Patents

Literature

3556results about How to "Increase coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spinal interbody fusion device and method

InactiveUS7022138B2Easy to copyAvoid injuryInternal osteosythesisBone implantSpinal columnIntervertebral disk

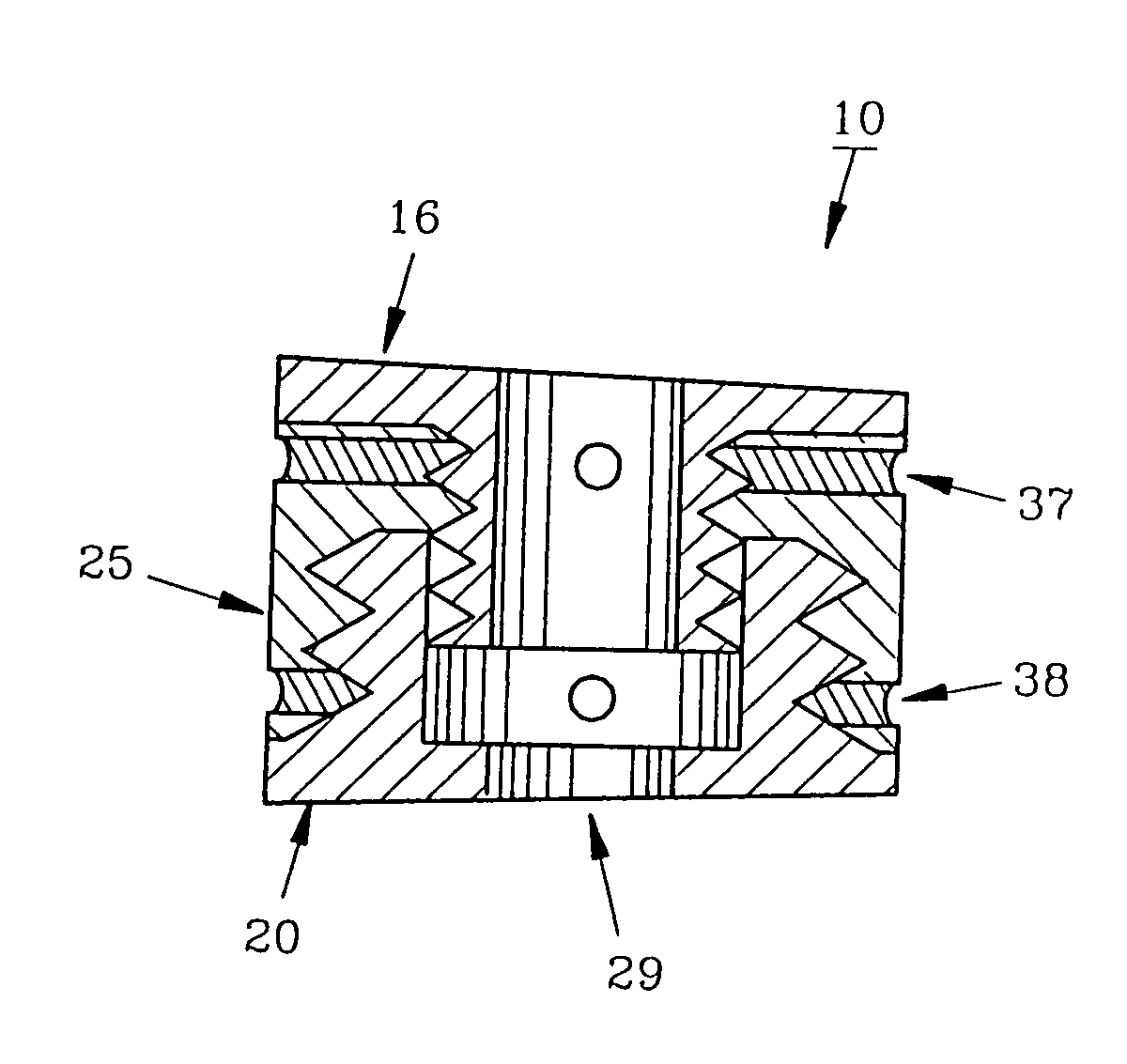

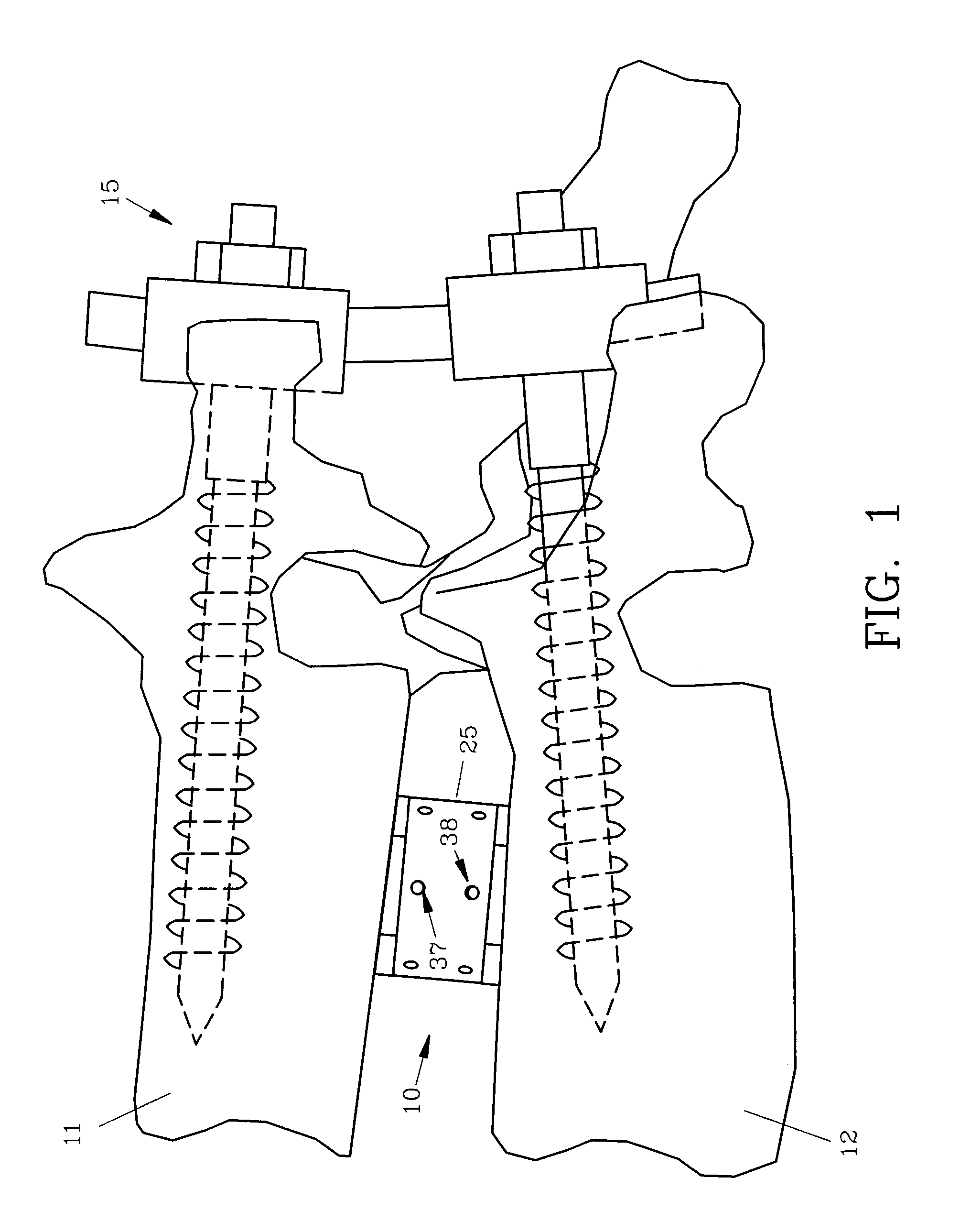

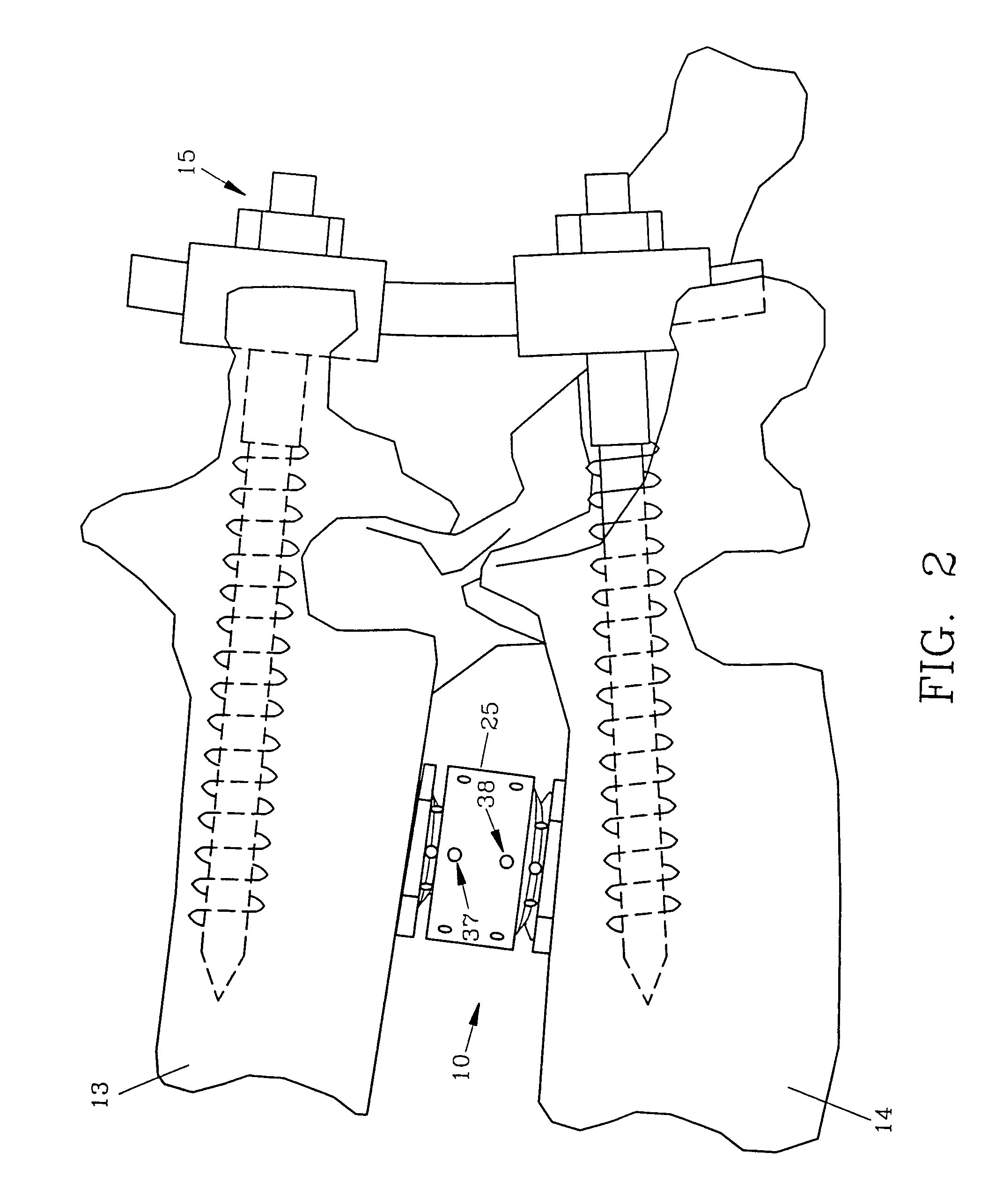

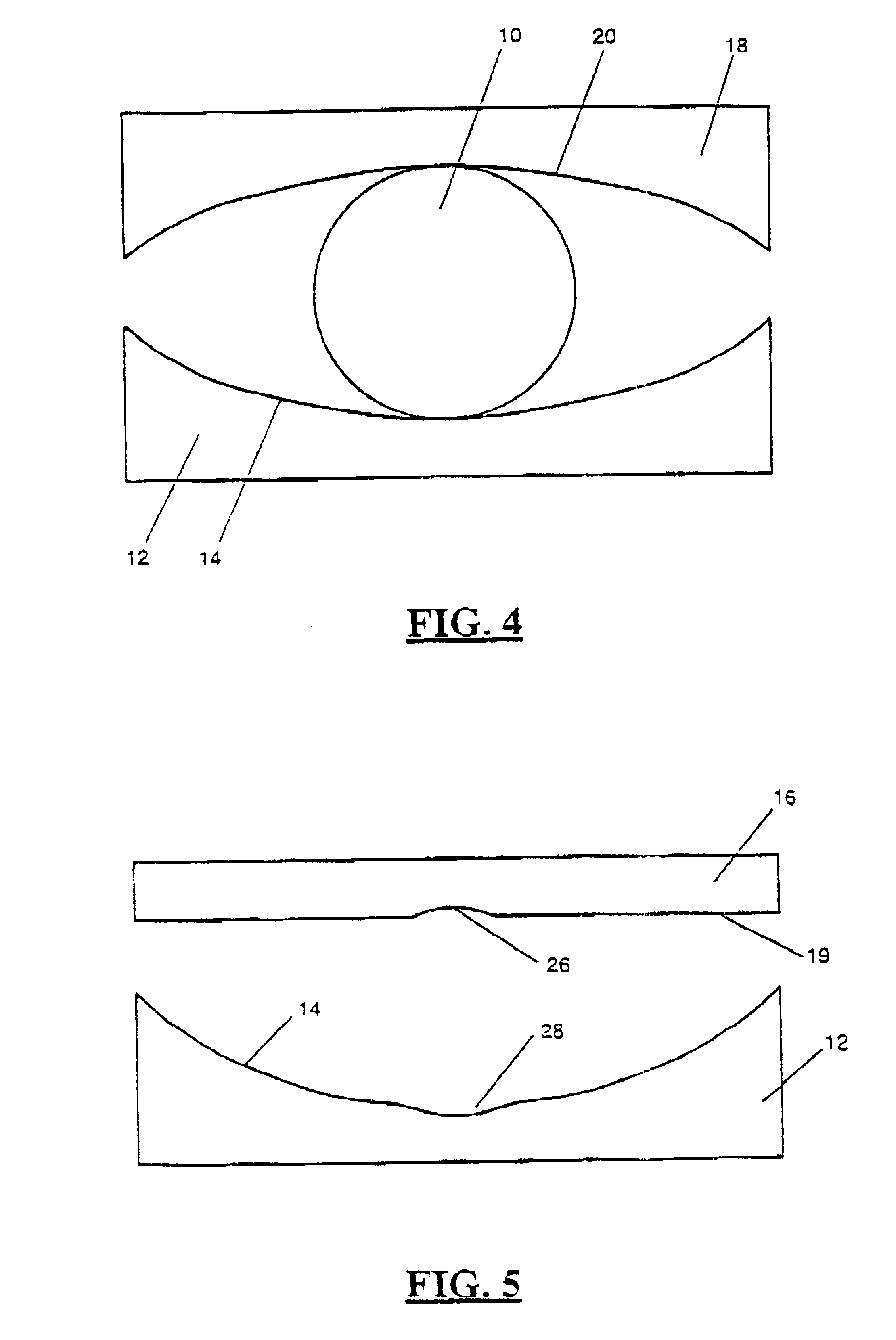

A disc replacement spinal interbody fusion device is provided having a central sleeve with oppositely left and right-hand threaded axial bores with different diameters. Circumferential threaded apertures are located on the sleeve and open into the sleeve bores. The device has two opposing plates which are oval-shaped and centrally, axially bored. Each plate has a perpendicular shaft with an axial bore which communicates with the plate bore. In situ, axial loading of the spinal column upon the fusion device creates a bending moment manifested by a flexing action of the plates to generate opposing axial directional forces which replicate the physiological function of shock absorption, load bearing and load transmission.

Owner:MASHBURN M LAINE

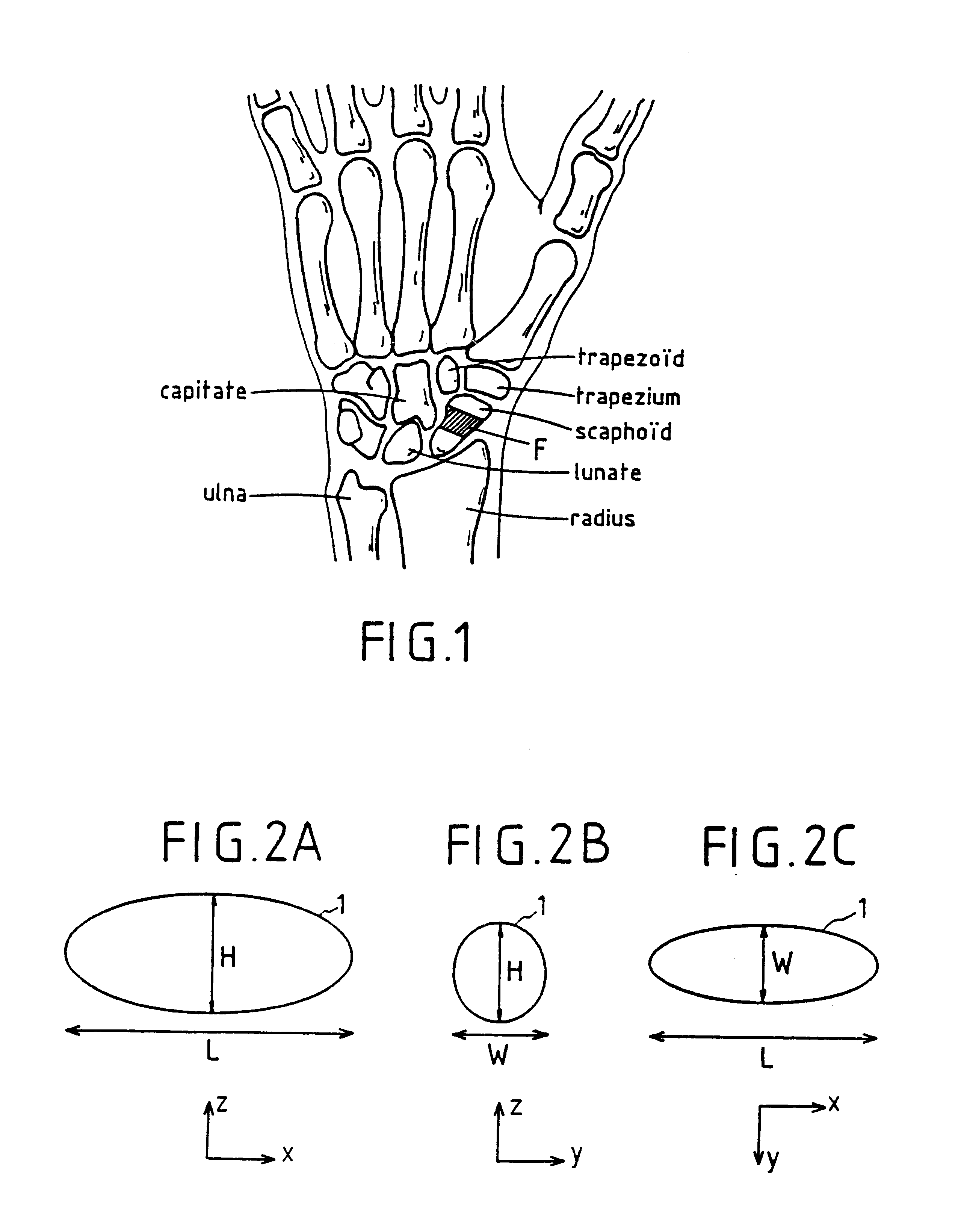

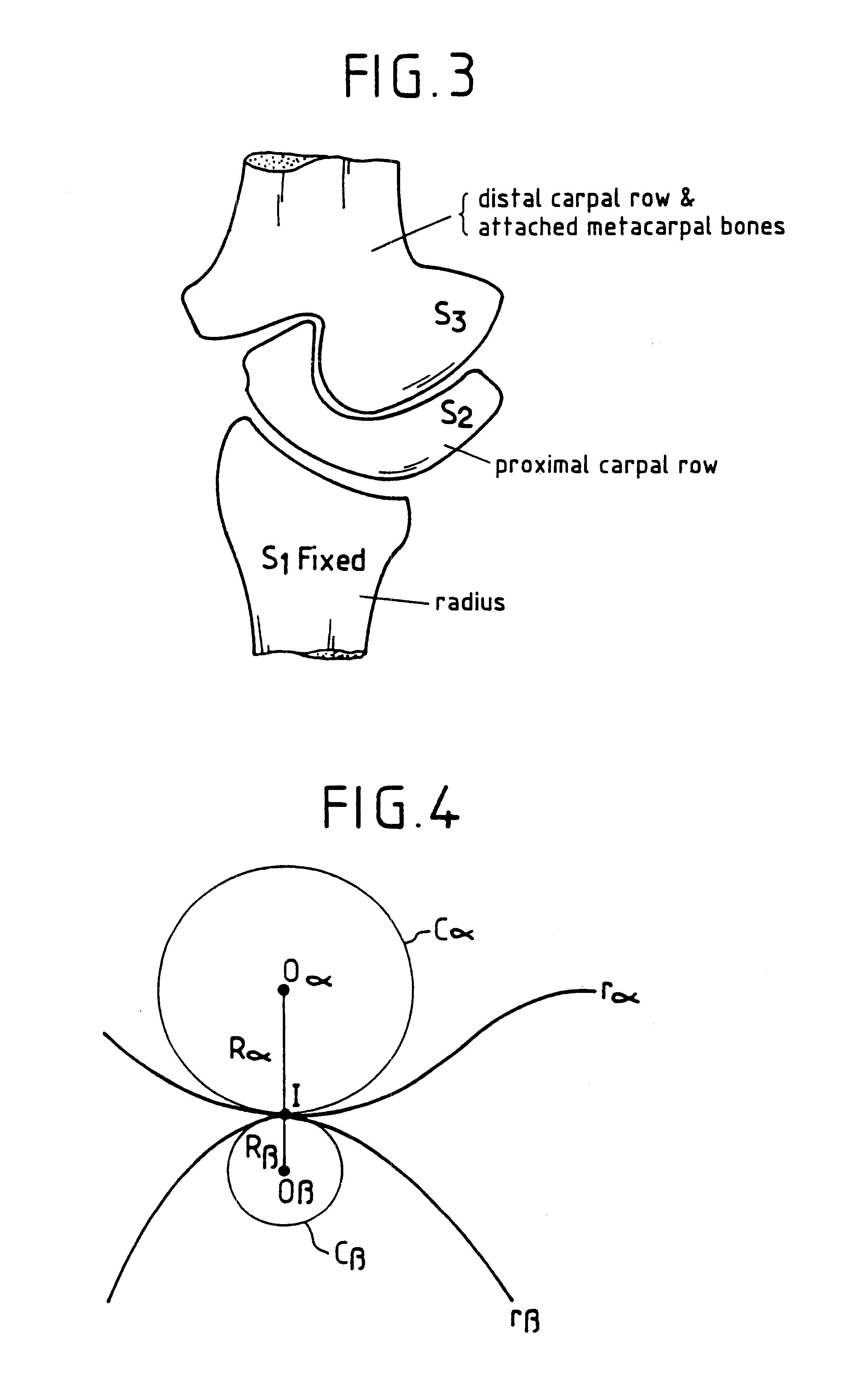

Implant for treating ailments of a joint or a bone

InactiveUS6436146B1Increase coefficient of frictionImprove stabilityFinger jointsWrist jointsDiseasePyrolytic carbon

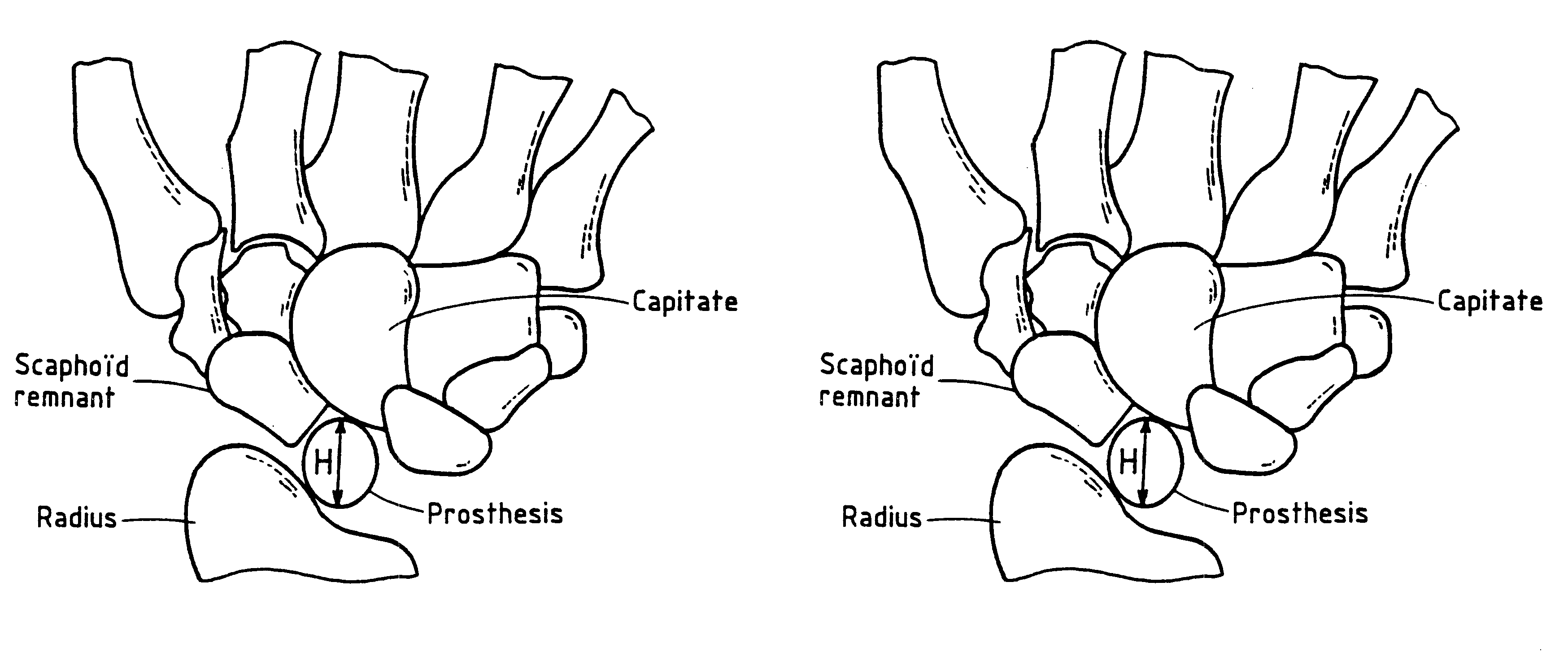

The implant has at least one contact surface portion, made of pyrolytic carbon, designed to be in mobile contact with at least one bony surface when the implant is implanted in a patient. Furthermore, the implant is free from any attaching means, so that it remains free with respect to the at least one bony surface when implanted in the patient.

