Patents

Literature

6013results about How to "Low impurity content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

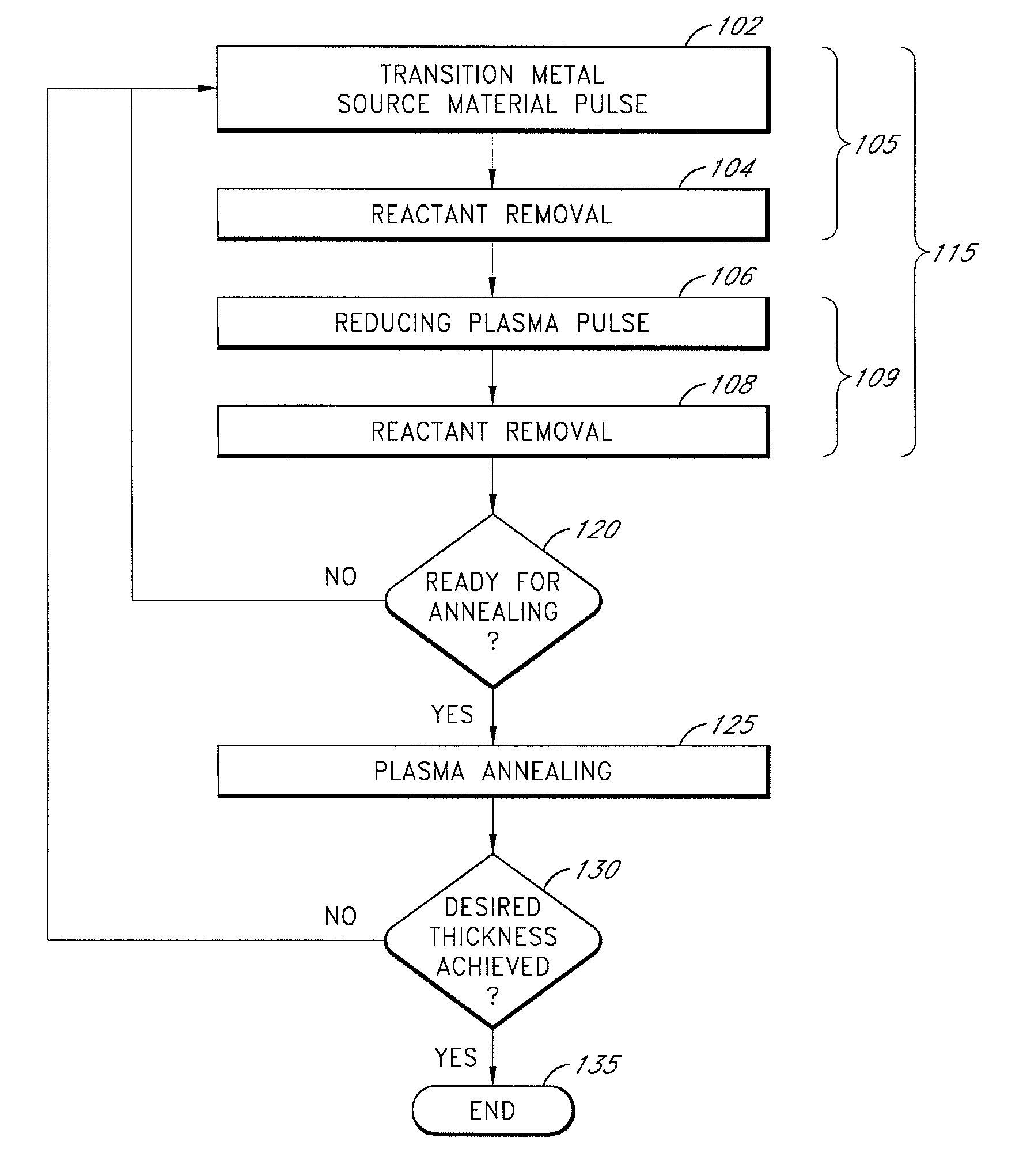

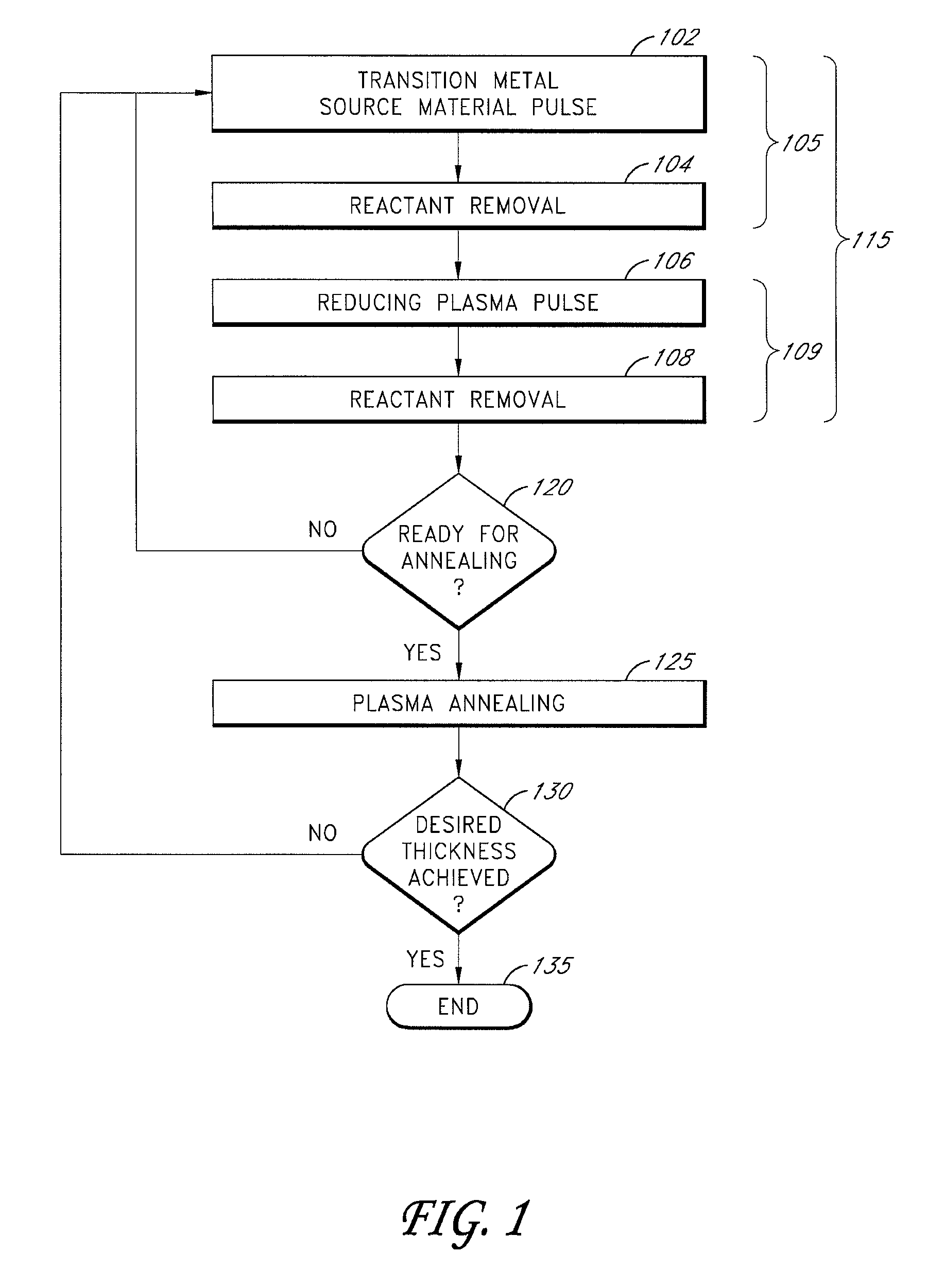

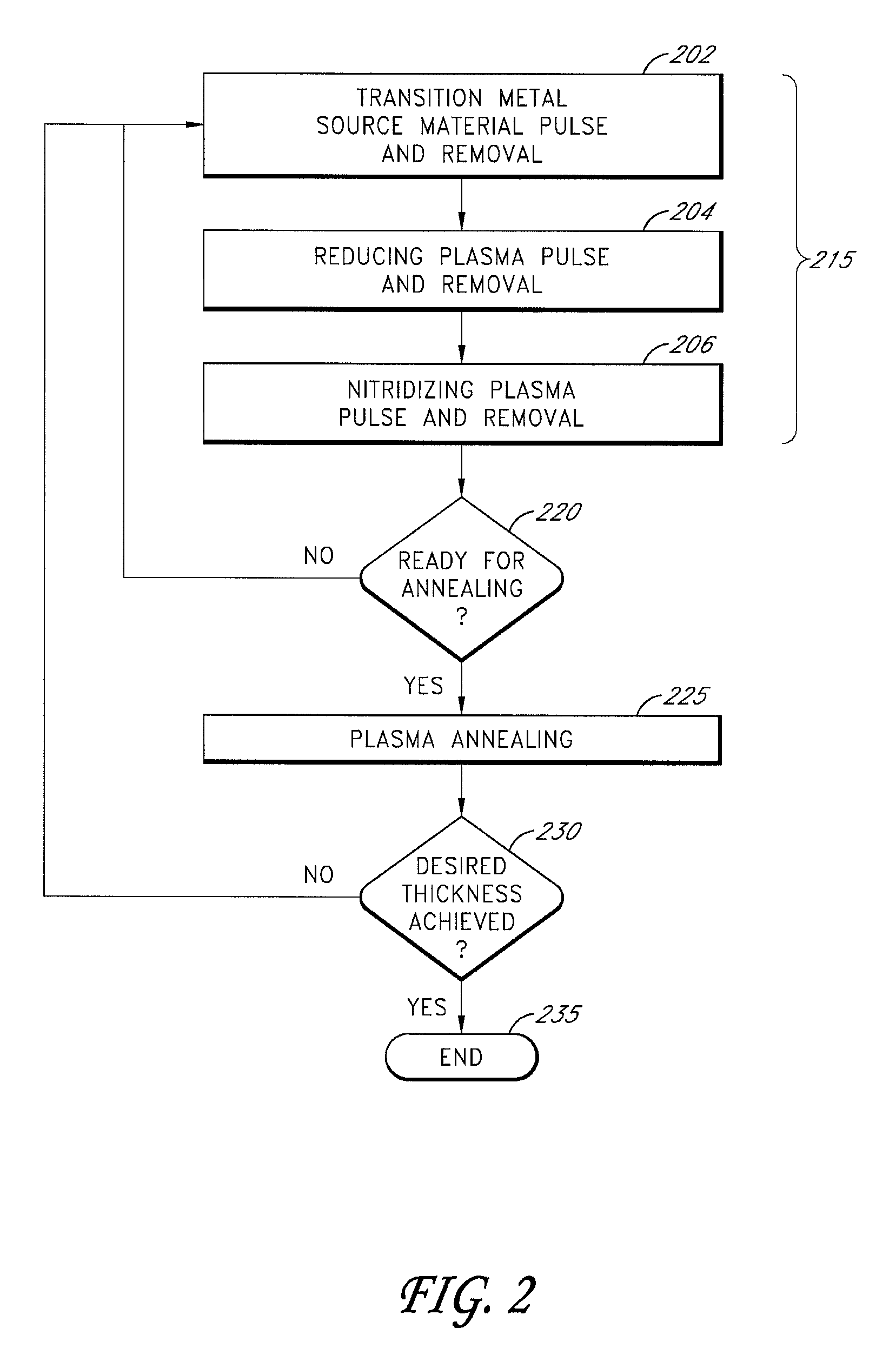

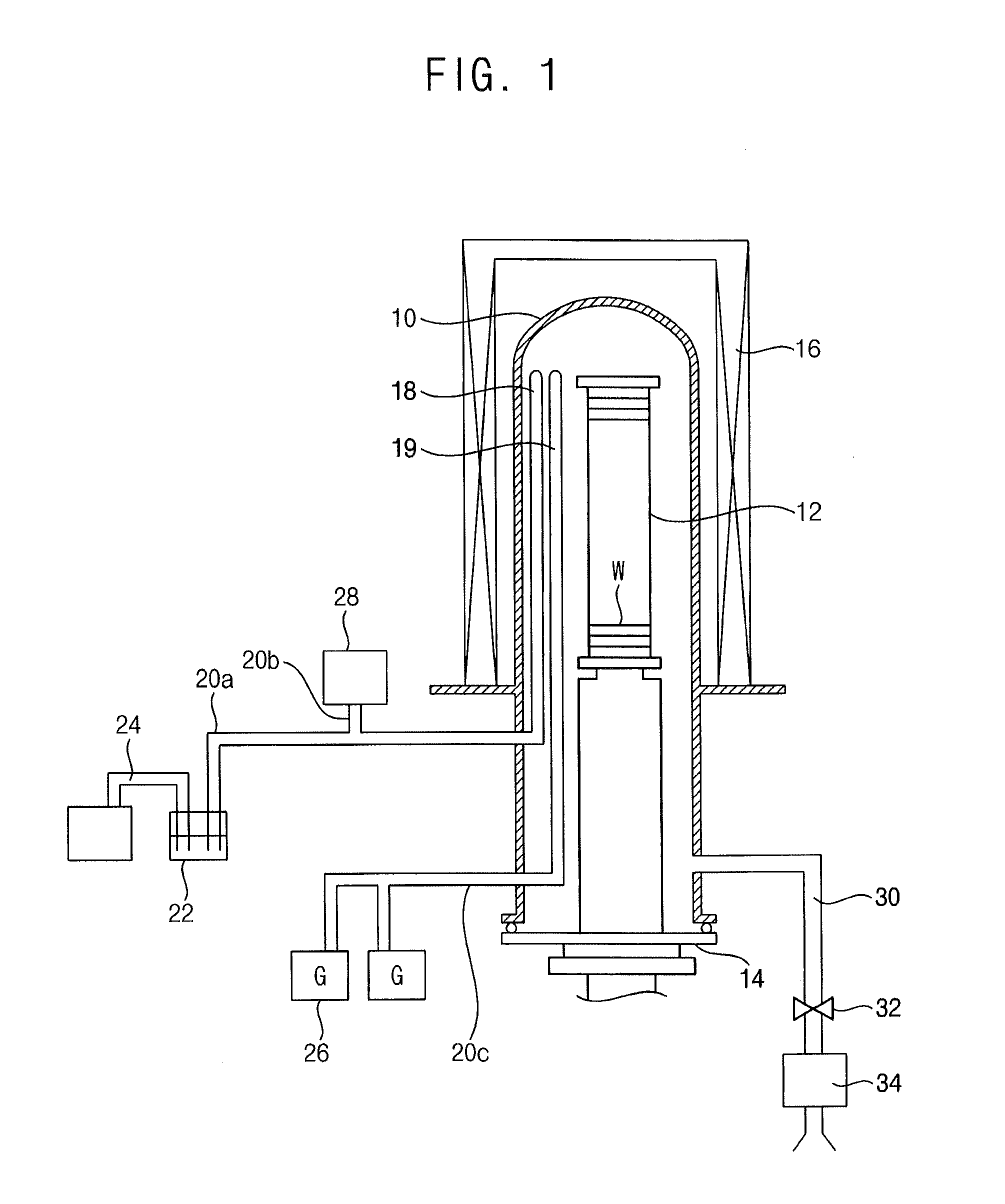

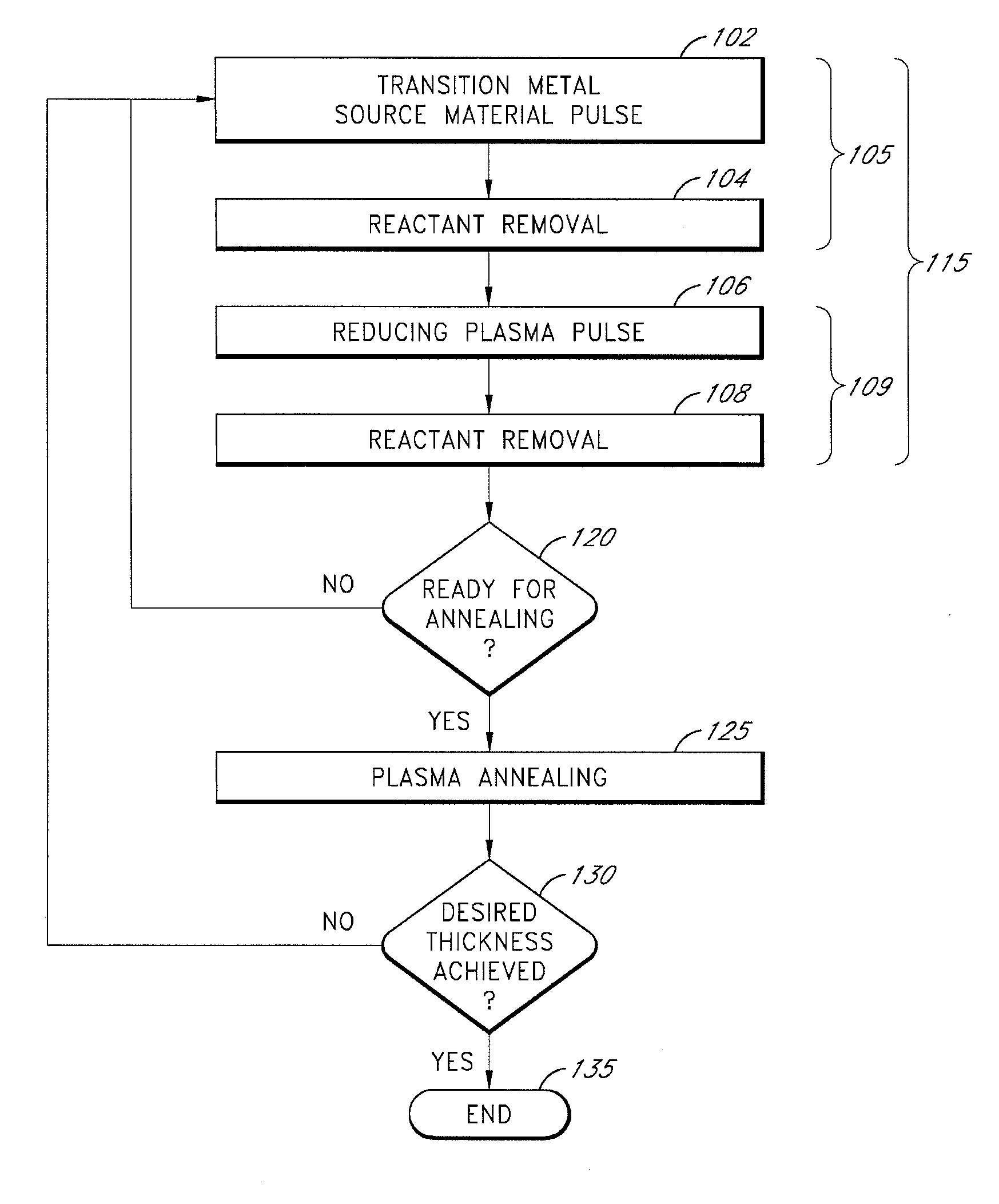

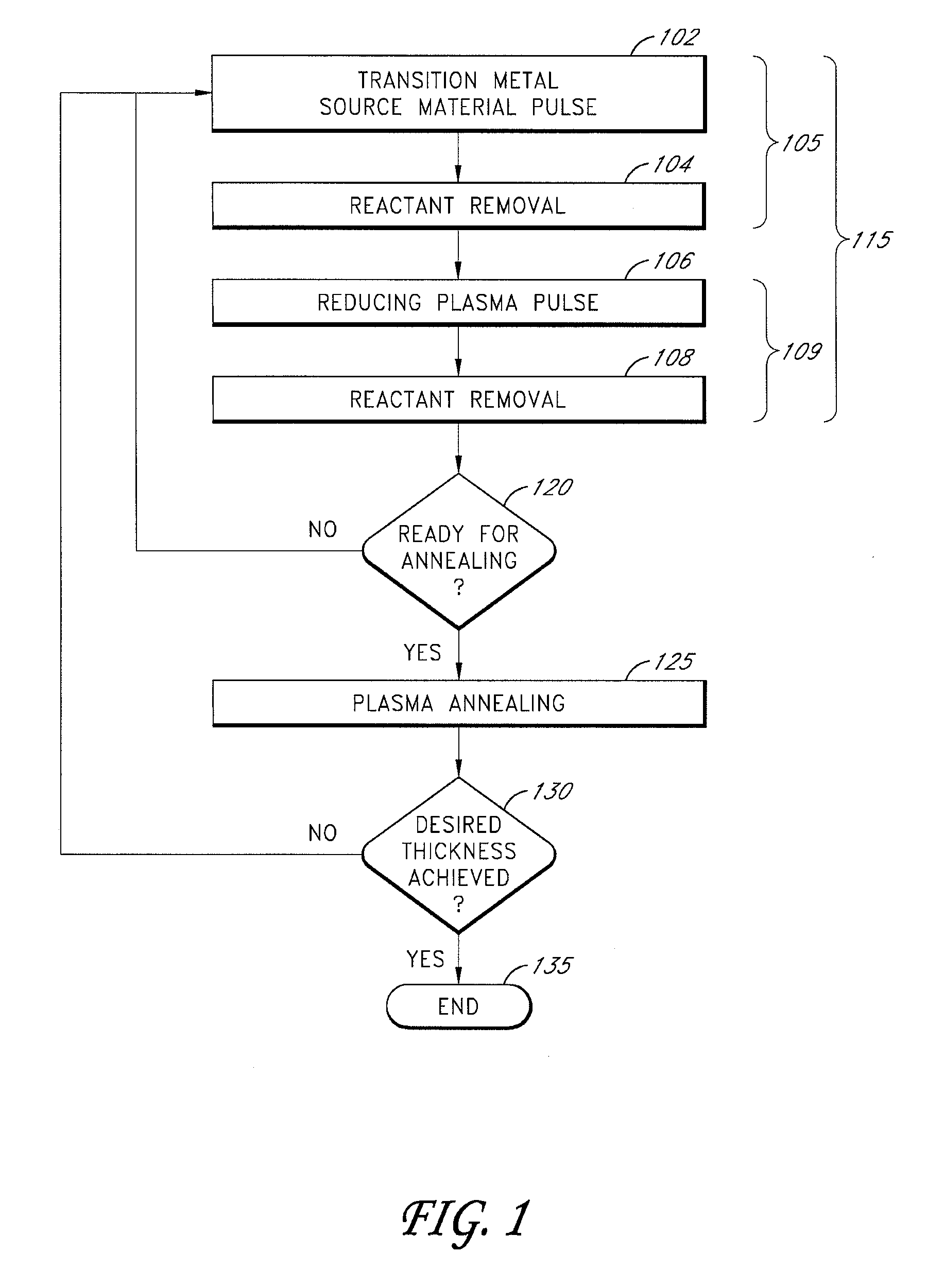

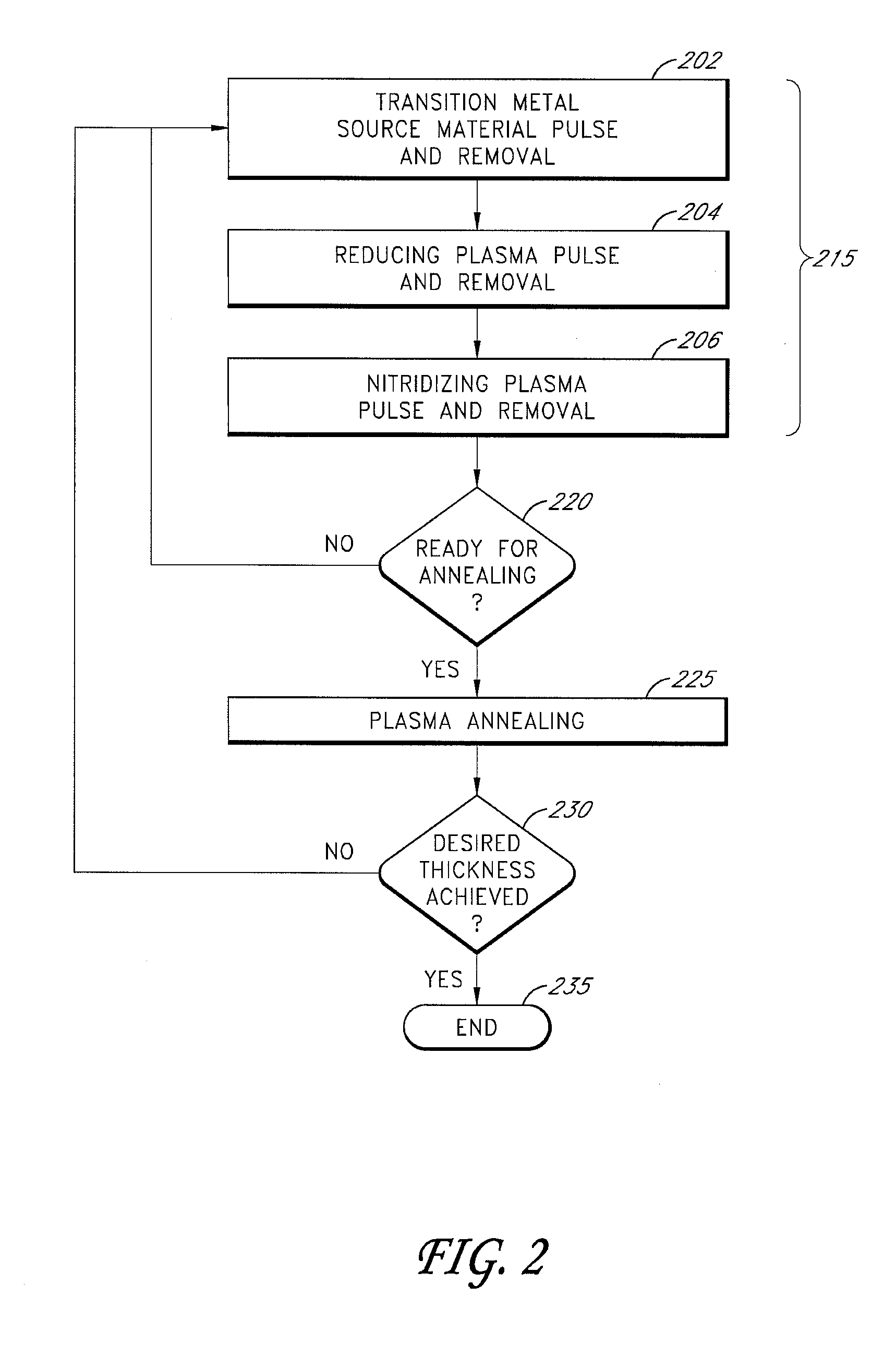

Periodic plasma annealing in an ALD-type process

ActiveUS7713874B2Increase probabilityReduce susceptibility to oxidationPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseVapor phase

