Patents

Literature

215 results about "Straight pull" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Straight pull actions differ from a conventional bolt action mechanisms in that the manipulation required from the user in order to chamber and extract a cartridge predominantly consists of a linear motion only, ...

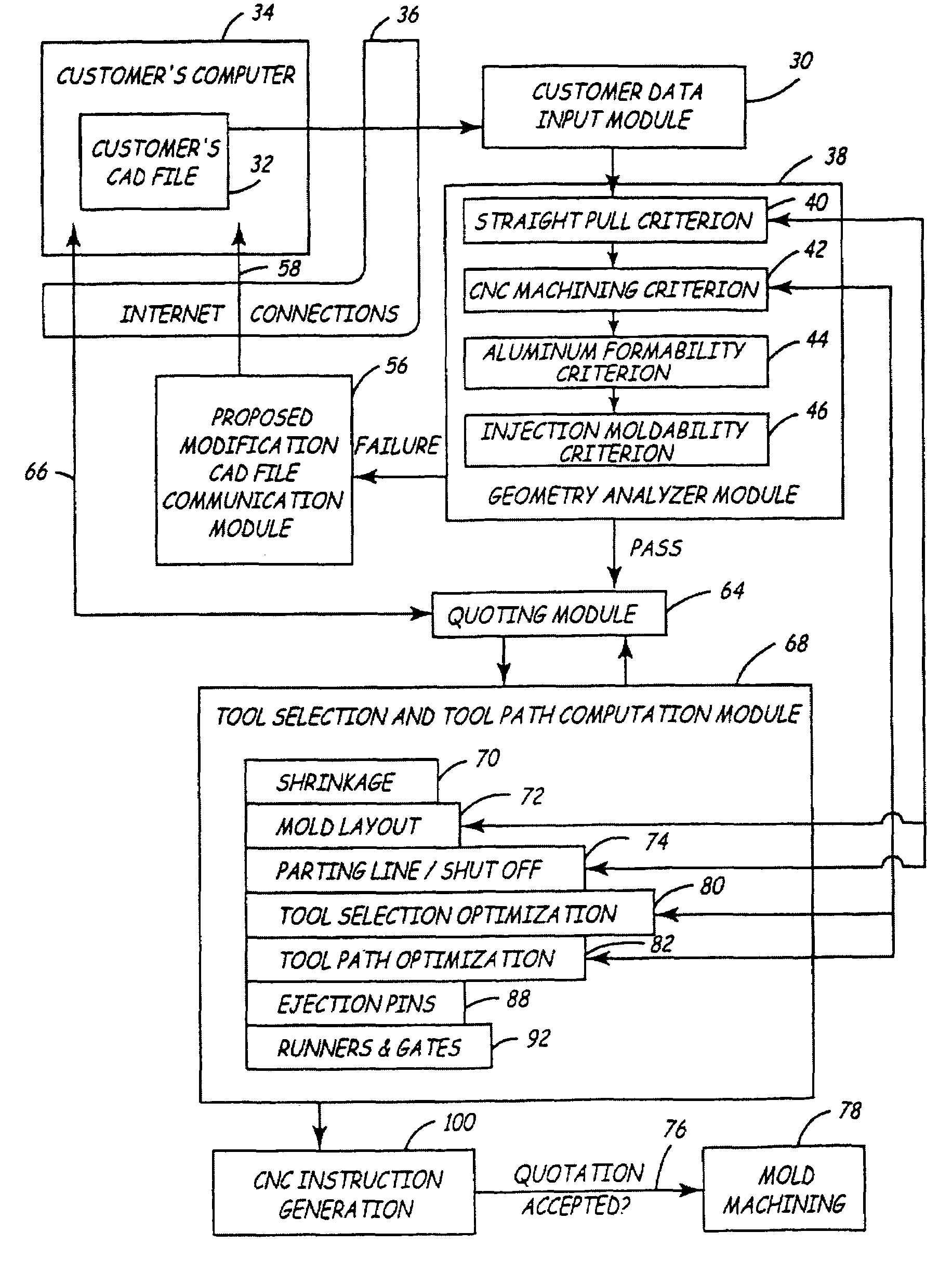

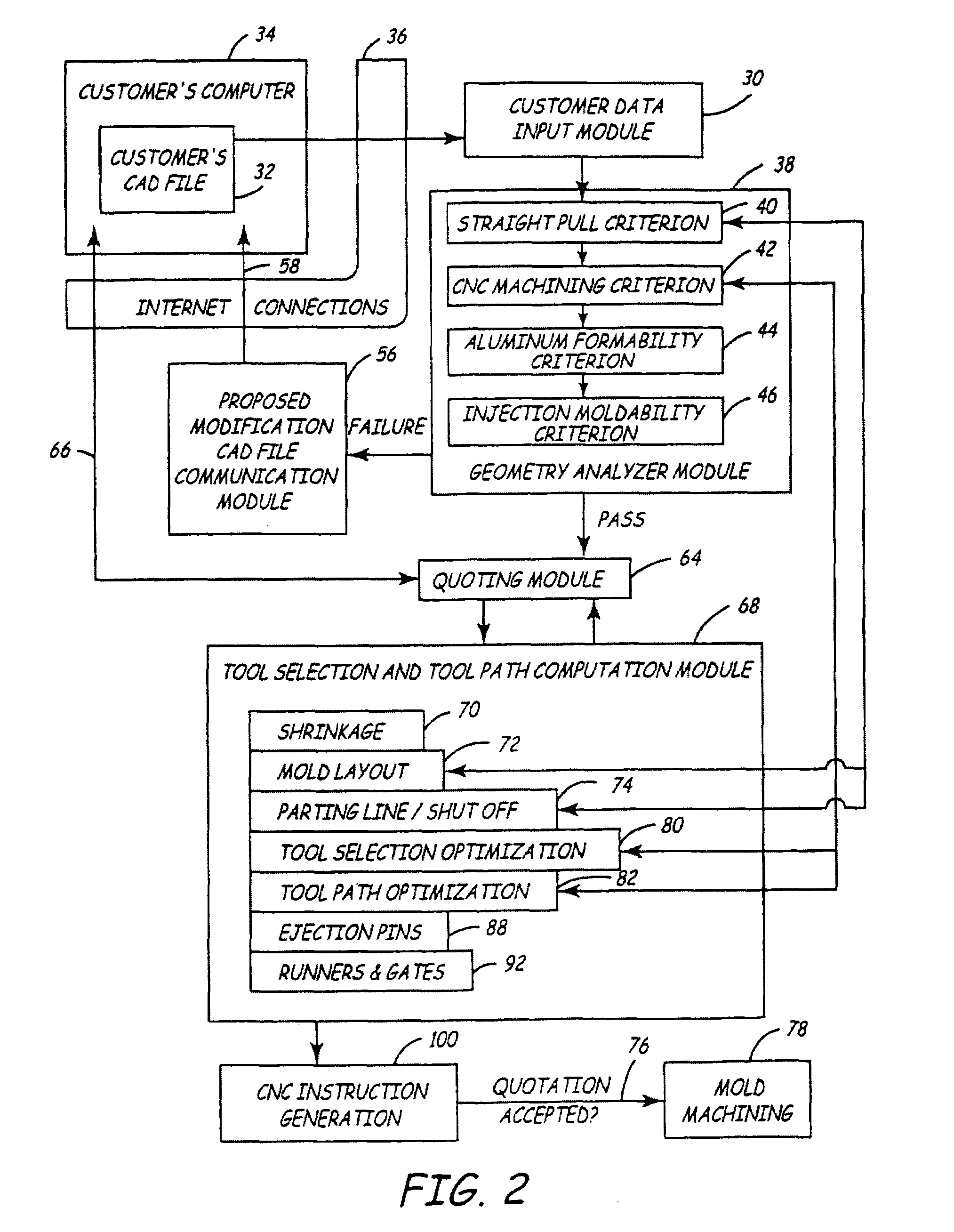

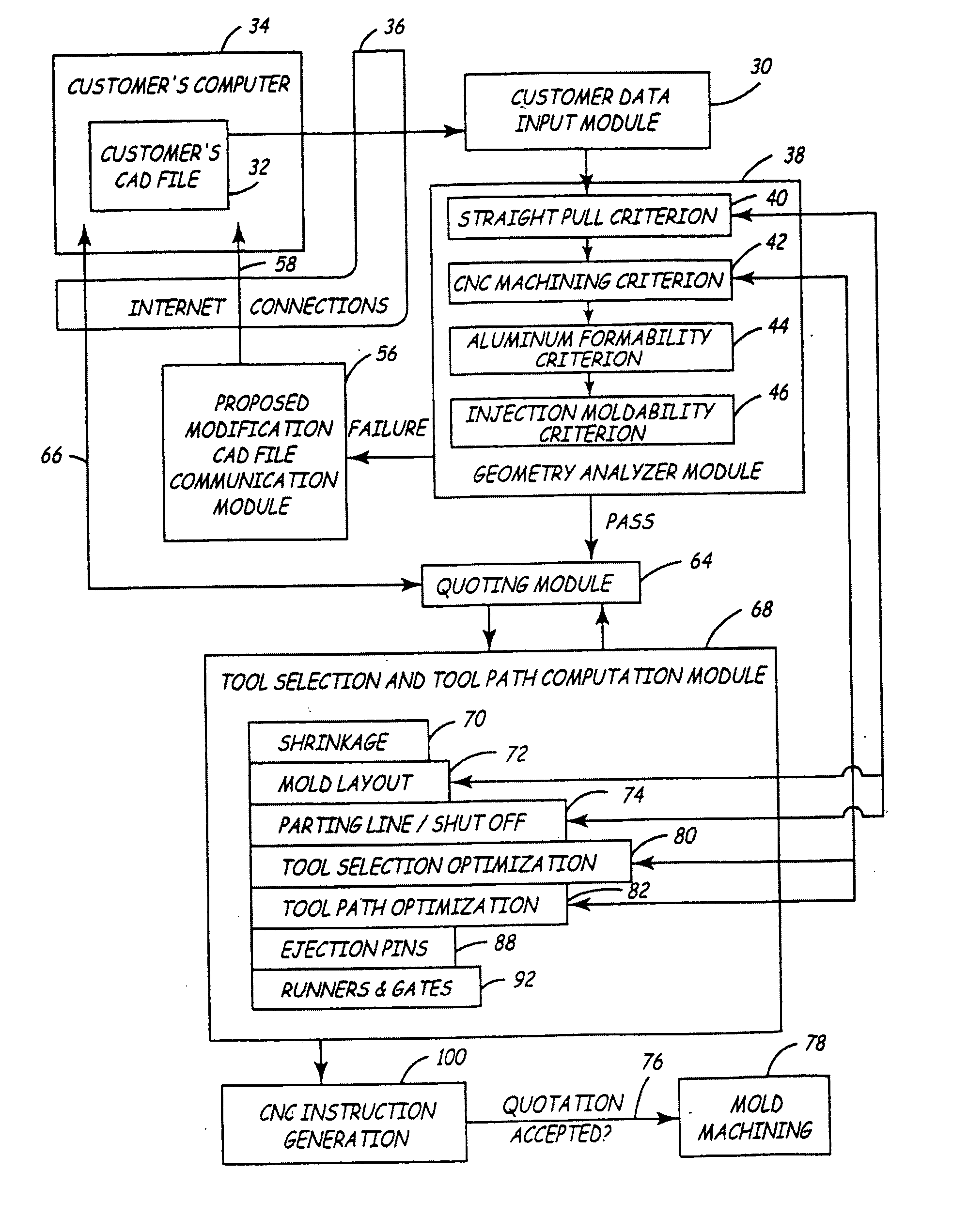

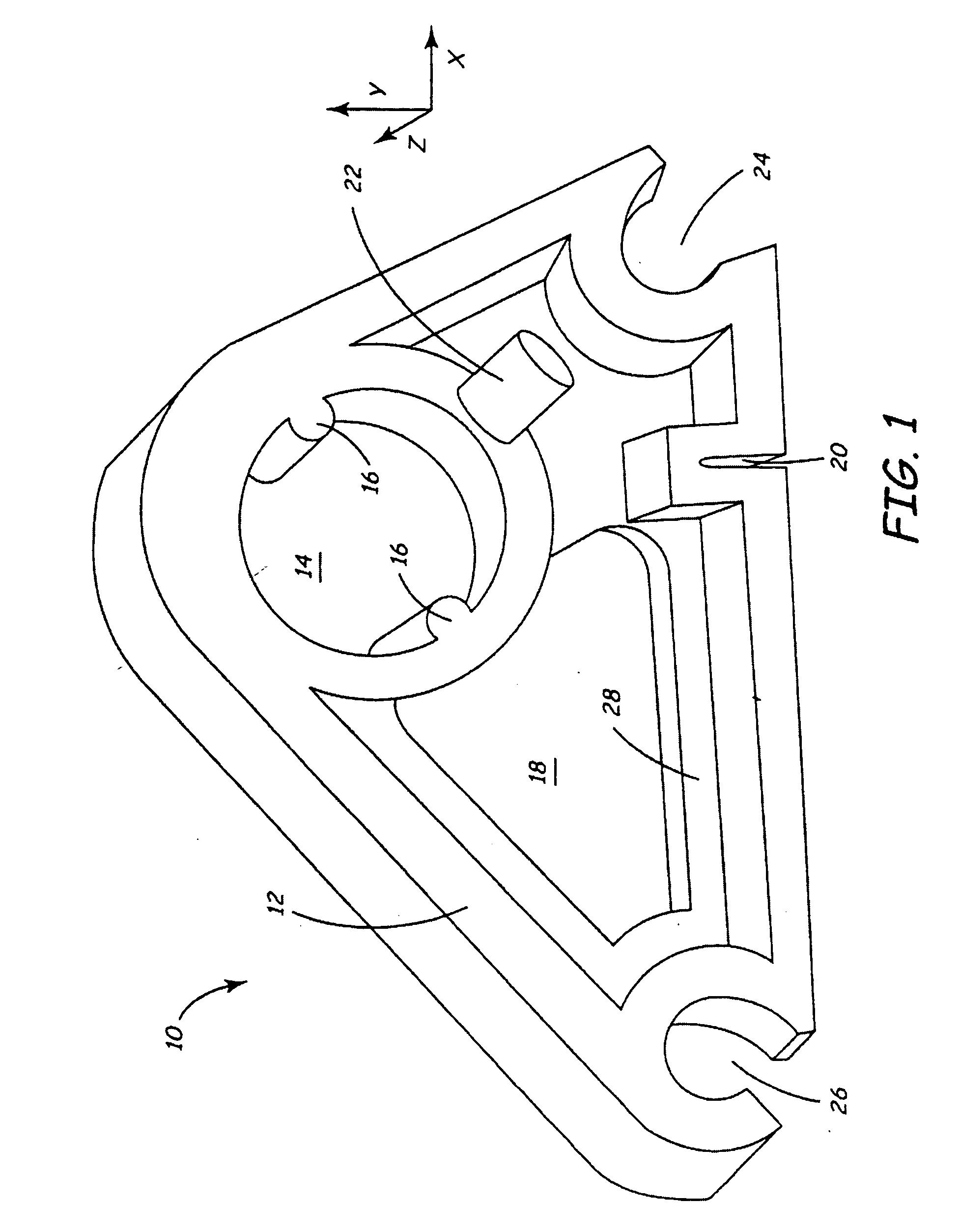

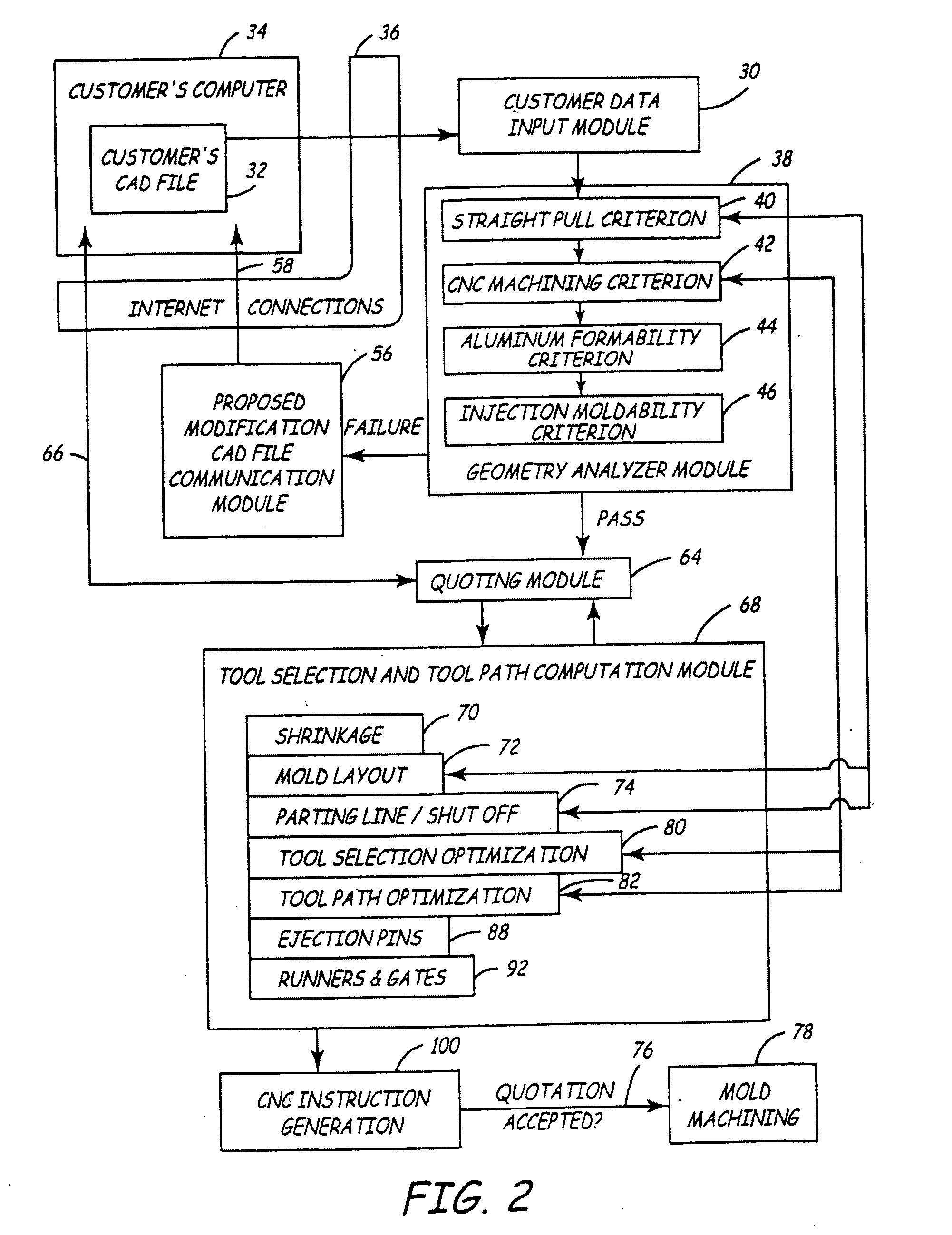

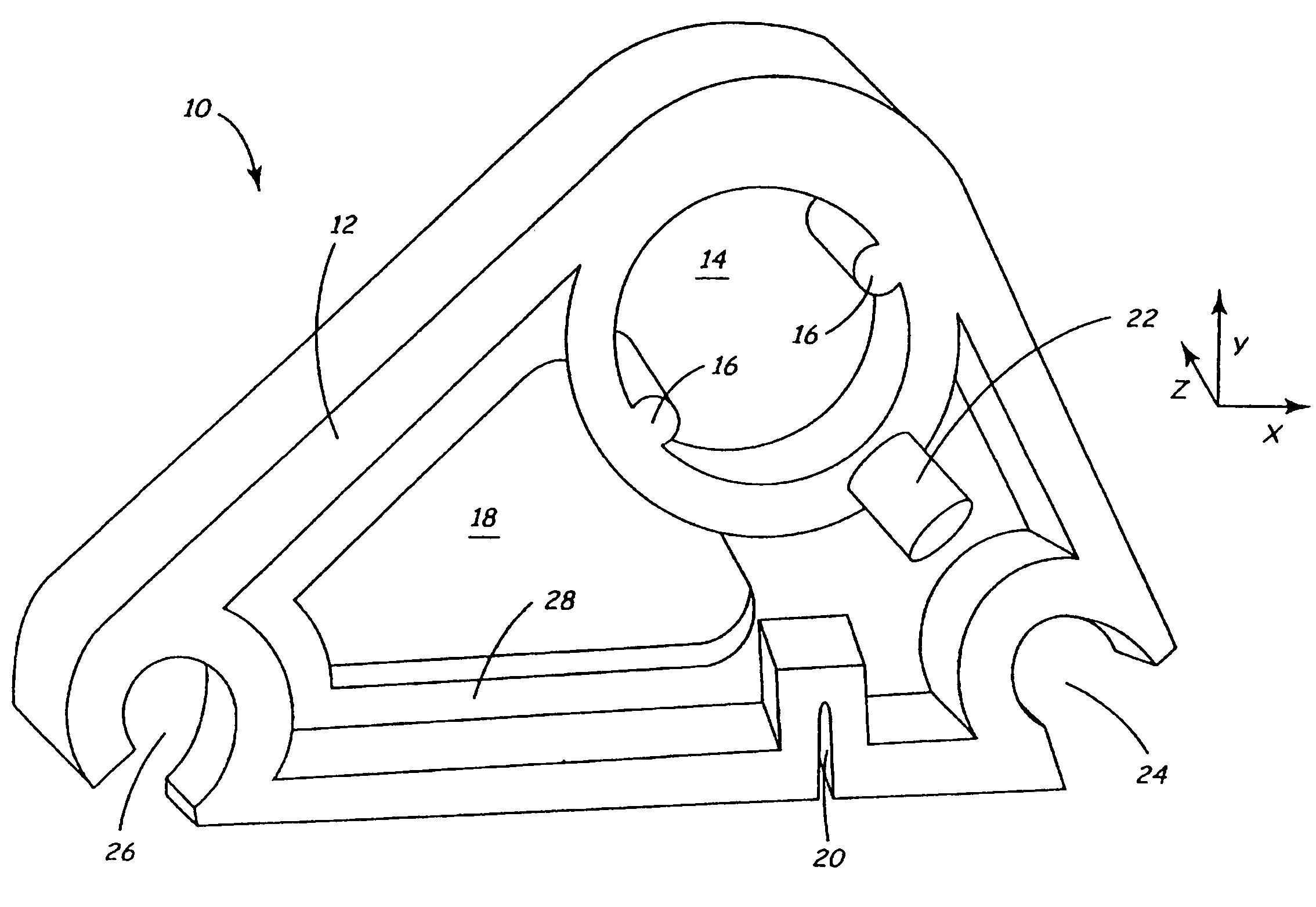

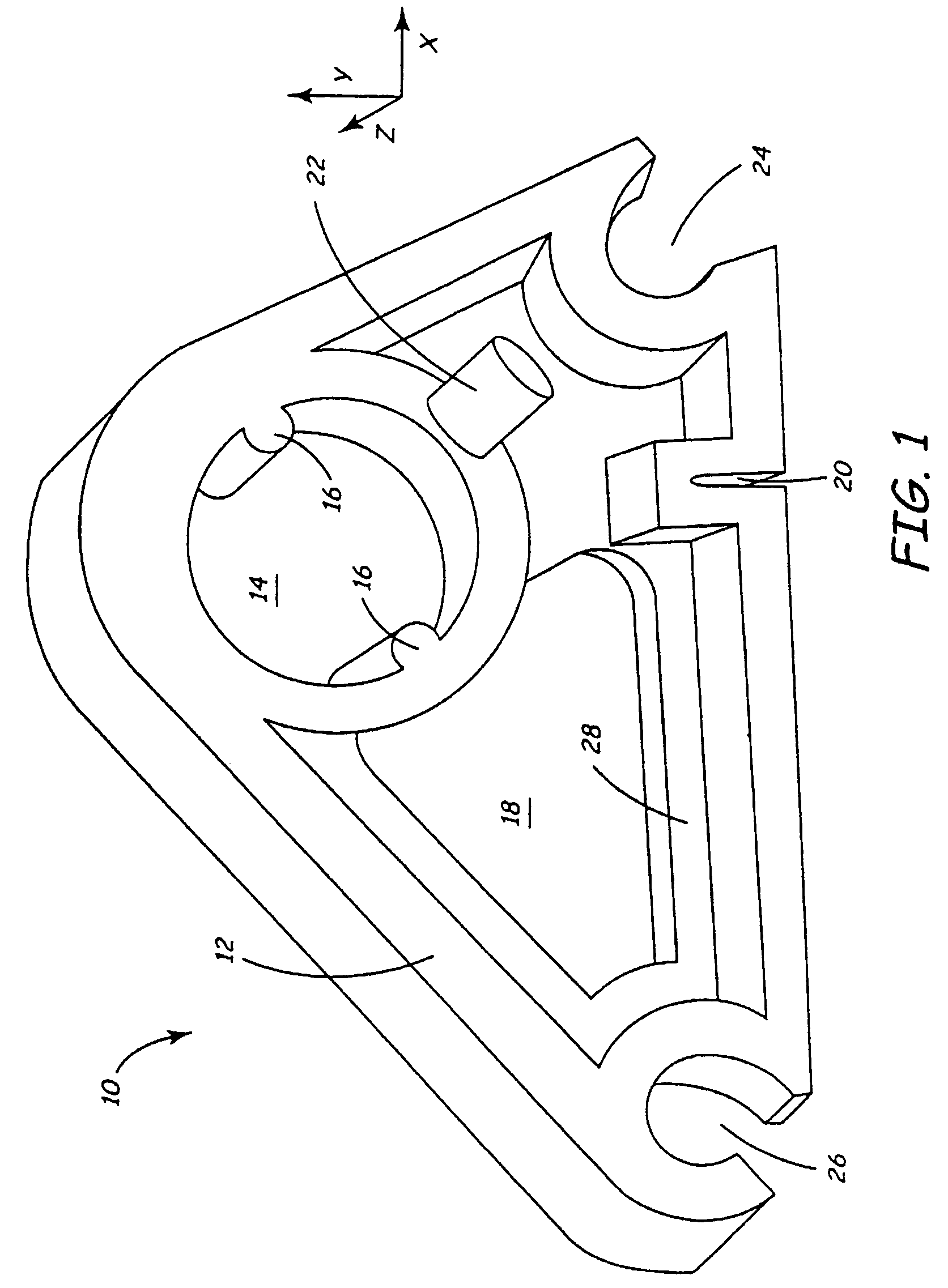

Automated quoting of molds and molded parts

InactiveUS7496528B2Increase flexibilityImprove interactivityBuying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

Owner:PROTOLABS INC

Automated quoting of molds and molded parts

InactiveUS20050125092A1Increase flexibilityImprove interactivityBuying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

