Hot-rolled steel strip used for enamel and having ultra-deep-punching performance and preparation method of hot-rolled steel strip

A technology for deep-drawing performance and hot-rolled steel is applied in the field of hot-rolled steel strip for enamel and its preparation, which can solve the problems of inability to meet the needs of ultra-deep-drawing and cannot be replaced, and achieve good deep-drawing performance, low cost, and high technology. Simple and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

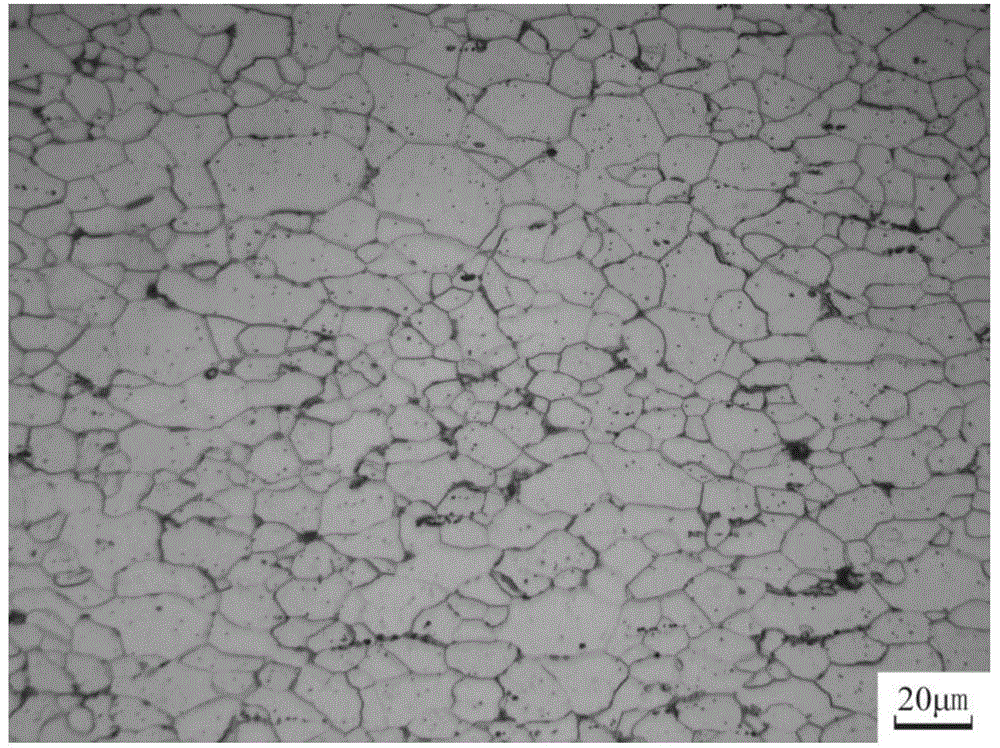

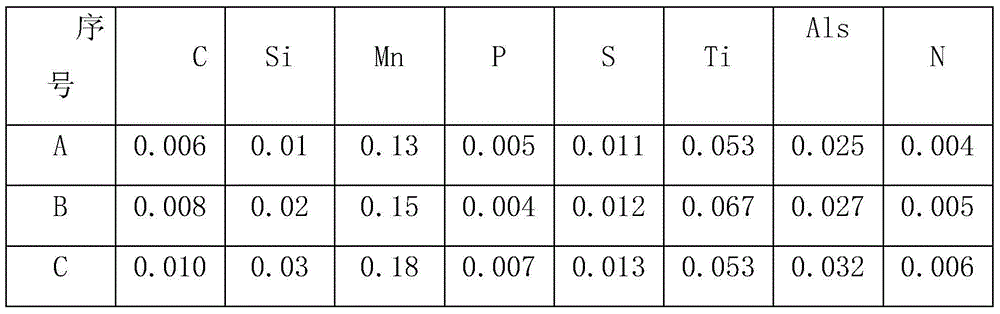

[0031] Embodiment 1-6: The present invention will be further described below. The invention is a hot-rolled steel strip for enamel with extra-deep drawing performance, and its chemical composition weight percent is: 0.005%≤C≤0.010%, Si≤0.05%, 0.10%≤Mn≤0.30%, 0.040%≤Ti ≤0.080%, P≤0.025%, 0.010%≤S≤0.035%, 0.010%≤Als≤0.060%, N≤0.006%, and the balance is iron and unavoidable impurities. The composition of molten steel for smelting is shown in Table 1.

[0032] The preparation method comprises the following steps: vacuum treatment of molten steel → casting billets → heating → descaling with high-pressure water → rough rolling → hot coil box coiling → finishing rolling → cooling → coiling → levelling.

[0033] Table 1 Chemical composition of enamelled steel of the present invention (% by weight)

[0034]

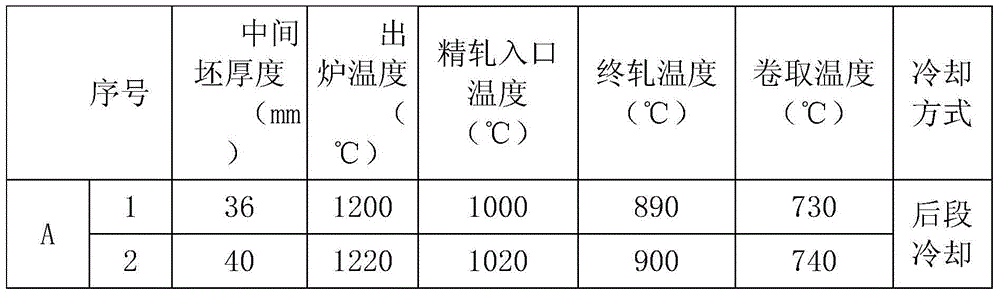

[0035] After the molten steel with the three components in the above table is vacuum-treated, it is cast into a steel slab by a conventional continuous casting method. Heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com