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

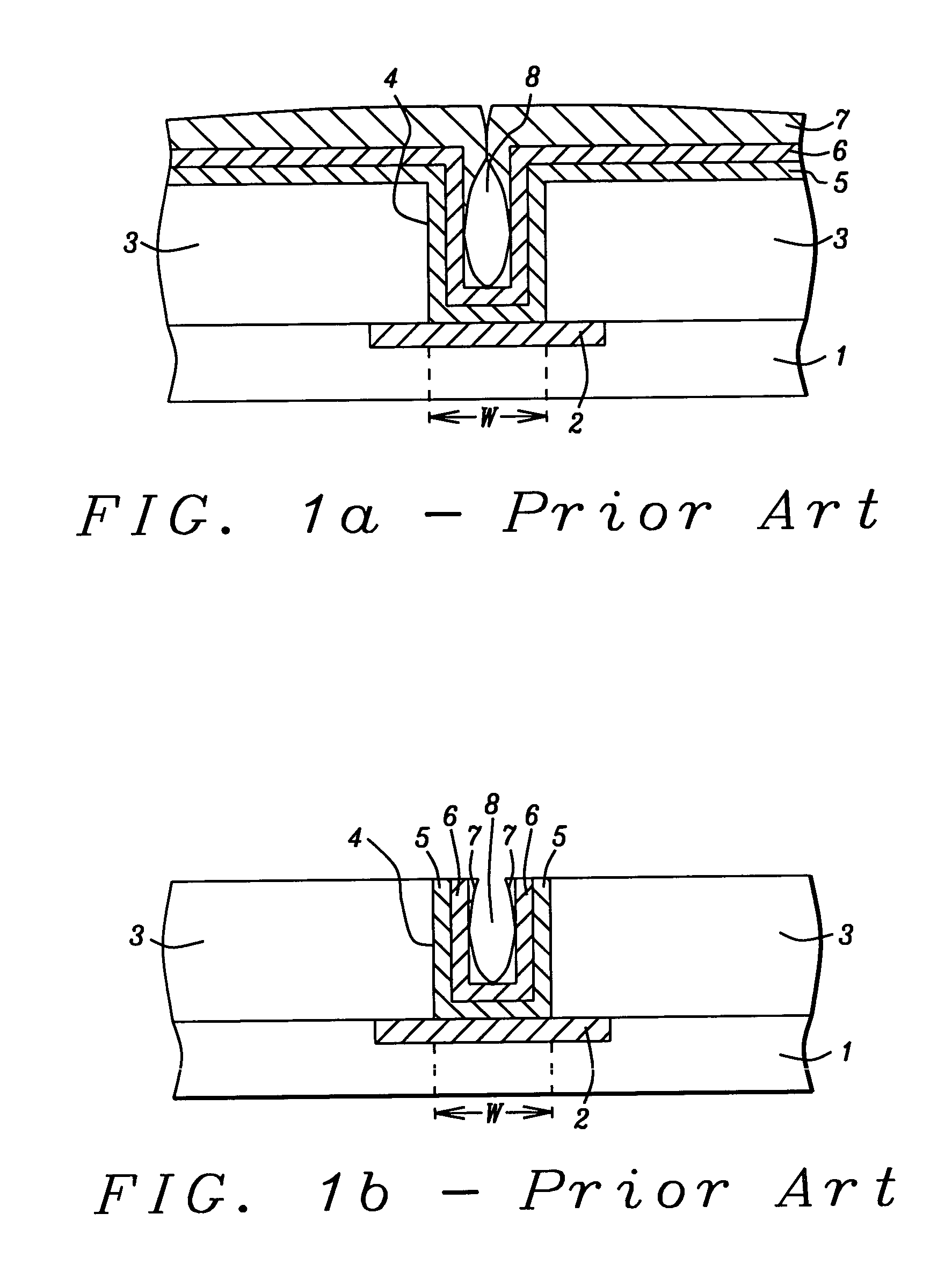

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS7235482B2Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionContamination

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrat. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

Method of forming a dielectric layer and method of manufacturing a semiconductor device using the same

InactiveUS20110159680A1Low impurity contentExcellent shrinkage and etch propertySolid-state devicesSemiconductor/solid-state device manufacturingOxideSemiconductor

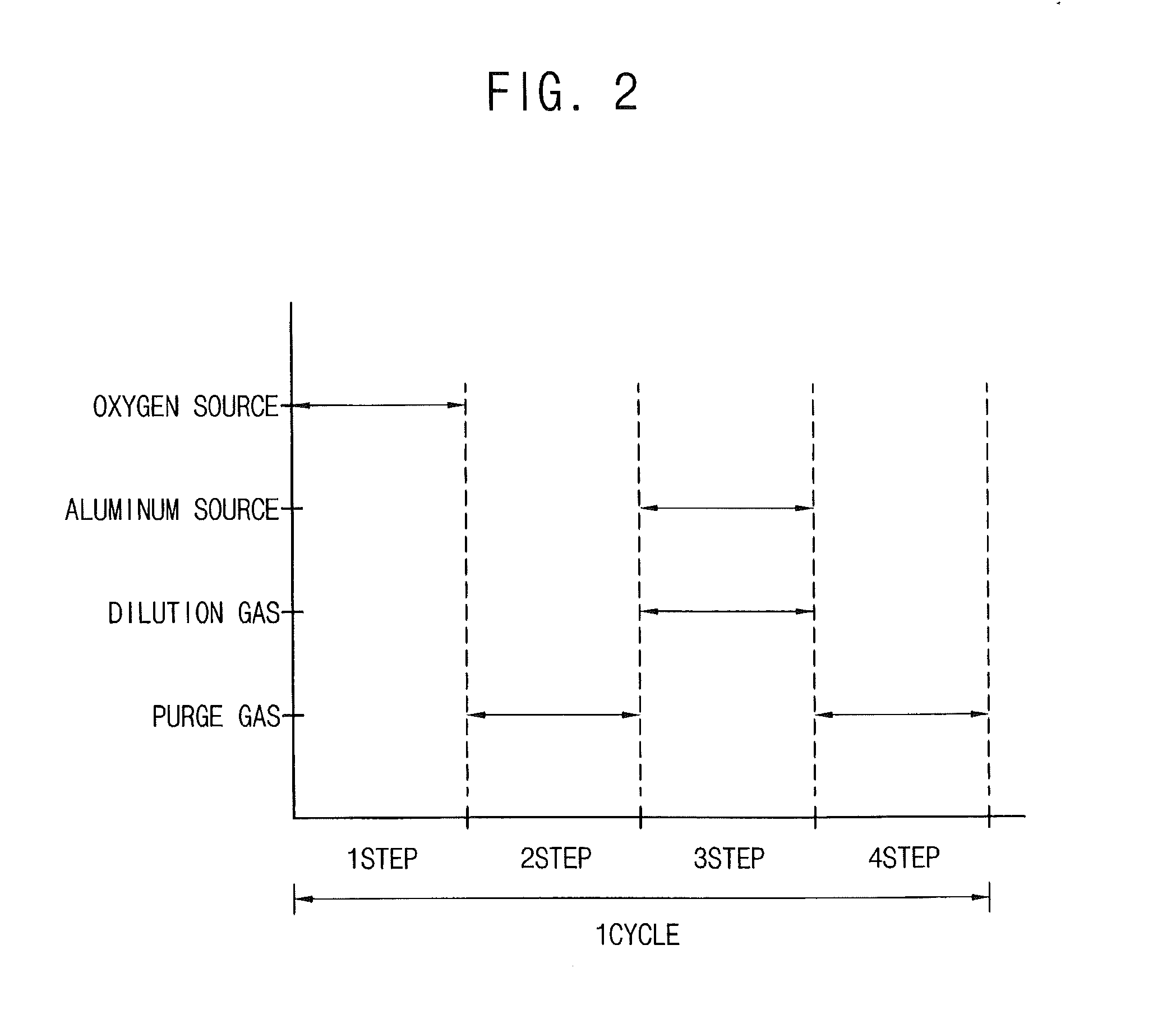

In a method of forming an aluminum oxide layer, an aluminum source gas and a dilution gas can be supplied into a chamber through a common gas supply nozzle so that the aluminum source gas may be adsorbed on a substrate in the chamber. A first purge gas can be supplied into the chamber to purge the physically adsorbed aluminum source gas from the substrate. An oxygen source gas may be supplied into the chamber to form an aluminum oxide layer on the substrate. A second purge gas may be supplied into the chamber to purge a reaction residue and the physically adsorbed remaining gas from the substrate. The operations can be performed repeatedly to form an aluminum oxide layer having a desired thickness.

Owner:SAMSUNG ELECTRONICS CO LTD

Oxide catalyst composition

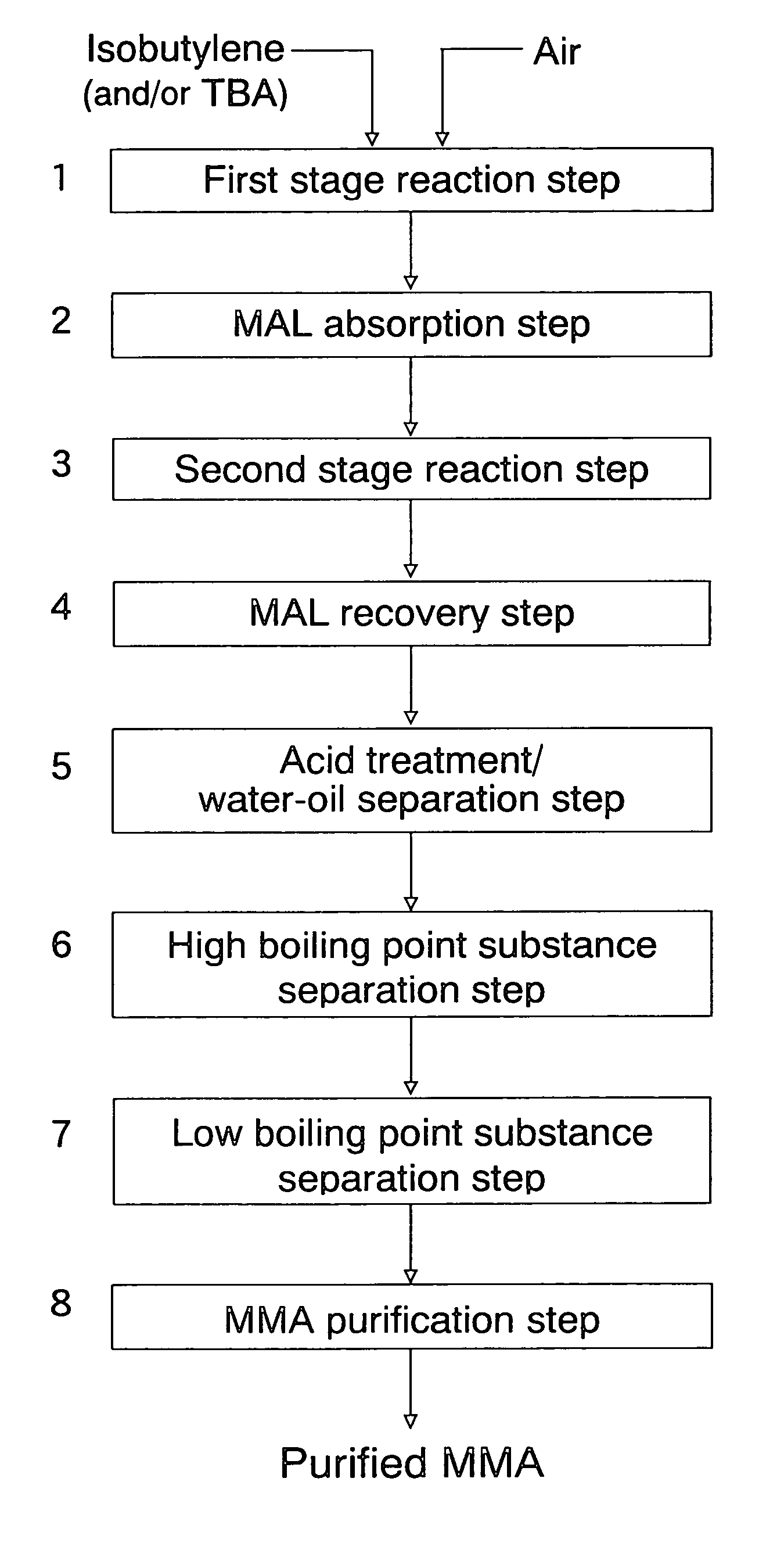

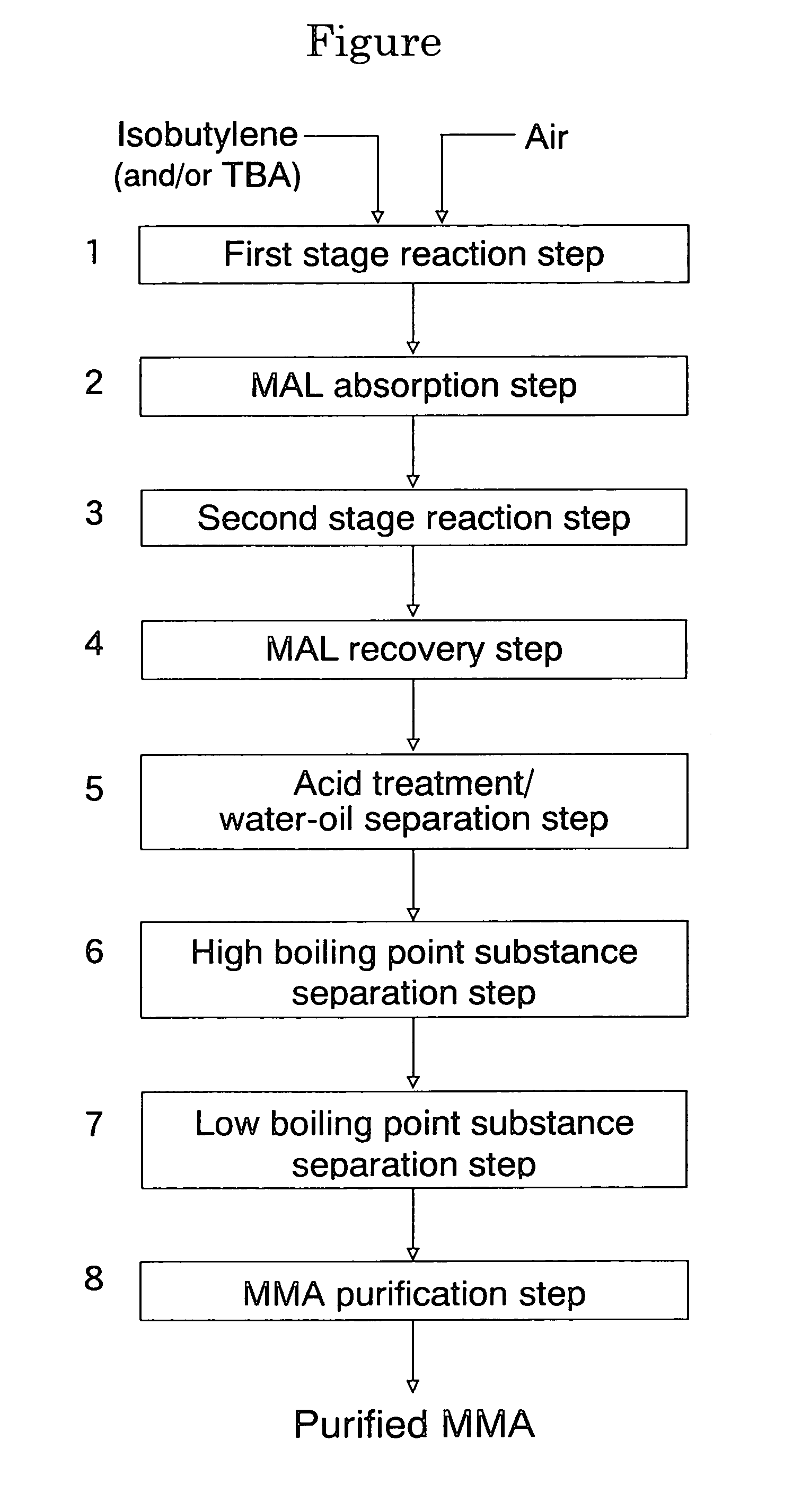

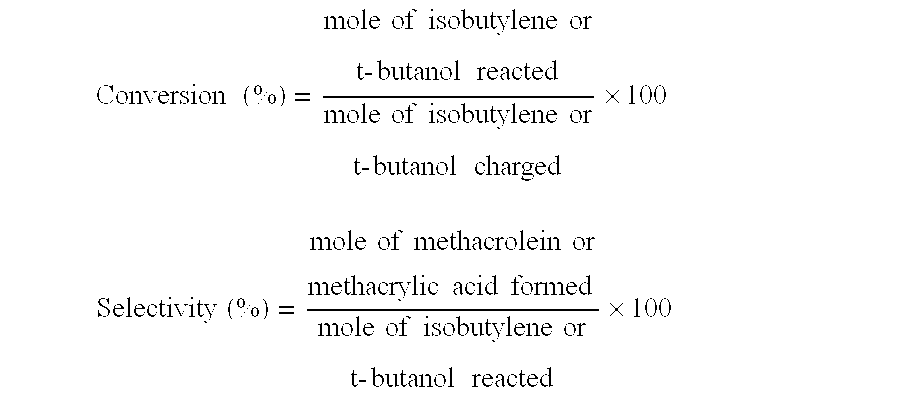

InactiveUS7012039B2High selectivityLow selectivityOrganic compound preparationCarboxylic acid esters preparationLanthanideMethacrolein

An oxide catalyst composition for use in producing methacrolein or a mixture of methacrolein and methacrylic acid, wherein the oxide catalyst composition is represented by the formula (Mo+W)l2BiaAbBcFedXeSbfOg, wherein: A is at least one member selected from the group consisting of Y and the elements of the lanthanoid series exclusive of Pm; B is at least one member selected from the group consisting of K, Rb and Cs; X is Co solely, or a mixture of Co and at least one member selected from the group consisting of Mg and Ni; and a, b, c, d, e, f and g are, respectively, the atomic ratios of Bi, A, B, Fe, X, Sb and O, relative to twelve atoms of the total of Mo and W, wherein the atomic ratios (a to f) of the elements and the relationship between the amounts of the elements are chosen so as to satisfy specific requirements.

