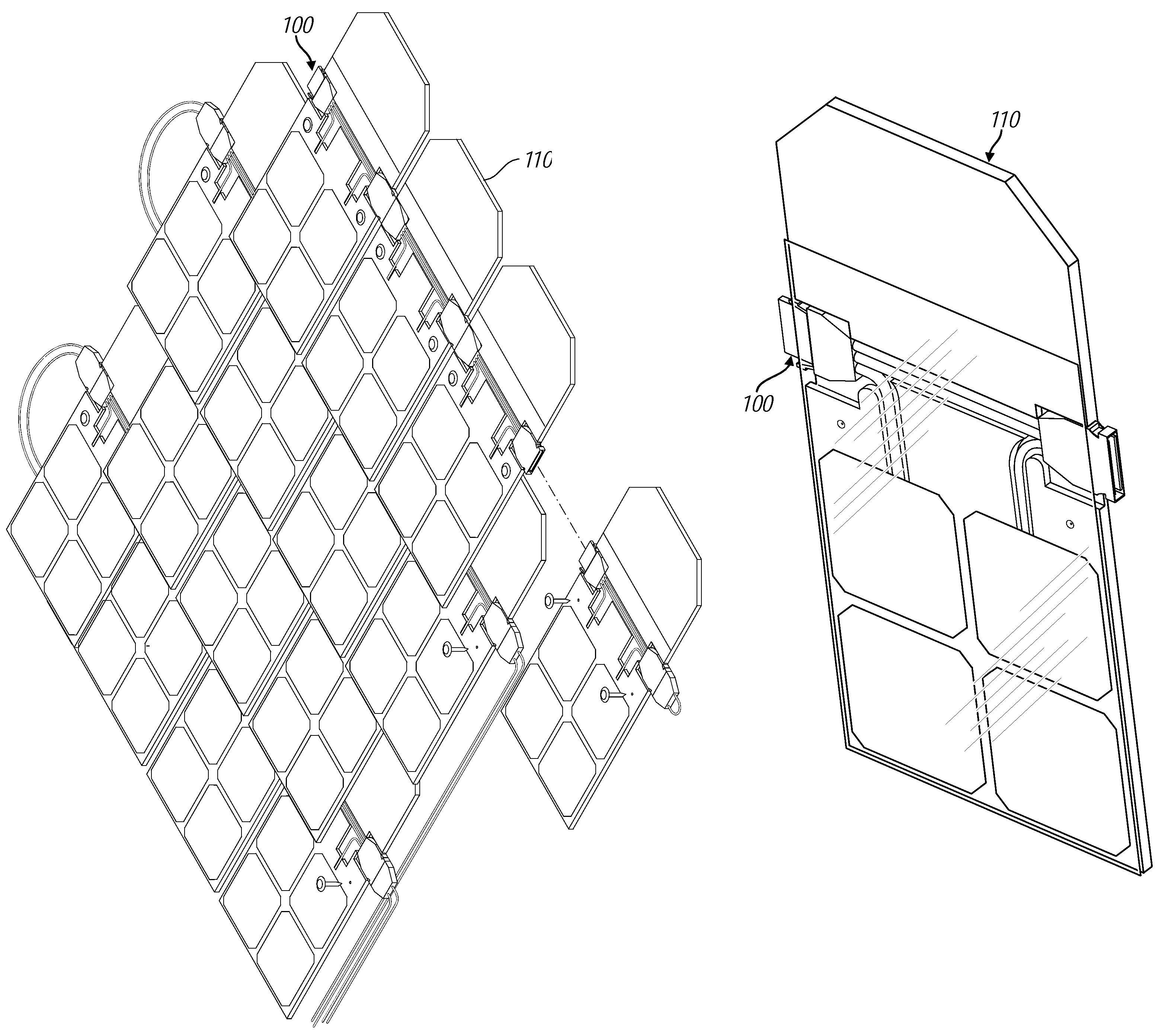

Photovoltaic roofing tile with a plug and socket on 2 opposite edges

InactiveUS7713089B2Improve aestheticsEasy to usePhotovoltaic supportsPV power plantsRoof tileModularity

Owner:REDWOOD RENEWABLES

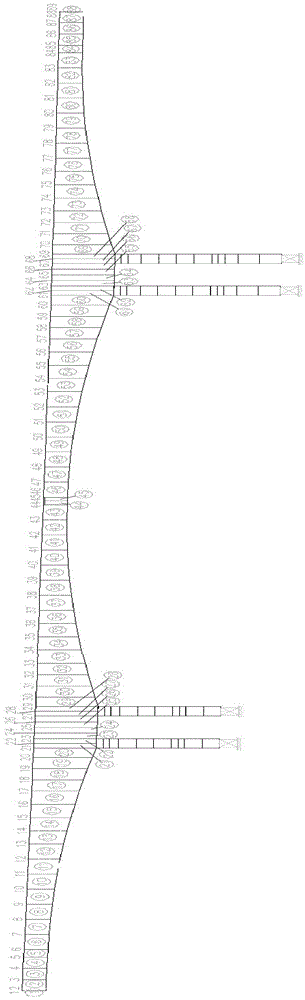

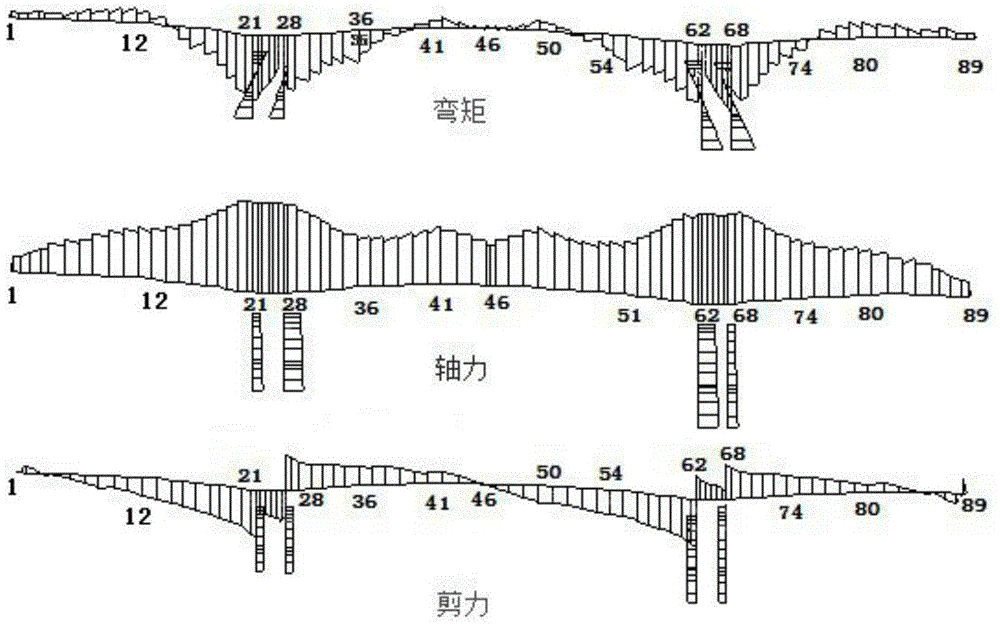

Bridge field static load test evaluation method

ActiveCN104933285AEffective and comprehensive assessmentImprove securitySpecial data processing applicationsElement modelEvaluation Interval

The present invention relates to a bridge field static load test evaluation method, which is mainly a method for evaluating the bearing capacity and adaptation performance of a bridge by means of a field static load test. The method comprises the following steps: (1) determining specific content and method for collecting relevant data for early stage preparation work; (2) establishing a reasonable and accurate bridge structure finite element model according to the collected data; (3) calculating and analyzing a result according to an endogenous force and a stress of the bridge under dead and live loads, and determining theoretical force bearing safety and live load force bearing characteristics; (4) in combination with a traditional key section of the bridge, determining a bridge test section and completing static load test solution designing; (5) performing the field static test for the bridge and processing the test data; (6) studying an evaluation interval corresponding to a preset test evaluation indicator; and (7) making a reasonable and comprehensive assessment on the structural performance of the bridge. The evaluation method and indicator according to the present invention can more effectively indicate the practical bearing capacity and applicability of the bridge in a refined manner, and improving the reasonability and accuracy of the evaluation result.

