Patents

Literature

221results about How to "Keep tidy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

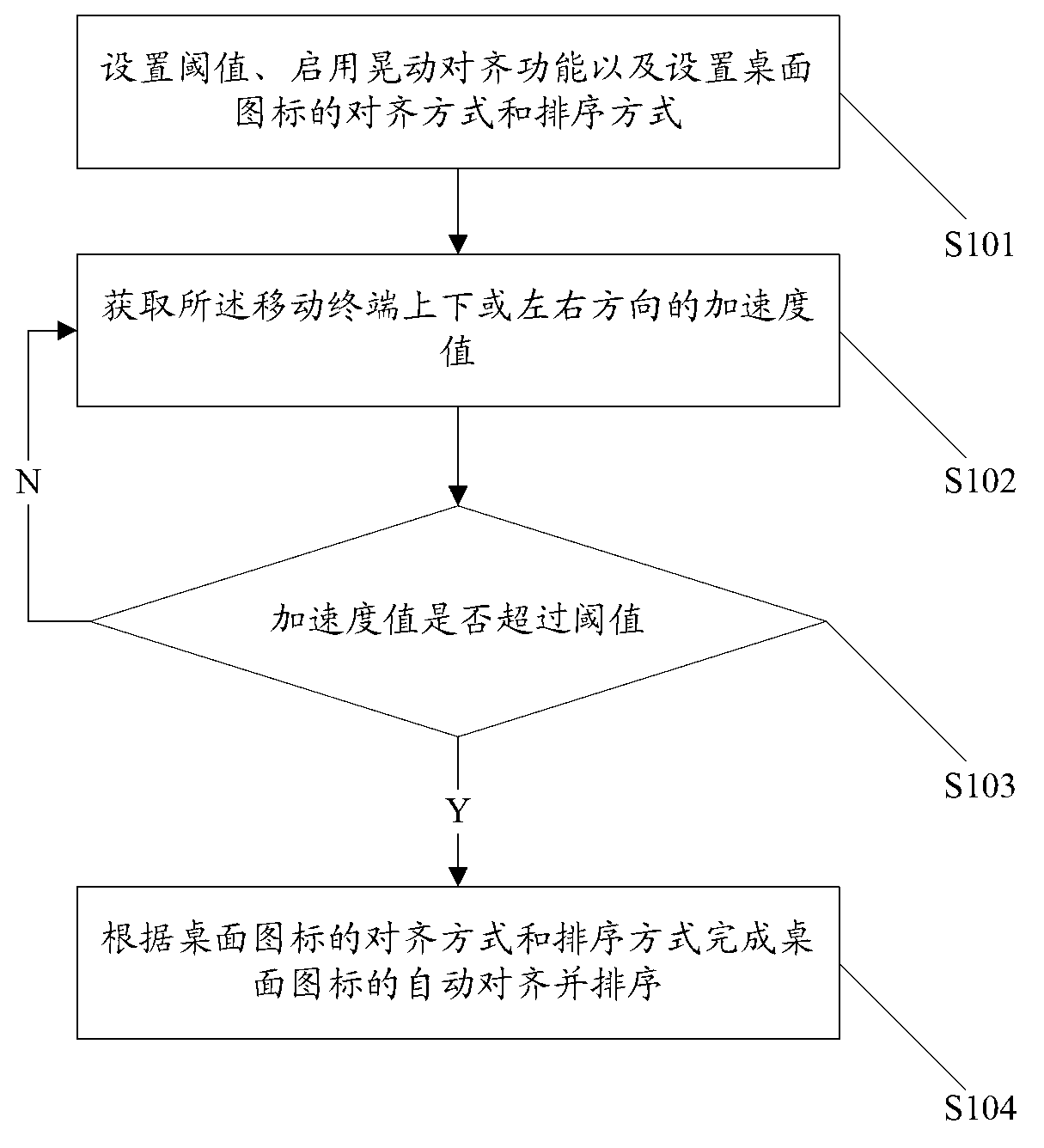

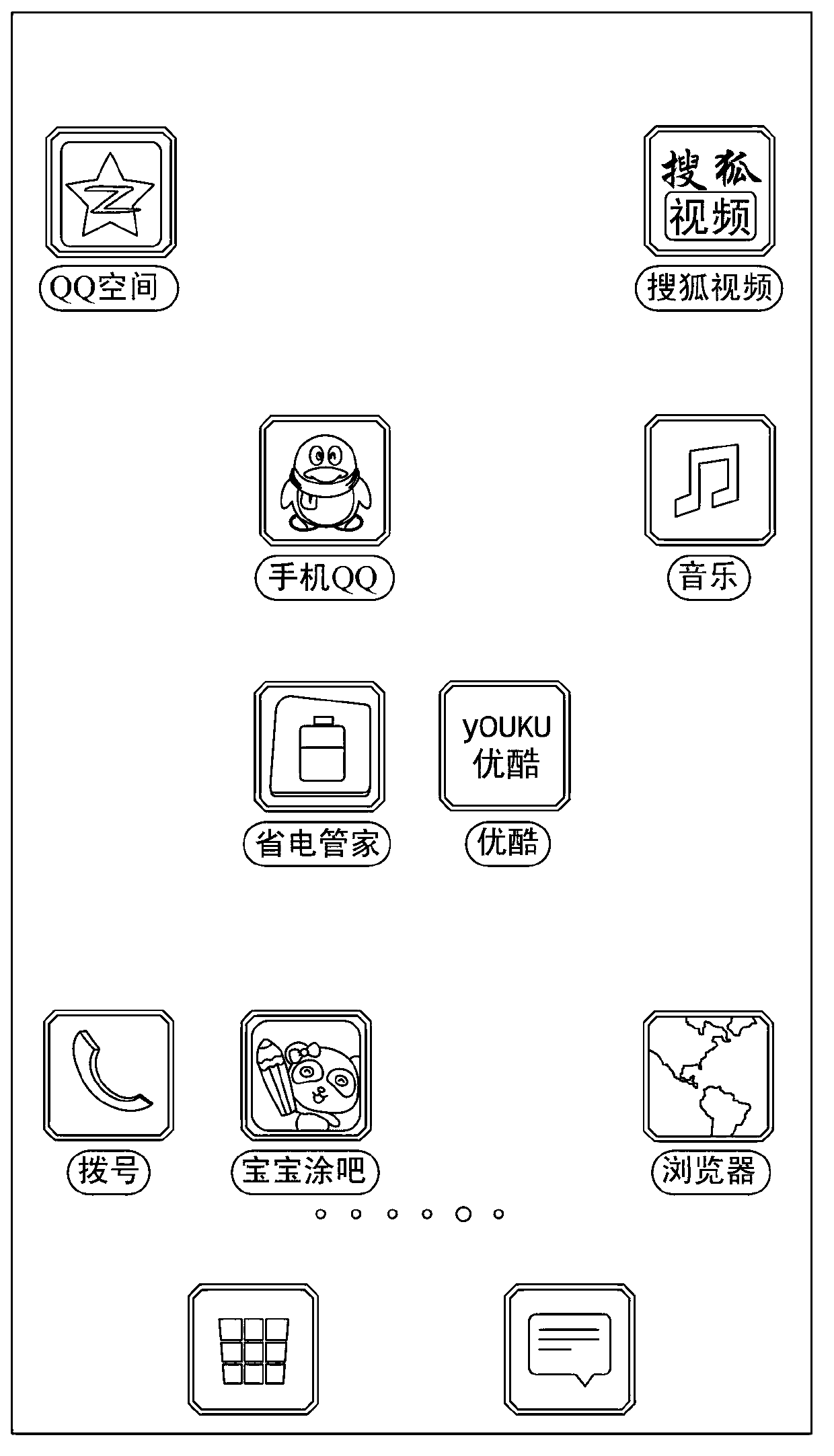

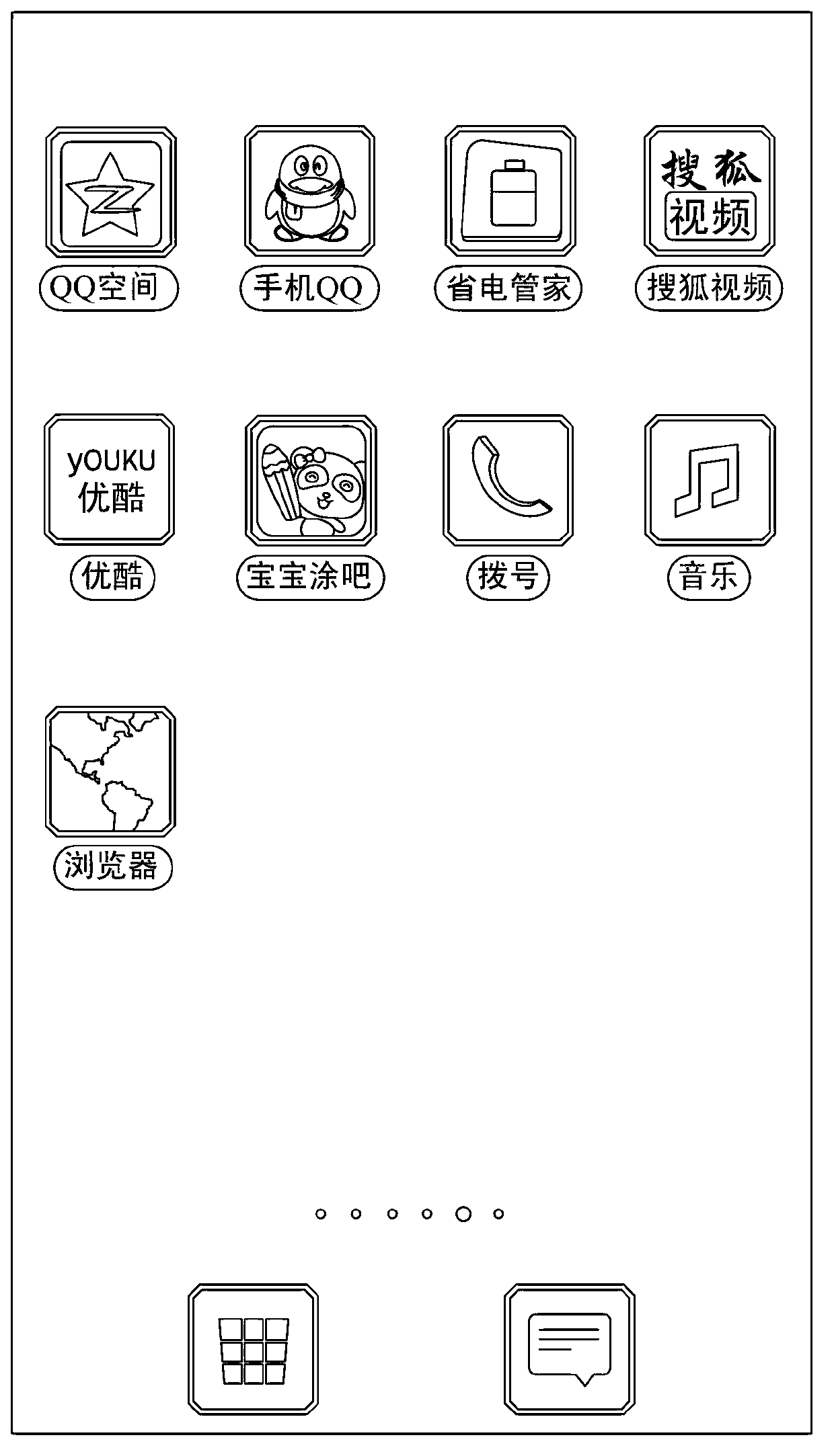

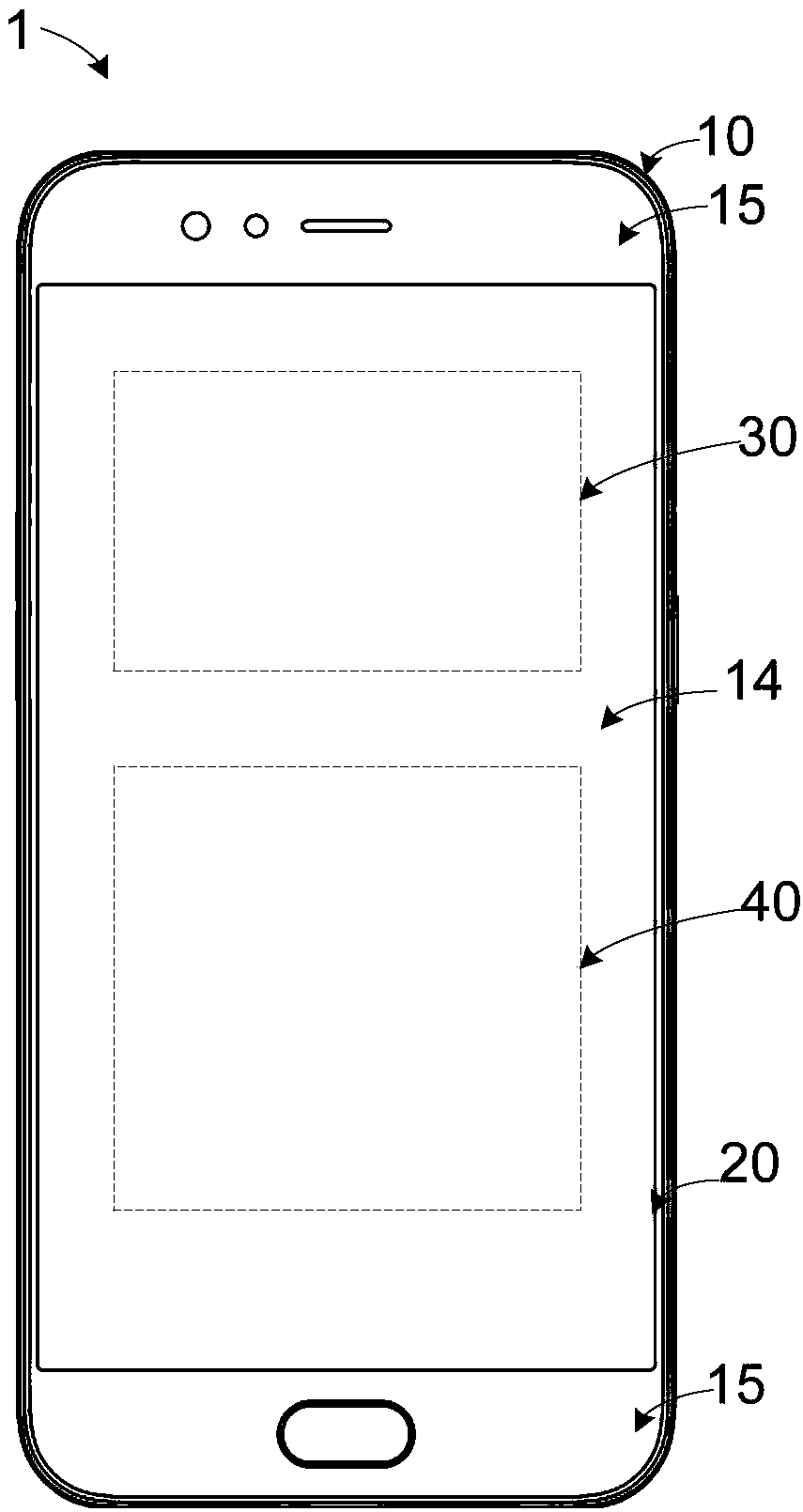

Method and mobile terminal for realizing automatic alignment and sorting of desktop icons by shaking

InactiveCN102968247AKeep tidyImprove user experienceInput/output processes for data processingComputer engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

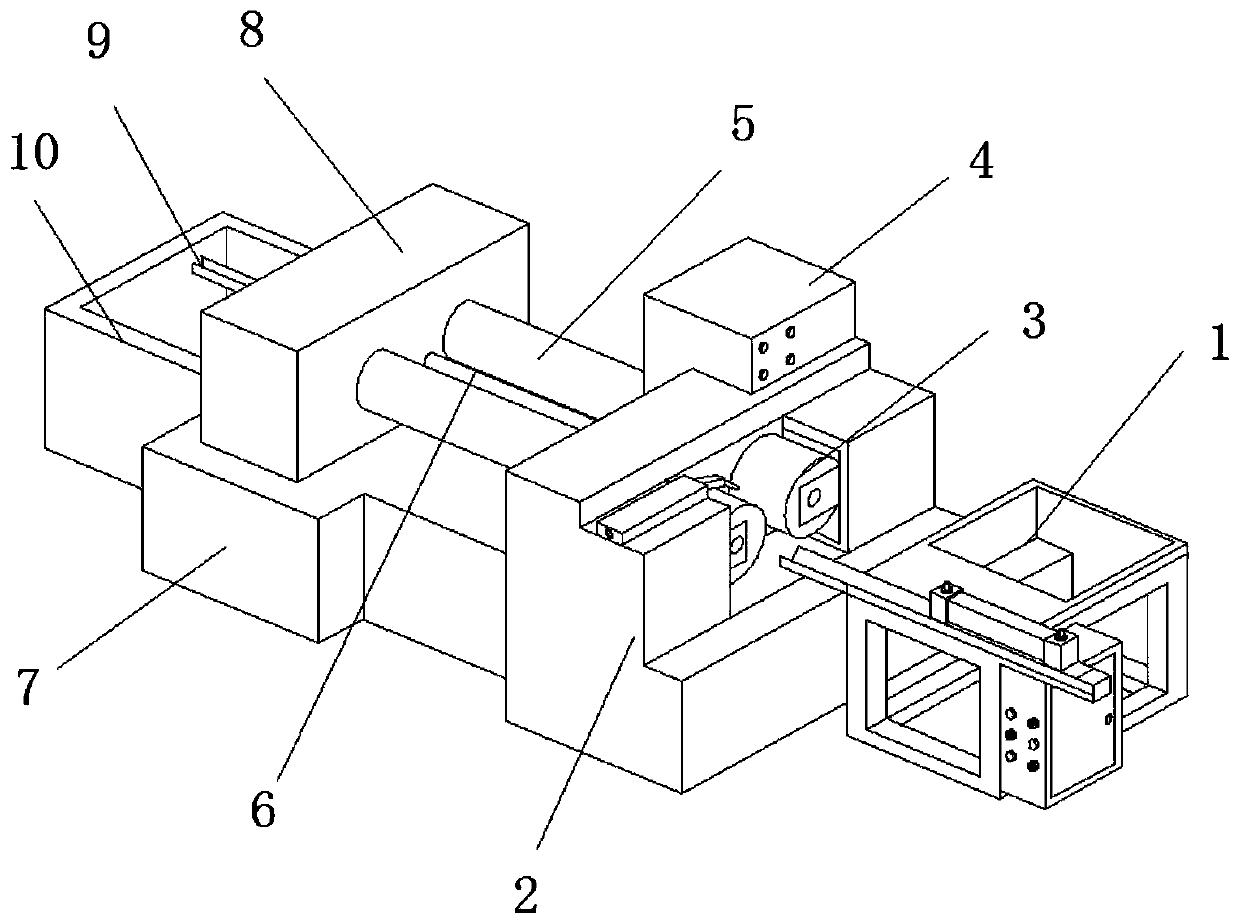

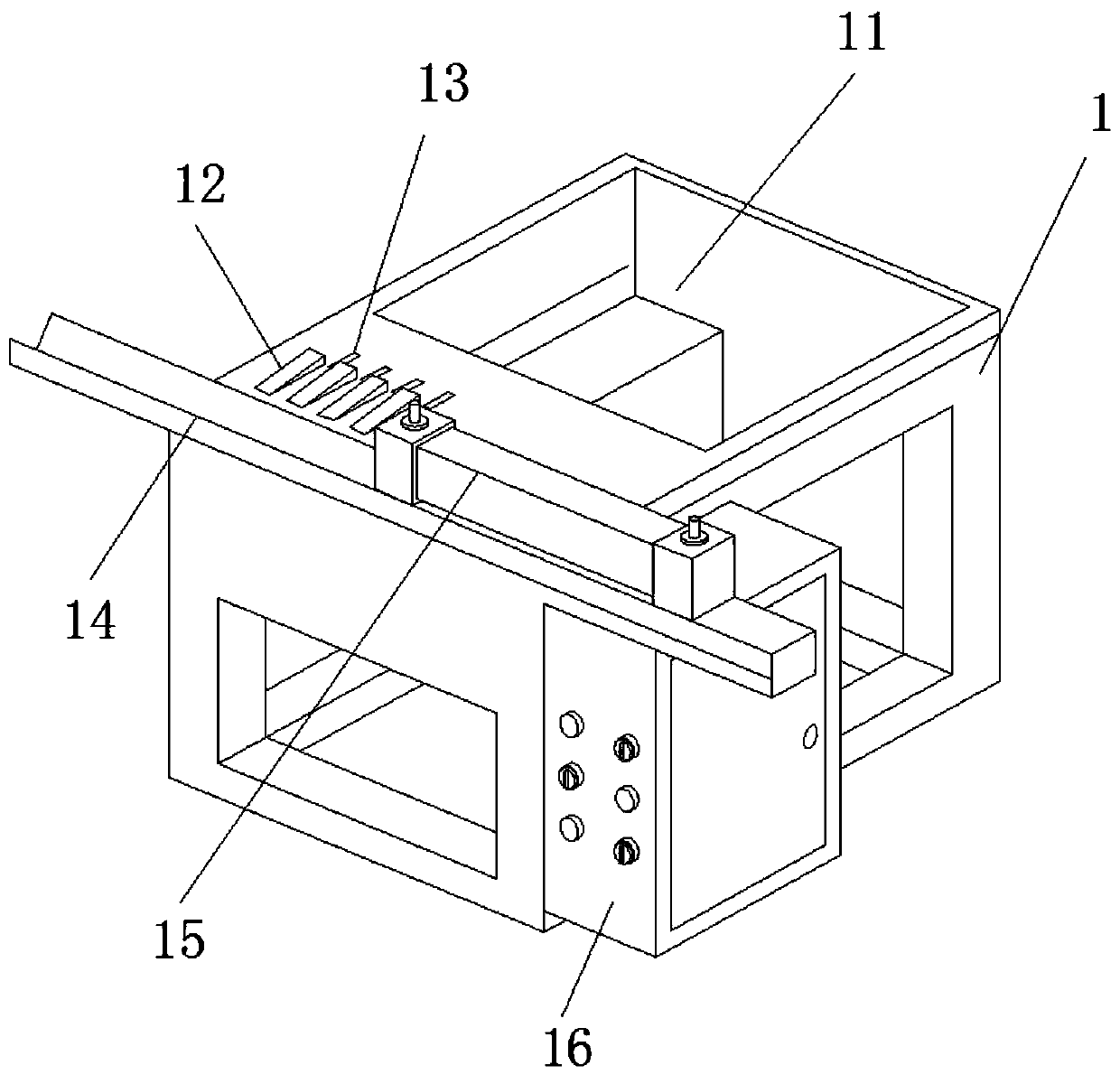

Screw thread rolling machine

InactiveCN110586818APersonal safetyReduce scatterMetal-working feeding devicesScrew-threads articlesKey pressingEngineering

The invention discloses a screw thread rolling machine. The machine comprises a feeding mechanism, wherein one end of the feeding mechanism is fixedly provided with a storage box, and falling stop blocks are fixedly arranged at the upper end of the feeding mechanism; discharging through grooves are formed in the ends, close to the storage box, of the falling stop blocks, a feeding channel is fixedly arranged at the end, away from the discharging through grooves, of the falling stop blocks, a feeding air cylinder is fixedly arranged on the feeding channel, and a discharging push block is fixedly arranged on the feeding air cylinder; and an electric control box is fixedly arranged on the outer side of the feeding mechanism, a maintenance door is movably arranged on the electric control box,a function key is fixedly arranged at the end, adjacent to the maintenance door, of the electric control box, and an adjusting knob is fixedly arranged on the outer side of the function key. According to the screw thread rolling machine, the feeding mechanism capable of automatic feeding is added, so that an operator can be liberated, only raw materials in the storage device are required to placeon the feeding mechanism, therefore the direct contact between the operator and the equipment is reduced, and the operator is better protected.

Owner:浙江君悦标准件有限公司

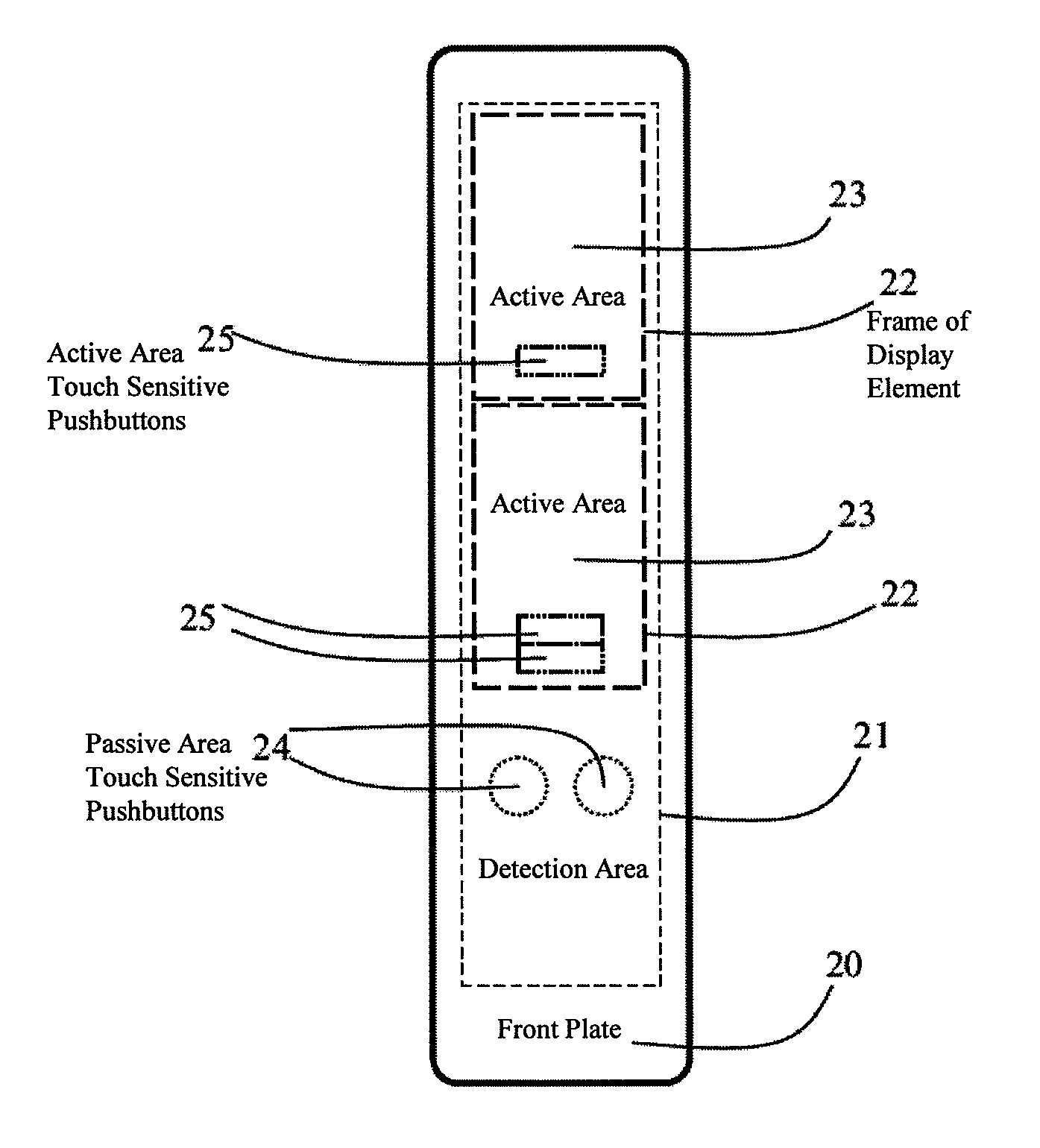

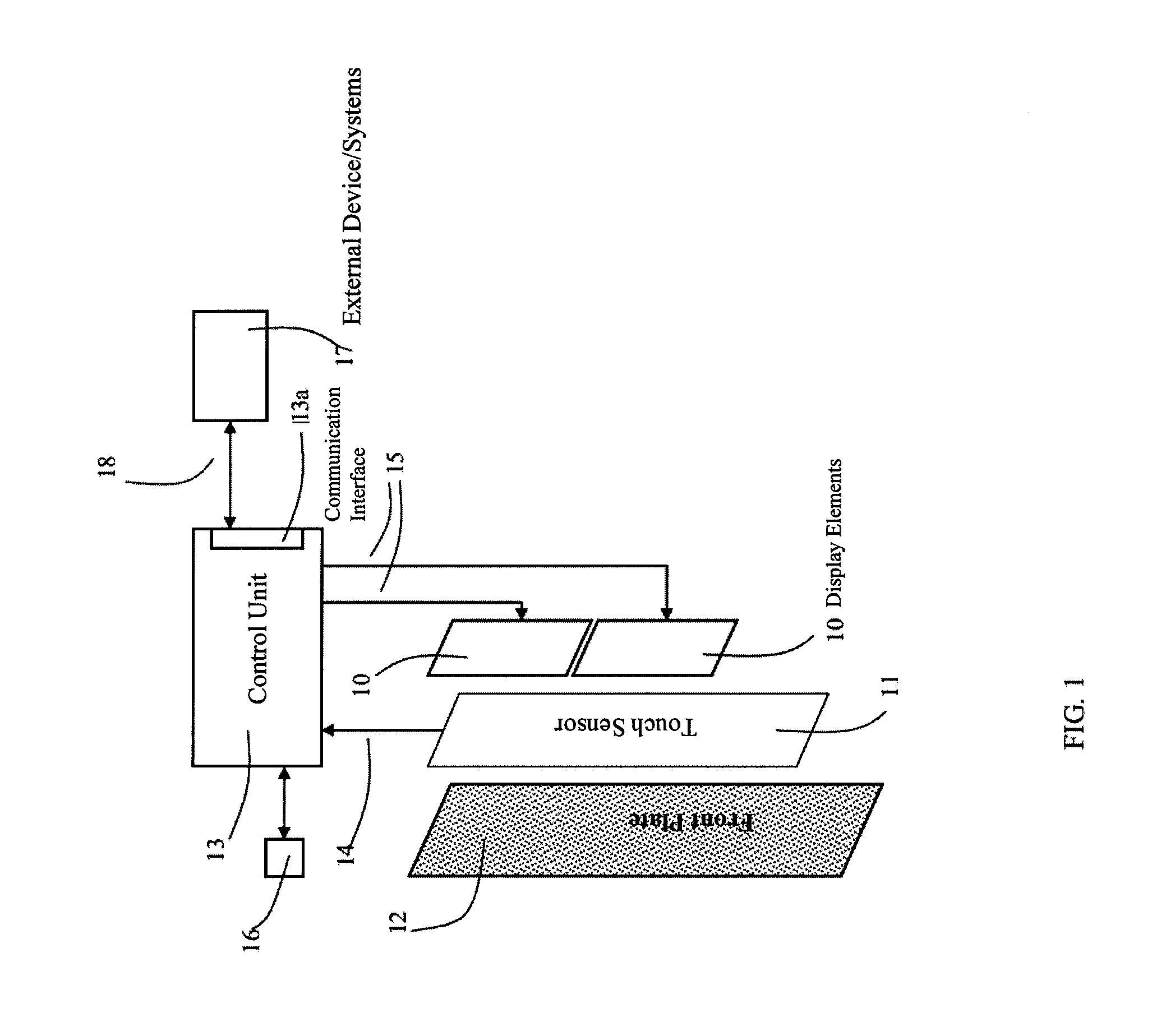

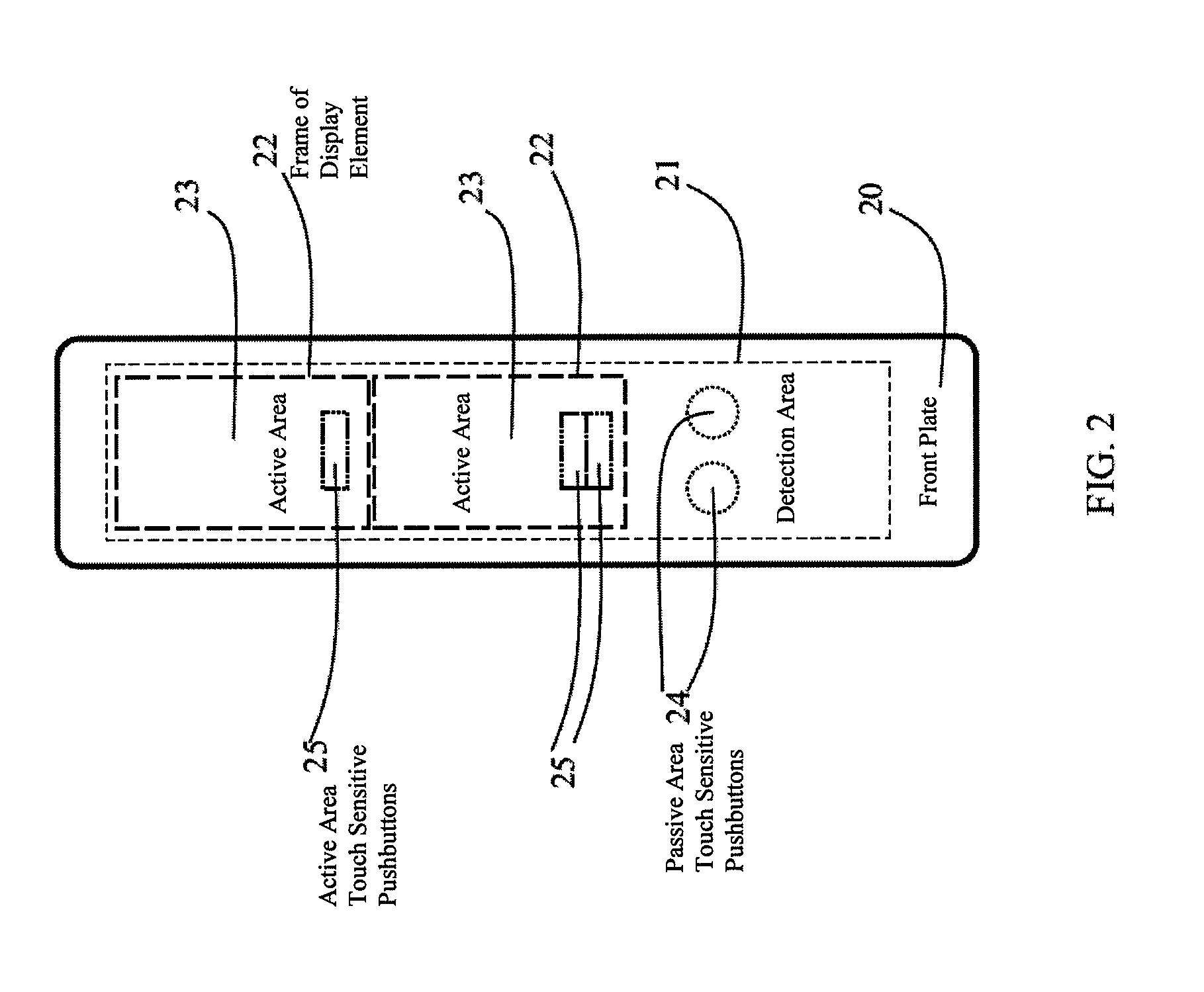

Touch based elevator call panel

The present invention presents a call panel of an elevator or of an elevator system including one or more display elements, a front plate covering the call panel, in connection with which front plate a touch sensor is fitted, and also a control unit to which the display elements and also the touch sensor are connected. The detection area of the touch sensor covers both an active area, and a passive area, where the active area additionally utilizes display elements, while the passive area lacks display capability and remains outside at least some of the aforementioned active area, in which one or more touch-sensitive pushbuttons are disposed in the passive area. The control unit is arranged to react to a touch of the touch-sensitive pushbuttons specified for the aforementioned detection area.

