Patents

Literature

1984 results about "Thin slab" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

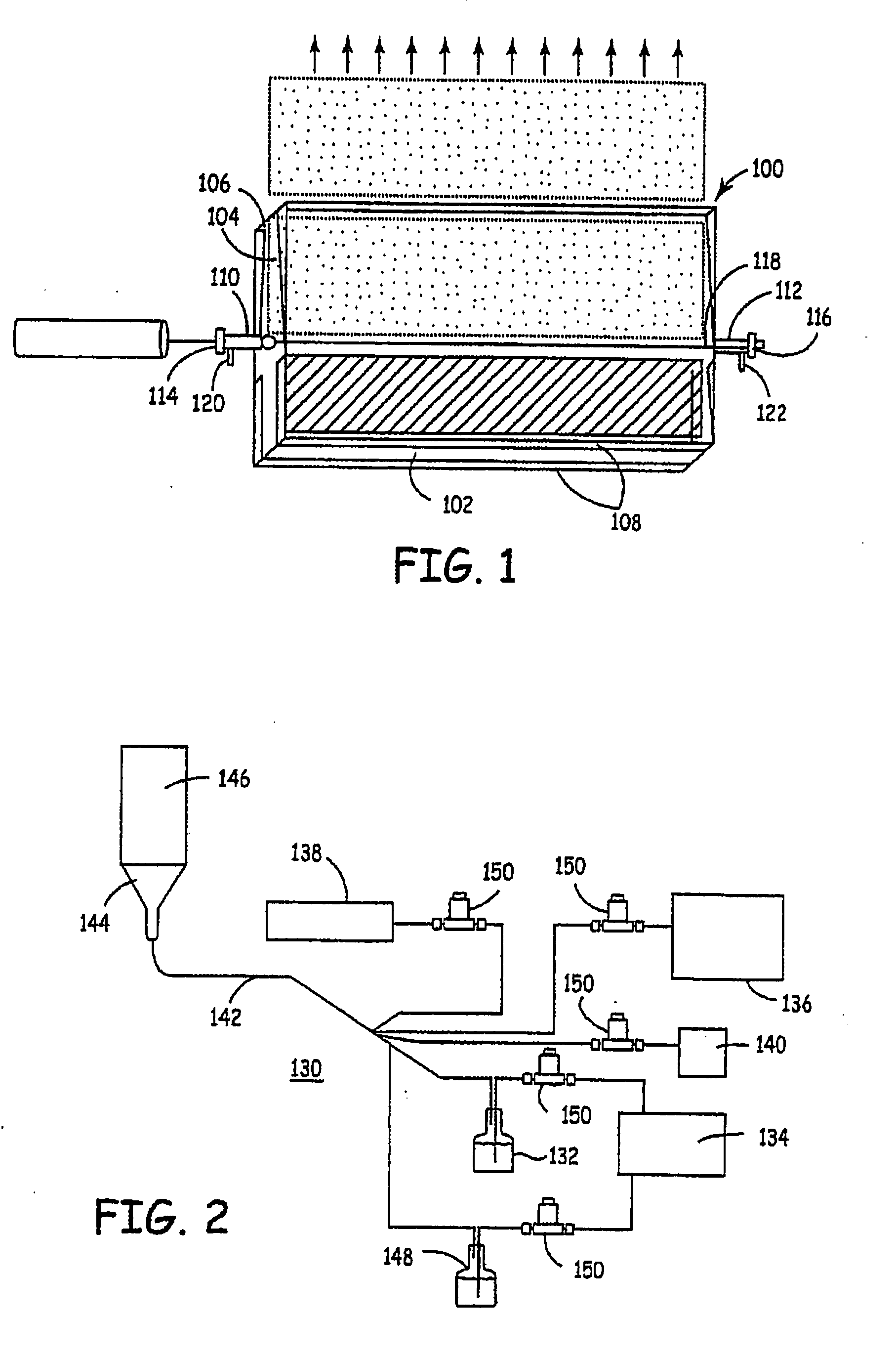

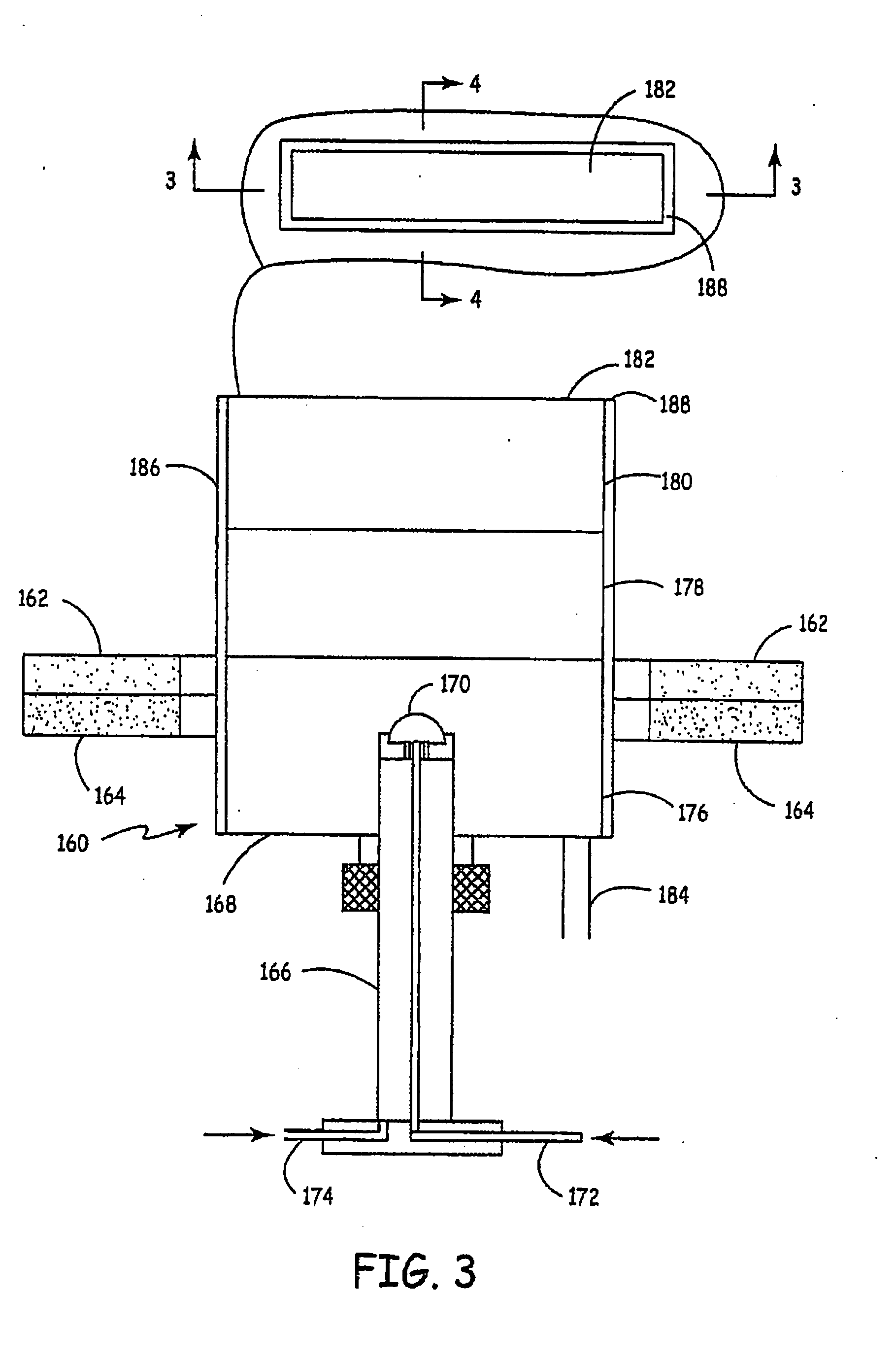

Thin silicon or germanium sheets and photovoltaics formed from thin sheets

Thin semiconductor foils can be formed using light reactive deposition. These foils can have an average thickness of less than 100 microns. In some embodiments, the semiconductor foils can have a large surface area, such as greater than about 900 square centimeters. The foil can be free standing or releasably held on one surface. The semiconductor foil can comprise elemental silicon, elemental germanium, silicon carbide, doped forms thereof, alloys thereof or mixtures thereof. The foils can be formed using a release layer that can release the foil after its deposition. The foils can be patterned, cut and processed in other ways for the formation of devices. Suitable devices that can be formed form the foils include, for example, photovoltaic modules and display control circuits.

Owner:NANOGRAM

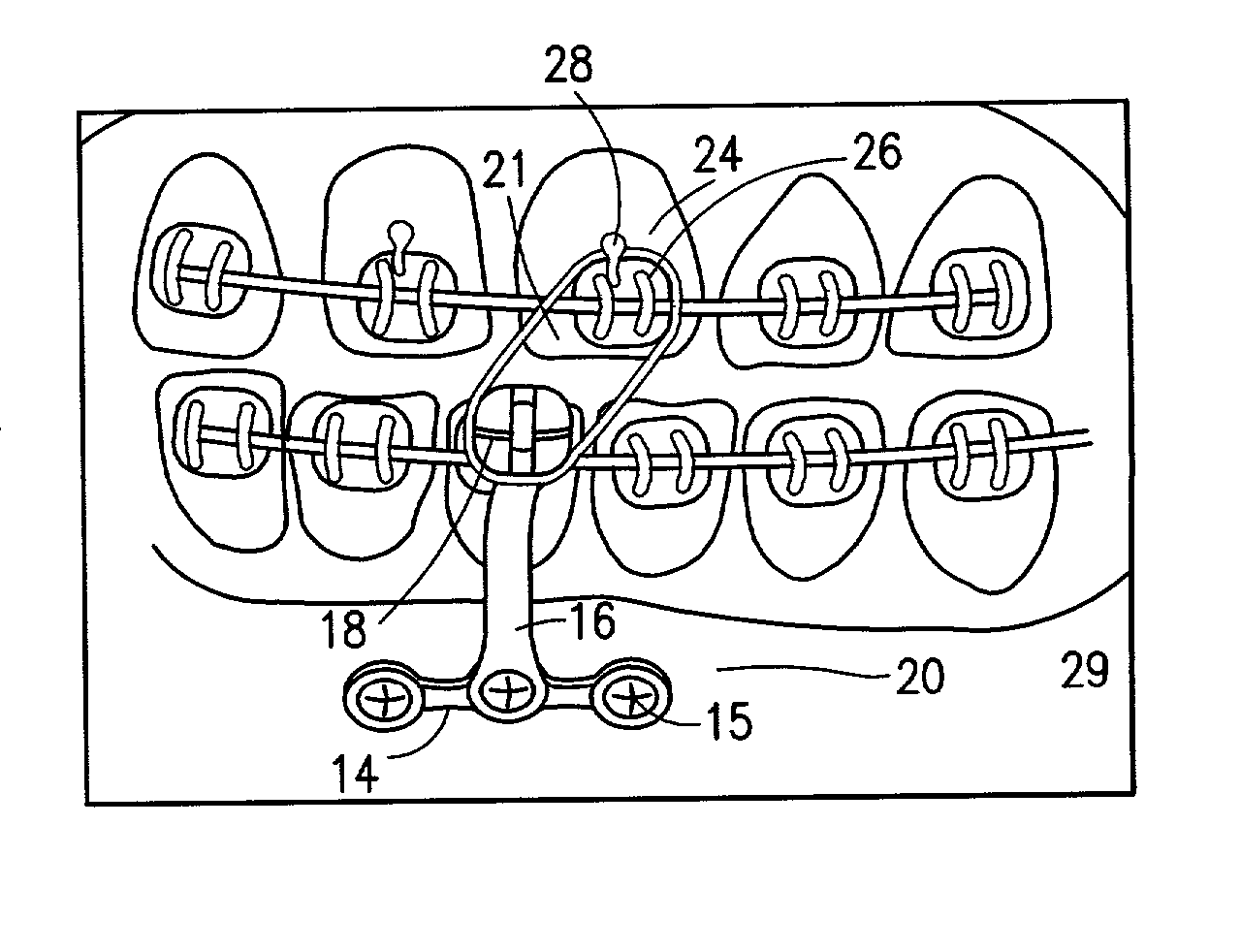

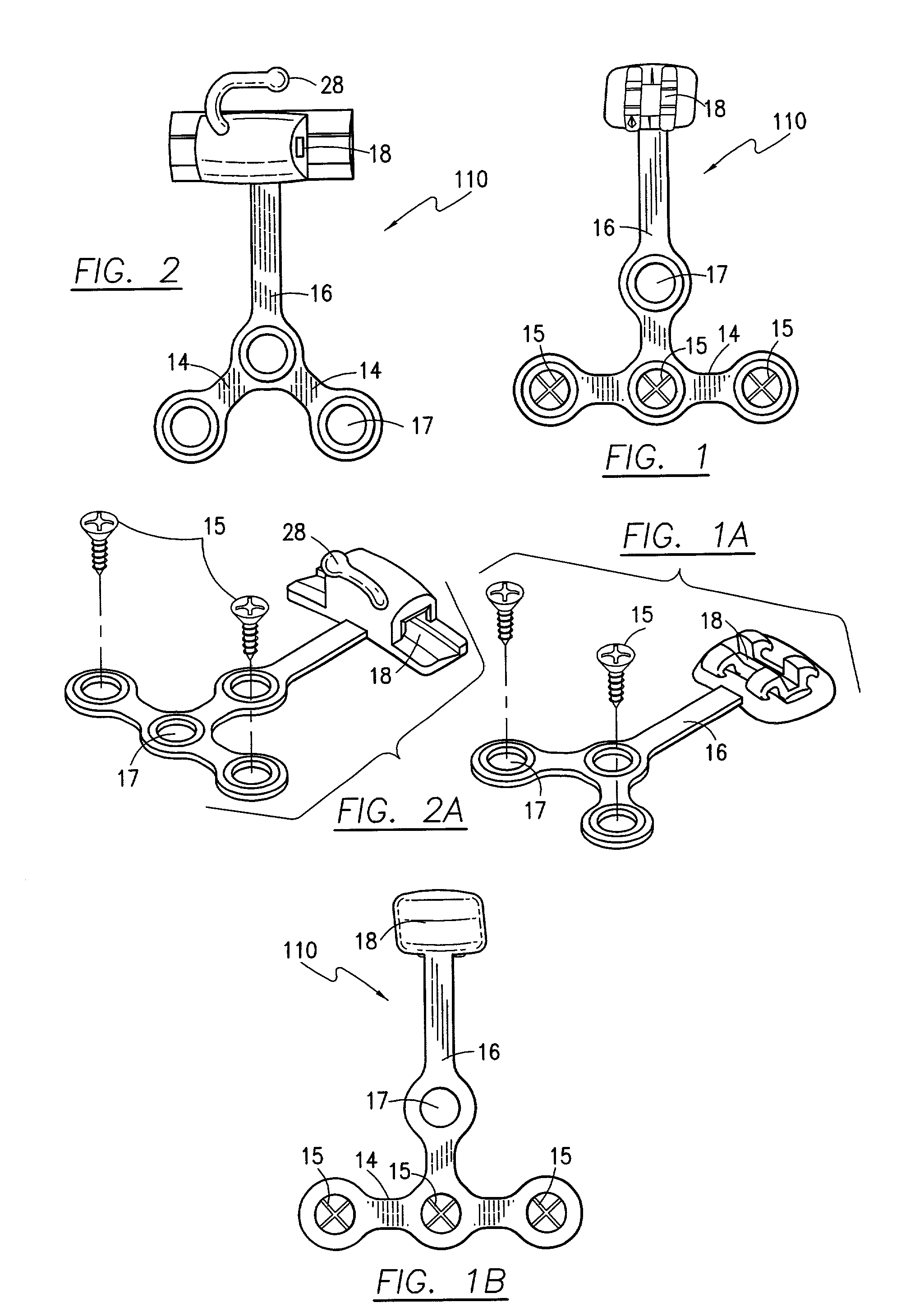

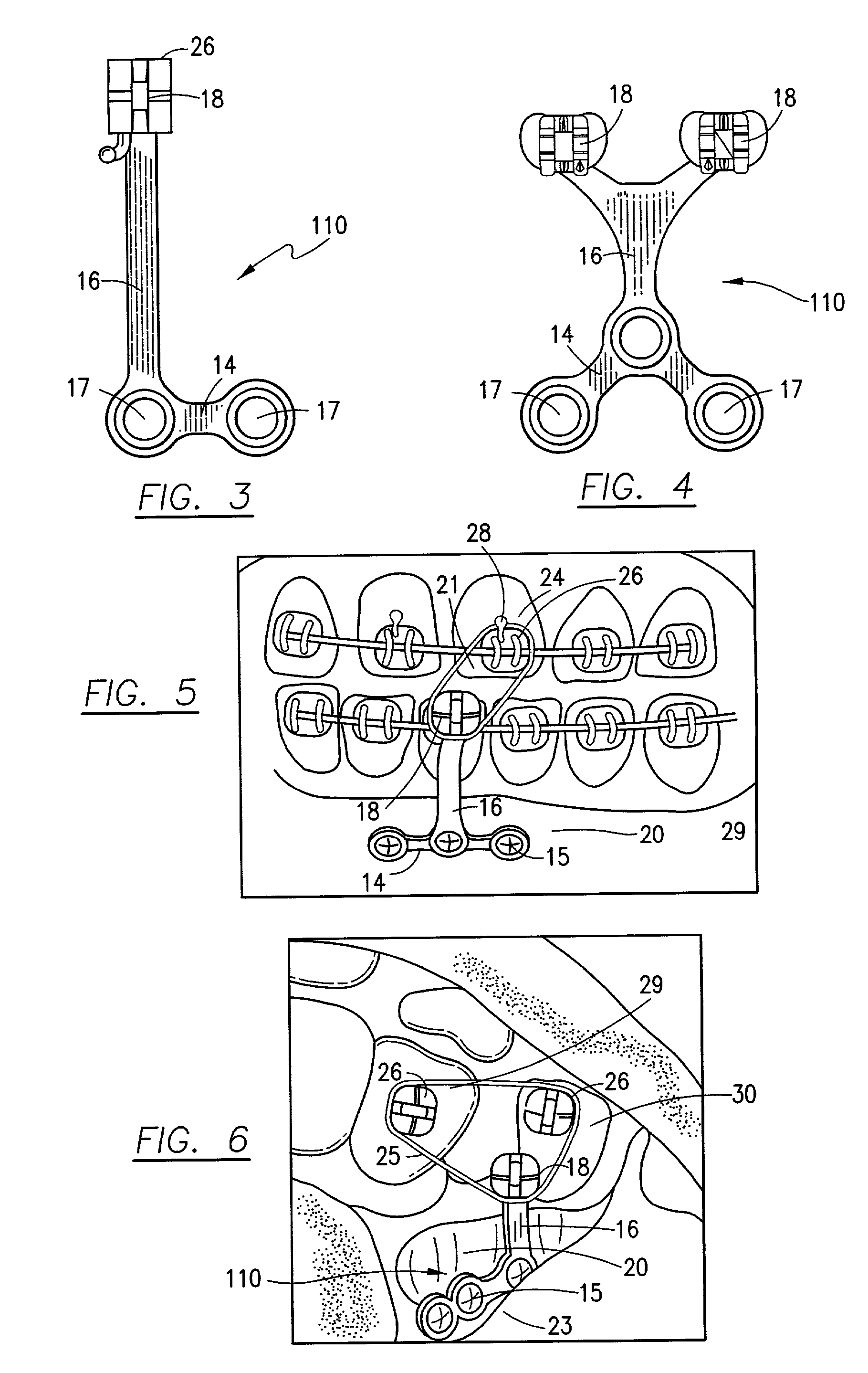

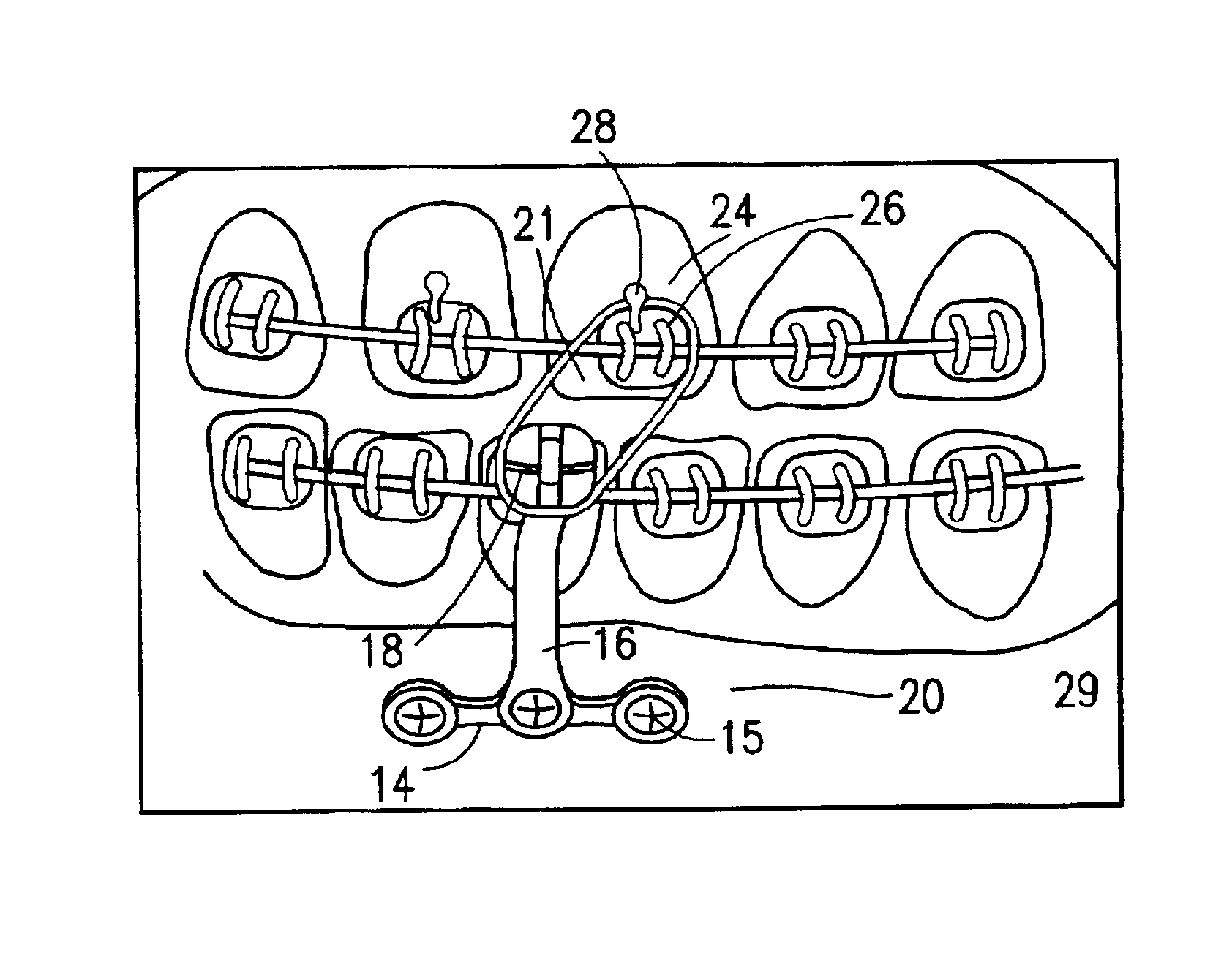

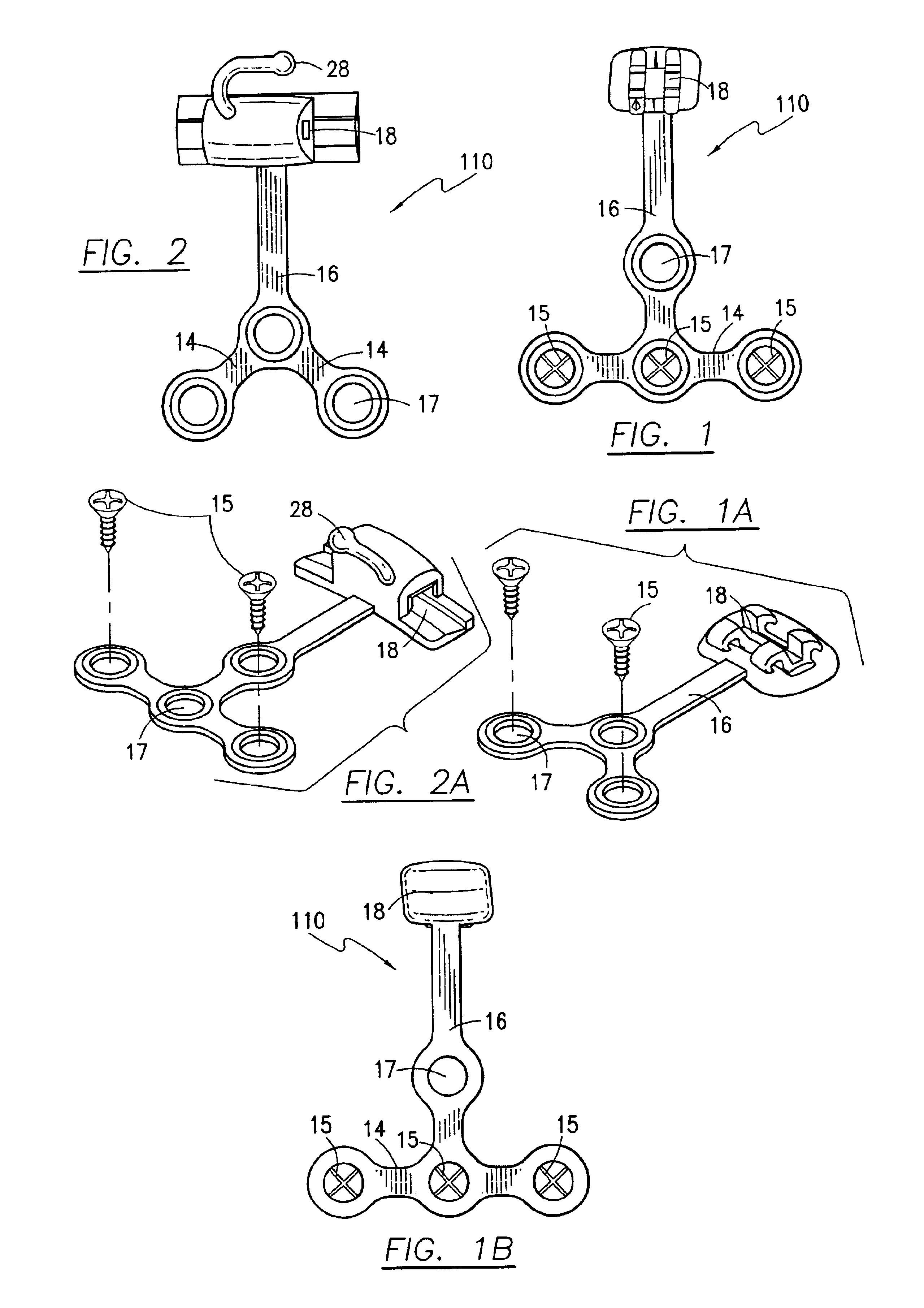

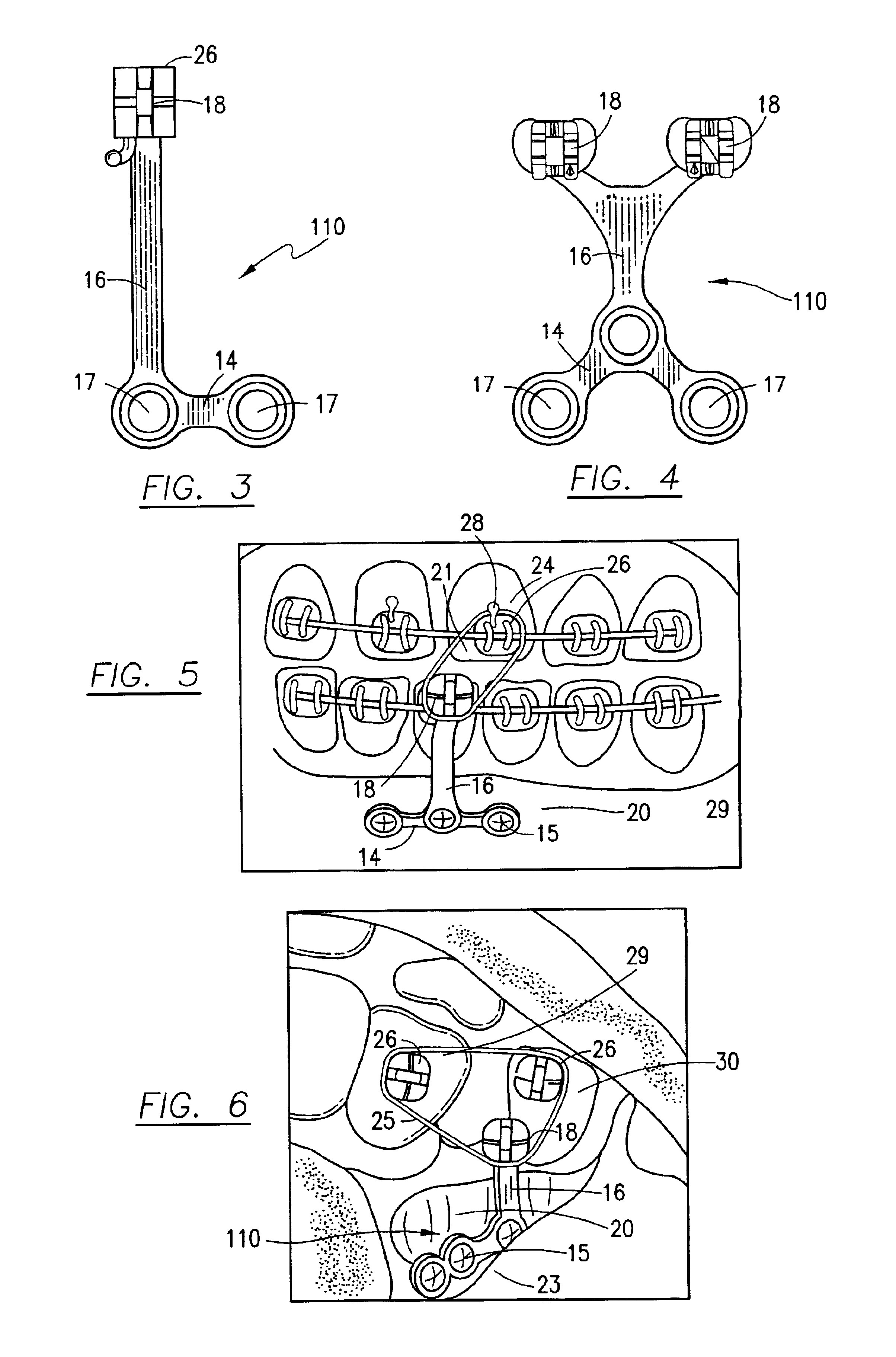

Skeletal transmucosal orthodontic plate and method

An orthodontic appliance anchored to the bone of the patient's mouth, the appliance having a wire guide for use with orthodontic tension bands to alleviate the use of other teeth as anchors. The device and method utilize a thin plate anchor body having at least one aperture, a bone fastener receivable through the anchor body aperture, and a tension band and / or wire guide channel affixed to the anchor plate body.

