High non-linear single polarization single-mould photonic crystal fiber

A technology of photonic crystal fiber and single polarization, which is applied in cladding fiber, optical waveguide light guide, optics, etc., can solve the problems of cladding structure asymmetry, small mode field area and low confinement loss characteristics at the same time, and achieve small Mode field area, simple fabrication, excellent effects of nonlinear characteristics and loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

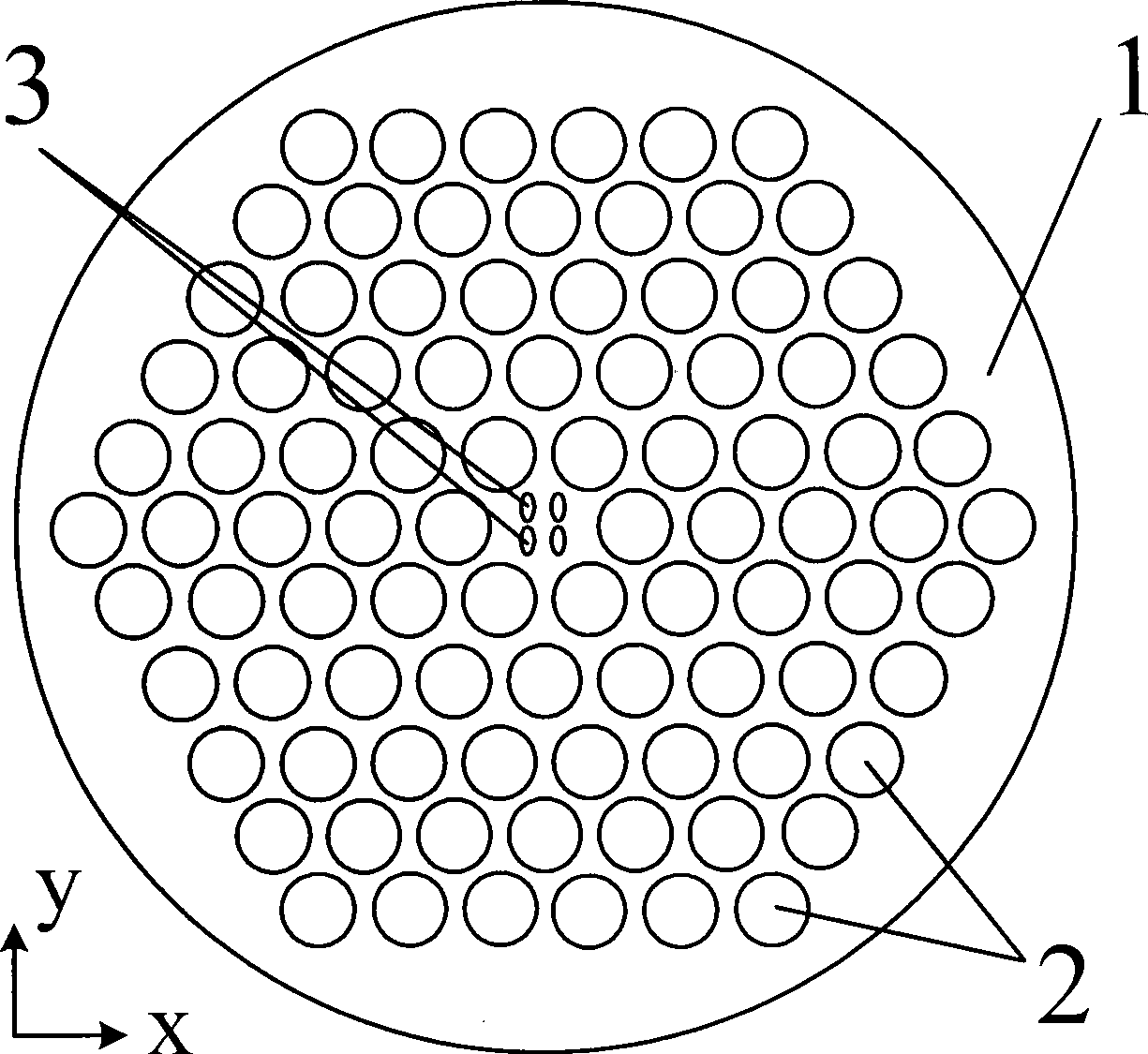

