High-melt-strength polypropylene micro-foaming material and preparation method thereof

A technology of high melt strength and polypropylene, which is applied in the field of polymer materials, can solve the problems affecting the mechanical properties of foam materials, the decrease of melt strength, and the collapse of cells, so as to promote stability, improve melt strength, and foam Dense and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The polypropylene micro-foaming material with high melt strength in this embodiment is composed of 98wt% polypropylene composite material and 2wt% chemical blowing agent;

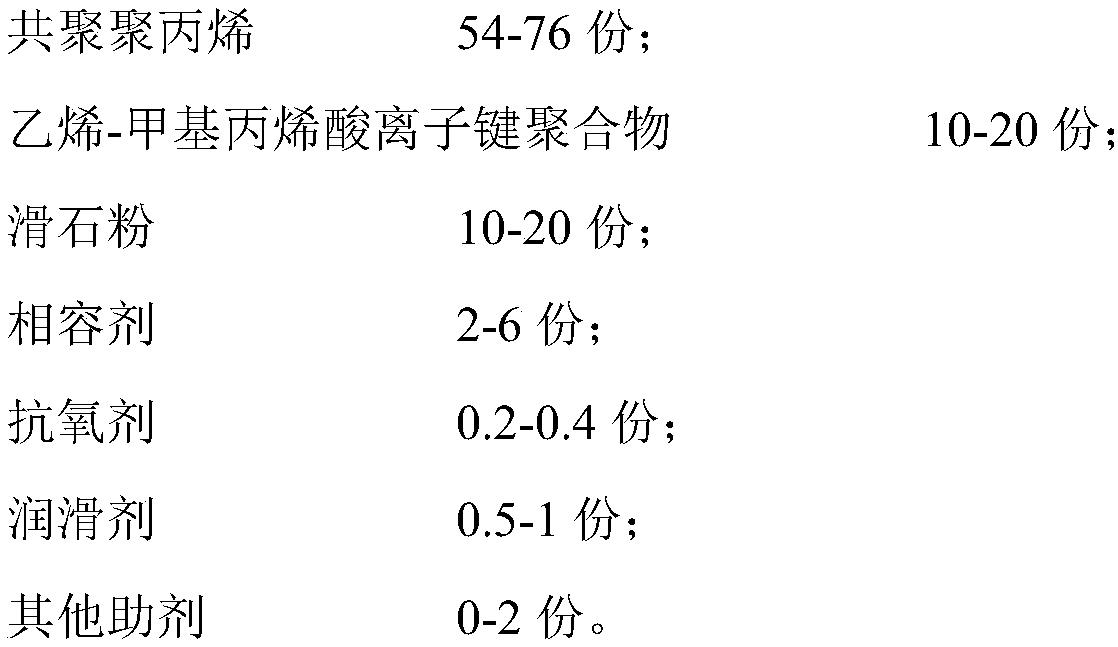

[0023] The polypropylene composite material is prepared from the following raw materials in parts by weight:

[0024]

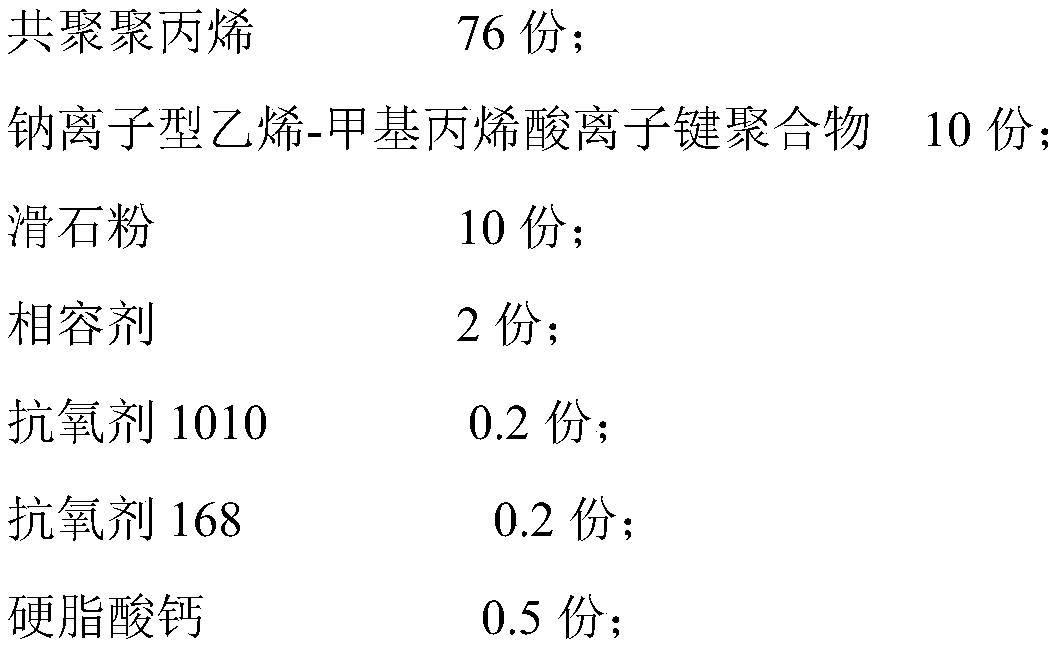

[0025] Concrete preparation method comprises the following steps:

