Patents

Literature

4355results about How to "Guaranteed aesthetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Household security system and household security method

InactiveCN101673422AGuaranteed aestheticsSolve the problem of pulling many communication cablesIndividual entry/exit registersBurglar alarmWireless transmissionWireless video

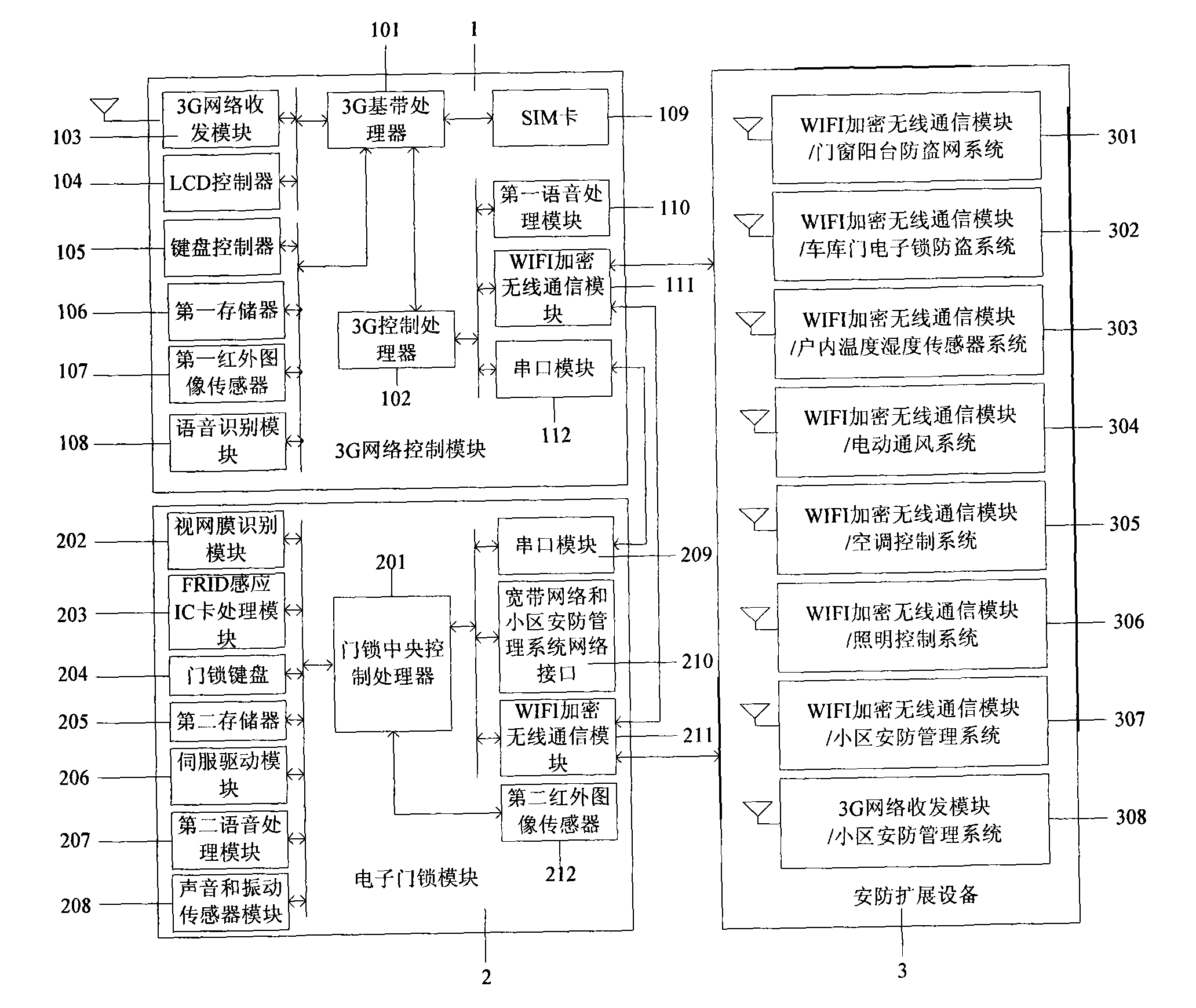

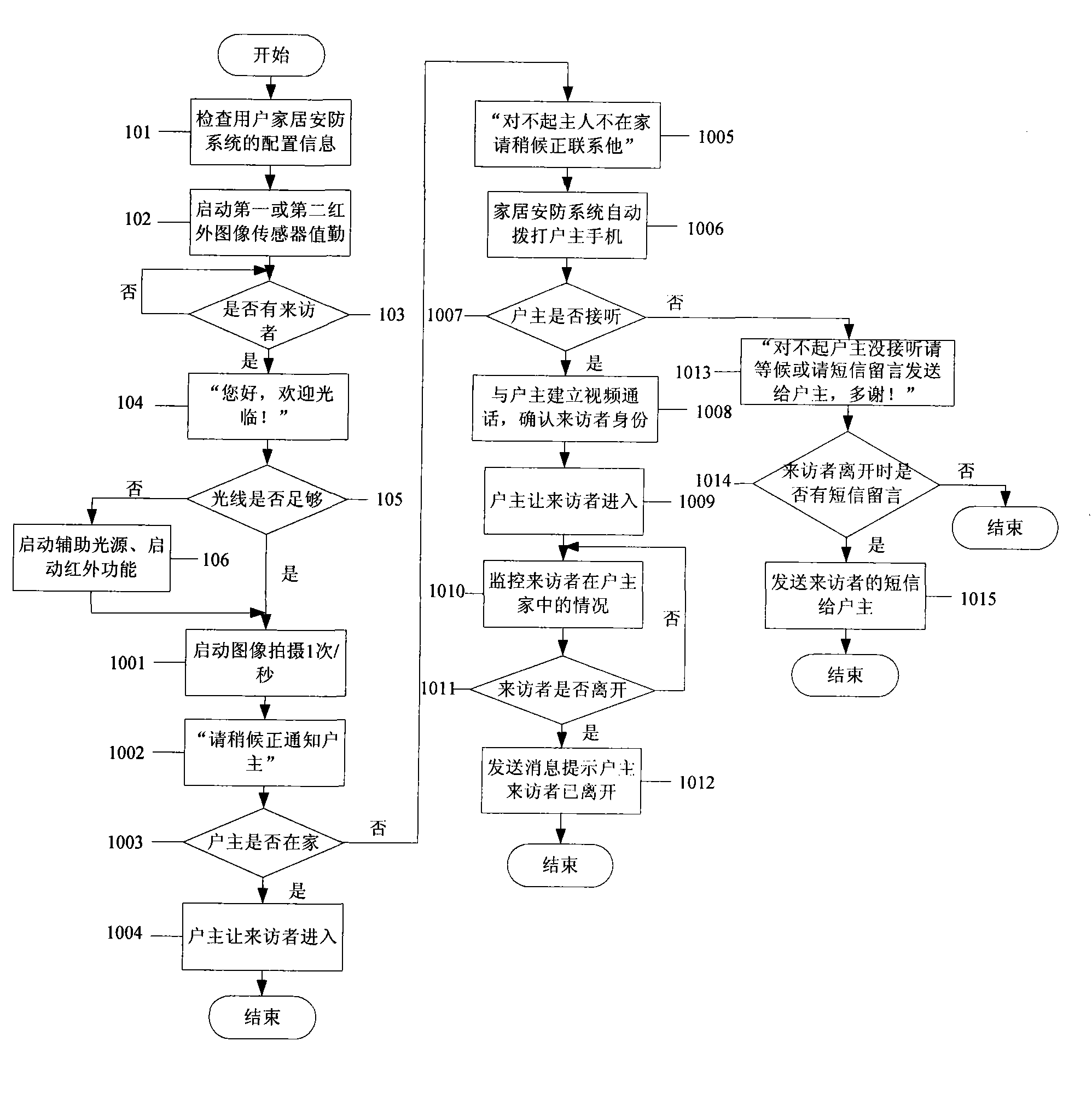

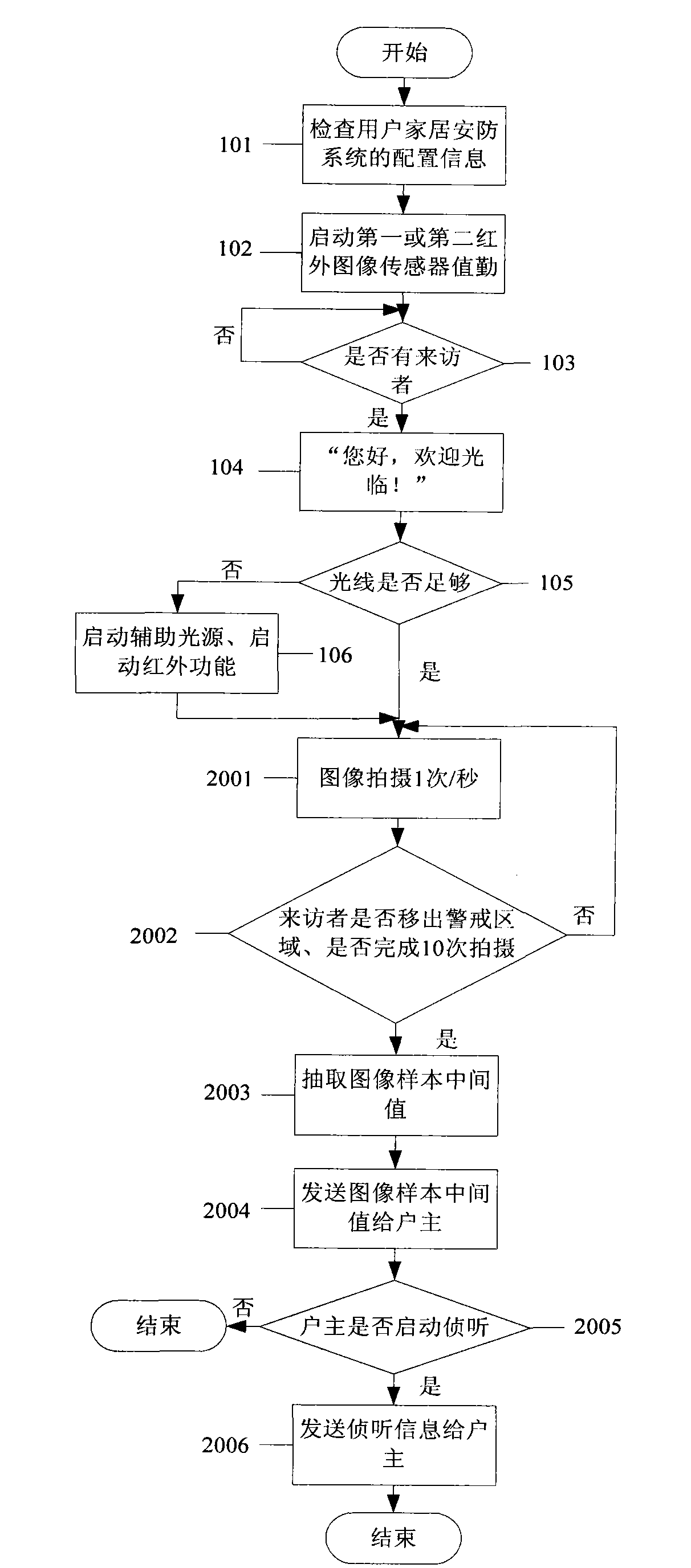

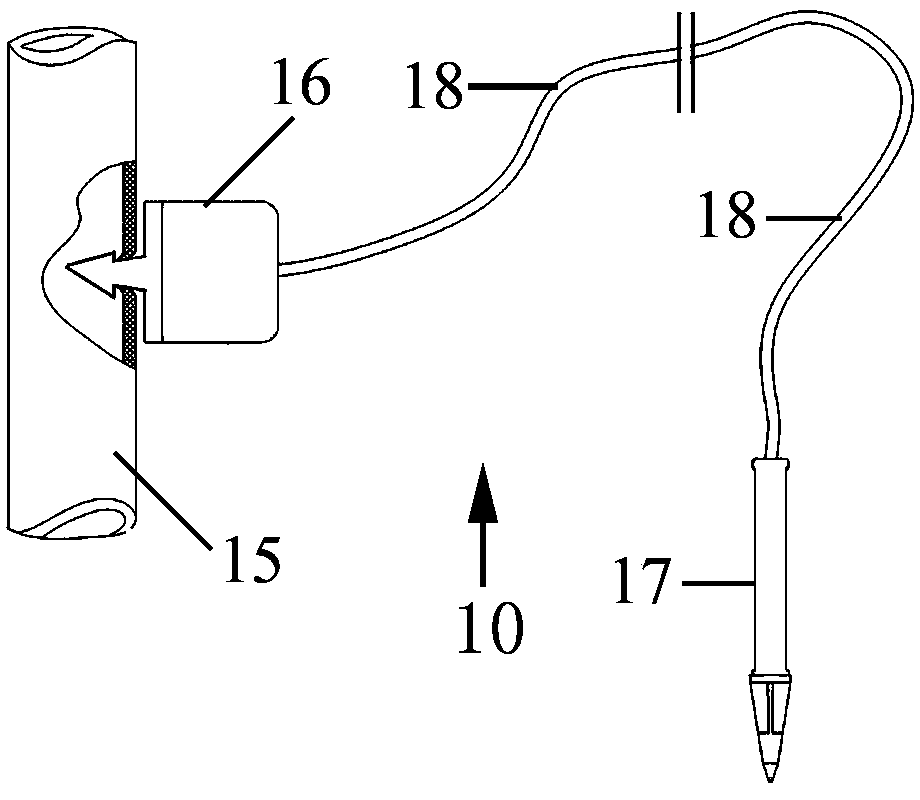

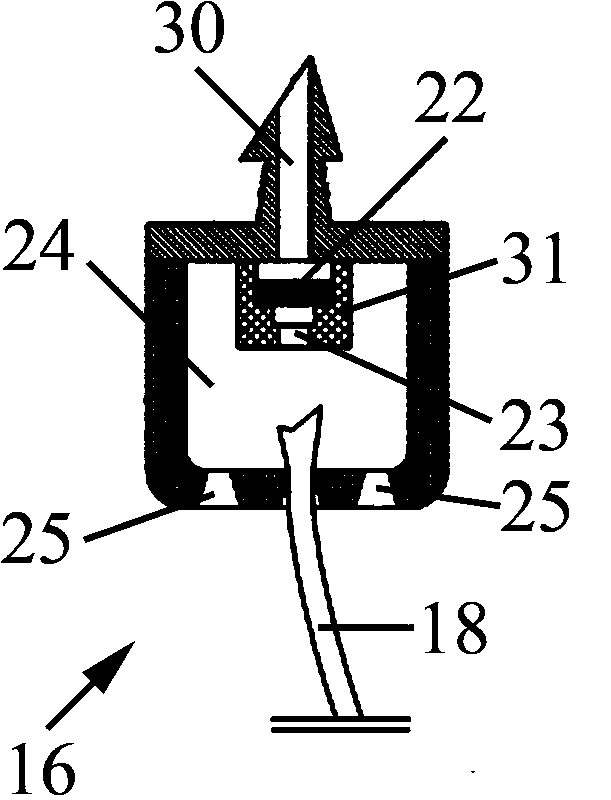

The invention discloses a household security system and a household security method. The system comprises a 3G network control module and an electronic door lock module, wherein the 3G network control module is used for implementing wireless video session, short message communication control and intrusion information reminding with a householder, implementing wireless video session and intrusion information reminding with a cell security management system, and implementing wired video session and intrusion information reminding through a bandwidth network and a network interface of the cell security management system; and the electronic door lock module is used for implementing door opening, visitor reminding and identification. The intelligent level and the safety performance of the household security system are improved, the expansion performance of the whole security system is improved, and the problem that a common security system needs a great number of communication cables due to the adoption of wireless transmission technology is solved at the same time.

Owner:SHANGHAI SIMCOM LTD

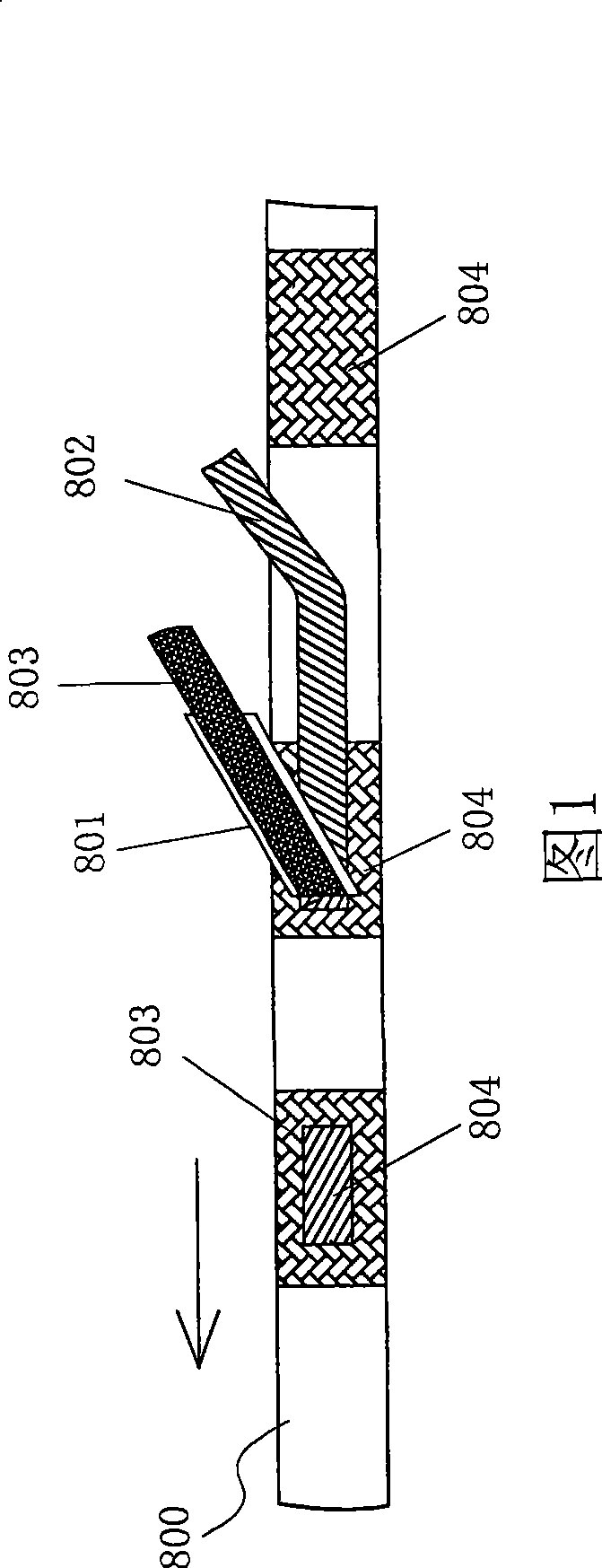

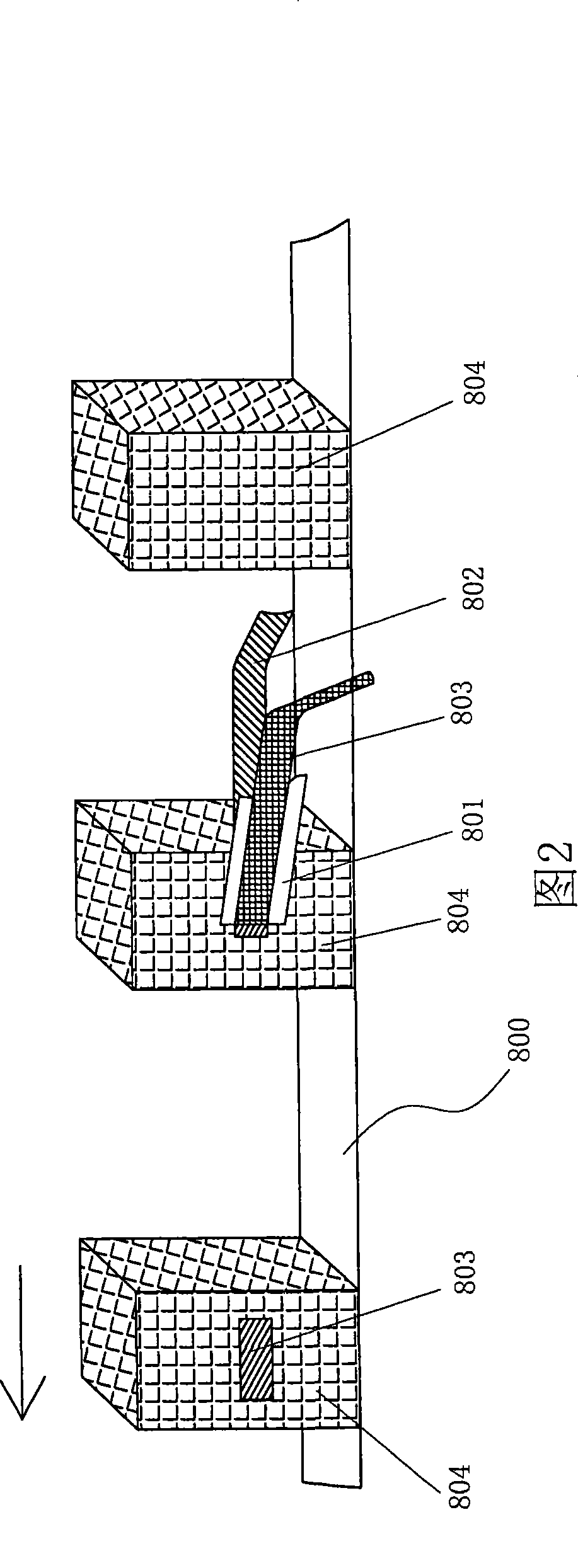

Dried hanging thermal insulation decorative curtain wall and mounting process thereof

InactiveCN101302782AReduce construction costsShorten construction timeCovering/liningsWallsThermal insulationKeel

