Patents

Literature

1547 results about "Sphericity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sphericity is a measure of how closely the shape of an object resembles that of a perfect sphere. For example, the sphericity of the balls inside a ball bearing determines the quality of the bearing, such as the load it can bear or the speed at which it can turn without failing. Sphericity is a specific example of a compactness measure of a shape. Defined by Wadell in 1935, the sphericity, Ψ, of a particle is the ratio of the surface area of a sphere with the same volume as the given particle to the surface area of the particle: Ψ=π¹/³(6Vₚ)²/³/Aₚ where Vₚ is volume of the particle and Aₚ is the surface area of the particle.

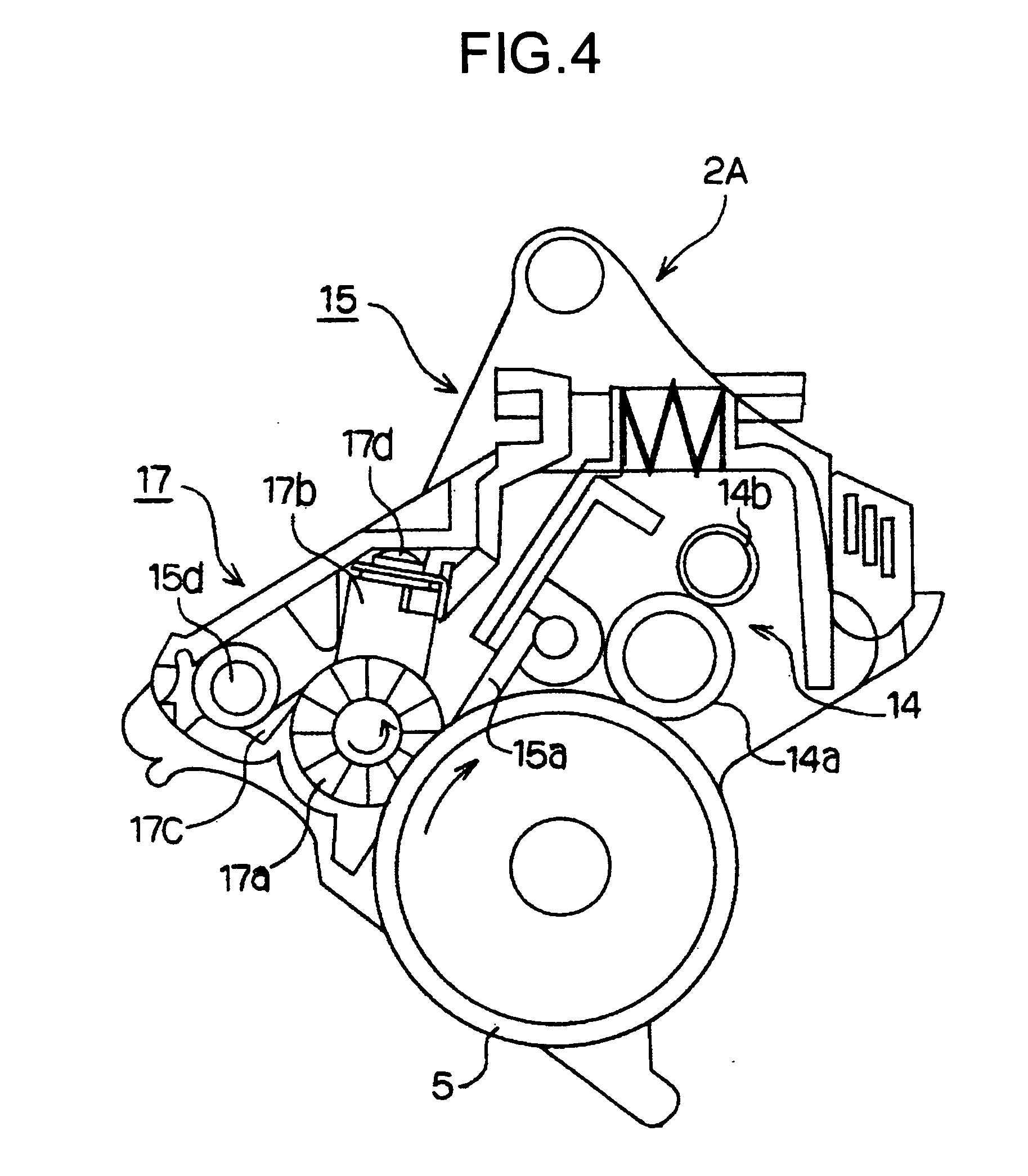

Refraction measuring instrument

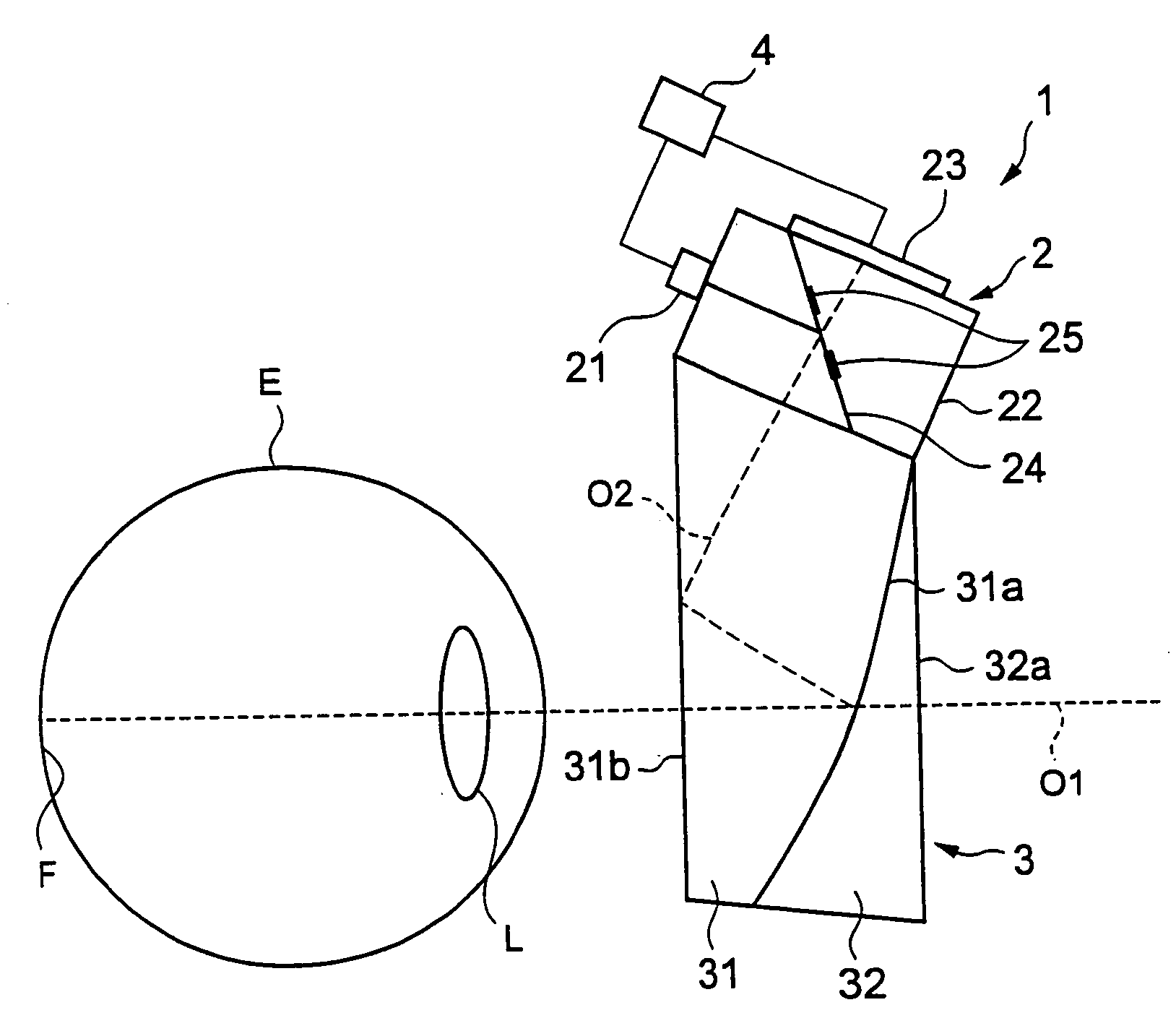

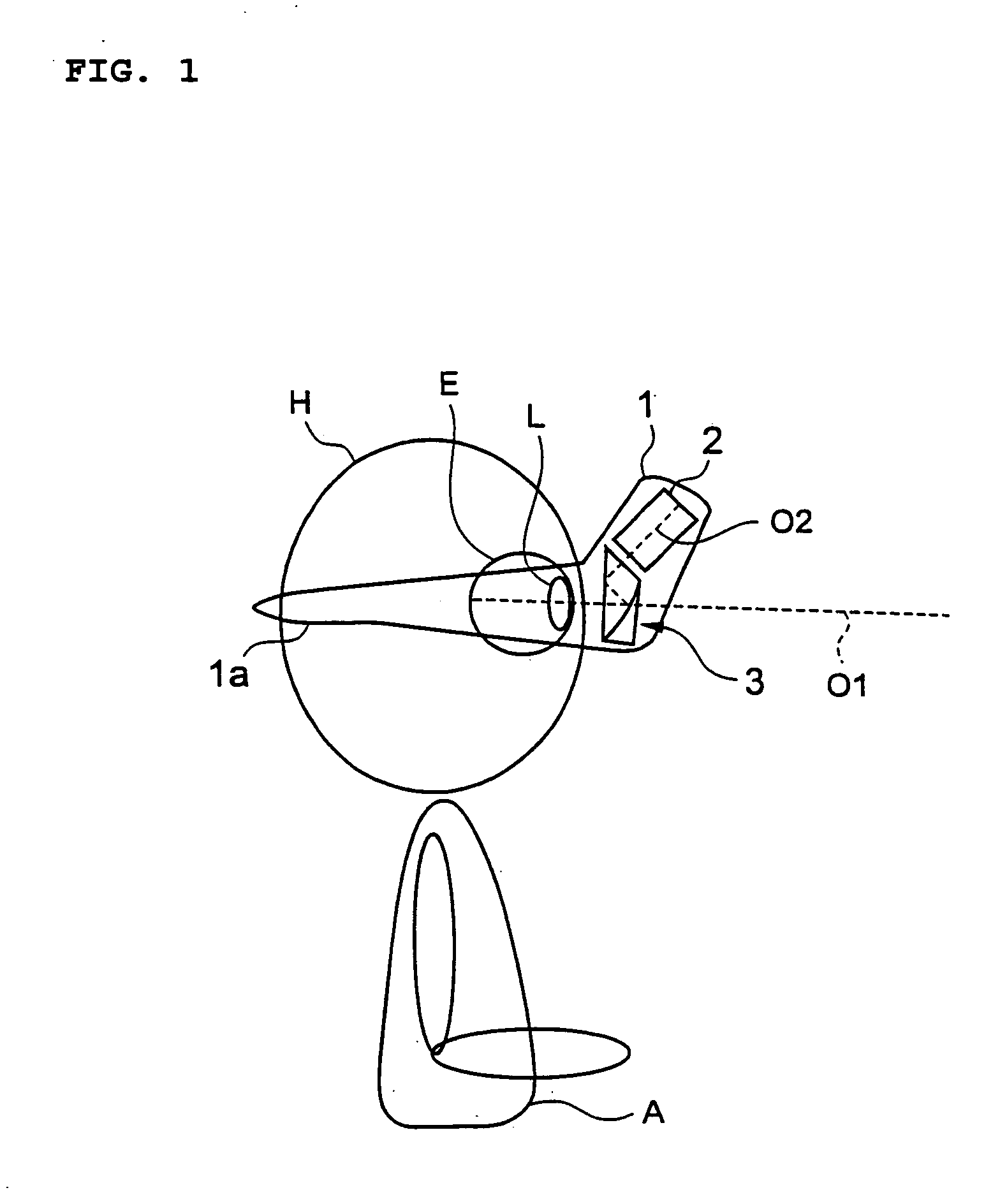

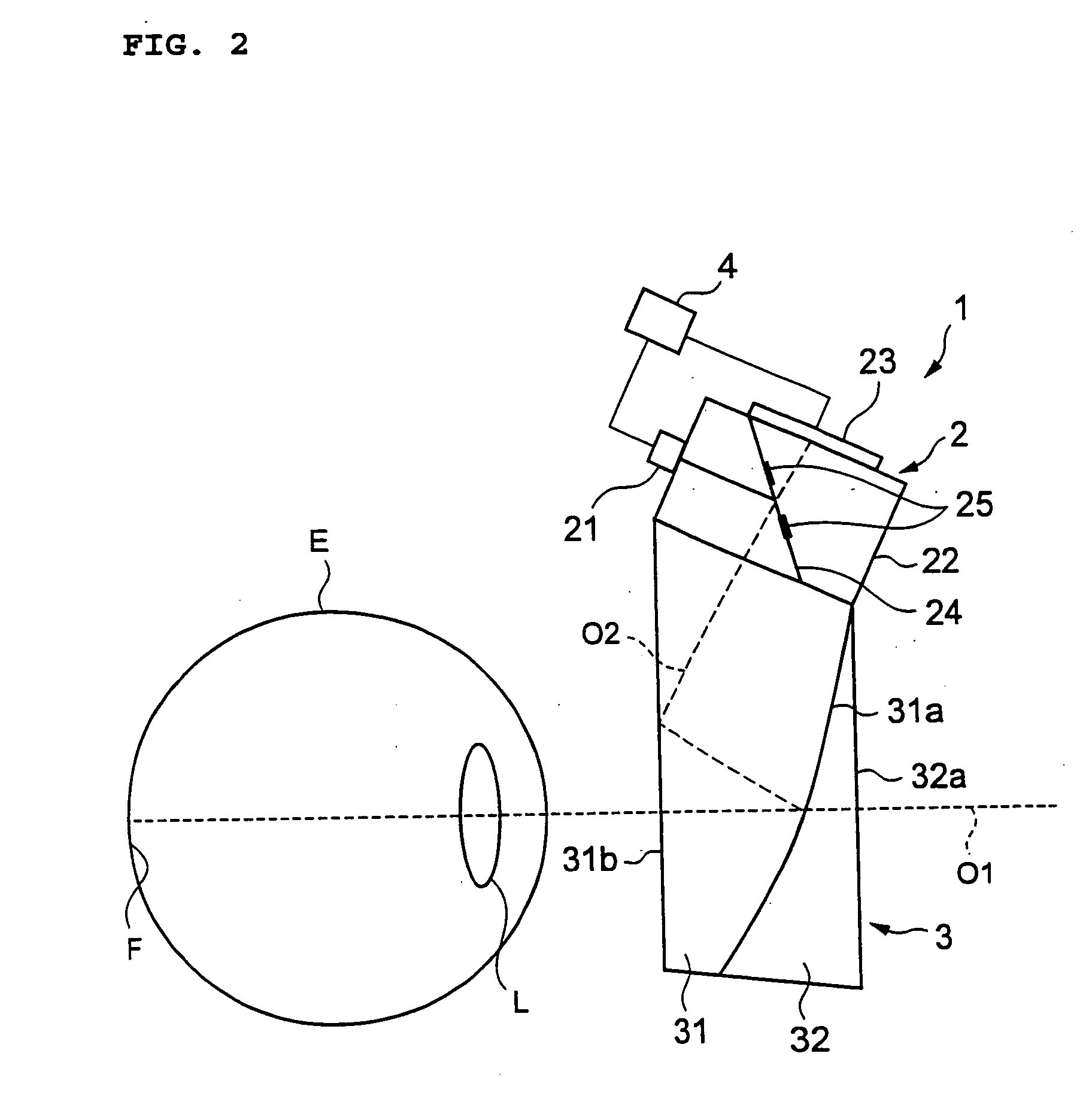

InactiveUS20060215111A1Small sizeReduce weightRefractometersSkiascopesMeasuring instrumentBeam splitting

A refraction measuring instrument for measuring the refraction of an eye to be examined while the subject is viewing an external object in a more natural posture. A measuring light beam from a light source 21 is reflected from a mirror 25, shaped into a beam with a ring cross section, directed to a free curved surface prism 31 along an optical axis O2, reflected from a surface 31b and a beam splitting surface 31a, guided to an eye E along an optical axis O1 together with the visible light from outside the instrument, and form a ring pattern on the fundus F. The measurement beam reflected from the fundus F is received by a CCD 23 through the free curved surface prism 31 and a prism 22, and a ring pattern is imaged. A calculation control device 4 analyzes the imaged ring pattern and calculates the sphericity, the degree of astigmatism, and the astigmatic axis angle. For measurement, the subject A wears the refraction measuring instrument 1 on the head H through a wearing section 1a.

