Patents

Literature

729 results about "Interface bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/copper composite and preparation method thereof

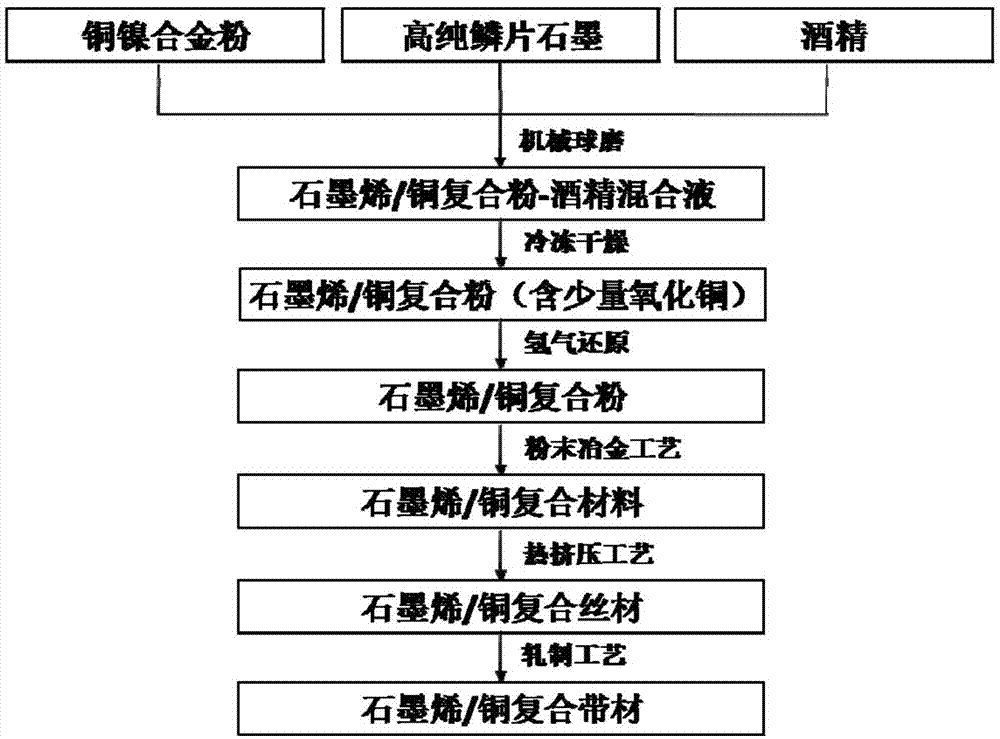

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

Grafting modification method for solution-polymerized styrene-butadiene rubber with low gel rate

The invention relates to a preparation method of polar solution-polymerized styrene-butadiene rubber with low gel rate. The method involves grafting polar monomers on solution-polymerized styrene-butadiene rubber by means of free radical solution method, so as to change the polarity and further improve the interface bonding force of styrene-butadiene rubber and carbon black or white carbon black, so that the wet-skid resistance, wear resistance and dynamic mechanical property of vulcanized rubber are improved and the rolling resistance is reduced. The polar monomers used comprise maleic anhydride, acrylic acid, acrylamide, N-vinyl pyrrolidone and the like. The grafting rate of modified styrene-butadiene rubber is 1-5% and the gel rate is 1-3%; and the rubber polarity changes obviously.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Preparation method for vertically oriented boron nitride/high polymer insulating heat conducting material

InactiveCN106832877AImprove insulation performanceImprove thermal conductivityLayered productsHeat-exchange elementsHeat conductingBoron nitride

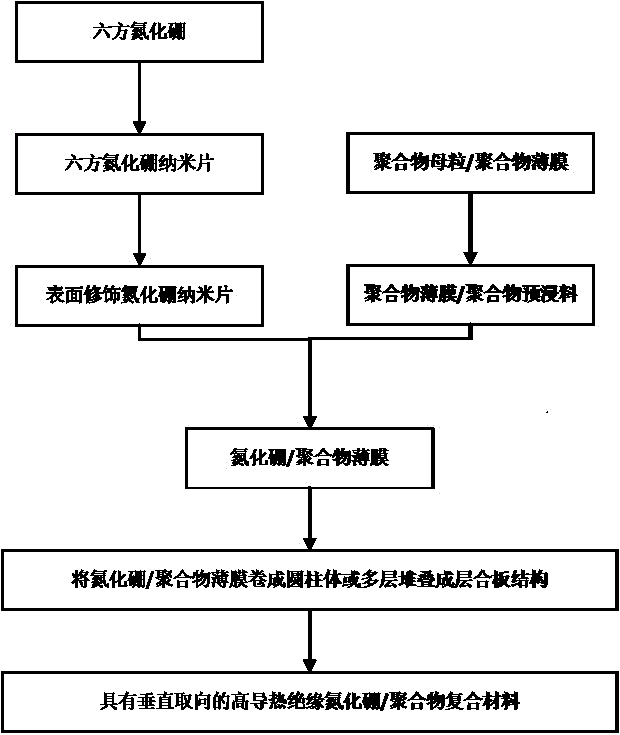

The invention provides a preparation method for a vertically oriented boron nitride / high polymer insulating heat conducting material, and belongs to the field of radiating material preparation. The method comprises the following steps: first, modifying the surfaces of boron nitride nano-sheets by using dopamine or a silane coupling agent; then, coating the modified boron nitride nano-sheets between two layers of high polymers; next, pressing the three layers of materials into a thin film with a certain thickness by utilizing a hot pressing process; finally, laminating the thin film into a block body or winding the thin film into a cylinder. The preparation method is simple in process and suitable for batch production; the boron nitride cannot aggregate in the polymers, and a highly oriented heat conducting network is formed, and quick conducting of heat is facilitated. The surface of the boron nitride is modified; the interface bonding between the boron nitride and resin can be enhanced; the mechanical properties and the thermal properties are further improved. The boron nitride / high polymer composite material has high heat conductivity, excellent mechanical properties, and the electrical properties of high insulating and low dielectric loss, and has wide application in the field of electronics.

Owner:PEKING UNIV +1

Preparation of nano-HAP coating/magnesium alloy composite biological material

InactiveCN101302638AHigh bonding strengthImprove biological activityElectrolytic inorganic material coatingProsthesisMagnesium phosphateBiocompatibility Testing

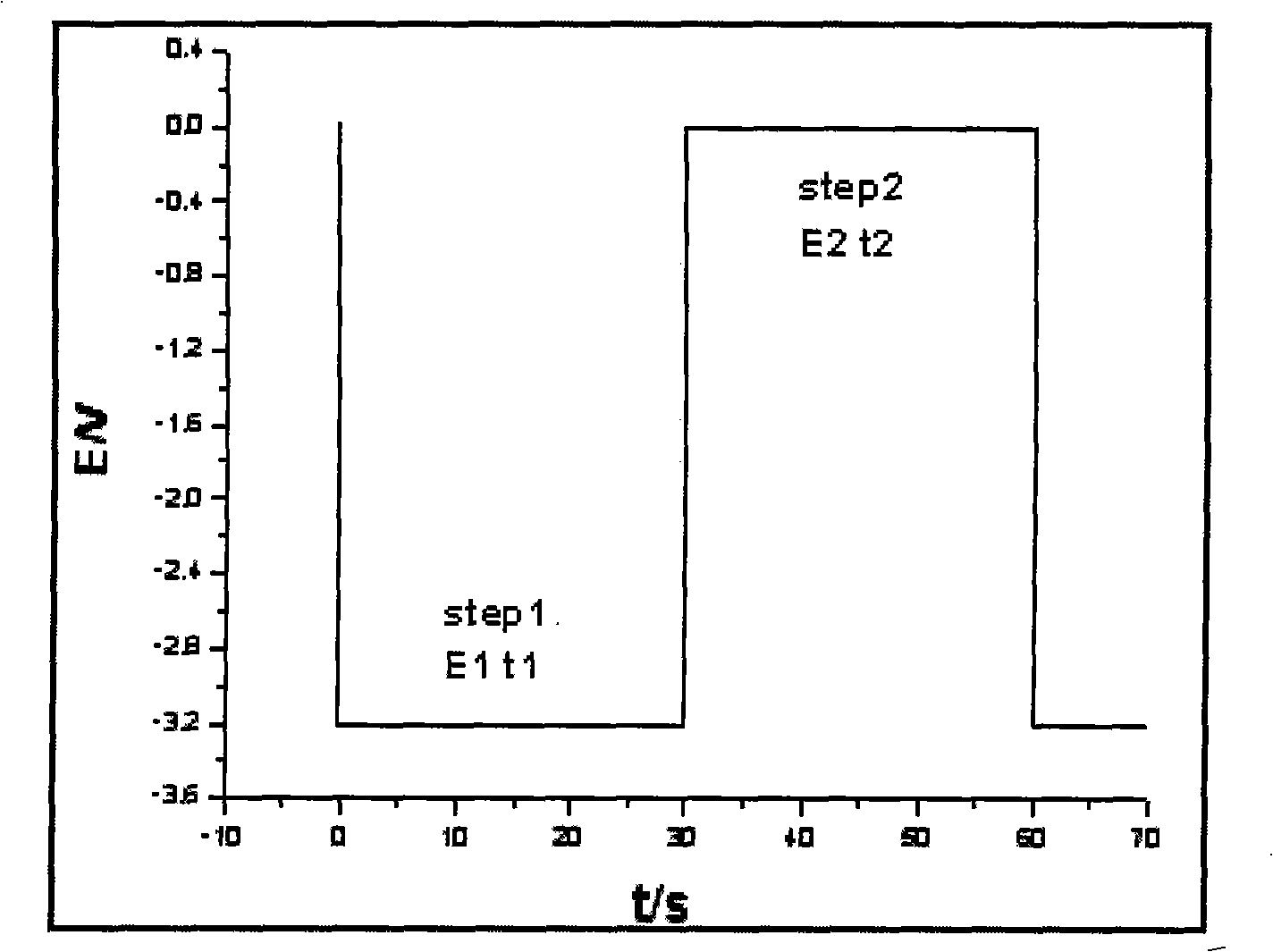

The invention provides a method for making a nano HAP coating / magnesium alloy composite biomaterial. The method is as follows: the method takes a magnesium alloy as a cathode and graphite as an anode; the magnesium alloy and the graphite are placed in electrolyte containing NH4H2PO4, NaHO3 and Ca(OH3)2.4H2O so as to carry out stepped electrodeposition at a temperature of between 60 and 95 DEG C and a voltage of between minus 5 V to minus 1 V and 0 V, thereby effectively improving the interface bonding between a coating and a matrix and reducing hydrogen evolution during electrodeposition; meanwhile, the increase of magnesium ions at an interface can realize in-situ doping of magnesium ions and hydroxyapatite so as to generate a magnesium phosphate transition layer on the surface of the magnesium alloy and to increase bonding strength; thus, a degradable nano acicular hydroxyapatite / magnesium alloy coating composite biomaterial with excellent mechanical property, biocompatibility and corrosion resistance can be obtained. Meanwhile, the method also has the advantages of low cost of raw materials and simple technological operation, etc.

Owner:ZHENGZHOU UNIV

Preparation method of carbon fiber/graphene/epoxy resin prepreg and carbon fiber composite material

A method for preparing carbon fiber / graphene / epoxy resin prepreg and carbon fiber composite materials, belonging to the field of carbon fiber composite material preparation. In this invention, graphene prepared by the modified Hummers method is surface modified, and -NH is grafted on the surface or edge of the graphene. 2 , improve its dispersion in the resin matrix, and at the same time, it can effectively increase the interfacial adhesion between micron-sized carbon fiber and epoxy resin matrix, reduce the existence of void defects, and thereby improve the mechanical properties of epoxy resin-based composite materials. The carbon fiber / graphene / epoxy resin composite material provided by the invention has optimal mechanical properties when the addition amount of graphene is 0.5wt%, with a bending strength of 1525.4MPa and an interlayer shear strength of 91.14MPa. Compared with carbon fiber reinforced rings, Oxygen resin composites improved by 15.41% and 14.14% respectively. The invention has the characteristics of simple process, low solvent toxicity, and is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

