Patents

Literature

120results about How to "Large elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

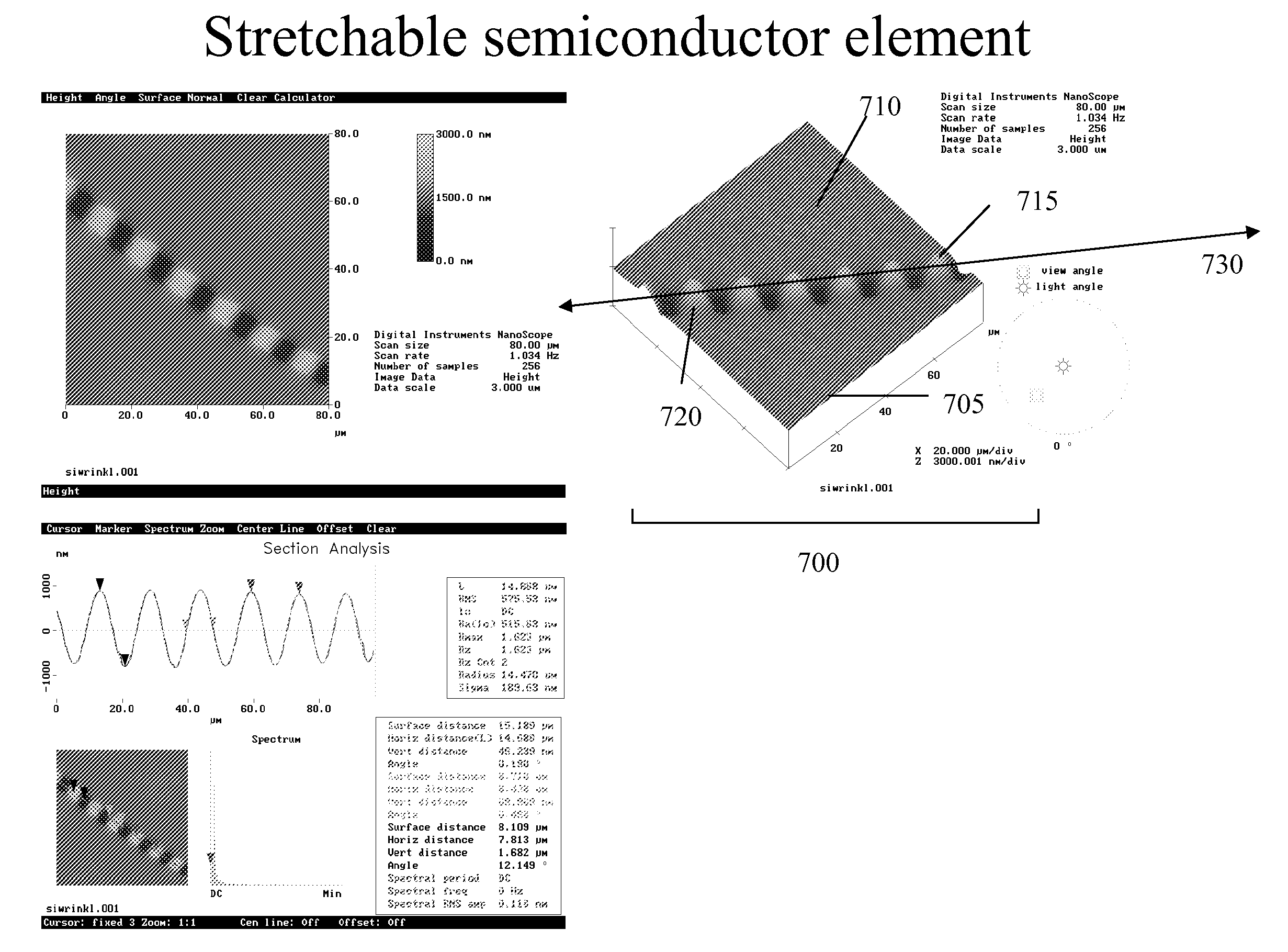

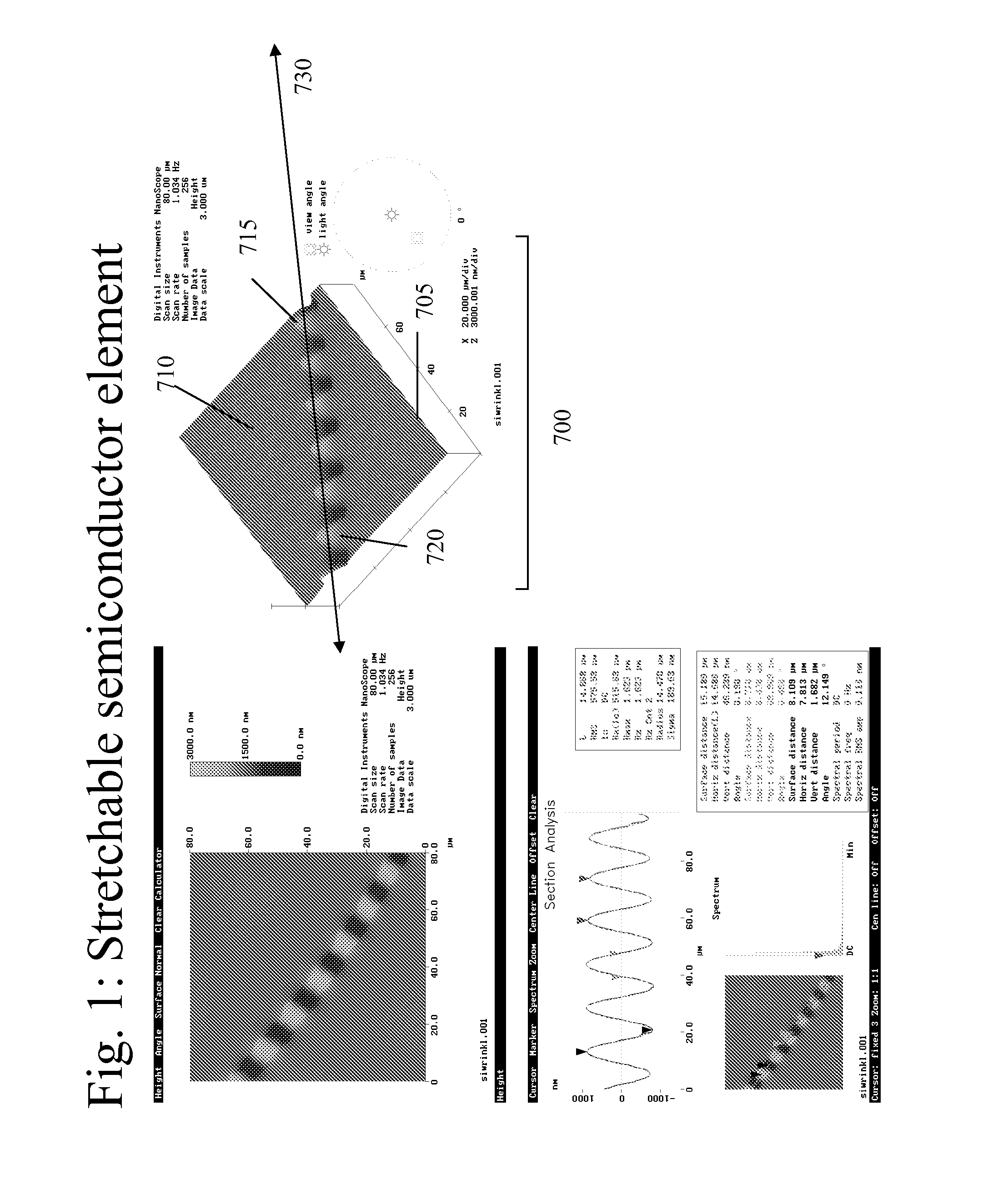

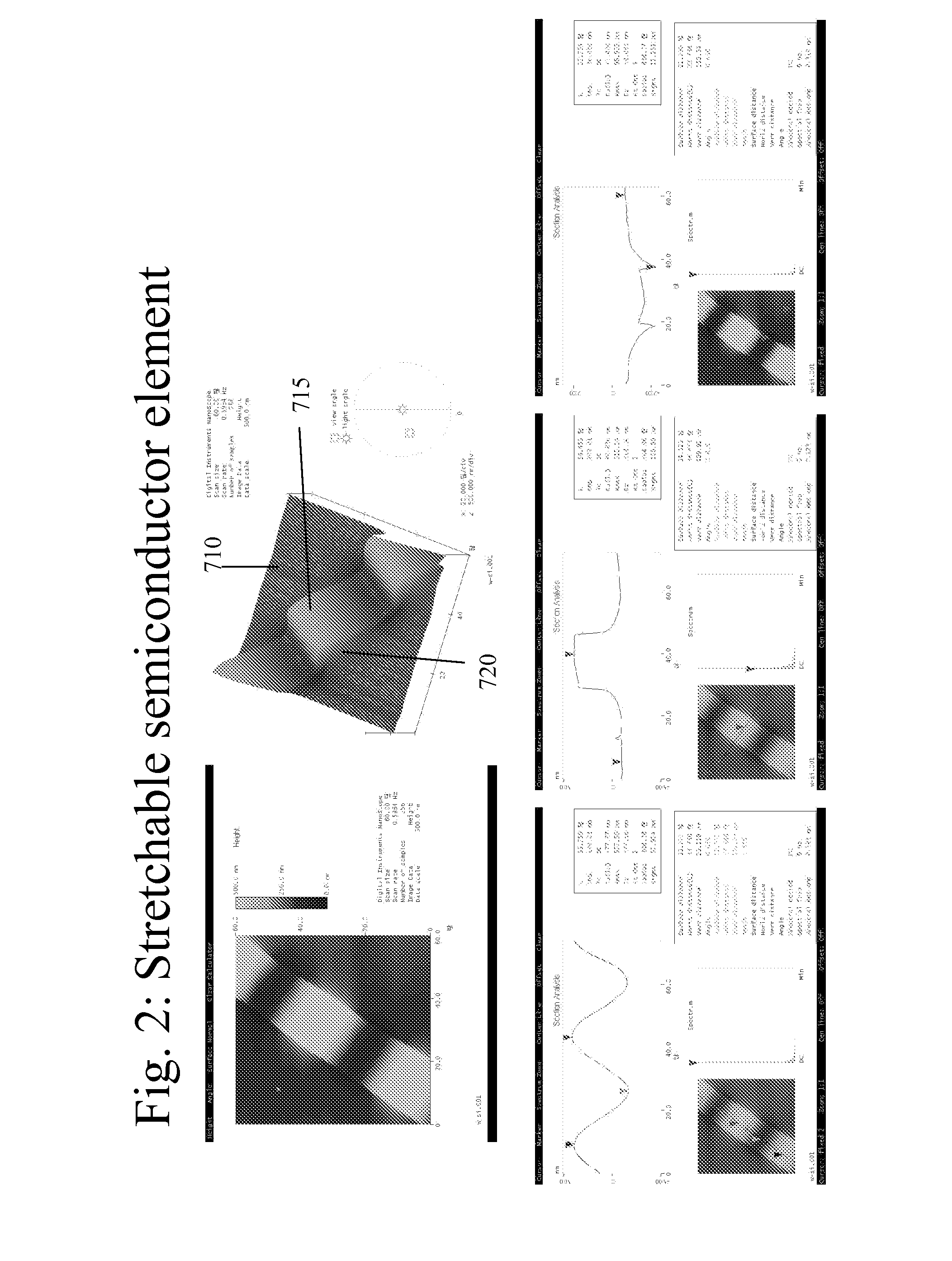

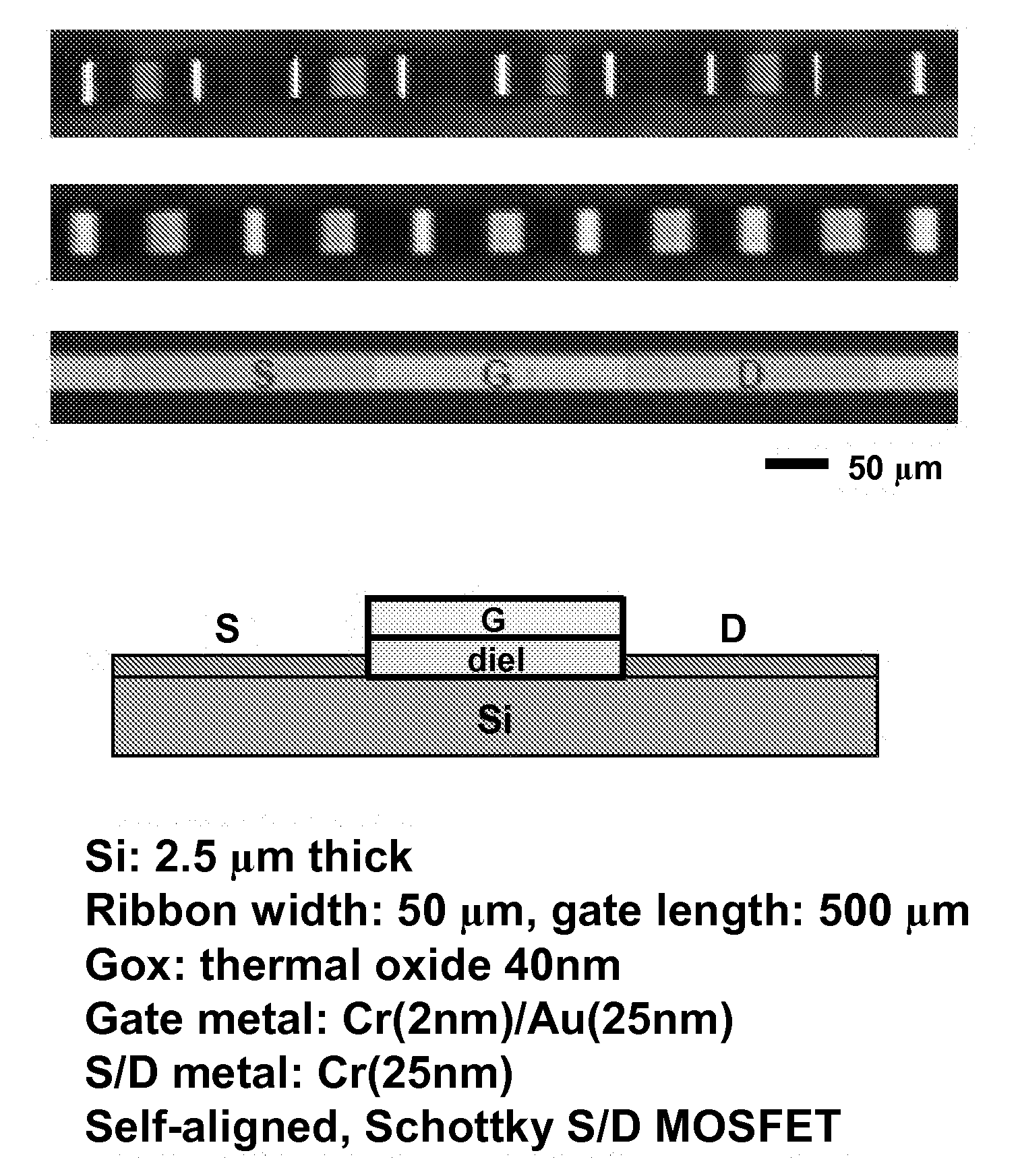

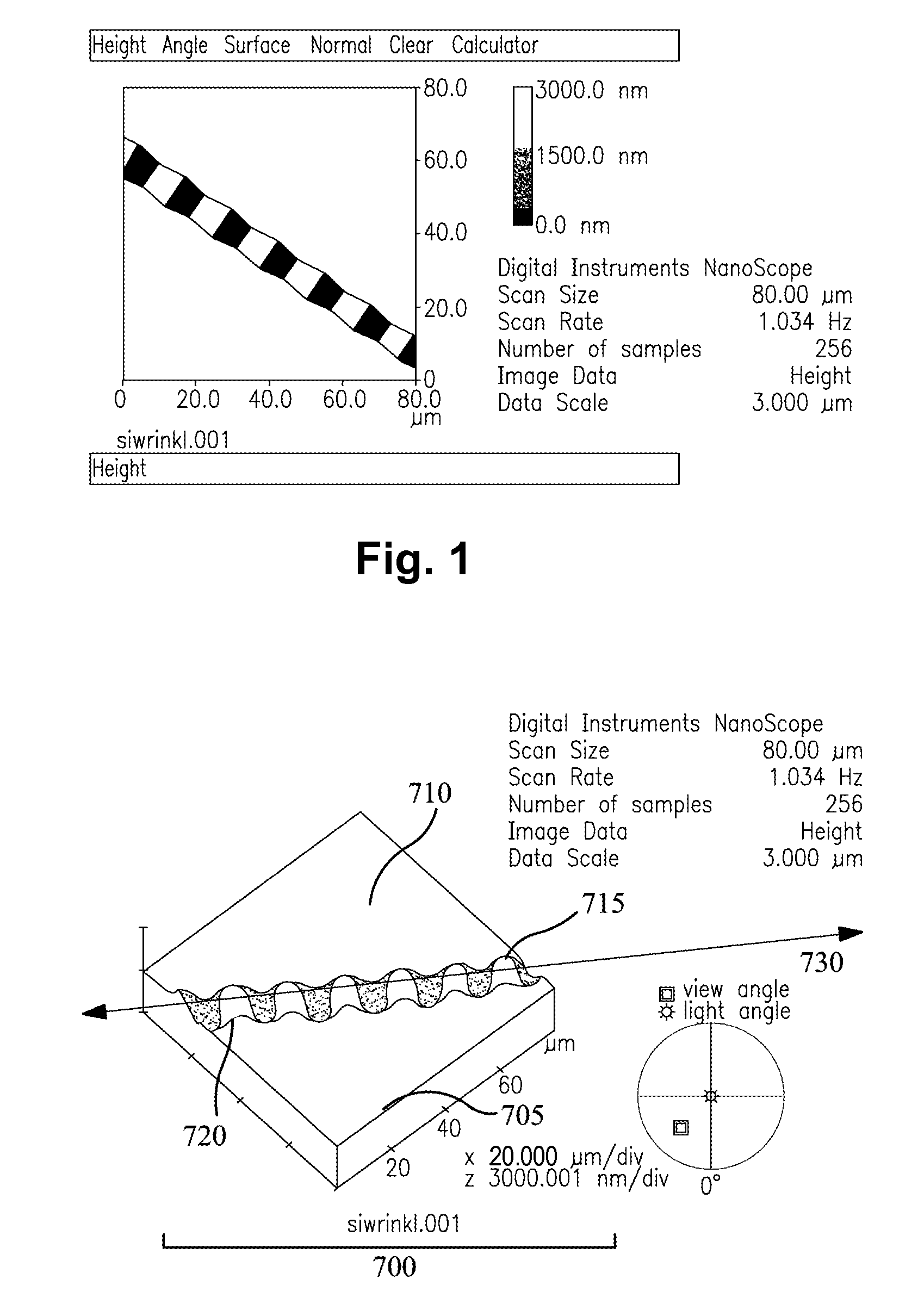

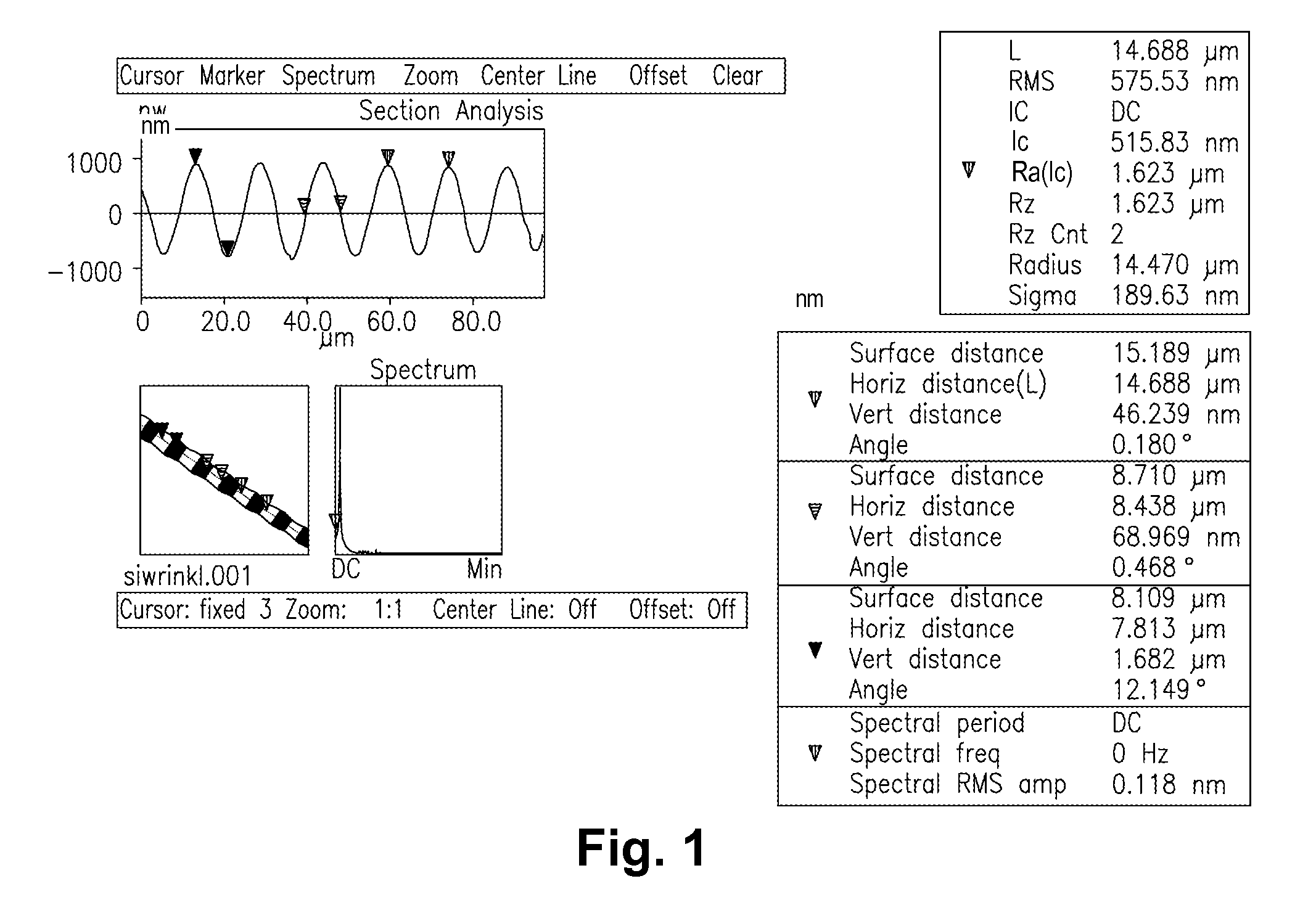

Stretchable form of single crystal silicon for high performance electronics on rubber substrates

ActiveUS7521292B2Large elongationSignificant flexingTransistorCircuit bendability/stretchabilityEngineeringFlexible electronics

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

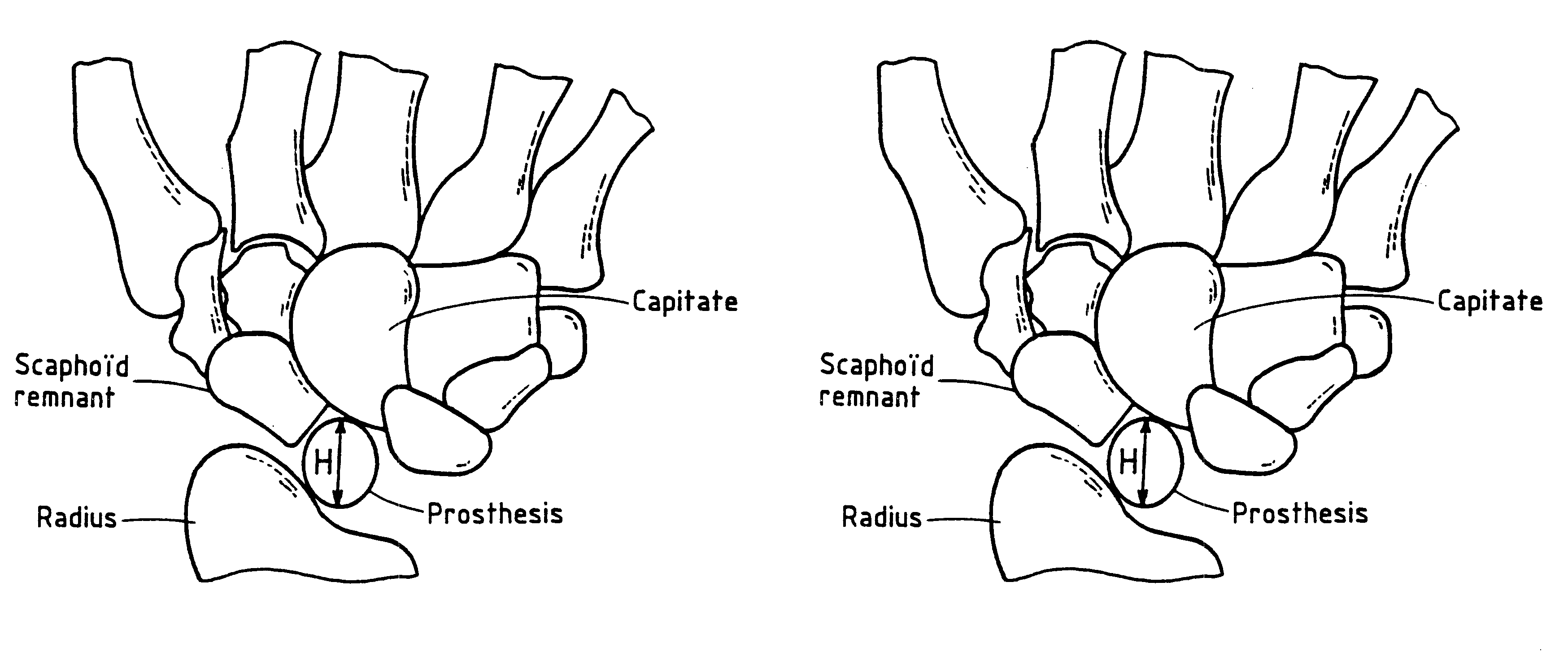

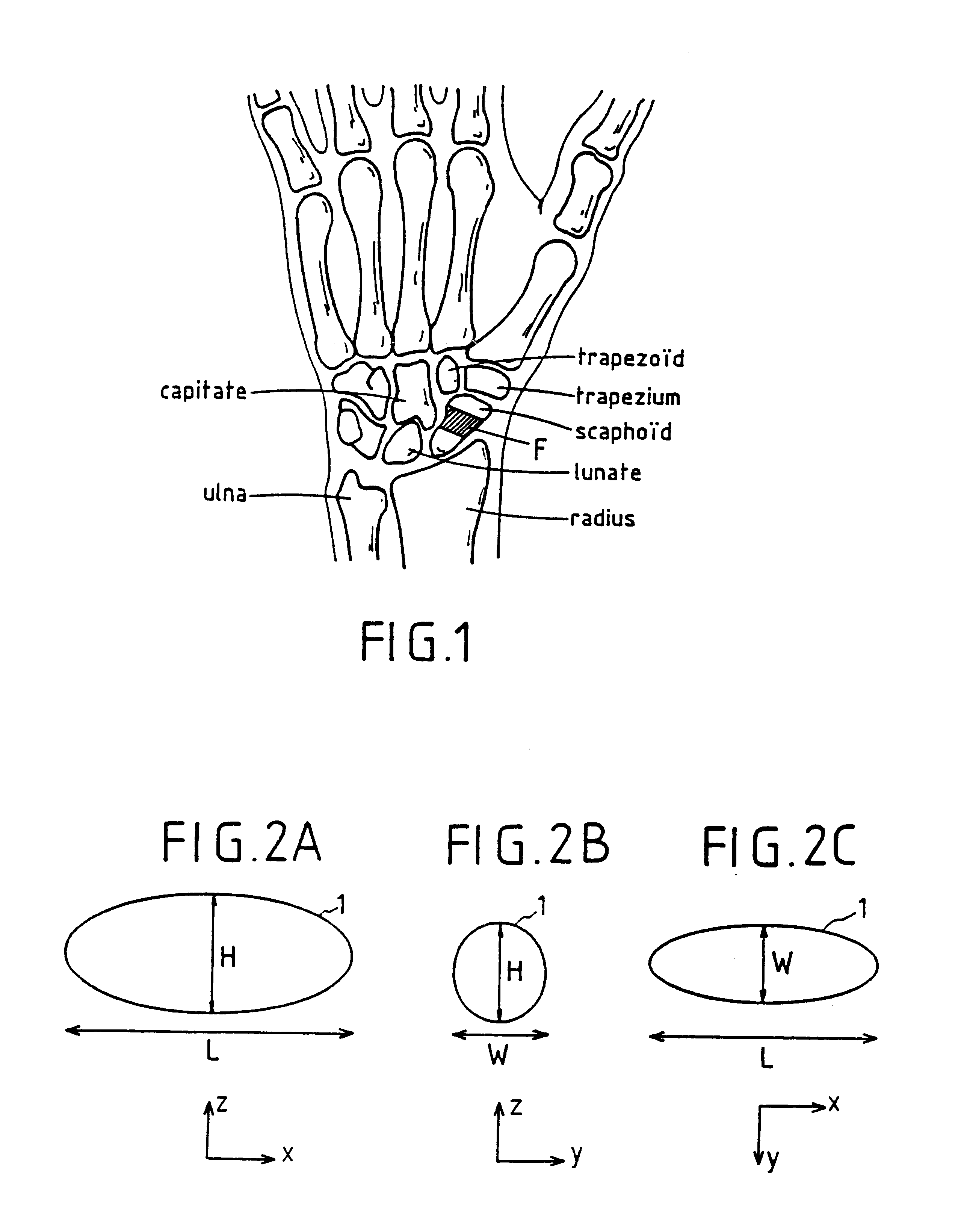

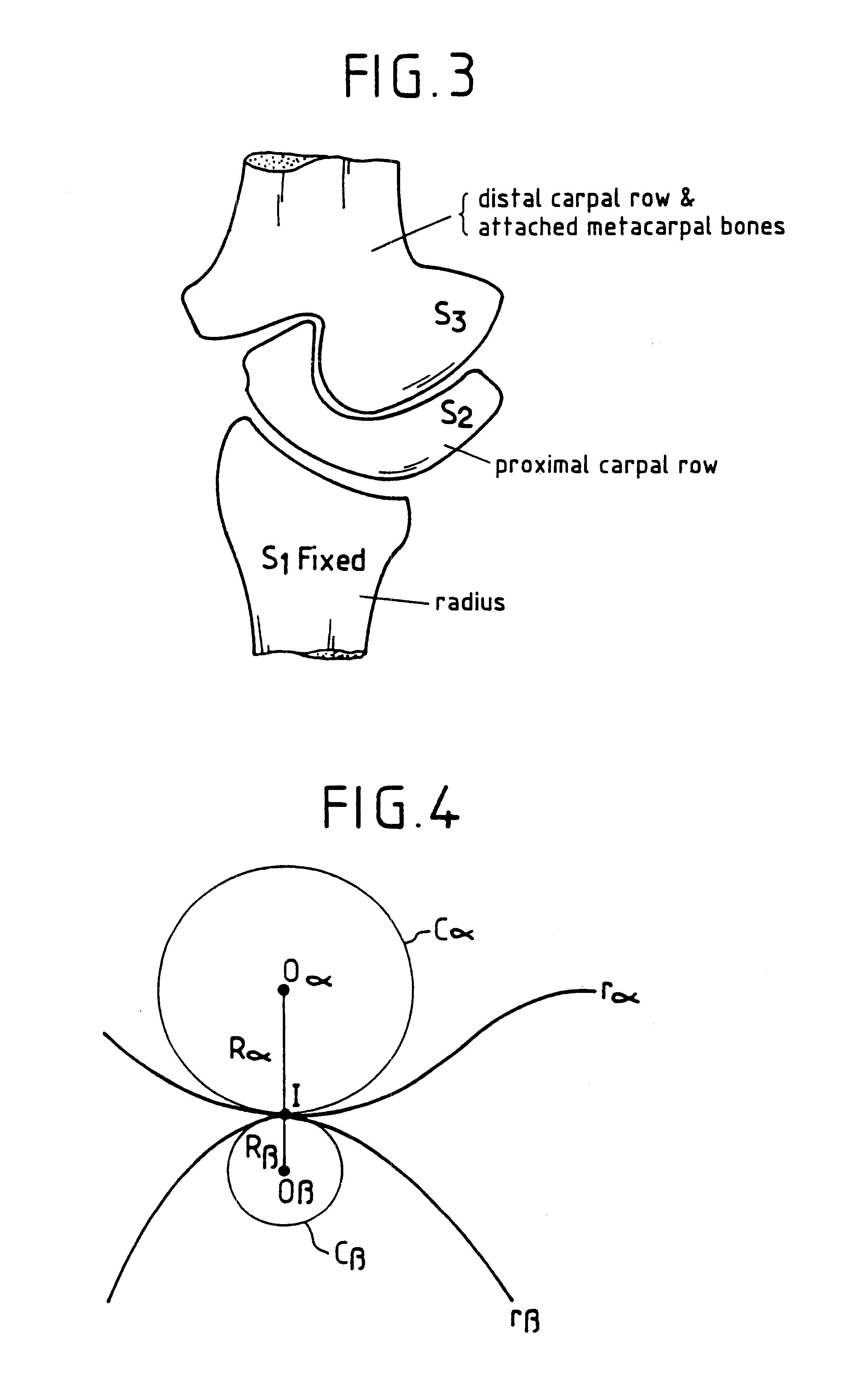

Implant for treating ailments of a joint or a bone

InactiveUS6436146B1Increase coefficient of frictionImprove stabilityFinger jointsWrist jointsDiseasePyrolytic carbon

The implant has at least one contact surface portion, made of pyrolytic carbon, designed to be in mobile contact with at least one bony surface when the implant is implanted in a patient. Furthermore, the implant is free from any attaching means, so that it remains free with respect to the at least one bony surface when implanted in the patient.

