Patents

Literature

328results about How to "Short cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

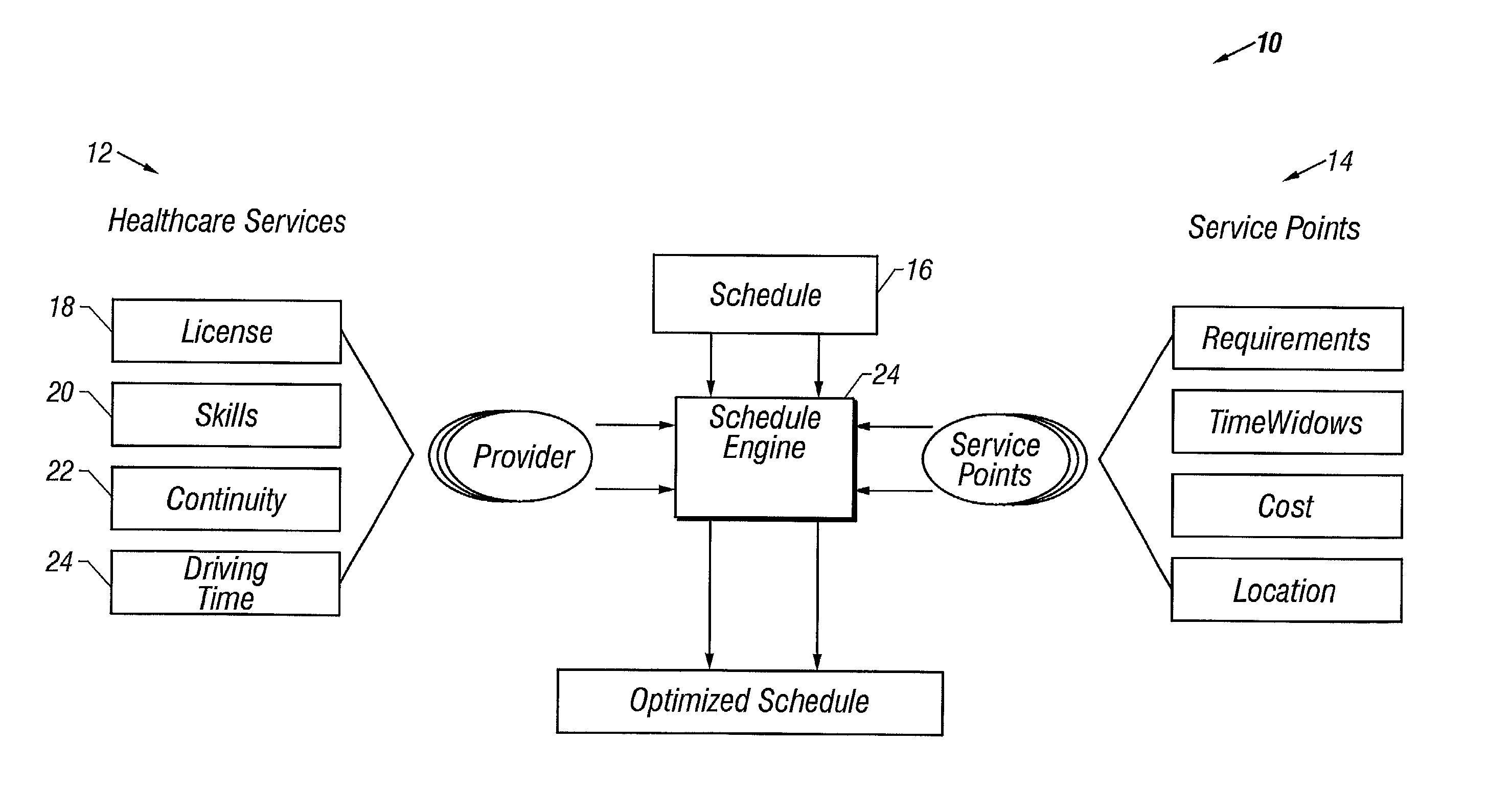

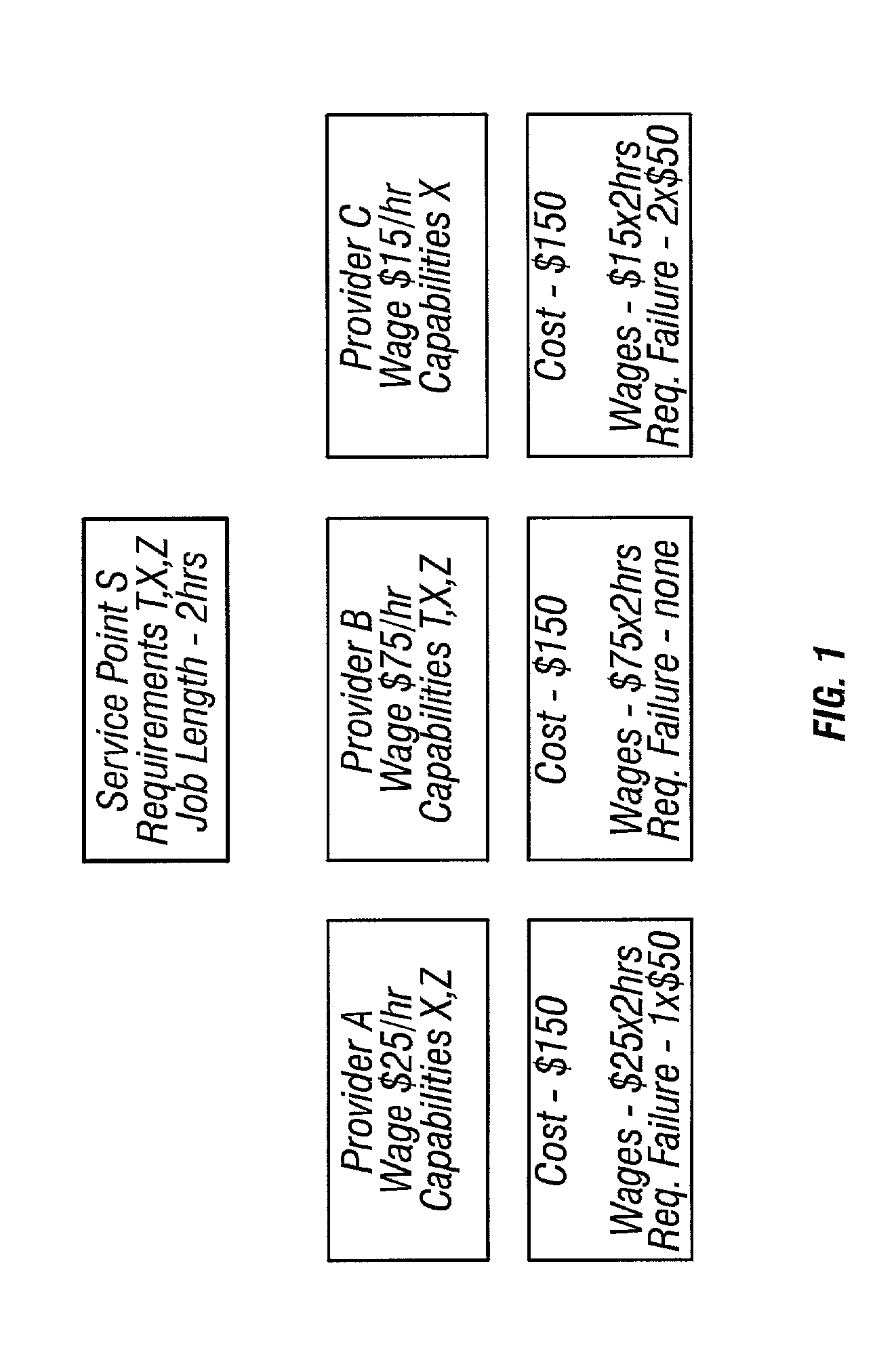

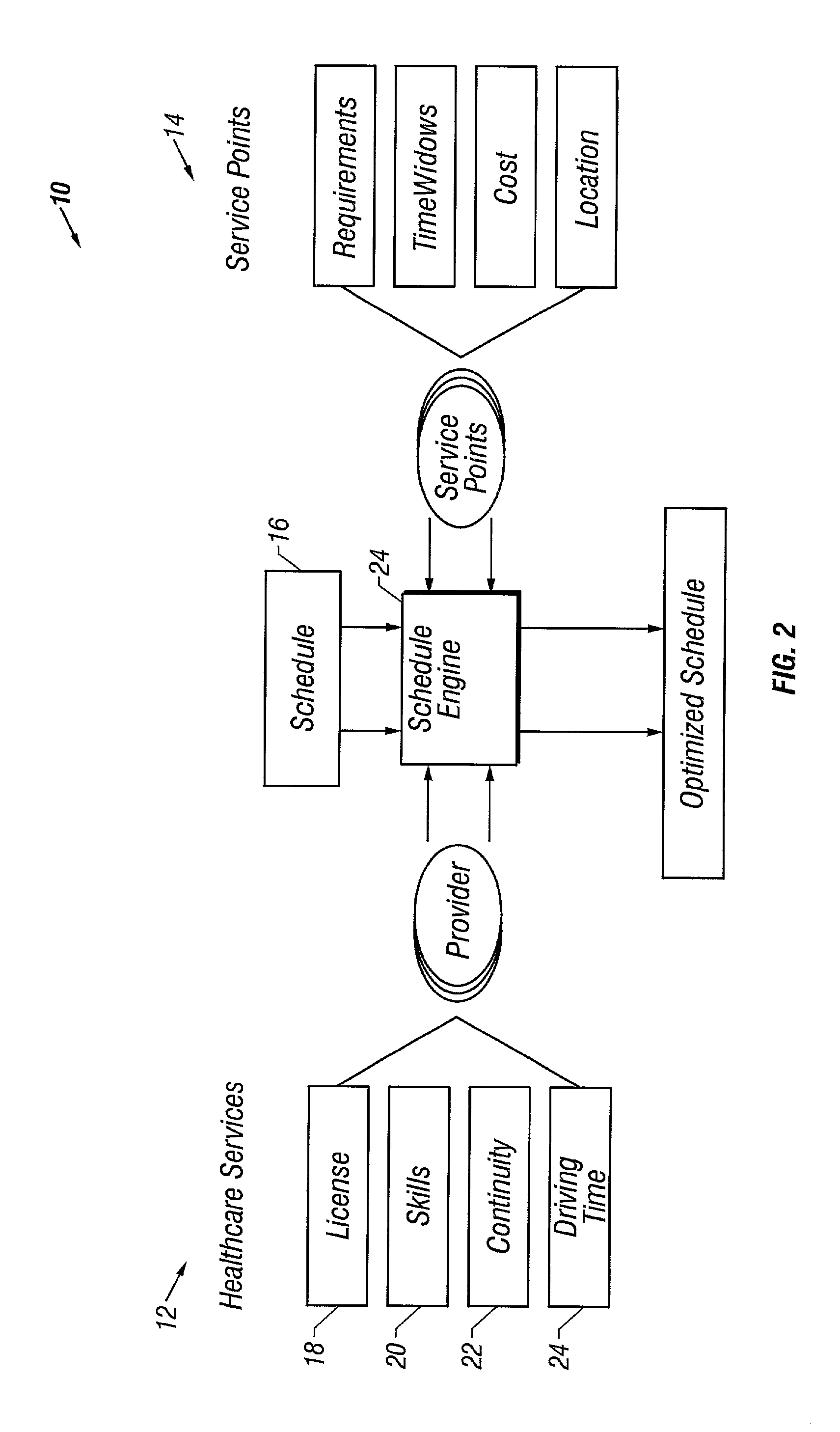

Multi-layer engine using generic controls for optimal routing scheme

A scheduling engine for optimally scheduling the allocation of a set of service providers to a defined set of service points includes a service point mechanism for collecting and processing a plurality of service point data elements, and a service provider mechanism for collecting and processing a plurality of service provider data elements. A generic multi-layer scheduling mechanism generates allocation schedules for allocating the set of service providers to the set of service points irrespective of nonlinearity or dependence amongst said plurality of service point data elements and said plurality of service providers data elements. The generic multi-layer scheduling mechanism employs a heuristic algorithm for use of an objective function relating to said plurality of service point data elements and said plurality of provider data elements and said control parameters that describe what is important to the customer and generating therefrom an optimal allocation schedule.

Owner:POINTSERVE

Non-toxic composite projectiles having a biodegradable polymeric matrix for hunting or shooting cartridges

InactiveUS6101949AShort costEasy to produceAmmunition projectilesShotgun ammunitionAliphatic hydrocarbonMetal particle

Composite spherical projectiles are provided for shotgun cartridges which are environmentally compatible, relatively inexpensive and have ballistic properties similar to lead shot or projectiles and which consist of metal particles dispersed in a biogradable polymeric solid matrix which includes a hydrocarbon binder containing ester functional groups which are linked to C1-20 aliphatic hydrocarbon chains, starch, and titanium dioxide.

Owner:SNPE MATERIAUX ENERGETIQUES

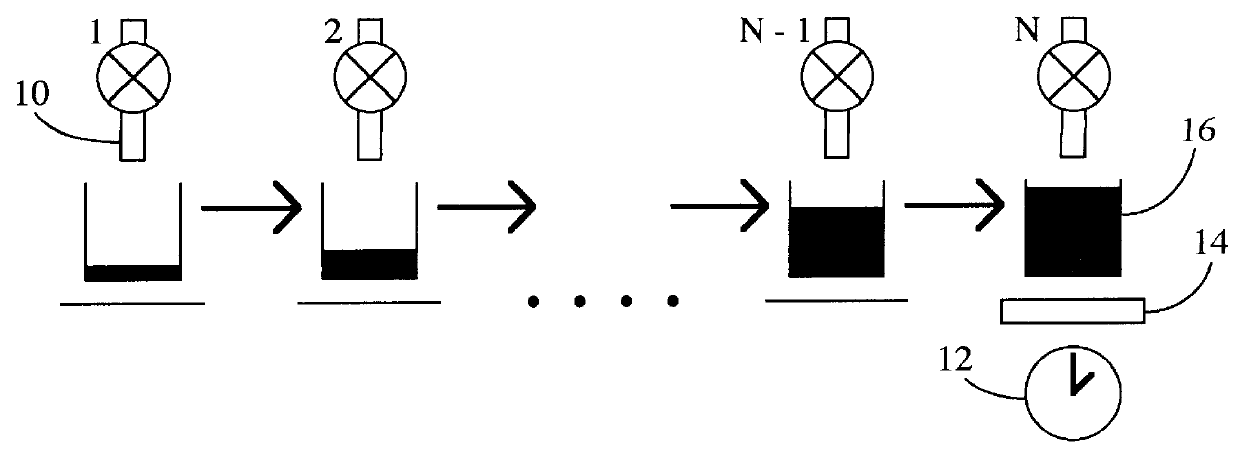

Fluid filling system with fill time optimization

A fluid filling system is disclosed wherein containers to be filled with fluid materials are supplied first to one or more time-metered filling stations, and then to a weight-metered filling station. At first, the time-metered filling station(s) is / are inactive, and only the weight-metered filling station is used to fill a first container to a desired final weight. A timer is used to monitor the filling time necessary to reach the desired final weight. When later containers are then supplied to the time-metered filling station(s), they are filled at each time-metered station for a filling time which is dependent on the previously measured filling time for the weight-metered filling station. These containers are then "topped off" by the weight-metered filling station to precisely fill them to the desired final weight, and the time required for such topping off is measured for use in subsequent modification of the filling times at the time-metered filling stations. For each container, the filling time at each time-metered filling station is dependent on the filling time at the weight-metered filling station in such a manner that the two will converge towards each other with successive containers until they are substantially or exactly equal. Preferably, the dependence between the time-metered filling time and weight-metered filling time are such that ttimed(t)=tN(t-1)+Qx[tN(t-1)-ttimed(t-1)]wherein tN(t-1) is the filling time at the weight-metering filling station for a prior container; ttimed(t) is the filling time at the time-metering filling station for the prior container; ttimed(t-1) is the filling time at the time-metering filling station for the prior container; Q is a predetermined real number.

Owner:IDEAL PAK MASSMAN LLC

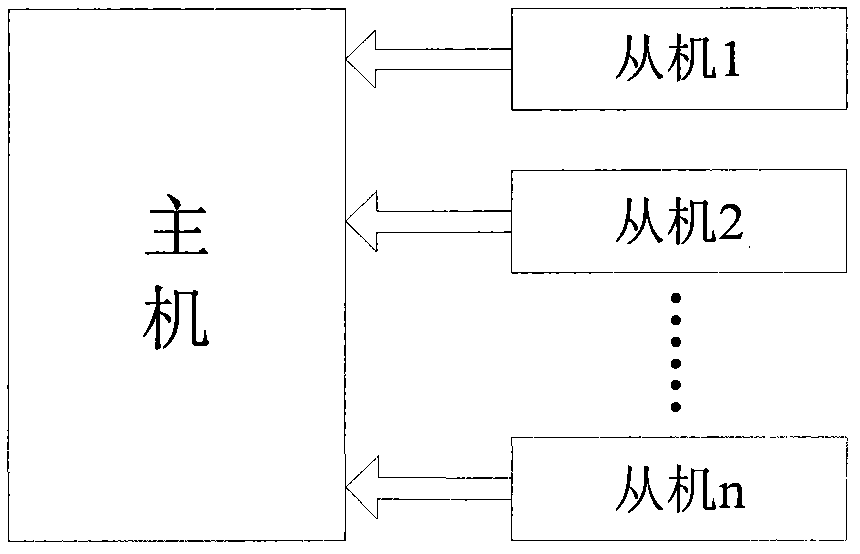

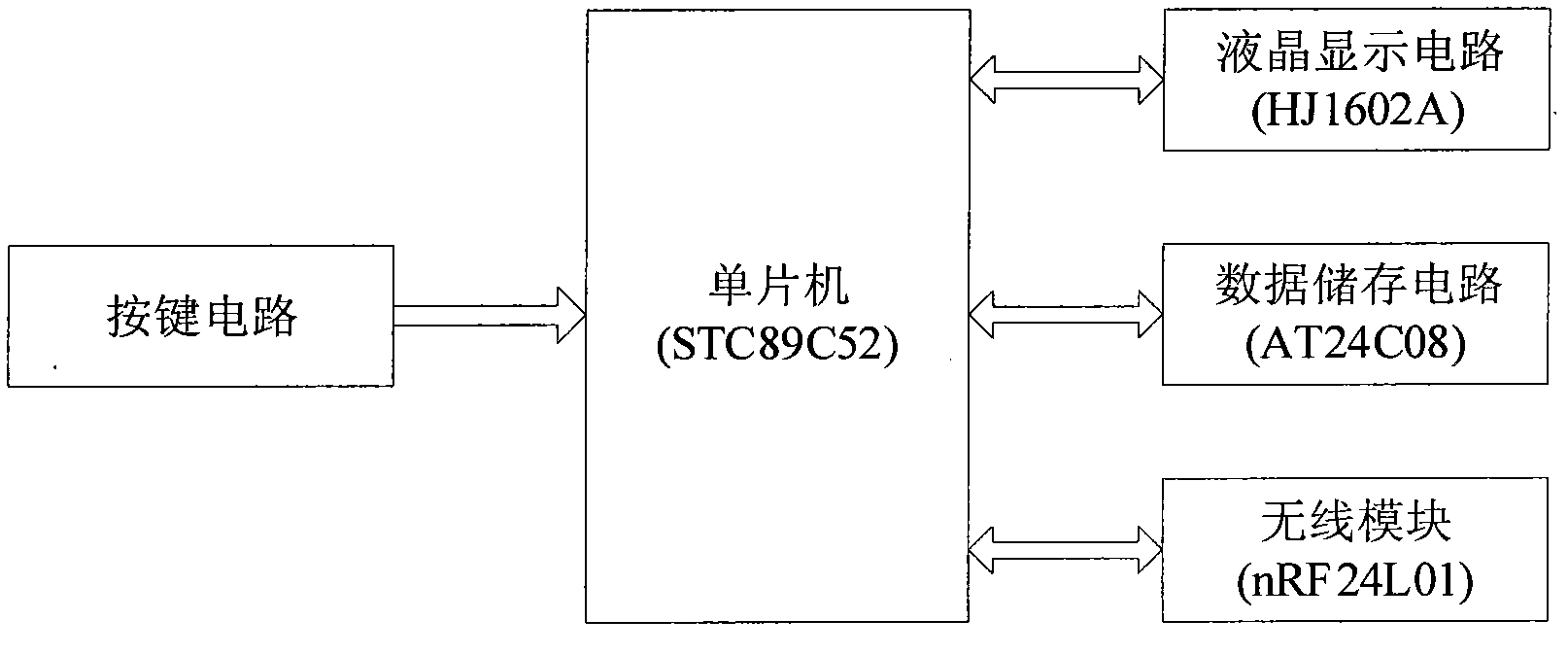

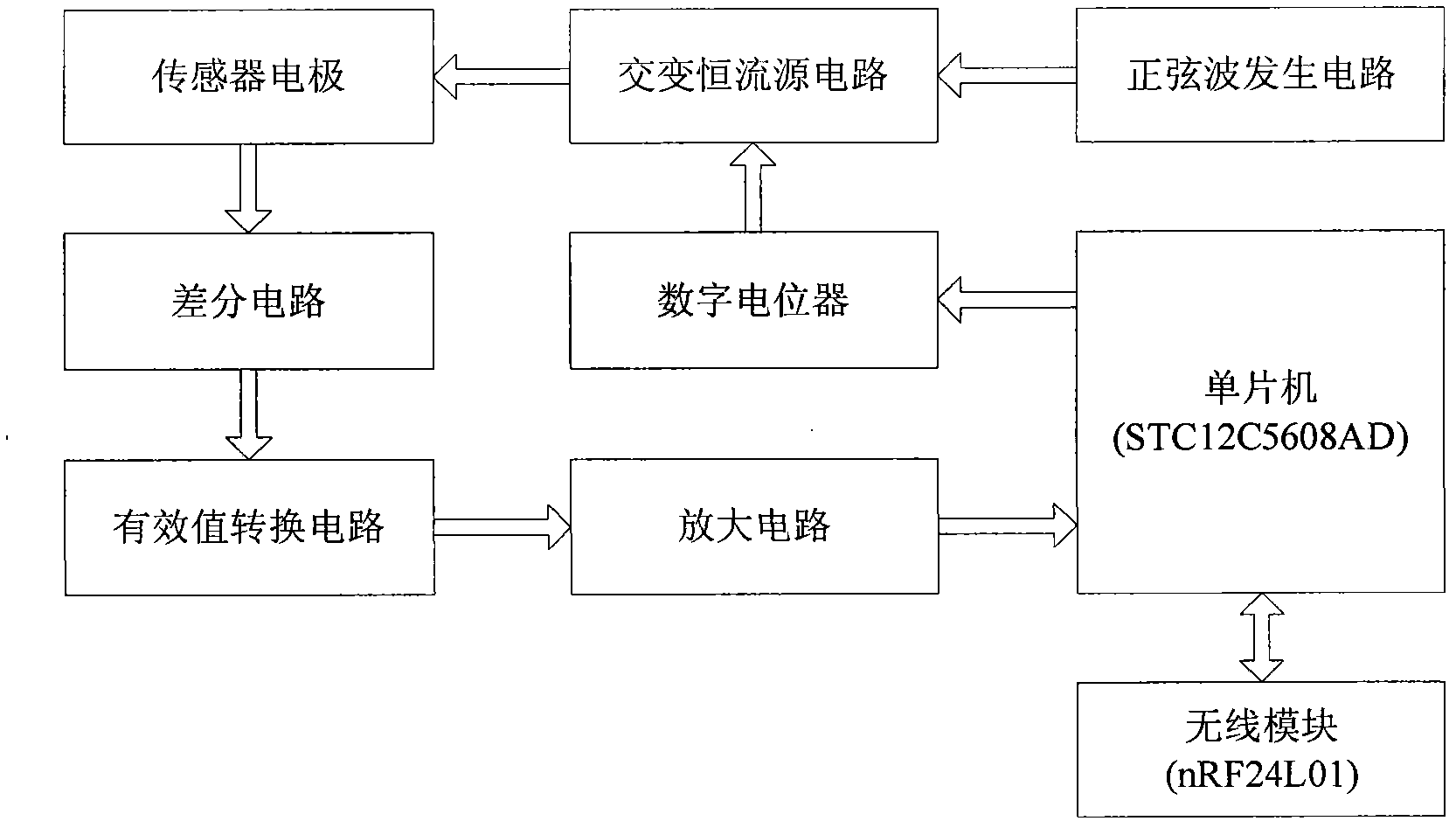

Wireless multipoint soil resistivity measuring system

InactiveCN102426297AEasy to measureShort costTransmission systemsResistance/reactance/impedenceSoil scienceInterference (communication)

The invention discloses a wireless multipoint soil resistivity measuring system. A soil resistivity measuring circuit is designed according to a principle of 'current-voltage four-electrode method', and a self-made mini-probe is used for reducing the interference on movement of a soil solute and can also carry out high-density distribution measurement. A wireless communication circuit of the wireless multipoint soil resistivity measuring system is an nRF24L01 wireless module which can form one 'one-to-many' communication network, thereby realizing multipoint measurement on the soil resistivity. The wireless multipoint soil resistivity measuring system establishes a measurement platform by a master-slave mode structure, a master machine finishes functions of receiving, processing, displaying and storing data of the soil resistivity, and a slave machine finishes functions of collecting and transmitting the data of the soil resistivity, thus a problem of consistency on multipoint soil resistivity real-time measurement is effectively solved. Based on test results, the wireless multipoint soil resistivity measuring system has excellent stability and practicability, and the soil resistivity, the saltness and the water content are of excellent linear relationship.

Owner:SHAANXI UNIV OF TECH

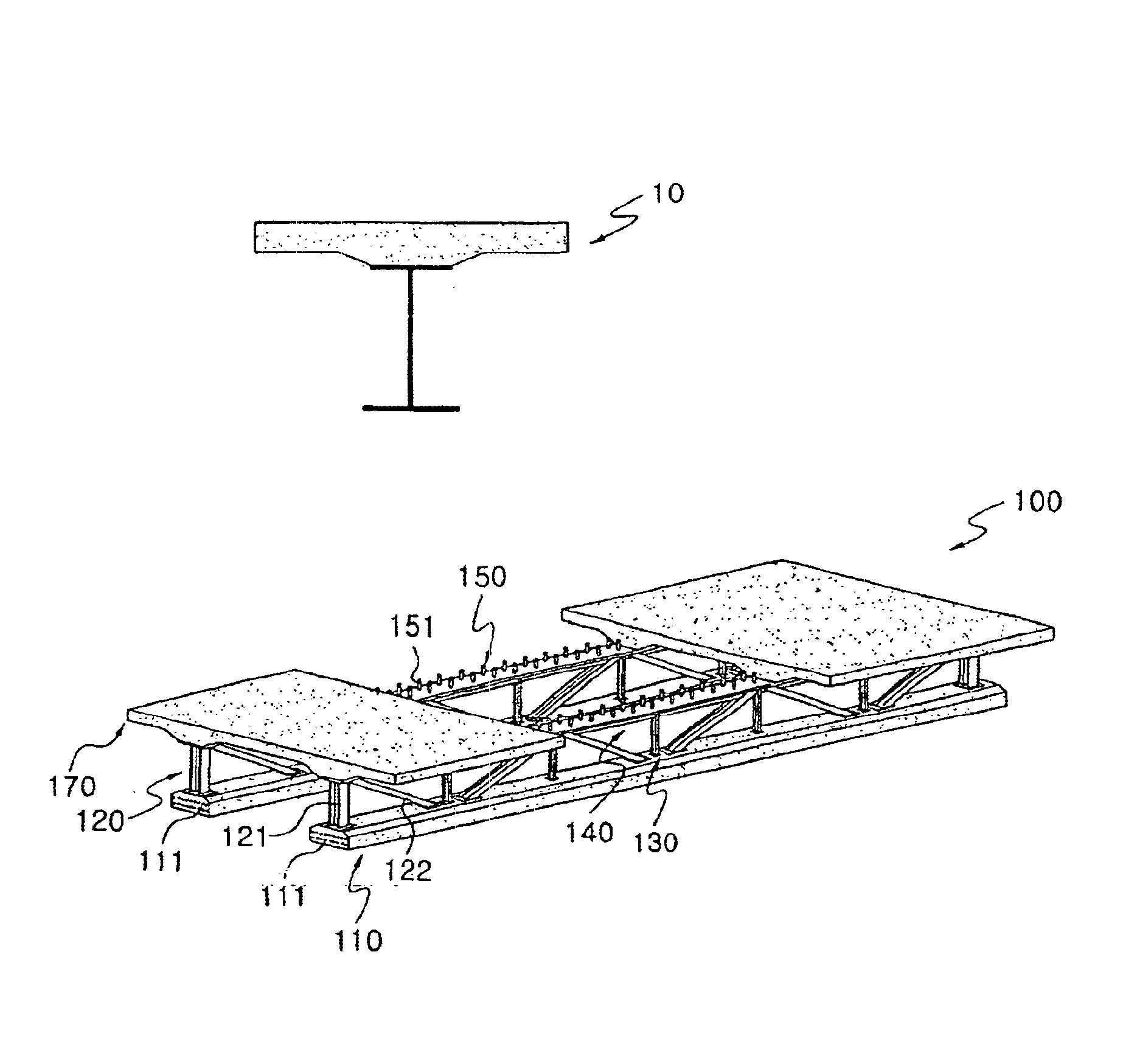

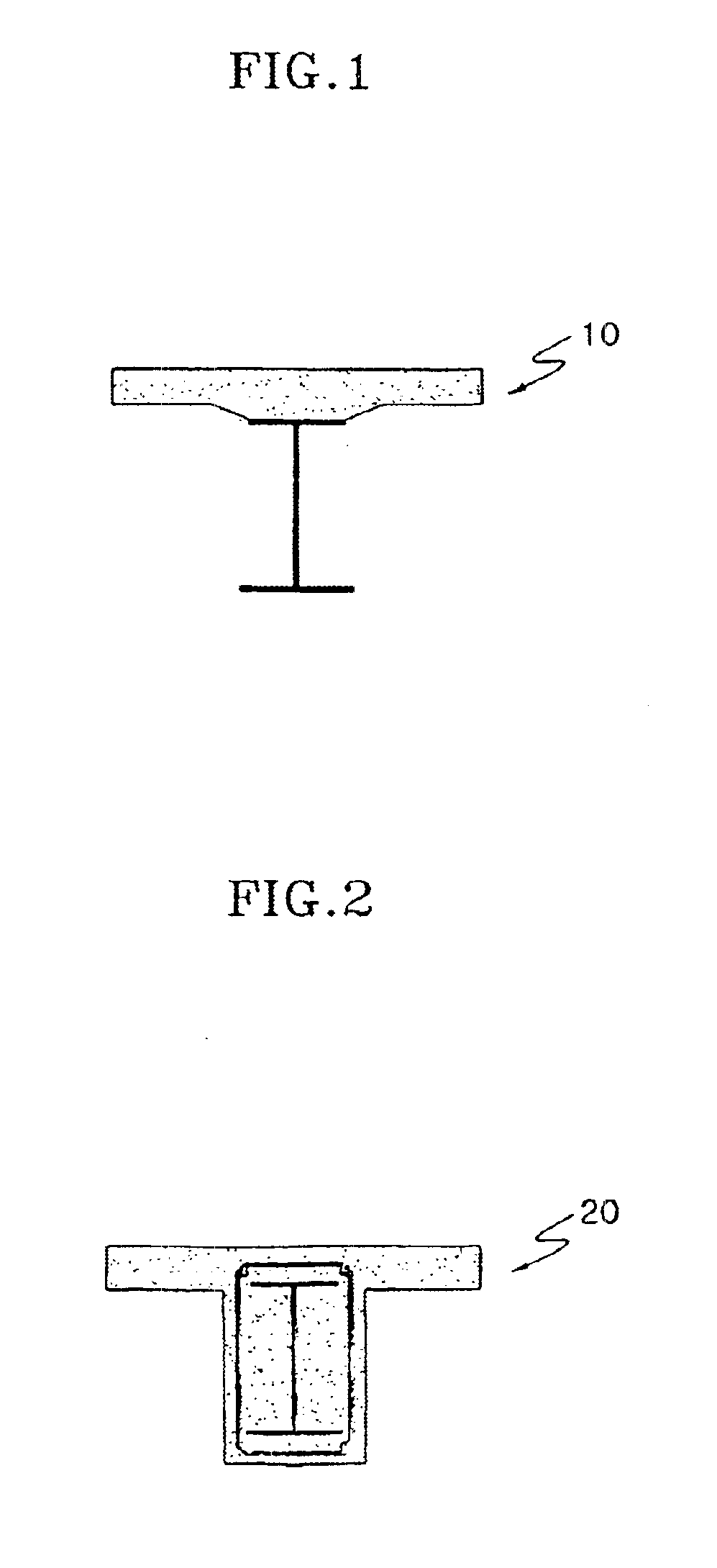

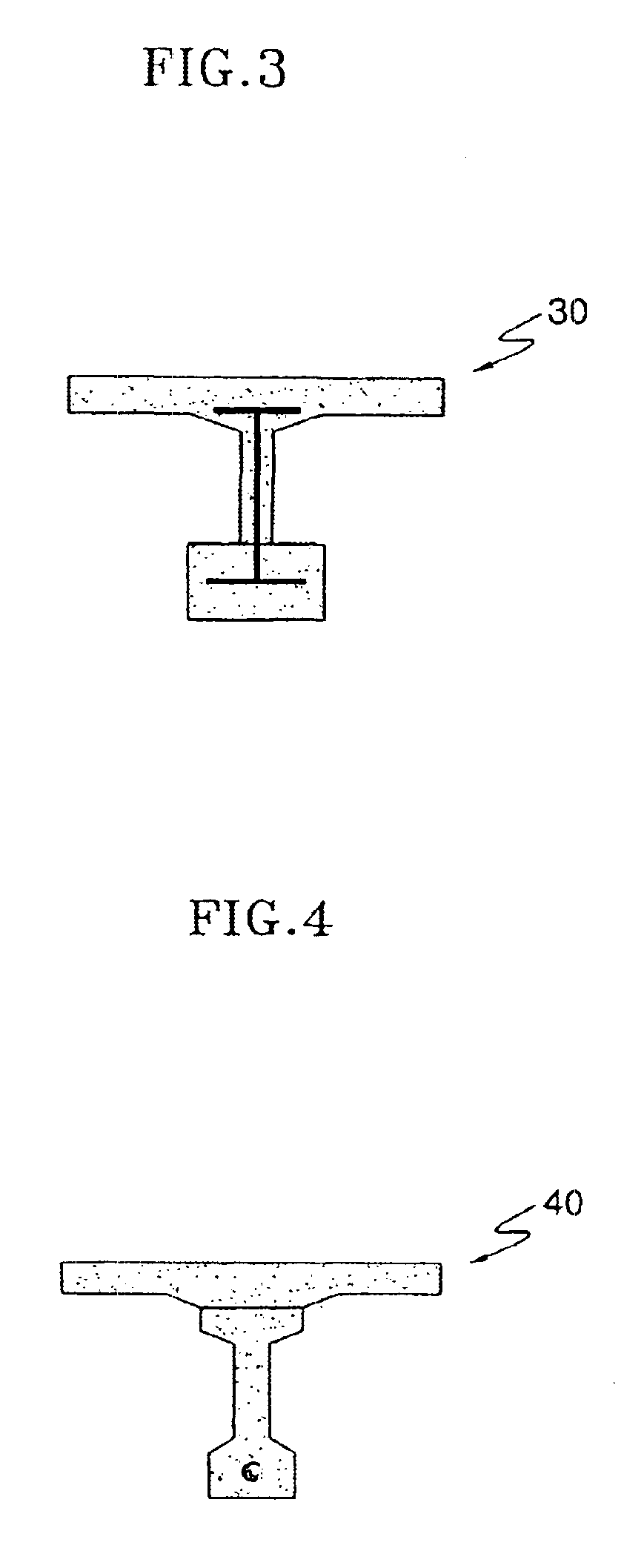

Prestressed composite truss girder and construction method of the same

InactiveUS6915615B2Maximizing material use efficiencyMaximize efficiencyTruss-type bridgeFloorsPre stressUltimate tensile strength

The present invention relates to prestressed composite truss girder and construction method of the same. The prestressed composite truss girder of the present invention comprises a concrete bottom plate having structure of composite truss; a lower-chord member being composed of prestressed concrete wherein prestress is induced to resist against the elongation strength generated when composing and not composing and to reduce the droop occurred at the state of composition and having perpendicular and horizontal cross-section of certain shape and certain length; web members wherein vertical chords and diagnal chords composed of rolled steel to upper plate of said lower-chord member; and upper-chord member combined with said web members along the longitudinal direction of said lower-chord member to resist against the compressive force generated before said concrete bottom plate being composed.

