Patents

Literature

161 results about "Finger force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

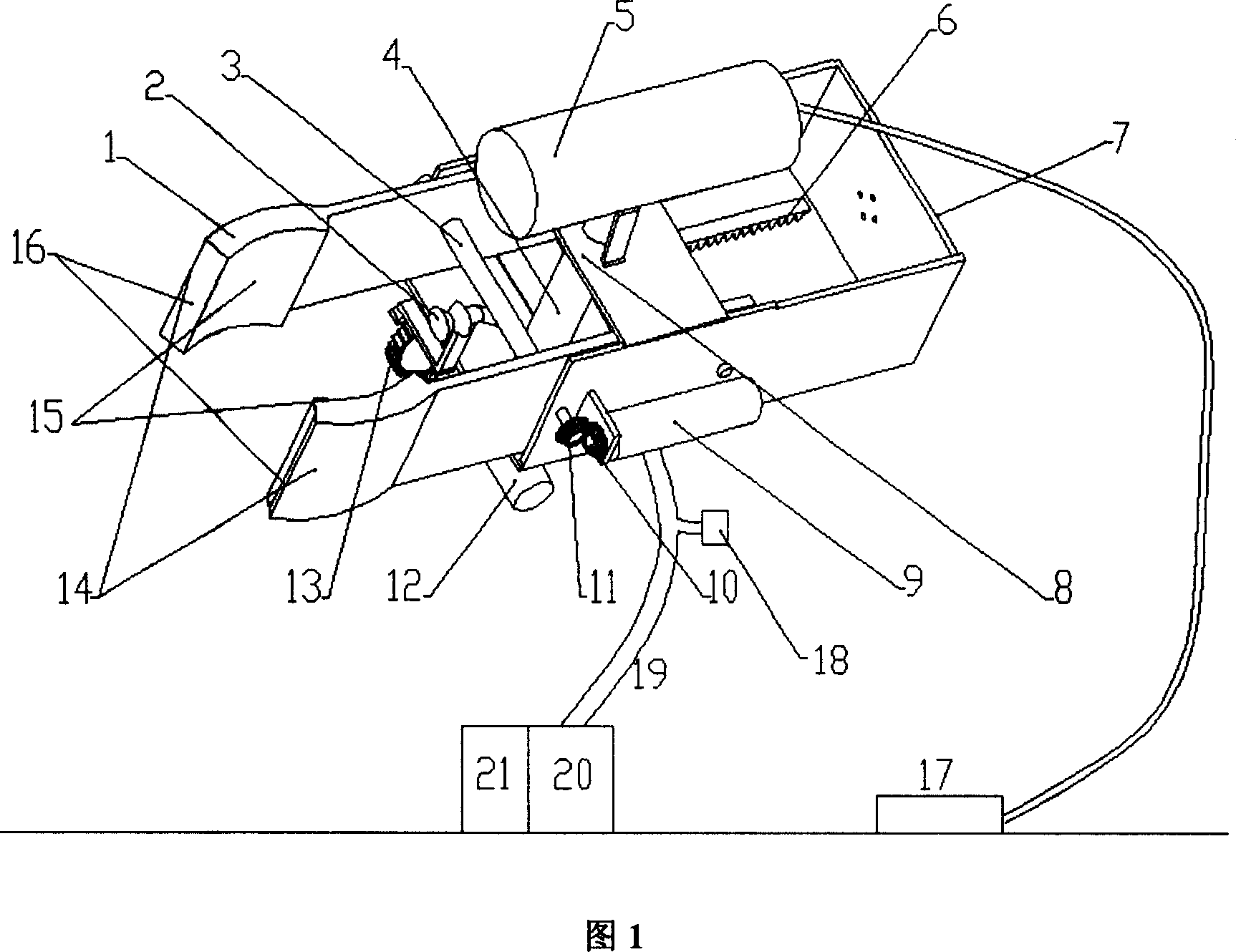

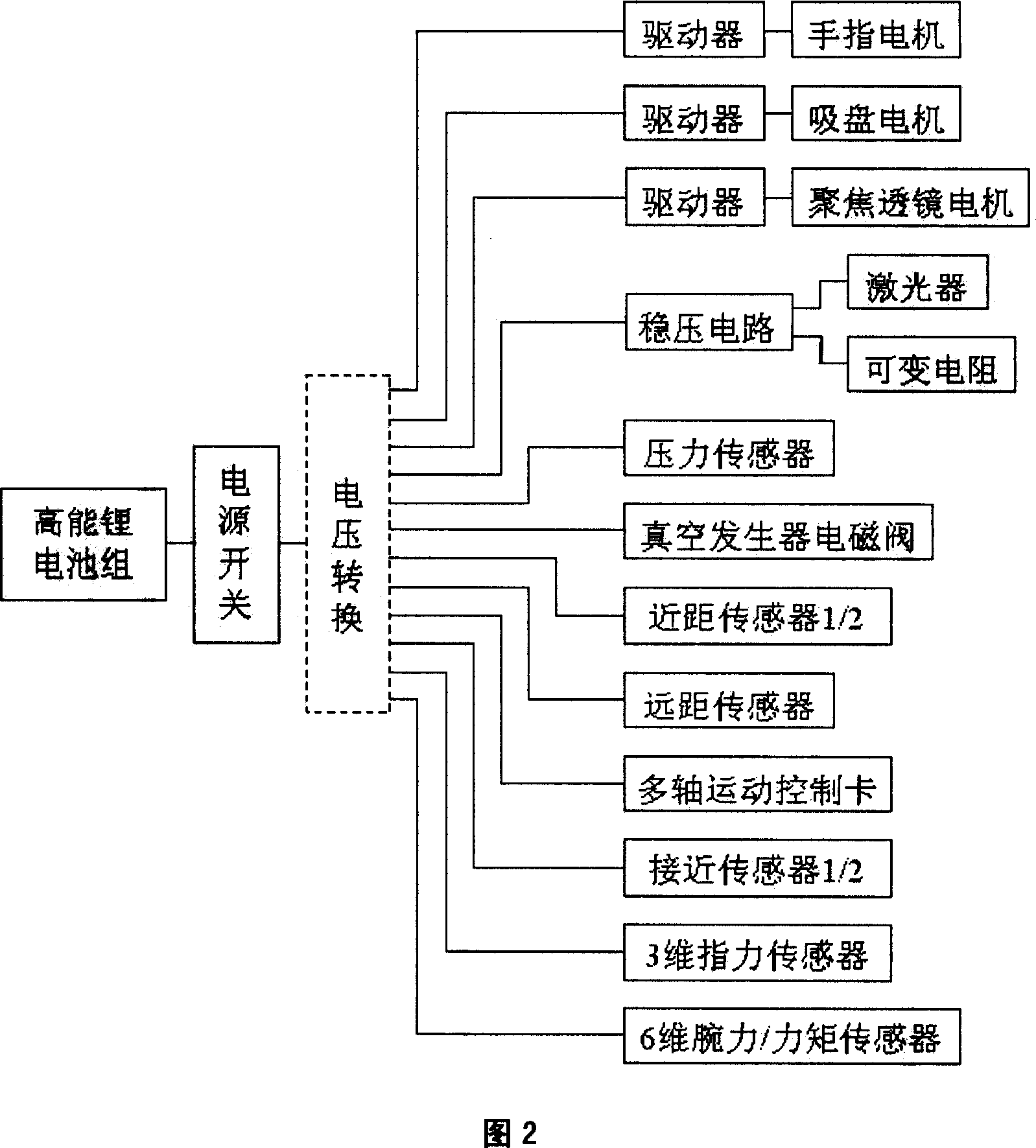

Terminal executor of fruit and vegetable picking robot

InactiveCN101019484ARealize intelligent pickingGuaranteed qualityProgramme-controlled manipulatorGripping headsProximity sensorHigh energy

The terminal executor of fruit and vegetable picking robot consists of an executing device, a sensing system and a power system. The executing device consists of a vacuum chuck mechanism, a holding finger mechanism and a cutting laser mechanism; the sensing system consists of a servo motor coder, a near distance sensor, a long distance approach sensor, a finger force sensor, a wrist force sensor and a pressure sensor installed in different parts of the executing device; and the power system powers the devices and elements in the terminal executor with high energy lithium battery and through voltage conversion. By means of the information sensing of the sensors, the present invention can adsorb, grab and separate to realize the intelligent picking of fruits in high quality.

Owner:JIANGSU UNIV

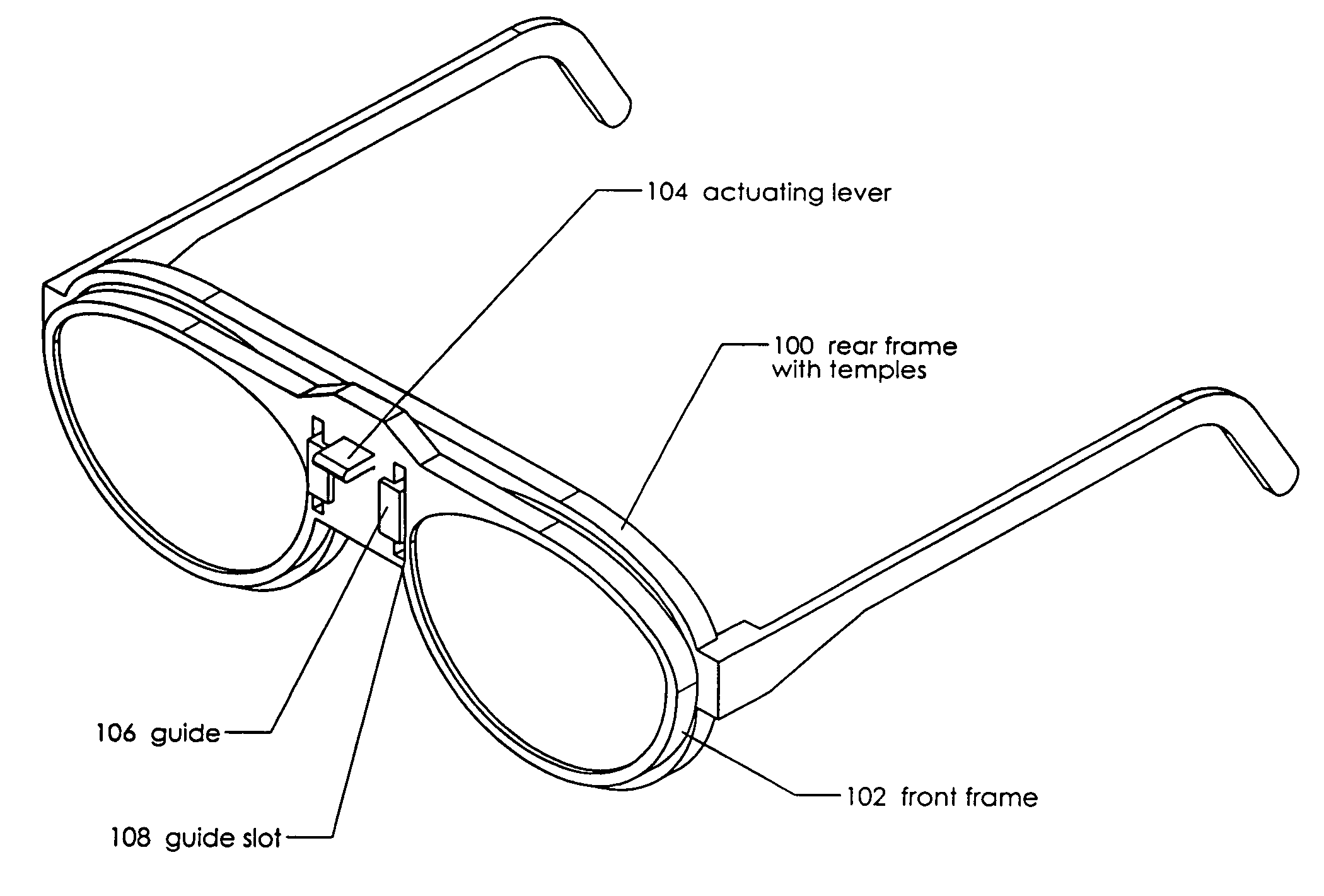

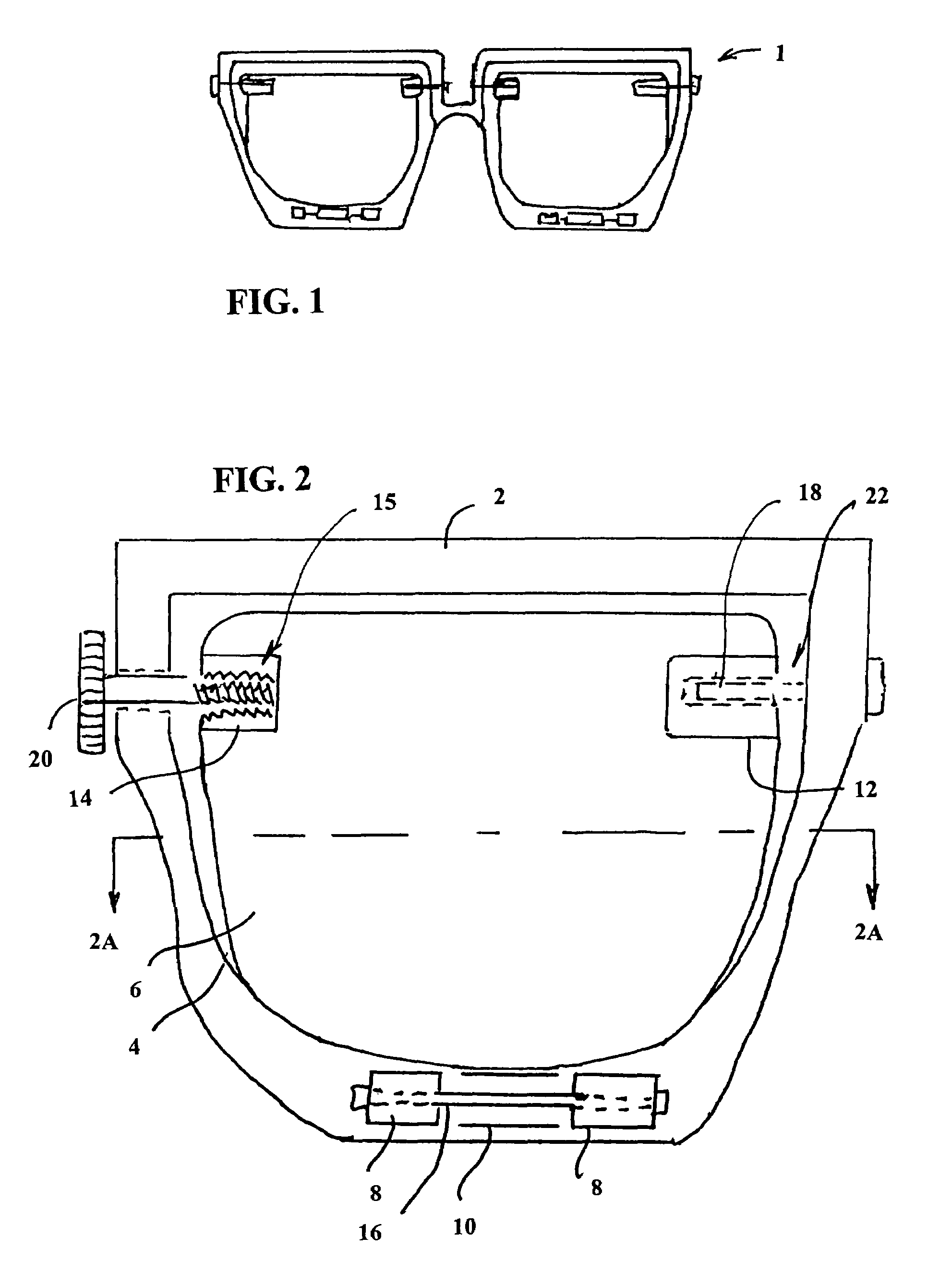

Adjustable focus lenses

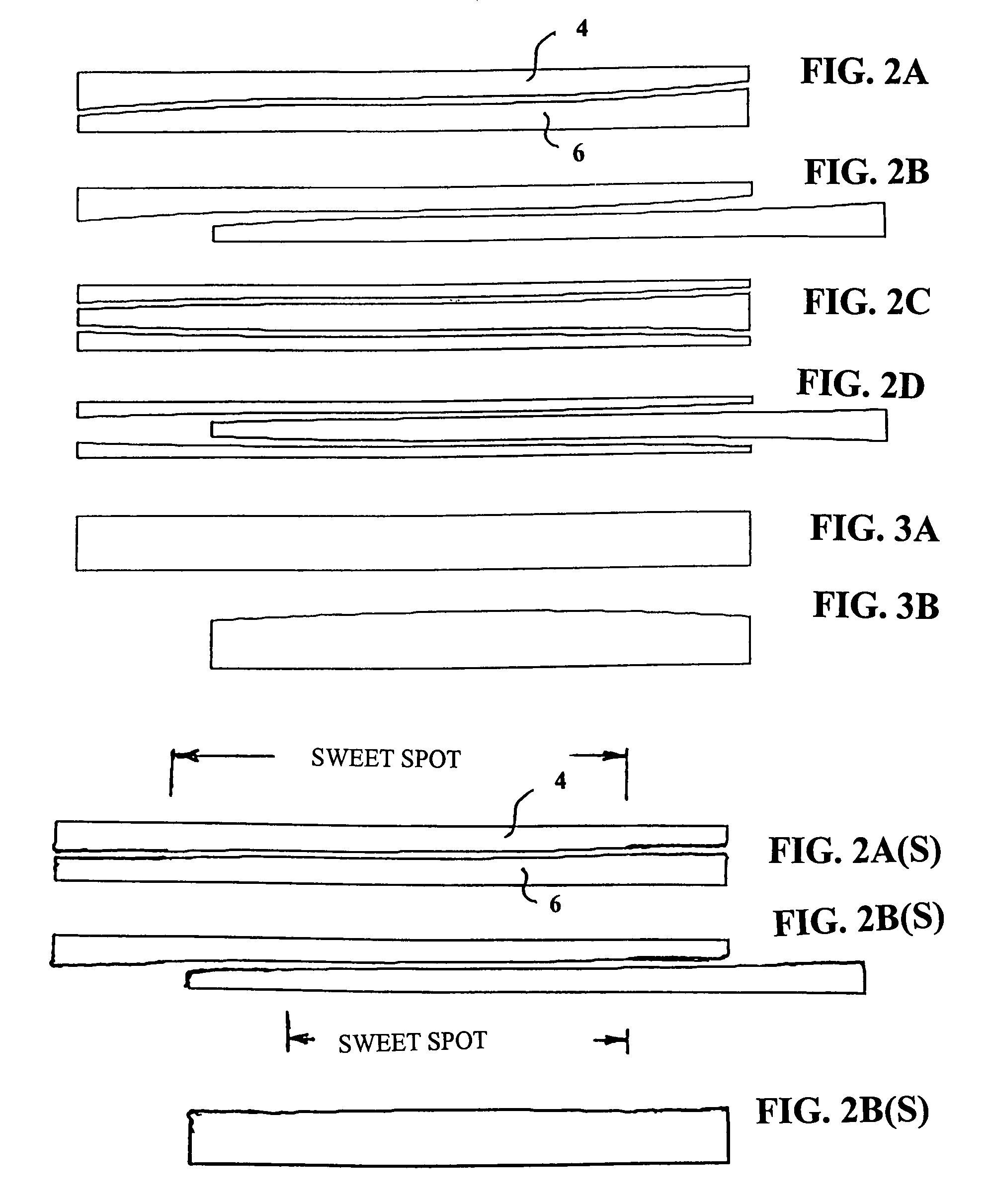

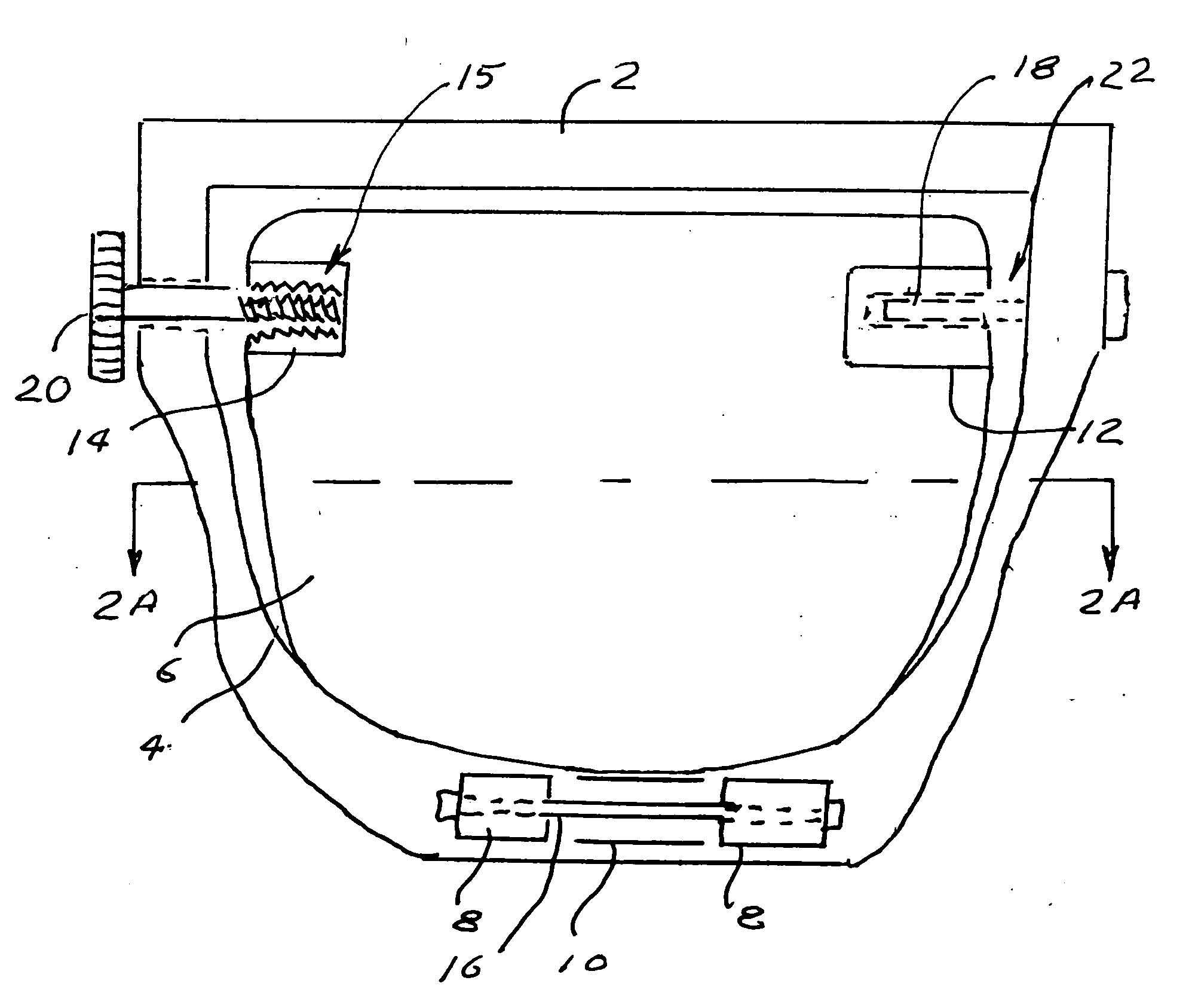

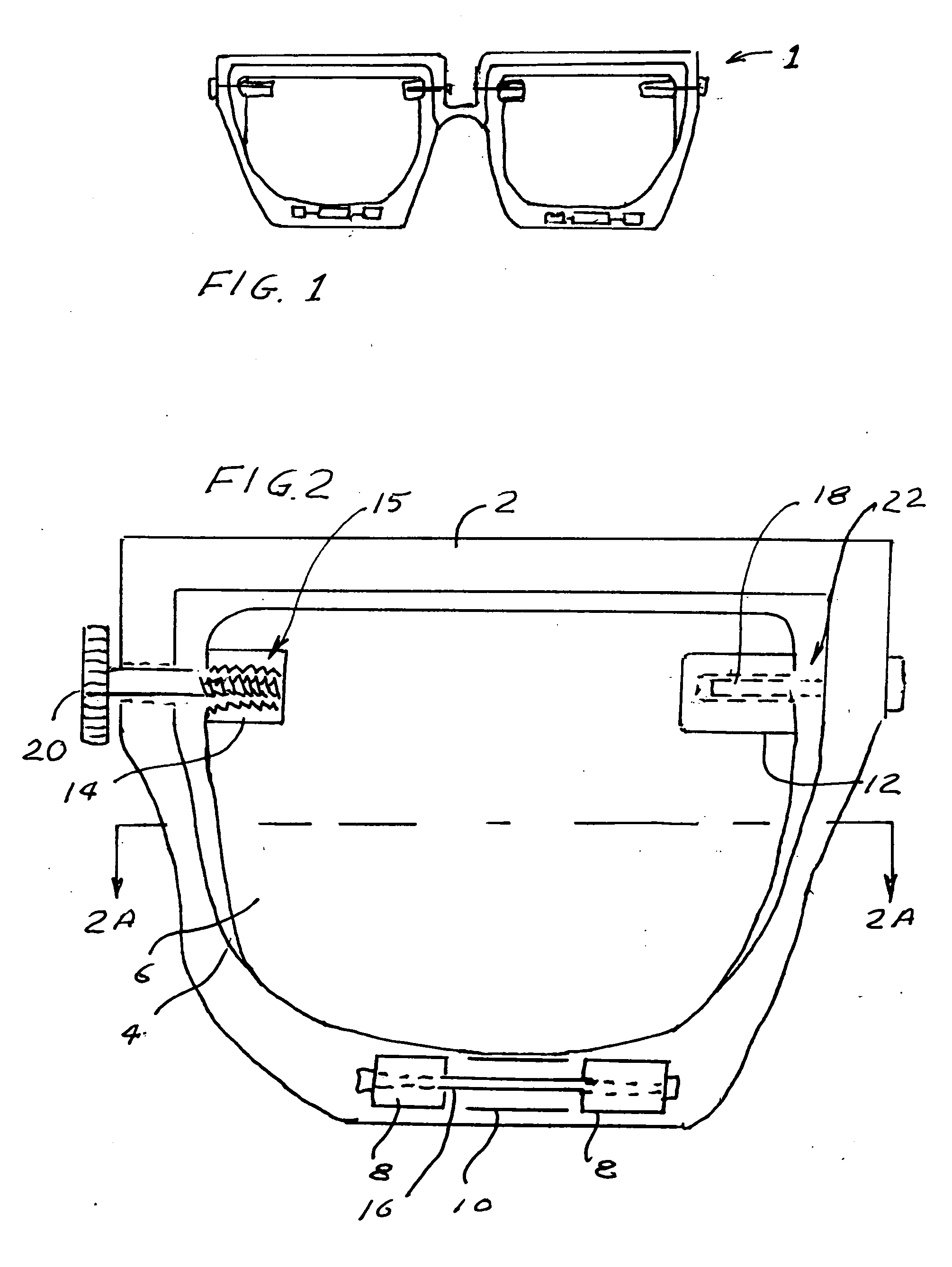

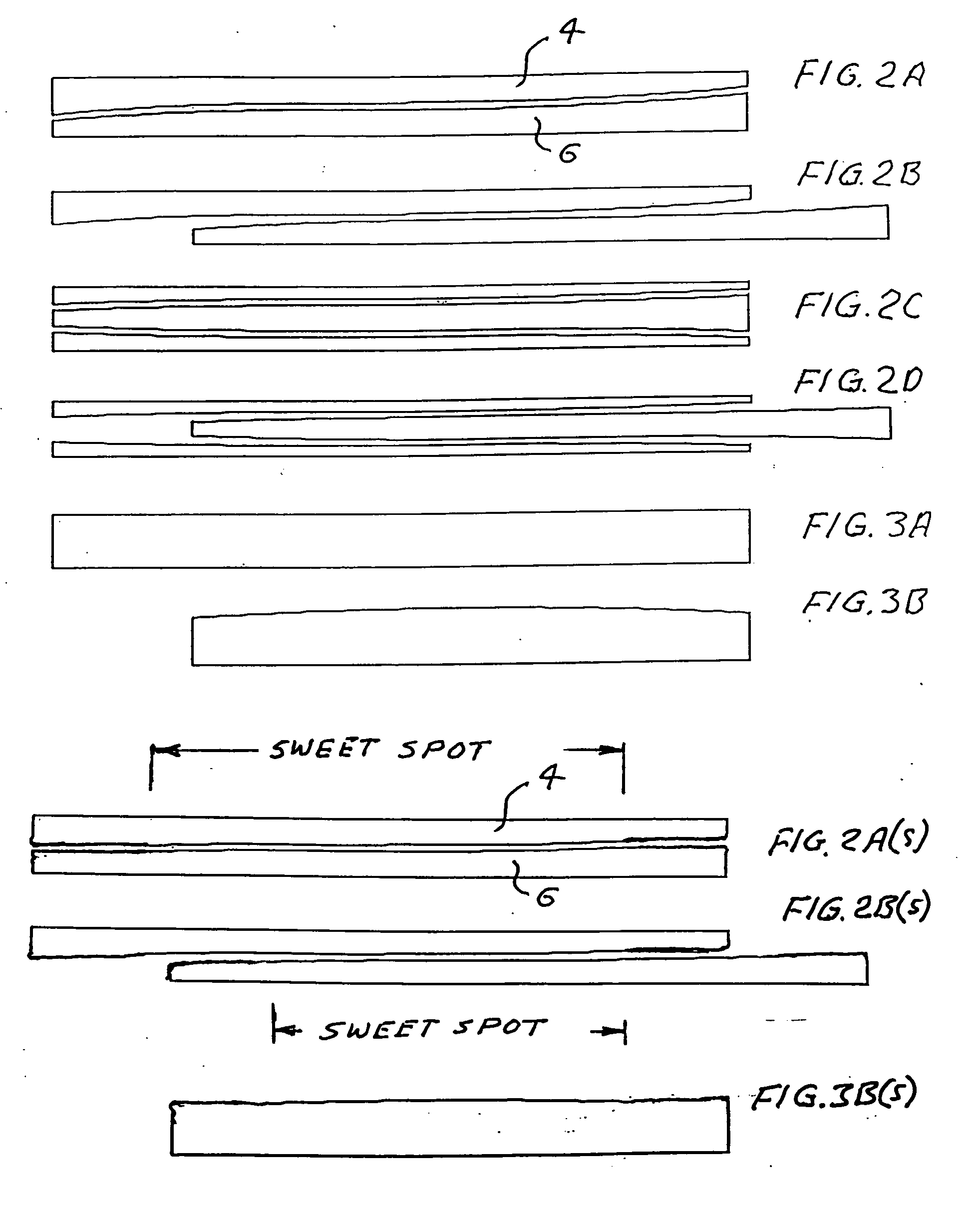

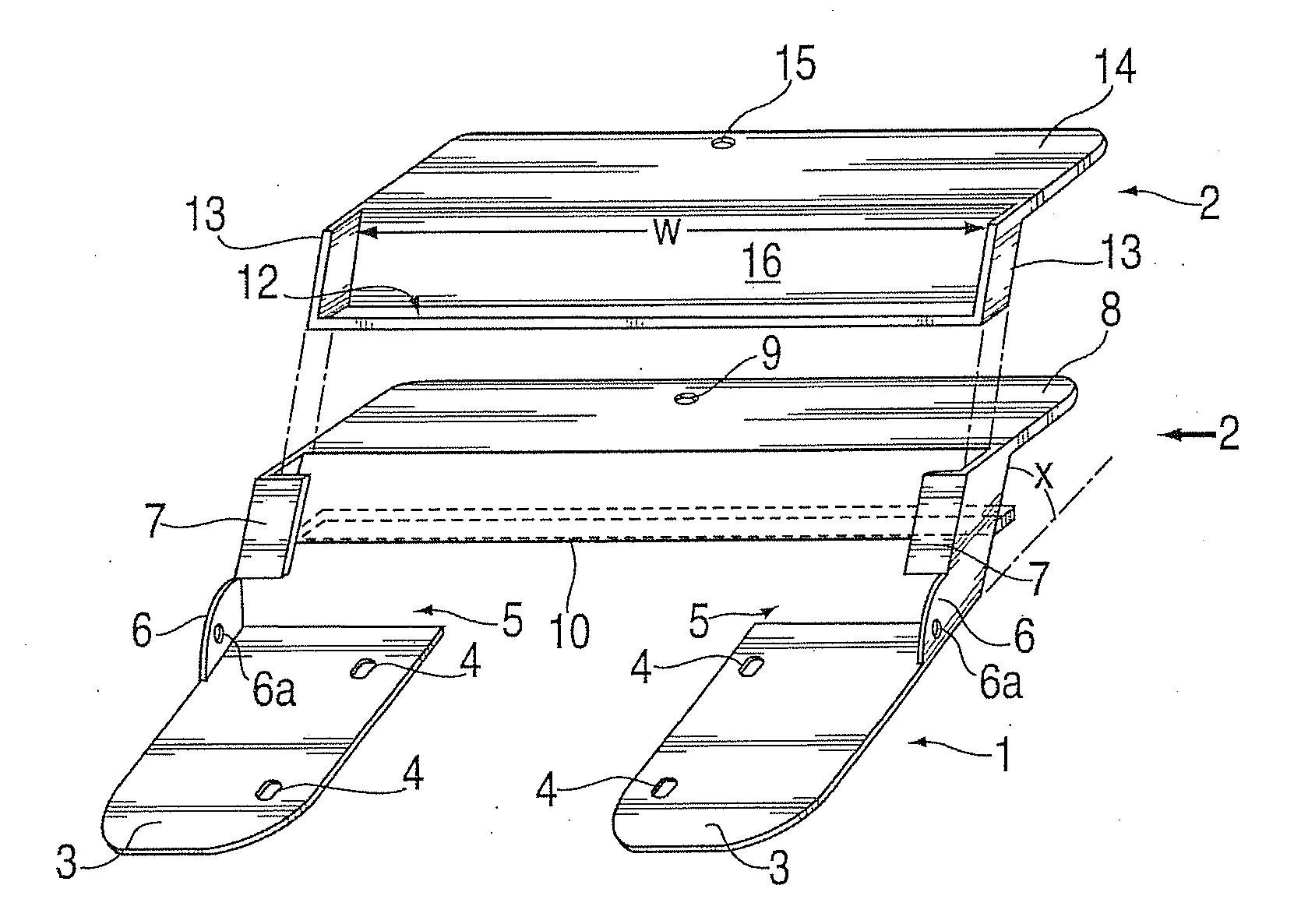

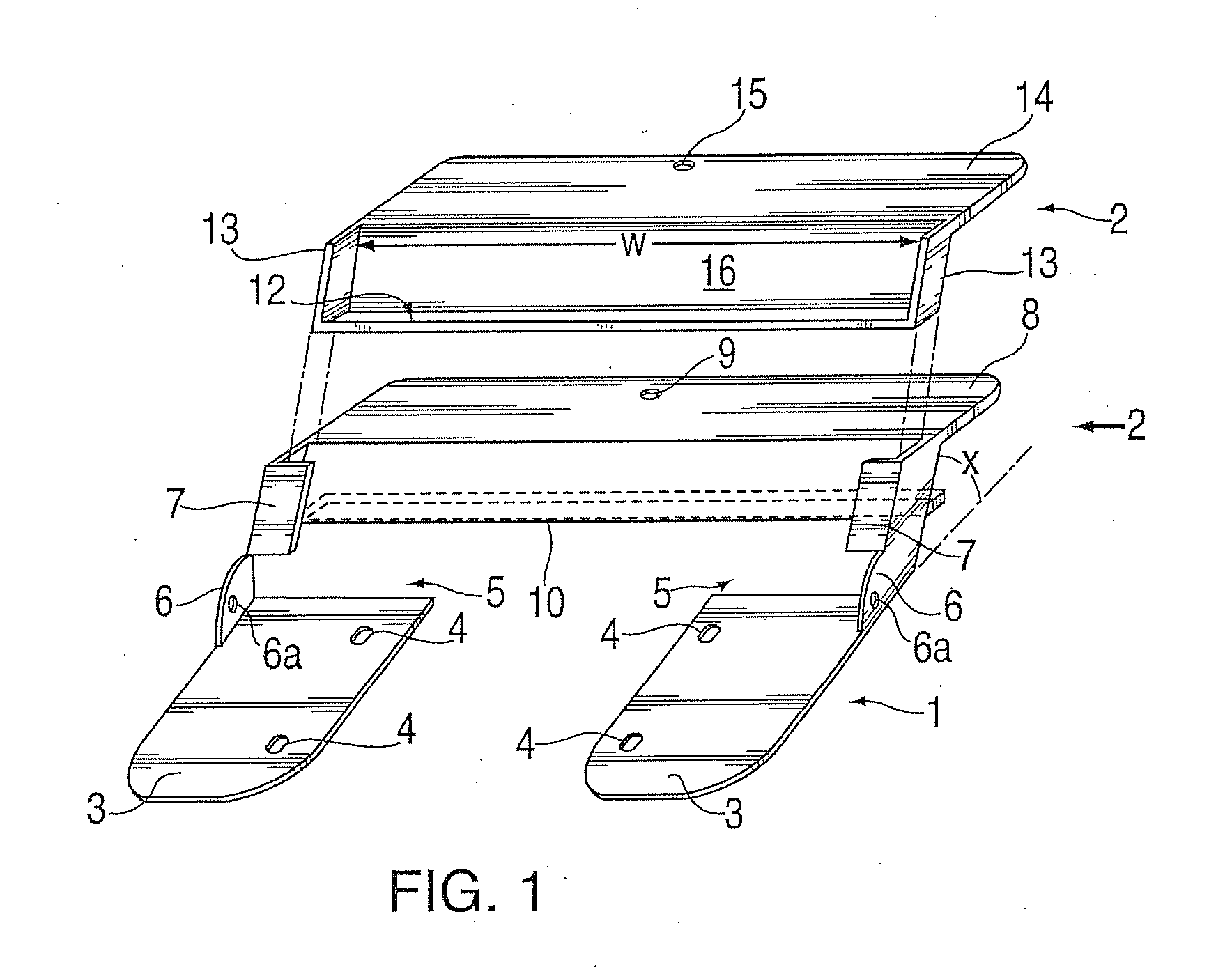

A lens unit with two lens elements each having special surfaces such that an adjustment of the position of one of the two lens elements relative to the other in a direction generally perpendicular to a viewing direction changes the focusing power of the lens unit. In preferred embodiments two lens units are mounted in a frame to provide eyeglasses with adjustable focus. Several frame designs are described. In preferred embodiments two lens units, each lens unit having two lens elements are mounted in a frame to provide eyeglasses with adjustable focus. Several designs are described. Some designs provide for movement side to side movement of the lens elements relative to each other. In other designs the relative motion is up and down. A simple technique is a thumbscrew adjustment that is operated by the wearer. Another design is based on finger force against a friction force. In some preferred embodiments separate frames holding the lens elements pivot about pivot points on the earpiece of a support frame. In other designs two rear lens elements are mounted in a support frame and the front lens elements are mounted in a separate frame that pivots about a point on the earpiece of the support frame. Another design includes a torsion bar assures that the movements of each lens element in one of the lens units is the same as the movements of the lens elements in the other lens unit. Techniques for automatic focusing of the lenses are also disclosed. Techniques for automatic focusing of the lenses are also disclosed.