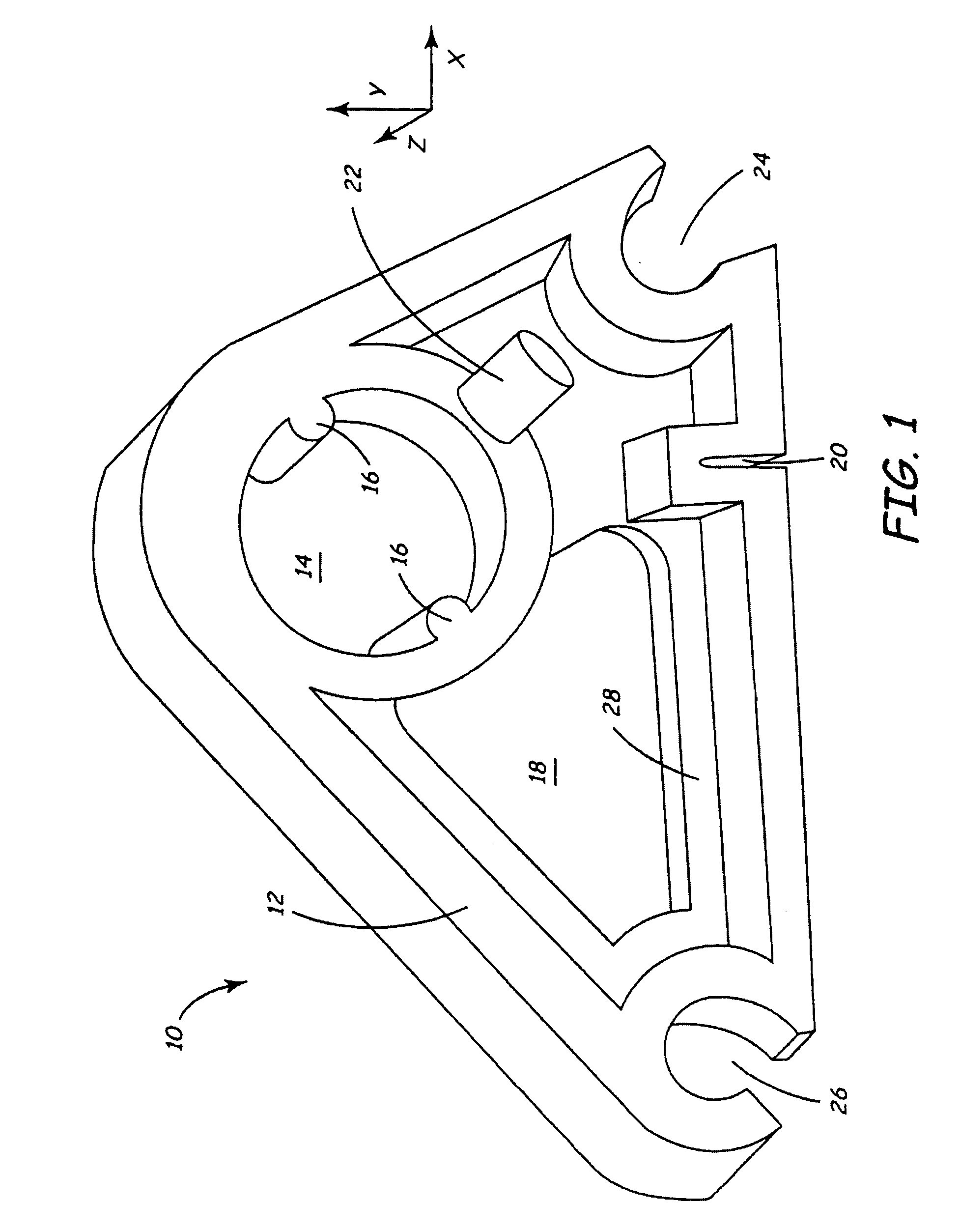

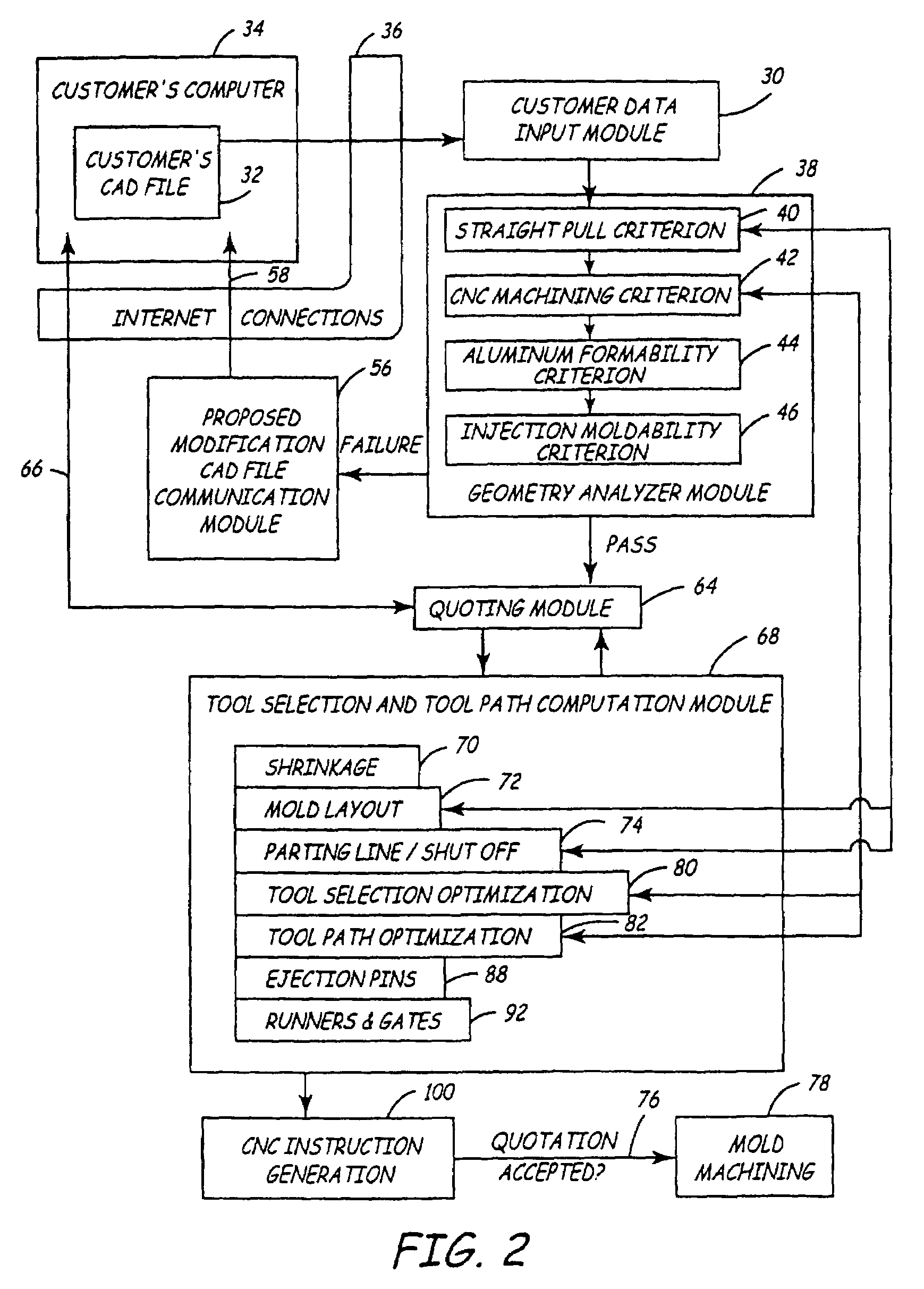

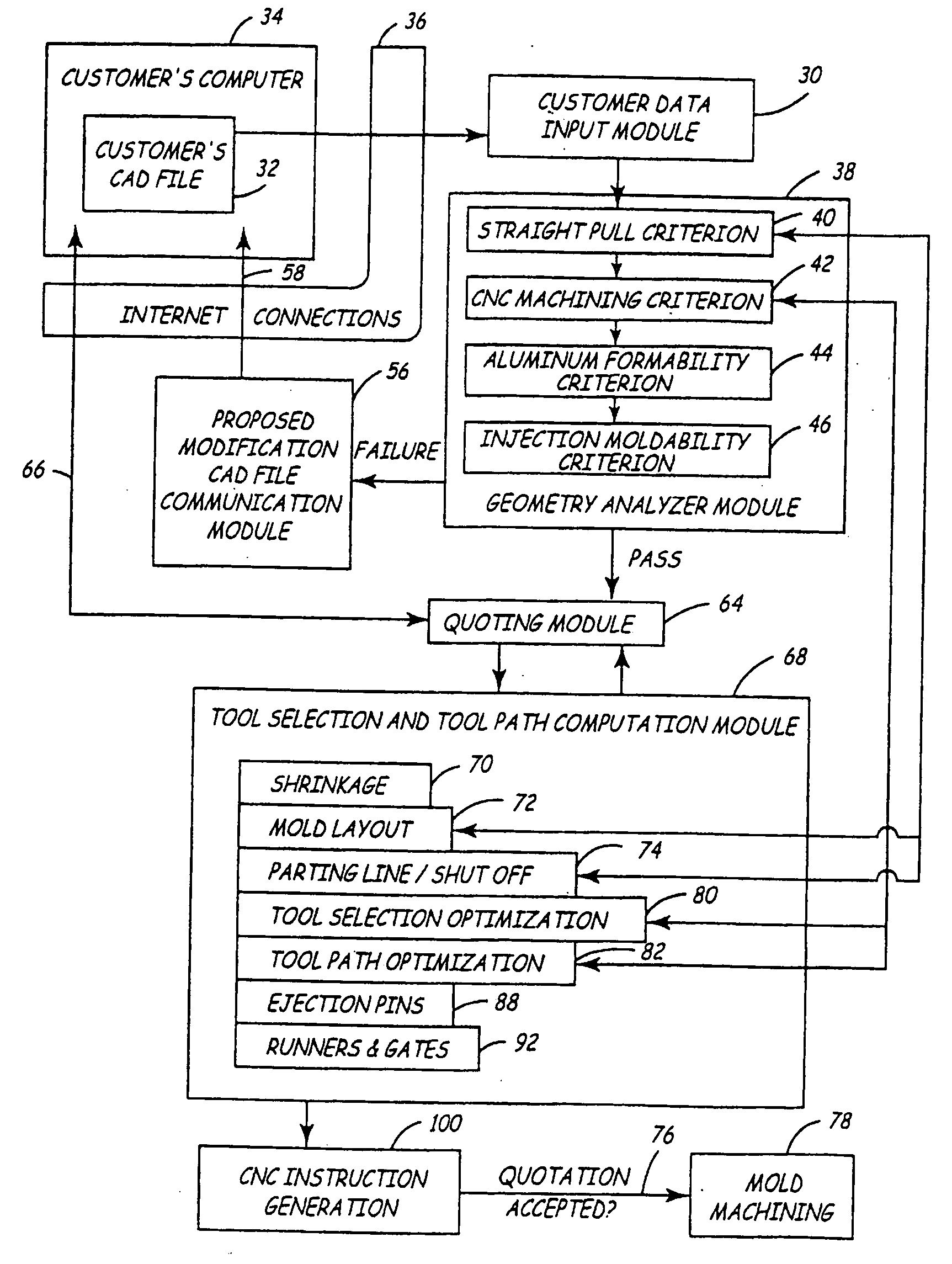

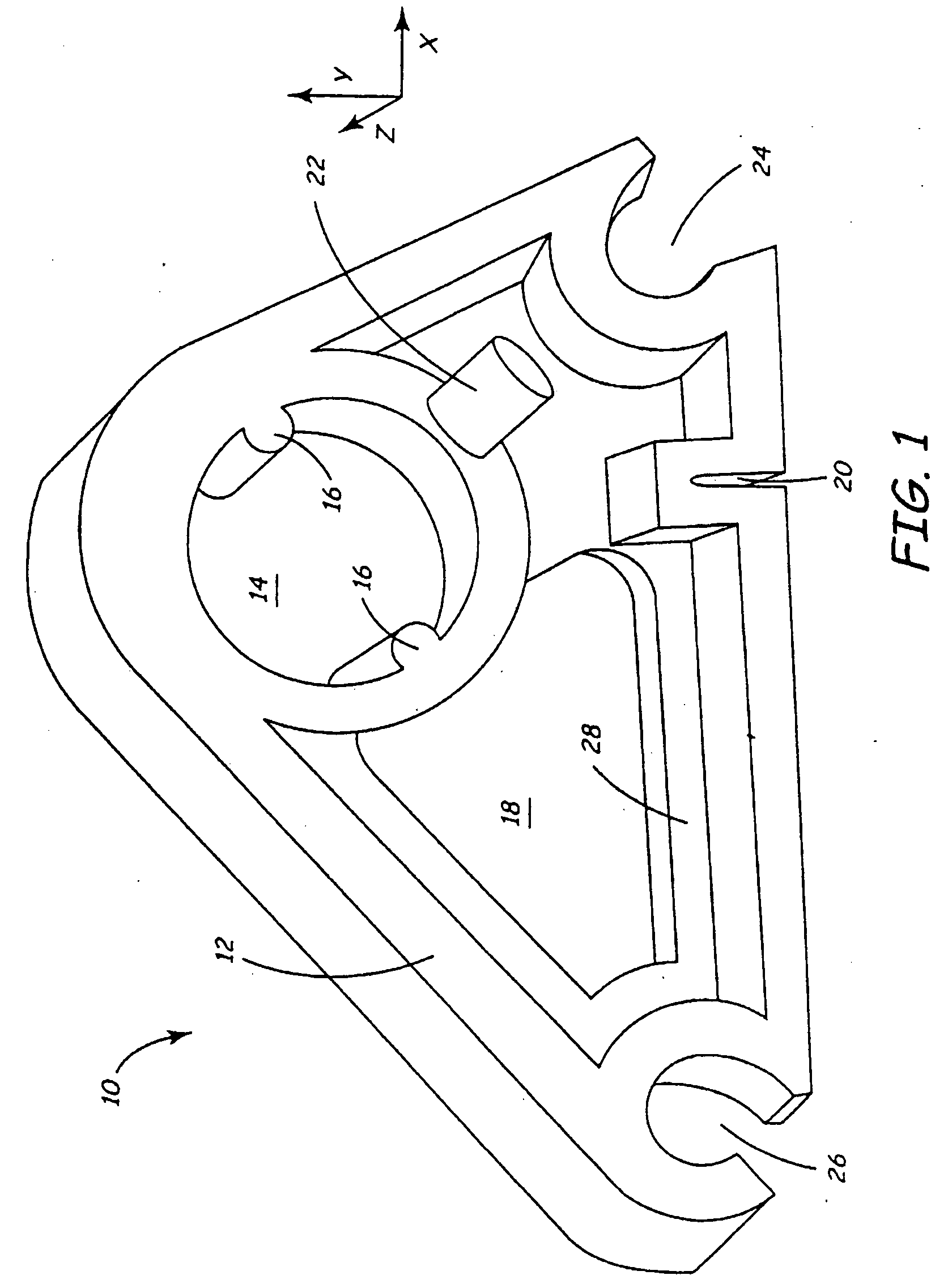

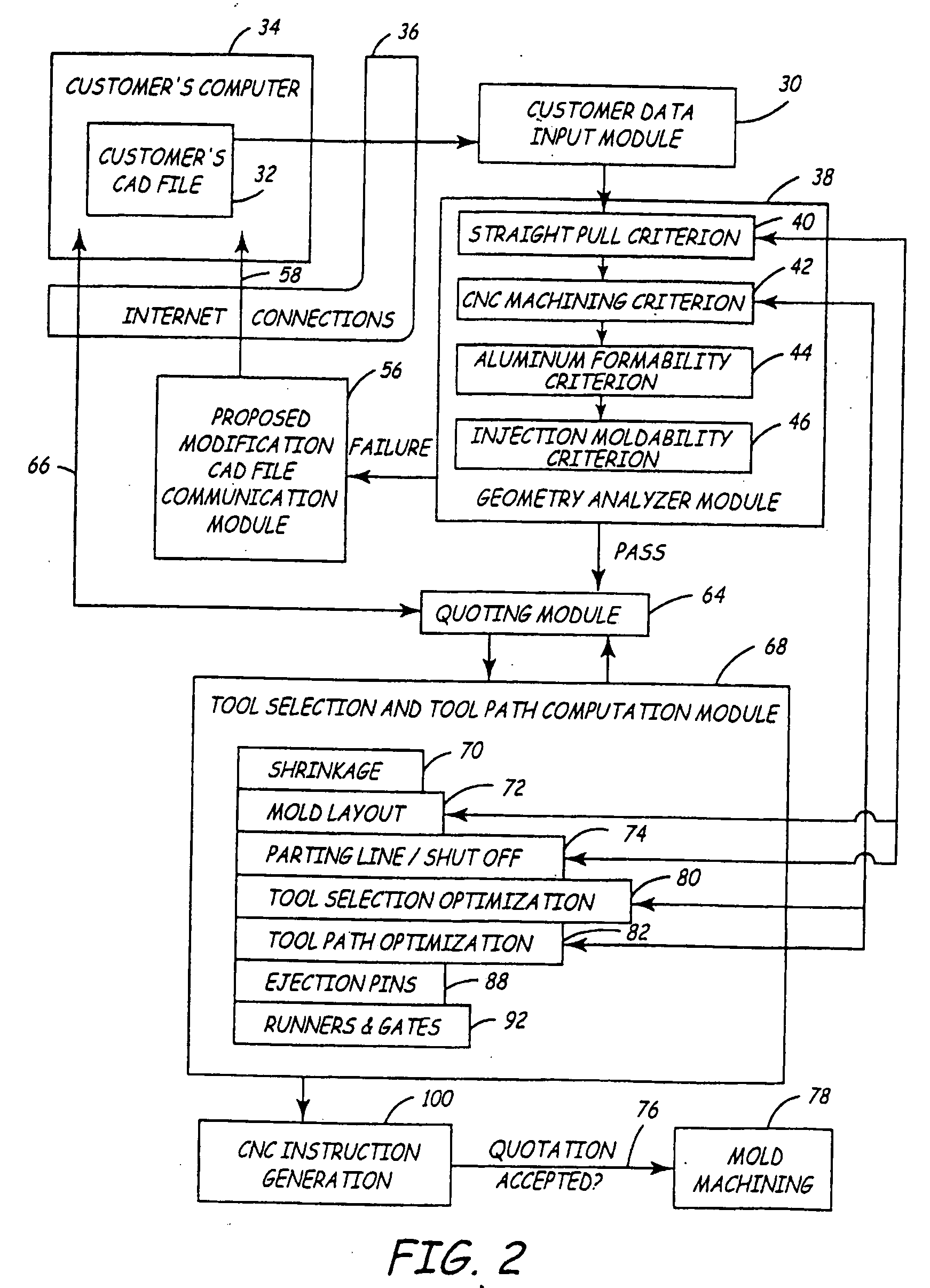

A customer sends a CAD file for the part to be molded to the system. The system assesses the CAD file to determine various pieces of mold manufacturing information. One or more acceptability criteria are applied to the part, such as whether the part can be manufactured in a two-piece, straight-pull mold, and whether the mold can by CNC machined out of aluminum. If not, the system sends a file to the customer graphically indicating which portions of the part need modification to be manufacturable. The system provides the customer with a quotation form, that allows the customer to select several parameters, such as number of cavities, surface finish and material, which are independent of the shape of the part. The quotation module then provides the customer with the cost to manufacture the mold or a number of parts. Budget-driven quotation is possible, wherein proposed modifications in the molding process are controlled by the budget of the customer. Interactivity is also achieved, with the customer being able to modify the quotation interactively by modifying one or more of the initially selected parameters, including selecting a different budgeted amount.

Owner:PROTOLABS INC

Automated quoting of molds and molded parts

InactiveUS7590466B2Buying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

Automated, custom mold manufacture for a part begins by creating and storing a collection of information of standard tool geometries and surface profiles machinable by each of the standard tool geometries. A customer sends a CAD file for the part to be molded to the system. The system assesses the CAD file to determine various pieces of mold manufacturing information. One or more acceptability criteria are applied to the part, such as whether the part can be manufactured in a two-piece, straight-pull mold, and whether the mold can by CNC machined out of aluminum. If not, the system sends a file to the customer graphically indicating which portions of the part need modification to be manufacturability. The system provides the customer with a quotation form, that allows the customer to select several parameters, such as number of cavities, surface finish and material, which an independent of the shape of the part.

Owner:PROTOLABS INC

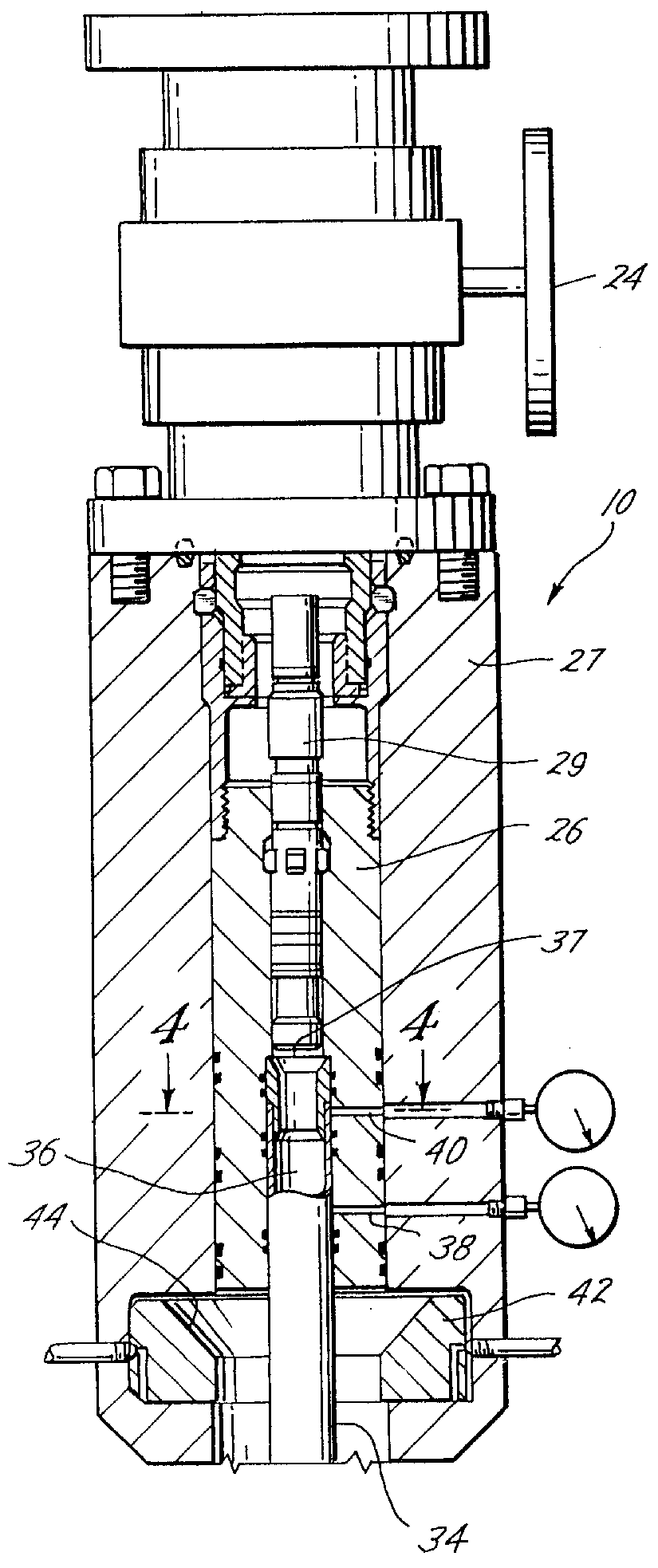

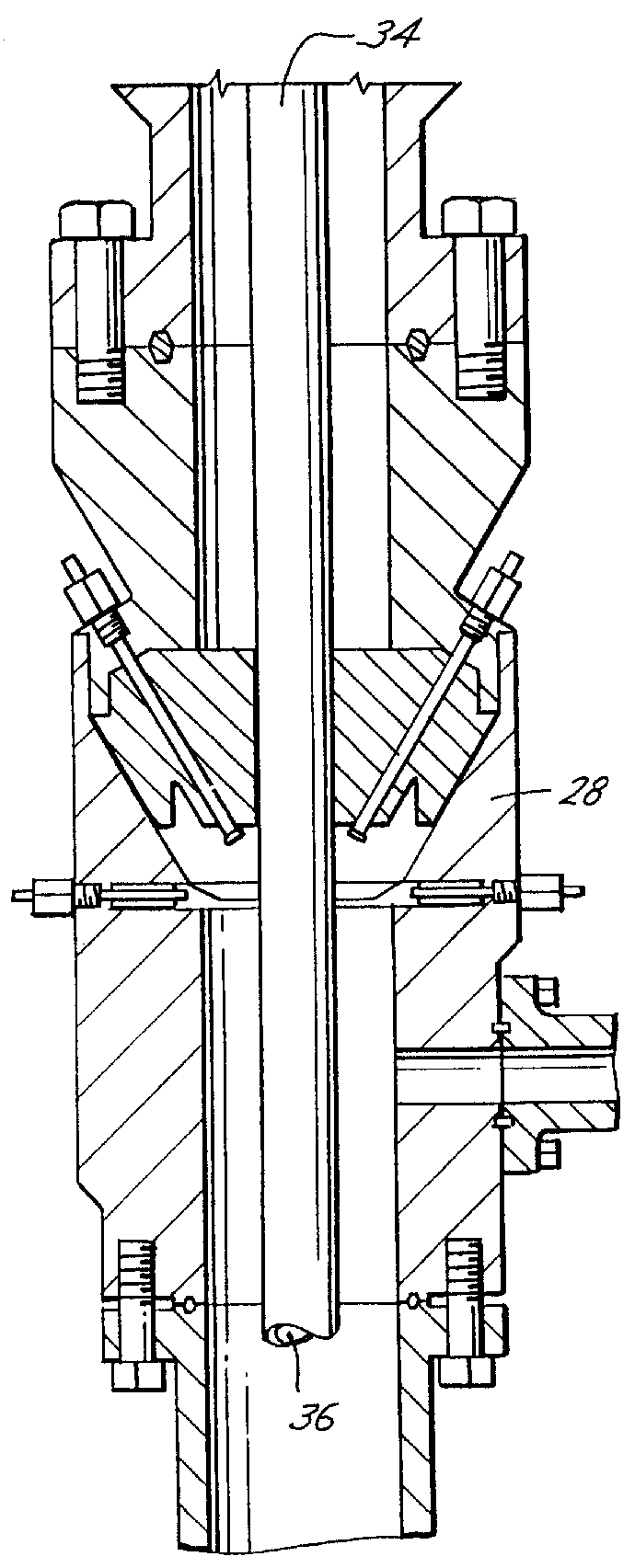

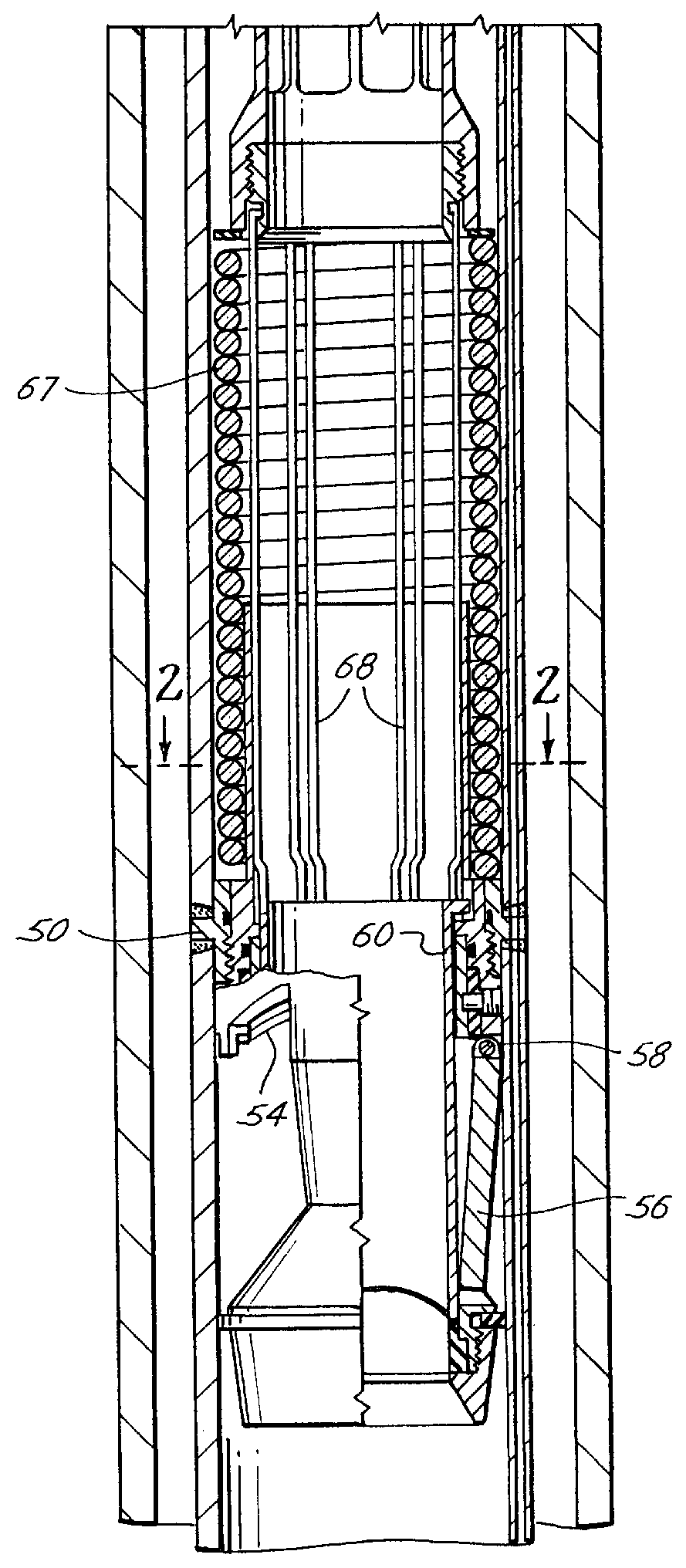

Spoolable flexible hydraulically set, straight pull release well packer

InactiveUSRE36525E1Avoid interferenceLongitudinal flexibilityDrilling rodsFluid removalProduction packerCoiled tubing

A coiled tubing completion system is provided with a plurality of completion apparatus, all of which is designed flush with the diameter of the coiled tubing outside diameter for avoiding upsets and are flexible, spoolable on a coiled tubing reel and having through bores large enough to pass wireline tools for performing other operations. The spoolable coiled tubing system may use standard coiled tubing well control equipment and can be used in live wells. The flush, flexible, spoolable and through bore completion equipment may include a tubing retrievable safety valve, an annular control valve, concentric gas lift valves, a zone packer, a landing nipple, a sliding sleeve, and may include at the end a non-flexible but flush and open bore production packer and pump out plug. The completion system may be retrieved through a retrieval system.

Owner:CAMCO INT

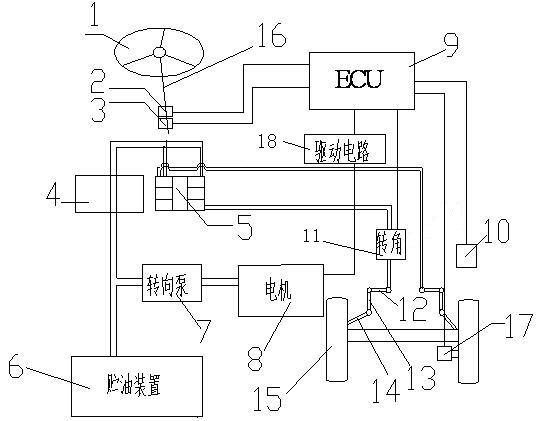

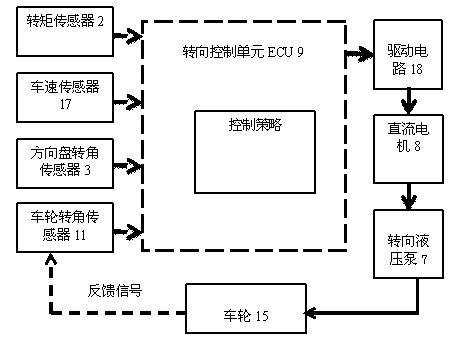

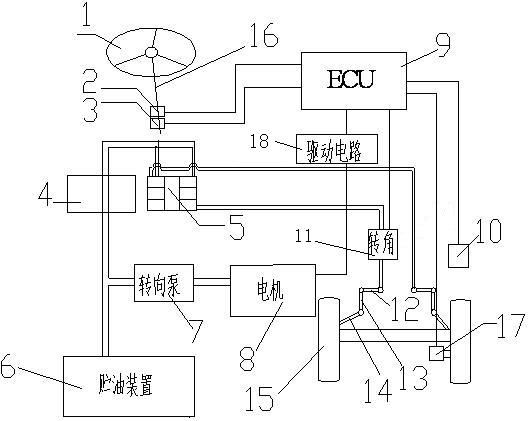

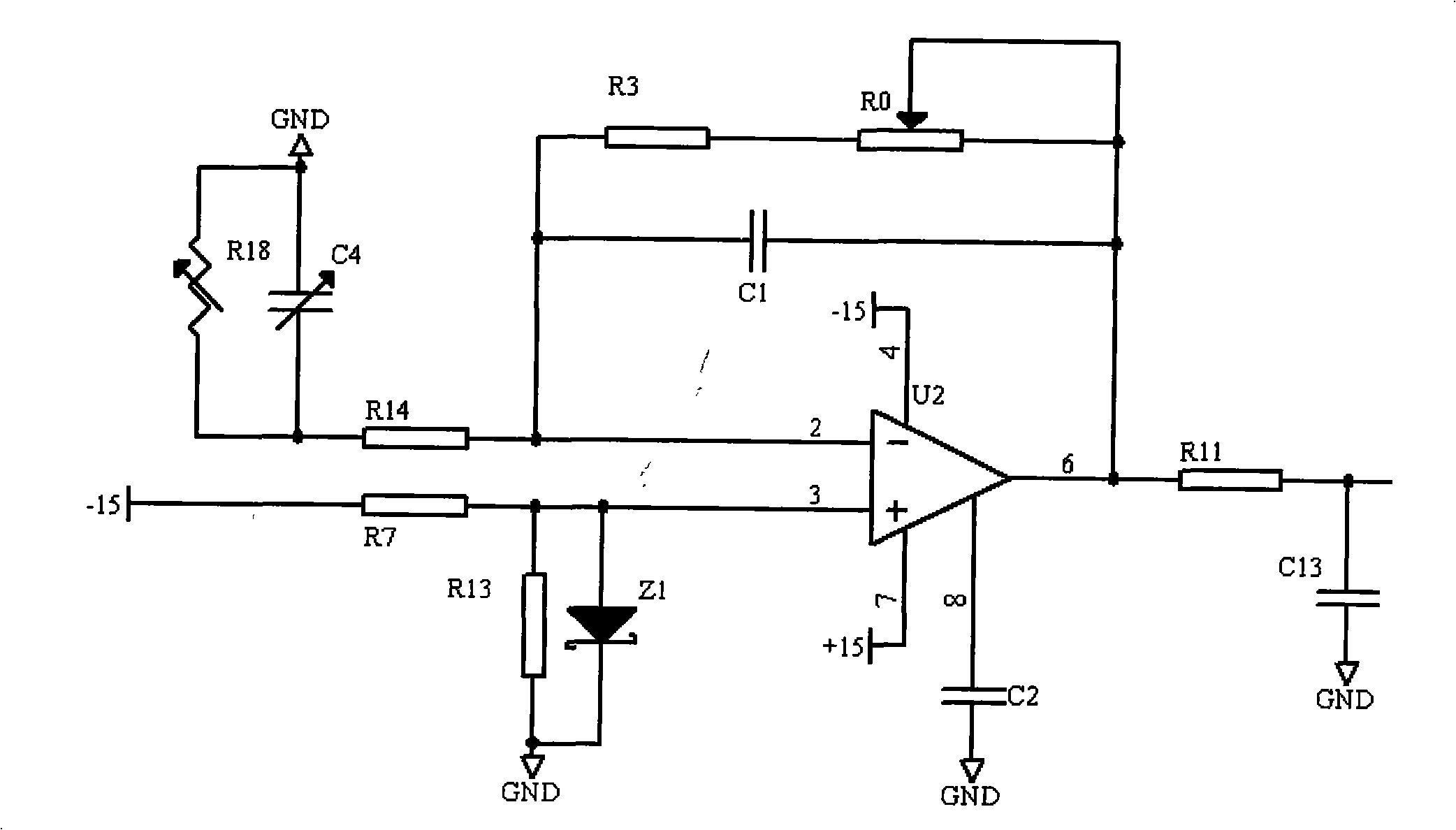

An electrohydraulic power steering system controlled based on vehicle speed and load signals

InactiveCN102267487AEnhanced signalMeet steering requirementsSteering linkagesFluid steeringClosed loop feedbackHydraulic pump

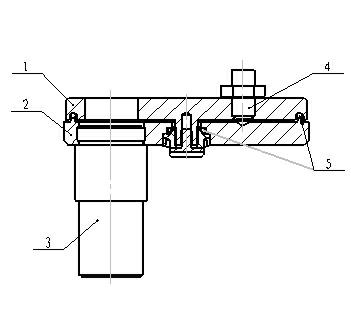

The invention discloses an electro-hydraulic power steering system for an engineering mechanical vehicle based on vehicle speed and load signal control. A steering hydraulic pump of the electro-hydraulic power steering system is connected with a rotary valve and is connected between an oil storage device and a direct current motor; the rotary valve is connected with a power-assisted steering oil cylinder; the direct current is connected with a steering control unit through a driving circuit; the steering assisted cylinder is connected with a steering gear plumbing arm; the other end of the steering gear plumbing arm is connected to a steering knuckle arm through a steering straight pull rod; the steering knuckle arm is connected with wheels; a wheel rotary angle sensor, a vehicle speed sensor, a steering shaft load sensor, a steering wheel rotary angle sensor and a torque sensor are respectively connected with a steering control unit; both the vehicle speed and the load are consideredin the whole control system; the steering control unit is controlled by closed loop feedback; the defects that a steering force is insufficient or over great caused by incomplete signal acquisition is prevented; the precision of steering control is improved; and the aim of saving energy is achieved.