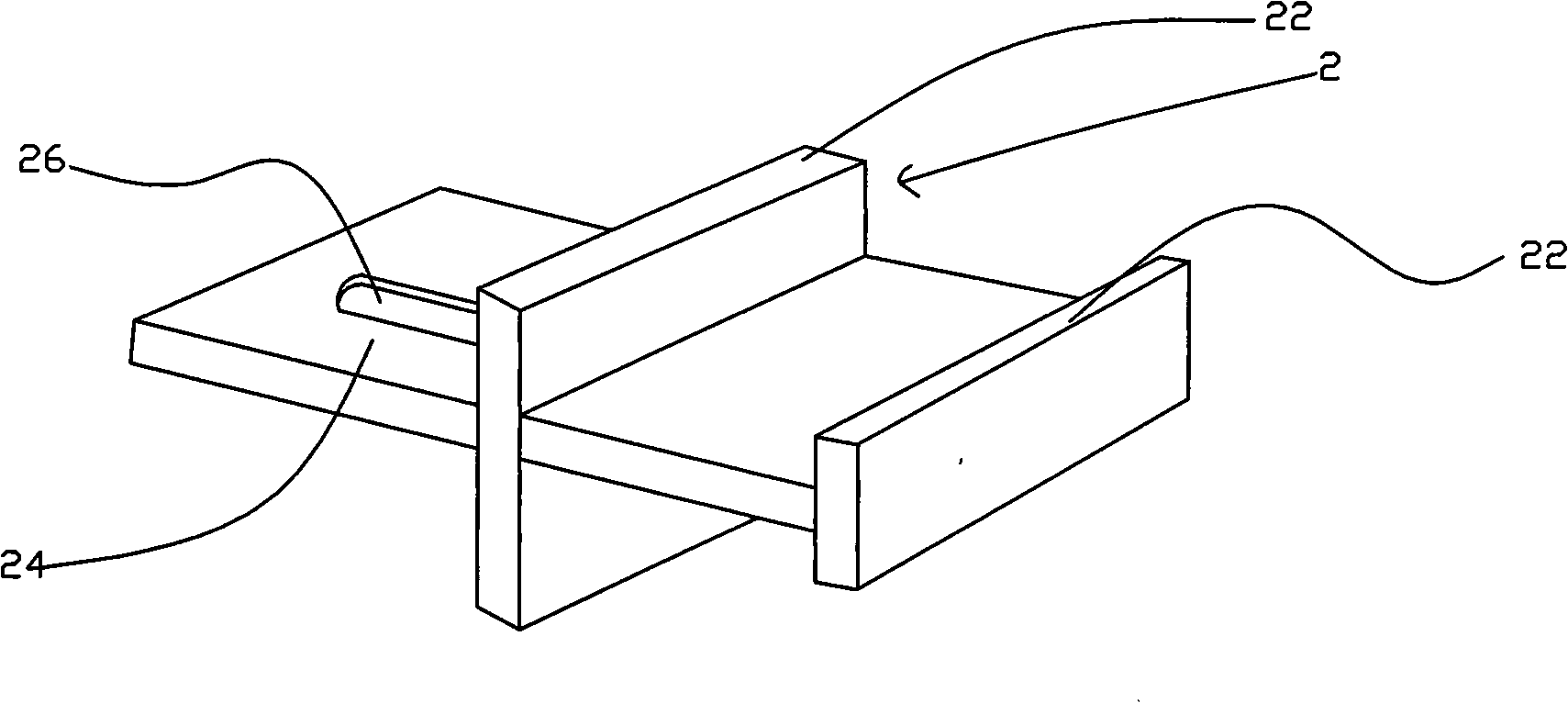

The invention discloses a dry-hanging curtain wall for thermal insulation and decoration and an installation technique thereof, which essentially comprises a 'duplex F' shape installation hanging part; the radial frameworks and the zonal frameworks of the 'duplex F' shape installation hanging part are vertically arranged; a first layer of the radial frameworks with two or more than two layers is level to the zonal frameworks and the radial framework at the last layer is at a certain distance from the tail end of the zonal framework; the width and thickness of the radial frameworks at every layer can be equal or not. Insulation boards can be fixed in a point-typed installation and location method by the installation hanging part, thus overcoming the defects of the prior art, providing an installation technique of the thermal insulation and decoration curtain wall without installing the horizontal and the vertical joist, simplifying the installation procedure, saving the installation raw materials and cost and overcoming the defect that the rain leakage is easy to happen in the splicing seam of the insulation board adopting the traditional method.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

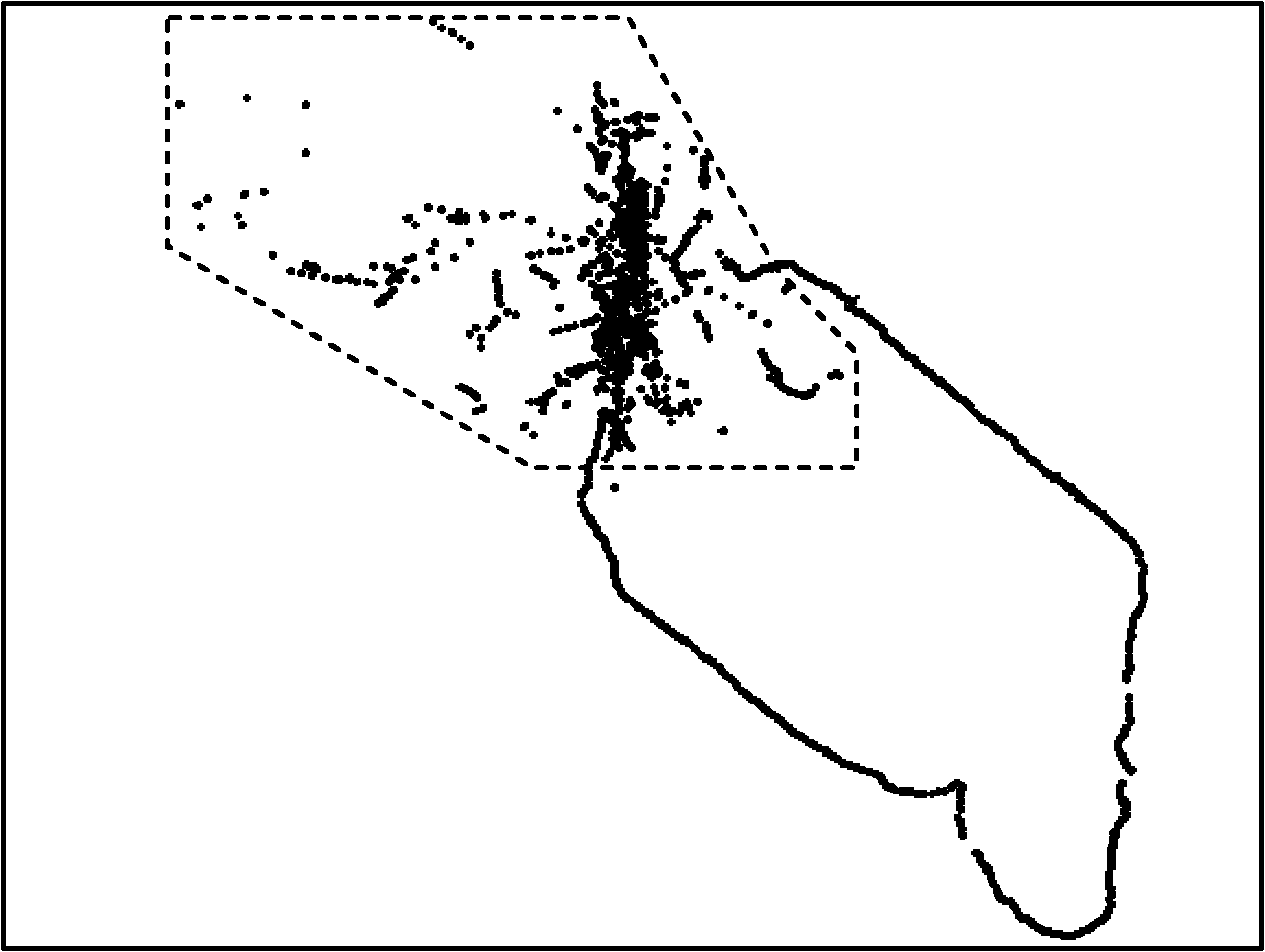

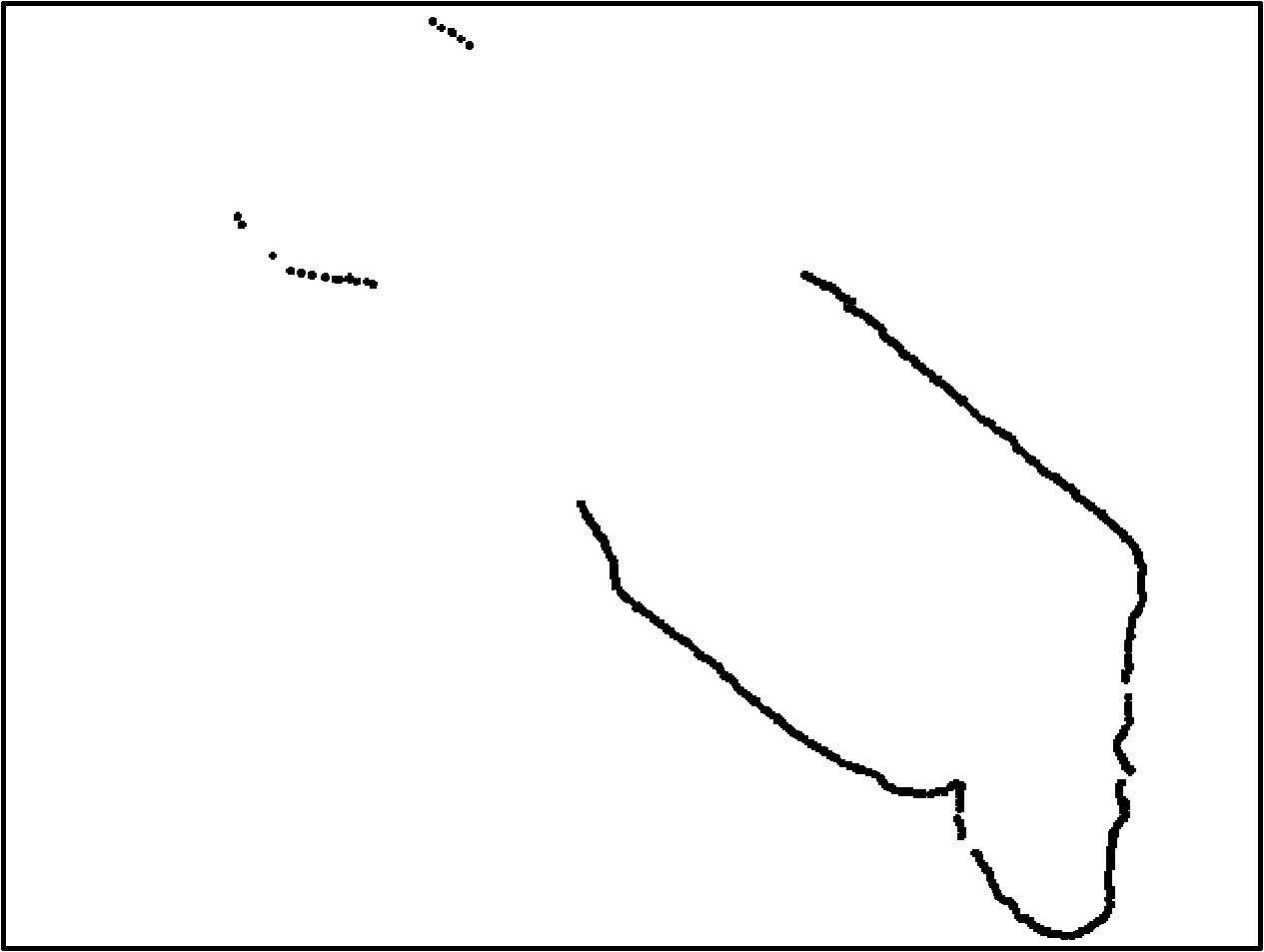

Method for filtering ineffective drift signal of global positioning system (GPS) equipment

ActiveCN102183773AGuaranteed to be correctGuaranteed aestheticsSatellite radio beaconingSpatial analysisGlobal Positioning System

The invention provides a method for filtering an ineffective drift signal of global positioning system (GPS) equipment. The method comprises the following steps of: recognizing and filtering an ineffective drift signal point produced by the static GPS equipment at first when an indoor signal or an outdoor signal is different; and then correctly recognizing an ineffective drift point without deleting normal trace points of a satellite signal difference by mistake by comprehensively using the GPS signal weakness and a space analysis result. By the method, the effectiveness of the GPS signal canbe determined accurately on a software layer; and ineffective positioning points can be filtered out to the maximum extent on the basis of guaranteeing the completeness of the normal trace.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

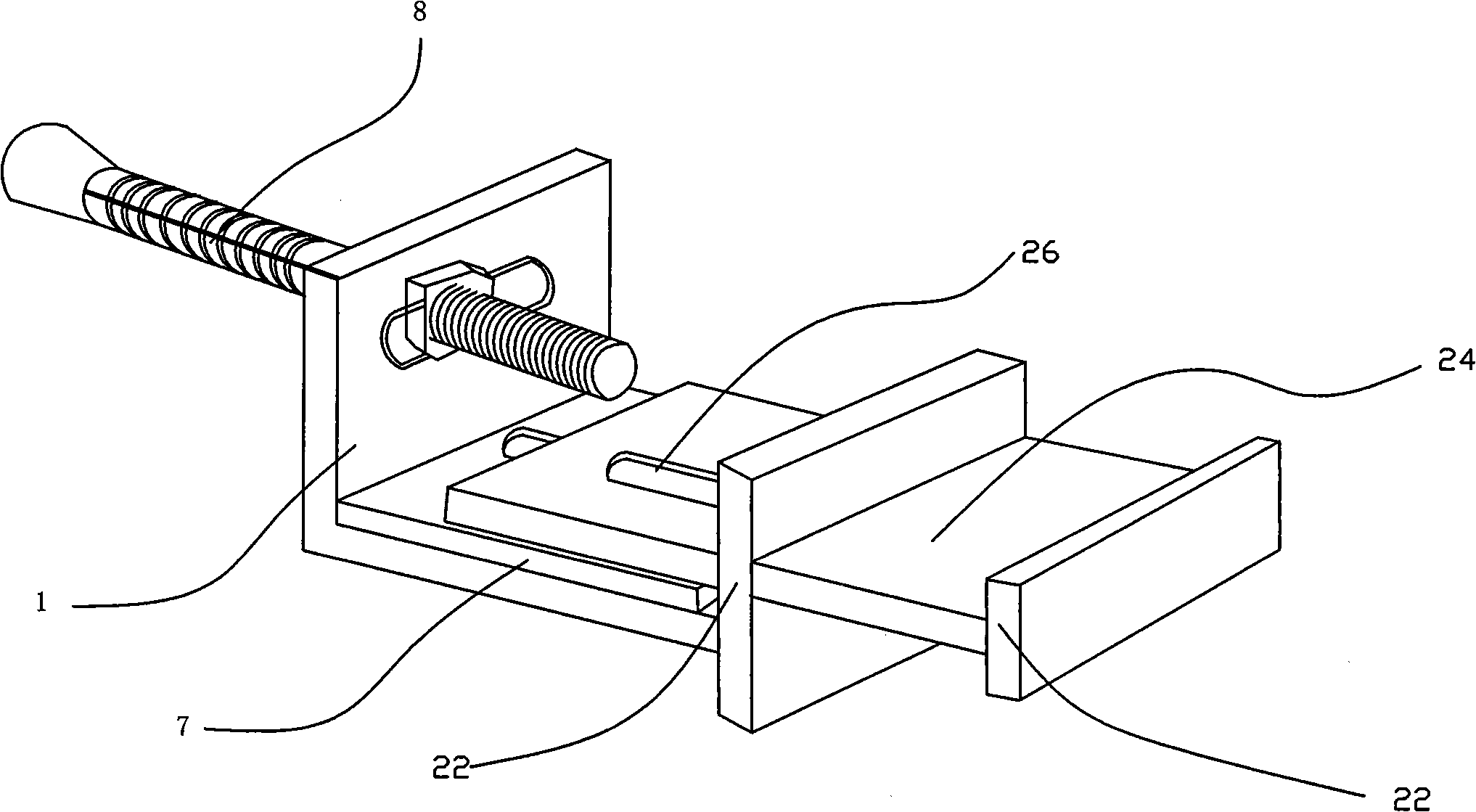

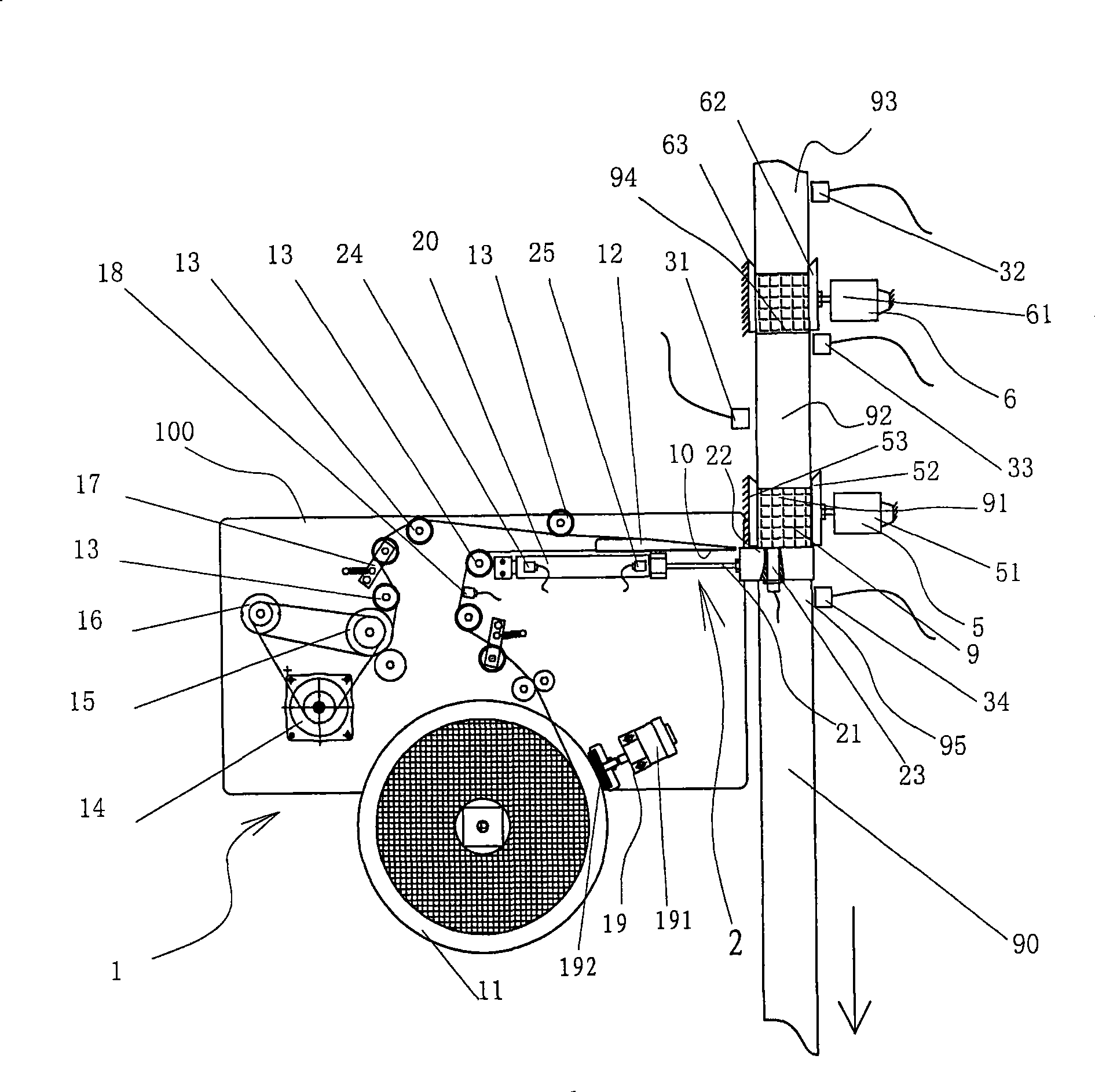

Labeler

The invention provides a labeling machine which comprises a label feeding and conveying device, a label coating device, a position detecting device and a controlling device, wherein, the label coating device comprises a telescopic rod and a picking and coating component arranged at the end part of the telescopic rod, and the position detecting device sends preset signals when a product reaches the preset trigger position of the label coating device; the controlling device controls the telescopic rod to move according to the signals, controls the telescopic rod to perform the extension motion when the product reaches the preset trigger position of the label coating device, and ensures the telescopic rod to extend to the extension position when the product reaches a preset coating position, to perform labeling to the front side surface of the product, and controls the telescopic rod to retract to a retracting position after the labeling is accomplished, to ensure the product which is labeled to be allowed to continuously move with a conveying chain. The labeling machine can automatically paste the label onto the front part of the product, the operating efficiency is improved, and the artistic appearance of the product is ensured.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

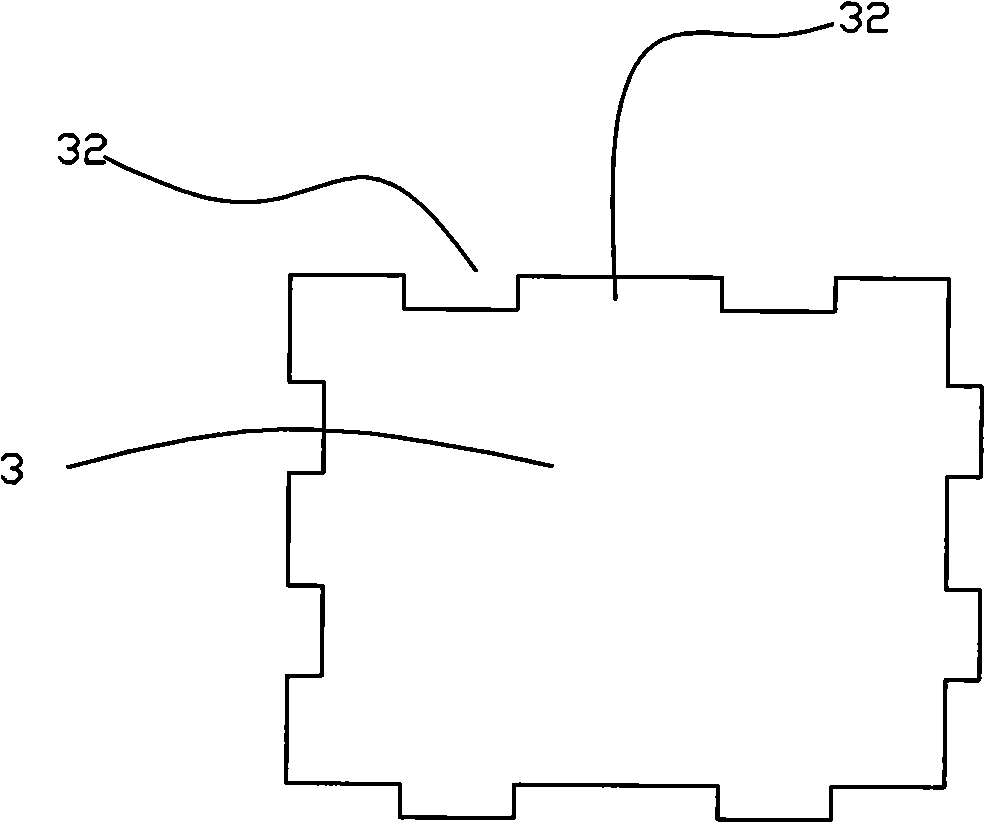

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

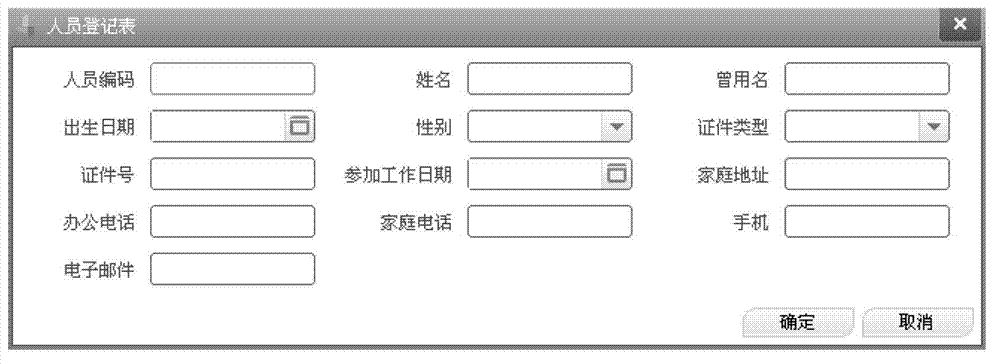

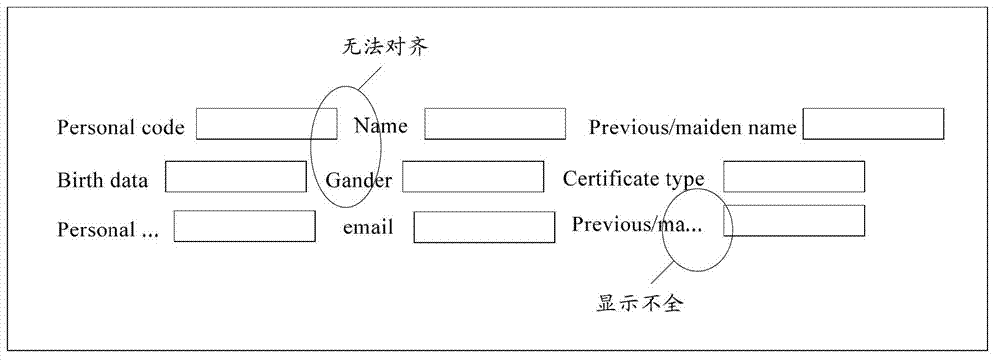

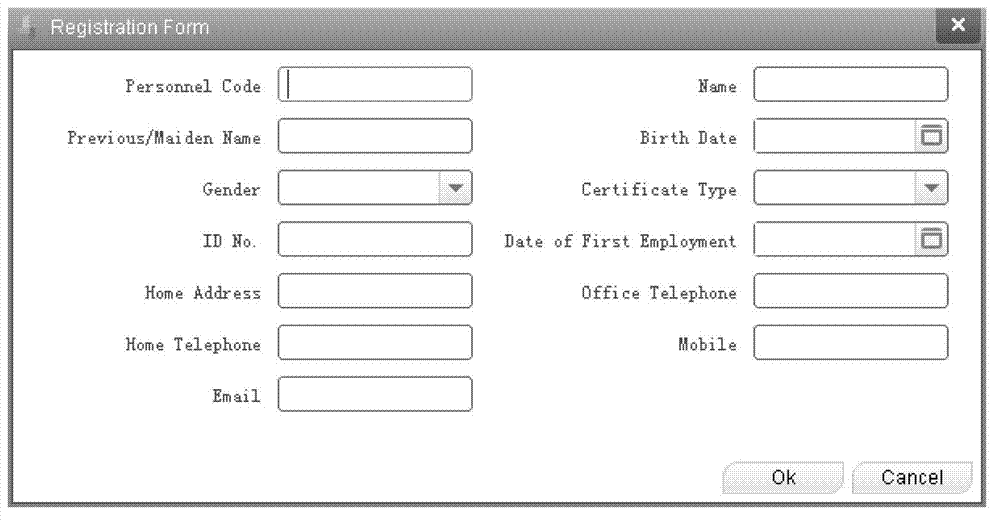

Interface control arrangement device and interface control arrangement method

ActiveCN102929603AGuaranteed aestheticsAutomatically adjust interface layoutSpecific program execution arrangementsSelf adaptiveElectrical and Electronics engineering

