Patents

Literature

755 results about "Vitreous enamel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vitreous enamel, also called porcelain enamel, is a material made by fusing powdered glass to a substrate by firing, usually between 750 and 850 °C (1,380 and 1,560 °F). The powder melts, flows, and then hardens to a smooth, durable vitreous coating. The word comes from the Latin vitreum, meaning "glass".

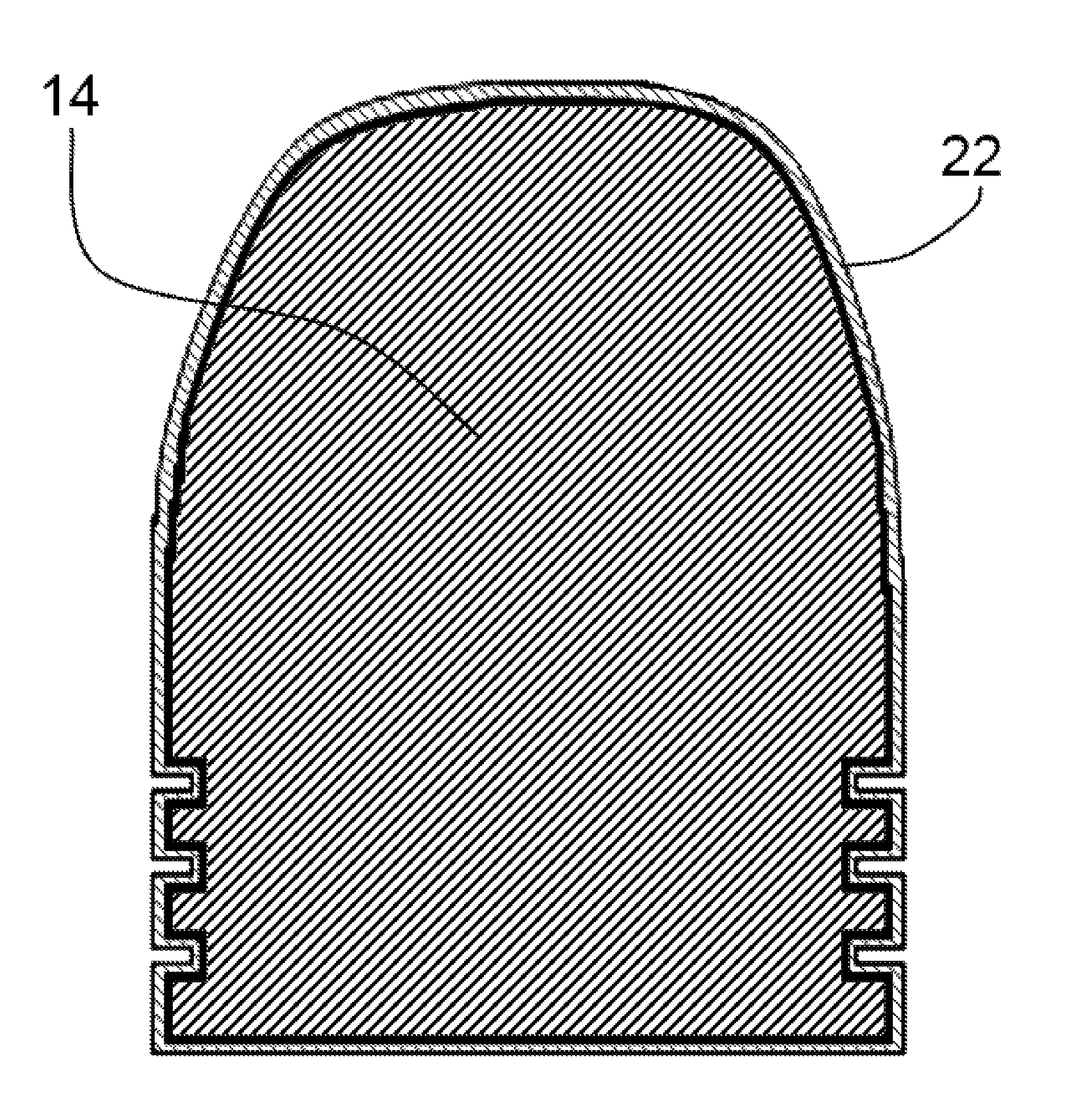

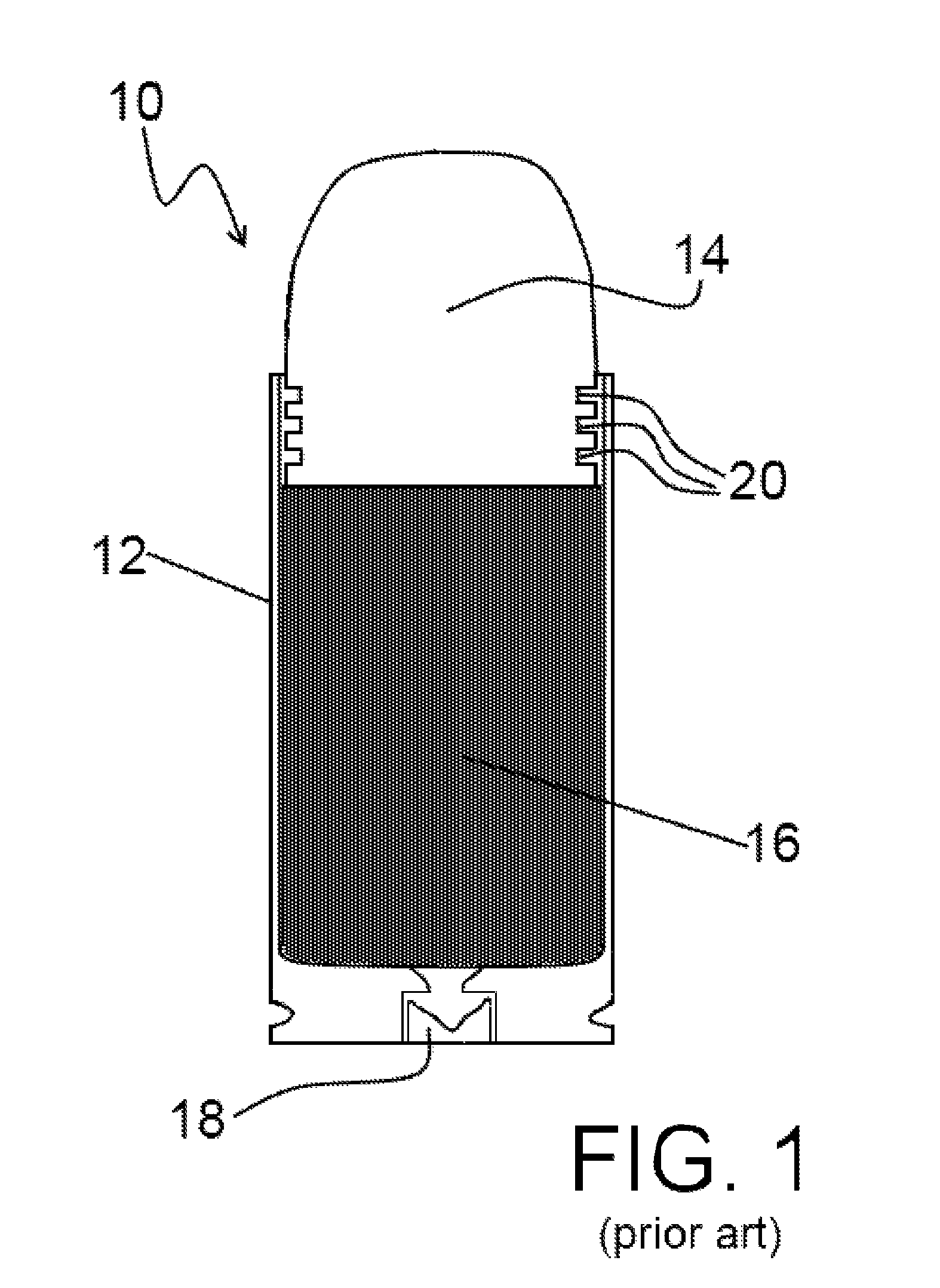

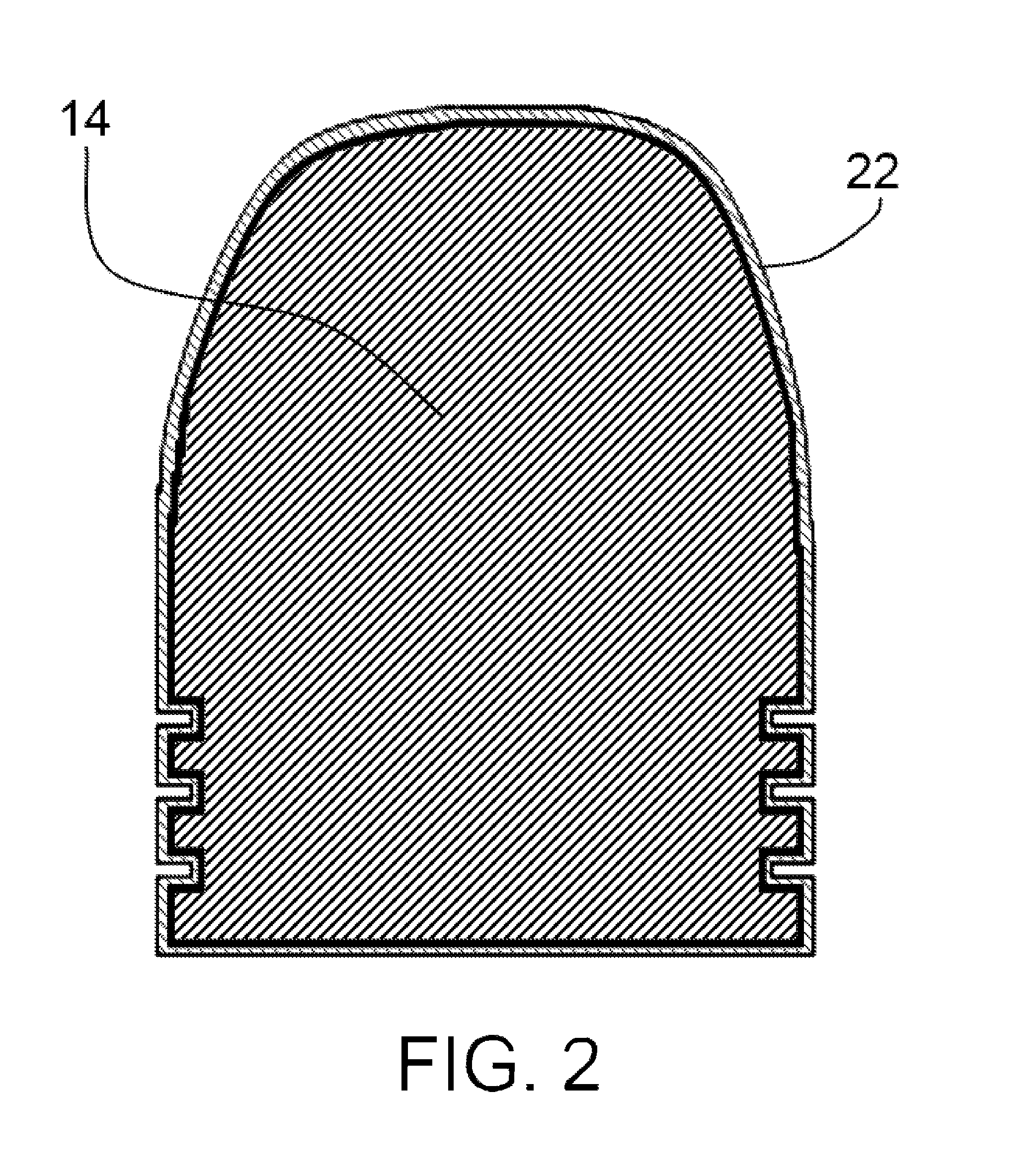

Enamel coated bullet, method of making an enamel coated bullet

ActiveUS9254503B2Reduces barrel depositsLess expensiveAmmunition projectilesLiquid surface applicatorsSufficient timeLacquer thinner

