Patents

Literature

80results about How to "Improve scratching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water surface treatment agent for precoating metal material, furface treated metal material and precoating metallic material

ActiveCN101560655AGood storage stabilityImprove scratching effectLiquid surface applicatorsAnti-corrosive paintsMetallic materialsMaterials science

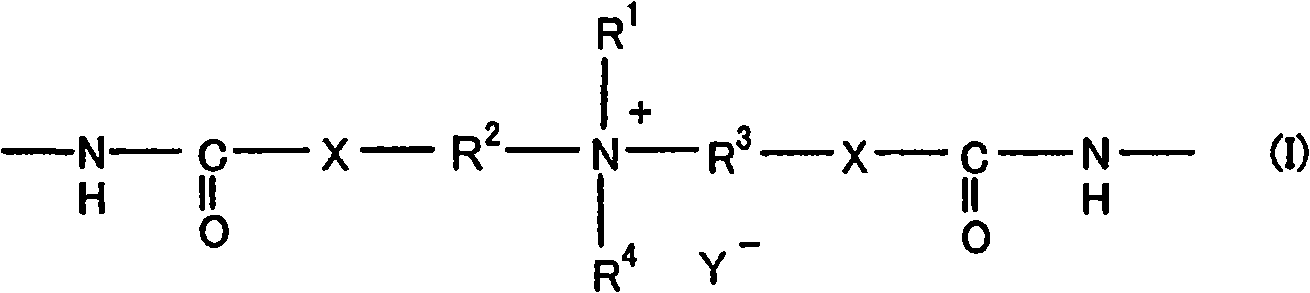

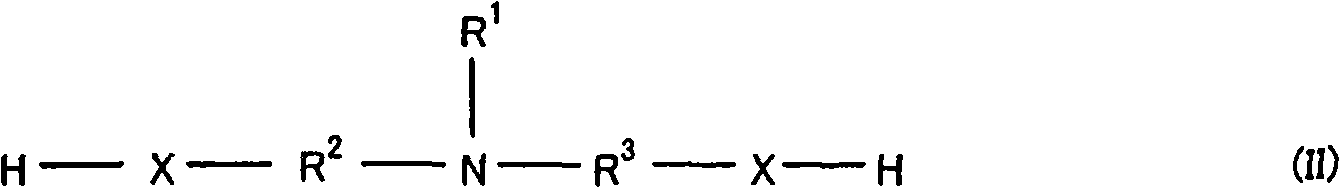

The invention provides an aqueous surface processing agent for a precoating metallic material, a furface treated metal material and a precoating metallic material. A non-chromium aqueous surface processing agent can be used for forming a film with good corrosion resistance(the corrosion resistance of the film cut part and end plane), one-time coating adaptation(at the normal temperature and in thecold condition), second coating adaptation, effective coin scrapeing resistance, deep drawing quality, alkali stability, acid-resistance and wet fastness, as well as storage stability. The aqueous surface processing agent is used as the substrate treating agent of the precoating metallic material, and comprises, at the specific ratio, silicone hydride coupling agent with primary amino radical (A), cationoid polyurethane resin with the specific structure and the class transition temperature of 0 to 100 DEG C (B), specific non-ionic or cationoid polycarbodiimide compounds (C), and further hexaflurate(D), metallic compound (E) and silicone hydride coupling agent with the functional group capable of reacting with the primary amino radical.

Owner:NIHON PARKERIZING

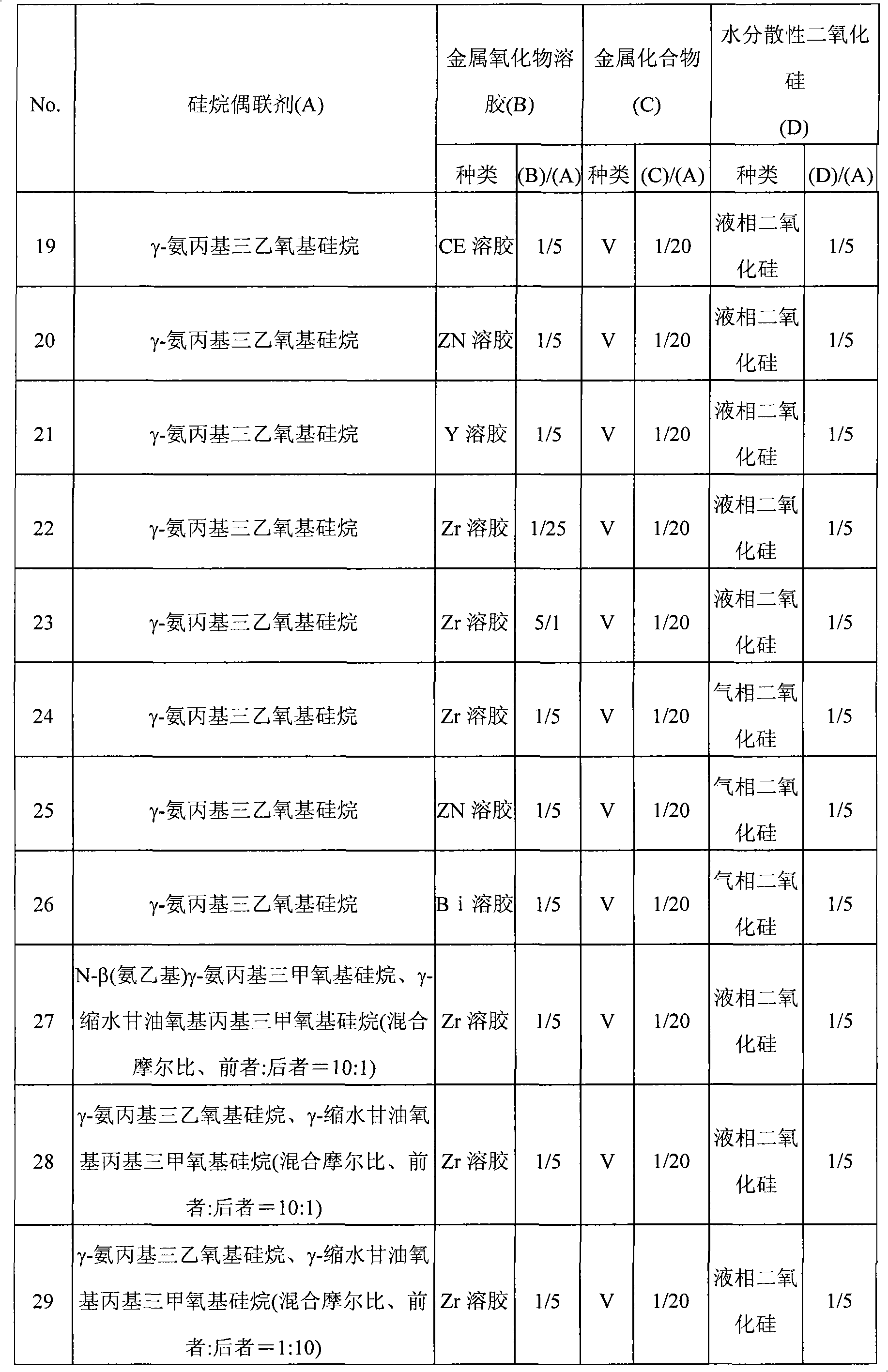

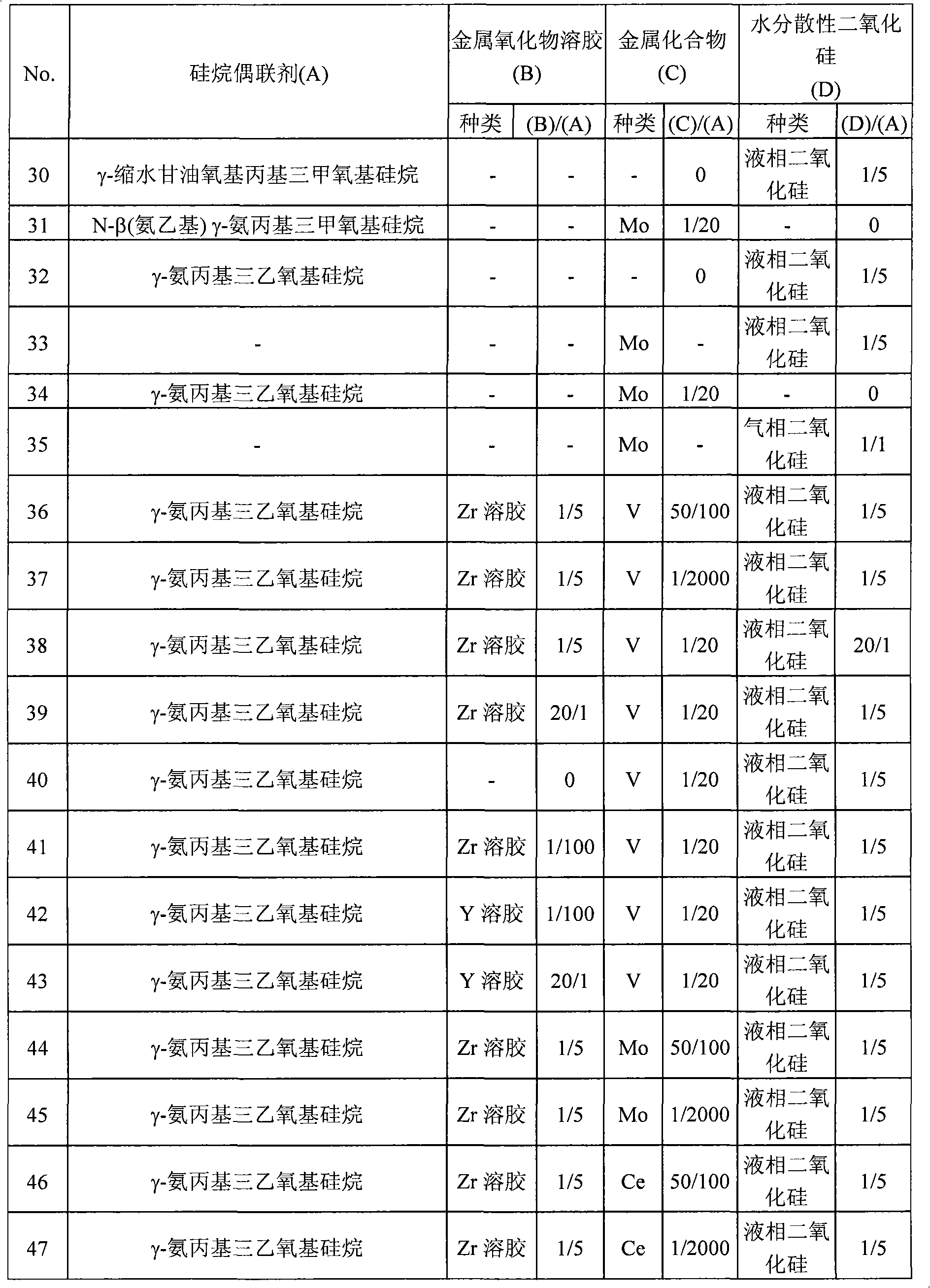

Aqueous surface treatment for environment-friendly precoated metal materials, surface-treated metal materials, and environment-friendly precoated metal materials

InactiveCN101542018AImprove moisture resistanceGood chemical resistanceAnti-corrosive paintsMetallic material coating processesWater dispersibleMetallic materials

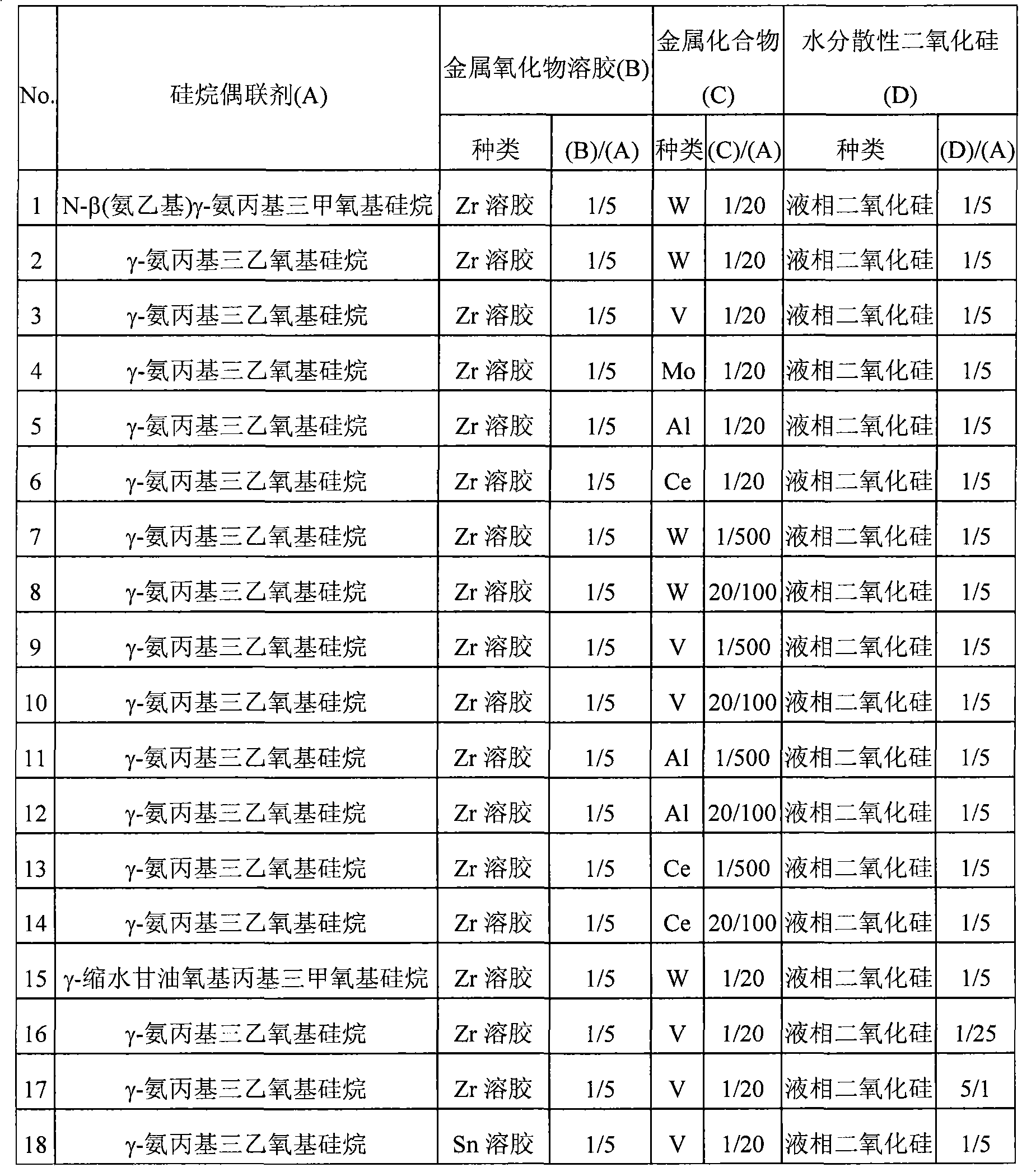

The invention provides a chromium-free aqueous surface treatment useful as primer in producing precoated metal materials which are excellent in corrosion resistance, tight adhesion of coat (primary adhesiveness and secondary adhesiveness of coat in T-bend test), and coin scratch resistance. An aqueous surface treatment for environment-friendly precoated metal materials which contains (A) a silane coupling agent and / or a condensate of a silane coupling agent, (B) a metal oxide sol, (C) a metal compound, and (D) water-dispersible silica, wherein the metal compound (C) is at least one member selected from among compounds of V, W, Mo, Al, Sn, Nb, Hf, Y, Ho, Bi, La, Ce and Zn, and the (B) / (A) mass ratio is 1 / 50 to 10 / 1, the (C) / (A) mass ratio is 1 / 1000 to 4 / 10, and the (D) / (A) mass ratio is 1 / 50 to 10 / 1; and metal materials and chromium-free precoated metal materials, which have films made from the surface treatment.