Owner:ASAHI KASEI CHEM CORP

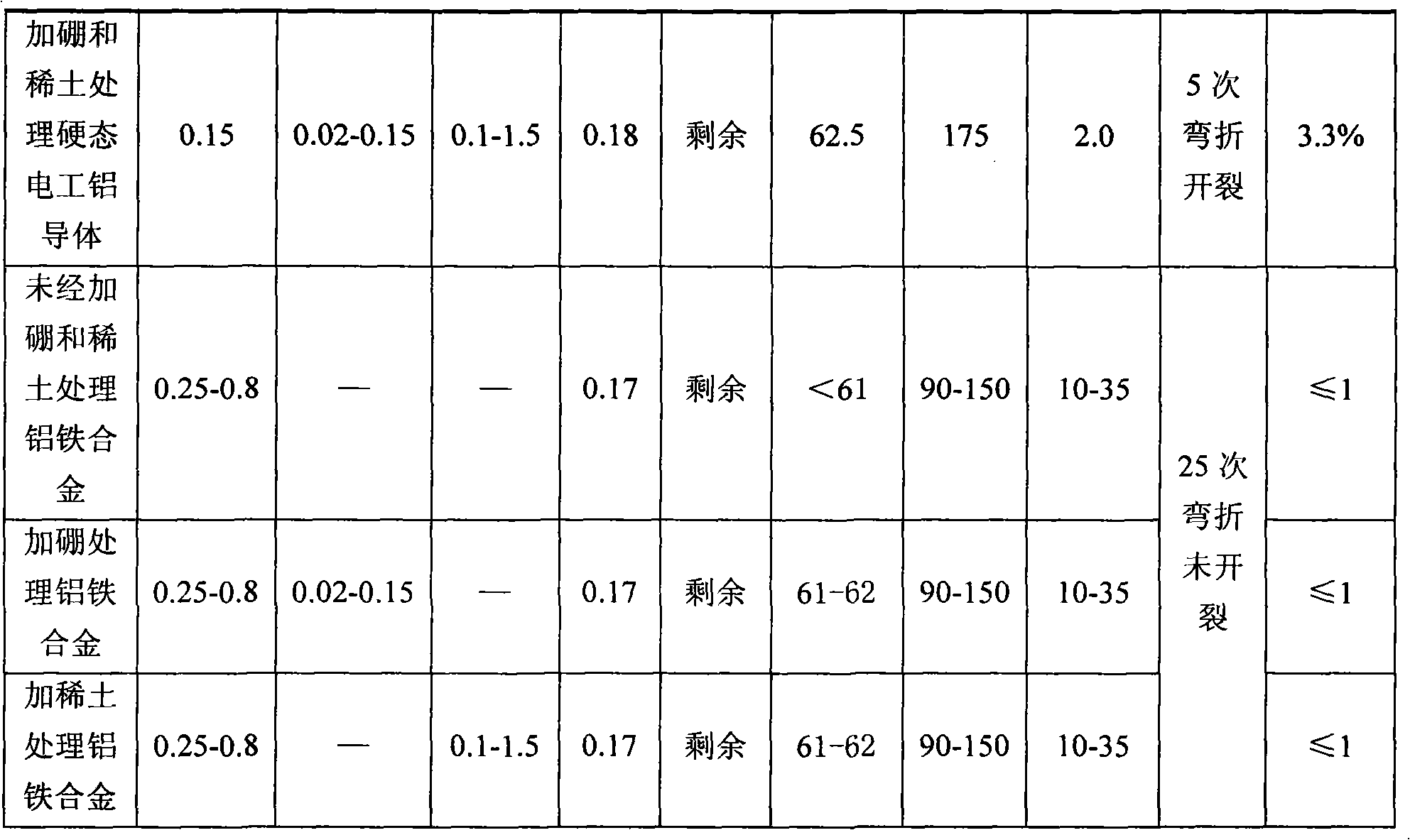

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

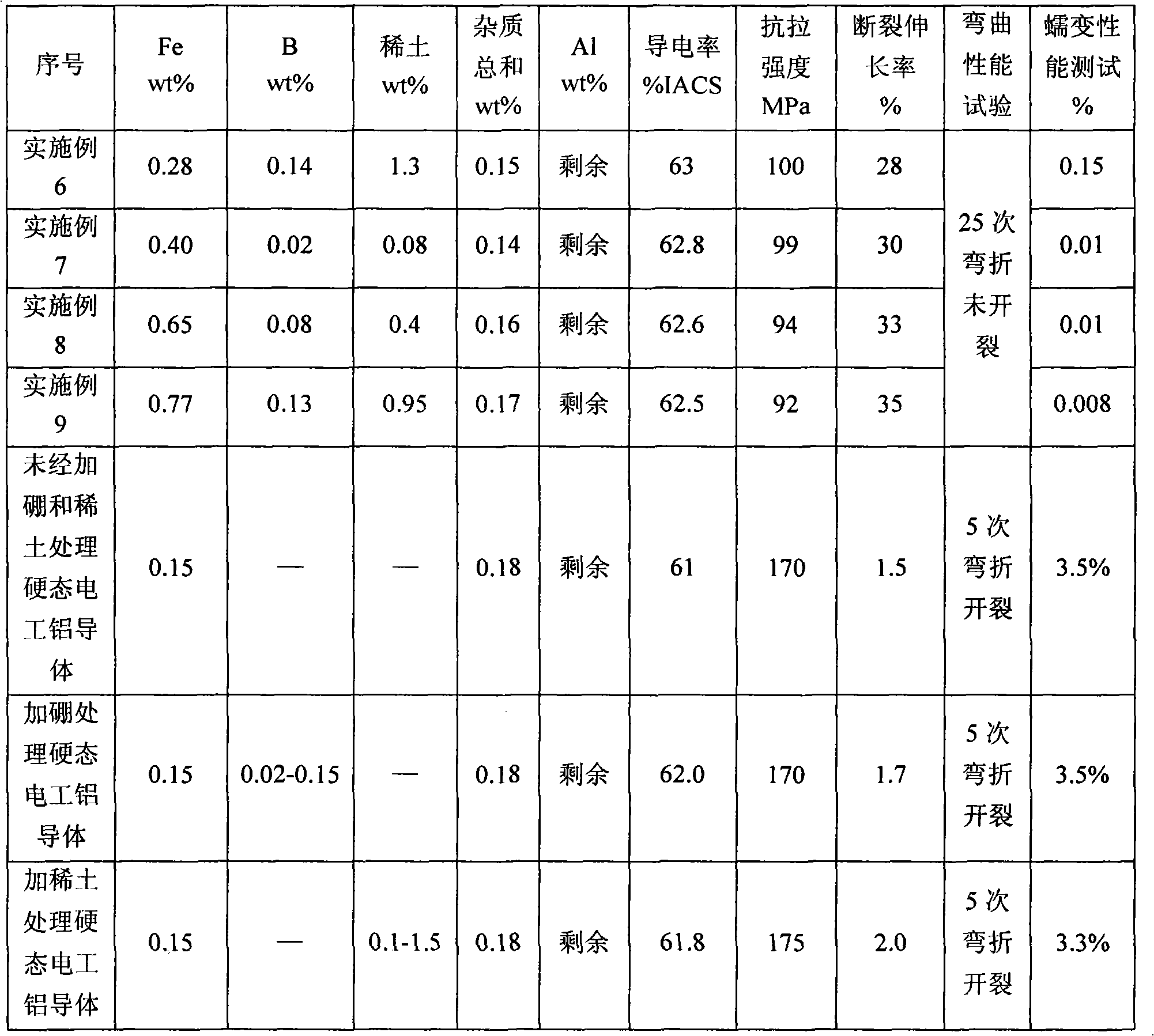

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

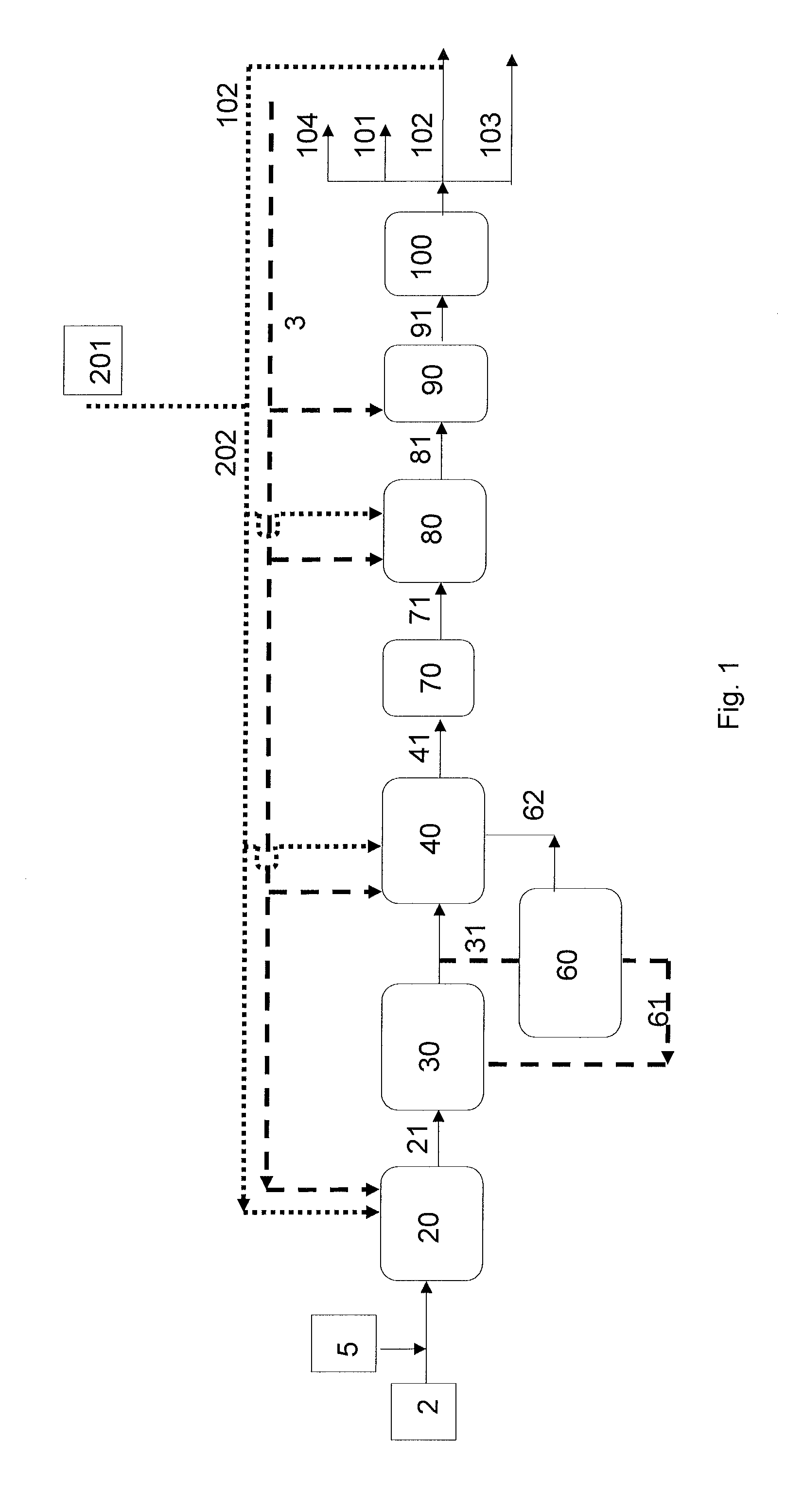

Process for producing a branched hydrocarbon component

InactiveUS20070135316A1Reduce carbon dioxide emissionsImprove stabilityOrganic compound preparationCatalytic naphtha reformingIsomerizationHydrodeoxygenation

The invention relates to a process for producing high-quality hydrocarbon base oil particularly of biological origin. The process of the invention comprises aldol condensation, hydrodeoxygenation, and isomerization steps. Aldehydes and / or ketones, preferably of biological origin are used as the feedstock.

Owner:NESTE OIL OY

Non-aqueous electrolyte secondary cell negative electrode material and metallic silicon power therefor

InactiveUS20060051670A1Improve cycle performanceLow costSiliconSynthetic resin layered productsImpuritySilicon

A metallic silicon powder is prepared by effecting chemical reduction on silica stone, metallurgical refinement, and metallurgical and / or chemical purification to reduce the content of impurities. The powder is best suited as a negative electrode material for non-aqueous electrolyte secondary cells, affording better cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

Process to produce aromatics from crude oil

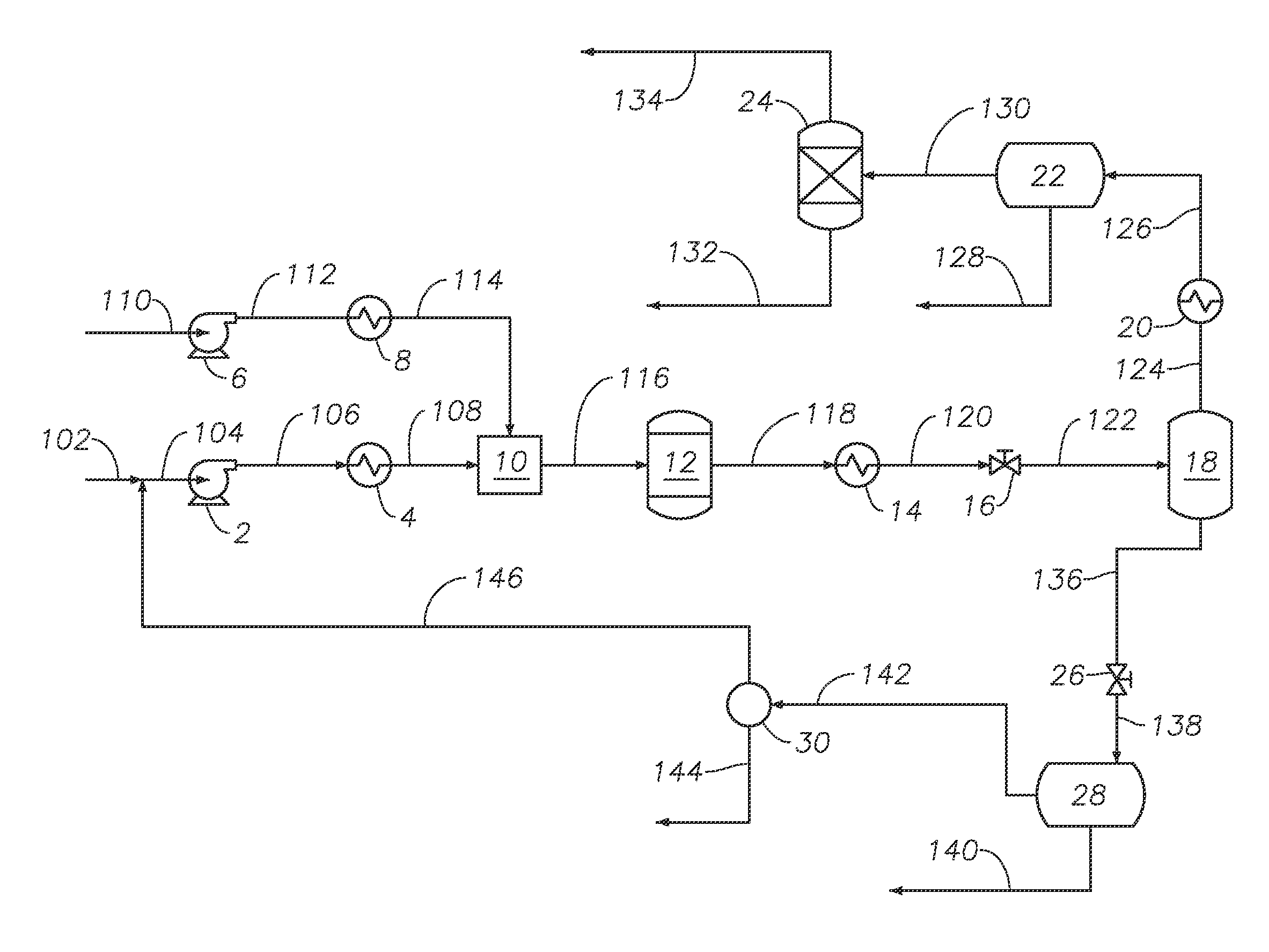

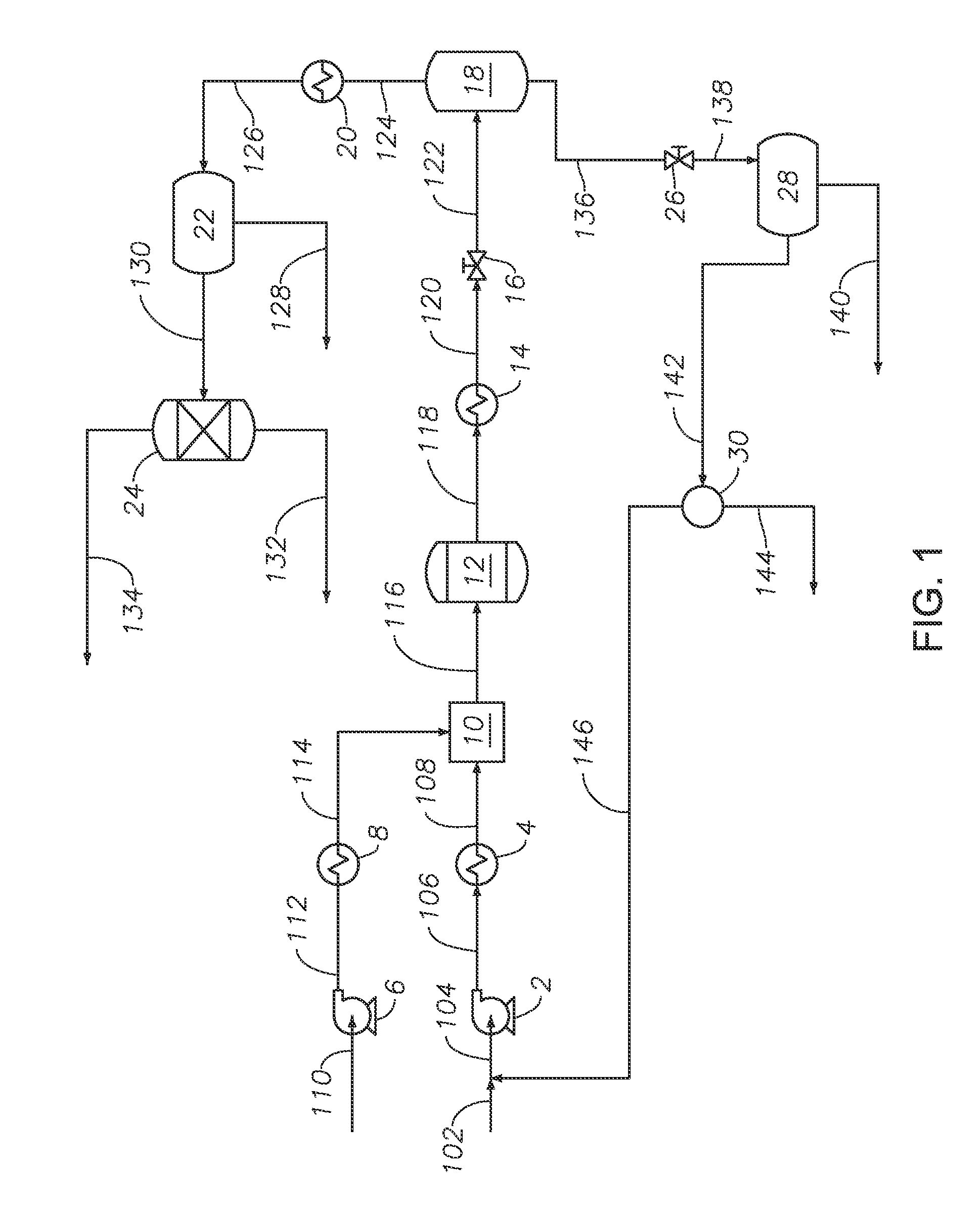

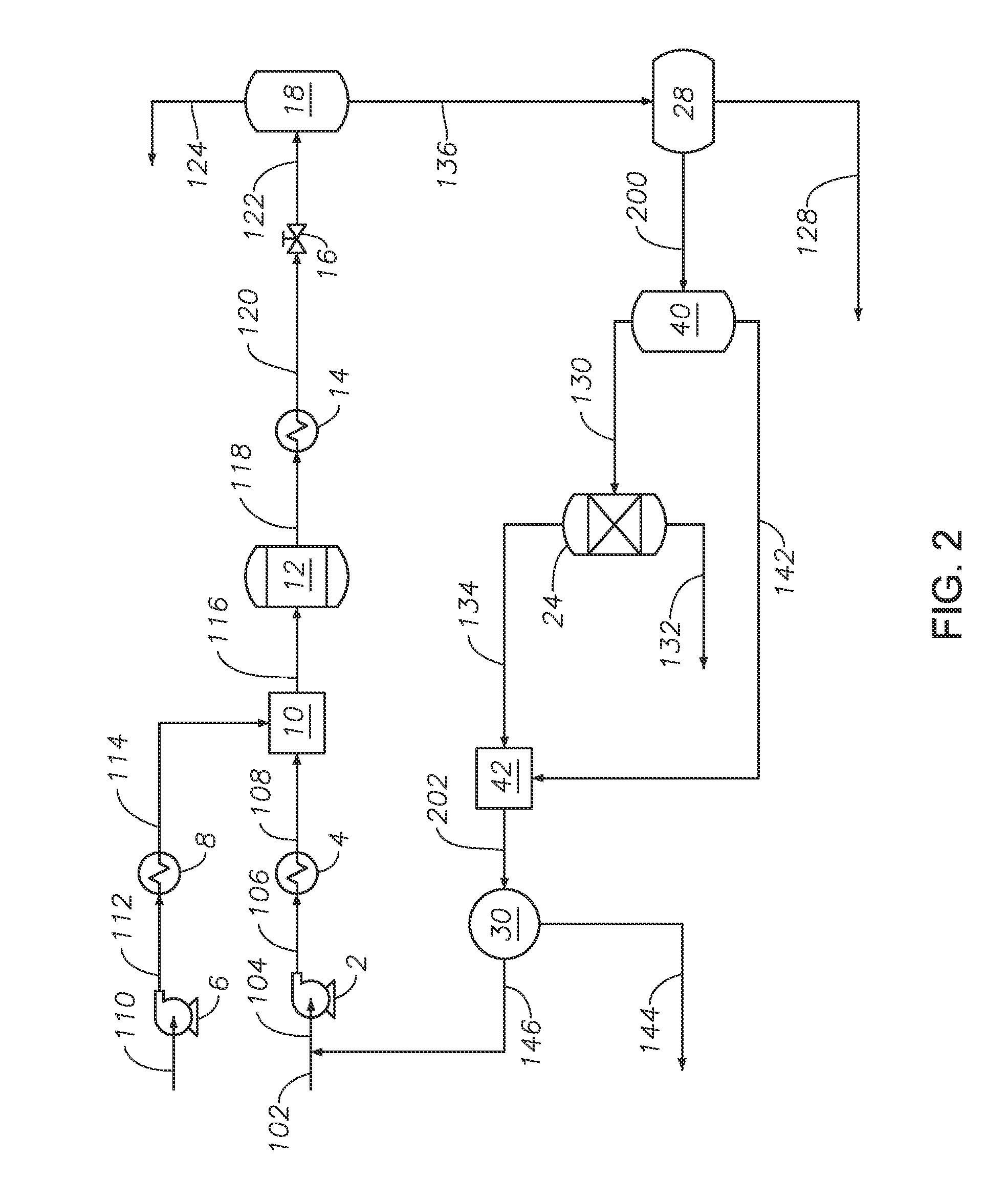

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

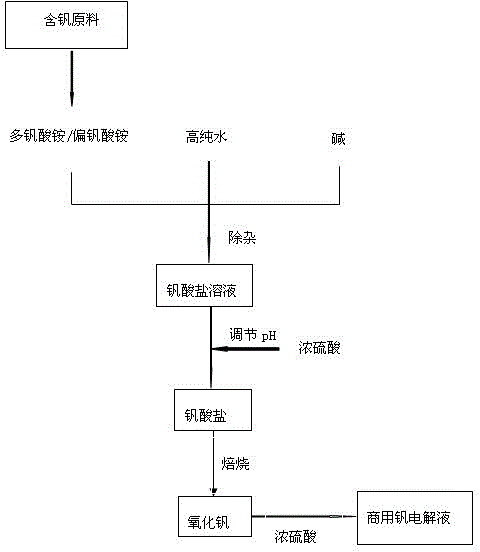

Preparation method for commercial vanadium battery electrolyte

ActiveCN103606694AHigh purityLimited service lifeIndirect fuel cellsAcid electrolytesSocial benefitsHydrogen

The invention discloses a preparation method for commercial vanadium battery electrolyte. According to the preparation method, vanadium electrolyte is prepared by one step through a chemical method; the preparation method comprises the following steps: dissolving raw materials containing vanadium by using an alkali; adjusting a pH (Potential of Hydrogen) value by acid-alkali regulation; repeatedly precipitating the vanadium to remove impurity elements; then roasting to obtain an oxide of the vanadium; finally, dissolving the oxide of the vanadium by using concentrated sulfuric acid to obtain the vanadium electrolyte. With the adoption of the method, impurities including iron, chrome, silicon, manganese and the like can be removed effectively and a process flow is shortened; the vanadium yield is improved, the impurity content is reduced and the process flow is shortened; the product purity can also be improved. The preparation method for the commercial vanadium battery electrolyte has important meanings on production technology levels and market competitiveness of the vanadium electrolyte; the method has good economic benefits and social benefits.

Owner:HEBEI IRON AND STEEL

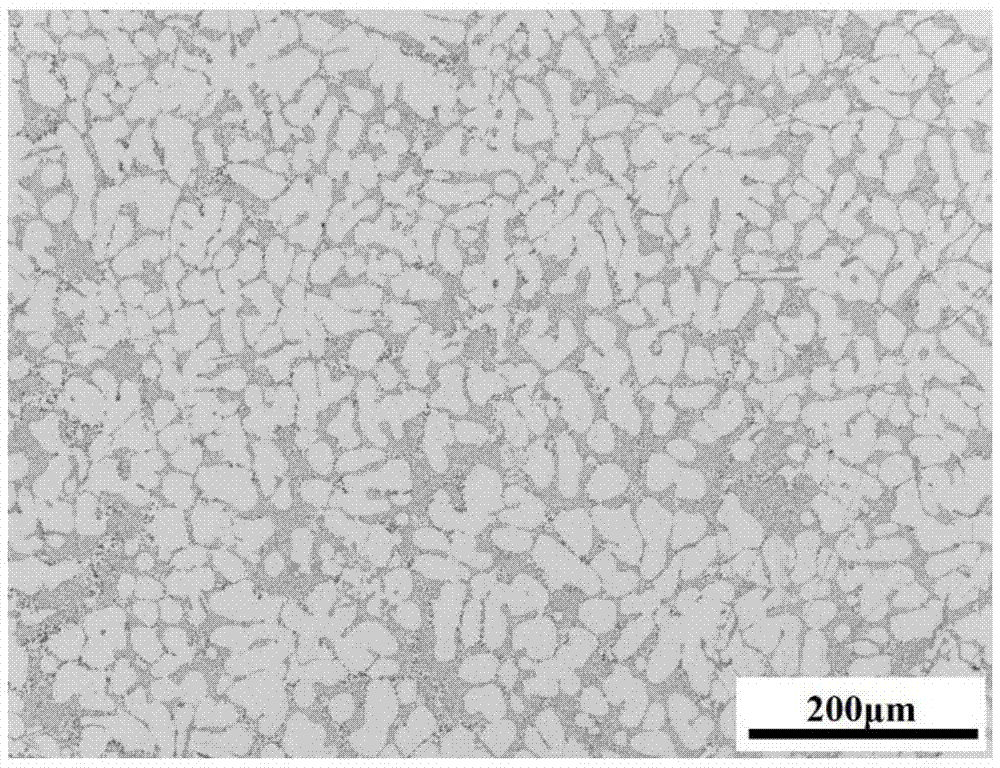

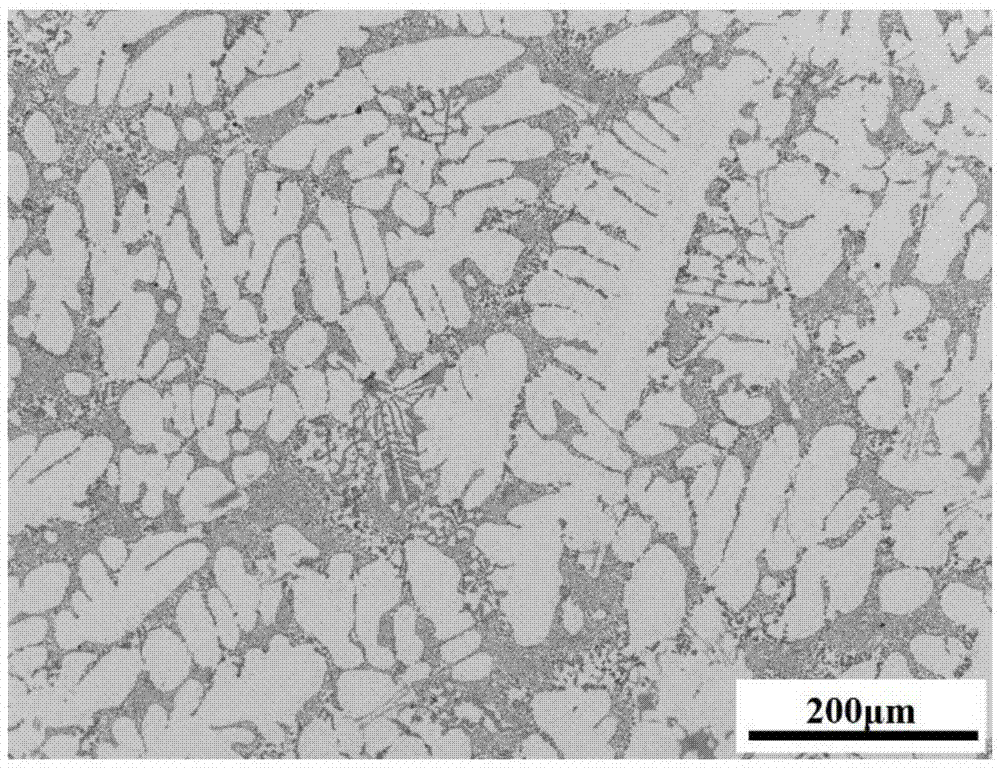

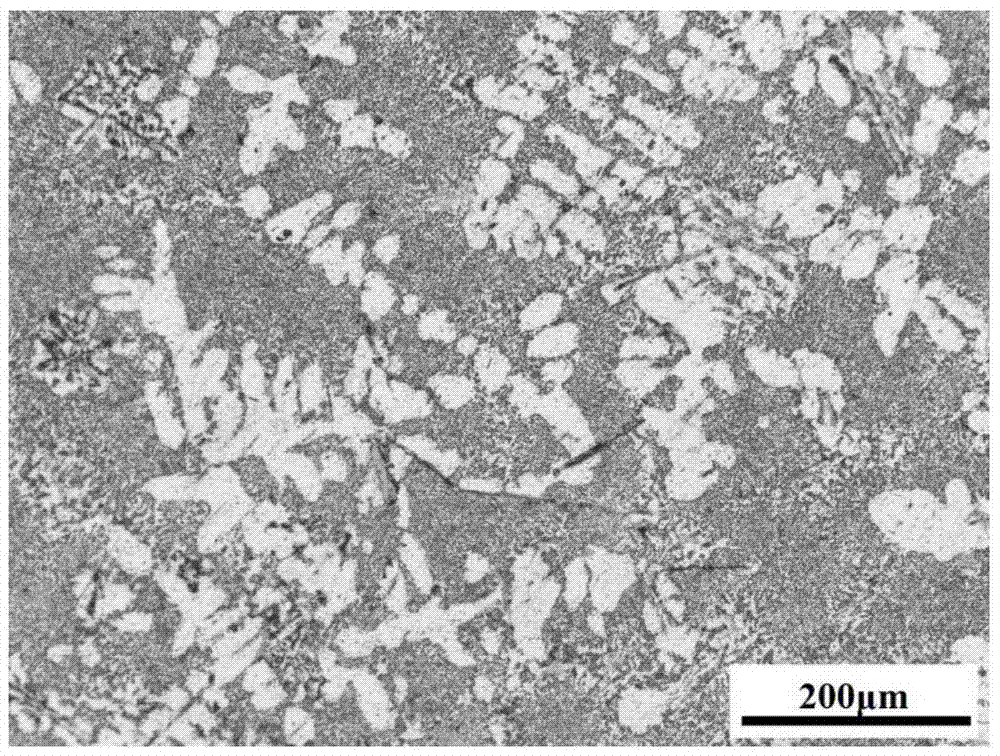

High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

The invention provides high-strength and high-corrosion-resistance cast aluminum alloy and a pressure casting preparation method thereof. The alloy is prepared from, by a certain weight percent, Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al, wherein M is at least one element of Ti, Zr and V, or the element RE is added in M. After the high-strength and high-corrosion-resistance cast aluminum alloy is subjected to pressure casting, the room temperature tensile strength sigma b of alloy not subjected to heat treatment is larger than or equal to 315 MPa, the room temperature ductility sigma of the alloy not subjected to heat treatment is larger than or equal to 3.0%, and good corrosion resistance is achieved; and the alloy can be applied to automobile parts without ageing or solid solution heat treatment, and the requirement for light automobile development is met.