Owner:PAYTON KEVIN L

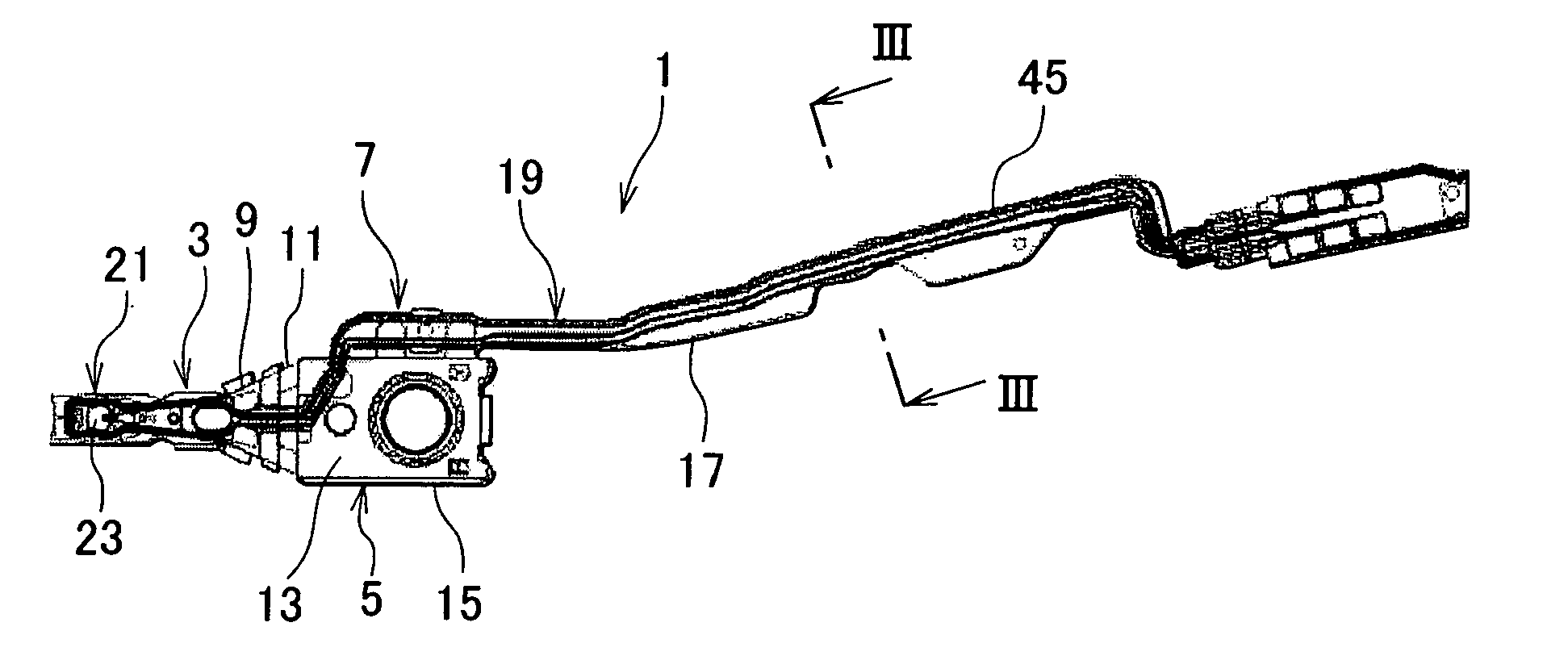

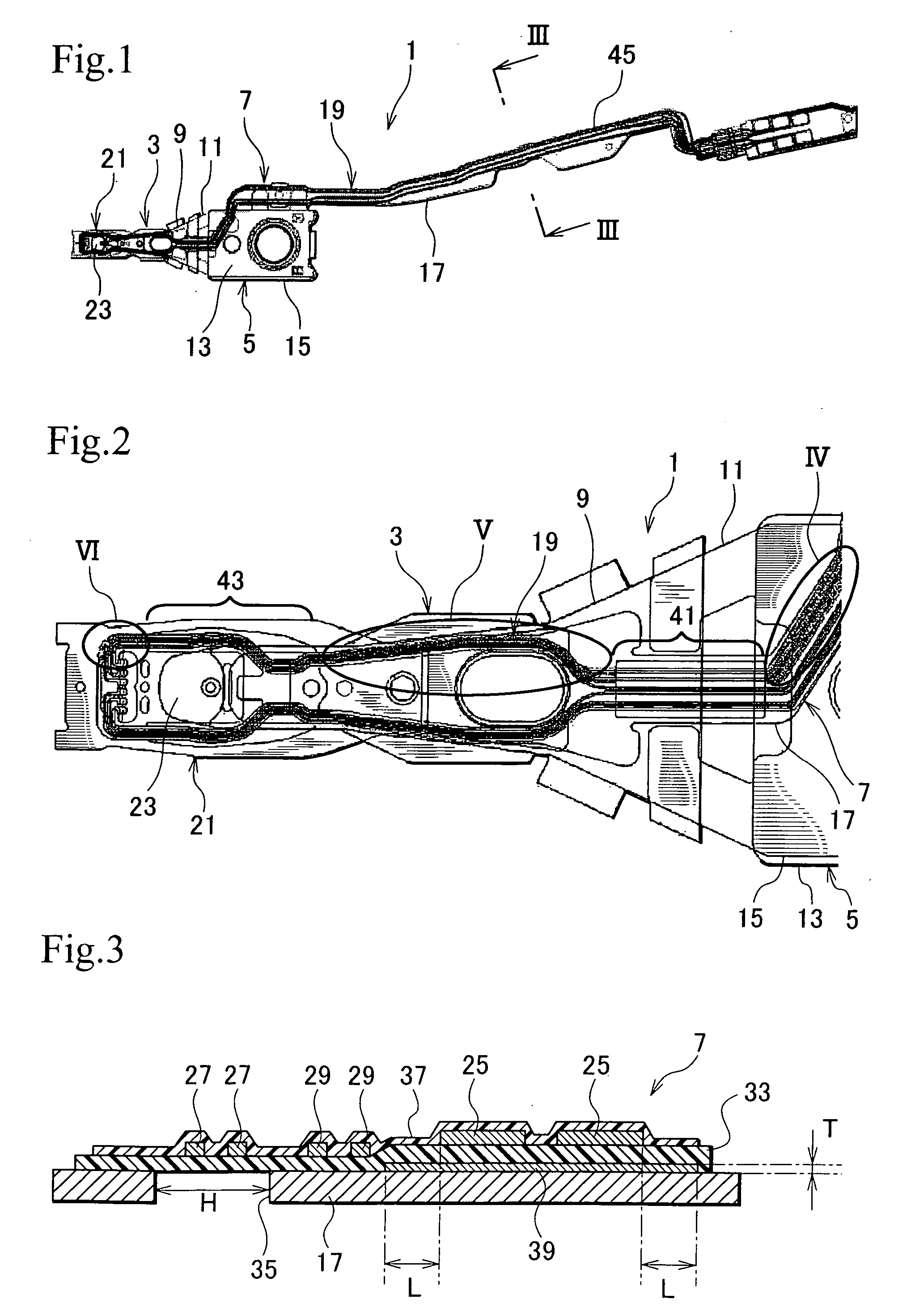

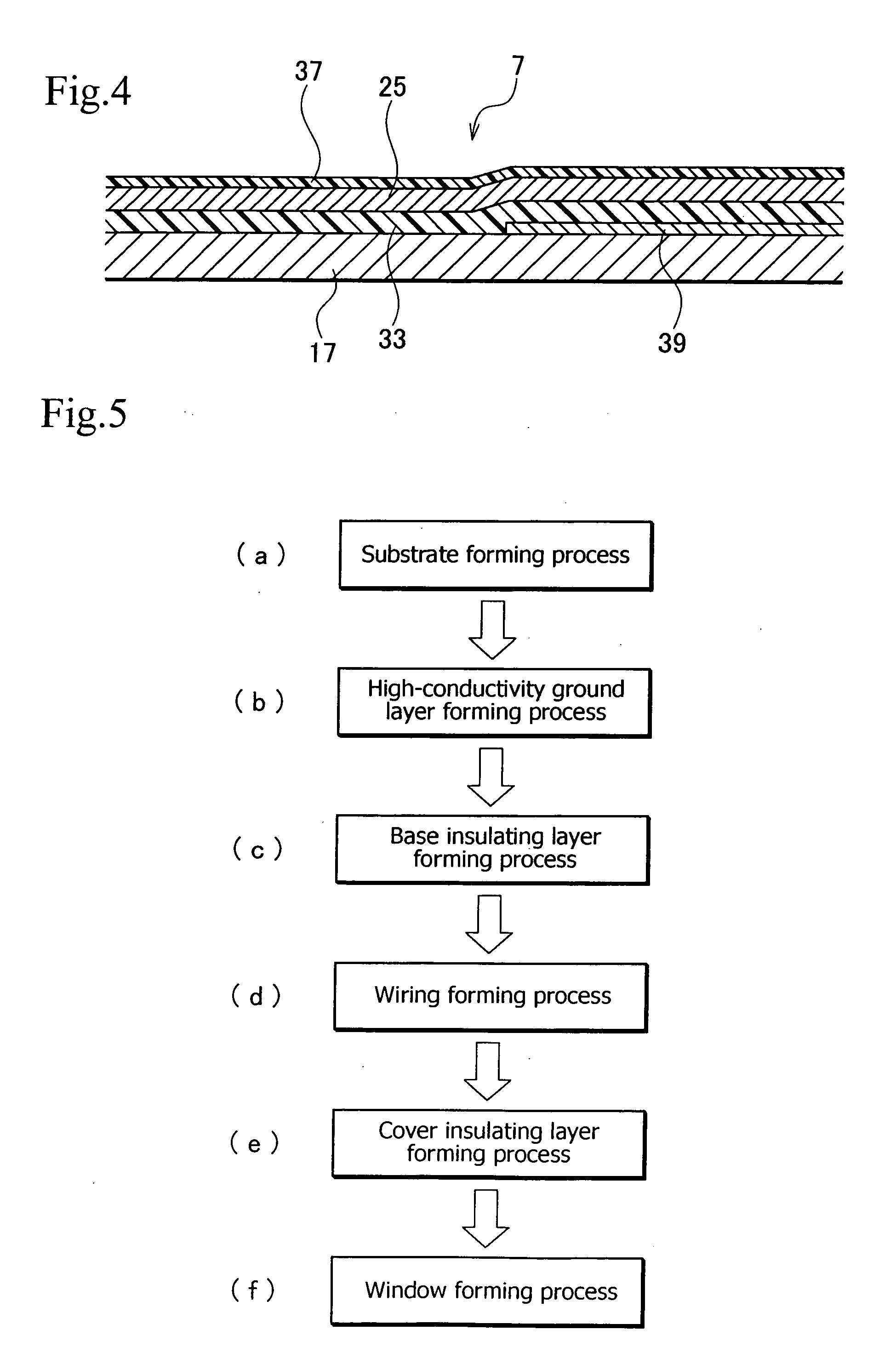

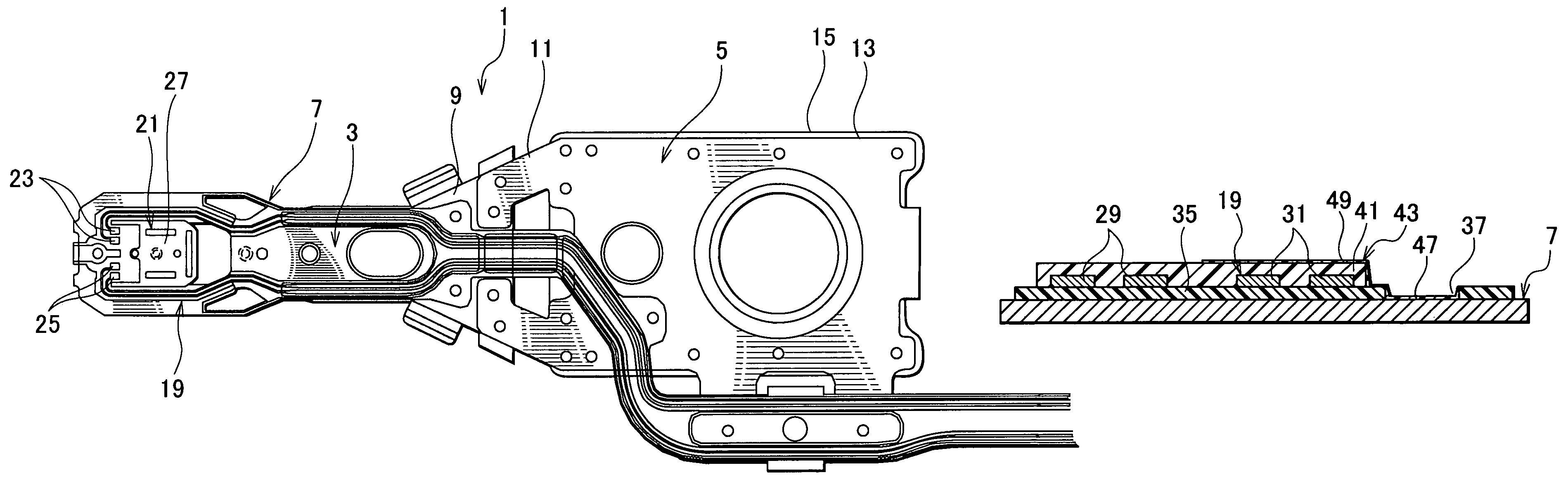

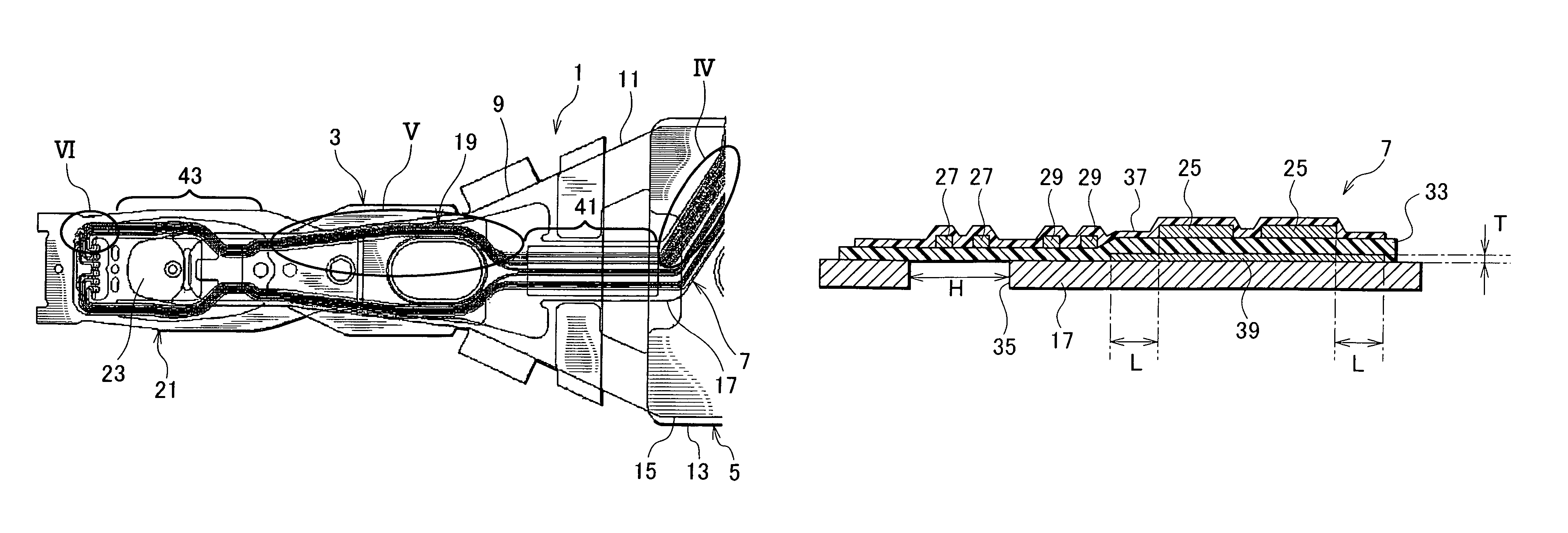

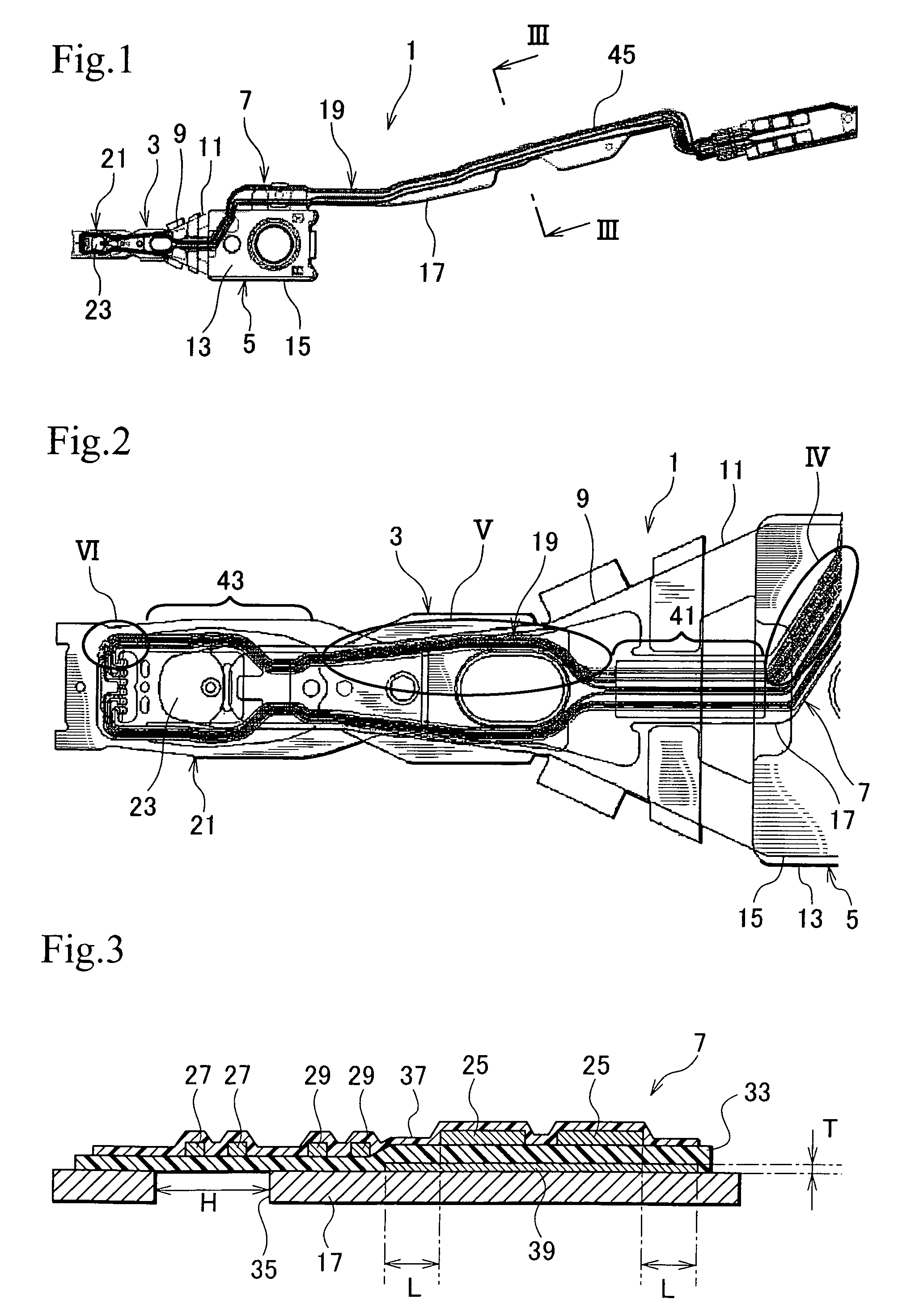

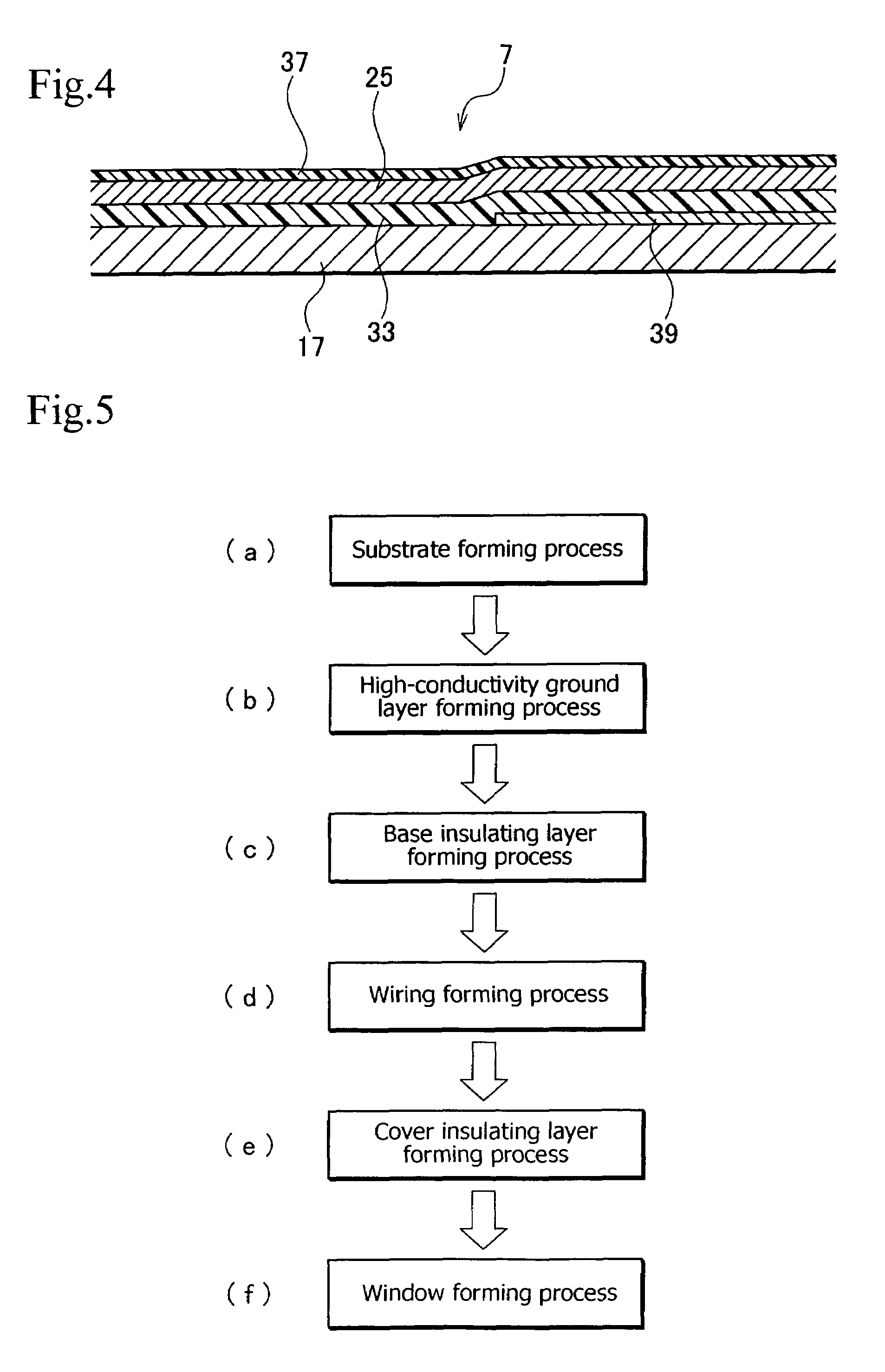

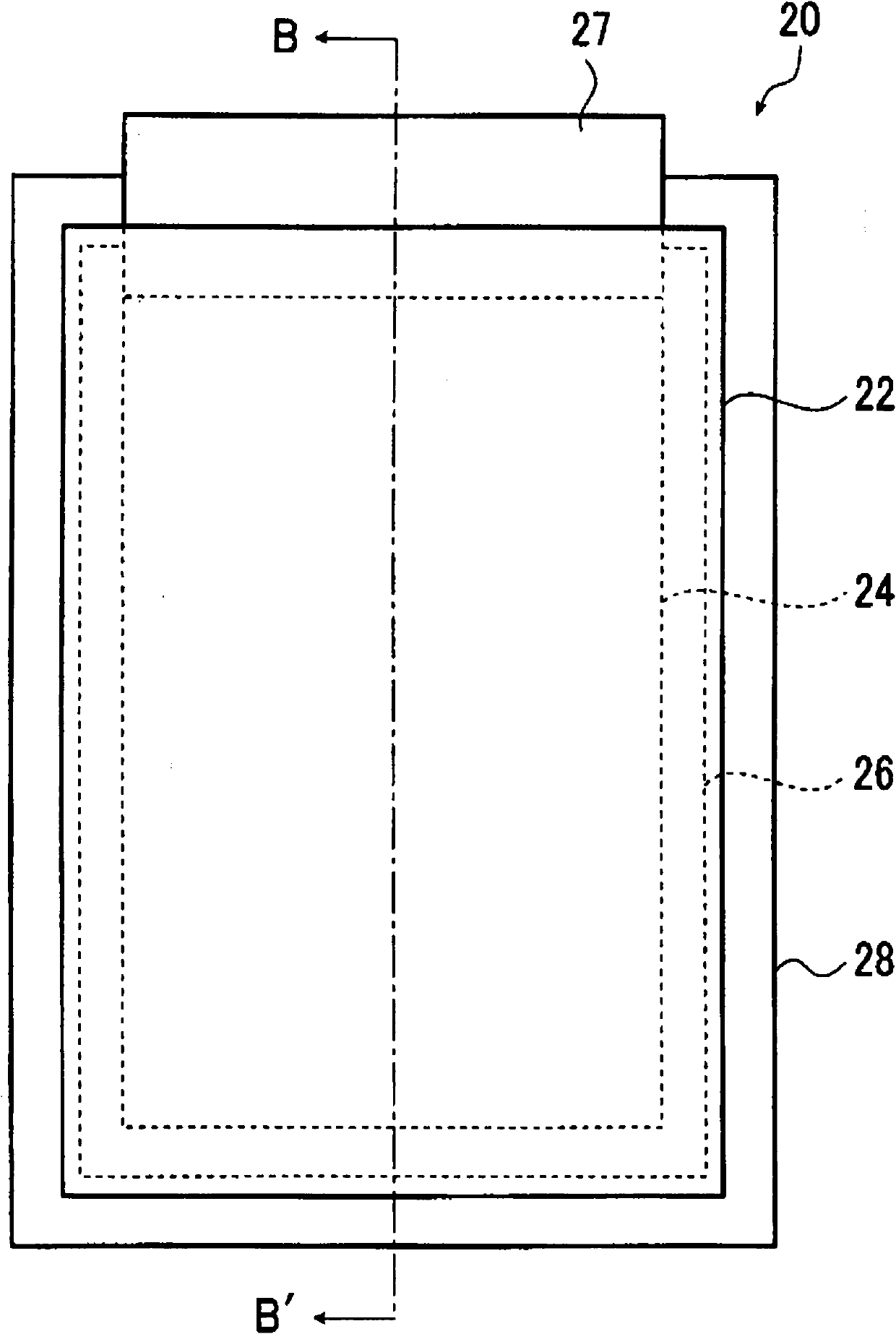

Head suspension with multilayer ground, flexure with multilayer ground, and methods of manufacturing them

ActiveUS20070133128A1Low wiring impedanceReduce transmission lossDisposition/mounting of recording headsRecord information storageThin slabEngineering

A head suspension includes a load beam to apply load onto a head that writes and reads information to and from the hard disk and a flexure attached to the load beam and supporting the head. The flexure has write wires and read wires connected to the head. The flexure includes a substrate made of a conductive thin plate, a base insulating layer made of flexible resin and formed on the substrate, and the wires are arranged on the base insulating film. A ground layer is formed at least partly between the substrate and the base insulating layer. The ground layer only corresponds to the write wires in a width direction of the flexure. The conductivity of the ground layer is higher than that of the substrate that is made of a conductive thin plate.

