Patents

Literature

224results about How to "Improve deep drawing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy strip for integrated battery cover plate and preparing method of aluminum alloy strip

InactiveCN107604212AImprove deep drawing performanceImprove Laser Welding PerformanceCell component detailsDetonationAluminium alloy

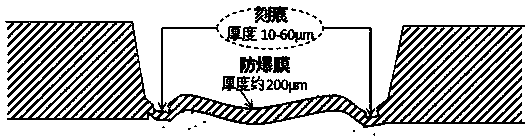

The invention discloses an aluminum alloy strip for an integrated battery cover plate and a preparing method of the aluminum alloy strip. The aluminum alloy strip comprises components including 1.2%-1.5% of Fe, 0.25%-0.5% of Mn, 0.05%-0.2% of Si, 0.005%-0.1% of Ti, smaller than or equal to 0.05% of Cu, smaller than or equal to 0.05% of Mg, smaller than or equal to 0.05% of Zn and the balance aluminum and inevitable impurities. Through component design and technology control, the characteristics that when an Al-Fe-Mn alloy is machined to a certain degree, softening happens, and a high laser absorbing rate and a low heat conductivity coefficient are achieved are utilized, during downstream manufacturing, the battery cover plate and an anti-explosion port are directly integrally punched and formed, annealing and welding are avoided, an anti-explosion sheet is uniform in thickness and stable in performance, the anti-explosion sheet and cover plate welding procedure and leakage, instable detonation pressure and other hidden danger caused by welding are reduced, and the preparing method of the aluminum alloy strip for the battery cover plate is novel.

Owner:CHINALCO RUIMIN +1

High-strength steel sheet excellent in deep drawing characteristics and method for production thereof

ActiveUS20060191612A1Avoid developmentIncrease valueHot-dipping/immersion processesFurnace typesHigh intensityMartensite