Owner:WARD TYLER

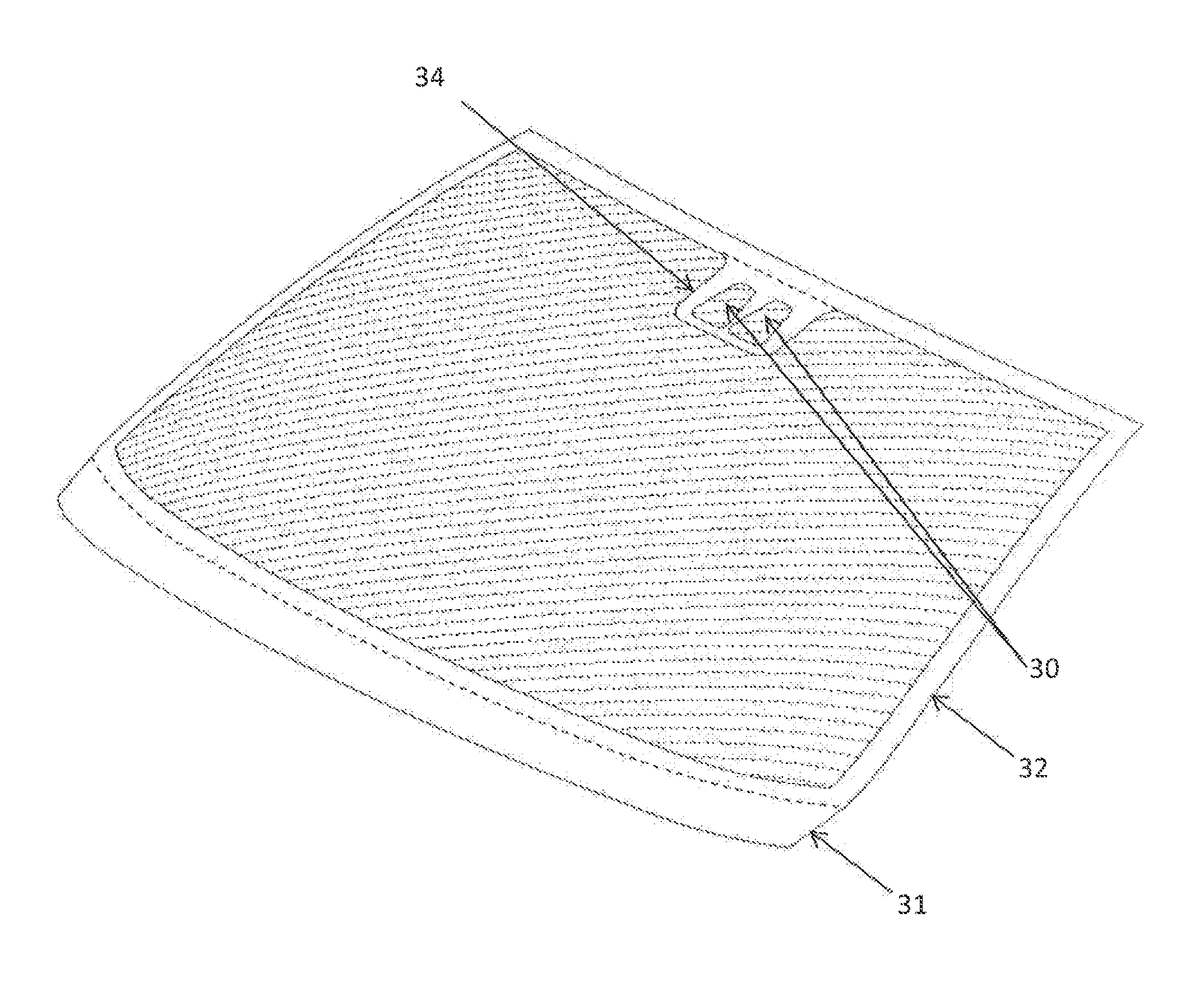

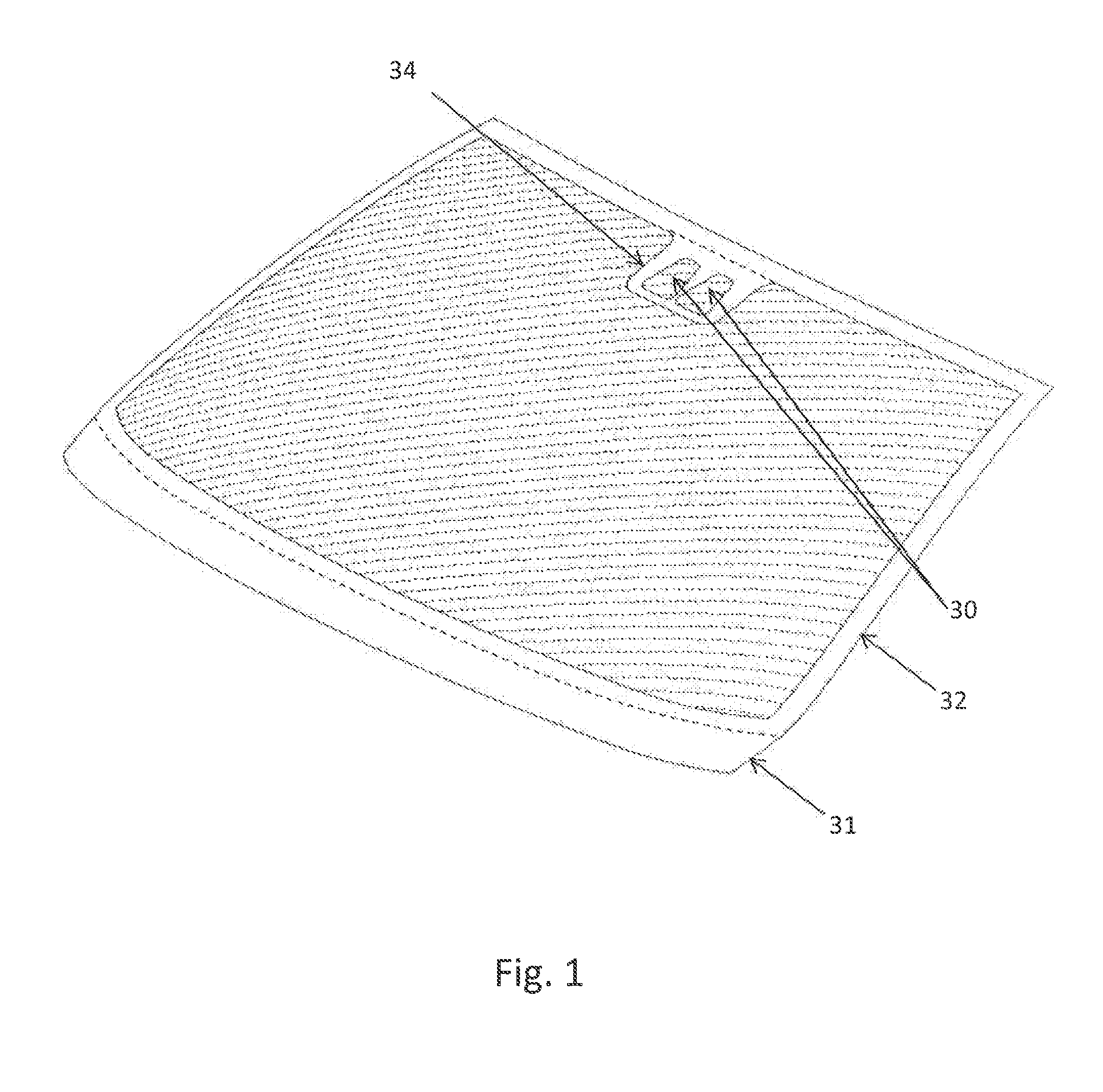

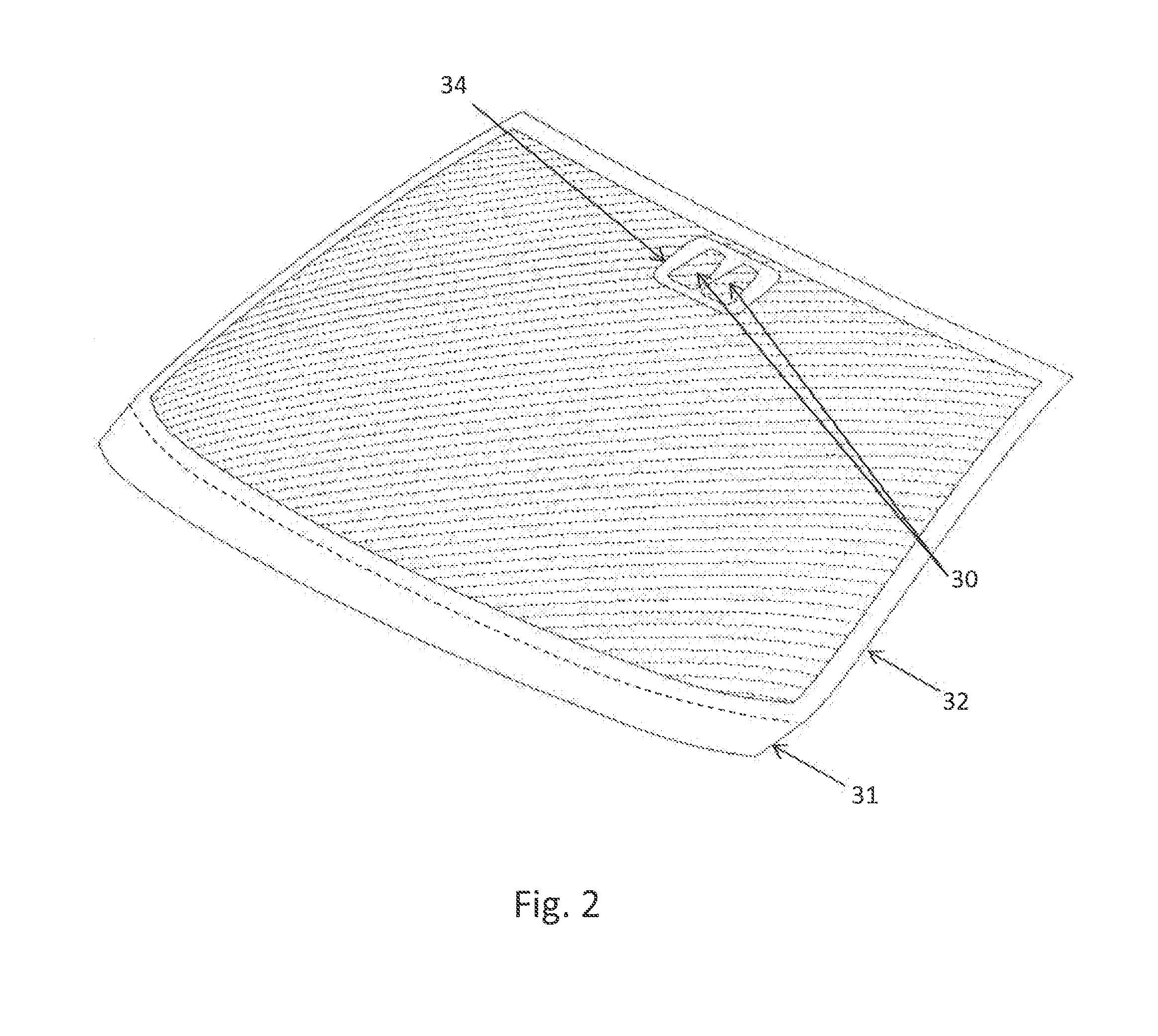

Obscuration having superior strength and optical quality for a laminated automotive windshield

ActiveUS20160243796A1Improve aestheticsAppearance differenceWindowsLamination ancillary operationsFritEngineering

Laminated automotive glazing including plastic layers and glass having an obscuration area produced by printing on the plastic layers of the laminate rather than printing and firing a black enamel frit onto the glass. This results in an obscuration having superior optical quality, higher strength and a lower probability of breakage as compared to a black enamel frit obscuration.

Owner:AGP AMERICA

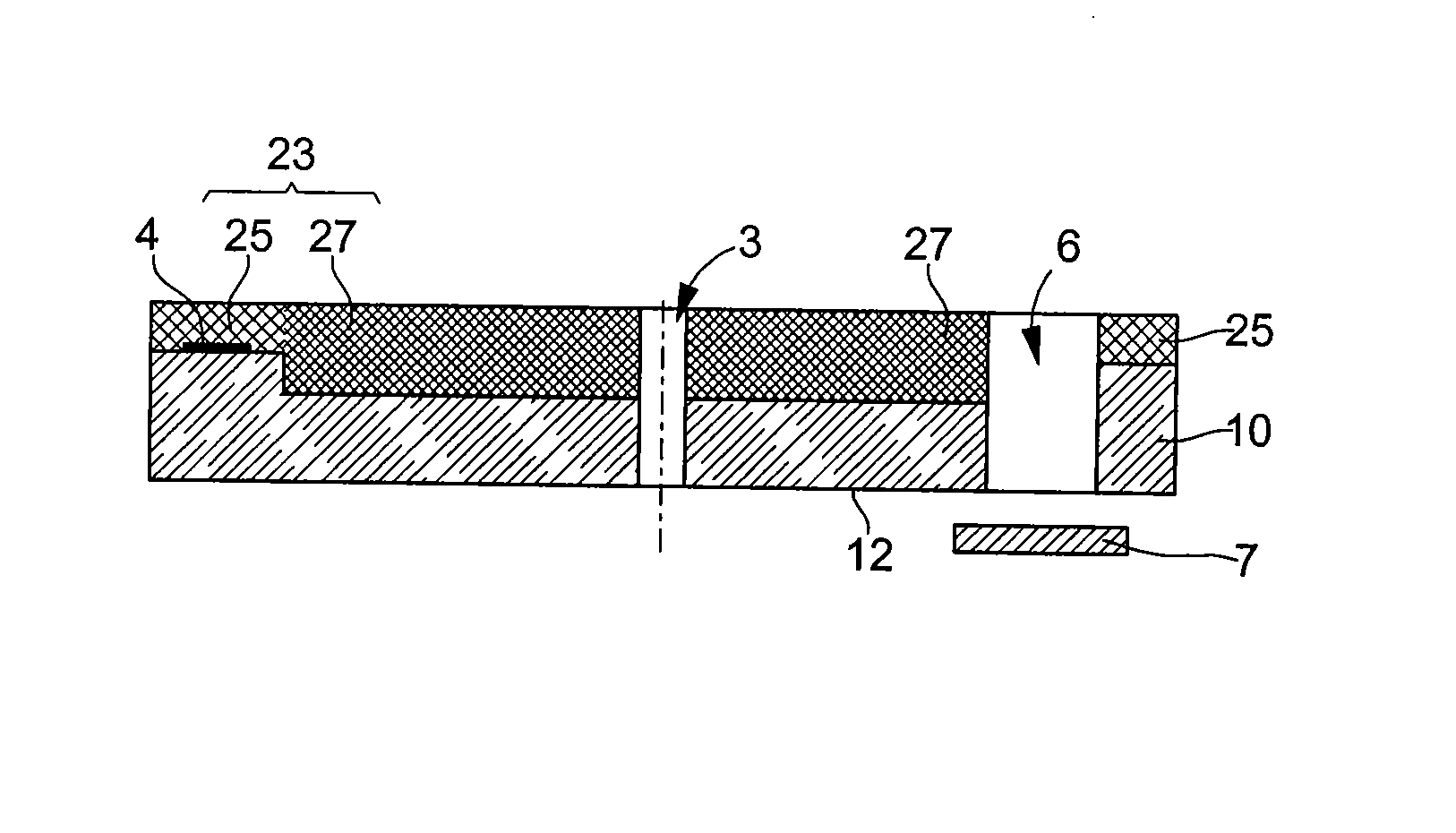

Cooking surface for cooking food having a glass ceramic surface with a glass coating thereon

InactiveUS6525300B1Reduction factorEasy to processCoil arrangementsHot plates heating arrangementsGlazeThermal expansion

The invention relates to lead- and cadmium-free glass for glazing, enamelling and decorating glasses or glass-ceramics which have a low coefficient of thermal expansion of less than 2x10-6 / K, having the composition (in % by weight) 0-6 Li2O, 0-5 Na2O, 0 to less than 2 K2O, where the sum Li2O+K2+Na2O is between 2 and 12, 0-4 MgO, 0-4 CaO, 0-4 SrO, 0-1 BaO, 0-4 ZnO, 3 to less than 10 Al2O3, 13-23 B2O3, 50-65 SiO2, 0-4 TiO2, 0-4 ZrO2 and 0-4 F, as replacement for oxygen and containing up to 30% by weight of a pigment which is resistant at the firing temperature, where the glass is suitable for glazing, enamelling and decoration in both primary and secondary firing, and both the full-area and sparse glaze, enamel or decoration layers have low abrasion susceptibility after firing, and it relates to processes for the production of a glass-ceramic coated therewith.