Owner:SHANGHAI JIAO TONG UNIV

Method for recovering waste/used lithium iron phosphate positive-pole material by acid leaching method

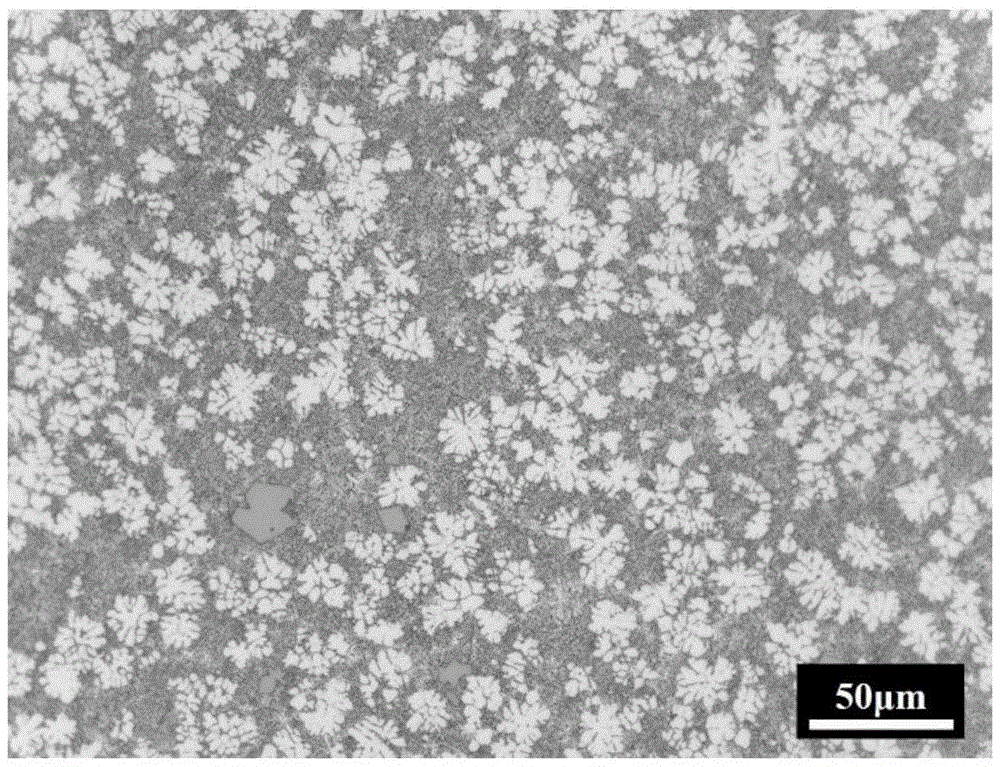

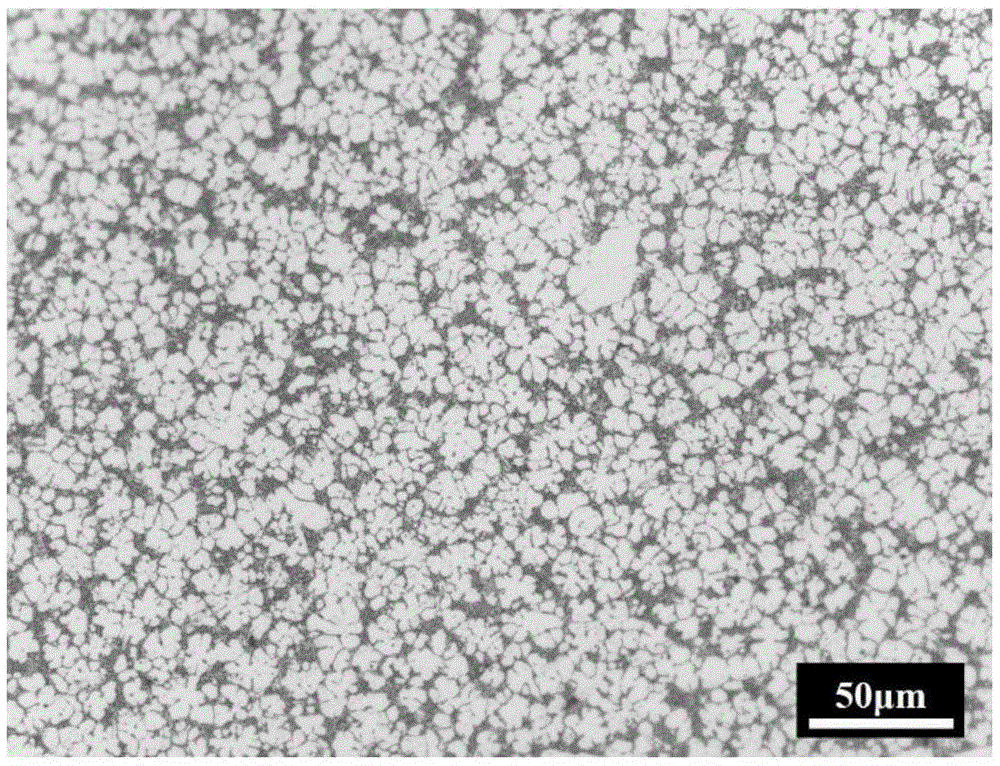

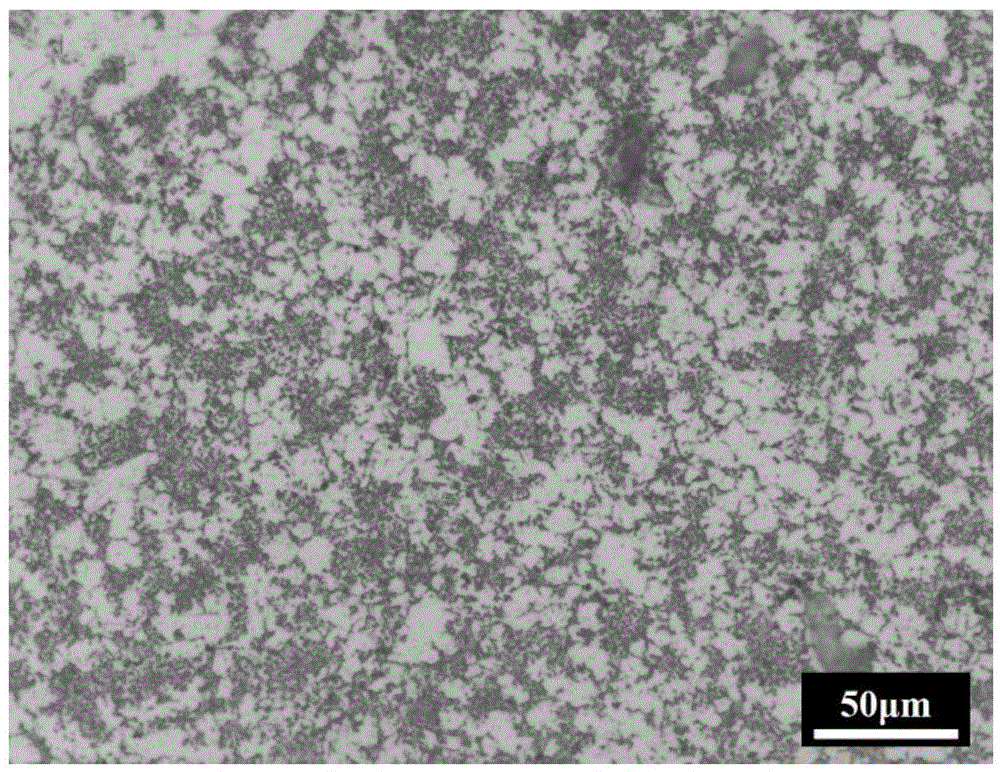

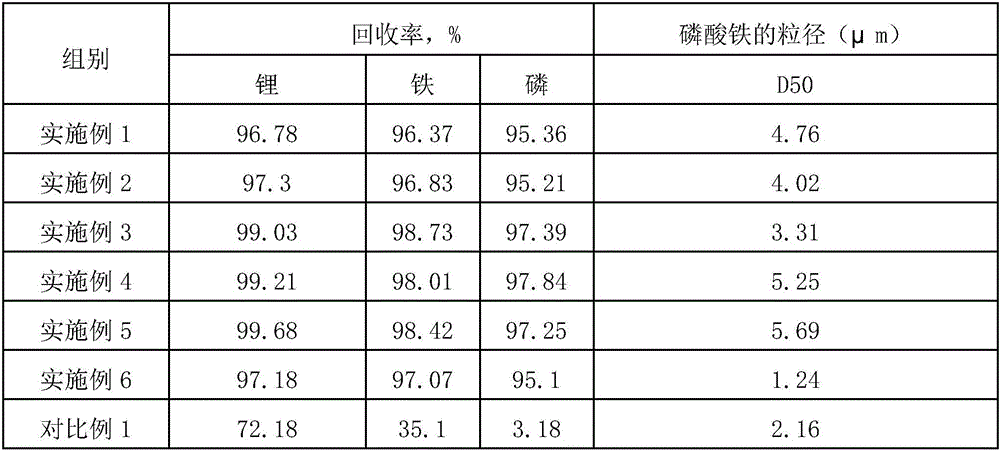

ActiveCN106684485AHigh recovery rateLow impurity contentWaste accumulators reclaimingBattery recyclingLithium electrodePhosphate

The invention belongs to the technical field of recovery of lithium-ion batteries and particularly relates to a method for recovering a waste / used lithium iron phosphate positive-pole material by an acid leaching method. The method provided by the invention comprises the following steps: (a) carrying out acid leaching: adding acid into the lithium iron phosphate positive-pole material for acid leaching so as to obtain a suspension, and carrying out filtration, so as to obtain filtrate; (b) carrying out oxidation: adjusting the pH value of the filtrate obtained in the step (a) to be smaller than 1, and adding an oxidant into the filtrate to oxidate ferrous ions in the filtrate into ferric ions, so as to obtain a mixed solution; (c) carrying out separation: adjusting the pH value of the mixed solution obtained in the step (b) to be 1.5 to 4, carrying out a reaction for 1 to 3 hours at the temperature of 60 DEG C to 95 DEG C so as to produce ferric phosphate precipitates, and carrying out filtrating and washing, thereby obtaining lithium-containing filtrate and ferric phosphate. The method provided by the invention is simple in process, continuous in cycle, low in cost and easy to industrialize and is environmentally friendly; the recovery rate of Li, Fe and P reaches 95% or more, subsequent prepared FePO4 is low in impurity content, the particle size is 1 to 6 microns, is uniform and is narrow in distribution, and the morphology is controllable, so that the FePO4 is battery-grade ferric phosphate.

Owner:TIANQI LITHIUM CORP

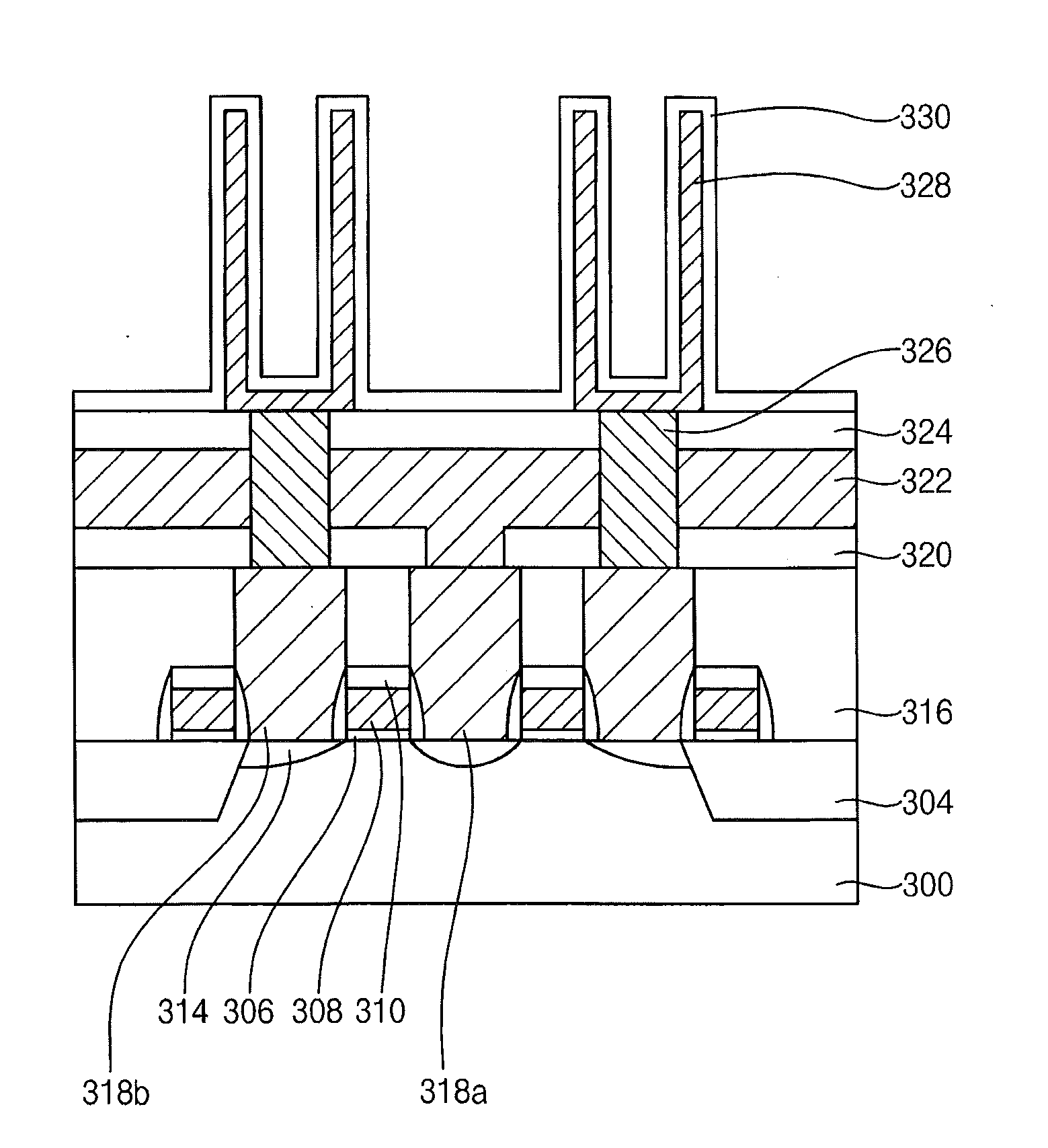

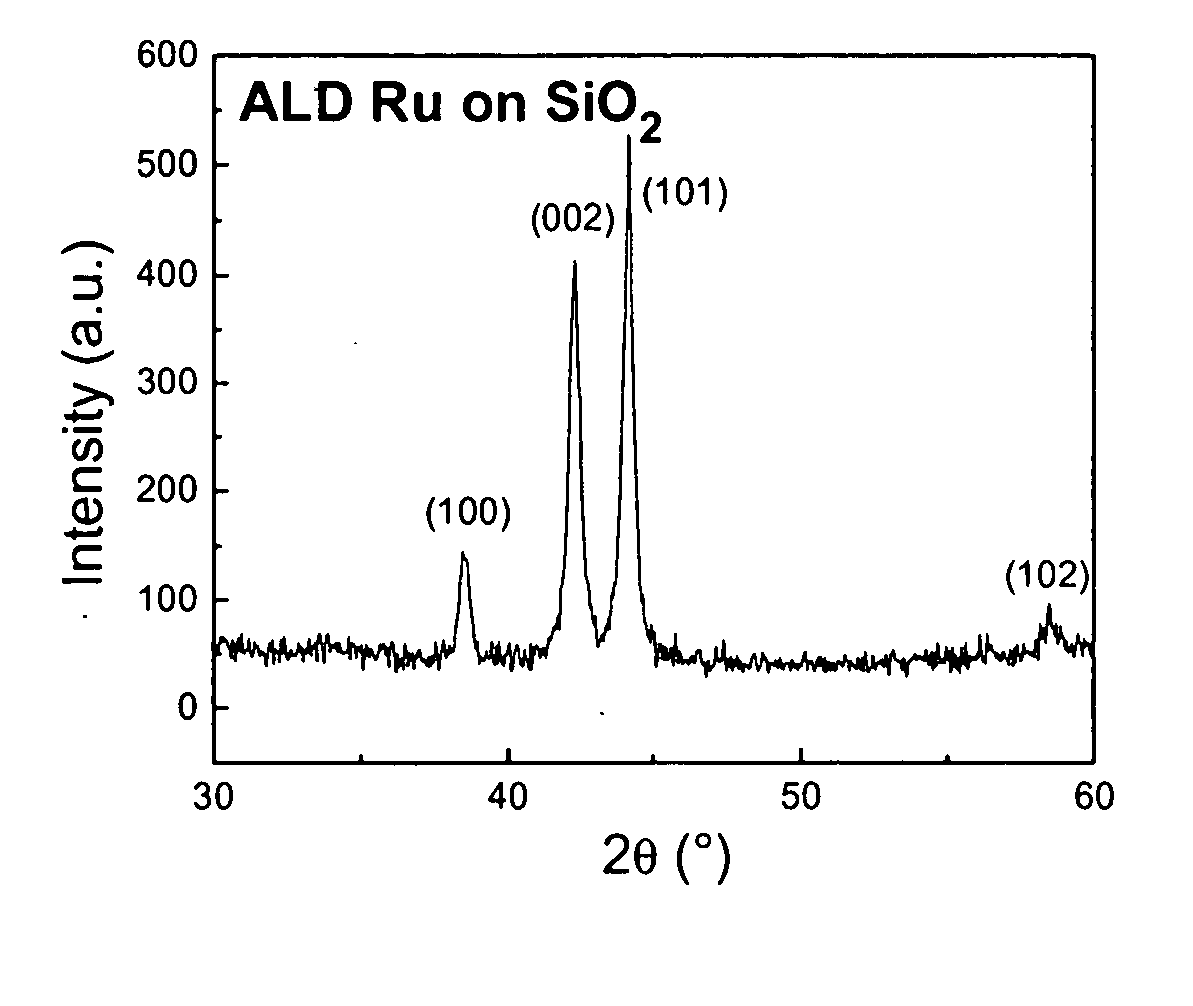

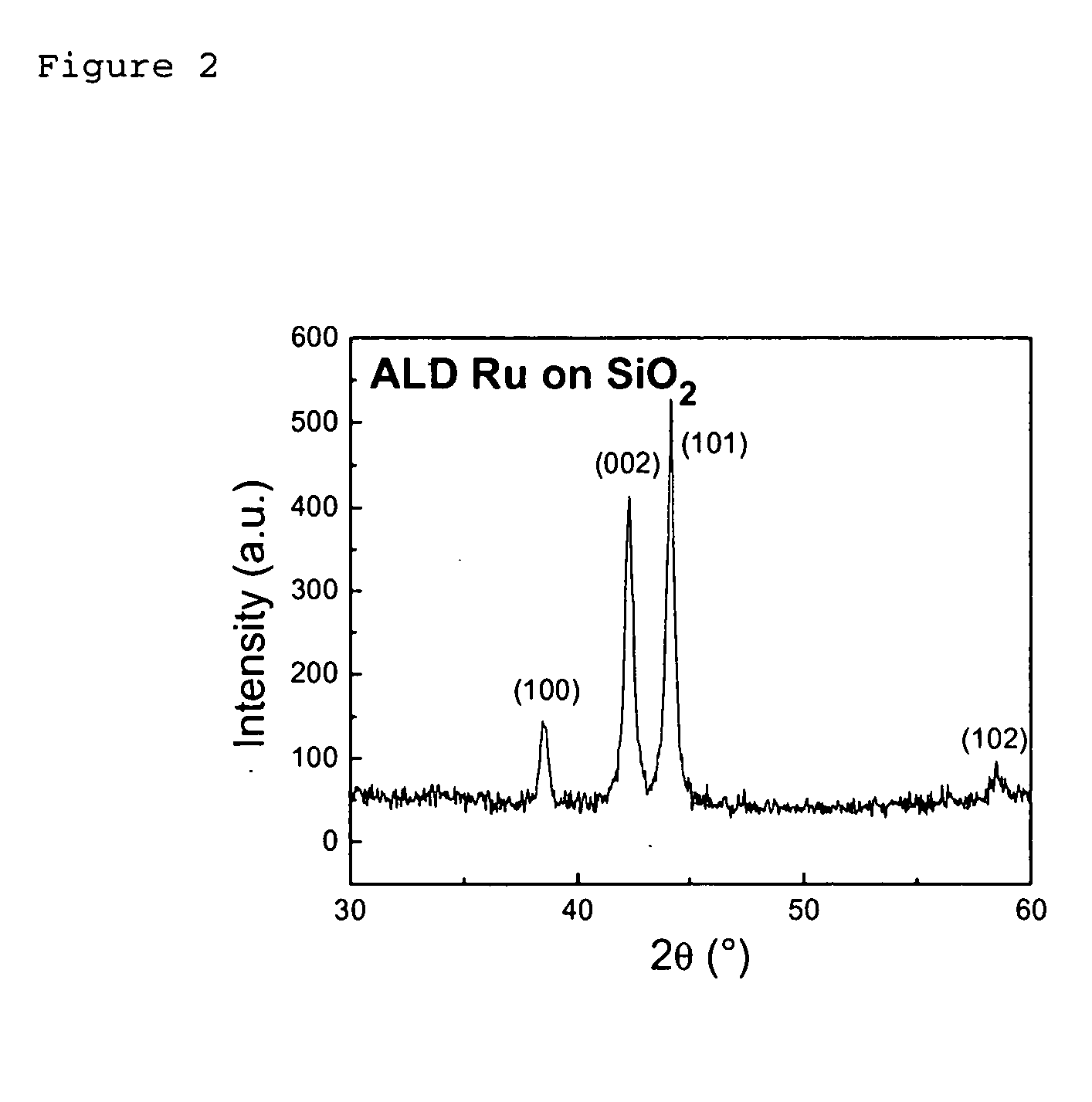

Ald deposition of ruthenium

InactiveUS20050118807A1None be problem freeLow impurity contentSemiconductor/solid-state device detailsSolid-state devicesCMOSCopper interconnect

A method to deposit nucleation problem free ruthenium by ALD. The nucleation problem free, relatively smooth ruthenium ALD film is deposited by the use of plasma-enhanced ALD of ruthenium underlay for consequent thermal ruthenium ALD layer. In addition, oxygen or nitrogen plasma treatments of SiO2 or other dielectrics leads to uniform ALD ruthenium deposition. The method has application as a direct plating layer for a copper interconnect or metal gate structure for advanced CMOS devices.

Owner:IBM CORP

Improved process for preparing porous microsphere active carbon

The improved process for preparing high strength porous microsphere active carbon includes the following steps: oxidizing thermosetting resin ball at 60-400 deg.c in oxygen containing atmosphere or pre-treating thermosetting resin ball at 60-300 deg.c in oxidizing acid, SO2 or SO3; carbonizing at 600-1200 deg.c in helium, nitrogen or their mixture atmosphere; and activating at 600-1200 deg.c in activating water vapor atmosphere to obtain high strength porous microsphere active carbon with grain size of 10 micron to 2 mm, BET specific surface area of 500-4000 sq m / g, and grain strength of 50-200 MPa. The process is simple, low in cost and high in yield, and the prepared microsphere active carbon has high strength and high purity and is one excellent medical active adsorption material.