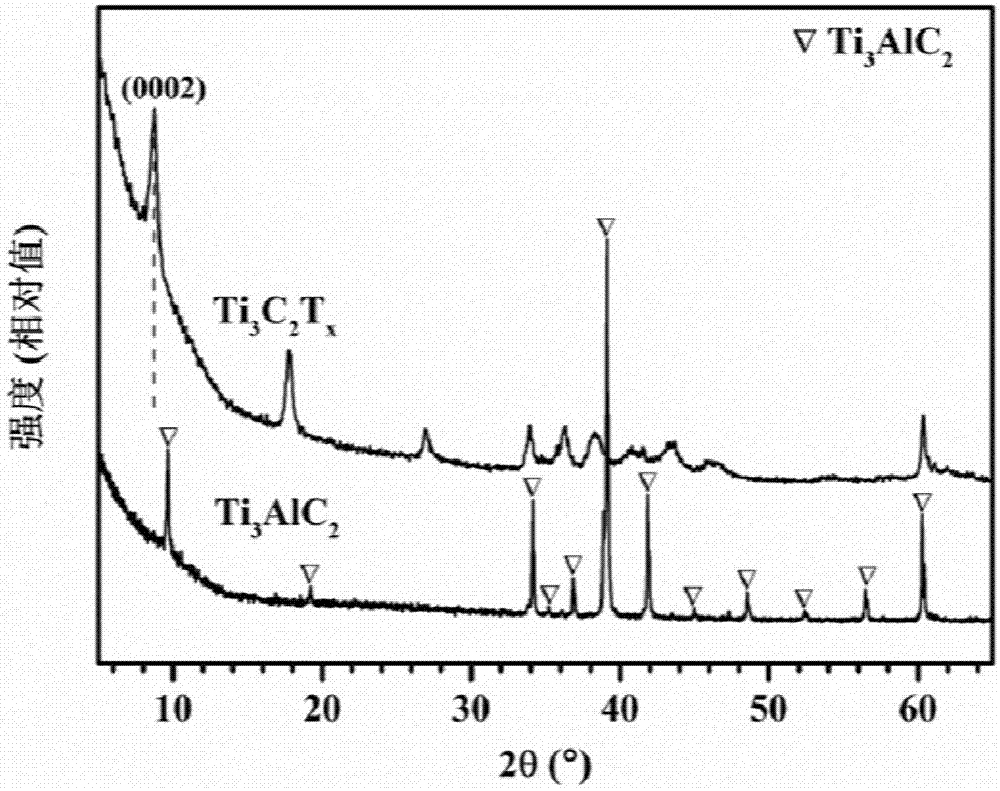

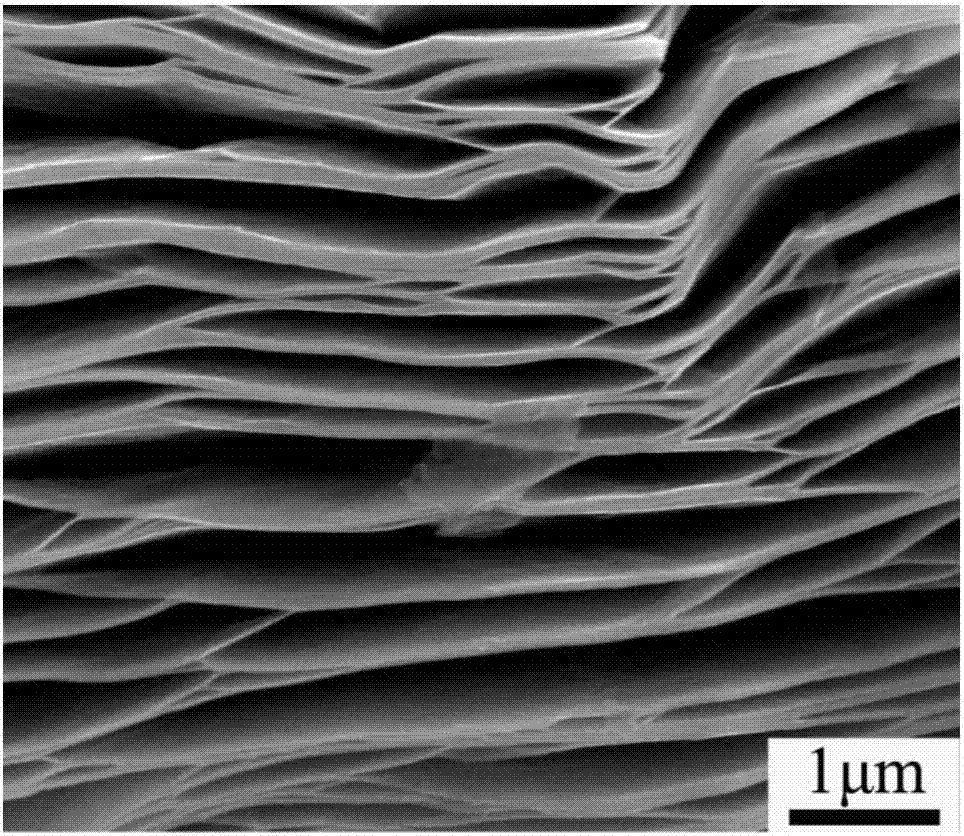

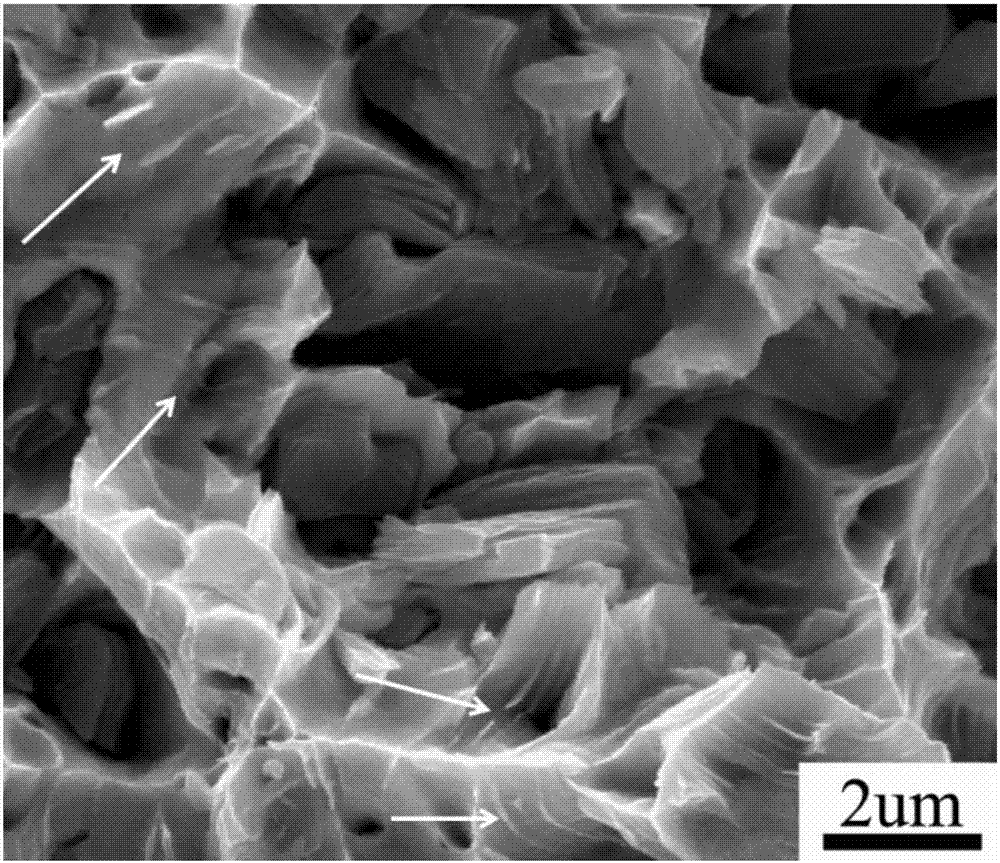

Two-dimensional slice material enhanced metal-based composite

The invention provides a two-dimensional slice material enhanced metal-based composite. According to the composite, metal is adopted as a base body, two-dimensional transition metal carbide or carbonitride, namely, MXenes is adopted as a reinforced phase, and MXenes particles are evenly dispersed in metal base body particles. Due to the fact that the MXenes material comprises a hollow carbon position and tends to metallicity, the metal base body has good wettability, and the interface bonding strength of the metal-based composite can be effectively improved. Therefore, the mechanical performance, wear resistance and other performance of the metal-based composite are enhanced. Meanwhile, the electronic coupling effect of the MXenes material and a metal base body interface is better, and the problem that in the prior art, the mechanical performance and corrosion resistance of the metal-based composite are improved through the reinforced phase, and meanwhile the heat conducting and electrical conducting performance of the metal-based composite is reduced can be avoided.

Owner:SHANGHAI UNIV +1

Method for performing amino functionalizing on carbon fiber surface

InactiveCN105113260AWill not damage the structureRetain high-strength and high-model featuresCarbon fibresFiberState of art

The invention relates to a method for performing amino functionalizing on a carbon fiber surface. The method comprises the steps that the fiber surface is coated with a copolymer coating containing a large amount of active amino by utilizing a Michael addition and Schiff base reaction of dopamine and poly-amino molecules through a one-step solution dipping method. Compared with the prior art, the method is simple in technology and mild in condition, does not damage a fiber body structure and can effectively increase active groups of the carbon fiber surface, and therefore the interface bonding property between fiber and resin is improved.

Owner:SHANGHAI JIAO TONG UNIV

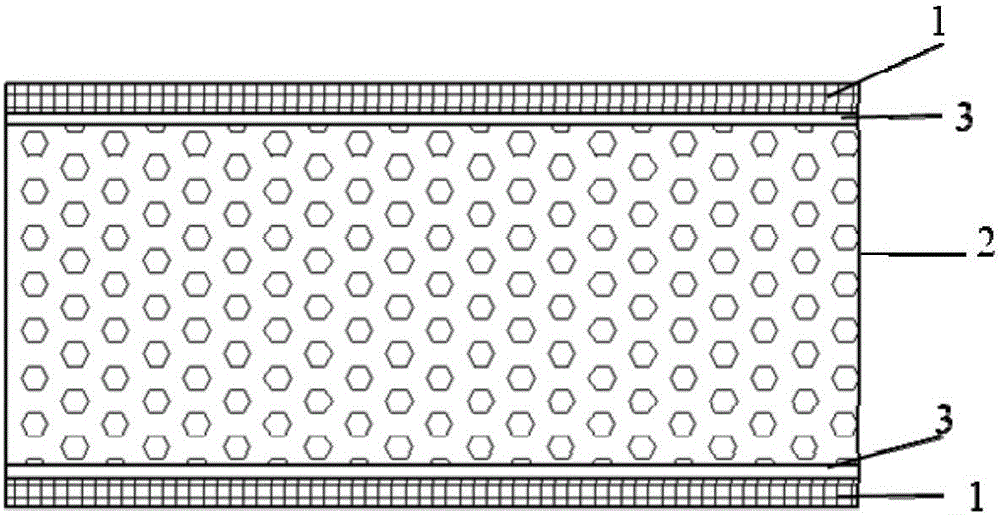

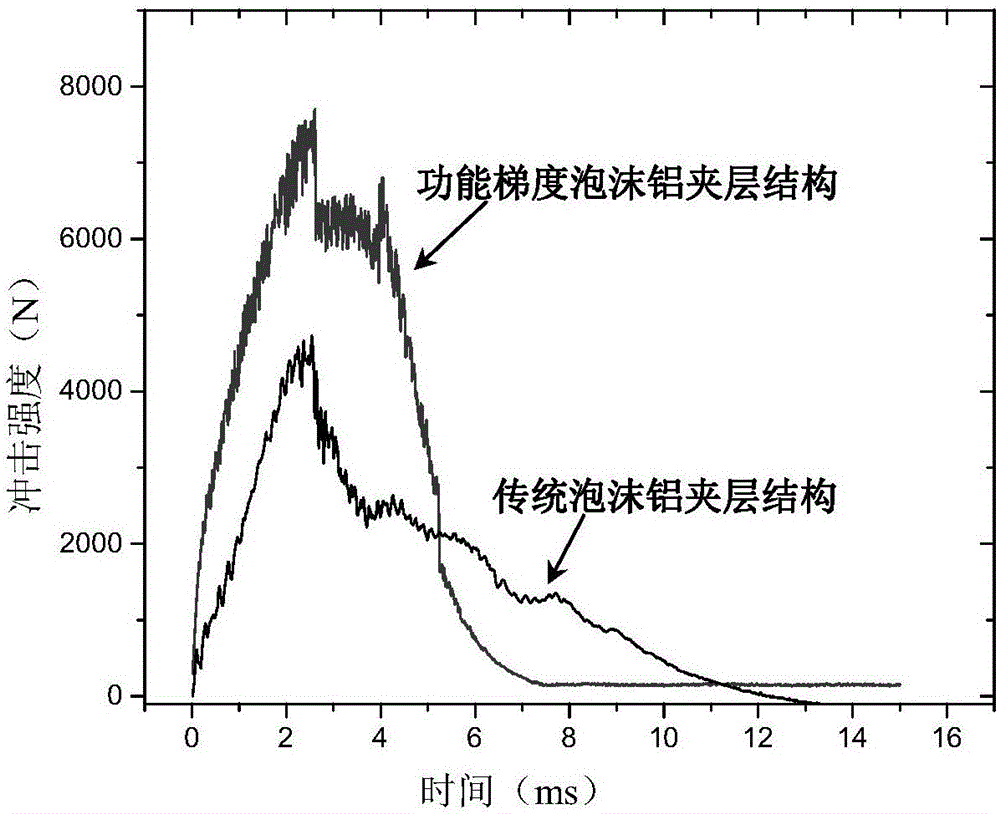

Foamed aluminum sandwich structure composite material and preparing method thereof

ActiveCN106273902AImprove the interface bonding strengthSmall difference in coefficient of thermal expansionSynthetic resin layered productsVehicle componentsFiberEpoxy

The invention provides a foamed aluminum sandwich structure composite material and a preparing method thereof. The foamed aluminum sandwich structure composite material comprises a foamed aluminum core material, a toughening interface layer and skin, wherein the toughening interface layer is located between the foamed aluminum core material and the skin, the toughening interface layer is made of an epoxy resin composite material, and the epoxy resin composite material is composed of an epoxy resin matrix, a toughening agent, a diluent, hollow microspheres, chopped fiber, a curing agent and an accelerant; pores in the surface of the foamed aluminum core material is filled with the epoxy resin composite material to form the toughening interface layer. According to the technical scheme, the toughening interface layer is formed between the composite material skin and the foamed aluminum core material by means of multi-component low-density epoxy filling adhesive, and interface bonding strength can be effectively improved; by means of the skin designed based on functional gradient, the interface bonding property of the foamed aluminum sandwich structure in a humid and hot environment is improved, and the impact resistance of the foamed aluminum sandwich structure is improved.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

High performance chlorinated polyethylene-epoxy resin anticorrosive coating system

InactiveCN101691464AGive full play to corrosion resistanceGive full play to the bonding effectAnti-corrosive paintsPolyamide coatingsChemical industryEpoxy

The invention discloses a high performance chlorinated polyethylene-epoxy resin anticorrosive coating system, which consists of a surface coating, an intermediate coating and a prime coating which are matched, wherein the surface coating is a high performance chlorinated polyethylene anticorrosive finish paint; the intermediate coating is a high performance chlorinated polyethylene / epoxy resin semi-interpenetrating network anticorrosive middle coating; and the prime coating is an epoxy resin micaceous iron oxide anti-corrosive primer. The preparation for the coating system comprises the preparation of surface coating and the intermediate coating; the coating construction is orderly multi-layer coating construction on the surface of a metal substrate; and finally the functionally graded anticorrosive coating is formed so as to effectively improve interface bonding force and adhesive force of various layers and fully exert the corrosion resistance of the high performance chlorinated polyethylene and the substrate bonding function of the epoxy resin; and the functionally graded anticorrosive coating has good corrosion resistance, such as the resistance to acid, alkali, saline water, gasoline and the like, and also has good physical and mechanical properties, such as shock resistance and flexibility, so the functionally graded anticorrosive coating has important application value in anticorrosive fields such as steel structures, bridges, metallurgy, chemical industry and the like, in particular heavy duty anticorrosive field of petrochemical industry.

Owner:郭再春

Wood-plastic composite material and preparation method thereof

The invention belongs to the field of high-molecular material modified technology, and discloses a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material is prepared by the following components of, by weight, 40-75 parts of a plastic substrate, 20-50 parts of wood powder and 5-10 parts of auxiliary agents. The preparation method of the wood-plastic composite material comprises the following steps of (1) mixing 20-50 parts of the wood powder, 40-75 parts of the plastic substrate and 5-10 parts of the auxiliary agents which are treated by silanization adequately, for 10-60 min; (2) extruding and granulating the uniform mixture obtained from the step (1) by using a double screw extruder, forming by introducing the obtained materials into an injection machine or flat-panel vulcanizing machine, or forming by introducing the uniform mixture obtained from the step (1) into the flat-panel vulcanizing machine. An inorganic layer is formed on the surface of the wood powder, thereby facilitating improving the interface bonding property between the inorganic layer and the plastic matrix, increasing heat resistant temperature of the wood powder and allowing the wood powder not to be decomposed in a processing process.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Thermal-oxidizing-aging resisting polypropylene composite

ActiveCN102604209AImprove interface bonding performancePrevent free diffusionLattice defectsAntioxidant

The invention discloses a thermal-oxidizing-aging resisting polypropylene composite. The thermal-oxidizing-aging resisting polypropylene composite comprises the following components in percentage by weight: 30%-85% of polypropylene, 0-10% of flexibilizer, 2%-10% of compatilizer, 10%-40% of filling agent, 0.1%-0.5% of nucleating agent, 1%-10% of load type functional agent and 0.2%-1.0% of processing agent. Due to the nucleating agent, the polypropylene spherocrystal is refined, the crystallization is uniform and regular and the degree of crystallinity is increased, so that the lattice defect of a substrate is avoided effectively, and the oxygen is prevented from dispersing to the inner part from the surface of the composite freely; due to the compatilizer, the interface bonding force of the polypropylene and the filling agent is improved, so that two phase interfaces are combined tightly, the and the oxygen is prevented from dispersing to the inner part from the surface of the composite freely, and the thermal-oxidizing-aging resistance is improved; and the load type functional agent solves the problem of dispersibility and solvent resistance of an antioxidant and a light stabilizer. The thermal-oxidizing-aging resisting polypropylene composite has a simple preparation method, is high in thermal-oxidizing-aging resisting efficiency and is widely applied to the field of household appliances such as electric cookers, microwave ovens, washing machines, dish-washing machines and the like.

