Manufacturing method of micro spherical titanium and titanium alloy powder

A technology of spherical powder and titanium alloy, applied in the field of preparation of fine spherical titanium and titanium alloy powder, can solve the problems of pollution, crucible erosion, shortening the service life of crucible, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

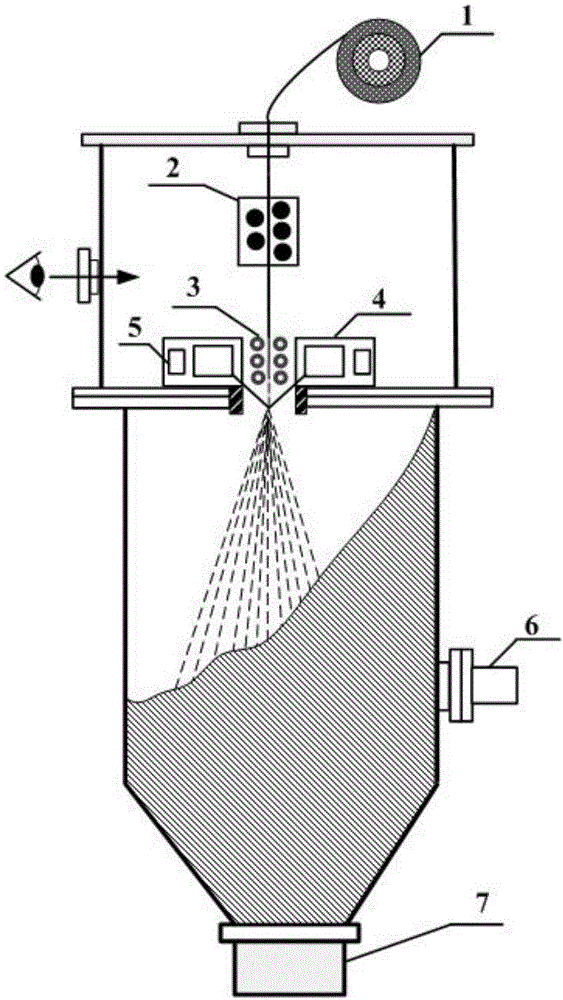

[0036] The preparation method of fine spherical titanium and titanium alloy powder of the present invention, at first, select raw material such as TA1 grade sponge titanium to be prepared into TA1, TC4 or TC11 etc. bar), the raw material wire (or bar) is sent into the smelting chamber through the continuous feeder 1 and the metal straightening mechanism (straightener) 2; the smelting chamber and the atomization chamber are pre-vacuumized by the vacuum system 6, Vacuum up to 1×10 -4 ~1×10 -3 Pa, the smelting chamber and the atomizing chamber are filled with high-purity inert gas for atmosphere protection, the oxygen content concentration is <0.00010%, to avoid the oxidation of the ingredients during the smelting process and the powder during the atomization process; 3 pairs of high-frequency induction coils containing titanium are used and titanium alloy wire (or bar) for smelting, the raw material feed rate is 0.2-5Kg / min, the power of the high-frequency induction coil 3 is 5...