Owner:NIHON PARKERIZING

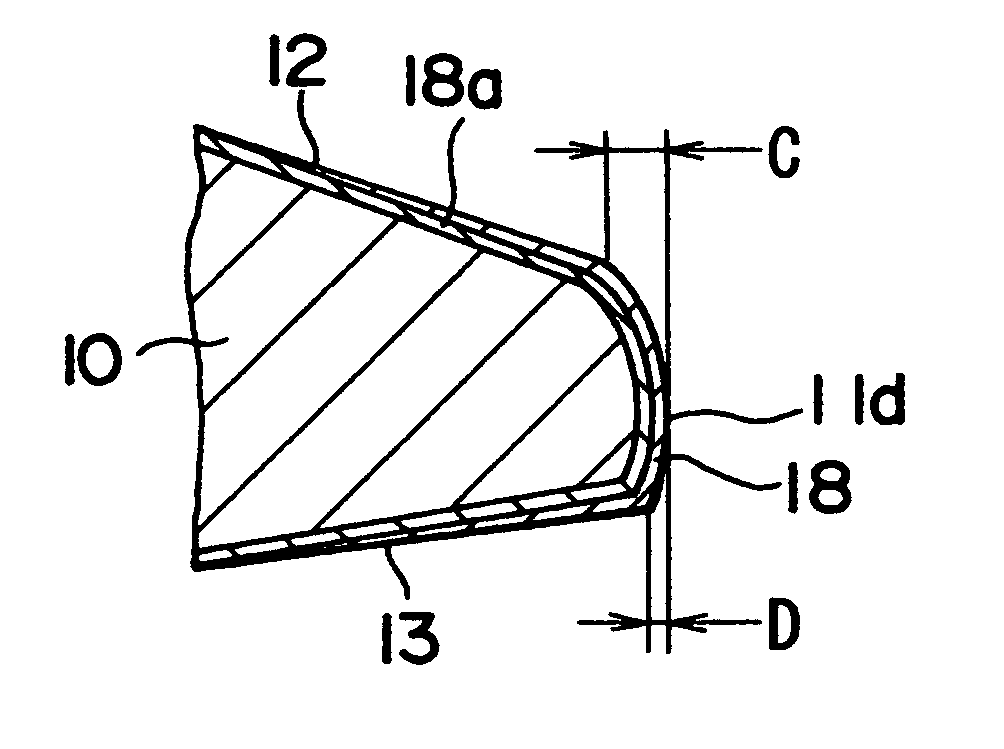

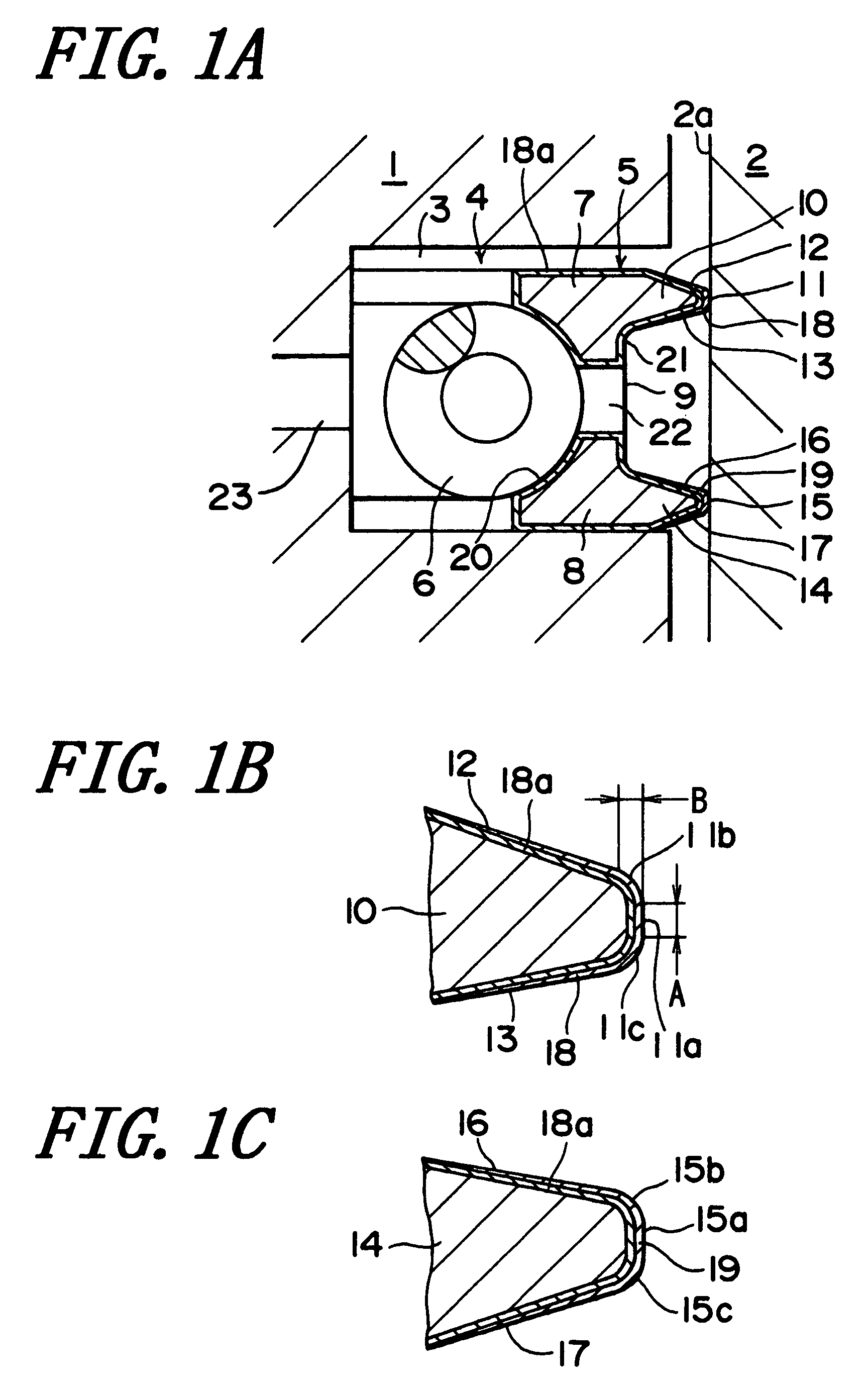

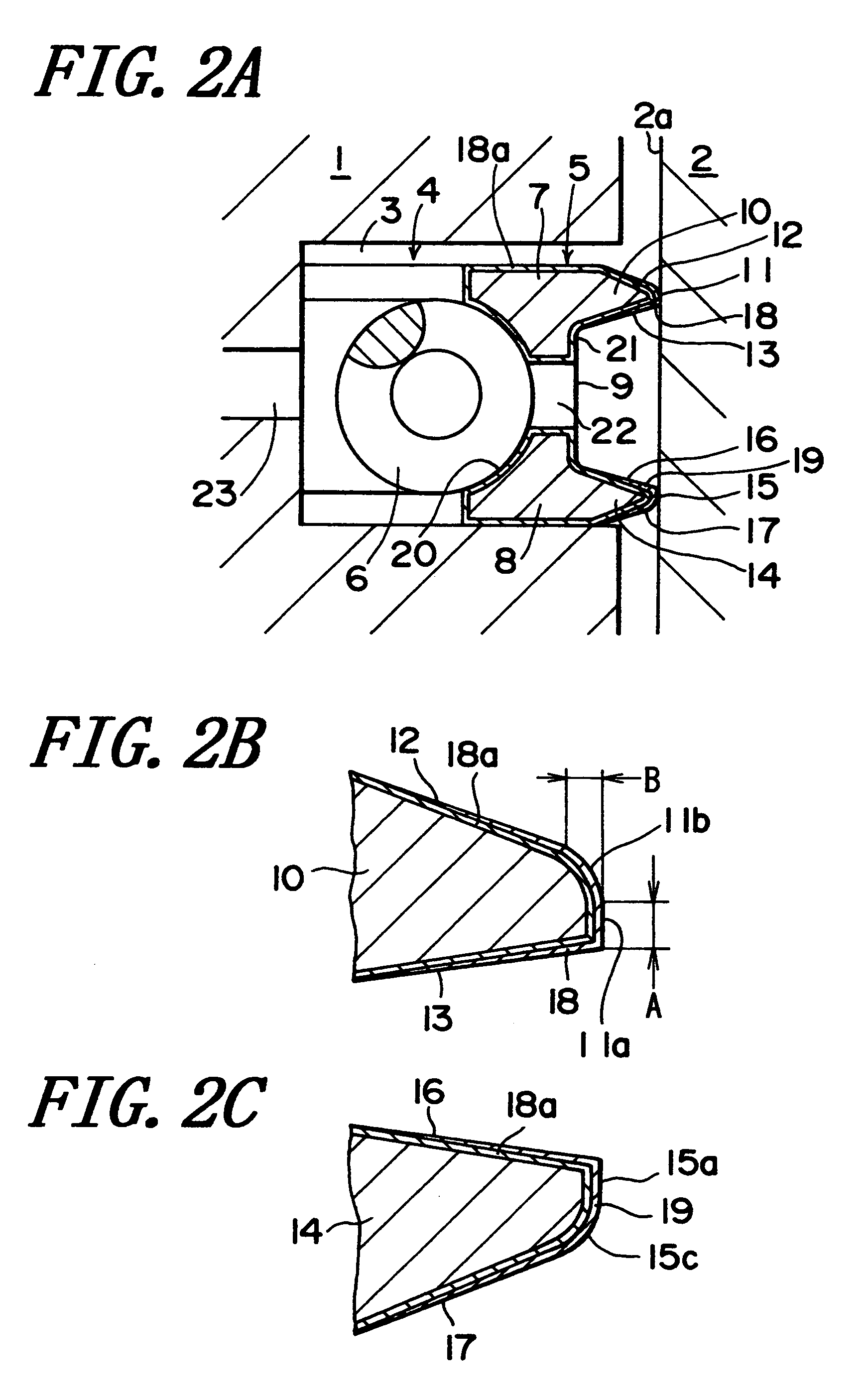

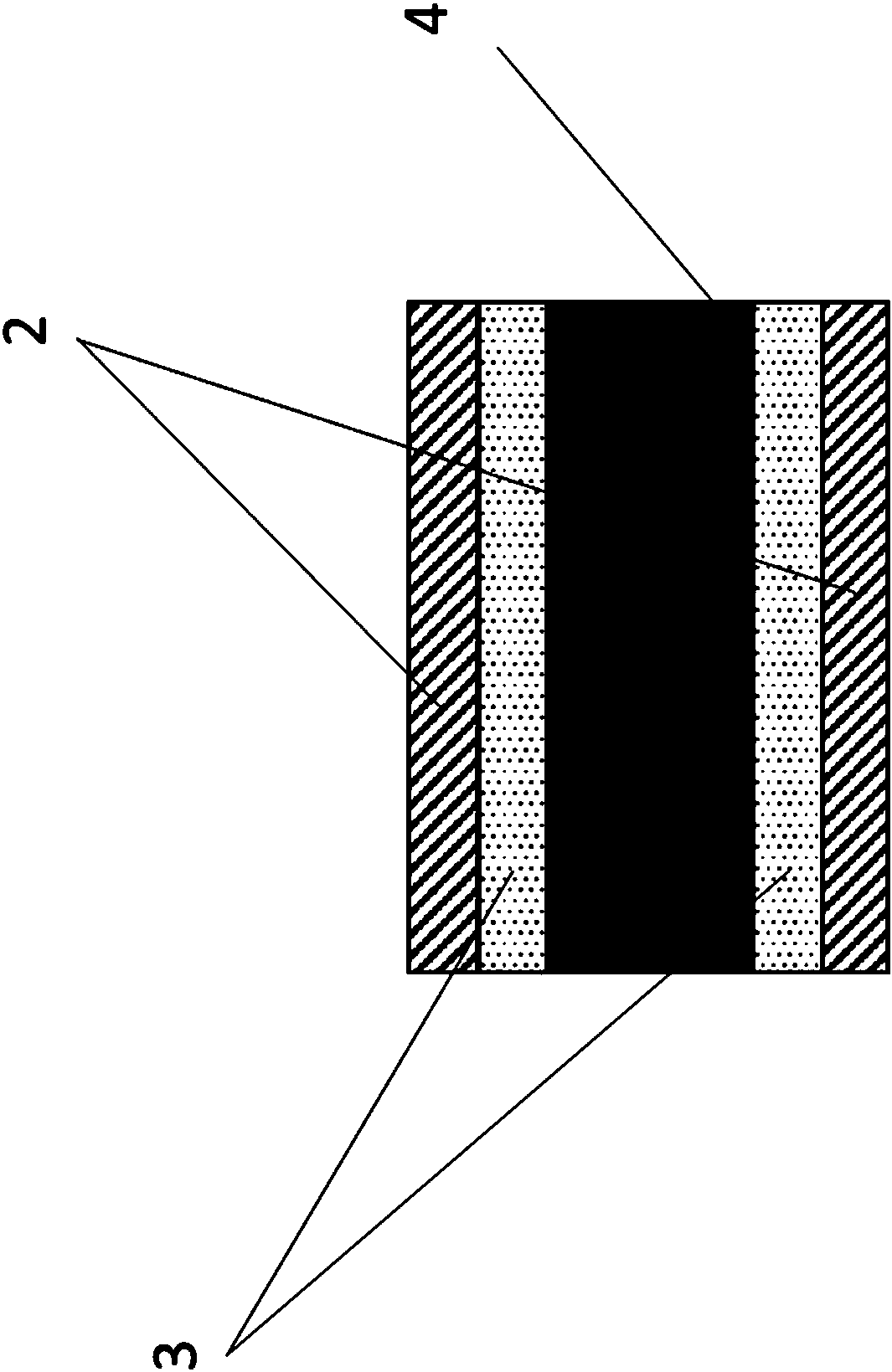

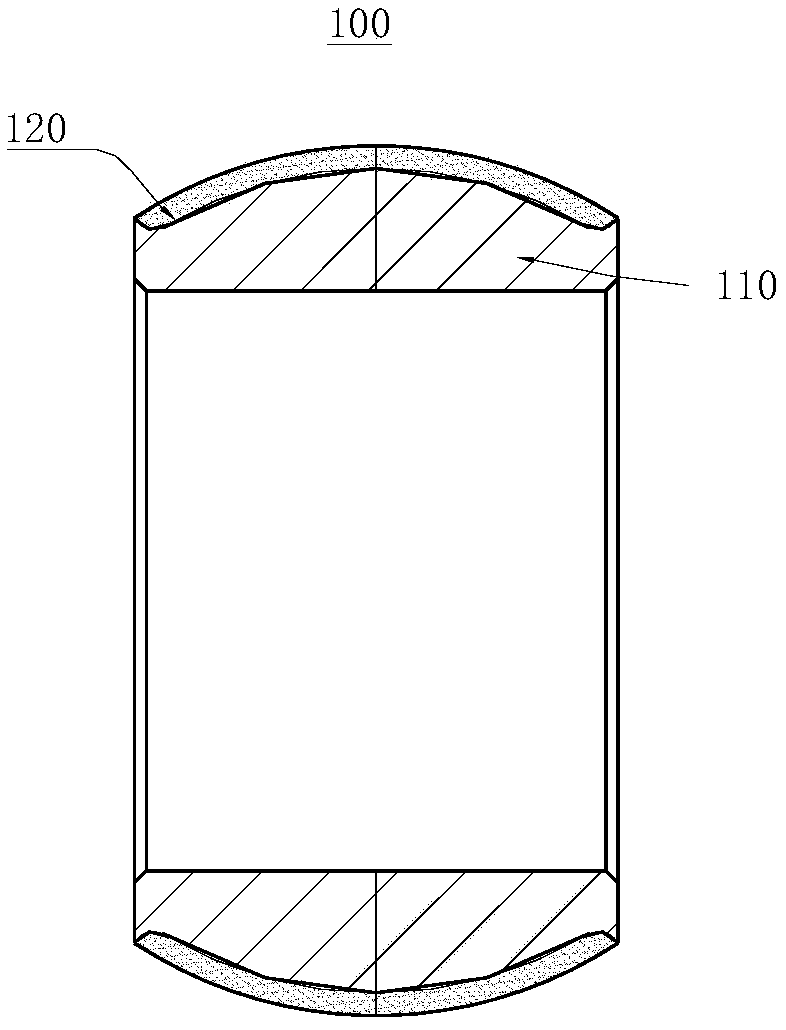

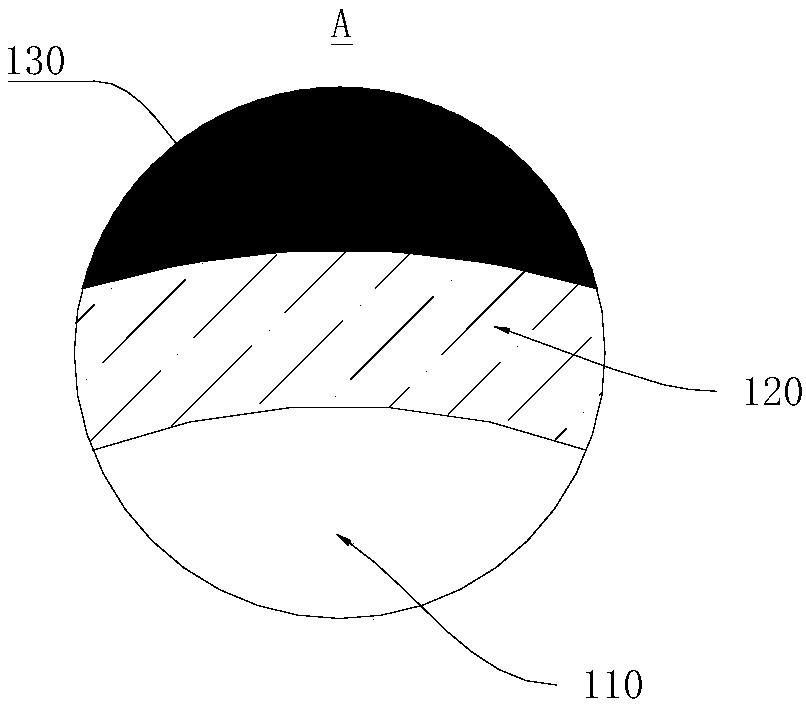

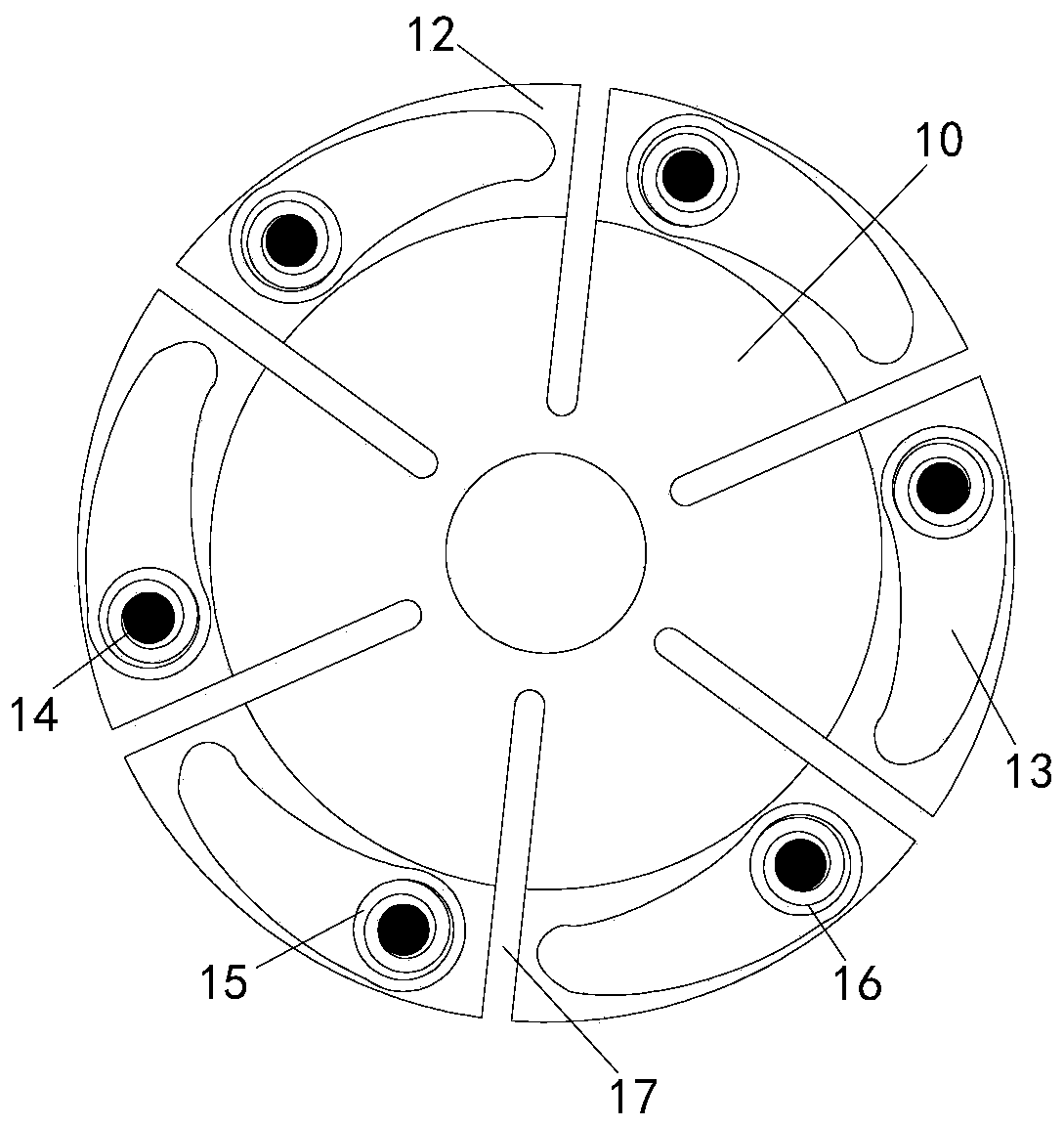

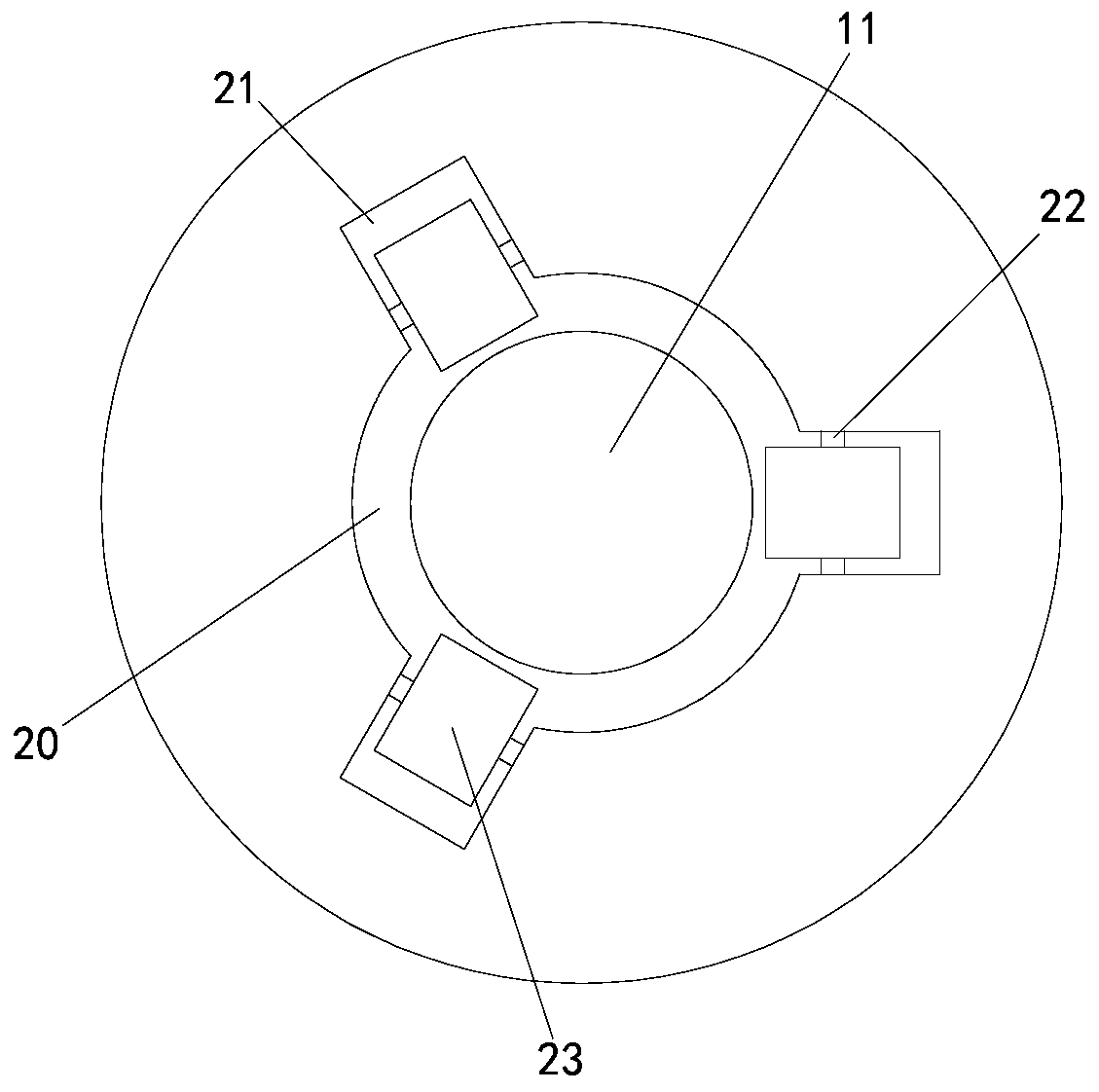

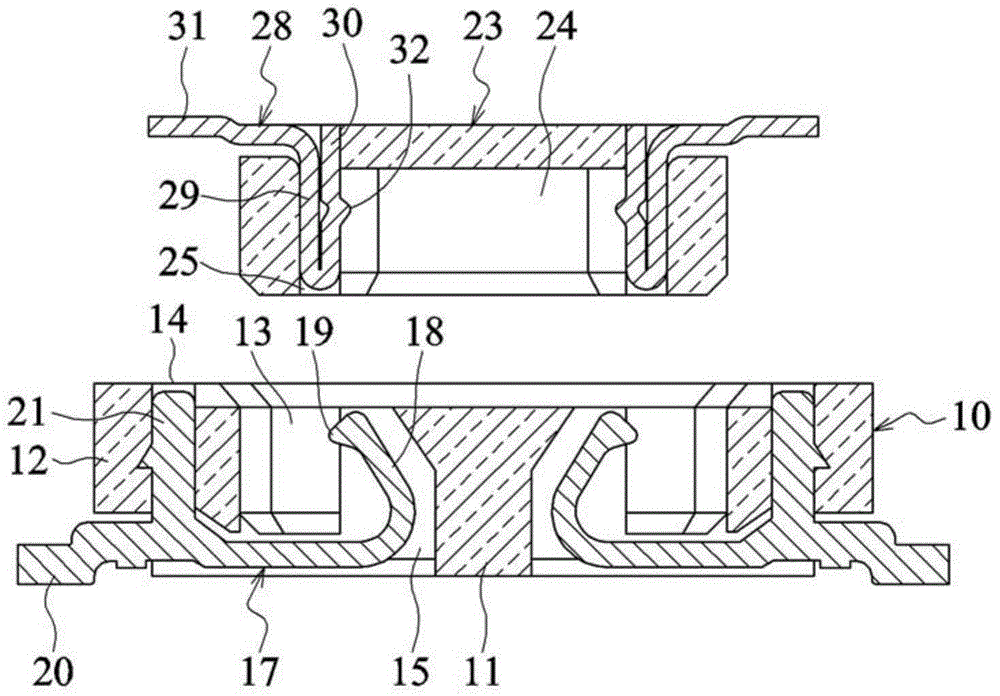

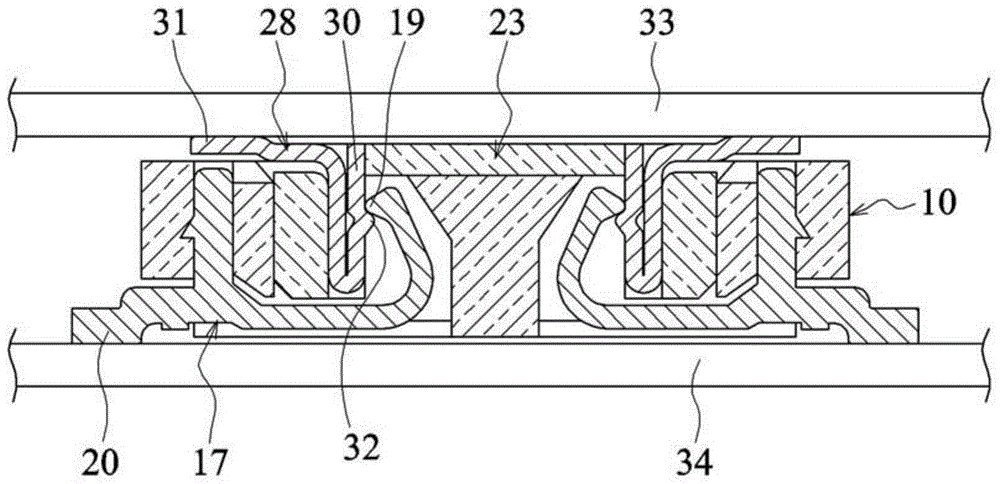

Combined oil ring

ActiveUS7077402B2Reduce frictionImprove scratching effectPiston ringsBraking action transmissionContact pressurePetroleum engineering

A combined oil ring 4 is comprised of an oil ring 5 having upper and lower rails 7 and 8, and an expander 6 for applying contact pressure radially outwards on the oil ring 5. The outer circumferential surface 11 of the upper rail 7 of the oil ring 5 is comprised of a flat surface 11a with an axial width of 0.05 to 0.3 millimeters, a curved surface 11b joining to the upper end of the flat surface 11a and to the upper surface 12 of the upper rail 7, and a curved surface 11c joining to the lower end of the flat surface 11a and to the lower surface 13 of the upper rail 7. The lower rail 8 is formed in the same way.

Owner:TEIKOKU PISTON RING CO LTD

Patching material for building tear and construction process thereof

InactiveCN101402518AImprove adhesionStrong stress resistanceSolid waste managementBuilding repairsWater immersionShock resistance

The invention discloses a patching material for processing building cracks, which is prepared from powders of group A, liquid materials of group B through mixing, wherein the weight proportion of the powders of the group A to the liquid materials of the group B is between 0.8 and 2 to 1. The content range of each composition of the powders of the group A is as follows: 30 to 80 percent of 425 Portland cement, 10 to 50 percent of quartz powders, 5 to 30 percent of nano-size calcium carbonate, 1 to 5 percent of polypropylene short fiber, 1 to 10 percent of wood fiber, 1 to 10 percent of methyl cellulose, and 1 to 10 percent of calcium formate; and the content range of each composition of the liquid materials of the group B is as follows: 10 to 80 percent of pure acrylic resin copolymer emulsion, 0.1 to 1 percent of defoamer, 1 to 11 percent of bactericidal preservative, 1 to 12 percent of alkaline swelling thickener, 0.5 to 12 percent of pH modifier, 5 to 20 percent of talc powders, and 10 to 40 percent of water. The construction process of the patching material is performed according to the following steps: base course processing, patching material scraping, and surface layer brushing. A product of the patching material has the advantages of strong cohesive force, high mechanical strength, impact resistance, shock resistance, insolation resistance, water immersion resistance, chemical corrosion resistance, no pollution, excellent physical and chemical properties of the product, strong stress resistance, and certain waterproof effect.