Owner:KINGFA SCI & TECH CO LTD +2

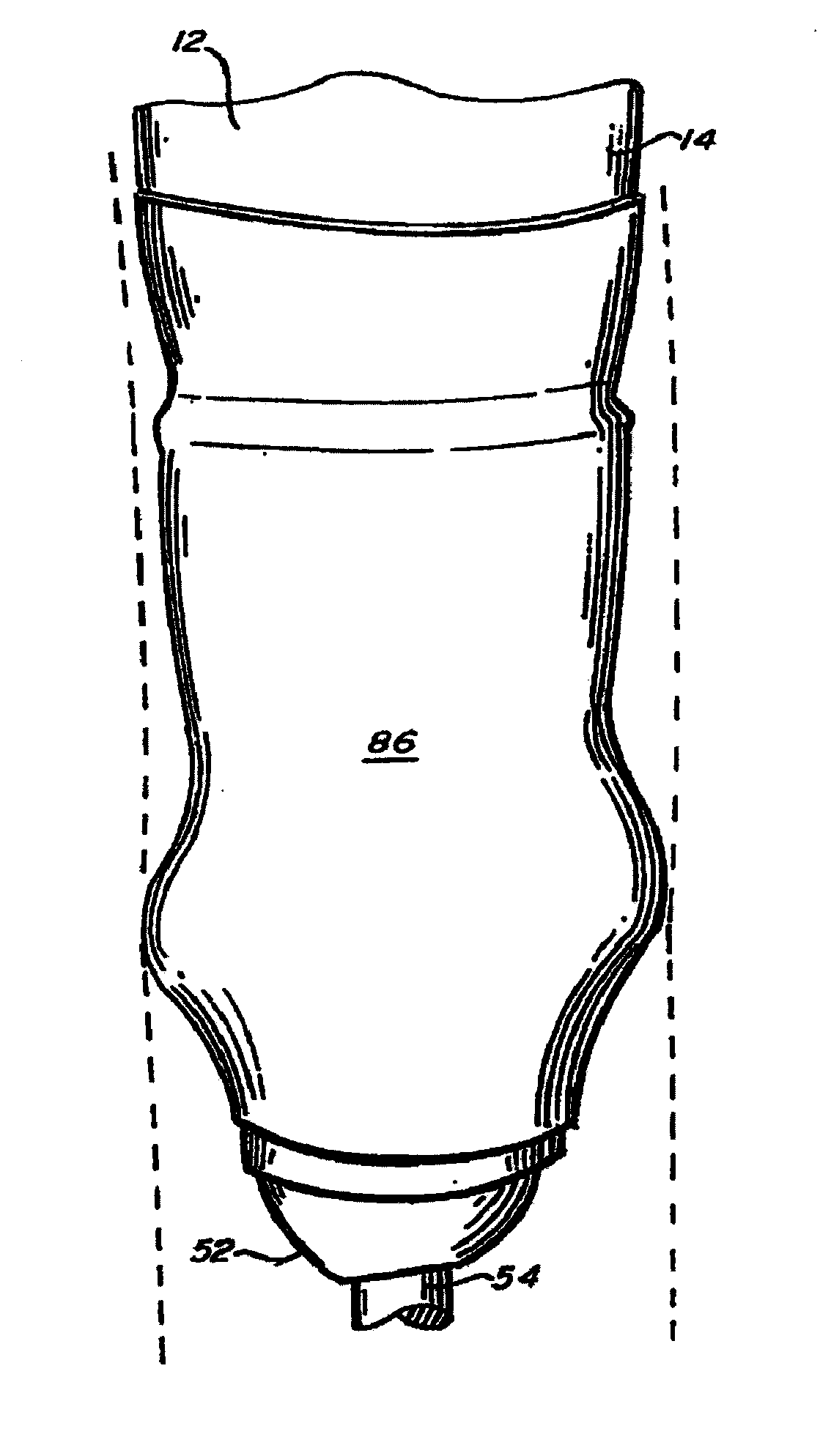

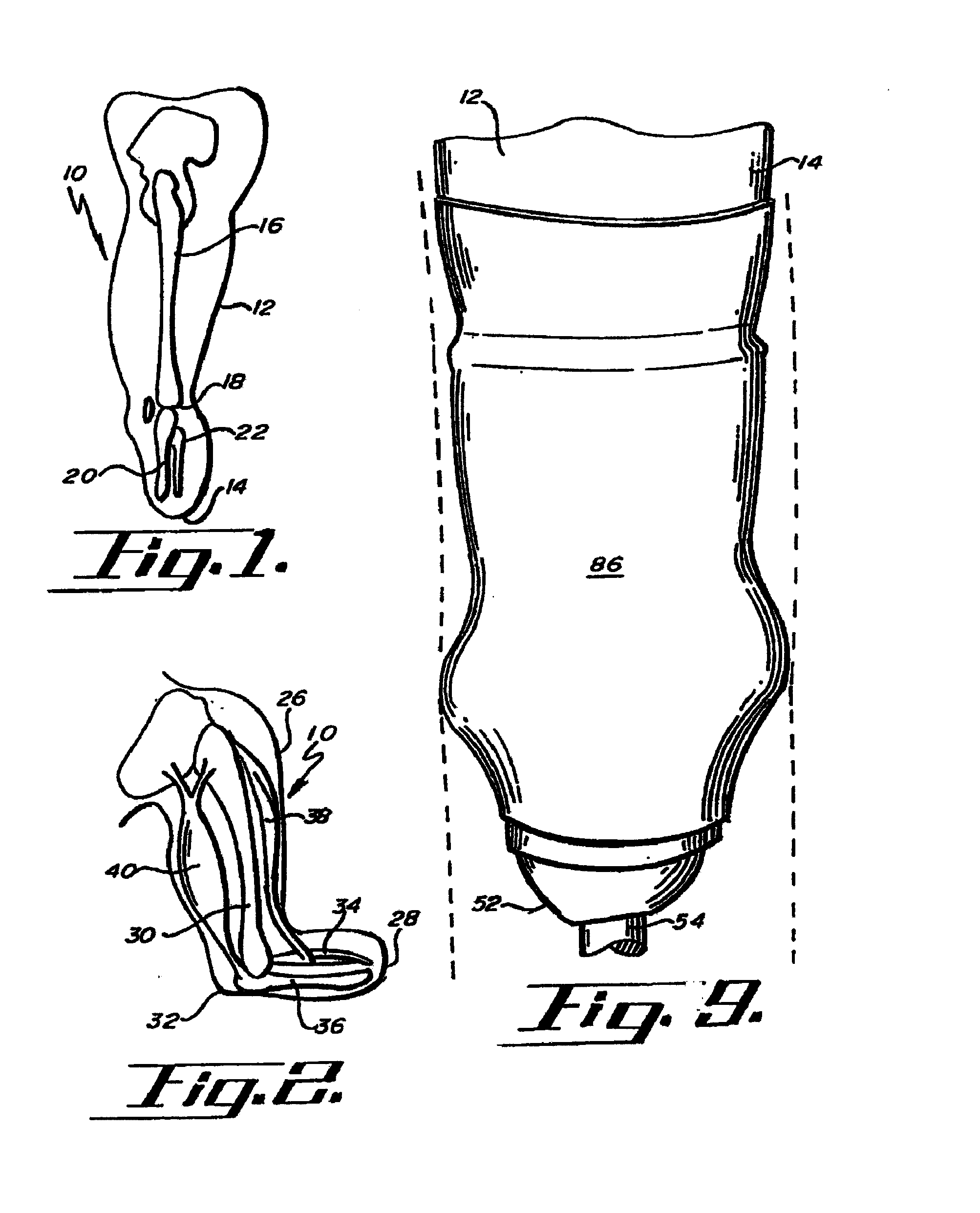

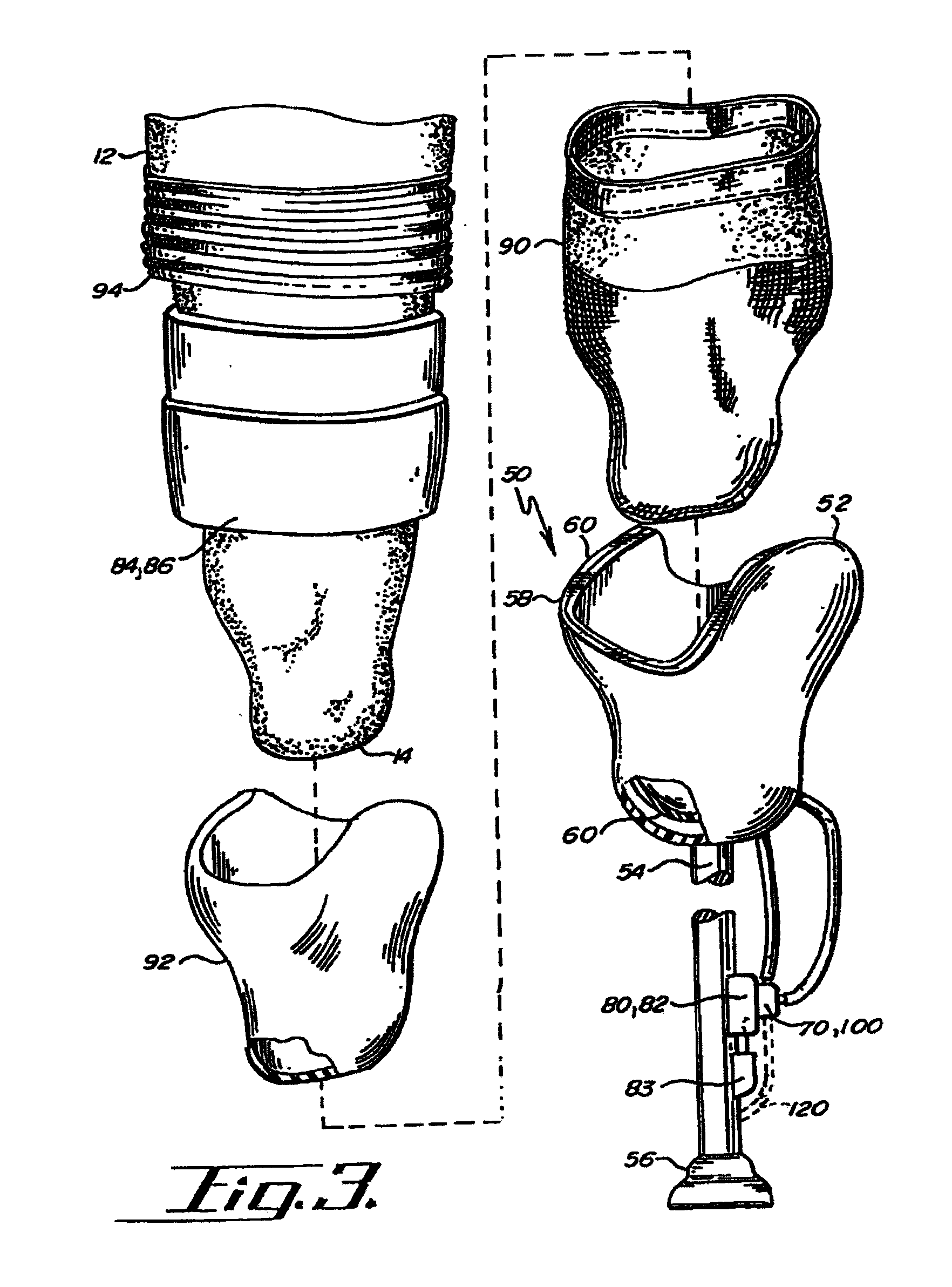

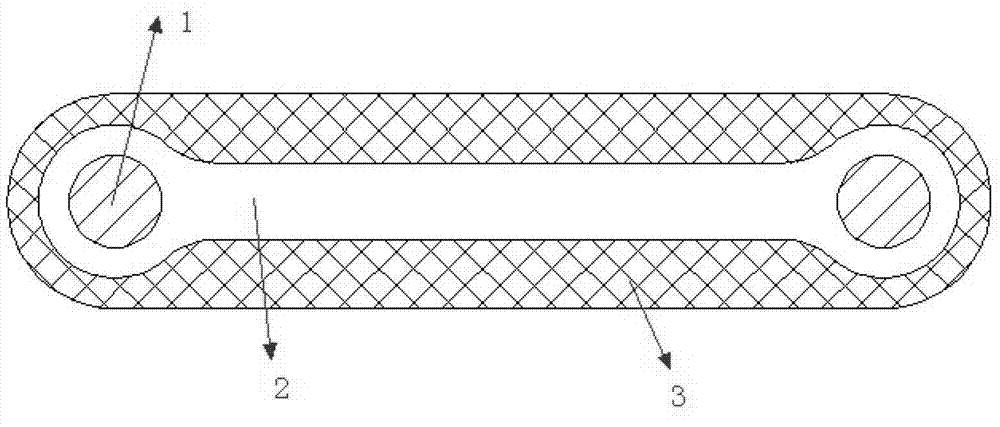

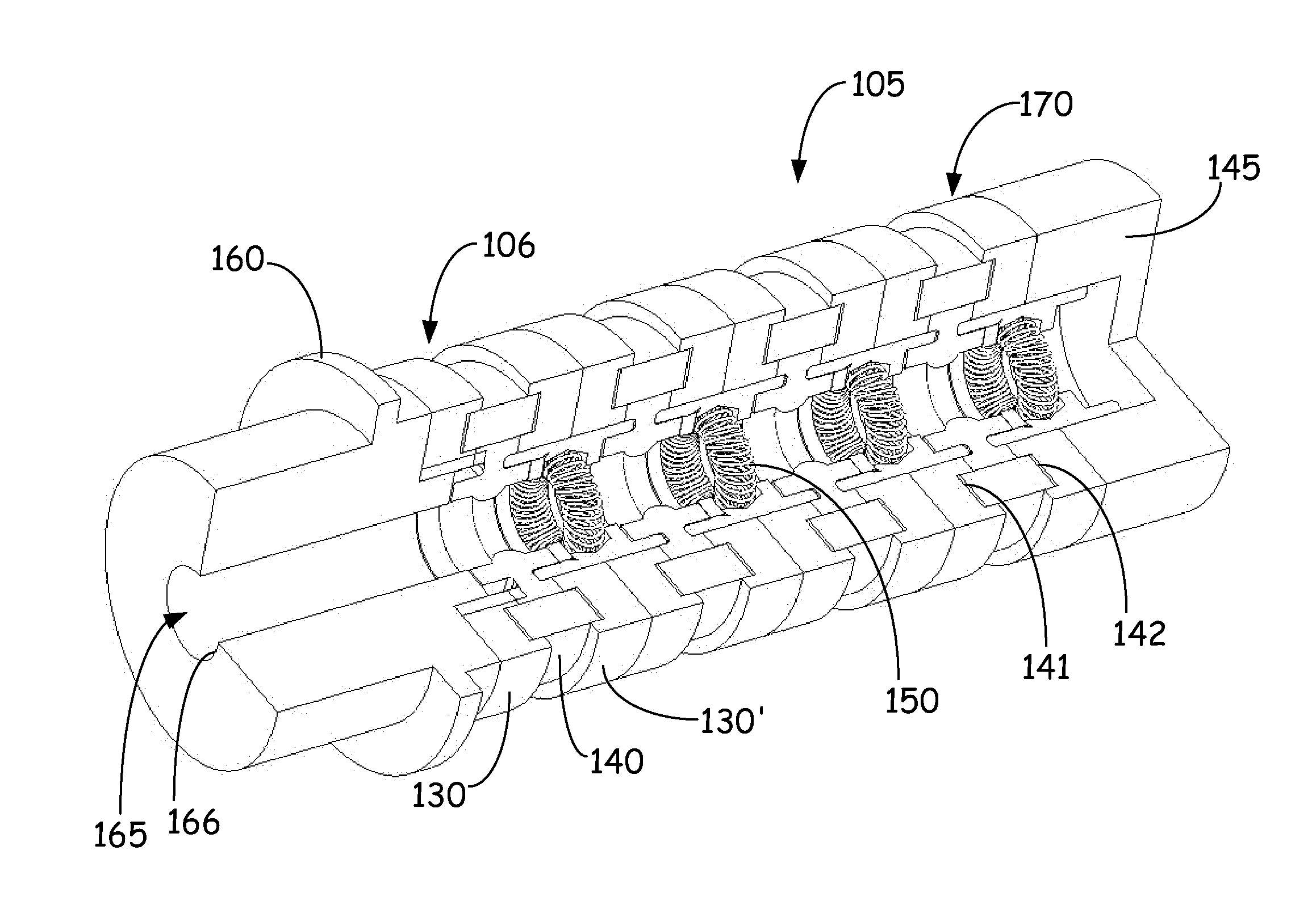

Socket liner for artificial limb

A hypobarically-controlled artificial limb for amputees includes a single socket with a volume and shape to receive a substantial portion of the residual limb. A sealed cavity is formed between the socket and the residual limb. The wearer may use a liner over the residual limb for comfort. A vacuum source is connected to a vacuum valve connected to the cavity to suspend the artificial limb from the residual limb and to control and minimize volumetric and fluid changes within the residual limb A liner for a hypobarically-controlled socket for an artificial limb, with a liner interface bonding the liner to the socket and forming a seal between the liner and the socket. The liner may be permanently attached to the socket or the liner may be removed from the socket for replacement.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