Owner:KONE CORP

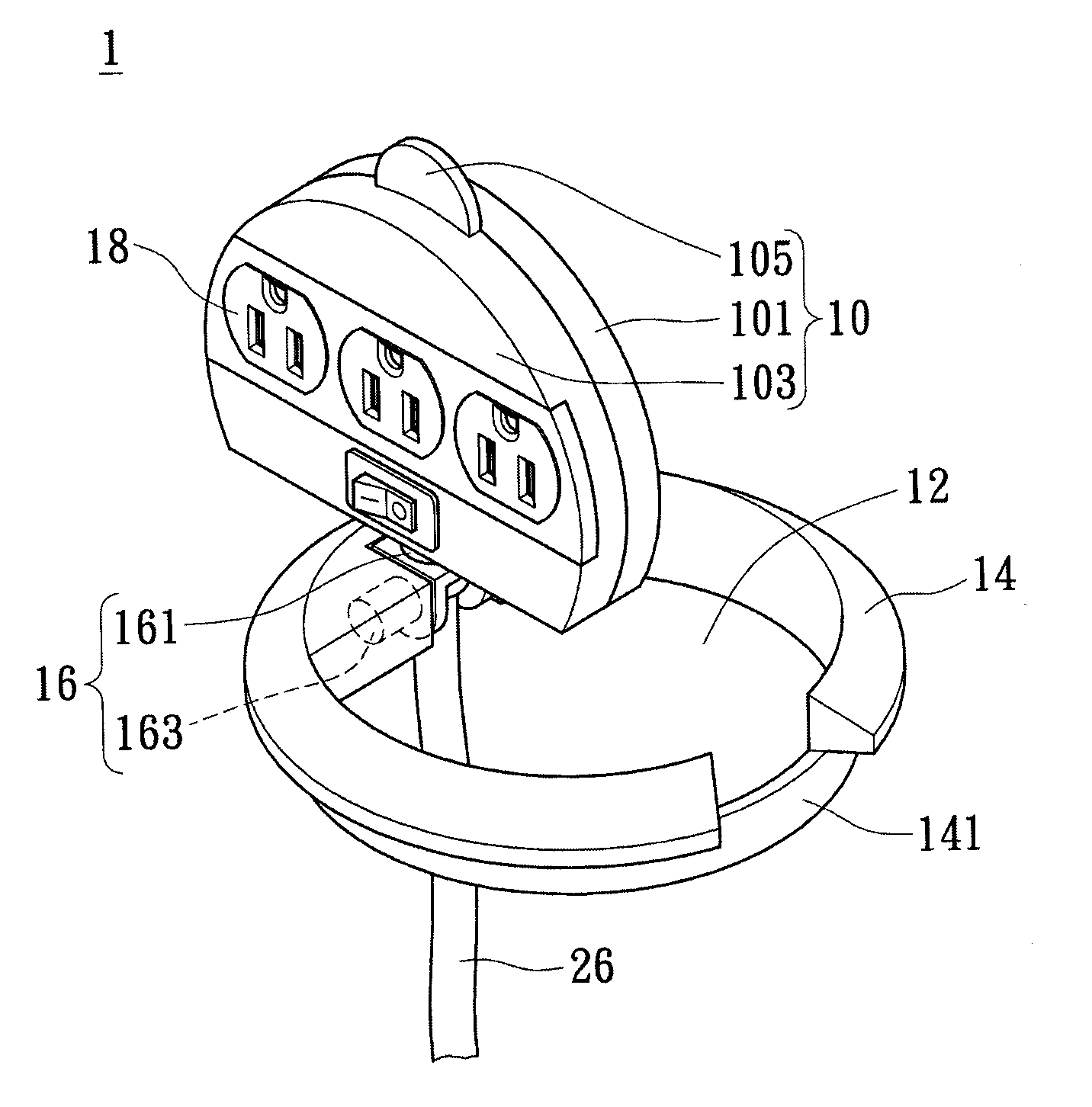

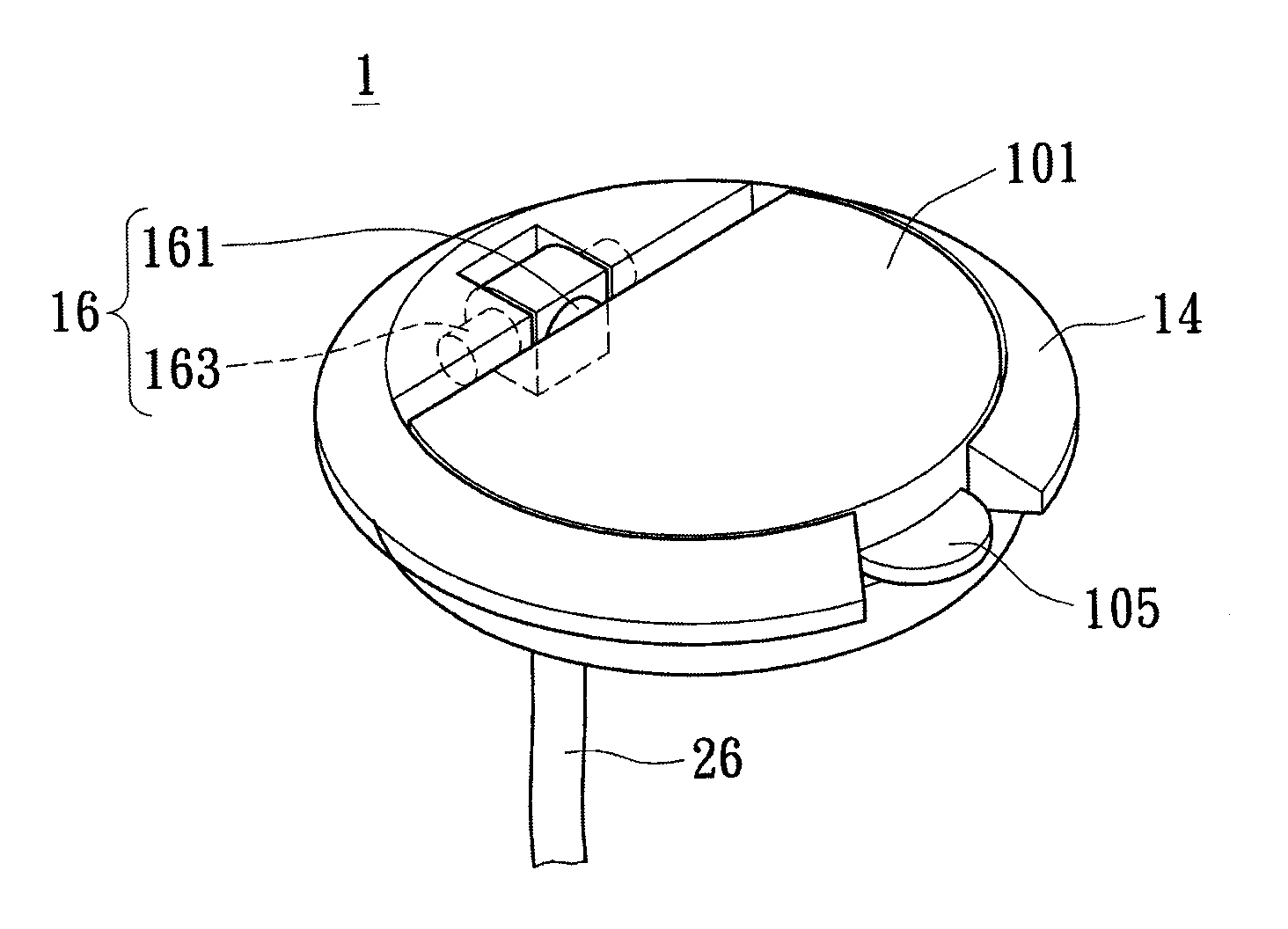

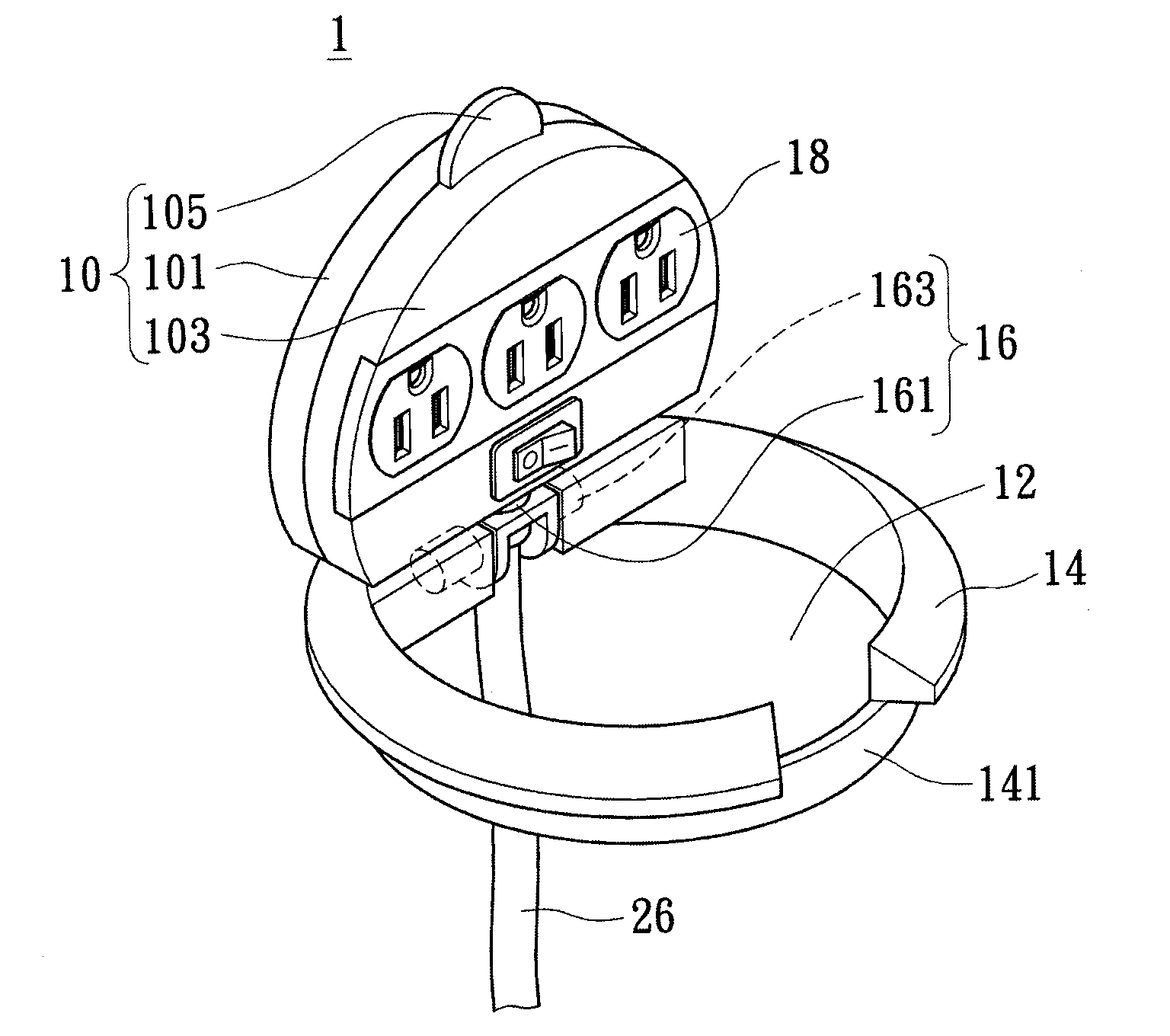

Concealed socket capable of rolling towards multi-directions

InactiveCN102148469AGood reversalEasy to open and closeCoupling device detailsFlexible/turnable line connectorsEngineeringMechanical engineering