Owner:NHK SPRING CO LTD

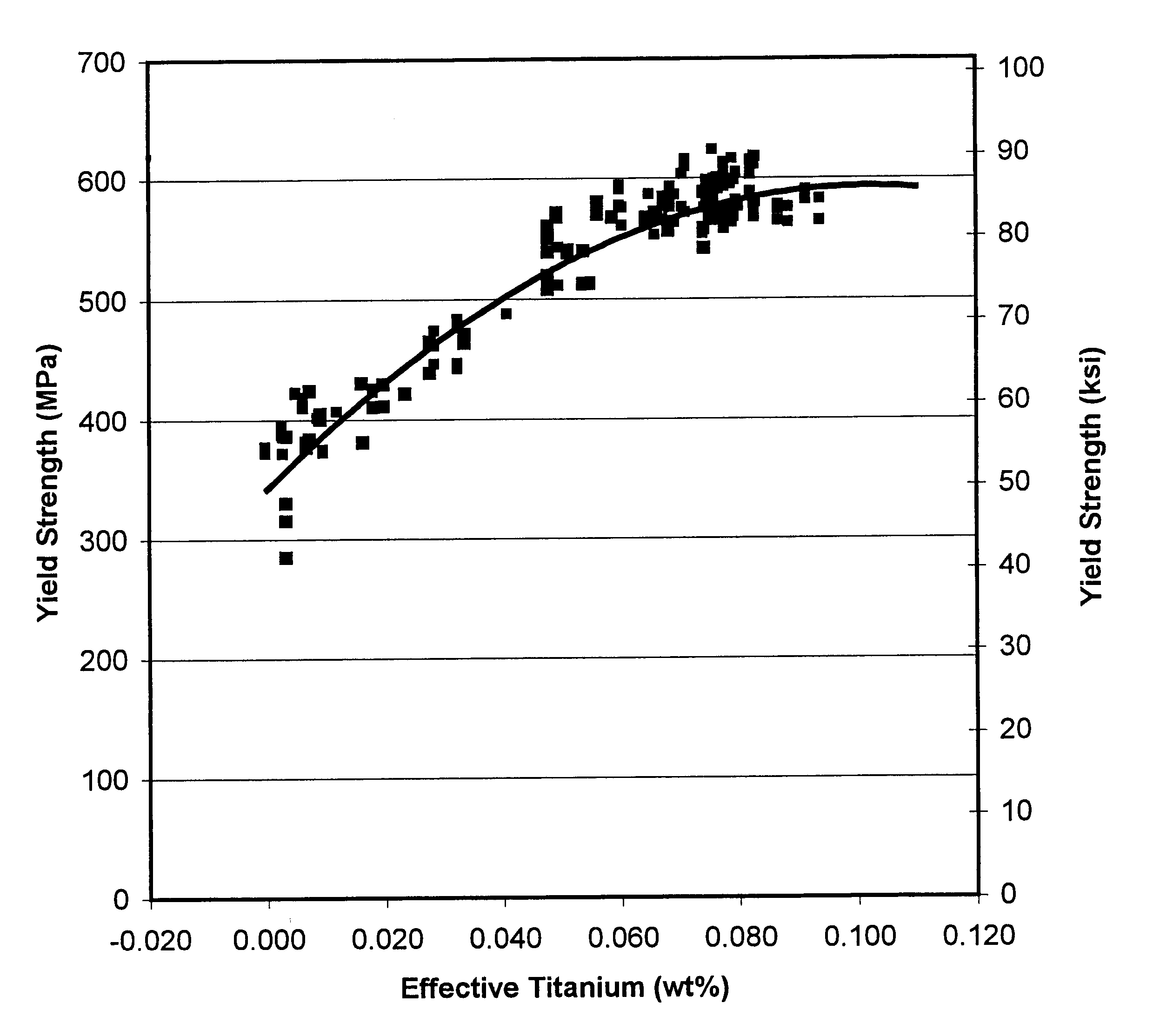

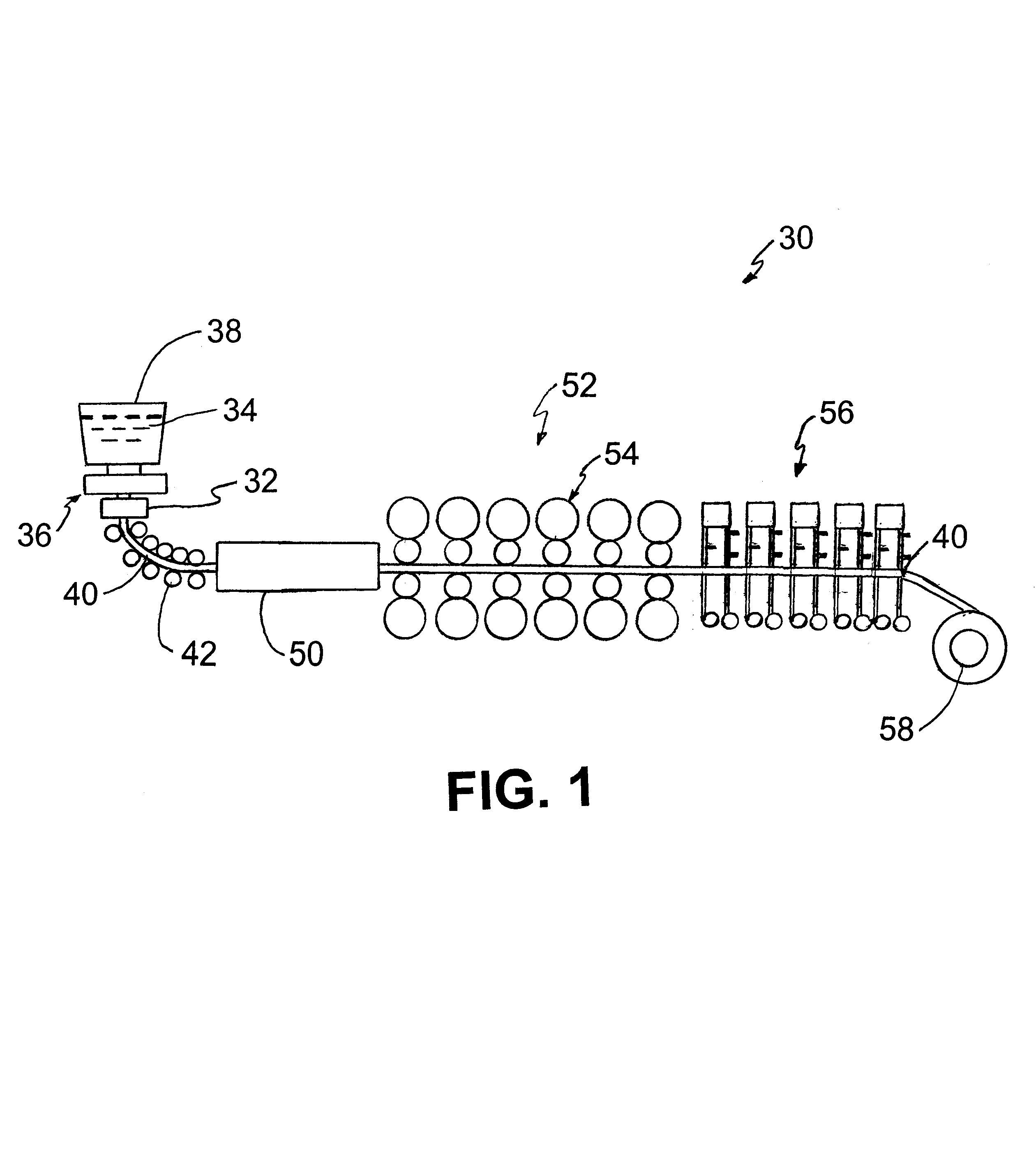

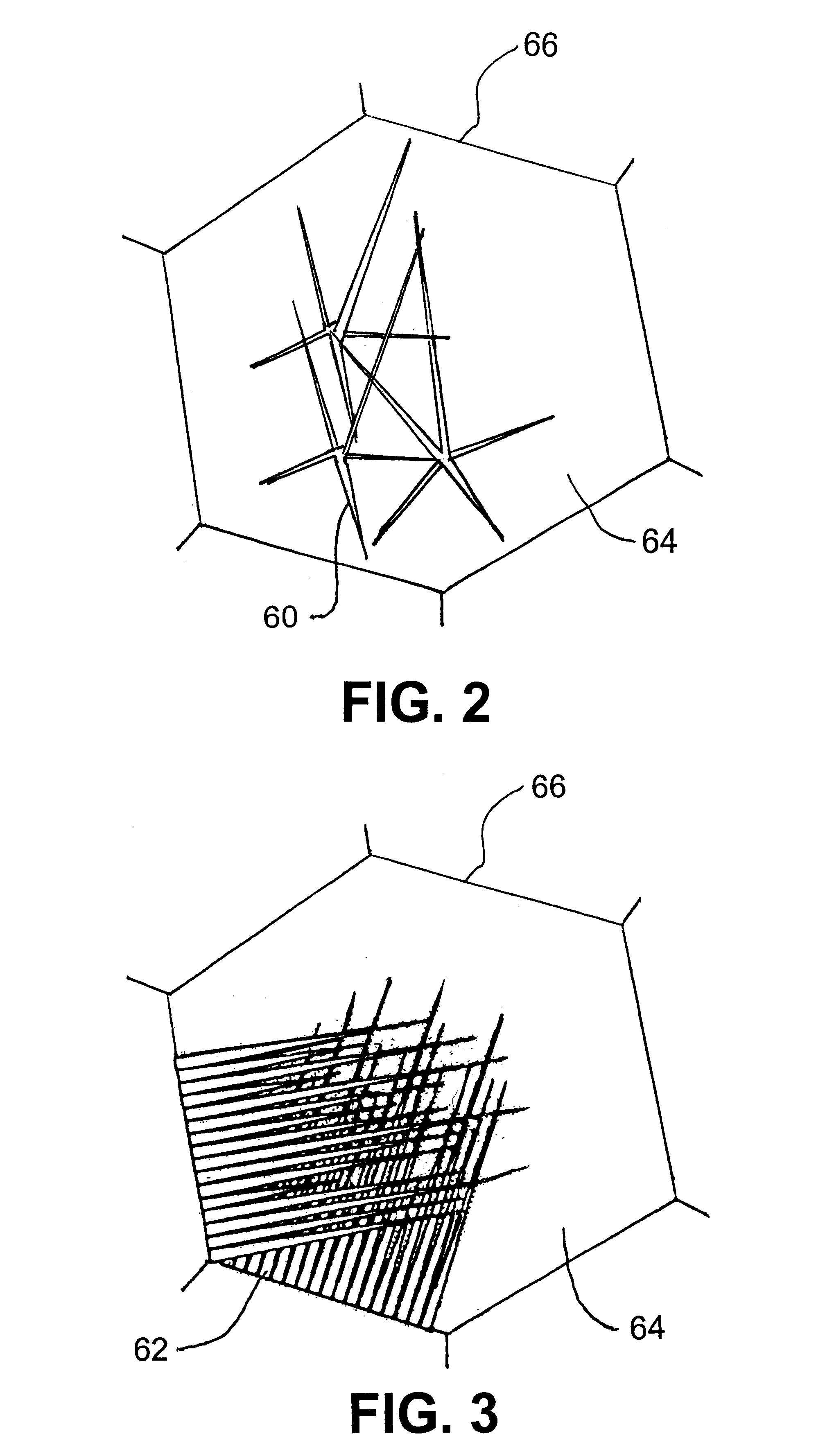

Method for producing titanium-bearing microalloyed high-strength low-alloy steel

A composition and method of making a high-strength low-alloy hot-rolled steel sheet, strip, or plate bearing titanium as the principal or only microalloy strengthening element. The steel is substantially ferritic and has a microstructure that is at least 20% acicular ferrite. The steel has a minimum yield strength of at least 345 MPa (50 ksi) and even over 621 MPa (90 ksi) adding titanium as the lone microalloy element for strengthening, with elongation of 15% and more. Addition of vanadium, niobium, or a combination thereof can result in yield strengths exceeding 621 MPa (90 ksi). Effective titanium content, being the content of titanium in the steel not in the form of nitrides, oxides, or sulfides, is in the range of 0.01 to 0.12% by weight. The manufacturing process includes continuously casting a thin slab and reducing the slab thickness using thermomechanical controlled processing, including dynamic recrystallization controlled rolling.

Owner:NUCOR CORP

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

Skeletal transmucosal orthodontic plate and method

An orthodontic appliance anchored to the bone of the patient's mouth, the appliance having a wire guide for use with orthodontic tension bands to alleviate the use of other teeth as anchors. The device and method utilize a thin plate anchor body having at least one aperture, a bone fastener receivable through the anchor body aperture, and a tension band and / or wire guide channel affixed to the anchor plate body.

Owner:PAYTON KEVIN L

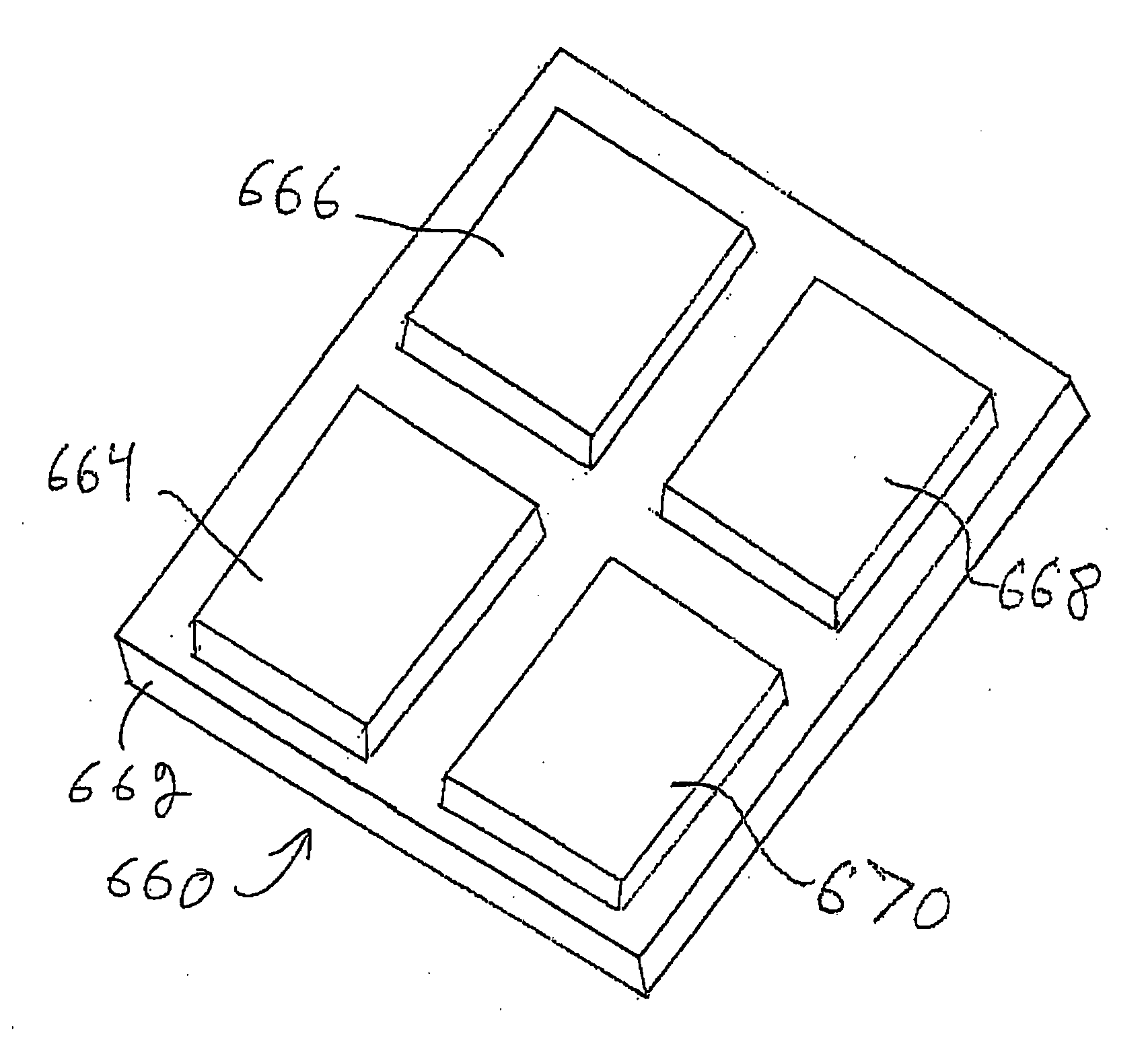

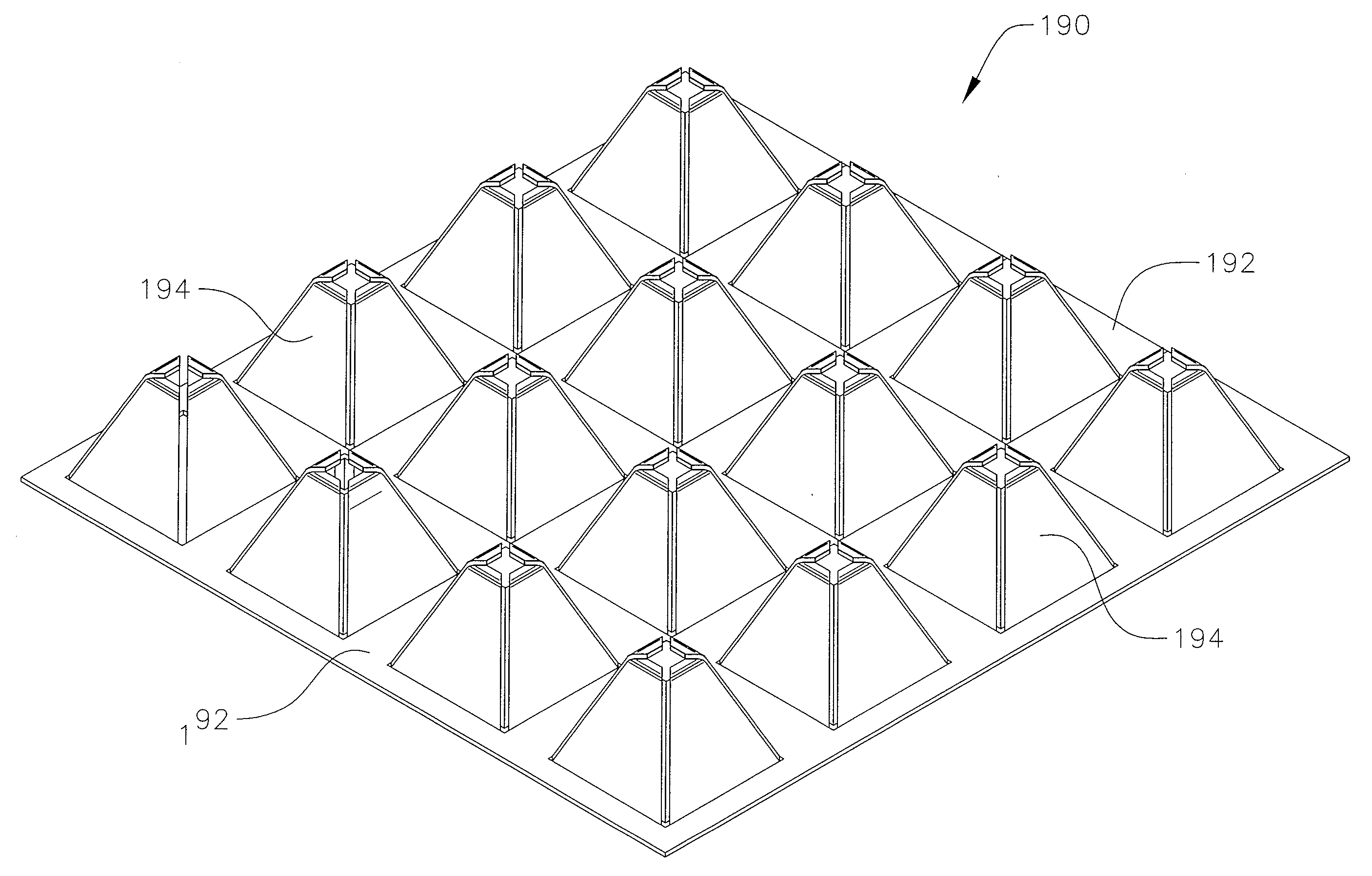

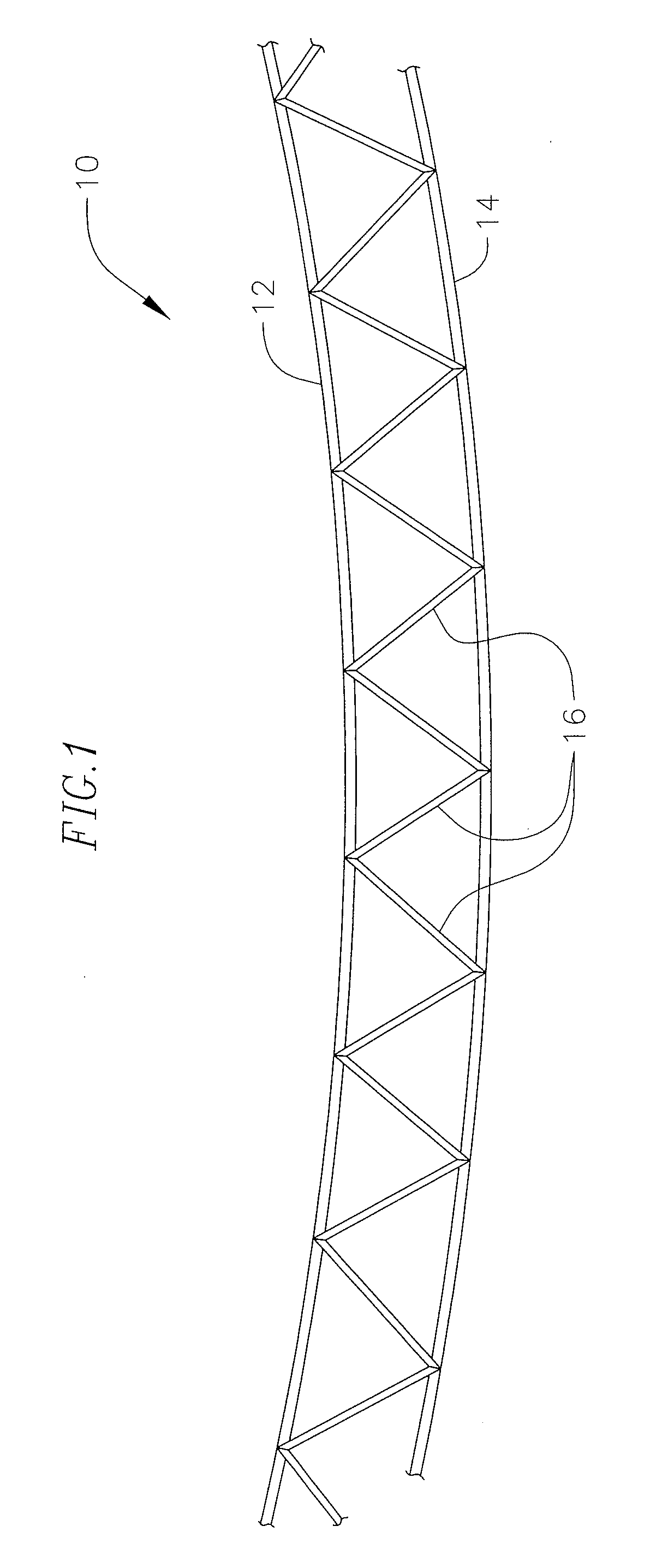

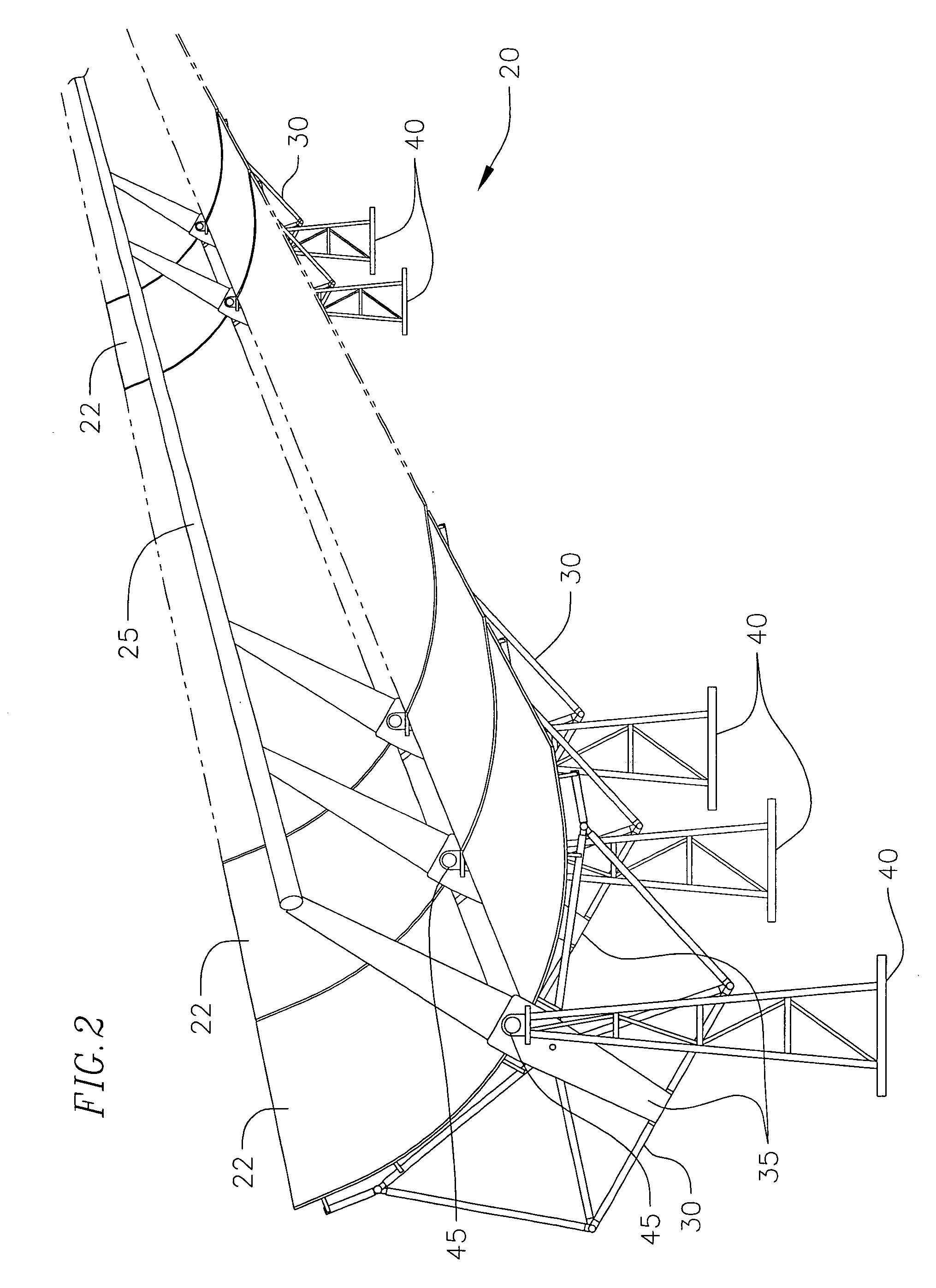

Mini-truss thin-sheet panel assembly

InactiveUS20090101195A1Improve rigidityLight weightSolar heating energySolar heat devicesThin slabThin sheet

A mini-truss thin-sheet panel assembly. In one embodiment, a substantially rigid thin-sheet panel assembly having a non-rigid thin-sheet component includes the thin-sheet component which has selected plan area and shape, a backer having a plan shape and area substantially similar to the thin-sheet component, and plural riser elements of selected height and configuration each extending from the backer to distal ends connected to a reverse surface of the thin-sheet component, the riser elements being configured and disposed in an array which causes the assembly to have substantial rigidity in a selected direction in the thin-sheet component.