The invention provides an interface control arrangement device and an interface control arrangement method. The device comprises a presetting unit, a label width determination unit, a column number determination unit, a control width determination unit, a calculation unit and an adjustment unit, wherein the presetting unit is used for presetting configuration parameters of a panel and presetting arrangement units which are needed to be displayed in the panel; the arrangement units comprise labels and controls; the label width determination unit is used for selecting the maximum value of text lengths of the labels in all the arrangement units as the width of the labels in each arrangement unit; the column number determination unit is used for determining the display column number of the arrangement units according to the configuration parameters of the panel; the control width determination unit is used for determining the width of the controls in each arrangement unit based on the configuration parameters, the display column number and the label width; the calculation unit is used for calculating the display position of each arrangement unit in the panel according to the configuration parameters, the label width and the control width; and the adjustment unit is used for adjusting the arrangement of the arrangement units in the panel according to the display position of each arrangement unit and the widths of the labels and the controls in the arrangement units. By the device and the method, the labels and the controls can be adaptively adjusted when displayed in different languages.

Owner:YONYOU NETWORK TECH

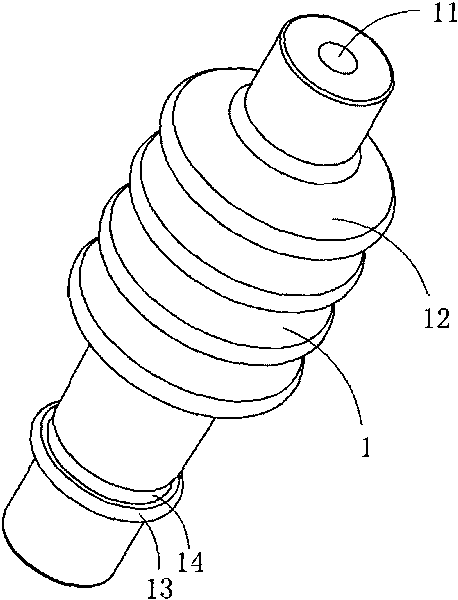

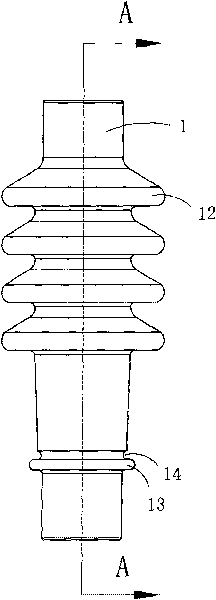

Ceramic insulator and high voltage power capacitor insulator device

ActiveCN101719402AImprove convenienceSolder undercutCapacitorsLead-in/lead-through insulatorsMetallurgyCapacitor

The invention discloses a ceramic insulator and a high voltage power capacitor insulator device. The ceramic insulator comprises a ceramic insulator body, wherein the middle outer wall is provided with a plurality of umbrella skirts, and the lower wall is provided with an annular locating lug boss; and an annular groove is arranged between the annular locating lug boss and the umbrella skirts. The insulator device comprises the ceramic insulator body, a wiring assembly and a mounting assembly; the mounting assembly comprises a metal mounting seat and a seal ring; the metal mounting seat is tubular, the upper end of the metal mounting seat is provided with a welding part, the lower end is provided with a blocking part, and the blocking part is positioned below the annular locating lug boss; the seal ring is positioned between the lower surface of the annular locating lug boss and the blocking part; the welding part is higher than the annular groove of the insulator body; and the inner wall of the welding part of the metal mounting seat, the outer wall of the insulator body and the annular locating lug boss enclose a welding space, and welding flux is arranged in the welding space. The invention is convenient to mount and operate and effectively enhances the production efficiency.

Owner:STATE GRID CORP OF CHINA +3

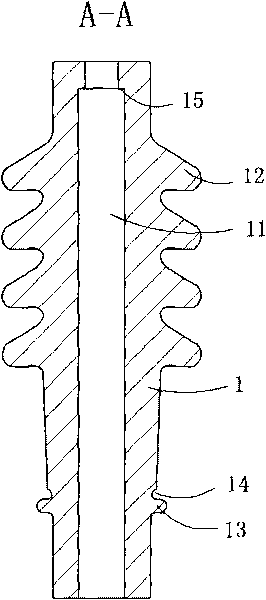

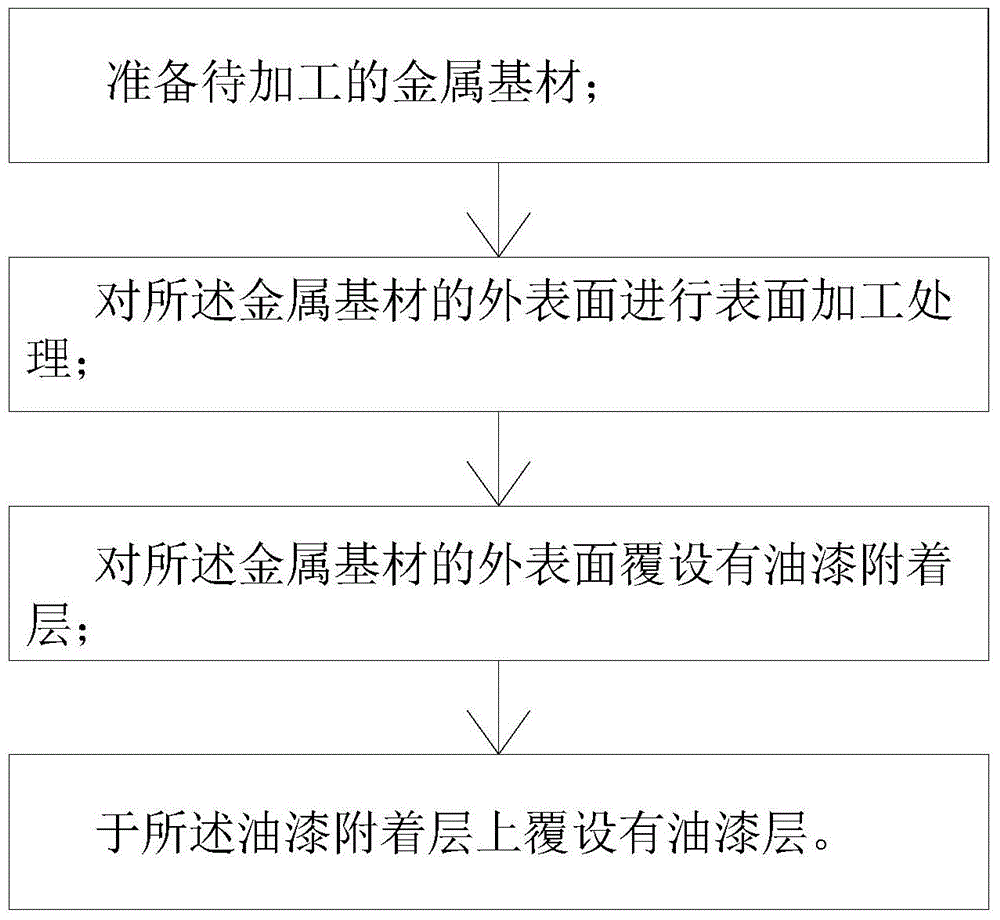

Metal workpiece and outer surface spray processing method of metal workpiece

ActiveCN104451549ASolve the problem of paint peelingAvoid prone to drop problemsVacuum evaporation coatingSputtering coatingMetallic substrateMetal substrate

The invention provides an outer surface spray processing method of a metal workpiece. The method comprises the following steps: preparing a to-be-processed metal substrate; carrying out surface processing treatment on the outer surface of the metal substrate; covering a paint attachment layer on the outer surface of the metal substrate; and covering a paint layer on the paint attachment layer. According to the outer surface spray processing method of the metal workpiece provided by the invention, the paint attachment layer mainly covers the outer surface of the metal substrate, wherein as the paint attachment layer firmly covers the outer surface of the metal substrate, a relatively large adhesive force is generated between the paint attachment layer and the paint layer, thus the paint layer can be firmly attached to the paint attachment layer while the paint layer is well attached to the outer surface of the metal substrate, thereby solving the problem that in the prior art, the paint layer which is sprayed on the metal substrate easily falls. The invention further provides the metal workpiece.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

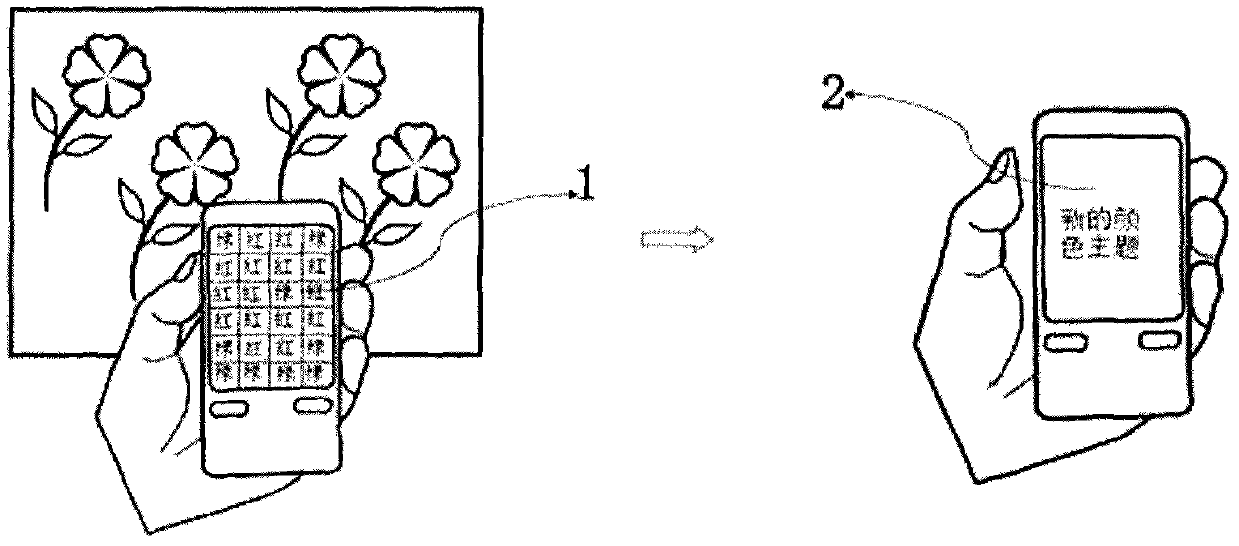

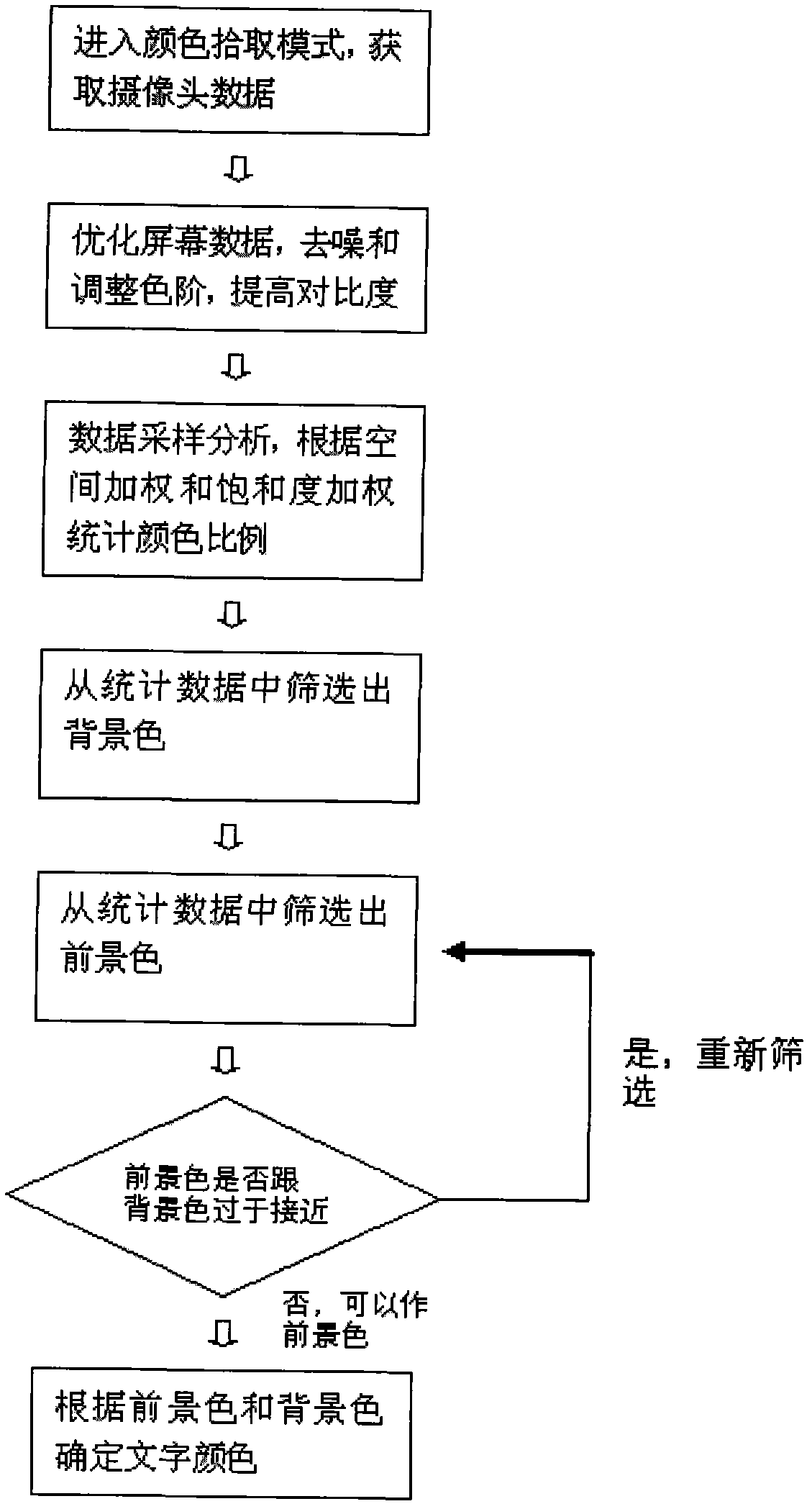

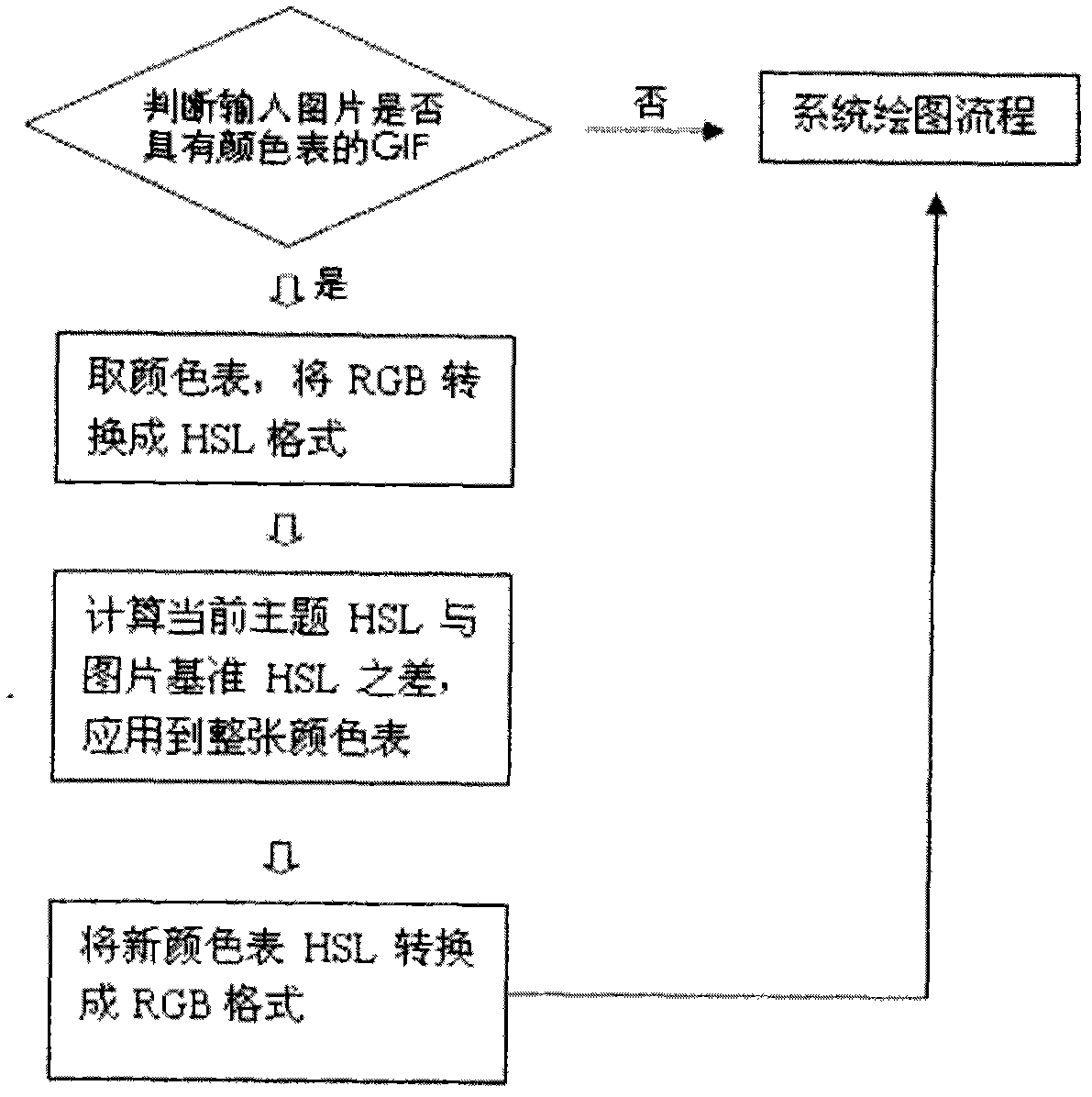

Method for extracting color and changing theme coloring by utilizing traditional camera

InactiveCN102568010ARemove the effect of colorImprove vividnessTelevision system details2D-image generationSpecial effectsGraphics Interchange Format

The invention discloses a method for extracting color and changing theme coloring by utilizing a traditional camera. The method mainly comprises a color extracting method and a theme coloring changing method. The color extracting process comprises the following steps: entering a color picking mode by a custom operation (entering a menu or pressing a specific key) at a terminal, opening the camera for starting automatic framing, and displaying the framing data after latticed special effect processing on the interface of the terminal for a terminal user to refer to the approximate color of the framing region of the camera at present. When the user finishes framing, the color extracting method starts to carry out color analysis and extraction on the data captured by the camera. In the method, color changing is performed by utilizing a GIF (graphics interchange format) picture so that the operation is greatly simplified and the efficiency is improved.