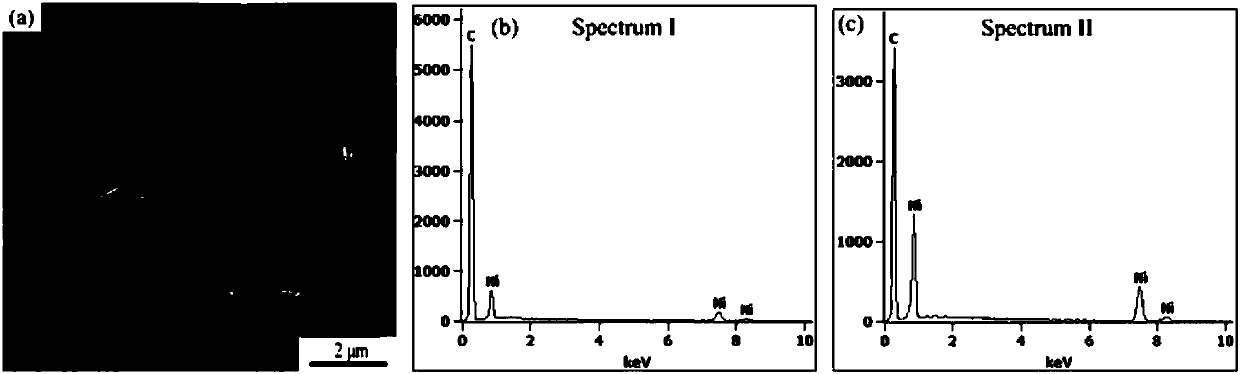

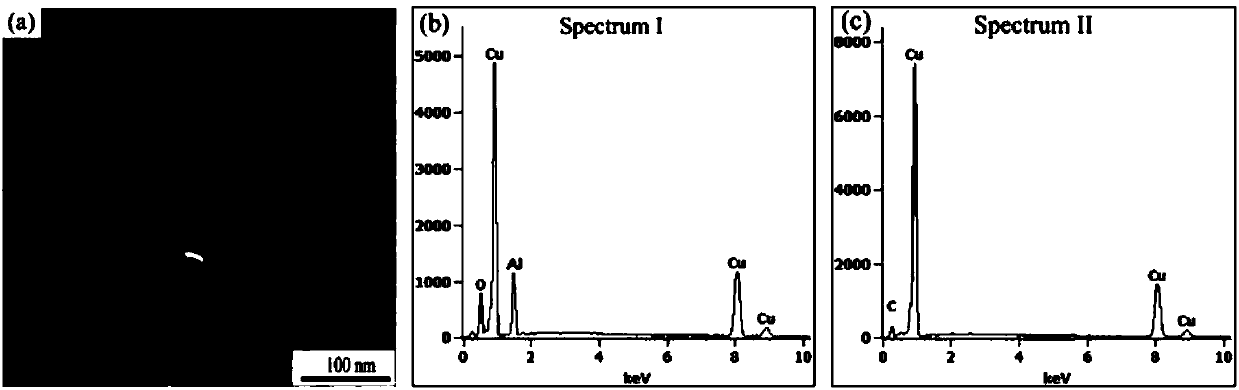

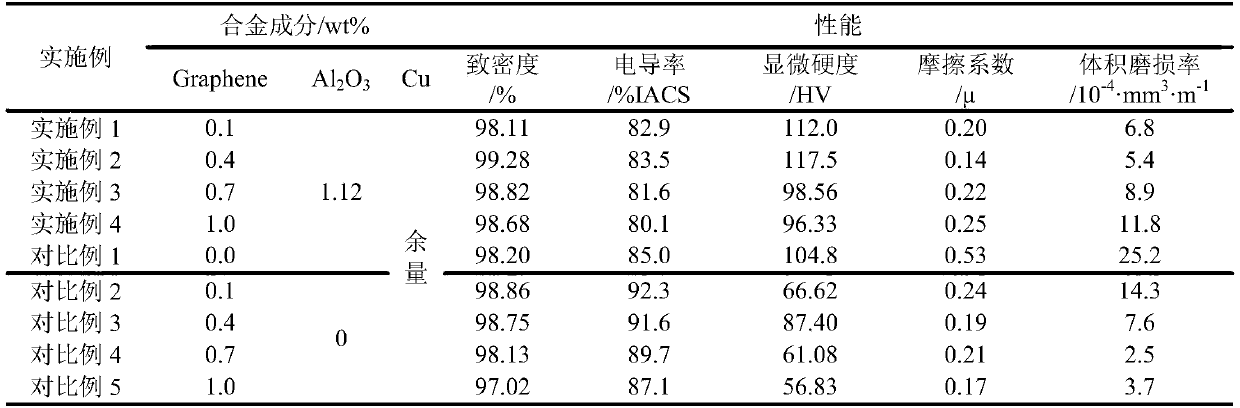

Graphene-aluminum oxide hybrid reinforced copper-based composite material and preparation method thereof

The invention discloses a graphene-aluminum oxide hybrid reinforced copper-based composite material. The composite material comprises 0.1-1.0 wt% of graphene, 1.0-1.2 wt% of Al2O3, and the balance copper. According to the copper-based composite material, the graphene and the aluminum oxide are adopted as complex-phase reinforcement bodies, zero-dimensional aluminum oxide particles can be effectively pinned through a special two-dimensional structure of a nano graphene sheet, a steric-hinerance effect is generated, accordingly, the agglomeration phenomenon of the particles is effectively reduced, and the particles are uniformly scattered; and the surface of the graphene is subjected to chemical nickel-plating and modification treatment, thus, the wettability and the interface bonding situation between the graphene / copper matrixes can be obviously improved, ideal interface bonding is achieved, accordingly, the synergistic effect between the graphene and the aluminum oxide particles is realized to the greatest extent, and the combination properties including strength, hardness, electrical conductivity, and friction and wear properties of the copper-based composite material are comprehensively improved.

Owner:ZOLTRIX MATERIAL GUANGZHOU

Wear-resistant hammer head of hammer crusher and preparation method thereof

ActiveCN103357470AReduce consumptionAdvanced technologyFoundry mouldsFoundry coresWear resistantInterface bond

The invention discloses a wear-resistant hammer head of a hammer crusher and a preparation method thereof. The wear-resistant hammer head comprises an end part of the hammer head and a handle part of the hammer head, and is characterized in that the end part of the hammer head is made of high-chromium cast iron which comprises the following components in percentage by weight: 2.40-3.20 percent of C, 0.30-1.50 percent of Si, 0.50-2.0 percent of Mn, 12.0-18.0 percent of Cr, less than or equal to 0.10 percent of P, less than or equal to 0.06 percent of S, 0.04 percent of Ce, 0.10-0.20 percent of V and the balance of iron; the handle part of the hammer head is made of medium carbon low-alloy steel which comprises the following components in percentage by weight: 0.30-0.50 percent of C, 0.30-1.0 percent of Si, 0.70-1.5 percent of Mn, 1.0-3.0 percent of Cr, 0.15-0.25 percent of Mo, less than or equal to 0.04 percent of P, less than or equal to 0.04 percent of S and the balance of iron; a liquid-liquid double metal composite wear-resistant hammer head is cast by using a hollow cavity of lost foam, and the casting process is controlled to prepare a double liquid-double metal composite hammer head with interfaces bonded through metallurgical bonding. The handle part of the hammer head is made of the medium carbon low-alloy steel, and the end part of the hammer head is made of the high-chromium cast iron. The service life of the hammer head can be improved by 2-3 times compared with that of a high-manganese steel hammer head without changing the manufacturing cost.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

