Patents

Literature

1002 results about "Filling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The fill rate represents a company’s ability to meet current demand with inventory on hand. Accountants and managers are typically responsible for determining how much inventory is necessary to have on hand at all times. A stock out occurs when the fill rate exceeds current inventory.

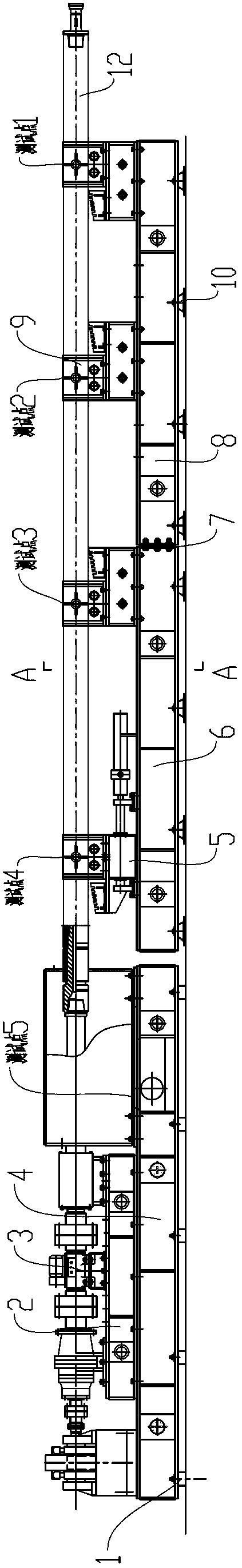

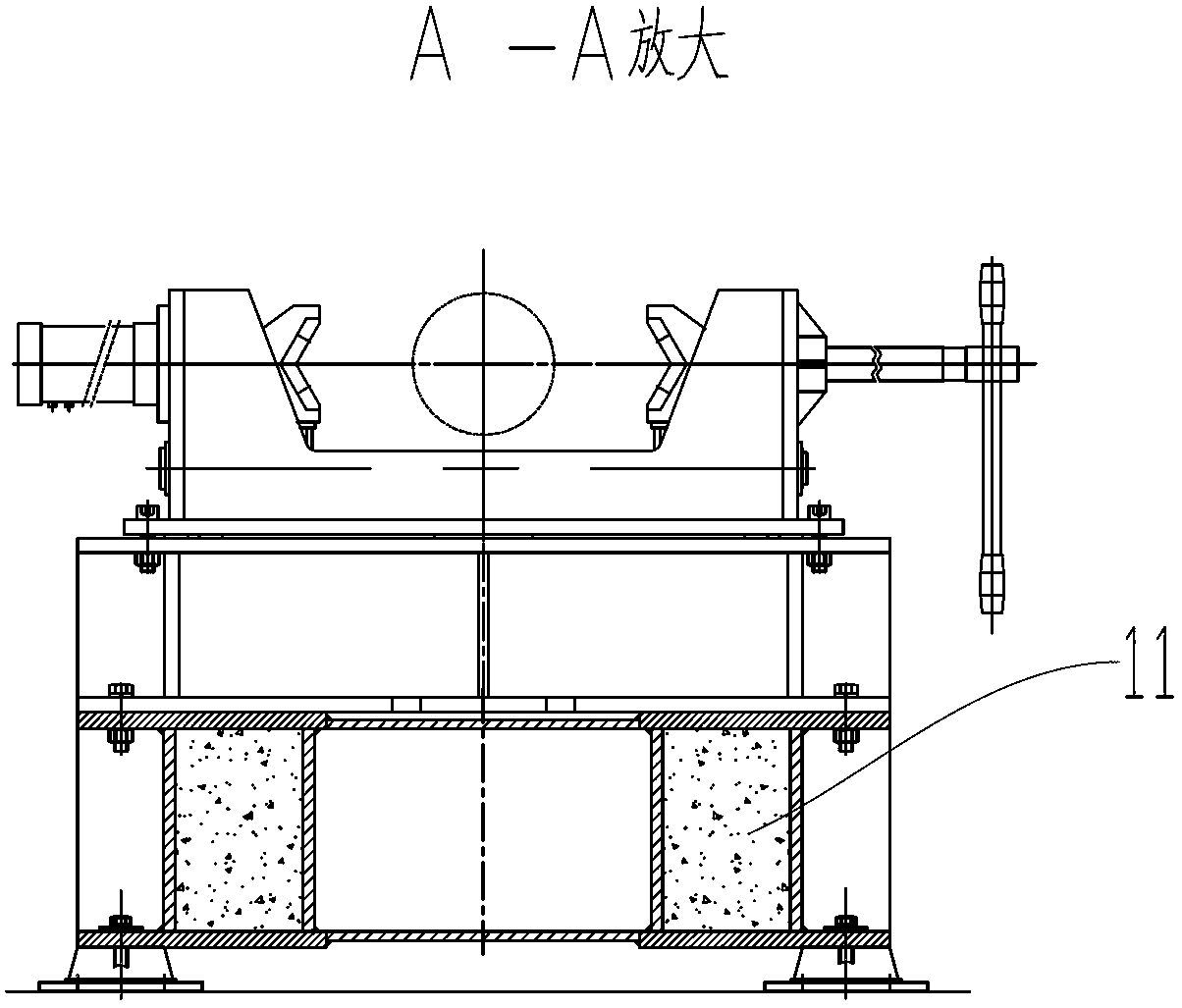

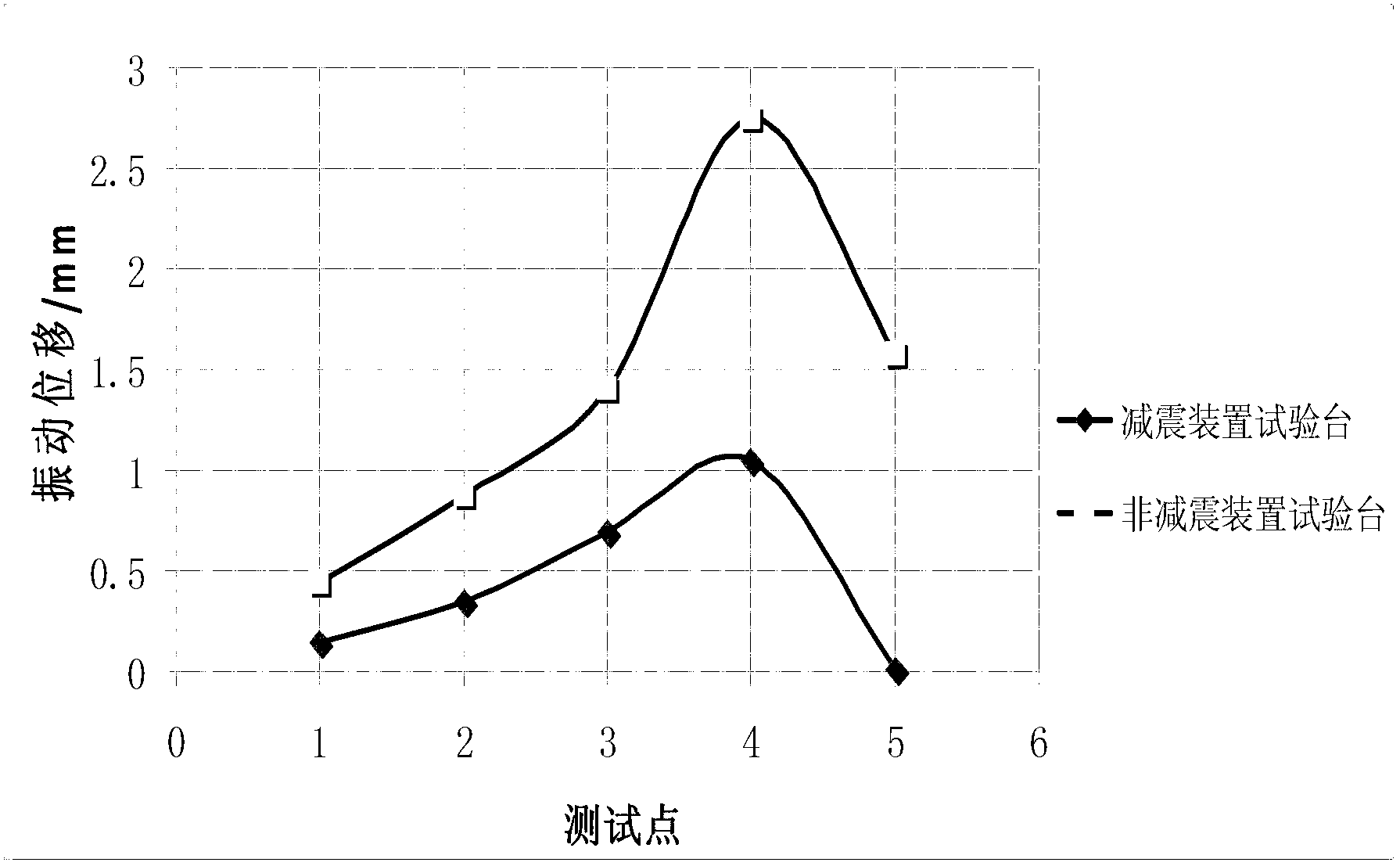

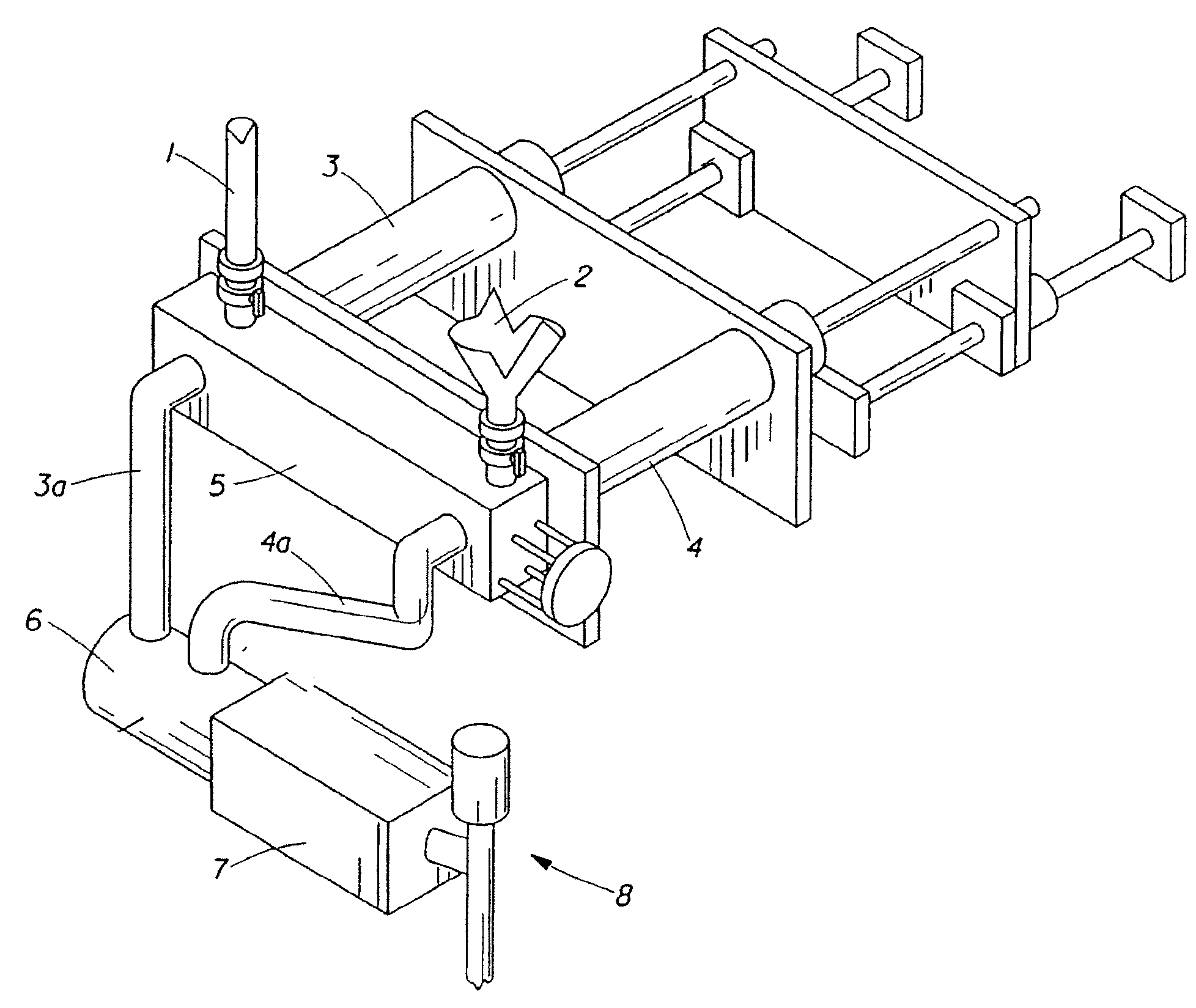

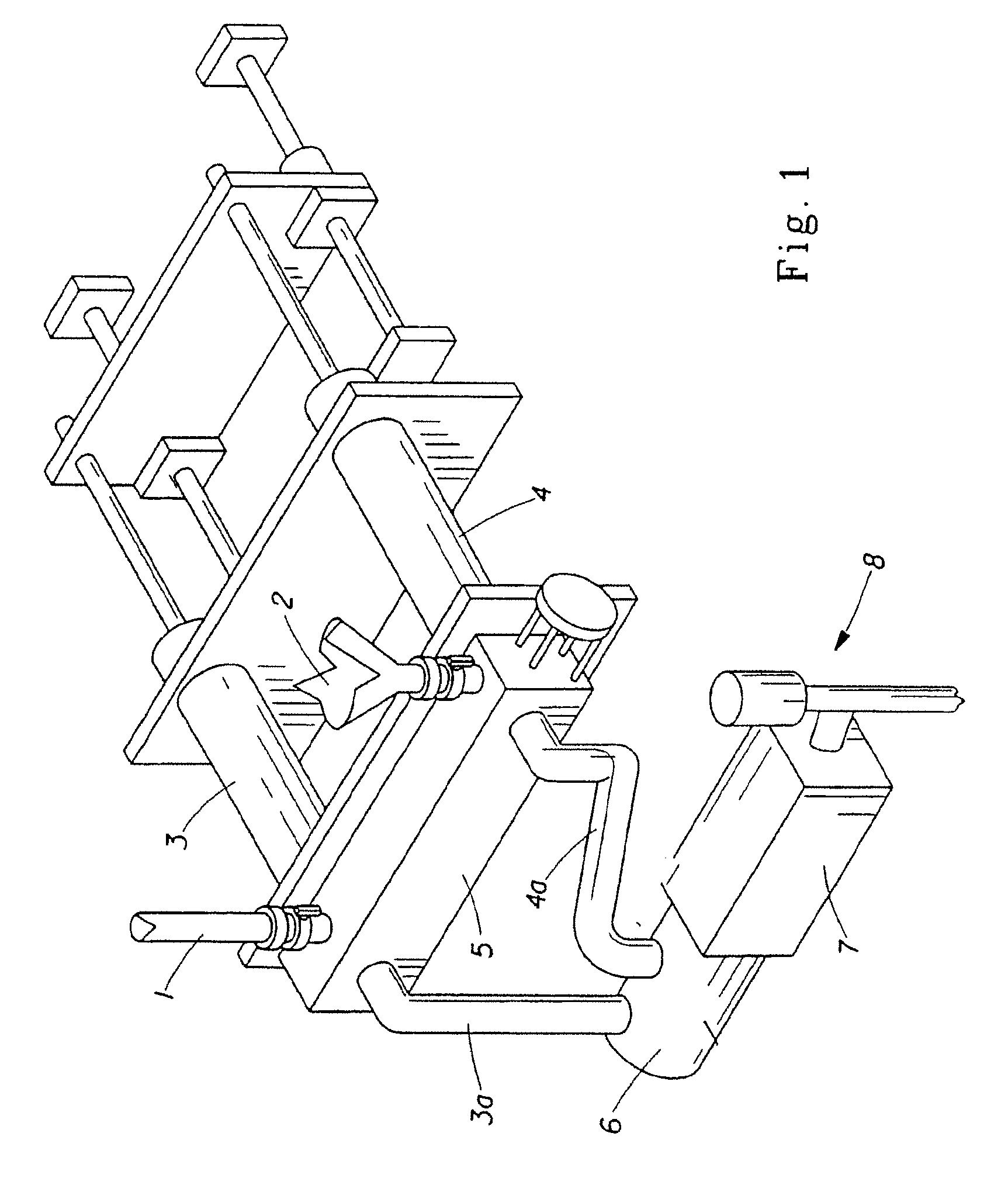

Combined vibration damper of screw drill complete machine test-bed and manufacturing method thereof

ActiveCN103245523AAchieve test accuracyThe test data is accurateStructural/machines measurementVibration attenuationResonance

