Patents

Literature

19162results about How to "Improve compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

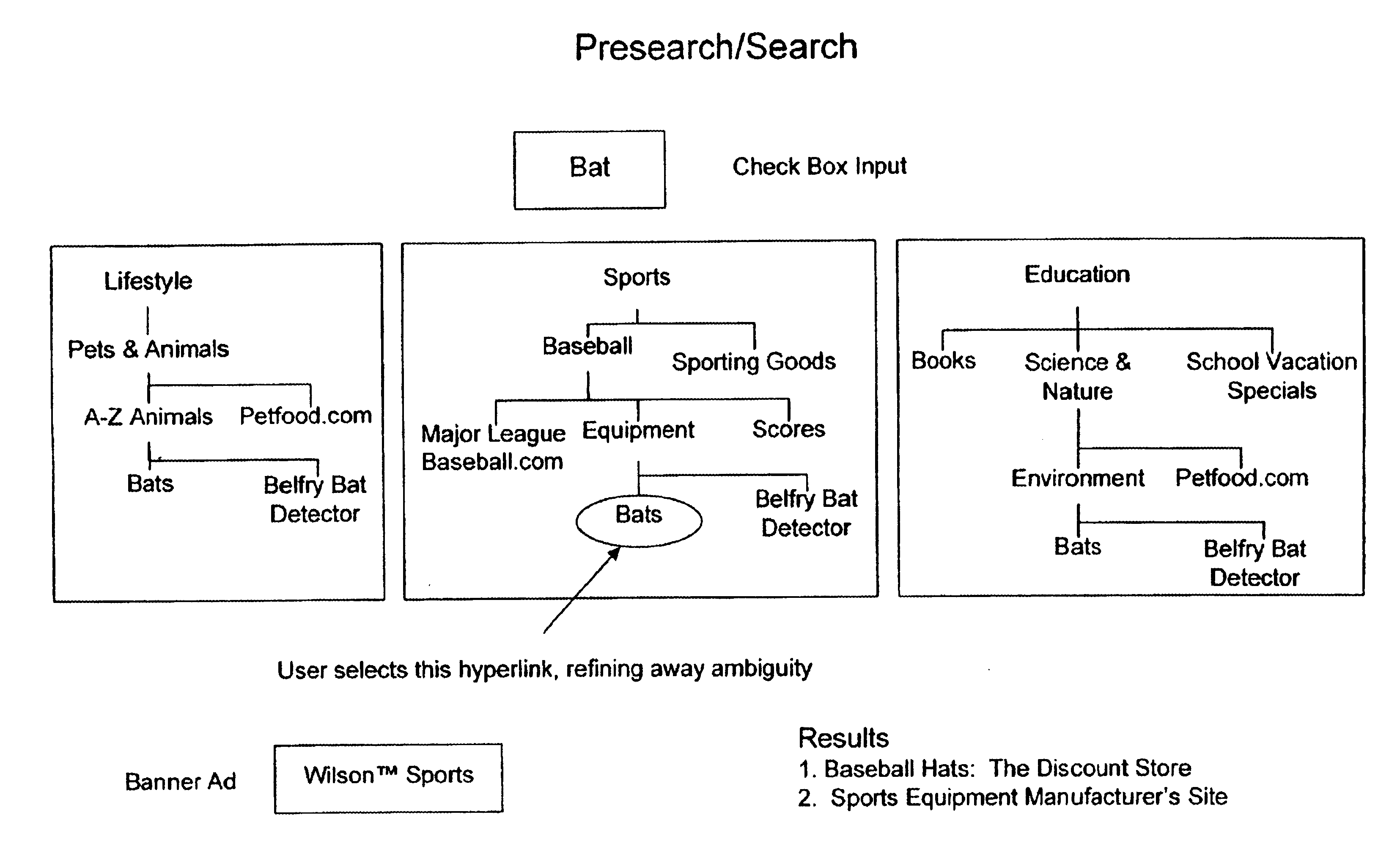

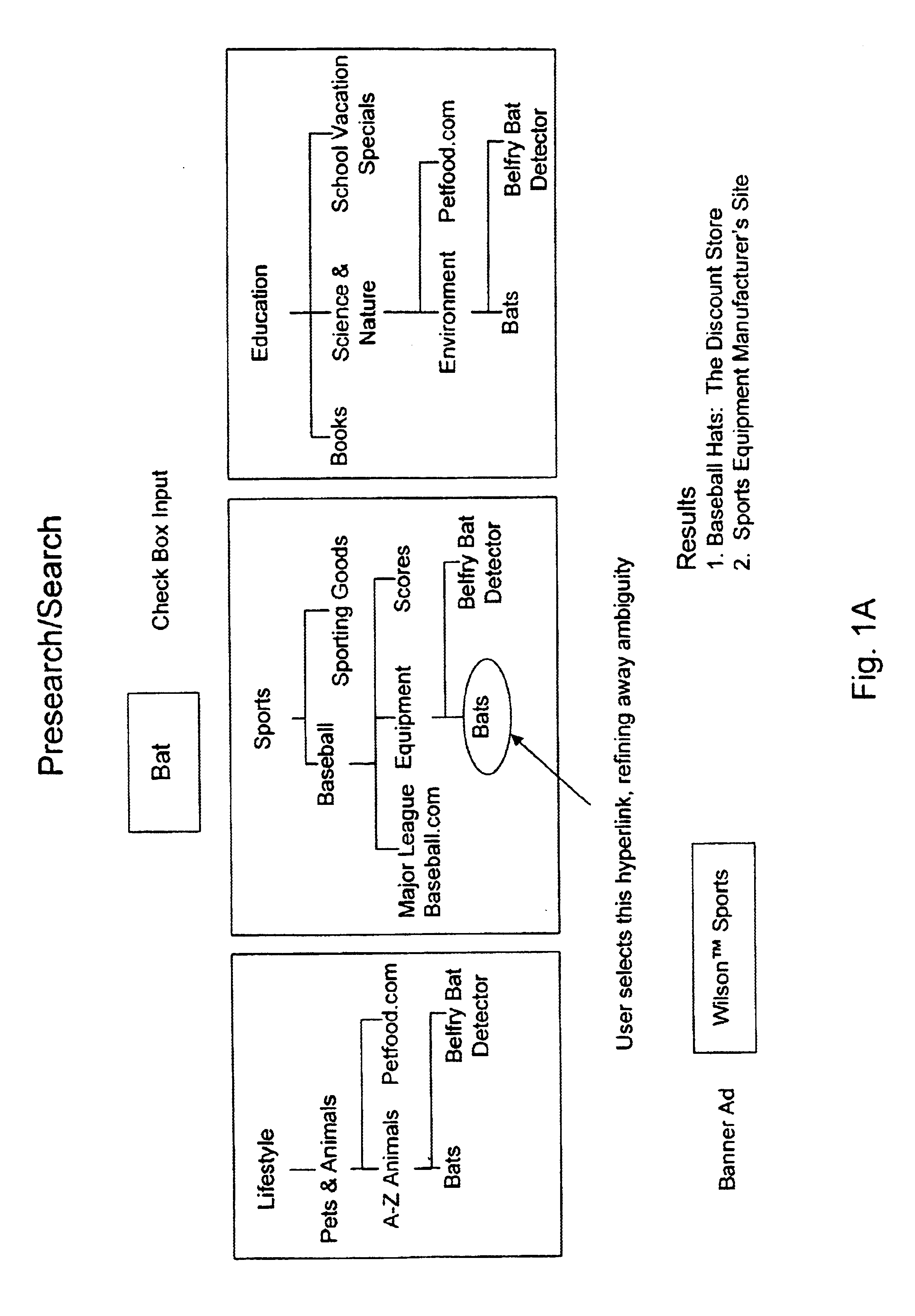

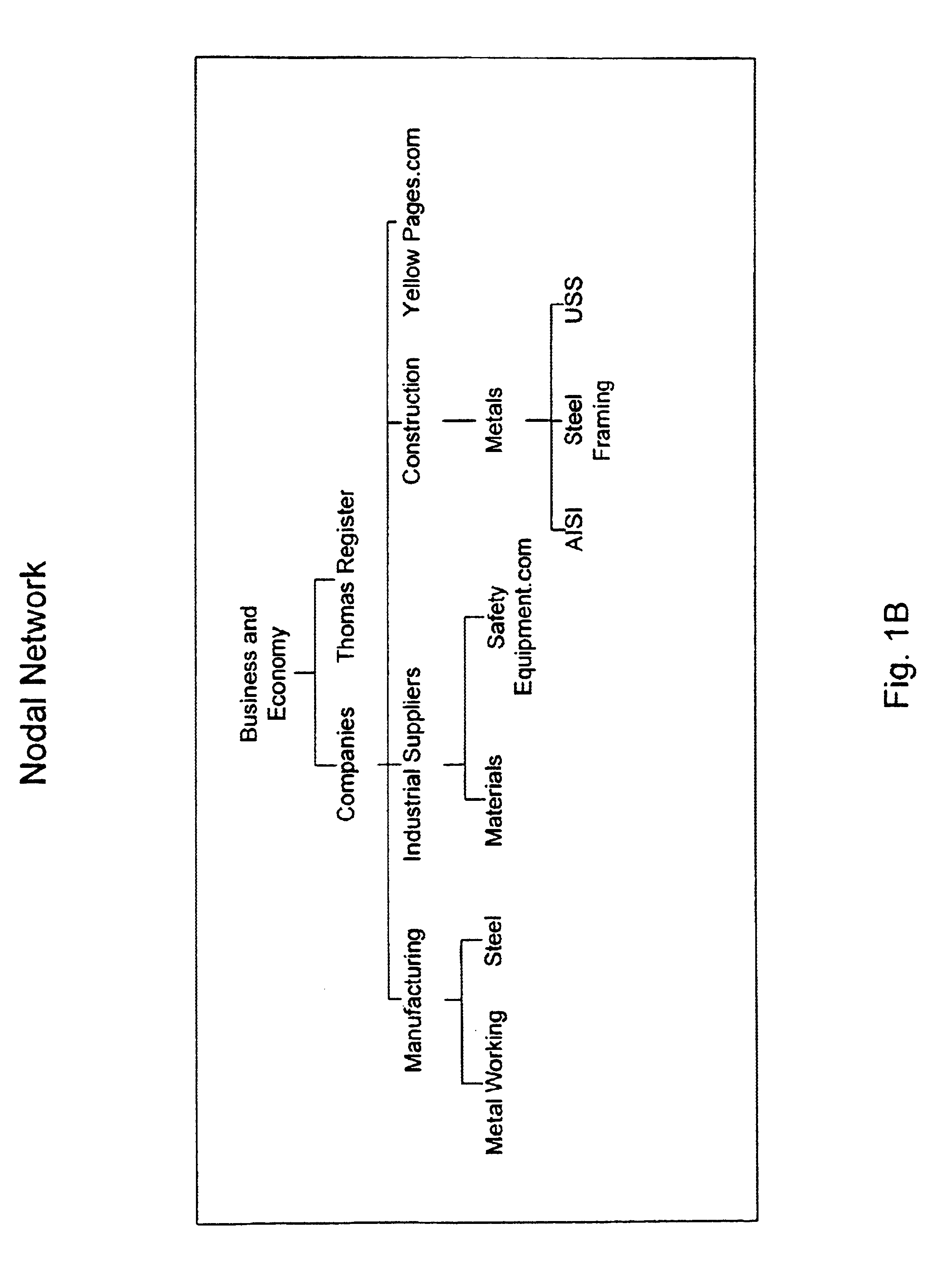

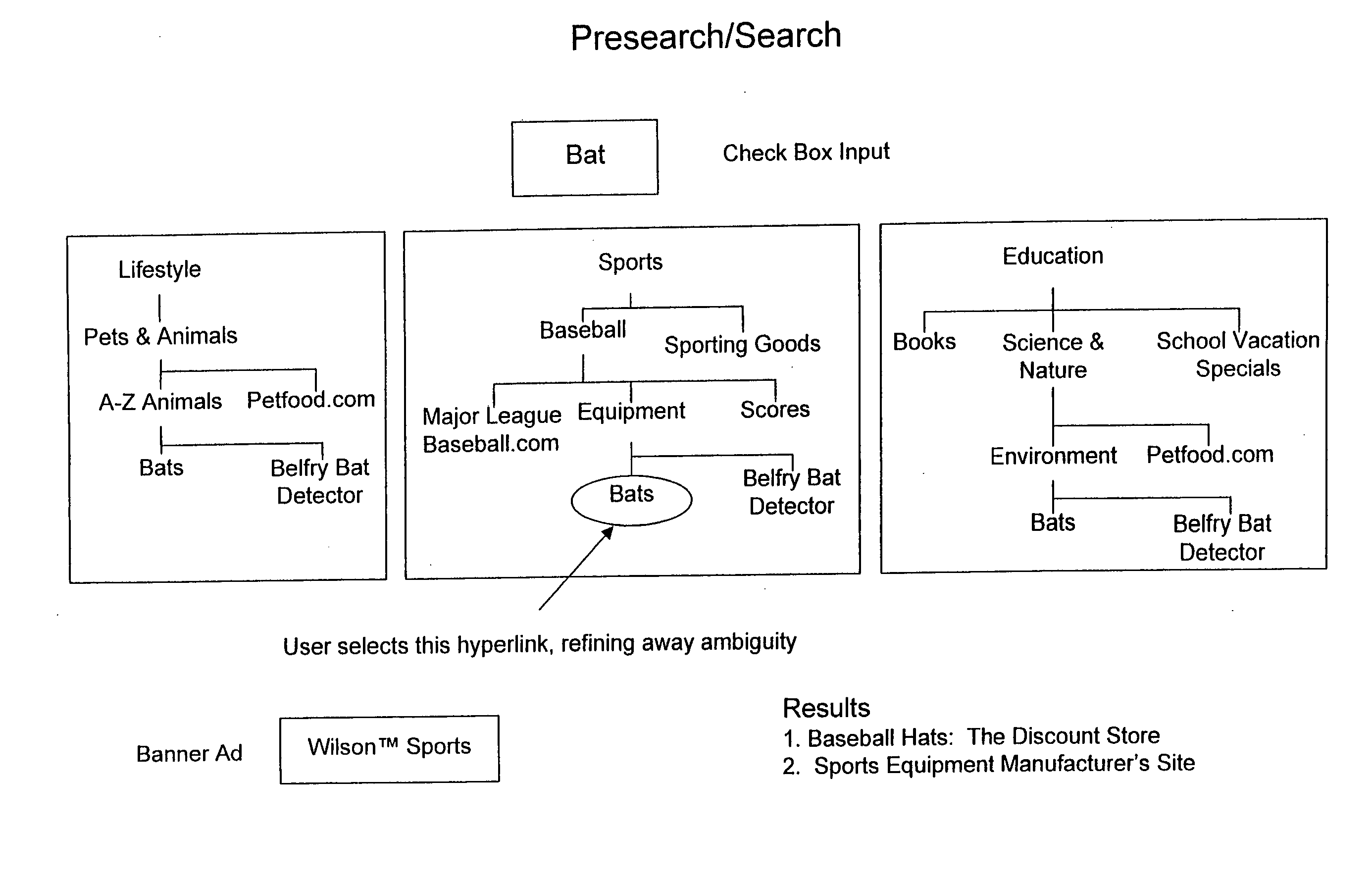

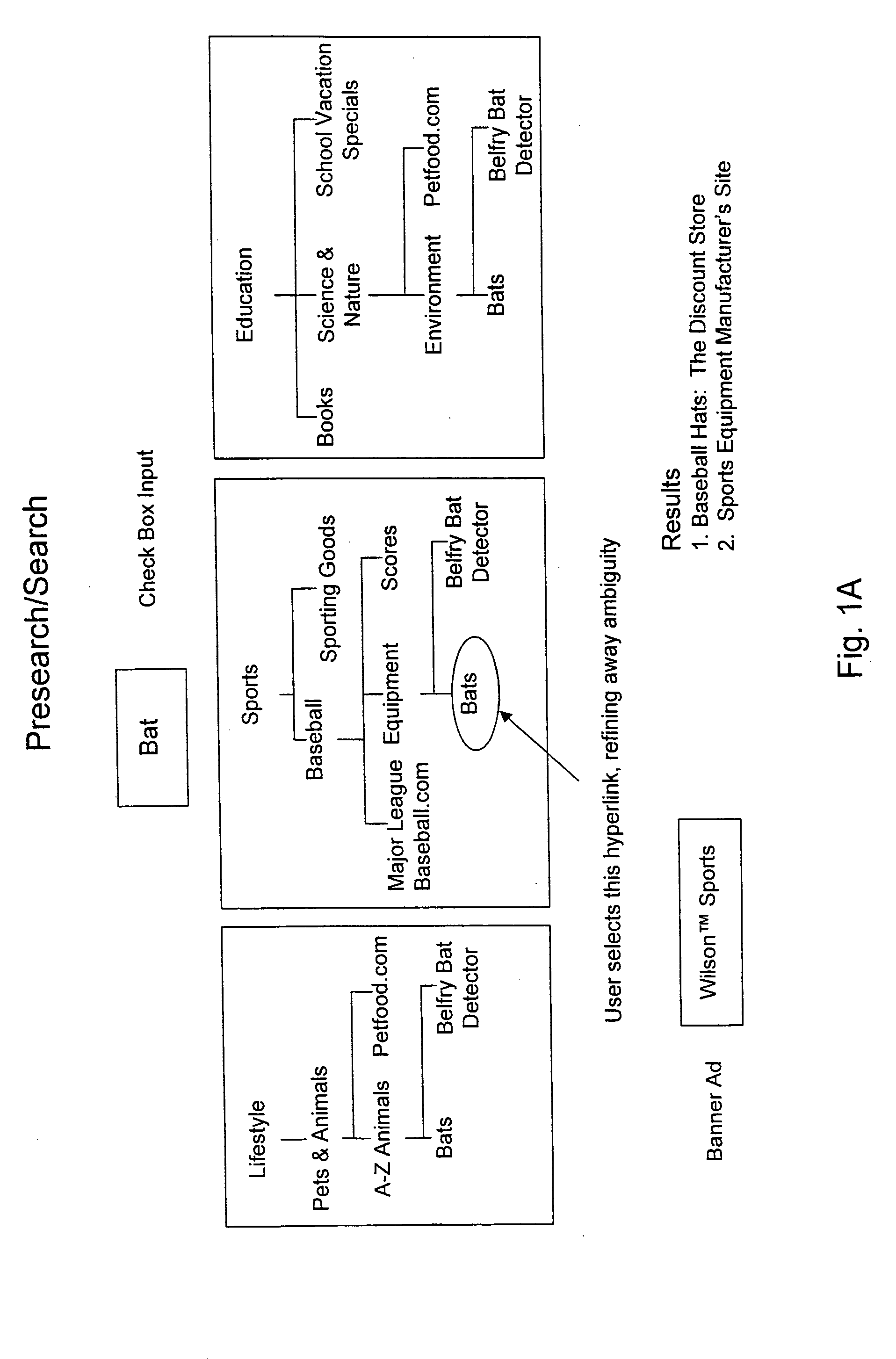

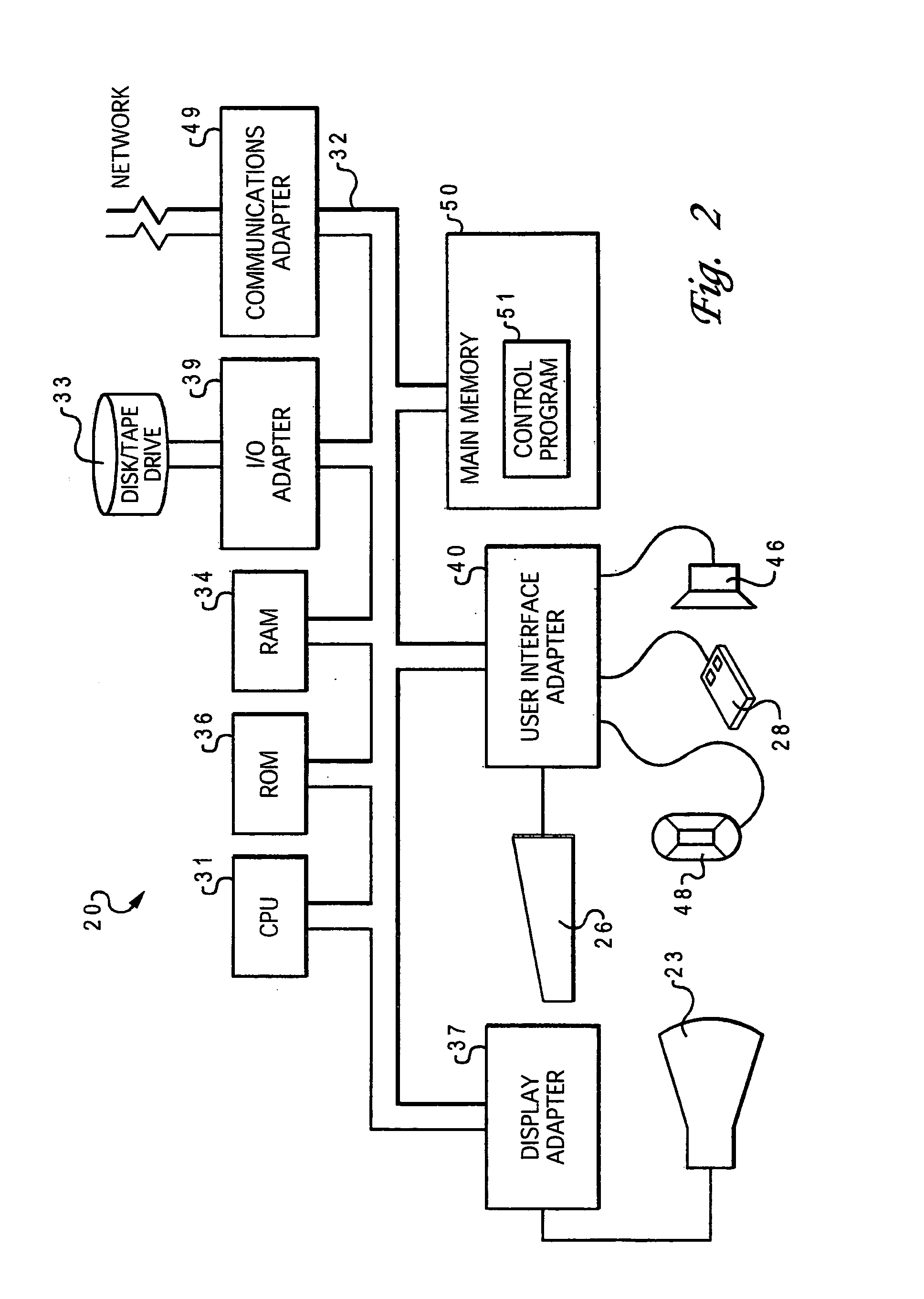

Computer graphic display visualization system and method

InactiveUS6868525B1Improve compactnessIncrease flexibilityDrawing from basic elementsAdvertisementsGraphicsCollaborative filtering