Owner:WON DAE YON

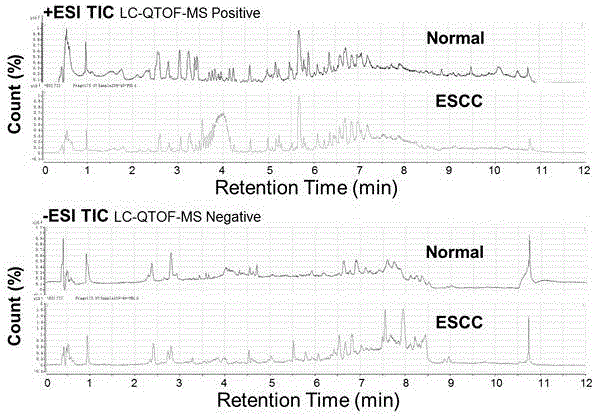

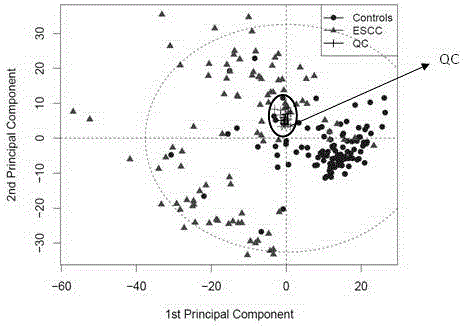

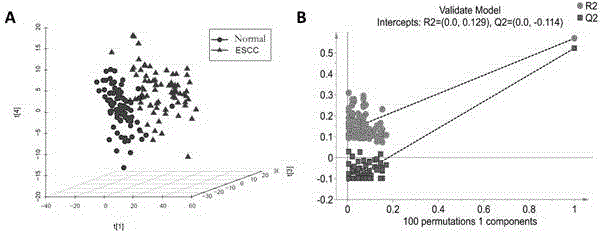

Diagnosis marker suitable for early-stage esophageal squamous cell cancer diagnosis and screening method of diagnosis marker

ActiveCN105044361AImproved prognosisReduce mortalityComponent separationBiological testingDiagnostic modalitiesScreening method

The invention discloses a diagnosis marker suitable for an early-stage esophageal squamous cell cancer diagnosis and a screening method of the diagnosis marker. Twenty five kinds of serum metabolic markers and ten relevant metabolic pathways are discovered; through the combination of the twenty five kinds of serum metabolic markers, the diagnosis marker used for an esophagus cancer diagnosis can be obtained. The screening method of the diagnosis marker has high operability; the diagnosis marker can be used for building a diagnosis model; the diagnosis model has the advantages of good effect, high sensitivity and good specificity, is suitable for a late-stage esophagus cancer diagnosis and is also suitable for the early-stage esophagus cancer diagnosis. The diagnosis model built by adopting the diagnosis marker provided by the invention has the advantages that the diagnosis can be realized only through blood sampling; the noninvasive effect is achieved; the cost is low; the modern internal invasive diagnosis mode can be well replaced; the pain of a patient is greatly reduced; in addition, the diagnosis speed is high; convenience is realized; the required time is short; the work efficiency is improved; the early discovery and early treatment of an esophagus cancer can be favorably realized; good clinic use and popularization value is realized.

Owner:SHANDONG RES INST OF TUMOUR PREVENTION TREATMENT

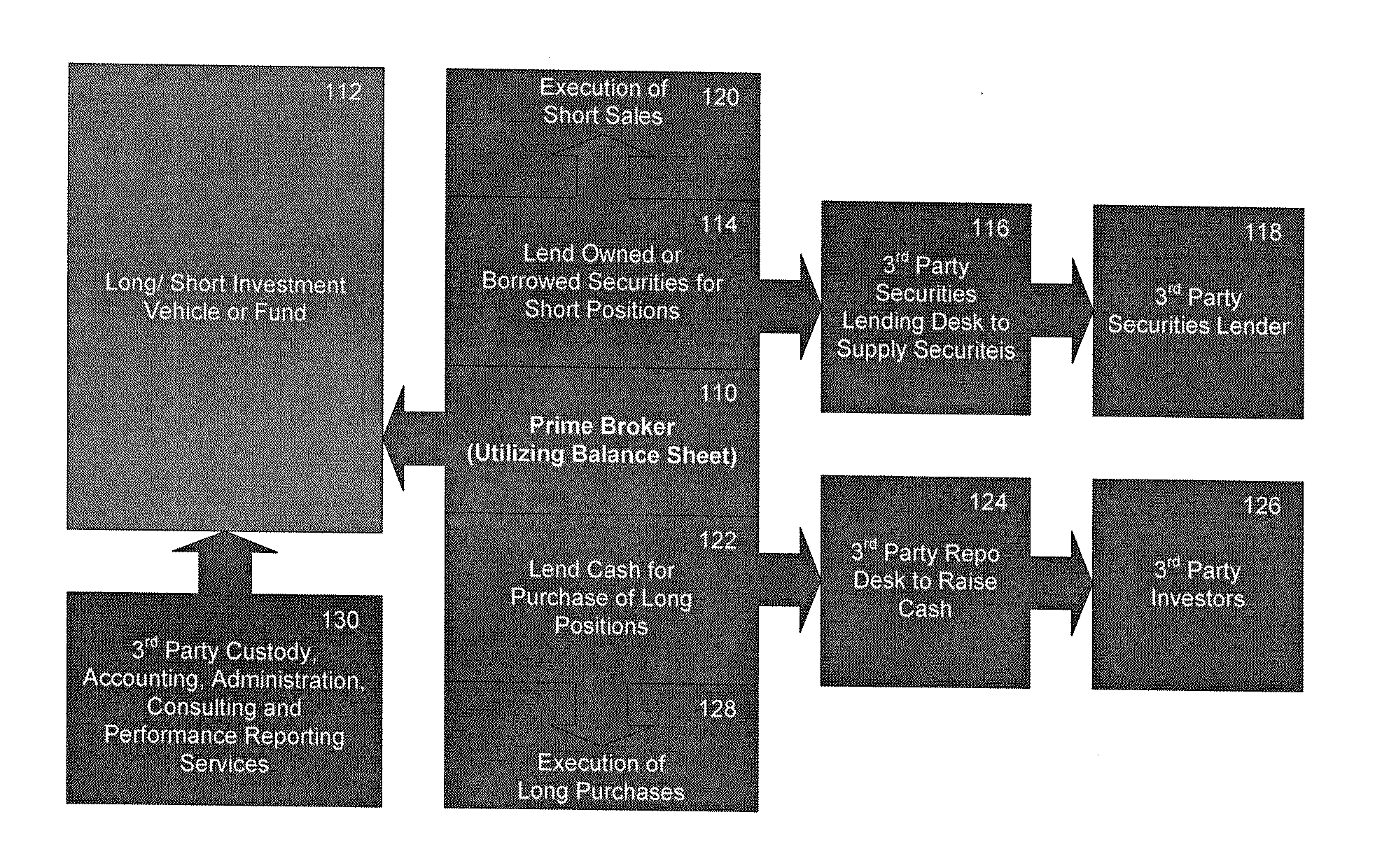

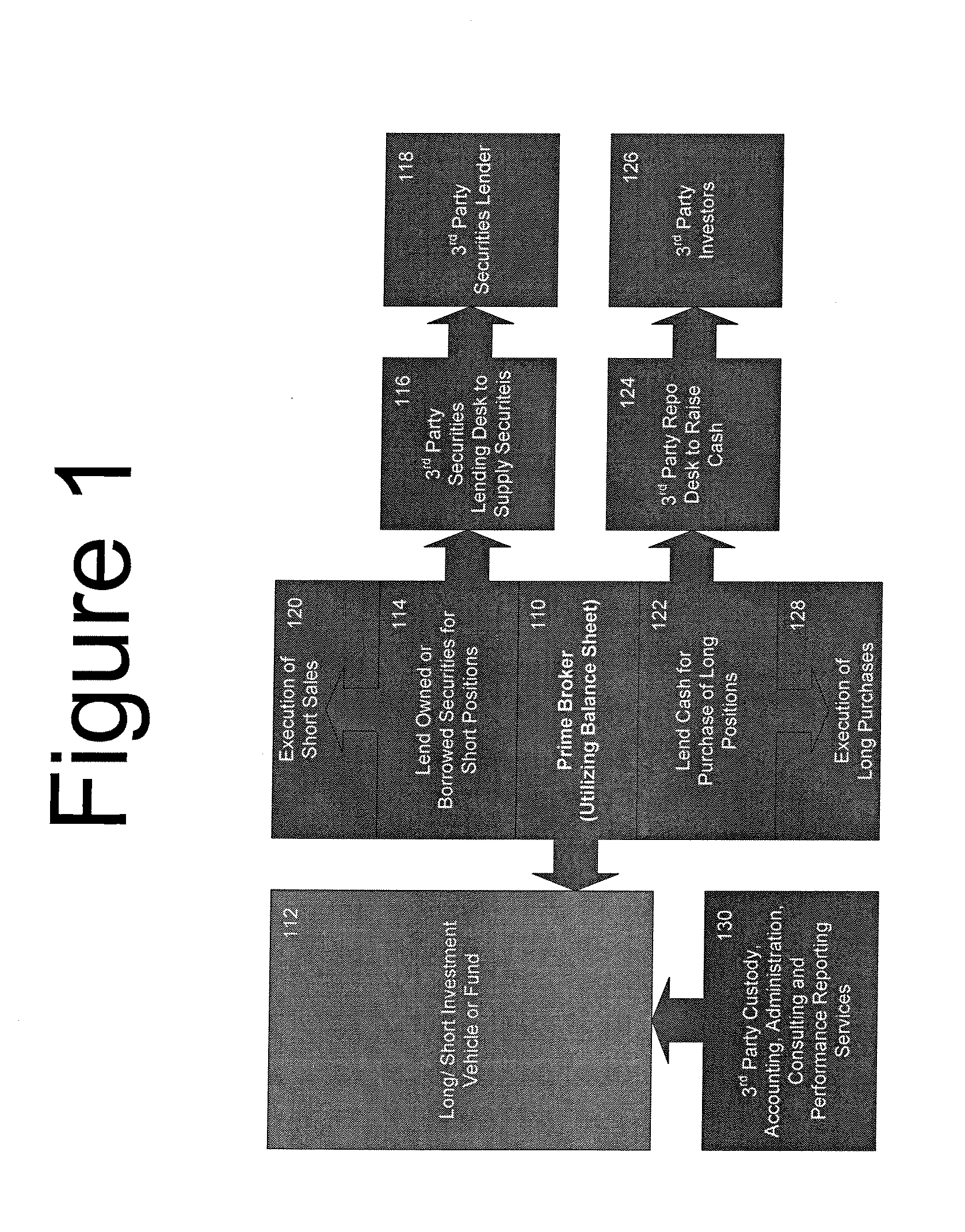

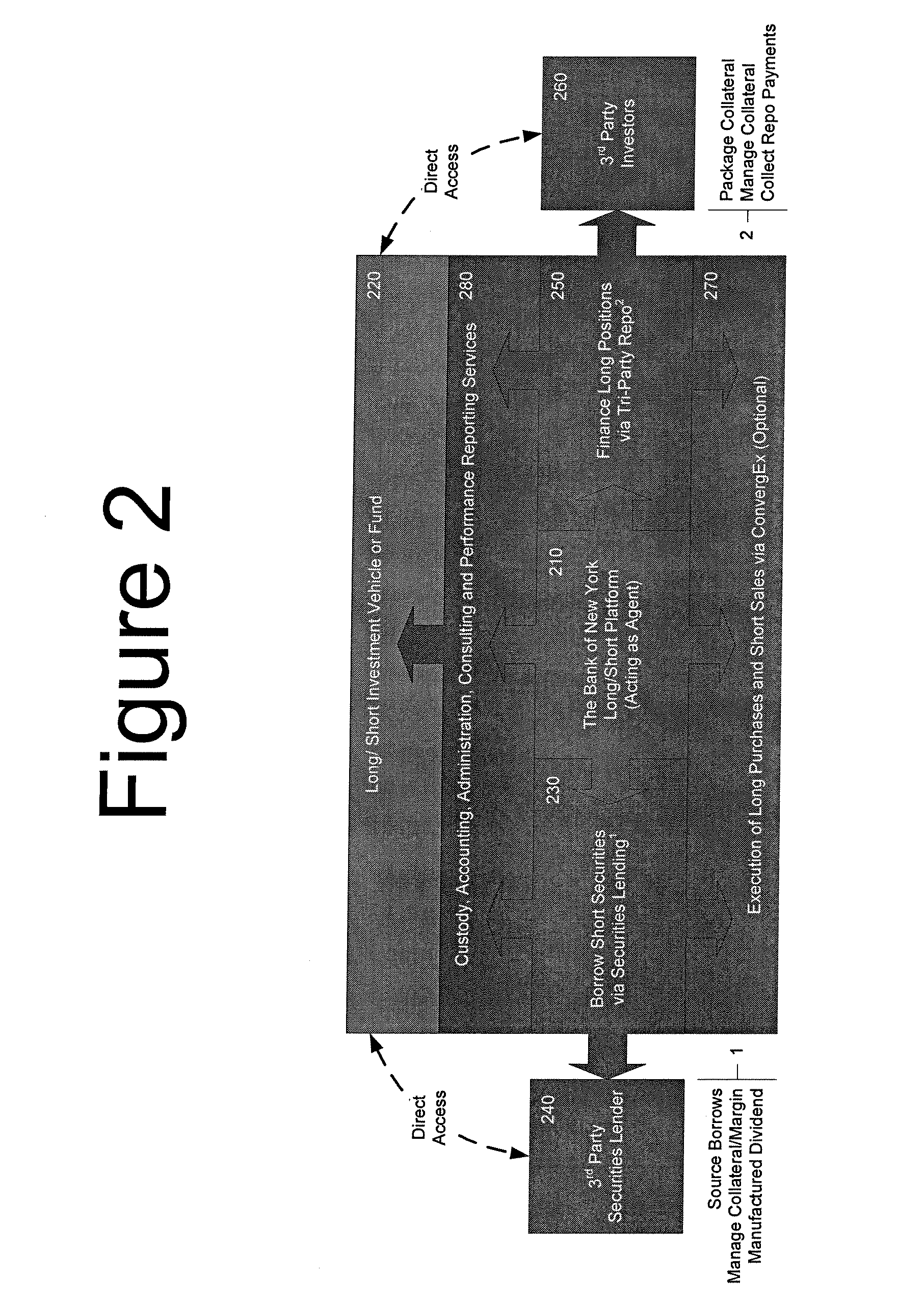

Systems and methods for providing financial services

A new method and system for providing financial services is provided. These methods and systems can include providing banking and investment services to hedge fund money managers and other customers without the assistance or need for a prime broker. While employing the present invention a money manager may receive prime brokerage services from a bank or other financial service while at the same time be able to pursue investment opportunities with this bank or financial institution and other banks, institutions, and brokerages. The prime brokerage services that a money manger may receive can include accounting services, loan services, and cash management.