Owner:TORNIER SA SAINT ISMIER

Stretchable Form of Single Crystal Silicon for High Performance Electronics on Rubber Substrates

ActiveUS20100059863A1Large elongationSignificant flexingTransistorCircuit bendability/stretchabilityFlexible electronicsSemiconductor

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

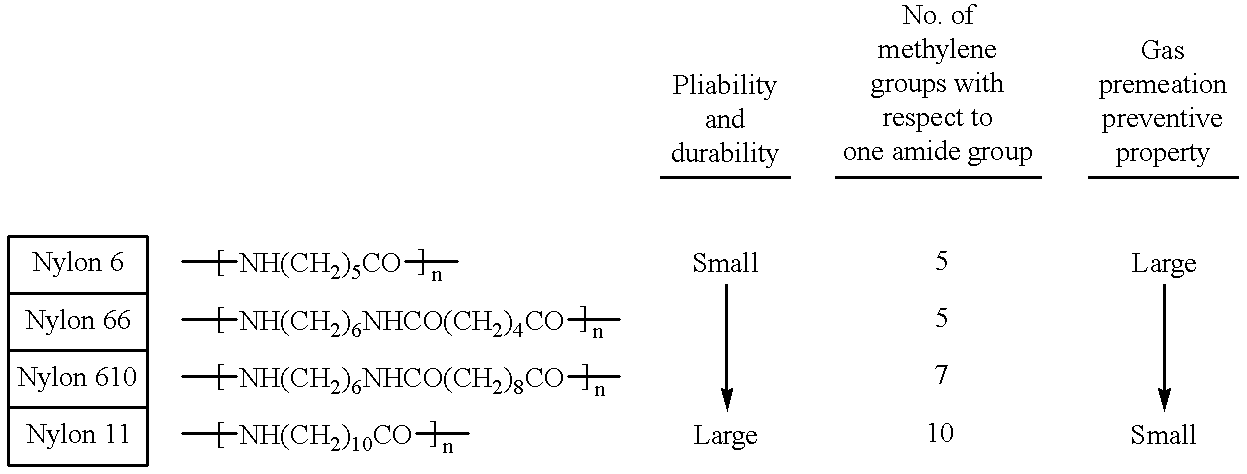

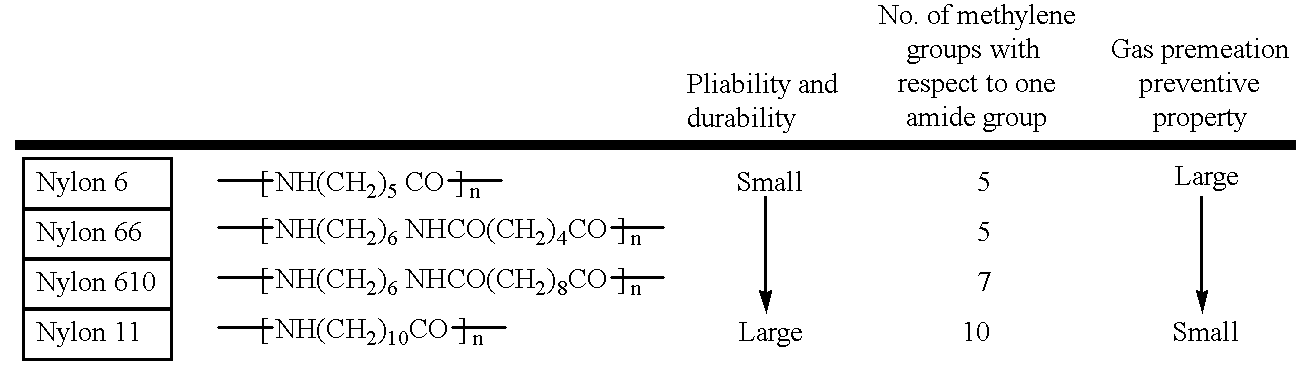

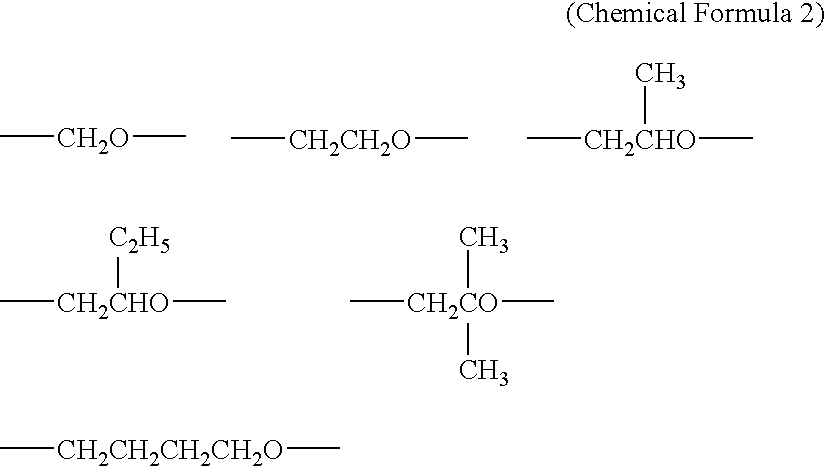

Thermoplastic elastomer composition, process for producing the same, and pneumatic tire and hose made with the same

InactiveUS6359071B1More flexibleLarge elongationSpecial tyresWheelsPolymer scienceThermoplastic elastomer

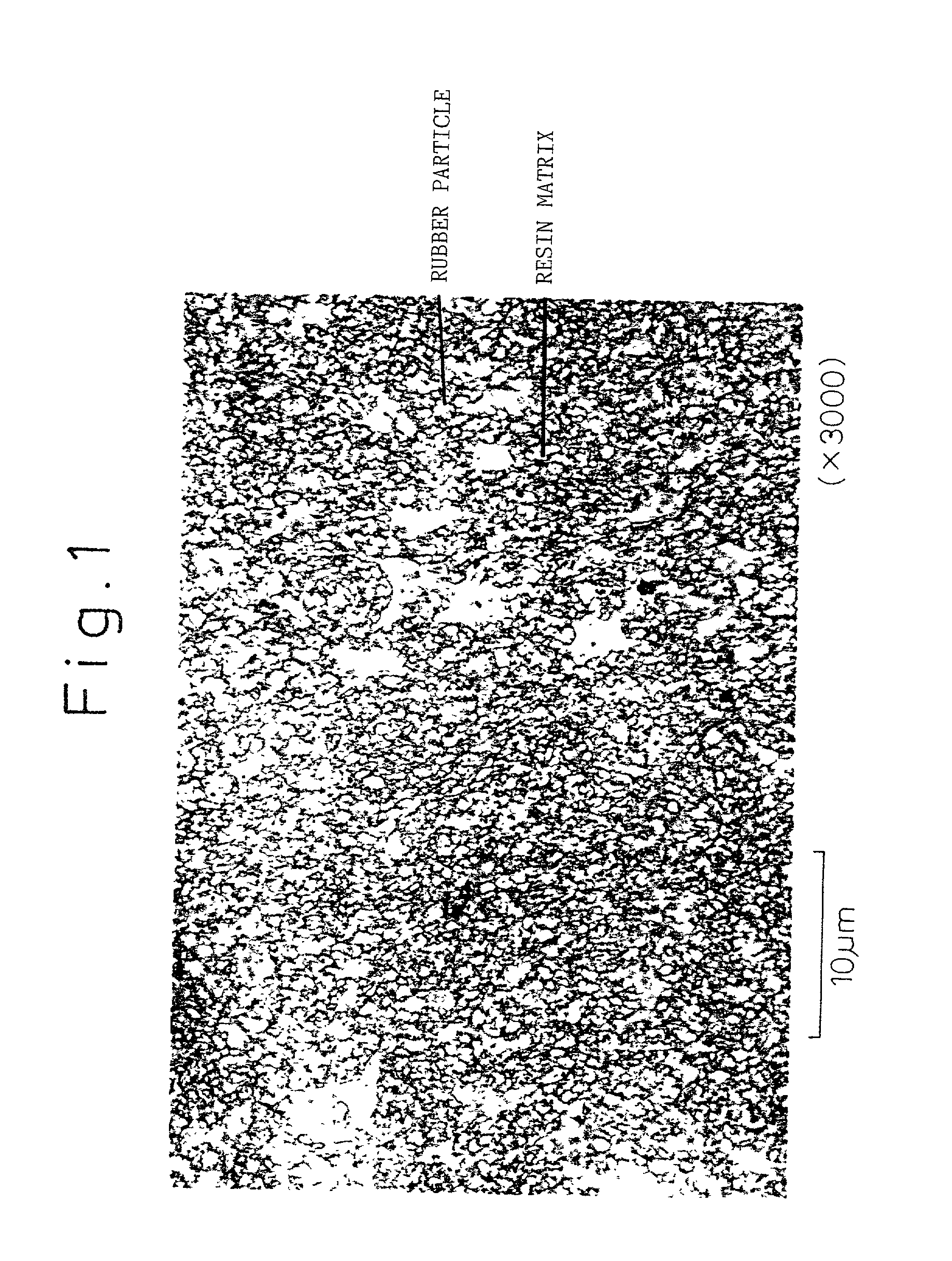

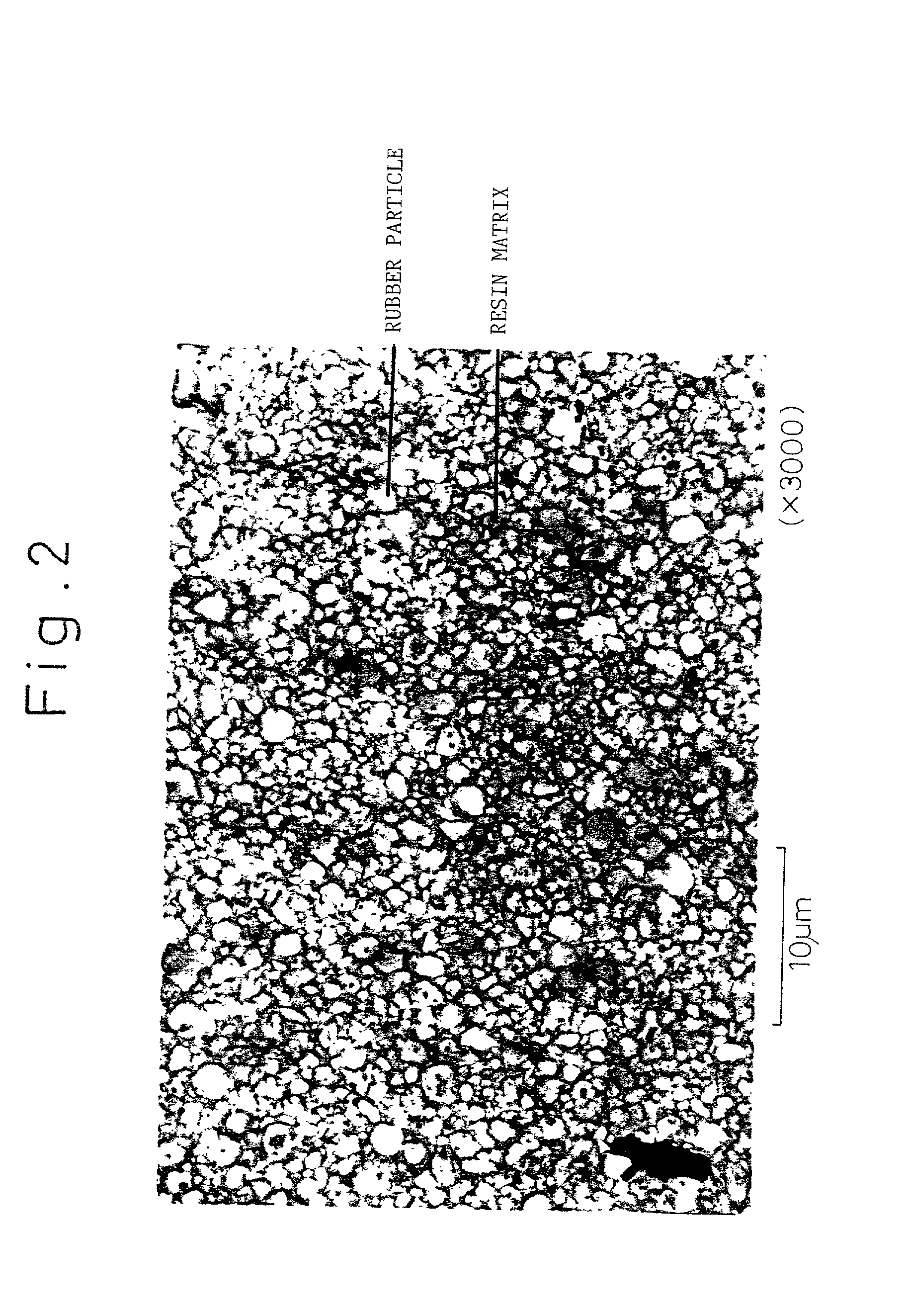

A thermoplastic elastomer composition dynamically vulcanized to a gelation rate of 50 to 95% which is superior in heat resistance and durability while maintaining flexibility and superior in air permeation preventive property which can be efficiently used as, for example, a pneumatic tire as an air permeation preventive layer. In particular, a thermoplastic elastomer composition having a reduced particle size of the domain rubber is produced by a material having a high rubber ratio by mixing a composition (C) mixed under conditions of a ratio of melt viscosities of the rubber composition (A) / resin (B) of 0.8 to 1.2 and the formula (phiA / phiB)x(etaB / etaA)<1.0 under conditions of a ratio of melt viscosities of the rubber composition (D) / composition (C) of 0.8 to 1.2 and the formula (phiD / phiC)x(etaC / etaD)<1.0, wherein phiA: volume fraction of rubber composition (A), phiB: volume fraction of resin (B), etaA: melt viscosity of rubber composition (A), etaB: melt viscosity of resin (B), phiC: volume fraction of composition (C), phiD: volume fraction of rubber composition (D), etaC: melt viscosity of composition (C), etaD: melt viscosity of rubber composition (D).

Owner:THE YOKOHAMA RUBBER CO LTD

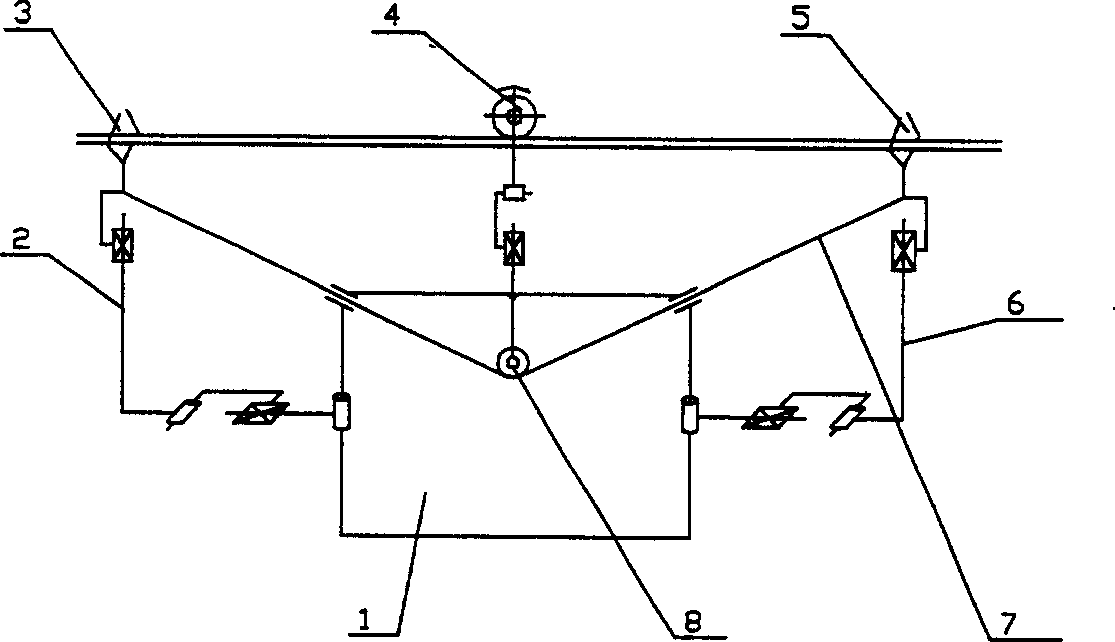

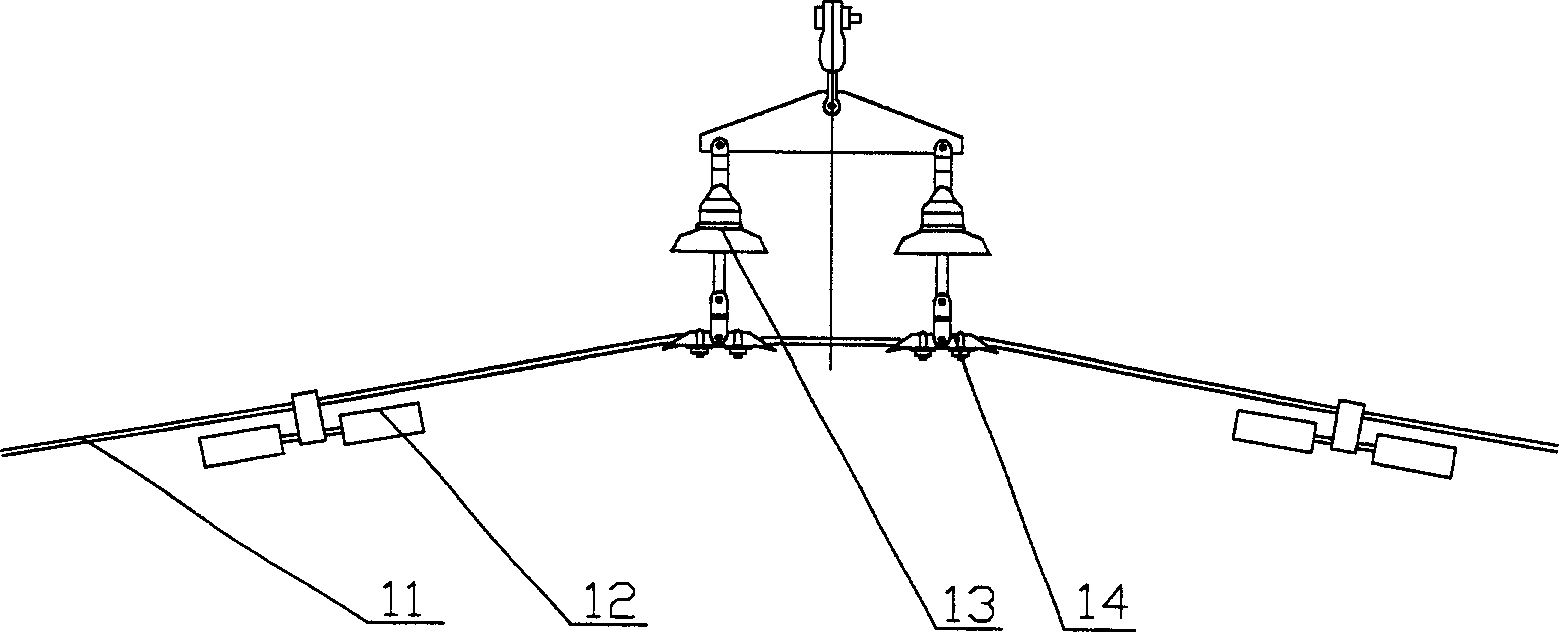

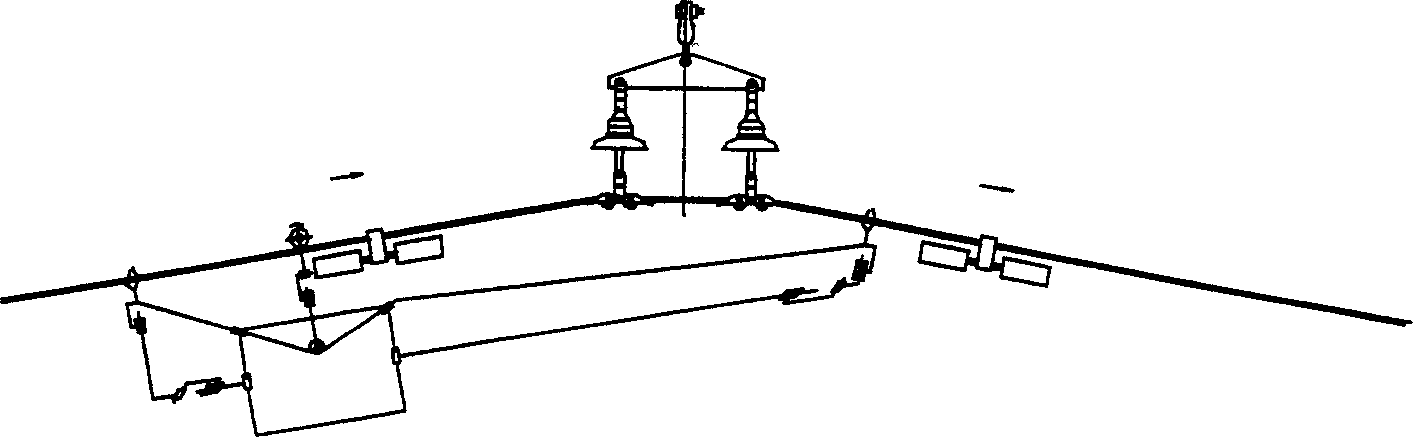

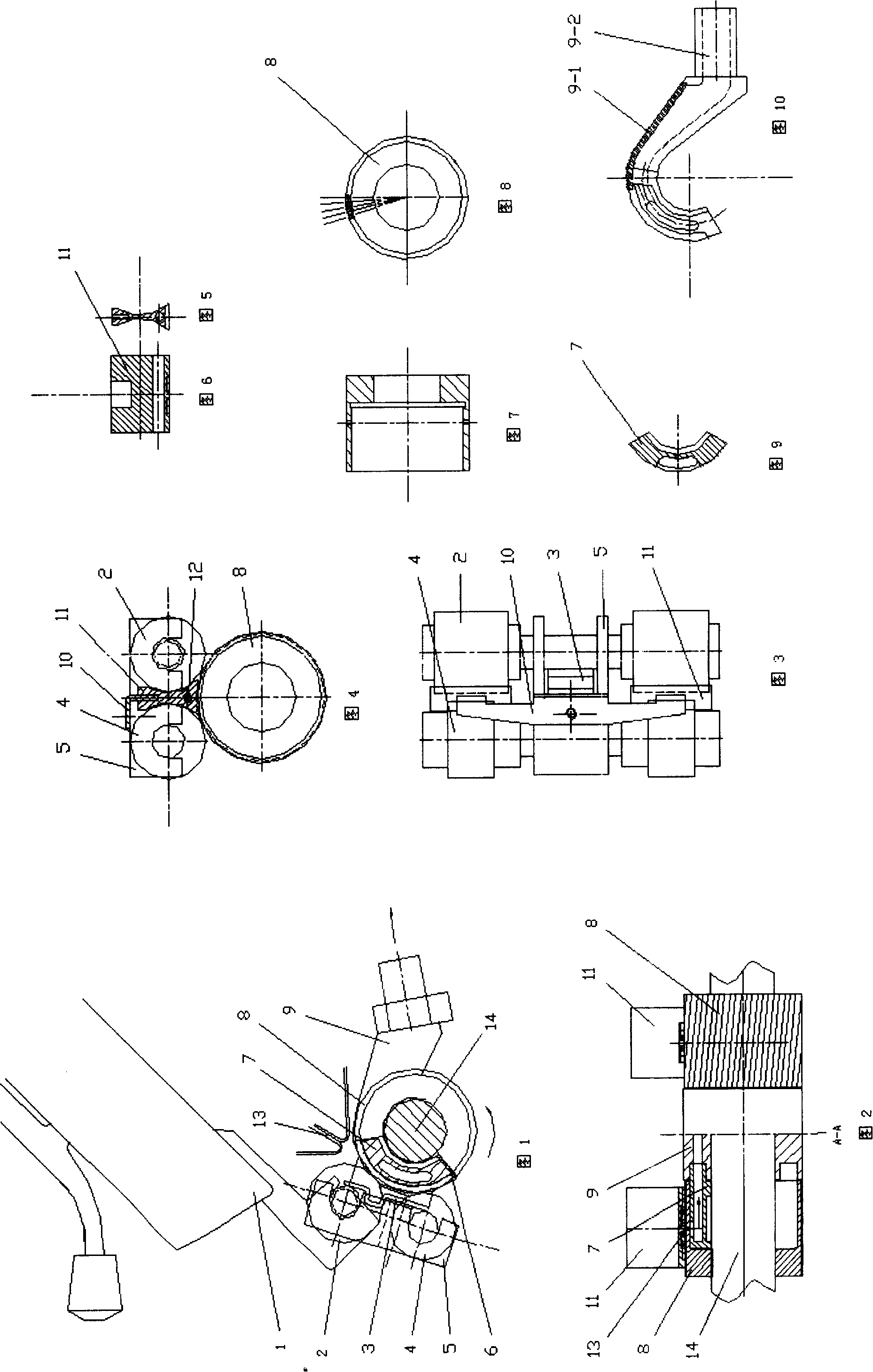

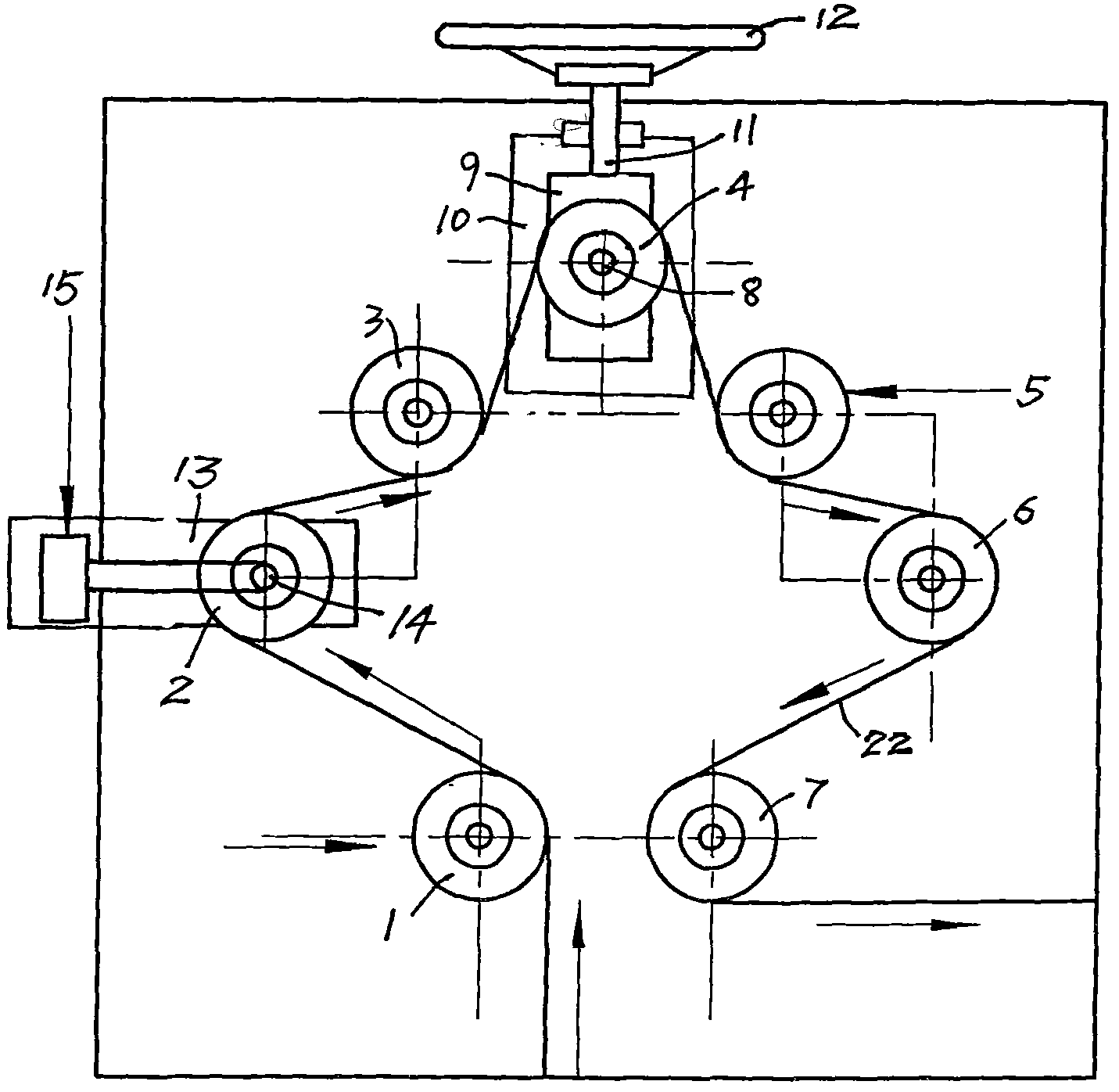

Super-voltage transmission line monitoring and detecting robot mechanism

InactiveCN1689769AEasy to walkConducive to overcoming obstaclesManipulatorMobile vehicleUltra high voltage