Owner:POWERTECH INDAL

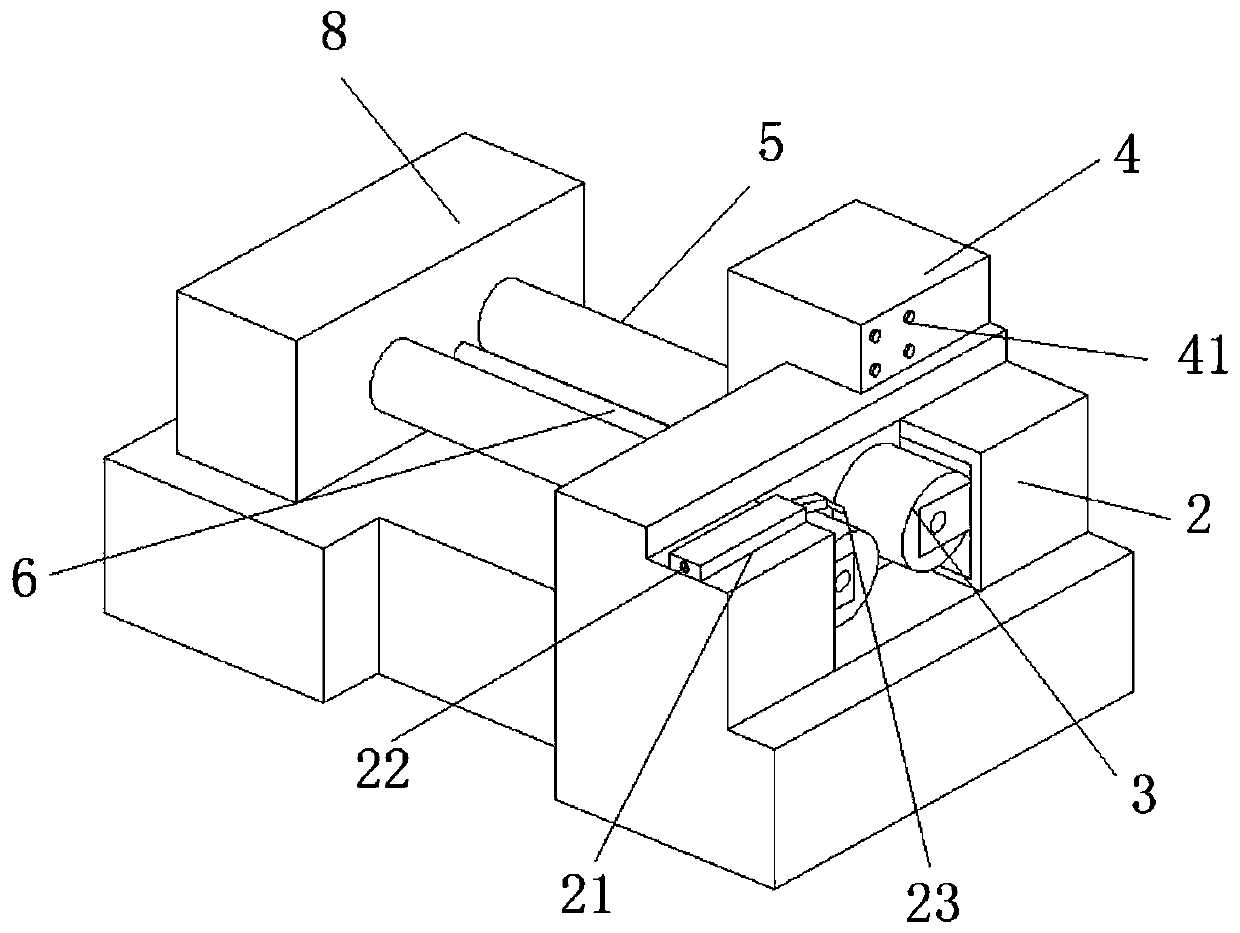

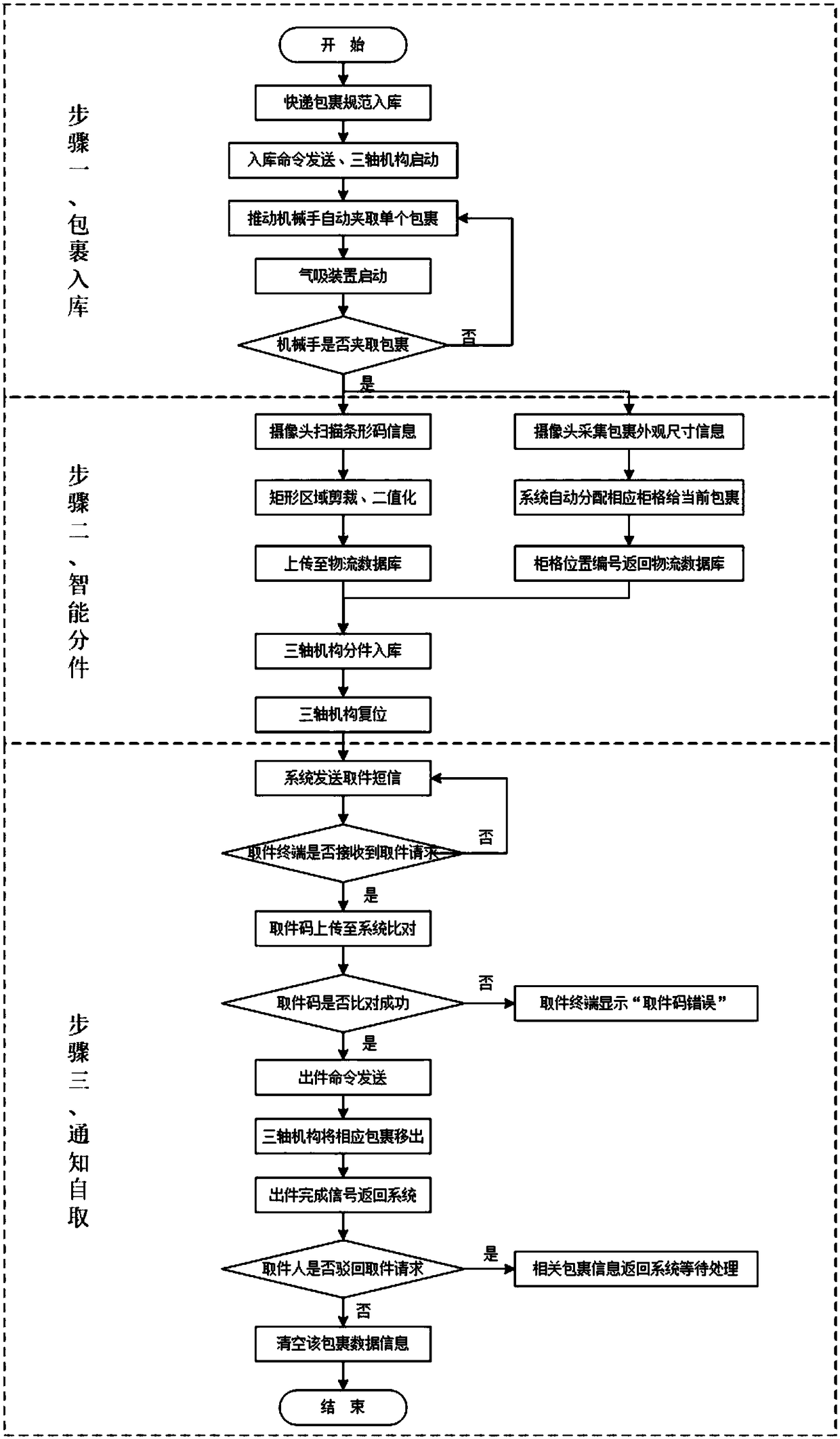

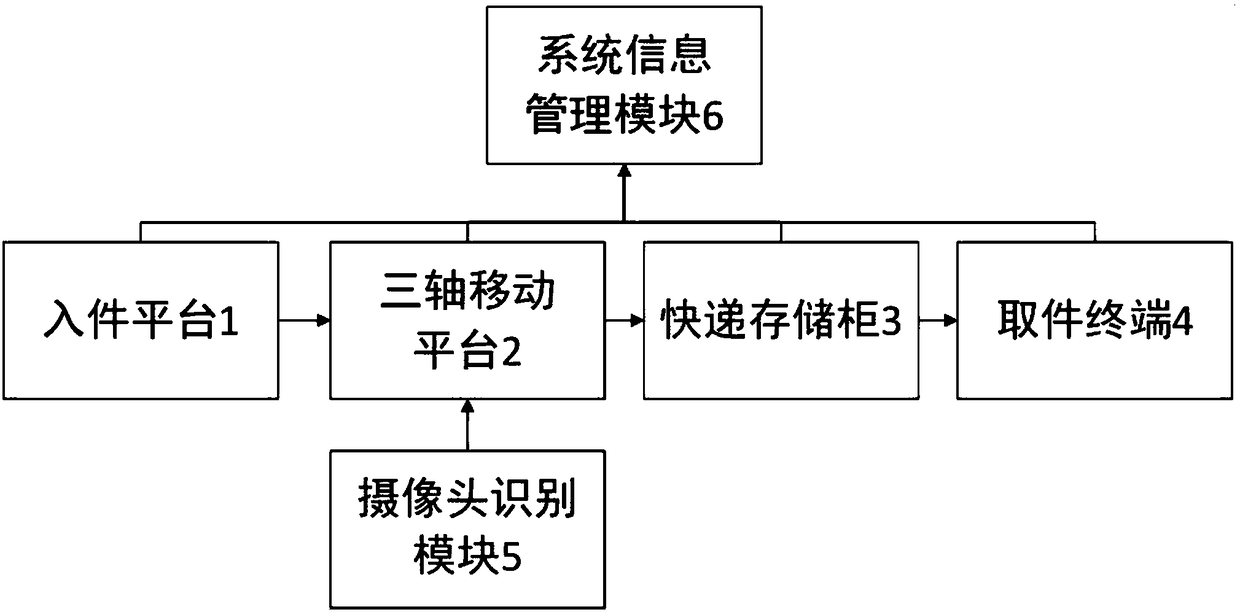

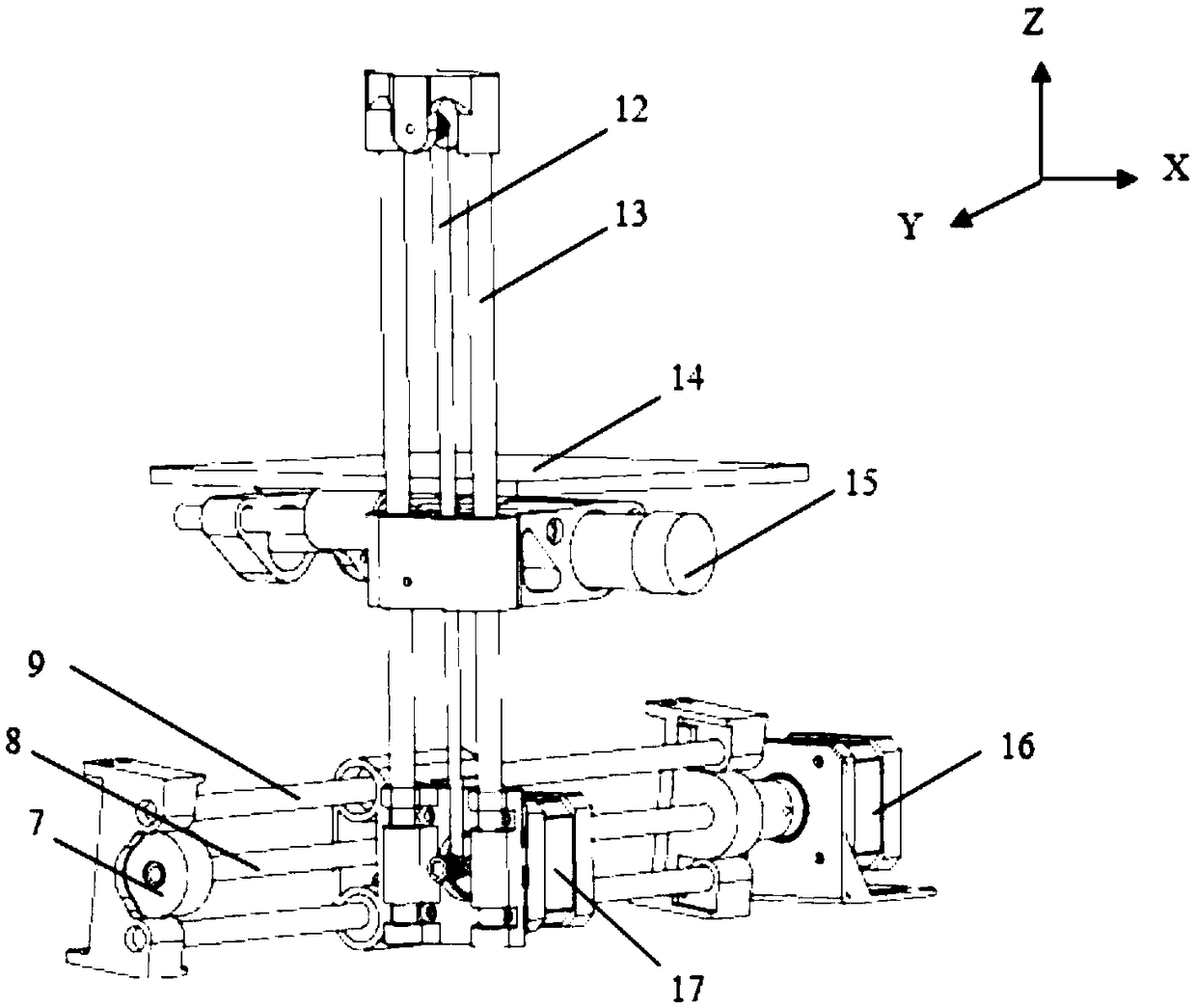

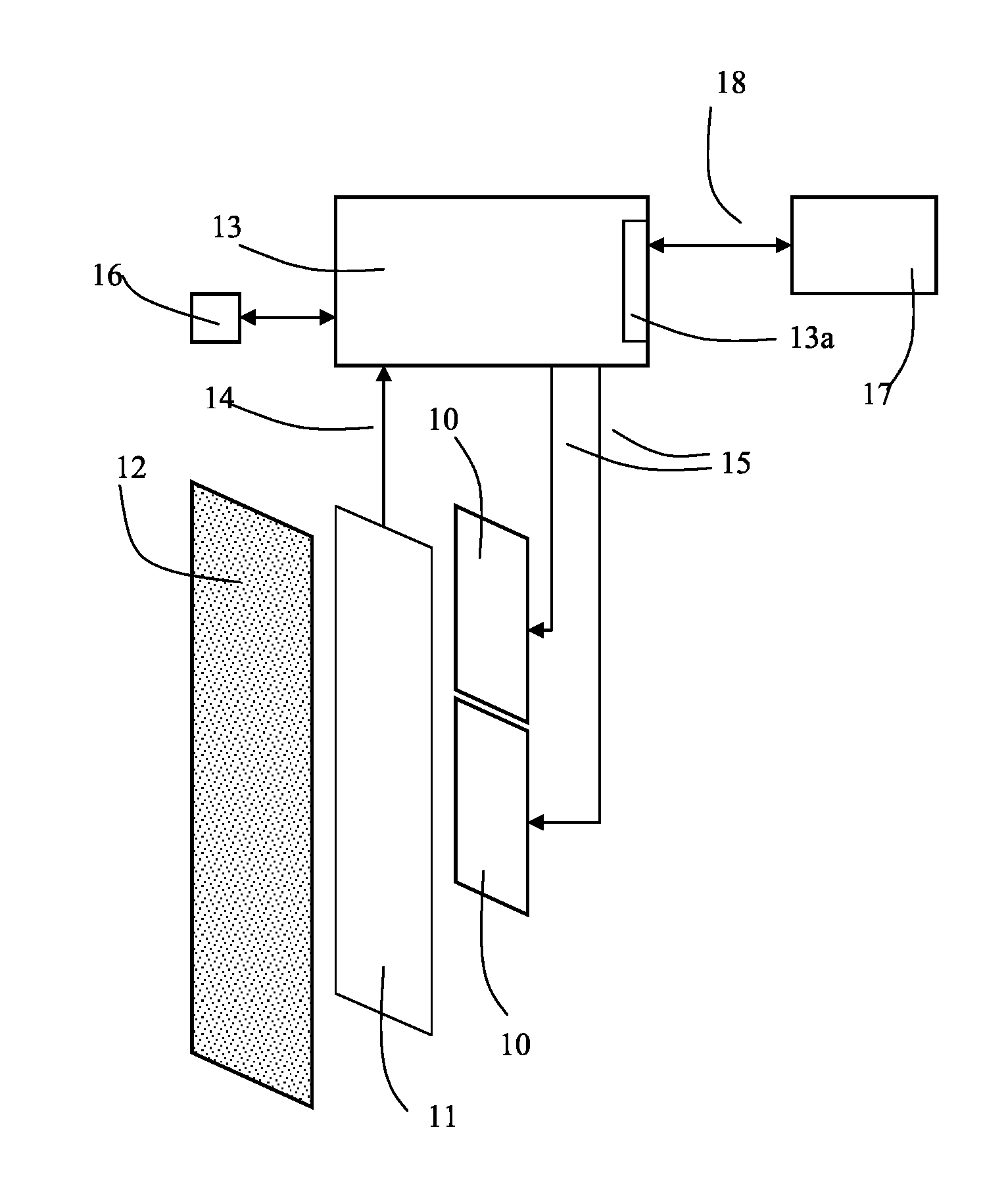

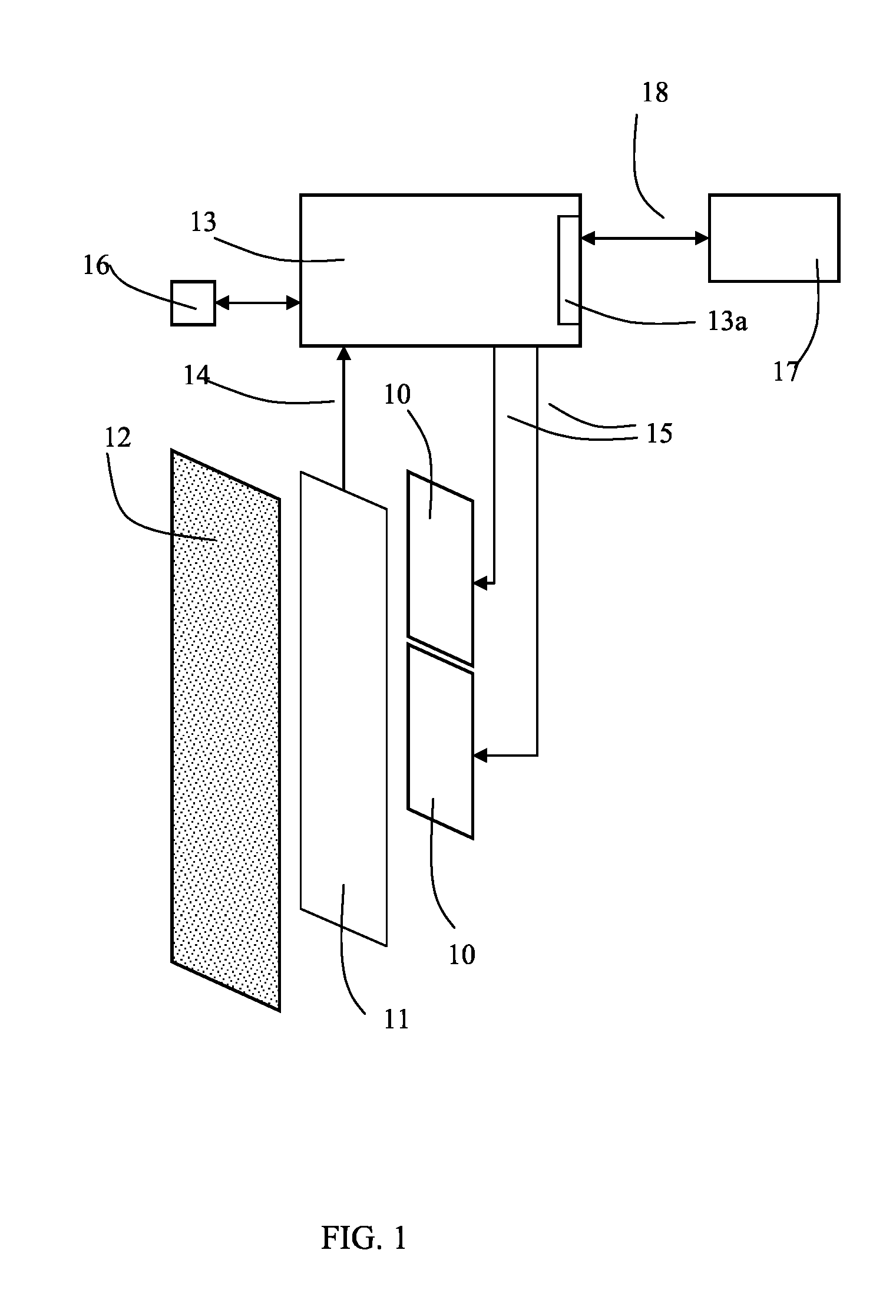

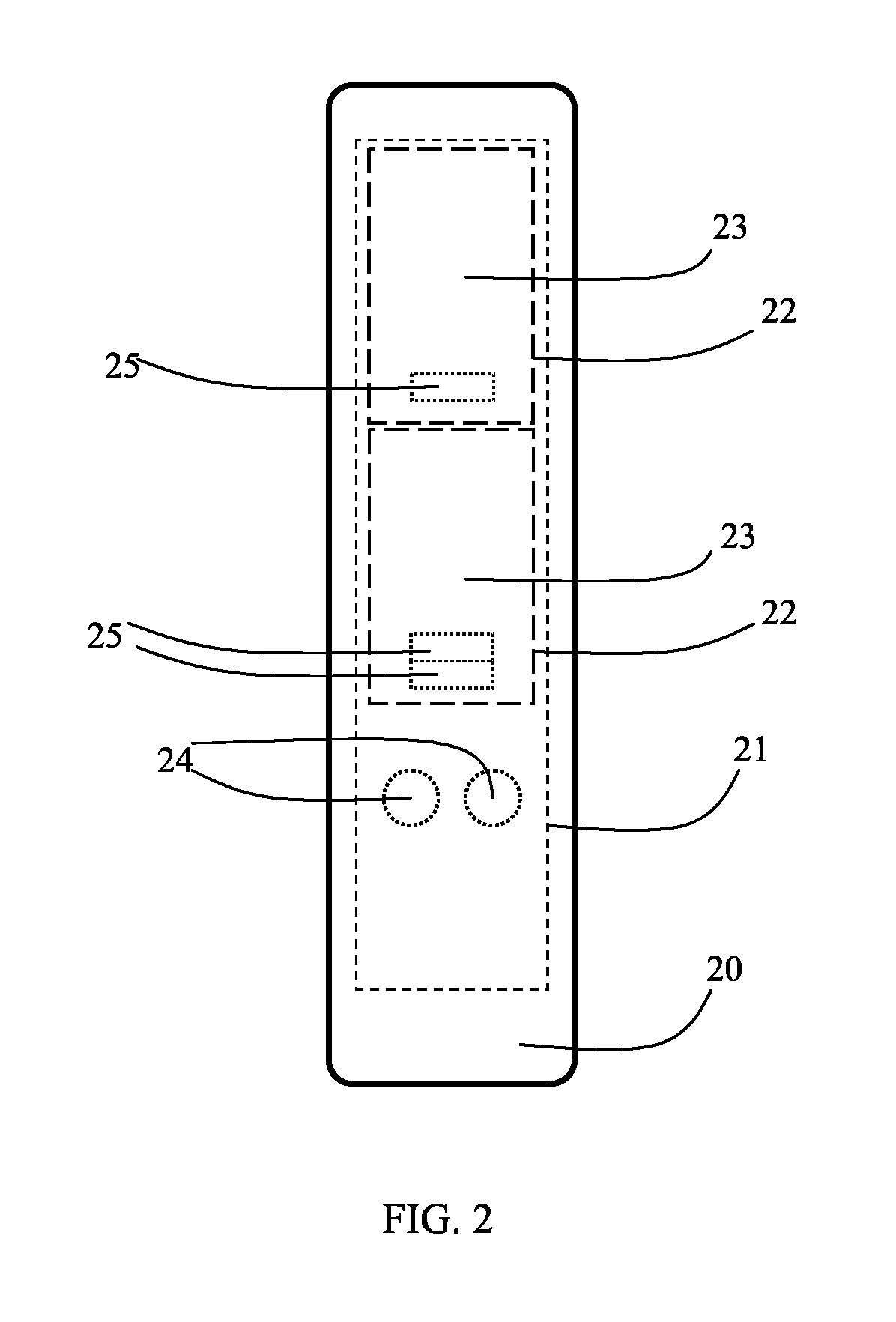

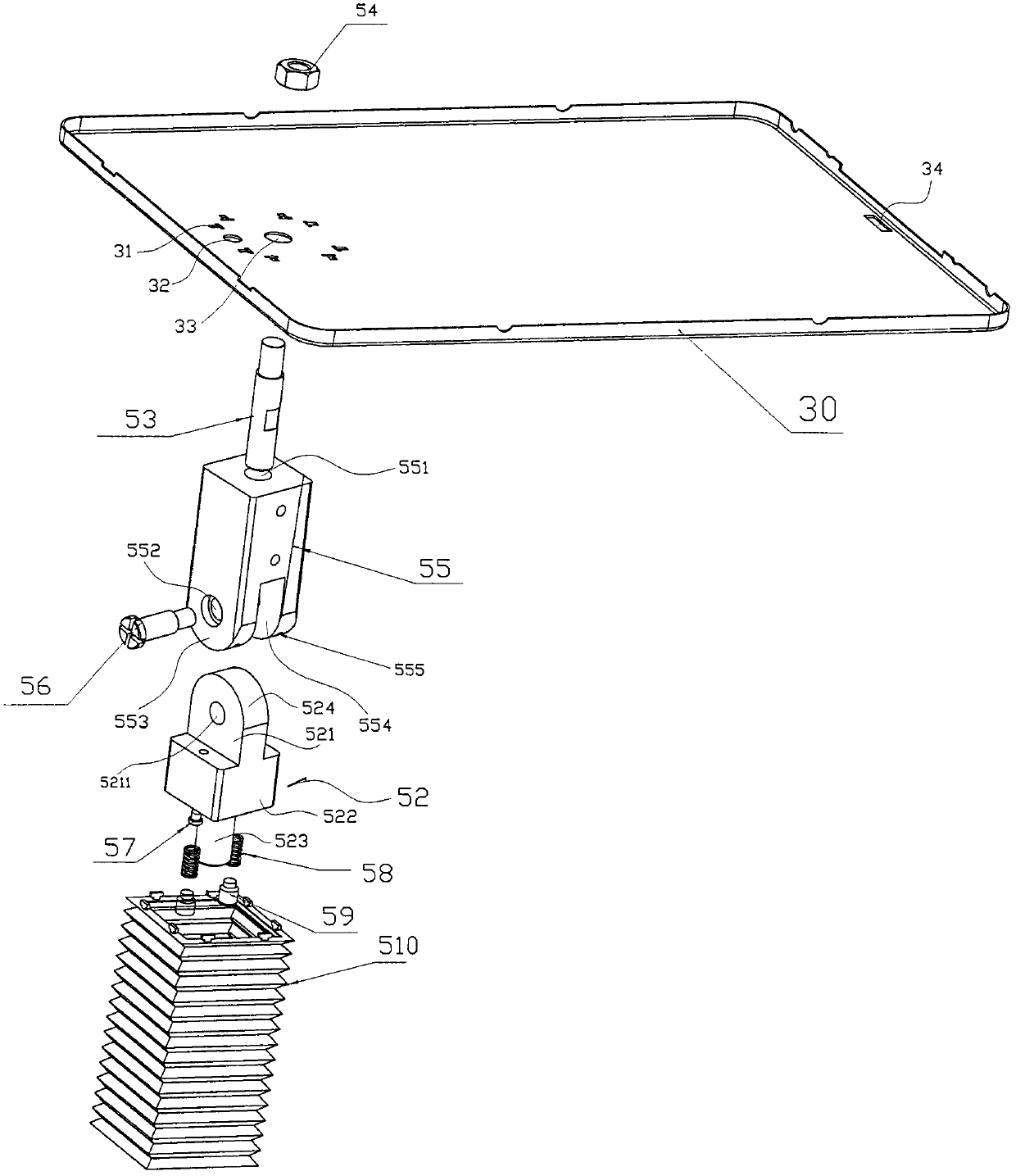

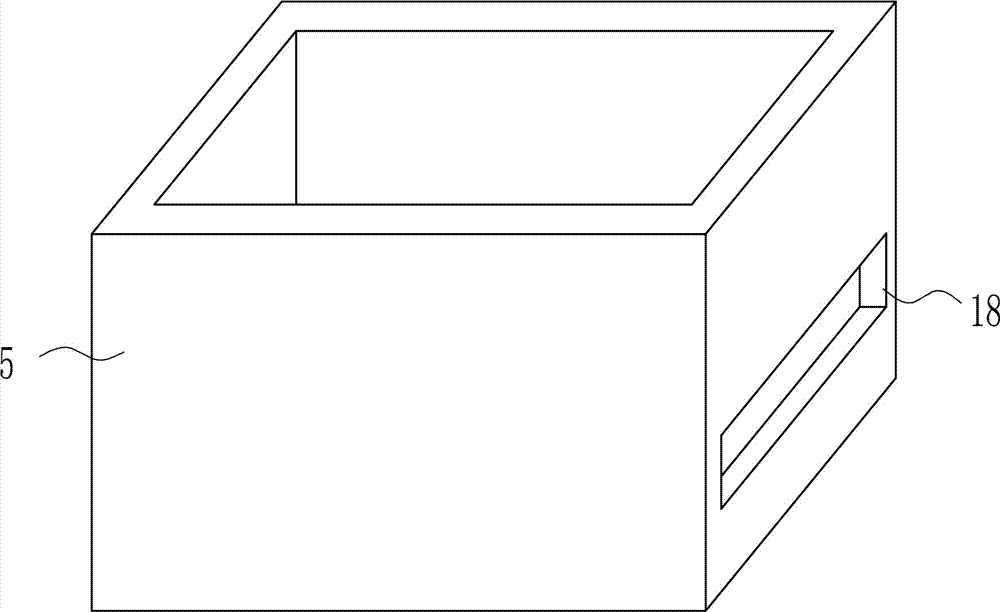

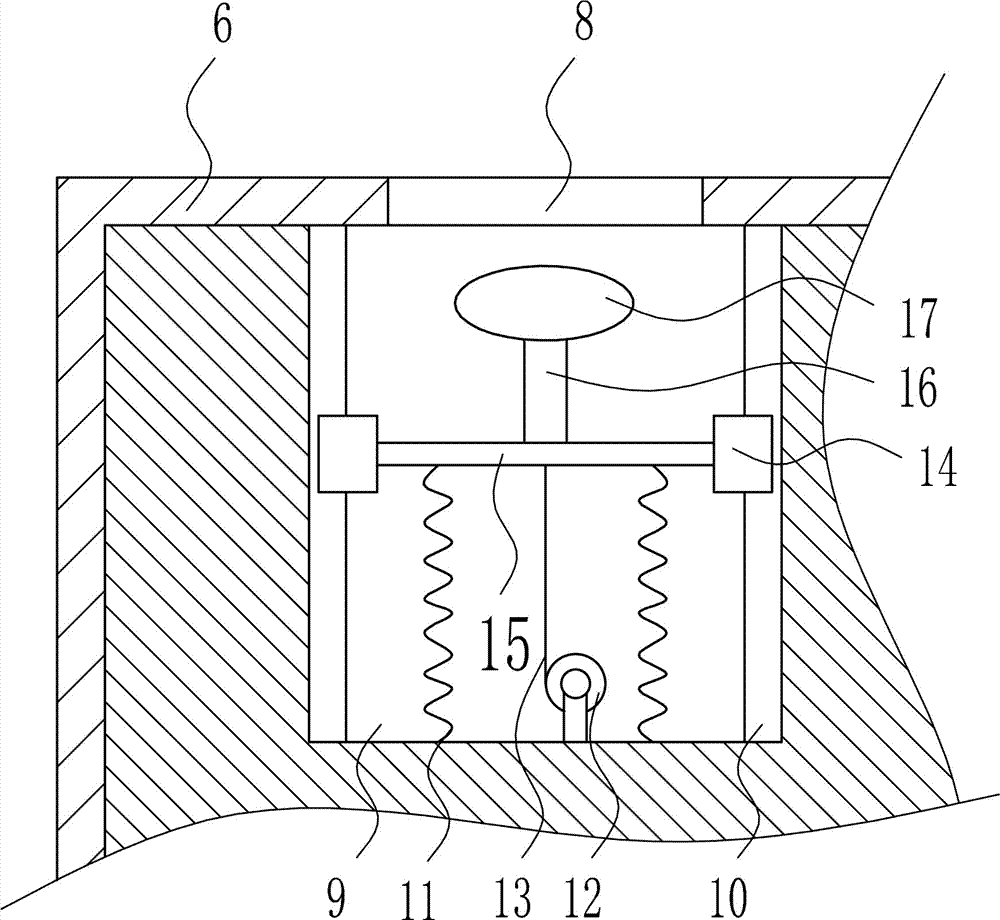

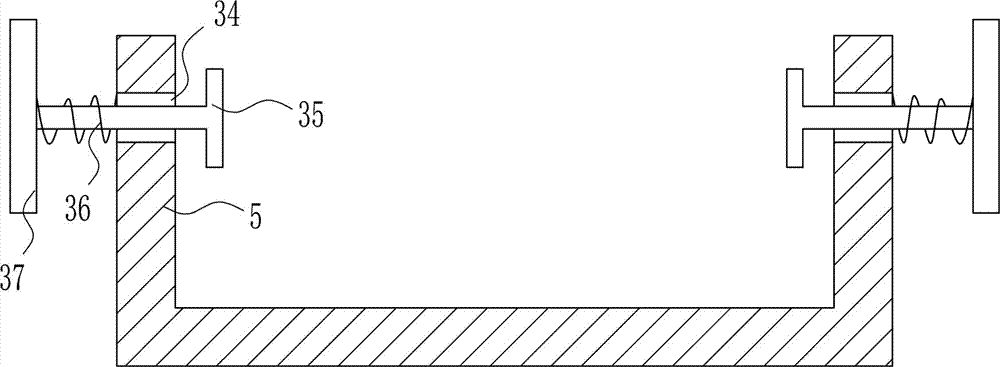

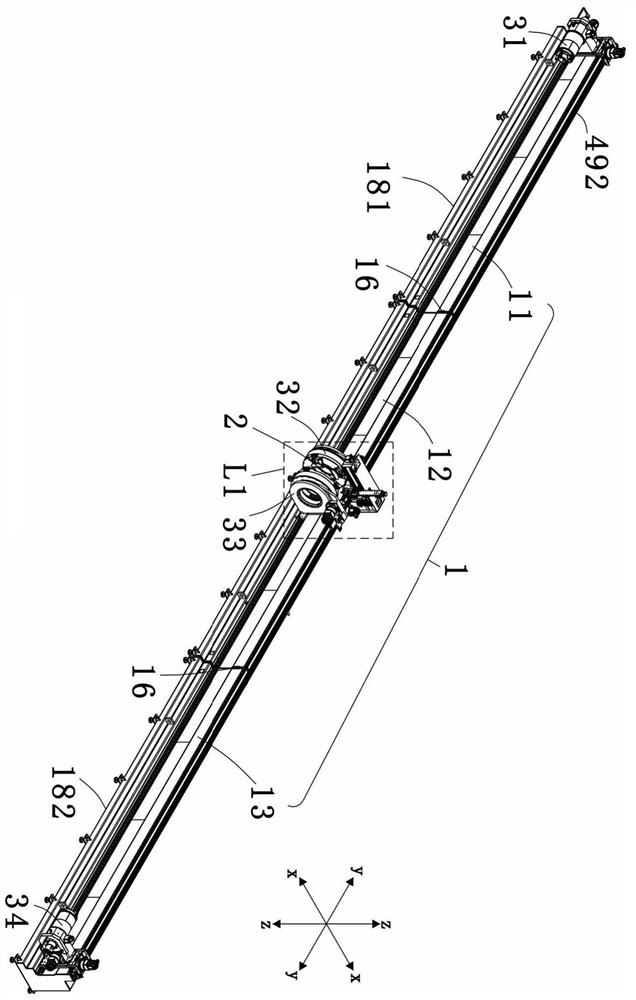

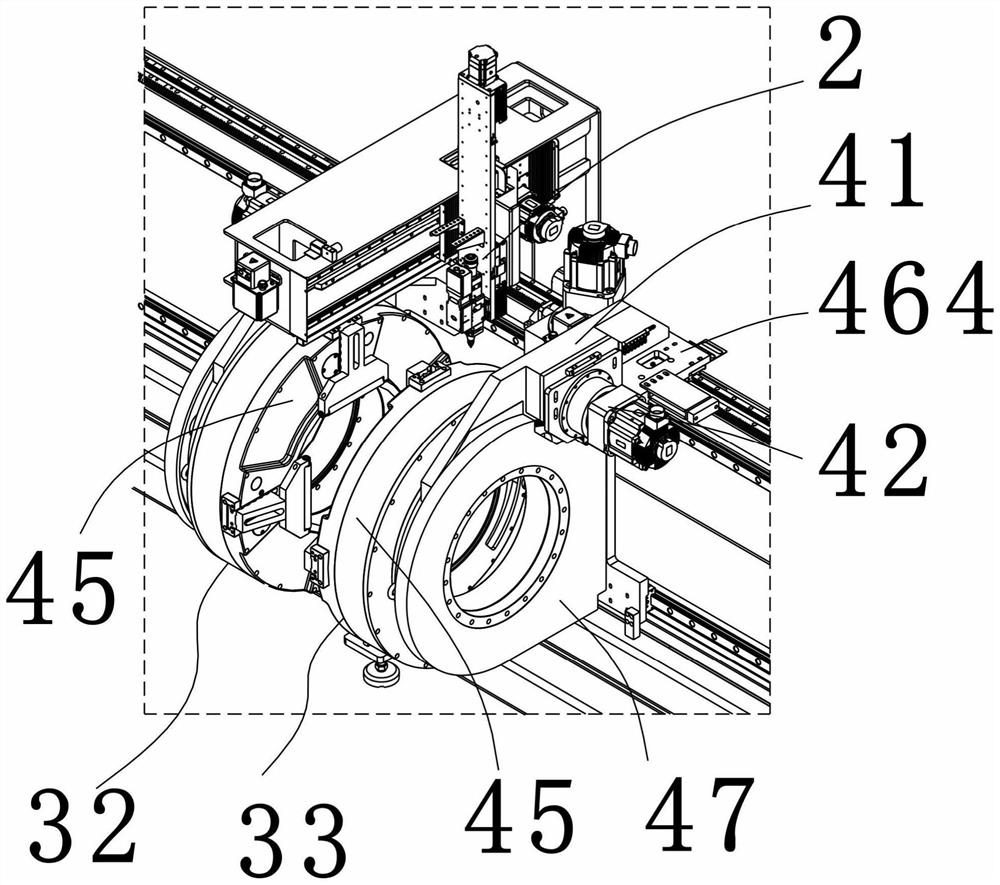

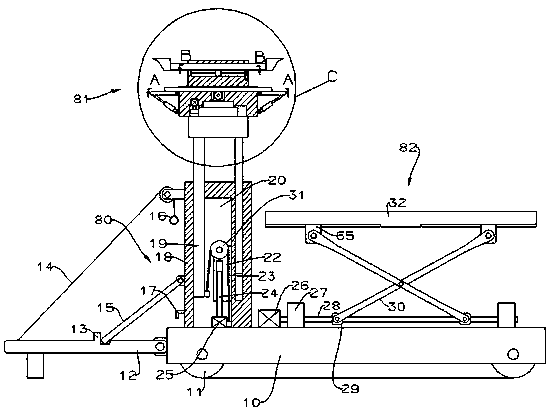

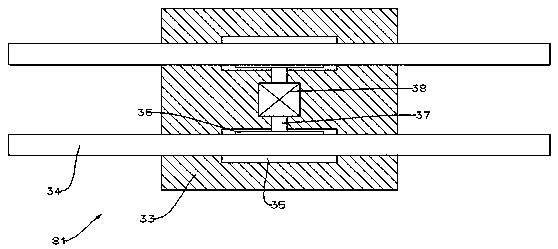

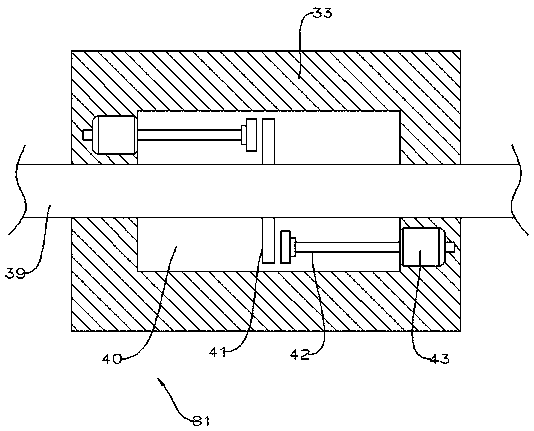

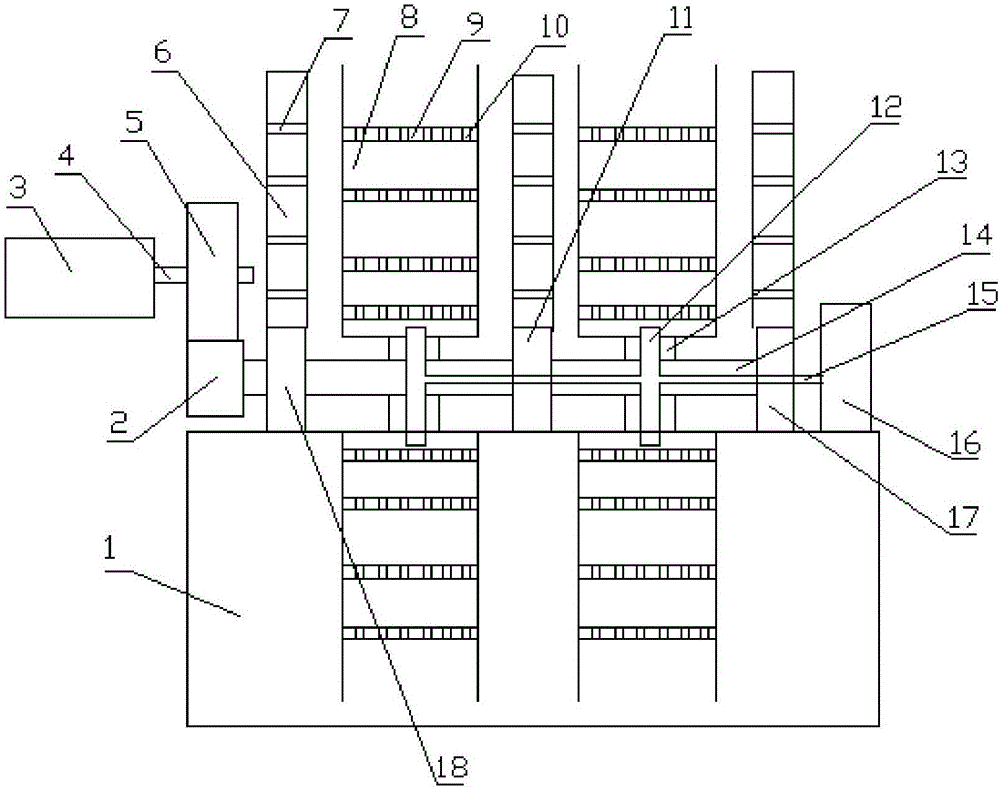

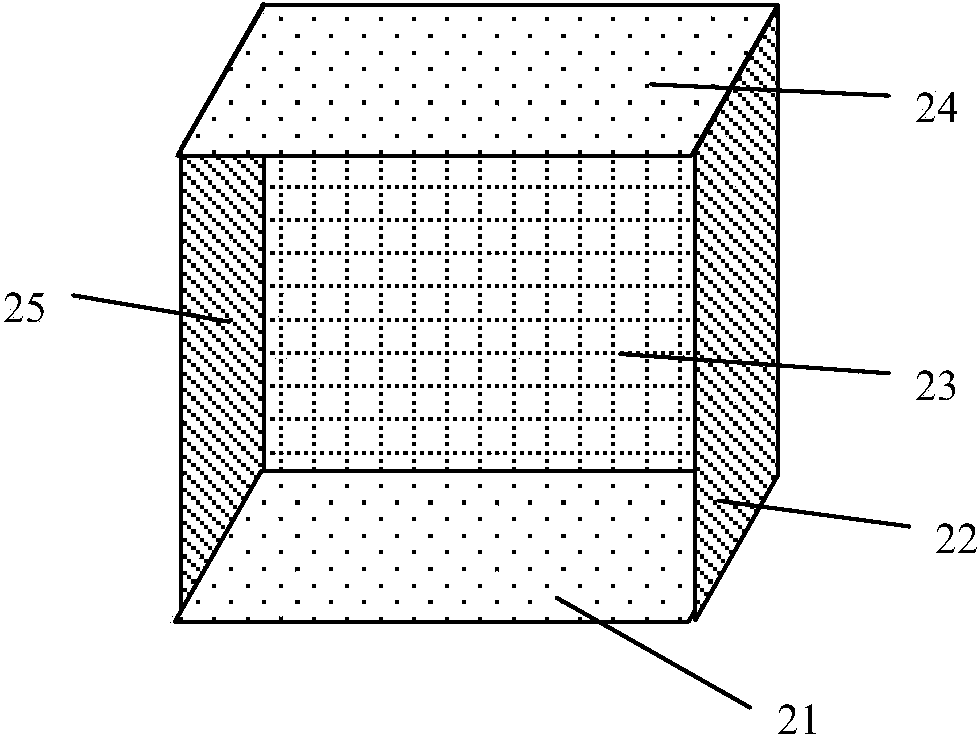

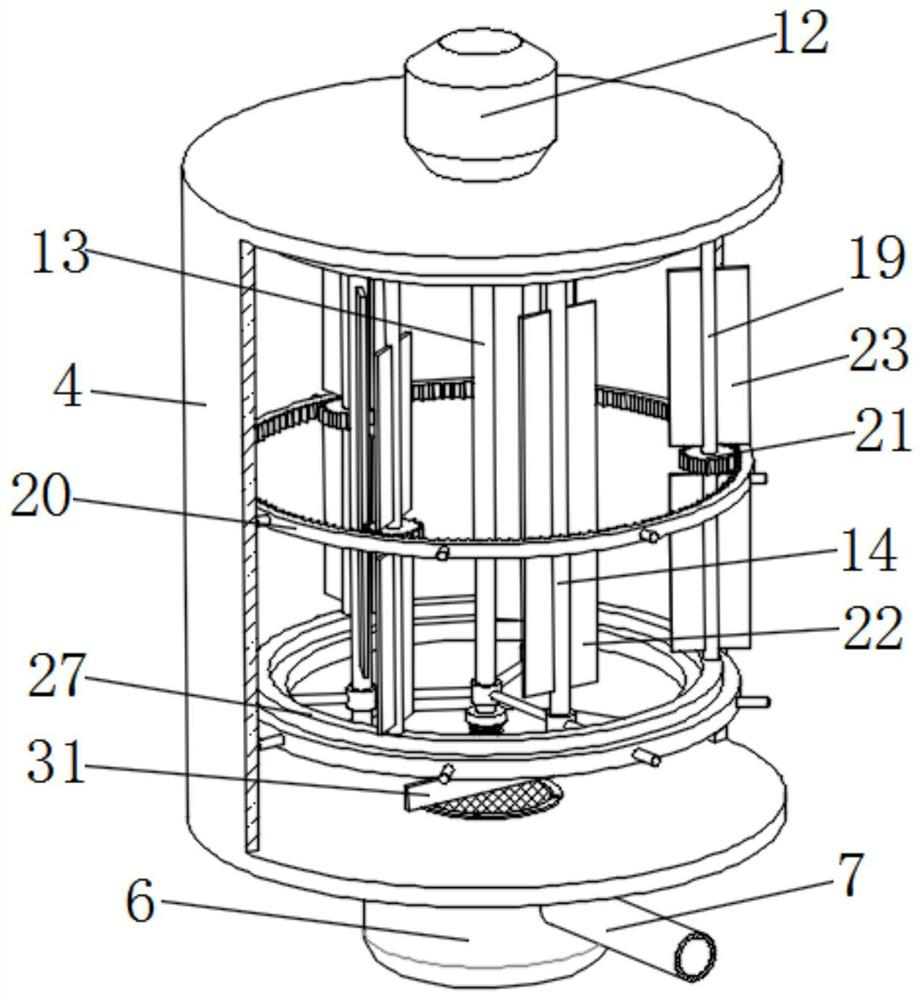

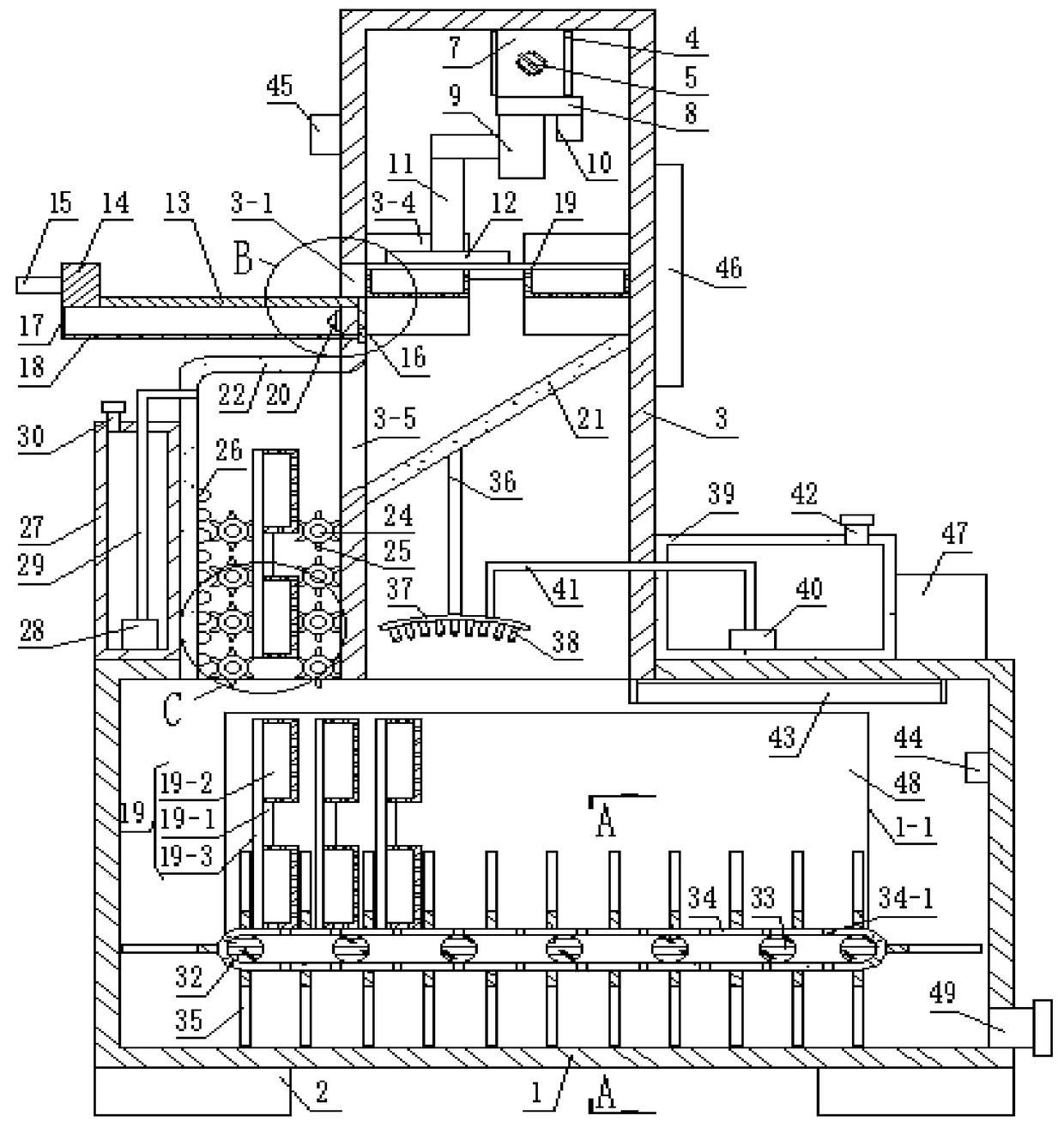

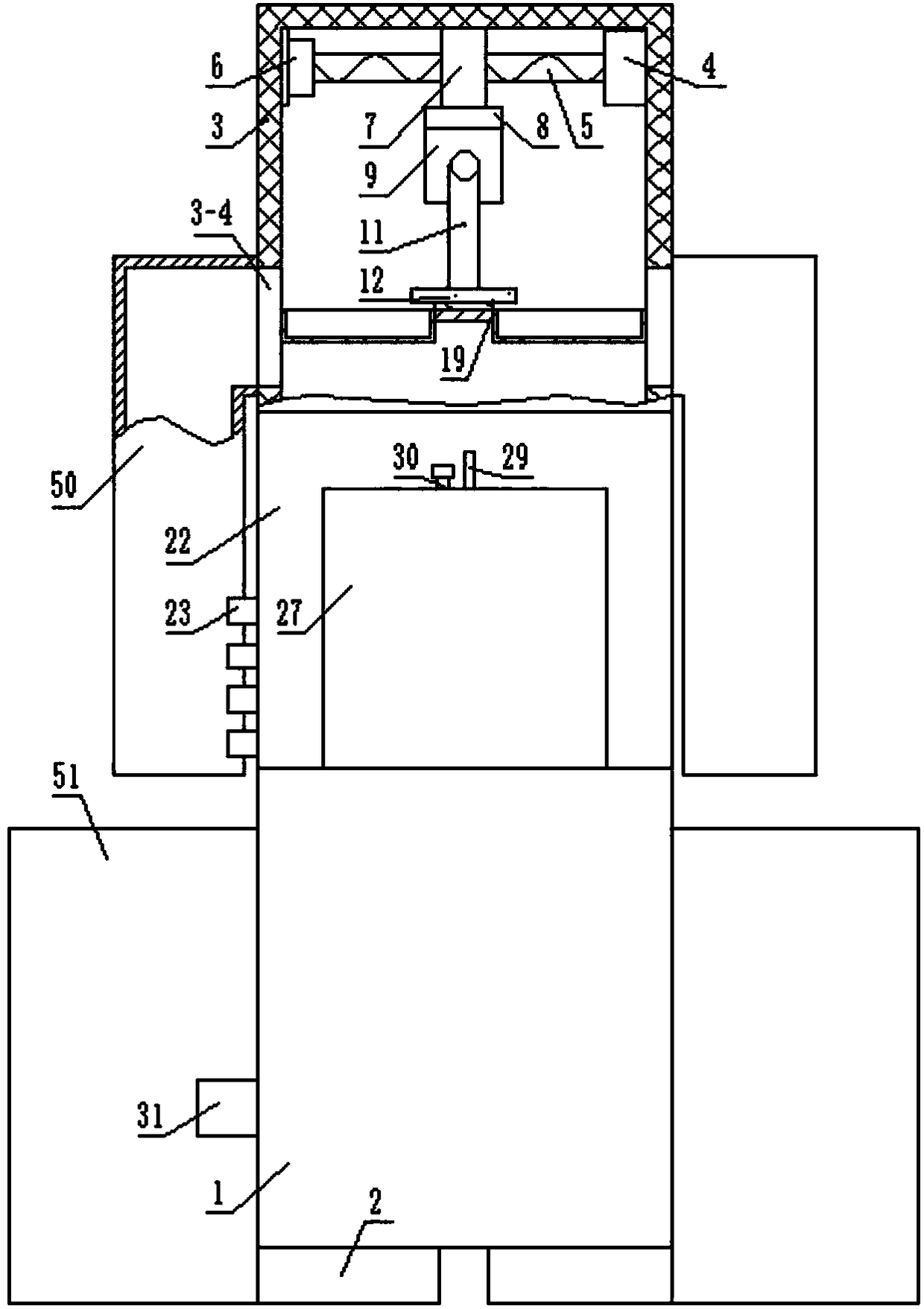

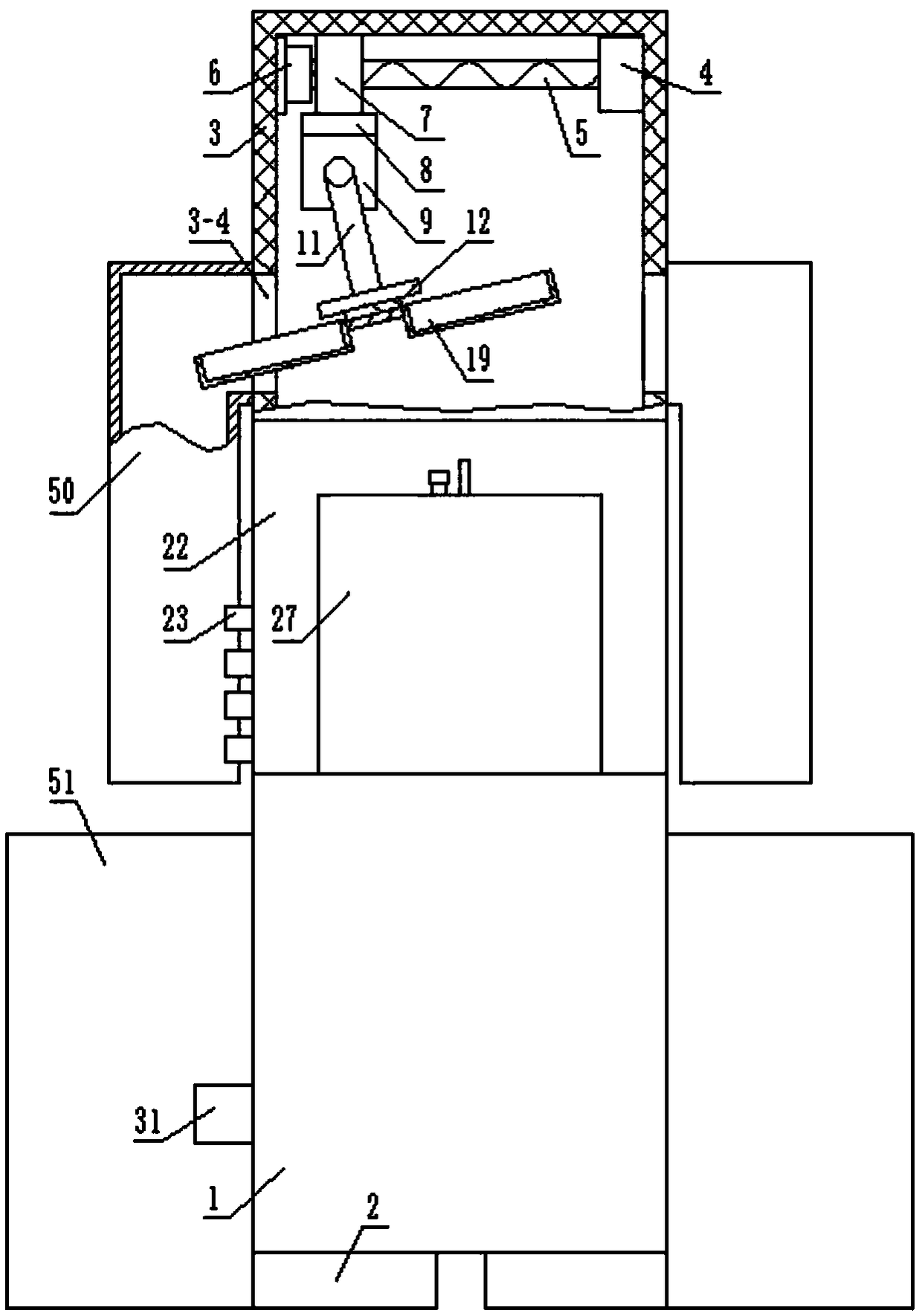

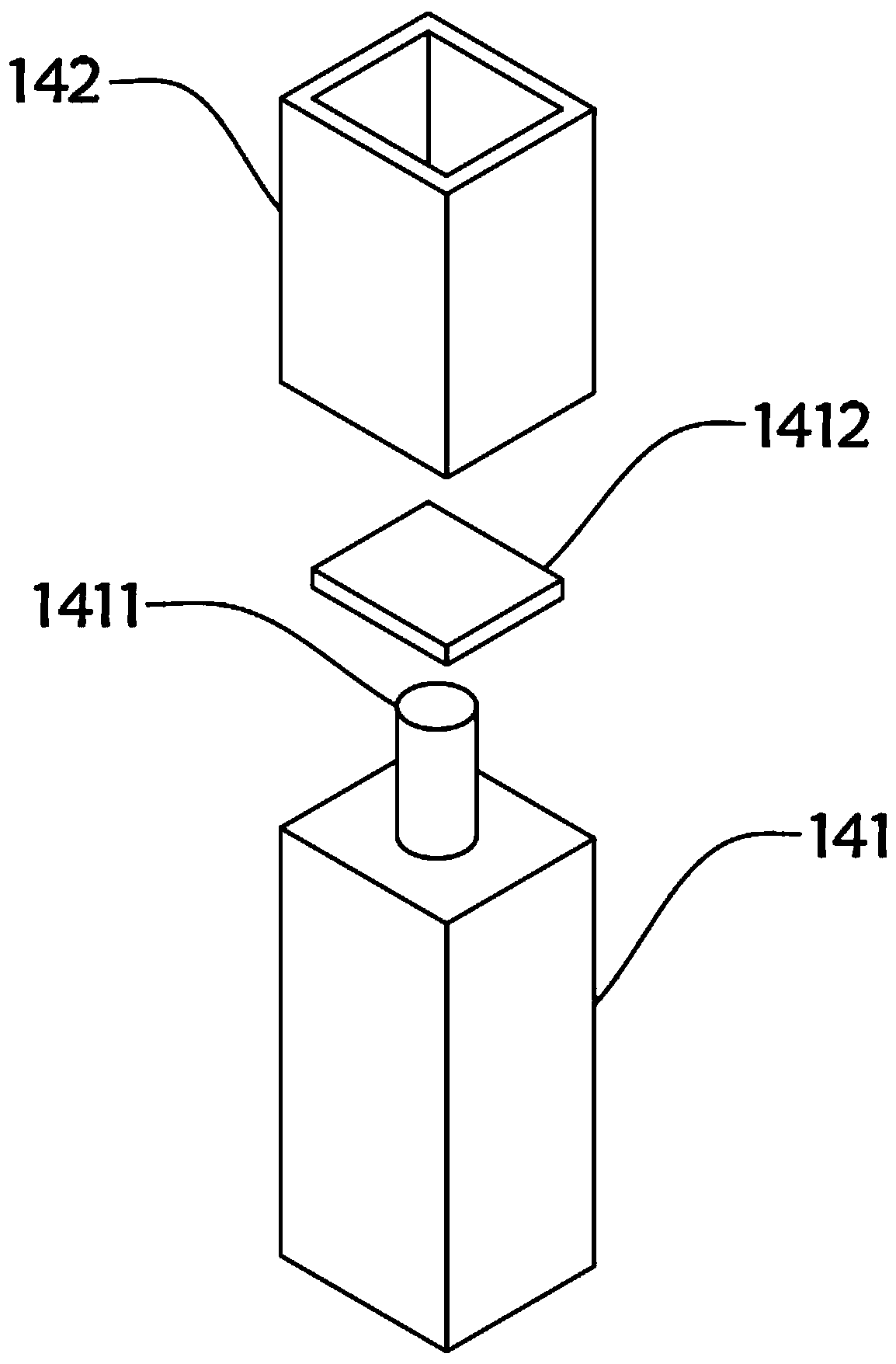

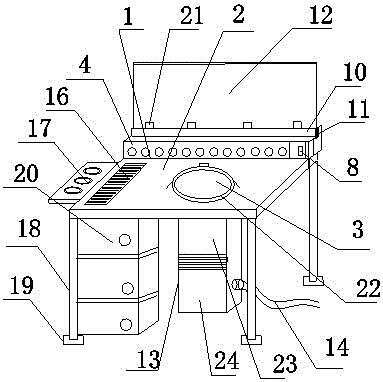

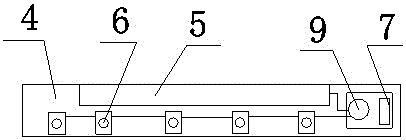

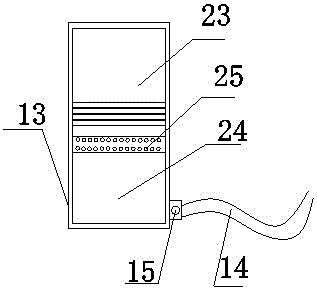

Express separation and self-fetching terminal system and method based on three-axis mobile platform

PendingCN108402866AAccurate storagePrecise deliveryKitchen equipmentDomestic articlesComputer moduleBarcode

The invention discloses an express separation and self-fetching terminal system and method based on a three-axis mobile platform, and belongs to the technical field of intelligent logistics terminals.The system includes an article inputting platform, the three-axis mobile platform, express storage cabinets, a pickup terminal, a camera recognition module and a system information management module;the method comprises the following steps that step 1, a package enters a system device through an article inlet port and is temporarily stored on a loading platform, and a mechanical arm is pushed topick up a single package; step 2, according to bar code information and package size information collected by the camera recognition module, the express storage cabinets are automatically allocated for current packages, and the three-axis mobile platform intelligently separates and stores articles; step 3, the system notifies that there is a self-fetching article by means of short messages, the system automatically finds and compares a pick-up code when the article is picked up, the three-axis mobile platform takes the article out of the storage cabinet, and a pickup result is fed back to thesystem information management module for next-step processing. The method is convenient, fast and reliable, greatly improves the speed rate of an express logistics terminal, and has strong practicability.

Owner:JILIN UNIV

Call panel

The present invention presents a call panel of an elevator or of an elevator system, which call panel comprises one or more display elements, a front plate covering the call panel, in connection with which front plate a touch sensor is fitted, and also a control unit to which the display elements and also the touch sensor are connected. The detection area of the touch sensor comprises active areas covered by the display elements as well as a passive area that remains outside at least some of the aforementioned active area, for which passive area one or more touch-sensitive pushbuttons are specified. The control unit is arranged to react to a touch of the touch-sensitive pushbuttons specified for the aforementioned detection area.