Owner:MAANSHAN TIANJINYUN PAINT IND

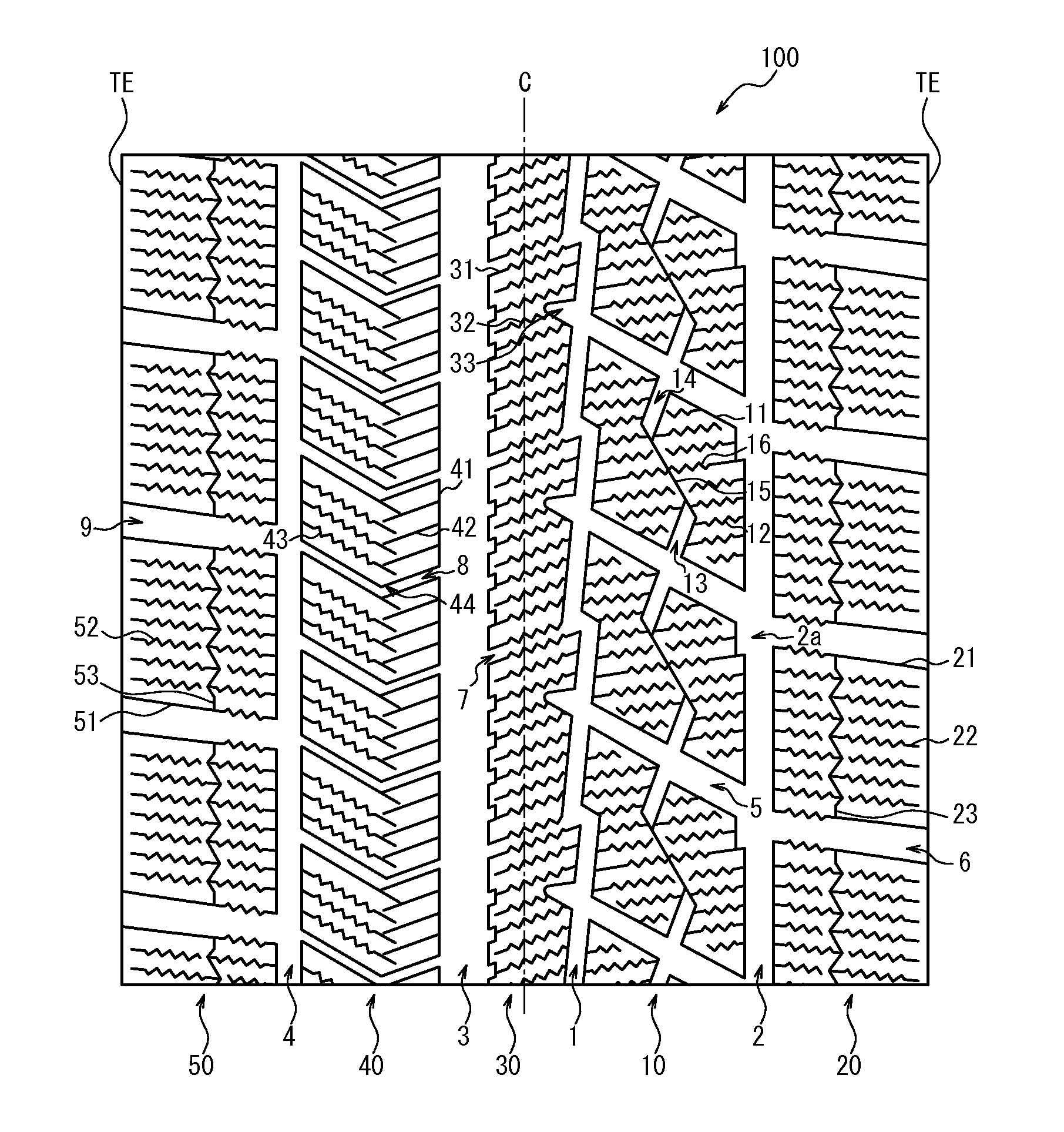

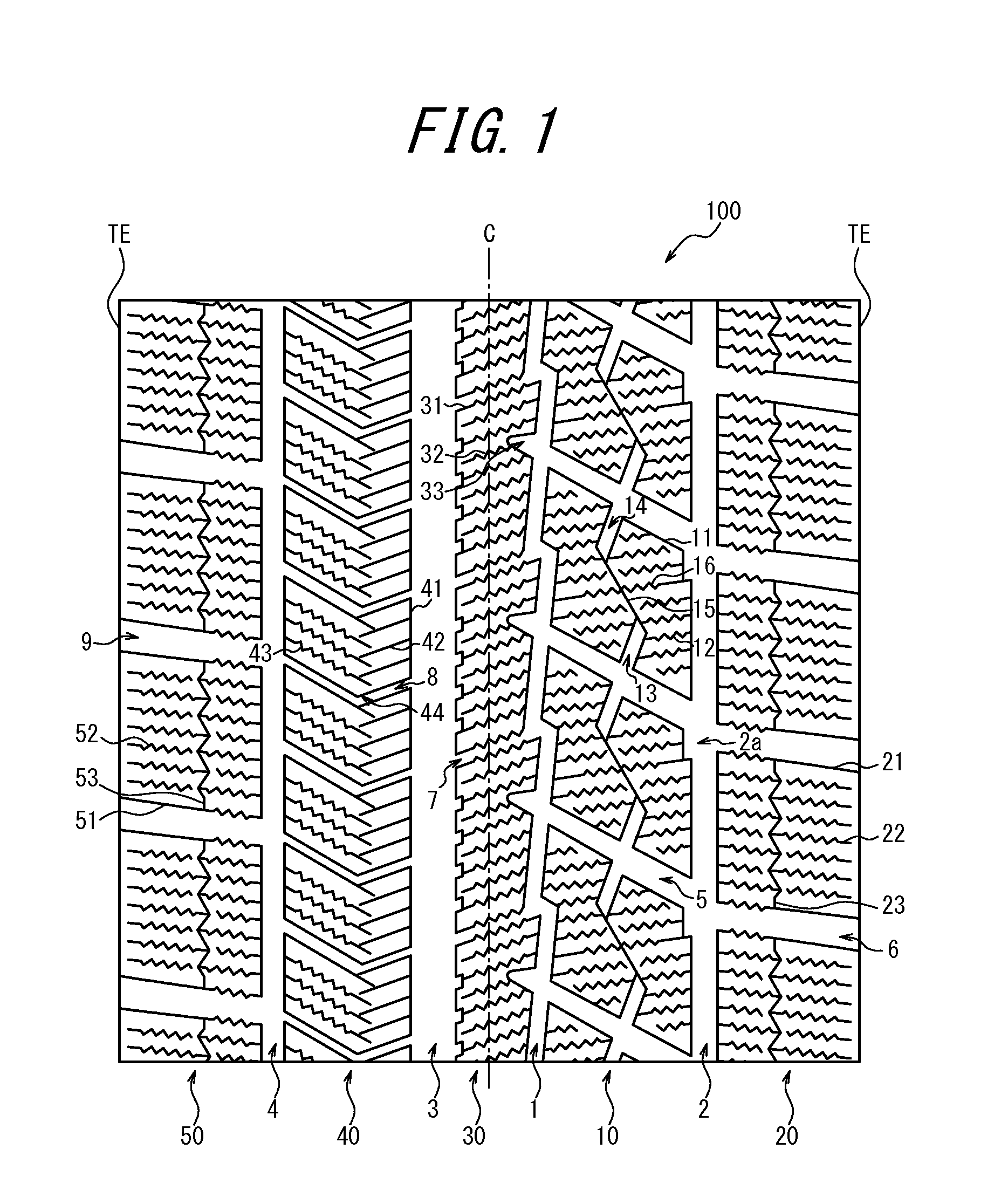

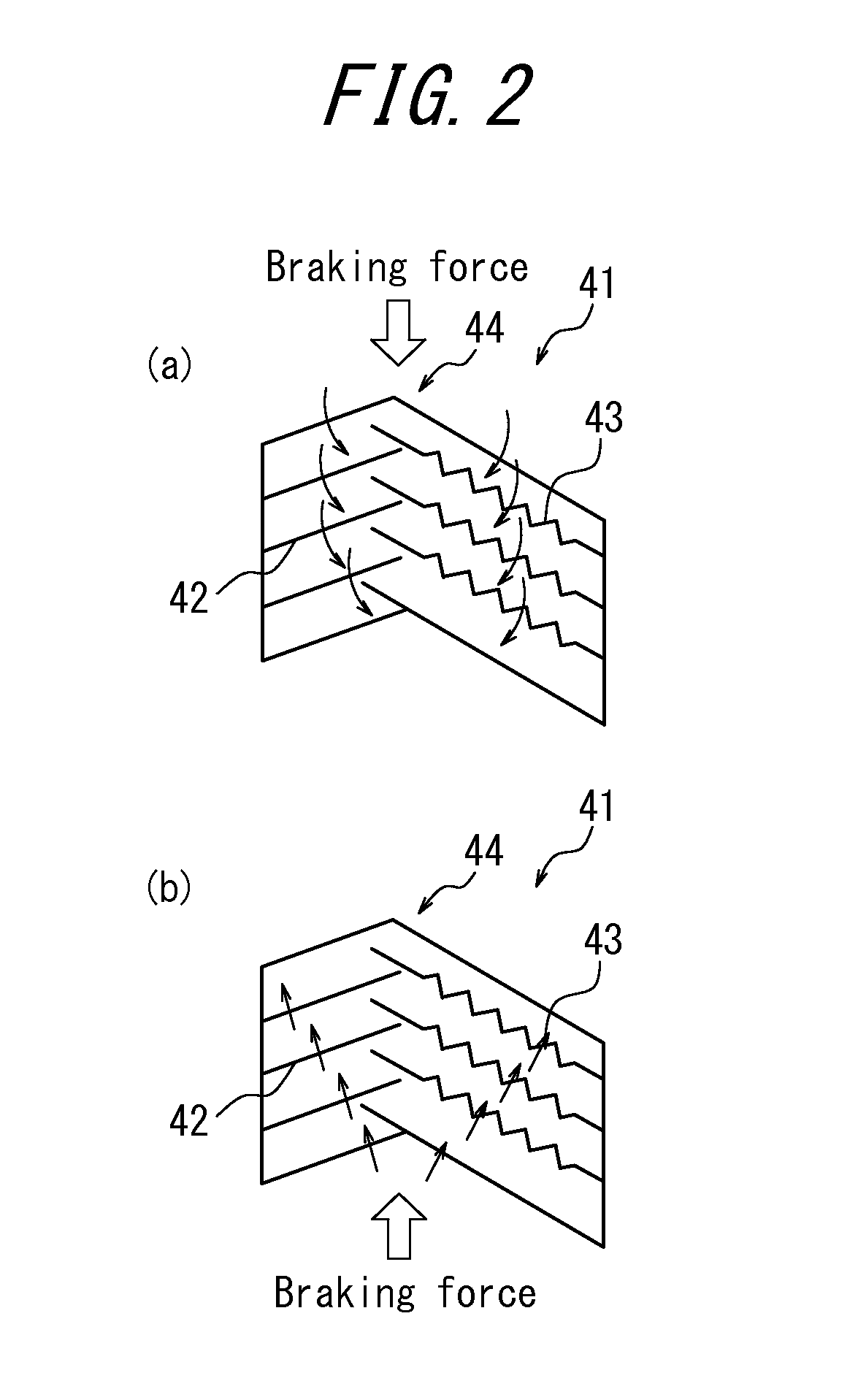

Pneumatic tire

ActiveUS20140224394A1Good friction propertiesImprove scratching effectTyre tread bands/patternsNon-skid devicesGroove widthEngineering

A pneumatic tire according to the present invention includes, one or more main grooves extending in the tire circumferential direction, and a plurality of lateral grooves extending in the tire width direction, the main grooves and the lateral grooves defining a block row formed by a plurality of blocks, at least one sipe being disposed in each block. Each block has a first cutaway groove with one end opening into a lateral groove located on one side of the block and the other end terminating within the block, a second cutaway groove with one end opening into a lateral groove located on the other side of the block and the other end terminating within the block, and a connecting narrow groove having a groove width narrower than that of the first and the second cutaway groove and connecting the first and the second cutaway groove.

Owner:BRIDGESTONE CORP

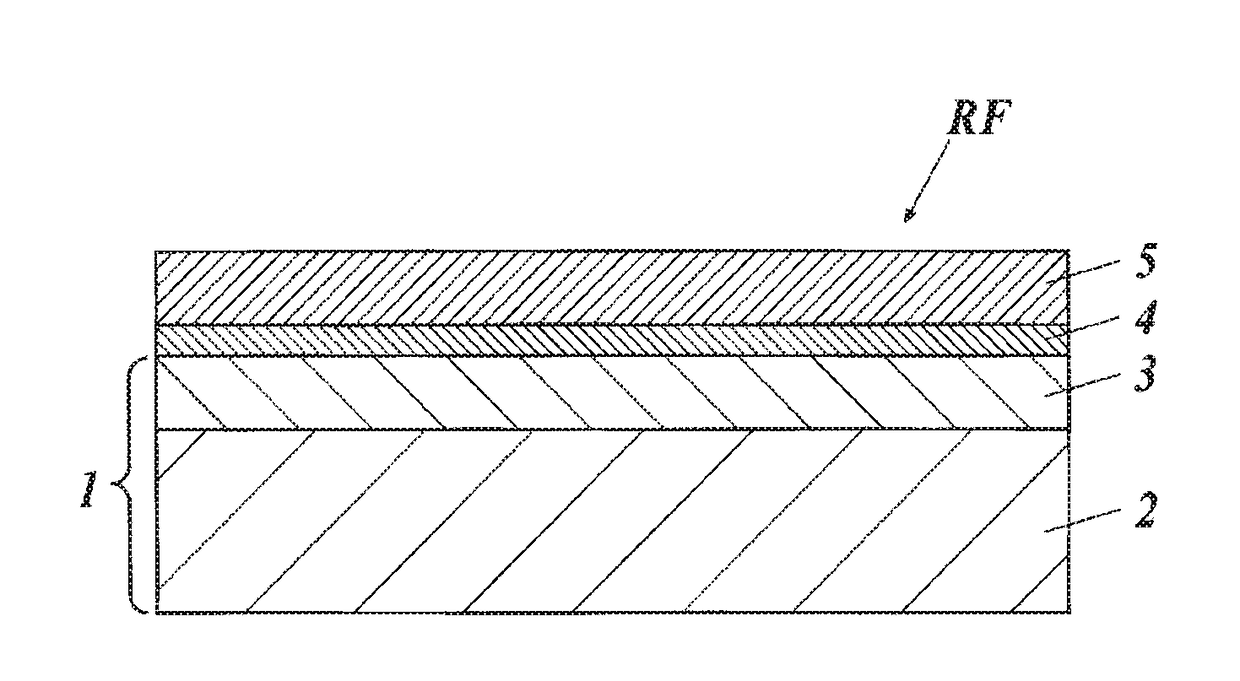

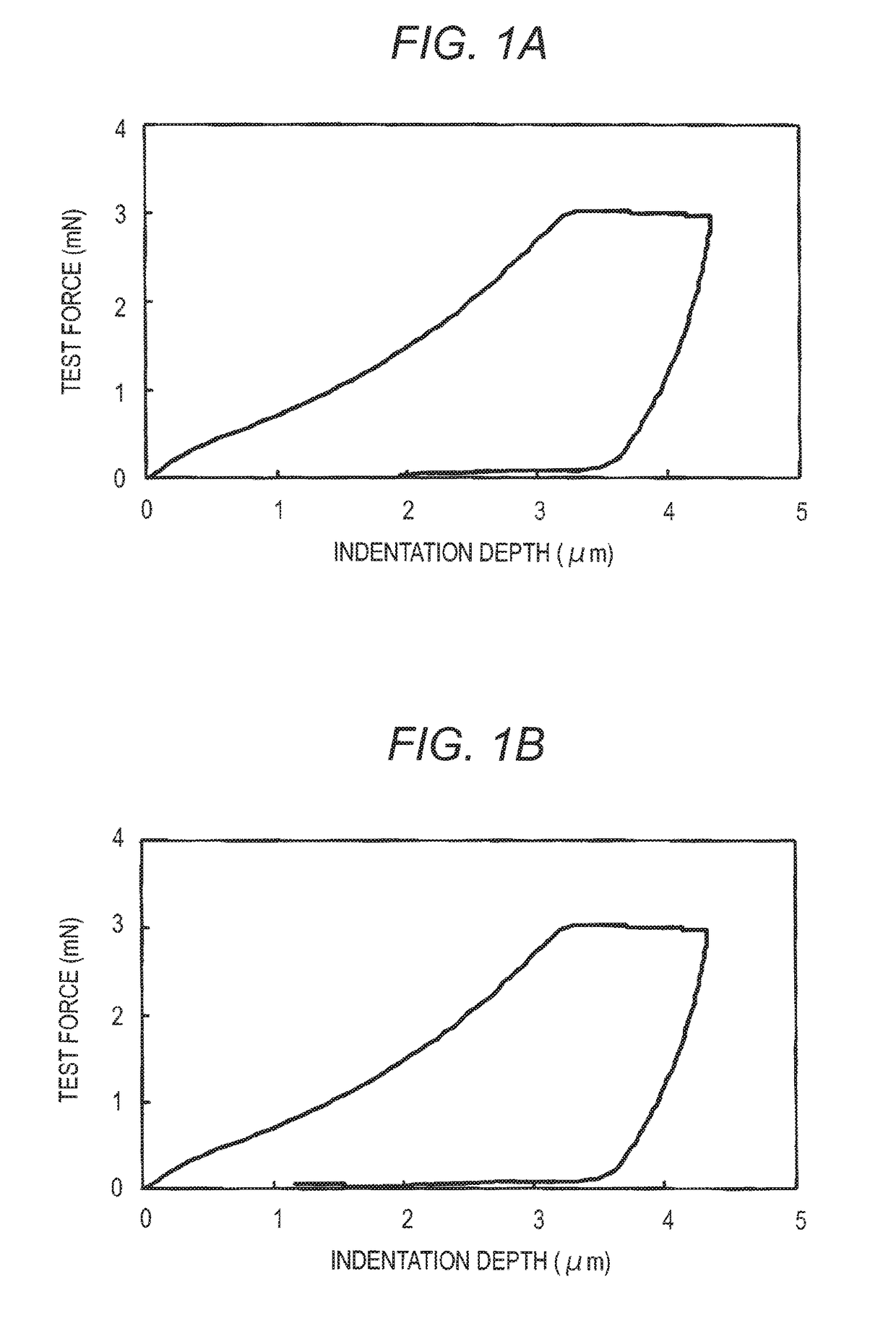

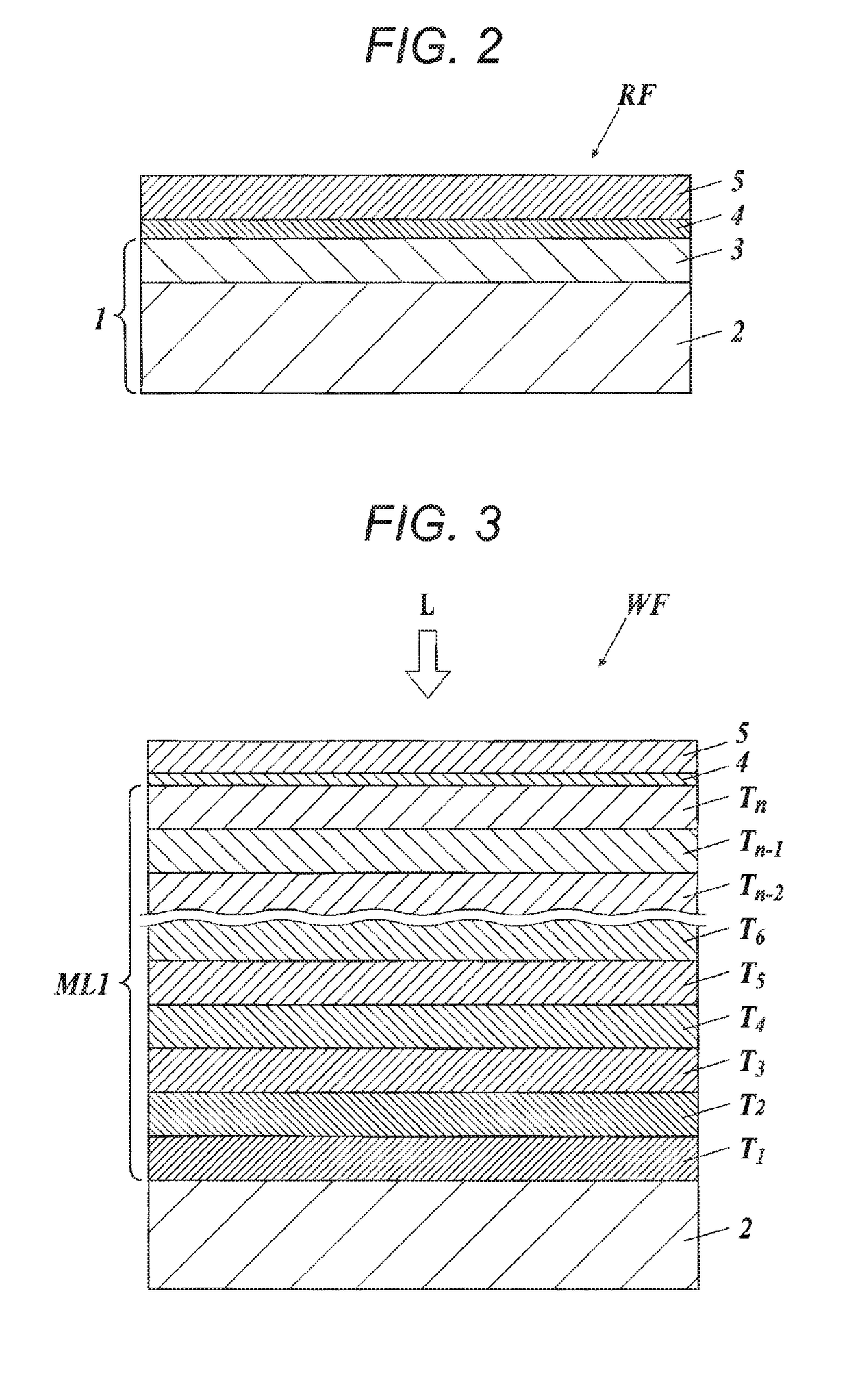

Light reflecting film, production method for light reflecting film, decorative molding method for light reflecting film, laminated glass, and curved surface body

InactiveUS20170254936A1Improve light resistanceImprove scratch resistanceOptical filtersOptical articlesOpticsPhysics

A light reflecting film may be provided that improves the self-restoring property of a stretched section thereof when stretched and attached to a curved surface and that has excellent scratch resistance and light resistance, a production method for the light reflecting film, a decorative molding method may also be provided for the light reflecting film, laminated glass, and a curved surface body.

Owner:KONICA MINOLTA INC

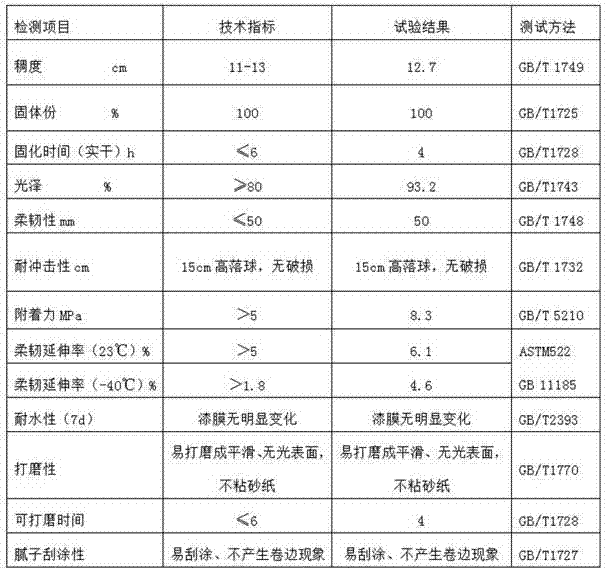

Polyurethane specular putty coating and preparation method thereof

The invention provides a polyurethane specular putty paint which comprises an A component and a B component, wherein the mass ratio of the A component to the B component is (8:1)-(4:1); the A component is prepared from the following raw materials in percentage by weight: 30-30% of polyester resin, 0.2-0.4% of wetting dispersant, 0.6-0.8% of defoamer, 1-2% of anti-settling agent, 20-30% of talcum powder, 17-27% of activated calcium carbonate, 5-10% of barite powder and 6-10% of titanium dioxide; and the B component is a diphenylmethane diisocyanate curing agent. The invention also provides a polyurethane specular putty paint preparation method which is high in production efficiency. The polyurethane specular putty paint has the characteristics of high gloss, mellow state, excellent coating property, good polishing property, strong adhesive force, good flexibility, low cost and small toxicity; and the workability is excellent, the defects on the surface of a substrate or a coating after the paint is coated can be effectively repaired and then the service life of the substrate can be prolonged, so that the polyurethane specular putty paint can be widely applied to the hole filling, repairing and coating of surfaces of engineering machinery such as glass fiber reinforced plastics, steels and the like.