Owner:GOSSAMER SPACE FRAMES

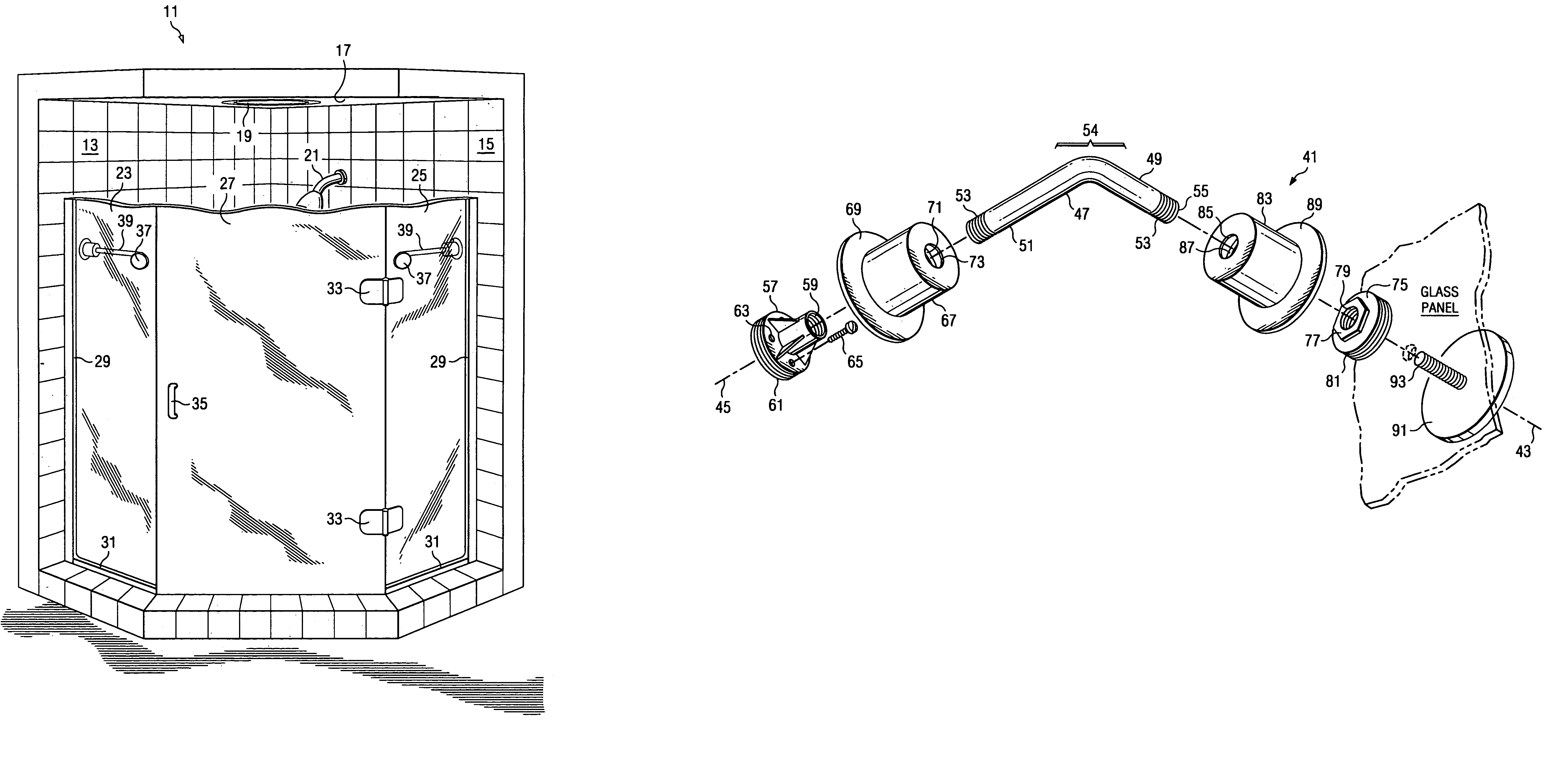

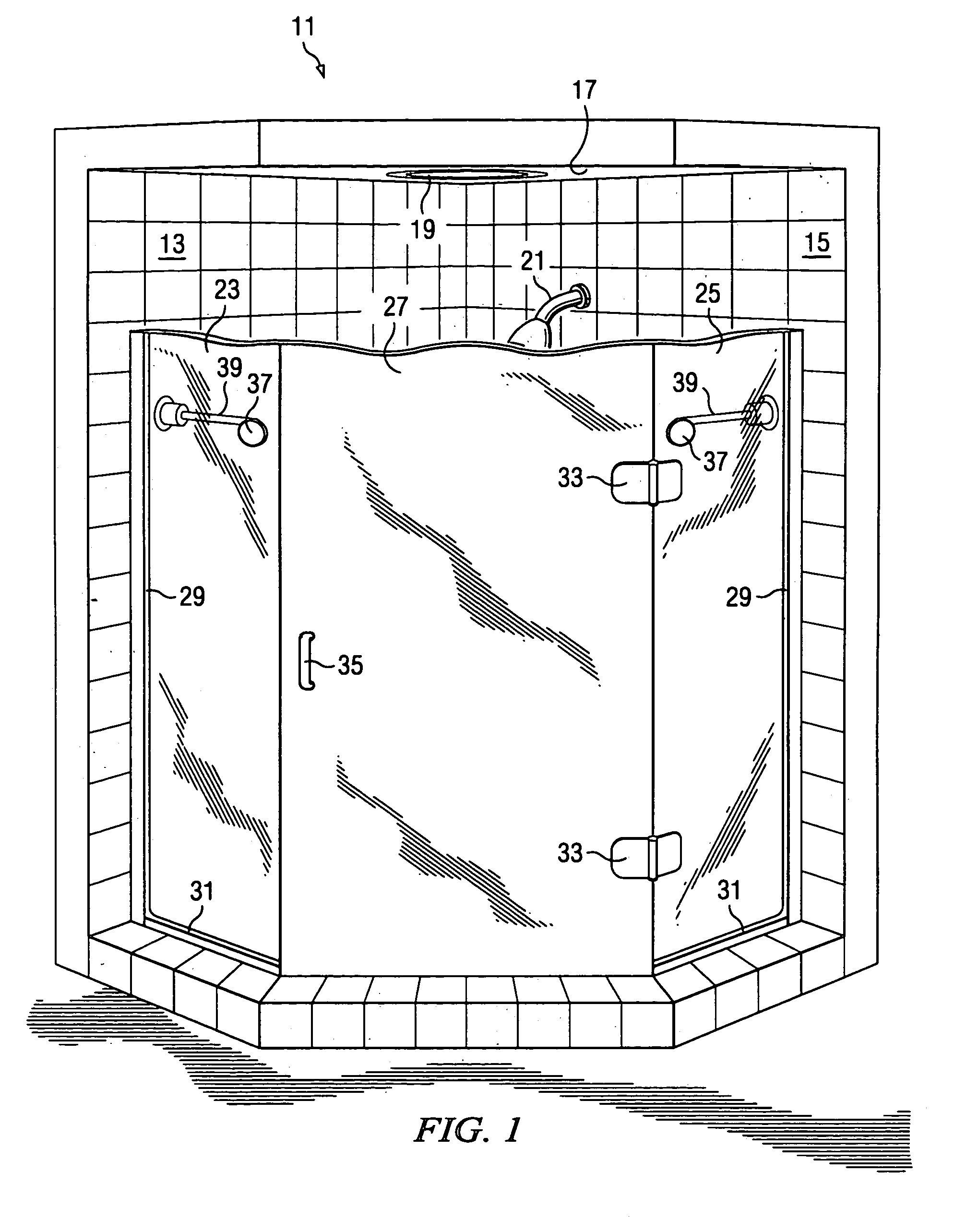

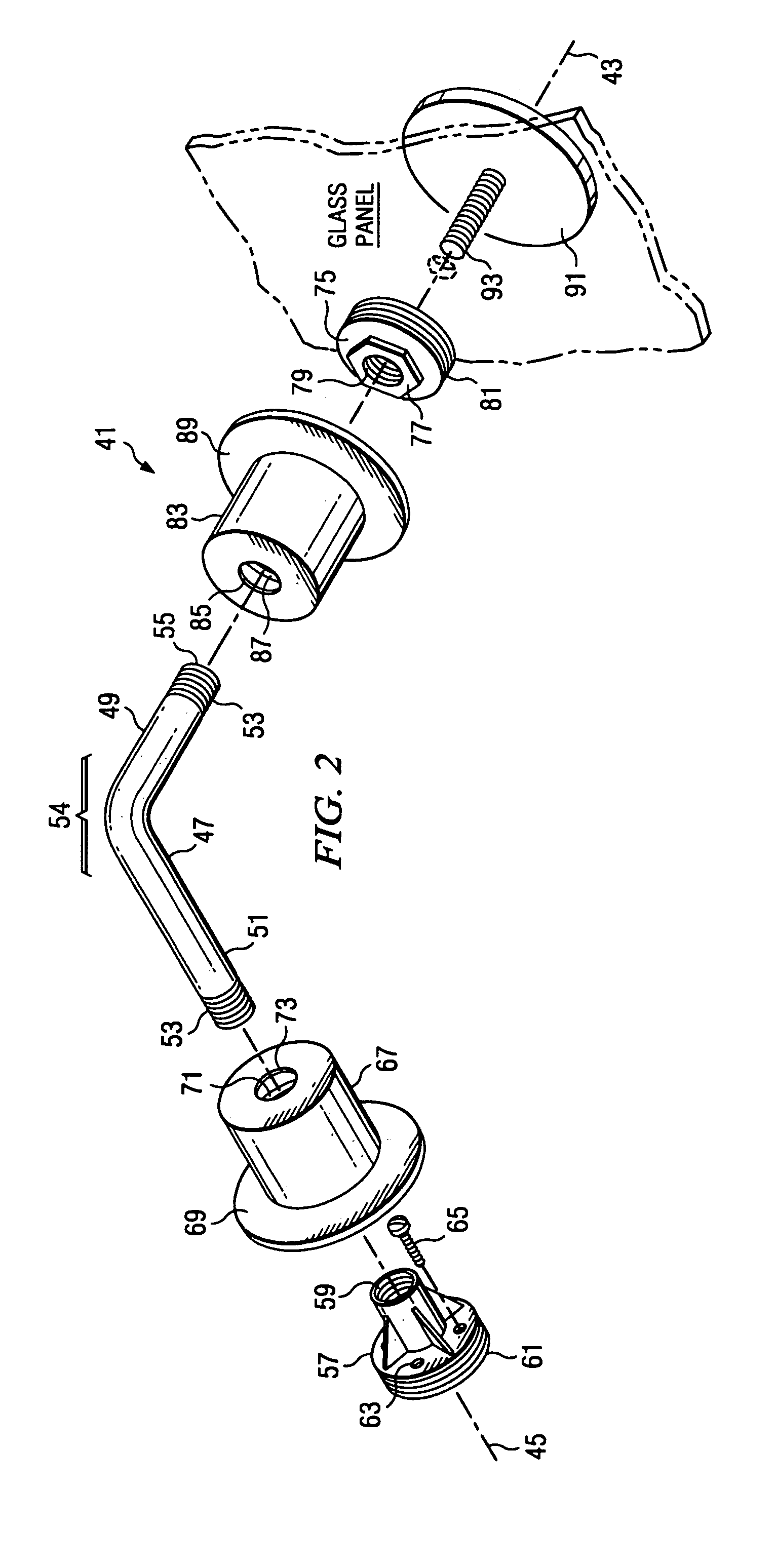

Method and apparatus for supporting a thin, rigid panel

A support arm apparatus and method for stabilizing an outward, distal portion of a thin, rigid panel attached at an inward, vertical edge opposite the outward, distal portion to a fixed vertical surface, comprising a support bar having externally threaded first and second ends and formed at an elbow angle nearer the first end; a first mounting assembly installed on the first end of the support bar for attaching the first end of the support bar to the thin panel at a first location thereon; and a second mounting assembly installed on the second end of the support bar for attaching the second end of the support bar to the fixed vertical surface at a second location thereon; wherein the externally threaded first and second ends of the support bar enable adjustment of the first and second mounting assemblies respectively along a longitudinal axis of each first and second end of the support bar to stabilize the outward, distal portion of the thin panel at a predetermined panel angle.

Owner:PENCE CHARLES

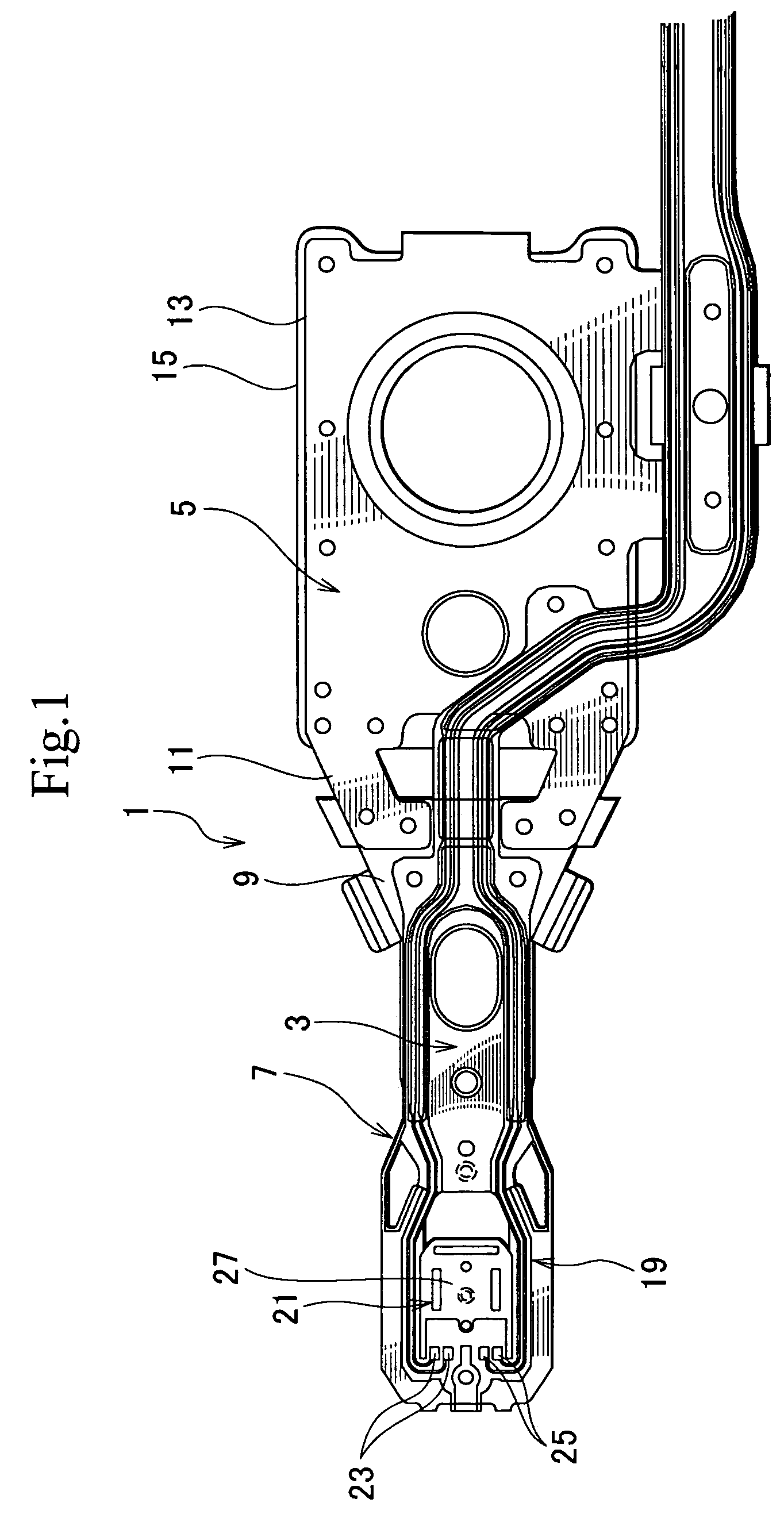

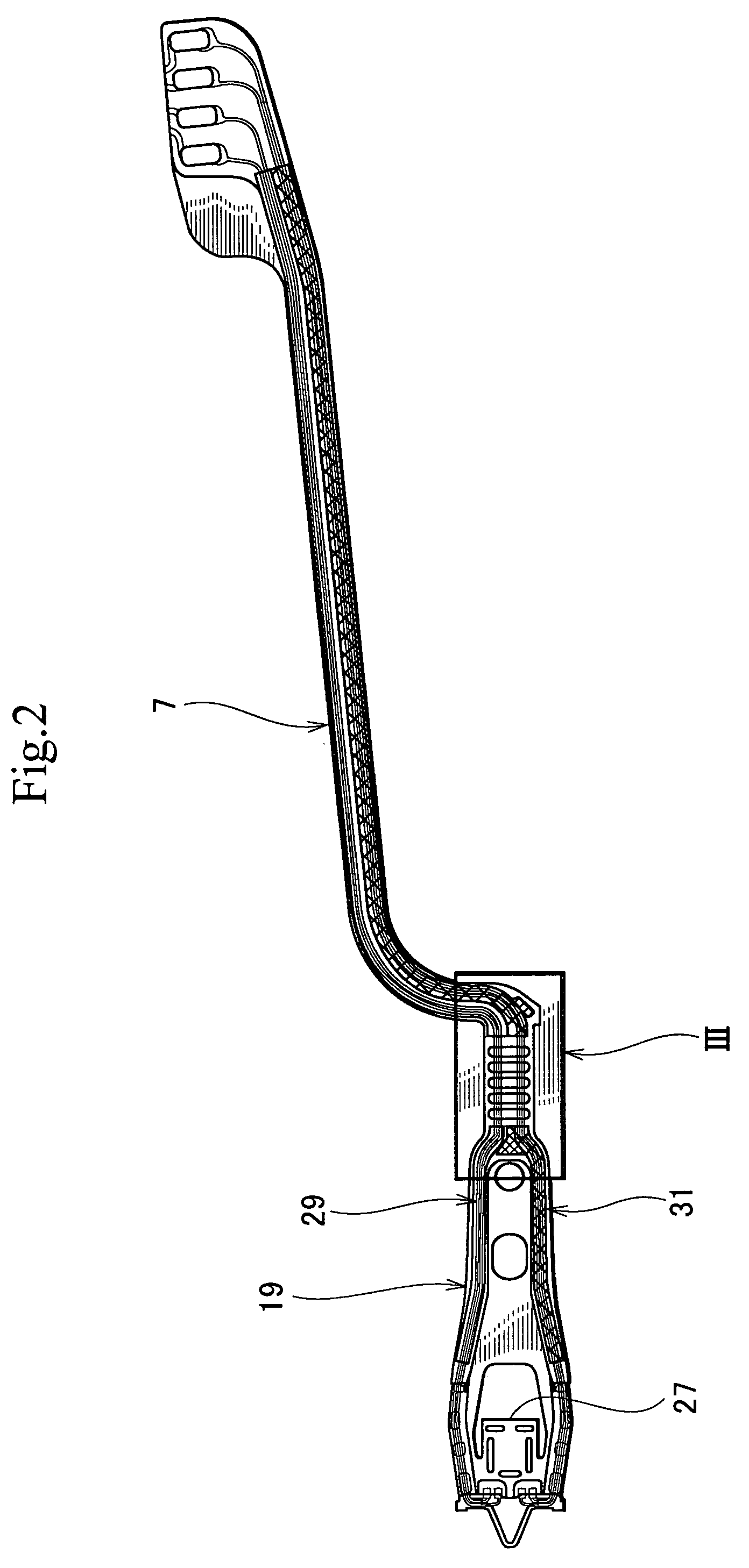

Head suspension having wiring disposed with conductive layer

ActiveUS7643252B2Avoid damageNot deteriorate write performanceHigh voltage circuit adaptationsRecord information storageThin slabEngineering

A head suspension prevents a read element from electrostatic discharge damage without employing a static electricity remover, and at the same time, secures the frequency characteristics of a write signal. The head suspension has a load beam to apply load to a slider that writes and reads data to and from a hard disk, a flexture made of a conductive thin plate attached to the load beam, to support the slider, write wires connected to the slider and formed on an insulating base layer that is made of flexible resin and is formed on the flexure, and coating made of conductive flexible resin to discharge static electricity. The coating is formed over the read wires and is extended to the surface of the flexure.