Owner:JIANGSU UNIV

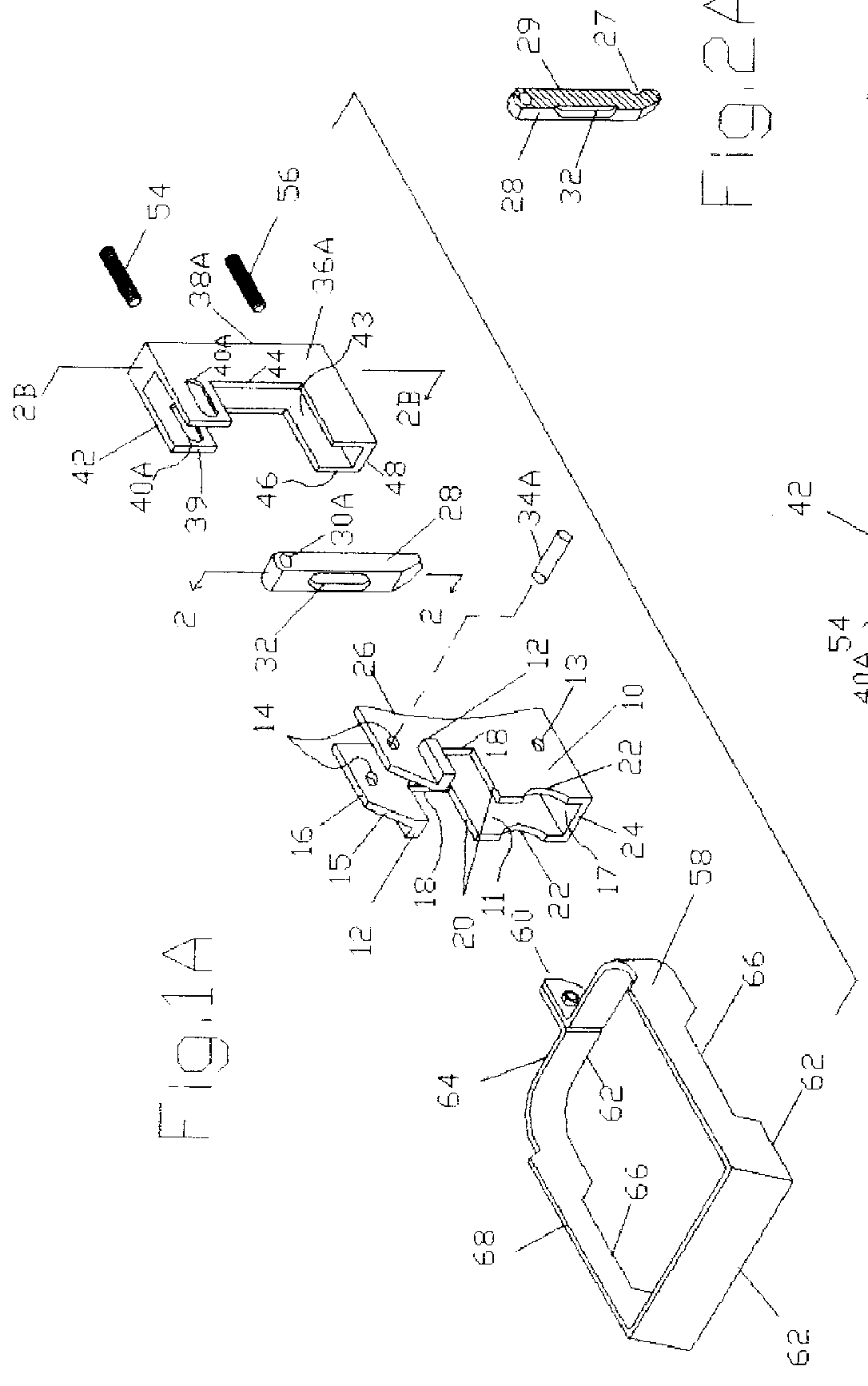

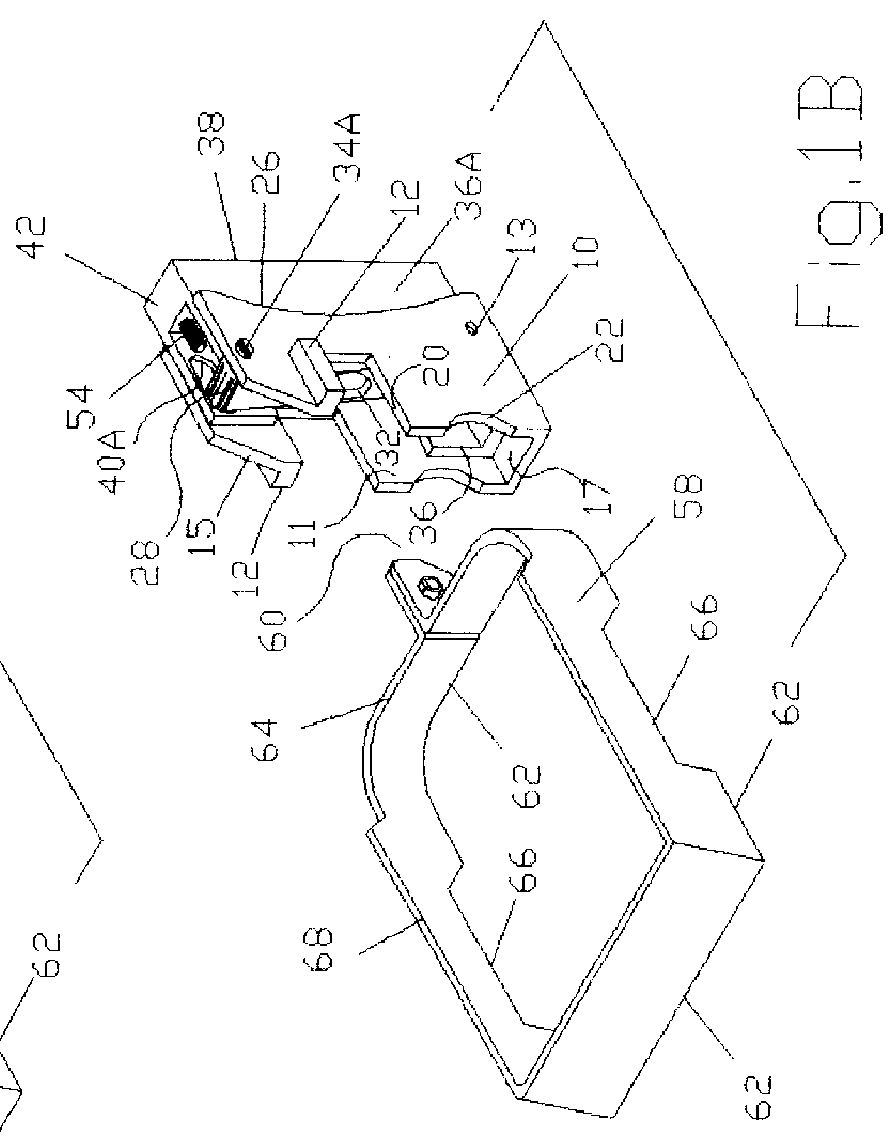

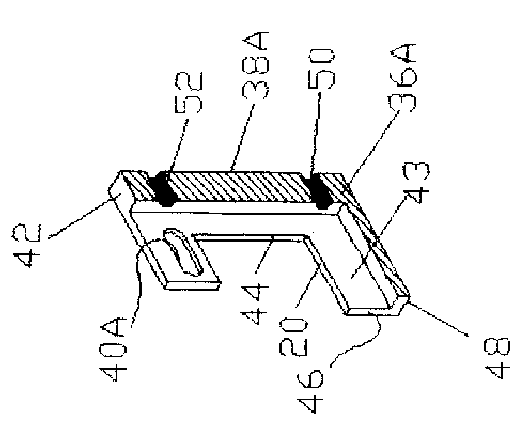

Device for reducing firearms trigger pull weight

A device comprises of independent trigger bow (58) supplied with overlapping recess (64) and a trigger block (10) having a bow guide recess (20), pivot hole (14) with axis pin (34A), primary lever (28) having a axis hole (30) at one end and a bow extender recess (32) and a trigger plate (36A) having a pre-load bar (56) and stopper bar (54) that can be assembled into a module to allow easy installation on trigger tunnel (85) of firearm(88) for reduce firearm trigger pull weight without altering firearm (88). Block (10) is being equipped with catches (12) extending sideways and adjacent with bow guide recess (20) which will overlap with recess (64) of bow (58) to allow both the bow (58) and block (10) to occupy in one same area which allow anchoring against a bow tunnel (83) end wall and supplied with magazine cut (15) disposed on the upper left of block (10) to allow for a magazine passage. As trigger plate (36A) is depressed with finger within a given point on trigger plate (36A) upon firing the finger force will be shifted directly into the adjustable preload bar (56) and synchronizes into the outermost lever end at point (27) of lever (28) producing a high torque leverage which reduces firearm trigger pull weight or load force from the trigger bow (58) energized from sear (70), hammer (72) and hammer spring (82). The trigger plate (36A) being retained with pivot pin (34A) through retaining slot (40A) is supplied with plate bearing (42) and bottom bearing (48) will slide against a frame upper bearing (79) and against s block plate bearing (17) of block (10) respectively, will function as an advancing global pivot point which will changed a rotational action of lever (28) into a linear straight pull action to maintain firearm standard straight action and reducing the trigger pull weight.

Owner:LEE ROBERTO R

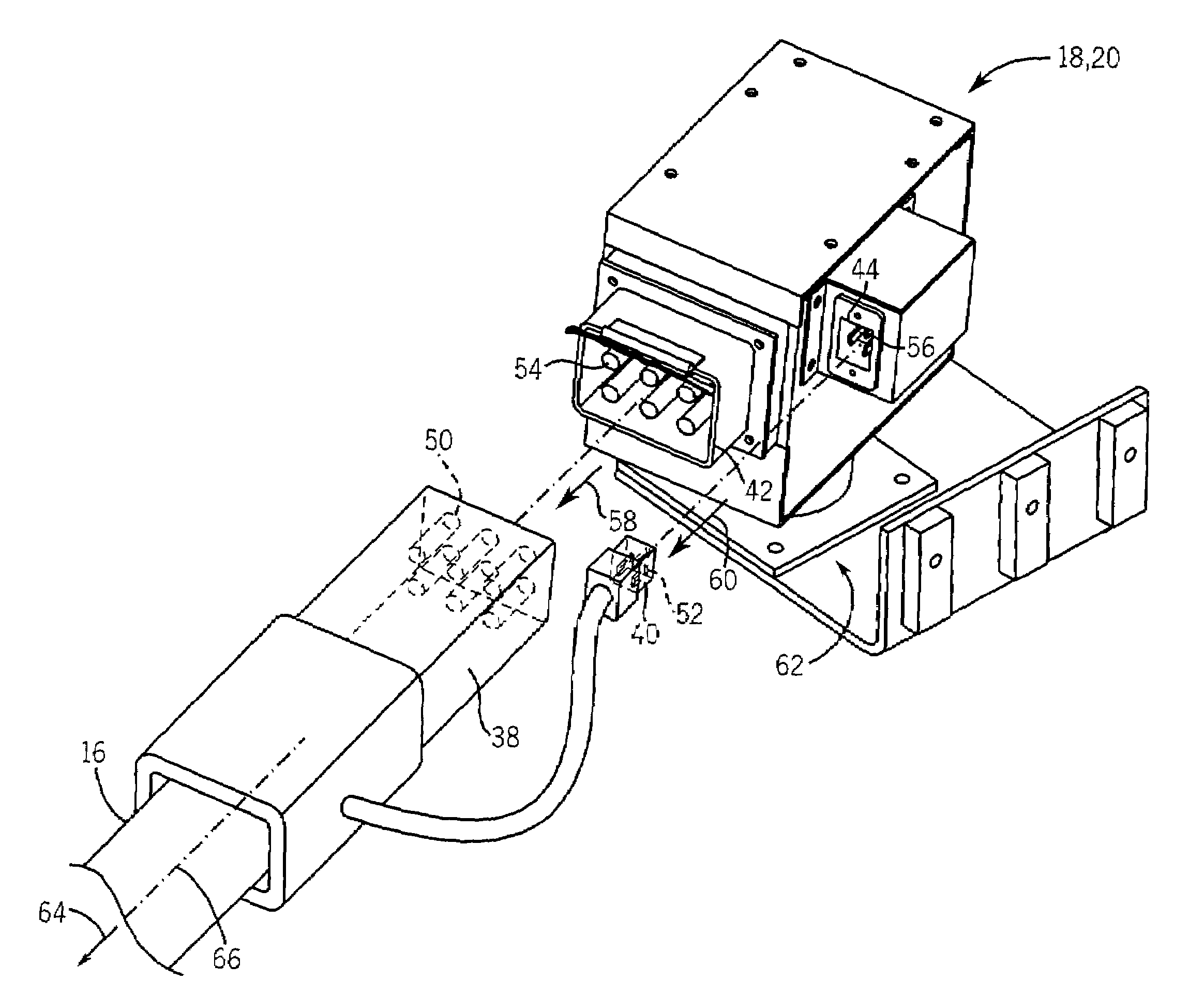

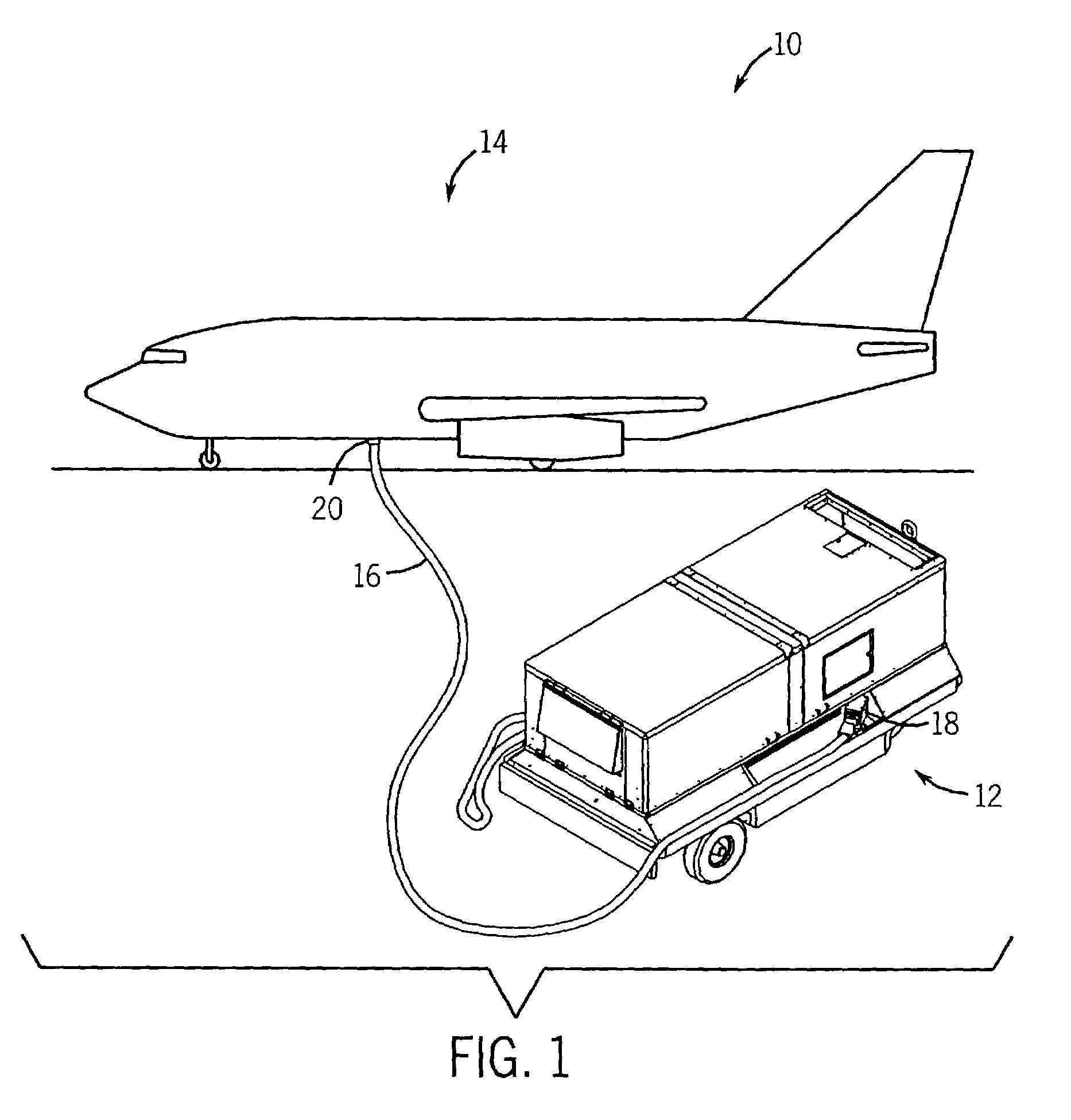

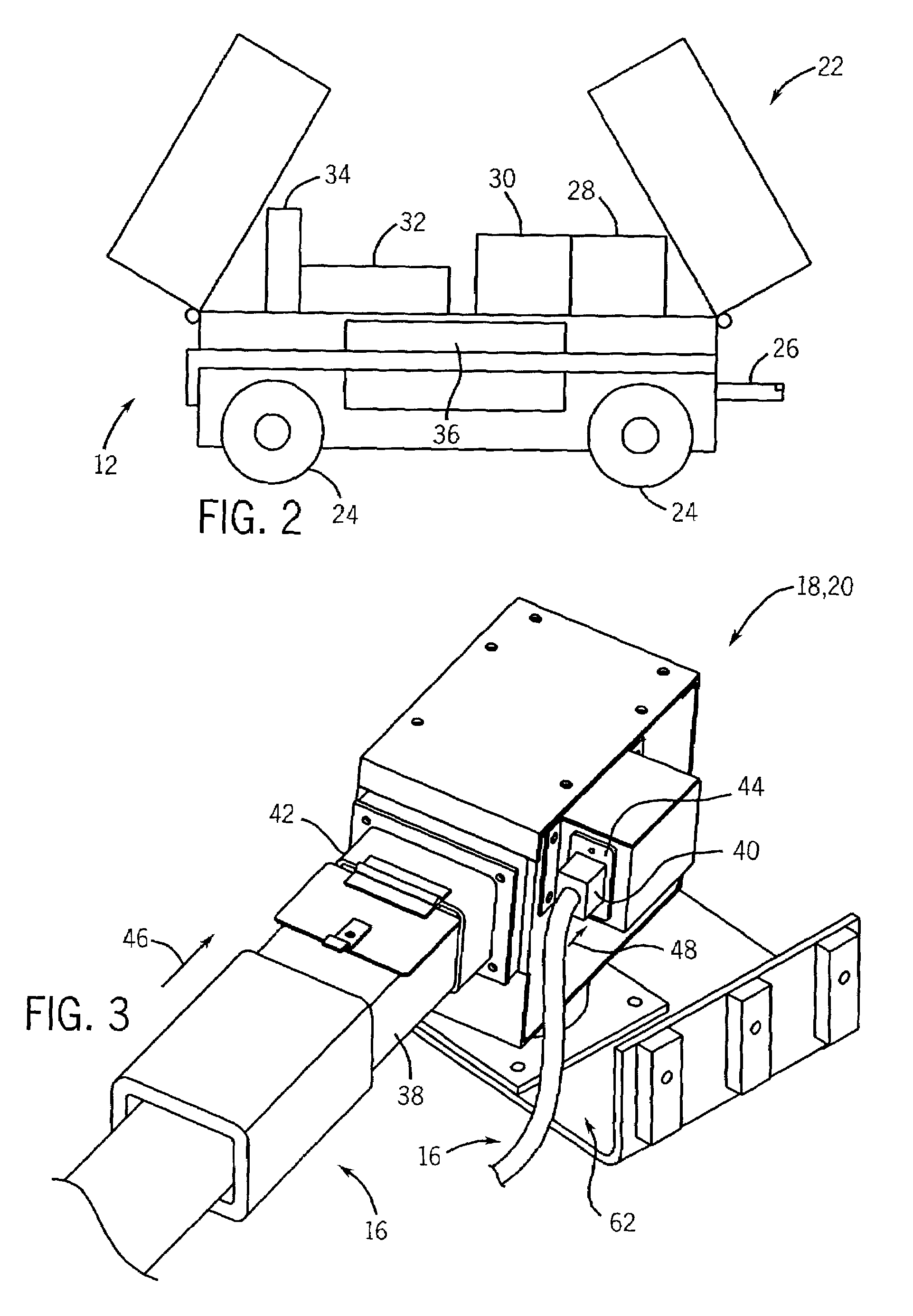

Aviation ground power unit connection system and method incorporating same

The present technique provides a system and method for automatically releasing a power connection between an aircraft and a ground power unit. The power connection may have a release mechanism, such as a straight-pull coupling, which disconnects in response to movement of the aircraft or the ground power unit. The release mechanism also may disconnect in response to a critical tension within a power cable of the power connection. The power connection also may have a rotatable mount for the release mechanism, such that the power cable is alignable with tension in the power cable. The present technique also may have a variety of sensors to trigger a power shutdown and automatic release of the power connection.