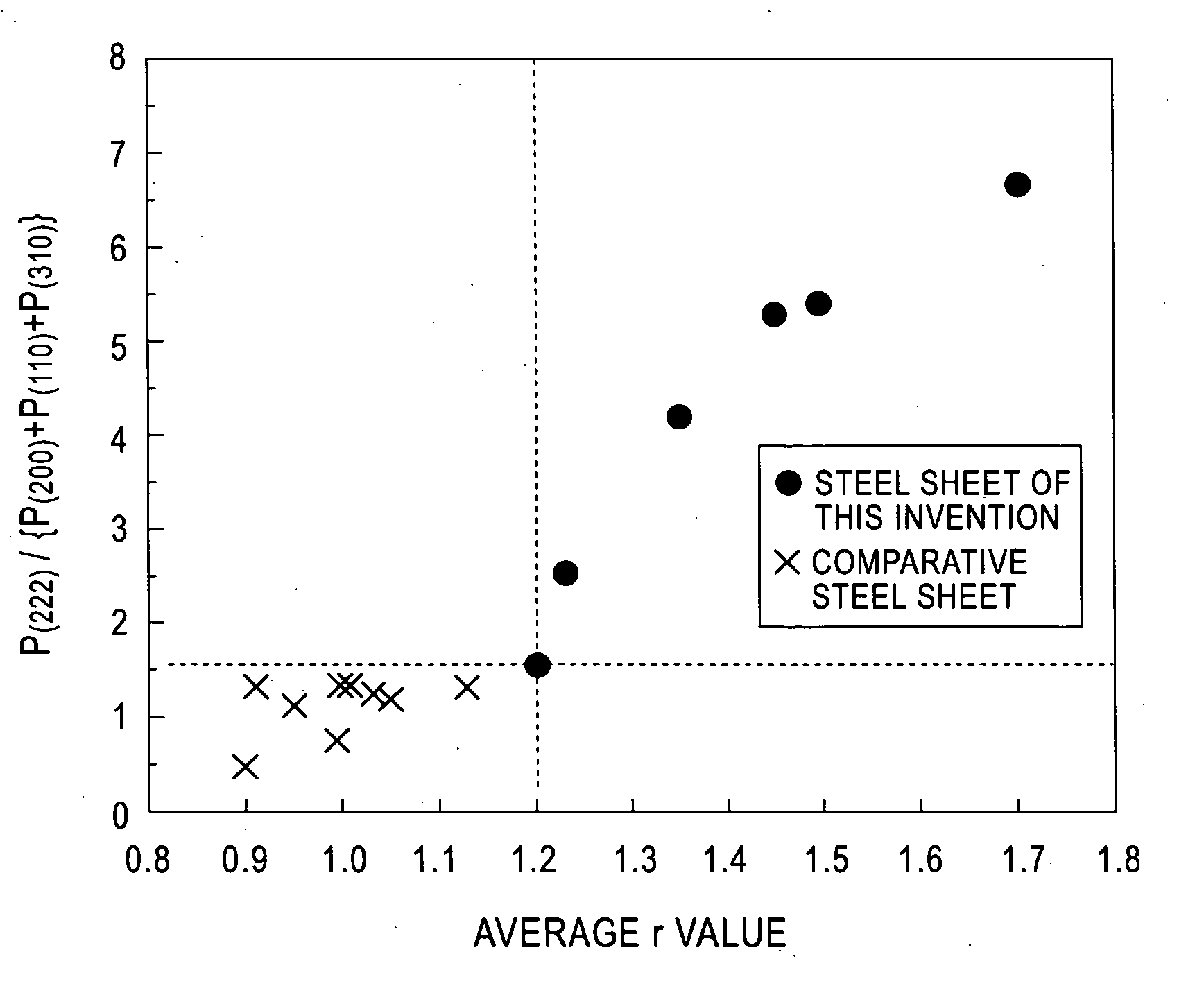

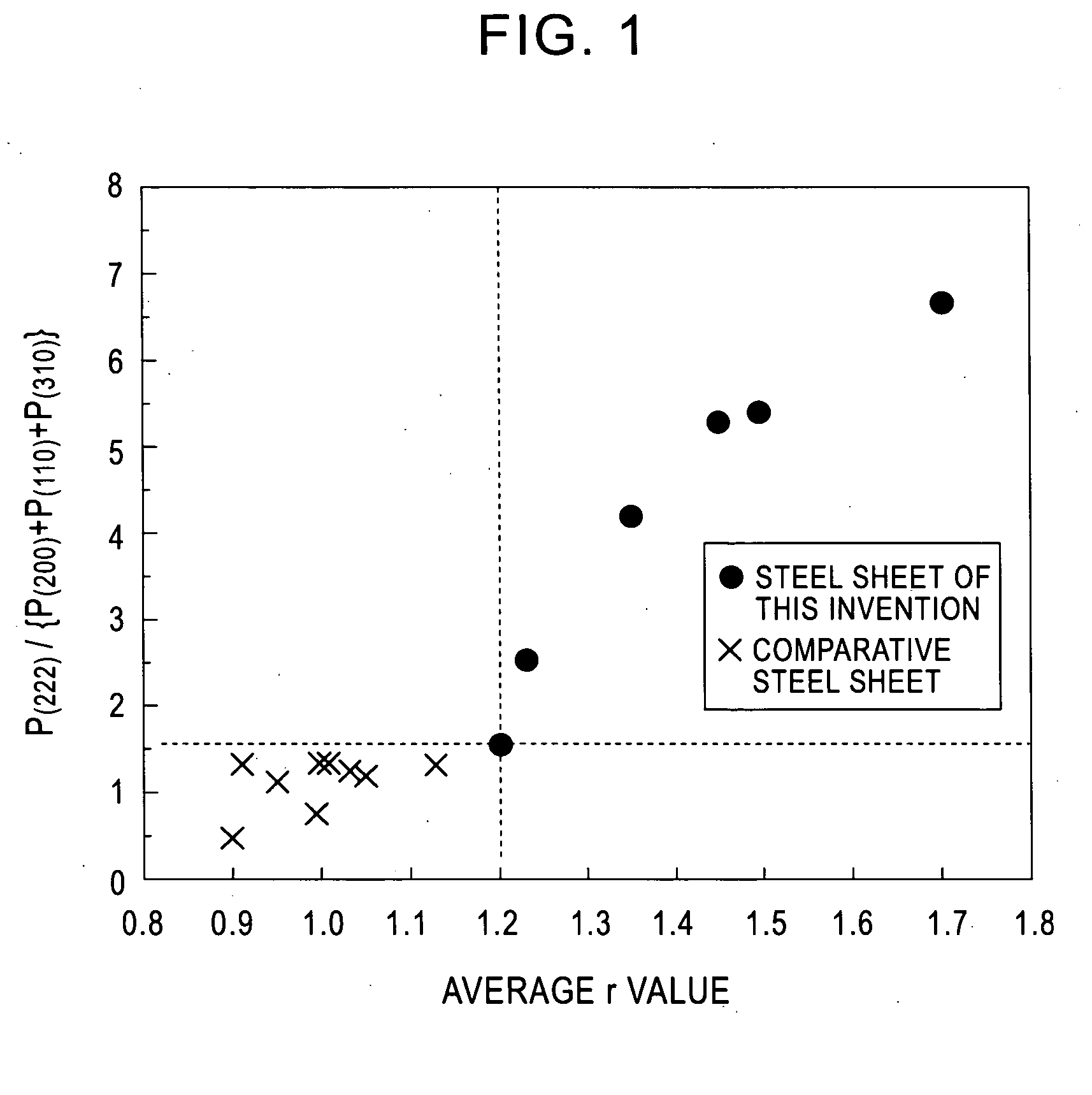

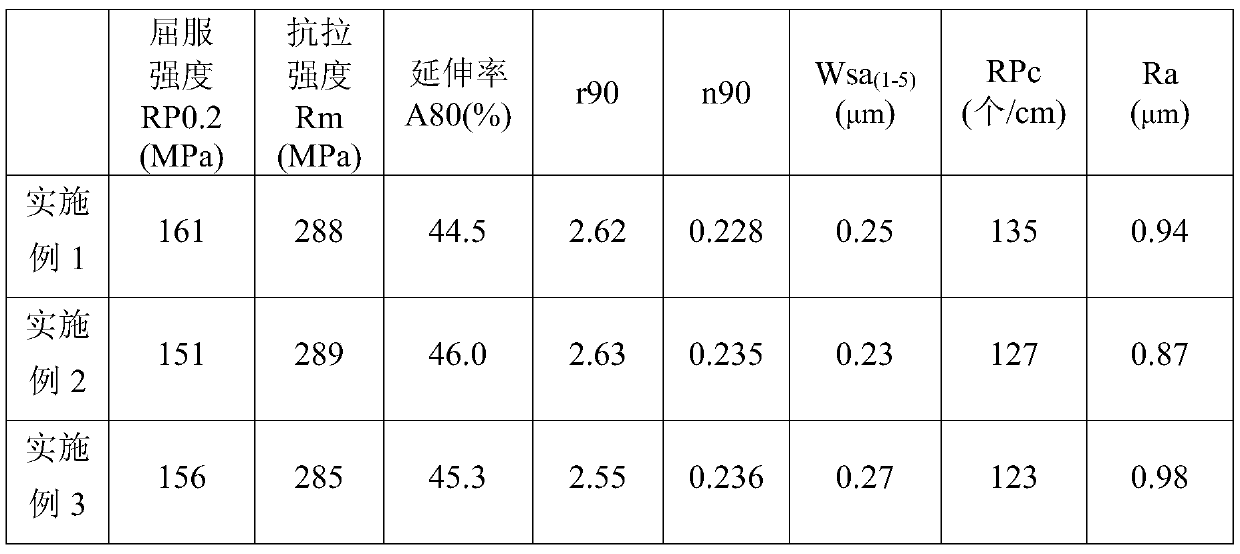

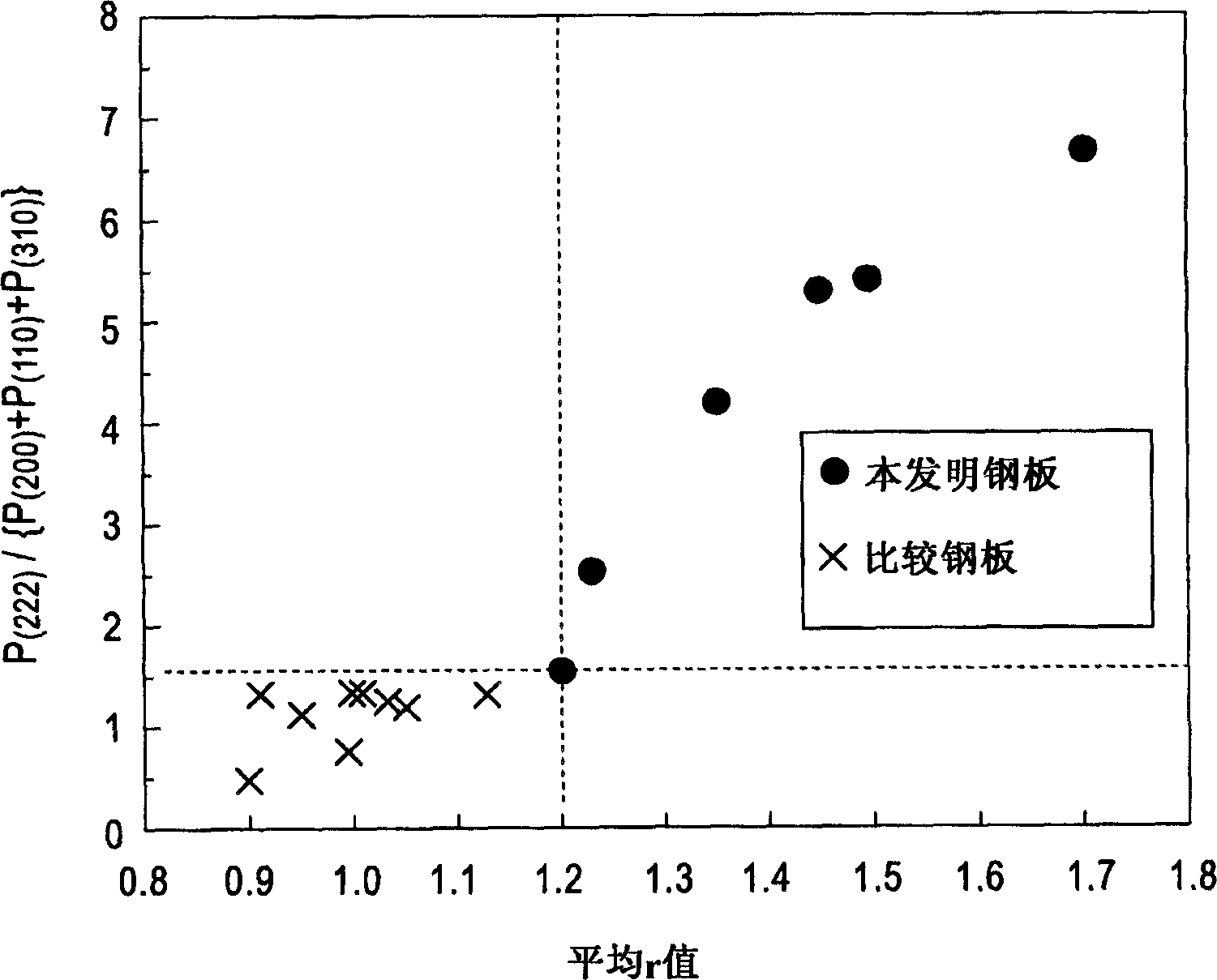

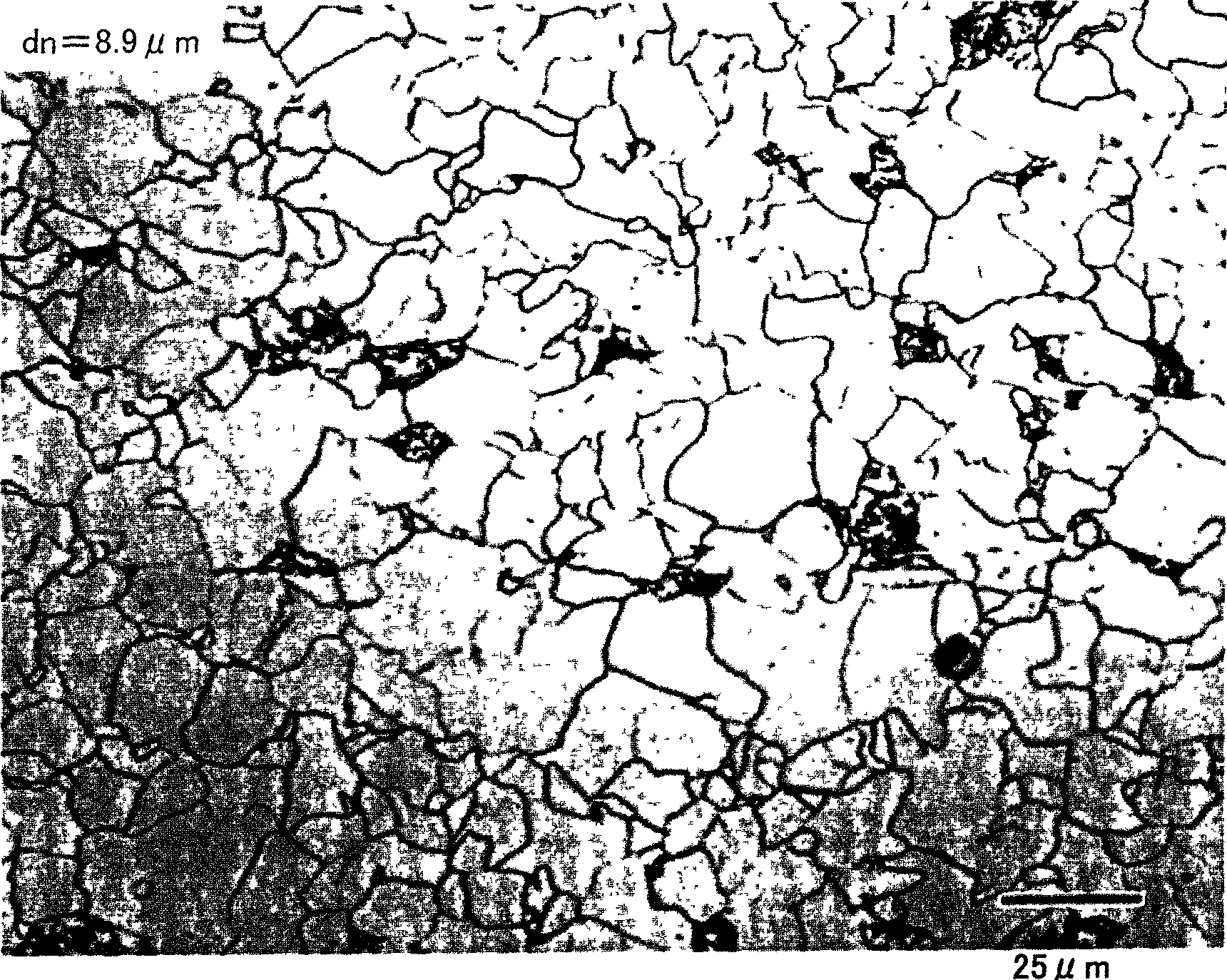

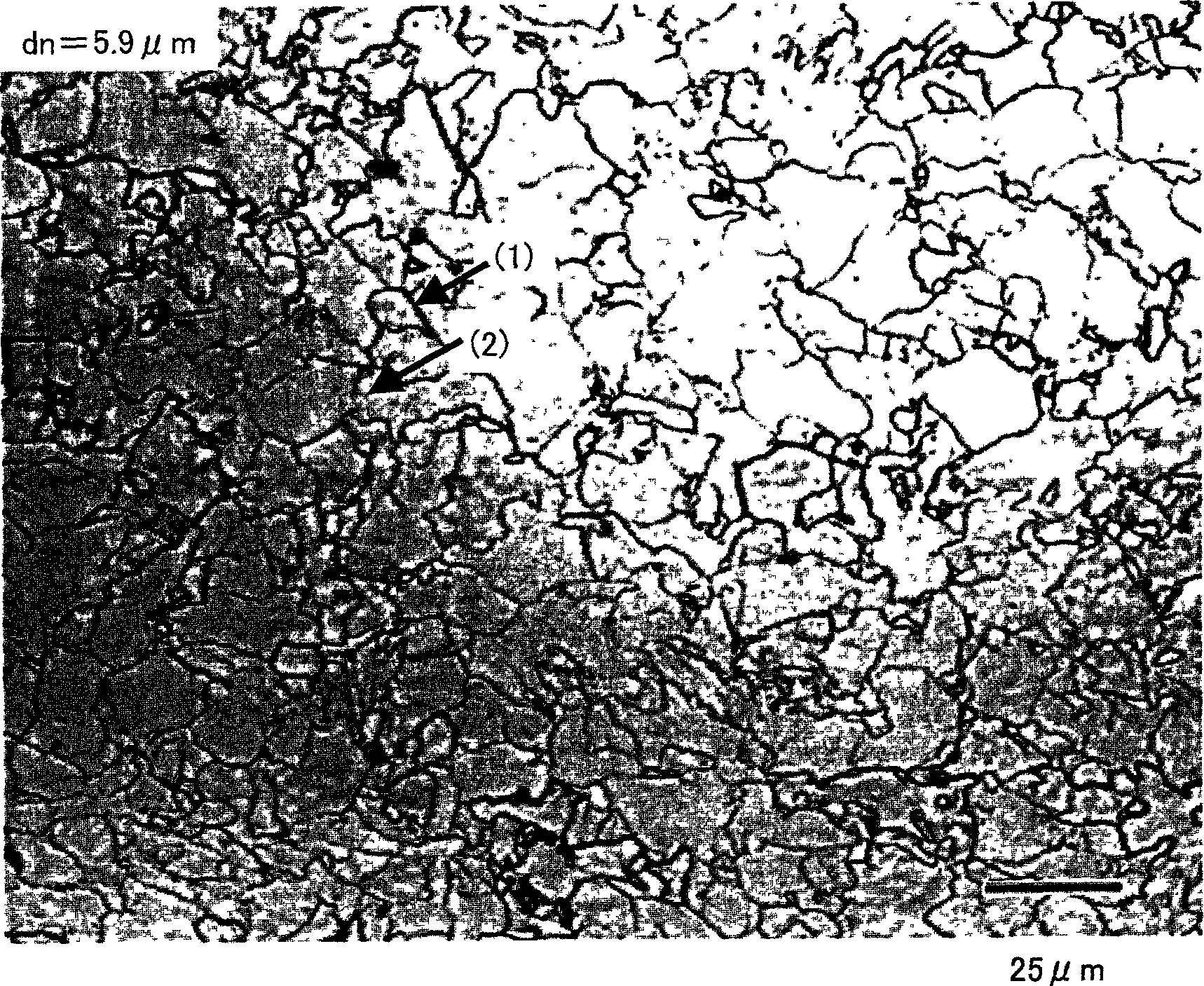

The present invention provides a high-strength steel sheet useful for applications to automobile steel sheets and the like and having excellent deep drawability, a tensile strength (TS) of as high as 440 MPa or more, and a high r value (average r value≧1.2), and a process for producing the steel sheet. The steel sheet has a composition containing, by % by mass, 0.010 to 0.050% of C, 1.0% or less of Si, 1.0 to 3.0% of Mn, 0.005 to 0.1% of P, 0.01% or less of S, 0.005 to 0.5% of Al, 0.01% or less of N, and 0.01 to 0.3% of Nb, the Nb and C contents in steel satisfying the relation, (Nb / 93) / (C / 12)=0.2 to 0.7, and the balance substantially including Fe and inevitable impurities. The steel microstructure contains a ferrite phase and a martensite phase at area ratios of 50% or more and 1% or more, respectively, and the average r value is 1.2 or more.

Owner:JFE STEEL CORP

Steel plate exhibiting excellent workability and method for producing the same

InactiveUS20040238081A1High strengthImprove deep drawing performanceHot-dipping/immersion processesFurnace typesMechanical engineeringChemistry

The present invention provides a steel sheet excellent in workability, which may be used for components of an automobile or the like, and a method for producing the same. More specifically, according to one exemplary embodiment of the present invention, a steel sheet excellent in workability, including in mass, 0.08 to 0.25% C, 0.001 to 1.5% Si, 0.01 to 2.0% Mn, 0.001 to 0.06% P, at most 0.05% S, 0.001 to 0.007% N, 0.008 to 0.2% Al, at least 0.01% Fe. The steel sheet having an average r-value of at least 1.2, an r-value in the rolling direction of at least 1.3, an r-value in the direction of 45 degrees to the rolling direction of at least 0.9, and an r-value in the direction of a right angle to the rolling direction of at least 1.2.