Embodiment 1

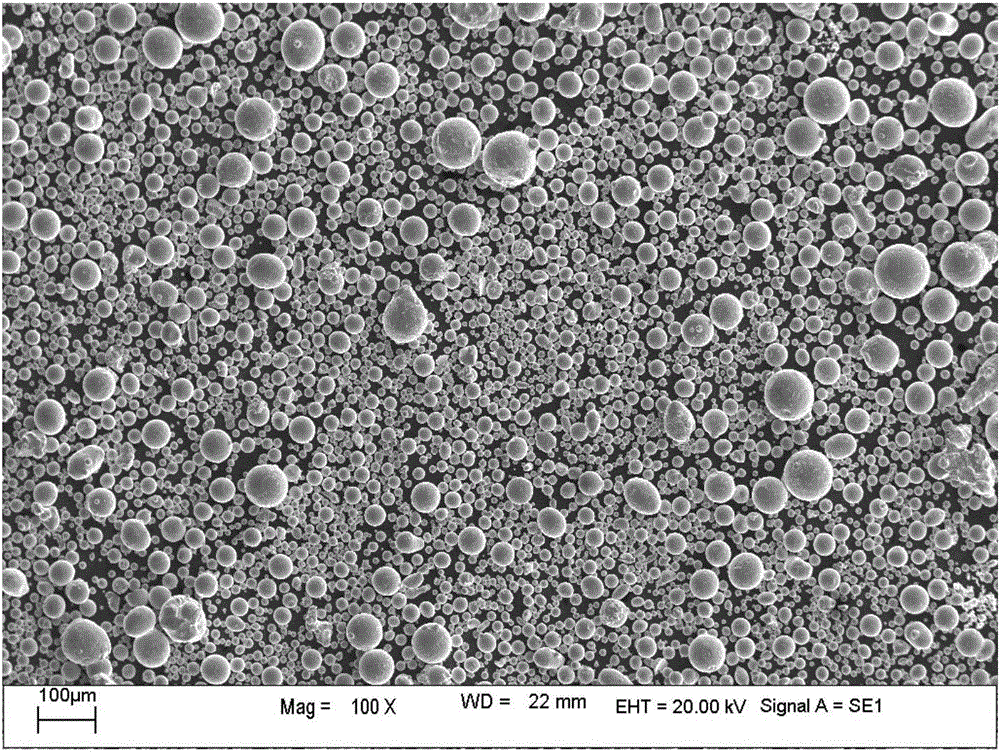

[0039] The preparation method of fine spherical titanium powder with an average particle size of 45 μm, the method is carried out in the following steps: first, select sponge titanium or pure titanium raw materials higher than or equal to the national standard TA1 grade to make a wire with a diameter of Φ8mm, and the melting chamber and atomization The chamber is pre-vacuumized, and the vacuum degree reaches 1×10 -3 Pa. Use high-purity argon as the protective gas to fill the melting chamber and atomization chamber with a pressure of 1.0×10 5 ~1.2×10 5 Pa, to avoid the oxidation of powder during alloy melting and atomization. The raw material wire is sent into the melting chamber through a continuous feeding mechanism and a straightener, and the titanium wire is heated and smelted by a high-frequency induction coil. The melting power is 10KW, the frequency is 500KHz, and the raw material feeding rate is 5Kg / min. The temperature is controlled at 1750°C. After the titanium wir...

Embodiment 2

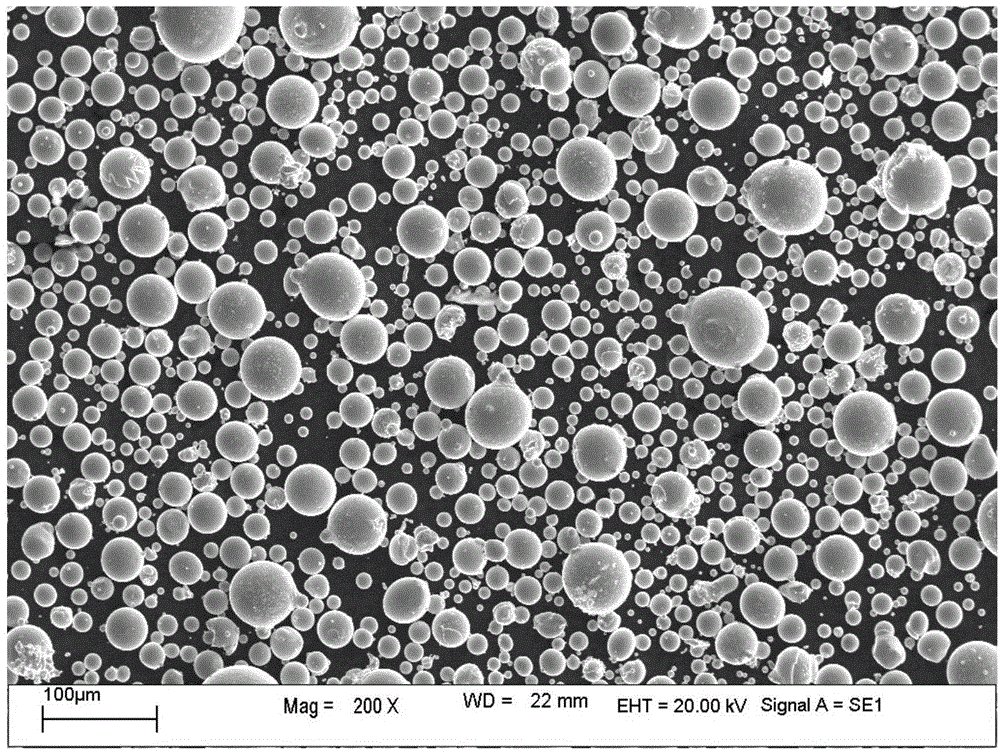

[0042] The gas atomization preparation method of fine spherical titanium alloy powder with an average particle size of 28 μm, the method is carried out as follows: first, sponge titanium, aluminum and vanadium are used as raw materials, wherein the purity of the sponge titanium, aluminum and vanadium is ≥99.9%. According to the proportion of TC4 (Ti-6Al-4V) alloy composition, it is made into a wire with a diameter of Φ2mm, and the melting chamber and the atomization chamber are pre-vacuumized, and the vacuum degree reaches 1×10 -4 Pa. Use high-purity argon as the protective gas to fill the melting and spraying chamber, and the equipment pressure is 1.2×10 5 Pa, to avoid the oxidation of powder during alloy melting and atomization. The raw material wire is sent into the melting chamber through the continuous feeding mechanism and straightener, and the titanium alloy wire is heated and smelted by a high-frequency induction coil. The melting power is 5KW, the frequency is 1MHz, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com