Owner:NHK SPRING CO LTD

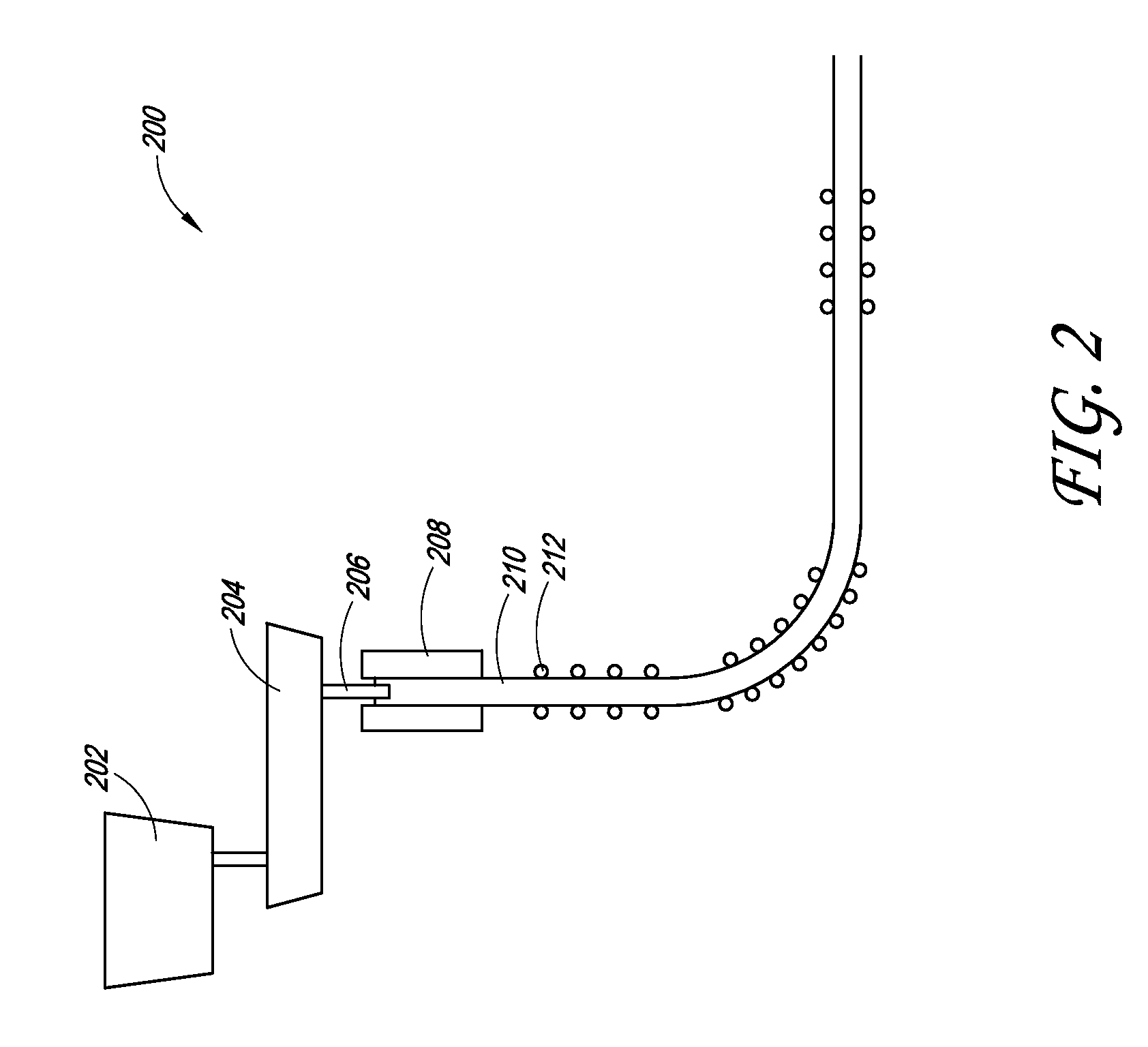

Parameter setting method of hot continuous rolling thin slab coiling device and coiling method of hot continuous rolling thin slab

The invention relates to a parameter setting method of a hot continuous rolling thin slab coiling device and a coiling method of a hot continuous rolling thin slab. The parameters to be set are as follows: an advance speed set value of each set of roller beds = a finish rolling final rack speed set value * (a total roller bed advance rate + advance rate of each set); a lagging speed set value of each set of roller beds = the finish rolling final rack speed set value * a roller bed lagging rate; the side guide plate pressure coefficient is 0.8 + / - 0.15; the side guide plate additional value is from +5 to +10 mm; and the pinch roll is set, and the pinch roll of the coiling device is standardized to ensure the regular standardization, the pinch roll advance rate, pinch roll lagging rate, pinch roll pressure coefficient, upper pinch roll diameter of the coiling device and lower pinch roll diameter of the coiling device. The coiling method is implemented by controlling the coiling device with a computer according to the setting parameters. By using the parameter setting method of the hot continuous rolling thin slab coiling device and the coiling method of the hot continuous rolling thin slab, the surface quality is improved and the rejection rate is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Head suspension with multilayer ground, flexure with multilayer ground, and methods of manufacturing them

ActiveUS7701674B2Lower impedanceReduce transmission lossDisposition/mounting of recording headsRecord information storageThin slabEngineering

Owner:NHK SPRING CO LTD

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

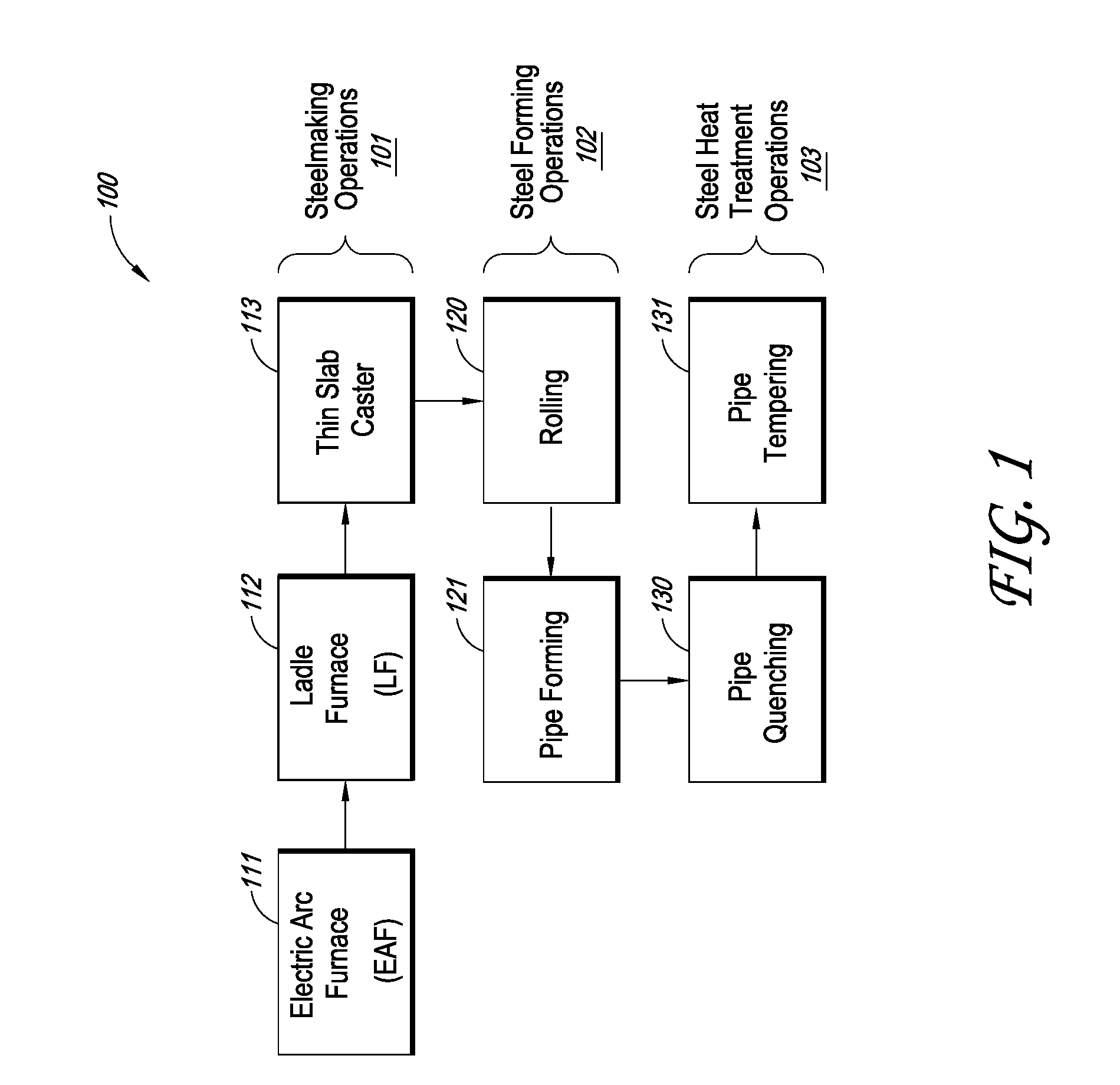

Compact strip or thin slab processing of boron/titanium steels

A method for casting medium carbon, B / Ti steel product using compact strip processing or thin slab casting. The method can include providing a steel composition including boron and titanium and casting the steel composition into a slab having a thickness between about 25 and 150 mm. The slab can have a cast composition including about 0.23 to 0.30 wt. % carbon, about 0.0010 to 0.0050 wt. % boron, about 0.010 to 0.050 wt. % titanium, about 1.15 to 1.50 wt. % manganese, less than 0.35 wt. % silicon and a Ti / N ratio greater than 2.9. The amount of each element is provided based upon the total weight of the steel composition. The steel slab can be free from cracks and significant defects. Furthermore, the steel slab can be used for electric resistance welded (ERW) products.

Owner:MAVERICK TUBE +1

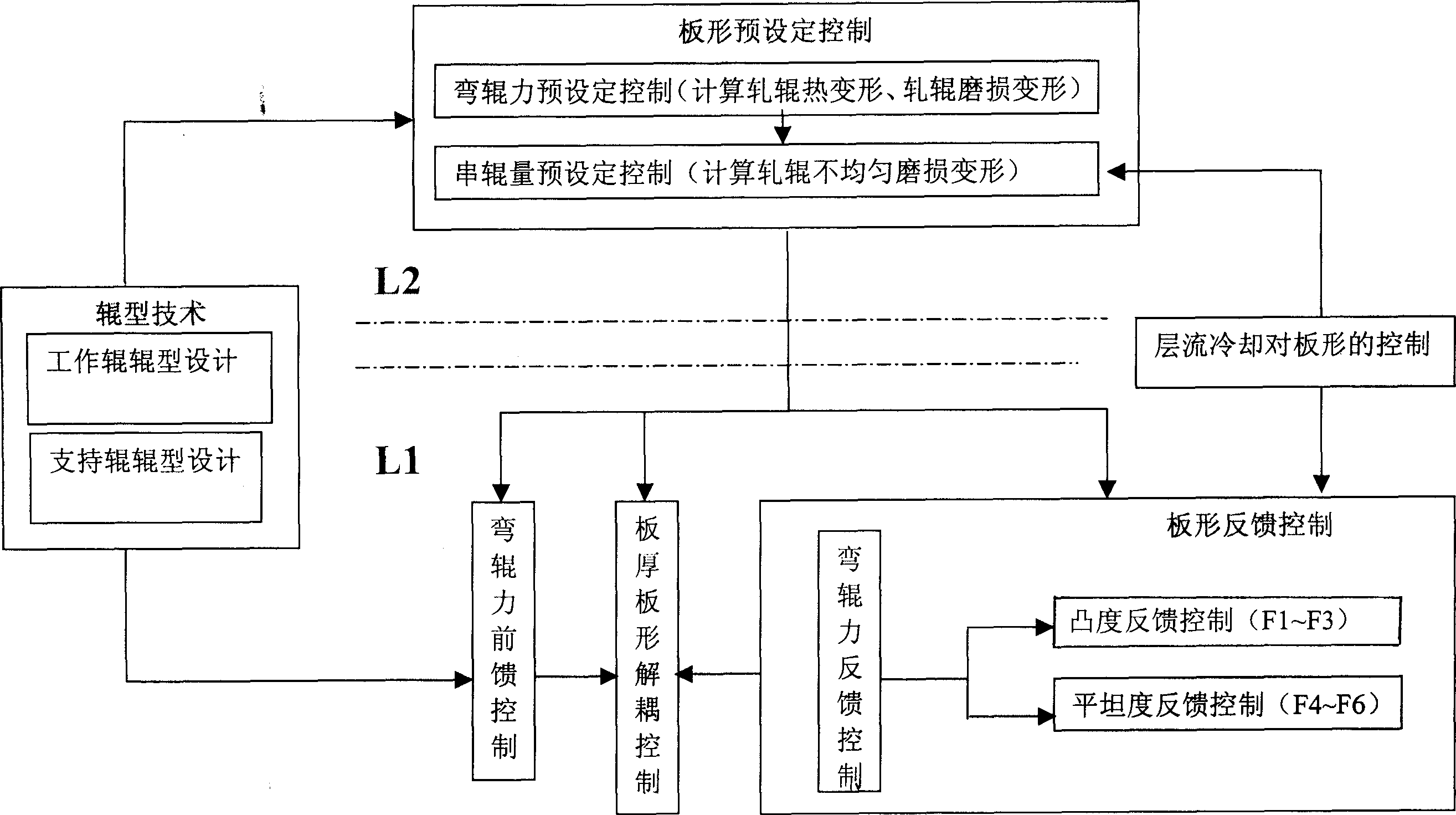

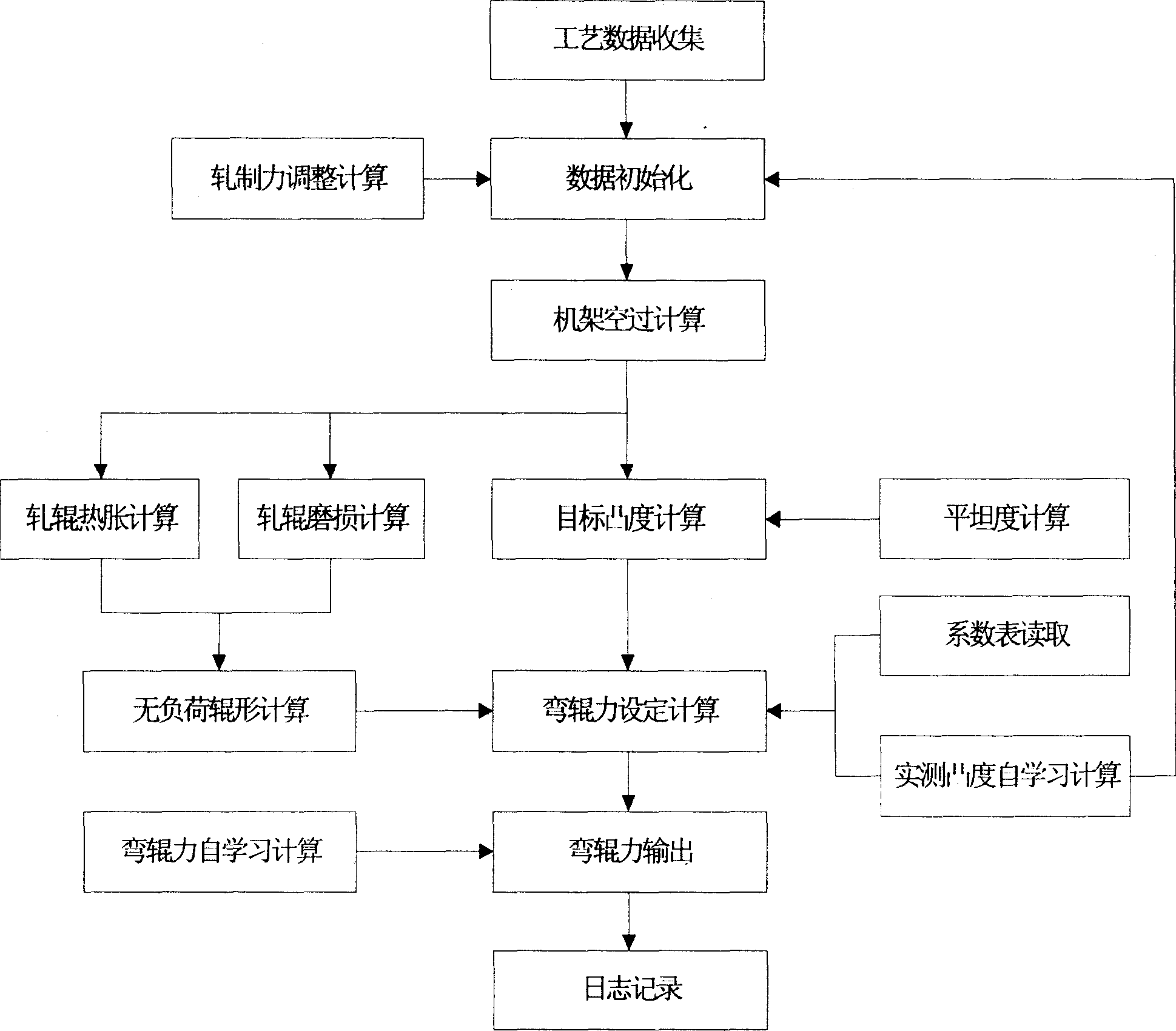

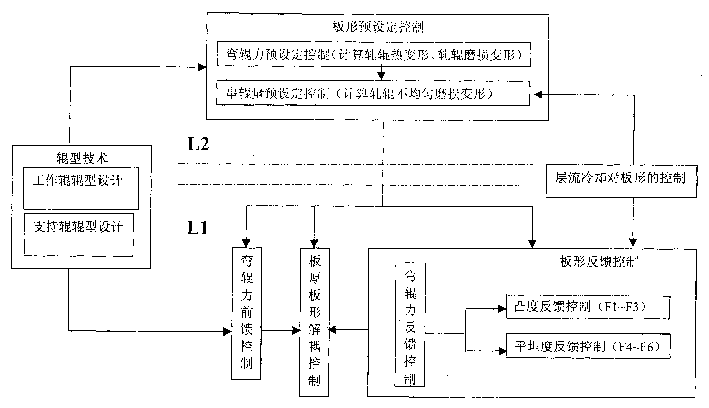

Method for controlling plate sizes of middle or thin plate planks in continuous casting and rolling processes

An integrated control method for the shape of medium-thin plate in conticasting and tandem rolling includes finishing shape setting control model, automatic thickness control AGC, the affection of laminar flow cooling to plate shape, and use of new roller technique. The roller bending force and the positions of serial rollers are set up and regulated by plate shape controlling model, which consists of presetting control model, dynamic control model and plate shape and thickness decoupling model.

Owner:ANGANG STEEL CO LTD

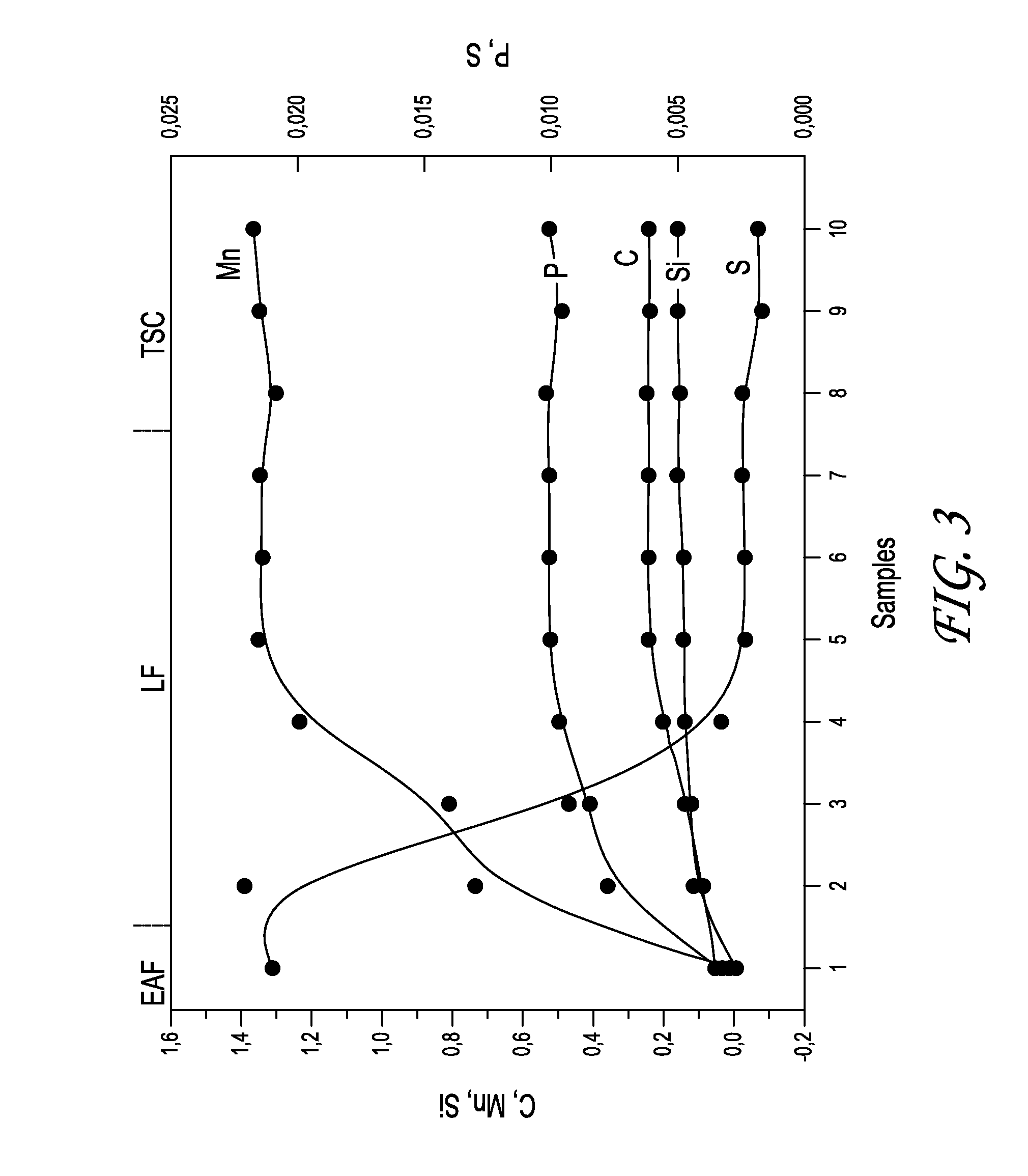

Method for producing low carbon bainite high-strength steel based on sheet bar continuous casting and rolling process flow

ActiveCN101254527ASimple metallurgical compositionImprove toughnessProcess efficiency improvementMetal rolling arrangementsThin slabLaminar cooling

The invention discloses a method for producing high-strength low-carbon bainite steel based on thin slab continuous casting and rolling process. The method includes the following steps: melting by using a rotary furnace or an electric furnace, refining molten steel in an LF furnace after the component analysis, performing the composition adjustment, continuously casting thin slabs, directly heating the thin slabs at the temperature of 950-1100 DEG C in a roller-hearth heating (soaking) furnace at a temperature not less than 1150 DEG C, controlling the tapping temperature of heated thin slabs in a range from 1050 DEG C to1160 DEG C, rolling by using a continuous rolling mill to produce plates, finishing at a temperature of 840-860 DEG C, performing laminar cooling, and coiling with a down coiler at a temperature of 550-600 DEG C to produce the steel coil. The method can produce non-tempered high-strength steel based on thin slab continuous casting and rolling process, and has the advantages of simple metallurgical composition of steel, low cost of alloying production, and stability in high toughness and good forming and welding properties of the steel coil.

Owner:湖南华菱涟源钢铁有限公司 +1

High ductility steel strip for J55 petroleum sleeve and manufacturing method thereof

InactiveCN101210299AImprove toughnessReduce contentManufacturing convertersMetal rolling arrangementsThin slabHigh pressure water

A steel strip for J55 petroleum casing with high strength and high toughness petroleum casing and a manufacture method thereof belong to the field of micro-alloyed steel production technology. The method comprises converter smelting, LF refining, medium-thin slab continuous slab, heating, high-pressure water descaling, hot rolling and laminar cooling, and reeling, wherein the chemical components of steel comprise (wt%) C 0.15 to 0.20, Si 0.15-0.30, Mn 1.00 to 1.45, P not larger than 0.020, S not larger than 0.010, Nb 0.020 to 0.040, Ti 0.015 to 0.040, Al 0.020 to 0.050, and allowance Fe and other in inevitable impurities. A J55 petroleum casing with a yield strength of 420 MPa can be produced by combining Nb and Ti, micro-alloying and reasonable production process, and the product has the advantages of high strength, high toughness and good solderability.

Owner:LAIWU IRON & STEEL GRP

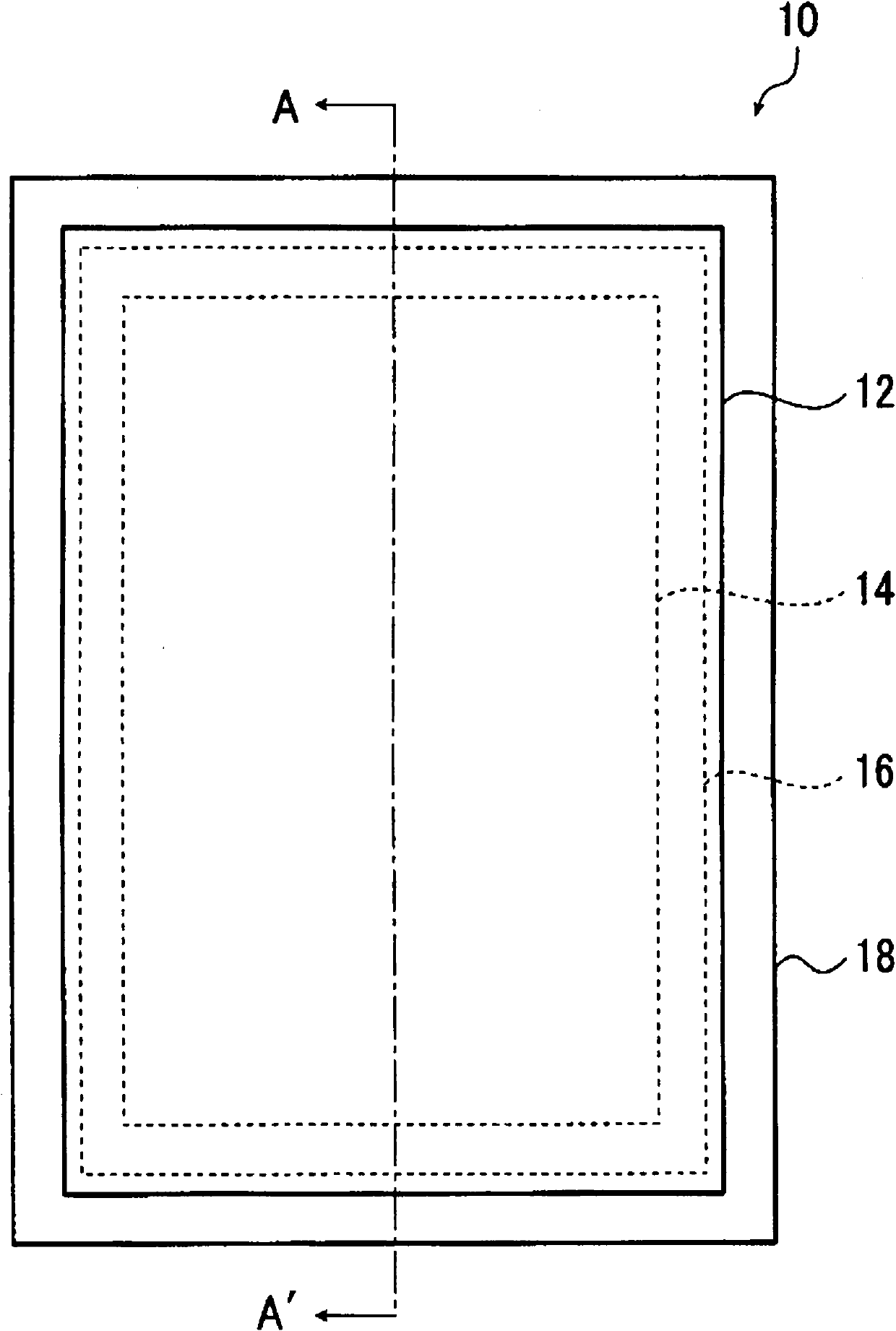

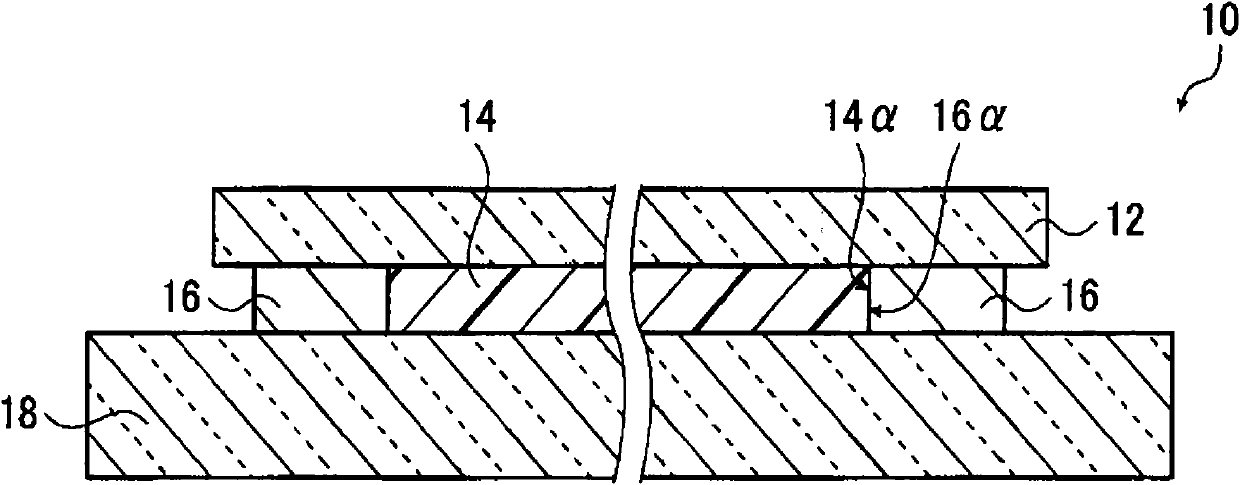

Glass laminate, display panel with support, method for producing glass laminate and method for manufacturing display panel with support

InactiveCN102007524AEasy to separateSuppression of glass defectsGlass/slag layered productsNon-linear opticsThin slabOptoelectronics

Disclosed is a glass laminate (10) comprising a thin glass substrate (12) having a first major surface and a second major surface, a supporting glass substrate (18) having a first major surface and a second major surface, and a resin layer (14) and an outer frame layer (16) arranged between the thin glass substrate (12) and the supporting glass substrate (18). The resin layer (14) is fixed to thefirst major surface of the supporting glass substrate (18) and is in close contact with the first major surface of the thin glass substrate (12), while having easy releasability from the first major surface of the thin glass substrate (12). The outer frame layer (16) surrounds the resin layer (14) on the first major surface of the supporting glass substrate (18) so that the outside air does not come into contact with the resin layer (14).