Owner:THE BANK OF NEW YORK MELLON

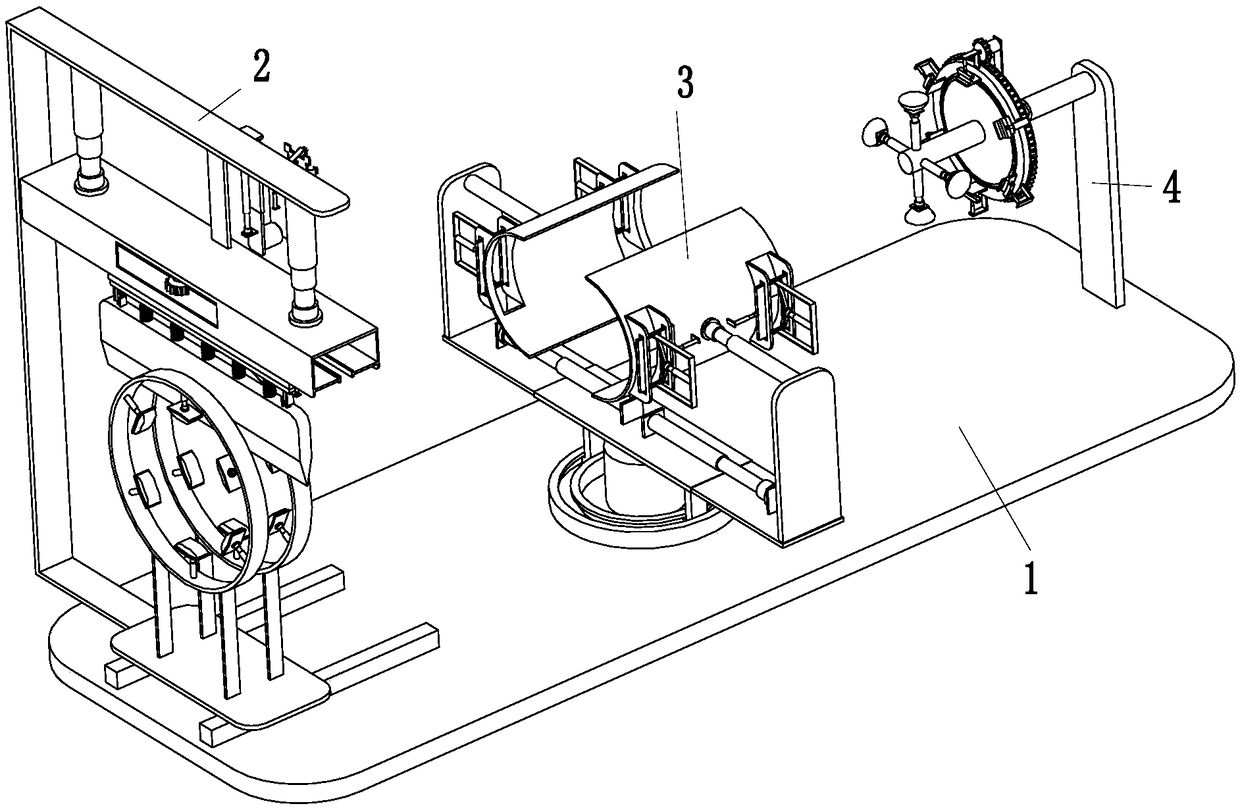

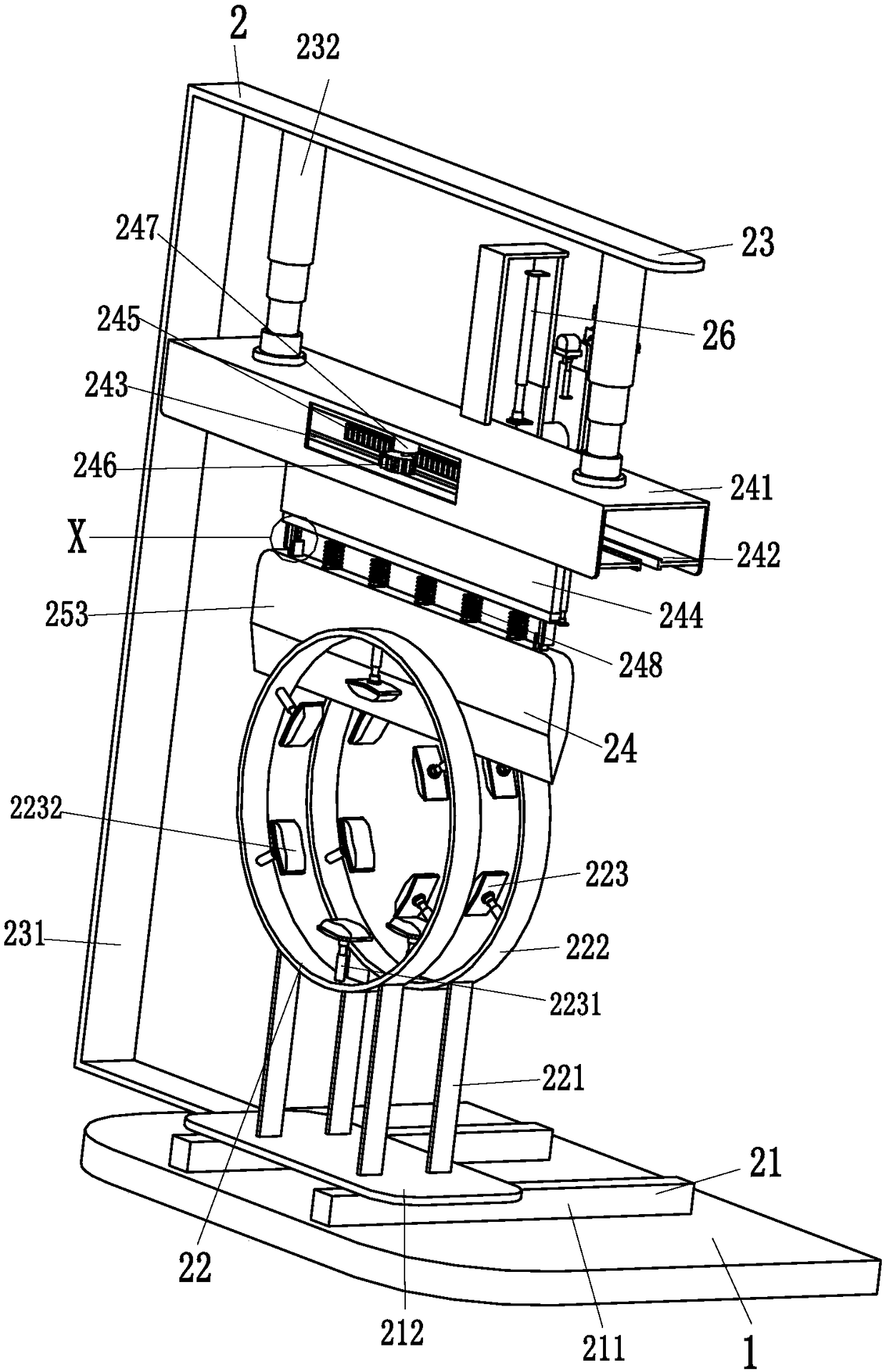

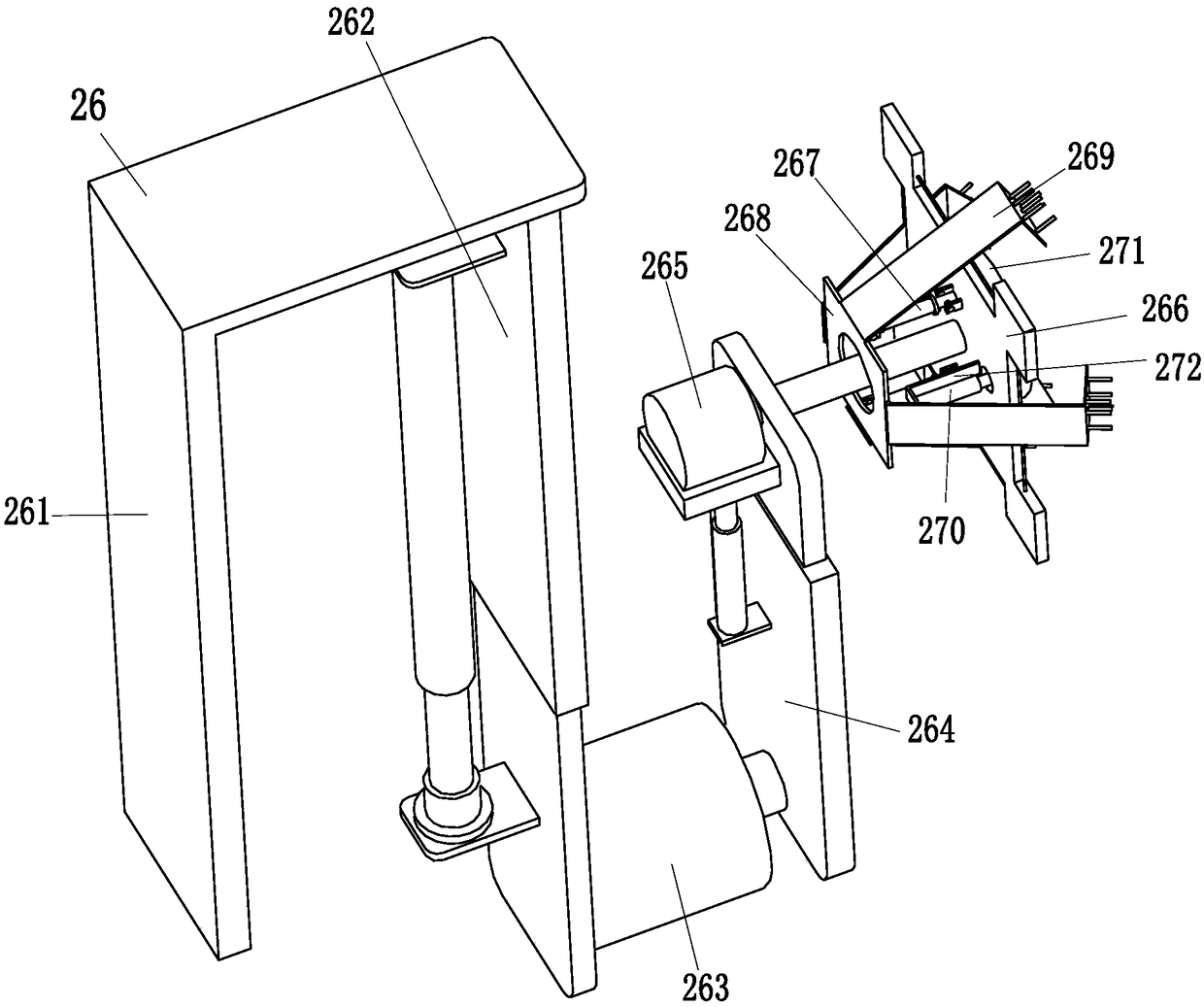

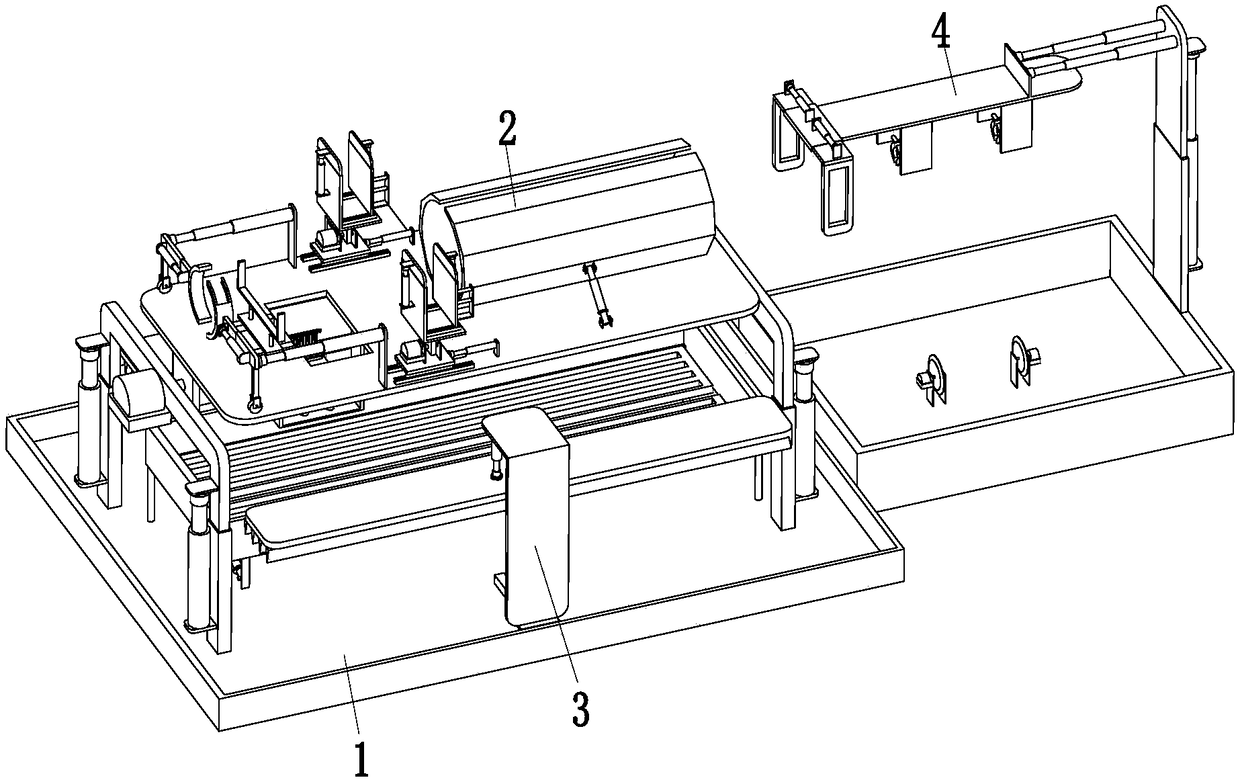

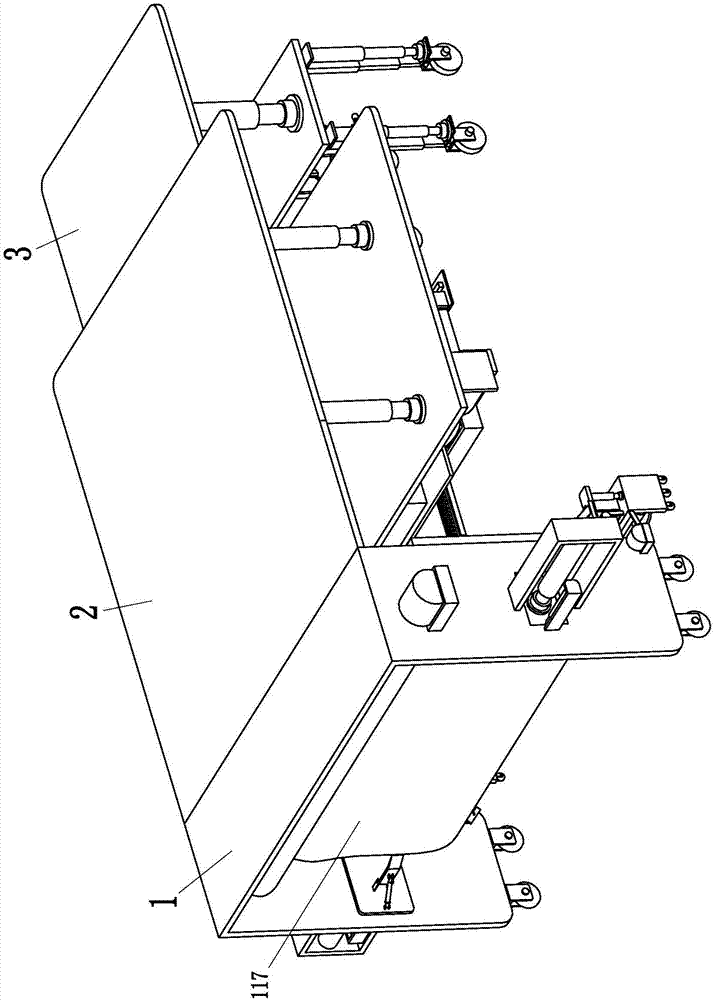

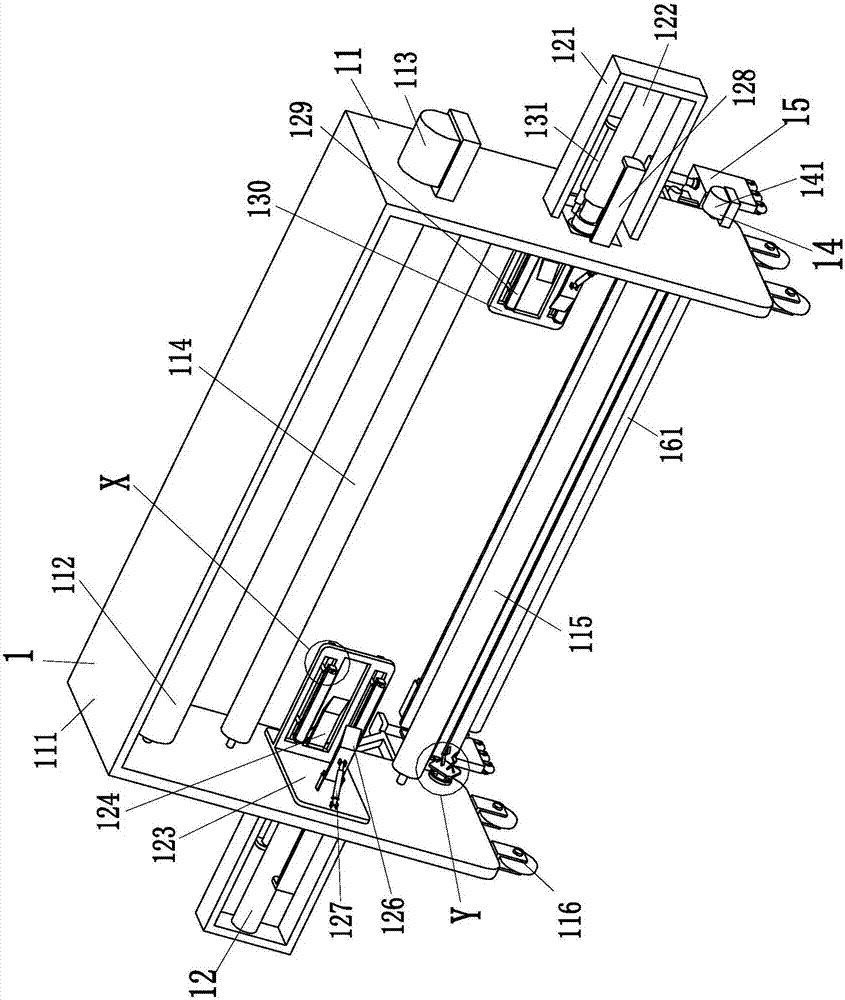

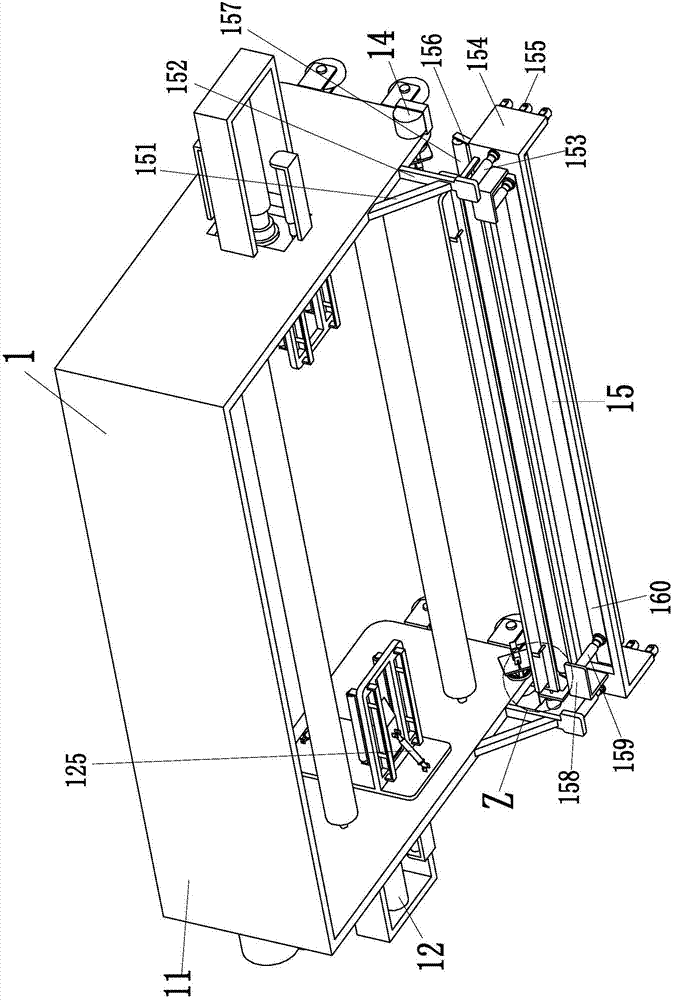

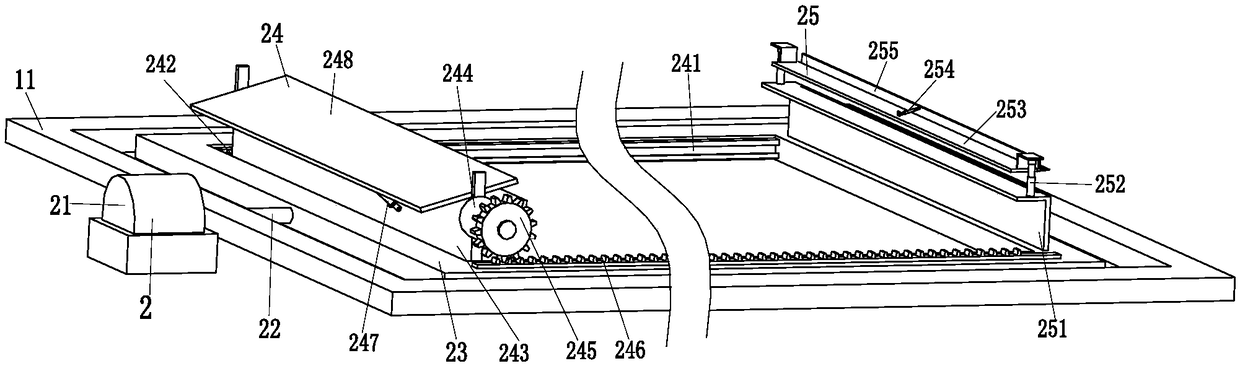

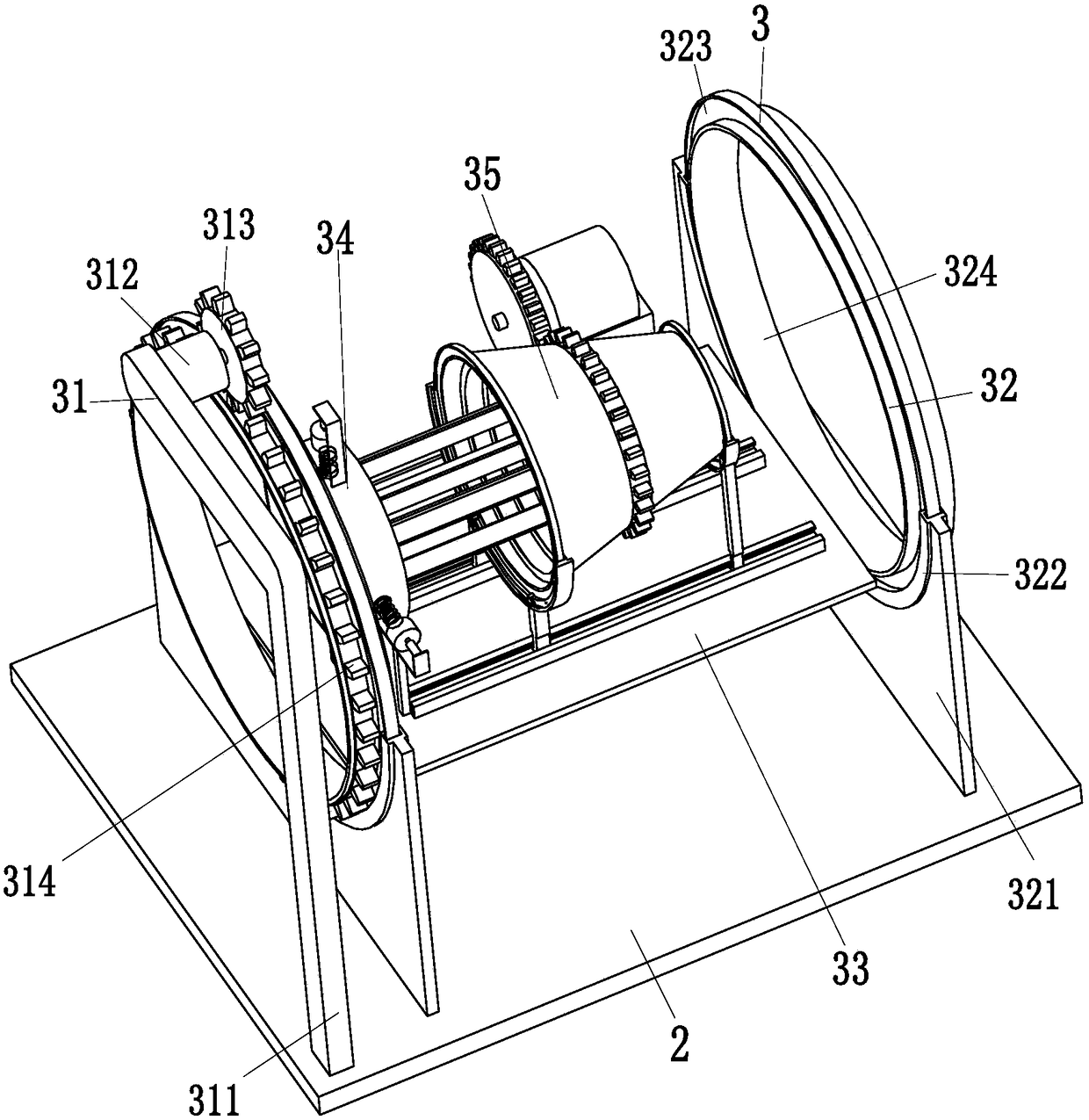

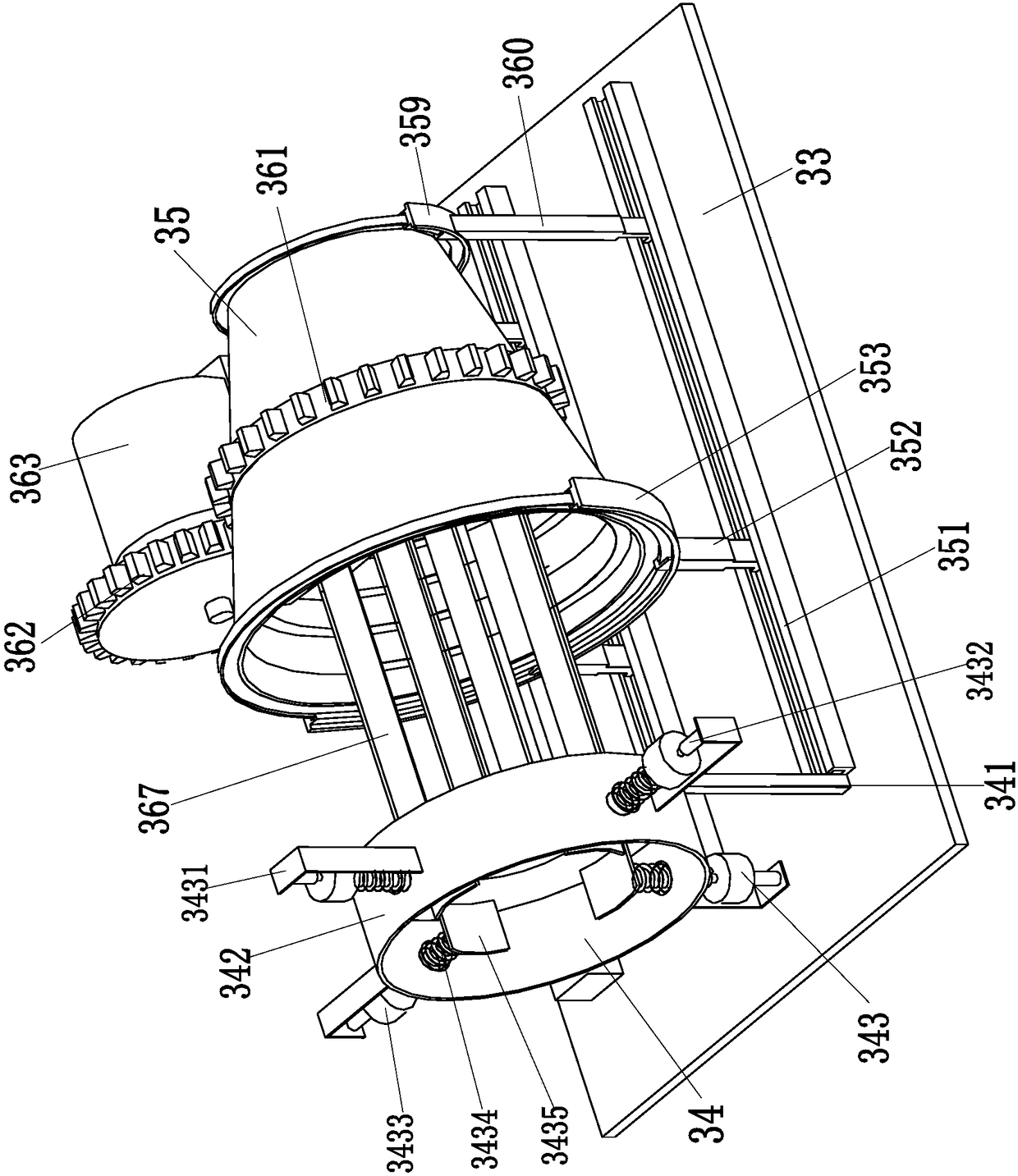

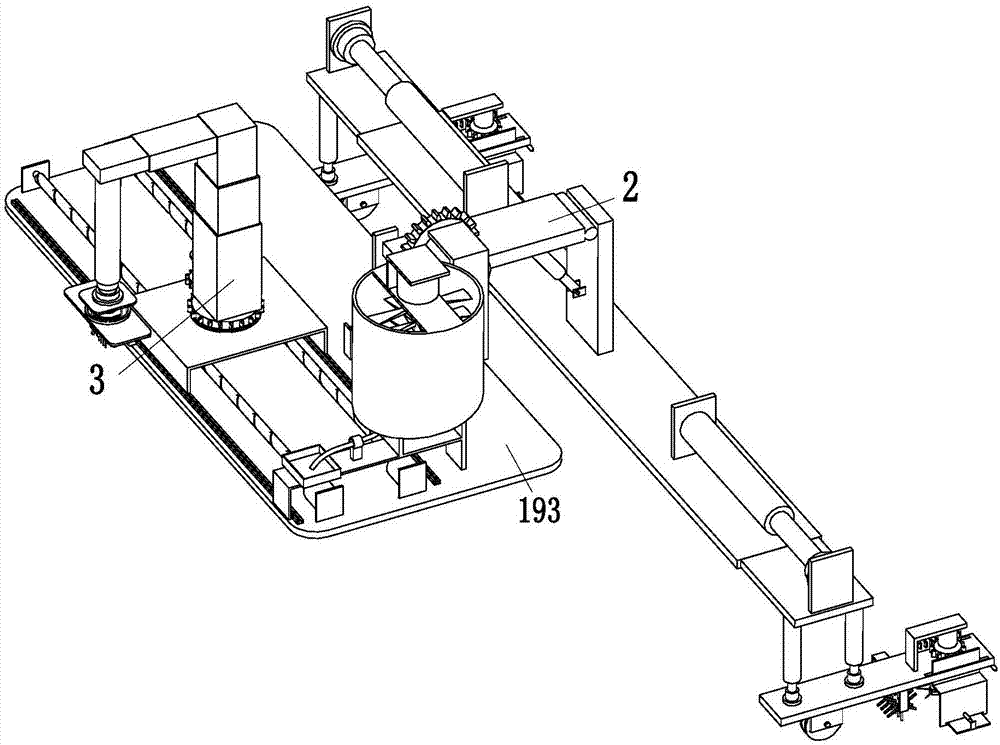

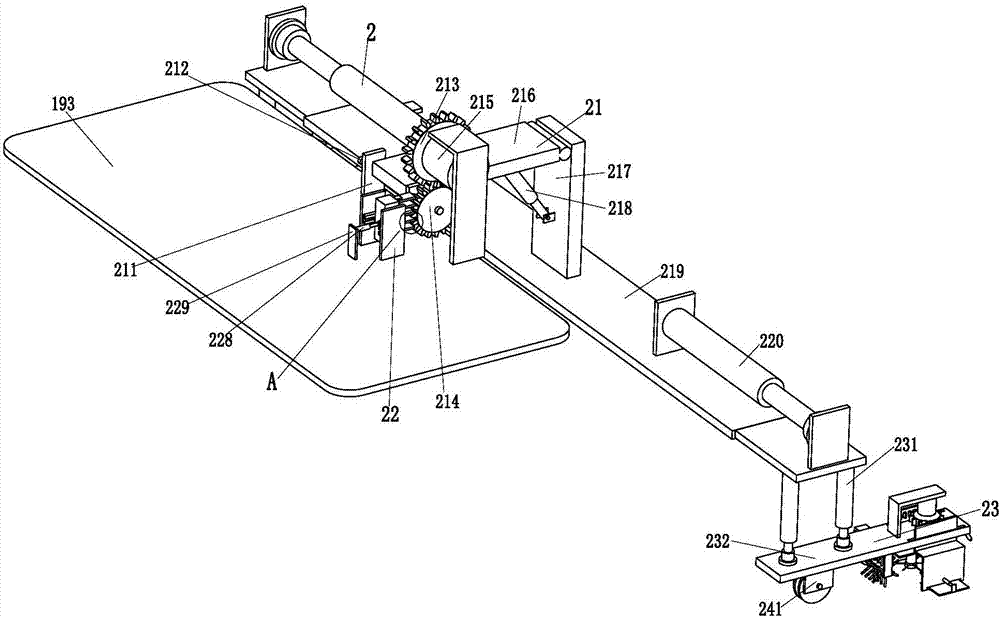

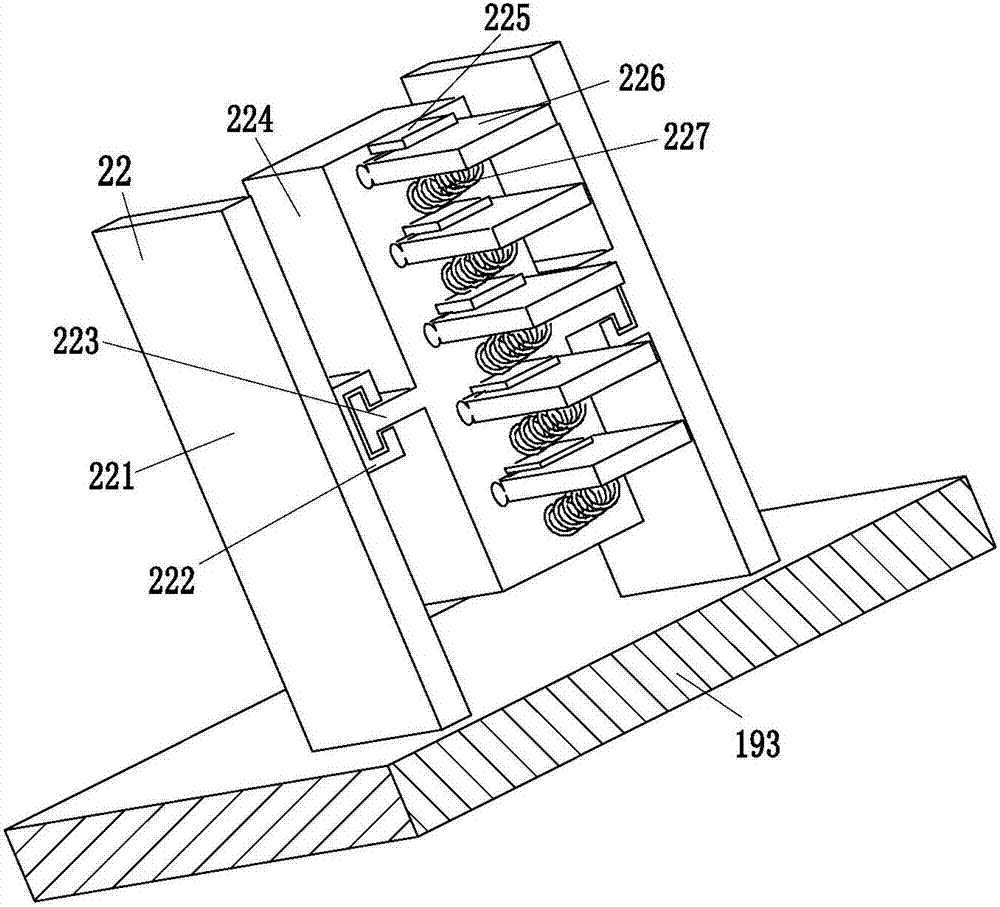

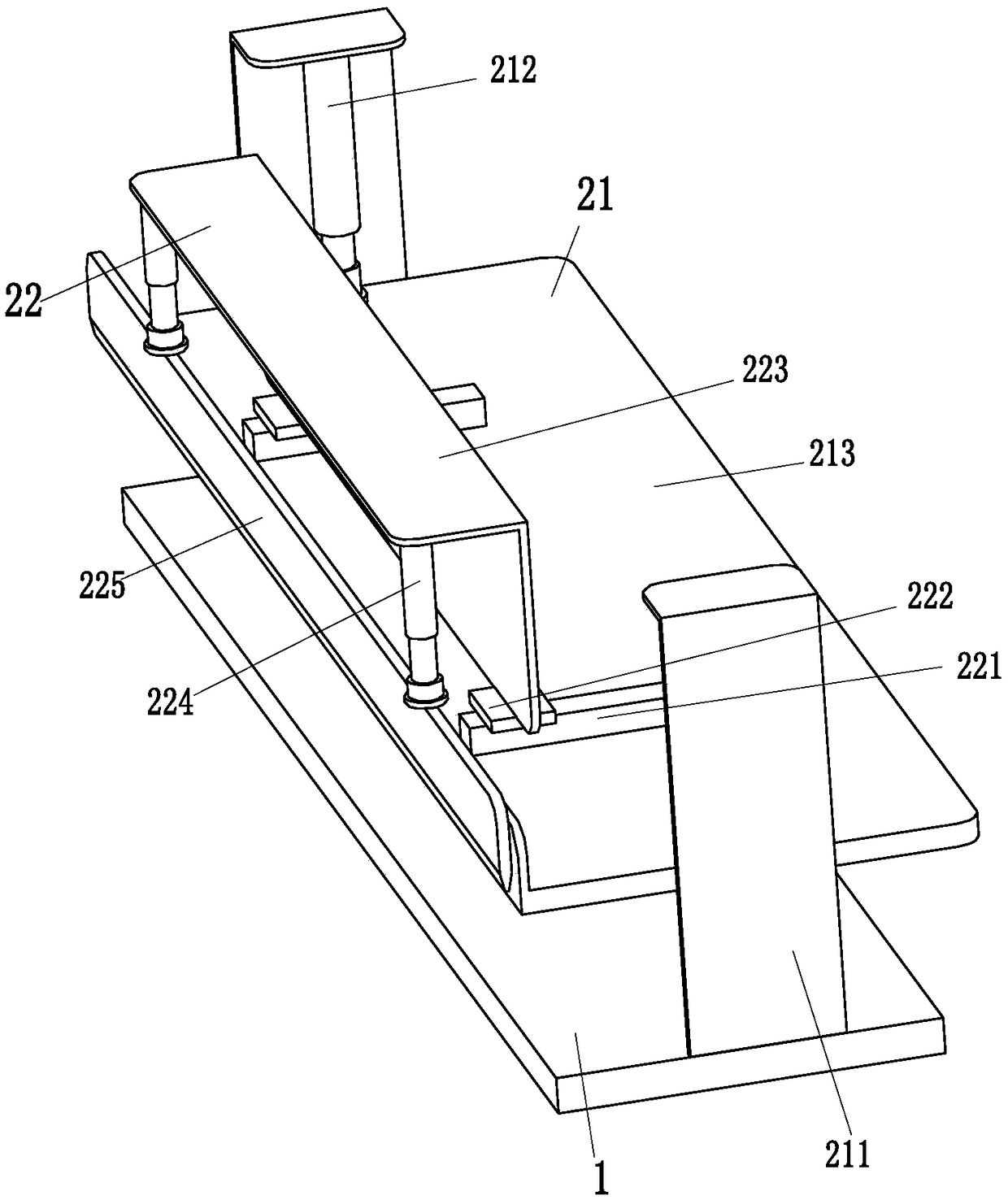

Machining equipment for communication cable

ActiveCN108515564AEasy to operateShort costEdge grinding machinesMetal working apparatusMachining processMotherboard

The invention relates to machining equipment for a communication cable. The machining equipment comprises a main plate, a cutting and deburring device, a middle limiting device and an end limiting device, the cutting and deburring device is installed at the front end of the main plate, the middle limiting device is installed in the middle of the main plate, and the end limiting device is installedat the back end of the main plate. According to the machining equipment for the communication cable, the problems that in the existing communication cable sleeve machining process, communication cable sleeves need to be manually limited and then cut, the process is tedious and complex, when the communication cable sleeves are limited, workers need to grab the communication cable sleeves with different structures in different modes, manual grabbing is single and unstable, when cutting is conducted, sleeve openings are likely to be uneven due to the fact that the positions are prone to deviating when manual cutting is conducted, burrs can be generated after cutting, the time consumed by the process is long, the labor intensity is high, and the efficiency is low can be solved, and the automatic limiting and cutting functions on the communication cable sleeves can be achieved.

Owner:以太龙精密机械江苏有限公司

New techn of utilizing crushed cotton stalk in cultivating edible fungi

The new technology of utilizing crushed cotton stalk in cultivating edible fungi includes crushing cotton stalk into filament, utilizing the filament as main material for the edible fungus culture medium, and spraying Gufengling bacterial liquid in proper amount. The edible fungus culture medium has the composition of cotton stalk 75-90 wt%, supplementary material 10-25 wt% and Gufengling bacterial liquid 0.01-0.05 wt%. The edible fungus culture medium of the present invention has the features of easy-to-obtain material, rich nutrients, low cost, high edible fungus yield, etc.

Owner:符振强

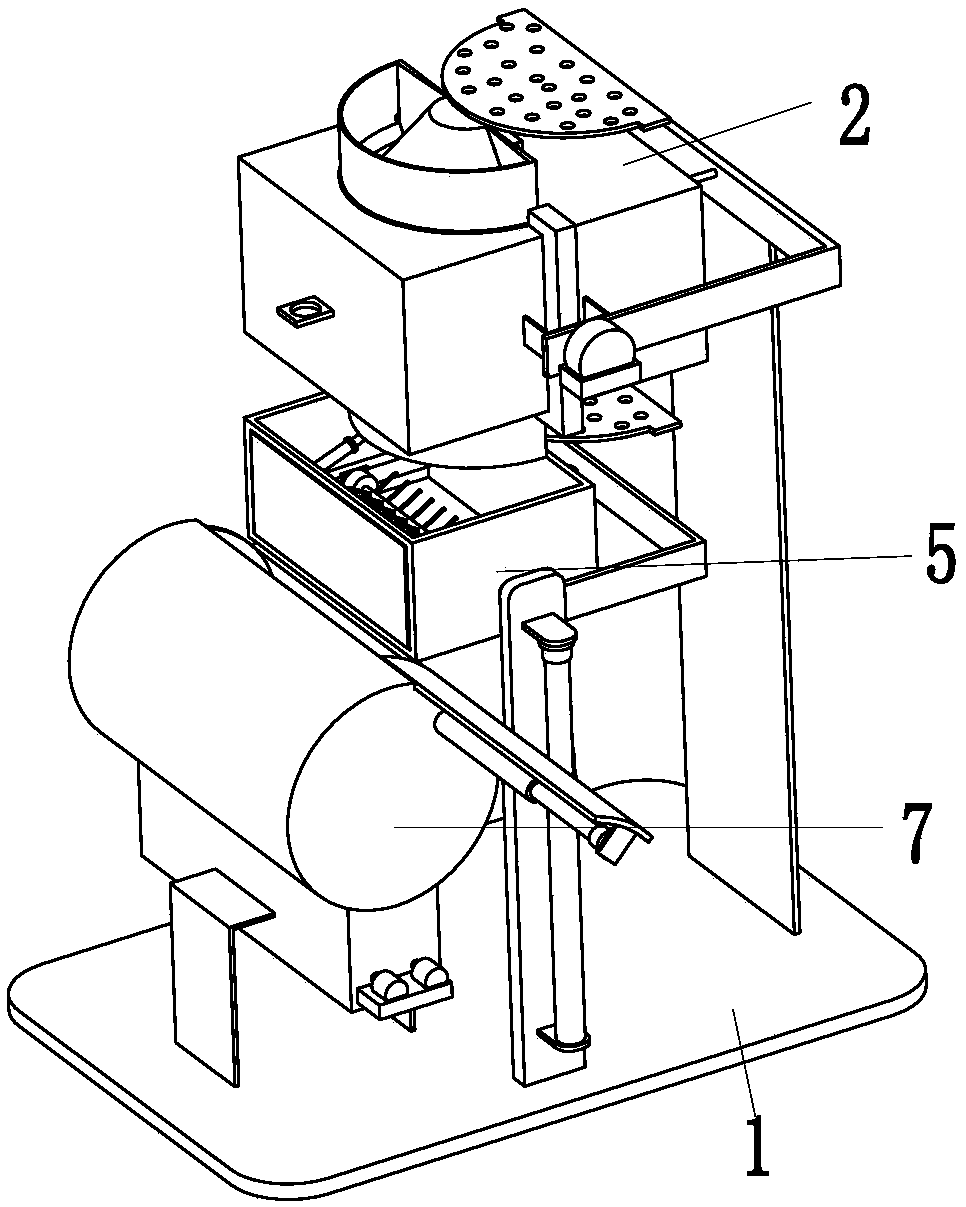

Medical equipment for hospital injector treatment

The invention relates to medical equipment for hospital injector treatment. The medical equipment comprises a main frame, a needle cylinder separation device, a needle cylinder crushing device and a syringe needle cutting device, wherein the needle cylinder separation device is arranged at the upper end of the main frame, and the upper end of the main frame is provided with the needle cylinder crushing device; the needle cylinder crushing device is located in the needle cylinder separation device, and the syringe needle cutting device is arranged at the rear end of the main frame. According tothe medical equipment, the problems are solved that when existing injectors are recycled, needle cylinders and syringe needles need to be manually separated, then the syringe needles are broken by pliers and the syringe cylinders are crushed; when the injectors are separated, the injectors need to be manually limited, and then the parts are separated, accordingly the manual separation efficiencyis low, piston parts in the syringe cylinders need to be taken out manually; the size of the syringe cylinders is small, manual separation is not easy, accordingly when the syringe cylinders are crushed, staff need to use tools to crush the cylinders, and part of fragments splash out in the crushing process; when the syringe needles are broken by the pliers, the syringe needles are thin and small,accordingly the syringe needles cannot be broken by the pliers manually.