Owner:SHANGHAI TRICHEER TECHNOLOGY CO LTD

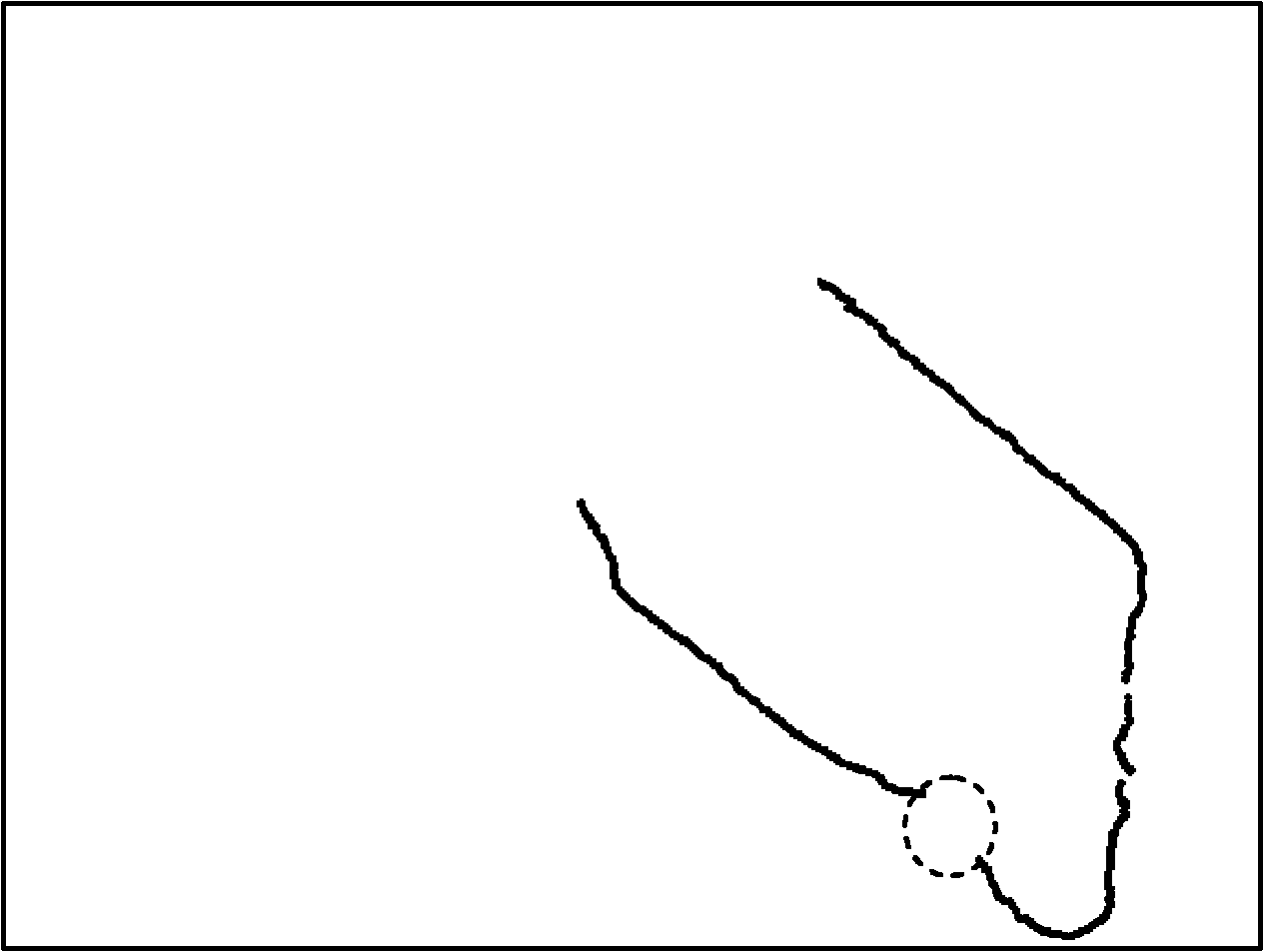

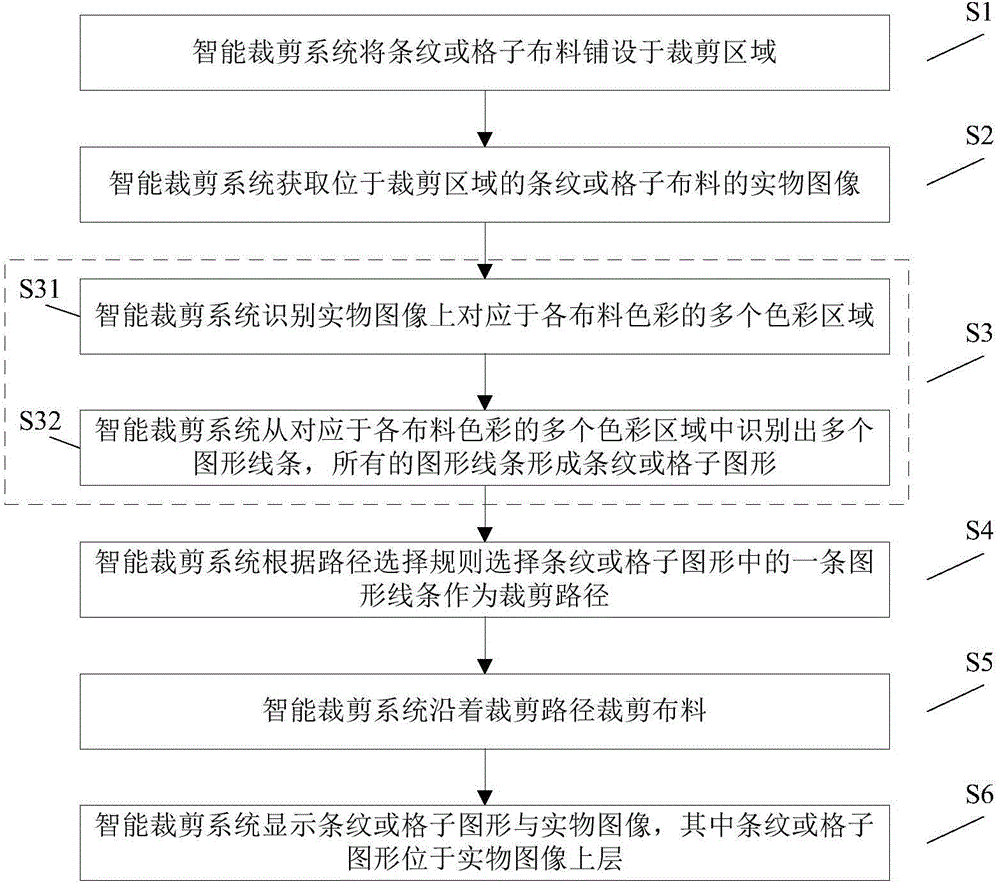

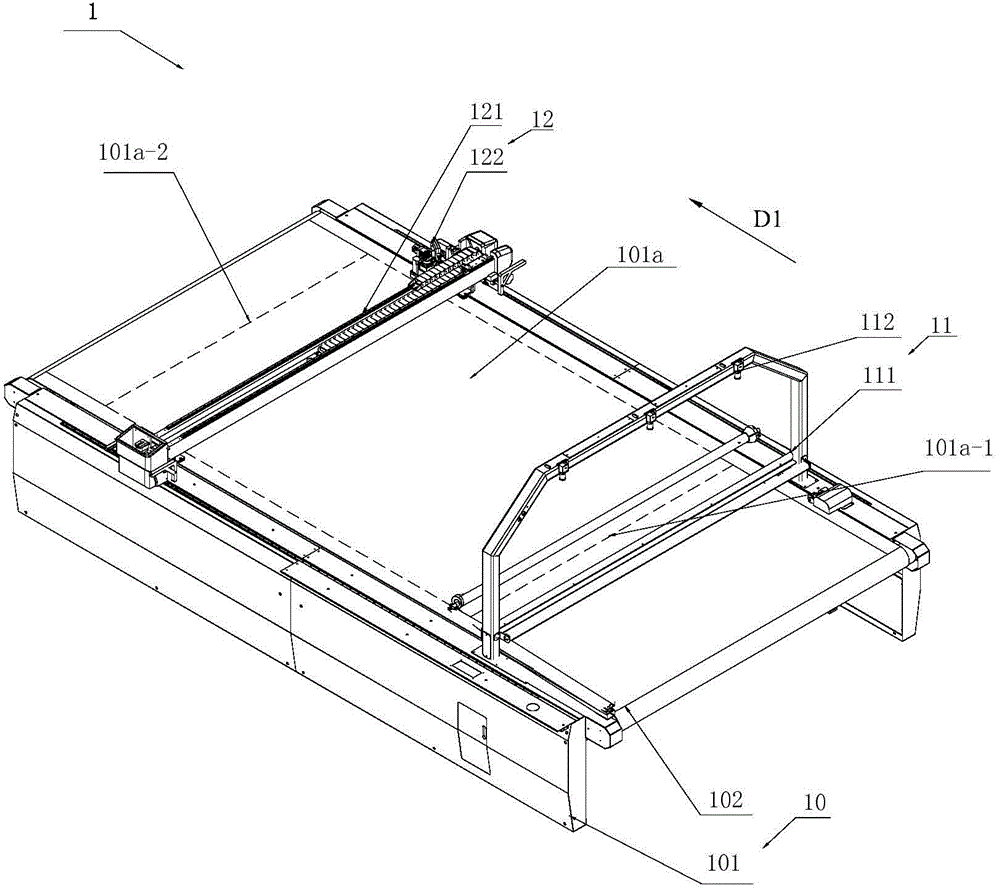

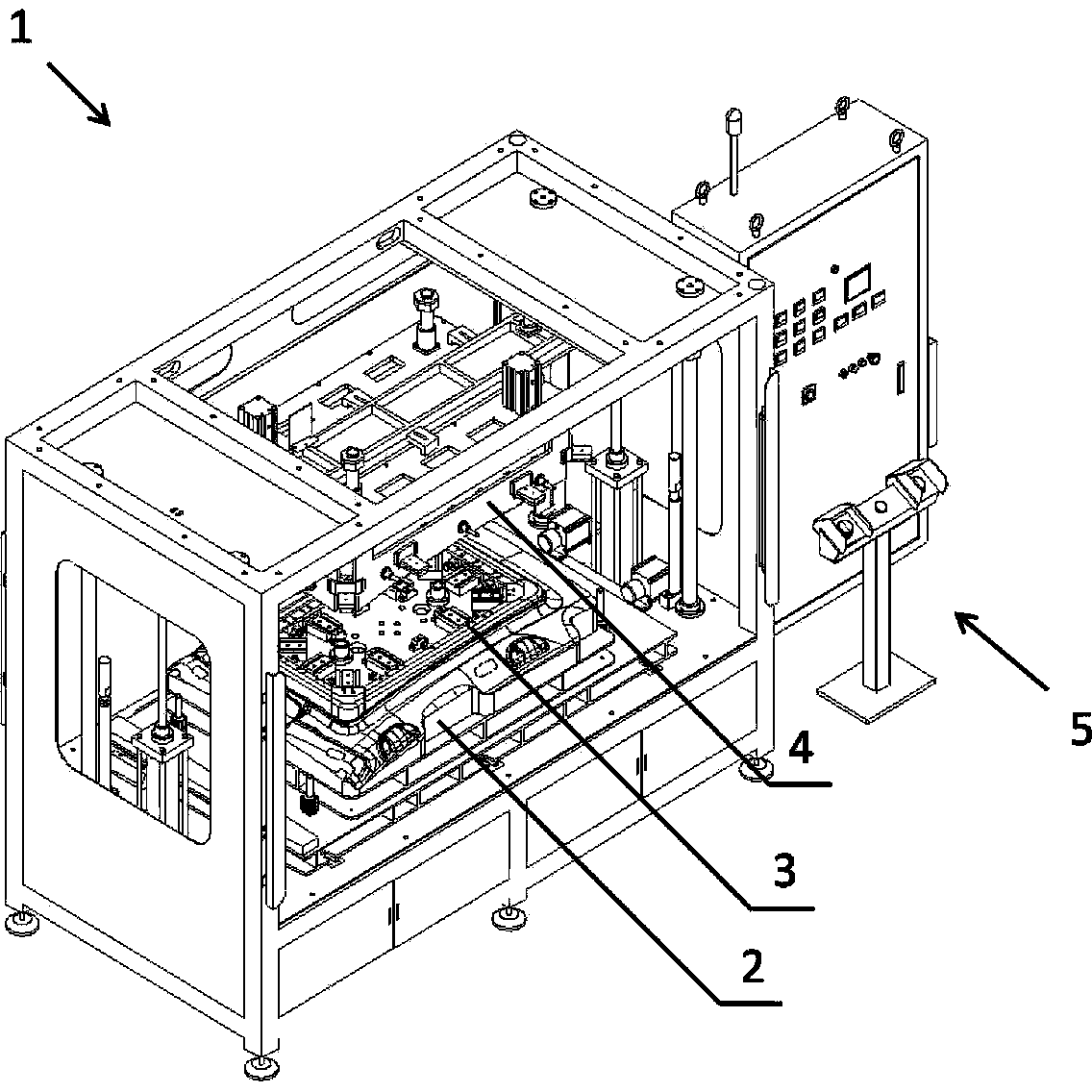

Intelligent cutting method and system

InactiveCN104818603AAvoid misalignmentGuaranteed aestheticsSevering textilesManufacturing engineering

The invention relates to the technology of automatic cutting, and discloses an intelligent cutting method and system. The method is used for cutting stripe or quadrille cloth, and is used for the intelligent cutting system with a cutting region. The method comprises the following steps: the intelligent cutting system enables the stripe or quadrille cloth to be laid in the cutting region; the intelligent cutting system obtains an object image of the stripe or quadrille cloth located in the cutting region; the intelligent cutting system recognizes the stripe or quadrille pattern from the object image; and the intelligent cutting system selects one line from the stripe or quadrille pattern according to a path stored in the intelligent cutting system, and enables the line to serve as a cutting path. The method and system prevents the stripe or quadrille pattern of cut cloth from being staggered, and guarantee the appearance beauty of a product made of the cloth.