Owner:NIPPON STEEL CORP

Production method of ultra-low-carbon steel for sedan car cortical plate

InactiveCN101096034AReduce manufacturing costLower recrystallization temperatureTemperature control deviceWork treatment devicesHigh energyHeating furnace

The invention provides a producing method for ultra low steel carbon used in car outer plate, characterized in that liquid steel is cast into plate slab in the pulling speed of 1.5-4m / min; the thickness of plate slab is 100-170mm; casting machine adopts dynamic light pressure and crystallizer electromagnetic braking technology and tundish superheat is 20-45deg.C; the plate slab is installed in heat directly and the charging temperature is more than 800deg.C; the plate slab is heated to 1150-1250deg.C in heating furnace; after the temperature is maintained for 30-90min rough rolling cogging is carried out. By adopting continuous rolling and casting short-flow process of medium-thin plate slab and collocating casting machine and heating furnace compactly quick charging is realized; charging material temperature is improved; problems of large investment and high energy consumption in conventional process are solved; inner limitation generated in continuous casting process of thin plate is eliminated; it is guaranteed that product is provided with good surface quality and stable mechanical property.

Owner:ANGANG STEEL CO LTD

Preparation method of magnesium alloy strip for cell phone shell

InactiveCN102352459AHigh strengthImprove plasticityRoll mill control devicesMetal rolling arrangementsImpurityMagnesium alloy

The invention discloses a preparation method of a magnesium alloy strip for a cell phone shell. The preparation method is characterized in that the magnesium alloy comprises the following components by weight percent: 2%-4.5% of Al, 0.5%-0.8% of Si, 0.7%-1.2% of Cu, 0.5%-1.0% of Mn, 0.1%-0.8% of Zn, 0.2%-0.3% of Ti and the balance of Mg and inevitable impurities. The preparation method comprises the following steps: smelting, performing homogenizing annealing, performing hot rolling and performing cold rolling. The tensile strength of the magnesium alloy strip is 190MPa-210MPa, the elongation at break is 8.0%-10.0%, and the earring rate is 2%-3%; and the magnesium alloy strip can meet the thin stretching and punching forming requirement of the cell phone shell.

Owner:YONGXIN PRECISION MATERIAL WUXI

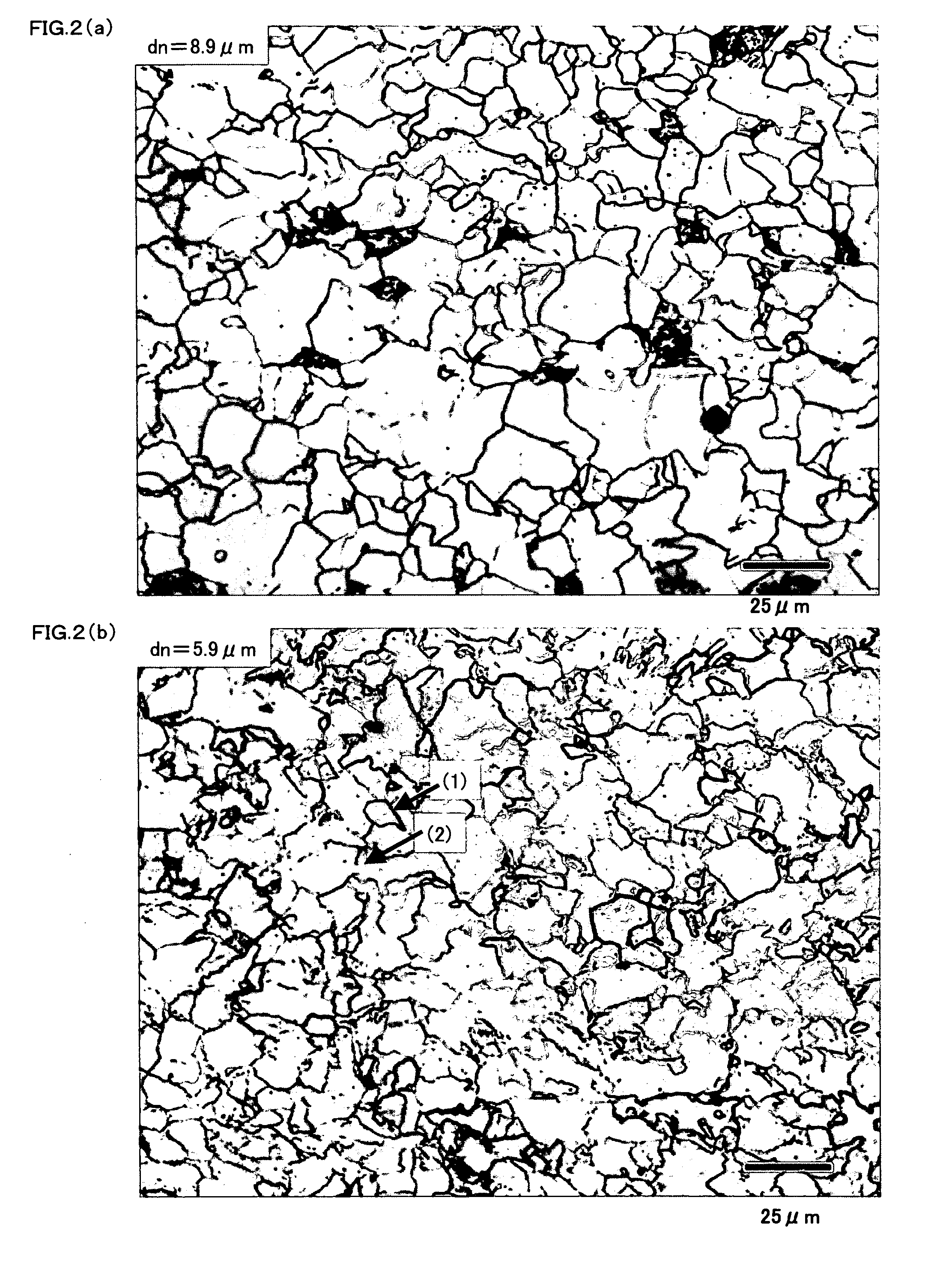

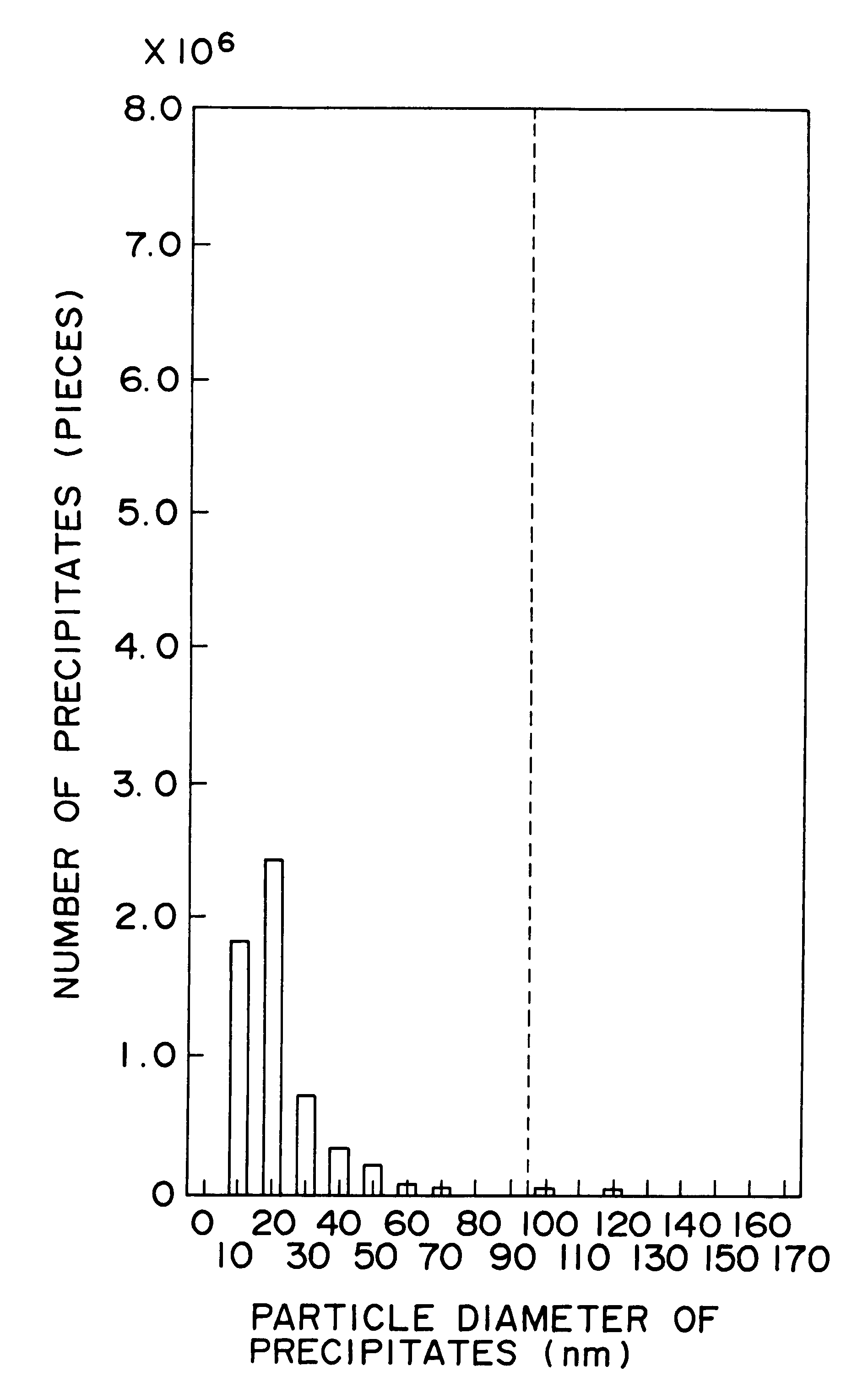

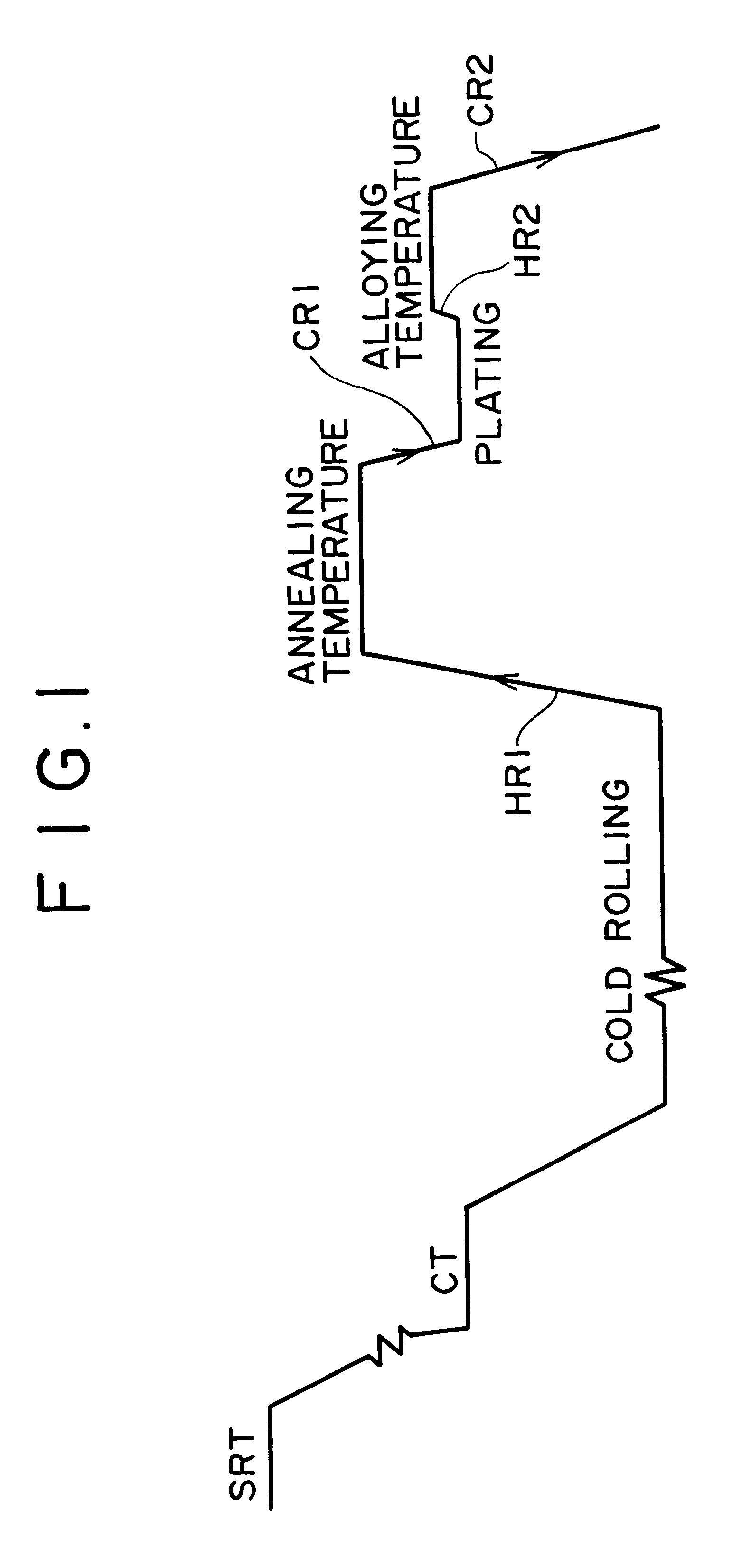

Galvannealed steel sheet superior in ductility and process for production thereof