Owner:QUEXTA

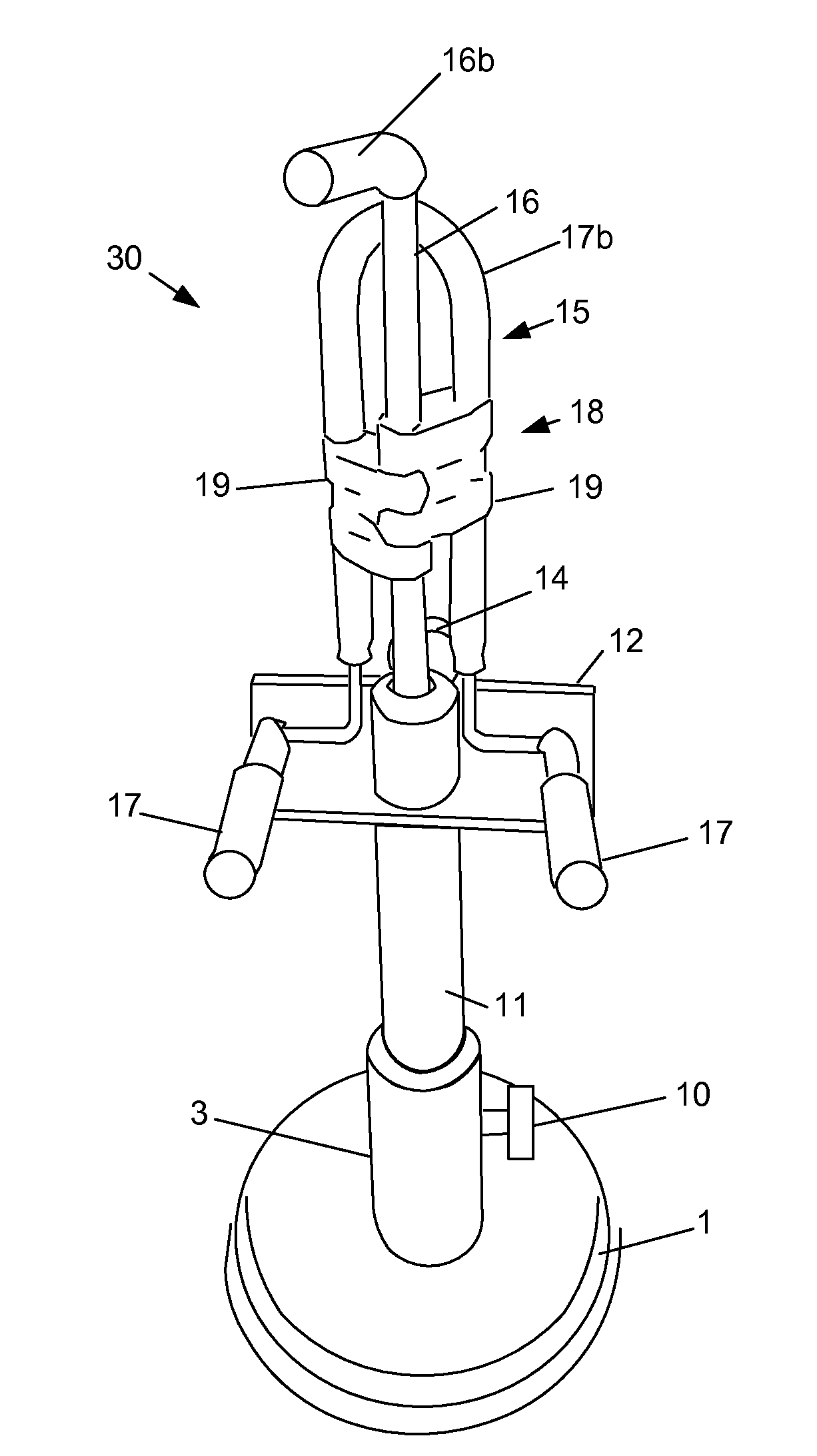

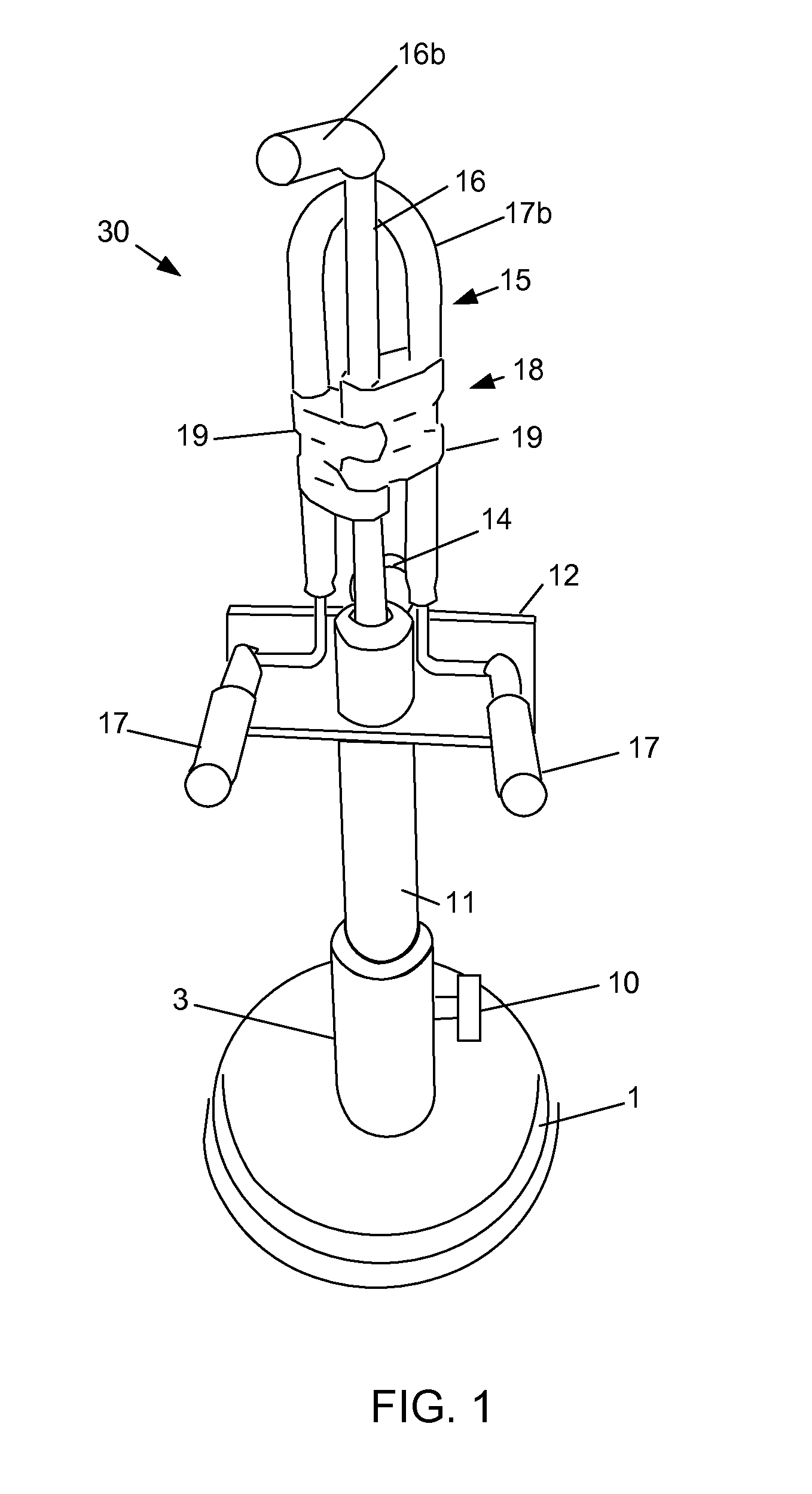

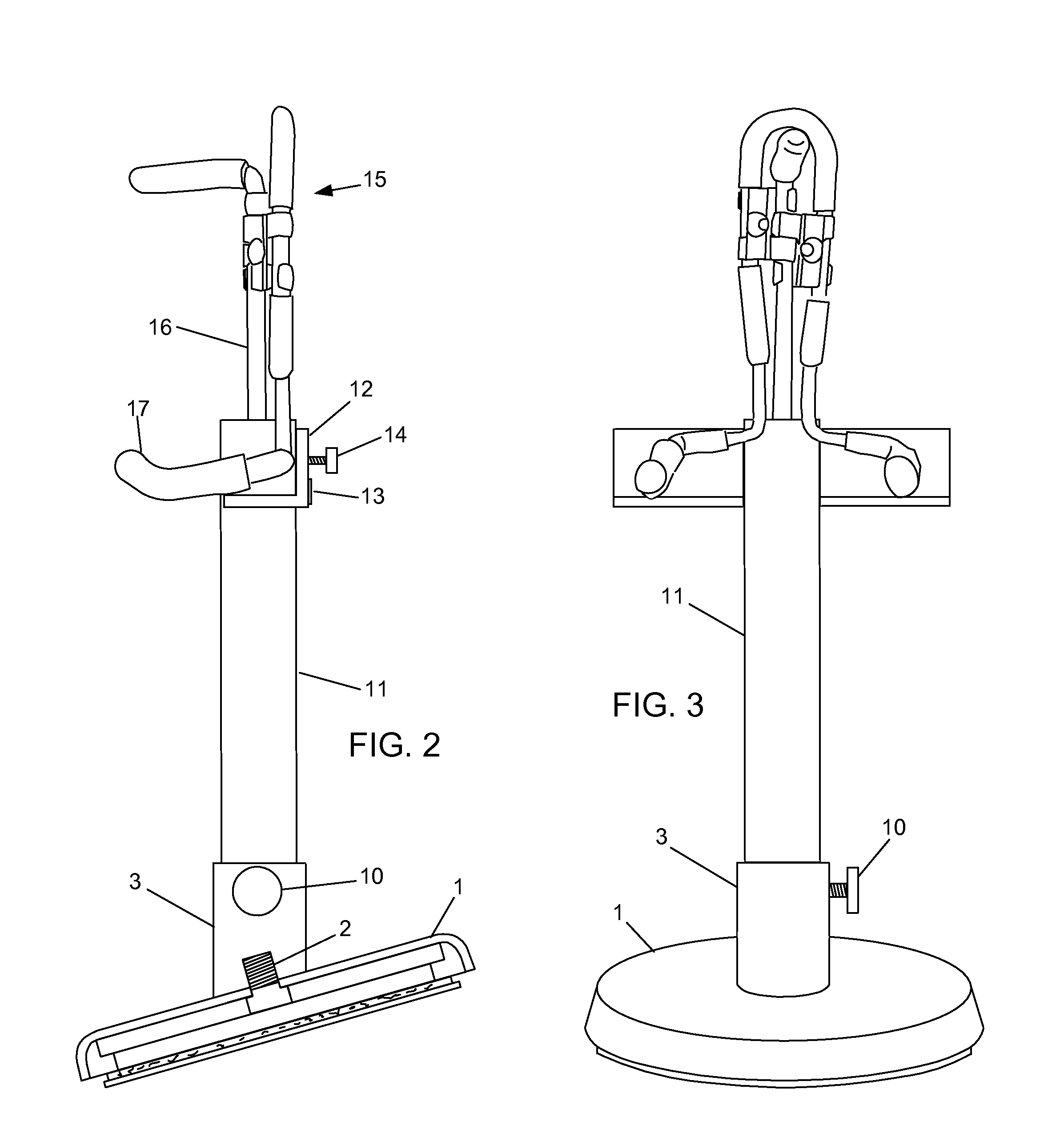

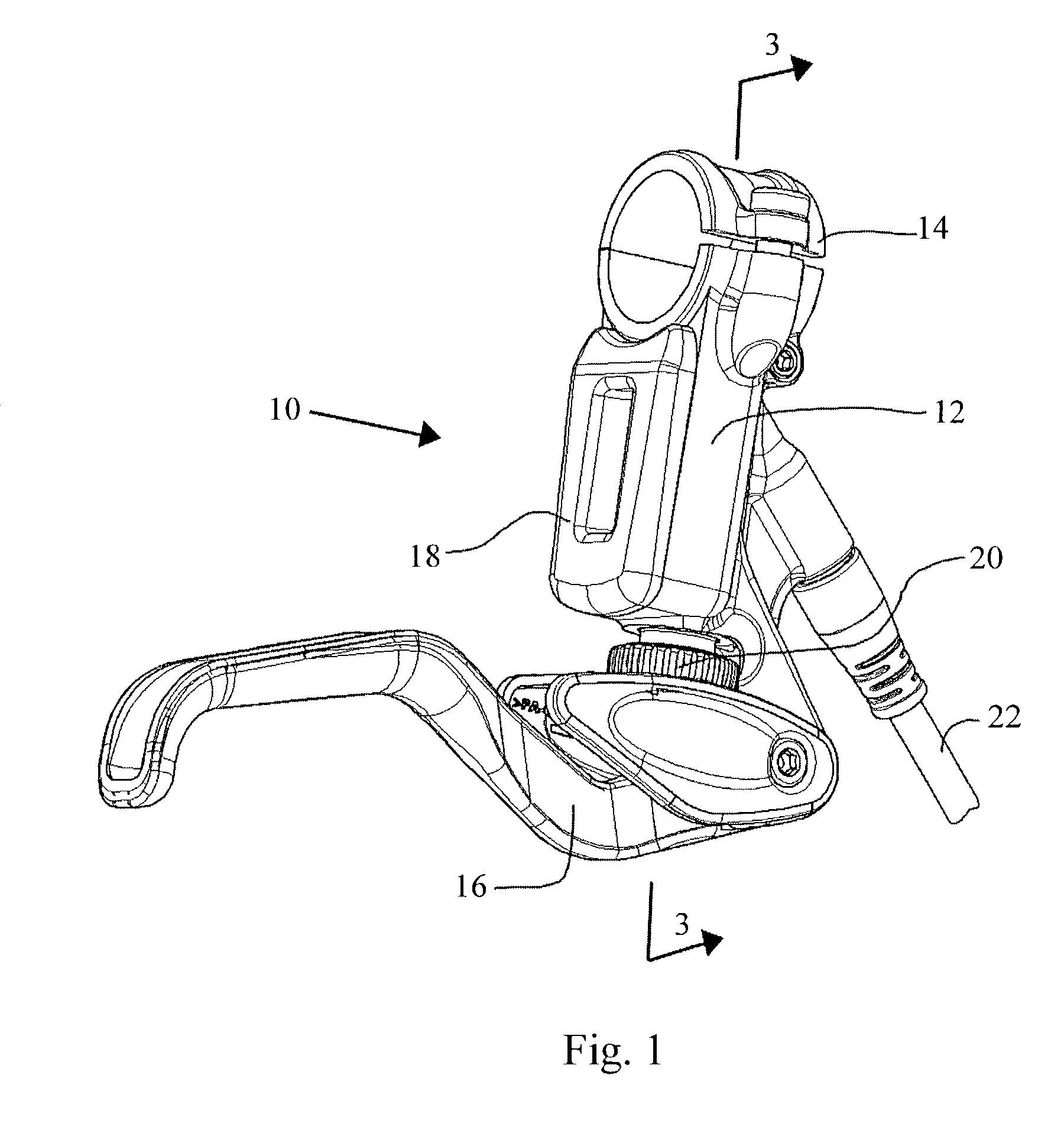

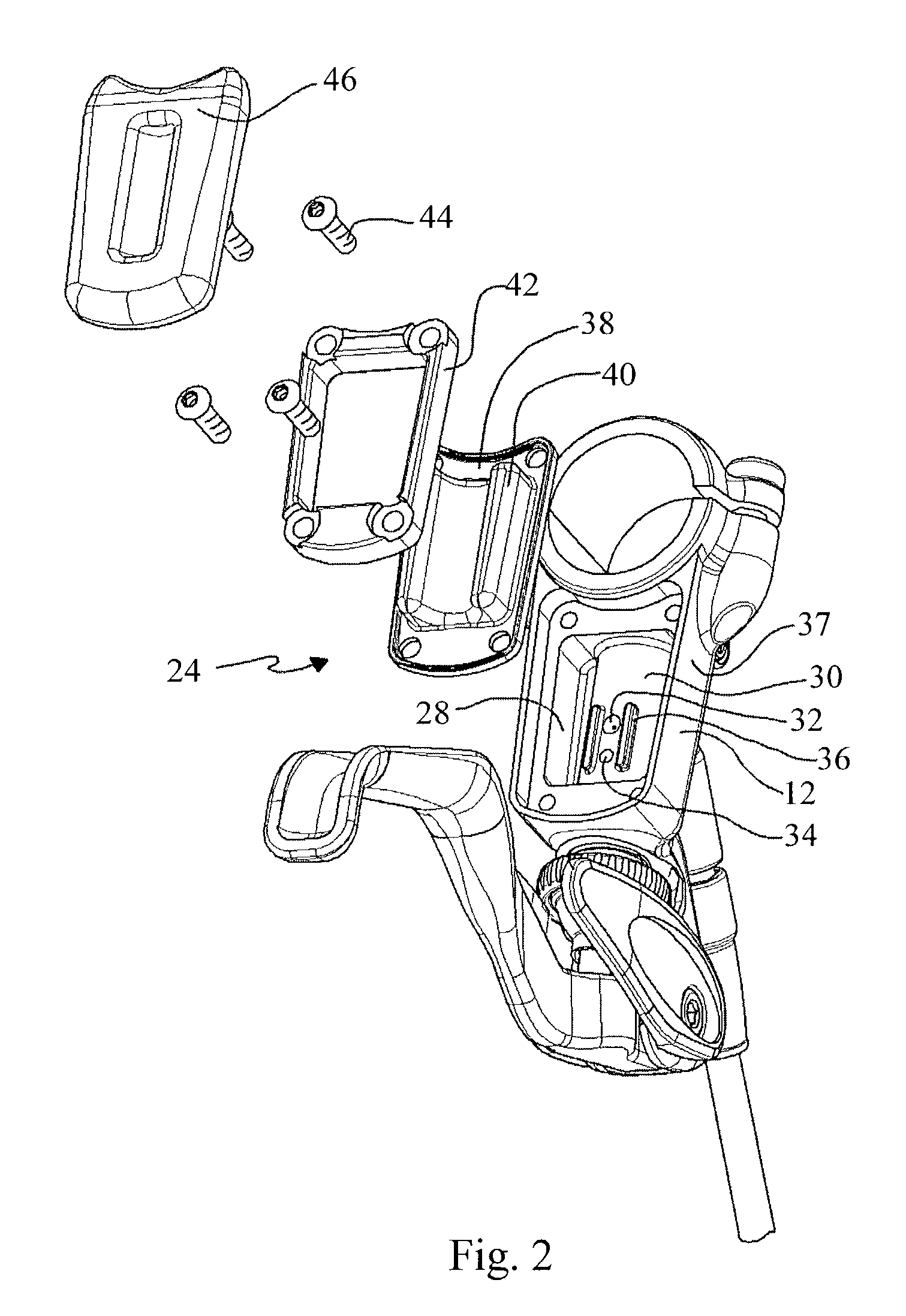

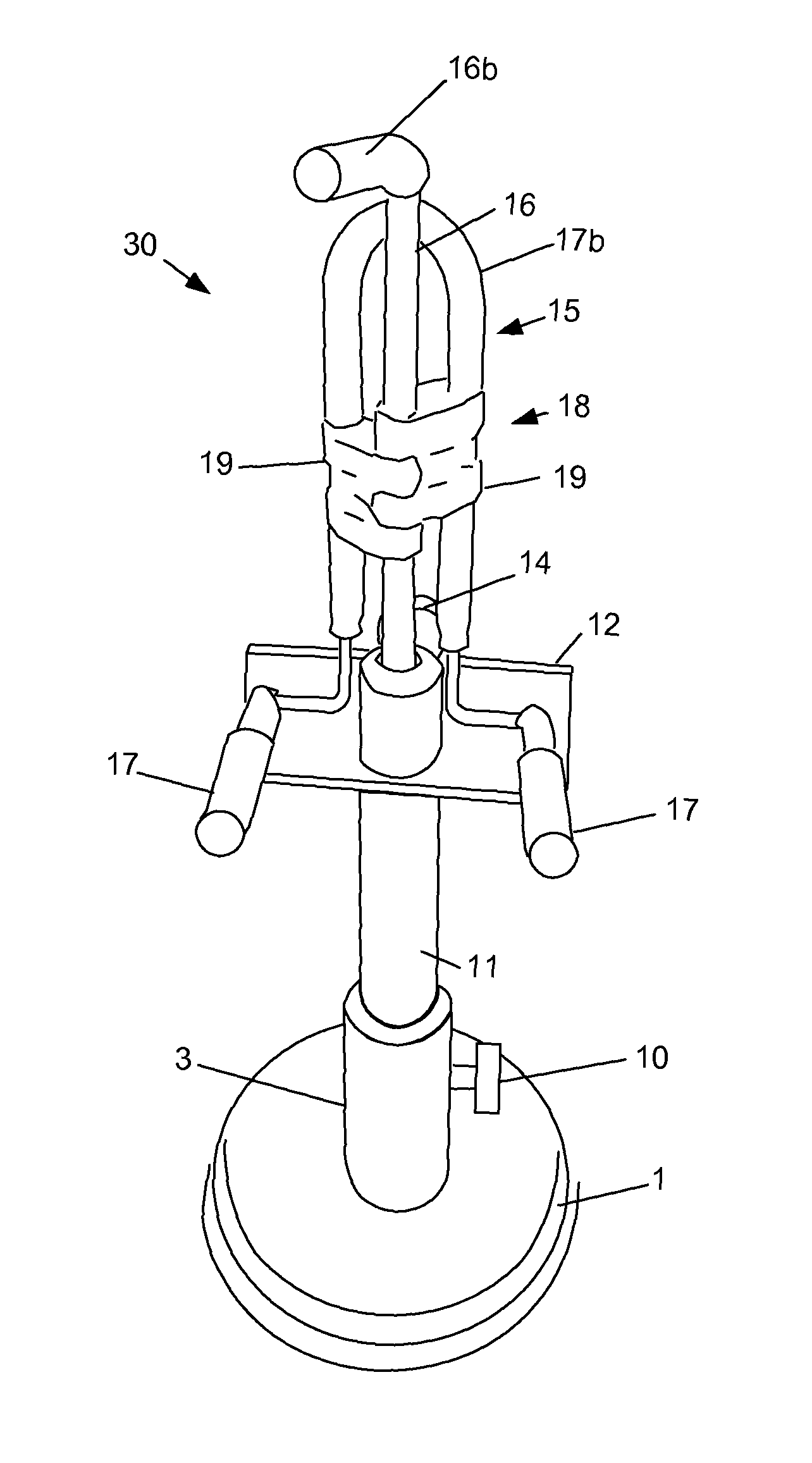

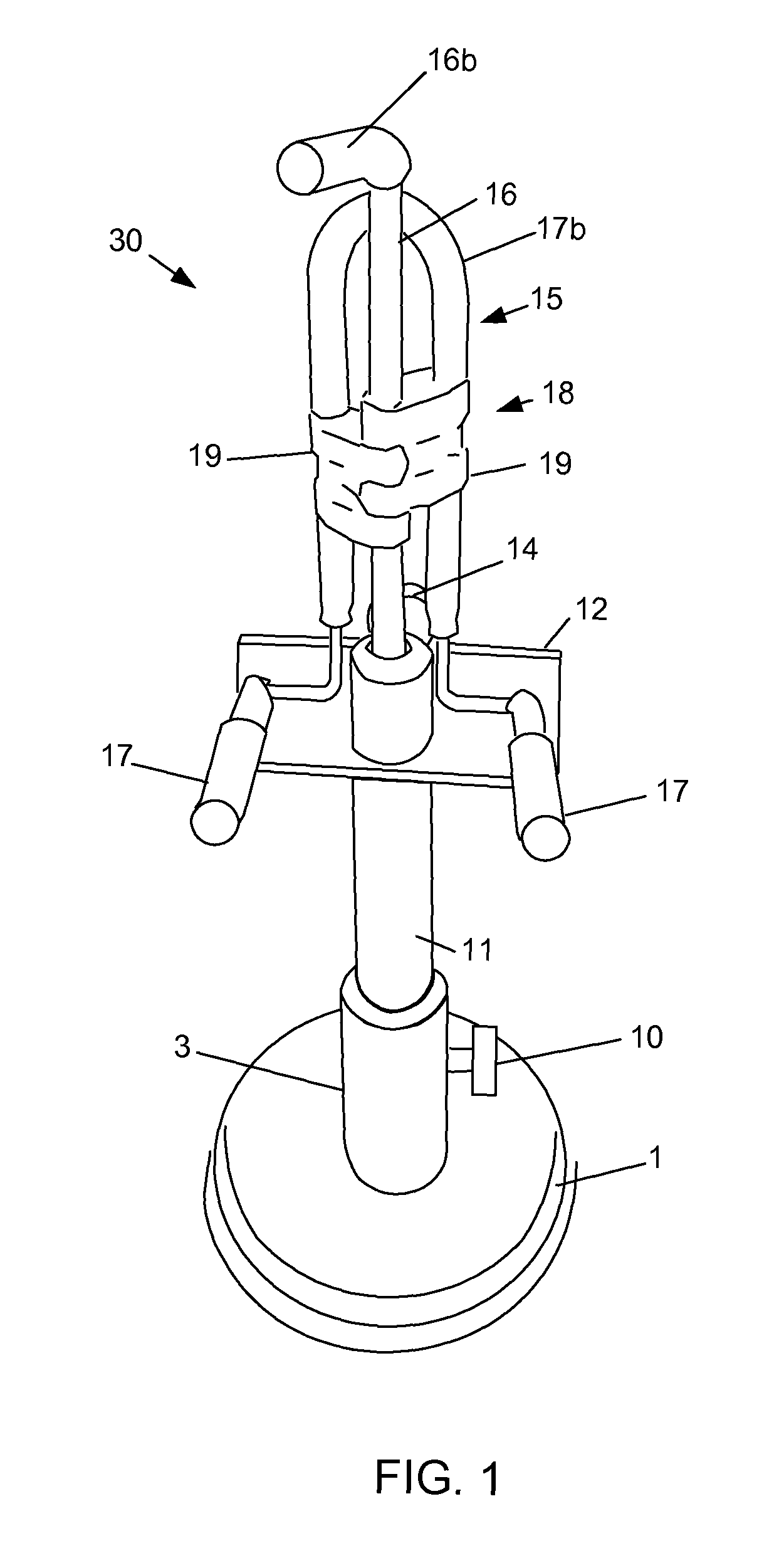

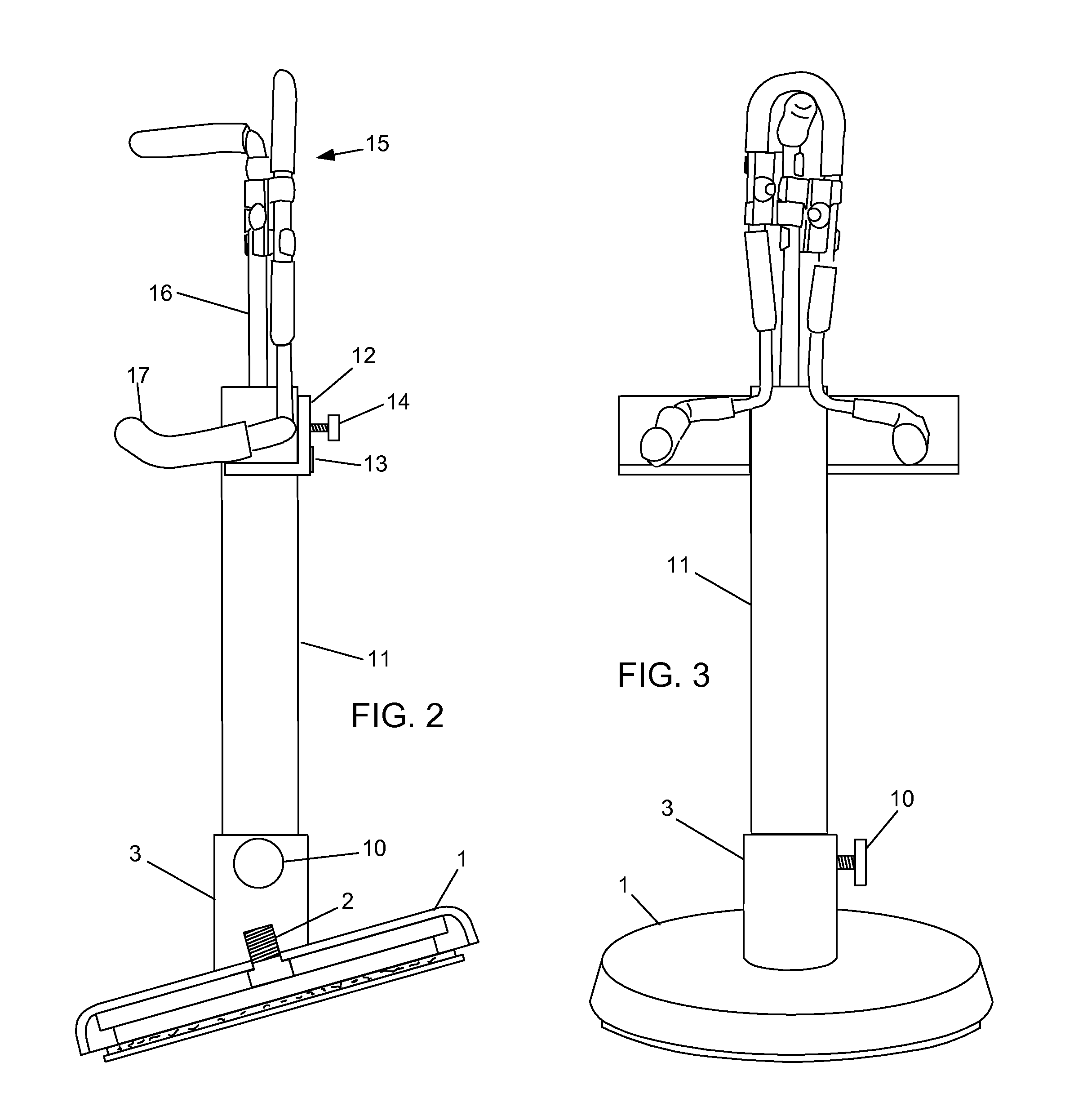

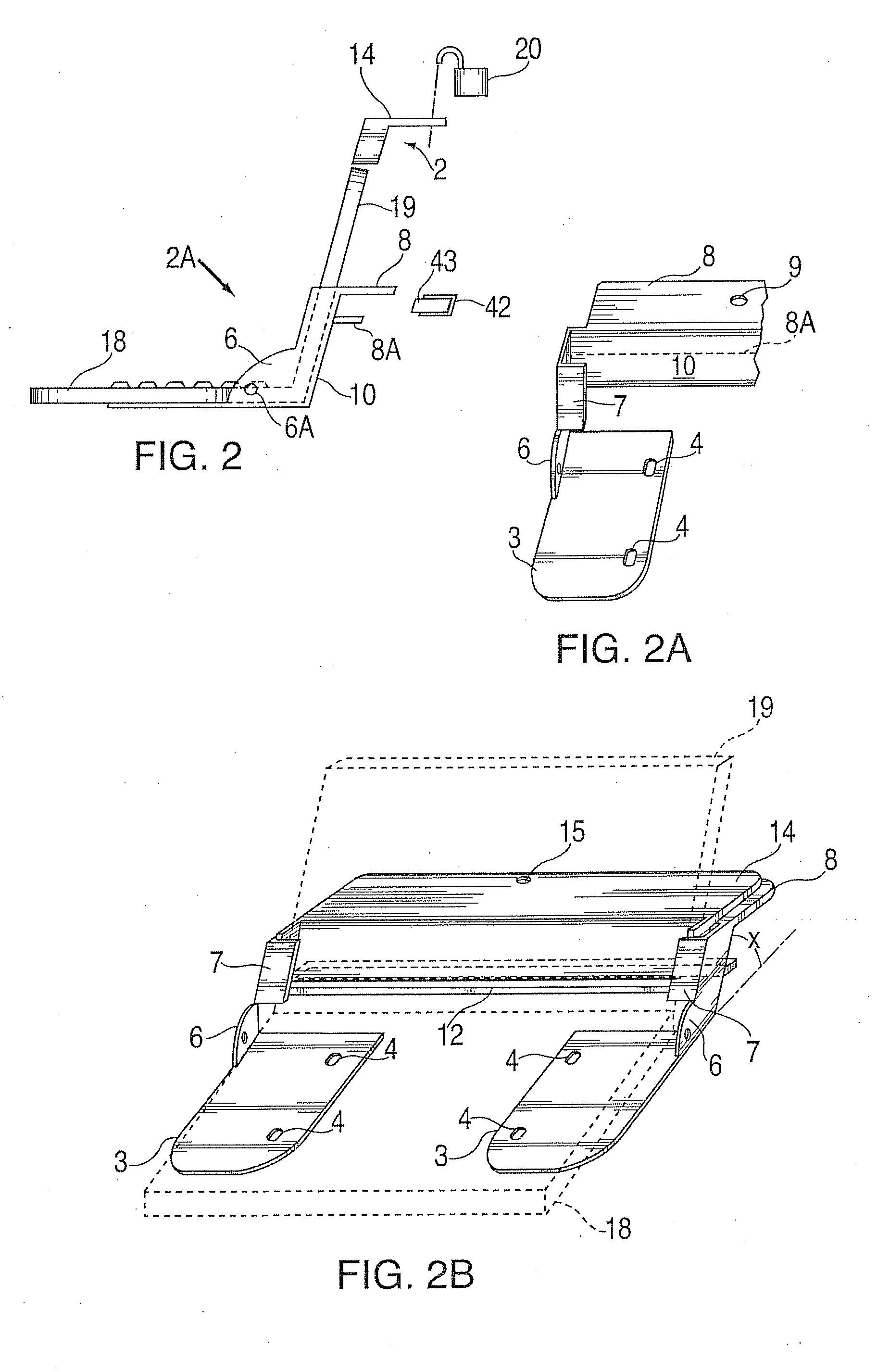

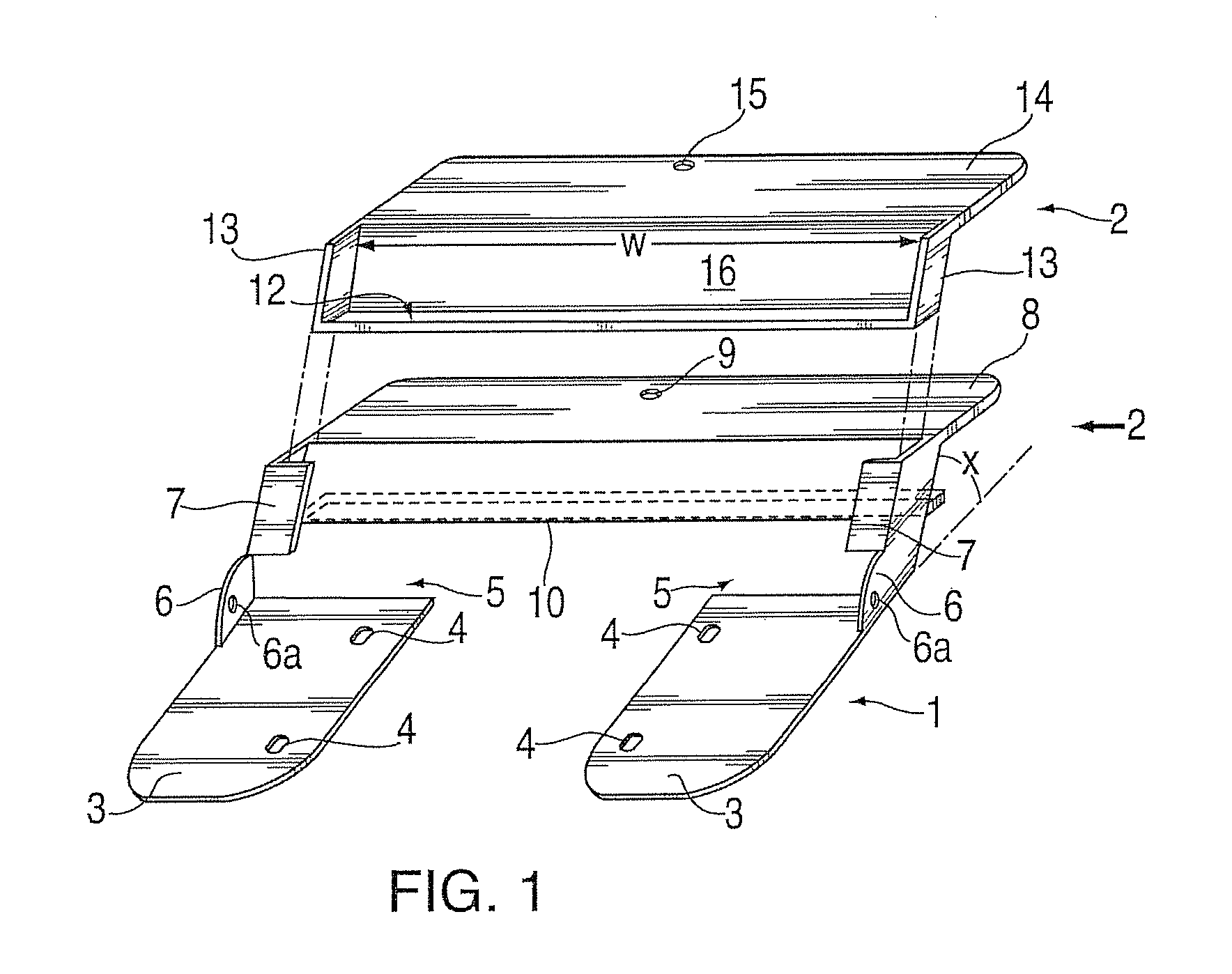

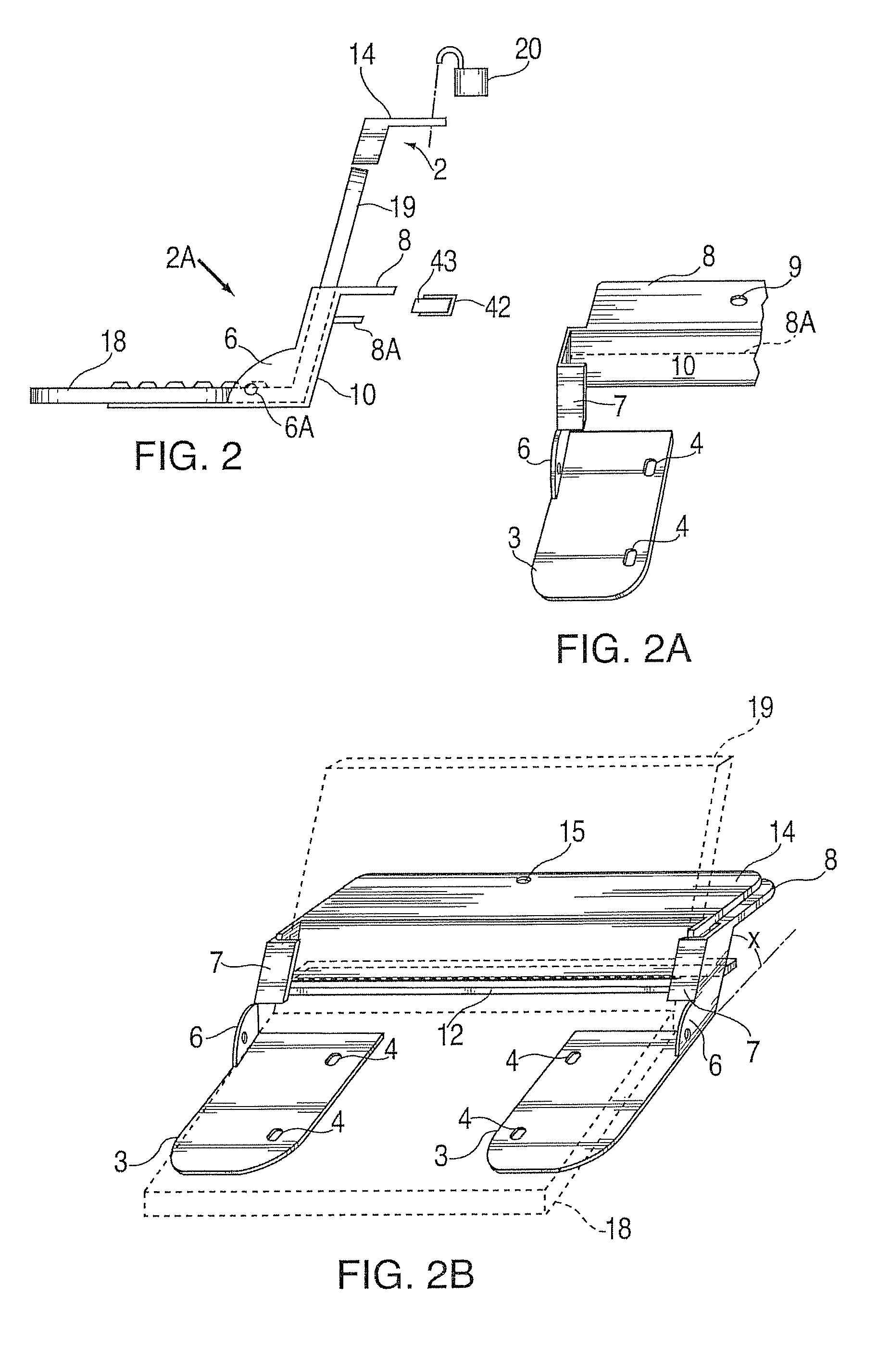

Personal electronic device holder

The present invention provides a portable electronic device holder. A lower adapter support piece supports two lower adapter arms. An upper adapter arm is supported by a adjustable rod. An adjustment fitting is connected to the lower adapter support piece and the adjustable rod is slidingly connected to the adjustment fitting and can be slid up and down by utilization of finger force. A portable electronic device is mounted and held secure as it is squeezed between the upper adapter arm and the two lower adapter arms. In a preferred embodiment the portable electronic device holder is mounted by either inserting the adjustable rod into a hollow pedestal attached to a base or by attaching the lower adapter arm support piece to a dual T mount of a separate mounting device.