Owner:长园和鹰科技(河南)有限公司

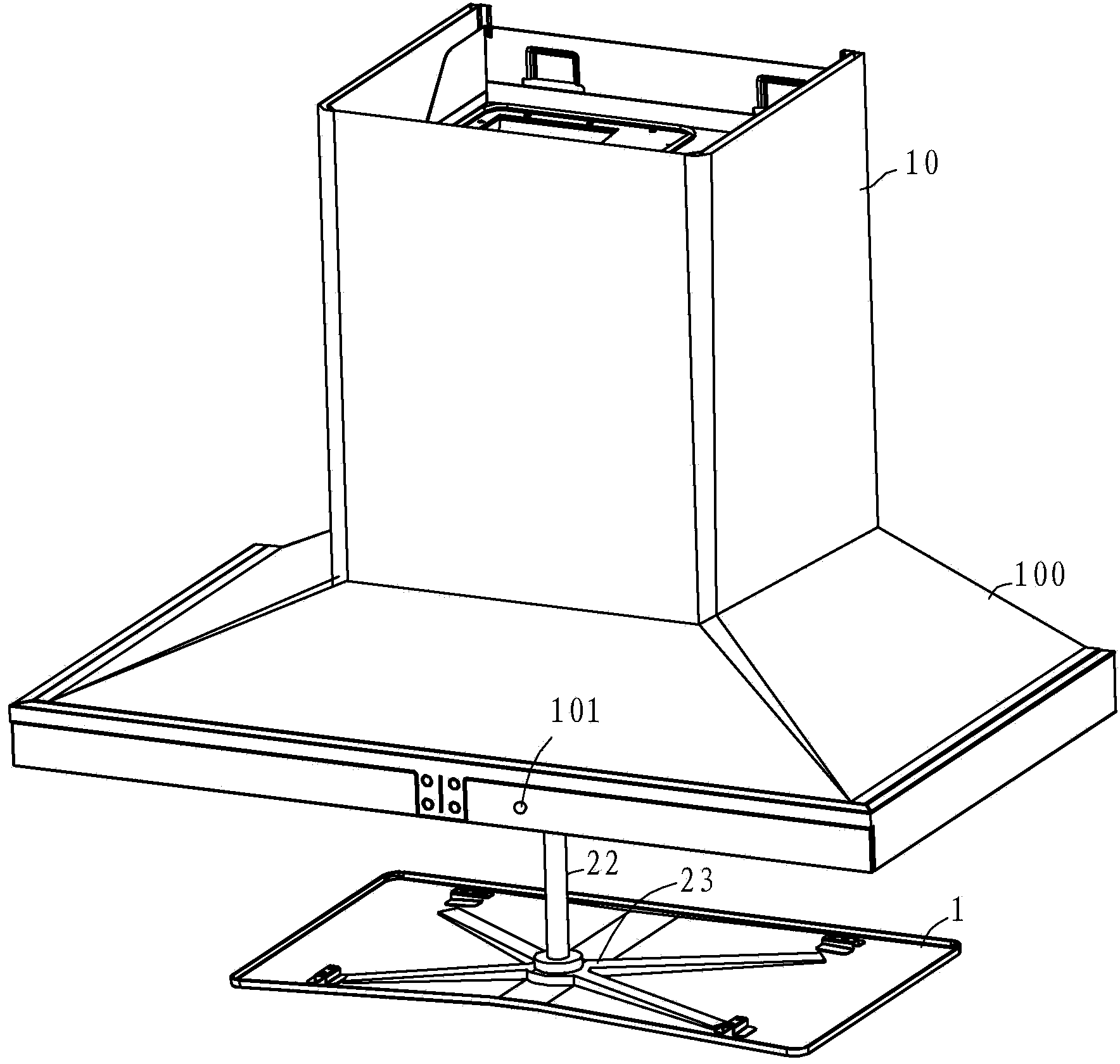

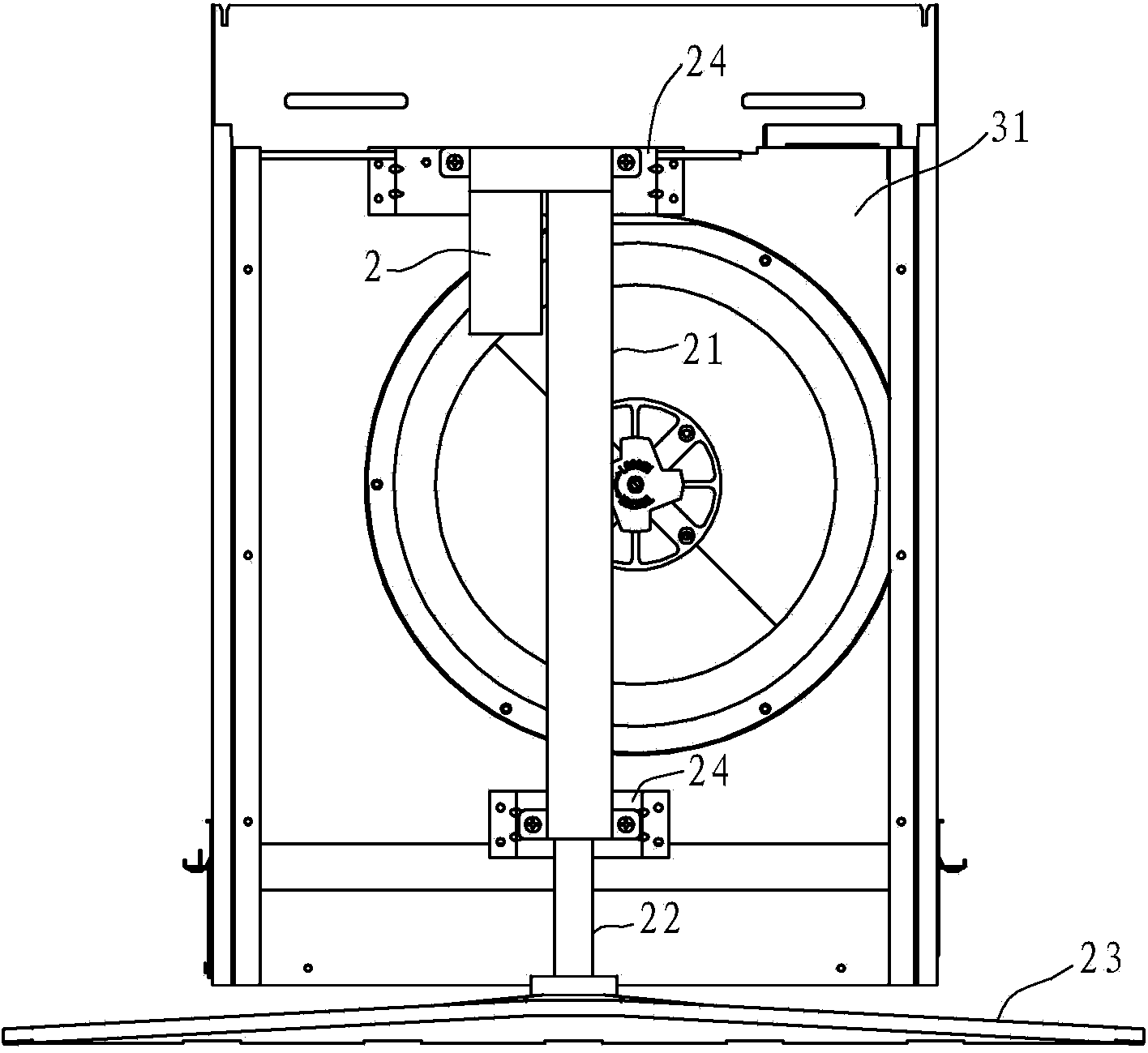

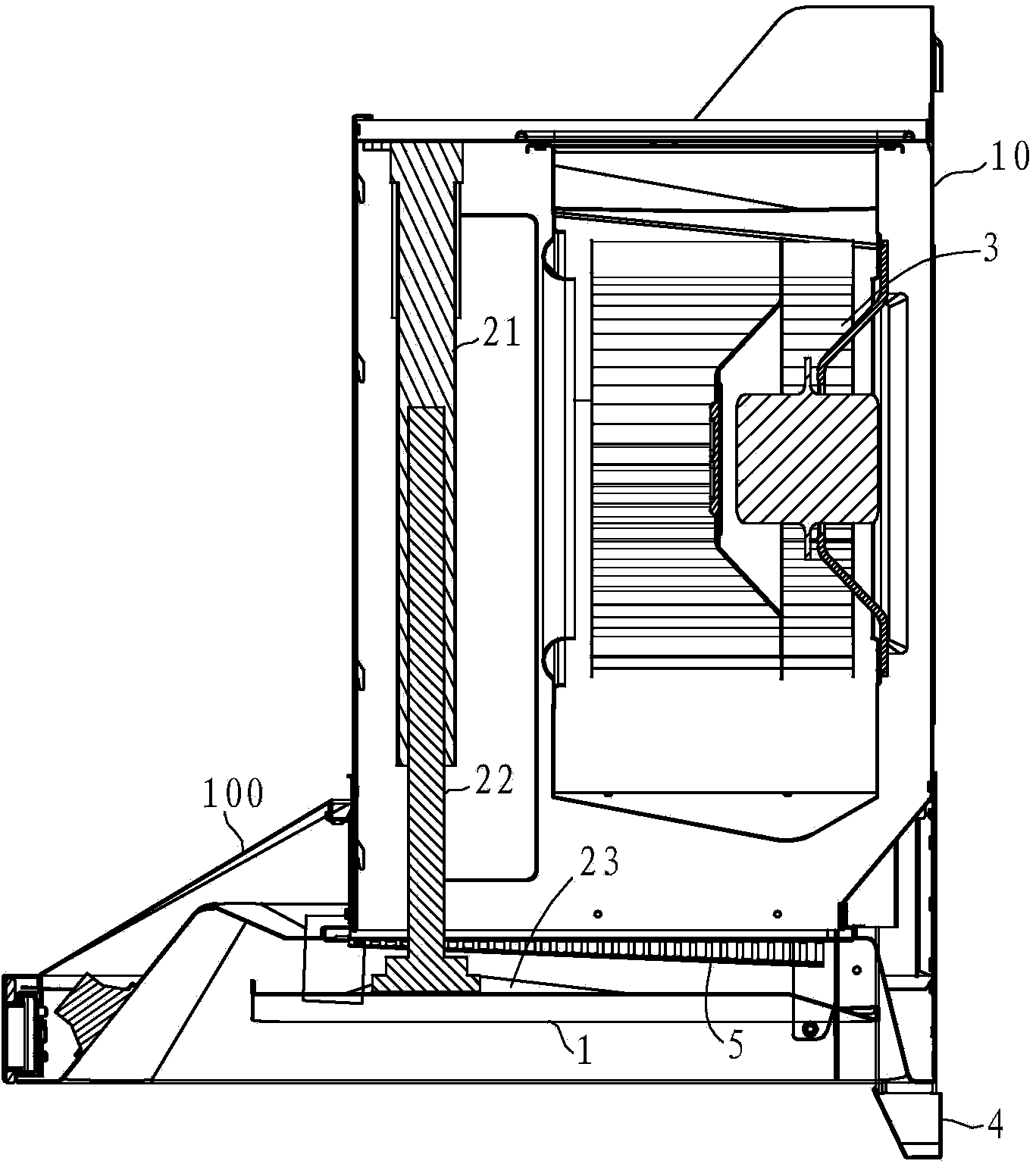

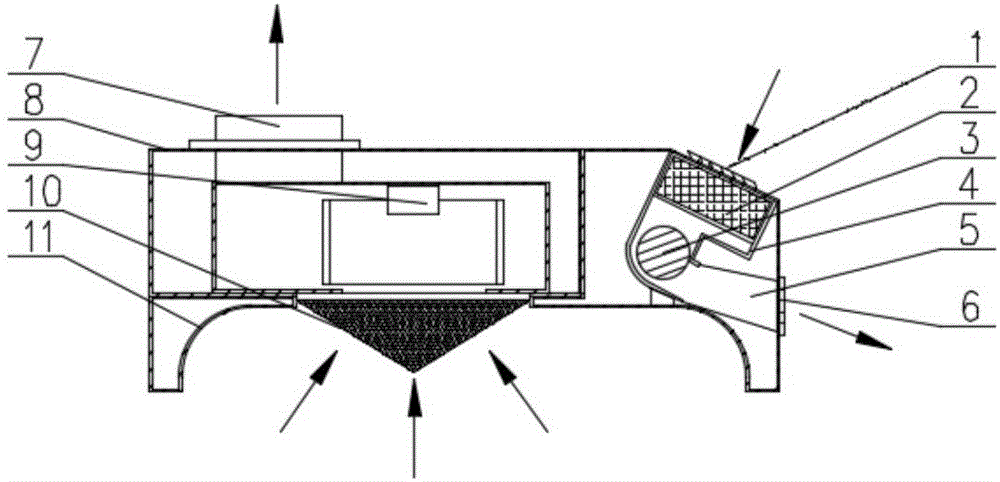

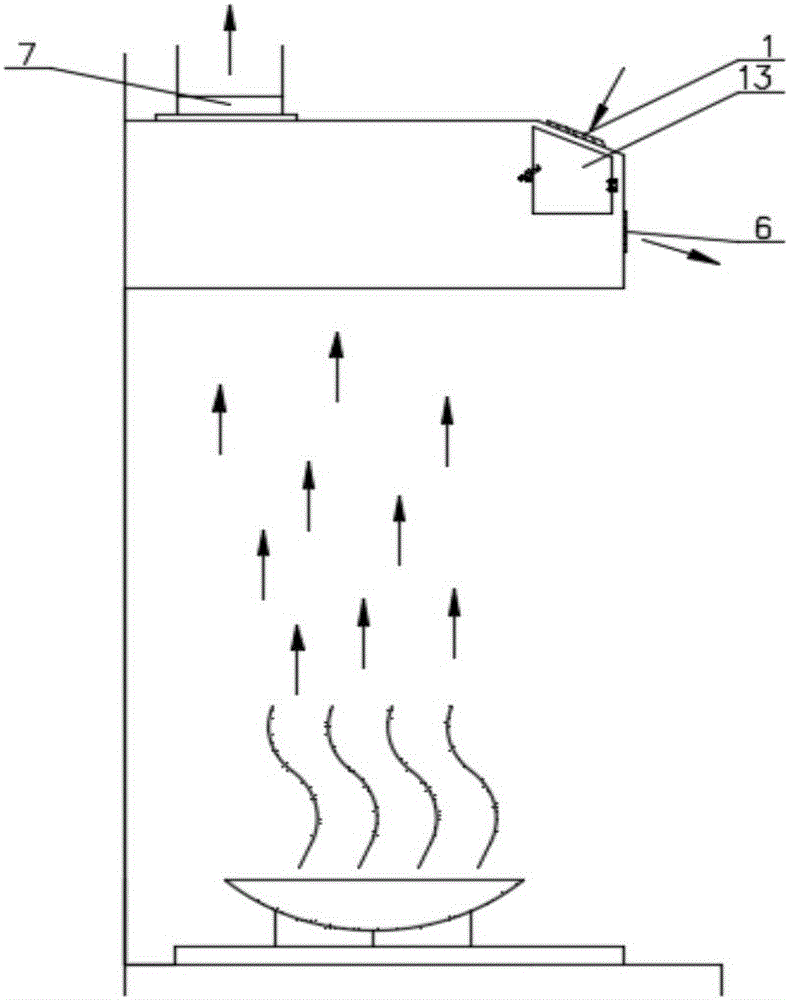

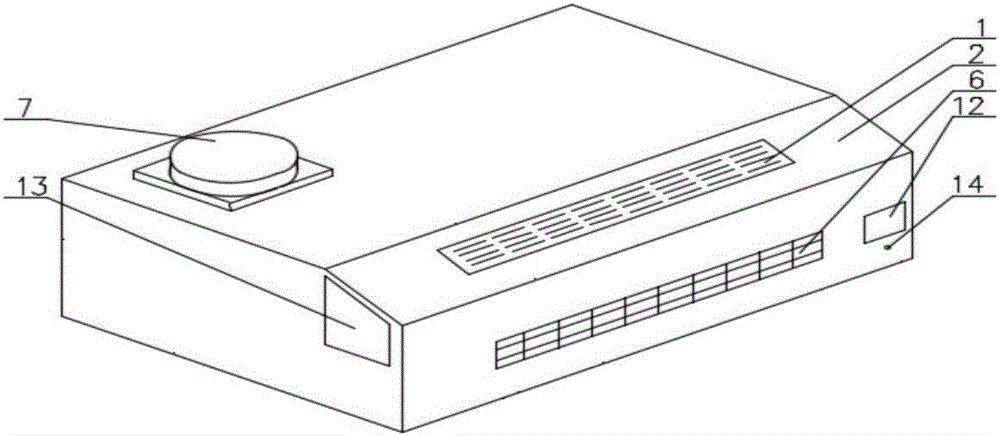

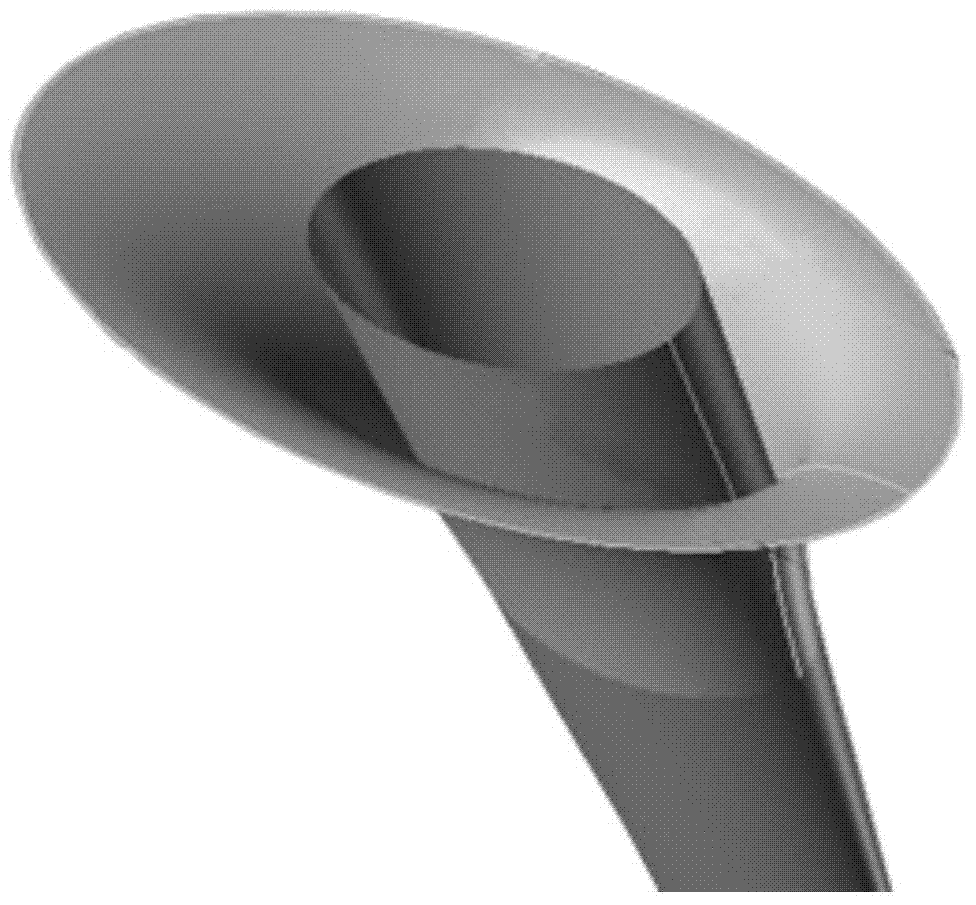

Ceiling-mounted range hood

ActiveCN103486636AReduce distanceGuaranteed cleanlinessDomestic stoves or rangesLighting and heating apparatusBiochemical engineeringCeiling mount

The invention relates to a ceiling-mounted range hood. The ceiling-mounted range hood comprises a machine body, a smoke collection cover, a fan and a rectifying plate, wherein the smoke collection cover is provided with an air inlet from bottom to top, the rectifying plate is right opposite to the air inlet and forms an air inlet passage which is used for the lampblack to pass through with the wall of an inner cavity of the smoke collection cover, the machine body is longitudinally arranged on the top of the smoke collection cover, the fan is arranged inside the machine body, and the ceiling-mounted range hood is characterized in that the rectifying plate is arranged in the air inlet of the smoke collection cover in an elevation manner. Compared with the prior art, the ceiling-mounted range hood has the advantages that through the elevation design of the rectifying plate, a concealing state, a working state and a washing state of the rectifying plate can be realized, and convenience in use can be realized.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Production technology of full-dry desulfurizing gypsum building material product

The invention relates to a production technique of a total drying desulfurizing gypsum building material product, which comprises the following steps: desulfurizing gypsum, phosphor gypsum or natural gypsum are taken as the raw materials, through roasting, sieving, adding water and inorganic silicon water repellent compound, the raw materials are still dry powder; then the gypsum building material product with high consistency is obtained through installing by a paver and shaped by high pressure. The product has high strength, good rigidity, without shrinkage and no need of release agent. The gypsum product needs no drying to produce and greatly saves energy, and the energy-saving effect is good. The gypsum product having simple production technique saves energy consumption without discharge of contamination, and has no poison and damage with very low production cost. The invention can completely satisfy various requirements of users.

Owner:重庆金仓龙新型建材有限公司

Range hood with personalized air purifier

InactiveCN106225037AGuaranteed aestheticsReduce spillageDomestic stoves or rangesLighting and heating apparatusControl systemEngineering

The invention discloses a range hood with a personalized air purifier. The range hood comprises a shell and a control system. A self-balance type air inlet is formed in the front side of a top plate of the shell. A double-layer shutter air supply outlet is formed in a front face plate of the shell. A controller and a PM2.5 mass concentration sensor are installed on the front face plate of the shell. In the flowing direction, from the top of a kitchen to a human body breathing area, of primary air, a combined multilayer filter and a silent cross-flow fan are sequentially installed in the air purifier, and an air outlet is formed in the exhaust direction of the silent cross-flow fan. Due to the adoption of the device, it is ensured that the fan is stable and low in noise in the running environment, detection and overall control of the air quality in a human body head breathing area are achieved, harm of cooking fume particles and gas to human bodies is reduced, and meanwhile overflow of the cooking fume can be reduced through a lateral lower air supply curtain.

Owner:TIANJIN UNIV

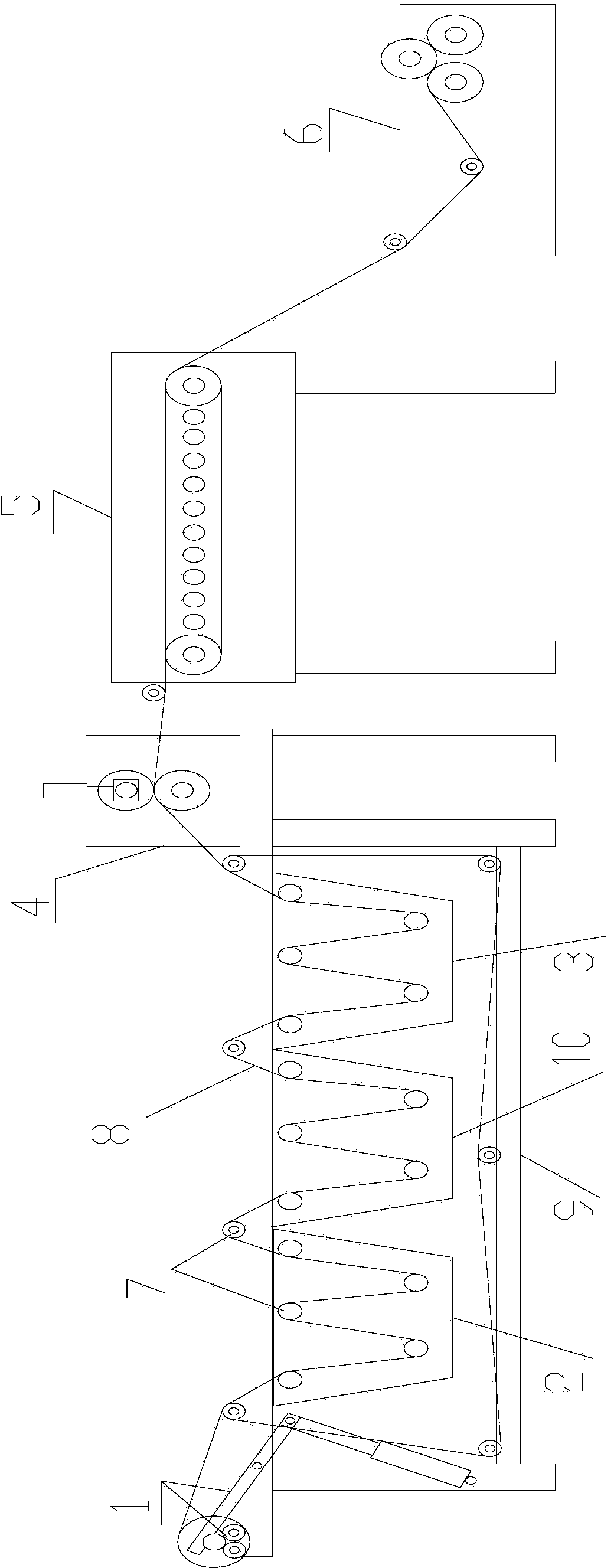

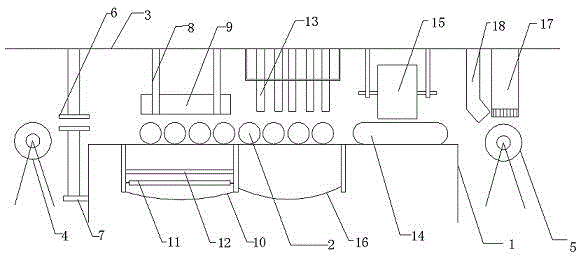

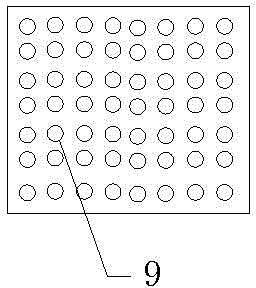

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

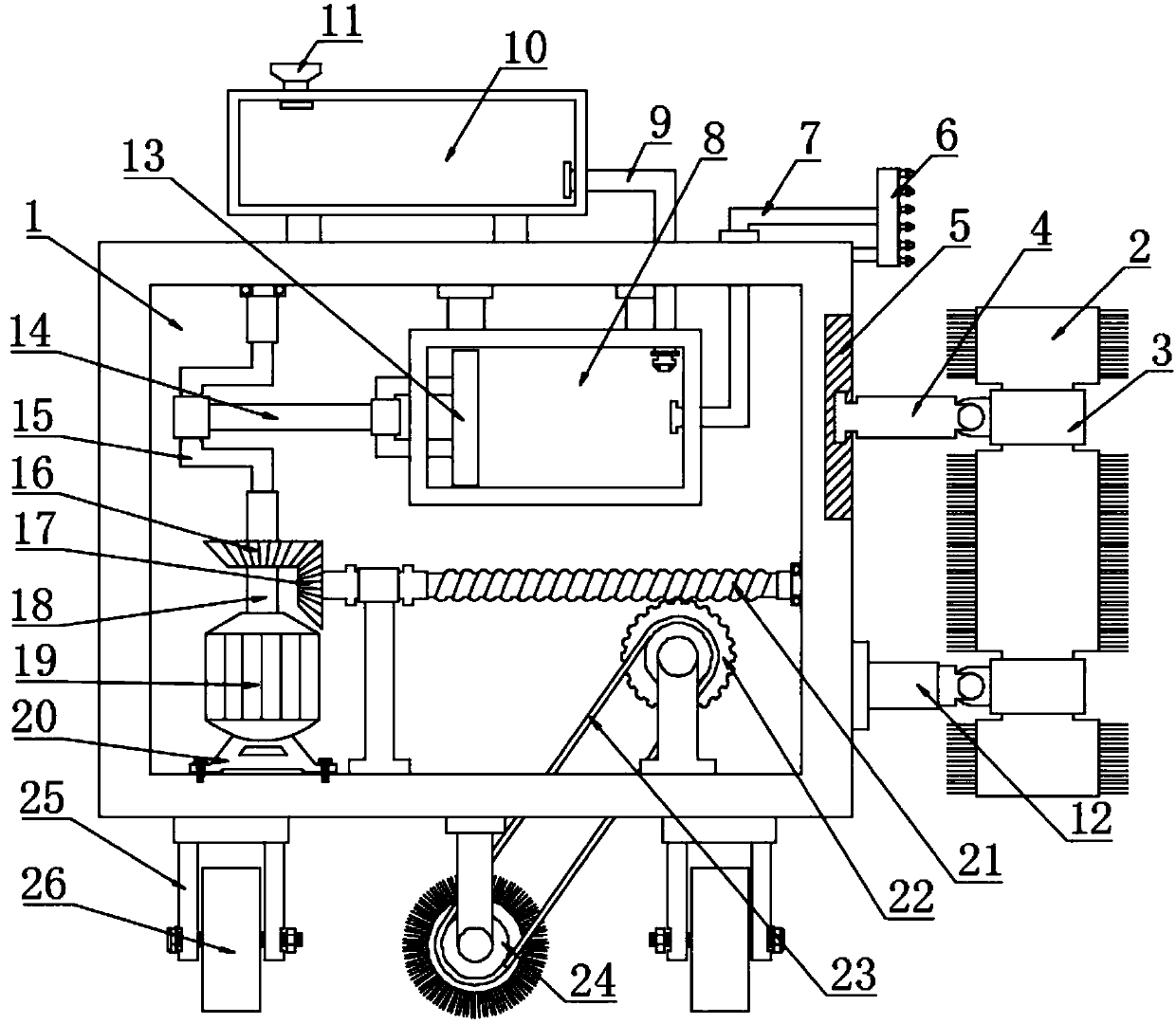

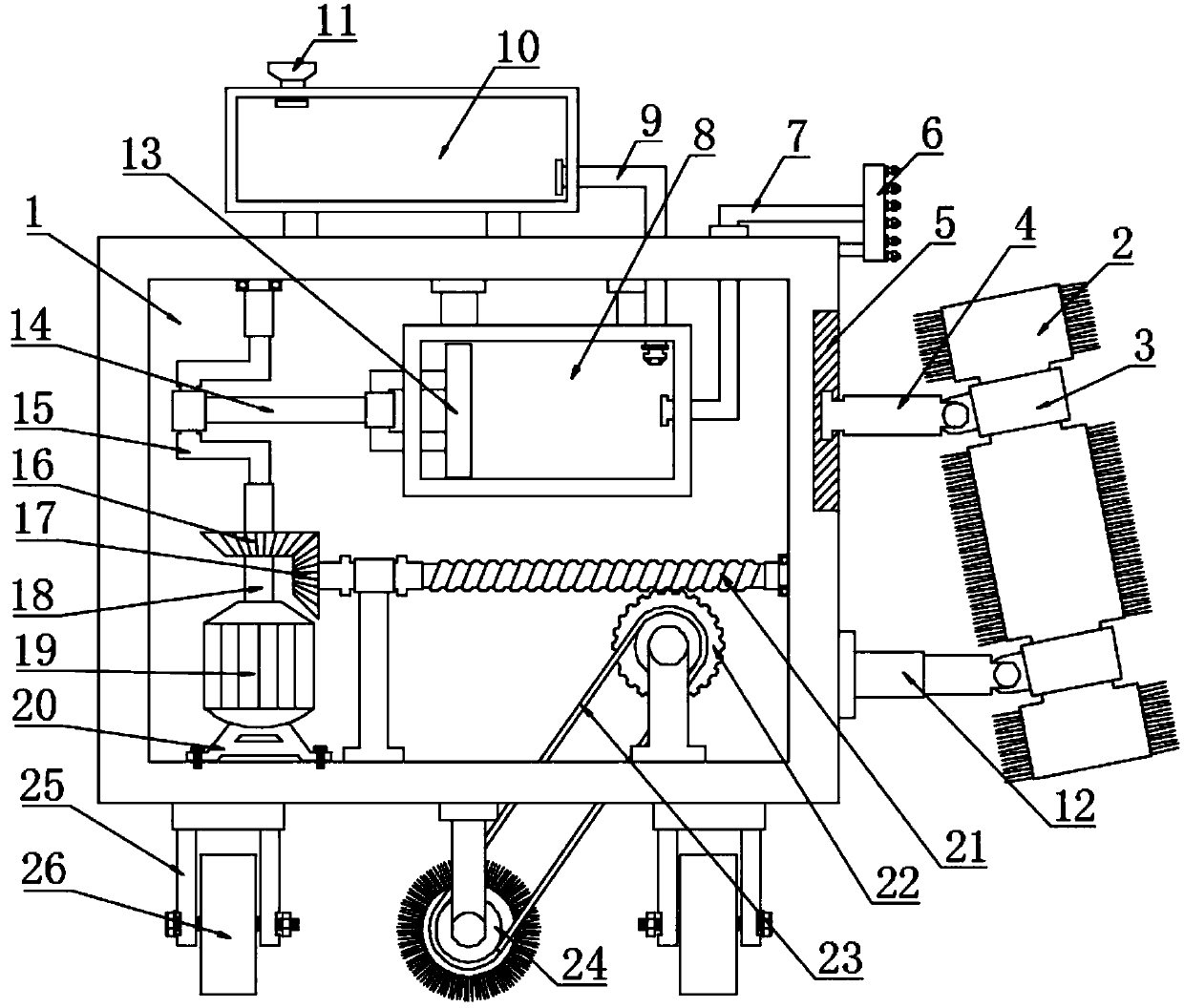

Cleaning device for municipal road guardrails

ActiveCN107604861AGuaranteed aestheticsEnsure driving safetyRoad cleaningHydraulic cylinderDrive shaft

The invention discloses a cleaning device for municipal road guardrails. The right end of a hydraulic cylinder is rotationally connected with a lantern ring; the lantern ring is connected to the lowerend of a cleaning roll in a sleeving mode; a supporting rod is arranged on the upper portion of the hydraulic cylinder; the left end of the supporting rod is slidably connected with a guide groove; the right end of an upper lantern ring is rotationally connected with another upper lantern ring, and the upper end of the cleaning roll is sleeved with the upper lantern ring; a drive motor is arranged inside the left end of a device body; the upper end of the drive motor is rotationally connected with a driving shaft; the upper end of the driving shaft is rotationally connected with a crankshaft;the upper portion of the crankshaft is rotationally connected with the device body through a bearing; and a first bevel gear is fixedly connected to the middle of the driving shaft. According to thecleaning device for the municipal road guardrails, the angle of inclination of the cleaning roll is adjusted through the hydraulic cylinder so that the road guardrails of different degrees of inclination can be cleaned, and the cleaning effect is good; a water suction roll is arranged at the lower end of the device body and used for preventing sewage generated during cleaning from flowing around,roads can be clean and attractive, and driving safety is ensured. The cleaning device for the municipal road guardrails is simple, reasonable and practical in structural design, the effect of cleaningof the road guardrails is greatly improved, and the problem that sewage generated during cleaning flows around is effectively solved.