Owner:KK TOPCON

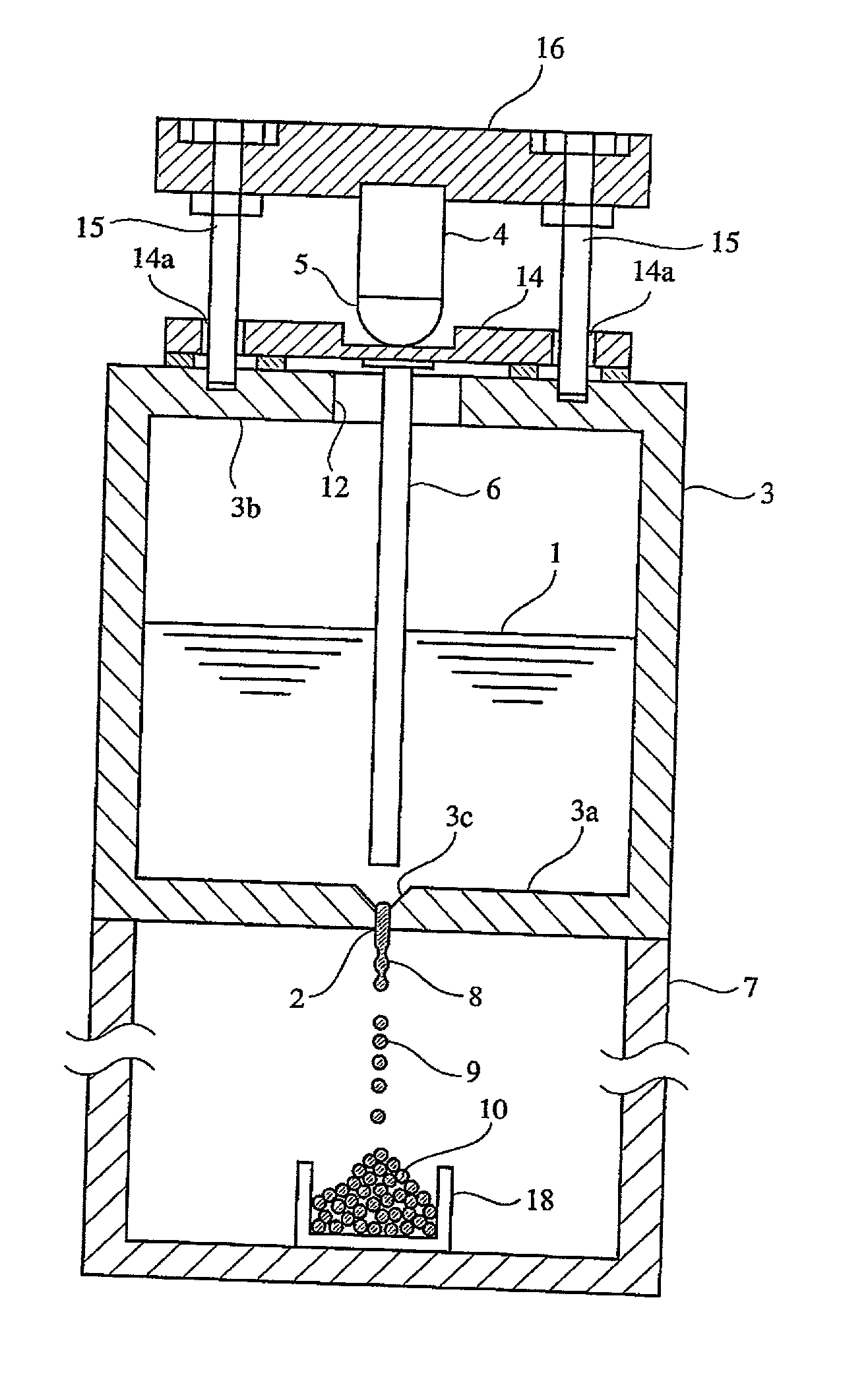

Solder ball and method for producing same

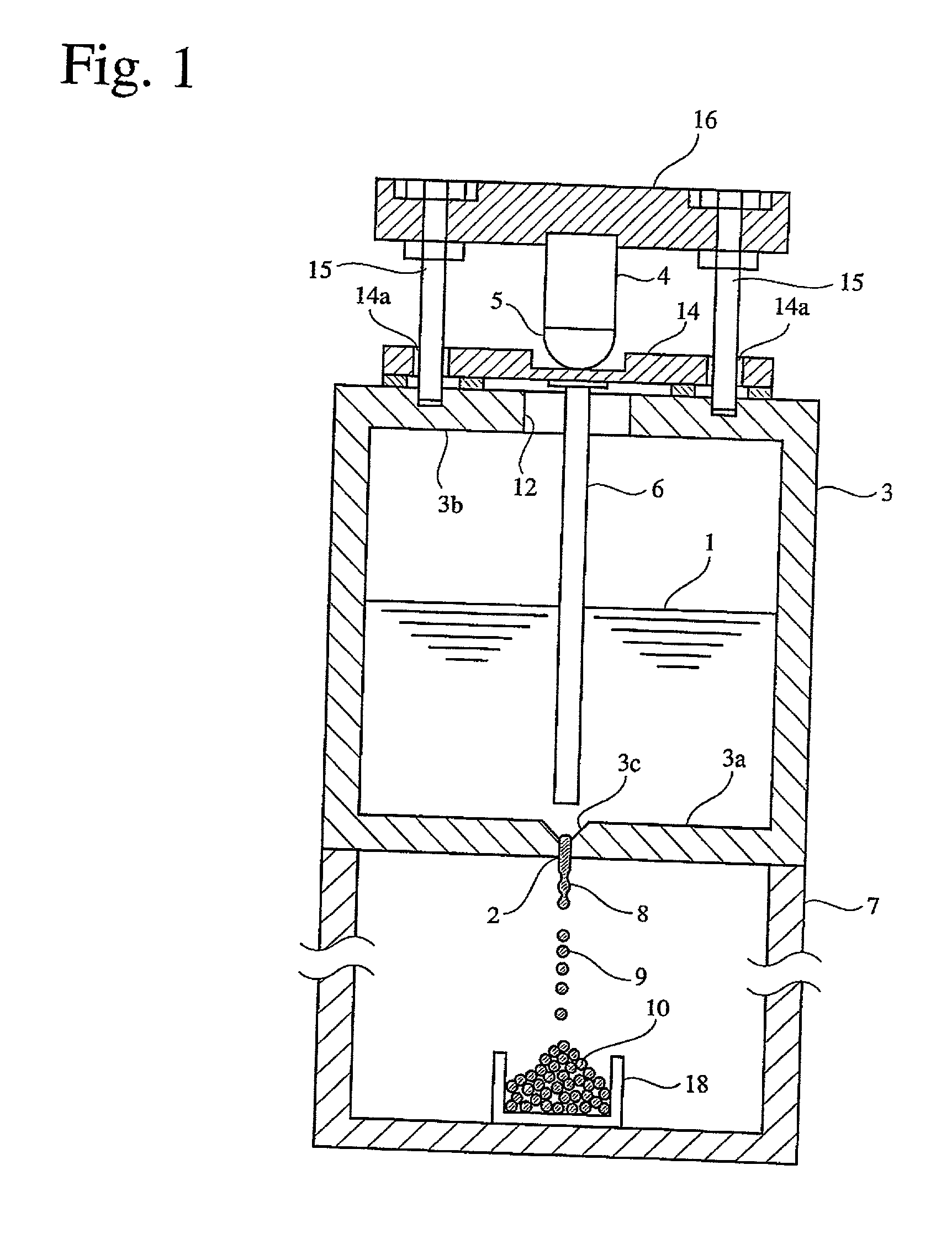

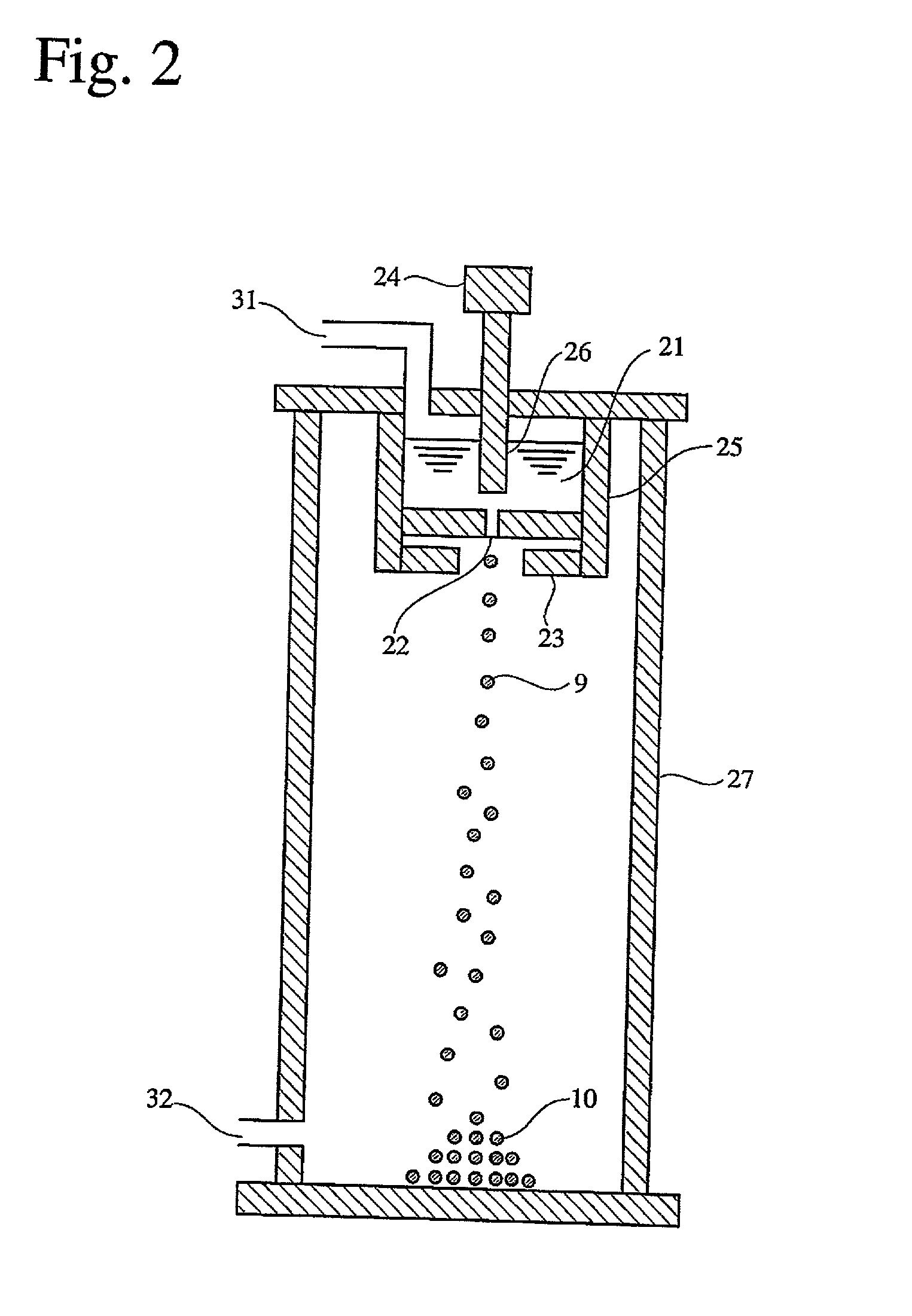

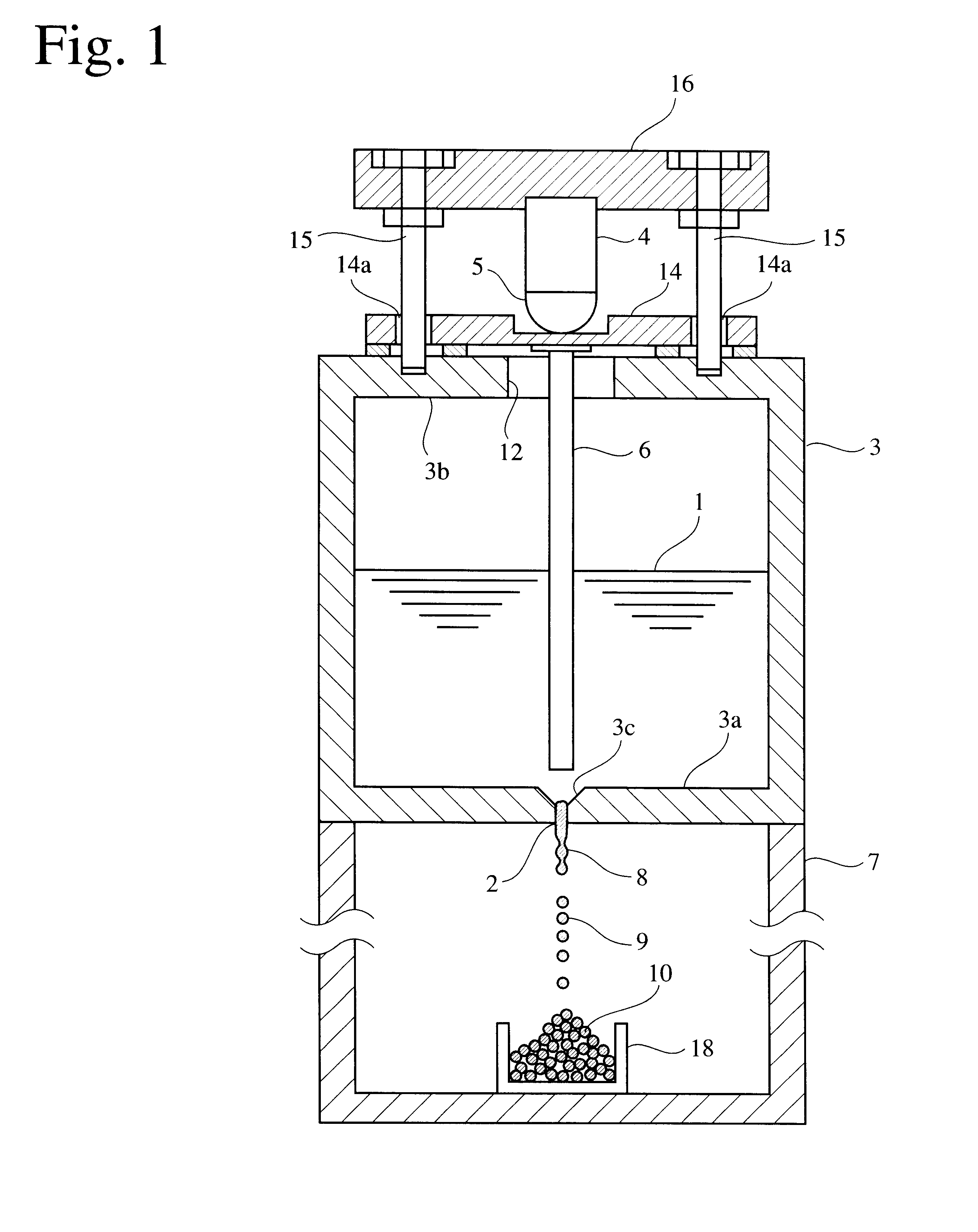

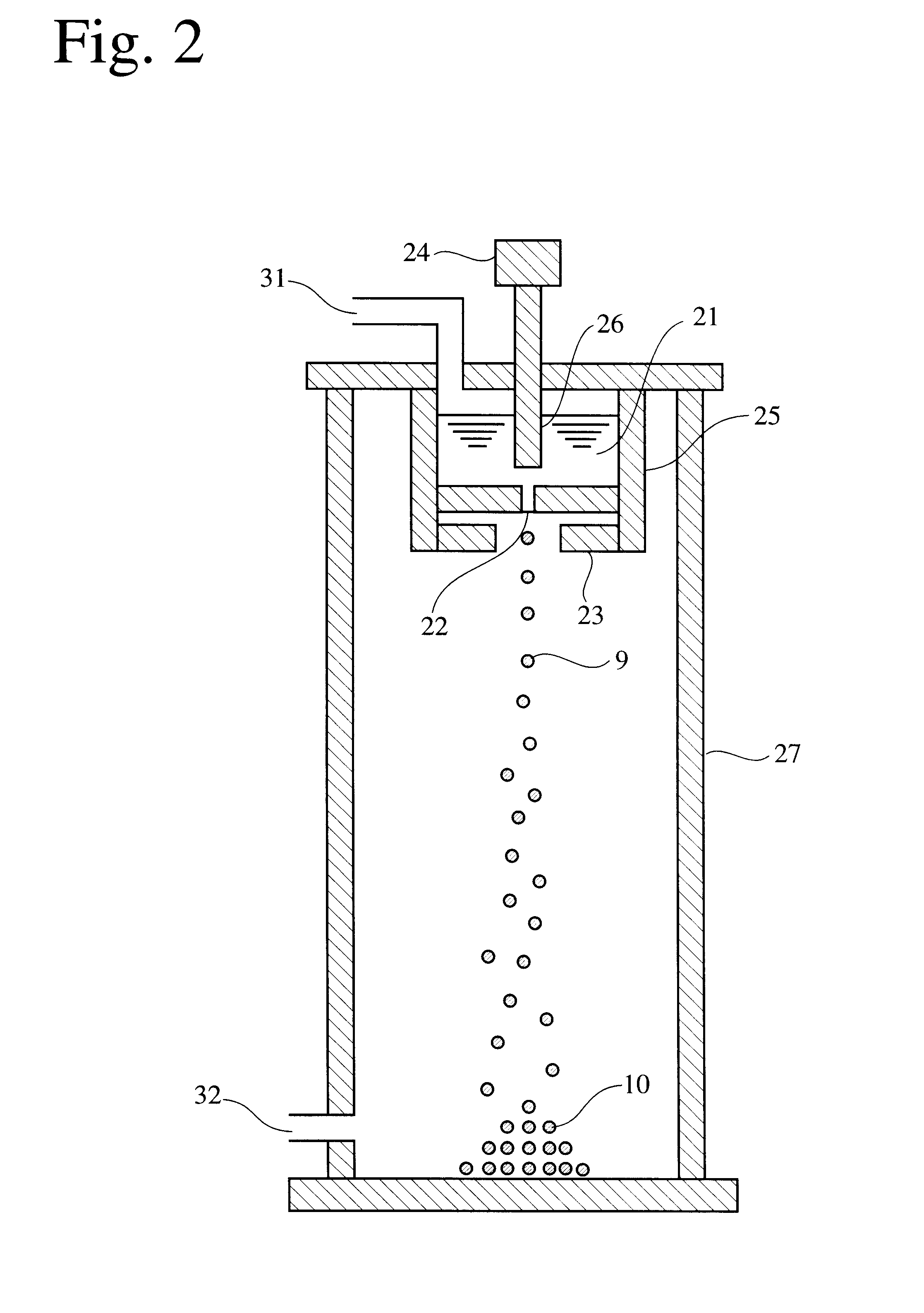

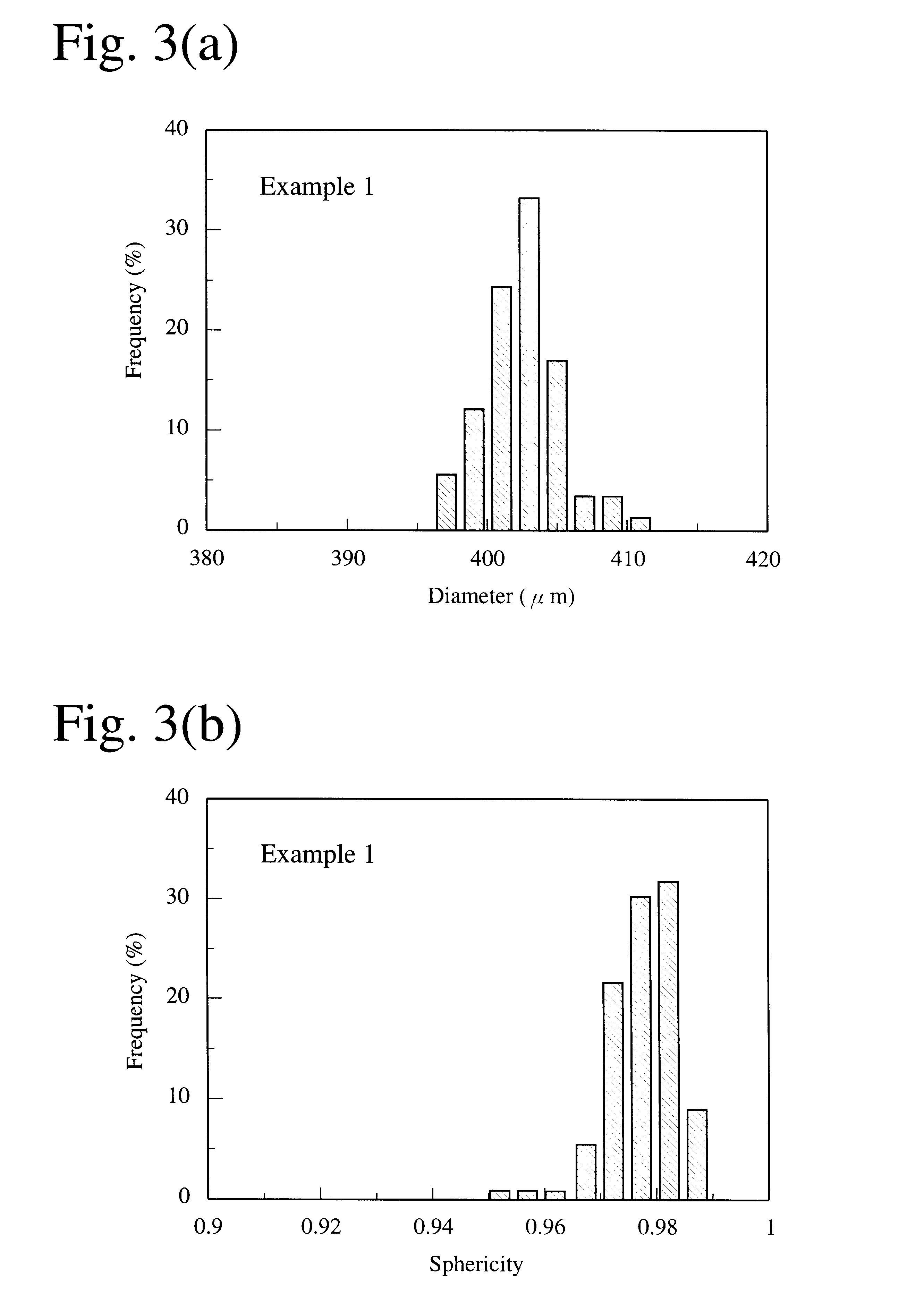

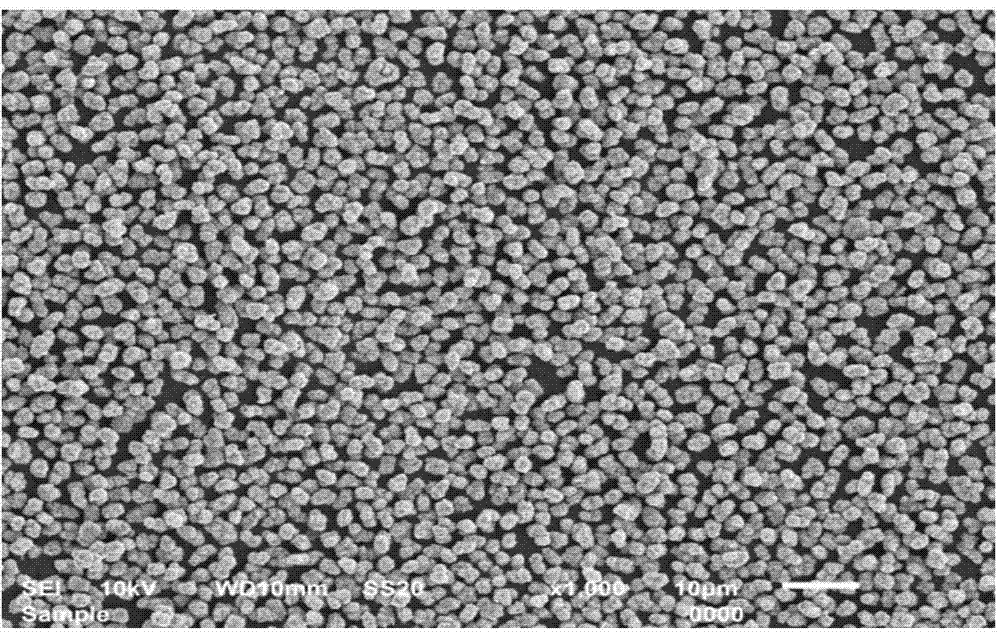

InactiveUS20020051728A1High degree of sphericityNarrow dimension distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

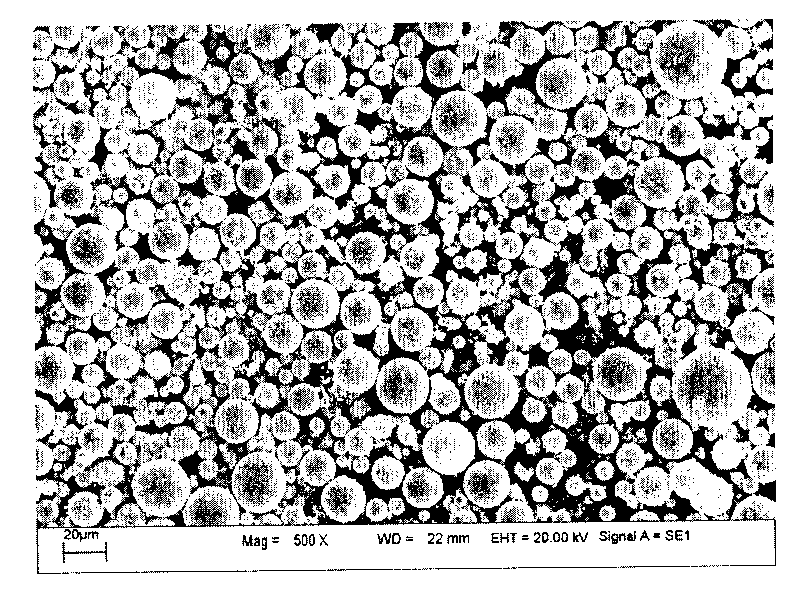

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass% of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

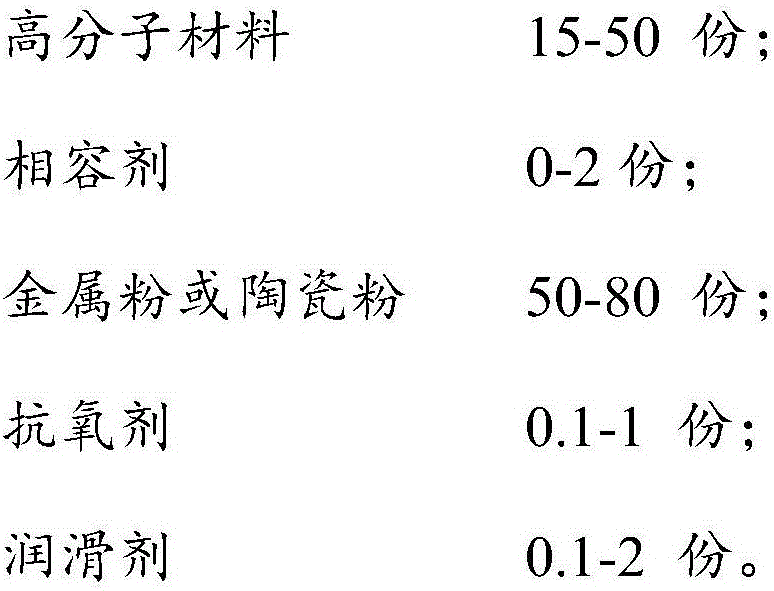

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

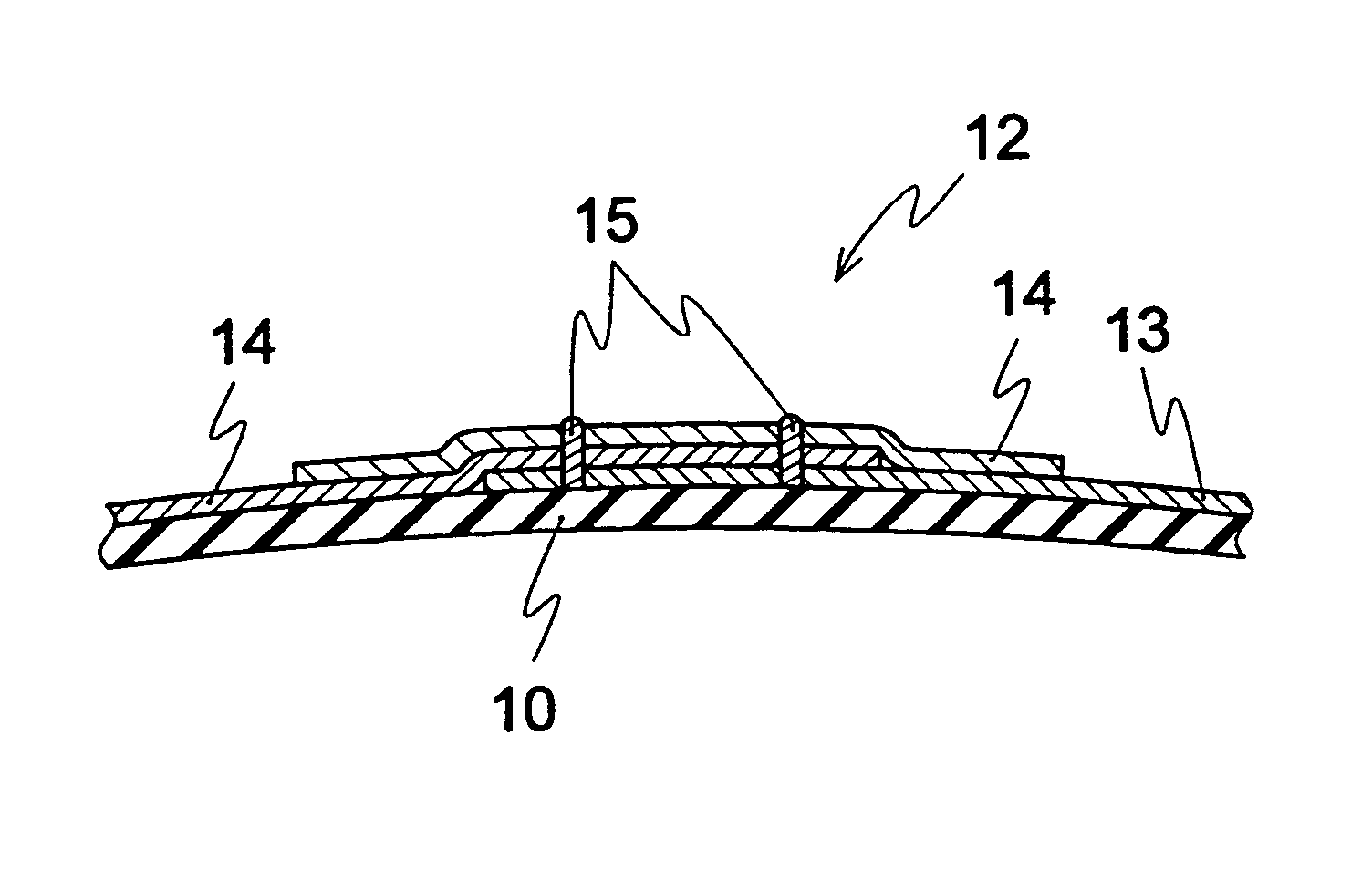

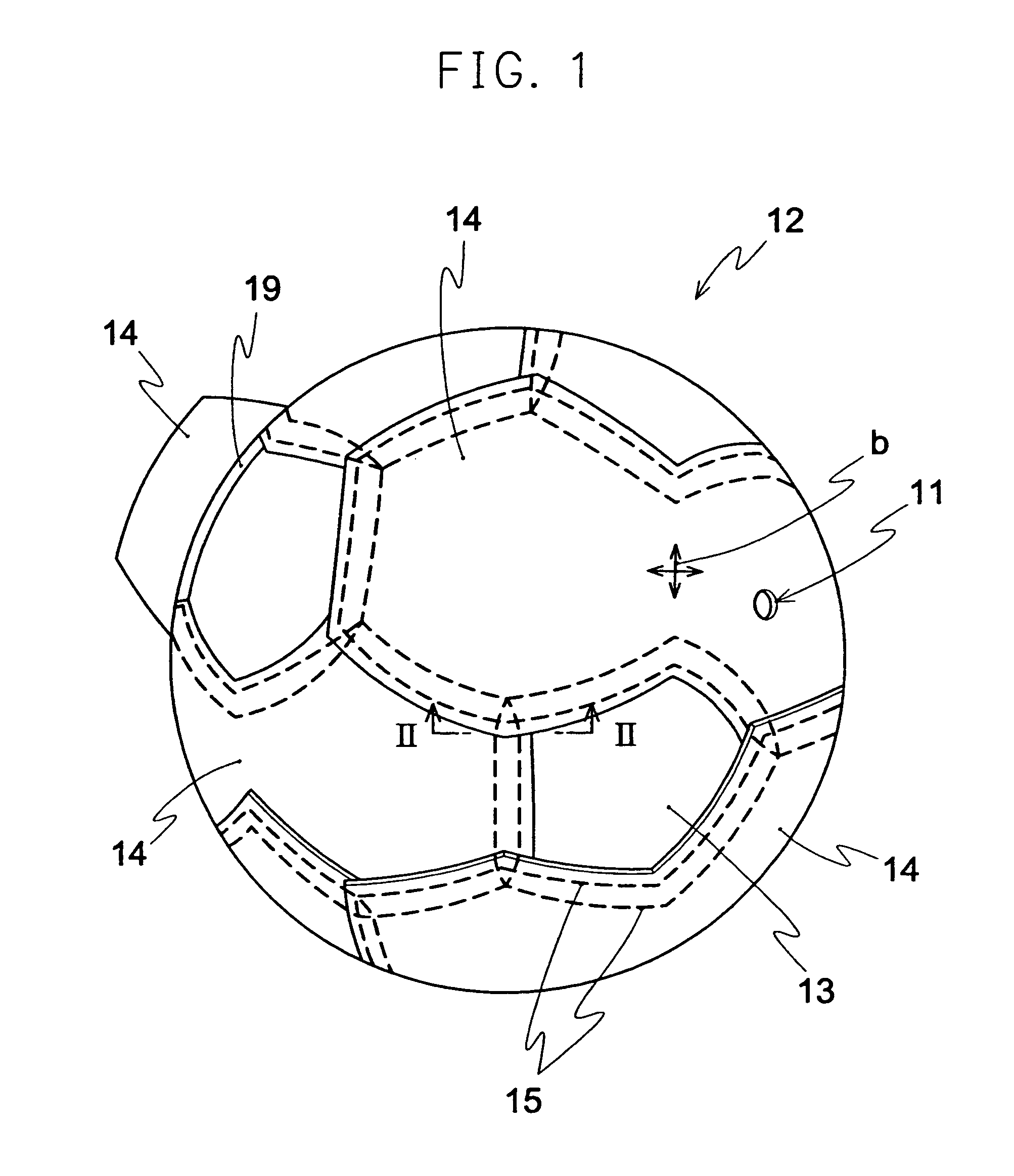

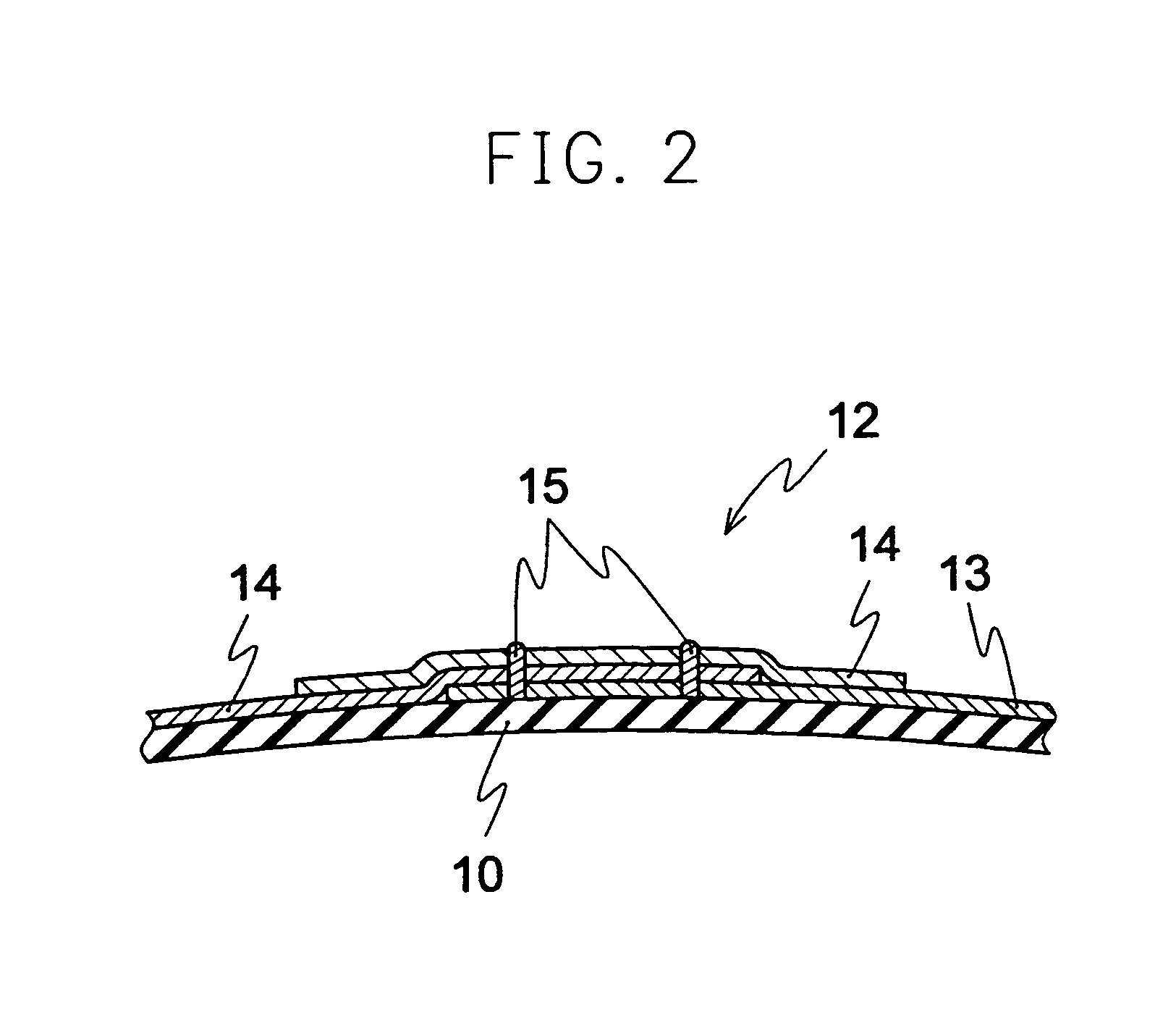

Ball for ball game and method for manufacturing the same

InactiveUS6971965B1Increase the number ofMaintain tensile strengthHollow inflatable ballsHollow non-inflatable ballsBall gameSpherical shaped

To provide a ball for ball game and a method for manufacturing the ball having superior sphericity, an ability to retain its original shape, durability, and soft feel. The fabric layer (12) is formed by sewing with a sewing machine for instance pentagonal first fabric pieces (13) together with composite shaped second fabric pieces (14) in which two hexagons are connected with each other, so that a spherical shape is formed. The marginal edge of the first and second fabric pieces are superimposed in the spherical surface direction, so that corner portions thereof are temporarily attached. Temporary attachment is achieved by inserting the needle into the needle through hole formed in the corner of the first and second fabric pieces, and welding by means of ultra sonic wave, such that the first and second fabric pieces (13, 14) are accurately aligned. The temporarily attached fabric pieces sewn together using a sewing machine along the guiding line (17) for sewing printed beforehand on the surface of the fabric pieces (13, 14).

Owner:MOLTEN CORPORATION +1

Spherical Particle and Method for Producing the Same

InactiveUS20100247665A1Improve versatilityImprove wear resistancePretreated surfacesPharmaceutical non-active ingredientsMass ratioAlcohol sugars

A spherical particle of the present invention contains a sugar alcohol and a crystalline cellulose and / or powdered cellulose, wherein the mass ratio between the sugar alcohol and the crystalline cellulose and / or powdered cellulose is within a range from 50:50 to 90:10, the particle size is within a range from 75 to 250 μm, the sphericity is not less than 0.8, and the bulk density is not less than 0.6 g / ml. Further, a method for producing the spherical particle of the present invention includes a granulation step of rolling a sugar alcohol having an average particle size of not more than 40 μm and a crystalline cellulose and / or powdered cellulose having an average particle size of not more than 50 μm while spraying a liquid thereon.

