Patents

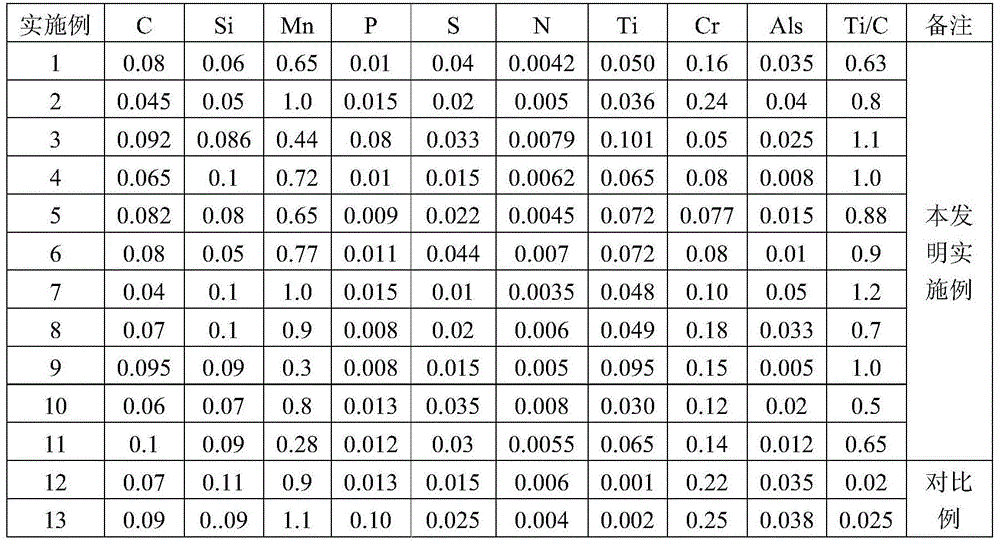

Literature

92results about How to "Excellent anti-scale explosion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