Owner:TORNIER SA SAINT ISMIER

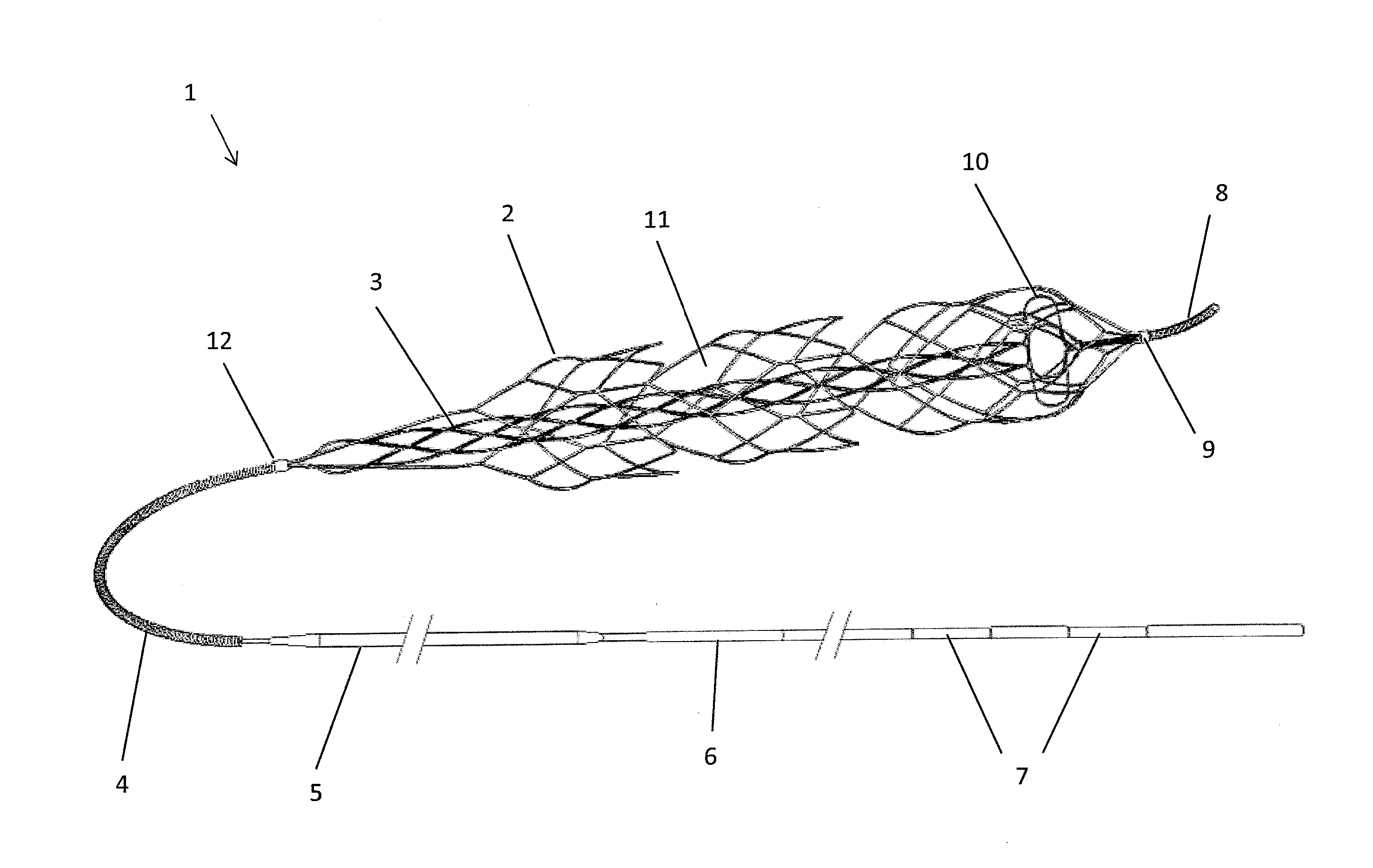

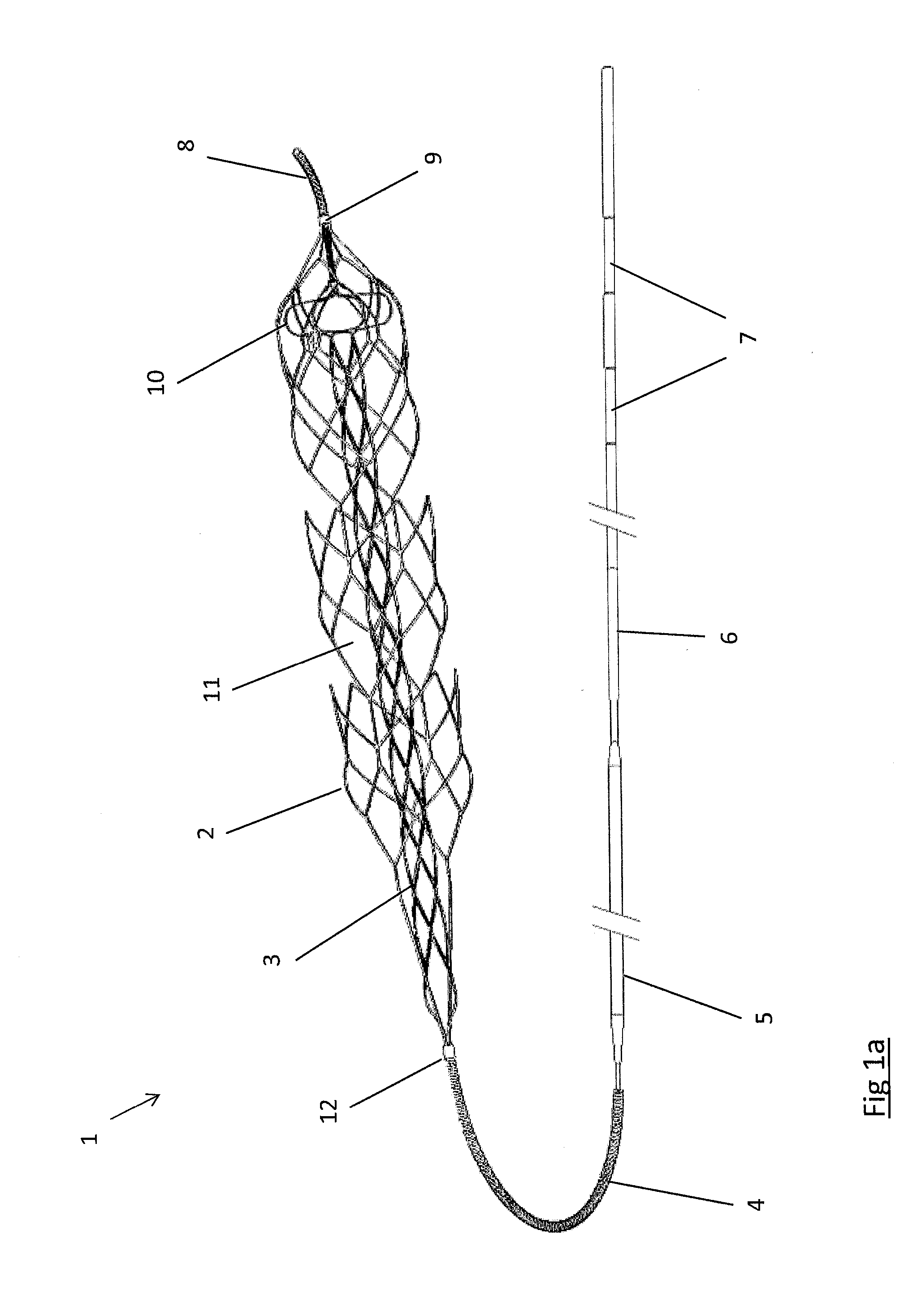

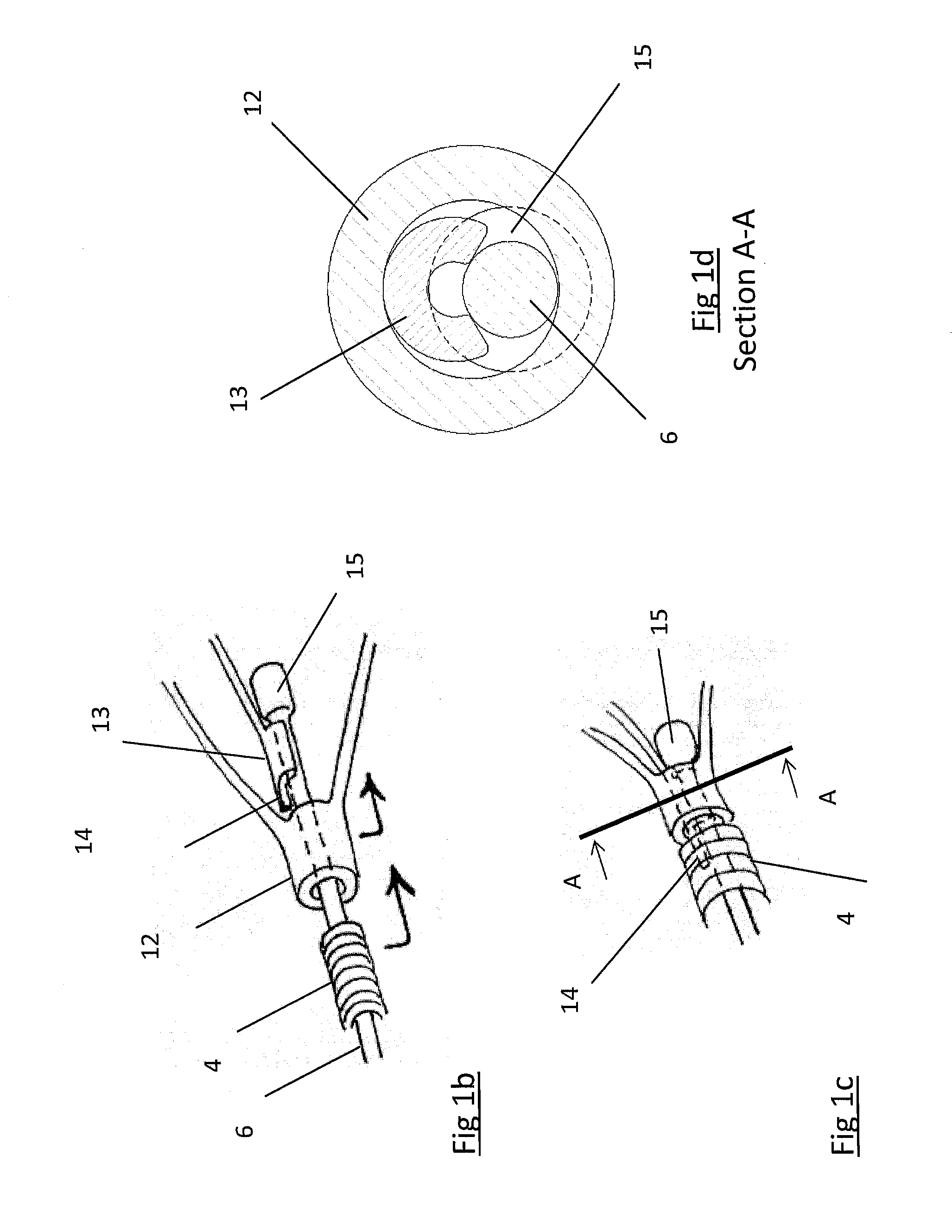

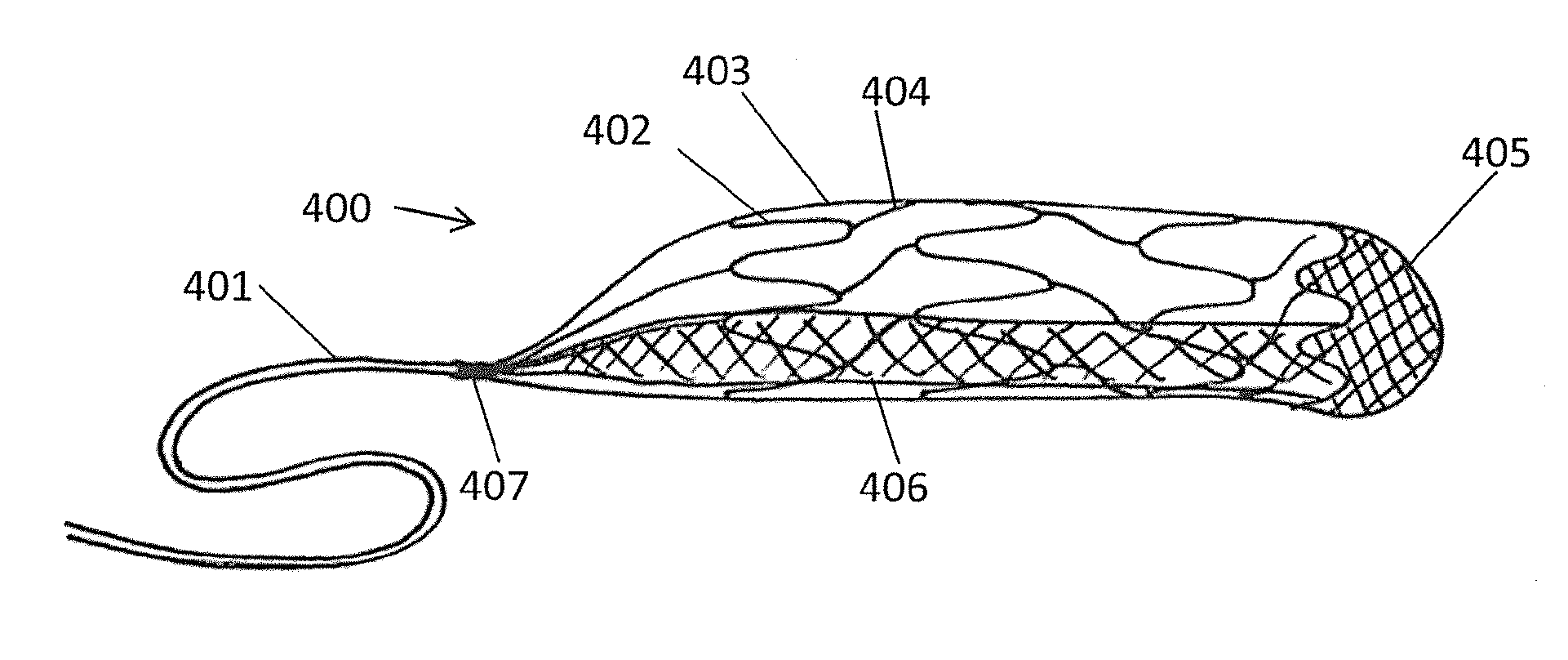

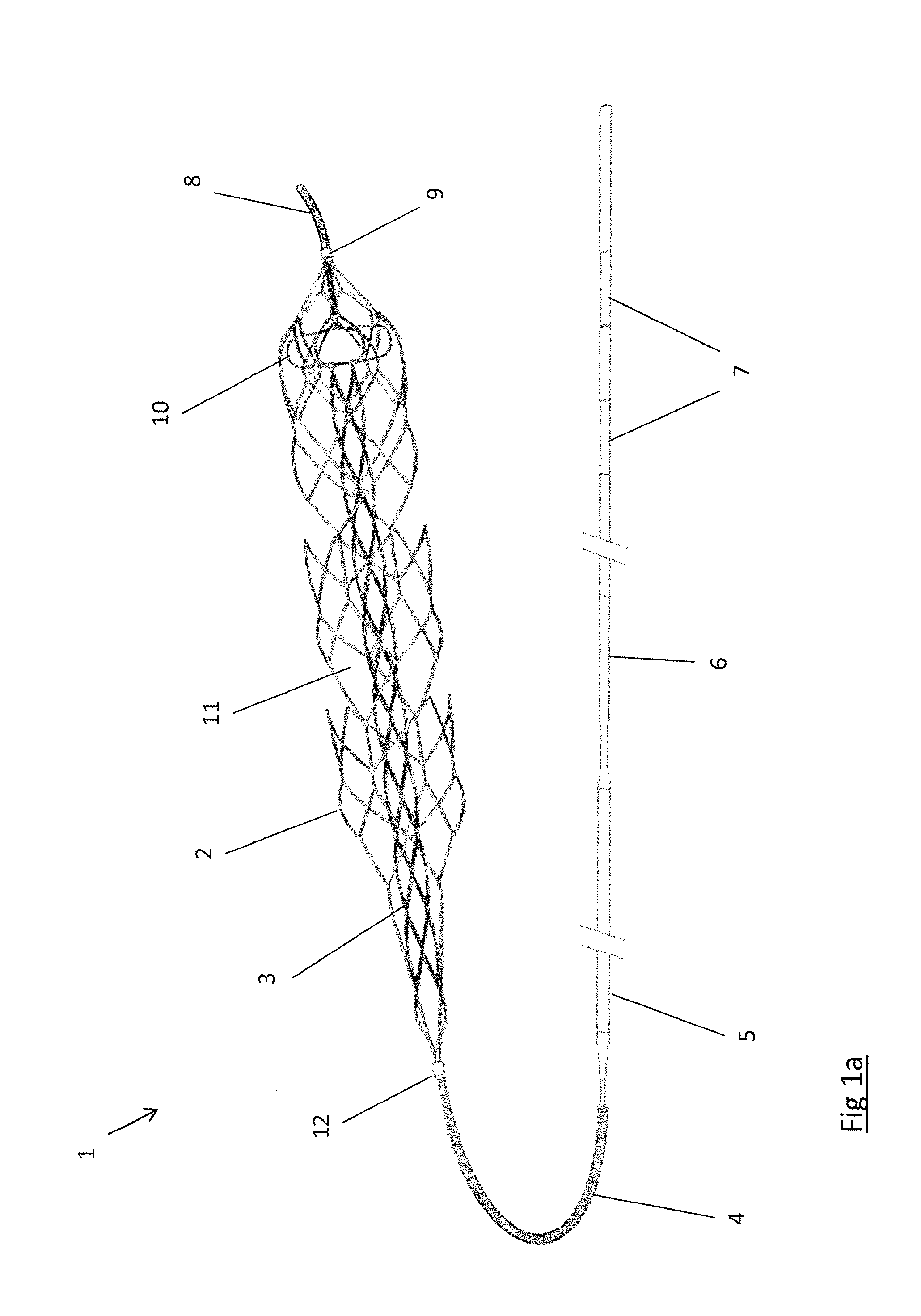

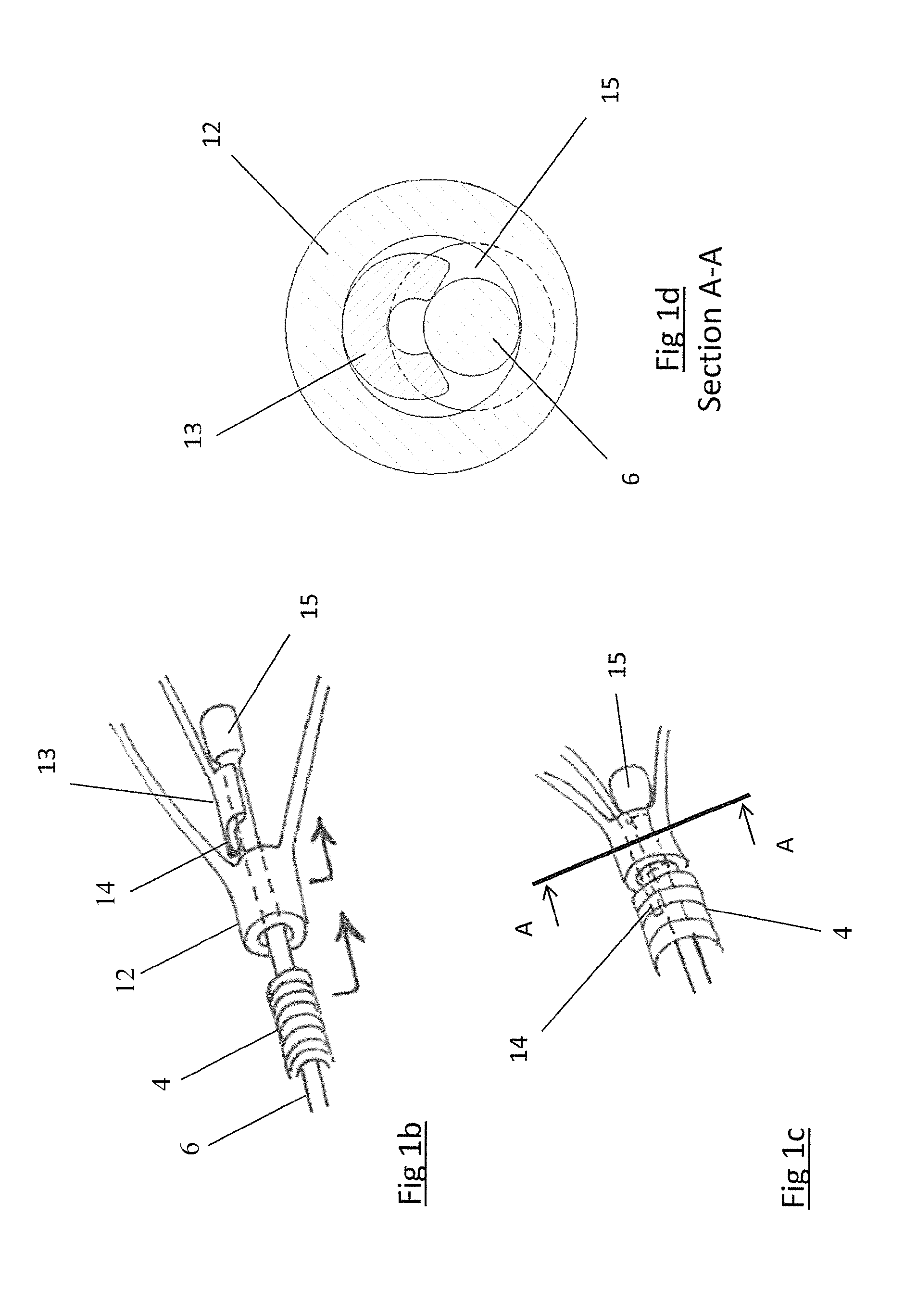

Clot retrieval device for removing occlusive clot from a blood vessel

ActiveUS20140371779A1Reduce radial forceMinimize compressionDilatorsExcision instrumentsBiomedical engineeringBlood vessel