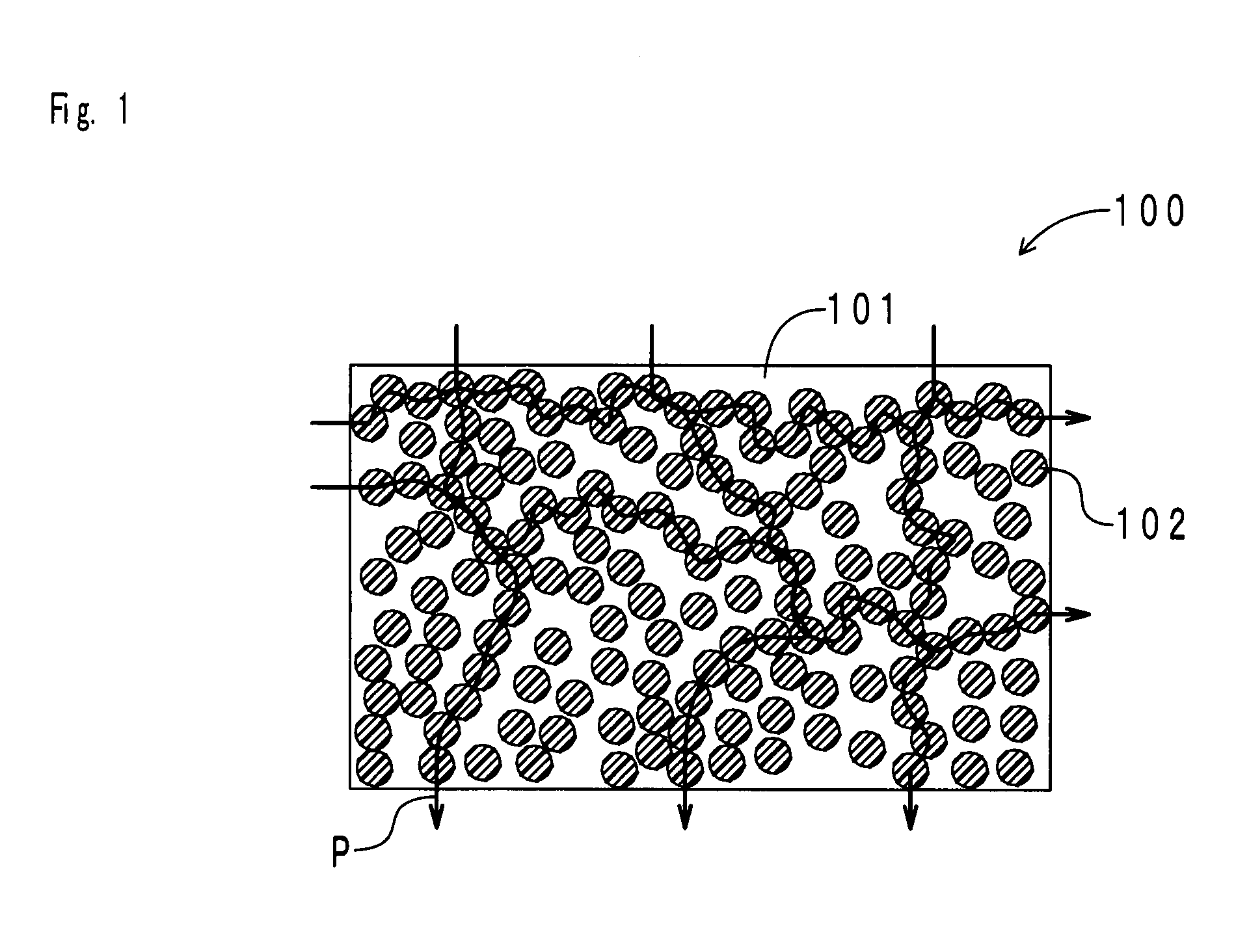

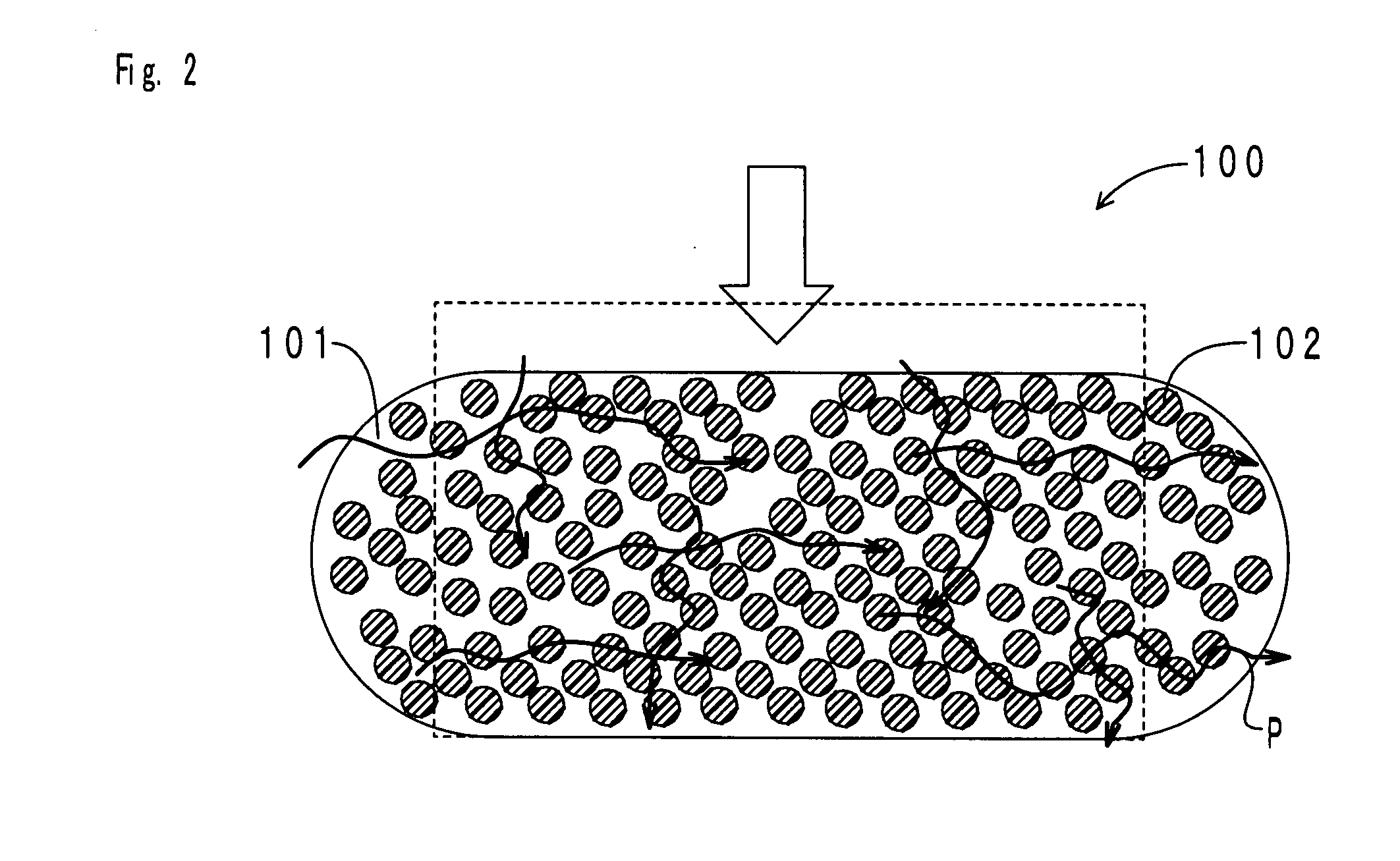

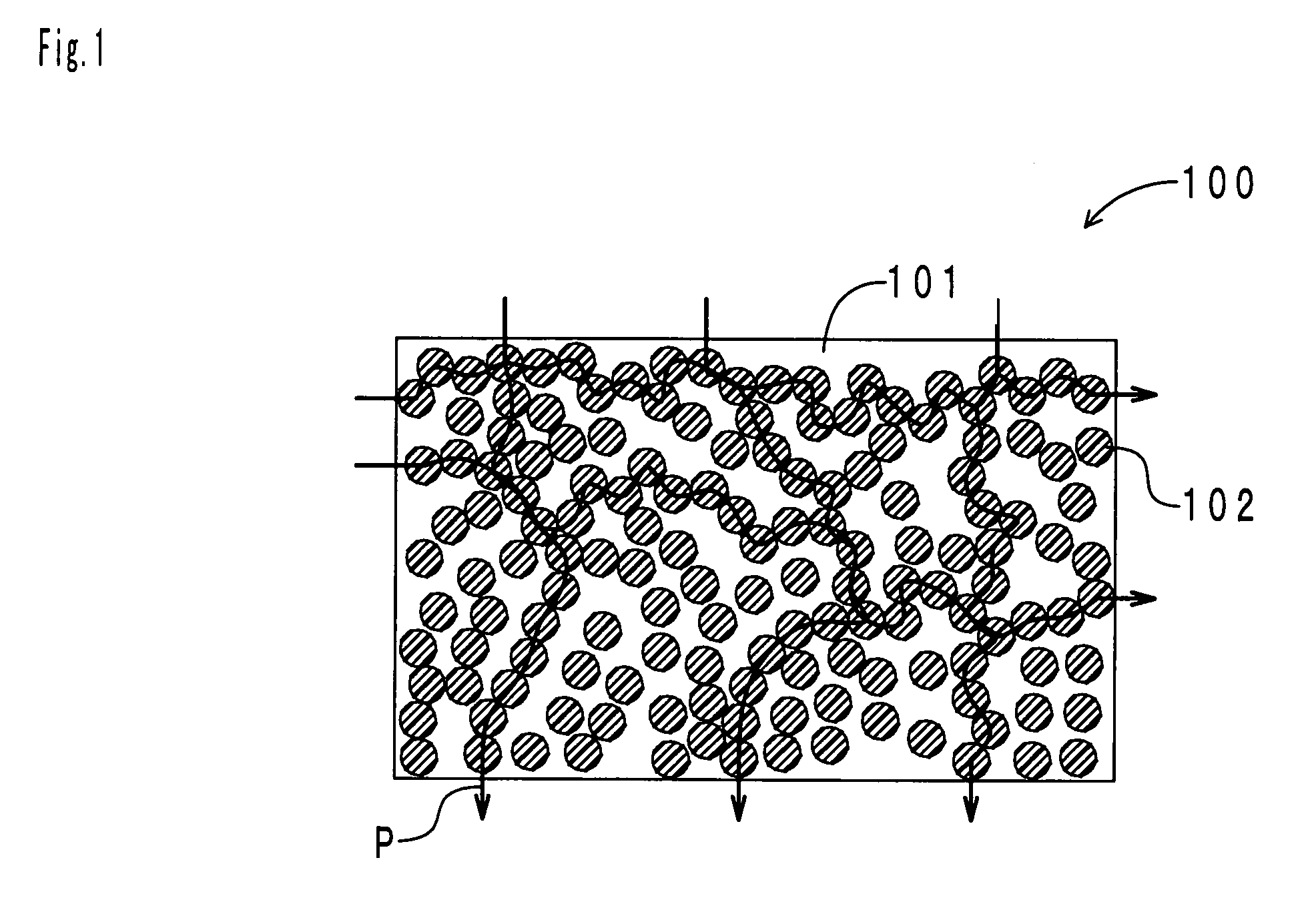

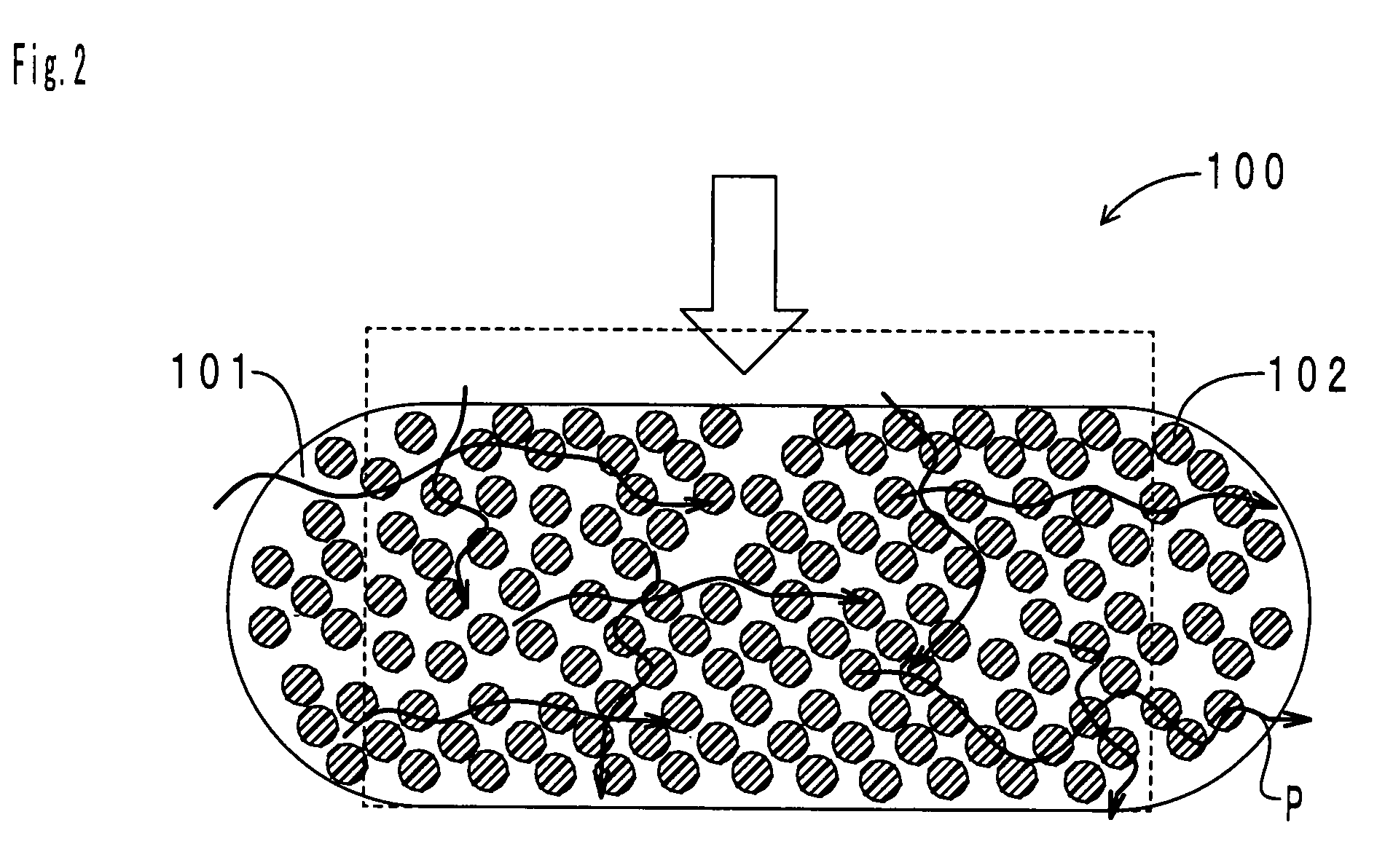

The invention discloses a combined vibration damper of a screw drill complete machine test-bed and a manufacturing method thereof. The combined vibration damper comprises a vibration attenuation base which comprises a loading system base, a first clamping system base and a second clamping system base, wherein the loading system base is arranged on an equipment foundation in a rigidity way; the first clamping system base and the second clamping system base are connected into a whole through a bolt and are arranged on the equipment foundation through a rubber vibration attenuation block; an interval of 30-50 mm is reserved between the loading system base and each clamping system base; the first clamping system base and the second clamping system base are respectively internally provided with a plurality of cubic cavities with an equal size; the volume of each cubic cavity is 0.1-0.2 cubic meter; discrete type balance weight sand is respectively filled into the cubic cavities, and the filling efficiency is 80-90 %; and the weight of the balance weight sand is 25-35 % of the total weight of the whole device. The test-bed is capable of restraining resonance and testing precisely in the testing process by the combined vibration damper, and the usage precision of surrounding working devices is not affected.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