Owner:FREUNT IND

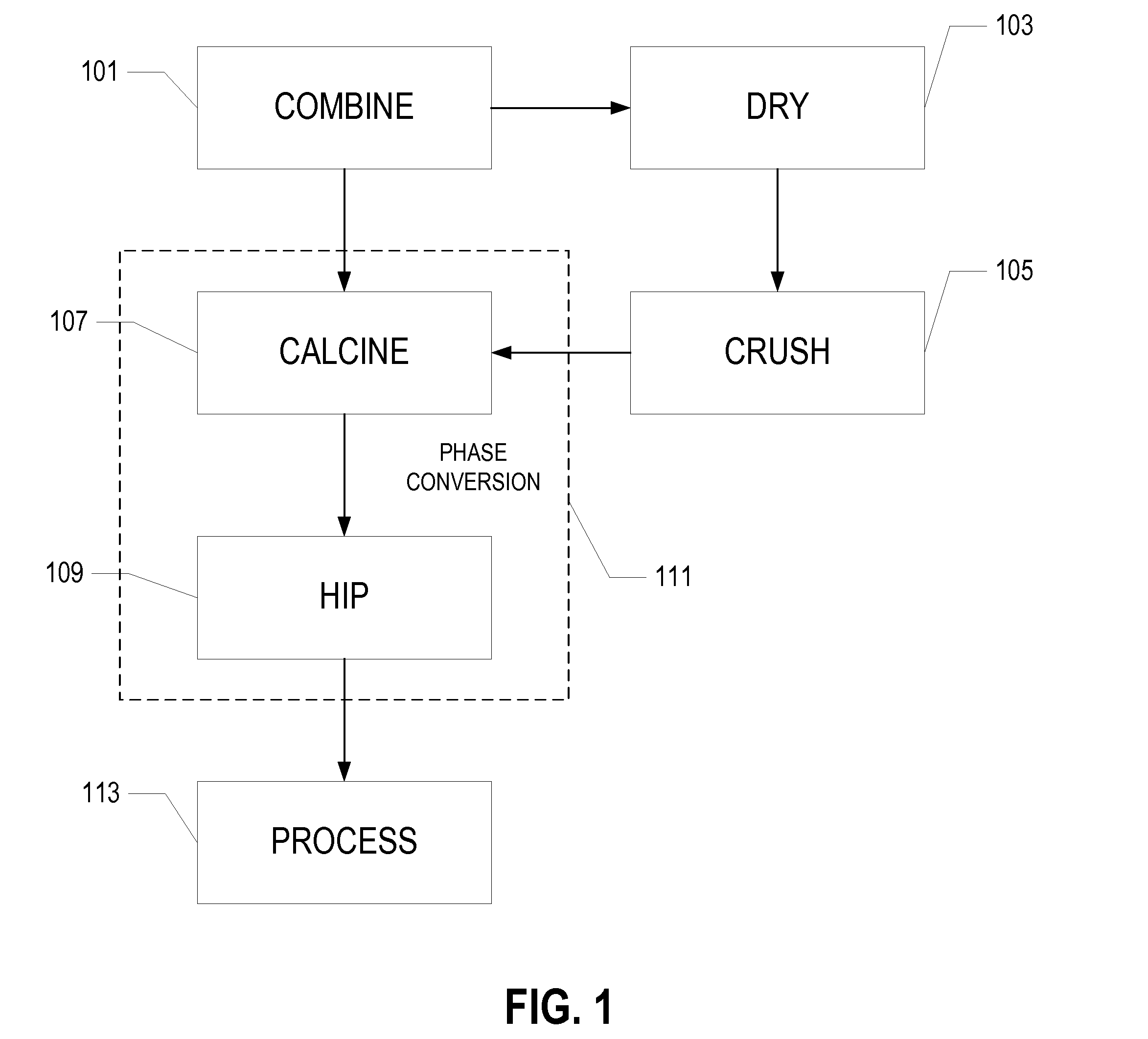

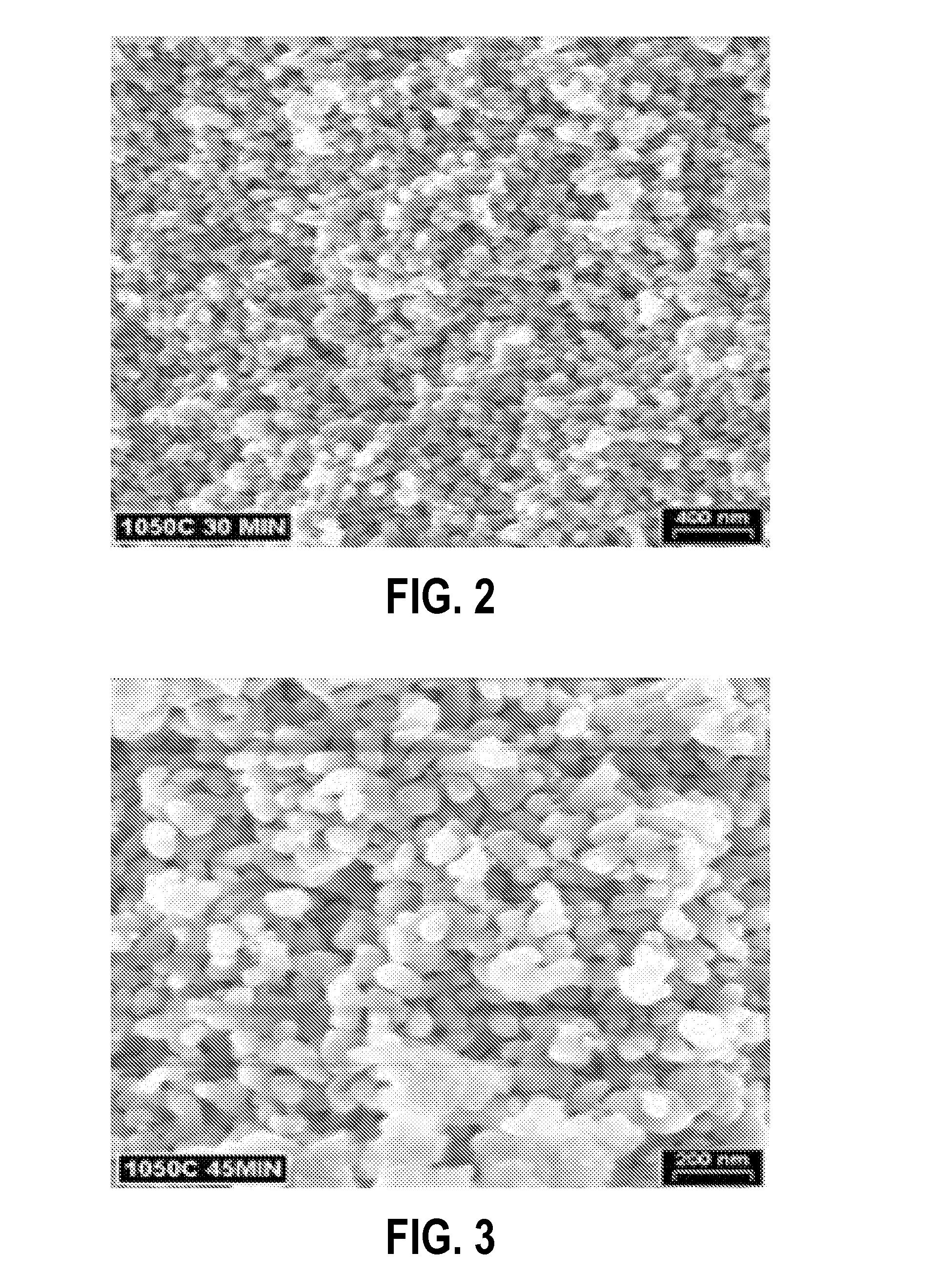

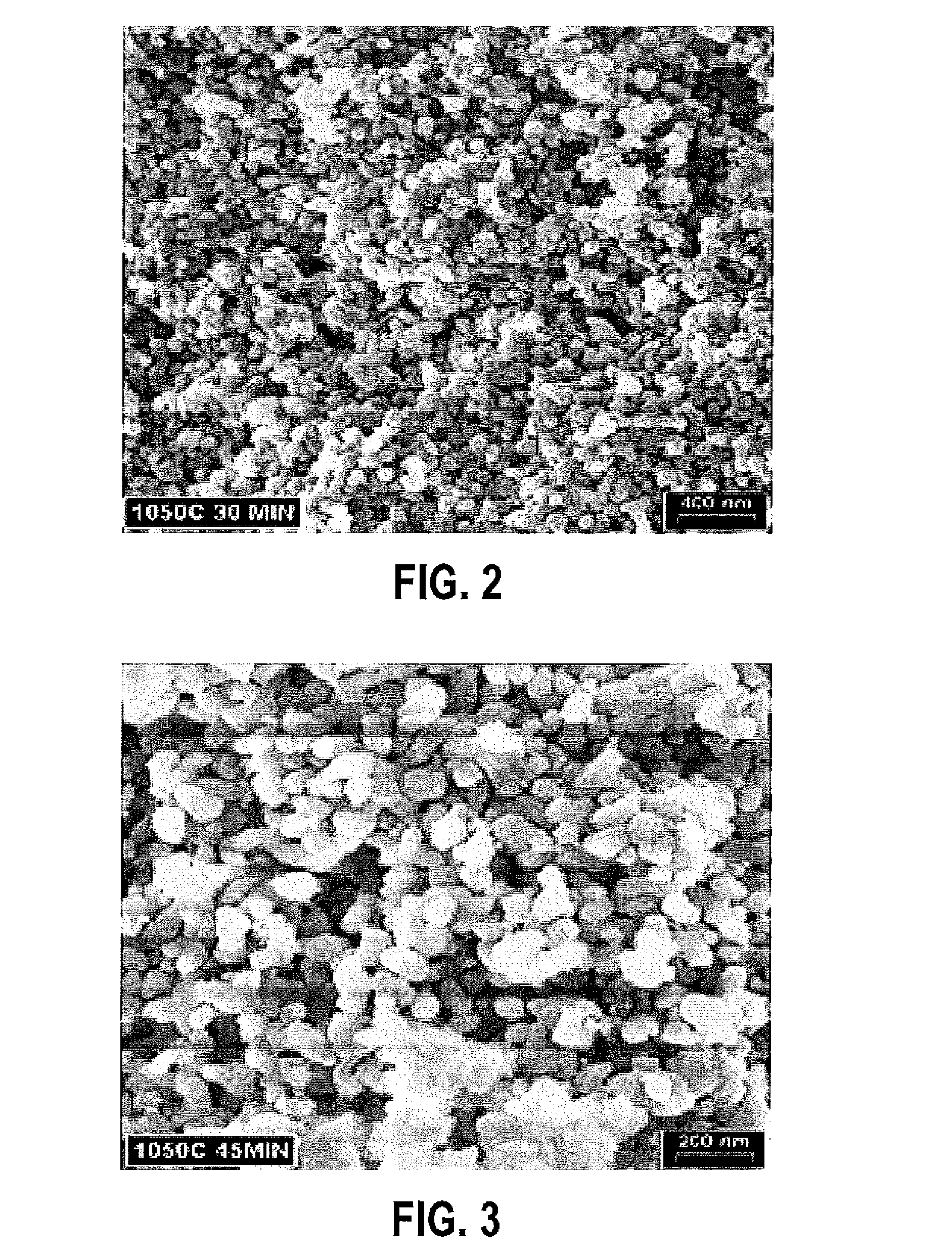

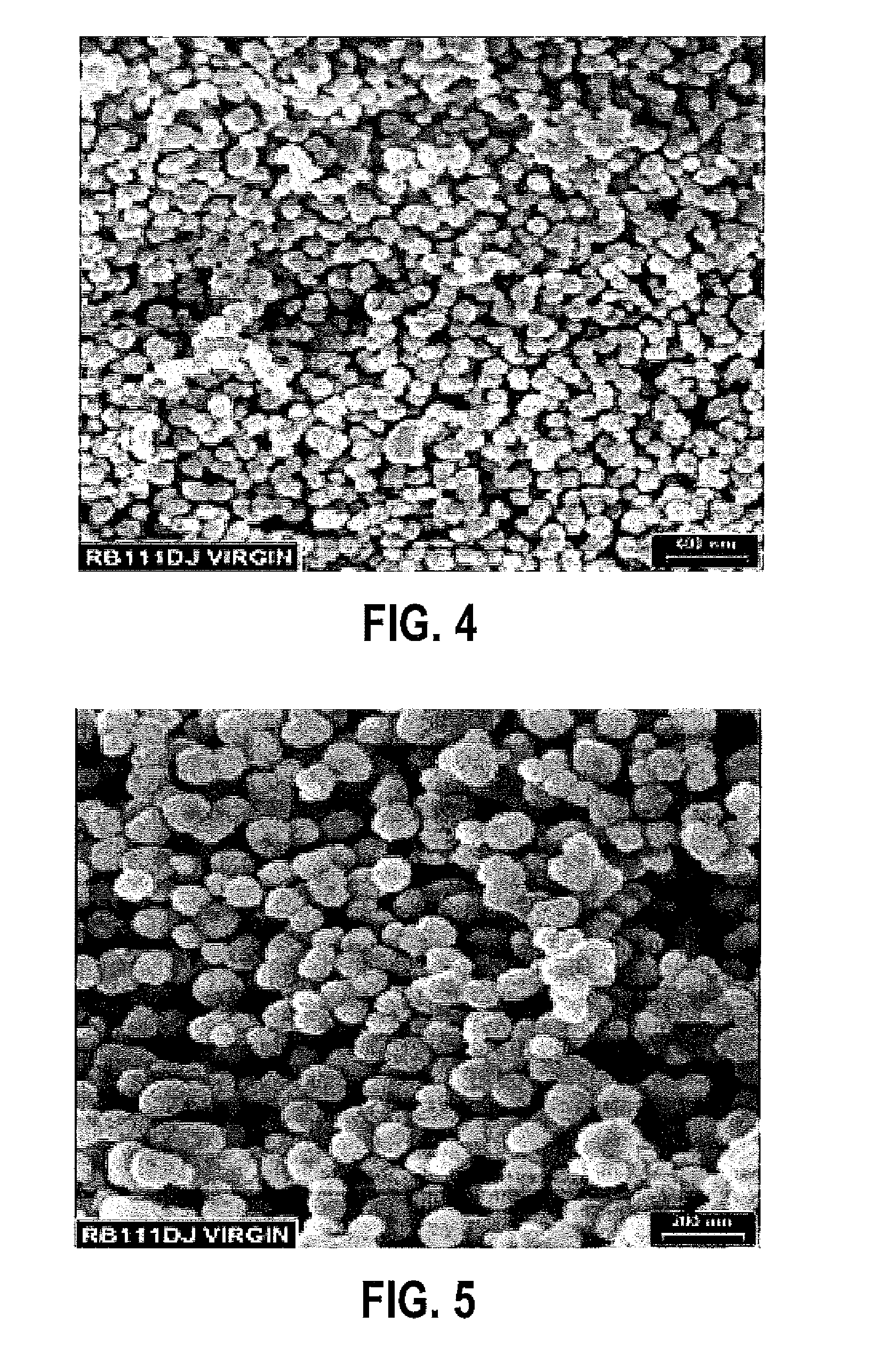

Ceramic particulate material and processes for forming same

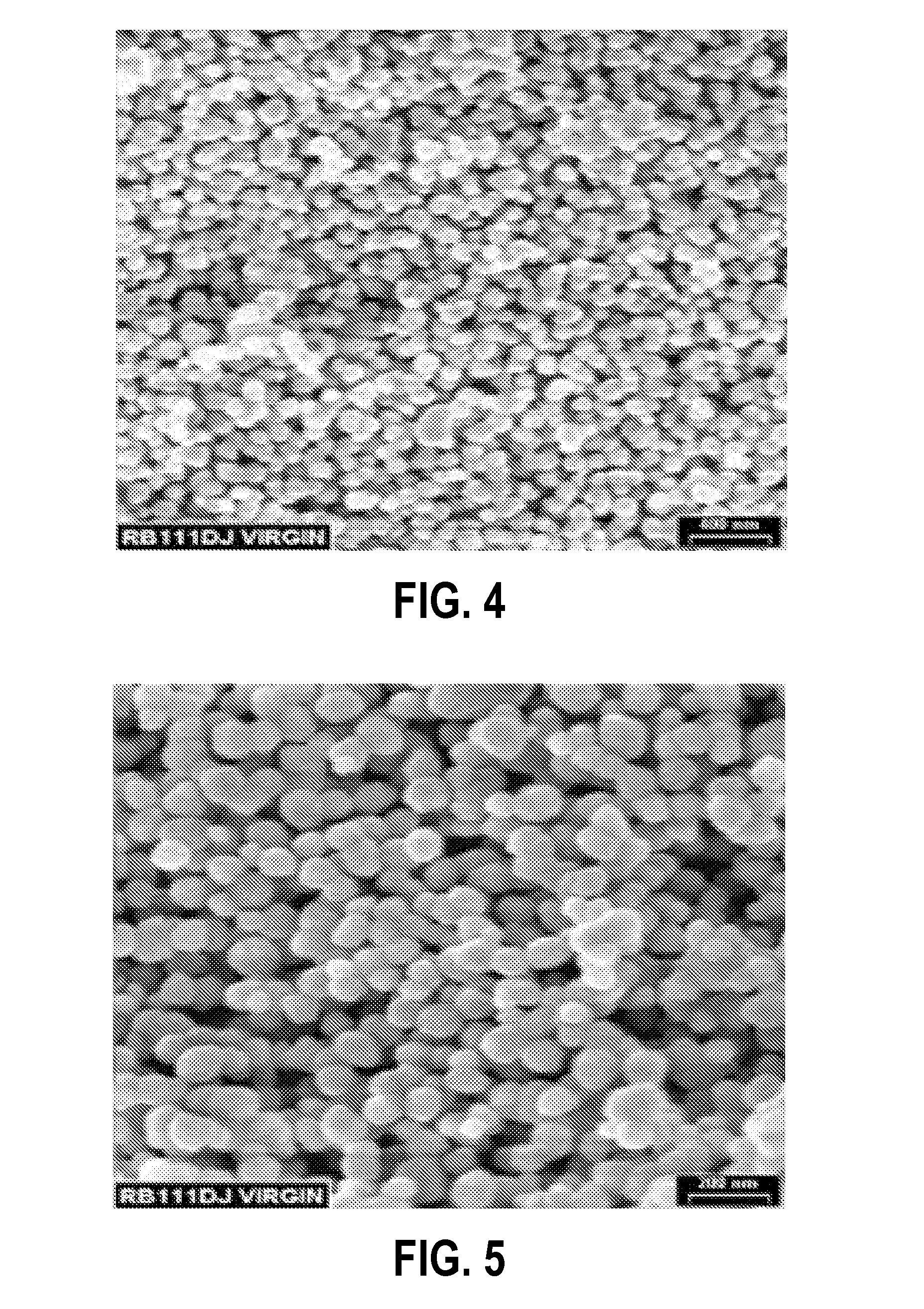

InactiveUS20080176075A1Material nanotechnologyCeramic shaping apparatusImaging analysisMaterials science

Ceramic particulate material includes alumina particles, the particles having a specific surface area (SSA) not less than 15 m2 / g and not greater than 75 m2 / g and a sphericity quantified by at least one of (i) a mean roundness not less than 0.710 as measured by Roundness Correlation Image Analysis, and (ii) a concavity less than 20%, wherein concavity is the percent of alumina particles based on a sample of at least 100 particles, which have a concave outer peripheral portion that extends along a distance not less than 10% of d50 by TEM inspection, the concave outer peripheral portion having a negative radius of curvature as viewed from an interior of the particle