Owner:KONE CORP

Multifunctional tray device capable of being attached onto seats or beds

The invention discloses a multifunctional tray device capable of being attached onto seats or beds, aims to overcome the defects that the vertical surface of the conventional table plate cannot be inclined and the function is single, and comprises a supporting disc, wherein a supporting rod is fixed on the lower surface of one edge of the supporting disc, the lower part of the supporting rod can be assembled in a fixed sleeve part of a handle of a seat or a bed in a rotating manner, and the multifunctional tray device is characterized in that the supporting rod is a supporting part capable of adjusting the inclination of the supporting disc. Furthermore, a lifting motor capable of controlling the lifting and falling of the supporting disc, a baffle piece part of the supporting disc, an USB interface part and an embedded hand controller can be additionally arranged on the device, the embedded hand controller is mounted on the handle of the seat or the bed and is connected with the general control circuit, so as to realize multifunctional controlling of intelligent furniture such as massaging, thermal therapy, audio frequency, video frequency, charging and illuminating, and enable the furniture to realize intelligentization accordingly.

Owner:唐文姬

Medical worktable convenient for doctors to use for diagnosis

ActiveCN106963125AProtect fileKeep tidyTablesRadiation diagnosticsMedical practitionerMedical treatment

The invention belongs to the technical field of medicine, and particularly relates to a medical worktable convenient for doctors to use for diagnosis. The medical worktable convenient for the doctors to use for diagnosis can be used for quickly and easily examining patients, improving doctor visiting quality of the patients and improving the work efficiency of the doctors. In order to achieve the technical purposes, the medical worktable convenient for the doctors to use for diagnosis comprises a bottom plate, table legs, a first box, a support, a placement frame, a second box, a glass cover, a first sliding rail, an elastic element, an electric winding wheel, a pulling rope, a first slider and the like. The table legs are connected to the right side of the top of the bottom plate through bolts. An X-ray machine is directly placed on the table legs so that the X-ray machine can move up and down in the second box, accordingly the doctors can conveniently use the X-ray machine, and the X-ray machine can be protected.

Owner:博兴兴博城建投资集团有限公司

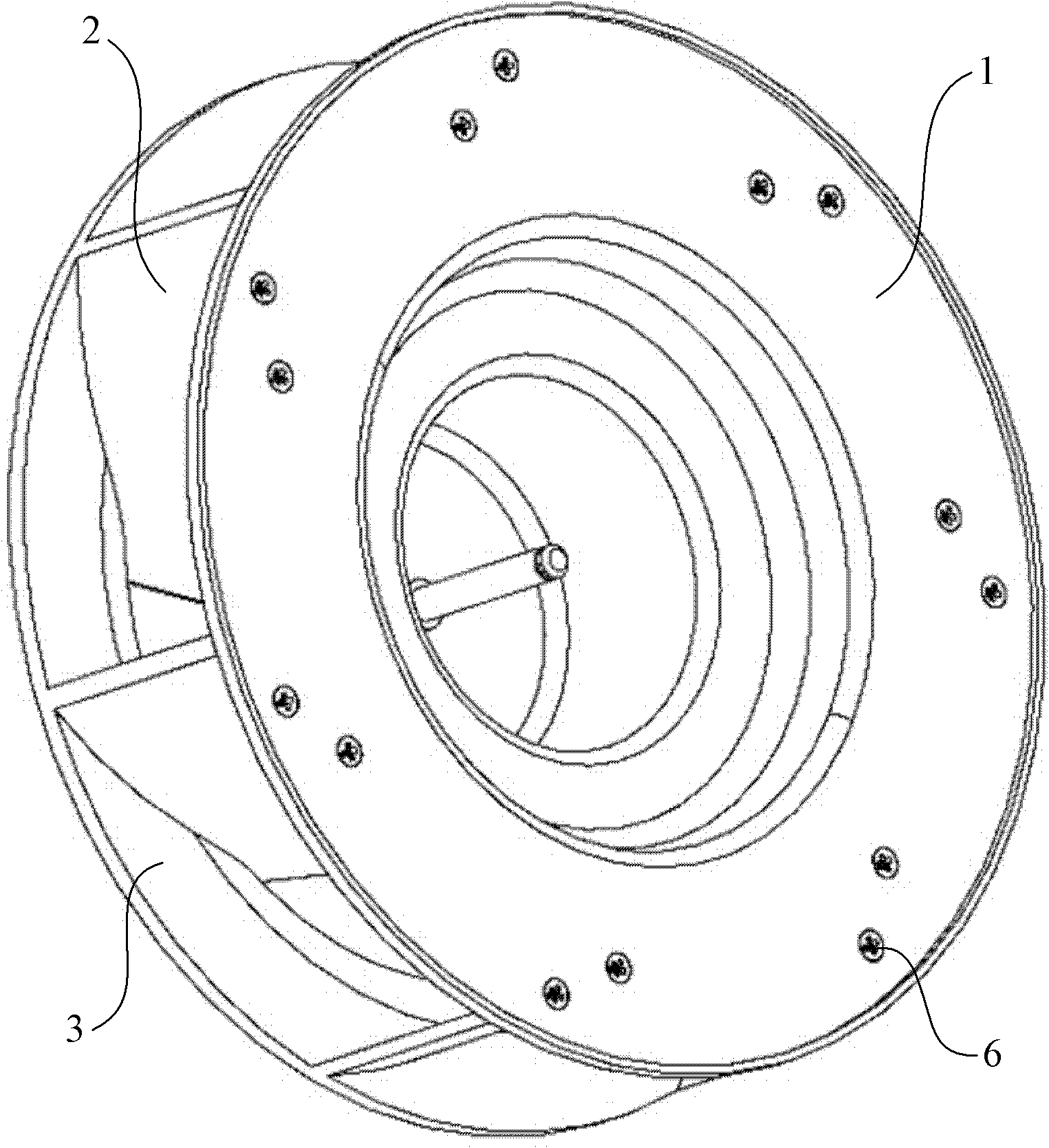

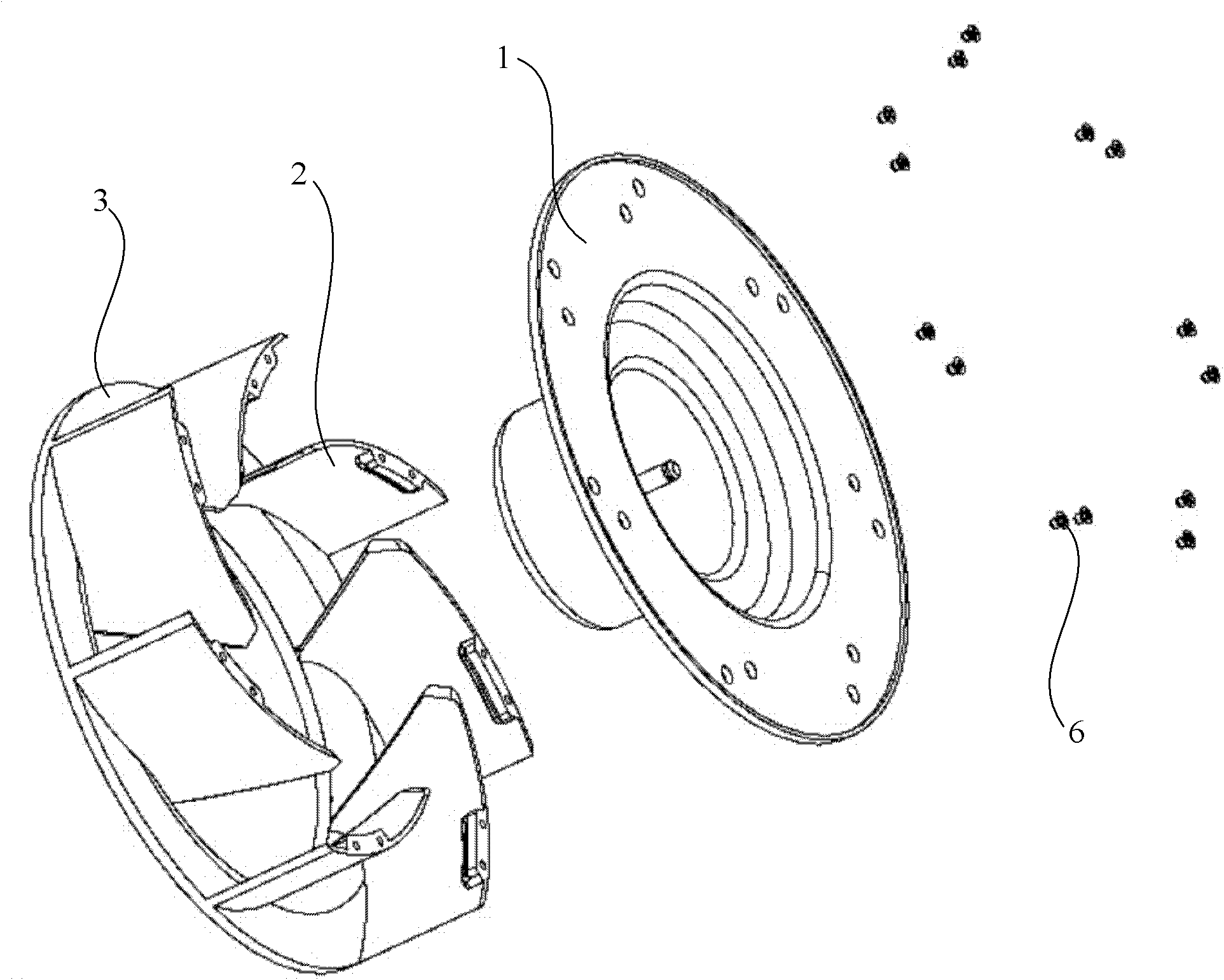

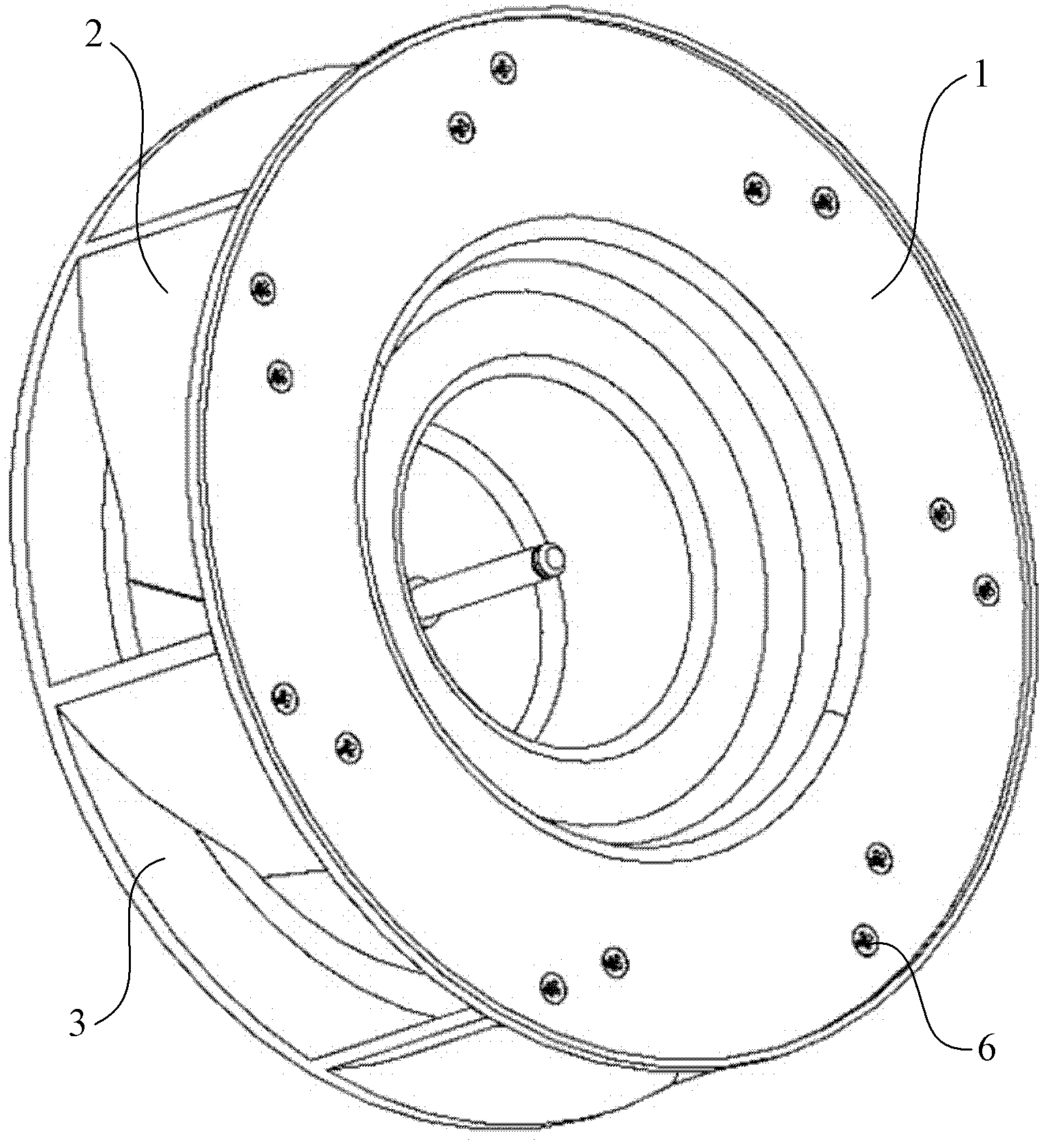

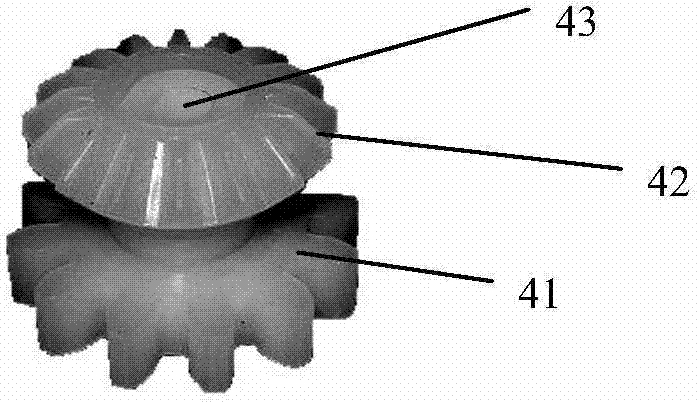

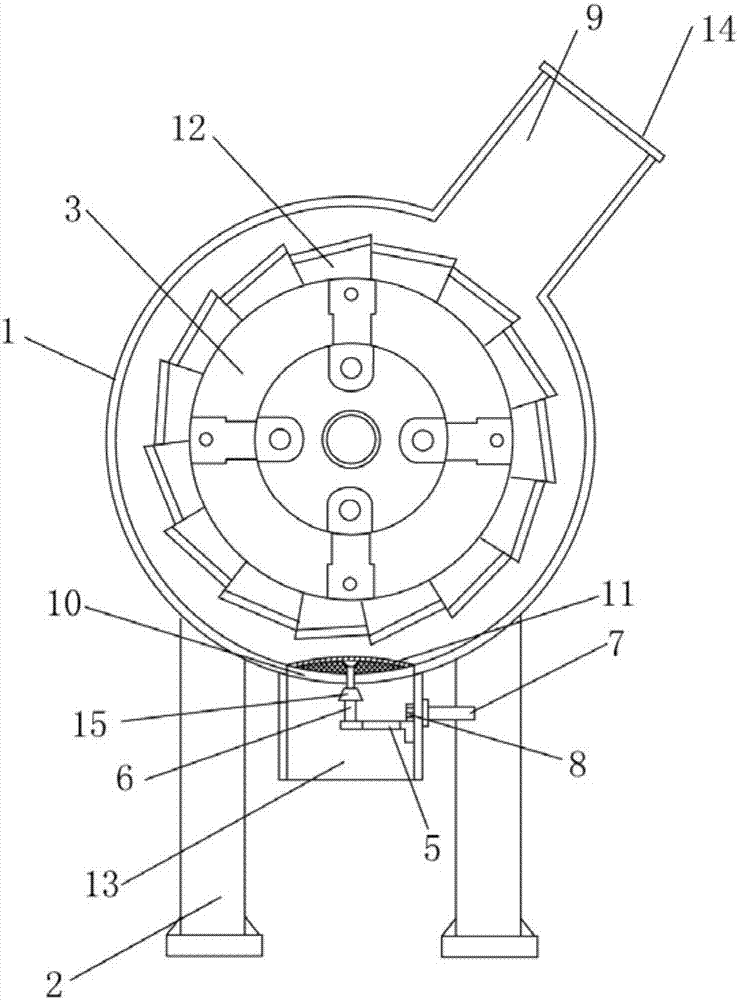

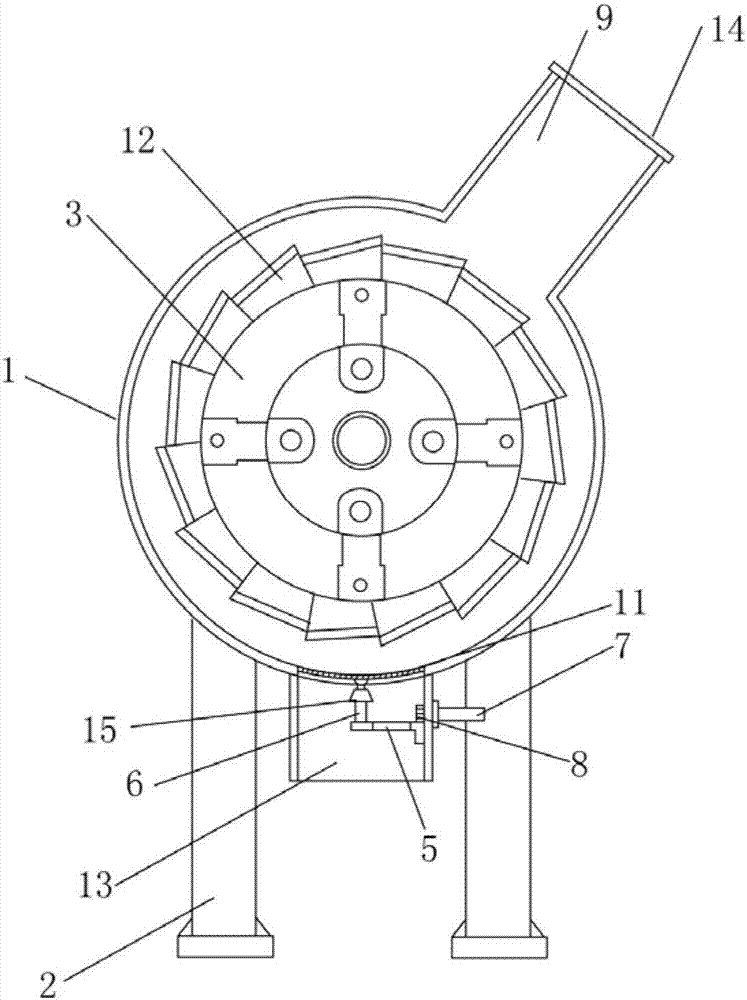

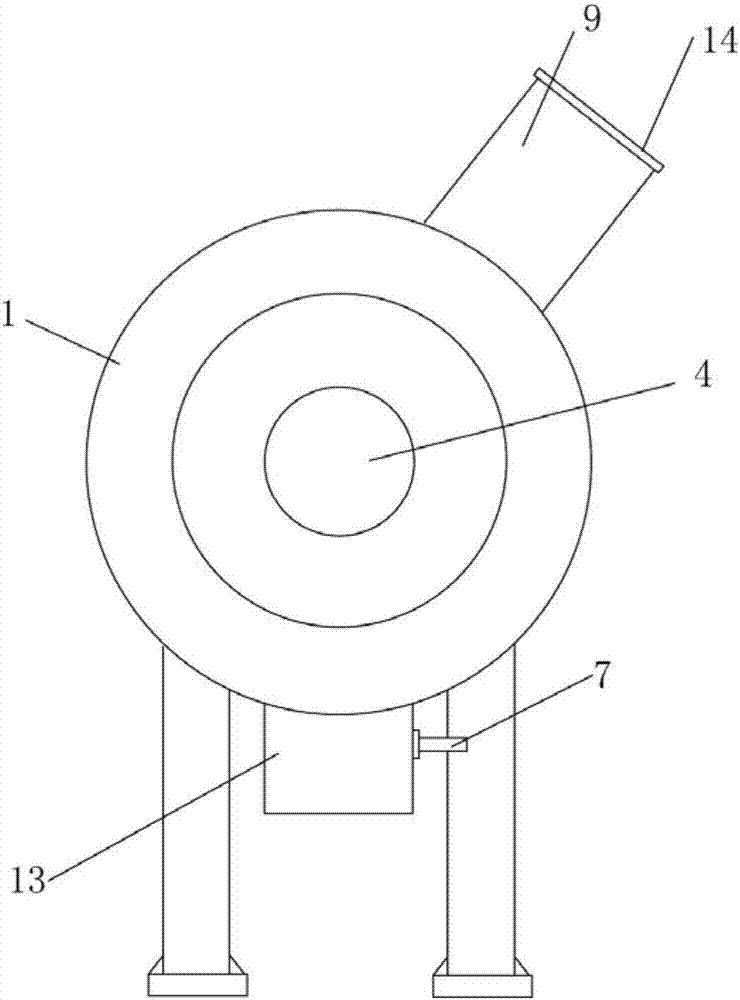

Centrifugal fan

InactiveCN102536895ARealize the exhaust effectKeep tidyPump componentsPumpsAgricultural engineeringFan blade