Owner:NEURAVI

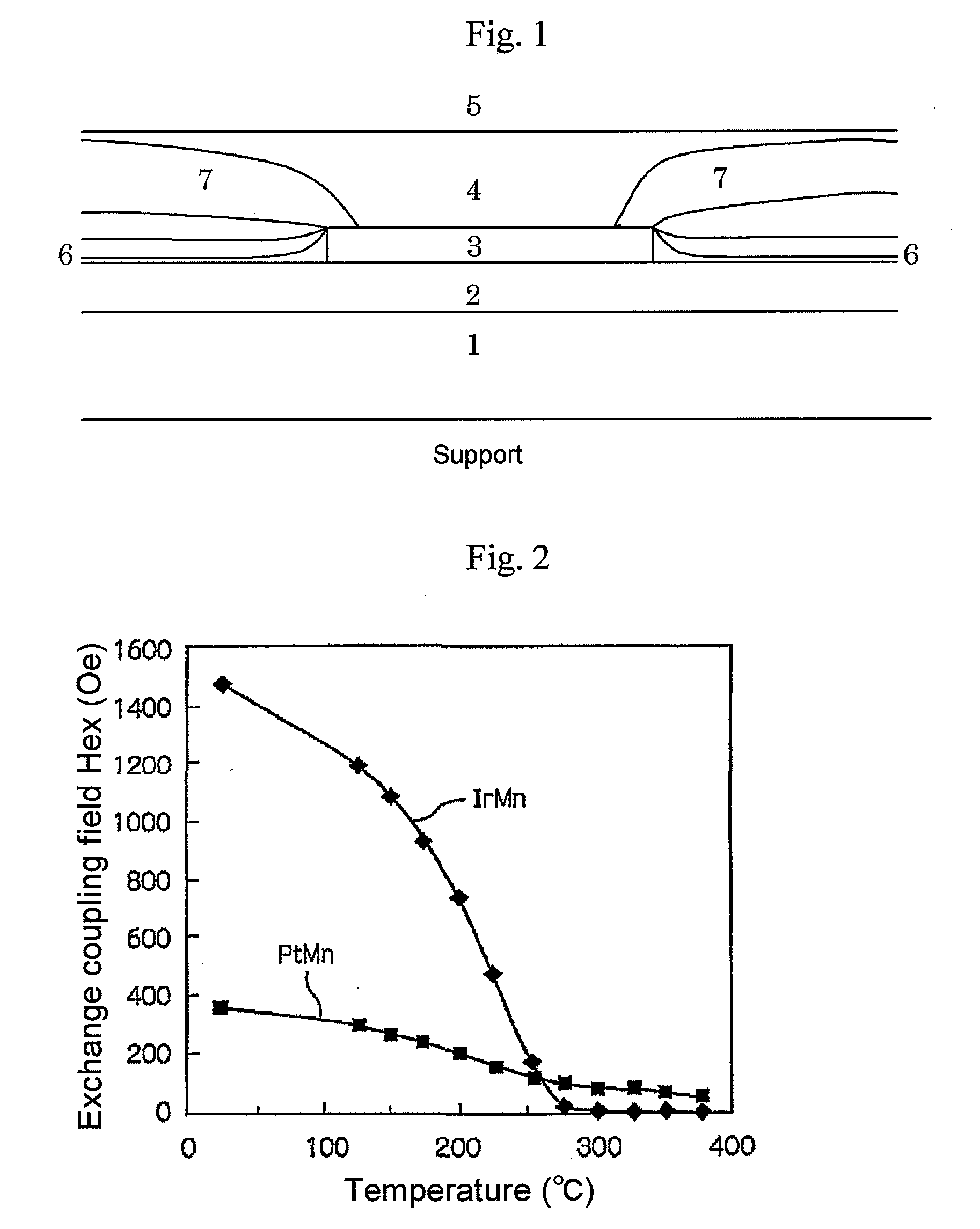

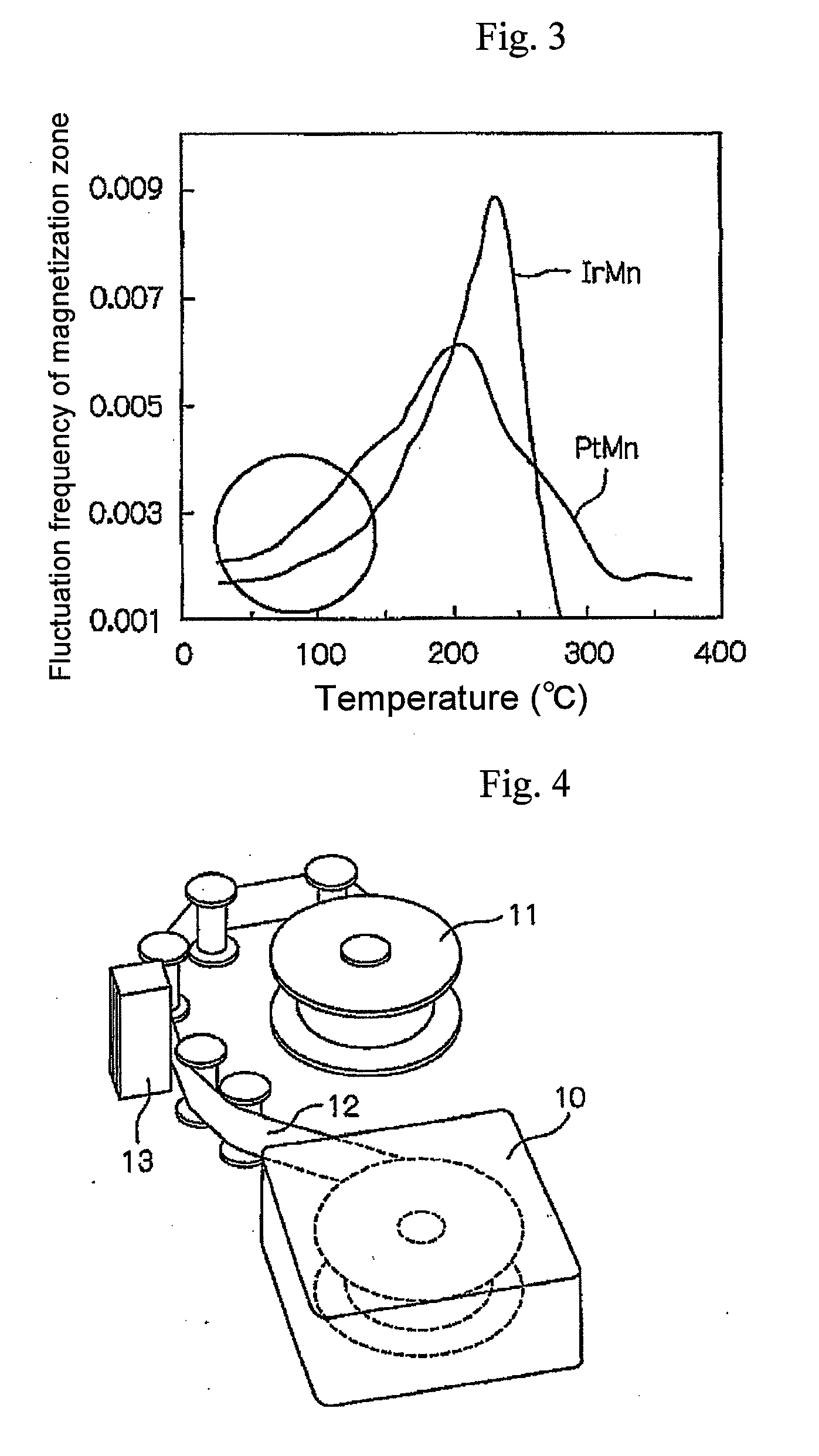

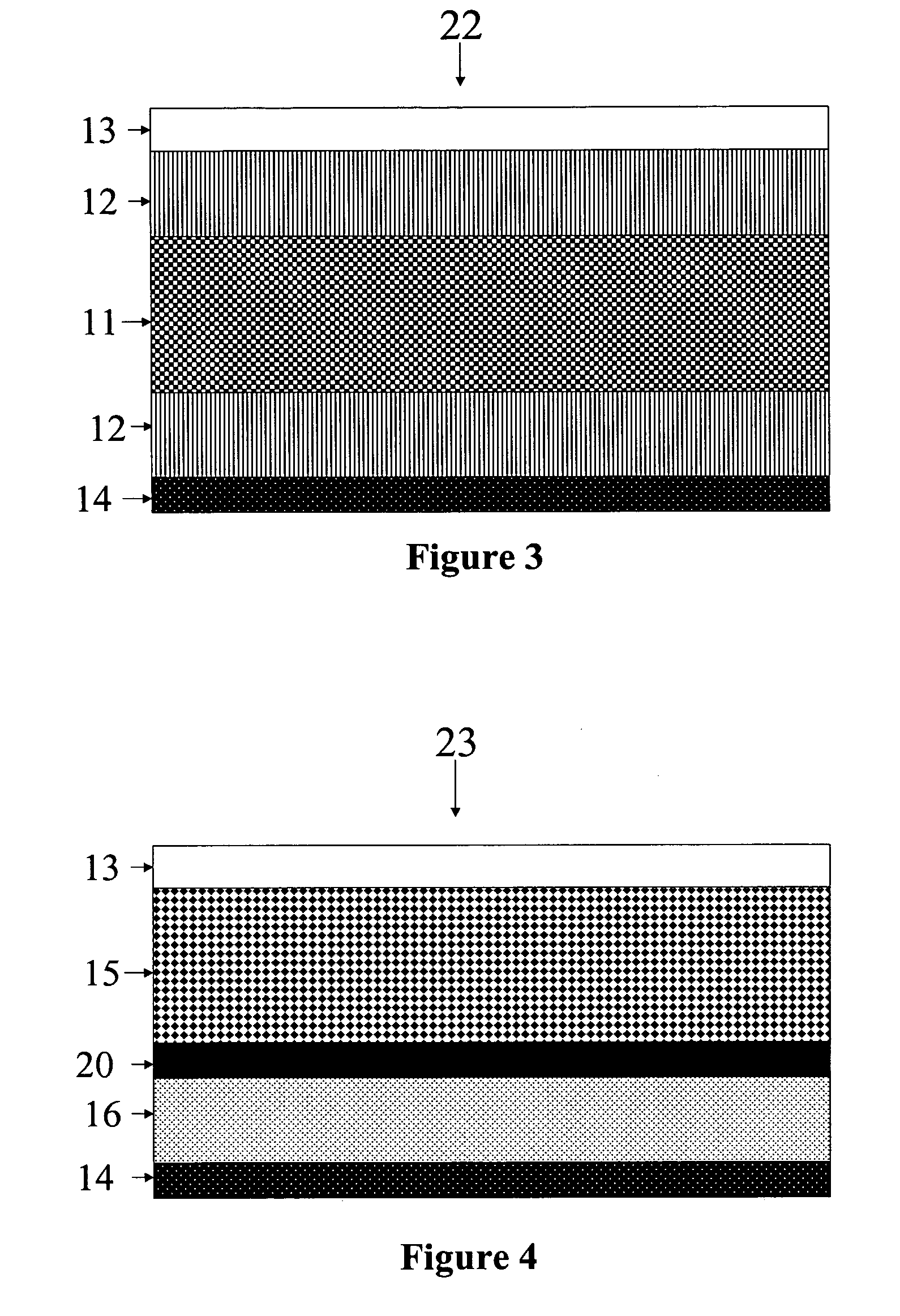

Magnetic signal reproduction system and magnetic signal reproduction method

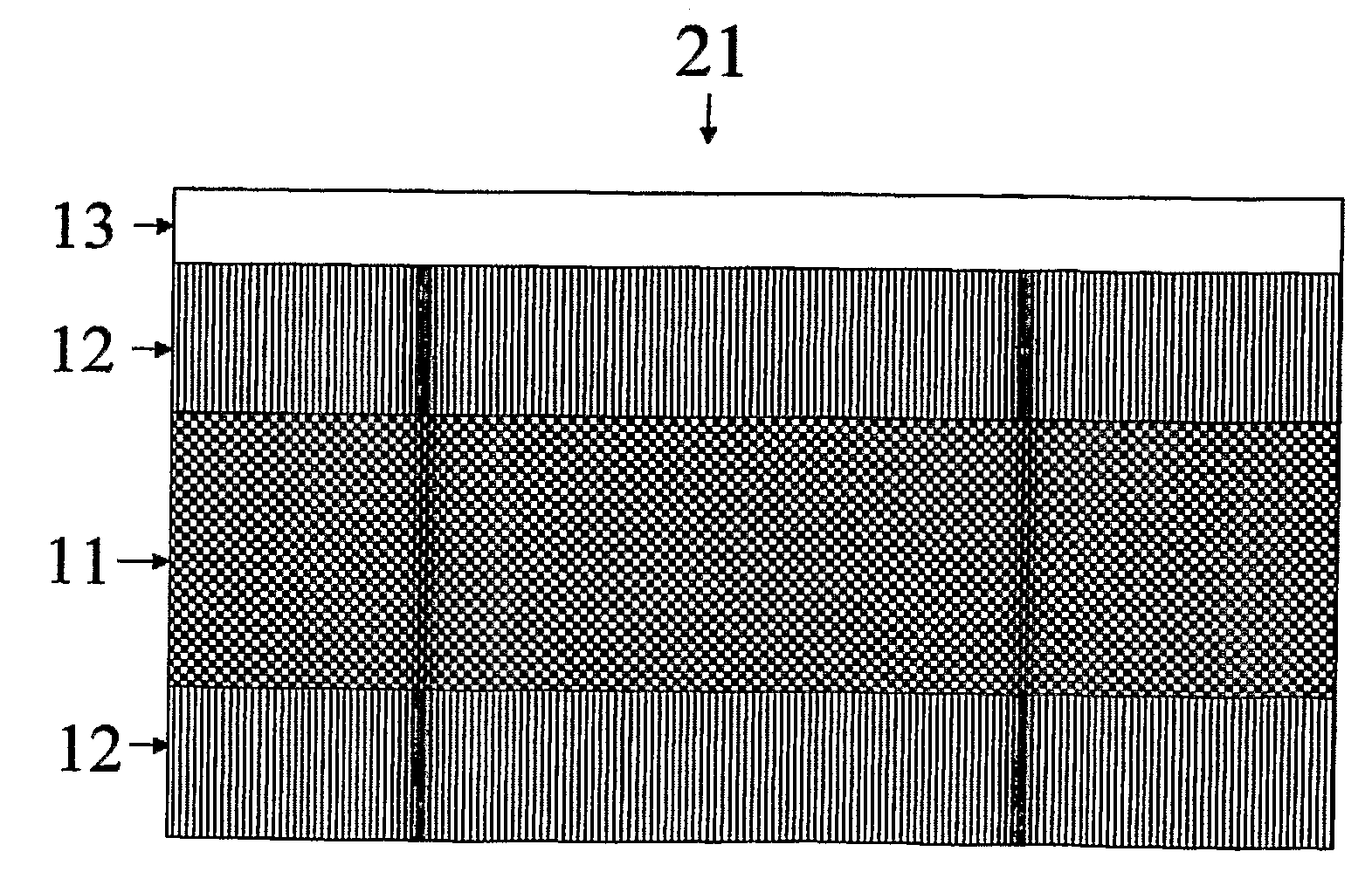

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

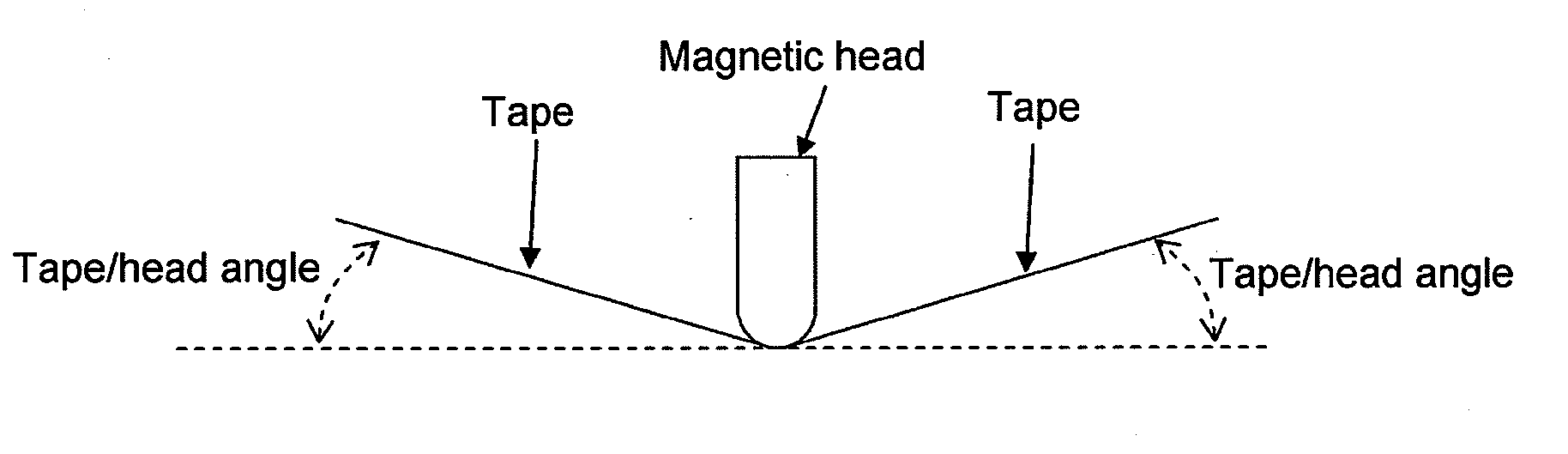

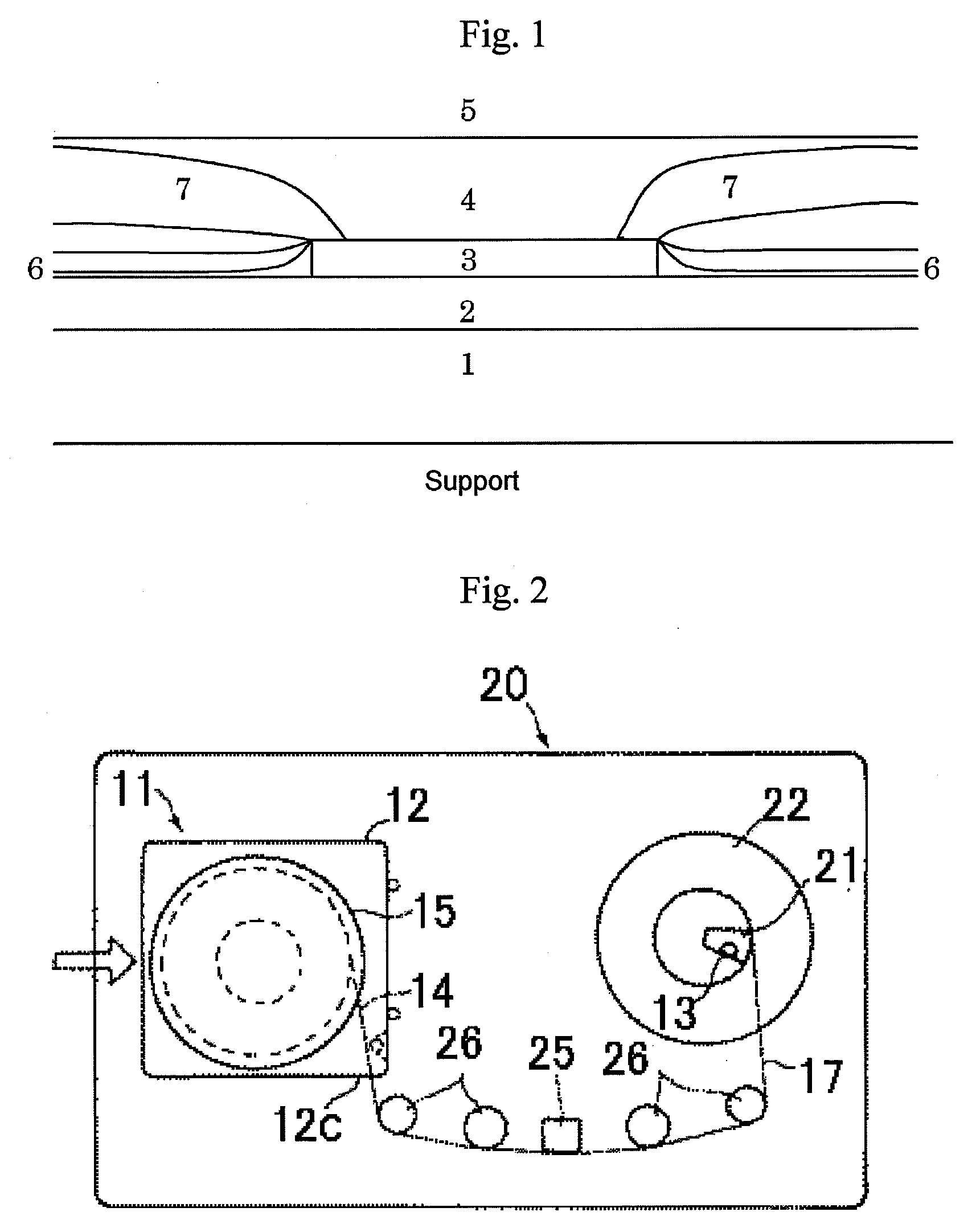

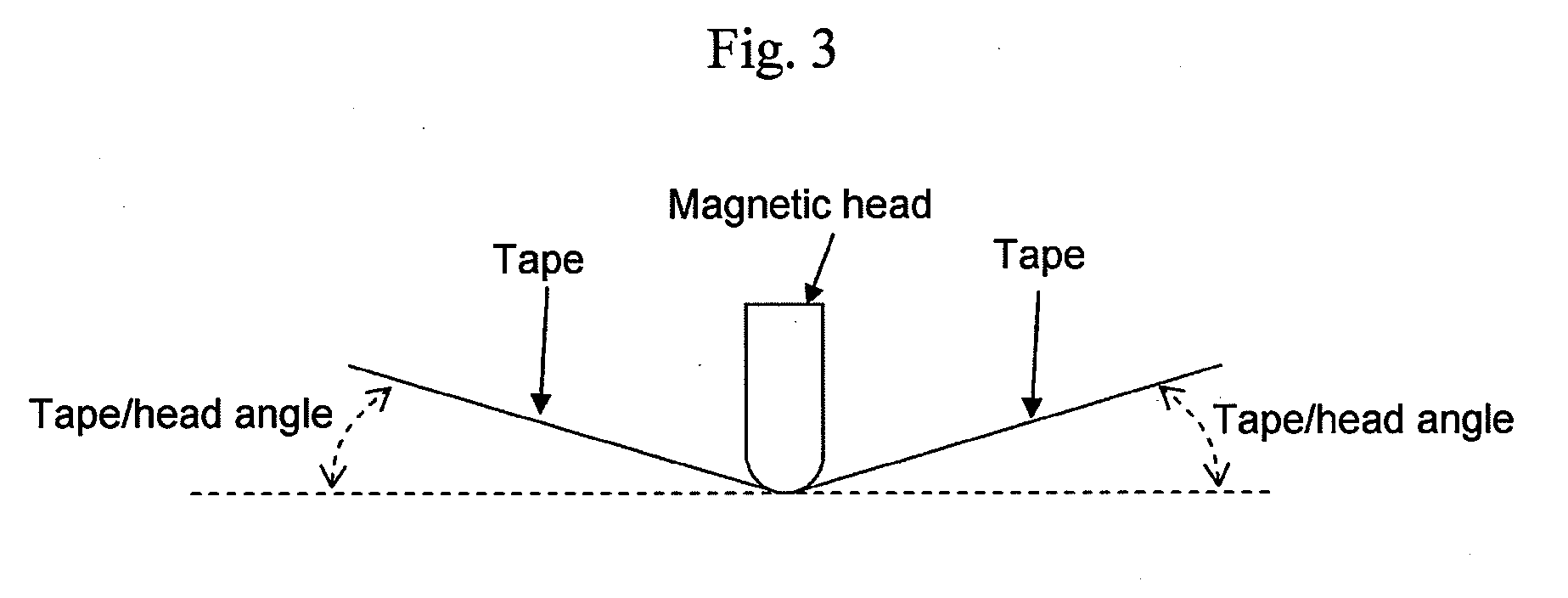

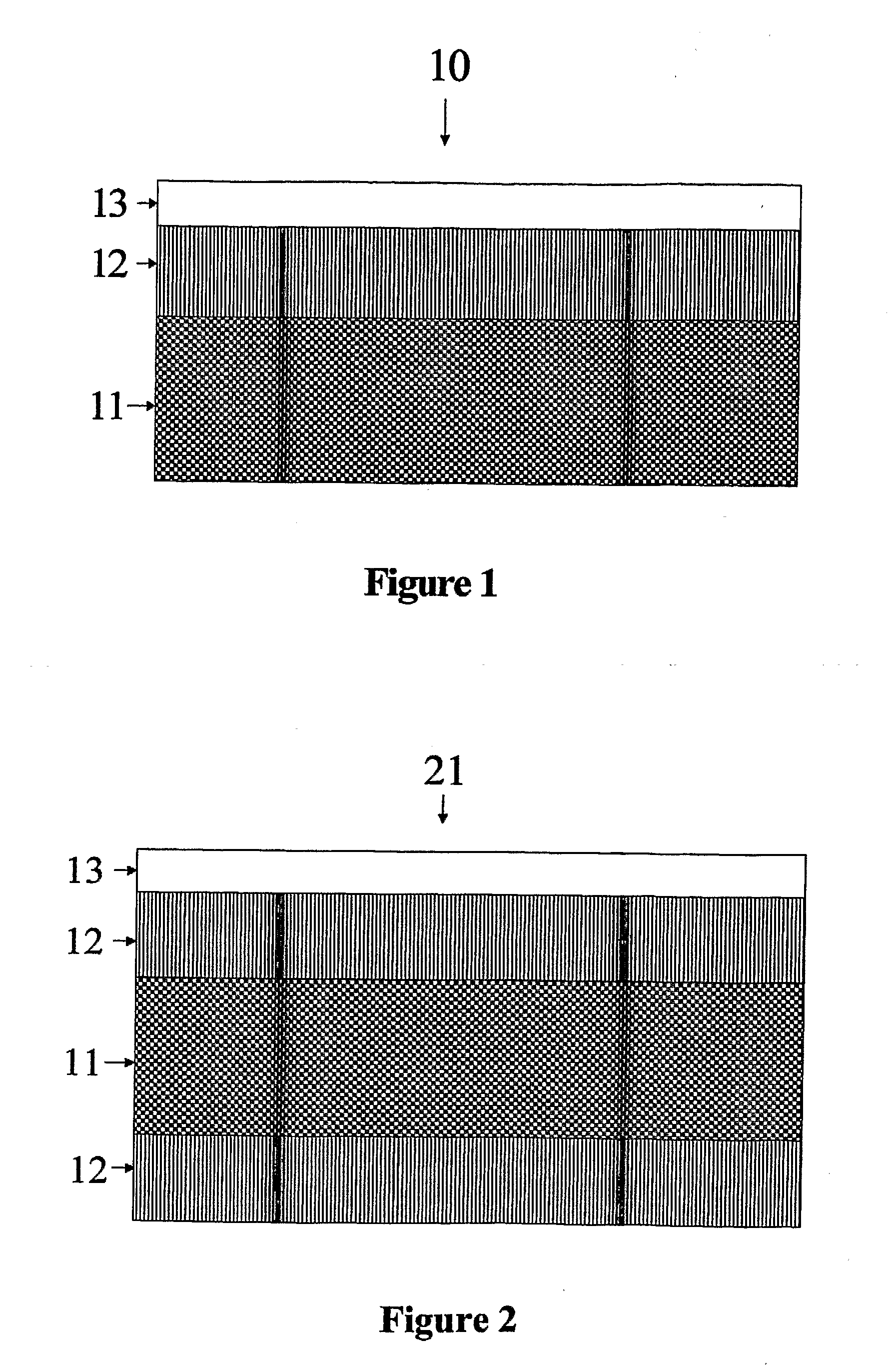

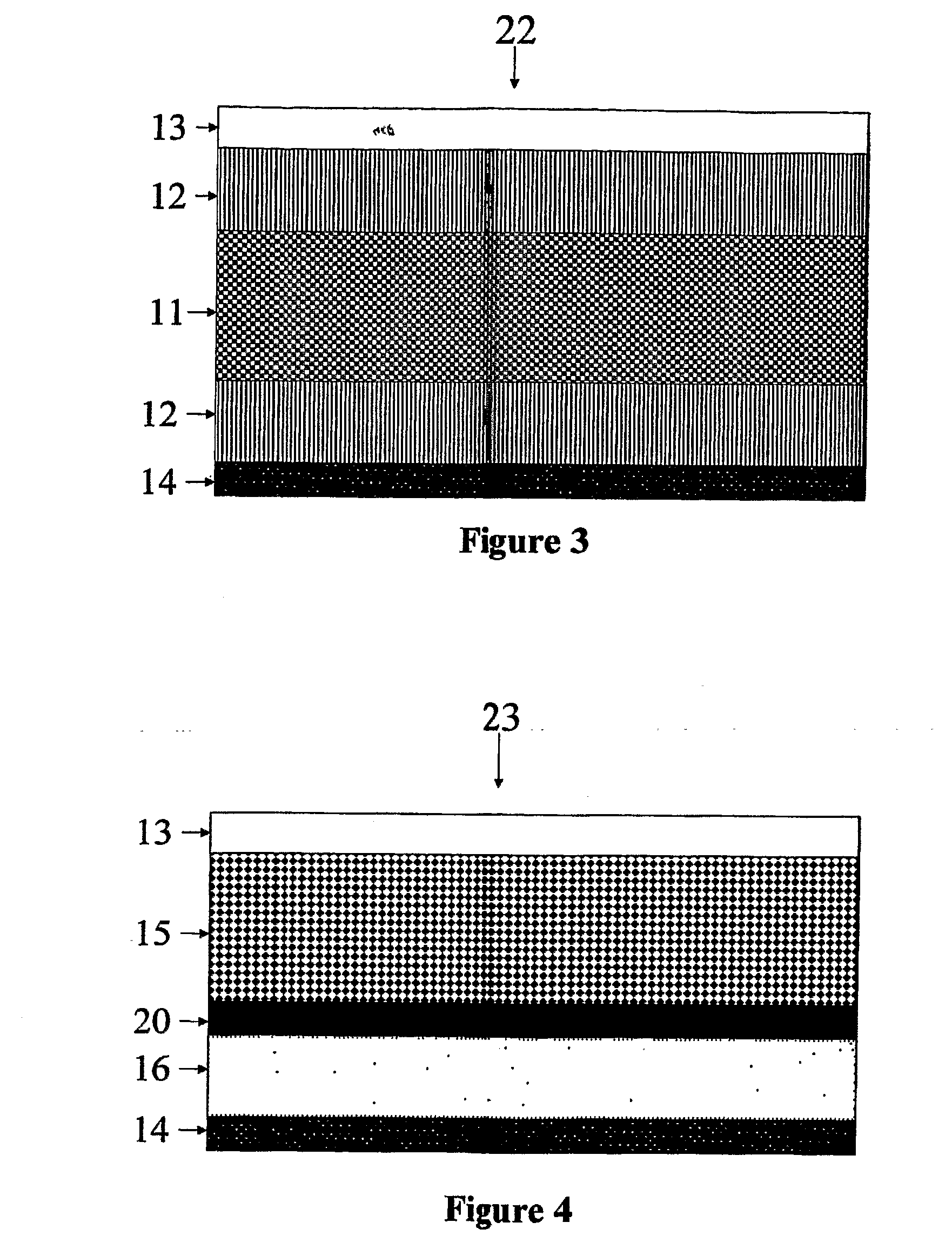

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

Magnetic signal reproduction system and magnetic signal reproduction method

ActiveUS20080297950A1Good electromagnetic characteristicImprove running stabilityTape carriersRecord information storageNuclear magnetic resonanceMicroscope

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support; and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, and the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer.

Owner:FUJIFILM CORP

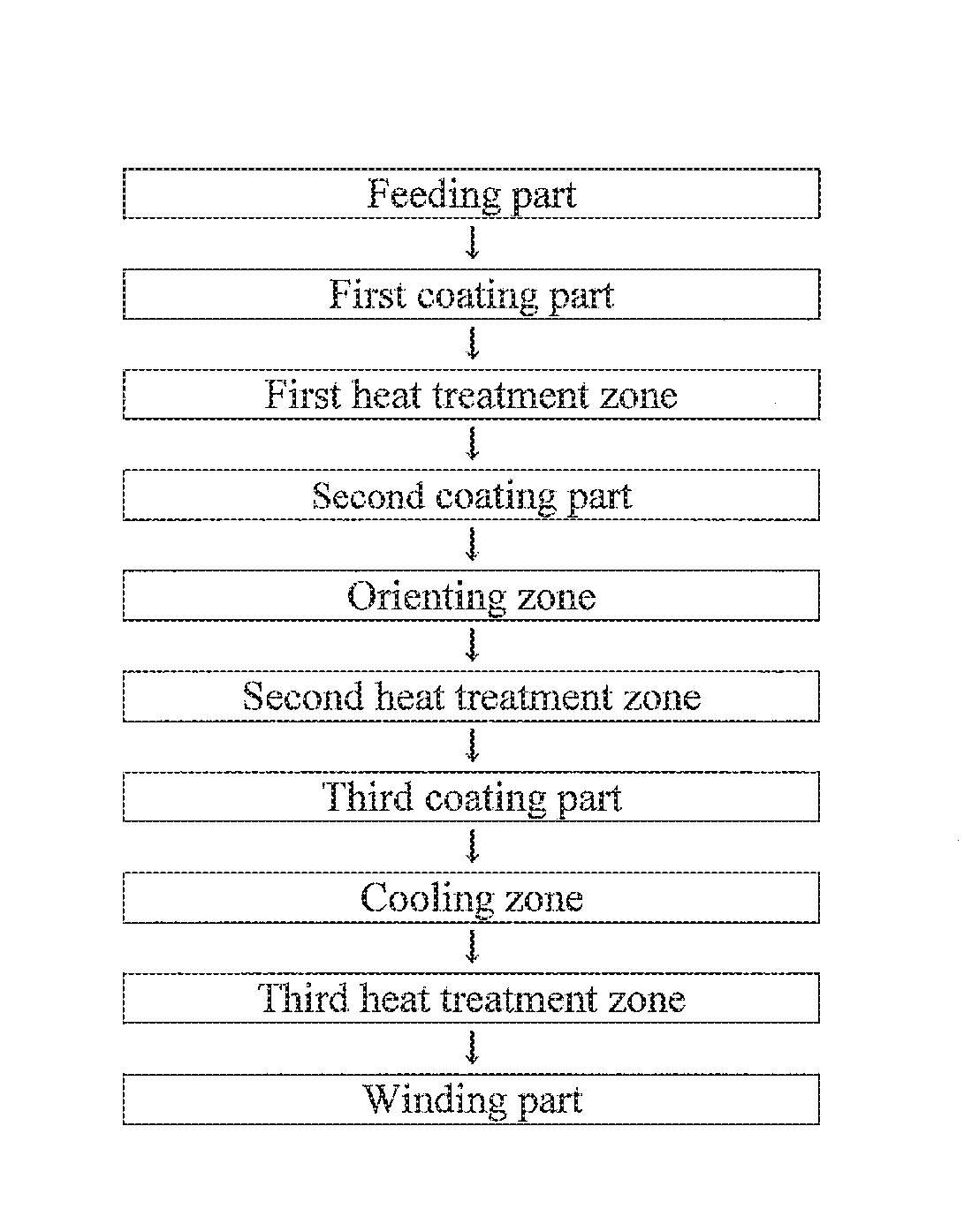

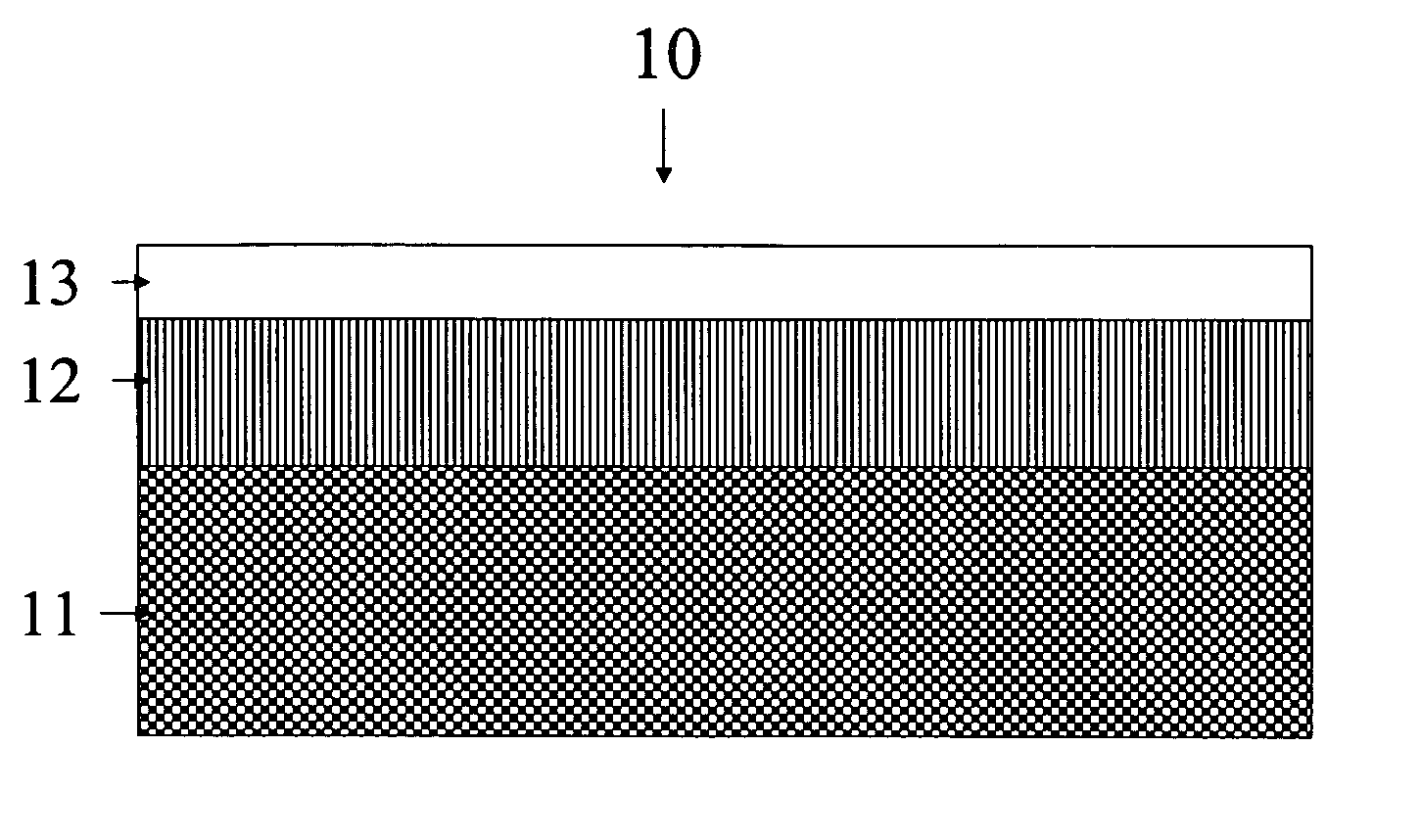

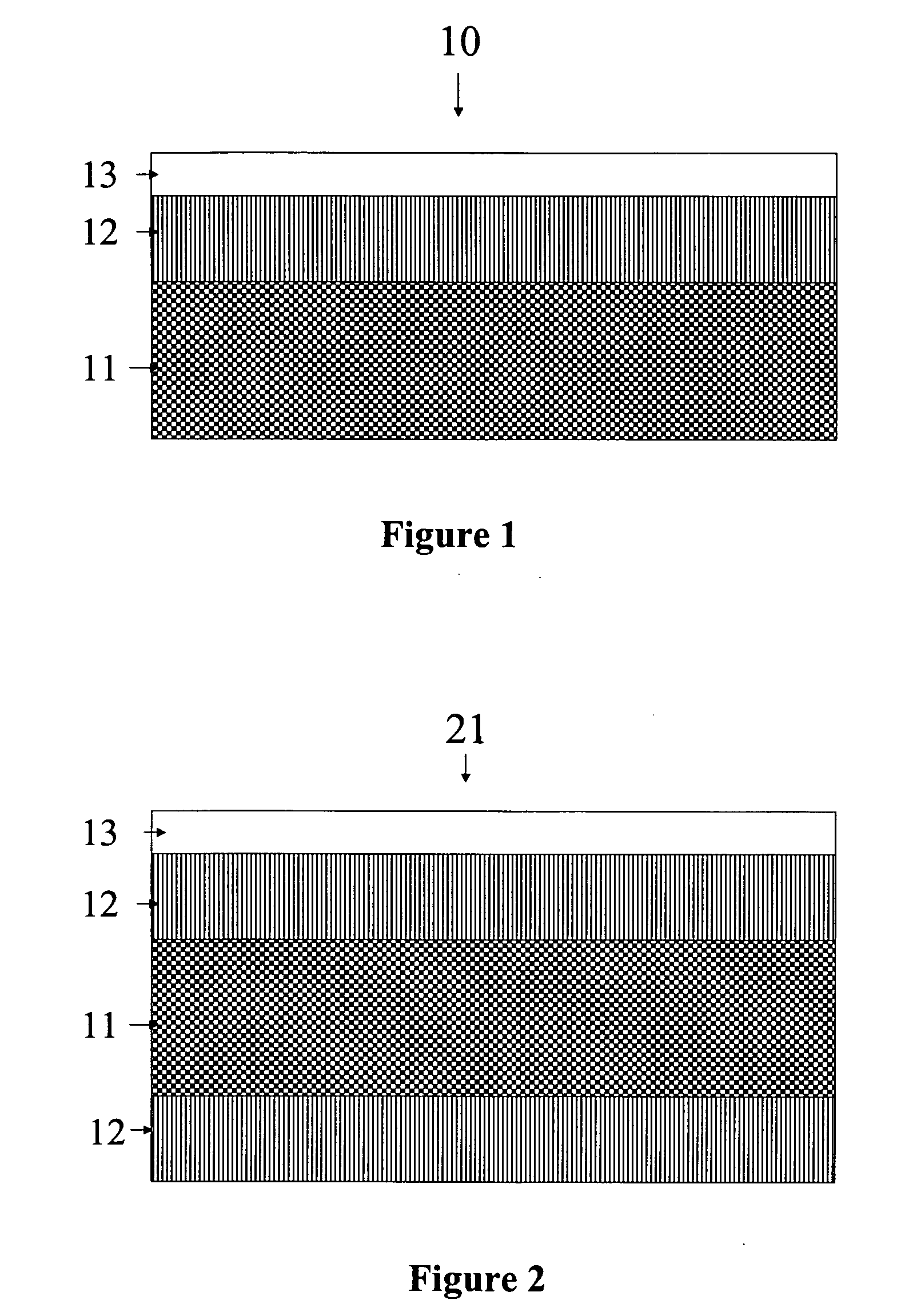

Magnetic tape, magnetic tape cartridge, magnetic recording and reproducing device, and method of manufacturing magnetic tape

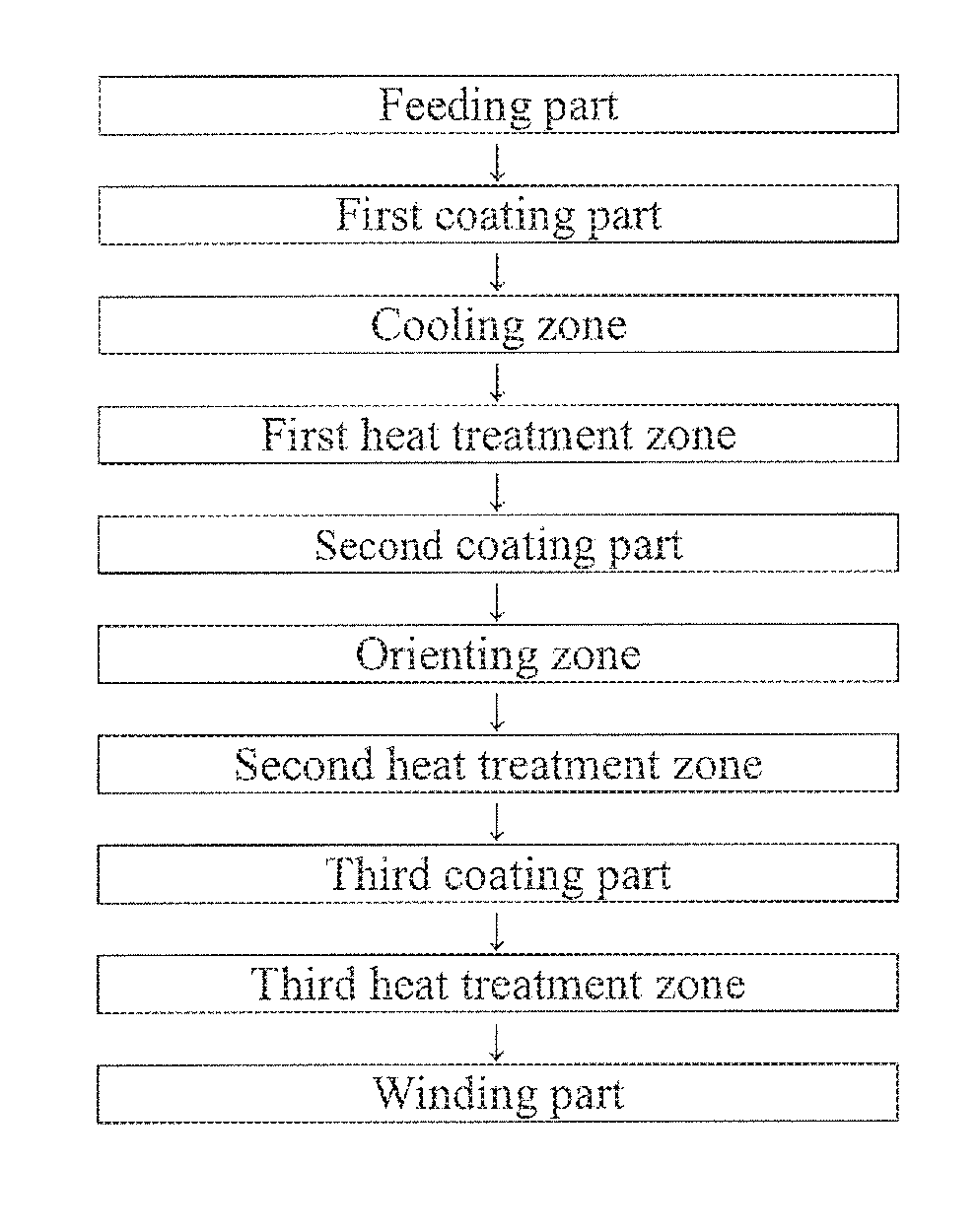

ActiveUS20170178676A1Good electromagnetic characteristicShorten the timeBase layers for recording layersRecord information storagePeak areaMagnetic layer

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer; wherein the combined thickness of the nonmagnetic layer and the magnetic layer is less than or equal to 0.60 μm, the coefficient of friction as measured on the base portion of the surface of the magnetic layer is less than or equal to 0.35, at least the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface of the magnetic layer is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9959894B2Solve the lack of durabilityHigh densityTape carriersRecord information storageMedicineMagnetic tape

The magnetic tape comprises a nonmagnetic layer comprising nonmagnetic powder and binder on a nonmagnetic support, and comprises a magnetic layer comprising ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester, a fatty acid amide, and a fatty acid are contained in either one or both of the magnetic layer and the nonmagnetic layer, with the magnetic layer and nonmagnetic layer each comprising at least one selected from the group consisting of a fatty acid ester, a fatty acid amide, and a fatty acid, a quantity of fatty acid ester per unit area of the magnetic layer in extraction components extracted from a surface of the magnetic layer with n-hexane falls within a range of 1.00 mg / m2 to 10.00 mg / m2, and a weight ratio of the quantity of fatty acid ester per unit area of the magnetic layer to a combined total of a quantity of fatty acid amide and a quantity of fatty acid, quantity of fatty acid ester / (quantity of fatty acid amide+quantity of fatty acid), per unit area of the magnetic layer falls within a range of 1.00 to 3.00 in the extraction components.