Owner:ILLINOIS TOOL WORKS INC

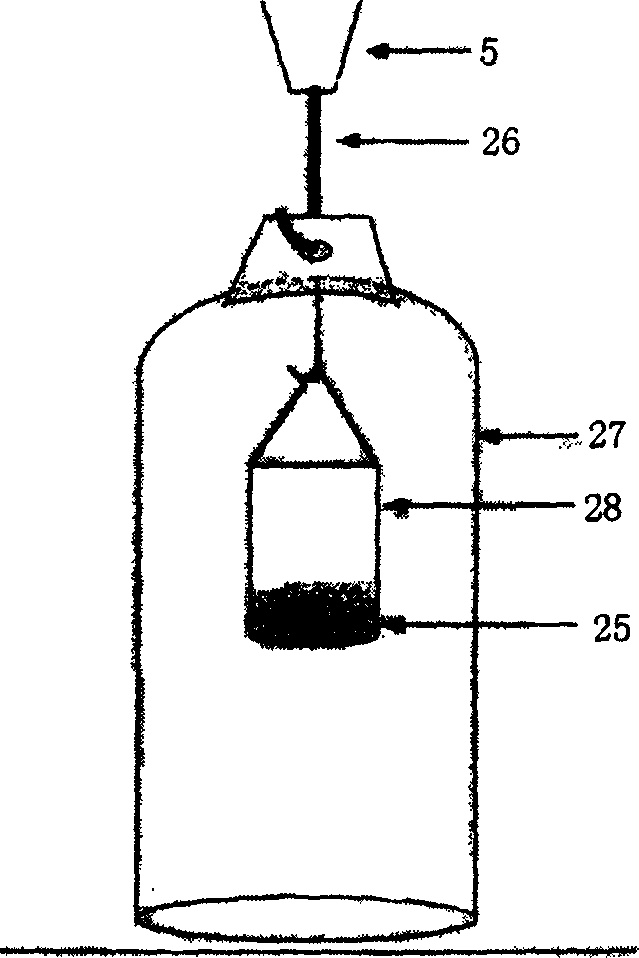

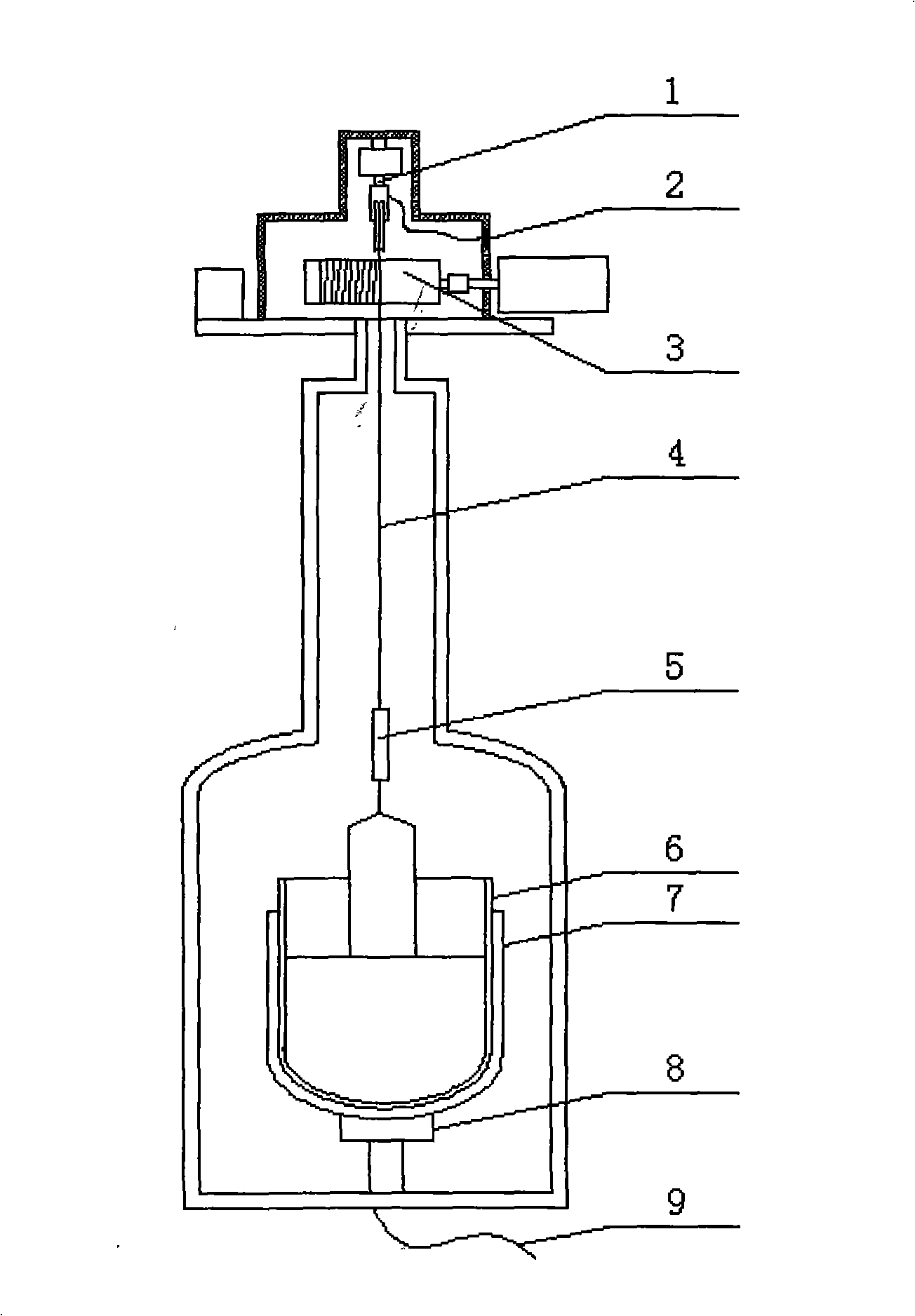

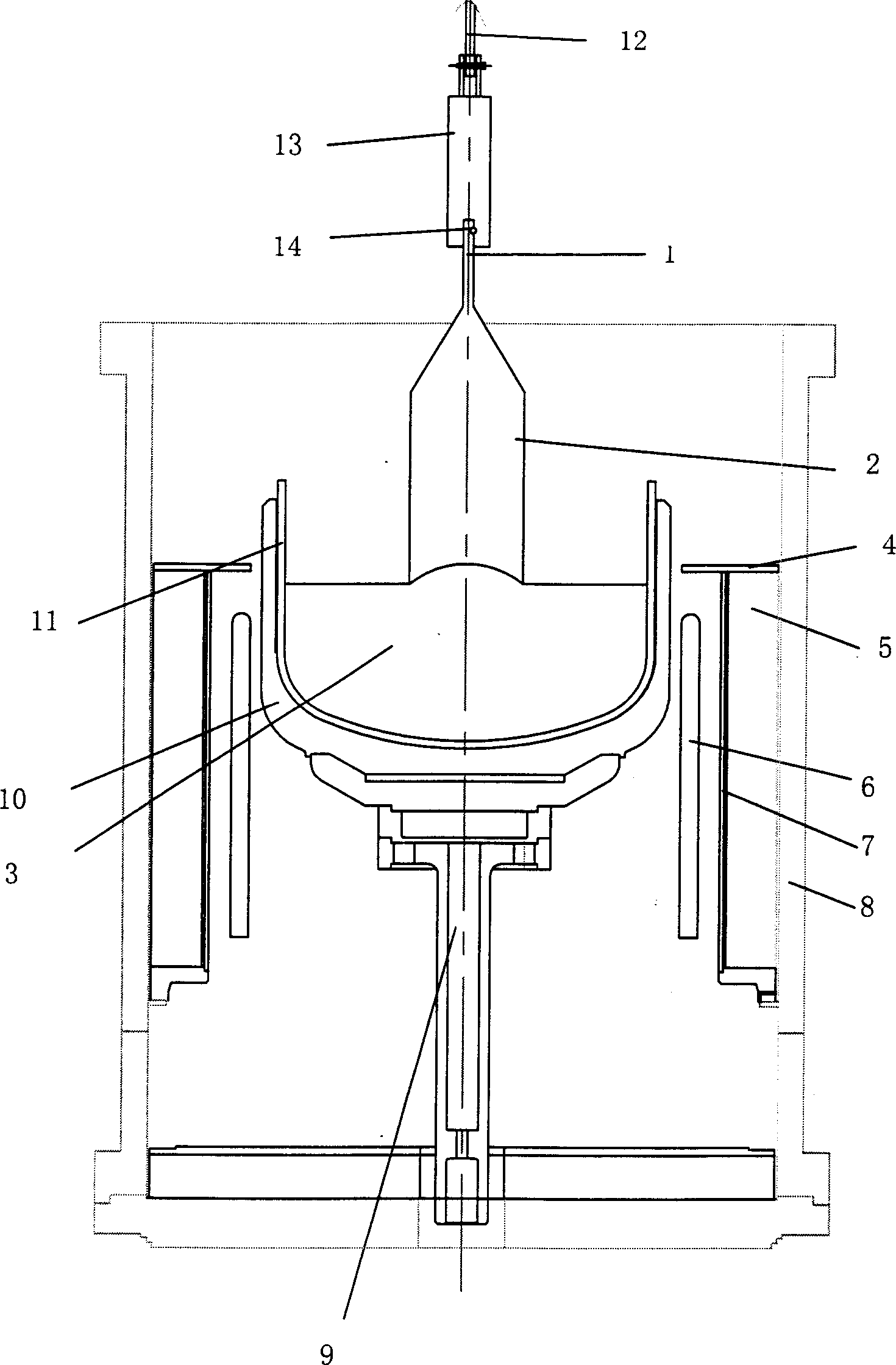

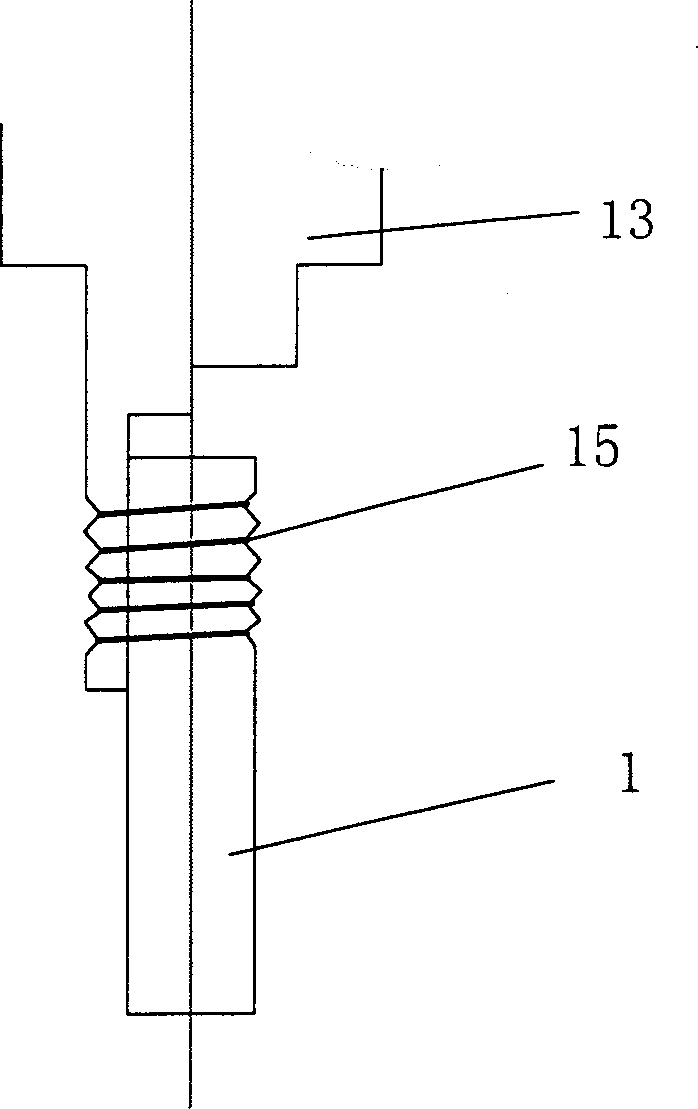

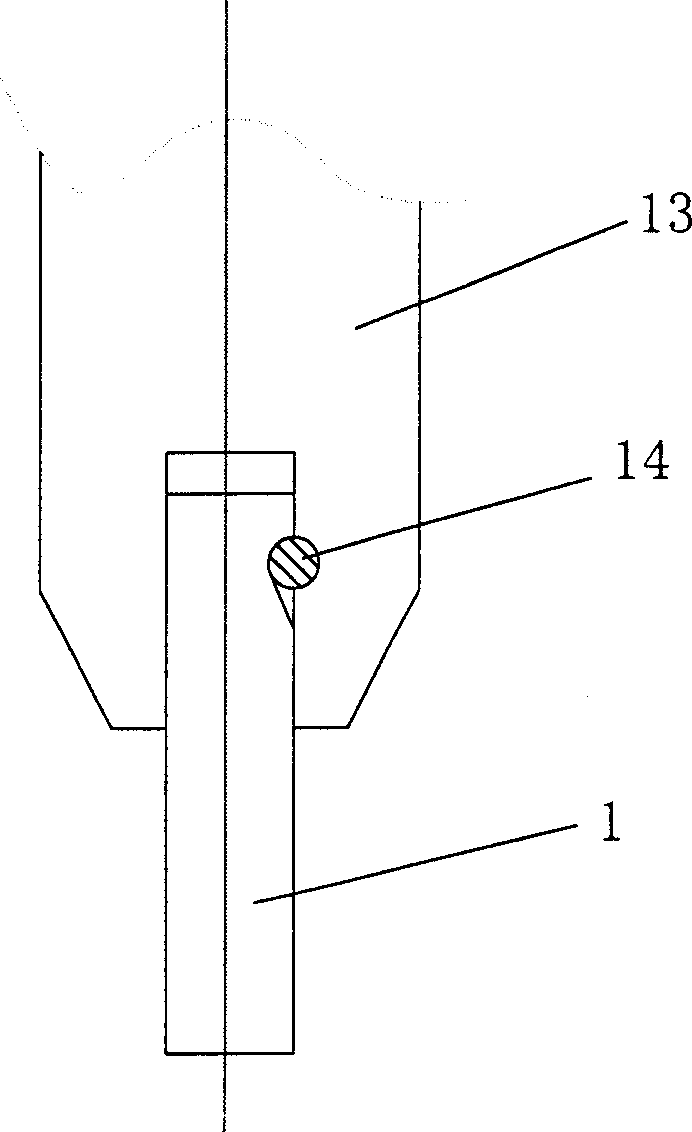

Adulterating method used for adulterating vertical pulling silicon mono crystal and its adulterating funnel

A doping hopper for preparing the heavyly doped monosilicon by straight pulling up is composed of main body with bottom discharge spout, cover and hanging hook. Its doping method includes loading the doping agent in said hopper, fully smelting polysilicon, lowering the hopper until its discharge spout has a 10-20 mm distance from the surface of molten silicon for doping Sb, or until its discharge spout into the molten silicon by 5-10 mm depth for doping P or As, and doping. Its advantage is high doping efficiency (90-100%).

Owner:金瑞泓科技(衢州)有限公司

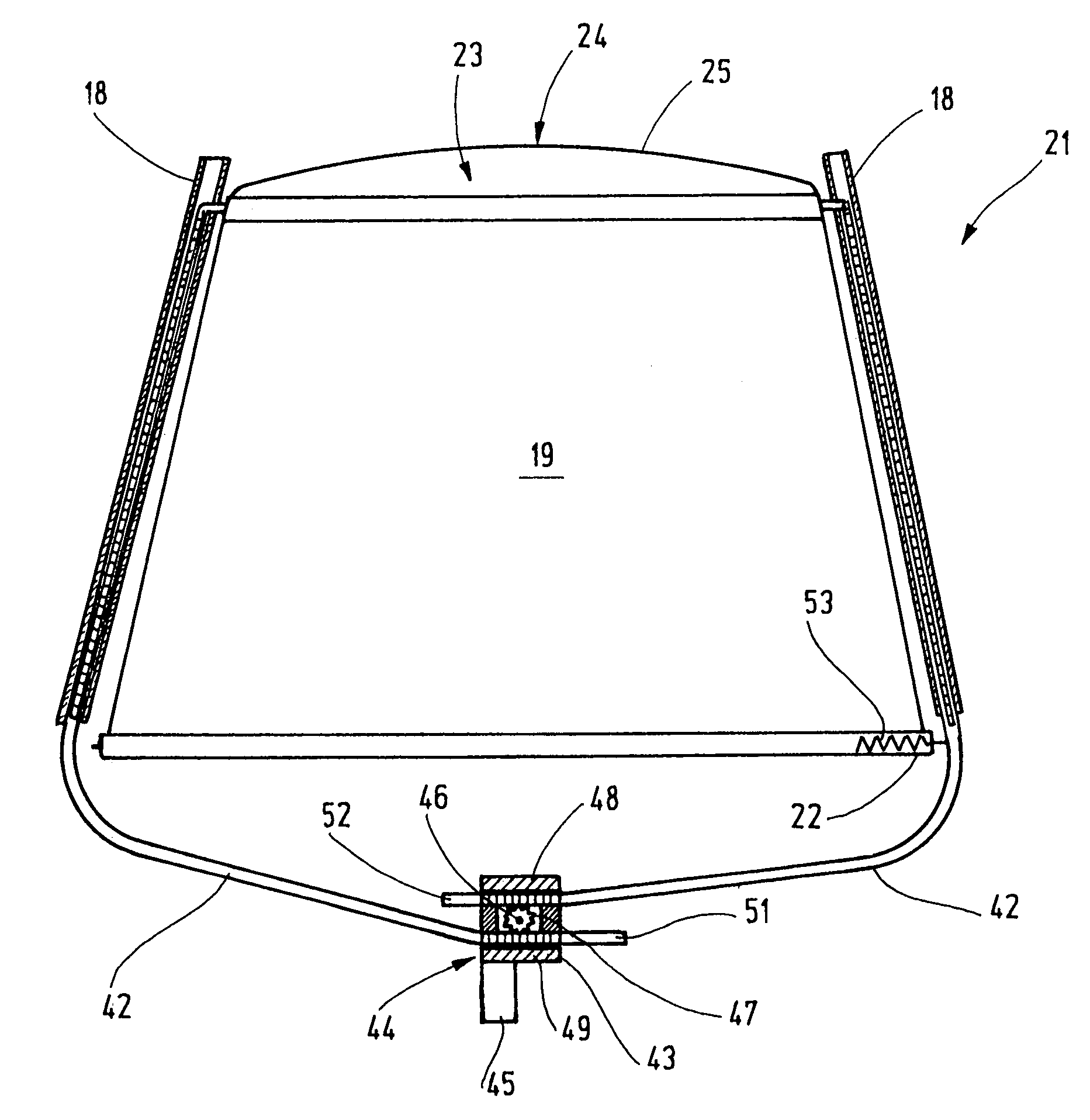

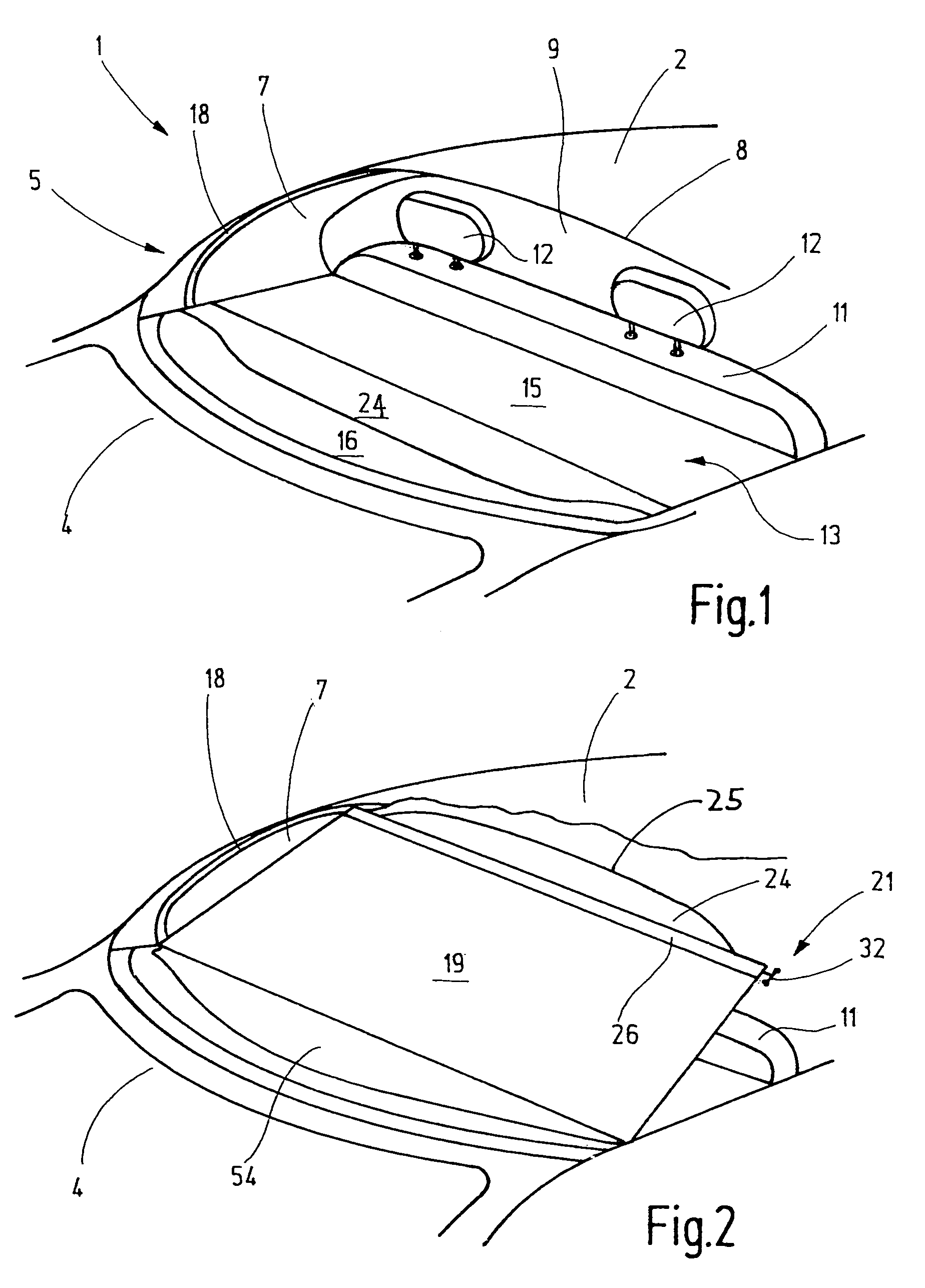

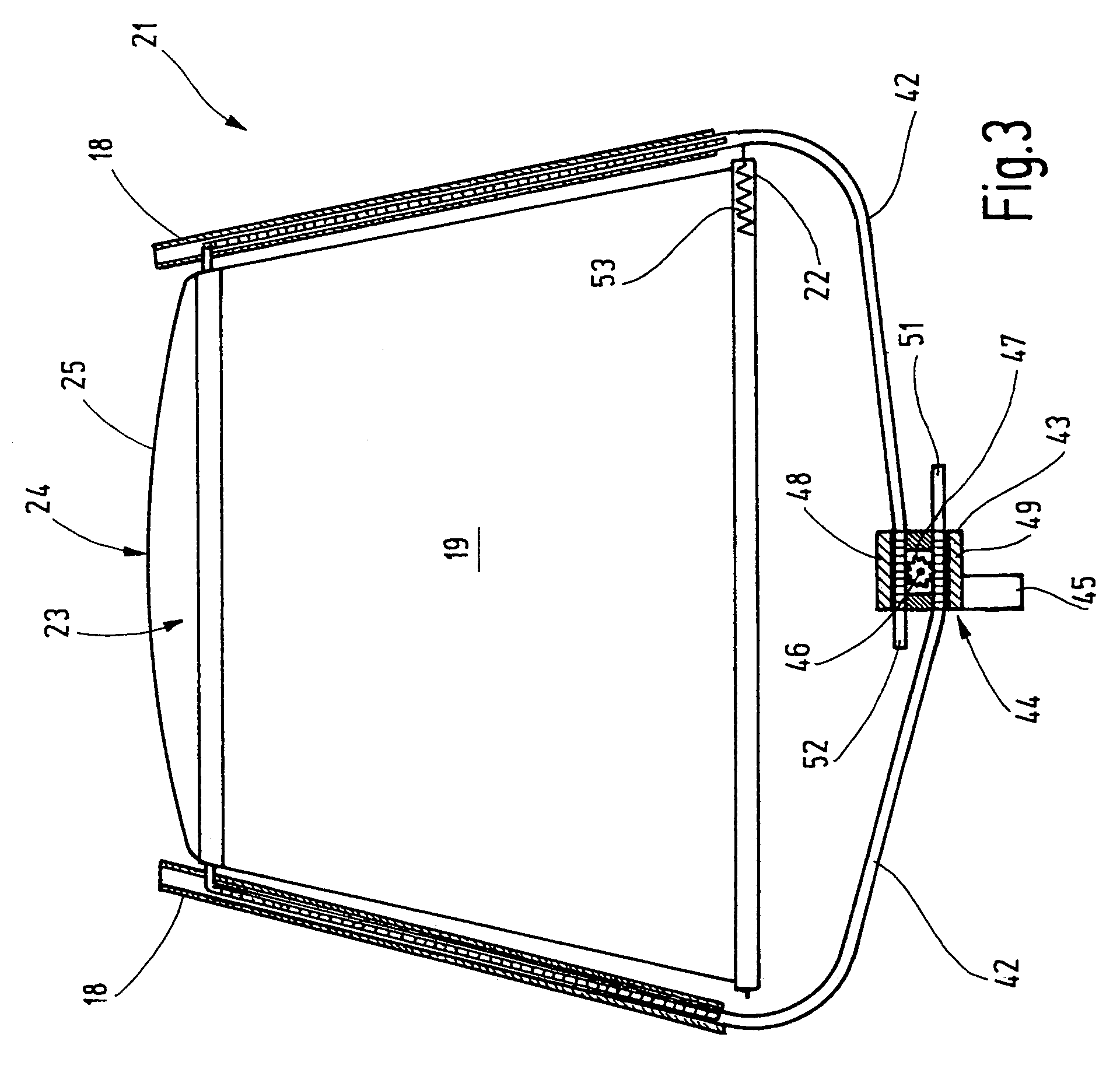

Rear-window roller blind without residual open gap

A rear window roller blind for motor vehicles which has a pull rod assembly with a contoured plate. The contoured plate is used to close the segmented residual gap between the straight pull rod assembly and the curved top edge of the rear window. In order for the contoured plate to lie flush with a rear shelf below the rear window when the roller blind is in a retracted position, it is pivotable about a longitudinal axis of the pull rod assembly during movement of the pull rod between its retracted and extended positions. Such rotational movement is controlled by the contour of guide rails within which the pull rod is guided during such pull out movement.

Owner:BOS

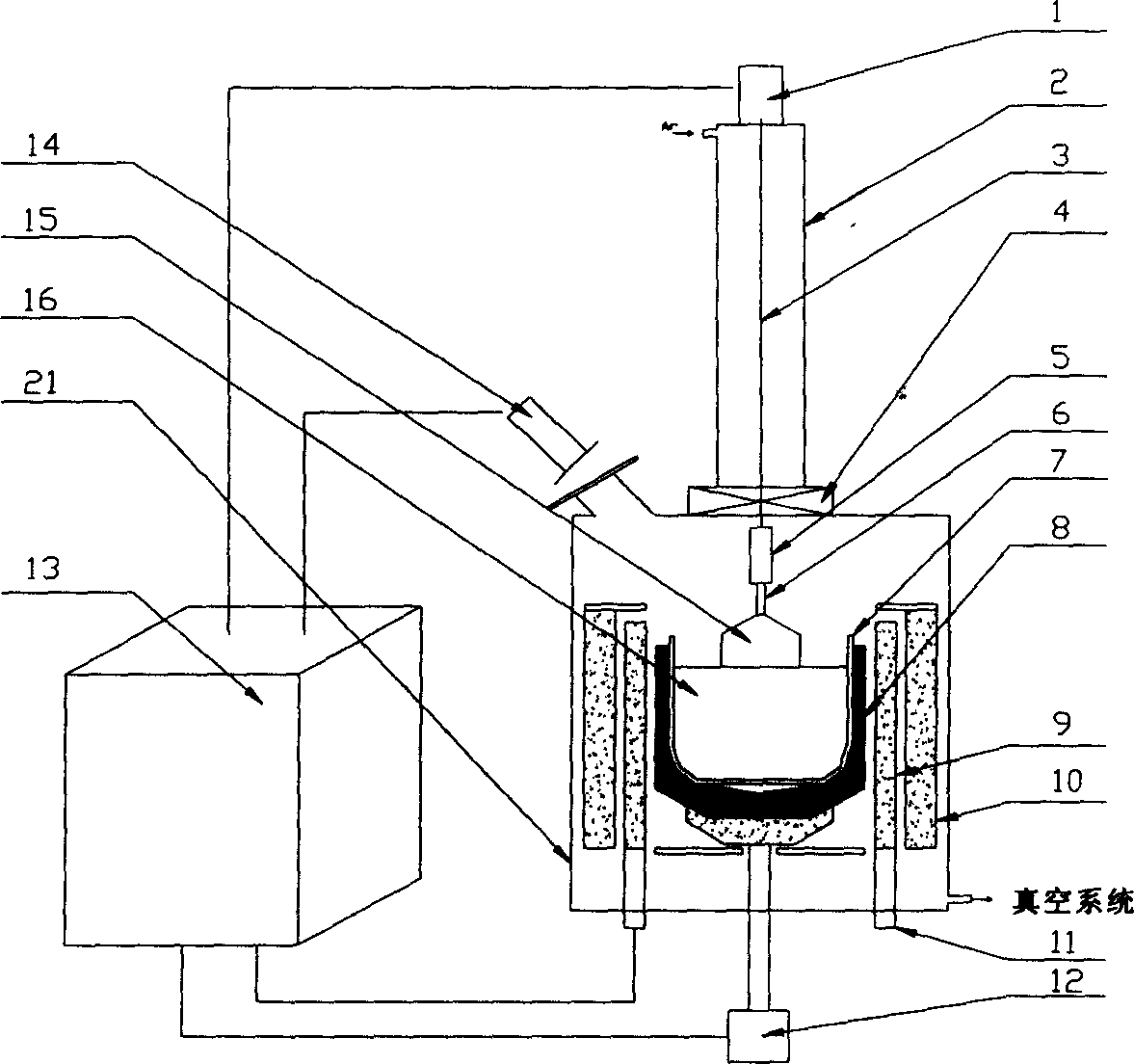

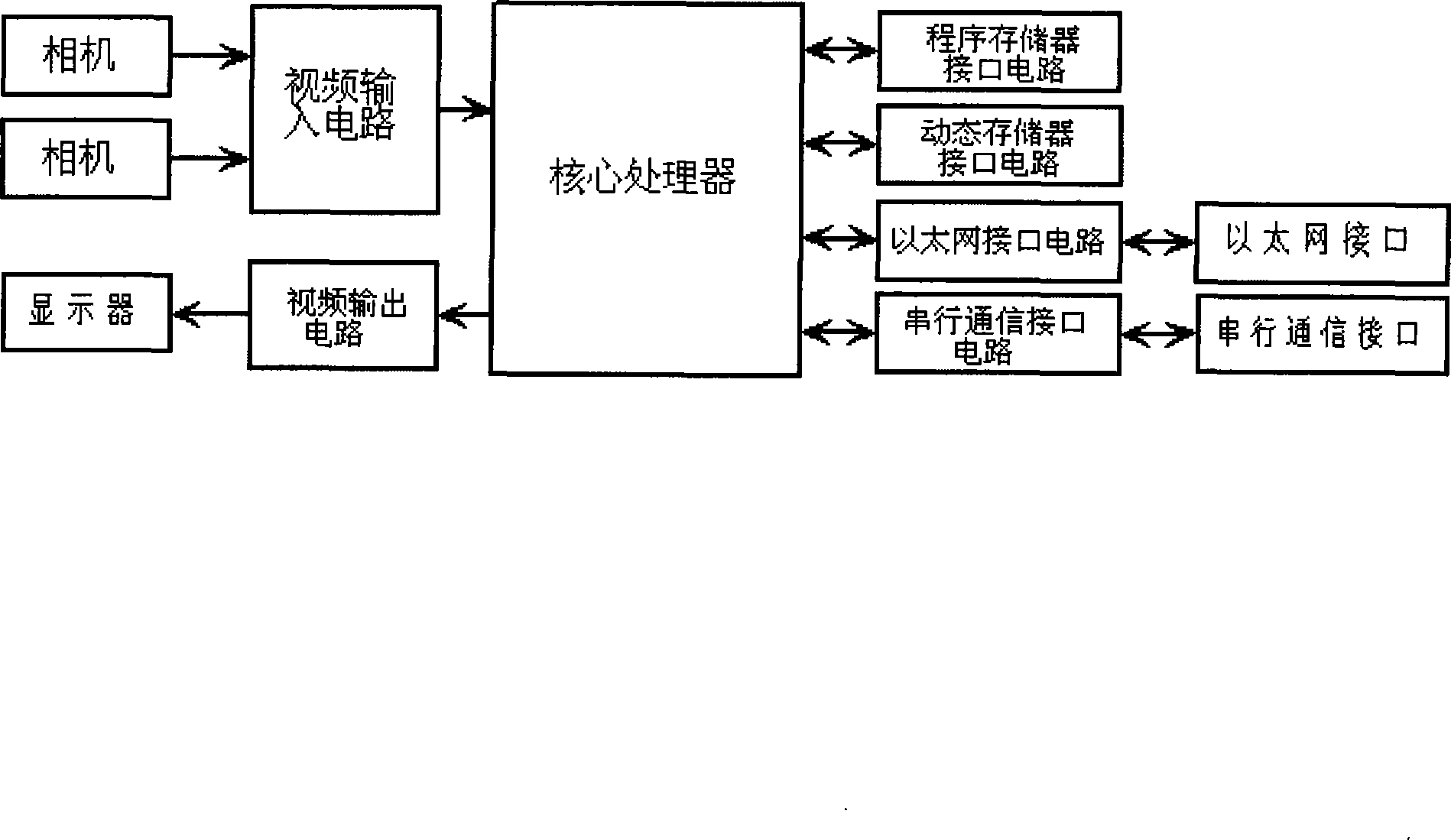

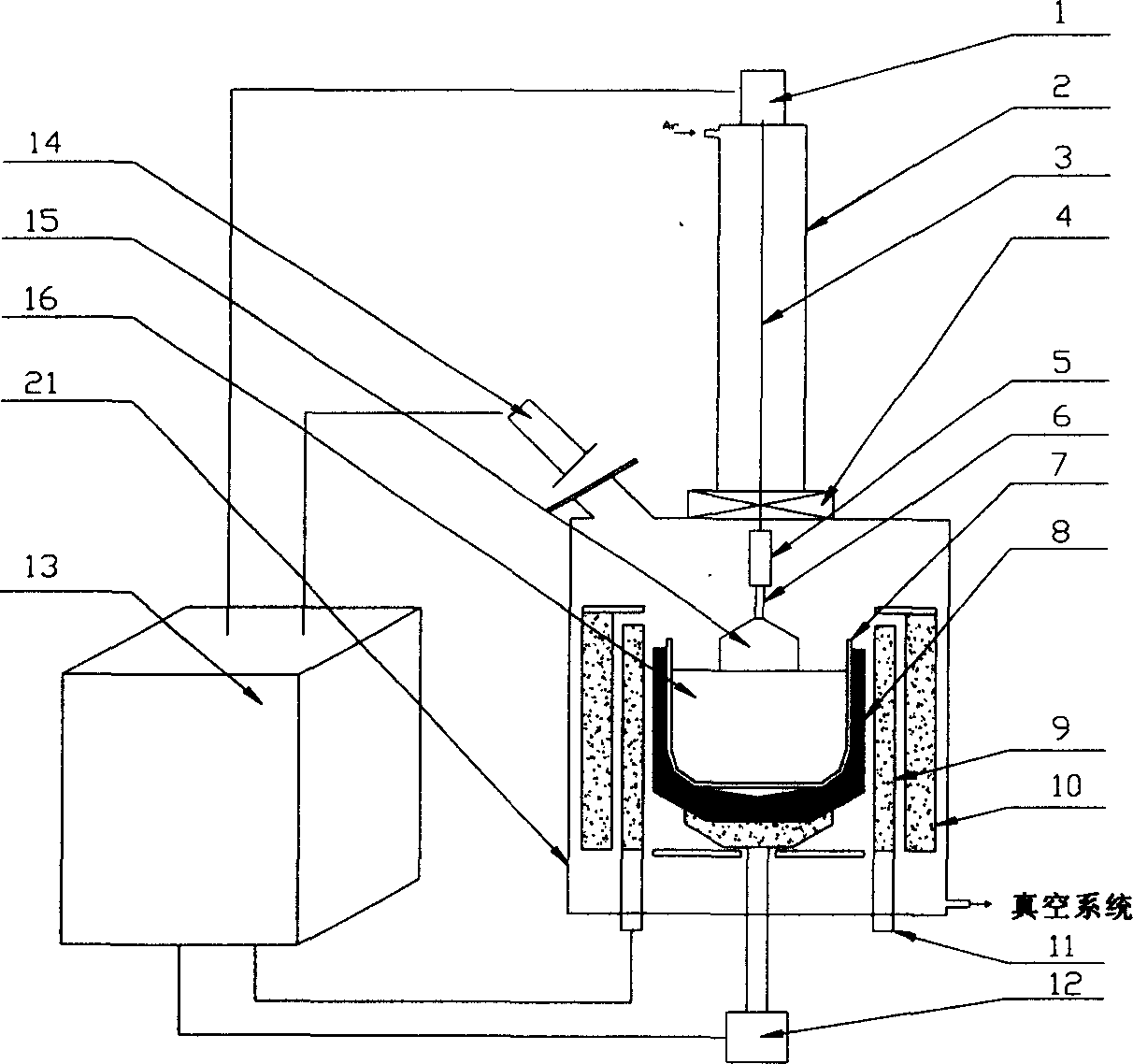

Method for measuring double-camera straight-pulling monocrystal diameter based on digital signal processor