Owner:ASAHI GLASS CO LTD

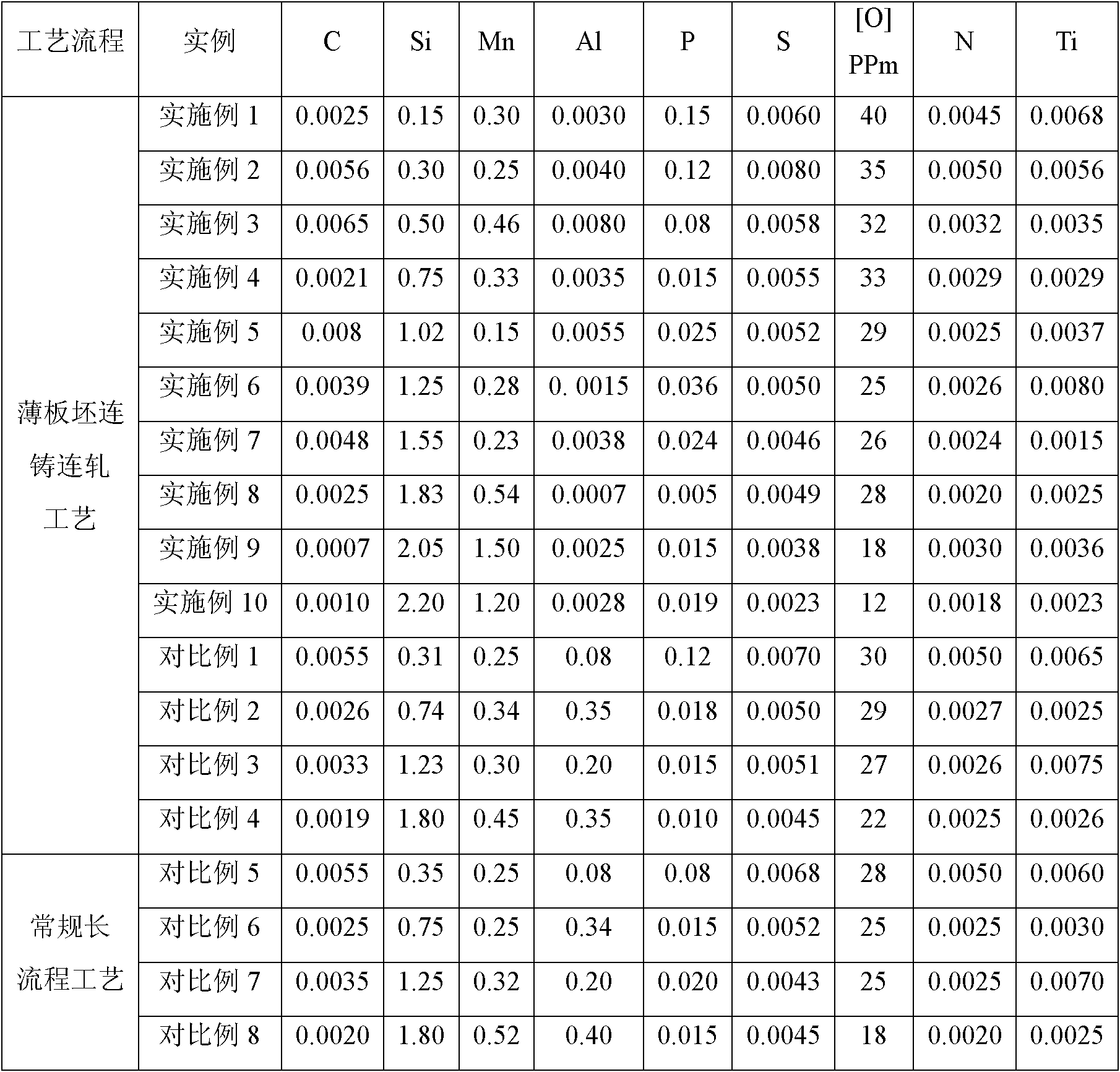

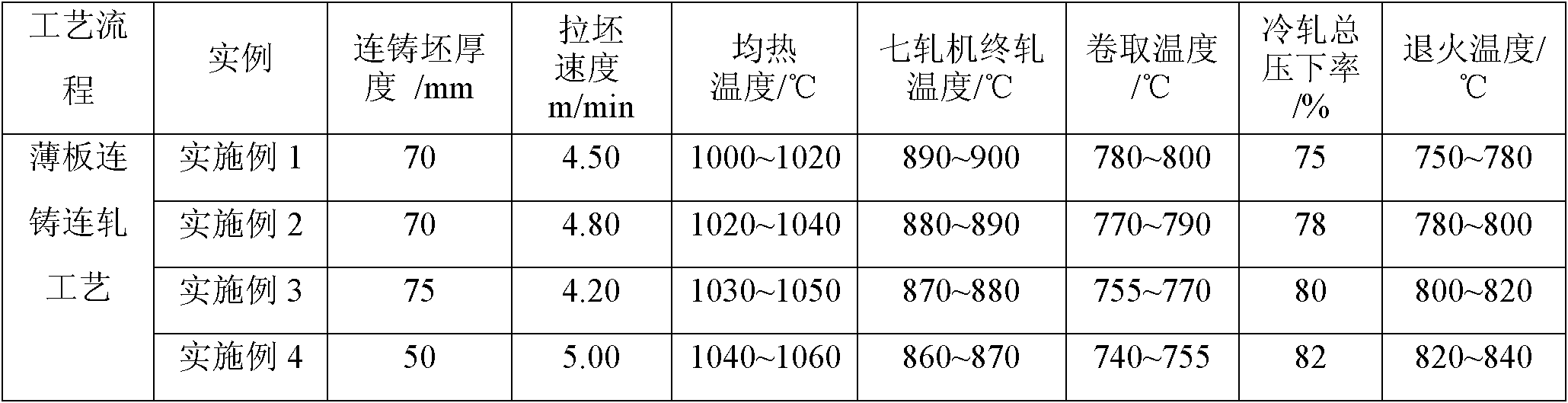

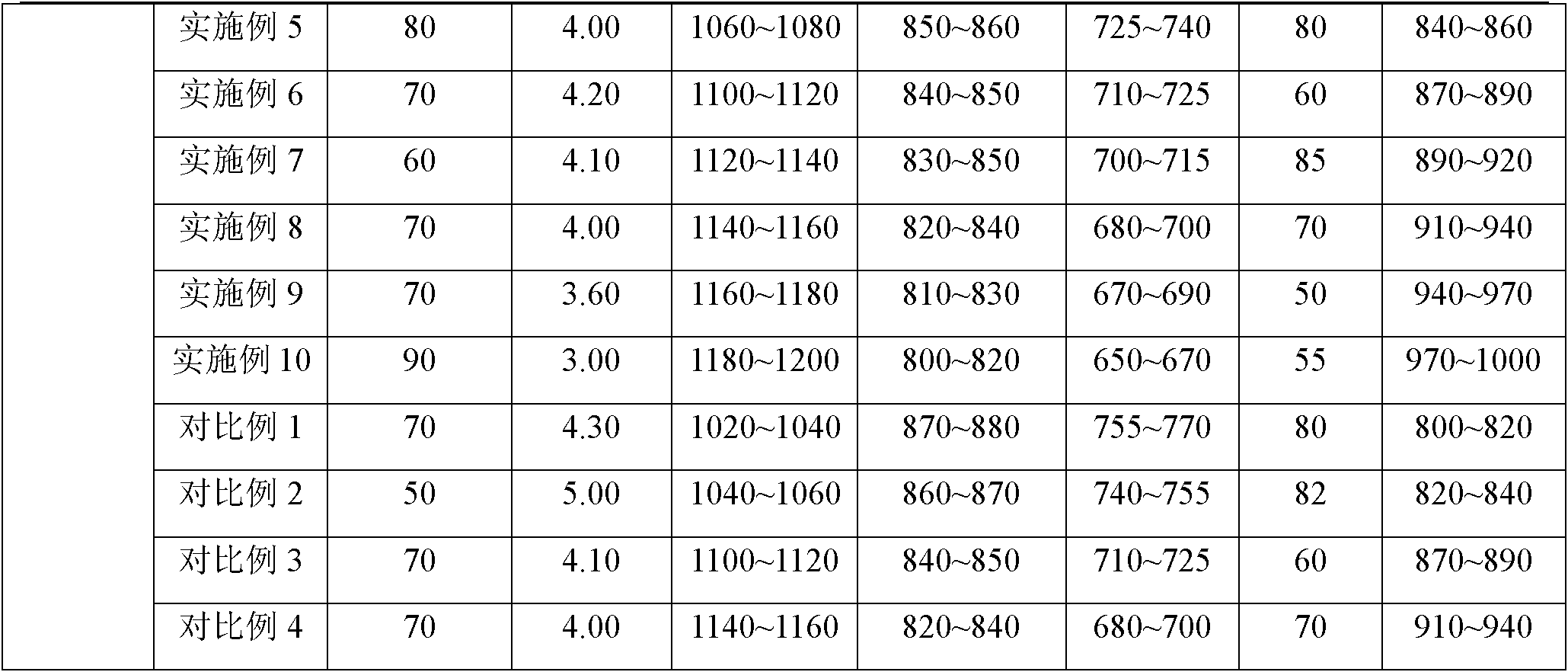

Non-oriented electrical steel for thin slab continuous casting-continuous rolling production and method thereof

InactiveCN102134675AReduce SiReduce Mn contentMetal rolling arrangementsTunnel kilnChemical composition

The invention relates to non-oriented electrical steel and a production method thereof. The non-oriented electrical steel comprises the following chemical compositions in percentage by weight: less than or equal to 0.008 percent of C, 0.15 to 2.2 percent of Si, less than or equal to 0.008 percent of Al, 0.15 to 1.5 percent of Mn, 0.004 to 0.15 percent of P, less than or equal to 0.008 percent of S, less than or equal to 40PPm of [O], less than or equal to 0.005 percent of N, less than or equal to 0.008 percent of Ti, and the balance of iron and inevitable impurities. The production method comprises the following steps of: smelting by using a converter and performing vacuum treatment; continuously casting into slabs with the thickness of 50-90 millimeters; soaking in a tunnel kiln; continuously rolling by using seven mills; coiling; performing pickling; performing cold rolling; performing recrystallization annealing; and obtaining the steel for later use. The alloy is reasonable in design and is not needed to be subjected to calcium treatment; the procedures are simple; the cost is reduced; the defect of low casting property in thin slab continuous casting-continuous rolling production can be effectively overcome; the advantages on cost and magnetic property of the non-oriented electrical steel in the thin slab continuous casting-continuous rolling production are fully shown, and the market competitiveness of the product is greatly improved.

Owner:武汉钢铁有限公司

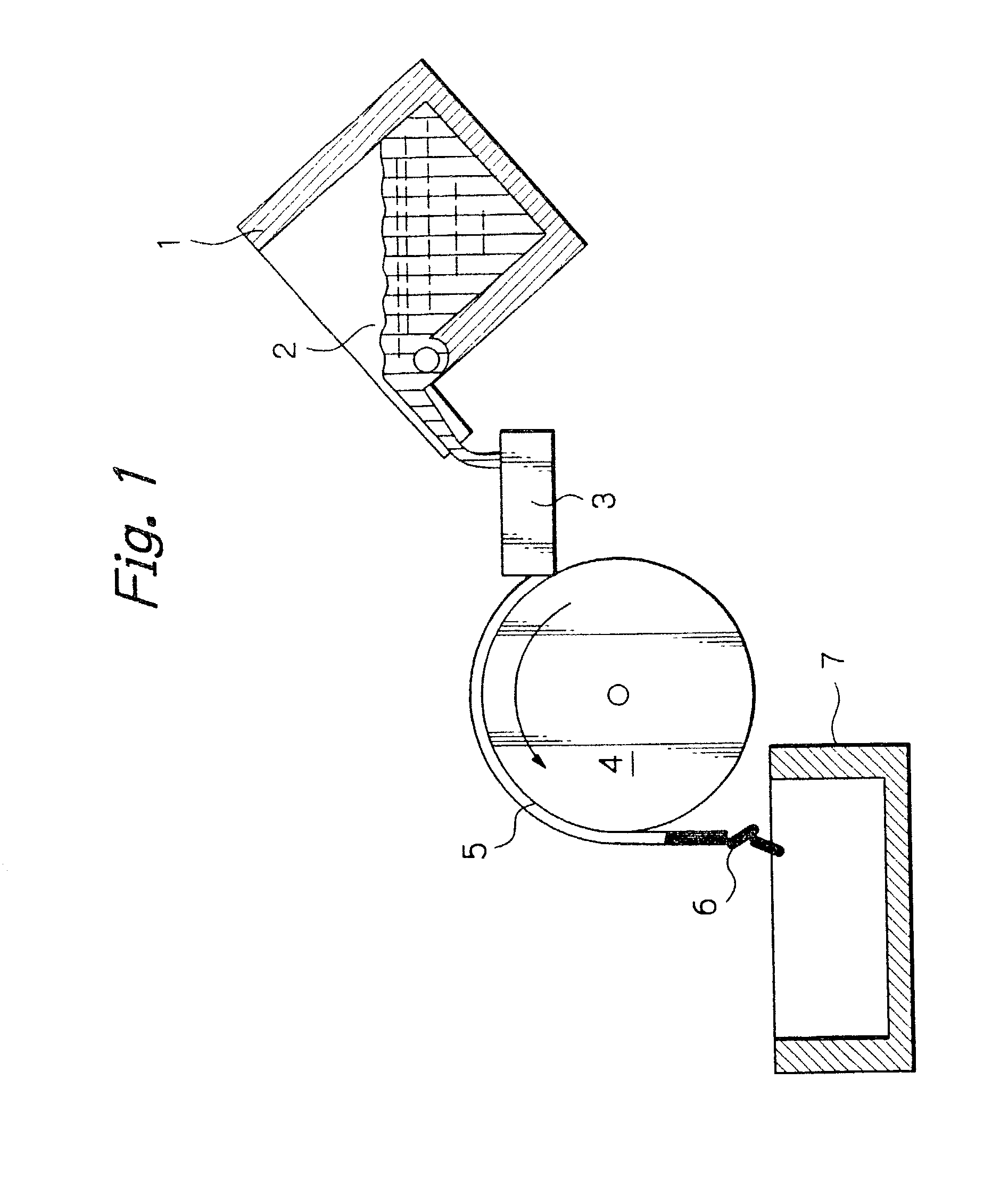

Refractory material for casting a rare-earth alloy and its production method as well as method for casting the rare-earth alloys

InactiveUS20030109372A1Improve melt flowImprove heat resistanceMelt-holding vesselsMuffle furnacesRare earthRefractory

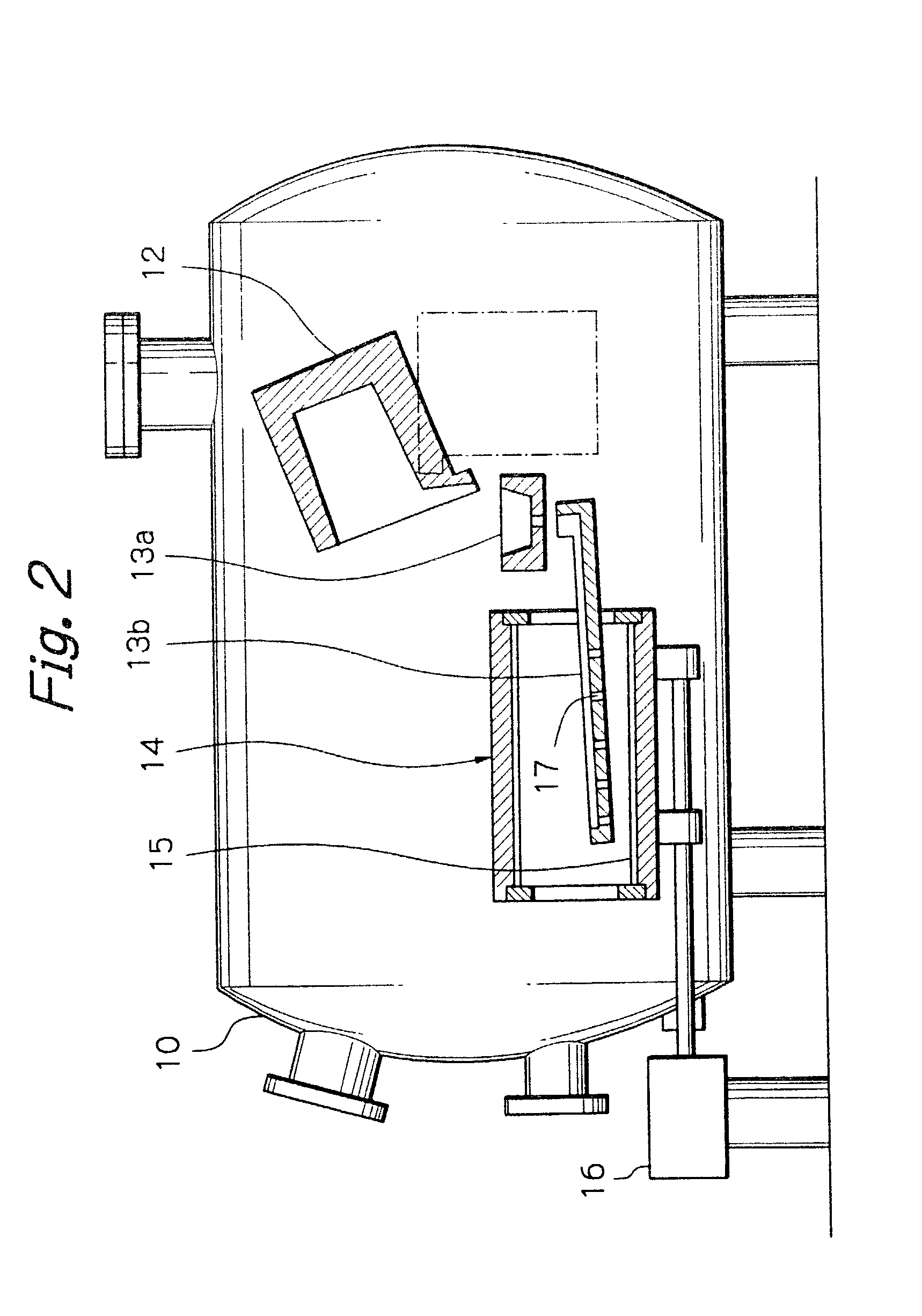

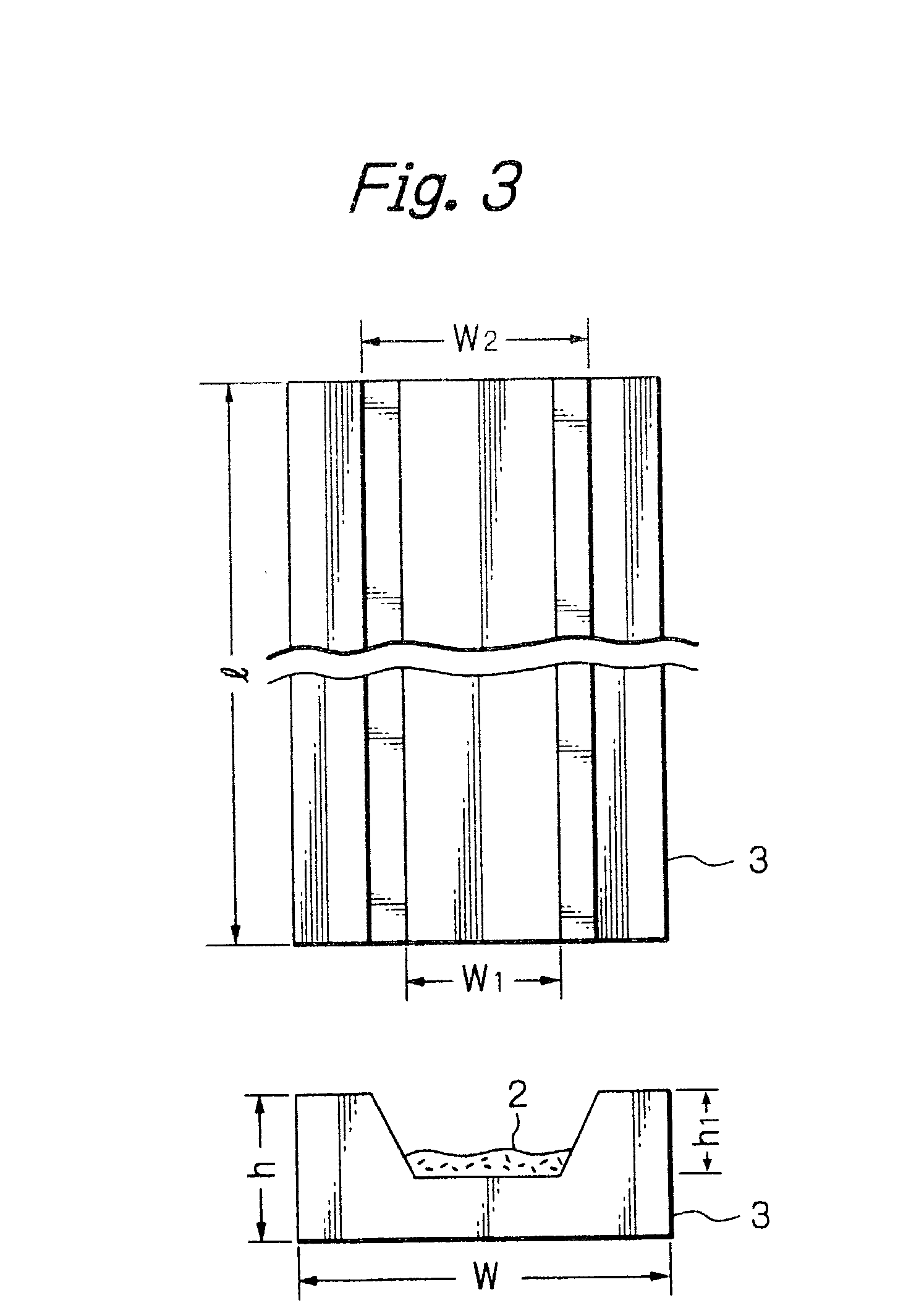

Rare-earth alloy is cast into a sheet (6) or the like by using a tundish (3, 13). The refractory material of the tundish used for casting does not necessitate preheating for improving the flowability of the melt (2). The refractory material used essentially consists of 70 wt % or more of Al2O3 and 30 wt % or less of SiO2, or 70 wt % or more of ZrO2 and 30 wt % or less of one or more of Y2O3, Ce2O3, CaO, MgO, Al2O3, TiO2 and SiO2. The refractory material has 1 g / cm3 or less of bulk density, has 0.5 kca / (mh° C.) or less of thermal conductivity in the temperature range of from 1200 to 1400° C., and has 0.5 wt % or less of ratio of ignition weight-loss under the heating condition of 1400° C. for 1 hour.

