Patents

Literature

3243results about How to "Apply evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

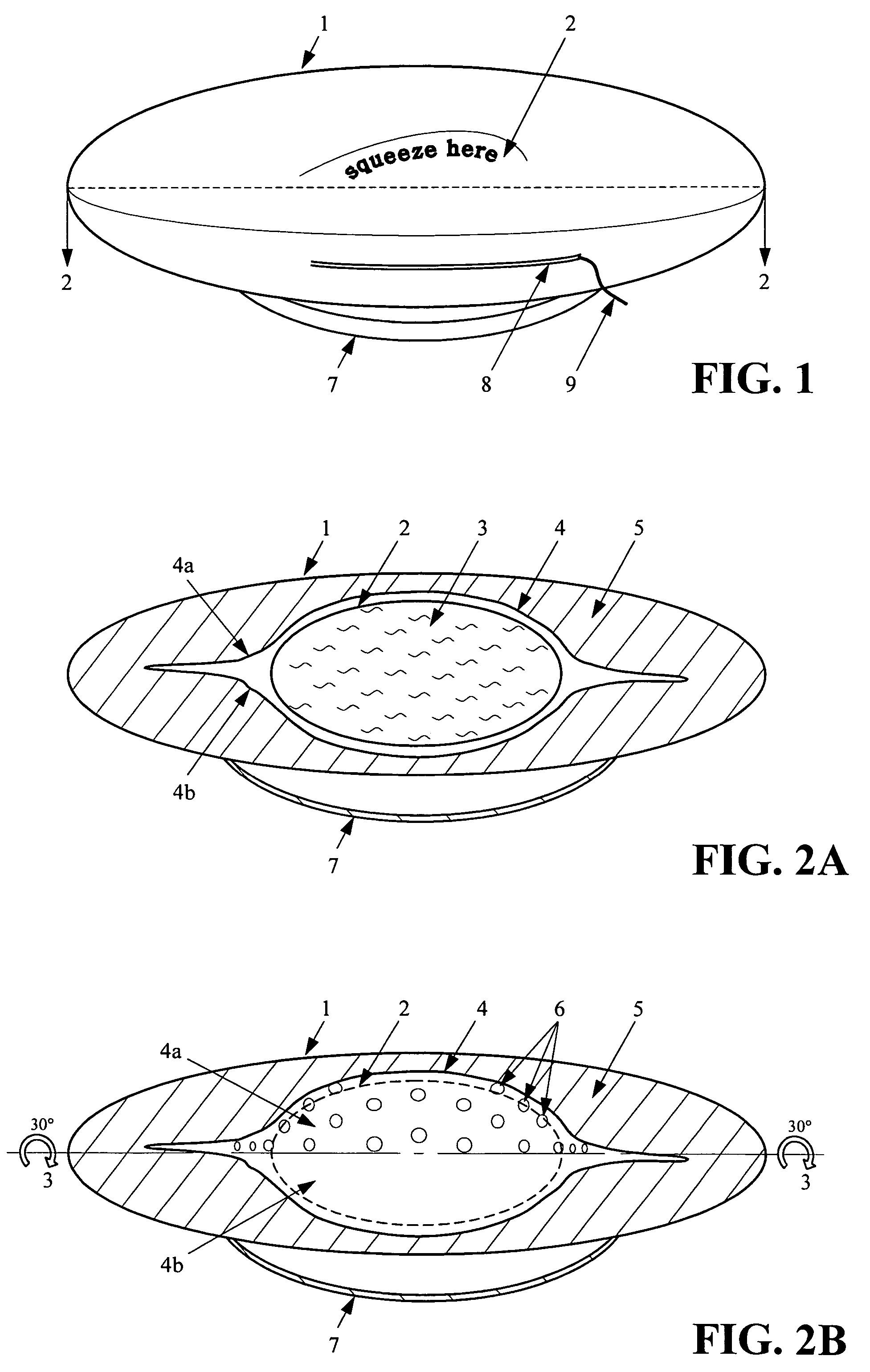

Hand applicator of encapsulated liquids

InactiveUS7419321B2Fast deliveryApply evenlyBathroom accessoriesMedical applicatorsHazardous substancePharmaceutical formulation