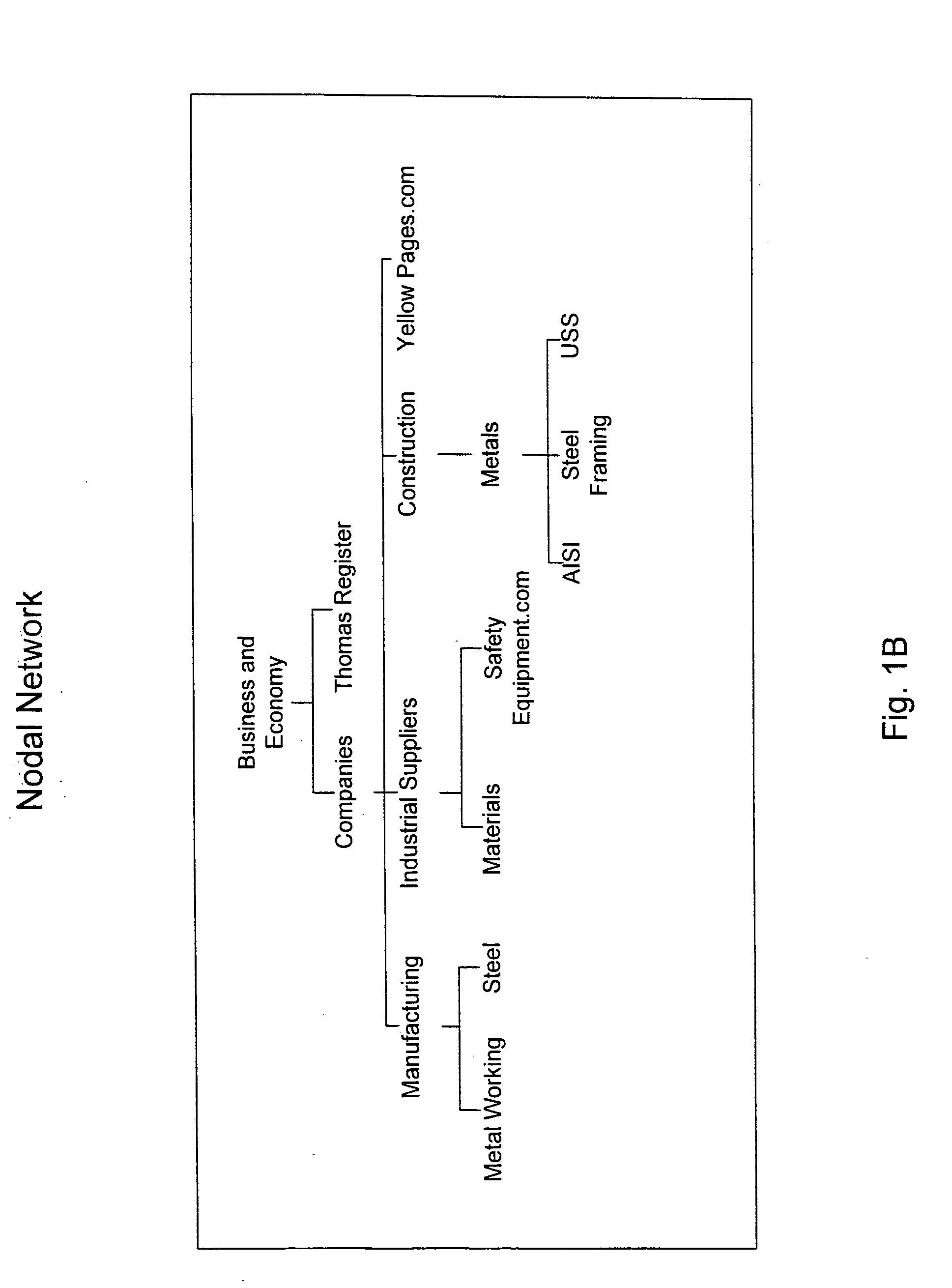

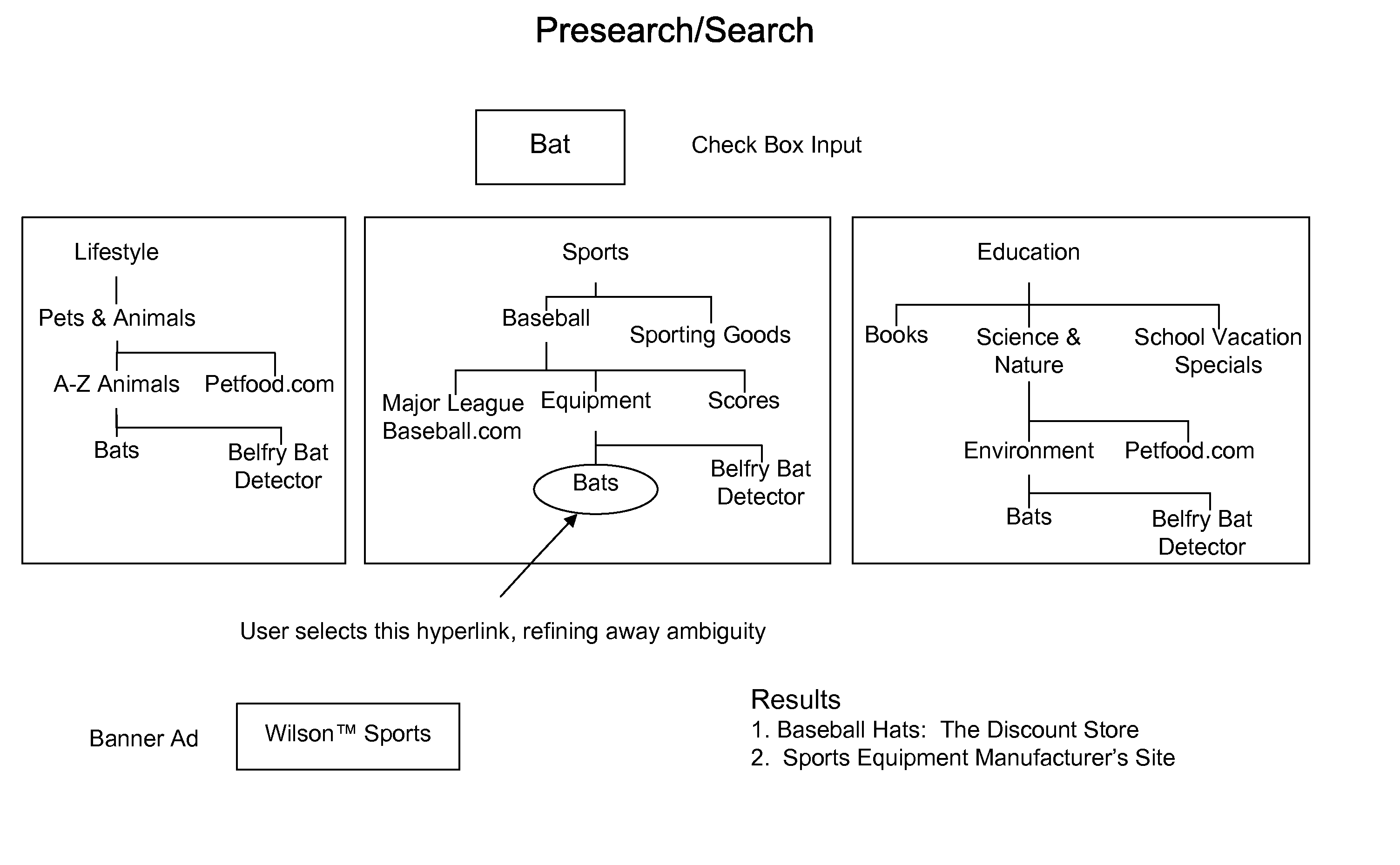

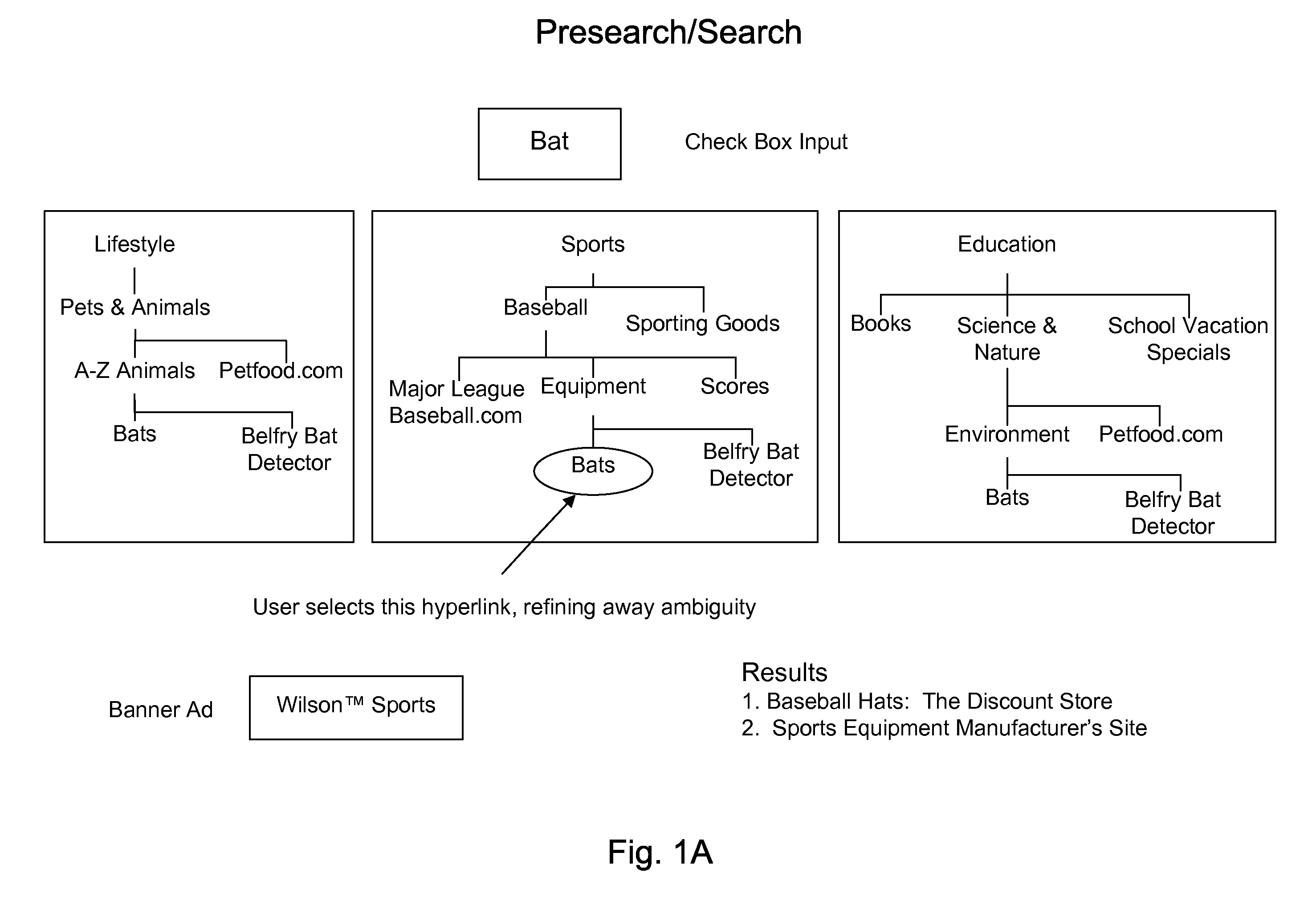

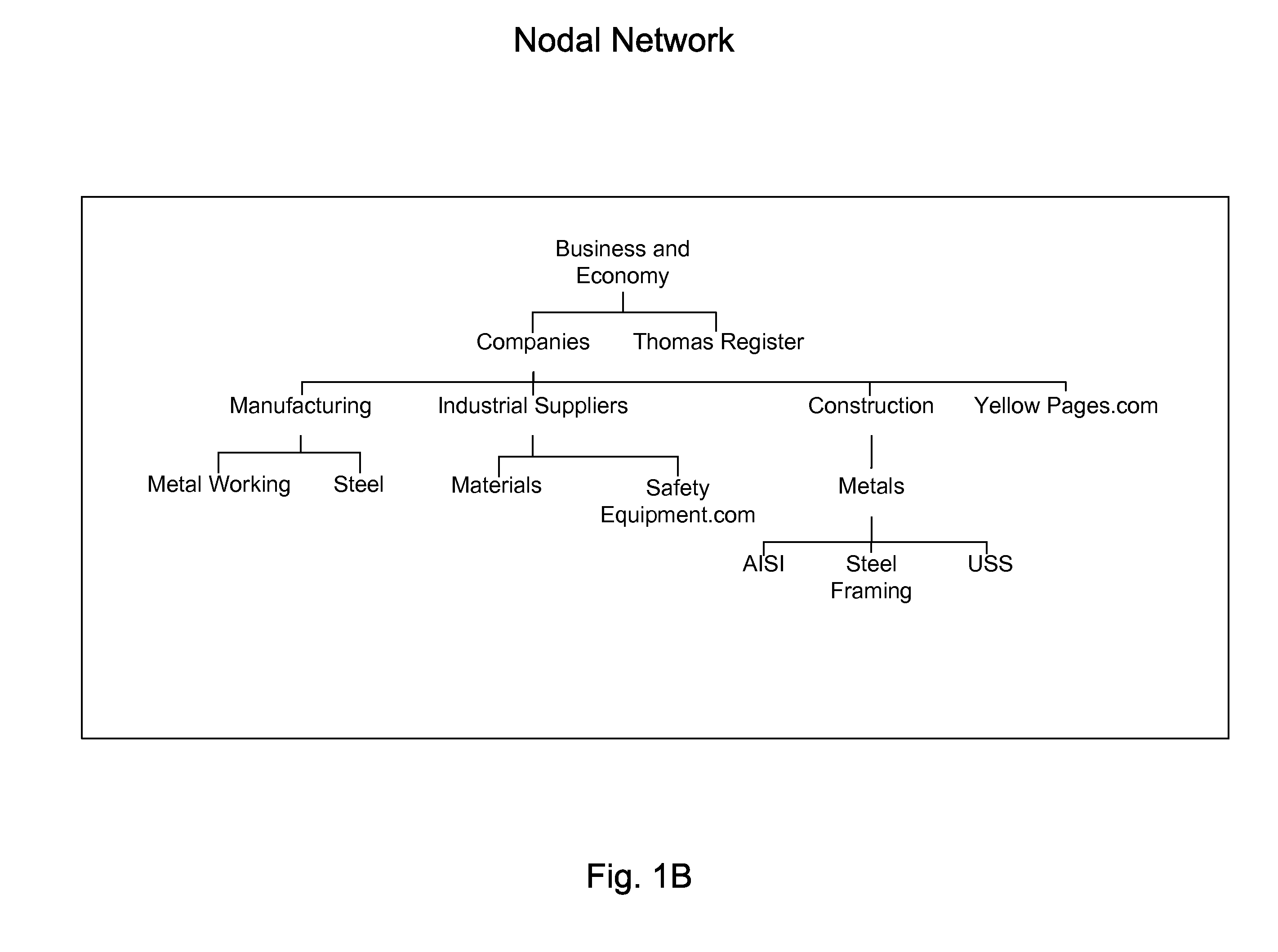

An improved human user computer interface system, providing a graphic representation of a hierarchy populated with naturally classified objects, having included therein at least one associated object having a distinct classification. Preferably, a collaborative filter is employed to define the appropriate associated object. The associated object preferably comprises a sponsored object, generating a subsidy or revenue.

Owner:RELATIVITY DISPLAY LLC

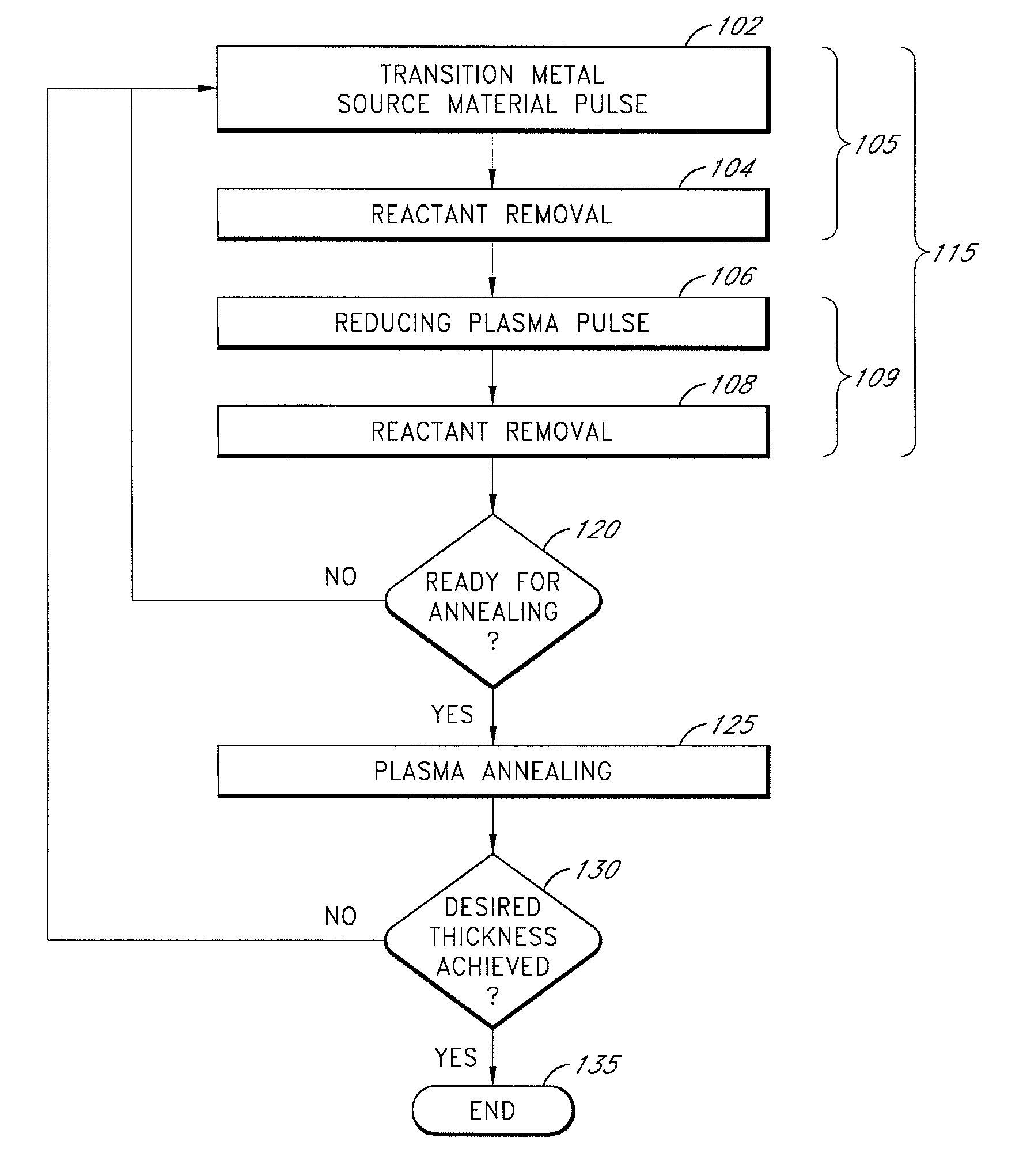

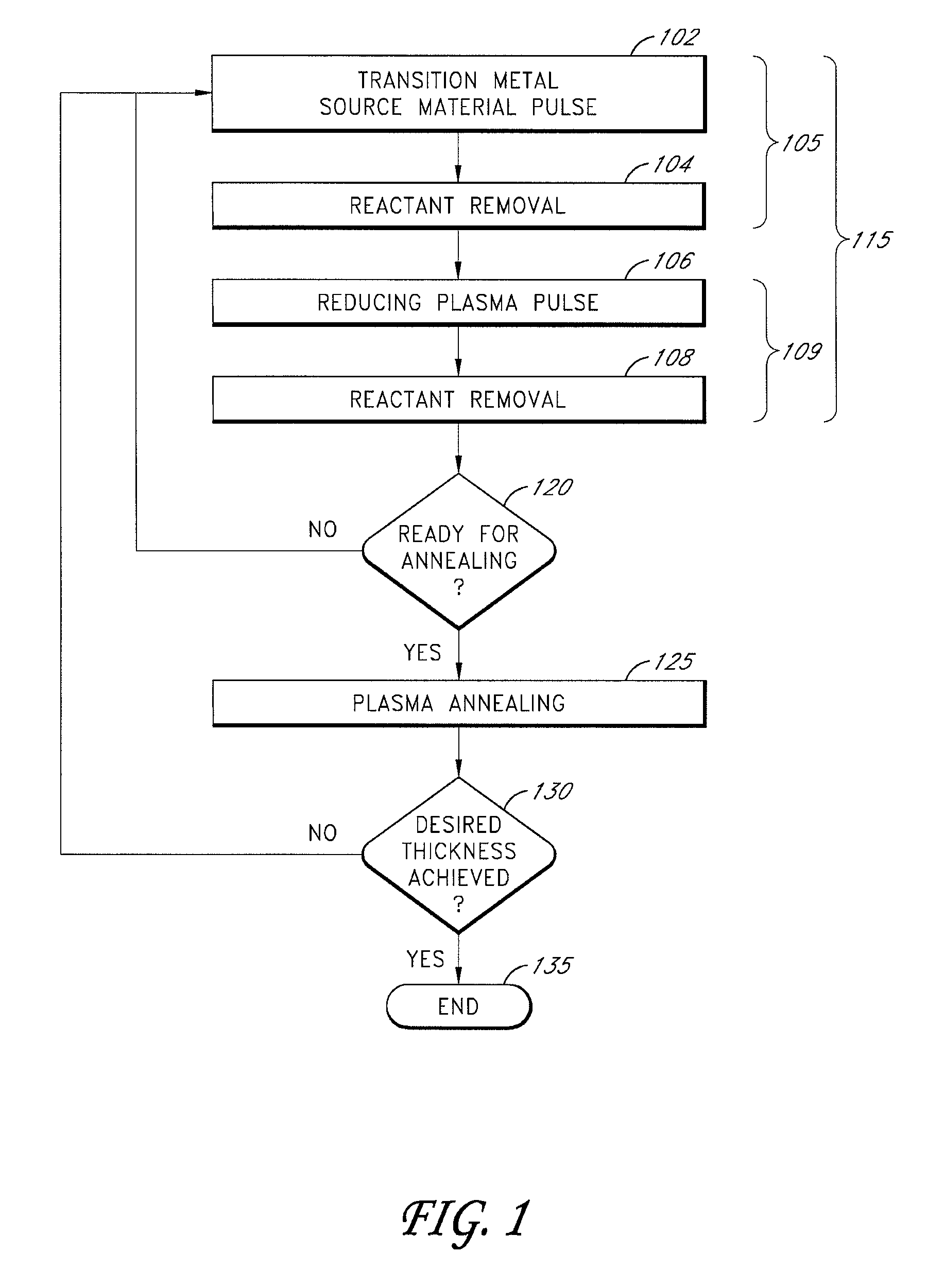

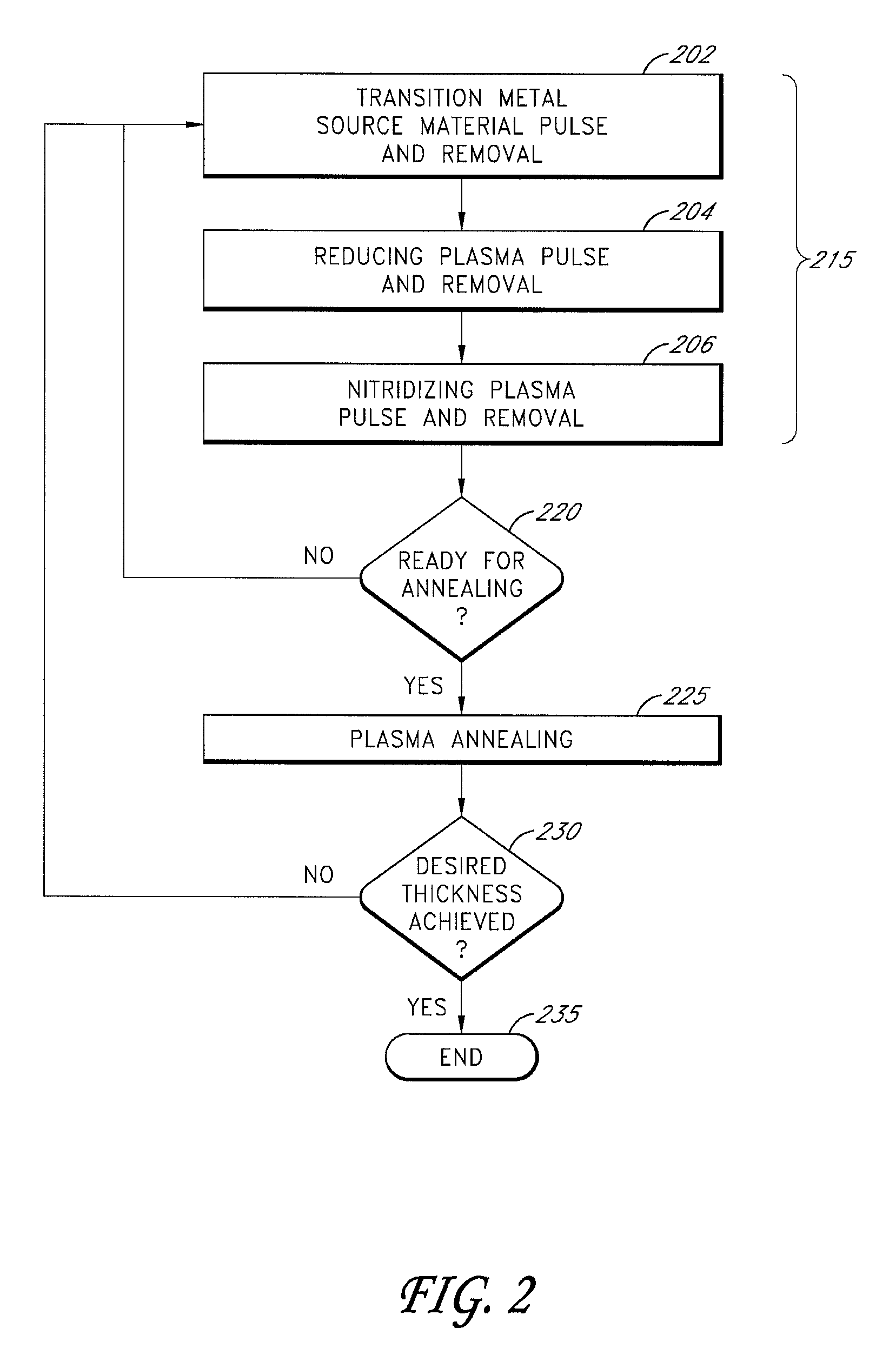

Periodic plasma annealing in an ALD-type process

ActiveUS7713874B2Increase probabilityReduce susceptibility to oxidationPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseVapor phase