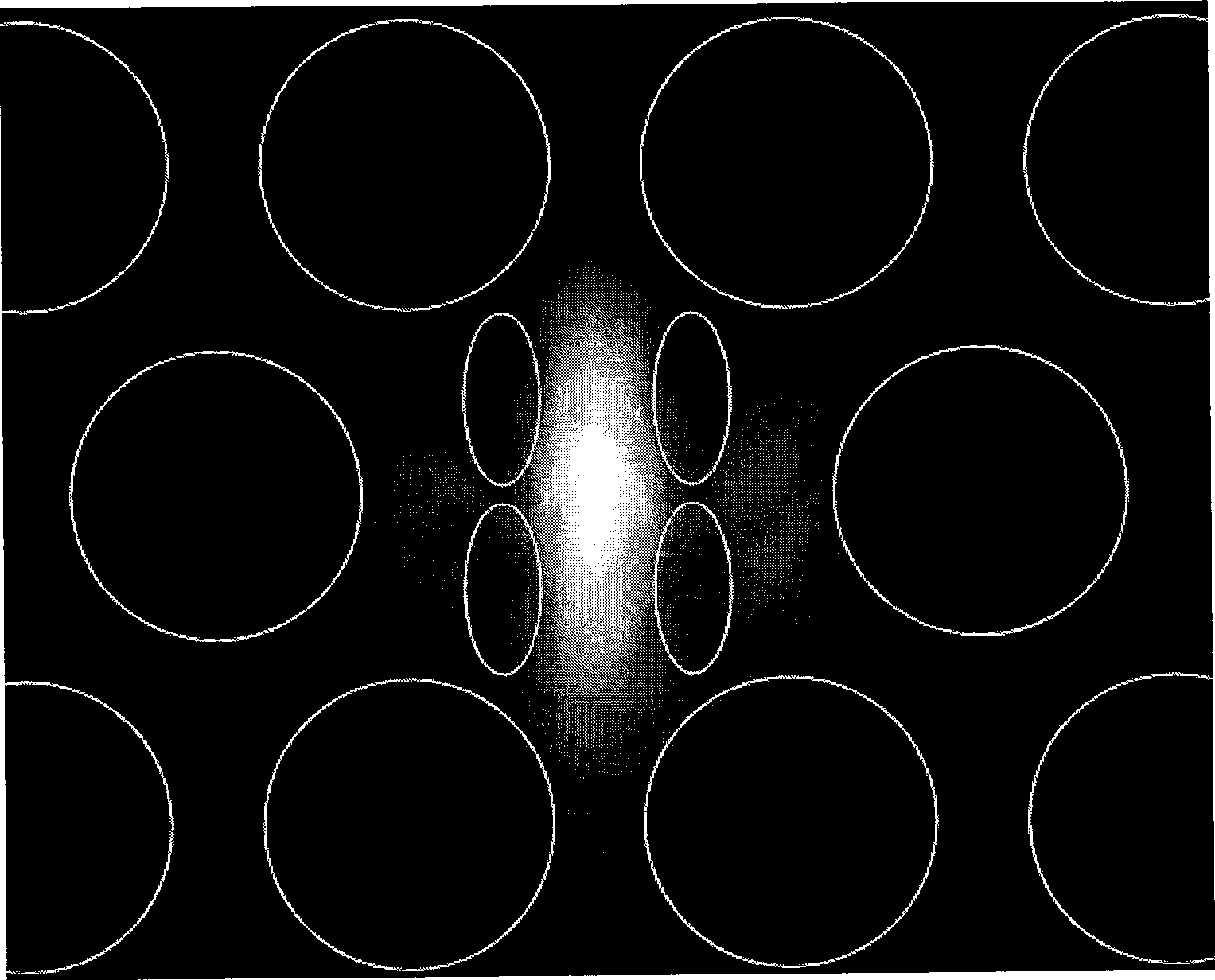

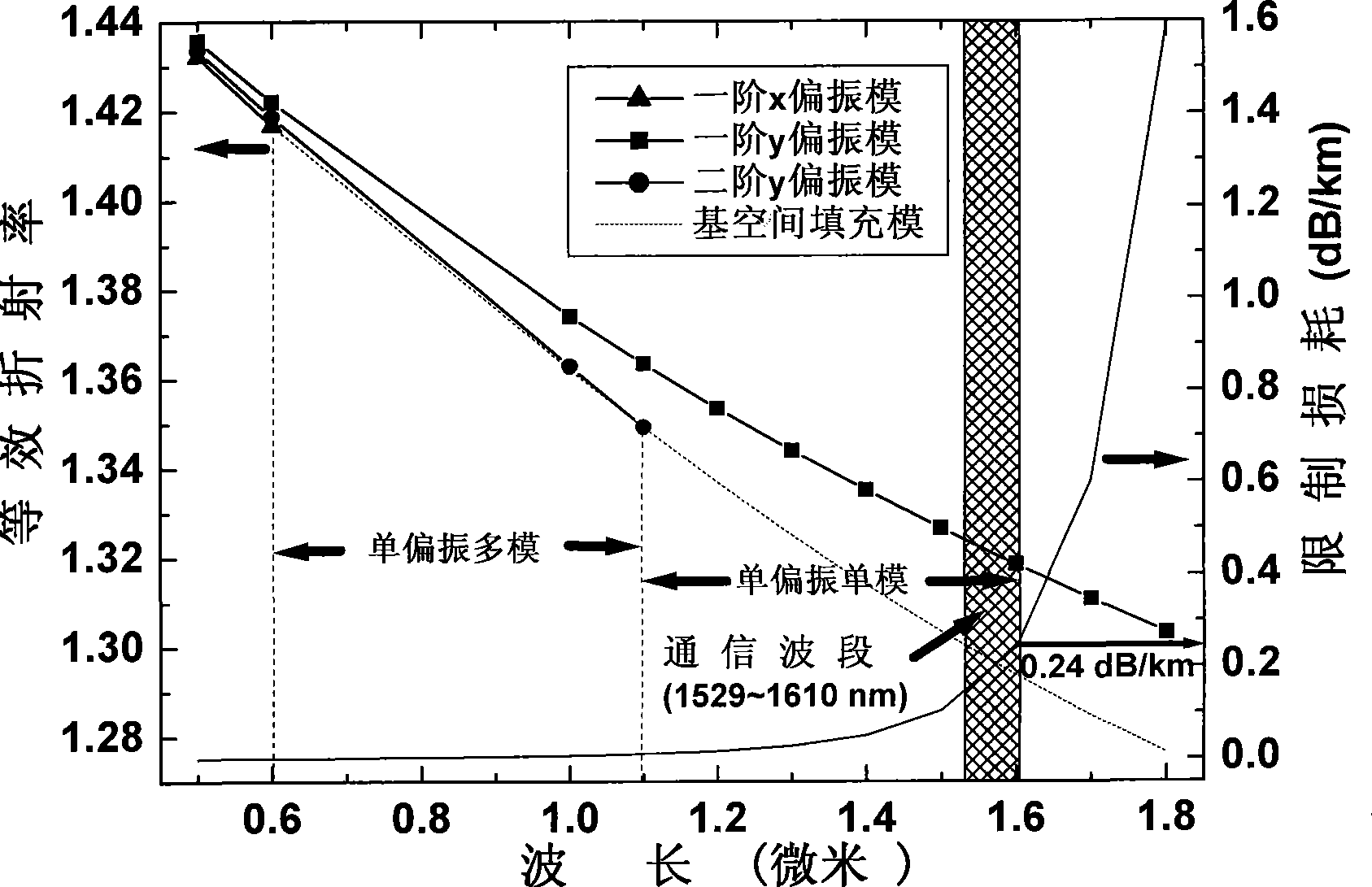

[0018] Refer to the attached Figures 1 to 3 , a photonic crystal fiber using four closely arranged rectangularly distributed air holes with large ellipticity in the core area, and the end face structure is as follows figure 1 As shown, the base material 1 of the optical fiber is quartz, the refractive index at 1.55 μm is 1.4457, and the air holes 2 in the cladding are uniformly arranged in the base material 1 according to the regular triangle rule commonly used in ordinary photonic crystal fibers known in the art. The diameter of each air hole 2 is d=0.76Λ, where Λ=2.2 μm is the center-to-center distance between adjacent air holes. The cross-section of the small air holes distributed in a rectangular shape in the core area is elliptical, the long axis is a=0.45Λ, the short axis is b=0.2Λ, and the center spacing in the vertical direction of the elliptical hole is Λ 1 =0.5Λ, the center distance in the horizontal direction is Λ 2 =0.5Λ. Using the full vector finite element me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com