Owner:西北永新涂料有限公司

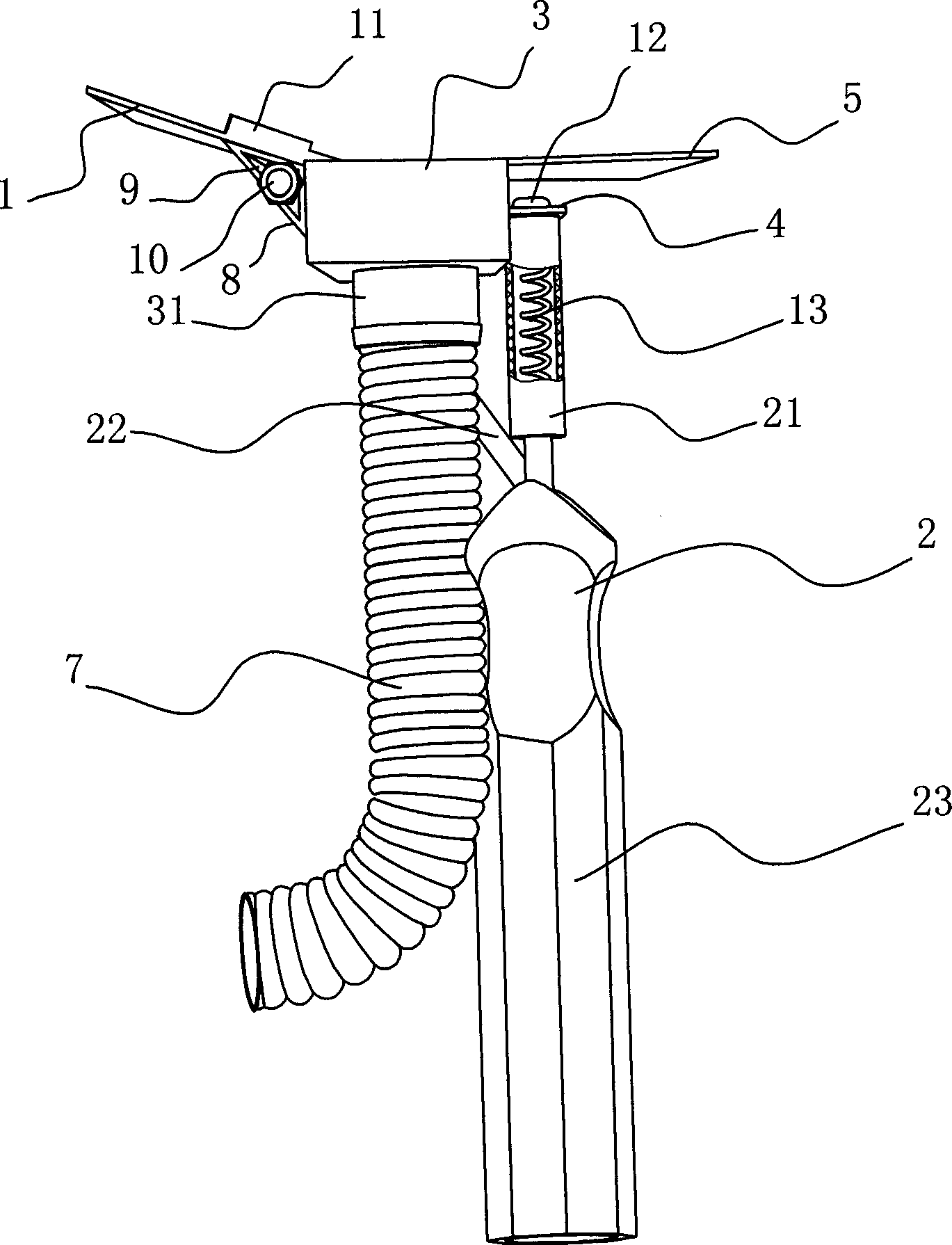

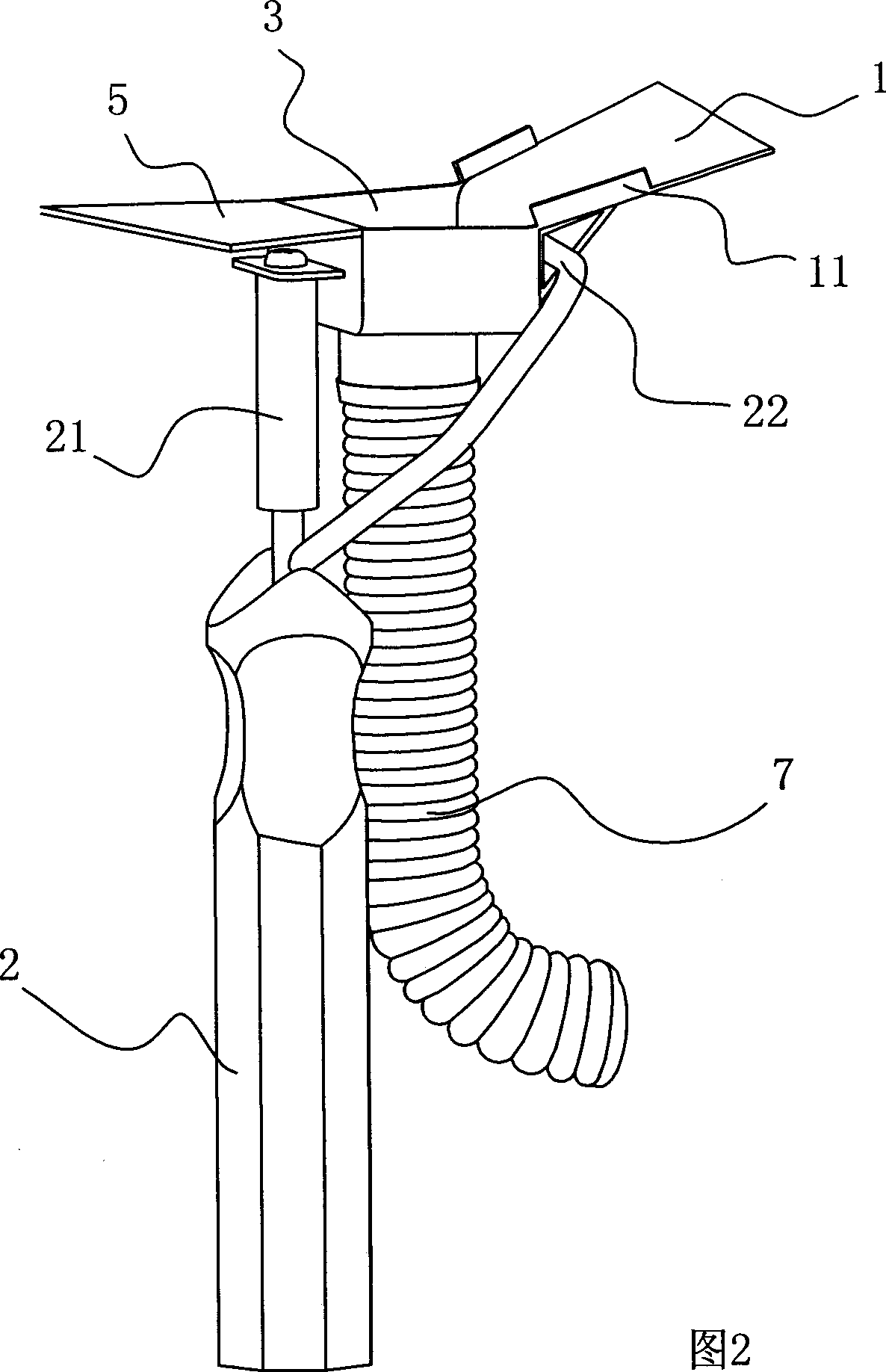

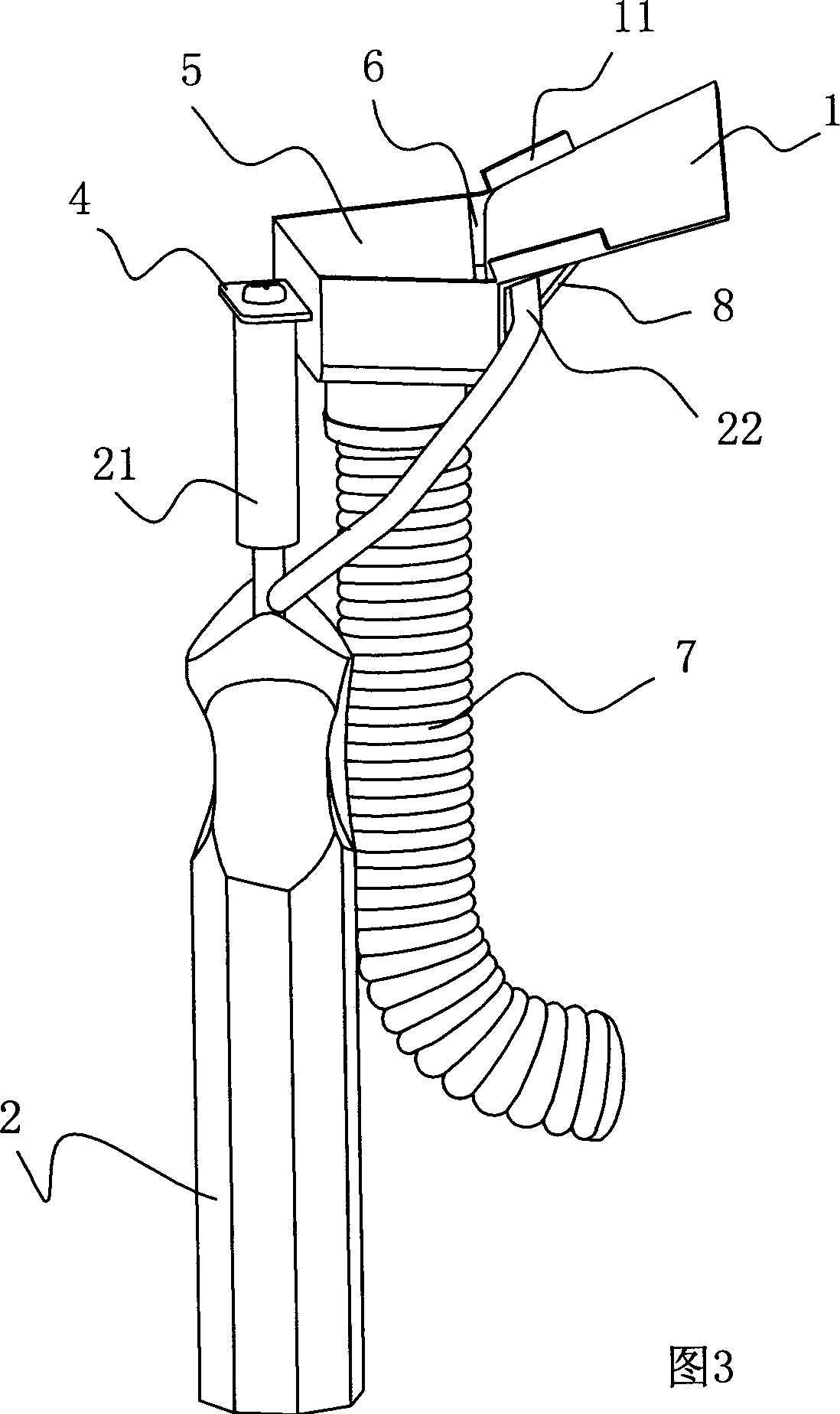

Latex paint finishing-slicking implement

The invention relates to a latex paint collecting and scraping smoother, comprising screed and handgrip, where the screed is provided with a box- type paint collection chamber with flip cover, the bottom of the collection chamber is provided with interface, and the interface is connected with a recovery pipe connected with the collection chamber; and the handgrip is of a bracket structure and connected at an adjustable angle with an integral component comprising the screed and collection chamber. And it has characters of reasonable design, use convenience and good smearing effect, and can make the latex paint smooth, have full handle, good smoothness and extremely good integrity.

Owner:周水苗

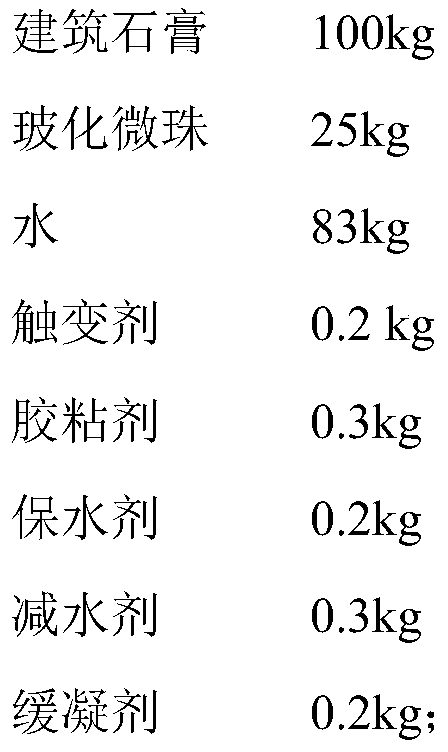

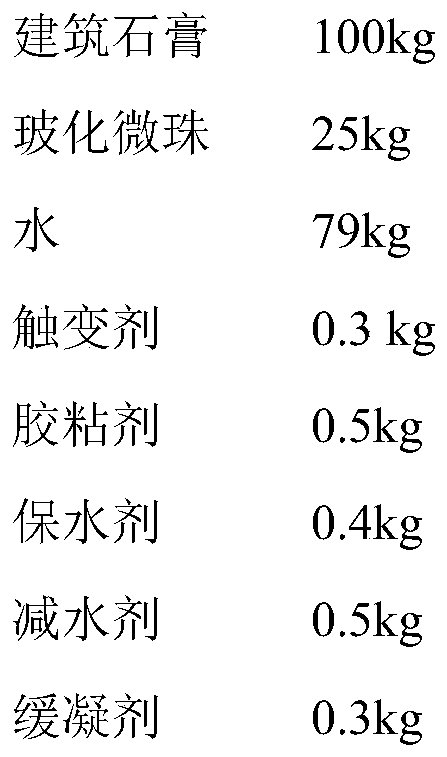

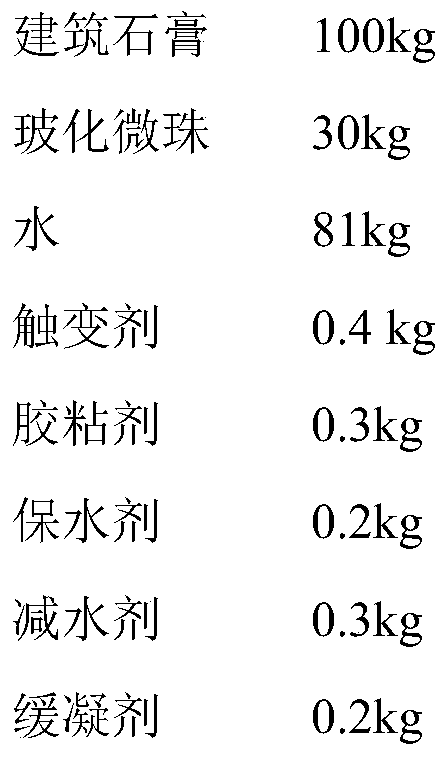

Anti-sagging light gypsum for ceiling and preparation method of anti-sagging light gypsum

The invention relates to anti-sagging light gypsum for a ceiling. The light gypsum comprises the following raw materials in parts by mass: 100 parts of calcined gypsum, 25-35 parts of glass beads, 75-85 parts of water, 0.2-0.5 part of a thixotropic agent, 0.2-0.6 part of an adhesive, 0.2-.05 part of a water retaining agent, 0.3-0.9 part of a water reduction agent and 0.2-0.5 part of a retarder. The light gypsum is prepared by composite means of overall grain composition optimization, appropriate additive proportioning, and the like, related problems in construction procedures of heat preservation on floors of different families can be solved, and the light gypsum which is capable of preventing sagging and has high bonding strength can be prepared, so that the light gypsum is very applicable to ceiling construction, meanwhile, has excellent heat preservation performance, thus is capable of greatly reducing building operation energy consumption, and can be applied to industrial production.

Owner:CHONGQING JIANDA BUILDING MATERIAL

Pigment layer and method of permanently scribing a substrateby means of high-energy radiation

ActiveCN101491984AIncrease contrastImprove scratching effectDecorative surface effectsRadiation-absorbing paintsPolymer scienceHigh energy

Pigment layer intended particularly for the permanent marking of glass, based on a polymer matrix which reacts predominantly with pulverization to a high-energy beam, more particularly to laser irradiation, comprising at least one titanium donor and a carbon donor which provides free carbon under energy irradiation.