Owner:绍兴集知汇信息科技有限公司

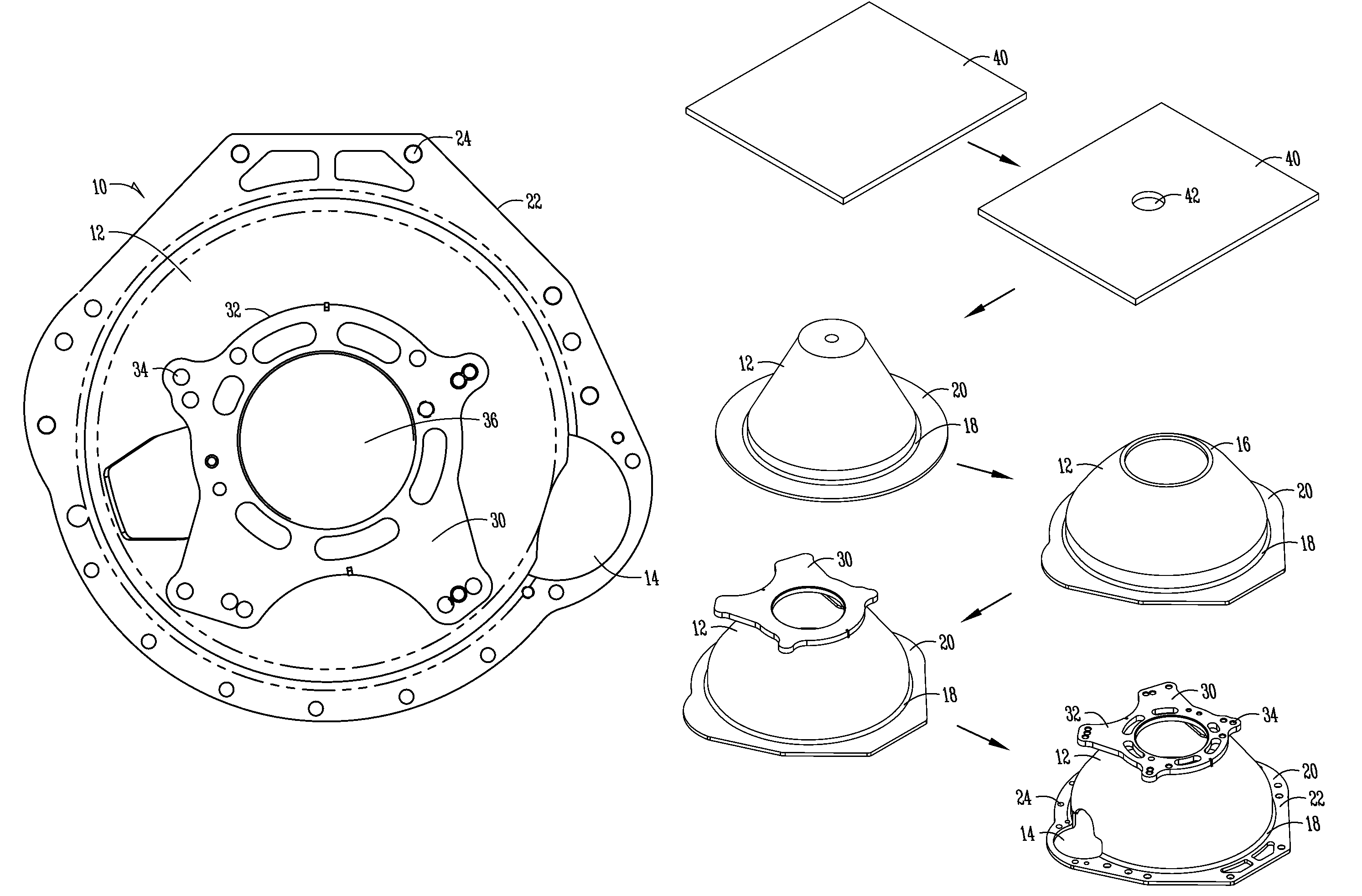

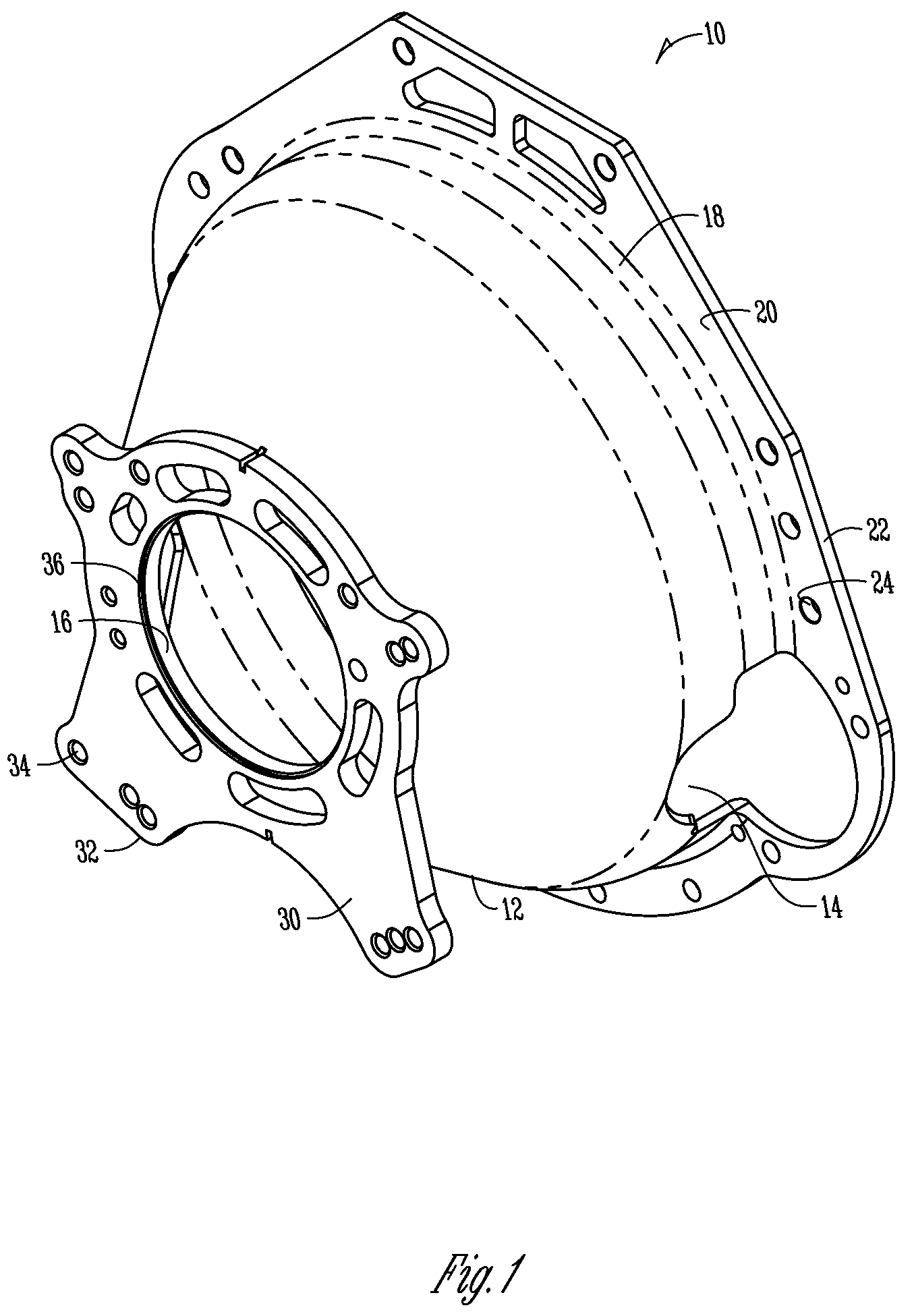

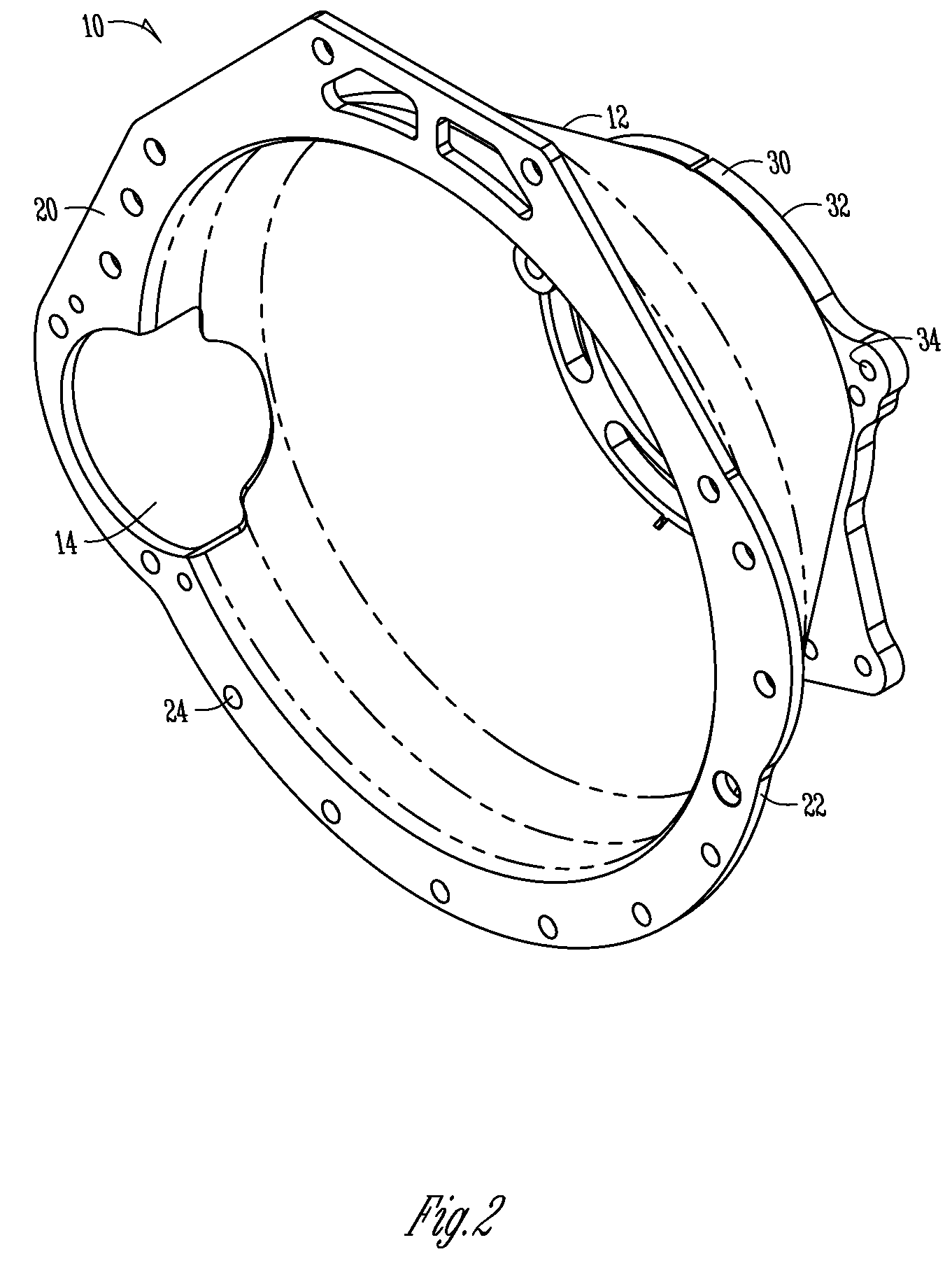

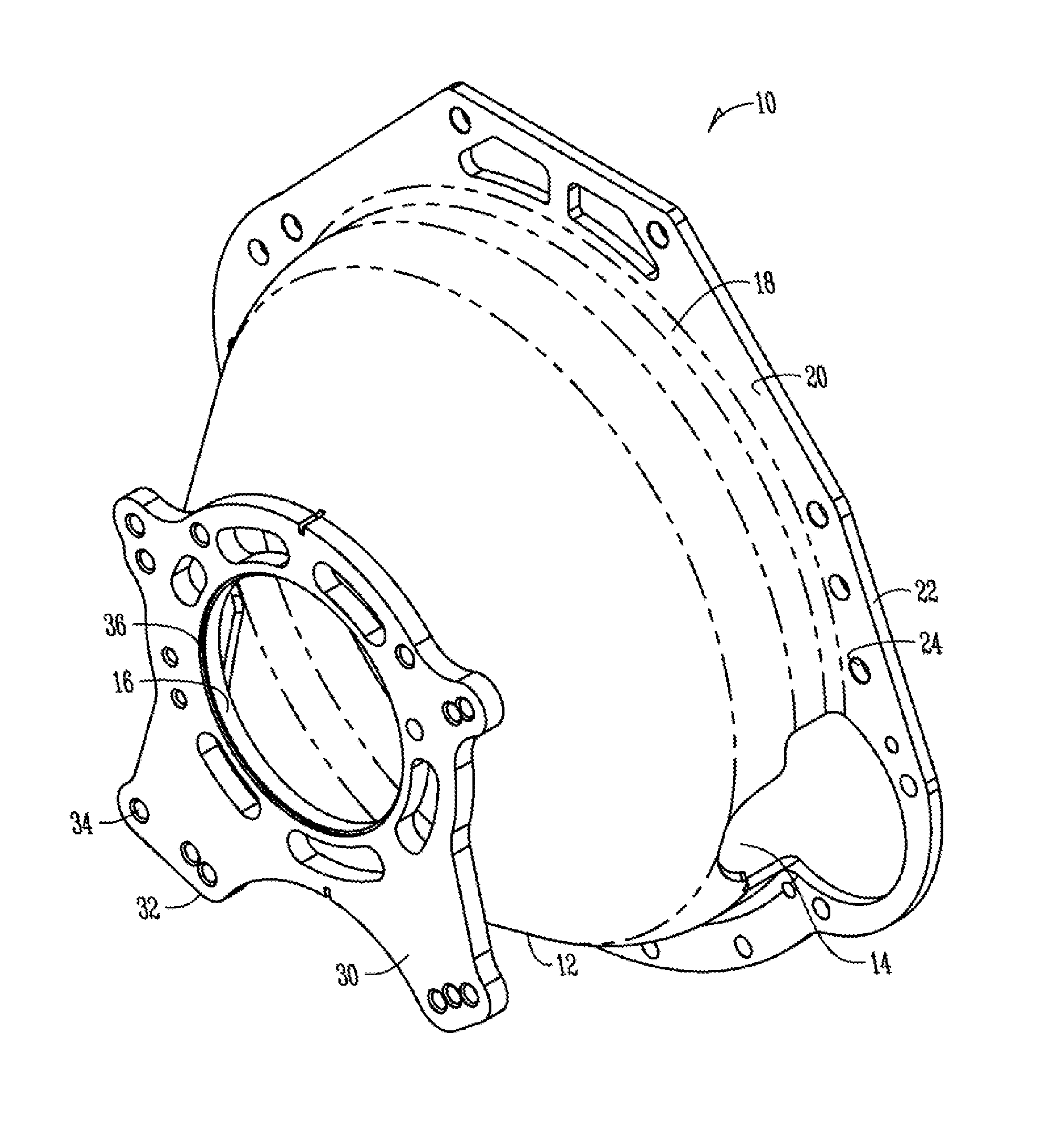

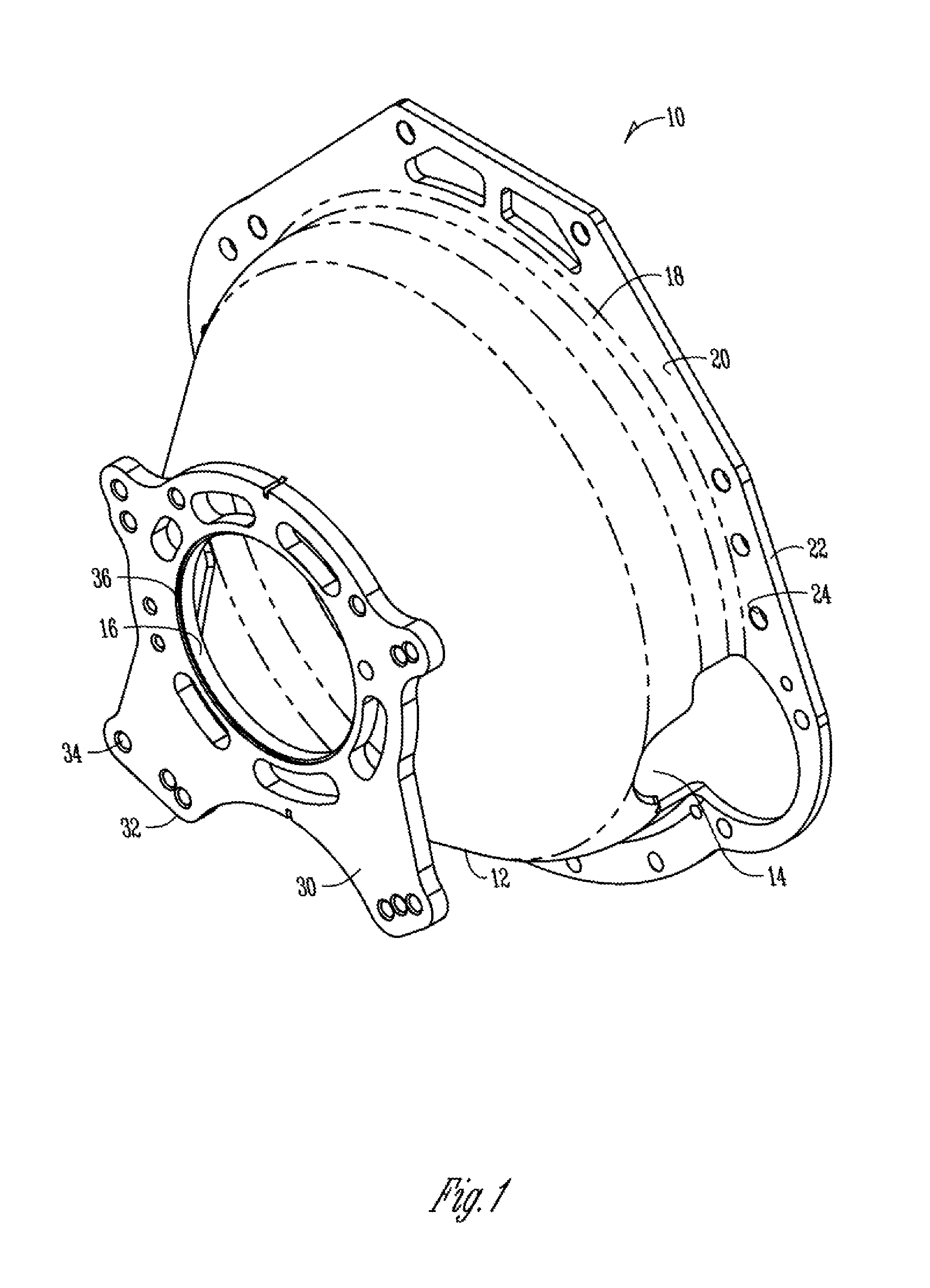

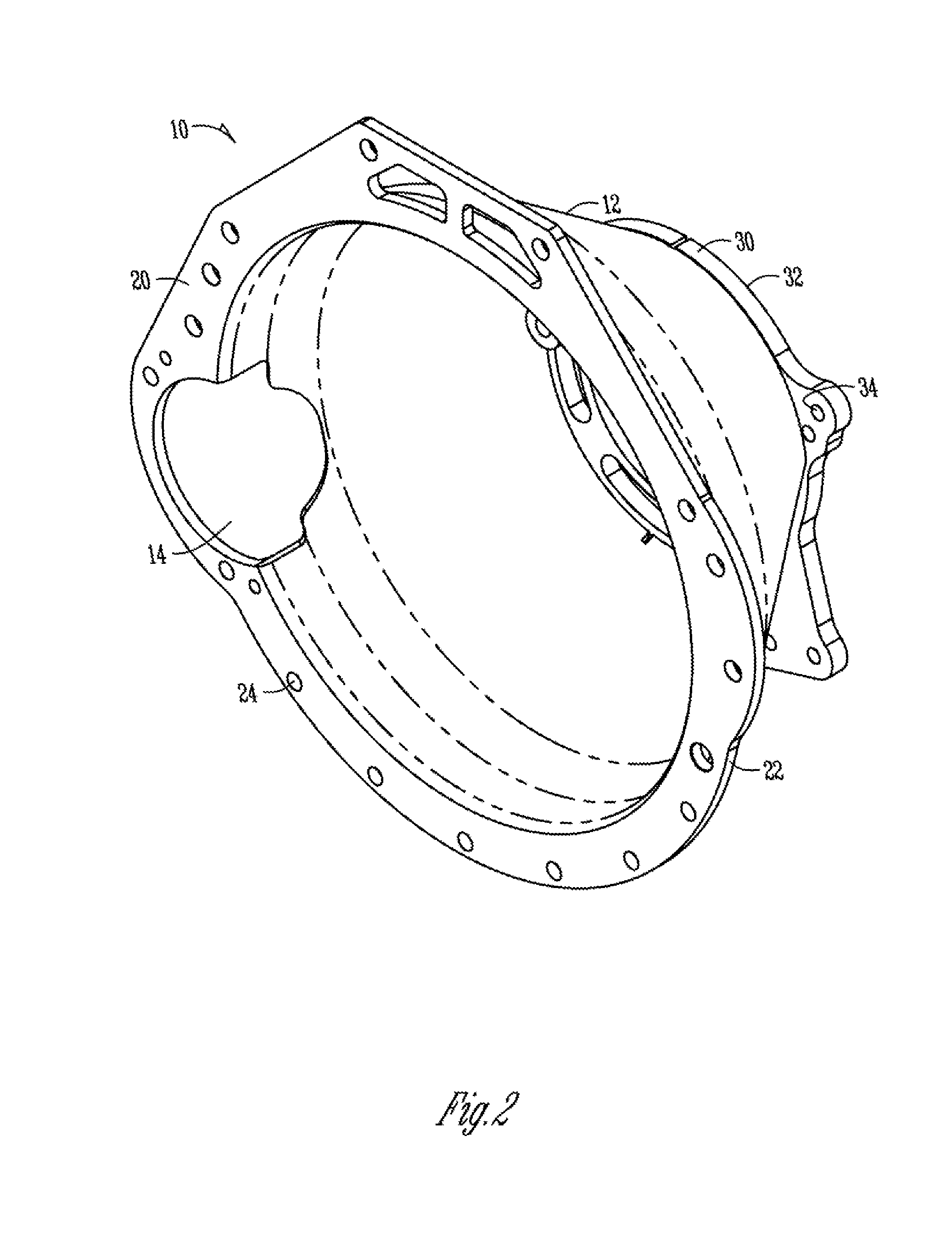

Method to provide a universal bellhousing between an engine and transmission of a vehicle

ActiveUS8561283B1Improve safety factorReduce residual stressCasingsGearboxesEngineeringAutomotive engine

A universal bell housing which may be adapted to a variety of automotive engine and transmission combinations and method of making the same is disclosed. The bell housing is made by spin forming a sheet of steel and welding a transmission plate onto the cone. The cone and transmission plate are indexed to mount to a specified engine-transmission combination.

Owner:ACCEL PERFORMANCE GRP

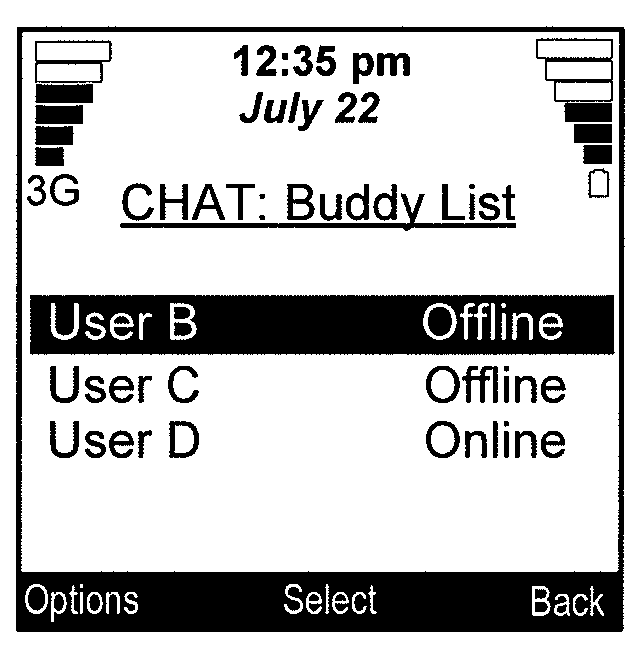

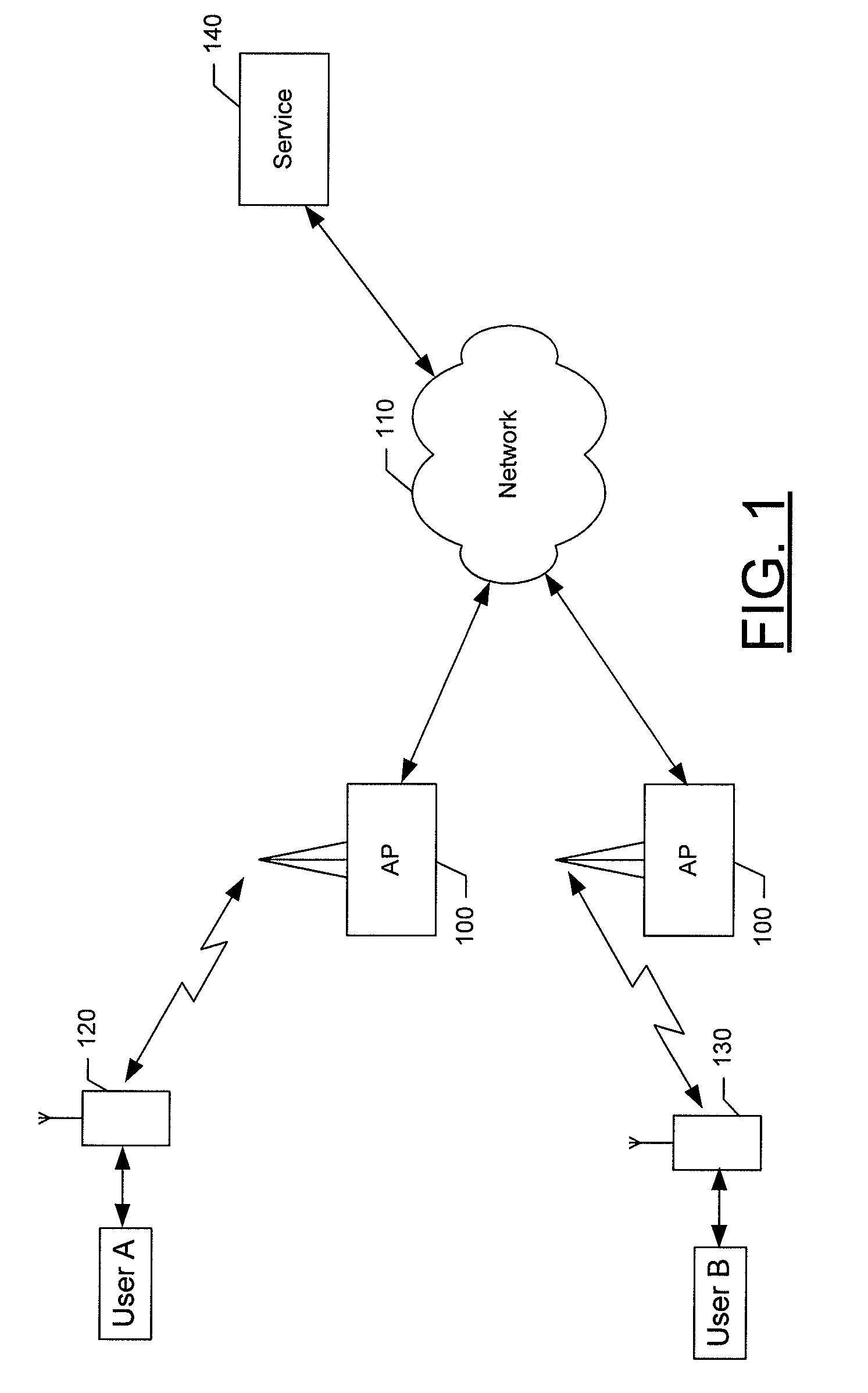

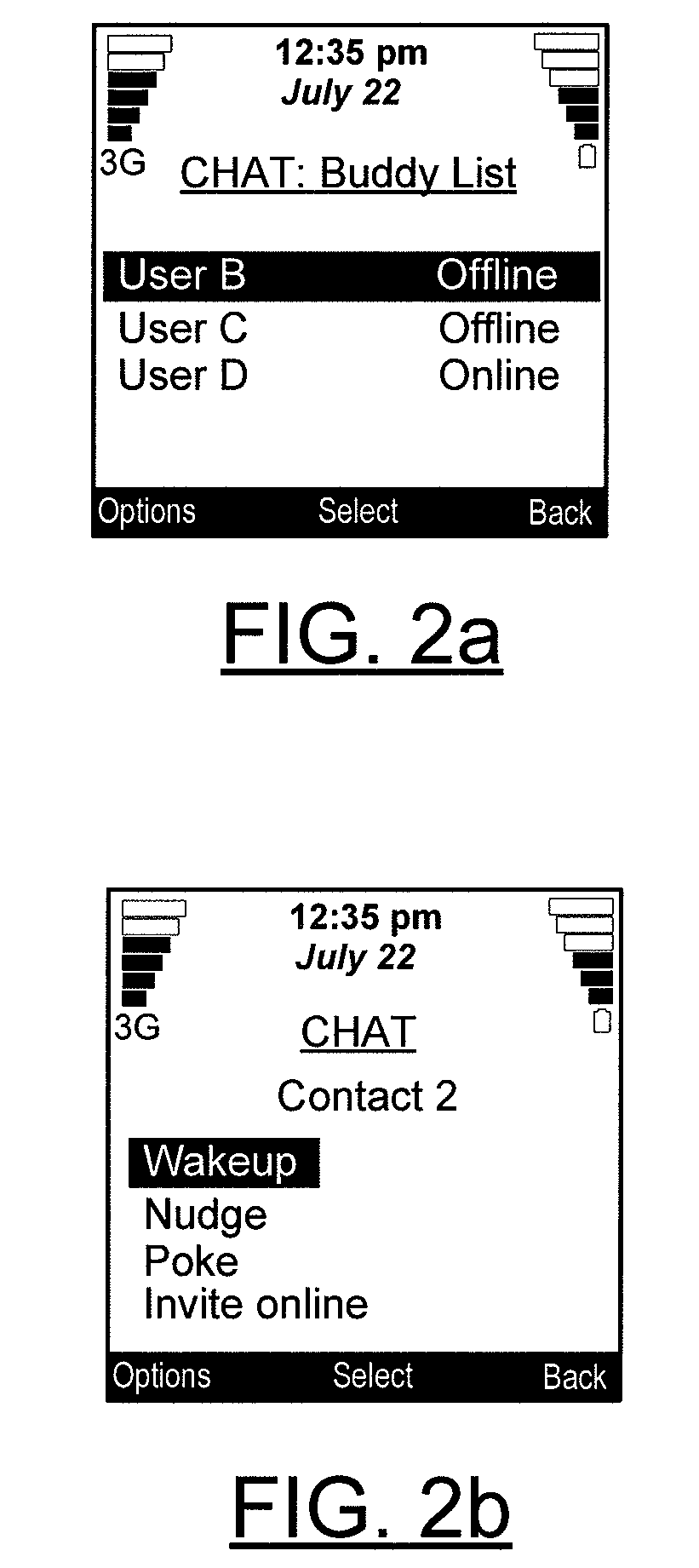

Method, Apparatus, and Computer Program Product for Application-Based Communications

ActiveUS20100144377A1Limit and eliminates involvementAvoid excessive trafficSpecial service for subscribersMessaging/mailboxes/announcementsComputer programRegister data

An apparatus for application-based communications may include a processor. The processor may be configured to receive a message from a remote device at a receiving device. The message may have been generated based on application registration data associated with the receiving device. The processor may also be configured to execute an application based on content included in the message. Associated methods and computer program products may also be provided.

Owner:NOKIA TECHNOLOGLES OY

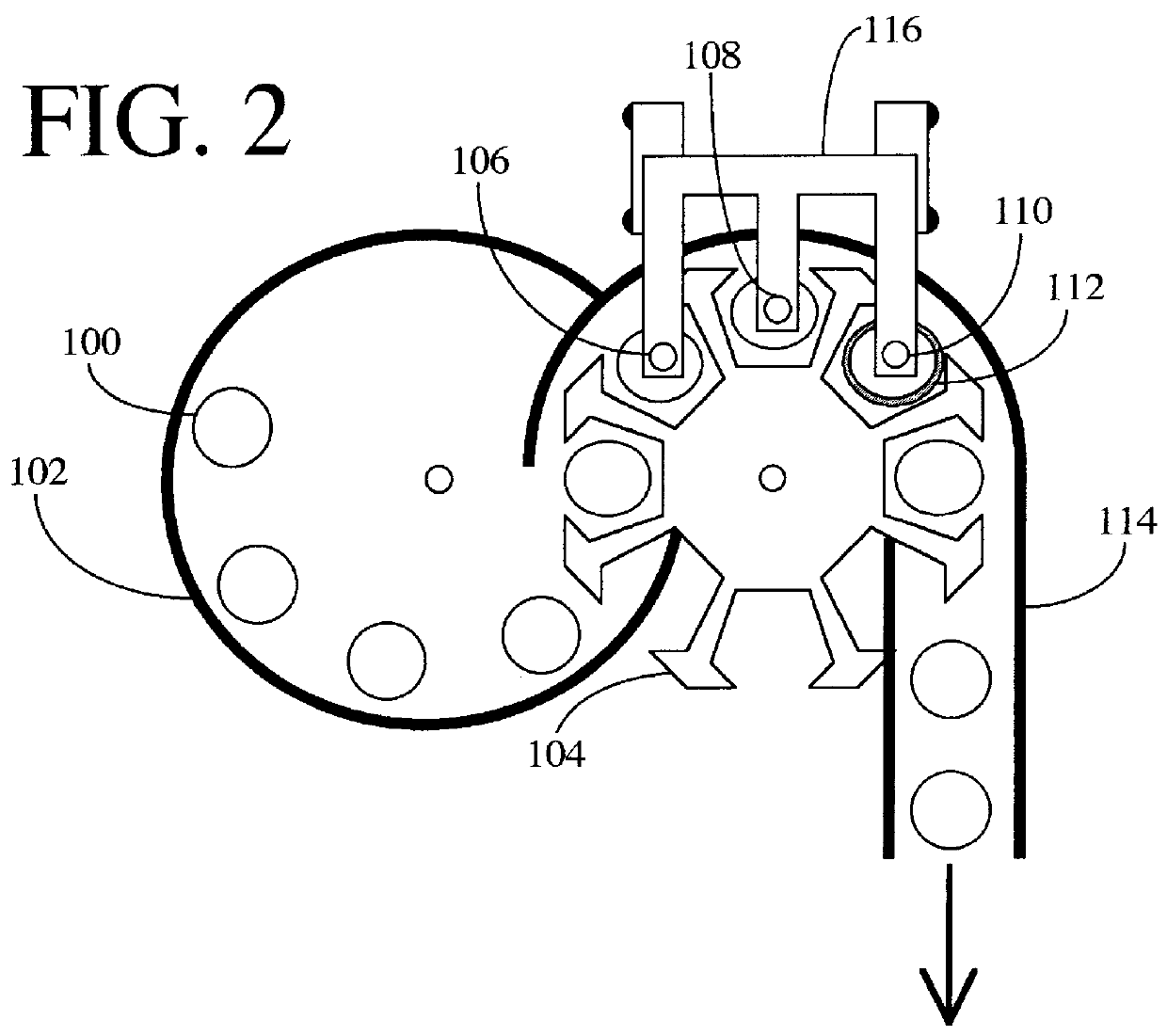

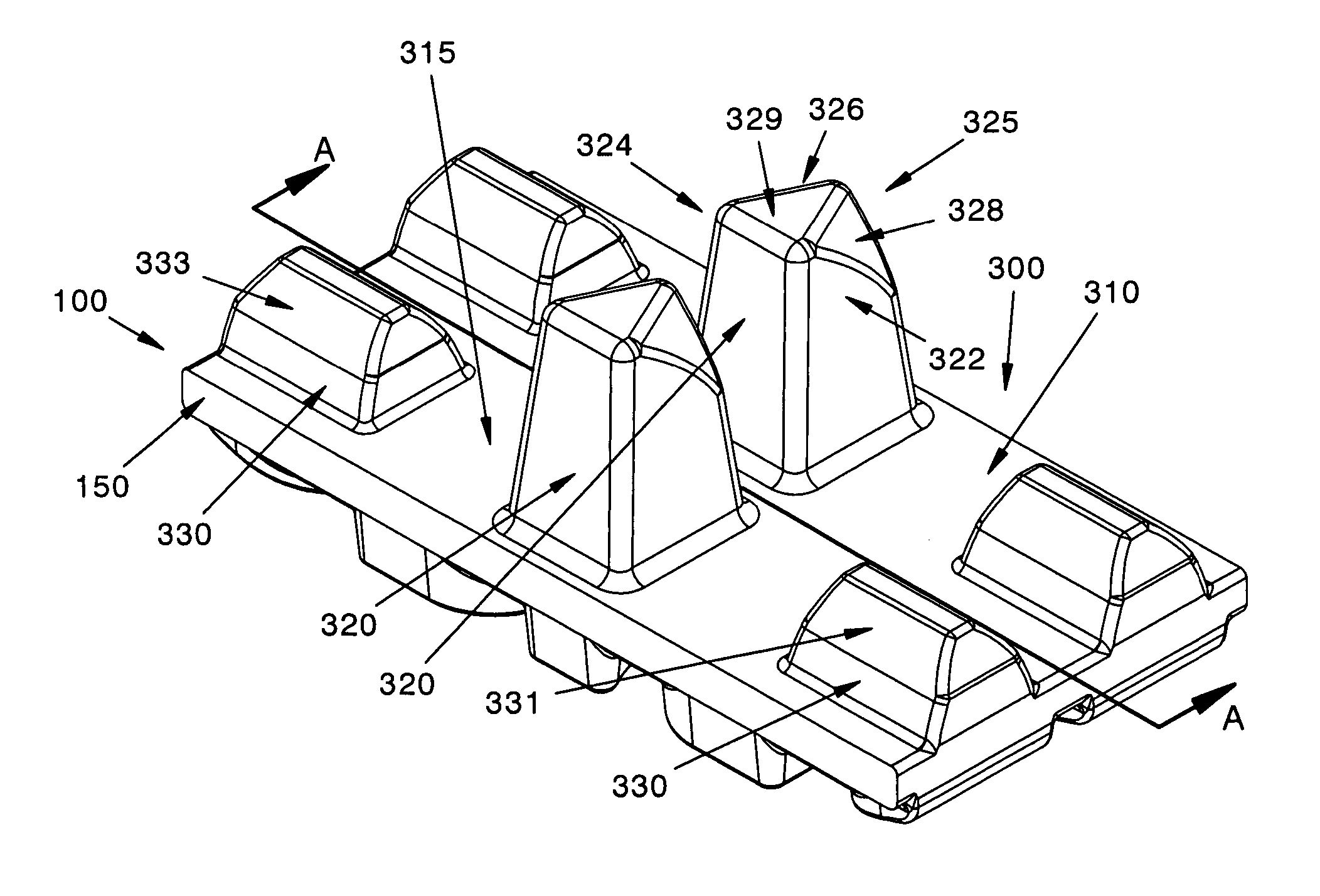

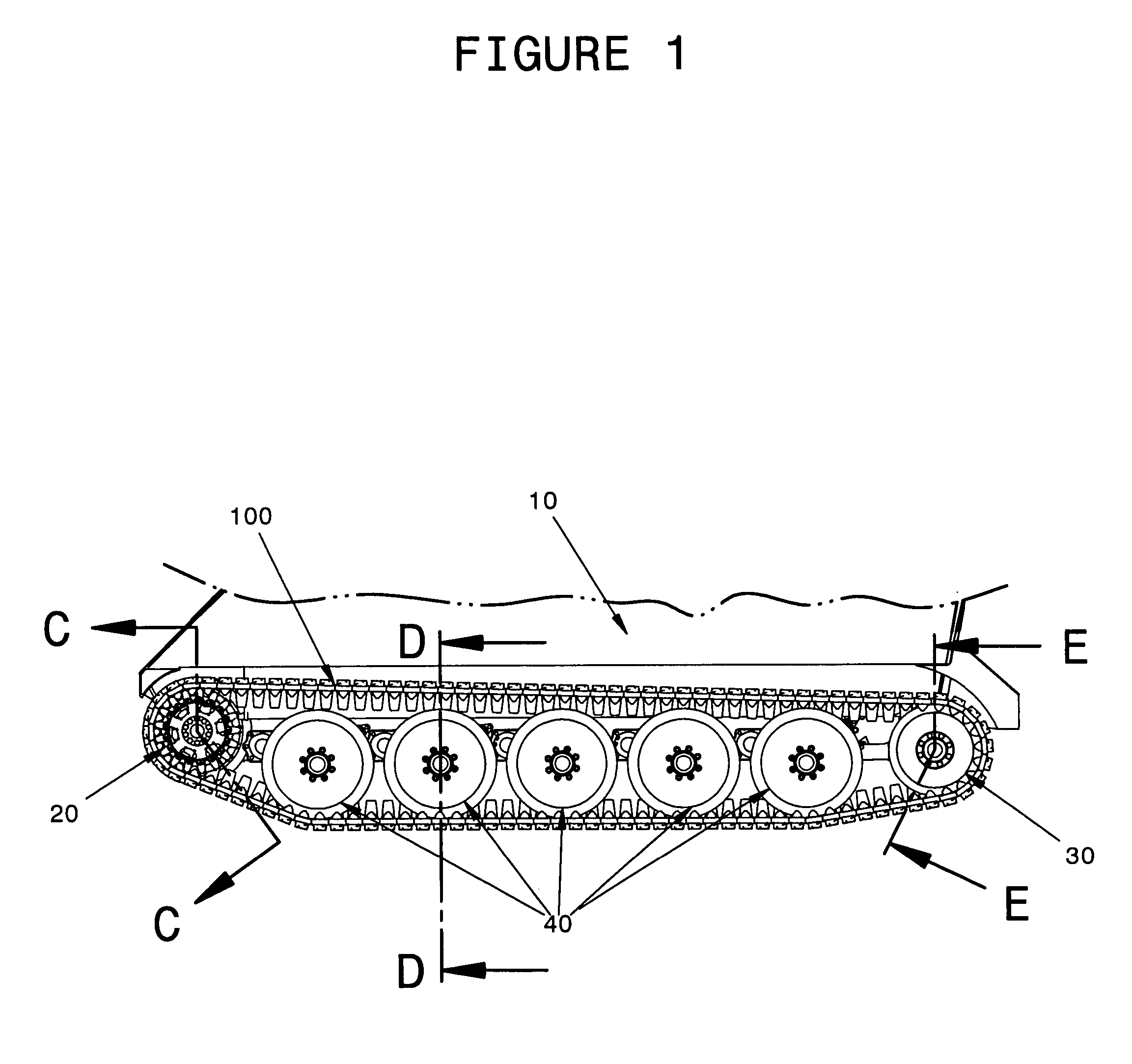

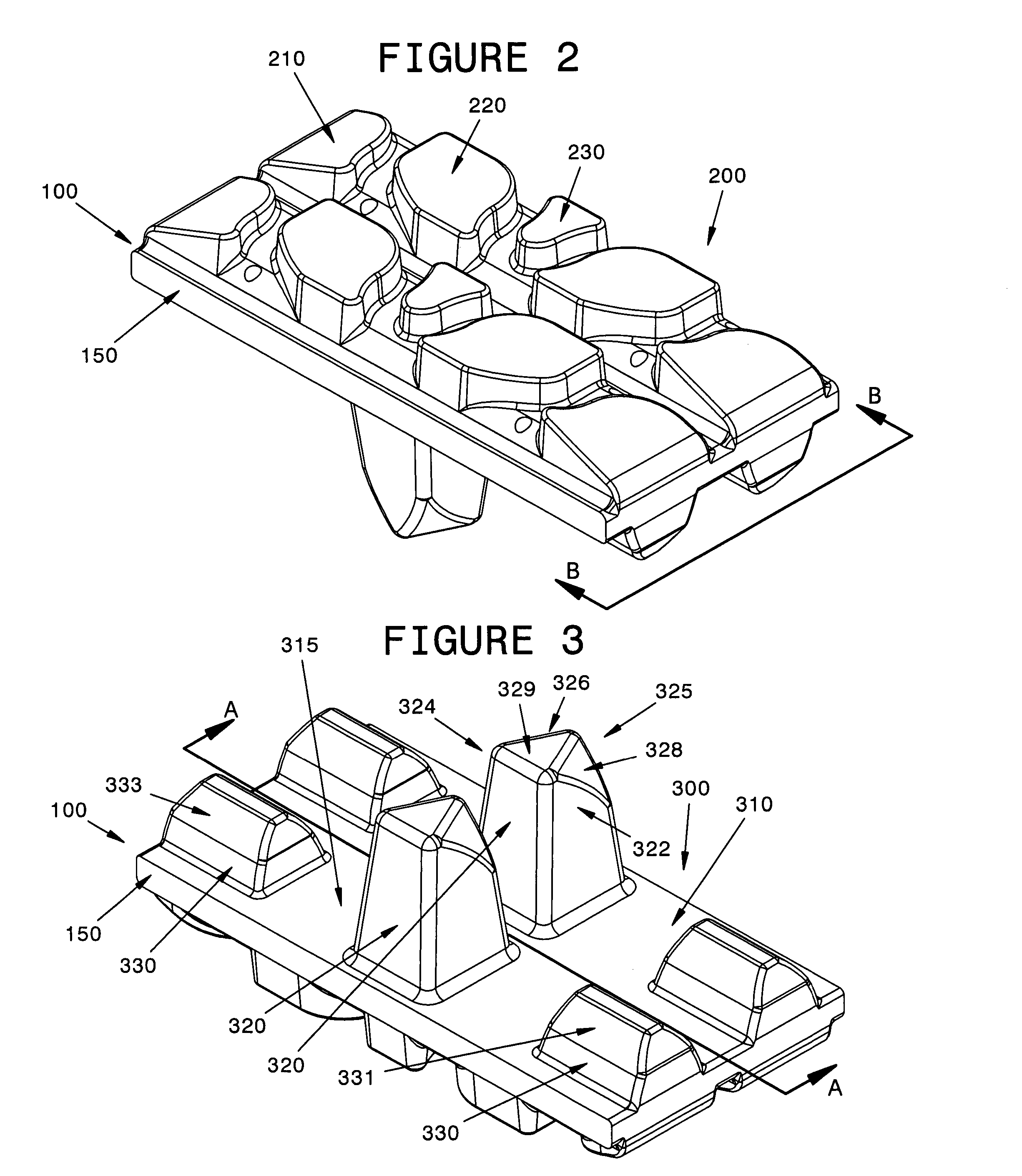

Endless track for high speed multi-terrain vehicles

This invention relates to endless tracks and systems used to propel track laying vehicles [i.e., vehicles which use endless tracks rather than tires to contact the terrain over which they are driven, e.g., tractors, tanks, bulldozers, etc.] and, more particularly, to an improved rubber track design and system allowing the endless track to be driven more efficiently at highway speeds. The track is made from a polymer adapted to travel over a drive sprocket, a plurality of guide wheels and a tensioning wheel, the track having a first exterior ground engaging surface and a second interior drive sprocket engaging surface, the track comprising: a carcass portion in which reinforcements are embedded into the polymer; a plurality of tread lugs disposed on the first engaging surface; a plurality of drive lugs disposed on the second engaging surface and a plurality of guide horns disposed on the second engaging surface.