Owner:CICCO MIKE

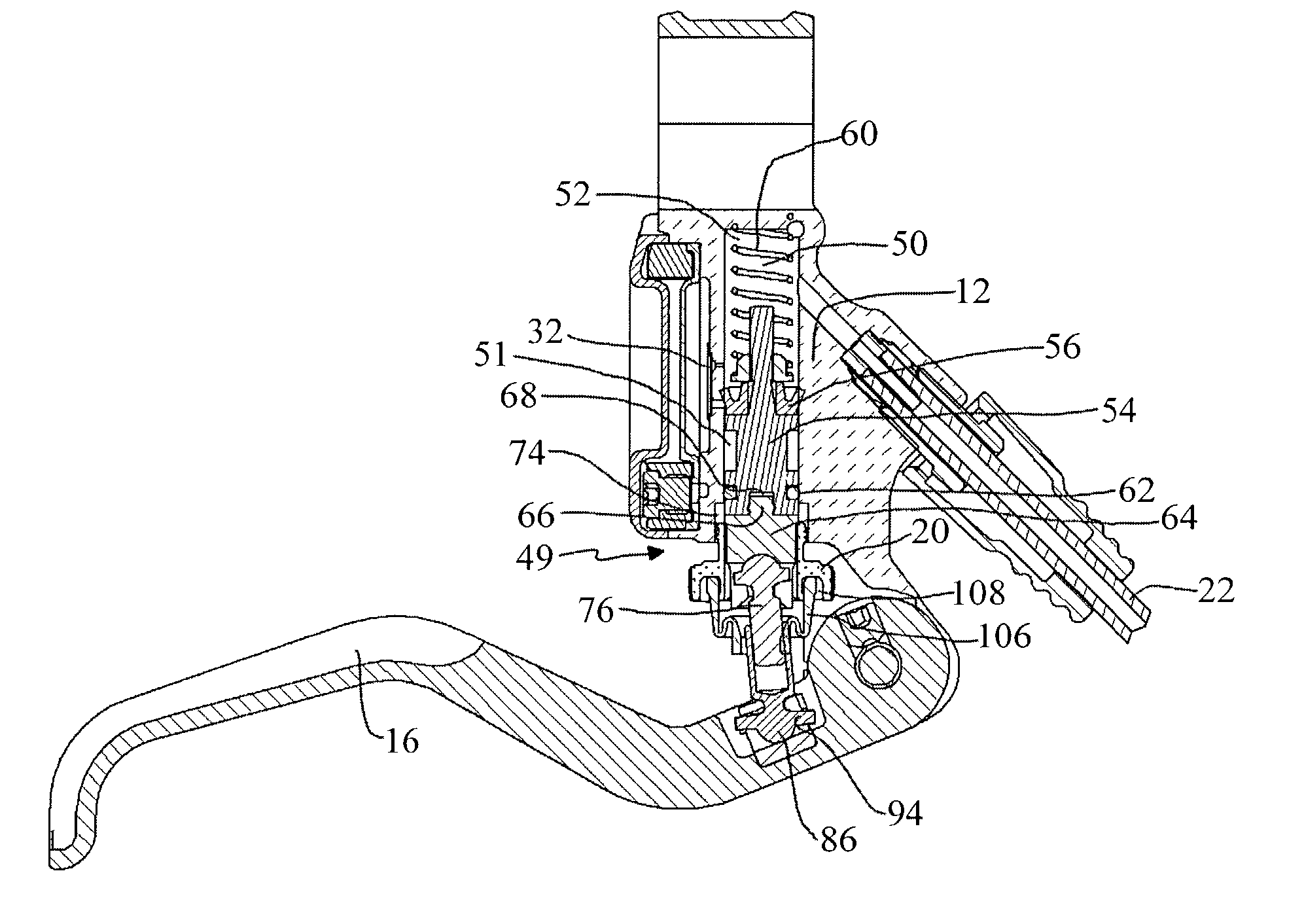

Master cylinder lever for a hydraulic disc brake having favorable handle pivot geometry

ActiveUS7204350B2Increased mechanical advantageImprove production safetyFluid braking transmissionCycle brakesMaster cylinderEngineering

A bicycle hydraulic disc brake master cylinder includes a housing having a bar clamp at one end configured for fastening the housing to a bicycle handle bar, the bar clamp receiving the handle bar along a clamp axis. A handle is pivotably connected to the housing to pivot about a pivot axis in operative association with a piston train to impart a drive force on the piston train. The handle defines a finger receptacle receiving at least one finger of a user defining an effective force point at a select distance from a distal end of the handle. A select ideal finger actuation path for the at least one finger of a user begins at a start point at the effective finger force point with the handle at an engagement point where the handle begins to drive the piston train against operative fluid resistance and extends along a line from the start point at a select angle relative to the clamp axis. A pivotable connection is provided between the handle and the housing and is located on the housing relative to the clamp axis so that with the handle actuated by a force applied to the effective finger force point along this select ideal actuation path, a mechanical advantage to the user resulting from the handle actuation does not diminish more than three percent as the handle is pivoted between the engagement point and a fully actuated position.

Owner:SRAM CORPORATION

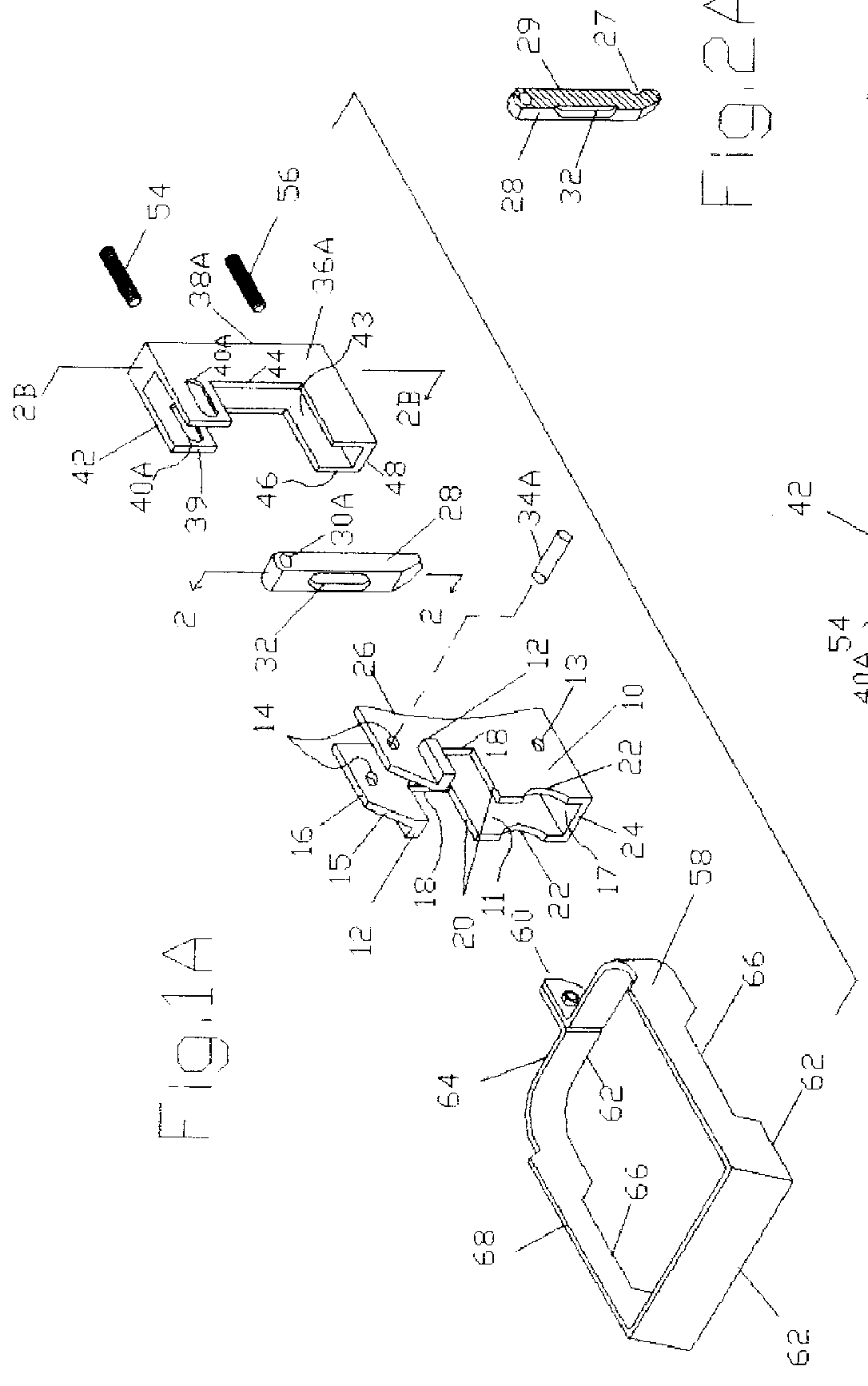

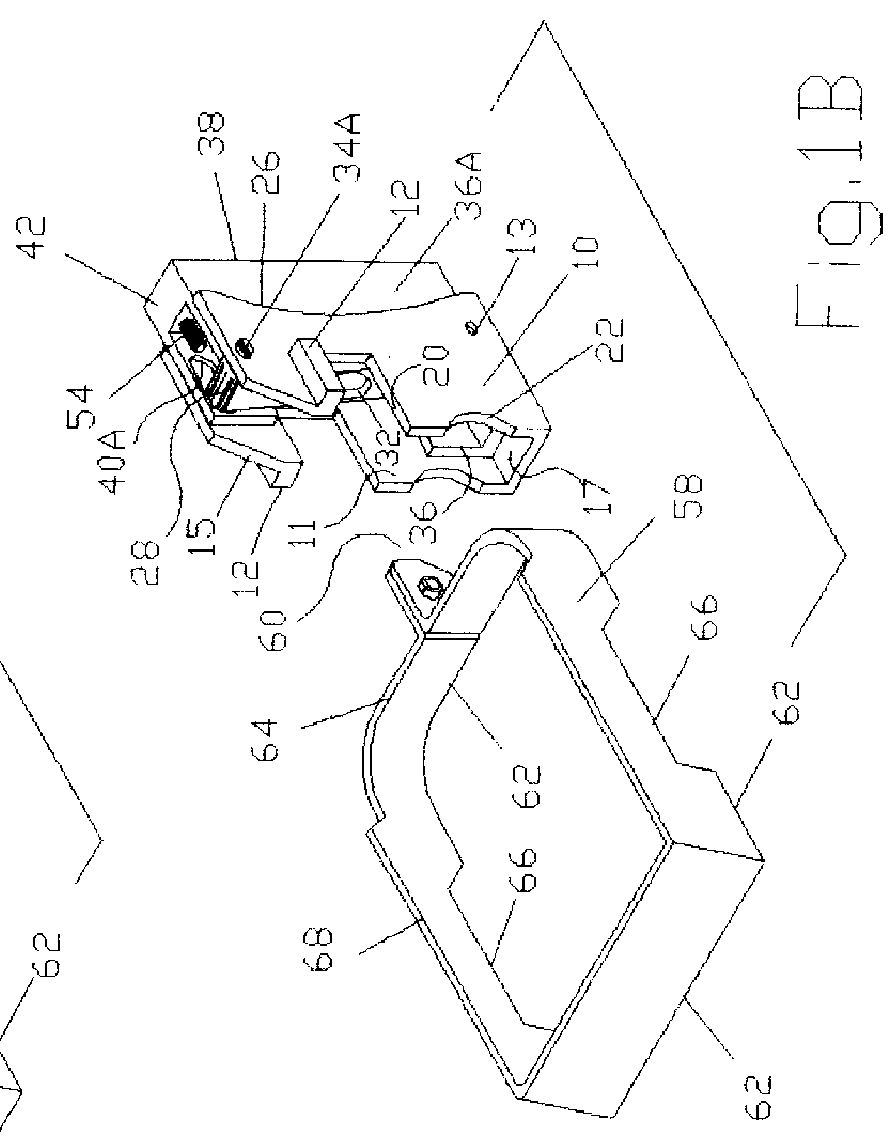

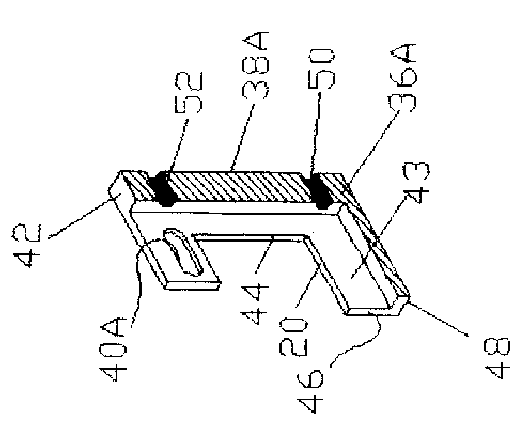

Device for reducing firearms trigger pull weight

A device comprises of independent trigger bow (58) supplied with overlapping recess (64) and a trigger block (10) having a bow guide recess (20), pivot hole (14) with axis pin (34A), primary lever (28) having a axis hole (30) at one end and a bow extender recess (32) and a trigger plate (36A) having a pre-load bar (56) and stopper bar (54) that can be assembled into a module to allow easy installation on trigger tunnel (85) of firearm(88) for reduce firearm trigger pull weight without altering firearm (88). Block (10) is being equipped with catches (12) extending sideways and adjacent with bow guide recess (20) which will overlap with recess (64) of bow (58) to allow both the bow (58) and block (10) to occupy in one same area which allow anchoring against a bow tunnel (83) end wall and supplied with magazine cut (15) disposed on the upper left of block (10) to allow for a magazine passage. As trigger plate (36A) is depressed with finger within a given point on trigger plate (36A) upon firing the finger force will be shifted directly into the adjustable preload bar (56) and synchronizes into the outermost lever end at point (27) of lever (28) producing a high torque leverage which reduces firearm trigger pull weight or load force from the trigger bow (58) energized from sear (70), hammer (72) and hammer spring (82). The trigger plate (36A) being retained with pivot pin (34A) through retaining slot (40A) is supplied with plate bearing (42) and bottom bearing (48) will slide against a frame upper bearing (79) and against s block plate bearing (17) of block (10) respectively, will function as an advancing global pivot point which will changed a rotational action of lever (28) into a linear straight pull action to maintain firearm standard straight action and reducing the trigger pull weight.

Owner:LEE ROBERTO R

Adjustable focus lenses

A lens unit with two lens elements each having special surfaces such that an adjustment of the position of one of the two lens elements relative to the other in a direction generally perpendicular to a viewing direction changes the focusing power of the lens unit. In preferred embodiments two lens units are mounted in a frame to provide eyeglasses with adjustable focus. Several frame designs are described. In preferred embodiments two lens units, each lens unit having two lens elements are mounted in a frame to provide eyeglasses with adjustable focus. Several designs are described. Some designs provide for movement side to side movement of the lens elements relative to each other. In other designs the relative motion is up and down. A simple technique is a thumbscrew adjustment that is operated by the wearer. Another design is based on finger force against a friction force. In some preferred embodiments separate frames holding the lens elements pivot about pivot points on the earpiece of a support frame. In other designs two rear lens elements are mounted in a support frame and the front lens elements are mounted in a separate frame that pivots about a point on the earpiece of the support frame. Another design includes a torsion bar assures that the movements of each lens element in one of the lens units is the same as the movements of the lens elements in the other lens unit. Techniques for automatic focusing of the lenses are also disclosed. Techniques for automatic focusing of the lenses are also disclosed.

Owner:QUEXTA

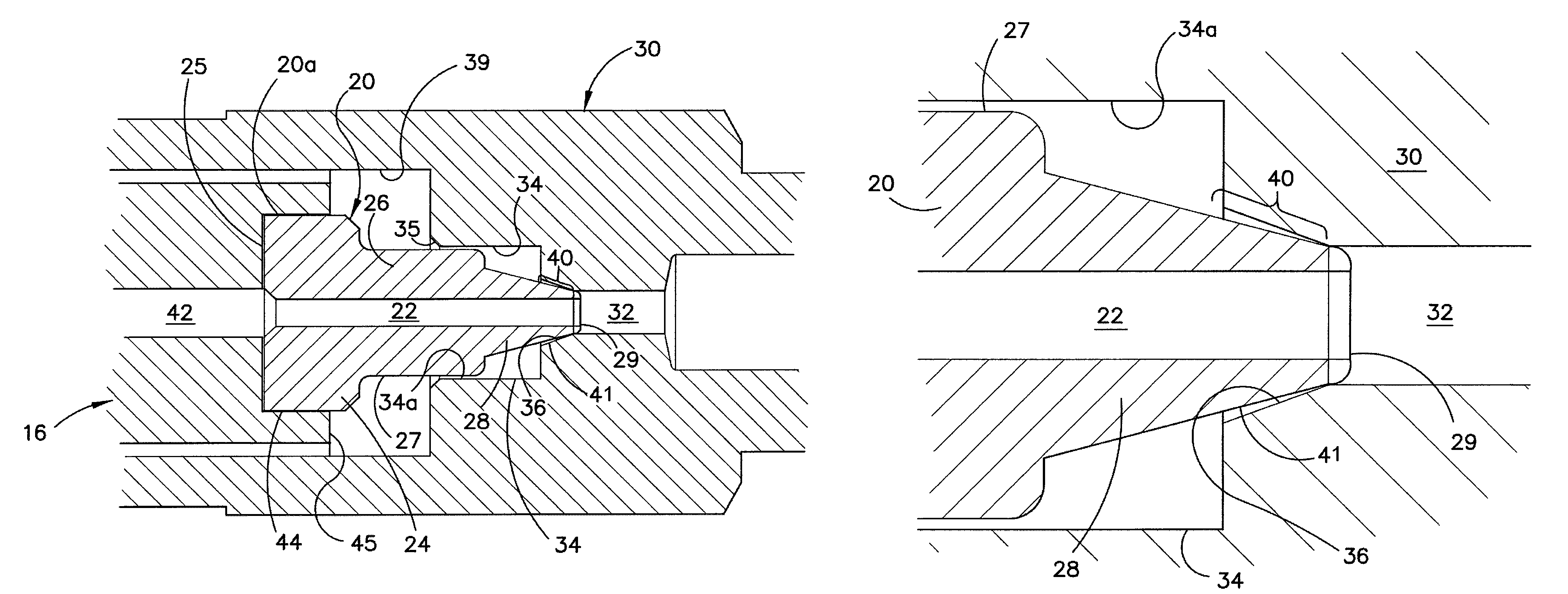

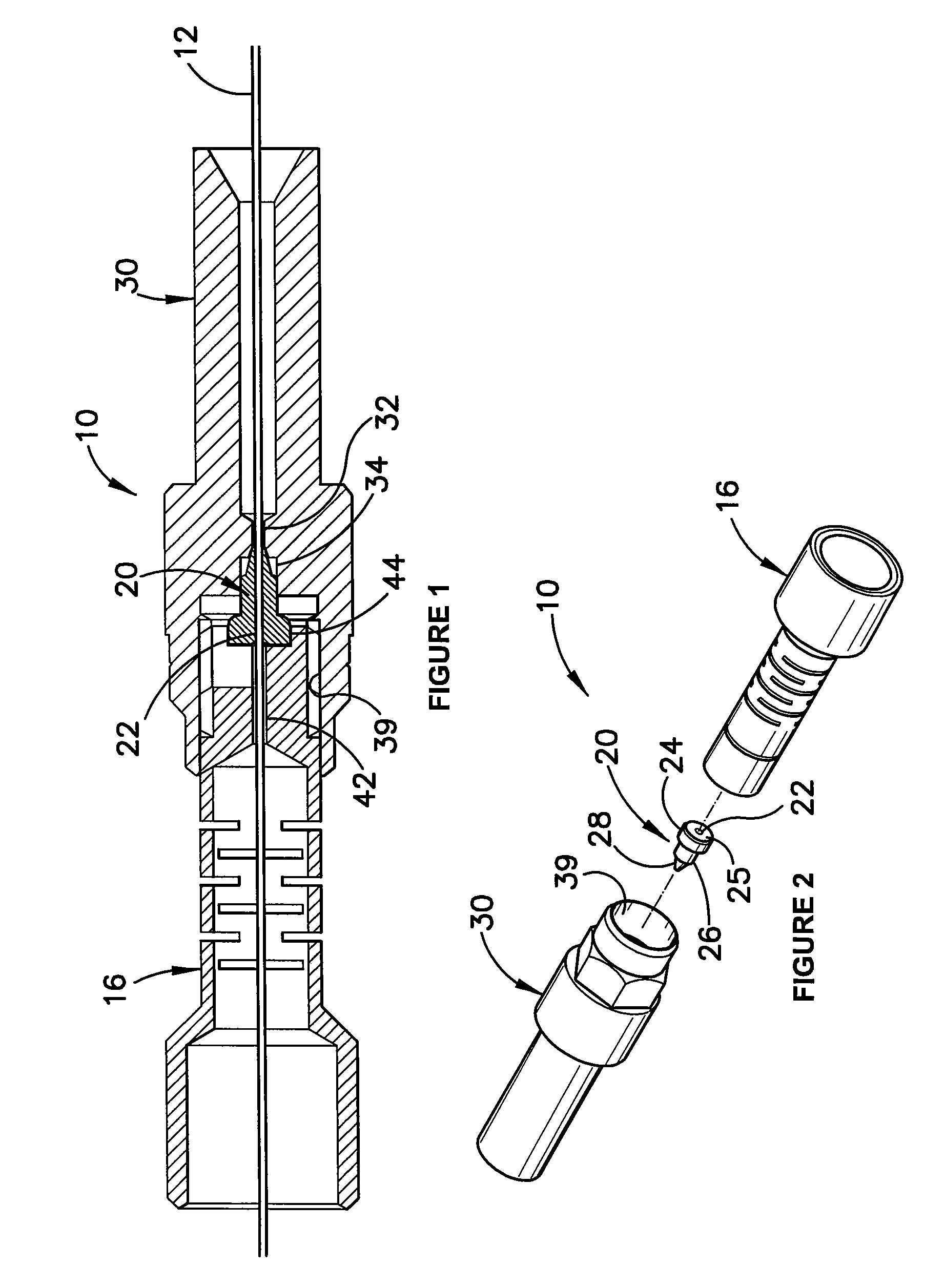

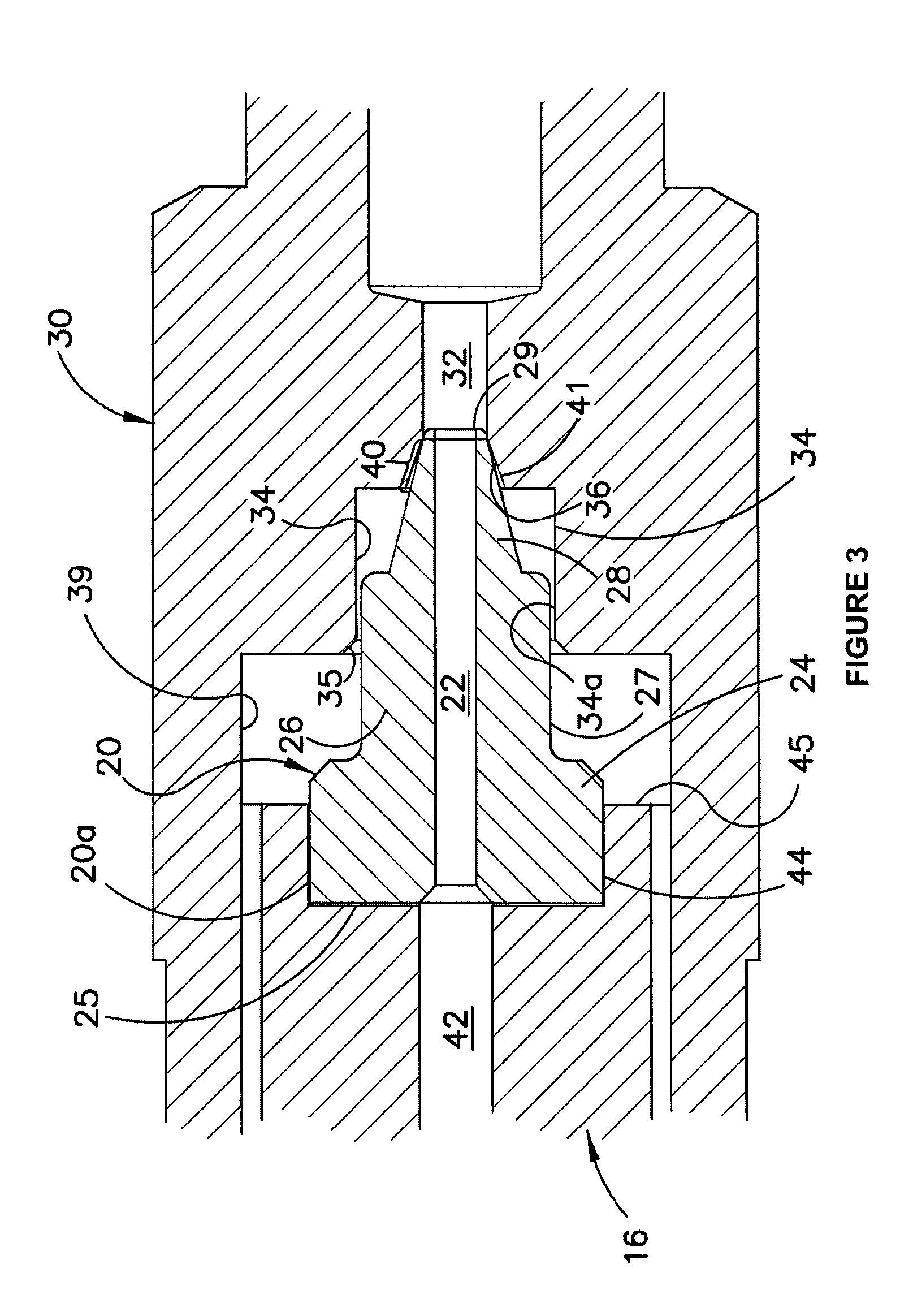

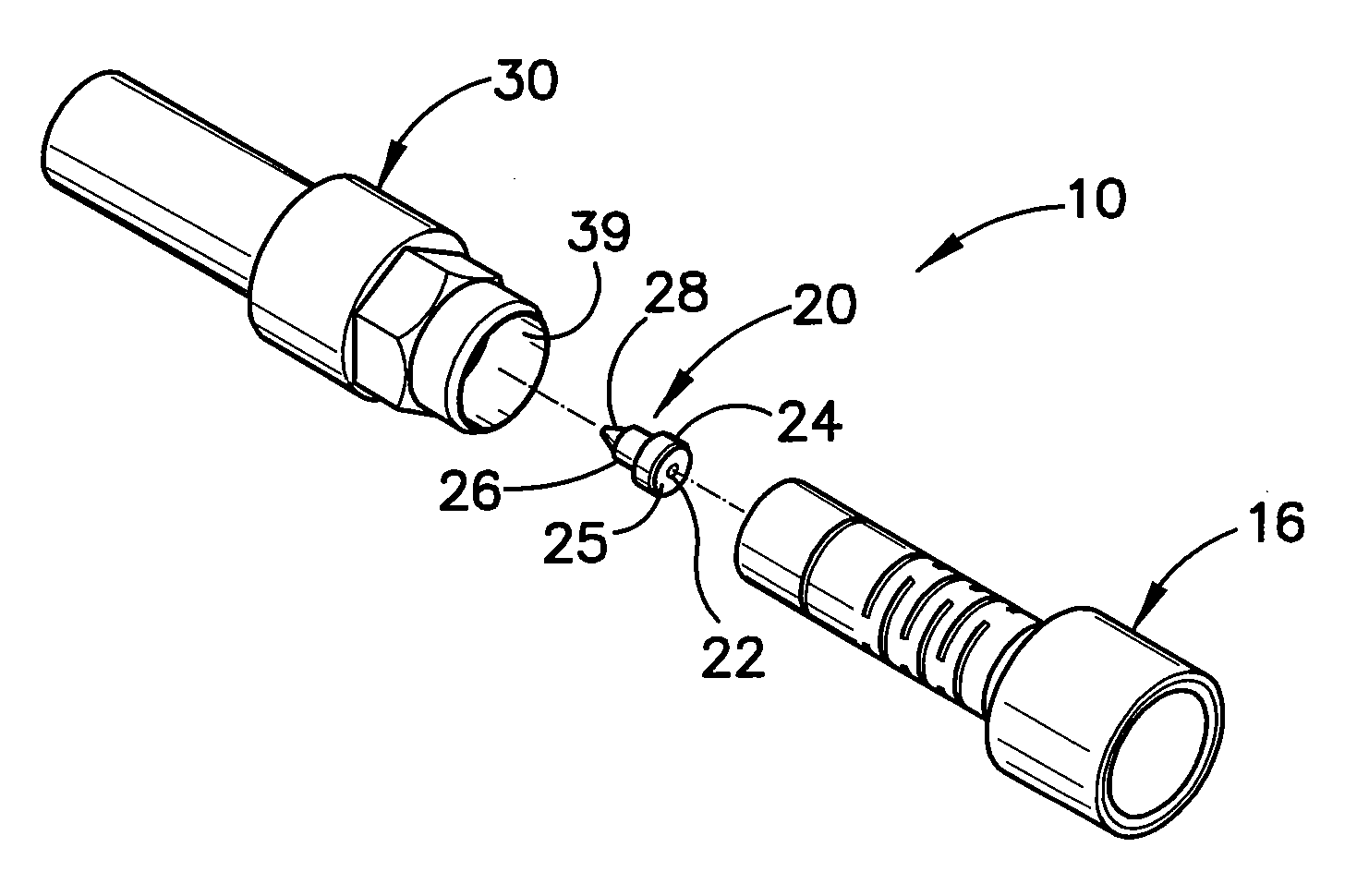

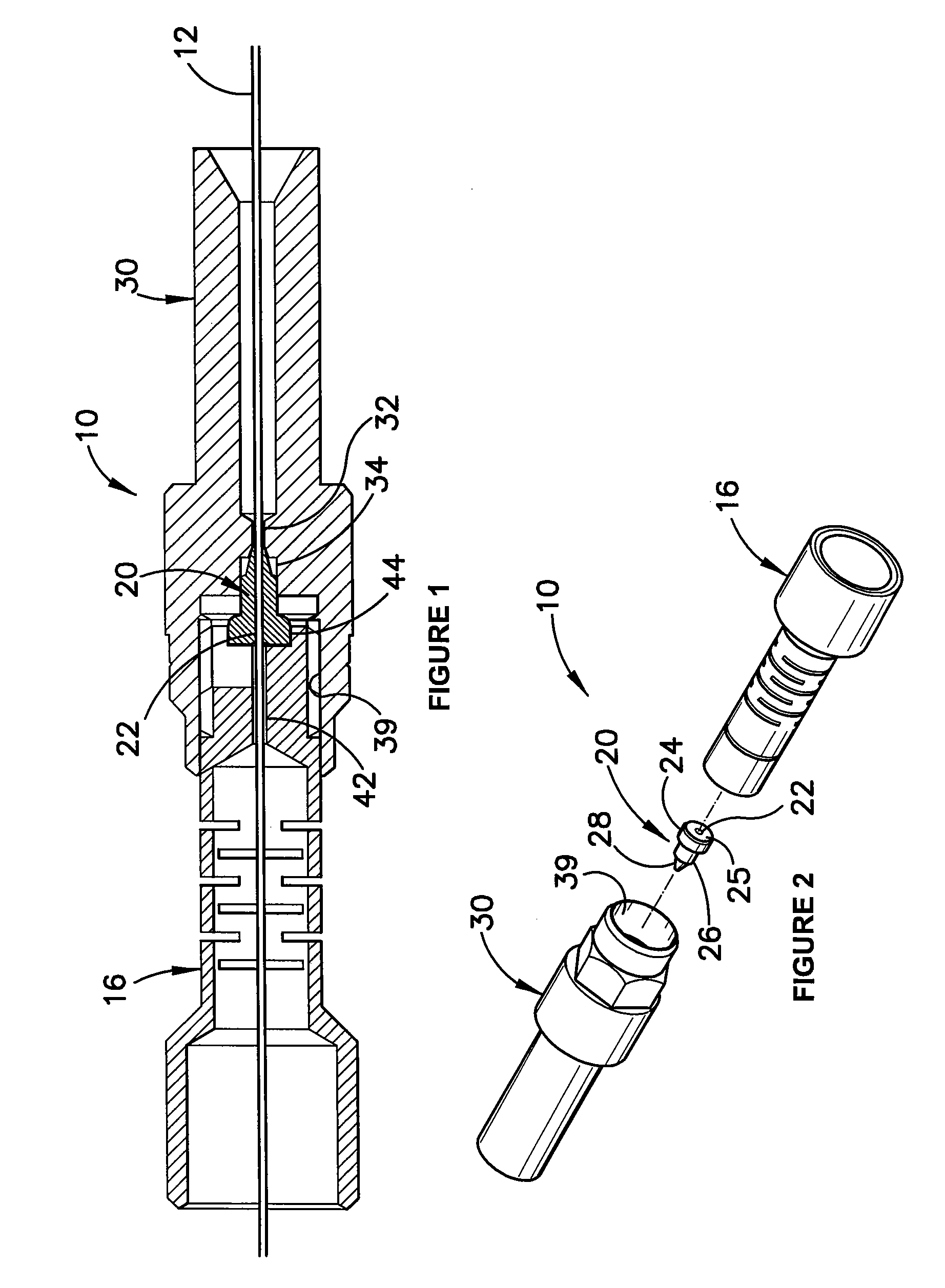

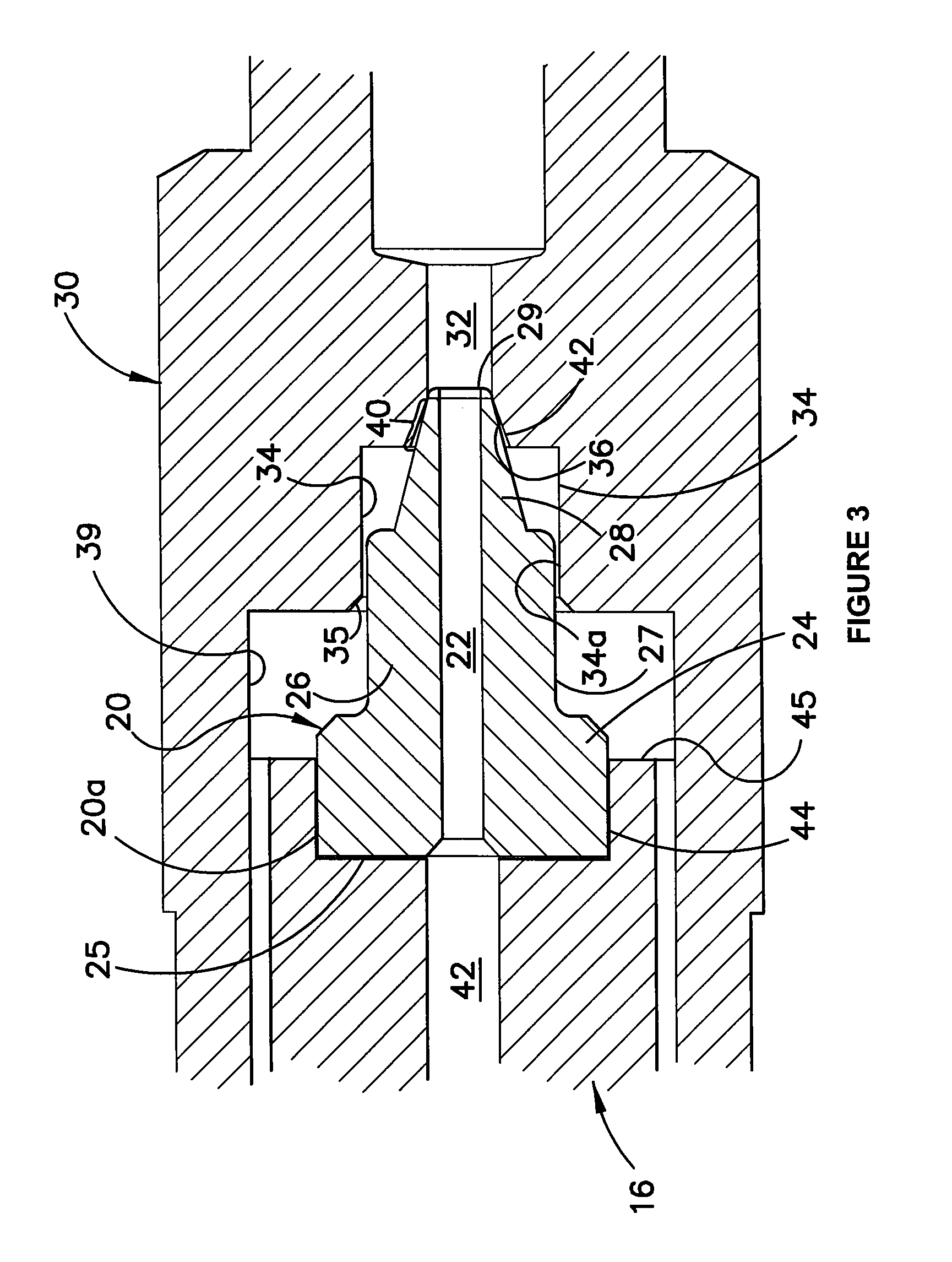

Ferrule for making fingertight column connections in gas chromatography

A ferrule arrangement for use in sealing connections to gas chromatography columns includes a generally tubular metal ferrule with an axial bore to receive a fracturable column with a protective coating. The ferrule has a forward part that tapers to a tip region of the ferrule. A generally tubular former has a socket portion to receive the ferrule and further has an internal conical surface that, after such receipt, engages the forward part of the ferrule. A portion is provided on either or both of said ferrule and the former by which the ferrule and former may be directly or indirectly relatively moved together by application of finger force. The taper and the internal conical surface exhibit relative taper angles and the tip region of the ferrule is sufficiently radially thin whereby the application of finger force (i) is adequate to move the ferrule axially into the former to cause the conical surface to engage the tip region of the ferrule and to deform the tip region into sealing engagement with the protective coating of the column, but (ii) does not break the column.