Owner:SHOWA DENKO KK

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

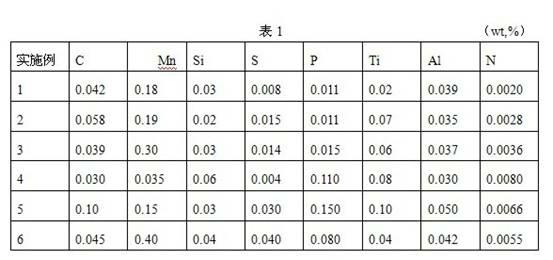

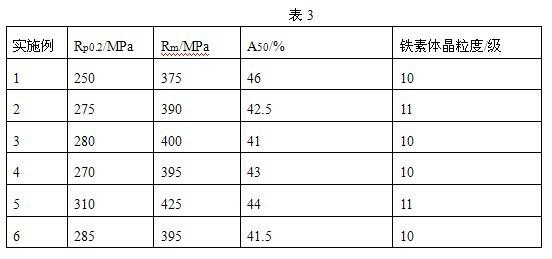

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

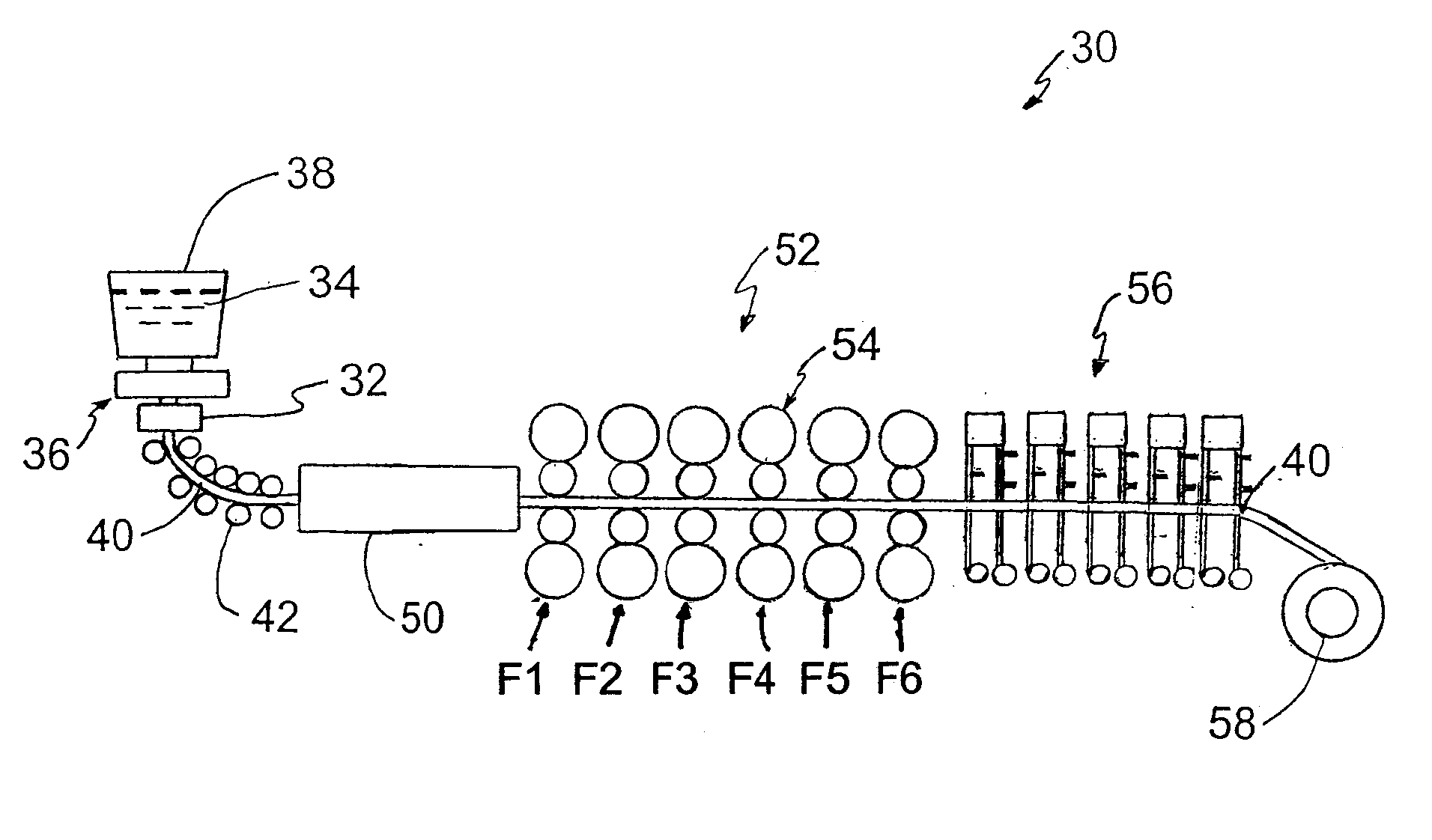

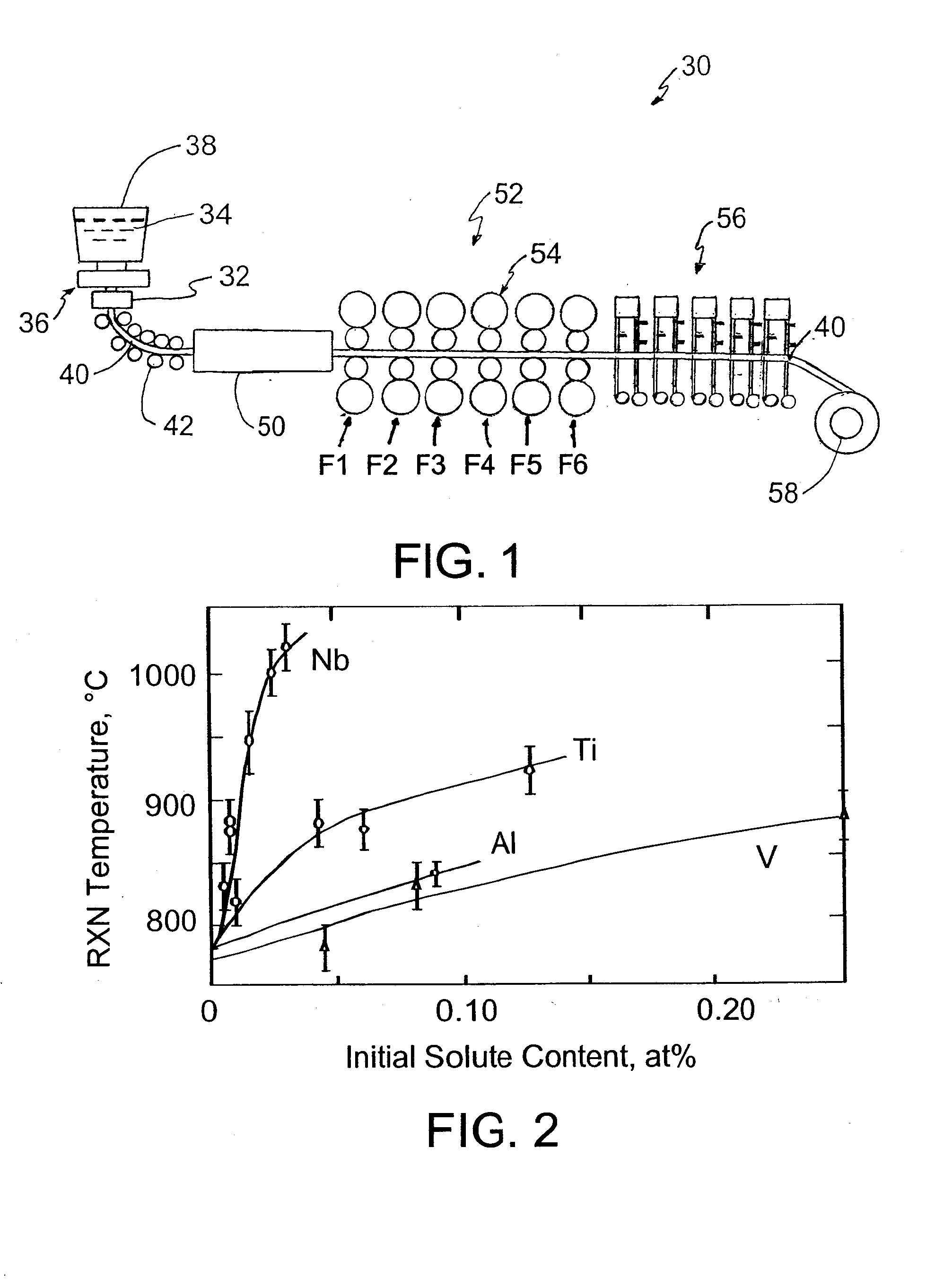

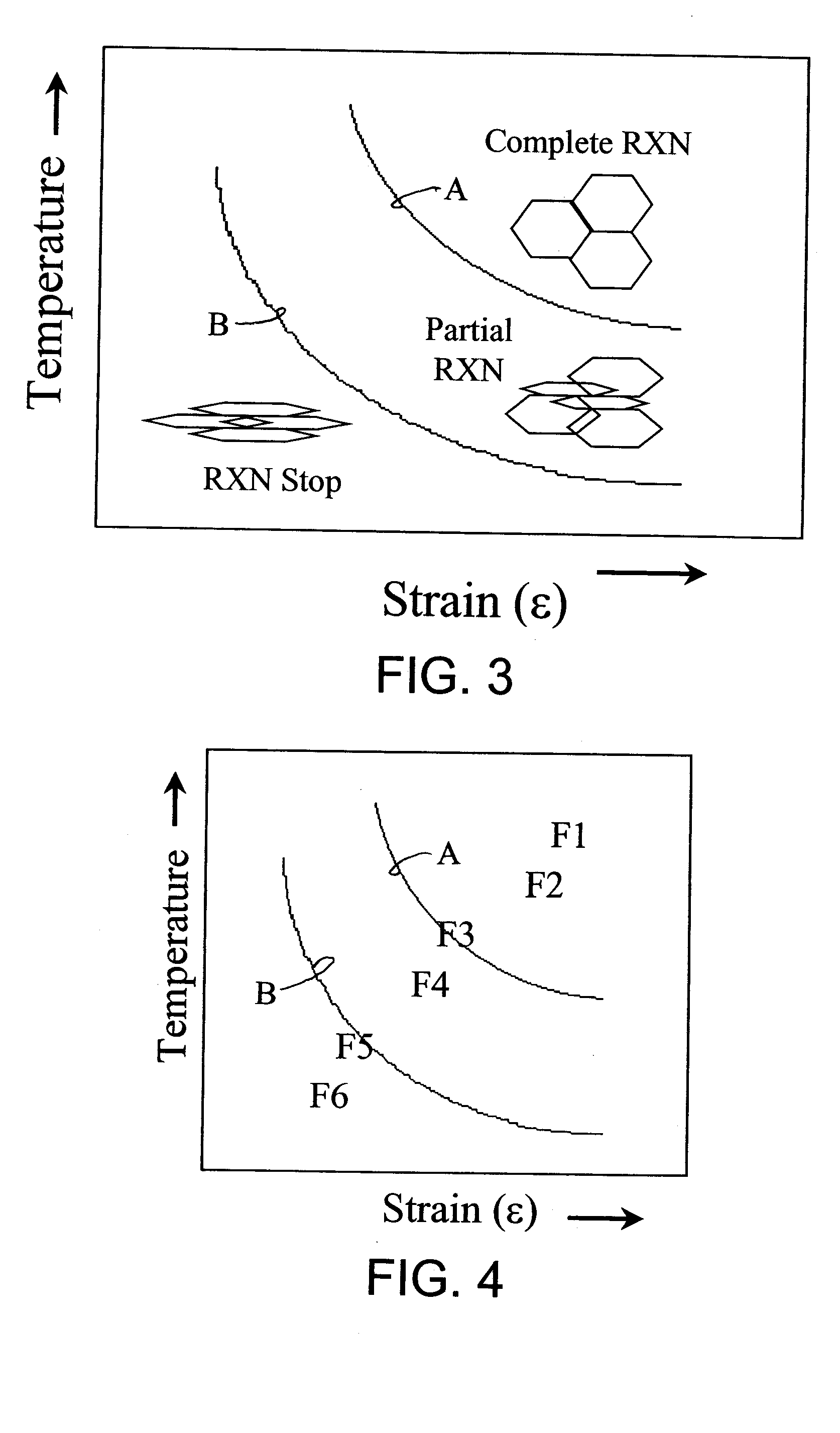

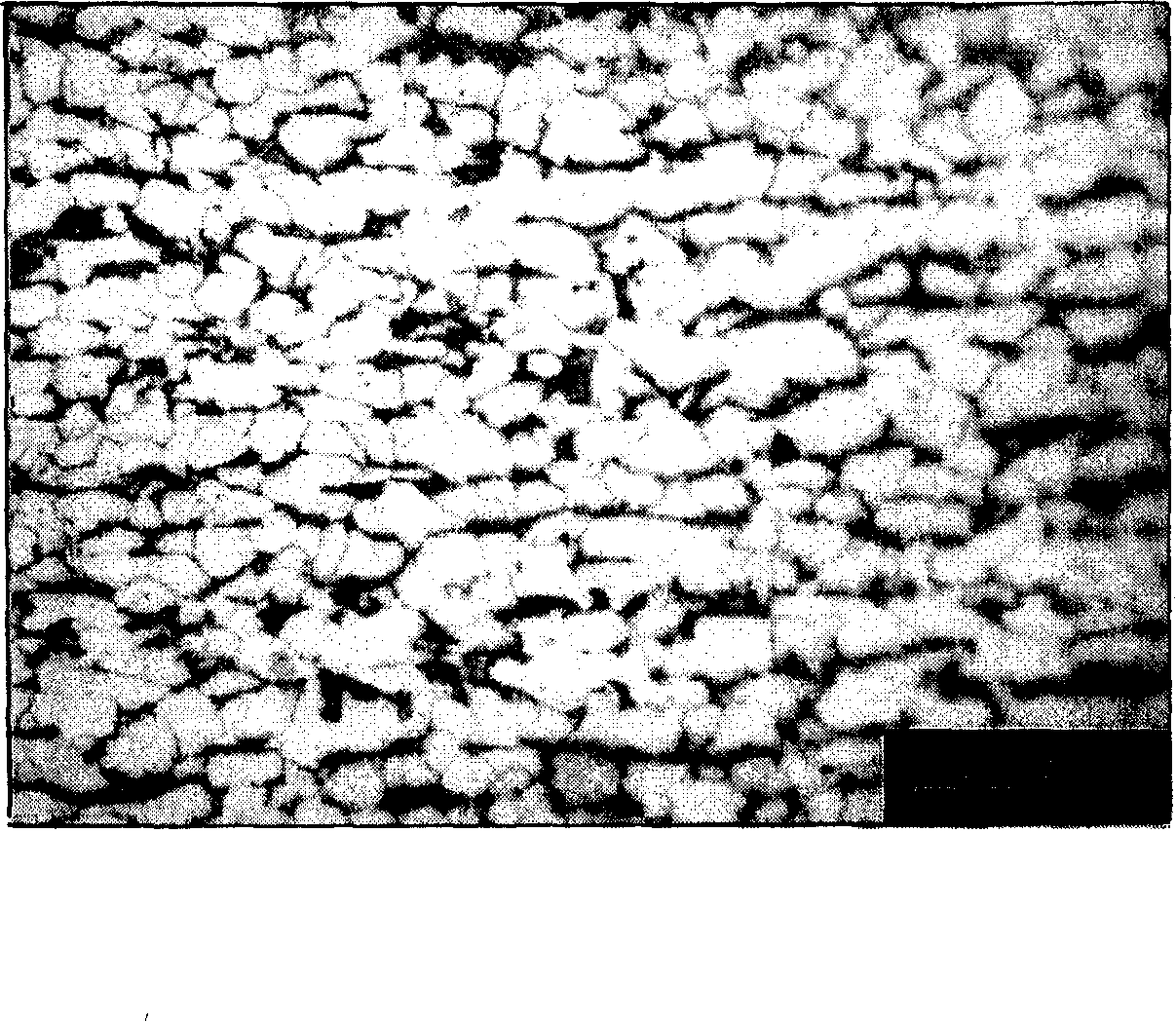

Thermomechanical processing routes in compact strip production of high-strength low-alloy steel

InactiveUS20050115649A1Accurate ultrasonic testingTime allowedMetal rolling arrangementsAustenite grainThin slab

Process for hot rolling of high-strength low-alloy steel cast in Compact Strip Production as a thin slab. The strain and temperature at initial roll stands where deformation occurs allows full recrystallization, and at latest roll stands where deformation occurs there is no recrystallization. Deformation is absent at strains and temperatures where partial recrystallization would occur, allowing increased recrystallization over conventional CSP rolling. The result may be beneficial for microalloyed high-strength low-alloy steel in permitting accurate ultrasonic testing of welds. The time allowed between deformation at passes through roll stands may be increased by eliminating deformation at one or more central roll stands. Combined with increased strain at the initial roll stands where the temperature of the steel is in the full recrystallization region, the process may result in a relatively fine and uniform austenite grain size.

Owner:NUCOR CORP

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Manufacturing method for thin-specification hot-rolled strip steel

ActiveCN106552831AIncrease profitReduce energy consumptionMetal rolling stand detailsWork cooling devicesProduction lineThin slab

Owner:NORTHEASTERN UNIV

600MPa grade high-strength weathering steel and preparation method thereof

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

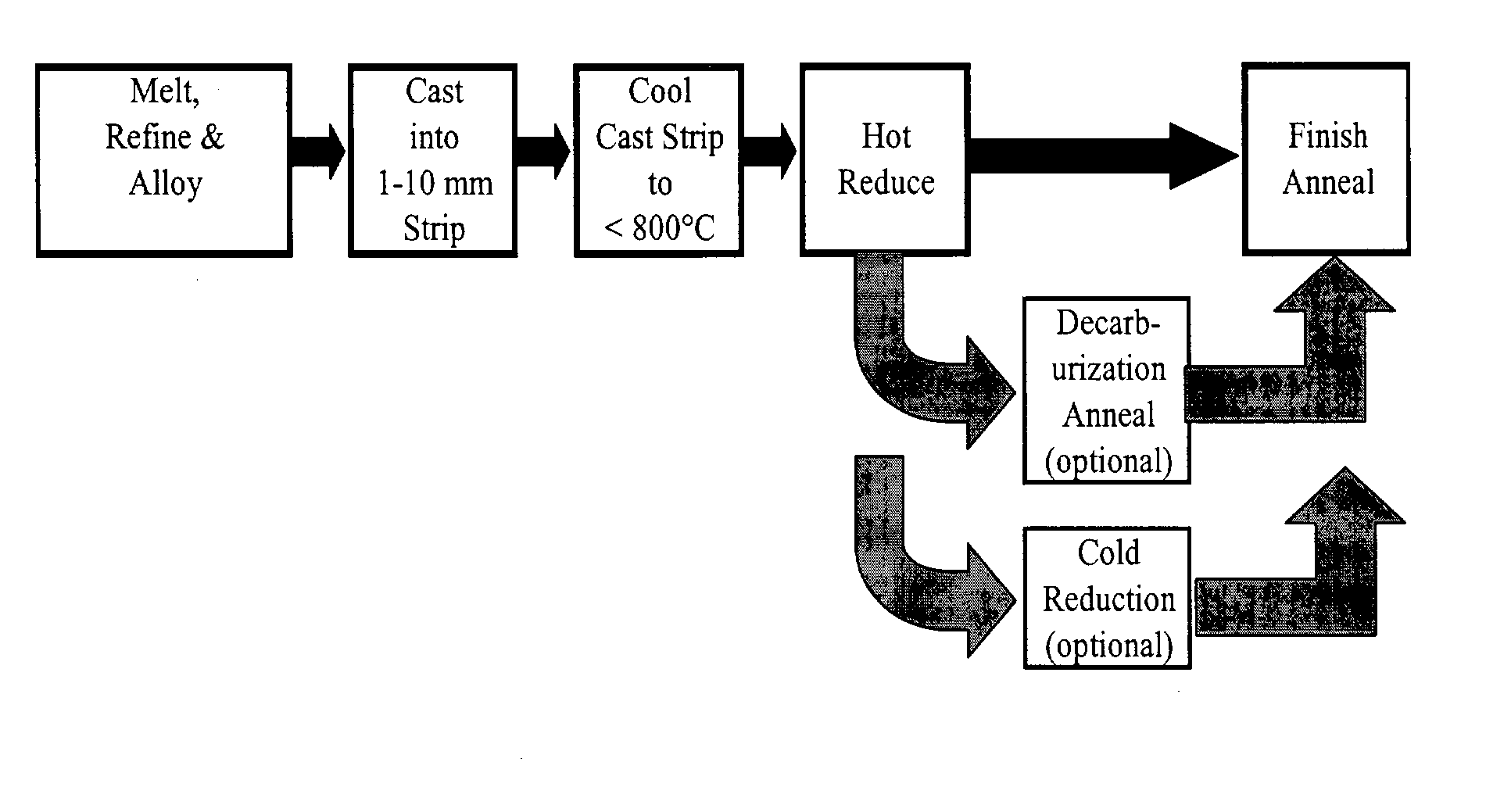

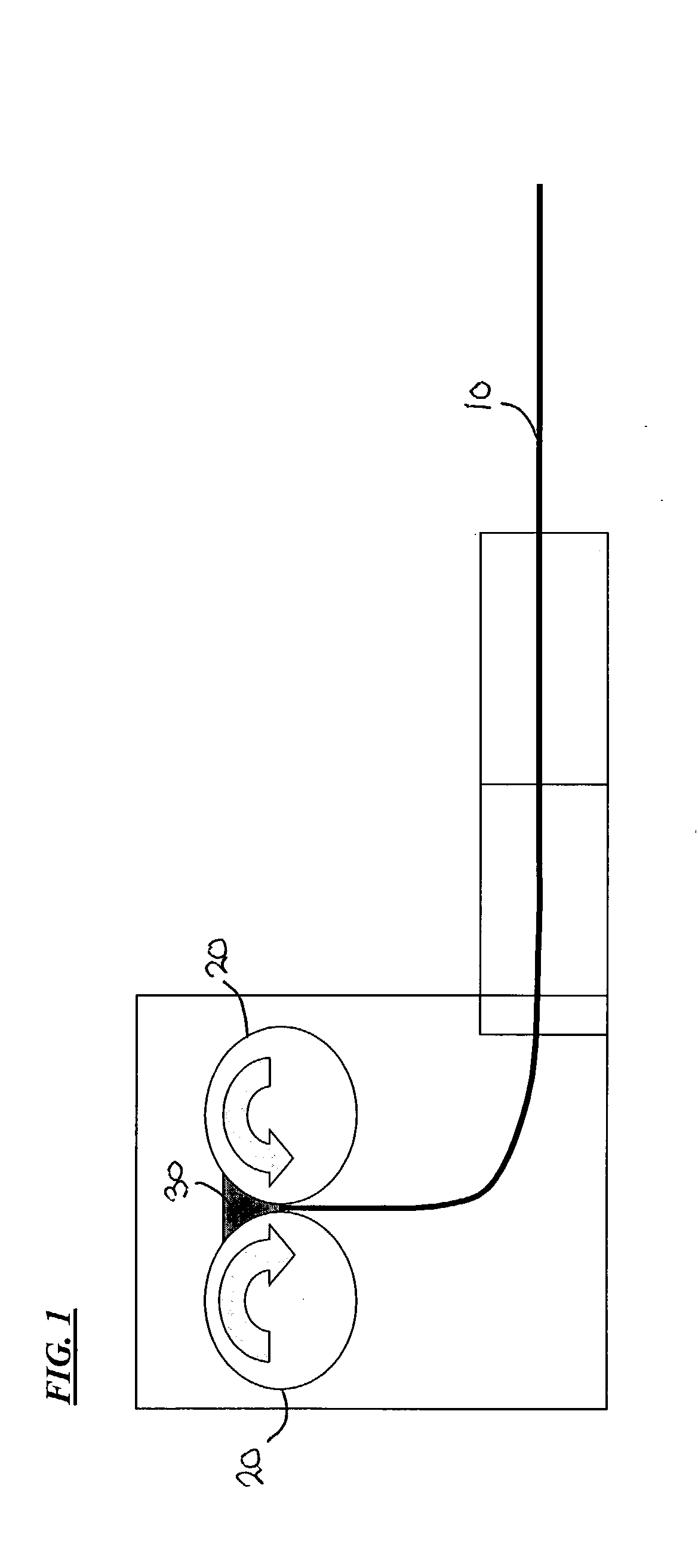

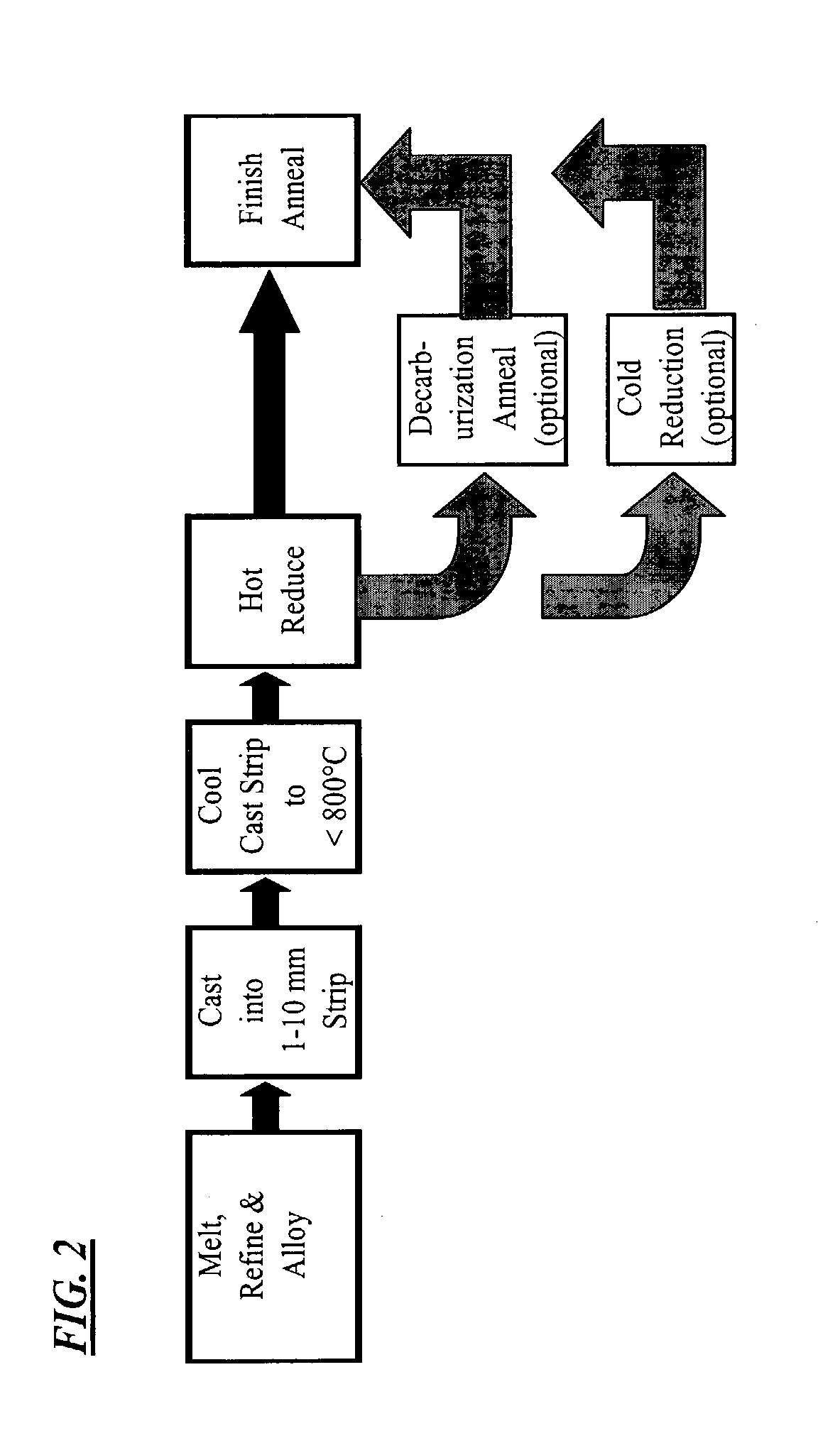

Method of continuous casting non-oriented electrical steel strip

InactiveUS20040016530A1Great resistanceImproved mechanical propertyMagnetic materialsElectric machineryMagnetic core

Non-oriented electrical steels are widely used as the magnetic core material in a variety of electrical machinery and devices, particularly in motors where low core loss and high magnetic permeability in all directions of the strip are desired. The present invention relates to a method for producing a non-oriented electrical steel with low core loss and high magnetic permeability whereby the steel is produced from a steel melt which is cast as a thin strip or sheet, cooled, hot rolled and / or cold rolled into a finished strip. The finished strip is further subjected to at least one annealing treatment wherein the magnetic properties are developed, making the steel strip of the present invention suitable for use in electrical machinery such as motors or transformers.