The present invention relates to movable robot mechanism, and is especially ultra high voltage power line polling robot mechanism. The polling robot mechanism consists of moving vehicle, back arm and front arm. The moving vehicle consists of vehicle body and walking wheel, the walking wheel is installed onto the vehicle body via horizontal rotation pair and moving pair and grasps the wire, and the vehicle body is connected via the rotation pair to the front arm and the back arm. The arm has hand claw in the end, the front arm and the back arm have the same structure, and each of the front arm and the back arm consists of two parts, upper arm and lower arm. The upper arm as one combined structure of link rod, ball lead screw and block is connected via horizontal rotation pair to the lower arm; and the lower arm is one great stroke telescopic mechanism. The present invention has great work space, light weight, low power consumption and powerful obstruction crossing capacity.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

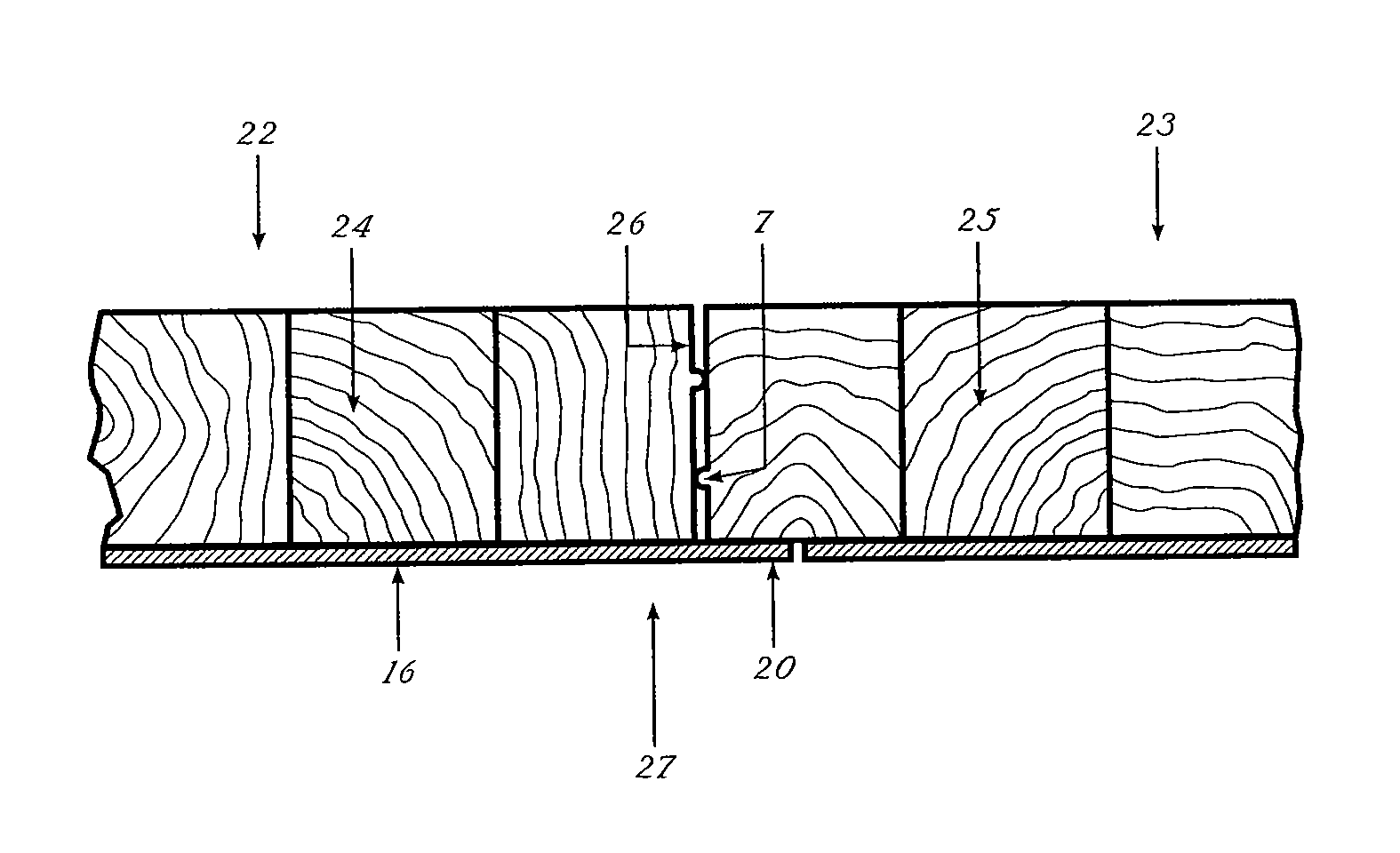

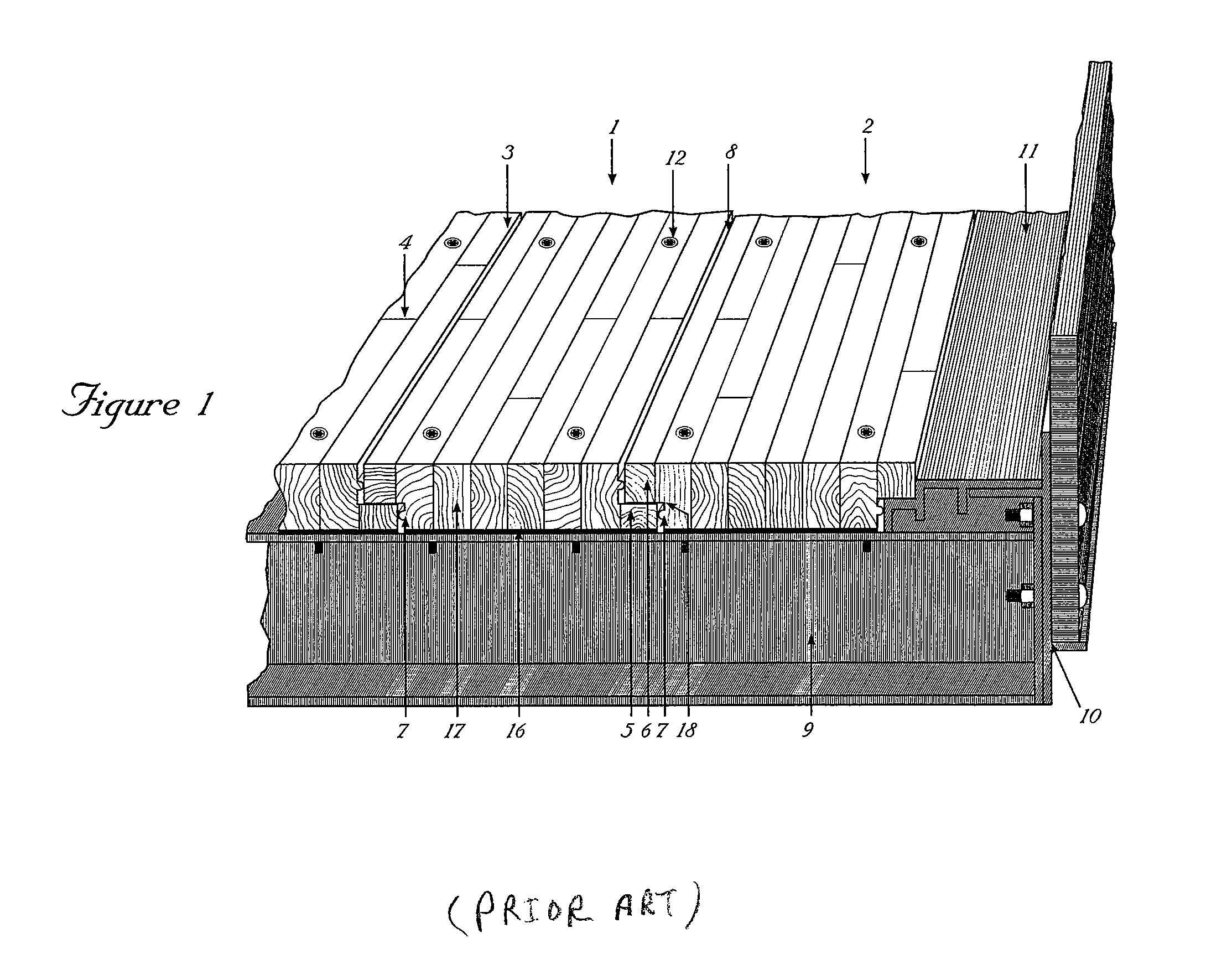

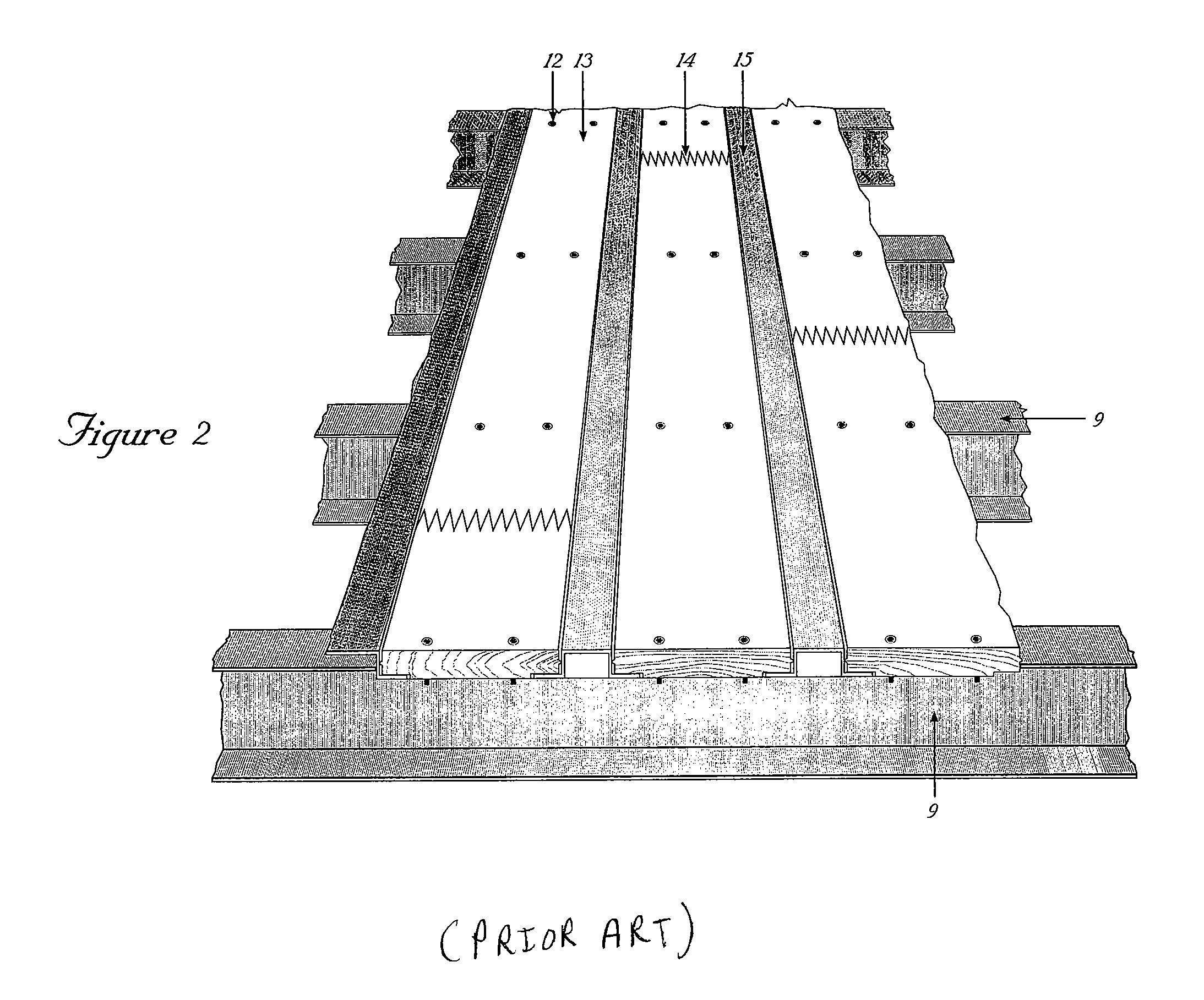

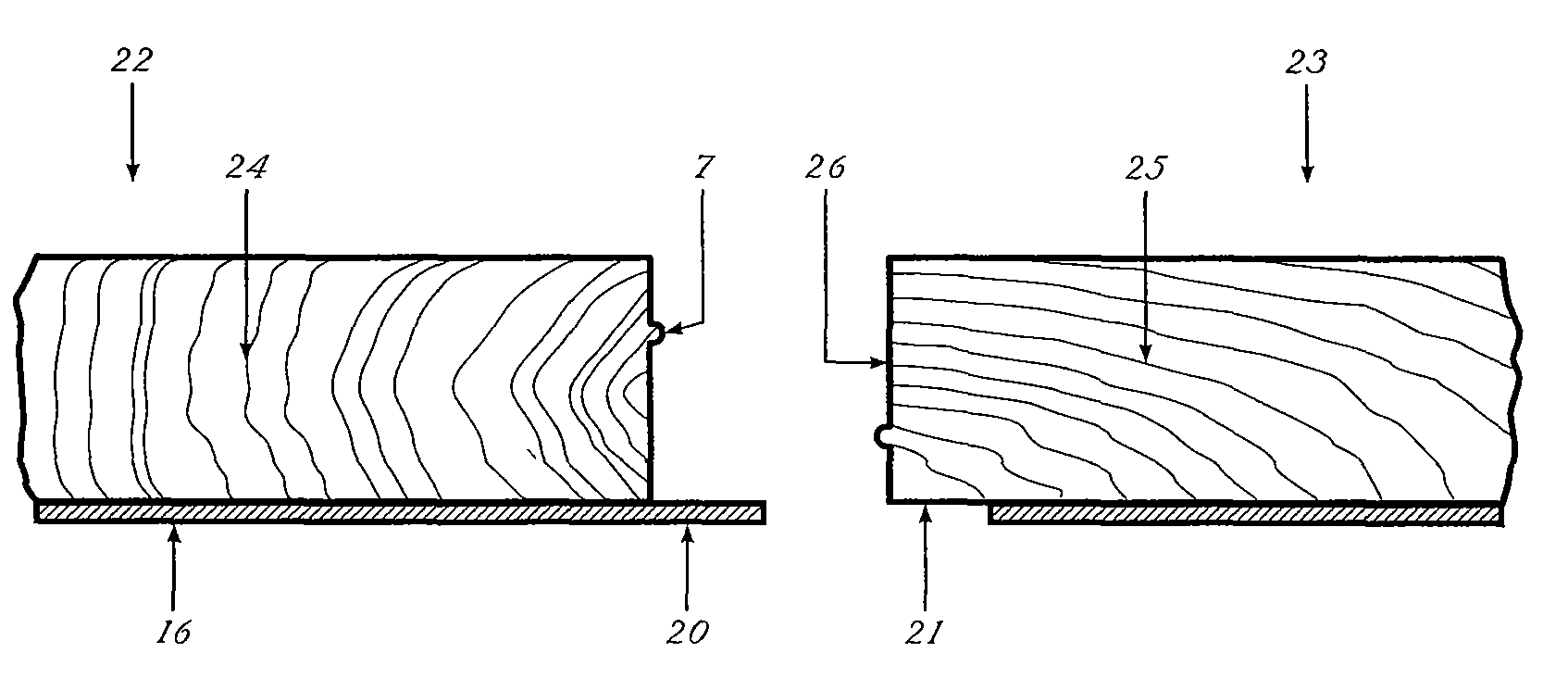

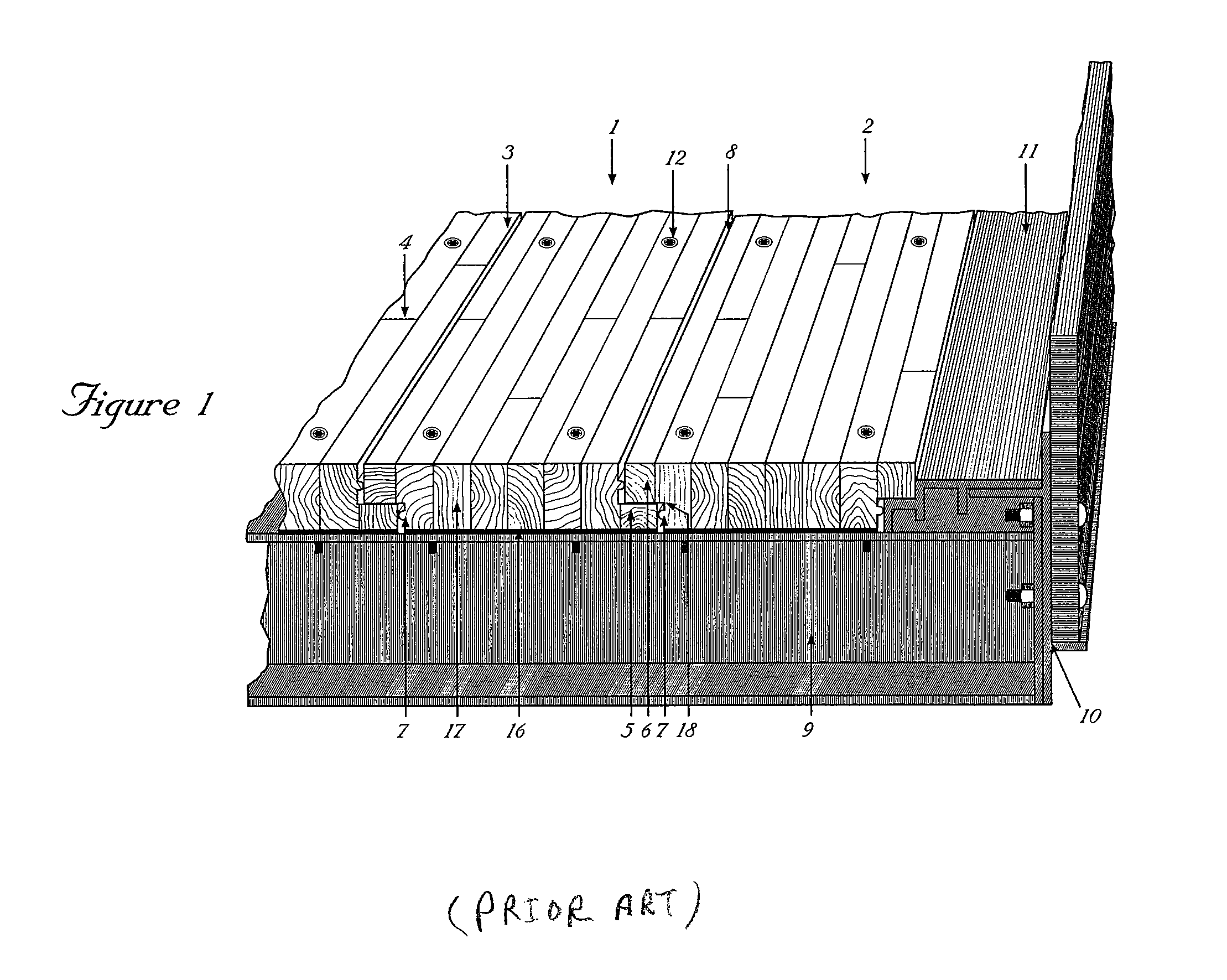

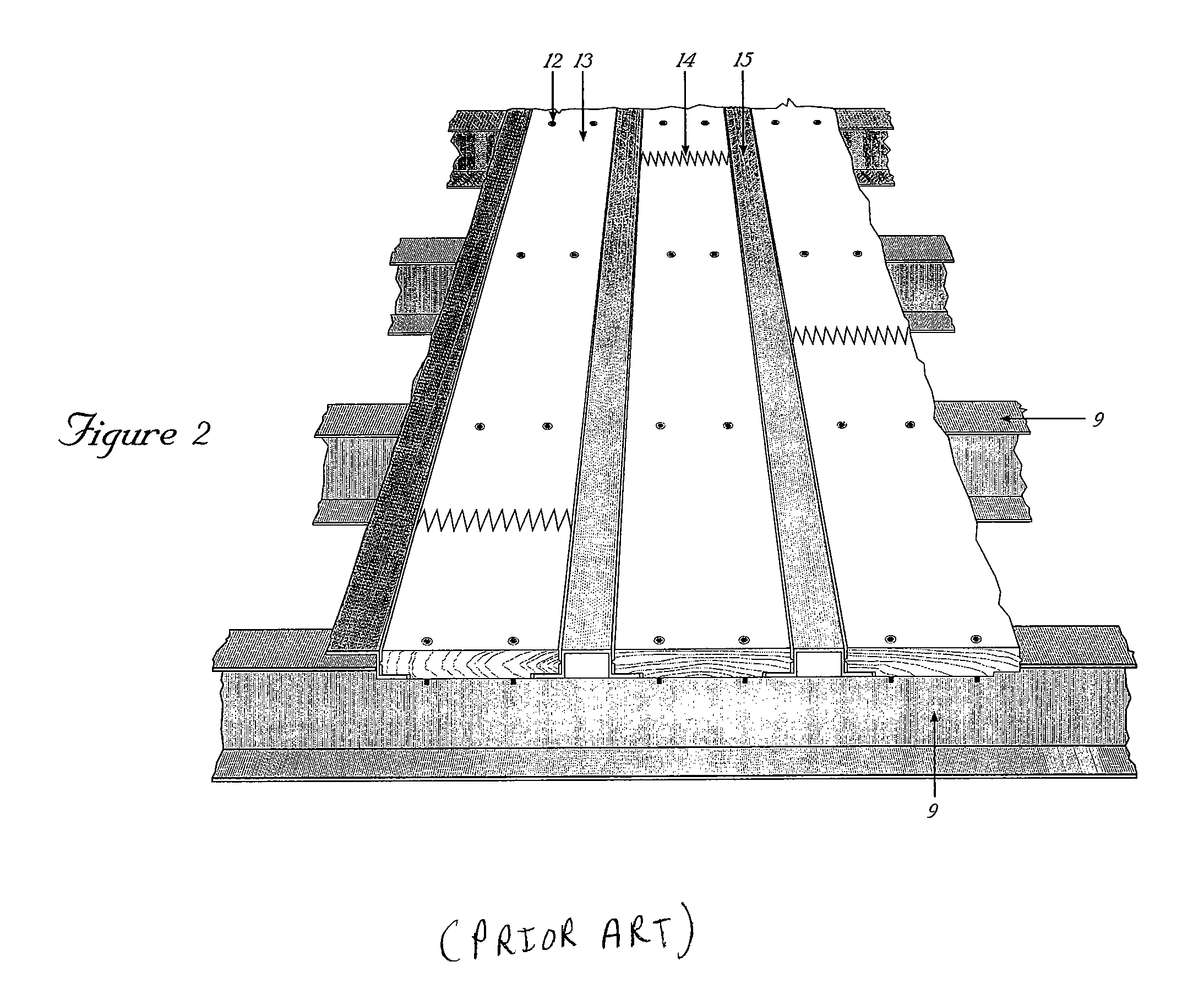

Fleixible composite lap joint for trailer flooring

A composite lap joint for the assembly of a first and a second floor board from a plurality of boards, used to make the floor for a vehicular trailer, each board composed of a layer of wood at the top side and a layer of fiber reinforced composite at the bottom side, wherein the composite layer is at least partly bonded to the wood layer; the composite layer of a first board forming a lip, wherein the lip is a lateral extension of the composite layer and the lip is disposed under the bottom side recess of an adjacent second board to form a composite joint, whereby the joint provides improved flexibility, moisture sealing ability at the seam of the joint and higher strength to the edges of the boards.

Owner:HAVCO WOOD PRODS

Flexible composite lap joint for trailer flooring

A composite lap joint for the assembly of a first and a second floor board from a plurality of boards, used to make the floor for a vehicular trailer, each board composed of a layer of wood at the top side and a layer of fiber reinforced composite at the bottom side, wherein the composite layer is at least partly bonded to the wood layer; the composite layer of a first board forming a lip, wherein the lip is a lateral extension of the composite layer and the lip is disposed under the bottom side recess of an adjacent second board to form a composite joint, whereby the joint provides improved flexibility, moisture sealing ability at the seam of the joint and higher strength to the edges of the boards.