Owner:SCHOTT AG

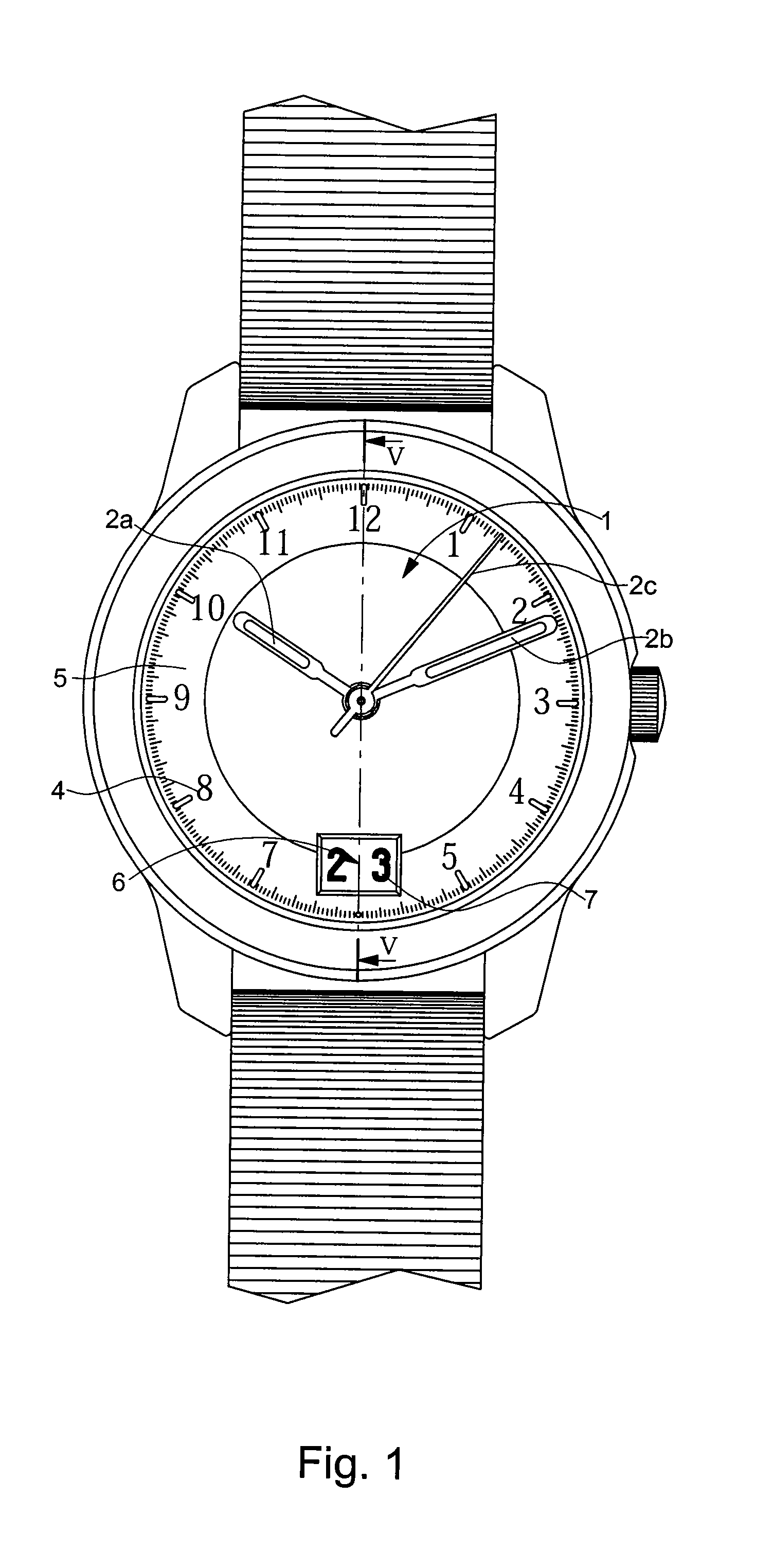

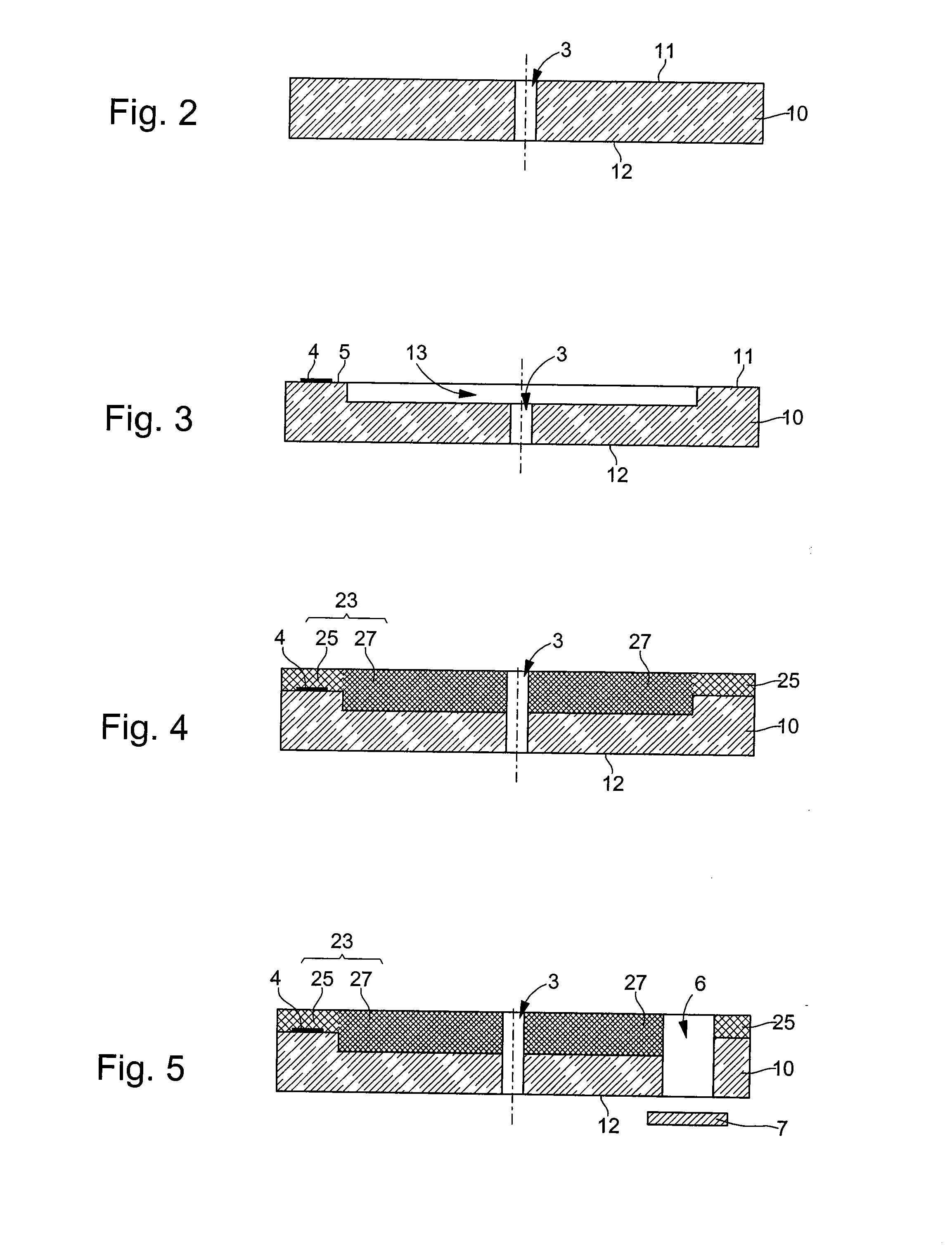

Technical or decorative piece associating a transparent material and a silicon based amorphous material and method of manufacturing the same

A transparent substrate (10) made of a transparent material resistant to temperatures higher than 500° C., such as sapphire, includes recesses (13, 14) in at least one of its faces (11, 12) and / or a groove (15) machined into its thickness, that are covered with opaque, translucent or transparent enamel depositions (23 to 30) that may or may not be coloured, depending upon the pigments used in the enamel composition.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Ceramic substrate for nonstick coating

InactiveUS20030059600A1Improve coating adhesionMore durableSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