Owner:TRAJAN SCI AUSTRALIA

Lawn rake and cross head assembly

A lawn rake (100) has a cross head assembly (130) attached to a handle (120). A truncated tee (150) mounted on the cross arm (145) of the cross head assembly (130) receives the handle (120). A plurality of tines (170) is carried by the cross arm (145). The cross arm (145) is tubular and has a plurality of pairs (162) of apertures (164). The apertures (164) are larger than the cross section of the tines (170). The tines (170) are inserted through, and loosely positioned by, the apertures (164). The plurality of tines (170) forms an array (160) that is generally coplanar. The array (160) may form an obtuse angle with respect to the handle (120). Embodiments of the rake include arrays of tines (170) configured to form alternating rows of tines or a curvilinear arrangement of tines. A looped bend (178) formed in the end of each tine (170) distal to the ground engaging tip (176), snaps around the cross arm (145) to pivotally mount each tine (170). The tines (170) are replaceable, and are mountable on and removable from the cross arm (145) by application of finger force. The tines (170) are releasable. During raking action, an impact load directed upwardly on a tip (176) may cause release of the looped bend (178) from the cross arm (145), thereby preventing breakage of the tine (170). The lawn rake (100) can be used in a push mode. The lawn rake (100) may be distributed as a kit of parts. Components of lawn rake (100) are preferably made from a thermoplastic material. In particular the thermoplastic material may be polyvinylchloride.

Owner:MILBURY THOMAS G

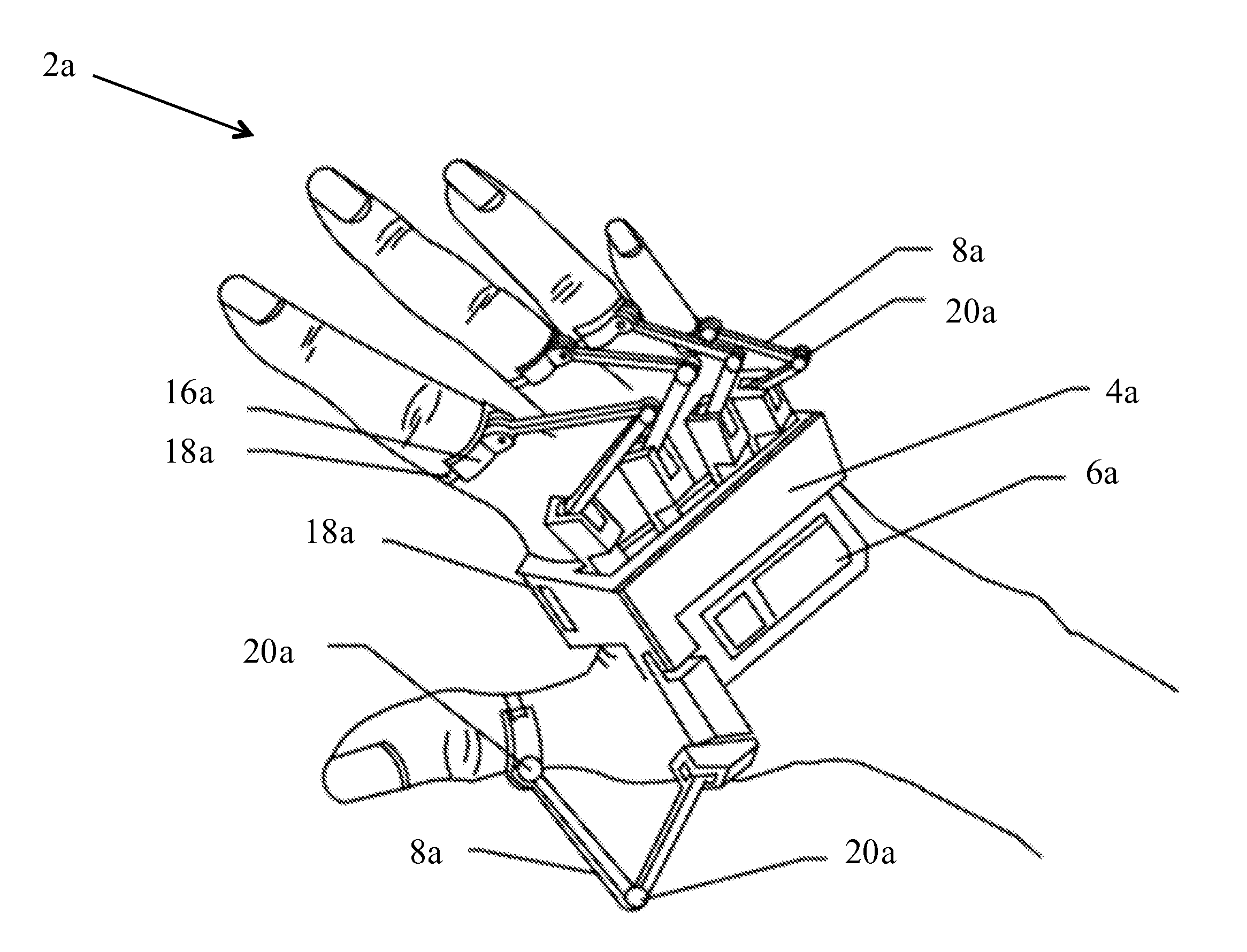

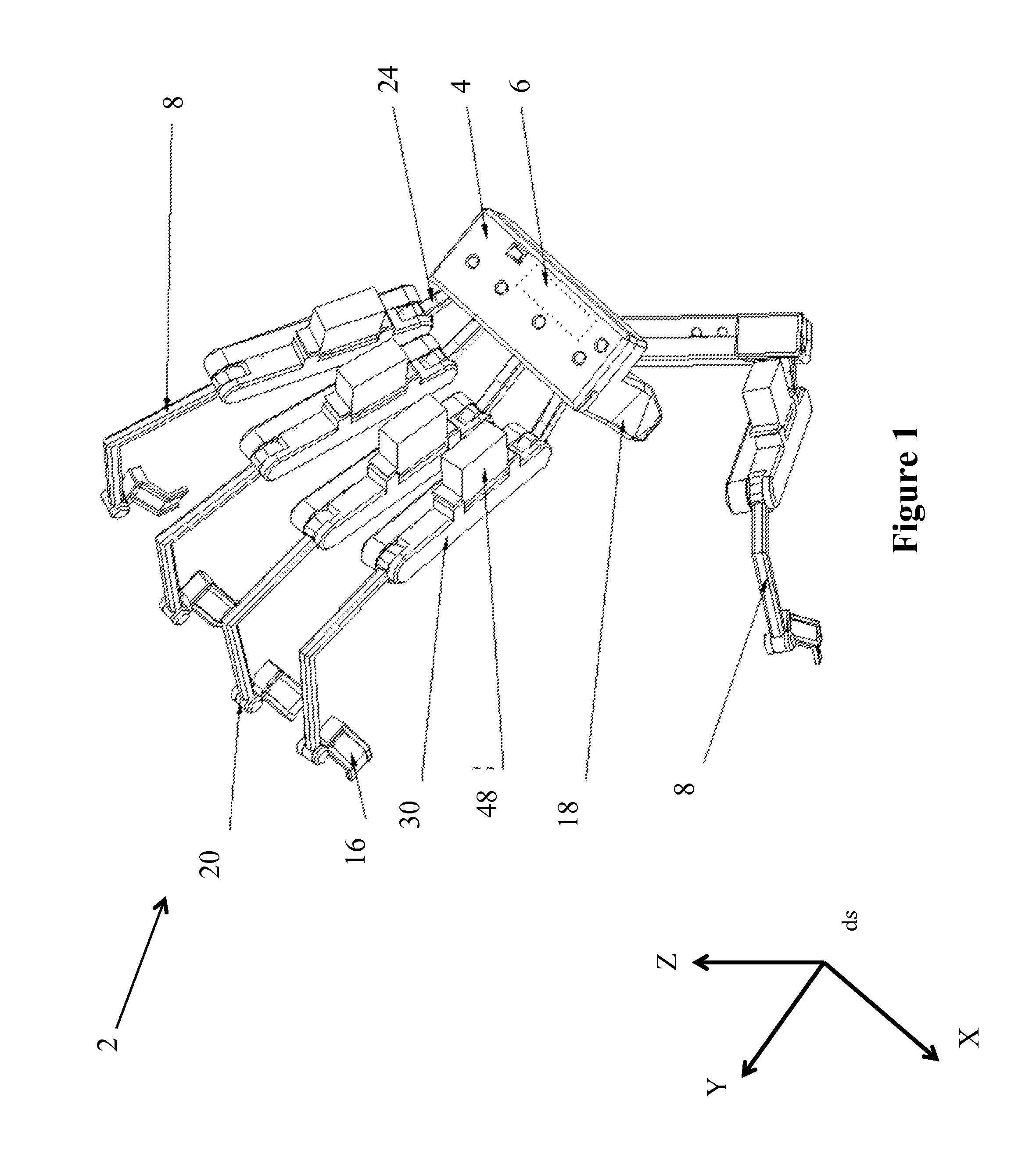

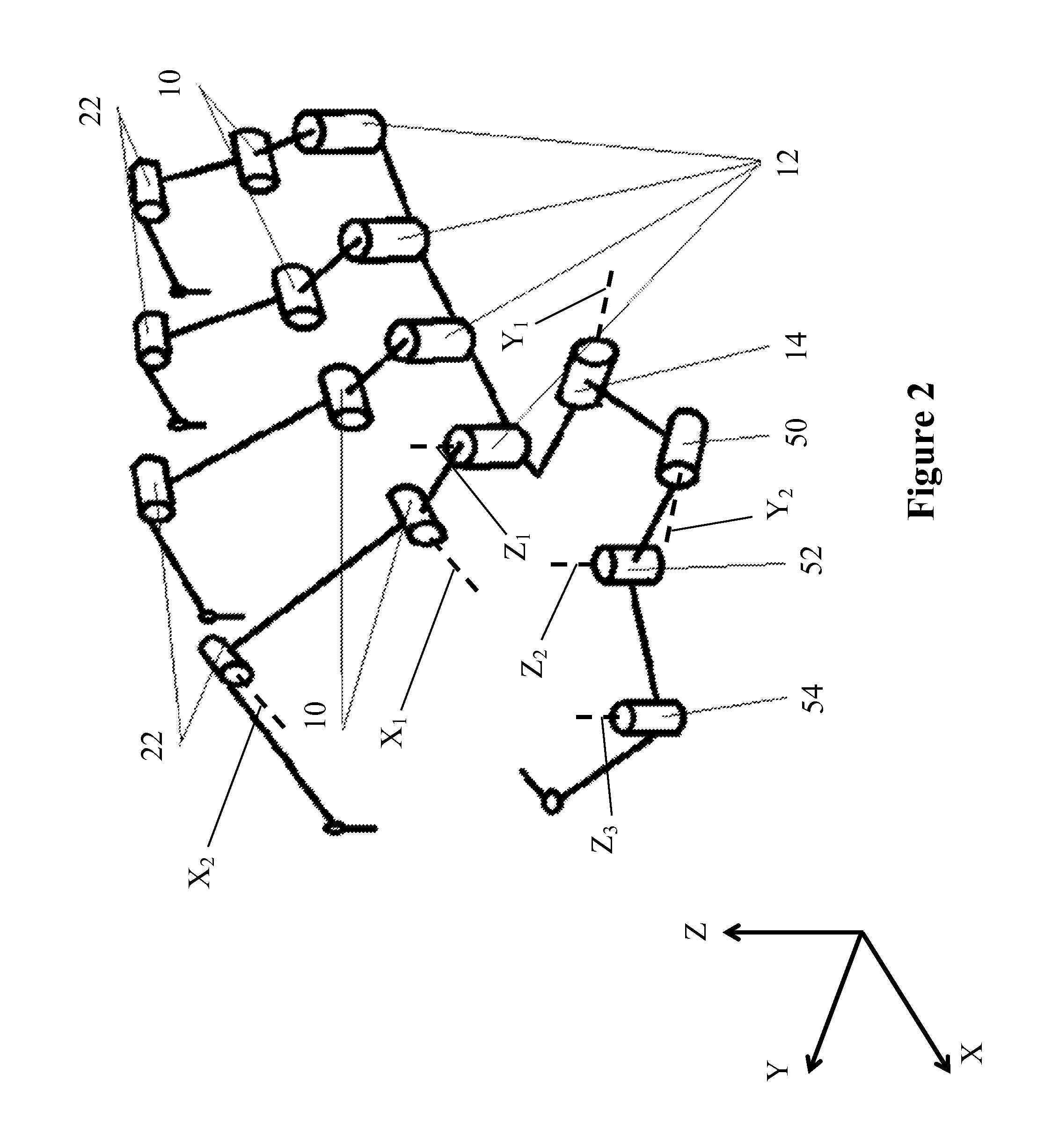

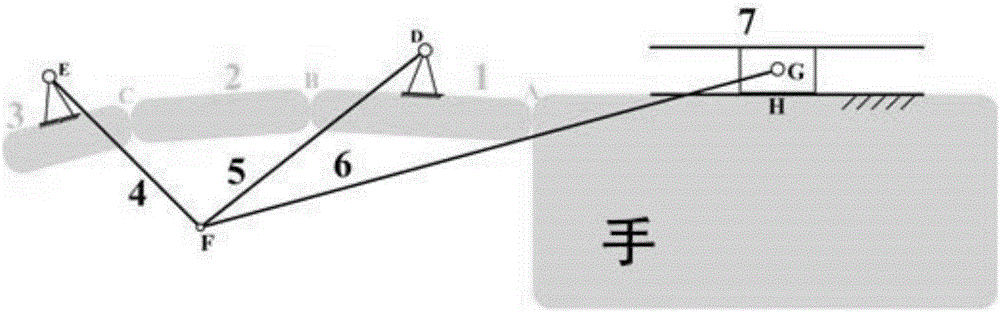

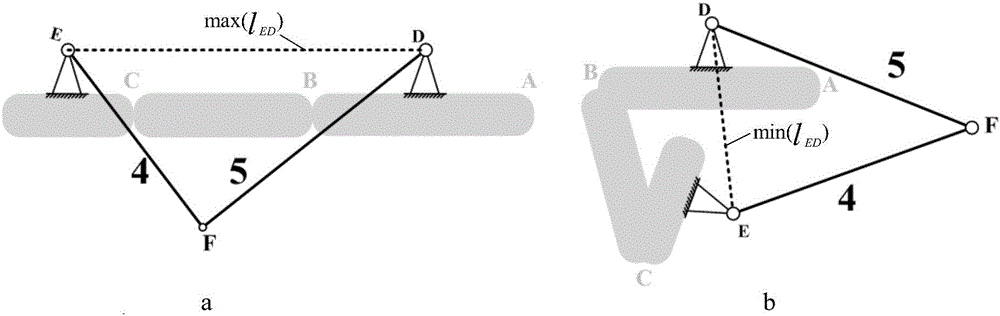

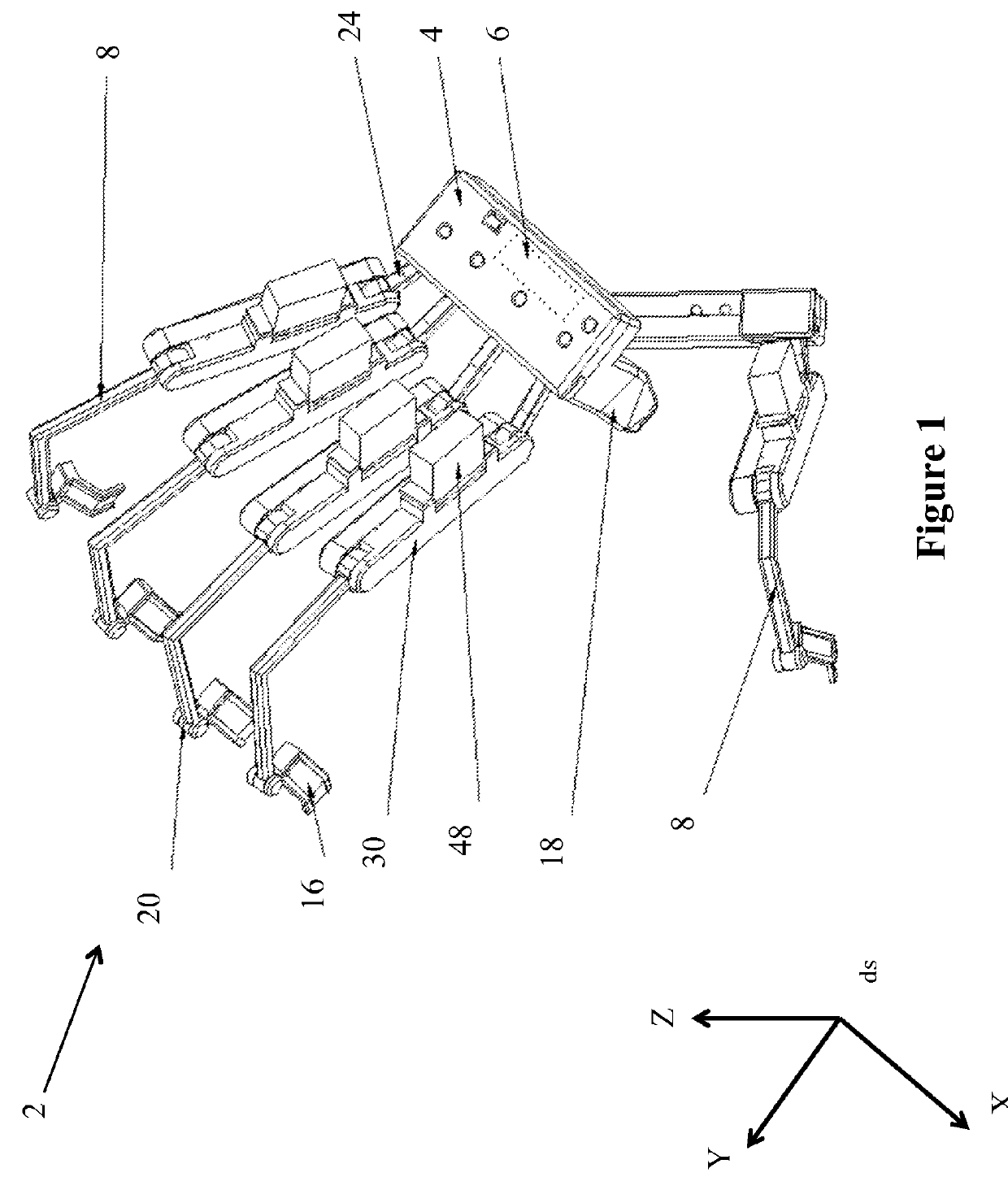

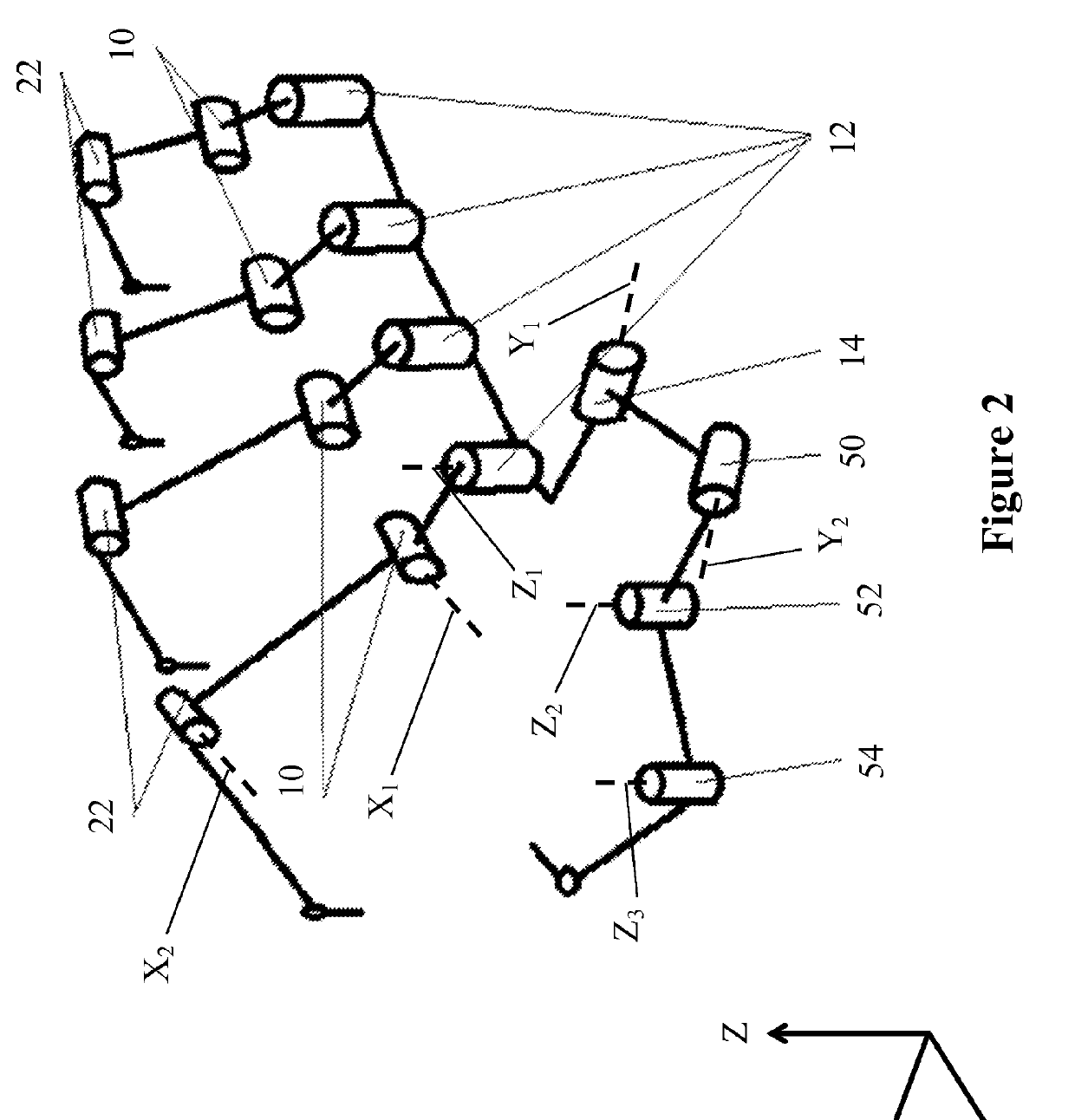

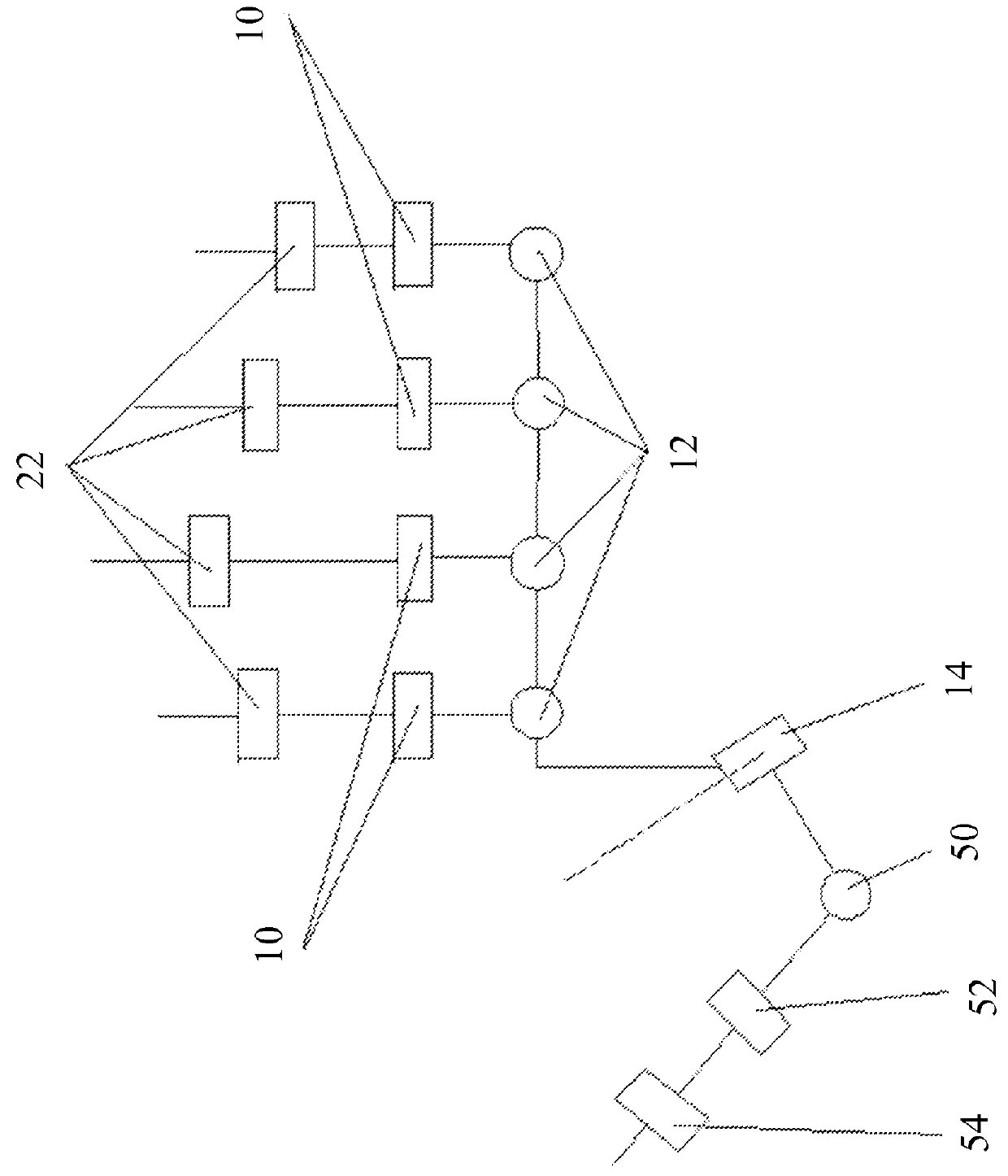

Hand motion-capturing device with force feedback system

ActiveUS20160018892A1Low costLittle omissionInput/output for user-computer interactionCathode-ray tube indicatorsLittle fingerElectricity

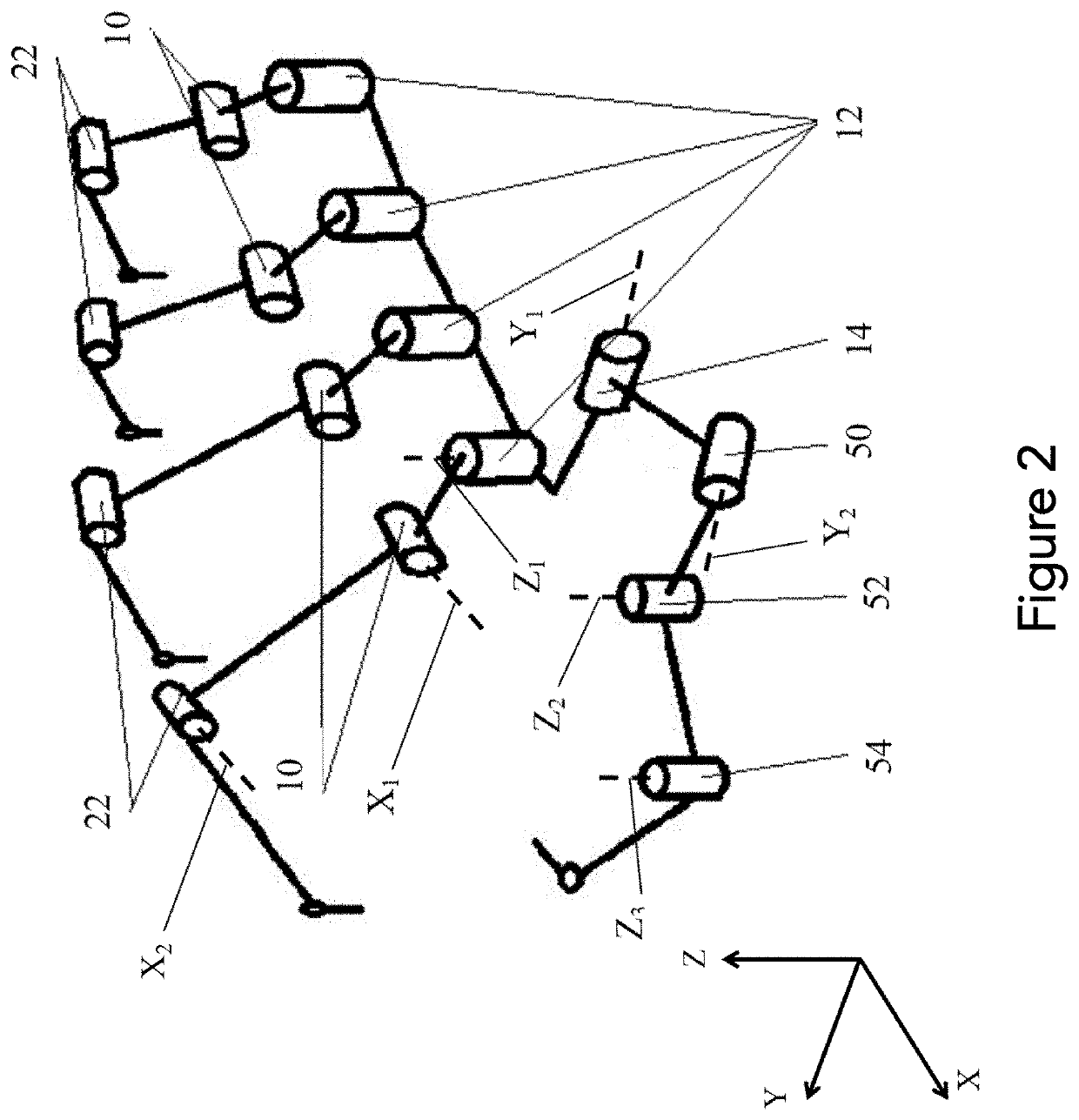

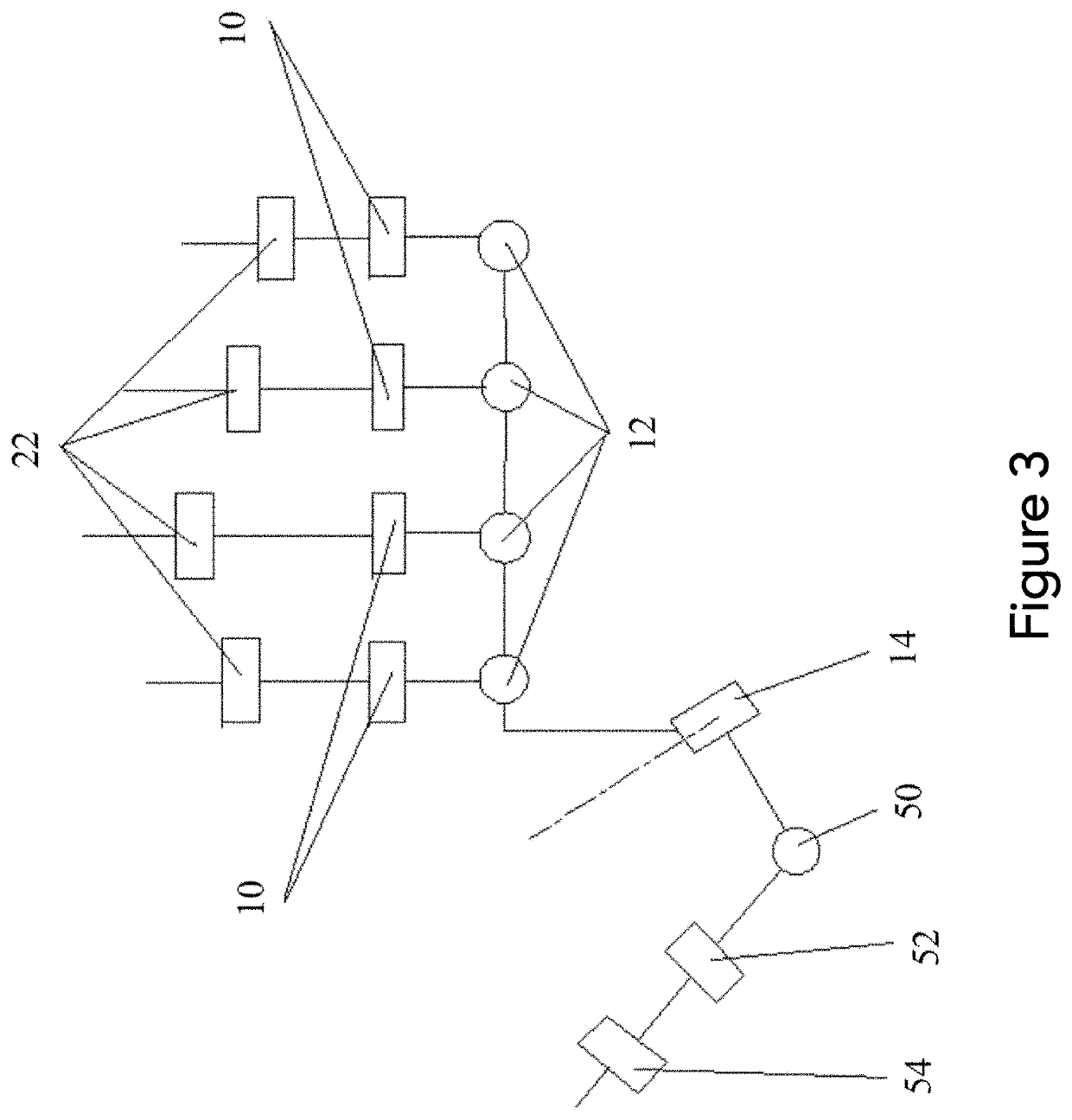

This disclosure includes a hand motion-capturing device with a force feedback system. In some embodiments the device includes a base, a microcontroller connected to the base, a thumb sensor module and four-finger sensor modules each electrically connected to the microcontroller. In some embodiments, the device may include five-link rods that interconnect the thumb sensor module to the base and each of the four-finger sensor modules to the base. In some embodiments, the device includes a thumb force feedback system adapted and configured to receive a human thumb and a four-finger force feedback system adapted and configured to receive an index finger, a middle finger, a ring finger, and a little finger. The thumb force feedback system and the four-finger force feedback system may each be movably connected to respective link rods and the thumb sensor module and four-finger sensor modules, respectively.