InactiveUS6316127B1Decrease in strengthIncrease ratioHot-dipping/immersion processesLiquid surface applicatorsHot-dip galvanizationDuctility

A P- and Ti-added galvannealed steel sheet superior in ductility, and a process for production thereof. It is made of a cold-rolled steel sheet and has alloyed hot-dip galvanizing on the surface thereof, said cold-rolled steel sheet having the chemical composition (in terms of wt %) of C: less than 0.010%, Si: no more than 0.5%, Mn: 1.0~3.0%, P: no more than 0.20%, S: no more than 0.01%, Al: 0.005~0.10%, N: no more than 0.0050%, Ti / 48-(C / 12+N / 14+S / 32): 0.0003~0.0018 with the remainder being chiefly Fe, and said cold-rolled steel sheet being characterized by rho1<=107 and rho2<=5x105, where rho1 is the number of precipitates whose particle diameter (D) is in the range of 10 nm<=D<100 nm and rho2 is the number of precipitates whose particle diameter (D) is in the range of 100 nm<=D.

Owner:KOBE STEEL LTD

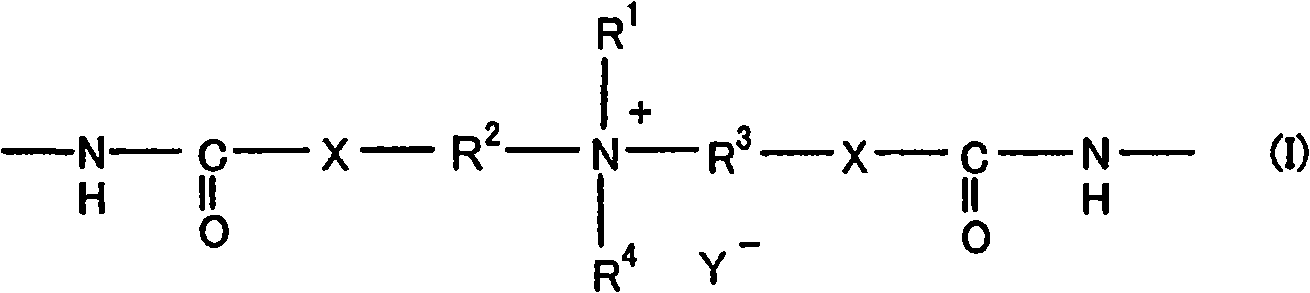

Water surface treatment agent for precoating metal material, furface treated metal material and precoating metallic material

ActiveCN101560655AGood storage stabilityImprove scratching effectLiquid surface applicatorsAnti-corrosive paintsMetallic materialsMaterials science

The invention provides an aqueous surface processing agent for a precoating metallic material, a furface treated metal material and a precoating metallic material. A non-chromium aqueous surface processing agent can be used for forming a film with good corrosion resistance(the corrosion resistance of the film cut part and end plane), one-time coating adaptation(at the normal temperature and in thecold condition), second coating adaptation, effective coin scrapeing resistance, deep drawing quality, alkali stability, acid-resistance and wet fastness, as well as storage stability. The aqueous surface processing agent is used as the substrate treating agent of the precoating metallic material, and comprises, at the specific ratio, silicone hydride coupling agent with primary amino radical (A), cationoid polyurethane resin with the specific structure and the class transition temperature of 0 to 100 DEG C (B), specific non-ionic or cationoid polycarbodiimide compounds (C), and further hexaflurate(D), metallic compound (E) and silicone hydride coupling agent with the functional group capable of reacting with the primary amino radical.

Owner:NIHON PARKERIZING

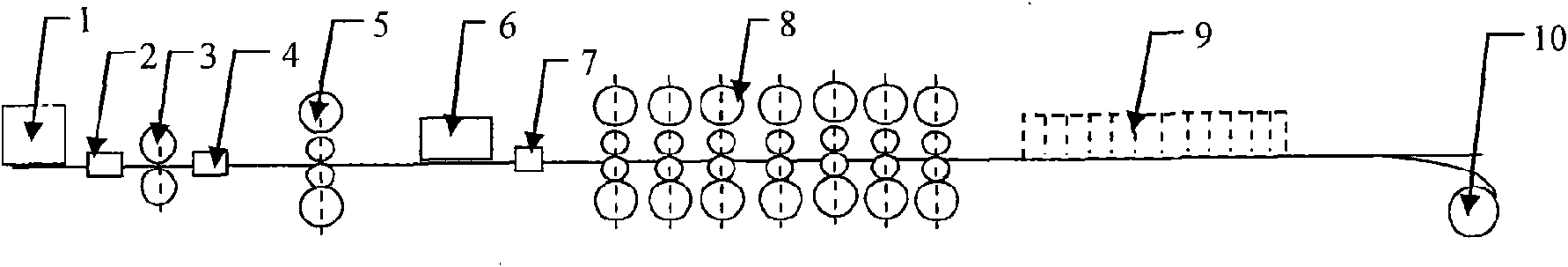

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

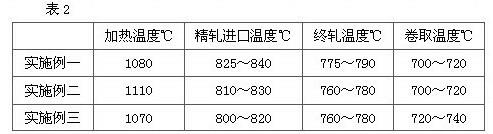

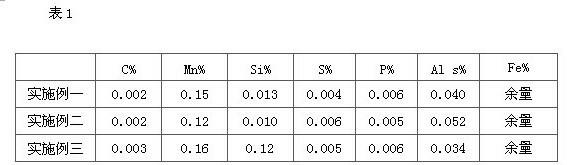

Method for rolling interstitial free steel ferrite on traditional hot rolling mills

ActiveCN101618396AImprove deep drawing performanceImprove organizational structureTemperature control deviceWork treatment devicesLaminar coolingHeating furnace

The invention relates to an IF steel rolling method, in particular to a method for rolling interstitial free steel ferrite on traditional hot rolling mills, which mainly solves the technical problem that finish rolling of the traditional IF steel austenite-region rolling is easy to fall into a two-phase region. The method for rolling interstitial free steel ferrite on traditional hot rolling mills comprises the steps of heating a slab through a heating furnace, performing rough rolling in a rough rolling mill, performing finish rolling in a finish rolling mill, performing laminar cooling and coiling. The method is characterized in that rough rolling is performed in an austenite region; the slab is cooled to the temperature at which an austenite structure is basically changed into a ferrite structure after rough rolling is over; finish rolling is performed in a ferrite region; the heating temperature of the slab is 1,130 + / - 20 DEG C; the inlet temperature of finish rolling is 850 + / - 20 DEG C; the final rolling temperature is 820 + / - 20 DEG C; the coiling temperature is 710 + / - 20 DEG C; and the thickness of an intermediate slab is 36 to 40 mm. The method mainly performs IF steel rolling on the traditional hot rolling mills.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

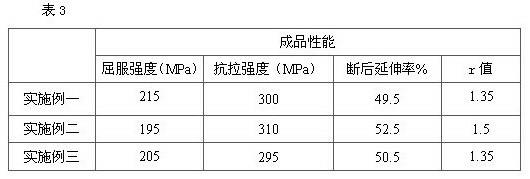

Processing method of low yield ratio high strength titanium coiled plate for heat exchanger

The invention provides a processing method of a low yield ratio high strength titanium coiled plate for a heat exchanger. The processing method of the titanium coiled plate comprises the following steps of: preparing a plate blank; rolling a hot coil; annealing the hot coil; performing surface treatment on the hot coil; cold rolling; degreasing; and annealing to obtain the low yield-ratio high titanium coiled plate for the heat exchanger. According to the processing method, the content of a titanium cast ingot is controlled, and the processing technology of a titanium tape is utilized, so that the tensile strength of a titanium plate is about 385+ / -15MPa, and the yield ratio is not greater than 70%; and with the improvement of the tensile strength of the titanium plate for the heat exchanger, the design thickness of the titanium plate can be reduced by more than 10%, and therefore, the titanium plate being 0.5 to 1.2mm in thickness can be prepared for the heat exchanger. Compared with the titanium coiled plate in the prior art, the titanium coiled plate processed by the method provided by the invention has high strength, low yield ratio and high deep drawing performance, and the production cost is also greatly decreased.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