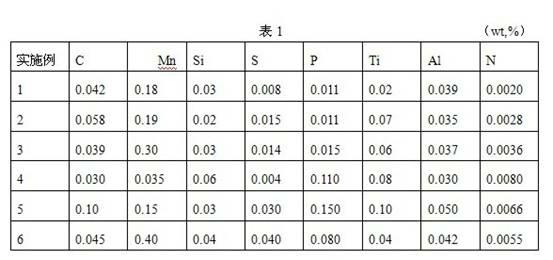

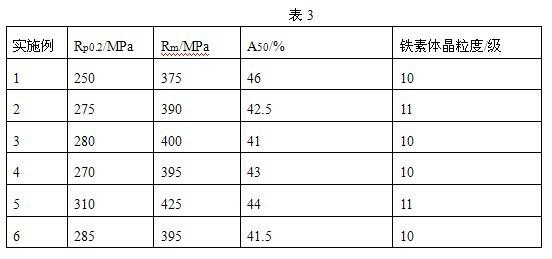

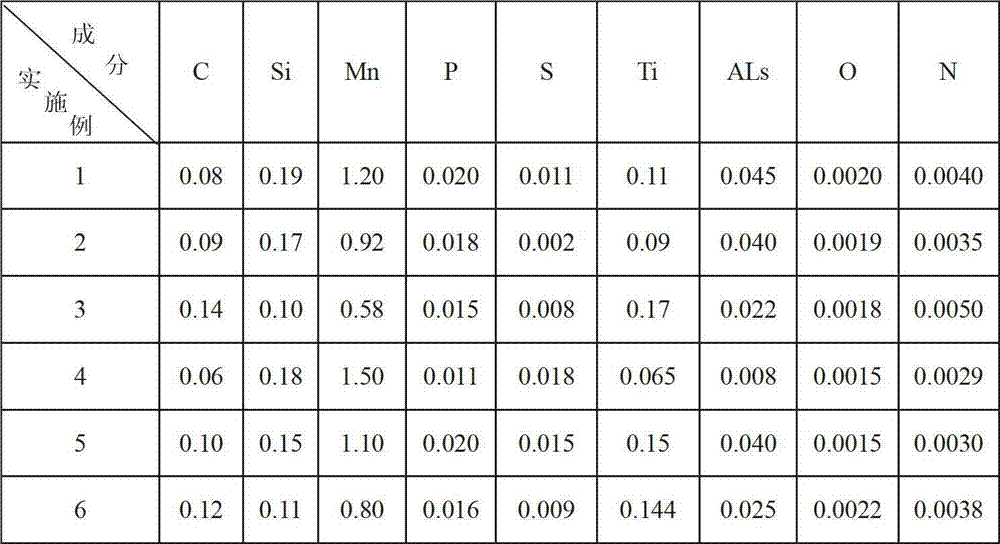

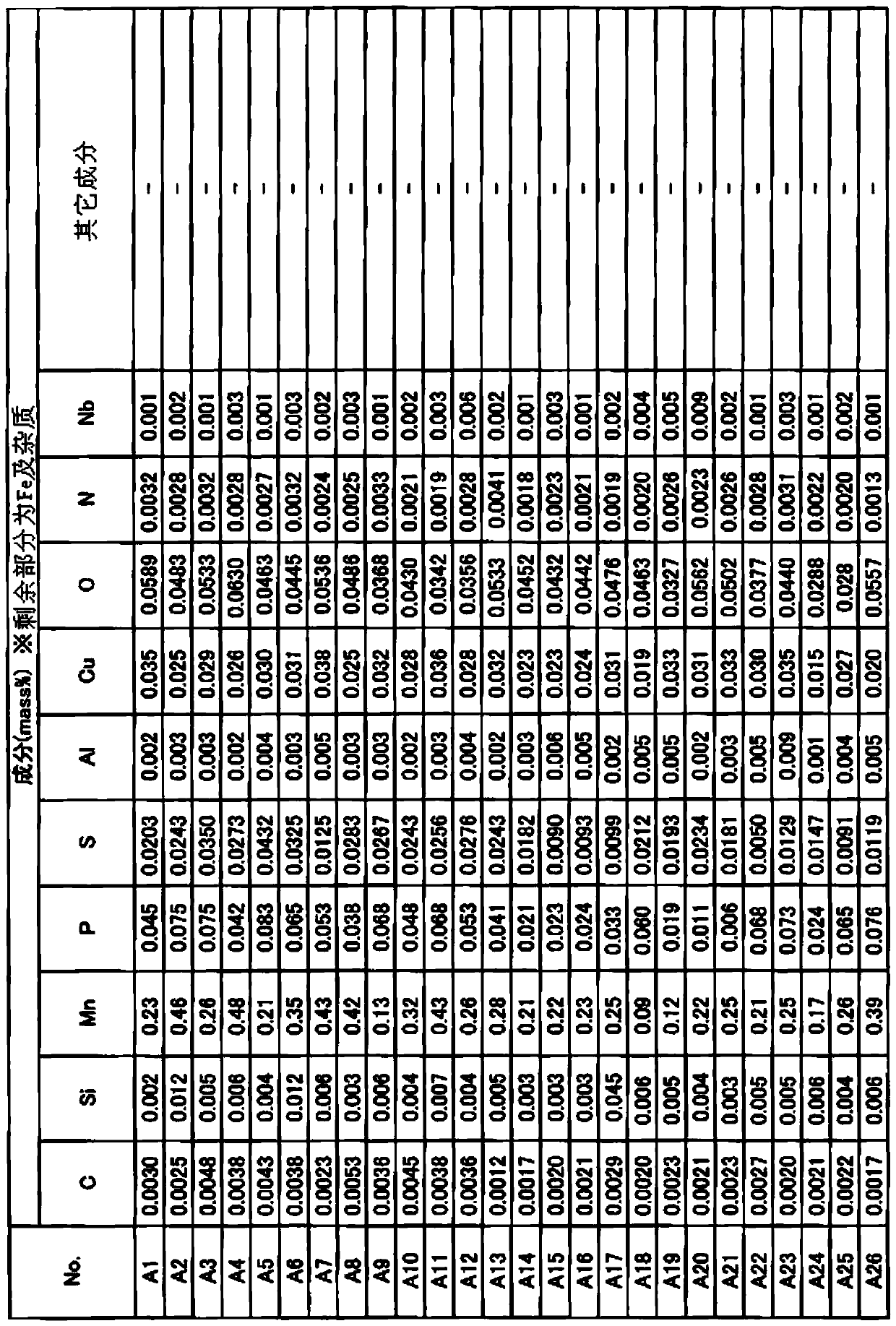

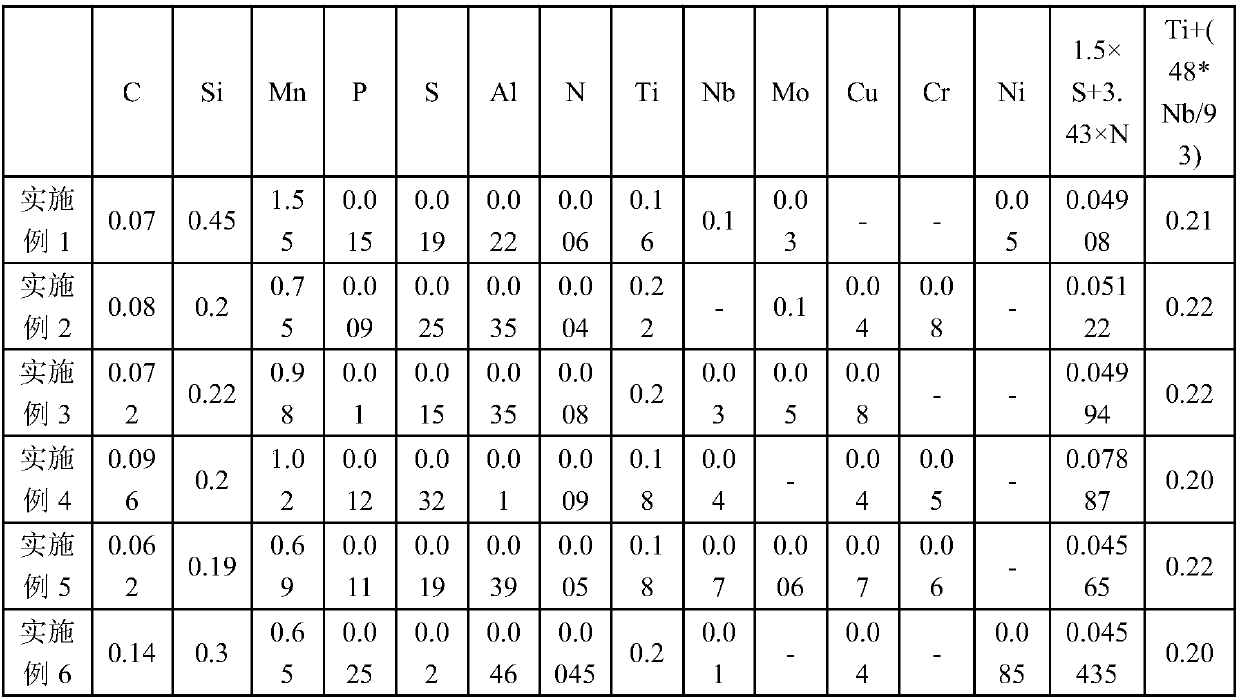

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

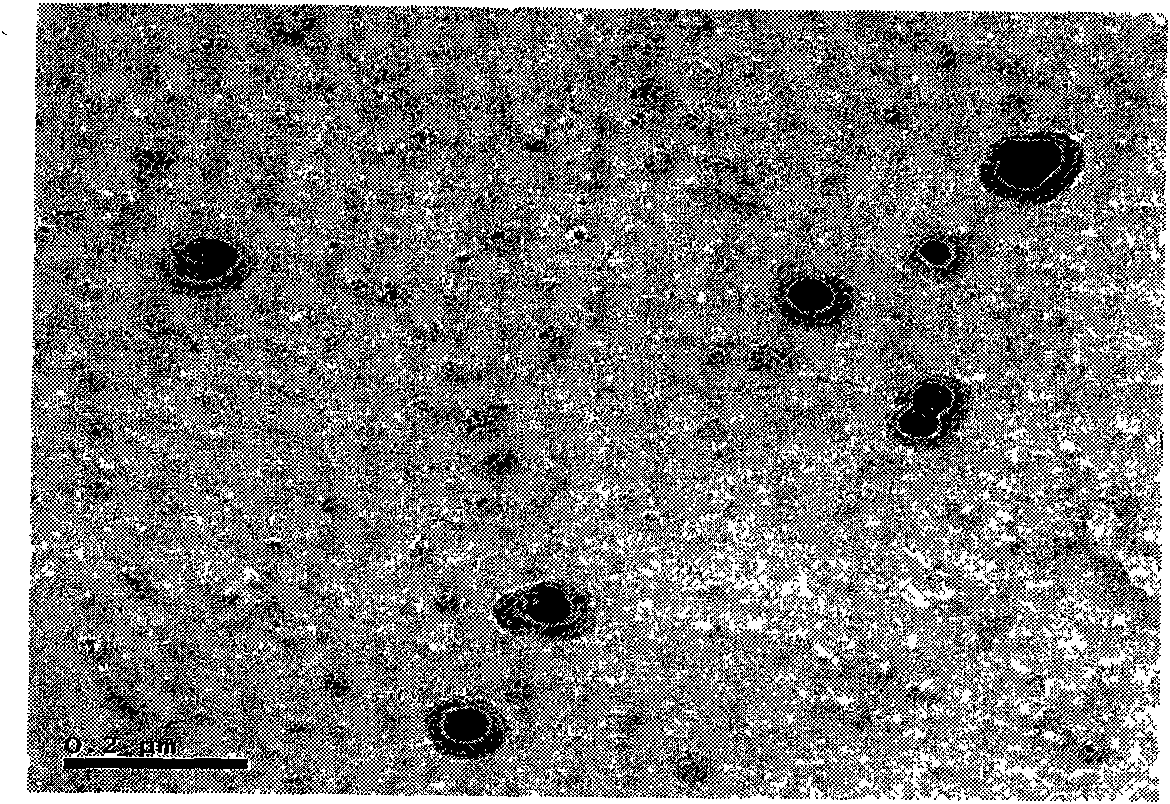

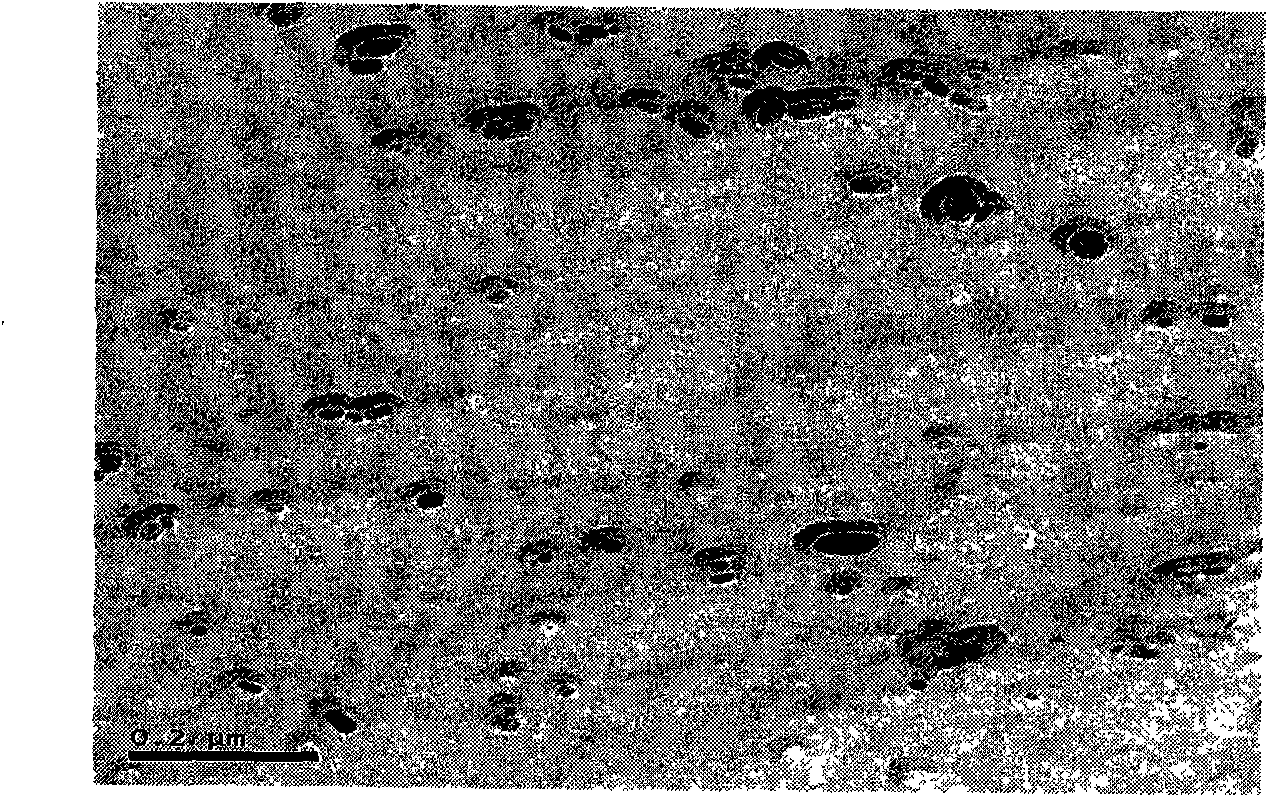

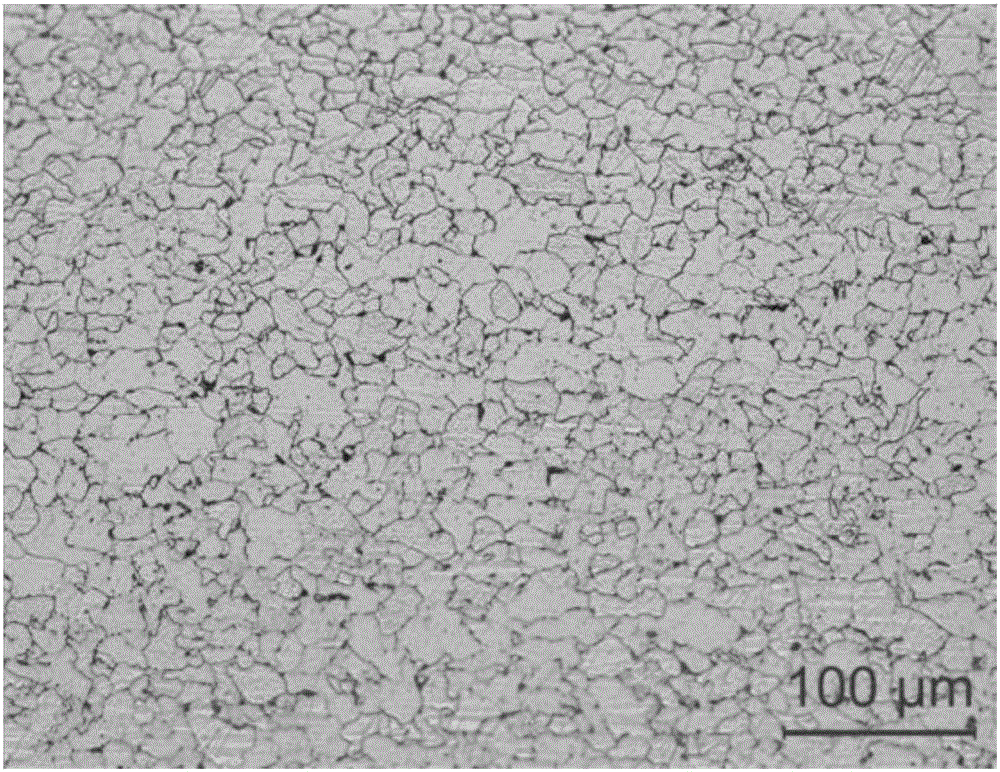

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

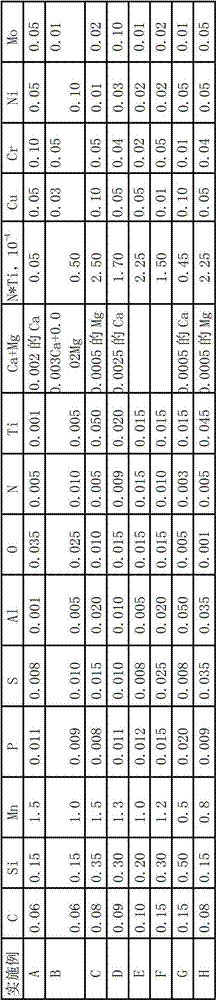

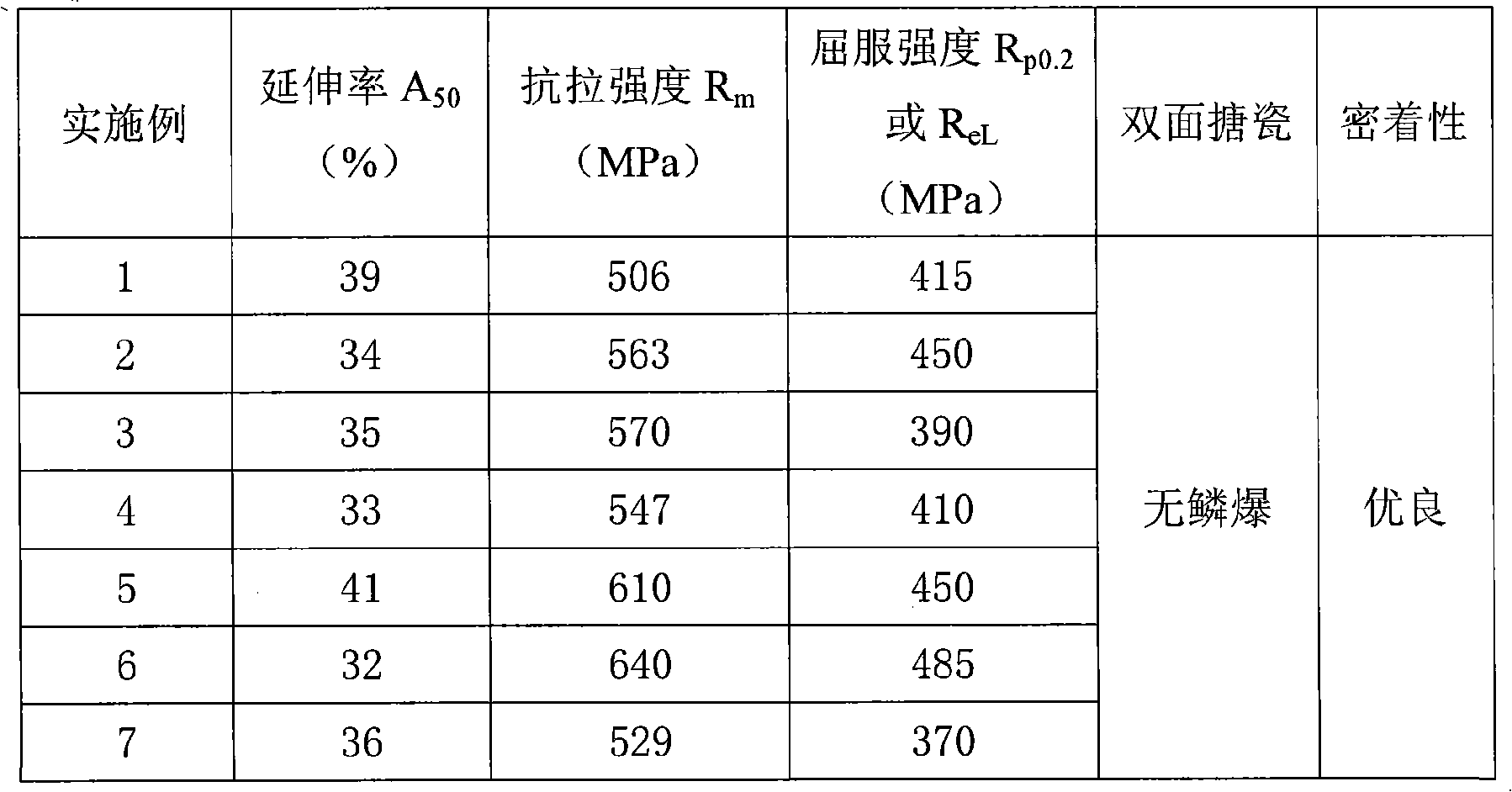

Hot-rolling high-strength medium plate for double-face enamel and manufacturing method thereof

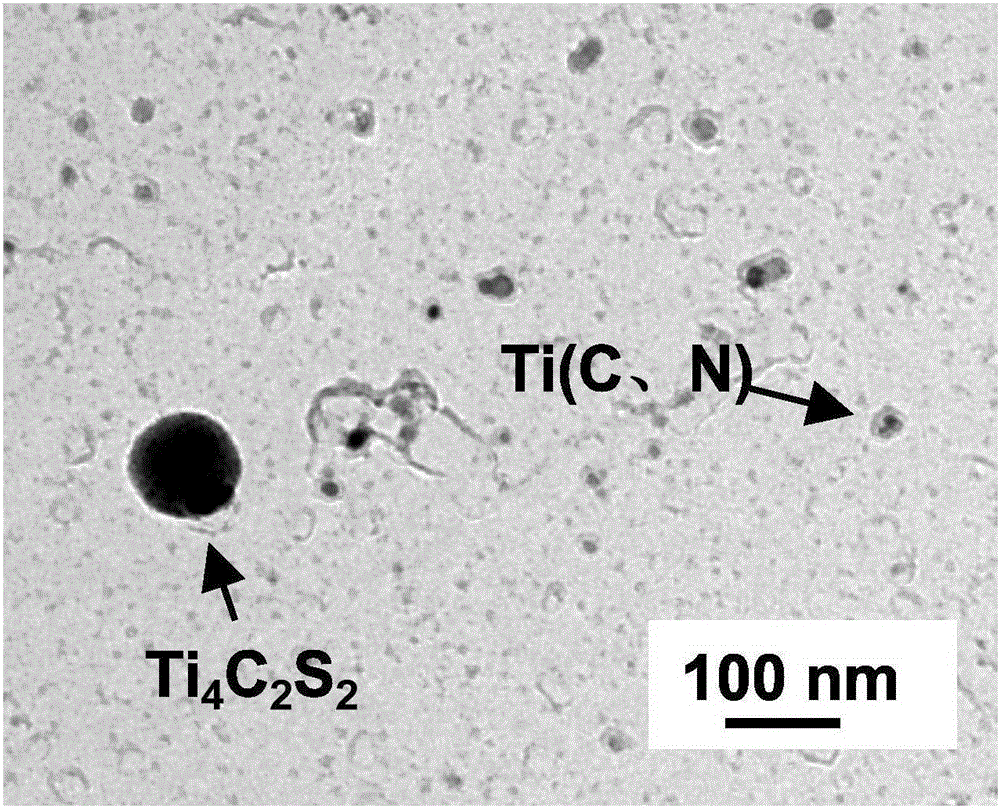

ActiveCN105331883AHigh strengthGood enamelling performanceLiquid surface applicatorsFurnace typesUltimate tensile strengthImpurity

The invention discloses a hot-rolling high-strength medium plate for double-face enamel. A base body of a microstructure of the medium plate is ferrite or a mixture of ferrite and pearlite. A Ti4C2S2 precipitated phase and a Ti(C,N) precipitated phase are distributed in the base body in a dispersed manner. The hot-rolling high-strength medium plate for double-face enamel comprises, by mass, 0.02-0.15% of C, 0.10-0.50% of Si, 0.3-1.5% of Mn, 0.006-0.035% of S, 0.01-0.08% of Al, 0.006-0.015% of N, 0.08-0.20% of Ti, 0.02-0.10% of Cu and the balance iron and other inevitable impurities. The hot-rolling high-strength medium plate for double-face enamel has the high strength and ductility, and meanwhile the steel plate has the good enameling performance and the good fish scaling resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength steel plate used for glass lining, and manufacturing method thereof

InactiveCN102766822AHomogeneous austenitized structureImprove low temperature toughnessFurnace typesHeat treatment furnacesUltimate tensile strengthMechanical property

The invention discloses a high-strength steel plate used for glass lining, comprising the following chemical components by weight: 0.06-0.15% of C, 0.15-0.50% of Si, 0.5-1.5% of Mn, less than or equal to 0.02% of P, 0.008-0.035% of S, 0.001-0.05% of Al, 0.003-0.015% of N, 0.001-0.035% of O, 0.001-0.05% of Ti, less than or equal to 0.10% of Cu, less than or equal to 0.10% of Cr, less than or equal to 0.10% of Ni, less than or equal to 0.10% of Mo, and the balance of Fe and other unavoidable impurities, wherein the product of Ti and N is less than or equal to 0.003%. Correspondingly, the invention further discloses a manufacturing method of the high-strength steel plate used for glass lining. The high-strength steel plate used for glass lining has the comprehensive mechanical properties of high strength, good plasticity, good scaling resistance, good sealing property and good welding property, and on the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot rolling high strength steel plate for two-sided porcelain enamel and manufacturing method thereof

InactiveCN101353758AHigh strengthMeet pressure requirementsLength control deviceChemical reactionSheet steel

The invention provides a hot-rolled high strength steel sheet used in double-face enamel and a preparation method thereof, comprising the following chemical composition: C: 0.05 to 0.15 weight percent, Si: less than or equal to 1.0 weight percent, Mn: 0.5 to 2.0 weight percent, P: less than or equal to 0.05 weight percent, S: less than or equal to 0.05 weight percent, Al: 0.01 to 0.10 weight percent, N: 0.008 to 0.015 weight percent, Ti: less than or equal to 0.05 weight percent, V: 0.02 to 0.2 weight percent, and the rest are Fe and inevitable impurities. By controlling the hot rolling technology and the cooling speed, second phase particles which are tiny and dispersed are ensured to be generated from vanadium and titanium in the steel, thus enhancing the strength, fish scaling resistance and adherence of the steel sheet; and the products after enamel firing can still maintain higher strength, thus better meeting the compression resistance requirements of different porcelain products, and being capable of being used for producing chemical reaction tanks and water treatment tanks and the like from double-face enamel.

Owner:BAOSHAN IRON & STEEL CO LTD

Cold-rolled enamelled steel and production method thereof

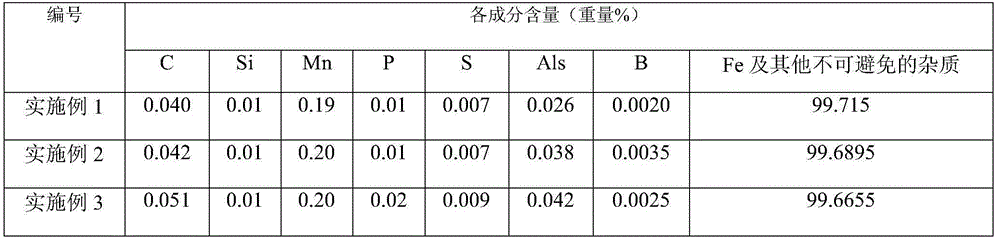

The invention belongs to the technical field of cold-rolled plate and strip production, and specifically relates to a method for producing cold-rolled enamelled steel by a continuous annealing production process. Cold-rolled enamelled steel is composed of the following ingredients in percentage by weight: 0.01-0.07% of C, not greater than 0.05% of Si, 0.10-0.60% of Mn, not greater than 0.030% of P, not greater than 0.025% of S, 0.015-0.070% of Als, not greater than 0.01% of N, 0.001-0.01% of B and the balance Fe and inevitable impurities. The cold-rolled enamelled steel prepared by the method disclosed by the invention has the characteristics of being excellent in surface quality, good in forming property and fish scaling resistance, good in economic benefits and the like; the continuous annealing method is used for producing the cold-rolled enamelled steel, and is simple in process and low in cost, the cooling speed of a rapid-cooling section of a steel plate is increased, and lots of cementites are separated out from the steel plate as hydrogen storage traps, thus improving the fish scaling resistance and the like of the steel plate.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Enamel steel and preparation method of cold rolled sheet thereof