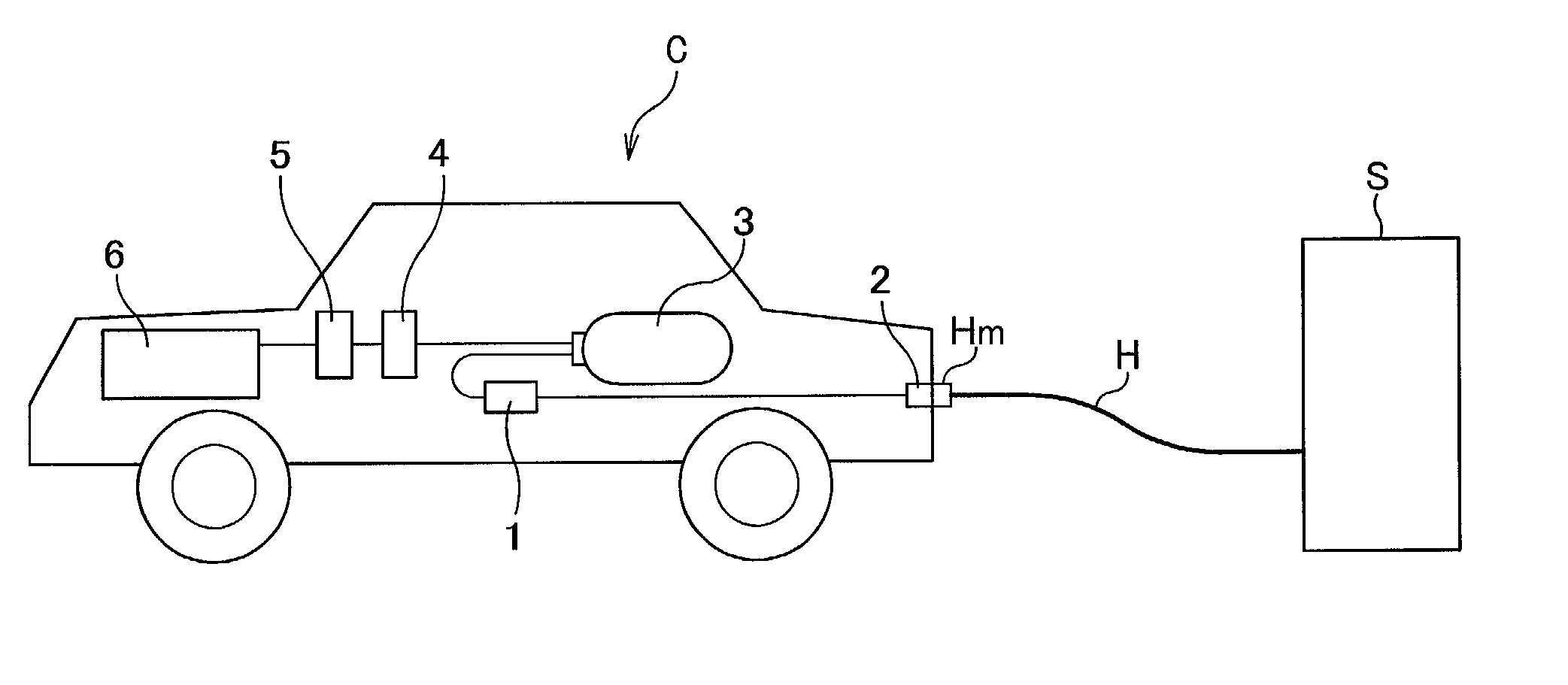

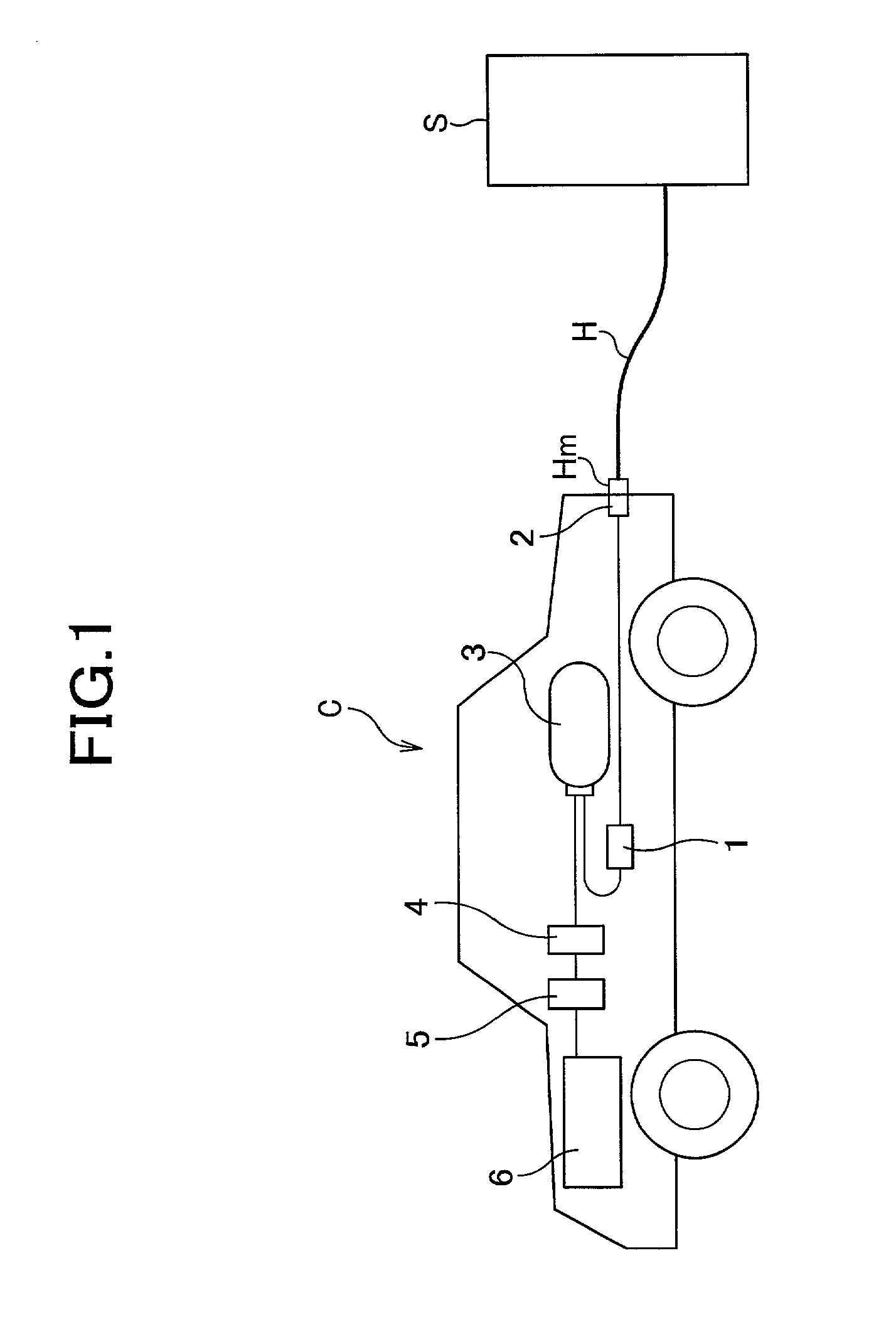

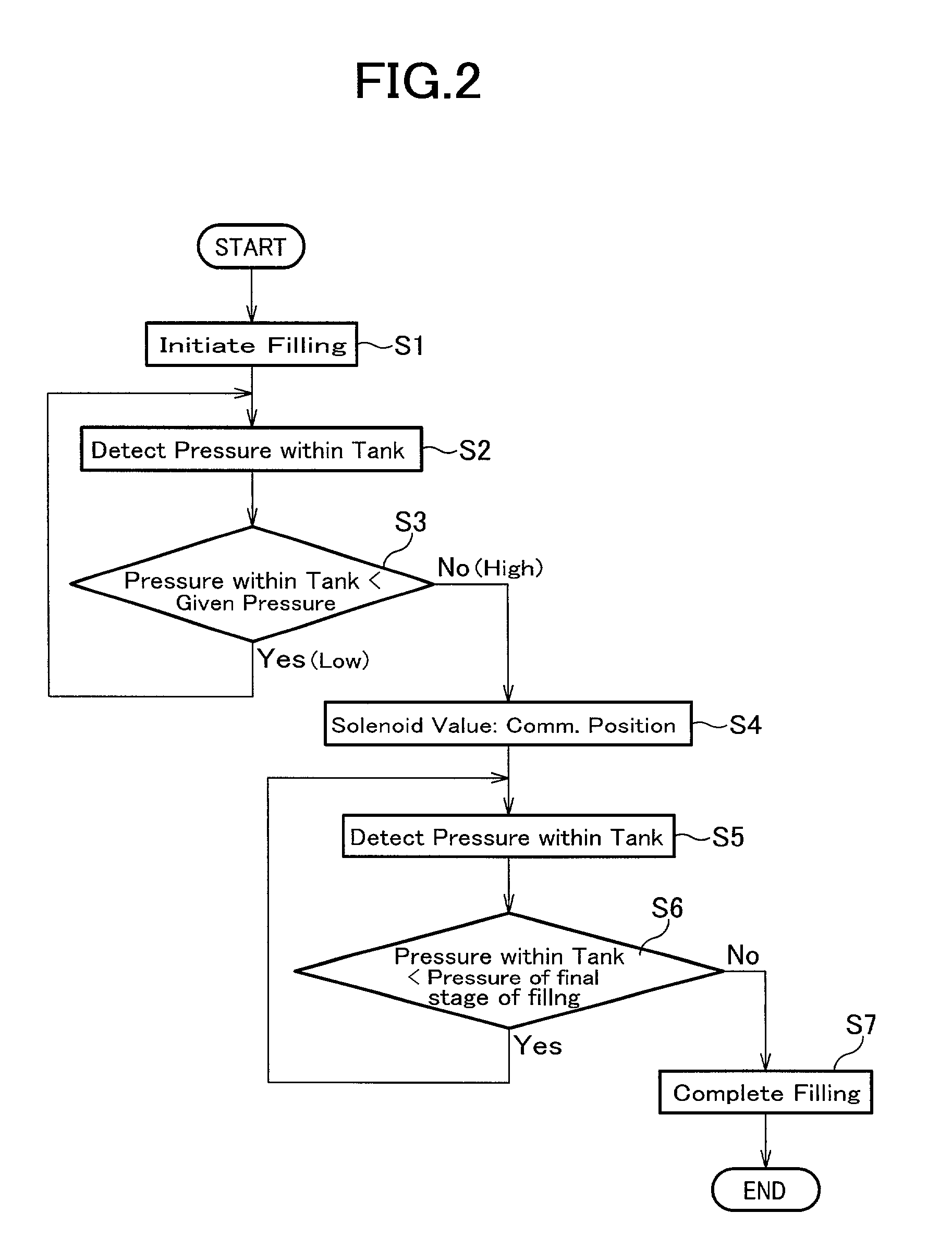

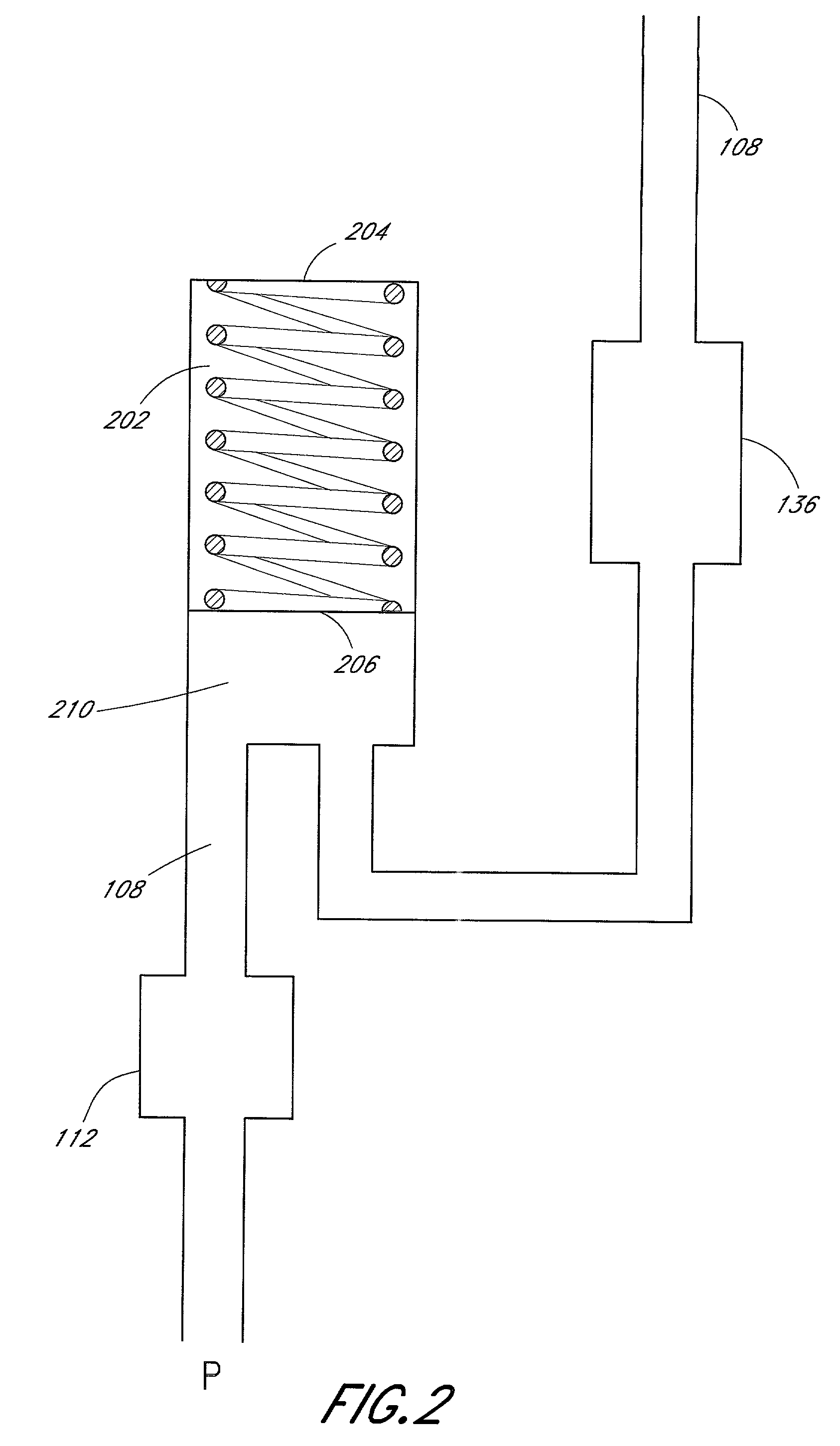

Apparatus and process for rapidly filling with hydrogen

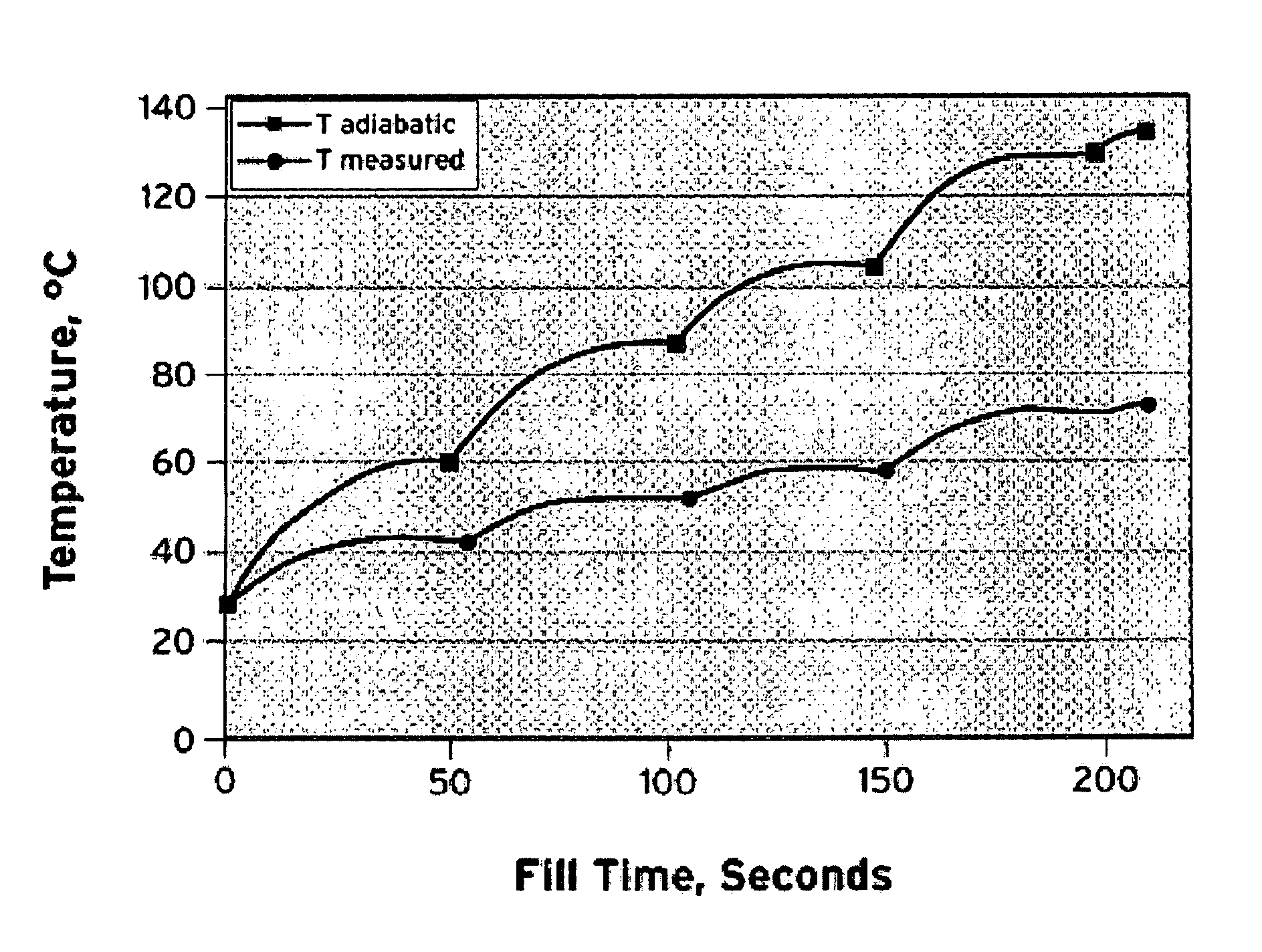

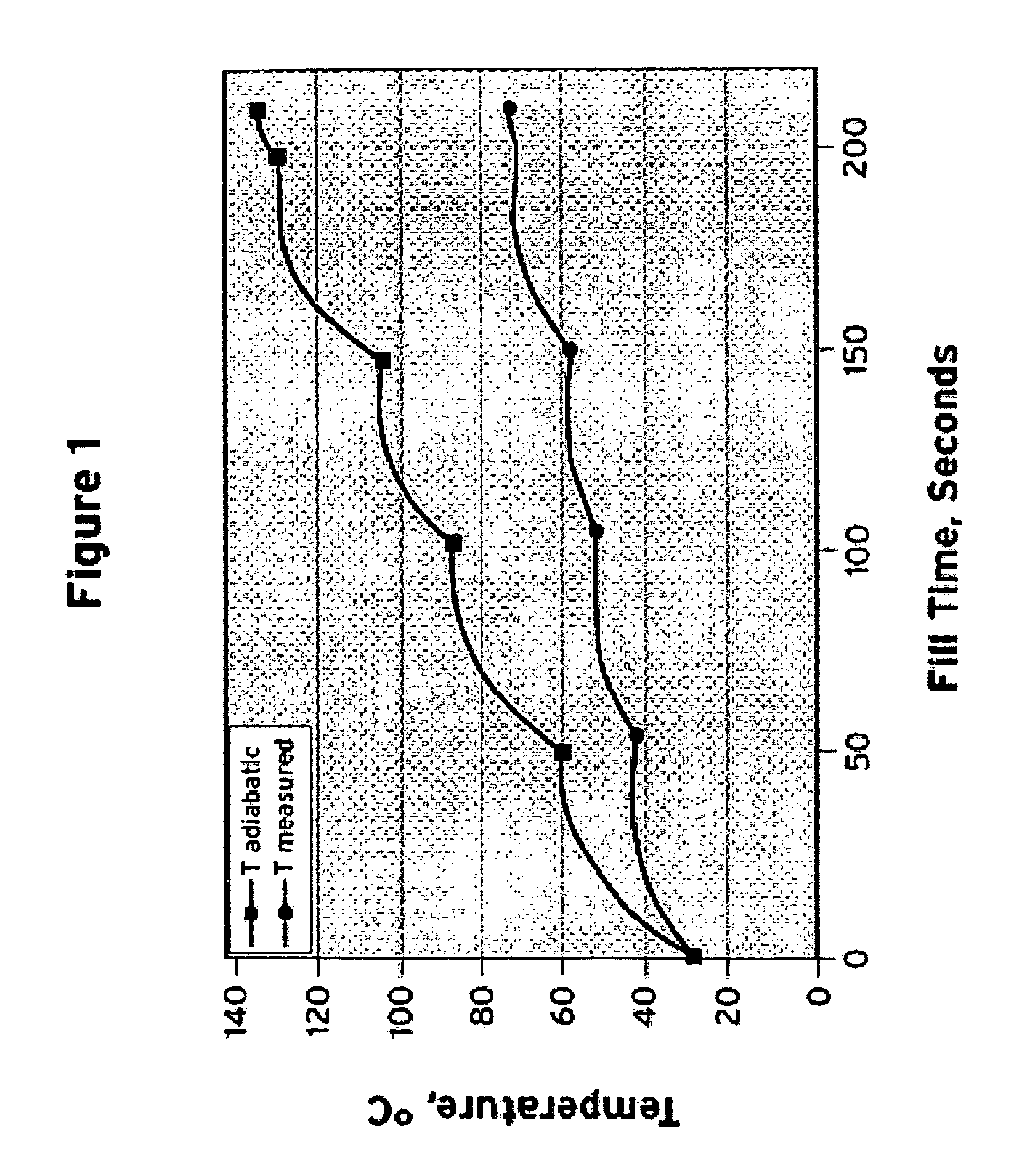

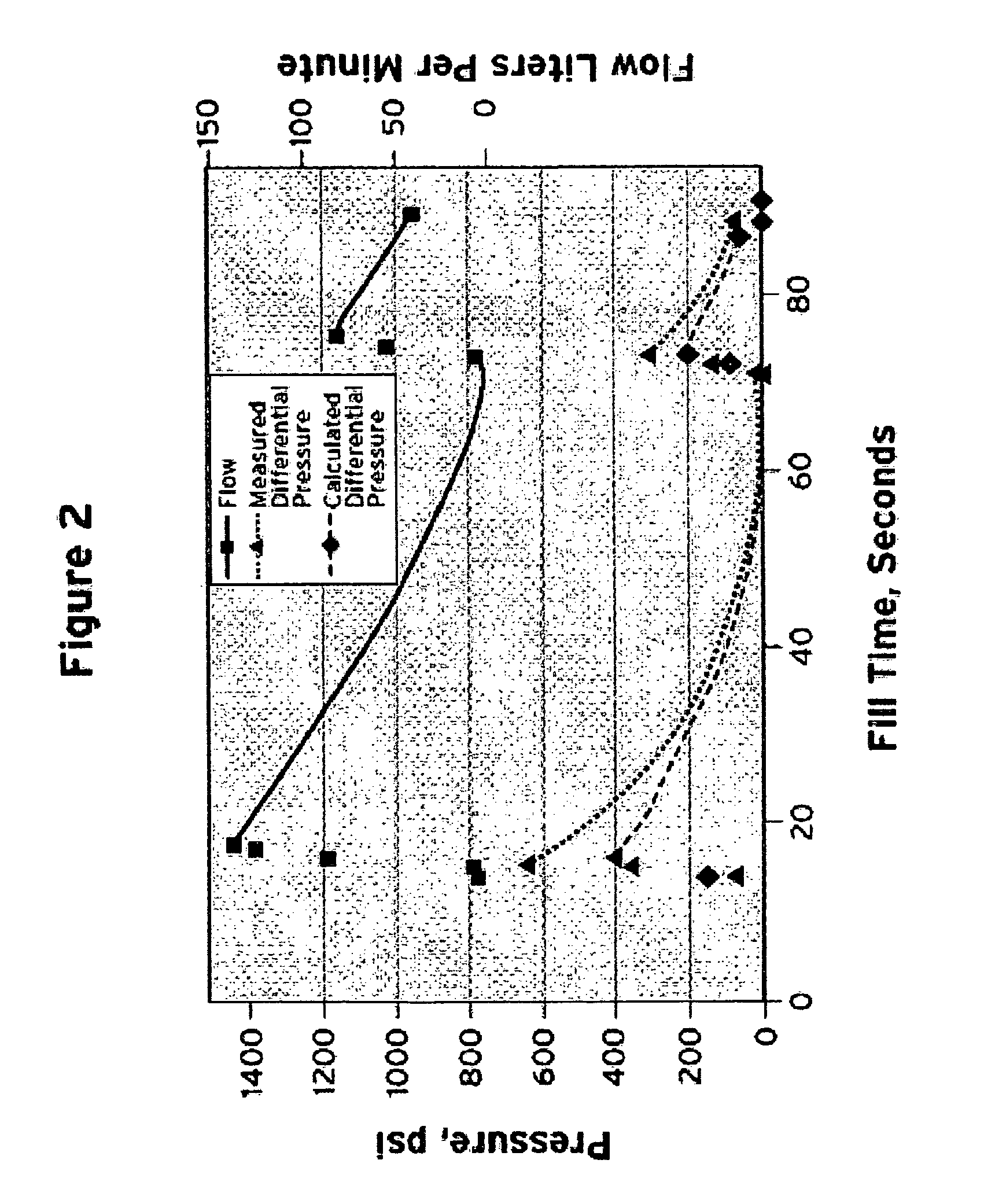

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

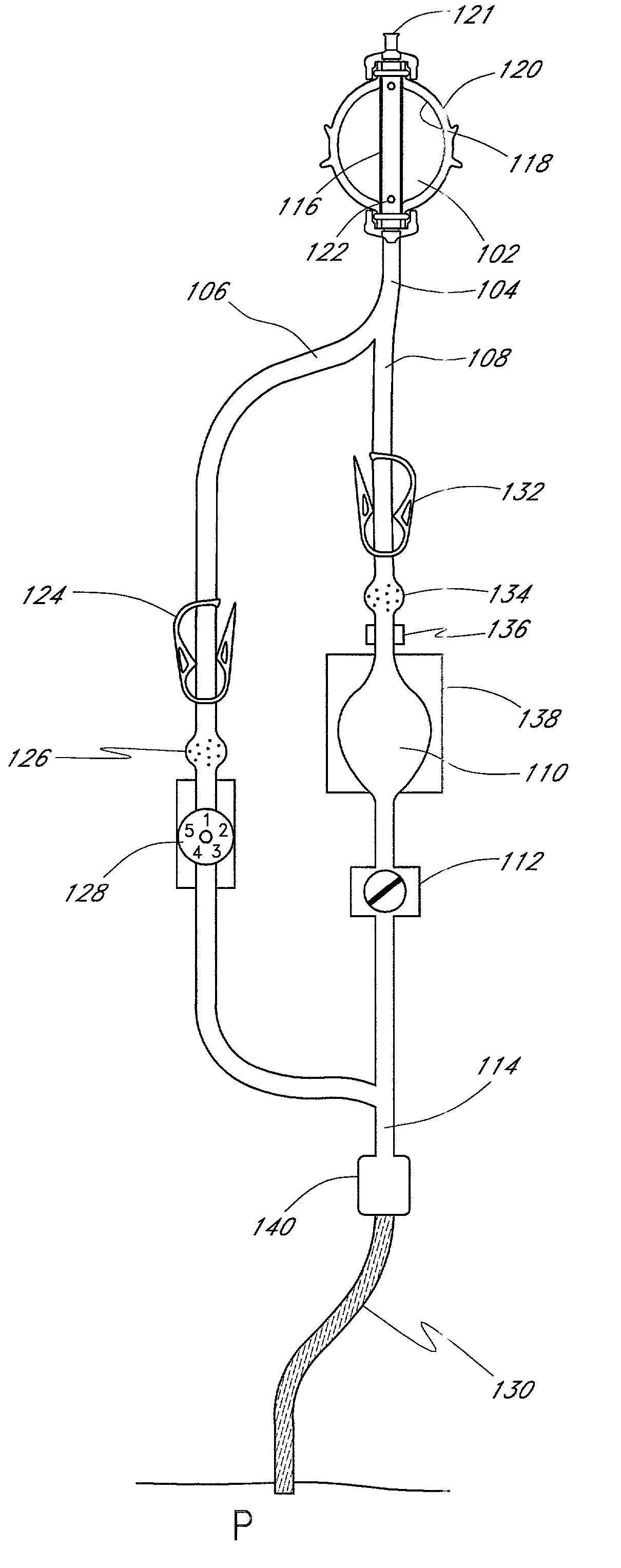

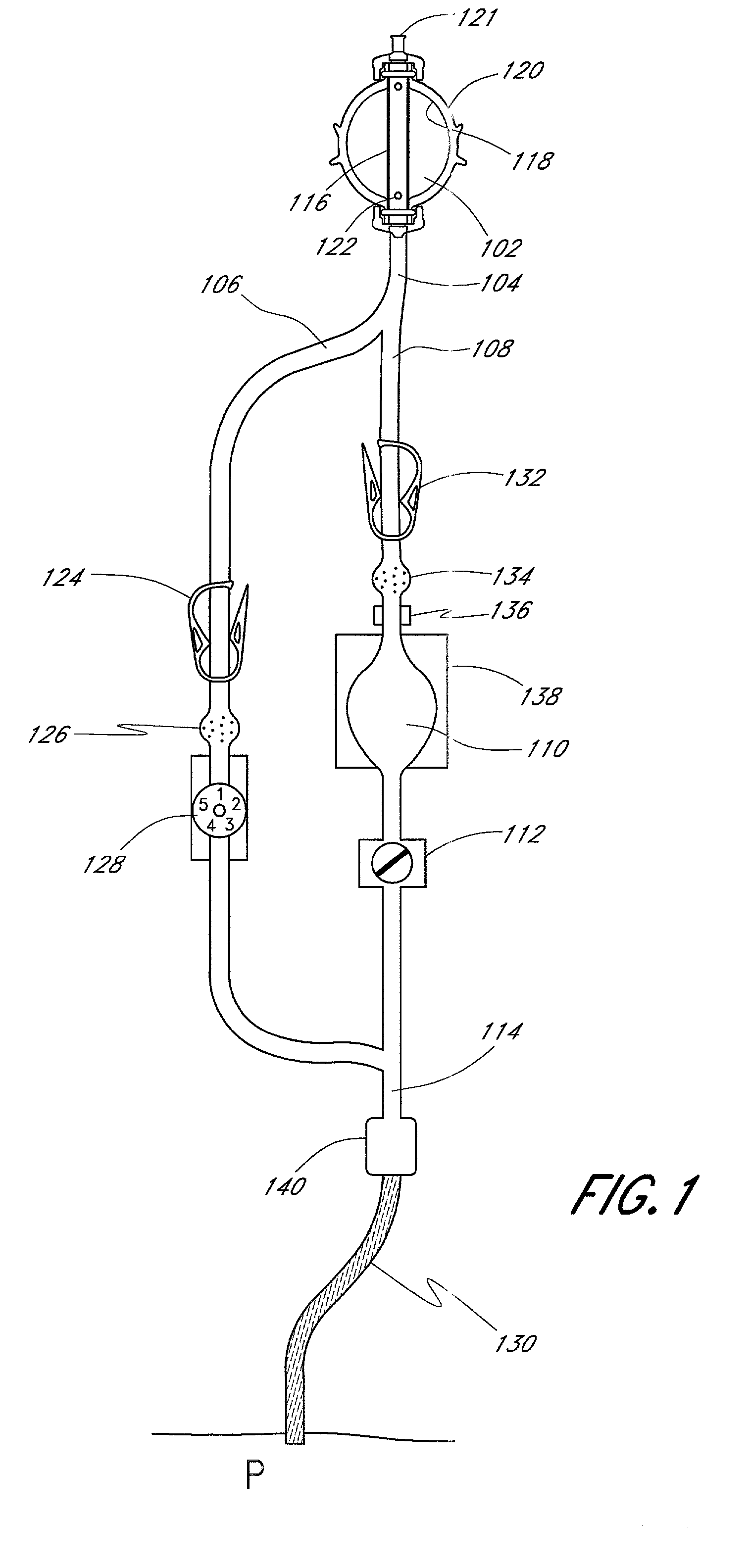

Large volume bolus device and method

A device and method for the infusion of medicinal fluid at a controlled flow rate to a wound site or the blood stream of a patient is disclosed. A pump delivers fluid under pressure from a fluid source through a continuous and substantially constant flow path and through a supplemental bolus dose flow path. A large volume bolus dose reservoir accumulates a large quantity of fluid from the bolus dose flow path and holds the fluid under pressure. A flow regulator controls the fill rate of the large volume bolus reservoir. The large volume supplemental bolus dose is released from the bolus reservoir upon patient activation of a valve. The release rate of the bolus dose is controlled by the decompression of an elastomeric sphere or spring chamber, by the pressure gradient at the valve and / or by optional flow control tubing. In one embodiment, a source of fluid under pressure is pumped at a continuous and substantially constant rate to a wound site or the blood stream of a patient and into a bolus syringe, which is capable of holding a large quantity of fluid under pressure. A plunger on the bolus syringe may be depressed to release a bolus dose of fluid into a chamber accumulator and then to the patient at a controlled release rate.

Owner:AVENT INC

Apparatus and process for rapidly filling with hydrogen

InactiveUS6598624B2Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

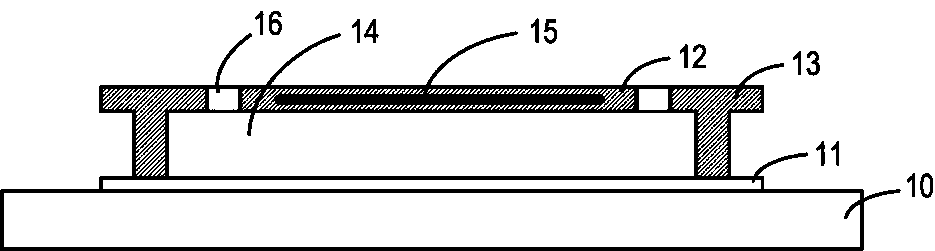

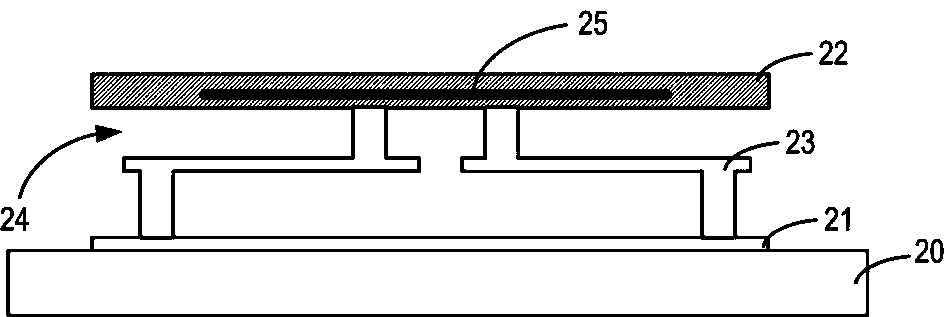

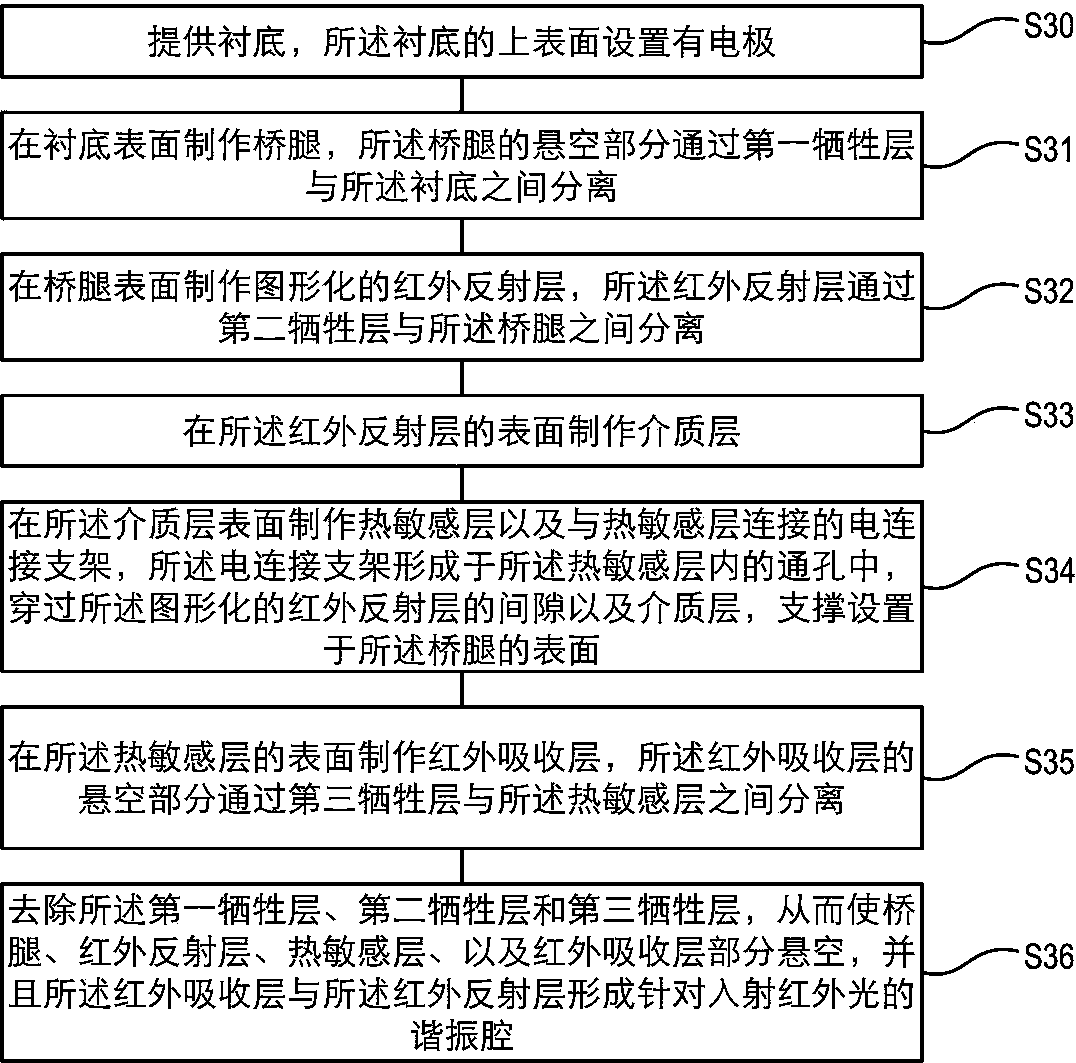

Infrared detector of microbridge structure and method for manufacturing same

ActiveCN103759838ALarge design spaceImprove infrared absorptionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesResonant cavityThermal isolation

The invention provides an infrared detector of a microbridge structure and a method for manufacturing the infrared detector of the microbridge structure. The detector comprises a reading circuit substrate, a microbridge leg, a heat sensitive layer, an infrared reflection layer and an infrared absorption layer. The infrared absorption layer is supported by and arranged above the heat sensitive layer, a resonant cavity for incoming infrared light is formed by the infrared absorption layer and the infrared reflection layer, and the microbridge leg is arranged below the infrared reflection layer and electrically connected with the reading circuit substrate. Through the structure, the infrared absorptivity of the device can be improved while thermal conductance of the device can be reduced, the filling rate of the device is improved, the defects of the resonant cavity are overcome, and thus the thermal isolation effect and the responsivity of the device are improved and the performance of the device is optimized.

