Globular titanium micro-powder or ultra-micro powder preparation device and method

A technology of titanium micropowder and ultrafine powder, which is applied in the field of powder material preparation equipment and processing, can solve the problems of low productivity, regular electrode replacement, electrode burning, etc., to improve sphericity and purity, ensure sealing performance, and reduce usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

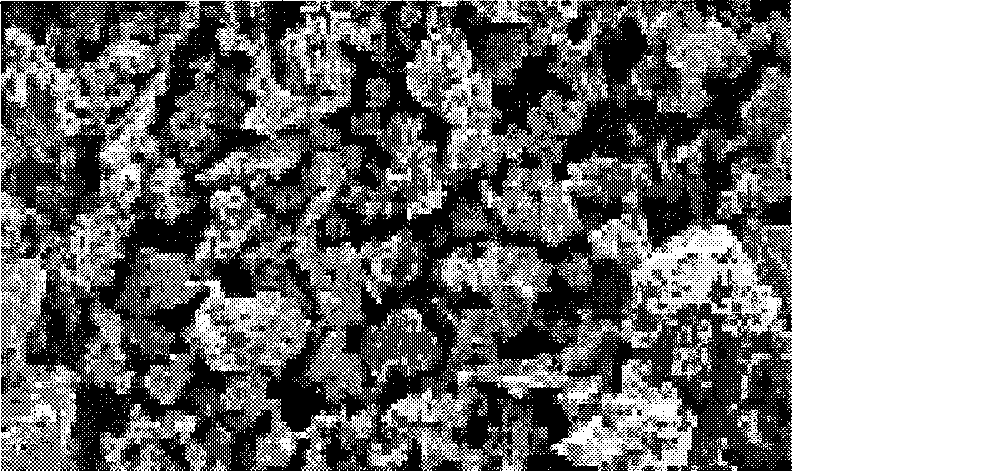

[0022] Process titanium powder with a plasma device according to the present invention, utilize the high-energy characteristic of radio frequency (RF) plasma, inject the plasma torch with carrying gas (argon gas) with carrying gas (argon gas) into the plasma torch, irregular titanium The raw powder particles are rapidly heated and melted, and the molten particles form highly spherical droplets under the action of surface tension, and rapidly solidify under a very high temperature gradient to form titanium powder with good sphericity.