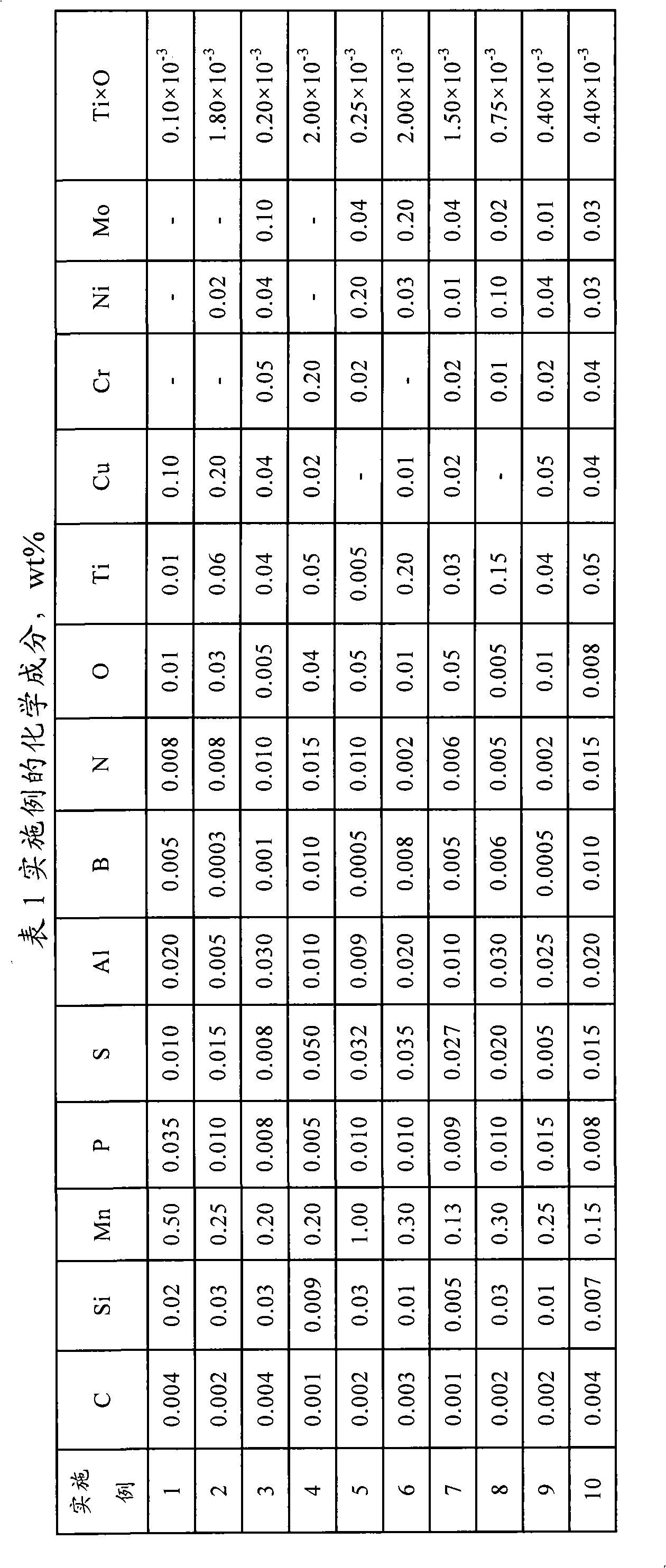

InactiveCN102251174AExcellent anti-pinhole performanceExcellent anti-scale explosion performanceReduction rateCompound (substance)

Enamel steel comprises the following chemical components by weight percent: less than or equal to 0.004% of C, less than or equal to 0.03% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.035% of P, less than or equal to 0.050% of S, less than or equal to 0.030% of Al, 0.0003-0.010% of B, less than or equal to 0.015% of N, 0.005-0.05% of O and 0.005-0.20% of Ti. The enamel steel also comprises one or more of 0.01-0.20% of Cu, 0.01-0.20% of Cr, 0.01-0.20% of Ni and 0.01-0.20% of Mo. The preparation method of the enamel steel comprises the following steps: smelting, casting; performing hot rolling, wherein the finish rolling temperature is 700-950 DEG C; pickling the rolled steel coils to remove oxide scales; performing cold rolling, wherein the total reduction rate is more than 60%; and performing continuous annealing or box annealing at 650-900 DEG C for 1 minute-20 hours. The enamel steel has good pinhole resistance and fish scaling resistance, and the adhesion between the steel plate and the glaze is good.

Owner:BAOSHAN IRON & STEEL CO LTD

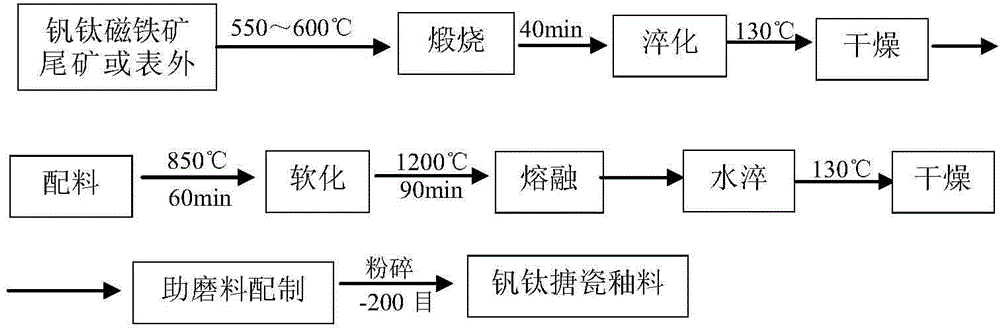

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

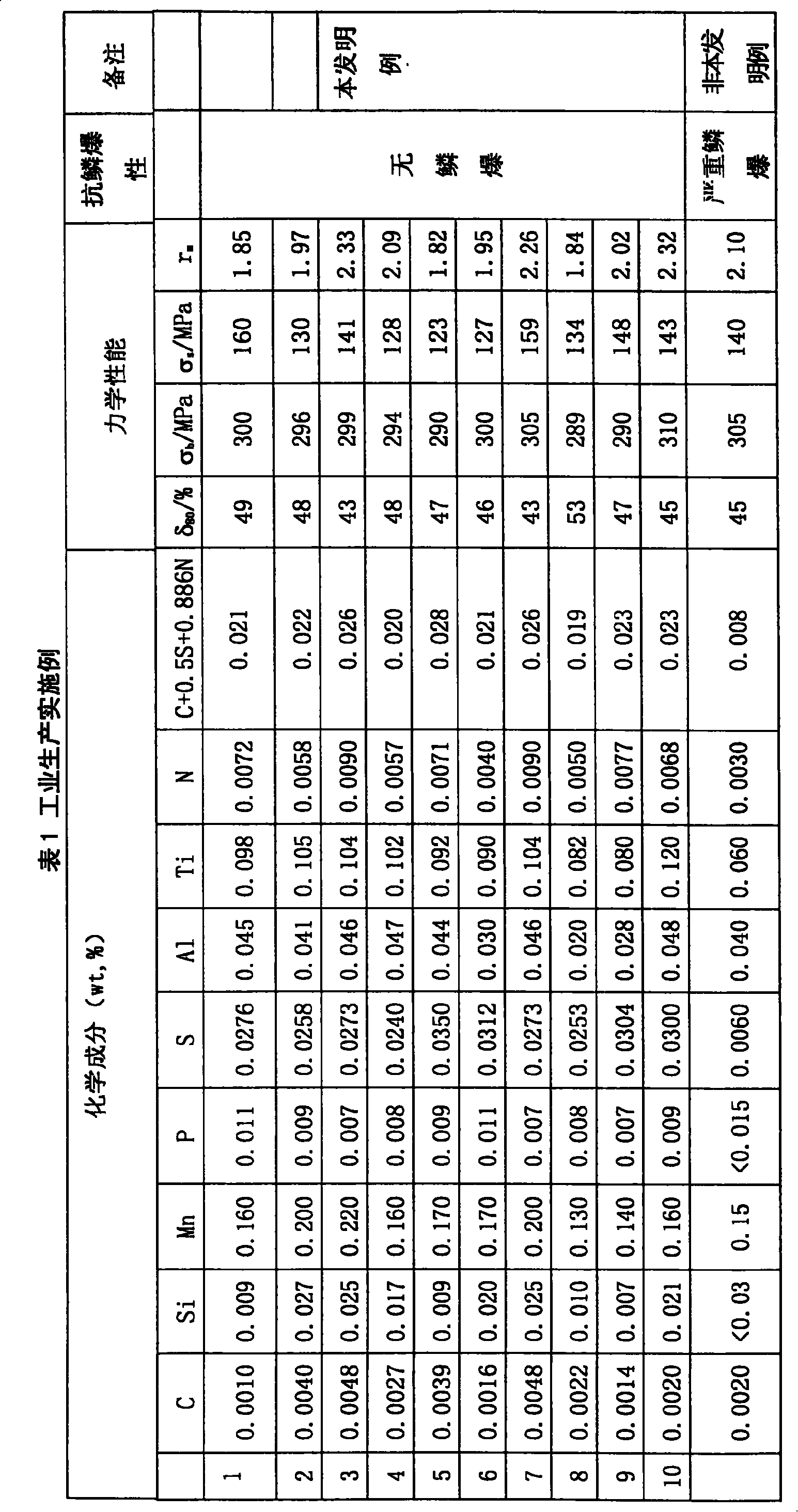

Cold rolling glass-lined steel having excellent scale cracking resistance and extra-deep drawing property and manufacturing method thereof

ActiveCN1704494AWith ultra-deep drawingExcellent anti-scale explosion performanceCrack resistancePhosphor

The invention relates to a cold rolling glass-lined steel having excellent scale cracking resistance and extra-deep drawing property, and the manufacturing method, the steel has the constituents (by weight percentage) of carbon <=0.005%, Si <=0.030%, manganese 0.10-0.30%, phosphor <=0.015%, sulfur 0.010-0.050%, aluminum 0.020-0.050%, nitrogen 0.004-0.015%, titanium content = 4C+3.42N+1.5S+0.02-0.04%, and balancing ferrum and unavoidable impurities, and 0.01%<=C+0.5S+0.886N<=0.03%.

Owner:BAOSHAN IRON & STEEL CO LTD

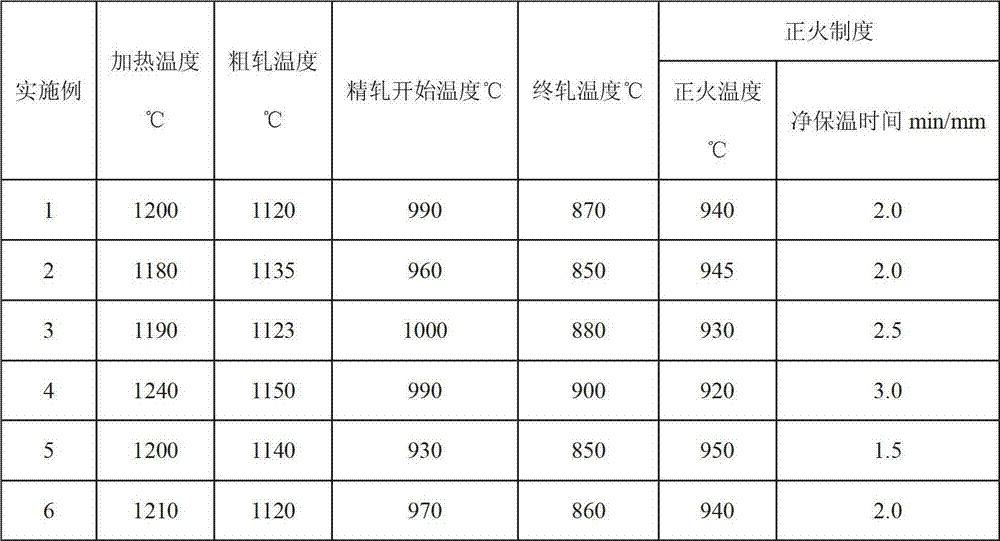

Steel plate used for glass lining and production method thereof

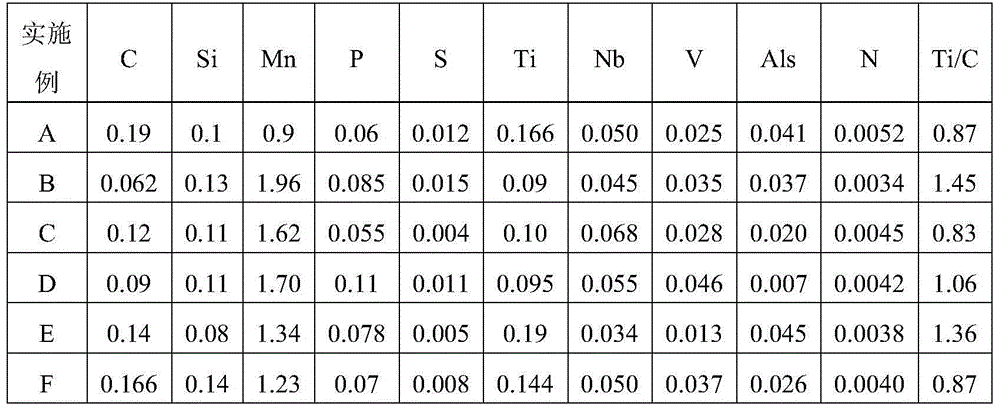

ActiveCN102899560AAdjust precipitation strengthening rangeExcellent anti-scale explosion performanceSheet steelChemical composition

The invention provides a steel plate used for a glass lining and a production method thereof. The steel plate comprises the following chemical components: 0.05%-0.15% of C, not more than 0.20% of Si, 0.50%-1.60% of Mn, not more than 0.025% of P, not more than 0.020% of S, 0.06%-0.18% of Ti, 0.005%-0.050% of Als, not more than 0.0030% of O, not more than 0.0060% of N and the balance of iron and inevitable impurities, wherein a ratio of Ti to C is 1.0-1.5. The production method of the steel plate comprises the steps of smelting, continuous casting, rolling and normalizing treatment, wherein the heating temperature of a casting blank is at 1180-1250 DEG C, two-stage rolling is adopted, the rolling temperature of a rough rolling stage is not less than 1100 DEG C, the rolling temperature of a finish rolling stage is at 920-1000 DEG C, the finish rolling temperature is at 900-840 DEG C, and the accumulated deformation quantity is not less than 60%; the normalizing temperature is at 920-960 DEG C, and the net thermal insulation time is 1.0-3.5 min / mm. According to the steel plate provided by the invention, through controlling the ratio of Ti to C to 1.0-1.5, the content of Ti is 0.06%-0.18%, the steel has good scale explosion prevention performance after lining burning, the lining burning frequency is reduced, the energy is saved, and the cost is saved for a user; after lining burning, the intensity level is stable, and a safe and reliable steel plate material is provided for manufacturing industry of glassed steel equipment.

Owner:ANGANG STEEL CO LTD

Super deep-drawing cold-rolled enamel steel produced by ASP diplex process and manufacturing method thereof

InactiveCN103469075AExcellent formability and scale resistanceBroaden the range of product varietiesAluminiumMetal

The invention belongs to the technical field of metal material manufacturing, and in particular relates to super deep-drawing cold-rolled enamel steel produced by an ASP diplex process and a manufacturing method thereof. The enamel steel comprises the following components in percentage by weight: less than or equal to 0.005% of carbon, less than or equal to 0.030% of silicon, 0.10 to 0.35% of manganese, less than or equal to 0.015% of phosphorus, 0.015 to 0.035% of sulfur, 0.015 to 0.050% of acid dissolved aluminum, 0.070 to 0.10% of titanium, 0.0040 to 0.0070% of nitrogen, and the balance of iron and unavoidable impurities. The manufacturing method comprises the following steps of: (1) smelting by a converter, (2) refining by an LF (ladle furnace), (3) vacuum-refining by an RH furnace, (4) continuously casting and rolling, (5) washing by acid, cold-rolling, annealing and flattening. By adoption of the LF and RH diplex process, the mass production of the super deep-drawing cold-rolled enamel steel is successfully realized on an ASP production line.