Owner:ZHEJIANG DALI TECH

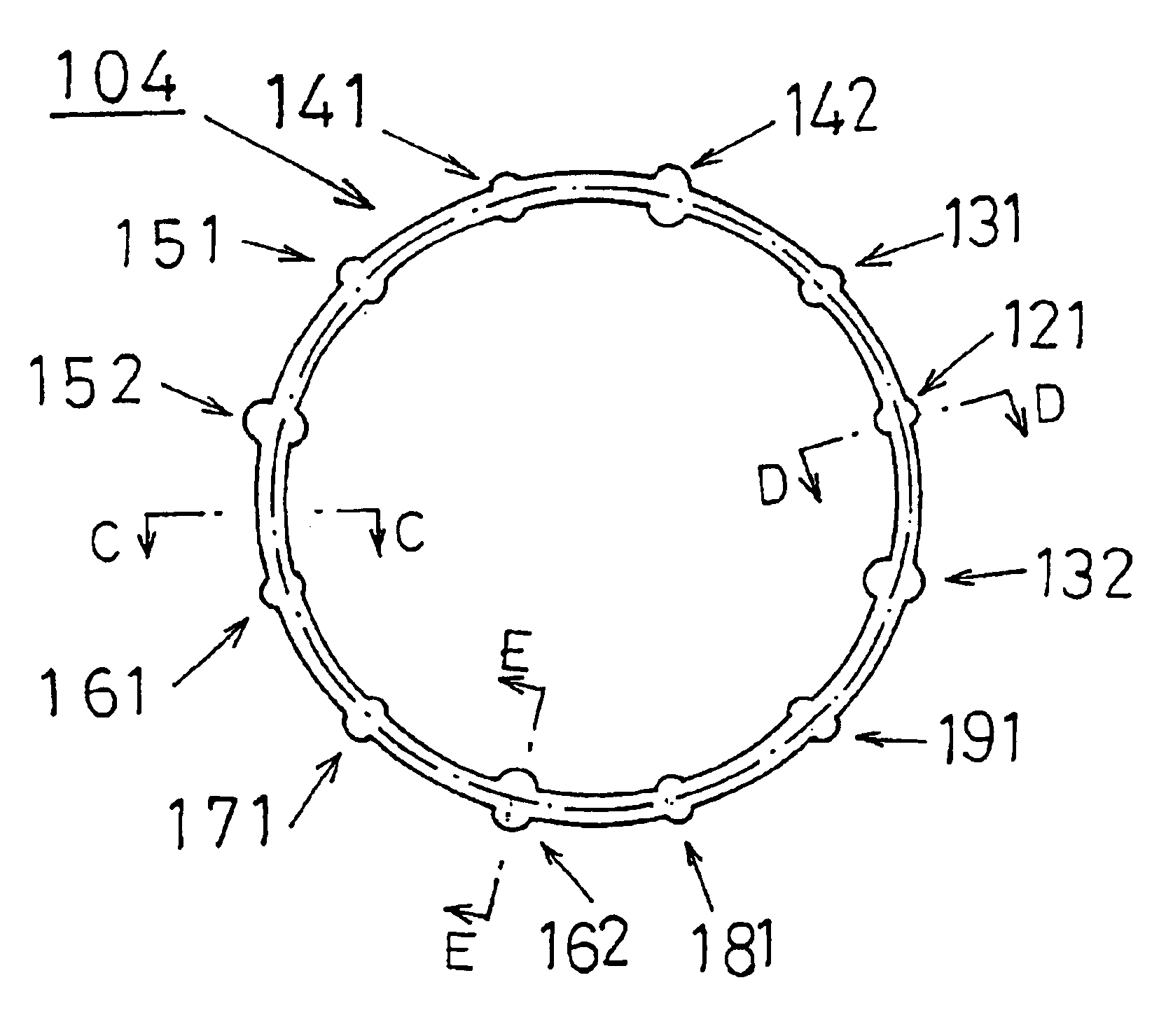

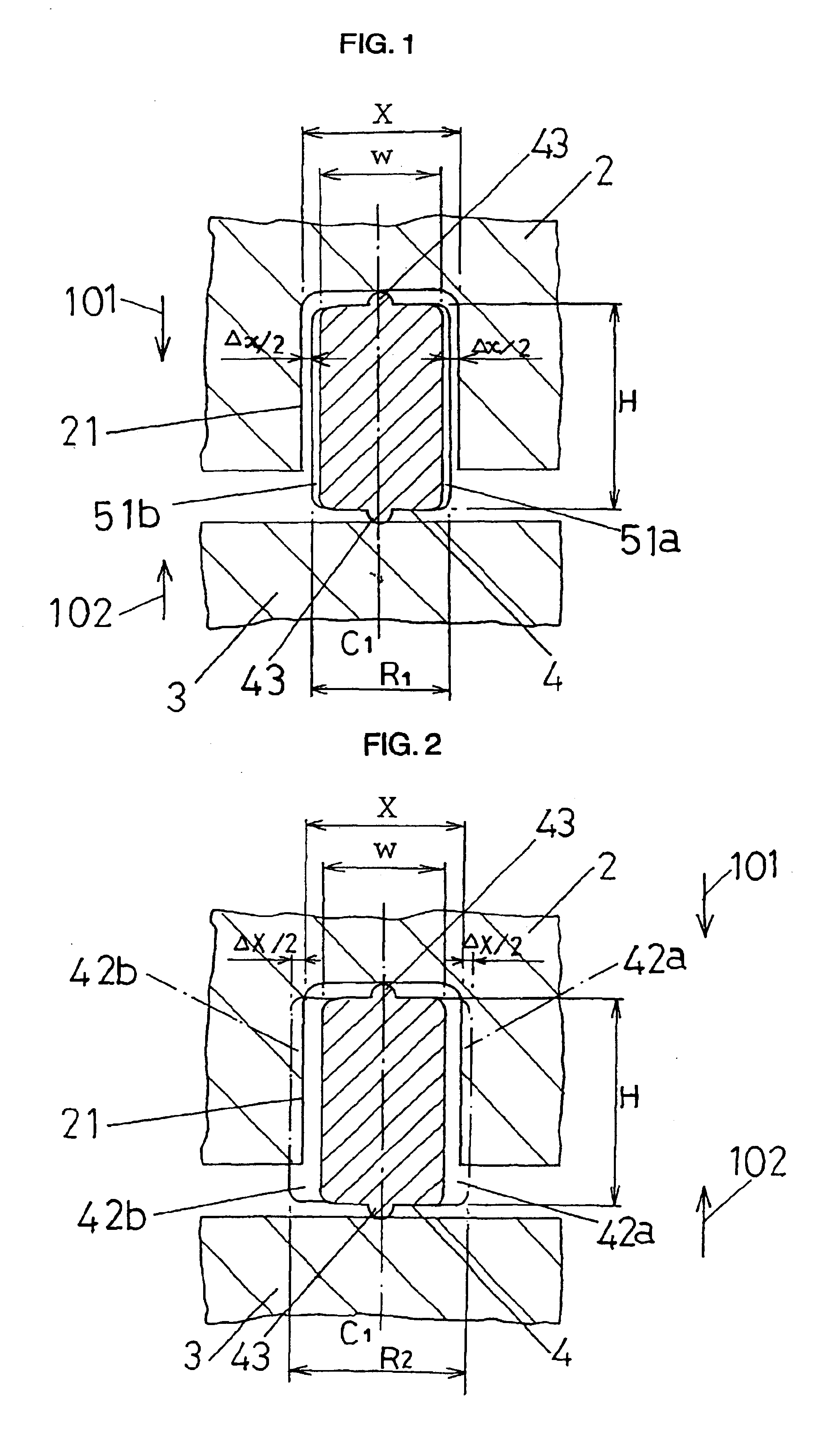

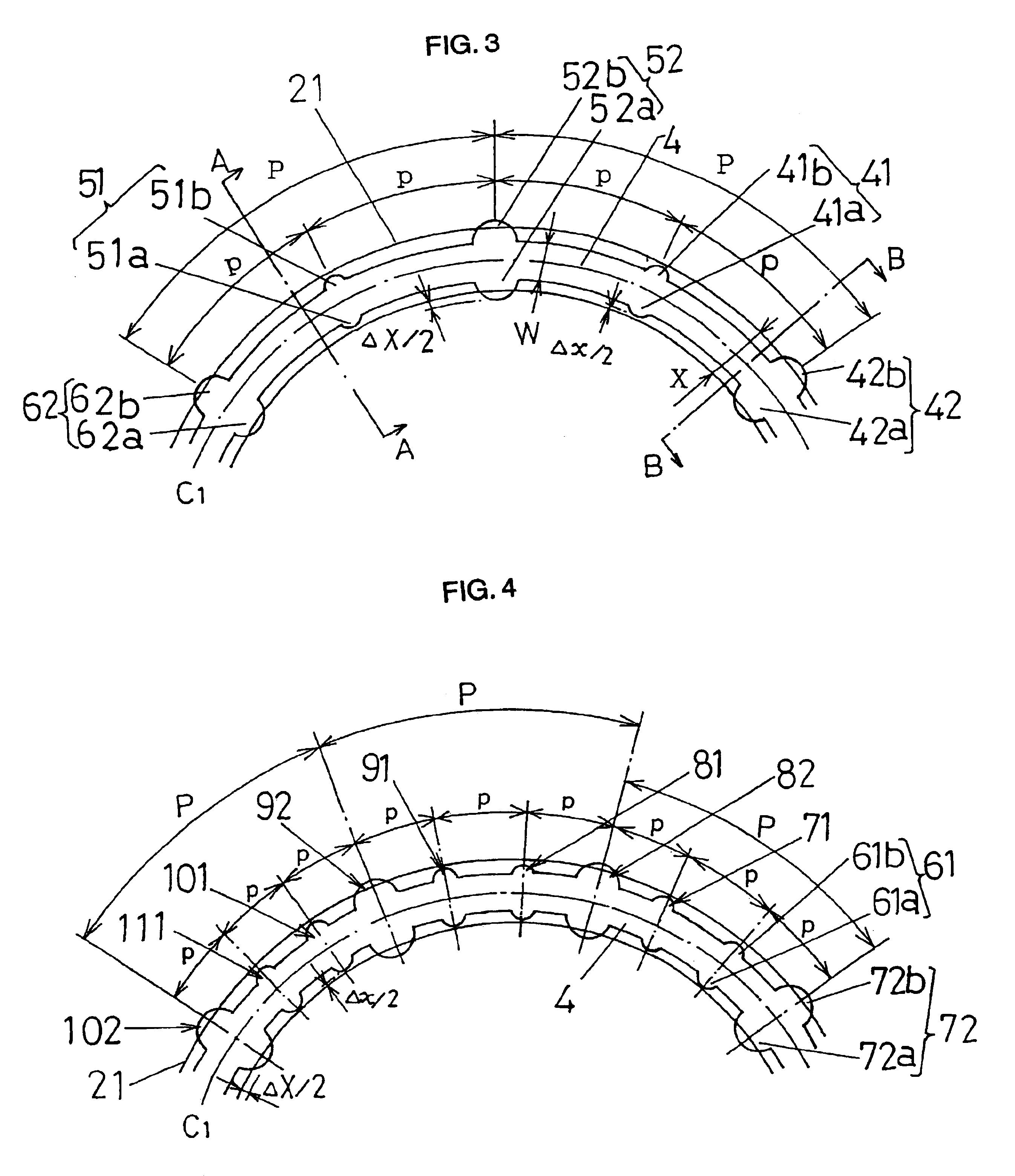

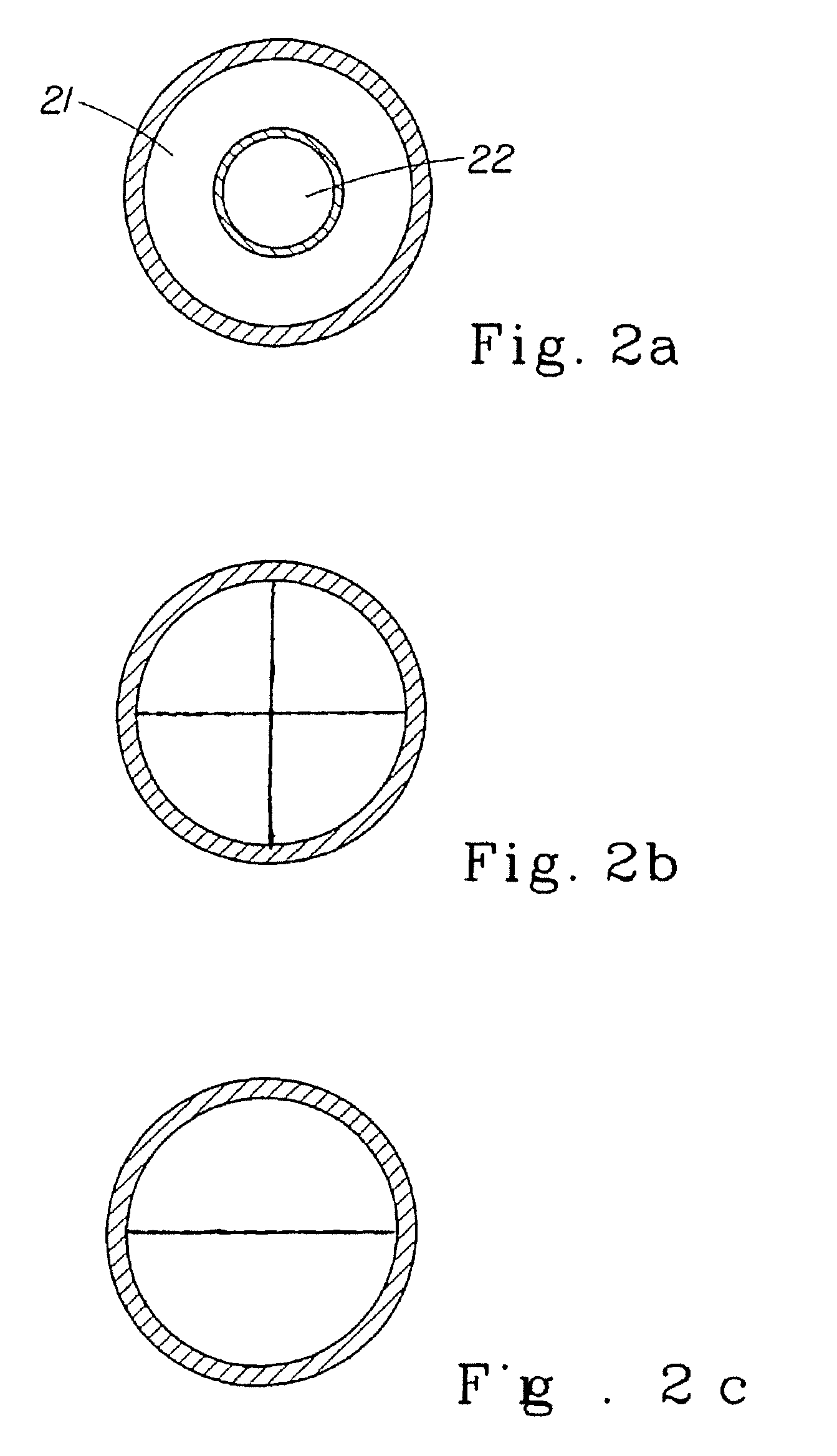

Gasket

A longitudinally-endless gasket mounted into a groove portion formed in one of members to provide sealing between this one member and another of the members when they are fastened to each other. The gasket has a sectional shape corresponding to a sectional shape of the groove portion with a ratio (H / W) between a height (H) and a width (W) of the sectional shape being 0.8 to 5.0. The gasket is provided with a plurality of large projecting portions at intervals of 30 to 100 mm and a plurality of small projecting portions at intervals of 5 to 15 mm in a longitudinal direction of the gasket. A width (R2) of each large projecting portion is larger than a width (X) of the groove portion by 0.01 to 0.9 mm. A width (R1) of each small projecting portion is smaller than the width (X) of the groove portion by 0.01 to 0.6 mm. A filling rate of the groove portion by the gasket when the members are fastened to each other is 80 to 100%.

Owner:UCHIYAMA MFG

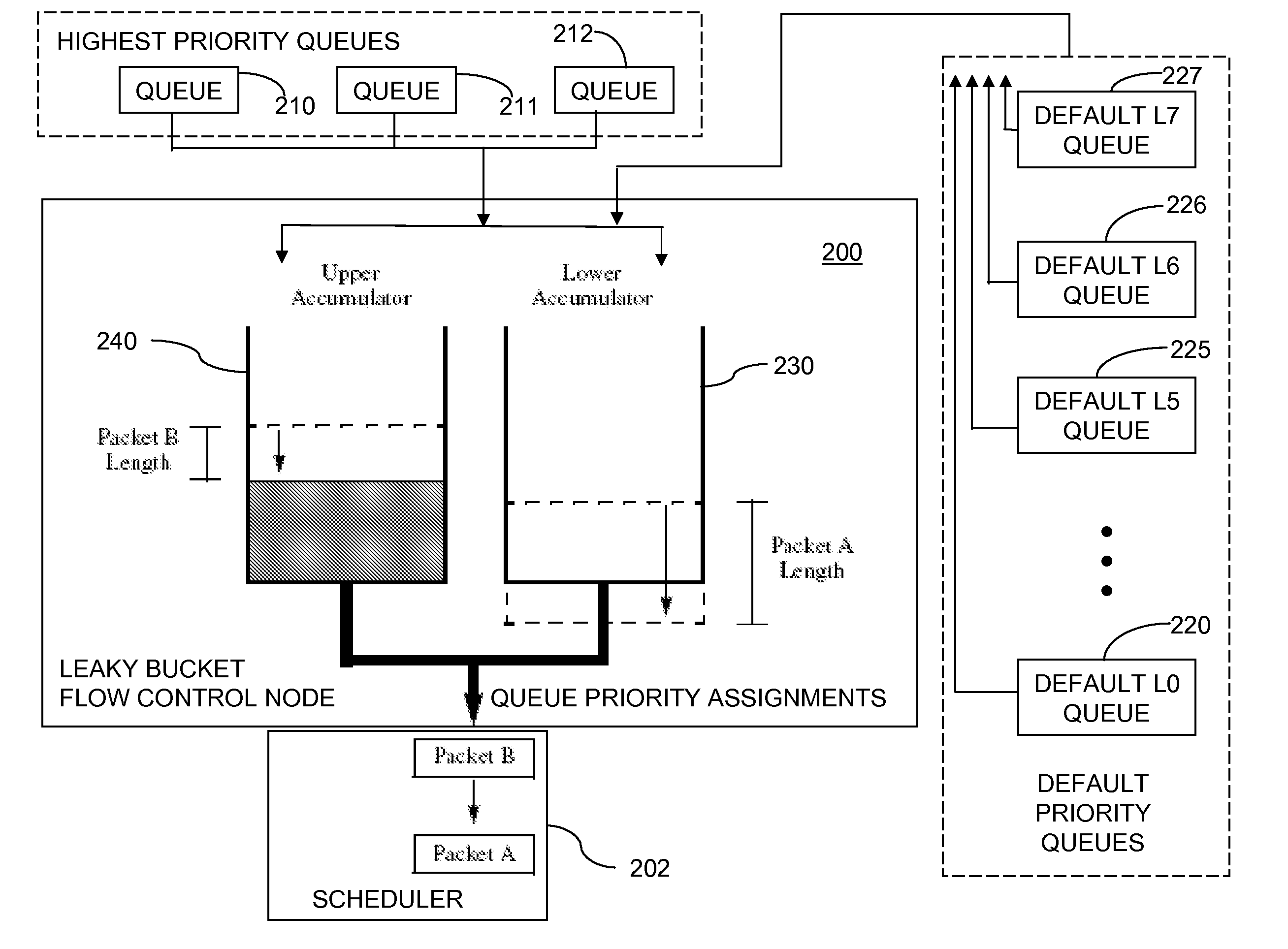

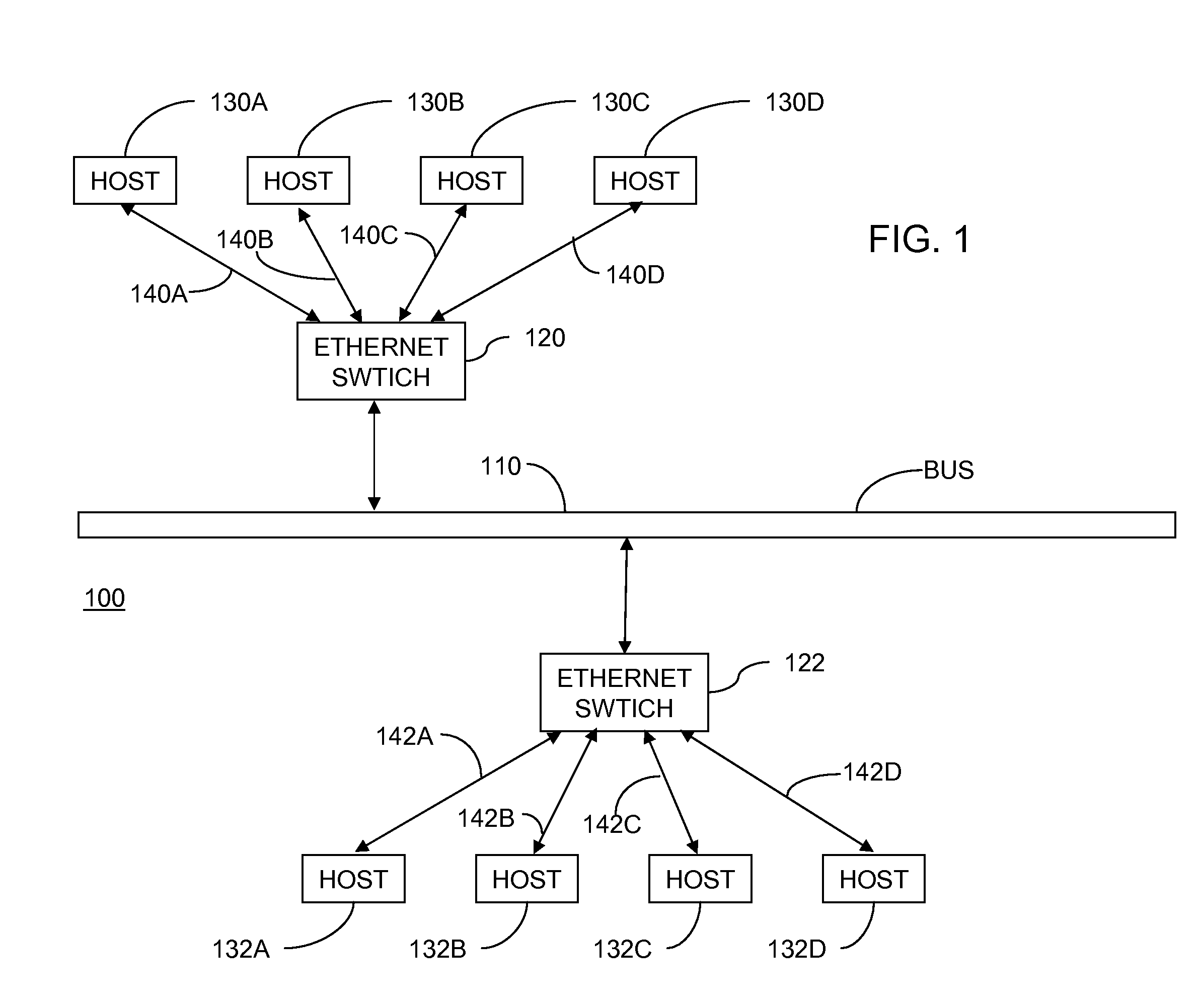

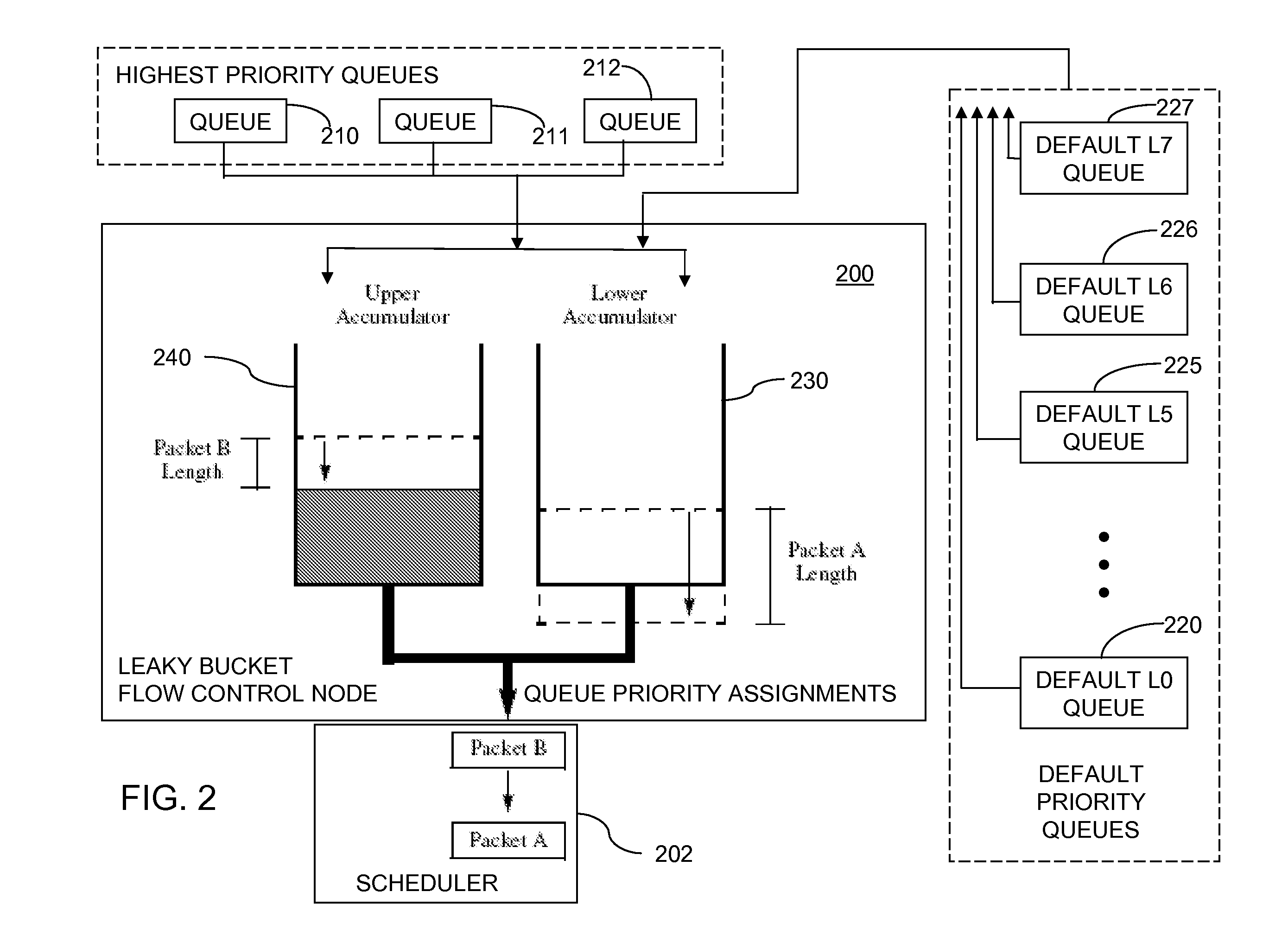

Dual Leaky Bucket Flow Control Method and System

A method for scheduling a network resource comprises adding tokens to first and second accumulators at first and second fill rates, respectively. A number of tokens corresponding to a size of a packet is subtracted from the first accumulator and a highest priority is assigned to a queue with which the packet is associated, if a number of tokens in the first accumulator is greater than zero. The number of tokens is subtracted from the second accumulator, and a default priority assigned to the queue, if the number of tokens in the first accumulator is less than zero and a number of tokens in the second accumulator is greater than zero. The network resource is assigned for transmission of the packet from the queue using a schedule that is based on the priority assigned to the queue. The packet is transmitted using the assigned network resource.

Owner:INTEL CORP

Process for Making Non-Uniform Patterns of Multiphase Compositions

A method of filling a container with a liquid composition, which comprises at least two visually distinct phases, comprising the steps of: a.) transferring said liquid composition to a container using a dispenser which has an initial fill rate; b.) rotating said container during said step a. at an initial speed of rotation and in an initial direction of rotation; c.) changing a feature selected from the group consisting of: the speed of rotation of said container, the fill rate of the dispenser, and the direction of rotation of said container; and mixtures of said features, each independently from the geometry of said container; and d.) completing the transfer of said liquid composition to said container.

Owner:THE PROCTER & GAMBLE COMPANY

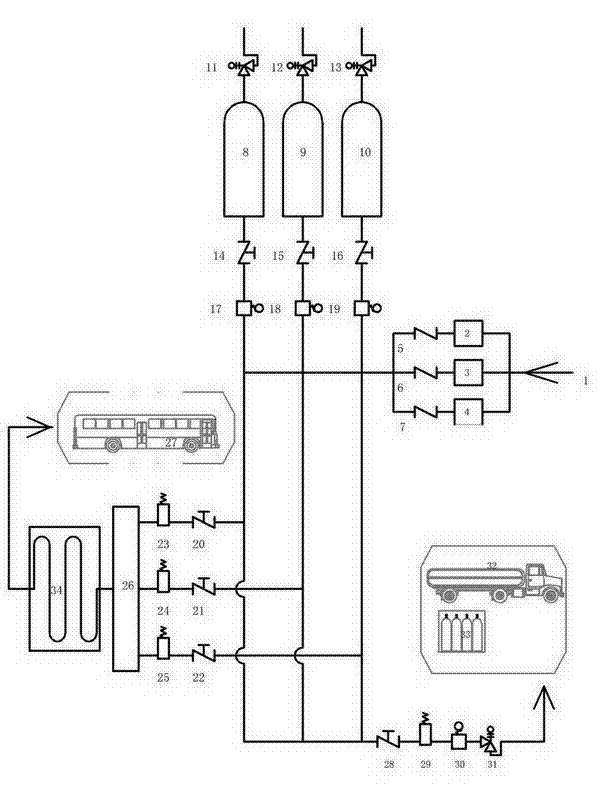

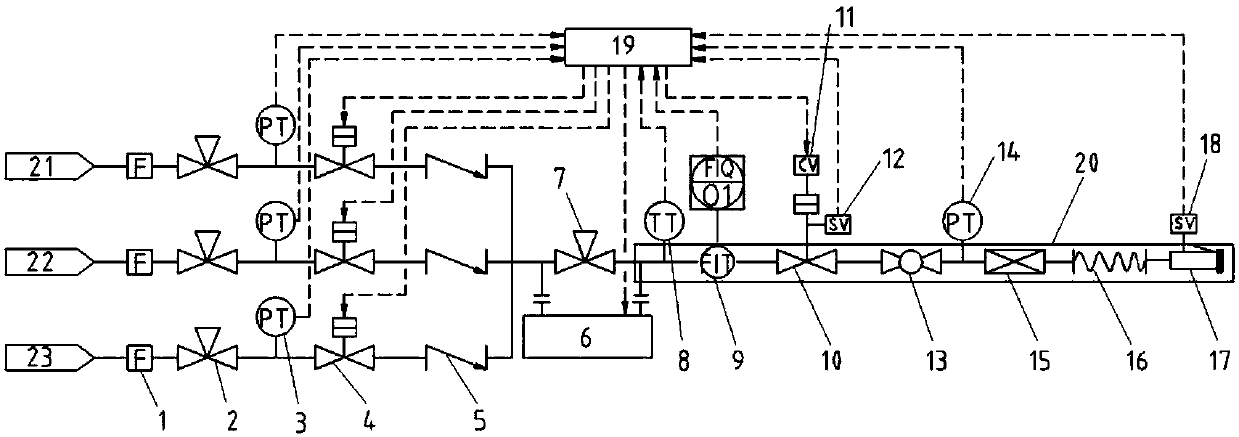

System and method for rapid hydrogen filling

InactiveCN103244825AImprove securityReduce temperature risePipeline systemsContainer filling under pressureGas cylinderHigh pressure hydrogen

The invention provides a system and a method capable of achieving balanced pressure-reducing rapid hydrogen filling by three storage tanks with hydrogen of any sources. The system comprises a hydrogen compression device, hydrogen storage devices and a hydrogen filling device. Hydrogen prepared by any methods is compressed via the hydrogen compression device and then is stored in the high-pressure hydrogen storage devices, and a hydrogen outlet of each hydrogen storage device is directly connected to a hydrogen dispenser or an industrial hydrogen cylinder filling system. A set of pressure-reducing balanced filling system is shared during automobile hydrogen (hydrogen for the energy purpose) filling and cylinder filling (industrial hydrogen). A pressure-reducing valve is not arranged in the system, so that pipe resistance of the system is lower, and filling rate is higher. Besides, a pre-cooling device is added to the system, so that temperature rise of a filling container is lower.