Owner:FUJIFILM CORP

Clot retrieval device for removing occlusive clot from a blood vessel

ActiveUS20150164523A1Prevent distal egressReduce radial forceDilatorsExcision instrumentsDistal portionBlood vessel spasm

Owner:NEURAVI

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170186456A1Increase frictionImprove featuresRecord information storageTape carriersMagnetic tapeMagnetization

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester is contained in at least the magnetic layer, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the ferromagnetic hexagonal ferrite powder has a crystallite volume as determined by X-ray diffraction analysis ranges from 1,000 nm3 to 2,400 nm3, and a ratio of the crystallite size Dx(107) obtained from a diffraction peak of a (107) plane to a particle size in a direction of an easy axis of magnetization DTEM as determined by observation with a transmission electron microscope, Dx(107) / DTEM, is greater than or equal to 1.1, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1: ΔSFD=SFD25° C.−SFD−190° C., ranges from 0.50 to 1.60.

Owner:FUJIFILM CORP

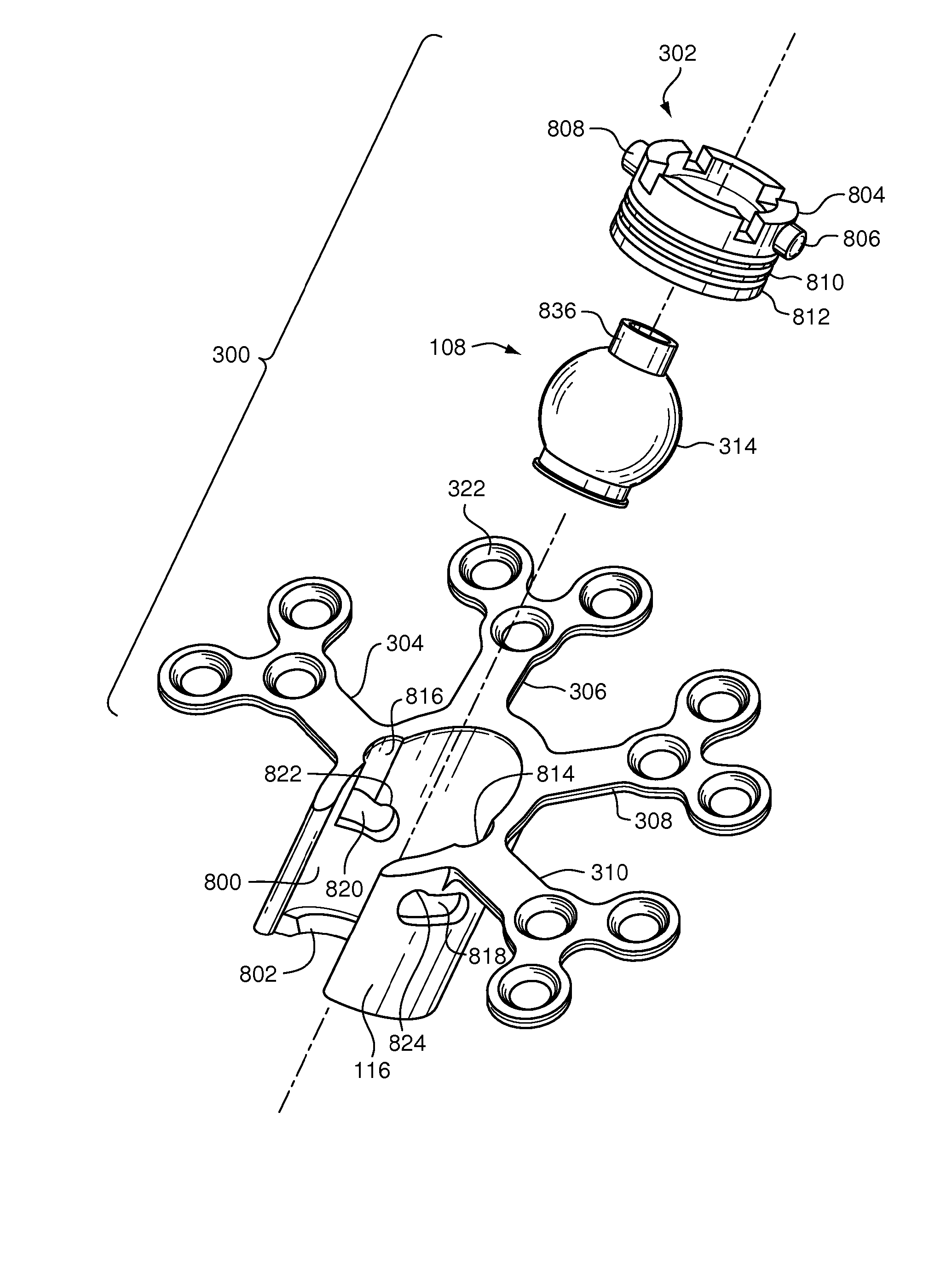

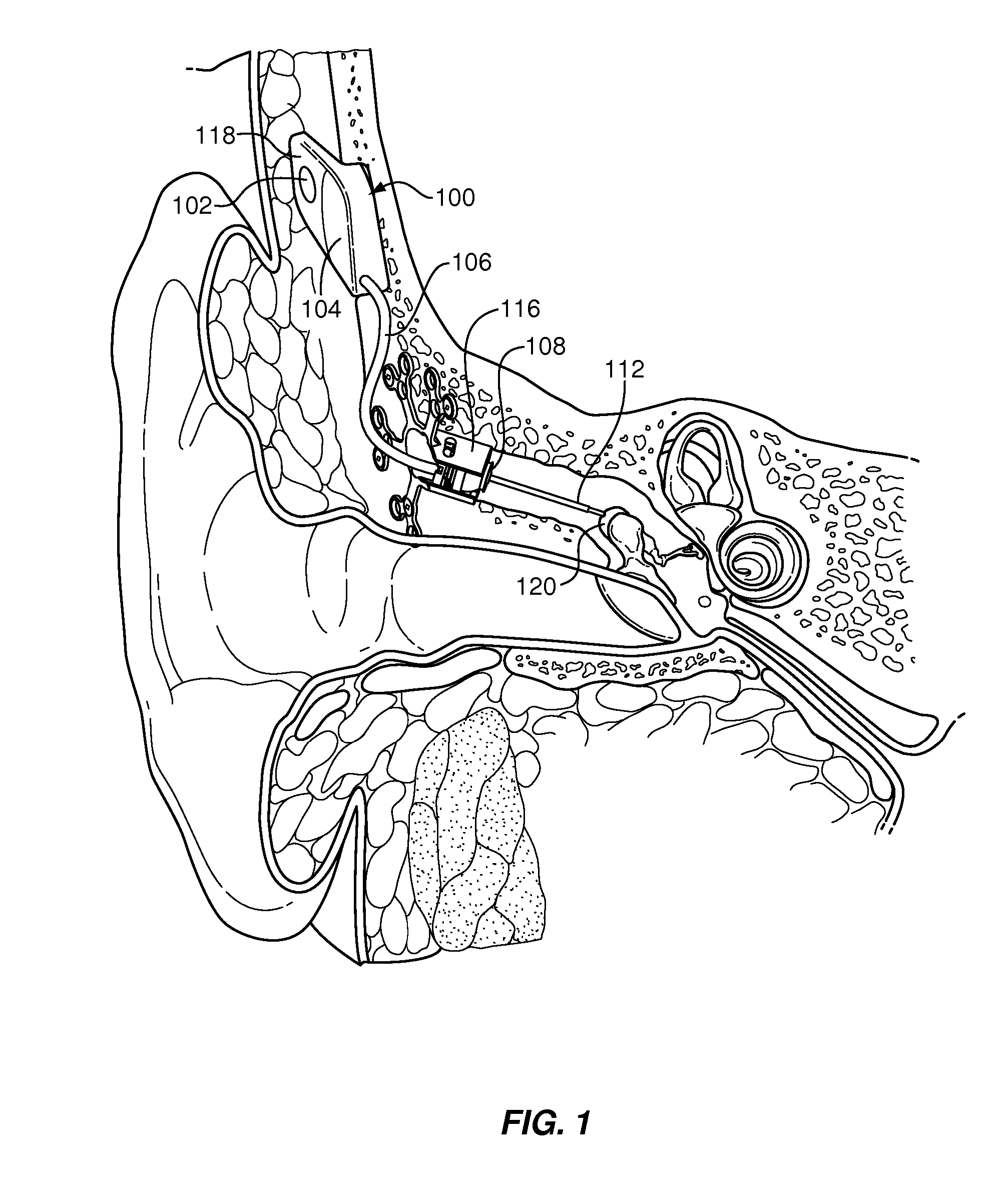

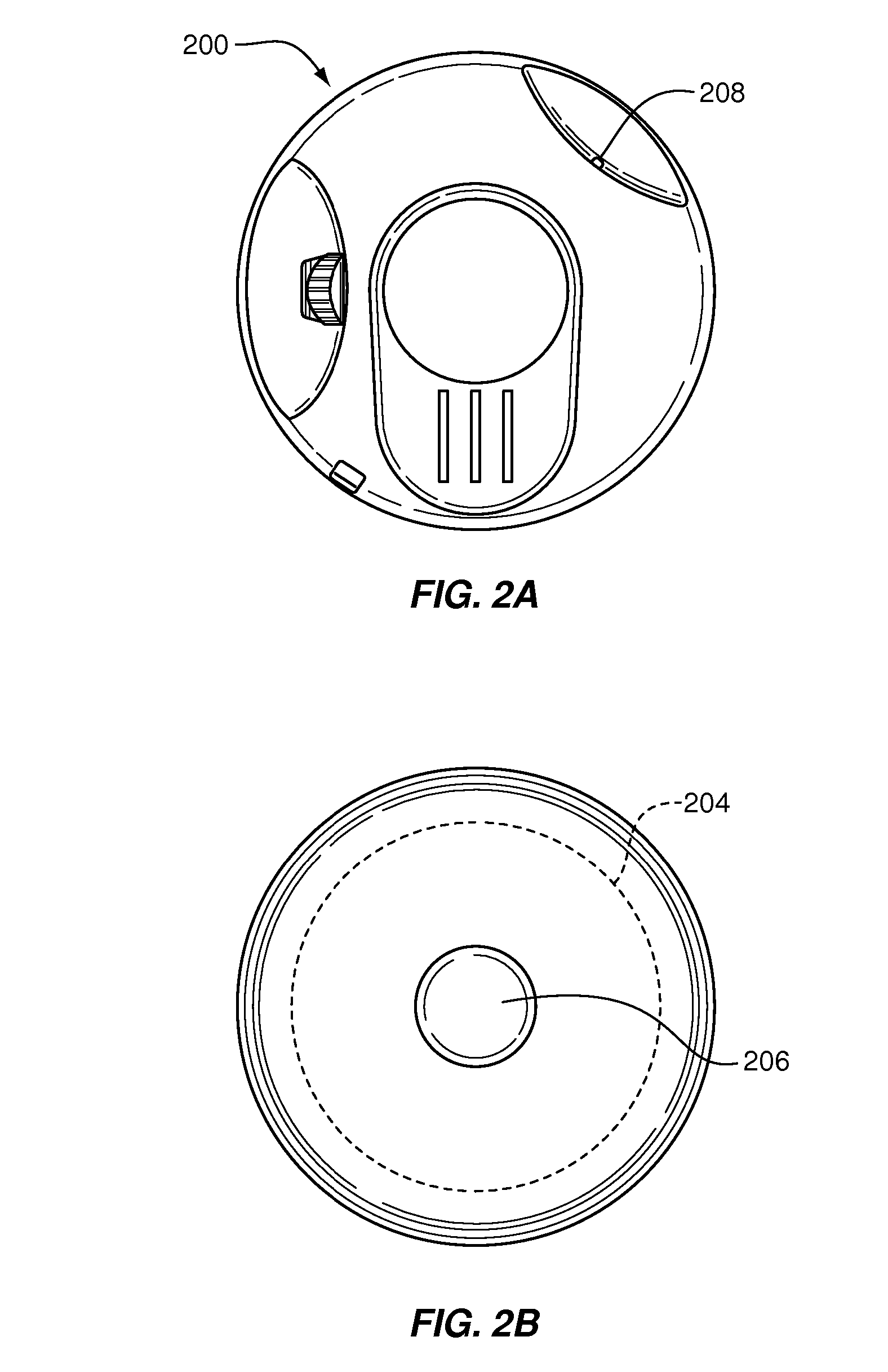

Simplified implantable hearing aid transducer apparatus

InactiveUS20080051623A1Simplify, andSimple methodTransducer detailsImplantable hearing aidsCouplingTransducer

An implantable hearing aid transducer apparatus provides a simplified approach for interface with a middle ear component. The transducer includes a transducer housing, an actuator for middle ear coupling, and a driver having a magnet or coil interconnected to the actuator to induce movement in response to driver signals. In one feature, the actuator may be advanceable through an aperture of the housing independent from operation of the driver. In another feature, a portion of the transducer may be rotatable. In another feature, a retention apparatus may function to selectively secure a rotatable portion of the housing in a selected position. In an additional feature, a seal may be disposed around a driver component and connected to the actuator.

Owner:COCHLEAR LIMITED

Reusable Outer Cover For An Absorbent Article Having Zones Of Varying Properties

ActiveUS20100179503A1Increase resistanceHigher static coefficient of frictionBaby linensTamponsCivil engineering

Owner:THE PROCTER & GAMBLE COMPANY

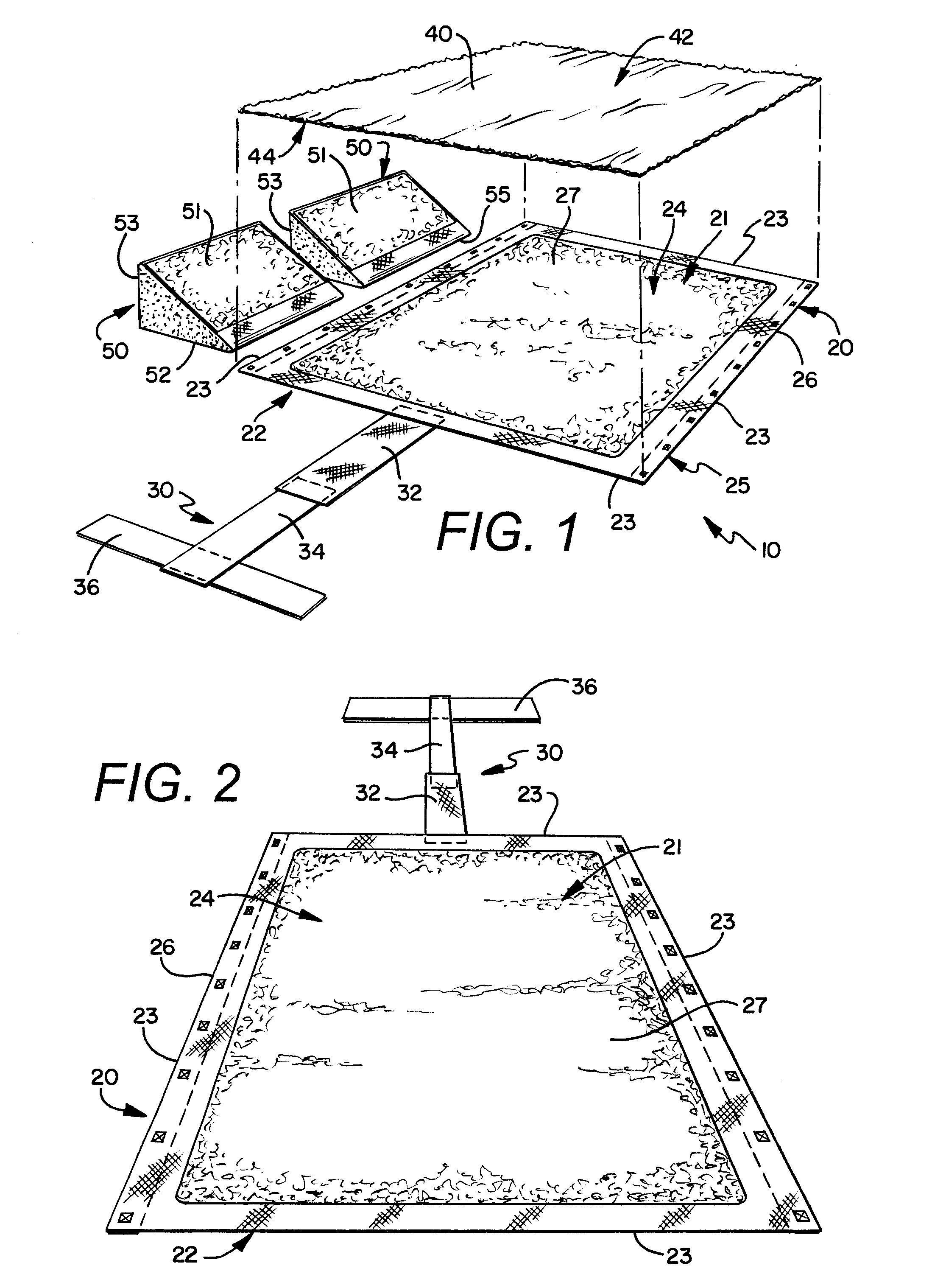

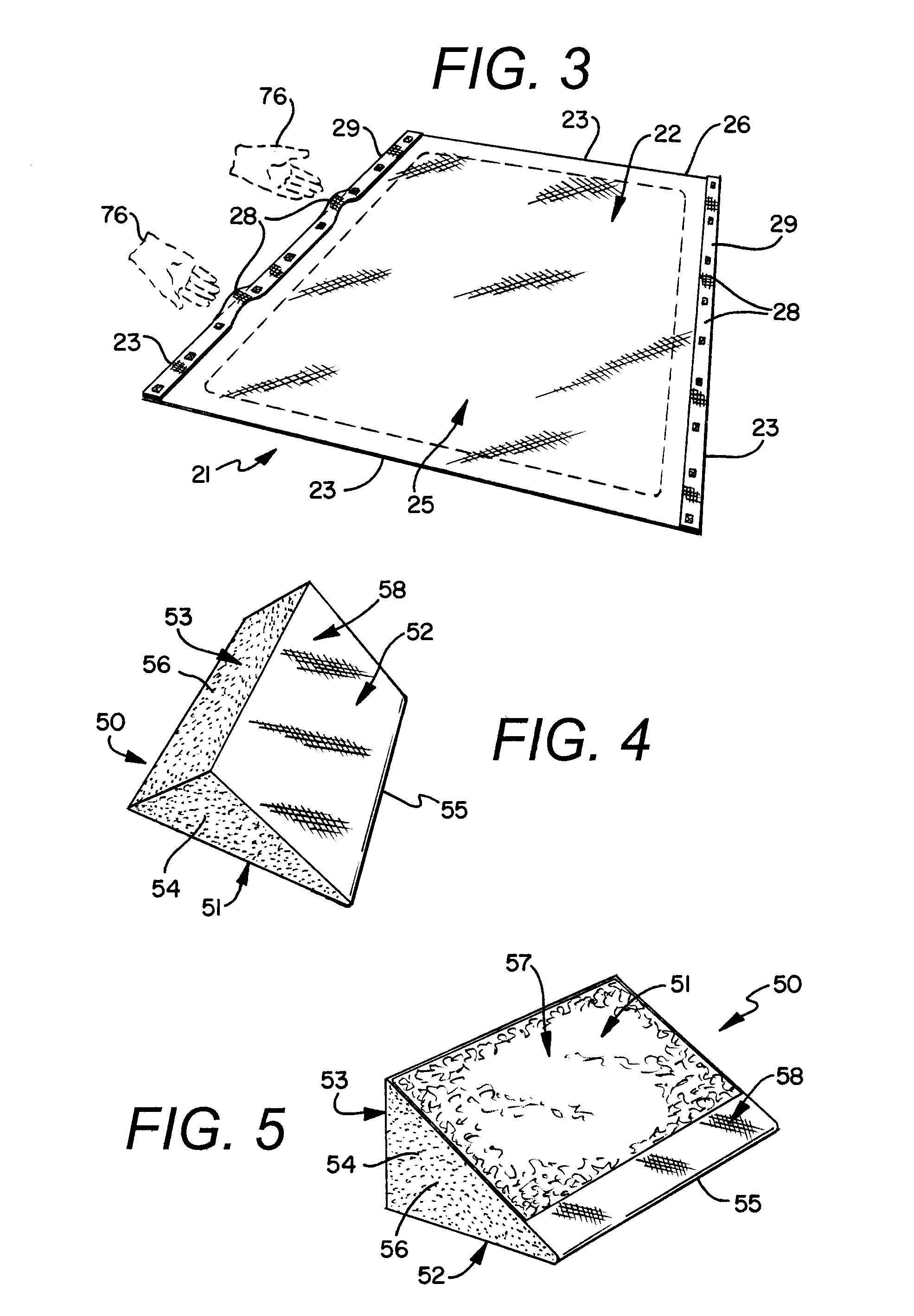

Skid resistant surfaces

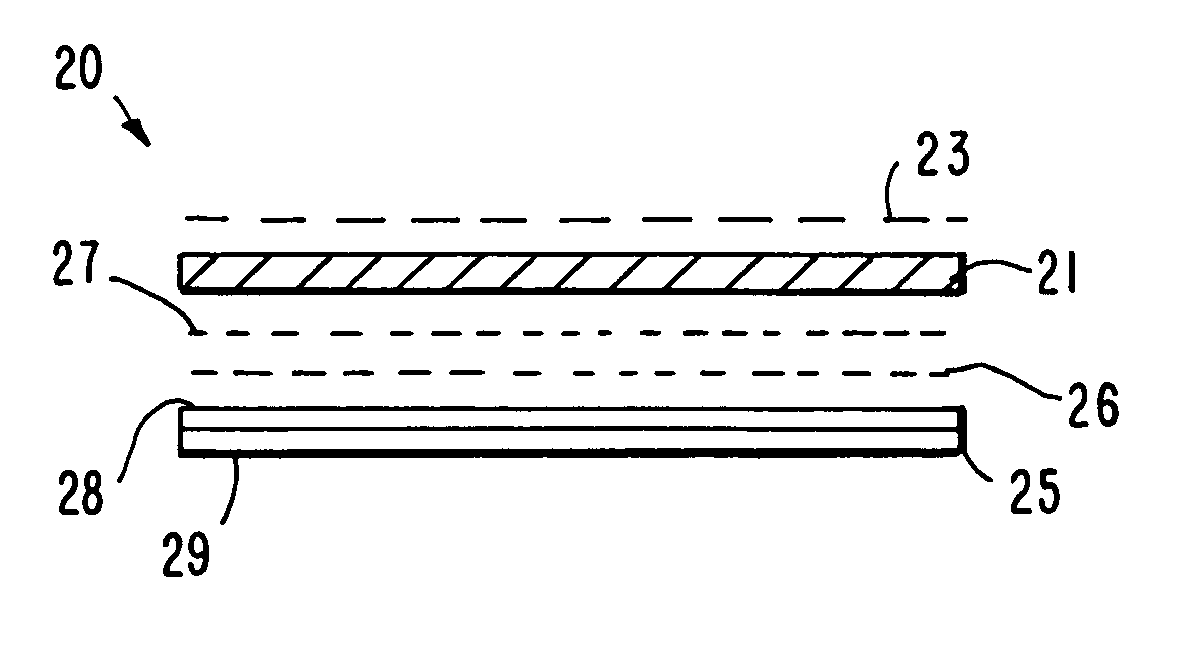

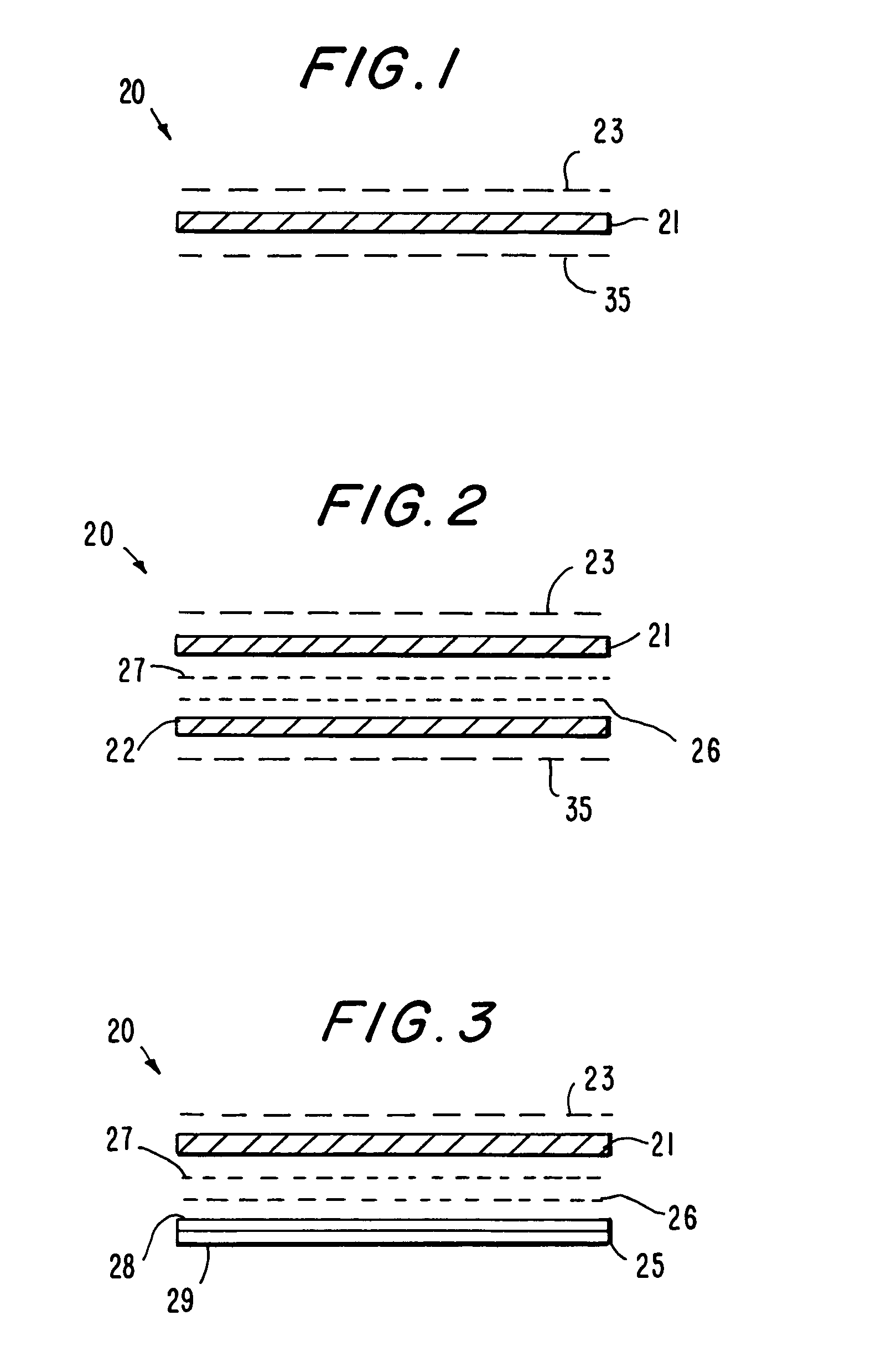

InactiveUS20070044397A1Good for scrollingExcellent skidTreadsRoof covering using flexible materialsPressure sensitiveCivil engineering

Skid-resistant surfaces as described having either a pressure-sensitive adhesive layer or a highly filled, textured binder to reduce skidding. The surfaces are applied to trafficable surfaces such as roof and floors. Products such as roof underlyments bearing the surfaces are described in particular.