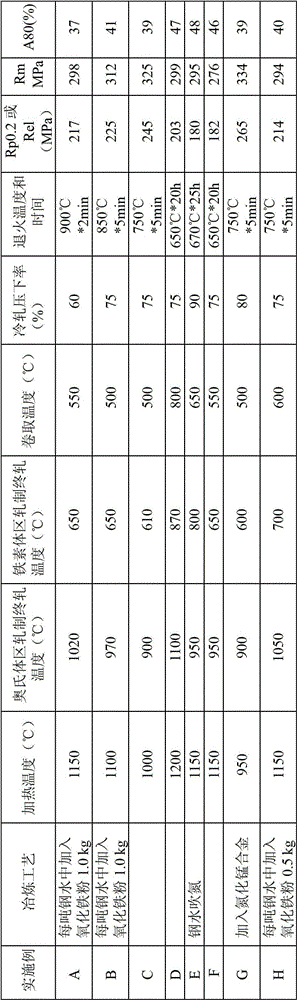

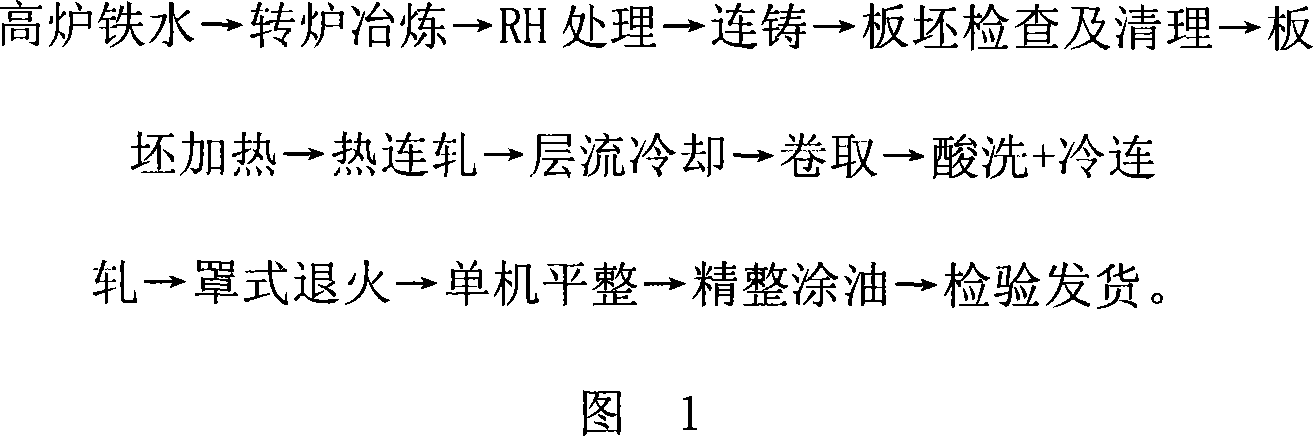

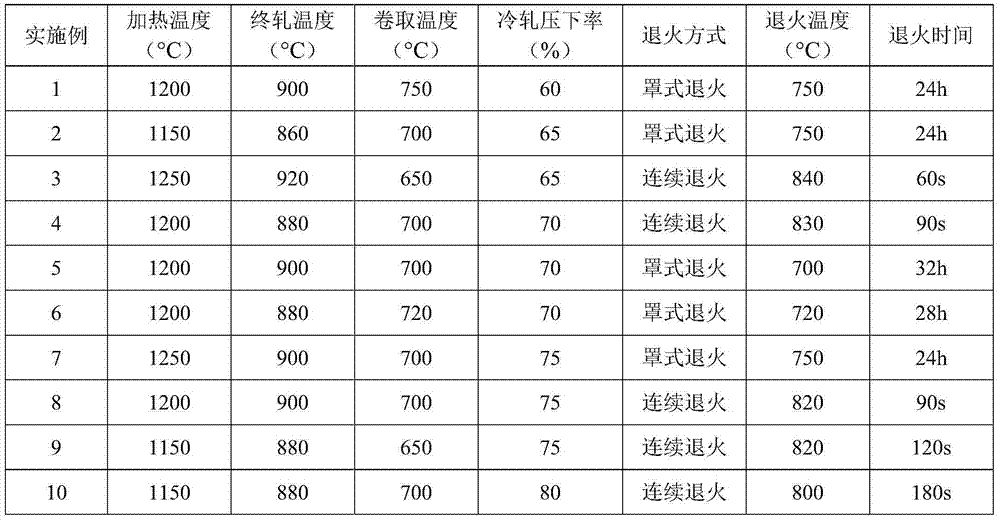

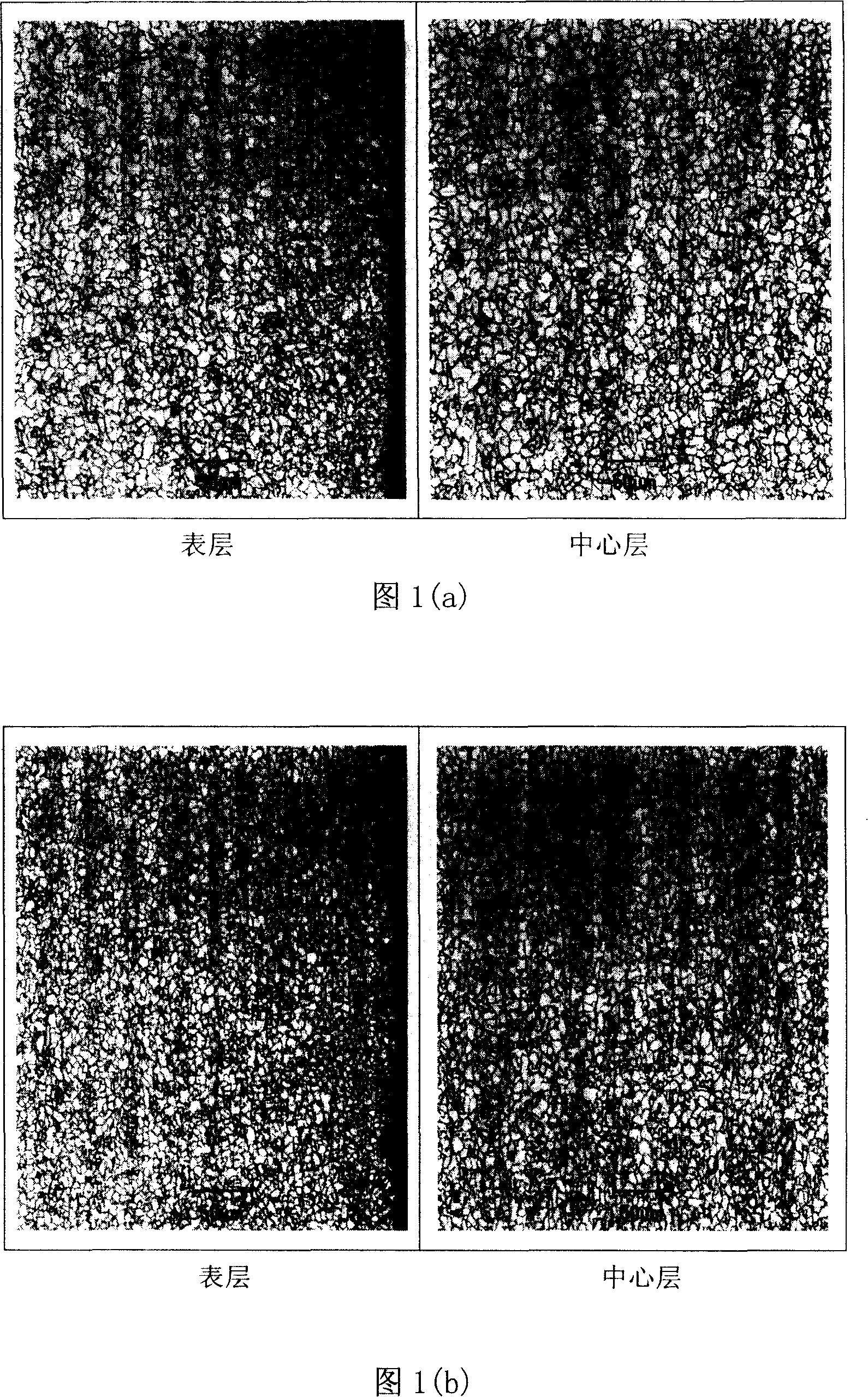

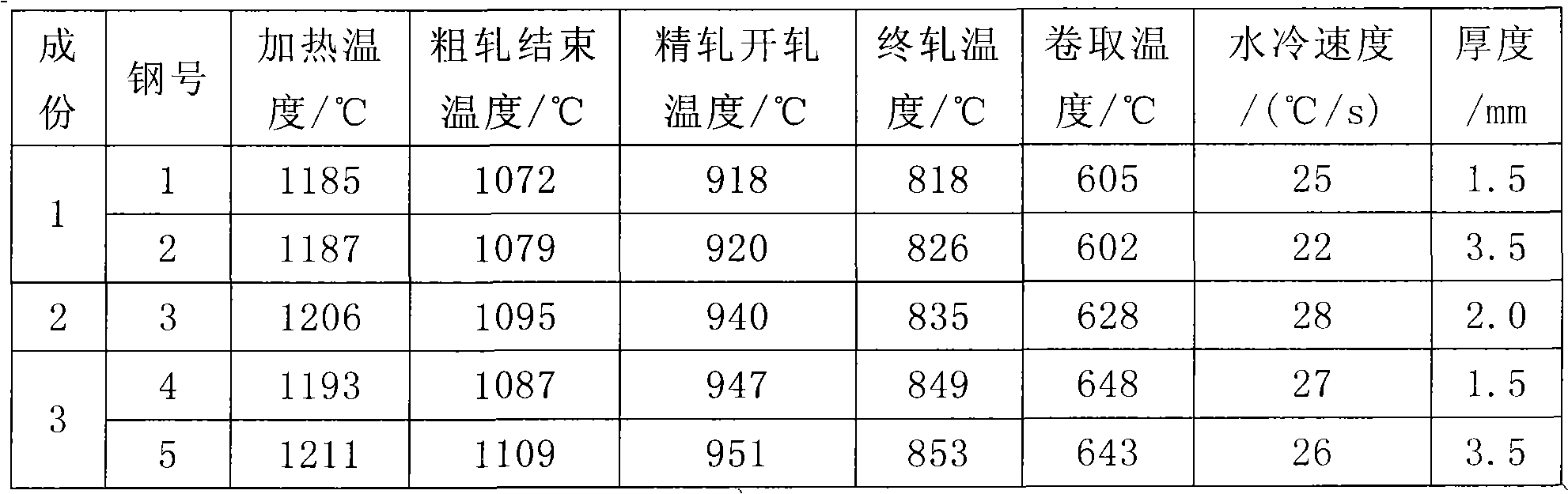

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

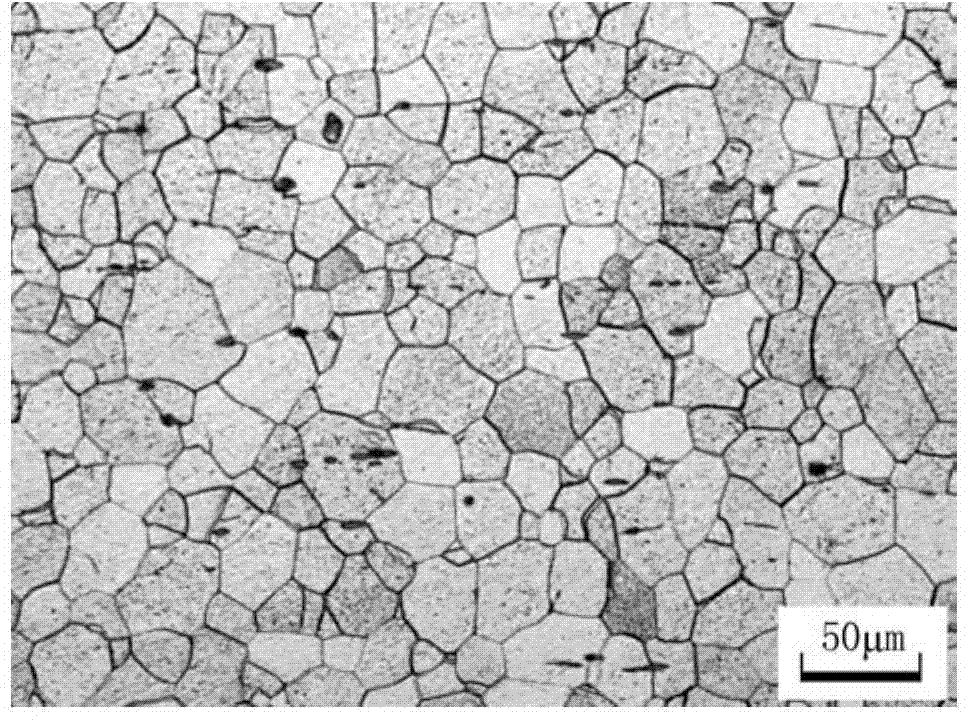

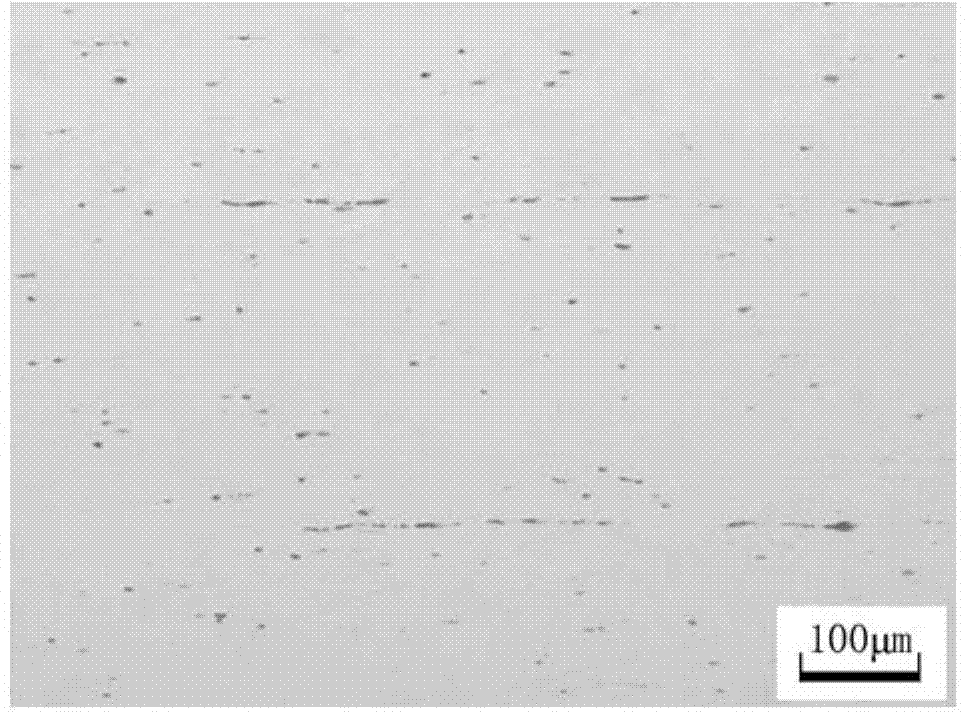

Steel for enamel and production method thereof

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultra-low carbon cold-rolling deep-punching glassed steel and method of production

InactiveCN101082107ADoes not affect deep drawabilityImprove deep drawing performanceTemperature control deviceProfile control deviceChemical compositionPunching

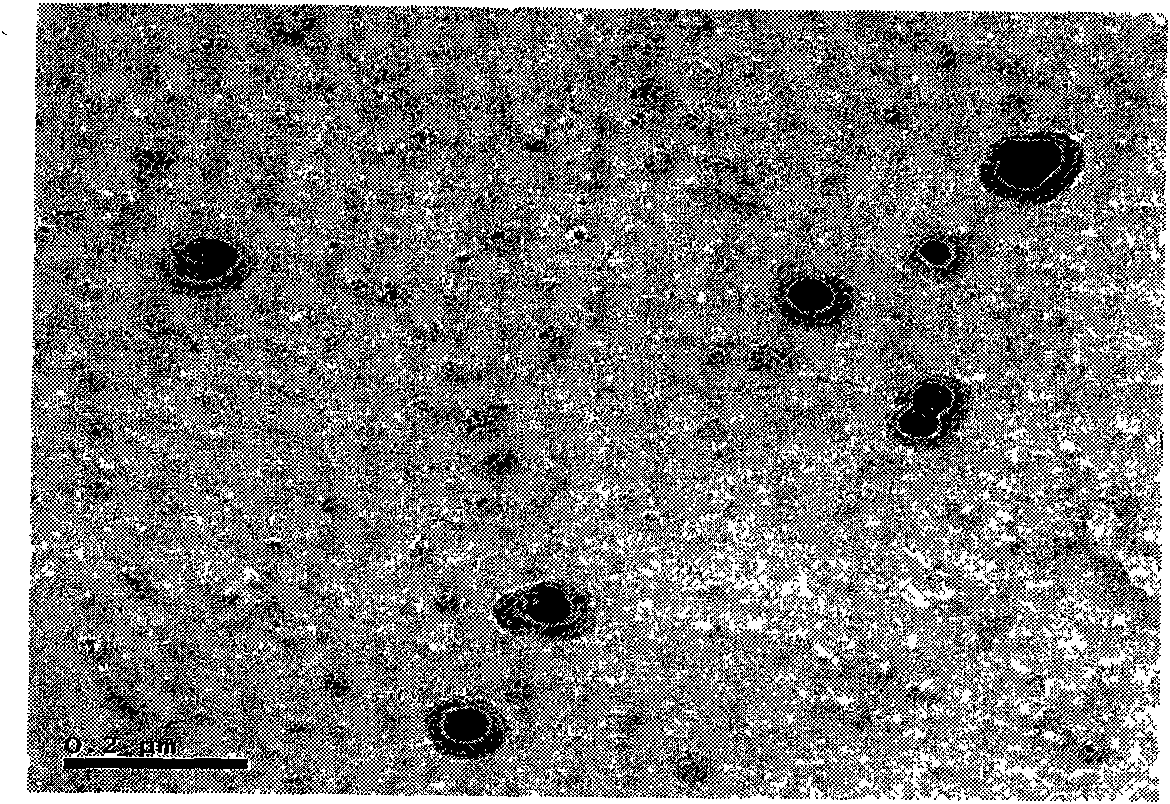

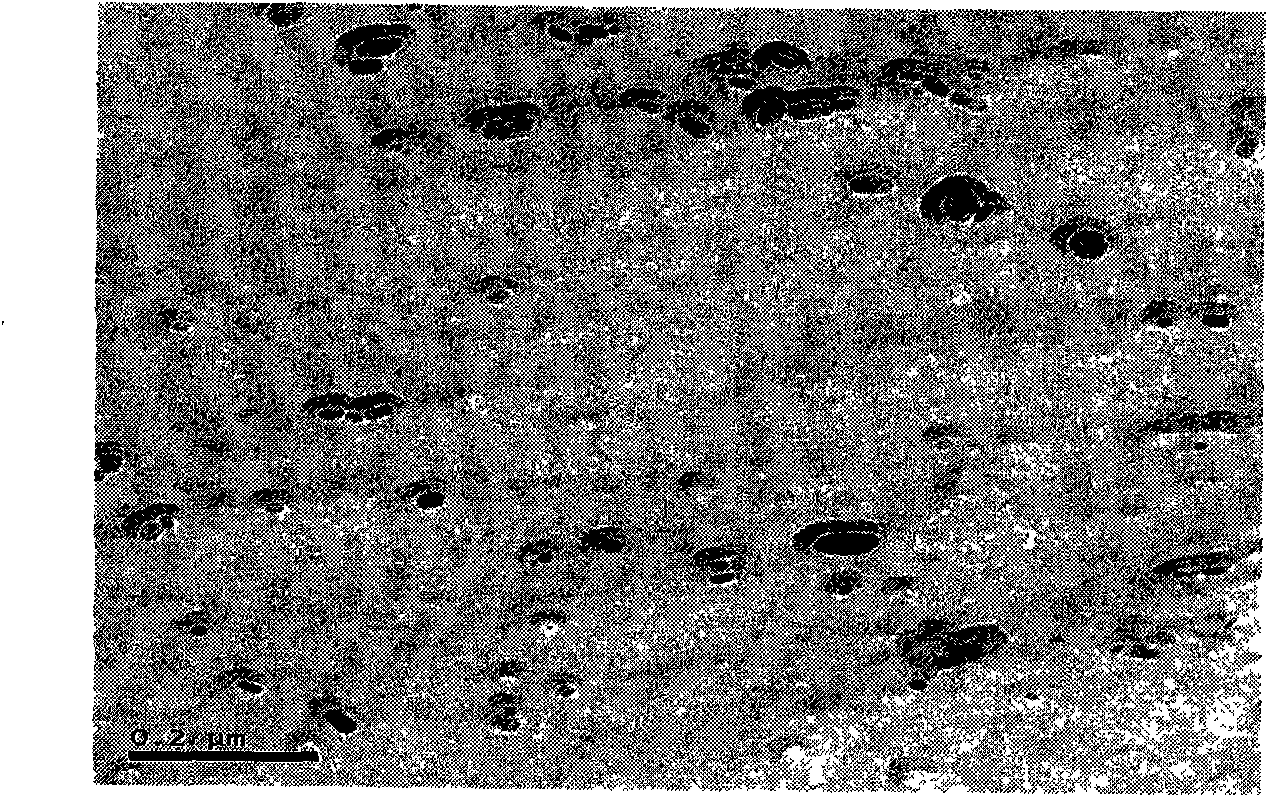

The present invention relates to ultralow carbon cold rolled deep drawing glass-lined steel and its production process. The glass-lined steel has the chemical components including C 0.002-0.005 wt%, Si 0.004-0.020 wt%, Mn 0.08-0.13 wt%, P 0.006-0.020 wt%, S 0.01-0.035 wt%, Als 0.010-0.040 wt%, Ti 0.05-0.09 wt%, N not more than 0.004 wt%, and Fe and inevitable impurities for the rest. The steel of the present invention is superior to IF steel, and has raised Ti and S contents for effective separation of biphase Ti4C2S2 particle, and effective fixing of H atom to avoid scale burst of enamel. It has excellent deep drawing performance and excellent enameling performance.