Owner:SOUCY INT

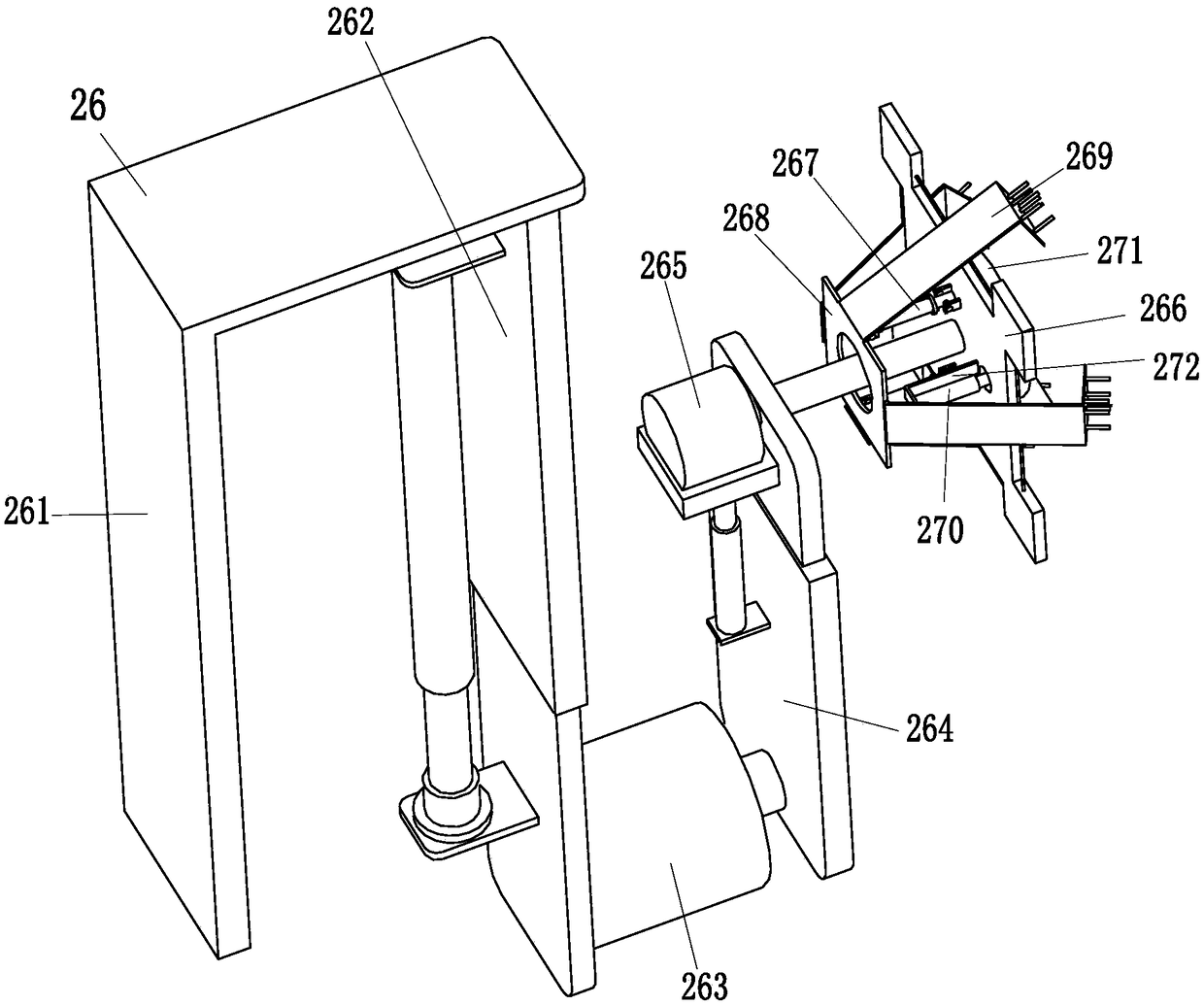

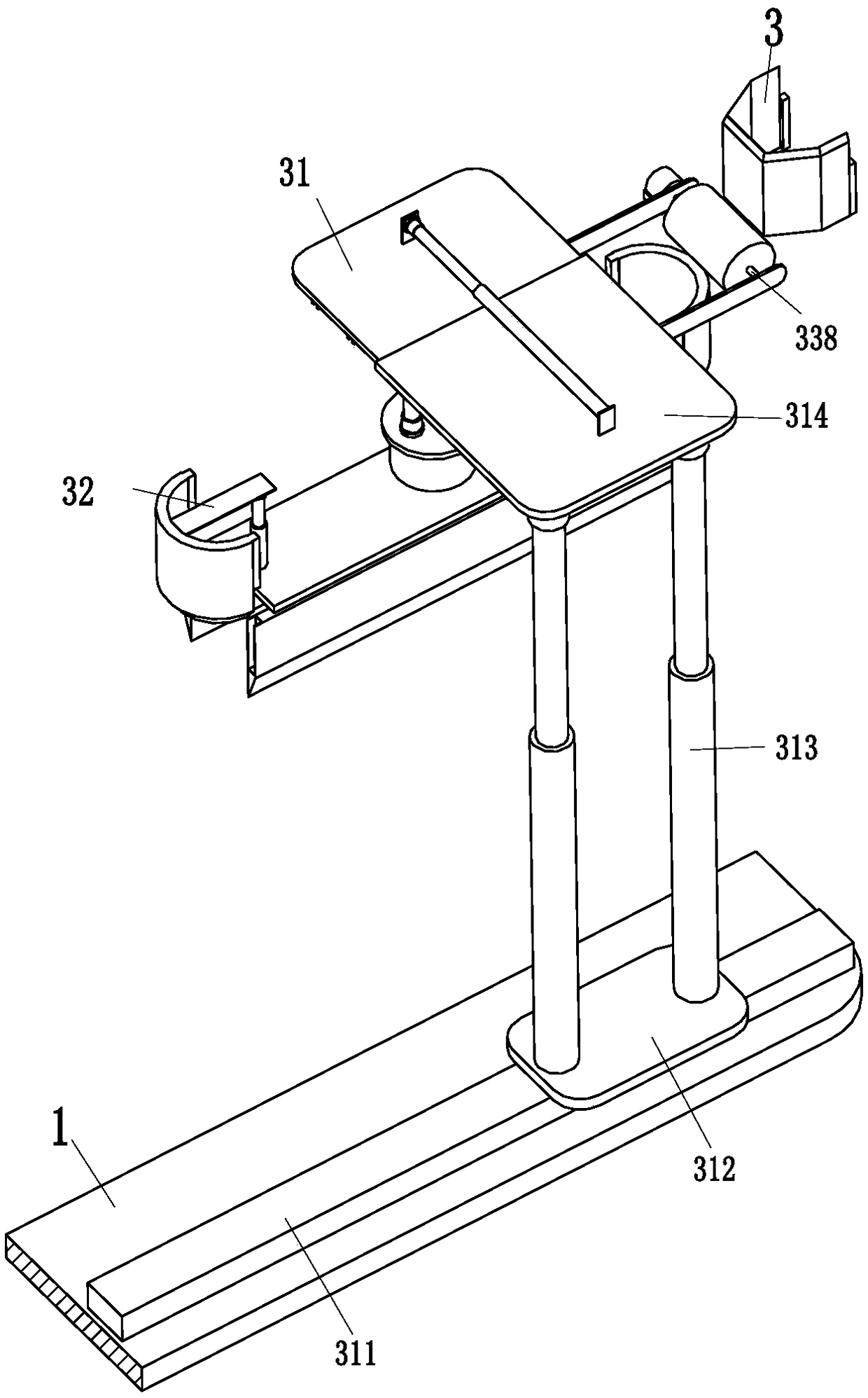

Architectural decoration device capable of automatically caulking indoor ceramic tile gaps

The invention relates to an architectural decoration device capable of automatically caulking indoor ceramic tile gaps. The architectural decoration device comprises a facing device, a gluing device,and an edge pressing device; the front end of the gluing device is provided with the facing device, and the rear end of the gluing device is installed at the front end of the edge pressing device. Thearchitectural decoration device capable of automatically caulking the indoor ceramic tile gaps solves the problems that when seams are traditionally ornamented, manual work is required to paste masking papers, and personnel need to inject glue and press edges by tools; when the masking papers are pasted, the personnel need to paste the masking papers manually, edges are pasted raggedly, and people may cut their hands during cutting the masking papers by the tools; during working, the papers may be folded, and the personnel need to straighten the folded masking papers to work; during gluing bya seam beauty agent, the personnel need to put a seam beauty agent in a seam ornamenting gun and then glue the gaps, and the personnel may cut the hands due to improper operation during cutting a rubber nozzle laterally; and during edge pressing, the personnel need to vigorously press the gaps after gluing by an edge pressing ball. The architectural decoration device capable of automatically caulking indoor the ceramic tile gaps can achieves the functions of automatic pasting paper, gluing, and edge pressing for ceramic tile gaps.

Owner:吴凡

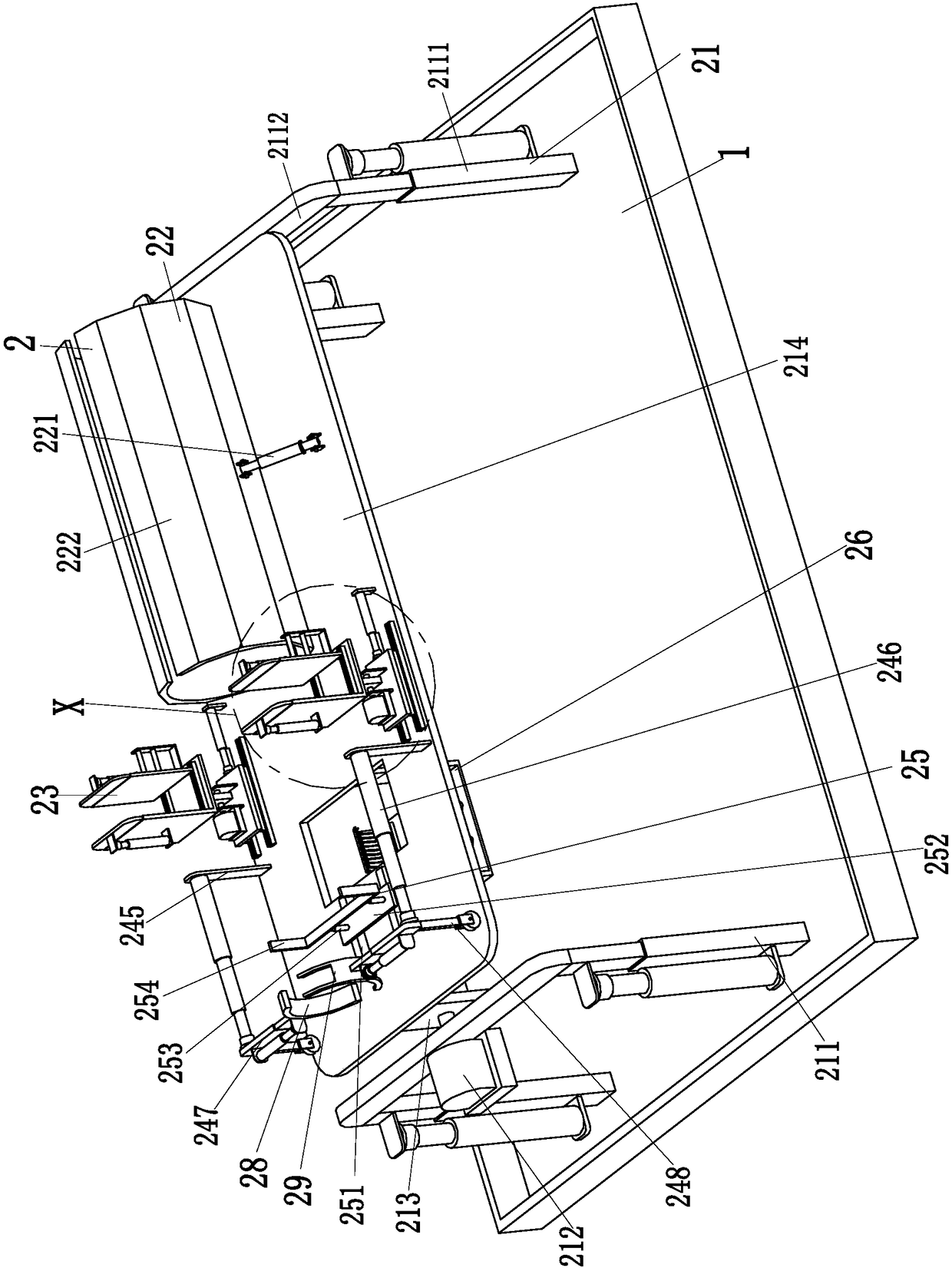

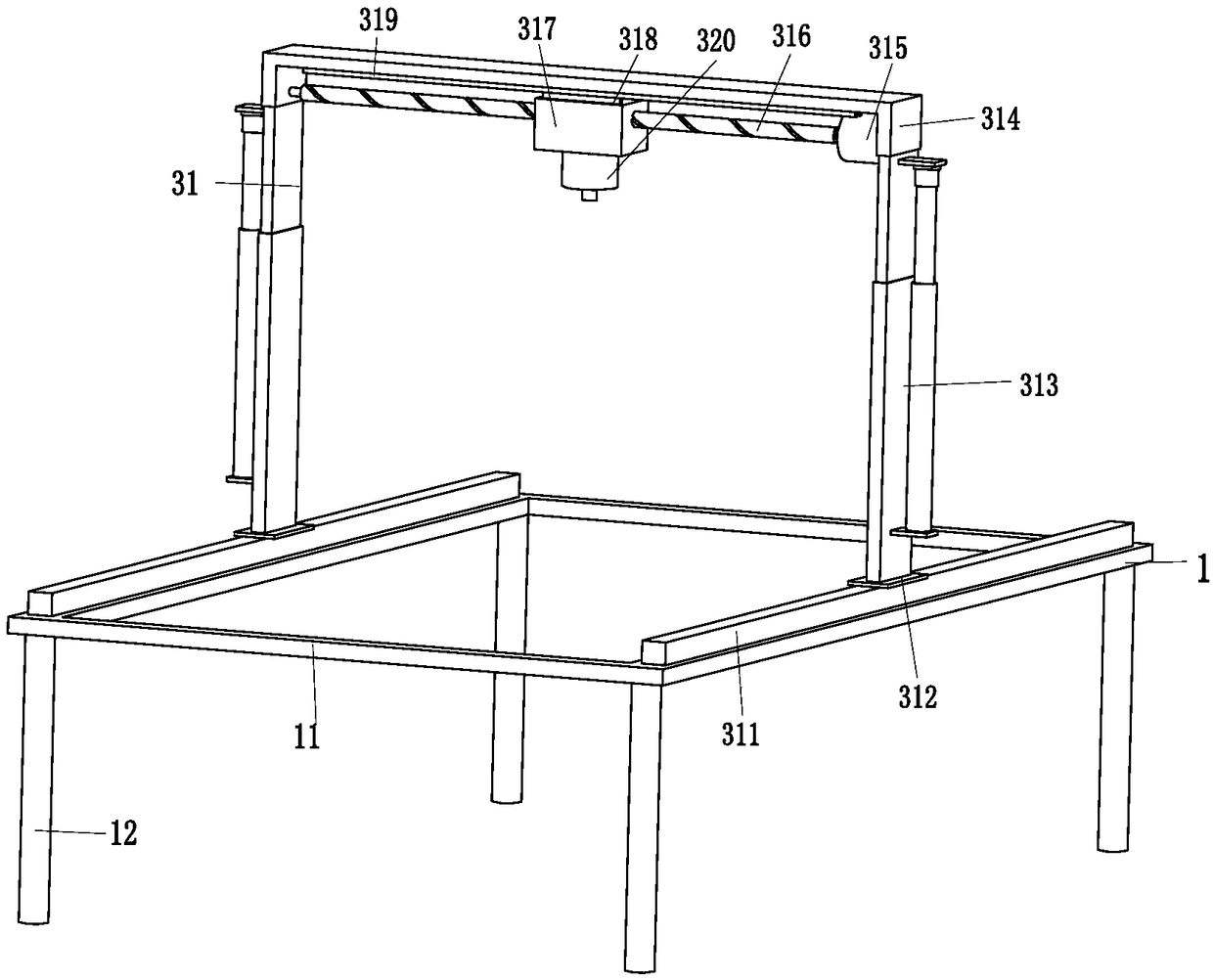

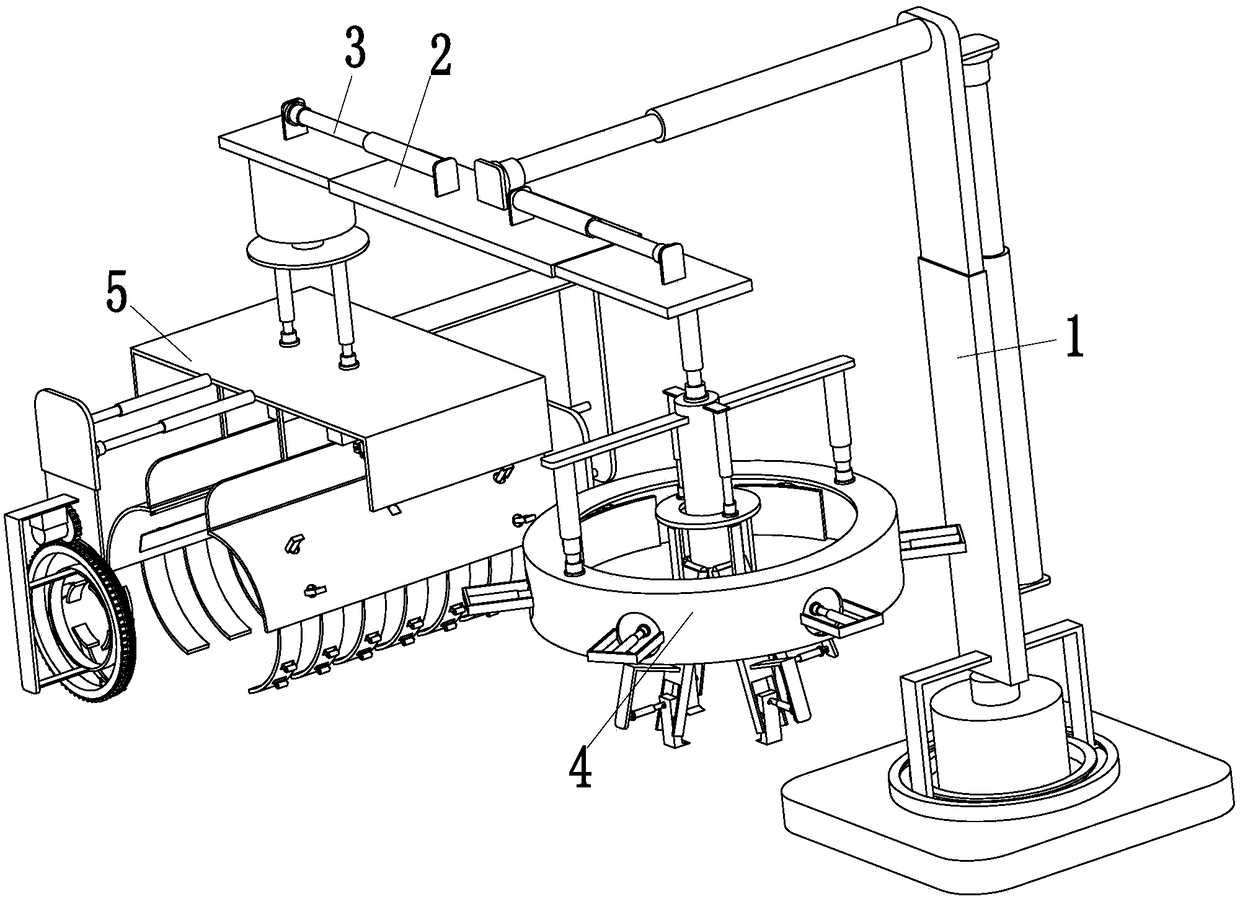

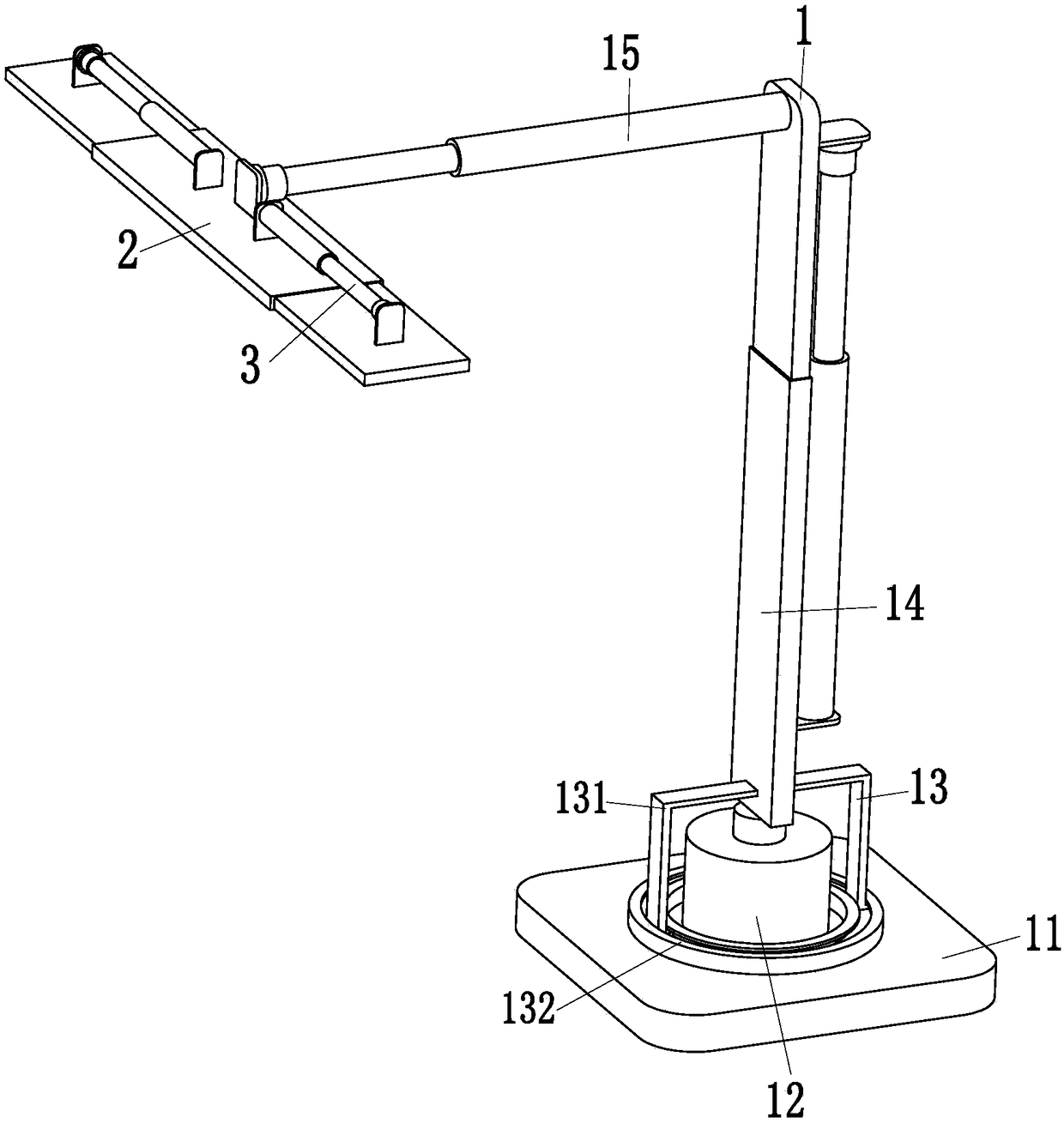

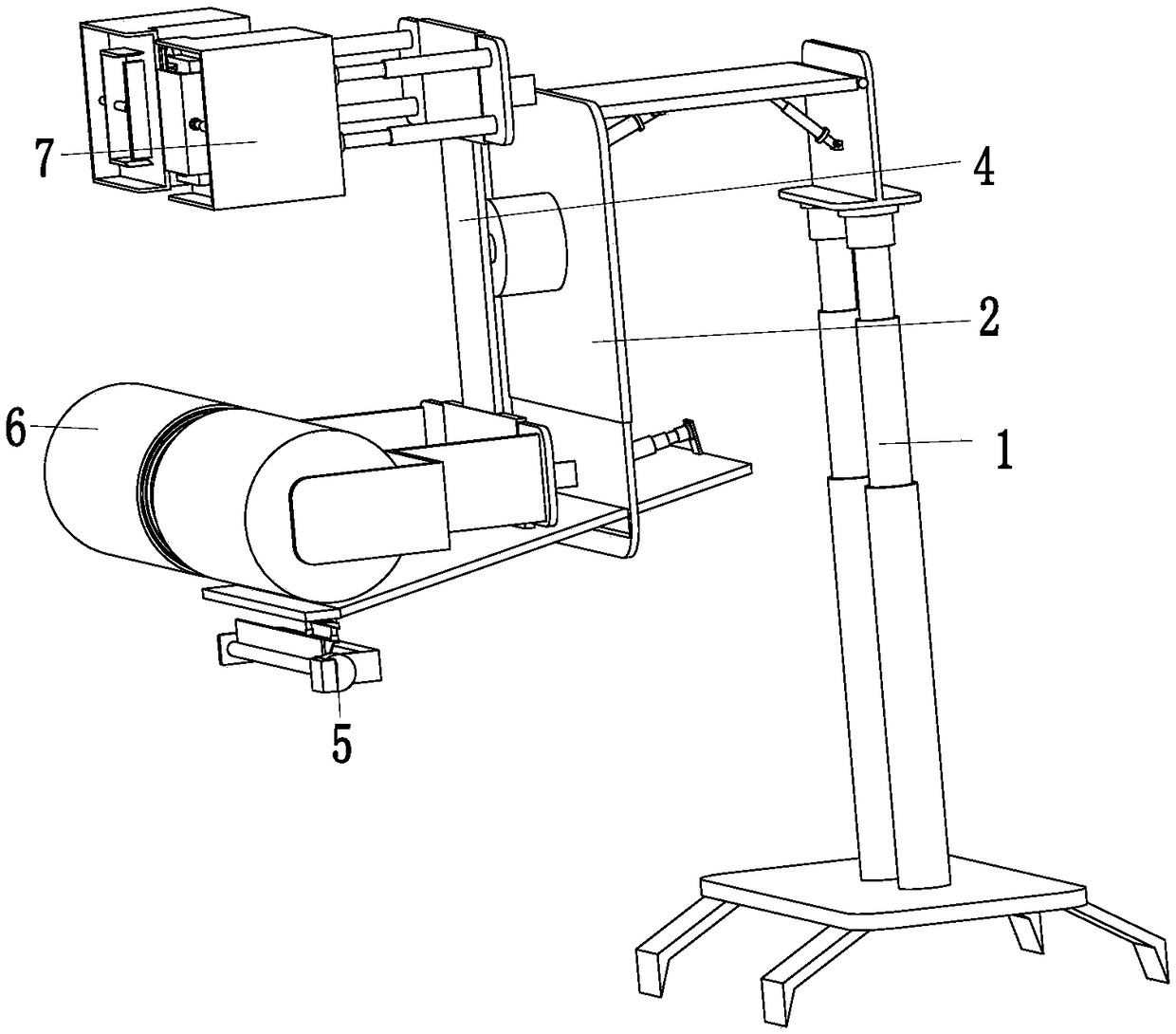

Aluminum-plastic panel coating processing system and aluminum-plastic panel coating technology

ActiveCN108816638AEasy to operateShort costLiquid surface applicatorsSpraying apparatusAluminiumEngineering

The invention relates to an aluminum-plastic panel coating processing system and an aluminum-plastic panel coating technology. The system comprises a support, a hold-down gear, a coating device and two discharging devices. The coating device is installed at the upper end of the support; the hold-down gear is arranged below the coating device; the hold-down gear is installed on the support; and left and right ends of the support are provided with the two discharging devices. In existing coating process, aluminium strips in coils need to be firstly fixed and then manually coated, and the processis tedious and complicated; existing equipment cannot stably fix the aluminium strips in coils and the aluminium strips in coils are not easy to stay in a tighten state for a long time; it is required to coat with various coatings of required thickness during coating; manual coating is not uniform, and residual coatings cannot be recovered timely; concave positions of a coating cannot be filled or leveled up timely; time consumption is high; labor intensity is high; and efficiency is low. By the use of the system and the technology of the invention, the above problems can be solved, and the function of automatically clamping and coating the aluminium strips in coils can be achieved.

Owner:力同铝业(山东)有限公司

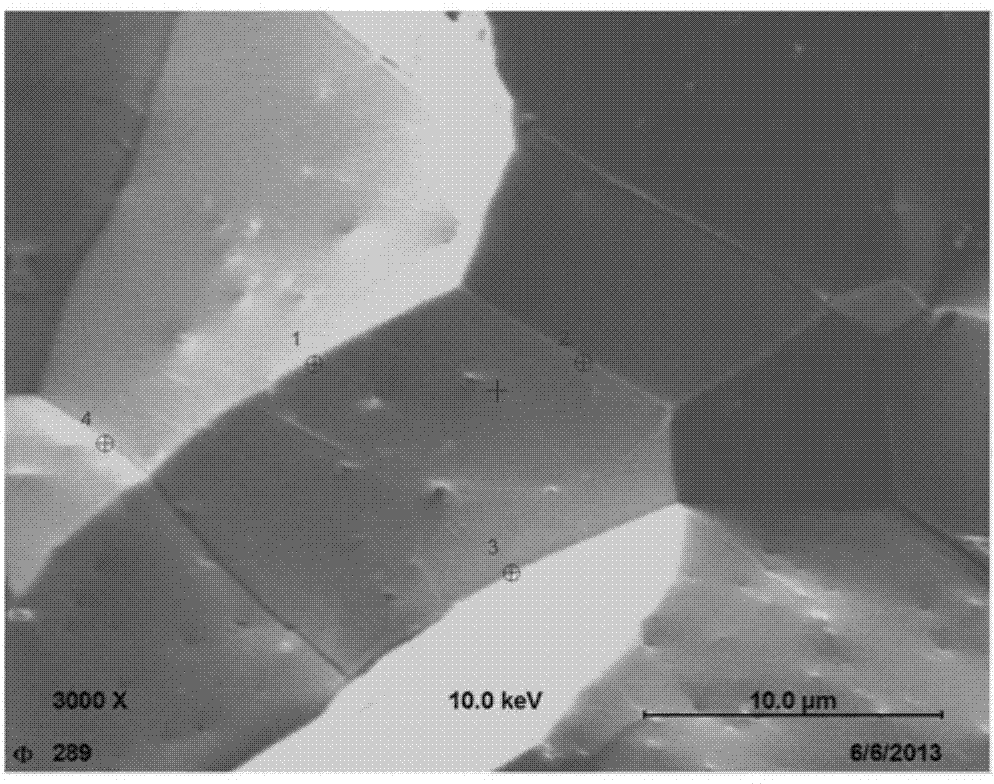

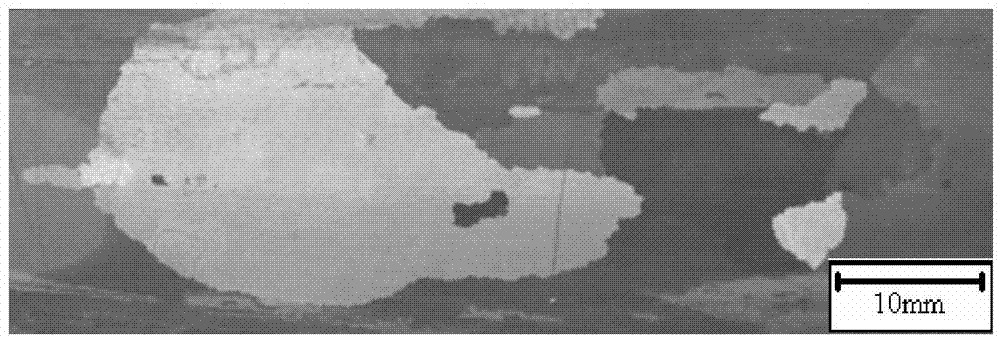

High-magnetic-induction oriented silicon steel prepared through thin slab continuous casting and rolling and preparation method thereof

ActiveCN103774042ALow heating temperatureAvoiding Insufficient Inhibition ProblemsChemical compositionThin slab

The invention provides high-magnetic-induction oriented silicon steel prepared through thin slab continuous casting and rolling and a preparation method thereof. The oriented silicon steel comprises the following chemical components by mass percent: 0.035-0.055% of C, 2.9-3.3% of Si, 0.09-0.15% of Mn, 0.1-0.2% of Cu, not more than 0.005% of S, 0.02-0.04% of AlS, 0.009-0.013% of N and 0.1-0.2% of Sn. The oriented silicon steel is prepared by the following steps: thin slab continuous casting, heating in a soaking pit, hot continuous rolling, normalizing, primary cold rolling, decarburizing annealing and high temperature annealing, wherein the heating temperature of the soaking pit is 1150-1180 DEG C and the soaking time is 30-60 minutes. The oriented silicon steel uses AlN as a main inhibitor and Cu2S as an auxiliary inhibitor, and meanwhile, the trace element Sn is added to the chemical components to avoid the problem of inadequate inhibiting capacities of the inhibitors caused by low temperature heating and serves as an auxiliary inhibitor thanks to the segregation capacity of Sn on the grain boundary. Therefore, the high-magnetic-induction oriented silicon steel can be produced by adopting the thin slab low temperature short-time soaking process, so that the casting blank heating temperature is effectively reduced and the soaking time is reduced. The preparation method has the advantages of short flow, low cost, low energy consumption, high production efficiency and the like.

Owner:CENT IRON & STEEL RES INST +1

Battery machining robot

ActiveCN108466273ANo manual operationEasy to operatePrimary cell manufactureAssembling battery machinesButton batteryBlurred vision

The invention relates to a battery machining robot. The battery machining robot comprises an adjusting device, a two-way telescopic plate, two symmetric air cylinders, a button battery clamping deviceand a cylindrical battery clamping device; the front end of the adjusting device is installed at the upper end of the two-way telescopic plate, the two symmetric air cylinders are installed in the middle of the two-way telescopic plate, and the top ends of the symmetrical air cylinders are installed at the outer ends of the two-way telescopic plate through flanges; and the button battery clampingdevice is installed on the right side of the lower end of the two-way telescopic plate, and the cylindrical battery clamping device is installed on the left side of the lower end of the two-way telescopic plate. According to the battery machining robot, the problems that in the present process of producing batteries, people need to grab the different types of batteries, when the button battery isgrabbed, due to the fact that the button battery is relatively small, jumping and flying of the button battery are prone to occurrence during grabbing by people, and people possibly have blurred vision and then miss grabbing the button battery during long-term grabbing, and in addition, when a cylindrical battery is grabbed, people usually grab the middle part of the cylindrical battery, and thenthe grabbed cylindrical battery possibly falls off due to sweating of hands can be solved.