The invention provides a centrifugal fan, which comprises a hub, a plurality of fan blades and a circular protection plate. The fan blades are annularly arranged on the hub in the same direction at intervals of the same angle, the circular protection plate is arranged on the fan blades, and the hub is detachably connected with the fan blades. By means of the structural design of the centrifugal fan, the working quality of the centrifugal fan can be ensured, the centrifugal fan is convenient to carry and mount, and the service life of the centrifugal fan is prolonged by means of fine protective measures. By the aid of the detachable hub of the centrifugal fan, the fan blades and the circular protection plate on the fan blades can be conveniently detached to clean accumulated dust and impurities, the detached fan blades can be maintained, and cleanness and the working quality of the whole centrifugal fan are kept.

Owner:SHANGHAI KAKU ELECTRIC EQUIP CORP

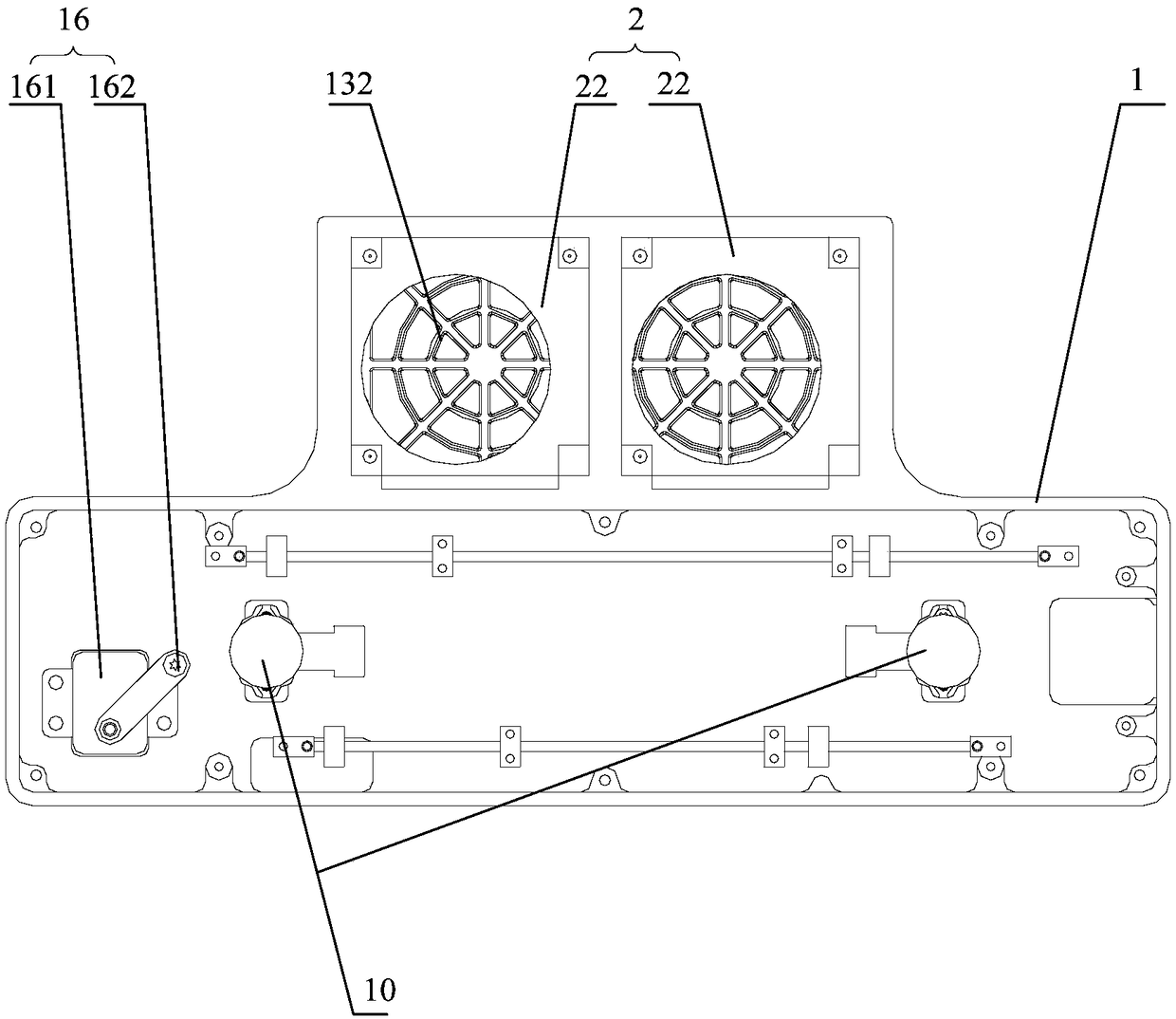

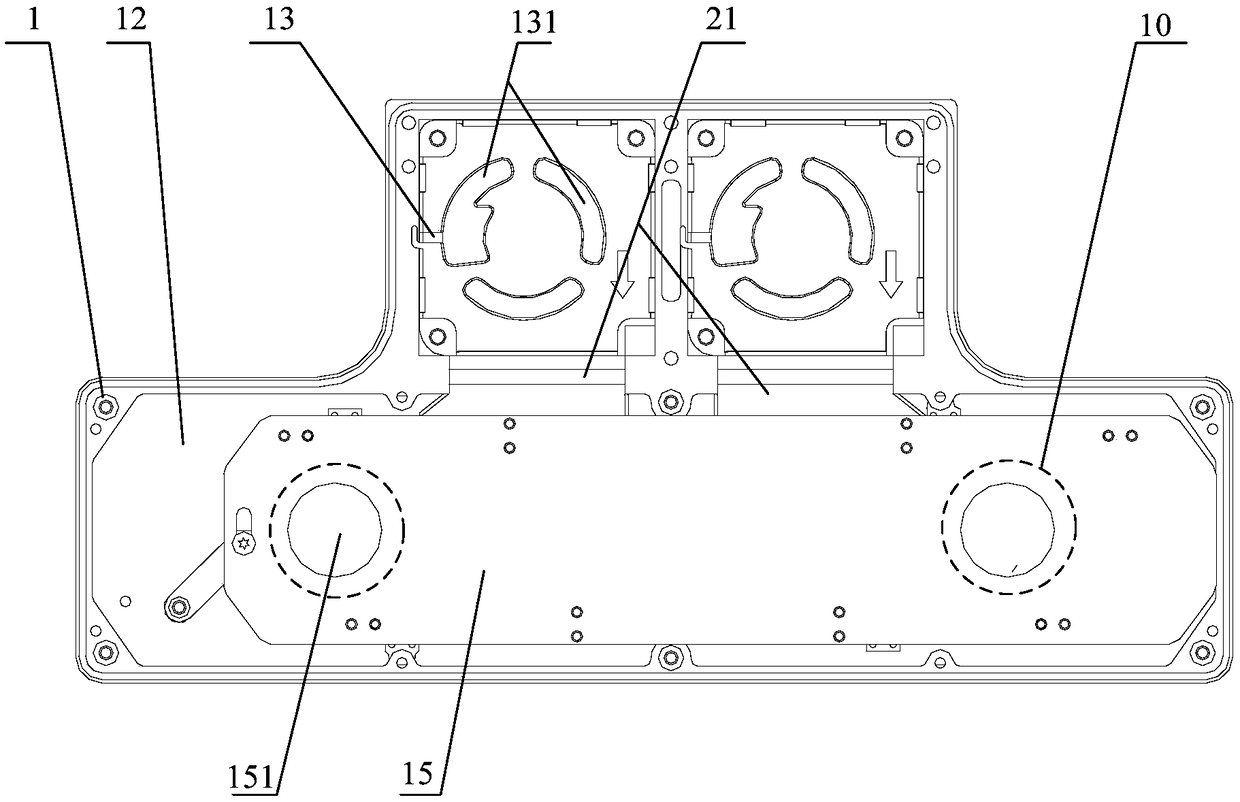

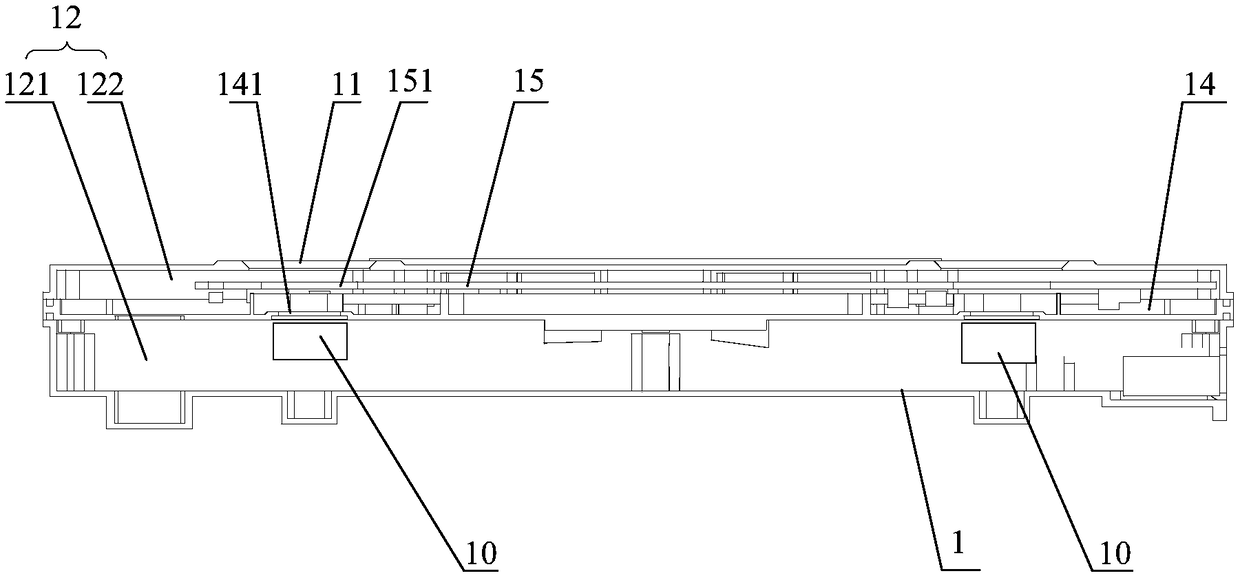

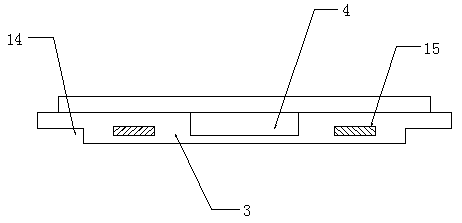

Dustproof structure, binocular sensor, and unmanned aircraft

InactiveCN109076207AAchieve isolationImprove cleanlinessAircraft componentsRemote controlled aircraftEngineeringImpurity

The invention provides a dustproof structure, a binocular sensor, and an unmanned aircraft. The dustproof structure (100) comprises a housing (1) for accommodating at least one camera (10), the housing (1) is provided with lens holes (11) corresponding to positions of the cameras (10), and the dustproof structre also comprises an airflow generator (2), the airflow generator (2) is used for blowingout airflows to the cameras (10) to form airflow interlayers between the cameras (10) and the lens holes (11). According to the structure, the influence of impurities including external dust and waterdrops on the sensing and imaging of the cameras can be avoided.

Owner:SZ DJI TECH CO LTD

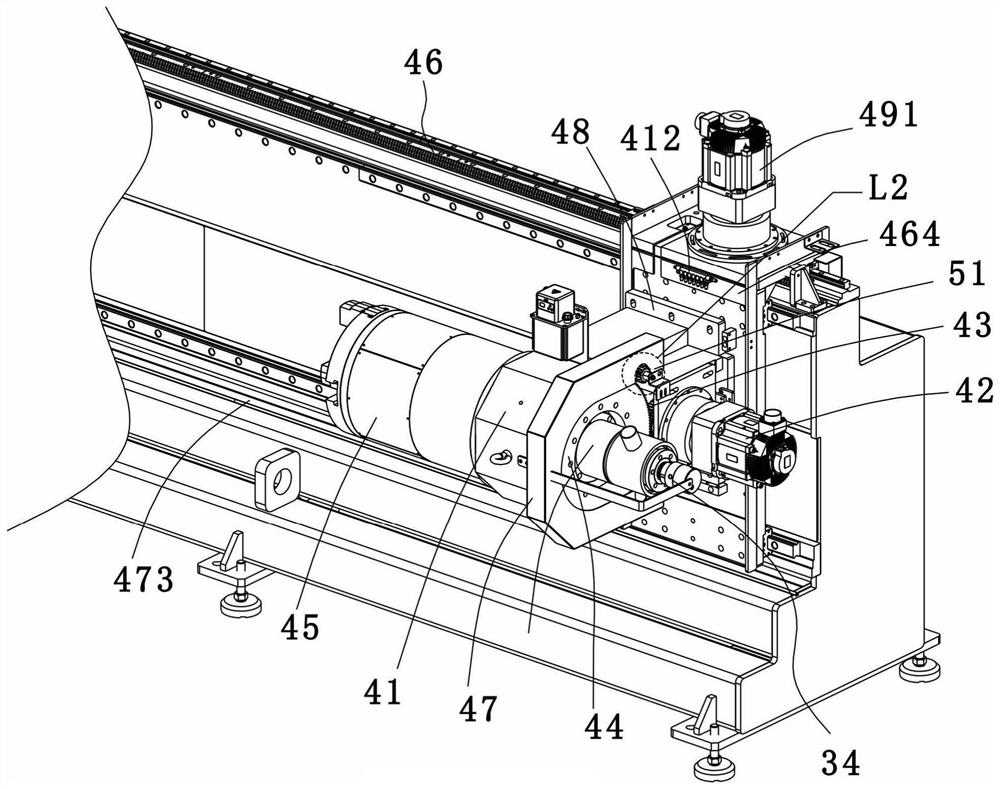

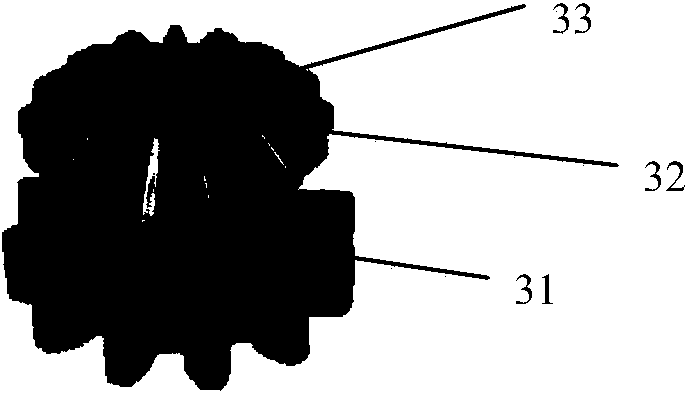

Four-chuck laser pipe cutting machine

InactiveCN112846545ALong lubrication maintenance intervalKeep tidyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryLubrication

The invention discloses a four-chuck laser pipe cutting machine. The machine comprises a base, a laser cutting assembly as well as a first chuck, a second chuck, a third chuck and a fourth chuck which are sequentially arranged from left to right and glidingly arranged on the base; each of the first chuck, the second chuck, the third chuck and the fourth chuck comprises a side hanging frame, a first driving motor, an output wheel, a driving wheel, a clamping device and a moving mechanism, a first lubricating component is arranged on the side hanging frame, an oil blocking cover is arranged on the outer side of the driving wheel, an oil return hole is formed in the bottom of the oil blocking cover, an oil collecting groove extending in the length direction of the base is formed in the base, and the oil return hole is connected to the oil collecting groove through an oil return pipe. According to the four-chuck laser pipe cutting machine, the output wheels and the driving wheels are continuously lubricated through the first lubricating components, the lubrication maintenance period is long, lubrication also can be achieved without the need of exposing the driving wheels and the output wheels are not exposed, and the cleanliness of the workshop environment is kept.

Owner:佛山汇百盛激光科技有限公司

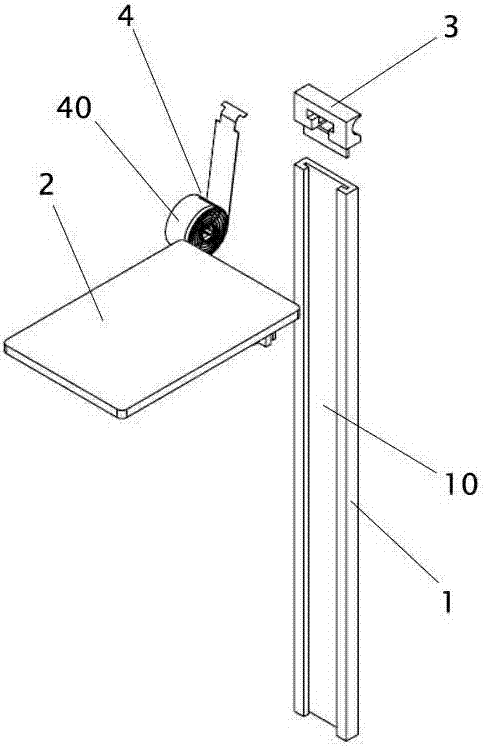

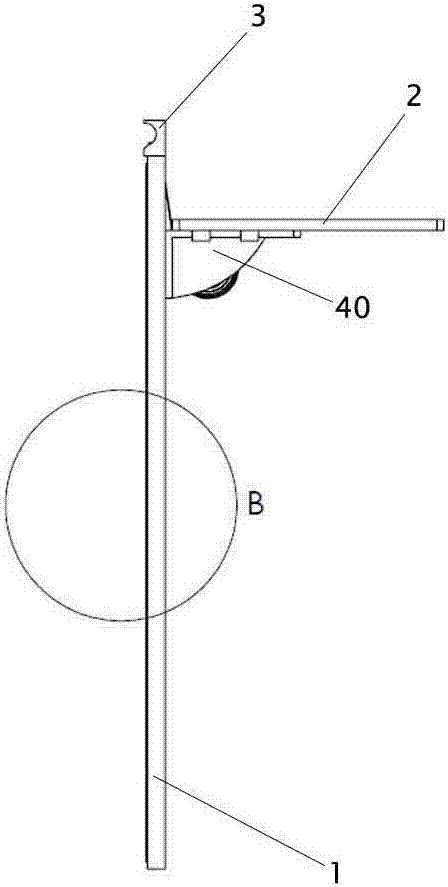

Construction site flat plate die dismantling equipment

InactiveCN110735533AProtection securityKeep tidyForm treatmentArchitectural engineeringElectric machinery

The invention discloses a construction site flat plate die dismantling device. The construction site flat plate die dismantling device comprises a base, the top surface of the base is fixedly providedwith a fixing seat, a telescopic space is arranged in the fixing seat, and a sliding rod is slidably installed on the telescopic space and the top surface of the base; when a flat plate die is dismantled, a first motor is started, the first motor drives a first threaded rod to rotate, the first threaded rod rotates to drive a lifting sliding block to slide upwards, a chain wheel moves upwards when the lifting sliding block slides upwards, the chain wheel moves upwards then the sliding rod can be driven to lift upwards, manual work can be replaced by the equipment for dismantling the flat plate die of a ceiling, the safety of workers can be protected, the flat plate die after dismantling can be directly connected without being stacked on the ground at will, the connected flat plate dies are collected together, subsequent processing is facilitated, and the tidy and the safety of the construction site are guaranteed.