Owner:HAVCO WOOD PRODS

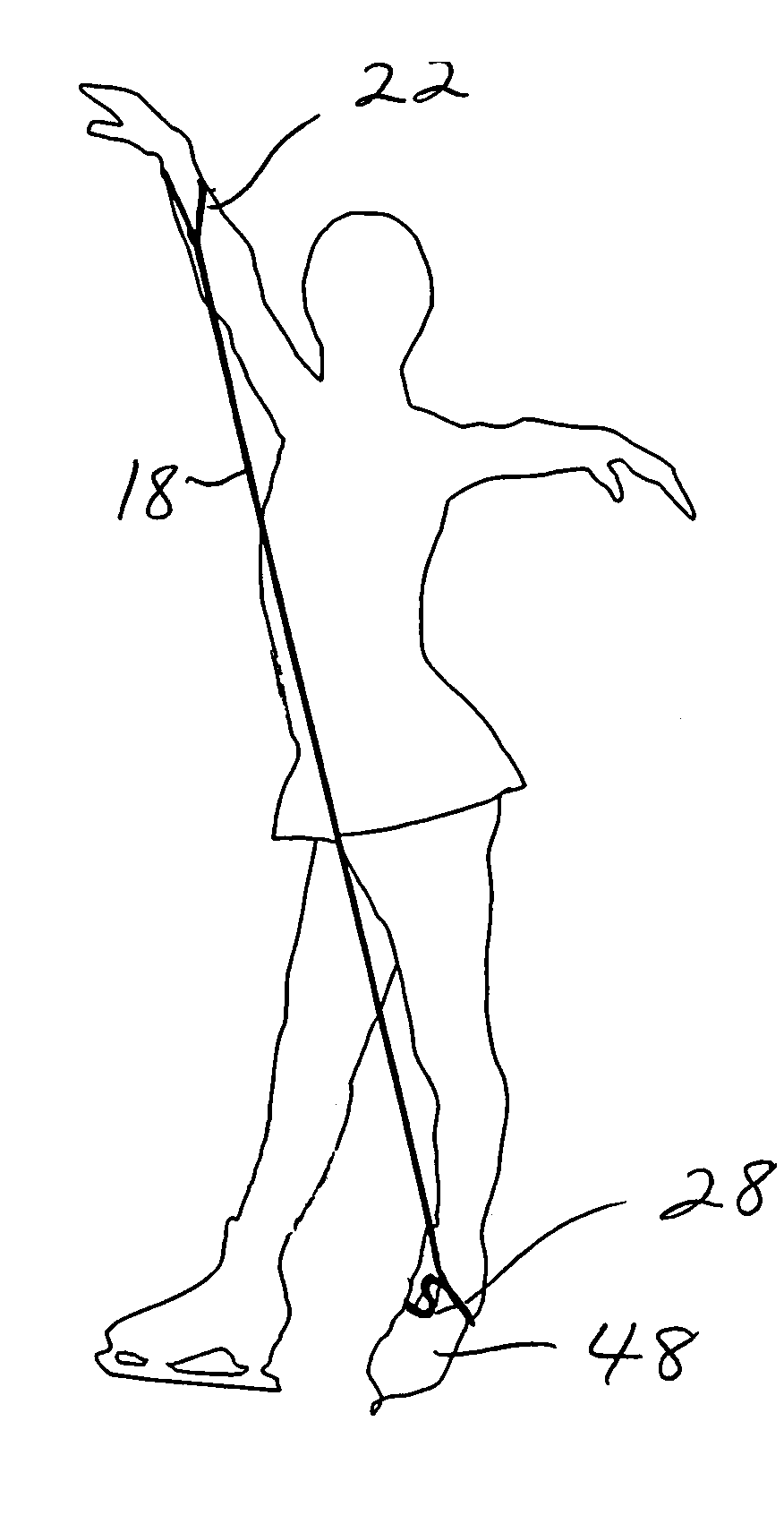

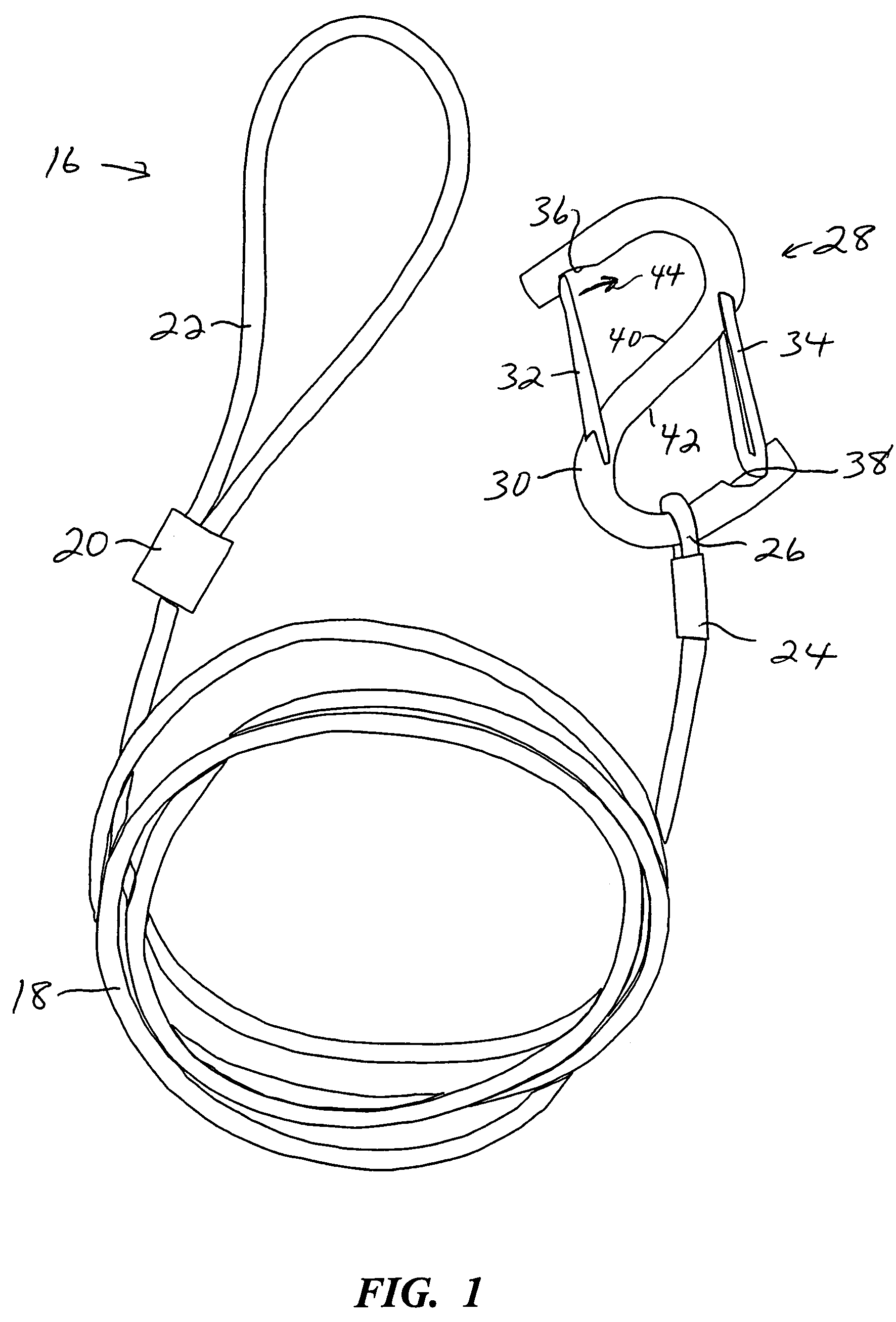

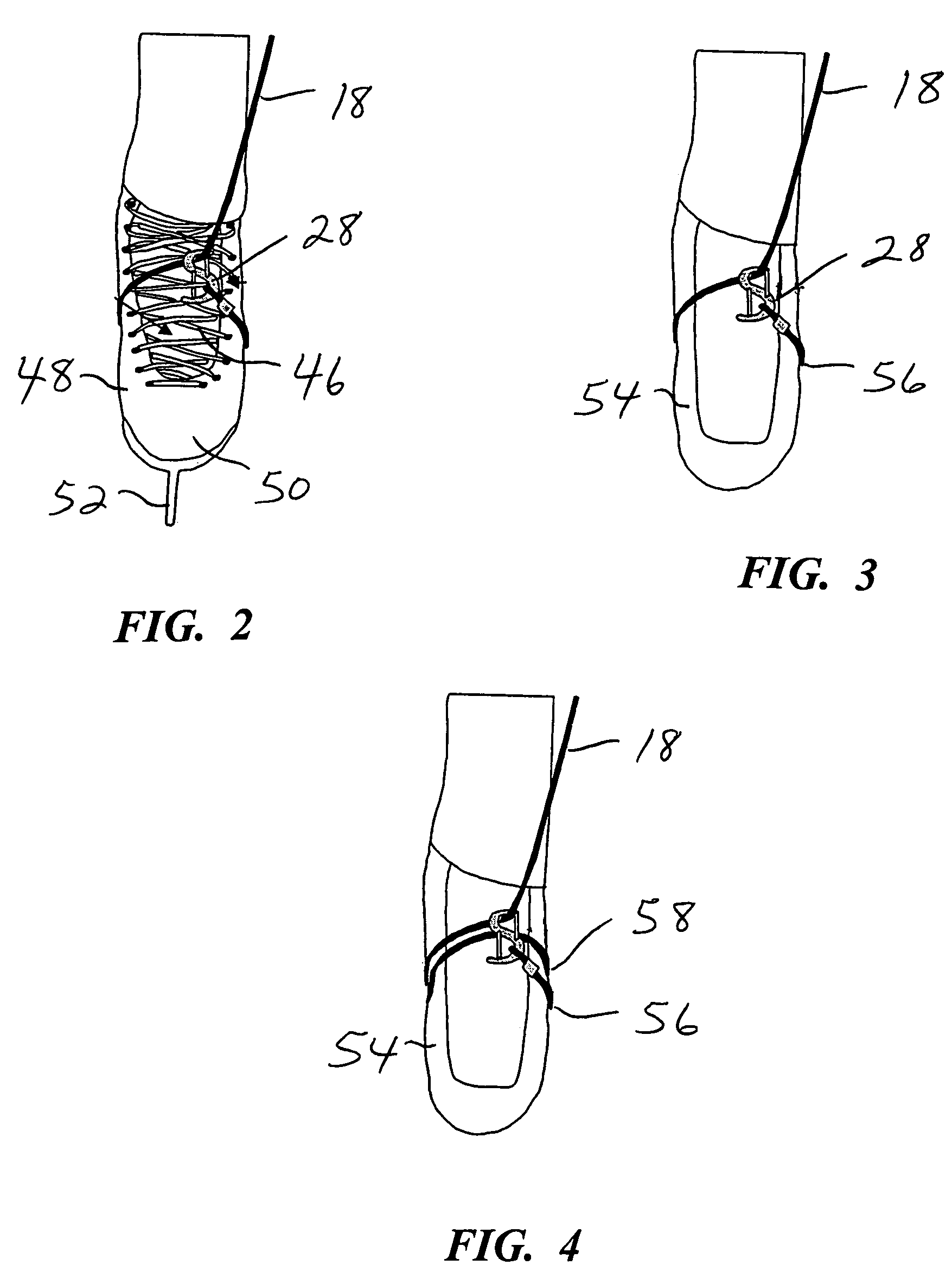

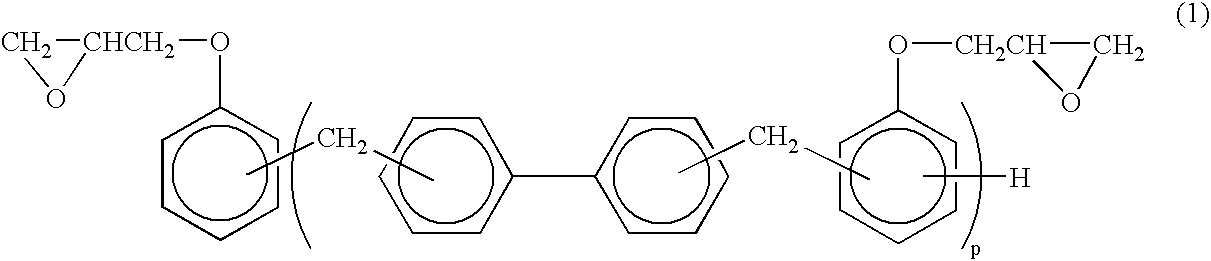

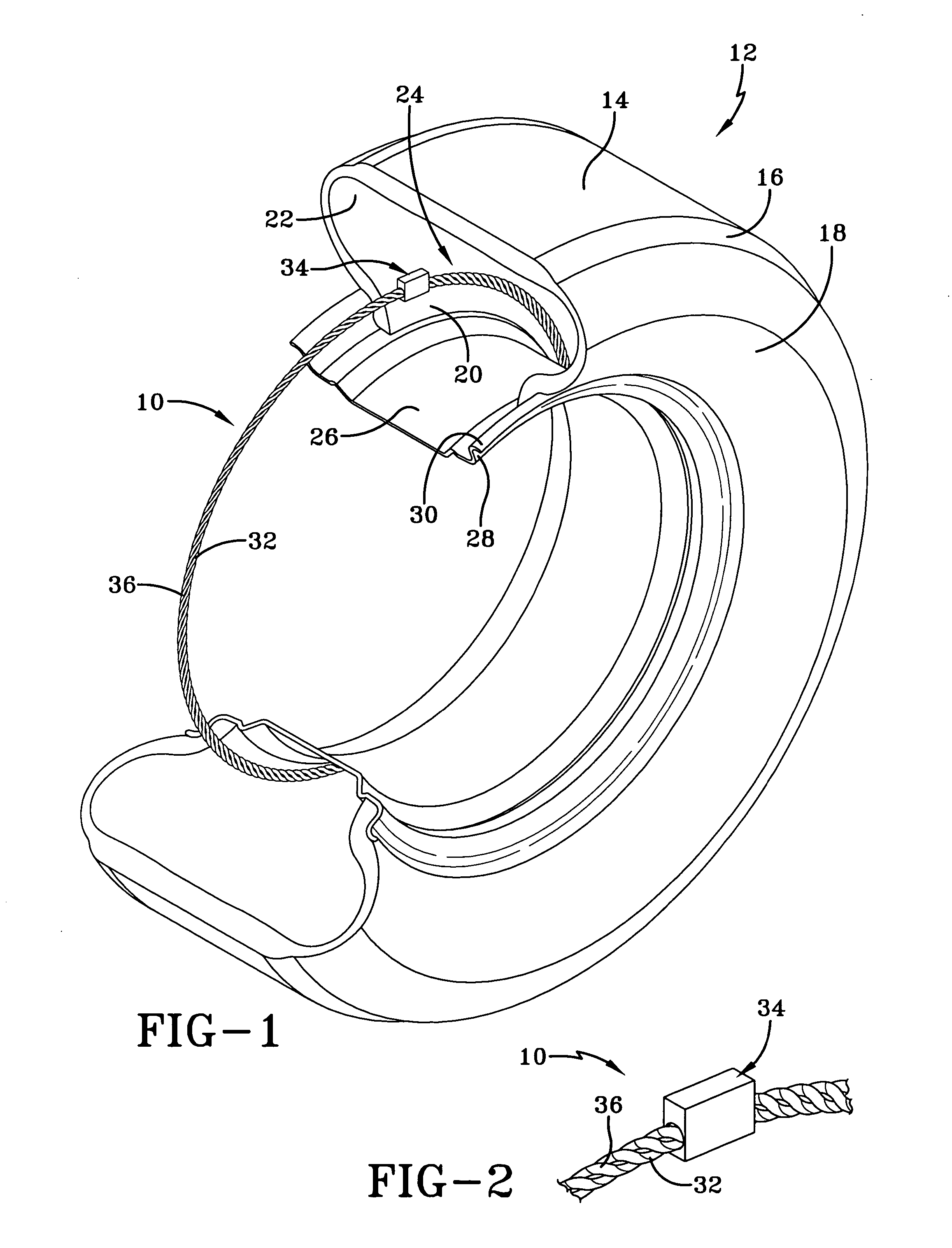

Athletic training device

ActiveUS7214171B2Minimal impactPrecise positioningResilient force resistorsPull forceAthletic training

A training device for figure skaters and other athletes includes an elongate bungee-type cord, and a clipping mechanism with two normally closed loops secured to one end of the cord. At the other end, the cord is secured to itself to form a loop designed to accommodate the user's wrist. With the loop on the wrist and with the other end of the cord secured to the skate or other footwear by the clipping mechanism, the user practices gliding, spinning, twisting, or jumping maneuvers. The elasticity of the cord is selected to provide a gentle tensile force that guides the relative positioning of the linked hand and foot as the maneuvers are performed, to positively reinforce the correct positioning for the maneuvers.

Owner:SHEILA THELEN

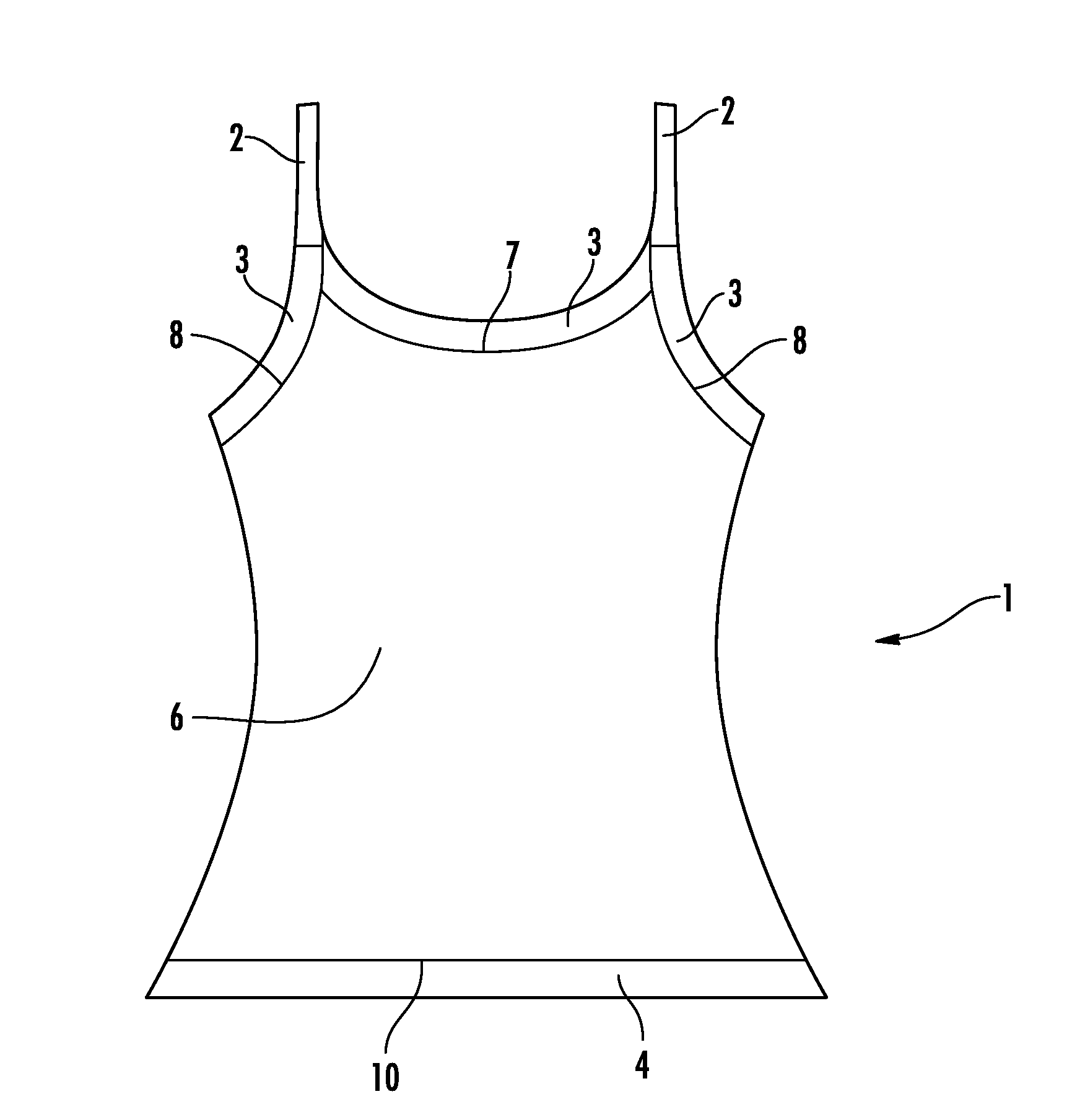

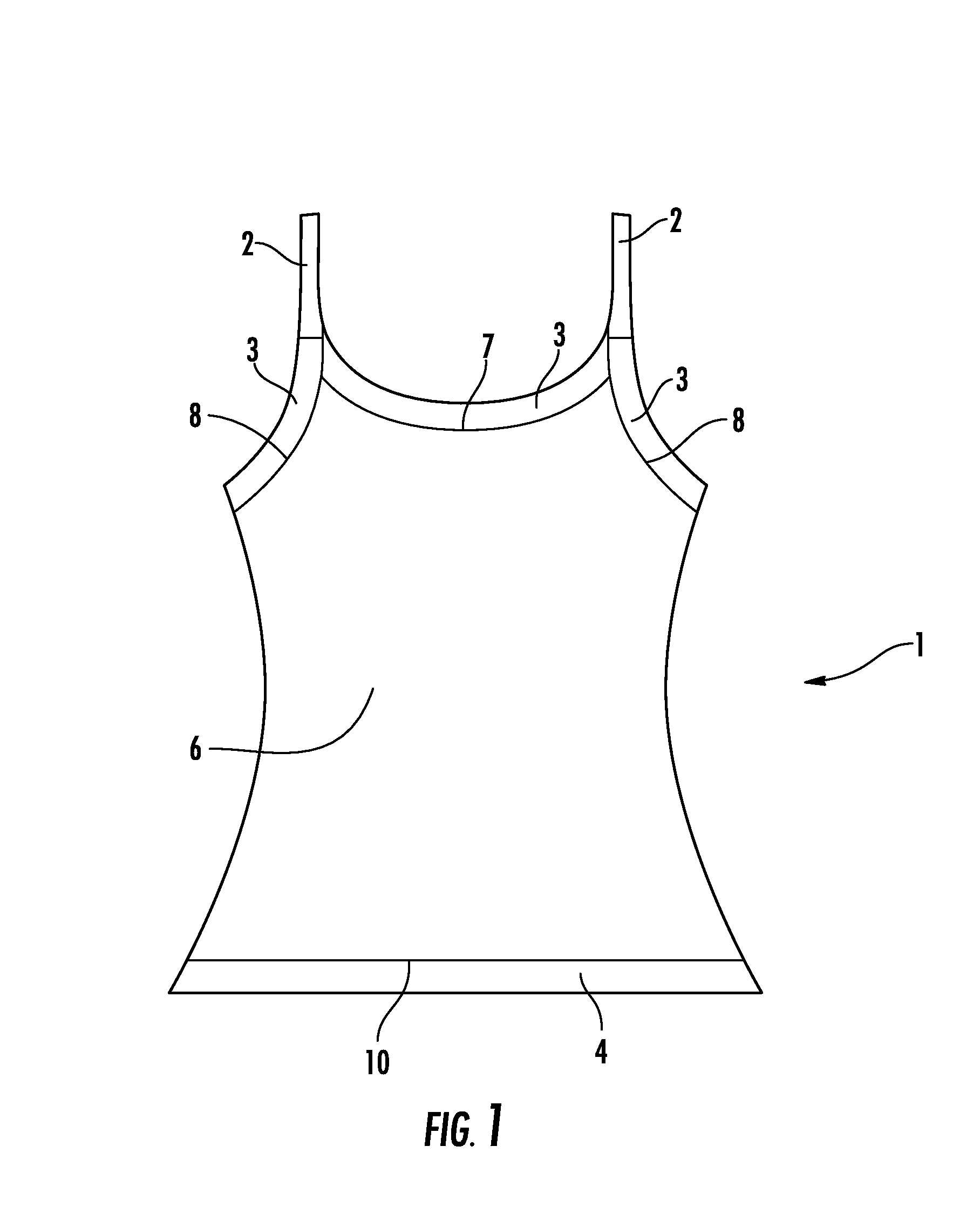

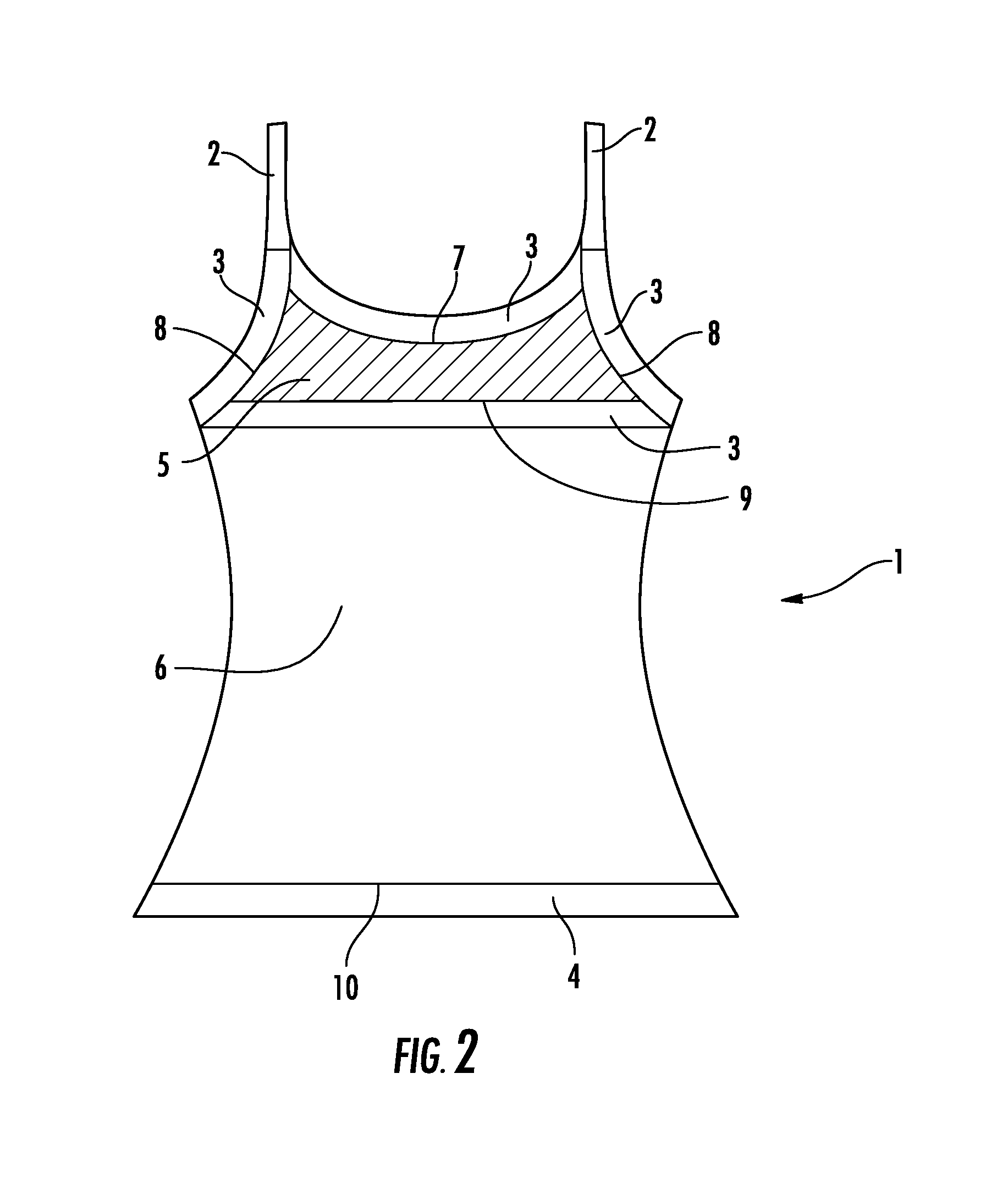

Self-adjusting shapewear garment

The present invention relates generally to a garment made from a stretchable fabric with a high yield strain and low hysteresis so that the garment is capable of stretching to comfortably fit and provide support for the unique shapes and curves of wearers within a single size group and across multiple size groups. More specifically, the claimed invention relates to shapewear. A shapewear garment constructed in accordance with the present invention could be made in a first standard size and comfortably flex and self-adjust to fit wearers across sizes extra-small (XS), small (S), and medium (M); and in a second standard size and comfortable flex and self-adjust to fit wearers across sizes large (L), extra-large (XL), and double extra-large (XXL); and the garment would retain its original dimensions when the force exerted on the garment by the wearer's body is removed.

Owner:MAIDENFORM

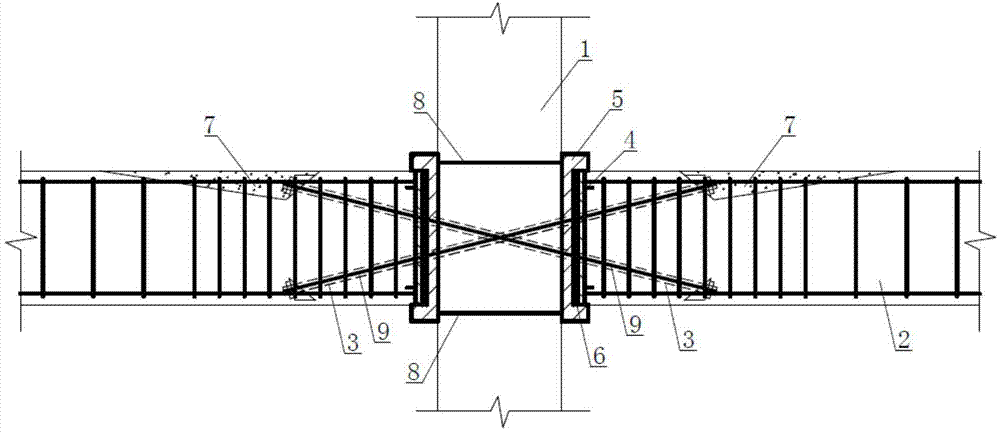

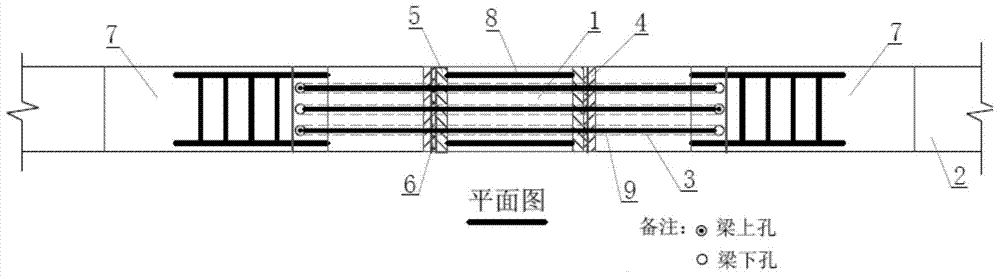

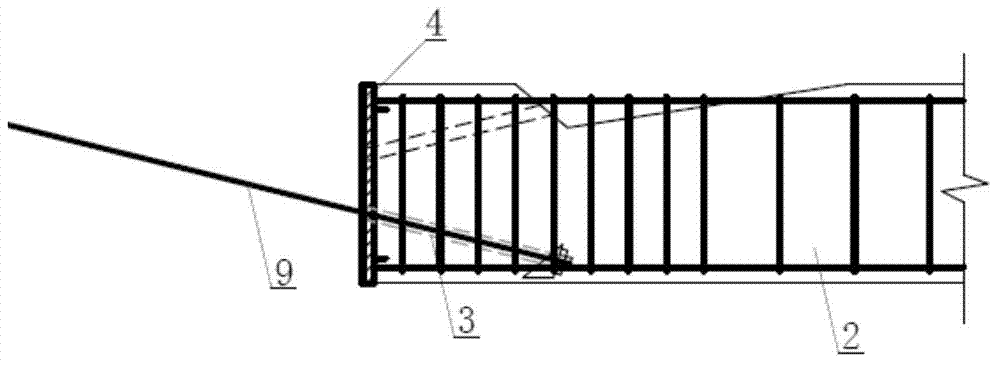

Prestress assembled concrete beam column joint structure and construction method thereof

InactiveCN104727441AArrangement length is shortSmall loss of prestressBuilding constructionsPre stressConcrete beams

The invention relates to a prestress assembled concrete beam column joint structure and a construction method thereof. The prestress assembled concrete beam column joint structure comprises a prefabricated column and a prefabricated beam. The prefabricated beam and the prefabricated column are in prepressing connection through the prestress formed by tensioning prestressed reinforced steel bars. The bottom of the beam end on one side of a joint is connected with the top of the beam end on the other side of the joint through the prestressed reinforced steel bars, and the prestressed reinforced steel bars are symmetrically crossed on a vertical face. When the prefabricated beam is manufactured, the prestressed reinforced steel bars and anchoring parts of the prestressed reinforced steel bars are pre-buried at the bottom of the beam end, prestressed reinforced steel bar pore channels and an anchoring area are reserved in the top of the beam end, and open type stirrups are adopted in the anchoring area. A force transmission steel plate is arranged on the cross section part of the beam end by the way that the cross section part of the beam end is welded with longitudinal bars. Slant prestressed reinforced steel bar pore channels are reserved in a prefabricated column joint area, groove-shaped steel plates are pre-buried on the two sides of the joint of the column, and high damping rubber layers are attached to the insides of the groove-shaped steel plates. In the connecting process, the beam is clamped into channel steel, and the prestressed reinforced steel bars penetrate through a joint core area to the top of the beam end on the other side of the joint and are anchored after being tensioned to be at the designed stress. According to the prestress assembled concrete beam column joint structure and the construction method thereof, assembling construction is convenient, and high shear-bearing capacity, energy-dissipating capacity and self-resetting capacity of the connecting joint can be achieved.