Owner:浙江辰基建设有限公司

Fabrication process for fully hand-made leather slippers

InactiveCN102150970AImprove aestheticsImprove physical performanceShoemaking devicesCoatingManufacturing engineering

The invention discloses a fabrication process for fully hand-made leather slippers. The leather slippers fabricated by the process are durable, artistic, soft, comfortable, air permeable and have good effect of relieving foot stress. The fabrication process is characterized in that the fabrication process comprises the following steps: fabrication of upper sleeves, which adopts the method of scribing first and then cutting; splitting and leveling process: the process can be completed mechanically and manually, in order to further ensure the quality of sheet stock; edging: component edges are trimmed into slope shape according to specification requirements; upper making: positioning dot lines are drawn, and the processing and the assembling of upper surface components are required to be performed according to specific standards and regulations; brush coating; edge making: brush coating is performed to sheared upper components, and the margins of the upper surface components are folded inward, cohered and flattened according to templates; edge trimming; splicing or lapping: all the components are assembled together through splicing; internal liner implantation: the shape of the internal liner is formed according to the shape of the sole of a person; sewing; and vamp decoration.

Owner:李照洪

Nano composite top facing paint with hydrophobic foul resisting sticking-proof and preparation process thereof

InactiveCN1861714AAchieving aging resistanceAchieve scrub resistanceAntifouling/underwater paintsPaints with biocidesMaterials scienceWetting

The invention relates to a nanometer compound cover paint which has the hydrophobicity and is resistance to the pollution and the sticking. The paint contains the film forming material, the antifouling component, the filler and the diluting agent, necessary the wetting agent, dispersant and the thickener. So it can be used for the antifouling of the high-end building and the protection for the outlook of the public utility.

Owner:江西中江纳米科技有限公司

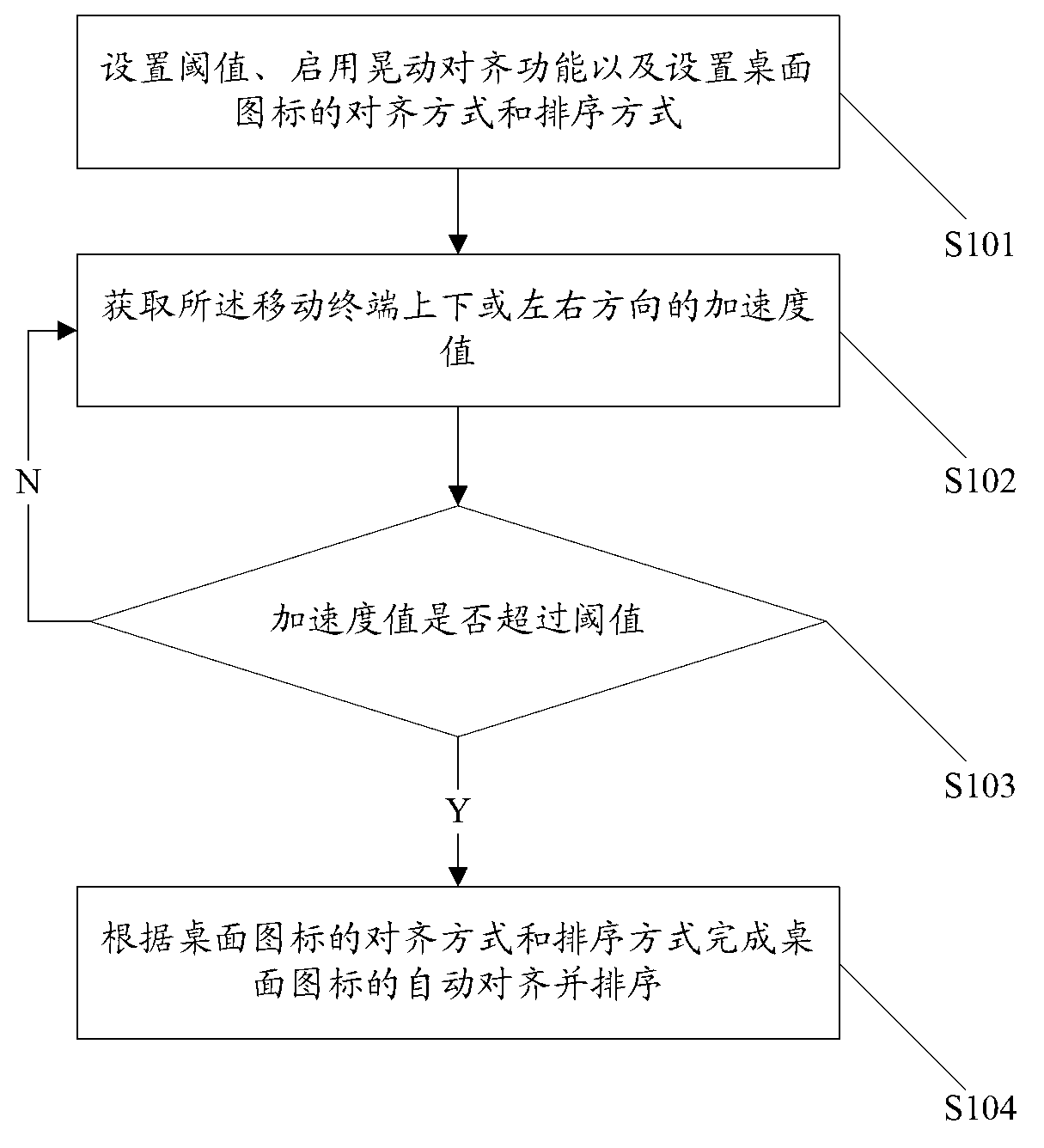

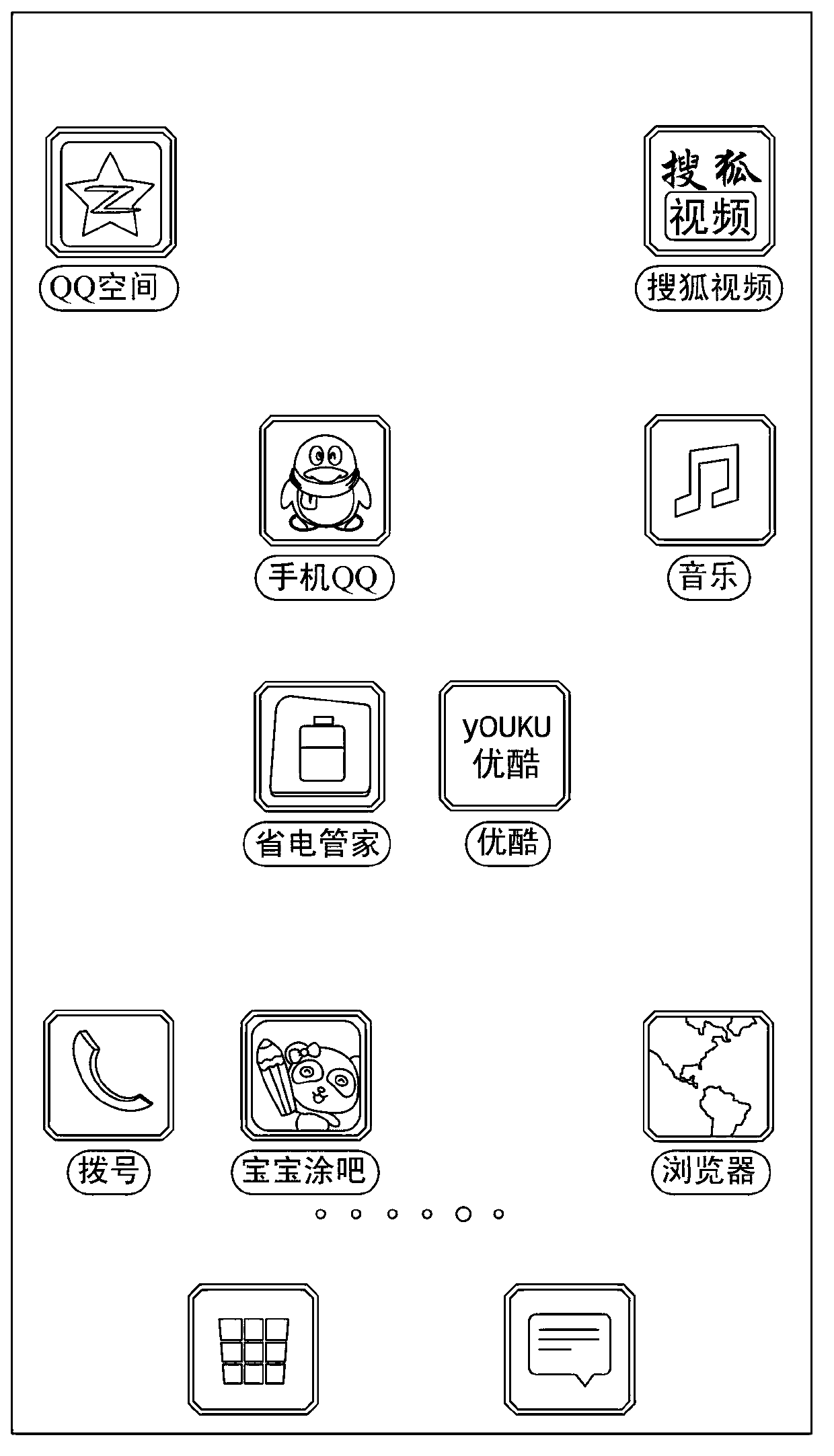

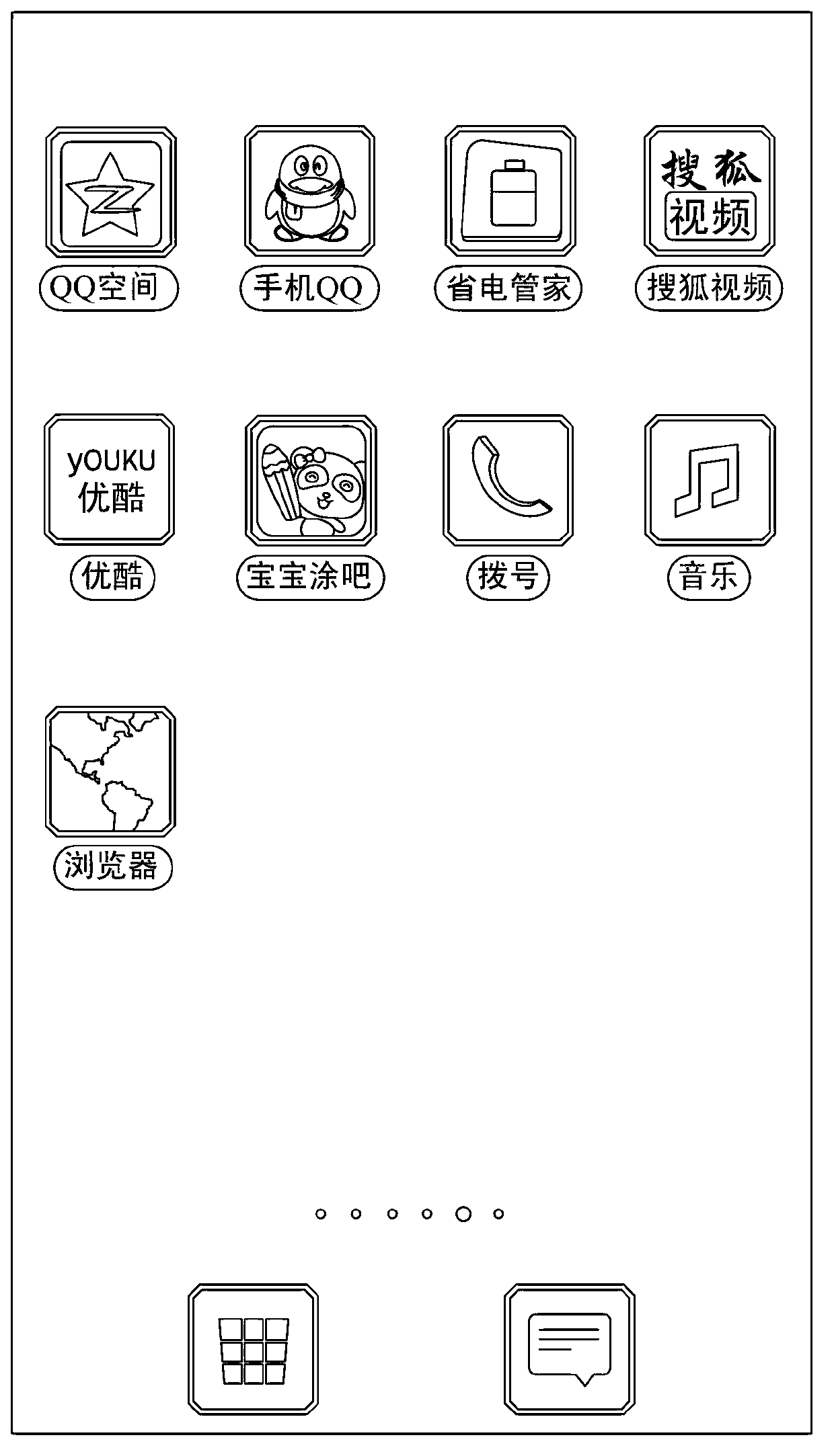

Method and mobile terminal for realizing automatic alignment and sorting of desktop icons by shaking

InactiveCN102968247AKeep tidyImprove user experienceInput/output processes for data processingComputer engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

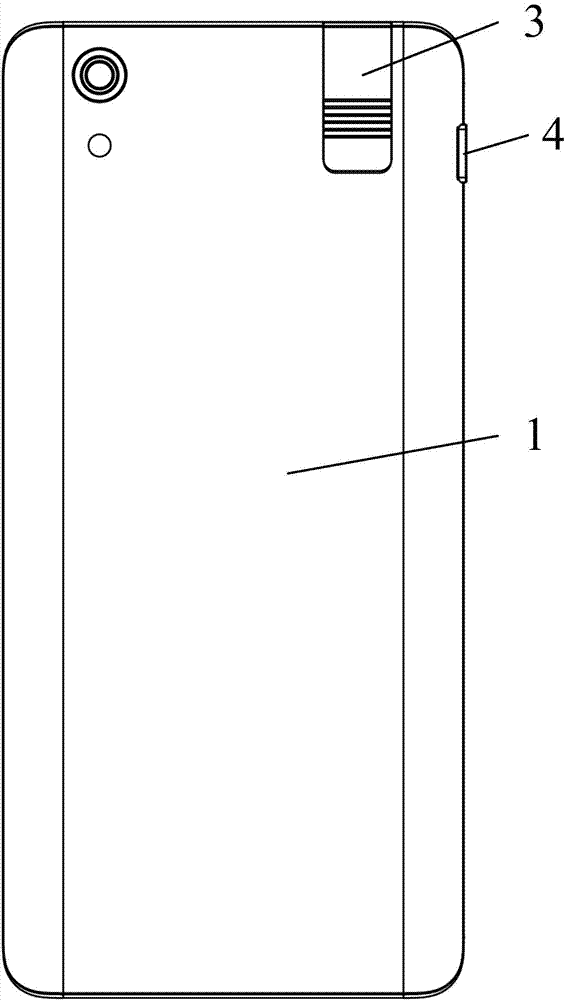

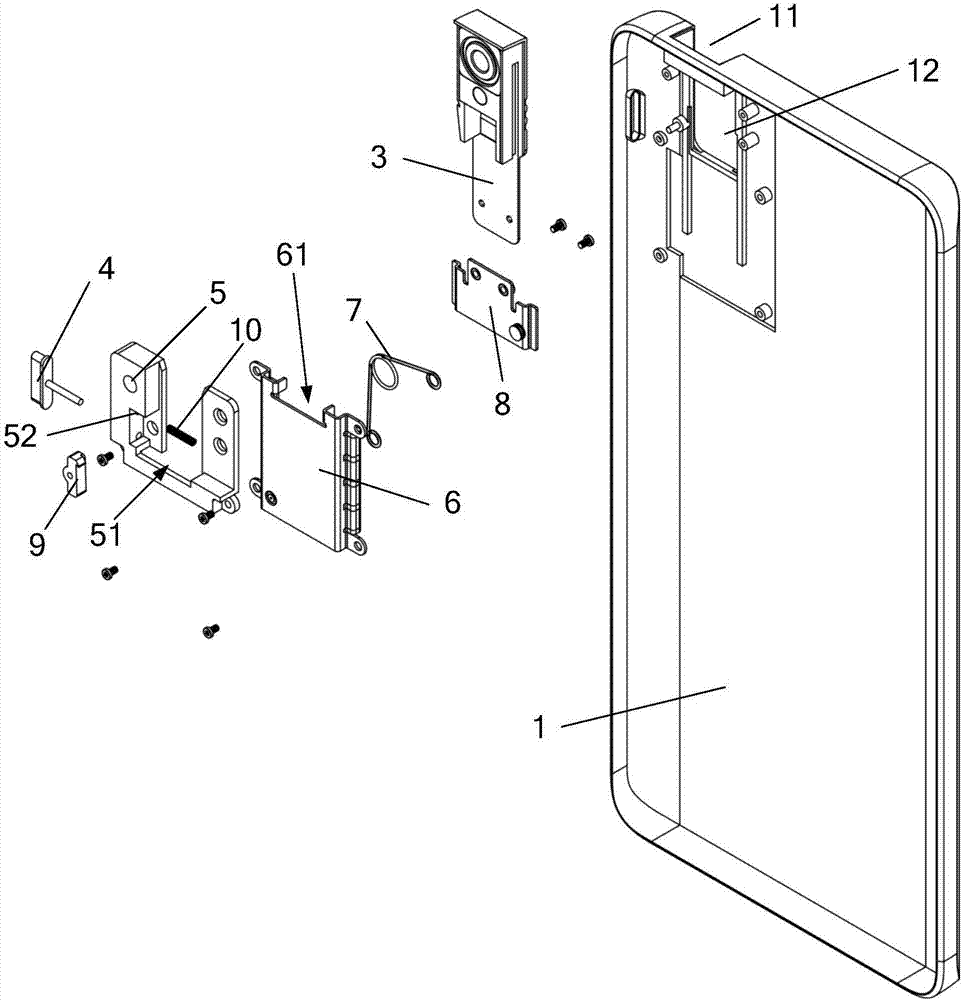

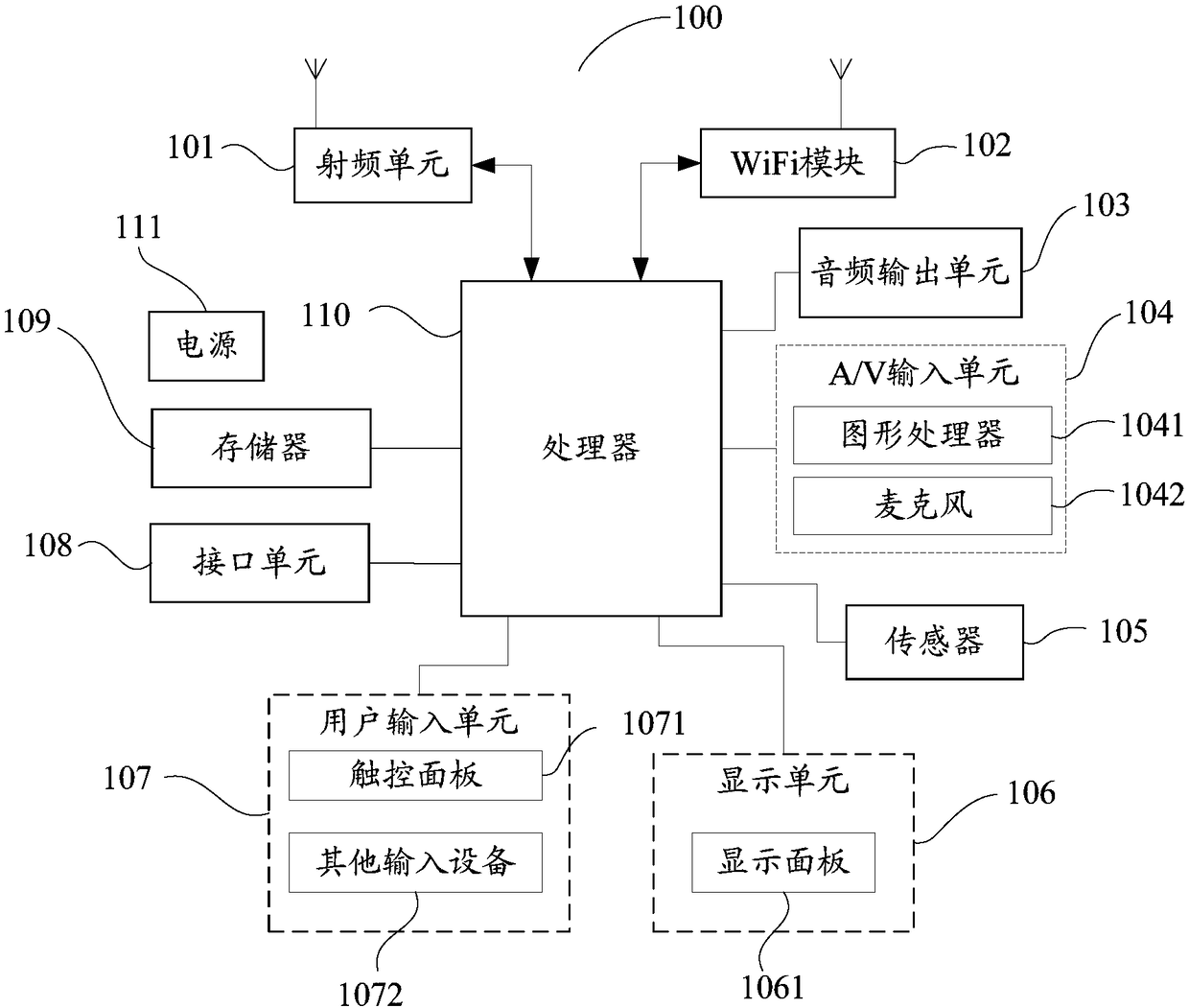

Mobile terminal

InactiveCN107483779AGuaranteed aestheticsImprove camera qualityTelevision system detailsDigital data processing detailsComputer terminalEngineering

The invention discloses a mobile terminal comprising a back shell; a display screen component installed at a front opening of the back shell, wherein a mounting cavity is enclosed between the back shell and the display screen component; a camera component movably installed in the mounting cavity and hidden behind the display screen component, wherein a popup structure and a limiting structure are arranged between the camera component and the back shell; and a trigger switch installed on the back shell, wherein a locking structure is arranged between the trigger switch and the camera component, and the locking structure locks the camera component, wherein the trigger switch is triggered, the locking structure unlocks the camera component, the popup structure pushes the camera component to move outward, so that a camera end of the camera component penetrates through the side wall of the back shell to stretch out from the mounting cavity, and meanwhile the limiting structure limits the other end of the camera component from deviating from the mounting cavity, when a front camera is installed on the camera component, the camera with a large size can be used, and the front camera does not occupy the front surface area of the display panel.