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

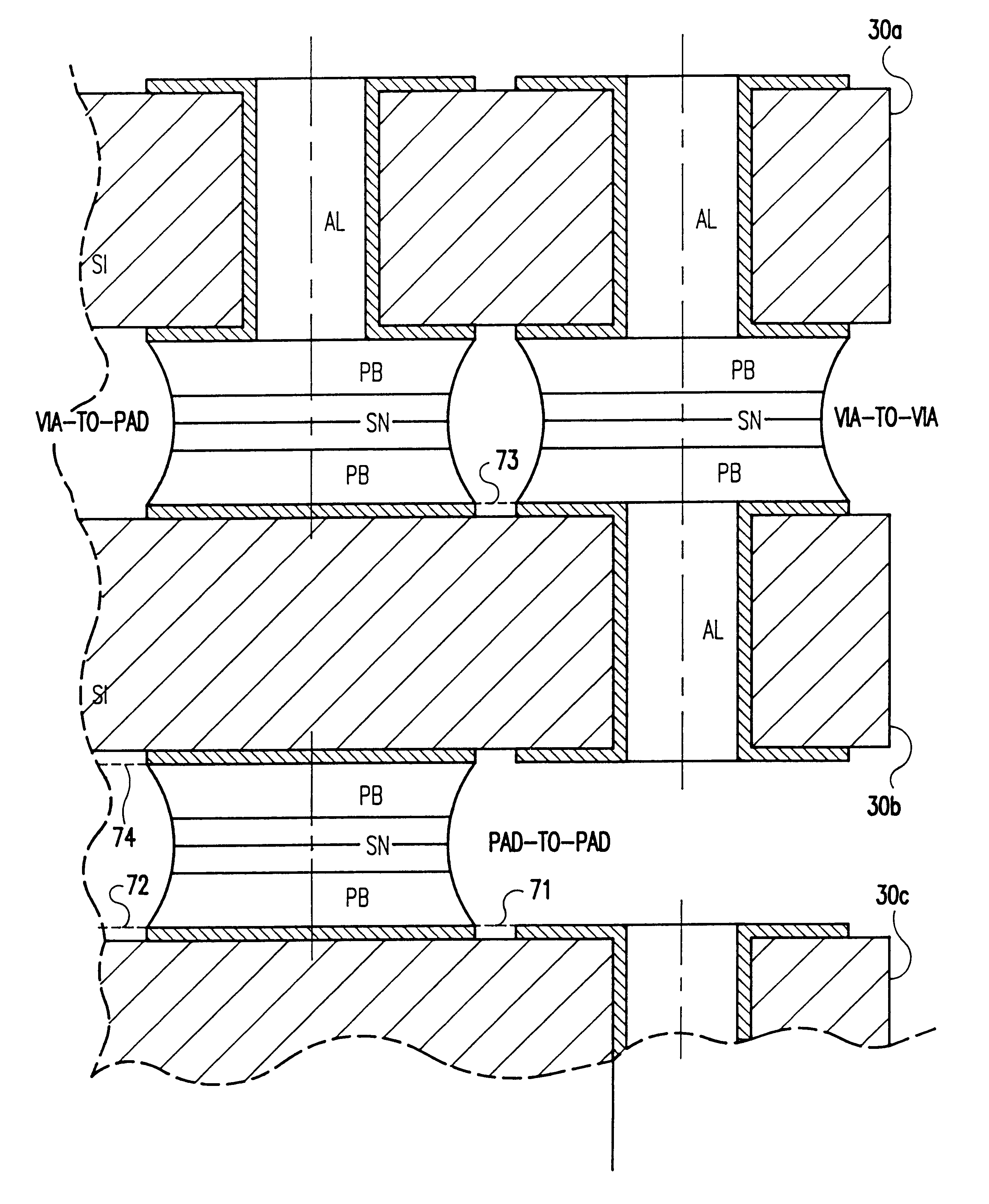

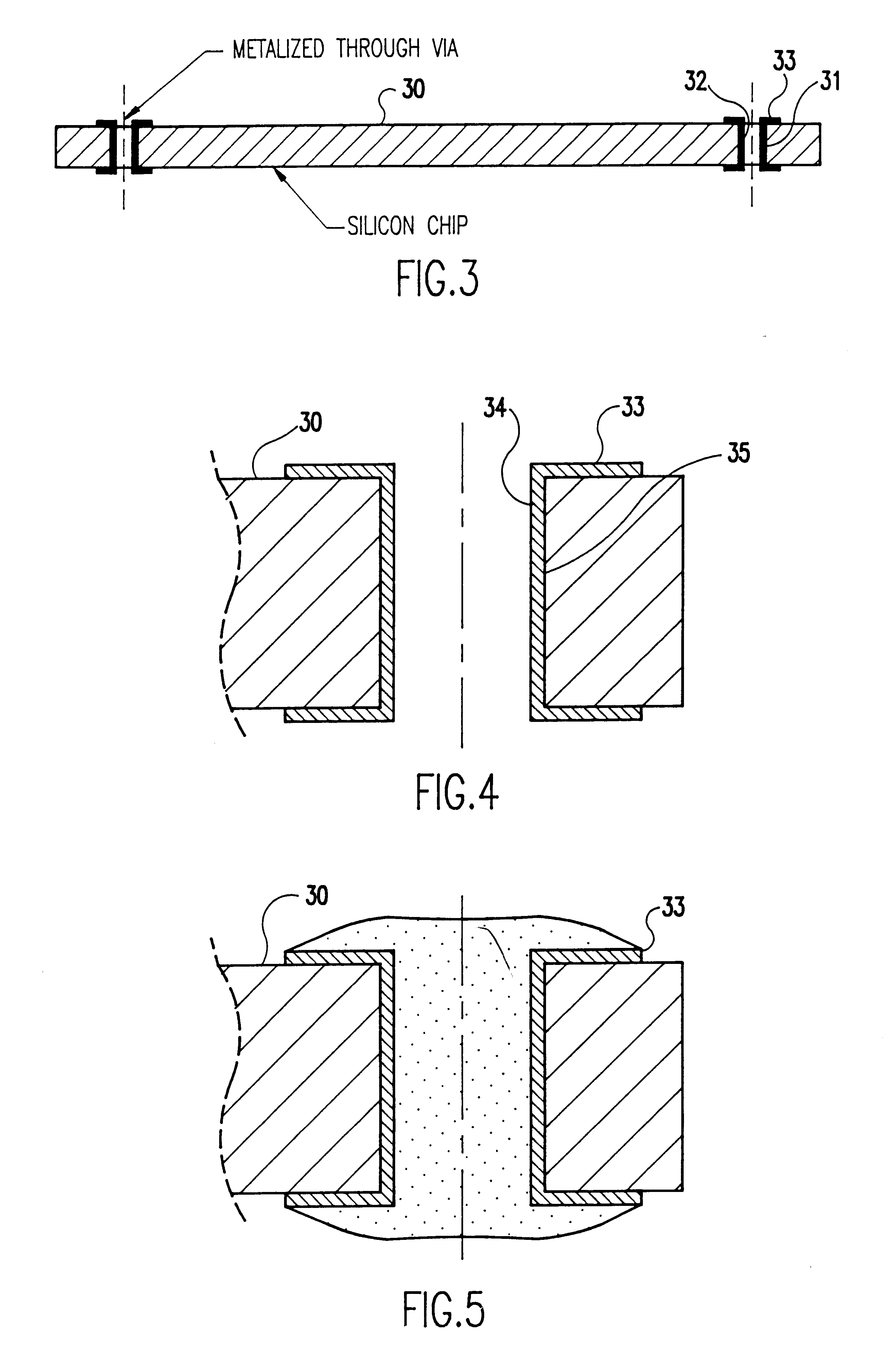

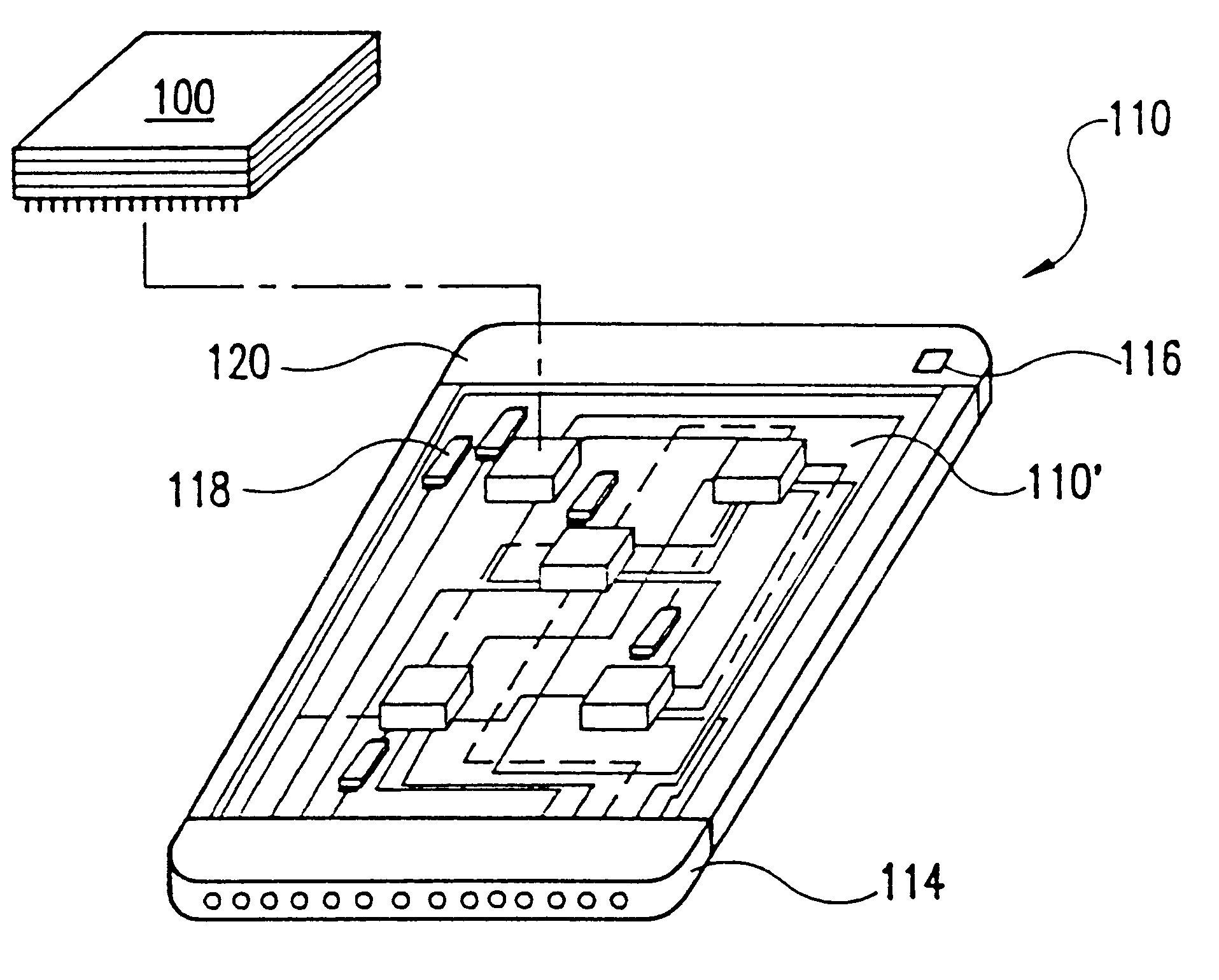

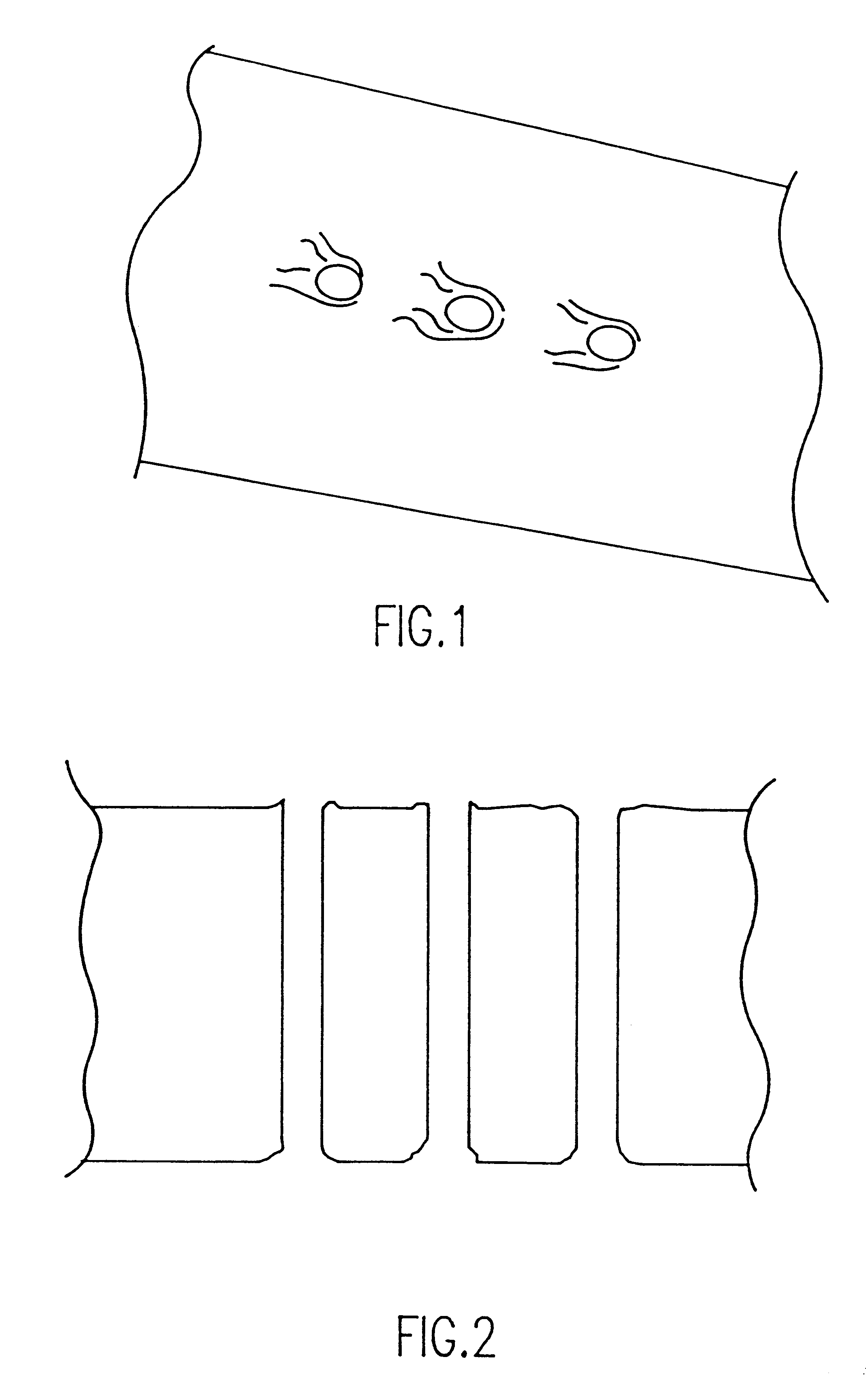

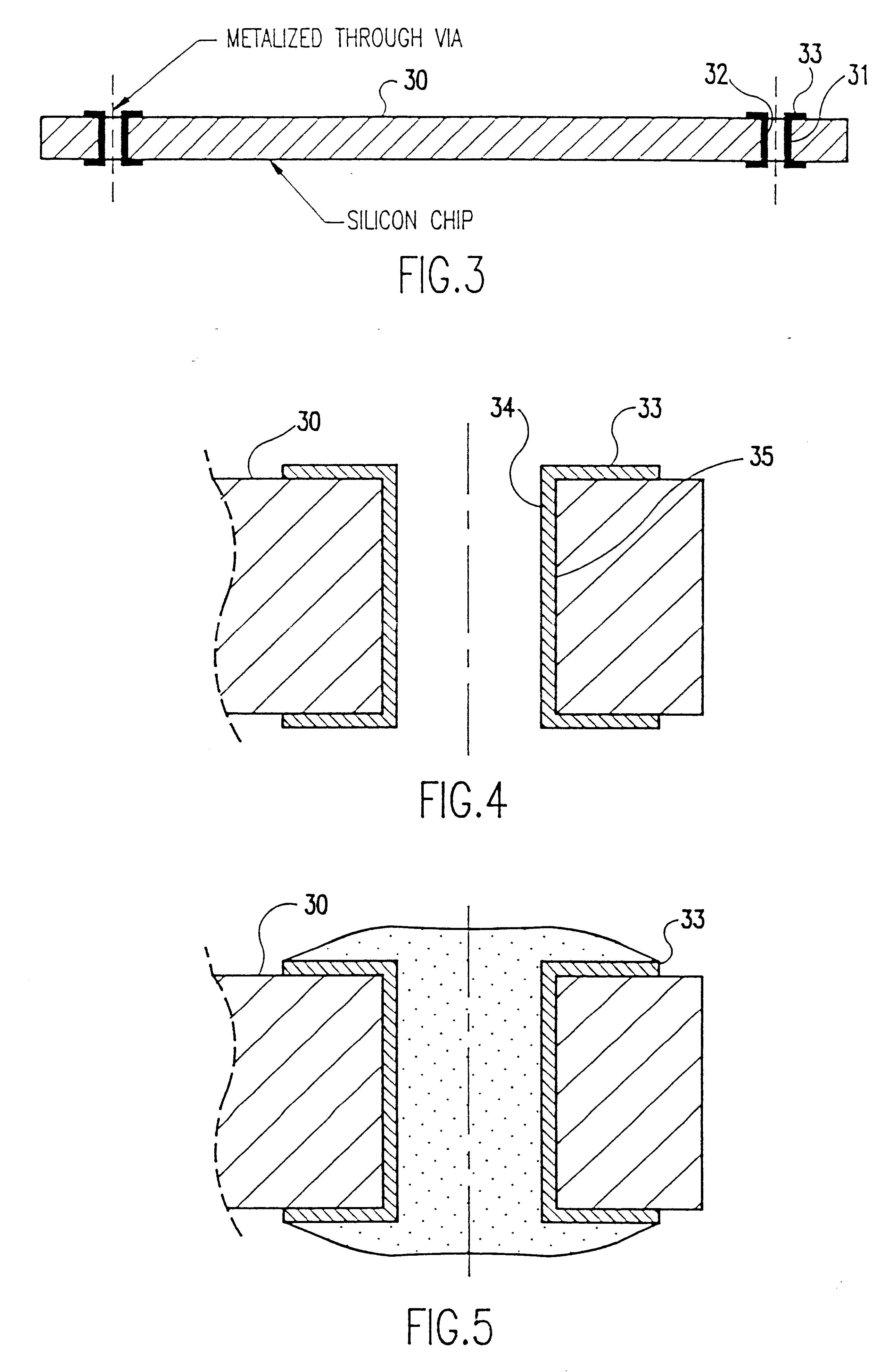

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

Tricalcium phosphates, their composites, implants incorporating them, and method for their production

InactiveUS20050031704A1Easily controlEnhance packing and densificationBiocideHeavy metal active ingredientsChemistryProsthetic implants

Methods for the synthesis of tricalcium phosphates are presented, as well as a series of specific reaction parameters that can be adjusted to tailor, in specific ways, properties in the tricalcium phosphate precursor precipitate. Particulate tricalcium phosphate compositions having an average crystal size of about 250 nm or less are provided. Compositions of the invention can be used as prosthetic implants and coatings for prosthetic implants.

Owner:PIONEER SURGICAL TECH INC

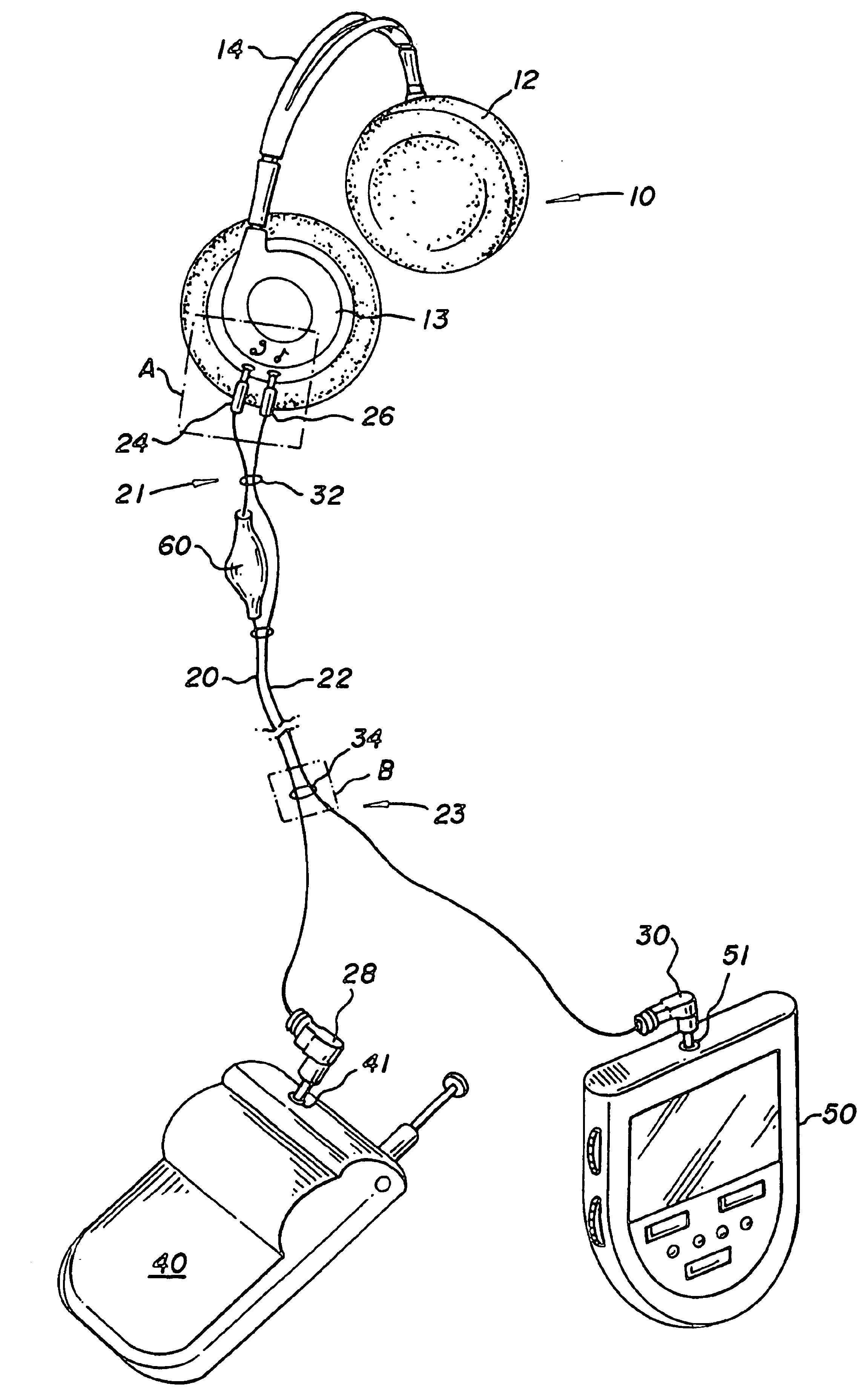

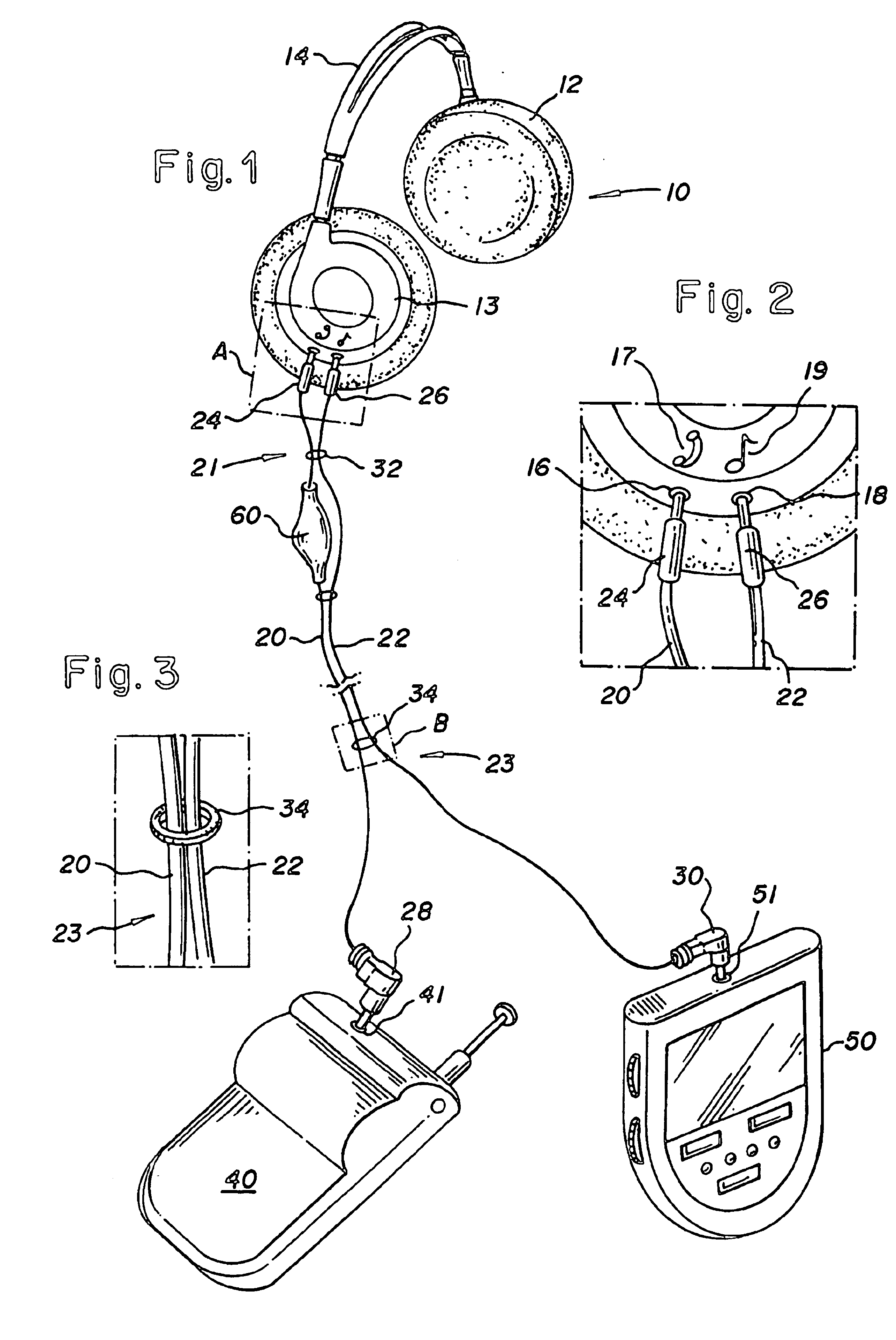

Wireless headphones with selective connection to auxiliary audio devices and a cellular telephone

InactiveUS6873862B2Easy to storeEasy to transportCordless telephonesHeadphones for stereophonic communicationCD playerEngineering

An apparatus comprising a pair of headphones which have selective port connections formed in their housings allowing connection with an auxiliary audio appliances such as an AM / FM radio, CD player, cassette players, MP3 player as well as a cellular telephone. The apparatus specifically has one port for connection to a cellular telephone which is connected to a switching circuit which when activated by the occurrence a telephonic connection interrupts the audio from the auxiliary audio appliance.

Owner:RESHEFSKY MARC ALAN

Computer graphic display visualization system and method

InactiveUS20050165766A1Improve compactnessIncrease flexibilityDrawing from basic elementsAdvertisementsGraphicsCollaborative filtering

An improved human user computer interface system, providing a graphic representation of a hierarchy populated with naturally classified objects, having included therein at least one associated object having a distinct classification. Preferably, a collaborative filter is employed to define the appropriate associated object. The associated object preferably comprises a sponsored object, generating a subsidy or revenue.

Owner:RELATIVITY DISPLAY LLC

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

Computer graphic display visualization system and method

InactiveUS20060288023A1Improve compactnessIncrease flexibilityDrawing from basic elementsAdvertisementsGraphicsCollaborative filtering

An improved human user computer interface system, providing a graphic representation of a hierarchy populated with naturally classified objects, having included therein at least one associated object having a distinct classification. Preferably, a collaborative filter is employed to define the appropriate associated object. The associated object preferably comprises a sponsored object, generating a subsidy or revenue.

Owner:RELATIVITY DISPLAY LLC

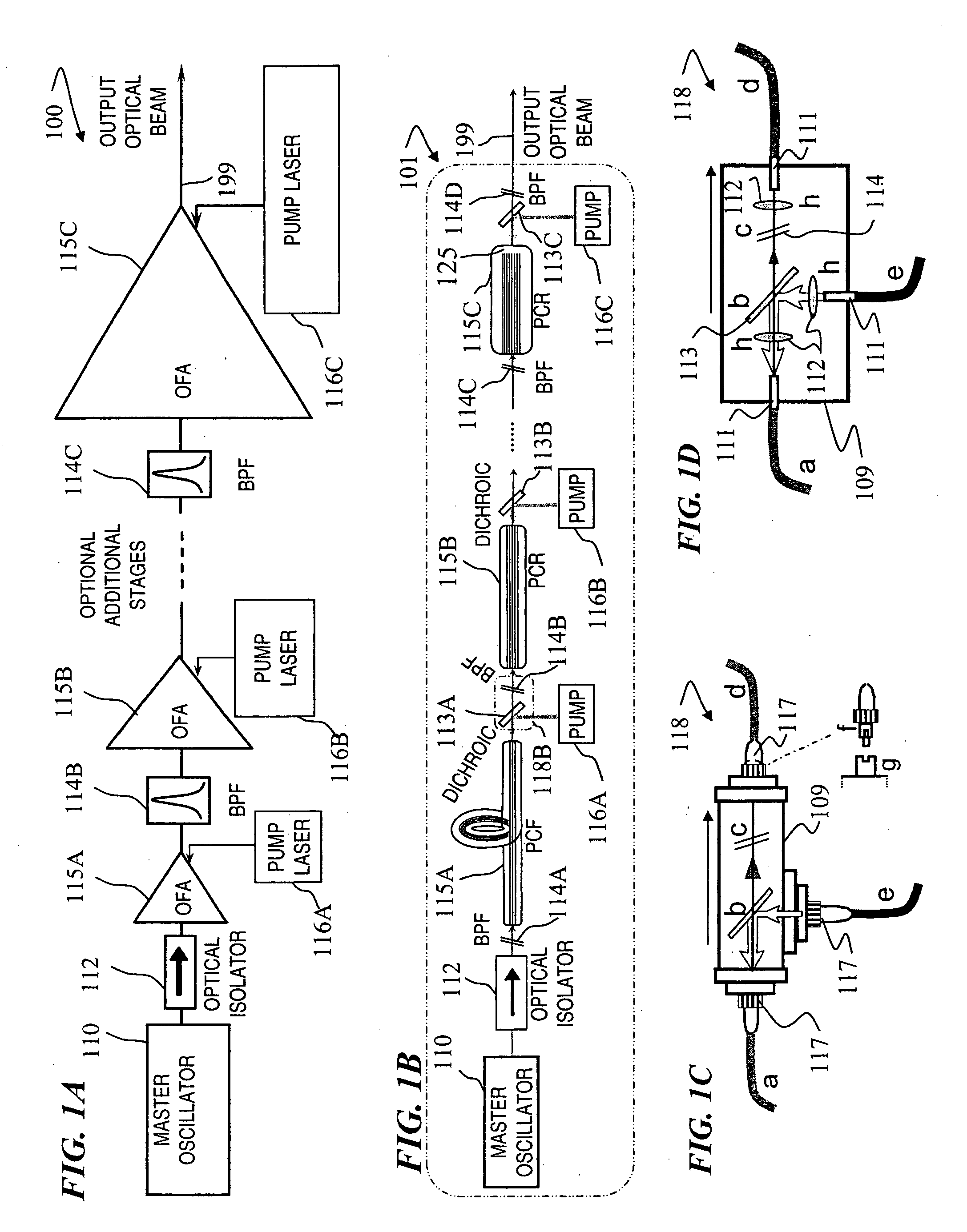

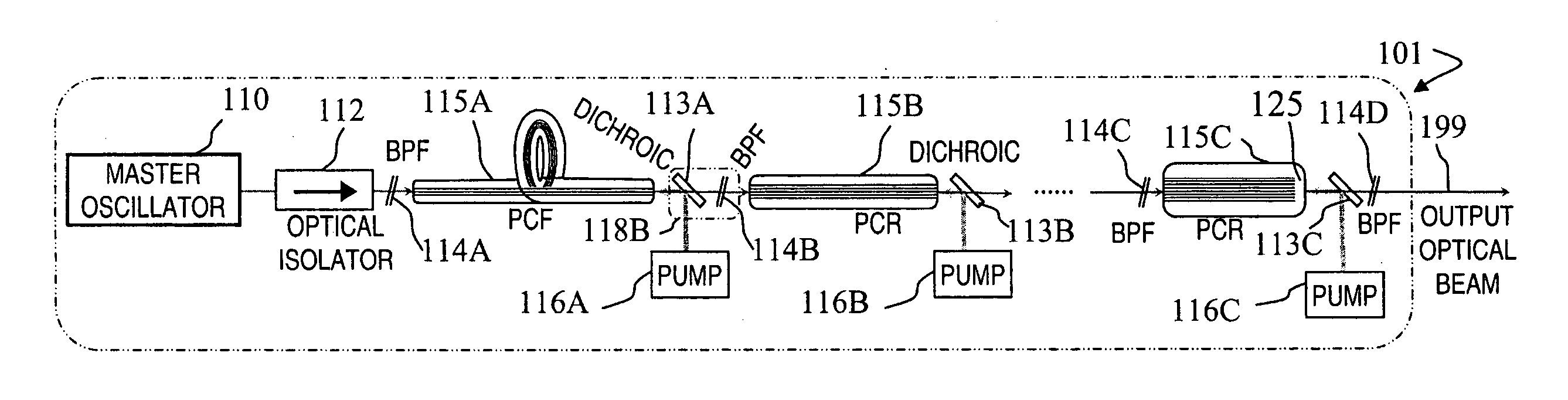

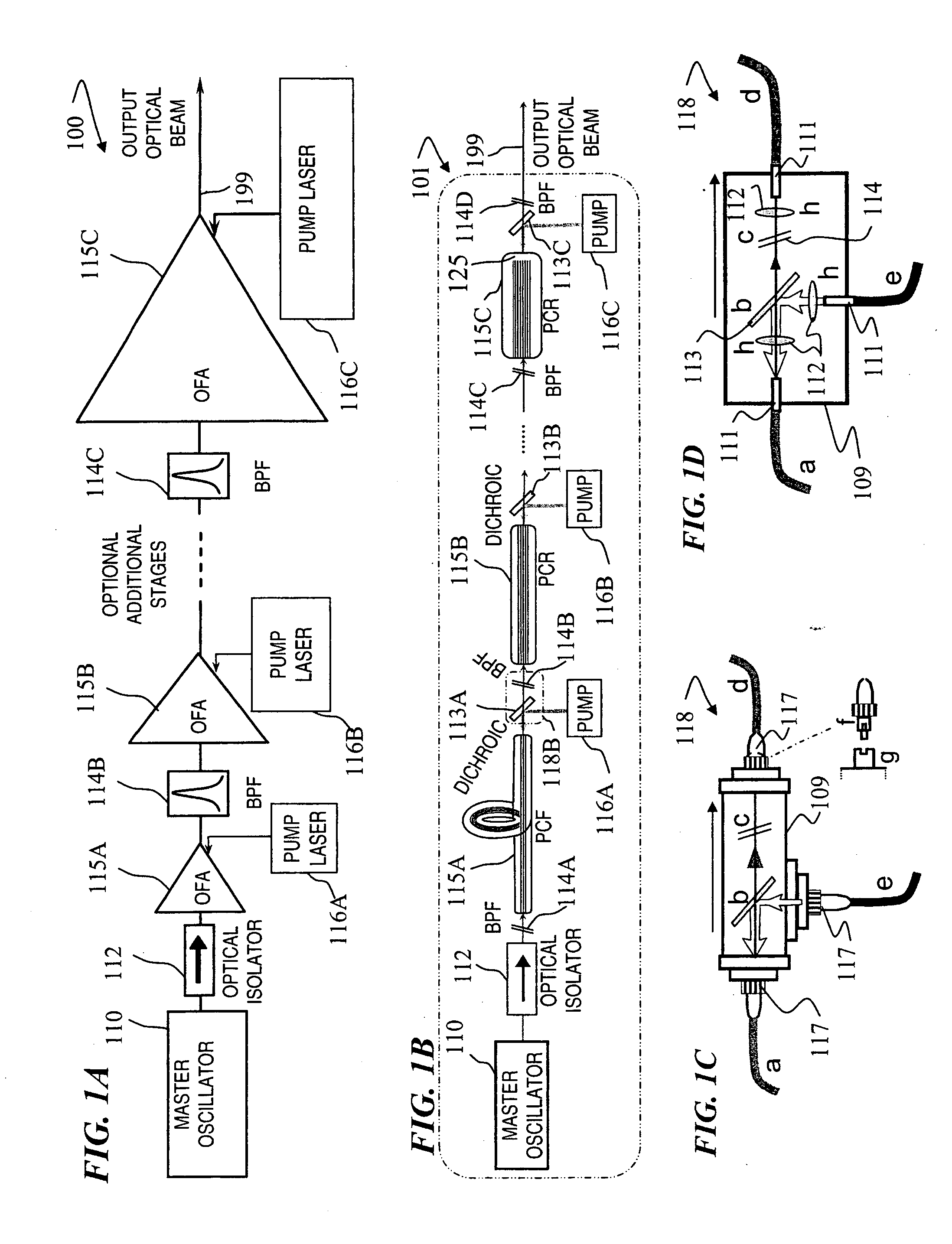

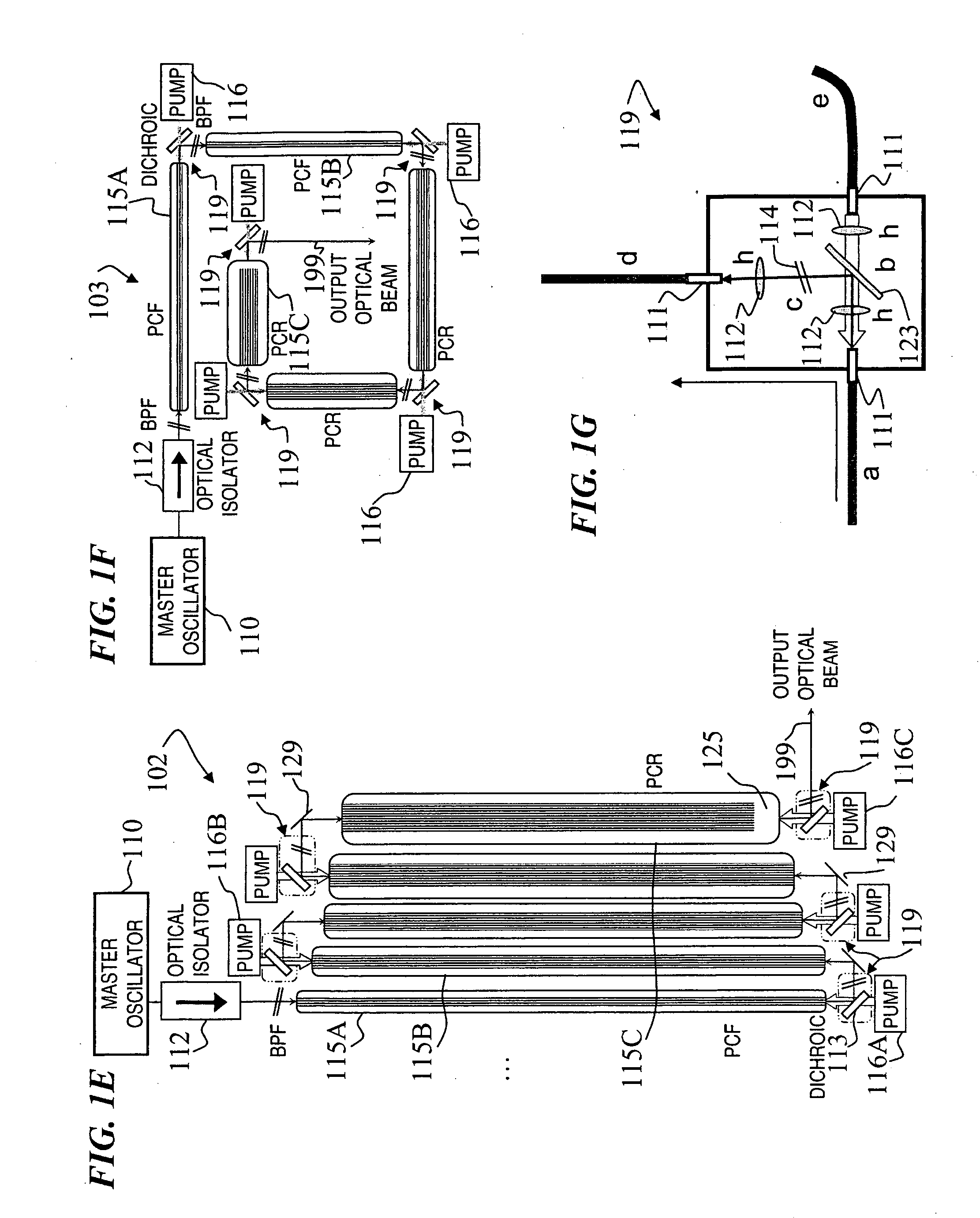

Fiber- or rod-based optical source featuring a large-core, rare-earth-doped photonic-crystal device for generation of high-power pulsed radiation and method

ActiveUS20070041083A1High peak powerHigh pulse energyGlass making apparatusOptical fibre with multilayer core/claddingRare earthEngineering

A method and apparatus use a photonic-crystal fiber having a very large core while maintaining a single transverse mode. In some fiber lasers and amplifiers having large cores problems exist related to energy being generated at multiple-modes (i.e., polygamy), and of mode hopping (i.e., promiscuity) due to limited control of energy levels and fluctuations. The problems of multiple-modes and mode hopping result from the use of large-diameter waveguides, and are addressed by the invention. This is especially true in lasers using large amounts of energy (i.e., lasers in the one-megawatt or more range). By using multiple small waveguides in parallel, large amounts of energy can be passed through a laser, but with better control such that the aforementioned problems can be reduced. An additional advantage is that the polarization of the light can be maintained better than by using a single fiber core.

Owner:LOCKHEED MARTIN CORP

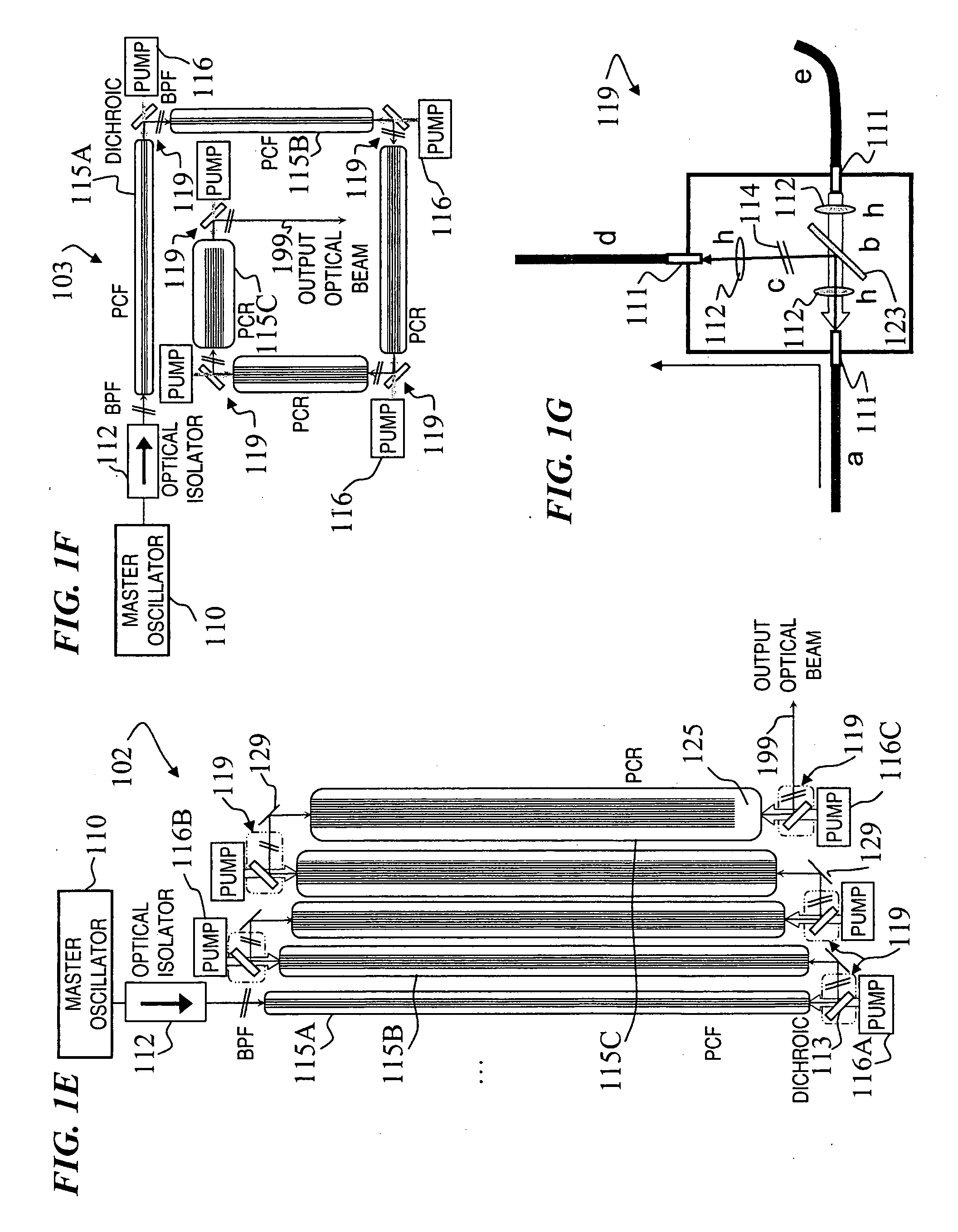

Image display apparatus

InactiveUS20060050169A1High level of portabilityEnlarged display screenTelevision system detailsColor television detailsComputer graphics (images)Image display

An image display apparatus have two frames, a flexible image display screen and a unit. The two frames mutually closable and openable are linked through a pivot. When the two frames are closed, the flexible image display screen is arranged inside the two frames, being folded into two with its part being curved. The image display screen is opened when the two frames are opened. The unit is supported by one of the two frames so as to pivot freely between a housed position and a position in the use of the display screen. The housed position is where the unit is placed on the display screen. When the display screen is in use, the unit is moved outside the display screen. By turning the unit to the housed position and closing the two frames, the unit is further housed in the position sandwiched by the folded display screen.