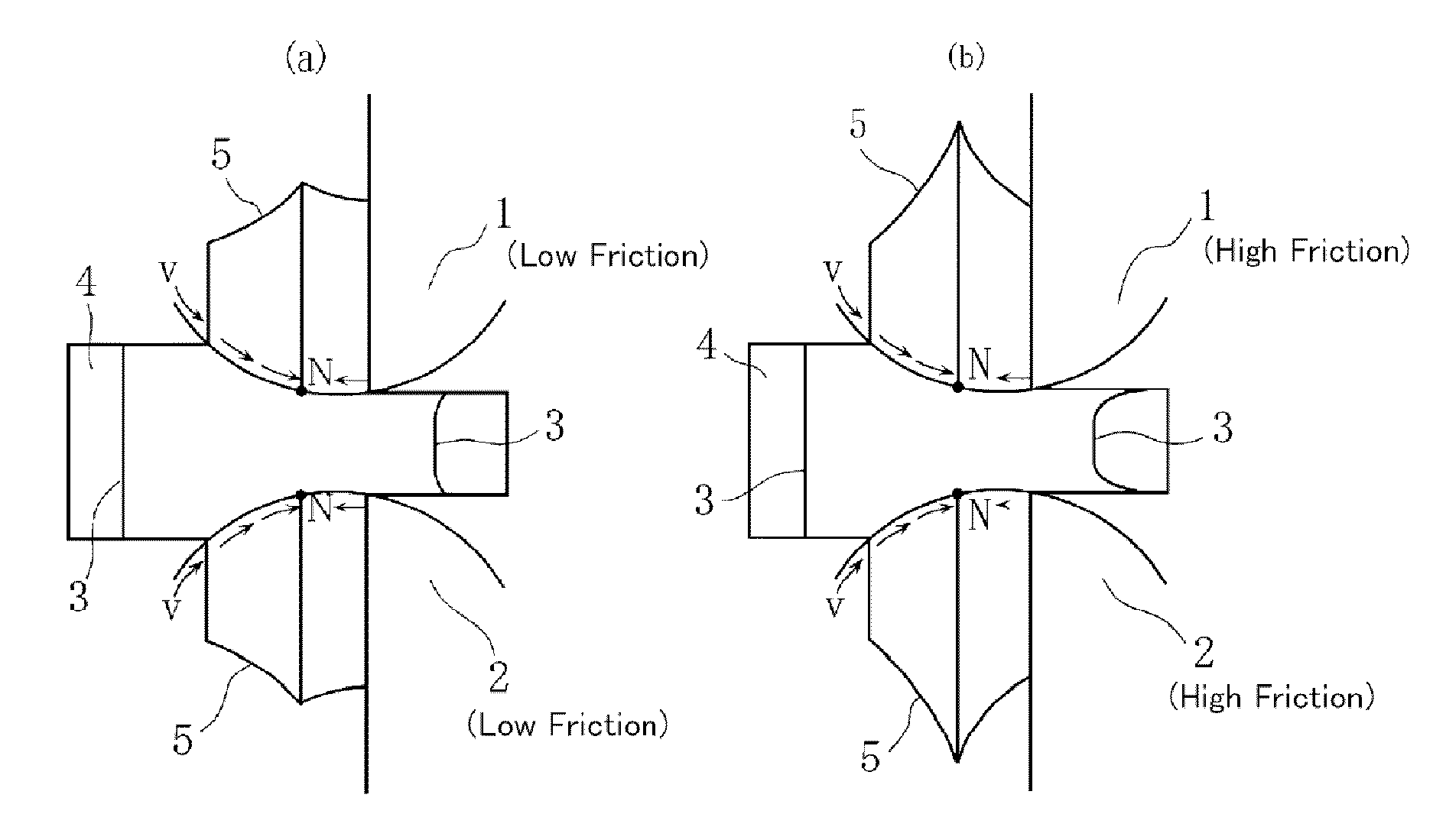

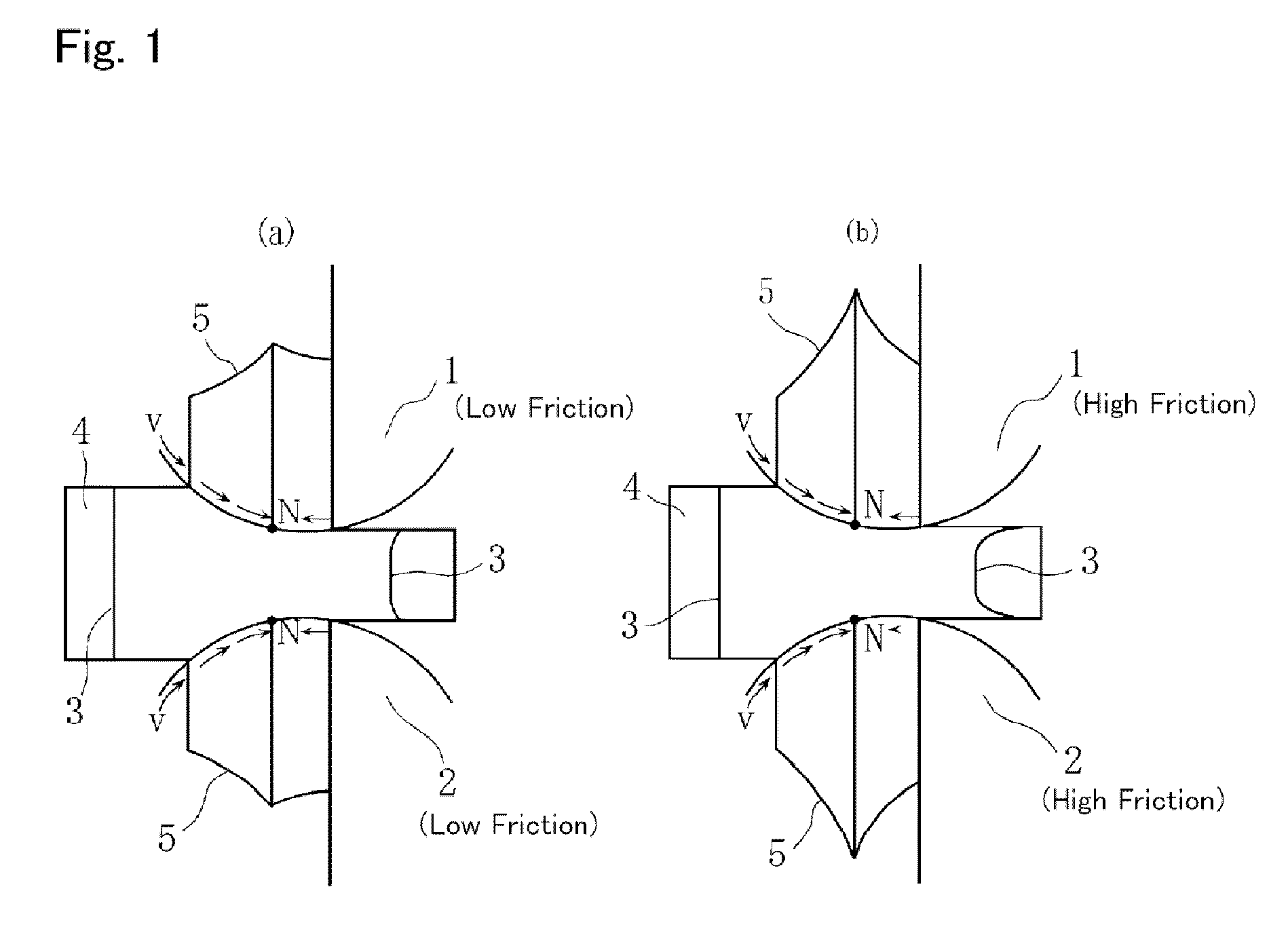

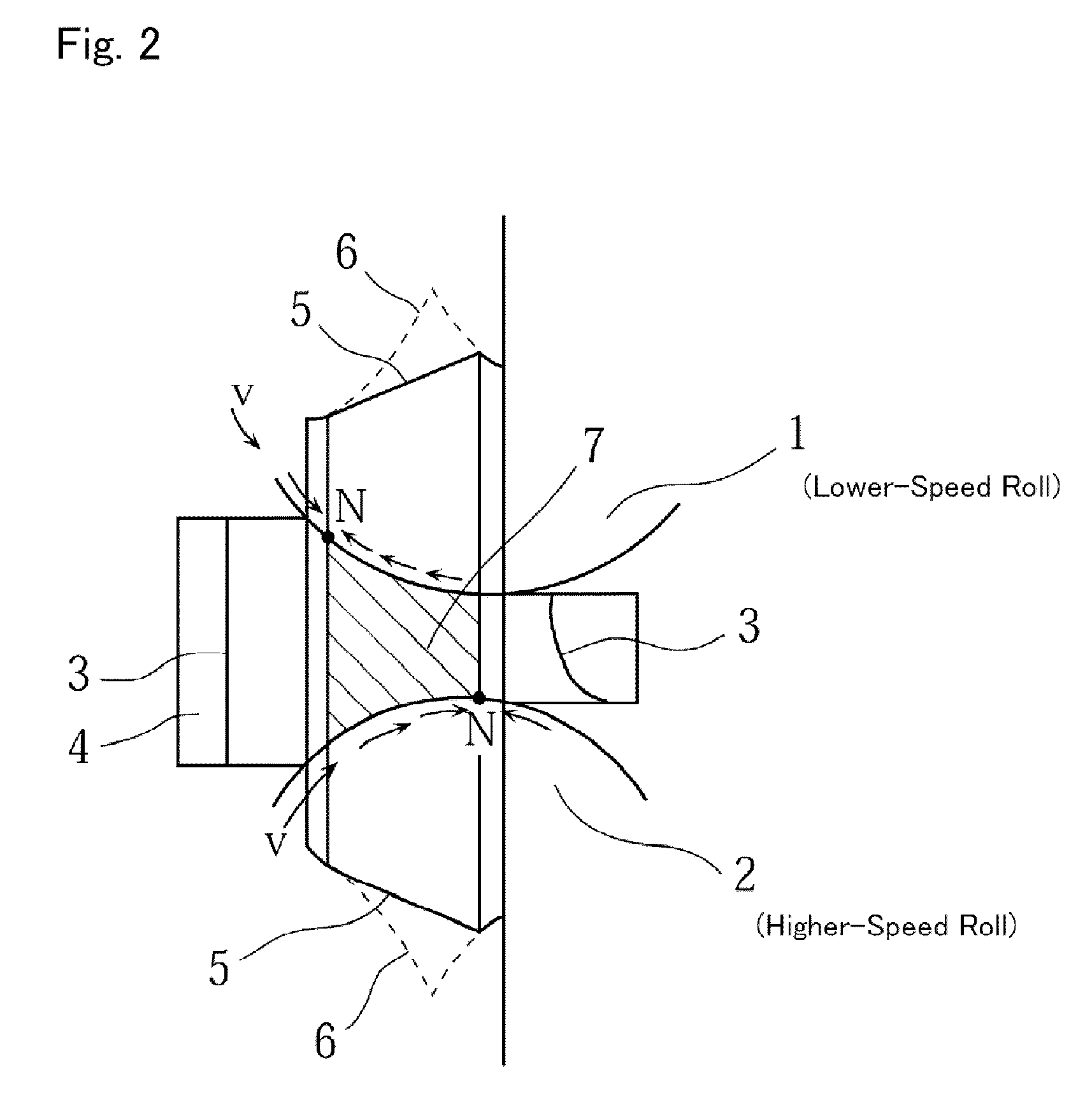

Metal sheet rolling method and rolled sheet manufactured by metal sheet rolling method

ActiveUS20100009212A1Low costImprove electromagnetic performanceLayered productsRollsMetal sheetLubrication

The present invention provides a metal sheet rolling method of rolling a metal sheet with a pair of rolls, as well as a rolled sheet manufactured by the metal sheet rolling method. In the metal sheet rolling method, respective interfaces between the pair of rolls and the metal sheet have mutually different frictions. Additionally at least one of the interfaces may be lubricated by a procedure other than lubrication by coating of a liquid lubricant agent. Alternatively at least one of the interfaces may be subjected to surface treatment by a procedure other than lubrication, or otherwise the pair of rolls may be made of mutually different materials.

Owner:NGK INSULATORS LTD

Micro-carbon aluminum-killed steel with low yield ratio and good deep drawing property and preparation method thereof

InactiveCN101798655AImprove deep drawing performanceTemperature control deviceMetal rolling arrangementsSheet steelYield ratio

The invention provides micro-carbon aluminum-killed steel with low yield ratio and good deep drawing property and a preparation method thereof, belonging to the technical field of automobile steel. The micro-carbon aluminum-killed steel is obtained by adding 0.001-0.008% of B on the basis of the components of the micro-carbon aluminum-killed steel and controlling the hot rolling and coiling temperature and the annealing temperature. The micro-carbon aluminum-killed steel has the following components in percentage by mass: 0.01-0.06% of C, not more than 0.5% of Si, not more than 0.4% of Mn, not more than 0.02% of P, not more than 0.02% of S, not more than 0.07% of Al, not more than 0.06% of N, 0.001-0.008% of B and the balance Fe and inevitable impurities. The element B in the steel is used for fixing N in the steel and is beneficial to obtaining coarse ferrite grains after annealing, thereby ensuring the annealed sheet steel to have low yield strength and high r value. The invention has the advantage of obtaining the micro-carbon aluminum-killed steel with yield strength being not more than 130MPa, yield ratio being not more than 0.39, r value being not less than 1.5 and good deep drawing property by hot rolling and low temperature coiling, cold rolling and continuous annealing.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum alloy strip applied to new energy power battery shells and preparation method thereof

The invention belongs to the field of preparation of aluminum alloy strips and particularly relates to an aluminum alloy strip applied to new energy power battery shells and a preparation method thereof. The aluminum alloy strip comprises the following components: 0.1-0.4wt% of Si, 0.4-0.7wt% of Fe, 0.06-0.14wt% of Cu, 1.0-1.2wt% of Mn, smaller than 0.05wt% of Mg, 0.01-0.03wt% of Ti and the balance of Al. Through the aluminum alloy strip, the components of the aluminum alloy strip are optimized on the basis of 3003 alloys; through reasonable distribution of homogenization heat treatment, a hot rolling process, an annealing process and a cold rolling process, the aluminum alloy strip can meet high deep drawing performance and can achieve effective laser welding with a cover plate. The preparation method of the aluminum alloy strip is economical and is easy to popularize.