Owner:TESA SE

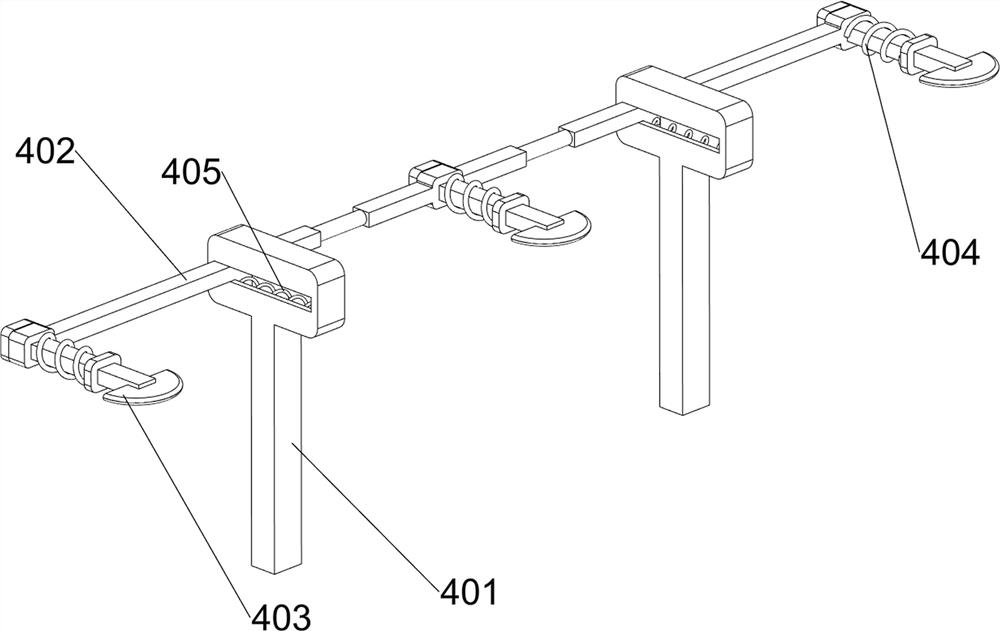

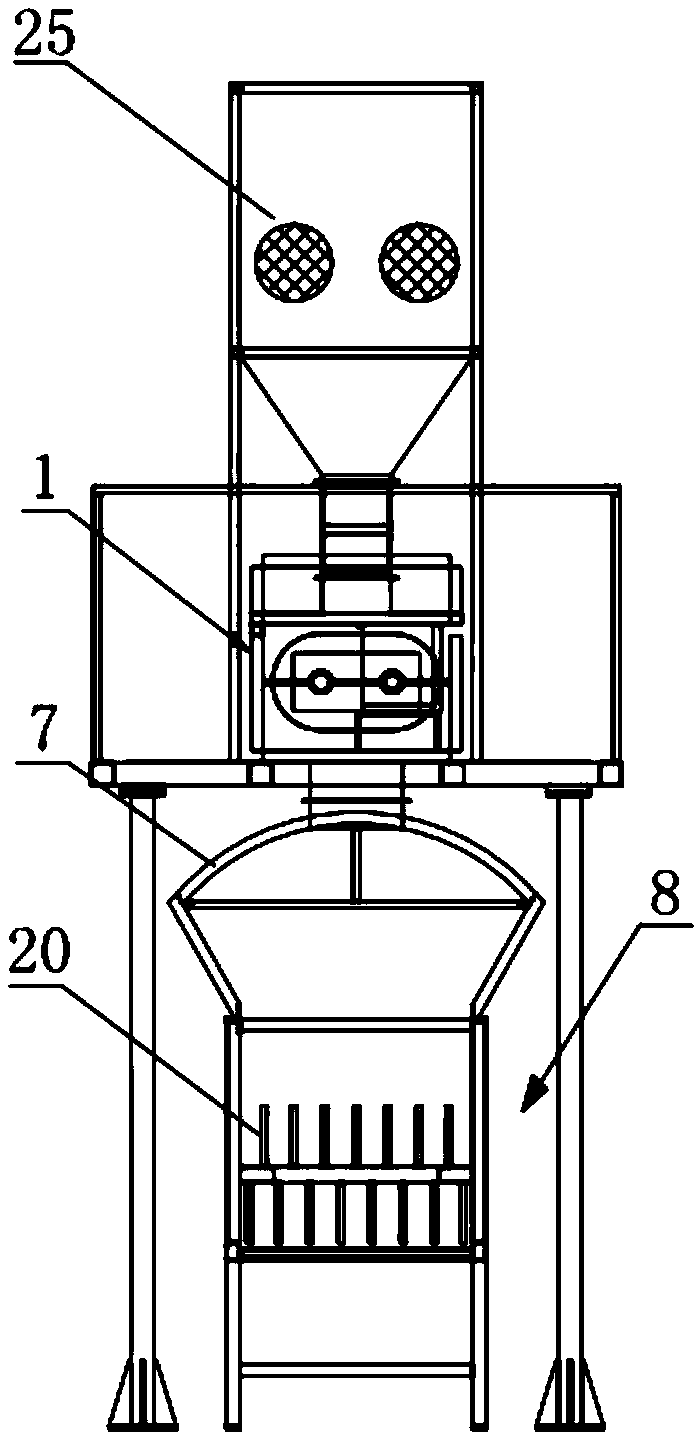

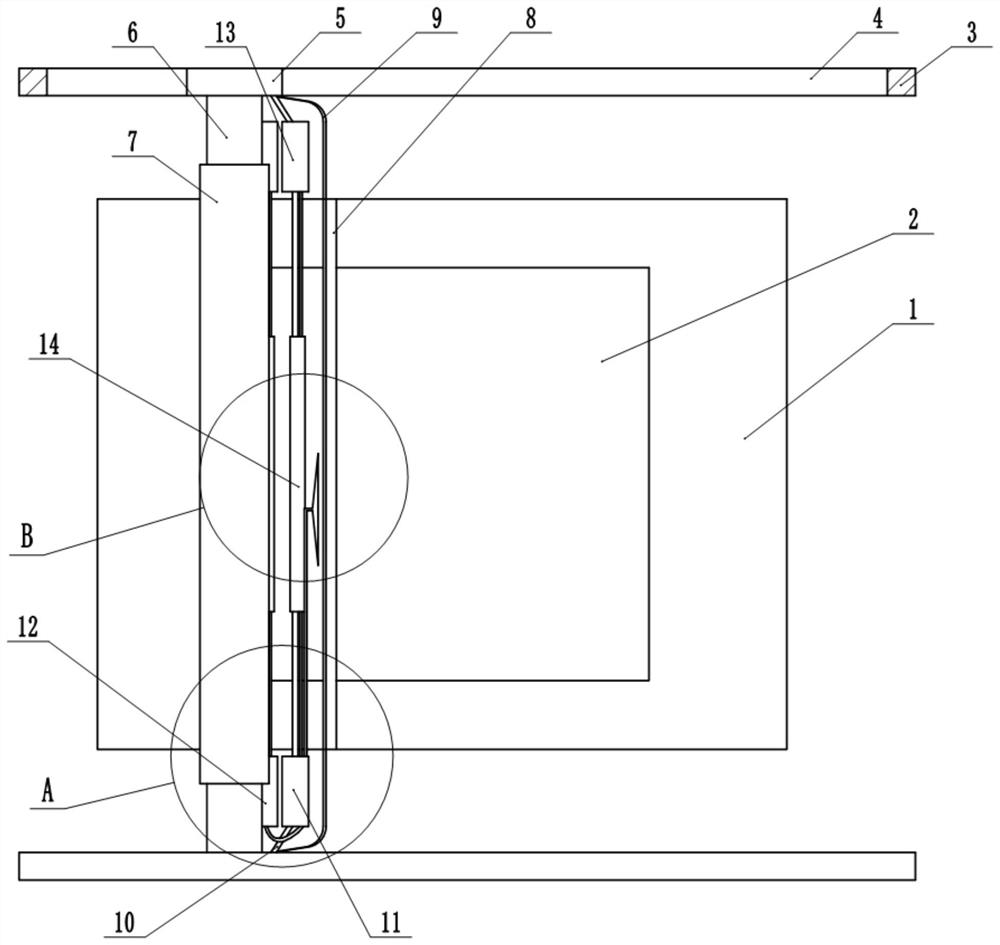

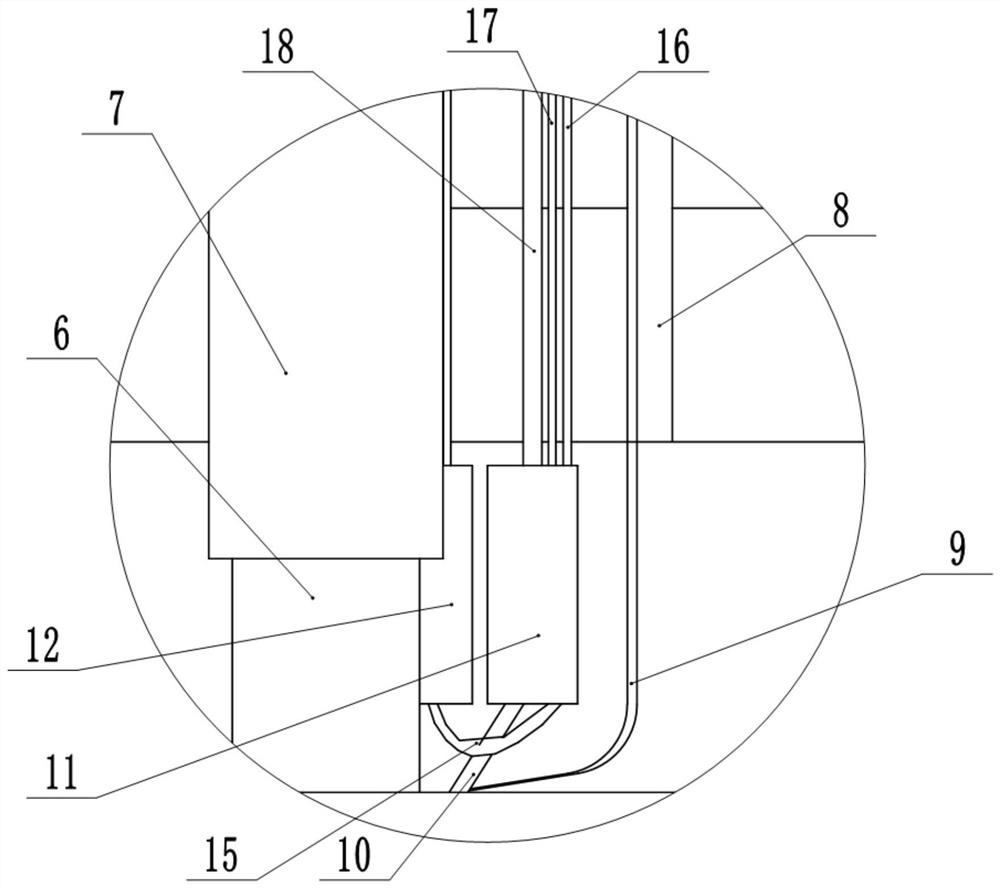

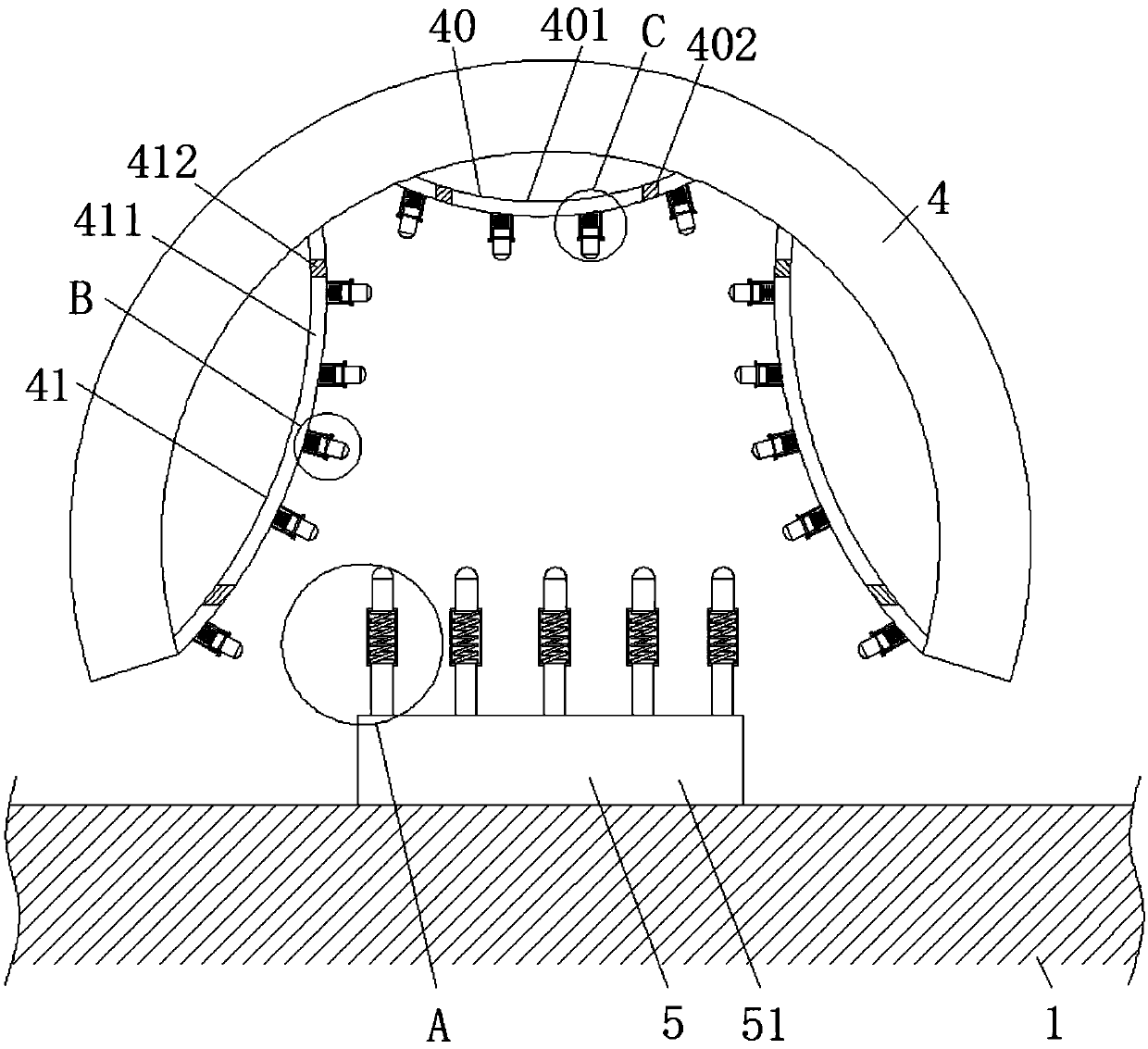

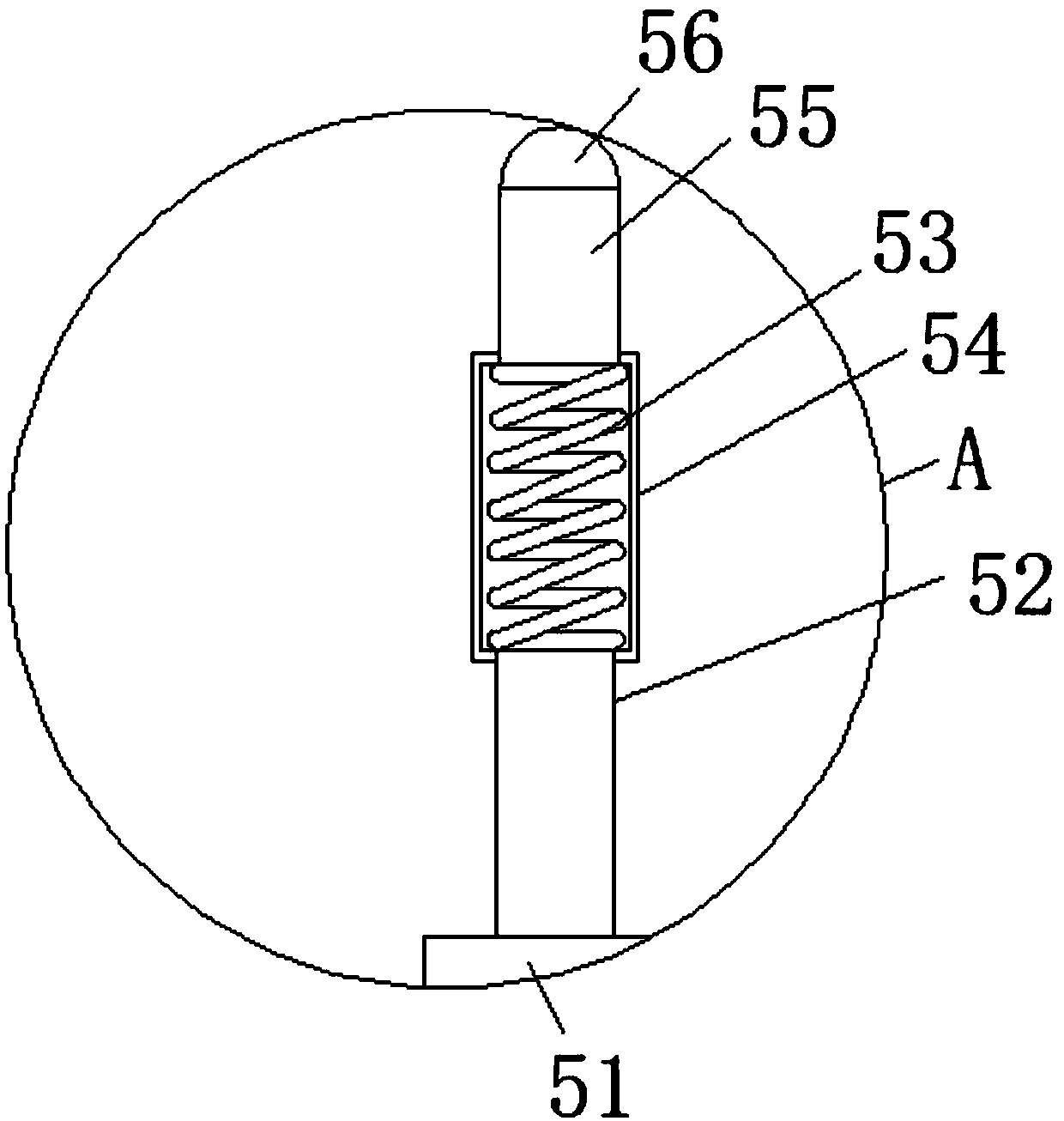

Ampoule bottle neck mark opening equipment for pharmacy department

ActiveCN112978653AWon't breakImprove work efficiencyOpening closed containersBottle/container closurePharmacyBottle neck

The invention relates to mark opening equipment, in particular to ampoule bottle neck mark opening equipment for a pharmacy department. The ampoule bottle neck marking equipment for the pharmacy department which has the advantages of automatic marking, good marking effect and convenience in operation is provided. According to the technical solution, the ampoule bottle neck mark opening equipment for the pharmacy department comprises a supporting frame, a placing assembly arranged at the upper part of the support frame, a pressing assembly arranged on one side of the upper portion of the supporting frame, and a scratching assembly arranged in the middle of the pressing assembly. The ampoule bottle neck mark opening device has the beneficial effects that under the action of the scratching assembly, when a scratching knife makes contact with an ampoule bottle, people rotate a first rotating shaft, the first rotating shaft can drive a placing frame and the ampoule bottle to rotate, so that the bottleneck of the ampoule bottle is scratched, and due to the fact that the ampoule bottle is a glass product, and under the buffering effect of a third spring, the scratching knife cannot damage the ampoule bottle.

Owner:南京市淑先科技有限公司

High-melt-strength polypropylene micro-foaming material and preparation method thereof

The invention provides a high-melt-strength polypropylene micro-foaming material and a preparation method thereof. The polypropylene micro-foaming material comprises a polypropylene composite materialand a chemical foaming agent, wherein the polypropylene composite material comprises co-polypropylene, talcum powder, a vinyl-methacrylate ionic bond polymer, a compatilizer, an antioxidant, a lubricating agent and other auxiliaries; the vinyl-methacrylate ionic bond polymer is subjected to blend to modify polypropylene; maleic anhydride grafted polypropylene is treated as an interface compatibilizer for improving the interface bonding force of polypropylene and the vinyl-methacrylate ionic bond polymer, and the vinyl-methacrylate ionic bond polymer is promoted to be uniformly dispersed in apolypropylene substrate, and thus the melt strength of polypropylene can be effectively improved, and the micro-foaming material with dense cells can be obtained. The polypropylene micro-foaming material is low in density, high in mechanical strength, low in low-temperature toughness, high in scraping resistance, capable of being directly injected to realize foaming, and simple in processes; and an effective light-weight material is provided for realizing light weight of automobiles.

Owner:ORINKO NEW MATERIAL CO LTD

Super-hydrophobic wear-resistant graphene composite coating and solar collector tube using the same

InactiveCN109423068AReduce dirtReduce cleaning workloadAntifouling/underwater paintsPretreated surfacesWear resistantUltraviolet lights

The invention discloses a super-hydrophobic wear-resistant graphene composite coating and a solar collector tube using the same. The super-hydrophobic wear-resistant graphene composite coating is formed by performing ultraviolet light curing on composite paint of graphene oxide and photocatalytic active nanoparticle titanium dioxide; the solar collector tube comprises a glass outer tube and a metal inner tube sleeved thereby, an airtight cavity is formed between the glass outer tube and the metal inner tube, the inner wall and the outer wall of the o glass outer tube are separately coated withanti-reflection coatings, and the outside of each of the anti-reflection coatings is coated with the super-hydrophobic wear-resistant graphene composite coating; and through physicochemical properties of graphene and titanium dioxide itself such as hydrophobicity and light transmittance, the solar collector tube coated with the same has the advantages of strong wear resistance, strong weather resistance, strong light transmittance and good self-cleaning capability, can effectively resist erosion of the collector tube by dust, and is suitable for desert areas with abundant light resources.

Owner:北京国信优控数字科技有限公司 +1

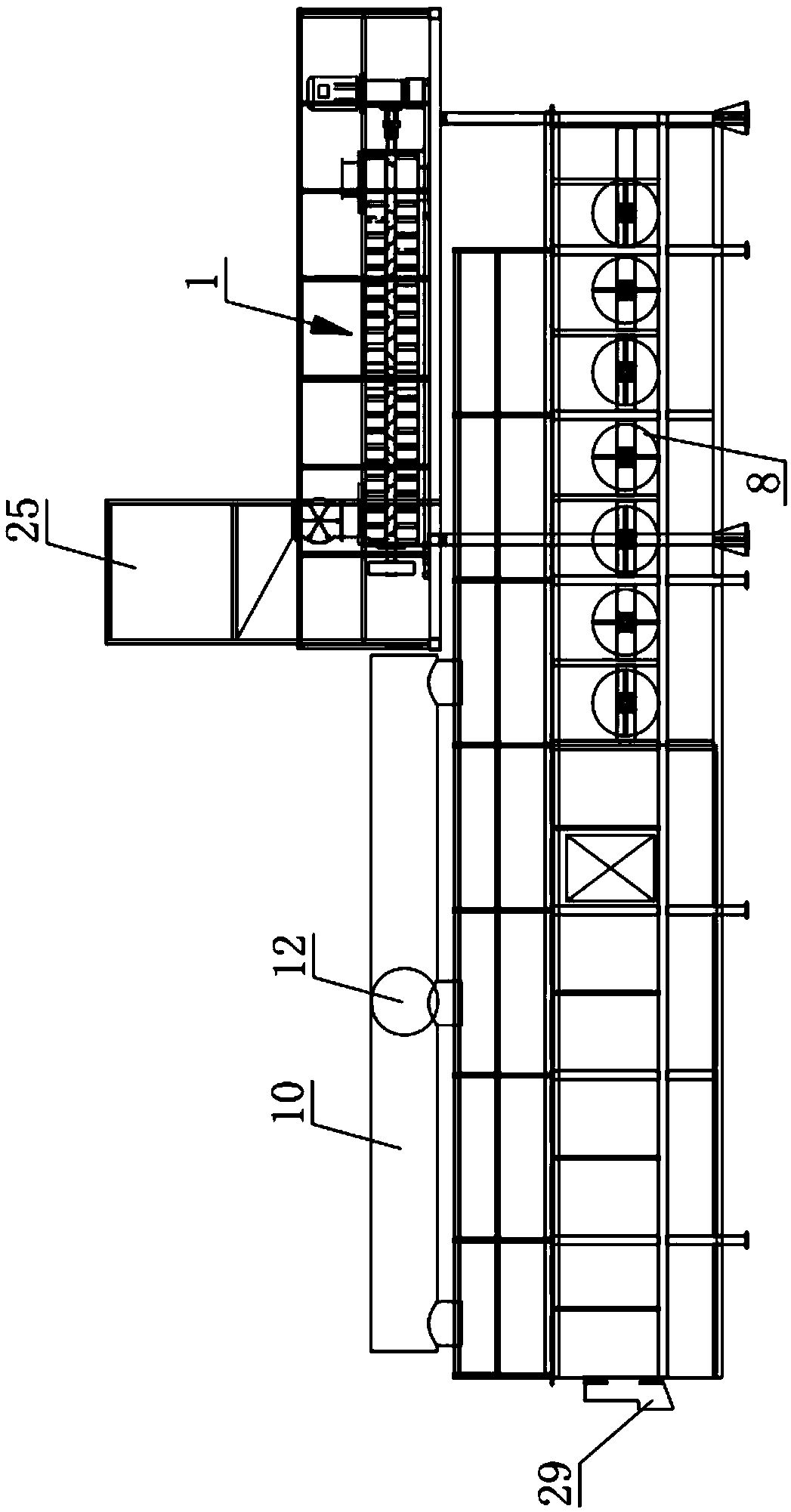

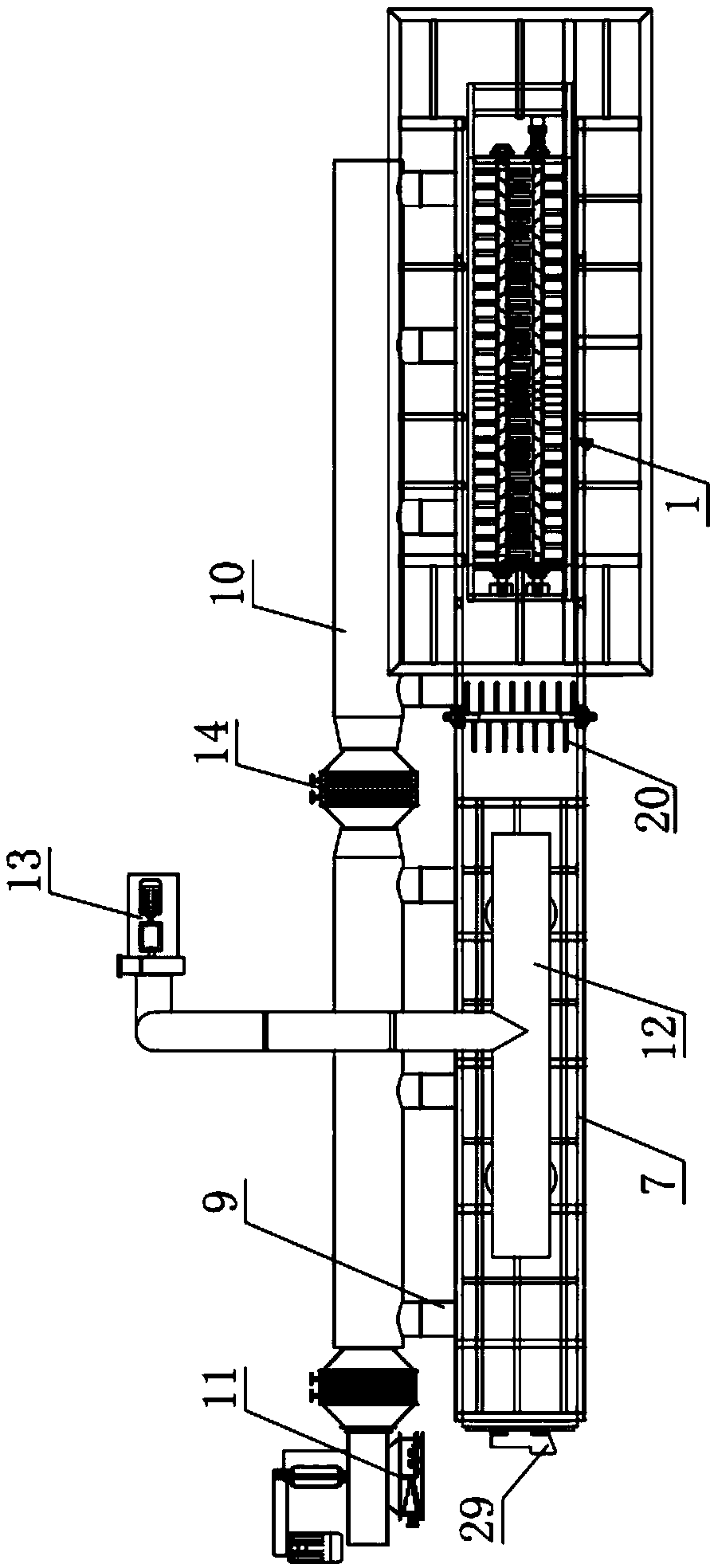

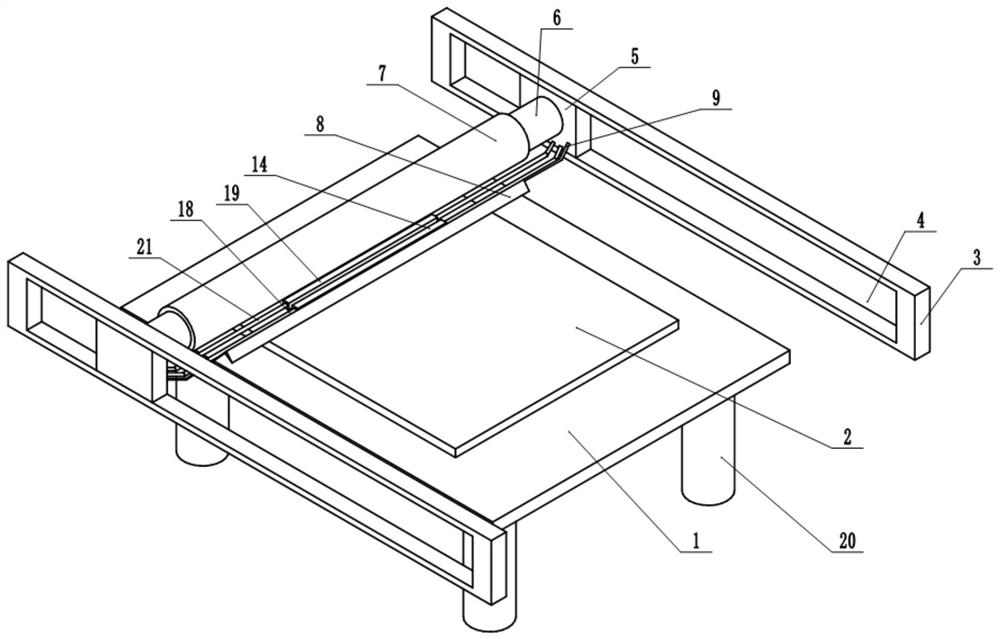

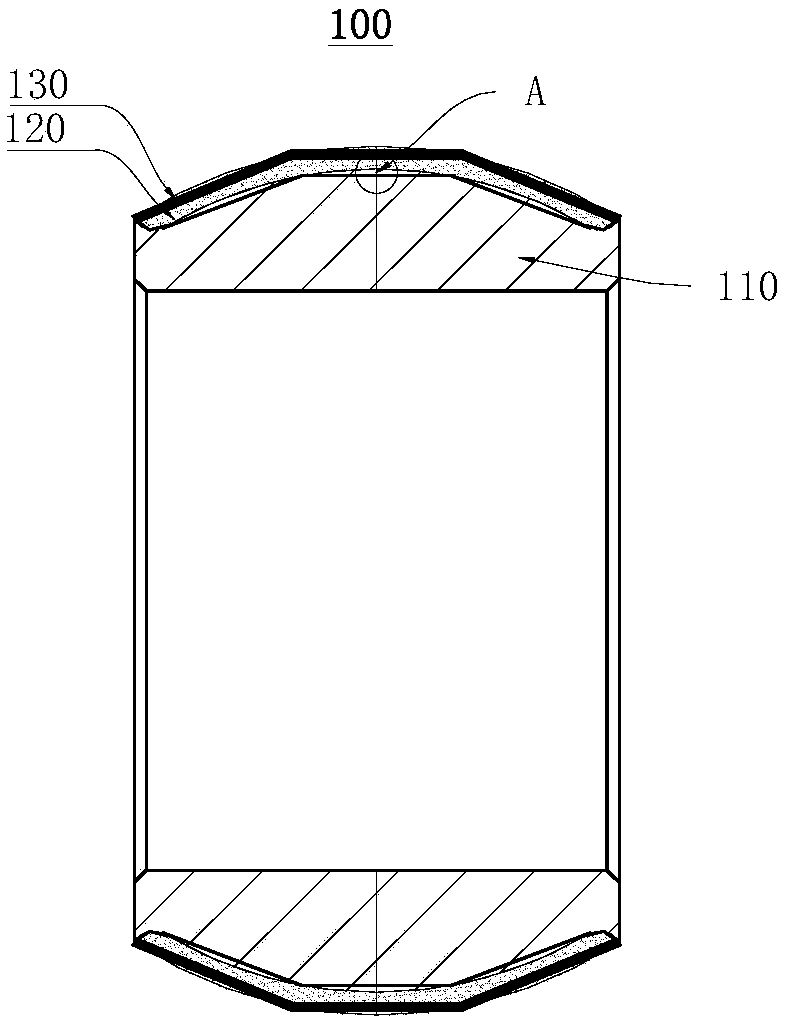

Fully-automatic continuous film-covering drying production line for plastic foam particles

The invention relates to the technical field of machining machinery for foam particles, and particularly relates to a fully-automatic continuous film-covering drying production line for plastic foam particles. The fully-automatic continuous film-covering drying production line for the plastic foam particles comprises a film-covering mechanism, a feeding mechanism, a spraying device and a drying mechanism, wherein the film-covering mechanism comprises a film-covering box body provided with an inner cavity and a stirring device arranged in the film-covering box body; the stirring device comprises a rotary shaft; spiral sheets are axially arranged on the rotary shaft in the axial direction of the rotary shaft; the spiral sheets comprise continuous spiral sheets used for pushing materials anddiscontinuous spiral sheets used for carrying out uniform and comprehensive stirring on a film-covering liquid and the particles to enable the surfaces of the particles to be uniformly wrapped with the film-covering liquid; each discontinuous spiral sheet is composed of a plurality of tooth sheets in a spiral manner and at intervals; the left tooth side of one tooth sheet of each two adjacent tooth sheets and the right tooth side of the other tooth sheet are arranged on a spiral line; and the outer-side tooth side of each tooth sheet is arranged in a manner of approaching to and being tangential with the inner wall of the film-covering box body. According to the fully-automatic continuous film-covering drying production line for the plastic foam particles, nonintermittent and continuous production is realized by pushing materials while stirring; and the fully-automatic continuous film-covering drying production line for the plastic foam particles is high in yield, uniform in coating, rapid in drying, low in energy consumption, and high in automation degree.