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

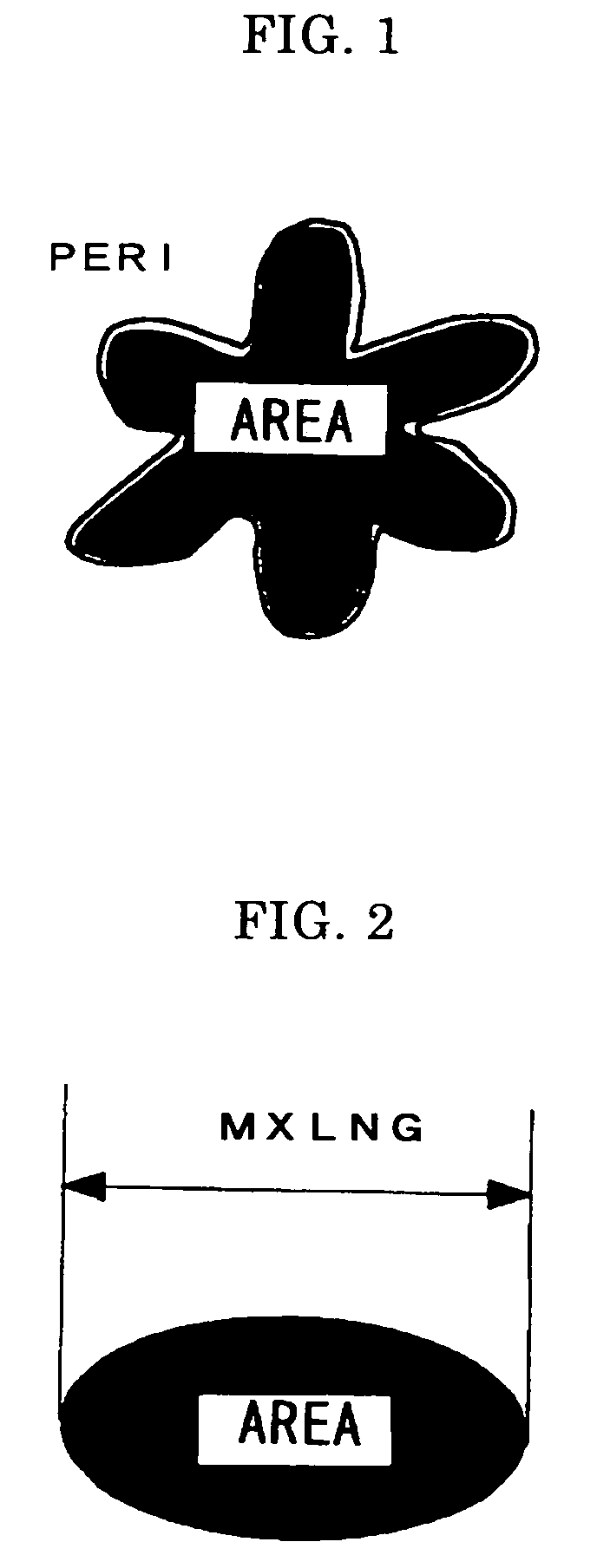

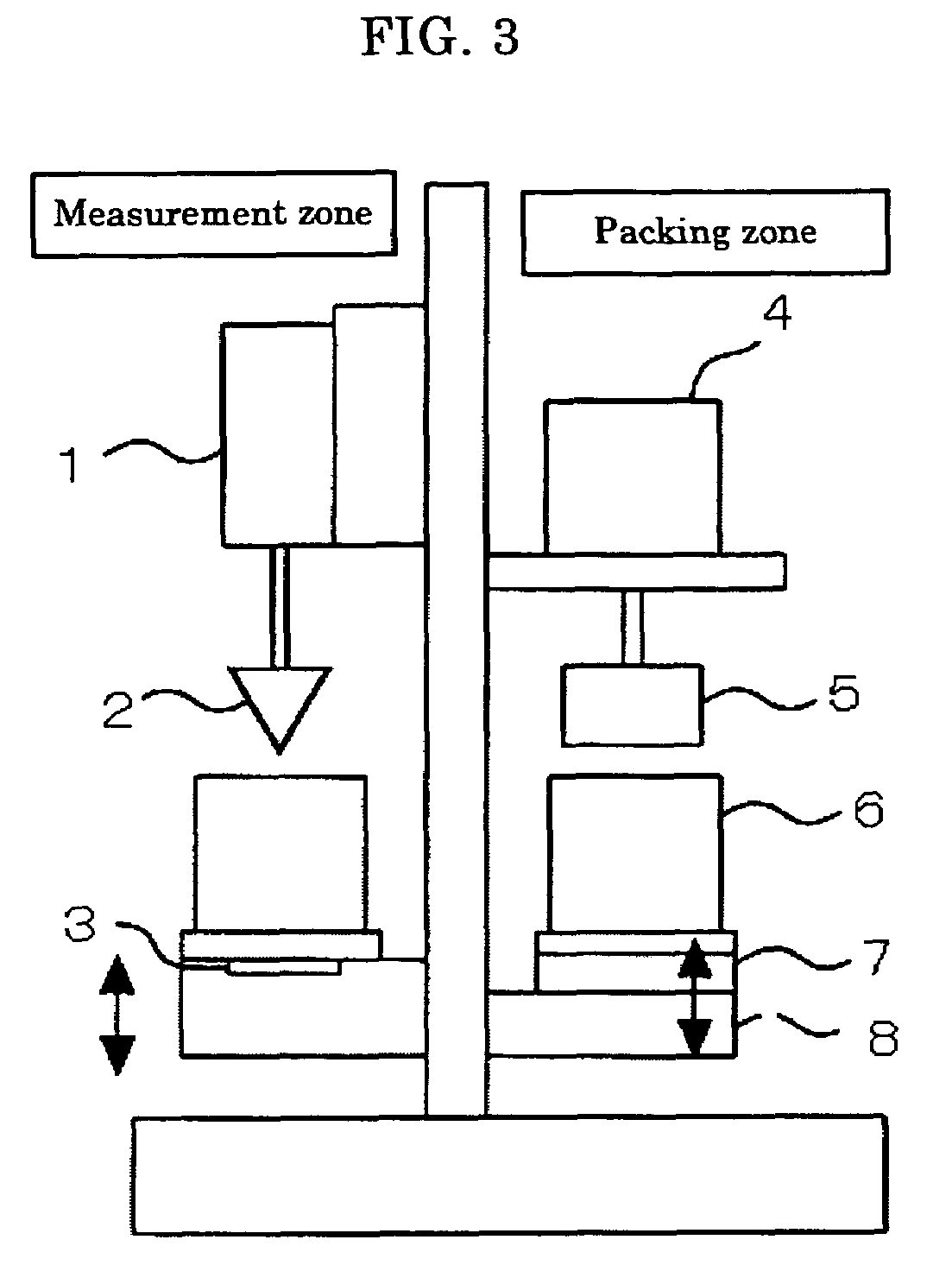

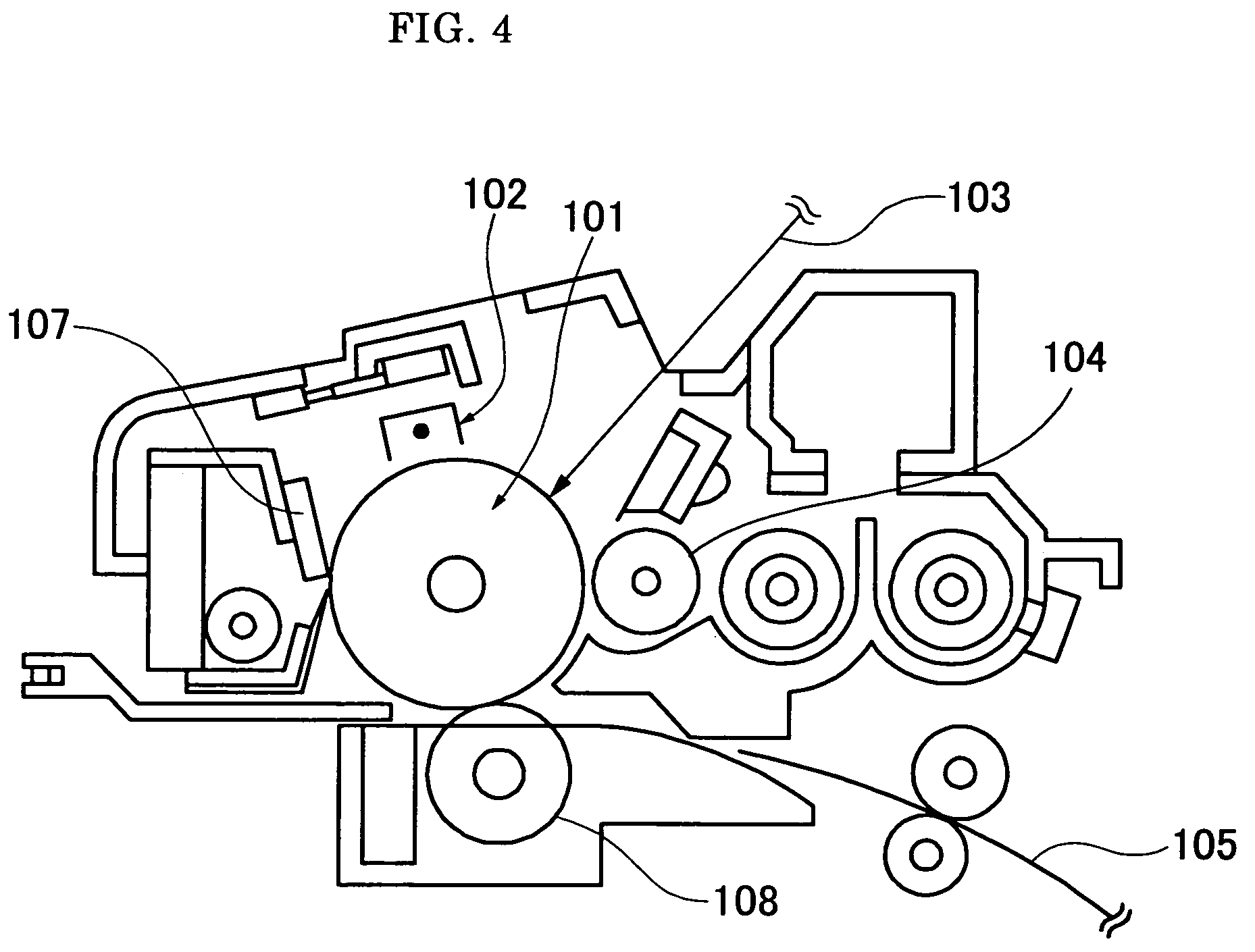

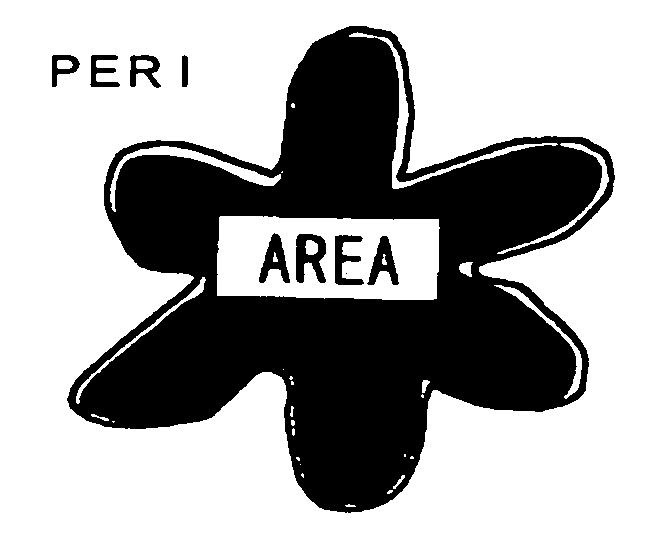

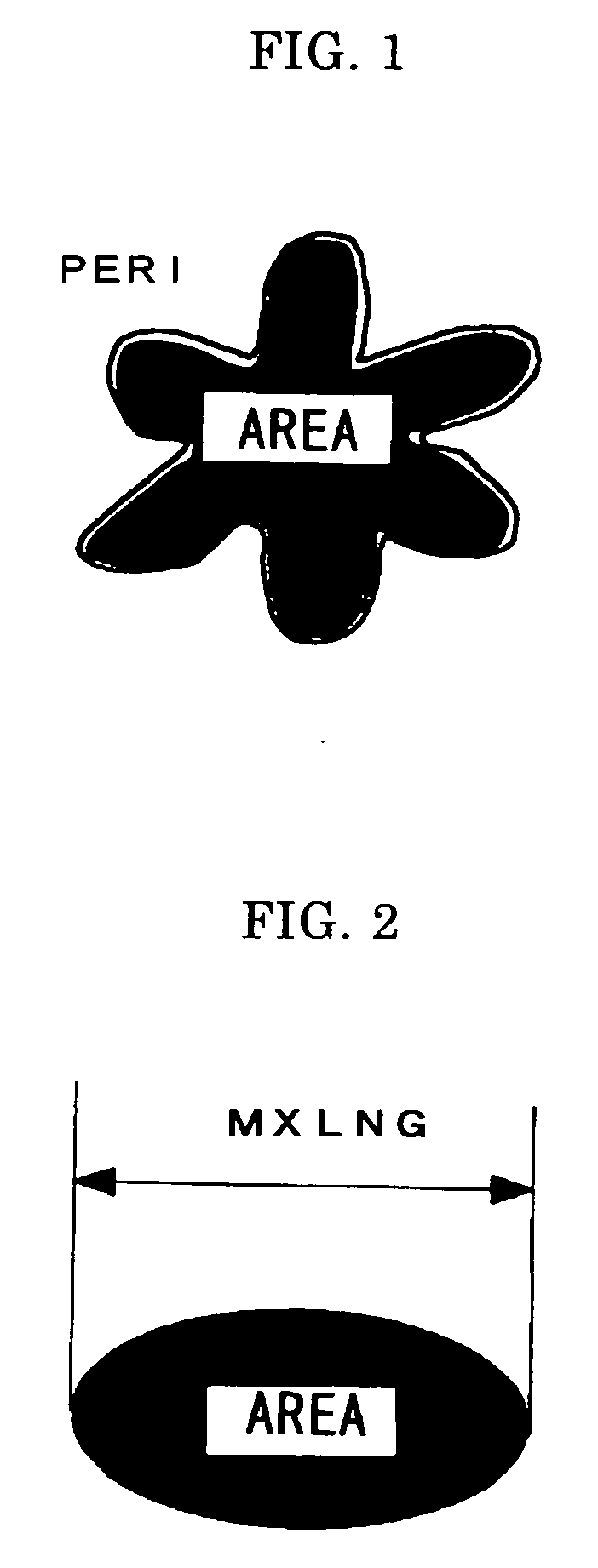

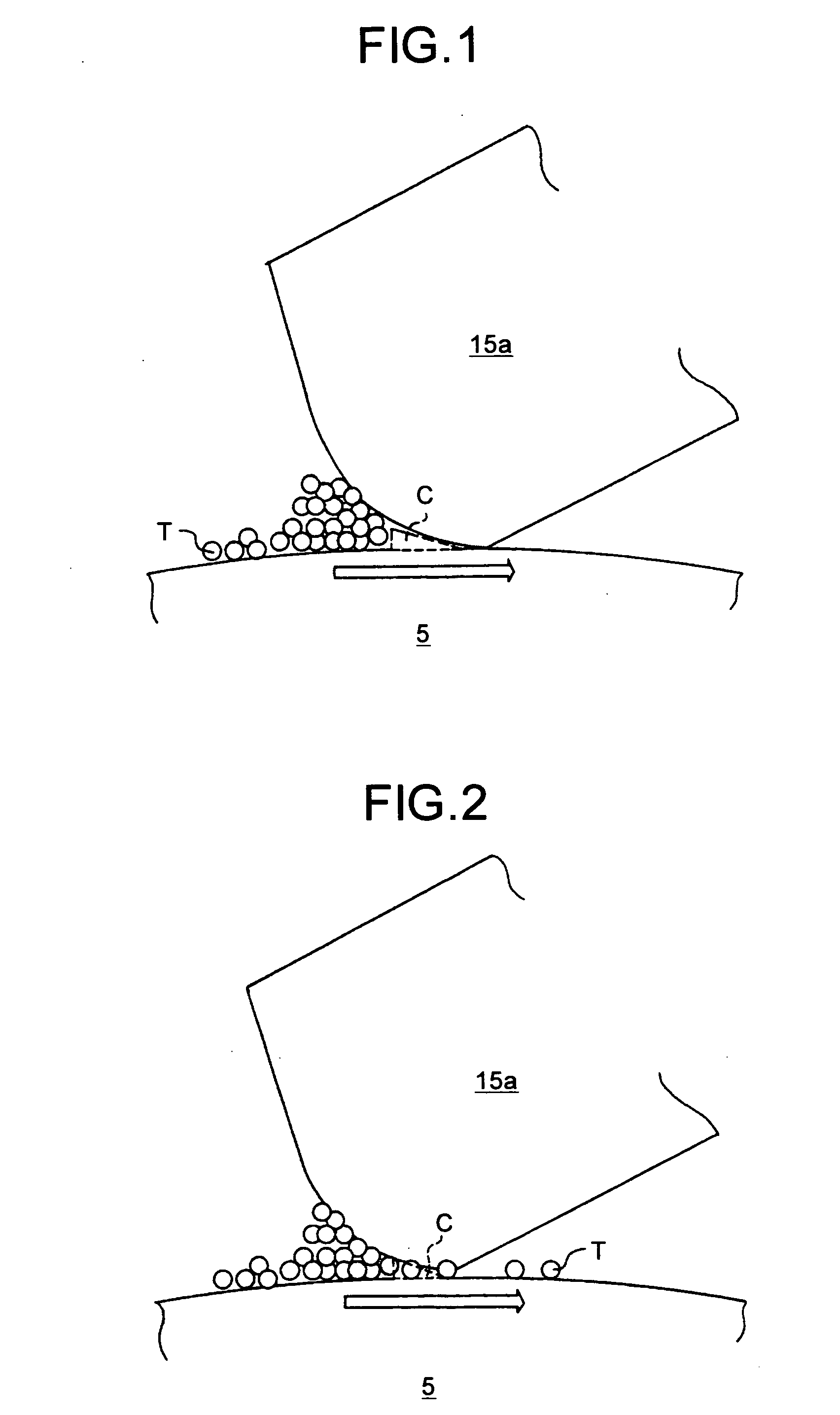

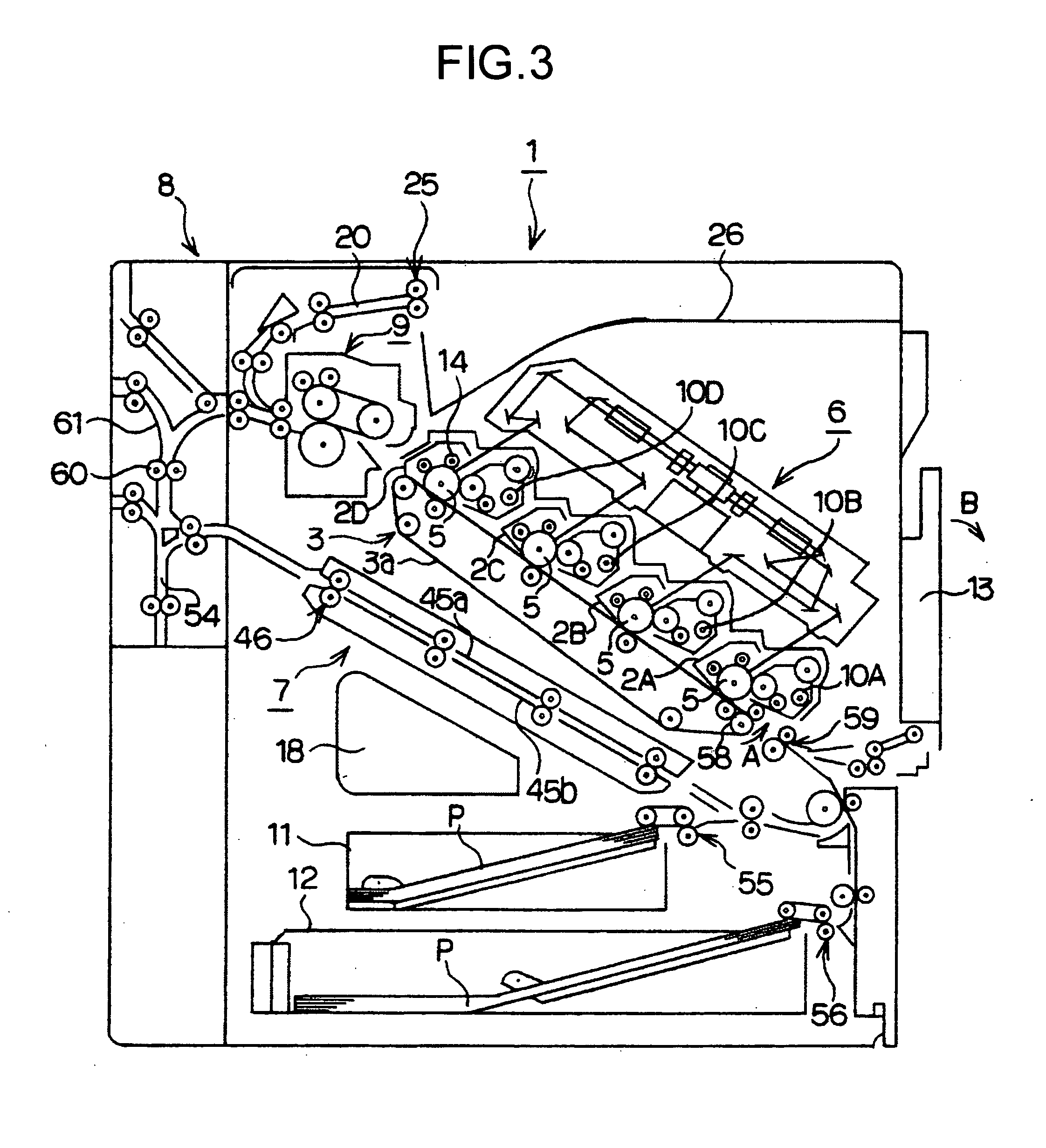

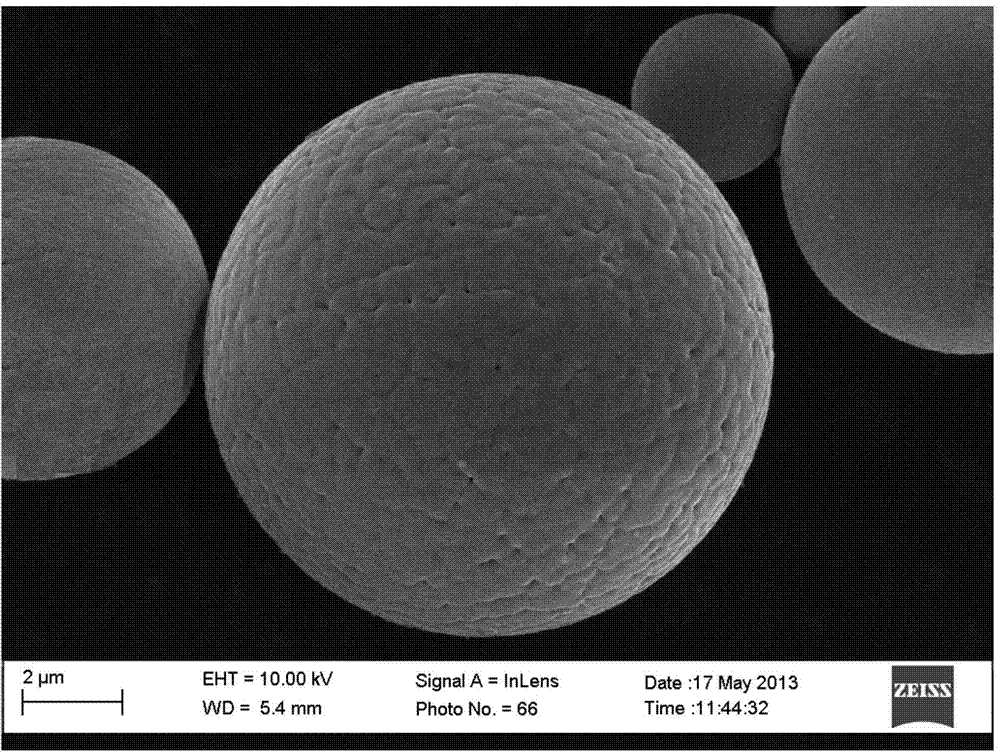

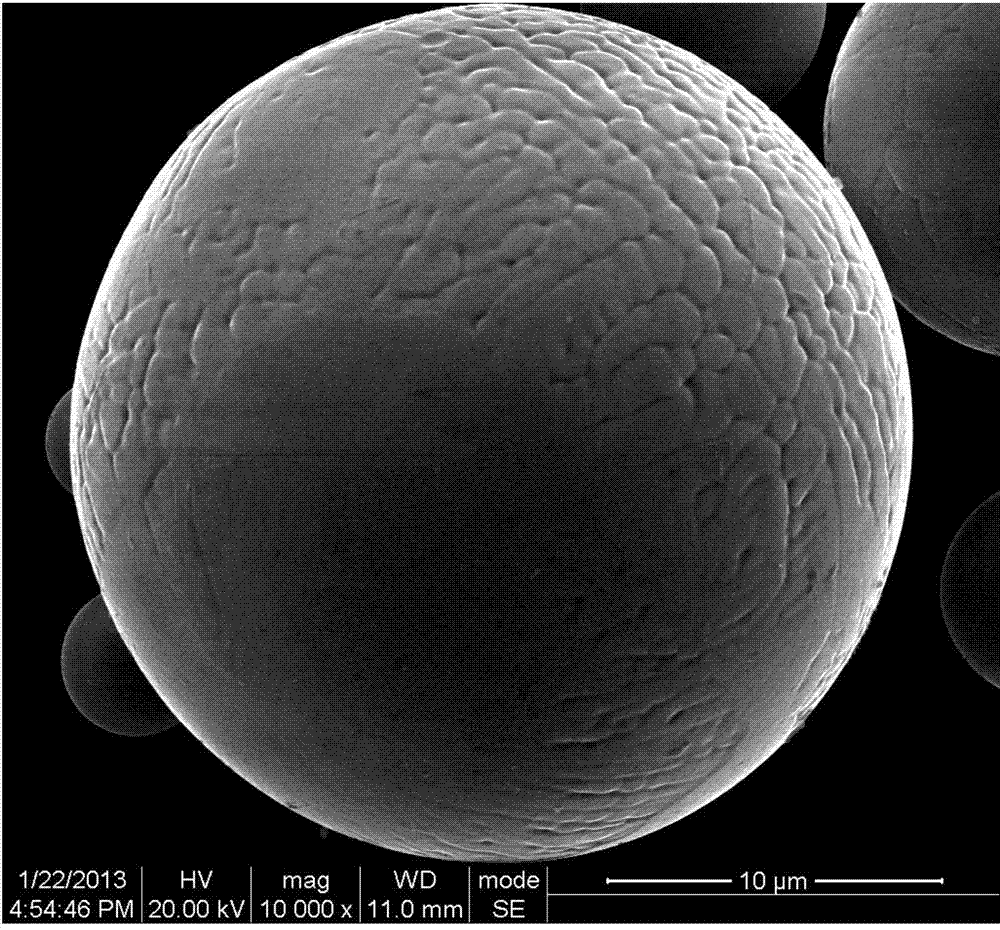

Toner, developer, toner container, process cartridge, image forming apparatus, and image forming method

ActiveUS7318989B2Reduce thicknessDevelopersElectrographic processes using charge patternImage formationSpherical shaped

To provide a toner that can provide long-term removability and high-definition images with reduced image layer thickness and densely-packed toner particles, a developer capable of forming high-quality images using the toner, a toner container for containing the toner, a process cartridge using the toner, an image forming apparatus using the toner, and an image forming method using the toner. The toner of the present invention is a toner having a substantially spherical shape with irregularities on its surface and containing at least a binder resin and a colorant, wherein a surface factor SF-1 that represents the sphericity of toner particles is 105 to 180, a surface factor SF-2 that represents the degree of surface irregularities of the toner particles is correlated with the volume-average diameter of the toner particles, and the toner particles have an inorganic oxide particle-containing layer within 1 μm from their surfaces.

Owner:RICOH KK

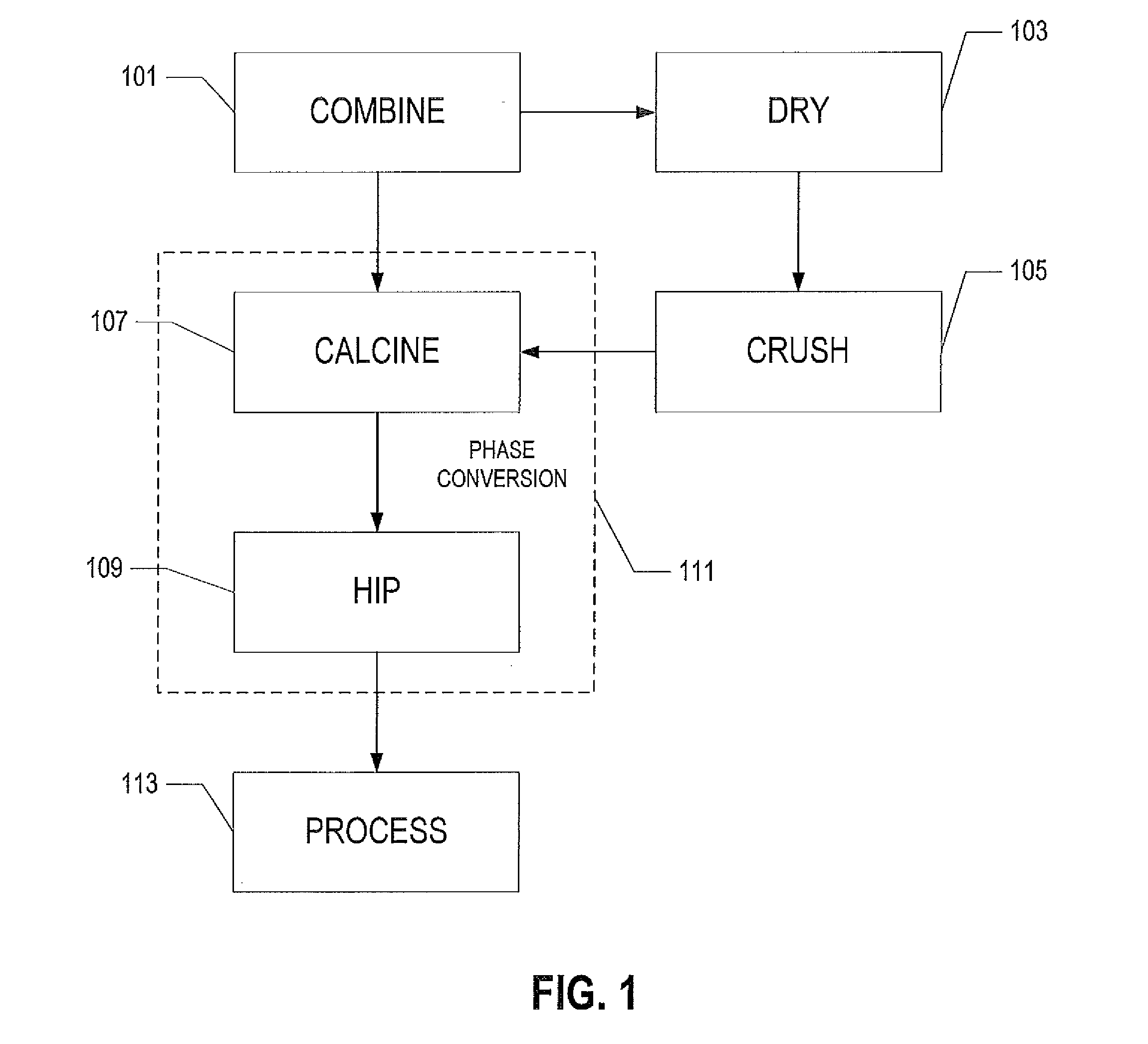

Ceramic particulate material and processes for forming same

ActiveUS20120153547A1Material nanotechnologyOther chemical processesImaging analysisMaterials science

Processes for forming ceramic particulate material. The ceramic particulate material includes alumina particles, the particles having a specific surface area (SSA) not less than 15 m2 / g and not greater than 75 m2 / g and a sphericity quantified by at least one of (i) a mean roundness not less than 0.710 as measured by Roundness Correlation Image Analysis, and (ii) a concavity less than 20%, wherein concavity is the percent of alumina particles based on a sample of at least 100 particles, which have a concave outer peripheral portion that extends along a distance not less than 10% of d50 by TEM inspection, the concave outer peripheral portion having a negative radius of curvature as viewed from an interior of the particle.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