Owner:CHINALCO RUIMIN

Aluminum alloy strip for mobile phone battery shell and manufacturing method thereof

The invention provides an aluminum alloy strip for a mobile phone battery shell and a manufacturing method thereof, relates to an alloy strip and a manufacturing method thereof, and solves the problems of low tensile strength, high elongation after breakage and high earing rate of a conventional 3003-H14 aluminum alloy strip applied to the mobile phone battery shell, and uneven grain structures of alloys prepared by the conventional manufacturing method. The aluminum alloy strip is made from Si, Fe, Cu, Mn, Mg, Zn, Ti and Al. The tensile strength of the aluminum alloy strip is between 190MPa and 210MPa, the elongation after breakage of the aluminum alloy strip is between 2.0 and 4.0 percent, and the earing rate of the aluminum alloy strip is between 3 and 4 percent. The manufacturing method comprises the following steps of: mixing the materials; melting, casting, homogenizing annealing, hot rolling, and cold rolling to obtain the aluminum alloy strip for the mobile phone battery shell. The aluminum alloy strip for the mobile phone battery shell can improve the strength of the mobile phone battery shell and reduce wall thickness at the same time so as to improve the capacity of the battery shell.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Extremely-thin steel sheets and method of producing the same

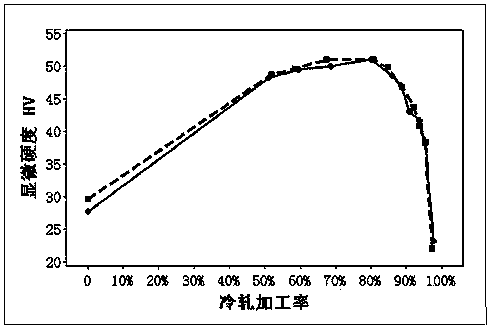

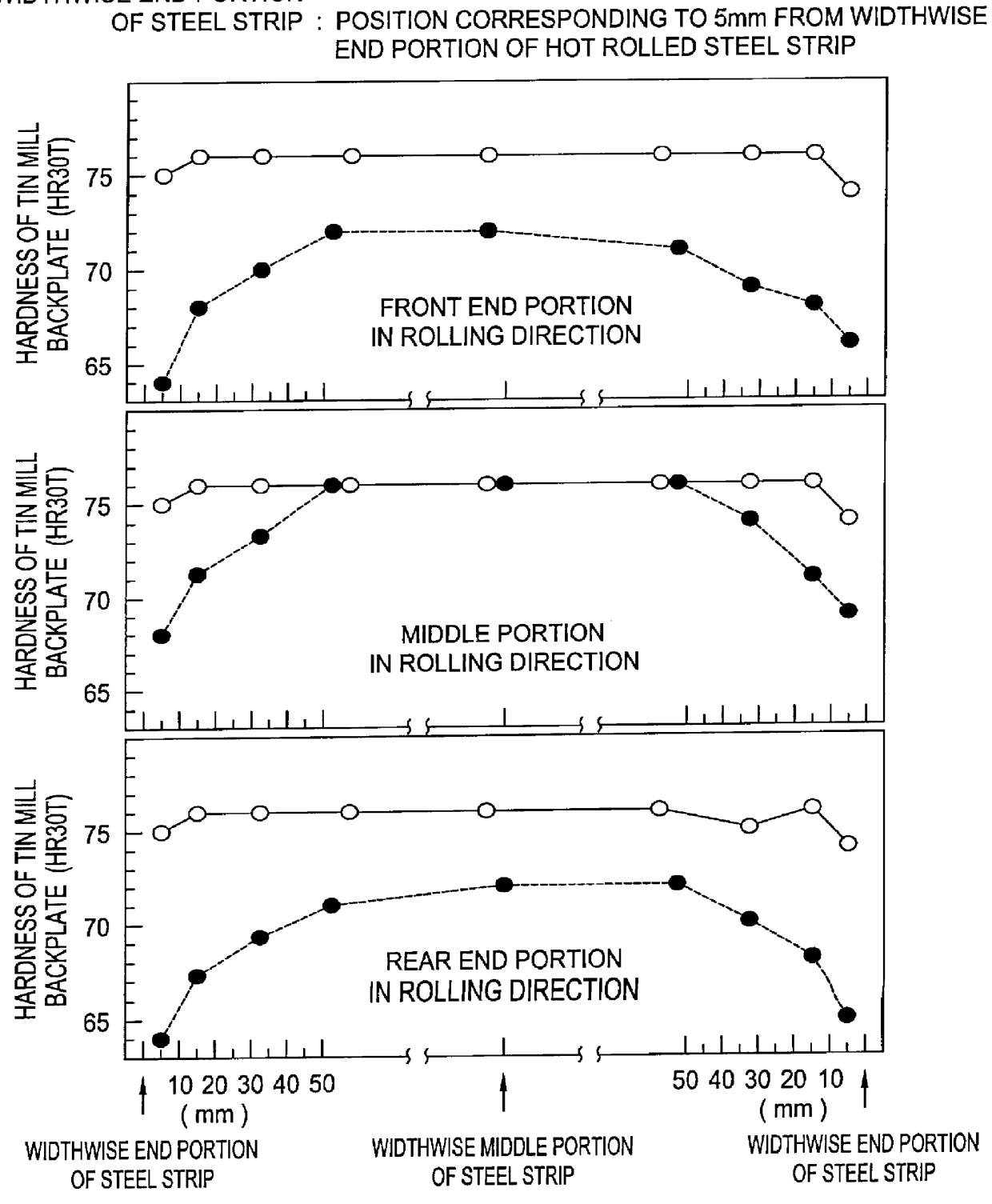

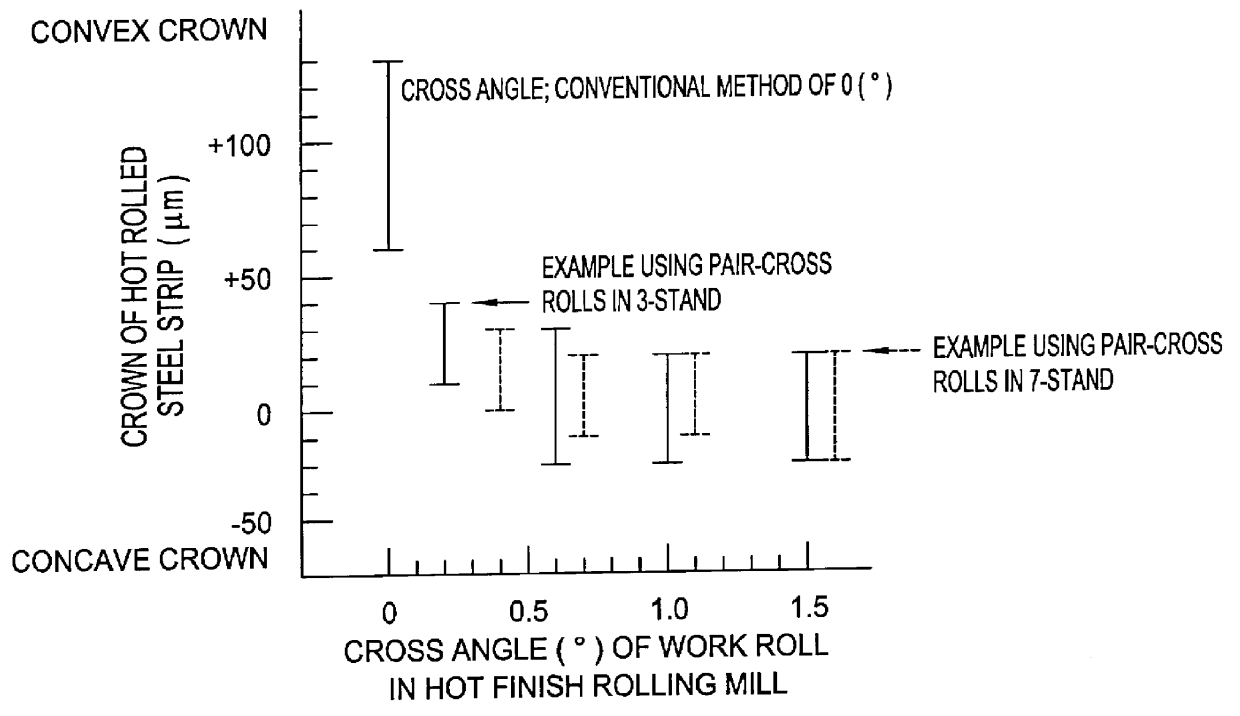

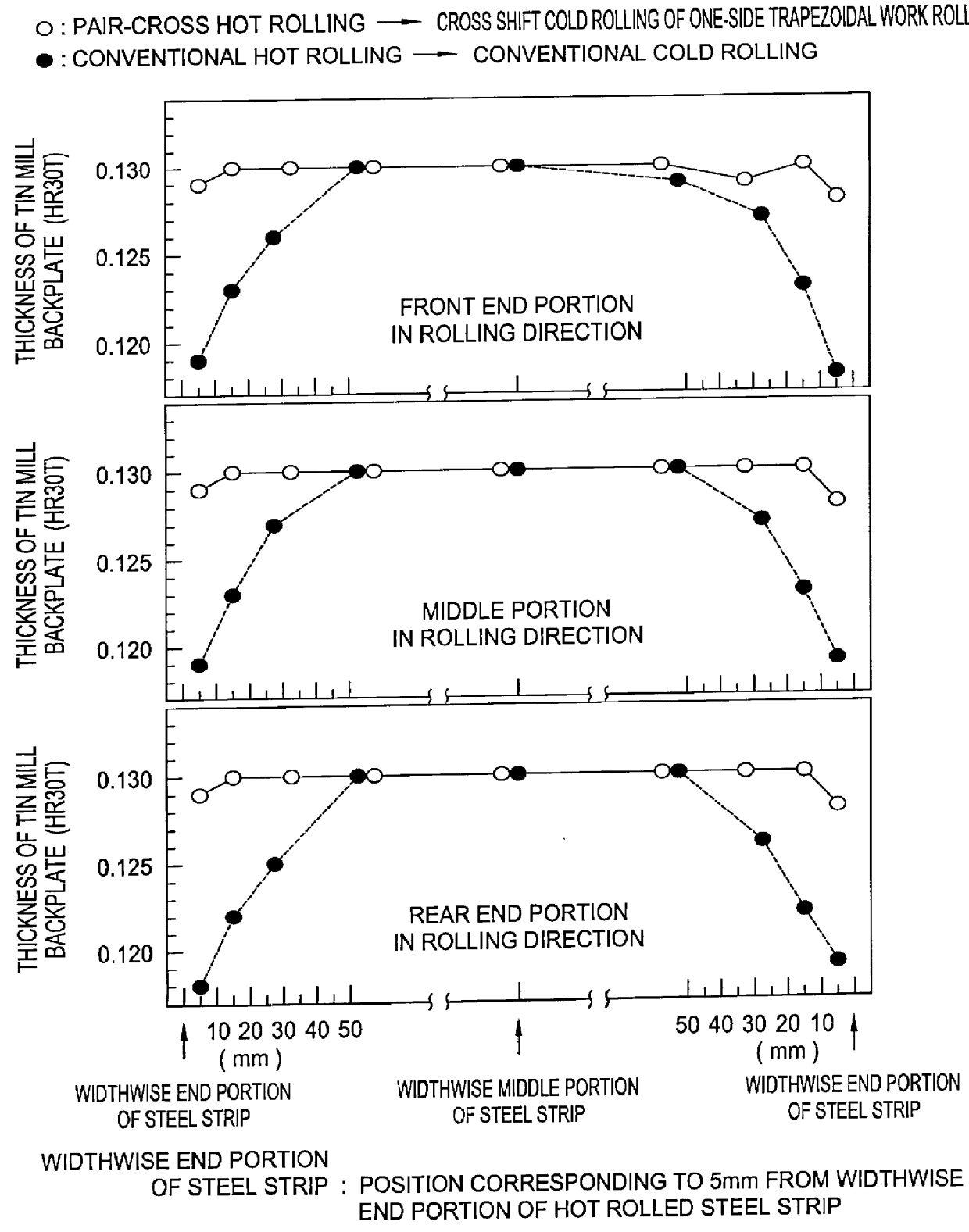

InactiveUS6042952AImprove workabilityImprove deep drawing performanceMetal rolling stand detailsFurnace typesSheet steelHardness

PCT No. PCT / JP97 / 00826 Sec. 371 Date Nov. 12, 1997 Sec. 102(e) Date Nov. 12, 1997 PCT Filed Mar. 14, 1997 PCT Pub. No. WO97 / 33706 PCT Pub. Date Sep. 18, 1997A steel slab is rough-rolled into a sheet bar and butt-joined onto a preceding sheet bar and a widthwise end portion of the sheet bar is heated by means of an edge heater and then subjected to a continuous finish rolling through pair-cross rolls rolling on at least 3 stands to provide a hot rolled steel strip having a width of not less than 950 mm, a thickness of 0.5-2 mm and a crown within + / -40 mu m, and the hot rolled steel strip is subjected to cold rolling, continuous annealing, temper rolling and, if necessary, plating treatment on the surface of the cold rolled steel strip, whereby there is obtained a steel sheet having an average thickness of not more than 0.20 mm and a width of not less than 950 mm, a thickness variation quantity in a widthwise direction is within + / -4% of the average thickness in a region corresponding to not less than 95% of the width of the steel sheet as cold rolled and a hardness (HR30T) variation in the widthwise direction is within + / -3 of an average hardness.