ActiveCN101226050ALow costHigh speedPicture taking arrangementsUsing optical meansDigital signal processingData compression

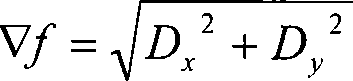

The invention discloses a two-camera diameter measurement method for Czochralski crystal based on a digital signal processor, which comprises a plurality of steps: collect the image at the stages of crystal growth and equi-diameter by adopting standard industrial double CCD camera; carry on the processes of edge detection, noise removal, data fitting, data filtering and data compression for the image information by utilizing a core processor with embedded structure based on DSP to realize the precise measurement on the diameter of monocrystalline silicon rod; finally, communicate the measurement radius and compressed image information with a host computer through the Ethernet interface and TCP / IP protocol. The two-camera diameter measurement method for Czochralski crystal based on a digital signal processor has the advantages that by utilizing the core processor with embedded structure, the measurement method has high reliability and no host machine resources are occupied; by adopting standard industrial double CCD camera to process the diameters at different stages respectively, the measurement method has high accuracy and low cost; by adopting the techniques of complex edge detection, noise removal, least squares fitting, extreme value filtering, data compression and algorithm level optimization, the measurement method has strong function, high accuracy and fast speed.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

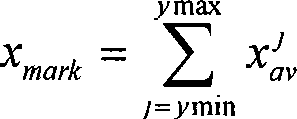

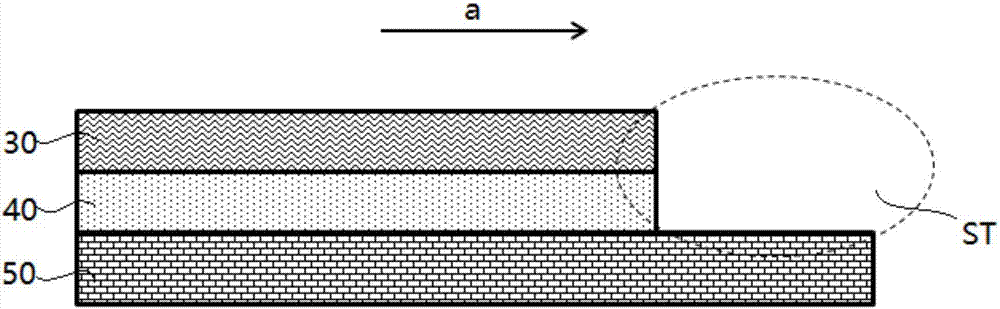

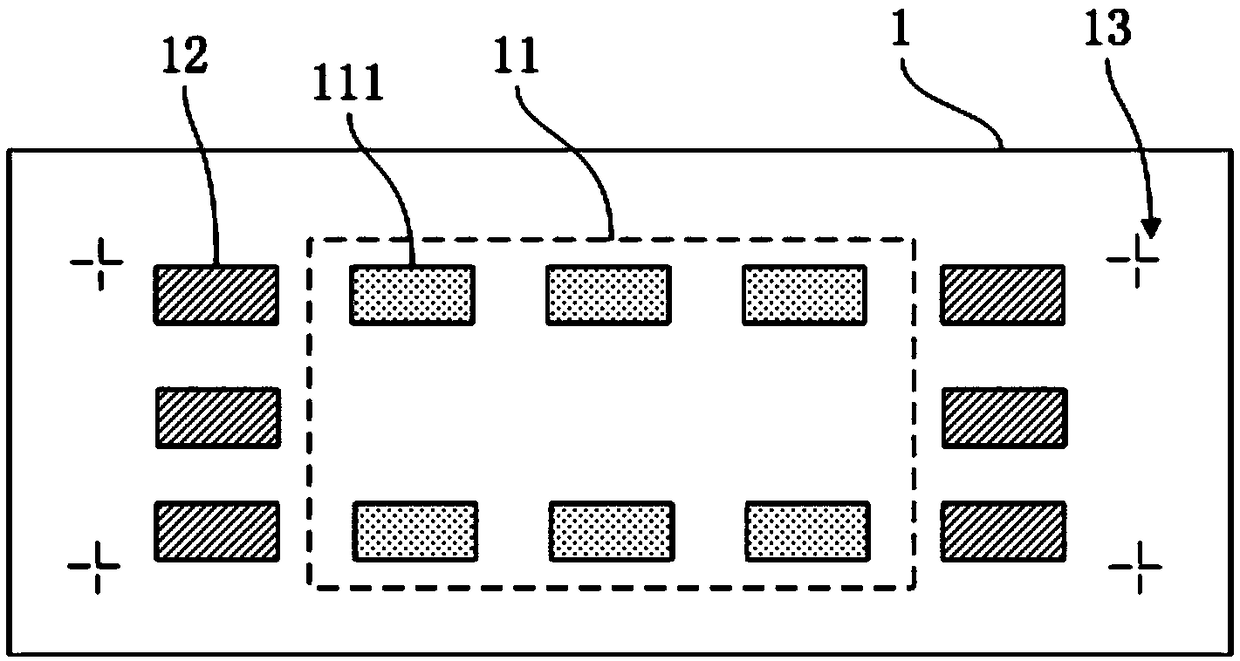

Display panel and display device

The invention discloses a display panel and a display device. The display panel comprises a first substrate, a second substrate opposite to the first substrate, multiple fan-out lines and multiple substrate bonding pads, wherein the length of the first substrate is larger than that of the second substrate in the first direction, so that a step area is formed, and the first direction is parallel with the substrate surface of the first substrate; the fan-out lines are arranged in the step area and comprise straight-pulling fan-out lines and oblique-pulling fan-out lines, the straight-pulling fan-out lines are in the first direction, and the direction of each oblique-pulling fan-out line is different from that of the corresponding straight-pulling fan-out line, and the area, where the straight-pulling fan-out lines are arranged, in the step area is a straight-pulling wiring area; the substrate bonding pads are electrically connected with the fan-out lines in a one-to-one correspondence manner and comprise in-area substrate bonding pads in the straight-pulling wiring area. With the adoption of the display panel and the display device, the width of a border of the display panel adopting a COF technique is further reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Upper thermal field used for six inch and eight inch adulterated phosphorus vertical pulling silicon mono crystal manufacture

ActiveCN1556257AImprove purging effectEffective blow offPolycrystalline material growthBy pulling from meltElectrical resistance and conductanceEngineering

A top heat field for preparing 6-inch and 8-inch heavyly doped monosilicon by straight pulling up is composed of an insulating cover consisting of the upper and lower hollow trancated cones, and an upper cover plate fixed to the top of said insulating cover and put on a supporting pipe. It can enhance the scavenge action of the airflow on the surface of molten body for removing the fine particles from the surface.

Owner:金瑞泓科技(衢州)有限公司

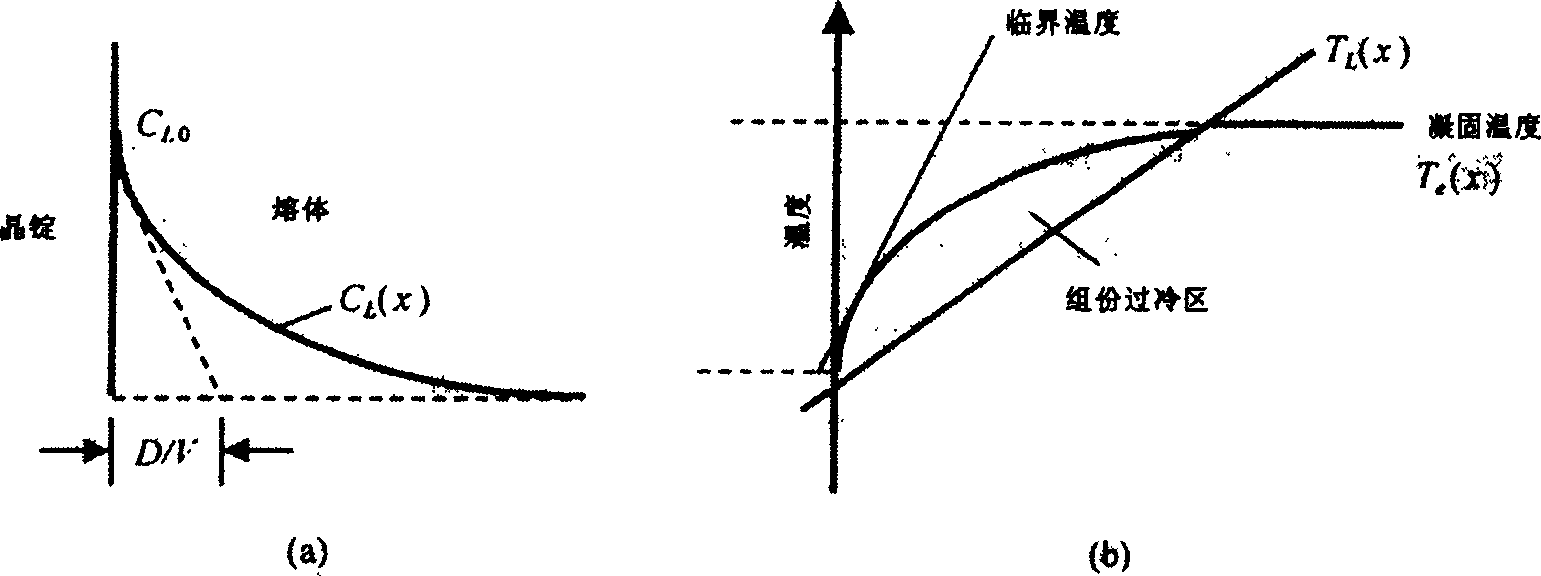

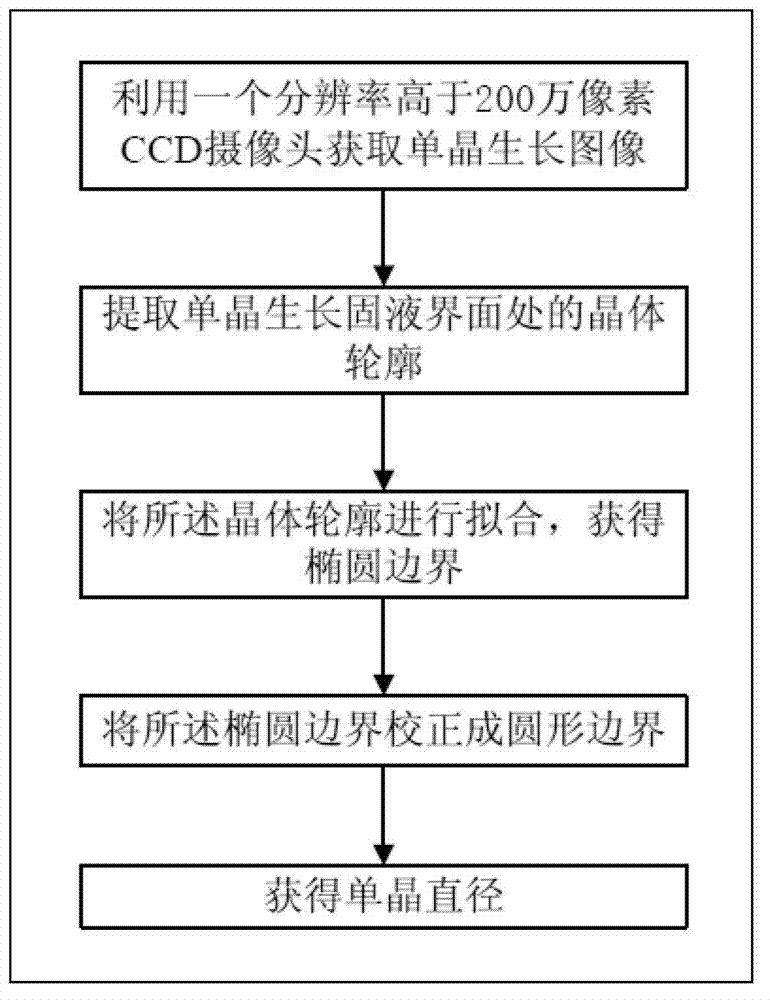

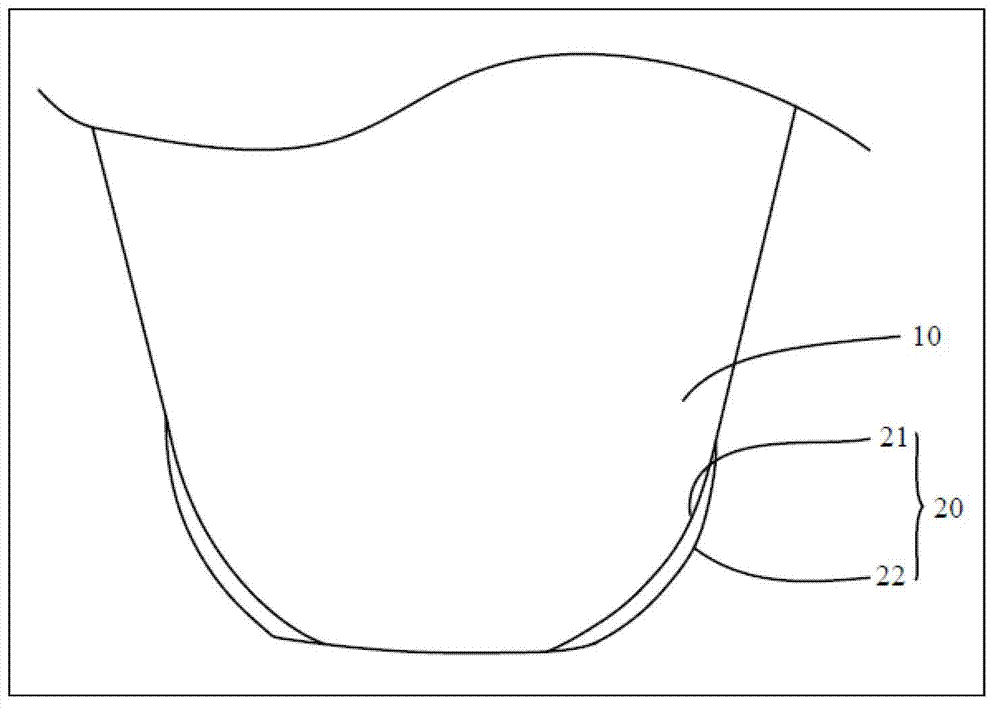

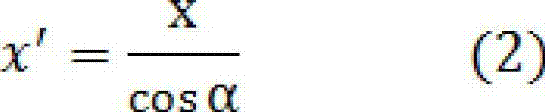

Diameter measurement method for straight pulling single crystal

InactiveCN103046128ANo noise disturbanceSimple and fast operationBy pulling from meltImage resolutionSingle crystal

A diameter measurement method for a straight pulling single crystal comprises the steps that a CCD (charge coupled device) camera is used for acquiring a single crystal growing image and the single crystal growing image is processed, and the resolution ratio of the CCD camera is higher than 2 million pixels; and the processing of the single crystal growing image comprises the steps as follows: extracting a crystal outline in a position of a single crystal growing solid liquid interface; fitting the crystal outline to obtain an elliptical boundary; correcting the elliptical boundary into a circular boundary; and obtaining the diameter of the single crystal. The diameter measurement method for the straight pulling single crystal is high in accuracy of a measurement result, can be operated easily, and is free from noise disturbance. The method can be used for single crystal diameter measurement during processes such as seeding, diameter enlarging, diameter conversion and equal diameters.

Owner:LONGI GREEN ENERGY TECH CO LTD

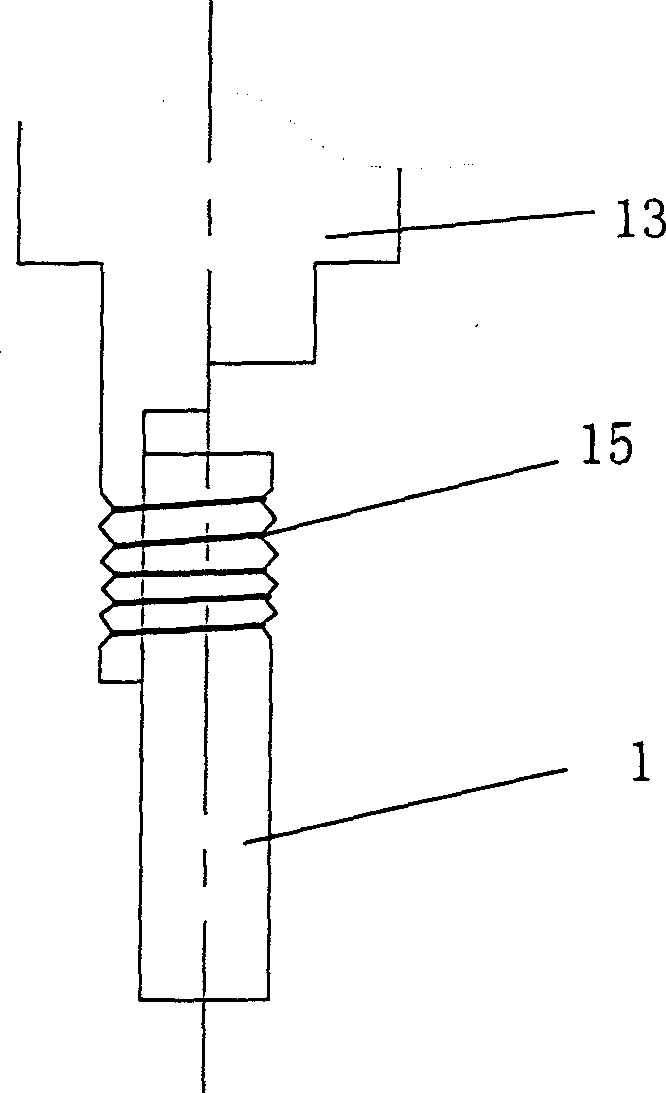

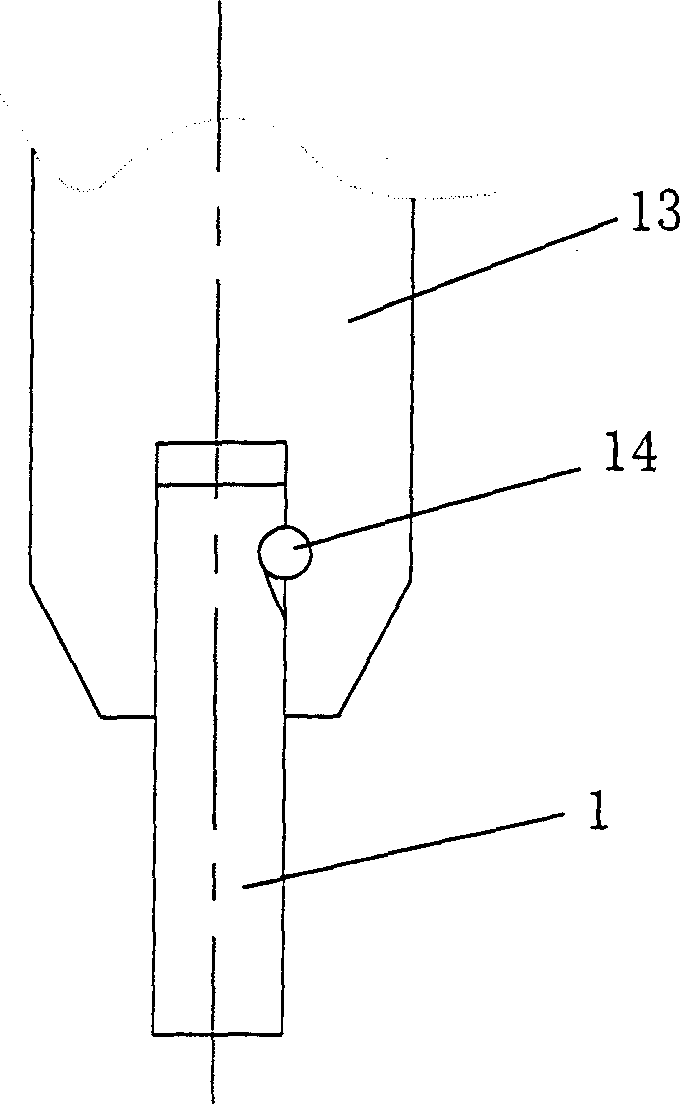

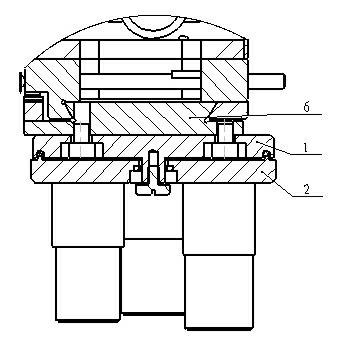

Silicon seed crystal holder for monocrystal silicon by vertical pulling process

A clamper of silicon seel crystal for growing the monocrystalline silicon by straight pull method has a top jointer for connecting the seed crystal axle, and a main body which is composed of an upper part and a lower part containing a through empty cavity with big diameter for upper half and small diameter for lower half. It can be used to prepare the silicon crystal with 500 kg in weight. Its advantage is high safety of silicon seed crystal which can not be broken.

Owner:有研半导体硅材料股份有限公司

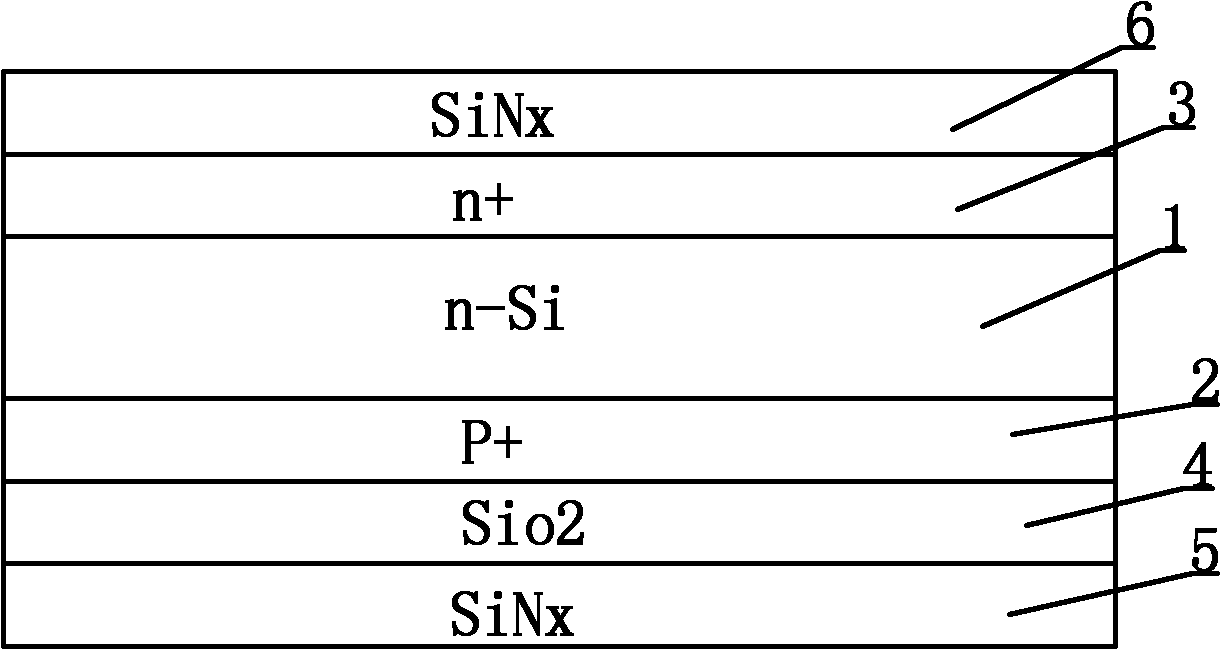

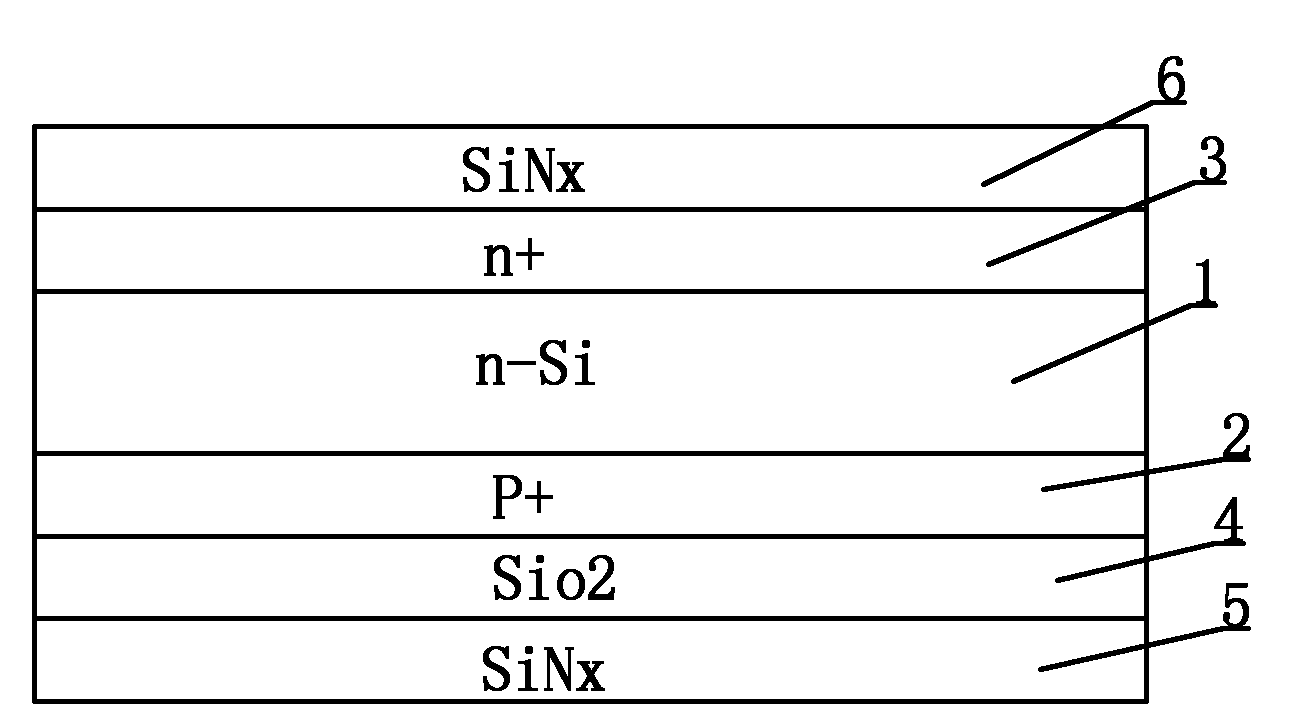

N-type solar battery prepared by film masking process of one multi-purpose film and preparation method of N-type solar battery

ActiveCN102176474ASimple processEasy to controlFinal product manufacturePhotovoltaic energy generationStraight pullSolar battery

The invention relates to the field of an N-type solar battery, particularly the N-type solar battery prepared by a film masking process of one multi-purpose film and a preparation method of the N-type solar battery. The N-type solar battery has the structure that: an n-type straight-pull monocrystalline silicon is used as a substrate, the backside of a silicon sheet is a P-type emitter junction prepared by boron diffusion of a SiO2 and SiNx coated dual-layer passivation film, and the front side of the silicon sheet is a front surface field prepared by phosphorous diffusion and a thin film playing a passivation and reflection reduction role covers on the front surface field. The preparation method of the N-type solar battery comprises the following steps of: with the n-type straight-pull monocrystalline silicon as the substrate, preparing the P-type emitter junction by the boron diffusion firstly, and then etching the P-type emitter junction on the front side; preparing the SiO2 film on the P-type emitter junction on the backside of the silicon sheet, wherein the SiO2 film is not only a mask film for preparing the front surface field by the phosphorous diffusion subsequently, but also the passivation film of the P-type emitter junction; and lastly, preparing the front surface field by the phosphorous diffusion. The invention has the advantages of simple technique process, easy control, low cost and high photoelectric conversion efficiency.