Owner:FUJIFILM CORP

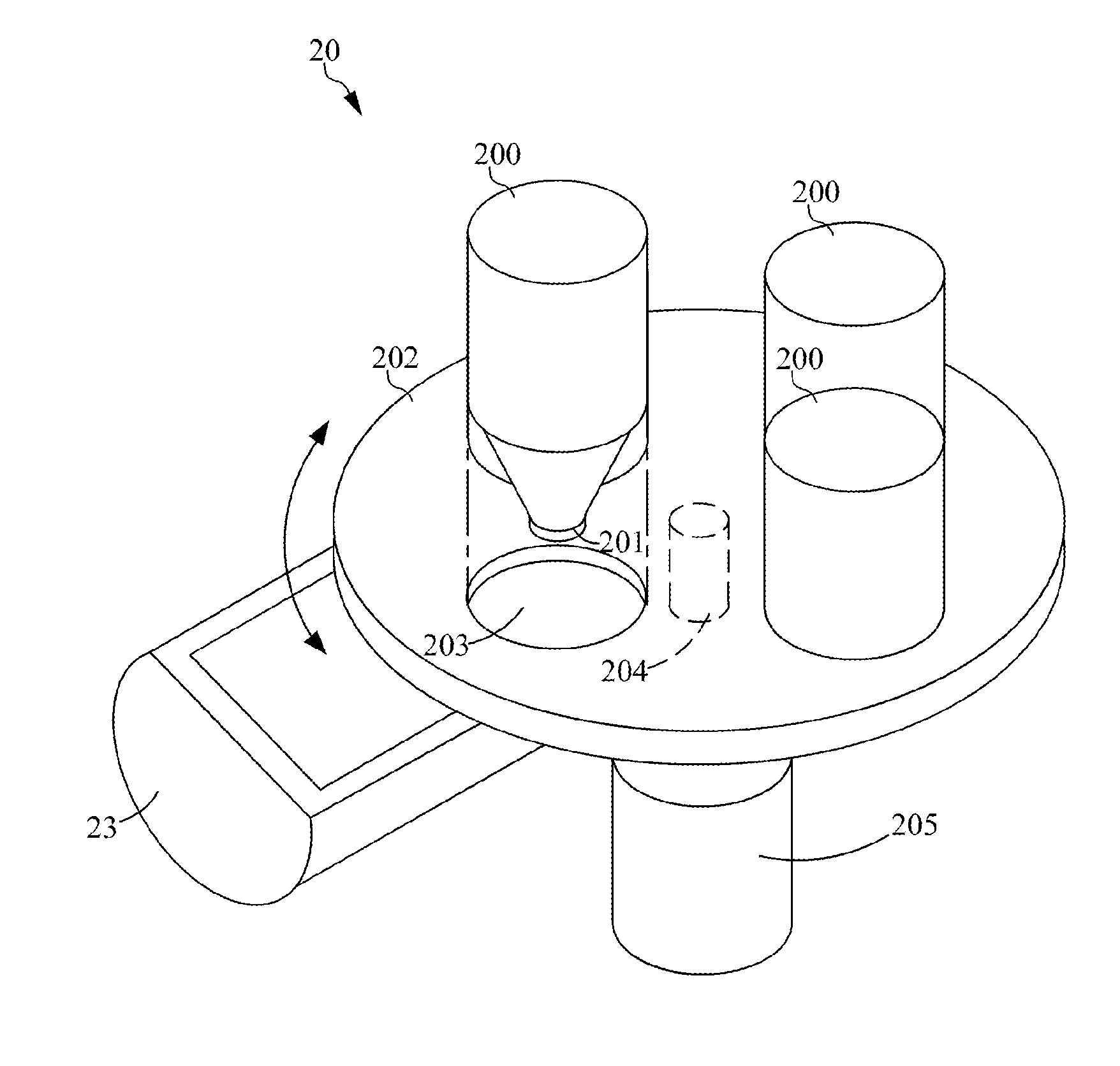

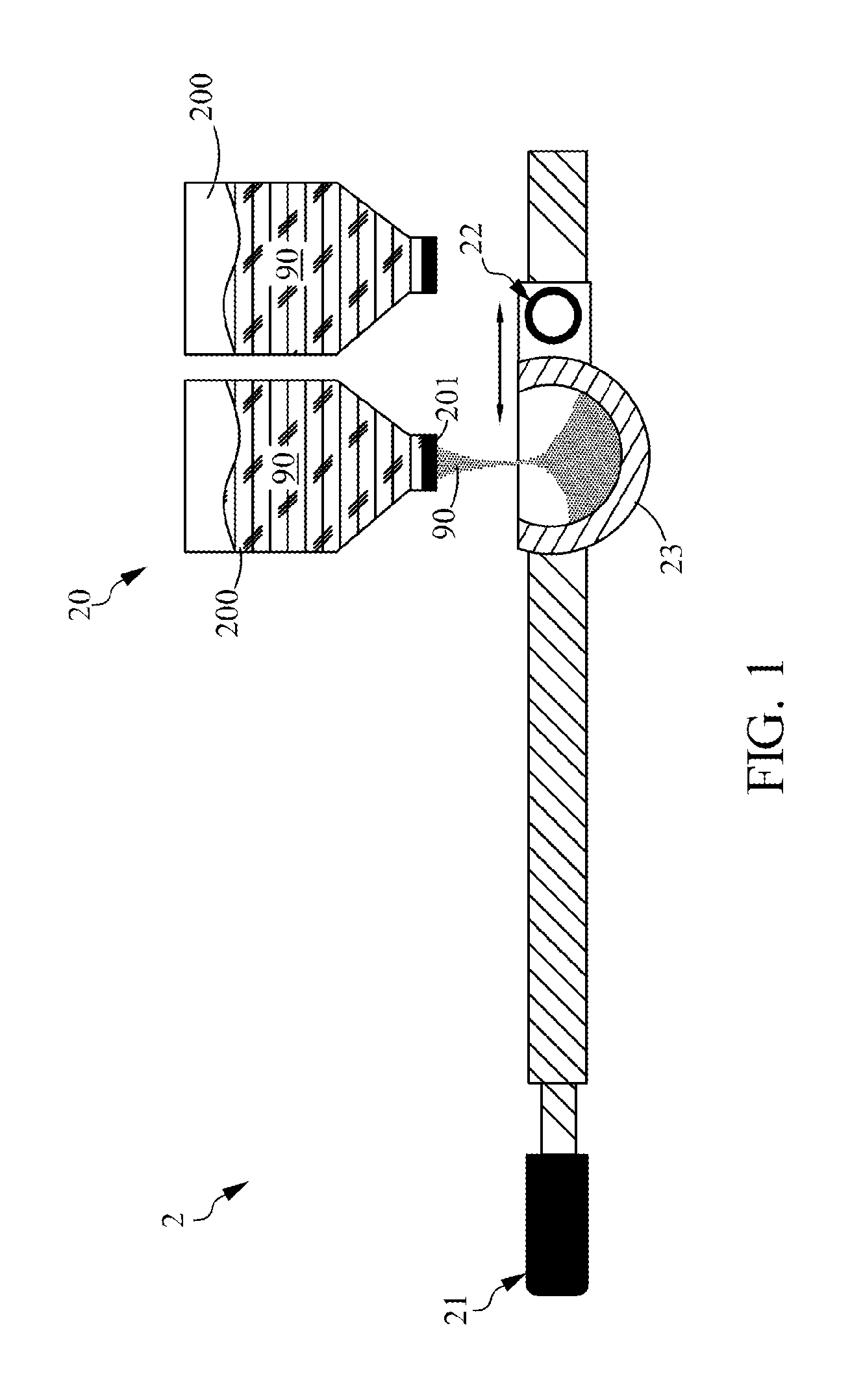

Device and method for powder distribution and additive manufacturing method using the same

ActiveUS20130186514A1Improve compactnessWell mixedLiquid surface applicatorsManufacturing driving meansMetallurgyThermal deformation

The present disclosure provides a device and method for powder distribution and an additive manufacturing method, wherein different size or kind of powders could be chosen to be accommodated within a receptacle. The receptacle can uniformly mix the powder by a rotation movement, pour out the powders by the rotation movement and distribute the powders for forming a layer by a translation movement. In another embodiment, the receptacle further comprises a heating element for preheating the powders. Not only can the present disclosure uniformly mix the powders so as to reduce the thermal deformation and distribute the powder layer compactly, but also can the present disclosure distribute different kinds of powder in different layer so as to increase the diversity in additive manufacturing.

Owner:IND TECH RES INST

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1569774AStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

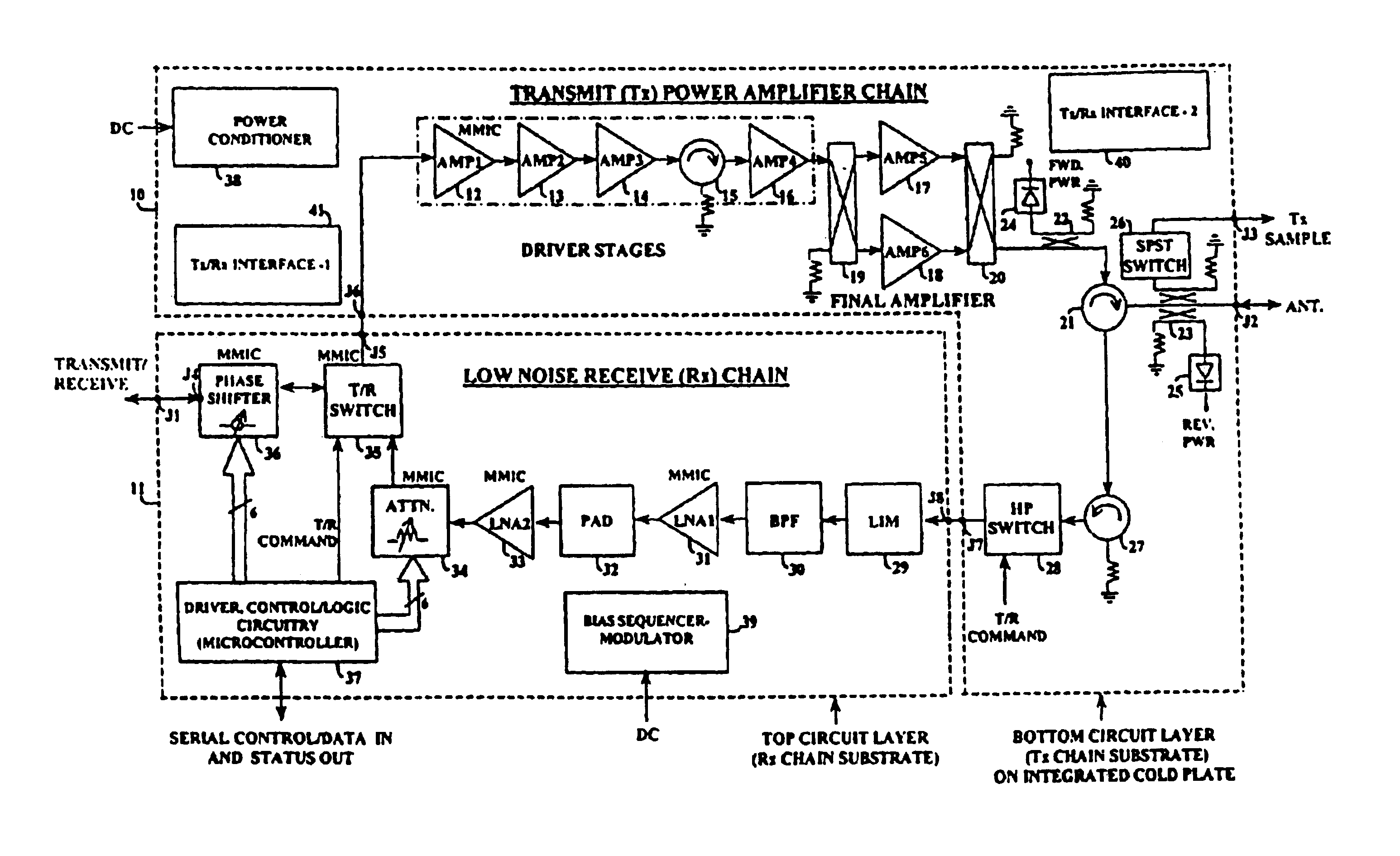

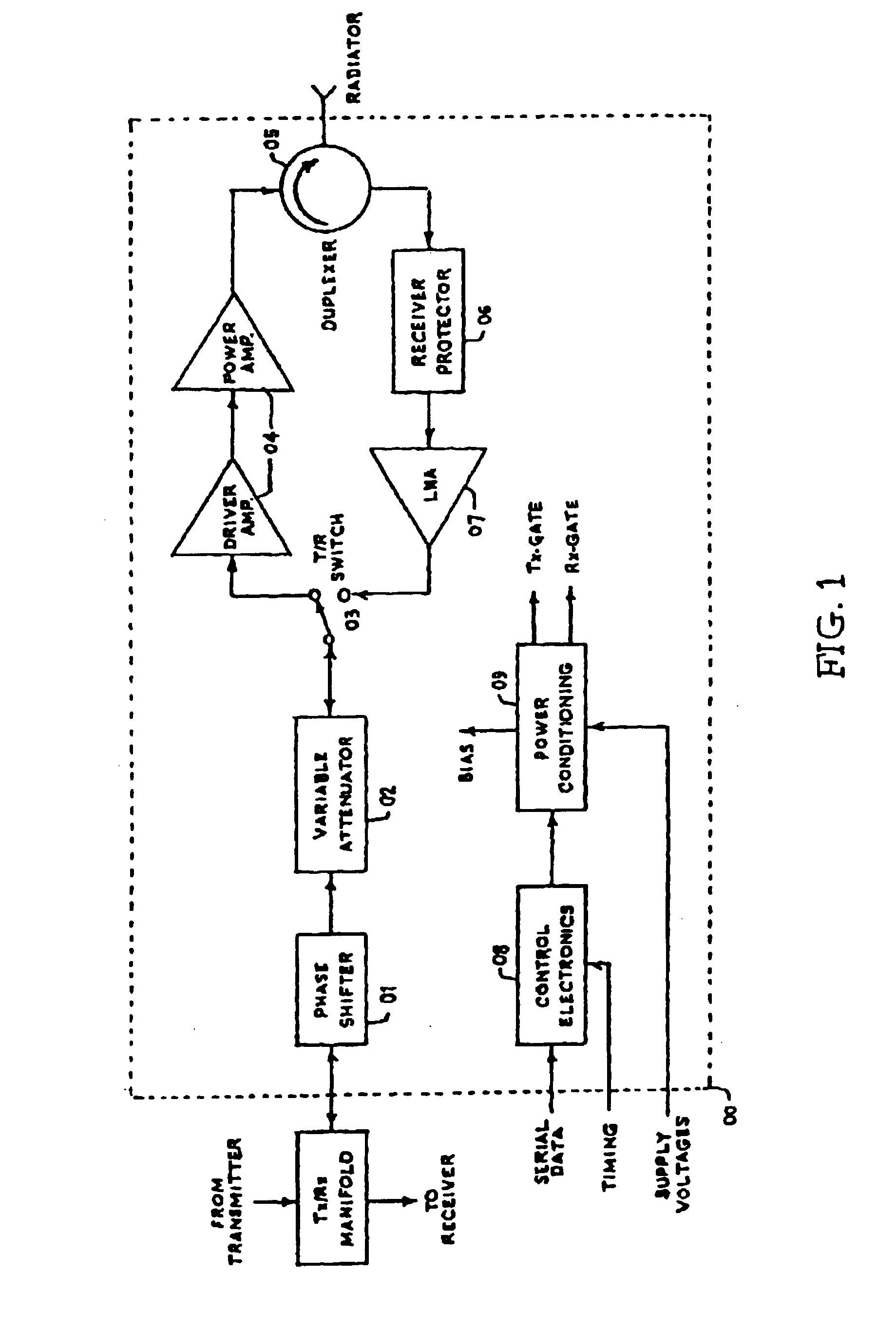

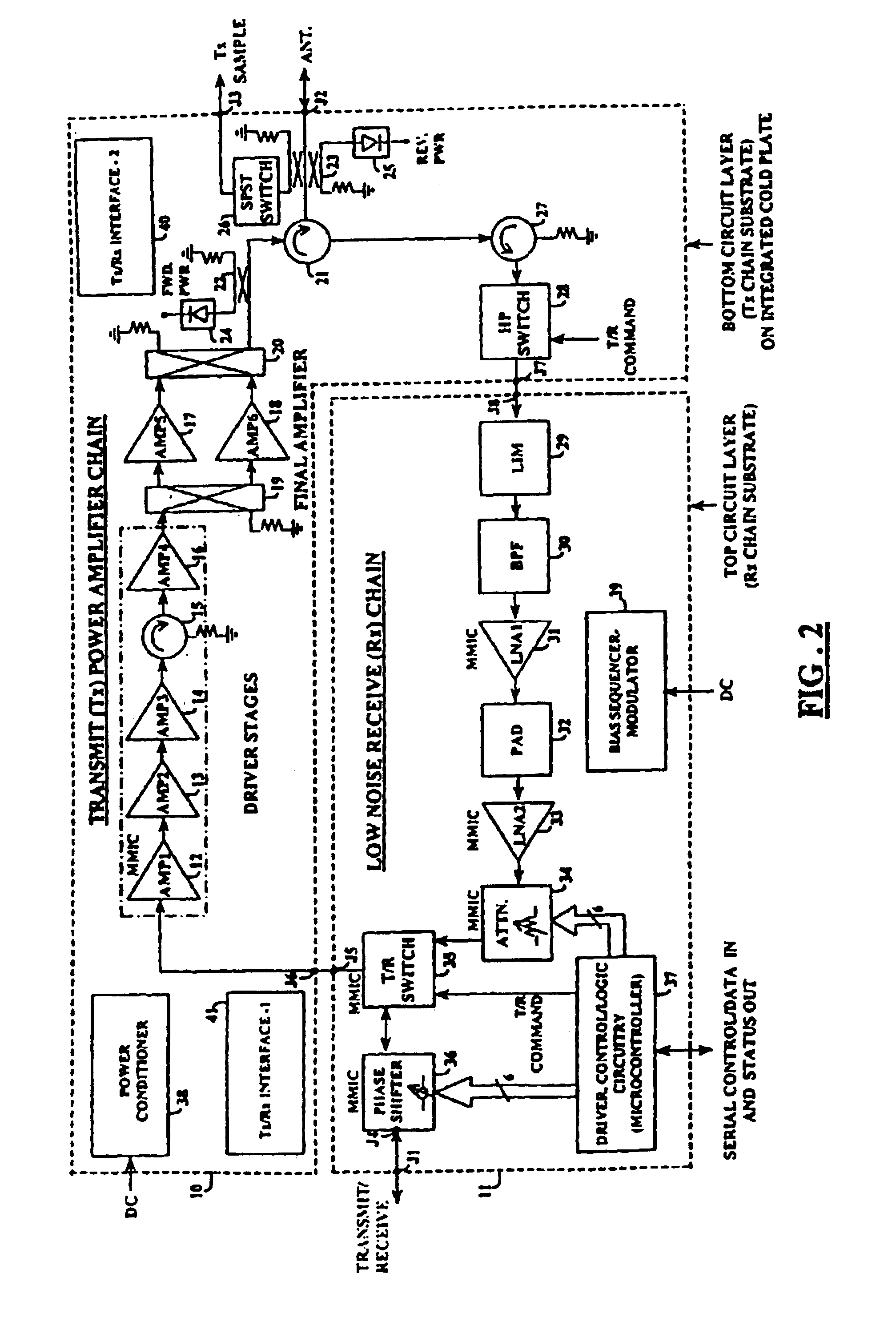

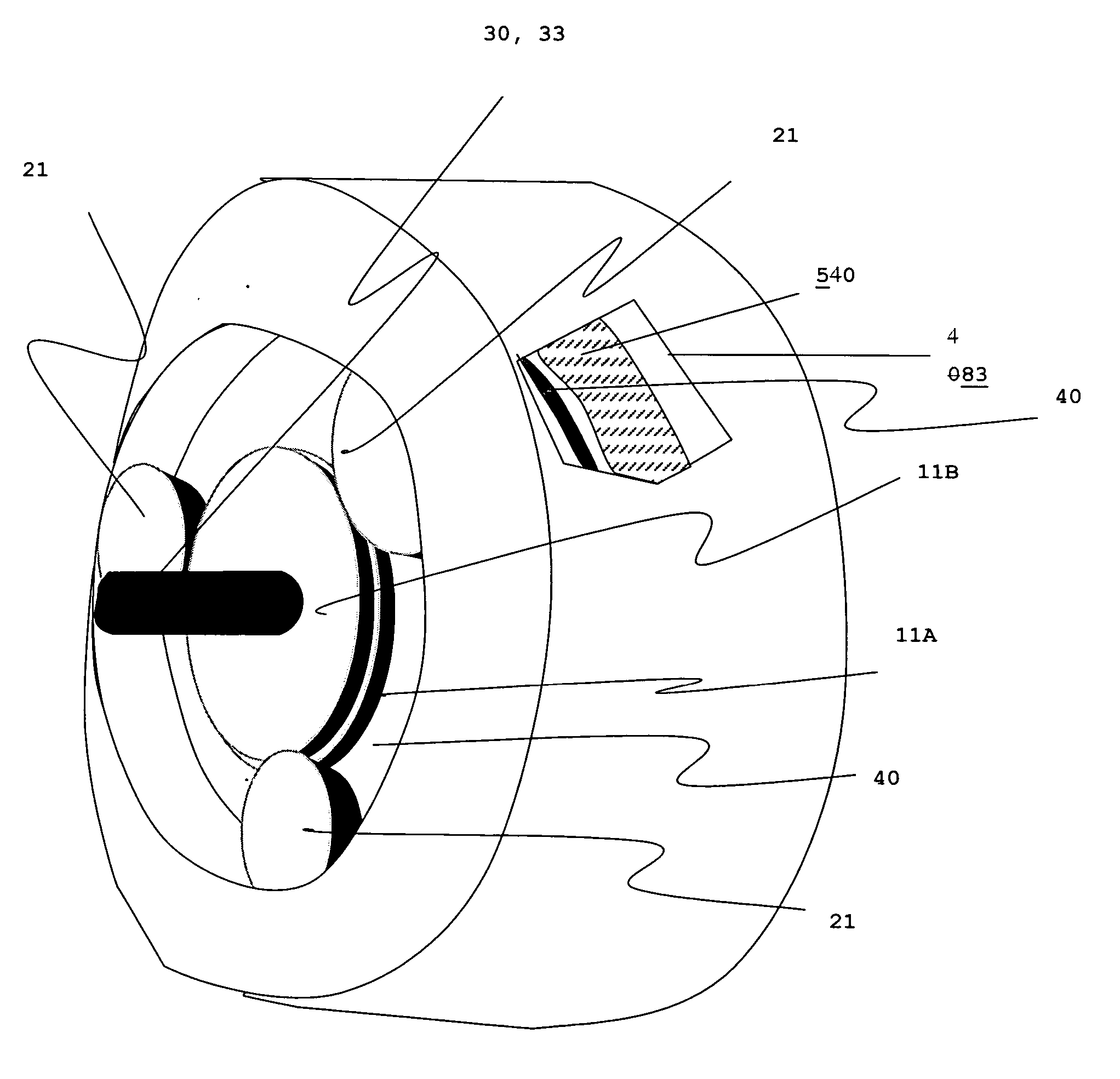

Transmit/receiver module for active phased array antenna

InactiveUS6784837B2Miniaturizing the complete T/R moduleImprove compactnessModular arraysRadio wave reradiation/reflectionLow noiseSoftware engineering

This invention relates to a transmit / receive module for a high power Active Phased Array Antenna system operating in L-band based upon a combination of Hybrid Microwave Integrated Circuit (MIC) as well as Monolithic Microwave Integrated Circuit (MMIC) technology. The transmit / receive module includes a power monitoring means, transmitter protector means, and a receiver protector means. The module comprises a signal transmit chain incorporating power conditioner and a signal receive chain incorporating control electronics and bias- sequencer modulator. The transmit chain has switching means for switching the module to transmit mode which is connected to the transmit amplifier chain through a shared digital phase shifter. The amplified signals from the transmit amplifier chain are conveyed to a duplexer means. In receive mode, the receive chain receives signal through drop-in circulator and high power switch and comprises of high power limiter, low noise amplifier means, and a digital attenuator means connected to the shared digital phase shifter through T / R switch means. Electronic means are connected through integrated control electronic., bias sequencer modulator and power conditioner for controlling the operation of the device.