Owner:EAST CHINA UNIV OF SCI & TECH

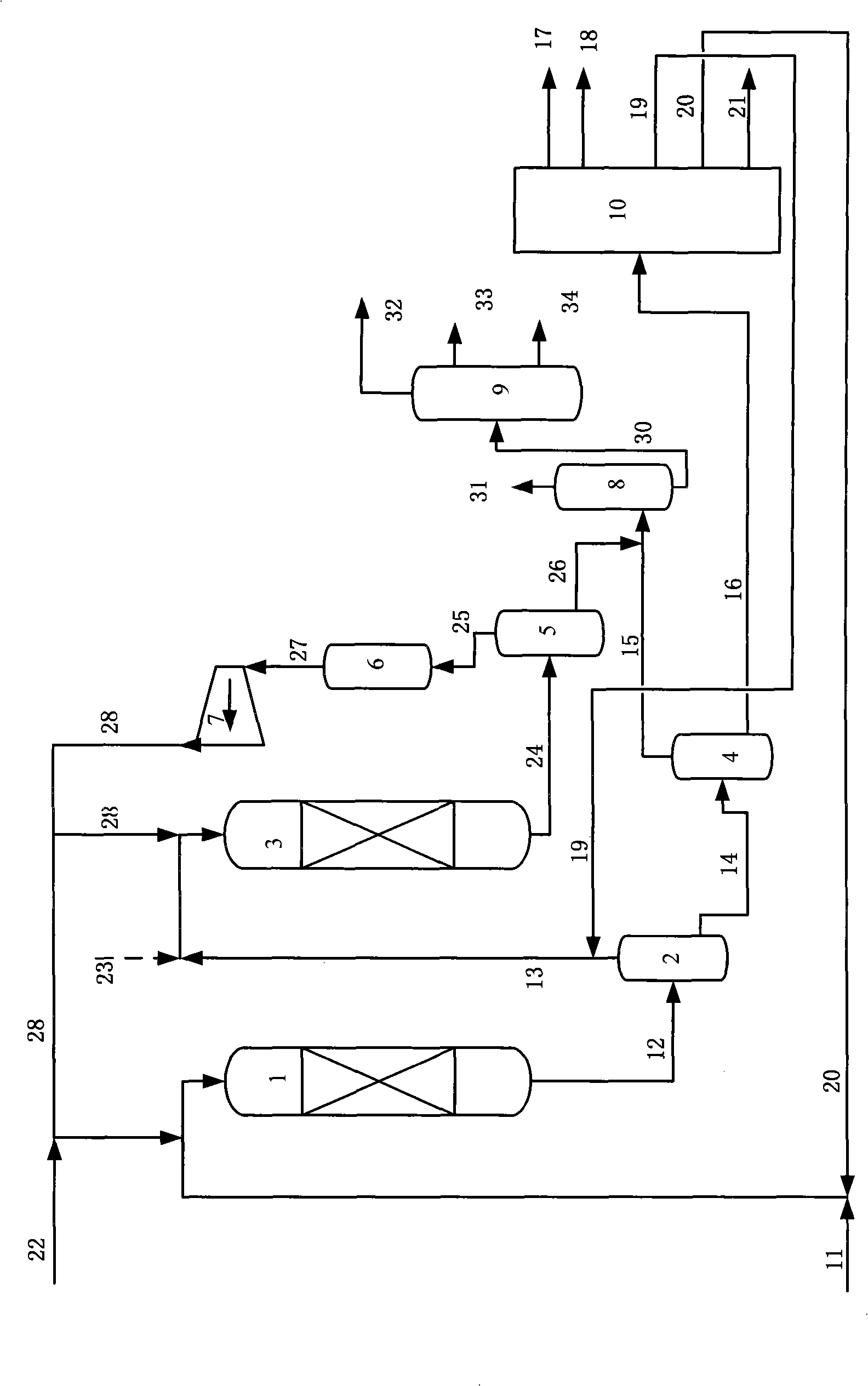

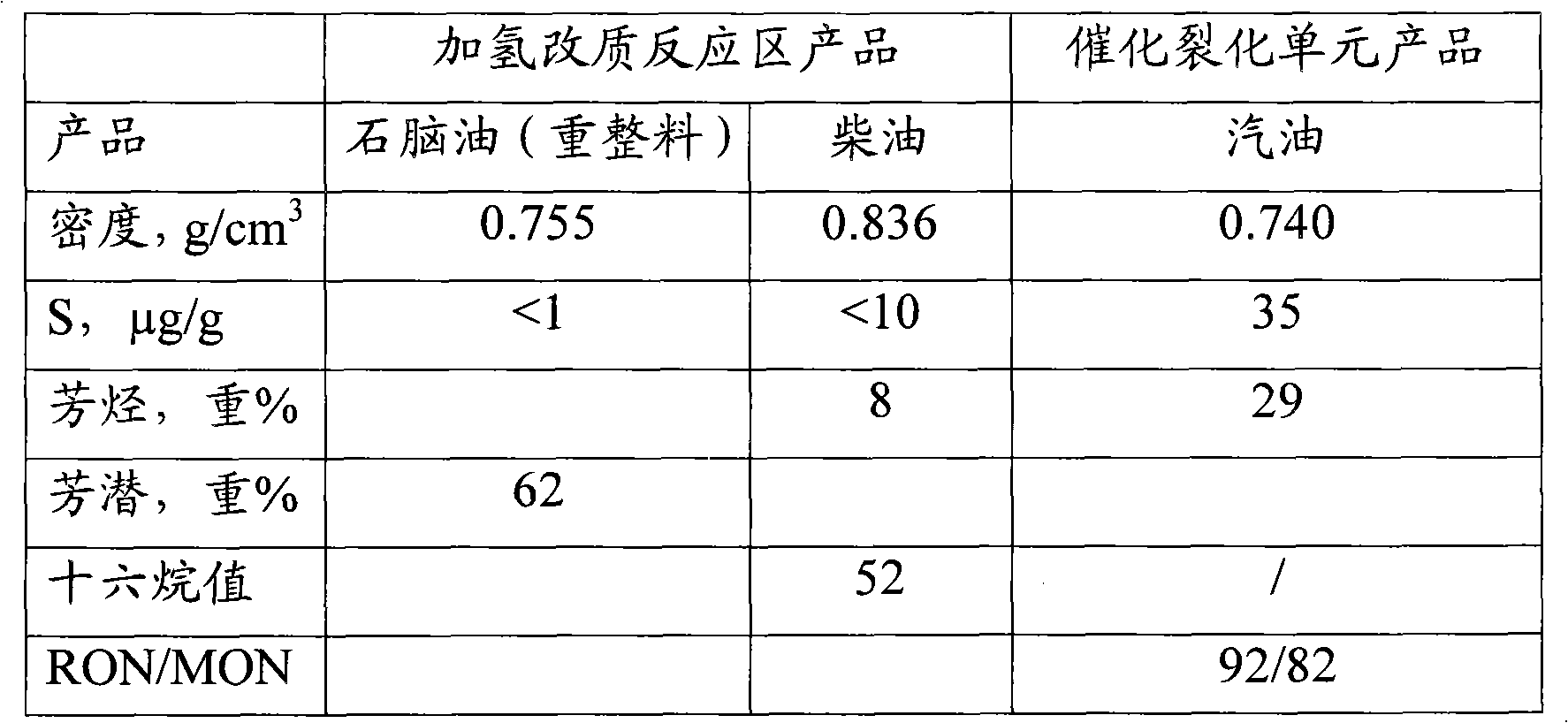

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

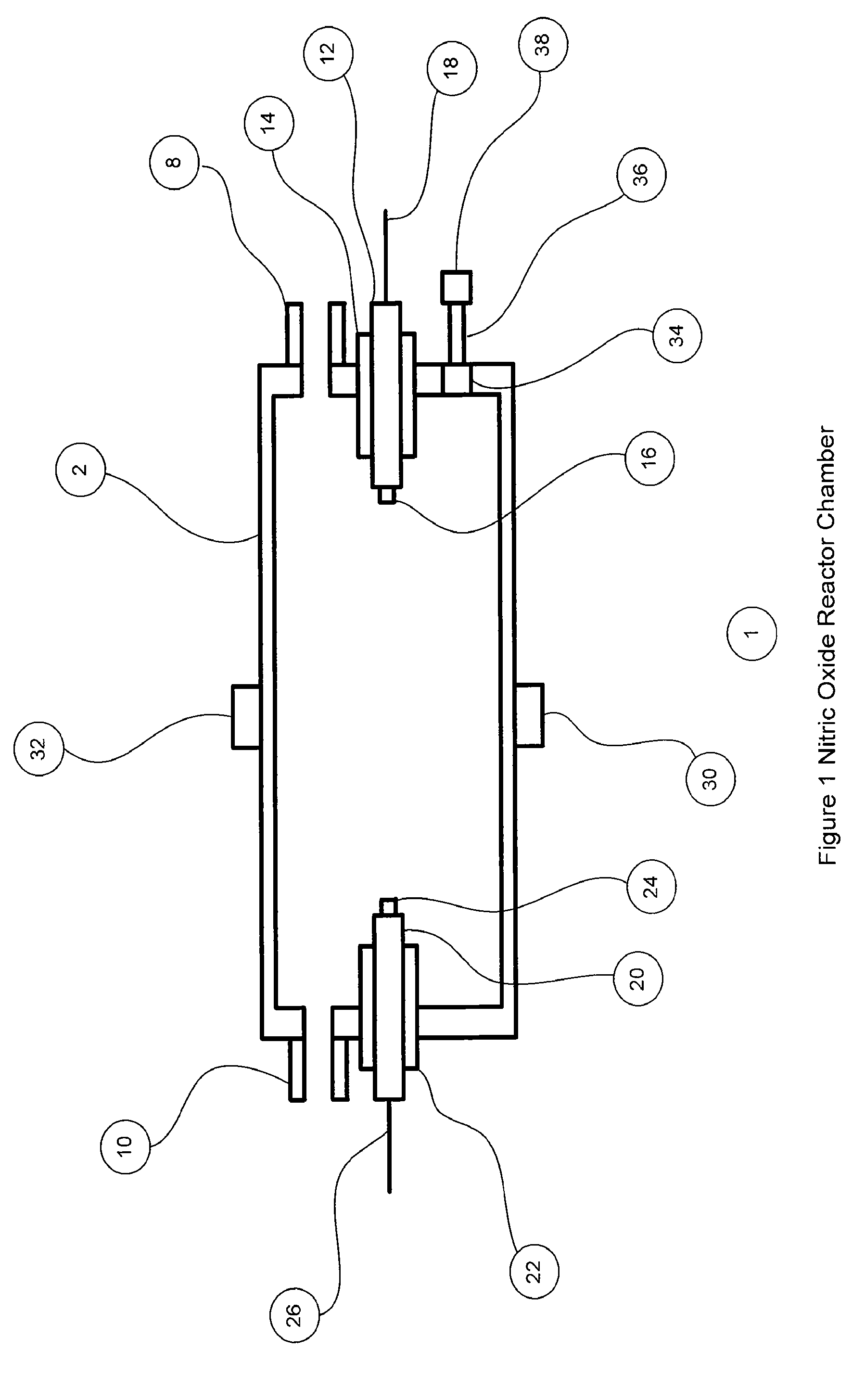

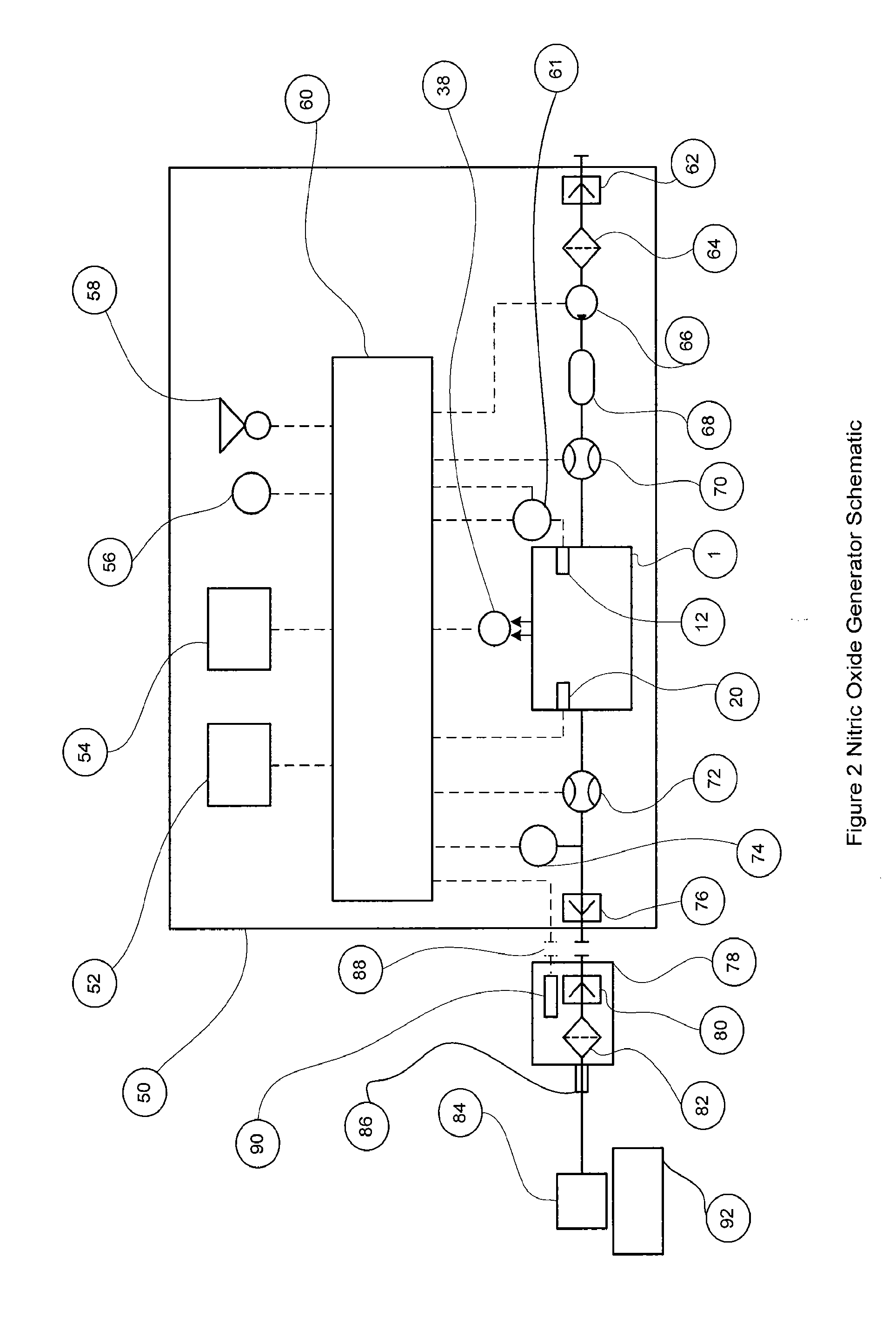

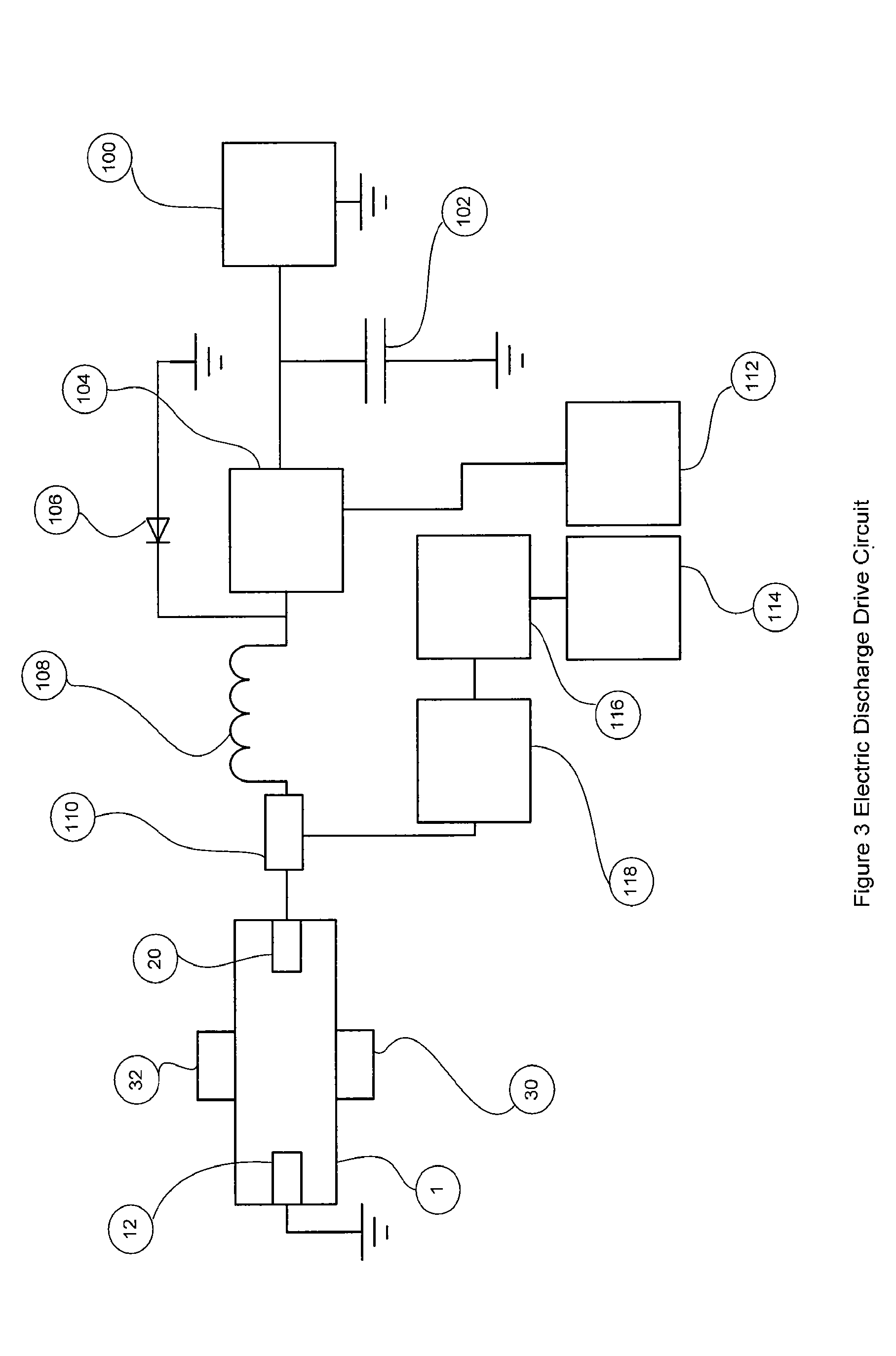

Apparatus and method for generating nitric oxide in controlled and accurate amounts

ActiveUS20140251787A1Remove adulterantAccurate representationCombination devicesAuxillary pretreatmentNitrogenNitric oxide

A nitric oxide generator generates nitric oxide from a mixture of nitrogen and oxygen such as air treated by a pulsating electrical discharge. The desired concentration of nitric oxide is obtained by controlling at least one of a frequency of the pulsating electrical discharge and duration of each electrical discharge pulse.

Owner:NITRICGEN

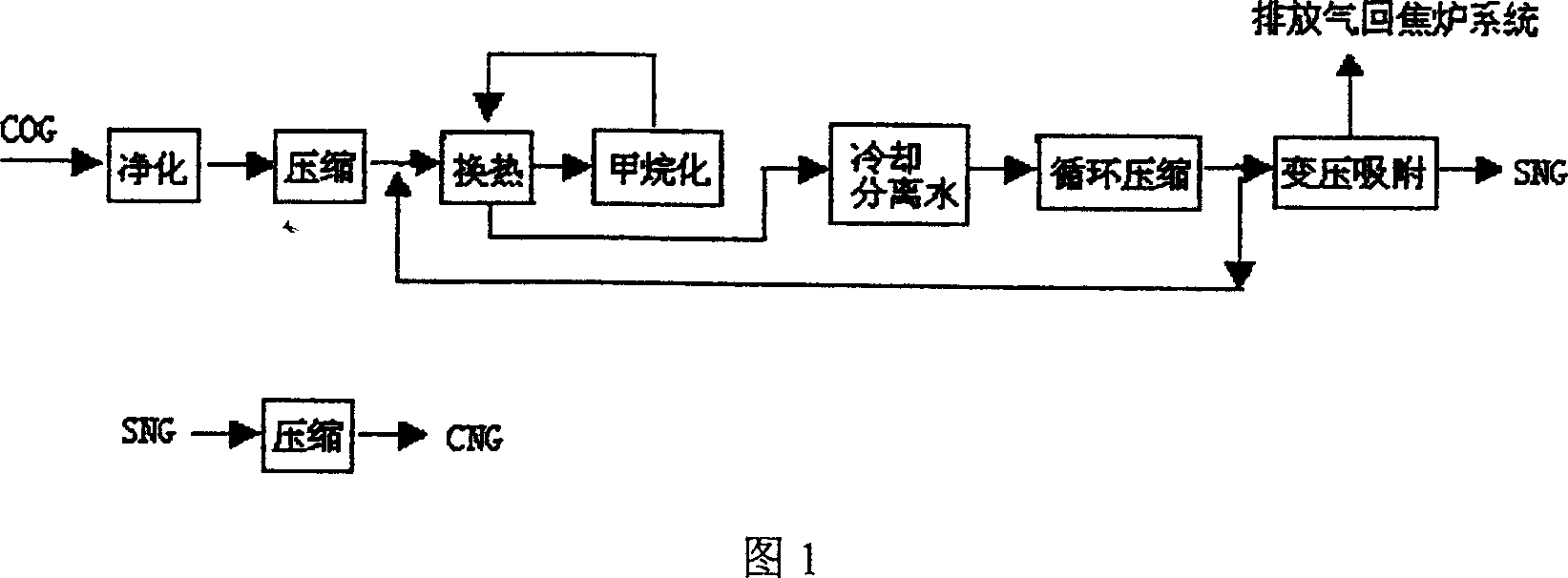

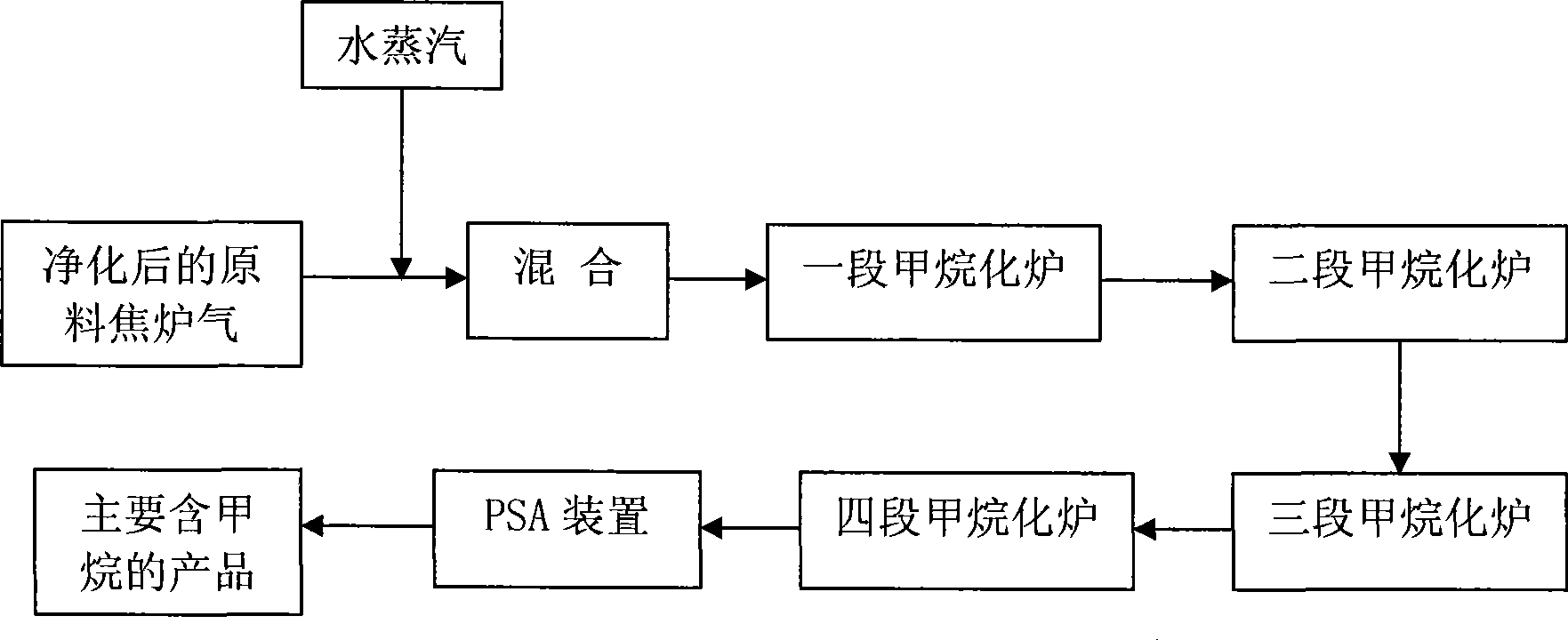

Method of preparing synthetic natural gas by coke oven gas

ActiveCN1919985AHigh calorific valueLow impurity contentGaseous fuelsCompressed natural gasMethanation

The invention discloses the method for producing natural gas with coking gas, comprising the following steps: purifying coking gas and removing benzene, naphthalene, hydrocarbon and sulphide, compressing, heat transferring, carrying out methanation reaction with catalyst, hydrogen in COG reacting with carbonic oxide and carbon dioxide to get methane; putting the mixture gas into pressure swing adsorbing device, and getting natural gas whose concentration is 90%. The natural gas has high caloric value, low impurity content.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