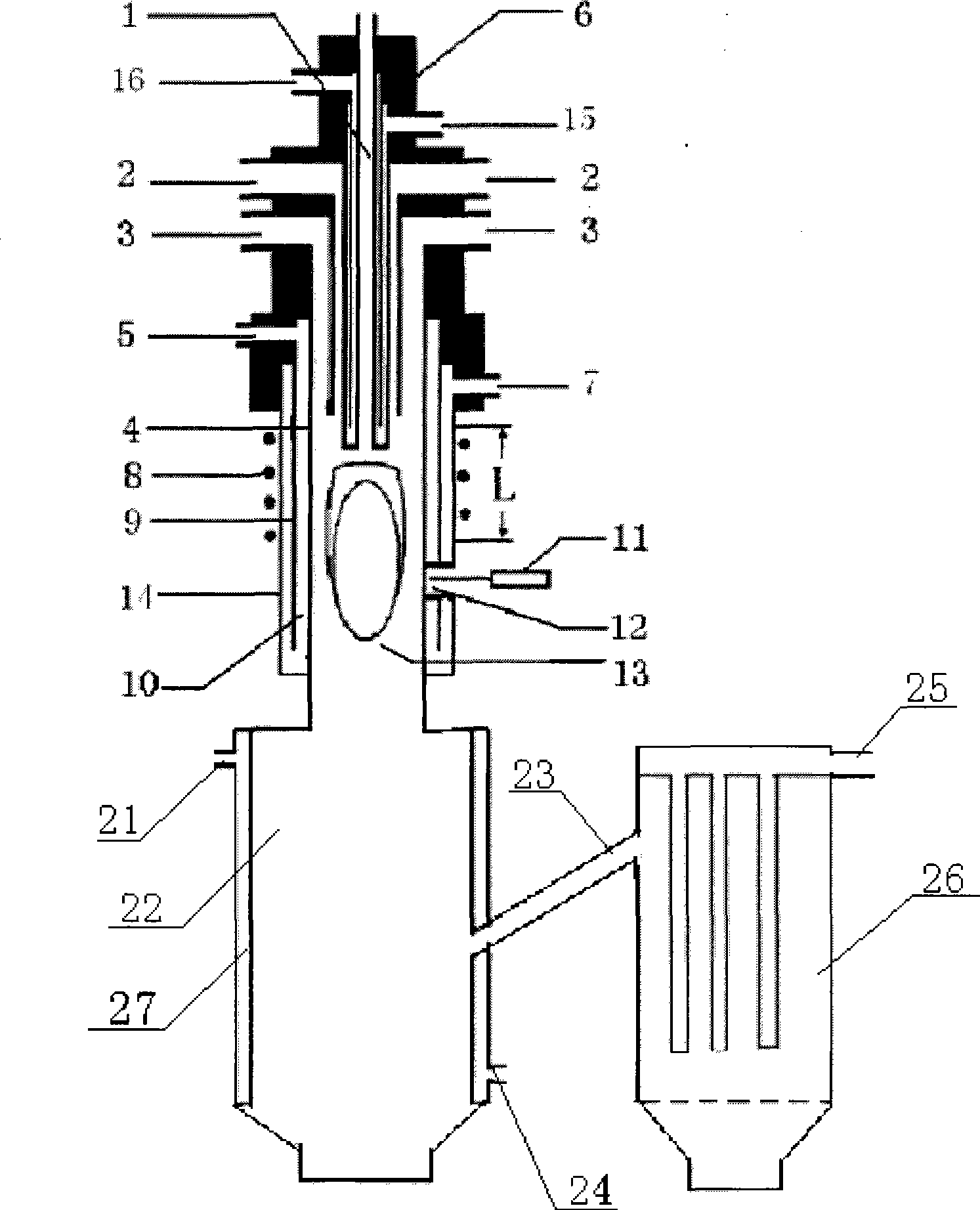

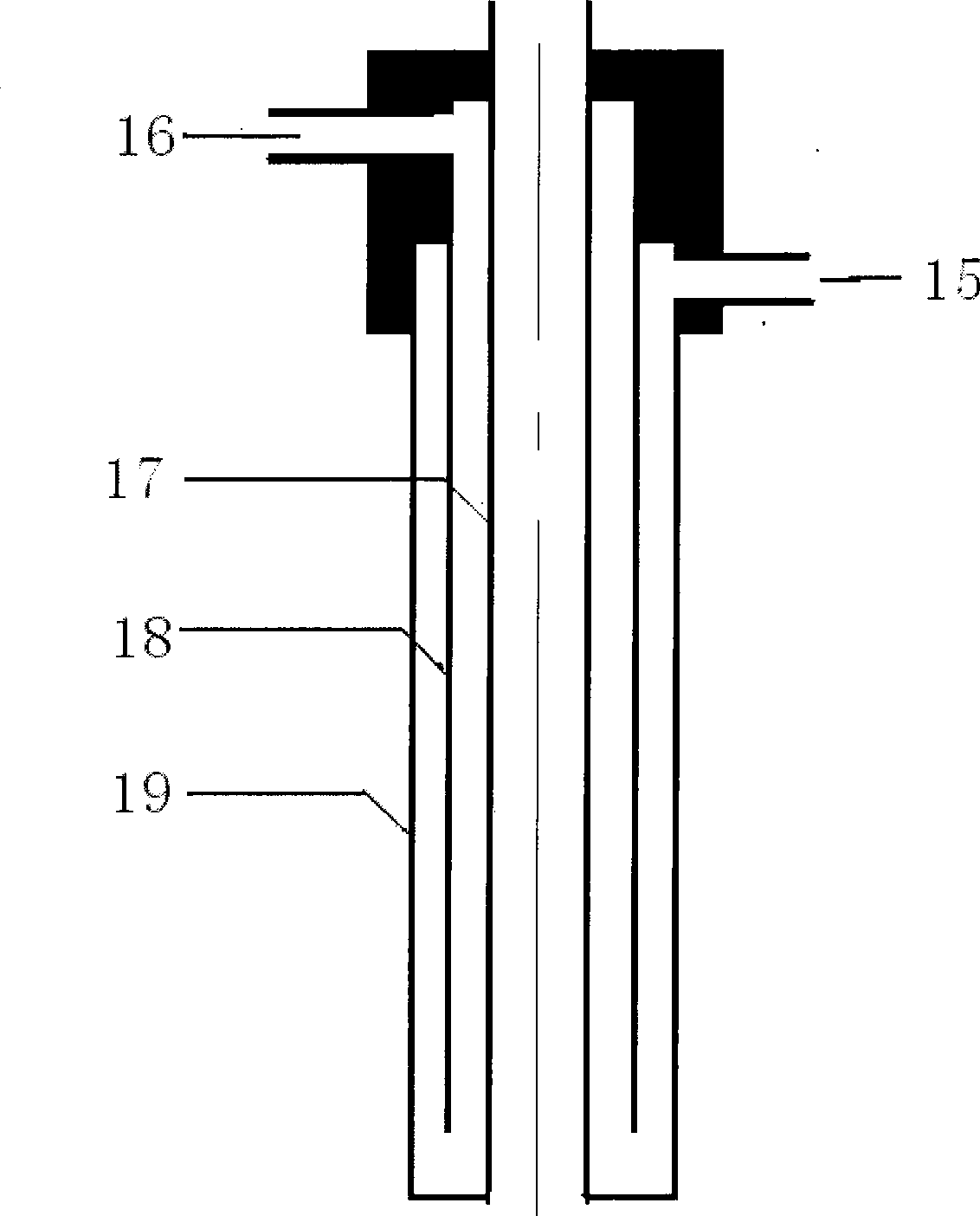

[0023] The device of the invention mainly includes a high-frequency plasma power supply, a plasma generator and a reactor, a feeder, a heat exchange chamber, a gas-solid separation chamber, a powder material collection chamber and a feeding gun. These devices form an industrialized production system with stable operation, continuous operation and high production capacity.

[0024] The invention adopts high-temperature spheroidization and rapid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com