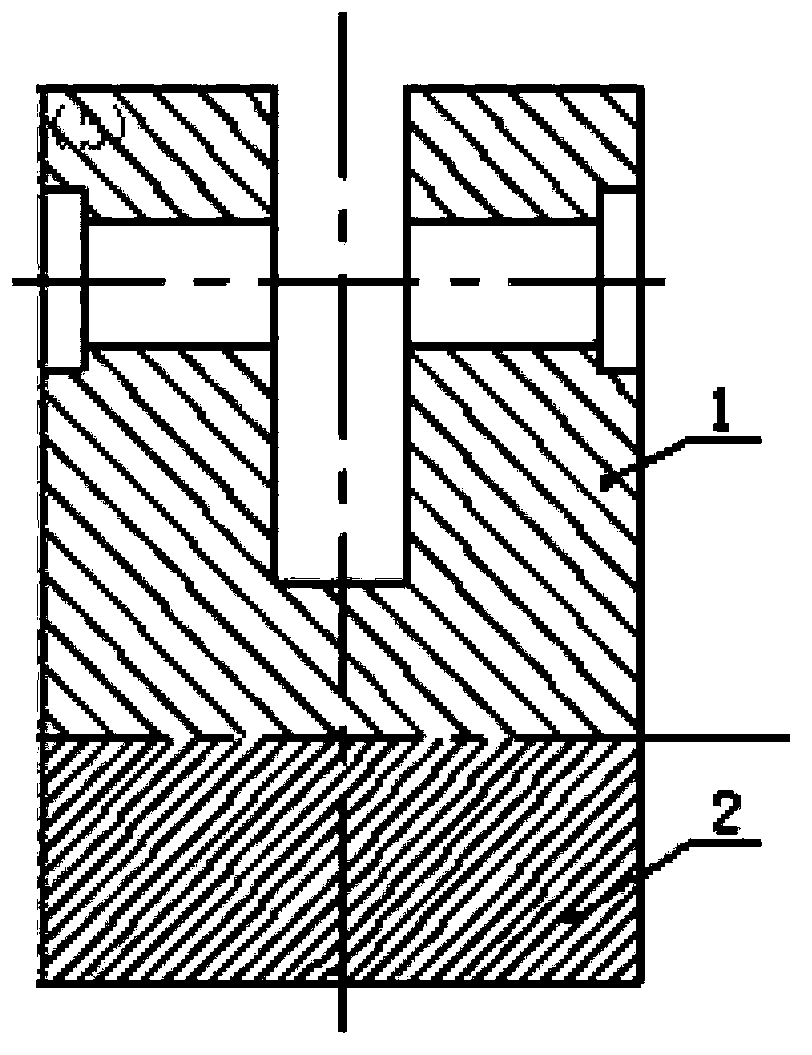

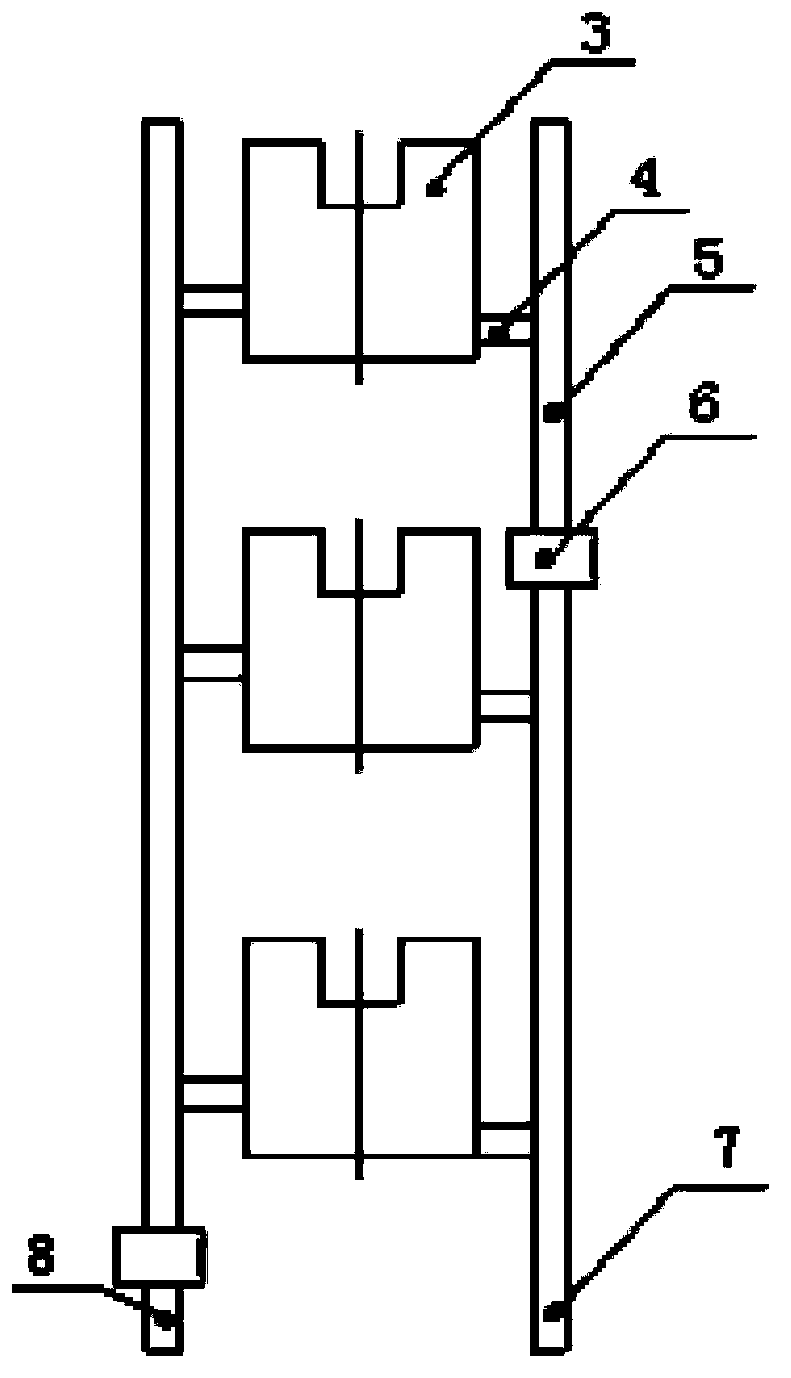

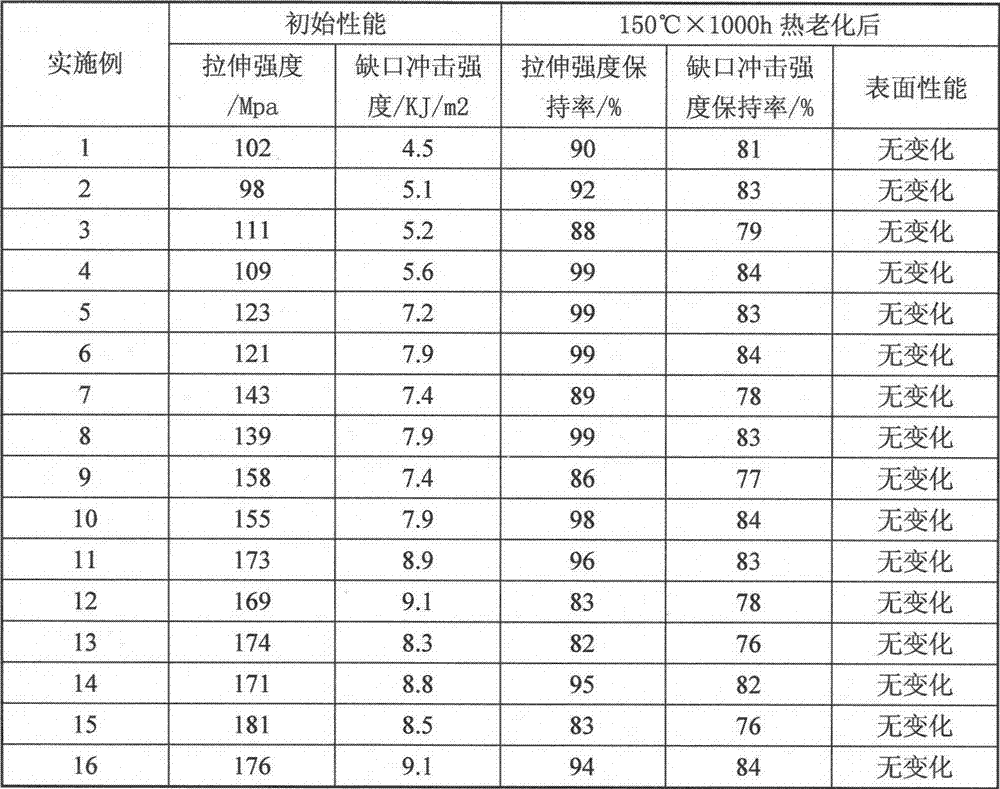

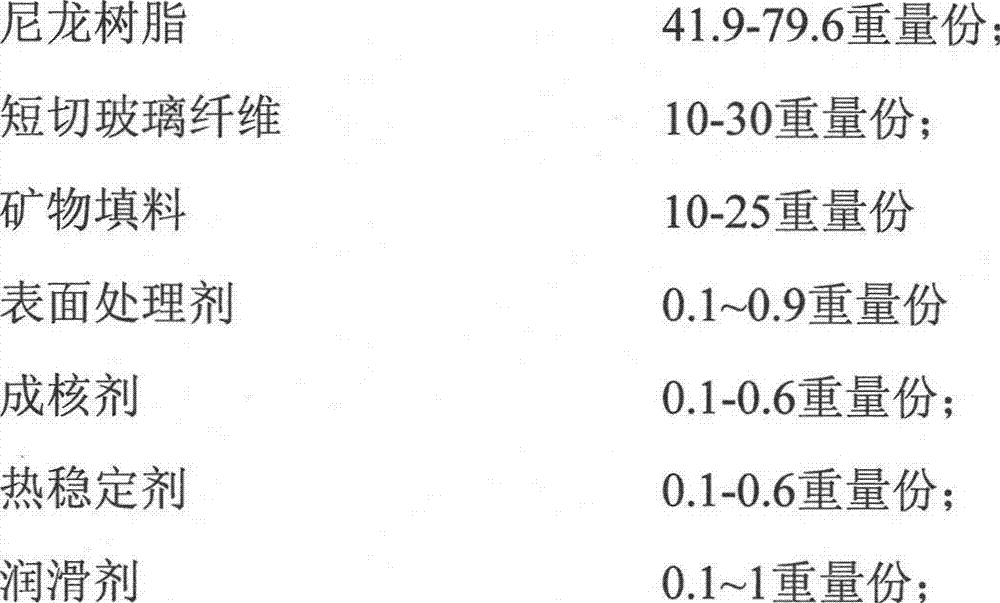

High heat resistance and low warping nylon 66 composite and preparation method thereof

ActiveCN103030972AEnhanced interface bindingImprove mechanical propertiesMechanical propertyAutomotive engine

The invention provides a high heat resistance and low warping nylon 66 composite and a preparation method thereof. The nylon 66 composite is characterized in that the composite comprises the following raw materials in parts by weight: 41.9-79.6 parts of nylon resin, 10-30 parts of chopped glass fiber, 10-25 parts of mineral filler, 0.1-0.9 parts of surface conditioning agent, 0.1-0.6 parts of nucleator, 0.1-0.6 parts of heat stabilizer, and 0.1-1 part of lubricant, wherein the nylon resin is nylon 66 of which the relative viscosity [eta] is 2.4-3.2 (Ubbelohde viscosimetry). According to the high heat resistance and low warping nylon 66 composite, the glass fiber and mineral powder are composited and filled, and aids such as the heat stabilizer, the nucleator and the lubricant are added. The glass fiber and the mineral powder subjected to surface treatment have a good interface bonding property with the nylon 66 resin. The prepared nylon composite has excellent dimensional stability, good mechanical property, and excellent long-term thermo-oxidative aging resistance, and can be widely applied to the fields of peripheral parts of an automobile engine, electric products and the like.

Owner:SHANGHAI KINGFA SCI & TECH +1

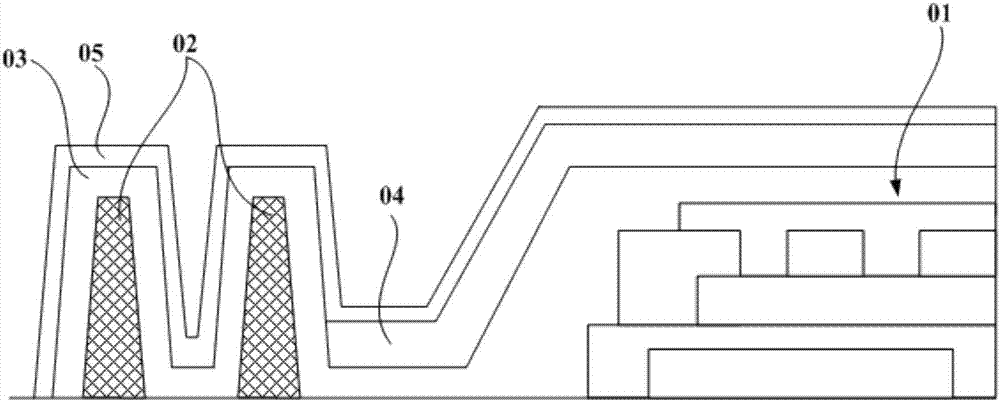

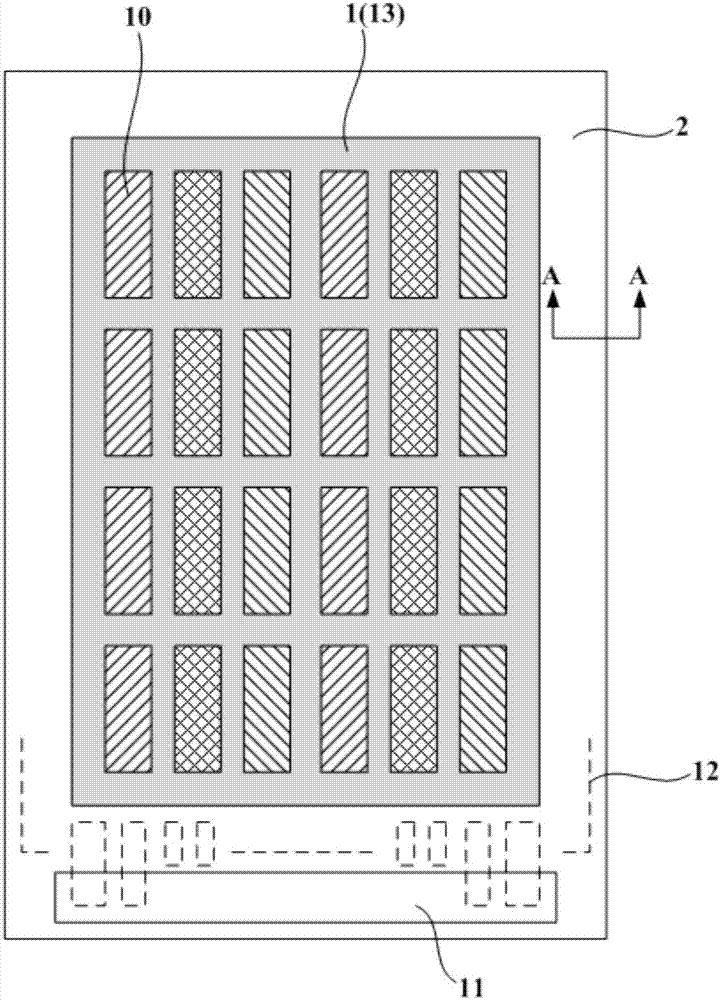

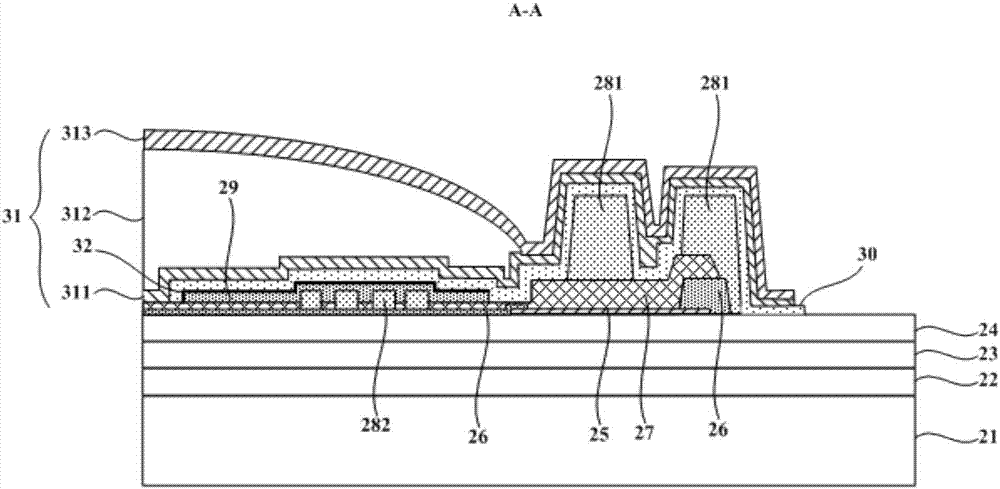

OLED display substrate and manufacturing method thereof, and OLED display device

ActiveCN107482042AReduce breakageAvoid erosionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention discloses an OLED (Organic Light-Emitting Diode) display substrate and a manufacturing method thereof, and an OLED display device. The objective of the invention is to improve the bending reliability and prolong the service life of an OLED display device. The OLED display substrate comprises: a display area, a non-display area arranged around the display area, a retaining wall arranged at the non-display area, a packaging structure layer configured to cover the display area and extending to cover the retaining wall, and a metal halide layer located between the retaining wall and the packaging structure layer and configured to at least cover the retaining wall. The metal halide layer is increased between the retaining wall and the packaging structure layer, and the interface bonding force between the metal halide layer and the retaining wall and between the metal halide layer and the packaging structure layer is good to reduce the fracture or delamination of the edges of the OLED display substrate so as to effectively prevent steam and oxygen from entering the internal portion of the OLED display substrate for erosion of an OLED device and prolong the service life of the OLED display device.

Owner:BOE TECH GRP CO LTD

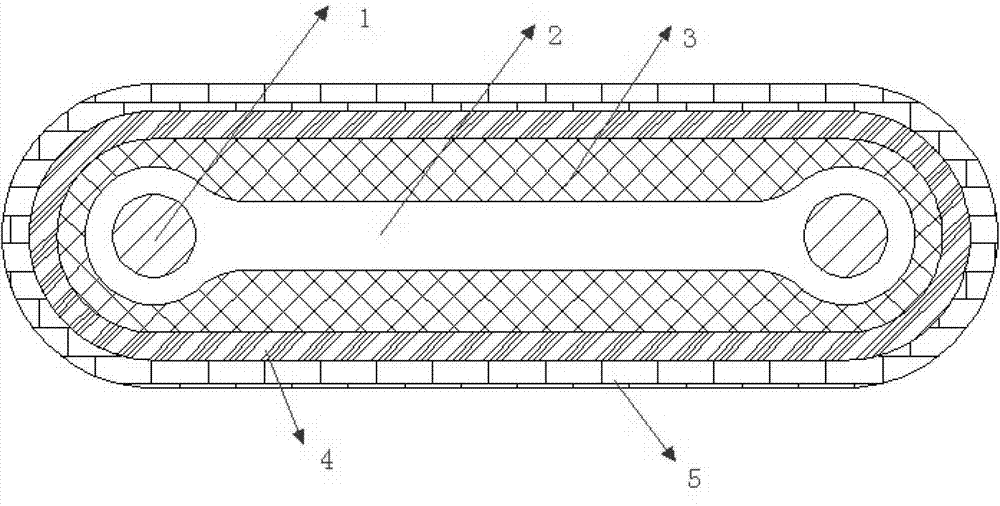

Polymer matrix conductive composite material and method for preparing temperature self-limiting heat tracing cable from same

InactiveCN103113668AImprove electrical performanceExtended service lifeCable/conductor manufactureElectrical resistance and conductanceSelf limiting

The invention discloses a polymer matrix conductive composite material, prepared from a first crystalline polymer, a second crystalline polymer, a conductive filler, an inorganic filler and a processing auxiliary. The invention also discloses a method for preparing a temperature self-limiting heat tracing cable from the composite material. The polymer matrix conductive composite material provided by the invention contains the second crystalline polymer which is capable of improving the interface bonding between the conductive filler carbon black and polyethylene, so that the stability of the conductive network in the composite material is enhanced and the interface resistance between the conductive composite material and the electrode after the heat tracing cable is placed at a high temperatures is reduced; and the prepared temperature self-limiting heat tracing cable has excellent resistance reproducibility and stability.

Owner:ANBANG ELECTRICAL GRP

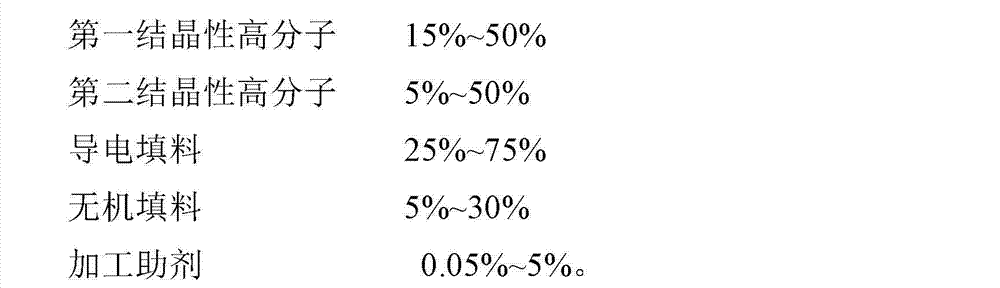

Diffusion bonded lead connector

A medical device lead connector includes electrically conducting contact rings spaced apart by an electrically insulating ring and in axial alignment. The electrically conducting contact ring and the insulating ring having an interface bond on an atomic level.