Owner:KAWASAKI STEEL CORP

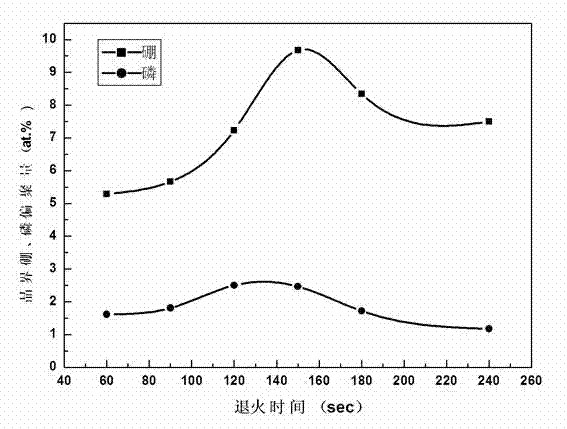

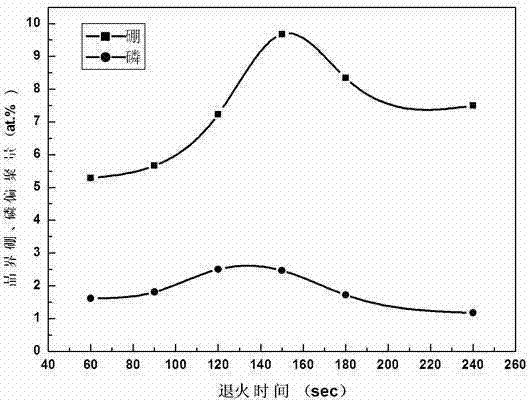

Steel containing P and used for intermediate frequency (IF) automotive panel and production method thereof

InactiveCN102644023AHigh strengthExcellent deep drawing performanceIntermediate frequencySurface plate

The invention relates to a steel containing P and used for an intermediate frequency (IF) automotive panel and a production method thereof. The steel comprises the following components by weight percent: less than or equal to 0.0048% of C, 0.04-0.06% of Si, 0.28-0.35% of Mn, 0.045-0.096% of P, 0.04-0.065% of Ti, 0.02-0.025% of Al, 0.0023-0.007% of B, less than or equal to 0.015% of S, less than or equal to 0.003% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and casting into a blank; heating and heat preserving the casting blank; rough rolling, finish rolling, reeling up, conventionally pickling, cold rolling and continuously annealing for later use. After a trace of B is added in the steel, a competitive grain-boundary segregation rule of B and P is utilized and a continuous annealing technological parameter is controlled, thereby the problem of secondary cold machining brittleness caused by P grain-boundary segregation is lowered, the value r achieves 1.9 and over 1.9 and the forming property is better and more stable.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Preparation method of copper-aluminum composite plate strip

The invention discloses a preparation method of a copper-aluminum composite plate strip. The preparation method comprises the following steps that a copper plate and an aluminum strip with the sizes conforming to the requirements are selected according to the requirement of a finished product, wherein the copper plate serves as a base plate material, and the aluminum strip serves as an embedded material; homogenizing annealing treatment is conducted on the copper plate, wherein the annealing temperature is 320-400 DEG C, and the heat preservation time is 0.5-3 hours; homogenizing annealing treatment is conducted on the aluminum strip, wherein the annealing temperature is 180-220 DEG C, and the heat preservation time is 1-3 hours, and water quenching is conducted after annealing treatment is completed; surface pre-treatment is conducted on the copper plate and the aluminum strip, grease, surface oxidated scale and other impurities are removed, and surface roughness polishing is conducted on the copper plate and the aluminum strip; the aluminum strip is embedded into an embedding groove of the copper plate, and then multi-pass cold rolling cladding treatment is conducted; high temperature thermal treatment is conducted on the copper-aluminum composite plate which is subjected to cold rolling cladding under the atmosphere protection, and the needed finished product is obtained; and through early thermal treatment, surface pre-treatment, the multi-pass cold rolling and thermal treatment annealing technology, the copper-aluminum composite plate with an interface transition structural layer excellent in property is accordingly obtained.

Owner:湖南科罗德新材料有限公司

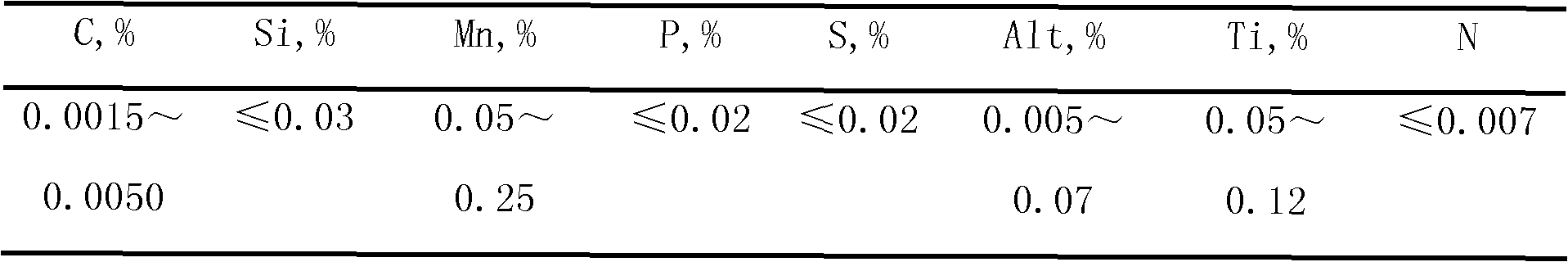

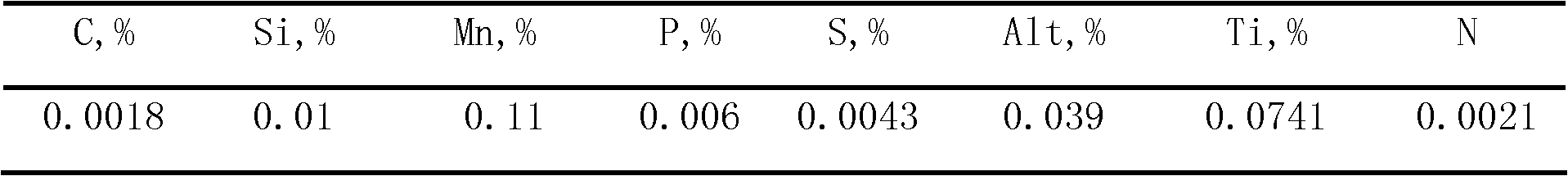

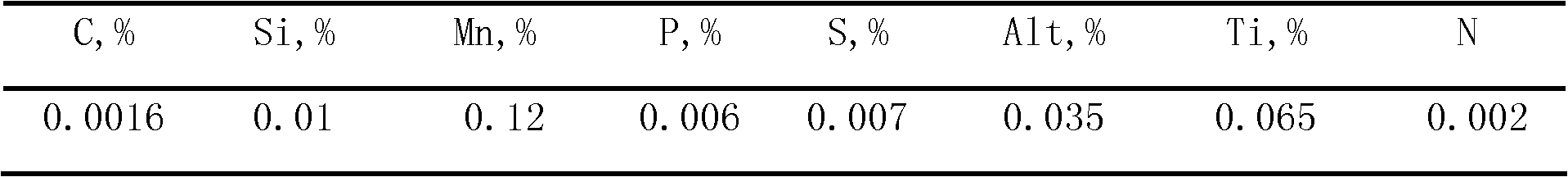

Method for preventing surface of Ti-IF steel from forming crack defects

InactiveCN102154586ANo forming defectsMeet the use requirementsRoll mill control devicesMetal rolling arrangementsChemical compositionHome appliance

The invention relates to a method for preventing the surface of Ti-IF steel from forming crack defects, which belongs to the technical field of thin plate production. The method comprises the following Ti-IF steel production processes of: smelting, continuously casting, heating plate blanks, performing hot tandem rolling, reeling, performing acid tandem rolling, continuously annealing, leveling, and reeling to obtain finished products. The Ti-IF steel comprises the following components in percentage by weight: 0.0015 to 0.0050 percent of C, less than or equal to 0.03 percent of Si, 0.05 to 0.25 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S, 0.005 to 0.07 percent of Alt, 0.05 to 0.12 percent of Ti, less than or equal to 0.007 percent of N and the balance of Fe. In the rolling process, the plate blank heating temperature is between 1,200 and 1,300 DEG C; the final rolling temperature is between 890 and 920 DEG C; the reeling temperature is between 640 and 700 DEG C; the acid rolling down rate is between 70 and 80 percent; and the annealing temperature is between 760 and 850 DEG C. The invention has the advantages that: plates do not have the crack defects after being stamped and meet the using requirements of automobile shell plates and O5 plates for home appliance shell plates by rationally matching chemical components and a hot rolling process on the premise of high deep drawability; and the method has great economic value.

Owner:SHOUGANG CORPORATION

Interstitial free (IF) hot rolled strip and manufacturing method thereof

ActiveCN101608285AReduce intensityImprove plasticityManufacturing convertersChemical compositionLiquid iron

The invention provides an interstitial free hot rolled strip and a manufacturing method thereof. The mass percents of the chemical constituents of the strip are as follows: 0<C<=0.005, 0<P<=0.018, 0<S<=0.015, 0<N<=0.004, 0<Si<=0.03, Mn 0. 10-0.20, Al 0.02-0.06, 0<Ti<=0.070, 0<Nb<=0.020, 0<Cr<=0.05, 0<Ni<=0.07, 0<Cu<=0.07, 0<Mo<=0.020 and the balance of Fe and other inevitable impurities. The manufacturing method comprises the steps of preparing continuous castings according to the constituent requirement and processing the continuous castings into the hot rolled strip. The manufacturing method of the strip comprises the following steps: A. preparing continuous castings to be desulfurized by liquid iron pretreatment, smelted in a top-bottom combined blowing converter, RH refined and continuously cast by heavy slabs; B. adopting the traditional hot continuous rolling process to process the continuous castings into the hot rolled strip; the finishing temperature is 880-930 DEG C; the hot rolled strip is quickly water-cooled to the temperature of 680-750 DEG C to be reeled up and then is cooled to the room temperature. The strip manufactured by the method has low strength, high plasticity and good processing technic.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Steel for seamless tin and manufacturing method thereof

ActiveCN101275196AImprove deep drawing performanceEasy to processRoll mill control devicesHeat treatment process controlContinuous annealingAustenite

The invention relates to steel for two piece can and a manufacturing method thereof, the proportion by weight percent of the steel is that: 0.001%<=C<=0.003%; Si<=0.02%, 0.1%<=Mn<=1.0%, P<=0.015%, S<=0.020%, Al<=0.1%, N<=0.005%, the proportion also comprises at least one of four elements: Nb<=0.01%, Ti<=0.01%, Cr<=0.02%, Ni<=0.02%, the rests are Fe and unavoidable impurities. The manufacturing method comprises the steps of: 1) smelting according to above ingredients to cast into the billet; 2) heating and rolling the billet in the range from 1100 to 1250 DEG C, finally rolling the billet in single phase austenite area at the temperature over Ar<3>, the thickness of hot rolling plate is less than 3mm, the coiling temperature is 500 to 700 DEG C; 3) cool-rolling the billet with deflection of 80-95% after pickling; 4) performing recrystallization annealing to the billet below the 730 DEG C in the continuous annealing furnace; 5) secondarily cool-rolling with the deflection of 2-10% to obtain the product having the thickness less than 0.24mm. The steel of the invention includes outstanding processing performance and deep draw performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling surface appearance of hot-dip galvanized ultra-deep drawing steel for automobile panel

ActiveCN110527921AImprove surface topographyGuaranteed cooling rateHot-dipping/immersion processesSurface roughnessProcess conditions

The invention discloses a method for controlling the surface appearance of hot-dip galvanized ultra-deep drawing steel for an automobile panel. The hot-dip galvanized steel strip comprises the following chemical components in percentage by mass: C is smaller than or equal to 0.0025%, Si is smaller than or equal to 0.020%, Mn is 0.10-0.15%, P is smaller than or equal to 0.012%, S is smaller than orequal to 0.010%, Als is 0.020-0.050%, Ti is 0.055-0.080%, N is smaller than or equal to 0.0040%, and the balance Fe and inevitable impurities. The manufacturing method comprises the steps of smelting, continuous casting, hot rolling, acid continuous rolling, hot galvanizing and the like. By controlling the production process, especially the process conditions of the cold continuous rolling stageand the hot galvanizing stage, the surface roughness and waviness of the hot galvanizing ultra-deep drawing steel can meet the requirements of automobile factories besides good tensile property.