Owner:BEIJING JONTON HYDROGEN TECH

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

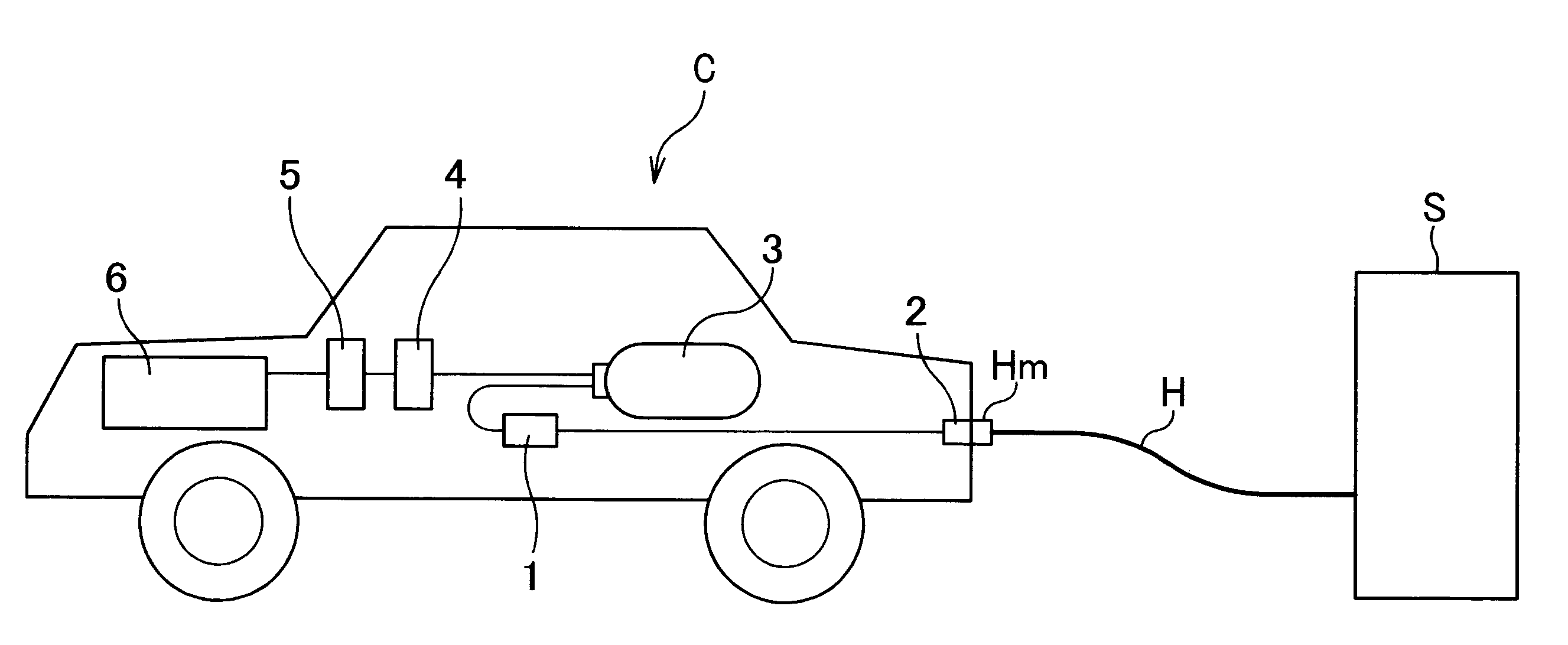

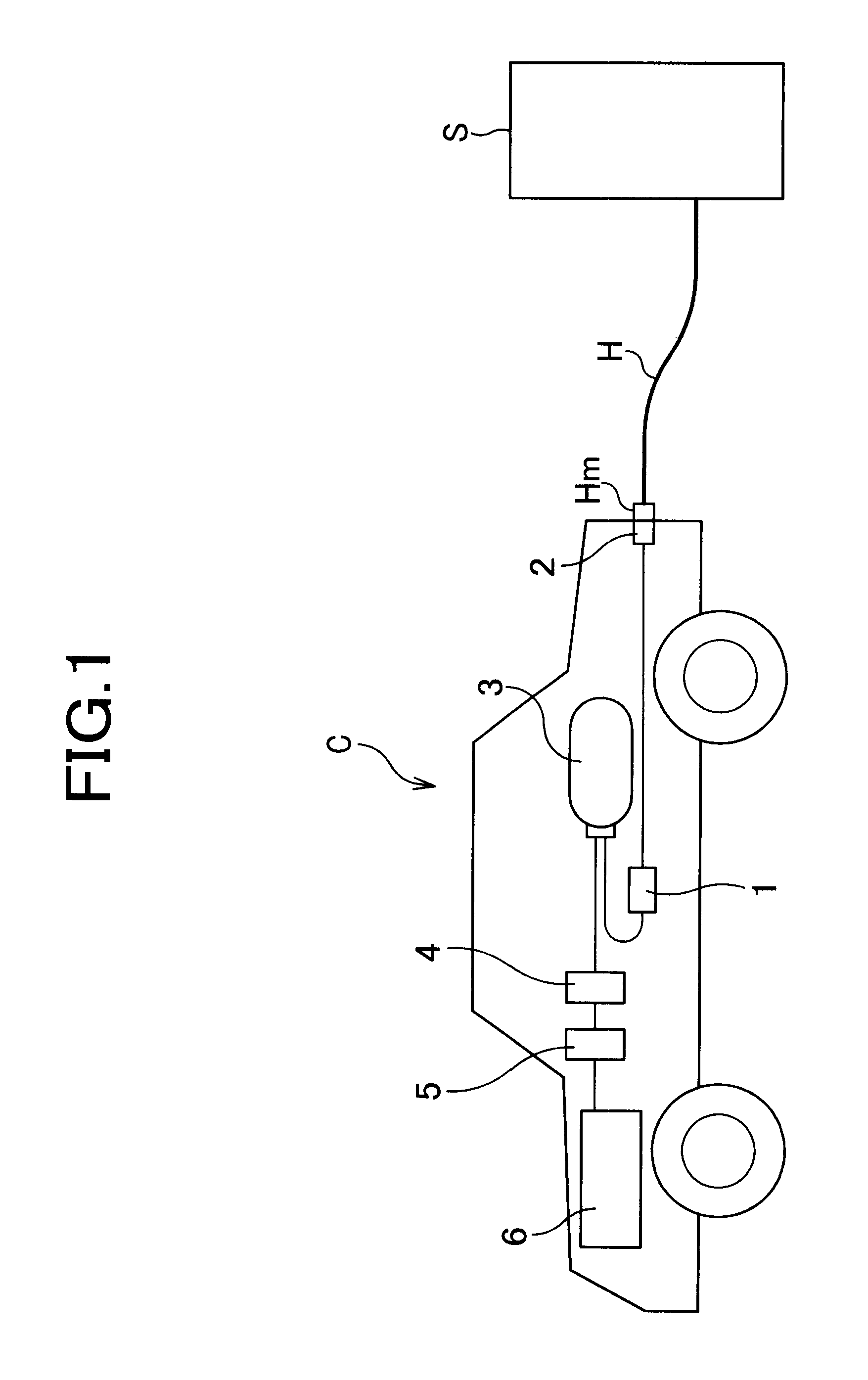

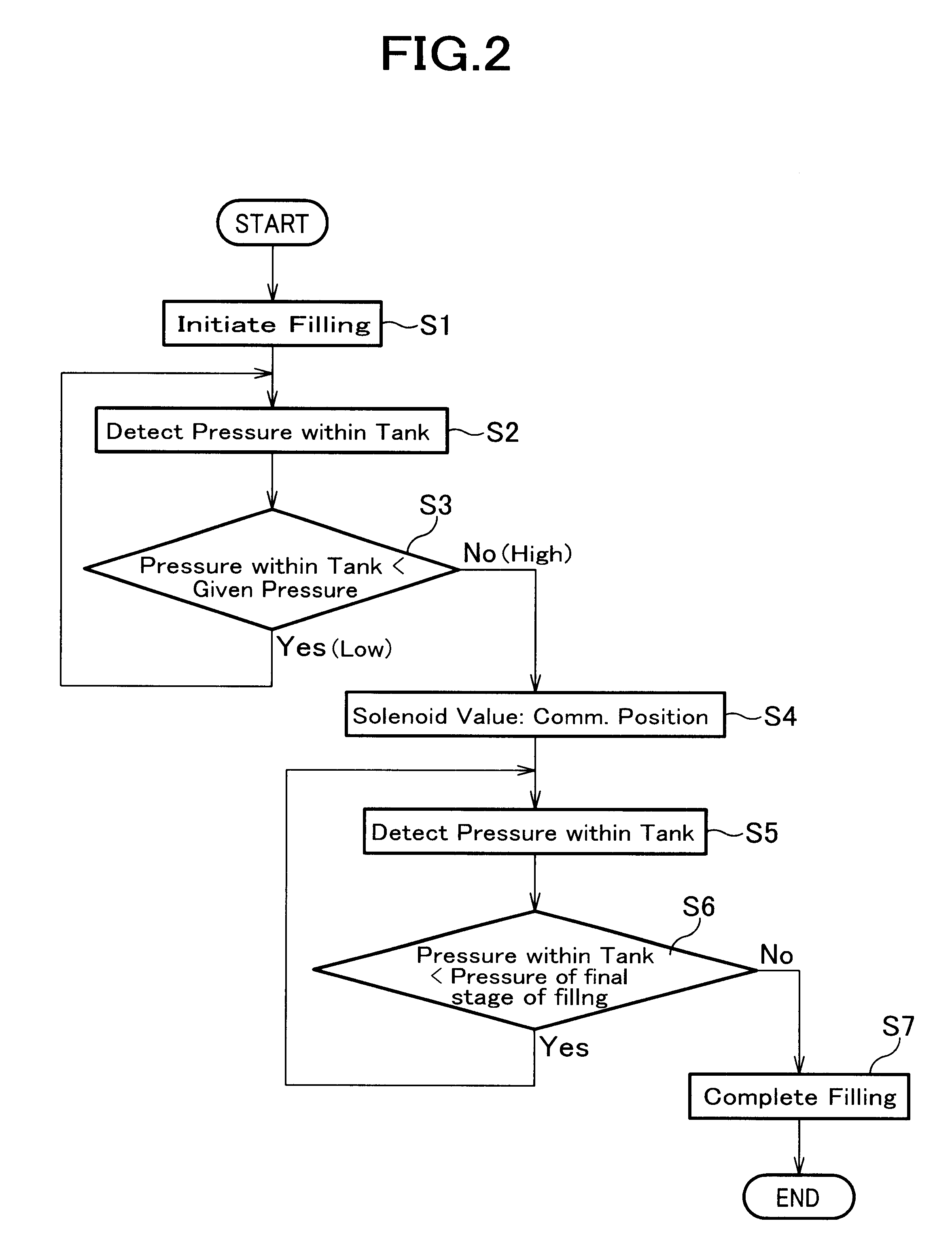

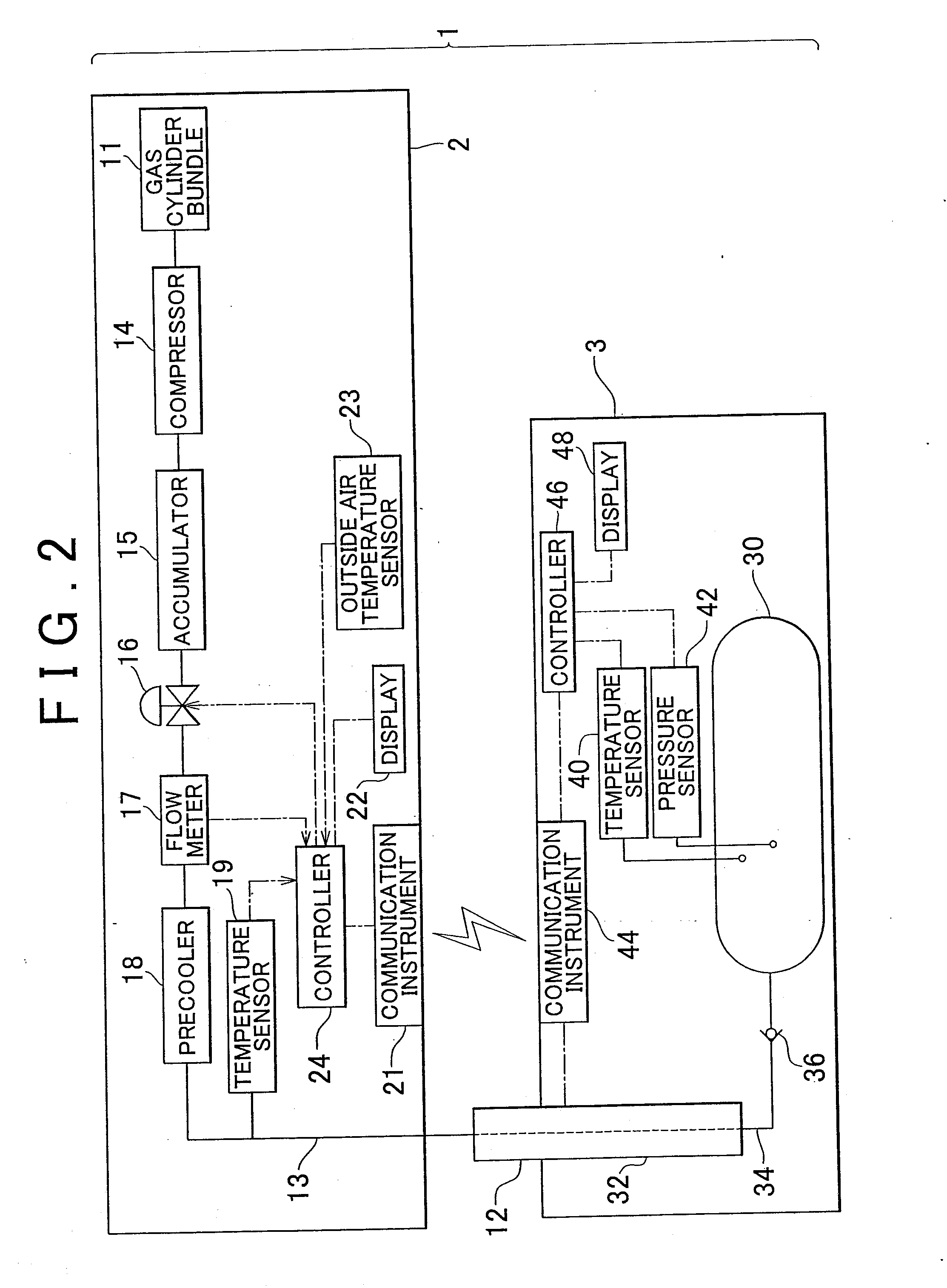

Gas filling system, gas filling method, and vehicle

ActiveUS20120227864A1Short timePrevent stateLiquid fillingGas handling applicationsFilling rateProcess engineering

A gas filling system (1) includes a gas tank (30); a gas filling device (2) that fills gas into the gas tank (30); and a controller (24) that calculates a temperature increase ΔT and a pressure increase ΔP in the gas tank (30) during a predetermined period of time (t seconds) that elapses from a start of gas filling. The controller (24) selects a filling rate map (Ma, Mb) from a prepared filling rate map group on the basis of the calculated temperature increase ΔT and the calculated pressure increase ΔP. The gas filling device (2) carries out gas filling using the filling rate map selected by the controller (24).

Owner:TOYOTA JIDOSHA KK

Method for calculating hydrogen temperature during vehicle fueling

InactiveUS7647194B1Convenient and accurate calculationSafe fueling experienceThermometer detailsThermometers using material expansion/contactionOn boardFilling rate

Methods for accurately and conveniently calculating the temperature of gaseous hydrogen during vehicle fueling are disclosed. The metered amount of hydrogen added to the on-board storage tank, the ambient conditions, The pressure measured at the dispenser, and a correlation to account for heat transfer are the inputs to the methods of the present invention. These inputs eliminate the need for obtaining temperature and pressure information from the vehicle which is out of the control of the dispenser and / or energy provider. In addition, the use of the equation of the present invention does not require the fill rate to be limited and the corresponding fill time to be extended.

Owner:TEXACO INC

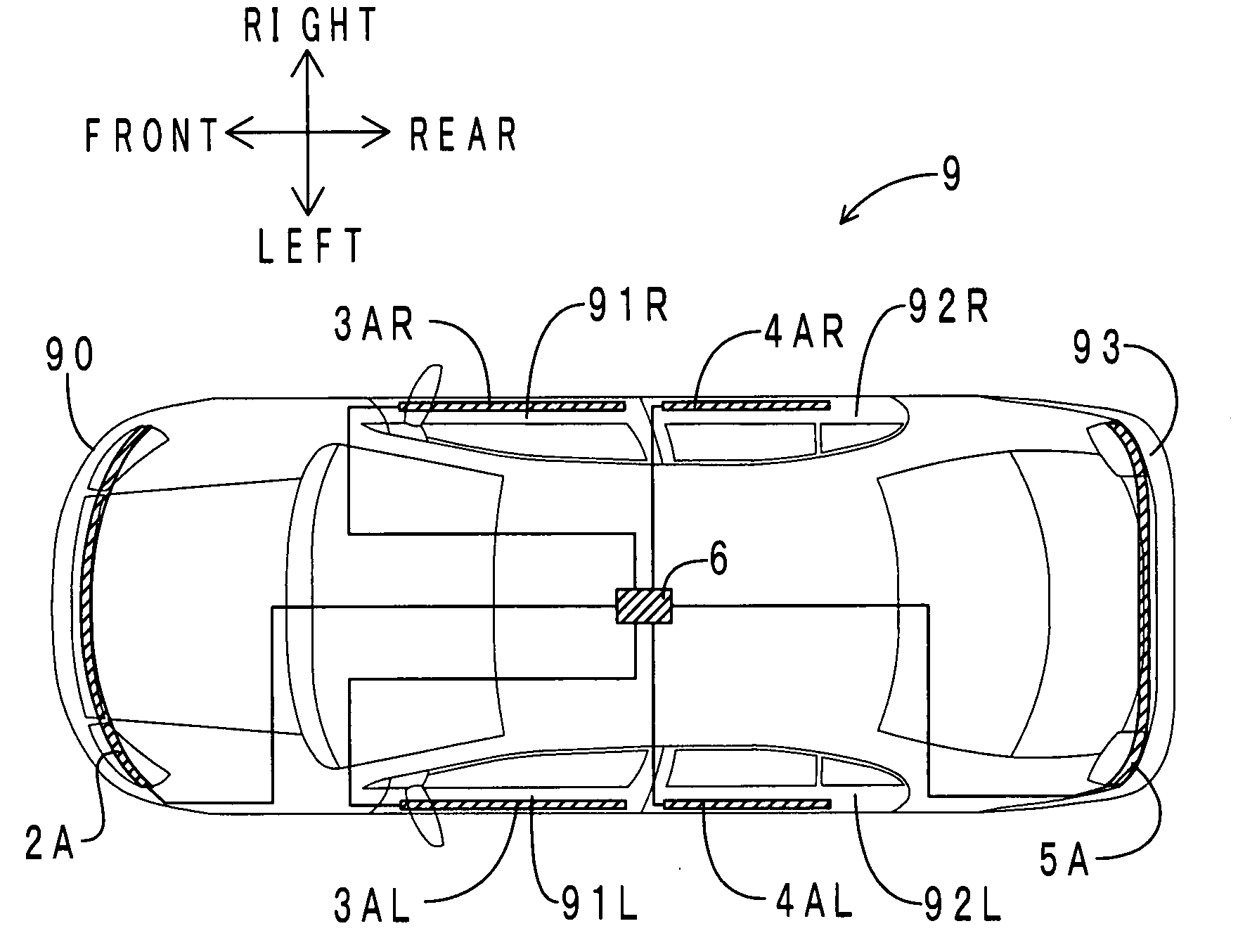

Deformation sensor

InactiveUS20080100046A1CompatibilityImprove compatibilityPedestrian/occupant safety arrangementForce measurementElastomerFilling rate

A first deformation sensor is arranged in a shock transmission member which is built in a vehicle and which constitutes a transmission path of a shock applied from the outside. A second deformation sensor is arranged in an exterior member which is exposed to the outside of a vehicle. Each of the first and second deformation sensors comprises a main body of sensor which has an elastomer and spherical conductive fillers blended in the elastomer in an approximately single particle state and with a high filling rate, and in which an electric resistance increases as an elastic deformation increases, and an electrode which is connected with the main body of sensor and is able to output the electric resistance.

Owner:SUMITOMO RIKO CO LTD

Method for predicting spare part demand in equipment manufacturing process

InactiveCN101853448AEasy to adjustThe calculation result is accurateForecastingMean time to repairPredictive methods

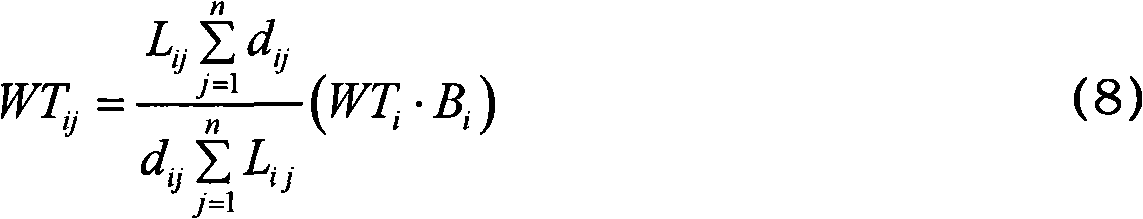

The invention discloses a method for predicting spare part demand in an equipment manufacturing process. The method comprises the following steps of: 1, directly acquiring an achieved availability (Aa) index, mean time between failures (MTBF), mean time to repair (MTTR) and mean preventive maintenance time (MPMT) of equipment; 2, acquiring mean waiting time (WT) of system level spare parts; 3, distributing the WT of the system level spare parts and acquiring waiting time WTi of a subsystem; 4, acquiring the waiting time WTij of each of line replaceable unit (LRU) level products which form the subsystem by a Dephi distribution method; 5, acquiring a spare part out-of-stock expected value EBOij and an inventory level sij of the LRU; and 6, acquiring a spare part fill rate according to the inventory level sij. A quantitative relation between spare part waiting time and equipment availability is established and spare part planning is always performed based on a user demand and a manufacturing requirement. Due to the combination of an equal distribution method and a Dephi method, the method has high flexibility and can be suitable for various stages of engineering development.