Owner:SHENZHEN DEXTA ROBOTICS CO LTD

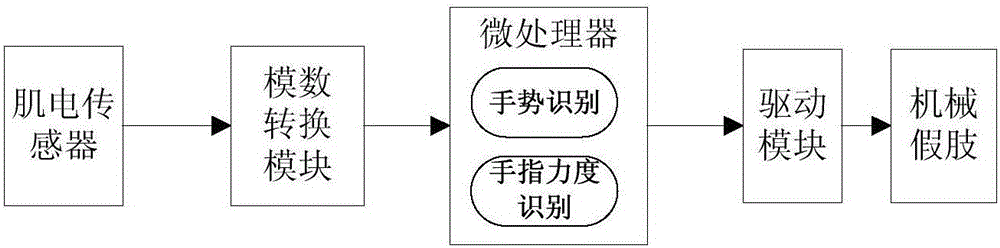

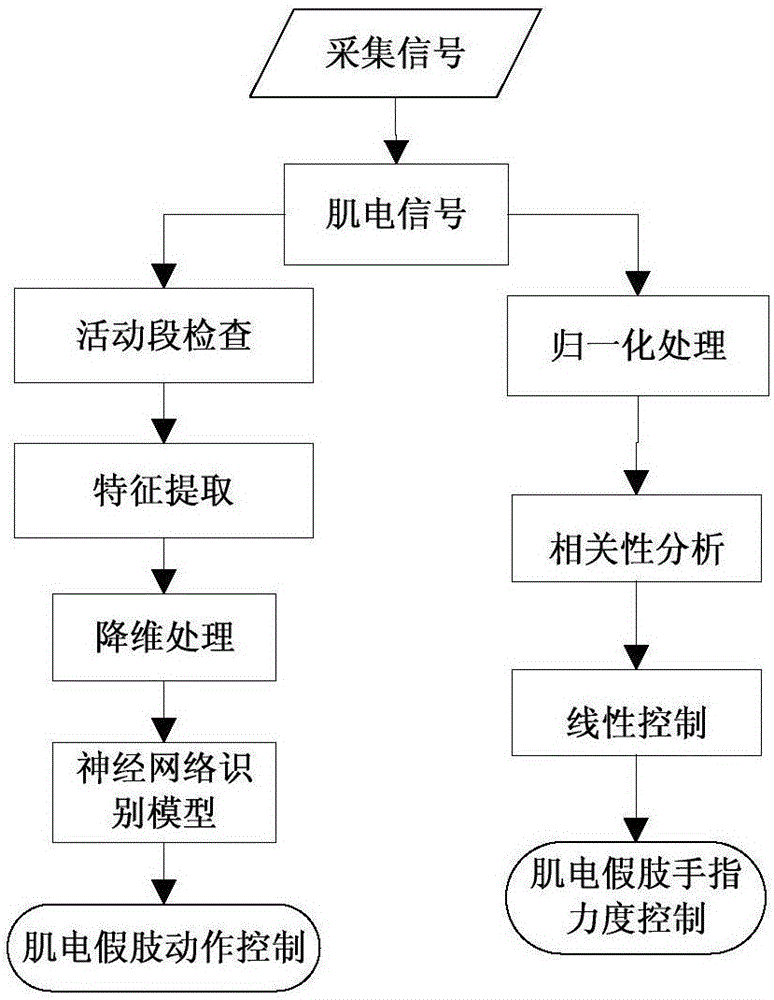

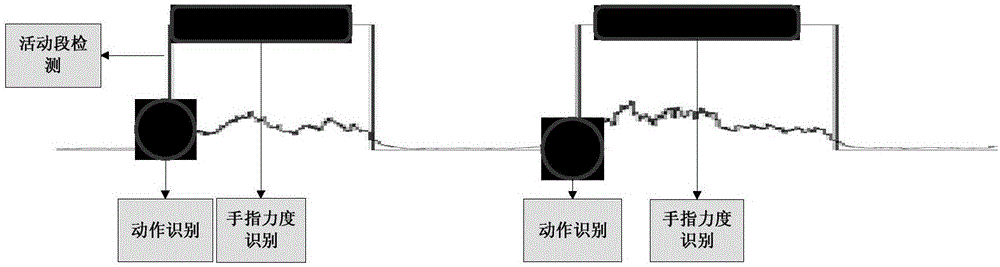

Myoelectric prosthesis gesture and force control method

InactiveCN106236336AImprove the sense of bodyImprove convenienceProsthesisLinear controlOriginal data

The invention relates to a myoelectric prosthesis gesture and force control method and belongs to the technical field of myoelectric prosthesis. The method comprises the steps of acquiring forearm surface electromyogram signals; transmitting the multiple channels of surface electromyogram signals into a gesture identification model and a finger force identification model by segments through a moving window; in the gesture identification model, detecting the mobile segment of each signal firstly, extracting biological electromyogram signal feature information, and conducting data dimension reduction on the feature information; conducting real-time action identification and classification according to the feature information obtained after dimension reduction; in the finger force identification model, conducting normalization on original data of the forearm surface electromyogram signals, selecting a channel of surface electromyogram signals most closely related to each finger force linearly through correlation analysis, and conducting linear control on the finger force of myoelectric prosthesis with the surface electromyogram signals corresponding to different fingers respectively. By the adoption of the method, a prosthesis user can naturally and directly control the gesture and finger force of myoelectric prosthesis to achieve basic daily movement, and therefore the identity sense and living convenience of the prosthesis user are improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

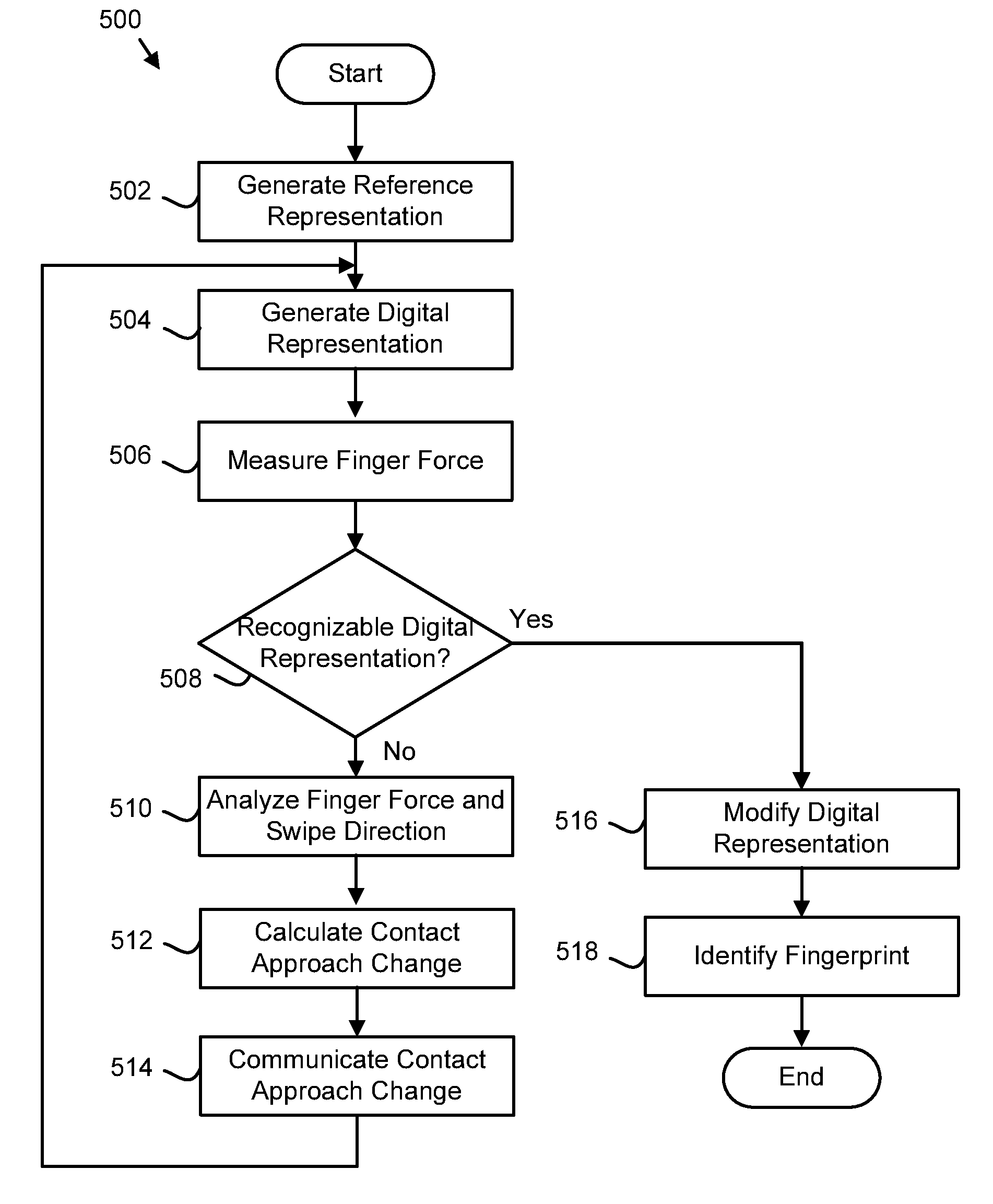

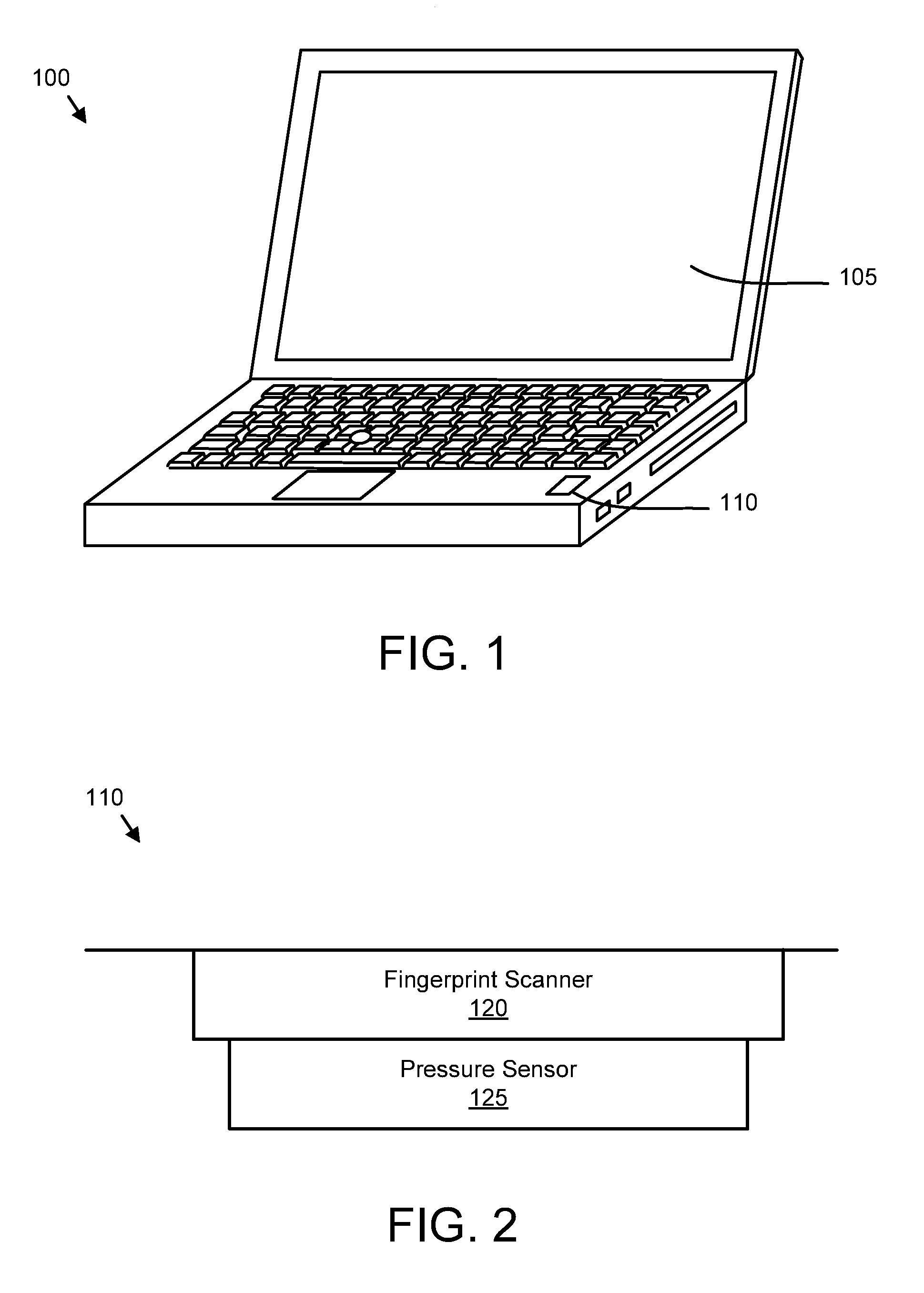

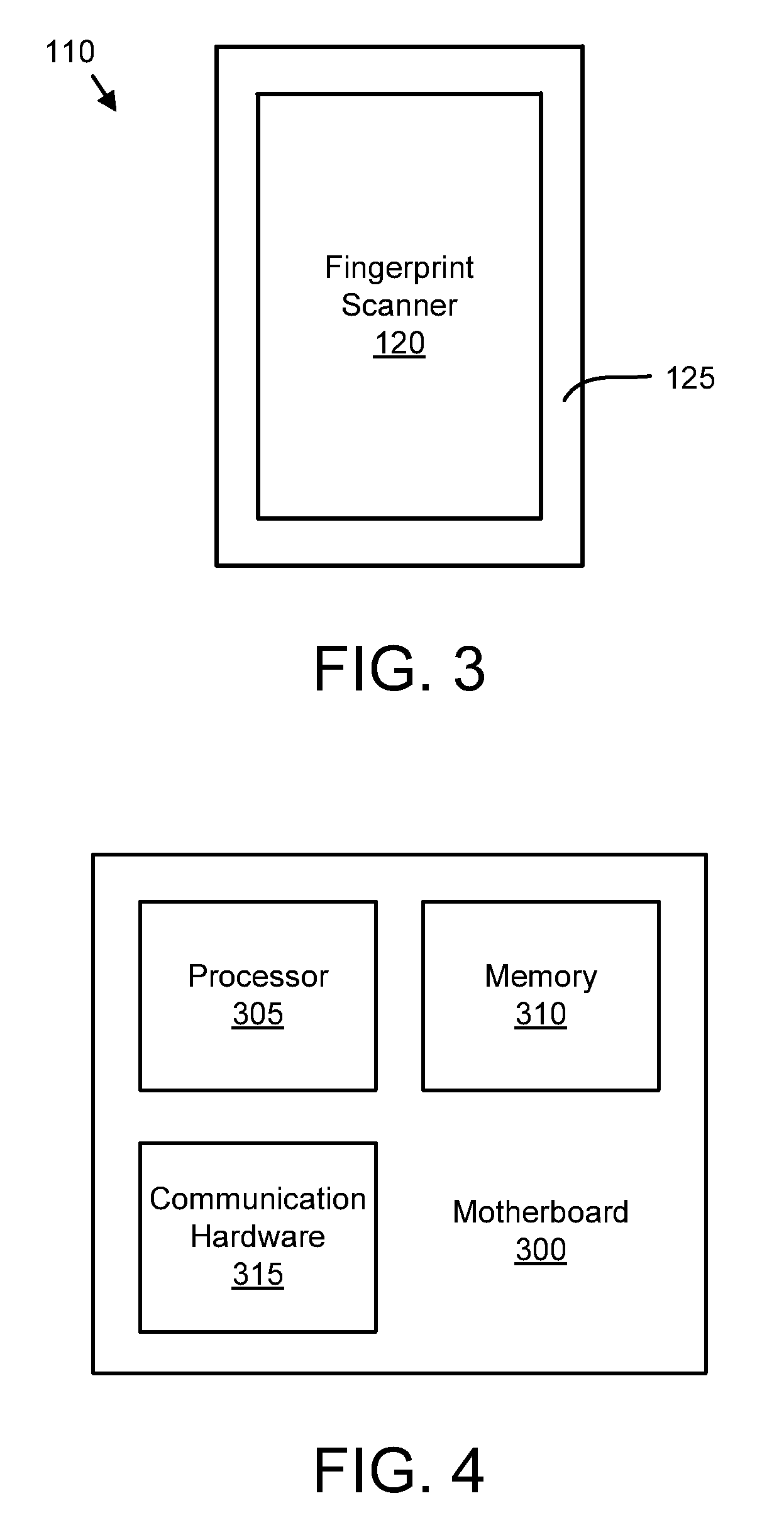

Utilizing force information to improve fingerprint reading

For utilizing force information to improve fingerprint reading, a fingerprint scanner generates a digital representation of a fingerprint for a finger in contact with the fingerprint scanner. A pressure sensor is in physical communication with the fingerprint scanner and measures a finger force of the finger.