Owner:菲尔普(青岛)新材料有限公司

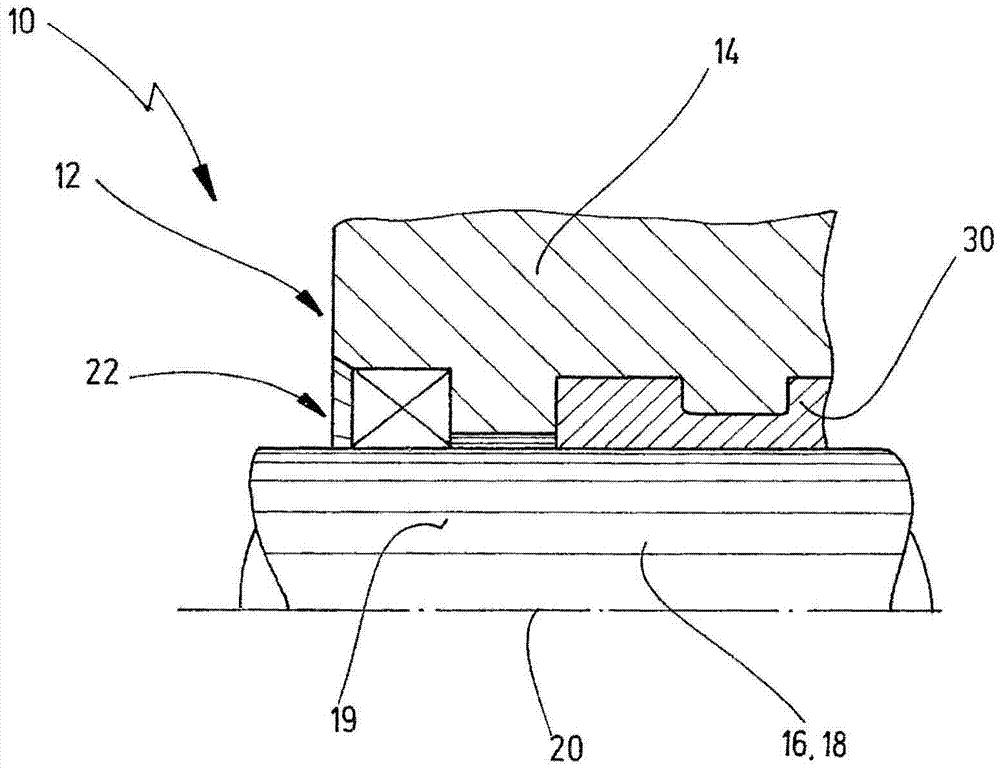

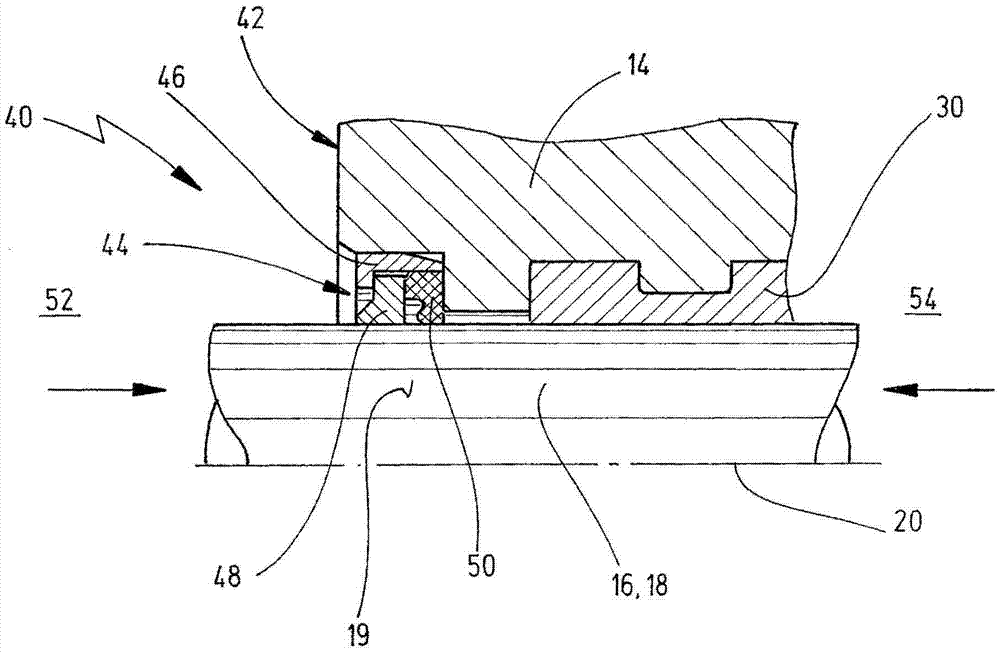

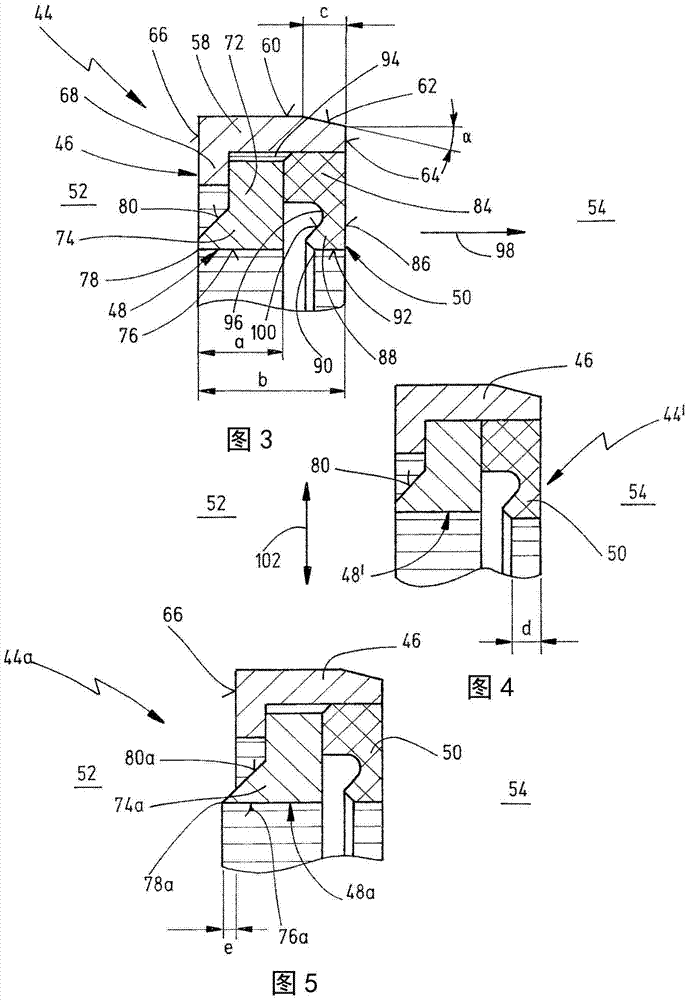

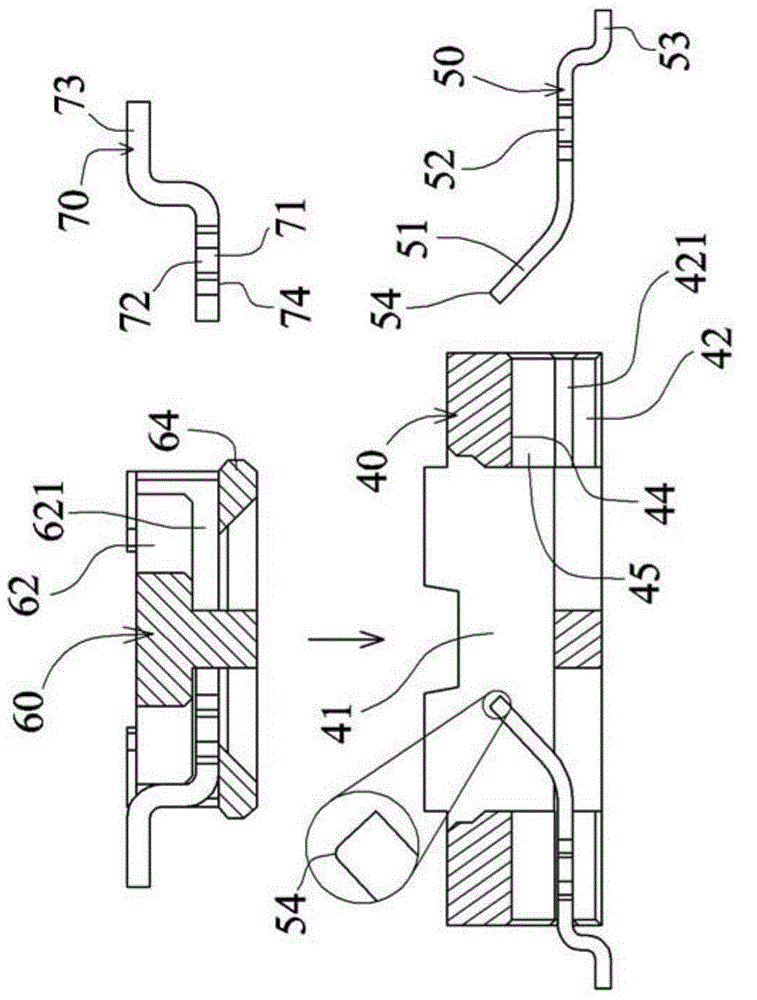

Stripper unit and hydraulic working apparatus having a stripper unit

ActiveCN105452677AReduce wall thicknessLow preloadEngine sealsCarpet cleanersSecondary sideMechanical engineering

The invention relates to a stripper unit (44) and to a hydraulic working apparatus (40) having a stripper unit (44). The stripper unit is formed in particular as an ice stripper for hydraulic working apparatuses for protecting a secondary side (54) against environmental influences which arise on a primary side (52), in particular for protecting guide arrangements and / or sealing arrangements (42), and is provided with a holding ring (46), which is formed in a substantially rotationally symmetrical manner about a longitudinal axis (20) and has a contact portion (58) for reception on a housing part (14), with a primary stripper (48), in particular an outer stripper, and with a secondary stripper (50), which is offset axially in the direction of the secondary side (54) in relation to the primary stripper (48), wherein a primary lip (74) is formed on the primary stripper (48) and a secondary lip (88) is formed on the secondary stripper (50), wherein the primary lip (74) and the secondary lip (88), when in a joined state, make sealing contact with a sliding surface (19) of a guided sliding partner part (16), in particular a piston rod, wherein the primary lip (74) protrudes like a collar in the direction of the primary side (52) and, on the side thereof which is remote from the guided sliding partner part (16) when in a joined state, tapers conically at least in certain portions in the direction of the primary side (52), and wherein the primary lip (74) has a contact surface (76) designed to bear against the sliding surface (19).

Owner:DR WALTER HUNGER BET GMBH & CO BESITZ

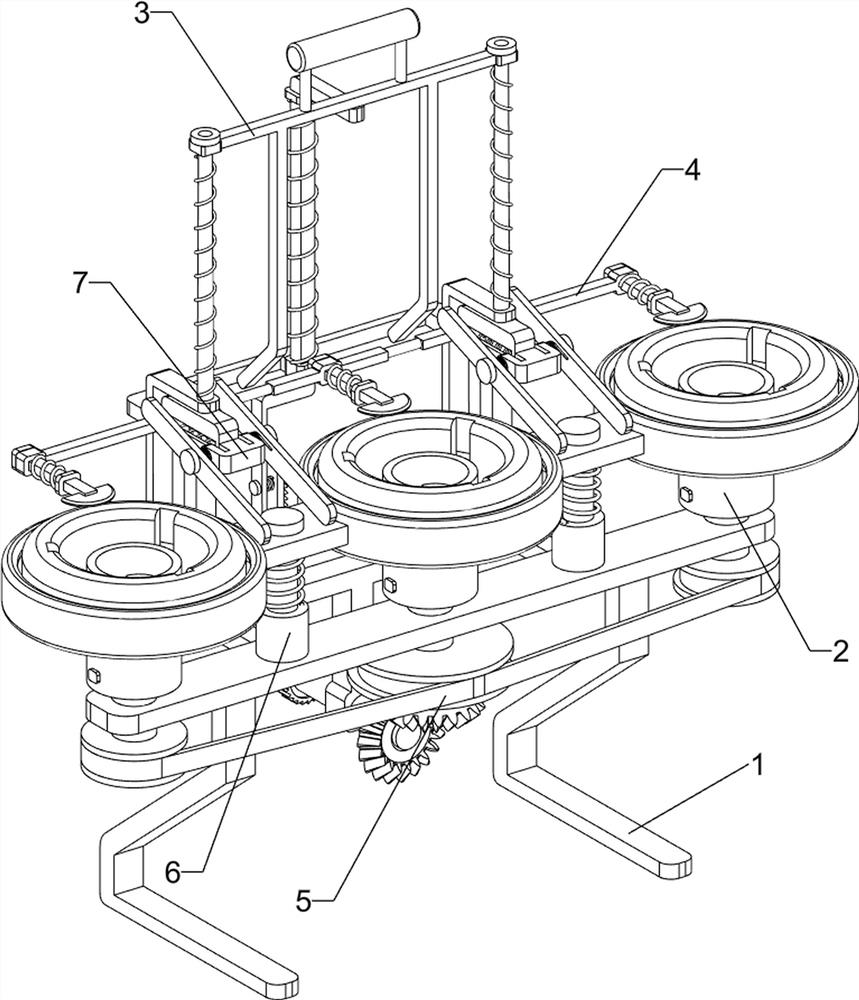

Curtain wall single-board cleaning device

ActiveCN111974714AEasy to cleanImprove scratching effectCleaning using toolsSingle plateCotton cloth

The invention belongs to the field of building processing, and particularly discloses a curtain wall single-board cleaning device. The curtain wall single-board cleaning device comprises a rack, wherein the rack is provided with a workbench used for placing a curtain wall single board; the rack is provided with a scraping mechanism, a wiping mechanism and an installation mechanism; the installation mechanism comprises fixing boards fixed on two sides of the workbench; each fixing board is provided with a sliding chute along the length direction of the workbench; a sliding board is in sliding connection in each sliding chute; the wiping mechanism comprises a rotary barrel rotatably connected between two sliding boards; the outer wall of the rotary barrel is fixedly provided with a cotton cloth layer; the scraping mechanism comprises a first scraping component, a second scraping component and a third scraping component, wherein the first scraping component is used for scraping the curtain wall single board along a sliding board sliding direction; the second scraping component and the third scraping component are both used for scraping the curtain board single board along the slidingboard sliding direction; and in addition, the scraping and wiping directions of the second scraping component and the third scraping component are opposite. By use of the scheme of the invention, theproblem that manual cleaning is troublesome can be solved.

Owner:闰大建筑幕墙(湖北)有限公司

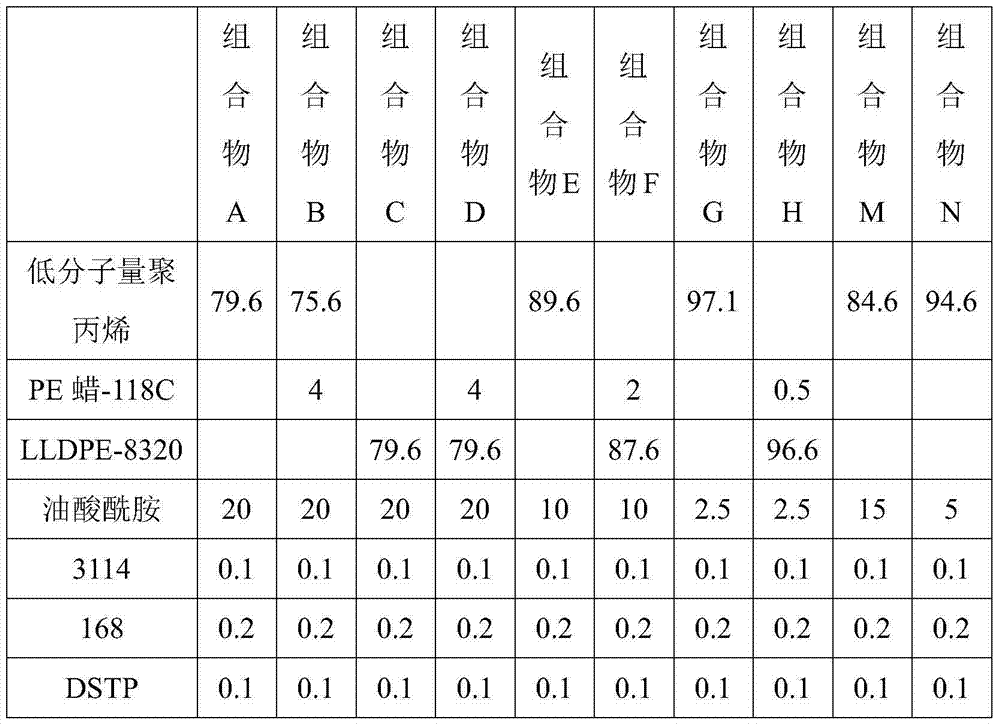

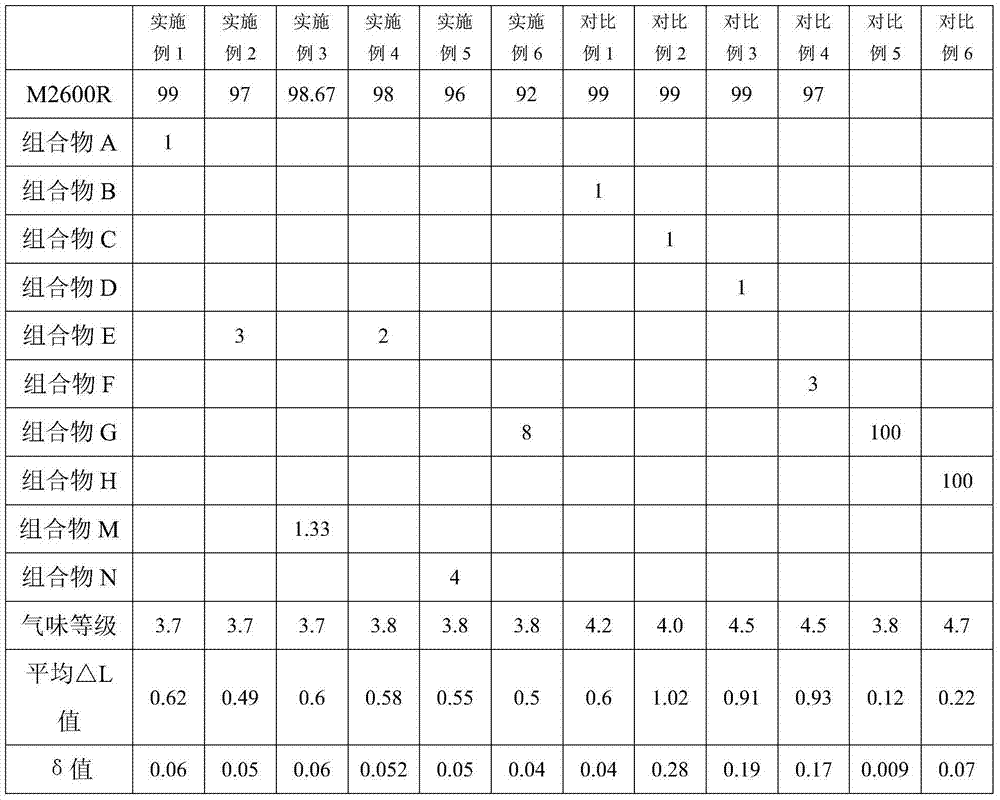

Low odor high dispersion scratch resistant additive masterbatch and preparation method thereof

The invention discloses a low odor high dispersion scratch resistant additive masterbatch and a preparation method thereof, the scratch resistant additive masterbatch comprises the following raw materials by weight: 75-94.9% of low molecular weight polypropylene, 5-25% of a scratch resistant additive and 0.1%-2% of an antioxidant, by use of the lubricity of the low molecular weight polypropylene and polypropylene excellent compatibility, the prepared scratch resistant additive masterbatch improves the scratch resistant additive dispersion, reduces the scratch resistant additive dosage, and improves the compatibility of the scratch resistant additive and the polypropylene material, the product is good in flavor, and the scratch resistant additive masterbatch can be used for an alternative for traditional scratch resistant additive adding method.