Owner:TRINA SOLAR CO LTD

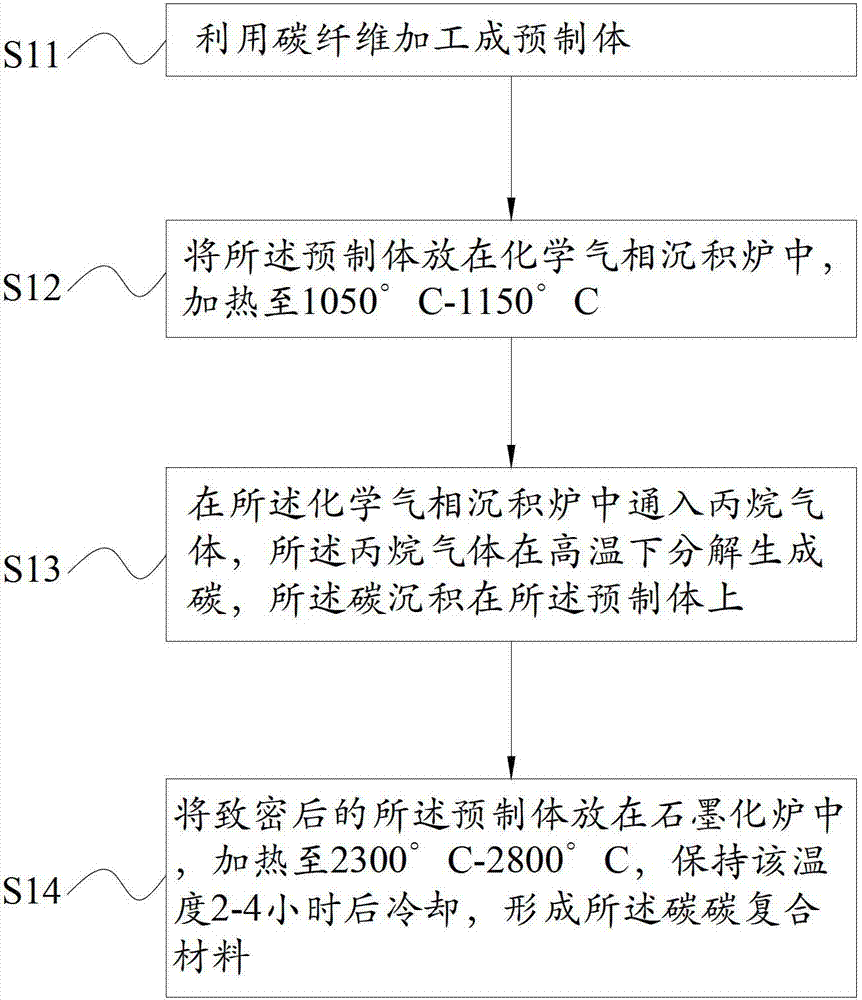

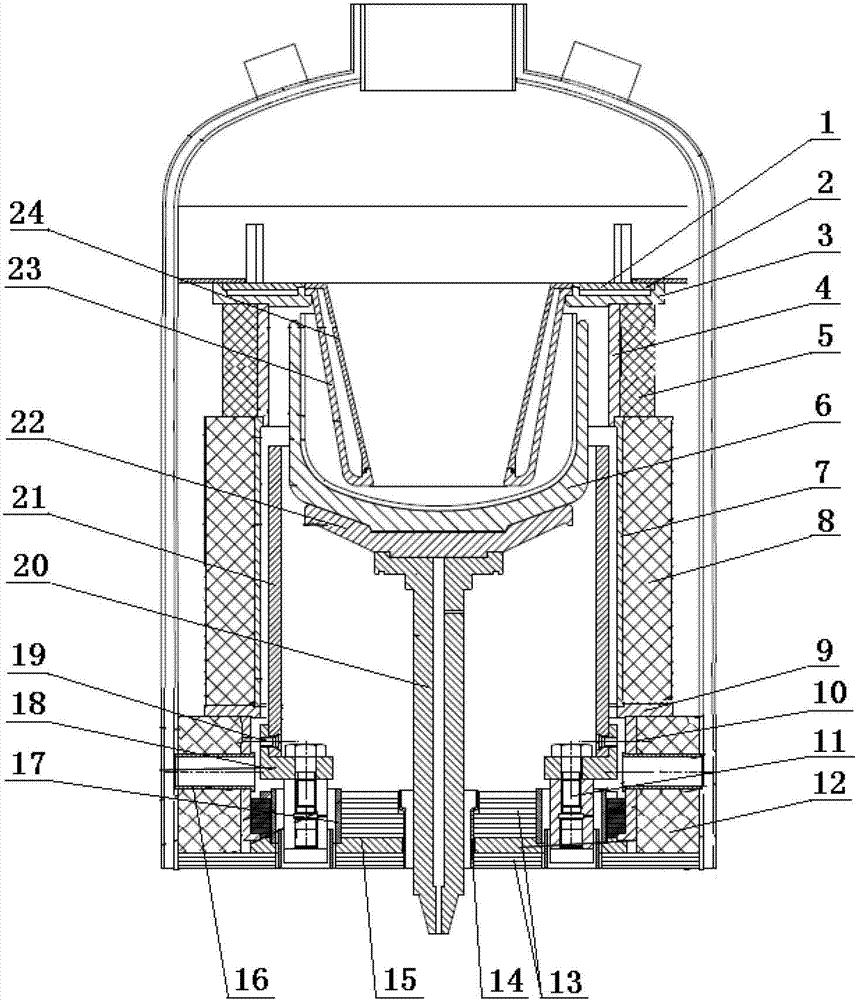

Straight pulling single crystal furnace and processing method of carbon-carbon composite material for straight pulling single crystal furnace

InactiveCN102731134ASimple processing methodContains less impuritiesBy pulling from meltFiberCarbon composites

The invention discloses a processing method of carbon-carbon composite material for a straight pulling single crystal furnace. The method comprises the steps of processing carbon fiber into a prefabricated body, then heating the prefabricated body in a chemical deposition furnace to 1050-1150 DEG C, and introducing propane gas, wherein the propane gas is decomposed at high temperature to generate carbon and the carbon is deposited in the prefabricated body; placing the compacted prefabricated body in a graphitization furnace; heating to 2300-2800 DEG C, and maintaining the temperature for 2-4 hours and cooling to form the carbon-carbon composite material. The invention further discloses the straight pulling single crystal furnace which comprises a heater processed by the carbon-carbon composite material. Density of the heater is greater than or equal to 1.8g / cm<3>. The processing method of the carbon-carbon composite material provided by the invention replaces a method of repeated impregnation by carrying out compacting treatment to the prefabricated body by using the chemical vapor deposition furnace, so that not only is the process simple, but also more impurities do not be doped in the compacting treatment process, and high temperature purification is not needed, thereby greatly simplifying the processing method.

Owner:BEIJING JINGYI CENTURY ELECTRONICS

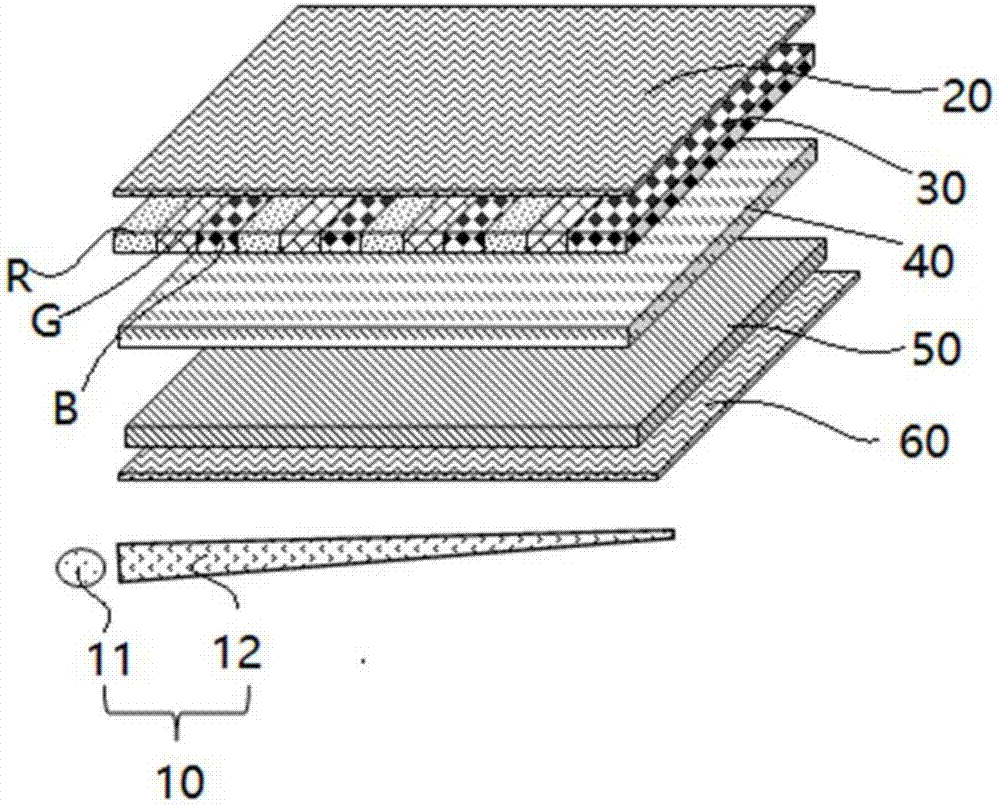

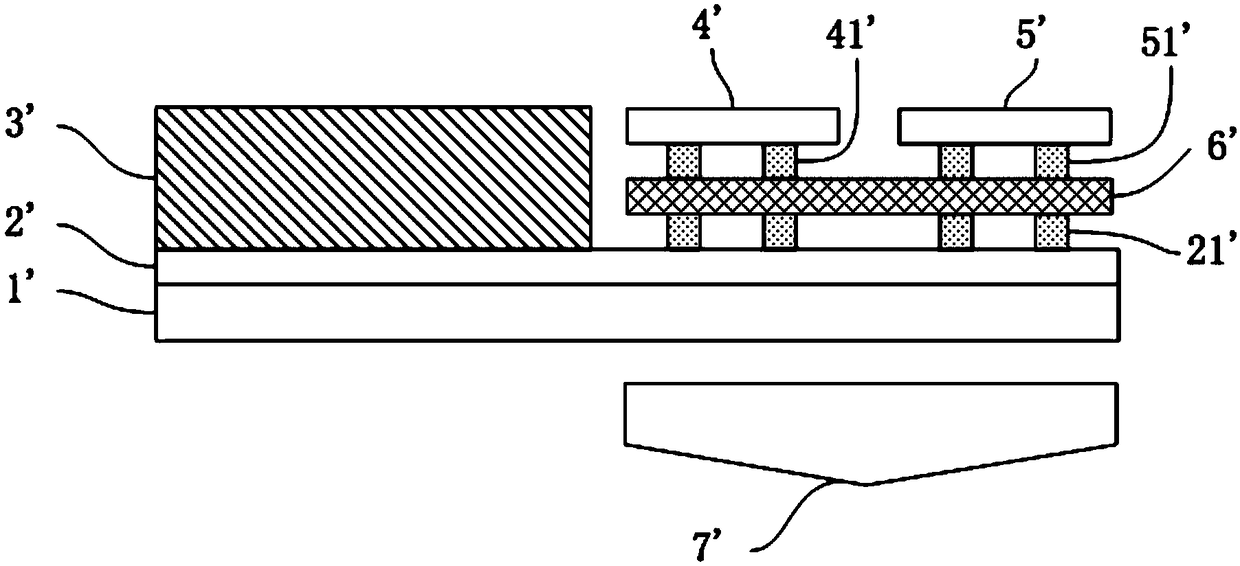

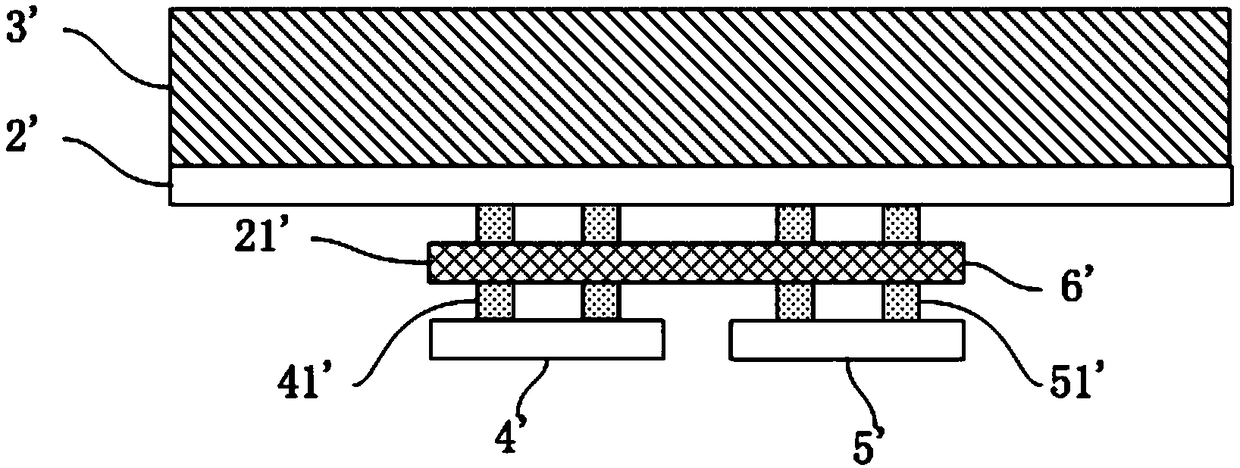

A straight pull display and a pressing method thereof

ActiveCN109118954AAvoid breakingLow costElectrical componentsIdentification meansCapacitanceAdhesive

The invention provides a straight pull display and a pressing method thereof. The method includes the steps that at least two first conductive blocks are formed on a display panel, and at least two second conductive blocks for aligning with that at least two first conductive blocks are formed on an IC panel; a conductive adhesive is coated on a binding area of the display panel and coating an insulating adhesive on at least two first conductive blocks; the IC panel is fixed above the display panel, so that the IC panel is parallel to the display panel, and the IC panel is moved along the parallel direction of the display panel so that at least two second conductive blocks and at least two first conductive blocks correspond one by one to form at least two capacitors respectively, and when the capacitance value of any one of the capacitors reaches the maximum, the IC panel is moved toward the display panel so that the IC panel and the display panel are stamped together. The invention canaccurately judge whether the binding area of the IC panel and the binding area of the display panel are aligned and pressed without passing an optical microscope.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

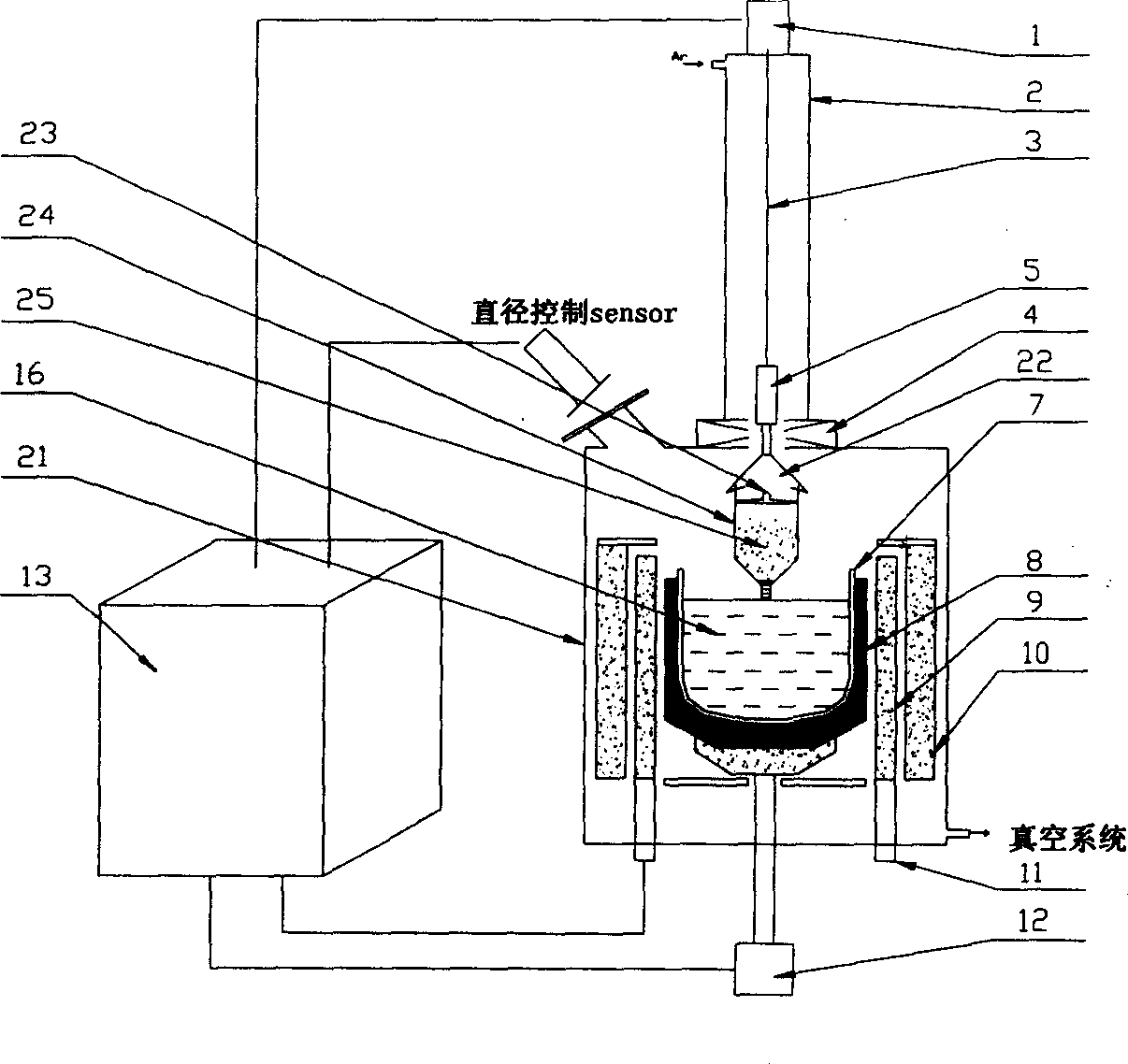

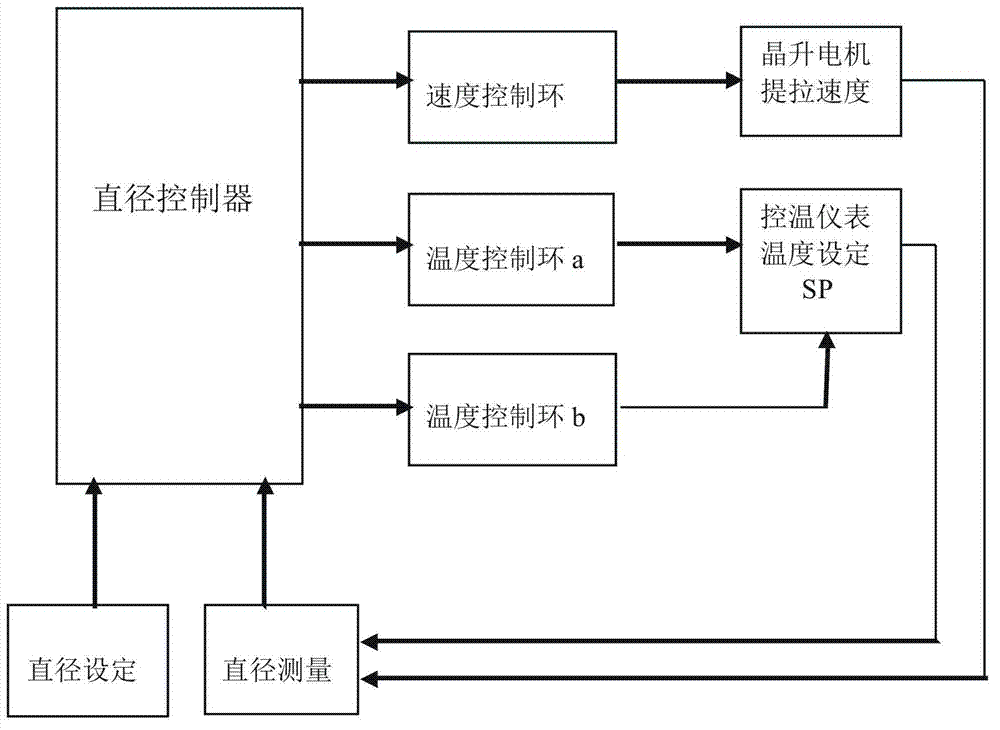

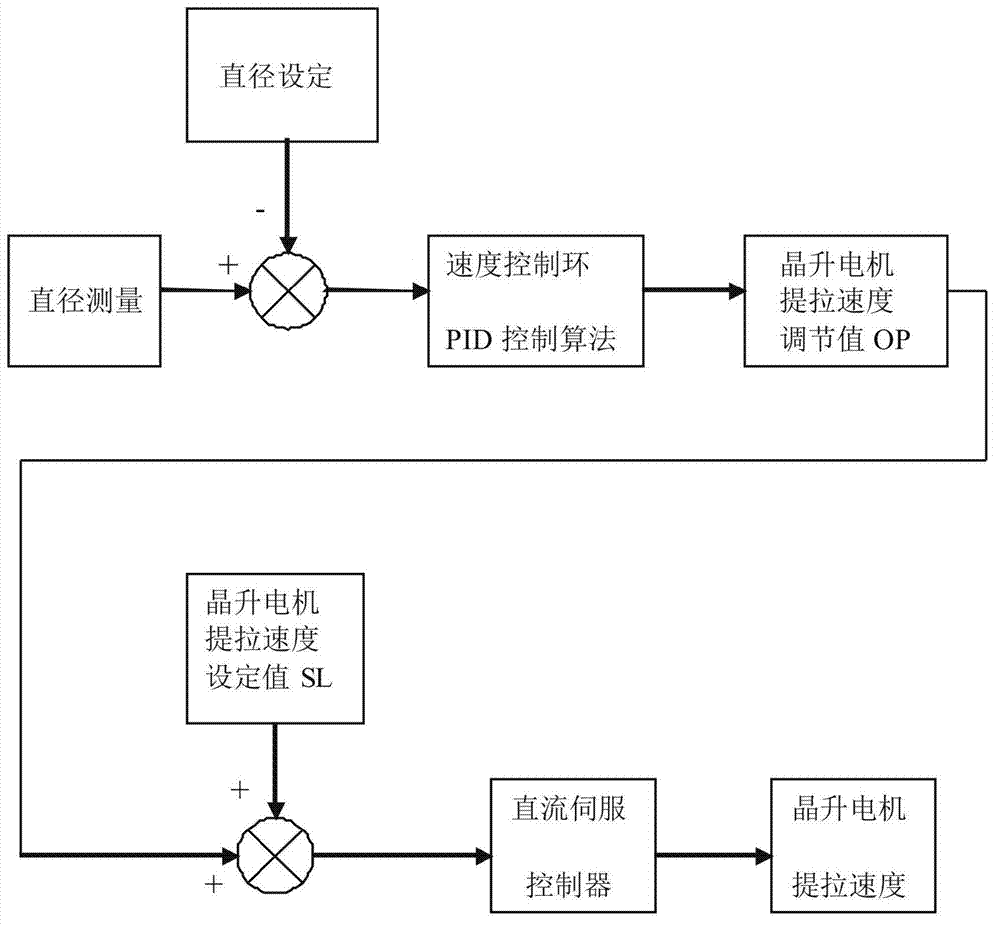

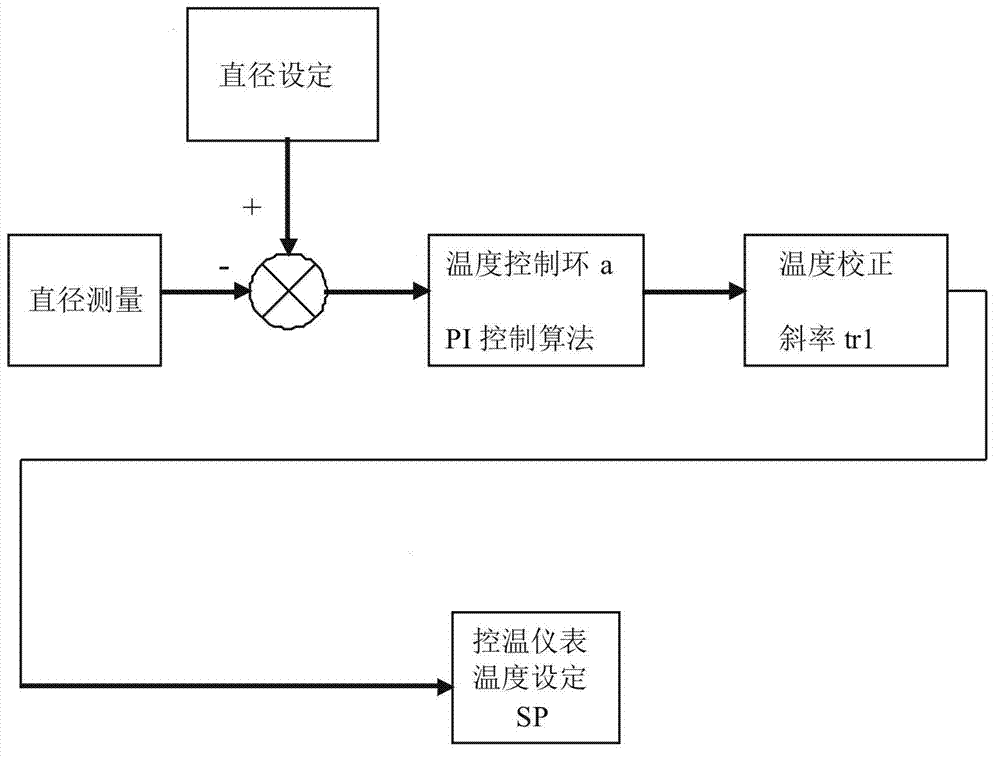

Automatic equal diameter controlling method for germanium single crystal straight-pull growth method

InactiveCN102758250AReduce wasteIncrease productivityBy pulling from meltTemperature controlSingle crystal

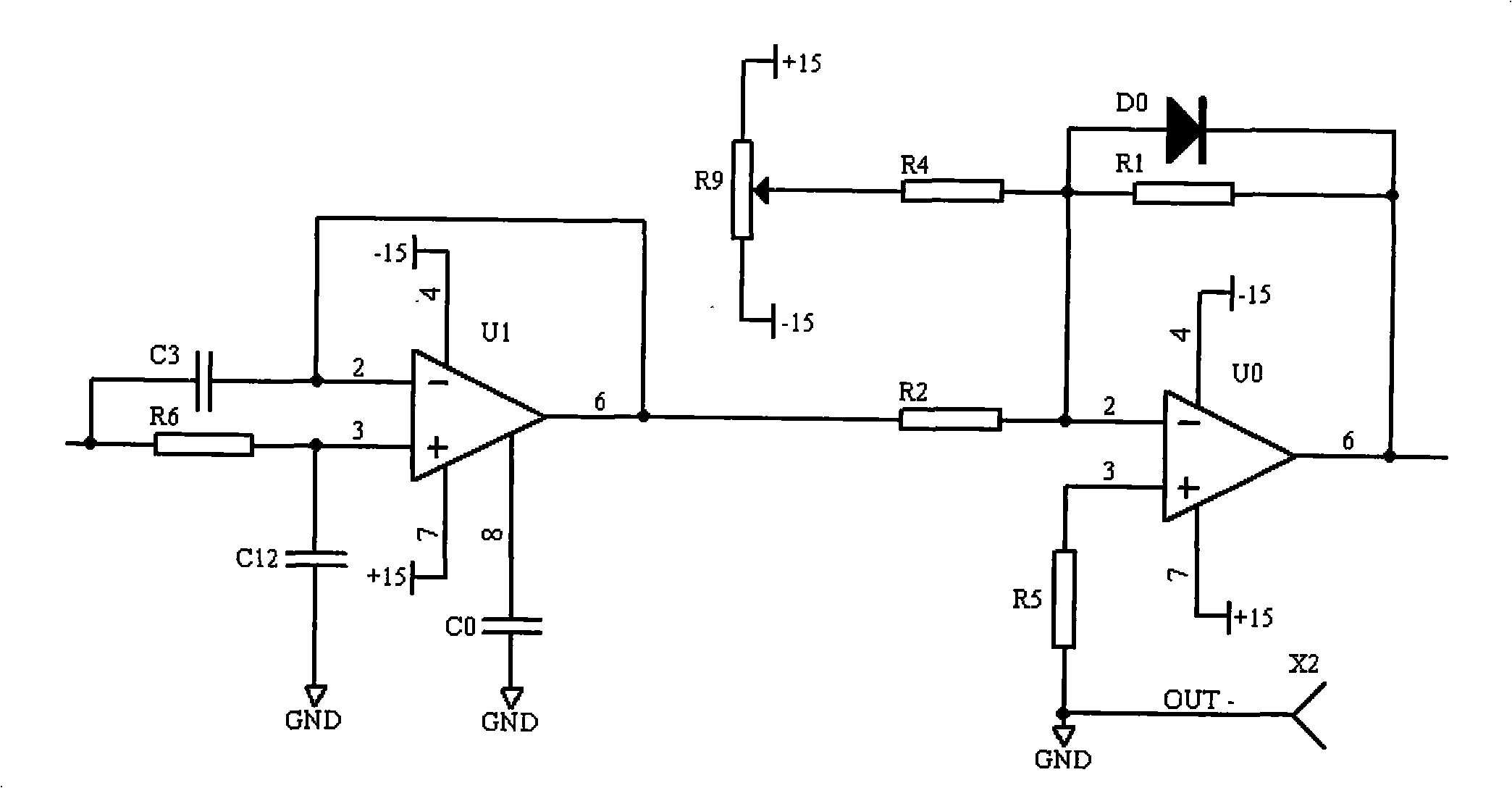

The invention discloses an automatic equal diameter controlling method for germanium single crystal straight-pull growth method, which includes the following steps: setting the diameter of the germanium crystal required to be prepared, setting the initial lifting speed SL of a crystal rise motor, and establishing a speed control ring, a temperature control ring a and a temperature control ring b. When a diameter measurement value deviates from a diameter set value during the growth process of the germanium single crystal, a diameter deviation e1 is formed between the diameter measurement value and the diameter set value, then the three control rings are matched mutually to automatically adjust lifting speed of the crystal rise motor and the temperature set SP of a temperature controller, so as to enable the diameter measurement value to be equal to the diameter set value. The automatic equal diameter controlling method improves the manual diameter control during the germanium single crystal production into automatic diameter control, improves the production efficiency, reduces the wastes caused by the follow-up polishing, rounding and slicing processes of the single crystal bar.

Owner:XAUT CRYSTAL GROWING TECH CO LTD

Automated quoting of molds and molded parts

InactiveUS20050096780A1Buying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

Automated, custom mold manufacture for a part begins by creating and storing a collection of information of standard tool geometries and surface profiles machinable by each of the standard tool geometries. A customer sends a CAD file for the part to be molded to the system. The system assesses the CAD file to determine various pieces of mold manufacturing information. One or more acceptability criteria are applied to the part, such as whether the part can be manufactured in a two-piece, straight-pull mold, and whether the mold can by CNC machined out of aluminum. If not, the system sends a file to the customer graphically indicating which portions of the part need modification to be manufacturable. The system provides the customer with a quotation form, that allows the customer to select several parameters, such as number of cavities, surface finish and material, which an independent of the shape of the part. The quotation module then provides the customer with the cost to manufacture the mold or a number of parts. The quotation is based in part upon mold manufacturing time as automatically assessed from the part drawings and based in part on the independent parameters selected by the customer. The customer's part is geometrically assessed so the system automatically selects appropriate tools and computes tool paths for mold manufacture. In addition to the part cavity, the system preferably assesses the parting line, the shutoff surfaces, the ejection pins and the runners and gates for the mold. The preferred system then generates CNC machining instructions to manufacture the mold, and the mold is manufactured in accordance with these instructions.