Owner:SOUTHWEST JIAOTONG UNIV

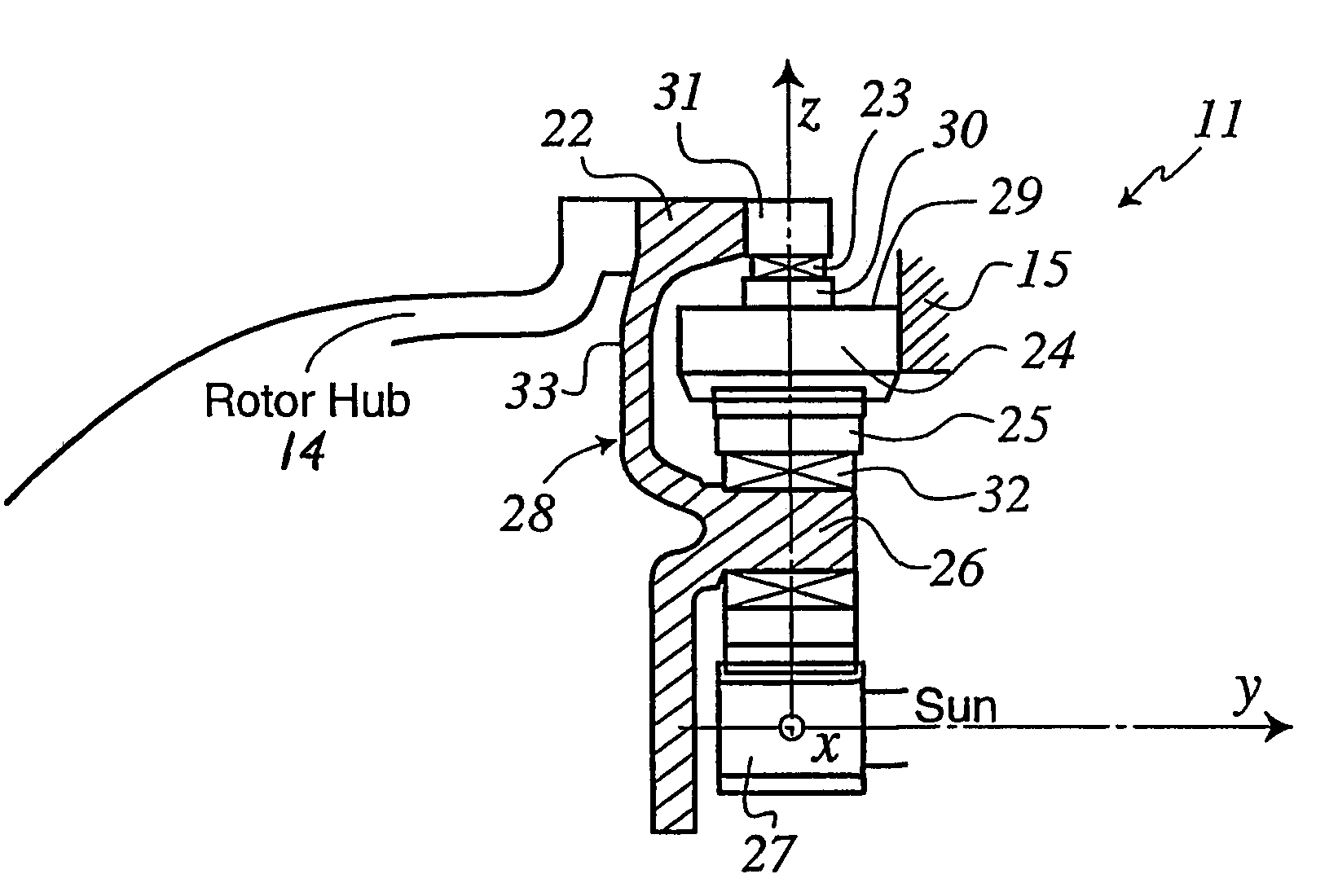

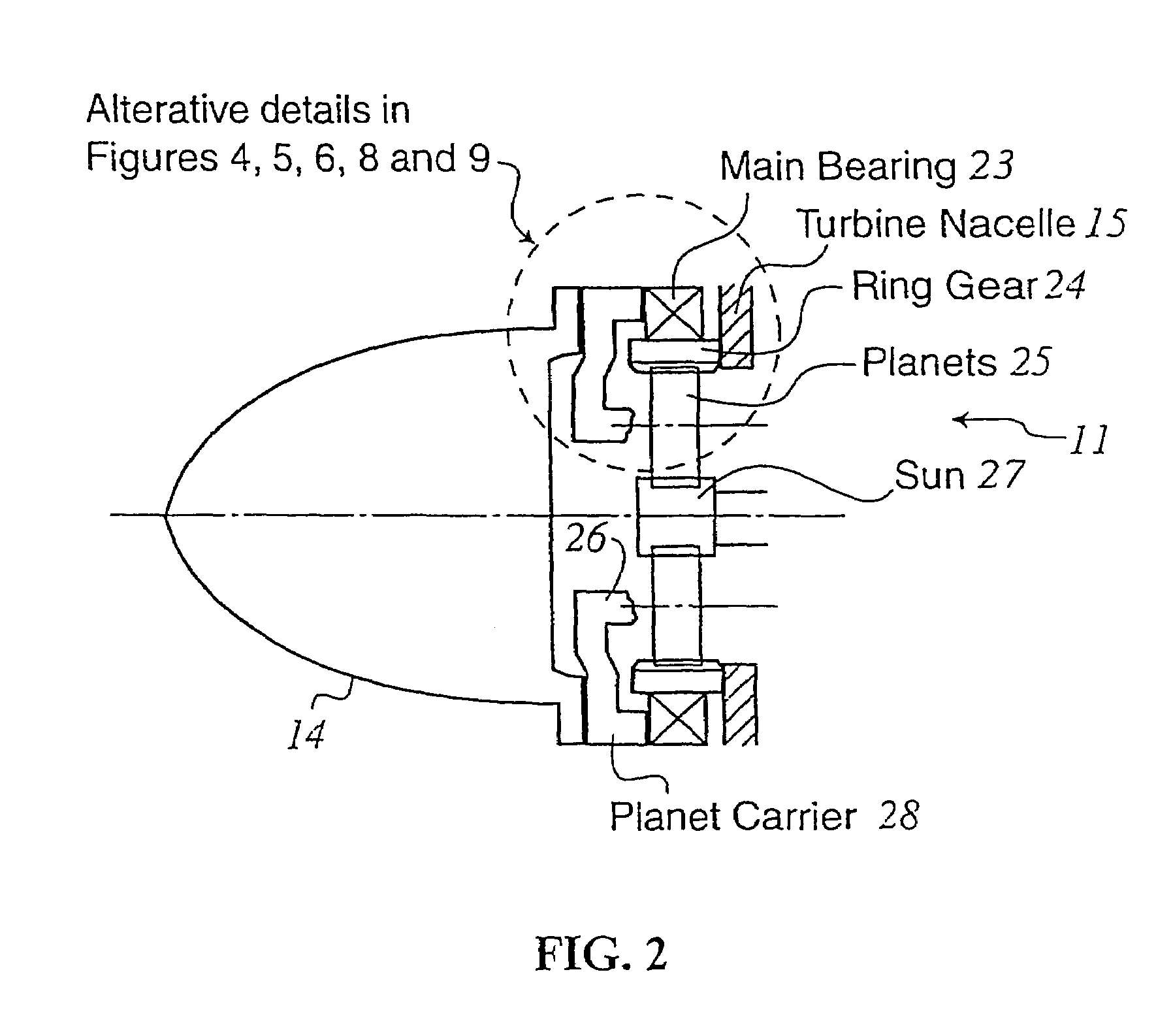

Drive assembly for wind turbines

A drive assembly for a wind turbine includes a rotor hub, a supporting structure, a planetary gear transmission unit having sun, planet and ring gears and a planet carrier. The ring gear is non-rotatably secured to the supporting structure. A main bearing rotatably supports the rotor hub and planet carrier relative to the ring gear and supporting structure. The drive assembly further includes two substantially independent force transmission paths for transmission of forces reacting with forces exerted by the wind turbine rotor hub. A first of the force transmission paths acts from the rotor hub via the main bearing to the supporting structure primarily for transmission of overhang load forces and bending moment forces and a second of the force transmission paths acts from the rotor hub via the planet carrier primarily for transmission of rotational forces.

Owner:HANSEN TRANSMISSIONS INT NV

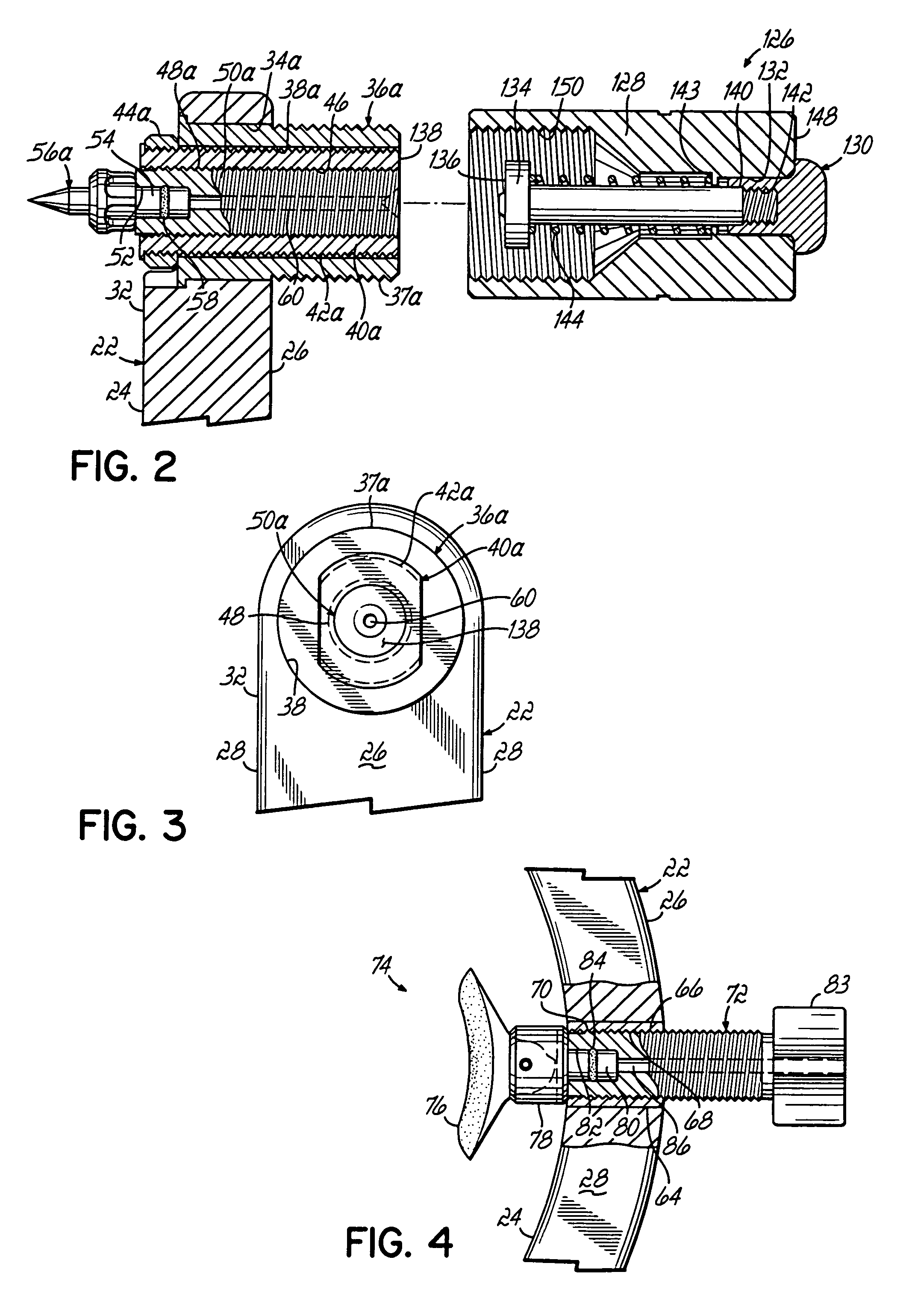

Radiolucent skull clamp with removable pin load applicator

ActiveUS7507244B2Reduce spacingEasy to set upDiagnosticsInstruments for stereotaxic surgerySkull clampBiomedical engineering

A skull pin assembly for use with a skull clamp includes a skull pin that is slidable into contact with a head of a patient. A pin load applicator is removably connectable to the skull pin assembly and includes a loading shaft that is able to apply a force against an inner end of the skull pin. The pin load applicator also has a biasing element operable to apply a force on the loading shaft that, in turn, transfers the force to the skull pin. A load force indicator is connected to the loading shaft and provides an indication of the force being applied by the skull pin. The pin load applicator permits the force being applied by the skull pin to be adjusted to a desired value; and thereafter, the pin load applicator is removed from the skull pin assembly without changing the desired skull pin force.