Owner:武汉钢铁有限公司

Enamel steel with scaling resistance and manufacturing method thereof

InactiveCN103484757ASimple chemical compositionReduce smelting costTemperature control deviceReduction rateAcid washing

The invention discloses enamel steel with scaling resistance. The enamel steel is prepared from the following components in percentage by weight: 0.0020-0.0050% of C, 0.30-0.50% of Mn, 0.0050-0.0100% of Si, 0.010-0.015% of P, 0.011-0.020% of S, 0-0.010% of Als, 0.011-0.020% of O and the balance of Fe and other inevitable impurities. A manufacturing method sequentially comprises the following steps: pretreatment of molten iron, smelting by a converter, refining, continuous casting, hot continuous rolling, acid washing, cold continuous rolling, annealing and finishing, wherein the heating temperature for hot continuous rolling is 1150-1250 DEG C, the finish rolling temperature is 860-920 DEG C, the winding temperature is 650-750 DEG C, and the cold rolling reduction rate of cold continuous rolling is 60-80%. The enamel steel disclosed by the invention has no scaling phenomenon and low production difficulty, and is suitable for being applied to the technical field of iron and steel smelting.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Hot-rolled fine-grained steel for electrostatic enamel and manufacturing method thereof

ActiveCN101063189AHigh strengthGood formabilityRoll force/gap control deviceTemperature control deviceManganeseAlloy

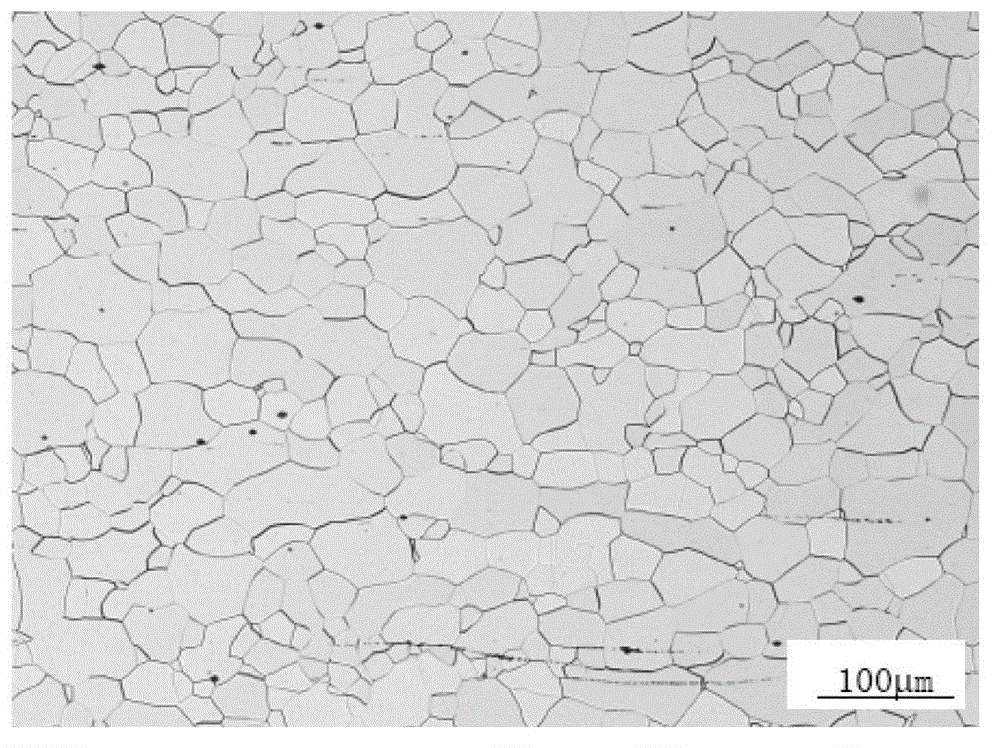

The invention discloses a preparing method of electrostatic enamel hot-roller fine-grained steel, which is characterized by the following: allocating mass percent as 0. 02-0. 10 carbon, not more than 0. 10 silicon, 0. 4-1. 0 manganese, not more than 0. 05 phosphor, 0. 02-0. 05 sulfur, 0. 01-0. 10 aluminum, 0. 003-0. 010 nitrogen, 0. 03-0. 10 titanium, surplus ferric and unavoidable impurity; setting the content of TiN at 0. 013-0. 044; setting ferrite tissue grain fineness number not less than 10 grade. This invention possesses good enamel adherence property and against squama knock property.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot-rolled high-strength steel plate for electrostatic enamel and method for manufacturing same

ActiveCN101139684ATemperature control deviceHeat treatment process controlHigh resistanceForeign matter

The invention provides a hot-rolled high-strength steel sheet for static enameling and a manufacturing method for the steel sheet. The main components by weight of the steel sheet are: C: 0.02-0.1%, Si<=0.1%, Mn: 0.2-1.5%, P: <=0.035%, S<=0.035%, Al: 0.01-0.1%, N: 0.001-0.01%, Ti: 0.01-0.1 %, Nb: 0.001-0.1%, and the remainder are iron and unavoidable foreign matters. The structure of the steel sheet comprises ferrite and pearlite, an the average particle diameter of the ferrite is not more than 11 micrometer. The manufacturing method of the steel sheet is, rolling twice the continuously cast or steel blanks after heating to 1100-1250 DEG C with total pressure-down amount <=50%, and final rolling temperature >=800 DEG C, then cooling section by section to coiling temperature 550-700 DEG C, and finally leveling the sheet. The hot-rolled high-strength steel sheet is applicable for pressure vessels such as bladders of water heaters, liquid-storing tanks and water buckets, etc. that are manufactured by static enameling process, is of high strength and good plasticity, high resistance to scaling bursting and air tightness.

Owner:BAOSHAN IRON & STEEL CO LTD

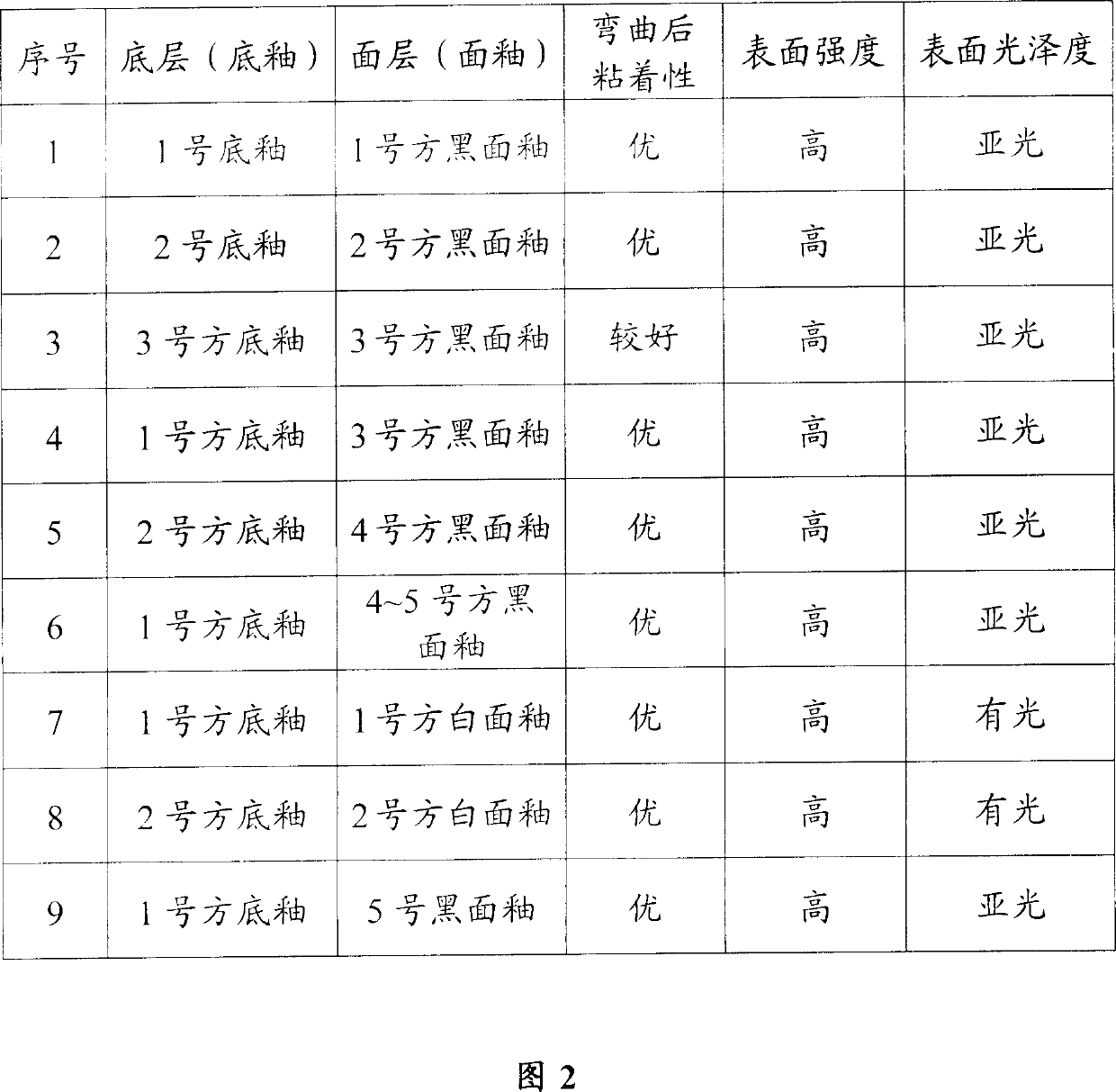

Method for producing blackboard and whiteboard made from enamel in super strength, and glaze of enamel

A process for preparing the super-strength enamelled black (or white) board includes such steps as praying the priming enamel, sintering at 680-740 deg.c for 3 min, spraying surficial enamel and sintering at 560-640 deg.C for 3-4 min. Its enamel contains Al2O3, B2O3, CaF2, Na2O or Li2O, BaO or PbO or CaO, and SiO2 or TiO2. Its advantages are super strength and high antiwear performance.

Owner:王强

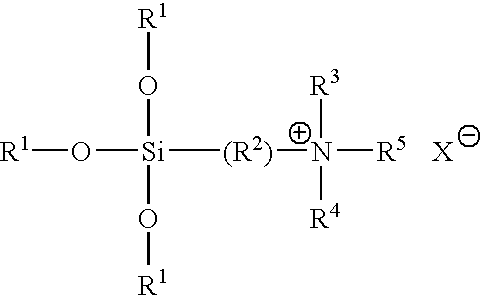

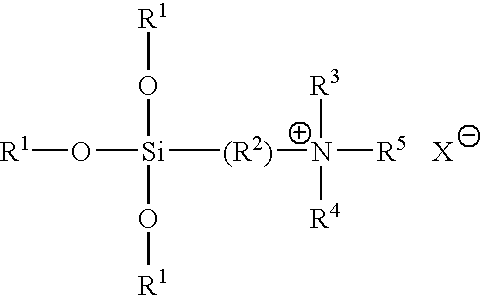

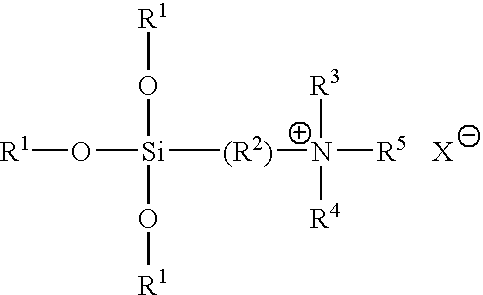

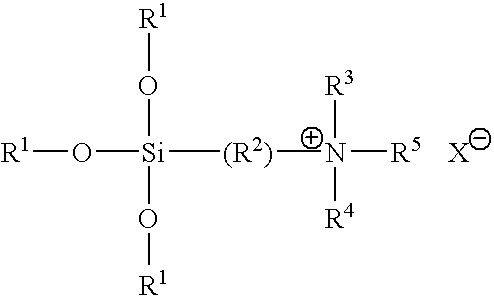

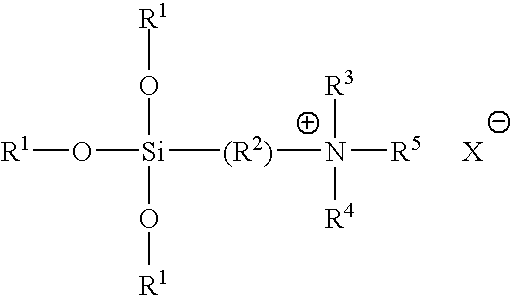

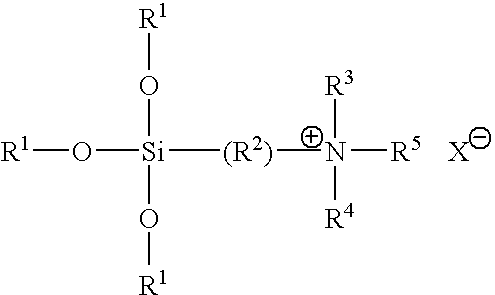

Cleaning and multifunctional coating composition containing an organosilane quaternary compound and methods of using

ActiveUS20050096250A1Improve adhesionIncreased durabilitySilicon organic compoundsCationic surface-active compoundsPolyesterSand granules

Cleaning and multifunctional coating compositions containing hydrogen peroxide and an organosilane quaternary compound in aqueous formulations are used to improve water and soil repellency and residual antimicrobial activity. Various surfaces may be treated including metal, glass, plastics, rubber, porcelain, ceramic, marble, granite, cement, tile, sand, silica, enameled appliances, polyurethane, polyester, polyacrylic, melamine / phenolic resins, polycarbonate, siliceous, painted surfaces, wood, and the like.

Owner:RESOURCE DEV LLC

Easy-to-clean matte acid resistant ground coat

InactiveUS6511931B1Good spot acid resistanceEasy to cleanGlass/slag layered productsSuperimposed coating processSheet steelAcid resistance

The present invention provides a ground coat composition for use in forming an enamel layer on sheet steel that exhibits good spot acid resistance, a satin finish, good bond, and is easy-to-clean. The composition according to the invention includes a glass component that includes a blend of from about 40% to about 70% by weight of a first glass portion including one or more alkali aluminophosphate frits, up to about 30% by weight of a second glass portion including one or more zirconia-phosphate frits, and up to about 30% by weight of a third glass portion including one or more alkali borosilicate frits.