Owner:PROTOLABS INC

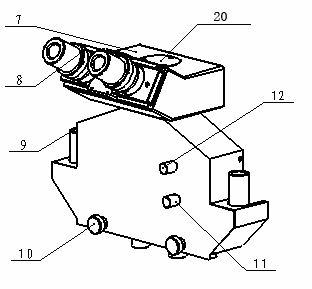

Field-splitting microscope for realizing rapid zooming function of object lens

InactiveCN102109672AIncrease distanceReduce the impactMicroscopesPhotomechanical exposure apparatusExit pupilStraight pull

The invention relates to an alignment observation device which is applied to an exposure machine, in particular to a field-splitting microscope for realizing a rapid zooming function of an object lens. The field-splitting microscope consists of an object lens rapid-zooming device, an object lens system, an eye lens system and the like. The field-splitting microscope has the beneficial effects that the original field-splitting microscope is taken as a prototype, the operating distance of the lens and the distance between an eye-point exit pupil position and a working face are unchanged, the distance between the object lens and a reflector is increased, an object lens rapid-zooming mechanism is additionally arranged at the mounting position of the object lens, and the rotation part of the zooming mechanism is set into the form that the object lens locating surfaces of a lower turntable are positioned on the same horizontal plane; optimization design is carried out on an illumination system, and illuminating light and imaging light in a new light path are independently propagated in the horizontal direction; a steering structure of the light path is changed from an upright shape to a turning shape; and an eye-distance adjusting structure for the lens is changed from a straight-pull light-splitting structure to a rotary light-splitting structure. By utilizing the field-splitting microscope, the rapid zooming function of the object lens can be realized in the case of switchover between coarse alignment and fine alignment.

Owner:THE 45TH RES INST OF CETC

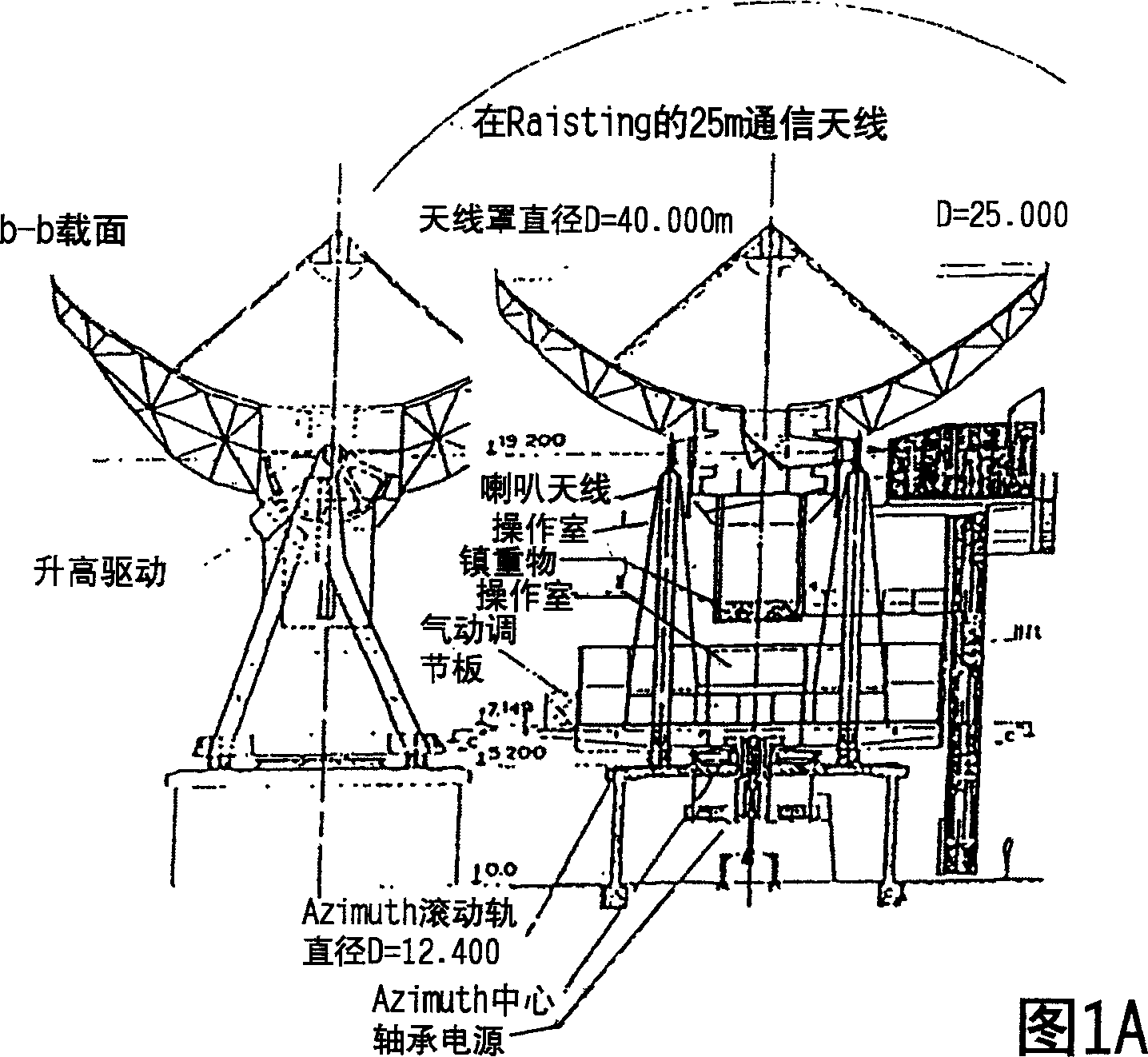

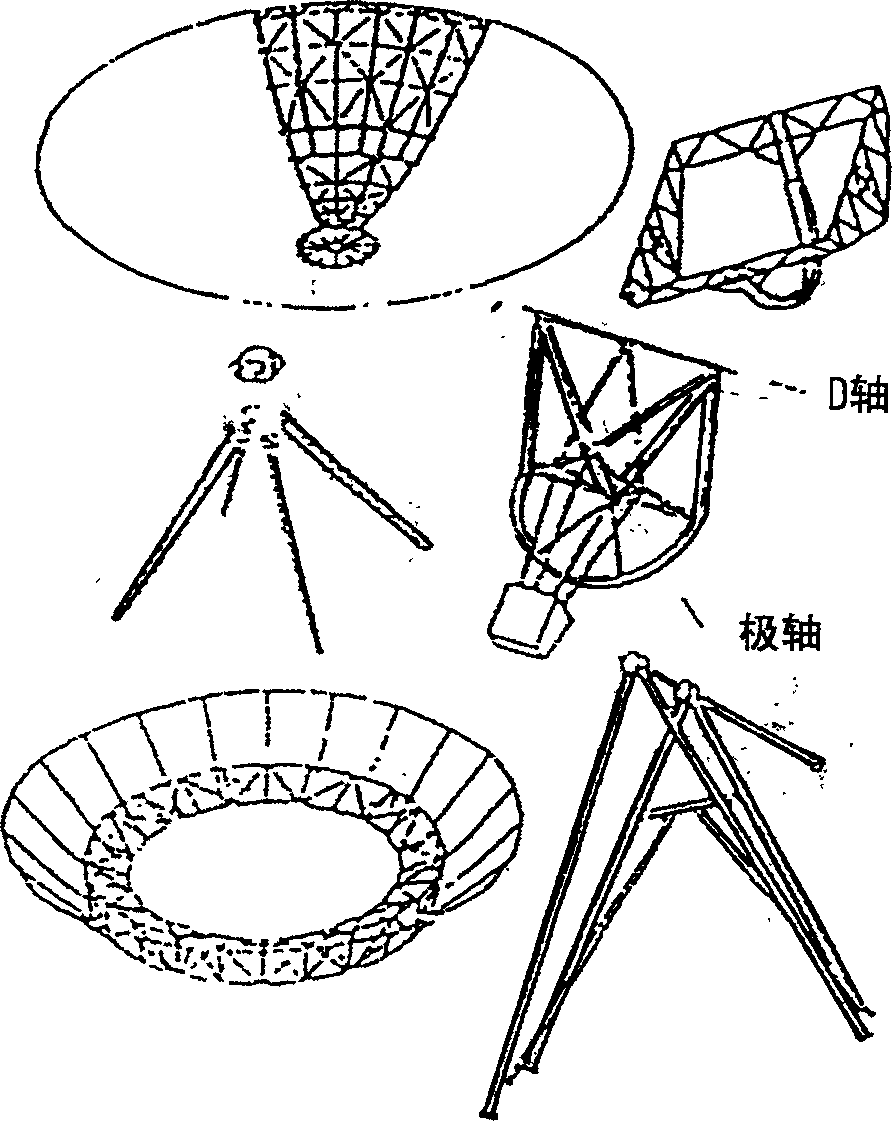

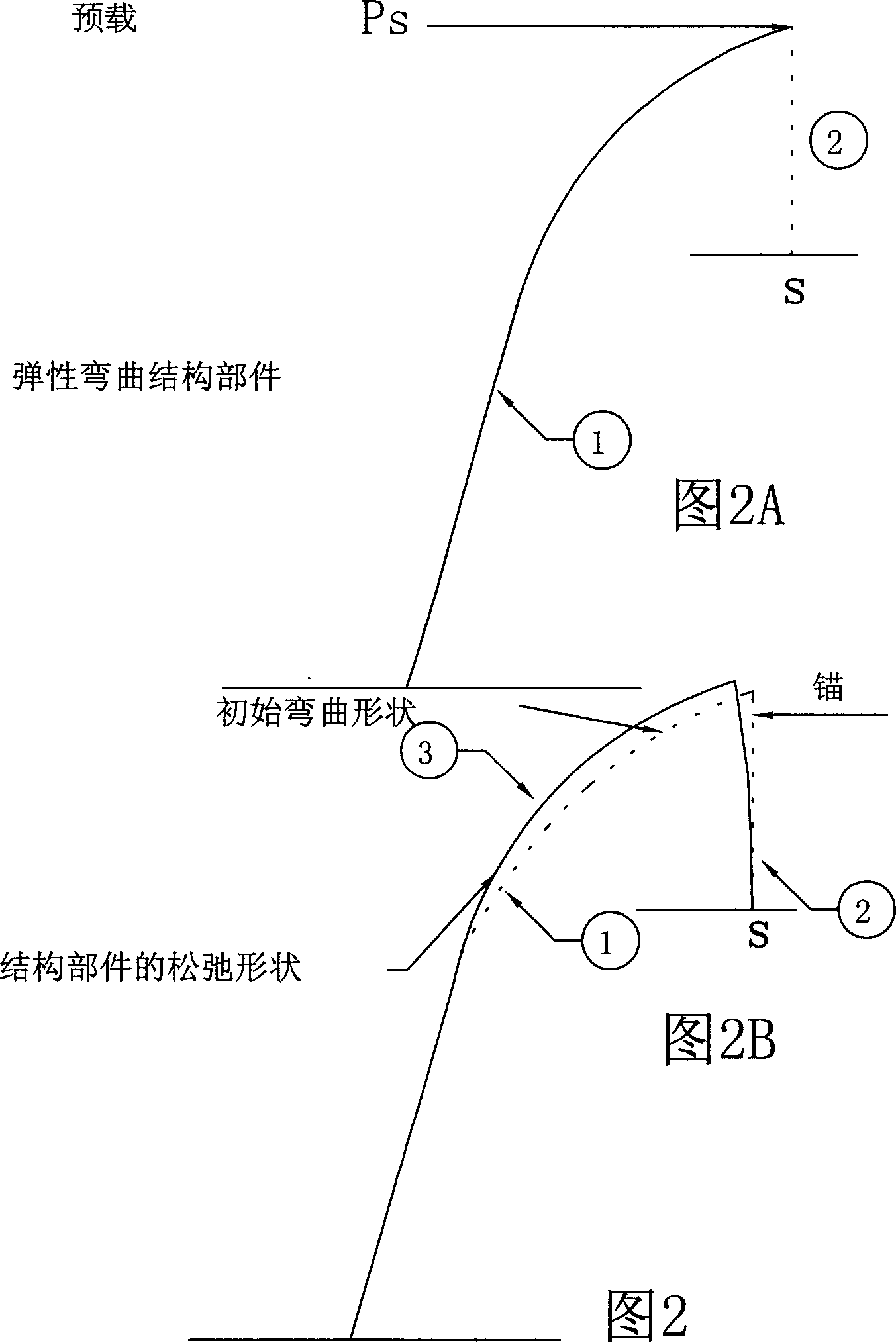

Preloaded parabolic dish antenna and method of making it

InactiveCN1444781AAvoid bouncingReduce weightVibration dampingWind-induced force reductionEngineeringStraight pull

The parabolic reflector antenna, by preloading its radially circumferentially placed straight support members to support its reflective surface, makes it significantly lighter and also plays a role in its installation. The support structure for the preloaded parabolic reflector antenna consists of a central hub, an assembly of an appropriate number of resiliently curved radial structural members, an equal number of straight structural members connected to the tips of the radial members at the outer rim of the parabolic antenna, and circumferentially located The straight brace components in the middle position are all tensioned to the specified prestress value when there is no wind load. The outermost rim part located at the periphery of the parabolic antenna forms the opening of the parabolic antenna. Fixing the radial part at an appropriate inclination angle and position at the hub, applying a force with a normal component at its tip to elastically bend the radial part with a curvature approximately the same as the parabolic curvature between the hub and the peripheral rim point, so that the supporting member Has a parabolic shape.

Owner:塔塔基础研究院

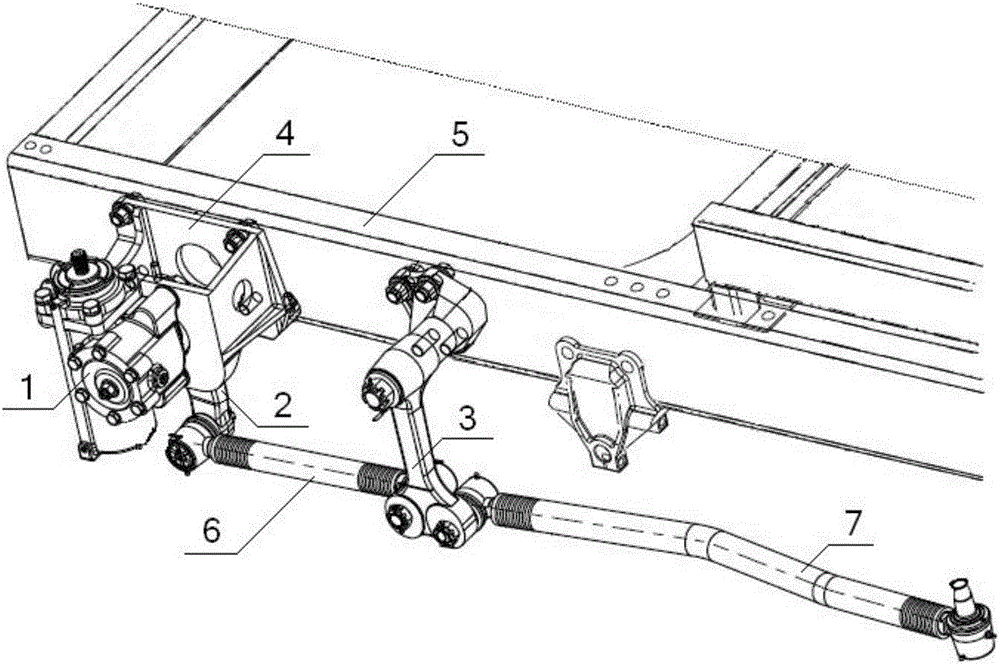

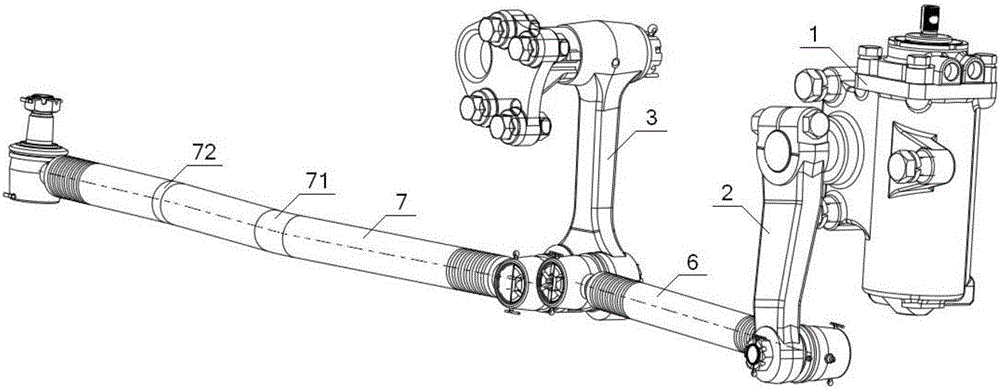

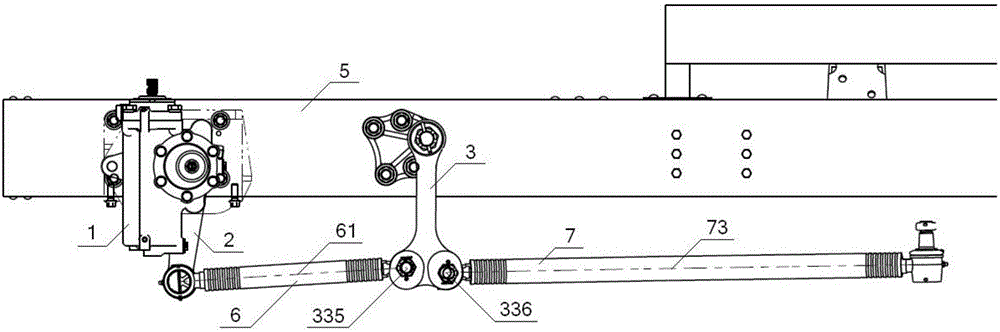

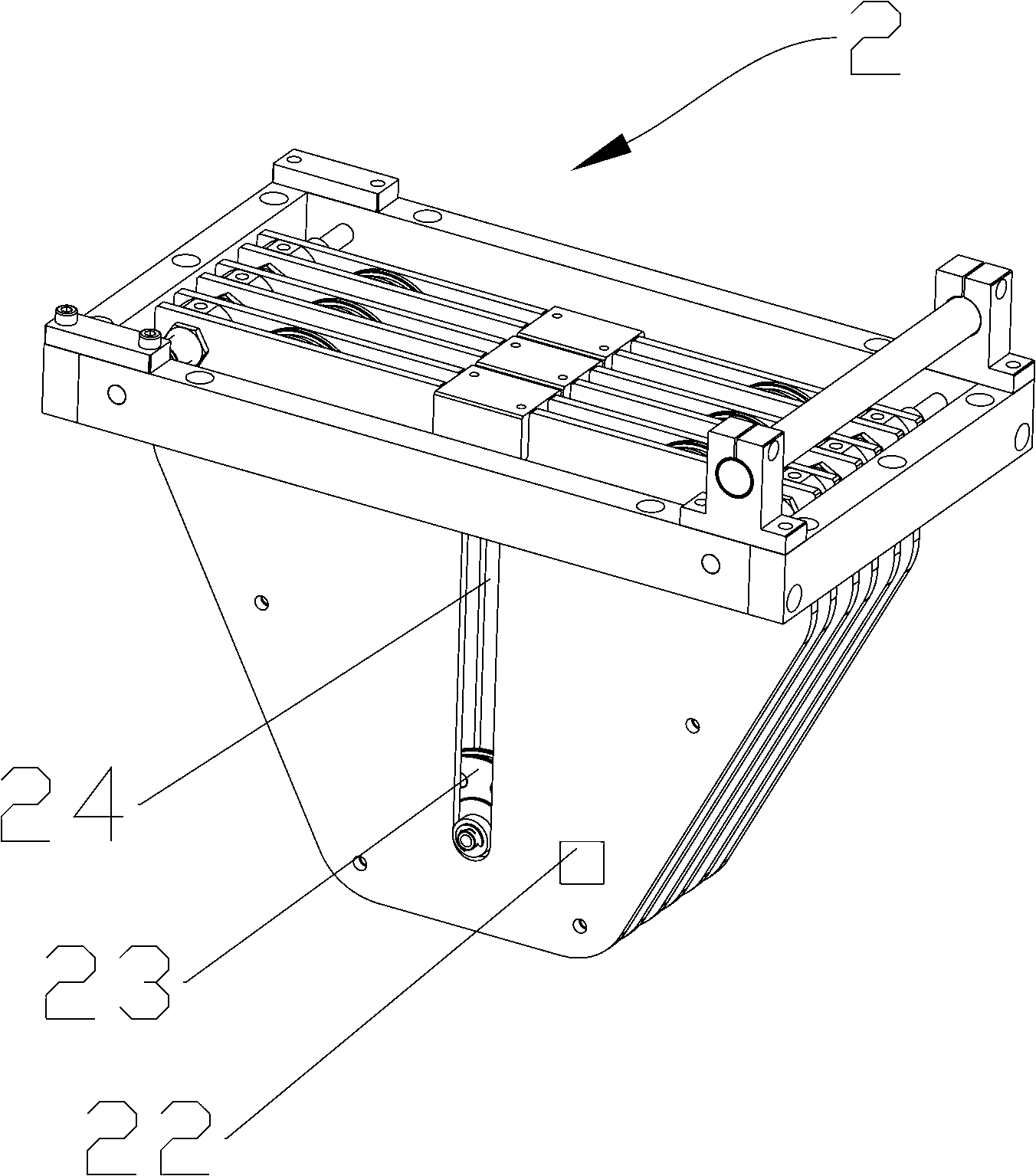

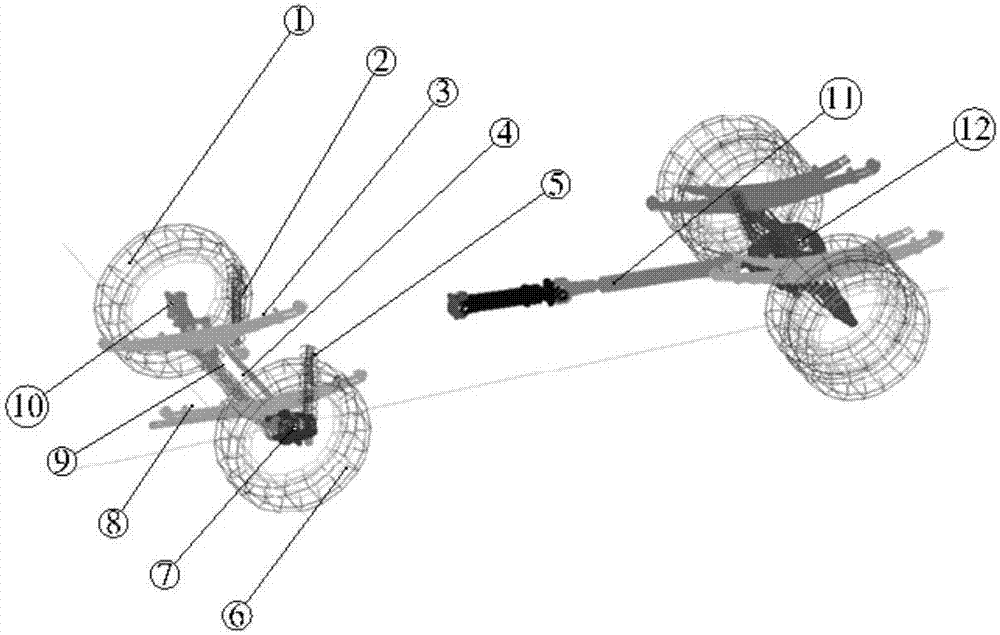

Arrangement structure of double-pull-rod steering system of passenger vehicle

An arrangement structure of a double-pull-rod steering system of a passenger vehicle comprises a steering machine, a steering vertical arm and a middle vertical arm assembly, wherein the middle vertical arm assembly comprises a middle vertical arm support, a vertical arm supporting shaft and a middle vertical arm; the steering machine is fixed into a vehicle frame left longitudinal beam through a steering machine support; the middle vertical arm comprises a vertical arm body, and a vertical arm rotating end and a vertical arm conical hole end which are connected with the two ends of the vertical arm body respectively; the middle vertical arm support is fixed to the vehicle frame left longitudinal beam; a conical hole 1 and a conical hole 2 are formed in the front end and the back end of the vertical arm conical hole end; one end of the steering vertical arm is connected with an output shaft of the steering machine; the other end of the steering vertical arm is connected with one end of a first straight pull rod; the other end of the first straight pull rod is fixed into the conical hole 1; one end of a second straight pull rod is fixed into the conical hole 2; the other end of the second straight pull rod is fixed into a conical hole in a front axle steering upper knuckle arm. The arrangement structure of the double-pull-rod steering system of the passenger vehicle not only occupies a small space and is conducive to arrangement of a whole vehicle, but also is uniform in steering force and light and convenient in steering manipulation.

Owner:DONGFENG COMML VEHICLE CO LTD

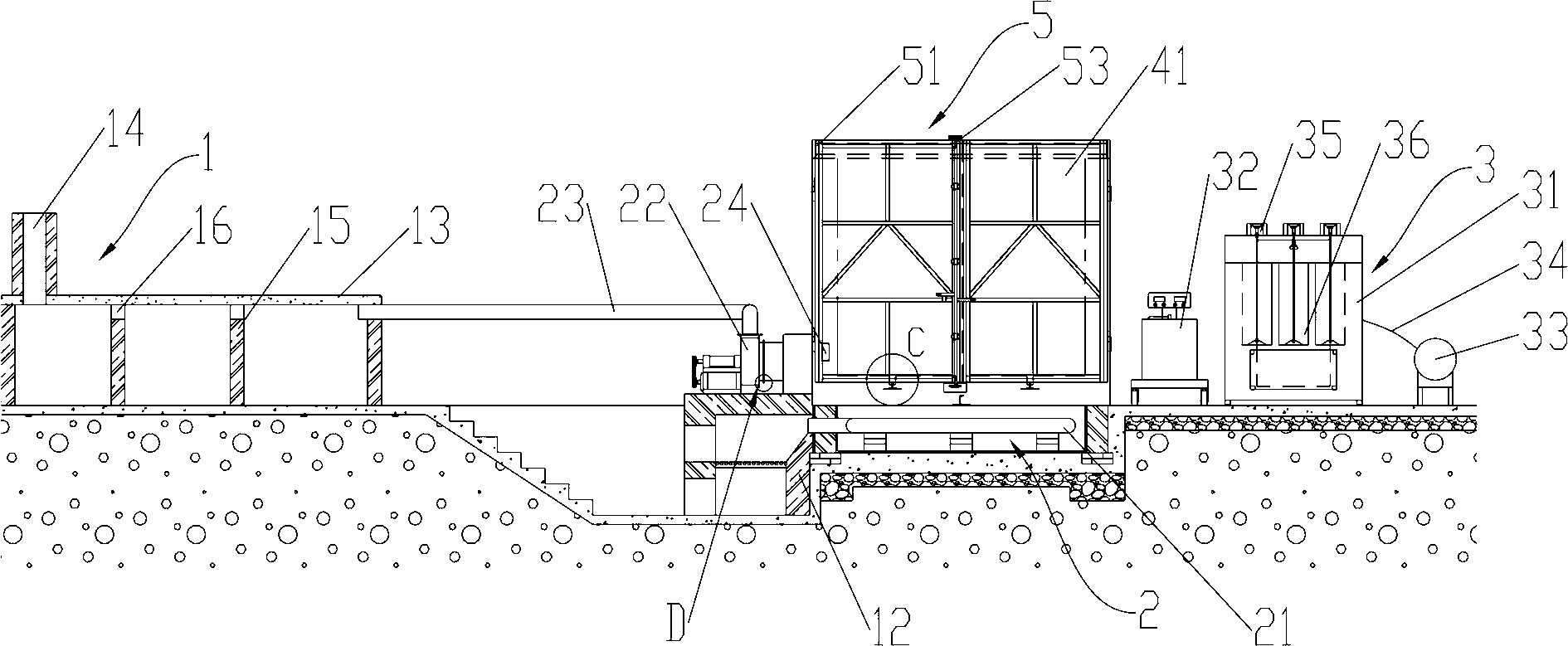

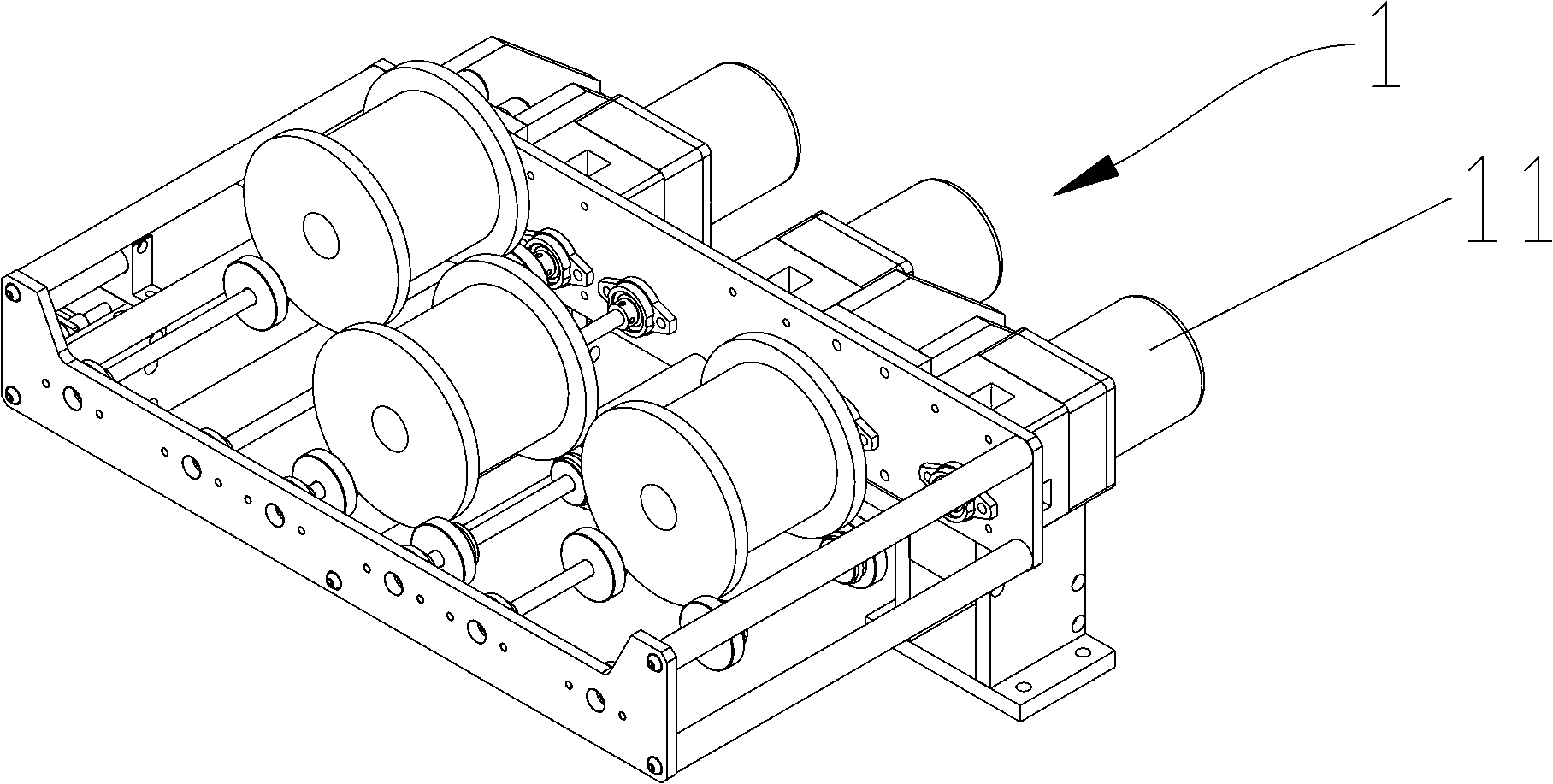

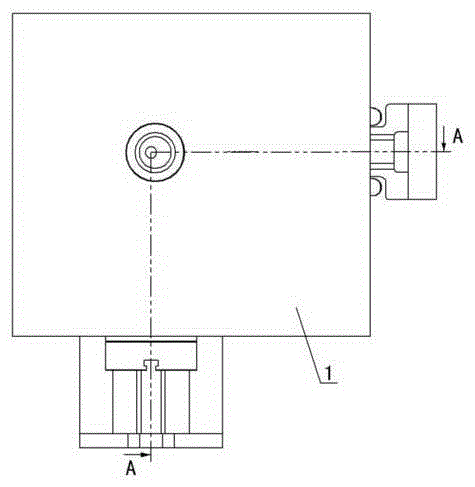

Metal stripped material uncoiling, buffer storage, straight pulling and shearing positioning device