Owner:WR GRACE & CO CONN

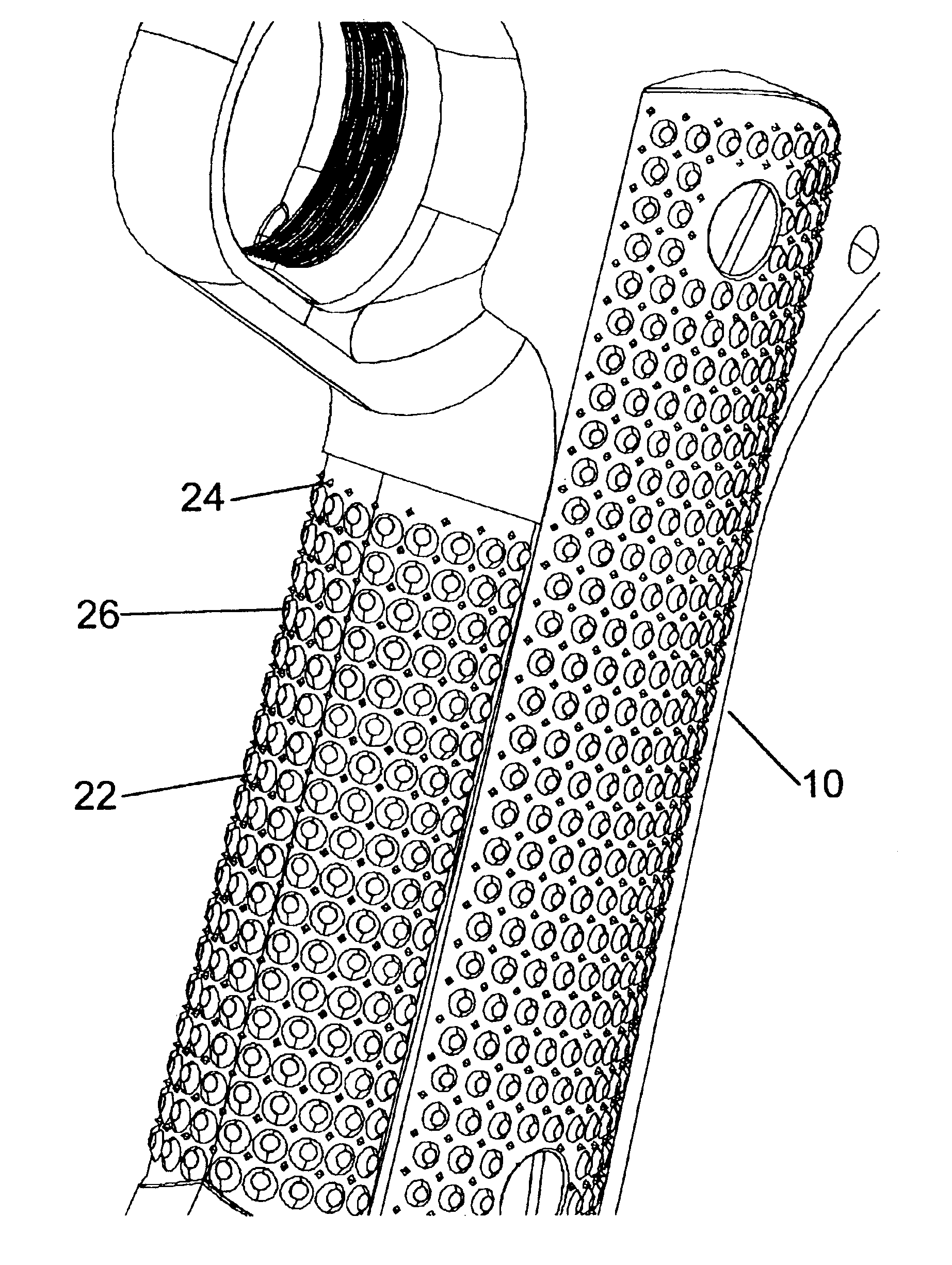

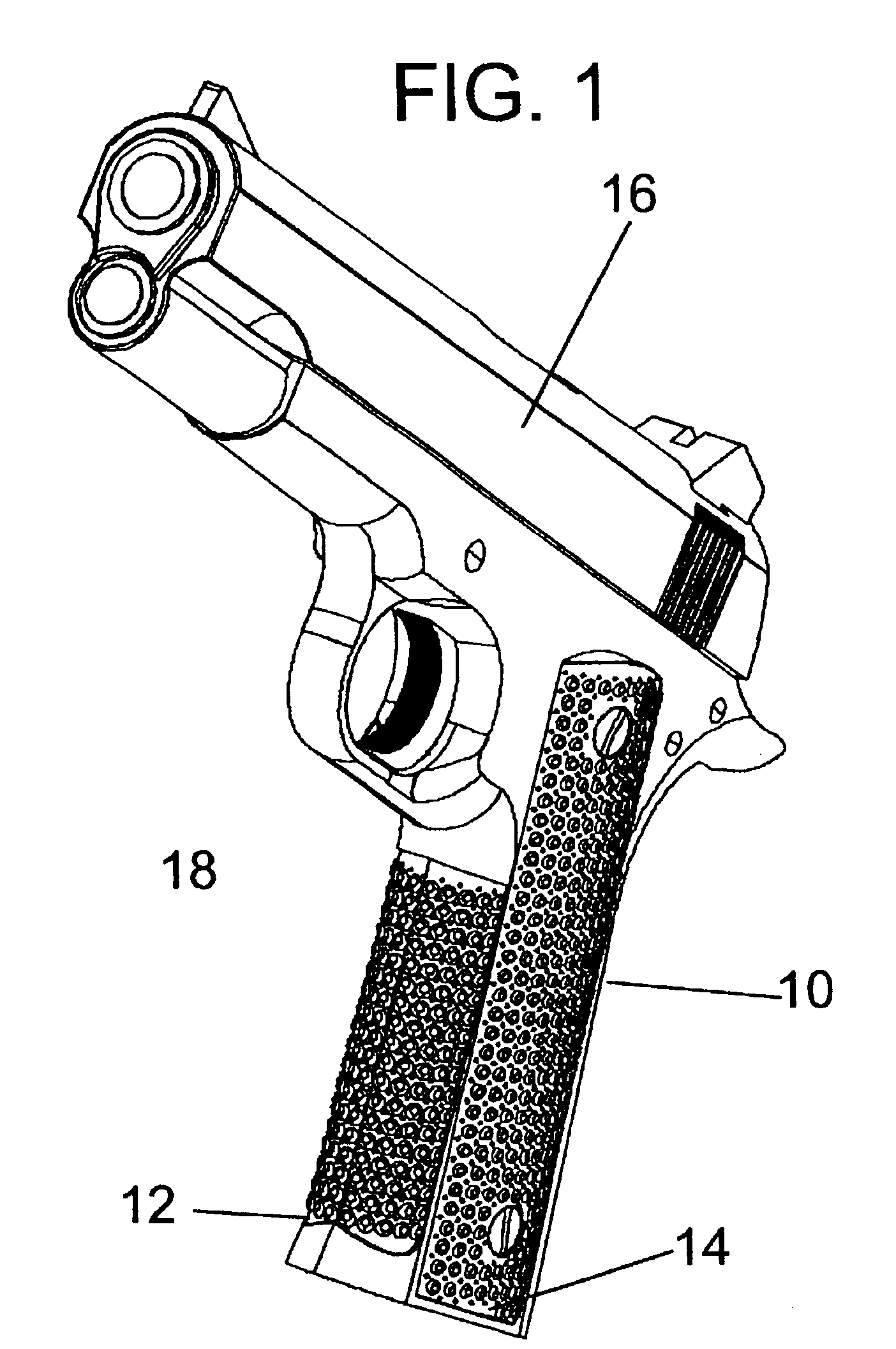

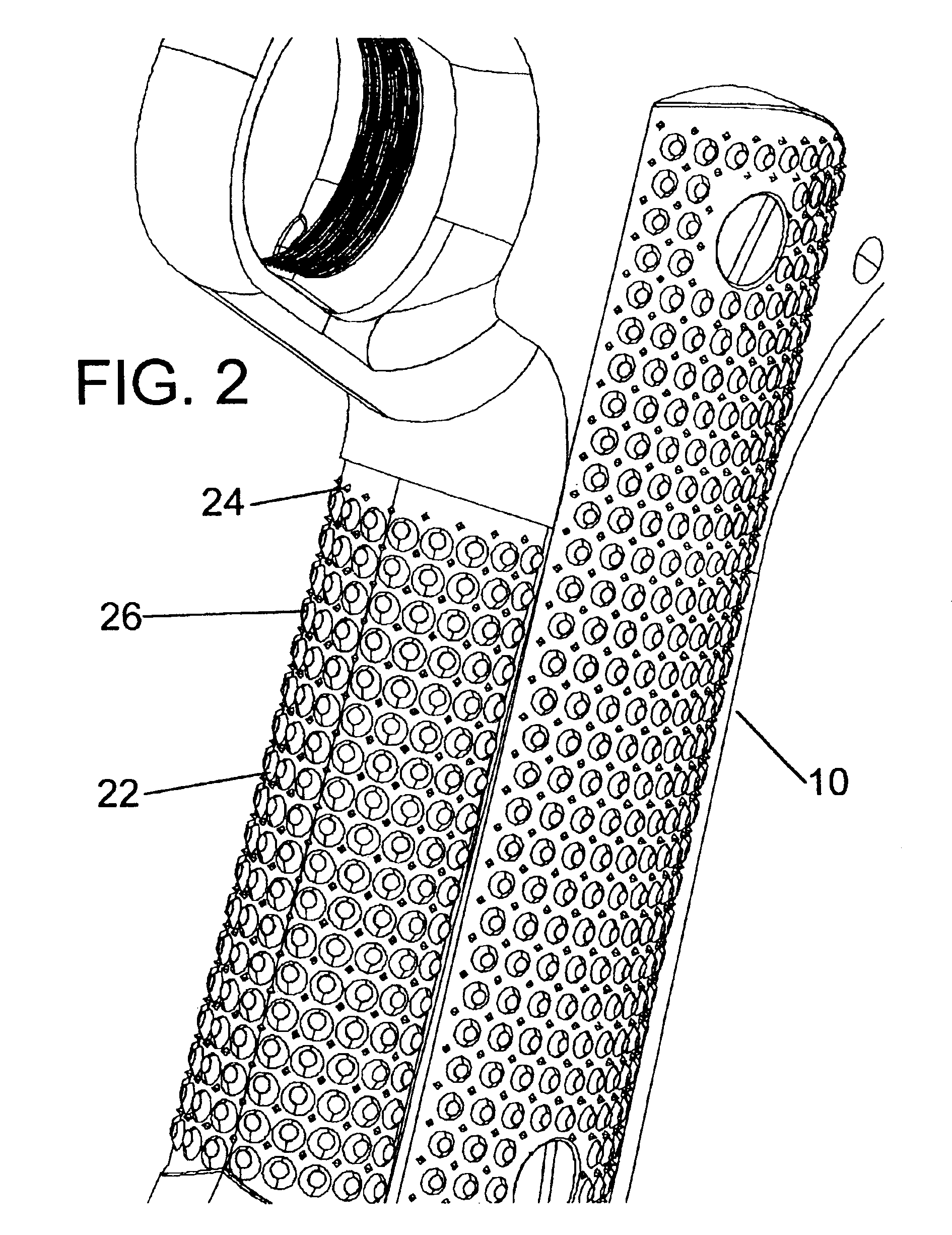

Grip friction pattern

The present invention discloses a grip fractioning pattern for any object, but specifically designed for handgun and rifle grips. The pattern consists of a series of spaces frusto-conical projections regularly spaced about the surface of the weapon's grip. Alternatively, the series may be interrupted by an interspaced series of pyramids, with their points not extending above the height of the frusto-conical projections. The grip pattern may be utilized in any circumstance where a user desires greater and more comfortable friction when gripping an object.

Owner:CHRISTIANSEN NED F

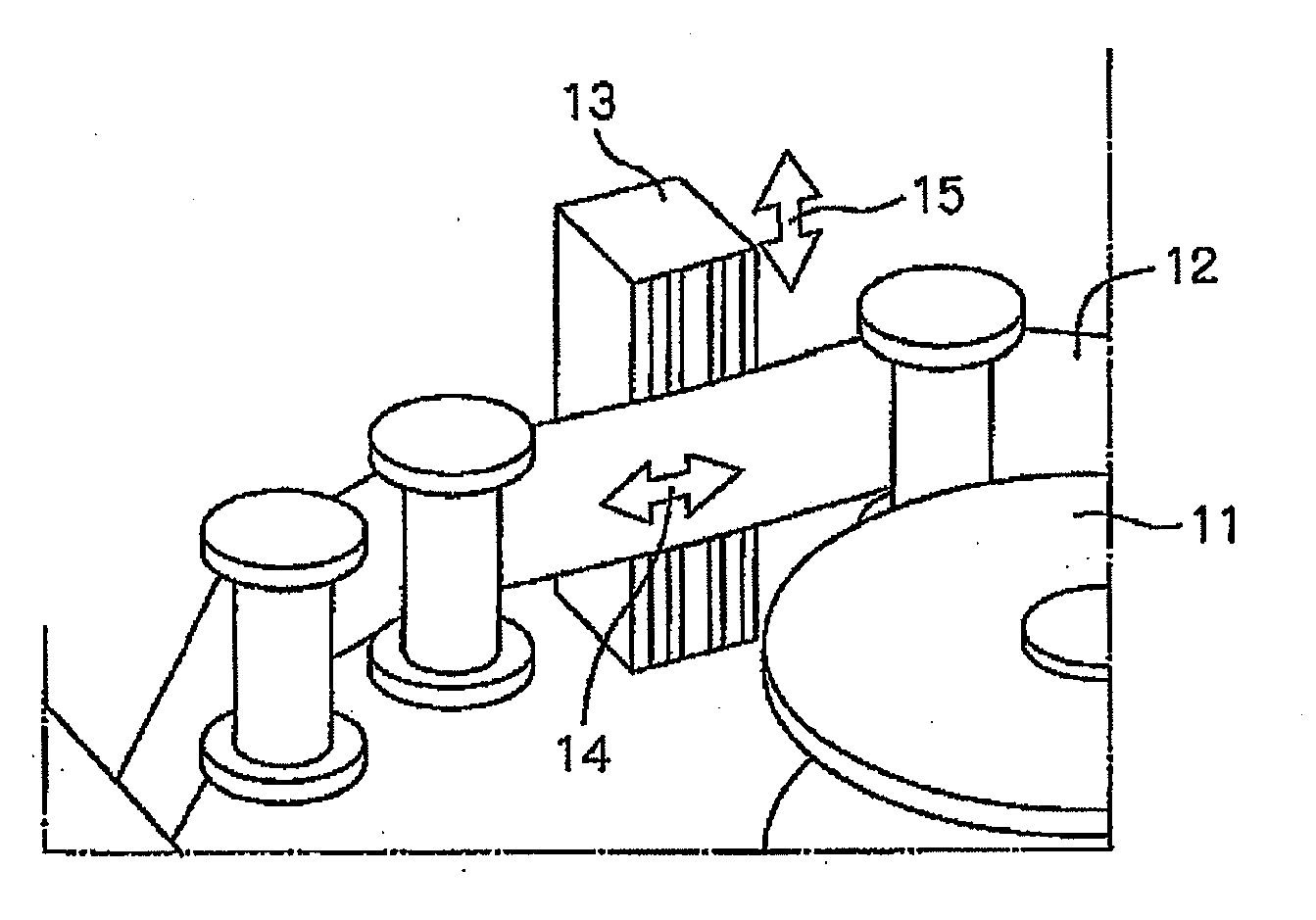

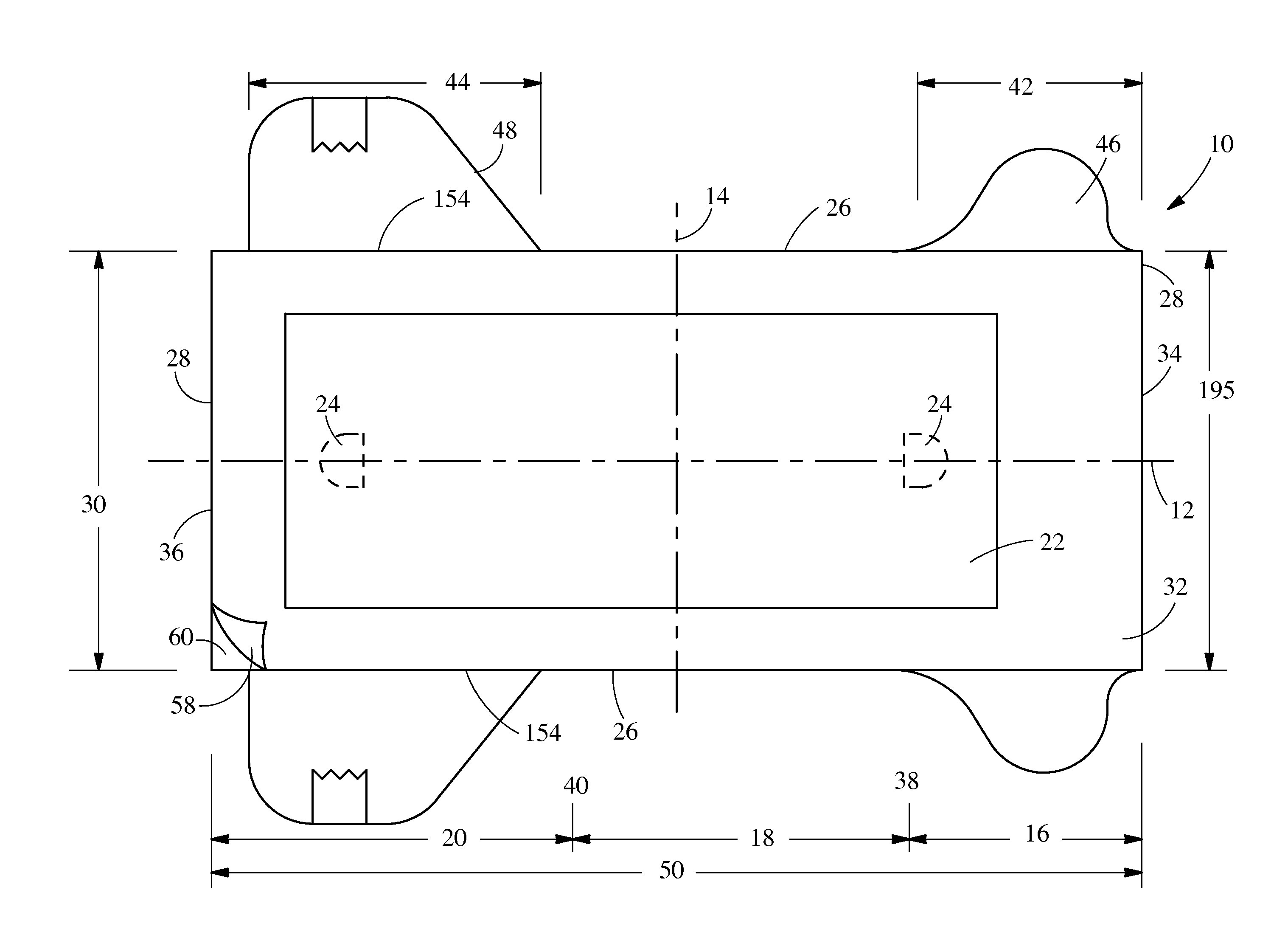

Energy absorber

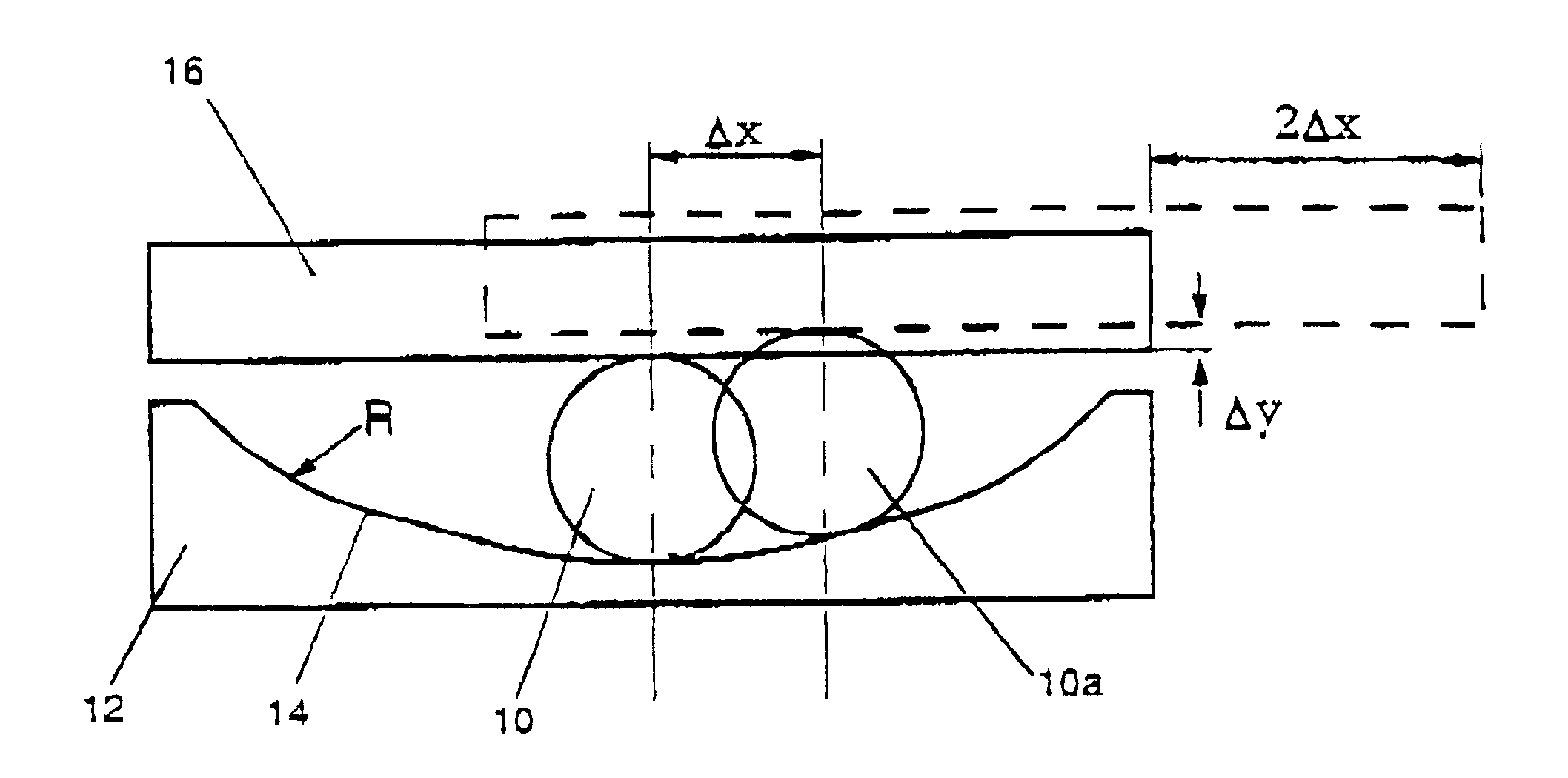

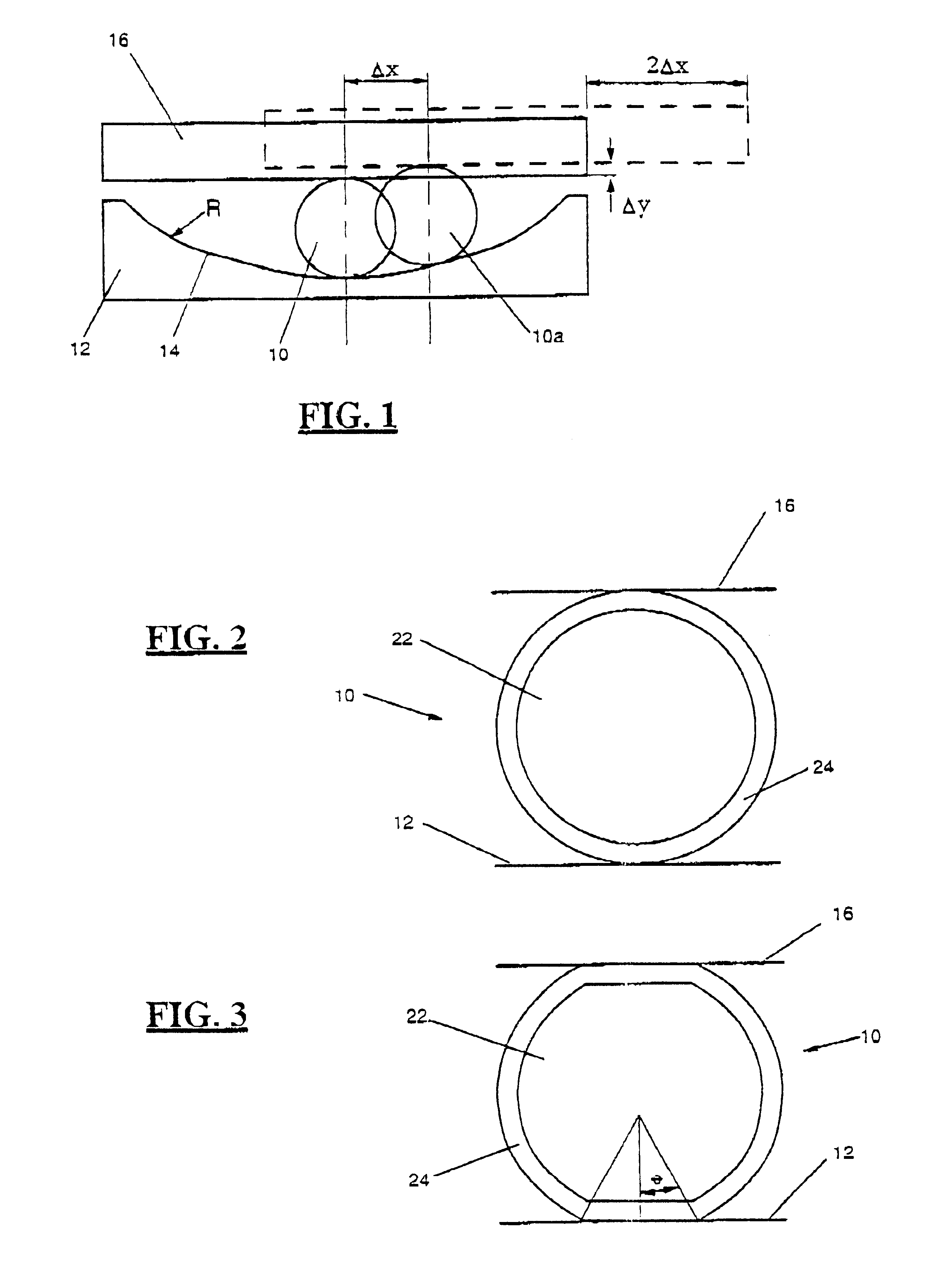

InactiveUS6321492B1Increase coefficient of frictionNon-rotating vibration suppressionProtective foundationRelative motionEngineering

The invention described is a system for seismic isolation or vibration of structures which is simple, relatively inexpensive and readily used for smaller structures. It involves use of bearings comprising a ball (10) and ball seats (12, 18) interposed between the structure and its foundation. Either the ball itself (24) or the seat surface (15) on which it rolls is compressible, the resistance to that compression providing a frictional braking force resisting rolling of the ball. This serves to dampen relative movement between the structure and its foundation. There are described several alternative constructions of the friction ball which is the preferred central element in the bearing device. There may be a plurality of balls (44, 47) in each combination of balls and seats.

Owner:ROBINSON SEISMIC

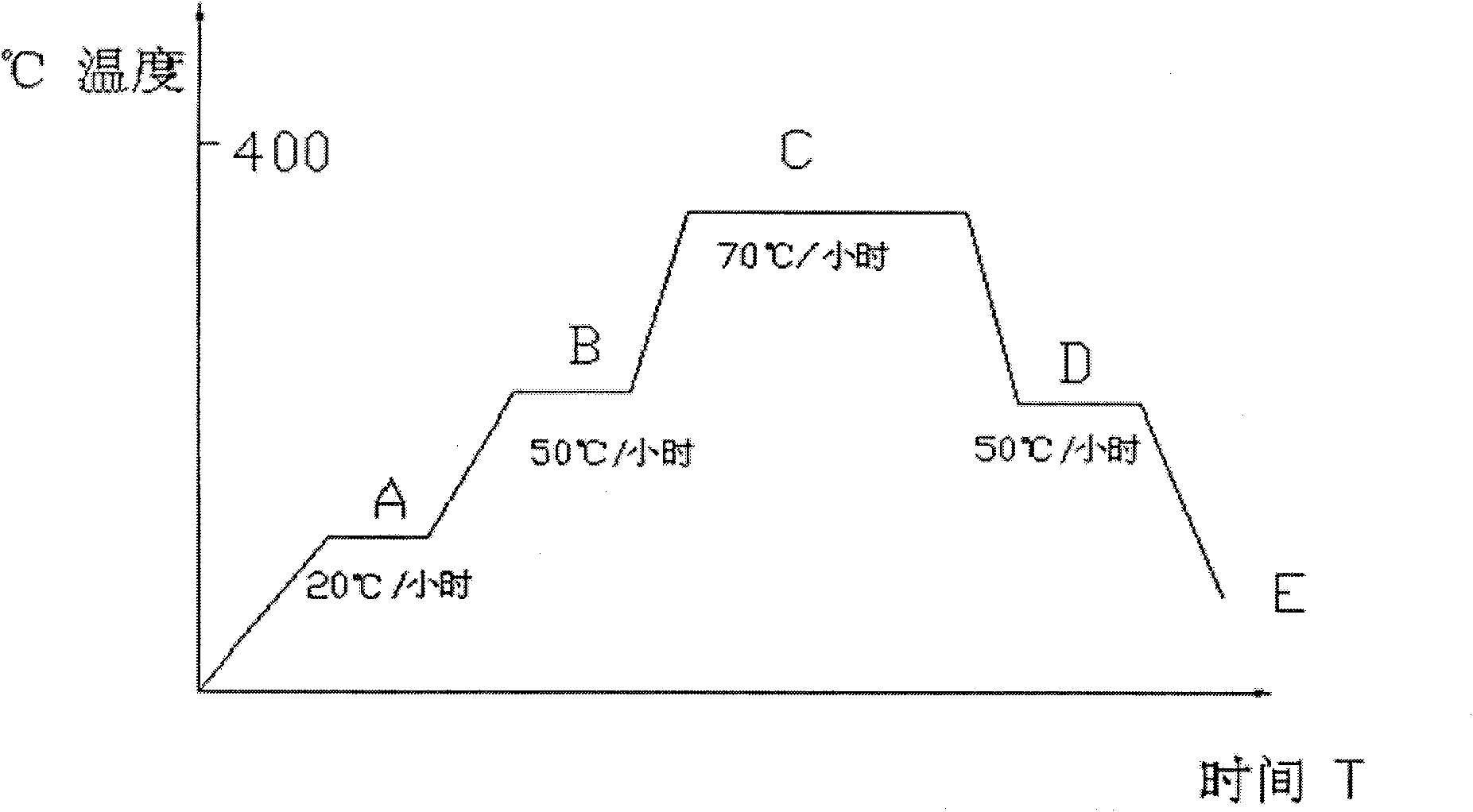

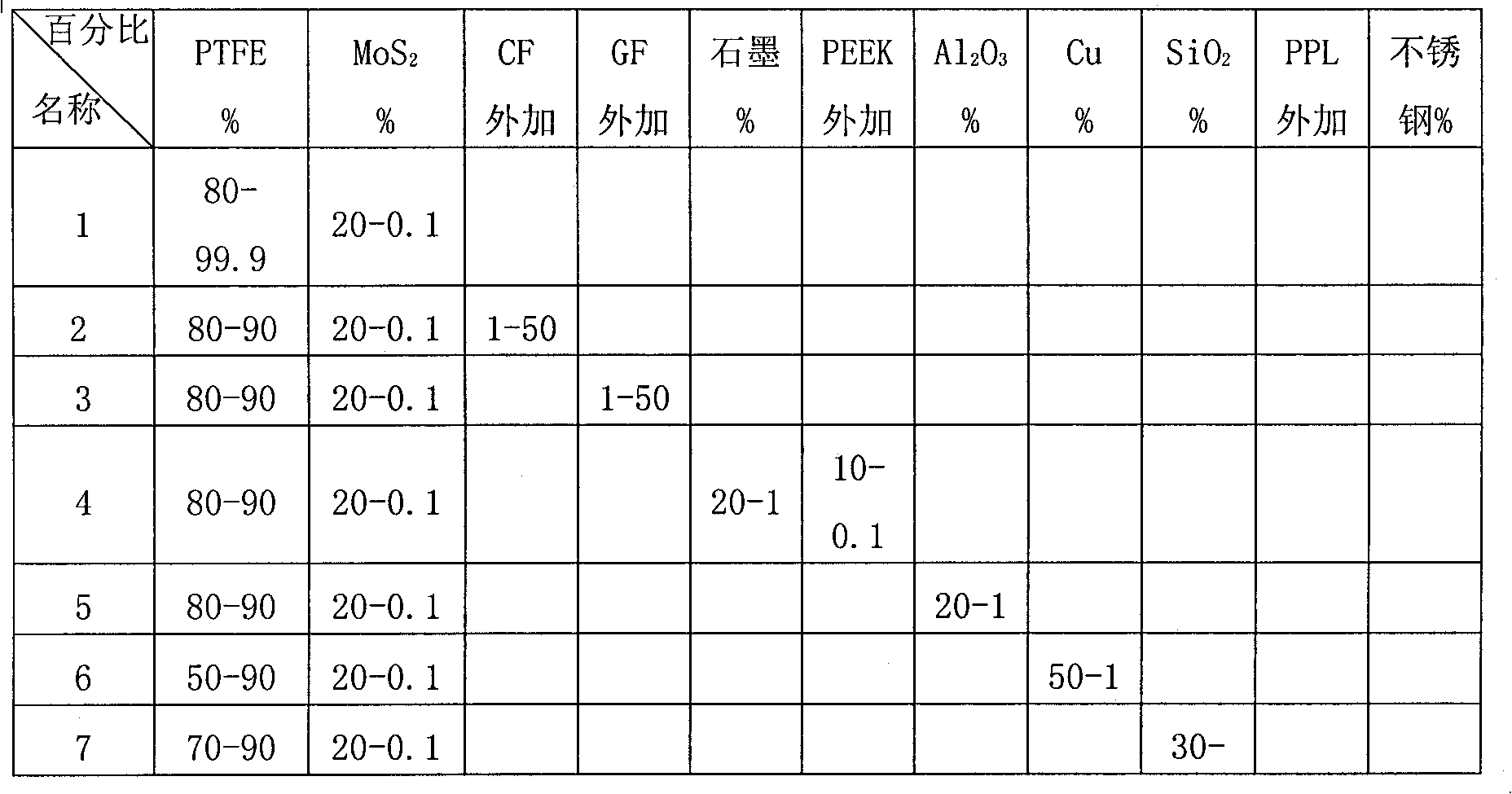

Polytetrafluoroethylene composite material and product preparation method thereof

ActiveCN101775186AImprove thermal conductivityImproved ball compressive strengthFiberTetrafluoroethylene

The invention discloses a polytetrafluoroethylene composite material, which comprises one or more of molybdenum disulfide, aluminum sesquioxide, copper powder, graphite, silicon dioxide and stainless steel powder and polytetrafluoroethylene, wherein the polytetrafluoroethylene composite material is a binary polytetrafluoroethylene composite material, which comprises 80 to 99.9 weight percent of the polytetrafluoroethylene, and the balance of other components. A product preparation method for the material comprises the following steps: compounding the materials of polytetrafluoroethylene (PTFE), molybdenum disulfide (MoS2), aluminium oxide (Al2O3), Cu powder, silicon dioxide (SiO2), polyphenylester (PPL), stainless steel powder, carbon fiber (CF), glass fiber (GF) and the like, molding the materials by a mold pressing sintering method, and then mechanically machining the materials to form an L-shaped sealing element.