Owner:MEDTRONIC INC

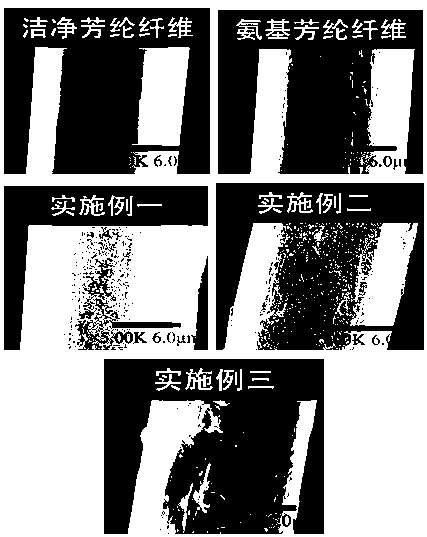

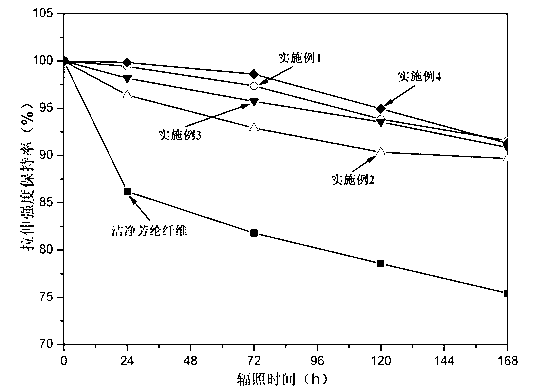

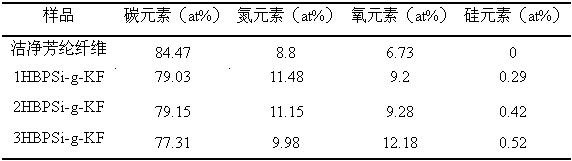

Surface grafting modified aramid fiber and preparation method thereof

The invention relates to a surface grafting modified aramid fiber and a preparation method of the fiber. The method comprises the following steps of: mixing gamma-glycidoxypropyltrimethoxysilane with the aramid fiber with amino on the surface, placing the above mixture into a mixed solution of gamma-methacryloxypropyltrimethoxylsilane and another alkoxy silane, adding deionized water and an organic solvent into the resulting product, and carrying out cleaning and drying after the reaction ends to obtain hyperbranched polysiloxane modified aramid fiber, wherein the surface of the obtained fiber is connected with methacryloxy and another active functional group through chemical bonds. The surface of the fiber provided by the invention not only has the group capable of resisting strong ultraviolet irradiation, but also has the active functional group with high reactivity, as well as is improved in interface bond performance with a resin matrix; the types of the active functional groups can also be changed by regulating process conditions to adapt to reactions with a plurality of different resin matrixes to obtain a plurality of composite materials with outstanding comprehensive performance; and the fiber provided by the invention has the characteristics of high flexibility, strong controllability and wide application field range.

Owner:SUZHOU UNIV +1

Carbon fiber-reinforced resin composite material and preparation method thereof

The invention belongs to the field of composite materials and particularly relates to a carbon fiber-reinforced resin composite material and a preparation method thereof. Graphene containing an active functional group in the surface is prepared through a modified Hummers method, and a carbon nano tube and the graphene can form a synergistic effect, so that the dispersibility of a nano-scale filler graphene and the carbon nano tube in a resin matrix is greatly improved, and meanwhile, the interface bonding force between the carbon fiber and the resin matrix can be improved due to the presence of the and the graphene and the carbon nano tube. Brominated epoxy resin is capable of improving the flame-retarding characteristic of the composite material; cyanate ester has high strength and reactivity is capable of improving the interface bonding capacity of the epoxy resin and the carbon fiber; and meanwhile, the cyanate ester is taken as a curing agent of the brominated epoxy resin. The carbon fiber-reinforced resin composite material has the advantages of being simple in process, friendly to environment and excellent in property of the composite material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

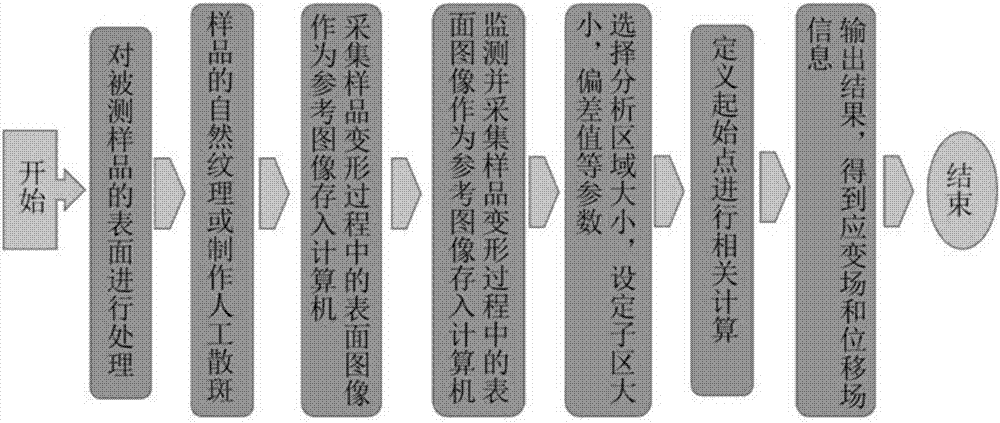

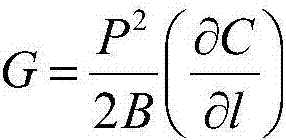

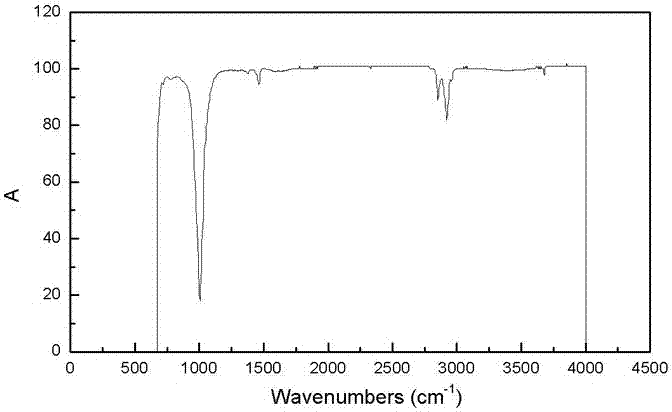

Method for measuring interface bonding strength of thermal barrier coating layer

ActiveCN107345898AAvoid disadvantagesMaterial strength using tensile/compressive forcesUsing mechanical meansTip positionAlloy

The invention relates to the measurement field of mechanical properties of materials and particularly relates to a method for measuring the interface bonding strength of a thermal barrier coating layer. The method comprises the following steps: (1) acquisition of stress-strain data: firstly preparing a measuring test piece, and acquiring and recording a load-displacement curve by virtue of a three-point bending method so as to acquire the stress-strain data; (2) calculation of crack length: representing the deformation of the measuring test piece by virtue of a digital image relevant method, and combining with the displacement of an open angle to determine a crack tip position, so as to calculate the crack length; and (3) calculation of energy release rate: after the stress-strain data and the crack length are acquired, calculating the energy release rate by virtue of a flexibility method. According to the method provided by the invention, by utilizing the characteristic that the breakable thermal barrier coating layer and a hard alloy matrix are different when being deformed by virtue of an external force, the external force is applied to an alloy basement by virtue of an improved three-point bending method, and the interface bonding strength of the thermal barrier coating layer with a deformed interface is represented by virtue of the digital image relevant method.

Owner:JIANGSU UNIV

Wear resistant and antistatic polyamide composite material and preparation method thereof

InactiveCN106967293AImprove heat resistanceIncrease coefficient of frictionFiberHexagonal boron nitride

The invention relates to a wear resistant and antistatic polyamide composite material and a preparation method thereof. The composite material is composed of a polyamide matrix, a wear-resistant material, filler, a toughening compatibilizer, modified graphene, carbon fiber, a dispersant and an antioxidant. The wear-resistant material is formed by mixing of a modified hexagonal boron nitride microchip and a silicon carbide capsule, the filler is formed by mixing of titanium dioxide, carbon black and glass powder, the toughening compatibilizer is POE-g-MAH, and the modified graphene is phosphonitrilic chloride trimer treated graphene oxide. The synergistic effect of the modified hexagonal boron nitride microchip and the silicon carbide capsule can improve the wear resistance of the composite material, modified graphene, carbon fiber and carbon black are bridged into a conductive path, so that the composite material can have antistatic effect, the toughening compatibilizer prepared by the invention can improve the toughness of the composite material and the interface bonding force of the addition materials and the polyamide matrix. The preparation process provided by the invention is simple, and the prepared polyamide composite material has high wear resistance, high dispersibility and antistatic effects.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite

The invention discloses a preparation method of a graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite. According to the method, oxidation treatment is performed onthe surface of carbon fiber, the surface of the carbon fiber is grafted with graphene oxide with a silane coupling agent grafting method, finally, carbon fiber with the surface modified with grapheneoxide is infiltrated into a polycarbosilane precursor solution with a precursor infiltration and pyrolysis method, then, curing and pyrolysis are performed, and the carbon fiber reinforced silicon carbide ceramic matrix composite is formed. In the preparation method, graphene oxide on the surface of the carbon fiber can protect the carbon fiber against physical and chemical damage and obviouslyimprove wetting property with the precursor solution and significantly increases the bonding interface between carbon fiber and a silicon carbide ceramic matrix, the interface bonding force between acarbon fiber reinforcement and the ceramic matrix is increased, and effective transfer of load between the ceramic matrix and the fiber reinforcement is guaranteed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Machining method for preparing Al/Mg/Al alloy composite board by rolling

InactiveCN104907334ANo peeling phenomenonSignificant changeTemperature control deviceMetal rolling arrangementsSurface cleaningAlloy composite

The invention provides a machining method for preparing an Al / Mg / Al alloy composite board by rolling. The method comprises: (1) a composite rolling process of cutting a Mg alloy board and aluminum boards, which are to be compositely rolled, into shapes with equal sizes, and performing surface cleaning and polishing treatment, sandwiching and fixing the Mg alloy board between the two aluminum boards and performing single-pass composite rolling on the fixed boards, wherein the rolling reduction ratio is 30 to 60 percent, the rolling temperature is 300 to 450 DEG C, and time for heat preservation before rolling is 5 to 15min; (2) a composite board annealing process of placing the rolled Al / Mg / Al alloy composite board into a heating furnace, heating the Al / Mg / Al alloy composite board to 150 to 230 DEG C, preserving heat for 1 to 12 hours, and taking out the Al / Mg / Al alloy composite board for air cooling. According to the method, a unique annealing process is adopted, and at proper annealing temperature, the interface bonding force of two alloys can be strengthened and the formation of a fragile phase is avoided, so that the phenomenon of stripping of the composite board in a serving process is avoided.