Owner:INTEGRA LIFESCI

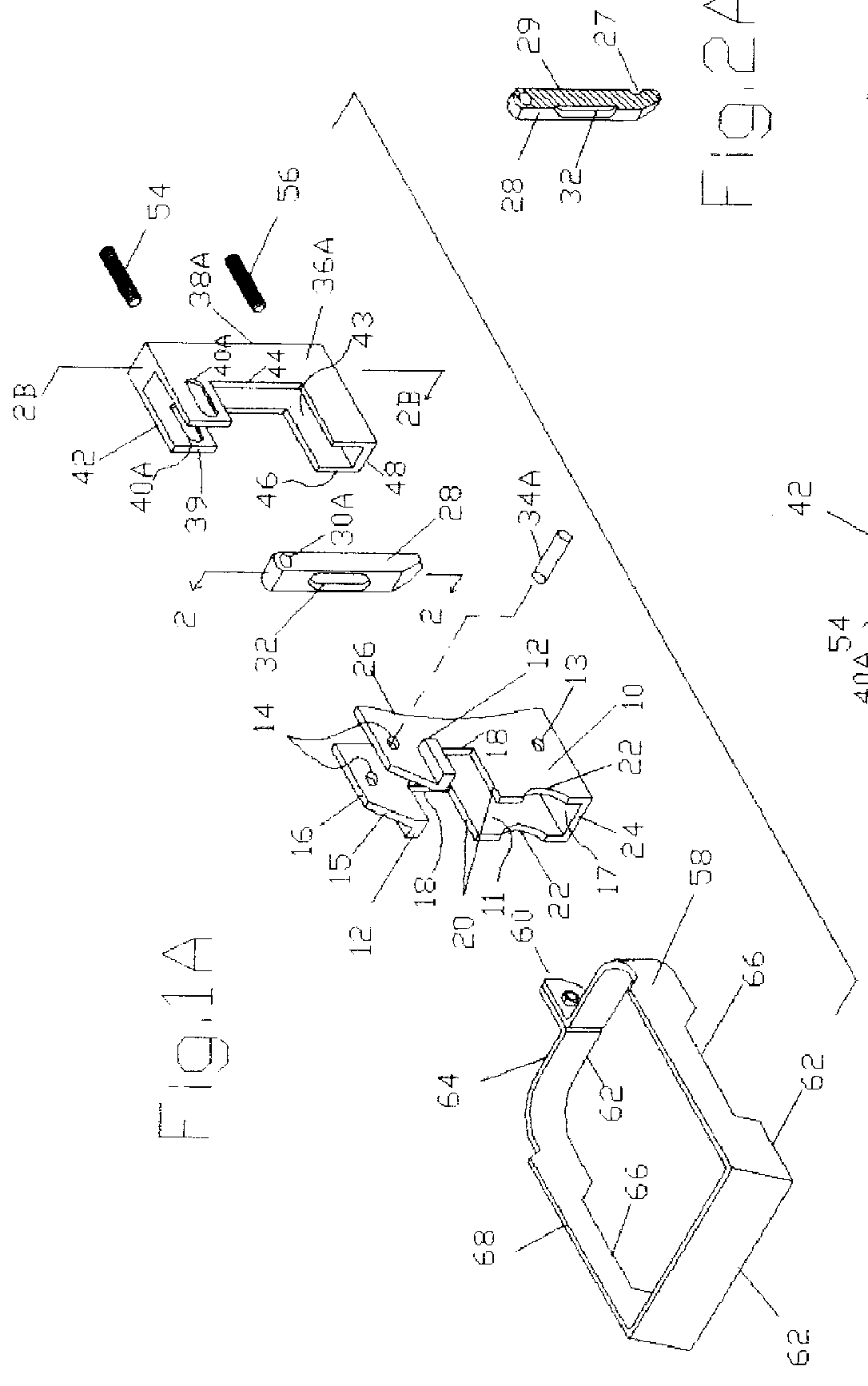

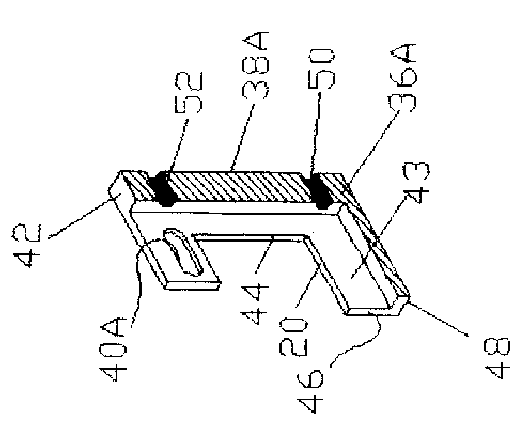

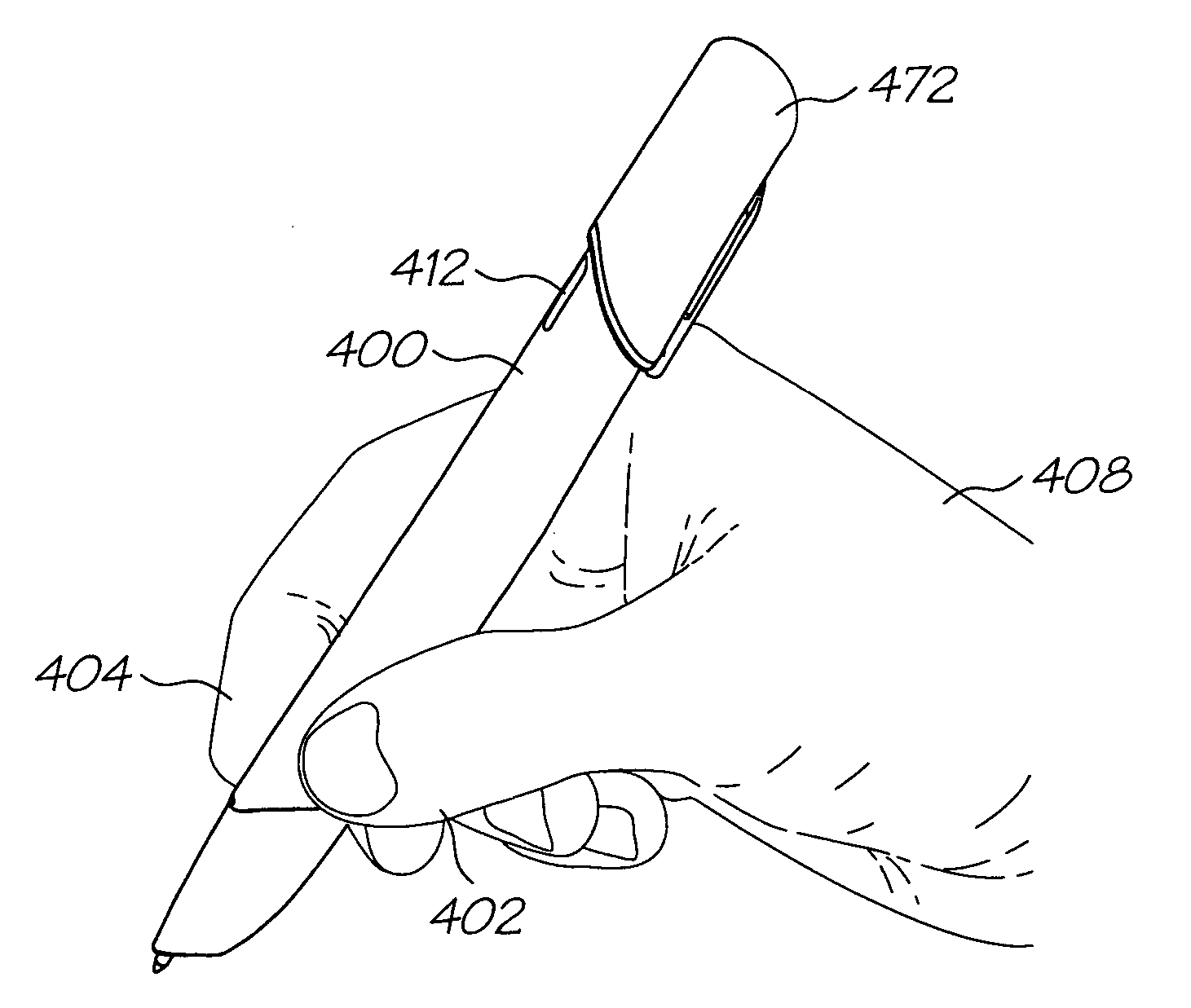

Device for reducing firearms trigger pull weight

A device comprises of independent trigger bow (58) supplied with overlapping recess (64) and a trigger block (10) having a bow guide recess (20), pivot hole (14) with axis pin (34A), primary lever (28) having a axis hole (30) at one end and a bow extender recess (32) and a trigger plate (36A) having a pre-load bar (56) and stopper bar (54) that can be assembled into a module to allow easy installation on trigger tunnel (85) of firearm(88) for reduce firearm trigger pull weight without altering firearm (88). Block (10) is being equipped with catches (12) extending sideways and adjacent with bow guide recess (20) which will overlap with recess (64) of bow (58) to allow both the bow (58) and block (10) to occupy in one same area which allow anchoring against a bow tunnel (83) end wall and supplied with magazine cut (15) disposed on the upper left of block (10) to allow for a magazine passage. As trigger plate (36A) is depressed with finger within a given point on trigger plate (36A) upon firing the finger force will be shifted directly into the adjustable preload bar (56) and synchronizes into the outermost lever end at point (27) of lever (28) producing a high torque leverage which reduces firearm trigger pull weight or load force from the trigger bow (58) energized from sear (70), hammer (72) and hammer spring (82). The trigger plate (36A) being retained with pivot pin (34A) through retaining slot (40A) is supplied with plate bearing (42) and bottom bearing (48) will slide against a frame upper bearing (79) and against s block plate bearing (17) of block (10) respectively, will function as an advancing global pivot point which will changed a rotational action of lever (28) into a linear straight pull action to maintain firearm standard straight action and reducing the trigger pull weight.

Owner:LEE ROBERTO R

Pre-loaded force sensor

InactiveUS20060028459A1Increase capacityAvoid the needCathode-ray tube indicatorsSteroscopic systemsEngineeringMechanical engineering

A force sensor comprising: a load bearing structure for contact with an input member subject to a force to be sensed; a sensor circuit for converting a force applied to the load bearing structure into a signal indicative of the force; and, a pre-load bias assembly for engaging the input member to bias it against the load bearing structure.