Owner:JIAXING HENGWEI BATTERY

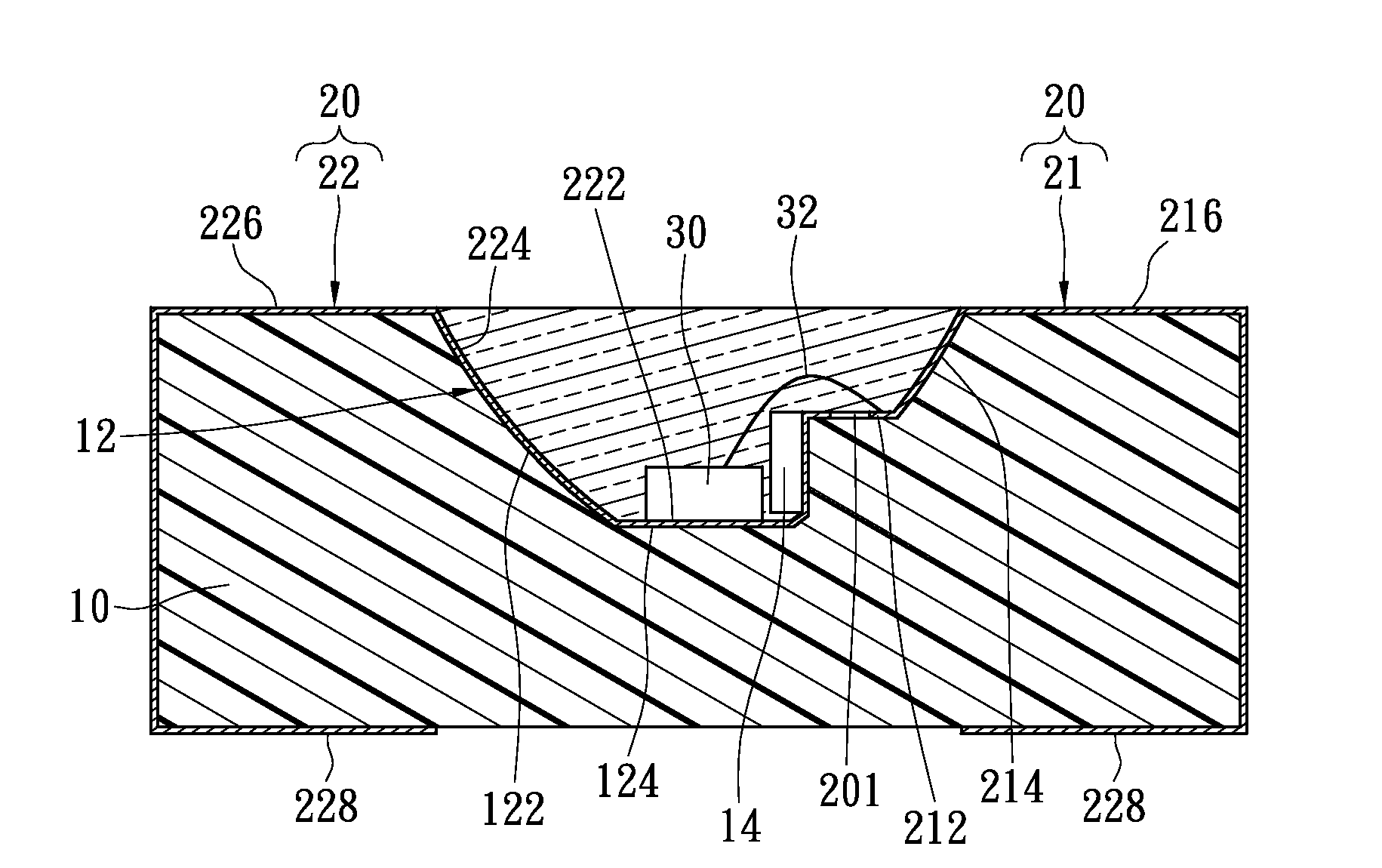

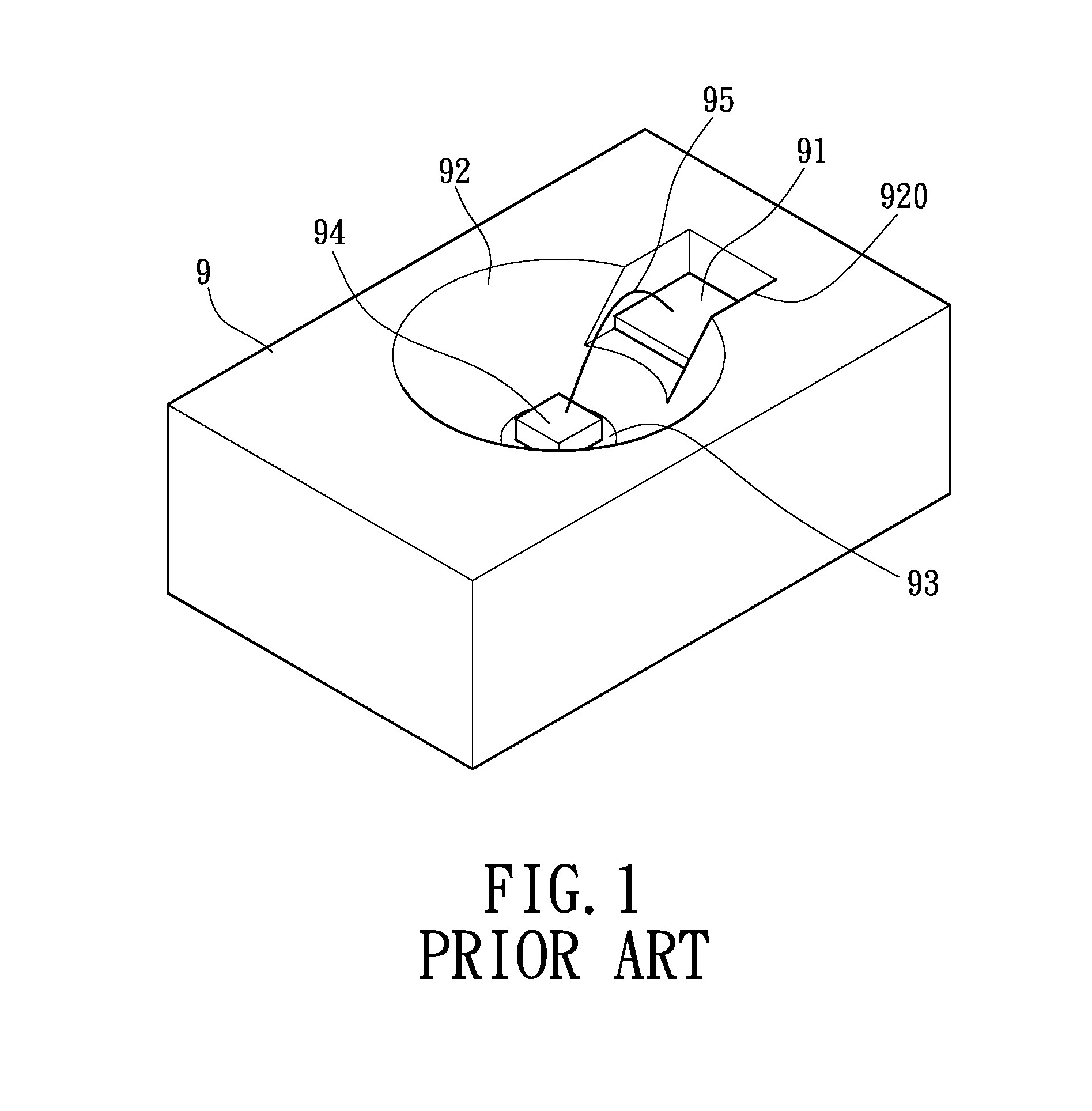

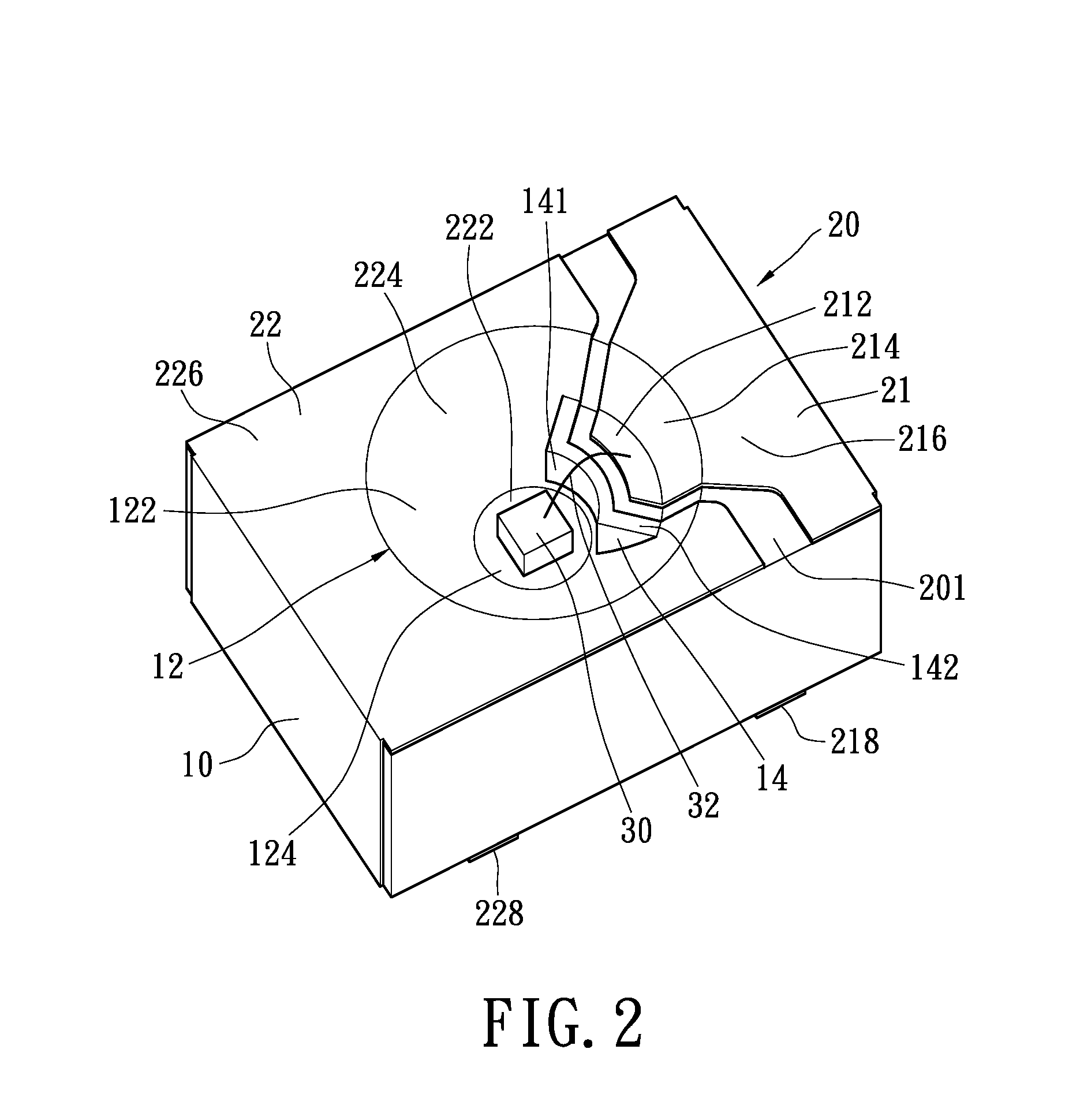

Surface mounted LED package and manufacturing method therefor

InactiveUS20130009191A1Shorten the lengthReduce the overall heightSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingEngineering

A surface mounted LED package includes an insulated body, a first conductive part, a second conductive part, a LED chip and a bonding wire. The insulated body has a receiving portion and a bond-pad island. The receiving portion is formed with an inner side wall and a flat bottom. The bond-pad island is formed with a bonding plane. The first conductive part has a LED chip and a first solder pin extended to an outer surface of the insulated body. The second conductive part has a second contacting portion and a second solder pin extended to an outer surface of the insulated body. The LED chip is disposed on the second contacting portion. The bonding wire connects the LED chip to the first contacting portion. The present application further provides a manufacturing method for surface mounted LED package.

Owner:LITE ON SINGAPORE PTE LTD

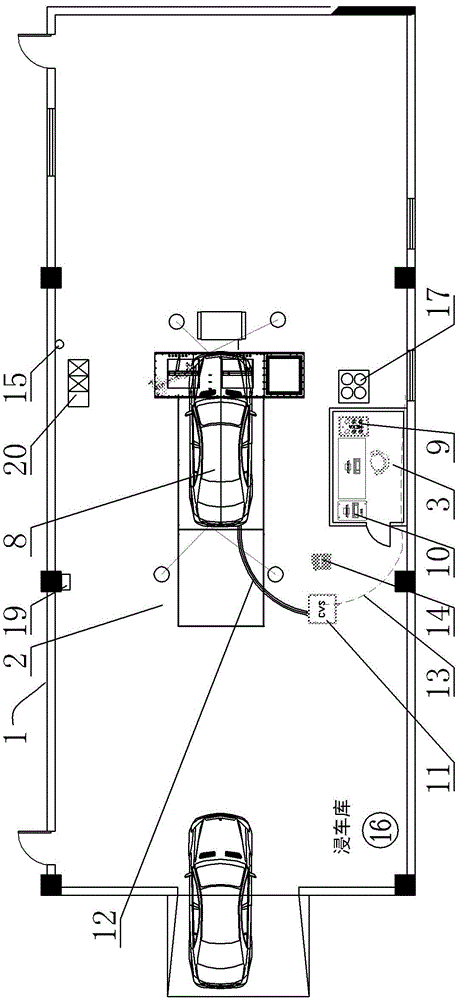

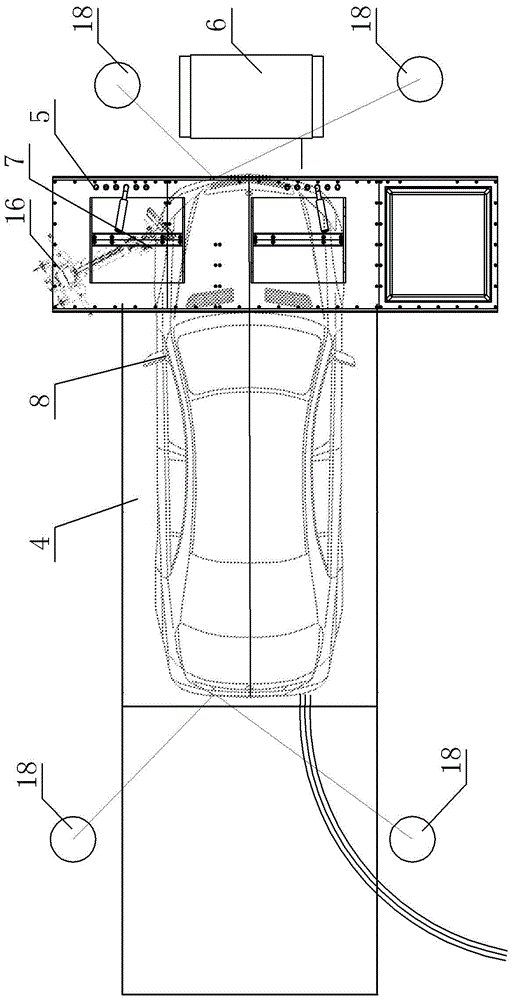

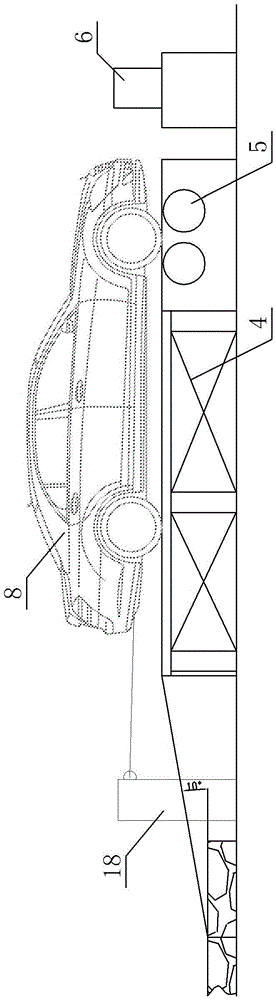

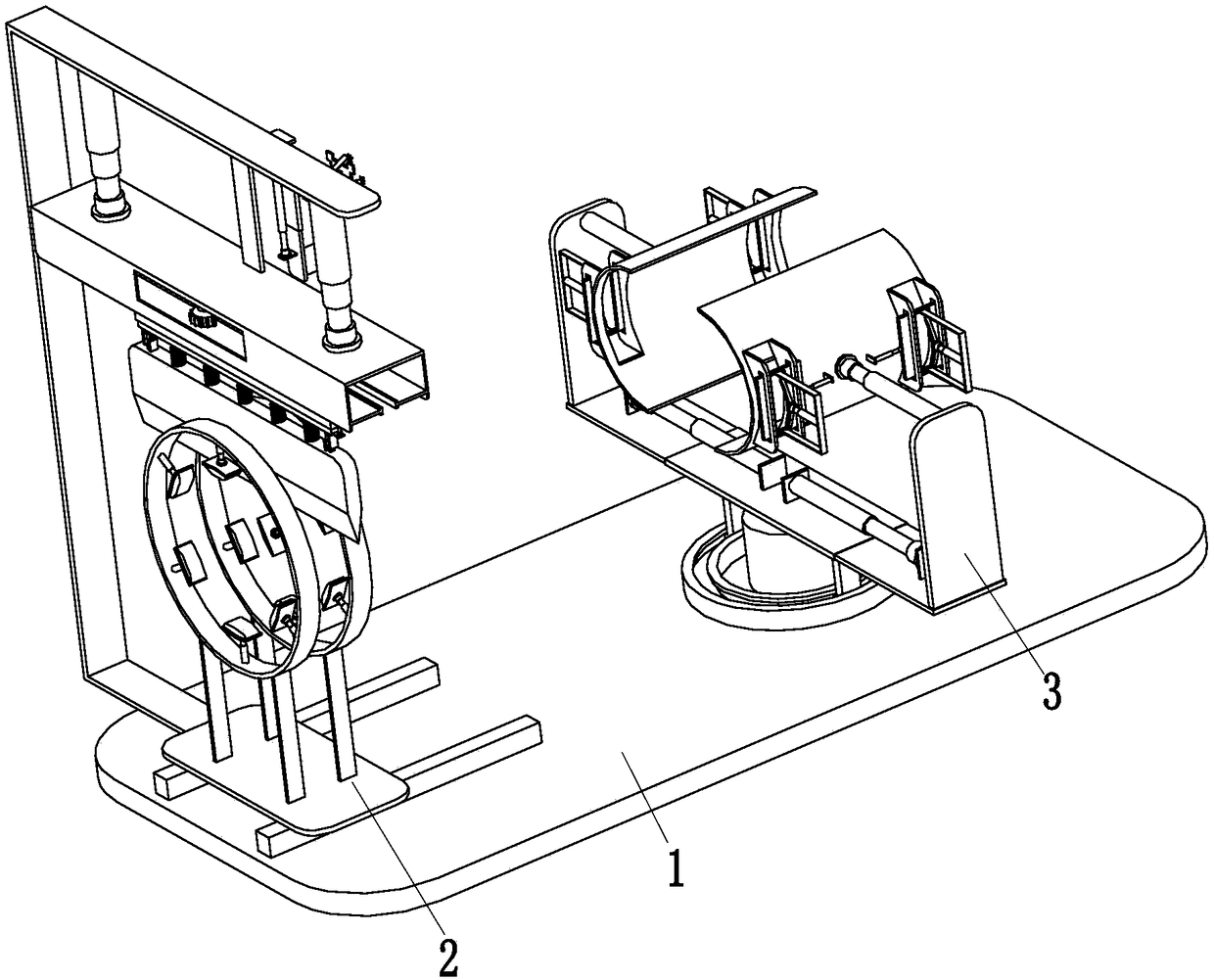

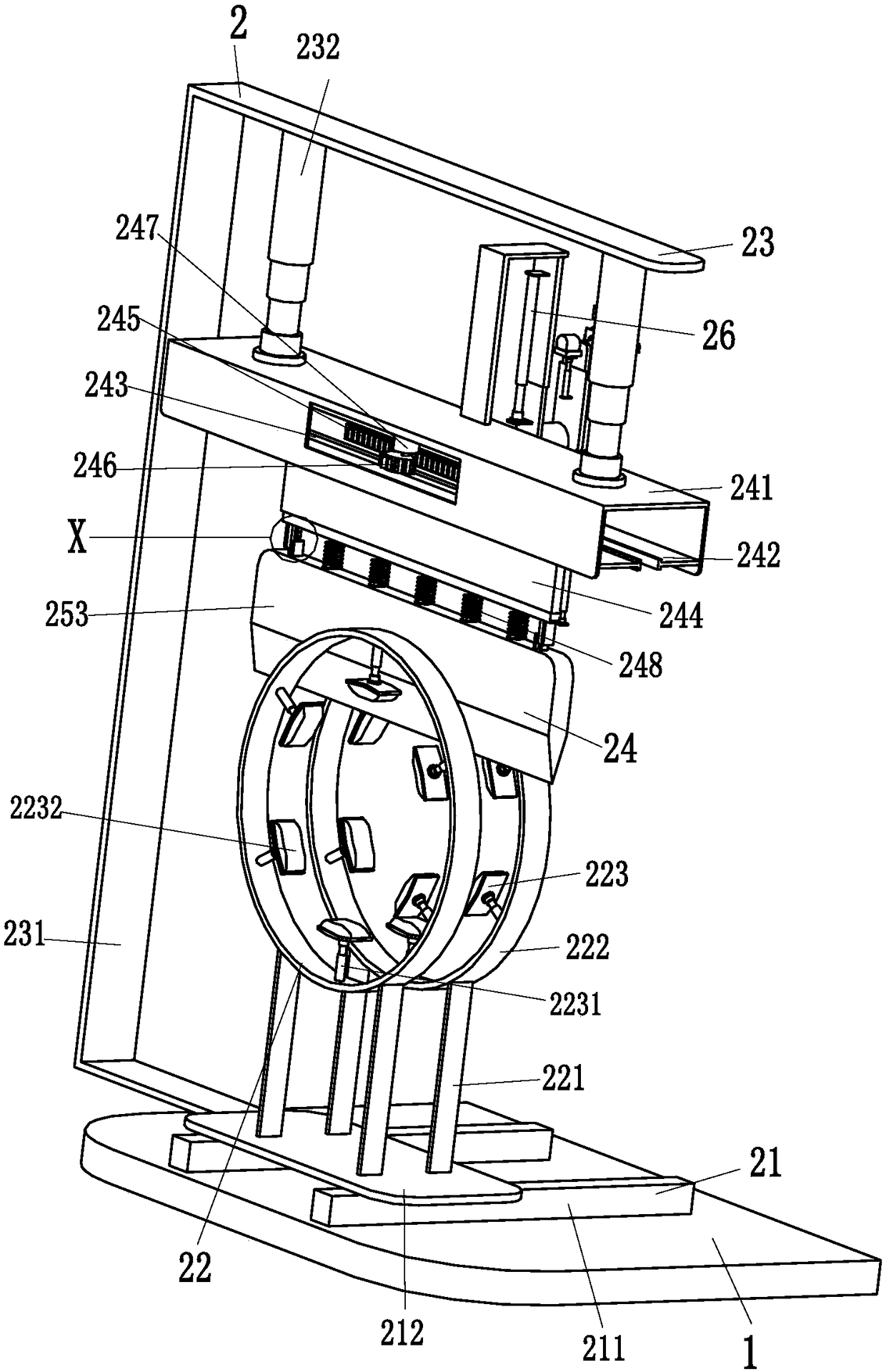

Simple system for testing emission of motor vehicle through transient working condition method

InactiveCN105675824AAddress emissions values that do not truly reflect actual road conditionsSolve the resultGas analyser construction detailsVehicle frameTest frame

The invention provides a simple emission testing system of a motor vehicle based on a transient working condition method, which simplifies the functions of the equipment on the basis of retaining the large-scale emission detection equipment, and ensures the reliability and traceability of the data source. It includes the field, which is equipped with a test area and a control area. The control area can observe the test area. The test area is equipped with a test frame, a chassis dynamometer, a fan, and a surveillance camera. The front of the test frame is set There is a chassis dynamometer, the fan is located in the front of the chassis dynamometer, the blower outlet of the fan is arranged towards the front of the vehicle to be tested, and the monitoring camera is used to record the real-time images of the vehicle to be tested; the control area is equipped with an emission analyzer, The detection mechanism uses a main control computer, and a constant-volume sampling unit and a connecting pipe are arranged between the test area and the control area. The exhaust gas of the vehicle to be tested is connected to the inlet of the constant-volume sampling unit through the input connecting pipe.

Owner:SUZHOU HUAYE DETECTION TECHNOLOGY SERVICE CO LTD

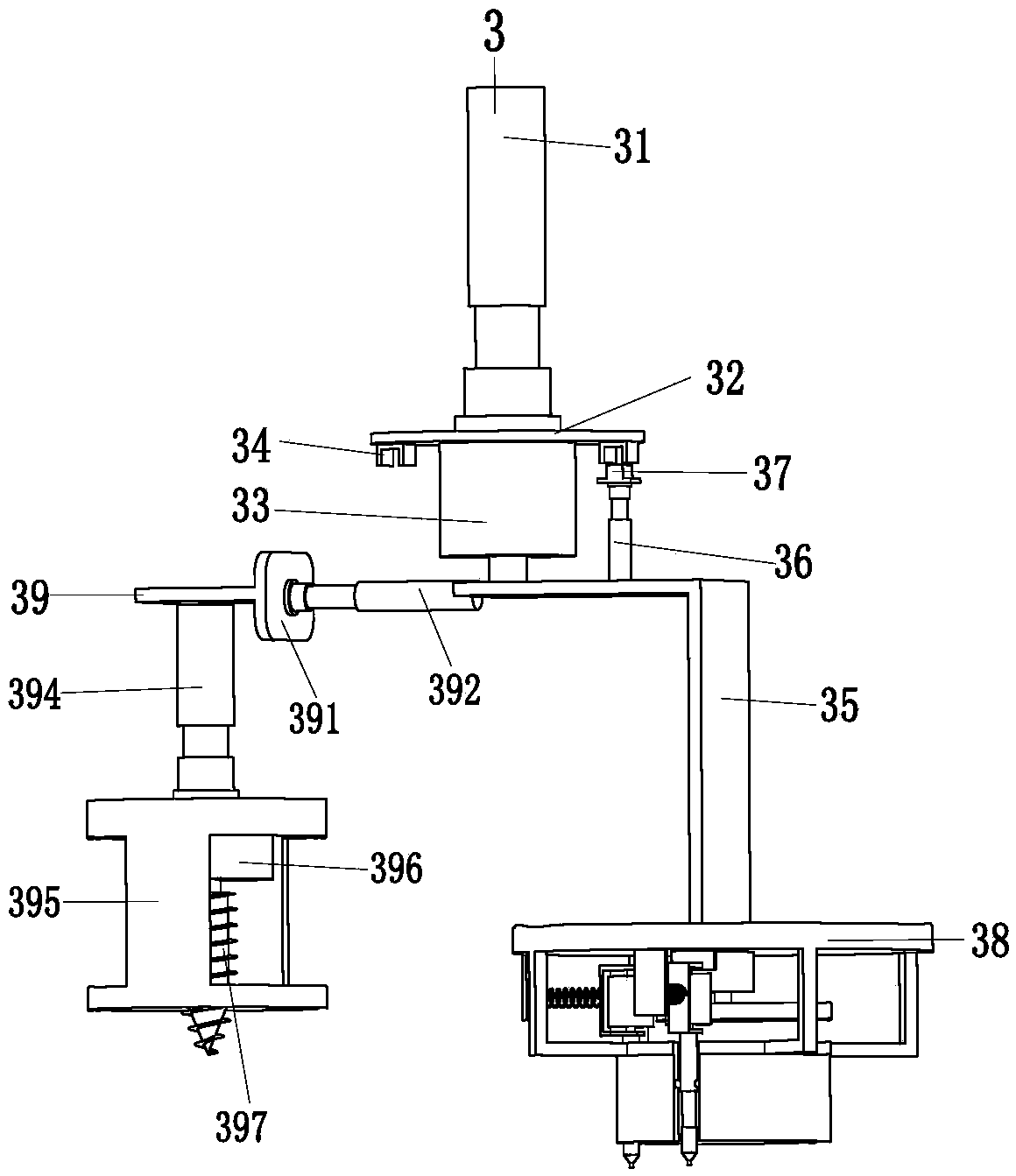

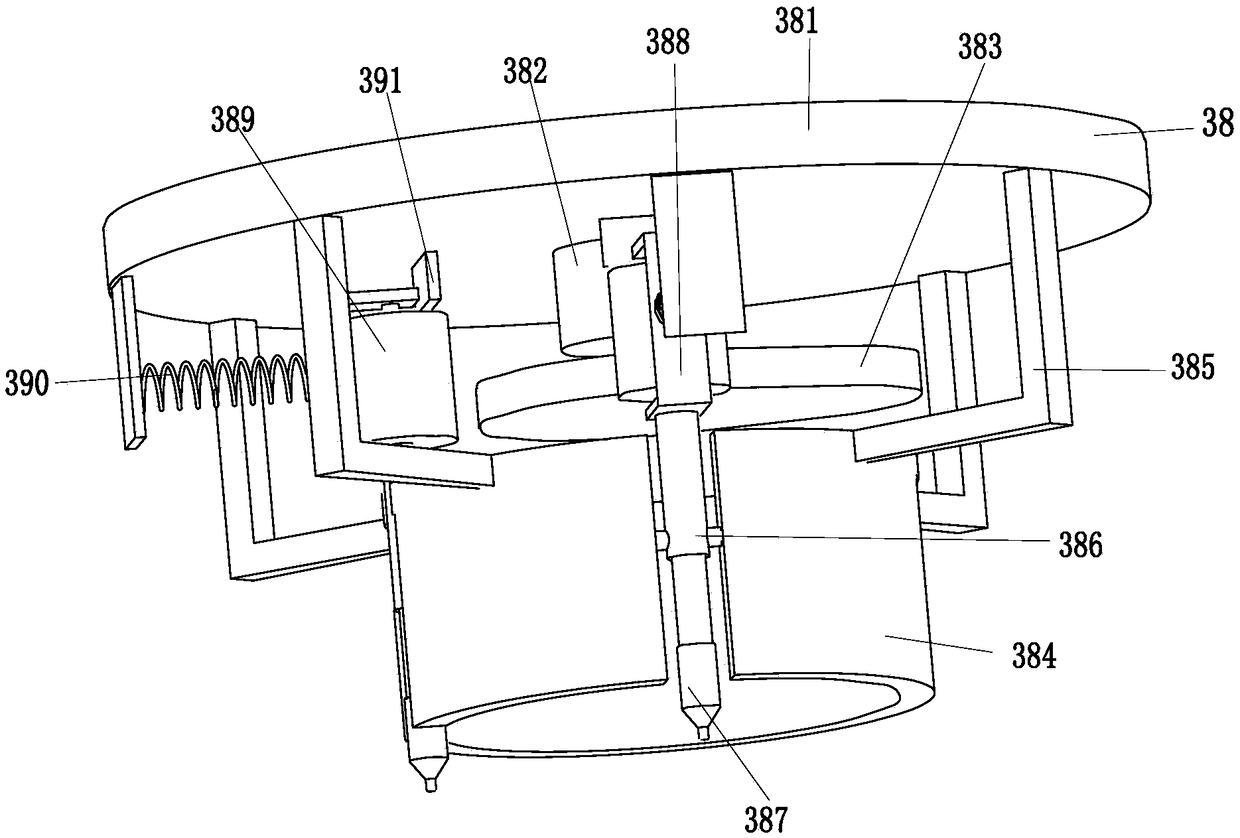

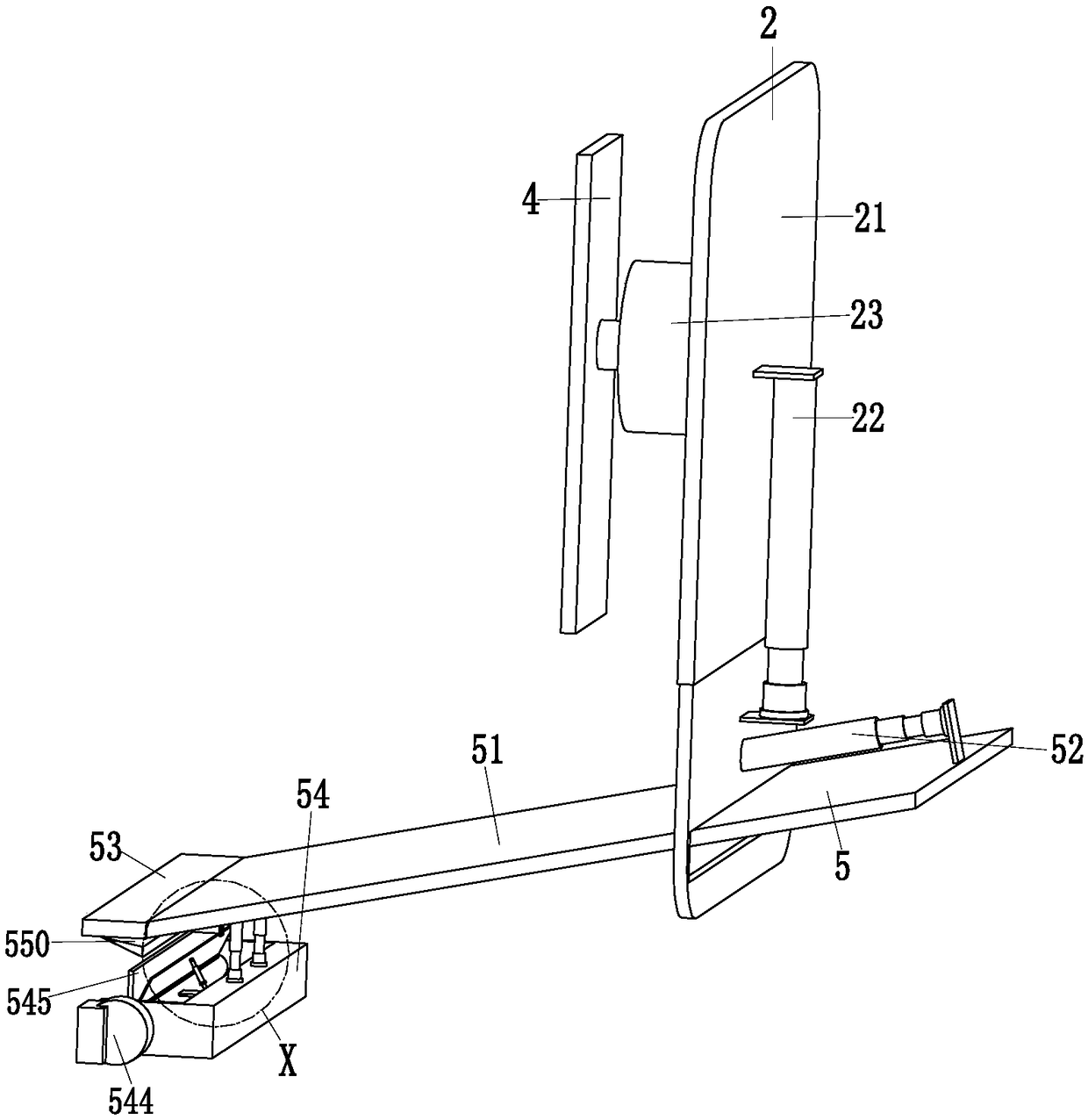

Cutting robot for processing communication cable

ActiveCN108406881ANo manual operationEasy to operateEdge grinding machinesMetal working apparatusMachining processProcess communication

The invention relates to a cutting robot for processing a communication cable. The cutting robot comprises a main board, a cutting and deburring device and a middle limiting device, wherein the frontend of the main board is provided with the cutting and deburring device, and the middle of the main board is provided with the middle limiting device. The cutting robot can solve the problems that inthe existing communication cable sleeve processing process, a communication cable sleeve needs to be limited by a worker and then be cut, the communication cable sleeves with different structures needto be grabbed in different ways by the worker when the communication cable sleeves are limited, and during cutting, pipe openings are not flat due to the fact the position is deviated easily during manual cutting, burrs are generated after the communication cable sleeve is cut, the consumed time of the process is long, the labor intensity is large and the efficiency is low. The cutting robot hasthe advantages that the communication cable sleeves can be limited and cut stably, the communication cable sleeves with different structures are limited targetedly, automatic cutting can be realized,the pipe openings are cut flatly, the burrs are automatically removed, manual operation is not needed, the consumed time is short, the operation is simple, the labor intensity is low, and the workingefficiency is high.