Owner:HARBIN ENG UNIV

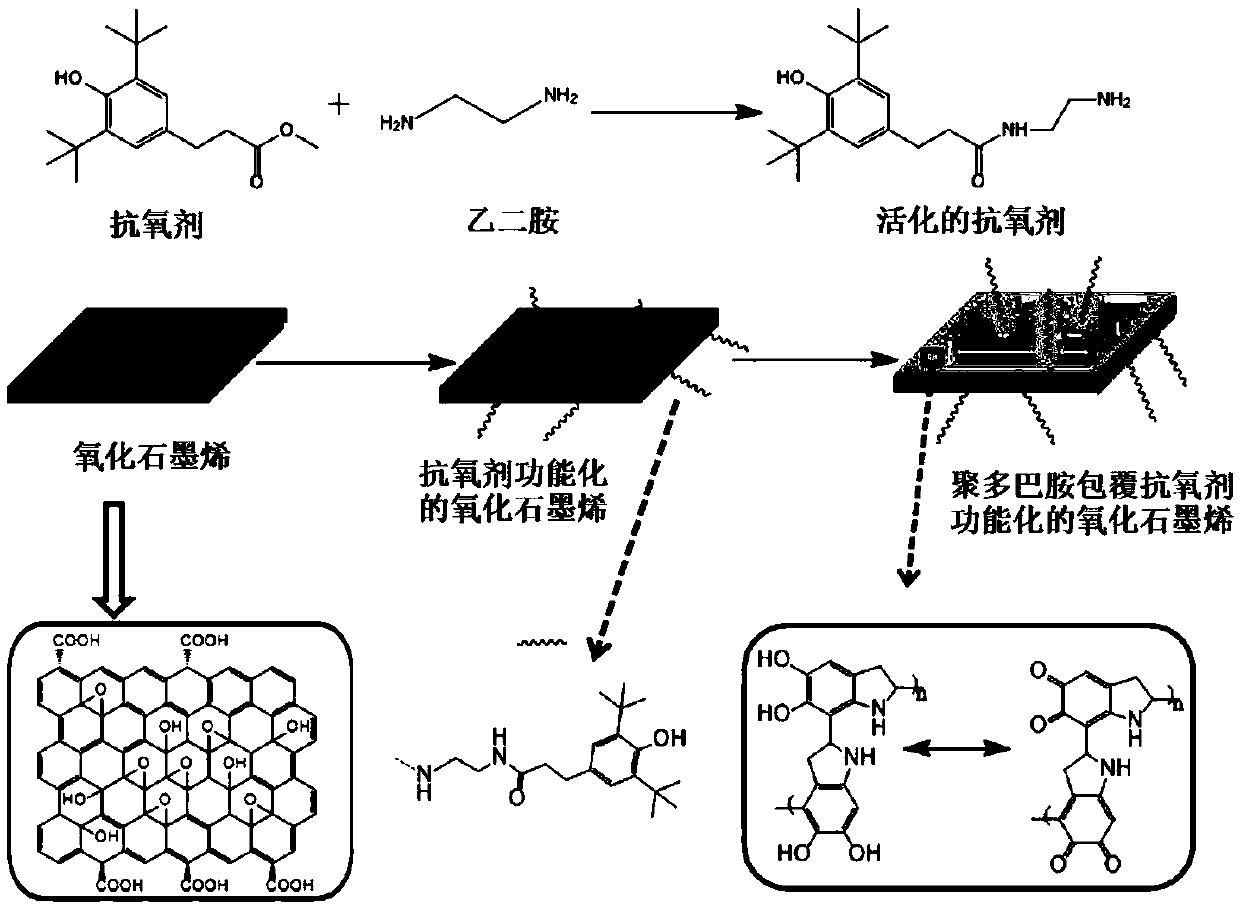

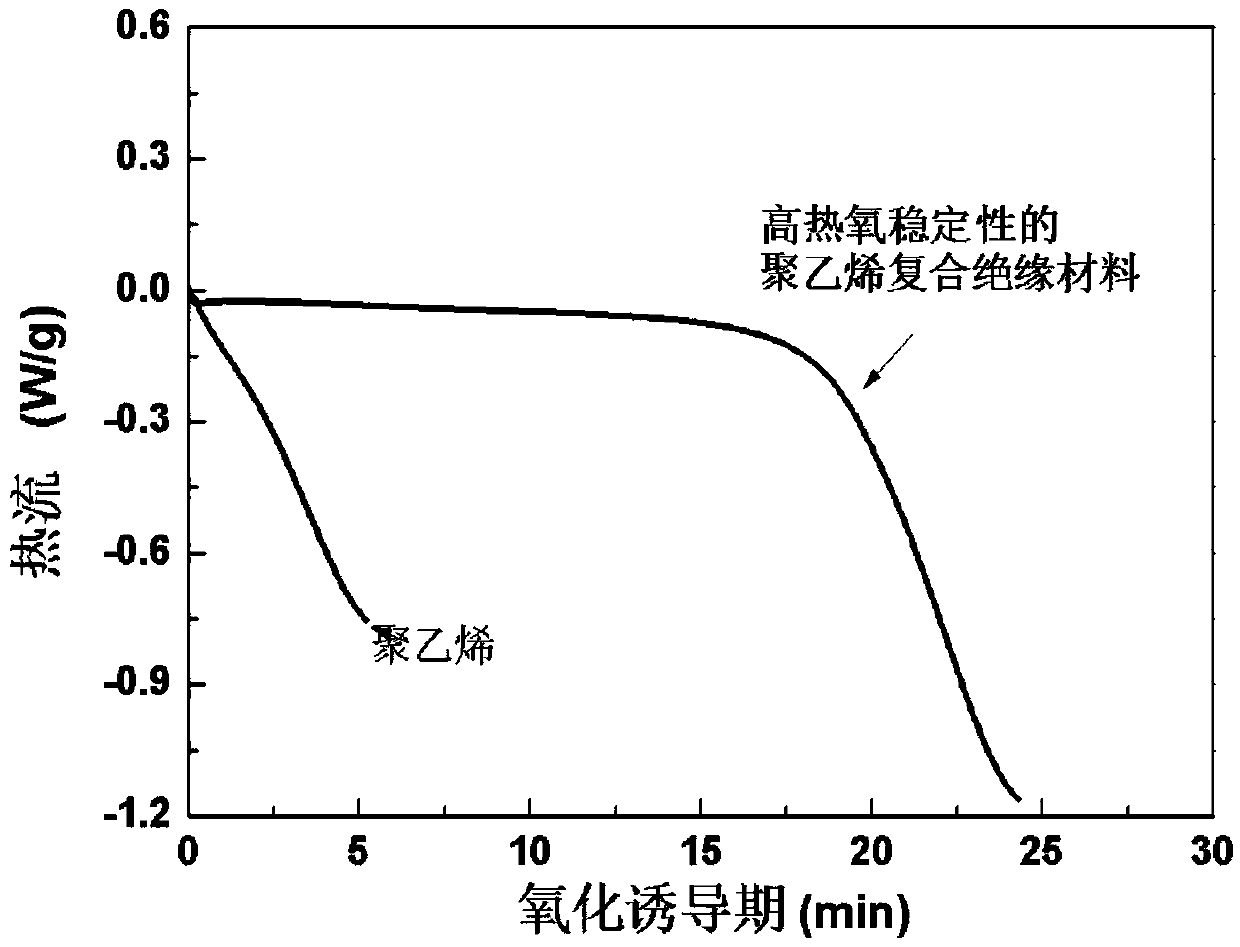

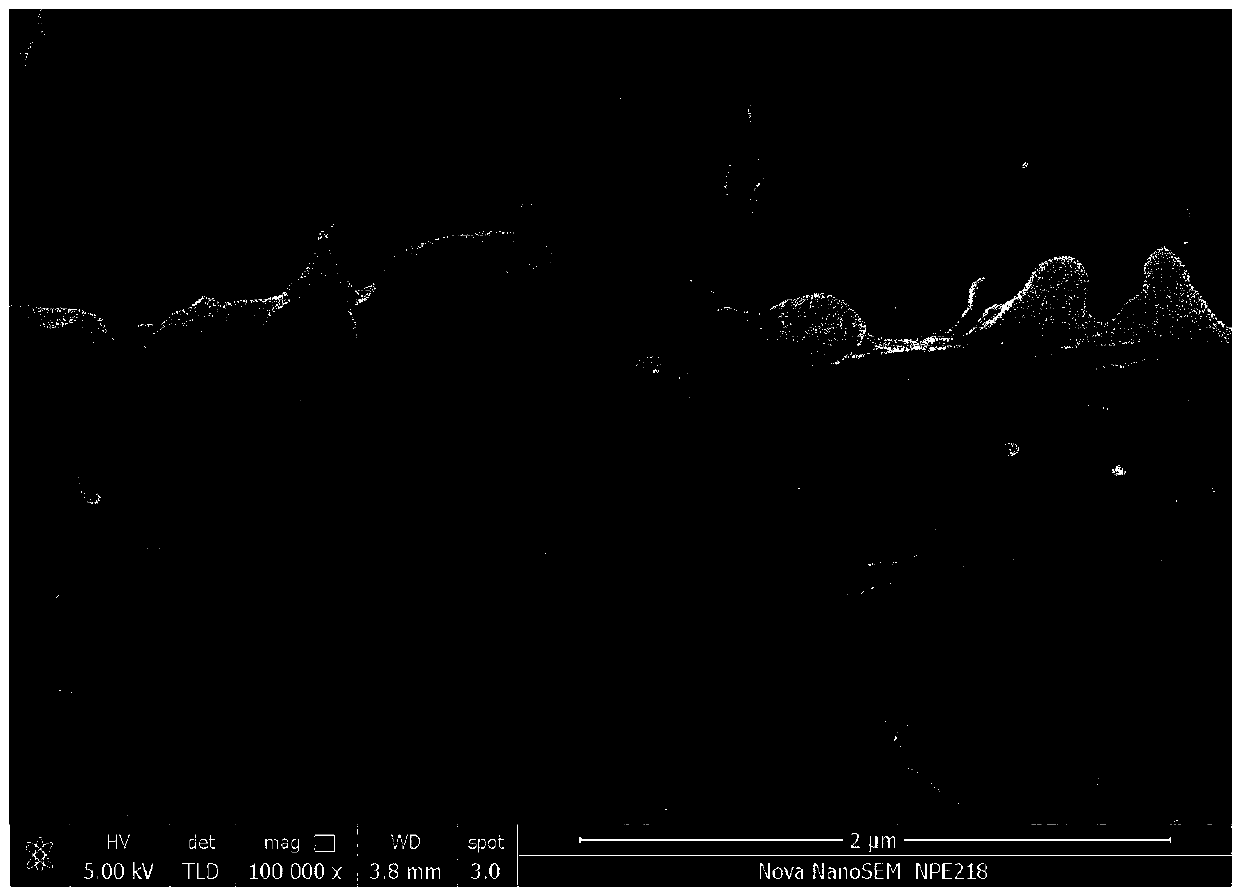

Polyolefin composite insulating material with high thermal-oxidative stability and preparation method thereof

ActiveCN105504453AImprove thermo-oxidative stabilityImprove insulation performancePlastic/resin/waxes insulatorsPolyolefinPolymer science

The invention discloses a polyolefin composite insulating material with the high thermal-oxidative stability and a preparation method thereof. The polyolefin composite insulating material is prepared from, by mass, 98%-99.5% of a polyolefin polymer matrix and 0.5%-2% of modified graphene oxide packing, wherein antioxidant-functionalized graphene oxide coated with polydopamine is adopted as the modified graphene oxide; through a grafted antioxidant, the thermal-oxidative stability of the material can be improved, and the graphene oxide can play a role in inhibiting migration of the antioxidant. By adopting the modified graphene oxide, not only can the interface bonding force between the polymer matrix and the packing be enhanced, but also the graphene oxide can be prevented from being deep reduced in the preparation process of the composite insulating material, and therefore the composite material keeps the good insulating property. The prepared polyolefin composite insulating material with the high thermal-oxidative stability has the advantages of being long in oxidation induction time, low in dielectric constant and dielectric loss and the like and is suitable for electric wire and cable insulating materials.

Owner:SHANGHAI JIAO TONG UNIV

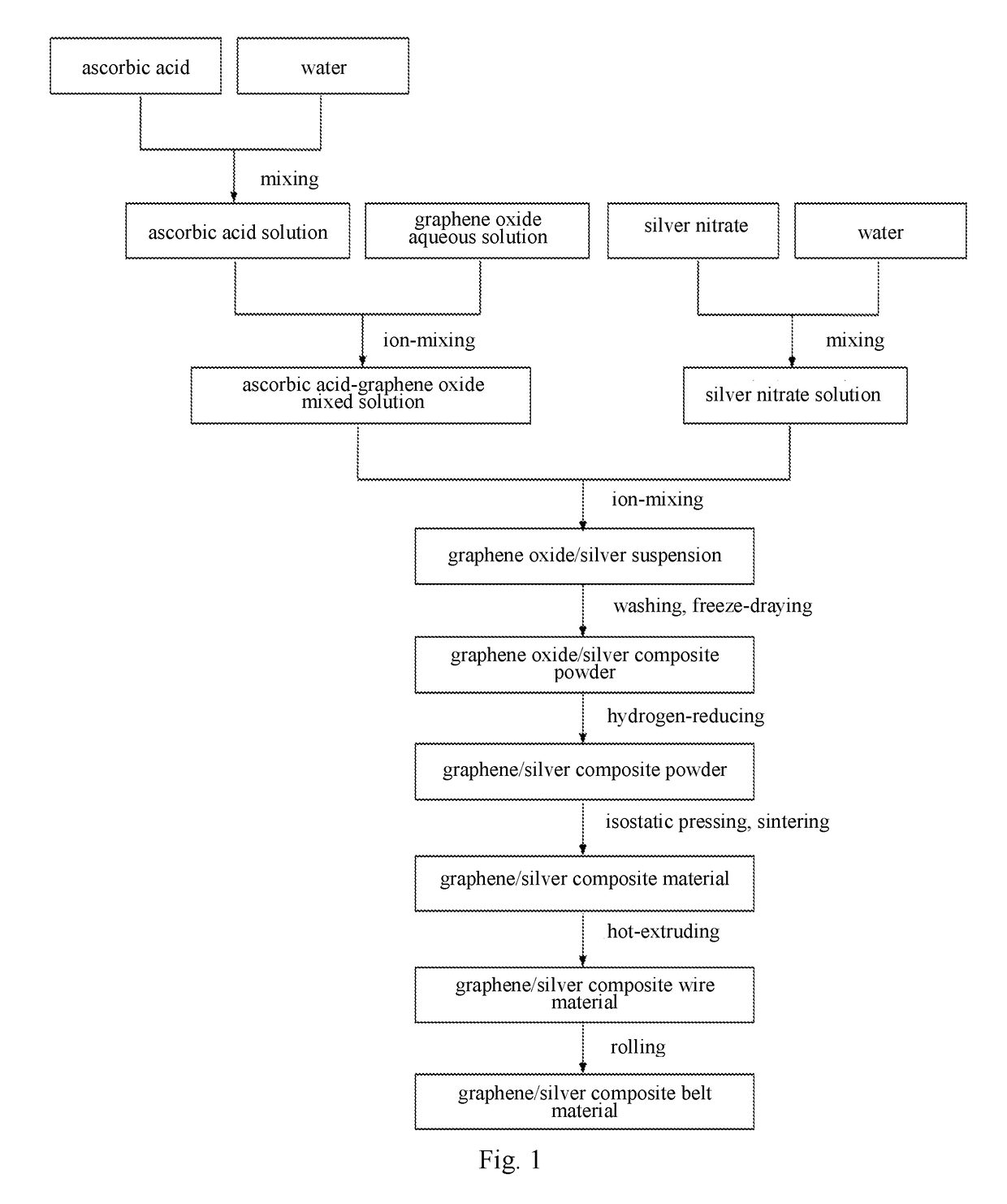

Gaphene/silver composite material and preparation method thereof

InactiveUS20180073105A1High density and electrical conductivityImprove controllabilityMetal/alloy conductorsCarbon-silicon compound conductorsInterface bondCvd graphene

A method for preparing graphene / silver composite material is provided. A reduction agent and silver nitrate are added successively into a graphene oxide solution; silver powder obtained by reduction is directly combined with graphene oxide in the solution, so as to preliminarily obtain graphene oxide / silver composite powder; graphene / silver composite powder is then obtained through drying and reducing; a graphene / silver composite block material, a graphene / silver composite wire material and a graphene / silver composite belt material are able to be obtained by powder metallurgy, hot-extruding and rolling techniques. According to the composite material of the present invention, graphene is dispersed uniformly, and interface bonding between a matrix and an enhanced body is sufficient, leading to excellent physical performance of the composite material. Meanwhile, the method of the present invention is simple and processes are easy to control, which is conducive to large-scale production and application.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

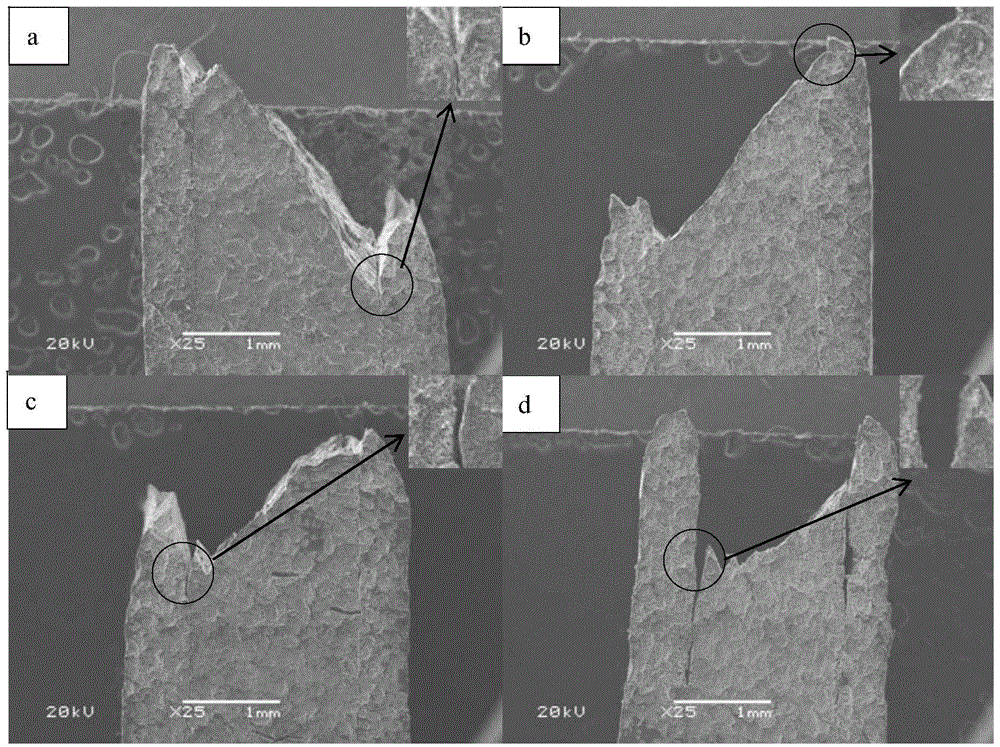

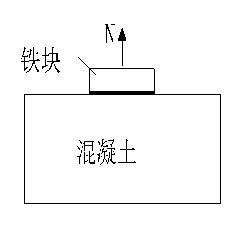

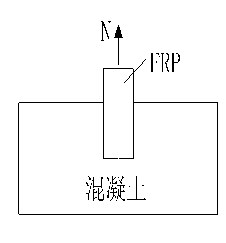

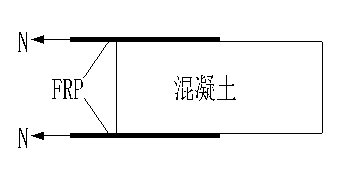

Method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on beam specimen

InactiveCN103344560ATruly reflect the state of stressEasy to operateUsing mechanical meansMaterial analysisInverted-T shapeEngineering

The invention discloses a method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on a beam specimen. The method comprises three steps of preparing a test specimen, arranging a test point and loading a test. The test specimen manufactured in the first step is the beam specimen and comprise two concrete test blocks, which are arranged at left and right and symmetric in shape; the two concrete test blocks are inverted T-shaped concrete test blocks; the upper parts in the middle of the two concrete test blocks are connected by a steel hinge; the steel hinge is divided into left and right halves; and the left and right halves are respectively adhered to the concrete test block at the corresponding side, and have the rotation ability. Compared with the traditional double shear test method for testing the interface bond behavior of the CFRP cloth-concrete, the effect of asymmetric loading on the data reliability is avoided; the method has a unique advantage of high accuracy of the test result; and the accuracy and the creditability of the detection result are improved.

Owner:ZHENGZHOU UNIV

Method for preparing layered titanium-based composite material based on powder laying - hot pressing sintering

ActiveCN106853530AGuaranteed interface bonding strengthComposition controllableTitanium matrix compositesMaterials preparation

The invention relates to a method for preparing a layered titanium-based composite material based on powder laying - hot pressing sintering. The method aims to solve problems that the interface bonding strength of the layered titanium-based composite material is low, the layer thickness and ingredients of each layer cannot be controlled easily and the material preparation process is complex. According to the method, in a powder mixing - powder layering - hot pressing sintering mode, after titanium alloy powder and an enhanced body are evenly mixed, manual powder laying is performed, the process of preparing a blocky material is omitted, each layer of material does not need to be prepared in advance and the titanium-based composite material is prepared through direct hot pressing sintering. By adjusting the content of the enhanced body and powder laying parameters, preparation of the layered material with the controllable ingredients and the adjustable layer thickness is implemented. The method is used for preparing the layered titanium-based composite material.