Owner:WUHAN UNIV OF TECH

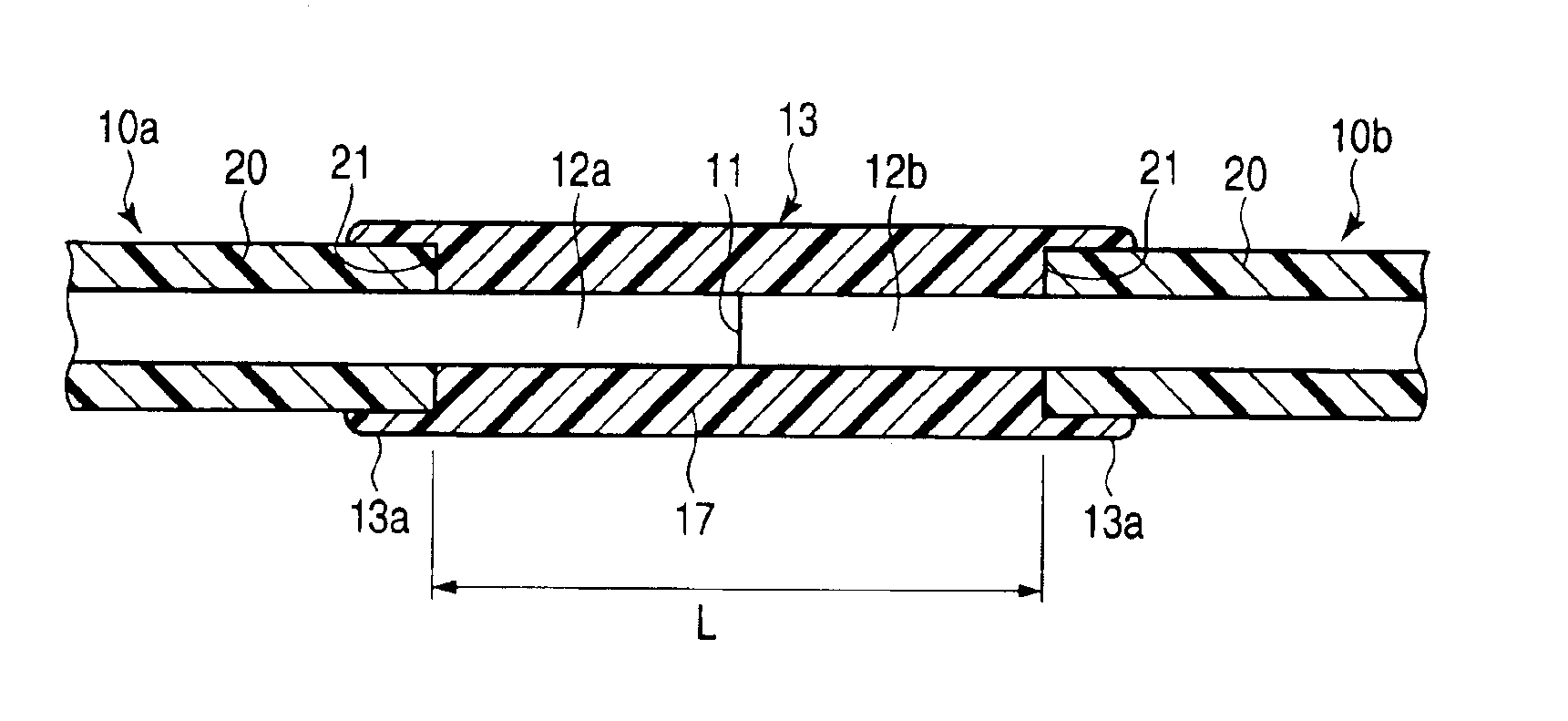

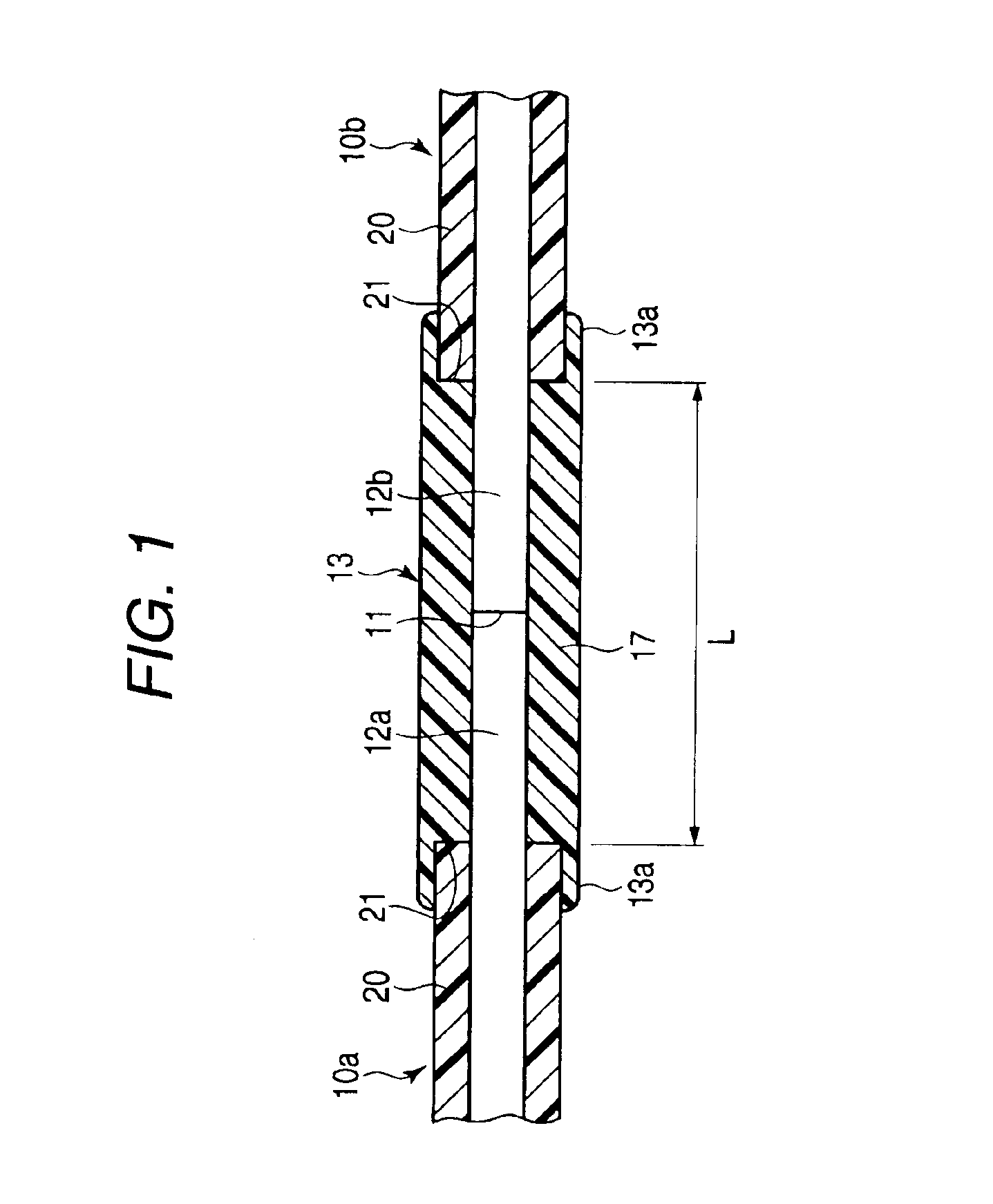

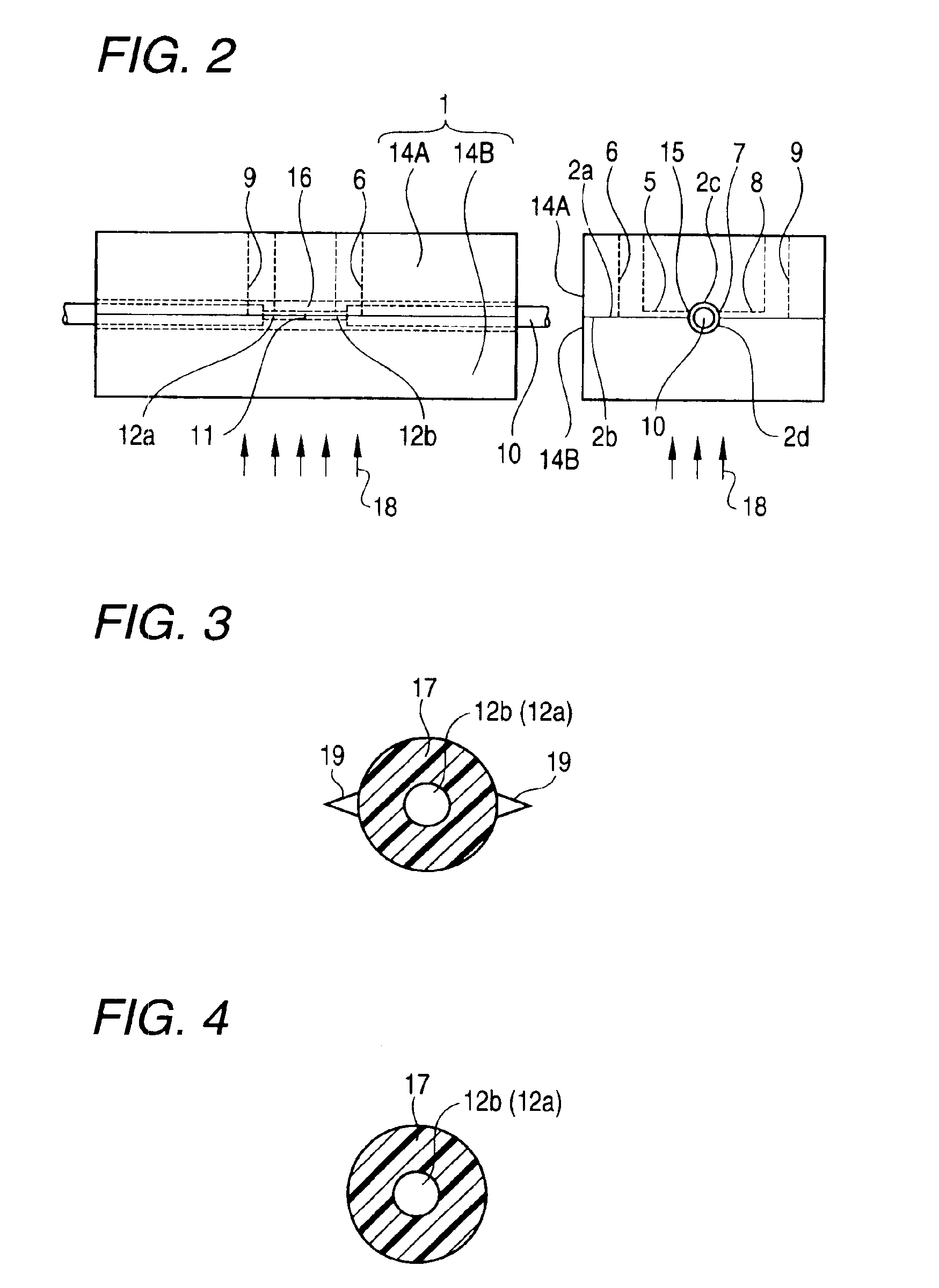

Method for molding optical fiber fusion spliced portion and optical fiber with molded fusion spliced portion

InactiveUS6908236B2Large elongationHigh tensile strengthCladded optical fibreOptical articlesBare fiberOptoelectronics

Owner:SUMITOMO ELECTRIC IND LTD

Thermoplastic elastomer composition and process for producing the same and pneumatic tire and hose using the same

InactiveUS20010018492A1More flexibleLarge elongationWith separate inflatable insertsSpecial tyresElastomerThermoplastic

A thermoplastic elastomer composition dynamically vulcanized to a gelation rate of 50 to 95% which is superior in heat resistance and durability while maintaining flexibility and superior in air permeation preventive property which can be efficiently used as, for example, a pneumatic tire as an air permeation preventive layer. In particular, a thermoplastic elastomer composition having a reduced particle size of the domain rubber is produced by a material having a high rubber ratio by mixing a composition (C) mixed under conditions of a ratio of melt viscosities of the rubber composition (A) / resin (B) of 0.8 to 1.2 and the formula (phiA / phiB)x(etaB / etaA)<1.0 under conditions of a ratio of melt viscosities of the rubber composition (D) / composition (C) of 0.8 to 1.2 and the formula (phiD / phiC)x(etaC / etaD)<1.0, wherein phiA: volume fraction of rubber composition (A), phiB: volume fraction of resin (B), etaA: melt viscosity of rubber composition (A), etaB: melt viscosity of resin (B), phiC: volume fraction of composition (C), phiD: volume fraction of rubber composition (D), etaC: melt viscosity of composition (C), etaD: melt viscosity of rubber composition (D). Further, a thermoplastic elastomer composition having an elastomer composition (A) as a dispersion phase and a thermoplastic resin composition (B) as a matrix and having a thermoplastic resin composition composed of a blend of at least two thermoplastic resins.

Owner:THE YOKOHAMA RUBBER CO LTD

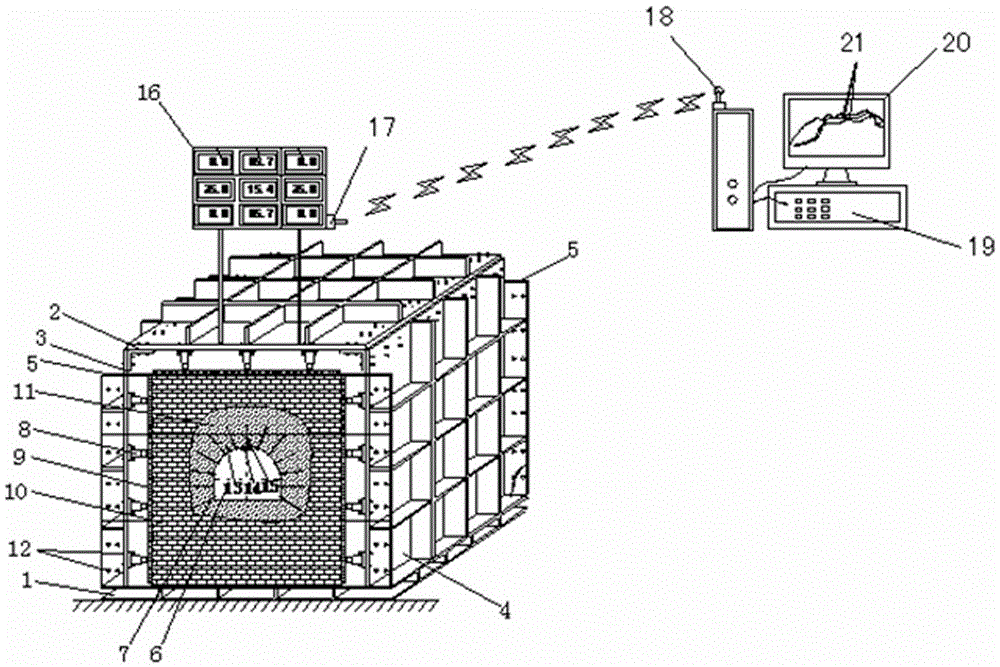

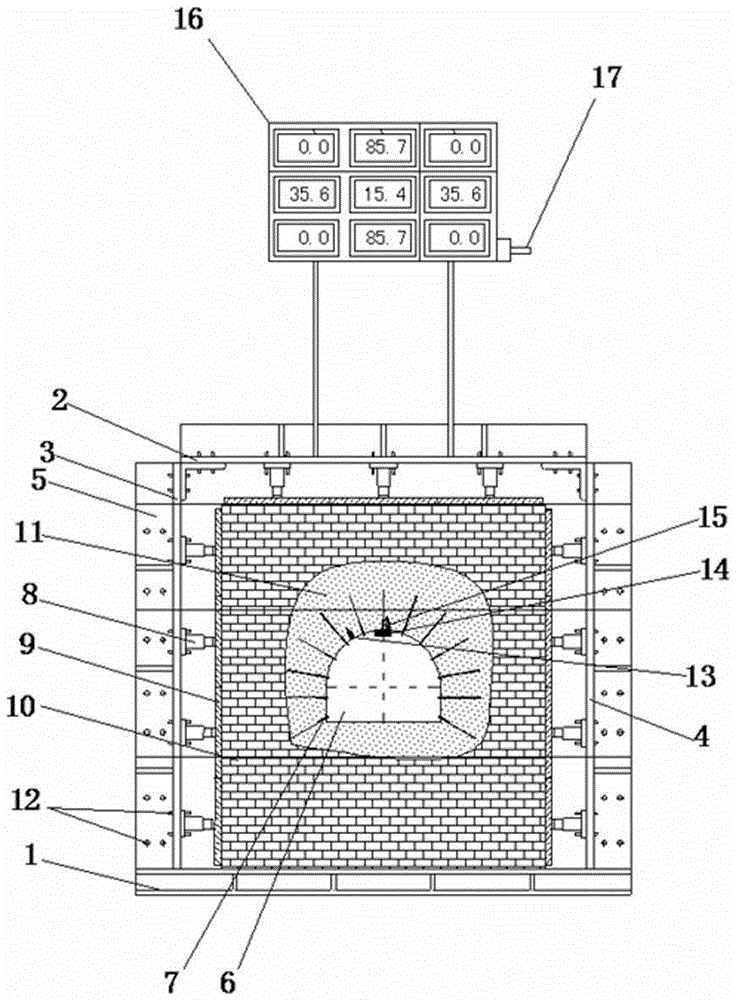

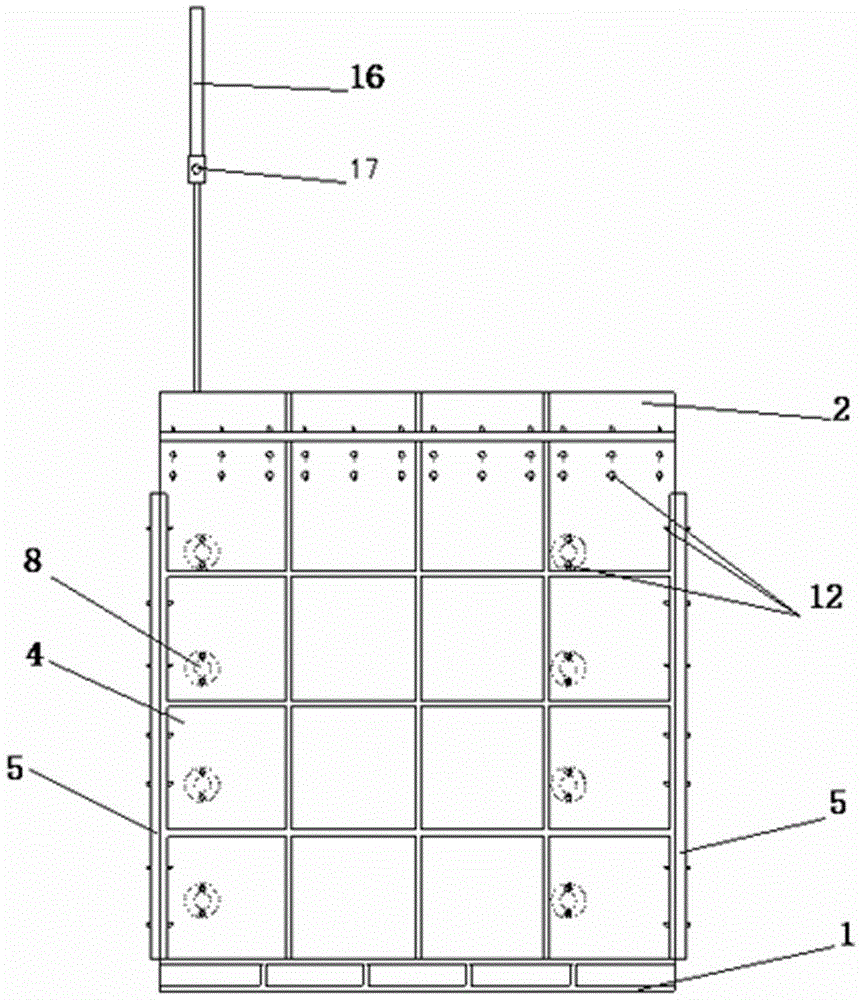

Physical simulation experiment system and method of deep-tunnel high-resistance extensible anchor pole support

ActiveCN105241656AHigh support resistanceLarge elongationMachine part testingHigh resistanceDisplay device

The invention discloses a physical simulation experiment system and method of deep-tunnel high-resistance extensible anchor pole support. The physical simulation experiment system comprises a simulation experiment table, a pressure loading apparatus, high-resistance extensible anchor poles, a tunnel model, a surrounding rock displacement sensor, an anchor pole dynamometer, an anchor pole dynamometer, a pole tail sleeve displacement sensor, a digital display screen, a data emission apparatus, a data receiving apparatus, a display and a data processing apparatus. The pressure loading apparatus is arranged at equal intervals between the outer side of the tunnel model inside the simulation experiment table, the multiple high-resistance extensible anchor poles are arranged between the anchorage zone rock and the hole of a tunnel, output of the surrounding rock displacement sensor, the anchor pole dynamometer and the pole tail sleeve displacement sensor is sent to the data processing apparatus for processing and is displayed by the display. The system provided by the invention is reasonable in structural design and simple to operate, enables people to visually observe deformation and support working states of the anchor pole and realizes simulation of the support mechanics characteristics and the support process of the anchor poles.