Owner:CLEVELAND CLIFFS STEEL PROPERTIES INC

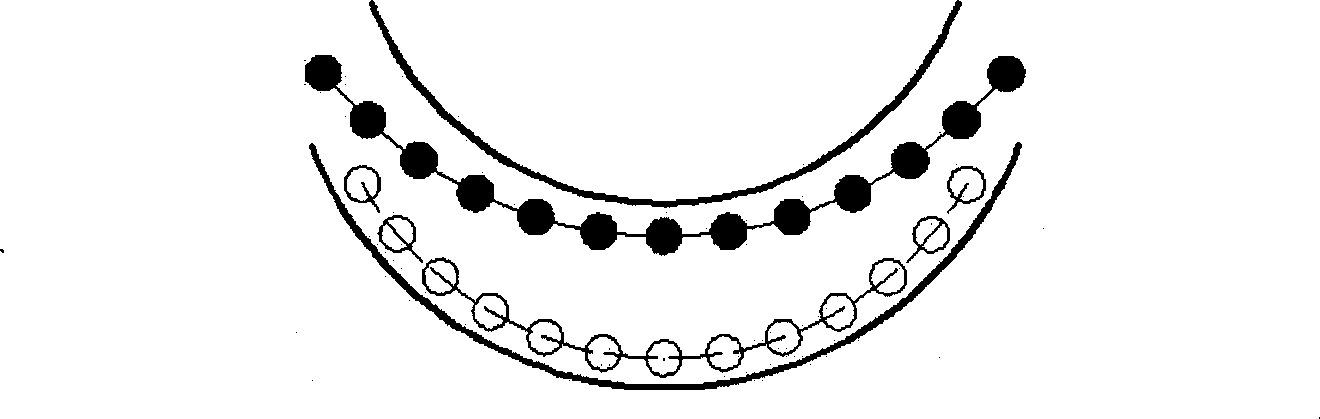

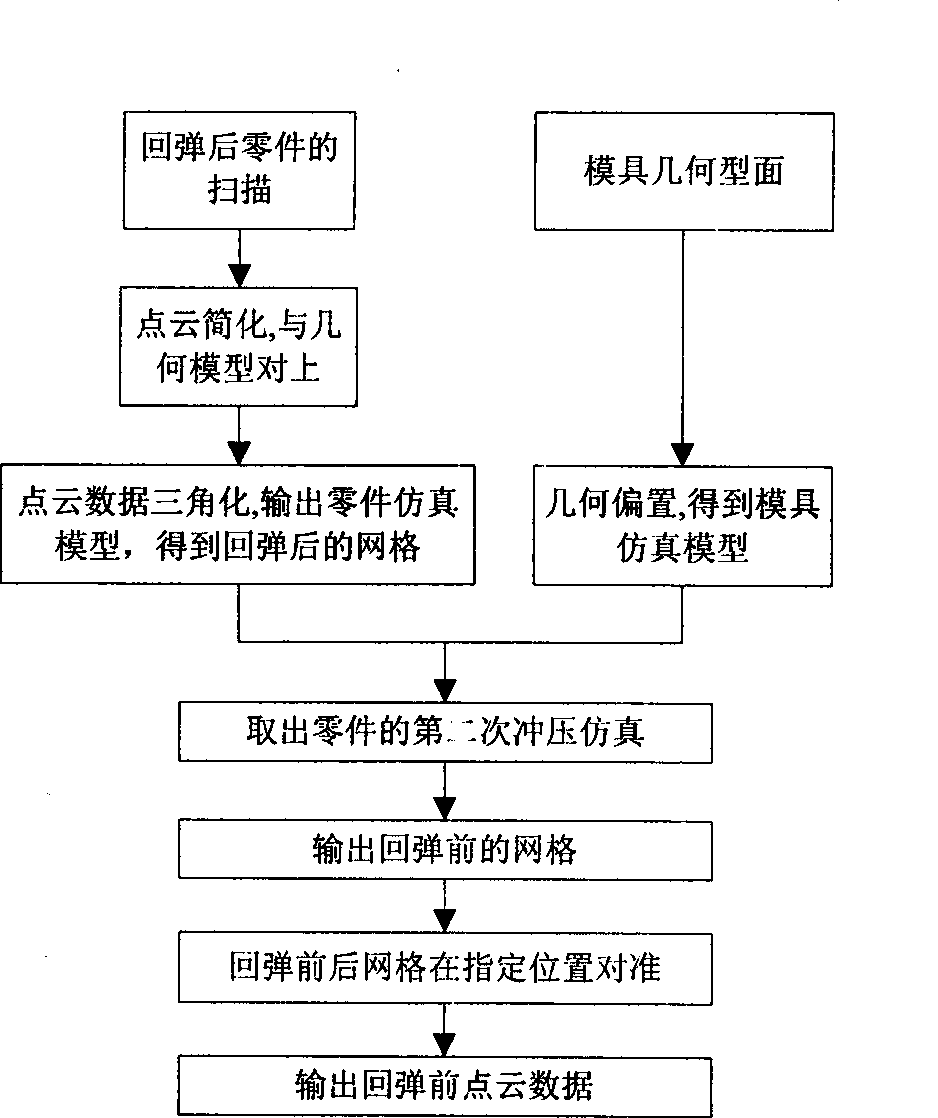

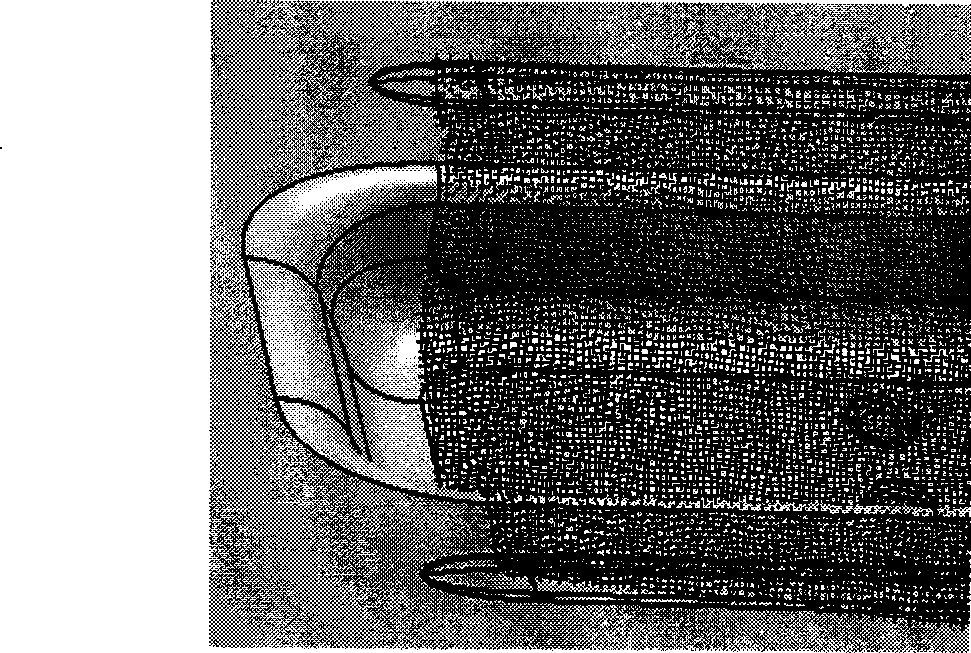

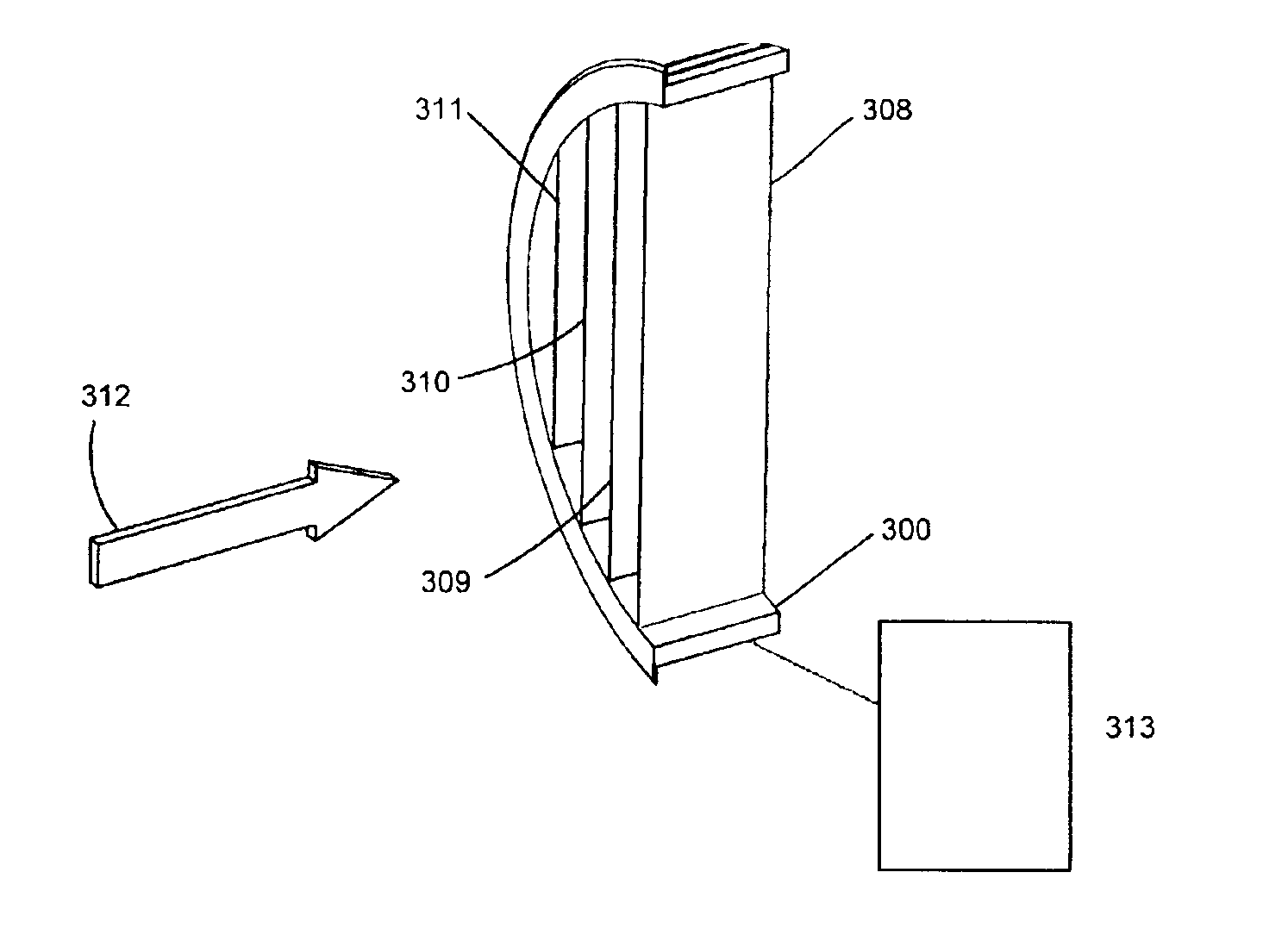

Method for confirming sheet stamping member measuring point cloud position before rebound based on finite element method

The invention relates to a method for determining the position of the measurement point cloud of the sheet stamping workpiece before rebound based on finite element method. The method comprises: transferring the point cloud data to the corresponding position in a geometric model; converting the data cloud data into triangle or quadrangle grids, and outputs into a finite element input format file to obtain the grid of sheet material; establishing simulation model according to the actual mould profile to obtain the mould profile grids; establishing a simulation model according to the mould and sheet material grids, and pressing the rebounded grid reversely the position before rebound; and outputting the nodes in the finite element to obtain the position of the measurement point cloud before rebound. Applying the invention can determine the rebounded compensation profile or the edge trimming line on the rebounded workpiece rapidly and accurately.

Owner:HUNAN UNIV

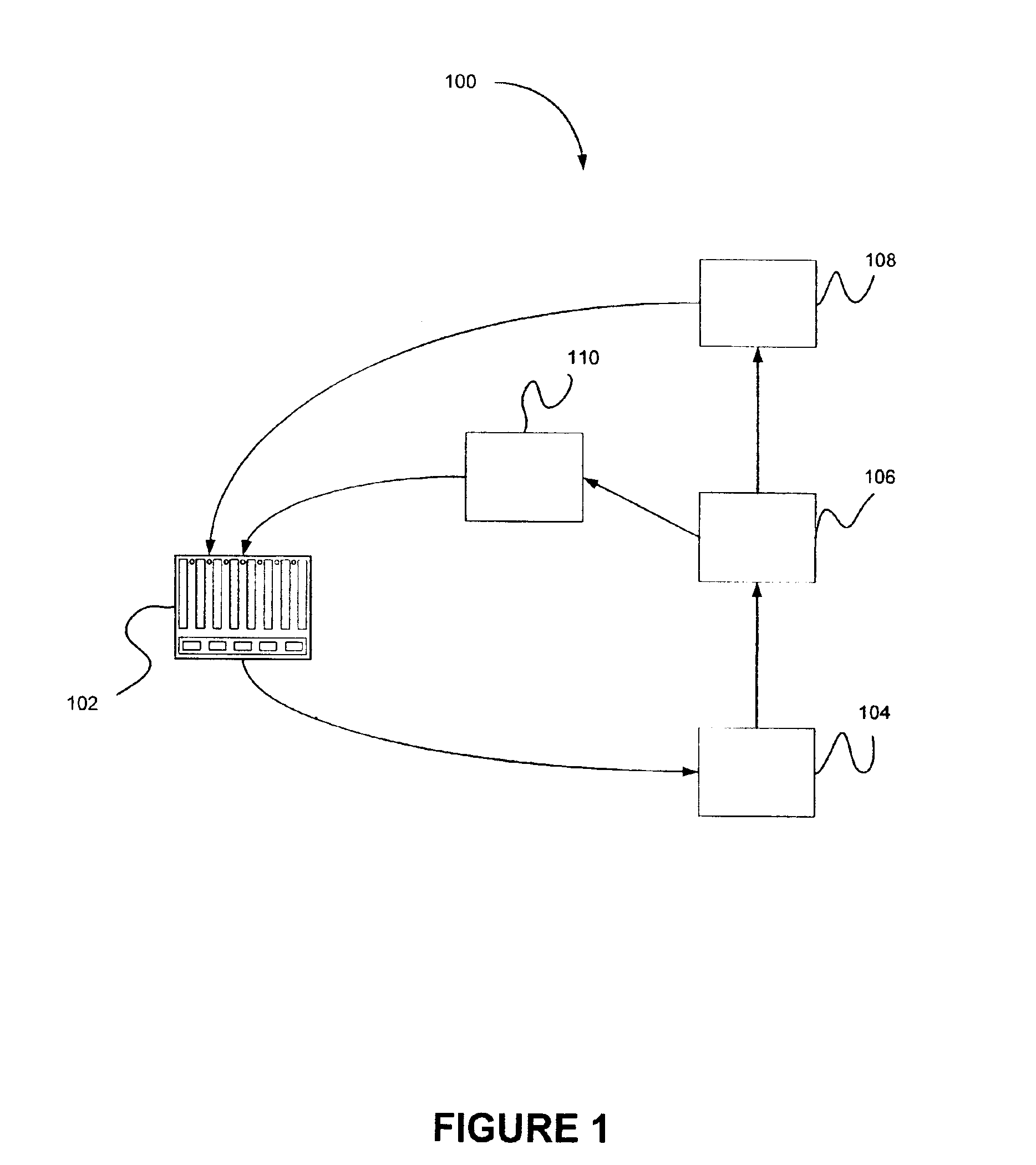

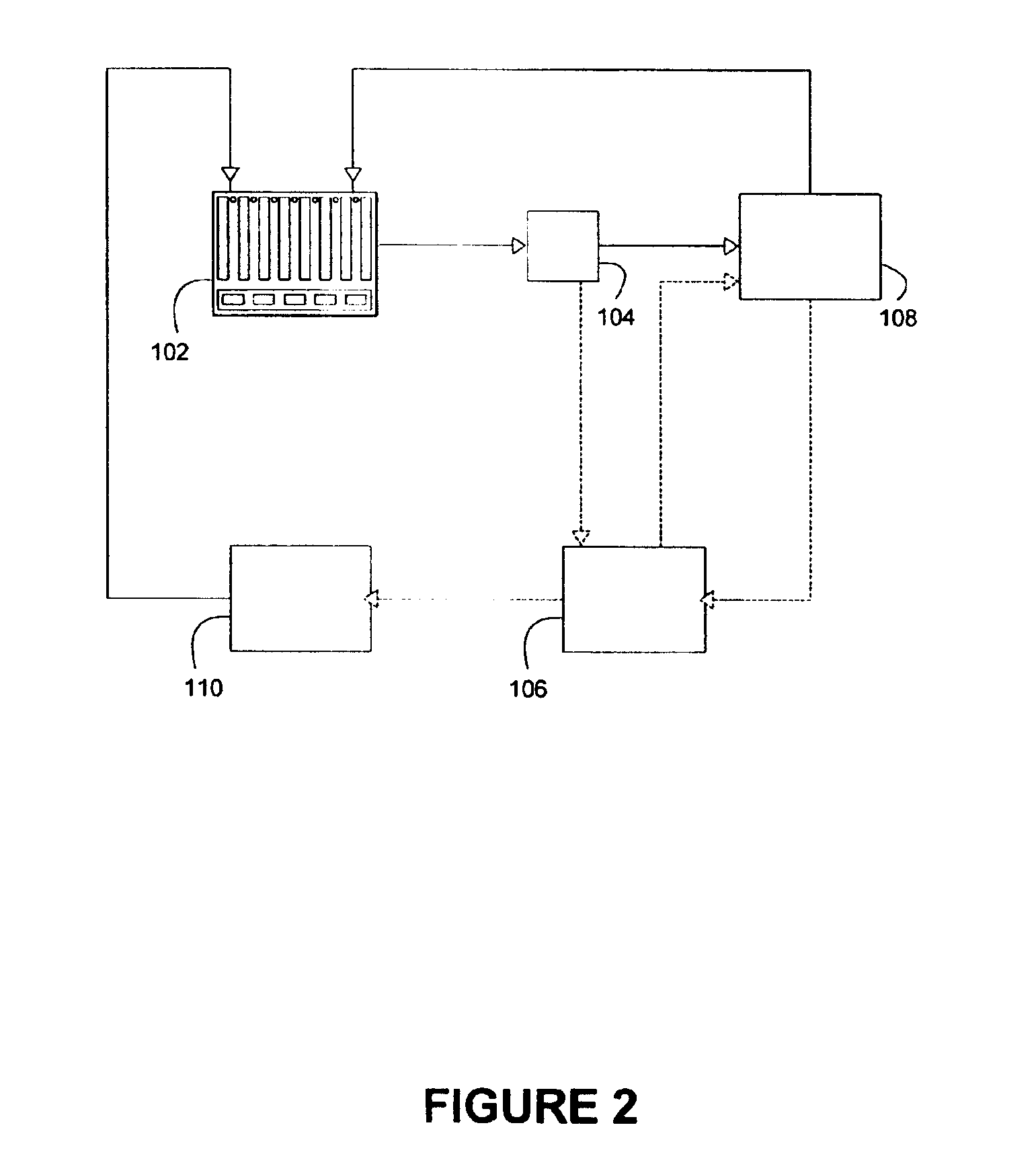

In-line filtration for a particle-based electrochemical power system

A system for filtering particles within a multiphase fluid that comprises a particulate phase is disclosed. The system comprises a first plurality of substantially parallel, substantially planar thin slabs separated by a predetermined distance to retain particles having a maximum cross-sectional dimension greater than the predetermined distance, and provides at least one flow path for at least part of the multiphase fluid. In one application, the system is used in connection with an electrochemical power source and components thereof, wherein the multiphase fluid comprises flowable fuel.

Owner:TECK COMINCO METALS LTD

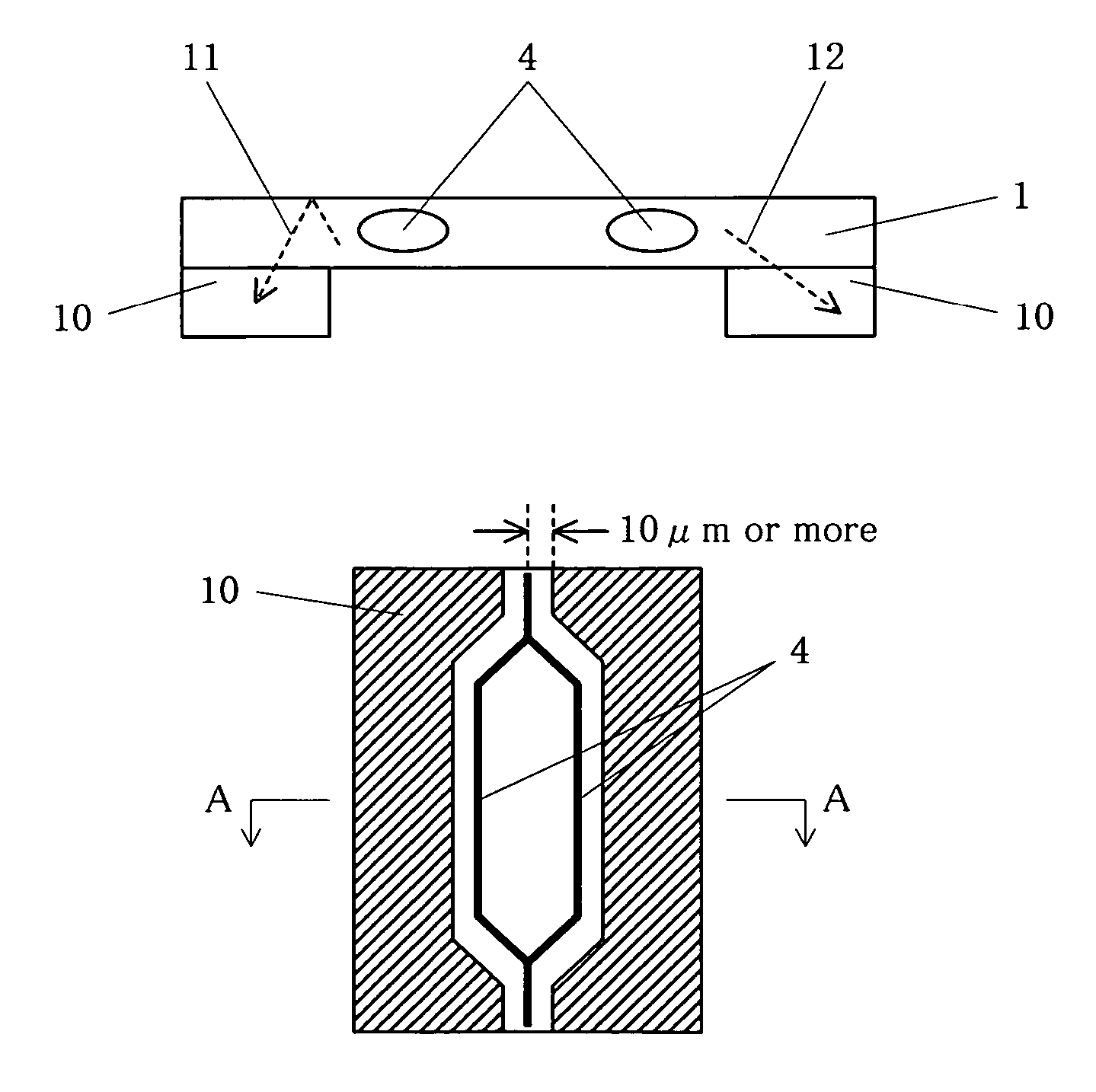

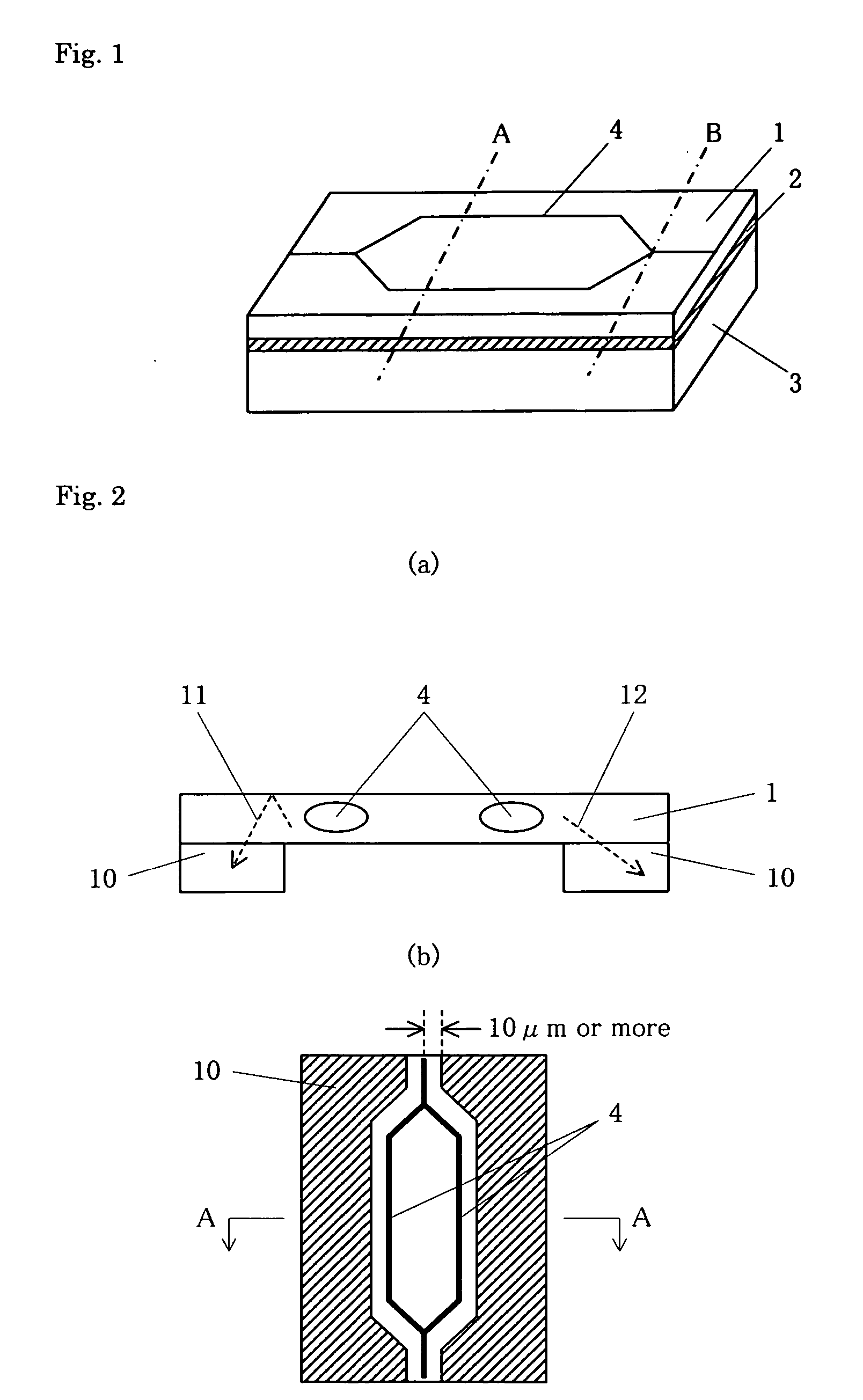

Optical modulator

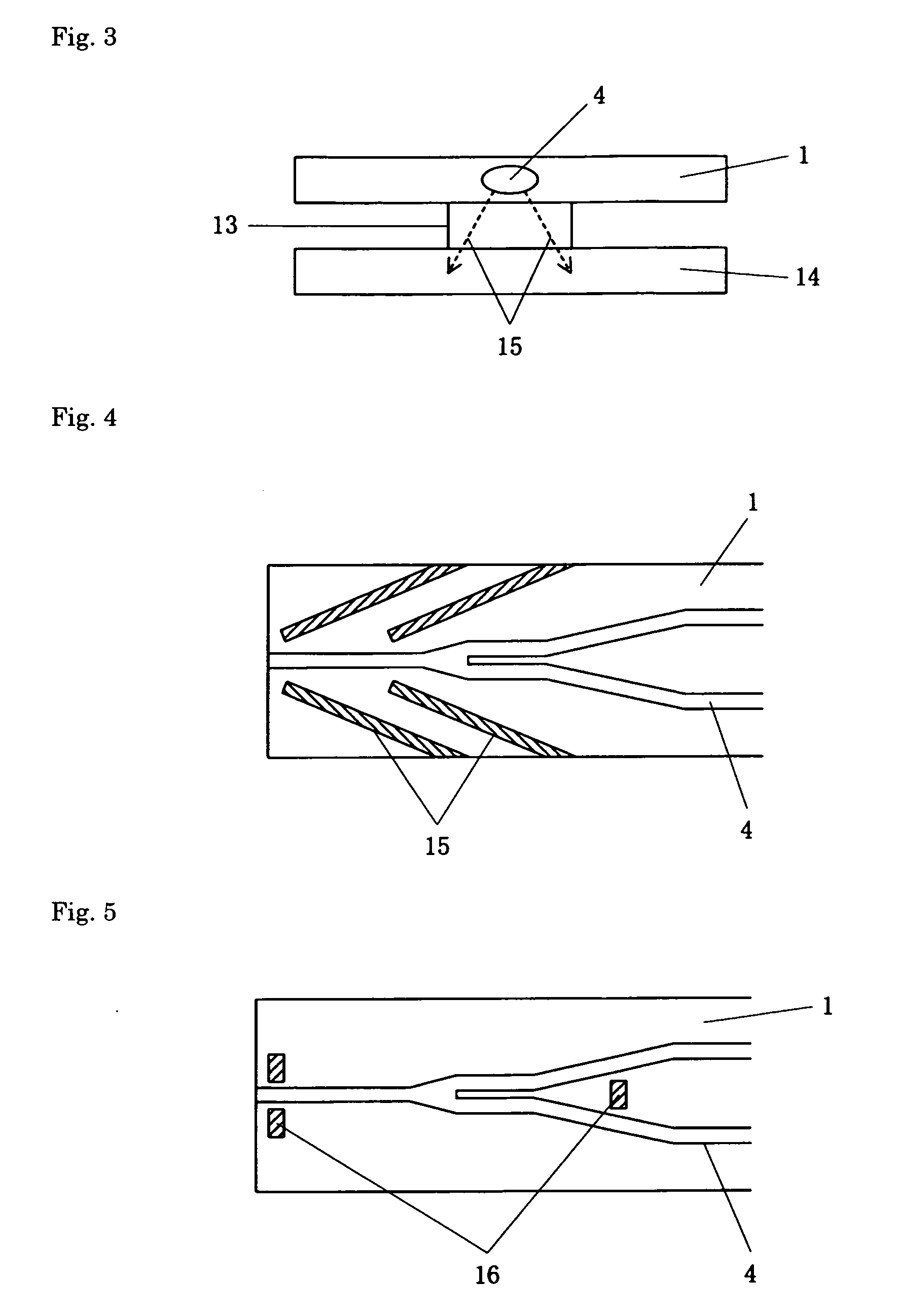

ActiveUS20070053625A1Improving an S/N ratio of an output lightOptical waveguide light guideNon-linear opticsThin slabWaveguide

An optical modulator using a thin plate capable of improving an S / N ratio of an output light is provided. The optical modulator including a thin plate 1 having an electrooptic effect and having a thickness of 20 μm or less, an optical waveguide 4 formed on a top or bottom surface of the thin plate, and a modulation electrode formed on the top surface of the thin plate to modulate light passing through the optical waveguide, wherein a stray light removing member 10 is disposed within the thin plate or in a vicinity of the thin plate.

Owner:SUMITOMO OSAKA CEMENT CO LTD

A method for preparing titanium alloy thin plates by cladding and rolling of steel plates

InactiveCN102274851AUniform vertical and horizontal performanceUniform transverse propertiesMetal rolling arrangementsThin slabMetal sheet

The invention discloses a method for preparing a titanium alloy thin plate by cladding and rolling of a steel plate, and relates to a processing method of a metal plate. It is characterized in that the rolling process is that the titanium alloy plate is hermetically covered by a steel plate to form a stacked rolling bag, and then rolling is carried out. The method of the invention has low rolling cost, and the titanium alloy thin plate is produced by cladding, welding, stacking and hot rolling, the process is simple, and the comprehensive performance of the obtained material is excellent.

Owner:BAOJI TITANIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com