Wear resistant and antistatic polyamide composite material and preparation method thereof

A composite material and polyamide technology, applied in the wear-resistant field of composite materials, can solve the problems of high material cost, difficult material manufacturing, poor surface gloss, etc., to improve interface bonding strength, improve latent heat energy storage performance, and small thermal expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

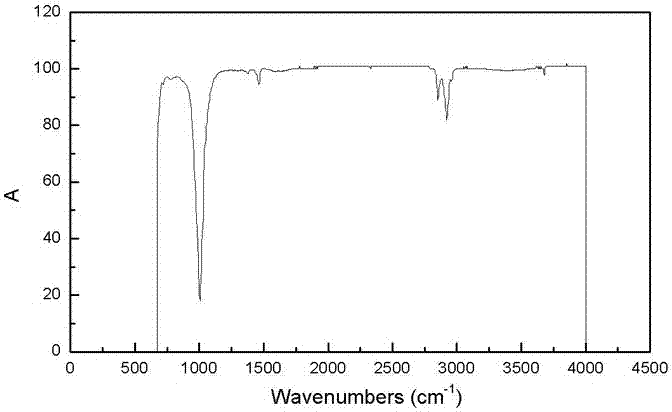

Image

Examples

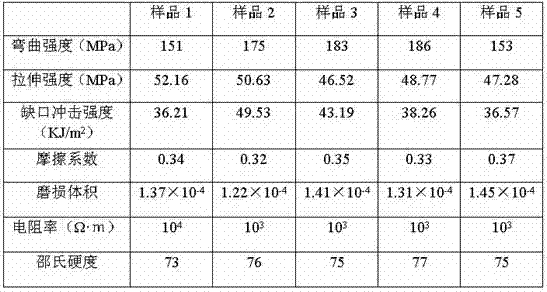

Embodiment 1

[0026] A wear-resistant and antistatic polyamide composite material, which consists of 70 parts of polyamide matrix, 8 parts of wear-resistant material, 10 parts of filler, 13 parts of toughening compatibilizer, 3 parts of modified graphene, and 8 parts of carbon fiber according to the weight ratio. 1 part, 1 part of dispersant and 0.5 part of antioxidant; the wear-resistant material is mixed with modified hexagonal boron nitride microchips and silicon carbide capsules with a weight ratio of 1:5; the filler is composed of It is formed by mixing titanium dioxide, carbon black and glass powder at 3:2:2; the polyamide matrix is PA66, the toughening compatibilizer is POE grafted maleic anhydride, and the modified graphene Graphene oxide is treated with hexachlorocyclotriphosphazene, and the weight ratio of the two is 1:10; the carbon fiber is 6K carbon fiber, and before use, the carbon fiber is firstly dissolved in acetone for 70 o C soaked in a constant temperature water bath f...

Embodiment 2

[0035] A kind of wear-resisting antistatic type polyamide composite material, by weight ratio, by polyamide substrate 65 parts, wear-resisting material 10 parts, filler 13 parts, toughening compatibilizer 16 parts, modified graphene 5 parts, carbon fiber 10 parts part, 2 parts of dispersant and 0.8 part of antioxidant; the wear-resistant material is mixed with modified hexagonal boron nitride microchips and silicon carbide capsules with a weight ratio of 1:5; the filler is composed of It is formed by mixing titanium dioxide, carbon black and glass powder at 3:2:2; the polyamide matrix is PA66, the toughening compatibilizer is POE grafted maleic anhydride, and the modified graphene Graphene oxide is treated with hexachlorocyclotriphosphazene, and the weight ratio of the two is 1:13; the carbon fiber is 6K carbon fiber, and before use, the carbon fiber is firstly dissolved in acetone for 70 o C soaked in a constant temperature water bath for 24 hours, then soaked in concentrat...

Embodiment 3

[0043]A kind of wear-resisting antistatic type polyamide composite material, by weight ratio, by polyamide matrix 60 parts, wear-resisting material 13 parts, filler 15 parts, toughening compatibilizer 18 parts, modified graphene 7 parts, carbon fiber 12 parts 1 part, 3 parts of dispersant and 1 part of antioxidant; the wear-resistant material is mixed with modified hexagonal boron nitride microchips and silicon carbide capsules with a weight ratio of 1: 6; the filler consists of a weight ratio of It is formed by mixing titanium dioxide, carbon black and glass powder at 3:2:2; the polyamide matrix is PA66, the toughening compatibilizer is POE grafted maleic anhydride, and the modified graphene Graphene oxide is treated with hexachlorocyclotriphosphazene, and the weight ratio of the two is 1:15; the carbon fiber is 6K carbon fiber, and before use, the carbon fiber is first soaked in acetone for 24 hours under the condition of a constant temperature water bath at 70°C, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com