Owner:FERRO CORP

Ceramic substrate for nonstick coating

InactiveUS6638600B2Easy to optimizeImprove adhesionSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

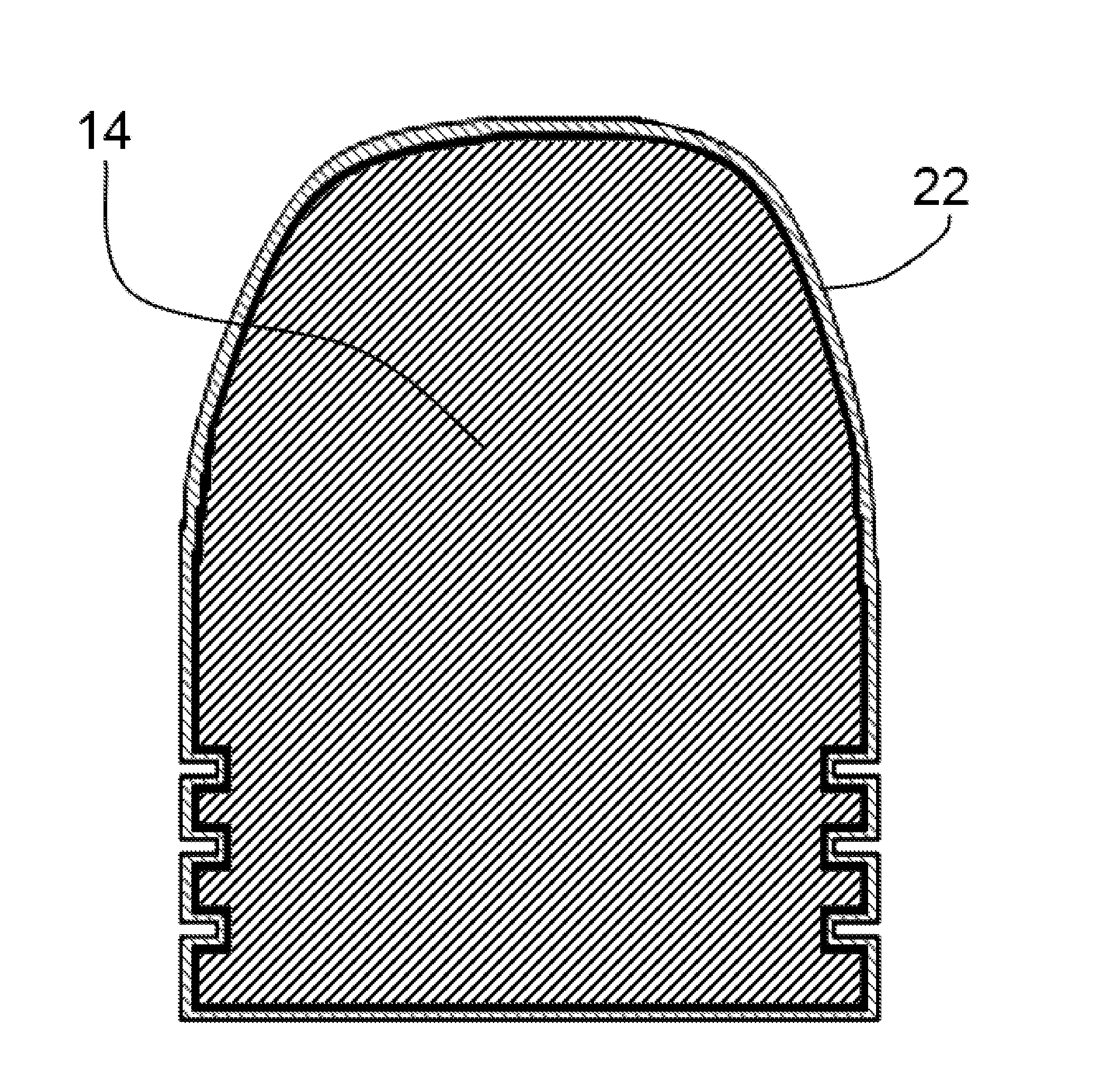

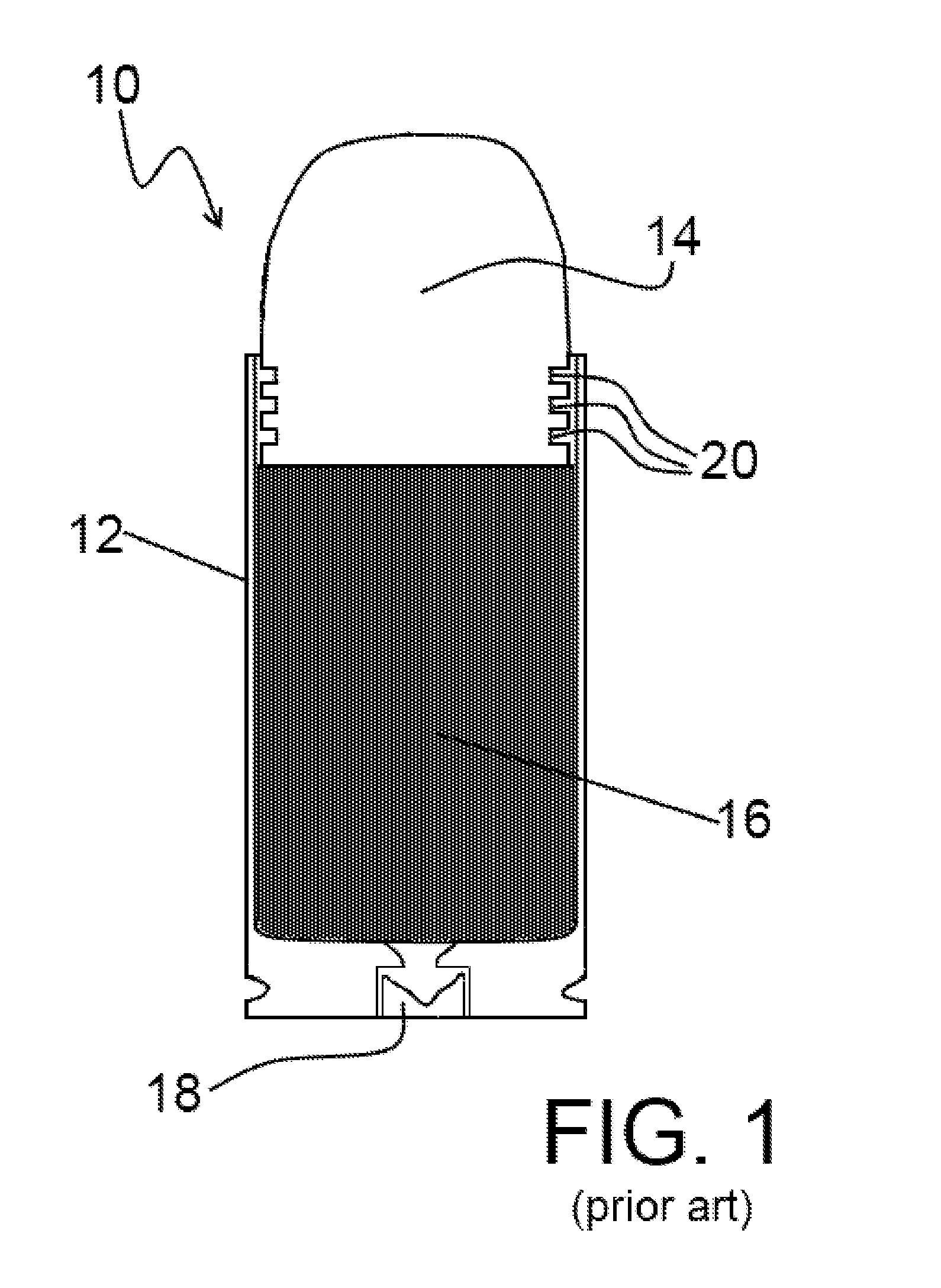

Enamel coated bullet, method of making an enamel coated bullet

ActiveUS20150330756A1CheapReduces barrel depositsAmmunition projectilesLiquid surface applicatorsSolventLacquer thinner

A method for manufacturing an enamel-coated bullet is described. The method starts with casting a bullet from a metal material and quenching the cast bullet. After the bullet cools, applying a lubricant to the bullet and sizing the bullet to the appropriate caliber and rinsing the bullets in a solvent. Thereafter, applying an enamel coating to the bullets. The coating uses about 1 part by volume lacquer thinner, about 1.5 parts by volume hardener, and about 2.5 parts by volume epoxy paint. The process continues by contacting the bullets with a moving fluid for a sufficient time that they become dry and heating the bullets in an oven at a temperature of between 150 and 250° F. for a time between 20 and 45 minutes. Finally, the process involves applying a lubricant to the coated bullet and resizing the bullet to the appropriate caliber.