Owner:HUNAN UNIV OF SCI & TECH

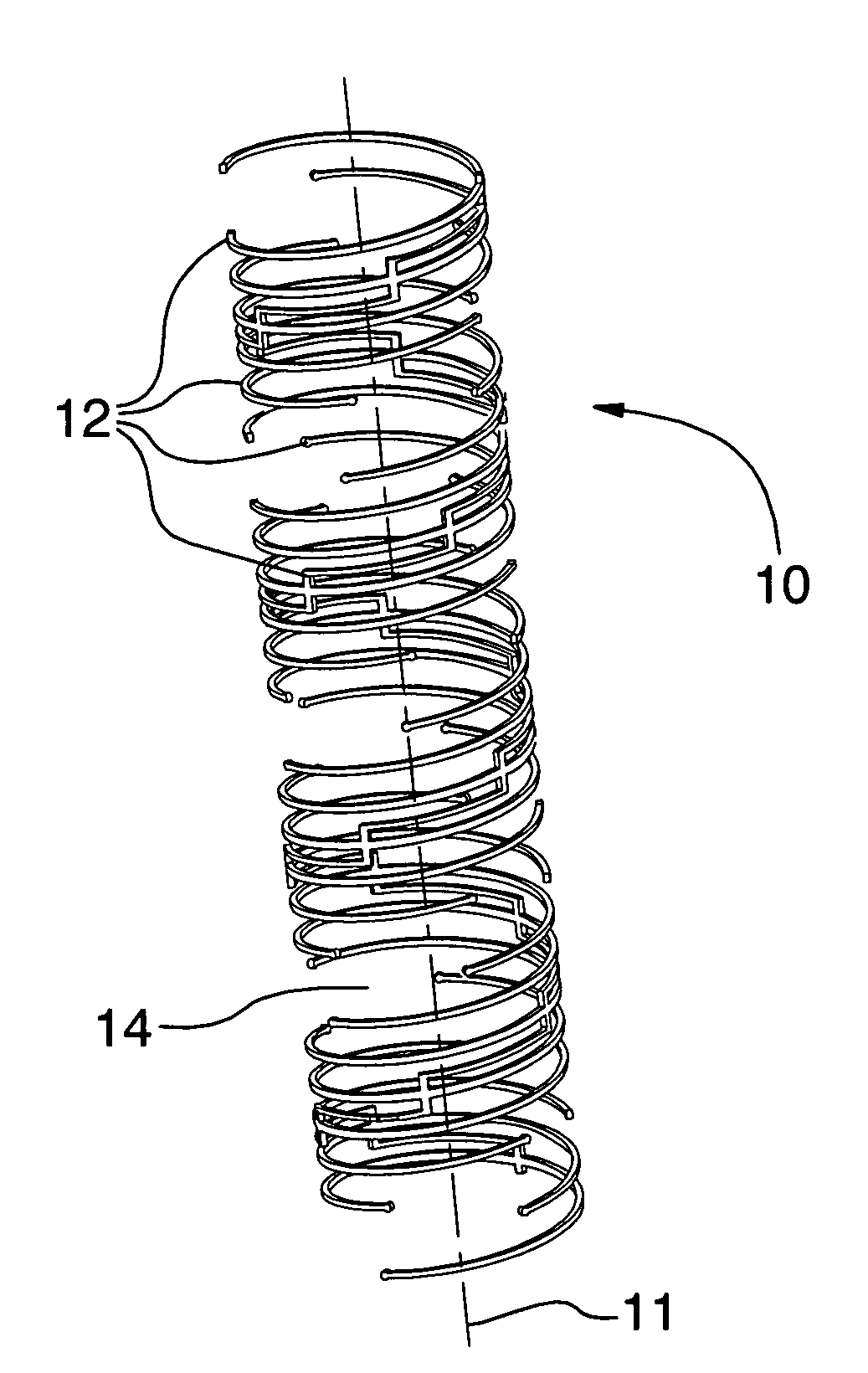

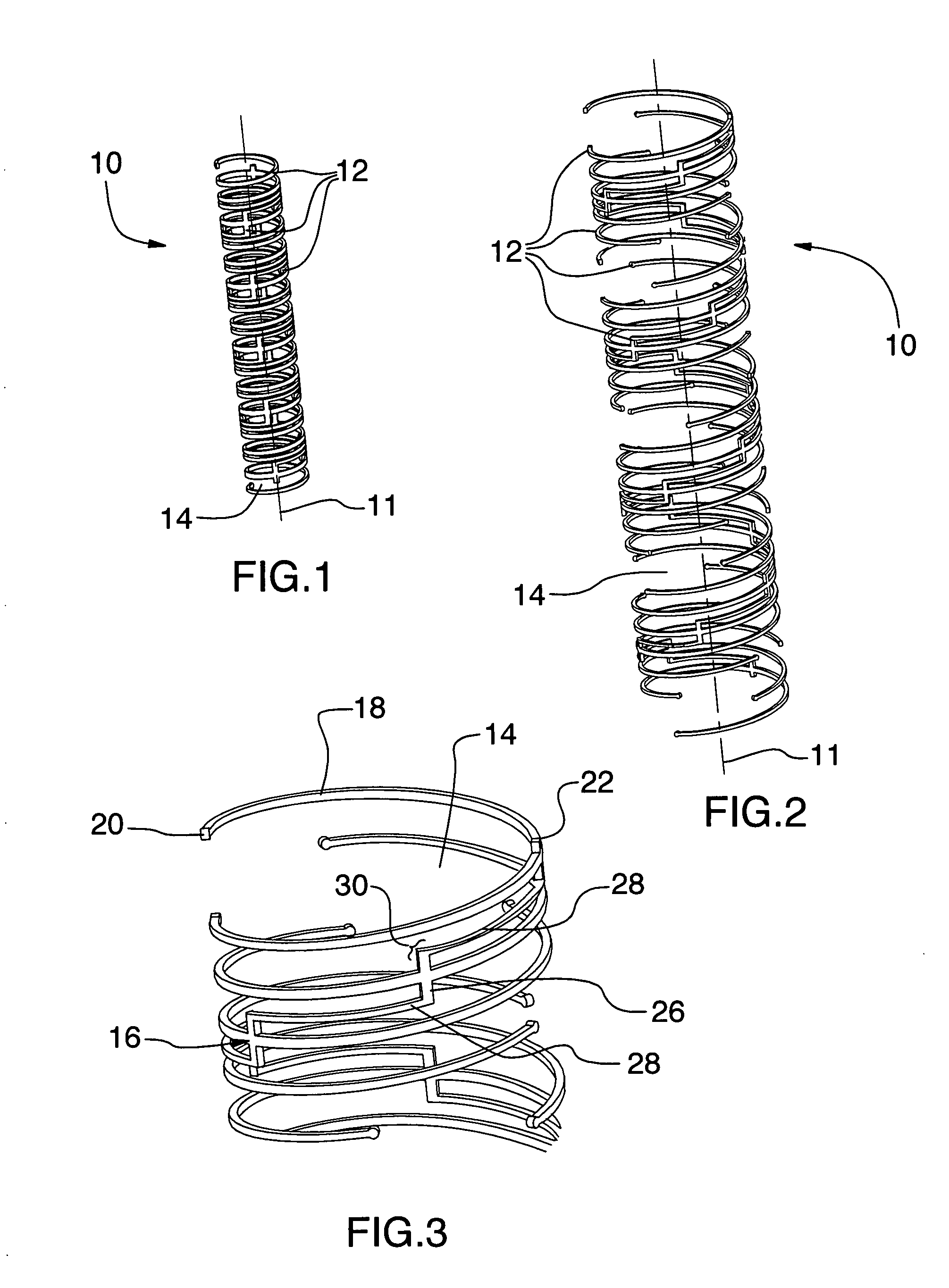

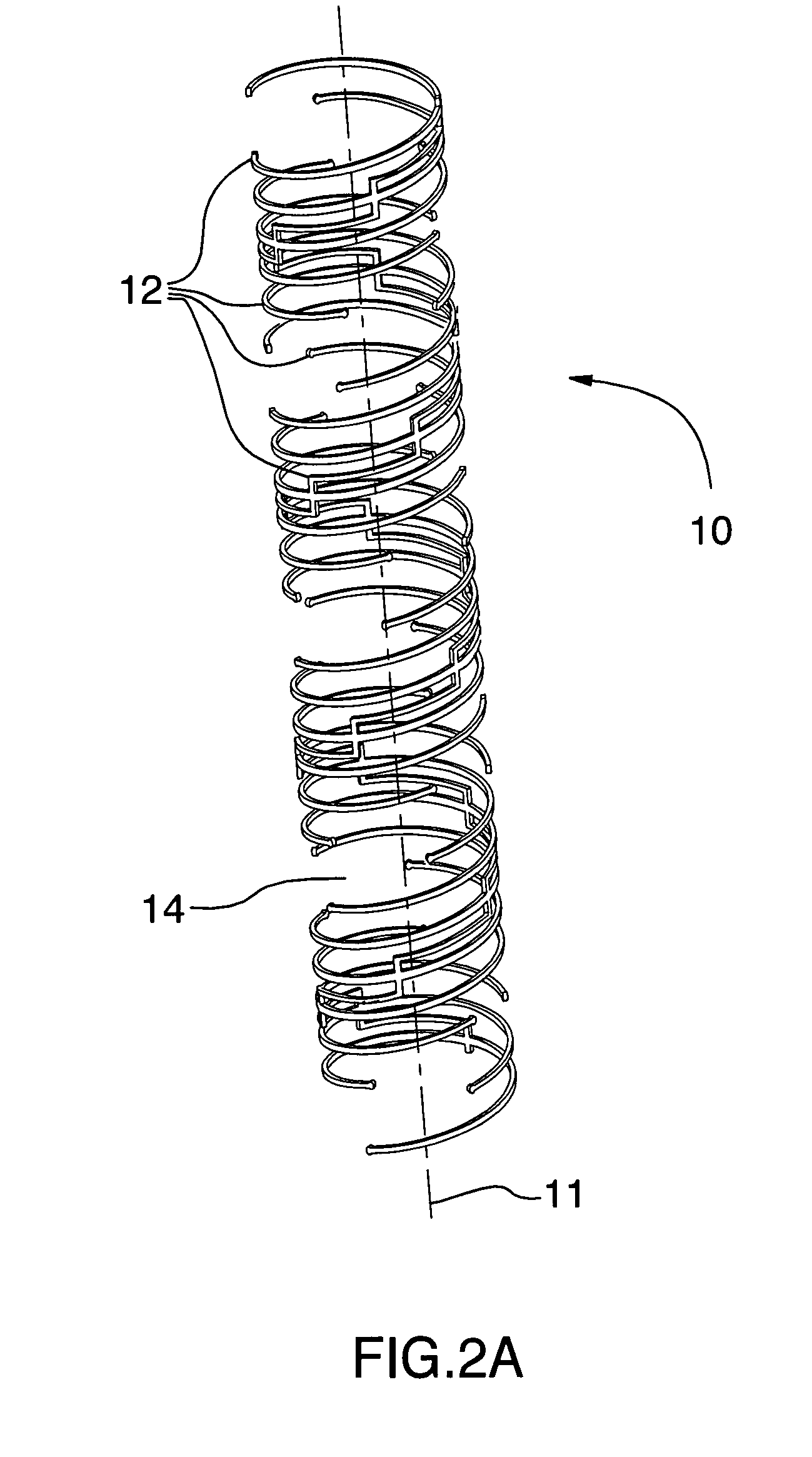

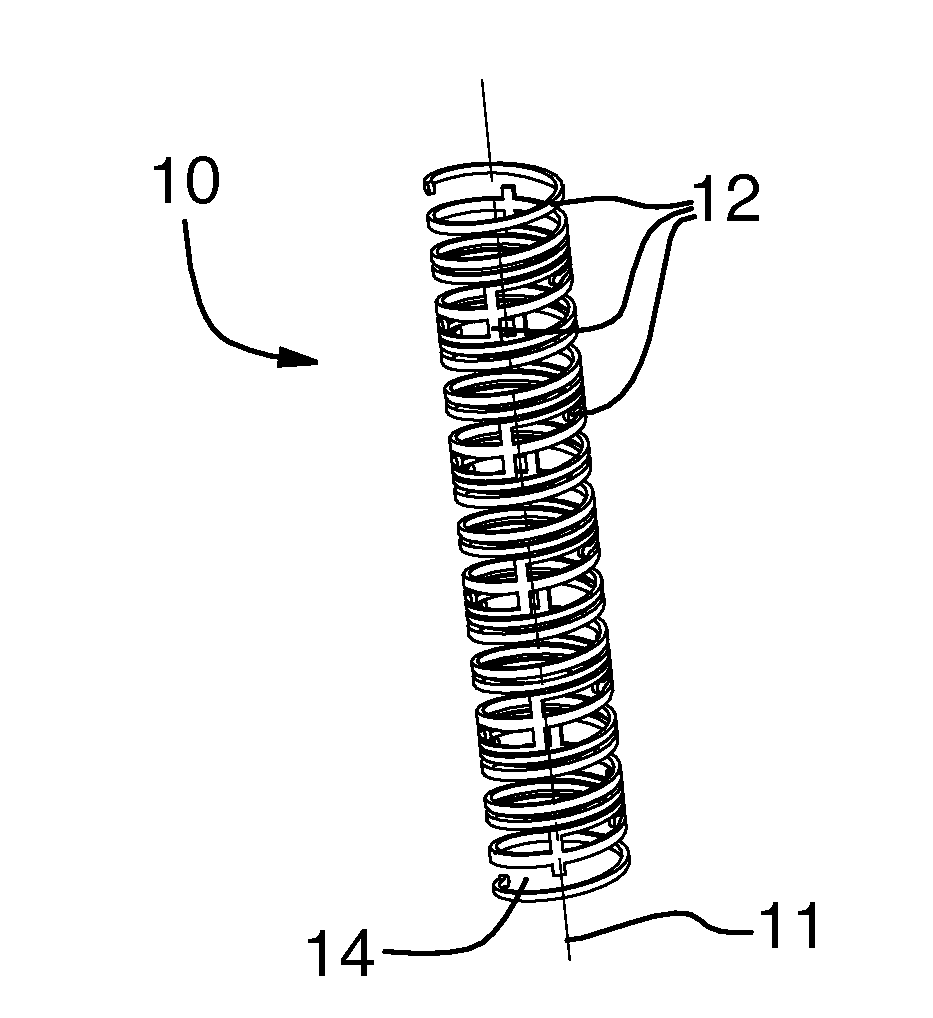

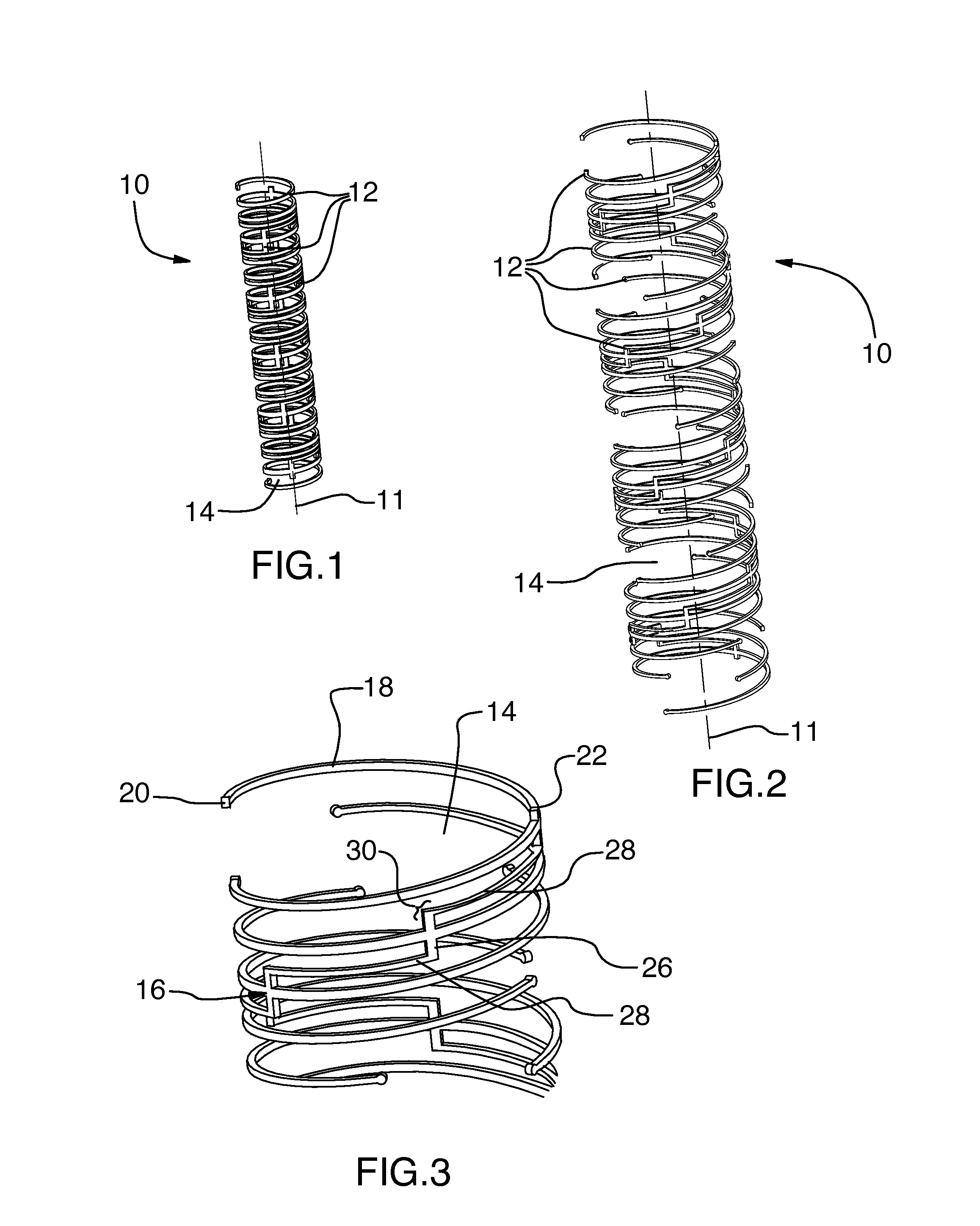

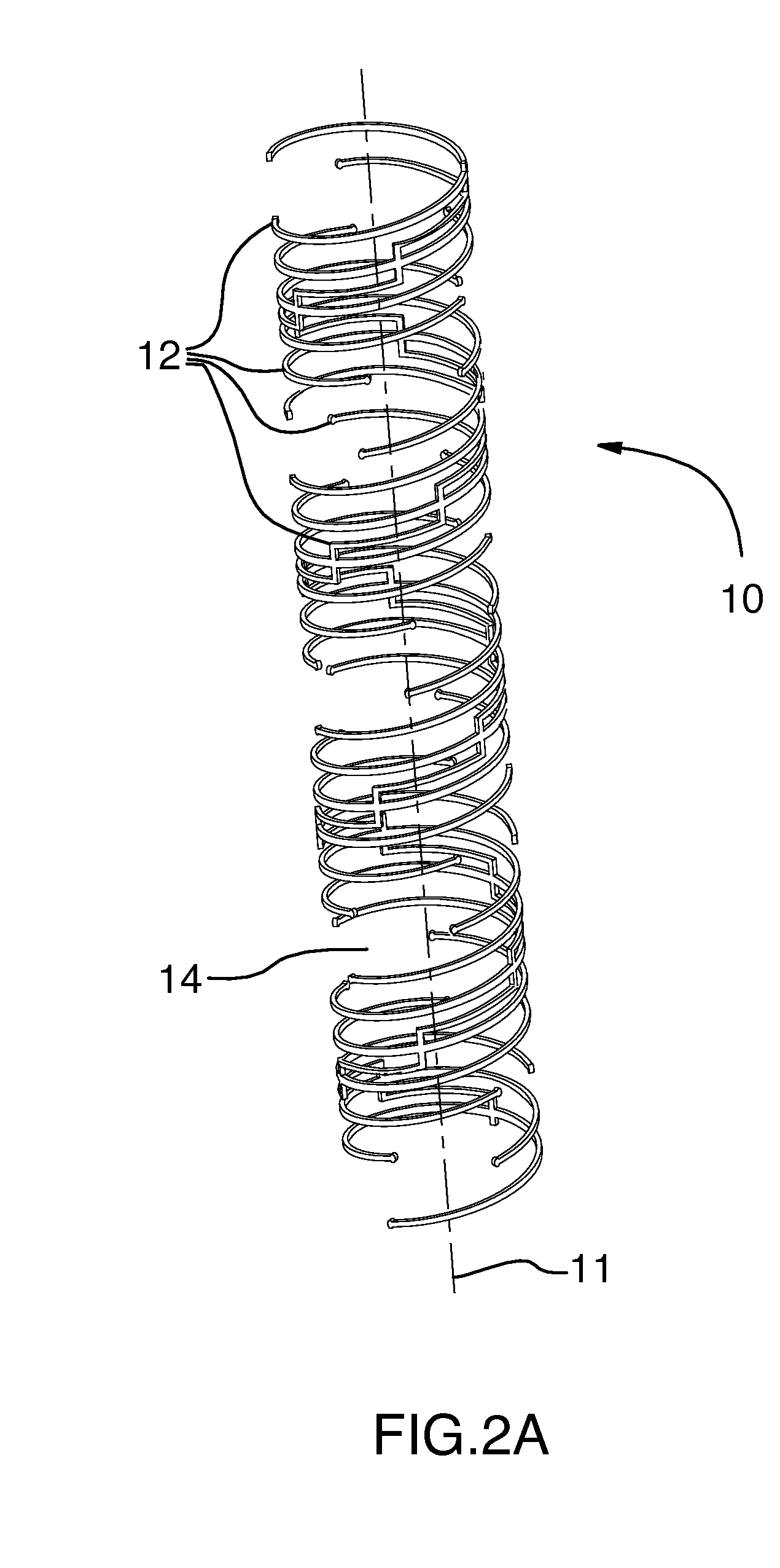

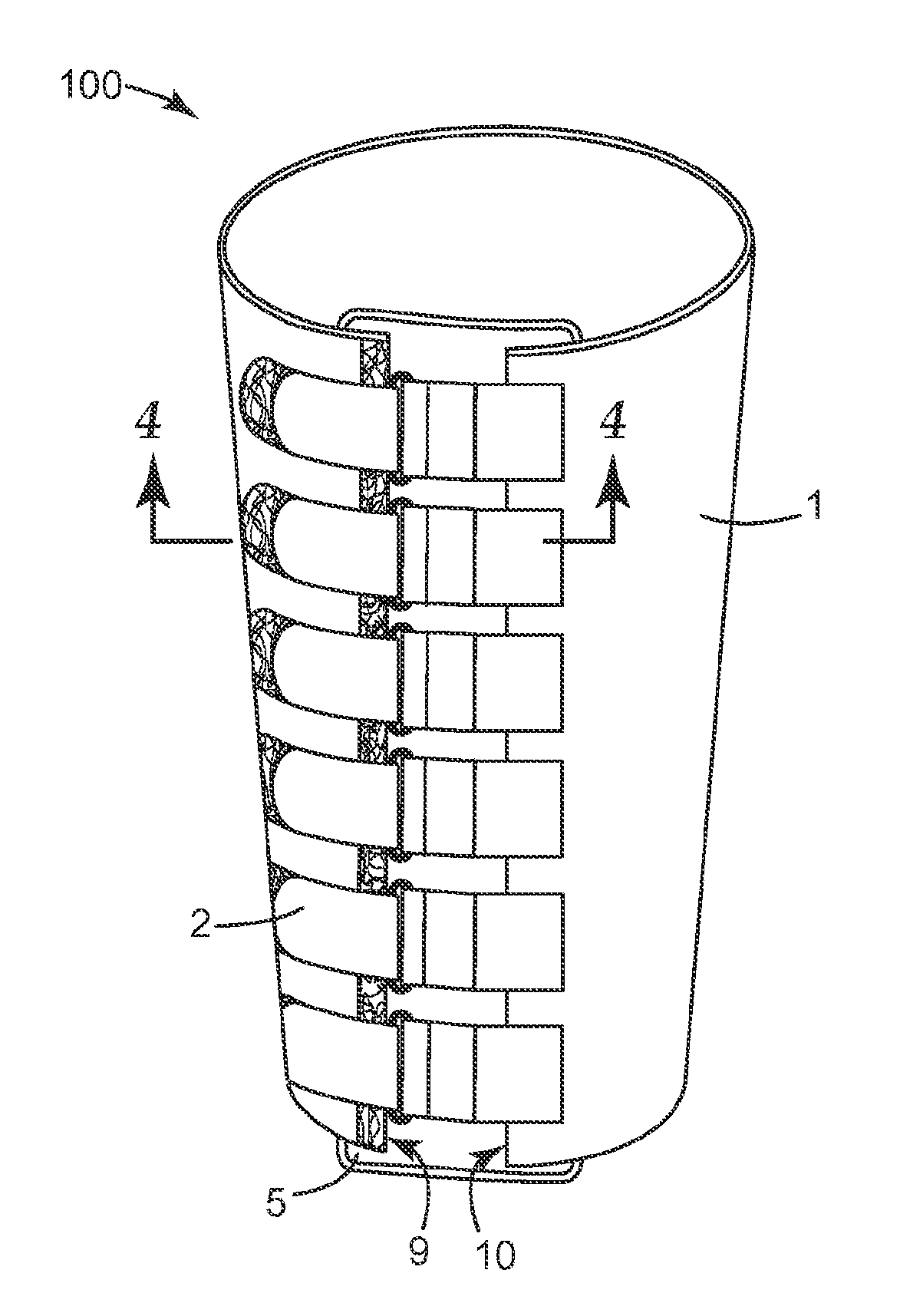

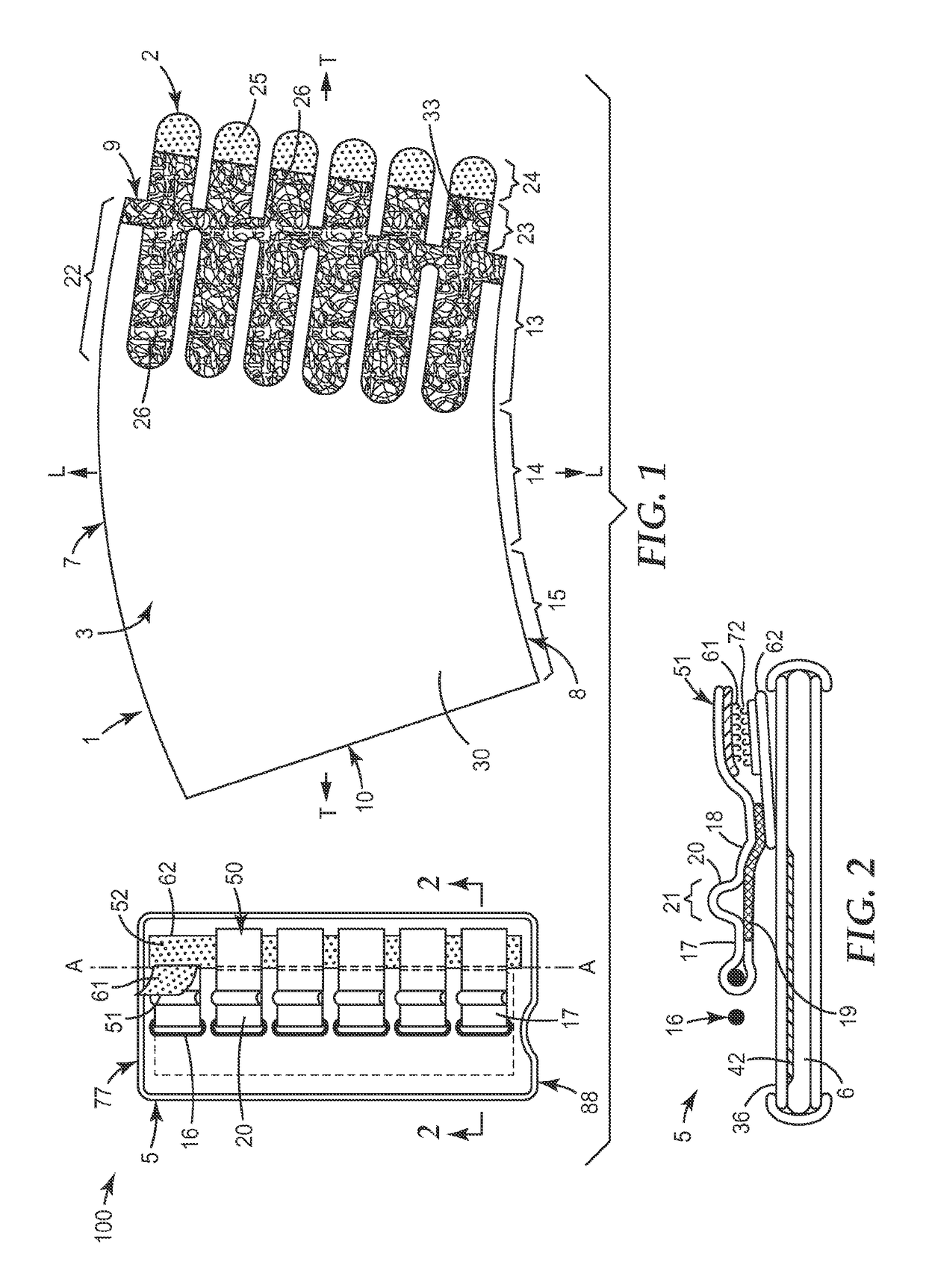

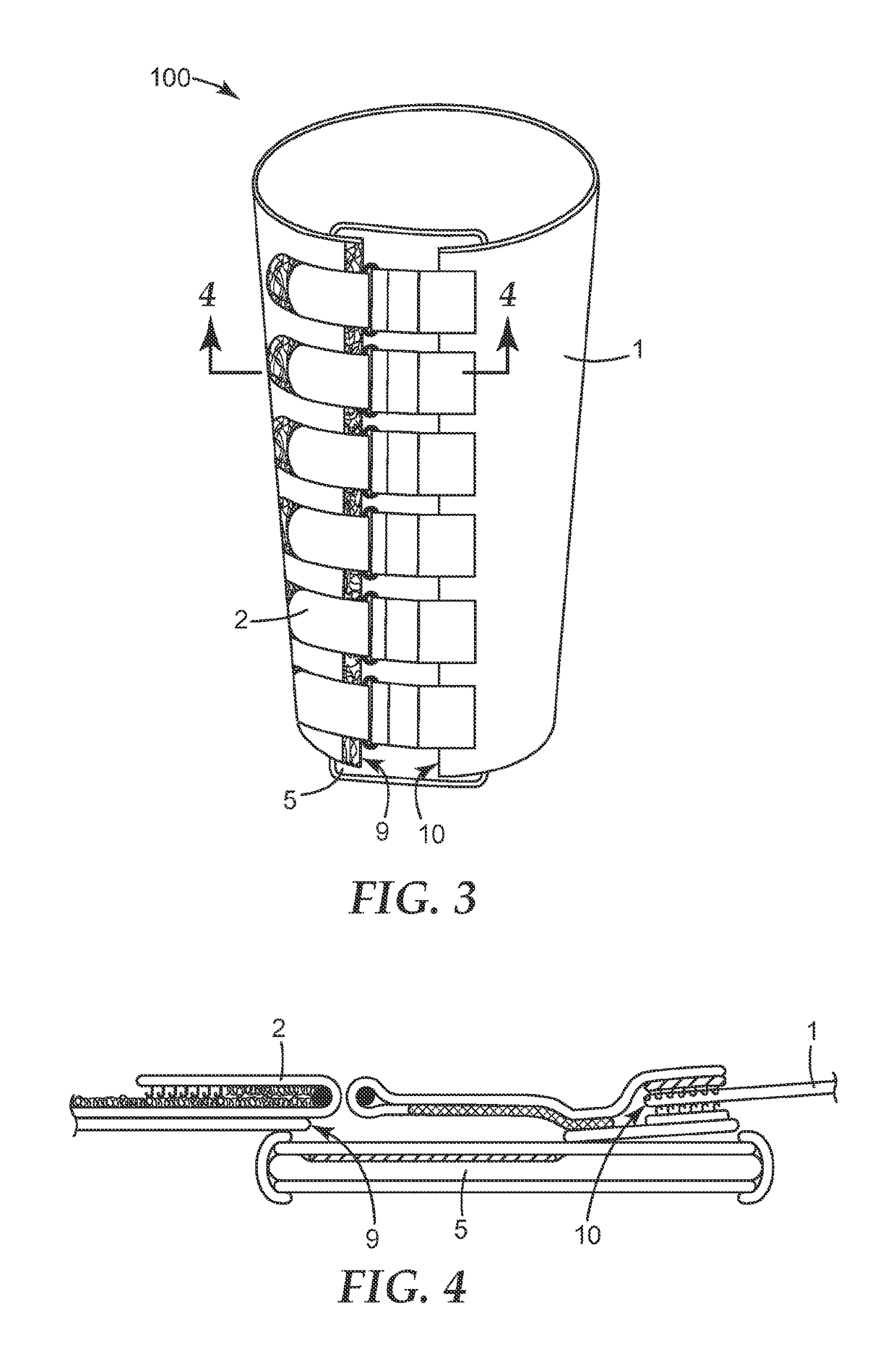

Stent

InactiveUS20070276465A1Reduce risk of damageLarge elongationStentsBlood vesselsBlood vesselVascular wall

A stent insertable in a body vessel, the body vessel defining a vessel wall. The stent includes a plurality of struts, the struts defining a substantially elongated stent passageway, the struts being configured, sized and operatively coupled to each other in a manner such that the stent is deformable between a first configuration and a second configuration. In the first configuration, the stent passageway has a first radial dimension and a first longitudinal dimension, and in the second configuration, the stent has a second radial dimension and a second longitudinal dimension, the second radial dimension being at least as large as the first radial dimension and the second longitudinal dimension being larger than the first longitudinal dimension. The stent is able to expand substantially longitudinally with the body vessel as the body vessel grows without reducing in diameter so as to reduce risks of damaging the vessel wall as the body vessel grows.