Owner:徐州海德力工业机械有限公司

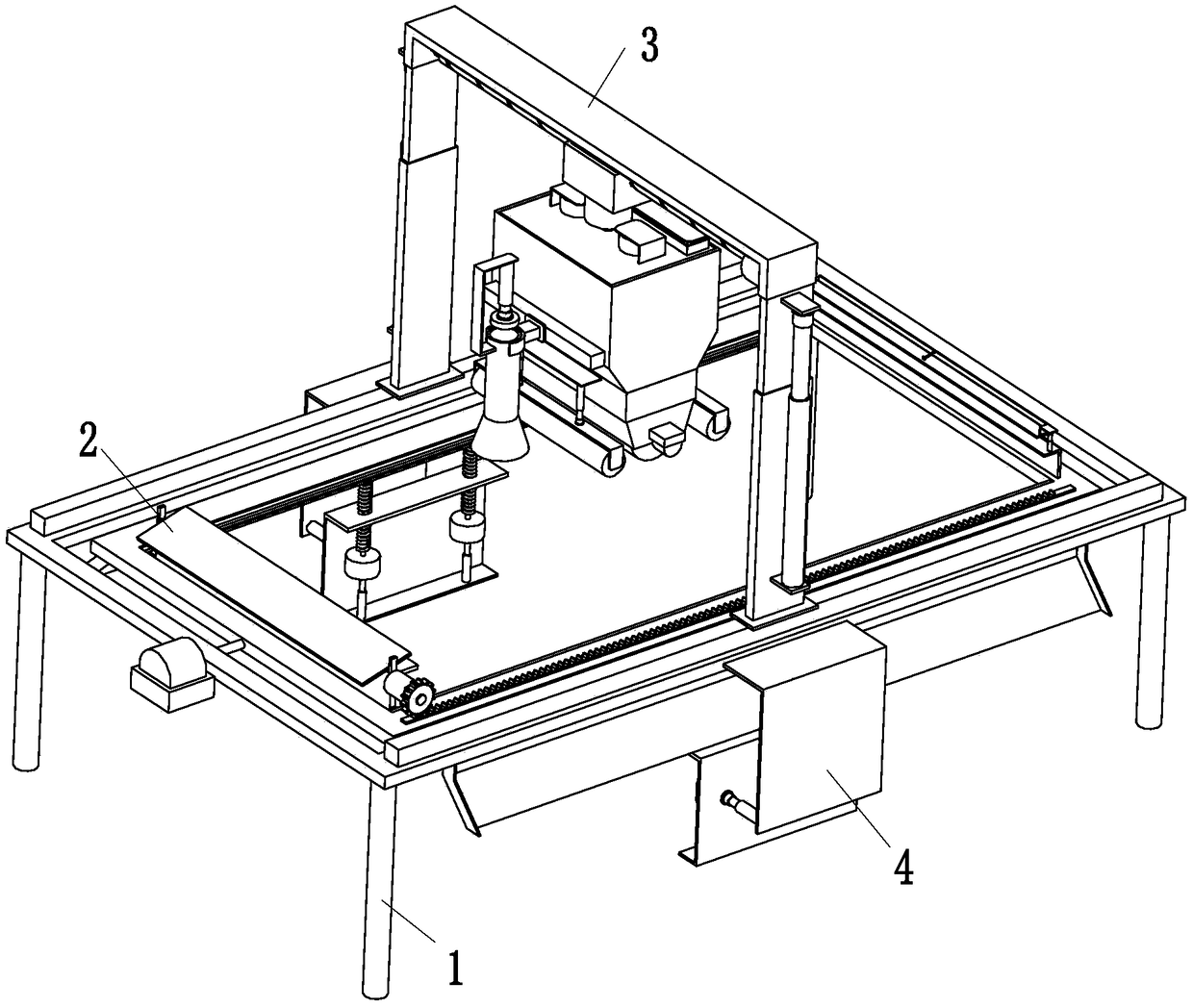

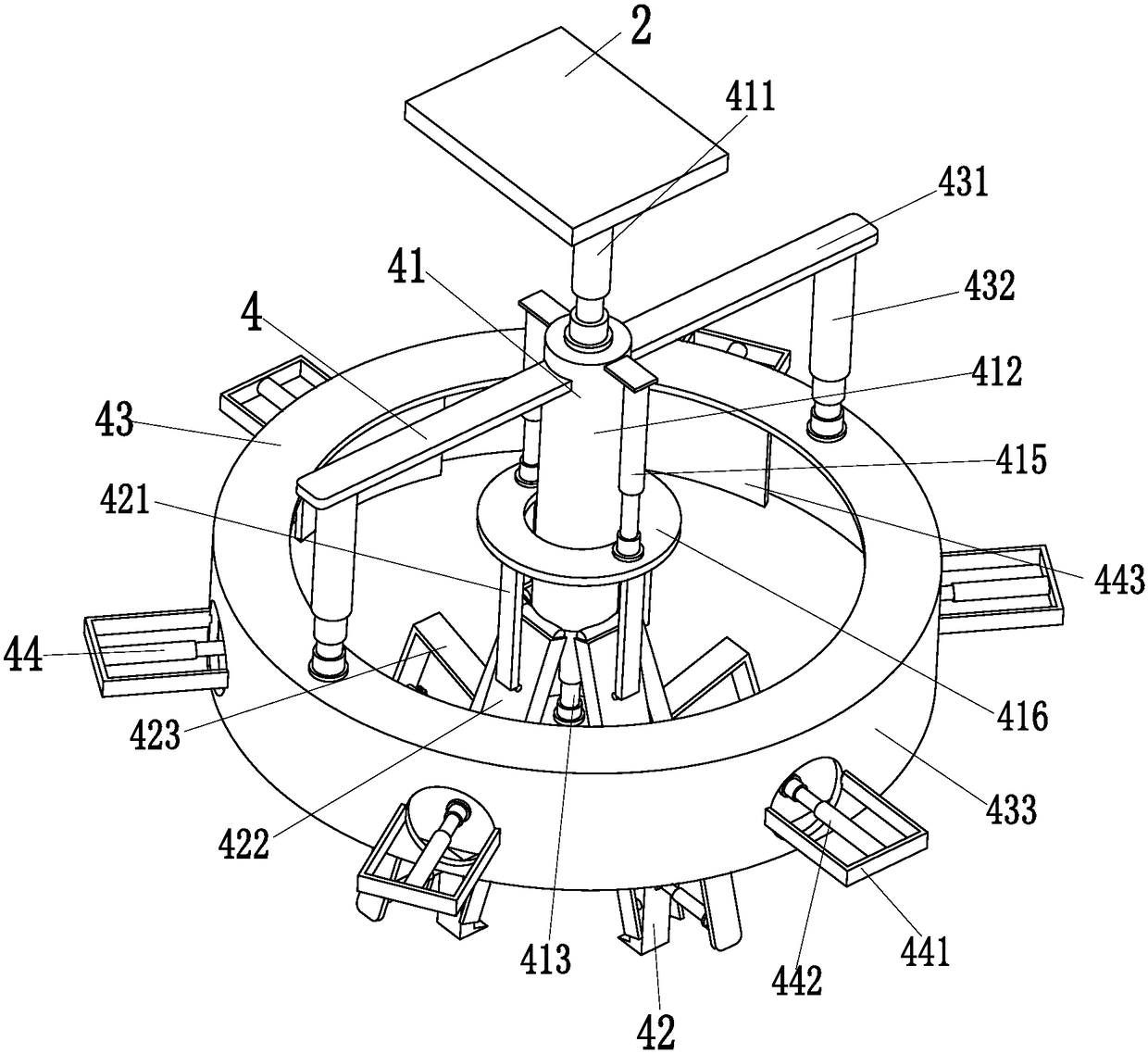

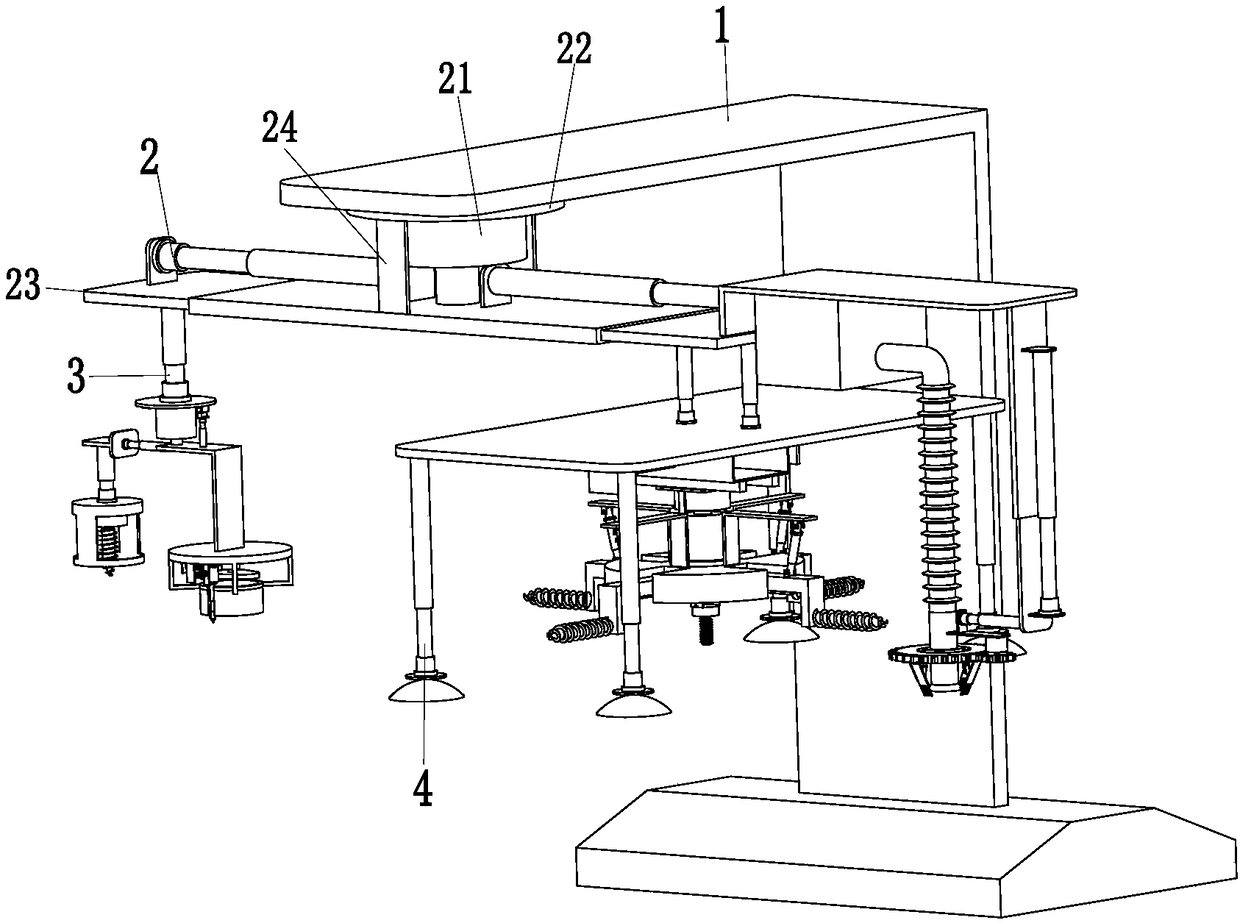

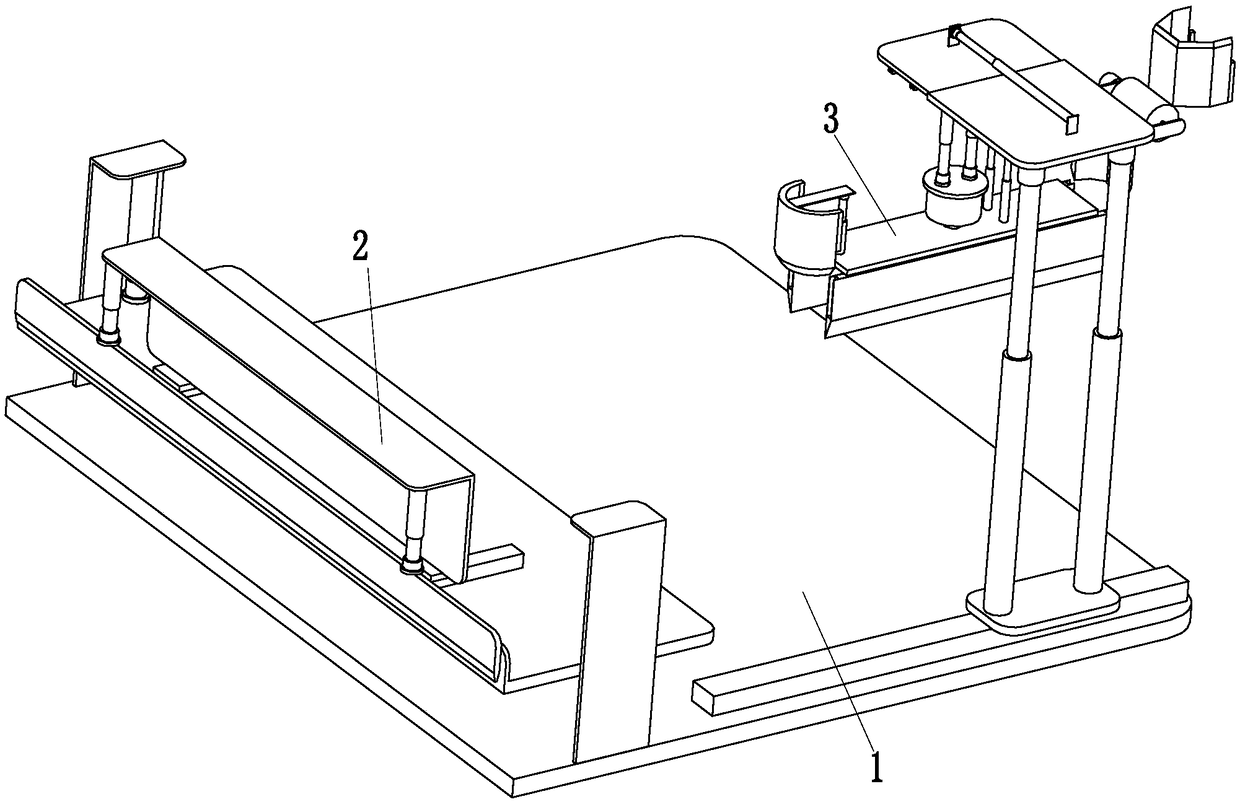

Automatic aluminum-plastic panel drilling and machining system and automatic aluminum-plastic panel drilling technology thereof

ActiveCN108941655AShort costEasy to operateLarge fixed membersOther workshop equipmentMachining systemDrill cuttings

The invention relates to an automatic aluminum-plastic panel drilling and machining system and an automatic aluminum-plastic panel drilling technology thereof. The automatic aluminum-plastic panel drilling and machining system comprises a supporting seat, a rotating device, a marking and boring device and a drilling device; the rotating device is mounted on the front side of the upper end of the supporting seat; the marking and boring device is mounted at the left end of the rotating device; and the drilling device is mounted at the right end of the rotating device. The problems that an existing aluminum-plastic panel drilling process requires manual drilling on an aluminum-plastic panel, personnel are required for marking and boring before drilling, the middle position of the aluminum-plastic panel is not easy to mark by the personnel, the personnel may slightly deviate from the drilling position when drilling with a tool, the personnel need to replace different drill bits for drilling according to different drilling sizes during drilling, the personnel cannot accurately drill into the drilling position when drilling with the tool, drill cuttings generated after the drilling cannot be discharged in time, the time consumed is long, the labor intensity is high, the efficiency is low, and the like can be solved. The functions of automatic marking, boring, drilling and chip removal of the aluminum-plastic panel can be realized.

Owner:深圳市精盛源精密模具有限公司

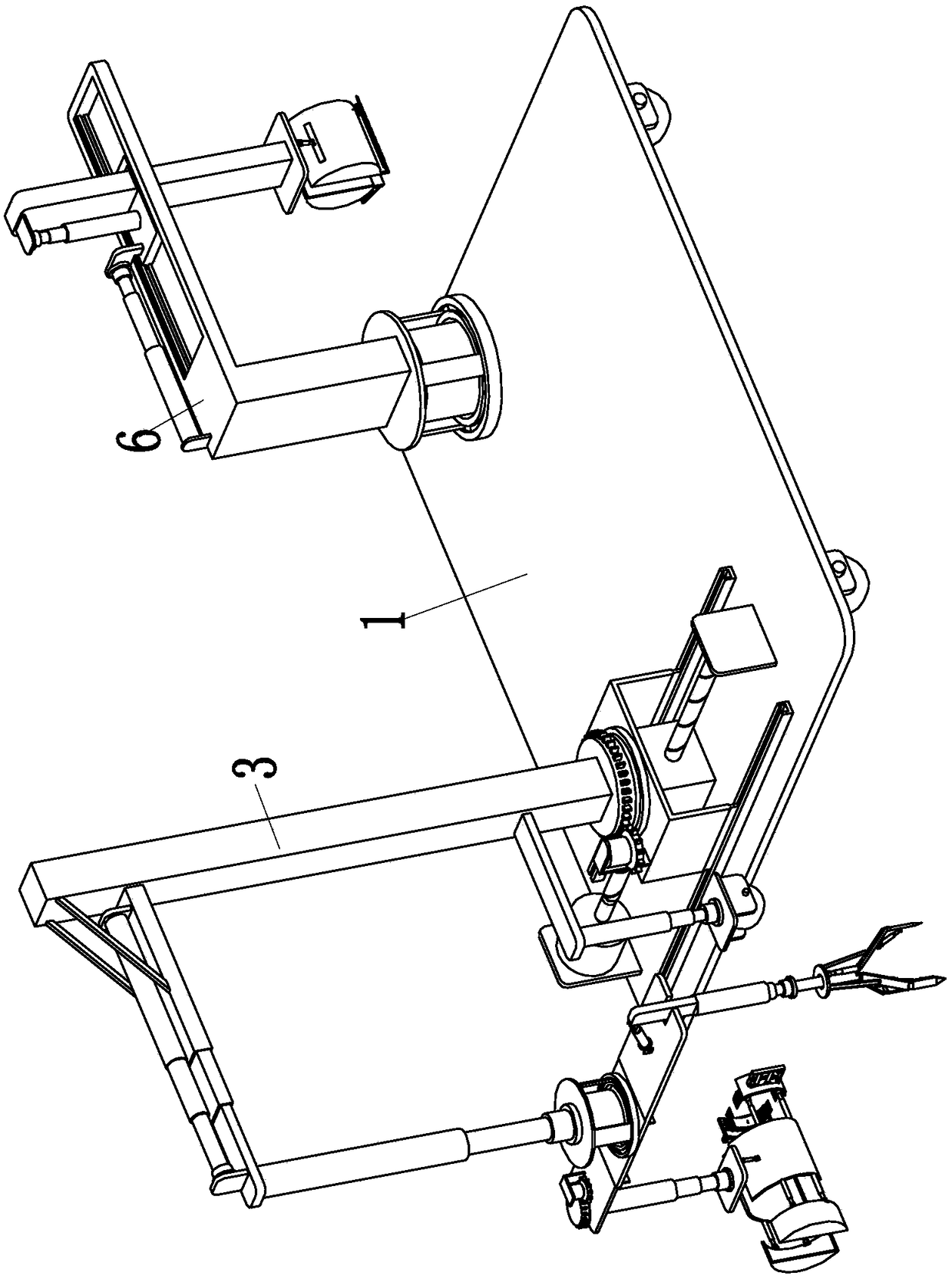

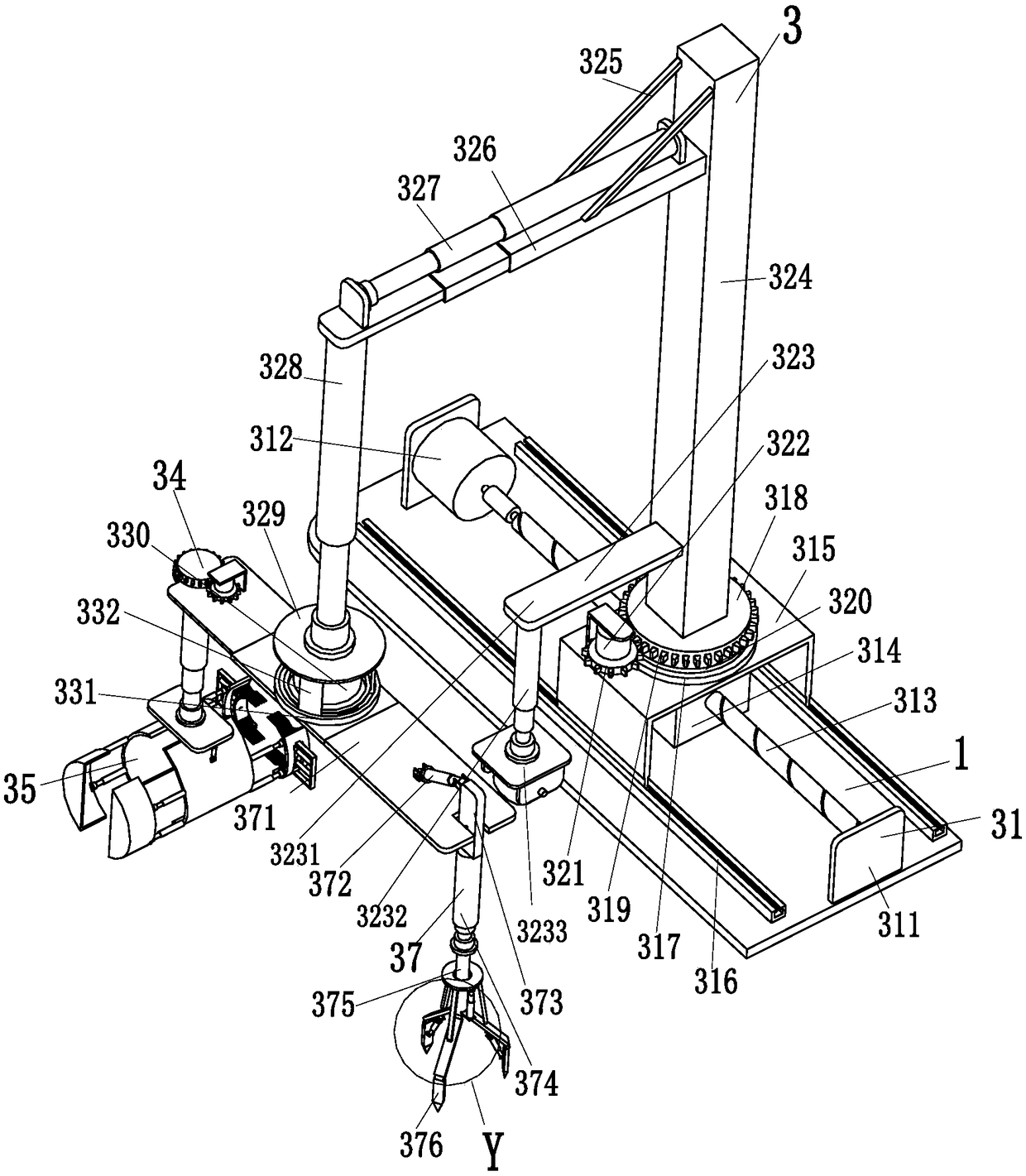

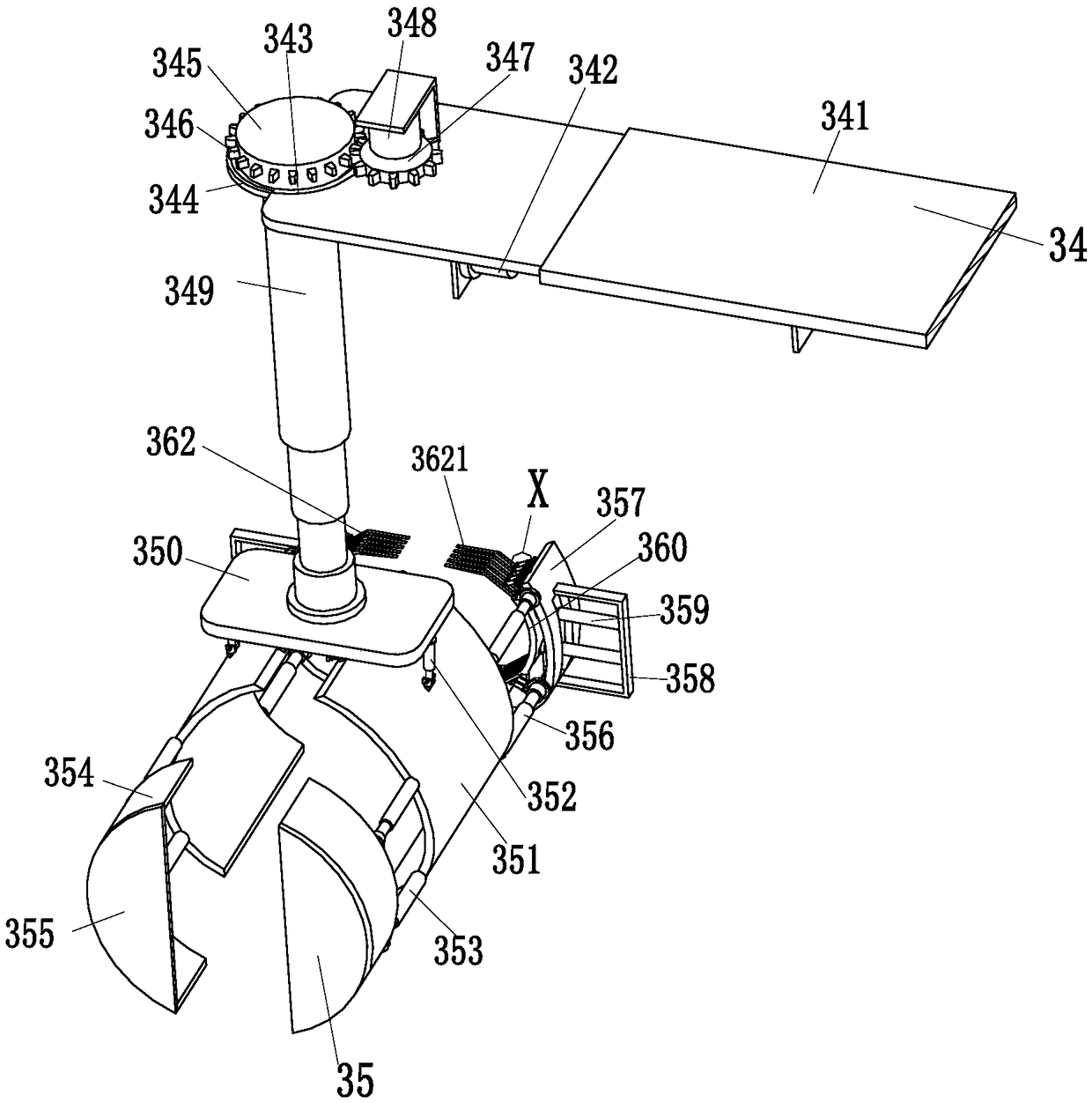

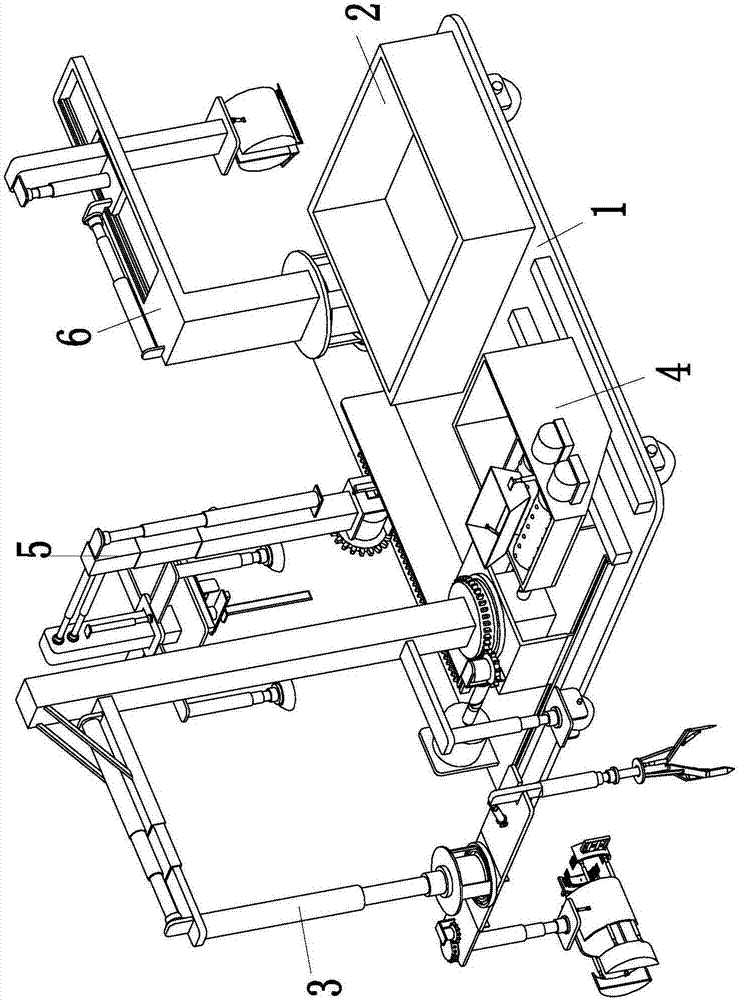

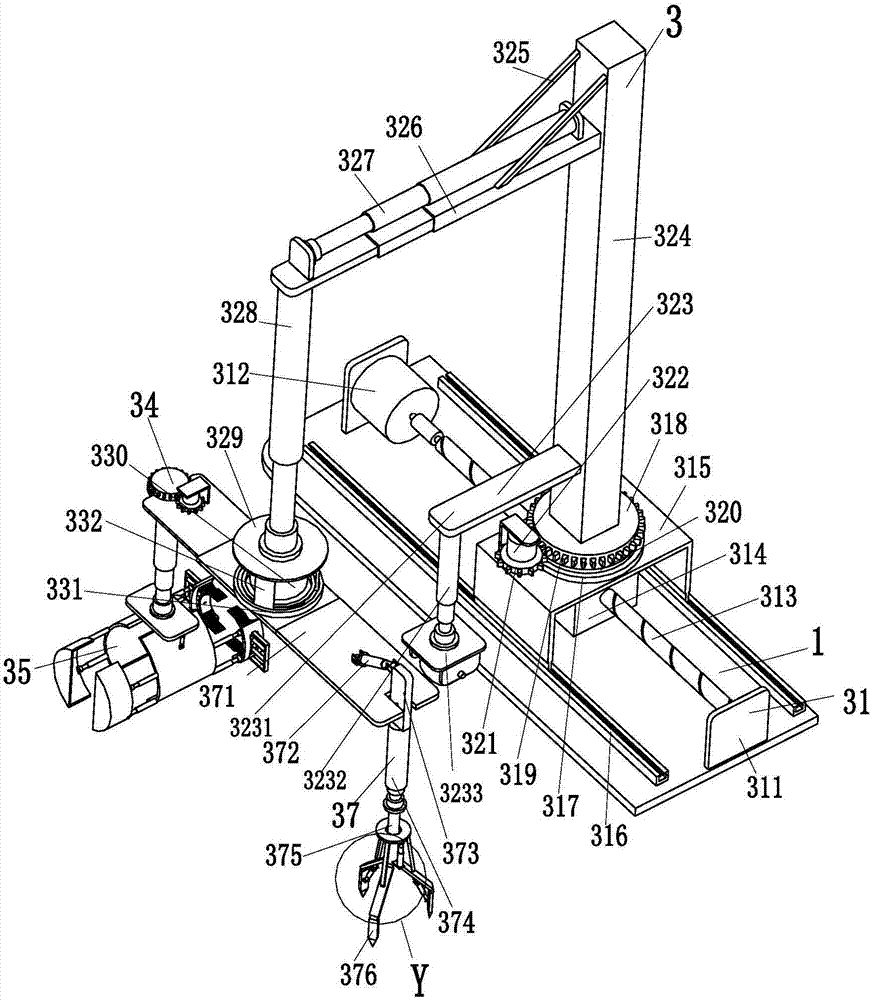

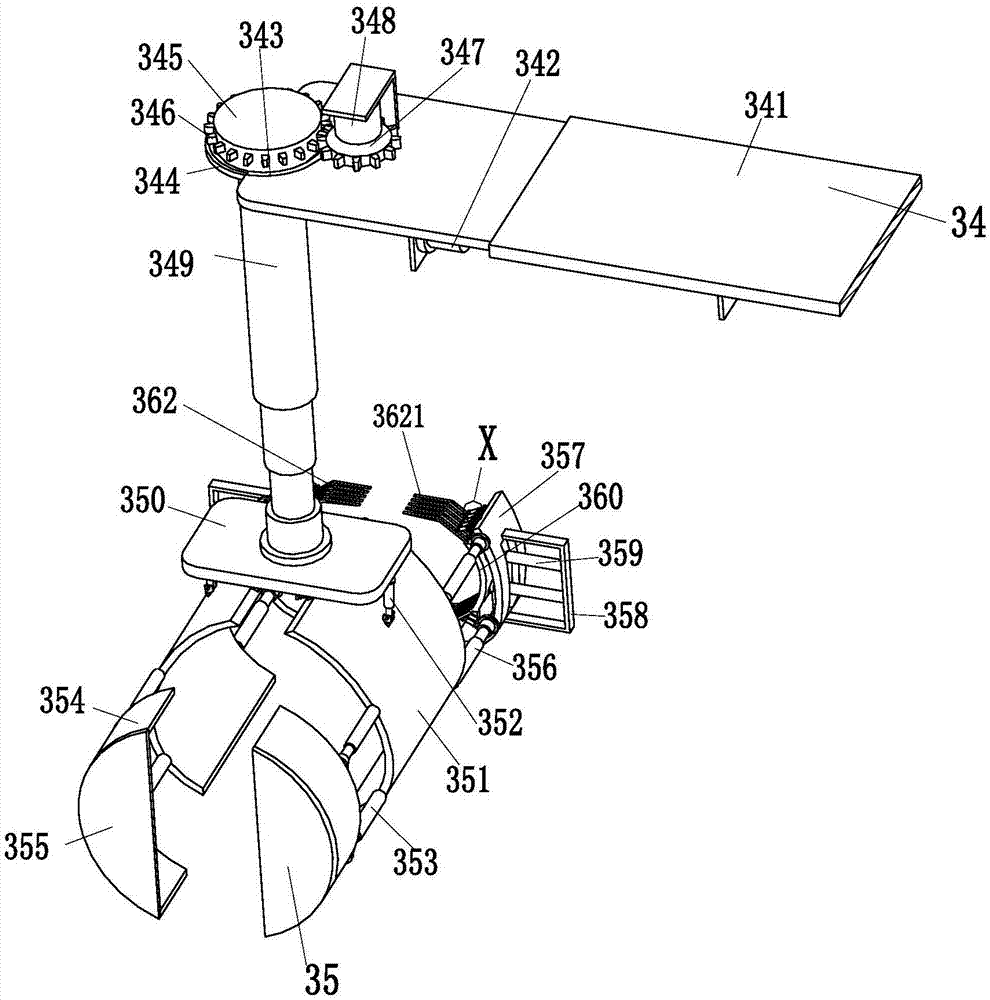

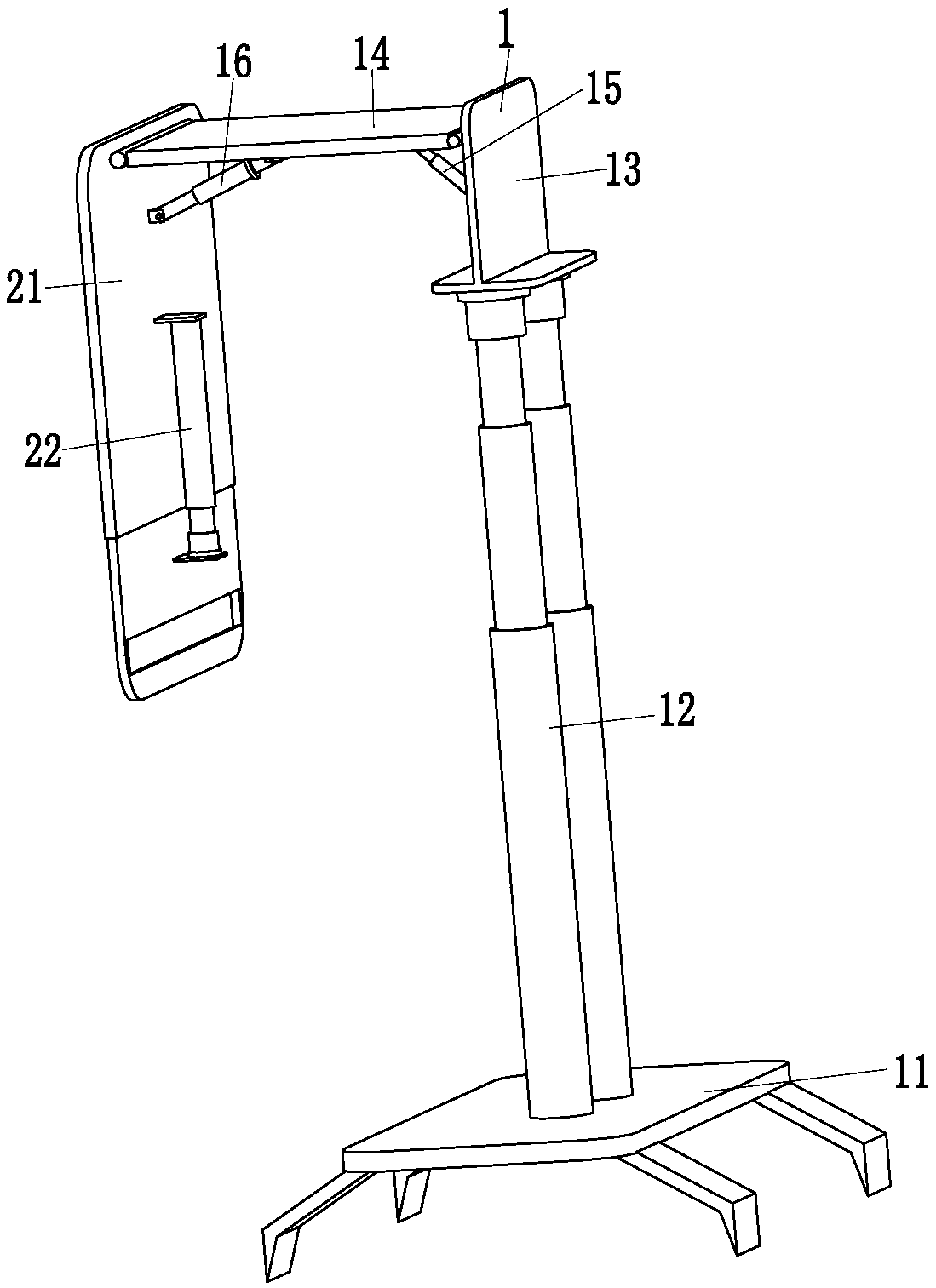

Automatic construction robot for installing solar street lamp

InactiveCN108068124AEnsure safetyExcavation levelingGripping headsTowersNew energySolar street light

The invention relates to an automatic construction robot for installing a solar street lamp. The automatic construction robot for installing the solar street lamp comprises a moving platform, a grabbing device and a digging device. The grabbing device is arranged on the front end of the moving platform; and the digging device is arranged on the rear end of the moving platform. The automatic construction robot for installing the solar street lamp can solve the problems that during an existing foundation laying process, workers need to use tools for clearing debris; when an earth is dug and thedebris is cleared by manpower, the workers need to use the tools and bend down to pick up, so that waist parts of the workers are injured by long-time bending down so as to cause potential safety hazard; the debris such as bottles need to be manually picked up by the workers and even need to be picked up by the workers for the second time due to smooth bottle bodies; and when the earth is dug, the workers need to use the tools to dig the earth, so that the waist parts of the workers are injured by excessive manual digging and long-time bending down for digging so as to cause potential safetyhazard, the time consumed for the process is long, the labor intensity is high, the efficiency is low, and the like. The automatic construction robot for installing the solar street lamp provided by the invention can realize a function of automatically clearing the debris and digging the earth for the new-energy environmentally-friendly lamp.