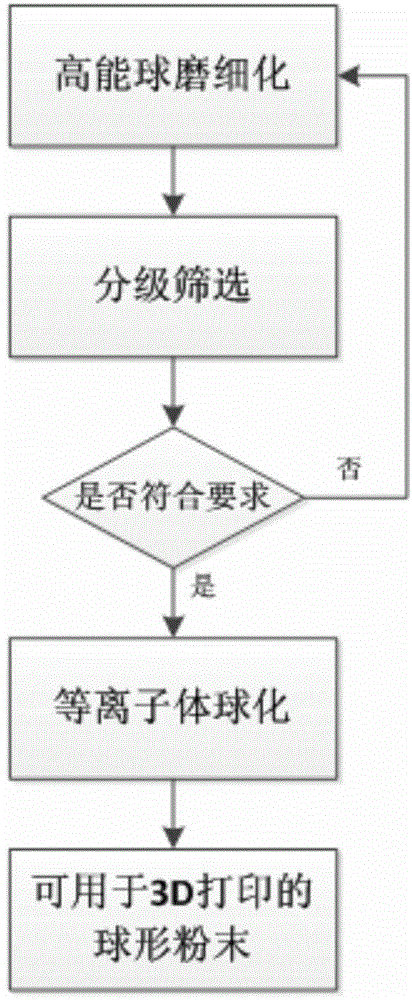

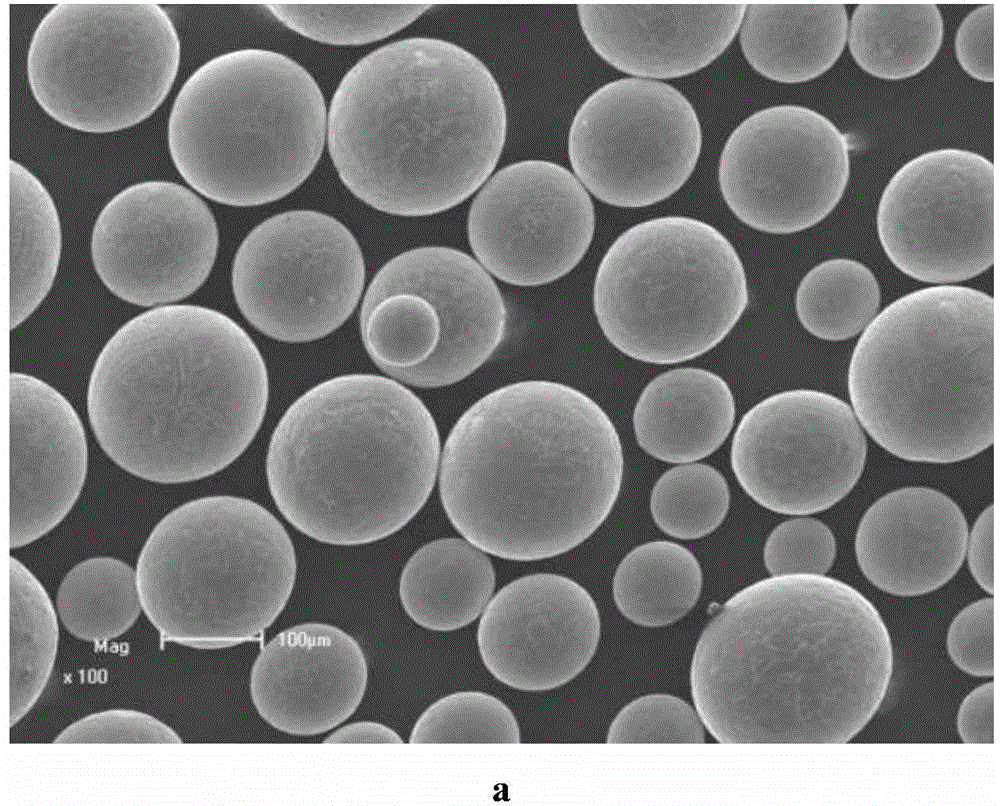

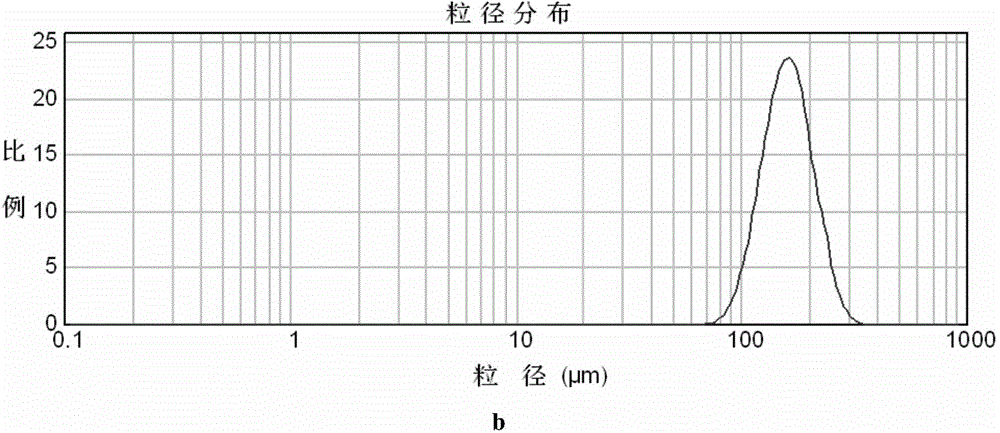

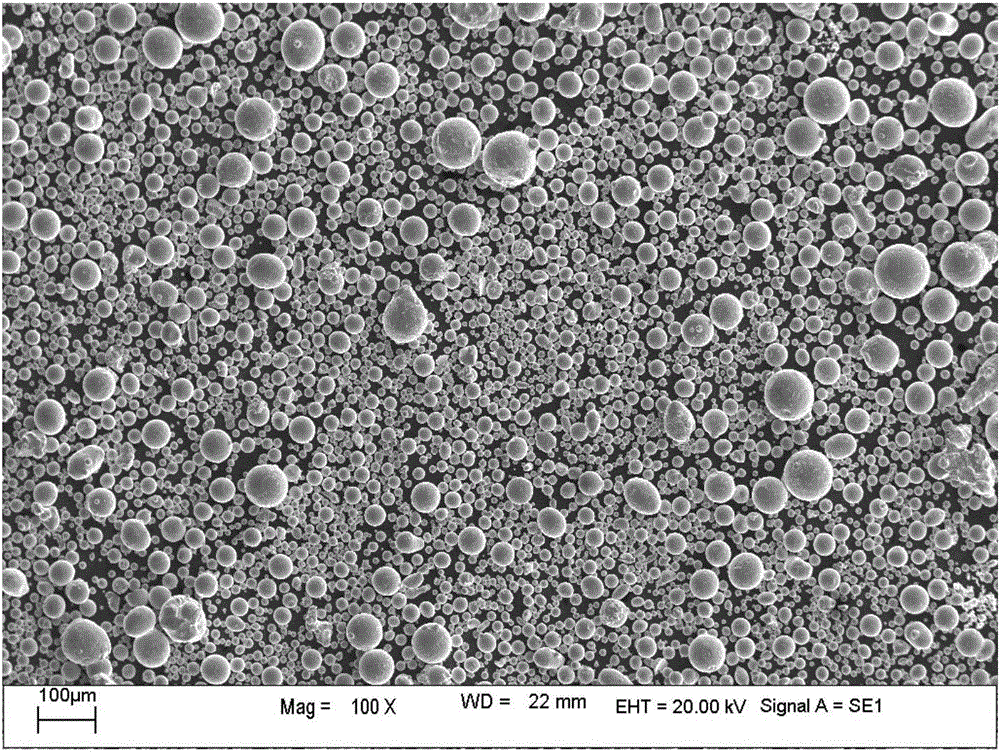

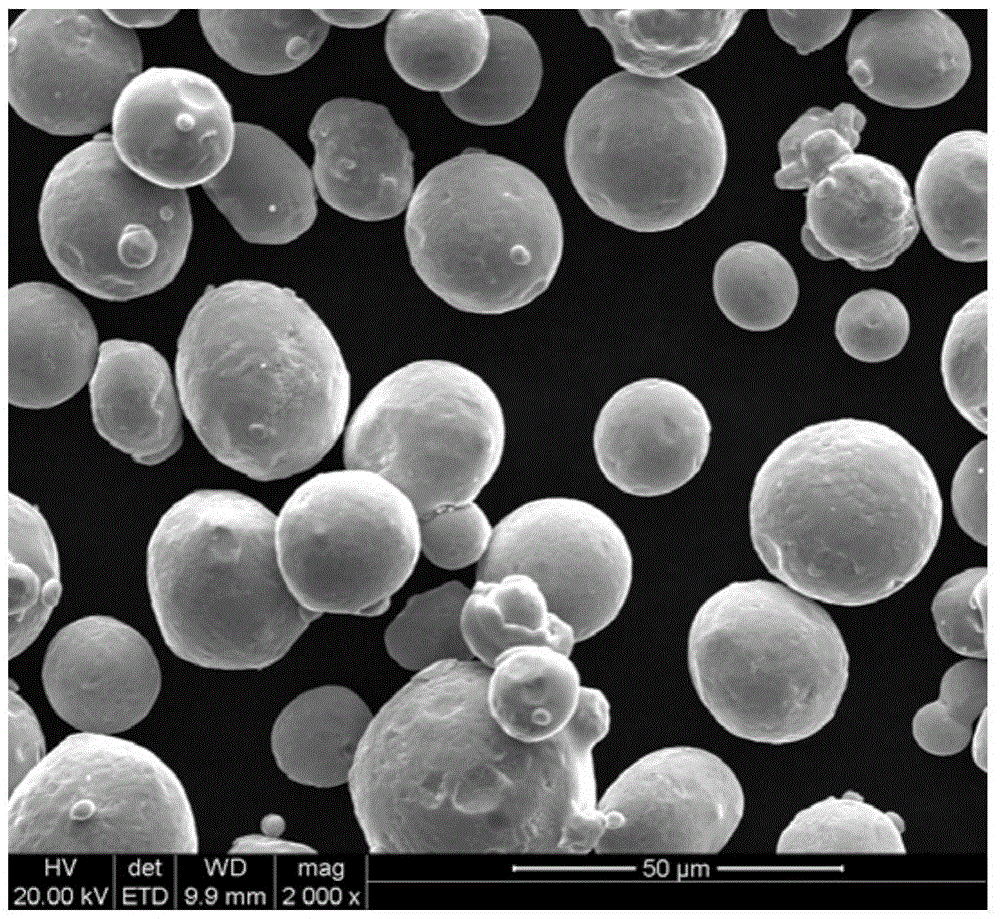

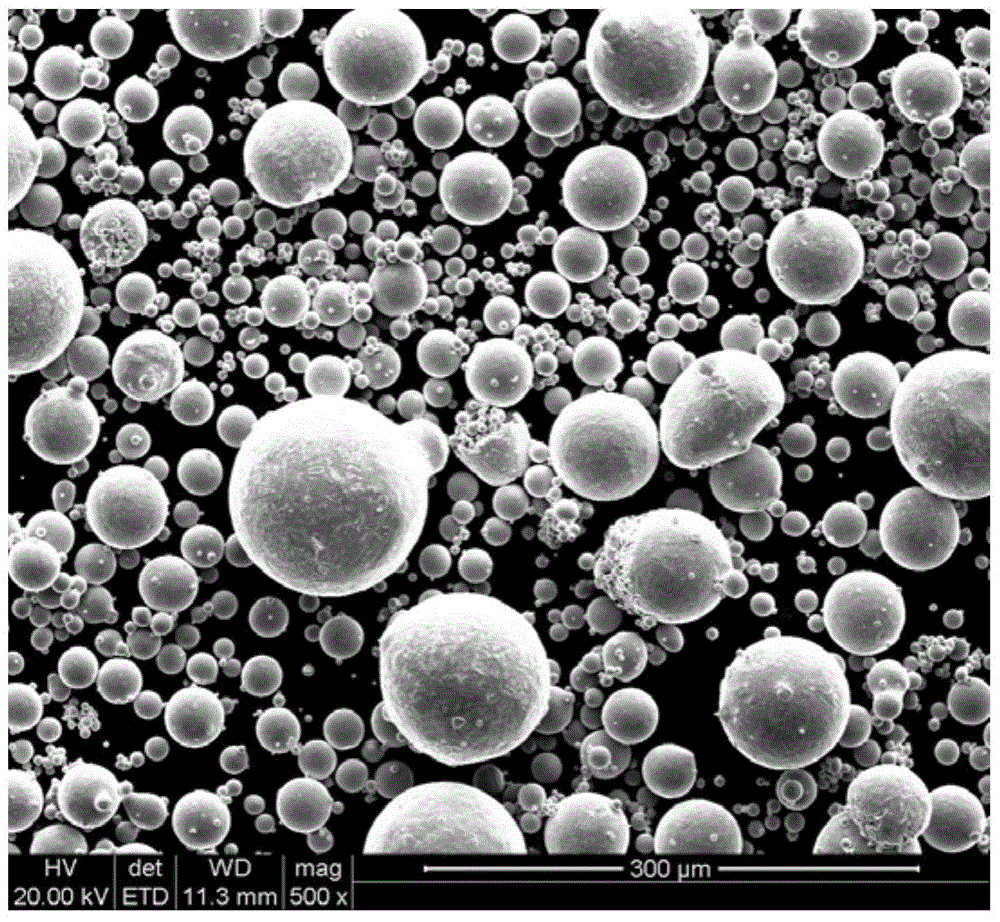

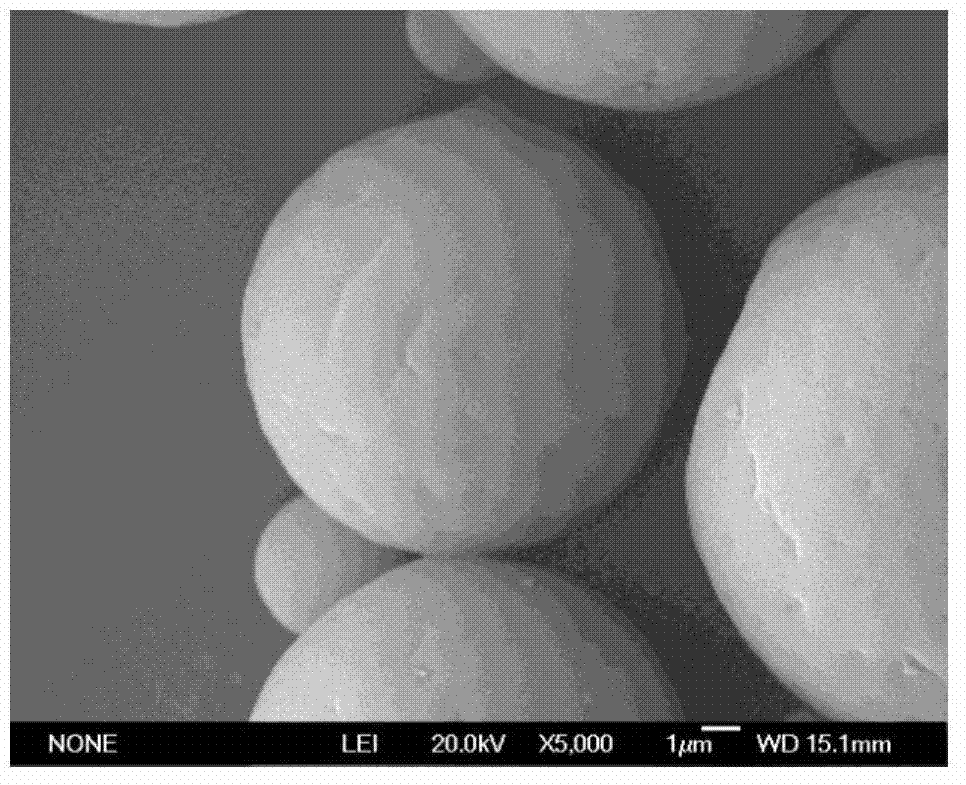

Method for preparing spherical powder material used for three-dimensional printing

The invention discloses a method for preparing a spherical powder material used for three-dimensional printing. The method includes the steps of raw material selecting, high-energy ball milling and radio-frequency plasma spherizing. Selected raw materials are metal or alloy powder in the step of raw material selecting; the step of high-energy ball milling is carried out under the argon shielding condition, petroleum ether serves as the ball milling medium, and the metal or alloy powder is aluminum alloy powder, or titanium alloy powder, or nickel-base alloy powder, or stainless steel powder or tungsten alloy powder; according to the step of radio-frequency plasma spherizing, the total gas flow is 100 L / min-200 L / min, the input power of plasma is 50 kW-100 kW, the negative pressure of a gas outlet of a system is minus 1000 Pa-minus 2000 Pa, and the powder conveying amount is 50 g / min-150 g / min. The manufactured spherical powder is high in sphericity degree, even in granularity, low in oxygen content and good in liquidity, has few defects and is suitable for three-dimensional printing. The method for preparing the spherical powder material used for three-dimensional printing has the advantage that the process is accurate and controllable.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

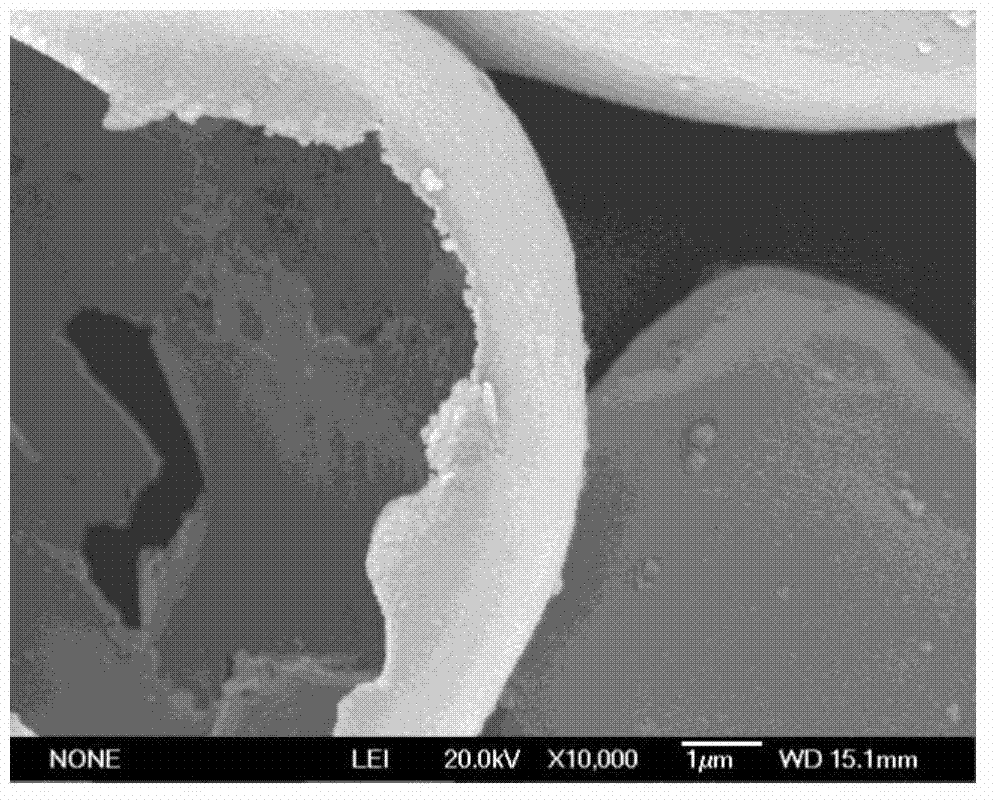

Preparation method of mesophase carbon microspheres from coal liquefaction residues

InactiveCN102225755ANarrow particle size distributionSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereQuinoline

The invention discloses a preparation method of mesophase carbon microspheres from coal liquefaction residues serving as raw materials, which comprises the following steps of: firstly carrying out solvent extraction on the coal liquefaction residues, then carrying out a series of processing to obtain refined asphalt with different contents of quinoline insoluble substances, and carrying out thermal polycondensation reaction on the refined asphalt in the presence of a chemical auxiliary agent and a nucleating accelerator at the temperature of 380-450 DEG C, the pressure of 0-5 MPa and the stirring rotation speed of 40-500 r / min for 1-20 hours to obtain the mesophase microspheres. According to the invention, the chemical auxiliary agent and the nucleating accelerator can be added during theheat treatment process to improve the yield and narrow the particle size distribution of the mesophase carbon microbeads, and the mesophase carbon microspheres are prepared from the coal liquefactionresidues serving as the raw materials and have the advantages of low cost, simple preparation process, high yield (up to 35%), narrow particle size distribution, good sphericity, etc.

Owner:ZIBO MINING GRP

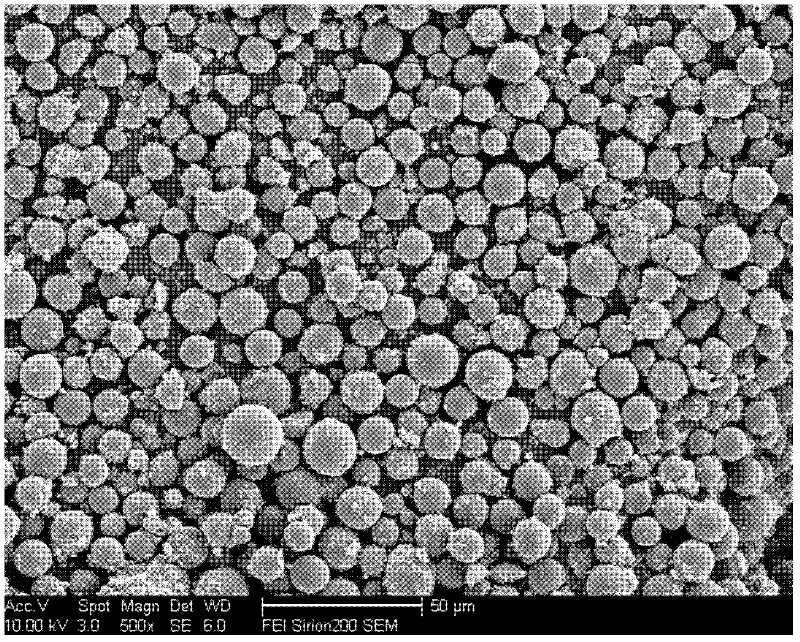

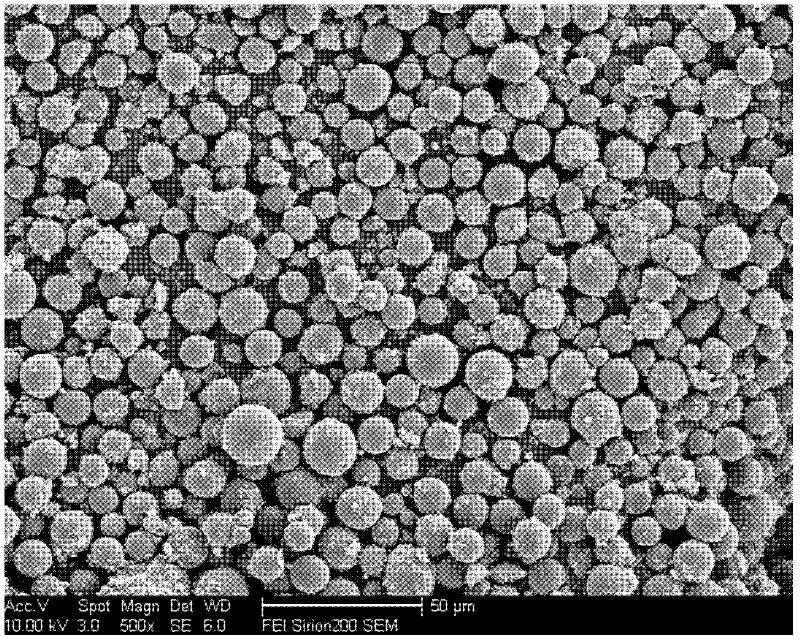

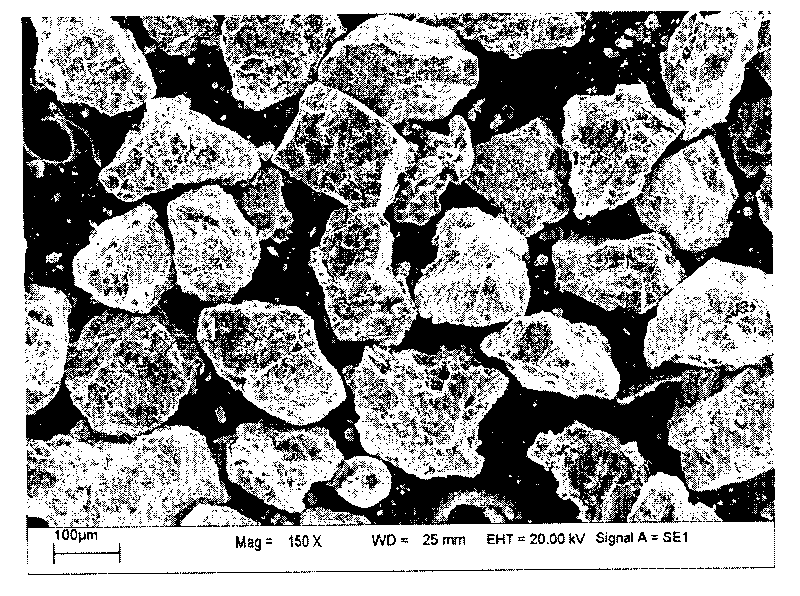

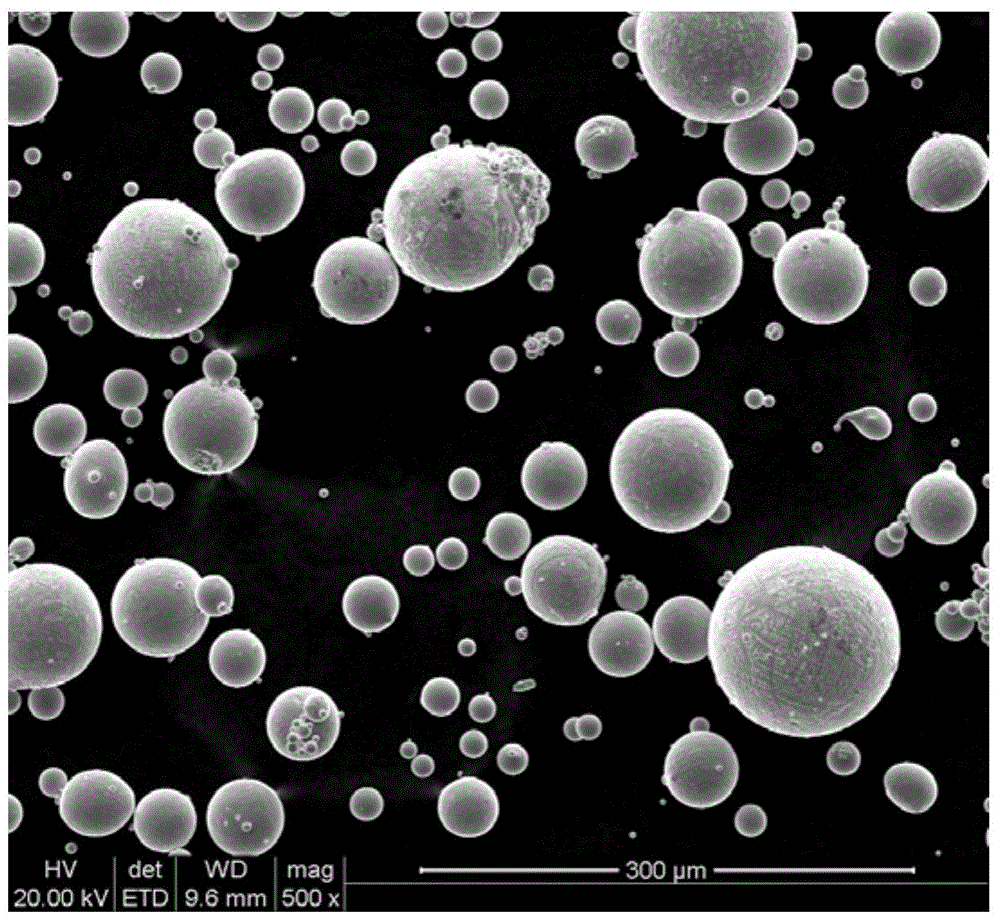

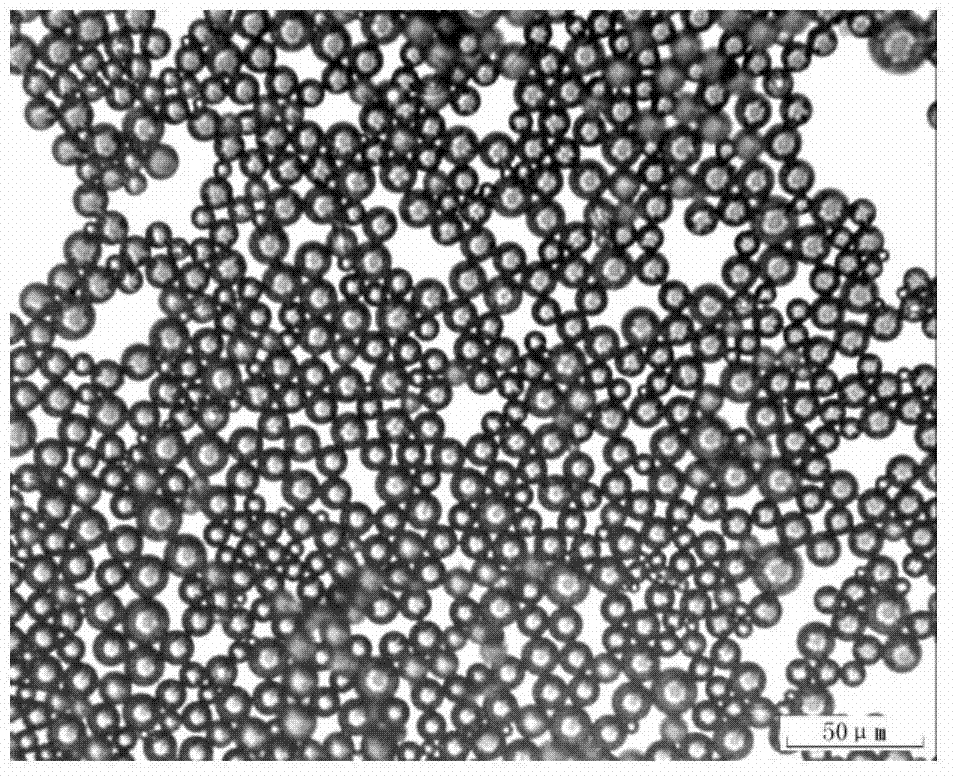

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

Solder ball and method for producing same

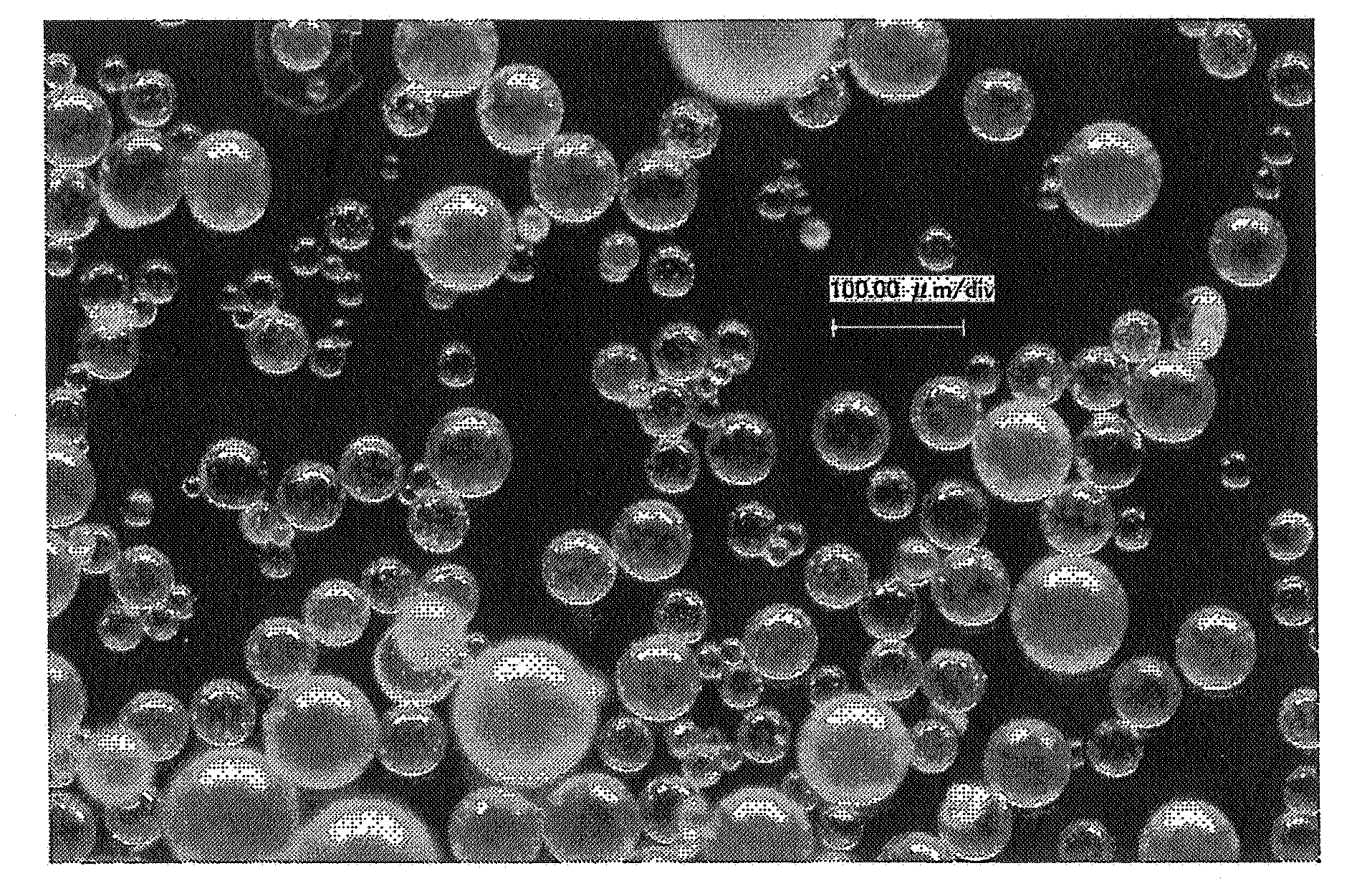

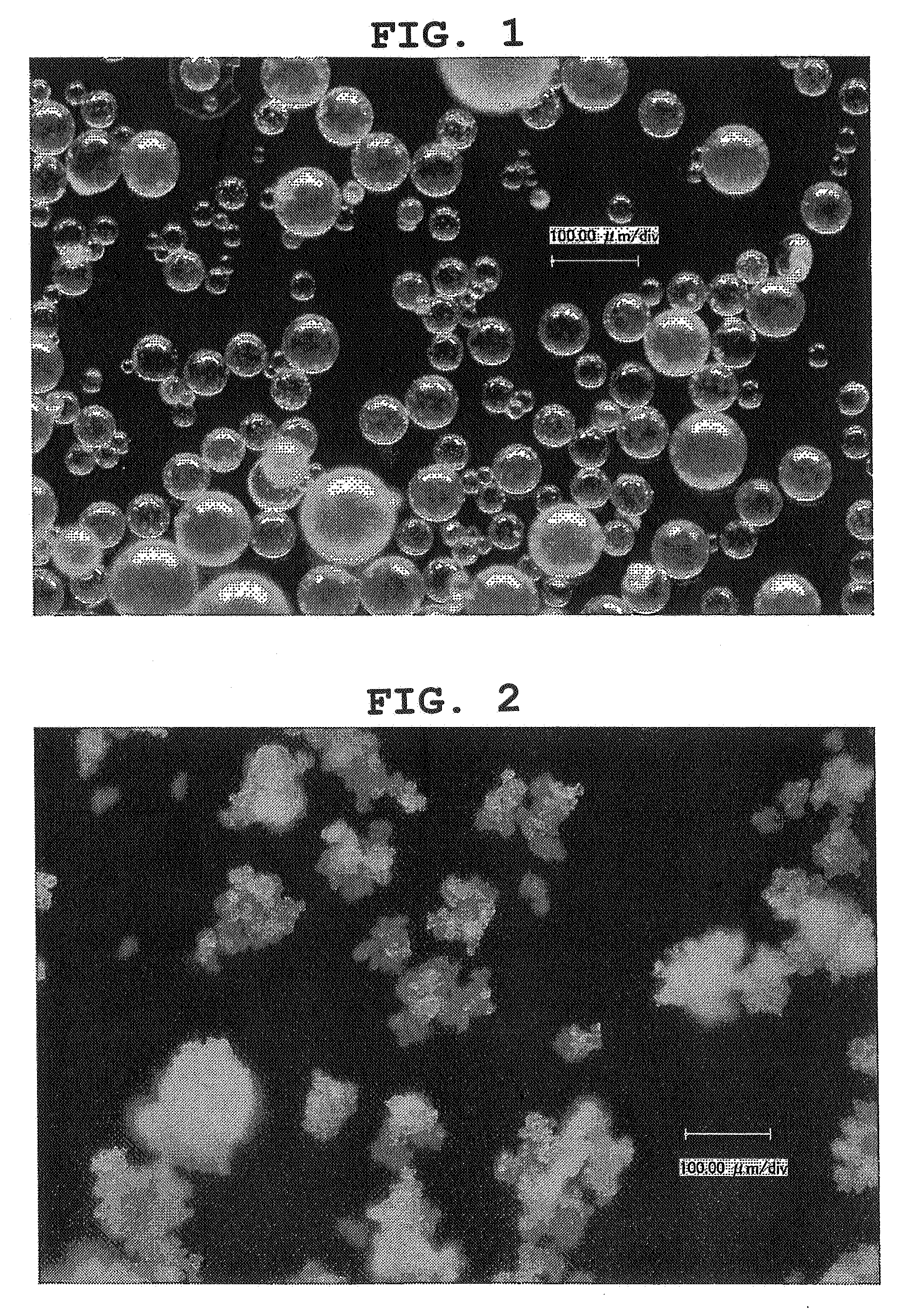

InactiveUS6517602B2High degree of sphericityNarrow distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass % of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