Owner:JIGANG GRP

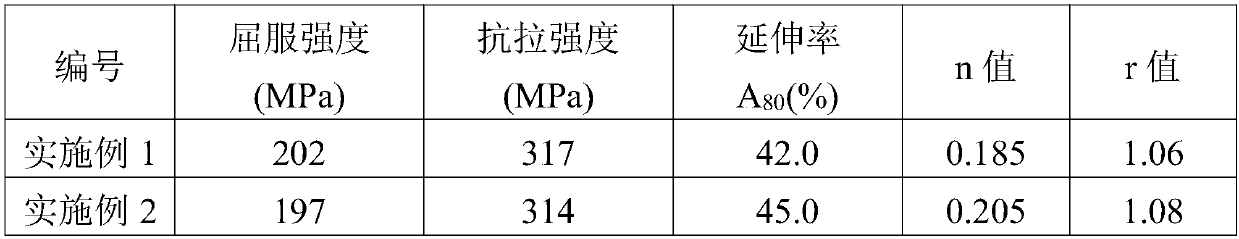

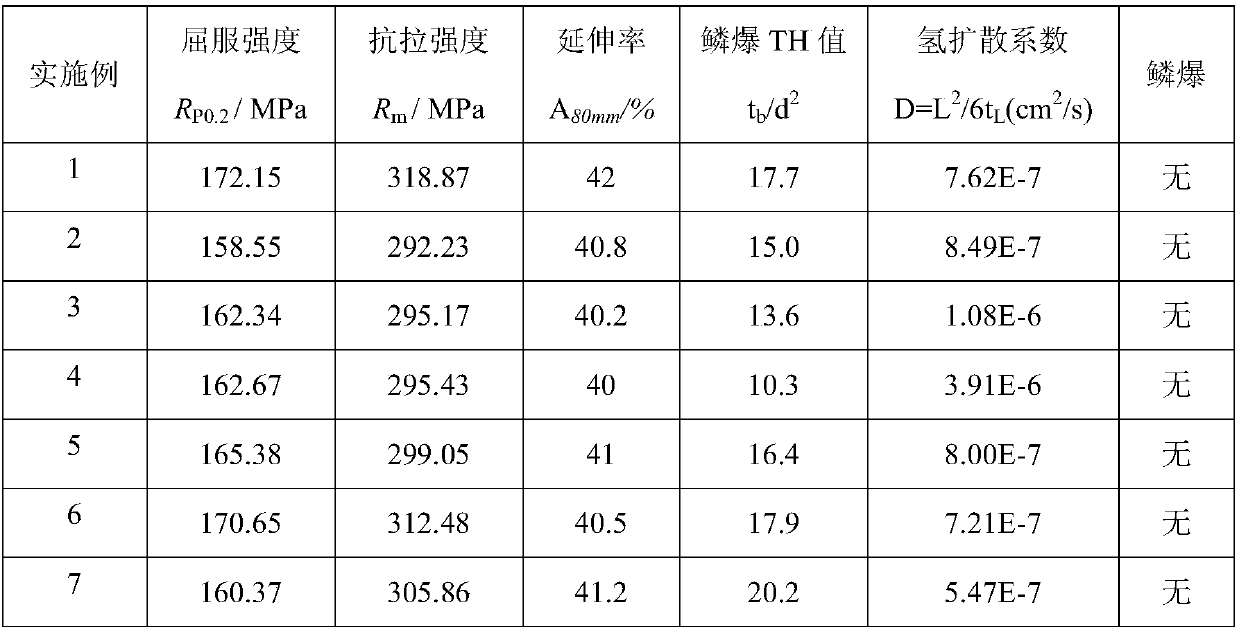

Economical deep drawing cold rolling enamel steel and production method

The invention discloses economical deep drawing cold rolling enamel steel and a production method. The economical deep drawing cold rolling enamel steel comprises the following chemical elements in percentage by weight: 0.005%-0.015% of C, equal to or less than 0.030% of Si, 0.15%-0.25% of Mn, equal to or less than 0.020% of P, 0.010%-0.020% of S, 0.030%-0.060% of Al and equal to or less than 0.0040% of N. The production method comprises the following steps: hot metal pretreatment, smelting in a converter, alloy fine adjustment station, refining in an RH furnace, hot rolling, acid pickling, cold rolling, continuous annealing and leveling. The economical deep drawing cold rolling enamel steel is produced through the working procedures of hot rolling, acid pickling, five-rack full six-roller cold continuous rolling and continuous annealing and leveling, wherein the yield strength is 160-190 MPa, the tensile strength is higher than 300 MPa, the A50 elongation is greater than 45%, n is greater than 0.2 and r is greater than 1.8.

Owner:MAANSHAN IRON & STEEL CO LTD

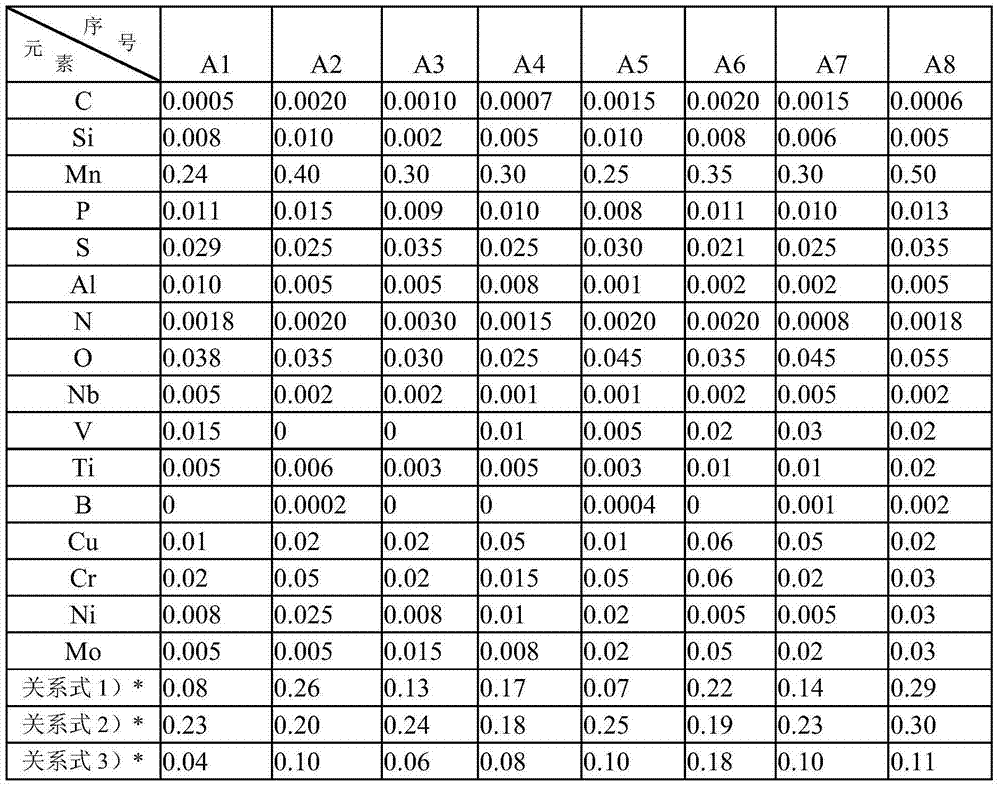

Enamel steel sheet for direct glazing and manufacturing method thereof

ActiveCN104775069AGood formabilityReduce timelinessProcess efficiency improvementSheet steelChemical element

The invention discloses an enamel steel sheet for direct glazing, which comprises the following chemical elements in percentage by mass: 0.0005-0.002% of C, 0.24-0.50% of Mn, 0.021-0.035% of S, 0.025-0.055% of O, at most 0.010% of Si, at most 0.015% of P, at most 0.010% of Al, at most 0.003% of N, and the balance of Fe and other inevitable impurities, wherein 0<=Mn-1.7*O+3.4*S<=0.30%, and 2.7*O+4.4*S>=0.14%. The invention also discloses a manufacturing method of the enamel steel sheet for direct glazing, which comprises the following steps: (1) molten iron pretreatment; (2) smelting and refining; (3) casting; and (4) hot rolling. The enamel steel sheet for direct glazing has excellent surface characteristics and favorable inherent quality.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-carbon enameled steel plate and manufacturing method thereof

InactiveCN105132806AExcellent adhesionExcellent anti-scale explosion performanceTwo stepCarbon steel

The invention discloses a low-carbon enameled steel plate and a manufacturing method thereof. The low-carbon enameled steel plate comprises, by mass, 0-0.010% of C, 0-0.03% of Si, 0-0.60% of Mn, 0-0.025% of P, 0-0.035% of S, 0-0.050% of Al, 0-0.0080% of N, Fe and inevitable impurity elements. According to the steel plate, the contents of N and S are controlled to be within an appropriate range, the certain content of Al is controlled, a certain amount of C is retained, and the proportion of C to S is controlled; sufficient Ti is added, and an appropriate amount of Cu, Cr, Ni and Mo remain in steel so as to improve the adherence performance and fish-scaling resistance of the steel plate. The steel plate has good fish-scaling resistance, and the adherence between the steel plate and enamel is outstanding. By means of the method, enameled steel with outstanding fish-scaling resistance, adherence performance and forming performance can be manufactured. The enameled steel is applicable to both a two-step enameling process and a one-step enameling process and can be used for the fields of the light industry, bathroom accessories, household appliances, architectural ornaments and the like; the production difficulty of the enameled steel is equivalent to that of conventional ultra-low carbon steel, but the production cost is low.

Owner:TANGSHAN IRON & STEEL GROUP

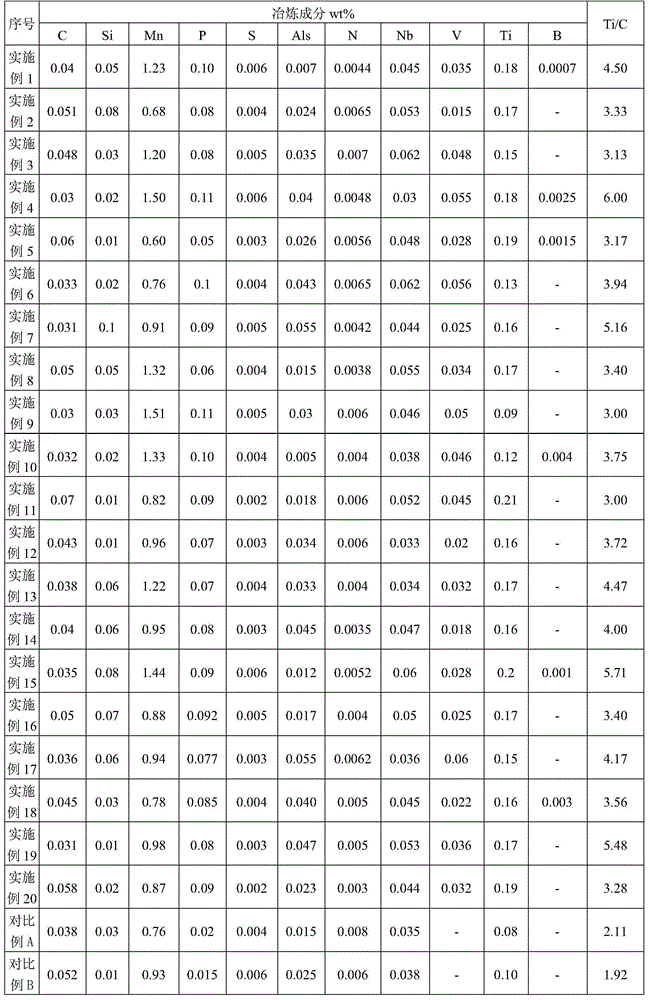

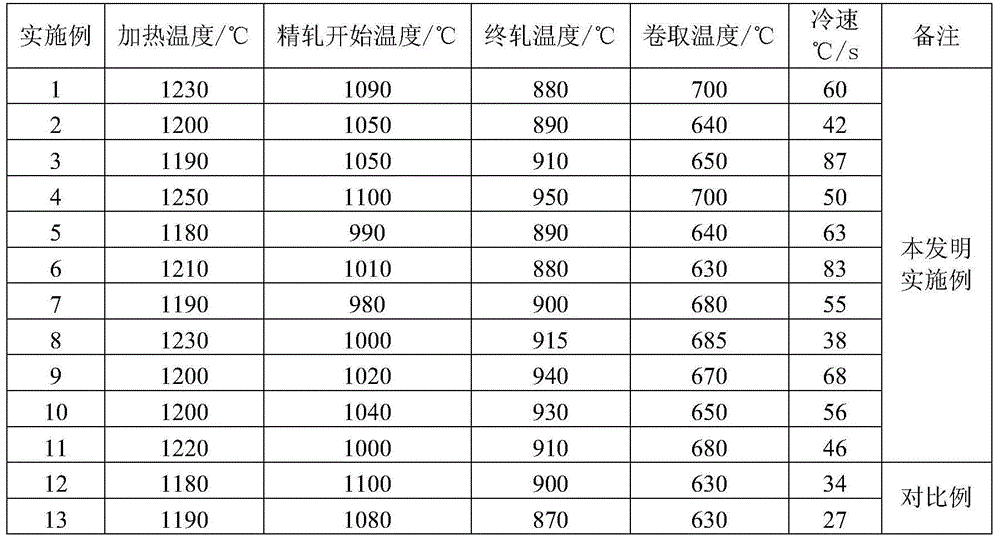

Hot-rolled steel plate for enameled high-strength double-face enamel and manufacturing method of steel plate

InactiveCN106480368AExcellent anti-scale explosion performanceGuaranteed Yield StrengthHigh pressure waterHigh pressure

The invention discloses a hot-rolled steel plate for enameled high-strength double-face enamel and a manufacturing method of the steel plate. When the thickness of the steel plate is smaller than or equal to 8 mm, the chemical components in the steel comprise, by weight percent, 0.030% to 0.070% of C, not larger than 0.10% of Si, 0.60% to 1.5% of Mn, 0.05% to 0.11% of P, not larger than 0.006% of S, not larger than 0.008% of N, 0.09% to 0.21% of Ti, 0.03% to 0.07% of Nb, 0.015% to 0.060% of V, 0.005% to 0.055% of Als, 3.0% to 6.0% of Ti / C and the balance is Fe and inevitable impurities, when the thickness of the steel plate is larger than 8 mm, B is added, the content of the B ranges from 0.0005% to 0.005%,. The casting blank with the above component is heated to 1180 DEG C to 1250 DEG C, after soaking, high-pressure water descaling and rough rolling cogging are carried out, the finish rolling cogging temperature ranges from 880 DEG C to 1100 DEG C, the finish rolling temperature ranges from 880 DEG C to 930 DEG C, rapid cooling to the reeling temperature is achieved with the cooling speed larger than or equal to 30 DEG C / S after rolling, and the reeling temperature ranges from 630 DEG C to 700 DEG C.

Owner:ANGANG STEEL CO LTD

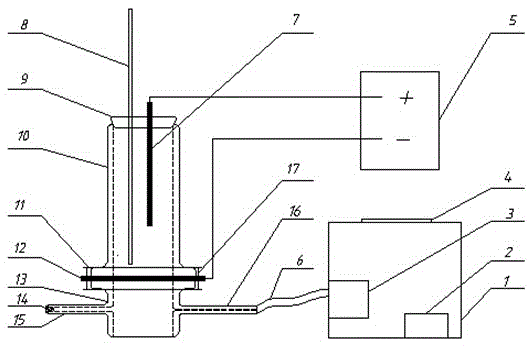

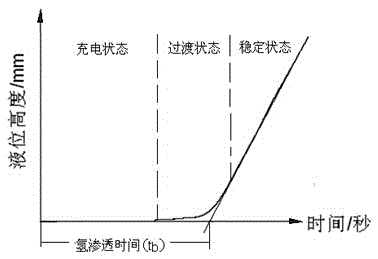

Apparatus and method for detecting fish-scaling resistance of steel for enamel based on principle of micro-differential pressure

InactiveCN105486739AConvenient instant checkEasy to storeMaterial electrochemical variablesDifferential pressureEngineering

The invention relates to an apparatus and method for detecting fish-scaling resistance of steel for enamel based on principle of micro-differential pressure. A hydrogen evolution groove and a hydrogen diffusion groove are respectively arranged at the upper side and the lower side of a steel sample to be measured; a hole wall of the hydrogen diffusion groove is provided with a hydrogen diffusion liquid charging tube and a hydrogen diffusion liquid discharging tube; a thermometer is placed in the hydrogen evolution groove by a rubber stopper; a platinum electrode is placed in the hydrogen evolution groove through the rubber stopper, and the platinum electrode is connected to an anode of a DC constant-current constant-voltage instrument by a lead; the steel sample to be measured is connected to a cathode of the DC constant-current constant-voltage instrument by a lead; the hydrogen diffusion liquid discharging tube is connected to a micro-differential pressure sensor by a silica gel tube; the micro-differential pressure sensor is connected to a computer, and the computer connects a digital display touch screen. Computer data processing and the digital display touch screen are combined for facilitating instant inspection and storage of detection data, and visually displaying relation of hydrogen evolution quantity and time change.