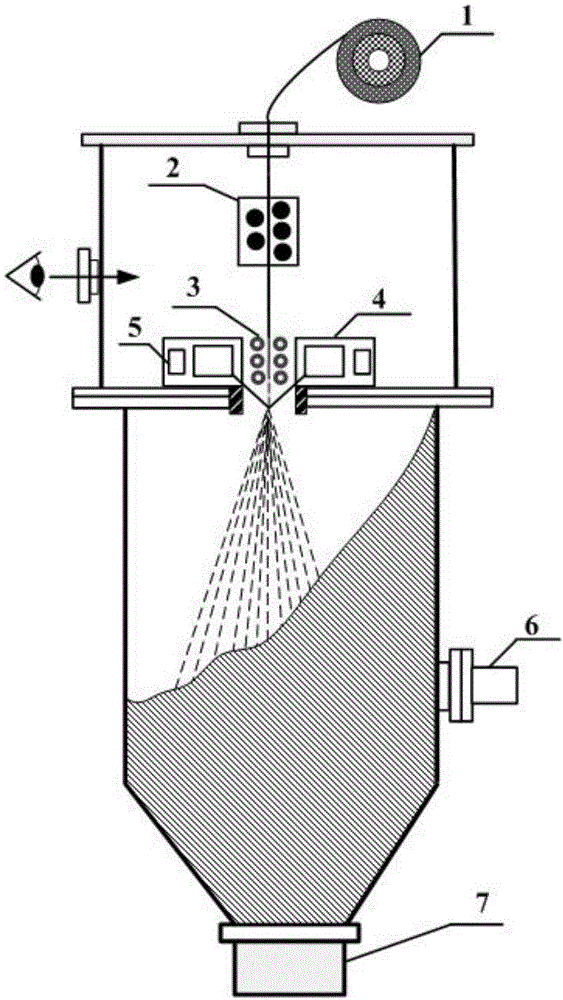

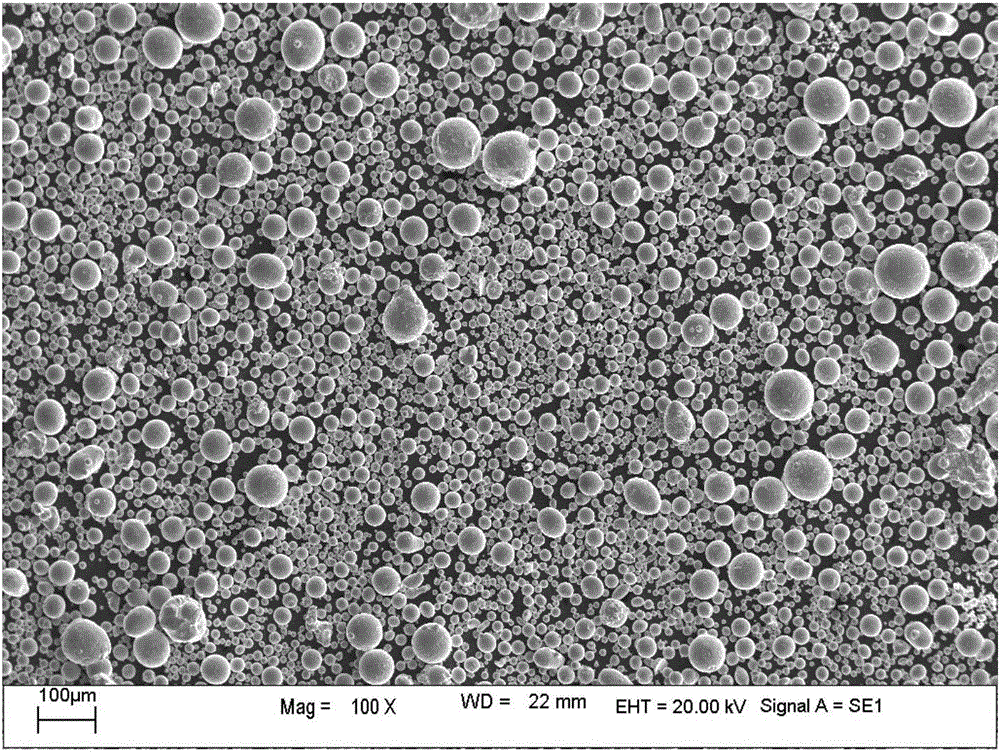

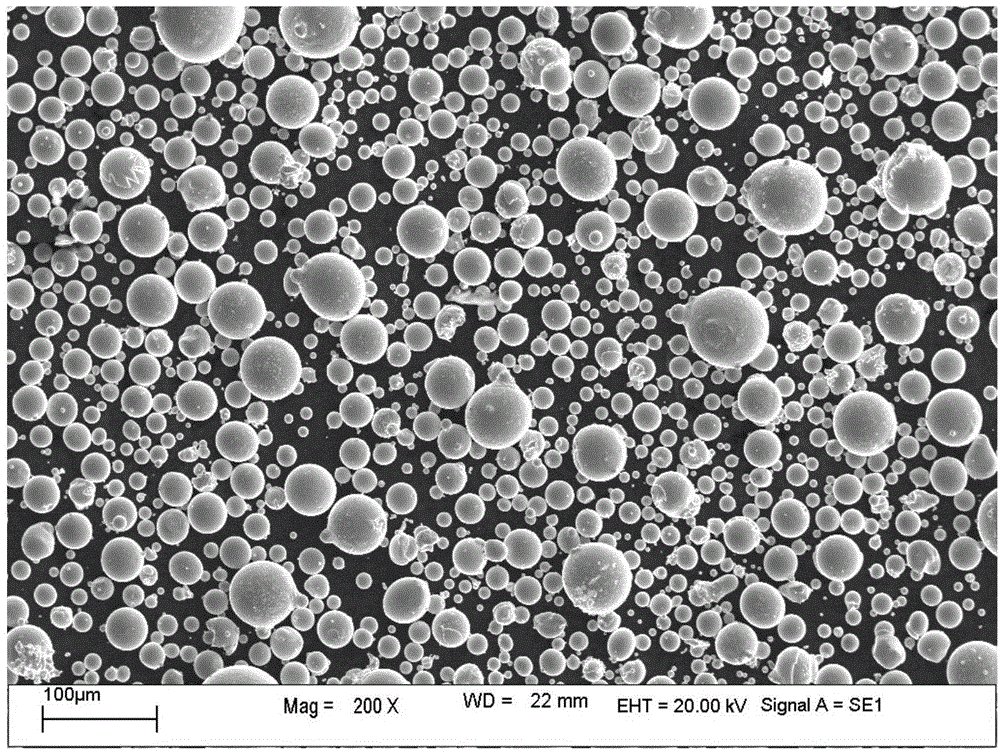

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

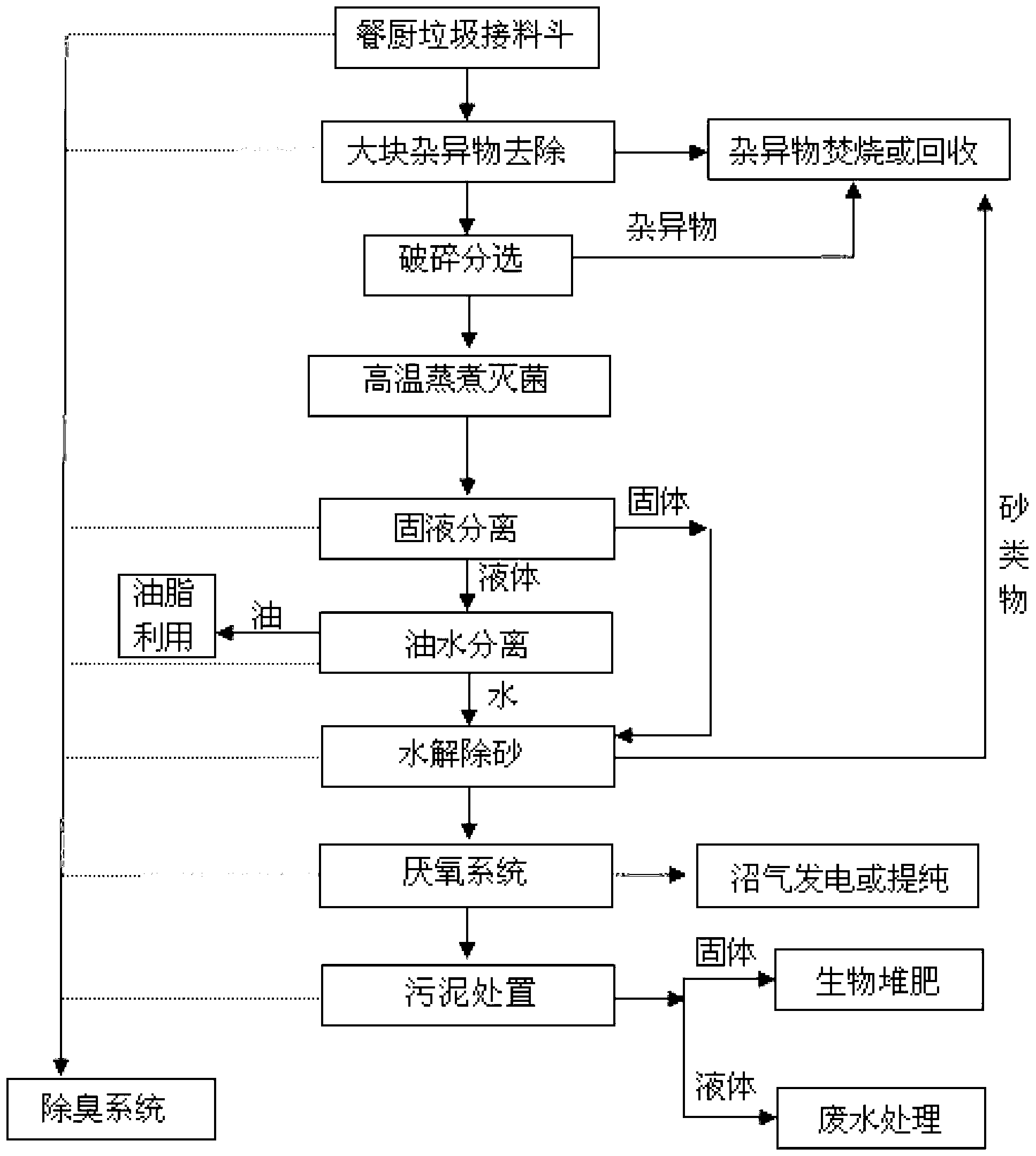

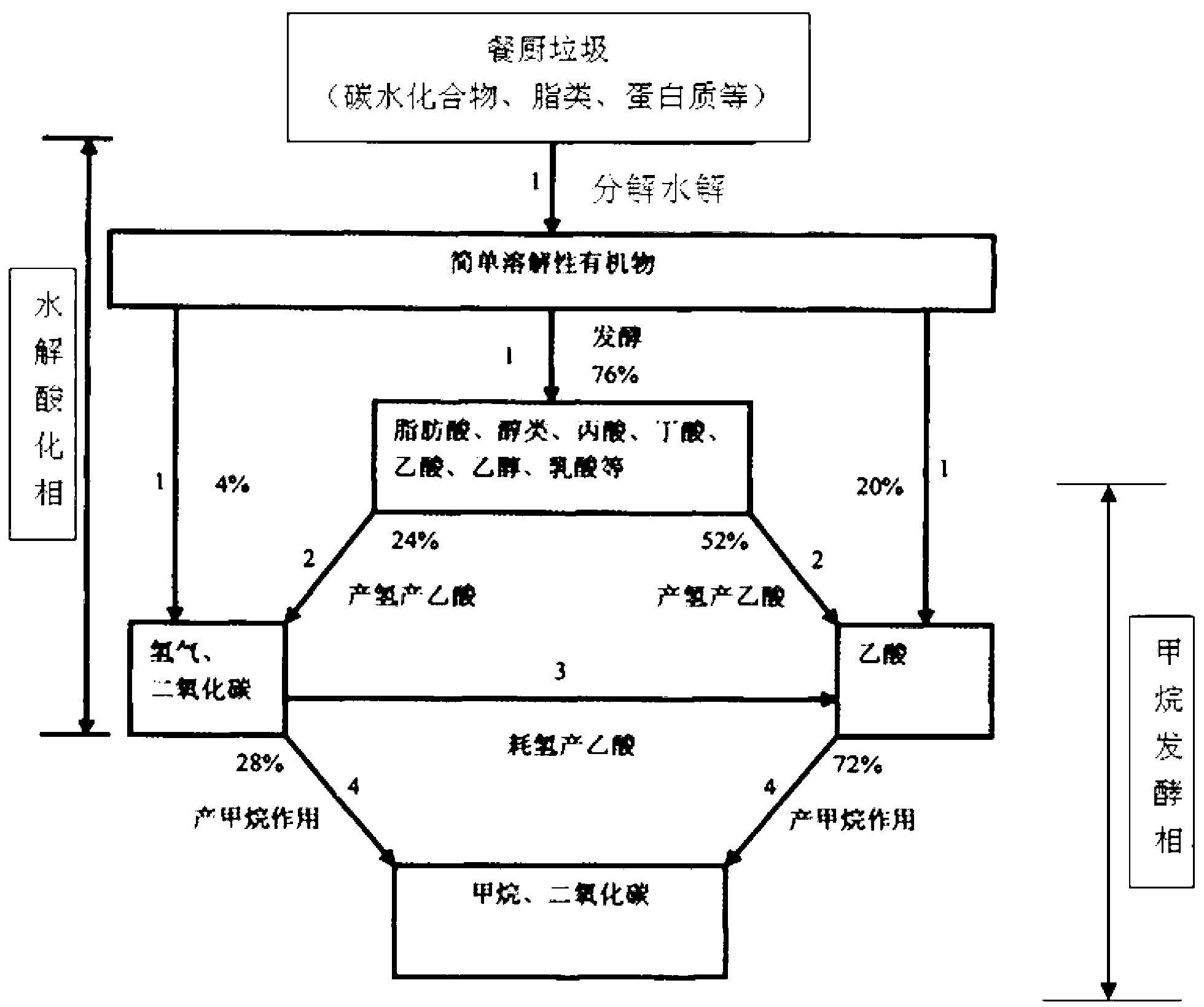

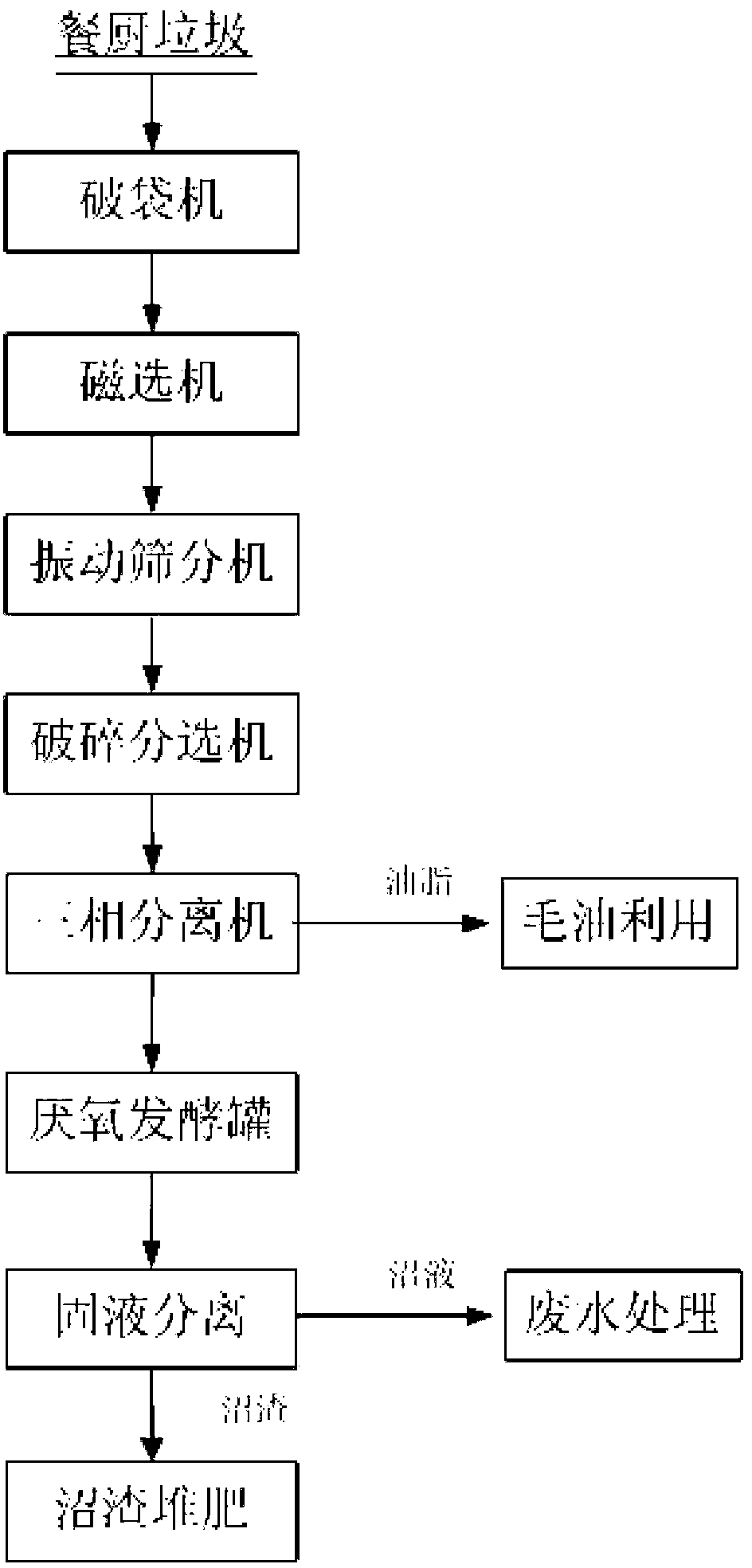

Efficient resourceful treatment method through separation and anaerobic fermentation for kitchen waste

InactiveCN103074381AHarmlessStable in natureFatty oils/acids recovery from wasteBio-organic fraction processingEconomic benefitsOil water

The invention discloses an efficient resourceful treatment method through separation and anaerobic fermentation for kitchen waste. The method includes the steps of firstly performing preliminary bag breaking and leachate collection on original kitchen waste, and removing chunks of miscellaneous and foreign materials; then performing breaking separation, high temperature sterilization, solid-liquid separation and the like; and then performing oil-water separation, hydrolytic sand removal, hydrolytic acidification, anaerobic fermentation and the like. The method has the advantages that not only harmless kitchen waste is achieved, but also extracted crude oil and produced biogas have high economic benefit simultaneously, and the impurity removal rate of the kitchen waste can reach above 90%.

Owner:SOUND ENVIRONMENTAL RESOURCES

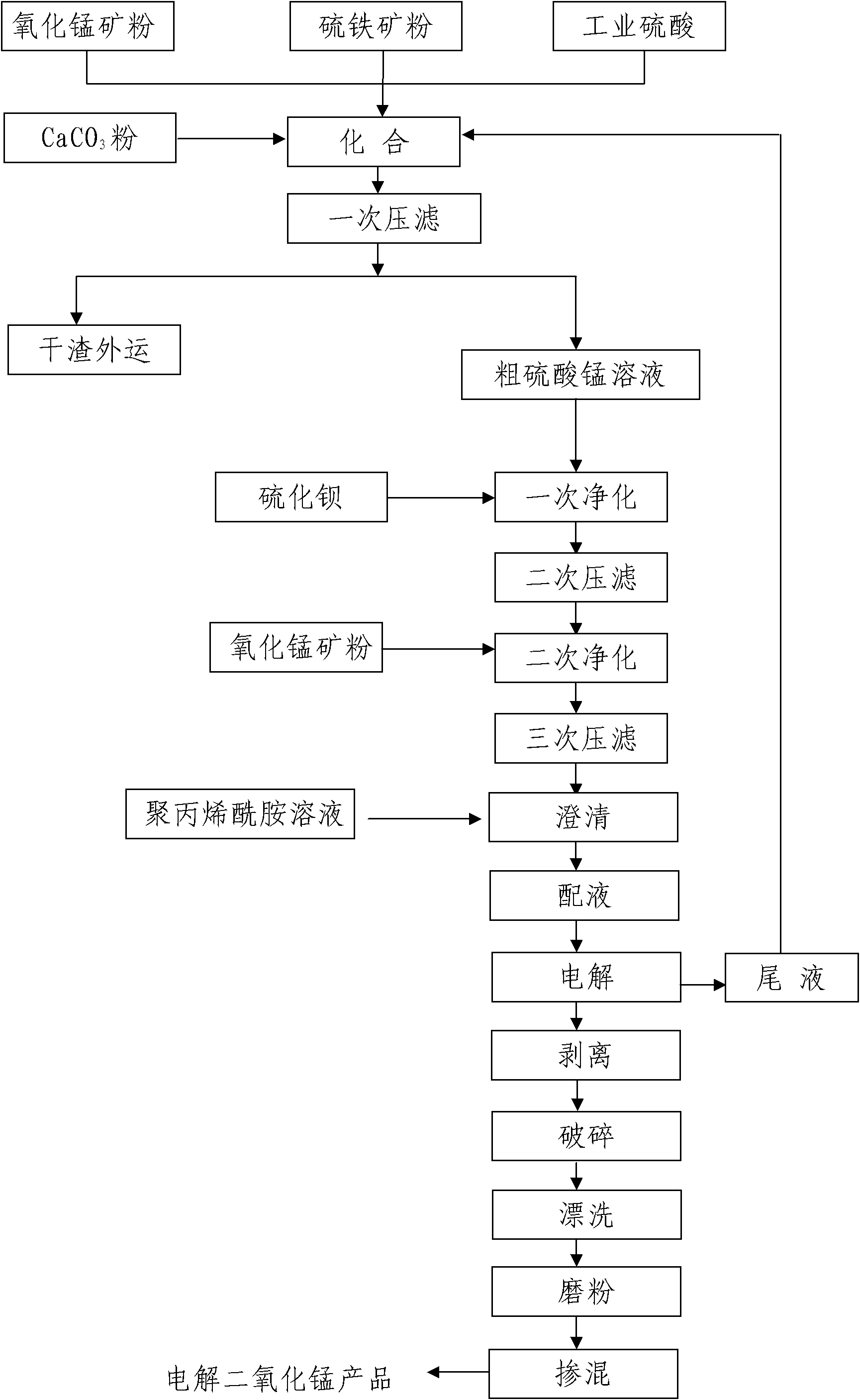

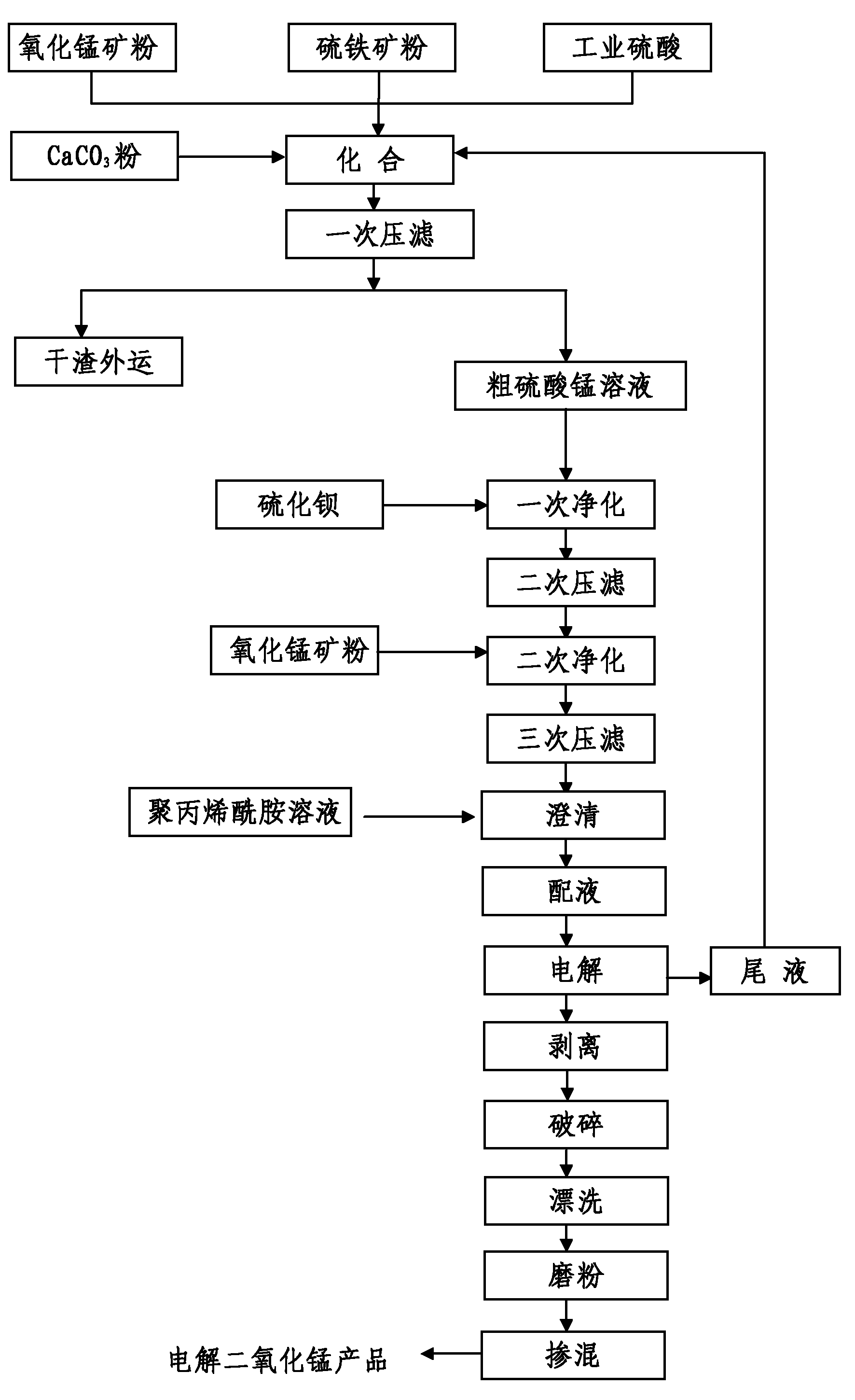

Production method for electrolytic manganese dioxide

ActiveCN102220490AWide adaptabilityShort processElectrolysis componentsCleaning using liquidsSlurryManganese oxide

The invention relates to a production method for electrolytic manganese dioxide. The method comprises the following steps of: A. preparing a mixed liquid of crude manganese sulfate and slurry; B. neutralizing the mixed liquid to remove iron; C. carrying out three-time deep purification on the crude manganese sulfate solution including first purification to remove heavy metals, second purification to remove trace element molybdenum and third purification to remove calcium sulfate and magnesium sulfate; D. electrolyzing; E. rinsing including six steps of washing acid with hot water, rinsing with a weak base, rinsing with a strong base, washing base with hot water, backwashing with a diluted acid and rinsing with hot water; F. milling; and G. mixing to obtain an electrolytic manganese dioxide product. According to the invention, low-grade manganese oxide ore is used as a main raw material to prepare a manganese sulfate solution, the manganese sulfate solution is subjected to deep purification treatment to obtain a high-purity electrolyte, high-performance electrolytic manganese dioxide special for mercury-free alkaline cells and automobile power cells can be respectively produced under different electrolysis conditions, and the obtained electrolytic manganese dioxide product has low impurity content and high quality.