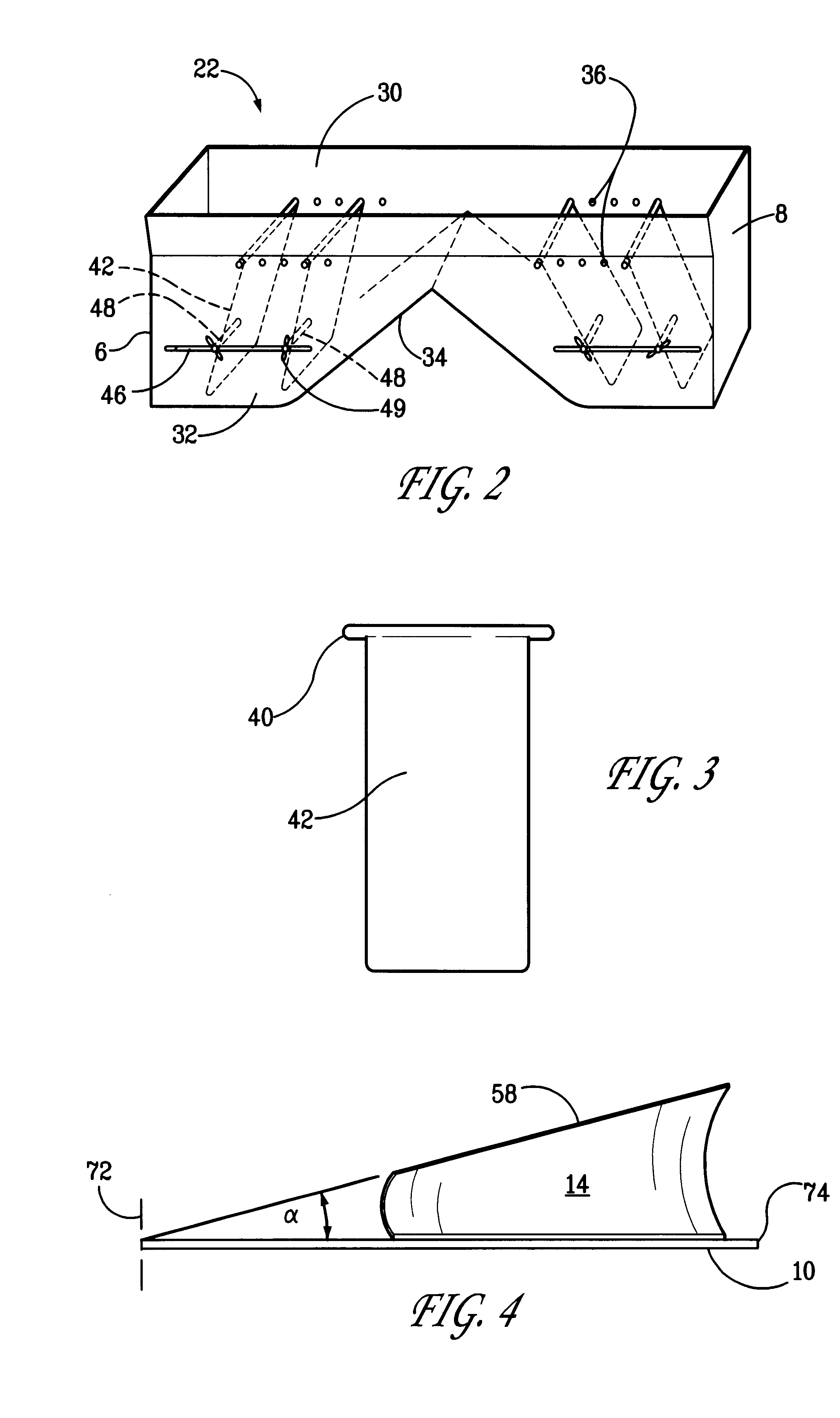

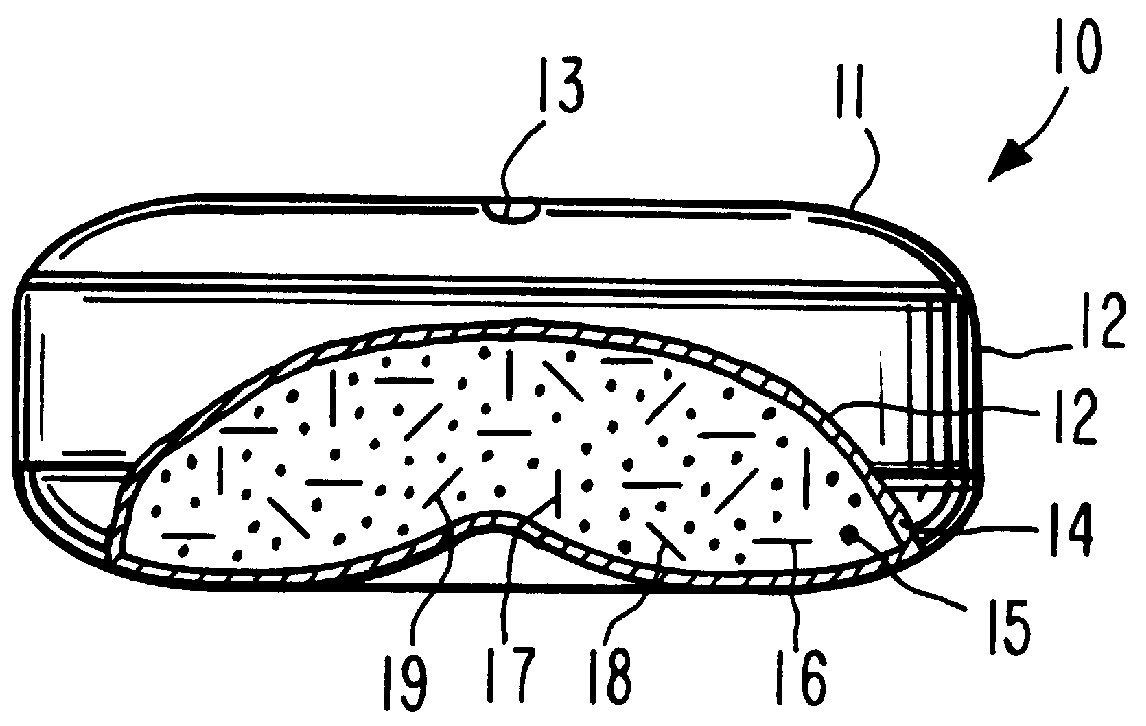

A hand applicator of encapsulated liquids, such as cosmetic, hygienic, and pharmaceutical formulations or household chemicals, of different viscosity. When the user squeezes the applicator in her hand, the capsule inside it ruptures, possibly with a clap, and releases a liquid that after being collected by the drain passes through the perforated dissector to get evenly distributed in the absorber and then evenly applied on skin or other surfaces. Inert and impermeable capsules ensure stability of stored liquid formulations. Pressurized capsules are easily tactilely located and crashed. A capsule may be permanently or elastically fixed within the applicator. The applicator may include several capsules that may contain different liquids. A refillable applicator can be refilled with new capsules and used more than once. A transparent impermeable back side the applicator enhances hygiene and creates visibility of the capsule. An impervious glove-applicator for applying hazardous substances is disclosed.