High-density small-particle-size nickel-cobalt-manganese hydroxide and preparing method thereof

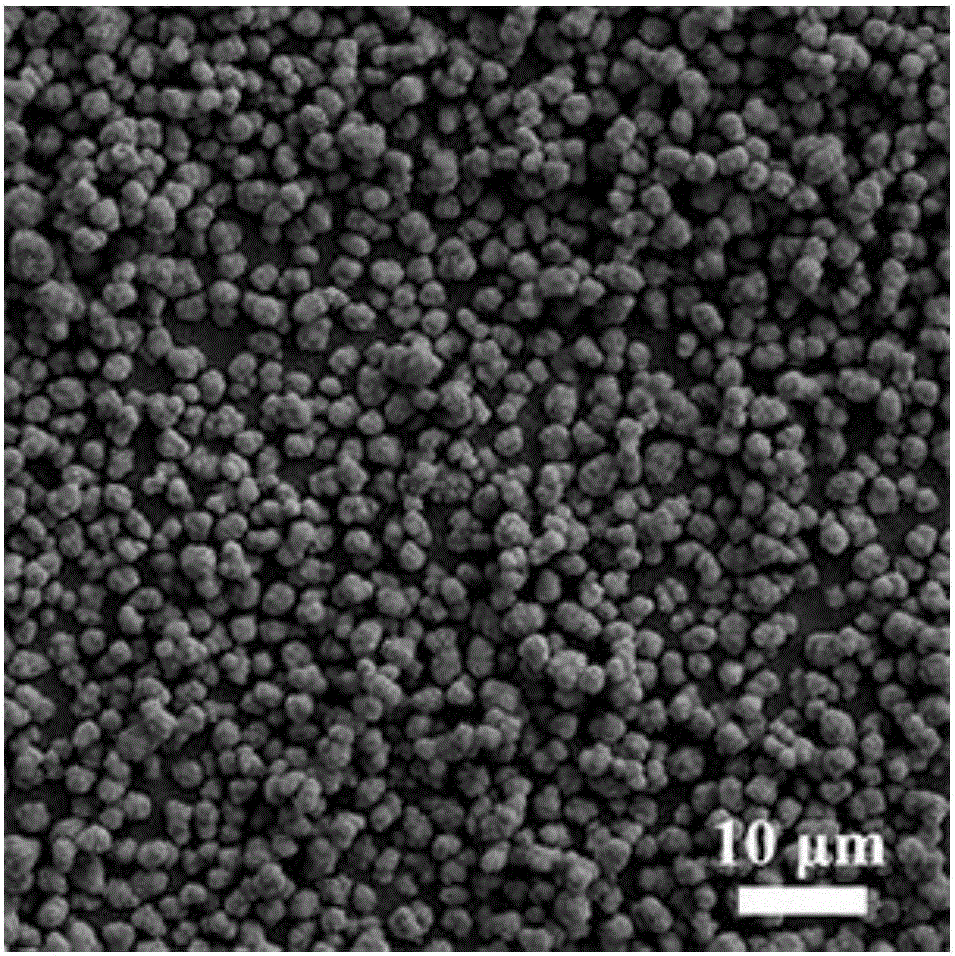

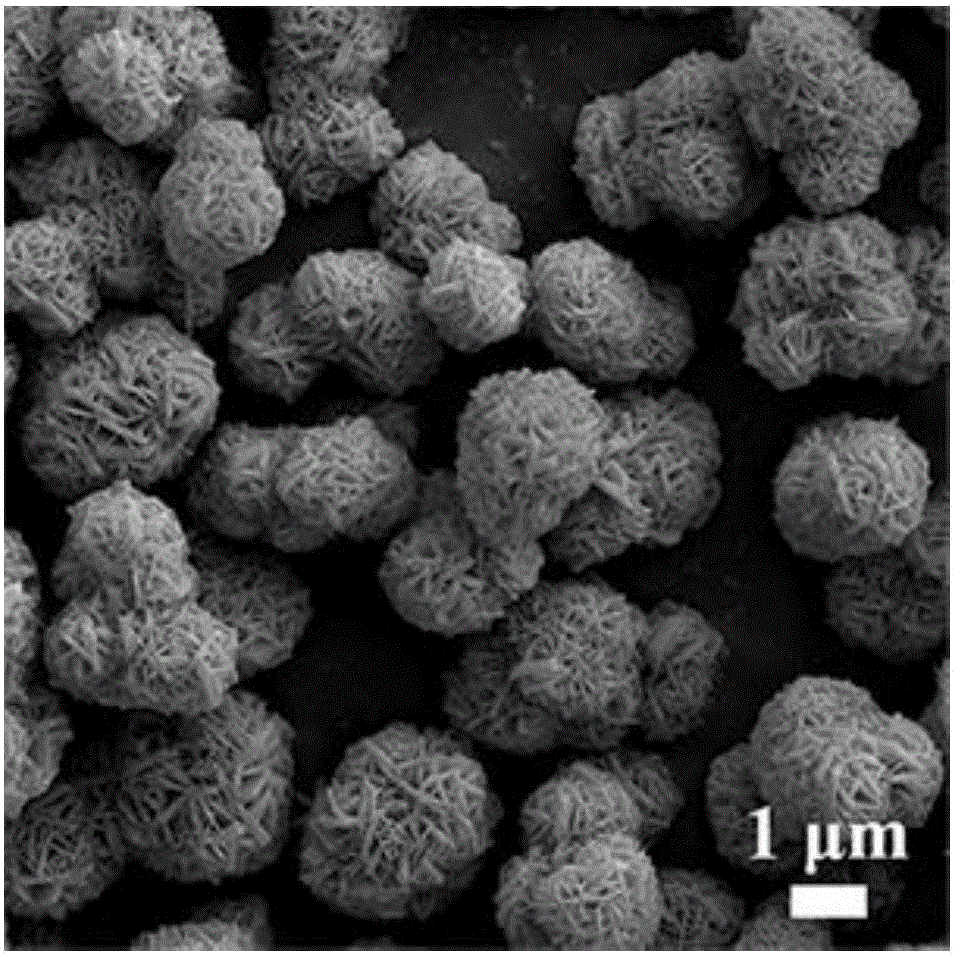

The invention relates to a high-density small-particle-size nickel-cobalt-manganese hydroxide and a preparing method thereof. The nickel-cobalt-manganese hydroxide and the preparing method thereof are characterized in that: the general chemical formula of the nickel-cobalt-manganese hydroxide is NixCoyMnz(OH)2, wherein the sum of the x, the y and the z is 1, the x is not more than 0.8 and not less than 0.3, the y is not more than 0.4 and not less than 0.1, and the z is not more than 0.4 and not less than 0.1. The nickel-cobalt-manganese hydroxide is provided, so that problems of small-particle-size nickel-cobalt-manganese hydroxides prepared by methods at present, namely nonuniform element distribution, poor particle appearance, loose surfaces, difficult particle size control, nonuniformity, low tap density, and the like are overcome. A complexing control crystallization coprecipitation method is adopted. By a special technical process of producing nucleuses, growing, and subjecting particles to continuous frictional collision under a continuously increased solid liquid ratio, an aqueous solution of a nickel-cobalt-manganese soluble salt and an aqueous sodium hydroxide solution are subjected to coprecipitation under complexing of ammonia to obtain the small-particle-size nickel-cobalt-manganese hydroxide having characteristics of uniform element distribution, good degree of sphericity, uniform particle size distribution and high tap density.

Owner:宁夏中色金辉新能源有限公司

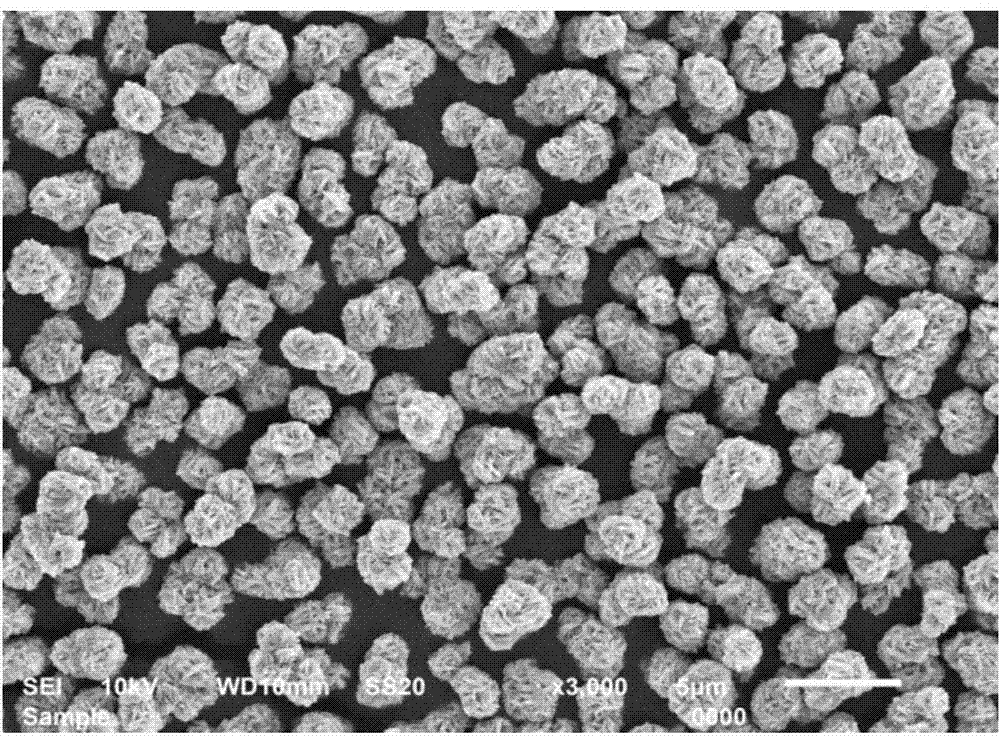

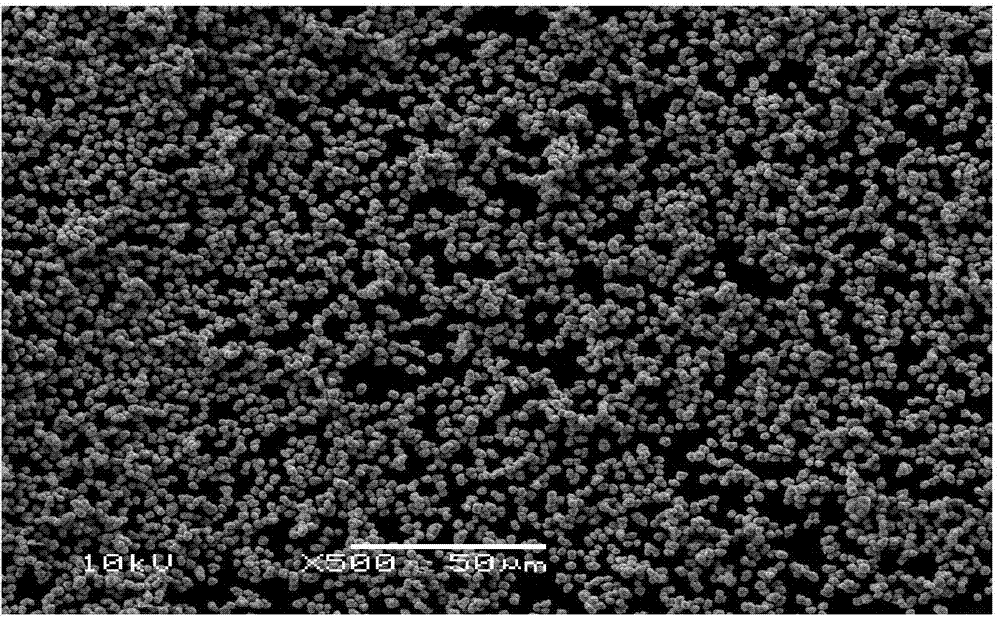

Short-flow preparation method of micro-sized spherical titanium powder

ActiveCN101716686AReduce dehydrogenation processShort processTransportation and packagingMetal-working apparatusDehydrogenationDie casting

Owner:江苏金物新材料有限公司

Method of forming ceramic beads

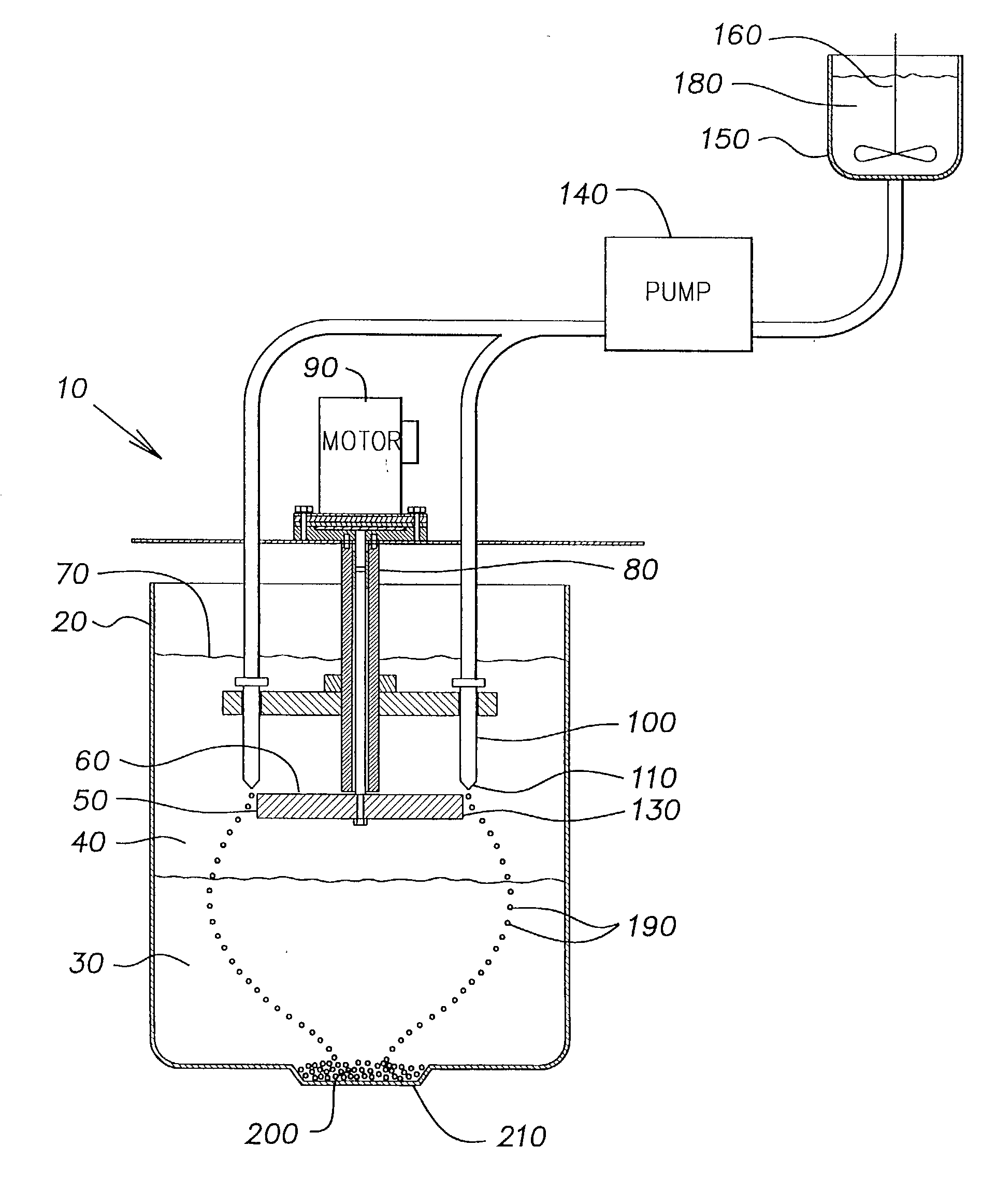

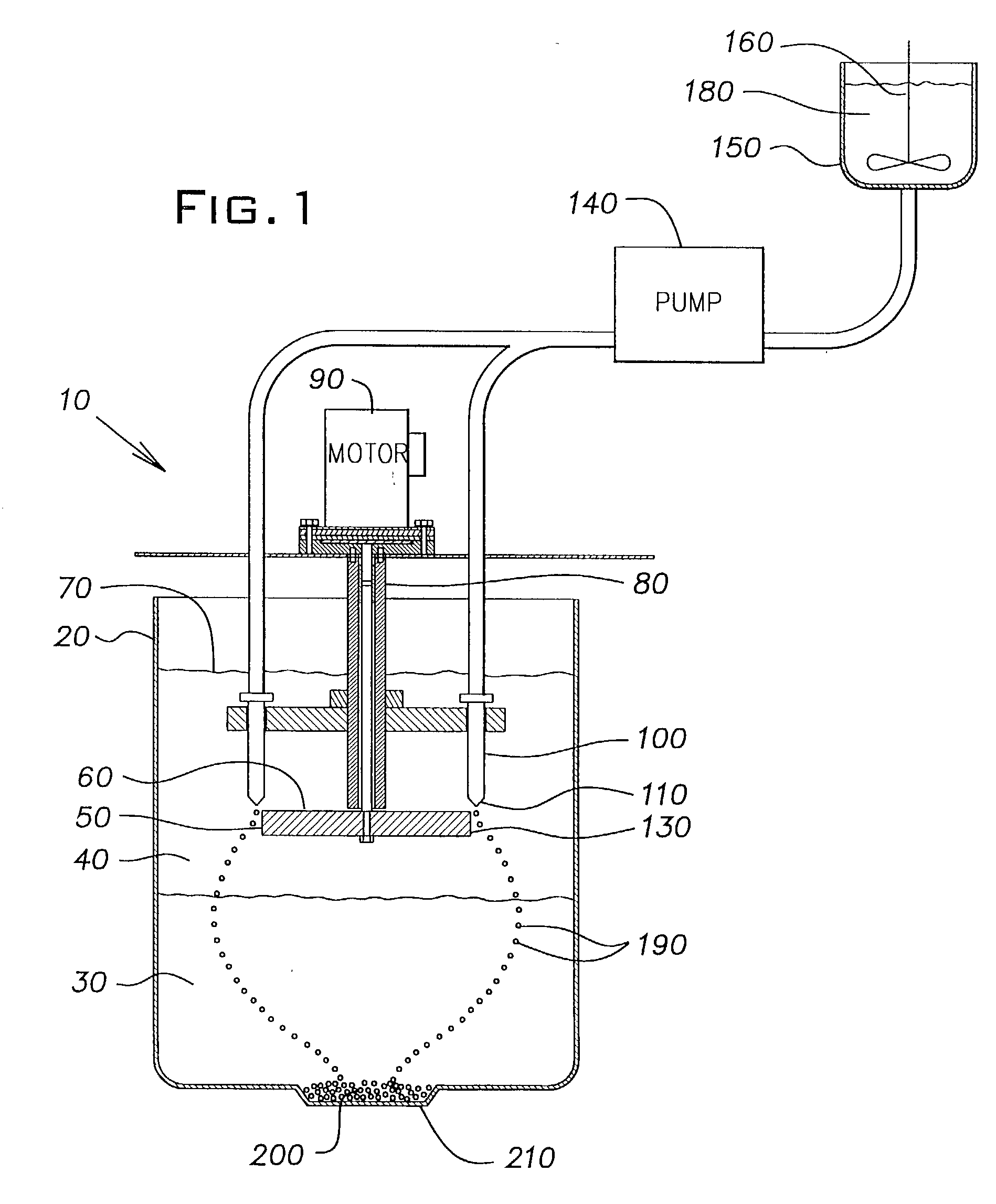

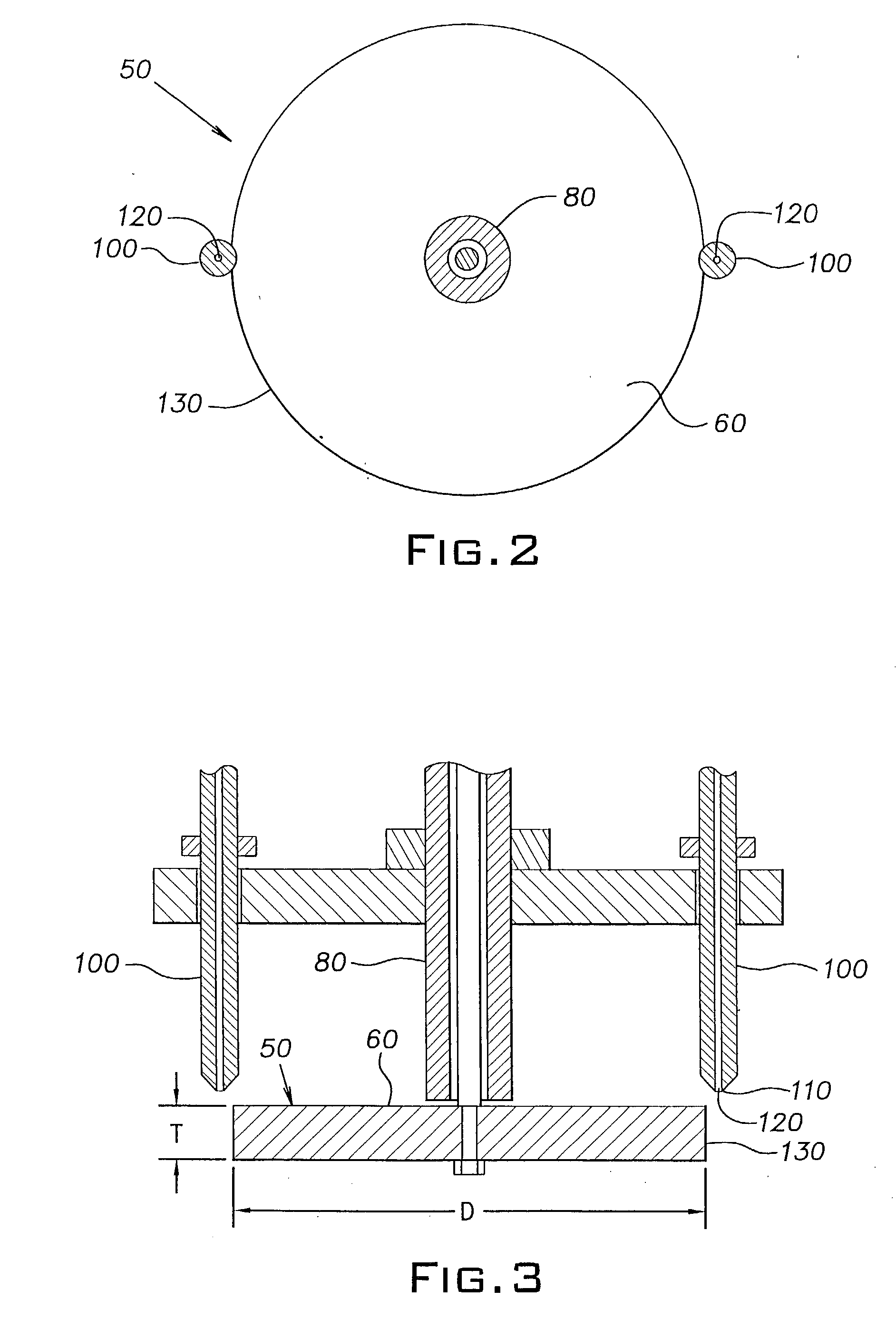

InactiveUS20040007789A1Reduce blemishesGood dispersionGranulation by liquid drop formationCeramic shaping apparatusMetallurgyFluid layer

A method of forming substantially spherical ceramic beads that includes conveying an aqueous ceramic slurry to a nozzle tip that is immersed in an inert water-immiscible fluid layer. The nozzle tip is spaced a predetermined distance away from a rotating disk that is also immersed in the immiscible fluid layer. The rotating disk creates a shear force that at the nozzle tip that dislodges droplets of the aqueous ceramic slurry from the nozzle tip into the immiscible fluid layer. Once dislodged, the droplets assume a substantially spherical shape and a substantially mono-modal size distribution. The droplets are permitted to pass from the immiscible fluid layer into an aqueous gelling solution wherein the droplets are converted into rigid beads. In a preferred embodiment of the invention, the rigid beads are recovered from the gelling solution, washed, and then sintered to obtain a density of greater than about 98% of theoretical density and a sphericity of greater than about 0.95. The method can be used to fabricate substantially spherical zirconia-containing beads having a diameter within the range of from about 0.1 mm to about 2.0 mm that are useful, for example, as grinding media.