Owner:GUANGXI GUILIU CHEM CO LTD +1

Periodic plasma annealing in an ald-type process

ActiveUS20080274617A1Low resistivityIncrease wafer throughputPolycrystalline material growthSemiconductor/solid-state device manufacturingAmount of substanceVapor phase

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

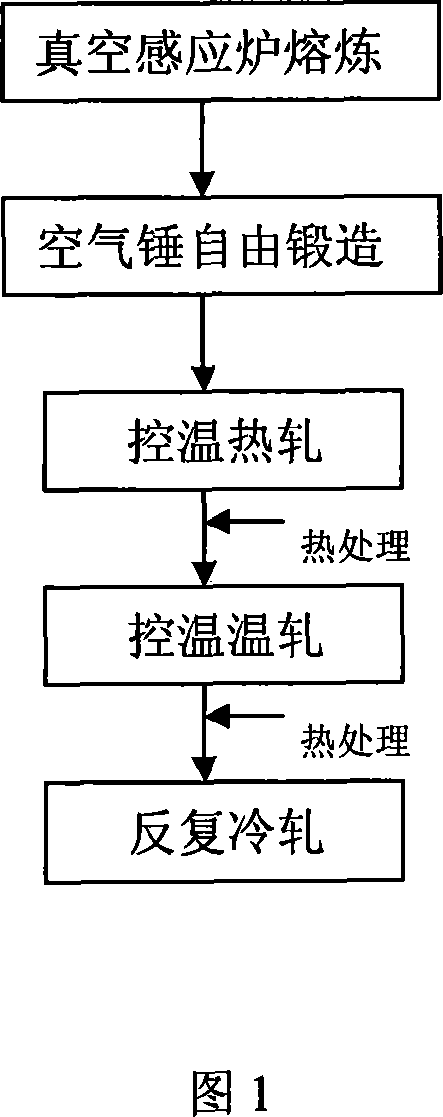

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

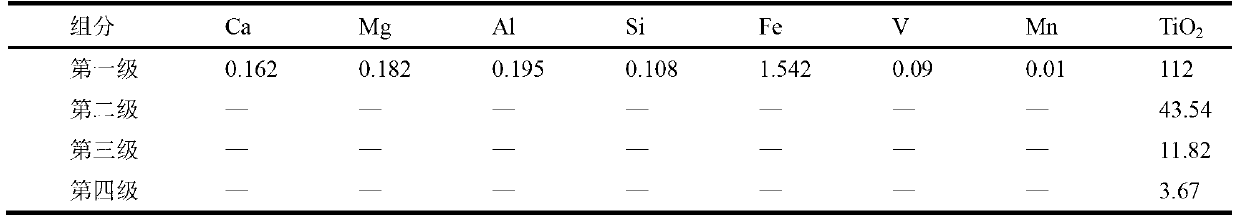

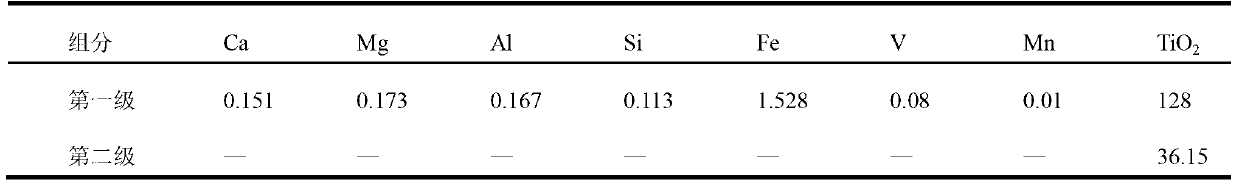

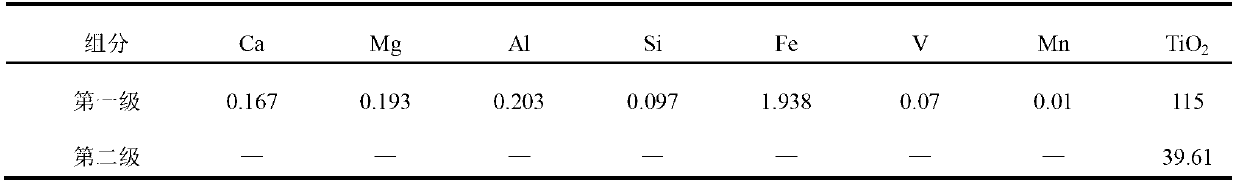

Method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates

ActiveCN103276207ASolve unexploitable puzzlesImprove resource utilizationProcess efficiency improvementSlagResource utilization

The invention belongs to the wet-process metallurgical filed and in particular relates to a method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates. The method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates comprises the following steps of: (1), mixing the vanadium-titanium magnetite concentrate with hydrochloric acid, and leaching to obtain an intermediate sizing agent; (2), filtering the intermediate sizing agent to obtain leaching liquor and leaching residues; (3), carrying out water-washing on the leaching slag to obtain washing water and washing slag; (4), carrying out fused-salt reaction on the washing slag to obtain fused-salt reaction materials; (5), carrying out water-washing and filtering on the fused-salt reaction materials to obtain water-washing materials; (6), carrying out acid pickling on the water-washing materials to obtain sizing agent, and filtering to obtain the acid-pickled sizing agent; (7), carrying out acid dissolving on the acid-pickled materials by using a sulfuric acid solution to obtain acid-dissolved materials; and (8), adding the acid-dissolved materials to the sulfuric acid solution for extracting, and filtering to obtain extracting solution which is the titanium solution. According to the method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates disclosed by the invention, the titanium in the iron concentrate is sufficiently utilized, so that the titanium resource utilization rate is high and the recovery rate of the titanium in the titanium concrete is higher than 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

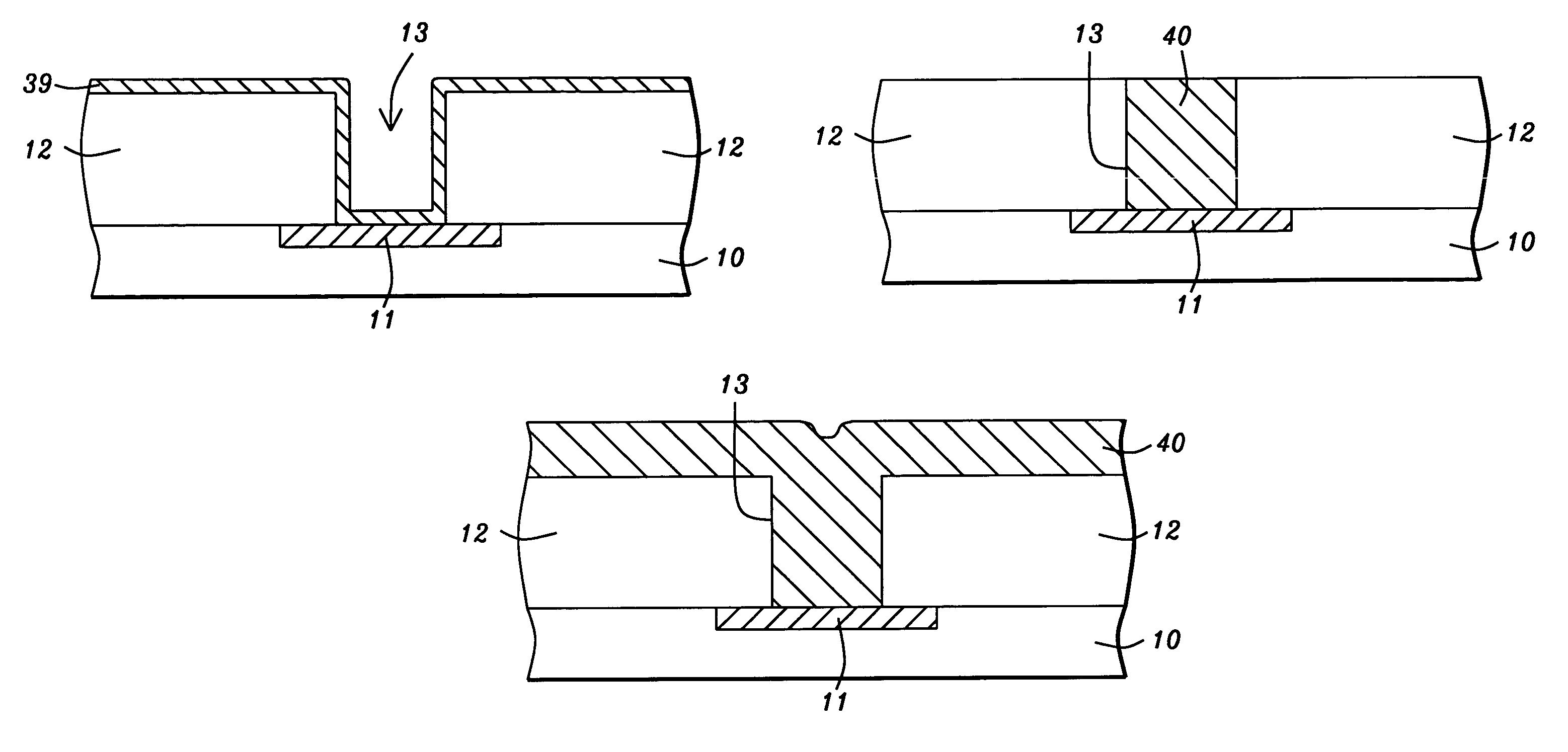

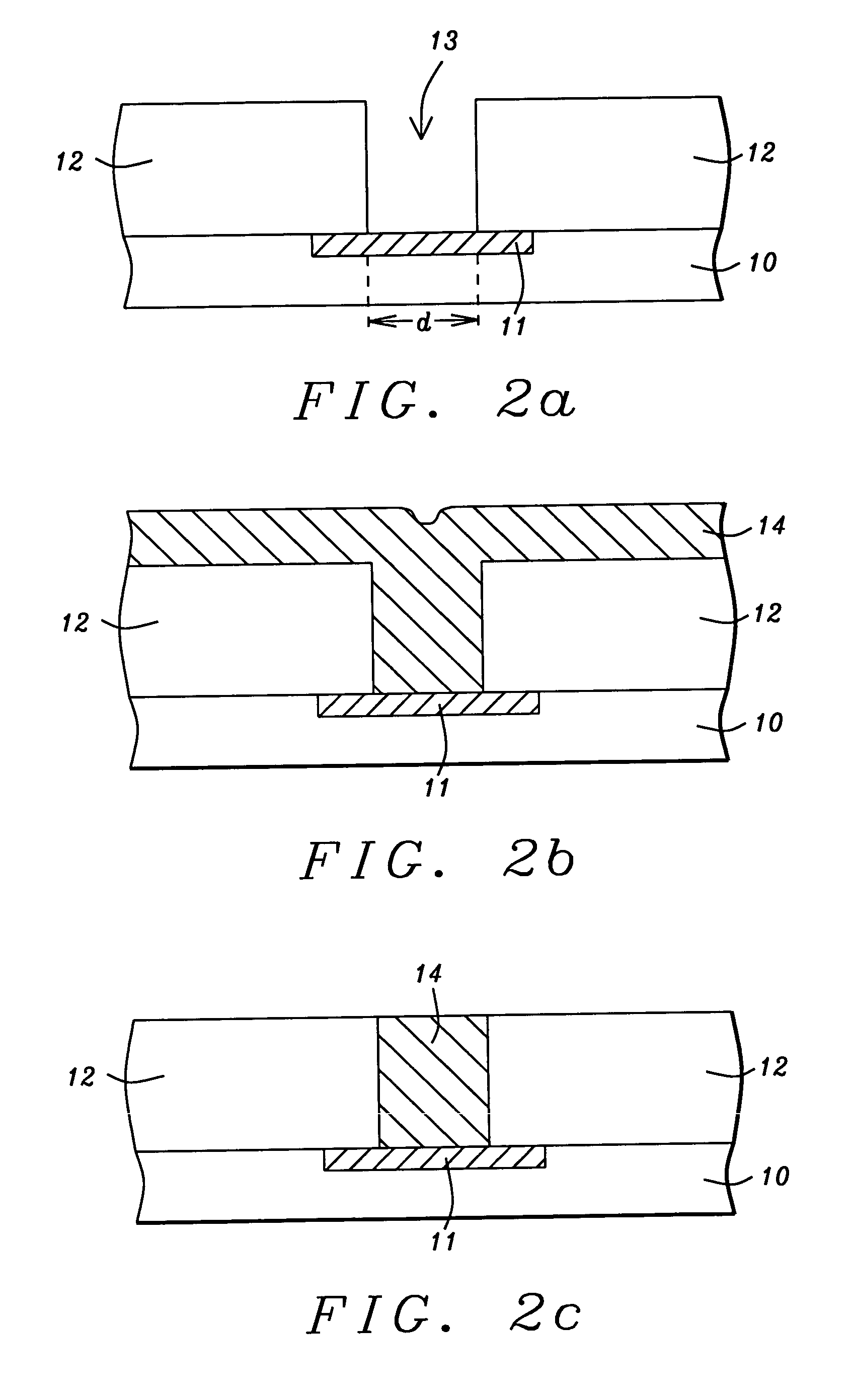

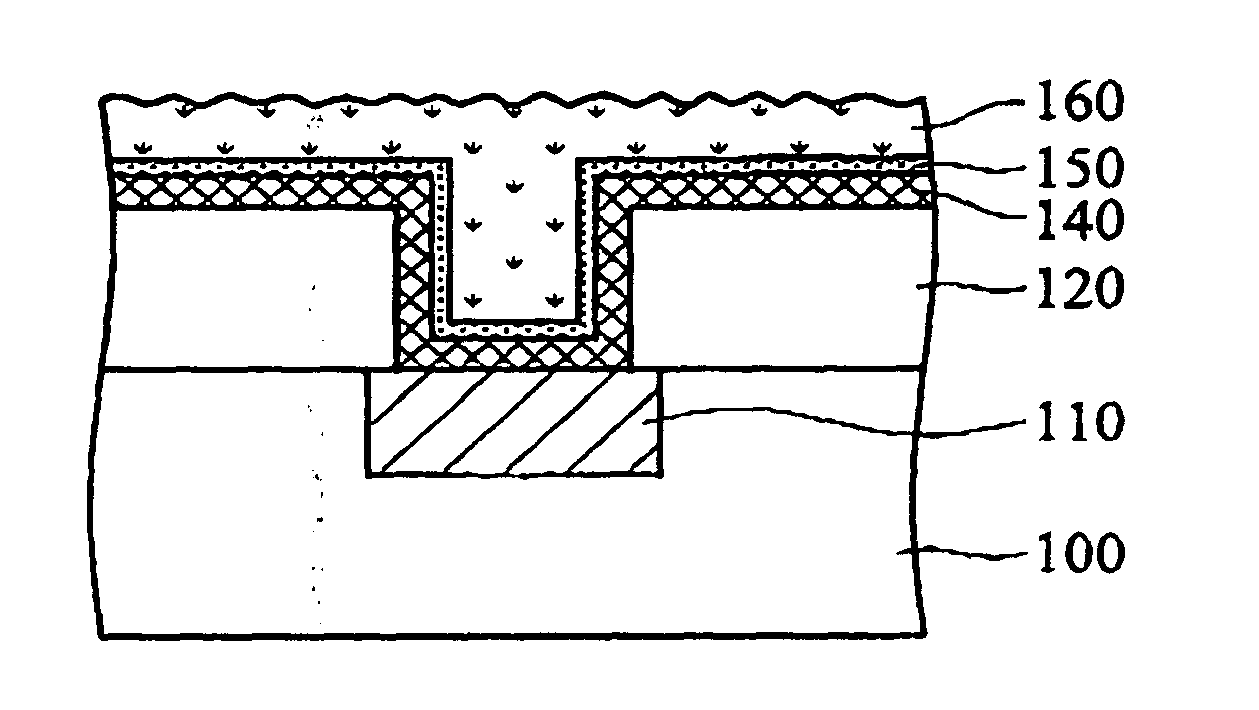

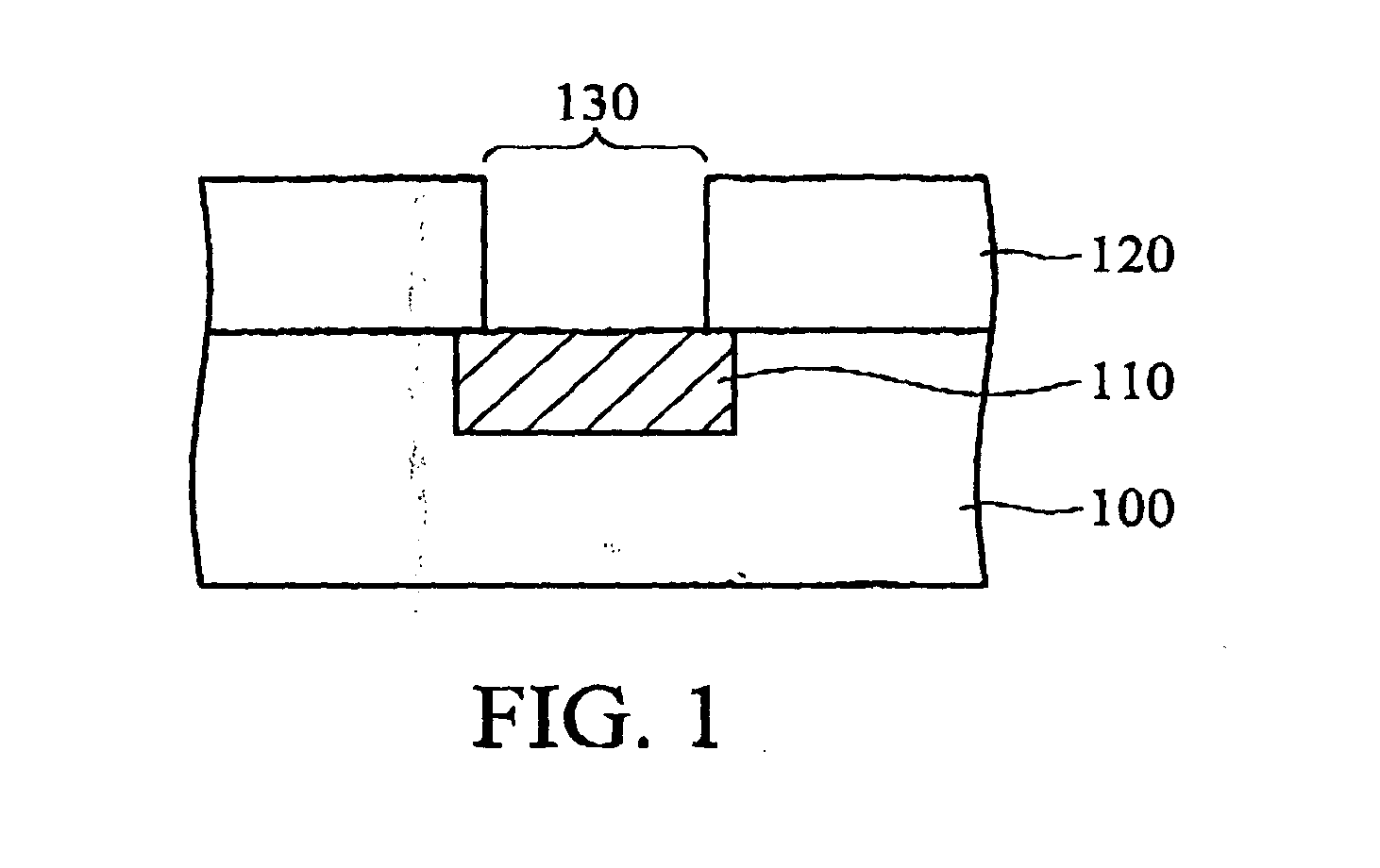

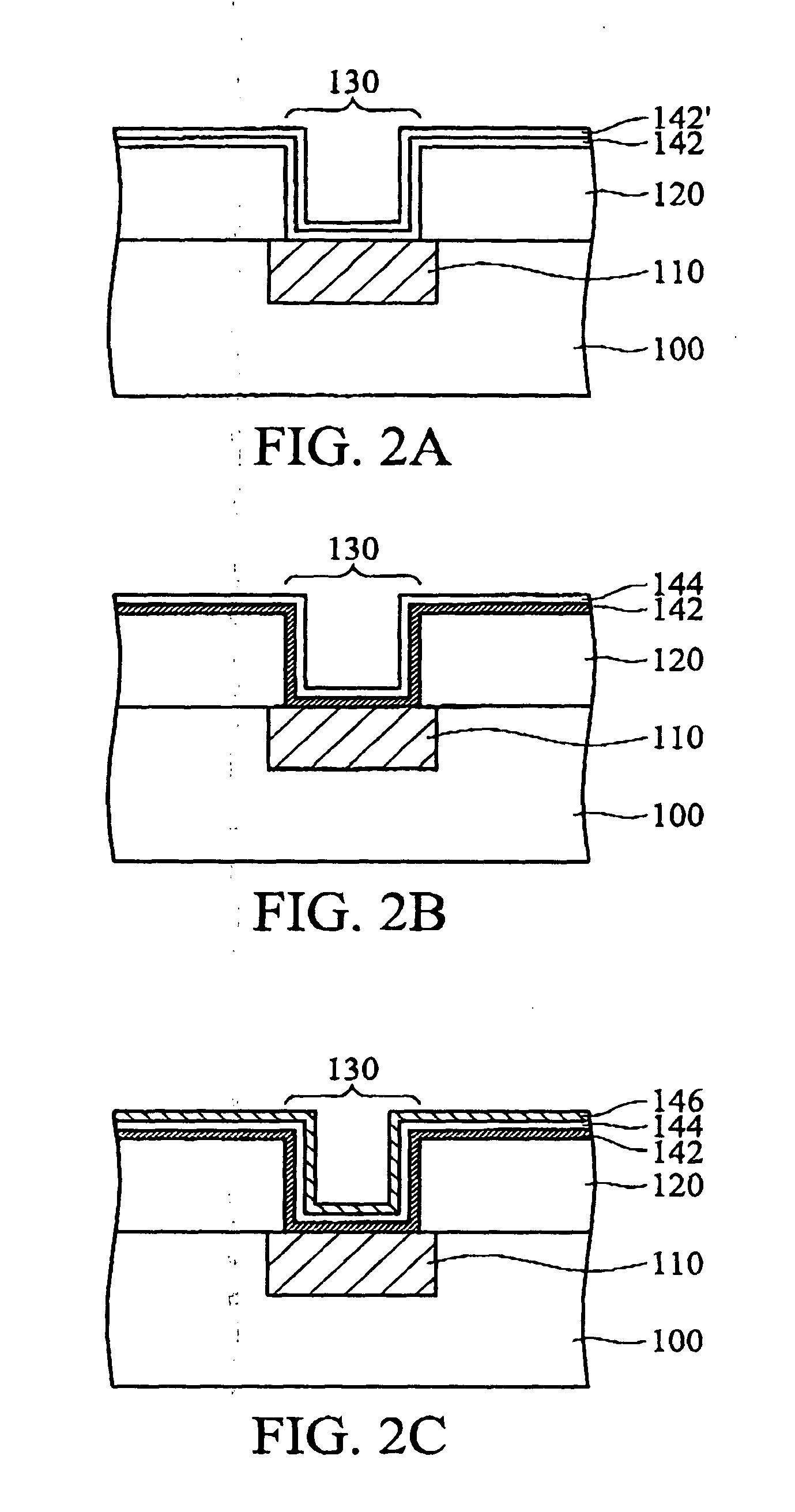

Interconnect with composite barrier layers and method for fabricating the same

ActiveUS20050054191A1Improve adhesionGood step coverageSemiconductor/solid-state device manufacturingDielectricTantalum nitride

Composite ALD-formed diffusion barrier layers. In a preferred embodiment, a composite conductive layer is composed of a diffusion barrier layer and / or a low-resistivity metal layer formed by atomic layer deposition (ALD) lining a damascene opening in dielectrics, serving as diffusion blocking and / or adhesion improvement. The preferred composite diffusion barrier layers are dual titanium nitride layers or dual tantalum nitride layers, triply laminar of tantalum, tantalum nitride and tantalum-rich nitride, or tantalum, tantalum nitride and tantalum, formed sequentially on the opening by way of ALD.