Owner:CHONGQNG PRET NEW MATERIAL +2

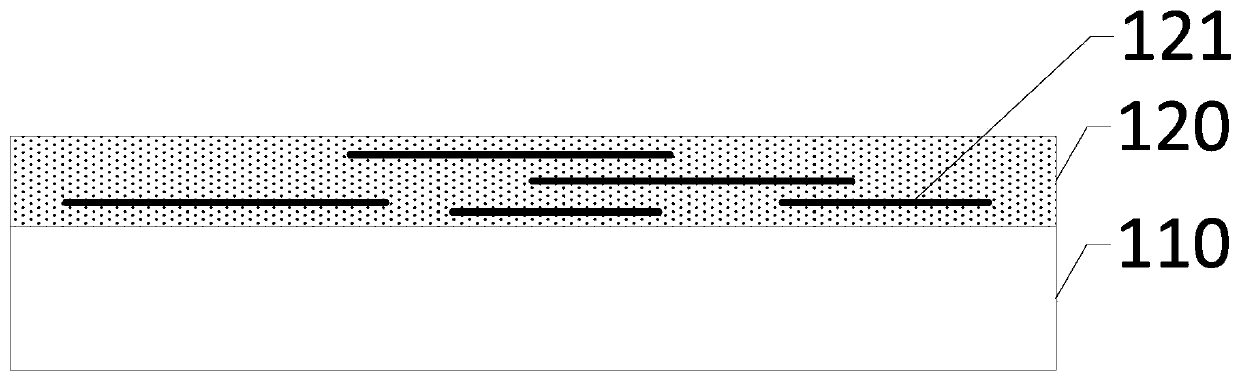

Flexible cover plate for display panel, preparation method of flexible cover plate, and display device

The invention discloses a flexible cover plate for a display panel, a preparation method of the flexible cover plate, and a display device. The flexible cover plate comprises a base plate, and a protecting layer arranged on the base plate, wherein the protecting layer internally comprises a plurality of fiber strips which are arrayed in mutually parallel and staggered modes. The flexible cover plate has the beneficial effects that according to the flexible cover plate for the display panel, the preparation method of the flexible cover plate, and the display device, by arranging the protectinglayer on the flexible base plate, the tensile strength of the flexible cover plate is improved, that is, the rigidity of the flexible cover plate is improved, and scraping performance of the flexiblecover plate can be improved; the protecting layer is made of materials of zirconium oxide, boron nitride and the like, and the flexible cover plate is stable in chemical property, high in strength, high in hardness and small in friction coefficient; the multiple fiber strips parallel to the length direction of the flexible base plate are arranged in the protecting layer, the fiber strips are madeof polyurethane fibers, the scraping resisting performance of the materials can be effectively improved, transverse sliding can be prevented, and thus the flexible cover plate has the sufficient rebound resilience; and a rotary coating technology is adopted in the preparation method of the flexible cover plate, and the simple and easy-to-operate effects are achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Burr-removing abrasive sand with ultrahigh strength and ultrahigh toughness and preparation method thereof

InactiveCN108546406AImprove toughnessImprove low temperature impact toughnessAbrasion apparatusAbrasive blastingUltimate tensile strength

The invention discloses a burr-removing abrasive sand with ultrahigh strength and ultrahigh toughness and a production method thereof. B40L is modified by a double screw extruder; B40L has the characteristics of lightness and good toughness; Surlyn has excellent low temperature impact resistant toughness and an excellent performance on resisting wear and scratch; in the double screw extruder, B40Lreacts with Surlyn 9320 at first, during the reaction process, Surlyn 9020 is added, reactions are kept on, the combination between B40L and functional groups of Surlyn 9320 and Surlyn 9020 is promoted, the strength of B40L is improved; after Surlyn 9320 and Surlyn 9020 are co-used, the combination between B40L and Surlyn 9320 / Surlyn 9020 is promoted, the using amount of modification additives isreduced, and the produced abrasive sand has the characteristics of ultrahigh strength and ultrahigh toughness. During the using process, the abrasive sand has a very good impact resistant performance, and can effectively process the surface of a rubber piece. Due to the toughness of the abrasive sand, the abrasive sand is resistant to breaking, and can be repeatedly used in cycle.

Owner:东莞市树林自动化科技有限公司

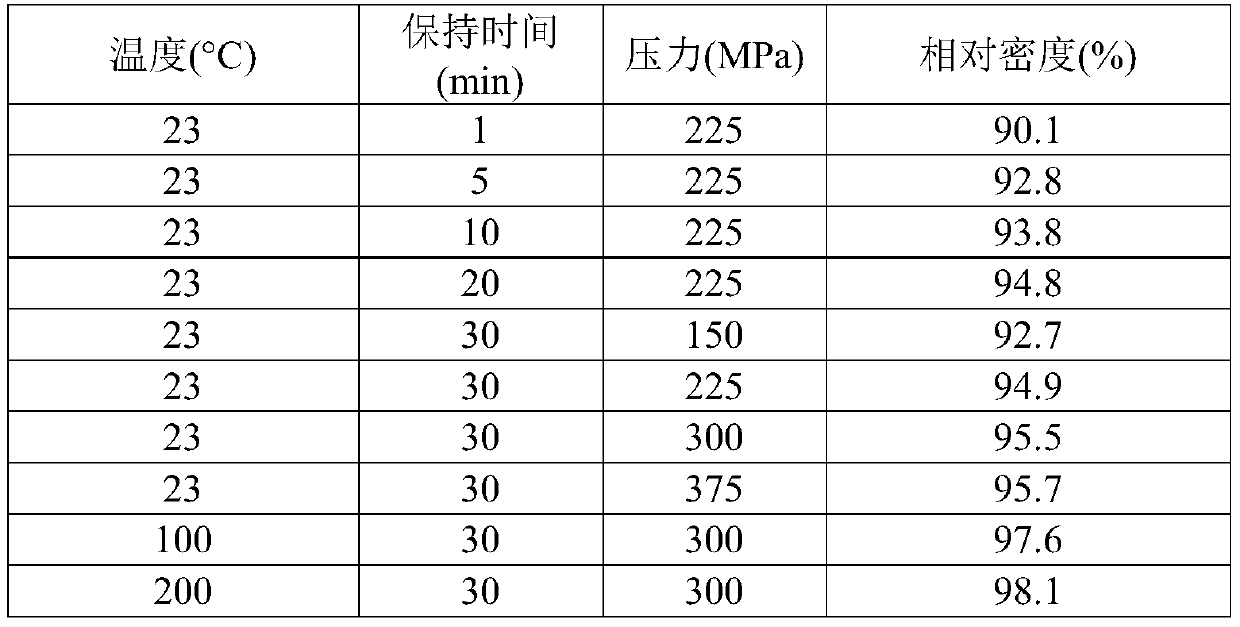

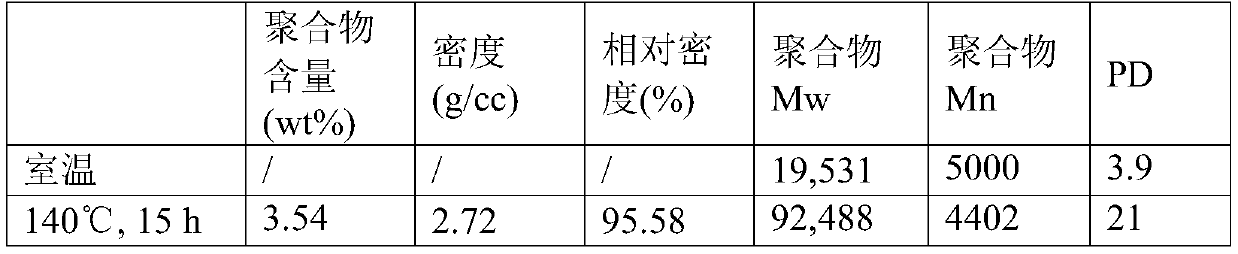

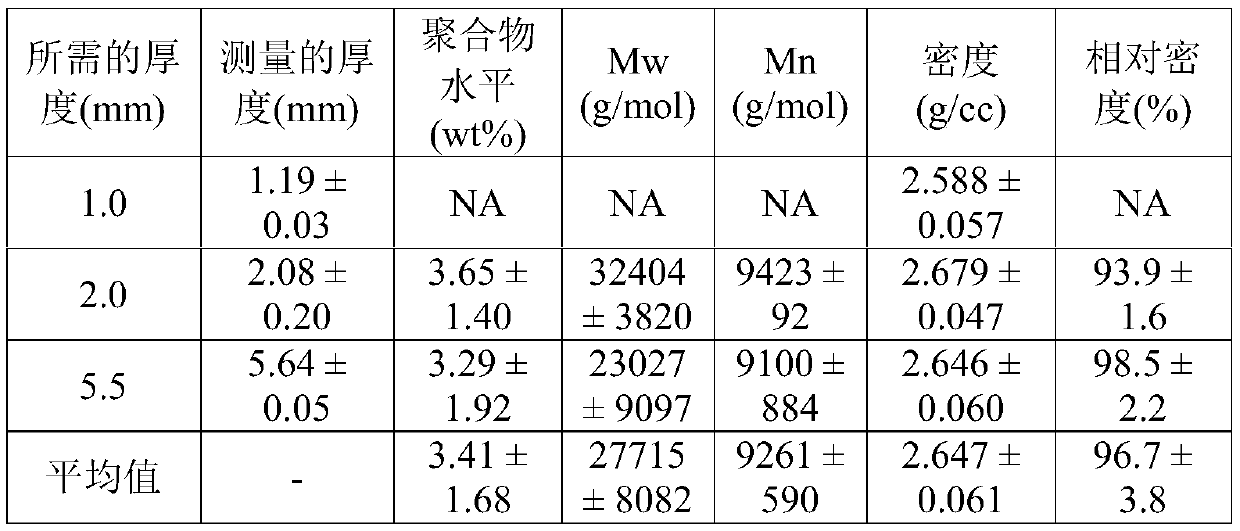

Ceramic-polymer composites obtained by cold sintering process using reactive monomer approach

InactiveCN110799473AImprove scratching effectImprove thermal conductivityCeramicwareOligomerPolymer composites

Described herein are cold-sintered ceramic polymer composites and processes for making them from ceramic precursor materials and monomers and / or oligomers. The cold sintering process and wide varietyof monomers permit the incorporation of diverse polymeric materials into the ceramic.

Owner:SHPP GLOBAL TECH BV

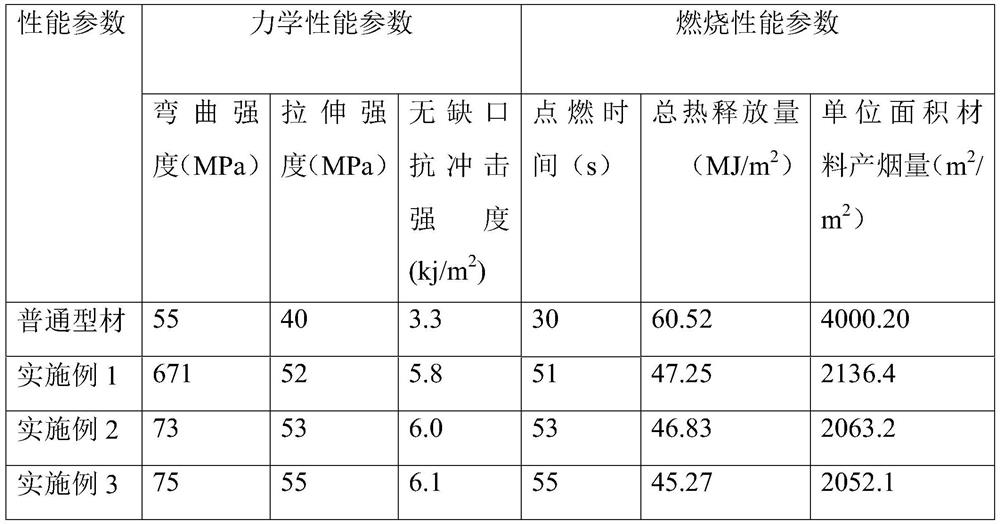

Preparation method of halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile

InactiveCN111806024AImprove flame retardant performanceHigh smoke suppression effectSynthetic resin layered productsPolymer sciencePhosphoric acid

The invention provides a preparation method of a halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile, which comprises the following steps of: (1) mixing high-density polyethylene, wood flour, a coupling agent, a lubricant, a plasticizer, expanded graphite and a composite halogen-free flame-retardant smoke suppressant, and granulating the mixture to obtain core layer material particles; (2) mixing sodium-zinc ionized resin, high-density polyethylene, expanded graphite, the composite halogen-free flame-retardant smoke suppressant and a coloring agent, and then granulating the mixture to obtain coating layer material particles; and (3) adding the core layer material particles into a charging barrel of a conical double-screw main extruder, adding the coating layer material particles into a charging barrel of a single-screw auxiliary extruder, simultaneously starting up the extruders for extrusion molding, and carrying out shaping and cooling after extrusion. Thecomposite halogen-free flame-retardant smoke suppressant is prepared from ammonium polyphosphate APP, a triazine charring agent CFA and silicon dioxide. The wood-plastic profile prepared by the preparation method provided by the invention has good flame-retardant and smoke-suppressing effects, does not release toxic and harmful substances at high temperature, and avoids secondary harm to human bodies.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

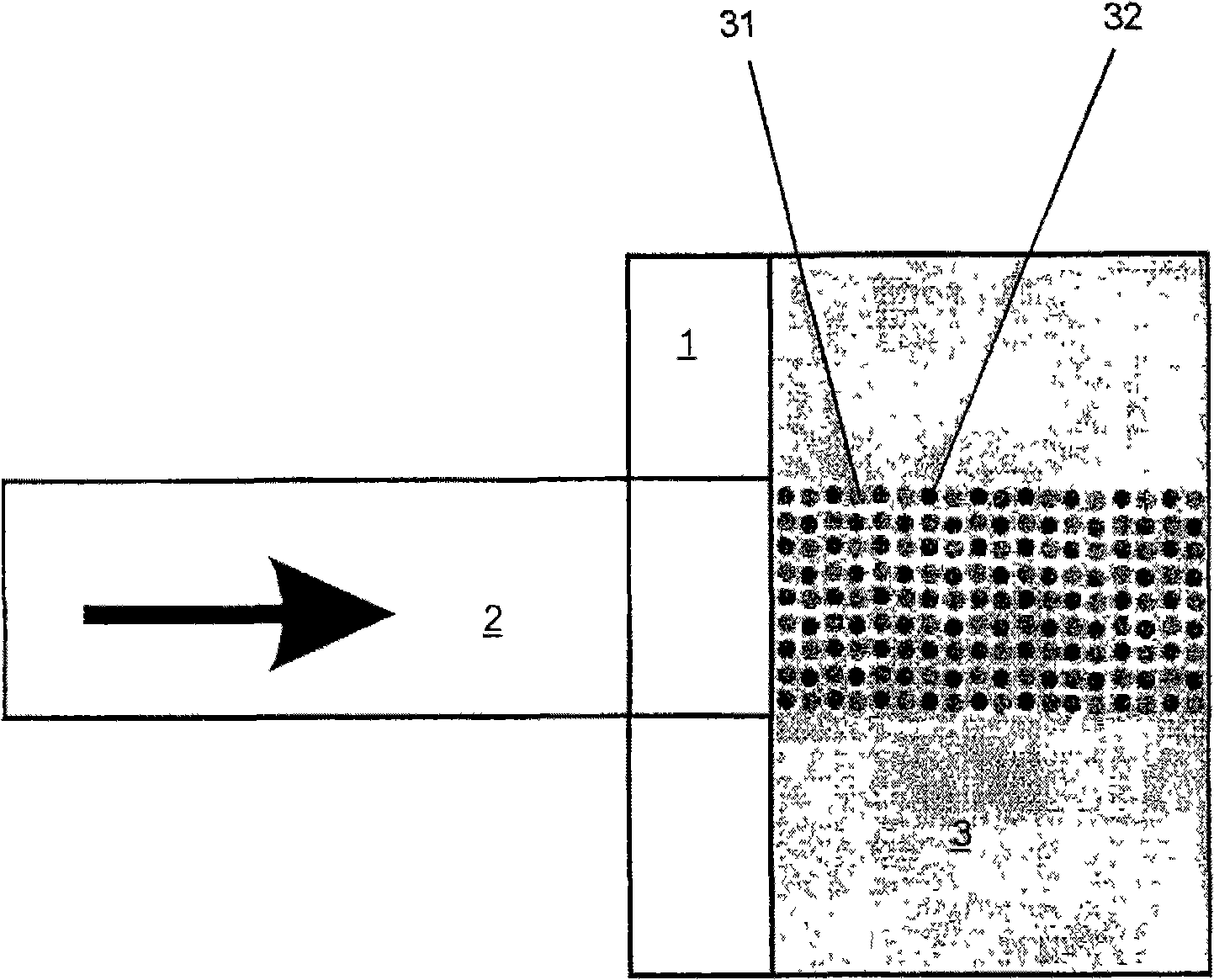

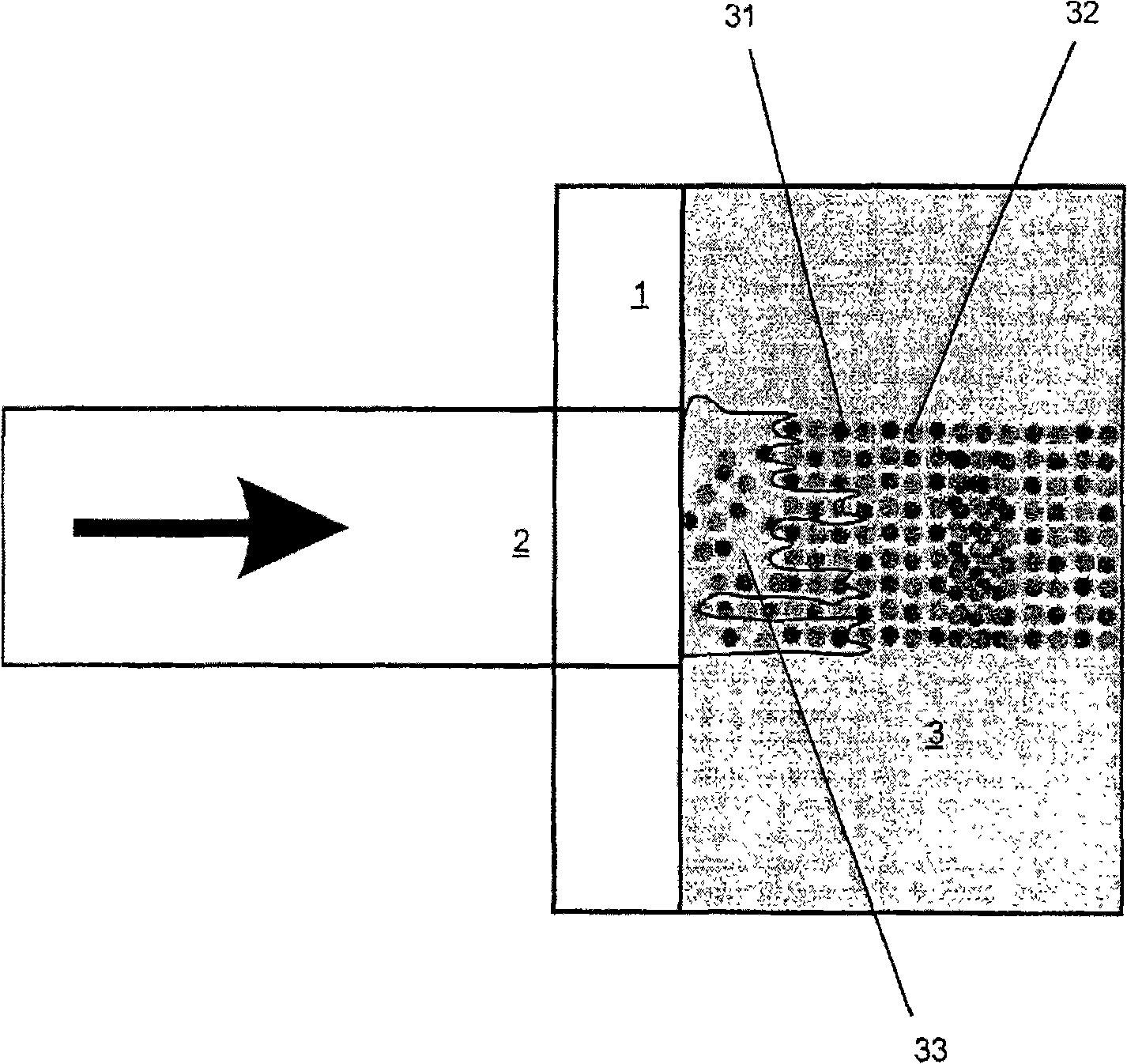

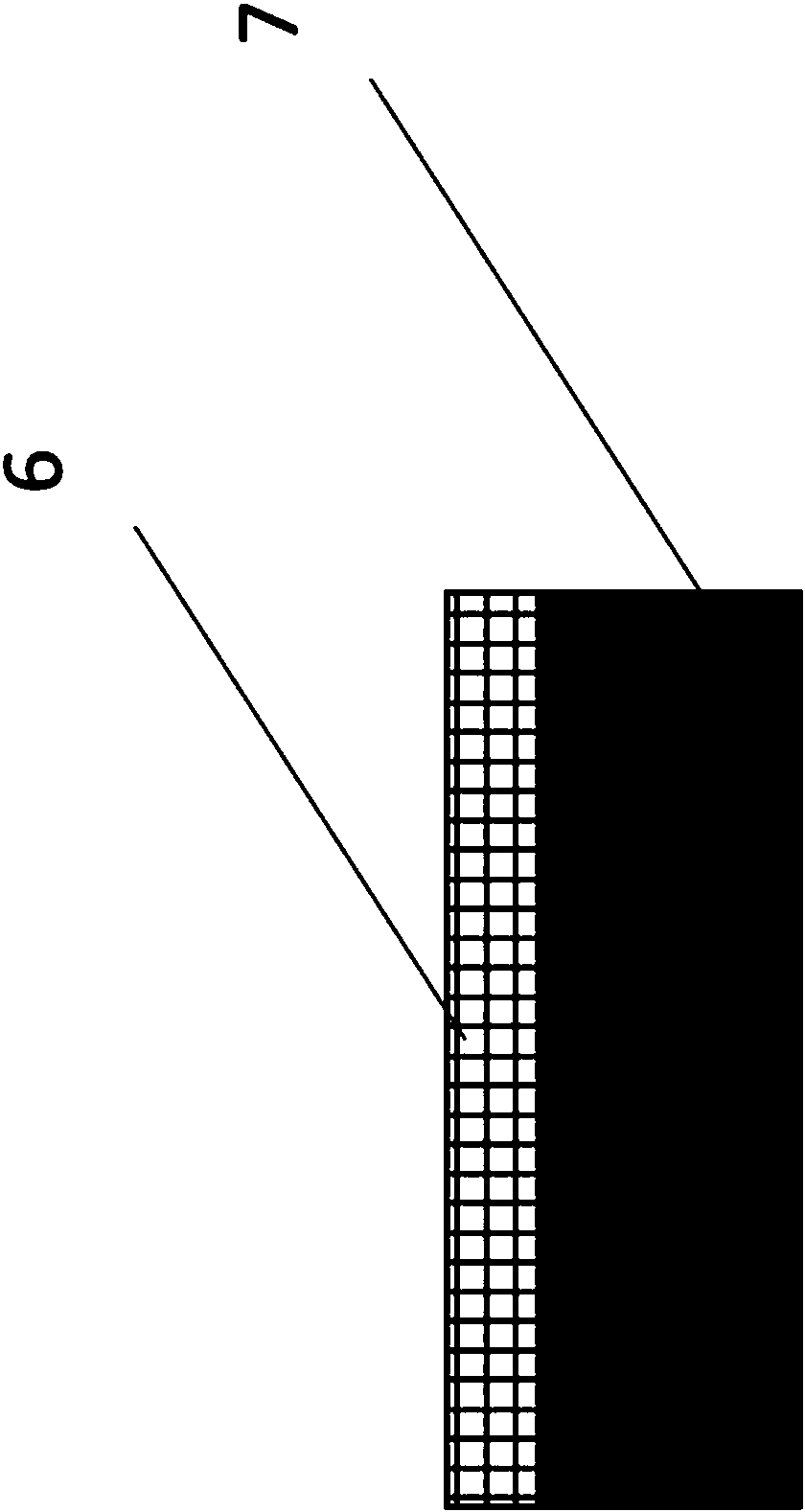

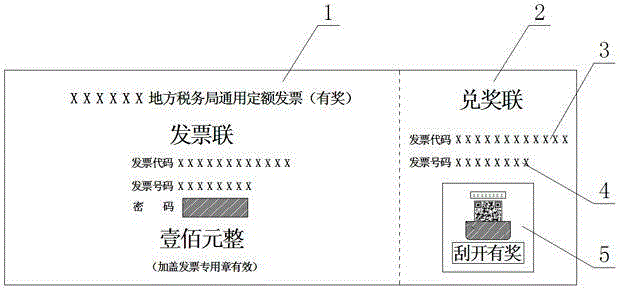

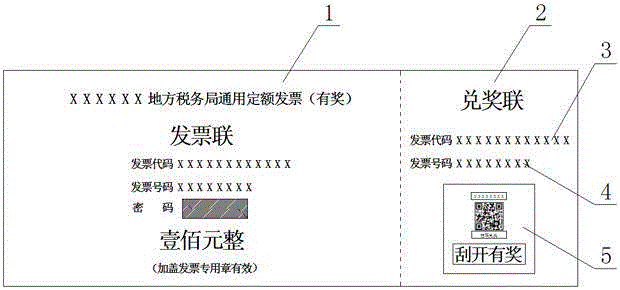

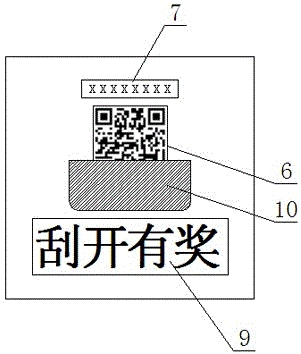

Invoice based on two-dimensional bar code rewarding

InactiveCN105095940AThe redemption process is convenientEasy to manageRecord carriers used with machinesComputer hardwareInvoice