Owner:LENOVO PC INT

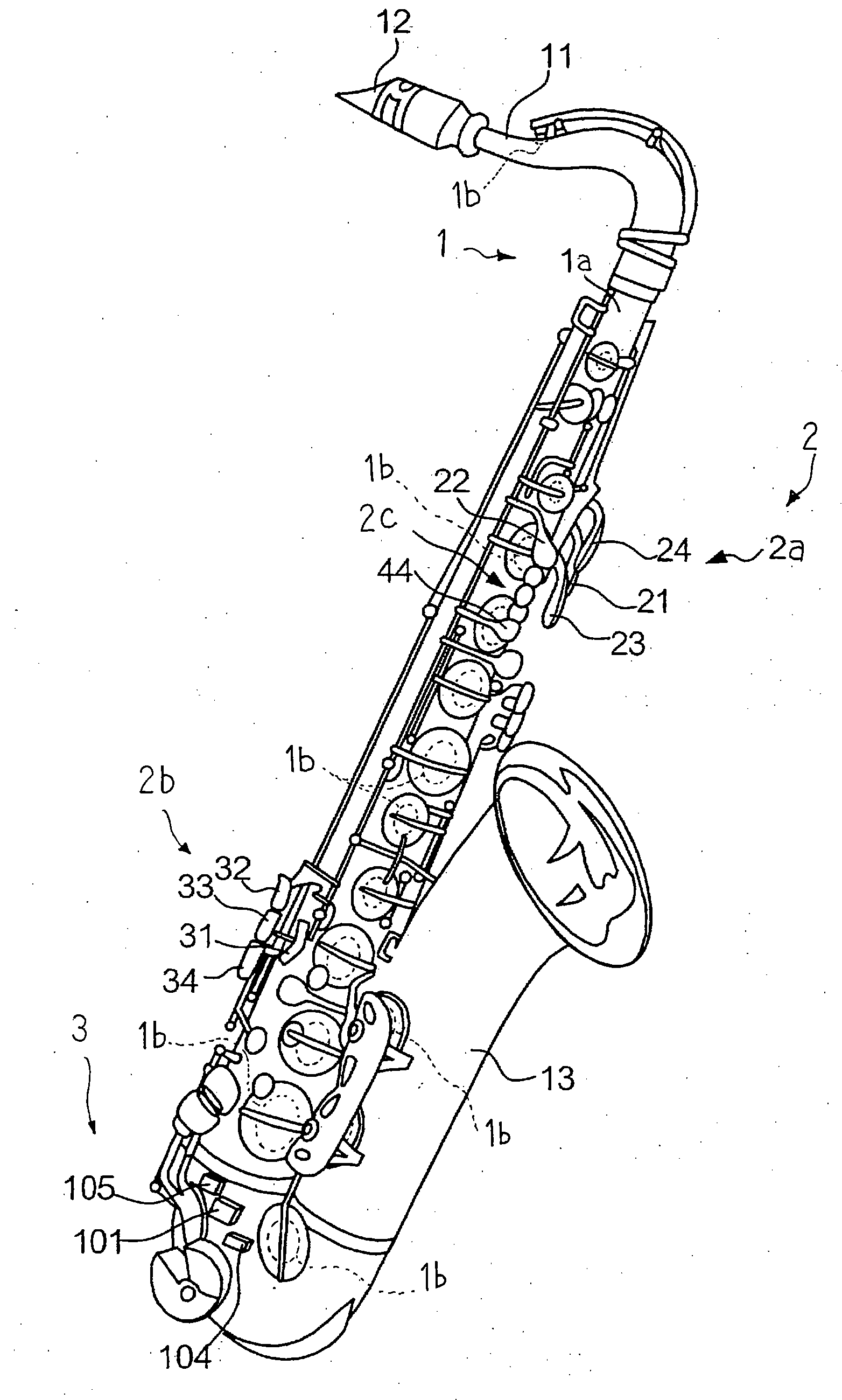

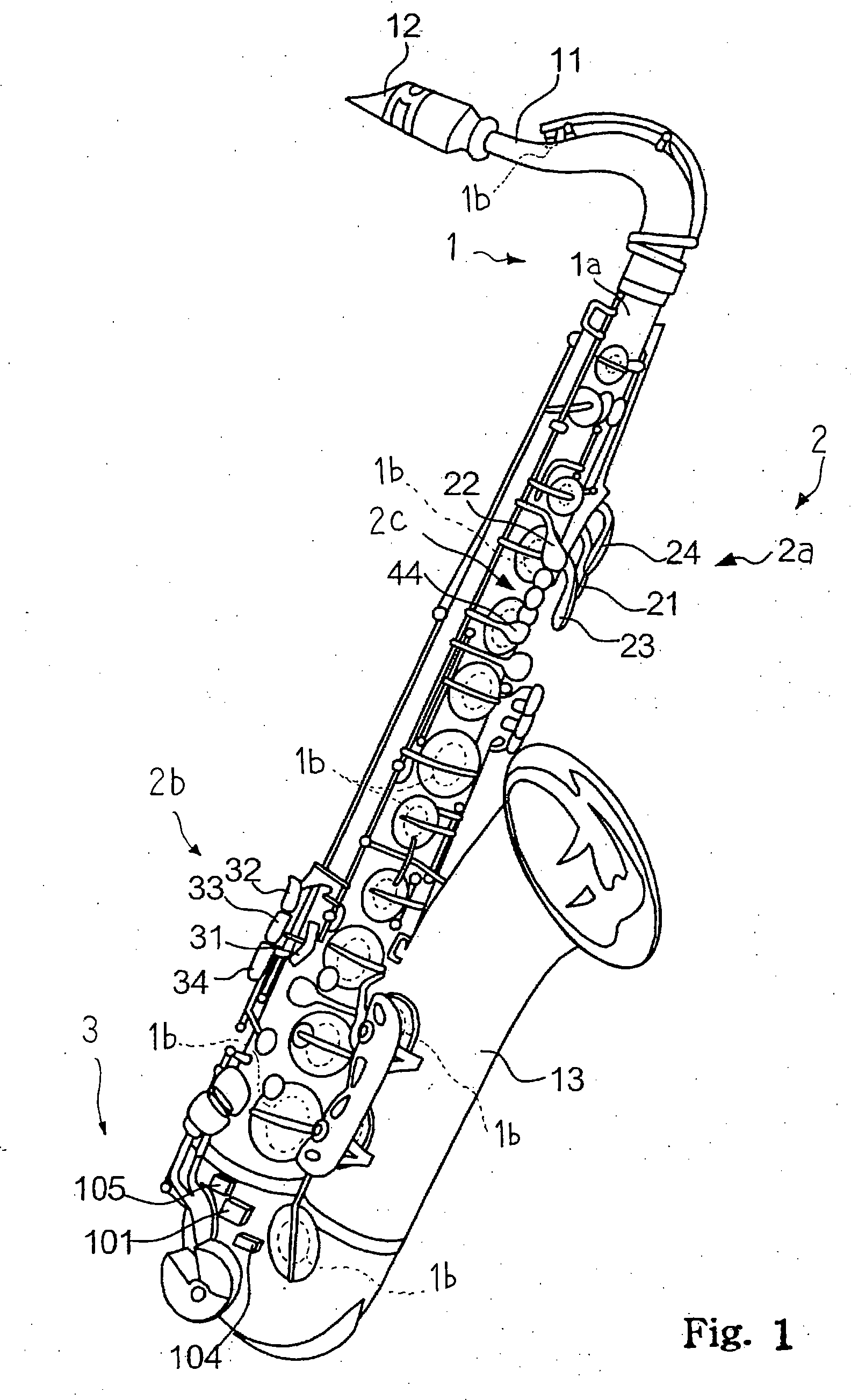

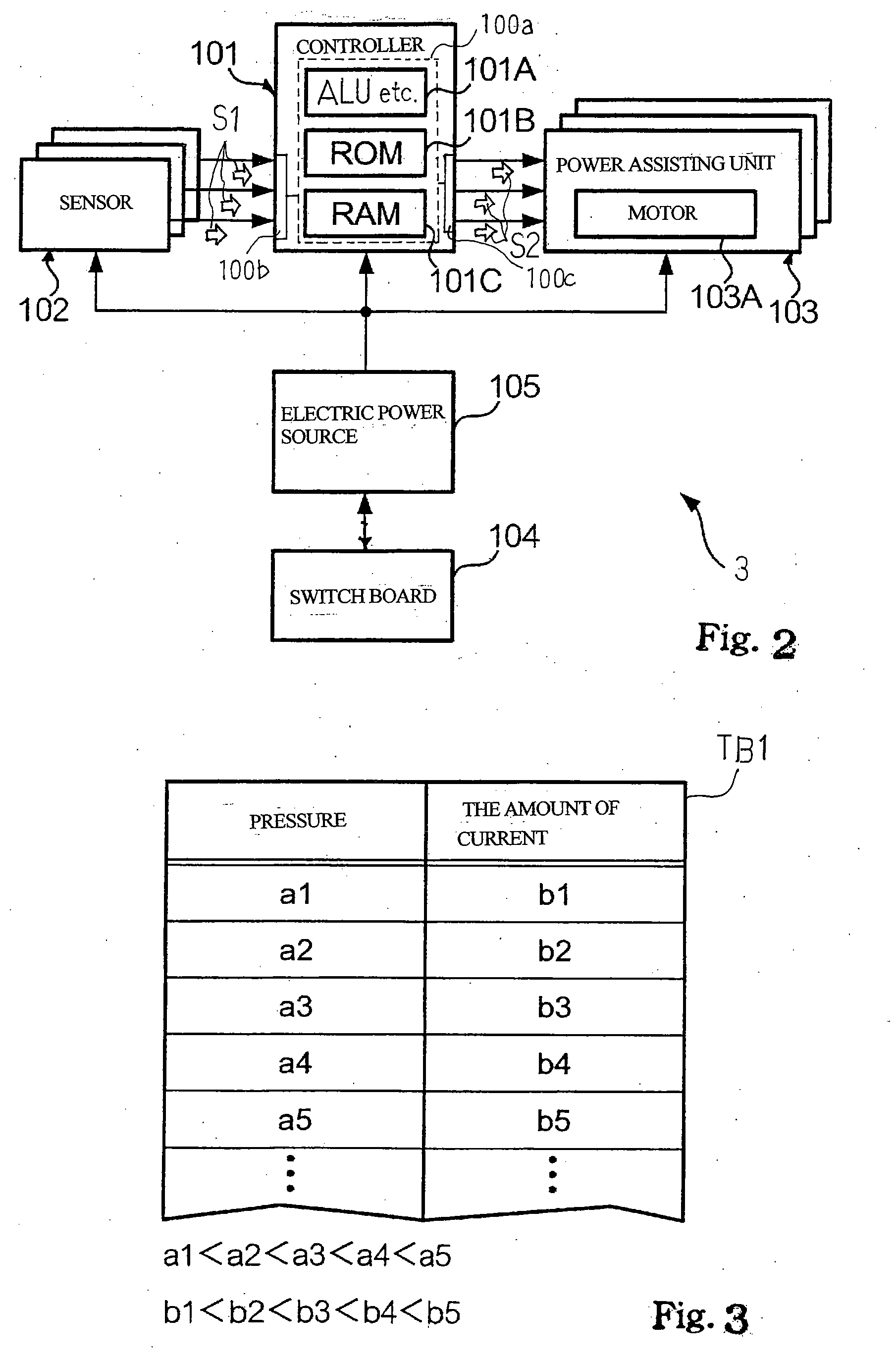

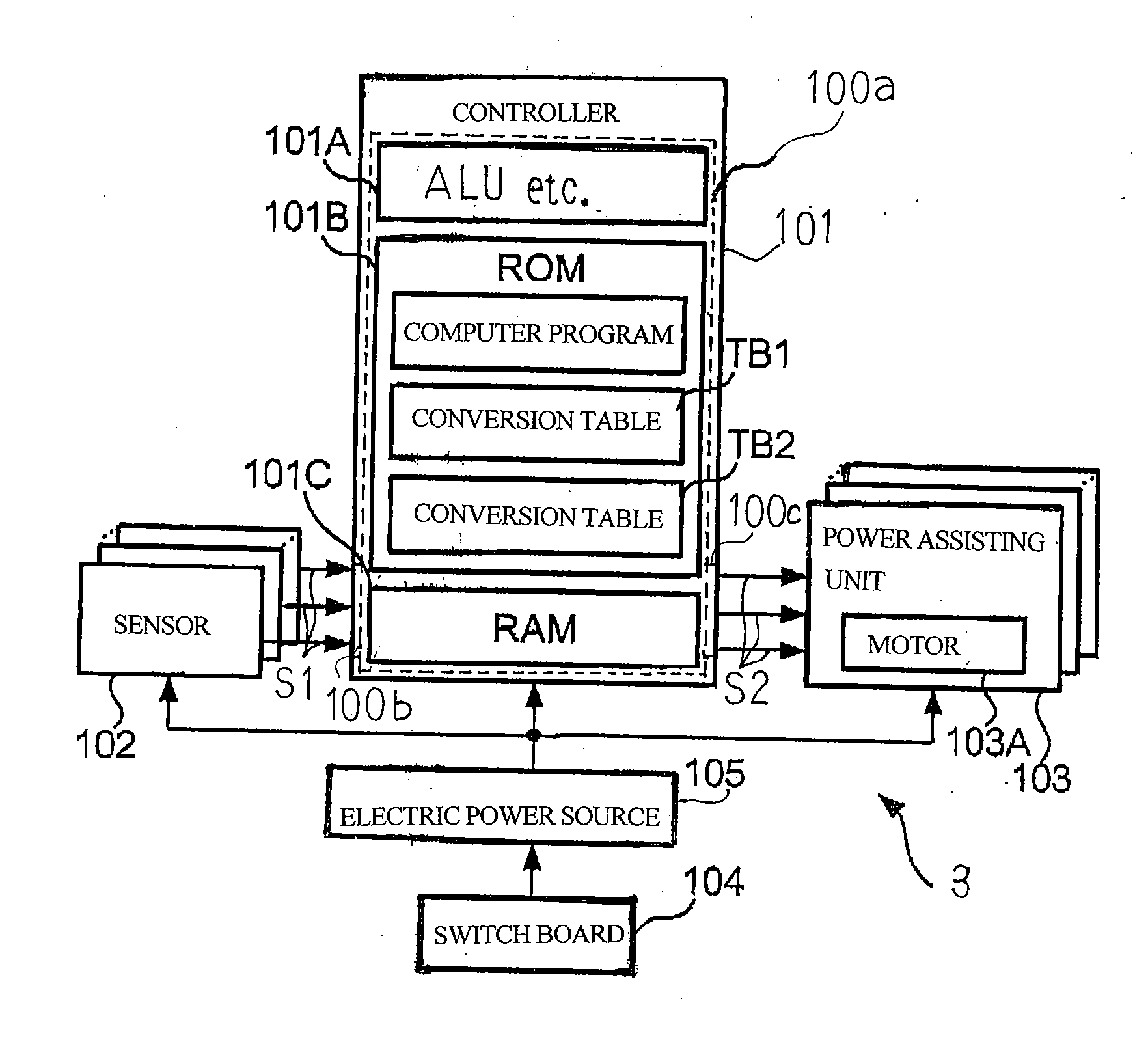

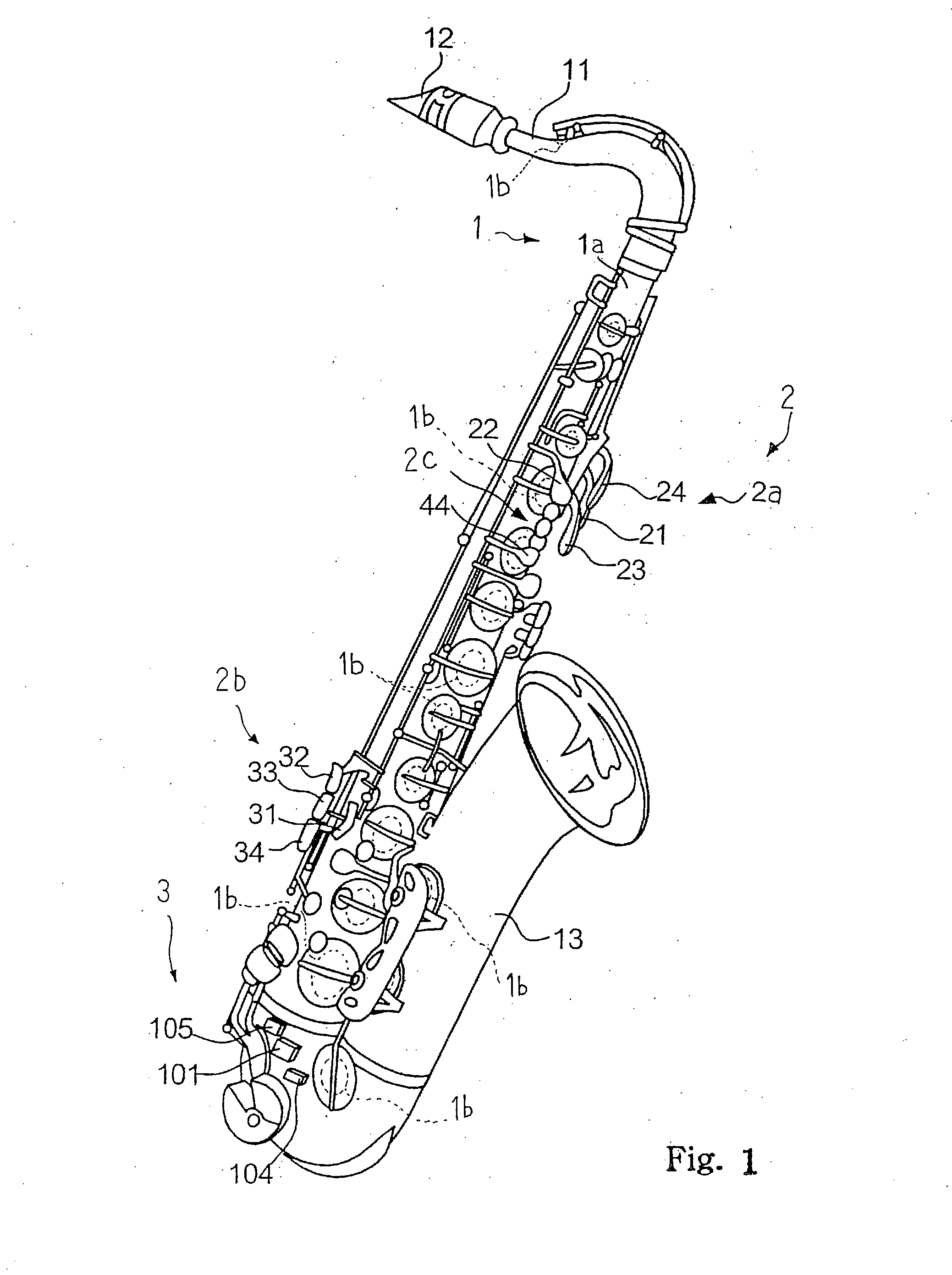

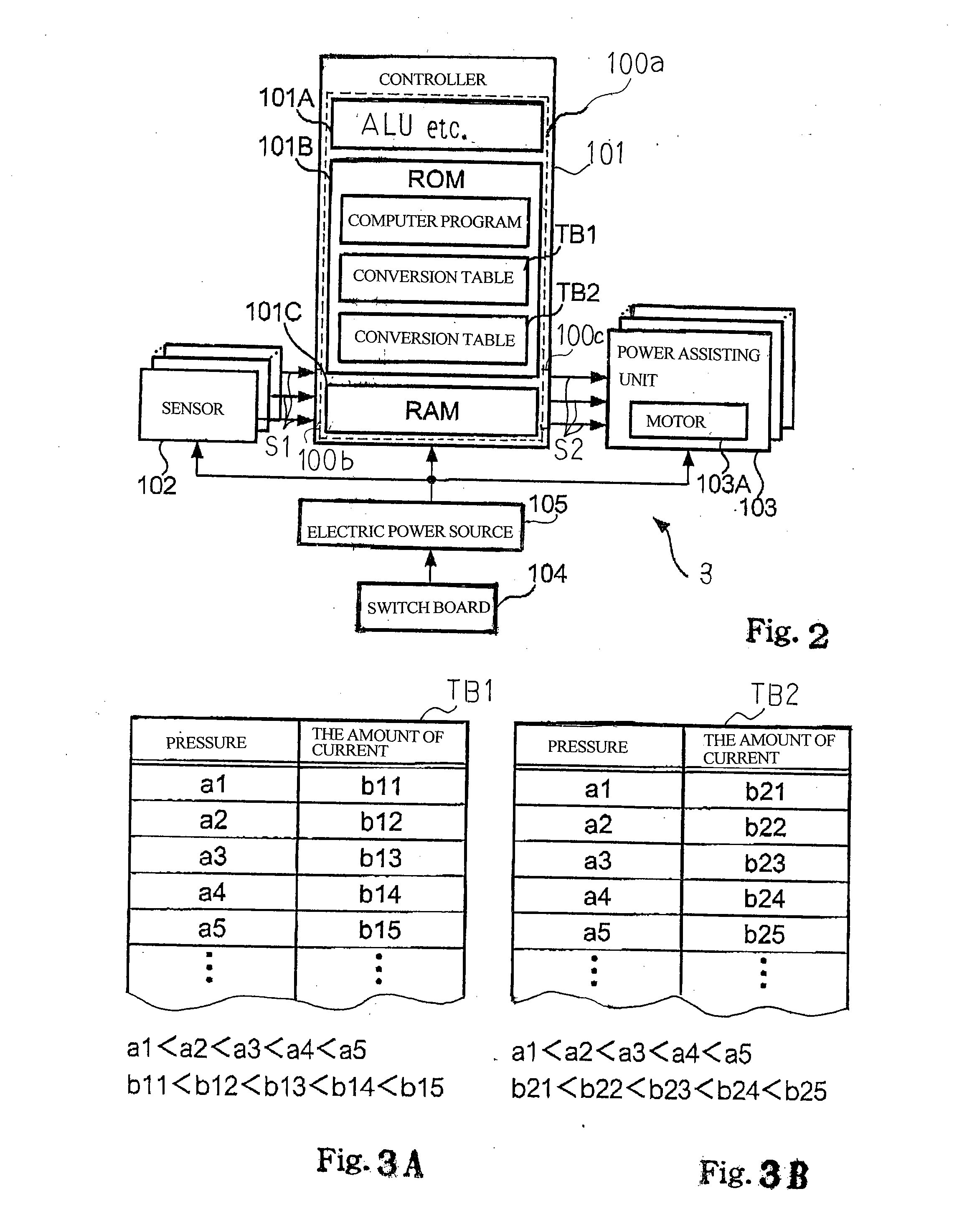

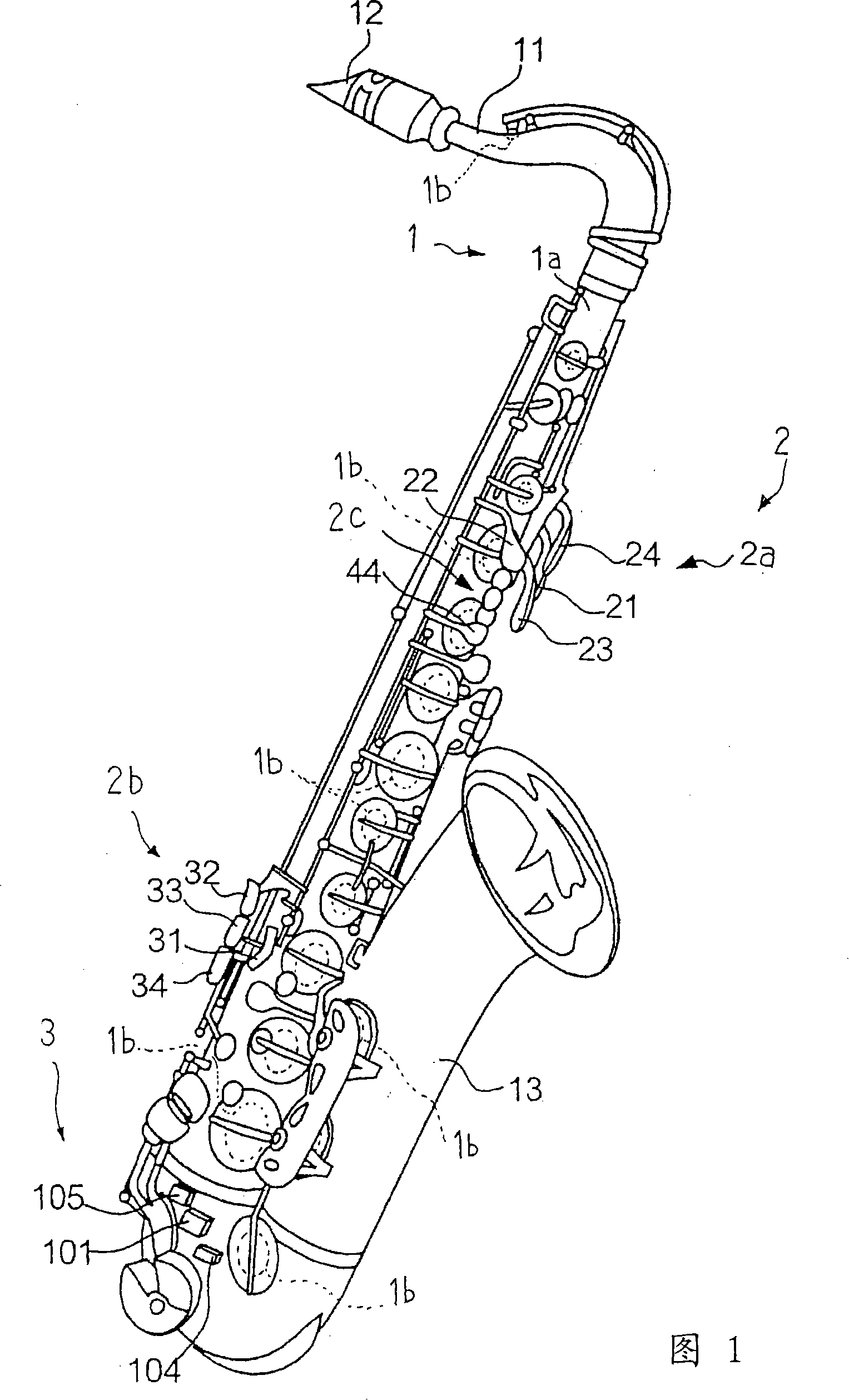

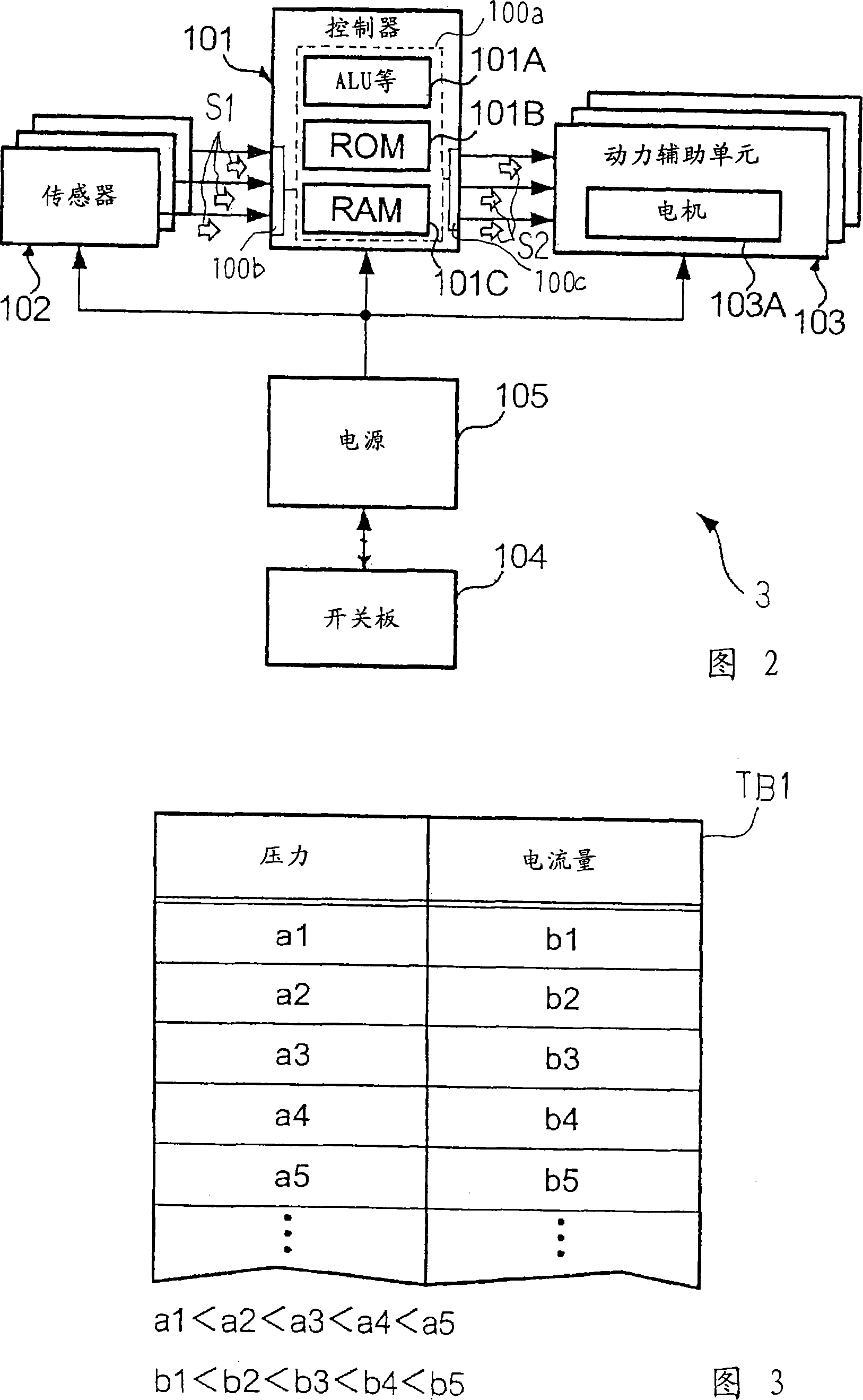

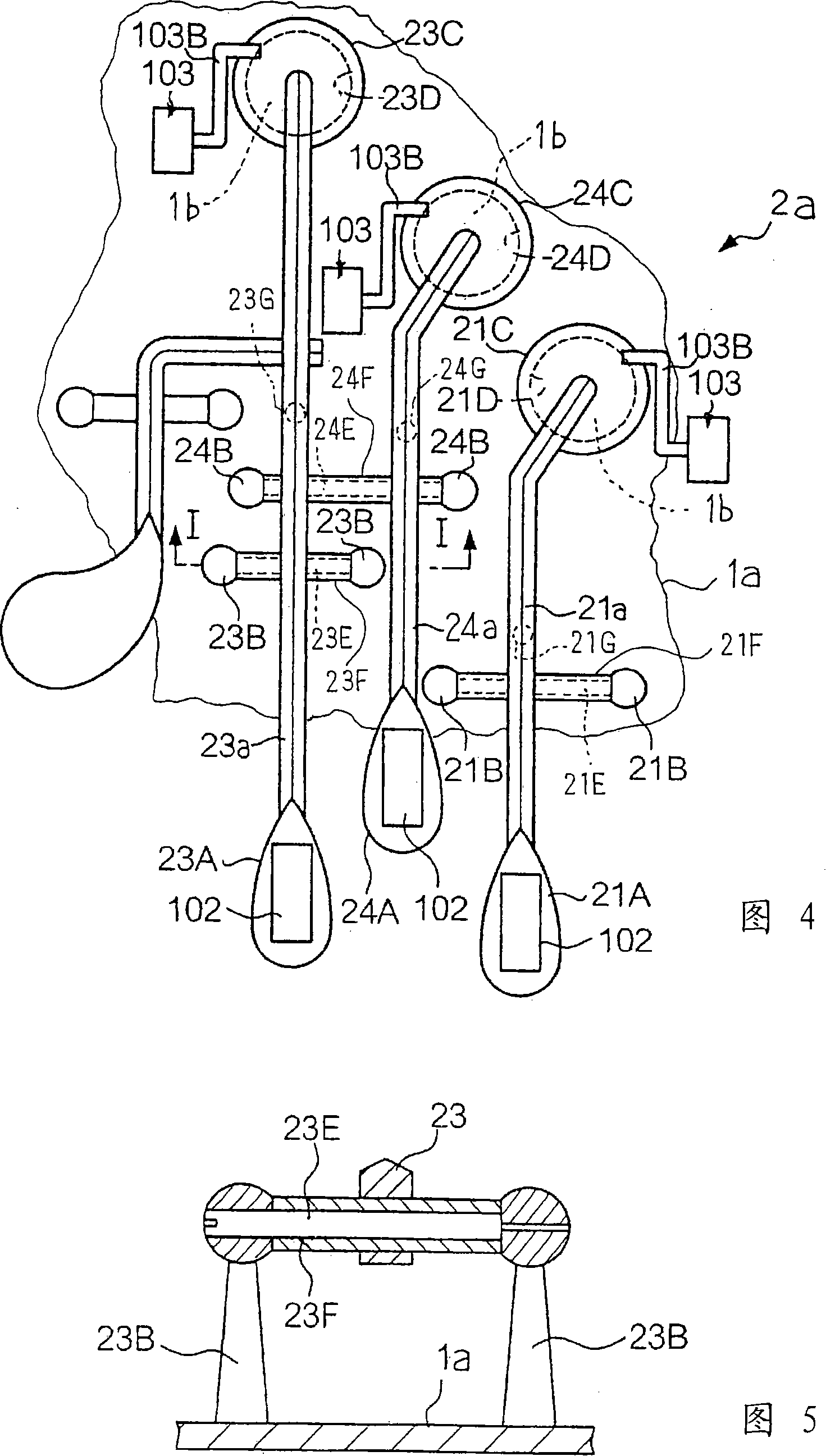

Musical instrument and supporting system incorporated therein for music players

A saxophone is equipped with a supporting system, and the supporting system assists a player in performance on the saxophone; the supporting system includes pressure sensors respectively adhered to the keys of the saxophone, torque motors provided in association with the keys for exerting assisting force on the keys and a controller for adjusting a driving signal to a certain amount corresponding to the pressure; since a conversion table is stored in the controller, the controller looks up the amount of driving current to be adjusted in the conversion table, and supplies the driving signal to the torque motor, whereby the keys are depressed by the total of finger force and assisting force.

Owner:YAMAHA CORP

Ferrule for making fingertight column connections in gas chromatography

A ferrule arrangement for use in sealing connections to gas chromatography columns includes a generally tubular metal ferrule with an axial bore to receive a fracturable column with a protective coating. The ferrule has a forward part that tapers to a tip region of the ferrule. A generally tubular former has a socket portion to receive the ferrule and further has an internal conical surface that, after such receipt, engages the forward part of the ferrule. A portion is provided on either or both of said ferrule and the former by which the ferrule and former may be directly or indirectly relatively moved together by application of finger force. The taper and the internal conical surface exhibit relative taper angles and the tip region of the ferrule is sufficiently radially thin whereby the application of finger force (i) is adequate to move the ferrule axially into the former to cause the conical surface to engage the tip region of the ferrule and to deform the tip region into sealing engagement with the protective coating of the column, but (ii) does not break the column.

Owner:TRAJAN SCI AUSTRALIA

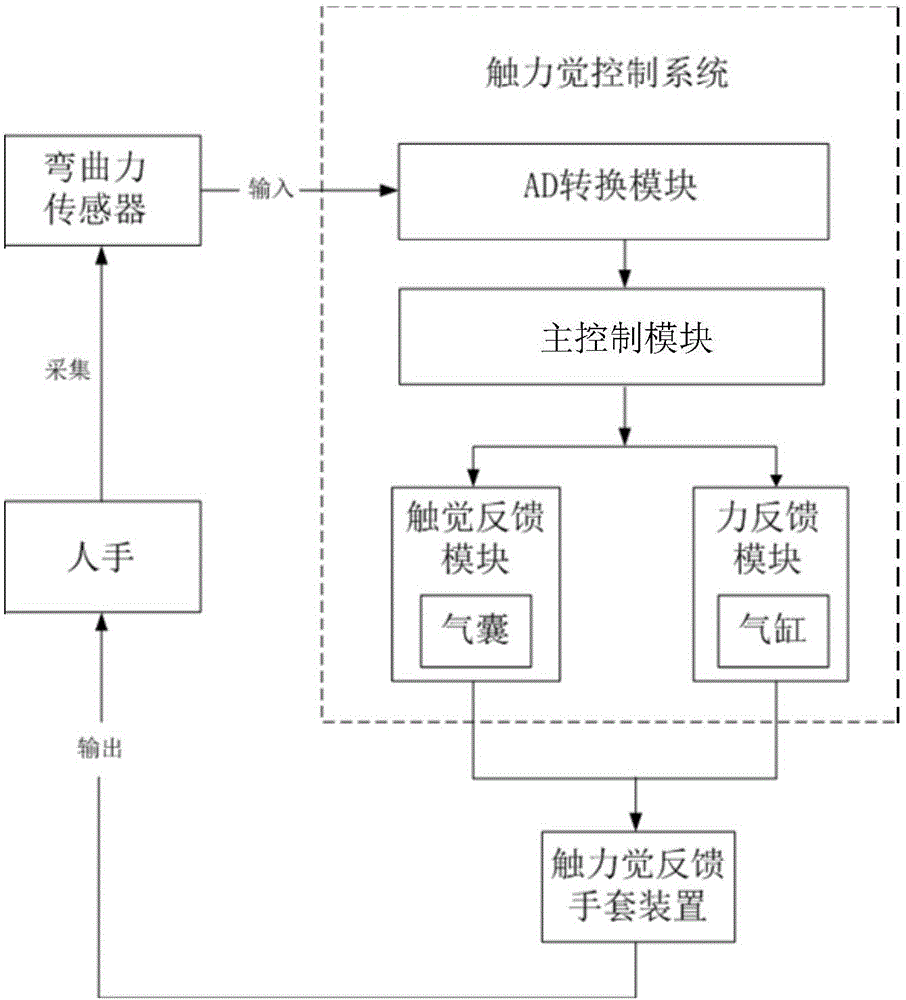

Pneumatically driven force feedback and tactile feedback apparatus

ActiveCN106249884AImprove compactnessImprove portabilityInput/output for user-computer interactionGraph readingDiaphragm pumpControl system

The invention discloses a pneumatically driven force feedback and tactile feedback apparatus. The force feedback and tactile feedback apparatus comprises a tactile-force feedback glove apparatus and a tactile-force control system, wherein the tactile-force control system comprises a main control module, a tactile feedback module, a force feedback module and an AD conversion module; the AD conversion module performs analog-digital conversion on finger force data acquired by a sensor arranged on the tactile-force feedback glove apparatus; the main control module controls the opening or closing of an air cylinder in the force feedback module according to the converted finger force data to generate force feedback, and controls a diaphragm pump in the tactile feedback module to fill an airbag with air according to the converted finger force data to generate tactile feedback; and the tactile-force feedback glove apparatus performs a movement according to the force feedback generated by a piston movement in the force feedback module and the tactile feedback generated by the airbag mounted on gloves in the tactile feedback module. The force feedback and tactile feedback apparatus has the advantages of safety, portability and low cost.

Owner:BEIHANG UNIV

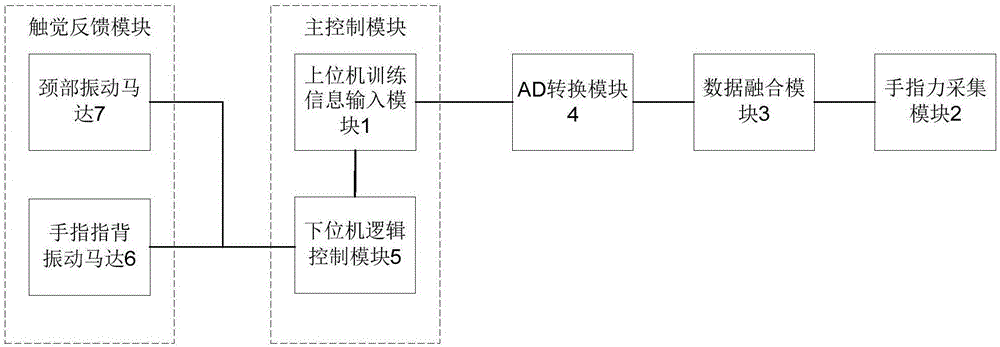

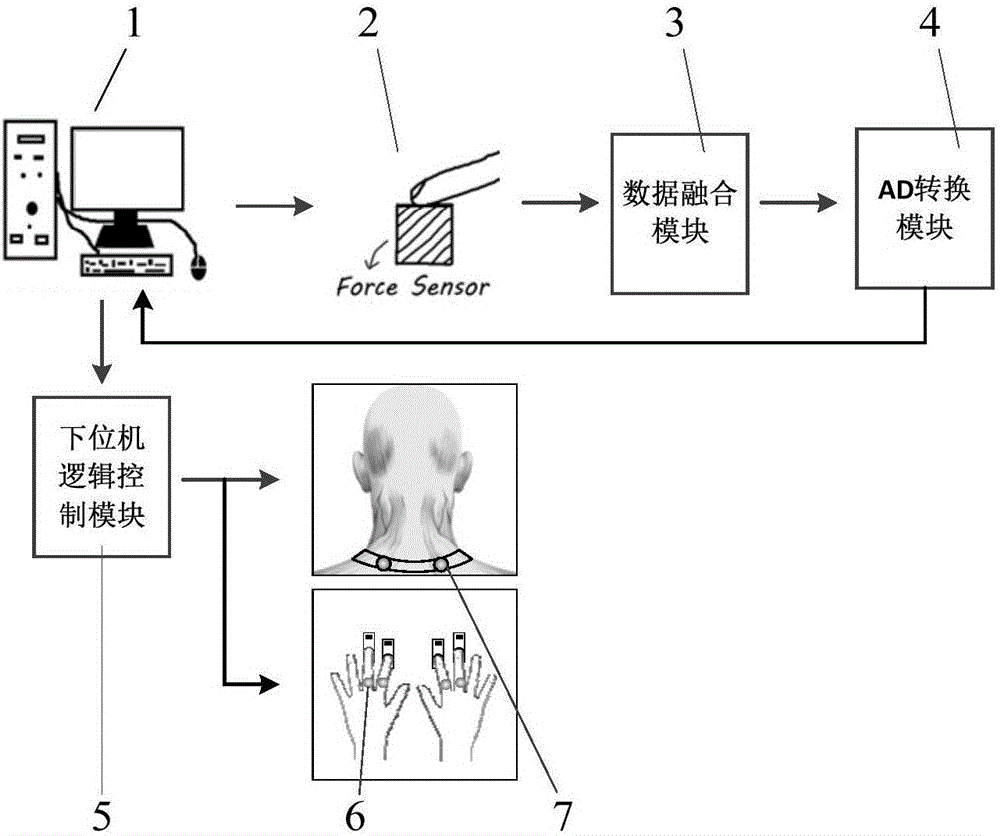

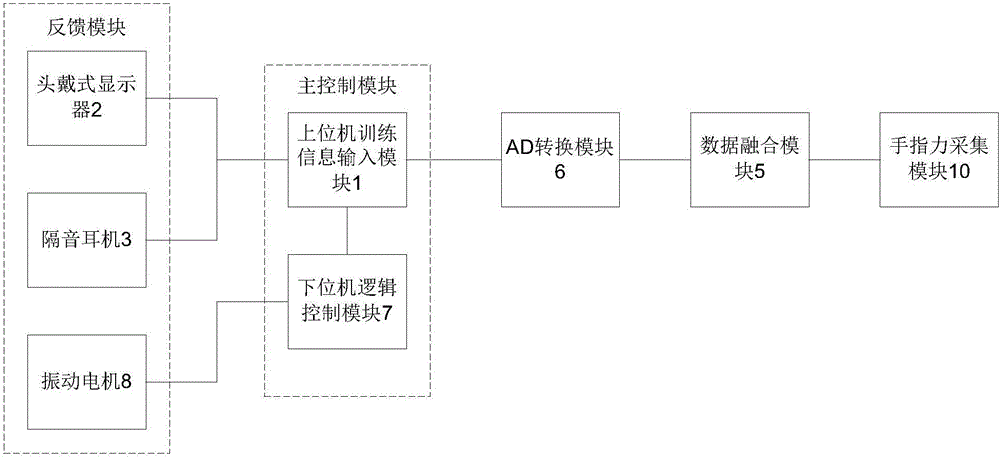

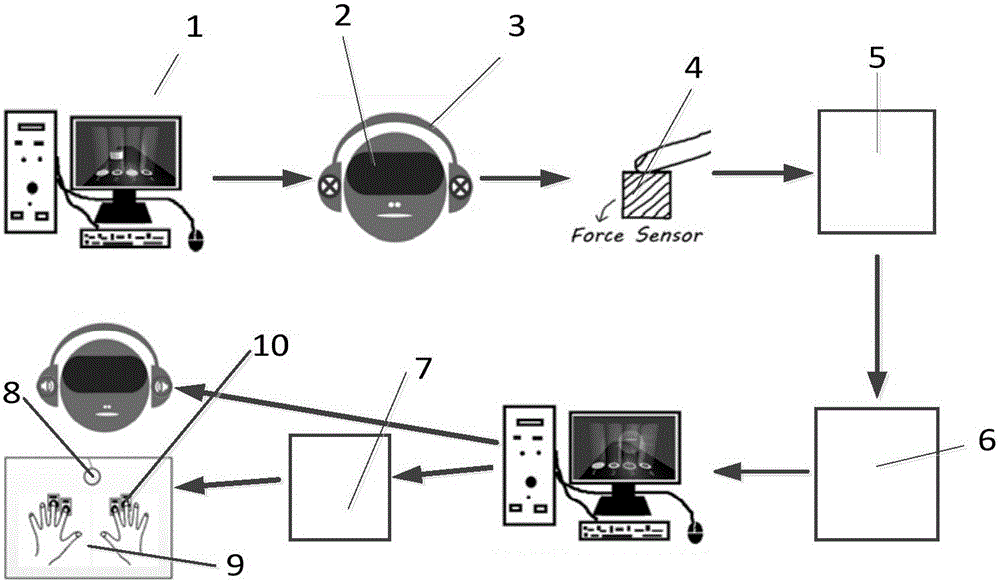

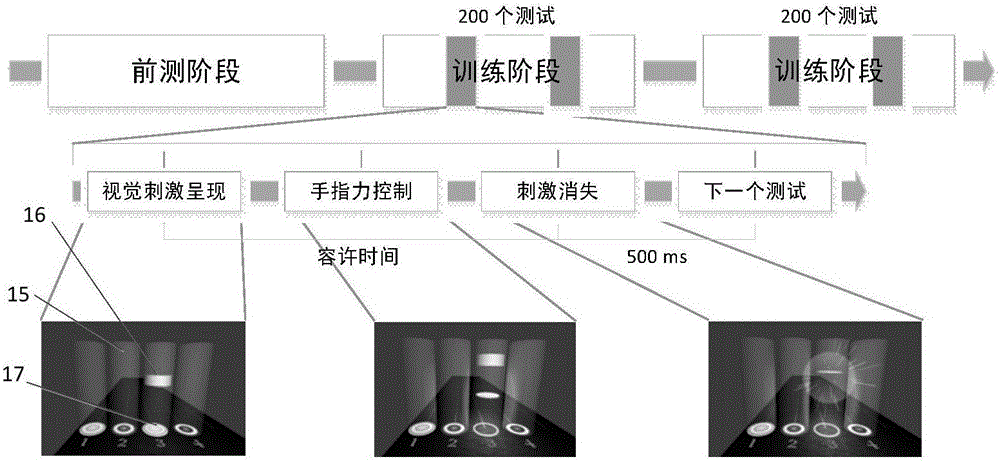

Pure touch sense feedback and continuous force control task combined attention training system

ActiveCN106340221AImprove concentrationInput/output for user-computer interactionGraph readingTouch SensesAttention training

The invention discloses a pure touch sense feedback and continuous force control task combined attention training system. According to the system, continuous attention as well as focusing movement of finger force of the fingertip(s) of single or multiple fingers is trained, the difficulty of a training task is adjusted automatically via a self-adaptive algorithm to adapt to continuously improving control capability of a user or individual differences of users, the user is highly enthusiastic in and pay much attention to the training task always, and thus, the attention and finger force control of target people are improved.

Owner:BEIHANG UNIV

Personal electronic device holder

The present invention provides a portable electronic device holder. A lower adapter support piece supports two lower adapter arms. An upper adapter arm is supported by a adjustable rod. An adjustment fitting is connected to the lower adapter support piece and the adjustable rod is slidingly connected to the adjustment fitting and can be slid up and down by utilization of finger force. A portable electronic device is mounted and held secure as it is squeezed between the upper adapter arm and the two lower adapter arms. In a preferred embodiment the portable electronic device holder is mounted by either inserting the adjustable rod into a hollow pedestal attached to a base or by attaching the lower adapter arm support piece to a dual T mount of a separate mounting device.

Owner:CICCO MIKE

Immersive attention training system combining vision and discrete force control tasks

ActiveCN106128201AImprove concentrationImprove finger controlCosmonautic condition simulationsSimulatorsMaximum levelAttention training

The invention discloses an immersive attention training system combining vision and discrete force control tasks. The system, by frequently conducting attention and finger force focusing activity training and through an adaptive algorithm, can automatically regulate the difficulty of training tasks so as to adapt to increasing control capacity of a user or individual difference of different persons; and meanwhile, the initiative and attention input of the user in the training tasks can be constantly kept at a maximum level, so that the purpose of improving the attention and finger force control of target people is achieved.

Owner:BEIHANG UNIV

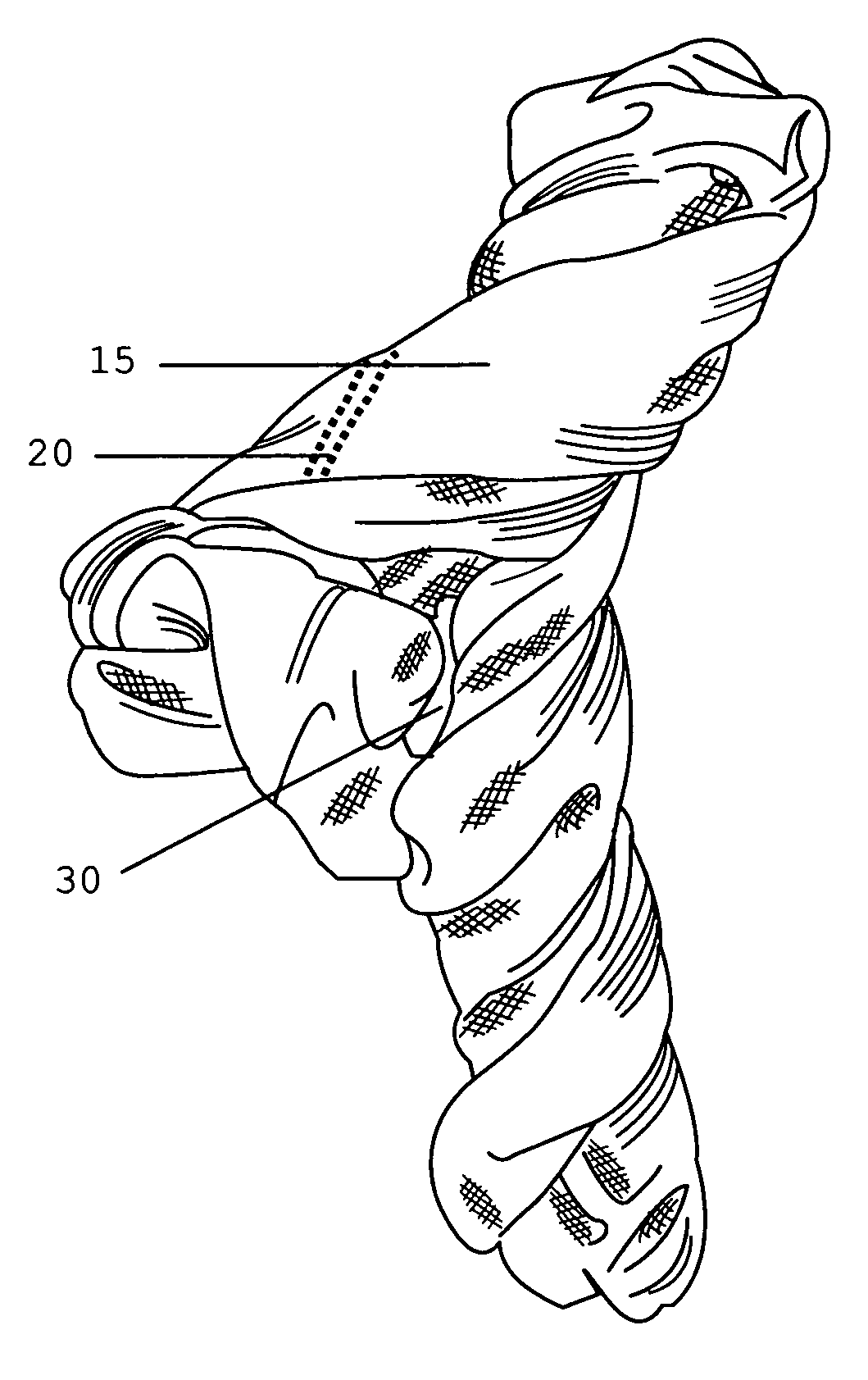

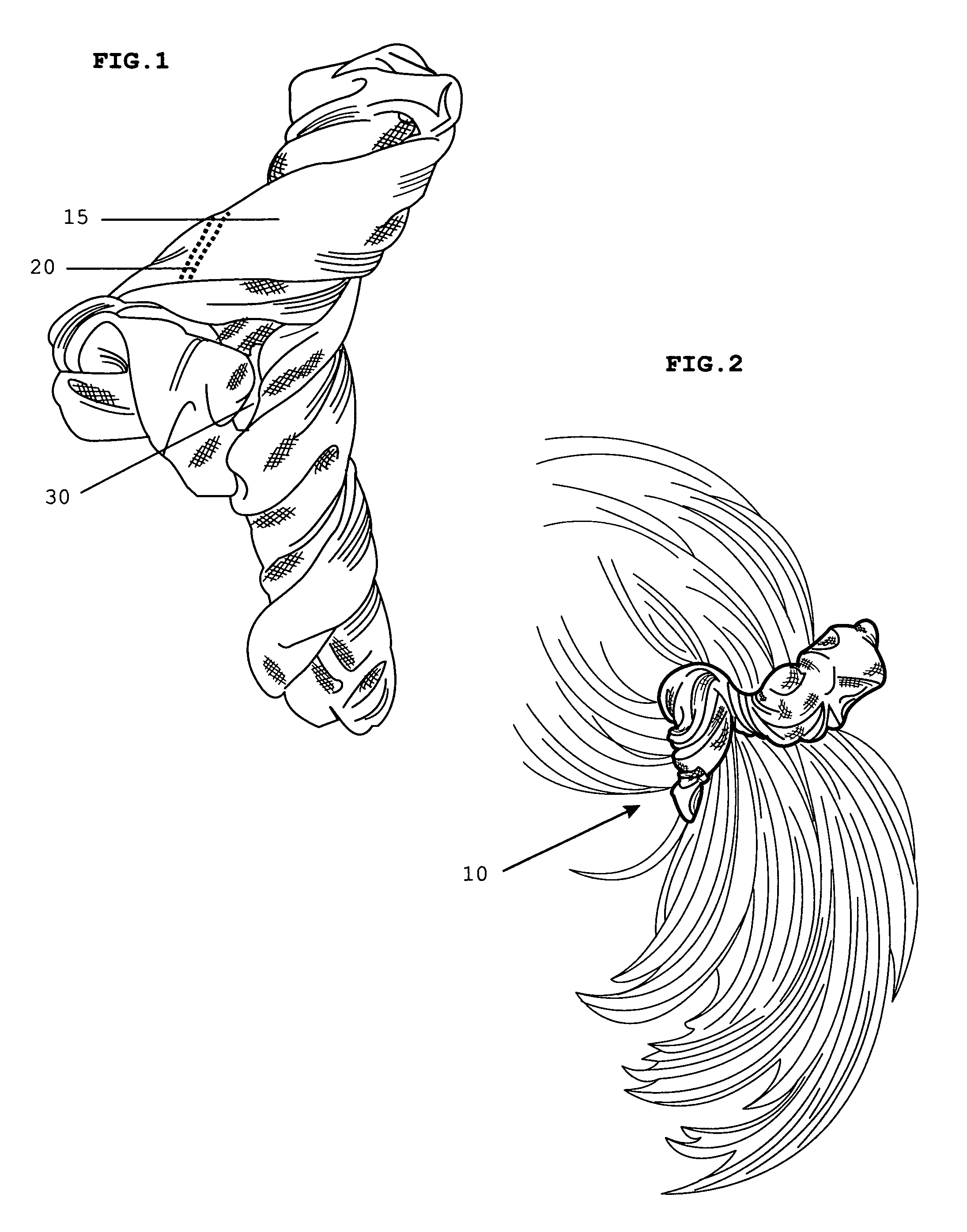

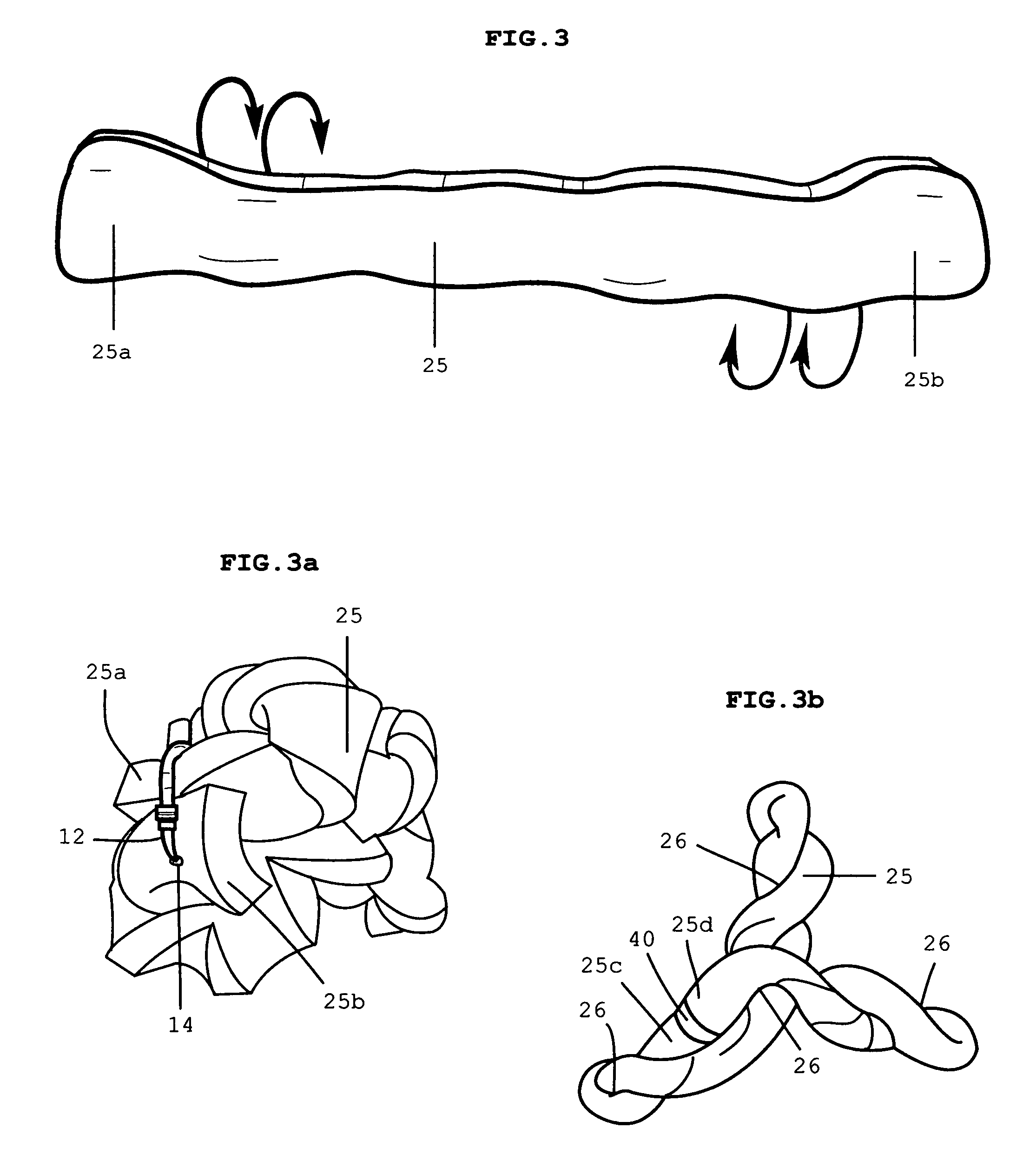

Convoluted hair band for creating many varying hairstyles

InactiveUS7637266B1Efficient use ofImprove gripCurling devicesTravelling articlesEngineeringFinger force

A convoluted internally stressed rubber member forms several twisted crossover loop portions. The user's fingers force open one or more loop portions to insert varying hair lengths, separate hair-pieces and / or decorative objects such as jewelry or strips of fabric, to be held therein. When the user's fingers separate from the device, the loop portions contract and grip the inserted items, with ‘non holding’ loops left free to contract onto themselves. The twisted rubber member is completely covered around its circumference with decorative fabric material. Many fabric compositions can be combined with varying rubber lengths, widths and shapes, and both can be incorporated into differing decorative or functional holding devices to create varying and unique holding embodiments. The device can further hold removable or attachable hair extensions, and or decorative items away from where the users hair is being held, or jointly together to create unique holding patterns.