Owner:TERESCHOUK MISHA

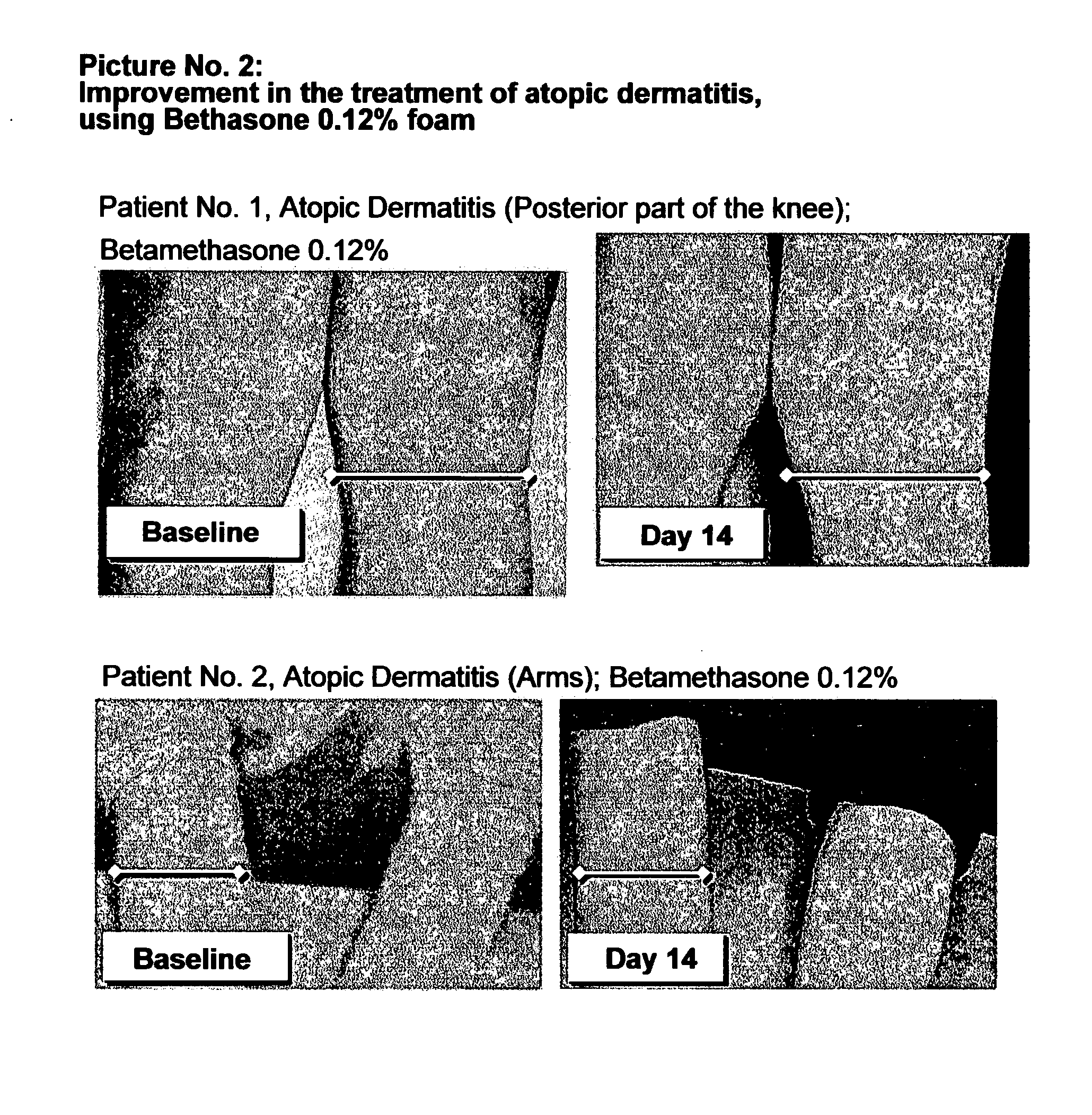