Owner:CHIEF CONTROLLER RES & DEV MINIST OF DEFENCE GOVERNMENT OF INDIA THE

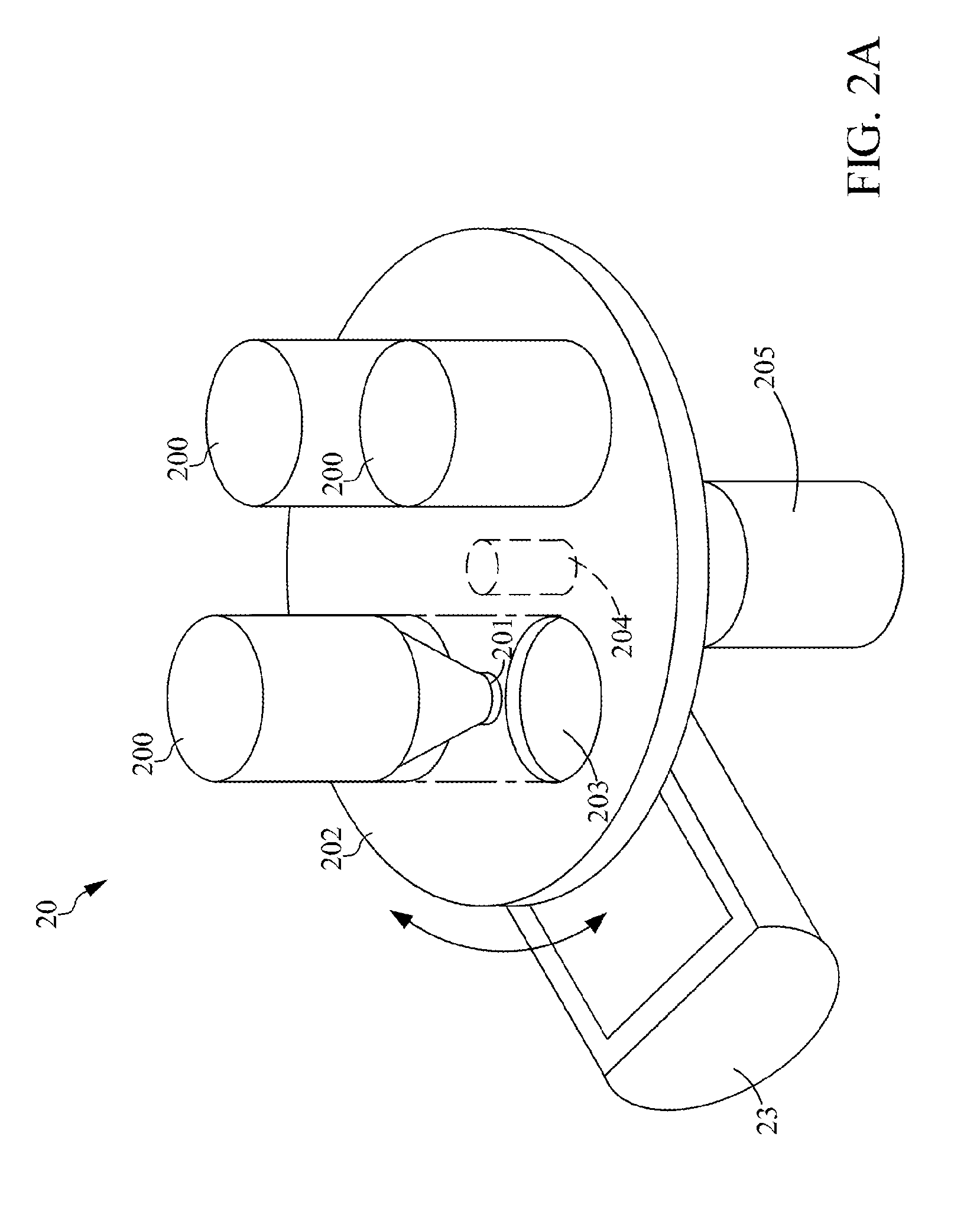

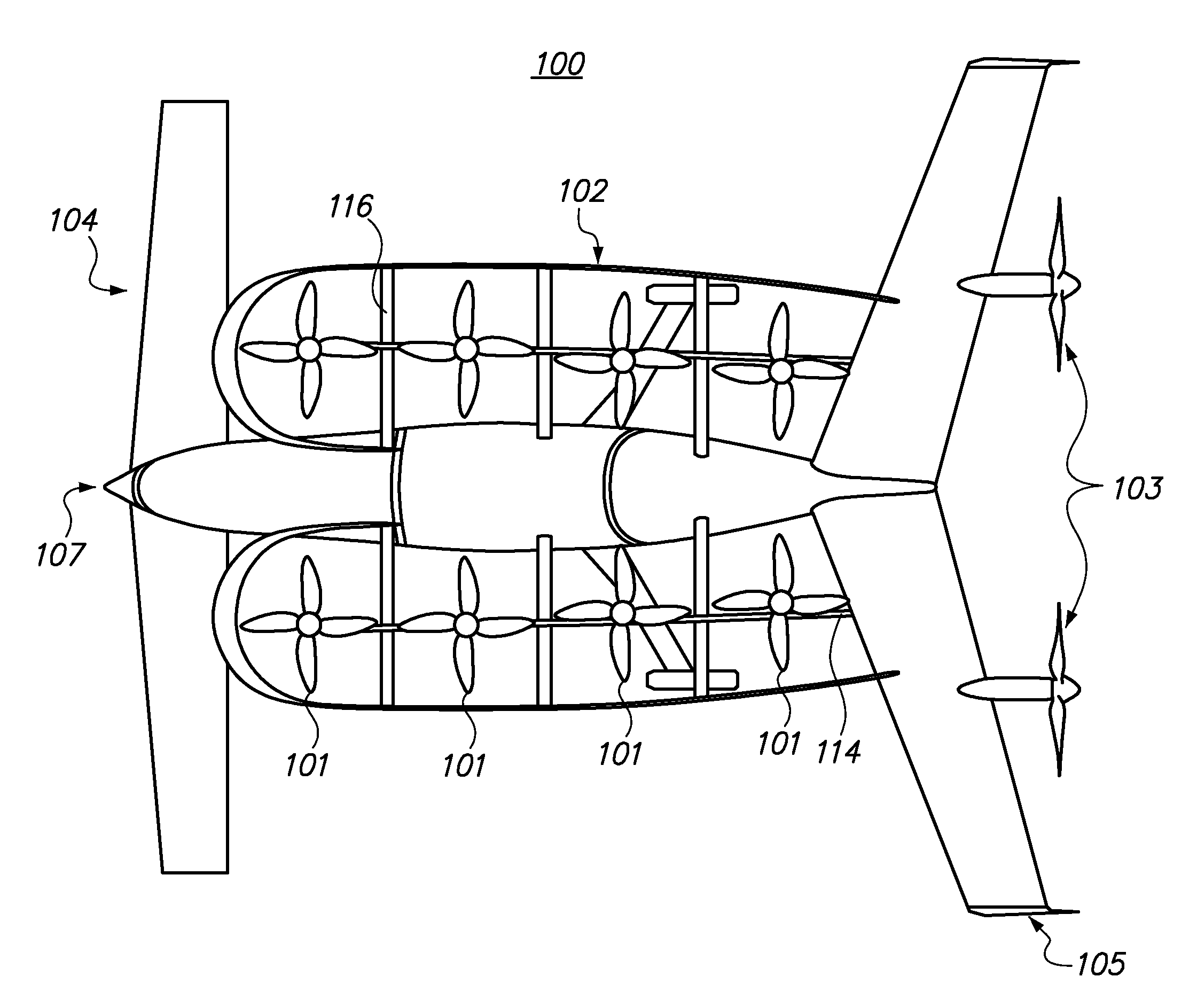

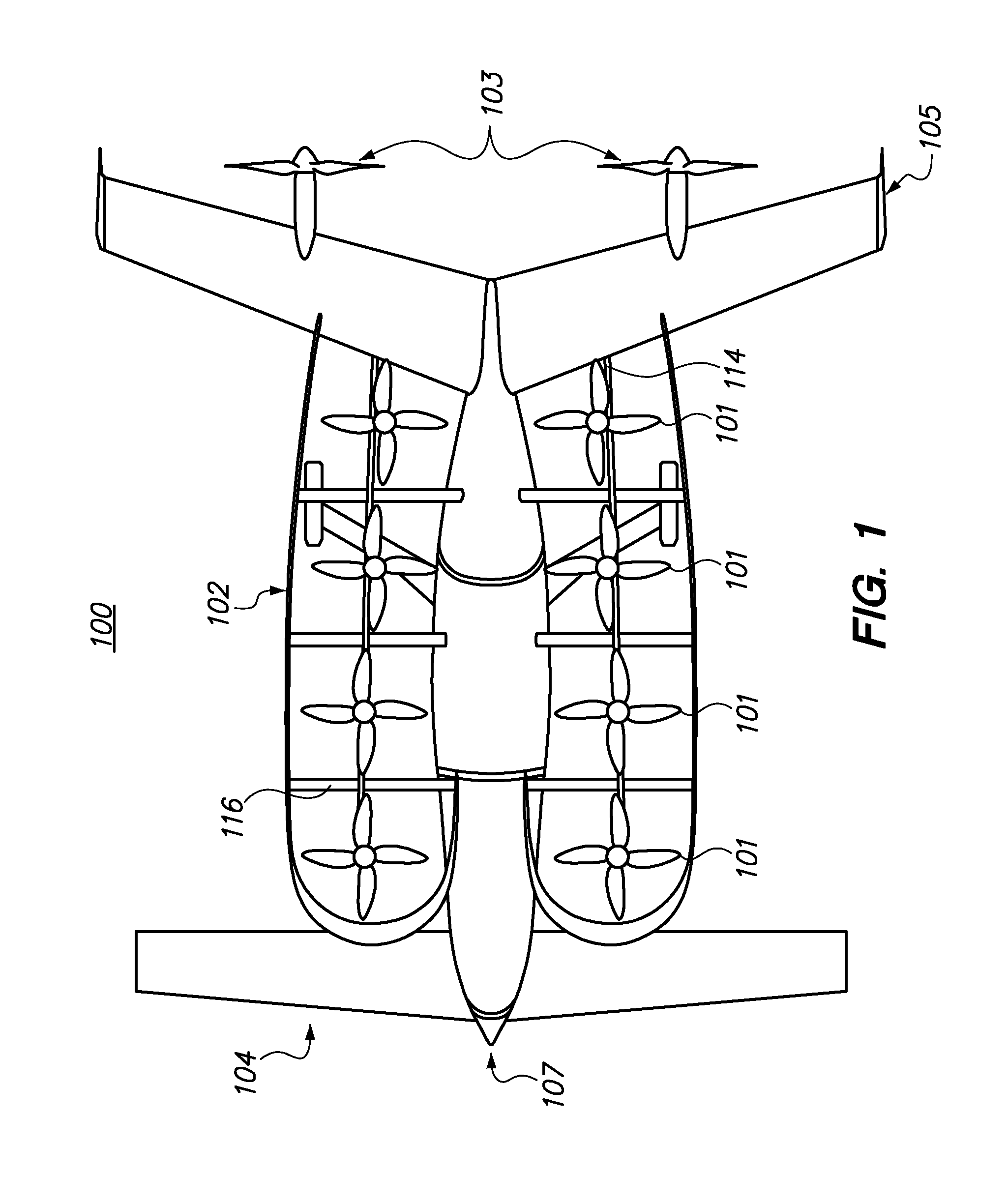

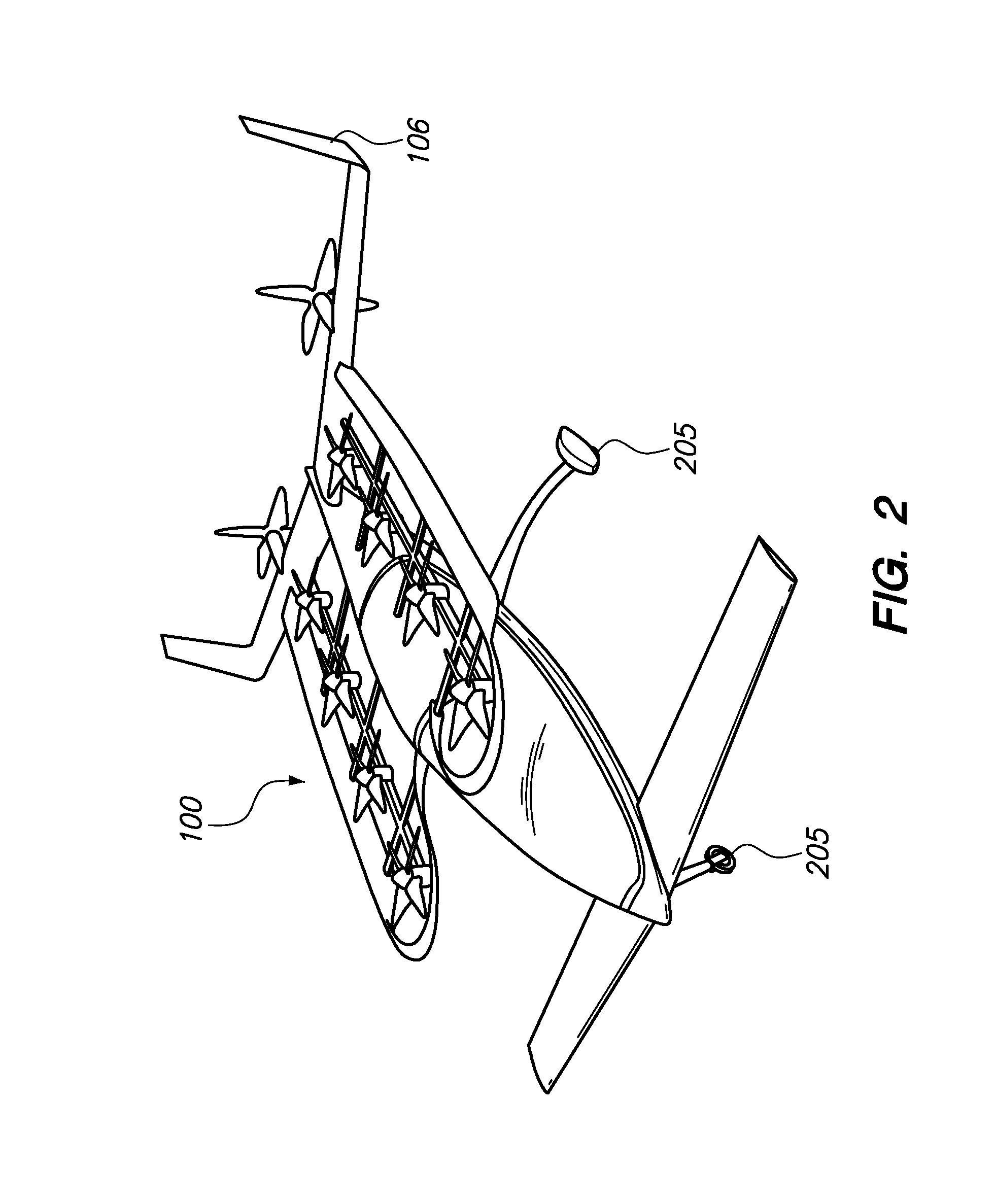

Personal aircraft

ActiveUS8393564B2Easy to controlImprove compactnessPower installationsEfficient propulsion technologiesJet aeroplanePropeller

A safe, quiet, easy to control, efficient, and compact aircraft configuration is enabled through the combination of multiple vertical lift rotors, tandem wings, and forward thrust propellers. The vertical lift rotors, in combination with a front and rear wing, permits a balancing of the center of lift with the center of gravity for both vertical and horizontal flight. This wing and multiple rotor system has the ability to tolerate a relatively large variation of the payload weight for hover, transition, or cruise flight while also providing vertical thrust redundancy. The propulsion system uses multiple lift rotors and forward thrust propellers of a small enough size to be shielded from potential blade strike and provide increased perceived and real safety to the passengers. Using multiple independent rotors provides redundancy and the elimination of single point failure modes that can make the vehicle non-operable in flight.

Owner:WISK AERO LLC

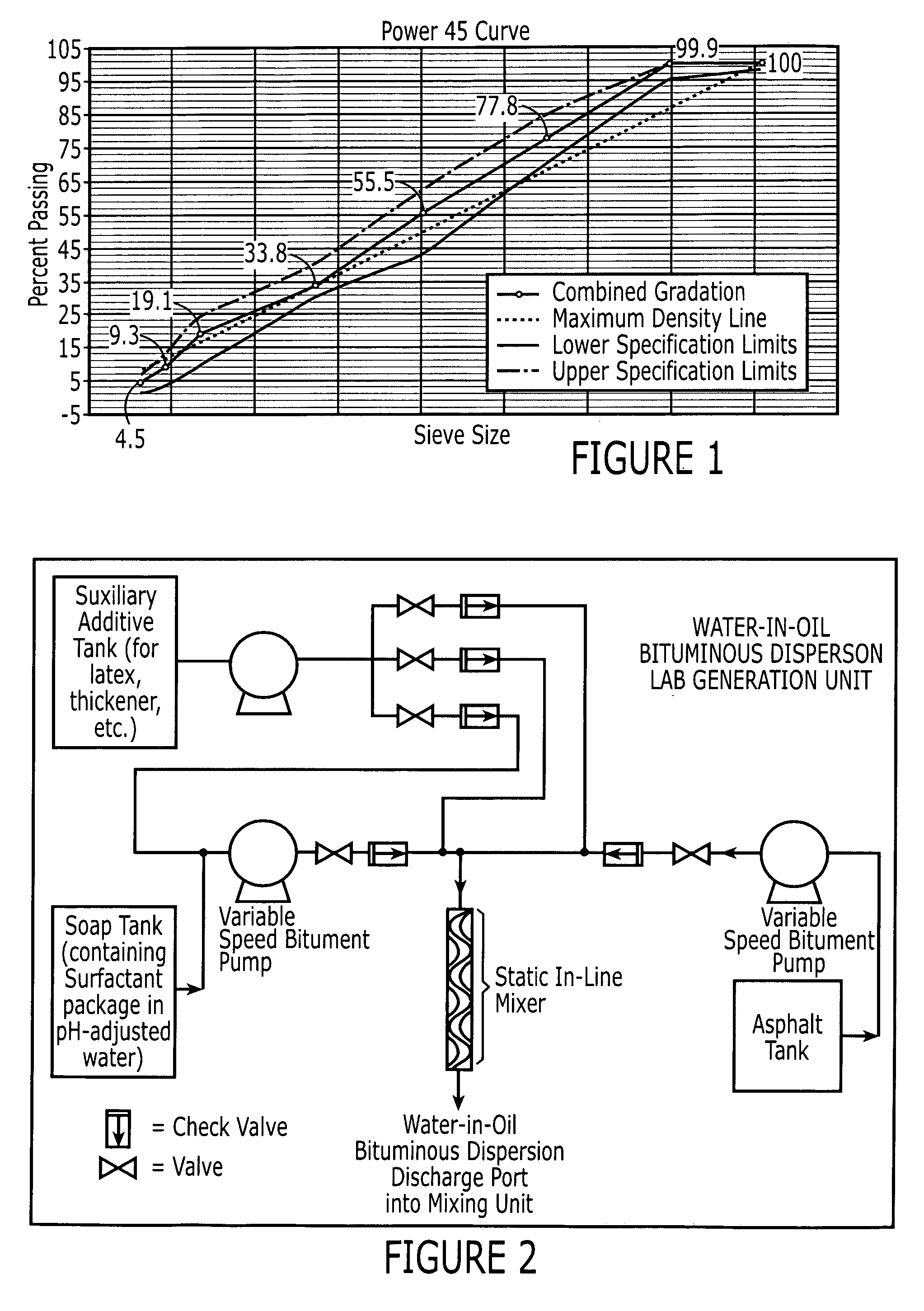

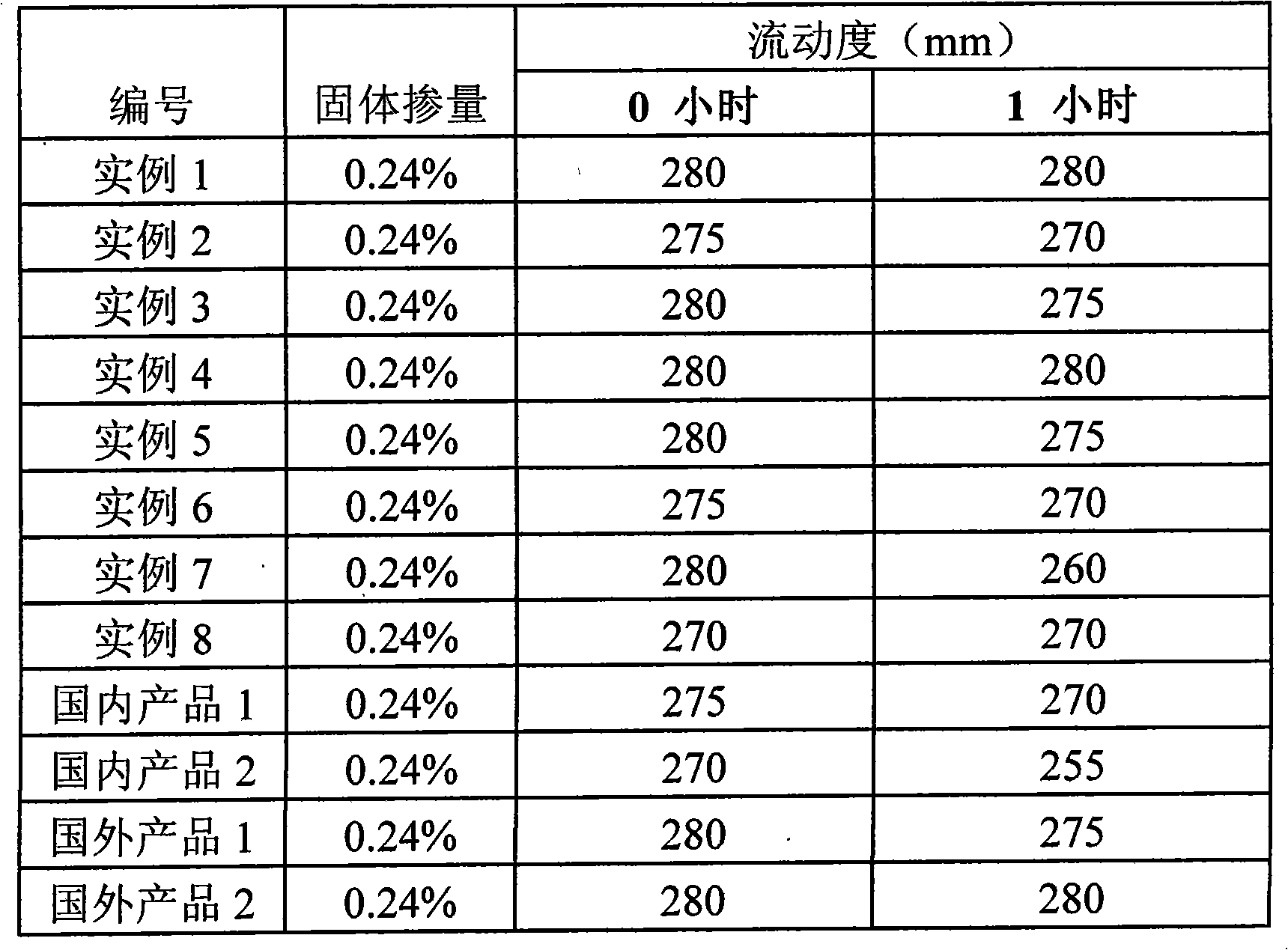

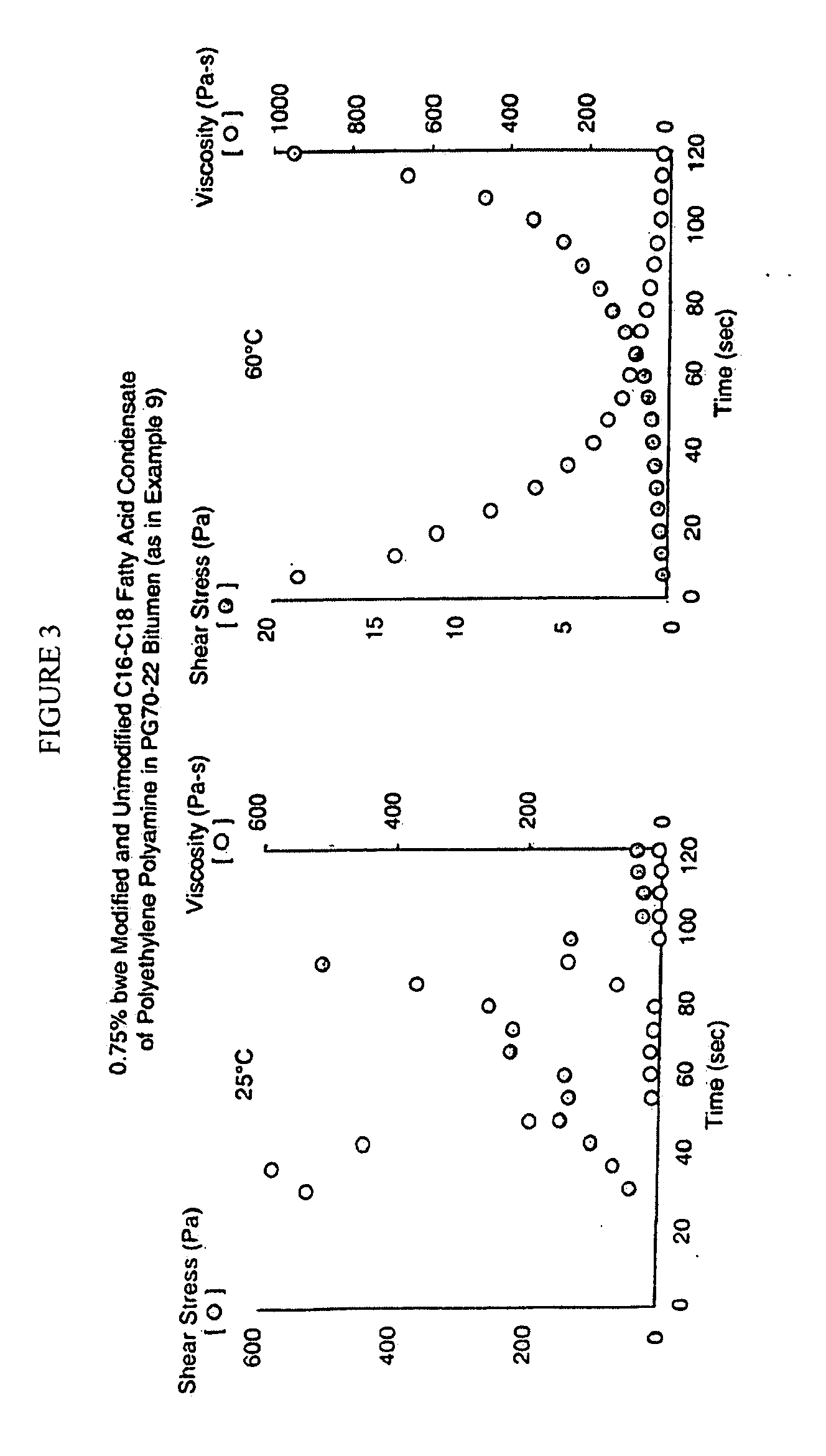

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

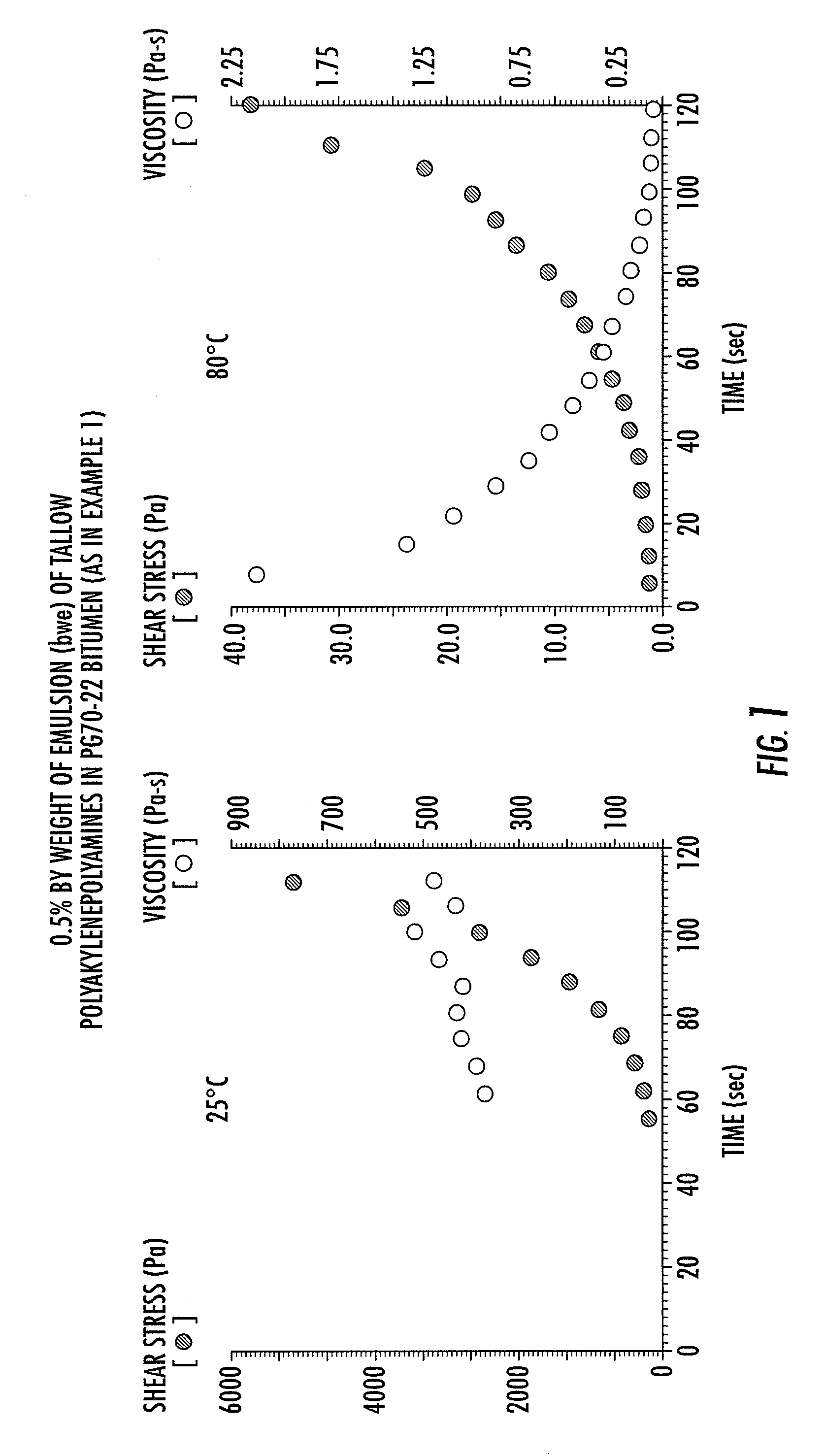

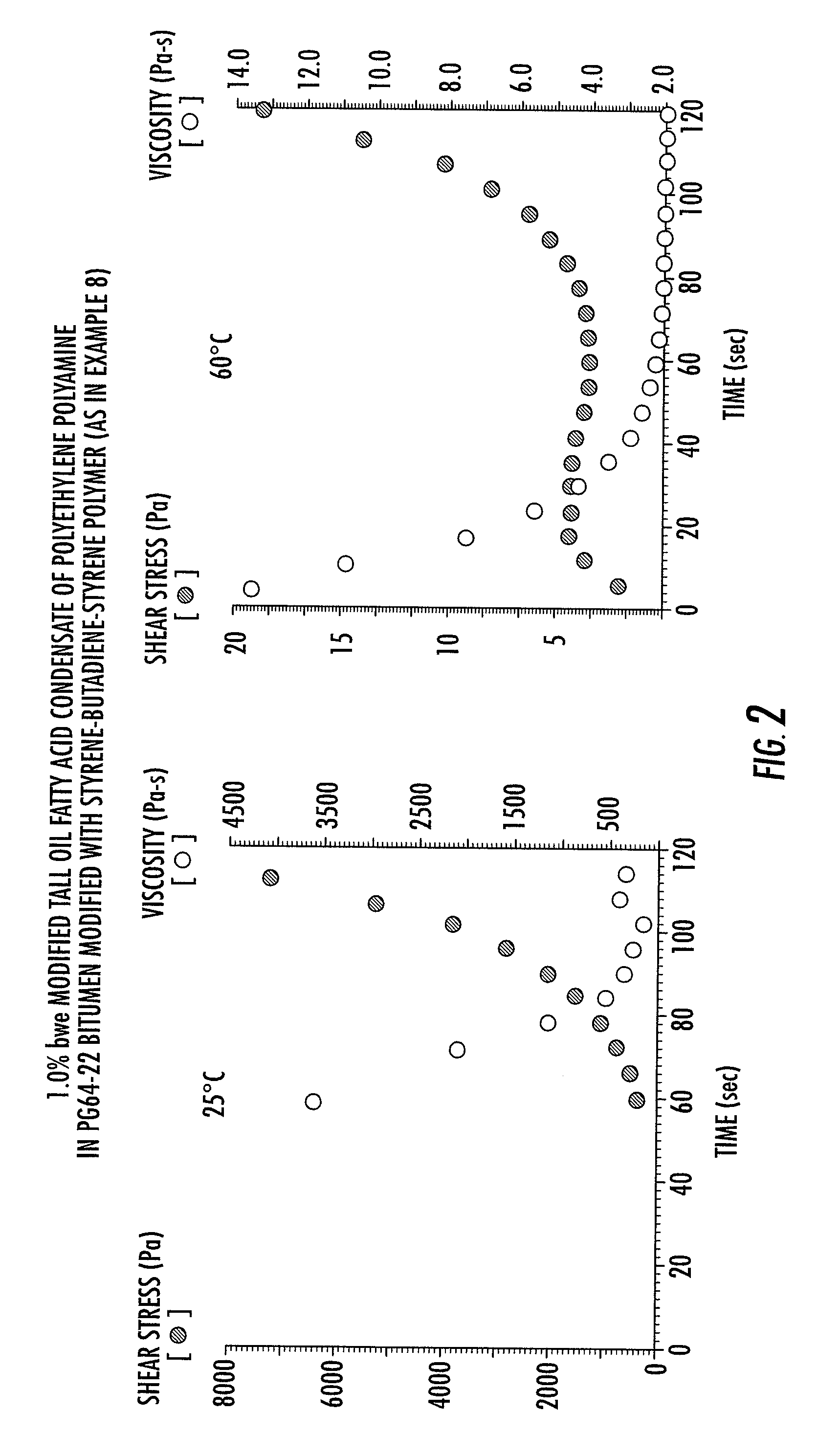

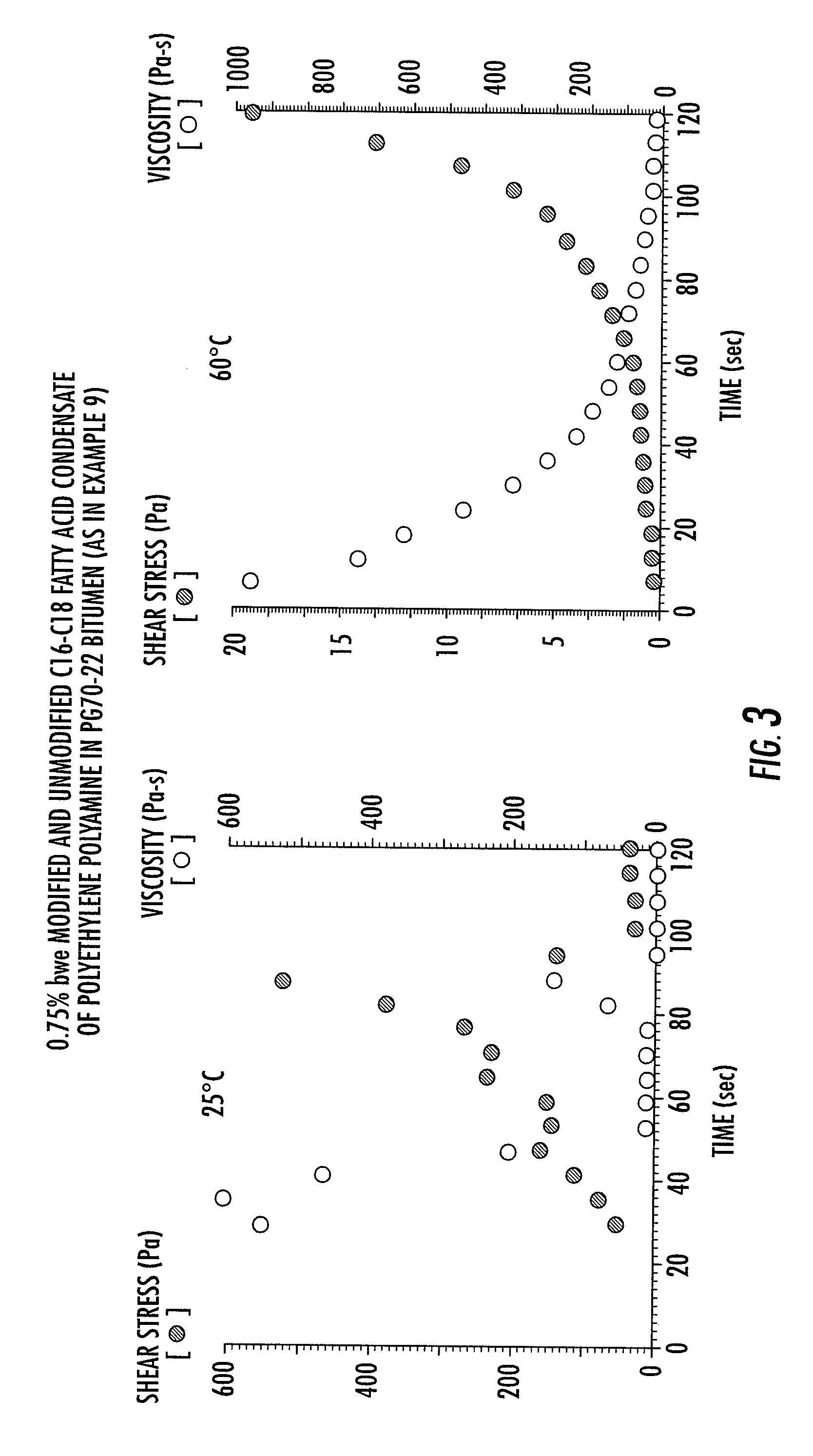

ActiveUS20070082983A1Low viscosityAccelerated strength developmentProductsIn situ pavingsSolvent freeSURFACTANT BLEND

There is provided a method for making bituminous compositions comprising water-in-oil bituminous dispersion and aggregate by the steps of: preparing a solvent-free, water-in-oil bituminous dispersion comprising: (1) bitumen, in an amount from about 75.0% to about 95.0% by total weight of the bitumen dispersion; (2) a surfactant in an amount from about 0.05% to about 2.0% by total weight of the bitumen dispersion; and (3) water in an amount to complete the water-in-oil bituminous dispersion, and producing the bituminous composition having a temperature from about 50° C. to about 120° C. by mixing: (1) the water-in-oil bituminous dispersion of step (A), having a temperature from about 75° C. to about 95° C., in an amount from about 2.0% to about 10.0% by total weight of the bituminous composition, and (2) aggregate, having a temperature from about 60° C. to about 140° C., in an amount from about 90.0% to about 98.0% by total weight of the bituminous composition.