Owner:GIBBONS ROGER C

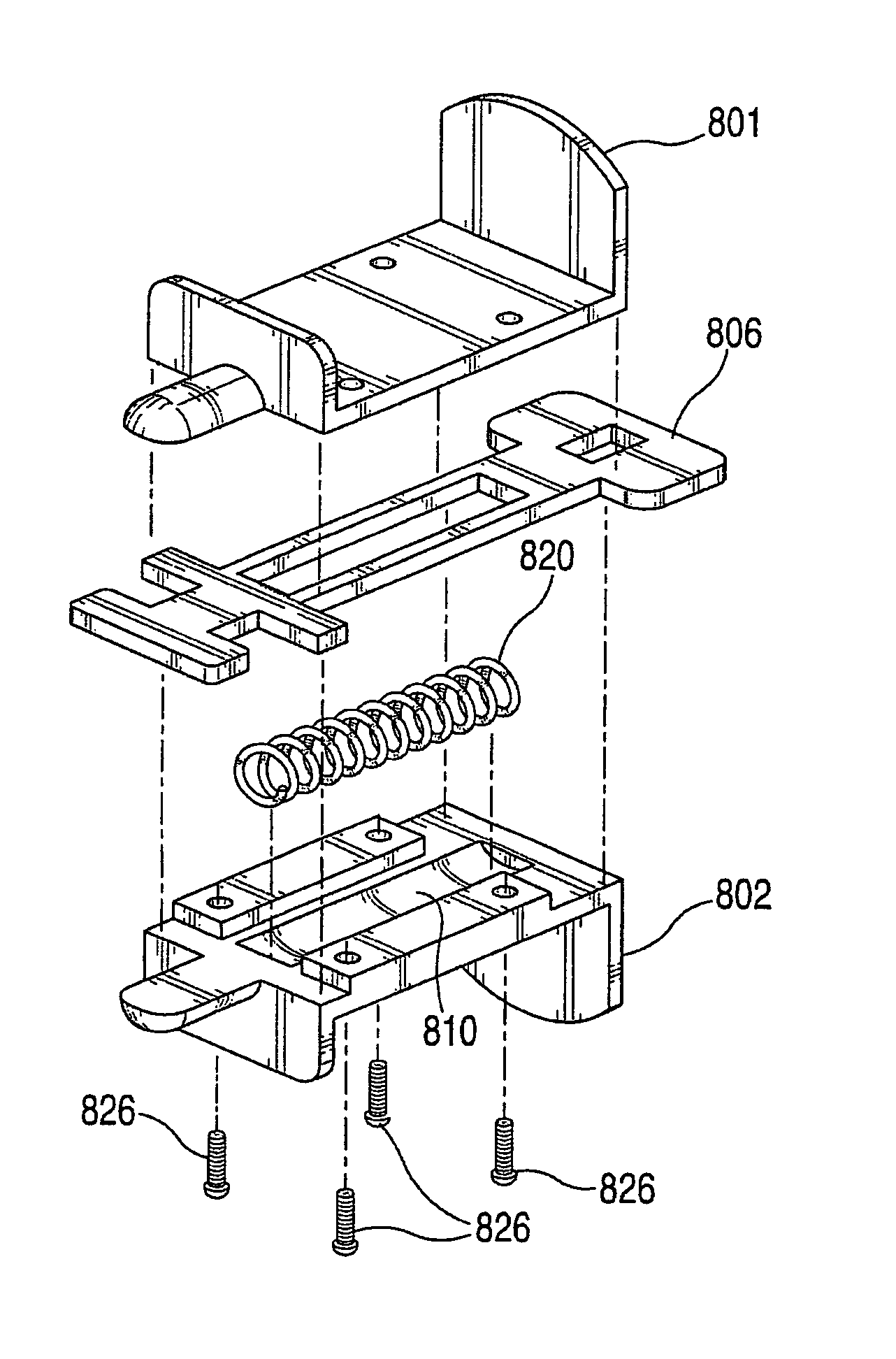

Spring loaded security slot attachment for portable device security

InactiveUS20120260698A1Prevent theftRule out the possibilityClothing locksDigital data processing detailsSpring forceElectronic instrument

A lock includes an assembly of a slot engaging member insertable in a slot of a piece of equipment being locked, such as a portable or desktop computer, a laptop, notebook or other handheld electronic device, a monitor, a television / video screen, a video game, an electronic instrument such as an oscillator or a medical centrifuge or other analytical device, or the like. A rotatable locking member engages an anchor sub-assembly having a rotatable element, wherein the rotatable element communicates with a spring force urging against the rotatable locking member. The rotatable locking member is alternately movable in and out of the slot in which it is inserted, and the locking element is rotatable by finger force overcoming said spring force against the locking member, wherein the lock is locked without use of a tool.

Owner:THINK PROD

Spring loaded security slot attachment for portable device security

InactiveUS8456836B2Prevent theftRule out the possibilityClothing locksDigital data processing detailsSpring forceElectronic instrument

A lock includes an assembly of a slot engaging member insertable in a slot of a piece of equipment being locked, such as a portable or desktop computer, a laptop, notebook or other handheld electronic device, a monitor, a television / video screen, a video game, an electronic instrument such as an oscillator or a medical centrifuge or other analytical device, or the like. A rotatable locking member engages an anchor sub-assembly having a rotatable element, wherein the rotatable element communicates with a spring force urging against the rotatable locking member. The rotatable locking member is alternately movable in and out of the slot in which it is inserted, and the locking element is rotatable by finger force overcoming said spring force against the locking member, wherein the lock is locked without use of a tool.

Owner:THINK PROD

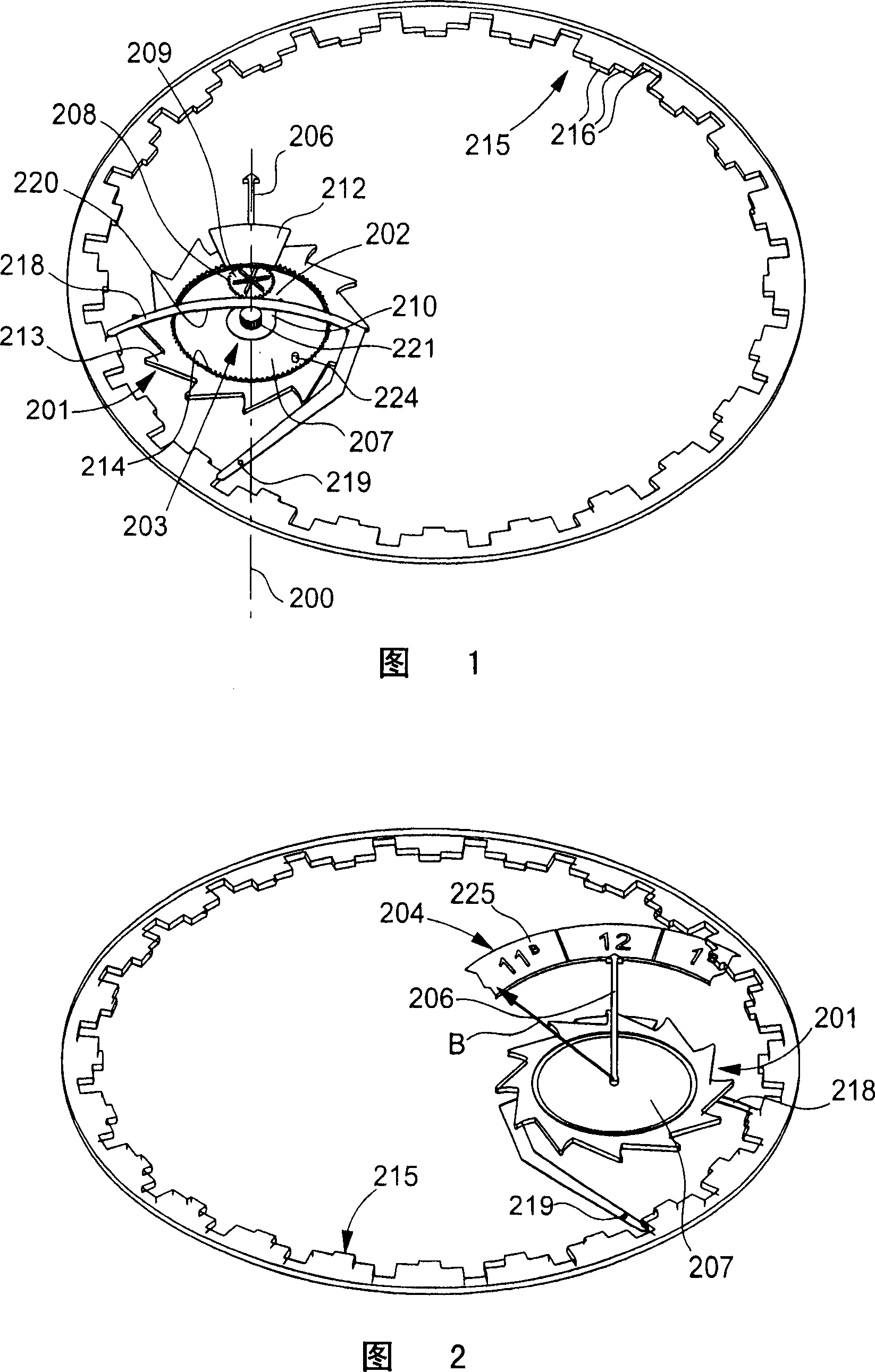

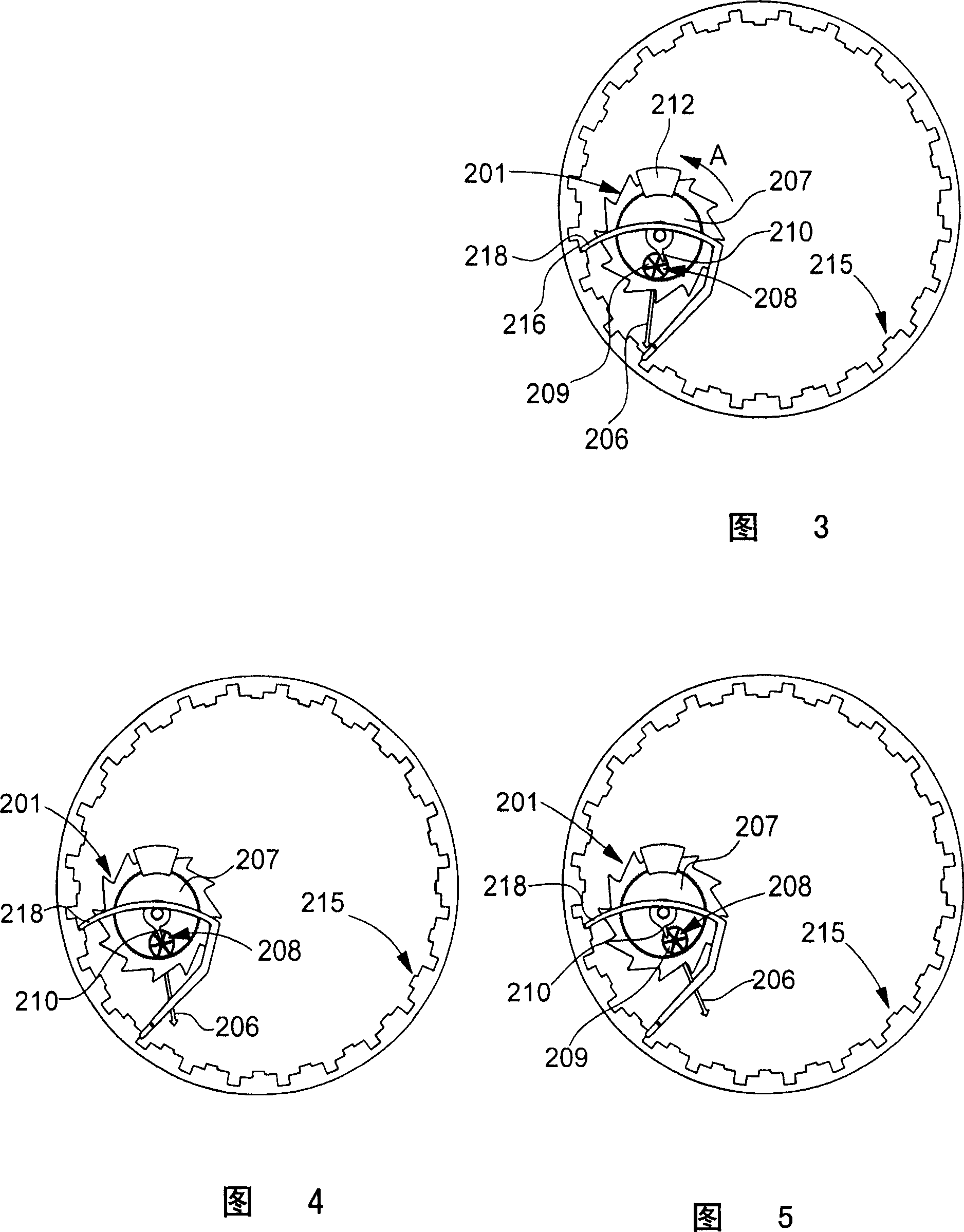

Mechanism displaying values in variable cycles, particularly in a lunisolar calendar

The invention concerns a lunar month display mechanism, for a lunisolar calendar mechanism. The mechanism includes concentrically a plate, which determines the position of the additional month in the bissextile years. The plate is provided with a hand associated with a scale of twelve months and carries a planetary wheel permanently braked by a restraining device. The drive wheel, driven over one twelfth of a revolution at each new moon, meshes with the planetary wheel and moves the plate and hand forward. At the start of a bissextile month, the stop finger forces the wheel to rotate overcoming the force of the restraining device while the drive wheel is rotating, such that the hand remains close to the number of the preceding month. The position of the stop finger is determined by a year cam. This mechanism can be used in particular in a Chinese calendar display.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

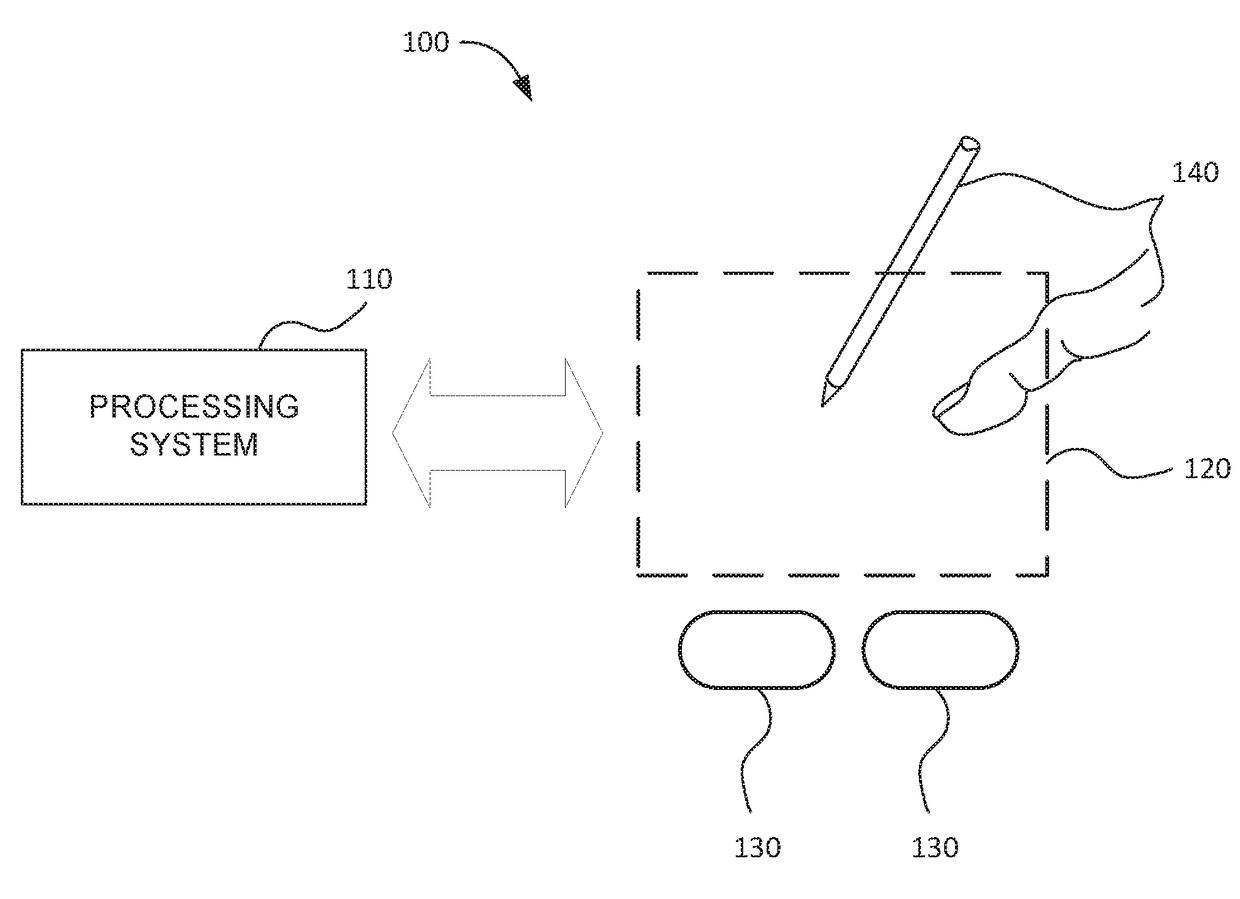

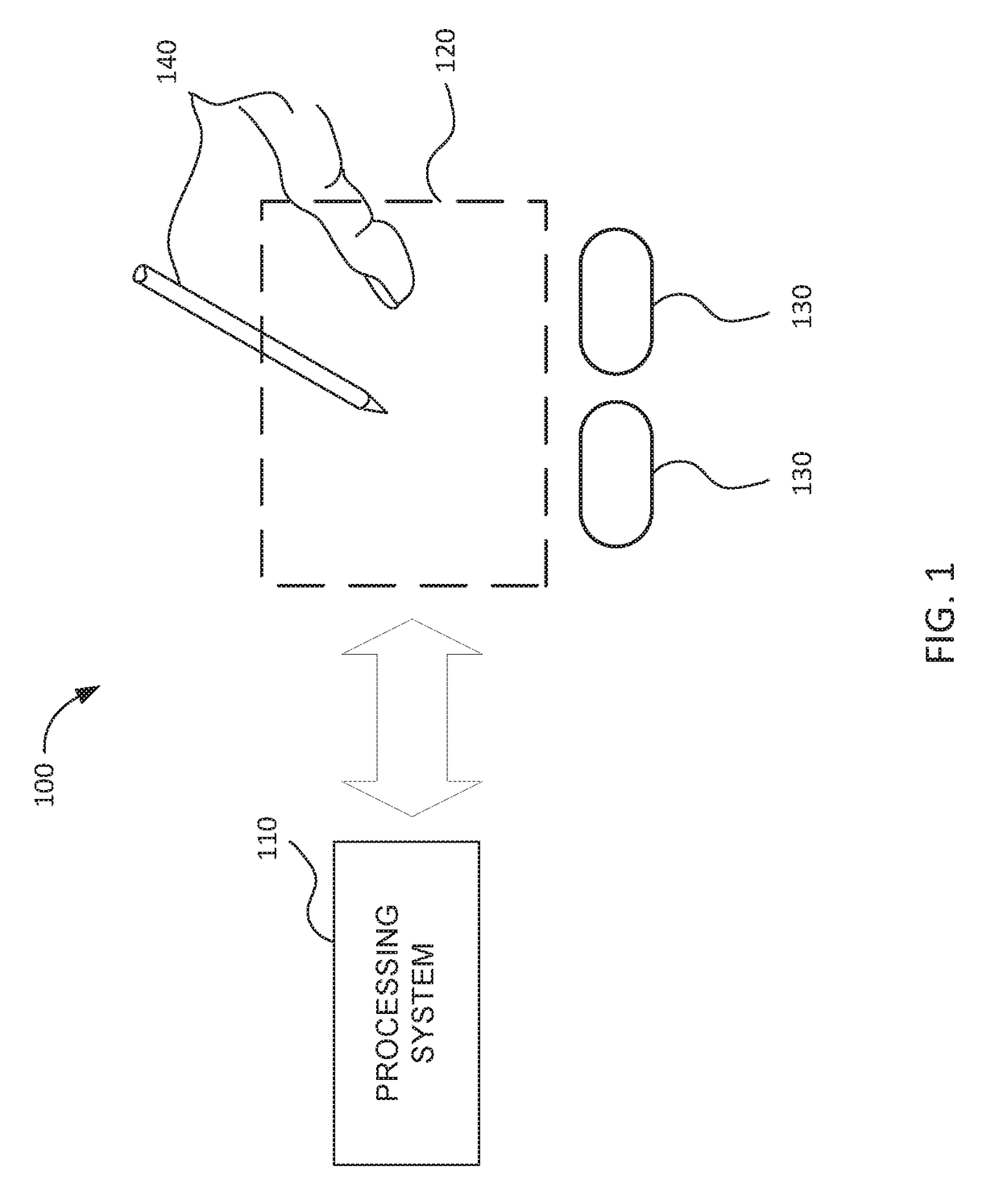

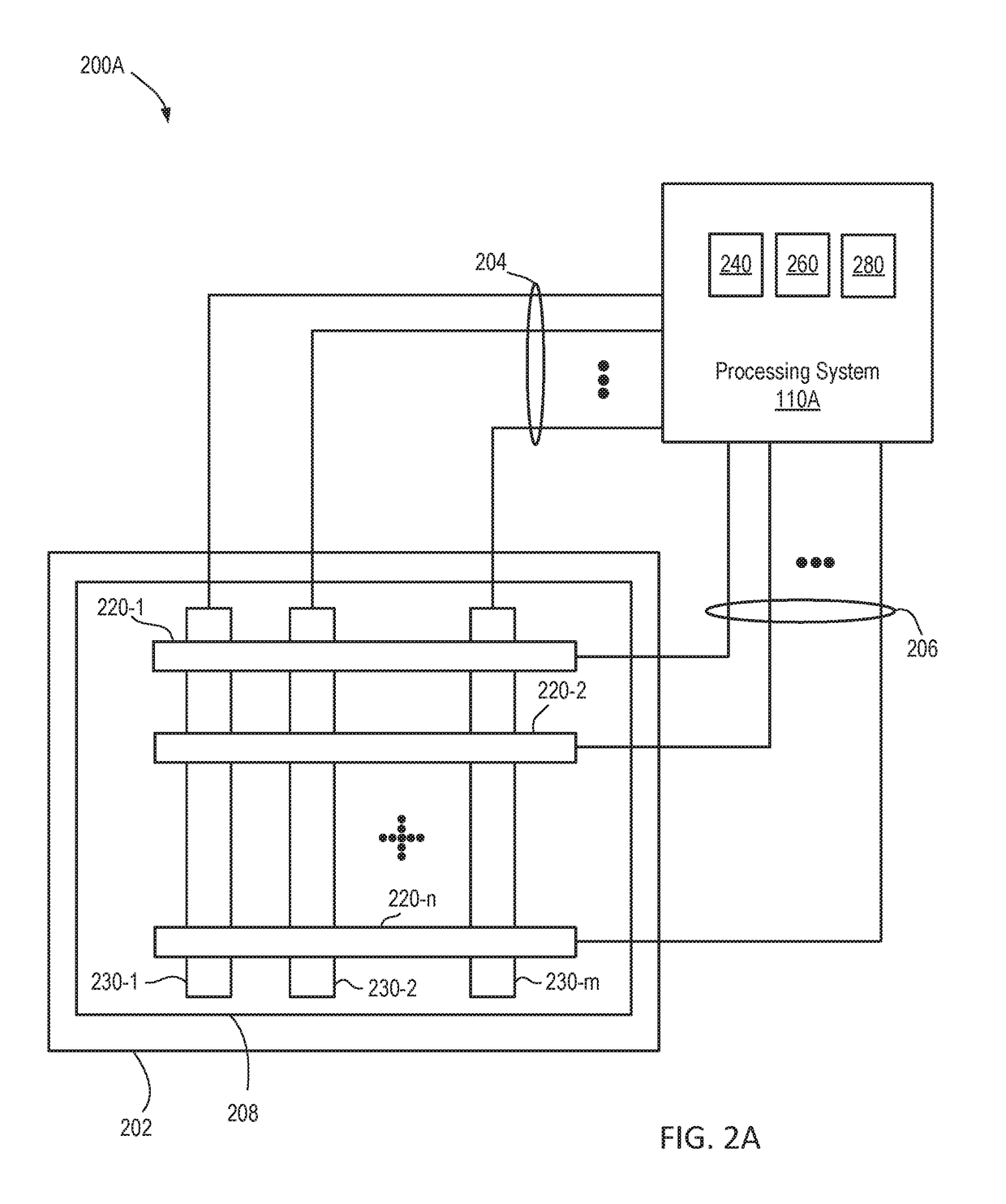

Per-finger force detection using segmented sensor electrodes

Techniques for obtaining force-based data of an input device are provided. The techniques include driving sensor electrodes in transcapacitive mode and in absolute capacitive mode, obtaining profiles for each of the modes, scaling the transcapacitive profile, and subtracting the scaled transcapacitive profile from the profile for absolute capacitive sensing. The result of this subtraction is force-based data that indicates the degree of force with that input object applies to the input device. These techniques may be used with an input device in which a plurality of sensor electrodes are divided into two or more segments. Independent sets of force-based data can be obtained for each segment, which allows for determination of a location associated with each set of force-based data.

Owner:SYNAPTICS INC

Musical instrument and supporting system incorporated therein for music players

A supporting system is provided on a saxophone for offering assistance to the player, and includes pressure sensors monitoring the touch pieces of the keys, power assisting units equipped with torque motors provided for the keys and a controller connected to the pressure sensors and the power assisting units; a conversion table for depressed touch pieces and another conversion table for released touch pieces are prepared in the controller, and different relations between the finger force and the amount of current to be supplied to the torque motor are respectively defined in the conversion tables, respectively; the amount of current to be supplied is read out from the conversion tables depending upon the increase and decrease of finger force so that the player quickly closes the tone whole with the padded cup without curious key touch.

Owner:YAMAHA CORP

Musical instrument and supporting system incorporated therein for music players

A saxophone equipped with an assisting system (3), the assisting system (3) assisting a player to perform the performance of the saxophone; the assisting system (3) comprises A pressure sensor (102) connected to the key (22, 23, 24) is provided in association with a torque motor (103A) that applies an auxiliary force to the key (22, 23, 24) and is used to adjust the driving signal to the controller (101) corresponding to a certain amount of pressure; since the conversion table (TB1) is stored in the controller (101), the controller (101) looks up the drive voltage to be adjusted in the conversion table (TB1). flow, and provide a drive signal to the torque motor (103), whereby the key is pressed by the sum of finger force and auxiliary force.

Owner:YAMAHA CORP

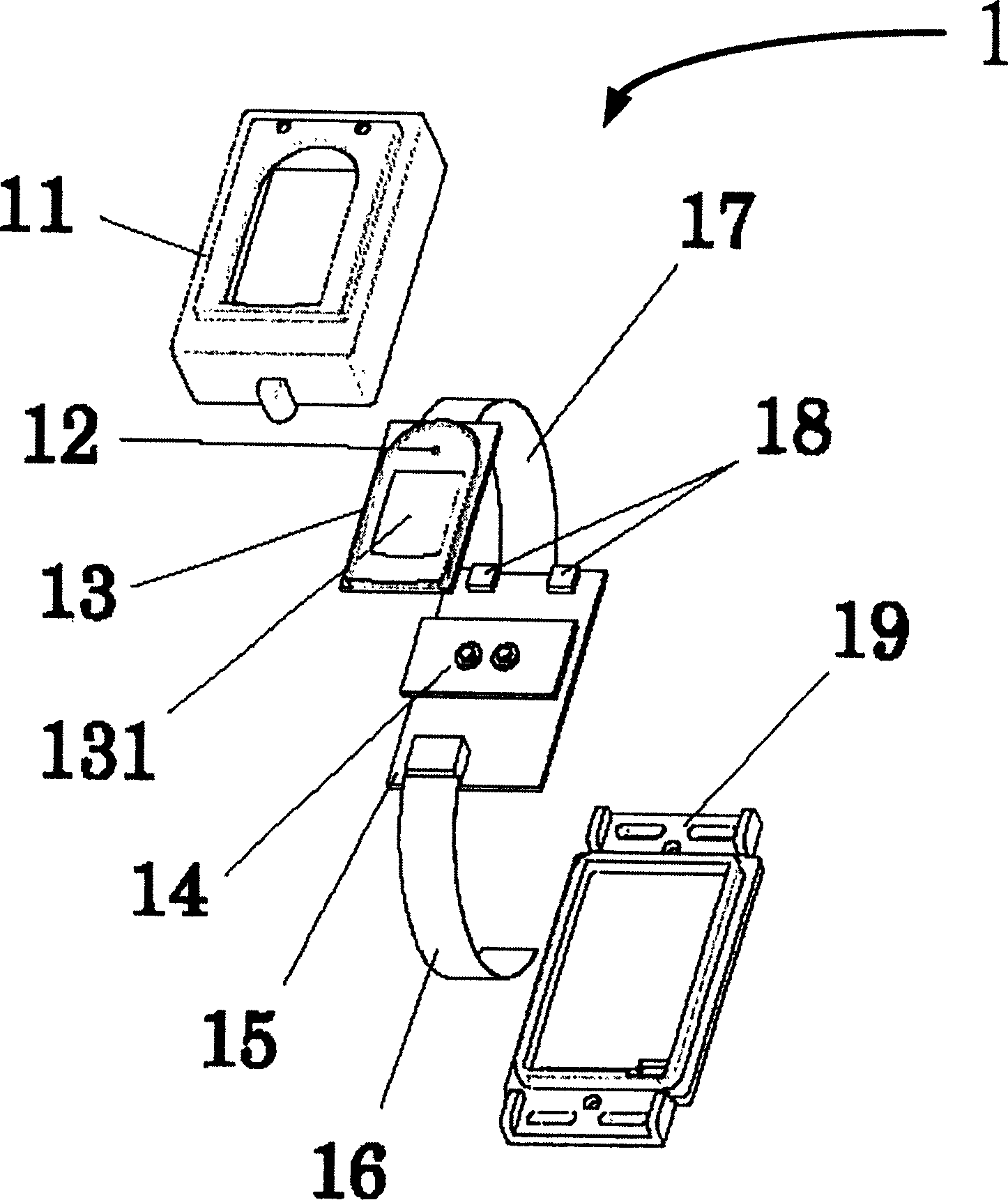

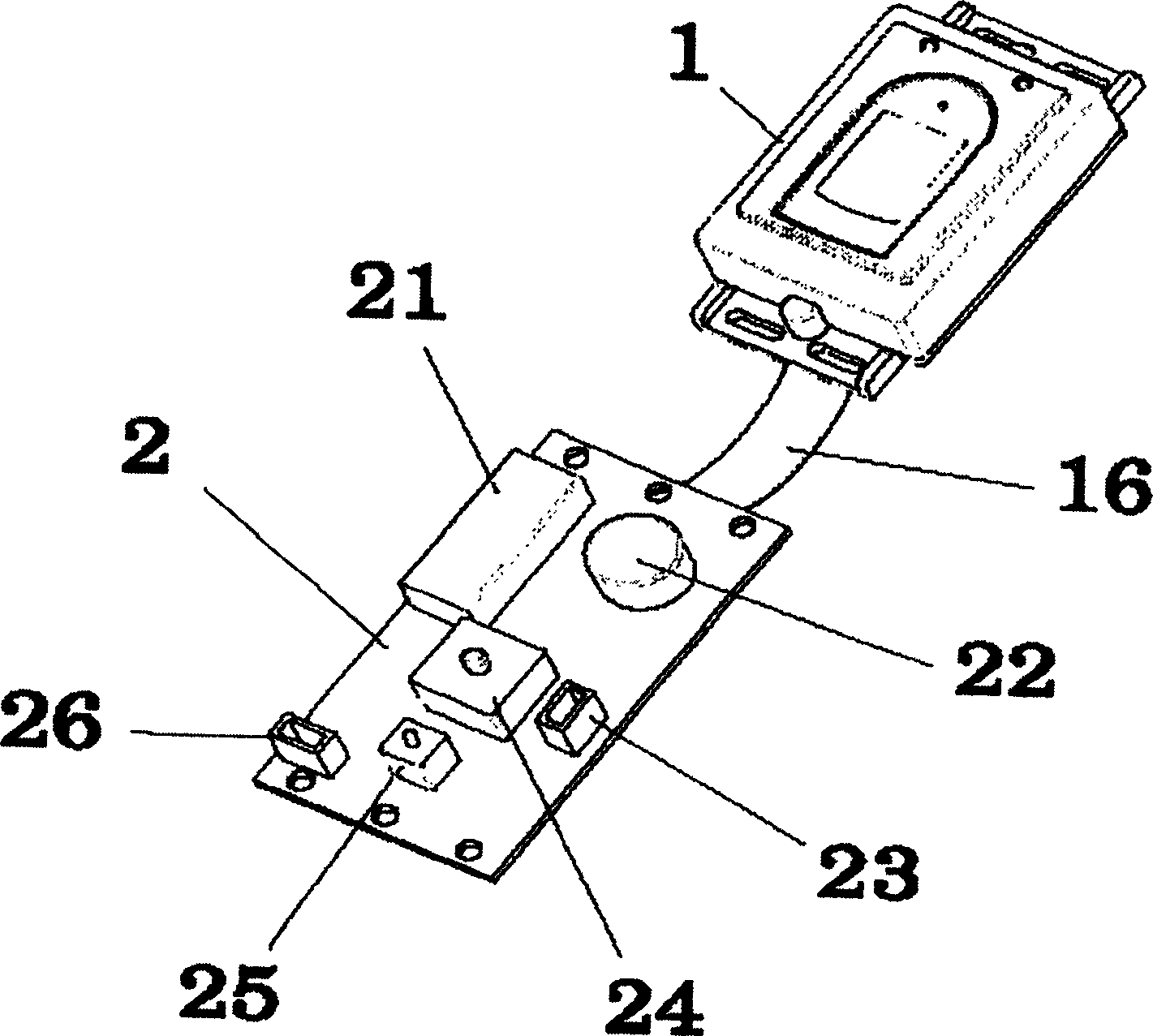

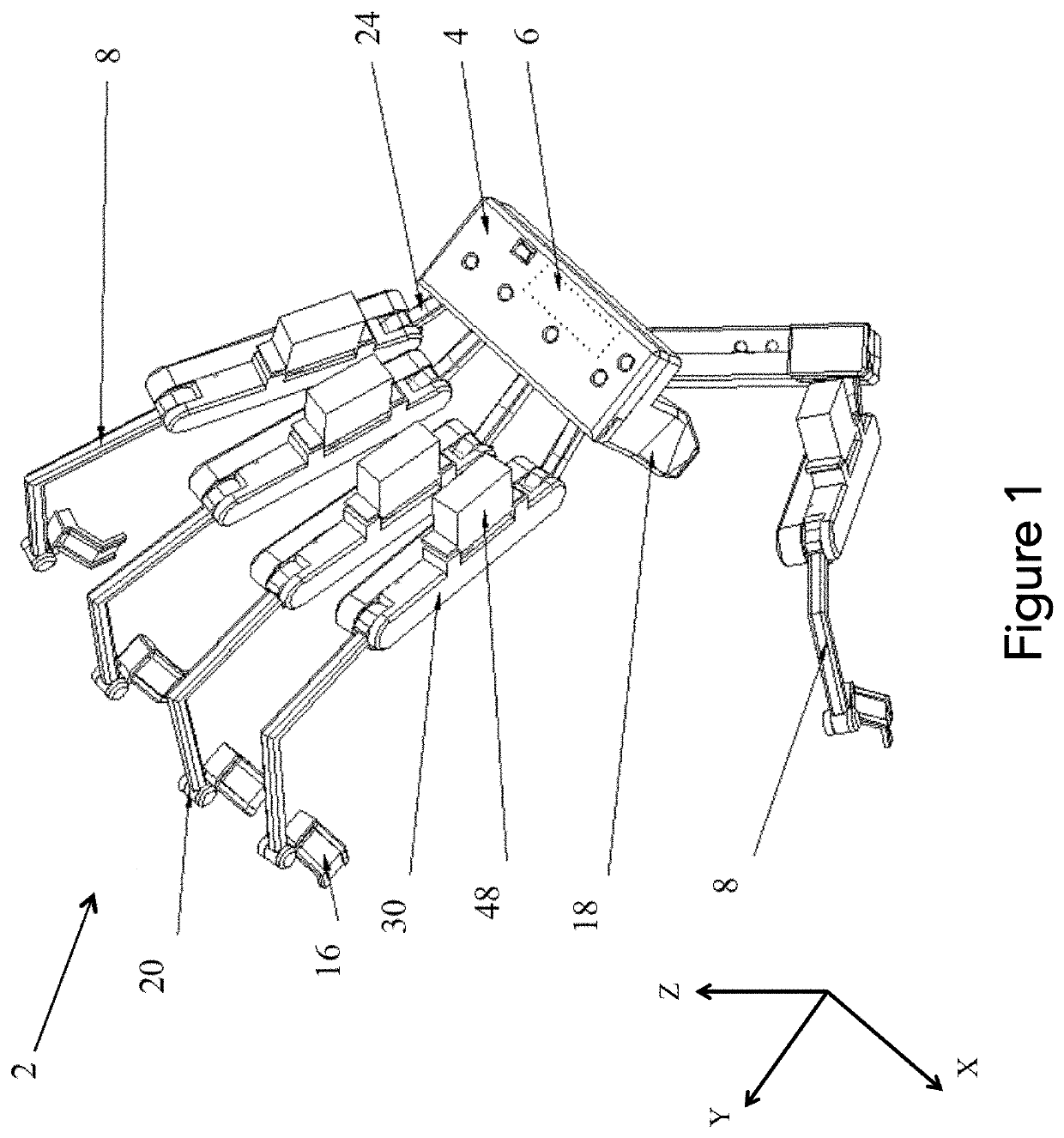

Hand motion-capturing device with force feedback system

ActiveUS9342151B2Low costLittle omissionInput/output for user-computer interactionGraph readingMicrocontrollerLittle finger

This disclosure includes a hand motion-capturing device with a force feedback system. In some embodiments the device includes a base, a microcontroller connected to the base, a thumb sensor module and four-finger sensor modules each electrically connected to the microcontroller. In some embodiments, the device may include five-link rods that interconnect the thumb sensor module to the base and each of the four-finger sensor modules to the base. In some embodiments, the device includes a thumb force feedback system adapted and configured to receive a human thumb and a four-finger force feedback system adapted and configured to receive an index finger, a middle finger, a ring finger, and a little finger. The thumb force feedback system and the four-finger force feedback system may each be movably connected to respective link rods and the thumb sensor module and four-finger sensor modules, respectively.