Owner:BEIHANG UNIV

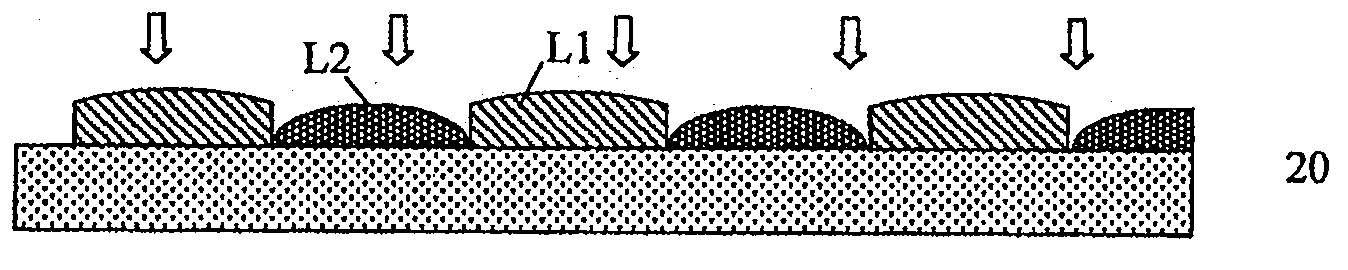

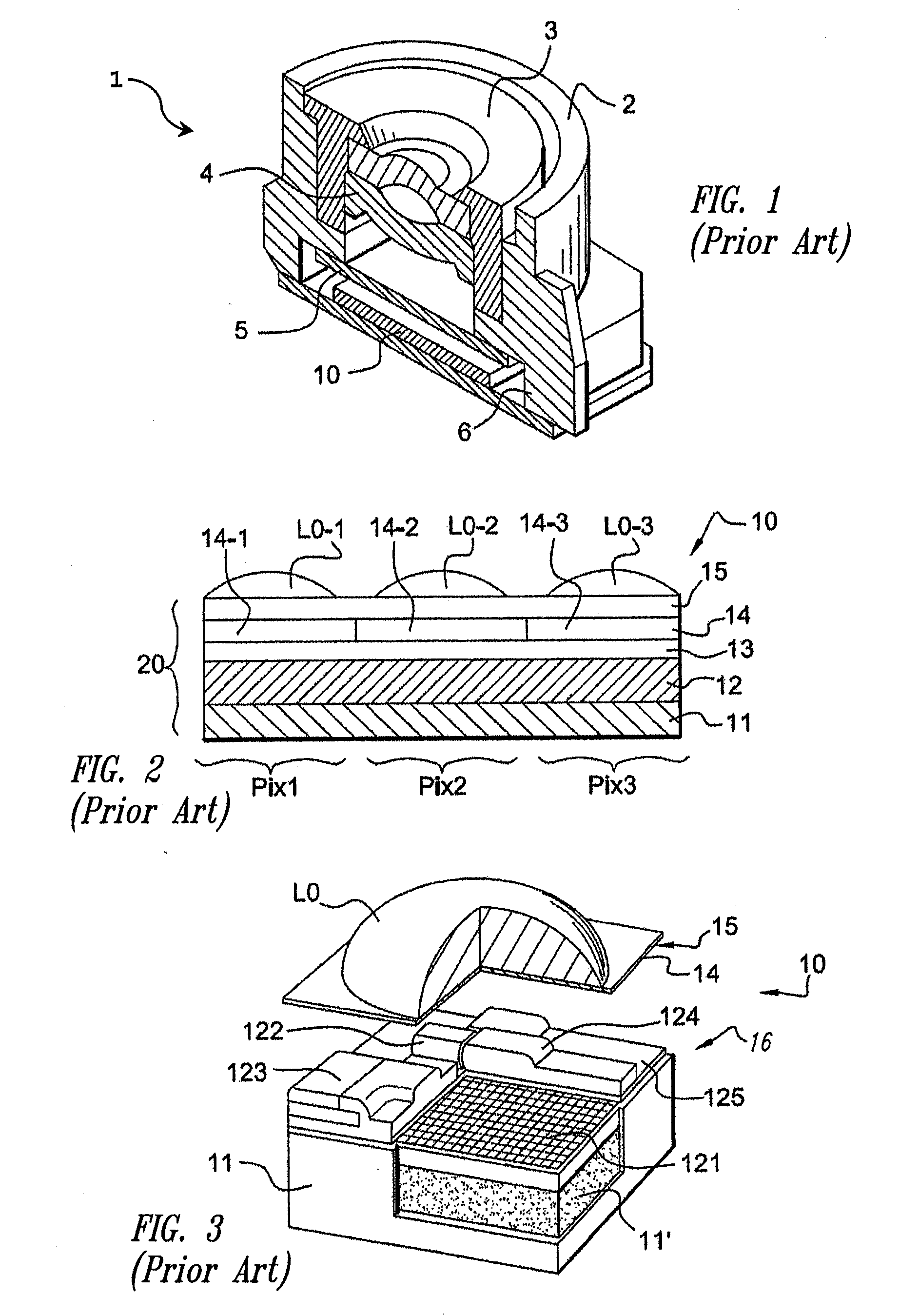

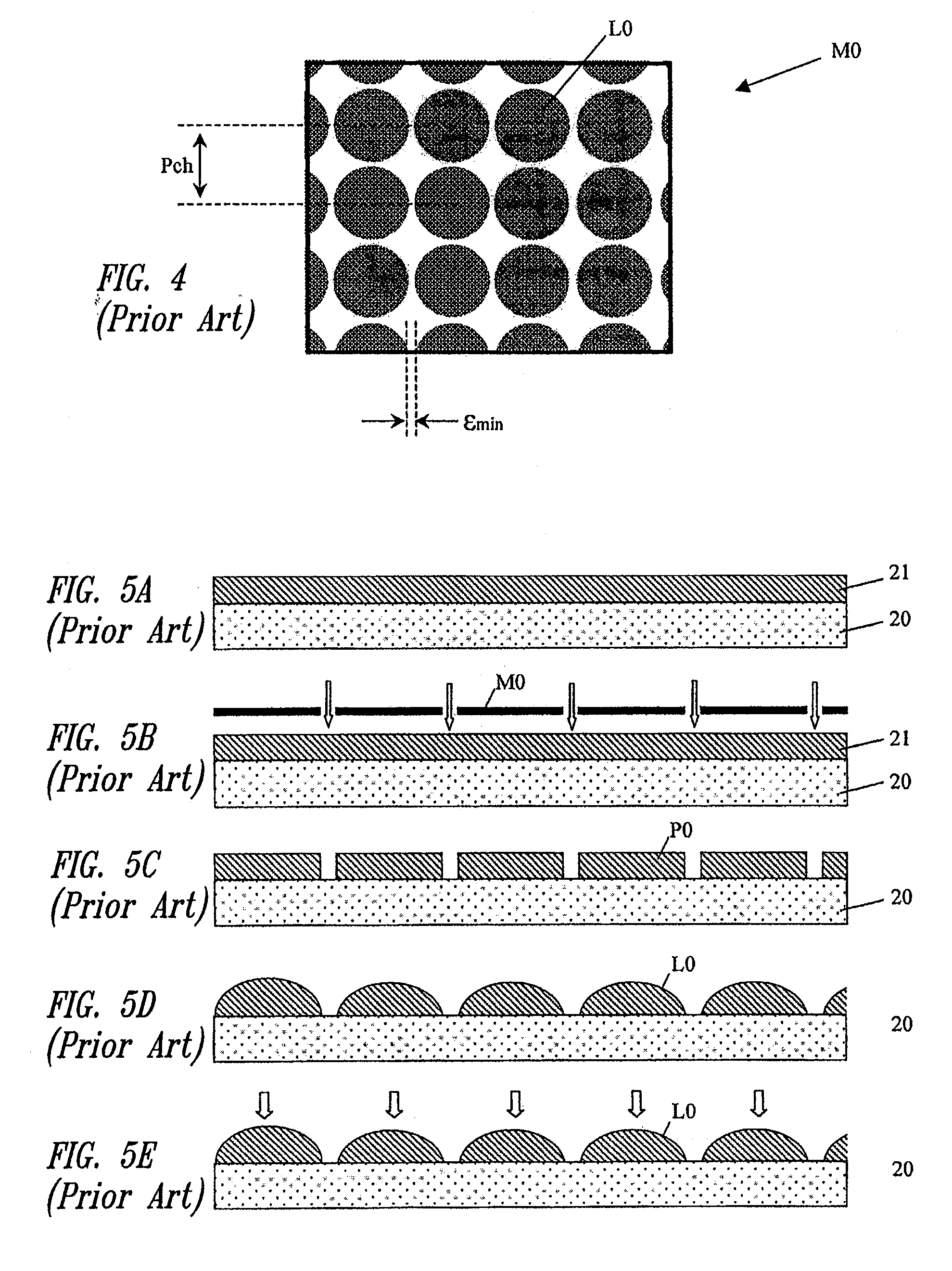

CMOS imaging device comprising a microlens array exhibiting a high filling rate

A CMOS imager includes a photosite array and a microlens array. The microlens array comprises microlenses of a first type and microlenses of a second type, the microlenses of first type being manufactured according to a first circular template having a first radius, the microlenses of second type being manufactured according to a second circular template having a second radius inferior to the first radius, and the first and second templates having overlap areas. One advantage is that the CMOS imager has a high fill rate.

Owner:STMICROELECTRONICS (ROUSSET) SAS +1

Wetting pretreatment for enhanced damascene metal filling

Disclosed are pre-wetting apparatus designs and methods. These apparatus designs and methods are used to pre-wet a wafer prior to plating a metal on the surface of the wafer. Disclosed compositions of the pre-wetting fluid prevent corrosion of a seed layer on the wafer and also improve the filling rates of features on the wafer.

Owner:NOVELLUS SYSTEMS

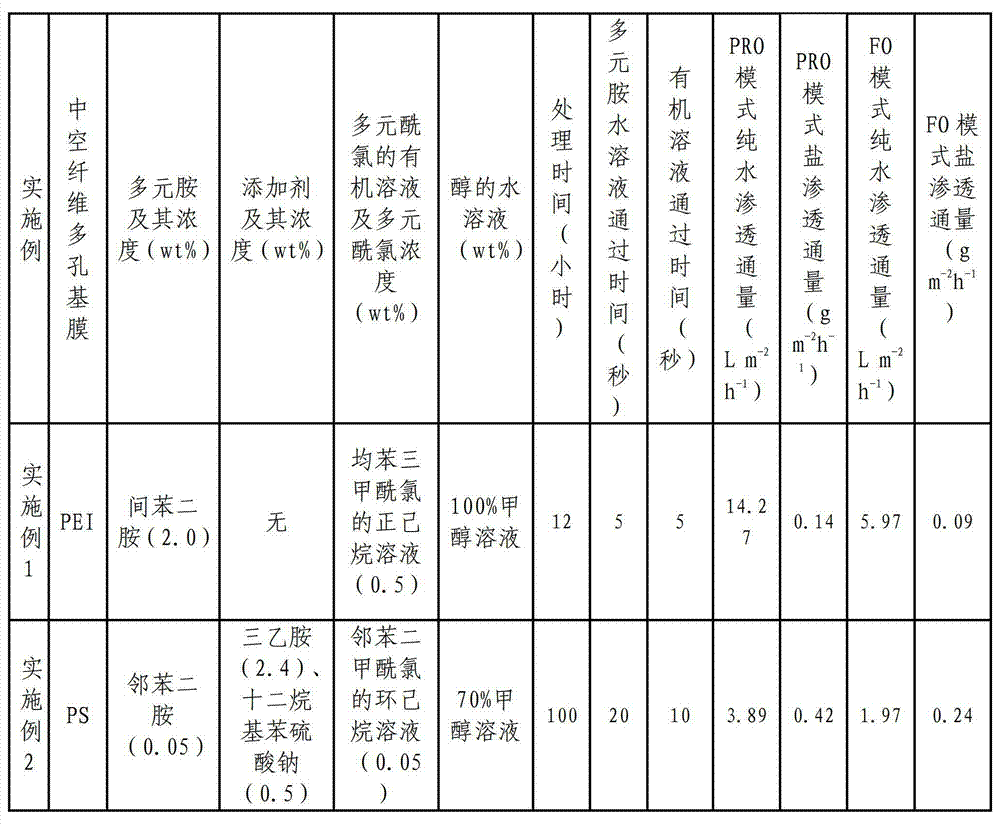

Method for preparing hollow fiber type forward osmotic membrane

ActiveCN102773024AUnique cross-network pore structureImprove fill rateSemi-permeable membranesFiltrationGlycerol

The invention discloses a method for preparing a hollow fiber type forward osmotic membrane, which specifically comprises the following steps that: 1, a hollow fiber substrate membrane is made into a membrane component, and the membrane component is put in a membrane filtration device; 2, the residual glycerol on the surface of the membrane component is washed with water, the residual water of the membrane component is removed, and the hollow fiber substrate membrane is dried; 3, a polyamine aqueous solution is prepared and is enabled to pass through the internal surface of the membrane component, and then, the residual water on the surface of the membrane component is removed; 4, an organic solution which contains multi-acyl chloride is prepared, and is enabled to pass through the internal surface of the membrane component to react for a certain while; and 5, after the reaction is completed, the aqueous solution which contains alcohol is used to treat the membrane which is obtained from the reaction, so the hollow fiber type forward osmotic membrane is obtained. The hollow fiber composite forward osmotic membrane which is prepared by the method for preparing the hollow fiber type forward osmotic membrane has high filling rate and pollution resistance, is easy to clean, has a large effective filter area compared with components of the same size, and is suitable for a forward osmotic separation process.

Owner:SUZHOU FAITH HOPE MEMBRANE TECH

Flux-cored wire for fusion welding butt joint of titanium-steel composite board and preparation method of flux-cored wire

InactiveCN104028917ASmall diameterEffective connectionArc welding apparatusWelding/cutting media/materialsFilling rateMaterials science

A flux-cored wire for fusion welding butt joint of a titanium-steel composite board comprises the components in percentage by mass as follows: 80-81% of vanadium powder and 19-20% of chromium powder, and the sum of the mass percentageof the components is 100%. The invention further discloses a preparation method of the flux-cored wire. The preparation method comprises the steps as follows: the vanadium powder and the chromium powder are dry-mixed to obtain flux core powder, the flux core powder is placed on a charging machine of flux-cored wire production equipment, a copper belt is placed on a belt unwinding machine, ultrasonic cleaning is performed, then U-shaped groove rolling and powder adding operations are performed, the powder filling rate is controlled, sealing of the copper belt is performed through a forming machine, and a wire with the diameter of 3.8 mm is formed; then the flux-cored wire is obtained through six reducing treatment processes and a nine-stage reducing finish drawing treatment process sequentially. By means of the flux-cored wire, a titanium layer and a steel layer weld structure of the composite board can be effectively joined together, and the fusion welding butt joint of the titanium-steel composite board is realized; an obtained weld joint has excellent toughness; and the preparation process is simple, and mass production is facilitated.

Owner:XIAN UNIV OF TECH

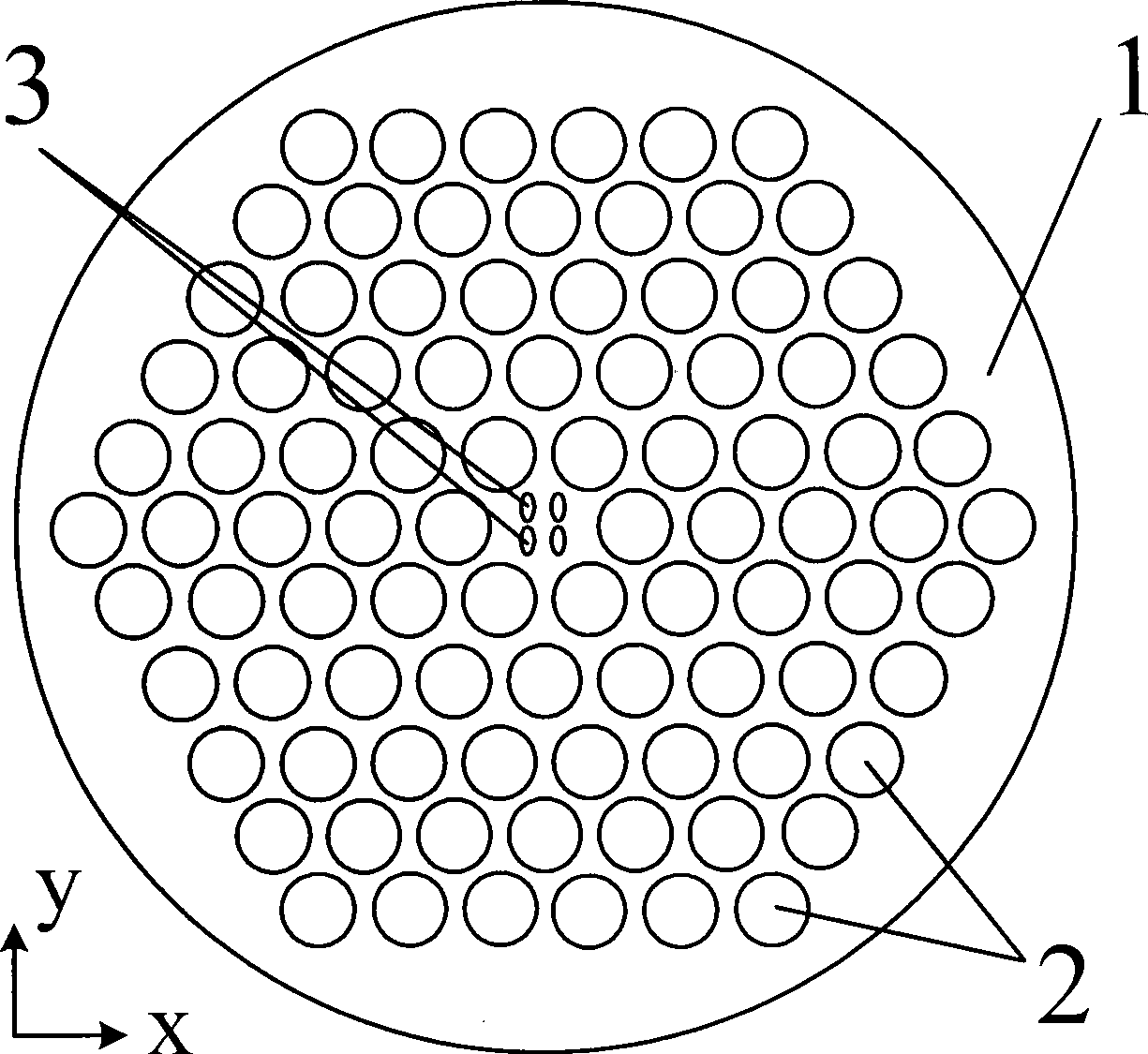

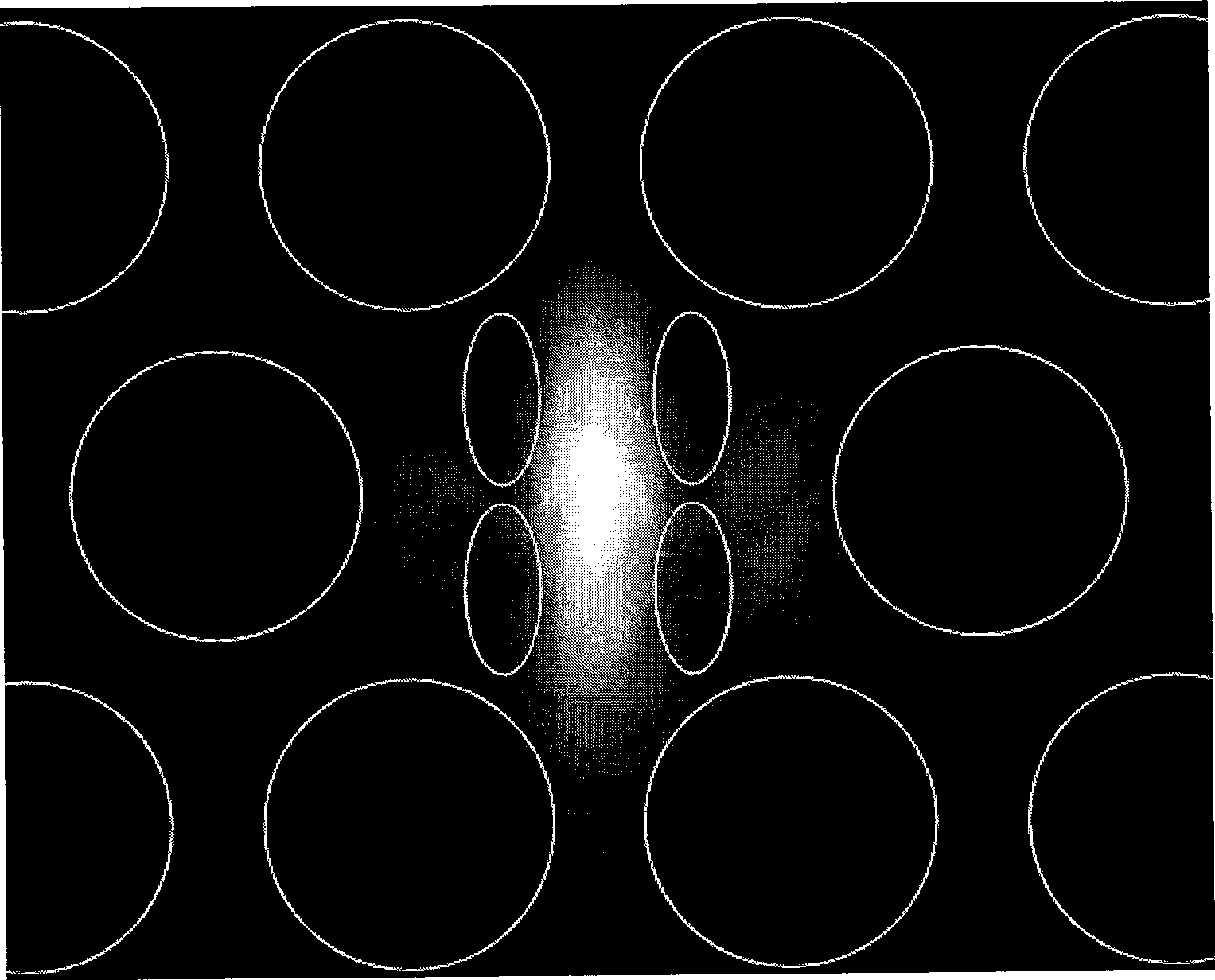

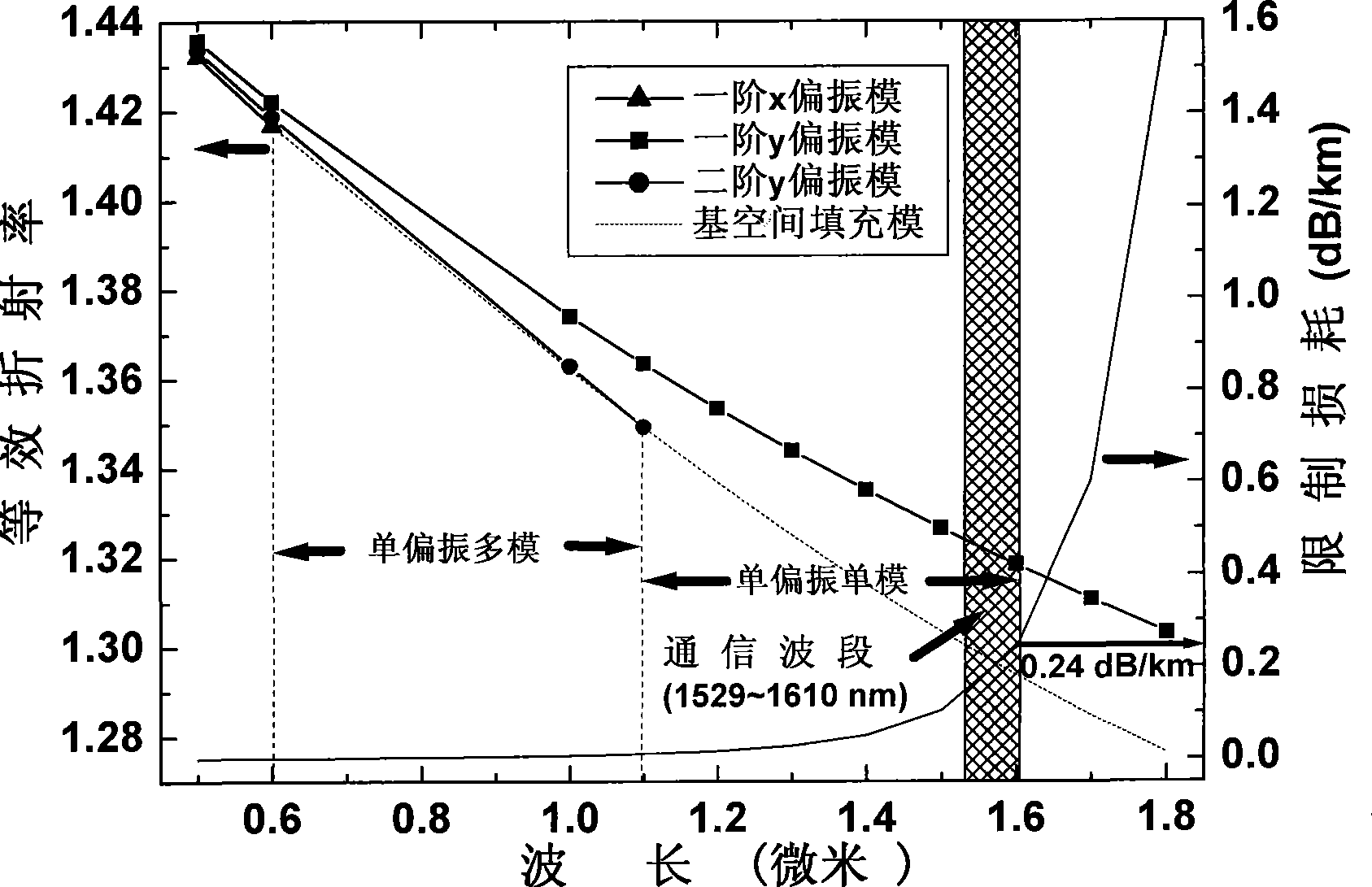

High non-linear single polarization single-mould photonic crystal fiber

InactiveCN101414026AAdd nonlinearitySmall mode areaCladded optical fibreOptical waveguide light guideFilling rateBasic mode

The invention discloses a single-polarization single-mode photonic crystal fiber with high nonlinearity. The cross section of the photonic crystal fiber comprises a fiber core and a cladding. The-cladding is a peripheral region which is the same as the normal photonic crystal fiber and is formed by evenly distributed air holes (2) with the same structure. The fiber core is composed of a substrate material (1) which is arranged on the center of the optical fiber end face as well as four high-ellipticity air holes (3) which are closely arranged, not mutually overlapped and in rectangular distribution. In the photonic crystal fiber, a cut off characteristic of two polarization modes of a basic mode can be adjusted by finely adjusting distance between centers of air holes, which causes one of the polarization modes to be cut off in the applied waveband, thus realizing the wide-bandwidth single polarization transmission. Meanwhile, the air holes (3) suppress the generation of high order mode, which allows the cladding to use a higher air filling rate on the premise of not changing the single-mode transmission characteristic of the optical fiber, therefore the mode area and the confinement loss are reduced. The single-polarization single-mode photonic crystal fiber with the high nonlinearity solves the problem that the high nonlinearity, low confinement loss and wide band single-polarization single-mode characteristic can not be realized at the same time in the existing photonic crystal fiber technology.

Owner:BEIHANG UNIV

Deformation sensor

InactiveUS7703333B2Improve machinabilityIncrease freedomMaterial strength using steady bending forcesUsing electrical meansWide areaElectrical resistance and conductance

A deformation sensor, which has excellent workability and a high degree of freedom in shape design and which can detect deformation and load in a wide area of components and portions, has a main body of sensor, electrodes which are connected to the main body of sensor and can output electric resistances, and a restraining component which restrains elastic deformation of at least a part of the main body of sensor. The main body of sensor has an elastomer, and spherical conductive fillers which are blended into the elastomer at a high filling rate in an approximately single-particle state, and is elastically deformable. In the main body of sensor, as an elastic deformation increases, the electric resistance increases.

Owner:SUMITOMO RIKO CO LTD

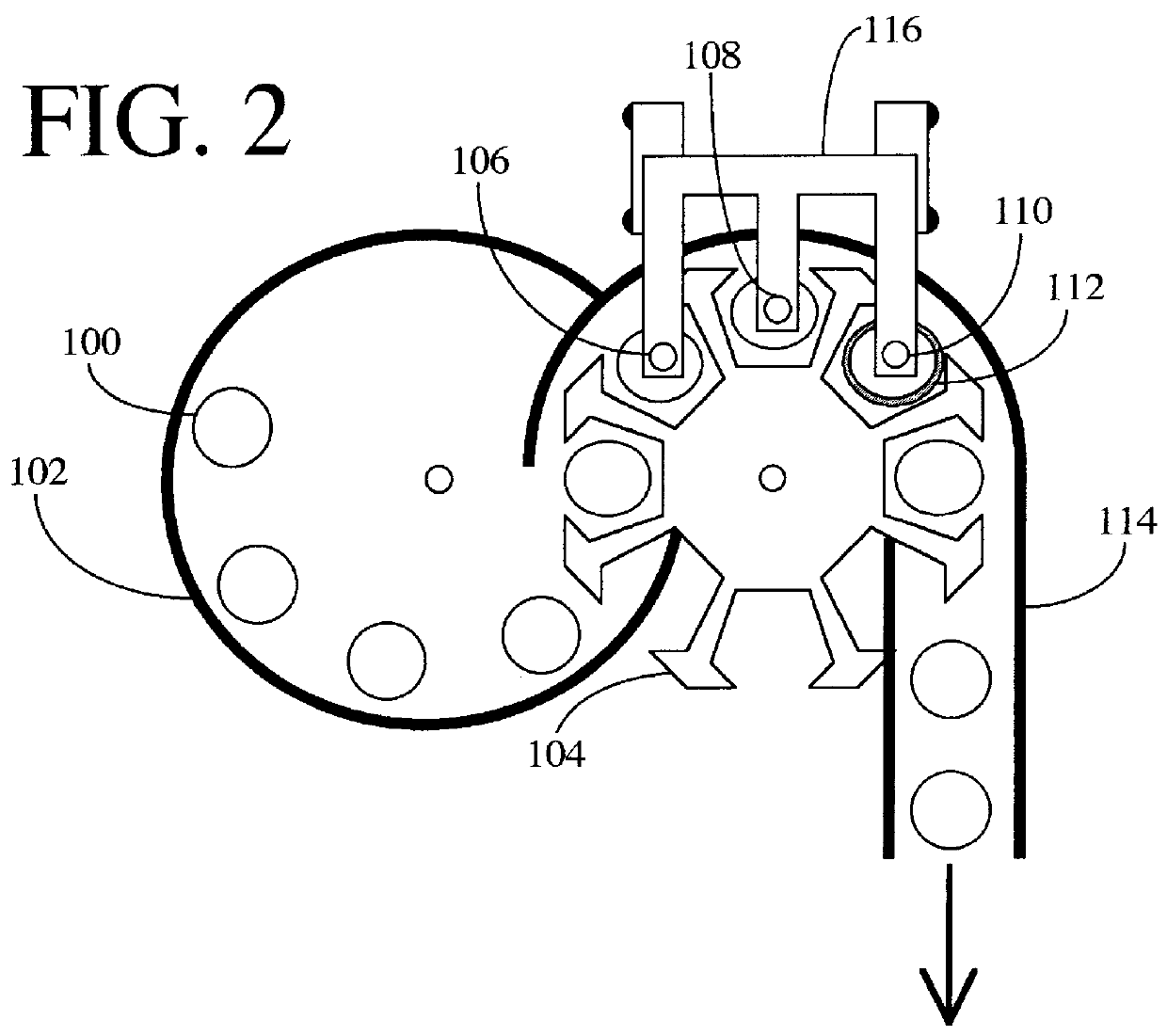

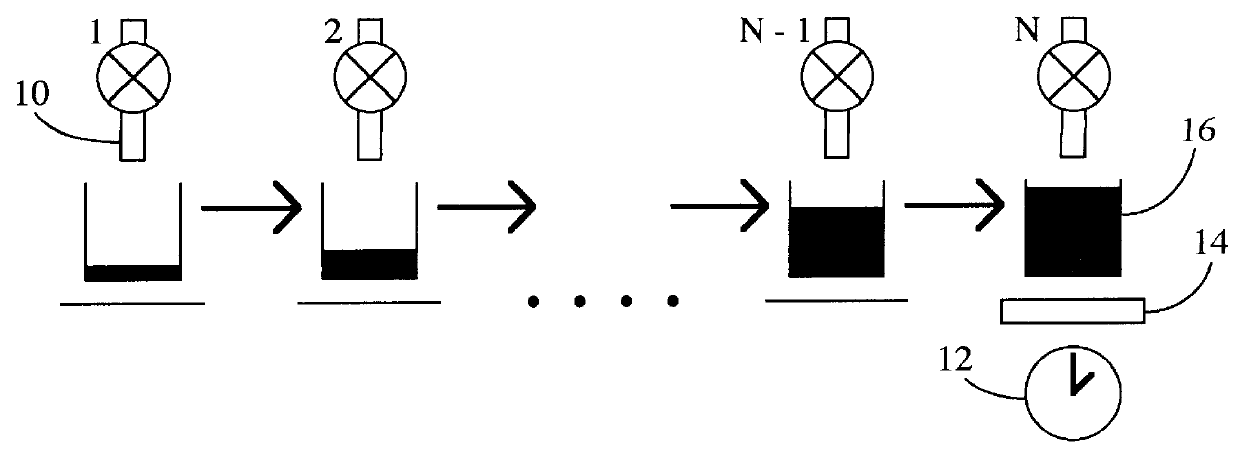

Fluid filling system with fill time optimization

A fluid filling system is disclosed wherein containers to be filled with fluid materials are supplied first to one or more time-metered filling stations, and then to a weight-metered filling station. At first, the time-metered filling station(s) is / are inactive, and only the weight-metered filling station is used to fill a first container to a desired final weight. A timer is used to monitor the filling time necessary to reach the desired final weight. When later containers are then supplied to the time-metered filling station(s), they are filled at each time-metered station for a filling time which is dependent on the previously measured filling time for the weight-metered filling station. These containers are then "topped off" by the weight-metered filling station to precisely fill them to the desired final weight, and the time required for such topping off is measured for use in subsequent modification of the filling times at the time-metered filling stations. For each container, the filling time at each time-metered filling station is dependent on the filling time at the weight-metered filling station in such a manner that the two will converge towards each other with successive containers until they are substantially or exactly equal. Preferably, the dependence between the time-metered filling time and weight-metered filling time are such that ttimed(t)=tN(t-1)+Qx[tN(t-1)-ttimed(t-1)]wherein tN(t-1) is the filling time at the weight-metering filling station for a prior container; ttimed(t) is the filling time at the time-metering filling station for the prior container; ttimed(t-1) is the filling time at the time-metering filling station for the prior container; Q is a predetermined real number.