Owner:NANJING COMPTECH MATERIALS

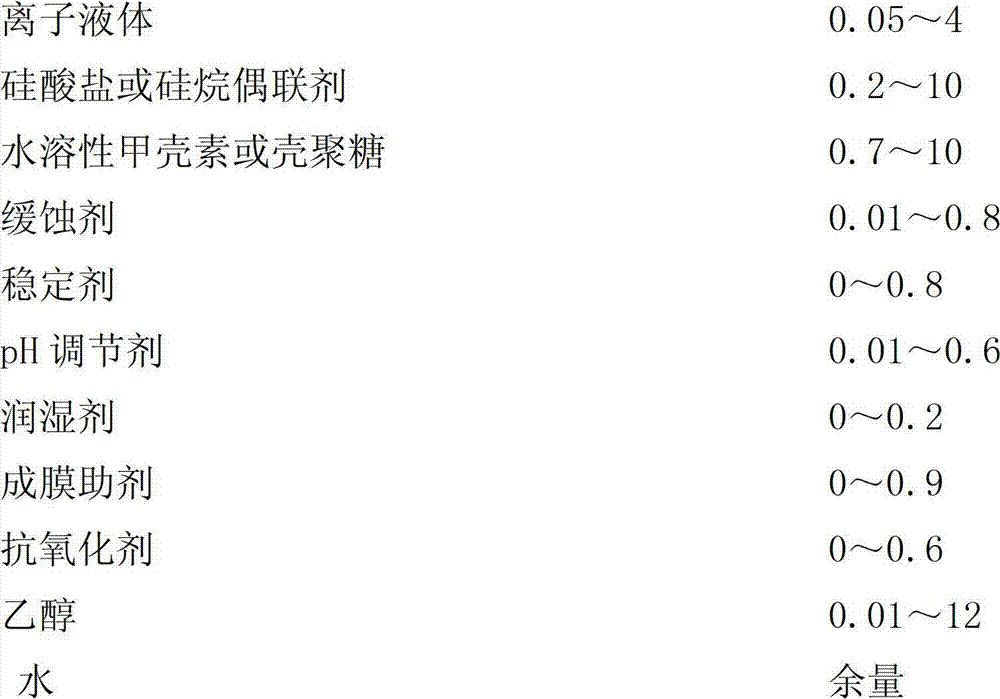

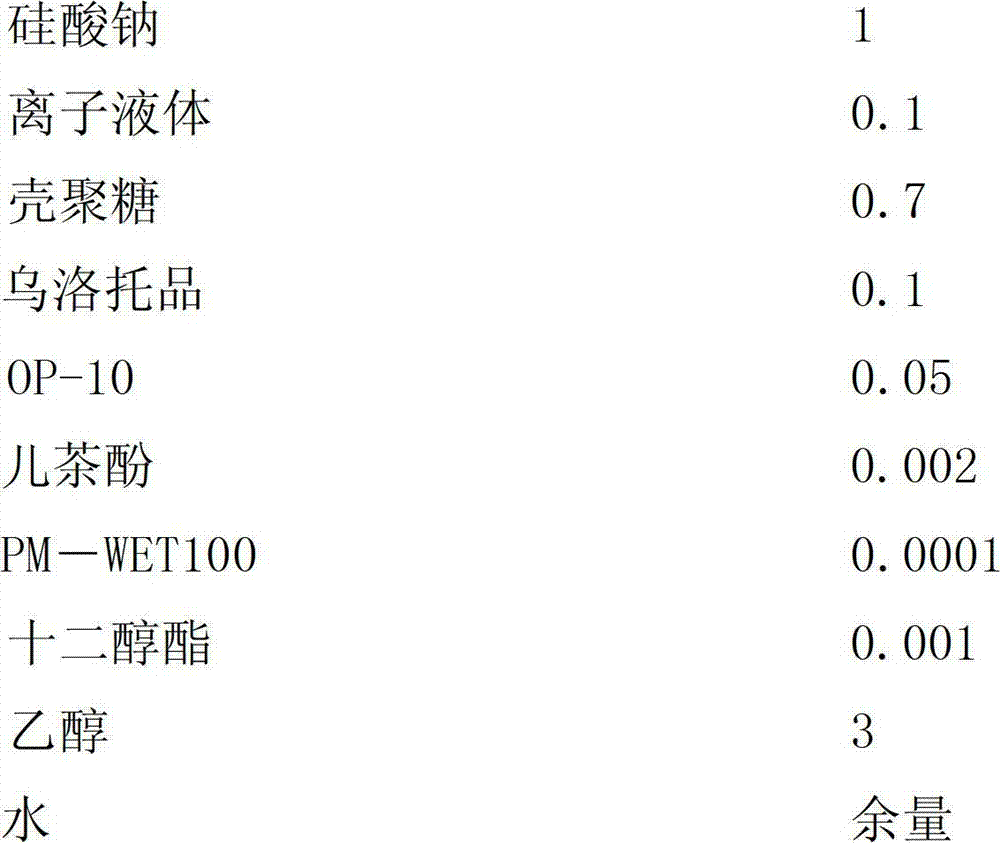

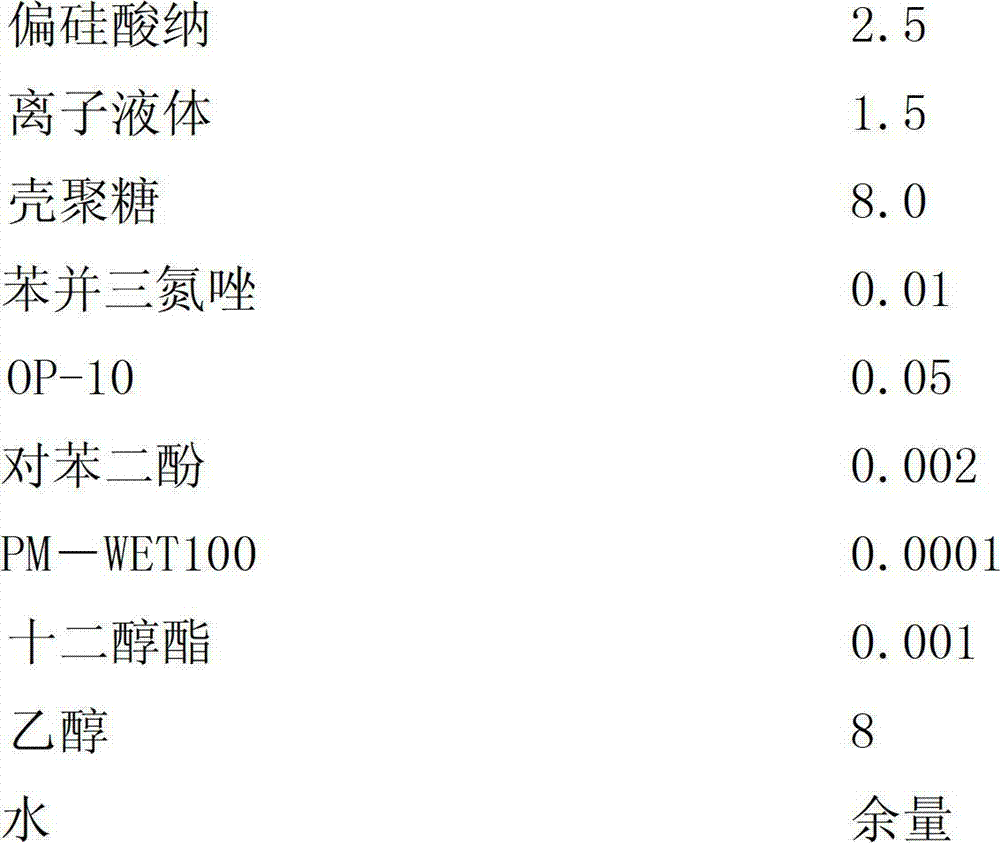

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

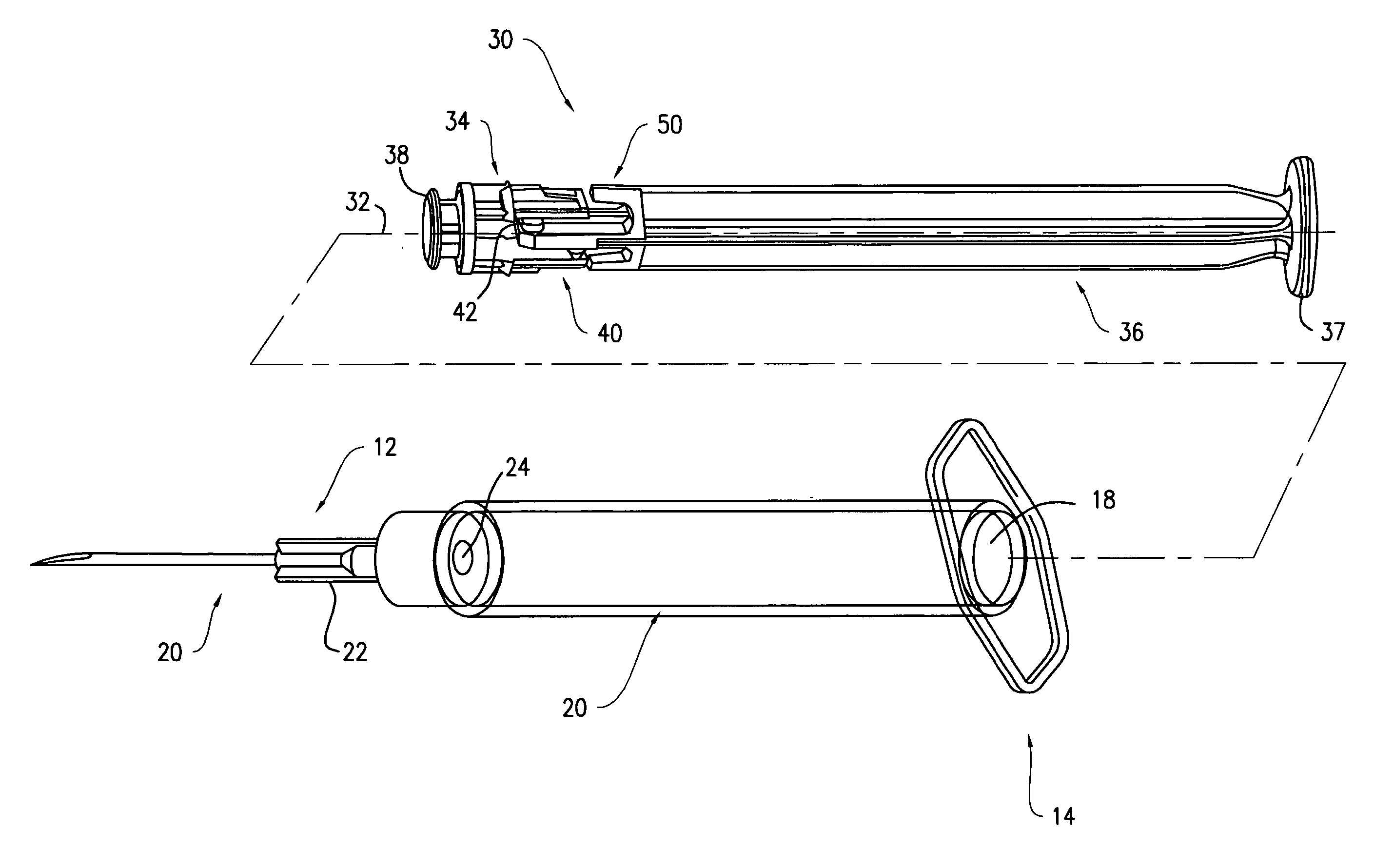

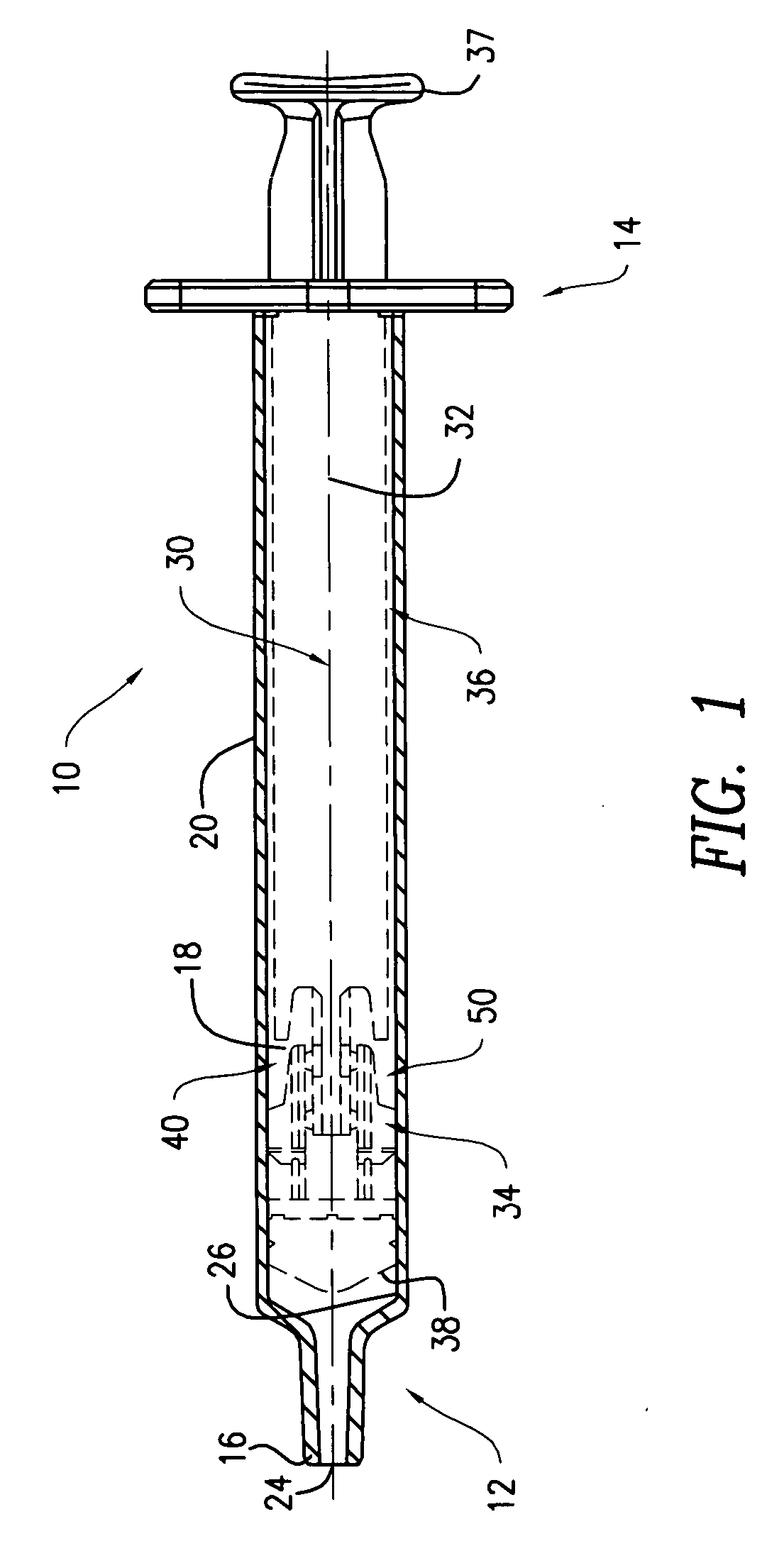

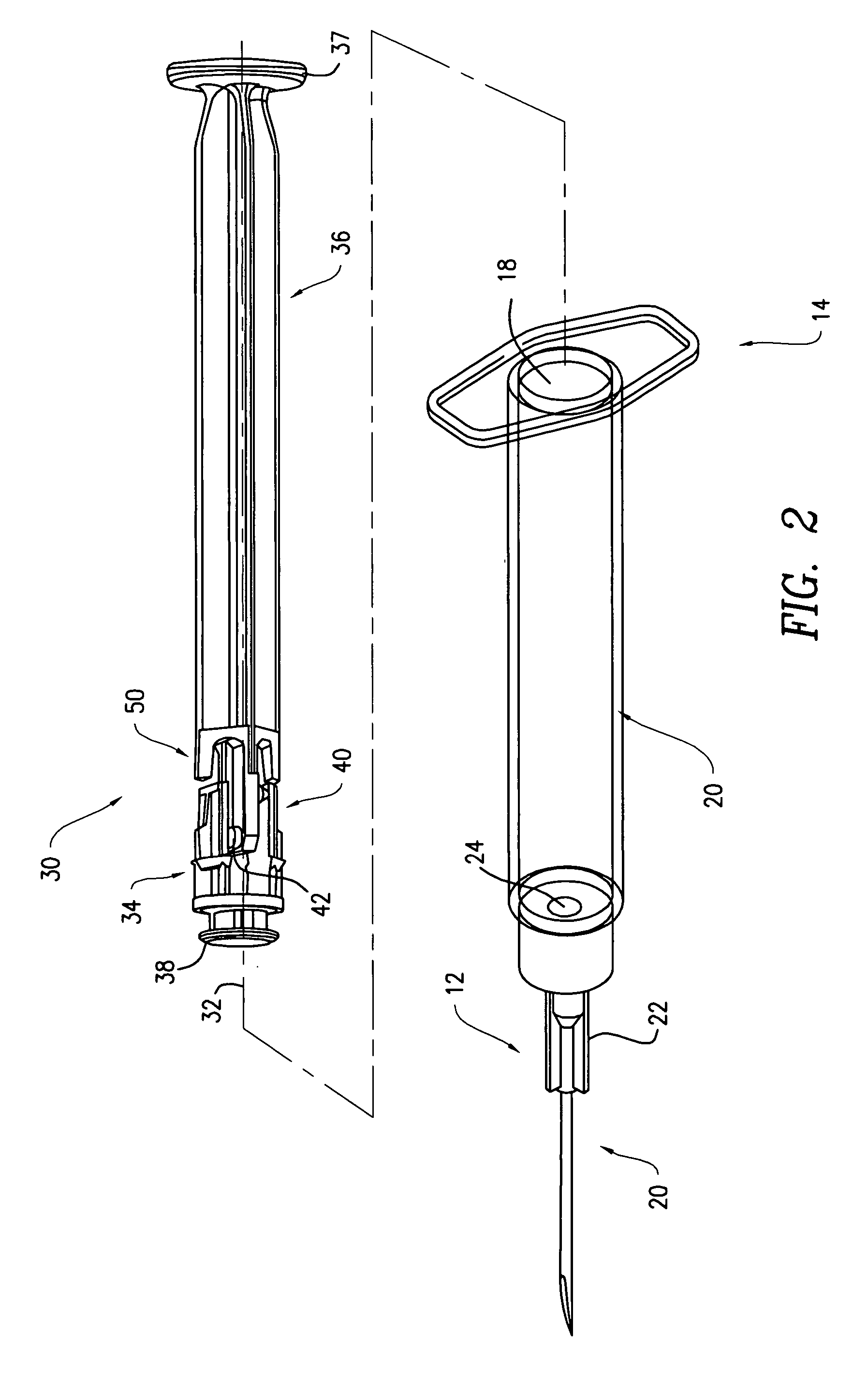

Single use syringe

A syringe including a plunger rod assembly including a proximal portion a distal portion with a stopper for expelling fluids from the syringe and a breakable connection between the proximal portion and the distal portion is disclosed. An impulse reduction system, which may be an elastic element or braking surfaces, reduces the contact impulse imparted by the proximal portion upon the distal portion when the connection between the distal portion and proximal portion breaks is also disclosed.

Owner:BECTON DICKINSON & CO

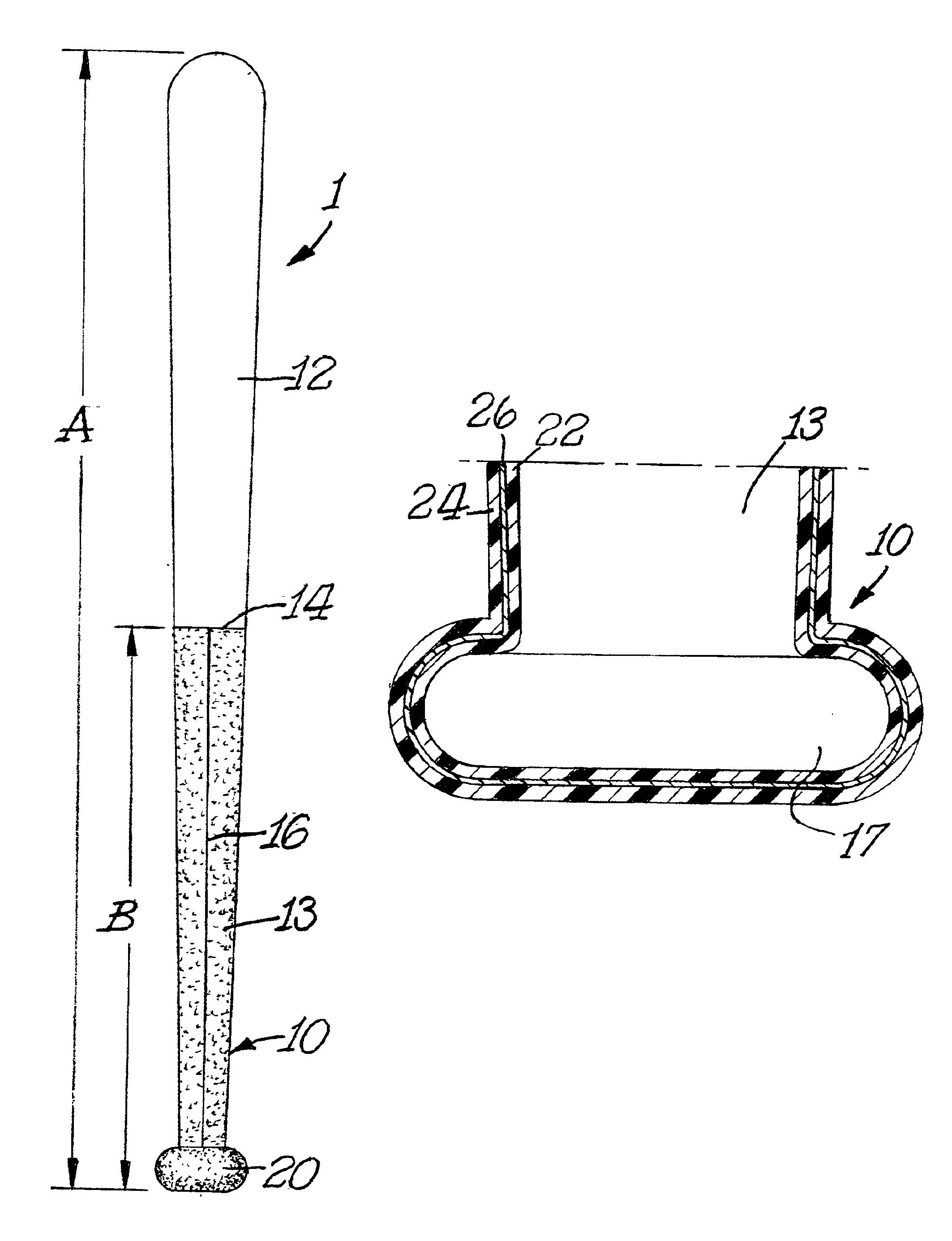

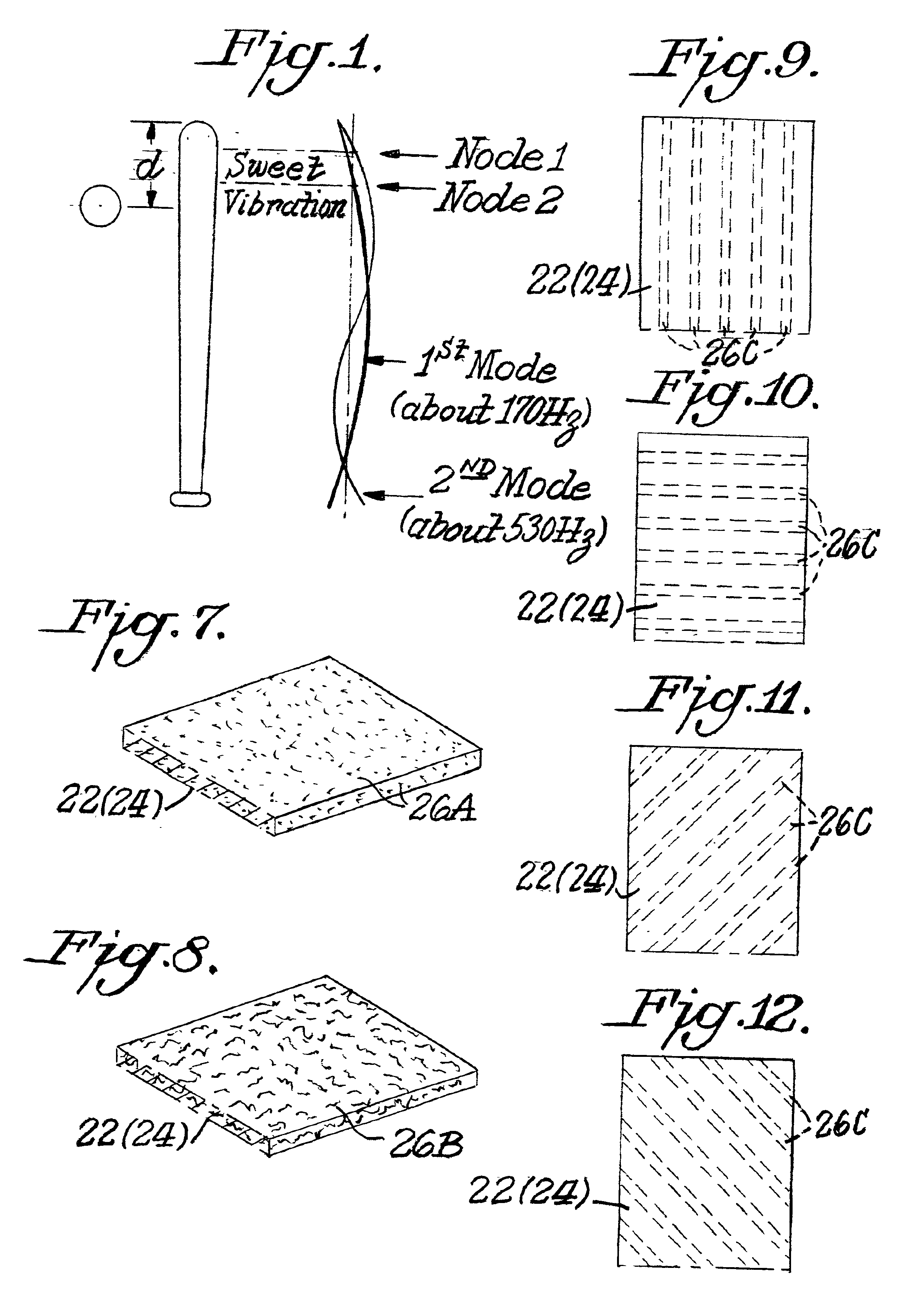

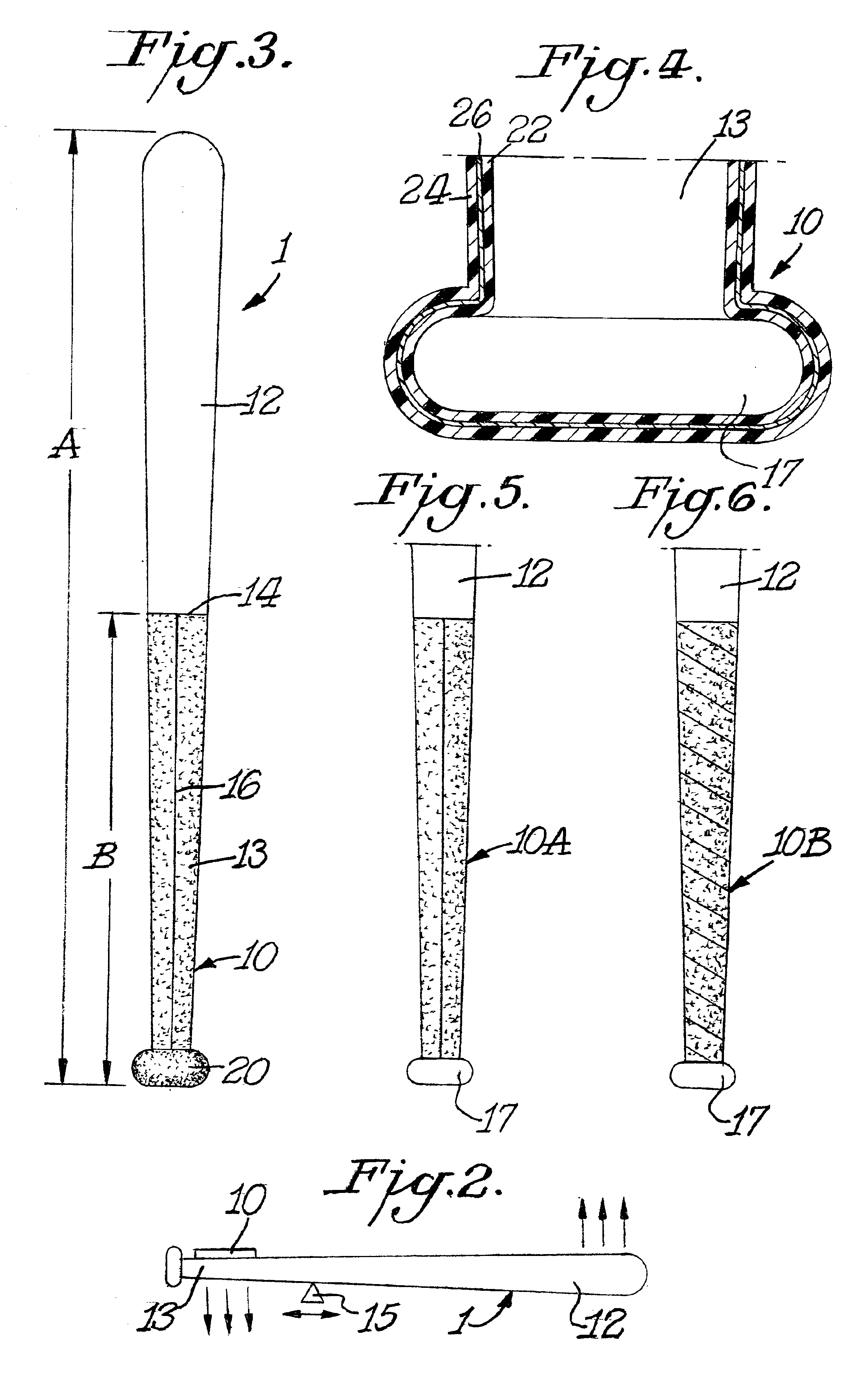

Sting minimizing grip for a hand held swinging athletic contact making article

InactiveUS6872157B2Minimize stingHigh coefficient of frictionGolf clubsMetal-working hand toolsPliabilityHigh energy

A grip for minimizing sting in a hand held swinging athletic contacting making article such as a bat, racquet, club or stick is secured to the handle of the article. The grip is a multilayer laminate having an inner layer made from an elastomeric material having high energy absorption and vibration damping characteristics. The laminate also includes an exposed outer layer made from an elastomeric material having a high coefficient of friction and being pliable. In addition, the laminate includes force dissipating material having the characteristics of absorbing and redirecting vibrational energy.