ActiveCN102700991ARealize automated productionPrecision Control OperationArticle deliveryMetal stripsNonferrous metal

The invention relates to a positioning device and discloses a metal stripped material uncoiling, buffer storage, straight pulling and shearing positioning device, which comprises a welding belt uncoiling device, a direction changing roller, a scaling powder soaking device, a scaling powder baking device, a welding belt sorting device, a buffer storage device, an air catching device and a welding belt guide device. The straight stripped nonferrous metal materials can be straightly pulled according to the set length, the stripped nonferrous metal materials can be pulled out according to the set length, after the materials are cut off, the materials can be precisely dragged and guided to the preset positions, and the obvious practical values are realized.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

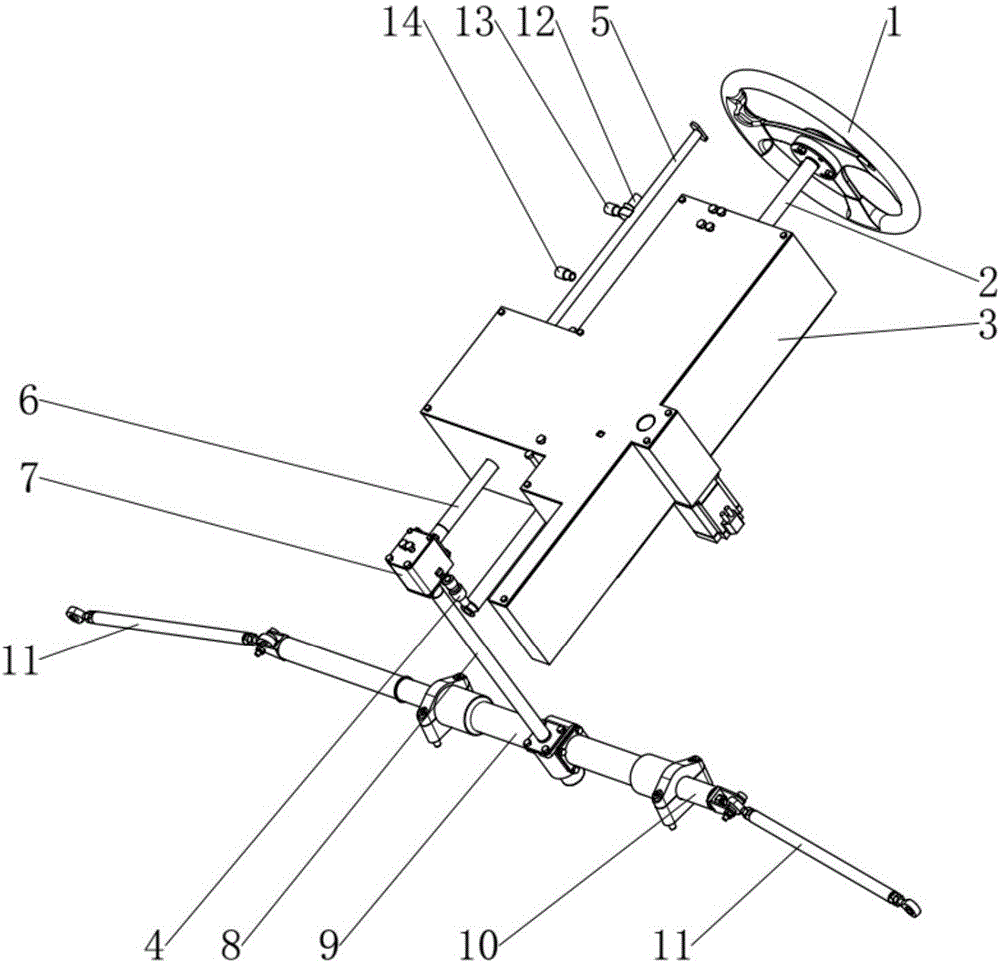

Aero-car control system

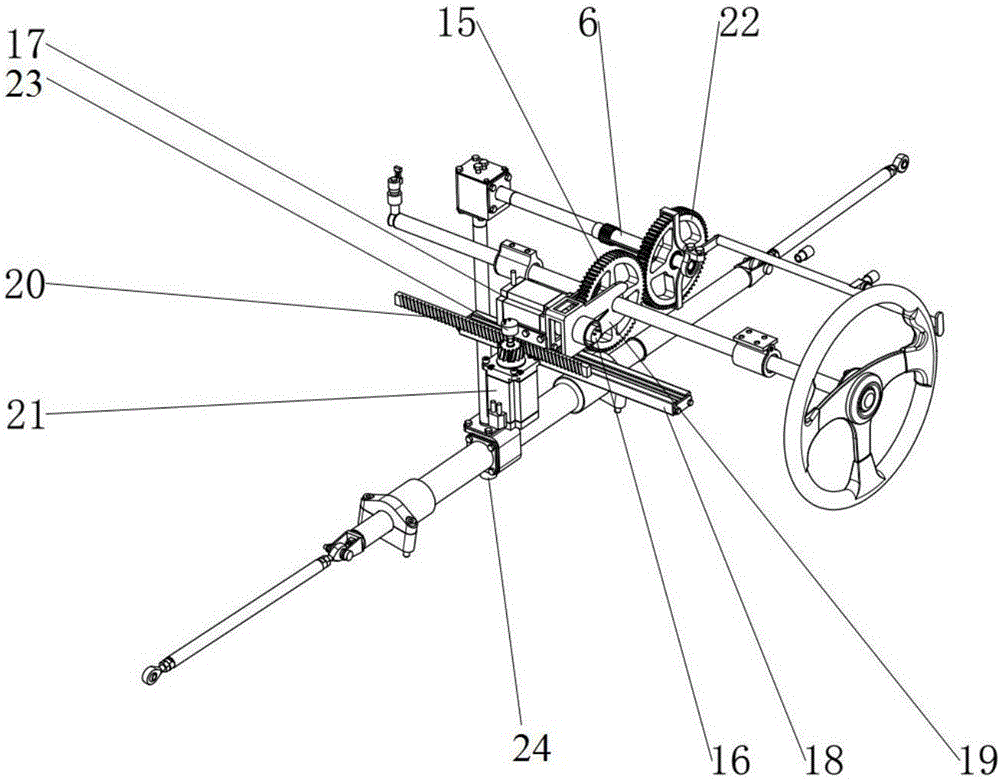

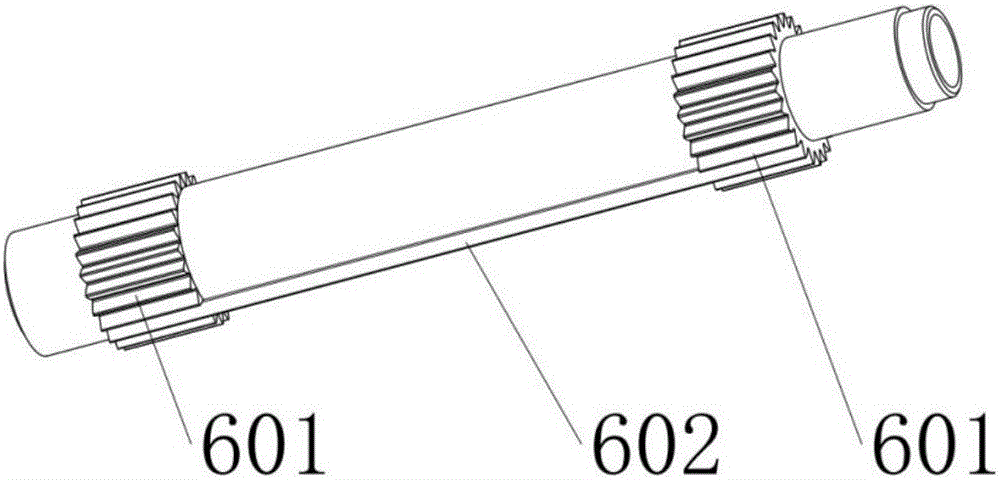

ActiveCN106494167ABig spaceAdapt to layoutSteering linkagesMechanical steering gearsSteering wheelDrive shaft

The invention discloses an aero-car control system and belongs to the technical field of mechanical control. The aero-car control system disclosed by the invention comprises an operating panel, an operating column, a hood, a steering shaft, a bevel gearbox, a steering driving shaft, a steering gear, a steering straight pull rod, a steering horizontal pull rod, a rotating force feedback mechanism, a push-pull force feedback mechanism and a mode switching mechanism. Through the aero-car control system, an aero-car can turn like a car on the ground and have excellent operation performance; the aero-car control system is able to control the attitude in air like using an aircraft operating panel and is flexible and convenient; the aero-car is allowed to realize the land-air mode switching in the take-off and landing processes, the switch of the operation mode is continuous and smooth and the switching efficiency is increased; a steering wheel is smartly integrated with the operating panel of the aircraft; a novel device is designed; a repeat mechanism is simplified; the wire control transmission is used for the wing operation; the structure is reliable; the weight is light; the operation is simple and convenient; and the aero-car control system is suitable for a wing folding mechanism.

Owner:BEIHANG UNIV

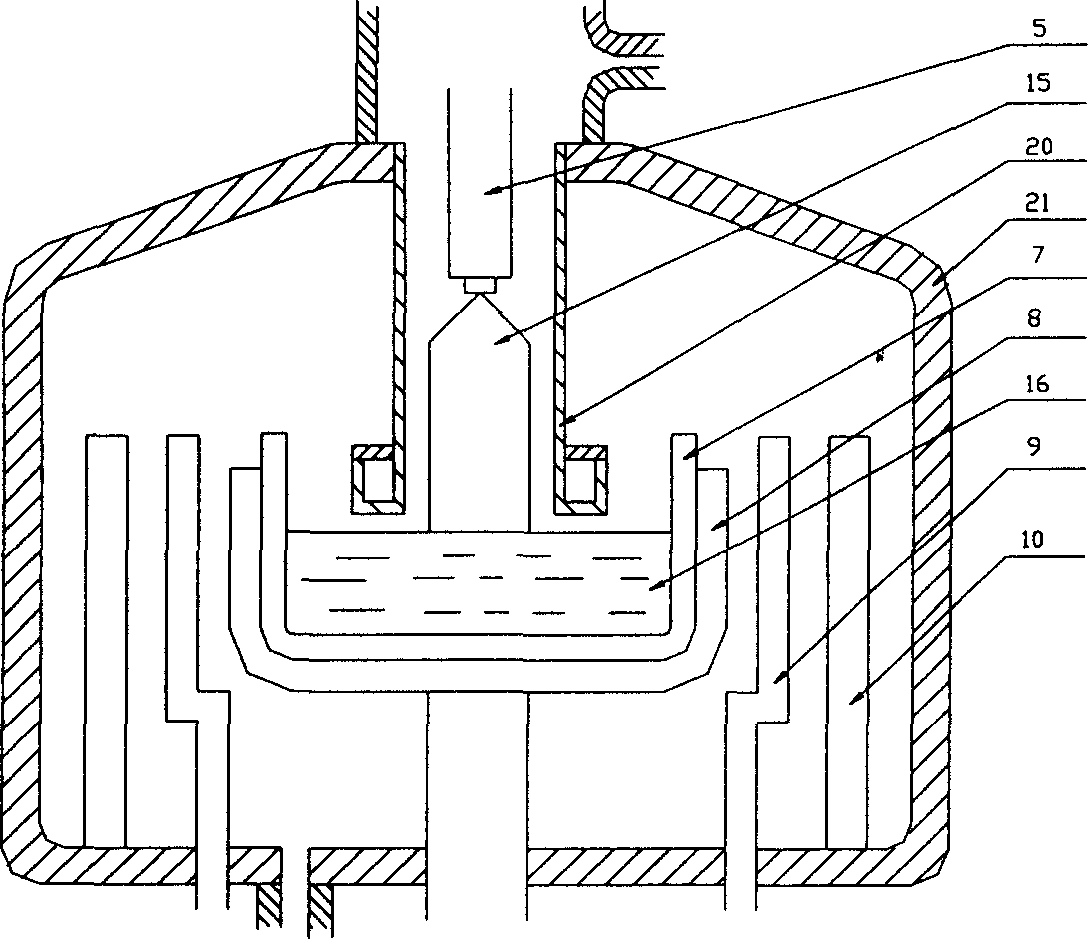

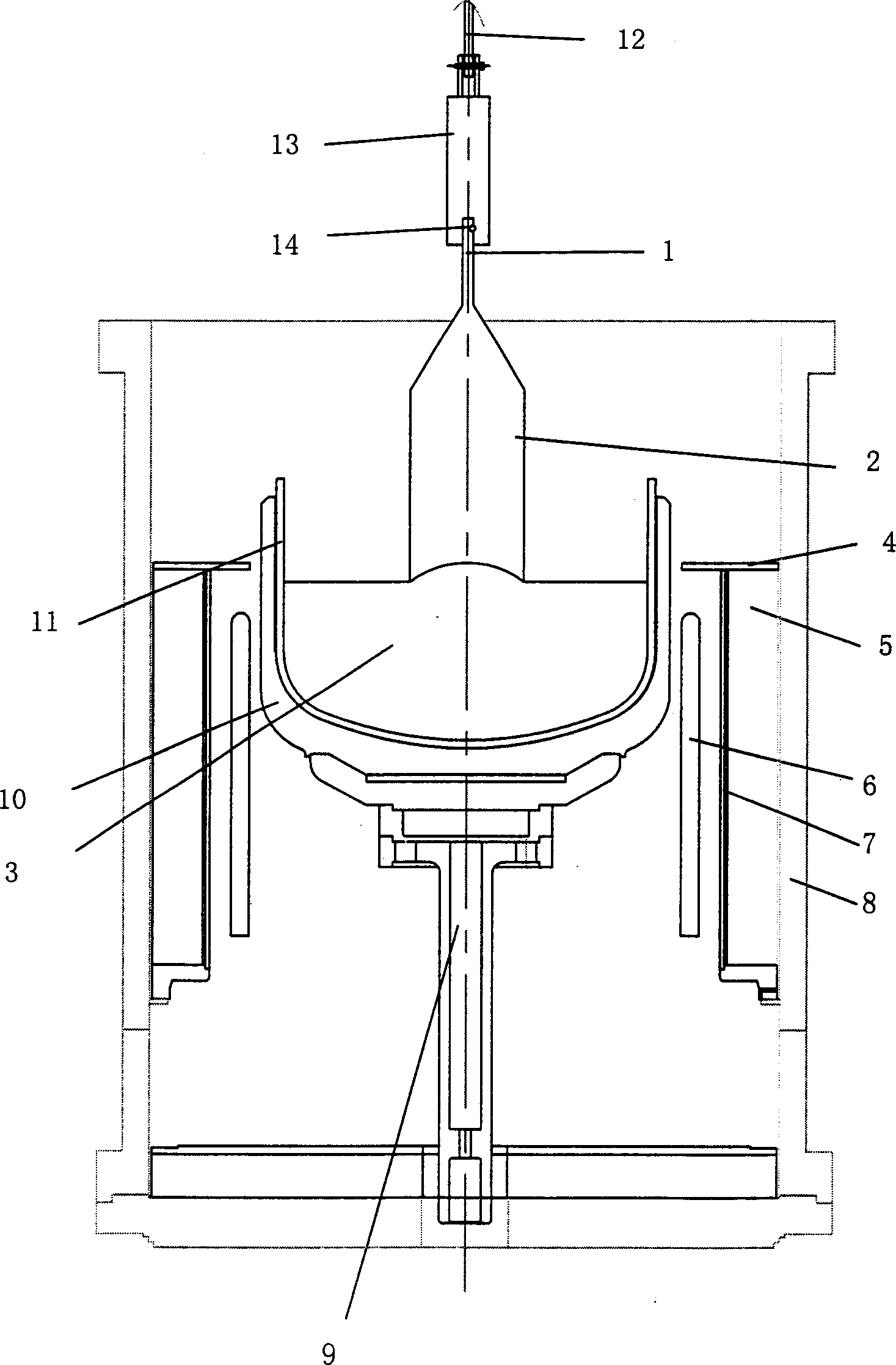

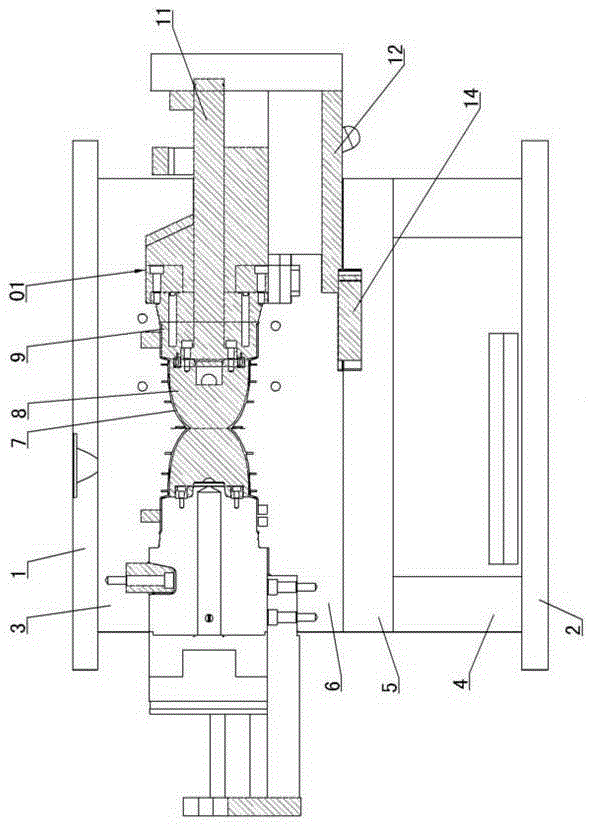

Apparatus for automatically detecting fusion jointing state of crystal and fusion silicon liquid level in vertical pulling type single crystal furnace

InactiveCN101407937APrevent Meltdown AccidentsHigh degree of automationBy pulling from meltPush offEngineering

The invention relates to a straight pulling type single crystal production technology, aiming at providing an automatic detecting device for the fusion state of the single crystal and a silica fused liquid surface in a straight pulling type single crystal furnace. The device comprise a pulley, a sector conductor, a cable rope pipe externally coated with insulation materials, a steel cable, a metal seedholder, a quartz crucible, a graphite crucible, and a crucible push-off pin and the sector conductor of conductive materials; wherein, the steel cable, the pulley, a furnace body and a detecting warning circuit form a loop. The device can automatically detect the fusion state of the crystal and the liquid surface, and judge the fusion time; avoid the fusion accidents of the seedholder resulted from seedholder over-descending due to human behaviors; can monitor the fusion state of the crystal and the liquid surface in real time during the whole process, and warn the separation of the liquid surface in time; reduce labor intensity, improve the automation degree of the straight pulling type single crystal furnace and provide key techniques for the full automatic design of the single crystal furnace.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

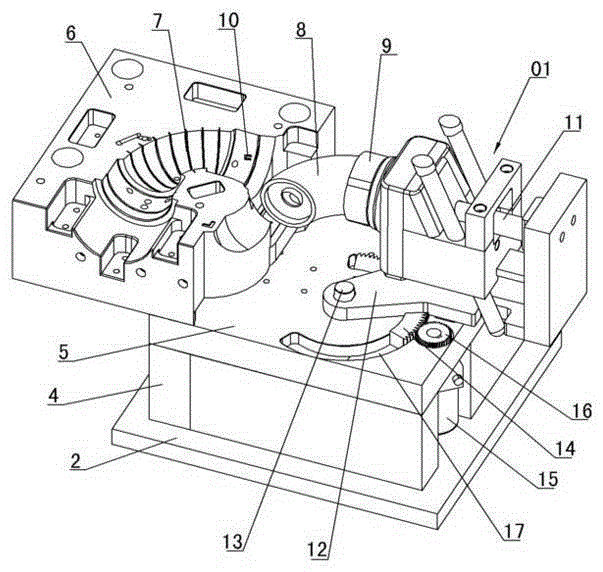

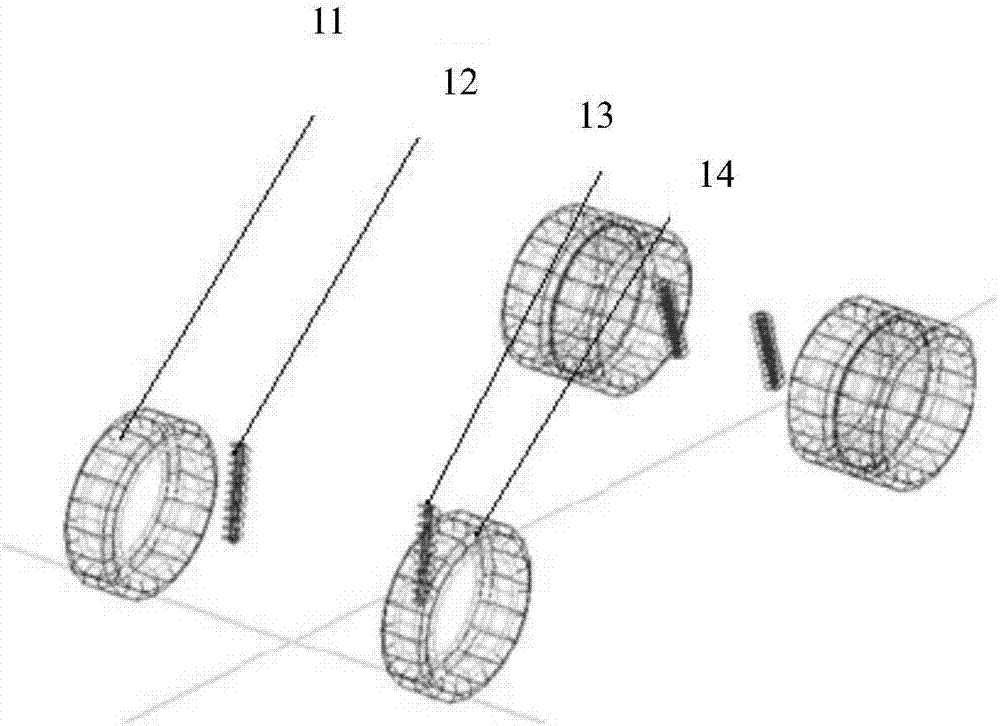

90-degree large bending rotating core pulling pipe fitting mold with inverted part

A 90-degree large bending rotating core pulling pipe fitting mold with an inverted part comprises a fixed mold plate, a movable mold bottom plate and a movable mold plate; a 90-degree bend pipe fitting is arranged between the movable mold plate and the fixed mold plate; the inverted part is arranged on a connector of the 90-degree bend pipe fitting; a 90-degree large bending core and a connector core are arranged in the inner wall; the connector core is driven by a straight pulling mechanism to perform core pulling; an inverted demolding mechanism is arranged on the connector core; the 90-degree large bending core is connected with a linkage rod which is connected with the straight pulling mechanism; a rotating plate is arranged on the movable mold bottom plate; the whole straight pulling mechanism is arranged on the rotating plate; an arc-shaped large bending rack is installed on the bottom face of the rotating plate; a motor is installed on the movable mold bottom plate; a gear on the motor is meshed with the arc-shaped large bending rack; the inverted demolding mechanism comprises a fixing hole formed in the connector core and provided with an opening; a fixing strip is installed in the fixing hole; an I-shaped inclined slide groove is formed in the fixing strip and provided with an inverted insert; the inverted insert is provided with an inverted mold cavity; and the inverted mold cavity is matched with the inverted part.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

Silicon seed crystal for straight drawing monocrystal growth and its process

A silicon seed crystal for growing monocrystalline silicon by straight pull method is composed of an upper part whose shape may be reverse circular table, reverse prismatic table, or reverse cylindrical table, and a lower cylindrical part, and is prepared by cutting the monocrystalline silicon. When the weight of silicon crystal reaches 500 kg, and seed crystal can not be broken.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

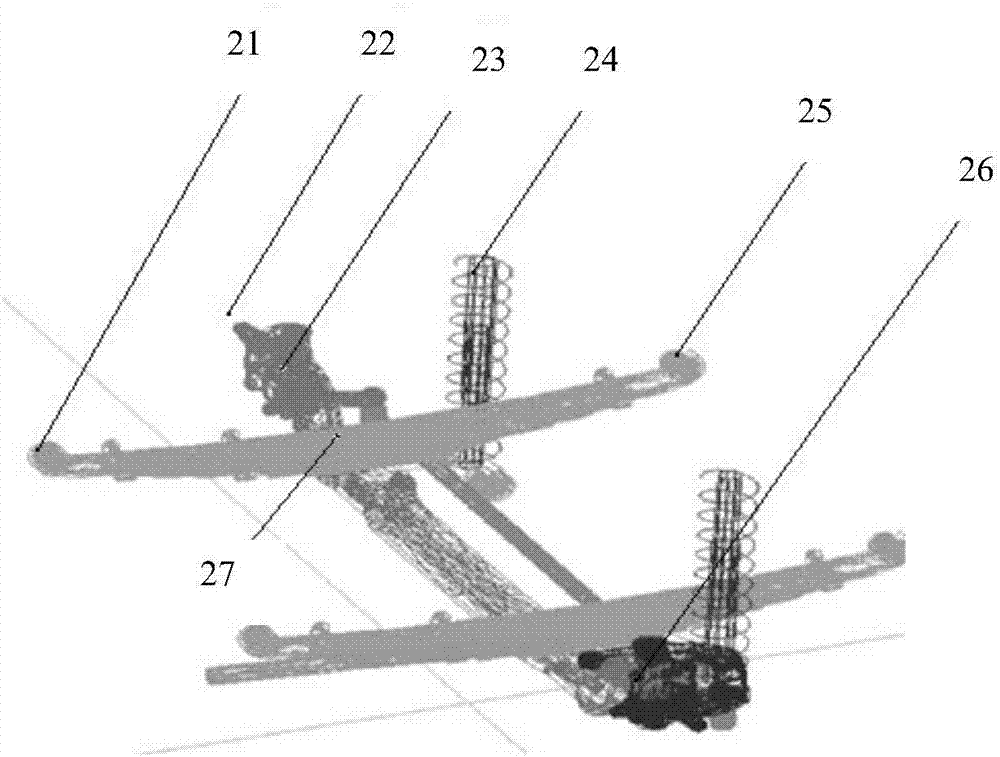

Commercial vehicle steering axle, vehicle frame and connecting piece dynamic simulation device

The invention provides a commercial vehicle steering axle, vehicle frame and connecting piece dynamic simulation device. The dynamic simulation device comprises a front axle model and a rear axle model, and also comprises a tyre and shock absorber dynamic model, a front axle and connecting piece kinematic pair model, a front axle tyre and road surface connection model and a front axle power assembly and steering straight pull bar model; the tyre and shock absorber dynamic model comprises a right front tyre, a right front shock absorber, a left front shock absorber and a left front tyre, the right front tyre is connected with the right front shock absorber, and the left front shock absorber is connected with the left front tyre; the tyre and shock absorber dynamic model is used for simulating the dynamic relationship between the tyre and the shock absorber; the front axle and connecting piece kinematic pair model is used for simulating the connection and dynamic effect of the front axle and connecting piece kinematic pair; the front axle tyre and road surface connection model is used for simulating the driving and friction effect between the front axle tyre and the road surface; and the front axle power assembly and steering straight pull bar model is used for simulating the dynamic relationship between the front axle power assembly and the steering straight pull bar.

Owner:CHINA AUTOMOTIVE ENG RES INST

Method for removing impurities in single crystal rod straight pulling process

InactiveCN101781791AHigh purityQuality improvementPolycrystalline material growthBy pulling from meltStraight pullSeed crystal

The invention relates to a method for removing impurities in single crystal rod straight pulling process. The method includes that polycrystalline silicon material is placed into a quartz crucible, gradual warming is carried out until the temperature is equal to or more than the melting point of silicone, and the polycrystalline silicon material starts to be melted; when little polycrystalline silicon material is not melted, temperature in the crucible is reduced to intermediate temperature, so that the melting of residual polycrystalline silicon material is slowed or the residual polycrystalline silicon material can not be melted, then all impurities which are floating on the surface of silicon solution and have melting point higher than silicon can be gradually absorbed on the residual unmelted polycrystalline silicon material, and then seed crystal is inserted and the residual polycrystalline silicon material absorbed with impurities is slung. Compared with the original technology, the method of the invention can reduce 1-2 hours for high temperature volatilization, and all impurities having melting point higher than silicon are not melted into silicon solution, thus greatly improving purity and quality of pulled single crystal rod.

Owner:ZHEJIANG XINGYU ENERGY TECH

Low oxygen control method in czochralski silicon monocrystal

The invention discloses a hypoxia controlling method of straight pulling monocrystalline, which is characterized by the following: initial magnetic density is 300-2500GS; terminal magnetic density is 1-10GS / min; running speed of crucible is 0. 1-10rpm; running speed of crystal is 10-30rpm; pulling rate of crystal is 0. 5-3mm / min; flow rate of argon gas is 2-7m3 / hr; furnace pressure is 1- 4KPa. It is effective to make oxygen content of the whole length of single crystal (charge amount of crucible: 15kg-60kg, diameter of single crystal: ªÁ2íÕ-ªÁ6) in one of three target zones (5. 5í‡1017a / cm3-7. 0í‡1017a / cm3, 5. 0í‡1017a / cm3-6. 5í‡1017a / cm3, 4. 0í‡1017a / cm3-5. 5í‡1017 a / cm3), wherein the oxygen content deviation of the whole length of single crystal is í‚0. 5í‡1017a / cm3, <heterogeneity of radial oxygen content íœ5%, yield of single crystalí¦60%.

Owner:JINGHUA ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com