Owner:IDEAL PAK MASSMAN LLC

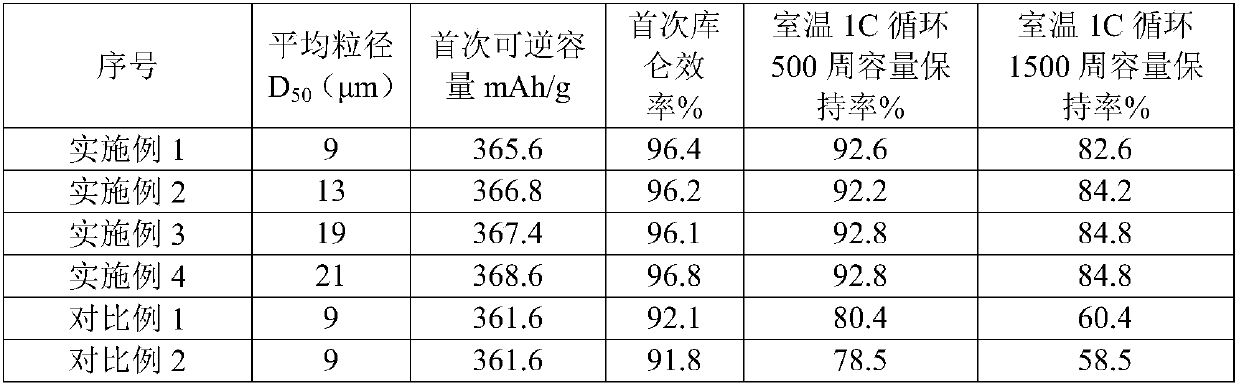

Long-life modified natural graphite cathode material as well as preparation method and use thereof

ActiveCN107814382AHigh sphericitySmooth particle surfaceCarbon compoundsCell electrodesFilling rateHigh pressure

The invention discloses a long-life modified natural graphite cathode material as well as a preparation method and use thereof. According to the preparation method, natural graphite powder and asphaltare dipped by virtue of a hot isostatic pressure machine, so that holes in graphite particles can be completely filled with asphalt at high temperature and high pressure conditions; and meanwhile, anasphalt coating layer is formed on the surface of the natural graphite powder, and graphitization is carried out so as to obtain the modified natural graphite cathode material with a core-shell structure, wherein synthetic graphite is embedded into the inside and surface of the natural graphite in situ, the filling rate of the synthetic graphite in the holes of the natural graphite is more than or equal to 94%, the surfaces of the particles are smooth, and the spheroidization degrees of the particles are high. According to the preparation method, the primary coulombic efficiency of the modified natural graphite cathode material is more than or equal to 96%, and the capacity retention ratio of the material after being circulated at a room temperature 1C for 1500 cycles is more than or equal to 80%, so that the prepared material is high in primary coulombic efficiency, long in service life and can be used for replacing synthetic graphite for producing powder battery cathode materials, and the cost is greatly lowered. The preparation method is simple in preparation process and low in cost and has relatively high practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

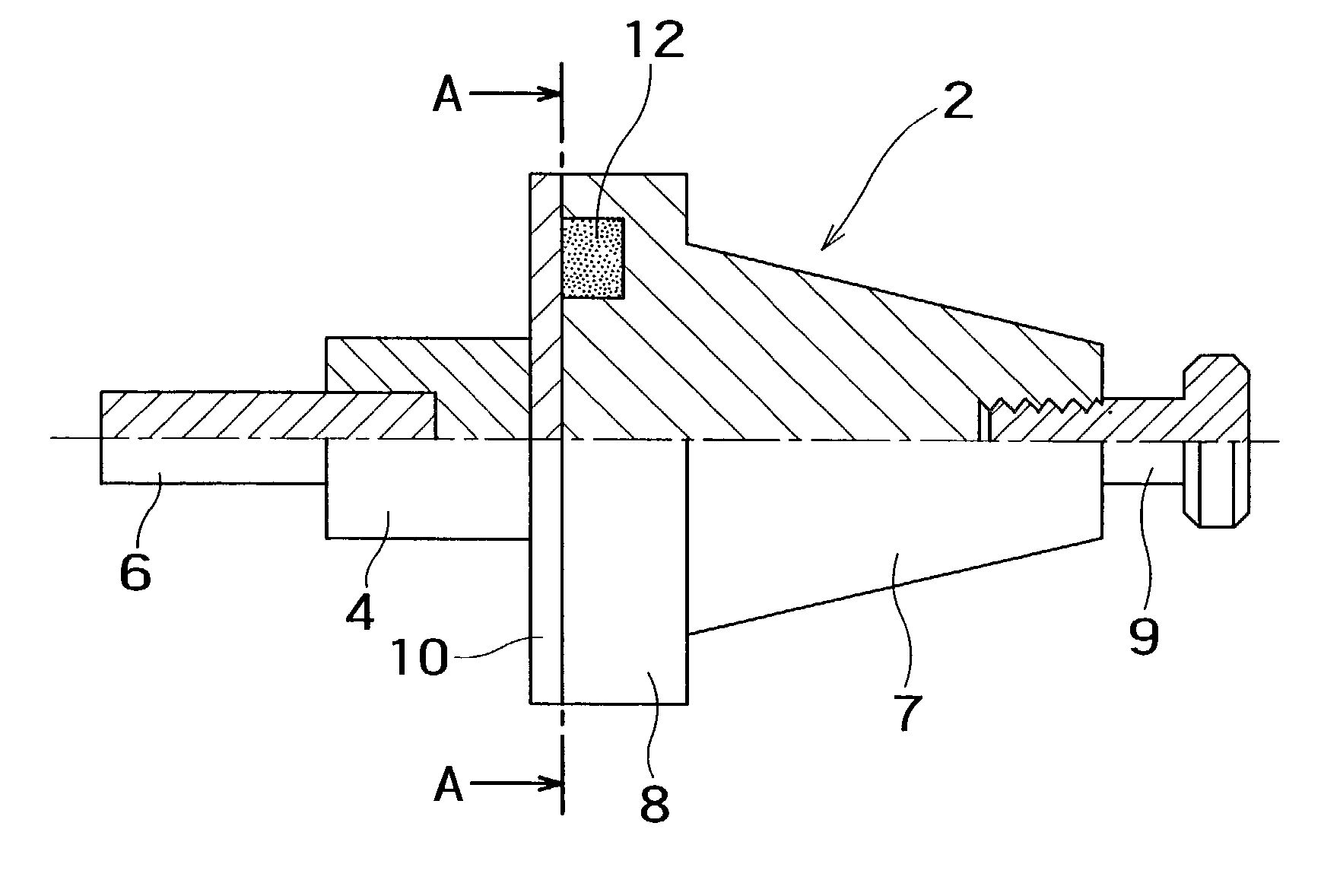

Tool holder

A tool holder has a cutter arbor. The cutter arbor has a shank portion detachably mounted on a spindle, and a mechanism for holding a cutting tool. In the cutter arbor portion, a cavity portion is formed. In the cavity portion, a vibration damping material is filled at a filling rate so as to be capable of obtaining predetermined vibration damping characteristics. Thus, it is possible to provide high vibration damping characteristics, effectively damp vibrations during cutting and improve working precision, without using any special materials, such as damping materials, although the tool holder has a usual shape.

Owner:TOSHIBA MASCH CO LTD

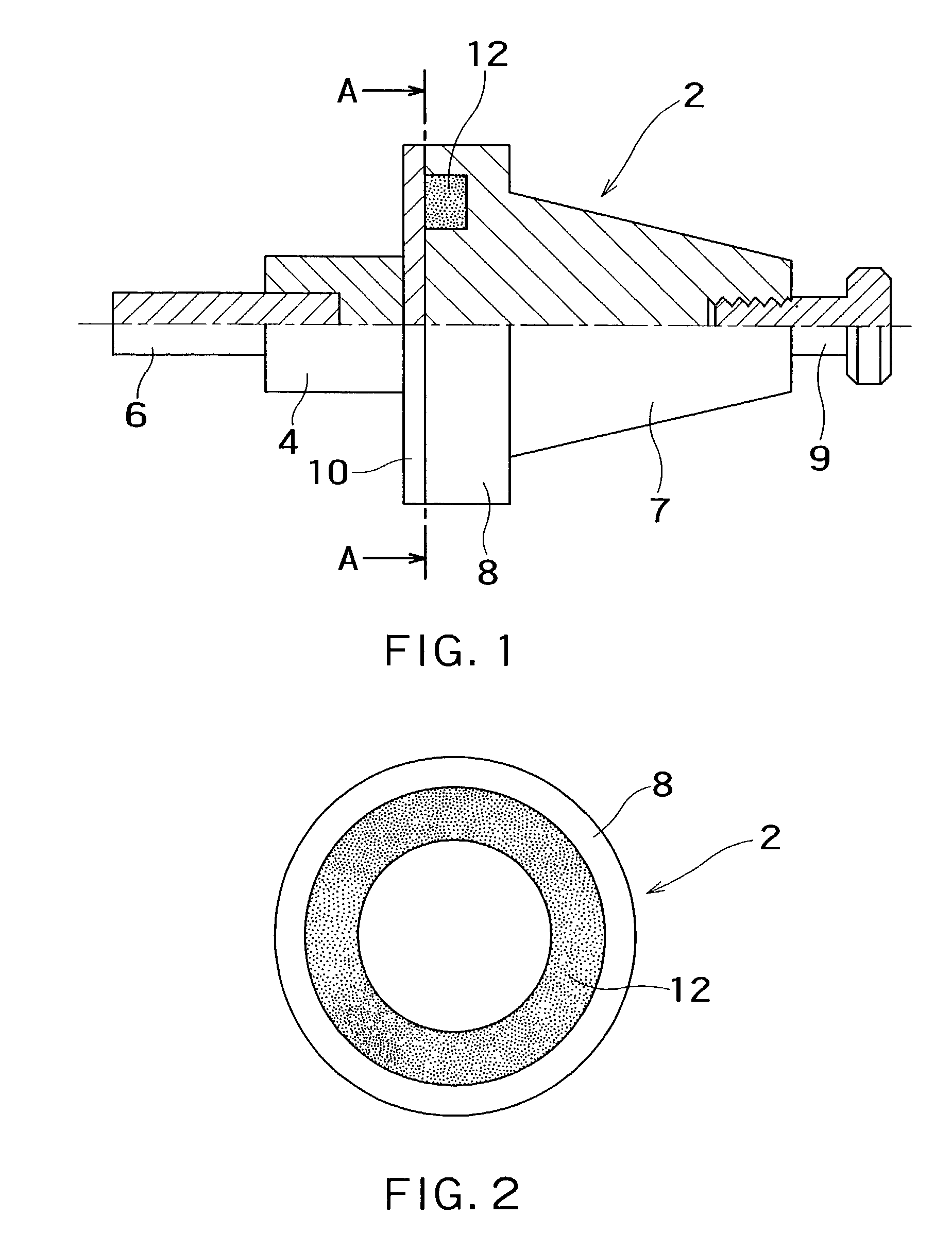

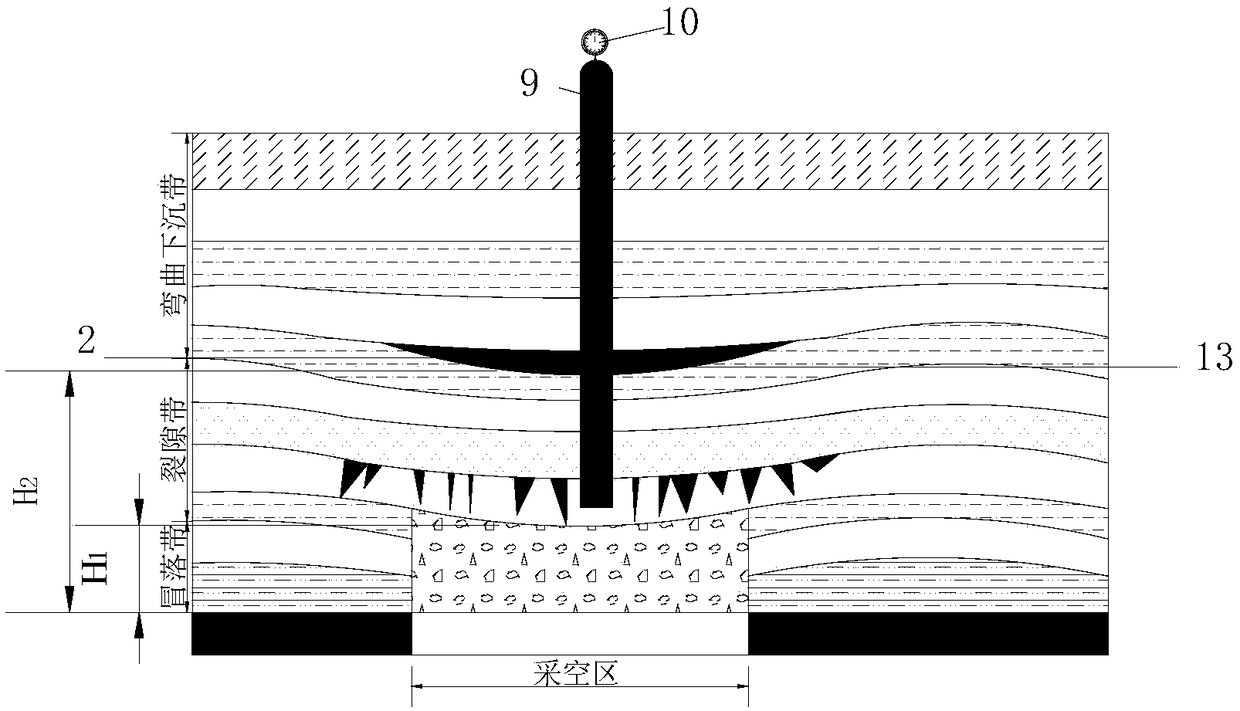

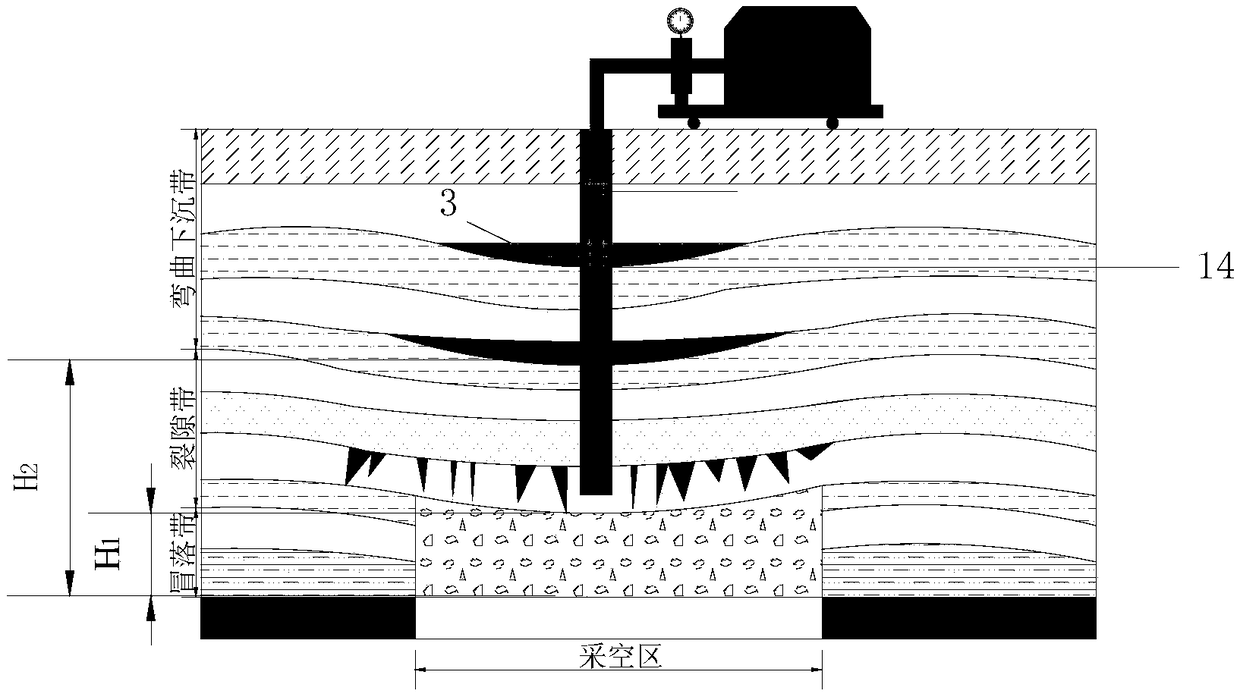

Hole multi-functionalization method for realizing water damage prevention and surface settlement control through surface borehole

InactiveCN108999634AAvoid safety hazardsThe grouting filling process is easy to controlMaterial fill-upHorizonFracture zone

The invention discloses a hole multi-functionalization method for realizing water damage prevention and surface settlement control through a surface borehole and belongs to the coal mine green miningtechnical field. According to a grouting filling method, a single ground grouting borehole is formed downward from the ground; overlying rock located at different horizons are grouted through the grouting borehole; grouting horizons in a curved sunk zone include a low-bed-separation horizon and a high-bed-separation horizon; overlying rock fractures in a fracture zone are grouted, so that a water-blocking layer can be formed to cut off a water bursting channel of underground bed separation water damage, and therefore, secondary roof water damage can be prevented; a larger proportion of grout is adopted as the filling material of the low-bed-separation horizon so as to form a high-volume-weight rock stratum filling body; and filling bodies formed by the low-bed-separation horizon and the high-bed-separation horizon in the curved sunk zone together act on the control of surface subsidence. According to the method of the invention, a multi-horizon grouting filling project is realized through the same grouting borehole, and therefore, the utilization rate of the borehole is high, cost is low, a filling rate is improved, the subsidence-reducing rate of the surface settlement is improved, and roof water damage prevention and control is achieved.

Owner:CHINA UNIV OF MINING & TECH

Hydrogenation rate control method and hydrogenation machine

PendingCN109827068AControl the rate of hydrogenationThe principle is simpleContainer discharging methodsContainer filling under pressureHydrogenValue set

The invention relates to a hydrogenation rate control method and a hydrogenation machine. The hydrogenation rate control method comprises the following steps that a control system of the hydrogenationmachine analyzes and calculates the ratio of the change value of the pressure intensity to the change value of the the temperature of a hydrogen cylinder of a vehicle within a set time and compares the ratio with the rated value set in the control system, when delta P / delta T is less than n, the filling rate of hydrogen is decreased, and when delta P / delta T is greater than m, the filling rate ofthe hydrogen is increased, so that delta P / delta T is greater than or equal to n and less than or equal to m. According to the hydrogenation rate control method and the hydrogenation machine, the control system analyzes the ratio of the change value of the pressure to the change value of the the temperature of the hydrogen cylinder in the vehicle and compares the ratio with the rated value in thecontrol system, then the hydrogenation rate can be timely controlled, the ratio of the change value of the pressure intensity to the change value of the the temperature is always within a set range,the filling rate of the hydrogen is not too large, so that the temperature in the hydrogen cylinder is always within a specified range, the filling rate of the hydrogen can be controlled only by comparing the ratio of the change value of the pressure to the change value of the the temperature of the hydrogen cylinder, the principle is simple, and the implementation cost is low.