Owner:SILVERBROOK RES PTY LTD

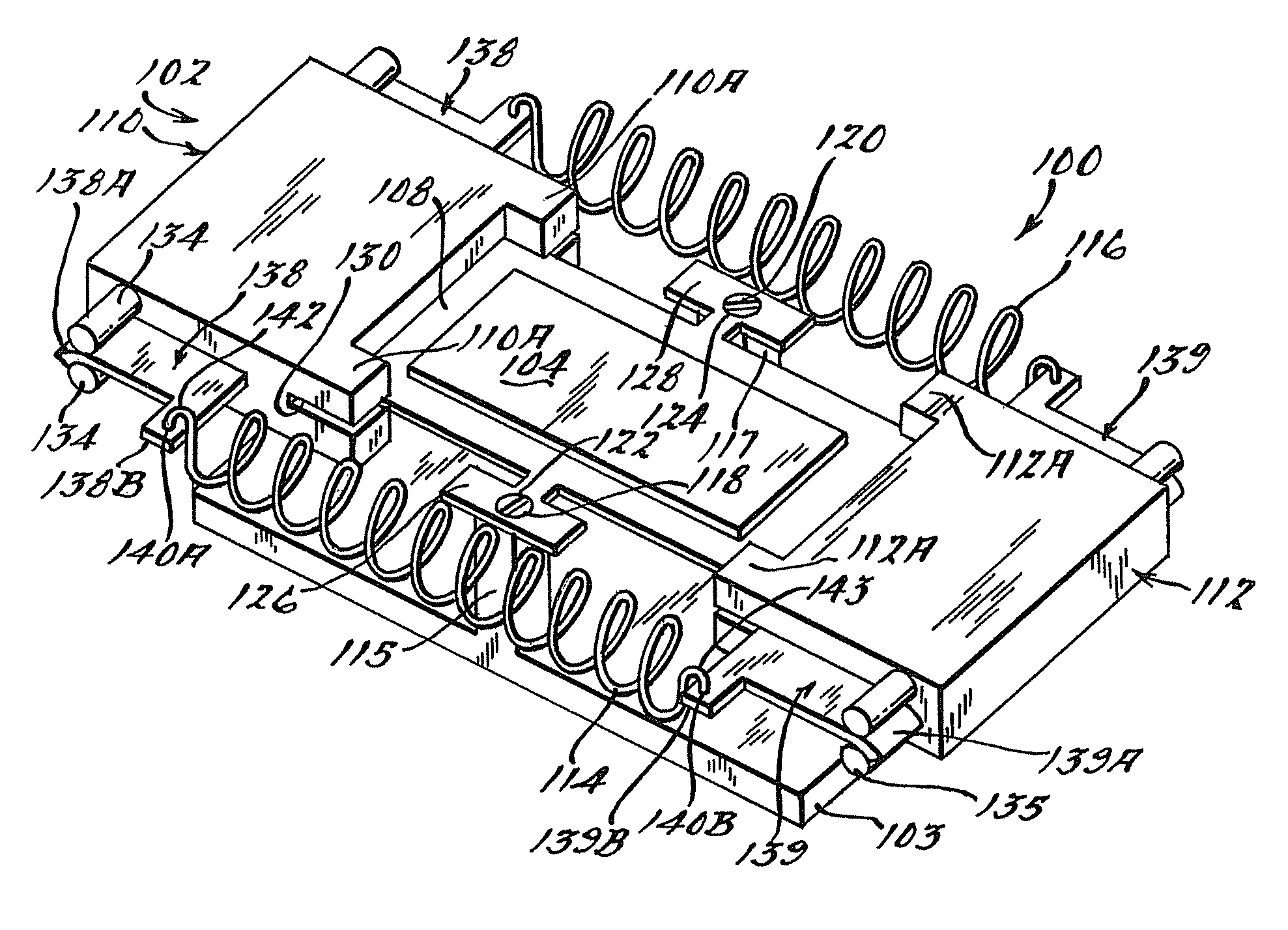

Strain energy shuttle apparatus and method for vibration energy harvesting

ActiveUS7521841B2Overcoming inherent structural stiffnessHighly susceptiblePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesStrain energyEngineering

An apparatus for use in low frequency vibration energy harvesting (VEH) and with actuators requiring a low deflection force. The apparatus includes a piezo flexure that is loaded with a compressive pre-load force to place the piezo flexure under compression. The piezo flexure may be supported at an intermediate point or at one end thereof. The compressive pre-load force produces flexes the piezo flexure into one or the other of two stable positions, these positions being offset on opposite sides of a longitudinal centerline representing the position of the piezo flexure that would be produced without the compressive pre-load force applied thereto. The compressive pre-load effectively provides a negative spring constant which “softens” the piezo flexure and enhances a responsiveness of the piezo flexure to low frequency vibration energy. The piezo flexure also operates over a much wider frequency bandwidth than conventional systems incorporating a tip mass.