Owner:刘秀娟

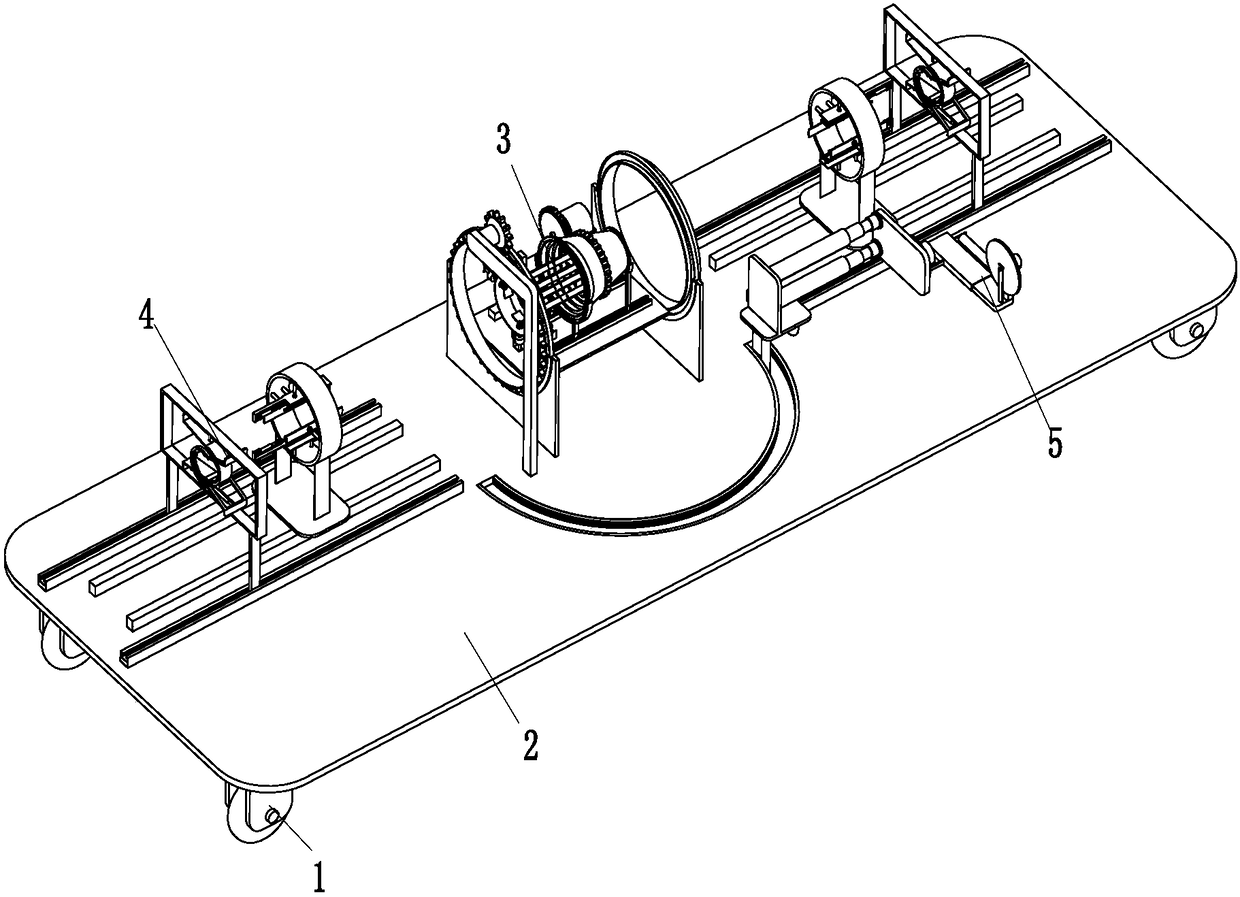

Intelligent connection equipment for reinforcement sleeve for building

The invention relates to intelligent connection equipment for a reinforcement sleeve for a building. The intelligent connection equipment comprises universal wheels, a main plate, a reinforcement sleeve limiting device, two reinforcement bar limiting devices and a cutting device; the universal wheels are uniformly installed at the lower end of the main plate; the main plate is provided with an arc-shaped groove; the reinforcement sleeve limiting device is installed at the middle part of the upper end of the main plate; the two reinforcement bar limiting devices are correspondingly installed atthe front and rear sides of the upper end of the main plate; and the cutting device is installed at the right side of the upper end of the main plate. The intelligent connection equipment provided bythe invention can solve the problems that an existing reinforcement sleeve and a reinforcement bar need manual connection and manual cutting in a connection process and are difficult to fix manuallyin connection because the reinforcement sleeve is small and smooth, meanwhile the reinforcement sleeve and the reinforcement bar cannot be fixed stably manually because the reinforcement bar is long,a person needs to move according to a cutting position in a cutting process, the eyes are easy to injury in a manual cutting process of the reinforcement bar and the like; and the intelligent connection equipment can realize the functions of automatically connecting the reinforcement sleeve with the reinforcement bar and also cutting the reinforcement bar.

Owner:闫西英

New energy source LED (Light Emitting Diode) lamp installation and construction equipment adopting solar photovoltaic power supply

InactiveCN107989096AImprove space utilizationEasy to operateSoil-shifting machines/dredgersRoad cleaningNew energyEngineering

The invention relates to new energy source LED (Light Emitting Diode) lamp installation and construction equipment adopting solar photovoltaic power supply. The new energy source LED lamp installationand construction equipment comprises a movable platform, an object carrying frame, a gripping device, a recycling device, an edge cutting device and a digging device, wherein the gripping device is mounted at the left side of the front end of the movable platform; the recycling device is mounted at the right side of the front end of the movable platform; the edge cutting device is mounted at theleft end of the movable platform; the object carrying frame is mounted at the right end of the movable platform; the digging device is mounted at the rear end of the movable platform. According to thenew energy source LED lamp installation and construction equipment provided by the invention, the difficulties that other things need to be cleaned and recycled by workers in an existing foundation laying process with the help of tools, soil is manually dug, the workers need to bow to pick the other things with the help of the tools in a process of cleaning the other things, space wastes are caused by large volumes of bottled sundries when the other things are cycled so that the space utilization rate is reduced when the soil is dug by the workers with the help of the tools in a soil diggingprocess can be overcome; functions of carrying out automatic cleaning and recycling of the other things, foundation edge cutting and soil digging on outdoor new energy source environment-friendly lampfoundations can be realized.

Owner:吴凡

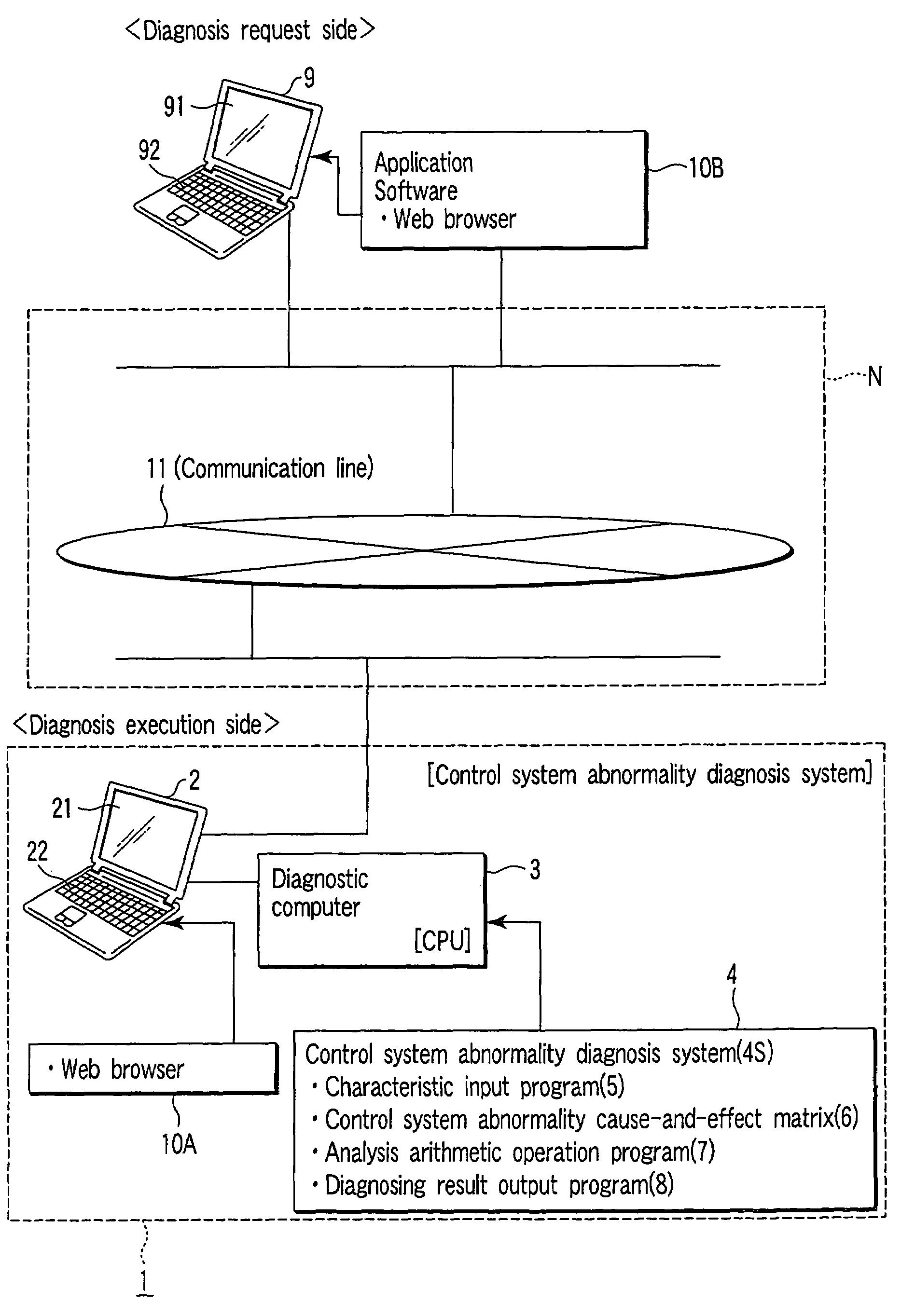

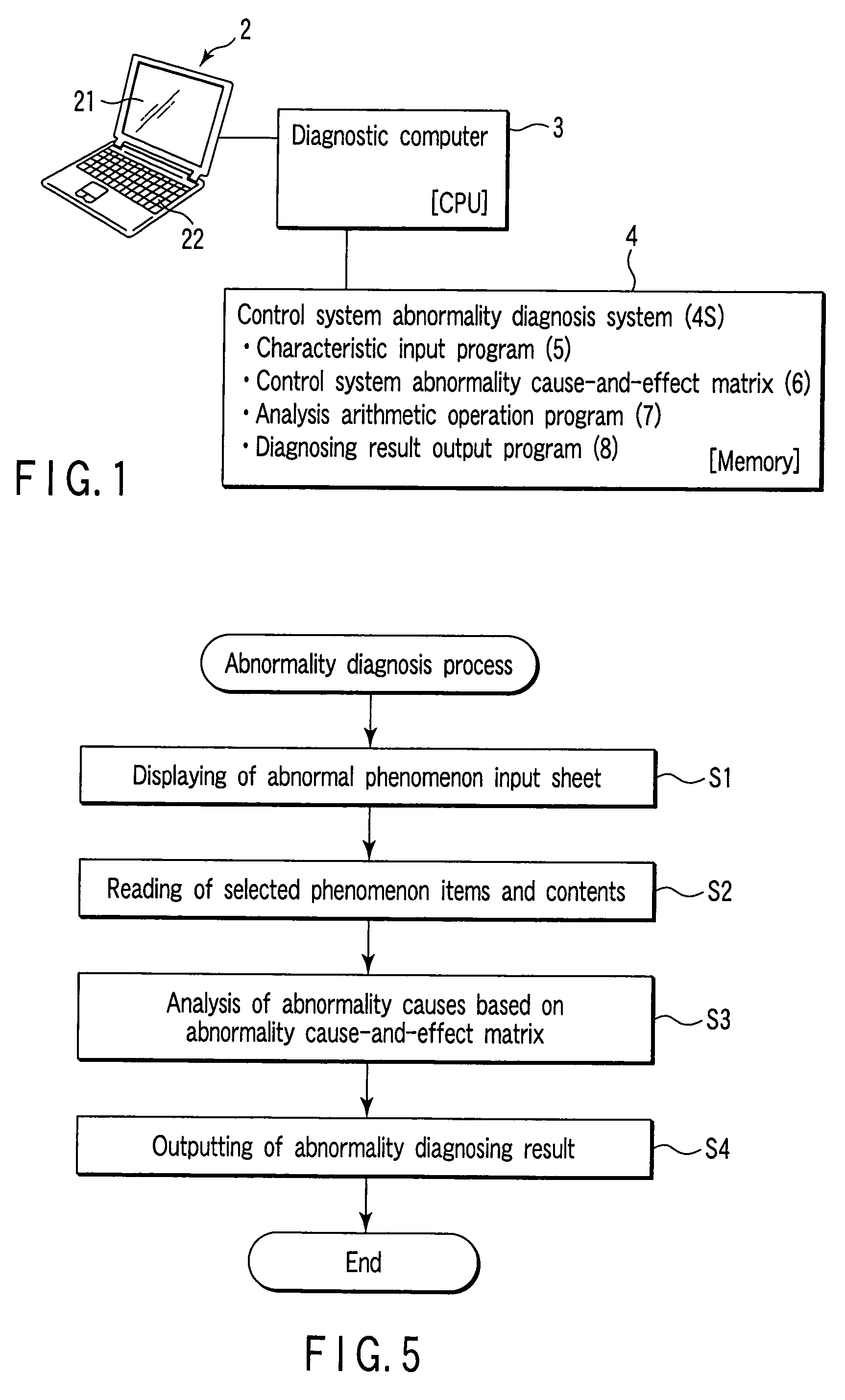

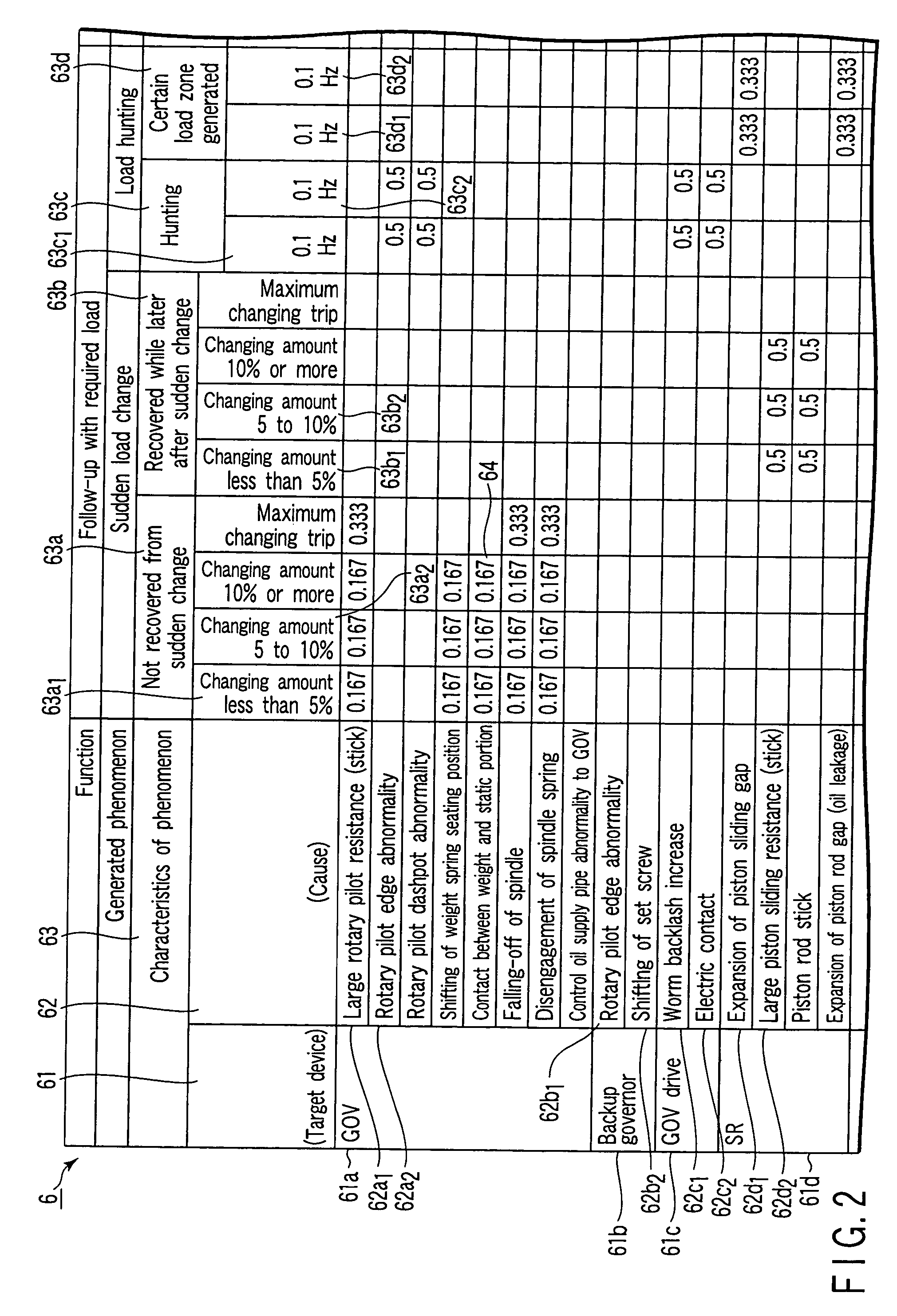

System and method for diagnosing abnormalities in plant control system

ActiveUS7212952B2Easy to implementShort costAnalogue computers for vehiclesDigital computer detailsControl systemEngineering

Owner:KK TOSHIBA

High speed railway track detection and maintenance robot

InactiveCN107952617AEnsure personnel safetyEasy to operatePretreated surfacesCleaning using toolsBrush deviceLacquer

The invention relates to a high speed railway track detection and maintenance robot, which consists of a rectangular plate, a cleaning device and a paint brushing device. The upper end front side of the rectangular plate is equipped with the paint brushing device, and the upper end rear side of the rectangular plate is equipped with the cleaning device. The robot provided by the invention solves the problems that manual cleaning and paint repair of tracks are needed in existing track maintenance, during scrubbing, the staff need to bend down to wipe and flush tracks with the help of tools, manual scrubbing cannot reach a clean effect, and long-term bending work can result in physical discomfort and cause potential safety hazard, during paint repair, the staff need to brush pain-peeled parts of tracks by tools, manual paint repair costs a lot of time and the brushing is uneven, in the process of manual pouring of paint into a box, paint can be spilled and wasted because of untimely stop, and when the weather becomes cold, long-term work outside of the staff can make the body chill and cause potential safety hazards. The robot provided by the invention can realize automated scrubbingand painting functions on high speed railway tracks.

Owner:汪美霞

Processing equipment for corrugated board

ActiveCN108749152AEasy to operateShort costMechanical working/deformationMetal working apparatusEngineeringUltimate tensile strength

The invention relates to processing equipment for a corrugated board. The processing equipment comprises a main frame, a folding line pressing device and a slotting punching device, the folding line pressing device is mounted at the front end of the main frame, and the slotting punching device is mounted at the right end of the main frame. The existing problems that when the corrugated board is formed, the corrugated board needs to be subjected to manual line pressing and slotting, the process is cumbersome and complicated, during line pressing, the manual line pressing position is not flat, during slotting punching, a person needs to use different tools to cut, the process takes a long time, the labor intensity is large, and the efficiency is low can be solved. The functions of automaticslotting punching and line pressing for the corrugated board can be achieved, line pressing is flat during automatic line pressing, the corresponding tools are automatically adjusted according to different cutting conditions, manual operation is not needed, the consumed time is short, and the processing equipment has the advantages of easy operation, small labor intensity, high work efficiency andthe like.

Owner:宜兴市明亿包装有限公司

Construction robot for environment-friendly wall decorations

The invention relates to a construction robot for environment-friendly wall decorations, which comprises an adjusting device, a telescopic device, a connecting plate, a cutting device, a dual-purposedevice and a shearing device, wherein the telescopic device is installed on the front side of the upper end of the adjusting device, and the shearing device is installed at the lower end of the telescopic device, the connecting plate is installed at the front end of the telescopic device, the shearing device is installed at the upper end of the connecting plate, and the dual-purpose device is installed at the lower end of the connecting plate. The invention can solve the existing problems: in case of seaming anti-mold wallpapers, personnel are required to push the excess paper material betweenthe two wallpapers into a convex shape by means of a ruler, and then cut the paper material with a cutter, and a plurality of people are needed to cooperate; in case of cutting, a manual cutting is not flush, and the cutting is not complete, and the wallpapers may be pulled and damaged or stretched due to personnel not pressing the wallpapers stable; and in case of cutting the redundant wallpaperat the skirting line, as the skirting line is too low, the personnel will have difficulties to cut even the personnel bend down, thereby resulting in a long time consumption, a large labor intensityand a low efficiency etc.

Owner:浙江金果知识产权有限公司

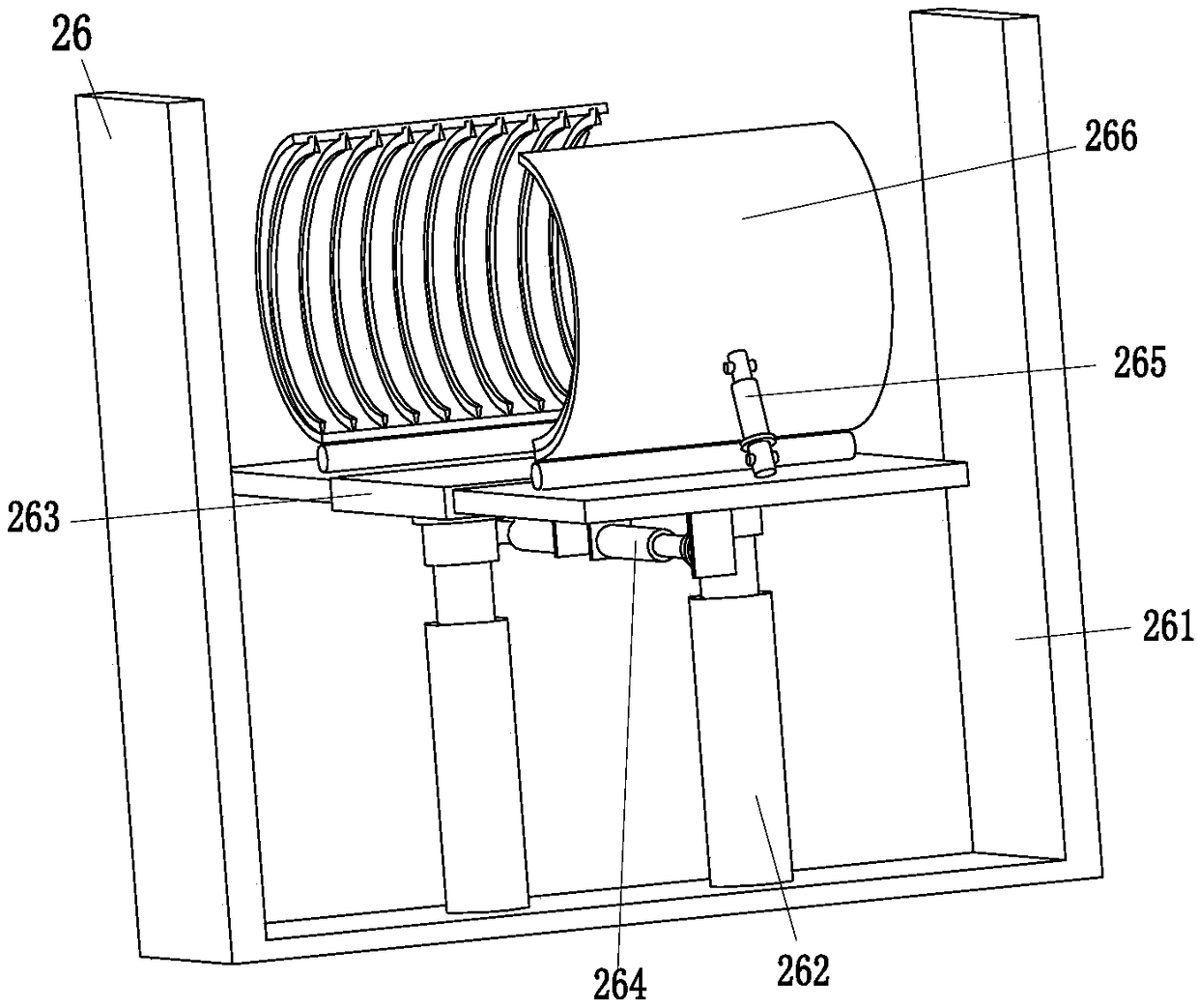

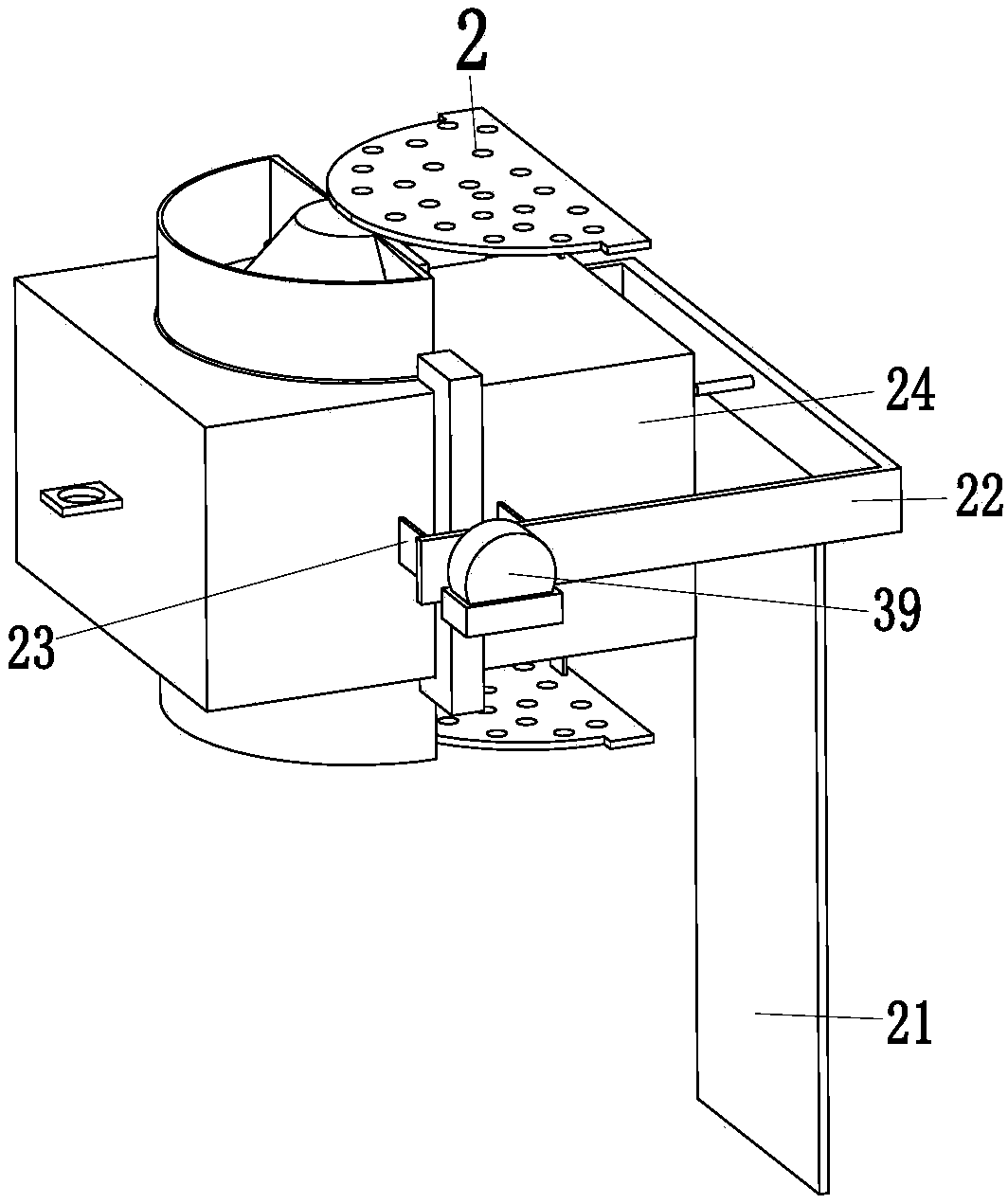

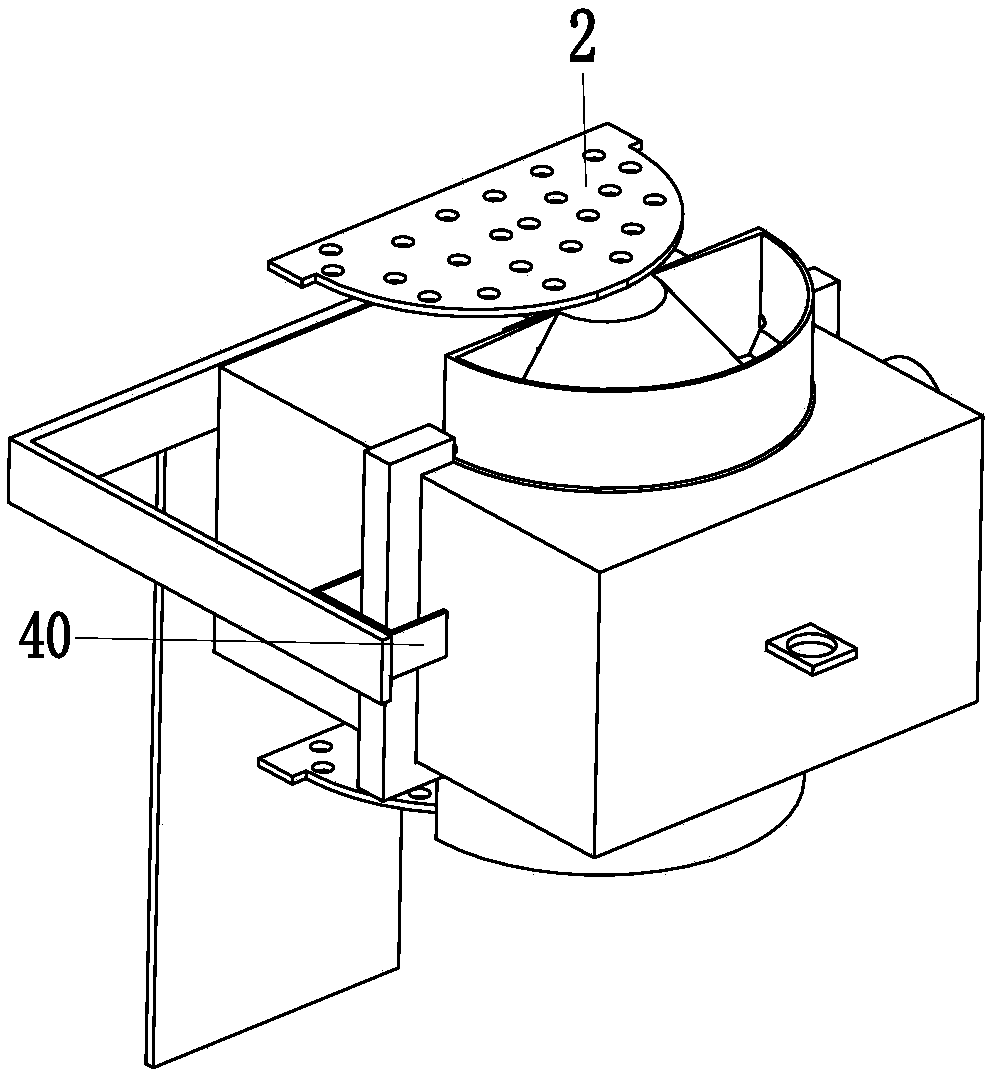

Automatic grinding system for pharmaceutical intermediates and automatic grinding method for pharmaceutical intermediates

ActiveCN109261275AIncrease productivityShort time spentCleaning using toolsGrain treatmentsEngineeringRaw material

The invention relates to an automatic grinding system for pharmaceutical intermediates and an automatic grinding method for the pharmaceutical intermediates. The automatic grinding system comprises abottom plate, a grinding device, a conveying device and a drying and discharging device, wherein the grinding device is mounted at the rear end of the bottom plate; the conveying device is mounted inthe middle of the bottom plate; the drying and discharging device is mounted at the front end of the bottom plate. By adopting the intelligent grinding machine, the difficulties that existing medicineraw materials are manually ground, the manual grinding effect is not good, the grinding is not complete, batch grinding is difficult to realize and ground medicine powder cannot be collected in realtime so that medicines are wasted, the medicine raw materials are easily influenced by water after being ground so that the medicine raw materials are agglomerated, the production efficiency is low, the consumed time is long and the like can be overcome; functions of automatically grinding the medicine raw materials into powder and drying the powder can be realized; the intelligent grinding machine has the advantages of capability of automatically grinding the medicine raw materials into the powder, capability of collecting the ground medicine powder in time, capability of carrying out dryingand secondary rolling on damp medicine powder, high production efficiency, short consumed time and the like.

Owner:宁夏恒康科技有限公司

Method, system and apparatus to provide for universal bellhousing between engine and transmission of vehicle

ActiveUS20140020505A1Reduce residual stressStrong lightGearboxesGear lubrication/coolingEngineeringAutomotive engine

A universal bellhousing which may be adapted to a variety of automotive engine and transmission combinations and method of making the same is disclosed. The bellhousing is made by spin forming a sheet of steel and welding a transmission plate onto the cone. The cone and transmission plate are indexed to mount to a specified engine-transmission combination.

Owner:ACCEL PERFORMANCE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com