Owner:绍兴多卡机械设备有限公司

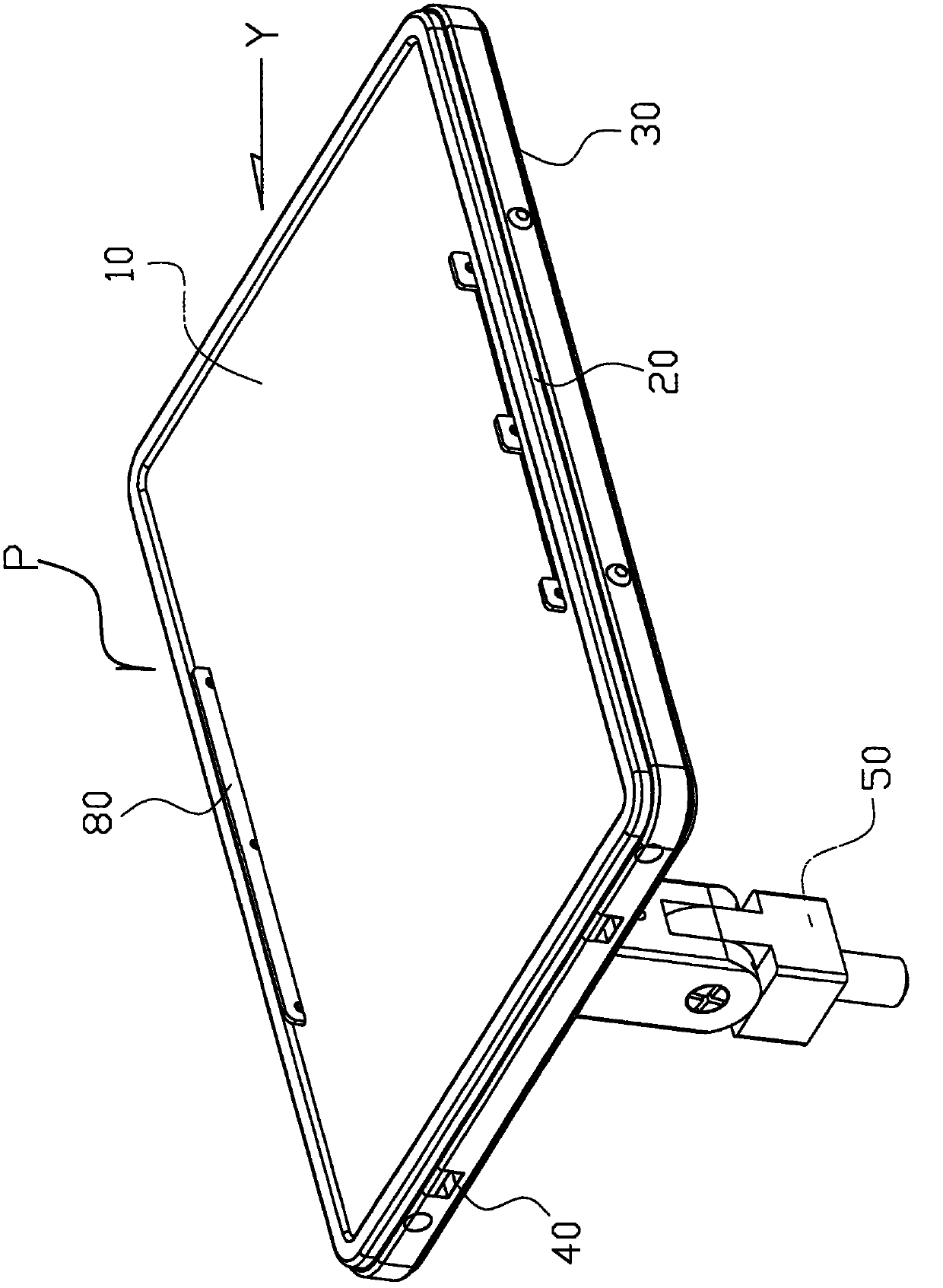

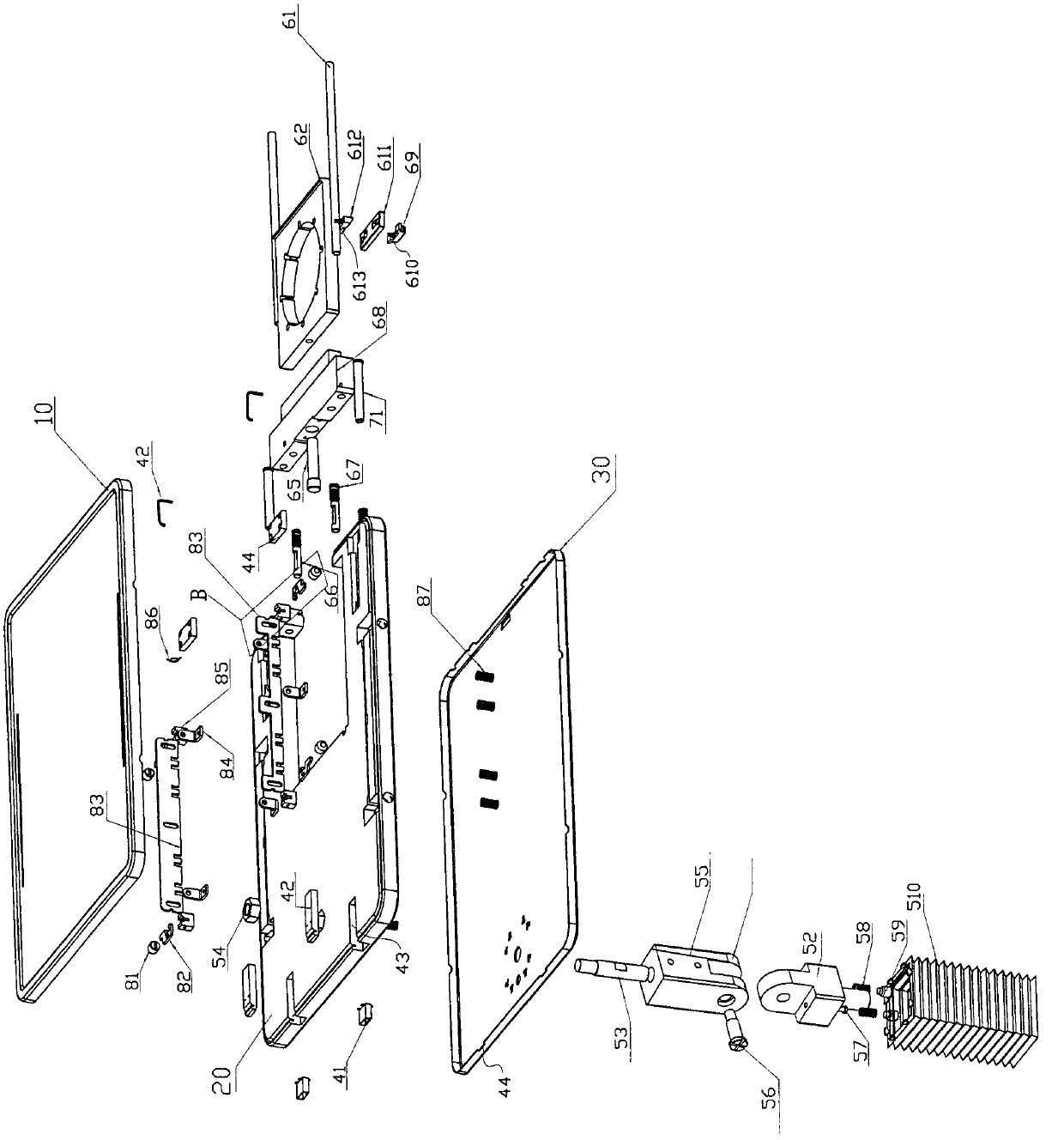

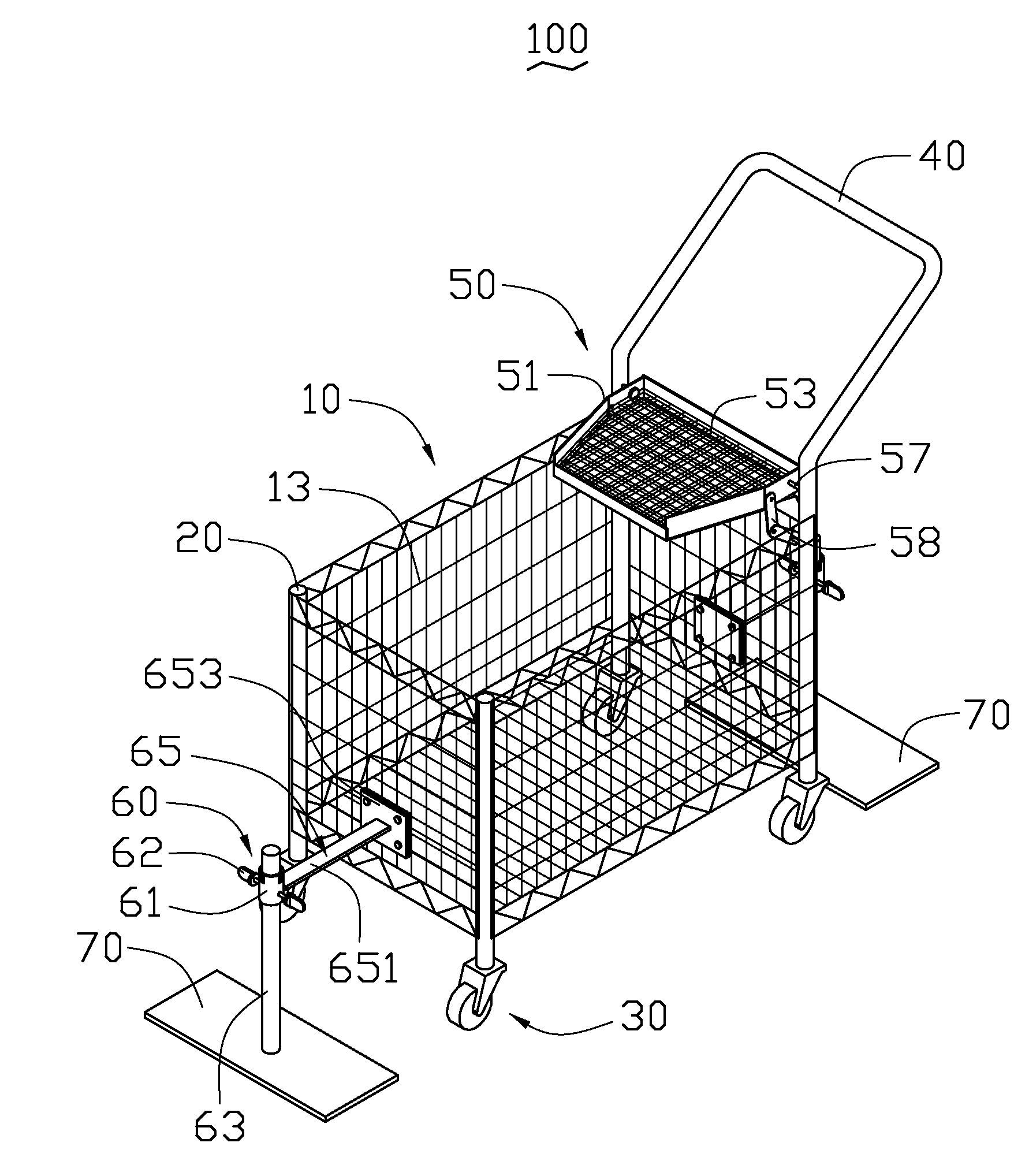

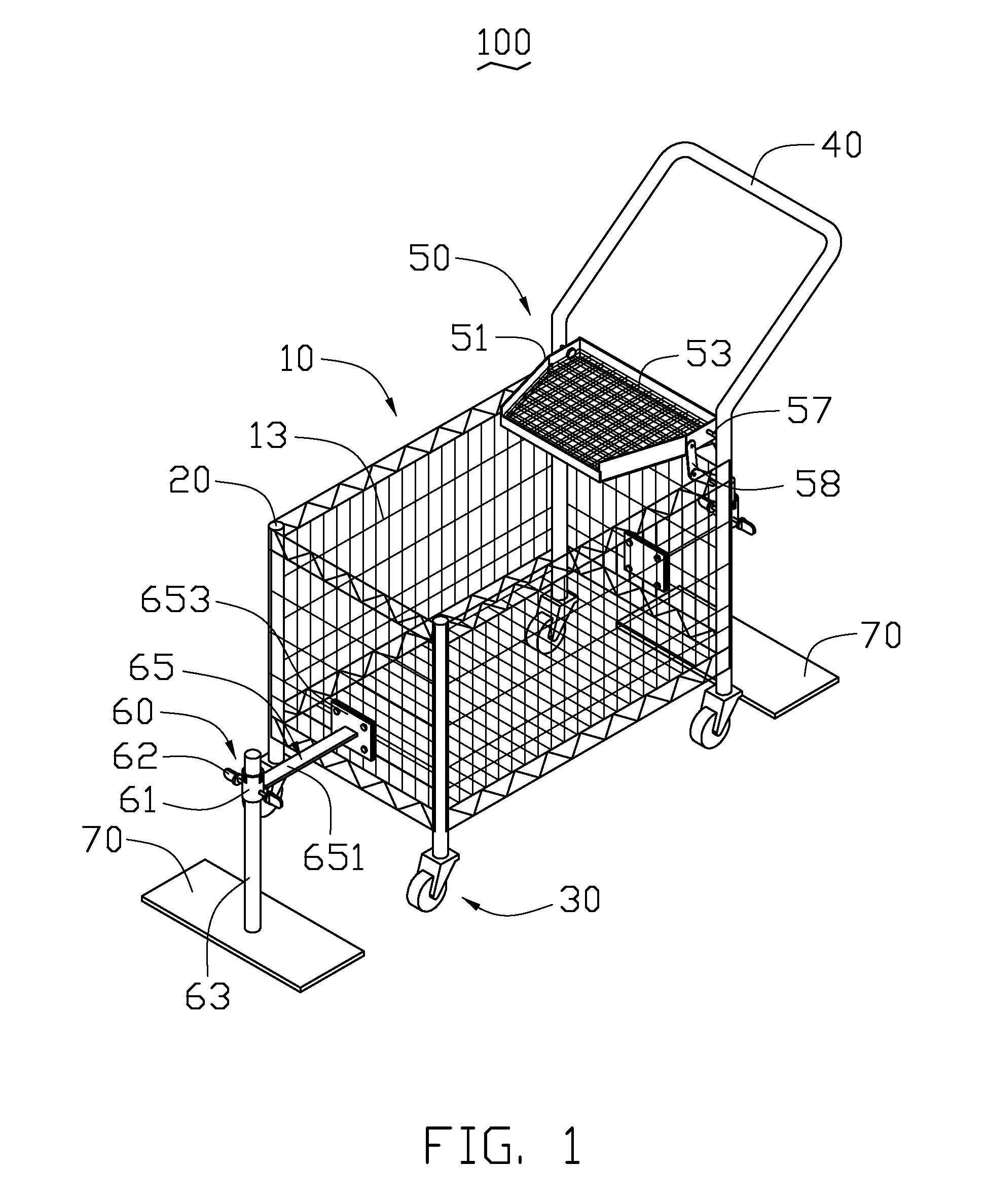

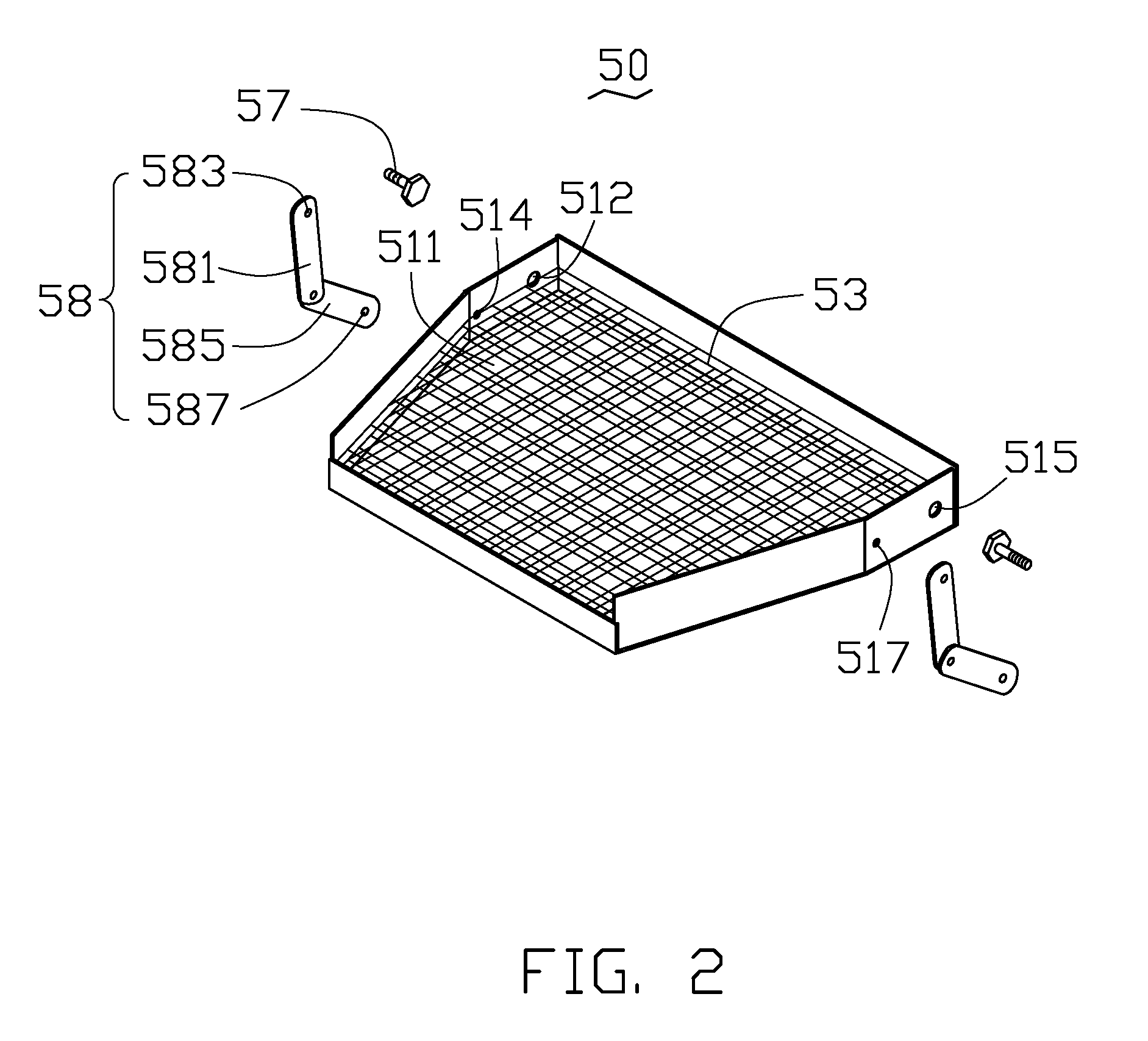

Recycling cart

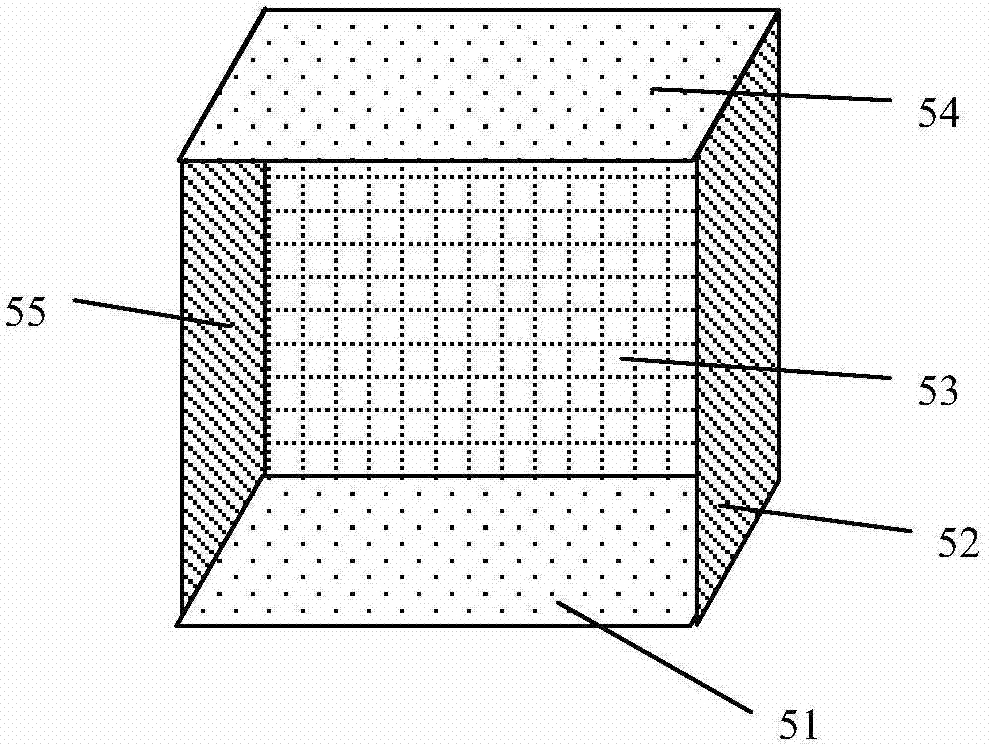

A recycling cart (100) for sorting, retaining, and transferring articles is provided. The recycling cart includes a waste container (10), at least four supporting members (20), at least four rotating members (30), and a sorting member (50). The supporting members are attached with the waste container. The rotating members are attached with the supporting members and configured for facilitating moving the recycling cart. The sorting member is configured for sorting articles. The sorting member is hinged with two of at least four supporting members and located above the waste container.

Owner:FIH (HONG KONG) LTD +1

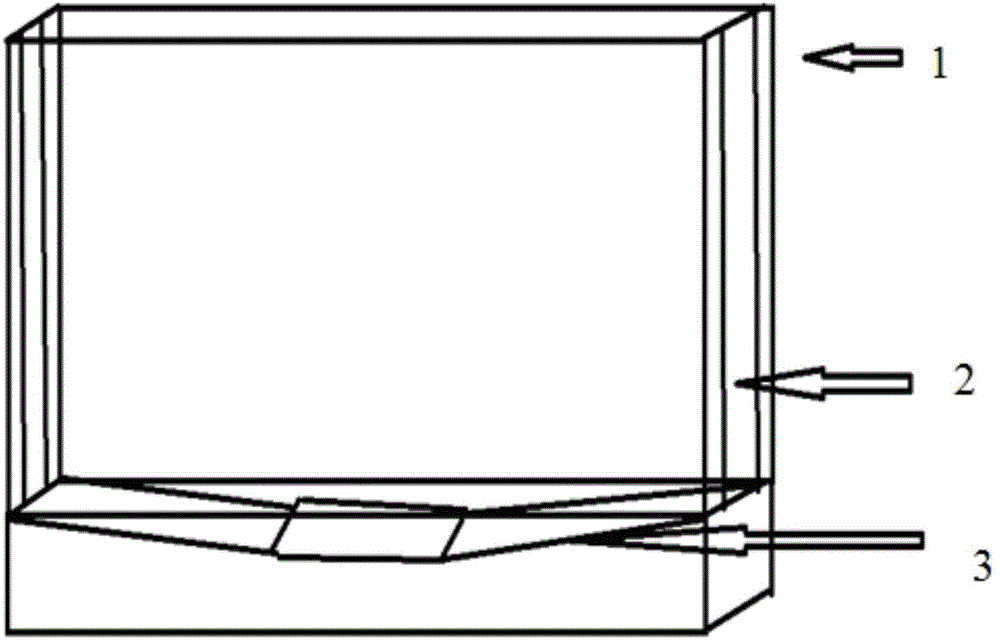

Automatic push type loading container for freezer

The invention discloses an automatic push type loading container for a freezer. The automatic push type loading container comprises a container body without a top cover. A propeller is arranged in the container body, and comprises a vertically arranged rail frame, a supporting plate moving along the rail frame up and down, and a power spring for driving the supporting plate to rebound upwards. A winding part of the power spring is arranged below the supporting plate, and the outer end of the power spring stretches upwards along the gap between the supporting plate and the rail frame and is fixed to the top of the rail frame through a fixing device. By means of combined unique folding design of the loading container, all space in the freezer can be more effectively organized, classified, divided and fully used, the space utilization rate is increased, products can be rapidly loaded and stored in the freezer, ice cream and other frozen products can be located on the upper layer of the freezer before being sold and stored at proper temperature, and the optimal edible taste is guaranteed.

Owner:杨震杰 +1

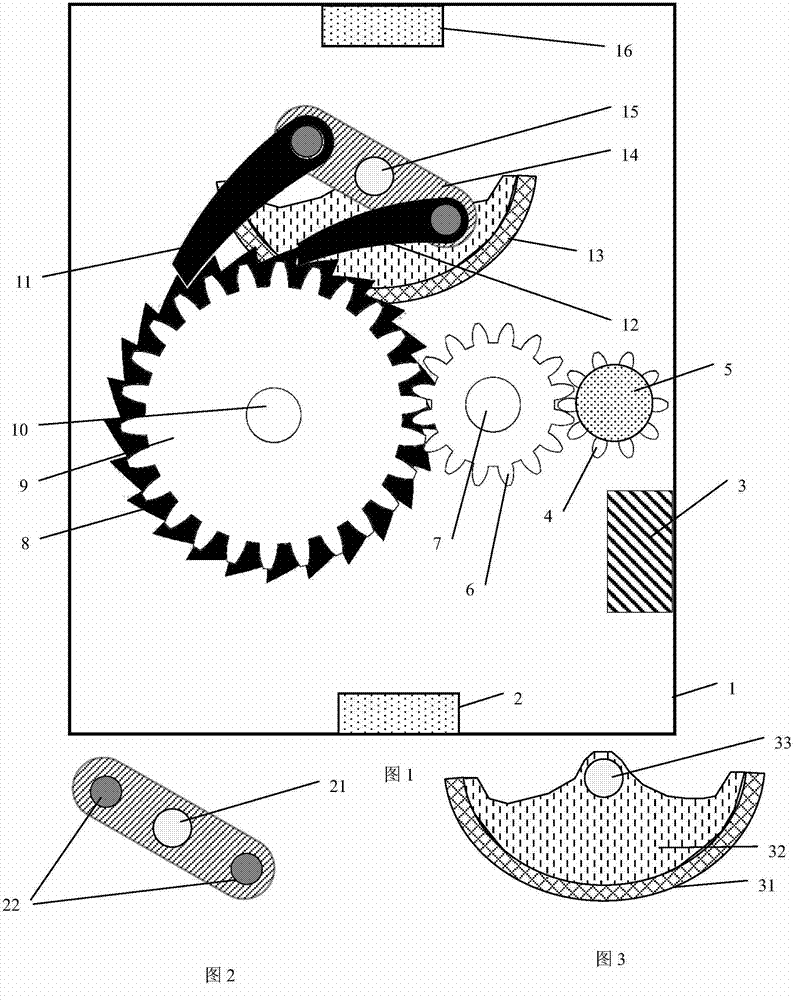

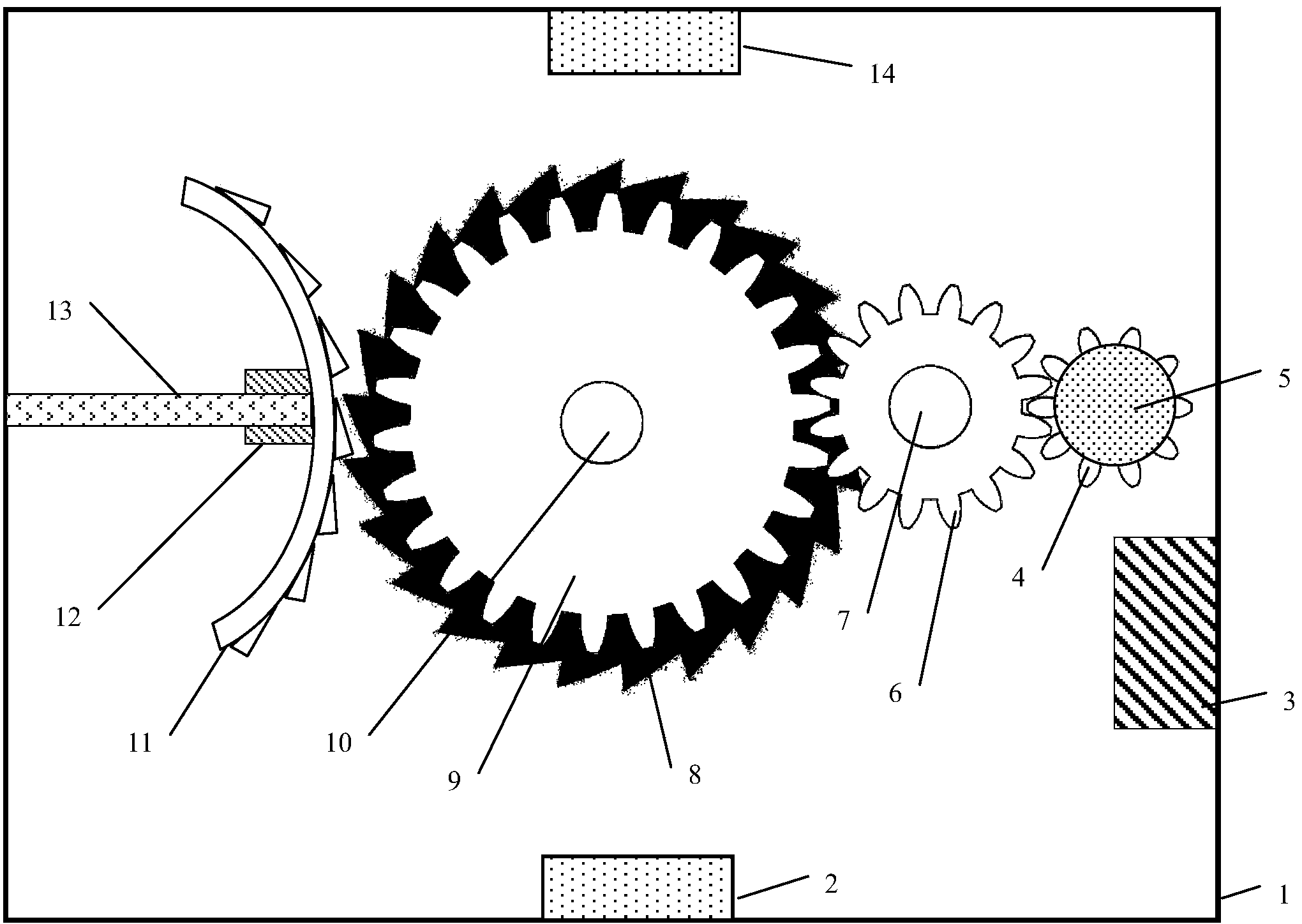

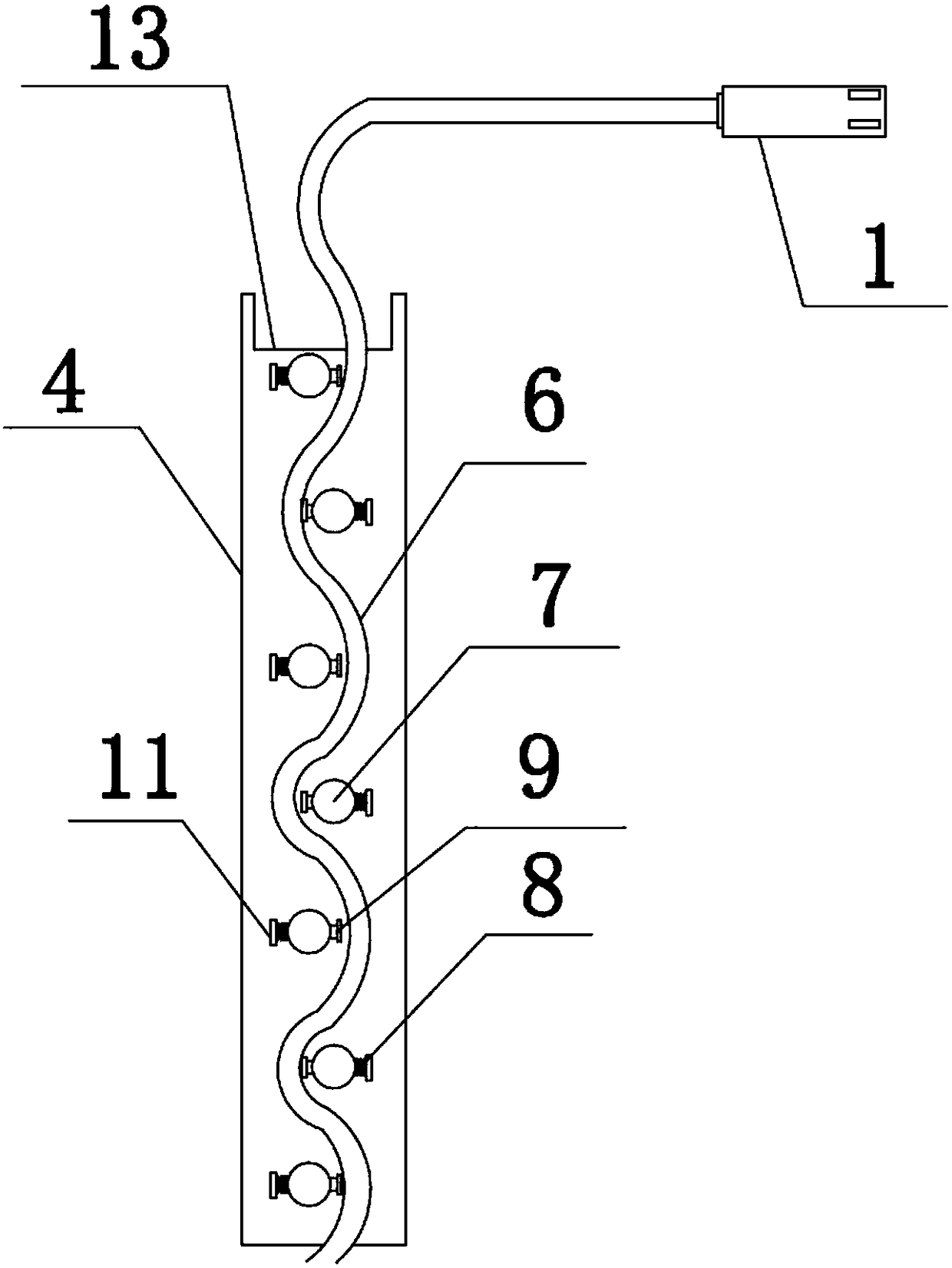

Vehicle vibration power generation device with USB interface

ActiveCN103715827AHigh vibration pickup efficiencyImprove electromechanical conversion efficiencyElectrical storage systemEnergy storageWorking lifeIn vehicle

The invention relates to a vehicle vibration power generation device with a USB interface. The device adopts a heavy hammer and a double-acting type ratchet wheel as a vibration pickup mechanism, a gear set is a vibration mechanical energy transmission mechanism, a direct current permanent magnet generator is an electromechanical energy conversion mechanism, and an electric energy processing circuit with a USB interface processes irregular direct current electric energy, and supplies power to a vehicle-mounted electronic device. The vehicle vibration power generation device uses the double-acting type ratchet wheel mechanism for vibration pickup, converts rectilinear motion in vehicle running to rotational motion, and drives the low damping permanent magnet direct current generator to work through the efficient gear mechanism, and compared with a common linear type vibration power generation device, the transmission and conversion efficiency of vibration mechanical energy can be significantly improved. The vehicle vibration power generation device with the USB interface generates power by renewable energy, the vibration pickup efficiency, and the energy transmission and conversion efficiency are high, the working life is long, the USB interface is adopted to be suitable for the use of most vehicle-mounted electronic devices, and the universality is strong.

Owner:天津融承科技有限公司

Rotatable rearing shed device

Owner:华蓥市农业园区管理委员会办公室

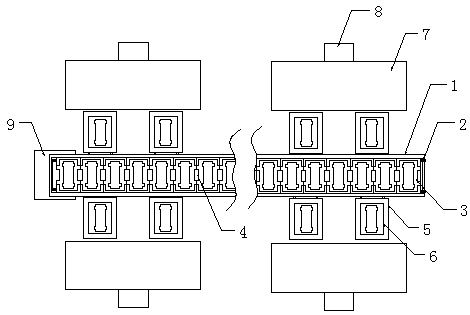

Automatic welding production line for hydrogen fuel cell bipolar plates

InactiveCN109048109ANo manual operationReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesProduction lineHydrogen fuel cell

The invention discloses an automatic welding production line for hydrogen fuel cell bipolar plates. The automatic welding production line comprises a conveying frame body. The conveying frame body iscomposed of an upper frame body, connecting supporting rods and a lower frame body. The upper frame body is fixedly connected with the lower frame body through the multiple connecting supporting rods,and the upper frame body is arranged over the lower frame body. Conveying chains are arranged on the two sides of the upper frame body and the two sides of the lower frame body. The conveying chainsare in transmission connection with the output end of a motor through rotating shafts, and the motor is installed in a motor case. By means of the automatic welding production line for the hydrogen fuel cell bipolar plate, due to the fact that the conveying frame body, moving frames and welding box bodies are arranged, automatic welding of the hydrogen fuel cell bipolar plates can be achieved without manual operation, the labor cost is greatly reduced, and the production efficiency is improved; and due to an arranged double-station welding table, two sets of bipolar plates can be welded at thesame time, the welding efficiency of the bipolar plates is improved, in addition, the upper moving frame body and the lower moving frame body are arranged, to-be-welded bipolar plates and welded bipolar plates can be conveyed separately, clear division of labor is achieved, and confusion is avoided.

Owner:合肥菲斯特激光科技有限公司

Vehicle vibration power generating device

ActiveCN103670983AReduce dependenceReduce fuel consumptionMachines/enginesMechanical energy handlingMechanical energyUSB

The invention relates to a vehicle vibration power generating device. The vehicle vibration power generating device adopts a cantilever beam and a ratchet wheel as a vibration picking mechanism, adopts a one-way bearing and a gear set as a vibration mechanical energy transmission mechanism and adopts a direct current permanent magnet generator as an electromechanical energy conversion mechanism, and an electric energy processing circuit with a USB interface processes irregular alternating electricity to supply electricity to vehicle-mounted electronic equipment. According to the vehicle vibration power generating device, the cantilever beam and ratchet wheel mechanism is used for pricking vibration, linear movement in the vertical direction in the running process of a vehicle is converted into rotary movement, an efficient one-way gear mechanism drives the low-damping permanent magnet direct current generator to work, and the transmission and conversion efficiency of vibration mechanical energy can be obviously improved compared with a common linear vibration power generating device. The vehicle vibration power generating device generates electricity with renewable energy sources, is high in vibration picking efficiency and energy transmission and conversion efficiency, is long in service life, adopts the USB interface, is suitable for most vehicle-mounted electronic equipment, and is high in universality.

Owner:HEBEI UNIV OF TECH

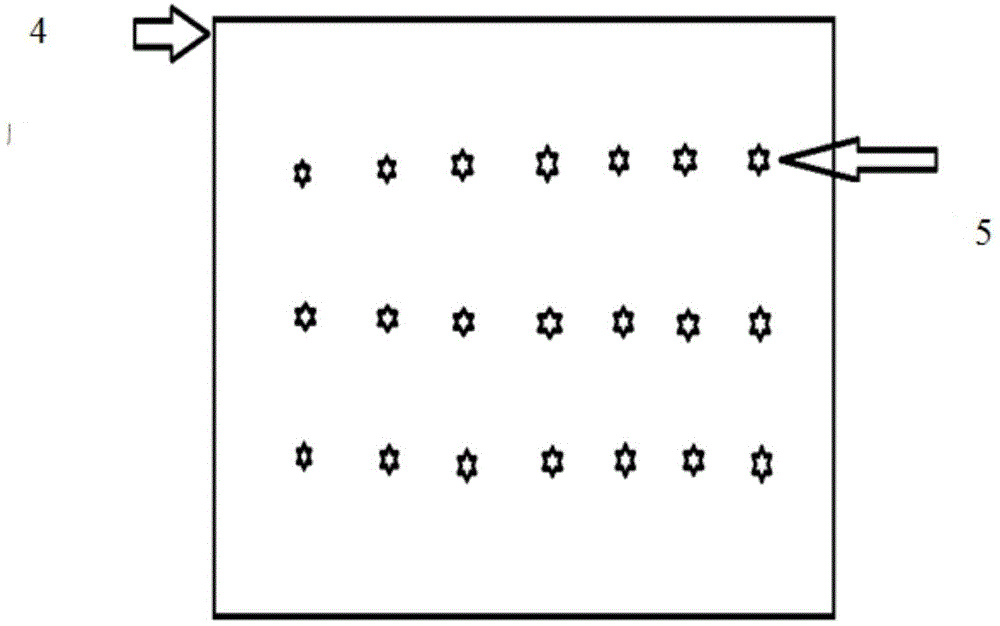

Blackboard without powder

InactiveCN105270046AConvenience guaranteedEnvironmentally friendlyWriting boardsHandwritingPressure sense

The invention provides a blackboard without powders. The blackboard comprises a pressure sensing switch (1), a powder eruption device (2), an air circulation system (3), and a thin board (4) which is hollow inside. A blackboard pen touches a pressure sensor on the surface of the blackboard. When the sensor receives a signal and generates static electricity on a handwriting position on the inner surface of a front board of the blackboard, the signal is transmitted to the powder eruption device (2) which is inlaid on a corresponding position on the rear board of the blackboard. After the powder eruption device (2) receives the signal, the powder eruption device (2) sprays powders, and the powders are absorbed on the inner surface of the front board because of static electricity, and part of unabsorbed powders fall in a groove under the blackboard and wait to be recycled after use ends. When the pressure sensor on the front surface of the blackboard senses pressure for the second time, a power switch on a corresponding position is turned off, and the static electricity disappears, the attached powders fall off, so as to ensure convenience of modification. After one time use, the power supply on the surface of the blackboard is turned off, and the powders fall in the groove on the lower part of the back board.