Owner:SHANGHAI INST OF TECH

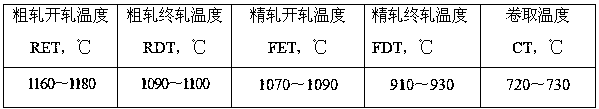

Hot-rolled steel strip used for enamel and having ultra-deep-punching performance and preparation method of hot-rolled steel strip

InactiveCN104789864AImprove deep drawing performanceExcellent anti-scale explosion performancePunchingHigh pressure water

The invention discloses a hot-rolled steel strip used for enamel and having ultra-deep-punching performance and a preparation method of the hot-rolled steel strip. The hot-rolled steel strip comprises the following chemical components in percentage by weight: not less than 0.005% and not more than 0.010% of C, not more than 0.05% of Si, not less than 0.10% and not more than 0.30% of Mn, not less than 0.040% and not more than 0.080% of Ti, not more than 0.025% of P, not less than 0.010% and not more than 0.035% of S, not less than 0.010% and not more than 0.060% of Als and not more than 0.006% of N. The preparation method comprises the steps of vacuum treatment of molten steel, steel billet casting, heating, high-pressure water descaling, rough rolling, coiling by a hot coil box, precision rolling, cooling, coiling and flattening. Compared with the prior art, the hot-rolled steel strip prepared with the method has good deep-punching performance, fish-scaling resistance and welding performance, meets a pressure-resistant requirement of a water heater container, and can be used for replacing cold-rolled steel for enamel to manufacture the water heater container with an ultra-deep-punching requirement.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

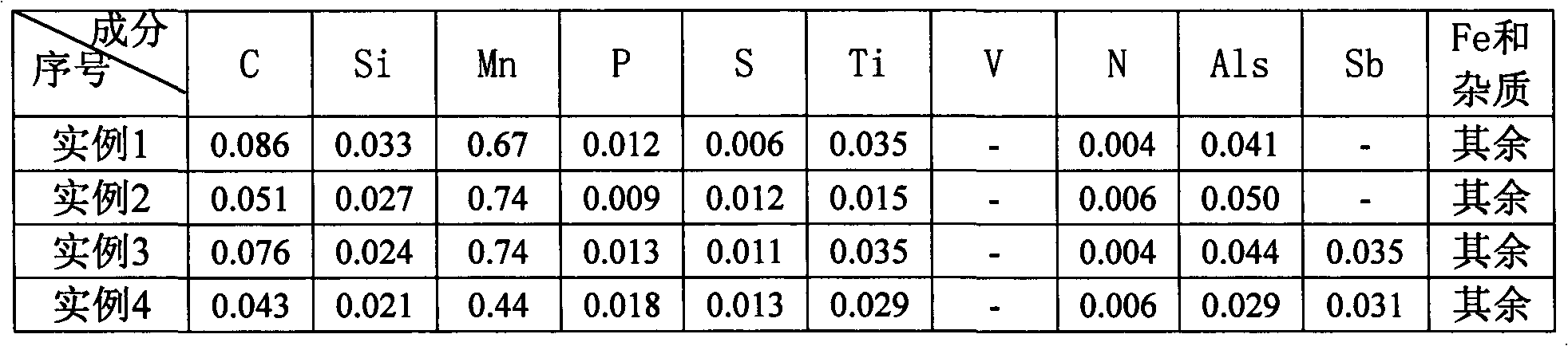

Hot rolled steel plate for double-faced enamel and production method thereof

InactiveCN102653847AReduce the risk of fish scale chipping defectsReduce the amount addedTemperature control deviceSteelmakingDetonation

The invention relates to a hot rolled steel plate for double-faced enamel and a production method of the hot rolled steel plate and belongs to the technical field of iron-base alloy. The production method of the hot rolled steel plate comprises the steps of: controlling the ingredients and mass percents of the hot rolled steel plate as follows: 0.02-0.1% of C, not larger than 0.1% of Si, 0.2-1.0% of Mn, not larger than 0.02% of P, 0.005-0.035% of S, 0.01-0.1% of Als, 0.002-0.01% of N, 0.01-0.1% of Ti, 0.01-0.05% of Sb, and the balance of ferrum and inevitable impurities; and simultaneously controlling the heating temperature of the continuous casting slab of the hot rolled steel plate to be 1150-1230 DEG C, controlling the temperature of a precise rolling inlet to be 1020+ / -20 DEG C, controlling the precise rolling ending temperature to be 840-920 DEG C, and controlling the coiling temperature after the precise rolling operation to be 550-650 DEG C. The hot rolled steel plate and the production method of the hot rolled steel plate fully utilize the inevitable products C, S and N elements of steelmaking production to replace the function of the Ti element to reduce the dosage of the Ti element; and a proper dosage of Sb element is added to prevent the scales detonation of the enamel and reduce the steelmaking cost, and the hot rolled steel plate with good double-faced enamel processing performance and small strength performance change after enamel is obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

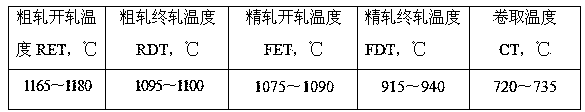

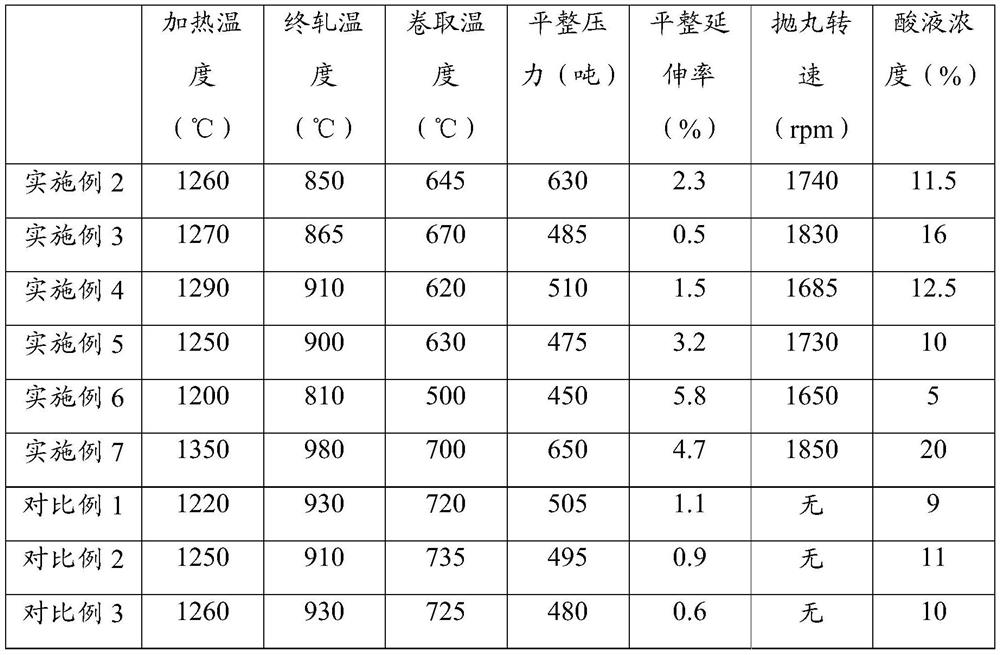

Enamel steel, as well as preparation method and application thereof

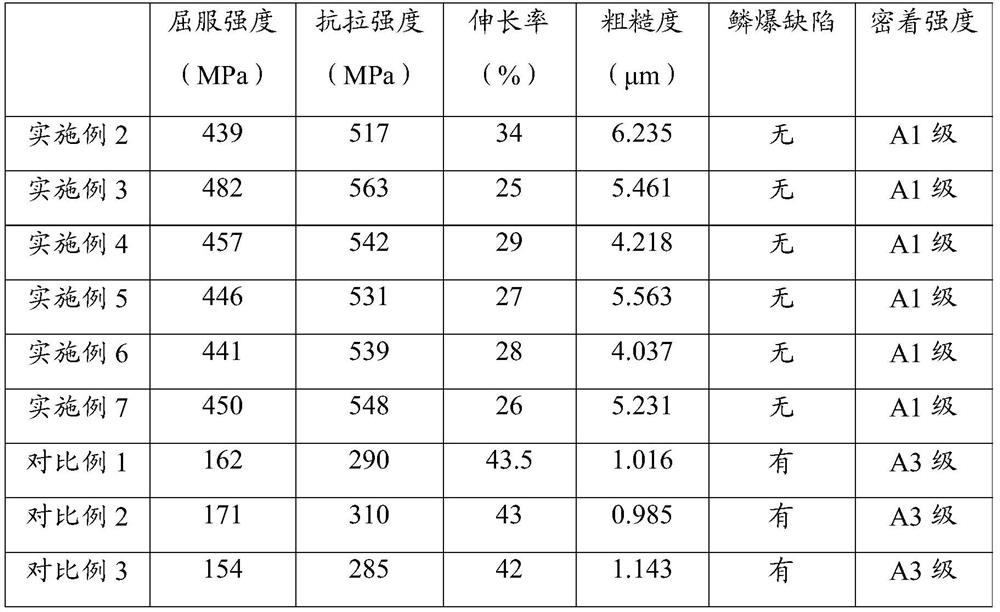

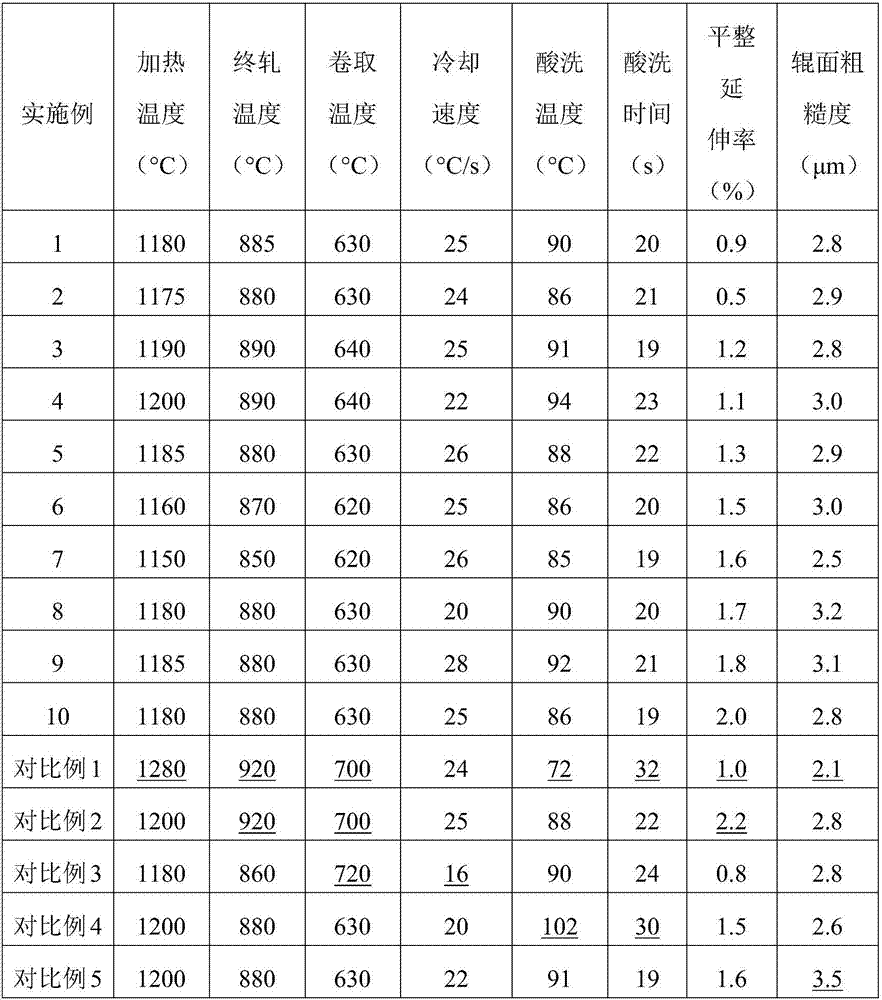

ActiveCN111996468AHigh strengthIncrease roughnessMetal rolling arrangementsHigh densityUltimate tensile strength

The invention belongs to the technical field of hot-rolled enamel steel, and particularly relates to enamel steel, as well as a preparation method and application thereof. The enamel steel is preparedfrom the components in percentage by mass: 0.01 percent to 0.14 percent of C, less than or equal to 0.10 percent of Si, 0.20 percent to 1.6 percent of Mn, less than or equal to 0.040 percent of P, less than or equal to 0.040 percent of S, 0.01 percent to 0.12 percent of Ti, 0.01 percent to 0.07 percent of Al, less than or equal to 0.010 percent of N, and the balance Fe and inevitable impurities,wherein Mn / S is larger than or equal to 30. The enamel steel provided by the invention has no scale explosion defect after being enameled, and has a good anti-scale explosion performance; the enamel steel has a high density strength grade (A1 grade); and the enamel steel can withstand 200,000 times of circulating pressure tests and pressure withstand tests with the pressure being 1.6 MPa, and after the test, no abnormal deformation, leakage or porcelain layer falling off occurs in a tank body, so that the operating requirements of a tank of a water heater are met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Production method of glassed steel

InactiveCN107916371AExcellent anti-scale explosion performanceImprove mechanical propertiesMolten steelMaterials science

The invention relates to a production method of glassed steel, belongs to the technical field of production of cold-rolled plates and strips, and provides the production method of glassed steel. The production method comprises the steps of casting molten steel into a billet, and carrying out hot rolling, acid pickling and cover annealing, so as to obtain glassed steel, wherein the annealing temperature of cover annealing is 690 DEG C to 730 DEG C. Through adoption of the production method, glassed steel with good fish scaling resistance and mechanical properties can be obtained even though alloy elements are not added and production is carried out with low carbon aluminum killed steel with low cost, and glassed steel has good cost decreasing and benefit increasing capabilities and market potentials.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