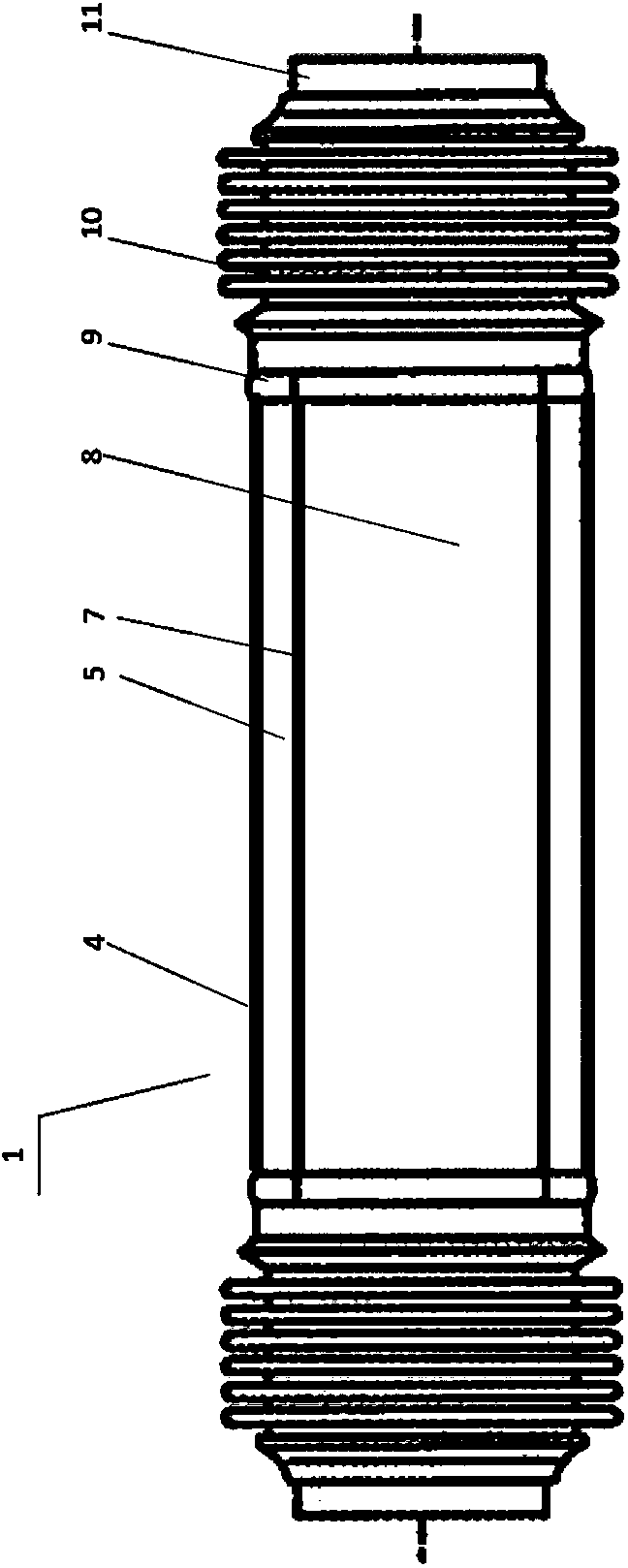

The invention discloses an invoice based on two-dimensional bar code rewarding. The invoice comprises an invoice copy (1) and a rewarding copy (2). An invoice code area (3), an invoice number area (4) and a rewarding area are printed on the rewarding copy (2). A two-dimensional bar code rewarding area (5) is internally provided with a two-dimensional bar code image attachment area (6), a two-dimensional bar code number attachment area (7), a code scanning prompt attachment area (8) and a cover coating layer (10). The cover coating layer (10) completely covers the code scanning prompt attachment area (8) and partially covers the two-dimensional bar code image attachment area (6) on which a two-dimensional bar code image is attached. Code scanning and rewarding can be performed by scraping the cover coating layer. If prizewinning appears after code scanning, a rewarding system prompts a prizewinner to provide personal information and bank, Alipay or Wechat and other cash collection account numbers, and the rewarding system automatically saves data and issues bonus so that the rewarding process is more convenient. The two-dimensional bar code image and an invoice number (code) are corresponding in a one-to-one way so that one-object one-code can be realized, and management of rewarding information is facilitated by a two-dimensional bar code number.

Owner:CHENGDU QIXIN TECH CO LTD

Bearing inner ring and preparation process thereof as well as self-lubricating joint bearing

PendingCN109139705AHigh surface hardnessImprove surface wear resistanceVacuum evaporation coatingSputtering coatingEngineeringHardness

The invention relates to a bearing inner ring and a preparation process thereof as well as a self-lubricating joint bearing, and belongs to the technical field of a joint bearing. The bearing inner ring comprises a bearing inner ring base body and a film-coating layer; the surface of the bearing inner ring base body is provided with a nitriding layer subjected to nitriding treatment; and the film-coating layer is arranged on the surface of the nitriding layer. The nitriding layer on the surface of the bearing inner ring base body can effectively enhance the surface hardness of the surface of the bearing inner ring base body; the film-coating layer on the surface of the nitriding layer further improves the surface hardness and the wear resistance of the surface of the bearing inner ring; the friction coefficient of the surface of the bearing inner ring is reduced; and the liner scratching resistance of the surface of the bearing inner ring is improved. The preparation process of the bearing inner ring comprises the steps of preparing the nitriding layer on the surface of the bearing inner ring base body by a vacuum plasma nitriding method, and preparing the film-coating layer on thesurface of the nitriding layer by a physical vapor deposition method. According to a self-lubricating bearing, the bearing inner ring and a self-lubricating liner form a friction pair, so that the wear rate of the liner is reduced and the service life of the joint bearing is prolonged.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

UV ink serial products special for novel 'scratch type' bills and application thereof

InactiveCN101608076AReach the level of slipperyImprove isolationInksOther printing apparatusIsolation effectSlurry

The invention relates to UV ink serial products special for novel 'scratch type' bills and application thereof, which comprise UV back black ink, UV isolating oil ink, UV silver adjusting oil ink and special silver slurry and application thereof. The invention provides the UV ink serial products special for the novel 'scratch type' bills, which have the advantages of high technical content, various varieties and wide applicability. The performance of the UV back black ink, the UV isolating oil ink, the UV silver adjusting oil ink and the special silver slurry can be adjusted and controlled according to the requirements of printing machine types and bill paper on printing finished products to achieve the controllable isolation effect, the controllable printing speed, the scratching difficulty, the drying speed, the printing thickness, the controllable back black printing and the controllable covering effect, and achieve coordinating and unifying so as to adapt to the modern high-speed printing and produce products satisfactory to users.

Owner:姚瑞刚 +4

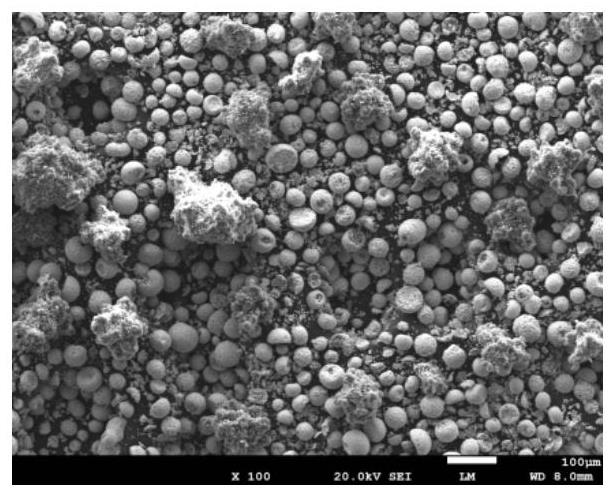

Conductive abradable seal coating material and preparation method thereof

PendingCN114479531AStrong resistance to water and oxygenImprove conductivityElectrically-conductive paintsPolyesterCoated surface

The invention belongs to the field of inorganic non-metallic materials, and particularly relates to a conductive abradable seal coating material and a preparation method thereof. The conductive abradable seal coating material comprises the following components in percentage by weight: 60 to 70 percent of rare earth silicate, 20 to 30 percent of conductive filler, 2.0 percent of lubricating phase and 8.0 percent of polyester. A powder material is prepared by adopting a solid-phase sintering and mechanical mixing method, a conductive abradable sealing coating is prepared by utilizing a plasma spraying process, and the surface configuration is processed by electric spark. The abradable seal coating material has the advantages of being good in interface matching performance with a ceramic matrix composite matrix, high in water and oxygen resistance, good in conductivity and the like, the surface of the coating is subjected to structural modeling through an electric spark technology, and the scraping matching performance of the abradable seal coating and a rotor material can be effectively improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

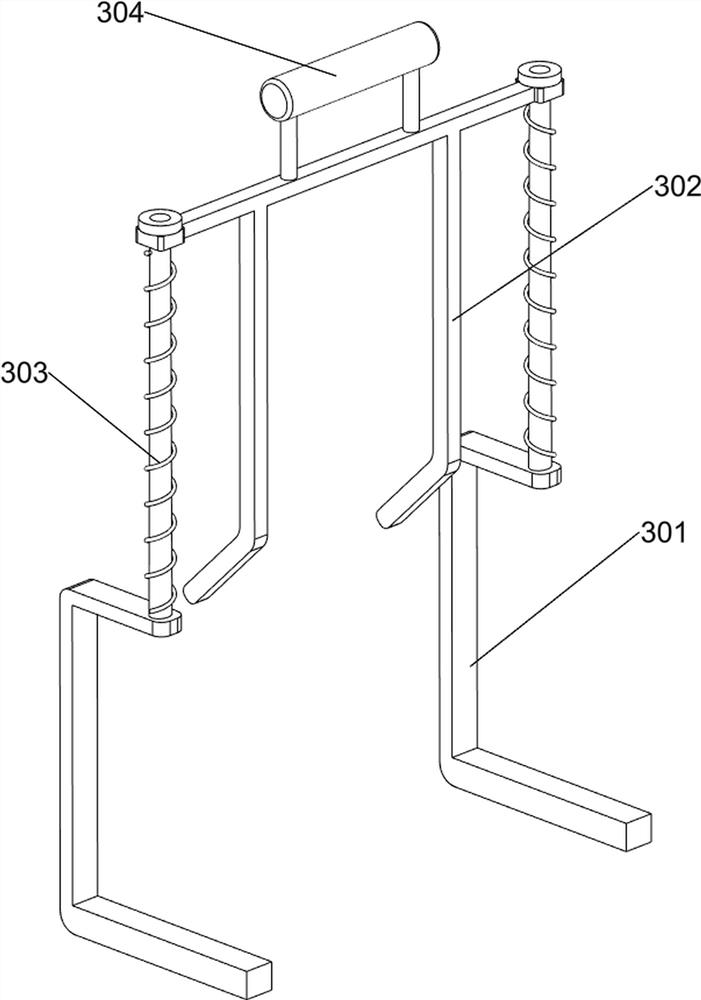

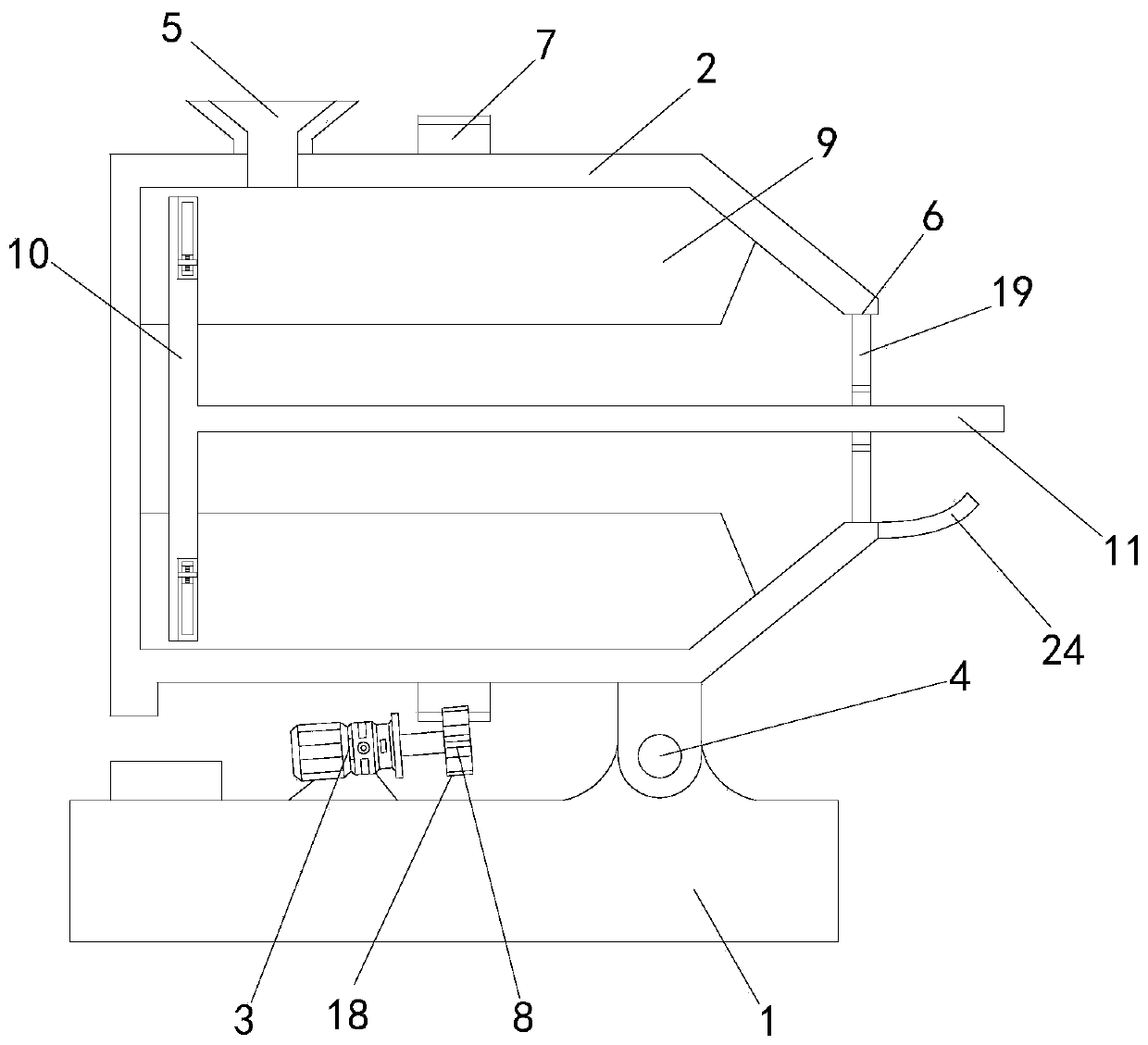

Concrete stirring equipment applied to construction site

InactiveCN110722680ARatio effectImprove scratching effectTransportation and packagingMixer accessoriesCircular discArchitectural engineering

The invention discloses concrete stirring equipment applied to a construction site, and belongs to the technical field of construction. The equipment comprises a stirring barrel, a fixed base and a driving motor; stirring blades are arranged in the stirring barrel; the direction of the stirring blades is parallel to the axis of the stirring barrel; the stirring blades are perpendicular to the inner wall of the stirring barrel; a disc for scraping concrete retained on the inner wall of the stirring barrel is arranged in the stirring barrel; after the concrete is poured out, the disc can thoroughly scrape off the concrete retained on the inner wall of the stirring barrel to prevent influence on subsequent concrete stirring ratio by the concrete retained on the inner wall of the stirring barrel; an arc plate is arranged around the disc, is elastically connected with the disc, and can abut against the inner wall of the stirring barrel; and the disc is provided with a third groove for enabling the stirring blades to pass through, so that the bonding force between the arc plate and the inner wall of the stirring barrel is increased, and the scraping effect on the retained concrete by thedisc is improved.

Owner:徐州念渠工程机械有限公司

Antistatic coaming box and preparation method thereof

InactiveCN111635591AImprove physical performanceImprove protectionBox making operationsPaper-makingProduction linePolymer science

The invention discloses an antistatic coaming box. A box body material of the antistatic coaming box is prepared from, by weight, 70 to 90 parts of co-polypropylene, 10 to 20 parts of a conductive filler, 10 to 15 parts of a calcium carbonate filler, 4 to 8 parts of a rubber flexibilizer, 5 to 10 parts of silicone powder, 1 to 1.5 parts of sodium stearate, 0.3 to 0.5 part of a coupling agent, 0.3to 0.5 part of an antioxidant and 0.3 to 0.5 part of a light stabilizer. The box body is prepared from the raw materials measured according to the proportion through the steps of plate forming, slitting, indentation and box forming, fixing and card inserting and the like. The manufactured antistatic coaming box can still keep a good electrostatic protection effect in a dry environment and can be used for transfer transportation of some high-precision parts and the like, the surface of the box body has good scratch resistance and abrasion resistance, and the antistatic coaming box is particularly convenient to use on a production line.

Owner:苏州佳硕塑胶包装材料有限公司

Water-resistant ceramic-like internal wall decorative paint and preparation method thereof

The invention discloses a water-resistant ceramic-like internal wall decorative paint which is prepared from the following components in parts by weight: 30-40 parts of silicone acrylic emulsion, 5-10 parts of urea-formaldehyde resin, 3-5 parts of VAE (vinyl acetate-ethylene) redispersible latex powder, 5-10 parts of nano kaolin, 1-5 parts of magnesium oxide, 1-5 parts of magnesium chloride, 3-5 parts of tea saponin, 15-20 parts of wollastonite powder, 5-10 parts of heavy calcium carbonate powder, 3-5 parts of sodium silicate, 1-1.5 parts of sodium hexametaphosphate, 0.5-1 part of hydroxyethyl cellulose, 1-2 parts of Texanol ester alcohol, 1-3 parts of sodium hydroxide, 10-15 parts of quicklime and 20-25 parts of water. The water-resistant ceramic-like internal wall decorative paint has the advantages of reasonable and scientific formula design, low cost, no toxicity, high safety, favorable smoothness, excellent water resistance and no sag after scratching. The invention also discloses a preparation method of the water-resistant ceramic-like internal wall decorative paint. The method has the advantages of simple processing steps and stable and controllable process, and is easy to implement and suitable for industrial production.

Owner:ZHEJIANG COLLEGE OF CONSTR

Electric connector

InactiveCN104810645AIncrease contactEnsure electrical connectionCoupling contact membersEngineeringMetal sheet

An electrical connector comprises a female base formed with a fitting slot; female terminals each arranged on one side of the female base and made of a metal sheet and integrally formed with an extension having a contact disposed in the fitting slot, a fixing portion fixed to the female base and a pin extending out of the female base; a male base mounted in the fitting slot; and male terminals each arranged on one side of the male base and made of a metal sheet and integrally formed with an extension having a contact elastically resting against the contact of the female terminal, a fixing portion fixed to the male base and a pin extending out of the male base. One of the male and female terminals is formed by bending a plate surface, and the fixing portions thereof are transversally fixed.

Owner:蔡周贤

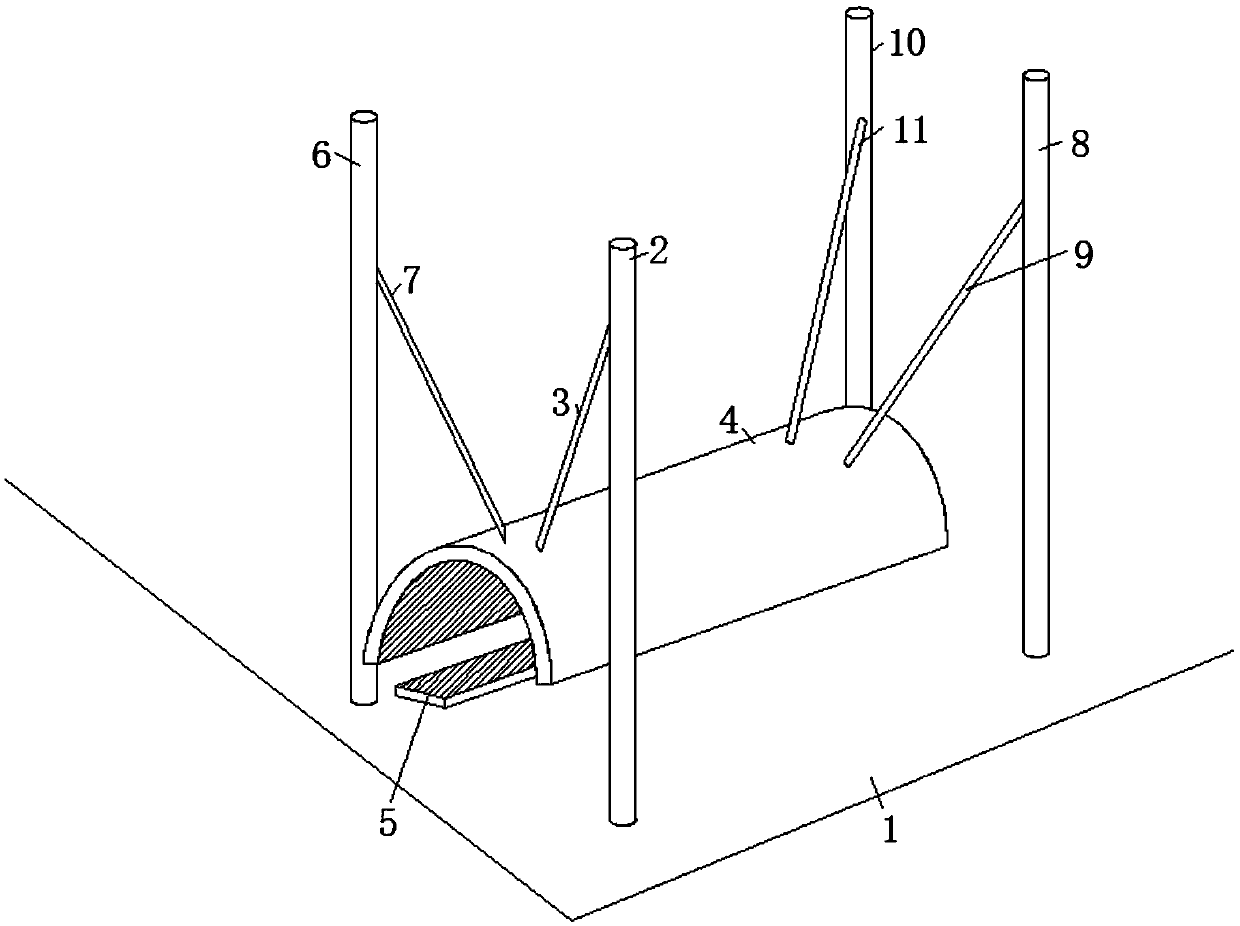

Tiger itch scratching device used in tiger park of zoo

The invention relates to the technical field of appliances used in zoos, in particular to a tiger itch scratching device used in a tiger park of a zoo. The tiger itch scratching device comprises a floor, wherein a column I is fixedly installed on the floor, the back side of the column I is fixedly connected with one end of a connecting rope I, the other end of the connecting rope I is fixedly connected with the top of a half tube, the top of the half tube is fixedly connected with one end of a connecting rope II, the connecting rope II is located behind the connecting rope I, the other end ofthe connecting rope II is fixedly connected with one side of a column II, the column II is fixedly installed on the floor and is located behind the half tube, the top of the half tube is fixedly connected with one end of a connecting rope III, and the connecting rope III is located on the right side of the connecting rope I. The tiger itch scratching device used in the tiger park of the zoo playsa very good itch scratching effect through the half tube in cooperation with the connecting rope I, the connecting rope II, the connecting rope III and a connecting rope IV, and the problem of body itch of tigers is solved.

Owner:许松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com