Owner:NANJING ZHUANCHUANG INTPROP SERVICES

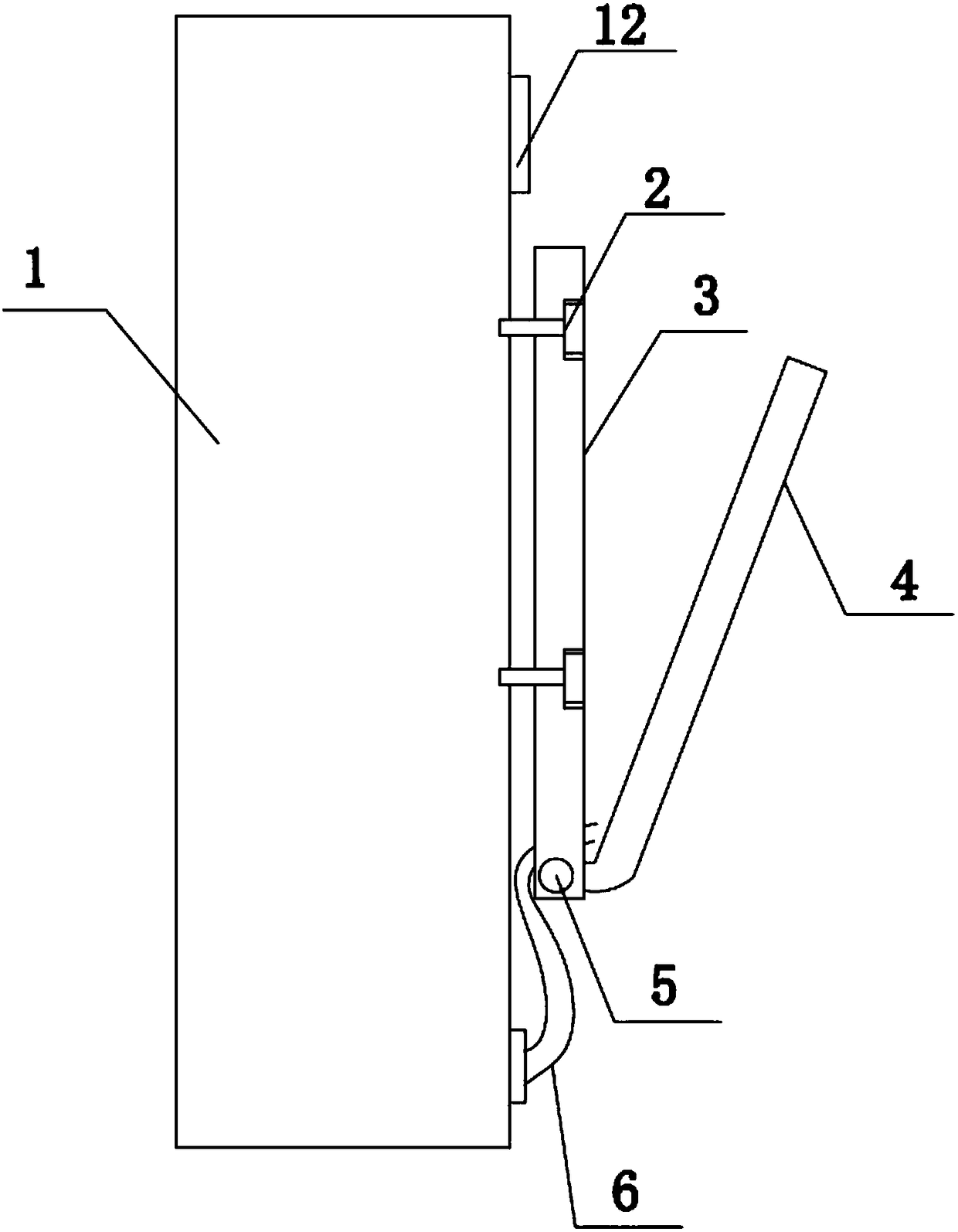

Charging pile for new energy vehicle

InactiveCN108944482ASolve the shortened service lifeKeep tidyElectric propulsionNew energyEngineering

The invention discloses a charging pile for a new energy vehicle. The charging pile for the new energy vehicle comprises a charging pile main machine. A charging wire is arranged at the bottom of thecharging pile main machine, a charging connector is arranged at the head of the charging wire, the charging connector is inserted into an interface inserting slot formed in the top of the charging pile main machine, a bottom plate is arranged on one side of the charging pile main machine, a supporting plate capable of being turned outwards is arranged at the outer side end of the bottom plate, andthe bottom of the supporting plate is rotatably installed in rotating shaft holes formed in both sides of the bottom plate through rotating shafts. The rotating shafts are sleeved with torsion springs, the rotating shafts are installed in the rotating shaft holes through the torsion springs, a row of positioning mechanisms which are longitudinally arranged are arranged on the inner side surface of the supporting plate, and the positioning mechanisms are formed by staggering more than one positioning device. The charging pile for the new energy vehicle mainly solves the problem that connectingwires of the charging pile are arranged in disorder and drag with the ground, and the neat placement of the charging wire can be effectively ensured through the supporting plate, and the problem thatthe service life is shortened due to the fracture of a charging wire interface caused by pulling the charging wire is solved.

Owner:郭嵩

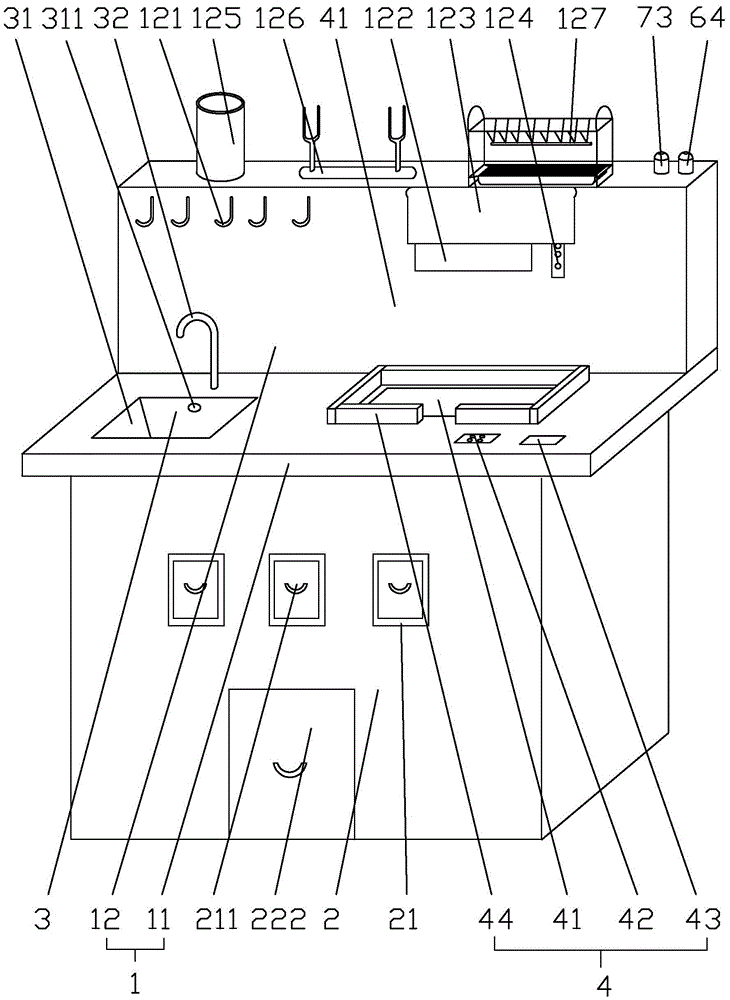

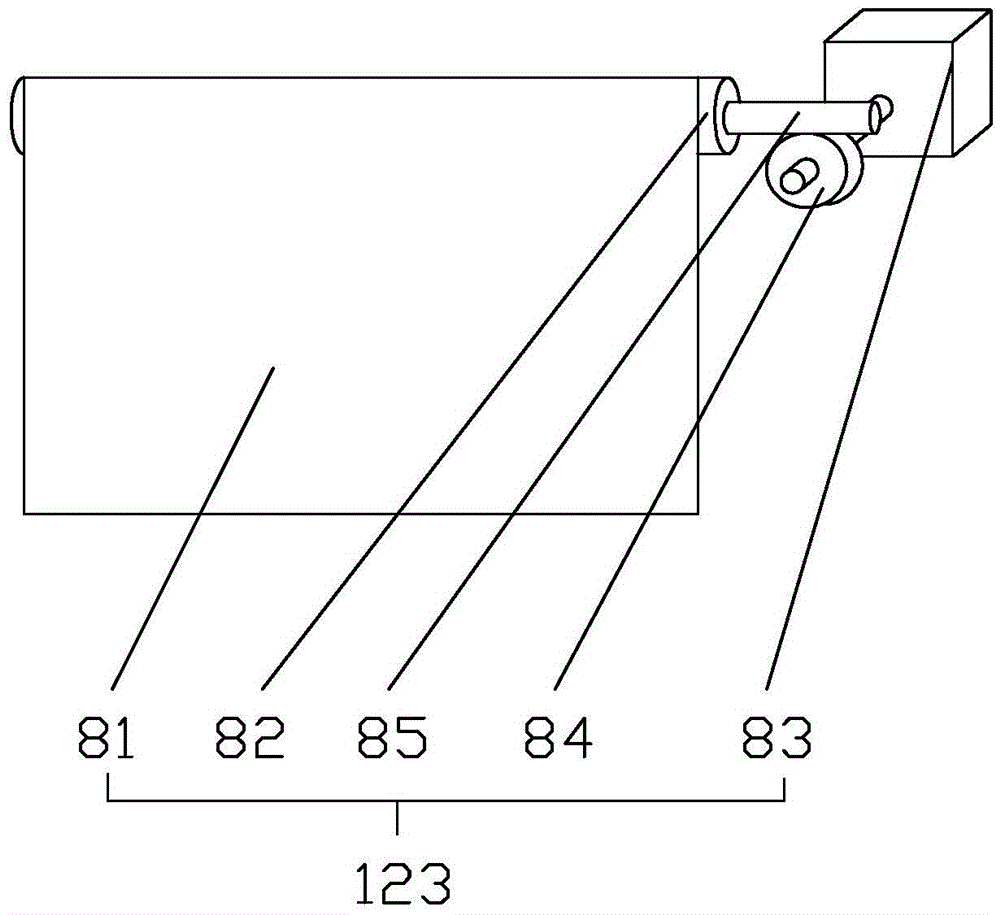

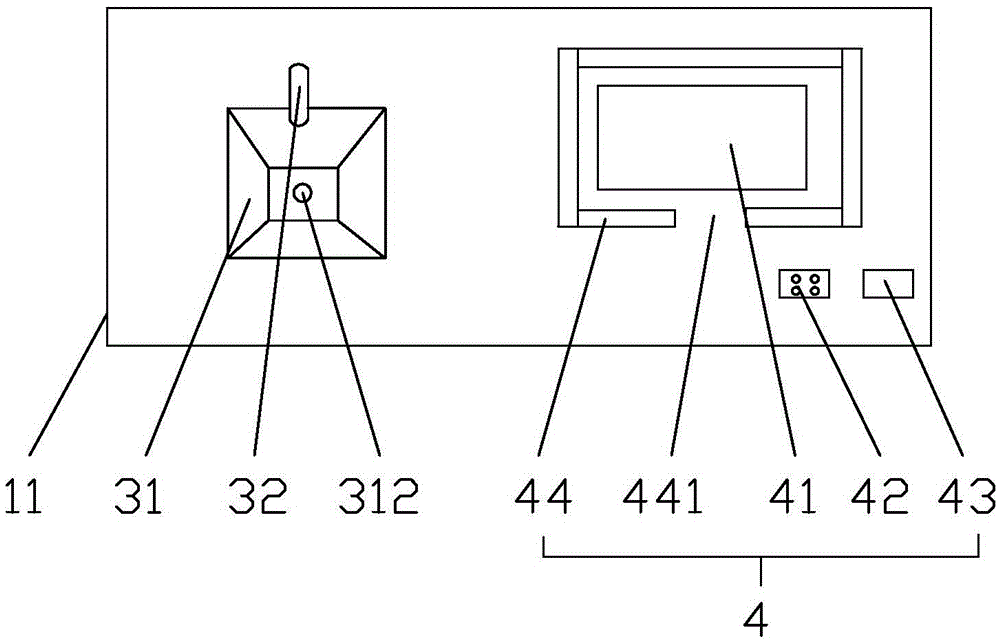

Cupboard with washing device

InactiveCN105476294AIncrease storage areaIncrease the use of functionsKitchen cabinetsFittingCookerControl unit

The invention mainly discloses a cupboard with a washing device. According to the technical scheme of the cupboard, the cupboard comprises a transverse table plate, a longitudinal table plate and a cabinet body; the washing device and an induction cooker are arranged on the transverse table plate; the washing device comprises a water tank, a faucet, a solid-liquid separation device and a water drainage pipeline, wherein the solid-liquid separation device and the water drainage pipeline are located below the water tank; the solid-liquid separation device comprises a first channel, a second channel and a third channel, wherein the second channel and the third channel are located above the first channel; a filter basket is arranged at the upper end in the first channel; a filter plate is arranged at the lower end in the first channel; a smashing device is arranged in the second channel; a blockage detection device is arranged in the third channel; the induction cooker comprises a heating unit, a control unit and a display unit; a temperature sensor is arranged in the heating unit and connected with the display unit. By means of the cupboard, materials in the water tank can be separated and smashed, sewer tunnels are prevented from being blocked, the induction cooker is added so that automatic cooking can be conducted and the cooking safety can be improved, and time and labor are saved.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

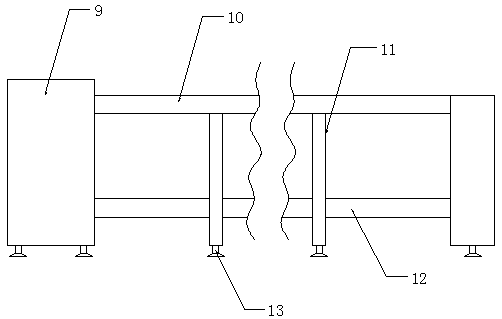

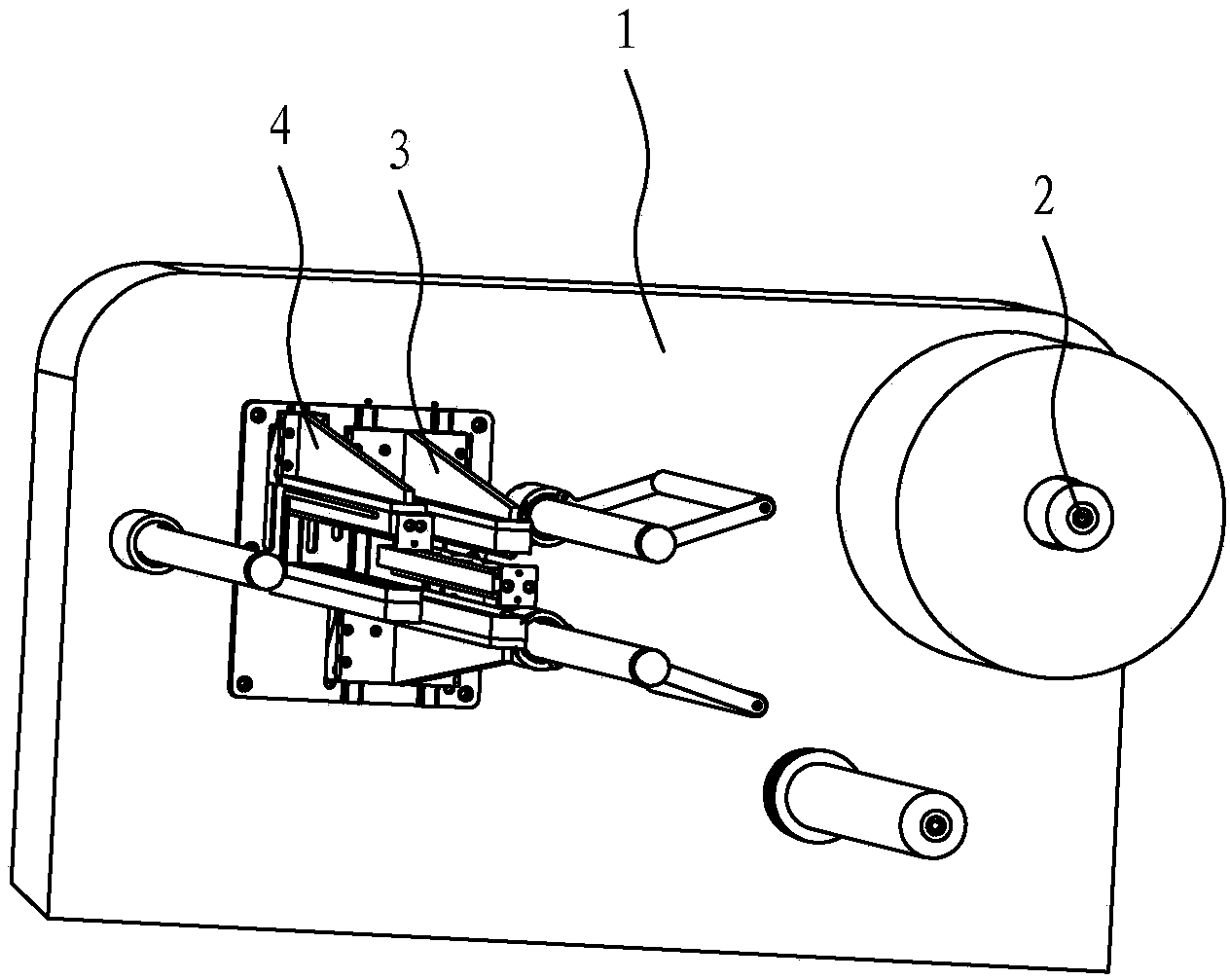

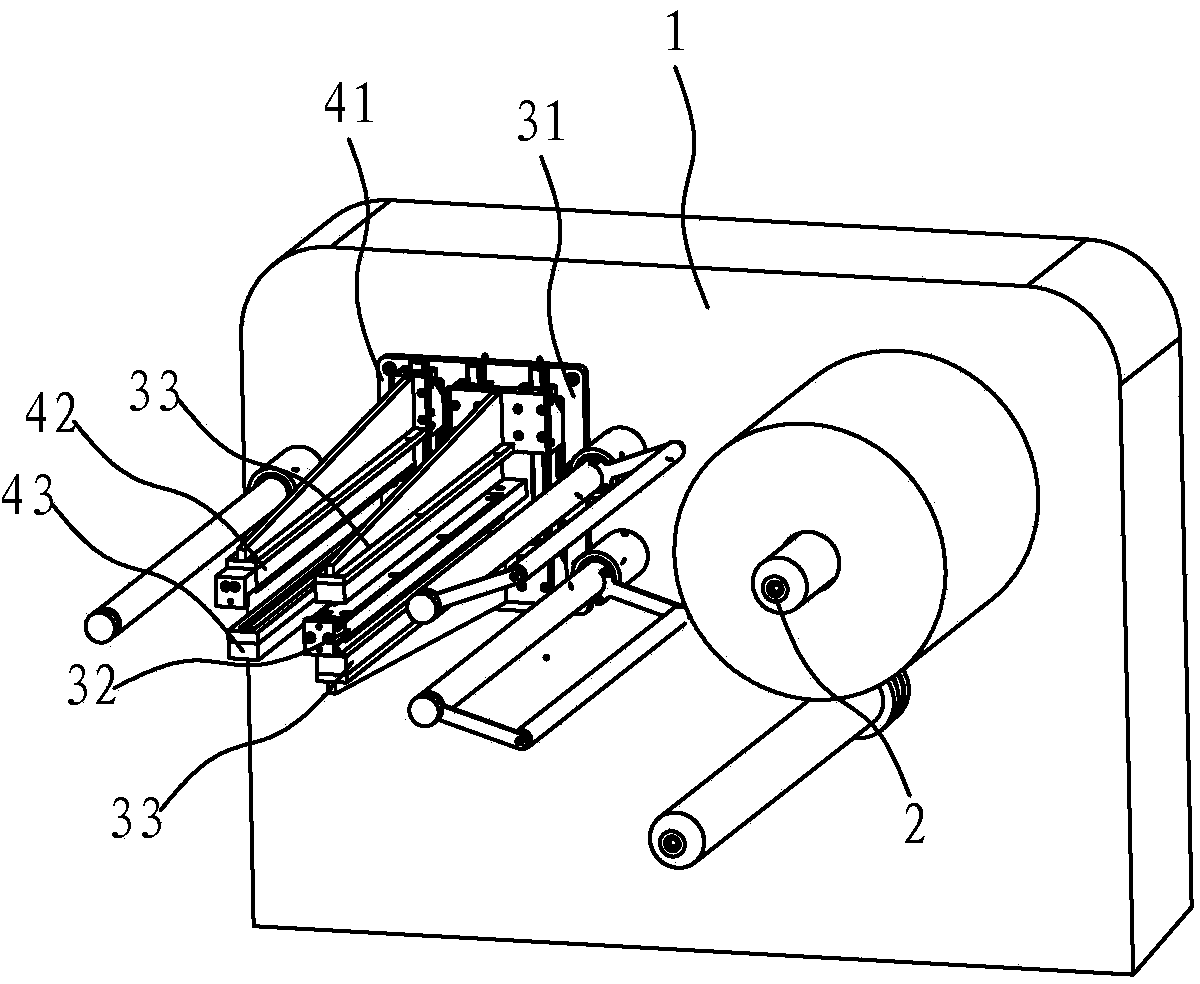

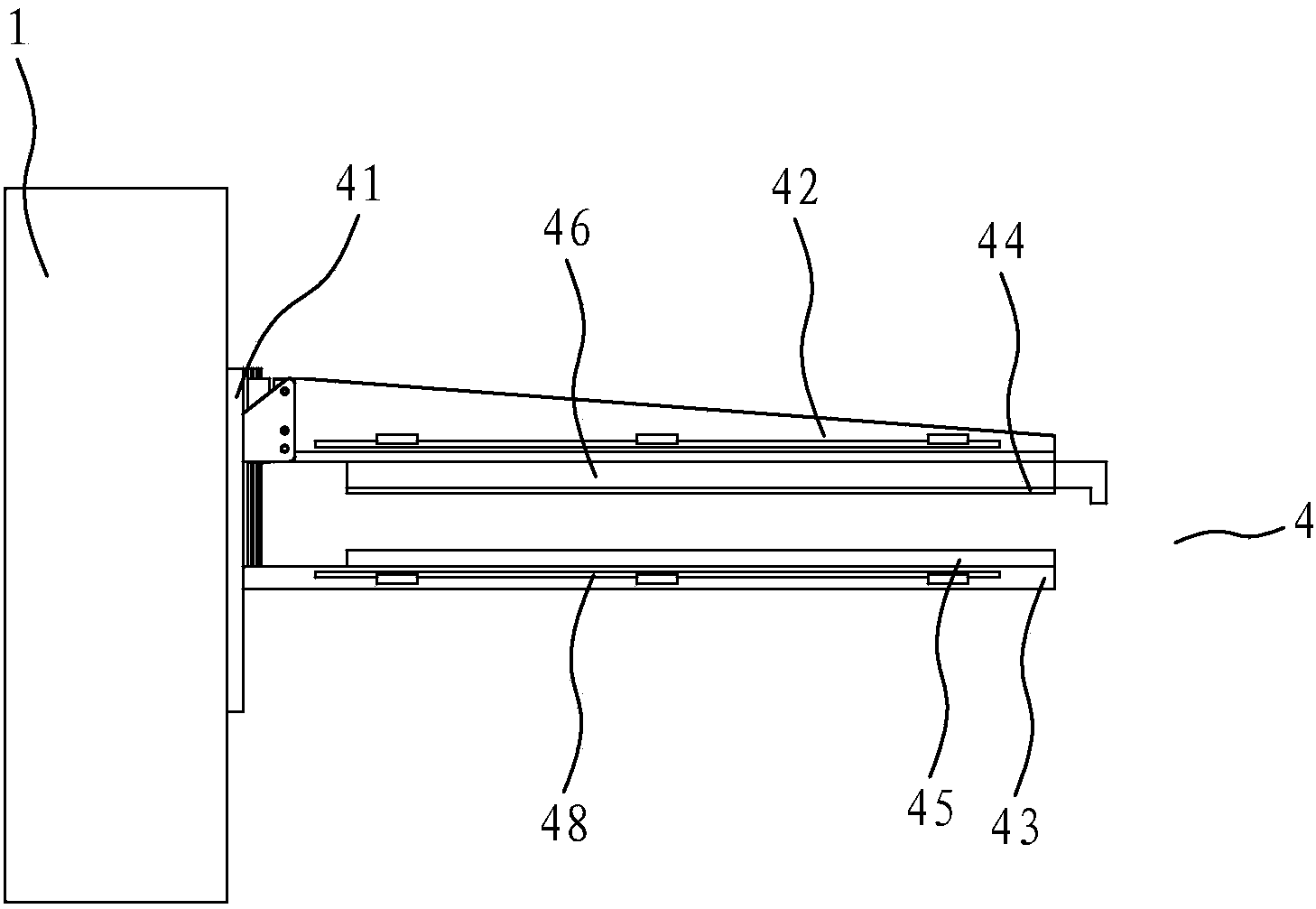

Device for achieving continuous supply of films automatically

The invention relates to a device for achieving continuous supply of films automatically. The device is simple in structure, high in working efficiency and capable of achieving automation film connection. The device comprises a machine frame, more than two unreeling rollers arranged on the machine frame in a rotary mode, a fusing device arranged in front of the unreeling rollers and used for cutting off the packaging films, a hot melting jointing device arranged in front of the fusing device and used for connecting two packaging films, and an electrical control system, wherein the fusing device comprises a support arranged on the machine frame, a fusing base arranged on the support, and a fusing driving device arranged on the support, two press-fit bases are arranged on the support and located above and below the fusing base respectively, the two press-fit bases can get away from or approach the fusing base under the driving of the fusing driving device, fusing wires communicated with an external power supply are arranged on the upper side and the lower side of the fusing base respectively, and the unreeling rollers, the hot melting jointing device, the fusing wires and the fusing driving device are all connected with the electrical control system.

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

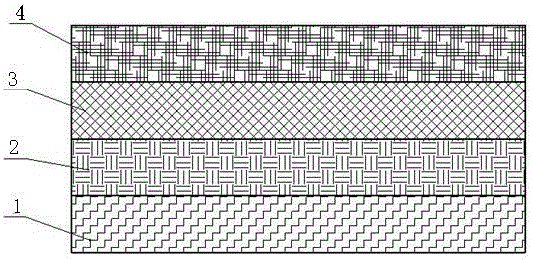

Warm-keeping and easy-to-finish suit fabric with good rigidity and hardness

The invention relates to warm-keeping and easy-to-finish suit fabric with good rigidity and harness. The suit fabric comprises a lining layer (1), a base layer (2), a breathable layer (3) and an outer layer (4), wherein a lining fabric layer is arranged on the back side of the lining layer and is prepared from braided fabric, and the braided fabric can comprise multiple pieces of warp yarn and at least one piece of weft yarn coupled with the multiple pieces of warp yarn; the braided fabric can further comprise multiple joint fibers, and the joint fibers can be positioned to be parallel to the warp yarn and / or parallel to the weft yarn. Besides, the joint fibers can be made of a material with a melting temperature lower than that of the warp yarn and weft yarn material for preparation of the braided fabric. The suit fabric feels mild and can keep outer draping sense, and the fabric keeps warm entirely and is easy to finish. The rigidity and the harness of the suit fabric are good.

Owner:JIANGYIN YIFAN IND & TRADE

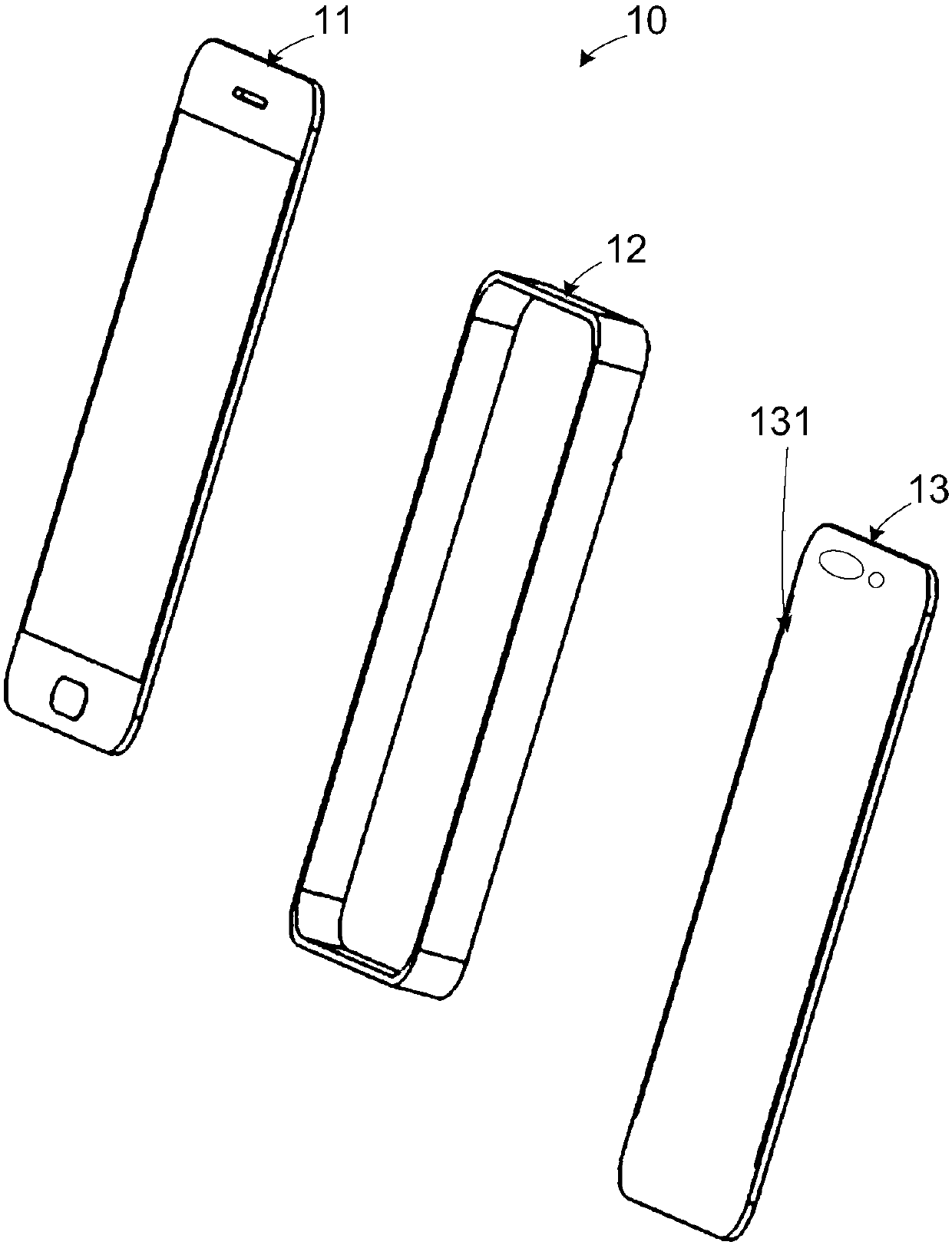

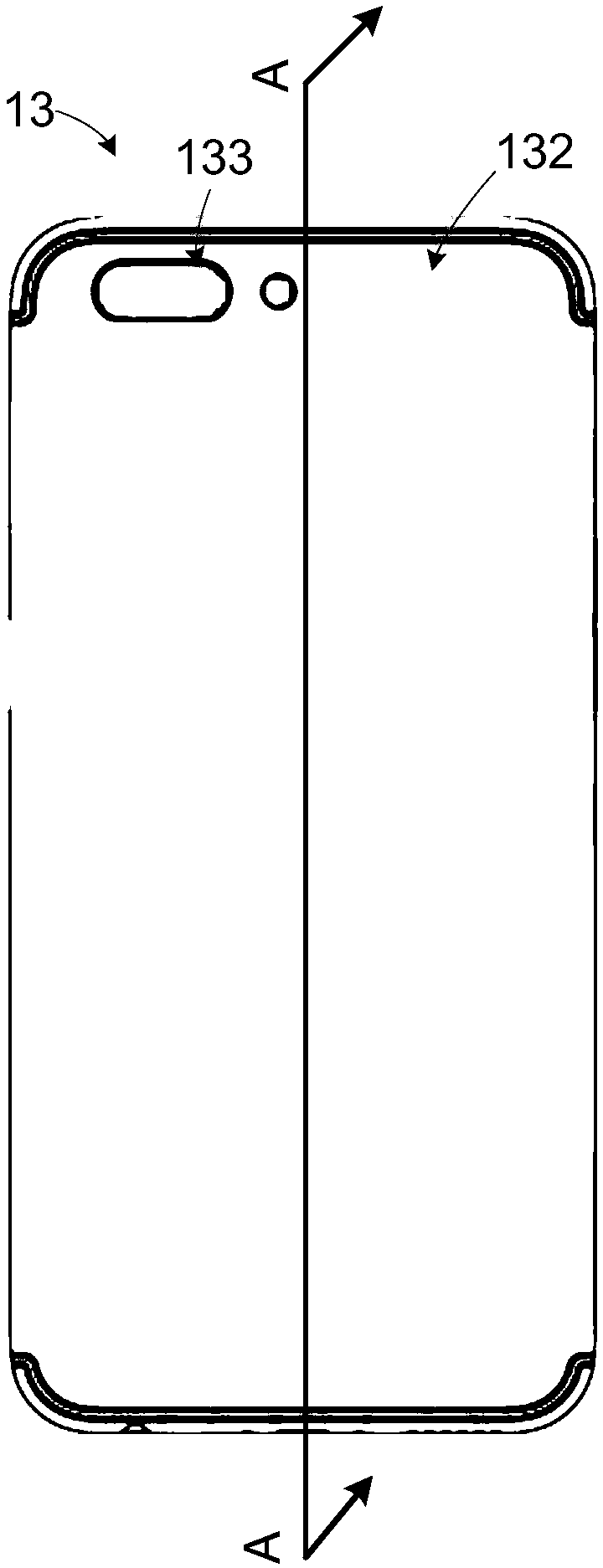

Shell fabrication method, shell and electronic equipment

InactiveCN107683044AExternal surface highlightSmooth outer surfaceCasings/cabinets/drawers detailsElectronPolymer

