Novel gluing machine for photovoltaic panel production and photovoltaic panel production process

A photovoltaic panel and bonding machine technology, applied in the cleaning method of tools, material gluing, mechanical equipment, etc., can solve problems such as clogging of the glue outlet pipe of the bonding device, affecting the glue application work, and uneven distribution of colloid components, etc., to achieve extension Service life, reduction of adhesion effect, effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

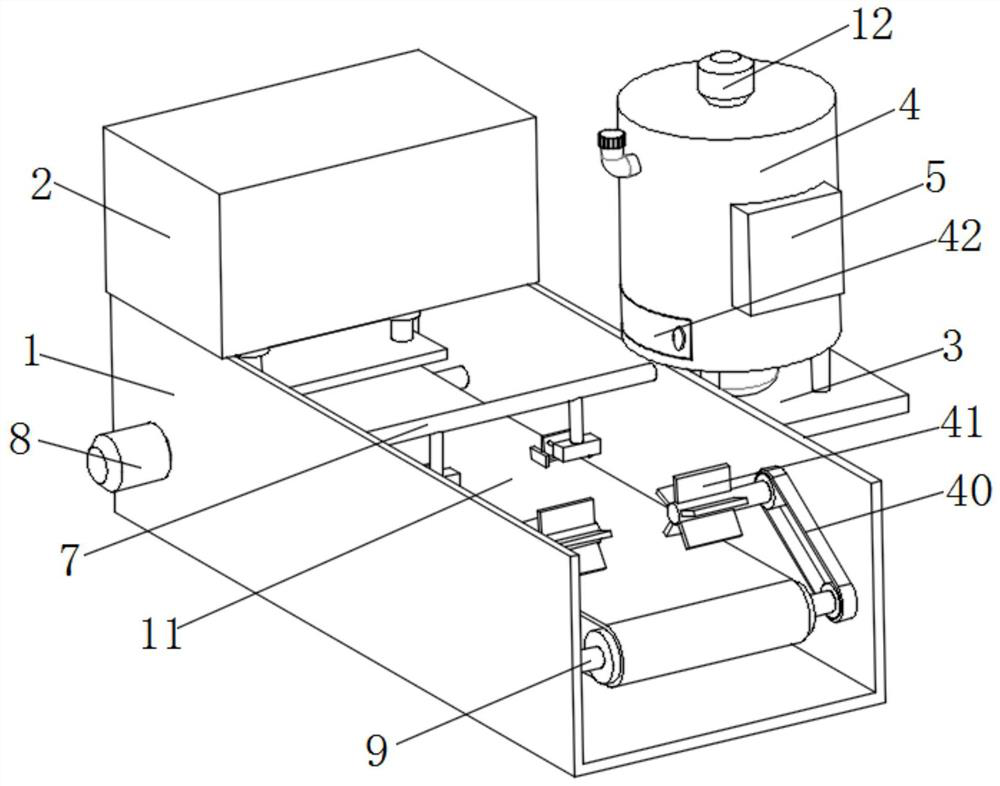

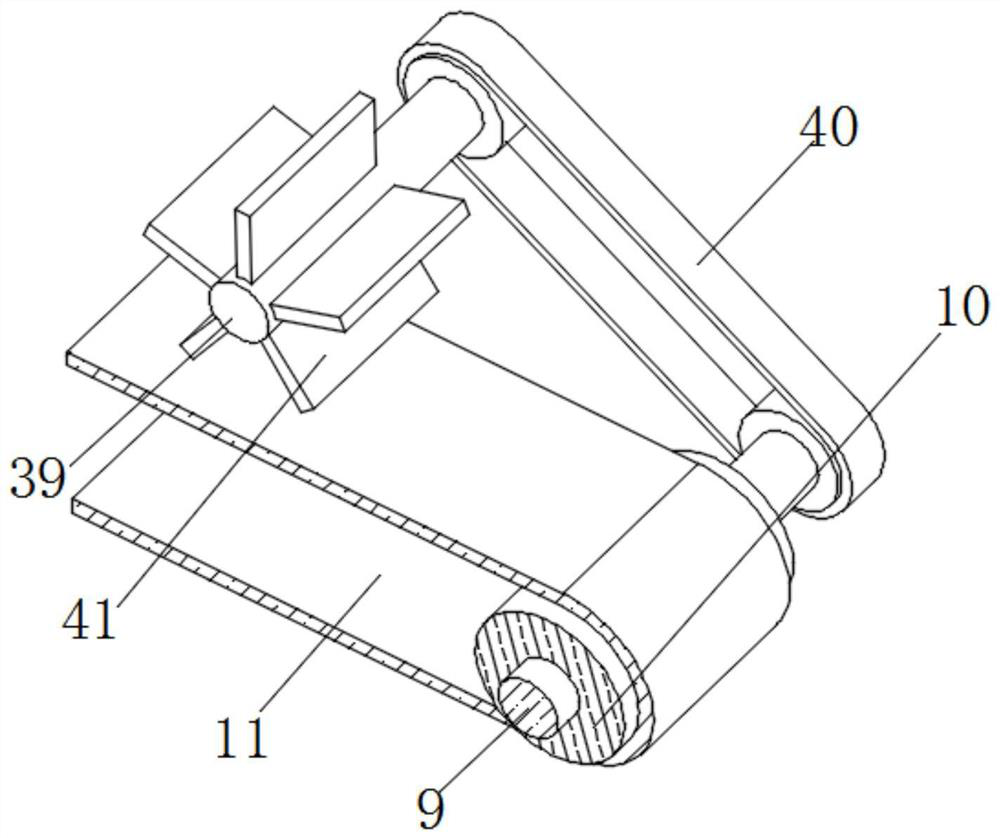

[0043] Example: Reference Figure 1-8 A new bonding machine for photovoltaic panel production is shown, including a U-shaped bottom plate 1, a bonding machine body 2 and a heating device assembly 5. The bonding machine body 2 is