Owner:INGEVITY SOUTH CAROLINA

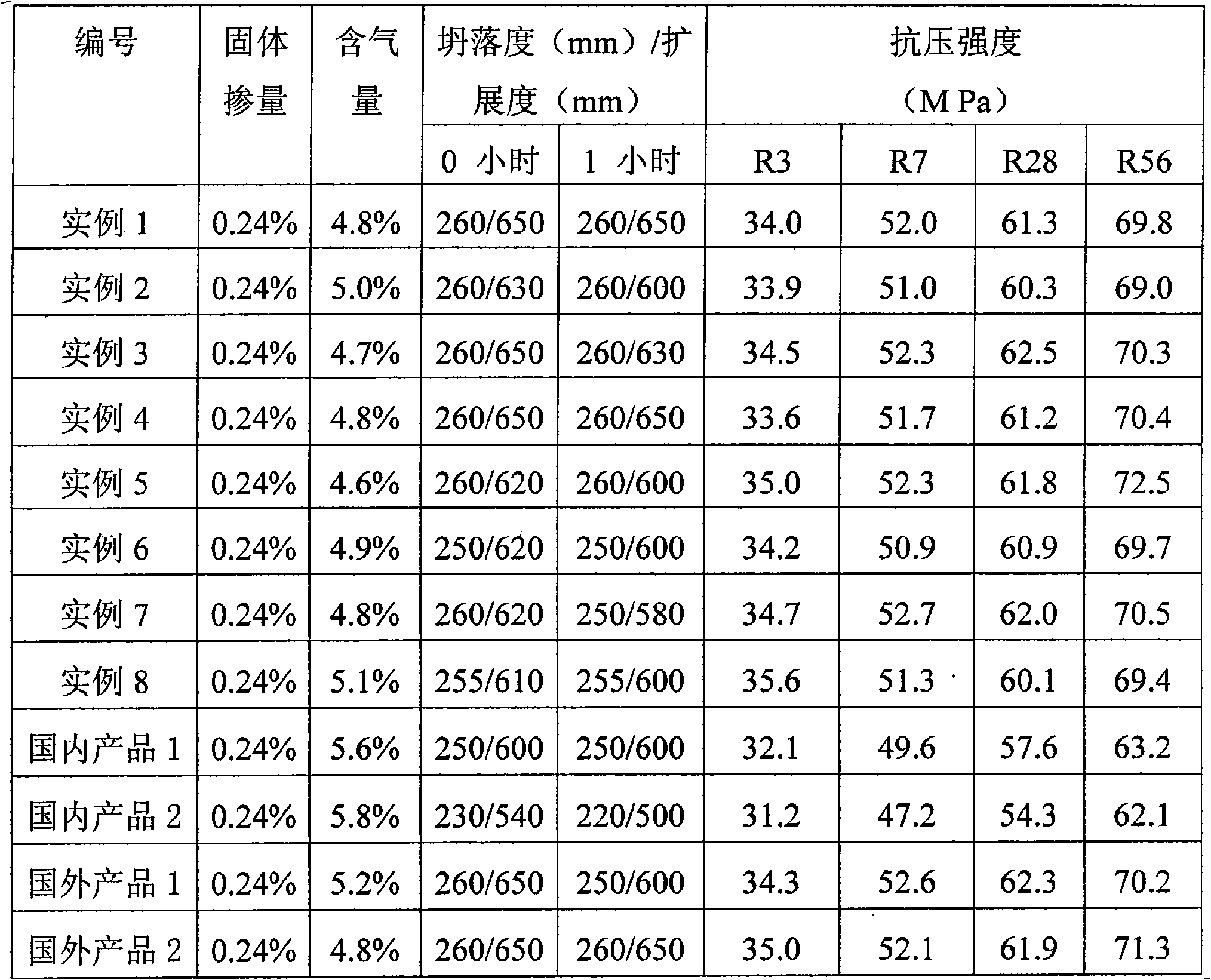

Polyether class polycarboxylic acid high-efficiency water reducing agent and preparation method thereof

The invention relates to a polyether class polycarboxylic acid high-efficiency water reducing agent and a preparation method thereof, belonging to the field of concrete materials, structures and engineering of building materials. The polyether class polycarboxylic acid high-efficiency water reducing agent raises the temperature of water solutions of 15-55 mass percent of allyl polyethenoxy ether and 0-6 mass percent of chain transfer agent is raised to 50-90 DEG C, one side is dropwise added with a water solution of 0.01-0.9 mass percent of an evocating agent, one side is dripwise added with miscible liquids of 3-15 mass percent of unsaturated acids and one or more than one derivative thereof, the temperature is kept unchanged, and the water solution and the miscible liquids are completely dropped within 2-6 hours, the temperature is preserved for 1-6 hours and naturally cooled to room temperature, and the mixed solution is neutralized by sig water till a PH value reaches 6.8-7.2 so as to obtain the polyether class polycarboxylic acid high-efficiency water reducing agent. The polyether class polycarboxylic acid high-efficiency water reducing agent and the preparation method thereof have simple technique, low cost and good property, can effectively reduce the water-cement ratio of concrete, improves the compaction rate of a pore structure of the concrete, enhances the strength and the durability of the concrete and has great significance on enhancing the engineering quality, prolonging the service life, reducing the engineering cost, reducing the environment pollution, and the like.

Owner:大连华健科技有限公司

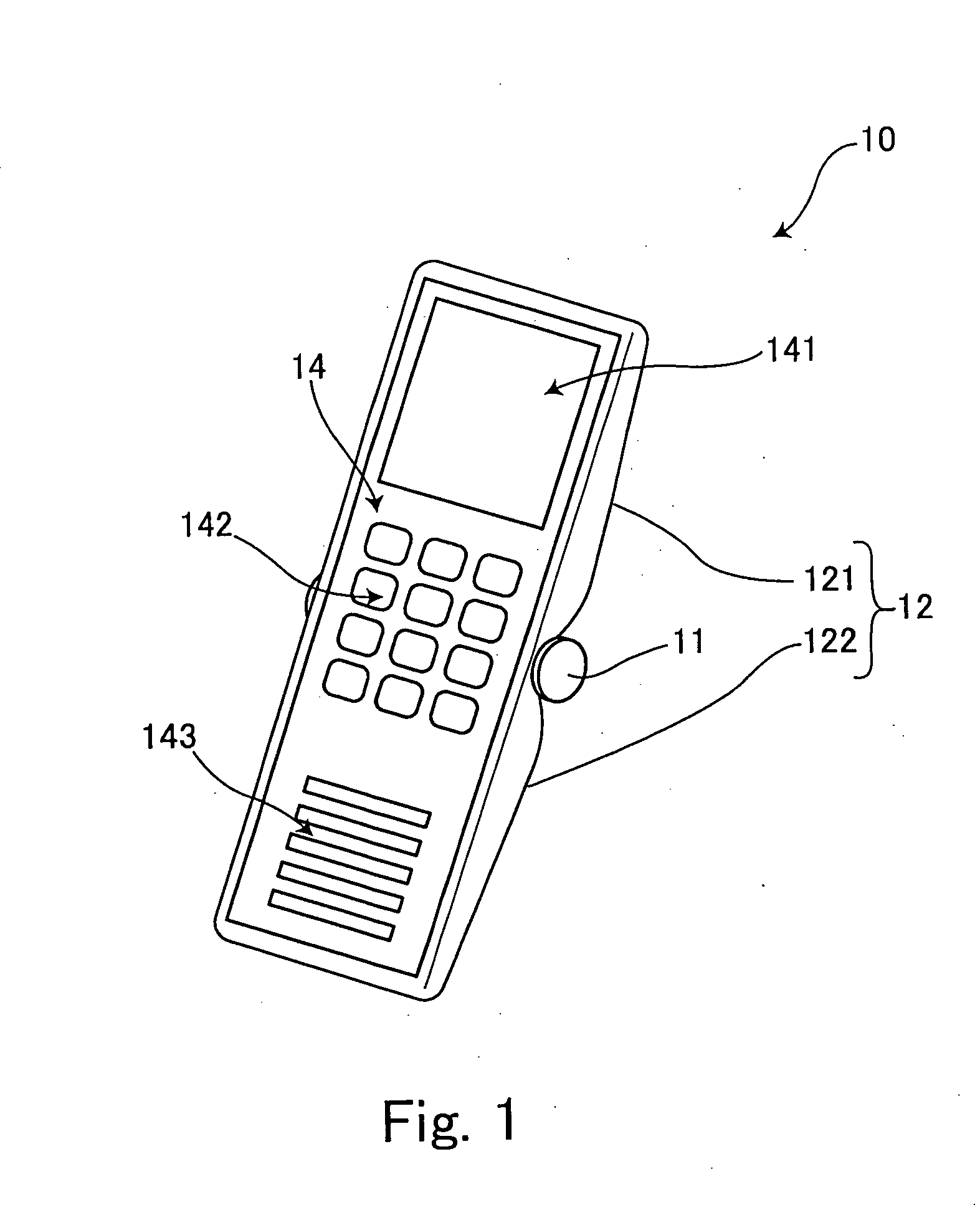

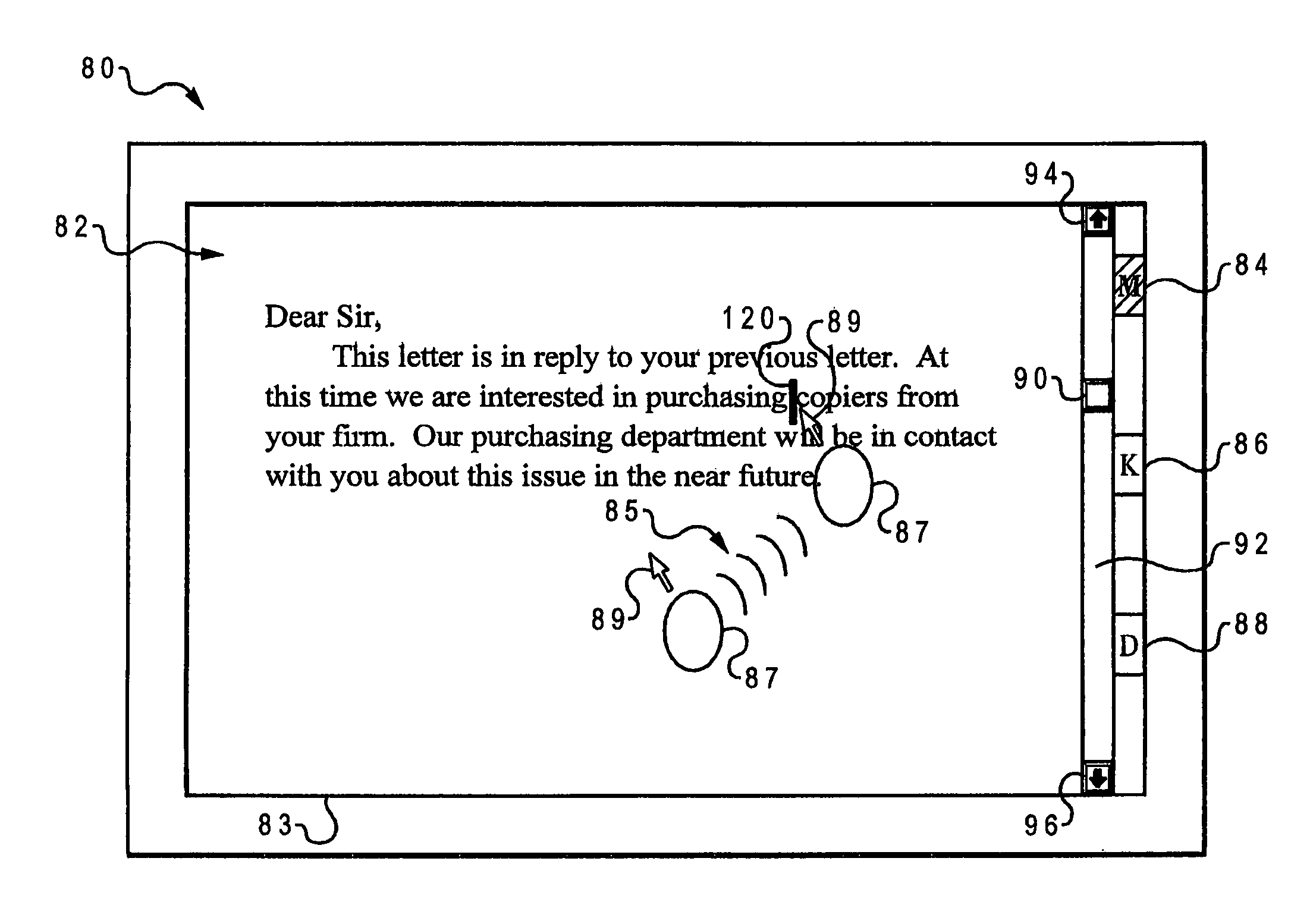

Method and system for touch screen keyboard and display space sharing

InactiveUS7768501B1Improve compactnessReduce space consumptionInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsUser input

A method and system in a portable computer having a display screen for increasing portable computer compactness. Data is displayed initially within the display screen. The display screen is then partitioned into a touch-sensitive input area and a display area, wherein data input at the touch-sensitive input area may be simultaneously displayed in the display area, in response to a particular user input. A test is performed to detect if a user's hands are positioned at the touch-sensitive input area. A touch-sensitive pad is thereafter graphically displayed at the touch-sensitive input area within the display screen, in response to detecting a user's hands positioned at the touch-sensitive area, wherein a user may enter data that may be simultaneously displayed in the display area. An additional test may then be performed to detect if the user's hands are no longer positioned at the touch-sensitive input area. The touch-sensitive pad is subsequently concealed from view, in response to detecting if the user's hands are no longer positioned at the touch-sensitive input area. The touch-sensitive pad graphically displayed at the touch-sensitive input area within the display screen may be composed of a touch-sensitive keyboard, which may in and of itself be an ergonomic keyboard.

Owner:IBM CORP

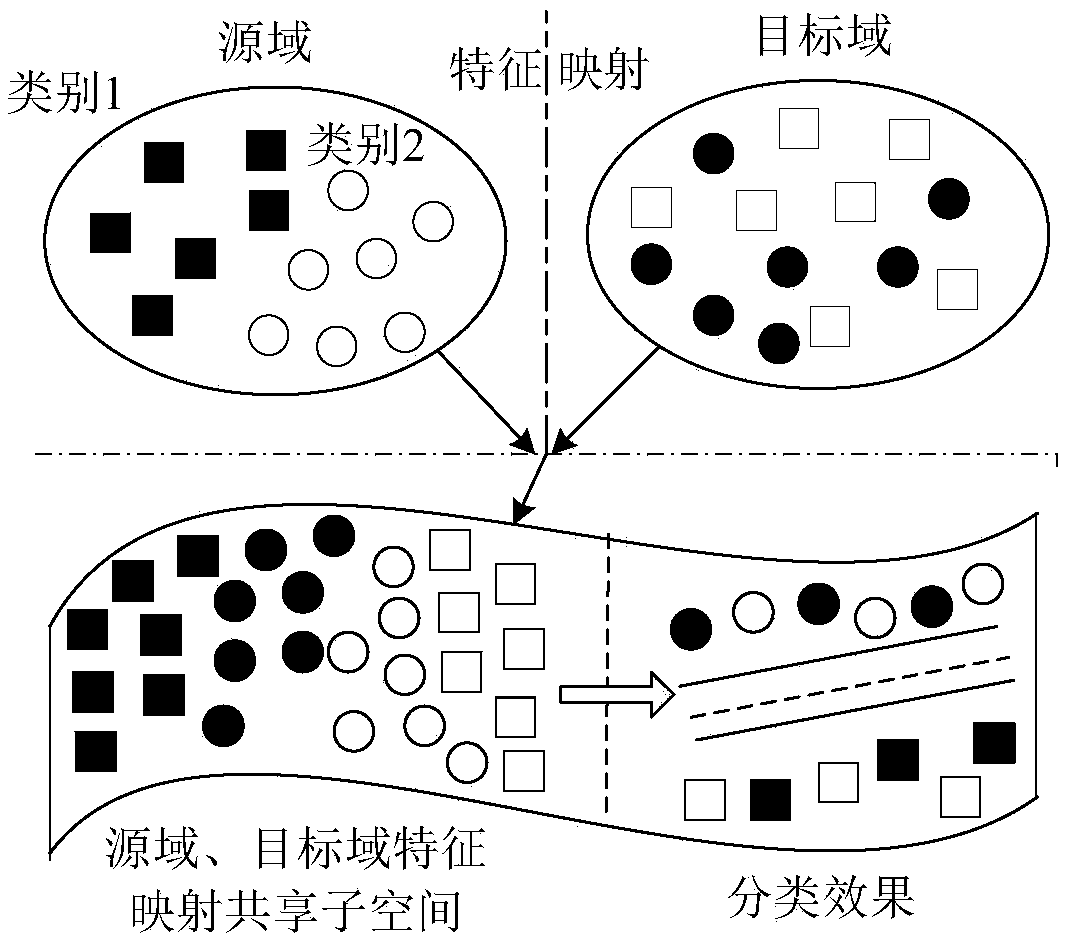

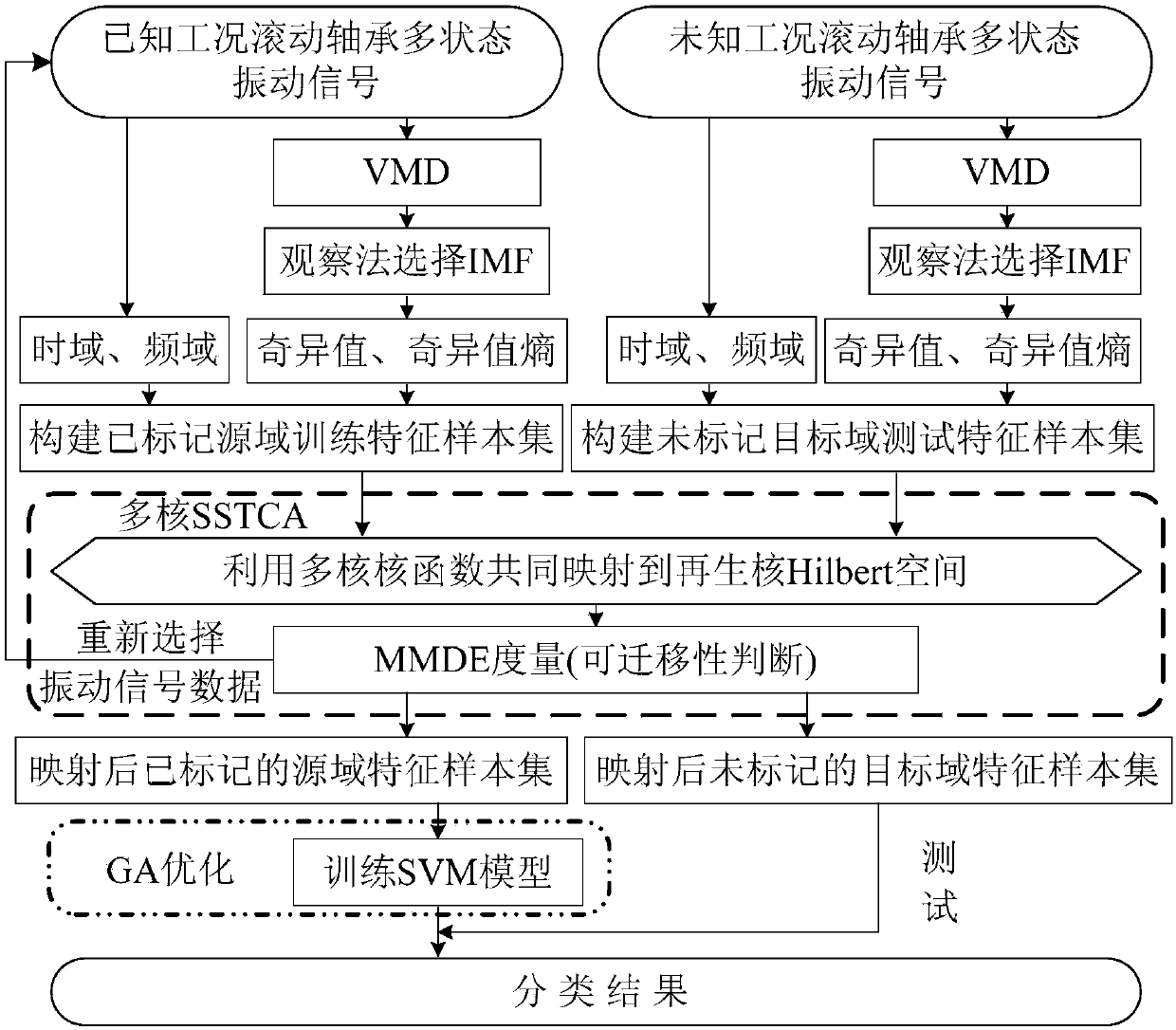

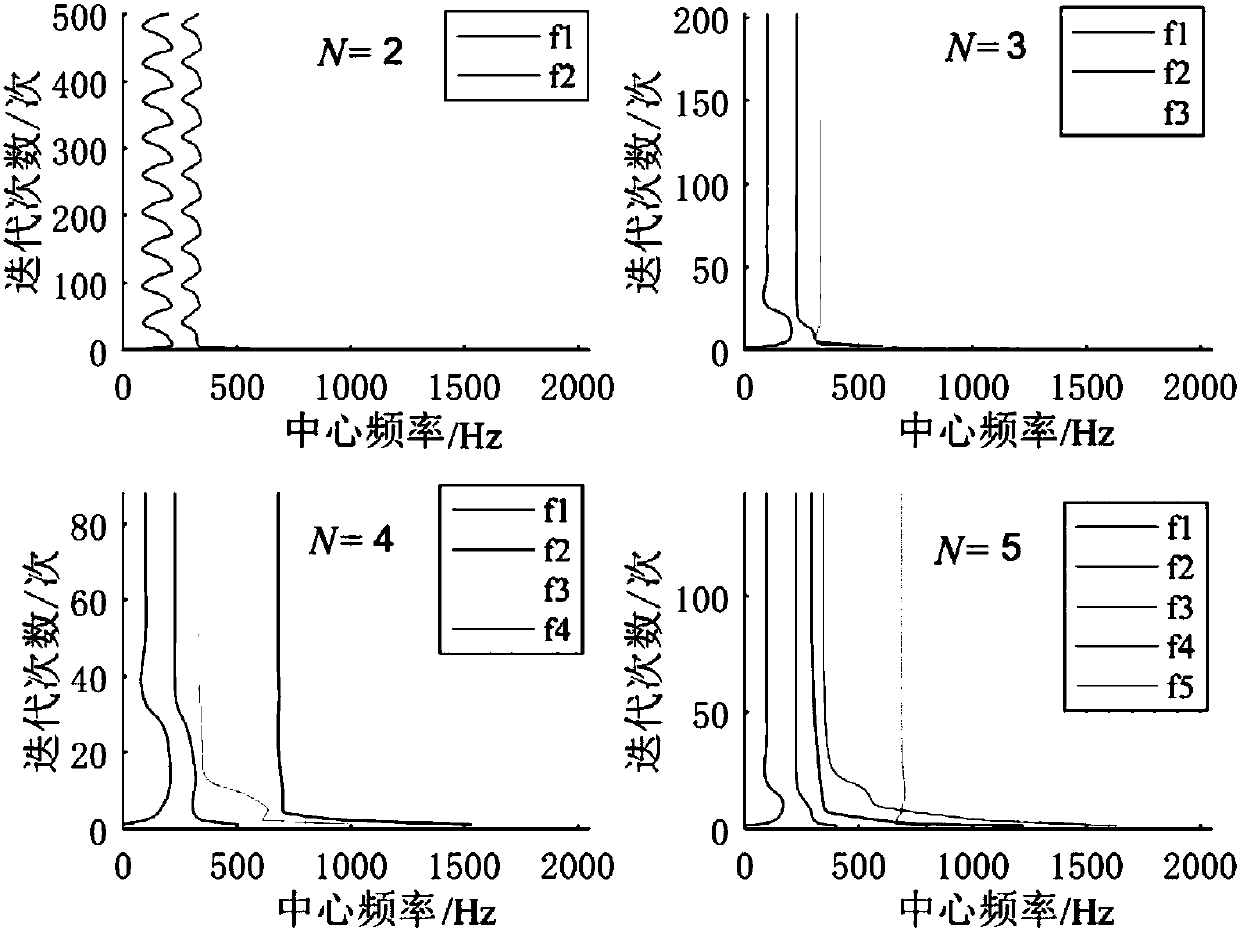

Rolling bearing fault diagnosis method in various working conditions based on feature transfer learning

ActiveCN108414226ABest mapped kernel matrixImprove accuracyMachine bearings testingSingular value decompositionDecomposition

The present invention provides a rolling bearing fault diagnosis method in various working conditions based on feature transfer learning, and relates to the field of fault diagnosis. The objective ofthe invention is to solve the problem that a rolling bearing, especially to various working conditions, is low in accuracy of diagnosis. The method comprise the steps of: employing a VMD (VariationalMode Decomposition) to perform decomposition of vibration signals of a rolling bearing in each state to obtain a series of intrinsic mode functions, performing singular value decomposition of a matrixformed by the intrinsic mode functions to solve a singular value or a singular value entropy, combining time domain features and frequency domain features of the vibration signals to construct a multi-feature set; introducing a semisupervised transfer component analysis method to perform multinuclear construction of a kernel function thereof, sample features of different working conditions are commonly mapped to a shared reproducing kernel Hilbert space so as to improve the data intra-class compactness and the inter-class differentiation; and employing the maximum mean discrepancy embedding to select more efficient data as a source domain, inputting source domain feature samples into a SVM (Support Vector Machine) for training, and testing target domain feature samples after mapping. Therolling bearing fault diagnosis method in various working conditions has higher accuracy in the rolling bearing multi-state classification in various working conditions.