Owner:CERCO

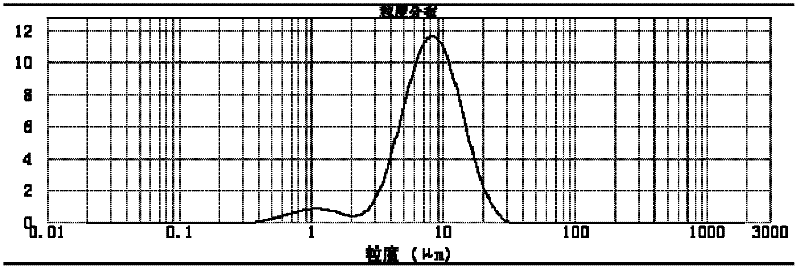

Preparation method of low-sulfur small-particle-size nickel-cobalt-manganese hydroxide

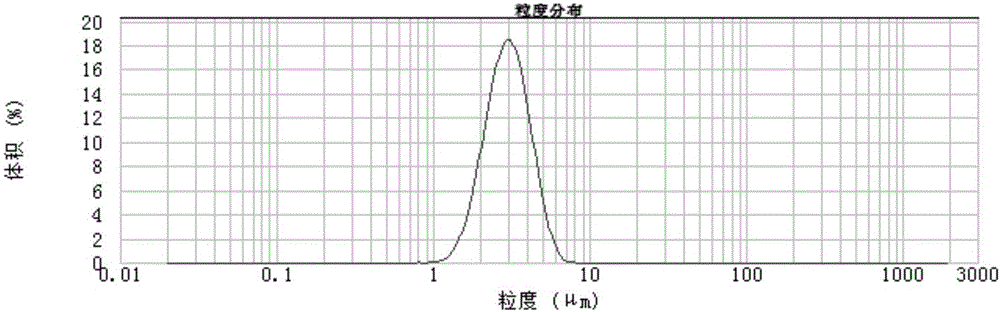

The invention belongs to the technical field of synthesis of lithium ion battery ternary anode material precursors, and particularly relates to a preparation method of a nickel-cobalt-manganese hydroxide. The method comprises the following steps: preparing a small-particle-size nickel-cobalt-manganese hydroxide by a nucleation / crystallization isolation method: introducing a nickel-cobalt-manganese mixed metal solution, sodium hydroxide and ammonia water under the condition of a high pH value at the same time for nucleation, adding a certain amount of additive at the end of nucleation to help a crystal nucleus to be dispersed rapidly, and entering a crystal nucleus growing stage to obtain a spherical particular nickel-cobalt-manganese hydroxide with D50 being equal to 2 to 3 mum, high dispersity and high degree of sphericity; controlling the washing condition, so that the sulfur content of the nickel-cobalt-manganese hydroxide is as low as 1,500ppm. The method has the advantages of easiness and convenience in operation, high flexibility, no need of modifying a reaction kettle, easiness for expanded production and the like.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

316L stainless steel powder for 3D printing technology and preparation method thereof

ActiveCN105537582AIncrease profitIncrease superheatAdditive manufacturing apparatusTransportation and packagingManufacturing technologyGranularity

The invention relates to 316L stainless steel powder for the 3D printing technology and a preparation method thereof. The vacuum melting technology is adopted for the method, an ultrasonic vibration and air flow classification method is used for matching powder of different granularities, and the 316L stainless steel powder suitable for the 3D printing technology of different types of metal is prepared through the vacuum degassing technology. Compared with the prior art, the 316L stainless steel powder has the advantages of being high in sphericity degree, uniform in granularity distribution, low in oxygen content, low in impurity content, capable of meeting performance requirements of different 3D printing technologies for powder material and promoting the development of the metal material increasing manufacturing technology and the like.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD +1

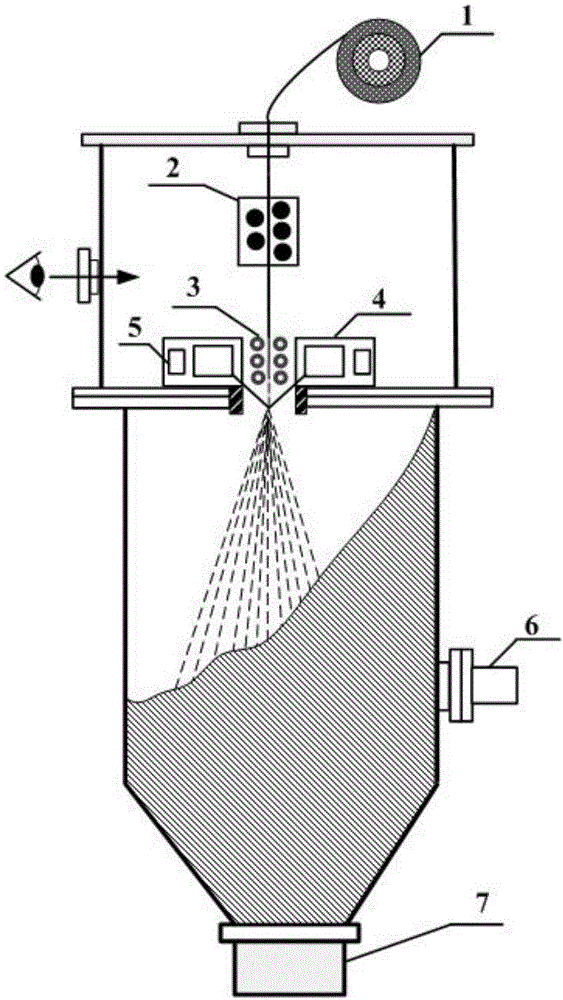

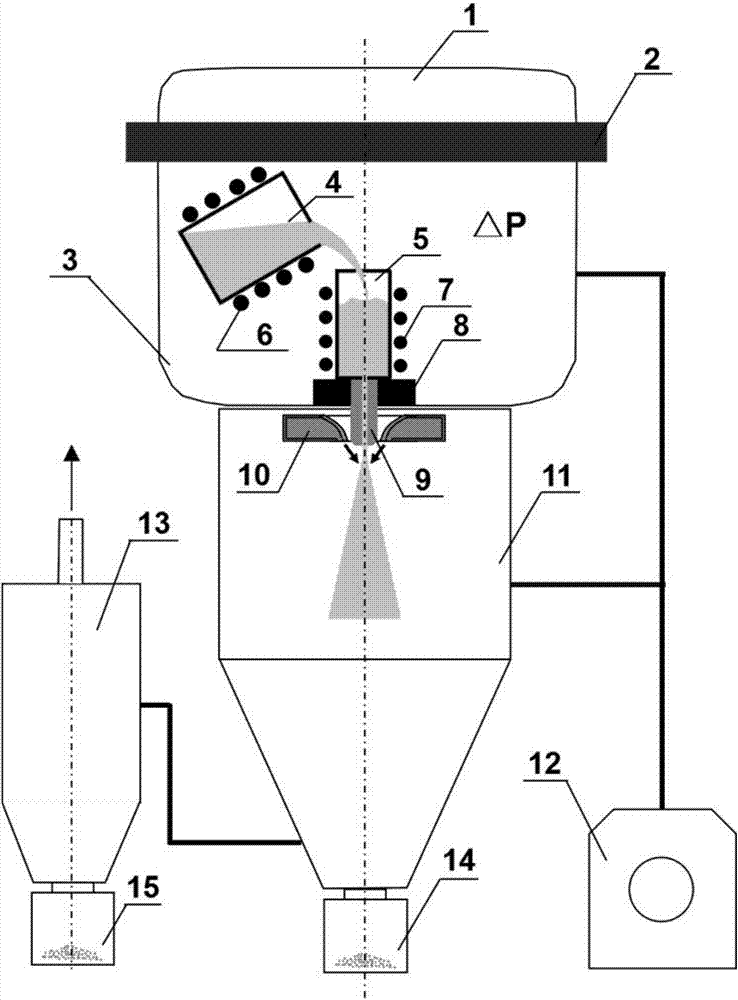

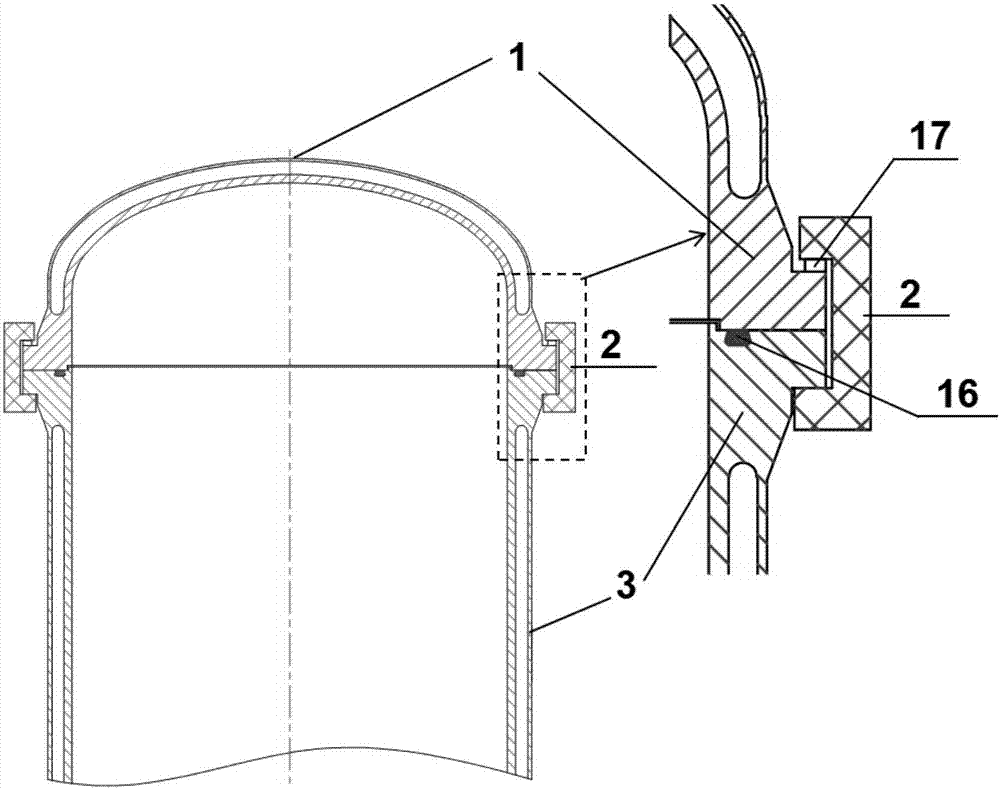

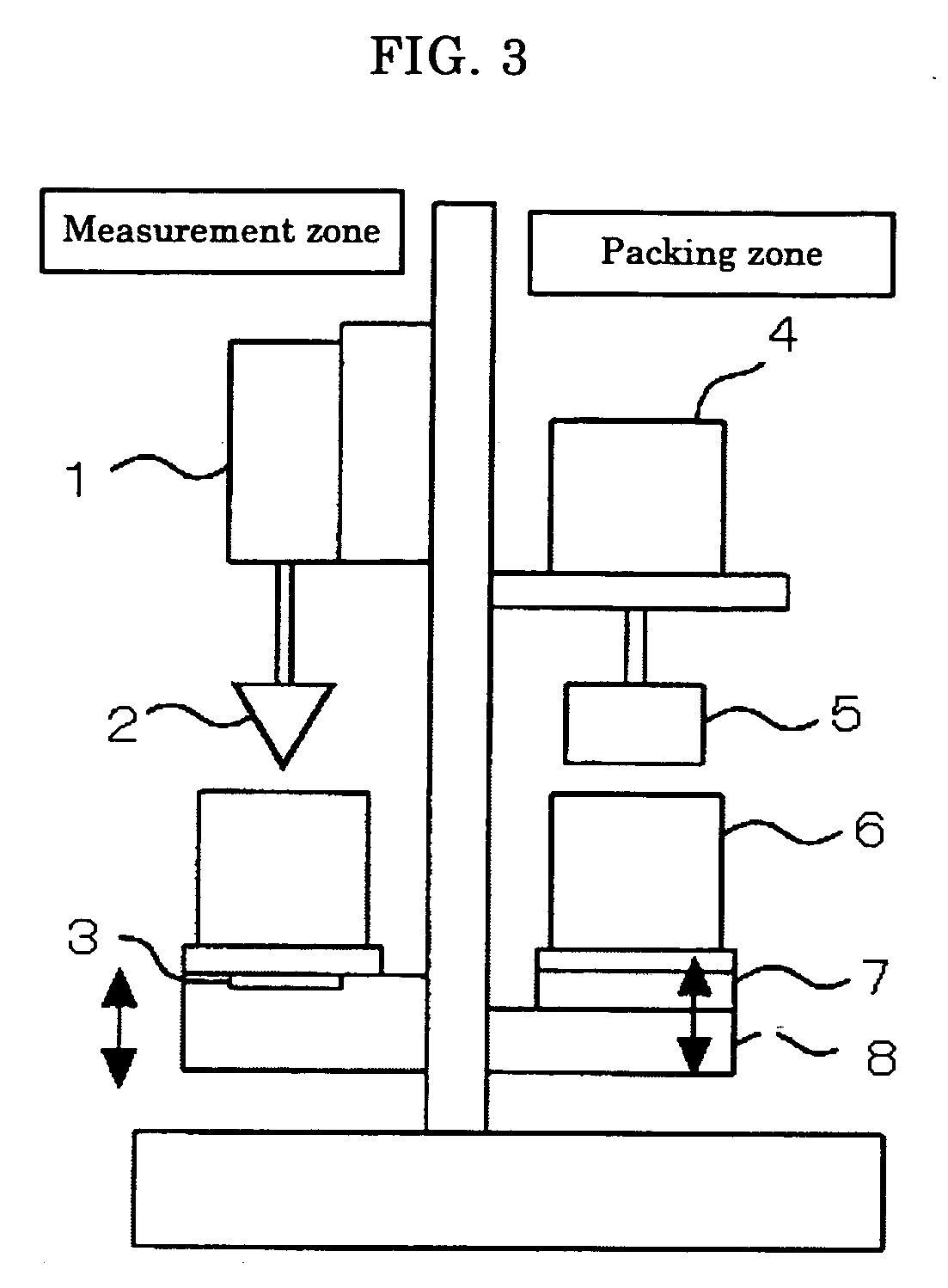

Gas atomization preparing method for micro spherical metal powder and equipment thereof

ActiveCN107262730AIncrease characteristic surface energyHigh yield of fine powderTransportation and packagingMetal-working apparatusPositive pressureProduct gas

The invention belongs to the technical field of preparing a metal powder material and provides a gas atomization preparing method for micro spherical metal powder and equipment thereof. The preparing method comprises the technological process of smelting a material, driving molten metal jet flow through positive pressure, atomizing gas, carrying out cooling, collecting powder, detecting performance, and carrying out screening, packaging and the like, by reducing the outlet hole diameter of a flow guide nozzle, inert gas is reversely filled into a smelting chamber to certain positive pressure, the smelting chamber in the gas atomizing equipment is designed into a pressure container, a locking sealing device is adopted in the connecting portion of a furnace cover and a furnace body, the smelting chamber and an atomizing tank are designed into cavities which are isolated mutually and communicate only through the flow guide nozzle, and the fine powder yield of the metal powder is effectively increased. Compared with the existing gas atomizing metal powder preparing technology, the fine powder yield of the metal powder prepared by the utilization of the method is high, size distribution is narrow, the sphericity degree is good, the oxygen content is small, atomized gas consumption is low, and the technology equipment is simple, high in continuity and suitable for industrialized production and can be widely applied.

Owner:有研金属复材技术有限公司

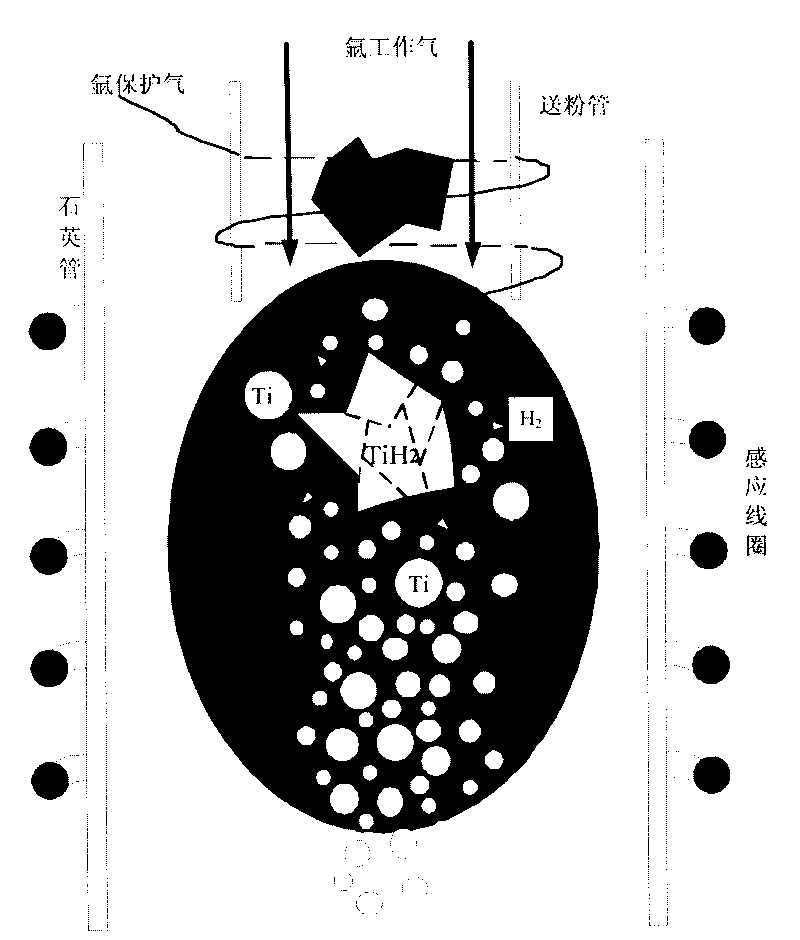

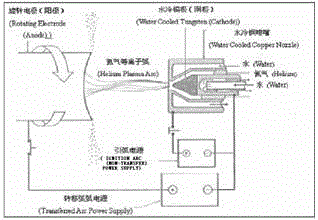

Globular titanium micro-powder or ultra-micro powder preparation device and method

The invention belongs to a process for preparing and processing powder material by taking plasma as a heat source, in particular to a process and an apparatus of metal titanium powder material for powder metallurgy, plasma spray, injection forming, gel injection molding and the like. The invention has the advantages that: the adoption of the high temperature spheroidization and rapid condensation special spheroidization technique can improve the sphericity and purity of titanium powder, and both a reactor and the titanium powder spheroidization process are cooled with circulating water, thereby ensuring the sealing performance of equipment, also reducing the use of inert gases, effectively reducing costs, improving the production efficiency and guaranteeing the purity of spherical titanium powder.

Owner:SOUTHWESTERN INST OF PHYSICS

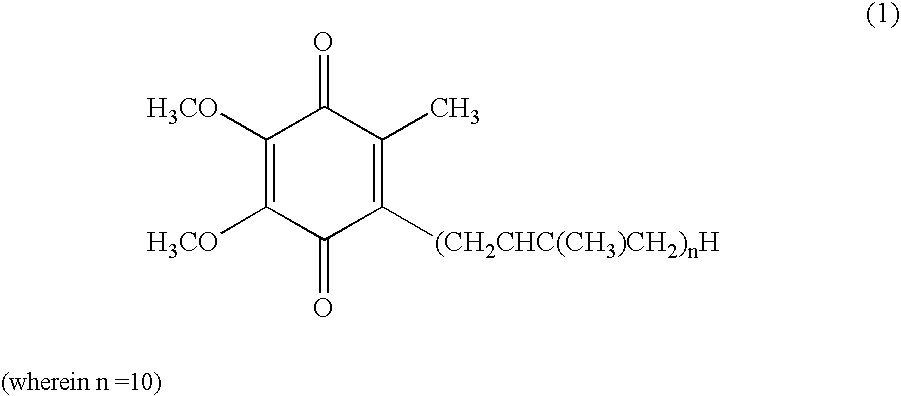

Particulate composition comprising bioactive substance and method of producing the same

InactiveUS20080102131A1High recovery rateAmeliorating issue of low recovery rateBiocidePowder deliverySolubilityParticulates

The present invention provides a particulate composition wherein an oil component (A) comprising a water-insoluble bioactive substance is poly-dispersed while forming a domain in a matrix comprising of a water-soluble excipient based on a water-soluble polymer, and wherein the sphericity of the particulate composition is not less than 0.9 and a method of producing the same. The particulate composition simultaneously has excellent water solubility, workability, tabletability and heat-resistance. It also provides a food, food with nutrient function claims, food for specified health uses, nutritional supplement, nutritional product, animal drug, drink, feed, pet food, cosmetic, pharmaceutical product, therapeutic drug, prophylactic drug and the like, which contain the particulate composition.

Owner:KANEKA CORP

Urea-formaldehyde resin coated epoxy acrylic resin microcapsule for resin-base self-repair coating and preparation method thereof

ActiveCN102773053AHigh speedSphericity RulesMicroballoon preparationMicrocapsule preparationAcrylic resinResin coating

The invention relates to a urea-formaldehyde resin coated epoxy acrylic resin microcapsule for a resin-base self-repair coating and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding capsule core raw materials epoxy acrylic resin and acrylate reactive diluent into a water solution containing an emulsifier and a defoaming agent, dispersing the capsule core with a homogenizer or emulsifying machine to form a stable emulsion; regulating the pH value of the stable emulsion system to 2-3, adding capsule wall raw materials urea, formaldehyde and crosslinking agent, stirring until the capsule is formed, and after the reaction finishes, regulating the pH value of the system to neutral; and repeatedly washing with hot water and acetone, centrifuging, and carrying out vacuum drying to obtain the epoxy acrylic resin microcapsule. The capsule provided by the invention has the advantages of favorable sealability, regular sphericity, controllable grain size and controllable capsule wall thickness, and can be widely used for self-repair of a UV-cured acrylic resin coating or epoxy resin coating at low temperature and room temperature, thereby prolonging the service life of the coating material and widening the application range of the resin-base coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Toner, developer, toner container, process cartridge, image forming apparatus, and image forming method

ActiveUS20070031748A1Reduced image layer thicknessStable formationDevelopersElectrographic processes using charge patternImage formationEngineering

To provide a toner that can provide long-term removability and high-definition images with reduced image layer thickness and densely-packed toner particles, a developer capable of forming high-quality images using the toner, a toner container for containing the toner, a process cartridge using the toner, an image forming apparatus using the toner, and an image forming method using the toner. The toner of the present invention is a toner having a substantially spherical shape with irregularities on its surface and containing at least a binder resin and a colorant, wherein a surface factor SF-1 that represents the sphericity of toner particles is 105 to 180, a surface factor SF-2 that represents the degree of surface irregularities of the toner particles is correlated with the volume-average diameter of the toner particles, and the toner particles have an inorganic oxide particle-containing layer within 1 μm from their surfaces.