Owner:MONGRAIN ROSAIRE +4

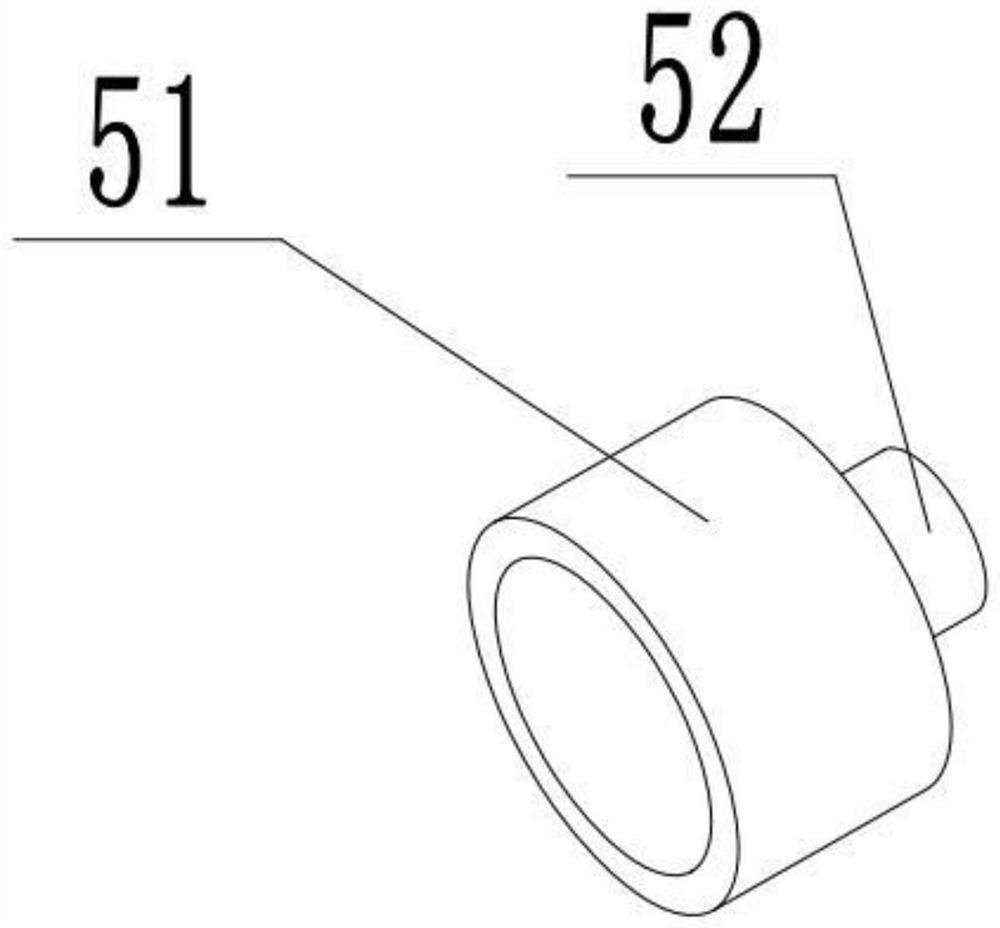

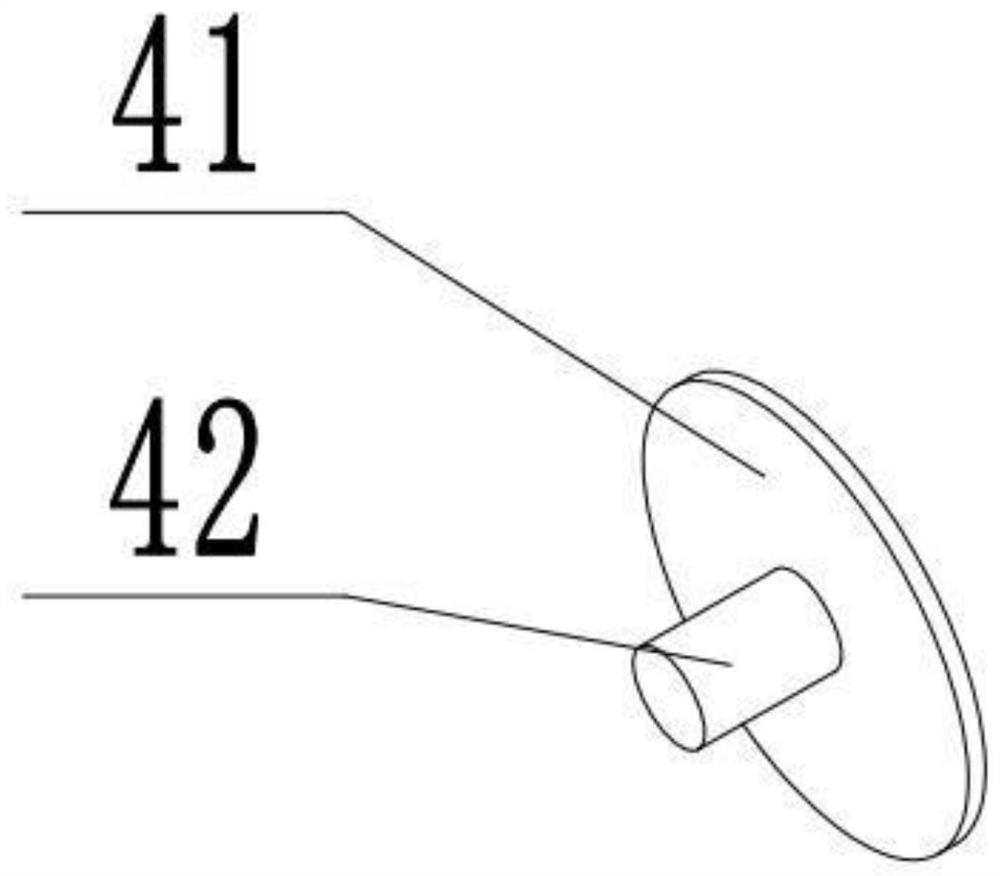

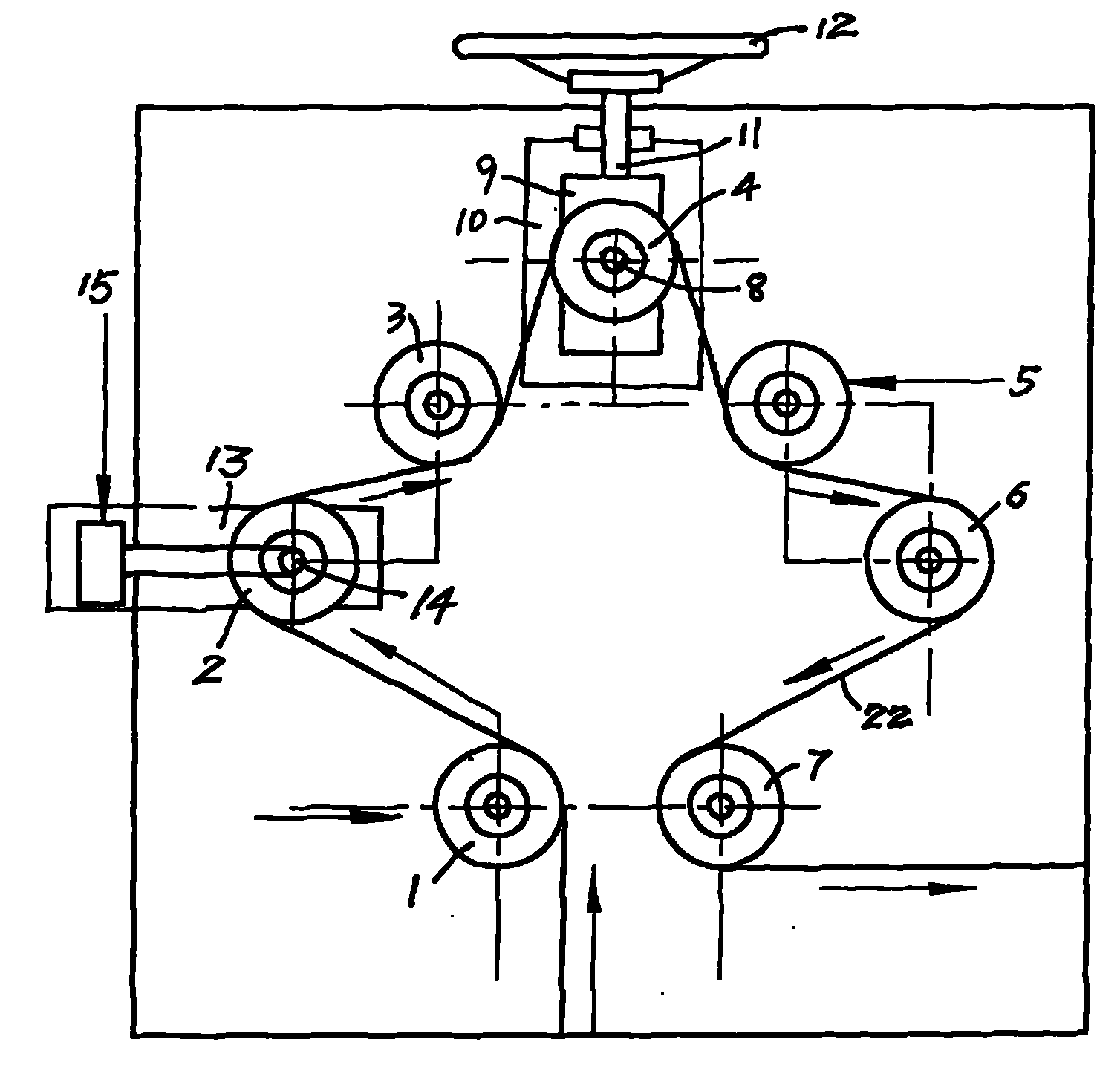

Double-fibre compact spinning device

The invention provides a novel double-fiber close spinning device, consisting of two main parts of a double top roller subassembly and a hollow roller subassembly, wherein in the double top roller subassembly, a top roller(2) and a top roller(4) are arranged on a top roller frame(5), on which an airflow orientation block(11) is arranged by a positioning board(10), a spring(3) is arranged on the top roller frame(5), a permanent magnet(12) is arranged on the airflow orientation block(11); in the hollow roller subassembly, a wide vacuum nozzle(7), an air suction base(9) and a baffle board(6) are jointly assembled in hollow roller rings(8), which are arranged on a main shaft(14) in pairs; the double top roller subassembly is arranged on a cradle(1) and exerts pressure on the hollow roller subassembly. The yarn spun by the device has few hairy feathers and little fly waste and is low in fiber strength.

Owner:陆节 +1

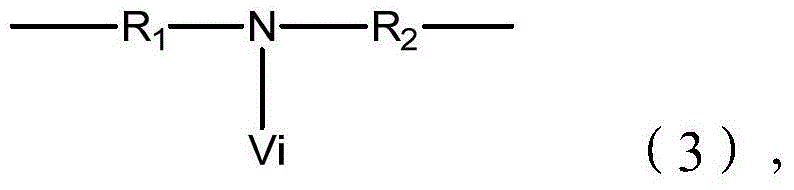

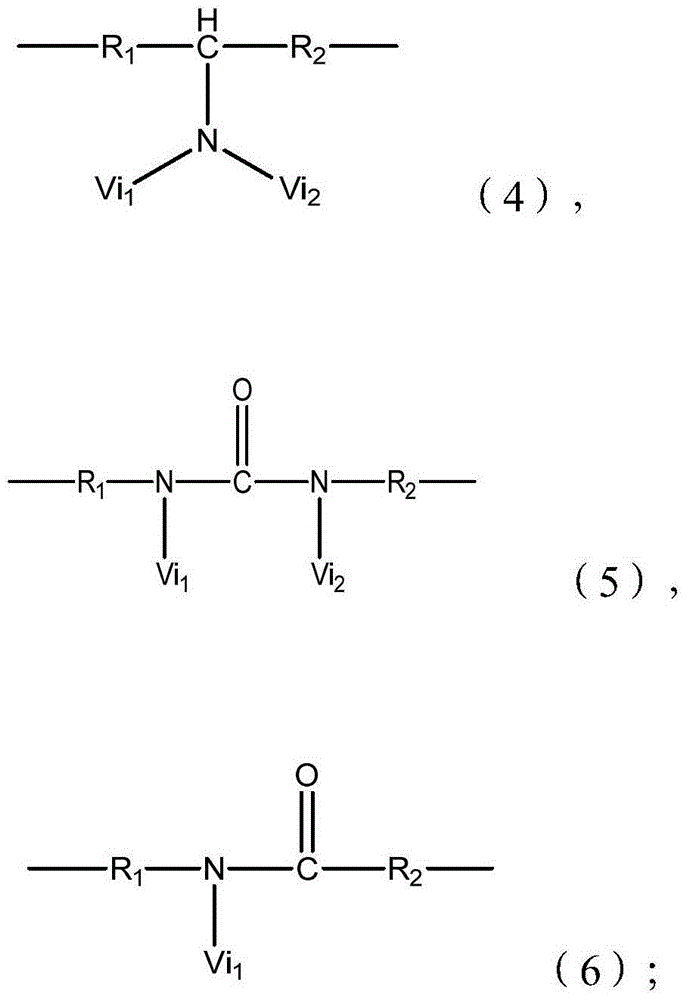

Application of polyurethane catalyst in synthesis of flexible polyurethane foamed plastic

ActiveCN104558469ASmall indentation hardnessGood physical propertiesThermal insulationCatalytic effect

A polyurethane catalyst comprises a sodium compound which is 1-60 wt% of the polyurethane catalyst, and a tertiary amine and / or pyridine compound. The sodium compound and the tertiary amine and / or pyridine compound achieve the synergistic effect; during the catalysis of the polymerization of isocyanate and polyalcohol, the speed of the polymerization reaction is increased; the prepared polyurethane material has excellent physical properties, does not contain any heavy metal element at all, has no volatile organic compound ingredient, is an environment-friendly low-odor catalyst, reduces the catalyst harm while achieving the catalytic effect of a non-environment-friendly catalyst in the prior art, and can be used for preparing a high-resilience polyurethane flexible sponge, a low-resilience polyurethane flexible sponge and other polyurethane flexible sponges; the obtained polyurethane flexible sponge / flexible polyurethane foamed plastic is light in weight, thermal-insulating, sound-absorbing, shockproof, and corrosion-resistant, and can be used as a filtering material, a sound insulation material, a shockproof material, a decoration material, a packaging material, a thermal insulation and a heat preservation material.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

Energy beam-curing inkjet ink composition

InactiveUS20110230582A1Improve tensile propertiesNot cause crackingInksThermographyChemistryOligomer

An energy ray-curable inkjet ink composition comprising polymerizable compounds containing a monofunctional monomer, (A) a reactive oligomer having a rate of elongation of 130% or more and a weight average molecular weight of not less than 800 and less than 3,000 and (B) a reactive oligomer having a rate of elongation of 130% or more and a weight average molecular weight of not less than 3,000 and not more than 8,000, provided that one of the reactive oligomers (A) and (B) is not more than difunctional and the other is not less than difunctional, at least one polymerization initiator selected from the group consisting of (C) an acylphosphine oxide initiator and (D) an α-aminoalkylphenone initiator, a surface tension modifier, and a colorant.

Owner:MAXELL SLIONTEC

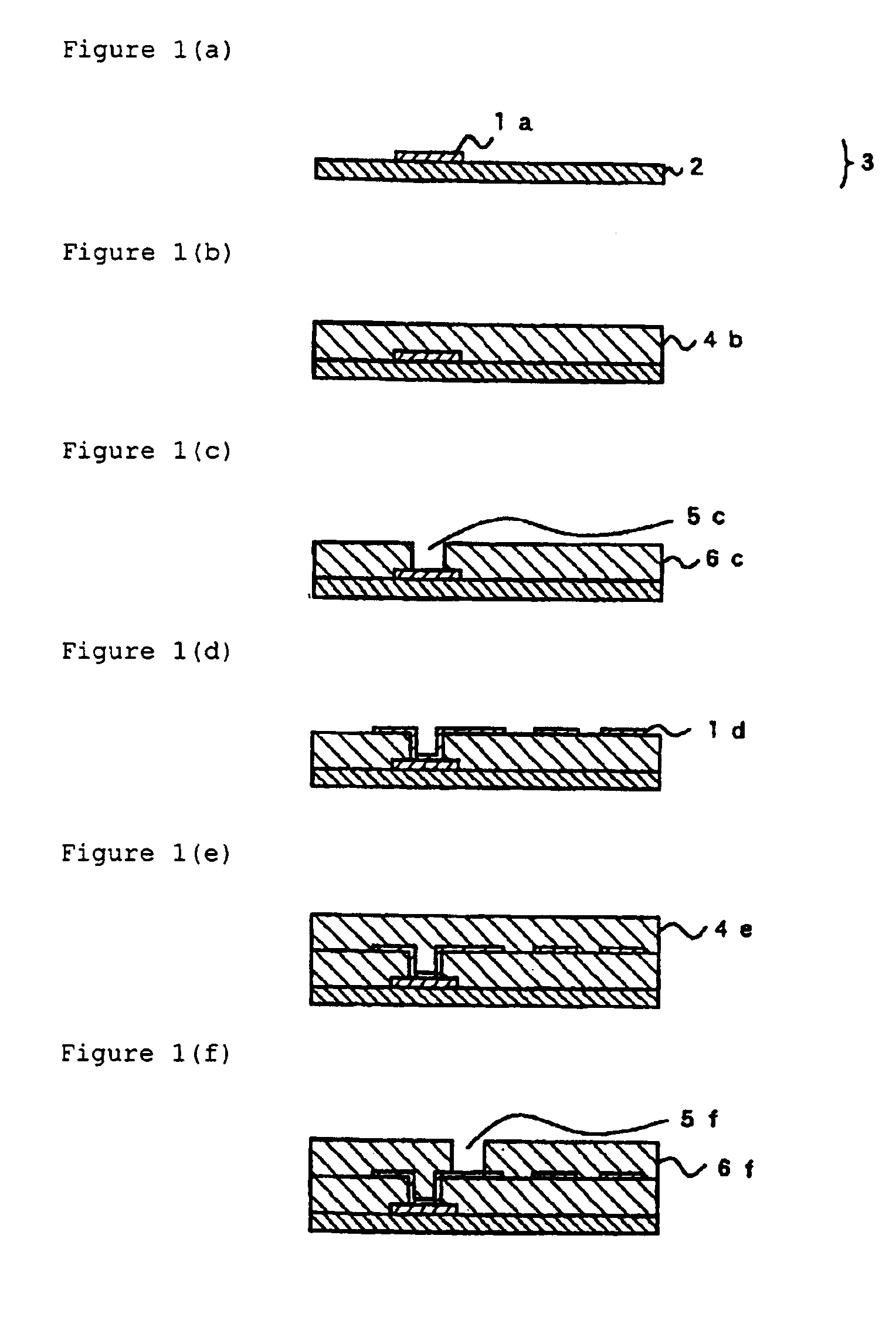

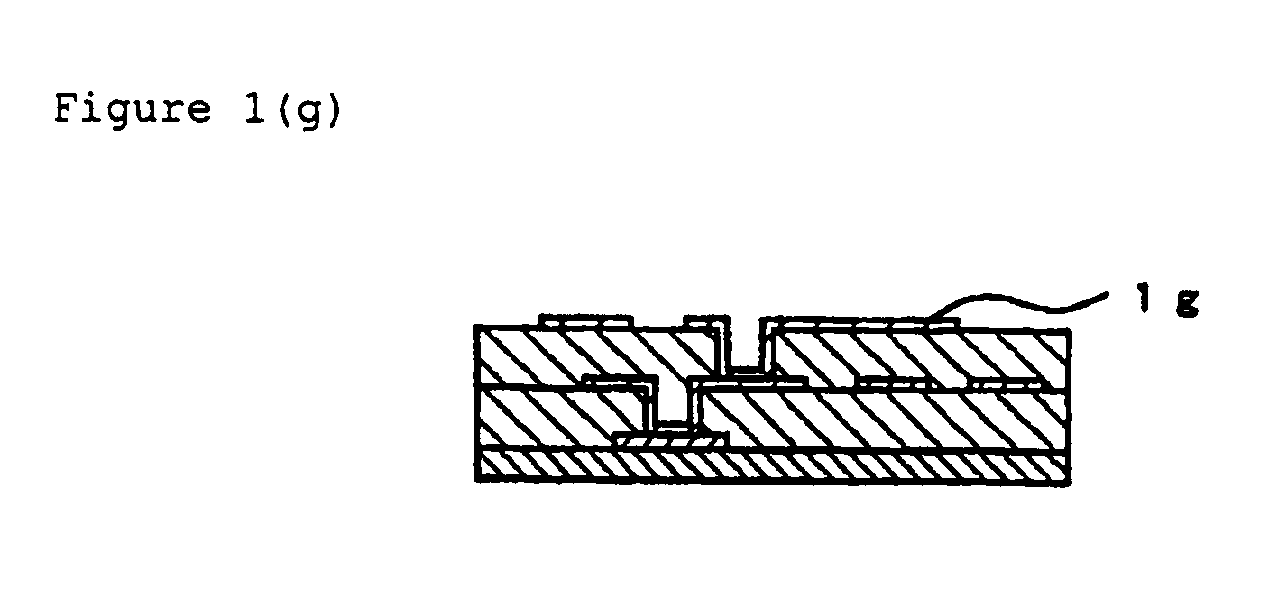

Method for preparing an insulating resin composition, insulating resin composition, multilayer wiring board and process for producing the same

InactiveUS6979712B2Large elongationMaintain good propertiesFilm/foil adhesivesSynthetic resin layered productsPolymer scienceCresol

Directed to an insulating resin composition which comprises (A) a novolak epoxy resin having a biphenyl structure, (B) carboxylic acid-modified acrylonitrile butadiene rubber particles, (C) a triazine ring-containing cresol novolak phenolic resin, (D) a phenolic hydroxyl group-containing phosphorus compound, and (E) inorganic filler, an insulating film having a support using the same, a multilayer wiring board, and a process for producing a multilayer wiring board.

Owner:RESONAC CORPORATION

Extra thick quenched and tempered steel plate for ocean platform tooth bar and production method thereof

The invention which belongs to the technical field of steel concretely discloses an extra thick quenched and tempered steel plate for an ocean platform tooth bar and a production method thereof. The extra thick quenched and tempered steel plate for the ocean platform tooth bar comprises the following components, by weight, 0.14-0.18% of C, 0.15-0.35% of Si, 0.95-1.30% of Mn, equal to or less than0.015% of P, equal to or less than 0.005% of S, 2.35-2.55% of Ni, 0.35-0.55% of Cr, 0.40-0.60% of Mo, 0.020-0.050% of Nb, 0.010-0.030% of Ti, 0.020-0.045% of total Al, and the balance Fe and inevitable impurities, and the thickness of the steel plate reaches 177.8mm. The extra thick quenched and tempered steel plate for the ocean platform tooth bar, which is prepared through carrying out steps ofsmelting by an electric furnace, steel ingot casting by a die, TMCP rolling, fully enclosed quenching and tempering by a well type heating furnace, and the like, has the advantages of high yield strength, good elongation, excellent Z-directional performance, good low temperature impact toughness, good layered tearing resistance, and low production cost.

Owner:WUYANG IRON & STEEL +1

Two-part curing high-durable polyurethane elastomer composition

A two-part curing high-durable polyurethane elastomer composition having excellent heat resistance and wet heat resistance, and excellent workability such that a viscosity after two-part mixing is suitable for casting workability which comprises (i) a polyisocyanate component, and (ii) an active hydrogen-containing compound comprising (A) a polyol having a hydroxyl value of from 25 to 55 obtained by reacting a castor oil fatty acid, 12-hydroxystearic acid, or a condensate of their fatty acids, with a polyol (X) having a molecular weight of from 400 to 1,500, and (B) a polyol having a hydroxyl value of from 100 to 500 obtained by ring opening an epoxidized fatty acid ester with a polyhydric alcohol.

Owner:NIHON GOSEI KAKO

Powder metallurgical gear

InactiveCN106001548AUniform densityHigh densitySolid state diffusion coatingCarbon fibersPolyethylene glycol

The invention discloses a powder metallurgical gear. The powder metallurgical gear is prepared from water atomization iron powder, copper powder, molybdenum powder, vanadium powder, nickel powder, yttrium powder, aluminum powder, magnesium powder, cobalt powder, lead powder, steel slag powder, iron-melted furnace slag powder, ferroalloy slag powder, modified tree ash powder, graphite powder, amino resin, polyether modified silicone, hydroxypropyl methyl cellulose, zinc stearate, polyethylene glycol, ethylene bisstearamide, stearic acid, carbon fibers, glass fibers, boron nitride, epoxypropoxy propyl trimethoxysilane, silicon dioxide, manganese sulfide, acrylate, an inhibitor, a binder, an enhancer, a cutting agent, a lubricant, a coupling agent and a dispersing agent. According to the powder metallurgical gear, by means of specific composition proportion, the overall density is uniform, the compactness is high, the elongation and reduction of cross section are high, the abrasion resistance, strength and hardness are good, the material utilization rate is high, and the materials are suitable for rapidly producing high-performance gears on large scale.

Owner:黄宇

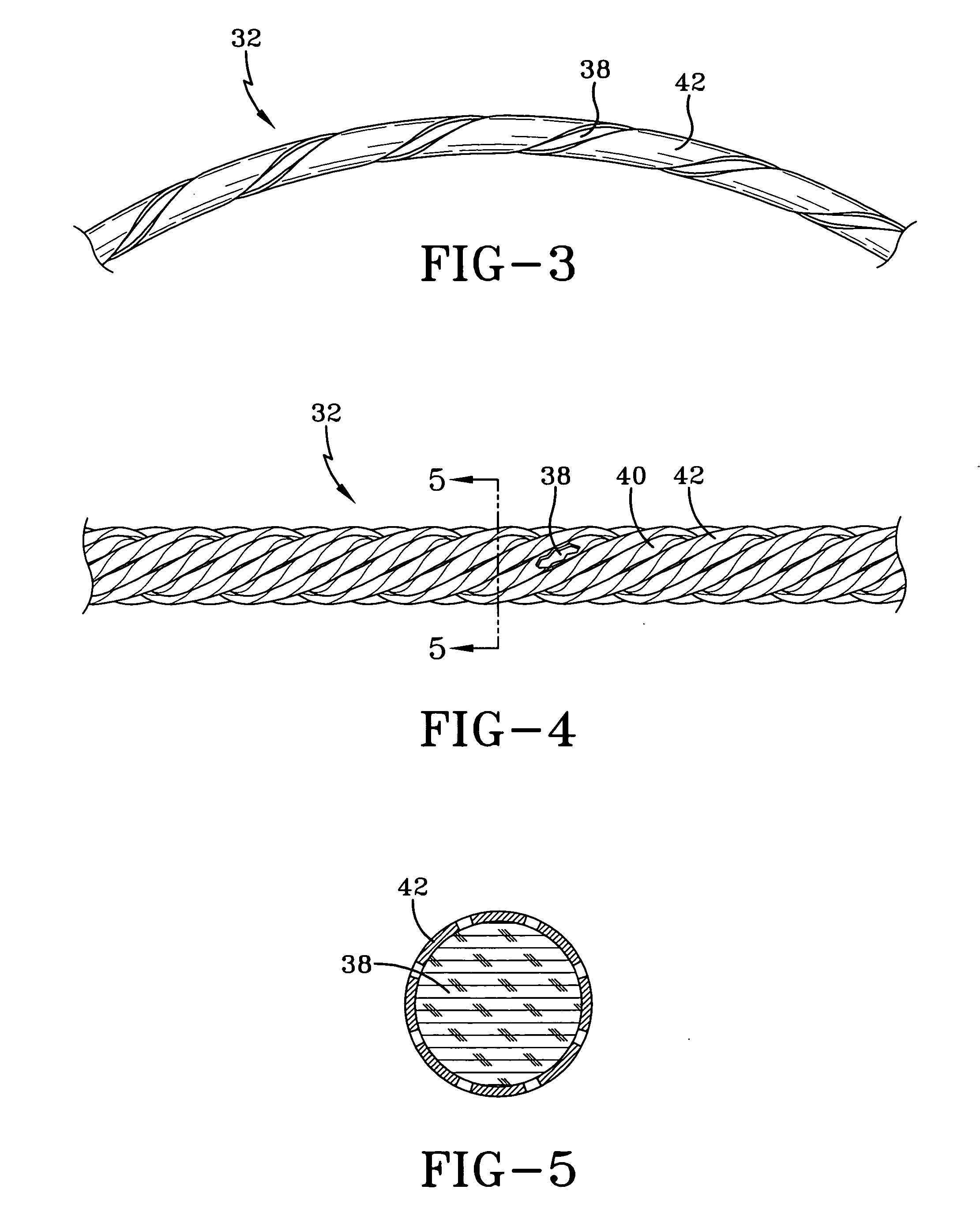

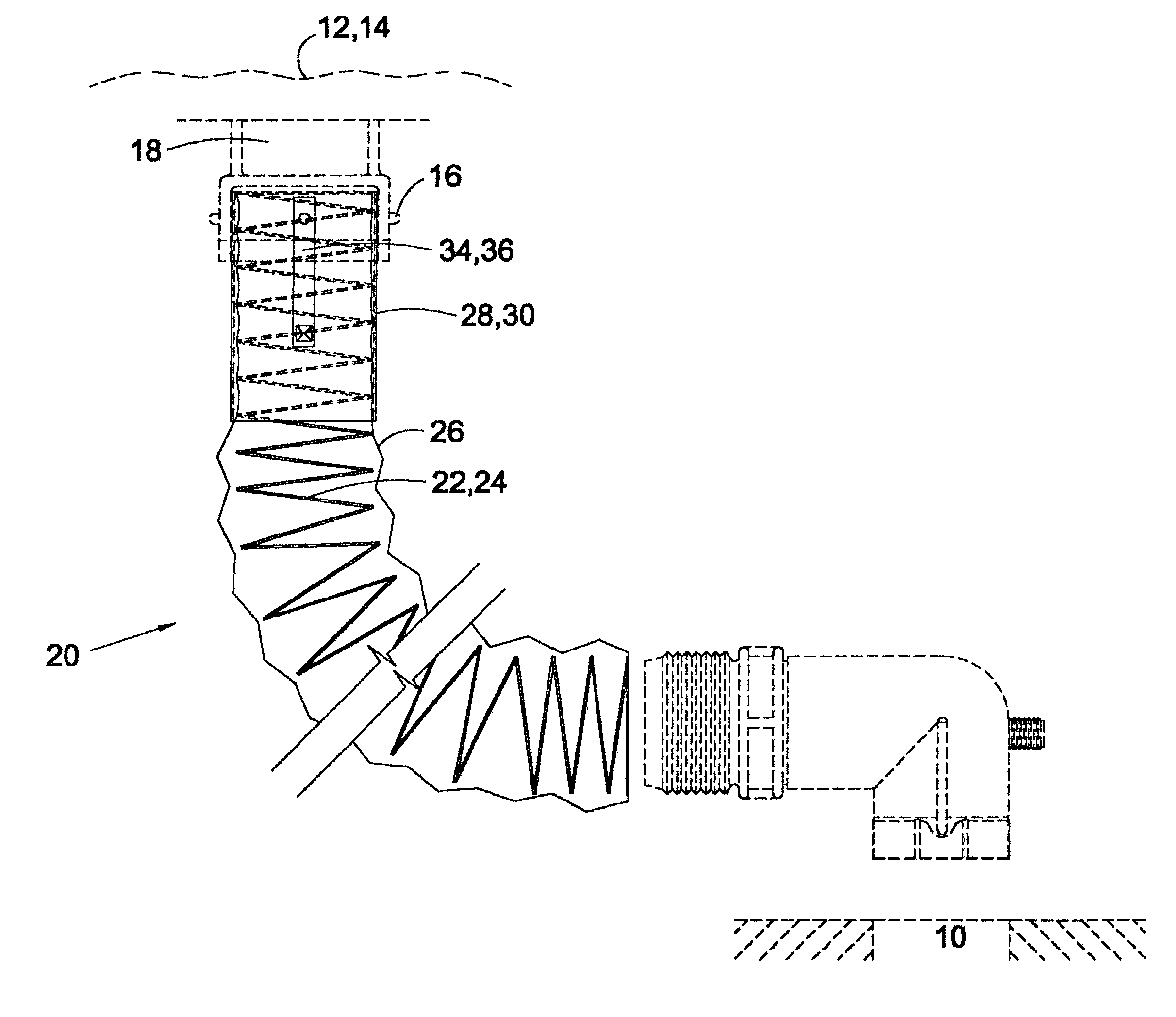

Flexible tinsel ribbon antenna and assembly method for a tire

InactiveUS20050132790A1Overcomes fatigue deficiencyConveniently transported and inventoriedAntenna supports/mountingsTyresElectrical conductorMonitoring system

An antenna system and method for tire monitoring systems provides a flexible conductor having sufficient elongation characteristics as an antenna in a tire monitoring sensor system. A conductive strand is formed by wrapping a conductive tinsel ribbon around an extensible strength member. One or more conductive strands are combined to form an antenna cable that affixes to the inner liner of a tire. According to one aspect of the invention a conductive strand is formed by spiral wrapping at least one conductive tinsel ribbon around the strength member. According to another aspect of the invention, multiple tinsel ribbons may be wrapped around the strength member in braided fashion.