Owner:WARD TYLER

Works for enameling and enameled products

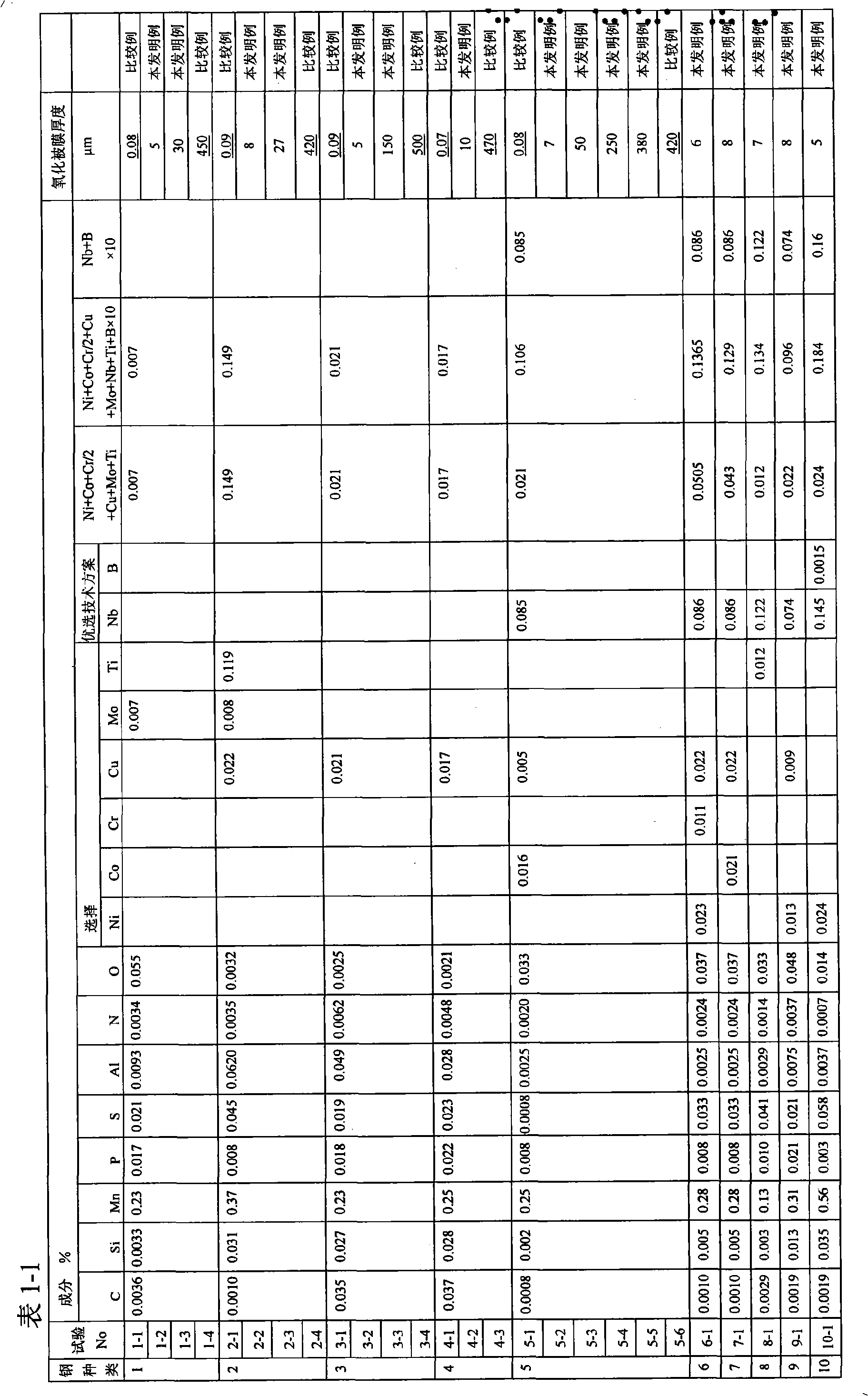

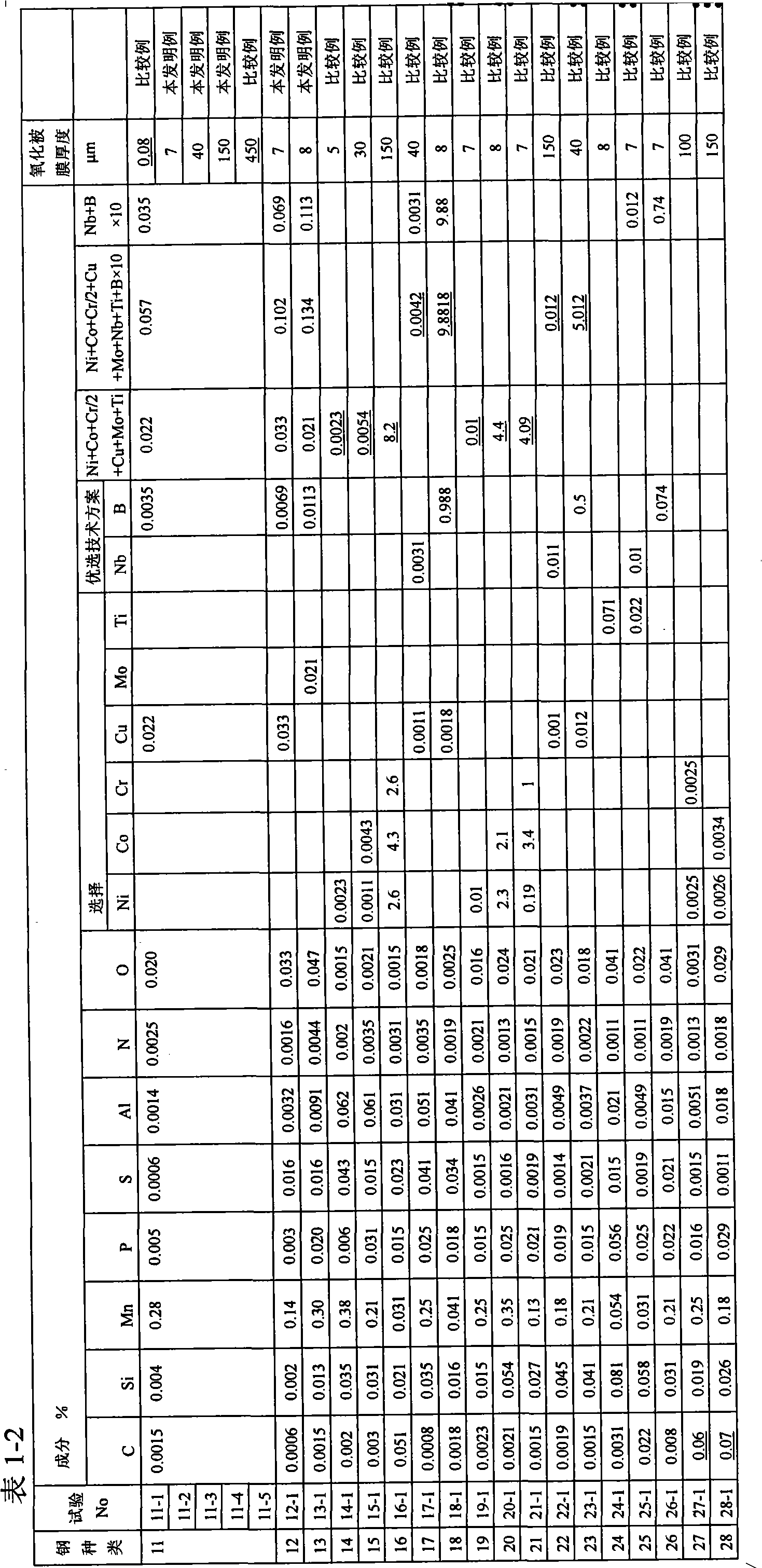

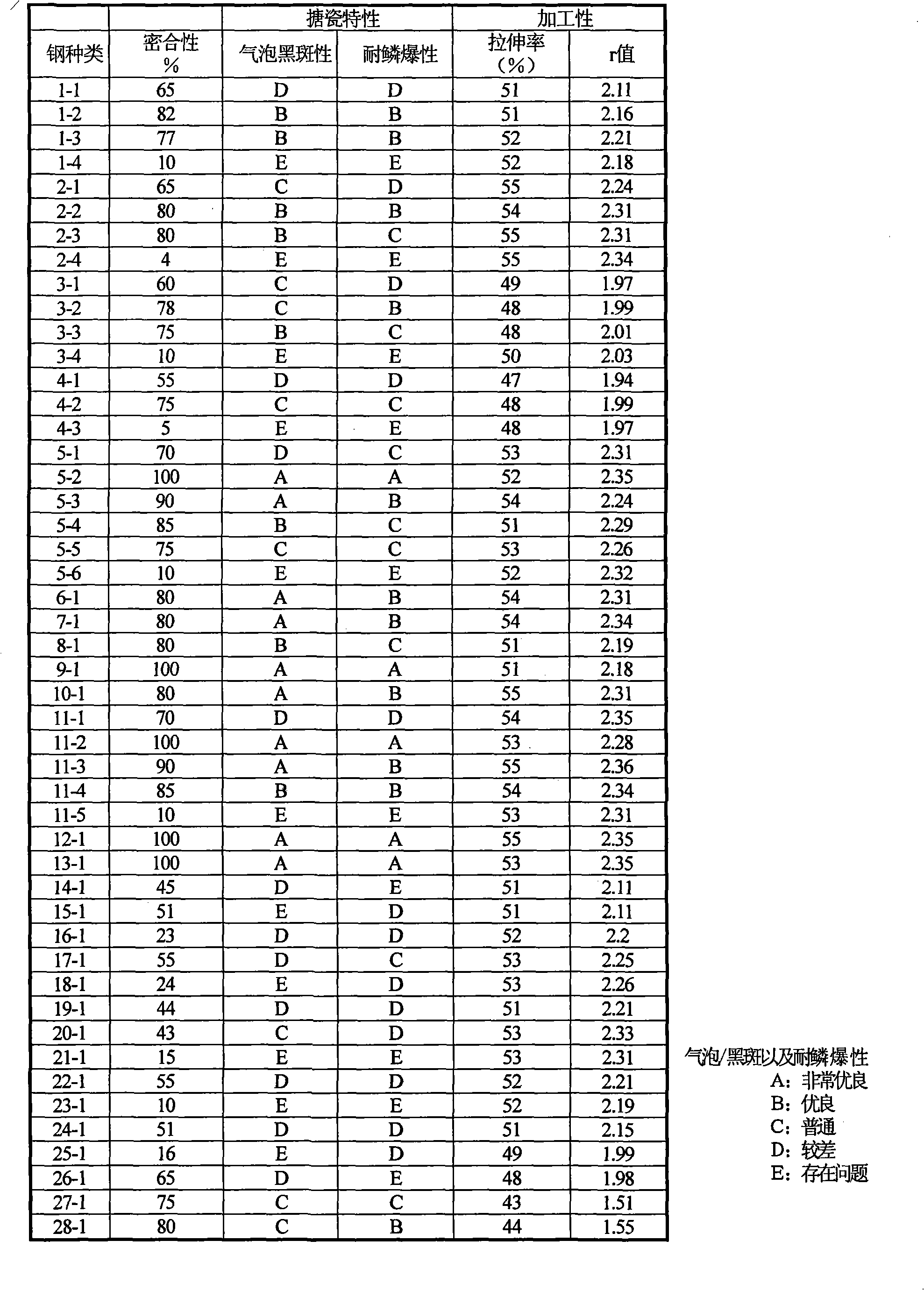

An enameling work capable of securing adhesion, blister / black speck resistance and fishscale resistance even when pretreatment or ground coating is omitted, which work is a steel sheet which contains by mass C: 0.0001 to 0.040%, Si: 0.0001 to 0.50%, Mn: 0.001 to 2.00%, P: 0.0001 to 0.10%, S: 0.0001 to 0.060%, Al: 0.0001 to 0.10%, N: 0.0001 to 0.015%, O: 0.0001 to 0.070%, and at least one selected from among Ni: 0.01 to 2.00%, Co: 0.0005 to 2.00%, Cr: 0.001 to 2.00%, Cu: 0.01 to 2.00%, Mo: 0.0001 to 2.00%, and Ti: 0.0005 to 0.50% with Ni+Co+Cr / 2+Cu+Mo+Ti: 0.010 to 8.0% and with the balance consisting of Fe and unavoidable impurities and whichhas on the surface a 0.1 to 400-[mu]m thick oxide layer consisting of the oxides of the components constituting the sheet; and enameled products.

Owner:NIPPON STEEL CORP

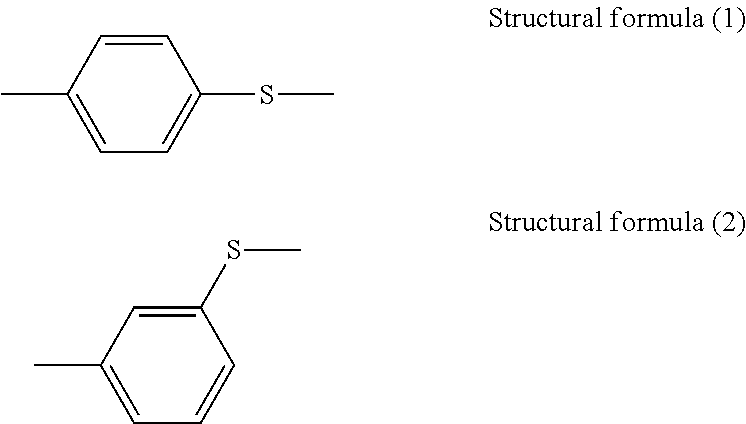

Insulated wire

ActiveUS20110226508A1Excellent solvent resistance and abrasion resistanceHigh voltagePlastic/resin/waxes insulatorsInsulated cablesResilient modulusMelt viscosity

An inverter surge-resistant insulated wire, having an enamel baked layer, an adhesive layer, and an extrusion-coated resin layer, around the outer periphery of a conductor, wherein the sum of the thickness of the enamel baked layer, the extrusion-coated resin layer, and the adhesive layer is 60 μm or more, wherein the thickness of the enamel baked layer is 50μm or less, and wherein the extrusion-coated resin layer is formed from a polyphenylene sulfide resin composition, which contains a polyphenylene sulfide polymer having a melt viscosity at 300° C. of 100 Pa·s or more, 2 to 8 mass % of a thermoplastic elastomer, and an antioxidant, and which has a tensile modulus of elasticity at 25° C. of 2,500 MPa or more, and a tensile modulus of elasticity at 250° C. of 10 MPa or more.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD +2

Lead and cadmium-free glass composite for coating porcelain glaze and enamel on and decorating glass or glass ceramics

The invention relates to lead and cadmium-free glass composite for coating porcelain glaze and enamel on and decorating glass or glass ceramics. Particularly, the invention relates to lead and cadmium-free glass for coating porcelain glaze and enamel on and decorating glass or glass ceramics, which takes high-quartz mixed crystal and / or keatite mixed crystal as a main crystal phase after crystallization, has low-heat expansion which is less than 2X10-6 at the temperature of between 20 and 700 DEG C, and comprises the following components in percentage by weight: 0 to 5 percent of LiO2, 0 to 5 percent of Na2O, 0 to 2 percent of K2O, 1 to 1 percent of sigma Li2O+Na2O+K2O, 0 to 3 percent of MgO, 0 to 4 percent of CaO, 0 to 4 percent of SrO, 0 to 4 percent of BaO, 0 to 4 percent of ZnO, 15 to 27 percent of B2O3, 10 to 20 percent of Al2O3, 43 to 58 percent of SiO2, 0 to 3 percent of TiO2, 0 to 4 percent of ZrO2, 0 to 2 percent of Sb2O3, 0 to 3 percent of F which is used for replacing oxygen, and at most 30 percent of dye which is stabilized at the sintering temperature.

Owner:SCHOTT AG

Enamel glaze material

The invention relates to an enamel glaze material for a steel plate. After the glaze material is calcinated, an enameled product has corrosion resistance, chemical resistance, weather resistance and decorative property, and the service life of the enamel can be prolonged. The technical problem to be solved is to provide the enamel glaze material. The enamel glaze material overcomes the defects that the conventional enamel glaze material is easy to deform and soften in high-temperature high-humidity environments. The enamel glaze material capable of resisting corrosion, softening and deformation is provided. The enamel glaze material comprises Ba2O3, Li2O, Na2O, MgO, Al2O3, SiO2, P2O5, SO3, K2O, CaO, TiO2, Cr2O3 and the like.

Owner:ZHEJIANG KAIER NEW MATERIALS

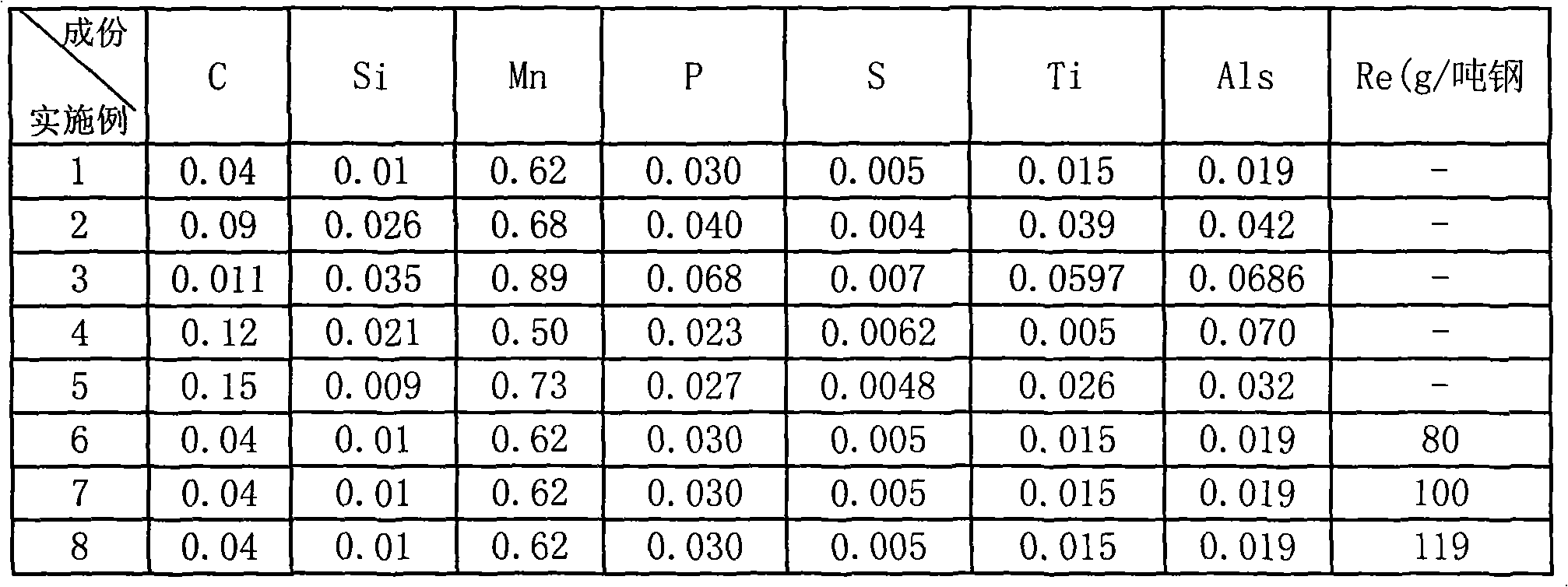

High-strength steel for water heater inner container and production method thereof

InactiveCN101255530AReduce manufacturing costEasy to weldRoll force/gap control deviceTemperature control deviceImpurityFormability

The invention relates to a high-strength steel for water heater containers, which solves the current drawbacks of complex welding process, non-once-forming steel plate, many alloy elements, low strength, poor pressure resistance and easy deformation to make enamel drop off. The steel is mainly composed of 0.01% to 0.15% by weight of C, no more than 0.04% by weight of Si, 0.50% to 0.90% by weight of Mn, no more than 0.070% by weight of P, 0.015% by weight of S, 0.005% to 0.060% by weight of Ti, 0.005% to 0.070% by weigh of Als, and the balance Fe and unavoidable impurity. The production method comprises the following steps: desulphurization of hot metal, and converter bottom-top composite blowing; argon blowing; all-protected casting to form a plate blank; and hot rolling by controlling rolling and controlling cooling. According to the invention, the microalloy elements are less, the production cost is low, the welding is convenient, the cold formability is good, the pressure resistance is superior, the yield stress reaches up to 360MPa, the plate is capable of bearing 320MPa or more strength, being once-formed, and directly being enameled to various heater containers.

Owner:武汉钢铁有限公司

Porcelain enamel composition

The present invention provides a composition for use in forming an opaque porcelain enamel coating on a metal substrate. A porcelain enamel coating formed using a composition according to the invention readily adheres to metal substrates such as, for example, steel, that are degreased-only. Furthermore, such a porcelain enamel coating displays an acid resistance of A according to ISO 2722 and good easy-to-clean properties. The composition according to the invention includes a glass component including by weight from about 45% to about 55% SiO.sub.2, from about 8% to about 17% B.sub.2O.sub.3, from about 1.8% to about 17.7% SrO+BaO, from about 1.9% to about 10% Li.sub.2O, up to about 6% ZrO.sub.2, from about 2% to about 11% TiO.sub.2, from about 1.5% to about 6% K.sub.2O, from about 1% to about 4% MoO.sub.3, from about 0.3% to about 13% Na.sub.2O, up to about 2% NiO, up to about 3% Al.sub.2O.sub.3, up to about 2.9% MnO, up to about 0.8% CoO, up to about 3% MgO, up to about 5% CaO, and up to about 2% Sb.sub.2O.sub.3.