Owner:NUBIA TECHNOLOGY CO LTD

Textile cleaning device

ActiveCN104452252AGuaranteed cleanlinessKeep it clean and aesthetically pleasingMechanical cleaningPressure cleaningYarnSprayer

The invention discloses a textile cleaning device. The textile cleaning device comprises a cleaning support. A main hanging bracket is arranged above the cleaning support. An upper shaving ball blade is arranged above the main hanging bracket. A lower shaving ball blade corresponding to the upper shaving ball blade is arranged on the support. A steam sprayer connected with a steam generating device is arranged above conveying rollers through hanging rods. A first sundry groove is formed below the conveying rollers and in the support. A plurality of upper dust suction pipes are arranged on one side of the steam sprayer and the main hanging bracket. A brush is arranged above a feeding roller through the main hanging bracket, and a secondary dust suction pipeline is arranged on one side of the brush through the main hanging bracket. Yarns can be rapidly cleaned, thread residues on products with large static electricity can be rapidly removed, the cleaned products are still very straight, a multi-time thread residue and woolen yarn removing device is adopted, cleaning is complete, the quality of the products is improved, and the economic benefits are increased for enterprises.

Owner:苏州品维纺织科研有限公司

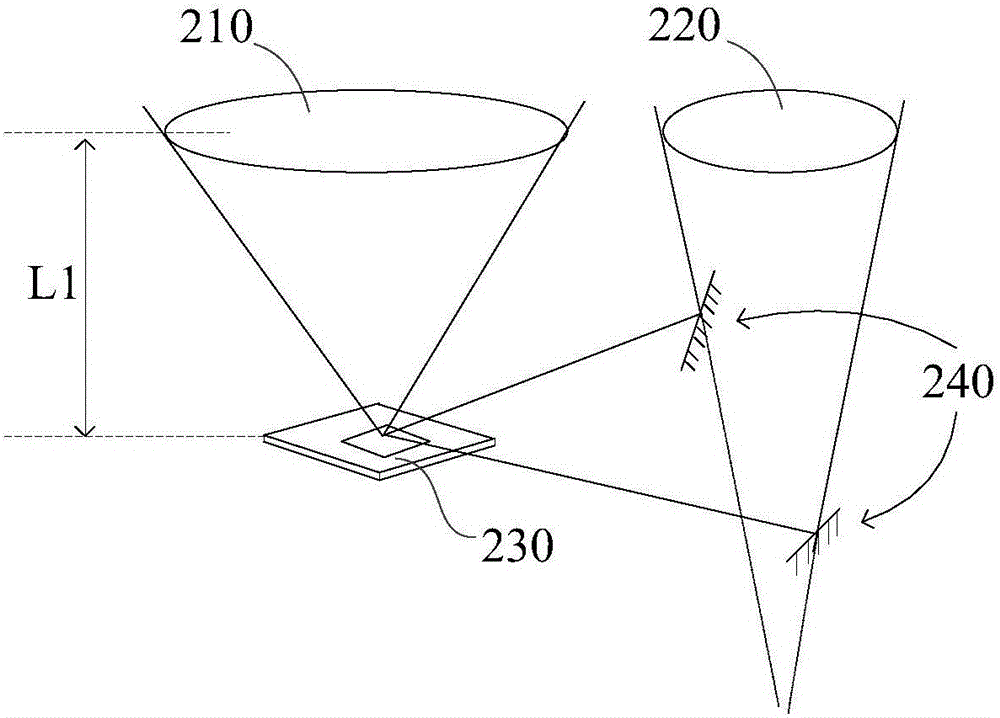

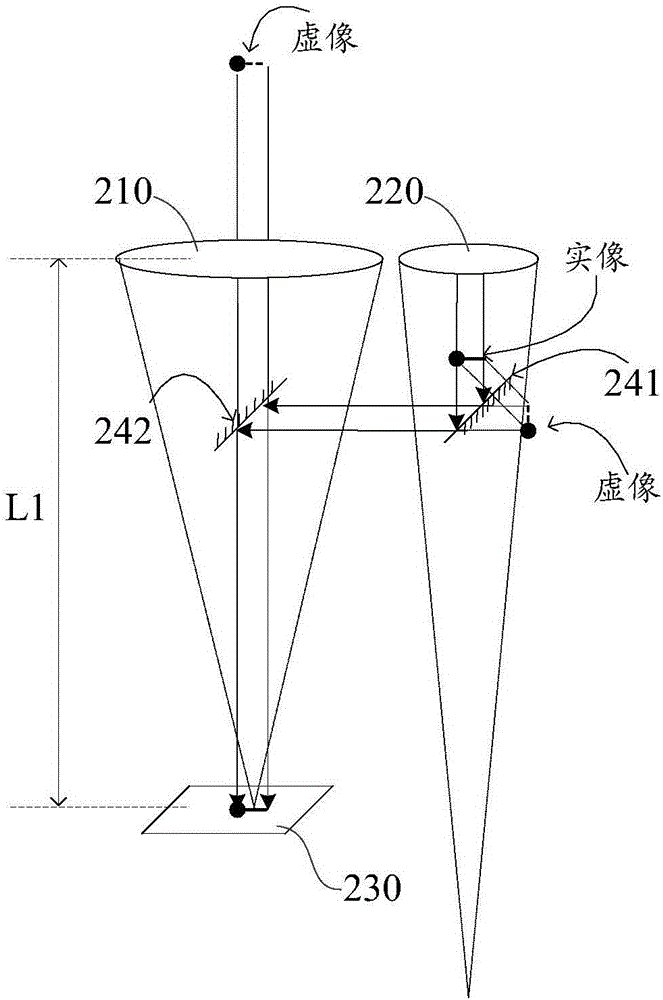

Method and device thereof for presenting three-dimensional image

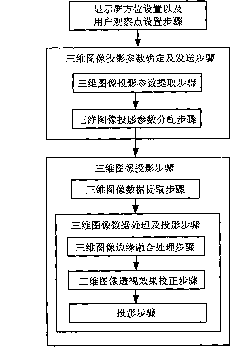

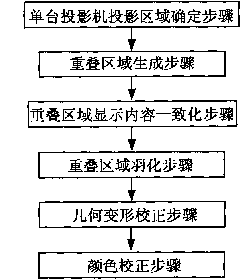

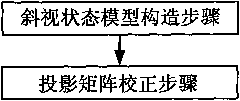

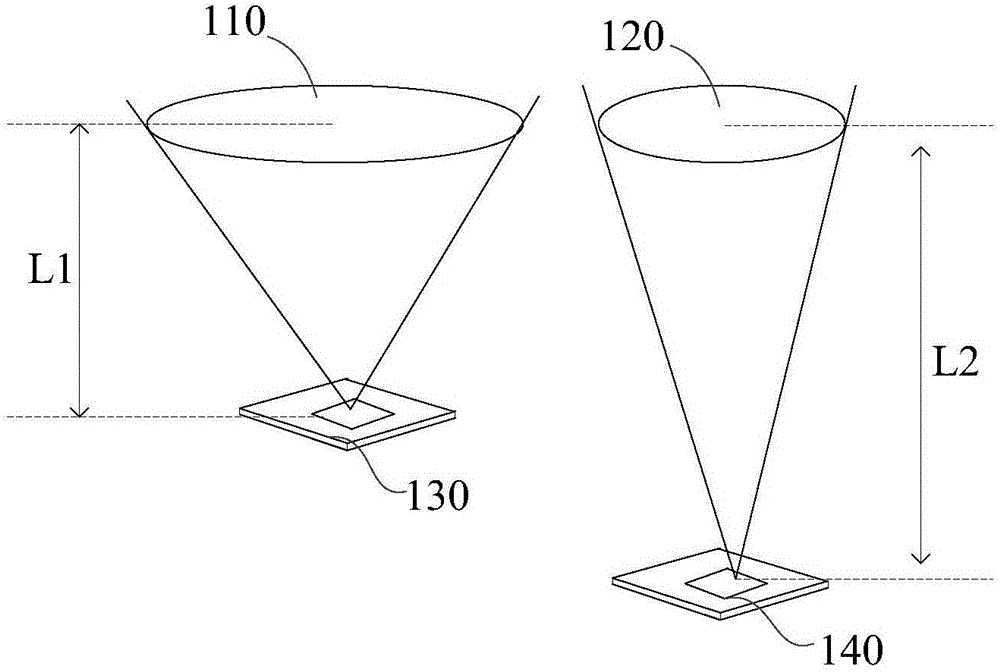

ActiveCN101800907AEliminate physical gapsIntegrity guaranteedTelevision system detailsColor television detailsComputer graphics (images)Observation point

The invention relates to a method and a device thereof for presenting a three-dimensional image, which belongs to the technical field of the digital three-dimensional multimedia, and aims at solving the problems such as the display, the observe mode, the display gap and the strabismus cone distortion. The method comprises the following steps that: the position of an image display screen and a user observation point is determined according to the space layout and the space structure; the image data is undertaken the image edge-blending splicing; the image data is undertaken the correction of the three-dimensional image strabismus cone; and the image after being processed is displayed in a projection way. The method ensures the completeness and beauty of the displayed image, enlarges the application way of the digital sand table, really realizes the three-dimensional perspective effect of the projected image, and greatly improves the application capacity of the digital sand table on the aspects such as the urban plan and design exhibition.

Owner:GLODON CO LTD

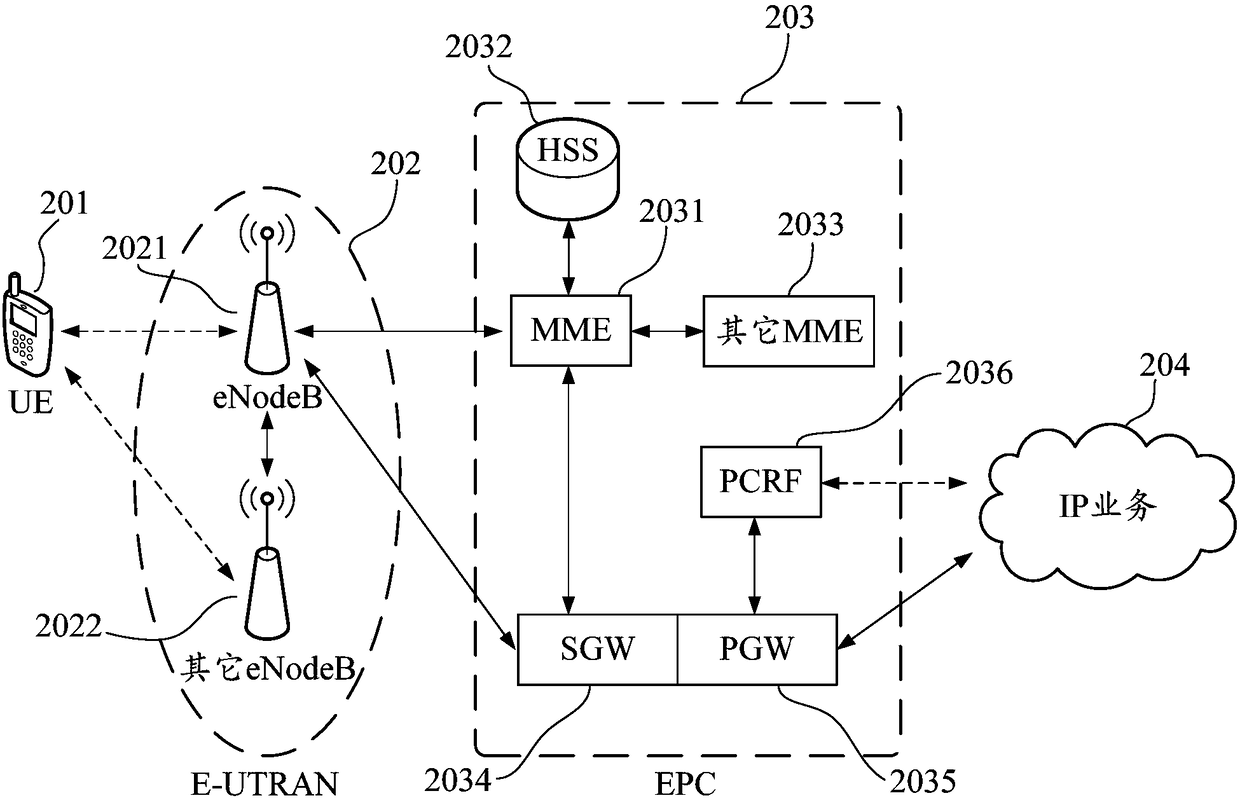

Photographing control method, camera module and mobile terminal

ActiveCN105959525AGuaranteed aestheticsImprove user experienceTelevision system detailsColor television detailsCamera lensImage sensor

The invention provides a photographing control method, a camera module and a mobile terminal. The camera module comprises a first lens group; a second lens group; an image sensor arranged at the imaging side of the first lens group and the second lens group; and multiple reflection elements of which reflection states are adjustable. The multiple reflection elements are arranged between the first lens group and the lens group, and the image sensor. Light rays of the second lens group and / or first lens group for photographing an image are reflected by the multiple reflection elements and then are projected on the image sensor for imaging. In this way, the problems that the cost is relatively high and the thickness of the module is relatively high due to the fact that independent image sensors are employed for double cameras in an existing camera module are solved; the beautiful appearance is ensured; and the user experience is improved.

Owner:VIVO MOBILE COMM CO LTD

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Black high-reflectivity solar cell backboard and a preparation method thereof

ActiveCN109713069AImprove utilization efficiencyImprove power generation efficiencyPhotovoltaic energy generationSemiconductor devicesHigh reflectivityWave band

The invention provides a black high-reflectivity solar cell backboard and a preparation method thereof. The backboard comprises a weather-resistant layer, a bonding layer, a PET substrate layer and ablack functional coating layer, which are sequentially arranged from top to bottom. According to the invention, through the black functional coating layer and the selection of PET substrates with different reflectivity, the infrared band has very high reflectivity when the beautifying effect is obtained. In particular, the reflectivity of 750-1600 nm wave band can reach 30-75%. The sunlight with the wave band of 750-1100 nm can be reflected to a crystalline silicon cell, the utilization efficiency of the sunlight is improved, the power generation power is improved, the sunlight with the wave band of 1100-1600 nm can also be reflected to the air, the reflection efficiency of solar heat is improved, the temperature of an assembly is reduced, and the power generation efficiency of a cell piece is improved.

Owner:CYBRID TECHNOLOGIES INC

Preparation method of ceramic tile with matte deep carving effect and ceramic tile

The invention provides a preparation method of a ceramic tile with a matte deep carving effect and the ceramic tile. The preparation method of the ceramic tile comprises the following steps: pressinga green body and drying; spraying water to the green body and applying ground coat; the temperature of the green body is kept at 40-45 DEG C, digital mold ink is printed, the ink amount of the digitalmold ink is 15-78 g / m<2>, and the digital mold ink is matte oily ceramic ink; drying, and spraying surface glaze in a reciprocating glaze spraying manner by adopting a high-pressure glaze spraying device, the specific gravity of the surface glaze being 1.5-1.52 g / cm<3>, and the glazing amount being 800-1000g / m<2>; patterns are printed in an ink-jet mode, and then digital matte protective glaze ink and digital bright protective glaze ink are printed; drying and sintering at high temperature; and lightly polishing and edging to obtain the ceramic tile. By means of the method, deeper, finer andmore vivid lines can be formed on the ceramic tile, the carving depth is adjustable by 0.1-5 mm, the method is more intelligent and convenient, and the obtained ceramic tile is attractive, natural andvivid.

Owner:FOSHAN SANSHUI CREATE TIDE

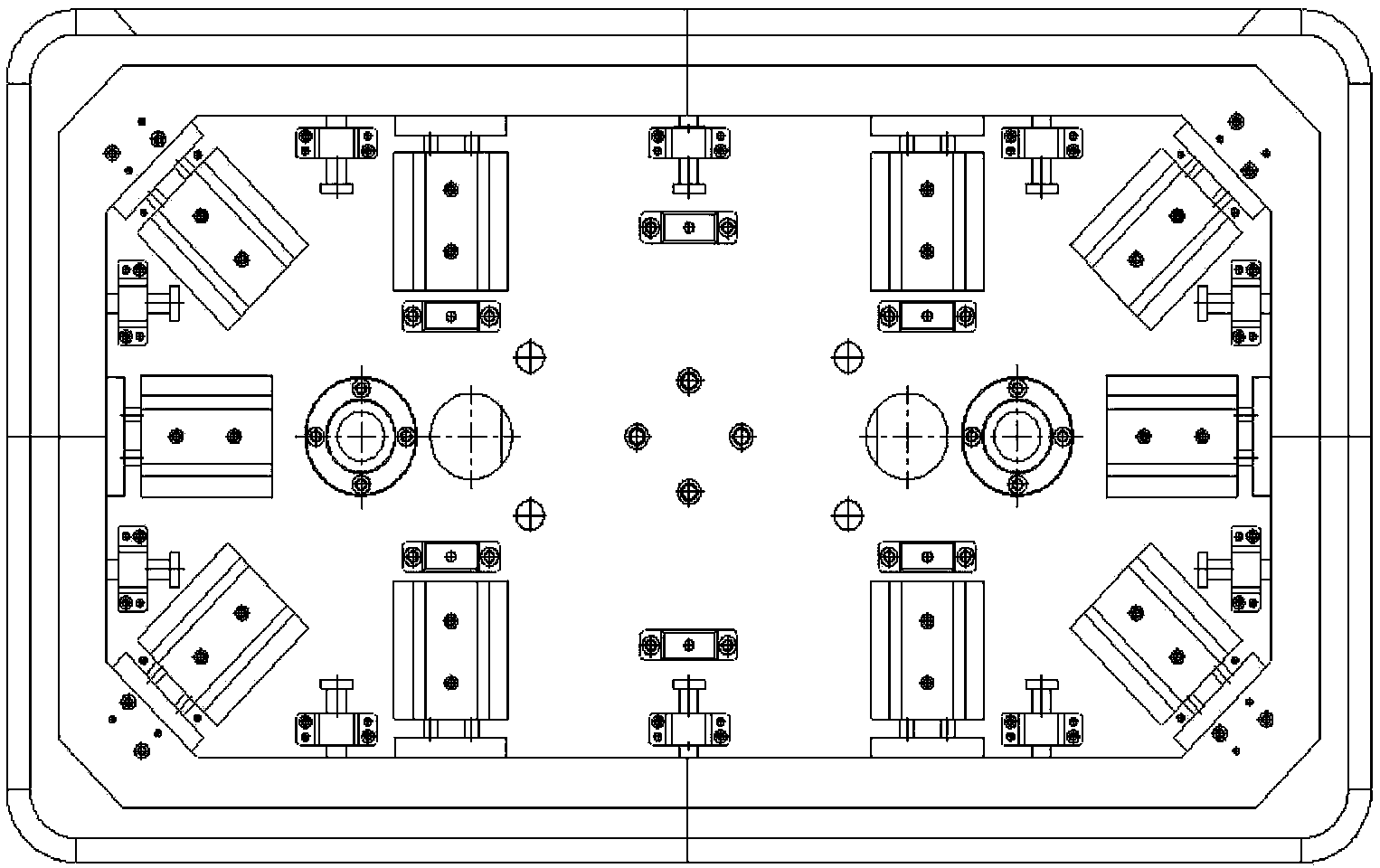

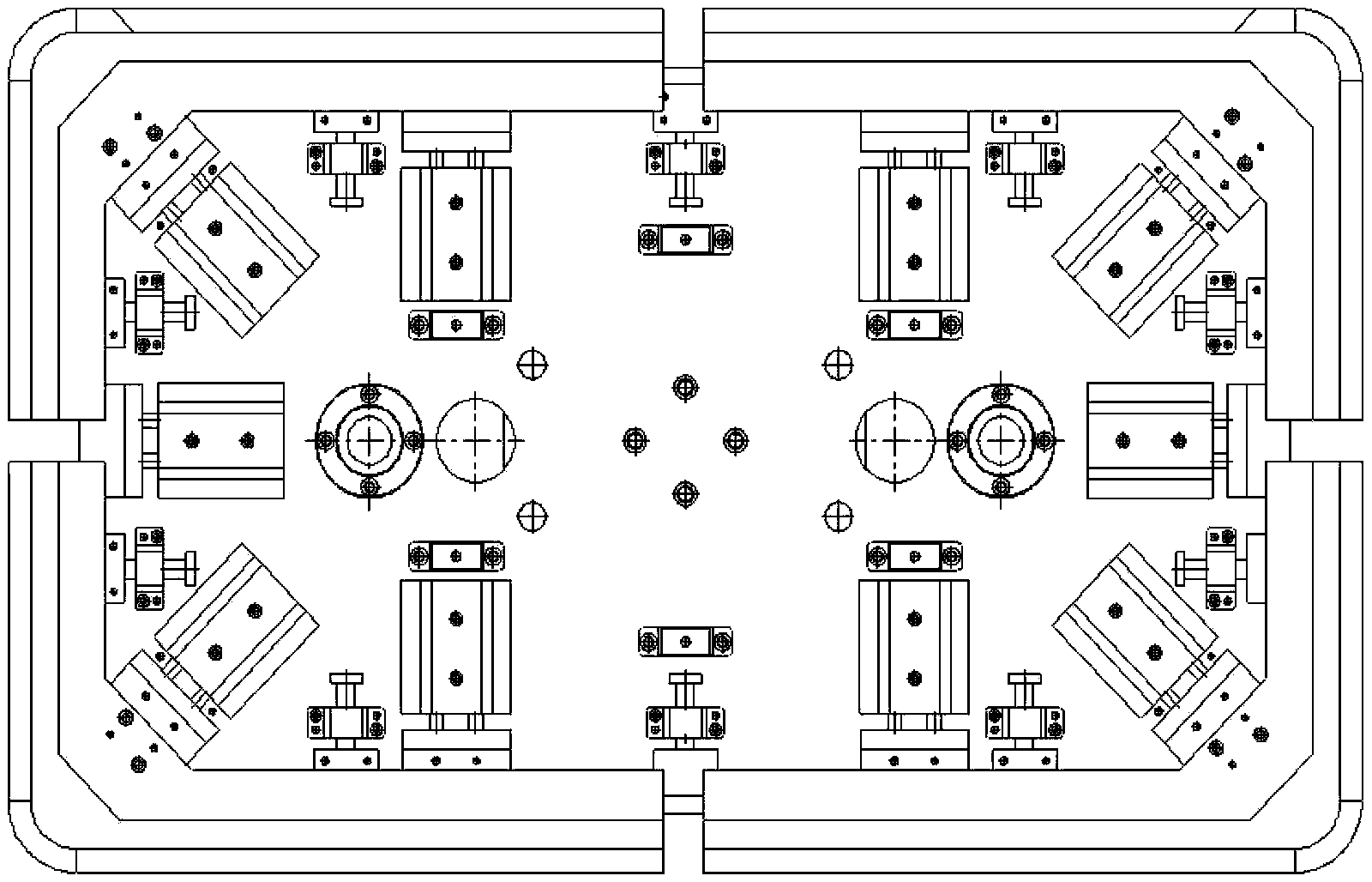

Turning device and edge covering equipment

ActiveCN104162976AGuaranteed aestheticsSolve wrinkleLaminationLamination apparatusMechanical engineeringSunroof