Owner:THE GOODYEAR TIRE & RUBBER CO

Curable composition and sealing method for ceramic siding boards

InactiveUS7473441B2Good weather resistanceLarge elongationCovering/liningsPretreated surfacesMeth-Plasticizer

Owner:KANEKA CORP

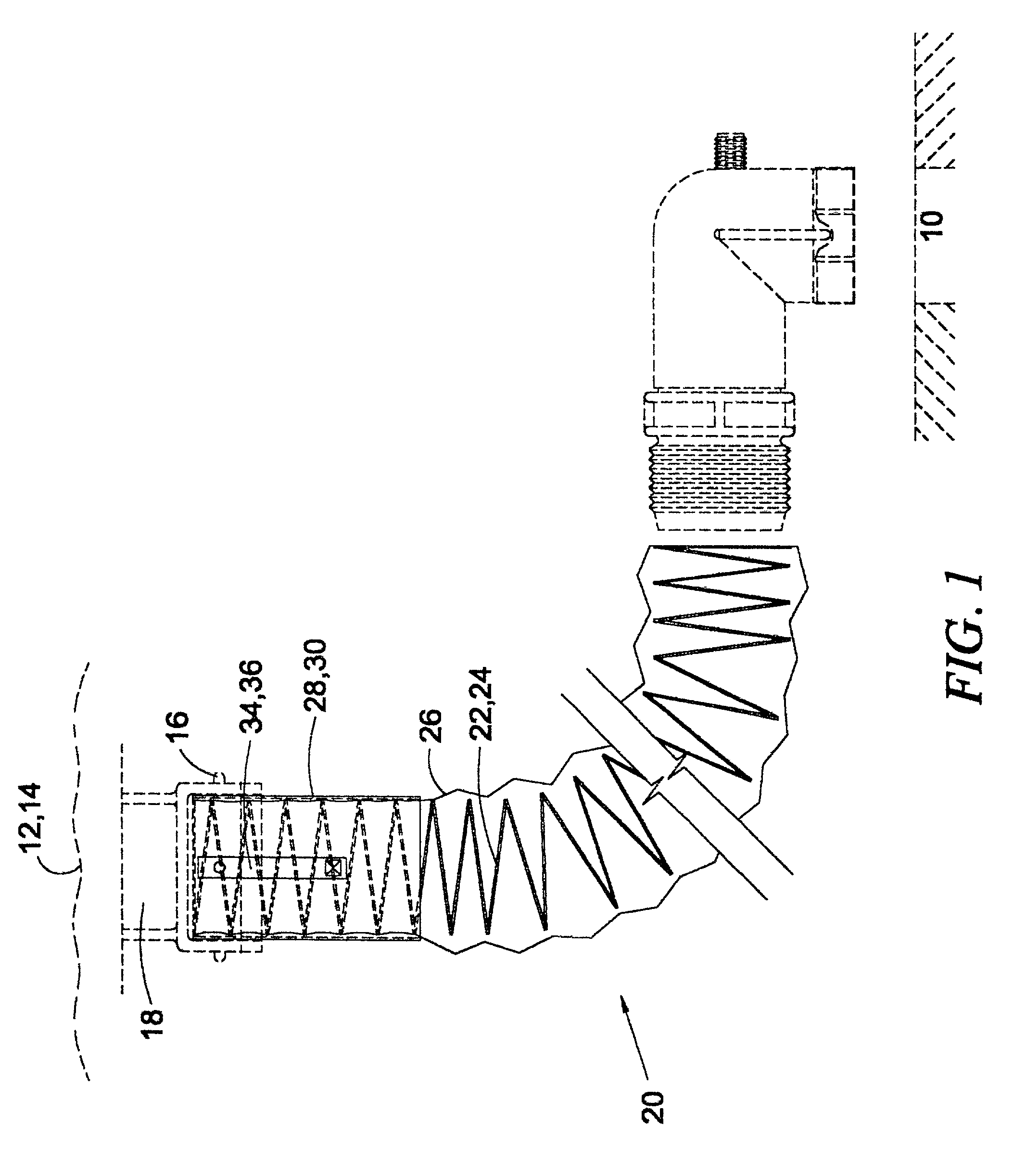

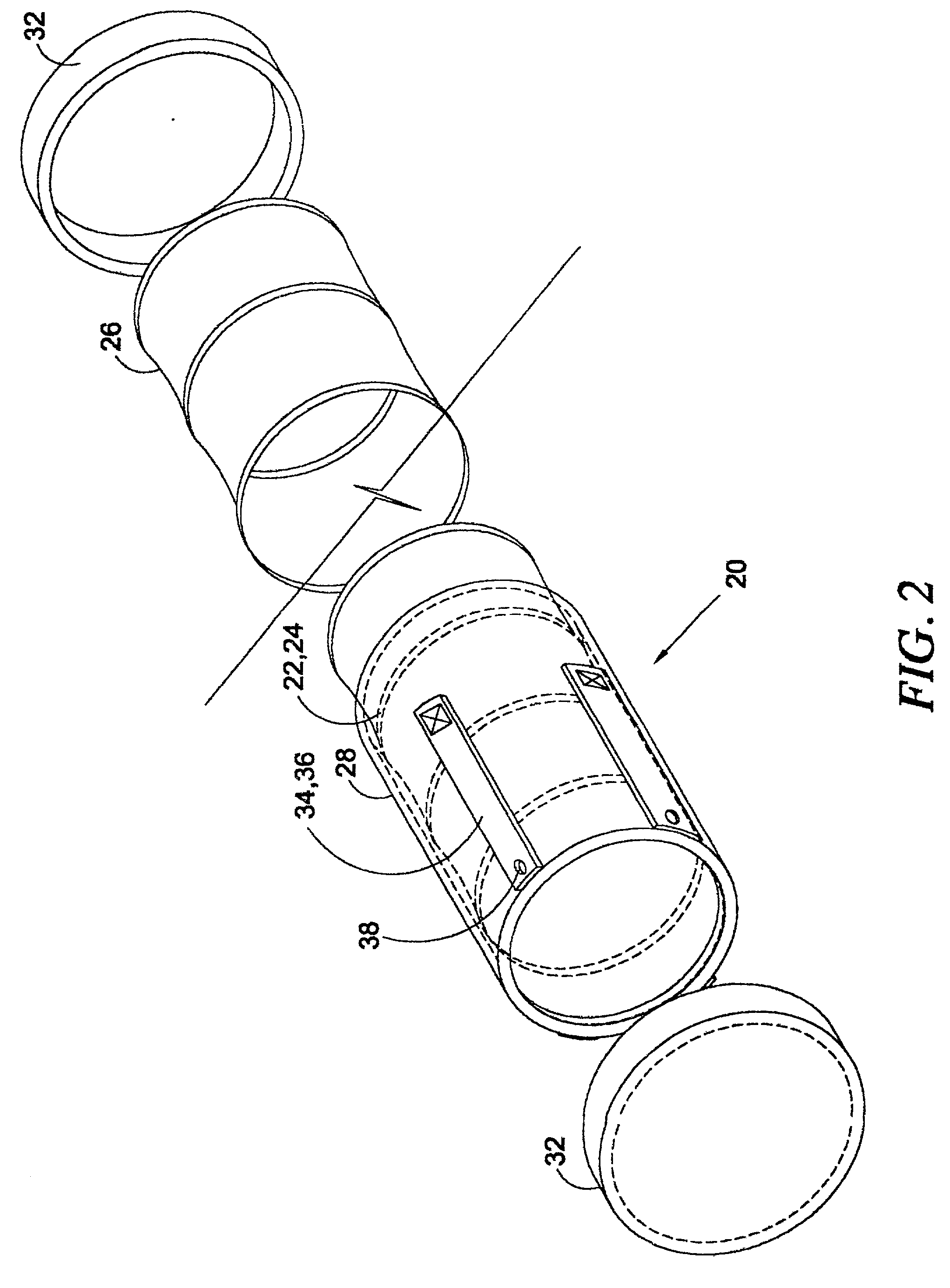

Disposable sewer hose

InactiveUS20020179169A1Compact and inexpensive disposableSimple methodClosuresFlexible pipesEngineeringMechanical engineering

Owner:SHANFELT DONALD Y

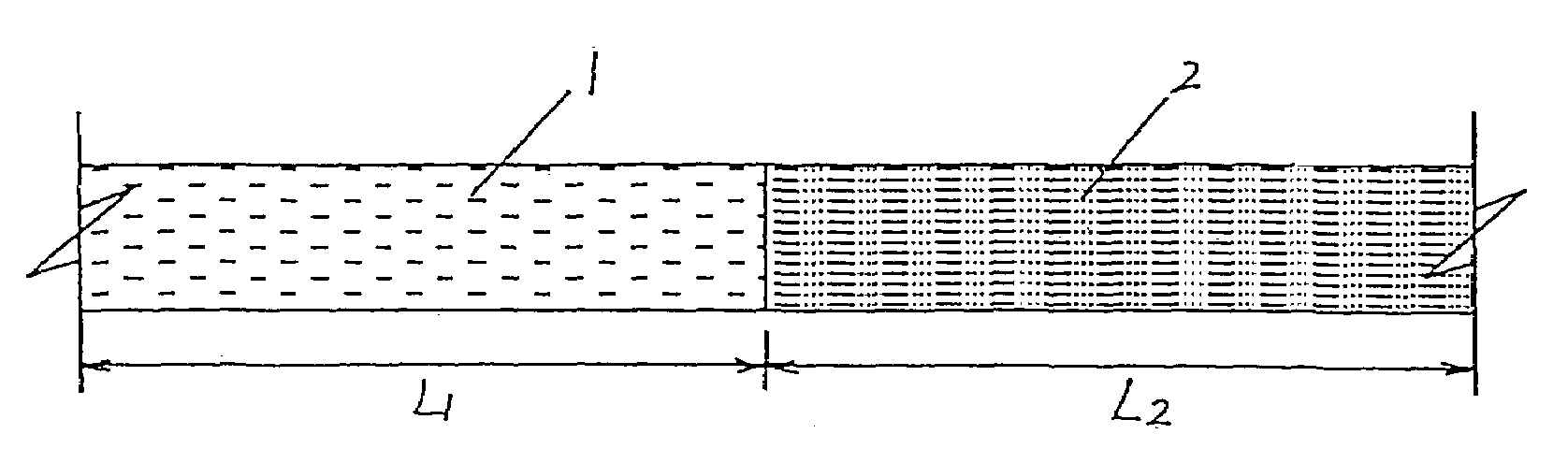

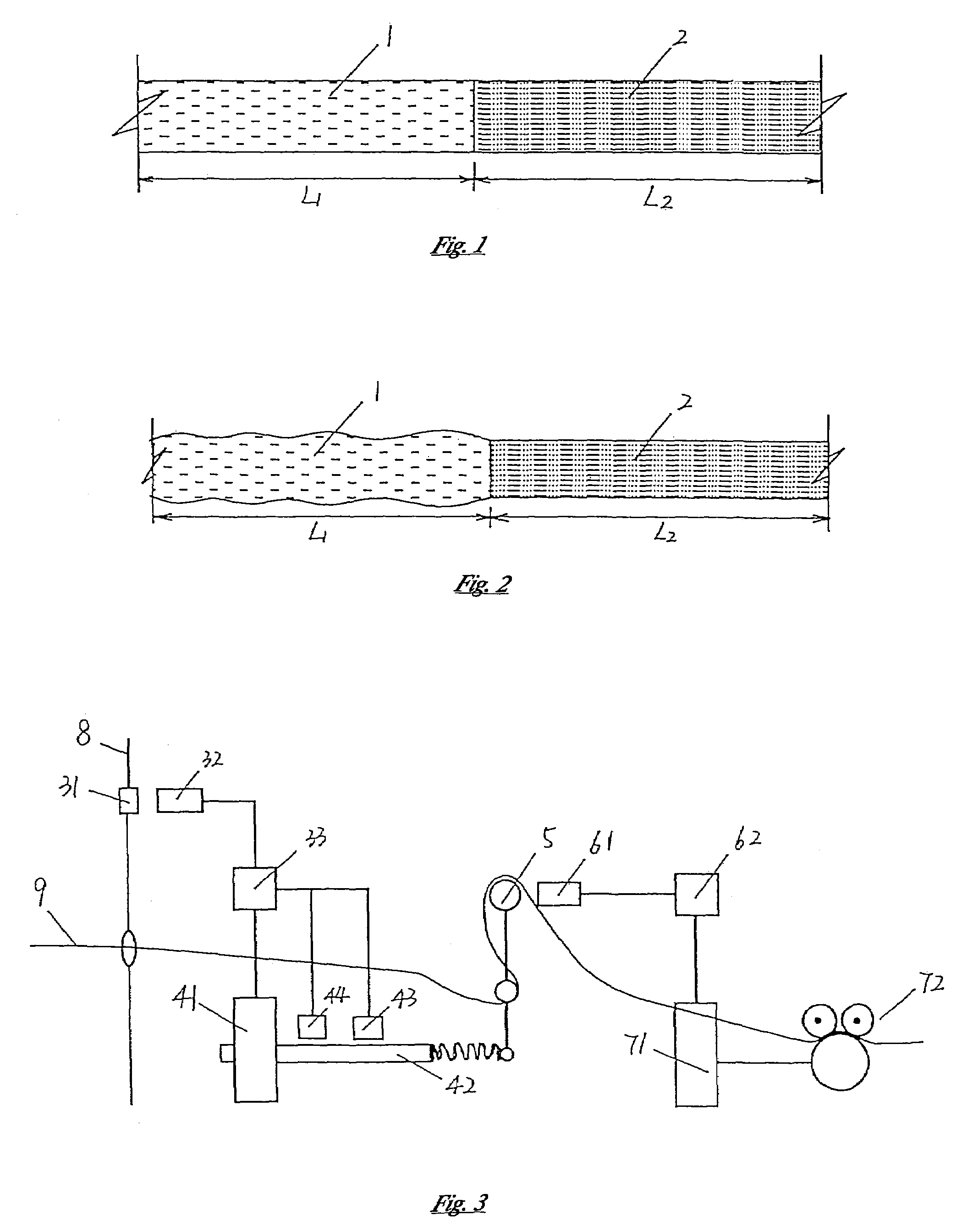

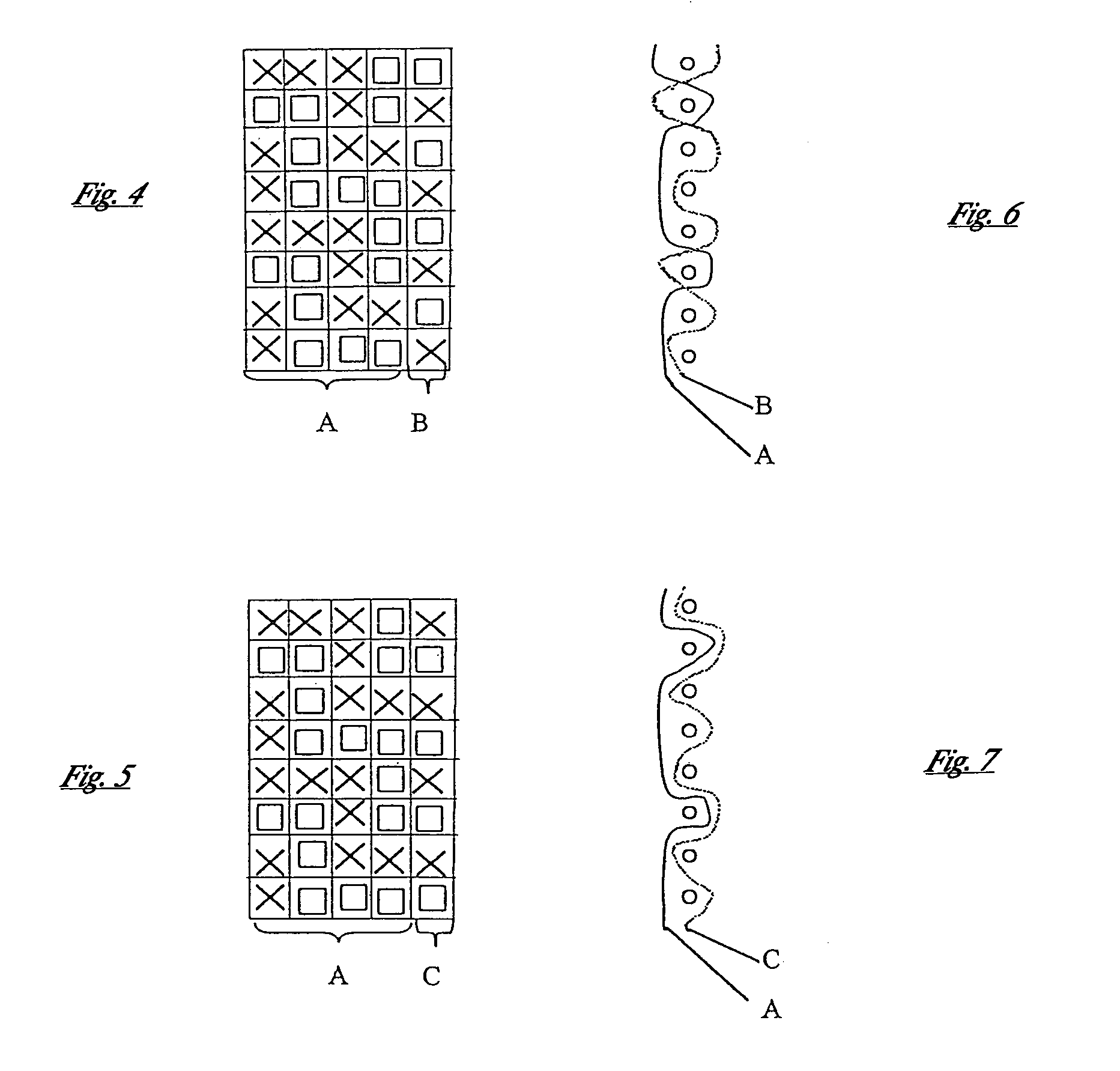

Elastic woven tape and a method of forming same

ActiveUS7117900B2Guaranteed aestheticsLarge elongationLayered productsShoulder strapContinuous integrationEngineering

An elastic woven tape is disclosed as being composed of at least two kinds of tape sections, each of which having a respectively different elongation and / or modulus, and formed by alternating and continuous integration of these two kinds of tape sections by weaving. The weaving method of the said elastic woven tape includes controlling the changes in the degrees of elasticity provided by elastic threads for the woven tape in mechanized weaving through the control of the feeding speeds of the elastic threads. The advantageous effects of this invention lie in the production of a woven tape composed of tape sections respectively with larger elongation but smaller modulus and with smaller elongation but larger modulus by means of their alternating and continuous integration by weaving, which simplifies the post-weaving operation and improves production efficiency. The resultant woven tape has no connections or joints, which assures the overall beauty of the apparel with the woven tape and the comfort of the apparel in wearing.

Owner:PIONEER ELASTIC FABRIC

Novel powder metallurgy transmission gear

InactiveCN105970106AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersSlag

The invention discloses a novel powder metallurgy transmission gear. The novel powder metallurgy transmission gear is prepared from water-atomized iron powder, copper powder, molybdenum powder, vanadium powder, nickel powder, yttrium powder, aluminum powder, magnesium powder, cobalt powder, lead powder, steel slag powder, cupola slag powder, iron alloy slag powder, modified tree ash powder, graphite powder, China wood oil-based alkyd resin, dimethyl silicone oil, ethylcellulose, zinc stearate, polyethylene glycol, ethylene bis stearamide, fatty acid, carbon fibers, glass fibers, boron nitride, epoxypropoxy trimethoxypropylsilane, silicon dioxide, manganese sulfide, acrylate, an inhibitor, a bonder, a reinforcer, a cutting agent, a lubricant, a coupling agent and a dispersant. Through the specific ingredient proportion, the novel powder metallurgy transmission gear is uniform in overall density, high in compactness, large in elongation and section shrinkage rate, good in wear resistance, strength and hardness, high in material utilization rate and suitable for large-batch rapid production of high-performance gears.

Owner:黄宇

Stent

InactiveUS20130073023A1Reduce risk of damageLarge elongationStentsBlood vesselsInsertion stentBlood vessel

Owner:MONGRAIN ROSAIRE +2

Compression device

ActiveUS20170273830A1Facilitate surface conformabilityFacilitate effective compressionFinger bandagesNon-adhesive dressingsBody regionEngineering

A compression system for applying compression to a body part of a user comprising a sleeve for substantially covering a portion of the body part of a user. The sleeve has two lateral side edges. The sleeve comprises a first lateral side region, a central region and a second lateral side region in a transverse direction from the first lateral side edge to the second lateral side edge. At least the central region of the sleeve comprises a material having elasticity in the transverse direction and longitudinal direction of the sleeve, The compression system further comprises a releasable closure system. The closure system is configured and arranged relative to the sleeve, such that, in use, upon closure of the closure system the sleeve is restrained and tightened about the body part of the user.

Owner:3M INNOVATIVE PROPERTIES CO

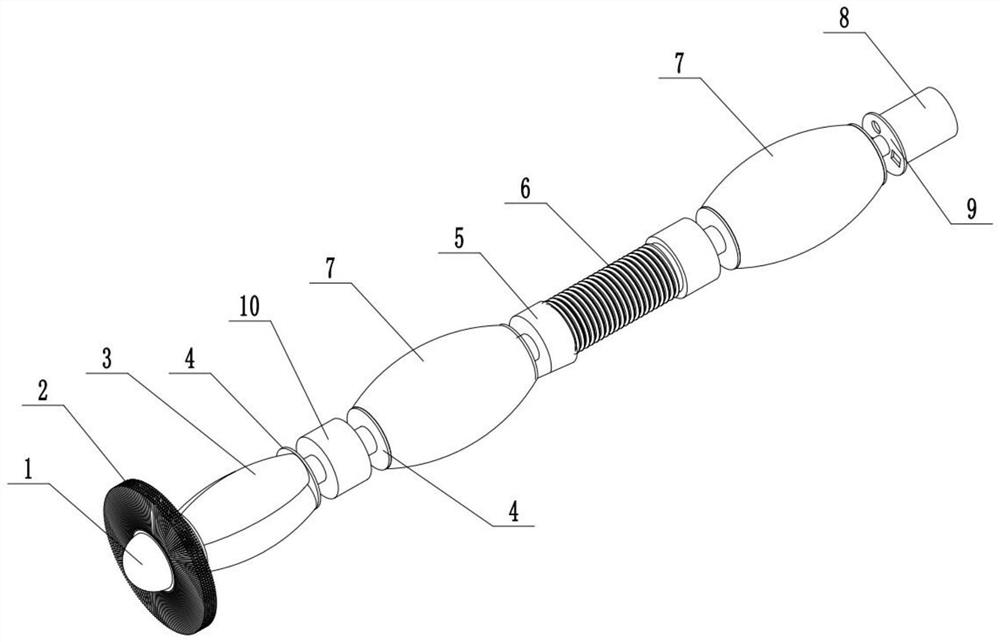

Pneumatic soft robot for pipeline

PendingCN112828870AGood stretch characteristicsSo as not to damageProgramme-controlled manipulatorSimulationAir pump

The invention relates to a pneumatic soft robot for a pipeline. The pneumatic soft robot comprises a functional module, an air pump, a direction adjusting air bag set, a walking driving part and two fixed air bags, wherein the two ends of the walking driving part are connected with one end of each of the two fixed air bags, and the air pump is mounted at the other end of one fixed air bag; one end of the direction adjusting air bag set is connected with the other end of the other fixed air bag, and the functional module is mounted at the other end of the direction adjusting air bag set; the walking driving part can be extended and shortened along with inflation and deflation; the direction adjusting air bag set comprises at least three ellipsoidal air bags, each ellipsoidal air bag is tightly connected with the adjacent ellipsoidal air bag together, expansion and contraction movements of the ellipsoidal air bags is independent of each other, and steering of the robot is achieved through coordinated movement of all the ellipsoidal air bags. The robot can flexibly adapt to pipelines with different calibers, flexible contact between the robot and the inner walls of the pipelines can be achieved, and multifunctional operation is achieved.

Owner:HEBEI UNIV OF TECH

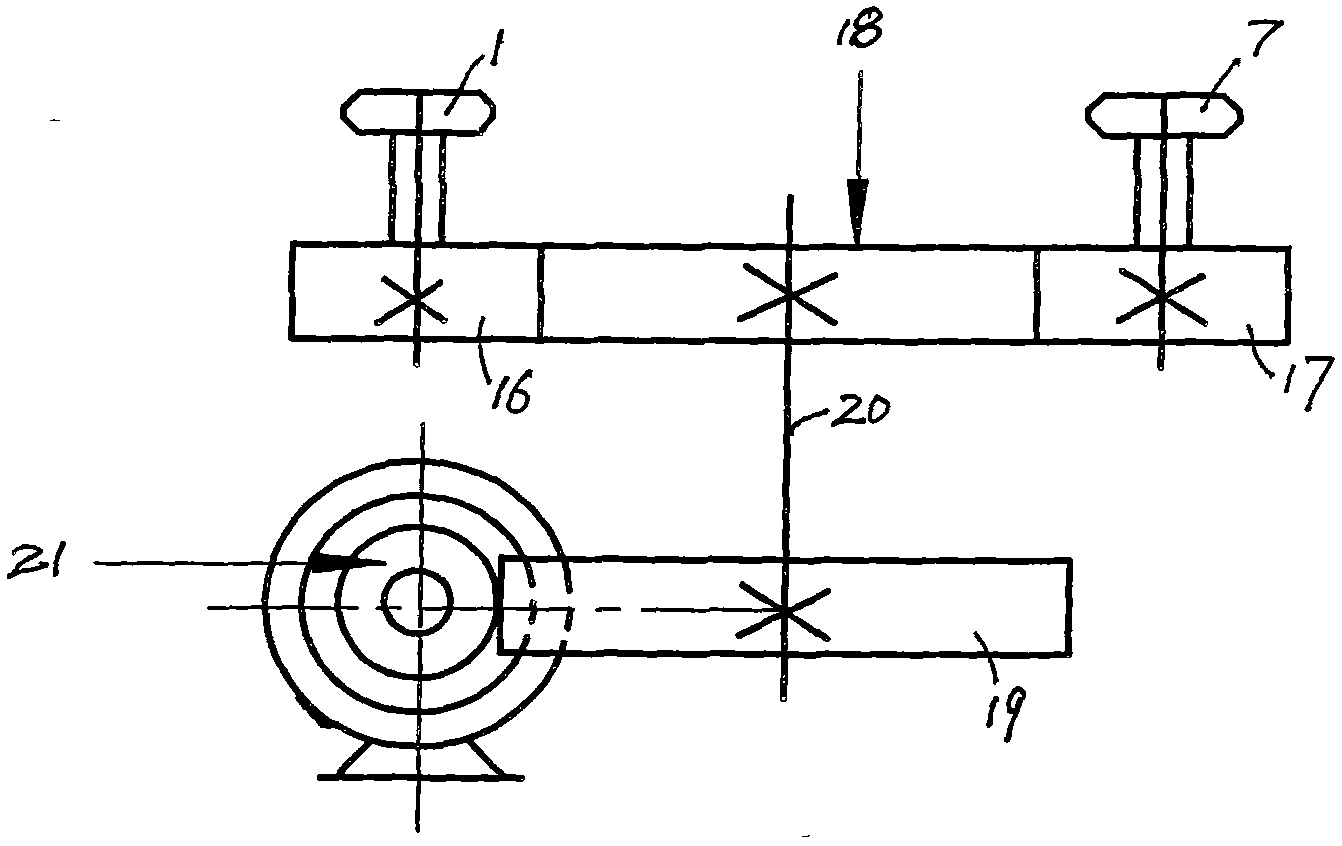

Movable pre-stretching device for chain

InactiveCN101797738AChange the pretension valueChanging the pre-tension value is unstable and the processing efficiency is lowWire toolsMetal chainsChange positionsMachining

The invention provides a movable pre-stretching device for a chain, which has the characteristics of stable pre-stretching value, large extension amount after stretching and high machining efficiency. The device comprises a chain feeding chain wheel, a stressing chain wheel and a chain discharging chain wheel on which the chain is wound in turn, wherein a stressing chain wheel shaft sleeved with the stressing chain wheel can be arranged on a stressing chain wheel seat in a way of moving along a radial direction. By changing position the stressing chain wheel, the pre-stretching value is changed and the pre-stretching value is stable, so the problems of unstable pre-stretching value and low machining efficiency caused by manual operation are solved.

Owner:NANJING LIMIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com