Owner:MATSCITECHNO LICENSING

Friction material for brakes

InactiveUS20080160260A1Low aggressivenessImprove abilitiesLayered productsSpecial ornamental structuresMetallurgyMaterials science

A friction material for brakes is formed by molding and hardening a raw material composition mainly containing a fibrous substrate, a friction adjuster, an organic filler, an inorganic filler and a binder in the form of a thermosetting resin. The friction material further contains aggregates of fine alumina particles, the aggregates having an average particle diameter of 30 to 60 μm, and the alumina particles having a particle diameter of 0.2 to 0.9 μm.

Owner:WADA NORIO +2

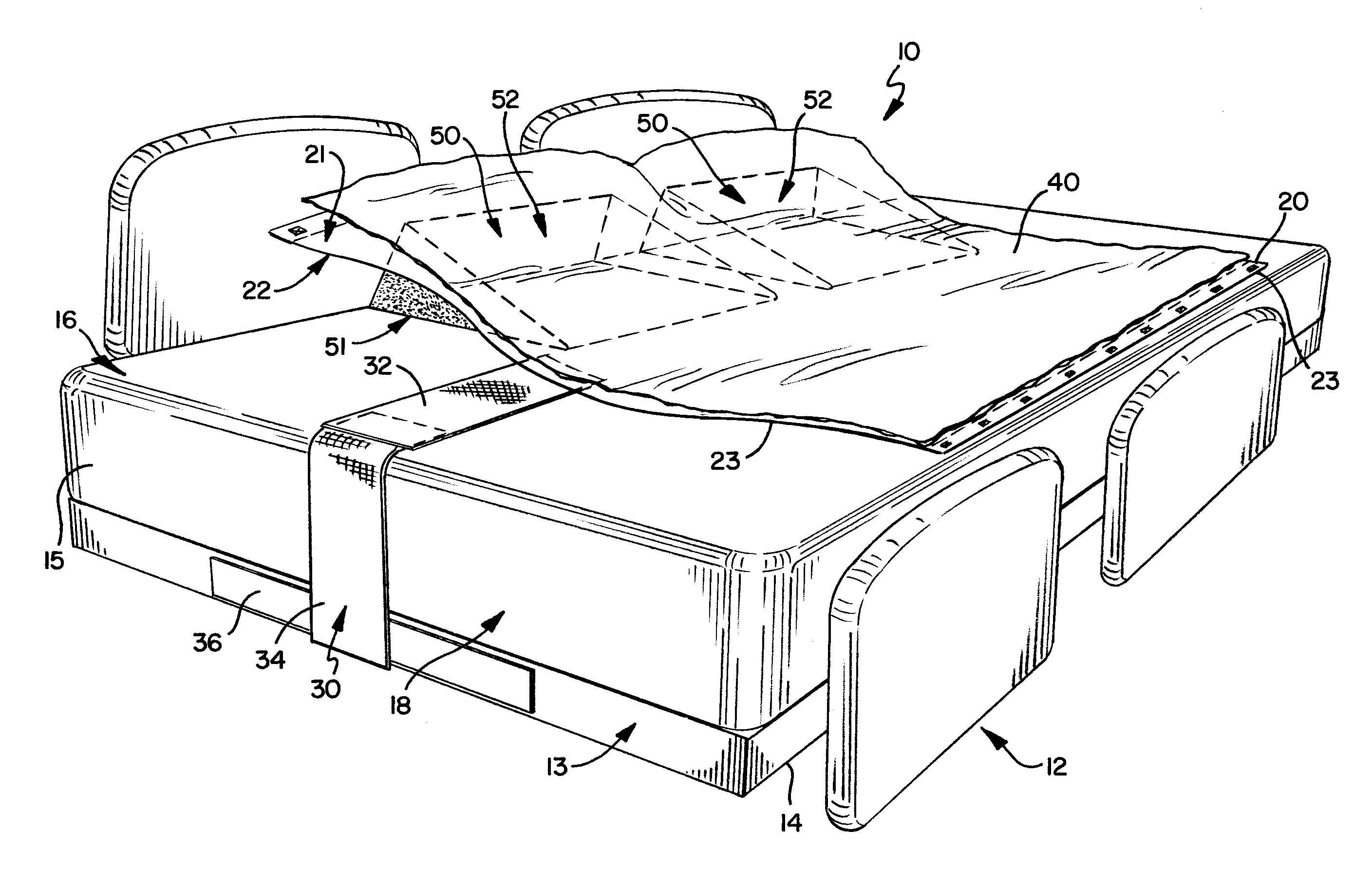

Method for turning and positioning a patient

ActiveUS8789533B2Reduce frictionIncrease the friction surfaceOperating chairsStretcherResistAbsorbent Pads

Owner:SAGE PRODS

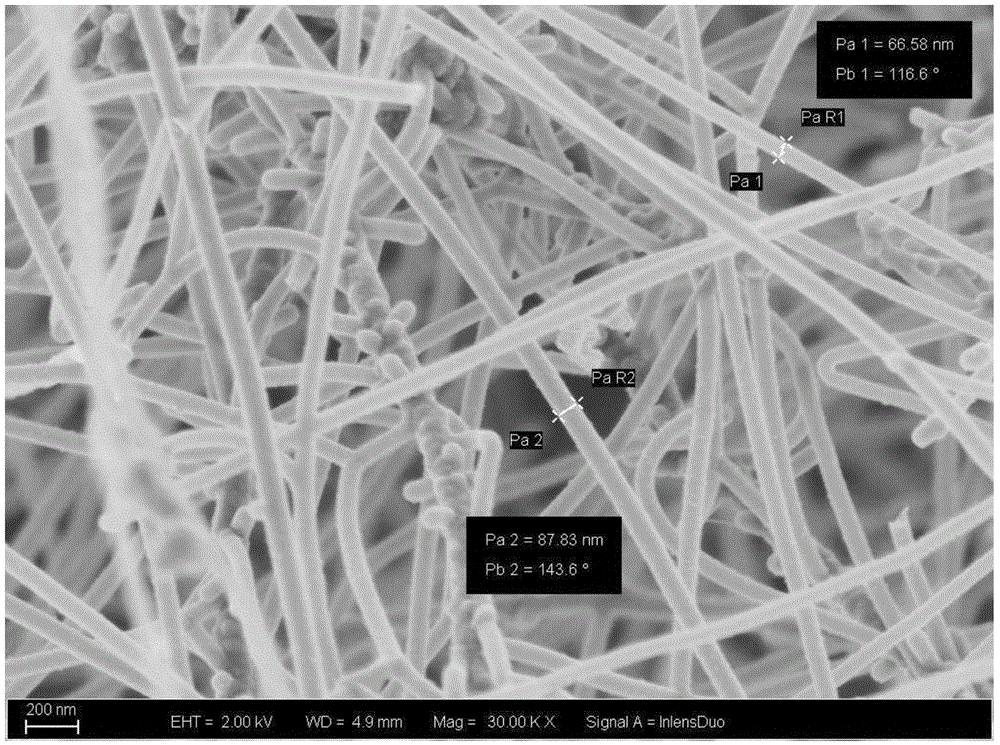

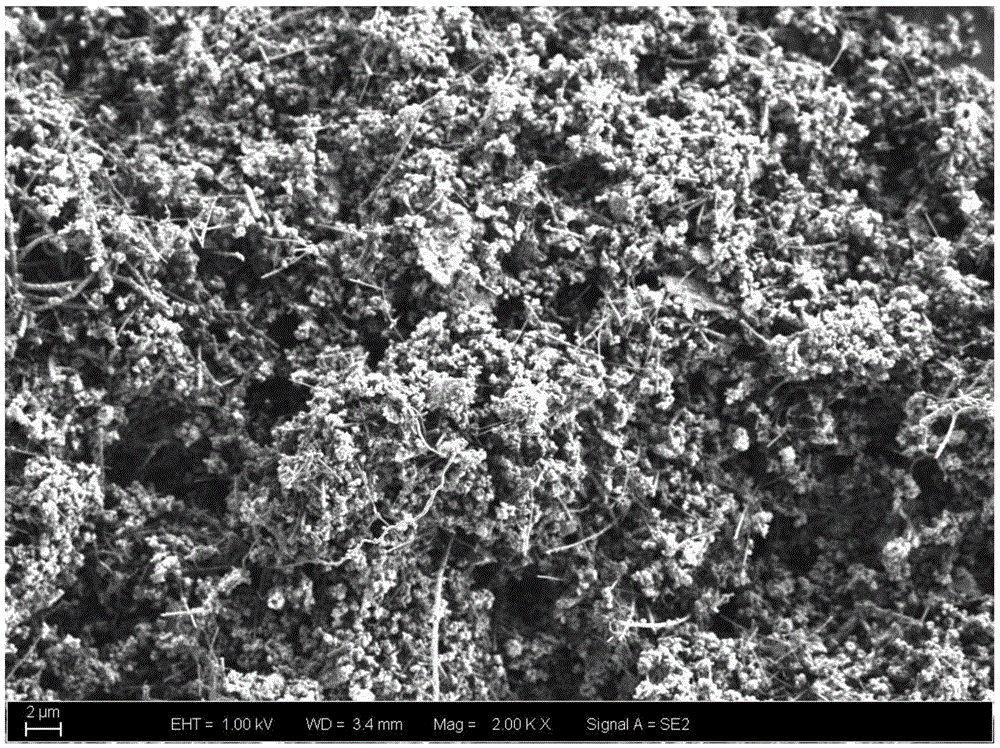

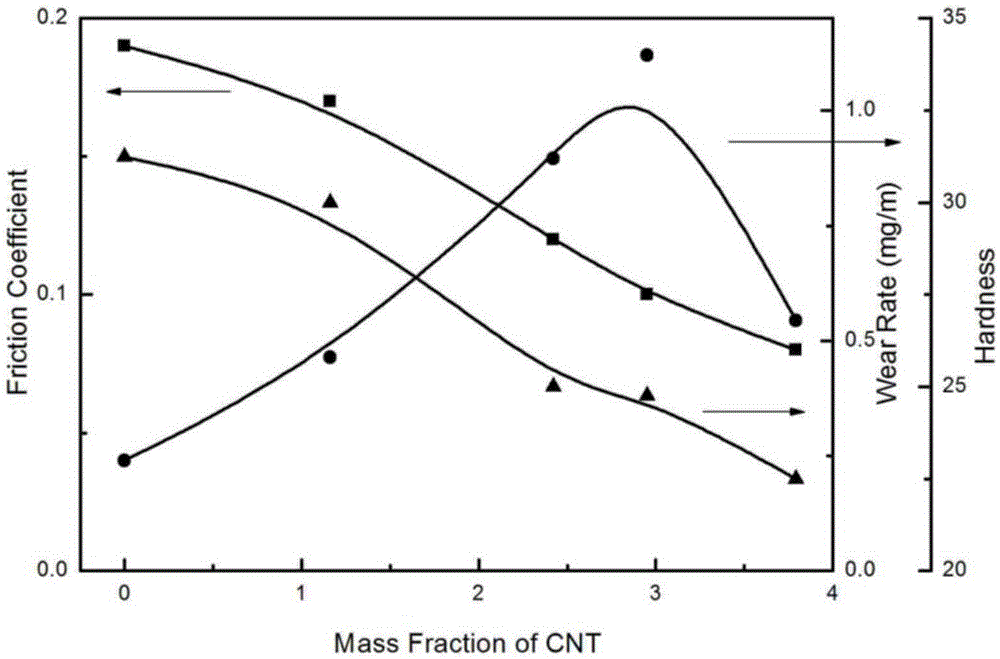

Nano-carbon-reinforced wear-resistant composite material

The invention belongs to the technical field of materials, and specifically relates to a nano-carbon-reinforced wear-resistant composite material. The nano-carbon-reinforced wear-resistant composite material comprises the following components in percentage by mass: 55-99% of metal powder, 0.1-35% of ceramic powder, and 0.01-15% of nano-carbon, wherein the metal powder is used as a composite material matrix; the ceramic powder is used as a wear-resistant filling material; and the nano-carbon comprises single-wall carbon nano-tubes, multi-wall carbon nano-tubes and other materials, and is mainly used for improving the heat-conducting performance, strength, toughness, wear resistance and other performances of the composite material. The wear-resistant composite material disclosed by the invention can keep a stable friction coefficient and a low wear rate under the conditions of a heavy load, a high speed, and long-time braking.

Owner:SUZHOU FIRST ELEMENT NANO TECH

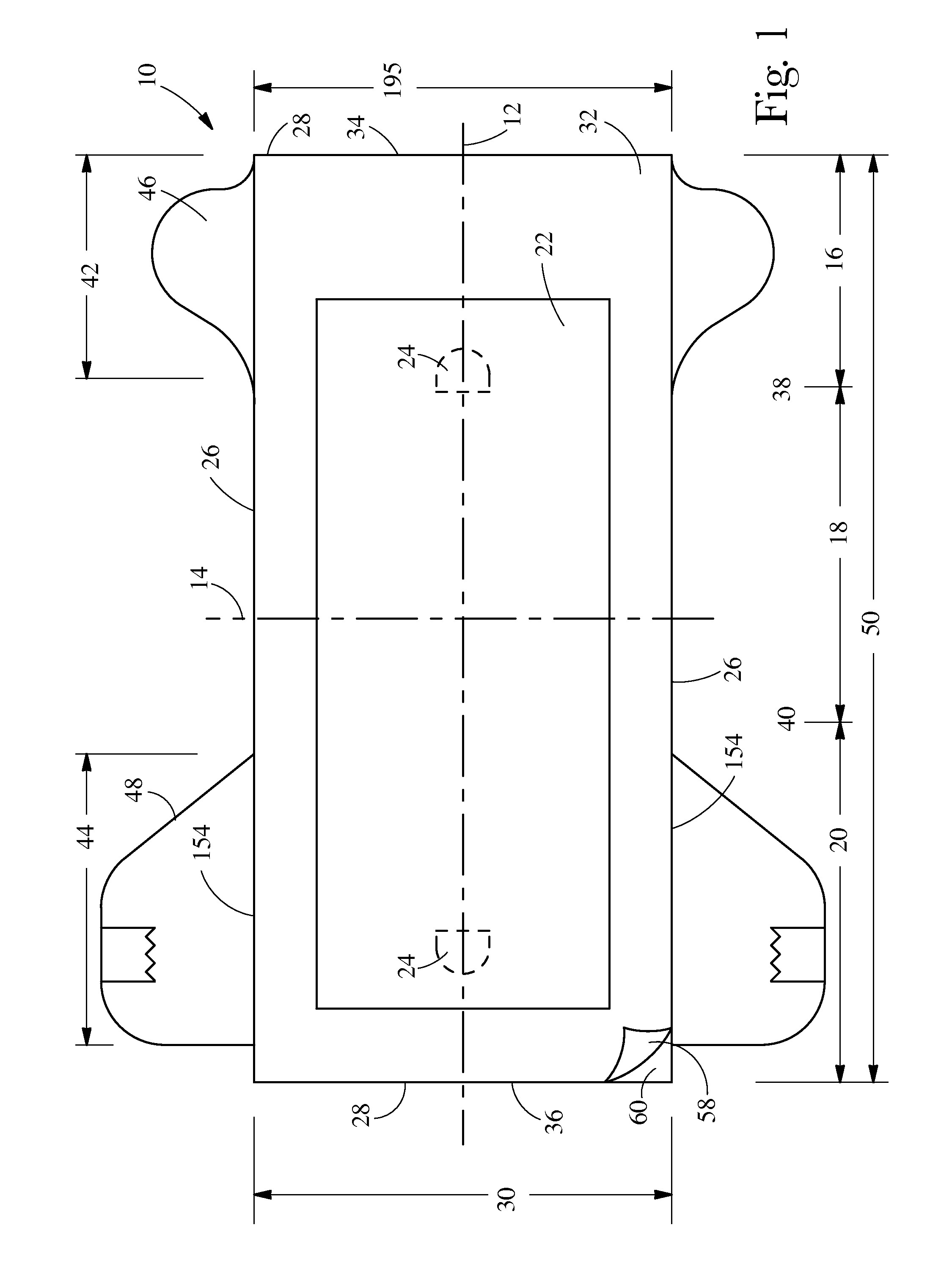

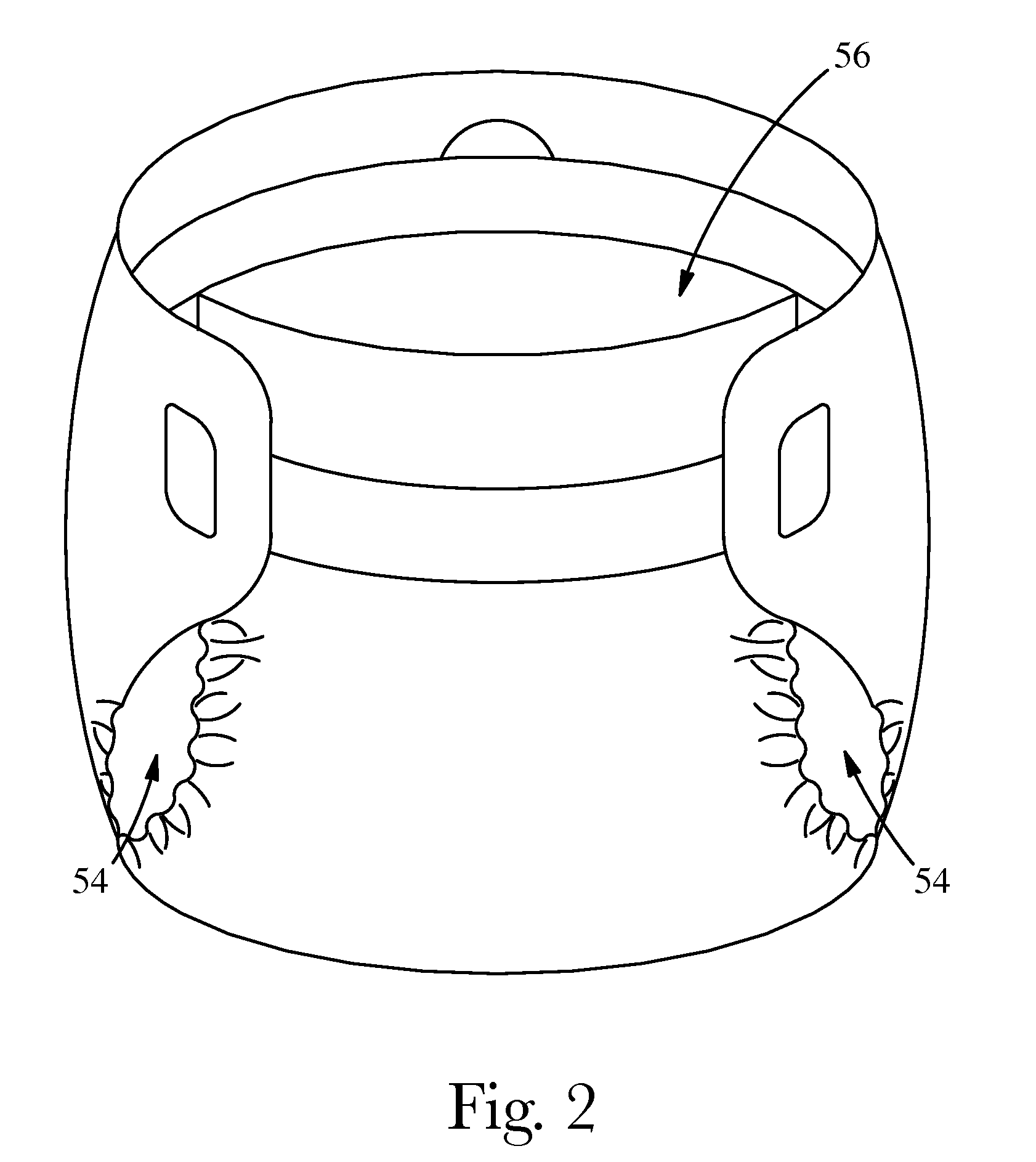

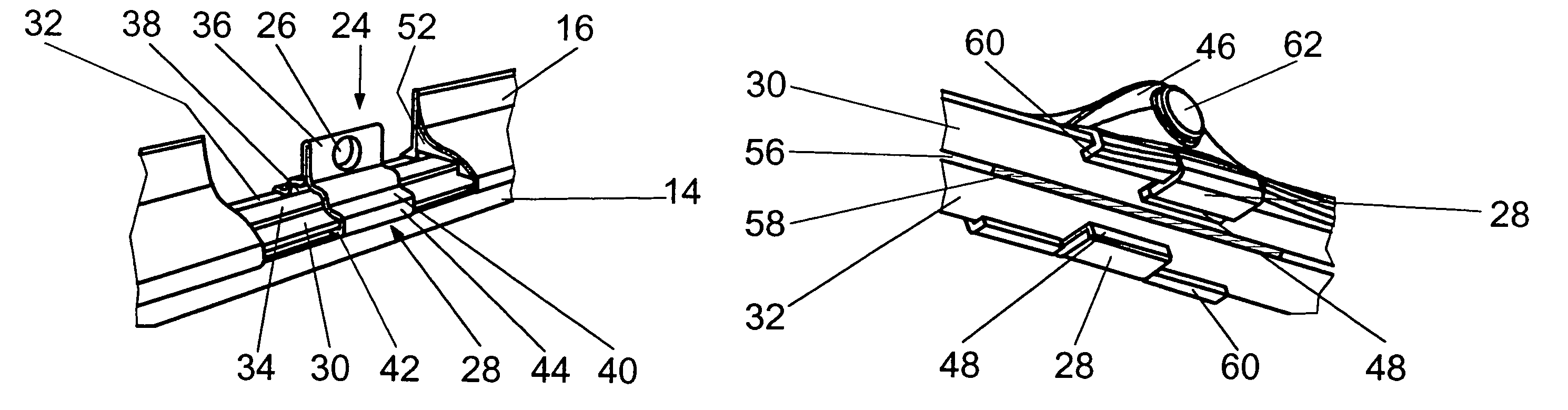

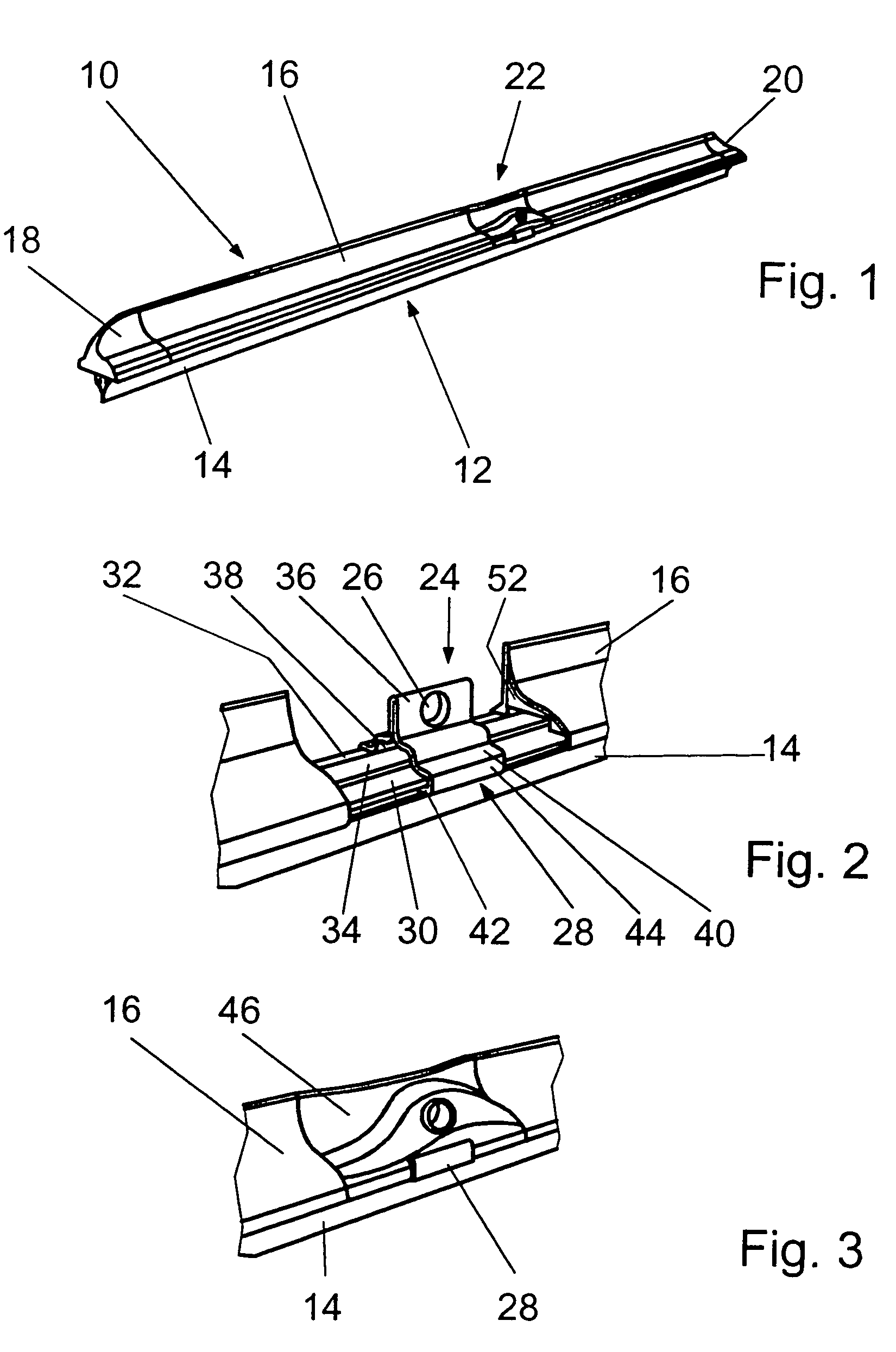

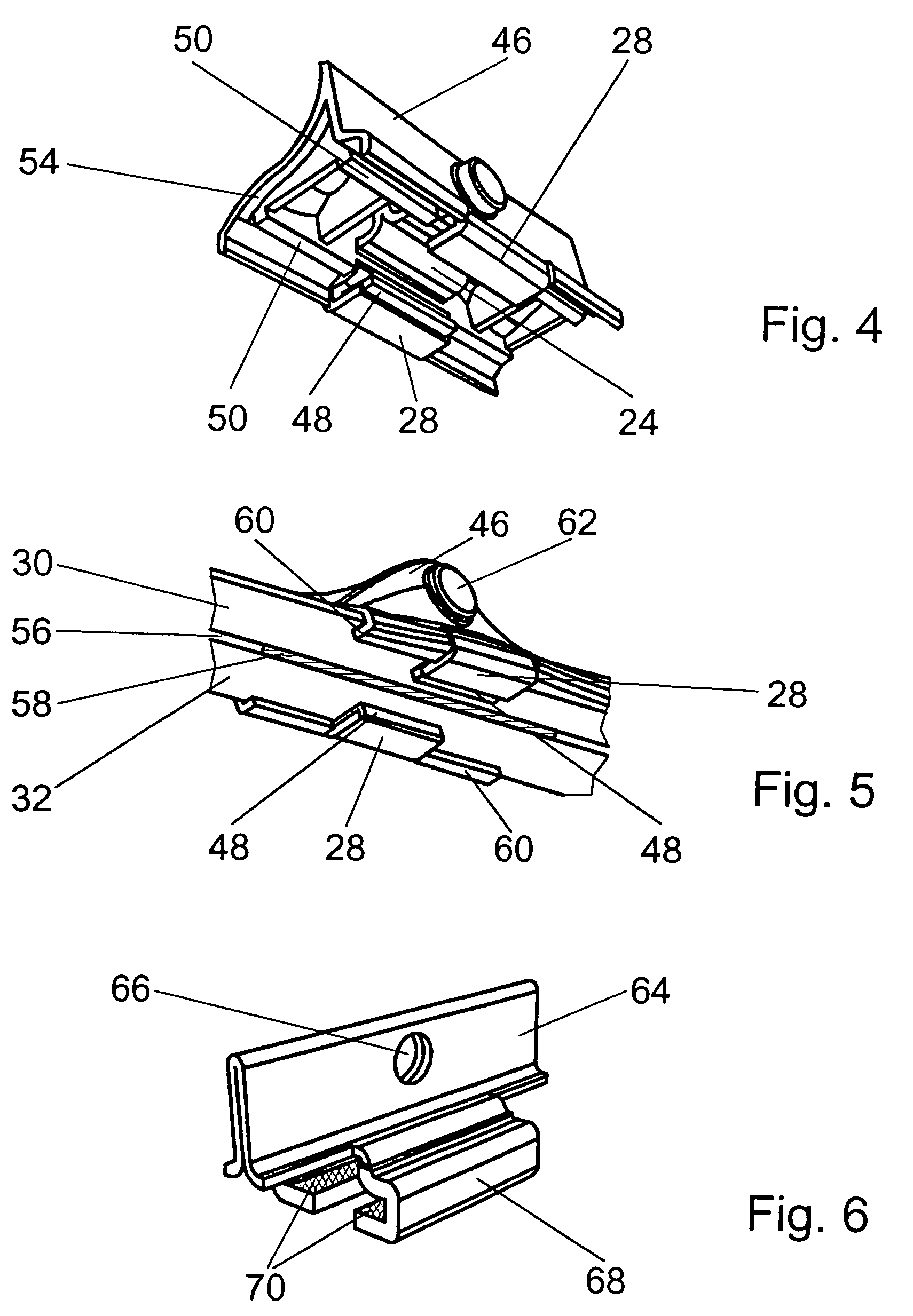

Wiper blade

InactiveUS8020246B2Increase coefficient of frictionEasy to installWindow cleanersVehicle cleaningEngineeringMechanical engineering

A non-articulated wiper blade (10), which is constructed of a wiper strip (12) having a wiper lip (14), two spring rails (30, 32) and a connecting device (22), wherein the spring rails (30, 32) engage in lateral longitudinal grooves of the wiper strip (12) that are open towards the outside and are clasped by claw feet (28, 68, 76, 108) of a sheet metal claw (24, 64, 72, 106) of the connecting device (22) from an outer narrow side. The claw feet (28, 68, 76, 108) are bent around the narrow sides of the spring rails (30, 32) during the assembly of the sheet metal claws (24, 64, 72, 106), wherein at least one layer (70) and / or an intermediate layer (48, 84) of plastic are provided between the claw feet (28, 68, 76, 108) on the one hand and the spring rails (30, 32) on the other hand, which layers are manufactured separately from the wiper strip (12) and are adapted to the claw feet (28, 68, 76, 108) as well as have a high coefficient of friction on their surface towards the sheet metal claw (24, 64, 72, 106) and towards the spring rails (30, 32).