The invention relates to a turning device and edge covering equipment. The turning device is used for outwards turning a decorative fabric glued on the inner surface of the skylight opening part of a vehicle interior ceiling and gluing the decorative fabric to the outer surface of the skylight opening part. The turning device comprises a frame mechanism and a control mechanism, wherein the size of the frame mechanism corresponds to that of the skylight opening part; the control mechanism controls the frame mechanism to operate; the frame mechanism comprises four corner turning blocks and four edge turning blocks, the corner turning blocks are matched with shapes of corners of the skylight opening part, the edge turning blocks are matched with shapes of edges of skylight opening part, and the corner turning blocks and the edge turning blocks are contacted through inclined surfaces. During turning, the corner turning blocks and the edge turning blocks can turn the fabrics at the corners and the fabrics on the edges respectively, so that the problem of wrinkling after the fabrics at the corners are turned is solved, and the integral attractiveness of a finished product of the interior ceiling can be kept.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

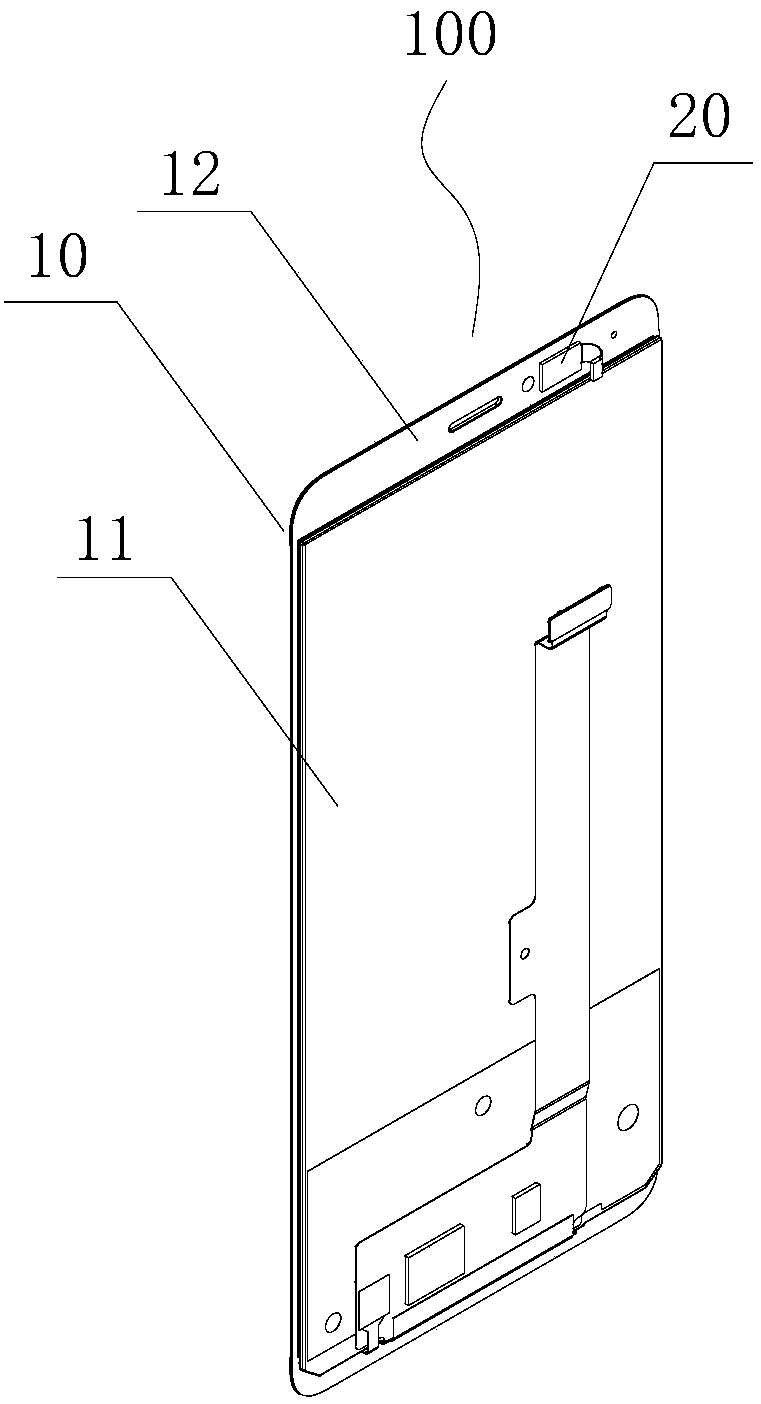

Terminal display screen, control method, mobile terminal and readable storage medium

InactiveCN108282561AGuaranteed aestheticsGuaranteed to passTelephone set constructionsFull screen effectCamera lens

The invention discloses a terminal display screen, a control method, a mobile terminal and a readable storage medium. The terminal display screen comprises a display screen body and liquid crystal glass, wherein a perspective hole is formed in the display screen body directly opposite to a camera lens, the liquid crystal glass is arranged on one side of the perspective hole, and the liquid crystalglass blocks the perspective hole; and the liquid crystal glass is electrically connected to a terminal processor that controls a camera. The terminal display screen control method includes the following steps: determining whether the camera is in a working state; if the camera is in the working state, determining whether the camera is a camera arranged on the display screen body; and if the camera is the camera arranged on the display screen body, connecting a circuit board with the liquid crystal glass to ensure that the current flows through the liquid crystal glass. By controlling the liquid crystal glass to be powered on or powered off, the liquid crystal glass can be in a transparent state when the camera needs to be used, and the light can normally pass, the liquid crystal glass can be in a non-transparent state when the camera is not needed, and the color of the liquid crystal glass can be consistent with the color of the display screen to achieve a similar full-screen effect.

Owner:NUBIA TECHNOLOGY CO LTD

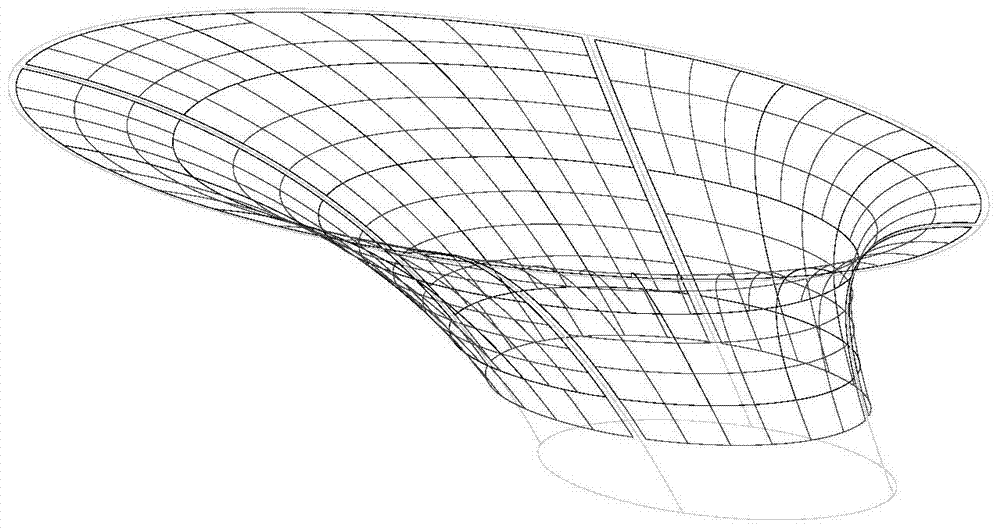

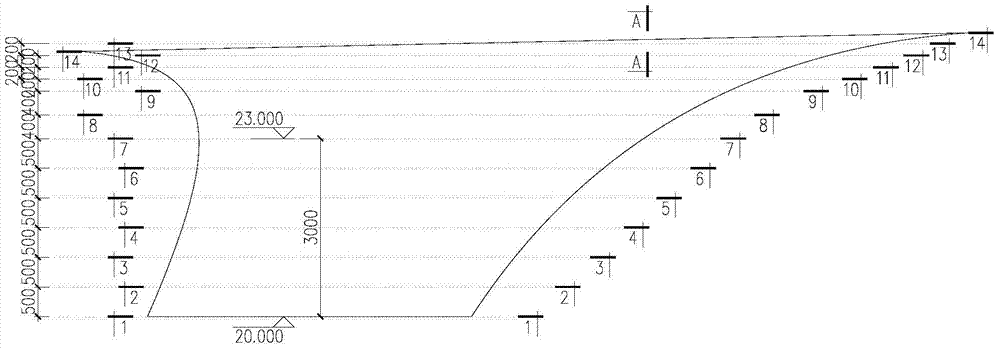

Construction method for using layering method to construct double-curved-surface stainless steel curtain wall

ActiveCN103541474AFast Construction CompletedSafe construction completedWallsBuilding material handlingSurface layerKeel

The invention discloses a construction method for using a layering method to construct a double-curved-surface stainless steel curtain wall. The method includes: building a double-curved-surface stainless steel curtain wall three-dimensional model and deepen drawing; decomposing the double-curved-surface curtain wall structure according to the model and deepen drawing into a surface layer and a keel layer; deepening construction drawings of the surface layer and the keel layer; machining and constructing the surface layer of the double-curved-surface stainless steel curtain wall; cutting and transporting the surface layer; constructing the keel layer of the double-curved-surface stainless steel curtain wall; mounting and seam welding the surface layer; processing the facing of the double-curved-surface stainless steel curtain wall. The construction method has the advantages that the layering method is used to construct the double-curved-surface stainless steel curtain wall, the surface layer with large welding and splicing work load is constructed in a factory, the keel layer is welded on site, filed structural features are combined to adjust and eliminate construction errors reasonably, coordinating and unifying of the curtain wall structure and a main body structure are guaranteed, and accurate curved surfaces and radian smoothness of the curtain wall are guaranteed.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

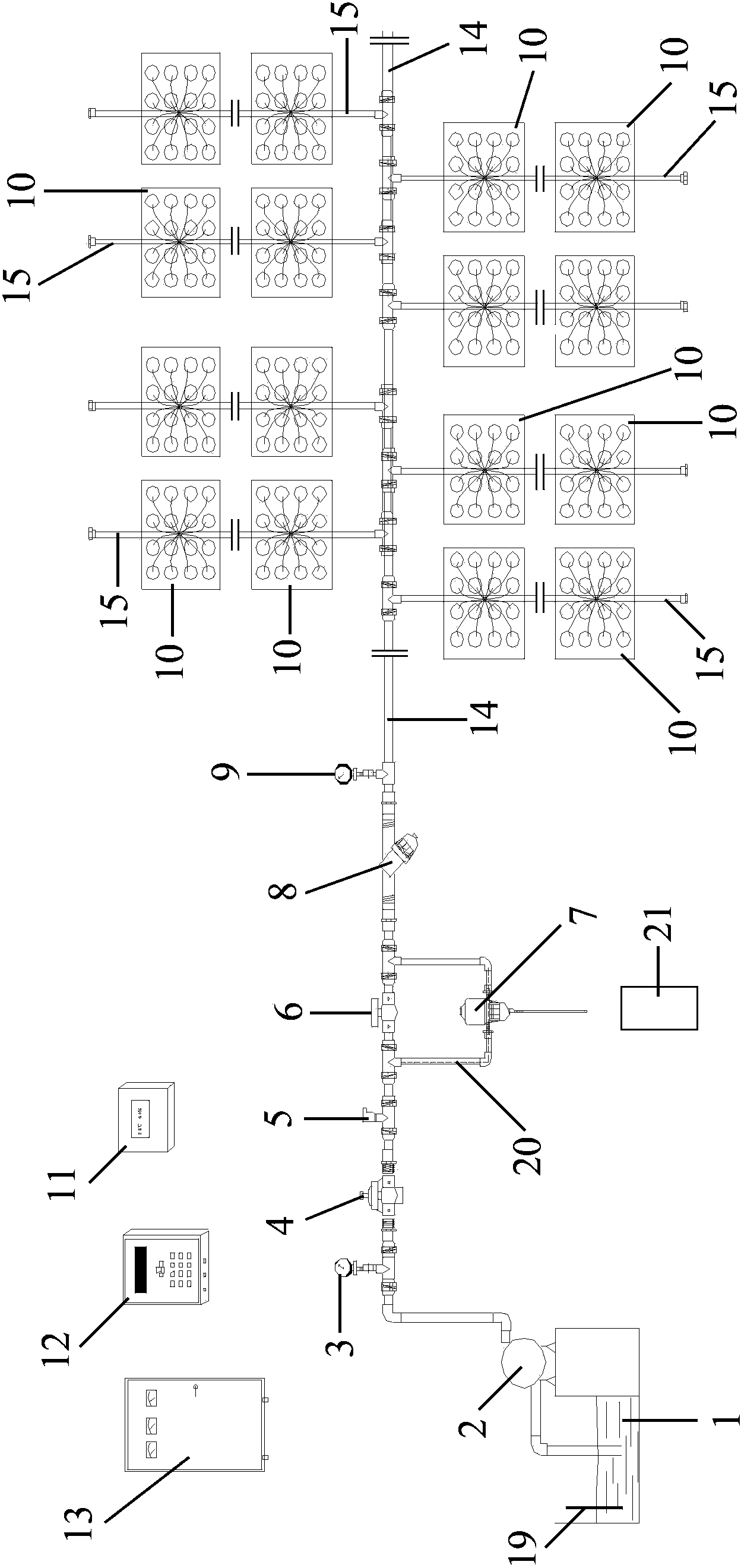

Dripping arrow irrigation automatic control system, manufacturing method of dripping arrow irrigation automatic control system and dripping arrow irrigation method

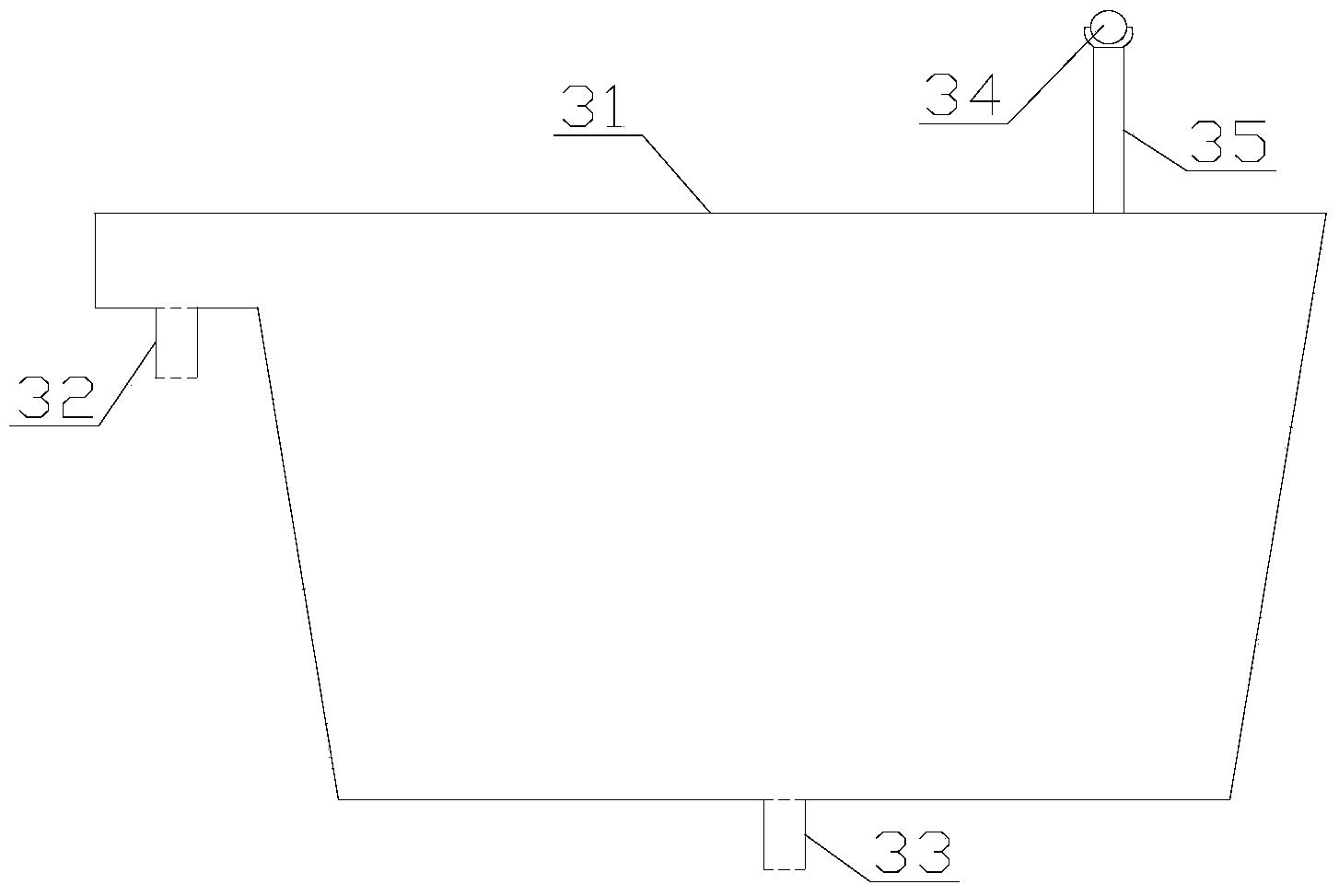

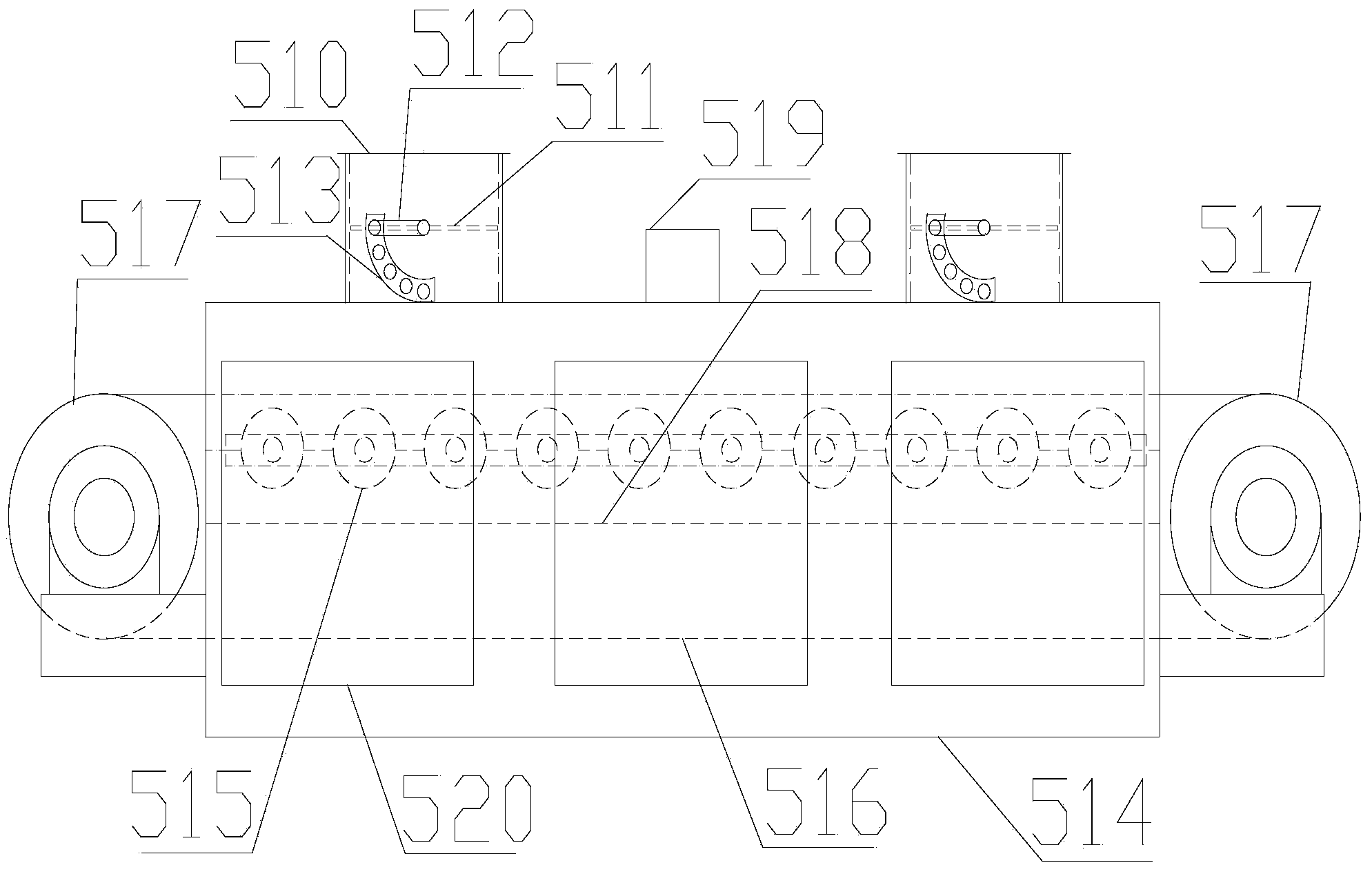

ActiveCN104380902APromote growthIncrease productionPressurised distribution of liquid fertiliserDirect liquid fertiliser deliveryExhaust valveAutomatic control

The invention relates to a dripping arrow irrigation automatic control system, a manufacturing method of the dripping arrow irrigation automatic control system and a dripping arrow irrigation method. The dripping arrow irrigation automatic control system consists of a reservoir, a water pump, a water level sensor, a conveying main pipeline, a fertilization pipeline, a conveying branch pipeline, a temperature sensor, a main controller, a start controller, a water taking pressure gauge, an electromagnetic valve, a suction and exhaust valve, a fertilization control valve, a filter and a water conveying pressure gauge; the reservoir is arranged at the initial end of the conveying main pipeline; the water level sensor is arranged in the reservoir; the water level sensor is connected with the main controller; the water pump is arranged on the reservoir and is used for drawing a water source in the reservoir; the water taking pressure gauge, the electromagnetic valve, the suction and exhaust valve, the fertilization control valve, the filter and the water conveying pressure gauge are sequentially arranged on the initial section of the conveying main pipeline; the fertilization control valve is mounted on the initial section of the conveying main pipeline; a fertilizer is uniformly conveyed into the conveying main pipeline by the fertilization conveying pipeline. The dripping arrow irrigation automatic control system is scientifically designed, has a reasonable structure and uniform flow, is reasonable in system arrangement, is stable in pressure in the pipelines, has wide applicability and has a wide application range; a dripping arrow takes effects of a water dropper and an insertion arrow, has a small size and high intensity, has powerful use functionality and is convenient to mount and use.

Owner:TIANJIN WATER RESOURCES RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com