Owner:HARBIN INST OF TECH

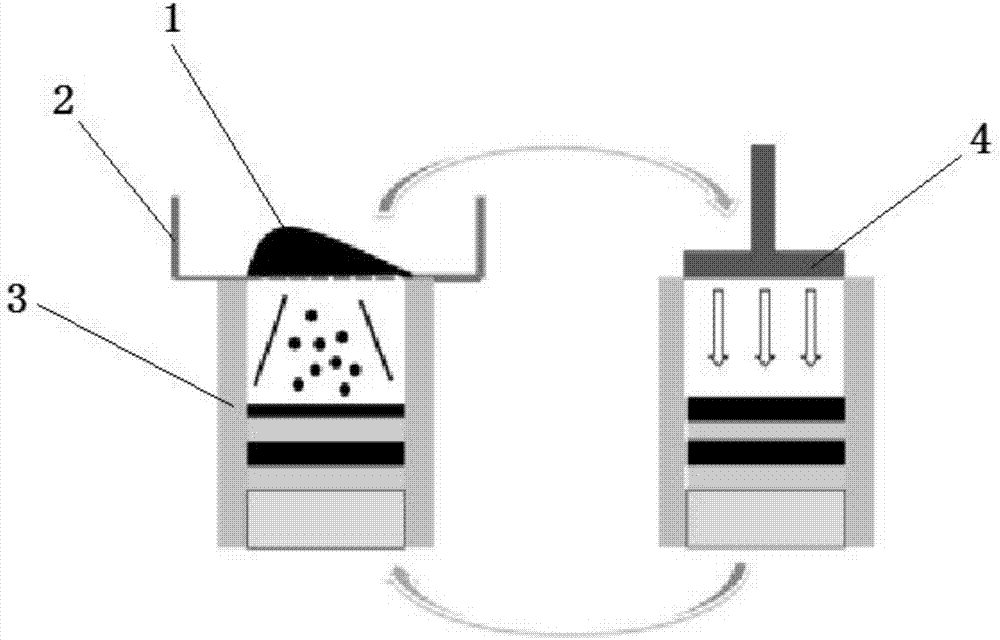

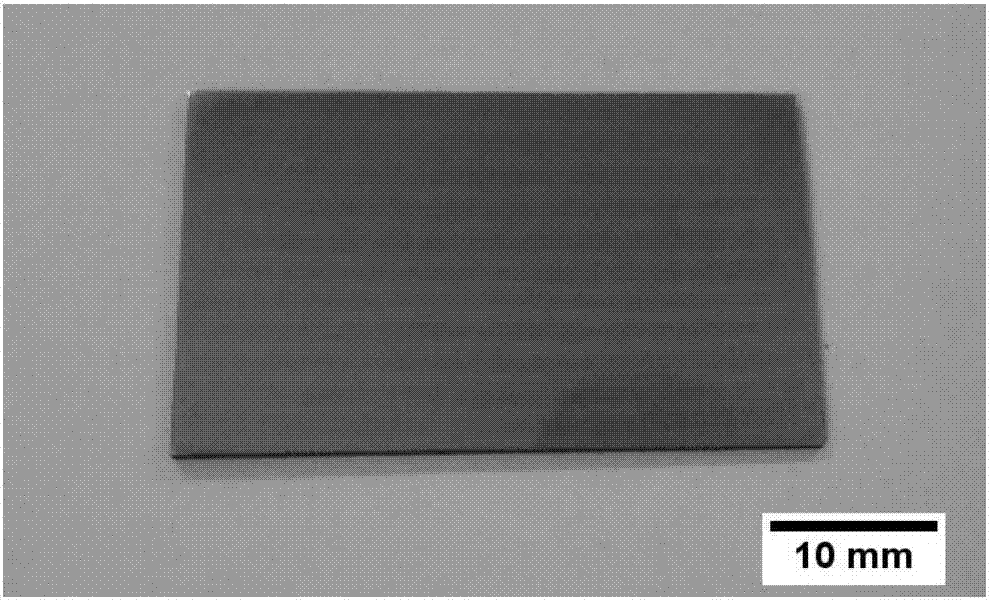

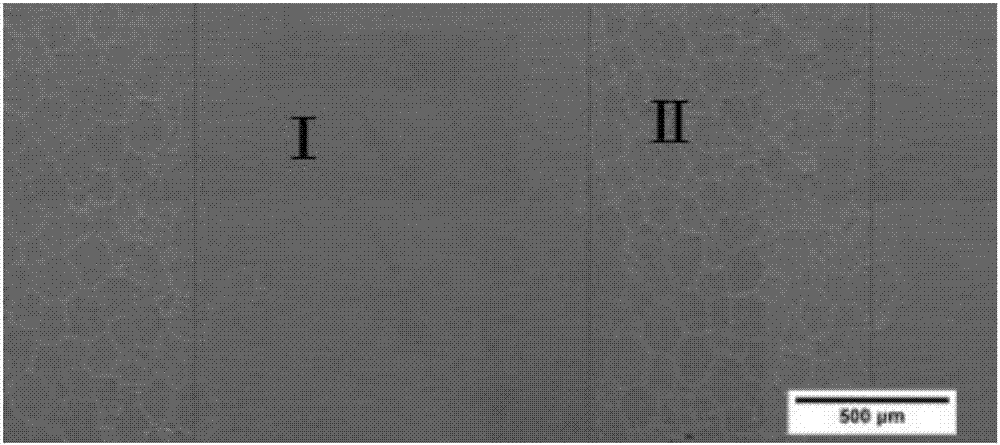

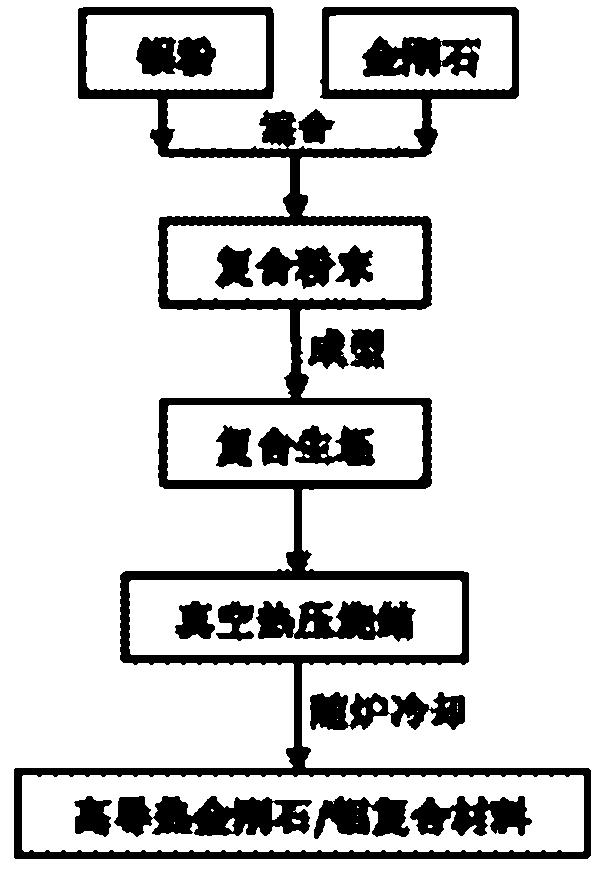

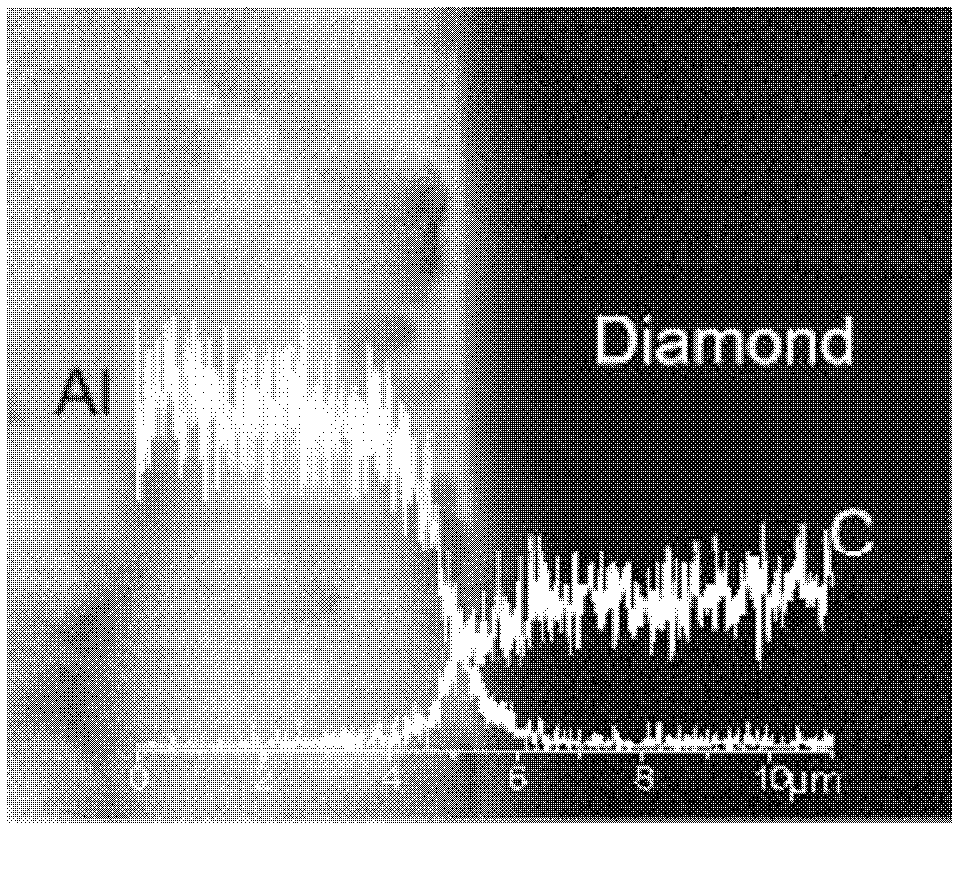

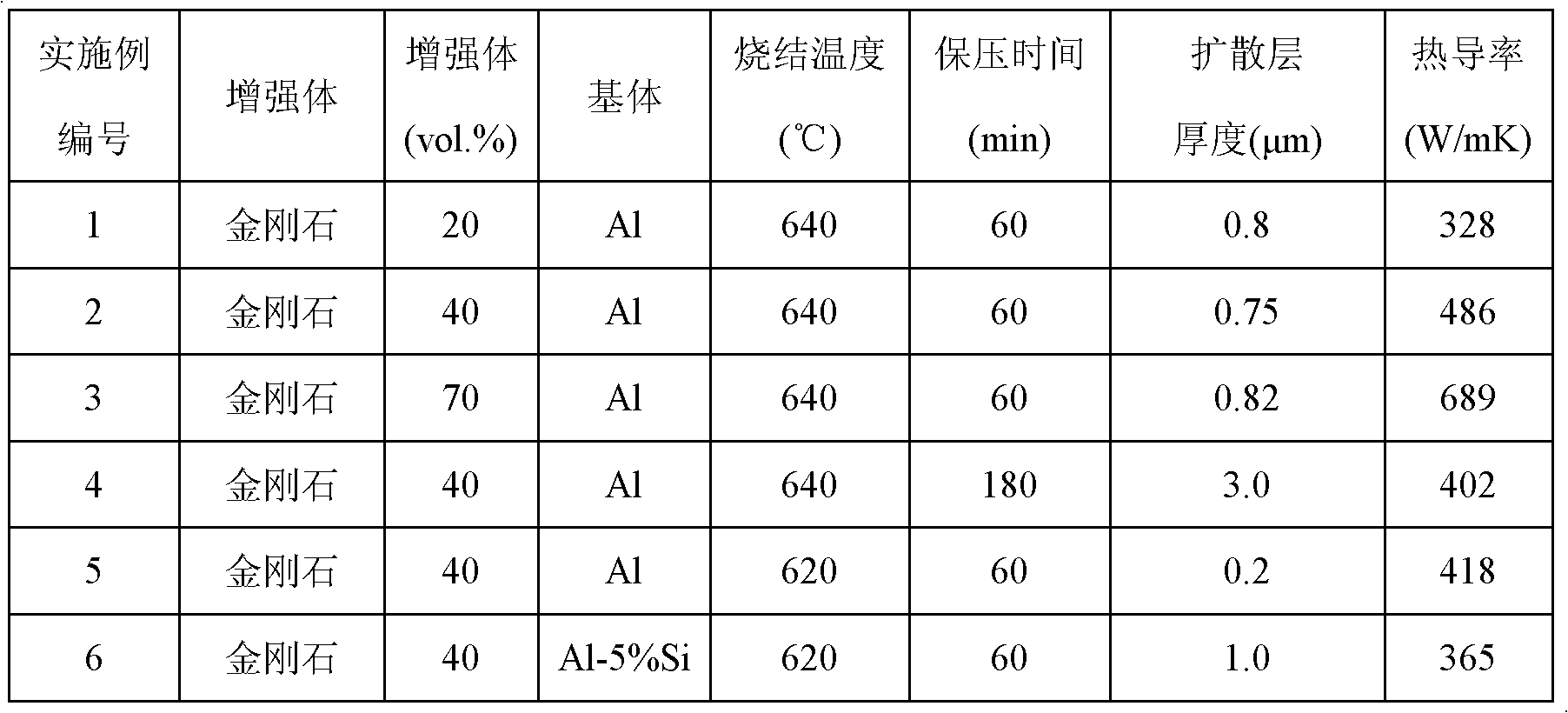

Method for preparing high conductivity diamond/aluminum composite material

ActiveCN102534331AEnhanced interface bindingHigh thermal conductivityMicrometerInterfacial thermal resistance

The invention discloses a method for preparing a high conductivity diamond / aluminum composite material. The method comprises the following steps of: uniformly mixing diamond and aluminum powder to obtain diamond / aluminum composite powder; performing cold pressing or cold isostatic pressing to obtain a diamond / aluminum powder compact; performing vacuum hot pressed sintering on the compact, and ensuring that an atomic diffusion layer with proper thickness is generated at a diamond / aluminum interface by controlling the sintering temperature and time; and cooling to obtain the high conductivity diamond / aluminum composite material. The atomic diffusion layer with the thickness of 0.01-5.0 micrometers is formed at the diamond / aluminum interface by controlling the temperature and time of the vacuum hot pressed sintering, so that good interface bond can be achieved, low interface thermal resistance can be achieved, and the high conductivity composite material is obtained. The method is simple and feasible, low in production cost and suitable for preparing large-size composite materials.

Owner:SHANGHAI JIAO TONG UNIV

Modified polypropylene crude fiber used for reinforcing concrete and preparation method

ActiveCN105316788AReduce the presence of air bubblesStrong mechanical propertiesArtificial thread manufacturing machinesMelt spinning methodsCross-linkWater baths

The invention provides modified polypropylene crude fiber used for reinforcing concrete, and belongs to the technical field of fiber. The modified polypropylene crude fiber is prepared by conducting melt blending and stretching on isotactic polypropylene and modified filler accounting for 0.1-40% of the weight of polypropylene. The modified filler is prepared from an organic modification agent, a coupling agent and inorganic modification filler. The modified polypropylene crude fiber is used for inorganic modified filler, antioxidant and dispersing agents, degradation of polypropylene is prevented, and dispersion of filler is improved. The preparation method includes the steps of adding polypropylene and modified filler in an extruder from different filler openings according to the proportion to be subjected to melt extrusion, the mixture is cooled in a water bath after being extruded out of a spinneret plate of the extruder, conducting thermal stability on fiber after polypropylene fiber is pulled and stretched, and conducting surface postprocessing, cut-off and packaging on fiber. According to the polypropylene crude fiber prepared through the method, silicon oxide groups or hydrophilic groups contained in modified filler can be subjected to chemical cross linking together with concrete, the interface bonding between the fiber and concrete is greatly improved, and the reinforcement effect of the fiber is improved.

Owner:宁波时科新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com