Owner:HARBIN UNIV OF SCI & TECH

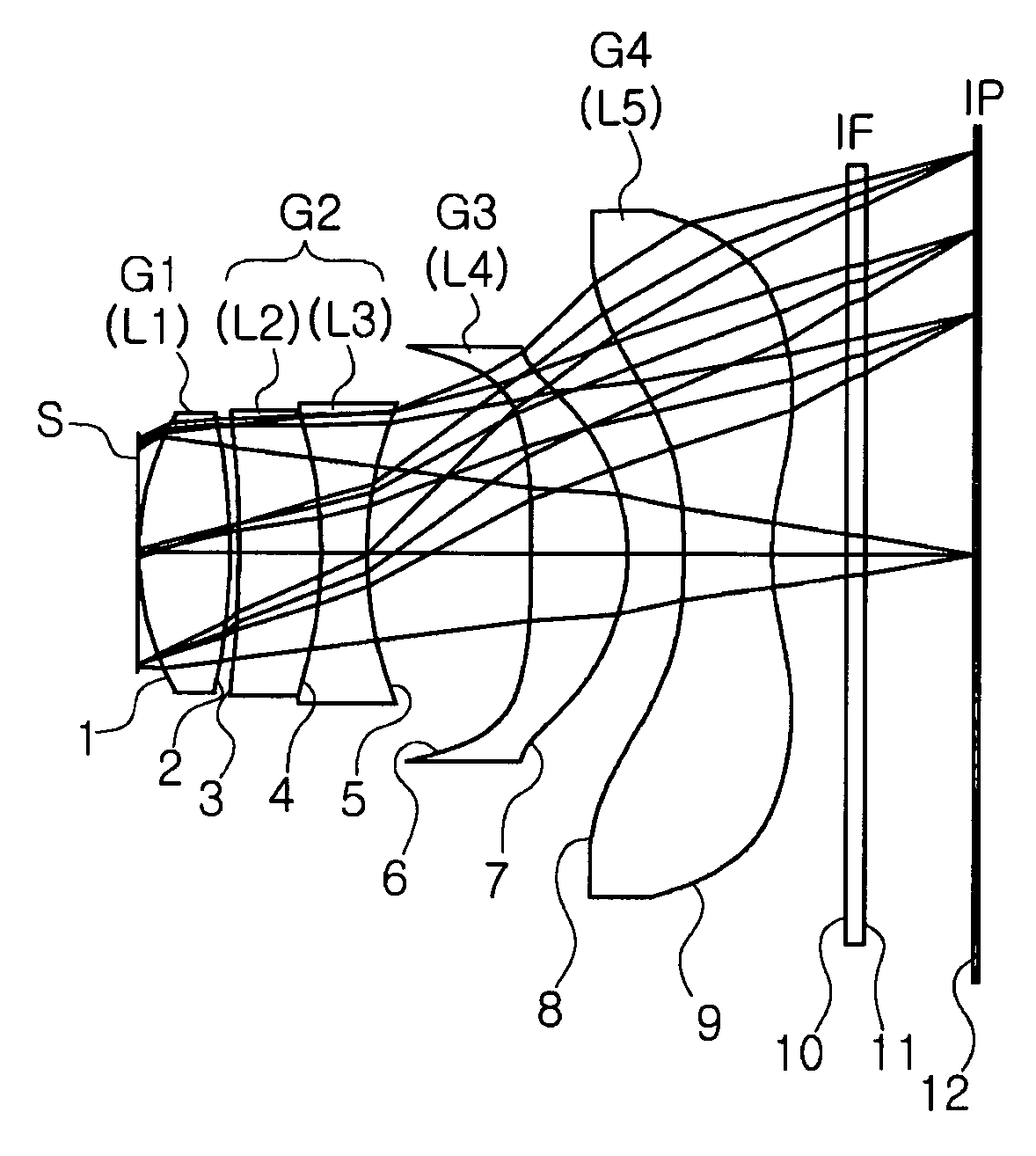

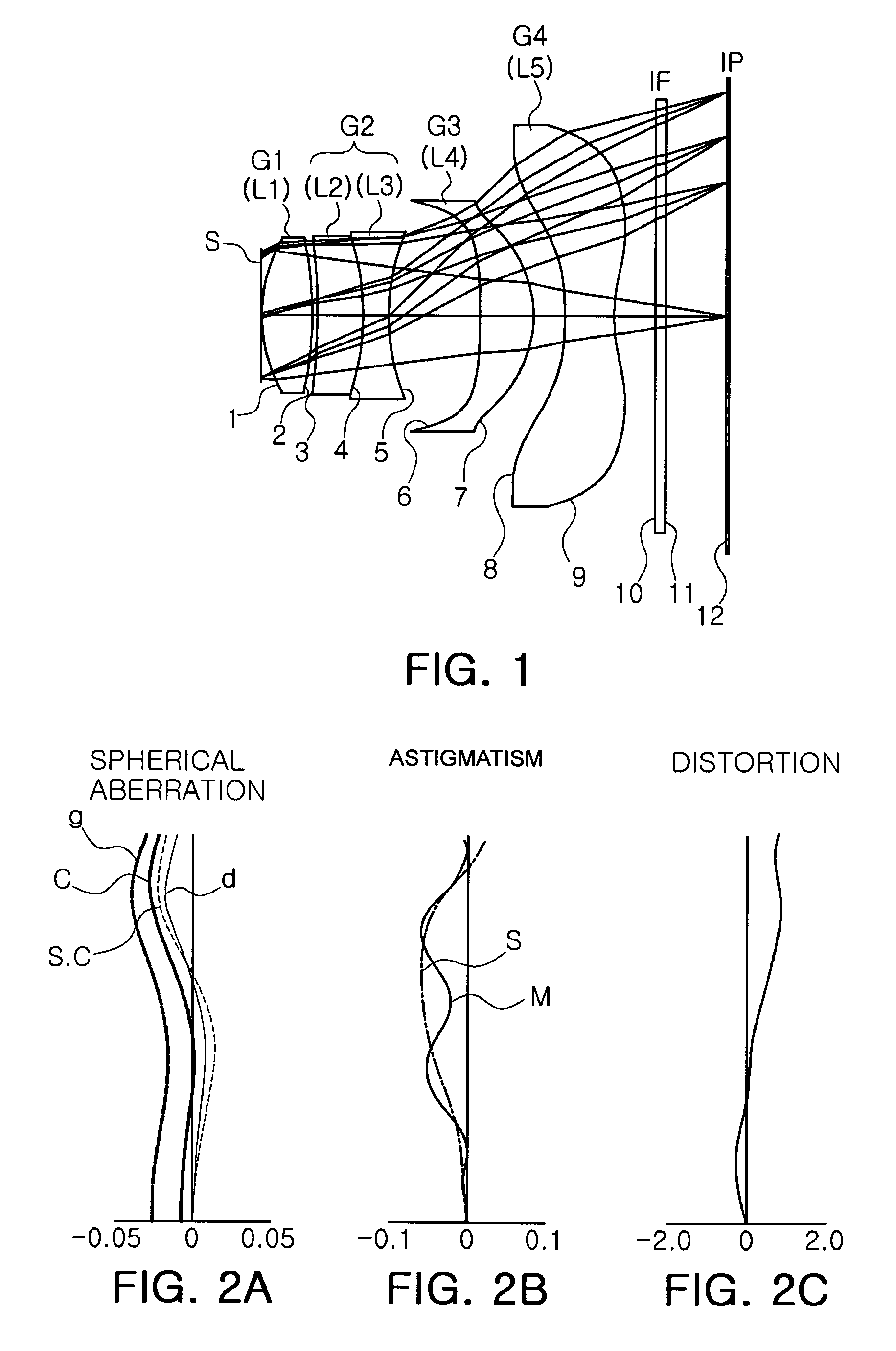

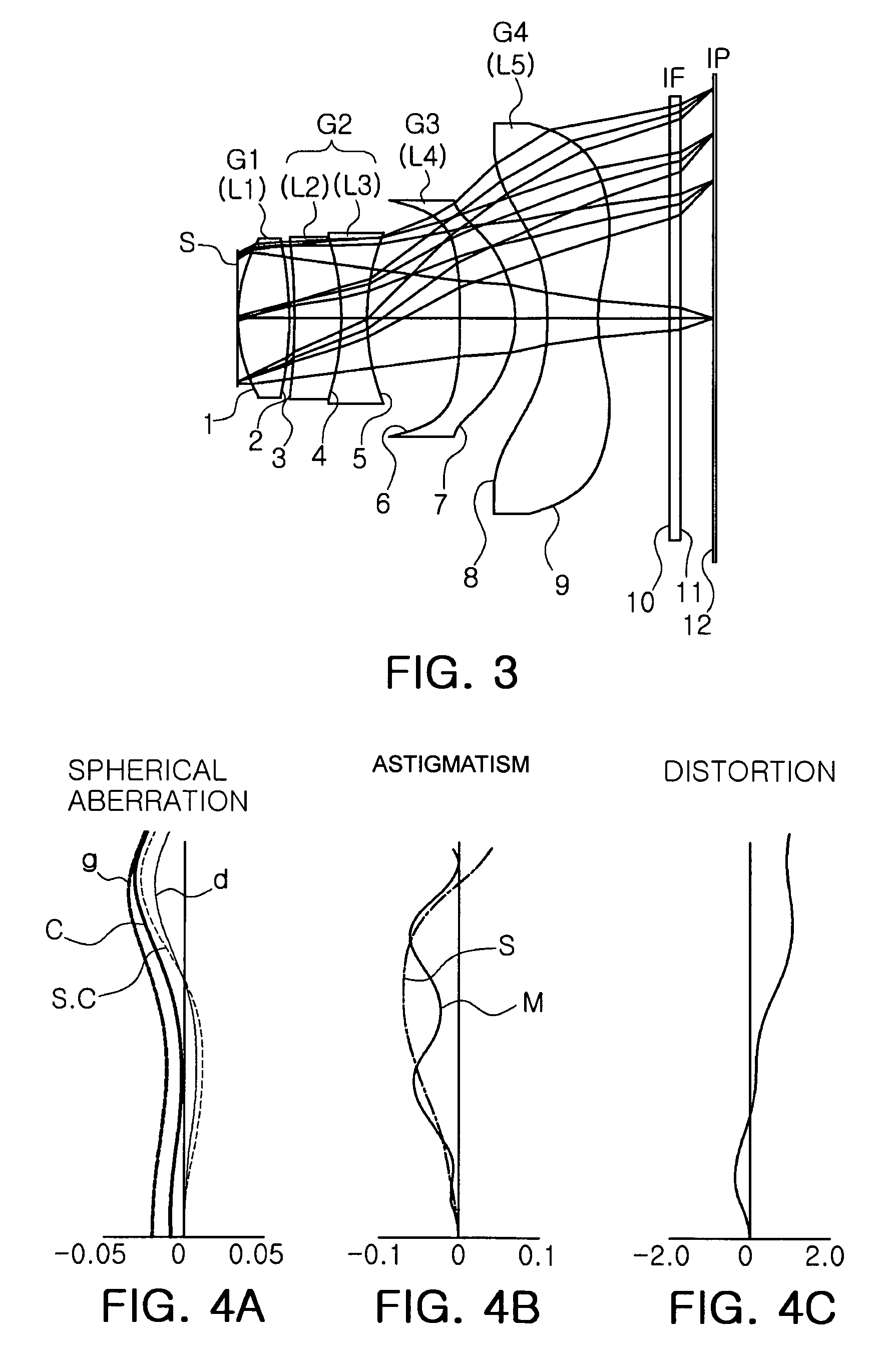

Imaging optical system

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

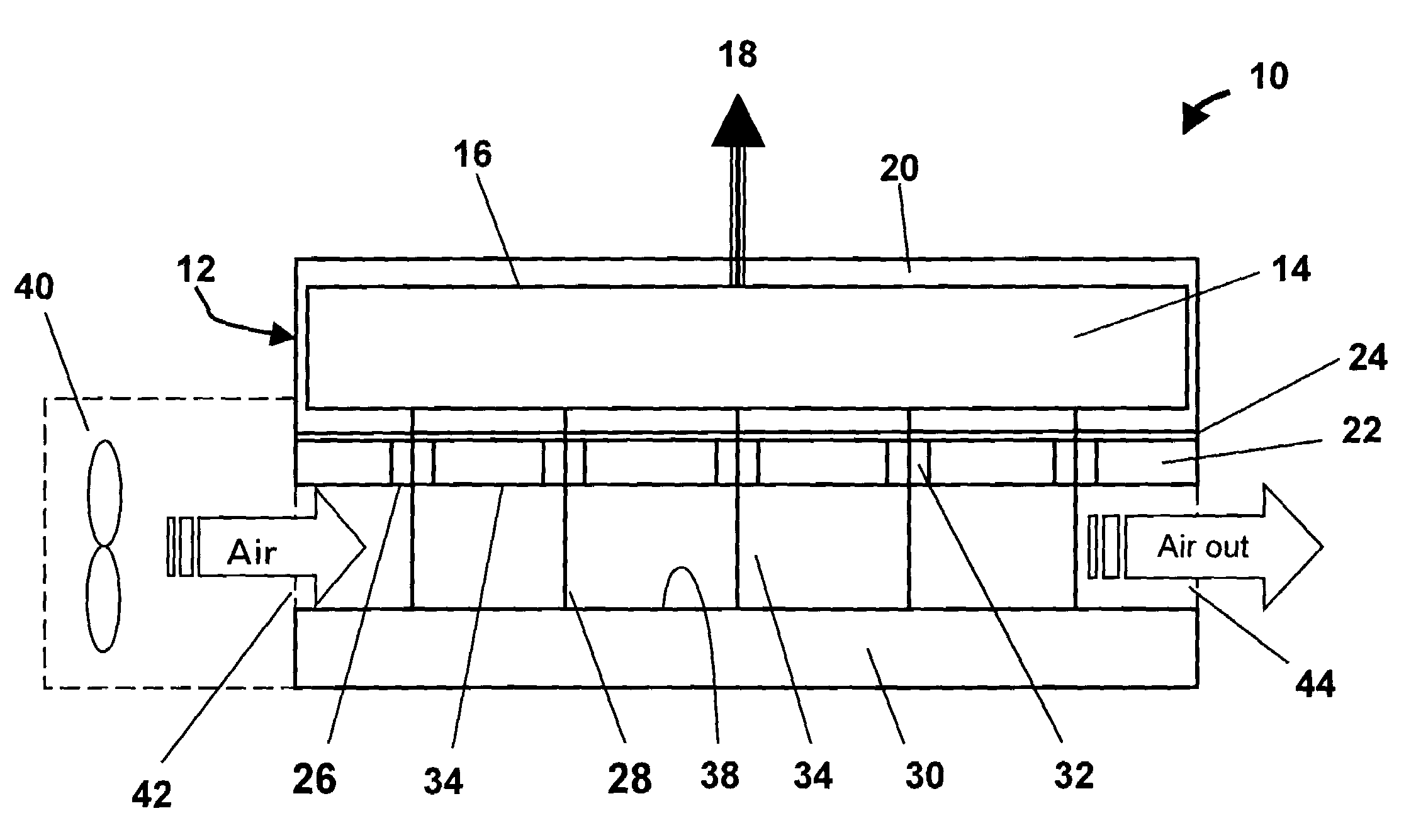

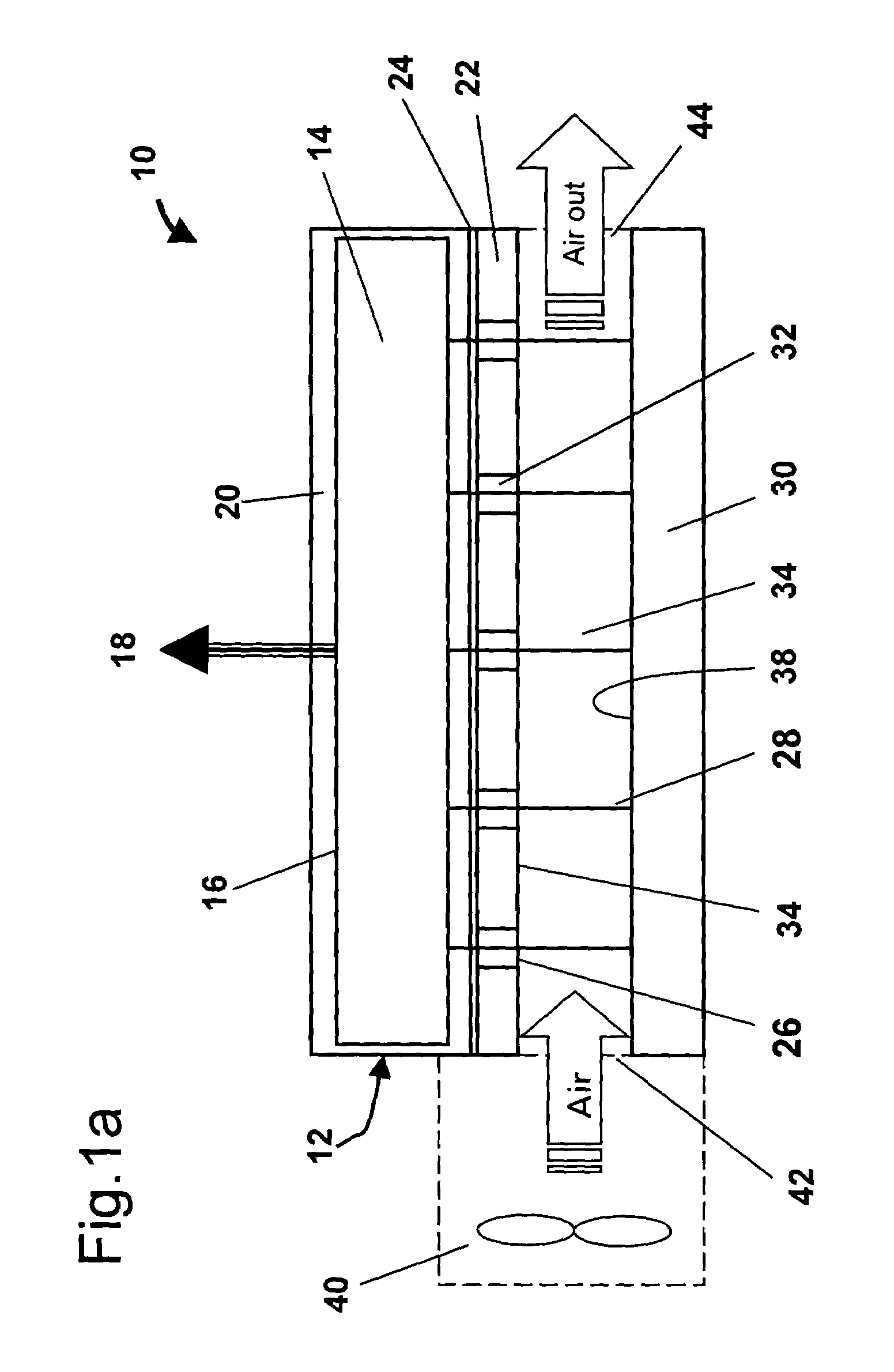

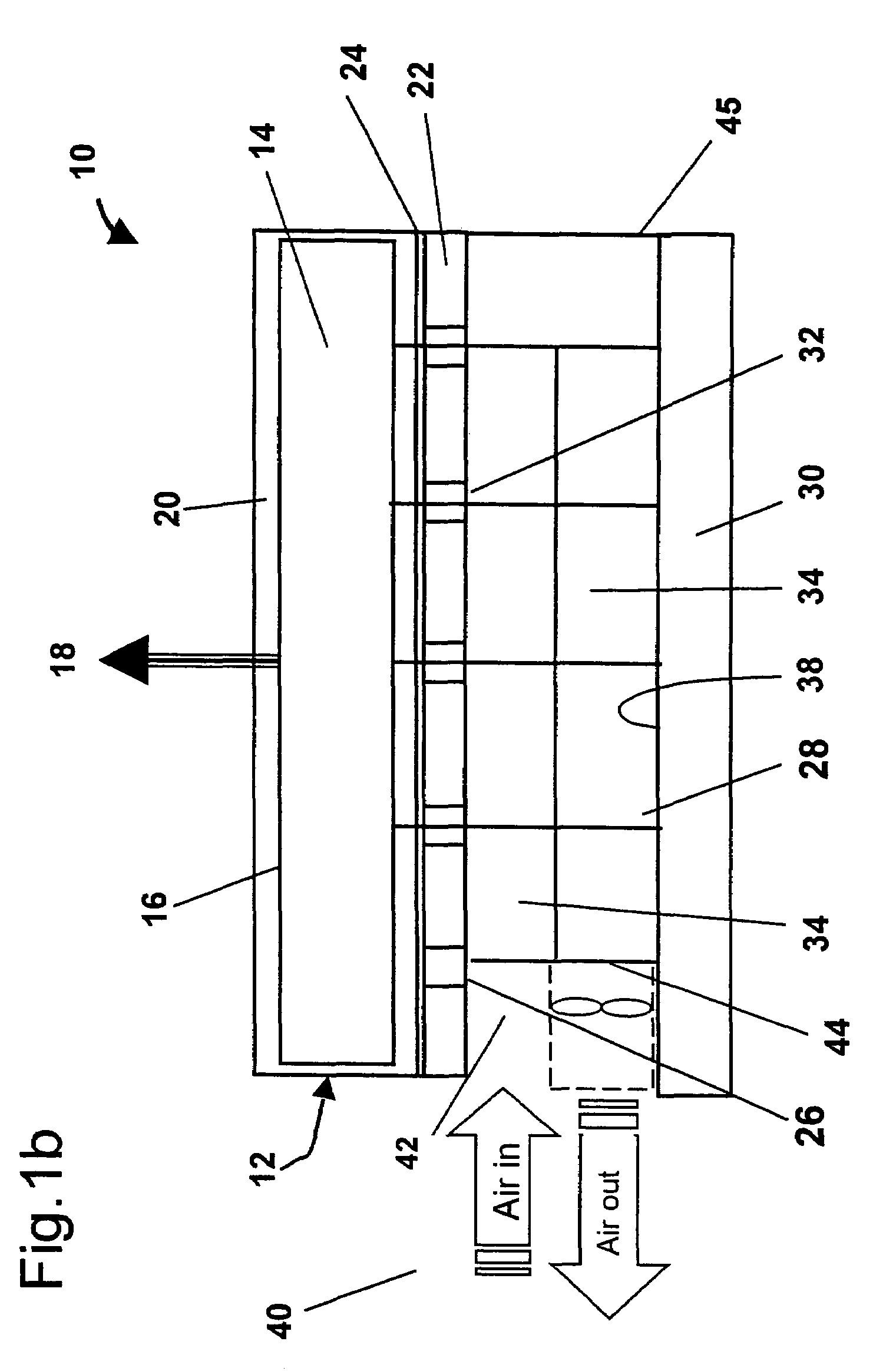

Light emission display arrangements

InactiveUS7157838B2Improve the display effectImproved cooling arrangementElectric discharge tubesStatic indicating devicesElectrical connectionEngineering

The present invention provides arrangements for electroluminescent displays 10 comprising a packaged semiconductor light emitting element 12 that has a light emitting display side 16. A heat sink 22 is disposed in the region of a rear side of the light-emitting element 12 opposite to the display side. Electrical connections 28 from the light emitting element 12 pass through said heat sink 22. Drive circuitry 30 for the light emitting element 12 is connected thereto by the electrical connections 28 and spaced apart from the heat sink 22 in such a manner that at least one cooling channel 34 is defined between the heat sink 22 and the drive circuitry 30 for the passage in use of a cooling fluid.

Owner:BARCO NV

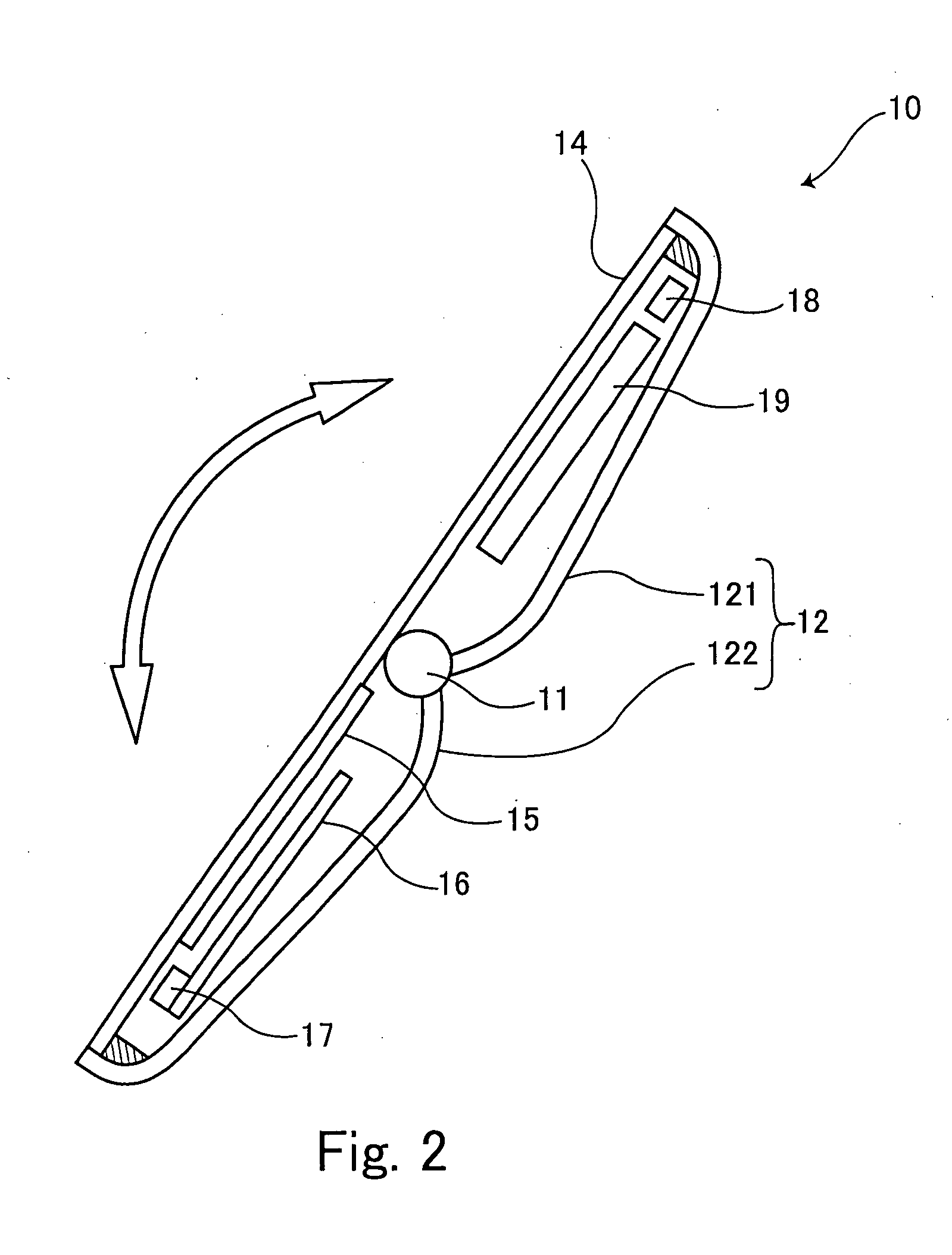

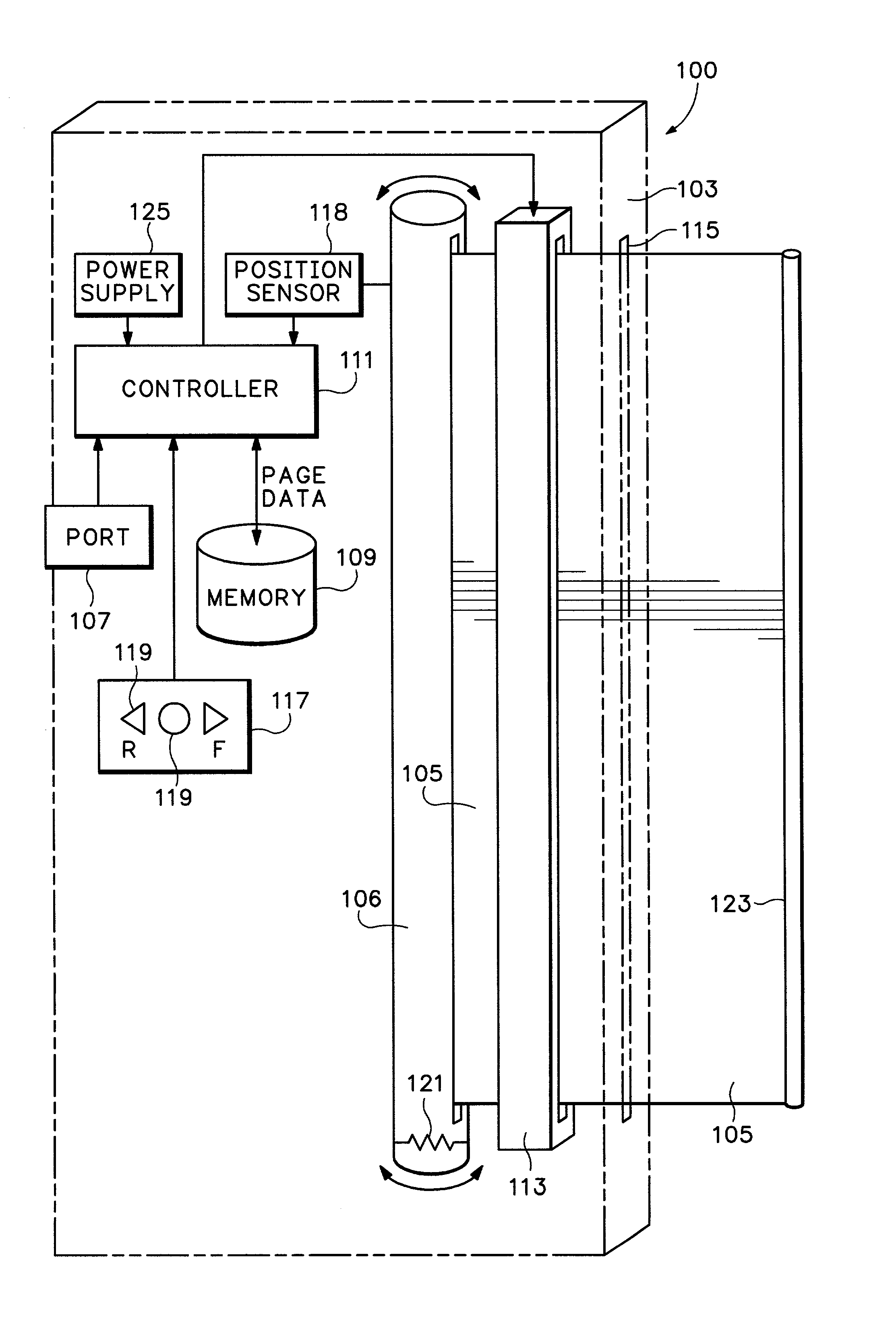

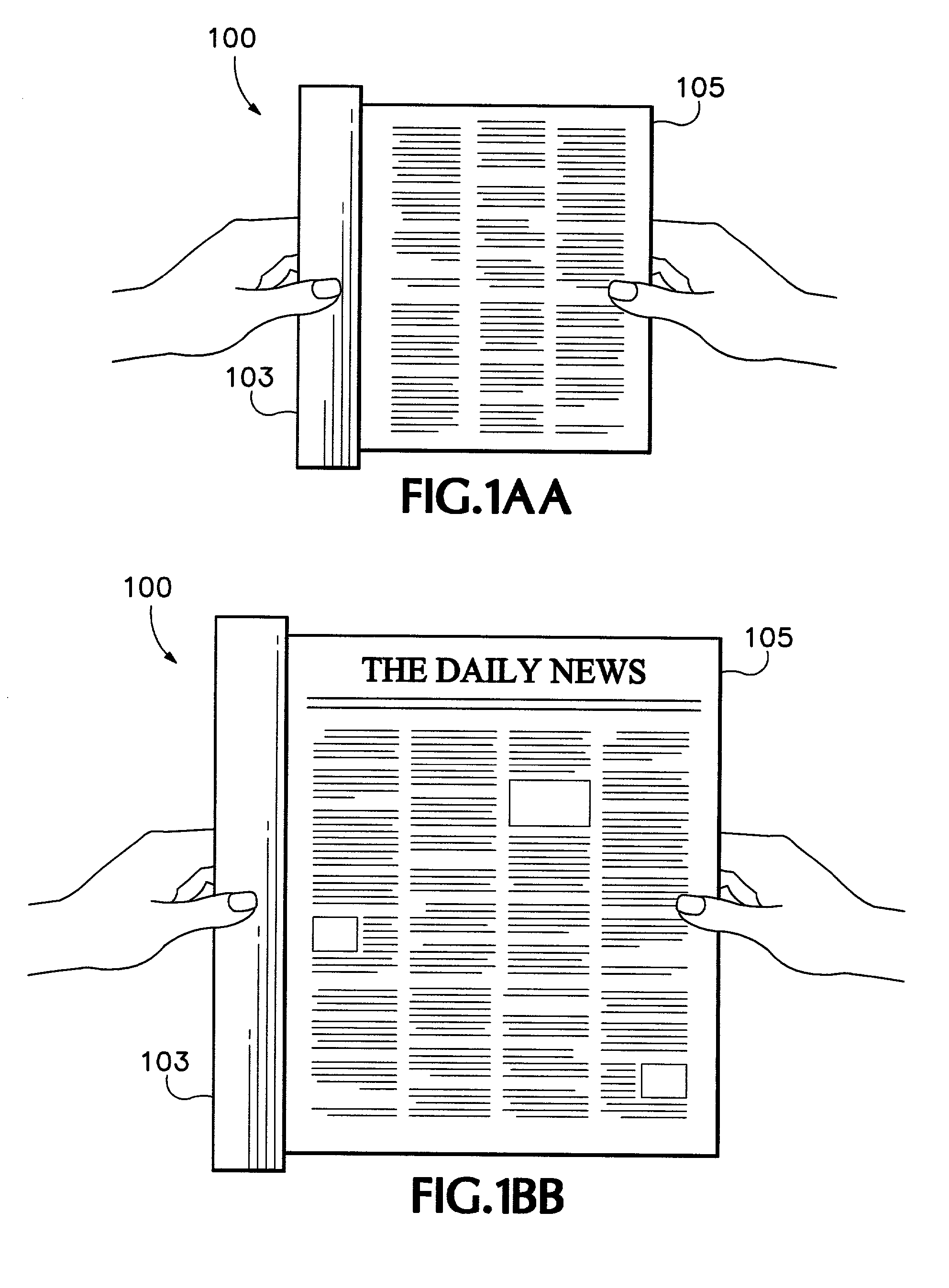

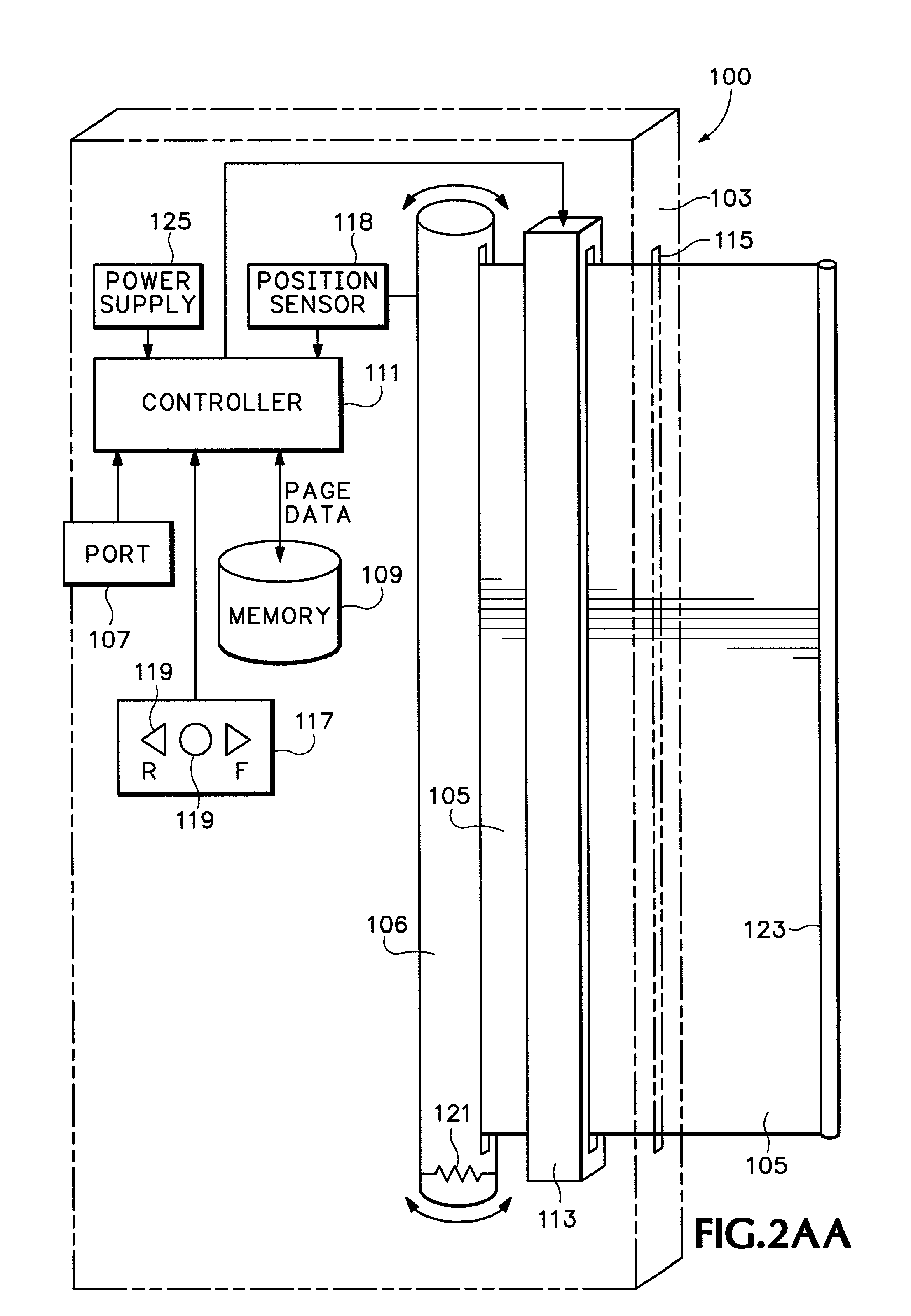

Portable electronic reading apparatus

InactiveUS20030071800A1Low costHard costCathode-ray tube indicatorsDetails for portable computersElectronic bookDocumentation

An electronic book, having a single screen, employs an electric field addressable, rewritable, colorant, preferably a bistable molecular colorant, for providing printed pages sequentially to a reader. The electronic book includes the rewritable screen coupled to an extraction-retraction device, an electrode array printer, a sheet position detector, and associated circuitry to download, store, sequence, and print images on the screen. Methods associated with document distribution are another aspect of the invention.