Owner:ROBERT BOSCH GMBH

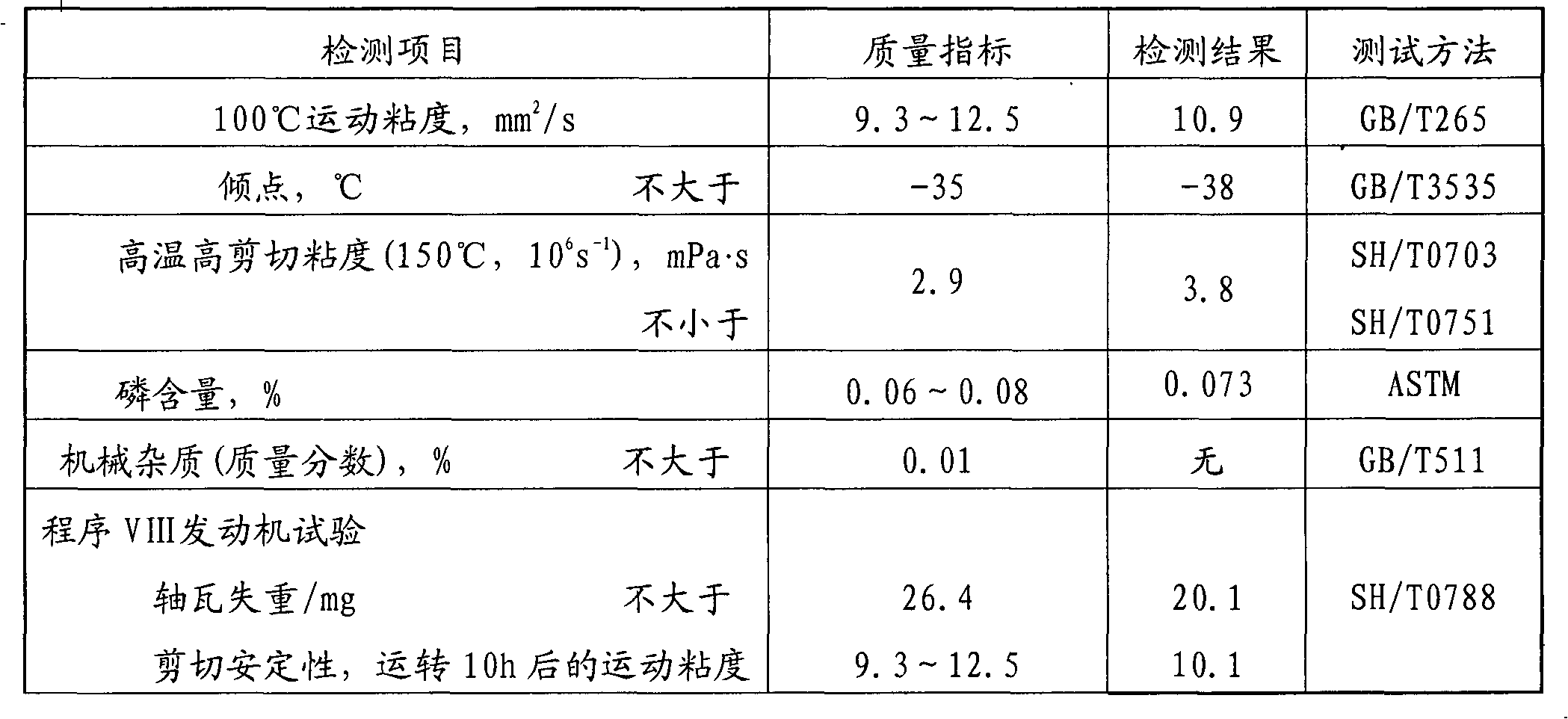

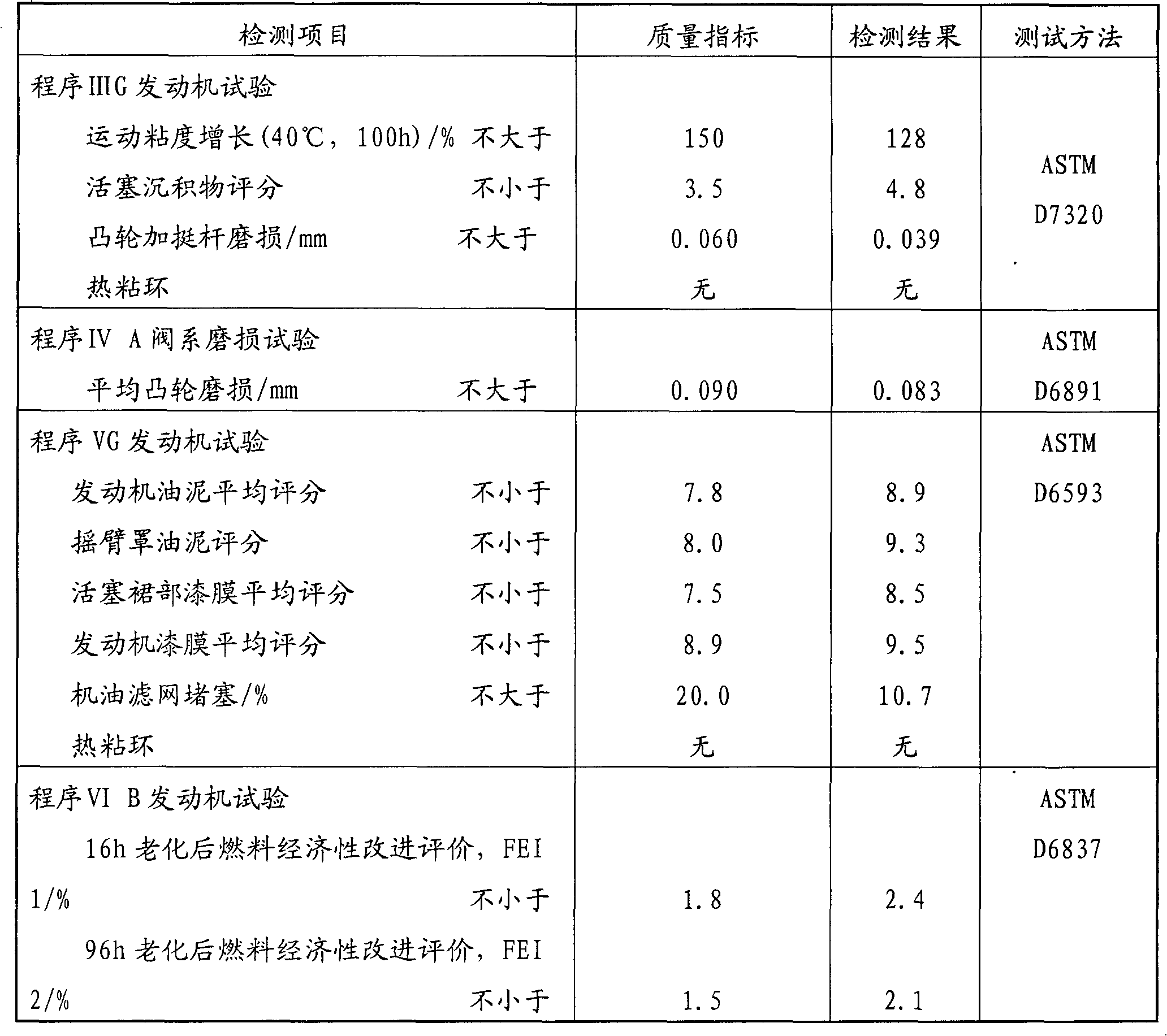

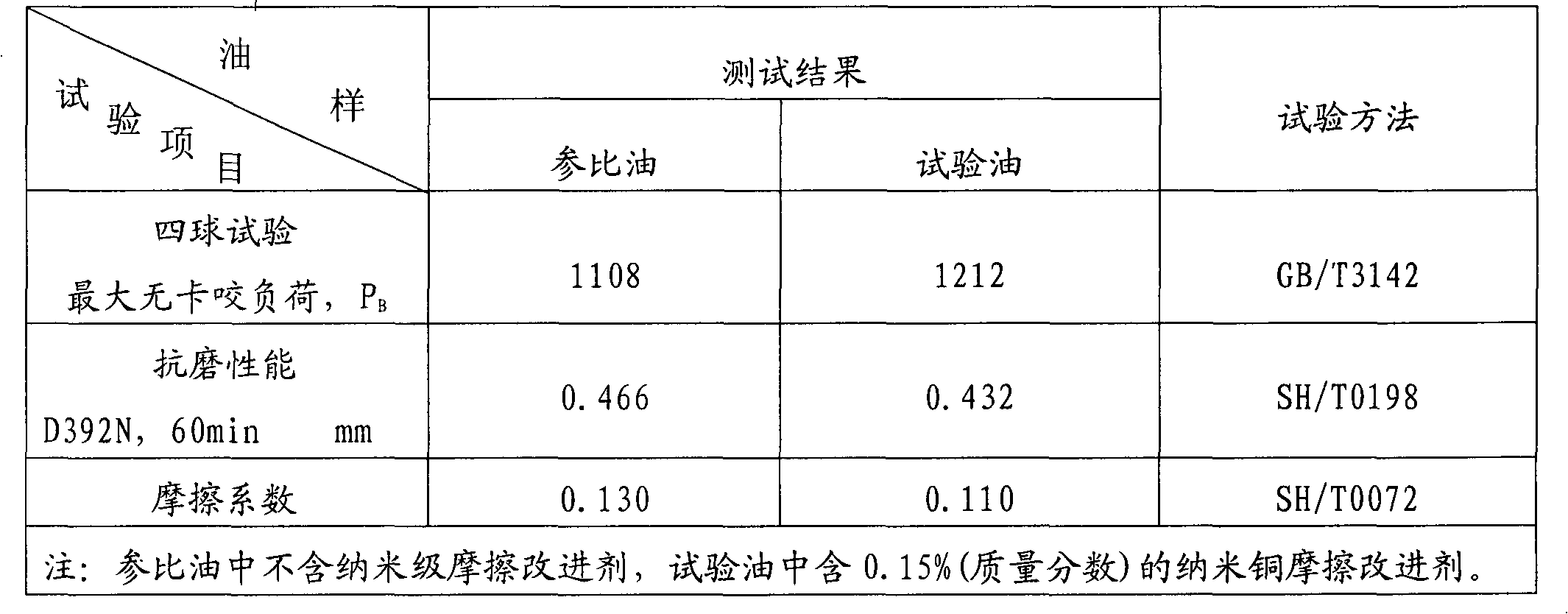

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

Skid Resistant Surfaces

InactiveUS20080289289A1Readily unrollableExcellent skidBuilding roofsCovering/liningsMechanical engineeringPedestrian

Pedestrian trafficable skid-resistant flexible articles (24) are described. These articles (24) include a flexible substrate (17) having a non-skid coating that may be either a pressure-sensitive adhesive (13) or a highly- filled, textured binder. These articles may be applied to trafficable surfaces such as roof and floors. Articles in the form of roof underlayments having a skid-resistant surface are described in particular.

Owner:WR GRACE & CO CONN

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

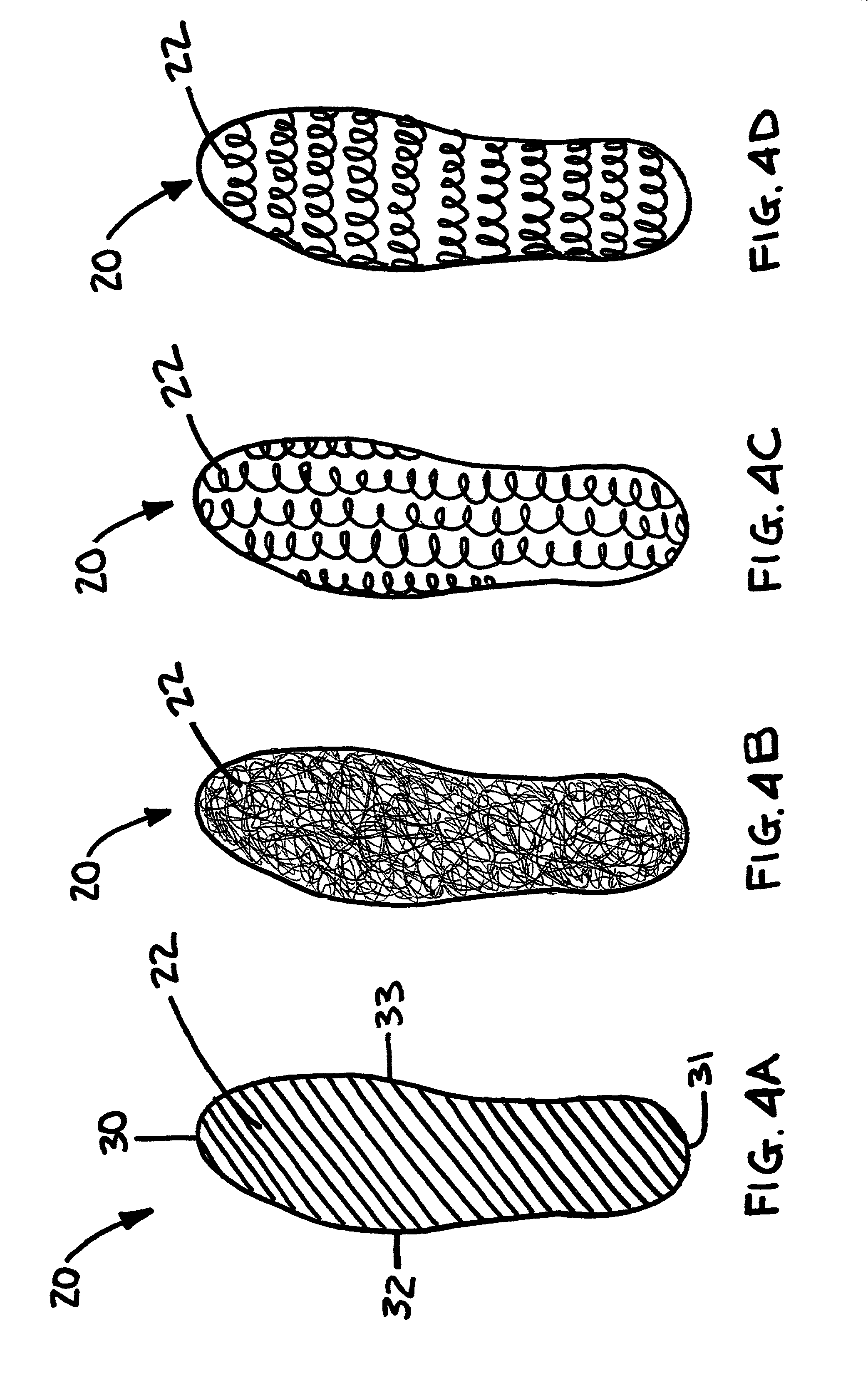

Disposable shoe insert

InactiveUS7047671B2High coefficient of frictionIncrease coefficient of frictionSolesInsolesDynamical frictionBiomedical engineering

A disposable shoe insert having a soft, durable, resilient, absorbent and “high coefficient of friction” surface in contact with the human foot is provided. The material in contact with the foot comprises of a nonwoven material that has a static of dynamic coefficient of friction of 0.52 or above when tested against material from a pair of standard women's pantyhose containing 80% nylon and 20% spandex fibers. The other side of the insert consists of a slip-resistant synthetic coating that minimizes shoe insert slippage after being placed and positioned in the shoe. The insert provides a low cost and simple method of keeping the feet dry, comfortable, healthy and odor free. The frequent replacement of the insert promotes the reduction of bacterial build-up in the shoe over time, which in turn reduces shoe odor and helps prolong the life of the shoe itself. Optional features may include deodorizer, such as a time release fragrance, and / or odor neutralizer to help reduce or eliminate foot odor. Other additional product features may include the addition of antimicrobial agents and / or medicinal ingredients.

Owner:STEED CHERYL +1

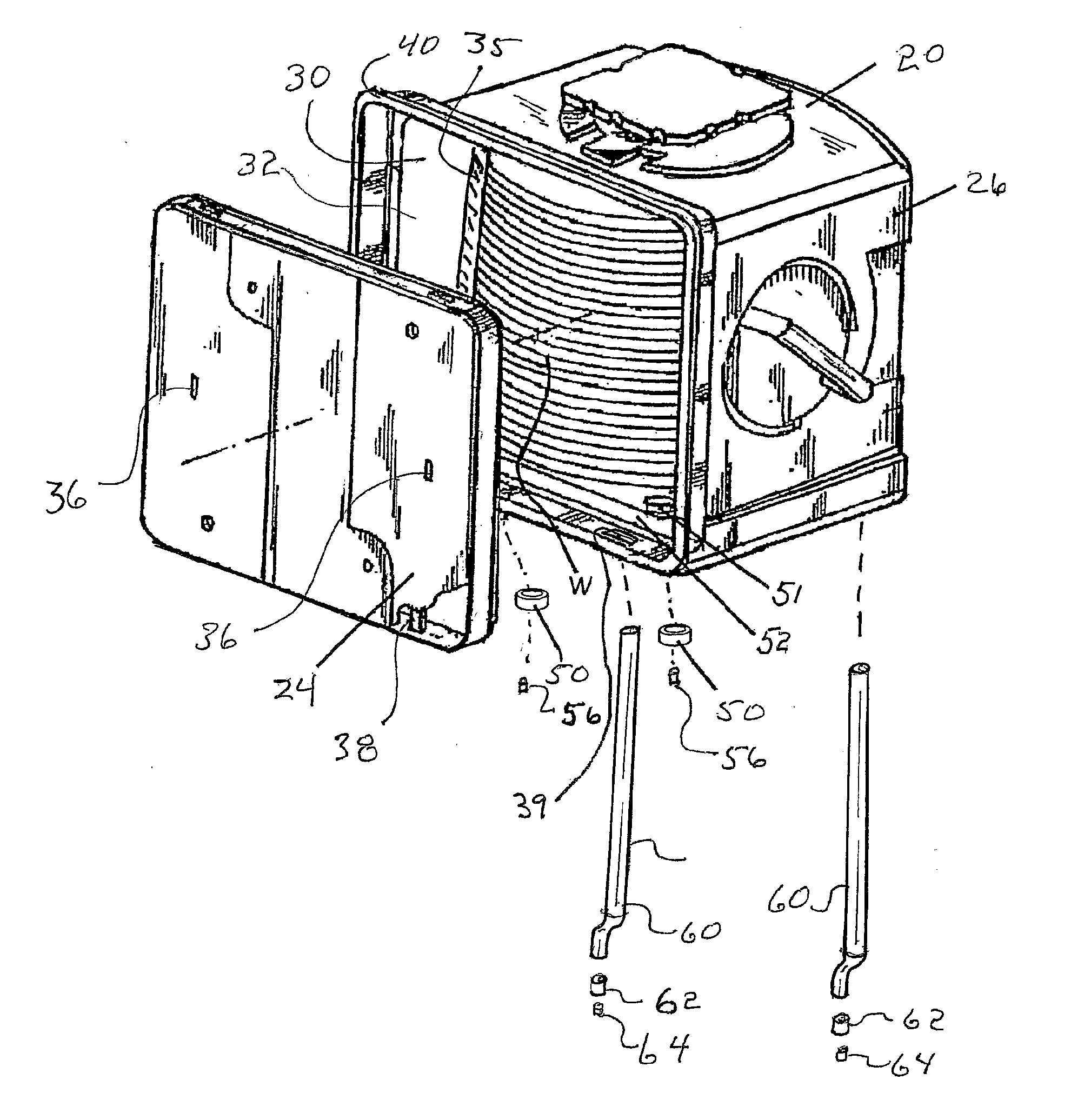

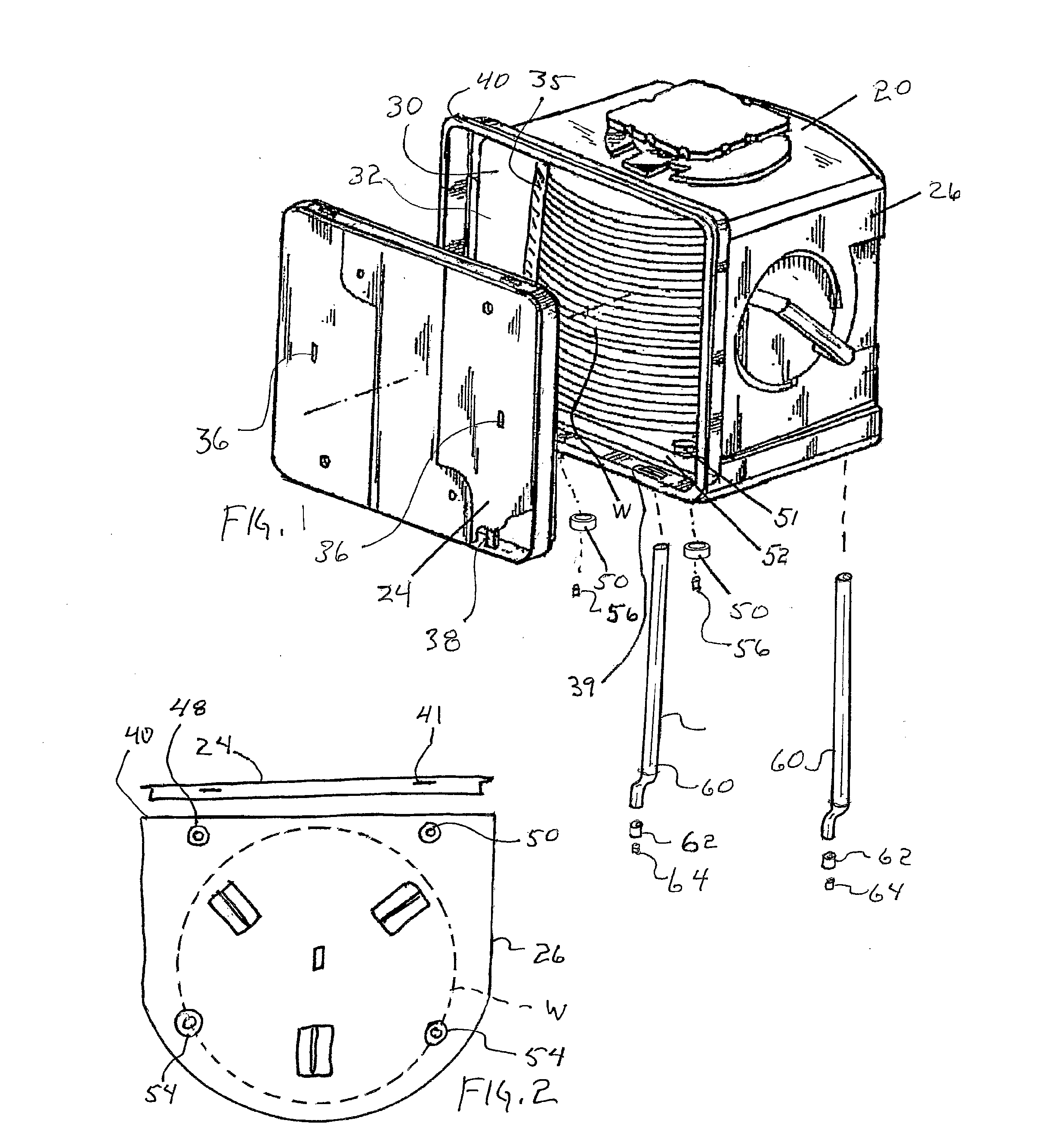

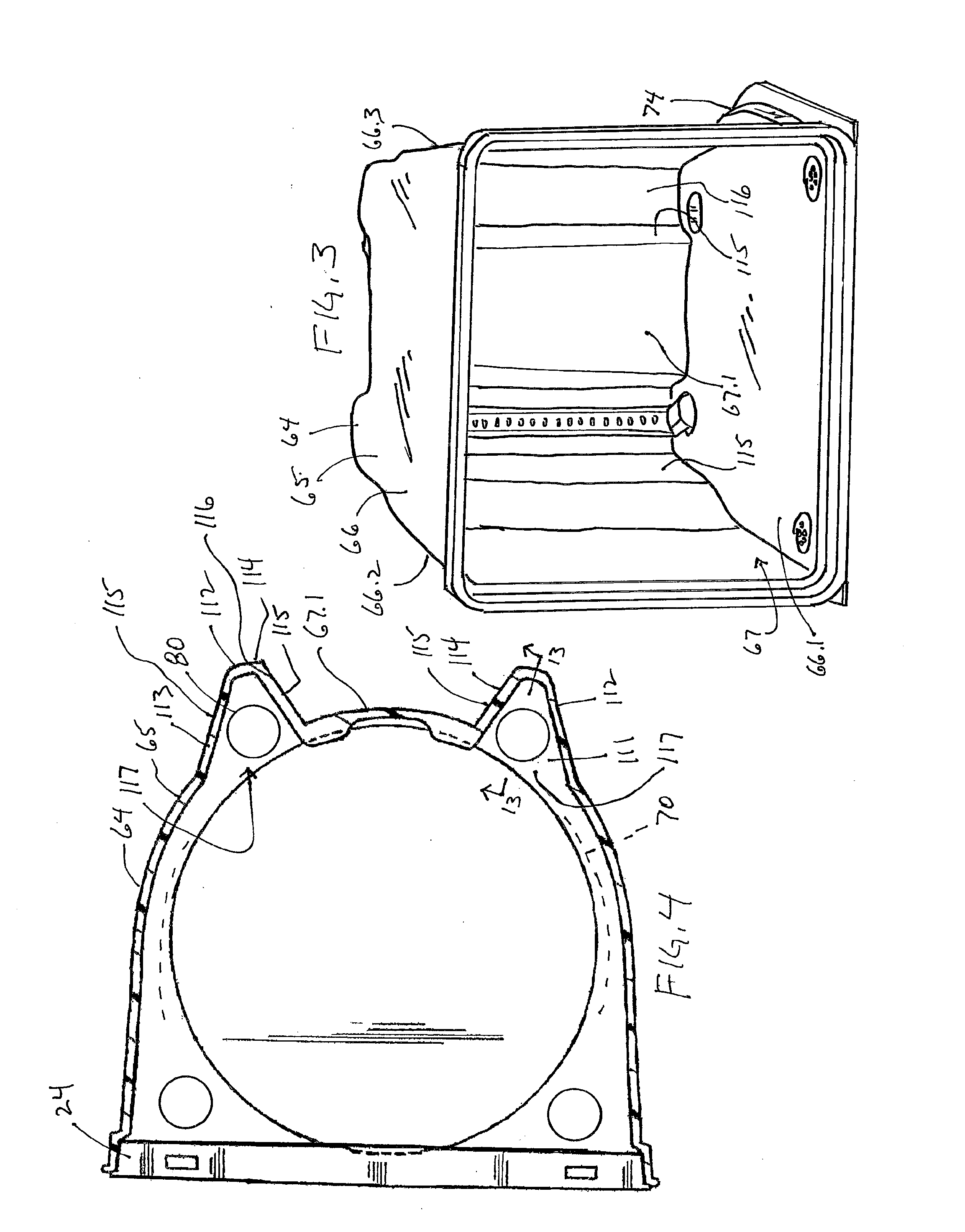

Wafer container with tubular environmental control components

ActiveUS20110114534A1Protected contentSuperior fluid flow characteristicSemiconductor/solid-state device manufacturingOther accessoriesFiltrationEngineering

A wafer container utilizes a rigid polymer tubular tower with slots and a “getter” therein for absorbing and filtering moisture and vapors within the wafer container. The tower preferably utilizes a purge grommet at the base of the container and may have a check valve therein to control the flow direction of gas (including air) into and out of the container and with respect to the tower. The tower is sealingly connected with the grommet. The tower may have a getter media piece rolled in an elongate circular fashion forming or shaped as a tube and disposed within the tower and may have axially extending. The media can provide active and / or passive filtration as well as having capabilities to be recharged. Front opening wafer containers for 300 mm sized wafers generally have a pair of recesses on each of the left and right side in the inside rear of the container portions. These recesses are preferably utilized for elongate towers, such towers extending substantially from a bottom wafer position to a top wafer position. In alternative embodiment, a tubular shape of getter material is exposed within the front opening container without containment of the getter other than at the ends. The tubular getter form is preferably supported at discrete locations to maximize exposure to the internal container environment. A blocker member can selectively close the apertures. An elastomeric cap can facilitate securement of the tubular component in the container portion.

Owner:ENTEGRIS INC

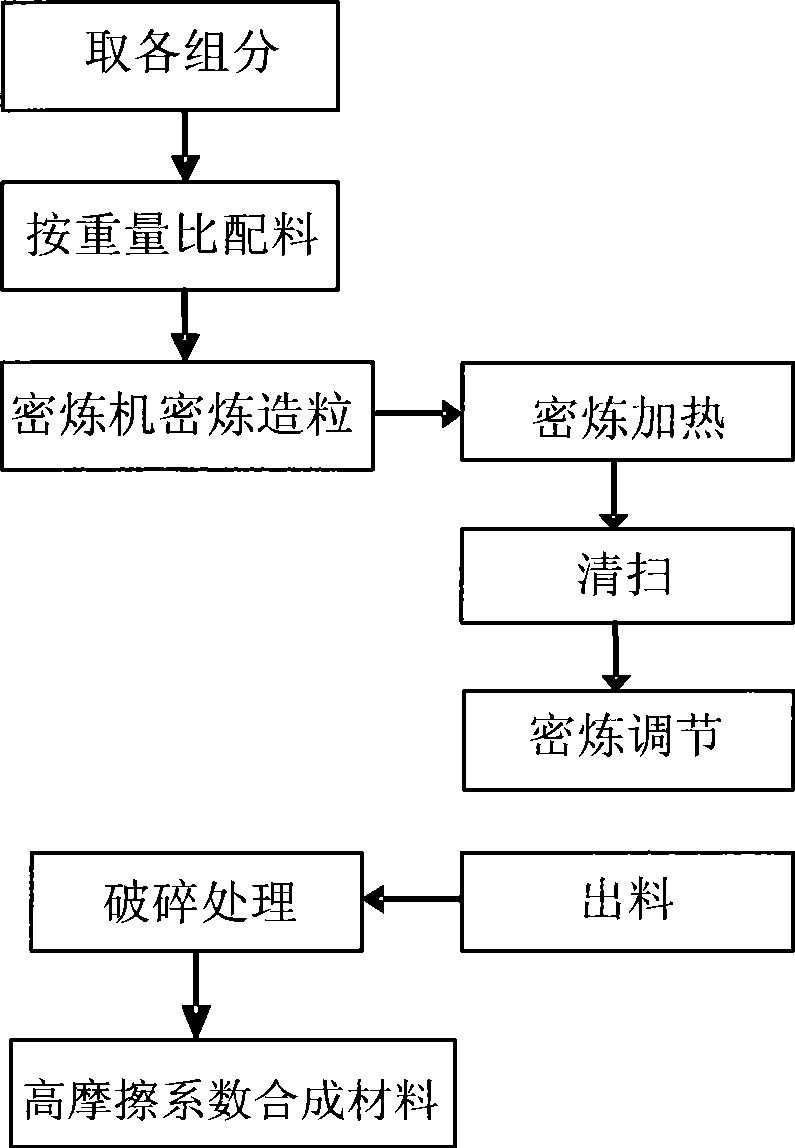

High friction coefficient synthetic materials and preparation method thereof

The invention discloses a high friction coefficient composite material and a manufacturing method thereof, wherein the material is prepared through material sealing and grain-making processing by the following compositions in weight percentage: 8 to 13 percent of butadiene-acrylonitrile rubber, 2 to 10 percent of styrene-butadiene rubber, 5 to 10 percent of cresol methyl-stage phenol-formaldehyde resin modified, 15 to 30 percent of steel fiber, 10 to 15 percent of magnesia, 5 to 10 percent of calcined petroleum coke, 2 to 5 percent of silicon carbide, 10 to 25 percent of mineral fiber, 5 to 10 percent of calcium hydroxide, 10 to 20 percent of barium sulfate, 5 to 10 percent of graphite, 1 to 5 percent of supramoly, 1 to 5 percent of carbon black, 1 to 3 percent of sulfur and 1 to 3 percent of accelerant. The material can be applied in a plurality of situations to prepare friction components, has stable friction performance and good abrasion resistance, effectively inhibits the phenomena of metal inlay, cracking, chip off-falling and so on, reduces the damage on vehicle wheels, has good impact resistance and good weathering resistance, can be used in the environment with large temperature variation for a long time, and has the application characteristics of wide application region and large difference of the regional environment.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com