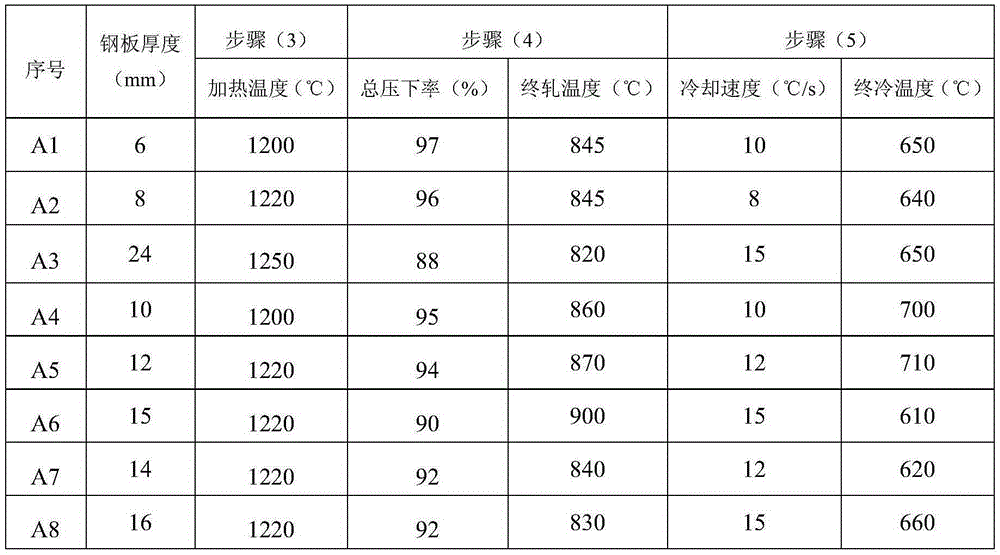

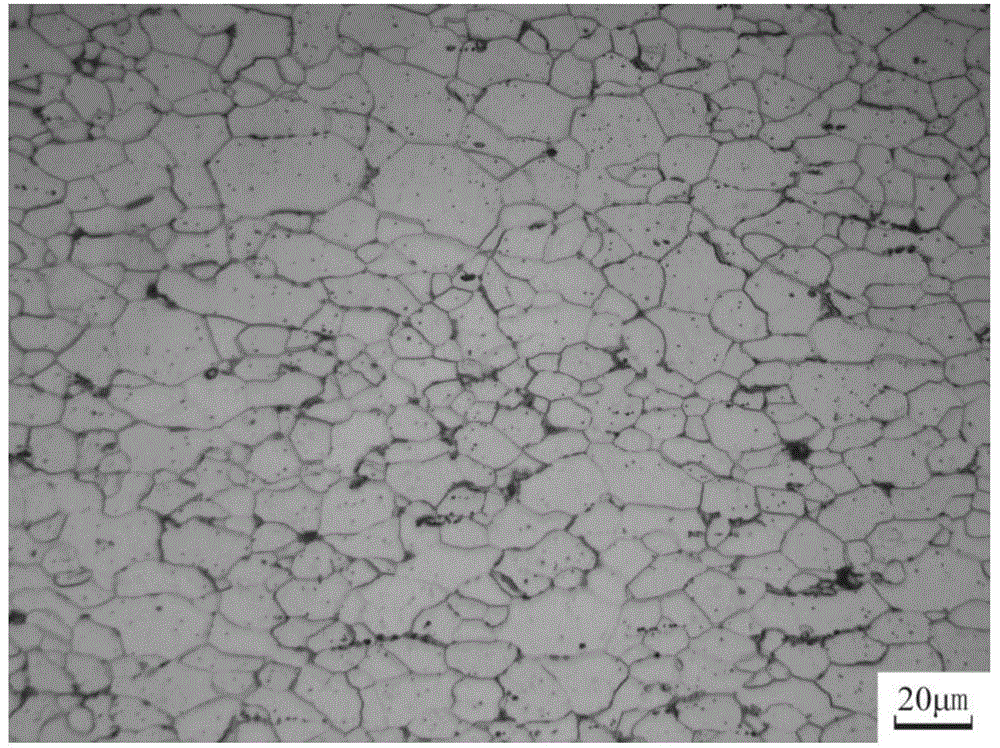

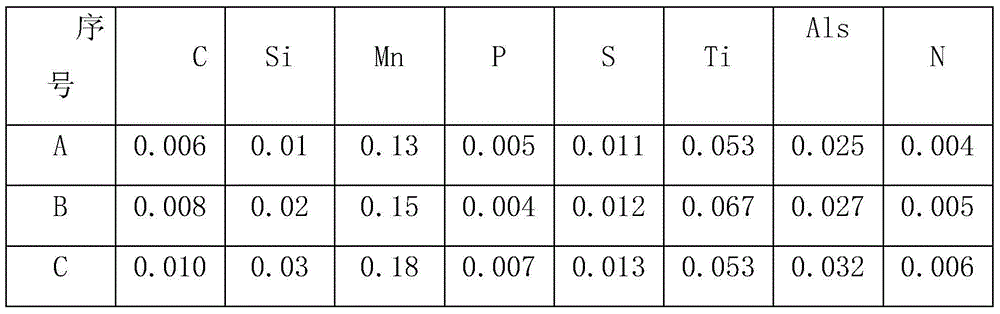

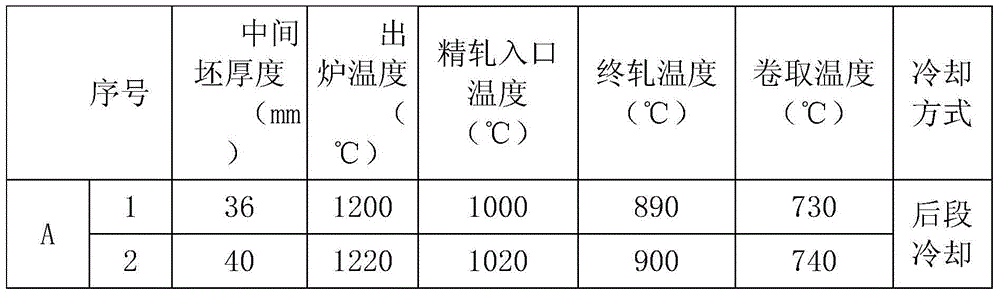

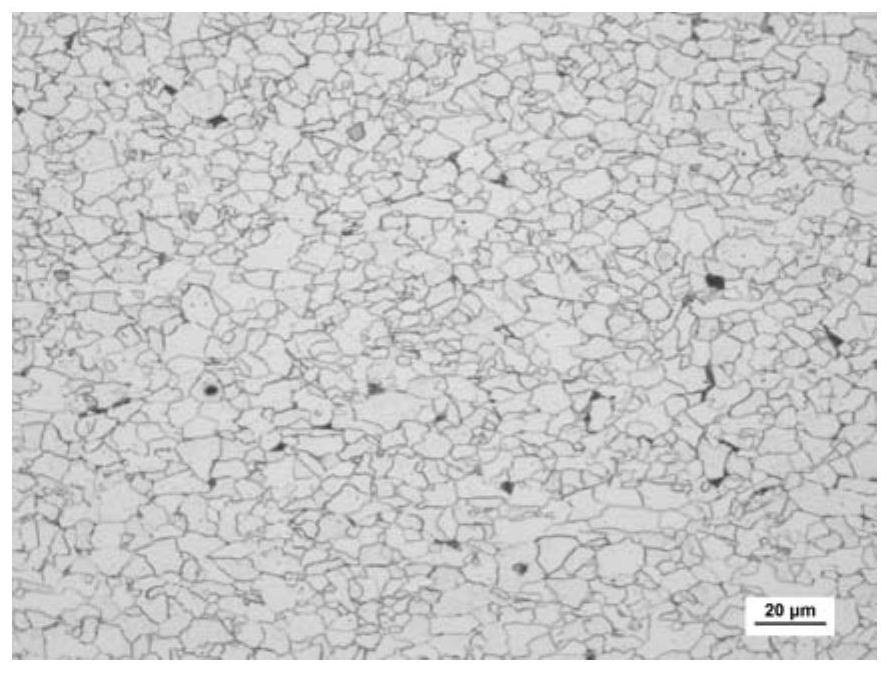

Hot-rolled enameled steel plate and preparation method thereof

The invention discloses a hot-rolled enameled steel plate and a preparation method thereof. The hot-rolled enameled steel plate comprises, by weight, 0.061%-0.089% of C, 0.11%-0.20% of Si, 0.60%-0.70% of Mn, 0-0.015% of P, 0-0.005% of S, 0.020%-0.050% of Alt, 0.1%-0.2% of Ti, 0-0.006% of N, and the balance Fe and inevitable impurities. According to the mass ratio, the ratio of the Ti to the C is 1.1-3.3. The method includes the steps that (1) molten iron is subjected to pretreatment, converter steelmaking and refining to obtain casting blank molten iron; (2) the molten iron is subjected to continuous casting, and accordingly a casting blank is made; (3) the casting blank is heated and the tapping temperature is controlled; (4) multi-pass rough rolling and finish rolling are carried out, so that a finish-rolled plate is obtained; and (5) reeling is performed at a certain temperature after laminar cooling, and a finished product can be obtained. According to the steel plate prepared through the method, the yield strength is 550-620MPa, the tensile strength is 630-730MPa, and the elongation at break is 22%-30%. According to the hot-rolled enameled steel plate after application of enamel, the yield strength is 350-410MPa, the tensile strength is 430-530MPa, the elongation at break is 33.5%-37%, and the enamel adhesive force reaches level A.

Owner:NORTHEASTERN UNIV +1

Cold-rolled enamel steel and manufacturing method thereof

InactiveCN109694999AExcellent anti-scale explosion performanceExcellent adhesionContinuous annealingImpurity

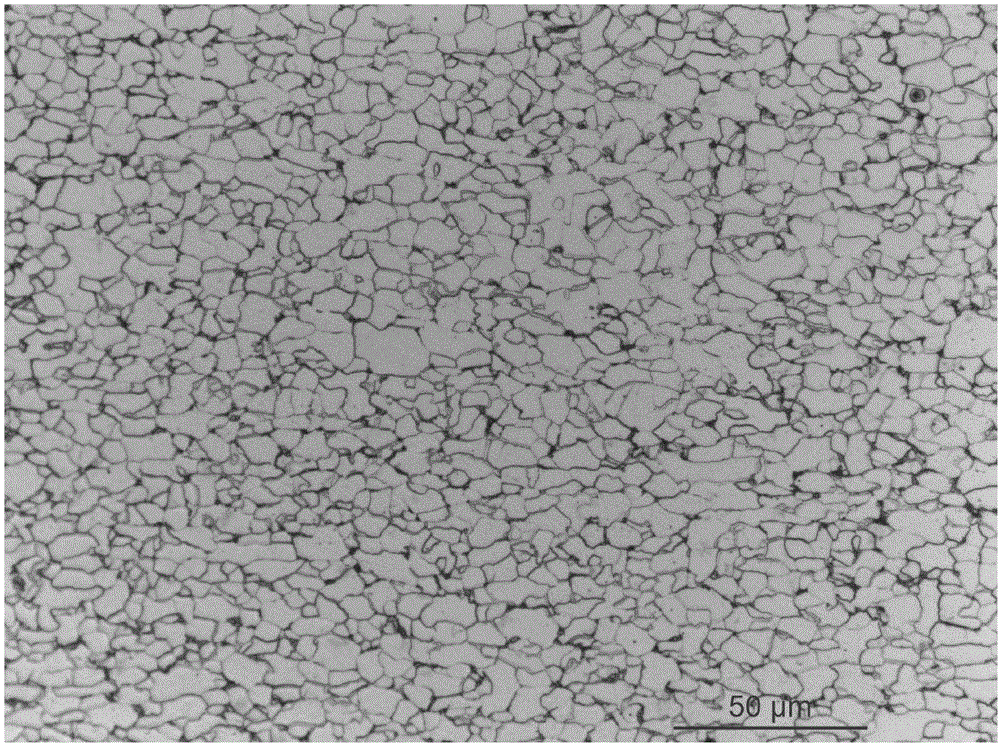

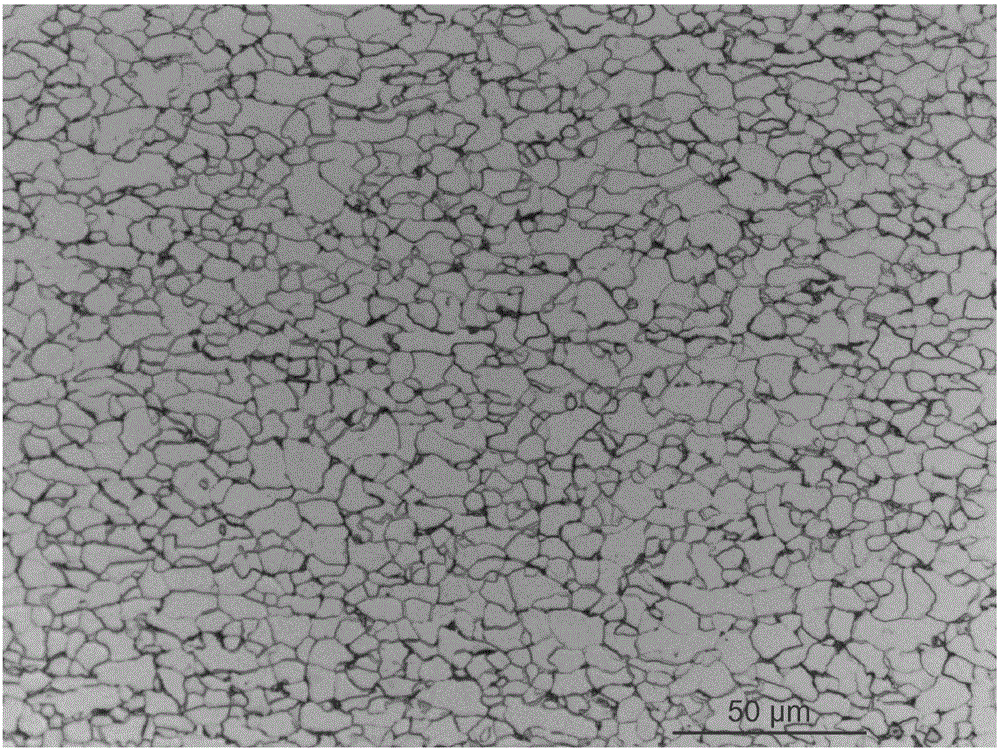

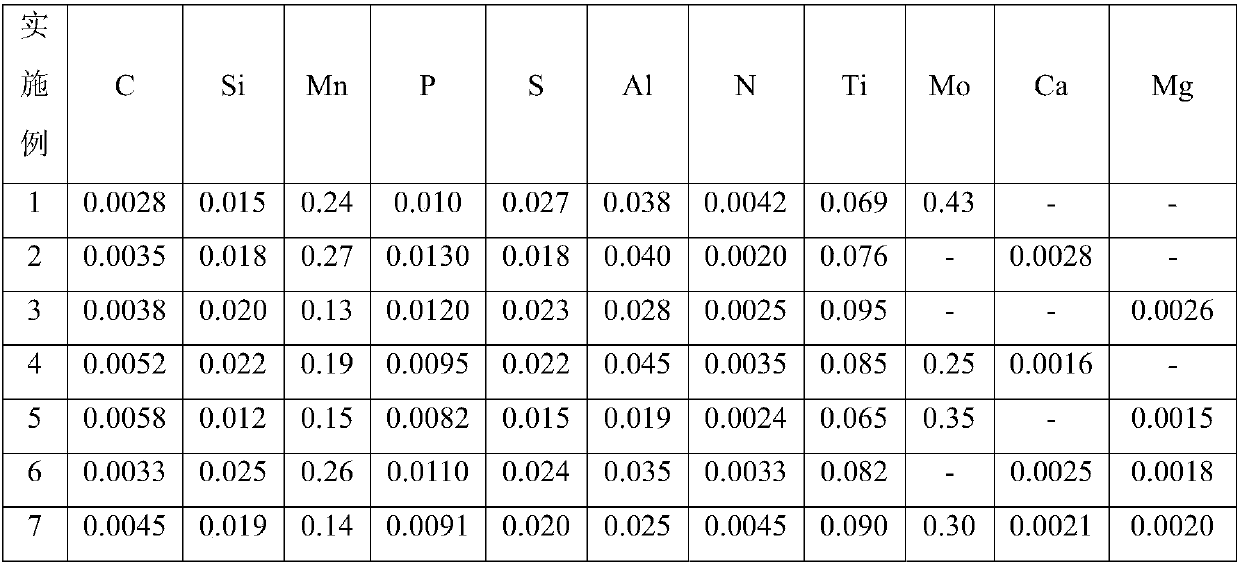

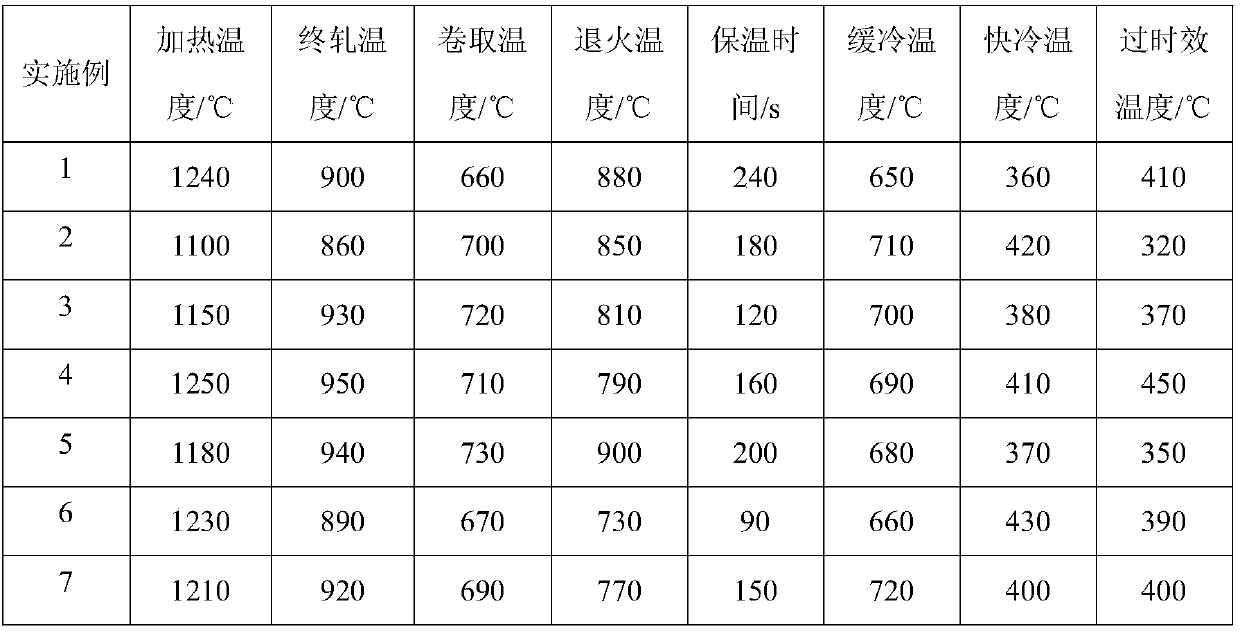

The invention provides cold-rolled enamel steel and a manufacturing method thereof. The components of a steel plate include, by weight percentage, 0.002-0.006% of C, 0.010-0.030% of Si, 0.10-0.30% ofMn, P which is less than or equal to 0.015%, 0.010-0.030% of S, 0.010-0.050% of Al, 0.0015-0.0050% of N, 0.060-0.10% of Ti, and one or more of 0.10-0.50% of Mo, 0.001-0.003% of Ca, and 0.001-0.003% ofMg, with the balance being Fe and inevitable impurities. The manufacturing method includes hot metal pretreatment, converter smelting, refining, continuous casting, hot rolling, cold rolling and continuous annealing. The produced cold-rolled enamel steel has excellent fish-scaling resistance, adhesion performance and formability, and is simple in manufacturing method and low in cost.

Owner:ANGANG STEEL CO LTD

Low-carbon cold-rolled steel plate for enamel and production method thereof

ActiveCN109943779AExcellent anti-scale explosion performanceExcellent elongationSheet steelChemical composition

The invention discloses a low-carbon cold-rolled steel plate for enamel and a production method thereof, and belongs to the technical field of metal materials. The low-carbon cold-rolled steel plate for enamel disclosed comprises the following chemical components in percentage, by mass, 0.010% to 0.030% of C, Si is less than or equal to 0.0030%, 0. 10% to 0.40% of Mn, P is less than or equal to 0.015%, 0.010% to 0.030% of S, 0.010% to 0.60% of Als, 0.010% to 0.040% of Ti, 0.0010% to 0.0070% of N, and the balance of Fe and inevitable impurities. The method aims to overcome the defects that in the prior art, the defects that the cold-rolled steel plate often generates scale explosion, poor adherence and the like in the enamel process are overcome, the low-carbon cold-rolled steel plate for enamel and a production method of the low-carbon cold-rolled steel plate for enamel has good anti-scale explosion performance, adherence property and pinhole resistance after enamel.