Owner:THE BOEING CO

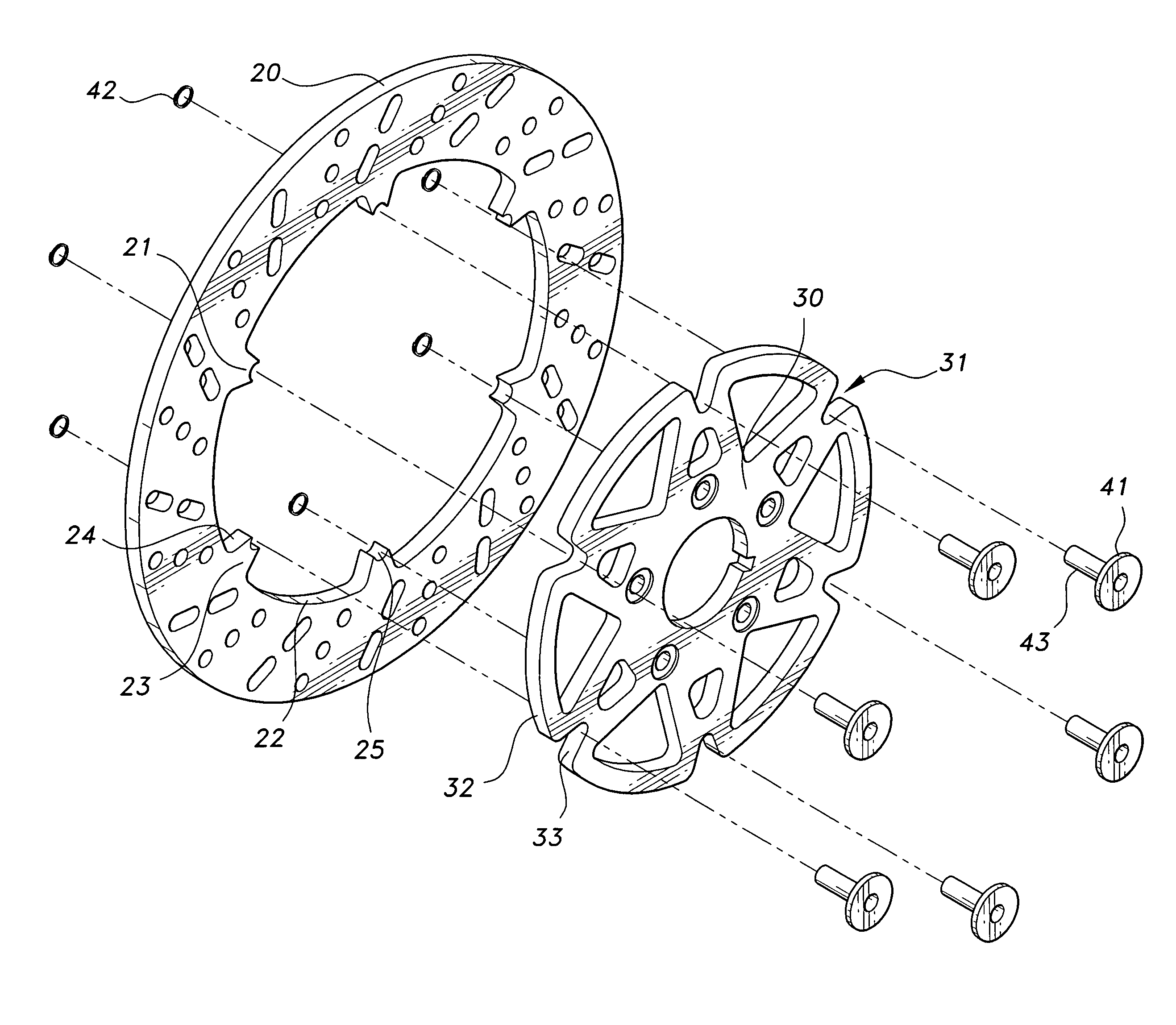

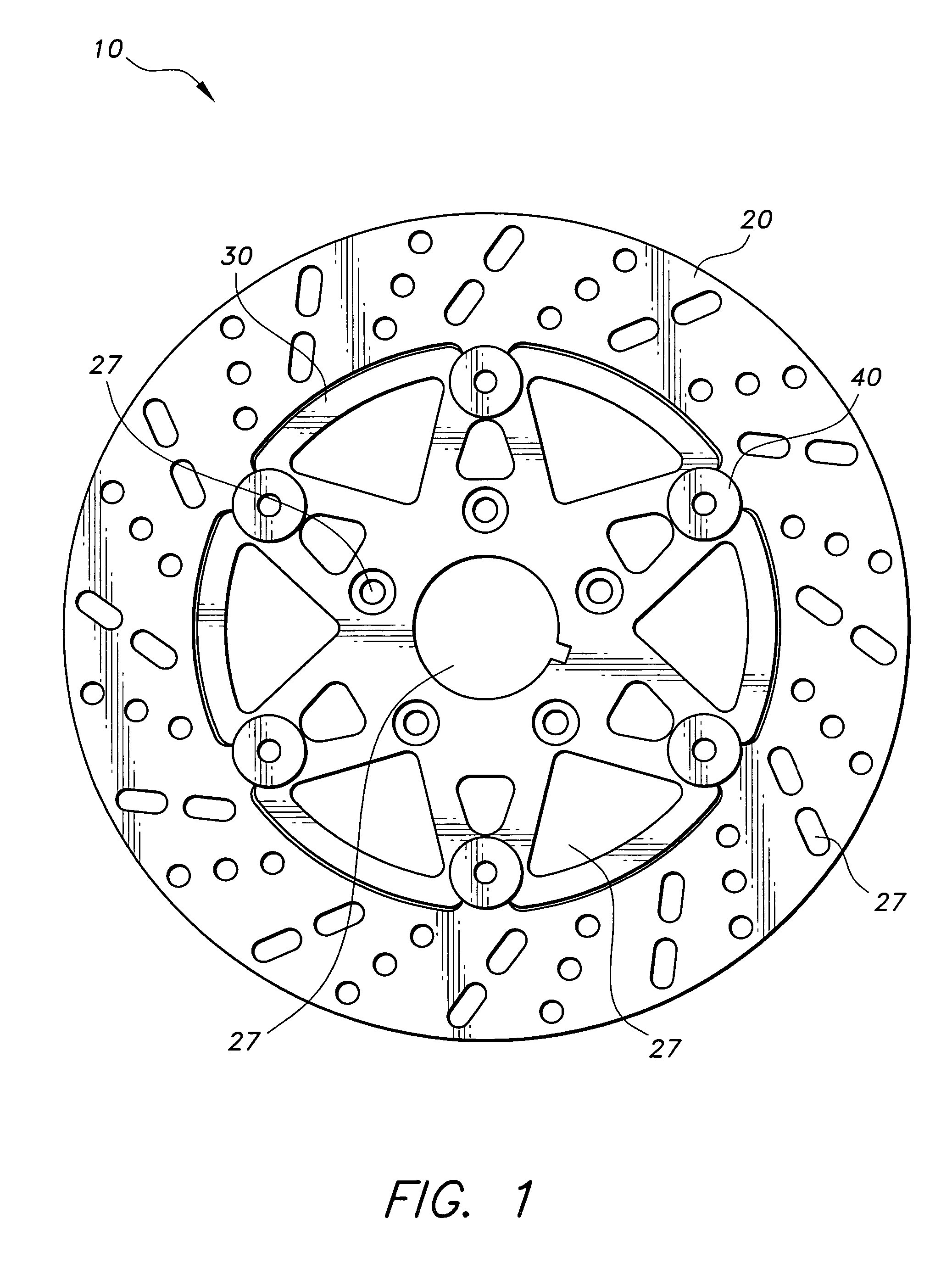

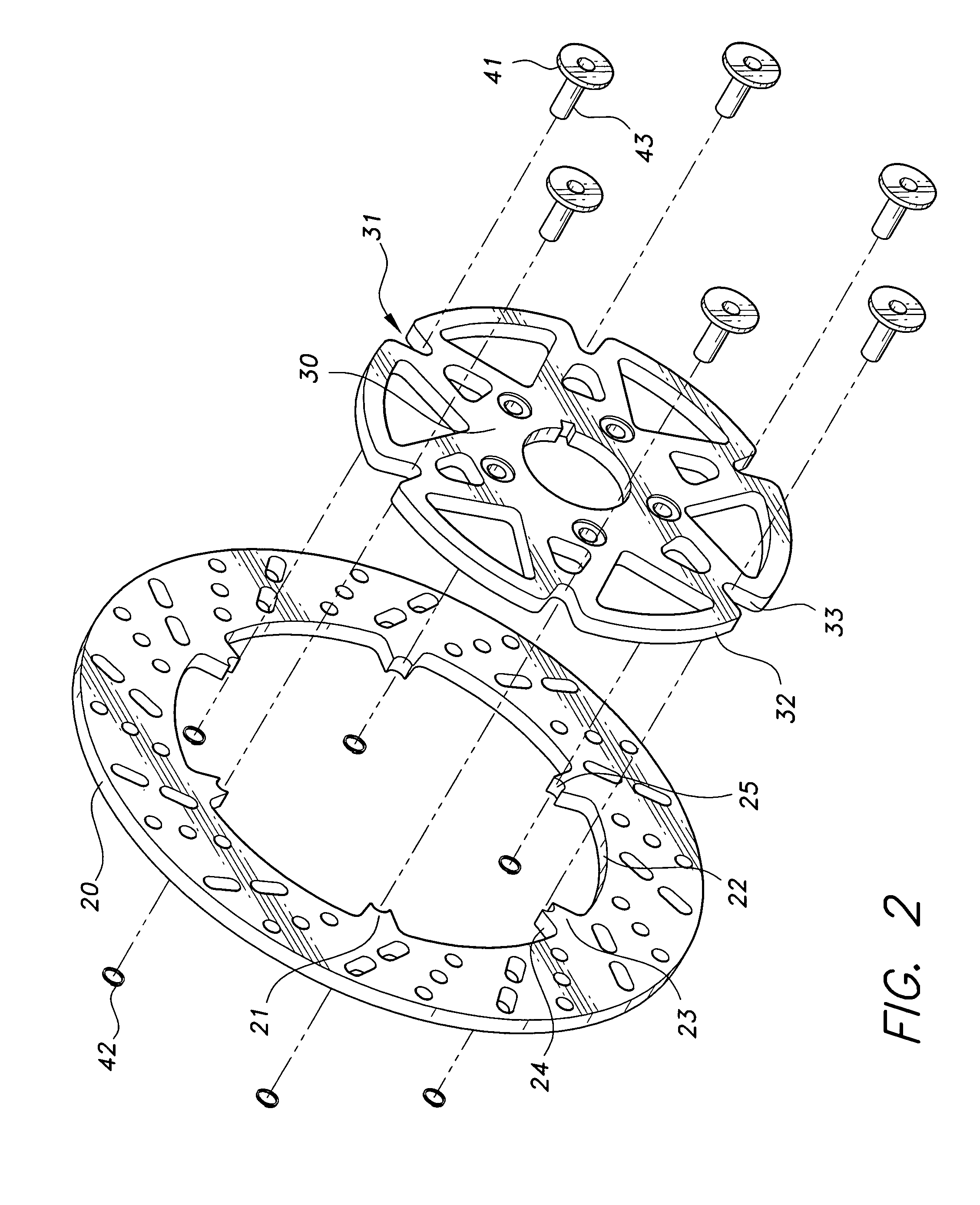

Floating brake rotor assembly with non-load bearing pins

InactiveUS6957726B2Ease in assembling and replacingIncrease the areaFluid actuated brakesBraking element arrangementsEngineeringMechanical engineering

The floating brake rotor assembly with non-load bearing pins includes a brake rotor and hub that are coplanar and are interconnected by pin and spring assemblies such that the pins do not bear rotational torque being transferred between the brake rotor and hub. The rotor has tooth-like protruding members along its inner edge that mate with recesses along the outer edge of the hub. When aligned, each protruding member and corresponding recess forms an aperture through which a pin is positioned, and allows for transfer of rotational torque without applying load force to the pin.

Owner:GEHRS JEFFREY W

Laser modified plastic container

InactiveUS20110089135A1Reduce manufacturing costIncrease flexibilityContainer decorationsLevel indicationsPolyethylene terephthalateEngineering

A polyethylene terephthalate container having a laser-formed area, wherein the laser-formed area is modified in response to radiation energy. In some embodiments, the laser-formed area of the container permitting localized contouring to permit or otherwise generally prevent flexural response to vacuum and / or loading forces. In some embodiments, the laser-formed area of the container comprises visible indicia formed to permit labeless containers.

Owner:AMCOR

Weight loading system for fitness equipments

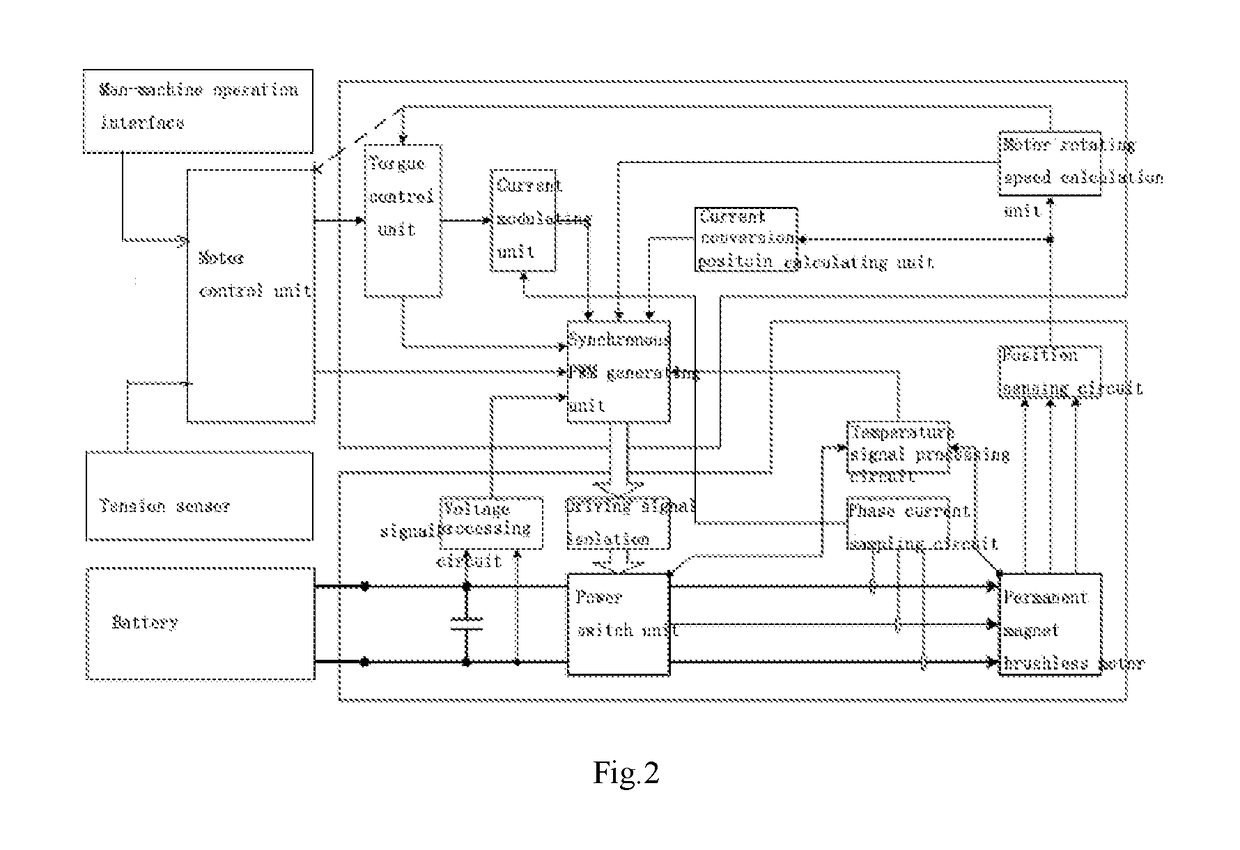

ActiveUS20170173396A1Increase load capacitySimple structureElectric motor controlWound field motor controlMotor driveMotor control

A weight loading system for fitness equipments includes a fitness equipment support, a rally rope, a motor, a motor driving and a motor control unit. The motor is a permanent magnet brushless DC motor with an external rotor structure, and the motor includes a stator mounted onto the fitness equipment support and an external rotor sheathed on the stator and rotatable with respect to the stator, and the rally rope is wound around the external rotor of the motor, and an end of the rally rope is coupled to the external rotor of the motor, and the other end of the rally rope is coupled to the power driving mechanism of the fitness equipment; the power driving mechanism is provided for driving the external rotor of the motor through the rally rope to rotate and generate a rally, and the motor control unit controls the motor to rotate in an opposite direction through the motor driving module, so as to produce a load force opposite to the rally. The weight loading system for fitness equipments structure is simple, lightweight, and achieves the effect of a stepless weight control.