Owner:FERRO FRANCE S A R L

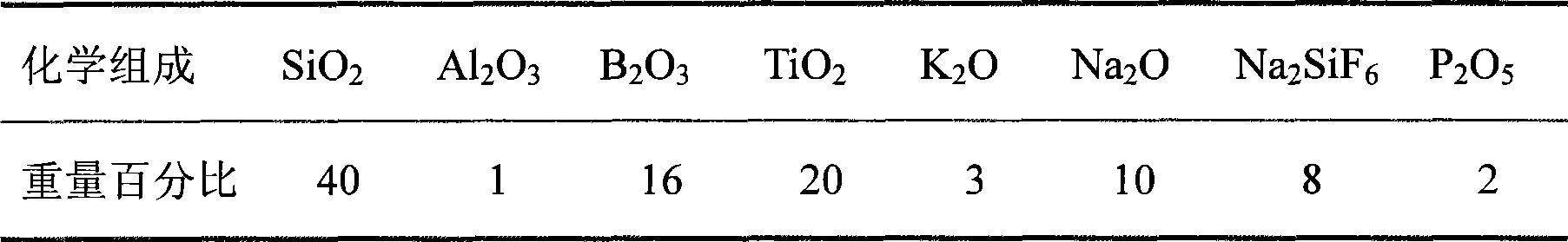

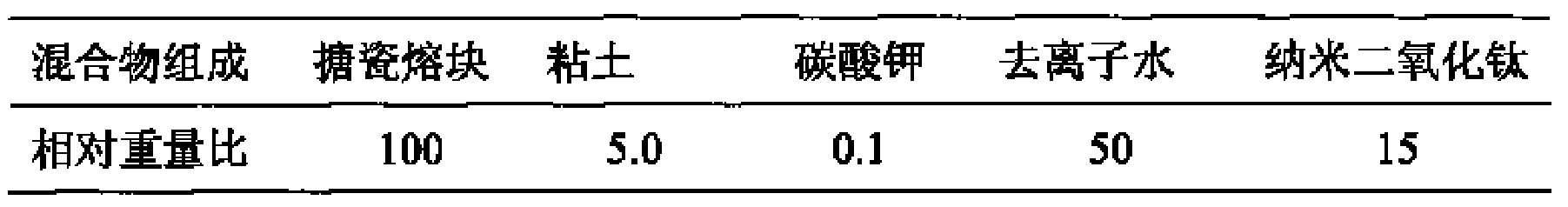

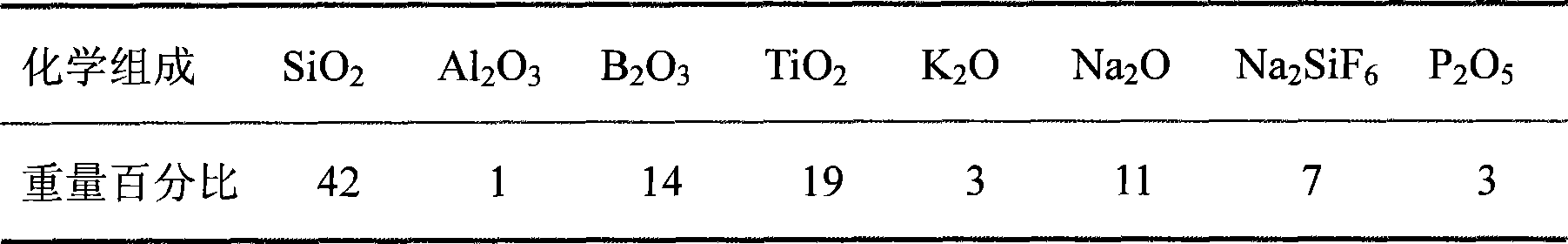

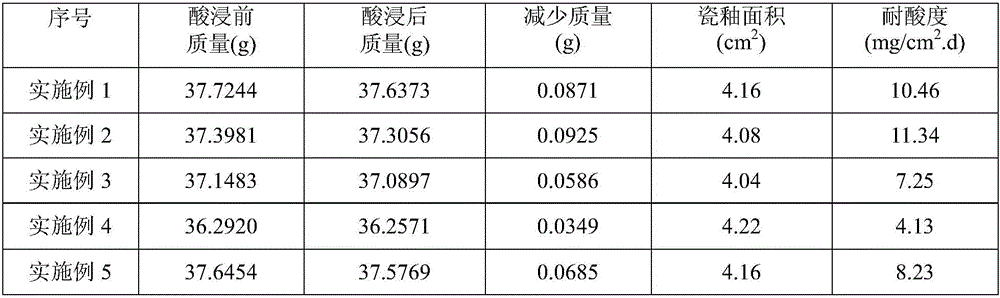

Photocatalytic self-cleaning nano-titania porcelain enamel substrate and method for preparing same

InactiveCN101519276AImprove catalytic abilityStable chemical propertiesPhysical/chemical process catalystsChemical compositionPhysical chemistry

The invention relates to a photocatalytic self-cleaning nano-titania porcelain enamel substrate and a method for preparing the same. Raw materials comprise the following chemical compositions in percentage by weight: 35.0 to 68.0 percent of SiO2, 0.5 to 3.0 percent of Al2O3, 10.0 to 20.0 percent of B2O3, 12.0 to 20.0 percent of TiO2, 1.0 to 5.0 percent of K2O, 5.0 to 12.0 percent of Na2O, 3.0 to 8.0 percent of SiF6 and 1.0 to 3.0 percent of P2O5. The preparation method comprises that: the raw materials are mixed, melted, quenched and dried to prepare a porcelain enamel melted block; the porcelain enamel melted block, nano-titania, and the like are mixed, ground and sifted to obtain porcelain enamel; a steel plate which is subjected to derusting treatment is coated with the porcelain enamel so as to obtain the photocatalytic self-cleaning nano-titania porcelain enamel substrate with excellent photocatalytic performance and chemical stability; and the photocatalytic self-cleaning nano-titania porcelain enamel substrate has a simple preparation process and low production cost.

Owner:SHANGHAI INST OF TECH

High strength enamel steel and producing technology and enamel firing technology thereof

InactiveCN101586210AEasy to produceReduce manufacturing costTemperature control deviceManufacturing convertersChemical compositionSand blasting

The invention discloses a high strength enamel steel in which the chemical compositions are as follows according to weight percentages: C is 0.01 to 0.12; Si is less than or equal to 0.03, Mn is 0.50 to 1.00, P is less than or equal to 0.070, S is less than or equal to 0.015, Nb is 0.020 to 0.050, Mo is 0.05 to 0.30, Als is 0.005 to 0.070, and the remainder is Fe and unavoidable impurities; simultaneously, the steel further meets that 10Nb is greater than or equal to Mo and 10Nb+Mo is greater than or equal to 0.30 and is less than or equal to 0.50. The steel yield strength is greater than or equal to 360 MPa. The production and enamel firing technology of the steel in turn comprises melted iron desulfurization, combined converting at converting top and bottom, argon blowing treatment, protective casting into plate blank, controlled rolling controlled cold rolling into hot rolled plate, acid cleaning, sand blasting, enamelling and high temperature enamel firing, having simple production working procedures, low production cost, multiple enamelling methods, good enamel adhesiveness and high-temperature resistant enamel firing.

Owner:武钢集团有限公司

Enamel glaze material, enamel slurry, and preparation method and application thereof

The invention specifically relates to an enamel glaze material, an enamel slurry, and a preparation method and an application thereof. The invention relates to the technical field of enamel materials. The invention aims at solving a technical problem of providing an enamel glaze material. The enamel glaze material is prepared by uniformly mixing the following raw materials, by weight: 40-45 parts of quartz sand, 9.5-10 parts of feldspar powder, 24-26 parts of borax, 2.5-3 parts of cryolite, 5.5-7.5 parts of sodium nitrate, 3.5-4 parts of lithium carbonate, 3.5-4.5 parts of fluorite powder, 2-4 parts of calcium carbonate, 3-4 parts of cobalt nitrate, 0.8-1.2 parts of nickel nitrate, 2-2.2 parts of manganese oxide, and 3.4-3.8 parts of zirconium dioxide. The enamel glaze material can be combined well with glass powder to produce the enamel slurry. The enamel slurry can be coated on the surface of a metal substrate to form an enamel coating. The coating has the advantages of smooth glaze surface, good gloss, no bubble, and no scaling. The coating can be firmly combined with a carbon steel substrate, and has good acid resistance.

Owner:PANZHIHUA UNIV

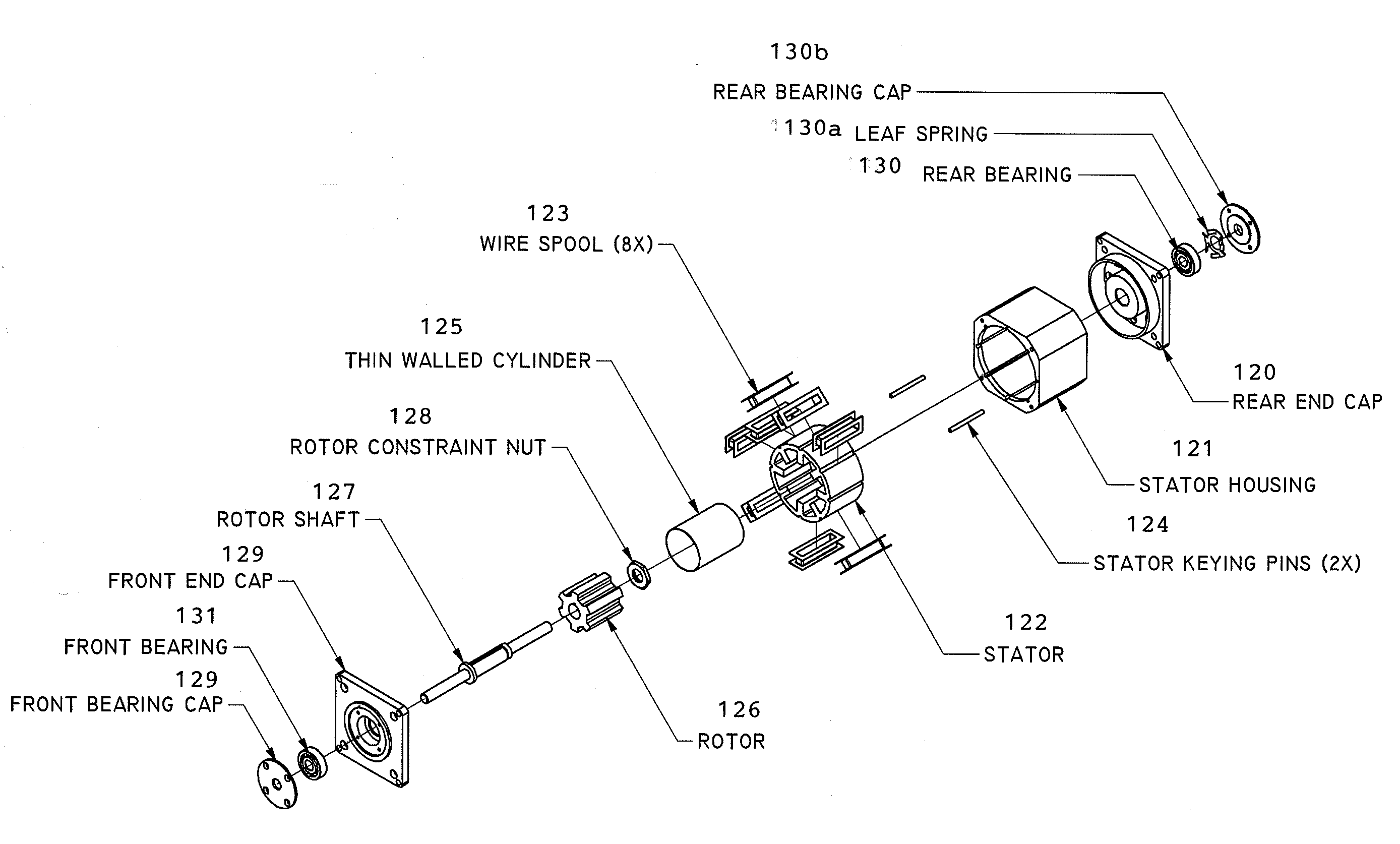

Motor for high temperature applications

ActiveUS20120025636A1Avoid debrisAvoid the needWindings insulation materialWindings insulation shape/form/constructionEpoxyAdhesive

A high temperature motor has a stator with poles formed by wire windings, and a rotor with magnetic poles on a rotor shaft positioned coaxially within the stator. The stator and rotor are built up from stacks of magnetic-alloy laminations. The stator windings are made of high temperature magnet wire insulated with a vitreous enamel film, and the wire windings are bonded together with ceramic binder. A thin-walled cylinder is positioned coaxially between the rotor and the stator to prevent debris from the stator windings from reaching the rotor. The stator windings are wound on wire spools made of ceramic, thereby avoiding need for mica insulation and epoxy / adhesive. The stator and rotor are encased in a stator housing with rear and front end caps, and rear and front bearings for the rotor shaft are mounted on external sides of the end caps to keep debris from the motor migrating into the bearings' races.

Owner:HONEYBEE ROBOTICS

Enamelling method of enamel heat transfer element

The invention discloses an enamelling method of an enamel heat transfer element, comprising the following steps of: (1) preparing enamel frit for later use; (2) making an electrostatic enamel powder which can be sprayed by the use of an electrostatic spray gun; (3) making glaze slip which can be used for wet spraying; (4) spraying the glaze slip obtained from the step (3) on the heat transfer element's grooves and slots which are not easy to spray by an electrostatic dry method; (5) drying the heat transfer element sprayed by the step (4), sending the dried heat transfer element into an electrostatic spraying device, and spraying the electrostatic enamel powder by using the electrostatic spray gun; (6) sending the heat transfer element which has undergone the above steps into a high temperature enamelling kiln for sintering, and cooling to obtain enamel heat transfer element with anticorrosion performance. According to the workpiece sprayed by the enamelling method of the enamel heat transfer element, enamels are greatly wrapped by edges after sintering. In addition, the grooves of the heat transfer element are greatly coated with enamel. The enamelling method is suitable for various shapes and wave patterns.

Owner:KUSN MEIBANG ENAMEL

Economical deep drawing cold rolling enamel steel and production method

The invention discloses economical deep drawing cold rolling enamel steel and a production method. The economical deep drawing cold rolling enamel steel comprises the following chemical elements in percentage by weight: 0.005%-0.015% of C, equal to or less than 0.030% of Si, 0.15%-0.25% of Mn, equal to or less than 0.020% of P, 0.010%-0.020% of S, 0.030%-0.060% of Al and equal to or less than 0.0040% of N. The production method comprises the following steps: hot metal pretreatment, smelting in a converter, alloy fine adjustment station, refining in an RH furnace, hot rolling, acid pickling, cold rolling, continuous annealing and leveling. The economical deep drawing cold rolling enamel steel is produced through the working procedures of hot rolling, acid pickling, five-rack full six-roller cold continuous rolling and continuous annealing and leveling, wherein the yield strength is 160-190 MPa, the tensile strength is higher than 300 MPa, the A50 elongation is greater than 45%, n is greater than 0.2 and r is greater than 1.8.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation method of white body ice crackle vitreous enamel and products produced from white body ice crackle vitreous enamel

The invention discloses a preparation method of white body ice crackle vitreous enamel and products produced from the white body ice crackle vitreous enamel. The white body ice crackle vitreous enamel is prepared by using common mineral raw materials and chemical raw materials to prepare body material and glaze material and burning at 1220 DEG C-1240 DEG C. The crackles of the surface of the glaze are as dense as fish scales, and are crackled obliquely. The large crackles and small crackles are overlapped, hidden and discontinuous on some positions, and form superposed layers of crackles. Thecolor of the crackles is glossy and crystalline. The crackles are thin and deep into the body of the vitreous enamel. The vitreous enamel brings a texture of crystalline surface of the glaze and scale-like convex inside of the glaze. According to the preparation method and the products provided by the invention, the limit that the Longquan ice crackle vitreous enamel is only prepared for grey body and greenish glaze is broken through. The adorning range of the ice crackle vitreous enamel is expanded. The application prospects of the white body ice crackle vitreous enamel in the high-end tea sets and the artistic porcelain are wide.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Surfactant-free cleansing and multifunctional liquid coating composition containing nonreactive abrasive solid particles and an organosilane quaternary compound and methods of using

ActiveUS20070010419A1Inhibition of attachmentInhibit growthCationic surface-active compoundsOrganic detergent compounding agentsPolyesterSolid particle

Cleansing and multifunctional coating compositions containing an organosilane quaternary compound, nonreactive abrasives, and hydrogen peroxide in aqueous formulations are used to improve water and soil repellency and residual antimicrobial activity on surfaces. Various surfaces may be treated including metal, glass, plastics, rubber, porcelain, ceramic, marble, granite, cement, tile, sand, silica, enameled appliances, polyurethane, polyester, polyacrylic, melamine / phenolic resins, polycarbonate, painted surfaces, wood, and the like.

Owner:RESOURCE DEV LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com