[0026] (1) 76 parts of copolymerized polypropylene, 10 parts of sodium ion type ethylene-methacrylic acid ionomer, 10 parts of talcum powder, 2 parts of compatibilizer, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.5 parts of calcium stearate were mixed in a high-speed mixer for 10 minutes, then put into a co-rotating twin-screw extruder, melted and extruded, and granulated to obtain a polypropylene composite material; wherein the extrusion temperature of the extruder was 180- 200°C, the screw speed is 350-400r / min, and the vacuum degree is -0.06—-0.08MPa.

[0027] (2) After mixing evenly the pol...

Embodiment 2

[0029] The polypropylene micro-foaming material with high melt strength in this embodiment is composed of 97wt% polypropylene composite material and 3wt% chemical blowing agent;

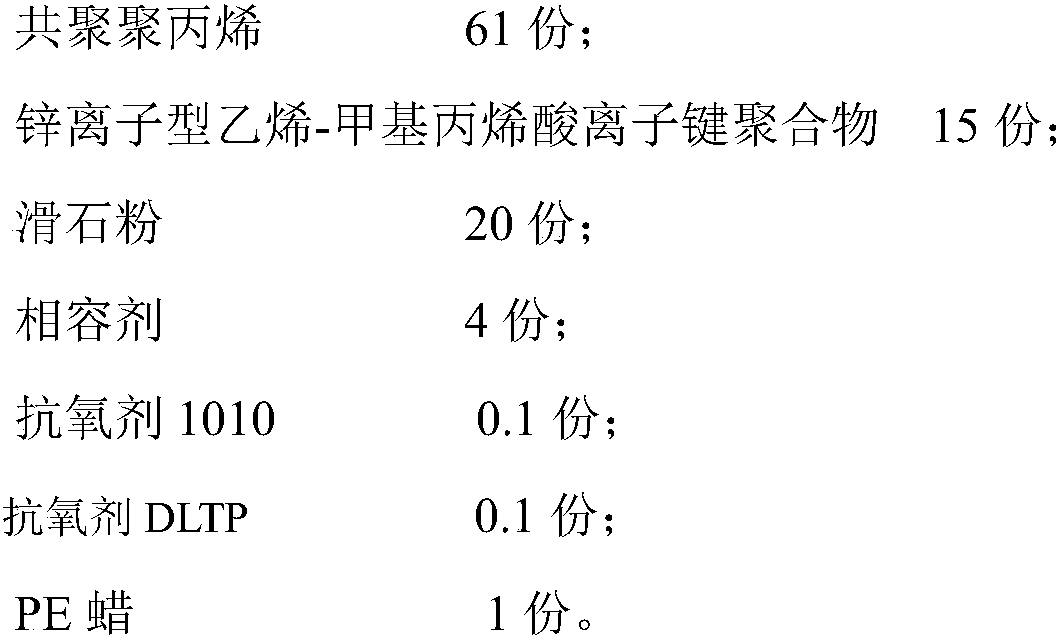

[0030] The polypropylene composite material is prepared from the following raw materials in parts by weight:

[0031]

[0032] Concrete preparation method comprises the following steps:

[0033] (1) 61 parts of copolymerized polypropylene, 15 parts of ethylene-methacrylic acid ionomer, 20 parts of talcum powder, 4 parts of compatibilizer, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, and 1 part of PE wax Parts are mixed in a high-speed mixer for 10 minutes, then put into a co-rotating twin-screw extruder, melted and extruded, and granulated to obtain a polypropylene composite material; the extrusion temperature of the extruder is 180-200 ° C, the screw speed It is 350-400r / min, and the vacuum degree is -0.06—-0.08MPa.

[0034] (2) After mixing evenly the polypropylene composite mate...

Embodiment 3

[0036] The polypropylene micro-foaming material with high melt strength in this embodiment is composed of 97wt% polypropylene composite material and 3wt% chemical blowing agent;

[0037] The polypropylene composite material is prepared from the following raw materials in parts by weight:

[0038]

[0039] Concrete preparation method comprises the following steps:

[0040] (1) 54 parts of copolymerized polypropylene, 20 parts of lithium-ion type ethylene-methacrylic acid ionomer, 20 parts of talcum powder, 6 parts of compatibilizer, 0.15 part of antioxidant 1010, 0.15 part of antioxidant 168, 1 part of calcium stearate, 0.5 part of ultraviolet light absorber, 0.5 part of light stabilizer, and 1 part of coloring agent were mixed in a high-speed mixer for 10 minutes, then put into a co-rotating twin-screw extruder, melted and extruded, granulated, The polypropylene composite material is obtained; the extrusion temperature of the extruder is 180-200°C, the screw speed is 350-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com