Owner:RICOH KK

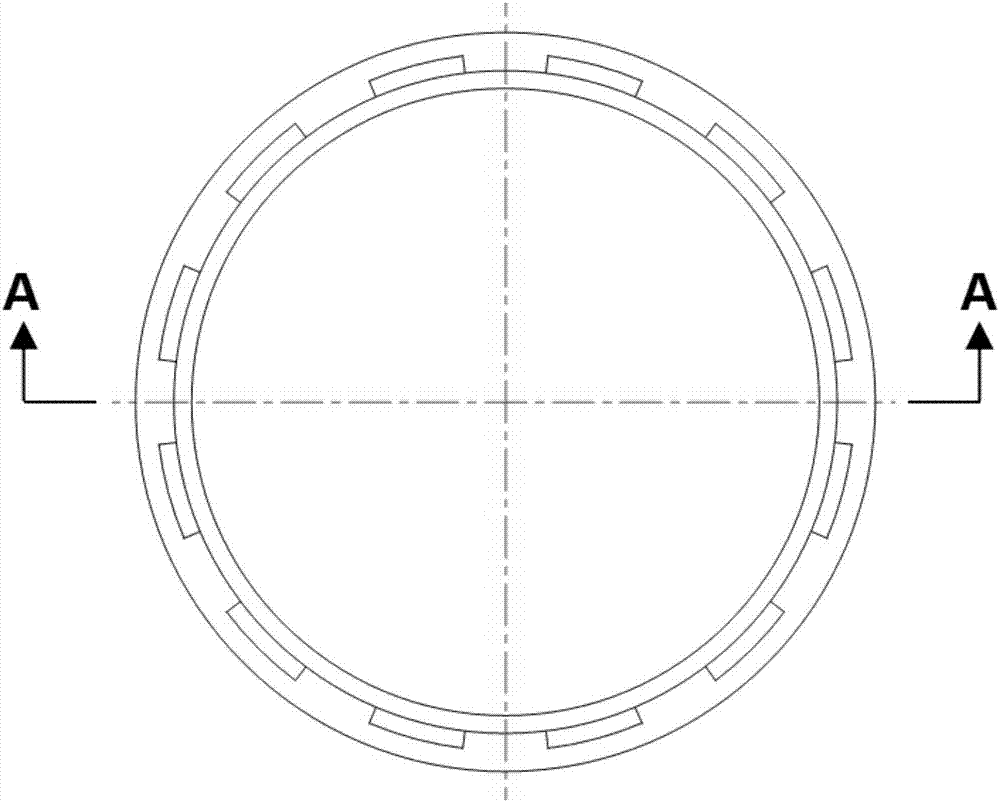

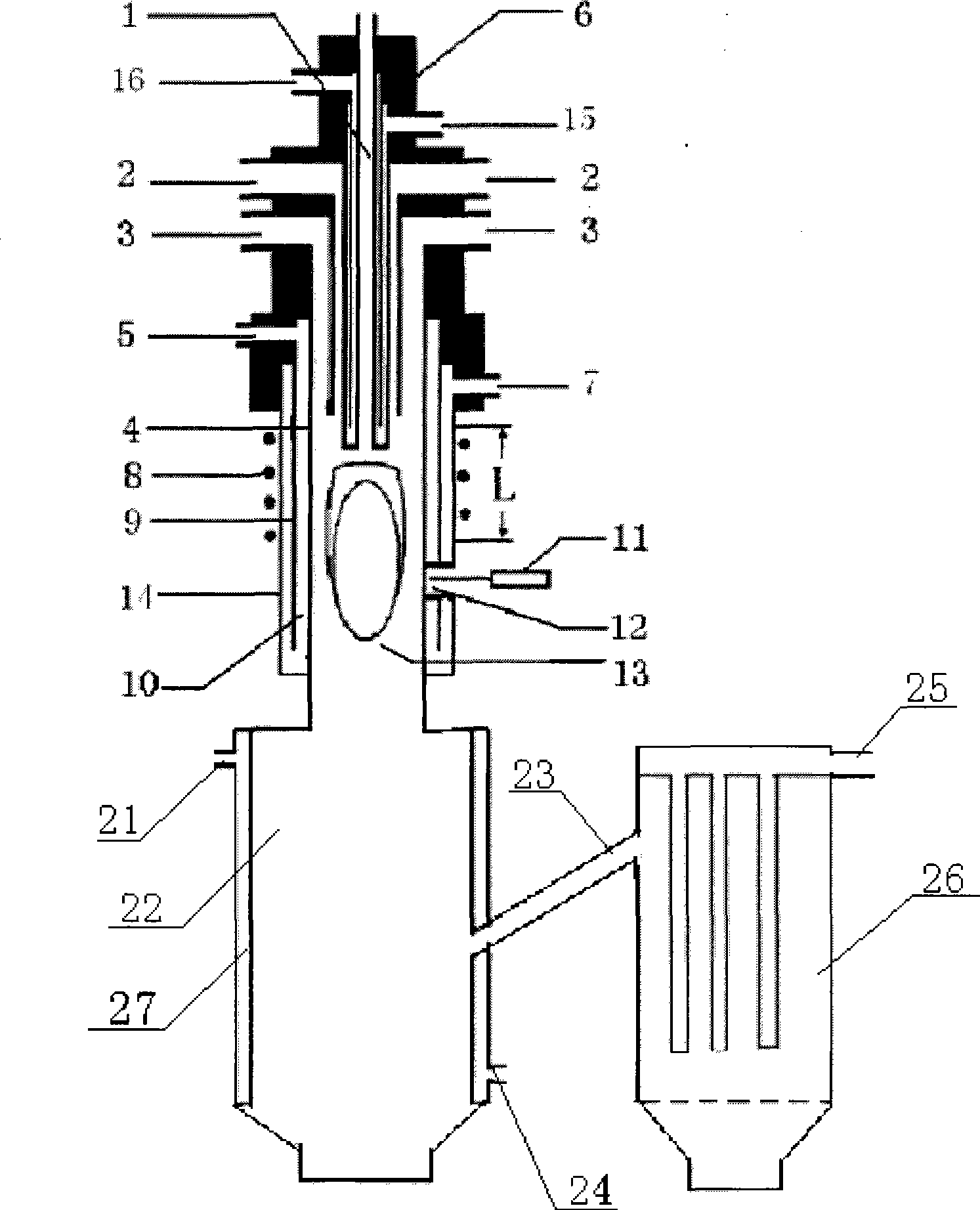

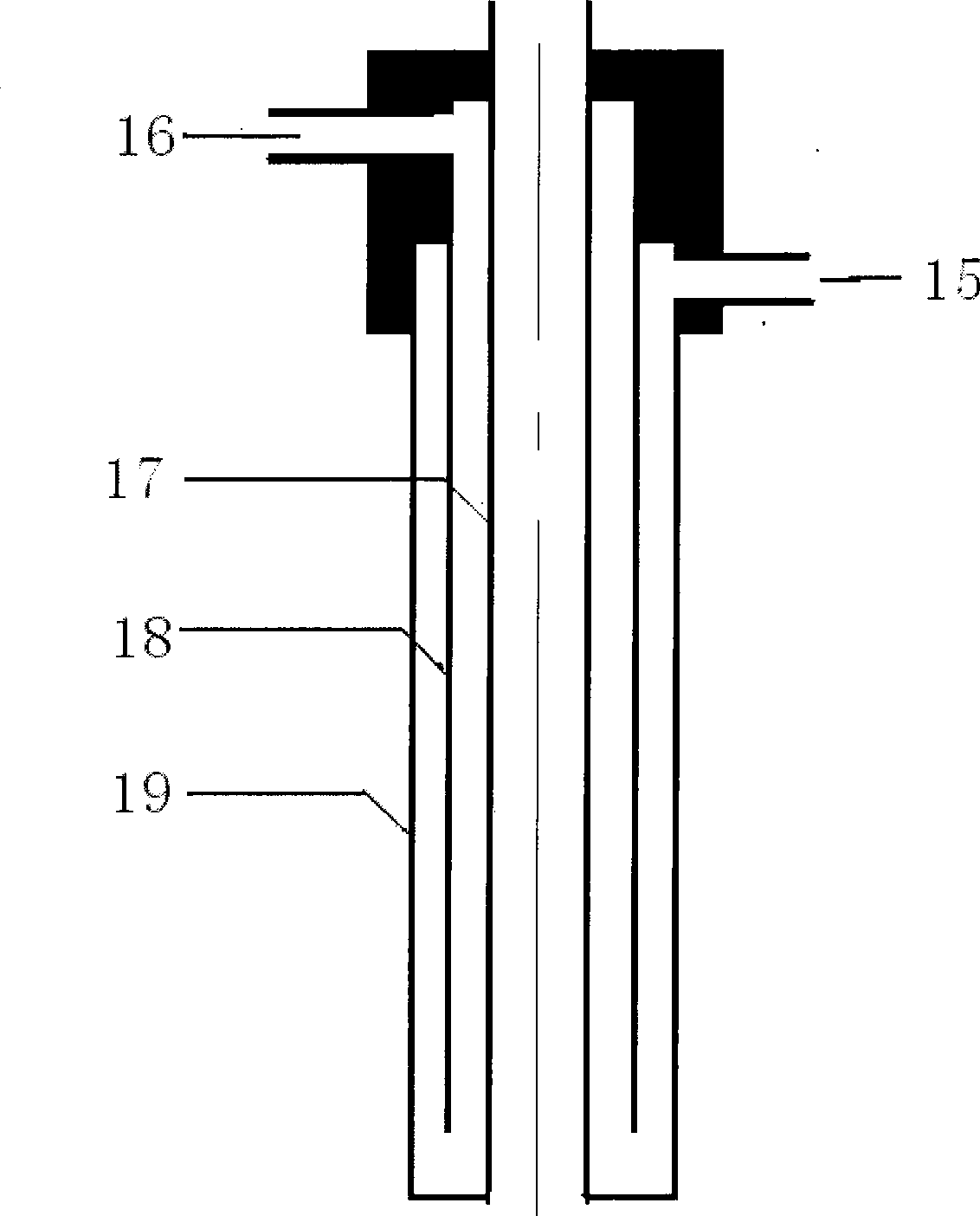

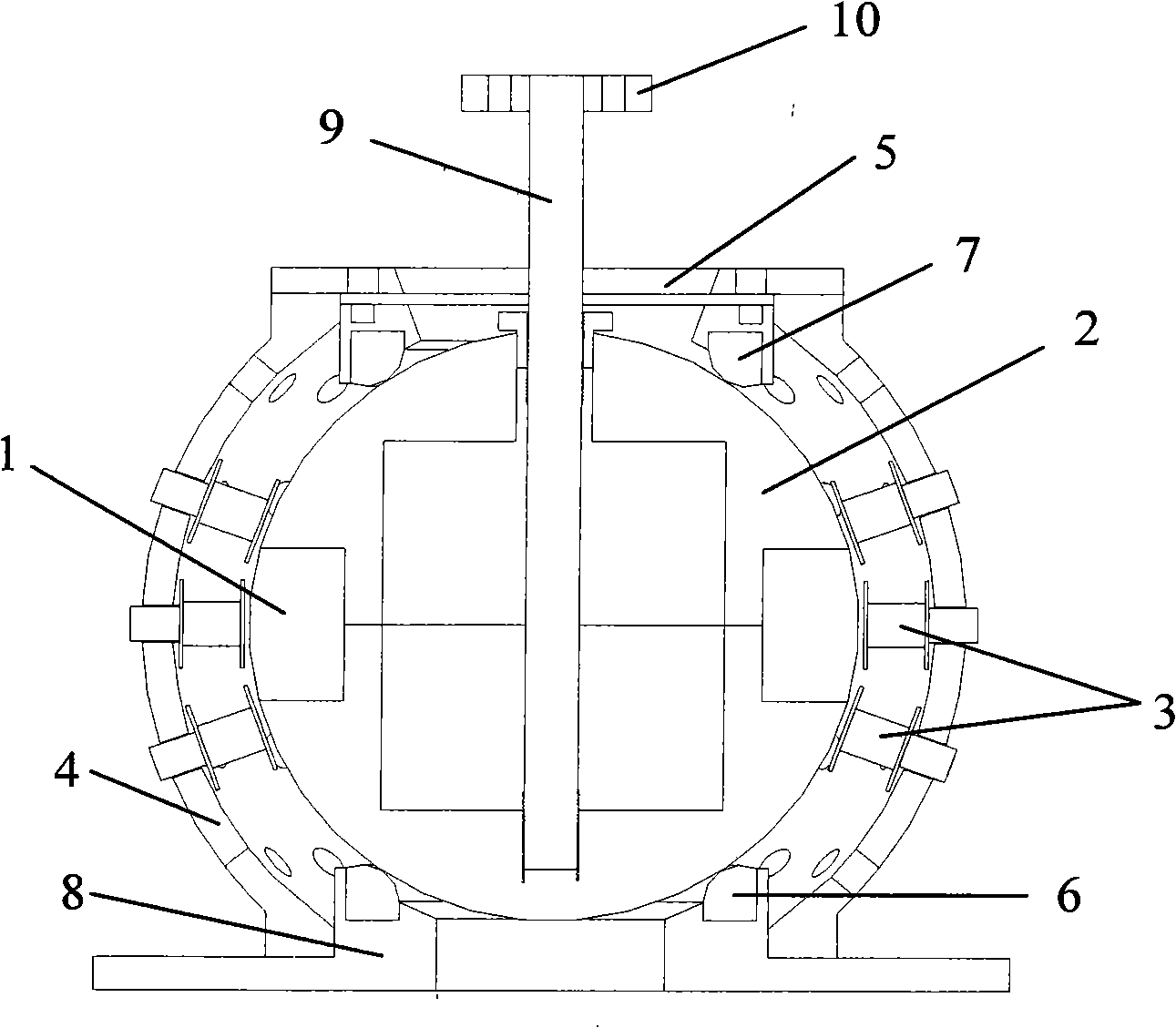

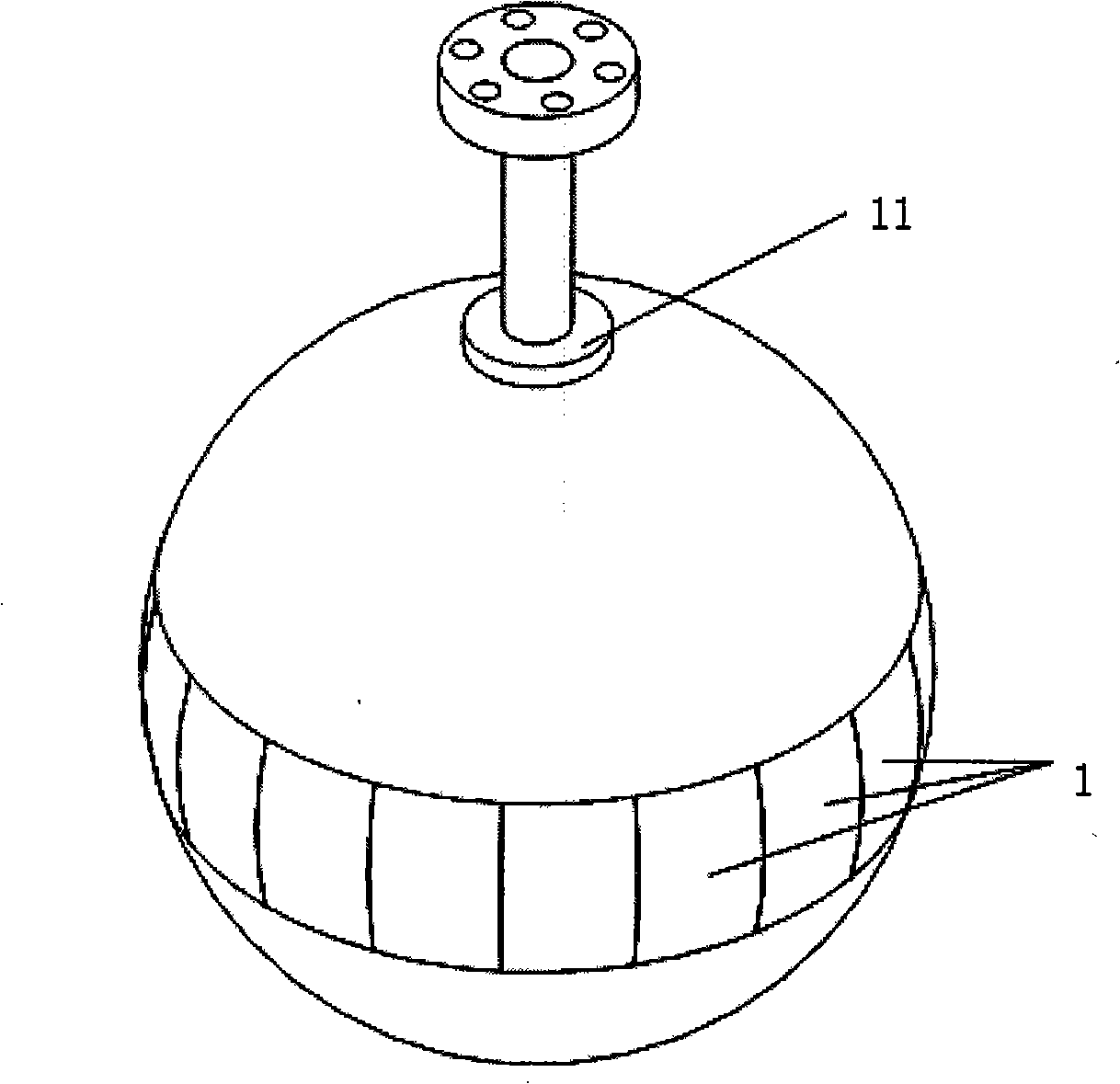

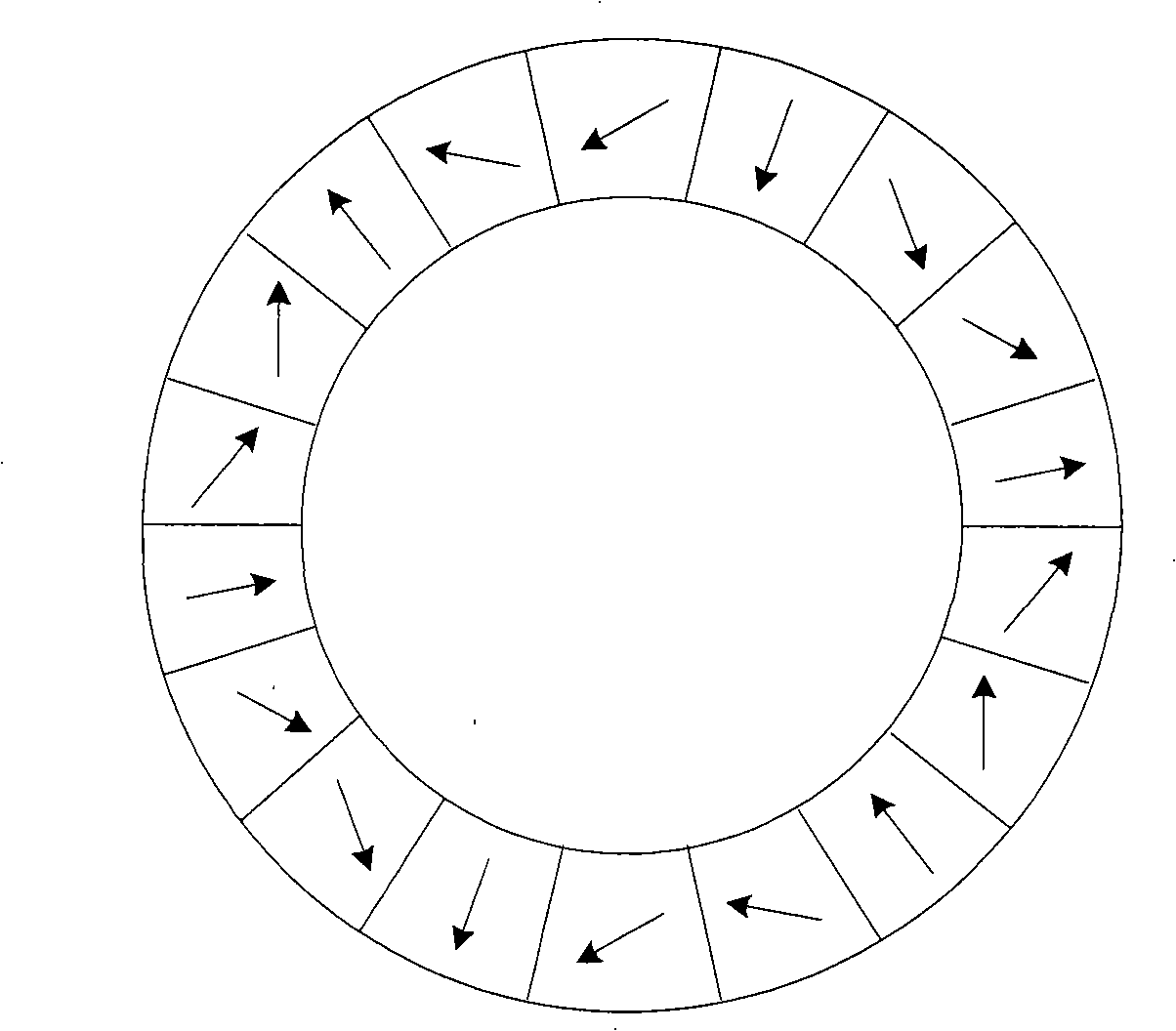

Three-freedom Halback array permanent magnetism sphericity synchronous motor

InactiveCN101282070AHigh positioning accuracySimple mechanical structureMagnetic circuit rotating partsSynchronous machine detailsFixed bearingSynchronous motor

The invention relates to a three-freedom degree Halbach array permanent magnetism spherical synchronous motor, belonging to spherical electric machine manufacturing technical field, which comprises a base, a support bearing positioned on the base, a spherical rotor body, an outside stator, an output shaft, the spherical rotor body comprises a hollow spherical rotor yoke made by non-guide magnetism materials and a Halbach array permanent magnetism body, the output shaft is through the upper of the hollow spherical rotor yoke and is fixingly connected with the hollow spherical rotor yoke, column-shaped slots are provided around a cycle of the hollow spherical rotor yoke equator, the Halbach array permanent magnetism body are fixed evenly on one cycle of the rotor yoke equator along the column-shaped slots, the contact surface of the rotor yoke lower and the support bearing is ring-shaped arc surface; the outer stator comprises a stator casing and multi-row coils, an adjustable fixing bearing is provided on the lower side of the stator casing cover. The spherical synchronous motor of the invention can realize three-freedom degree movement, has simple mechanical structure and improved dynamic and static performance of the drive system.

Owner:TIANJIN UNIV

Powder material for selective laser sintering and preparation method thereof

InactiveCN105985632AHigh sphericitySimple preparation processCoatingsSelective laser sinteringAntioxidant

The invention discloses a powder material for selective laser sintering and a preparation method thereof. The powder material is composed of, by weight, 10-90 parts of resin matrix, 5-90 parts of filler, 0.1-5 parts of coupling agent, 0.1-5 parts of dispersant, 0.1-5 parts of compatibilizer, 0.1-8 parts of flow promoting agent, 0.01-3 parts of antioxidant, 0.05-2 parts of light absorbing agent, 0.01-2 parts of lubricant and 0.05-4 parts of surfactant. The preparation method includes: treating the surface of the filler; blending raw materials; banburying the raw materials; powdering; spherifying powder; performing surface modification on the powder. Compared with the prior art, the powder material and the preparation method have the advantages that the preparation method is simple and supportive of continuous production; the preparation process is energy-saving, environment-friendly and pollution-free; resin in the powder material prepared by the method uniformly coats the surface of the filler, and the powder is high in sphericity and excellent in sintering performance.

Owner:HEFEI UNIV

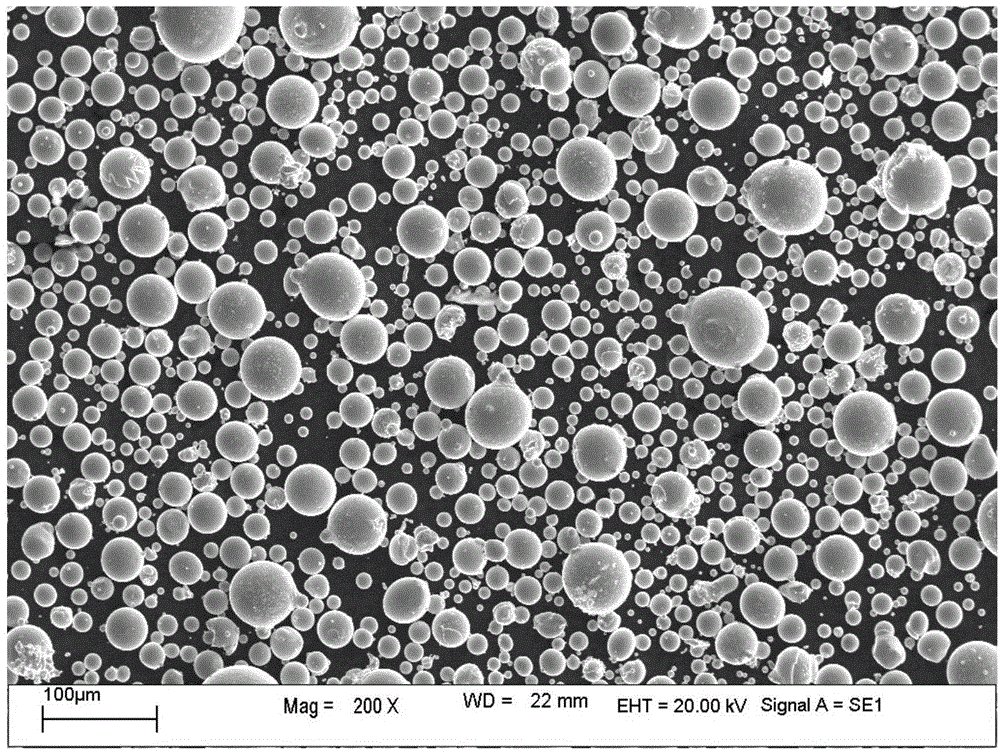

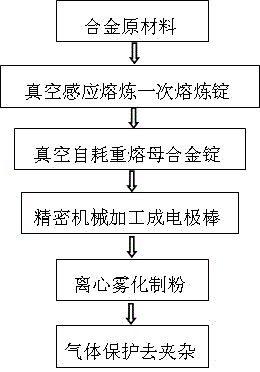

Preparation method of IN718 alloy spherical powder

InactiveCN104308167AReduce oxygen contentReduce contentElectrostatic separationNon-metallic inclusions

The invention discloses a preparation method of IN718 alloy spherical powder. The method comprises the following steps of step 1, smelting an IN718 alloy master ingot; step 2, processing the IN718 alloy master ingot into an IN718 alloy electrode bar with the diameter of 50 to 90mm and the length of 600 to 800mm, wherein the straightness of the electrode bar is controlled to be smaller than or equal to 0.1mm / m; step 3, placing the IN718 alloy electrode bar in a sealed furnace chamber protected by inert gas, rotating the IN718 alloy electrode bar at high speed, and heating the end part of the electrode bar by using a plasma gun to melt the electrode bar; step 4, atomizing the melted metal under the action of centrifugal force to enable melted metal to fly to form fine liquid droplets, wherein the liquid droplets are quickly cooled in inert gas to form spherical particles, and the spherical particles fall into a collector at the bottom of the furnace chamber to form the IN718 alloy spherical powder; step 5, under the protection of the inert gas, performing electrostatic separation processing on the prepared IN718 alloy spherical powder to remove non-metal impurities from the powder to obtain the pure IN718 alloy spherical powder. The method has the characteristics of good sphericity degree, fine particle size, low oxygen content and few impurities.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Lubricant for electrophotography, lubricant applying unit, process cartridge, and image forming apparatus

An lubricant for electrophotography is applied to a latent image carrier that is supplied with toner having a sphericity of 0.94 or more. The lubricant for electrophotography is added with an inorganic additive having the following relationship:2Y / 1000≦X≦Y / 10where Y is a toner particle size (micrometer), and X is an inorganic additive particle size (micrometer).

Owner:RICOH KK

Method for preparing ultrathin metal powder

The invention provides a method for preparing ultrathin metal powder and belongs to the field of material preparation. The method comprises the steps of smelting, atomization, cooling, solid-liquid separation and the like. In the step of atomization, one or more of water, nitrogen, helium and argon serves / serve as an atomizing medium. According to the method, the metal powder or alloy powder with the grain size smaller than 10 micrometers is basically obtained, the ratio of the metal powder or the alloy powder with the grain size smaller than 10 micrometers is over 50%, the sphericity of the obtained metal powder or the alloy powder is over 90%, the oxygen content is smaller than 100ppm, the gas consumption is small, the cooling efficiency is high, and the requirements for devices are low. The method for preparing the ultrathin metal powder is capable of satisfying the requirements of the metal powder or the alloy powder used for injection forming, thermal spraying, thermal spray welding and 3D printing.

Owner:四川有色金源粉冶材料有限公司

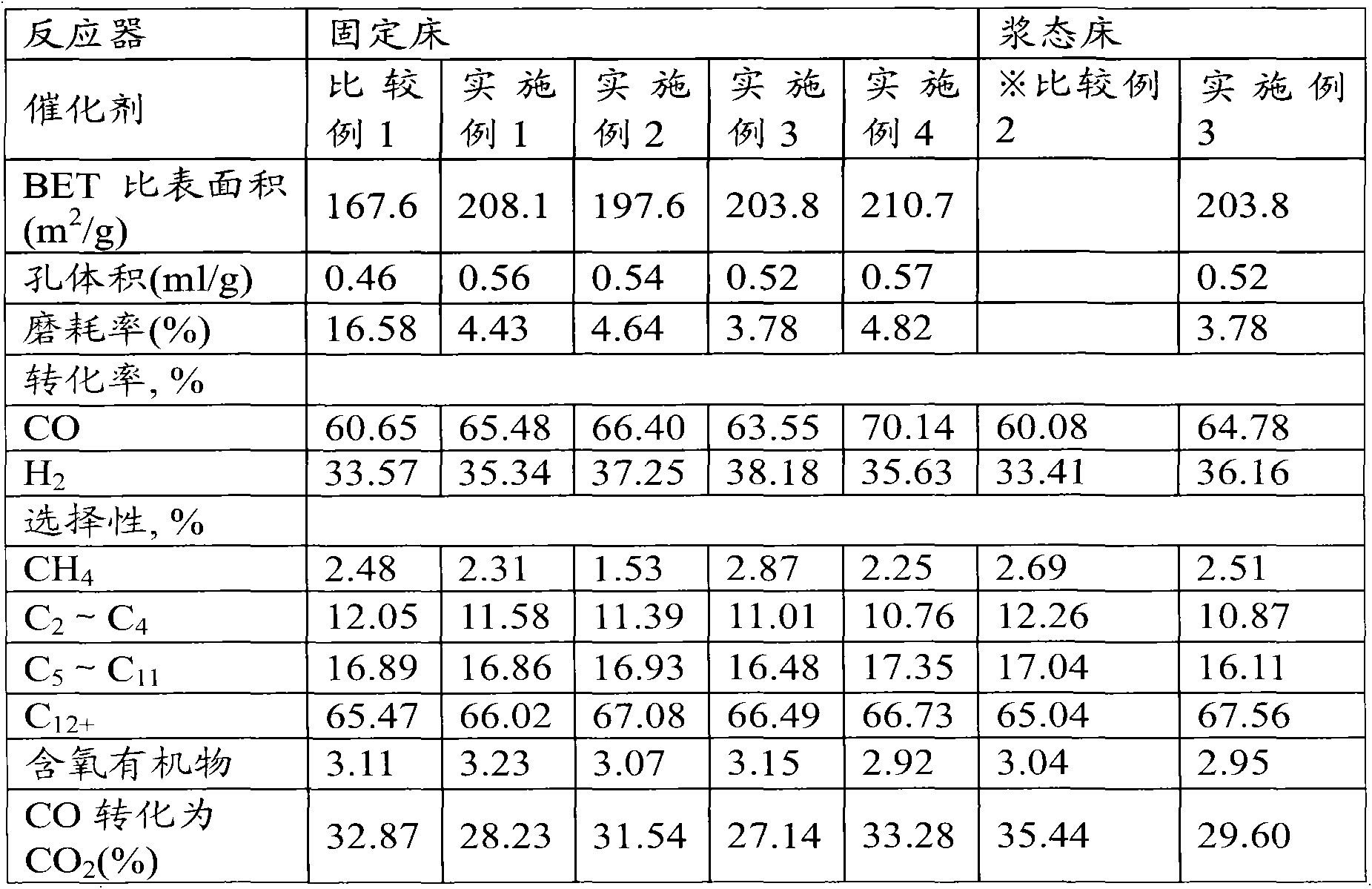

Precipitated iron catalyst for Fischer-Tropsch synthesis reaction, and preparation method and application thereof

ActiveCN101884926AHigh specific surface areaIncrease the areaCatalyst activation/preparationLiquid hydrocarbon mixture productionPrecipitationIon

The invention relates to a precipitated iron catalyst for Fischer-Tropsch synthesis reaction, and a preparation method and application thereof. The preparation method comprises the following steps of: (a) feeding ferric salt solution, aid saline solution, the solution of precipitator and a small amount of solution of silicon compounds in a form of concurrent flow into a precipitation reactor; (b)performing coprecipitation reaction on the mixture under certain process conditions in the reactor, and fast cooling, filtering and rinsing pulp obtained after the precipitation reaction is finished;(c) adding a silicon compound binder into a filter cake obtained after the rinsing, adding a nitric acid into the filter cake to adjust pH and performing secondary filtration; (d) performing secondary pulping on the obtained filter cake with de-ionized water or the mixed solution of the de-ionized water and the required aid saline solution; and (e) performing spray-drying molding and baking on the obtained catalyst pulp. The catalyst prepared by the method of the invention has high specific surface area, proper pore volume, high wear strength, high sphericity and smooth surface.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

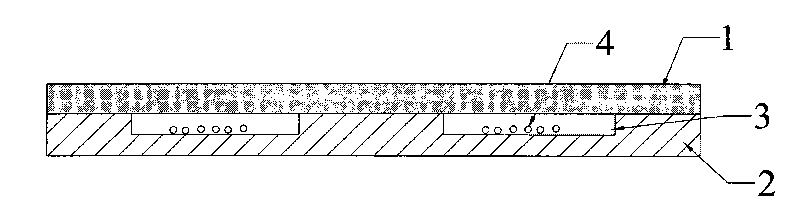

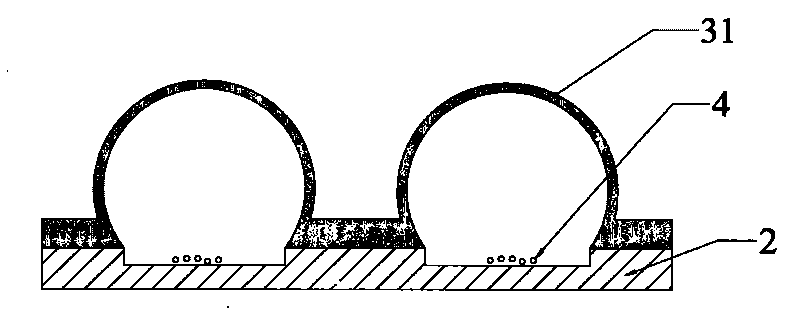

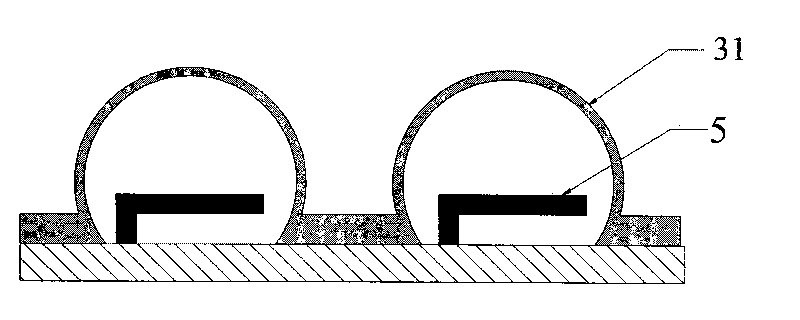

Manufacturing method of wafer level glass microcavity used for packaging MEMS

ActiveCN101734612AHigh forming heightLow costPrecision positioning equipmentSoldering apparatusMicrofabricationPositive pressure

The invention provides a manufacturing method of a wafer level glass microcavity used for packaging an MEMS, which comprises the following steps of: (1) etching a shallow slot on an Si wafer by an Si microfabrication process; (2) placing a right amount of high-temperature gas release agent in the shallow slot; (3) carrying out anodic bonding on the Si wafer and a Pyrex7740 glass wafer in air or vacuum and enabling the shallow slot on the Pyrex7740 glass to form a sealed cavity body; and (4) heating the bonded wafer in the air to the temperature of 810-890 DEG C, keeping the temperature for 3-5min, enabling molten glass corresponding to the sealed cavity body to be in a spherical shape by the high-temperature gas release agent because of positive pressure generated by gas generated by heating, cooling to the normal temperature, annealing and removing a silicon wafer to obtain a wafer level spherical glass microcavity array. The invention adopts the release of the high-temperature gas release agent to provide a gas source, is used for forming the glass microcavity and has the characteristics of low cost, simple method, high forming height and good degree of sphericity.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com