Owner:MAANSHAN IRON & STEEL CO LTD

Cold rolling glass-lined steel having excellent scale cracking resistance and extra-deep drawing property and manufacturing method thereof

ActiveCN100396808CWith ultra-deep drawingExcellent anti-scale explosion performanceCrack resistanceSulfur

The invention relates to a cold rolling glass-lined steel having excellent scale cracking resistance and extra-deep drawing property, and the manufacturing method, the steel has the constituents (by weight percentage) of carbon <=0.005%, Si <=0.030%, manganese 0.10-0.30%, phosphor <=0.015%, sulfur 0.010-0.050%, aluminum 0.020-0.050%, nitrogen 0.004-0.015%, titanium content = 4C+3.42N+1.5S+0.02-0.04%, and balancing ferrum and unavoidable impurities, and 0.01%<=C+0.5S+0.886N<=0.03%.

Owner:BAOSHAN IRON & STEEL CO LTD

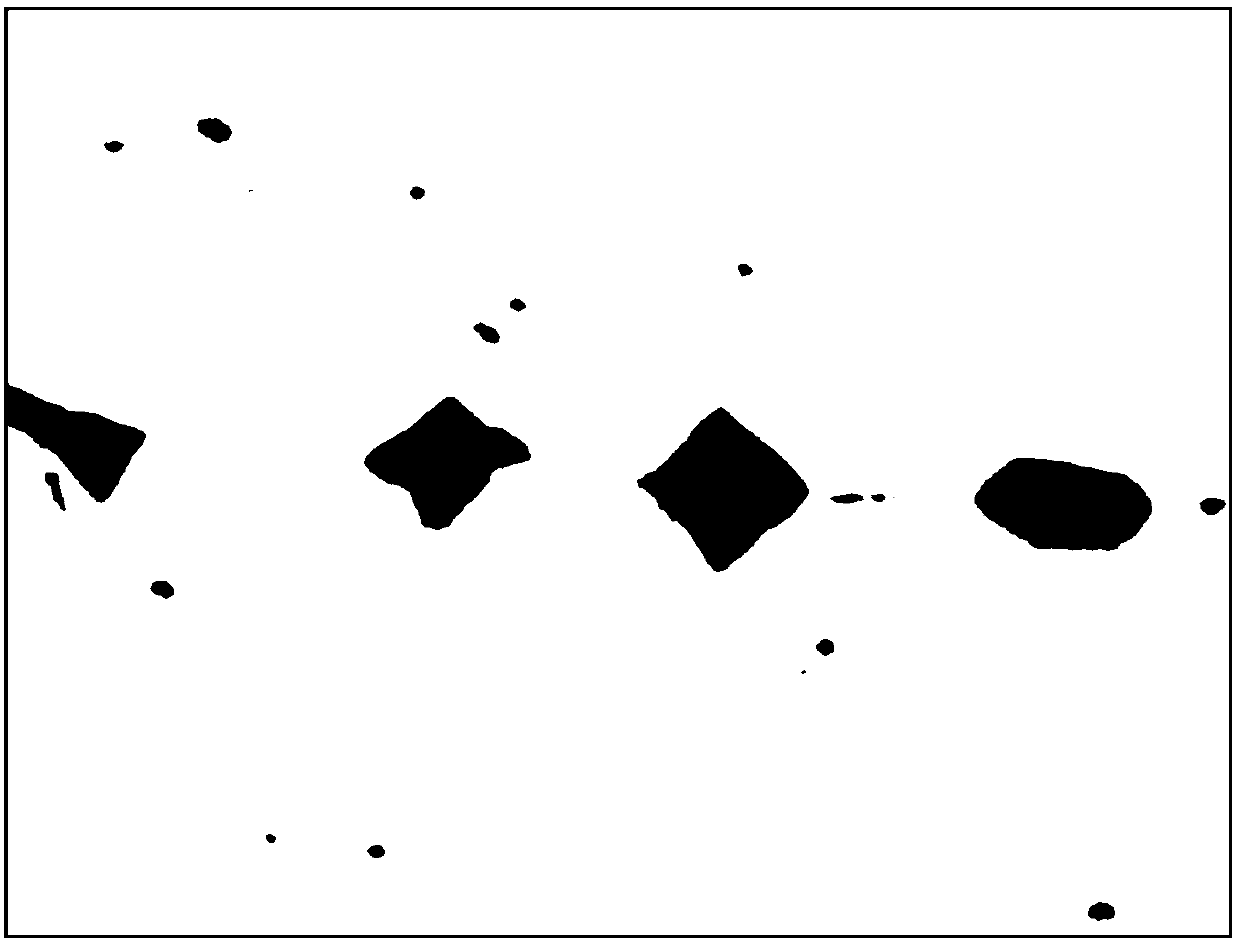

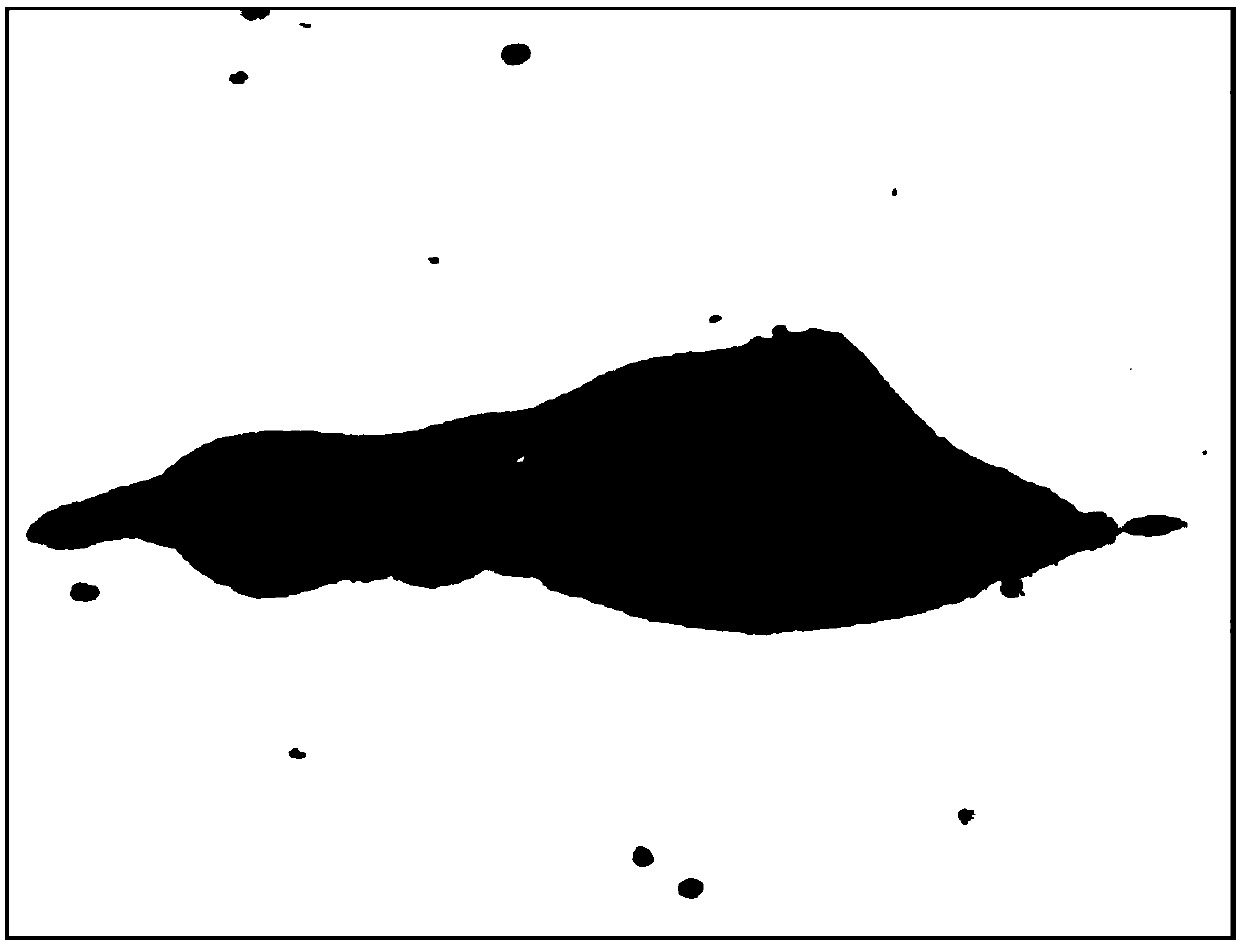

Glassed steel with good fish scaling resistance and manufacturing method of steel plate of glassed steel

InactiveCN106282846AExcellent anti-scale explosion performanceImprove performanceSheet steelHeating temperature

The invention discloses glassed steel with good fish scaling resistance and a manufacturing method of a steel plate of the glassed steel. The glassed steel comprises, by weight, 0.04%-0.10% of C, 0-0.10% of Si, 0.30%-1.0% of Mn, 0.03%-0.10% of Ti, 0-0.015% of P, 0.010%-0.045% of S, 0.003%-0.009% of N, 0.005%-0.050% of Als, 0.05%-0.25% of Cr, 0.5%-1.2% of Ti / C, and the balance Fe and inevitable impurities. The manufacturing method of the steel plate containing the components comprises the steps that the heating temperature of a continuous casting slab is 1180-1250 DEG C, the rolling starting temperature of precision rolling is 980-1100 DEG C, the finishing rolling temperature is 880-950 DEG C, a front stage cooling mode is adopted after rolling, the continuous casting slab is quickly cooled to the coiling temperature at the cooling speed higher than or equal to 30 DEG C / s within six seconds, the coiling temperature is controlled to be 630-700 DEG C, and the obtained steel plate has the good fish scaling resistance.

Owner:ANGANG STEEL CO LTD

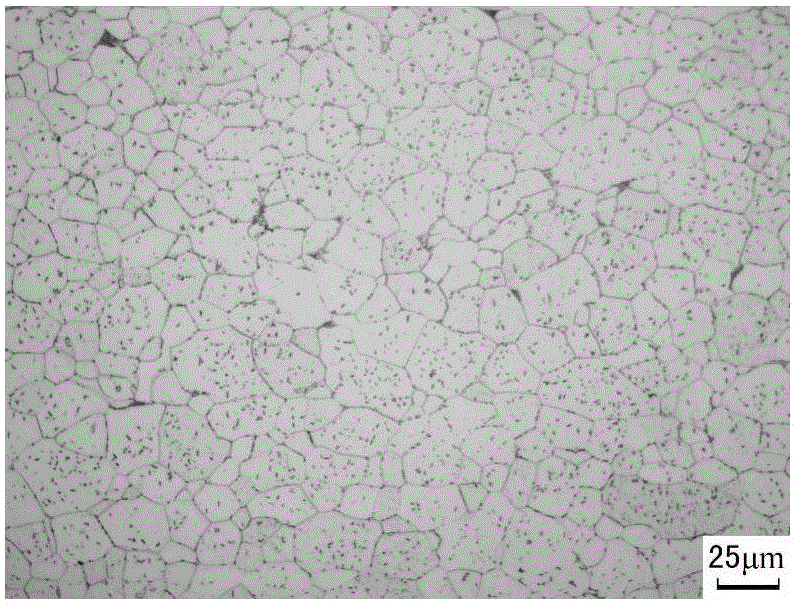

Steel sheet and enameled product

ActiveCN107949652AGood formabilityHigh strengthFurnace typesHeat treatment furnacesMetallurgyCrystal

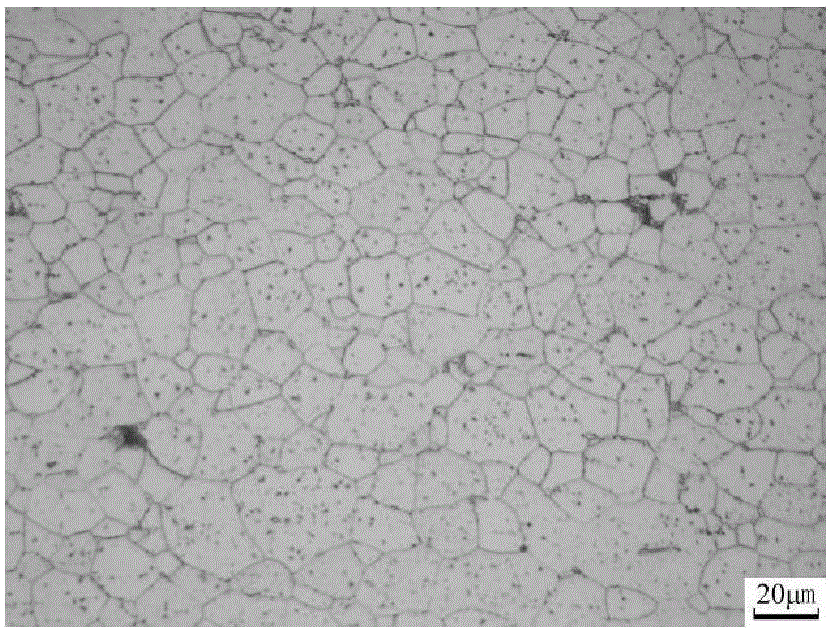

This steel sheet contains, in terms of mass%, up to 0.0060% C, 0.0010-0.050% Si, 0.05-0.50% Mn, 0.005-0.100% P, up to 0.0500% S, 0.0010-0.010% Al, 0.010-0.045% Cu, 0.0250-0.0700% O, and 0.0010-0.0045%N, with the remainder comprising Fe and unavoidable impurities. The steel sheet has a structure which comprises ferrite, and the ferrite located at a sheet-thickness-direction depth corresponding to1 / 4 the sheet thickness from a surface of the steel sheet has an average crystal-grain diameter of 20.0 [mu]m or smaller. The structure contains oxides containing Fe and Mn. Among the oxides, the number density of the oxides having diameters larger than 1.0 [mu]m but not larger than 10 [mu]m is 1.0*103-5.0*104 grains / mm<2>, and the number density of the oxides having diameters of 0.1-1.0 [mu]m is5.0*103 grains / mm<2> or greater.

Owner:NIPPON STEEL CORP

High-strength steel plate with excellent double-face enamelling performance and used for glass lining, and manufacturing method thereof