Owner:SHENZHEN DEXTA ROBOTICS CO LTD

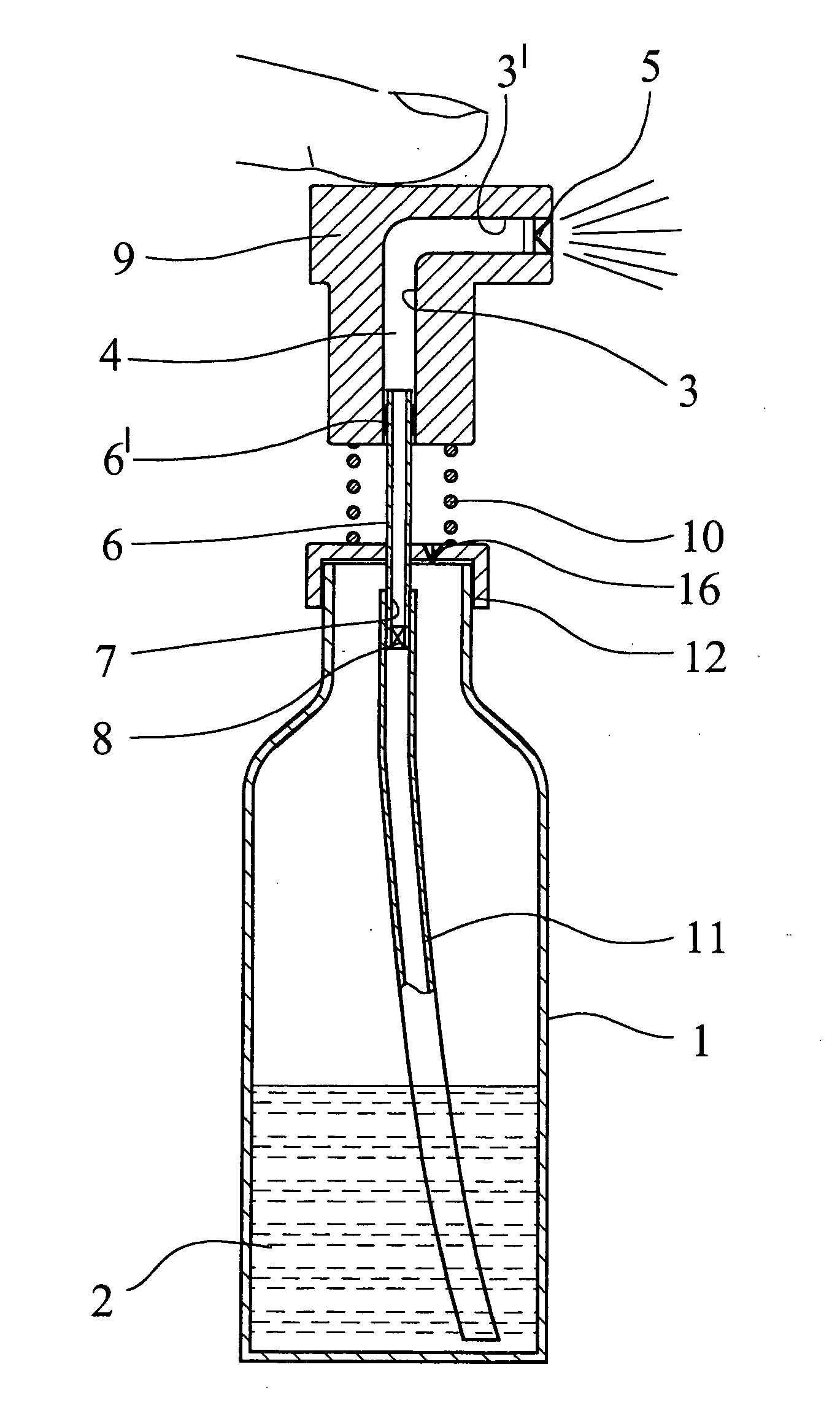

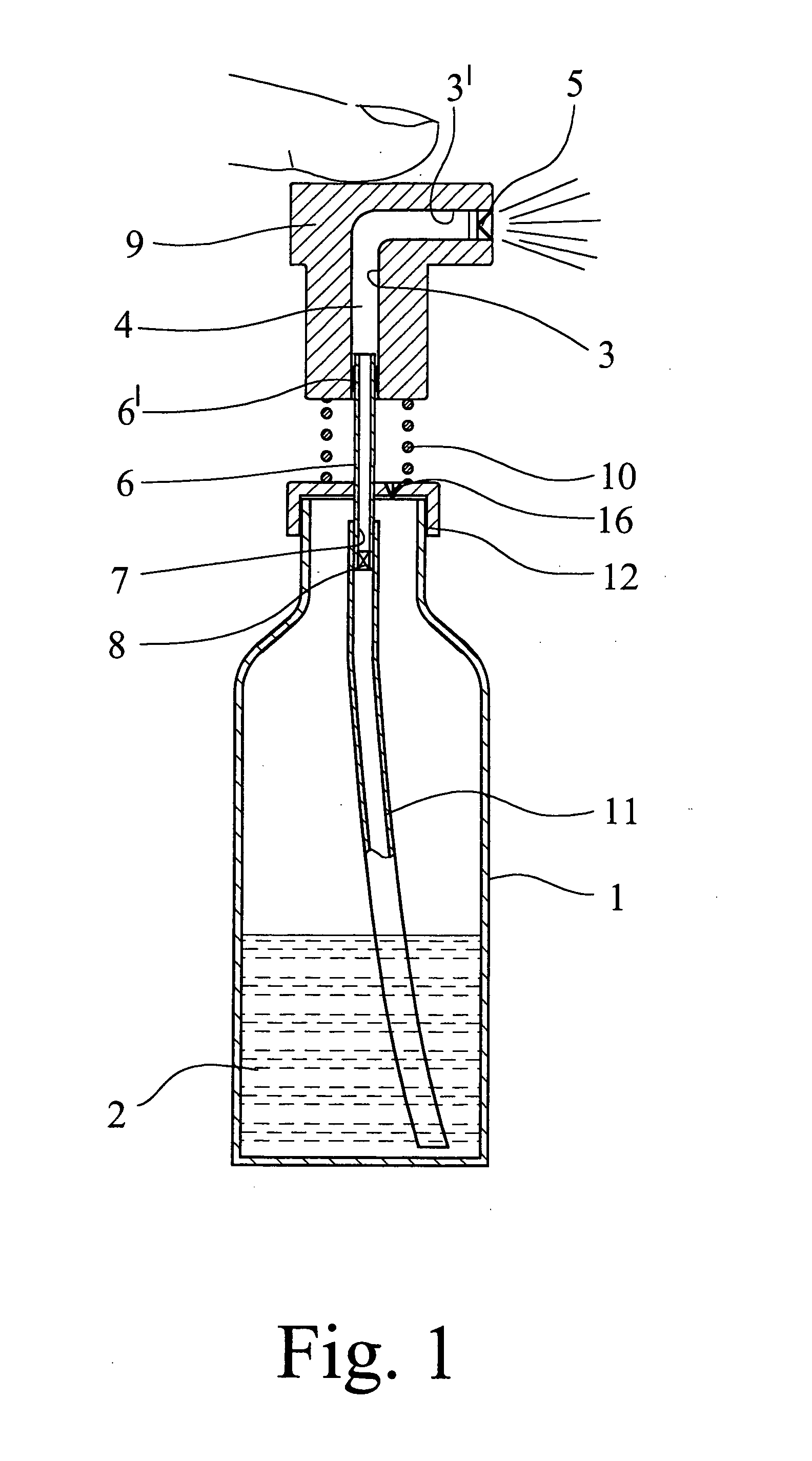

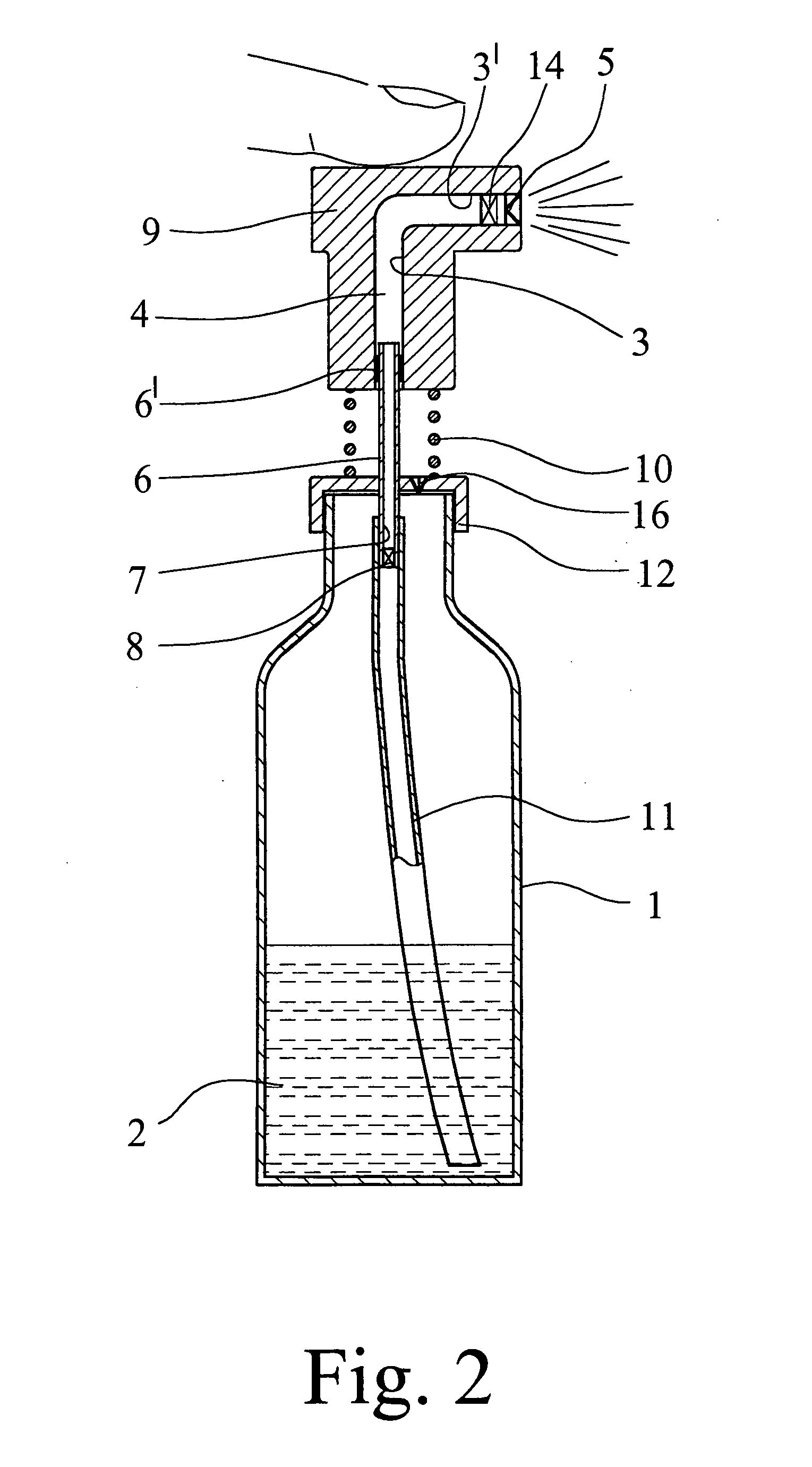

Finger operated spray pump

A finger operated spray pump has a liquid reservoir (1), a cylinder (3) for containing a portion of the liquid from the reservoir (1) which is connected at one end to an atomizer (5), a piston (6) sealingly mounted within the cylinder (3) and movable within the cylinder (3) in a spray stroke, a passageway (7) connecting the cylinder (3) with the liquid reservoir (1), a one way valve (8) at the passageway (7) for allowing a flow of liquid only from the supply of liquid (2) into the cylinder (3), and a finger operated actuator (9) which is displaceable relative to the liquid reservoir (1). The outer diameter of the piston (6) and the corresponding inner diameter of the cylinder (3) is between about 0.5 mm and about 4.0 mm, the nozzle diameter of the atomizer (5) is between 15 μm and 150 μm, the operating pressure within the cylinder (3) during the spray stroke with average finger force is between 10 bar and 400 bar and the atomizer (5), the cylinder (3), the piston (6) and the one way valve means (8) are designed to withstand the operating pressure.

Owner:BOEHRINGER INGELHEIM MICROPARTS

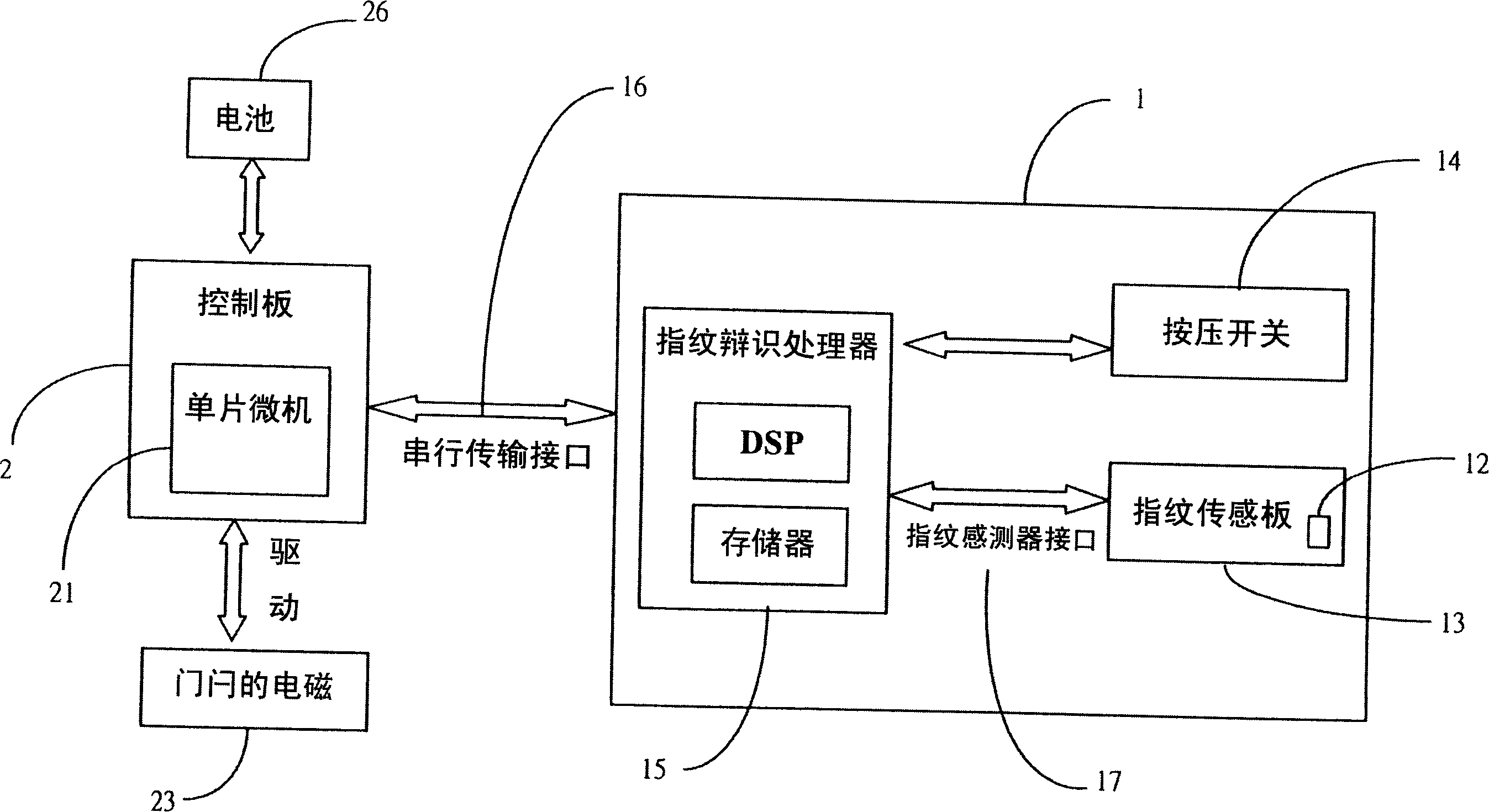

Push started fingerprint identification switch

InactiveCN1691056AExtend your lifeReduce power wasteCharacter and pattern recognitionGraph readingPattern recognitionFinger force

The invention provides a fingerprint recognition switch activated by pressing. The fingerprint recognition module comprises activator, to produce acute position signal and obtain power after receiving activate command that is finger takes action activator can receive; press switch, to run recognition program that is run by the program and produce recognition result if being pressed after obtain power; fingerprint sensing plate, that is on top of press switch and used to obtain fingerprint; and fingerprint recognition processor. When finger forces on fingerprint sensing plate, it presses indirectly the press witch; and as finger is very close to fingerprint sensing plate, ob needed fingerprint for recognition program, then run recognition program.

Owner:AIMGENE TECH

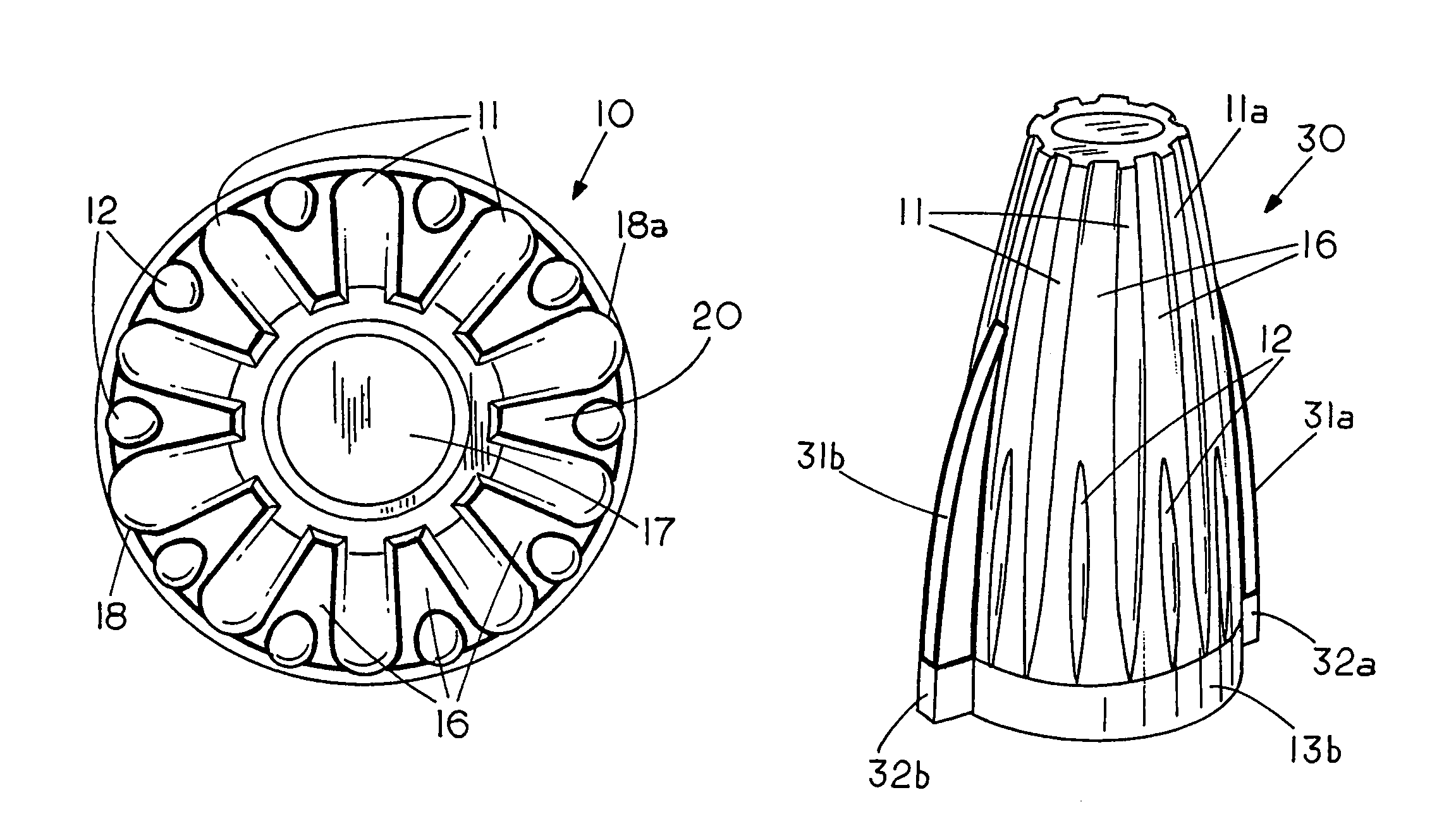

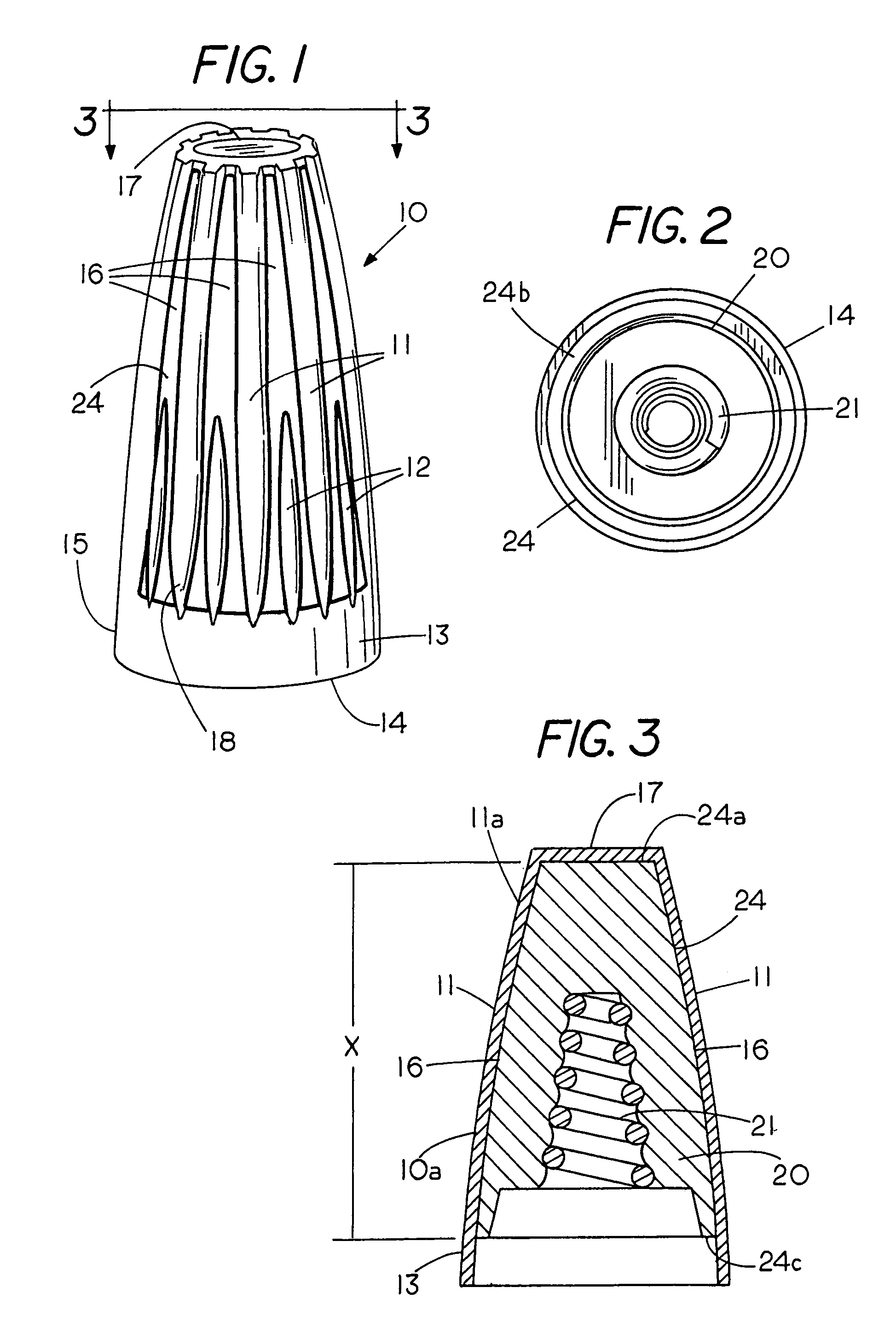

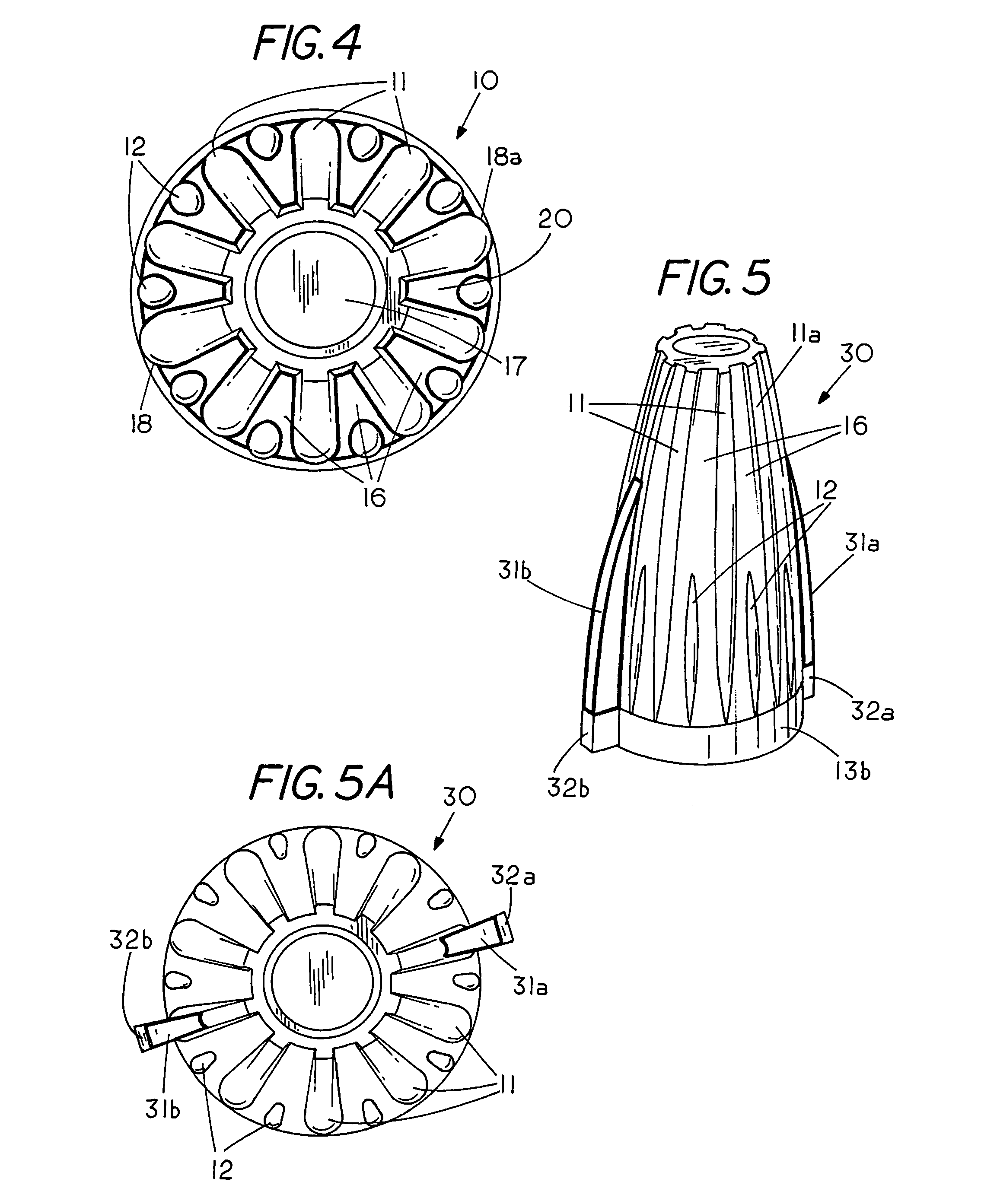

Finger friendly twist-on wire connector

A finger friendly twist-on wire connector having a spiral coil and an open end rigid shell secured to the spiral coil with the rigid shell having an outer surface with a circumferential band and a closed end supporting a finger cushion material integral to at least a portion of the outer surface of the rigid shell with the finger cushion material including a plurality of circumferentially spaced elongated ribs resiliently deformable in response to radially and tangential finger forces thereon as rotational finger forces are transmitted to the rigid shell through the finger cushion material to thereby inhibit finger fatigue and finger injury while allowing the user to maintain a feel of the wire engagement within the wire connector.

Owner:THE PATENT STORE

Hand exoskeleton force feedback system

ActiveUS20200050269A1Input/output for user-computer interactionProgramme-controlled manipulatorMicrocontrollerPhysical medicine and rehabilitation

This disclosure includes a force feedback system. In some embodiments, the system includes a base, a microcontroller communicatively coupled to a computing device, a thumb force feedback unit, and four finger force feedback units. The thumb force feedback unit may be configured to capture thumb motion and provide force feedback according to input from the computing device. Additionally, each of the four finger force feedback units may be configured to capture finger motion and provide force feedback according to input from the computing device. In some embodiments, the system includes at least one vibrational actuator configured to produce a physical stimulus.

Owner:SHENZHEN DEXTA ROBOTICS CO LTD

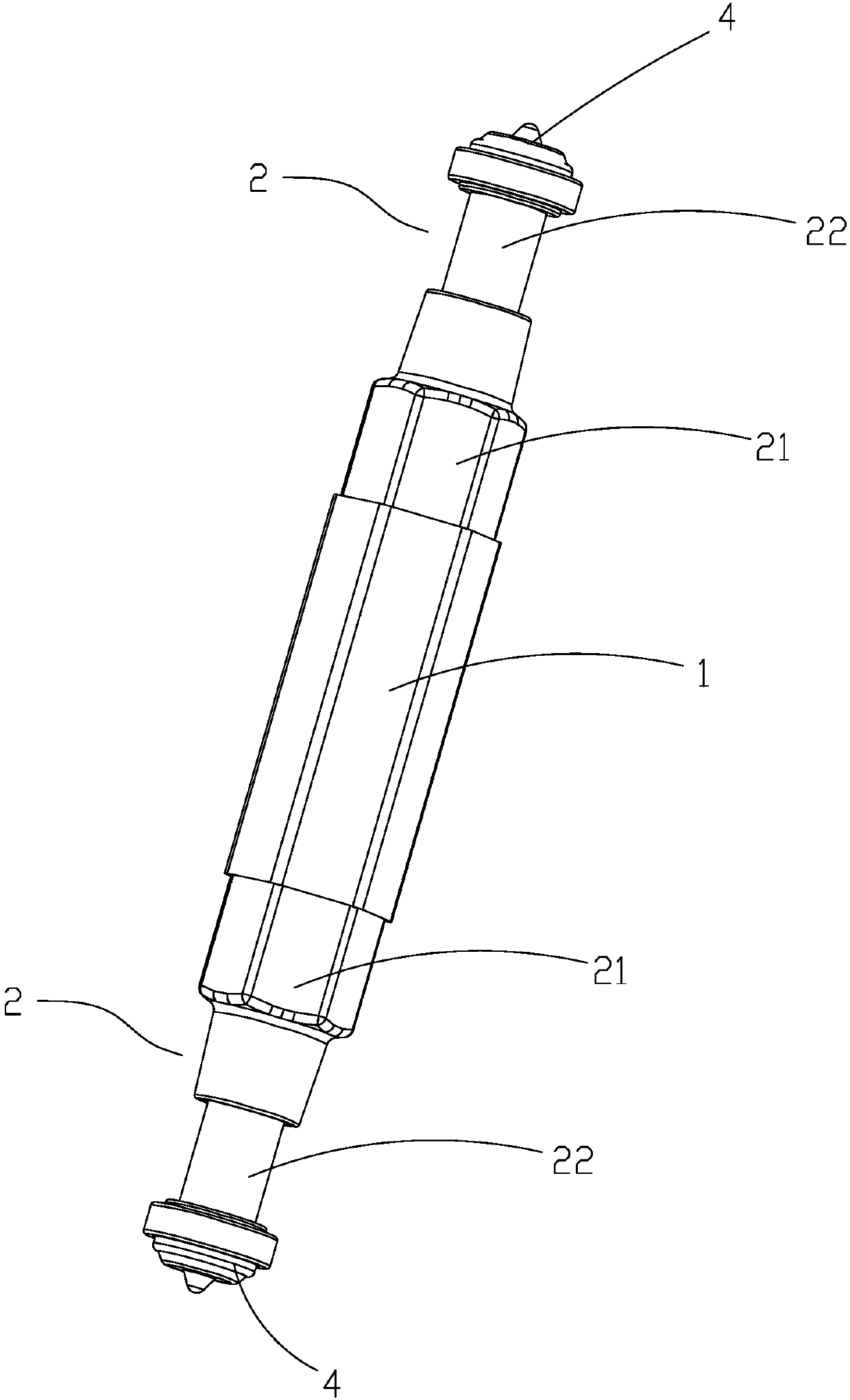

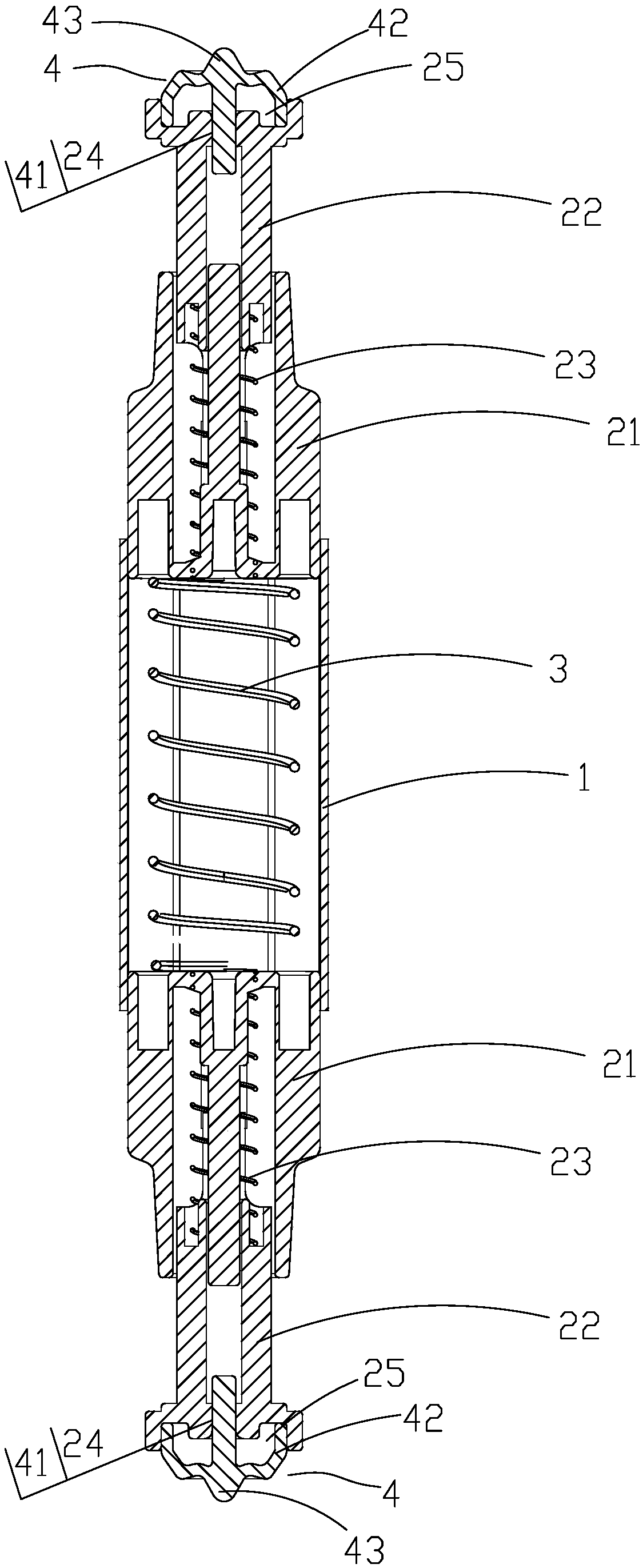

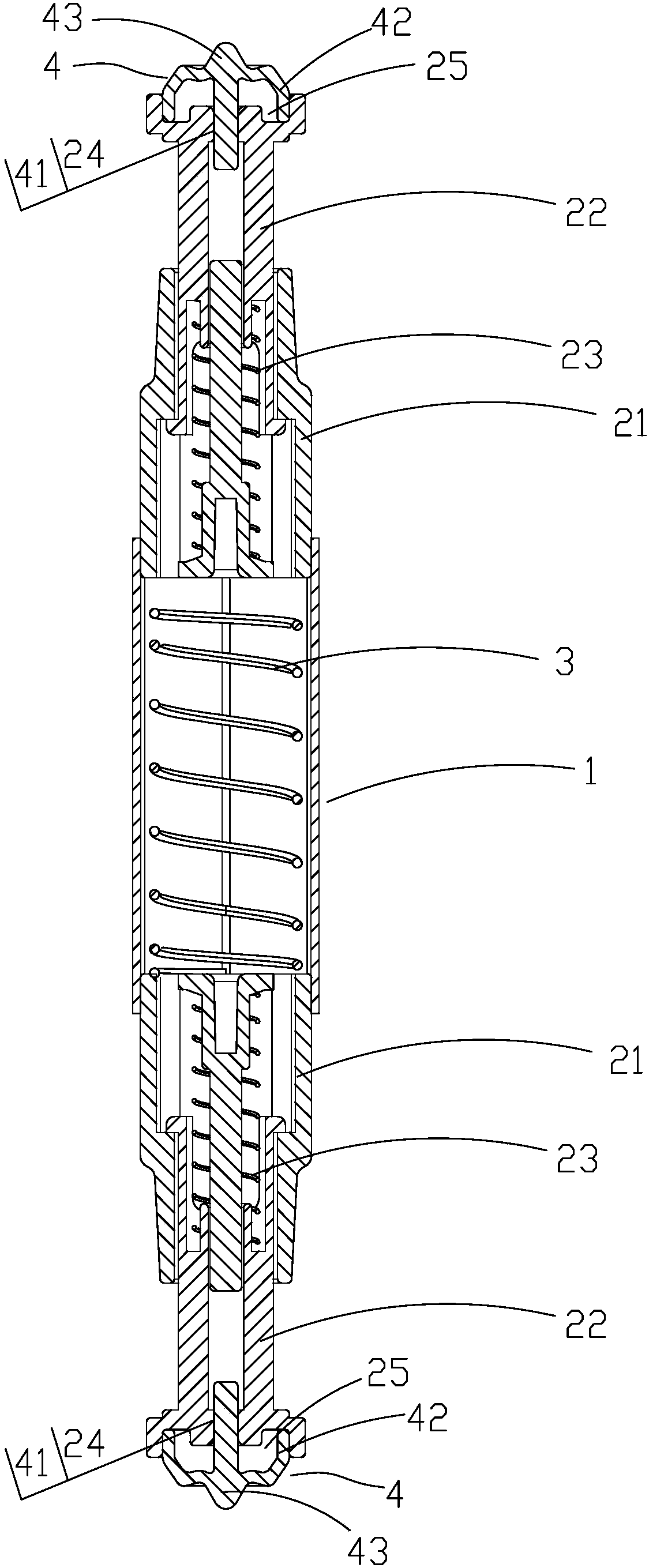

Piano finger force trainer

The invention discloses a piano finger force trainer which comprises a supporting cylinder (1). Finger pressing inserts (2) are inserted into two ends of the supporting cylinder (1) and can slide in the supporting cylinder (1) after being pressed, and first reset springs (3) are arranged in the supporting cylinder (1) and positioned among two groups of finger pressing inserts (2). The piano fingerforce trainer is simple in structure and convenient to carry, finger force can be independently trained, and spans among a thumb and other fingers can be trained.

Owner:姚溪浏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com