Owner:TAIWAN SEMICON MFG CO LTD

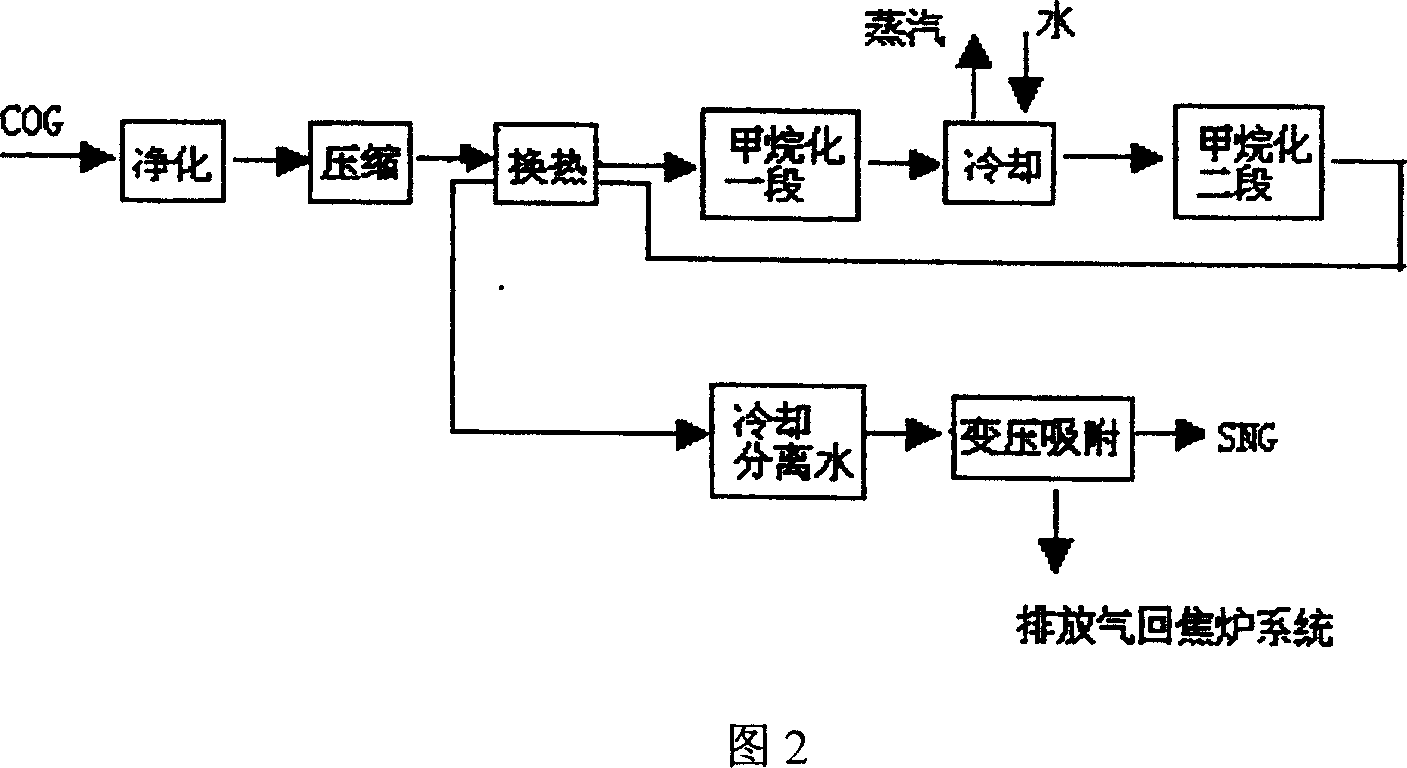

Method for synthesizing methane by using coke-oven gas

ActiveCN101391935AHigh methane contentHigh calorific valueHydrocarbon from carbon oxidesChemical industryWater vaporMethanation

The invention discloses a method for synthesizing methane by utilizing oven gas. Product gas with methane concentration of more than 90 percent is obtained through the main steps of purifying to remove impurities, compressing to exchange heat, adding water vapor, first stage of methanation reaction, second stage of methanation reaction, third stage of methanation reaction, PSA methane separation and the like. By adopting the method and utilizing the oven gas as raw materials, synthetic natural gas with high content of methane, low content of impurities and high heating value can be obtained, which is favorable to protecting the environment, saving energy and developing new energy; in addition, in the method, the addition of appropriate water vapor in the raw materials of oven gas before the fist sage of reaction properly inhibits the depth of the methanation reaction, reduces the heat amount released in the whole reaction process, conduces the cooling of the gas after the reaction and prevents the occurrence of carbon deposition reaction to devitalize the activity of a catalyst, thus being beneficial to the continuous normal operation of the whole synthesizing process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

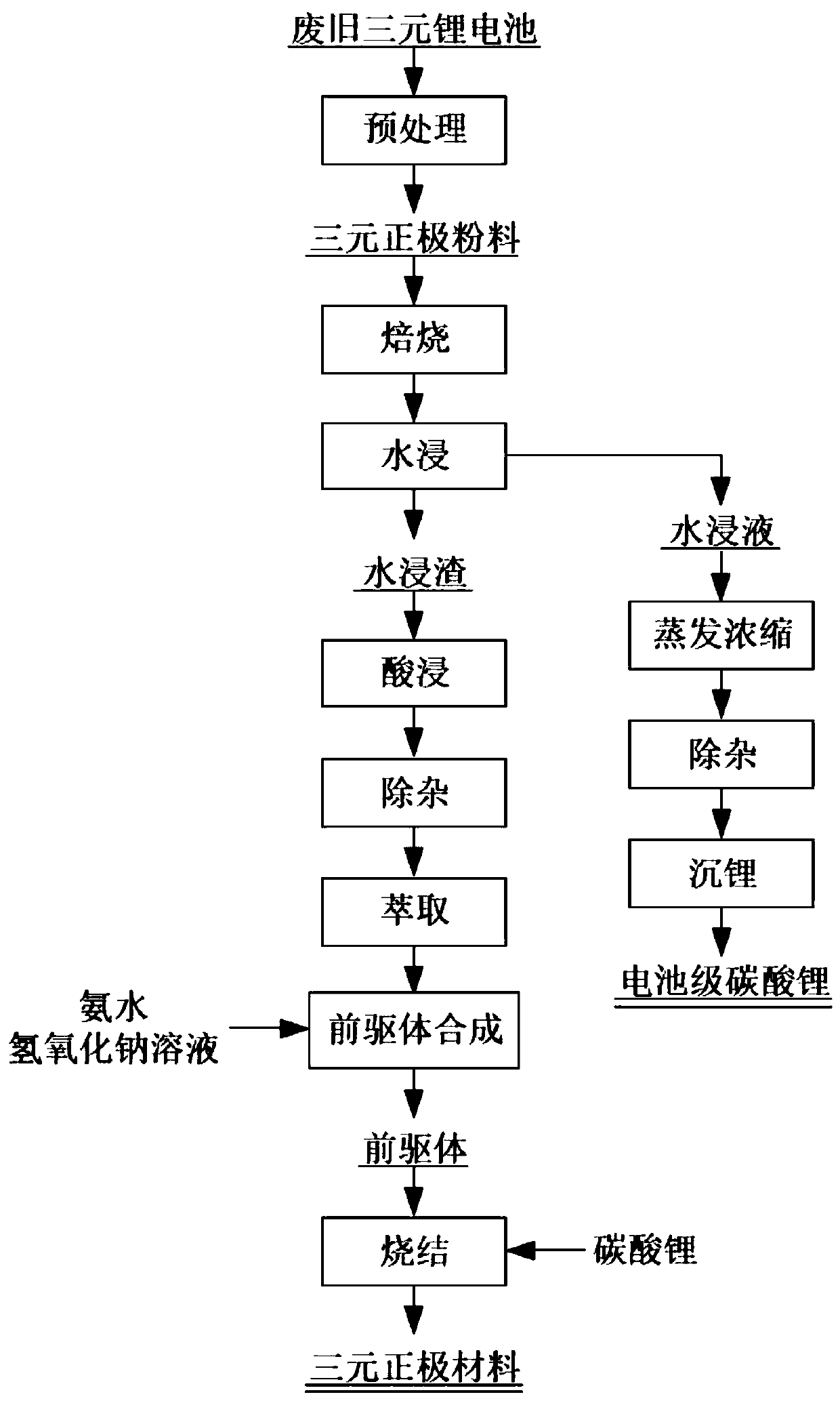

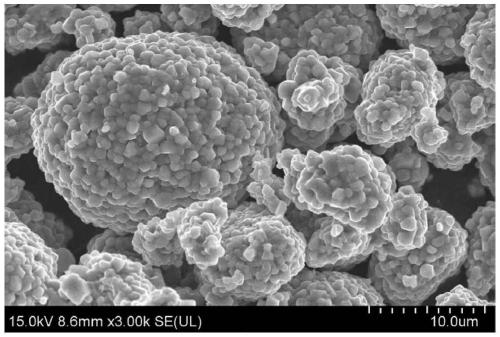

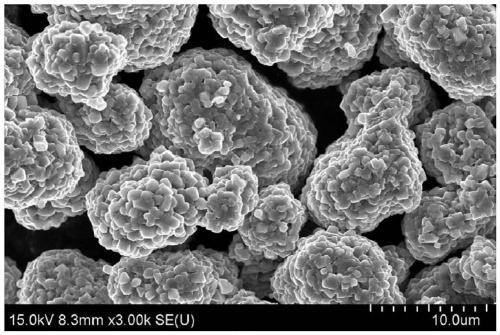

Method for preparing ternary positive electrode material through recovering waste ternary lithium battery

ActiveCN111206148AHigh recovery rateReduce recycling costsCell electrodesWaste accumulators reclaimingManganese sulphatePregnant leach solution

The invention provides a method for preparing a ternary positive electrode material through recovering a waste ternary lithium battery. The method comprises the following steps of 1) mixing pretreatednickel cobalt lithium manganate waste positive electrode powder with sulfate, and roasting to obtain a roasted product; 2) immersing the roasted product in water to obtain water immersion liquid andwater immersion slag; wherein the water immersion liquid contains lithium salt; 3) reacting the water immersion slag with an acid solution and hydrogen peroxide to obtain a nickel-cobalt-manganese leaching solution; 4) removing impurities from the nickel-cobalt-manganese leaching solution, then extracting cobalt, manganese and nickel, and saponifying and reversely extracting obtained organic phaseto obtain a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution; and 5) co-precipitating the nickel sulfate solution, the cobalt sulfate solution and the manganese sulfate solution with a sodium hydroxide solution and ammonia water, mixing obtained precursor with lithium carbonate, sintering, and screening iron to obtain the ternary positive electrode material. According to the method, lithium is extracted firstly, so that the influence of a lithium element on subsequent nickel-cobalt-manganese extraction is reduced, the impurity content in the ternary positiveelectrode material is reduced, and the recovery rate of nickel-cobalt-manganese is greatly improved; and meanwhile the recovery rate of the lithium can be improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Synthesis of sulfurized oligonucleotides

Methods for the formation of sulfurized oligonucleotides are provided. The methods allow for the formation of phosphorothioate linkages in the oligonucleotides or derivatives, without the need for complex solvent mixtures and repeated washing or solvent changes. Oligonucleotides having from about 8, and up to about 50, nucleotides can be sulfurized according to the methods of the invention with higher yields than have been previously reported.

Owner:IONIS PHARMA INC

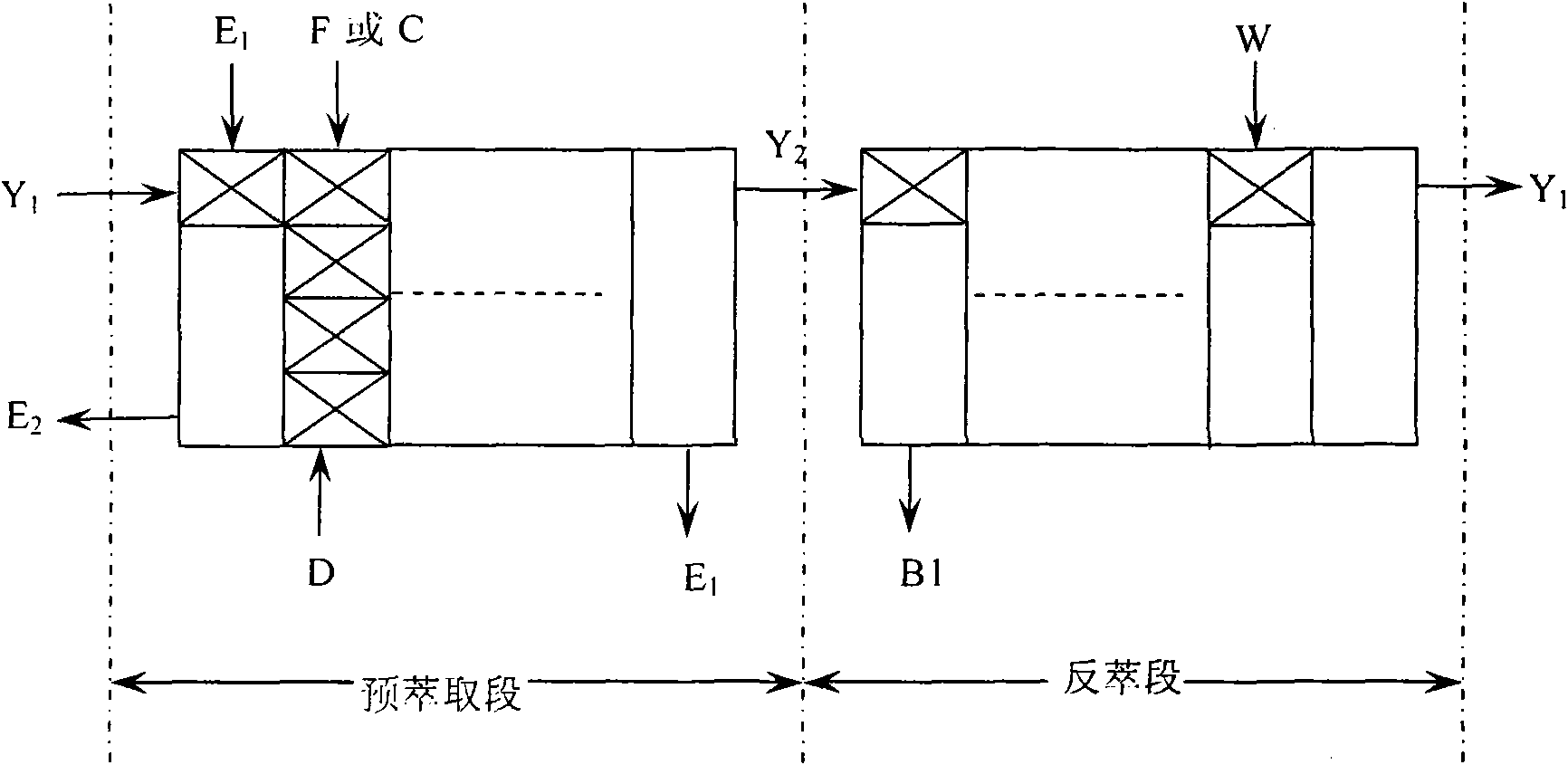

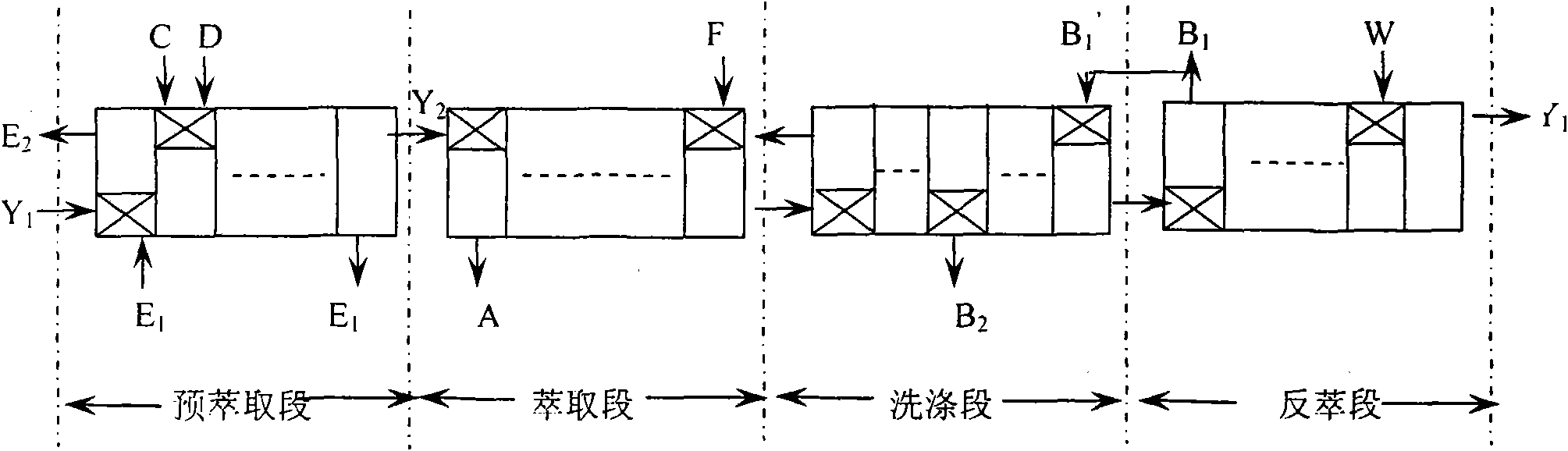

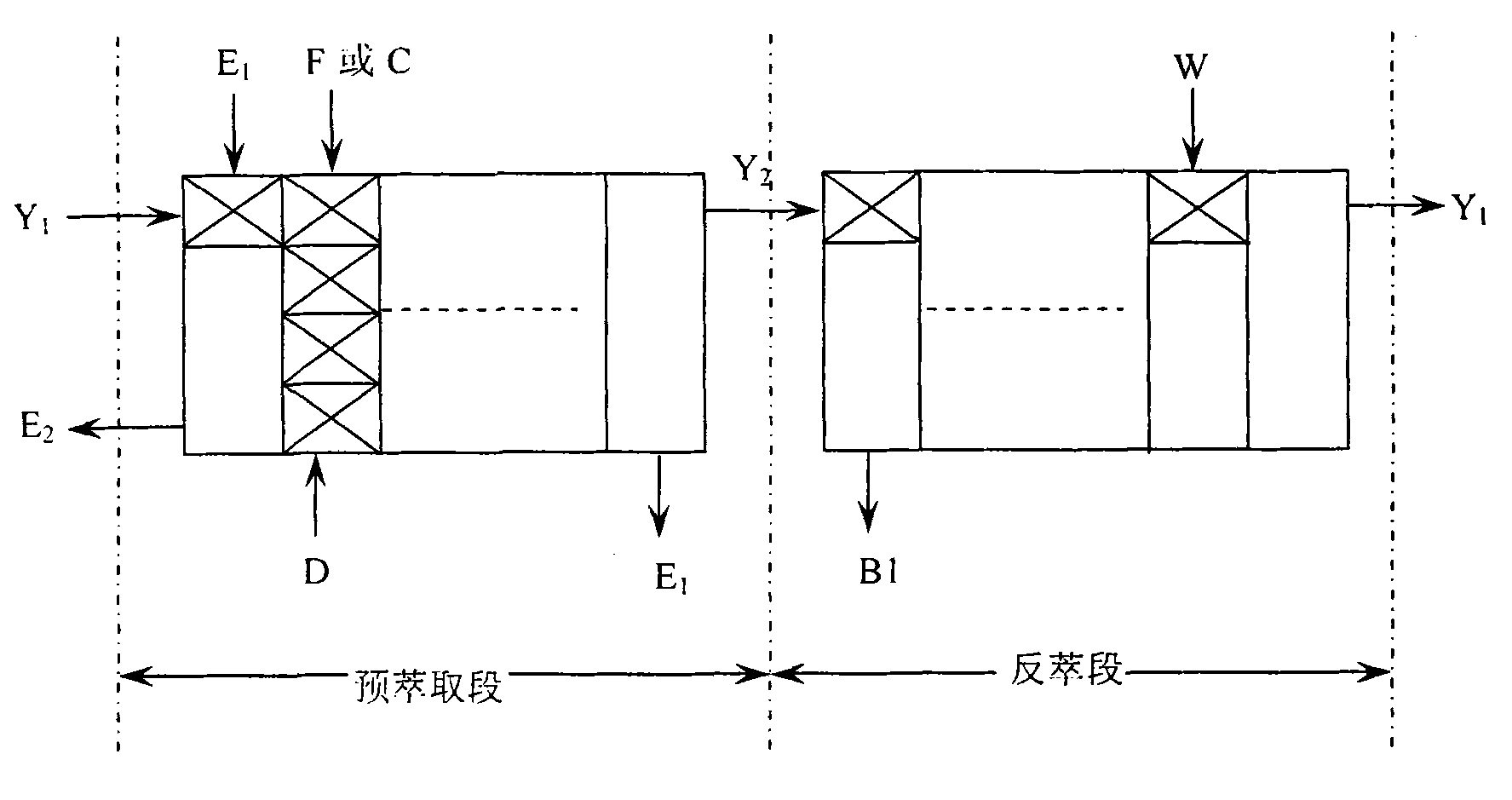

Process for extracting and separating rare-earth elements

ActiveCN101994004AEliminate pollutionReduce manufacturing costProcess efficiency improvementRare-earth elementOrganic acid

The invention provides a process for extracting and separating rare-earth elements. In the process, acid organic extracting agents such as P507, P204, C272 and naphthenic acid, aqueous solution of organic acid salt of magnesium and / or calcium, and rare-earth solution are mixed for pre-extraction; rare earth ions are extracted into an organic phase; and the organic phase is clarified to form a rare earth ion loaded organic phase used for extracting and separating mixed rare earth feed liquor. A single rare-earth compound or a concentrate of several rare-earth elements is obtained through multi-stage extraction-washing-back extraction. The aqueous solution of organic acid salt of magnesium and / or calcium is prepared by roasting minerals such as magnesite, limestone, calcite and dolomite and dissolving with organic acid; the contents of impurities such as silicon, iron and aluminium are low; three-phase substances are not generated in the pre-extraction and extraction and separation processes; the purity of rare earth products is not influenced; the organic phase is not subjected to ammonia saponification, and ammonia nitrogen wastewater is not generated; the production cost of the rare earth products is greatly reduced; and a great amount of three-waste treatment cost is saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

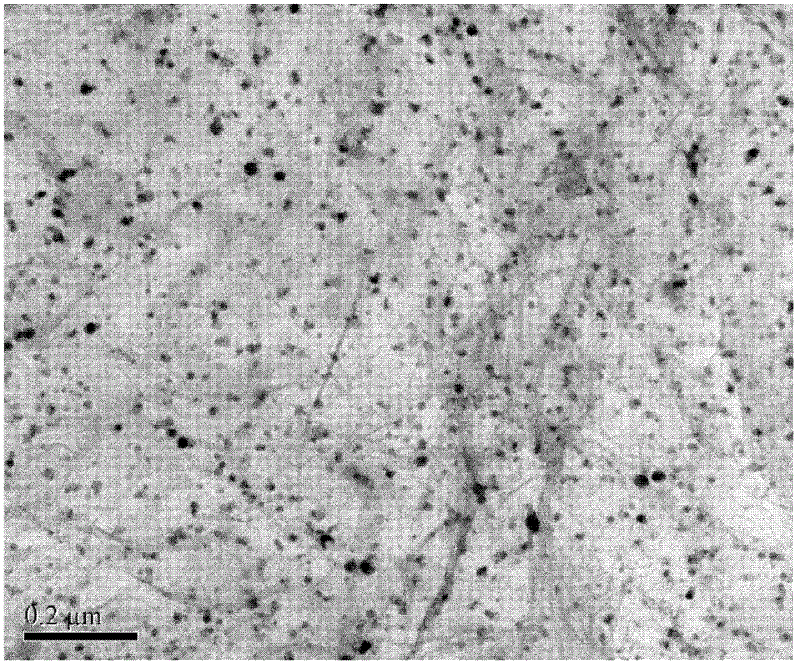

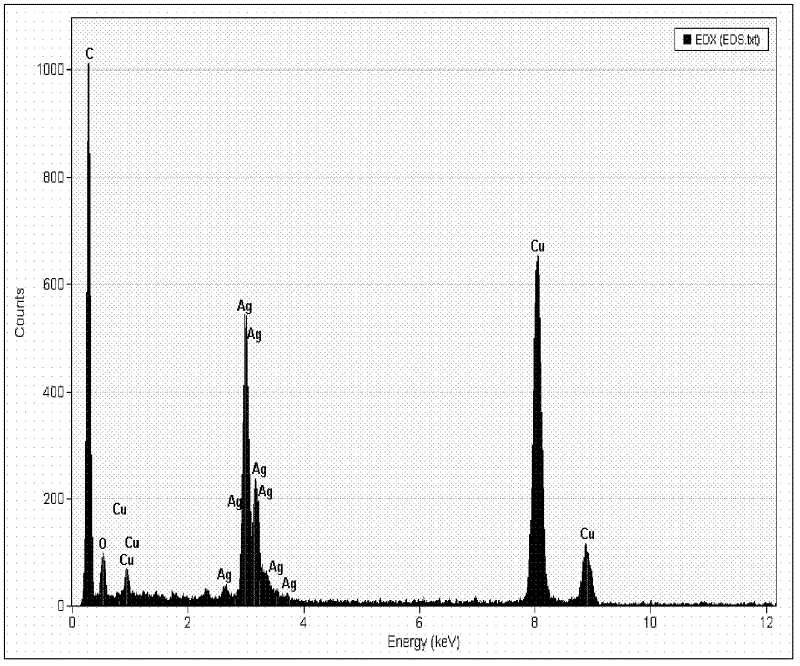

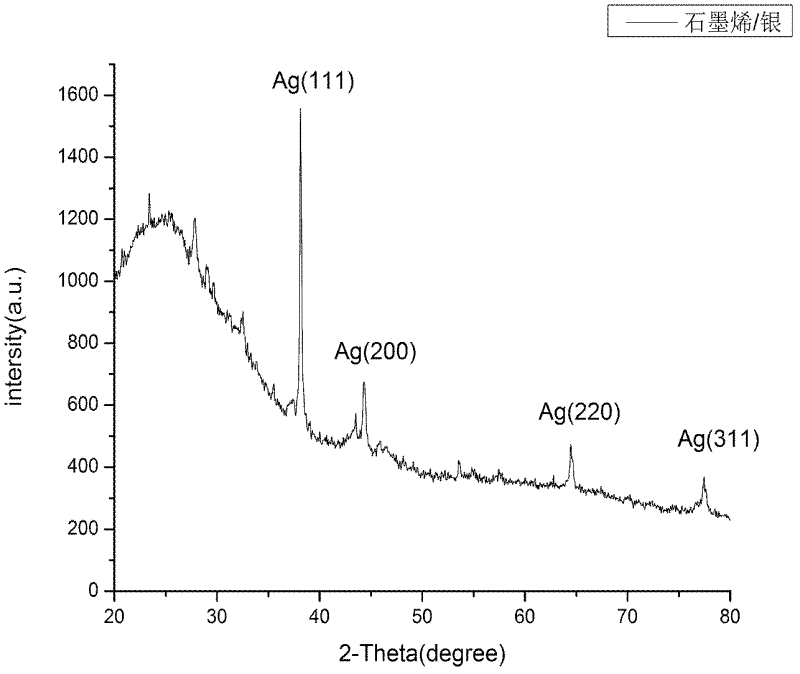

Method for preparing grapheme/silver nanoparticles composite material by using liquid phase method

ActiveCN102614871ALow impurity contentHigh bonding strengthMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsBond strengthElectron

The invention discloses a method for preparing a grapheme / silver nanoparticles composite material by using a liquid phase method. N and N-dimethyl formamide (DMF) serve as a reducing agent, grapheme powder with purity as high as 99% serves as a carrier, and silver forms a core and grows on a grapheme layer under a soft reaction condition to obtain the grapheme / silver nanoparticles composite material. The preparation method has the advantages of being simple, convenient, rapid and high-efficient in process, the grapheme / silver nanoparticles composite material prepared by using the method is high in purity and less in impurity content, and silver nanoparticles generated on the surface layer of the grapheme are small in particle size, uniform in distribution and high in bond strength with the grapheme. The silver nanoparticles are closely absorbed on the grapheme layer, aggregation of the grapheme is effectively avoided, and application of the grapheme / silver nanoparticles composite material in the fields of electron, catalysis, antibiosis and the like can be enlarged.

Owner:TIANJIN UNIV

High-strength high-corrosion-resistance cast aluminum alloy and gravity casting manufacturing method thereof

The invention provides high-strength high-corrosion-resistance cast aluminum alloy and a gravity casting manufacturing method of the high-strength high-corrosion-resistance cast aluminum alloy. The alloy is composed of Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al according to certain weight percentages, wherein the M is at least one of Ti, Zr and V or the RE element is added to the M. The cast aluminum alloy has the excellent cast performance and good mechanical property. The tensile strength, the yield strength and elongation are improved, good corrosion resistance is achieved, the aluminum alloy can be applied to automobile parts without solid solution heat treatment, and the requirement of low-weight development of automobiles is met.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com