Owner:SD STEEL RIZHAO CO LTD

Aluminum alloy strip material for capacitor outer shell and preparation method of aluminum alloy strip material

The invention belongs to the field of aluminum alloy strip materials and particularly relates to an aluminum alloy strip material for a capacitor outer shell and a preparation method of the aluminum alloy strip material. The components of an aluminum alloy comprise, by weight, 0.2-0.3% of Si, 0.3-0.6% of Fe, 0.06-0.20% of Cu, 1.05-1.35% of Mn, smaller than 0.05% of Mg, 0.01-0.03% of Ti and the balance Al, wherein Fe / Si=2-4, and Fe+Mn<1.95%. After burdening is conducted, aluminum alloy slab ingots are formed through semi-continuous casting, and after heat treatment, hot rolling and cold rolling techniques are conducted, the aluminum alloy strip material with the tensile strength being 155-165 MPa, the yield strength being 145-165 MPa and the earing ratio being smaller than 3% is obtained. According to the aluminum alloy strip material, the good deep stamping property can be met, and good laser welding can be achieved.

Owner:CHINALCO RUIMIN

High strength steel sheet excellent in deep drawing characteristics and method for production thereof

InactiveCN1833042AImprove deep drawing performanceFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention provides a high-strength steel sheet useful for applications to automobile steel sheets and the like and having excellent deep drawability, a tensile strength (TS) of as high as 440 MPa or more, and a high r value (average r value 1.2), and a process for producing the steel sheet. The steel sheet has a composition containing, by % by mass, 0.010 to 0.050% of C, 1.0% or less of Si, 1.0 to 3.0% of Mn, 0.005 to 0.1% of P, 0.01% or less of S, 0.005 to 0.5% of A1, 0.01% or less of N, and 0.01 to 0.3% of Nb, the Nb and C contents in steel satisfying the relation, (Nb / 93) / (C / 12) = 0.2 to 0.7, and the balance substantially including Fe and inevitable impurities. The steel microstructure contains a ferrite phase and a martensite phase at area ratios of 50% or more and 1% or more, respectively, and the average r value is 1.2 or more.

Owner:JFE STEEL CORP

High strength galvanized steel sheet having excellent deep drawability and stretch flangeability and method for manufacturing the same

ActiveUS20130292010A1Improve deep drawing performanceHigh R-valueHot-dipping/immersion processesFurnace typesMartensiteMaterials science

A high-strength galvanized steel sheet contains C: 0.010% or more and 0.06% or less, Si: more than 0.5% and 1.5% or less, Mn: 1.0% or more and 3.0% or less, P: 0.005% or more and 0.1% or less, S: 0.01% or less, sol.Al: 0.005% or more and 0.5% or less, N: 0.01% or less, Nb: 0.010% or more and 0.090% or less, and Ti: 0.015% or more and 0.15% or less, on a mass percent basis. The Nb and C contents of the steel satisfy the relation of (Nb / 93) / (C / 12)<0.20. C* satisfies 0.005≦C*≦0.025. Ferrite constitutes 70% by area ratio or more of the steel sheet. Martensite constitutes 3% by area ratio or more of the steel sheet. C*=C−(12 / 93)Nb−(12 / 48){Ti−(48 / 14)N}, wherein C, Nb, Ti, and N denote the C, Nb, Ti, and N contents of the steel.

Owner:JFE STEEL CORP

Production method for ultra-thin cold-rolled enamelled steel strips

ActiveCN105689392AMeet quality requirementsImprove deep drawing performanceWork cleaning devicesMetal rolling arrangementsBlack spotHydrogen

The invention discloses a production method for ultra-thin cold-rolled enamelled steel strips. The production method is characterized in that the ultra-thin cold-rolled enamelled steel strips have thicknesses of 0.18-0.20mm, and are obtained through the steps of carrying out hot-rolling production for cold-rolled materials, chlorohydric acid pickling, primary cold-rolling, primary intermediate annealing, and secondary cold-rolling to prepare ultra-thin cold and hard steel strips, and then carrying out smoothing and texturing, rewinding and tension losing, secondary intermediate annealing, and strip shape straightening. According to the method, the products have excellent deep drawing properties, and have no fish-scaling phenomenon, and moreover, with the adoption of a 950mm single-stand six-roll reversible cold-rolling mill, single-stand smoothing and texturing, severe-convection full-hydrogen bright bell-type annealing furnace annealing, the equipment is simplified, and the products achieve high-accuracy and ultra-thin requirements; the surfaces are smooth, and free from bonding, chromatic aberration, black spots, dots, oil stain and other defects; and the production method achieves the quality requirements of ultra-thin deep-drawn cold-rolled enamelled steel strips, is suitable for the fields of kitchen sanitary ware and ovens, water heater liners, decoration panels and the like, and has a broad market prospect.

Owner:山东泰山轧钢有限公司

IF isotropic steel with stamping forming improved and manufacturing method thereof

The invention discloses IF isotropic steel with stamping forming improved and a manufacturing method of the IF isotropic steel. The IF isotropic steel is composed of, by weight percent, 0.0012% to 0.0026% of C, not larger than 0.026% of Si, 0.28% to 0.52% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, 0.042% to 0.082% of Al, 0.046% to 0.066% of Ti, not larger than 0.0030% of N and the balance Fe and inevitable impurities. According to the IF isotropic steel, in the subsequent hot rolling, cold rolling, continuous annealing, flattening and bridging production processes, the rolling temperature is controlled to range from 580 DEG C to 620 DEG C, the cold rolling reduction rate is controlled to range from 85% to 95%, the annealing temperature is controlled to range from 708DEG C to 742 DEG C, the flattening ductility is controlled to range from 1.0% to 2.0%, and the bridging ductility is controlled to range from 0.03% to 0.10%; and according to the obtained IF isotropicsteel, the surface roughness Ra ranges from 0.36 micrometer to 0.56 micrometer, the peak concurrent Pc is larger than or equal to 126, the hardness ranges from 95 HV to 110 HV, the plastic strain ratio r90 value is larger than or equal to 1.8, the work-hardening exponent n90 value is larger than or equal to 0.18, and the delta r value is smaller than or equal to 0.20. The beneficial effect that when a round component is deeply stamped, no earing or galling defect is generated is achieved.

Owner:新余钢铁股份有限公司

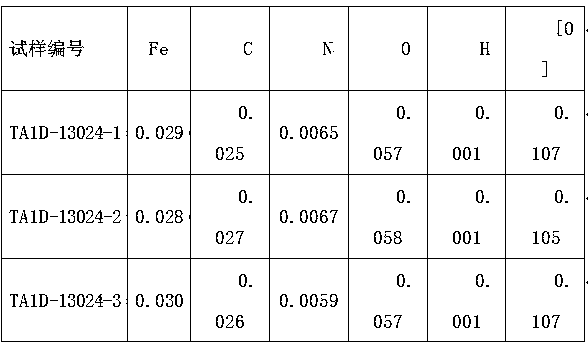

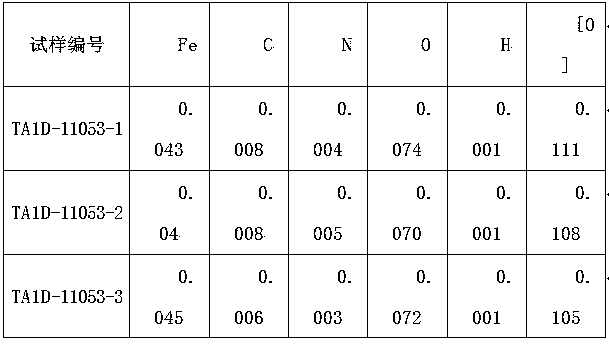

Preparation method of titanium plate for deep drawing

Disclosed is a preparation method of a titanium plate for deep drawing. Titanium sponge which is not lower than the 0A level and meets the conditions that the O content is smaller than or equal to 0.05%, the N content is smaller than or equal to 0.006% and the Fe content is smaller than or equal to 0.05% is used as a raw material and subjected to smelting casting and forging, and two or more timesof drawing-out and / or upsetting are carried out in the forging process, so that a plate blank with a good structure and tiny texture is prepared; and then the plate blank is subjected to hot rolling,cold rolling and rolling in changed directions in combination with the steps of annealing and subsequent processing, so that the pure titanium plate with proper crystalline grains, qualified performance and a high Erichsen value is obtained. Through the method, the pure titanium plate can be made to be short in production procedure, high in efficiency and good in deep drawing performance.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Sheet enamel steel for subway decoration and production method thereof

The invention discloses sheet enamel steel for subway decoration and a production method thereof. The thickness of the sheet enamel steel is 1.0 to 2.0mm, wherein the sheet enamel steel comprises the following chemical components in percentage by weight: 0.001 to 0.003 percent of C, less than or equal to 0.10 percent of Si, 0.05 to 0.10 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.01 to 0.02 percent of Als, 0.20 to 0.25 percent of Ti, 0.010 to 0.020 percent of N and the balance of Fe and inevitable impurities. The production method of the sheet enamel steel for the subway decoration comprises the following steps: carrying out desulfurization on molten iron, combined blowing on the top and bottom of a converter, continuously casting plate blanks, soaking through a soaking pit furnace, hot continuous rolling, controlled rolling and controlled cooling, reeling, washing with acid, detecting quality, processing and forming, shot blasting, washing with alkaline, spraying enamel and firing enamel. Through the hot rolled enamel steel, the excellent cooperation of high strength and high deep-drawing property is achieved; the enamel steel is liable to form and weld, low in production cost, high in efficiency and wide in application prospect.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Corrosion resistant cupronickel alloy material for plate heat exchanger and processing technique thereof

ActiveCN101100715AMeet the requirements of corrosion resistanceLow costPlate heat exchangerCupronickel

A corrosion-proof German silver band for plate heat exchanger and its production are both disclosed herewith. It contains (wt%): Ni 9.0-11.0, Mn 0.5-1.0, Fe 1.0-1.8, Ce 0.05-0.2, and waste Cu alloy with Cu balanced, and with impurity not more than 0.7. It is produced by: weighing, smelting, casting, hot rolling, end-surface milling, primary rolling, inter-annealing, cold rolling, inter-annealing, edge cutting, pre-rolling, inter-rolling, fine rolling, final annealing, surface treating, cutting, and packing. It is of size (0.4-8.5mm)X(300-1000mm)X(500-3000mm), performance of Rm not less than 320MPa, A11.3 not less than 30%, Hv1 not less than 85, grain 0.015-0.045mm, and Ra larger than 0.2um without scratches, and can meet demands of PHE and bactericidal washing machine.

Owner:中铝洛阳铜加工有限公司

Corrosion resistant brass alloy material for plate heat exchanger and processing technique thereof

A corrosion-proof brass band for plate heat exchanger and its production are both disclosed herewith. It contains (wt%): Cn 76-79, Al 1.0-3.5, Ni 0.3-1.5, B 0.002-0.015, As 0.01-0.1, Ce 0.05-0.2, and balanced with Zn, and with impurity not more than 0.3. It is produced by: weighing, smelting, casting, hot rolling, end-surface milling, primary rolling, inter-annealing, cold rolling, inter-annealing, edge cutting, pre-rolling, inter-rolling, fine rolling, final annealing, surface treating, cutting, and packing. It is of size (0.4-8.5mm)X(300-1000mm)X(500-3000mm), performance of Rm not less than 410MPa, A11.3 not less than 40%, Hv1 not less than 90, grain 0.010-0.030mm, and Ra larger than 0.2um without scratches.

Owner:中铝洛阳铜加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com