connected to the top of the U-shaped bottom plate 1, and the U-shaped bottom plate 1 One side of the U-shaped bottom plate 1 is fixedly connected with a supporting plate 3, the supporting plate 3 can be any flat plate in the prior art, such as a metal plate, and the supporting plate 3 can be fixedly connected with one side of the U-shaped bottom plate 1 by welding.

[0044] All around the top of the supporting plate 3 are fixedly connected with support rods, the supporting rods can be any straight rod in the prior art, such as metal straight rods, and the supporting rods can be fixedly connected around the top of the supporting plate 3 by welding.

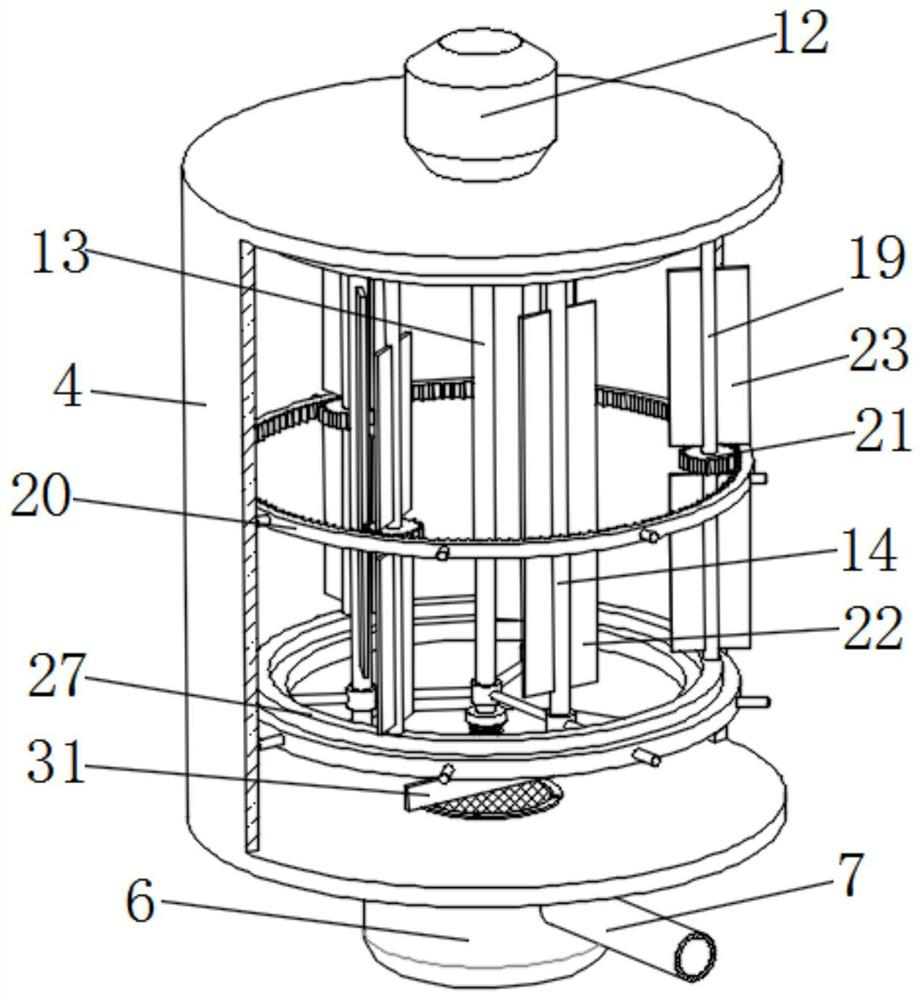

[0045] The tops of the four support rods are fixedly connected with a rubber bucket 4, one side of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com