Owner:NINGBO JADA HEALTH TECH

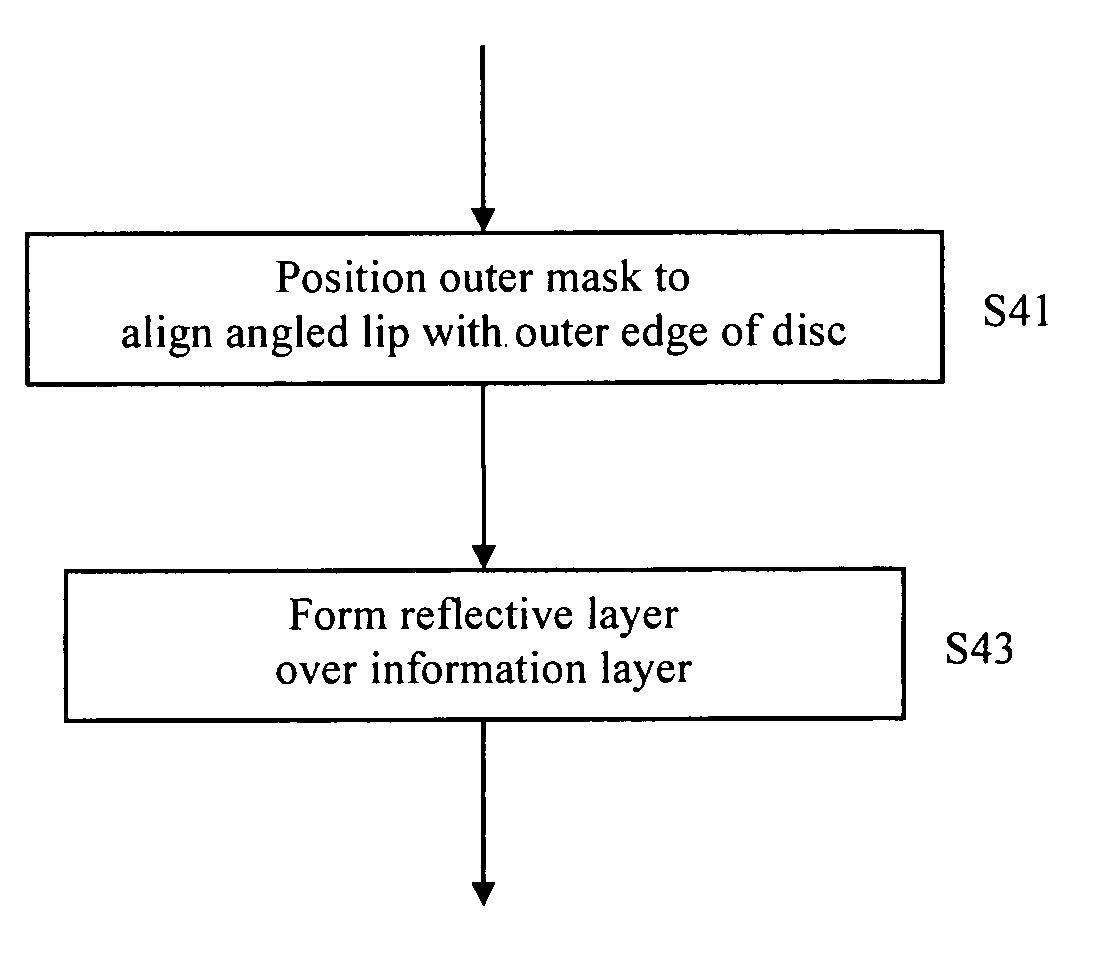

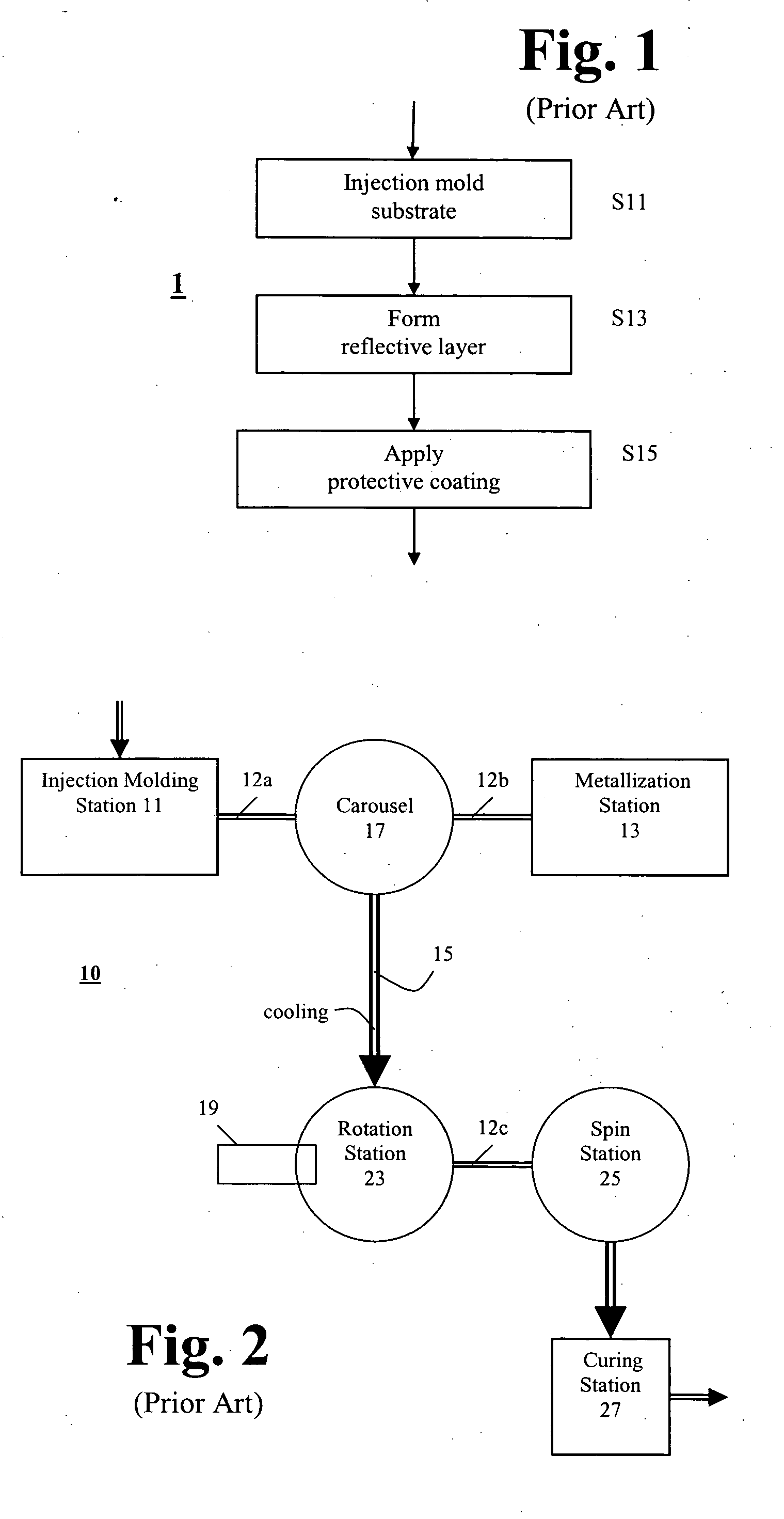

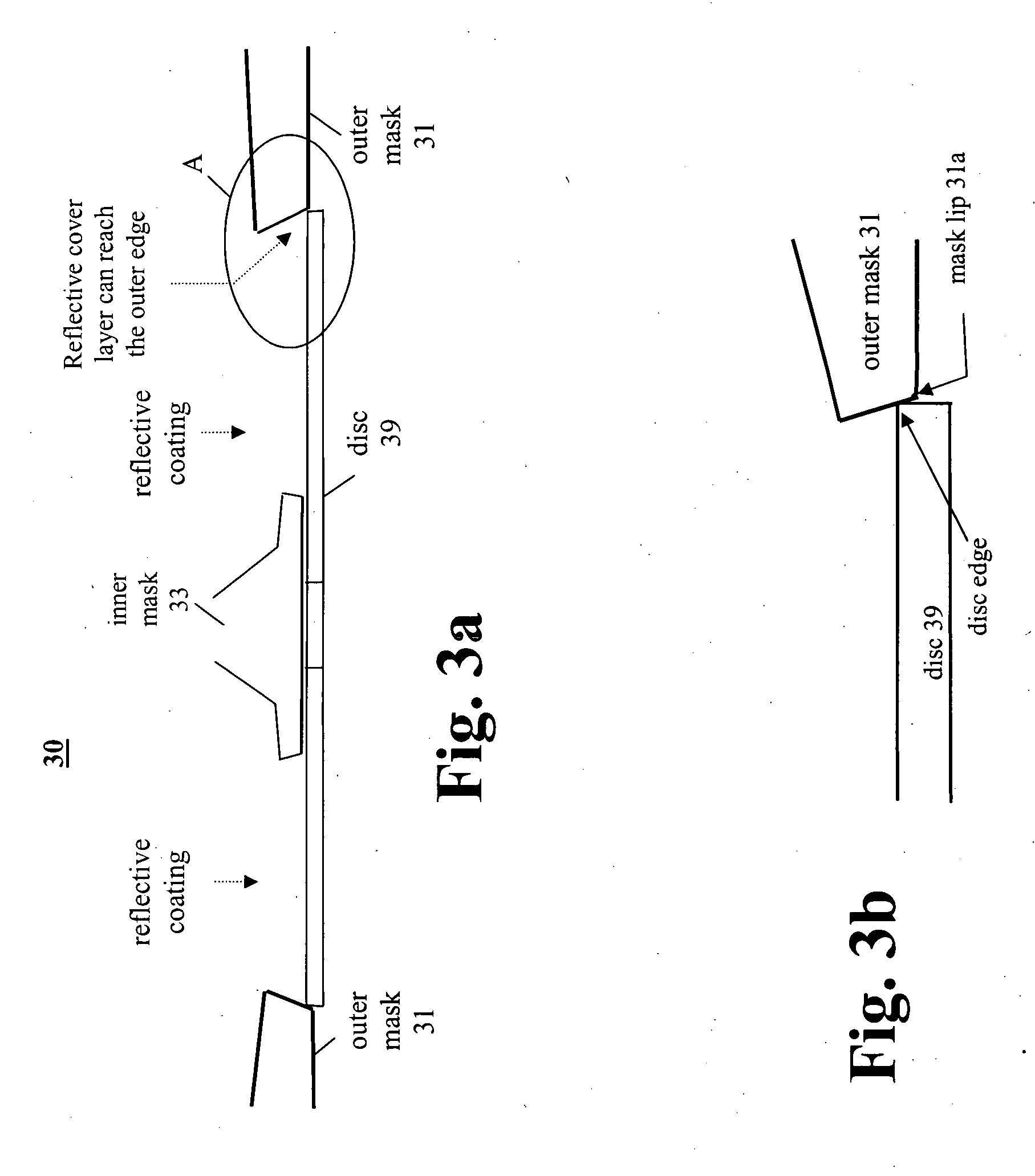

Apparatus and method for forming reflective layer of optical disc

InactiveUS20060270080A1Easy to optimizeLiquid surface applicatorsLayered productsInformation layerComputational physics

Improved techniques for forming a reflective layer of an optical disc are provided. One improvement includes forming the reflective layer over an information layer of the disc by utilizing a metallizer and a masking device having an angled lip configured to align to an outer edge of the information layer. The masking device allows the applied reflective layer to extend to the outer diameter edge of the information layer, and shields plasma generated by the metallizer from reaching internal components of the metallizer. The masking device may include a pusher having a spring mechanism attached to an inner masking portion of the masking device. When the disc and the pusher are brought into relative contact with each other by application of a first force to at least one of the masking device and the disc towards the other, the pusher is spring-loaded and is pushed up into a recess of the inner masking portion, and when the first force is removed, the spring-loaded force of the pusher pushes the disc away from the masking device.