Owner:ZHENGZHOU YUTONG BUS CO LTD

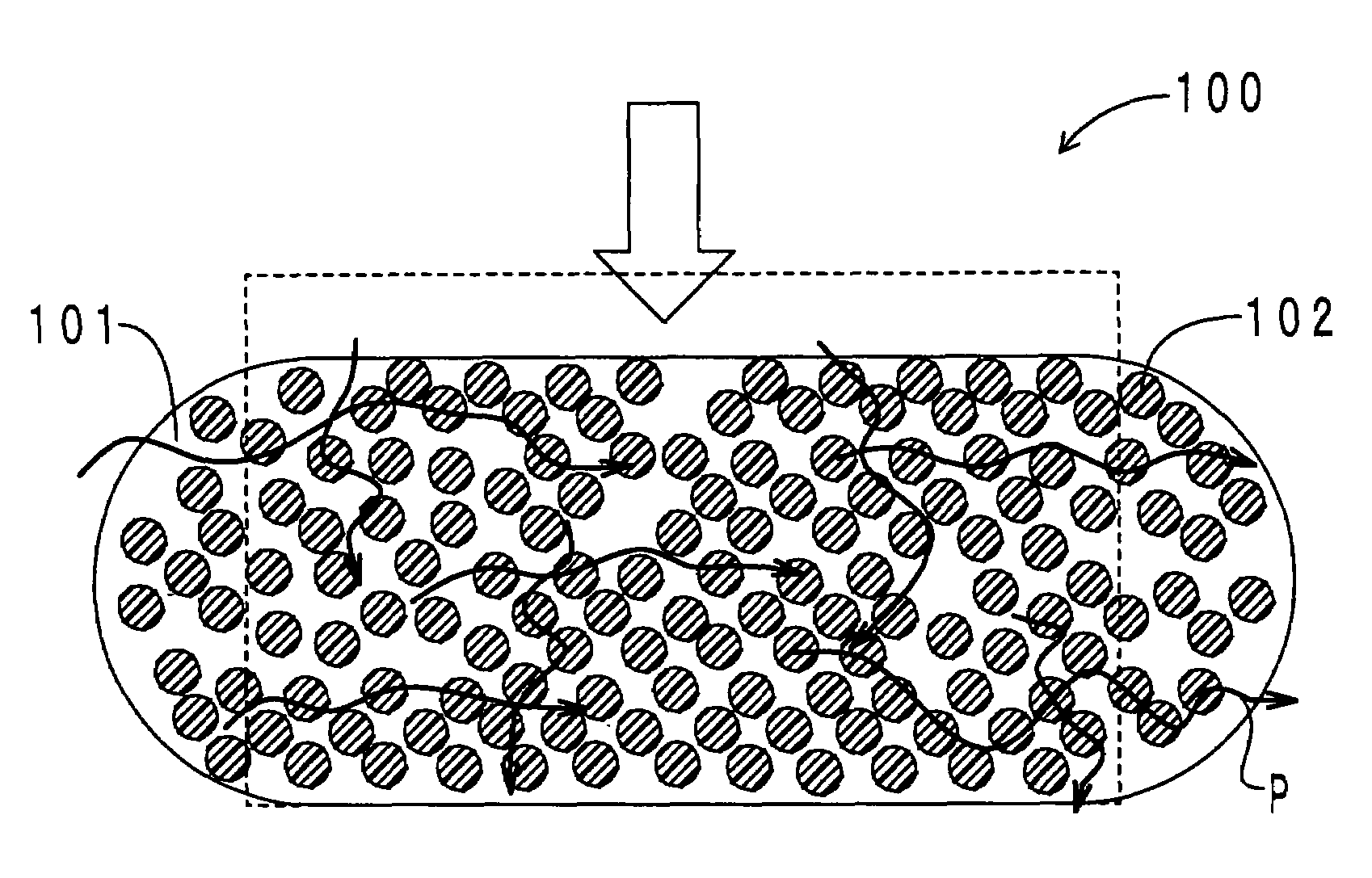

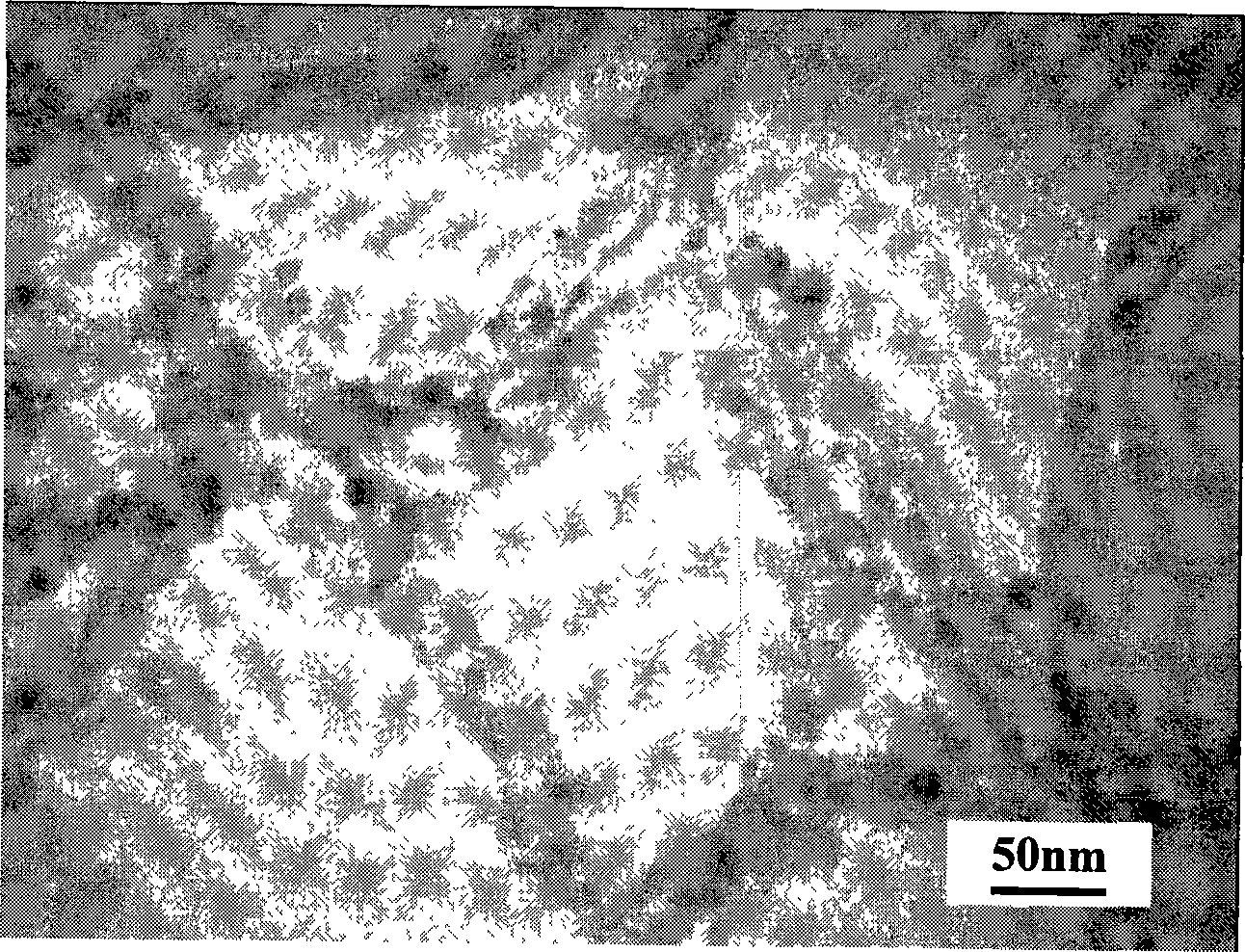

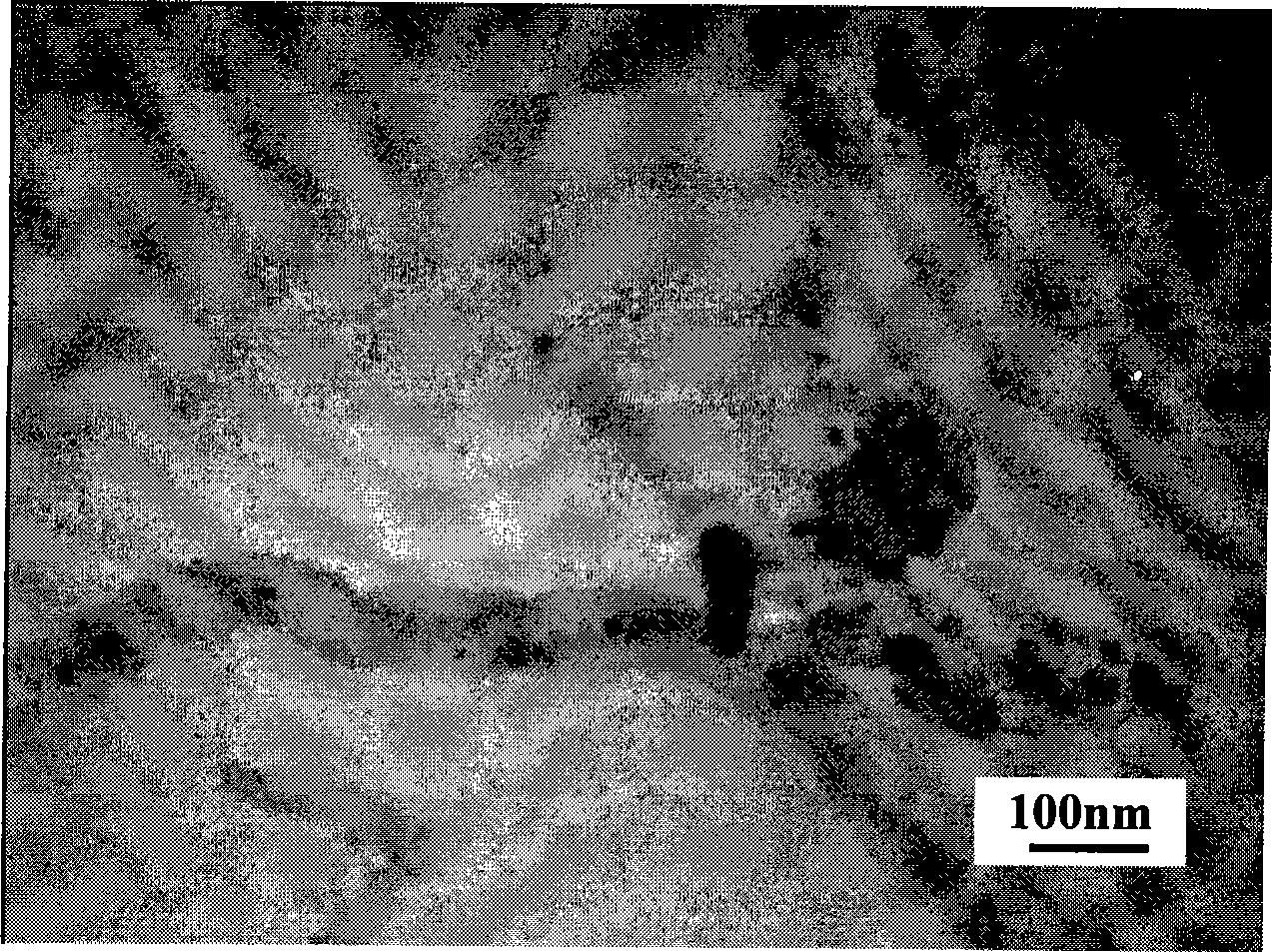

Method for filling carbon nano tube with magnetic nano metal iron particles

The invention belongs to the technical field of preparation and application of nano composite material, and in particular relates to a method for preparing a magnetic nano metallic iron particle / carbon nano tube functional composite material. The invention discloses a method for filling a carbon nano tube with magnetic nano metallic iron particles. The method comprises the following steps: carrying out refluxing treatment on the carbon nano tube in concentrated nitric acid, introducing functional groups such as carbonyl, hydroxyl, carboxyl and the like on the surface of the carbon nano tube, carrying out ultrasonic dispersion and electromagnetic mixing on the treated carbon nano tube in aqueous solution of bivalent ferric salt, filling the bivalent ferric salt in the carbon nano tube through capillary action, thermally treating the carbon nano tube at inert atmosphere, decomposing the bivalent ferric salt filled inside the carbon nano tube into ferric oxide, and reducing the ferric oxide into the magnetic nano metallic iron particles by hydrogen to obtain the composite material for filling the magnetic nano metallic iron particles into the carbon nano tube, wherein the magnetic nano metallic iron particles can be filled in the carbon nano tubes the calibers of which are 10 to 100 nanometers and which have different structures, and the carbon nano tubes with different calibers as templates can accurately control the size of the magnetic nano metallic iron particles. The method has the advantages of simple process and good controllability, can make the magnetic nano metallic iron particles evenly filled in the carbon nano tube with high filling rate, and is convenient for industrialized production; and the prepared nano magnetic composite material has good application prospect in the fields of high-density magnetic recording materials, wave-absorbing materials, electromagnetic shielding materials, nuclear magnetic resonance imaging materials.

Owner:BEIJING UNIV OF CHEM TECH

Titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron

InactiveCN102248325AEasy to use on siteImprove wear resistanceWelding/cutting media/materialsSoldering mediaMachine partsWear resistant

The invention discloses a titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron, and the flux-cored wire provided by the invention comprises the following chemical components in percentage by weight (wt%): 60 to 70% of high-carbon ferrochrome, 1 to 2% of high-carbon ferromanganese, 1 to 3% of ferrosilicon, 1 to 3% of ferrovanadium, 1 to 3% of ferromolybdenum, 2 to 8% of TiC, 15 to 25% of graphite, and 1 to 2% of aluminum / magnesium powders; and the flux-cored wire has a low-carbon steel strip serving as an outer wrapper. The flux-cored wire is made by use of flux-cored wire production equipment which has a flux powder filling rate of 37%to 45%, and drawn by a wire drawing machine 2 to 5 times until the outside diameter of the flux-cored wire reaches the level F4. The flux-cored wire disclosed by the invention can be applied to overlay-welding under the conditions of no preheating before welding and no heat treatment after welding, and is very convenient in on-site use. By virtue of overlay-welding using the flux-cored wire disclosed by the invention, deposited metals have a high hardness up to HRC63-67 and better wear resistance andare not liable to stripping, and the service lives of large-sized high-chromium cast iron wear-resistant parts are 2 to 4 times those of integrally-machined parts.

Owner:YANSHAN UNIV

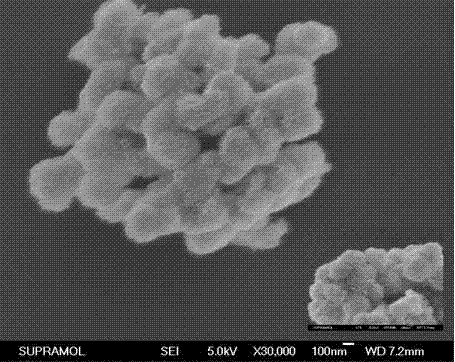

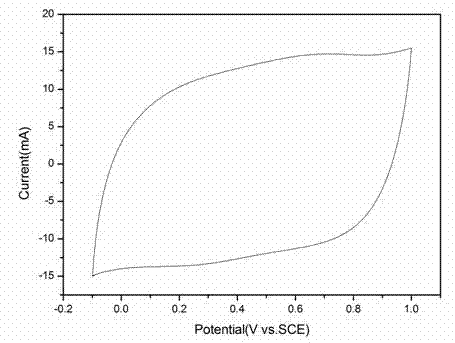

Flower-like manganese dioxide electrode material for super-capacitor and preparation method thereof

InactiveCN102730763AParticle size controllableHigh activityElectrolytic capacitorsNanotechnologyManganeseFilling rate

The invention relates to a flower-like manganese dioxide electrode material for a super-capacitor and a preparation method thereof, and is characterized in that the preparation method comprises the following steps: respectively dissolving potassium permanganate and a manganous salt in deionized water; carrying out stirring for 10 to 30 min under the condition of strong stirring, adding a manganous salt solution into a potassium permanganate solution, wherein the molar ratio of the manganous salt to potassium permanganate is 1: 0.1-10, and transferring a mixed solution to a hydrothermal reaction kettle for a hydrothermal reaction so as to obtain a brownish black precipitate, with a filling rate being 50 to 95%, hydrothermal reaction temperature being 100 to 160 DEG C and hydrothermal reaction time being 2 to 3 hours; and carrying out rinsing with deionized water until a filtrate is colorless and drying a filter cake at a temperature of 40 to 160 DEG C for 1 to 48 hours so as to finally obtain flower-like manganese dioxide. According to the invention, flower-like manganese dioxide with a controllable crystal form and a controllable particle size is rapidly prepared by adopting a hydrothermal method; prepared manganese dioxide has a flower-like structure and a large specific surface area, and the utilization rate of manganese dioxide in a super-capacitor is increased.

Owner:CHINA FIRST AUTOMOBILE

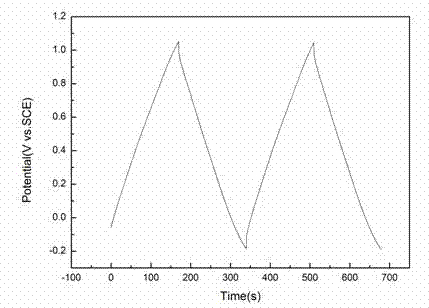

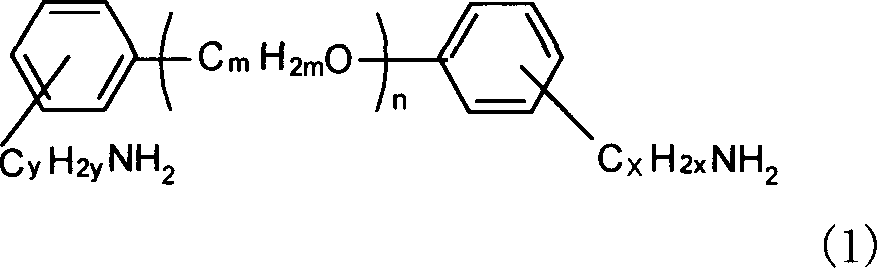

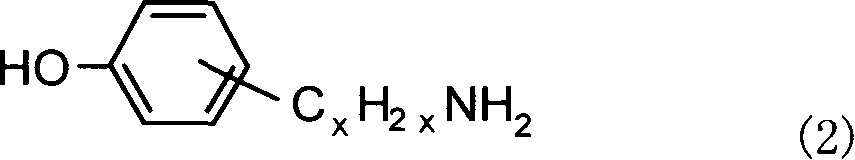

Alpha, omega end amino polyether used as epoxy resin curing agent and method for preparing the same

The provided alpha, omega-end polyaminoether as the new curing agent for epoxy resins belongs to the compound with general formula as (1) (wherein, all m, x and y for integer, 10>=m>=2, 6>=x+y>=1 and n for repetitive unit of polyether chain segment)or the mixture with aromatic polyaminoether, contains substituents on ortho-, meta- or para-position of benzene ring, and has high strength and ductility and filling rate without toxin.

Owner:WUHAN UNIV OF TECH

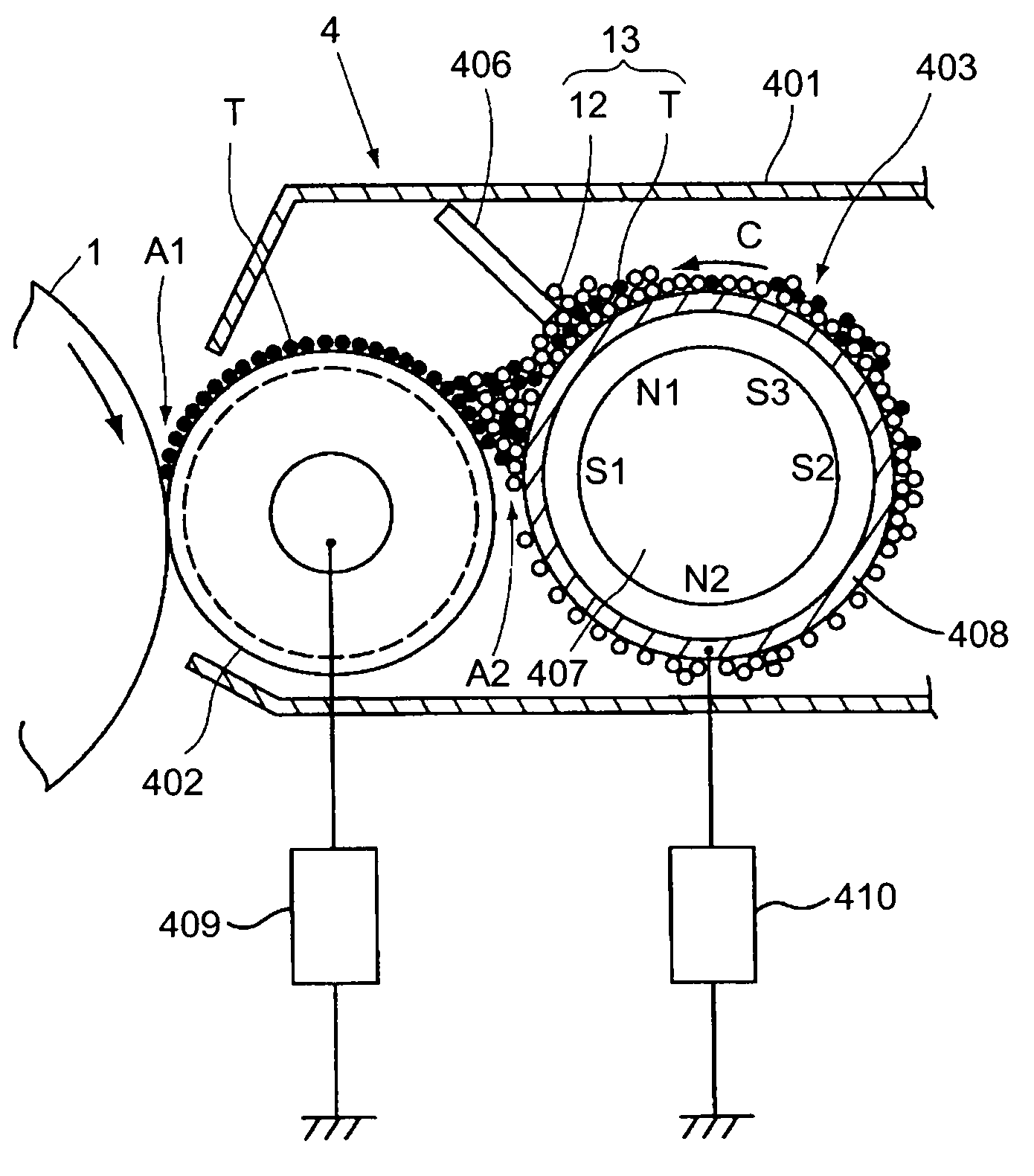

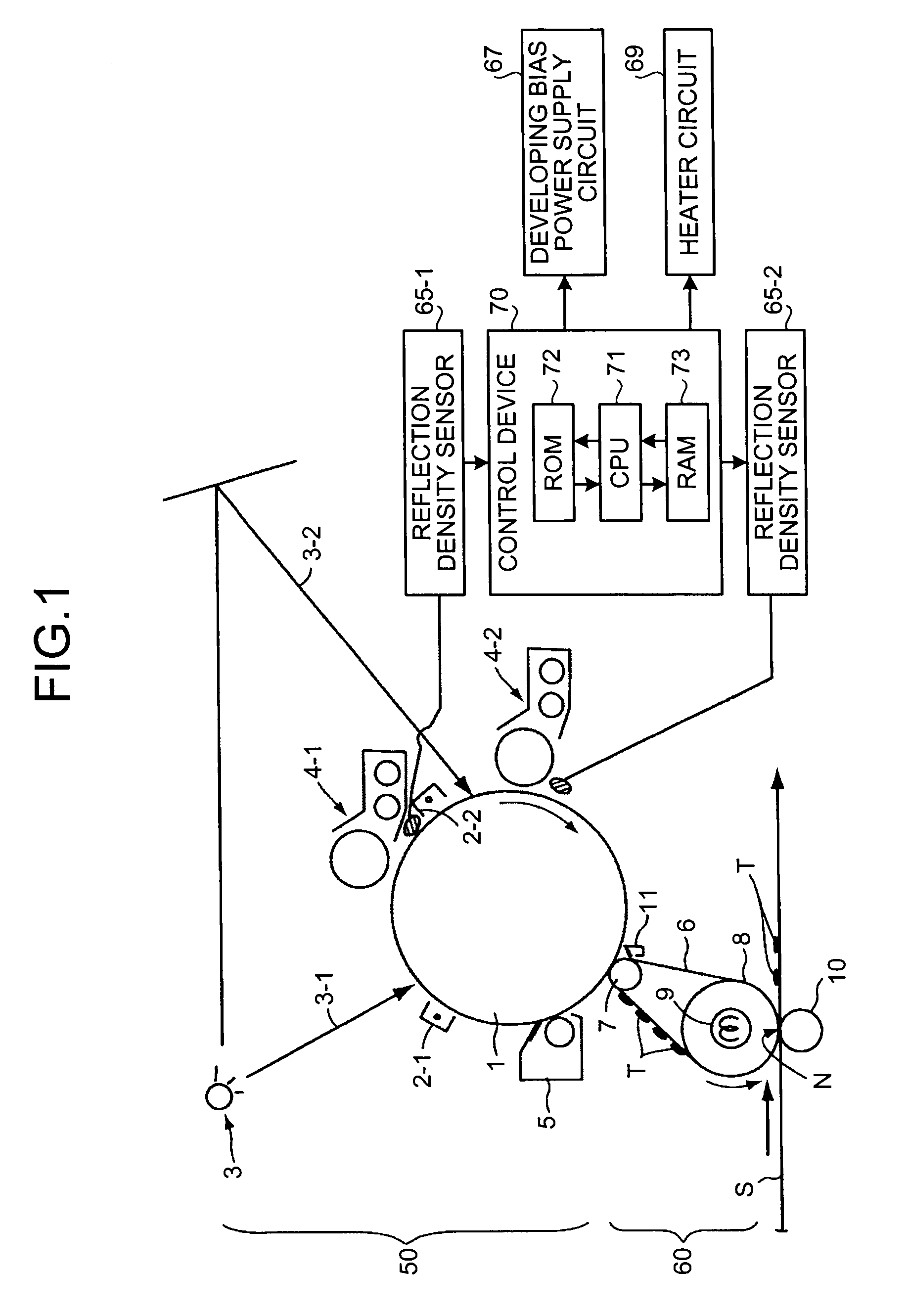

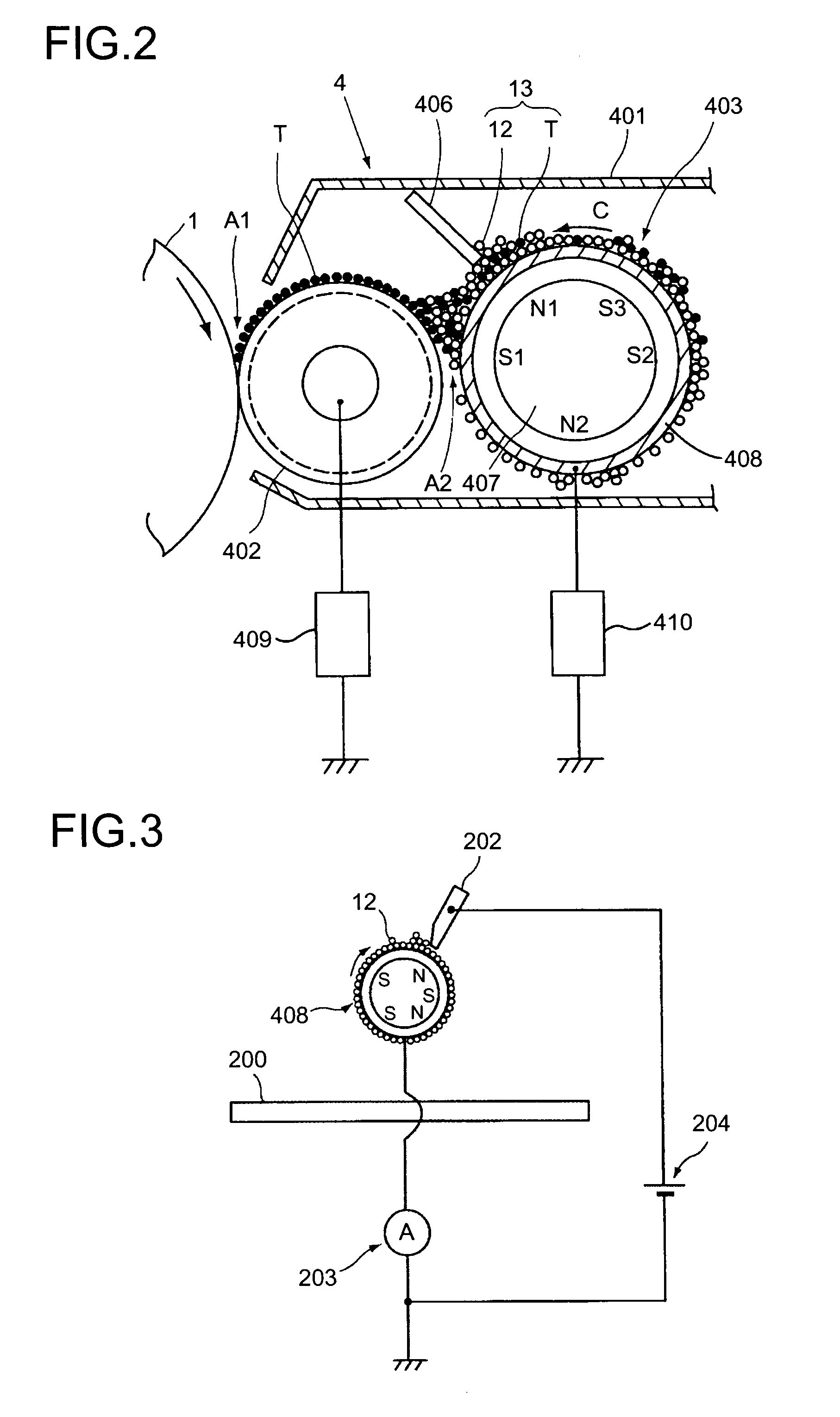

Image forming apparatus

An image forming apparatus includes a toner-layer filling-rate lowering unit that causes a toner layer of toner images to be formed on an image carrier so that the toner layer has sufficient optical transparency for exposing and the toner-layer filling rate is set relatively low; and a toner rolling rate adjusting unit that rolls the toner images at a predetermined toner rolling rate in accordance with the toner-layer filling rate when the toner images are transferred to the transferring / fixing unit.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com