Owner:HEWLETT PACKARD DEV CO LP

Organic-inorganic all-solid-state composite electrolyte as well as preparation and application methods thereof

PendingCN106785009AIncrease transport activityImprove wettabilitySolid electrolytesSecondary cellsElectrical conductorComposite electrolyte

The invention relates to organic-inorganic all-solid-state composite electrolyte as well as preparation and application methods thereof, belonging to the field of lithium ion batteries. According to the organic-inorganic all-solid-state composite electrolyte, a highly-ordered three-dimensional connection network skeleton is formed by an inorganic fast lithium ion conductor, and a three-dimensional connection network is filled with a polymer and lithium salt. The organic-inorganic all-solid-state composite electrolyte which is flexible and has a controllable three-dimensional connection network structure is prepared. The electrolyte is high in lithium ion conductivity, wide in electrochemical window, good in mechanical property and stable to lithium metal. A lithium ion secondary battery assembled by a composite electrolyte membrane prepared by the method is high in capacity, stable in cycle performance, low in interface impedance and good in interface stability.

Owner:UNIV OF SCI & TECH BEIJING

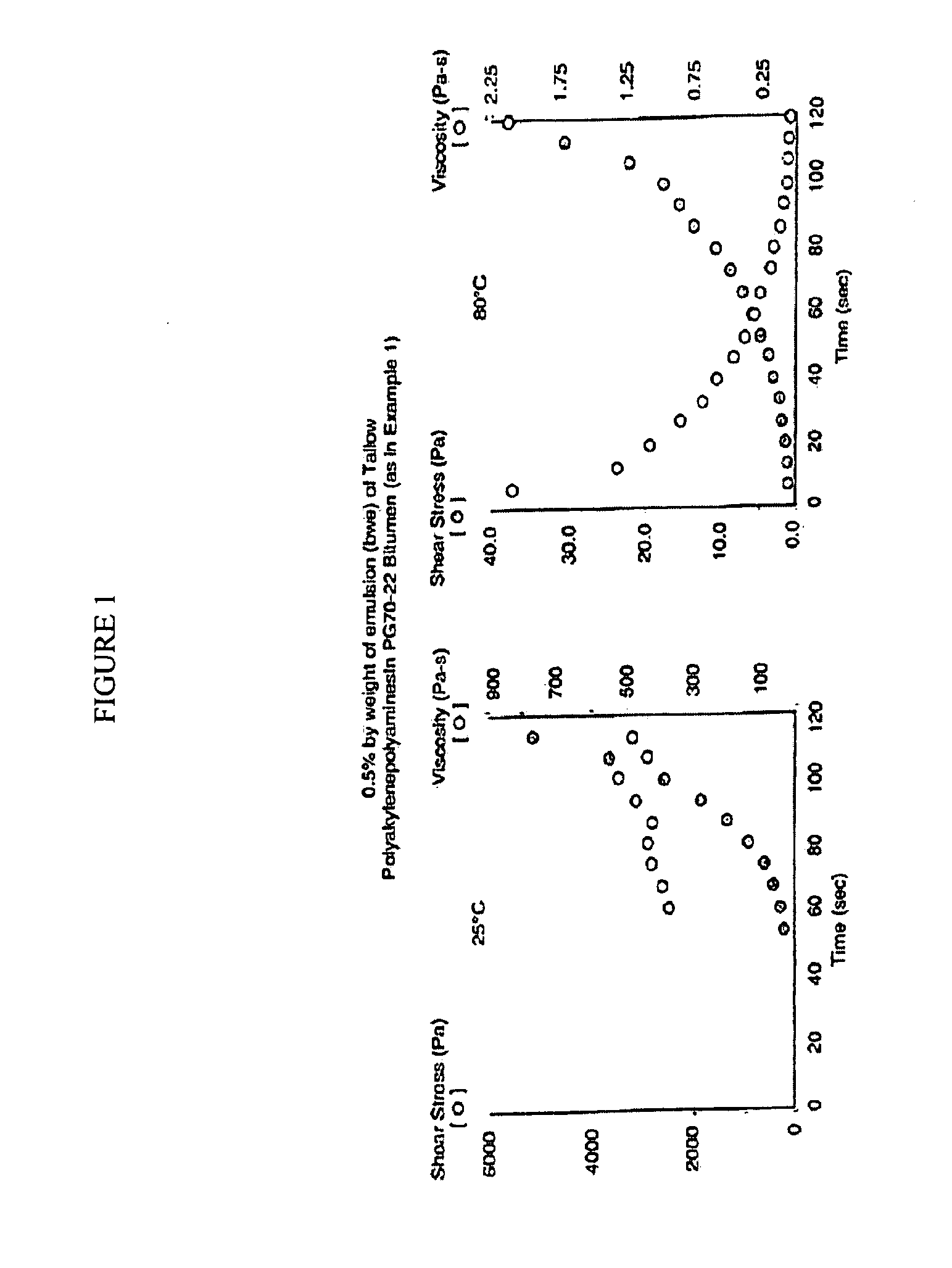

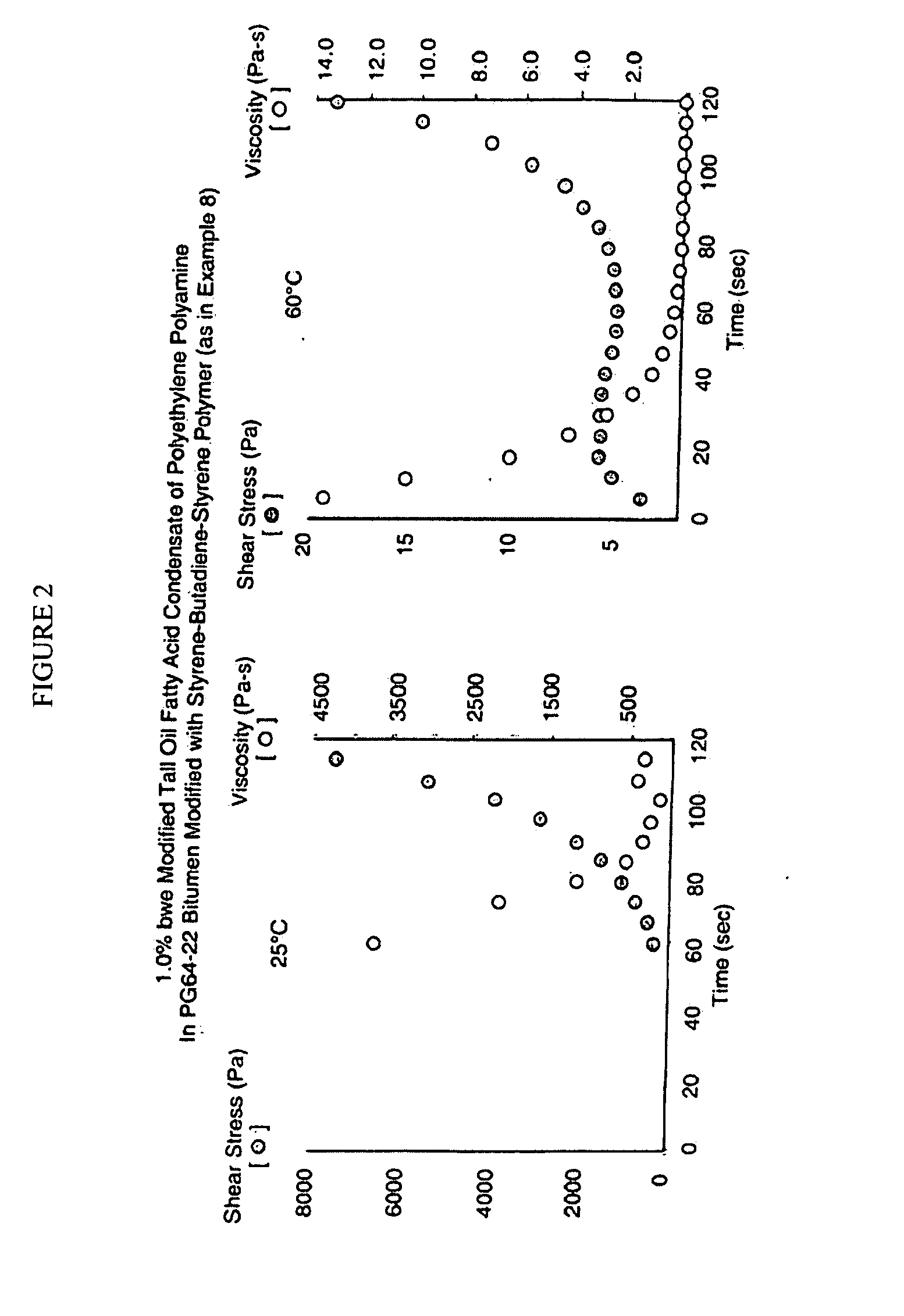

Method for producing bitumen compositions

ActiveUS20080060551A1Low viscosityHighly preventive effectBuilding insulationsBitumen emulsionRoad surface

The present invention relates to bituminous compositions suitable for use in paving applications containing bitumen emulsion of performance-grade bitumen that is substantially free of volatile solvents and made by controlling temperature-dependent interfacial rheology through the use of selected emulsifiers. The invention bituminous paving compositions are suitable for the construction of load-bearing pavements with improved compaction to densities similar or superior to those achieved in the conventional hot mix bituminous paving compositions. Cure rate of the invention bituminous compositions is higher than those of cold mix bitumen emulsion-based paving compositions, and at least equal to those of hot mix bituminous paving compositions. Additionally, the invention bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to those of hot mix bituminous paving compositions, and at rates faster than those of cold mix bituminous paving compositions.

Owner:INGEVITY SOUTH CAROLINA

Multi-segment photonic-crystal-rod waveguides for amplification of high-power pulsed optical radiation and associated method

InactiveUS20070104431A1High peak powerHigh pulse energyLaser detailsCladded optical fibreOptical radiationPromiscuous behaviour

A method and apparatus use a photonic-crystal fiber having a very large core while maintaining a single transverse mode. In some fiber lasers and amplifiers having large cores problems exist related to energy being generated at multiple-modes (i.e., polygamy), and of mode hopping (i.e., promiscuity) due to limited control of energy levels and fluctuations. The problems of multiple-modes and mode hopping result from the use of large-diameter waveguides, and are addressed by the invention. This is especially true in lasers using large amounts of energy (i.e., lasers in the one-megawatt or more range). By using multiple small waveguides in parallel, large amounts of energy can be passed through a laser, but with better control such that the aforementioned problems can be reduced. An additional advantage is that the polarization of the light can be maintained better than by using a single fiber core.

Owner:LOCKHEED MARTIN CORP

Method for preparing magnetic filling with biological affinity, hydrophilicity and activity for water treatment

InactiveCN1522972AEasy to grow and compactGood compatibilitySustainable biological treatmentBiological water/sewage treatmentInjection molding machineInjection moulding

The present invention relates to a preparation method of biological affinity hydrophilic active magnetic seed filling material for treating water. It is characterized by that said method includes the following steps: mixing biological affinity substance, hydrophilic substance, magnetic powder and active carbon or magnetic powder and calcium carbonate in the high-molecular base material, and adding dispersion lubricating agent, uniformly stirring them, placing them into injection moulding machine, utilizing filling mould to make extrusion moulding and magnetizing, so as to obtain the invented filling material. It has biological affinity and hydrophilicity, at the same time can induce microbial activity and enzyme activity, and can raise oxygen utilization rate in water and water treatment efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing bituminous compositions

InactiveUS20070039520A1Low viscosityHighly preventive effectOrganic chemistrySingle unit pavingsEmulsionSolvent free

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:MEADWESTVACO CORP

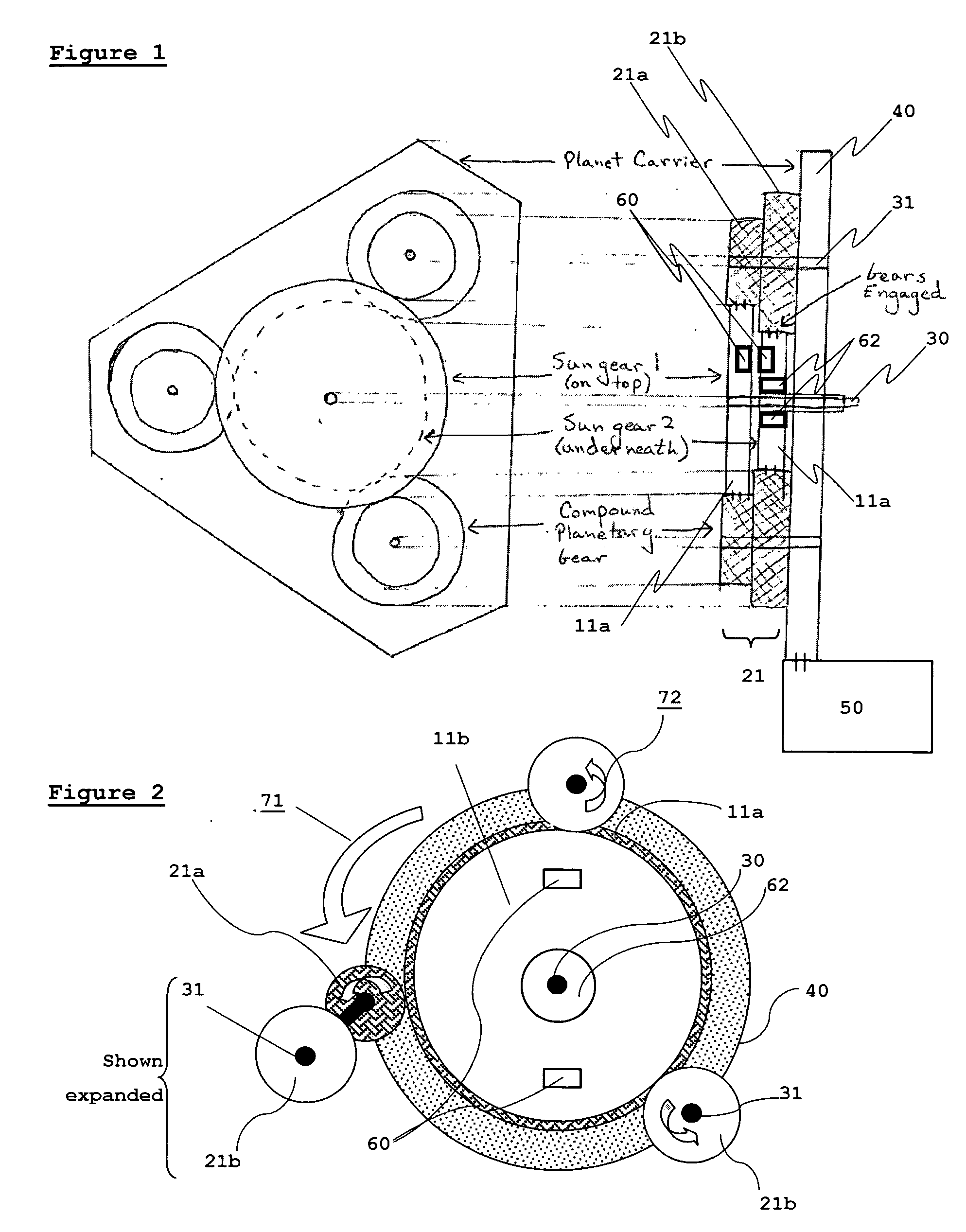

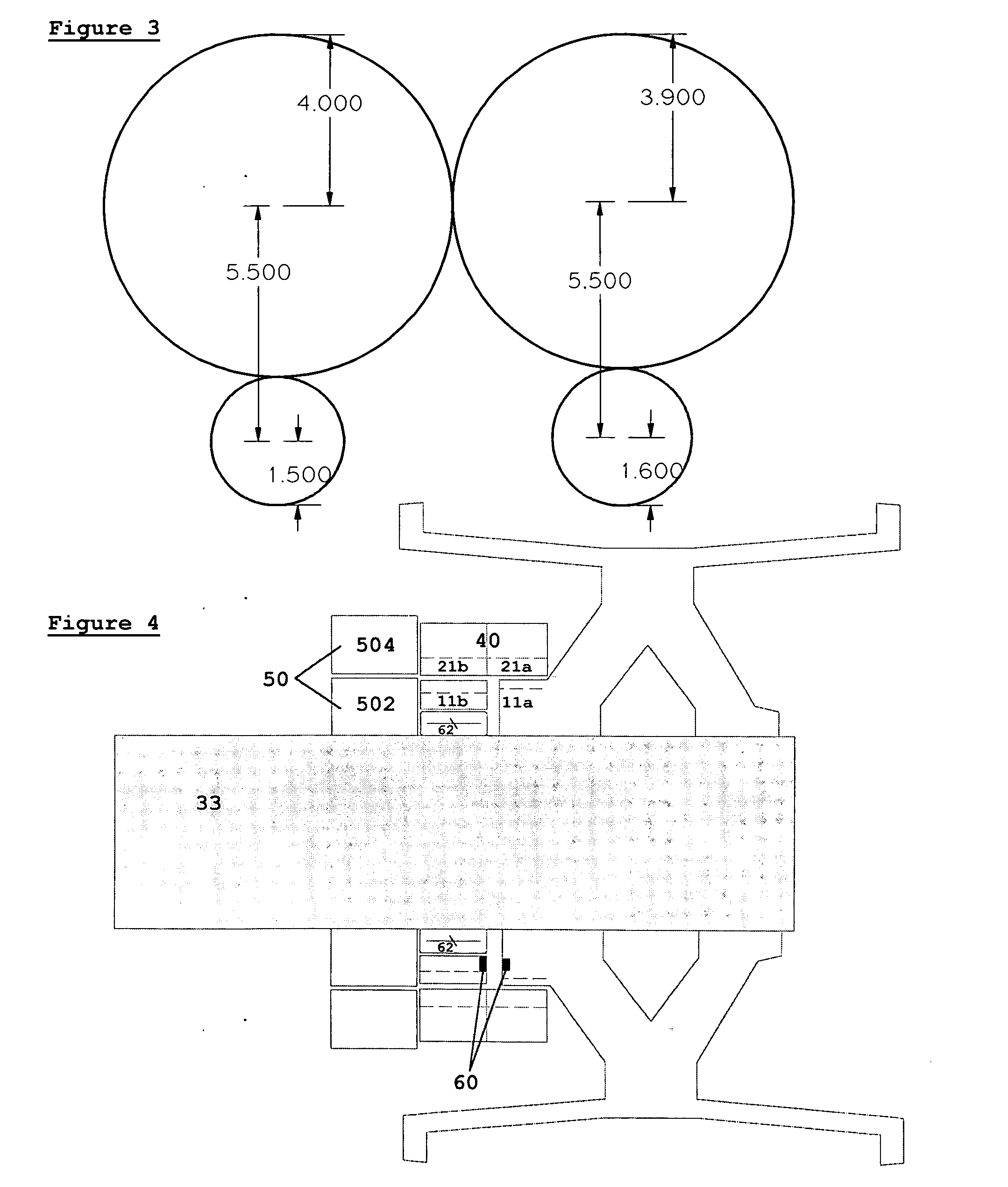

Geared wheel motor design

The present invention is directed to an apparatus for driving an aircraft having an undercarriage wheel, comprising aircraft drive means for driving an undercarriage wheel, and a clutch disposed between said driven means and said wheel, wherein said drive means and said clutch are directly connected to the undercarriage apparatus. Said apparatus may have gears disposed between said drive means clutch, or between said clutch and said wheel. In a most preferred arrangement, the apparatus of the invention fits inside the hub of said wheel. When the invention is applied to an aircraft undercarriage wheel, the clutch allows the wheel to be disengaged for takeoff and landing.

Owner:EDELSON JONATHAN SIDNEY +1

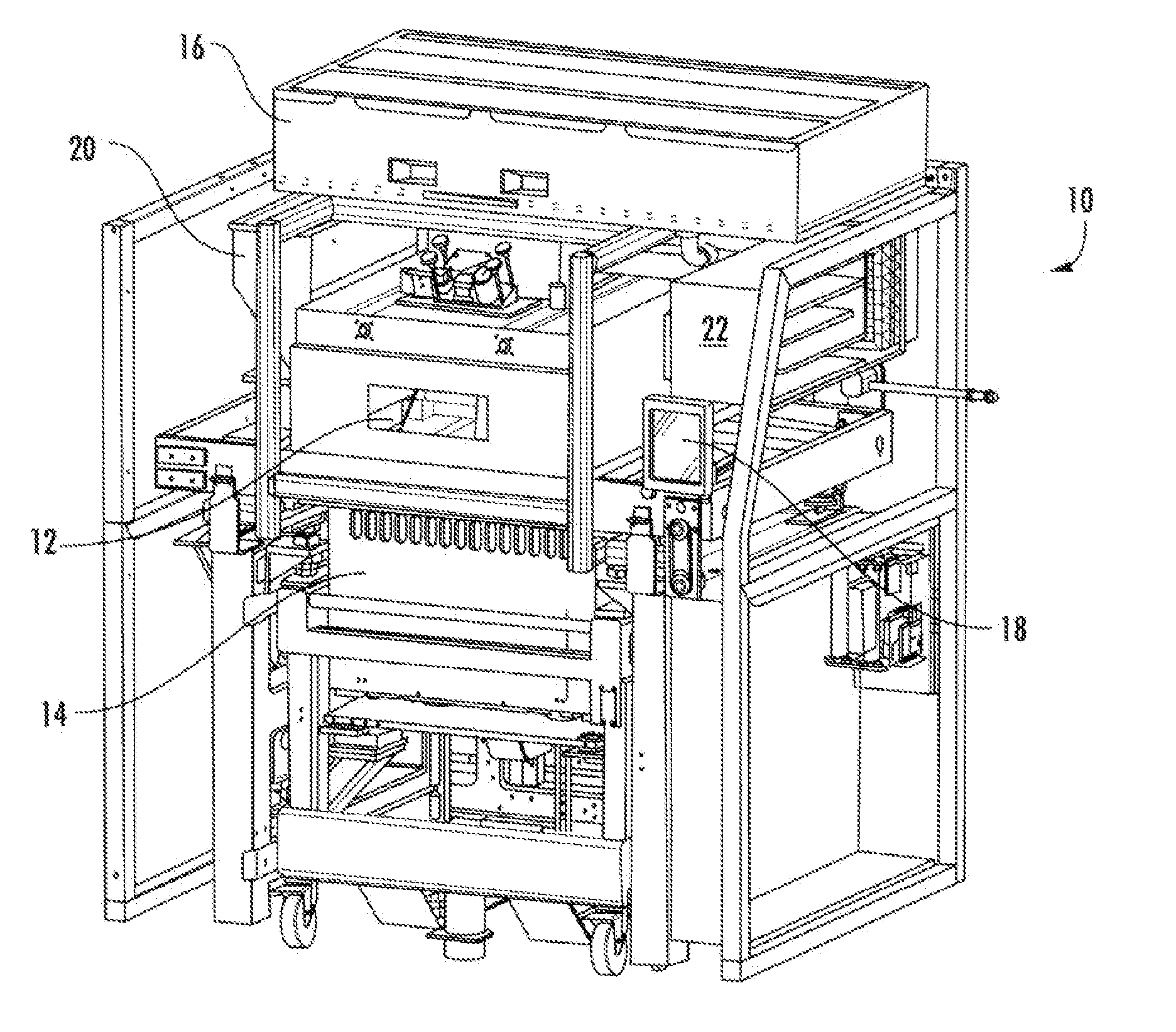

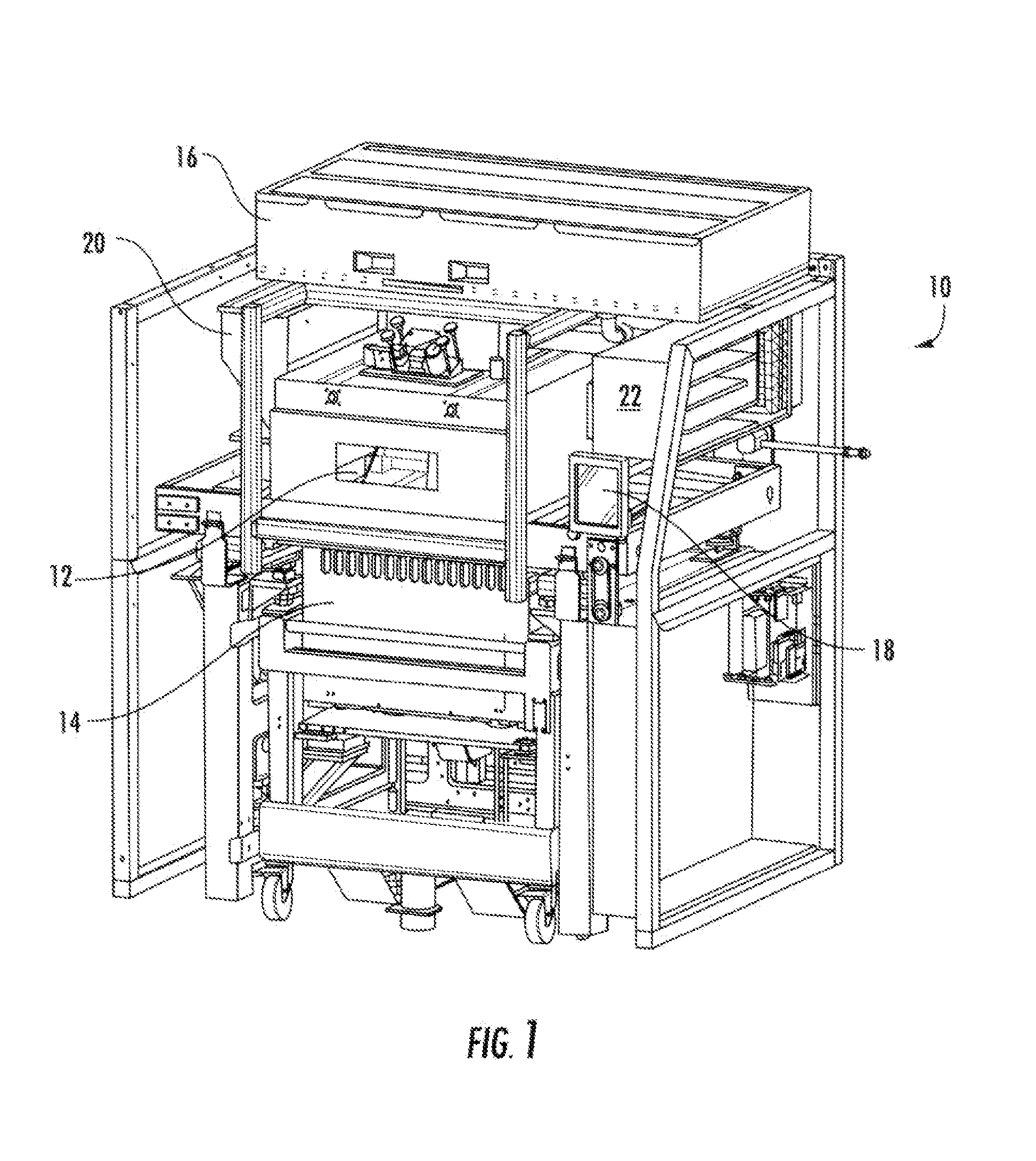

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com