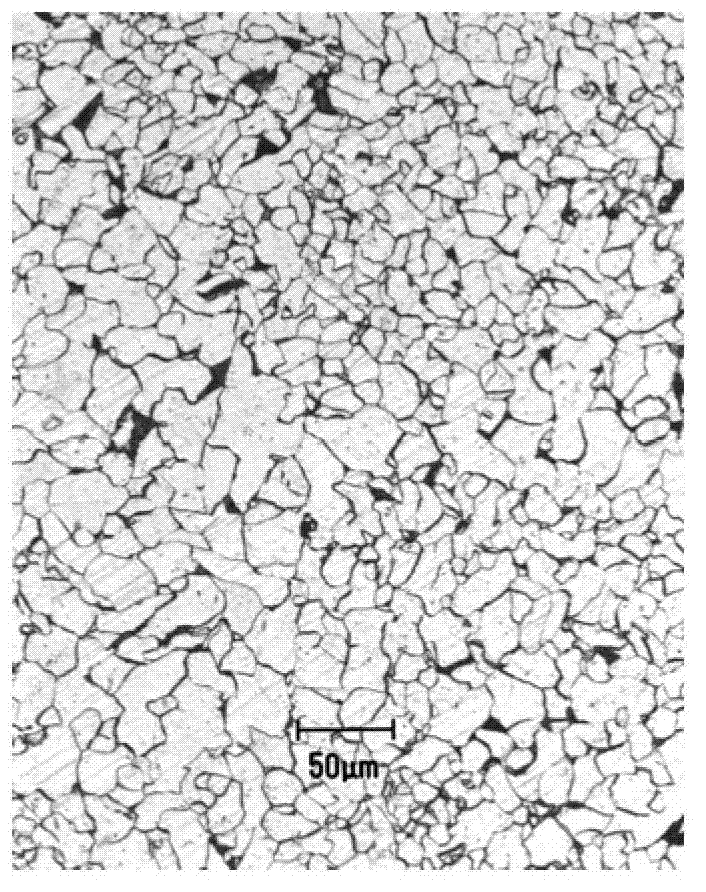

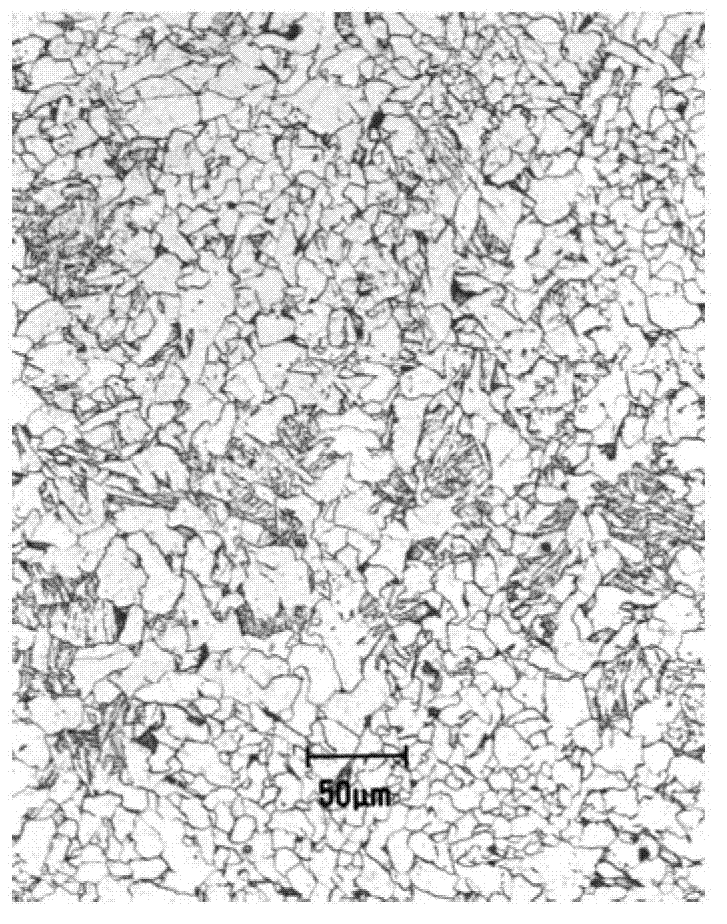

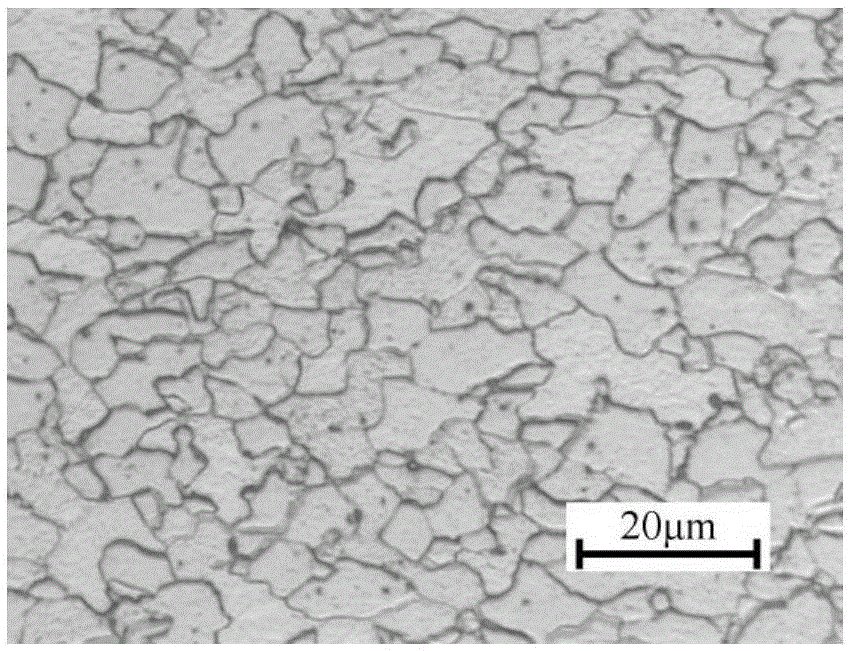

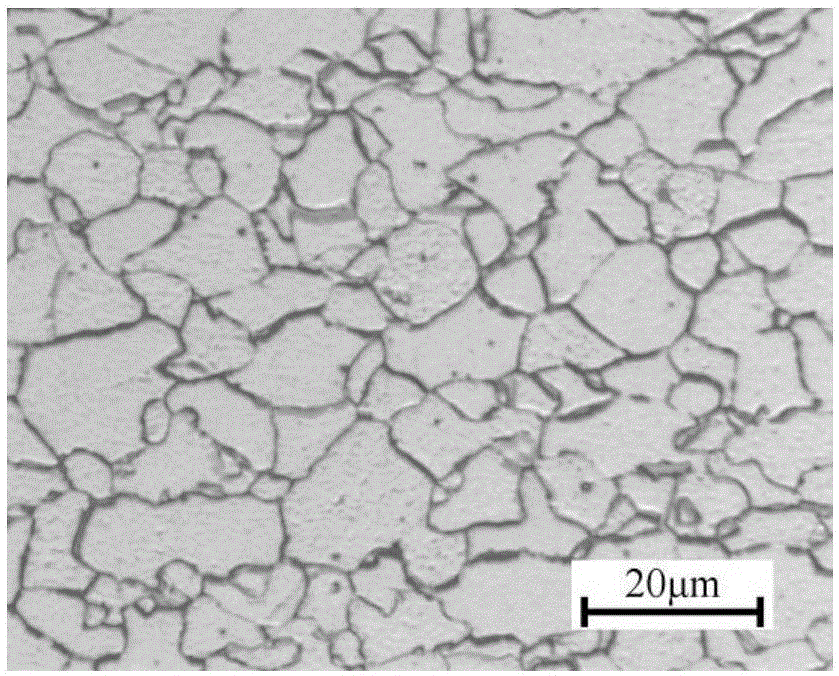

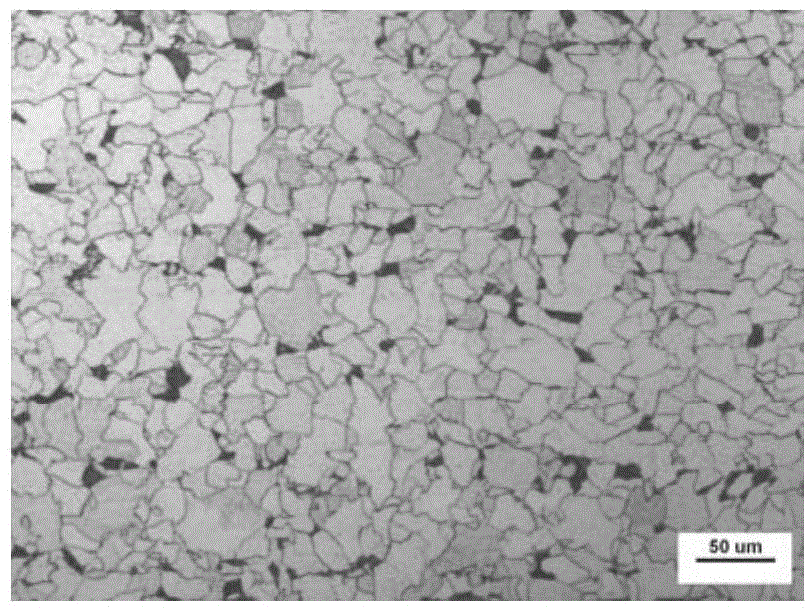

ActiveCN107794460AExcellent anti-scale explosion performanceExcellent double-sided enamelling performanceCrystalliteMicrostructure

The invention discloses a high-strength steel plate with excellent double-face enamelling performance and used for glass lining. The high-strength steel plate with excellent double-face enamelling performance and used for glass lining comprises, by mass, 0.06 to 0.15% of C, 0.16 to 0.50% of Si, 0.6 to 2.0% of Mn, 0.010 to 0.035% of S, 0.001 to 0.05% of Al, Als<=0.05%, 0.15 to 0.25% of Ti, 0.0035 to 0.010% of N, 0 to 0.10% of Nb, and the balance Fe and other inevitable impurities. The microstructure of the high-strength steel plate possesses ferrite and TiN particles taken as a precipitated phase; the surfaces of the TiN particles are planes; and irreversible small cavities are formed between the TiN particles and the ferrite crystal grains with curved surfaces. The invention also disclosesa manufacturing method of the high-strength steel plate with excellent double-face enamelling performance and used for glass lining. The high-strength steel plate is excellent in double-face enamelling performance and strength, and no fishscaling is caused.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength hot rolled steel plate for glass lining and manufacturing method thereof

InactiveCN106282811AExcellent anti-scale explosion performanceStable productionWater coolingCooling temperature

The invention discloses a high-strength hot rolled steel plate for glass lining and a manufacturing method thereof. The high-strength hot rolled steel plate comprises, by weight, 0.06%-0.20% of C, 0-0.15% of Si, 0.80%-2.0% of Mn, 0.05%-0.12% of P, 0-0.020% of S, 0.09%-0.20% of Ti, 0.03%-0.07% of Nb, 0.01%-0.05% of V, 0.005%-0.050% of Als, 0-0.0060% of N, 0.5%-1.5% of Ti / C, and the balance Fe and inevitable impurities. The heating temperature of a continuous casting slab is 1180-1250 DEG C, the rolling temperature of the rough rolling stage is larger than or equal to 1100 DEG C, the rolling starting temperature of the precision rolling stage is 900-980 DEG C, the finish rolling temperature is 840-900 DEG C, the cooling speed of water cooling after rolling is controlled to be 10-40 DEG C / s, and the finish cooling temperature is 580-730 DEG C. The yield strength of the obtained steel plate is 450 MPa or above.

Owner:ANGANG STEEL CO LTD

Enameled steel plate and production method thereof

The invention discloses an enameled steel plate. The enameled steel plate comprises components including, by weight percent, smaller than or equal to 0.05 of C, smaller than or equal to 0.03 of Si, smaller than or equal to 0.40 of Mn, smaller than or equal to 0.020 of P, smaller than or equal to 0.015 of S, and larger than or equal to 0.020 of Alt. The invention further discloses a production method of the enameled steel plate. According to the enameled steel plate and the production method thereof, by optimizing and controlling the component content and the parameter of the rolling technology, the production cost of the obtained enameled steel plate is low, and no precious metal element needs to be added. The defects in the quality aspects such as swelling upheaval, cold crackle, fish scale crackle, scale crackle, pitted bubbles and holes do not exist, the market prospect is wide, and the requirement of social development is met beneficially. The production method of the enameled steel plate is suitable for industrialized production, and the preparation method is simple.

Owner:BAOTOU IRON & STEEL GRP

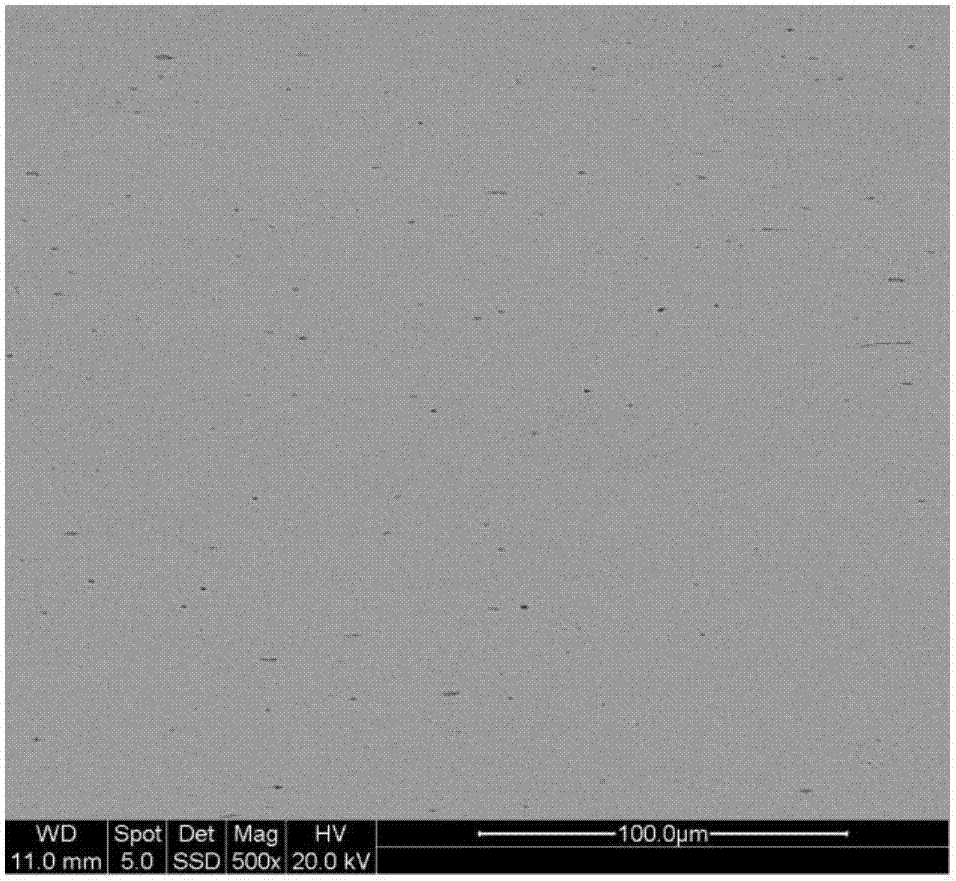

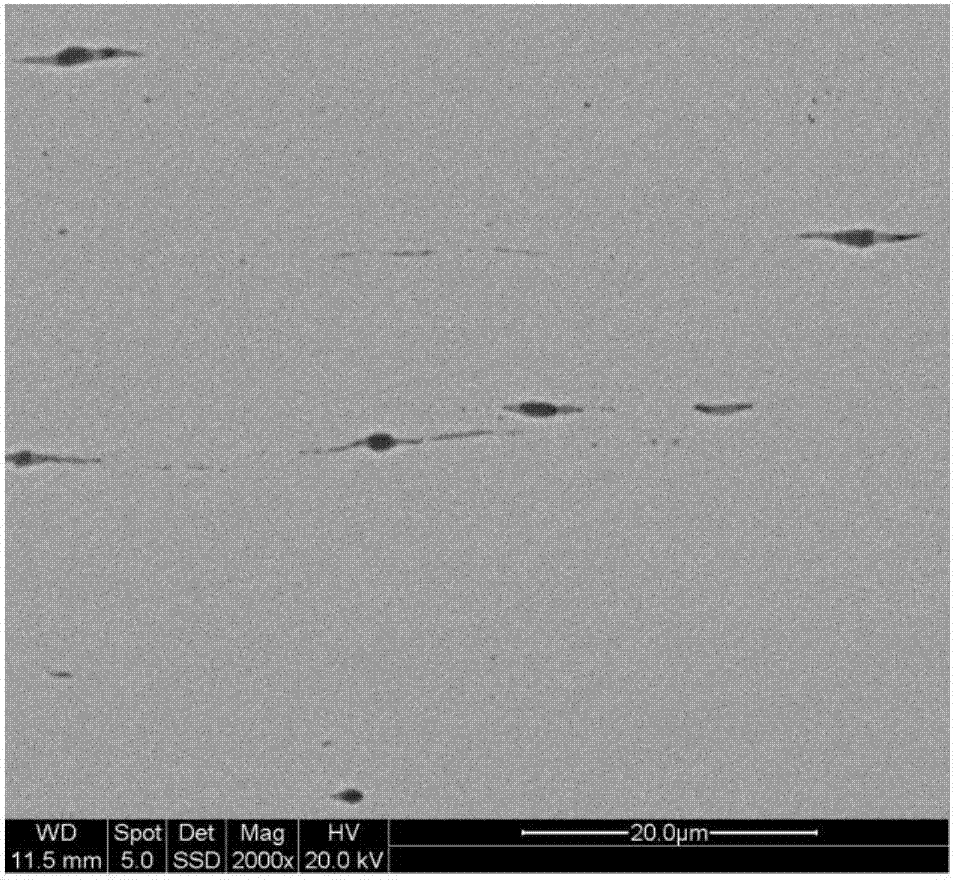

Hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling and manufacturing method thereof

The invention discloses a hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling and a manufacturing method of the hot-rolled pickled steel plate with excellentenameling performance for double-sided enameling. The hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling comprises, by weight, 0.010%-0.020% of C, 0.5%-1.0% of Mn, not larger than 0.10% of Si, not larger than 0.02% of P, 0.03%-0.05% of S, not larger than 0.01% of Als, 0.20%-0.40% of Cu, 0.03%-0.06% of Nb, 0.004%-0.010% of O and the balance Fe and otherinevitable impurities. The structure of the hot-rolled pickled steel plate is ferrite and a small amount of cementite, and a large number of spherical and linear compound type impurities are evenly distributed in steel. According to the hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling and the manufacturing method of the hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling, through ingredient design and smelting control, a large number of evenly-distributed impurities are formed in the steel and can be usedas traps to avoid the enamel fish-scaling defect, the fish-scaling resistance of the hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling is greatly higher than that of an ordinary pickled steel plate, and the hot-rolled pickled steel plate can be used for double-sided enameling; the impurities exist in the spherical and linear composite state, a large number of plastic impurity particles exist, and therefore the adverse influence of the impurities on the machining performance of the steel plate is lowered.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com