Owner:CT ACQUISITION HOLDCO

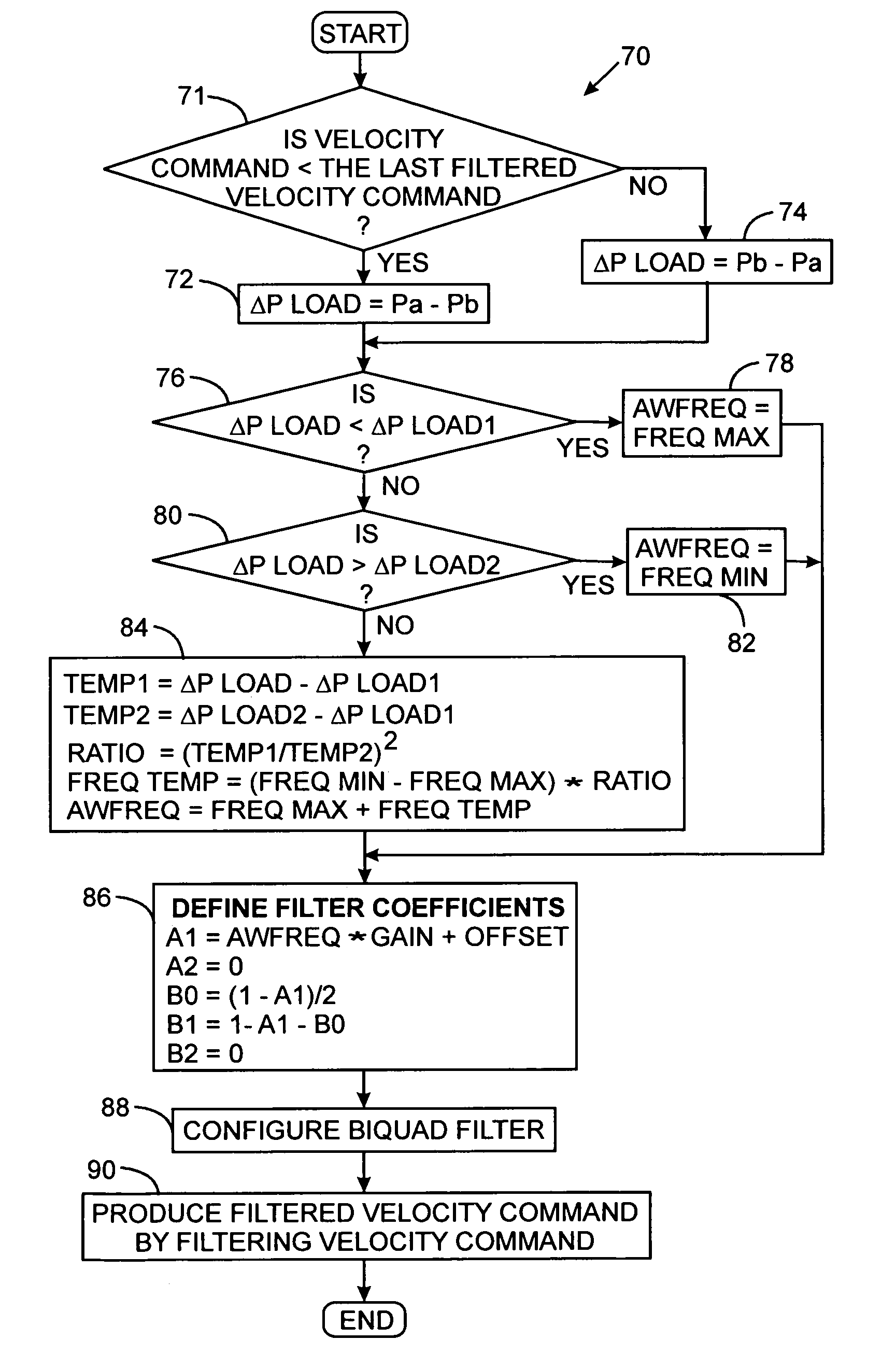

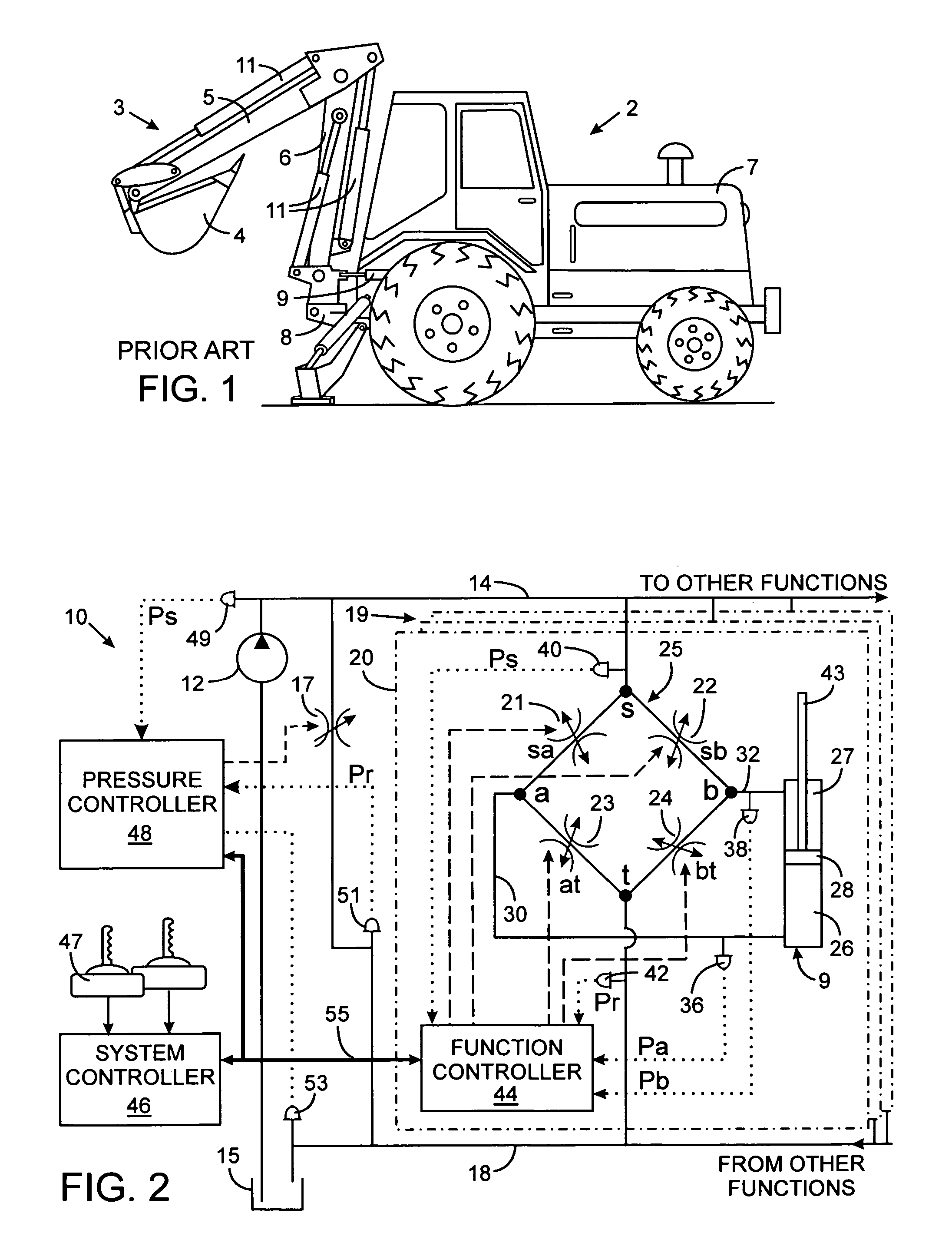

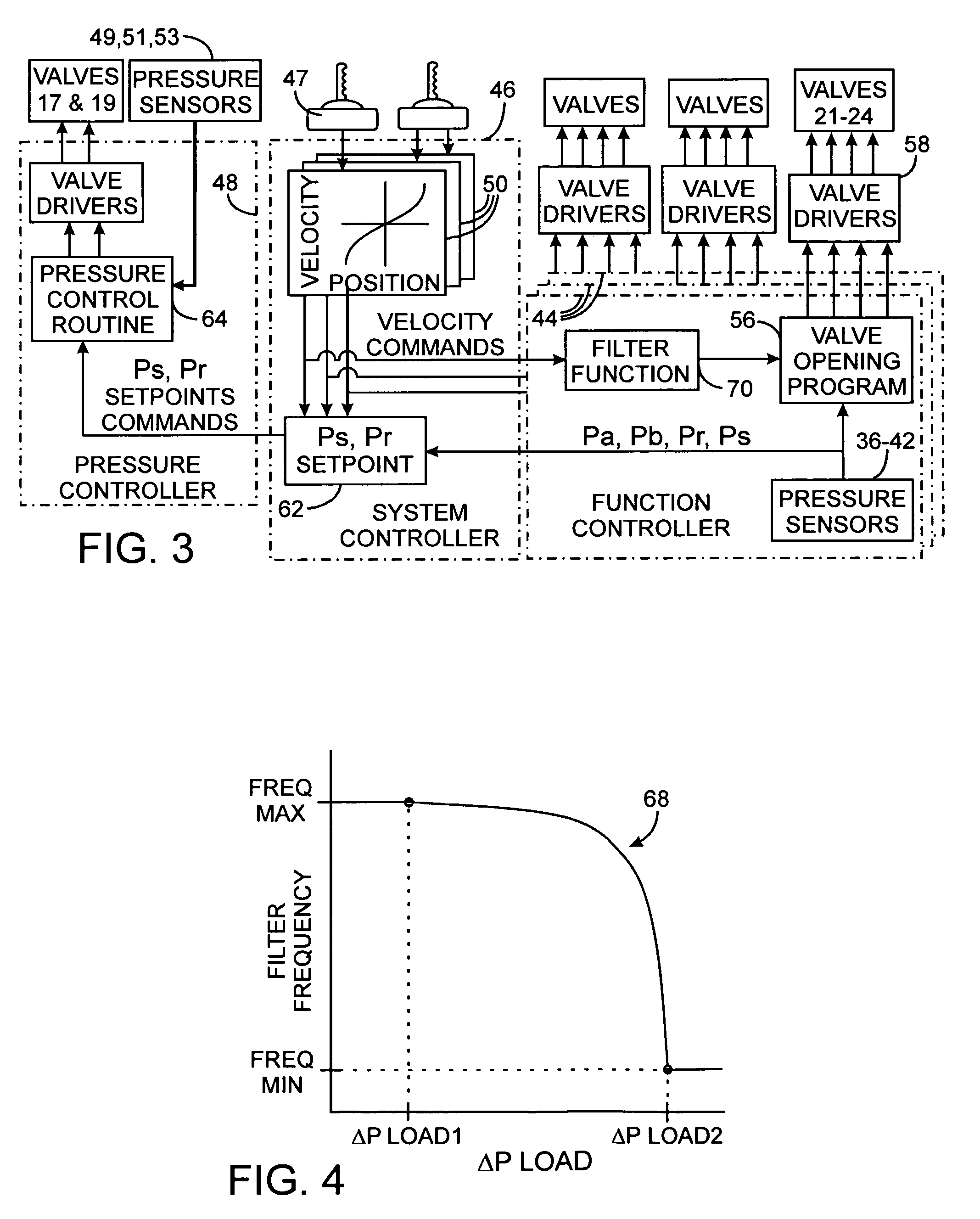

Apparatus for controlling deceleration of hydraulically powered equipment

Owner:HUSCO INT INC

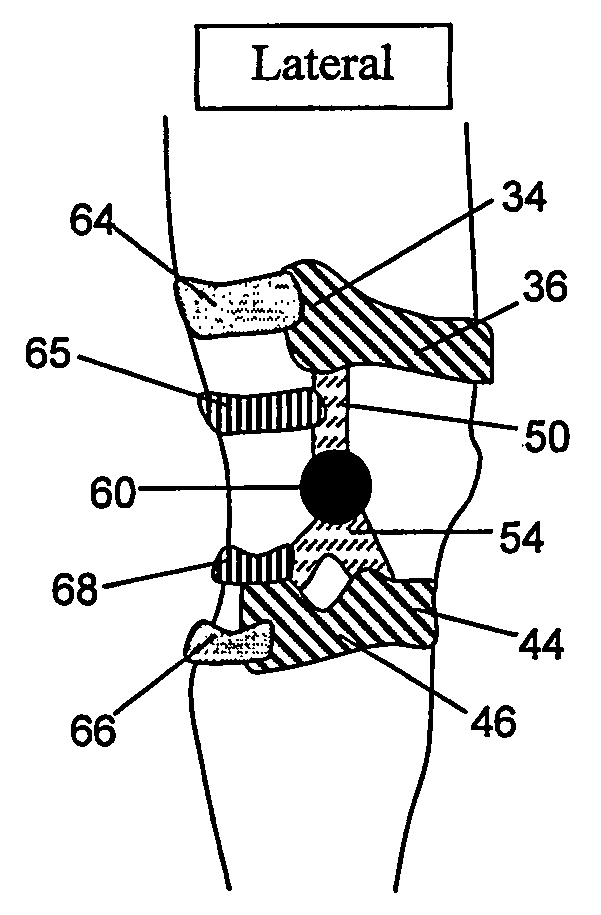

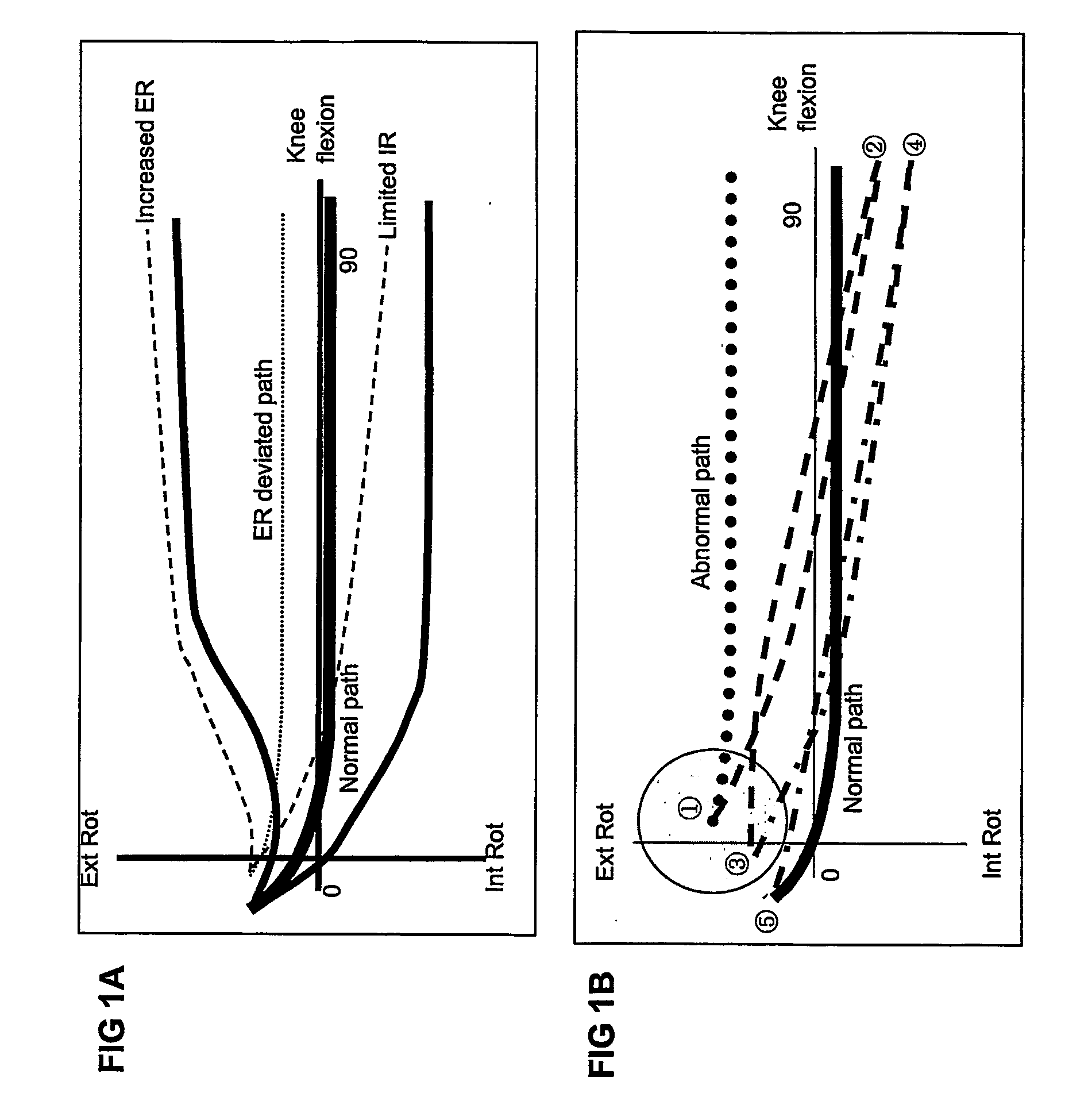

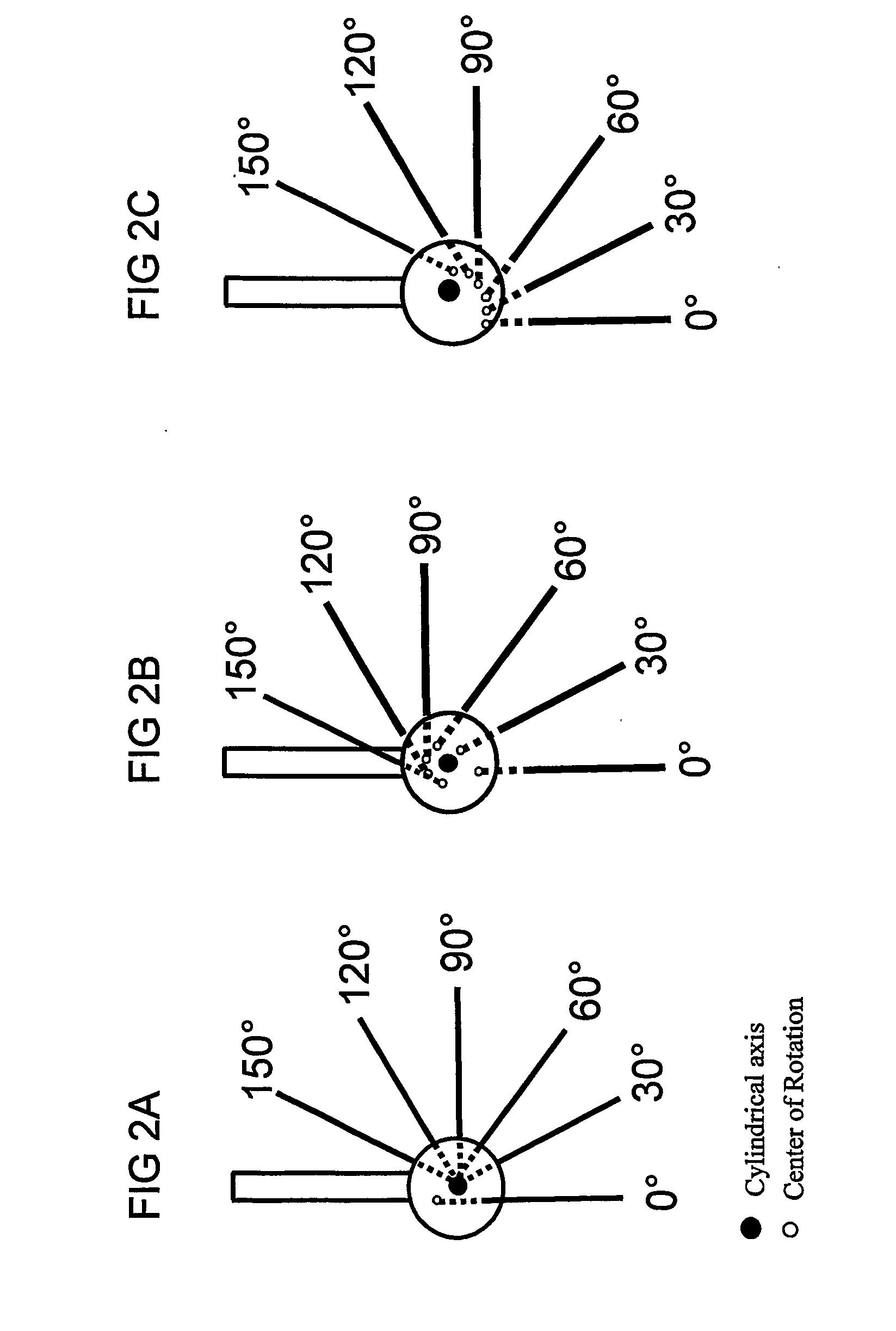

Non-surgical correcting abnormal knee loading

InactiveUS20070100265A1Reduce impactReduce alignmentNon-surgical orthopedic devicesKnee loadingPhysical medicine and rehabilitation

The invention provides hinges for use in knee braces to correct and prevent knee pathology. Further provided are knee braces comprising the hinges of the present invention to correct and prevent knee pathology including osteoarthritis. Also provided are methods of treating knee pathology by using the hinges and braces of the present invention to apply a corrective rotational force and an off-loading force to the affected knee compartment.

Owner:UNIV OF COLORADO THE REGENTS OF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com