The embodiment of the invention discloses a shell fabrication method, a shell and electronic equipment. The shell fabrication method comprises the steps of providing a substrate, polishing an outer surface of the substrate, spraying paint on the outer surface of the polished substrate, and forming a paint layer. The paint layer comprises a protection paint layer containing a fluorine polymer additive, thus, an outer surface of the shell can be bright and smooth, a fingerprint is difficult to paste, and the clean and the attractiveness of the outer surface of the shell can be maintained.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

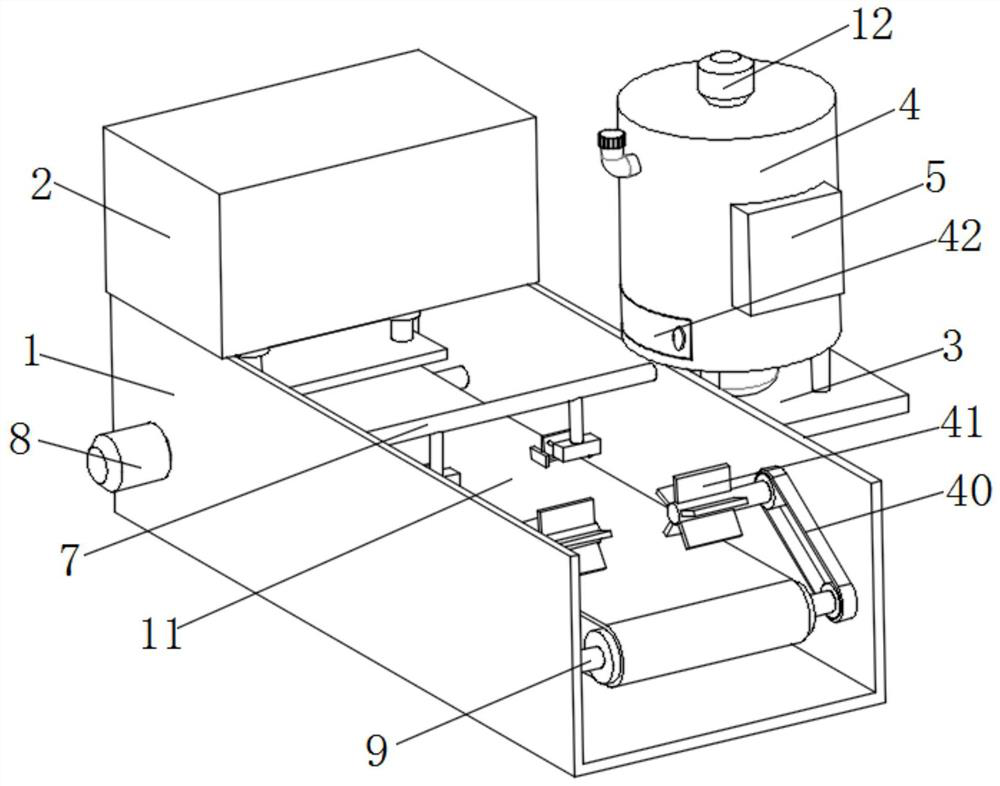

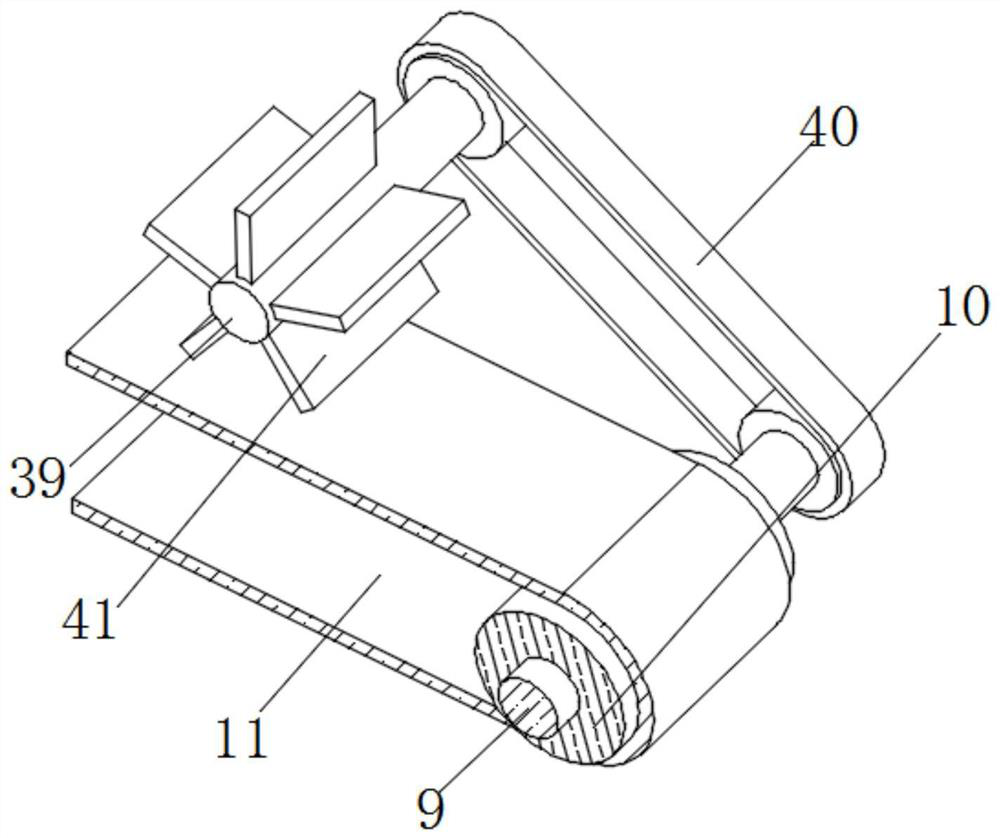

Novel gluing machine for photovoltaic panel production and photovoltaic panel production process

ActiveCN113210201AAvoid cloggingExtended service lifeLiquid surface applicatorsMaterial gluingElectric machineryEngineering

The invention discloses a novel gluing machine for photovoltaic panel production and a photovoltaic panel production process, and relates to the technical field of gluing devices. The novel gluing machine comprises a U-shaped bottom plate, a gluing machine body and a heating device assembly. The gluing machine body is connected to the top of the U-shaped bottom plate, and a supporting plate is fixedly connected to one side of the U-shaped bottom plate. Supporting rods are fixedly connected to the periphery of the top of the supporting plate, a glue barrel is fixedly connected to the top ends of the four supporting rods, a sealing door is arranged on one side of the glue barrel, the heating device assembly is fixedly connected to the side wall of the glue barrel, and an infusion pump is fixedly connected to the bottom of the glue barrel. A stirring motor drives an outer stirring shaft to rotate around a main rotating shaft and rotate around self axis, so that inner stirring blades and outer stirring blades are driven to stir glue, the temperatures of all positions tend to be uniform when the glue is heated by the heating device assembly, and the glue is prevented from being solidified due to the too low temperature and blocking a liquid pump or a glue conveying pipe to affect the glue coating work.

Owner:ZHEJIANG XINGYU MECHANICAL & ELECTRICAL TECH CO LTD

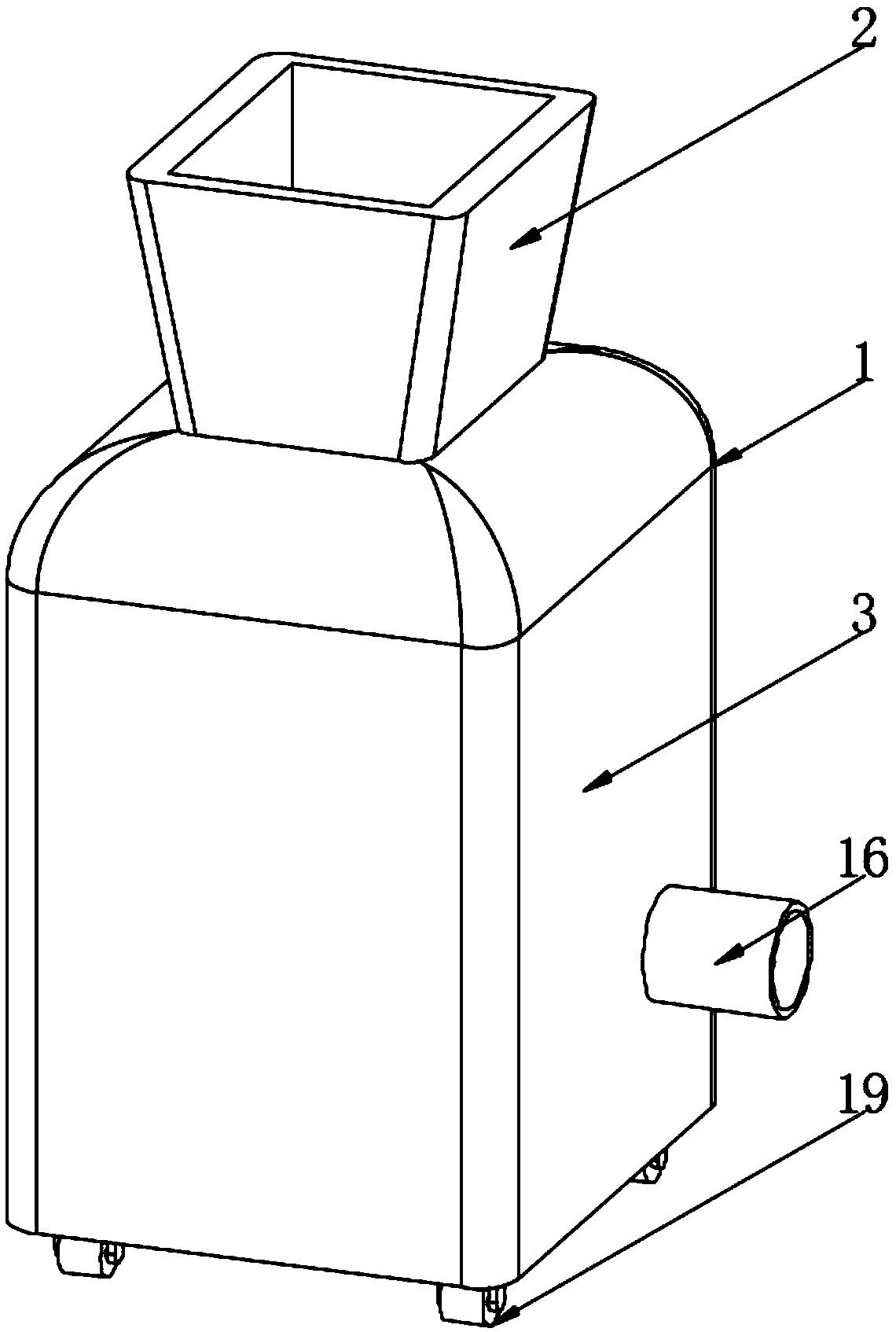

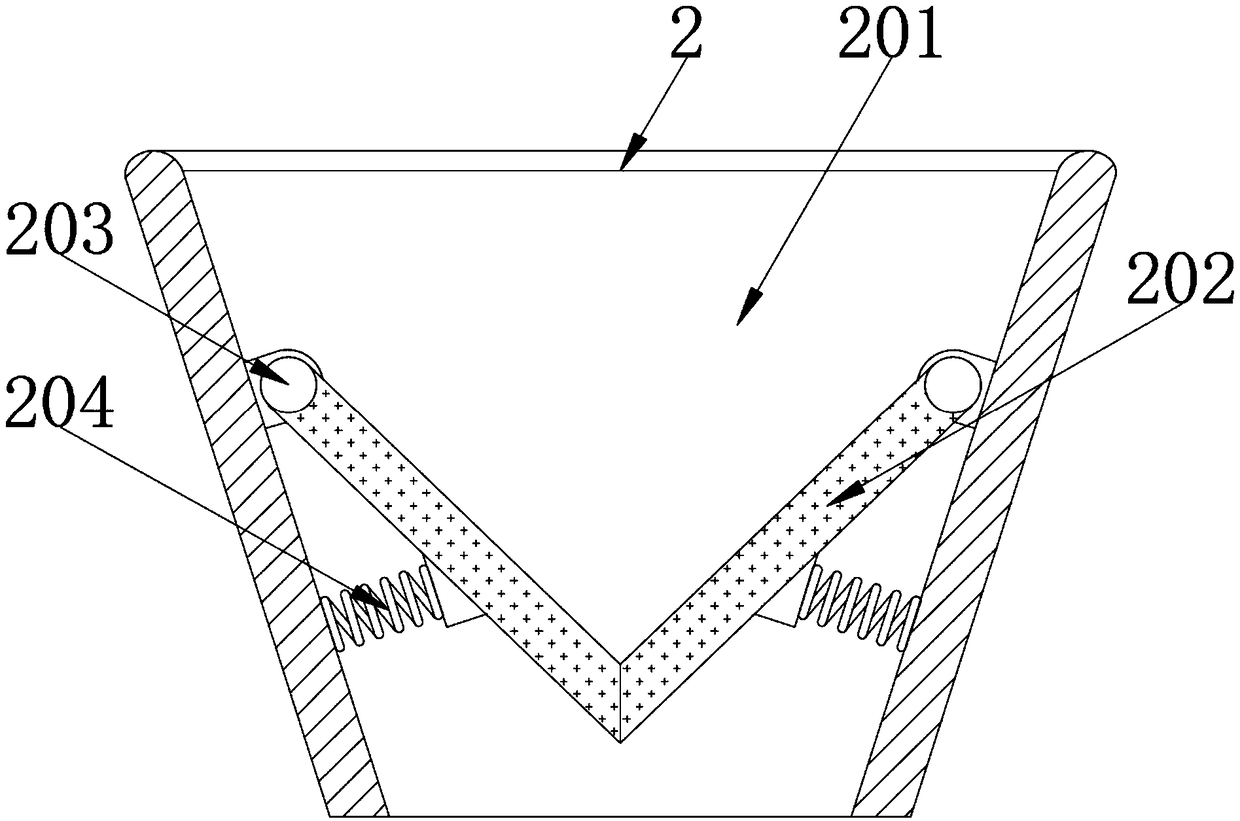

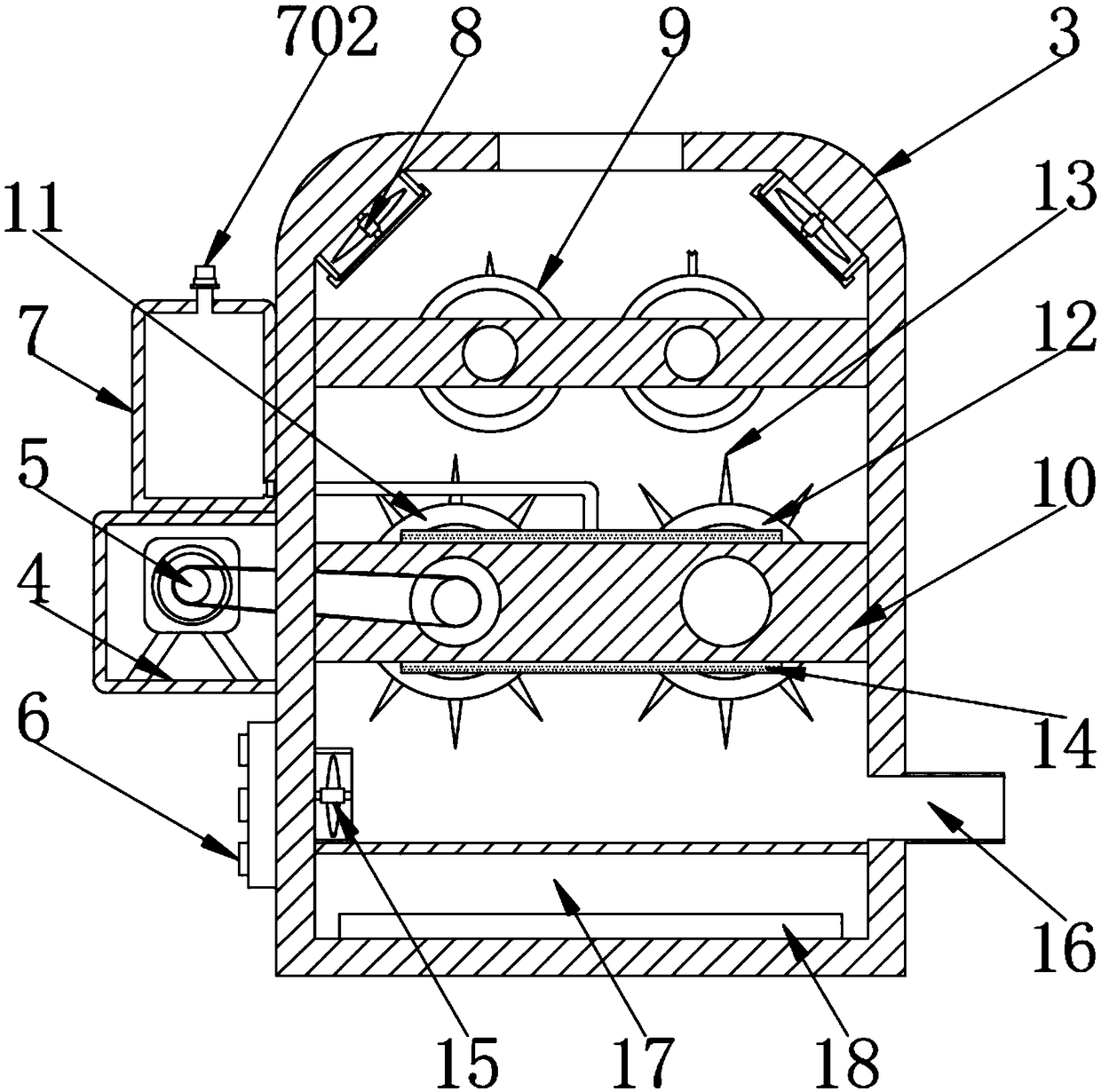

Material crushing machine

InactiveCN107335513AUniform sizeImprove the problem that the size difference is too largePlastic recyclingGrain treatmentsRespiratorPulp and paper industry

The invention relates to the field of plastic processing equipment, in particular to a material crushing machine. The material crushing machine is characterized in that a support is welded to the lower portion of a machine shell; a screen with the size larger than that of a discharging opening is fixed to the discharging opening; a rotary disc is arranged in the machine shell; a motor is fixed to the outer portion of the machine shell, and an output shaft of the motor is connected with a middle shaft of the rotary disc; a crushing tool is fixed to the periphery of the rotary disc; a discharging opening cover is welded to the outer portion of the discharging opening; one end of a fixed plate is welded to the discharging opening cover; the lower end of a first air cylinder is fixed to the other end of the fixed plate, and the upper end of the first air cylinder is connected with the middle of the screen; a hairbrush is located in the discharging opening cover and is arranged above the fixed plate in an attachment manner; and a second air cylinder is fixed to the outer portion of the discharging opening cover, and the piston rod end of the second air cylinder is connected with the hairbrush. The sizes of waste plastic fragments crushed out by the material crushing machine are quite uniform.

Owner:TIANJIN CHUANHAO PLASTICS

Agricultural straw smashing device

The invention discloses an agricultural straw smashing device. The agricultural straw smashing device comprises a device body. The top end of the device body is provided with a feeding component. Thefeeding component comprises a feeding port, a baffle plate, a rotation shaft and a reset spring. The interior of the feeding component is provided with the feeding port. The side wall of the interiorof the feeding port is rotatably provided with the baffle plate through the rotation shaft. The reset spring is fixedly installed between the baffle plate and the side wall of the feeding port througha spring fixing base. The agricultural straw smashing device is scientific and rational in structure, safe and convenient in use, and provided with the feeding component. After straw is smashed, thestraw adhered to the inner wall of the device body can be effectively blown away through a cleaning fan, and the adhered straw is recovered, so the clean and tidy interior of the device body is effectively guaranteed. Through a dust blocking screen plate, the straw can be effectively prevented from entering the cleaning fan after smashed, so that the cleaning fan is failure and cannot be used. Through a fixing ring and an internal thread, the dust blocking screen plate is conveniently detached and cleaned.

Owner:徐州丰姚农业发展有限公司

Catering robot for school canteen

PendingCN108309186AReduce workloadImprove efficiencyTableware washing/rinsing machine detailsEngineeringFlange

The invention discloses a catering robot for a school canteen. The catering robot comprises a box A, a plurality of supporting columns are uniformly and fixedly arranged at the bottom of the box A, abox B is fixed to the top of the box A in a penetrating manner, a motor A is fixed to the top of the inner wall of the box B, a driving end of the motor A is fixedly connected with a lead screw, a flange bearing is fixed to the side face of the inner wall of the box B, a ball nut matched with the lead screw is mounted on the lead screw, a horizontal plate is fixed at the bottom of the ball nut, amotor B is fixed at the bottom of the horizontal plate, a driving end of the motor B is fixedly connected with a vertical rod A, the vertical rod A is perpendicular to the driving end of the motor B,an electromagnet is fixed at the bottom of the vertical rod A, and a battery A is fixed at the bottom of the horizontal plate. Dinnerware cleaning, arranging and disinfecting can be integrated, a controller controls the motor A and the motor B to classify residual food on the dinnerware, the workload of dining hall workers is relieved, time and labor are saved, and the catering robot is high in use efficiency, practical and reliable.

Owner:王达

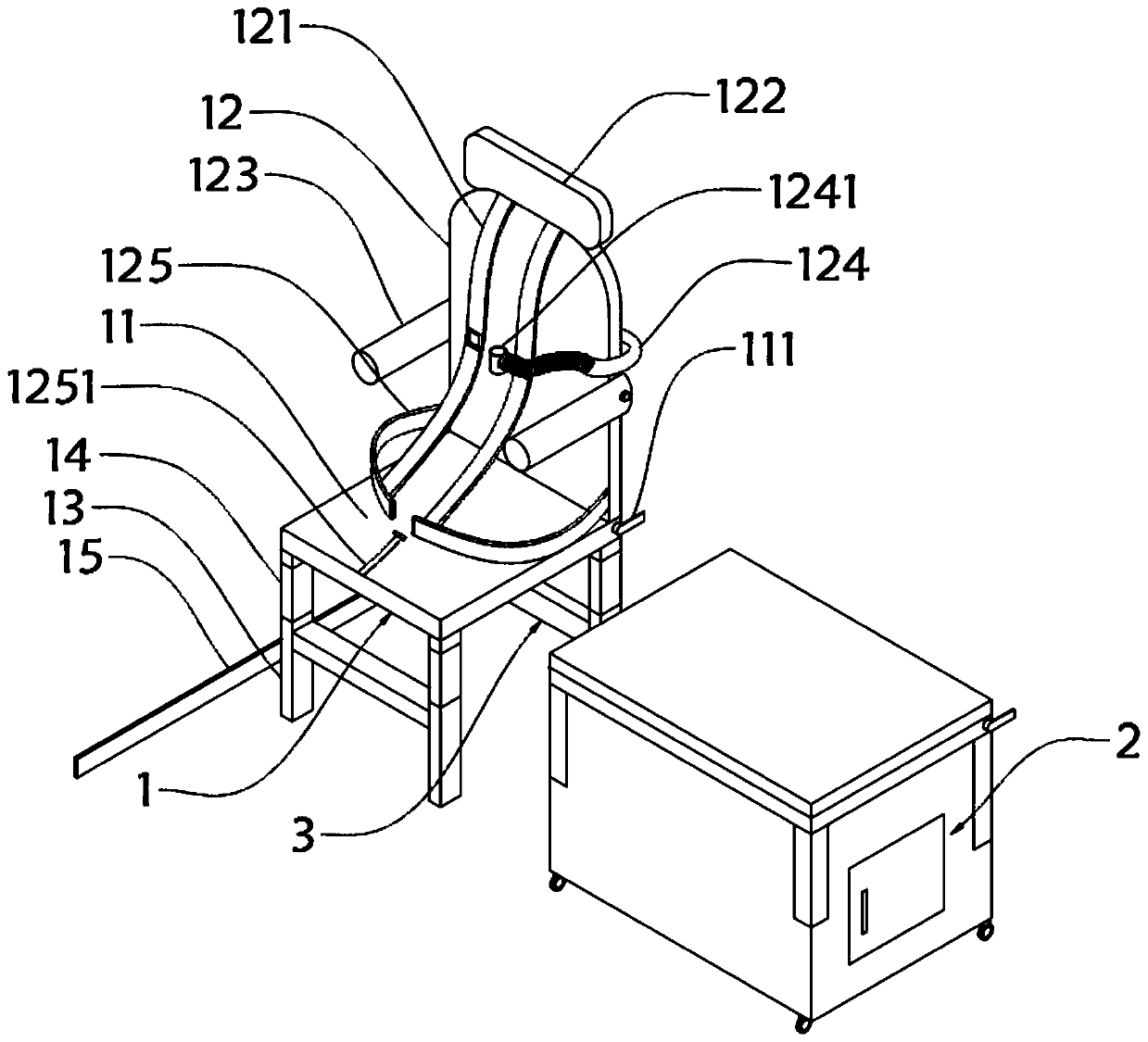

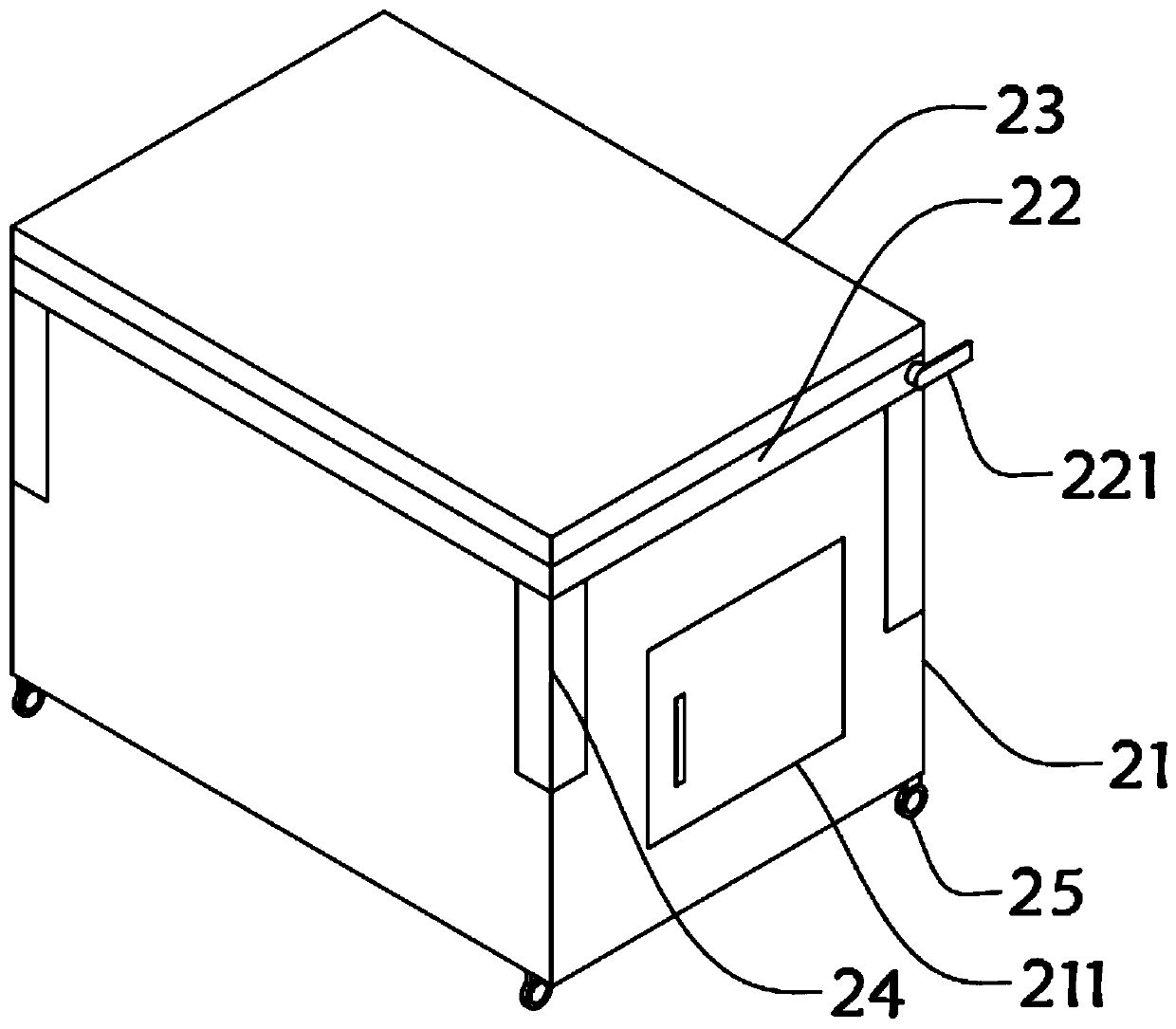

Multifunctional primary-secondary chair for aerosol inhalation

PendingCN110973876AWith height adjustmentWith angular functionStoolsAdjustable chairsPhysical medicine and rehabilitationNursing care

The invention relates to the technical field of atomization auxiliary equipment. Particularly, the invention relates to a multifunctional primary-secondary chair for aerosol inhalation. The multifunctional primary-secondary chair comprises a main seat, an auxiliary seat is arranged below the main seat, the main seat comprises a main seat plate, a main seat adjusting handle is arranged on one sideof the main seat plate, a main seat backup plate is arranged on one side of the top of the main seat plate, the bottom of the main seat backup plate is rotationally connected with the main seat platethrough a rotating shaft, one end of the main seat adjusting handle is tightly welded to the rotating shaft at the bottom of the main seat plate, and a shoulder safety belt is vertically arranged on one side of the main seat backup plate. According to the design, the height and angle adjusting function is achieved, patients with different ages, heights and different body positions can be subjectedto atomization treatment, the functions of the support, storage and the like are obtained so as to meet the nursing requirements of family members of a patient, especially family members of a child patient needing nebulizer therapy, a fixed or movable chair can be provided according to the treatment environment and the requirements of the patient, the clinical nursing requirements are met, and the cleanliness of the treatment environment can be guaranteed.

Owner:BEIJING CHILDRENS HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

Novel water-saving commode with drying function

The invention discloses a novel water-saving washstand with a drying function, comprising a water-saving washstand body, the water-saving washstand body including a holding main board; a ceramic face washing table is arranged in the center of the holding main board Basin; the side of the holding main board is provided with a drying strip; the drying strip is provided with a heating wire and an air blower; the right side of the drying strip is provided with a timer, and above the timer is provided with The start button is electrically connected; the output end of the timer is electrically connected with a reset device; the rear part of the drying strip is welded with a washing mirror mounting frame; a groove is arranged in the washing mirror mounting frame; the A water-saving device is welded under the ceramic washbasin; one side of the water-saving device is provided with an output pipe. The present invention has a simple structure, a stable structure, a drying function, and keeps the clean table dry and tidy, and has a water-saving function , greatly improving the utilization rate of water resources, saving water sources, and conducive to sustainable development.

Owner:安聪聪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com