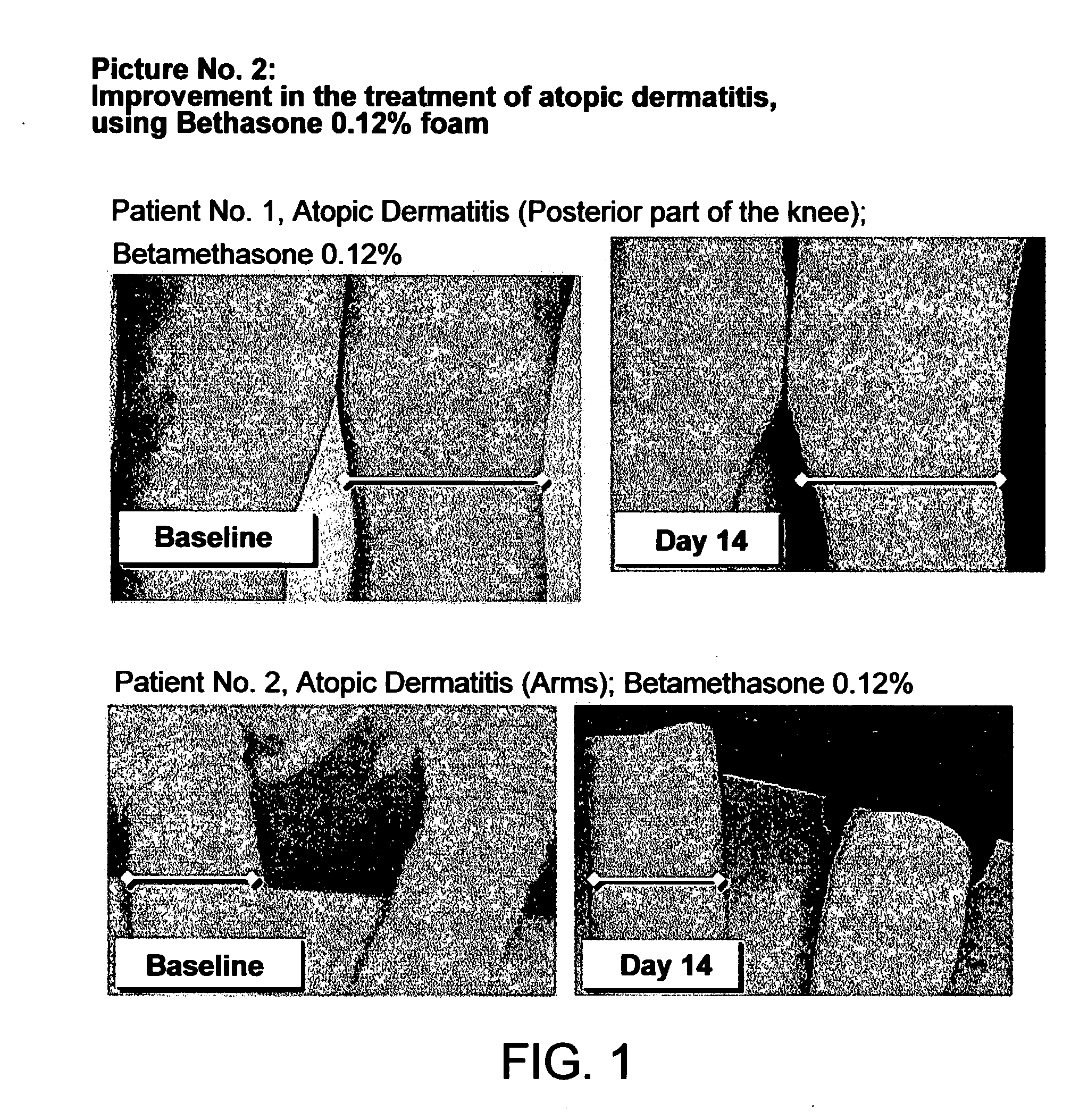

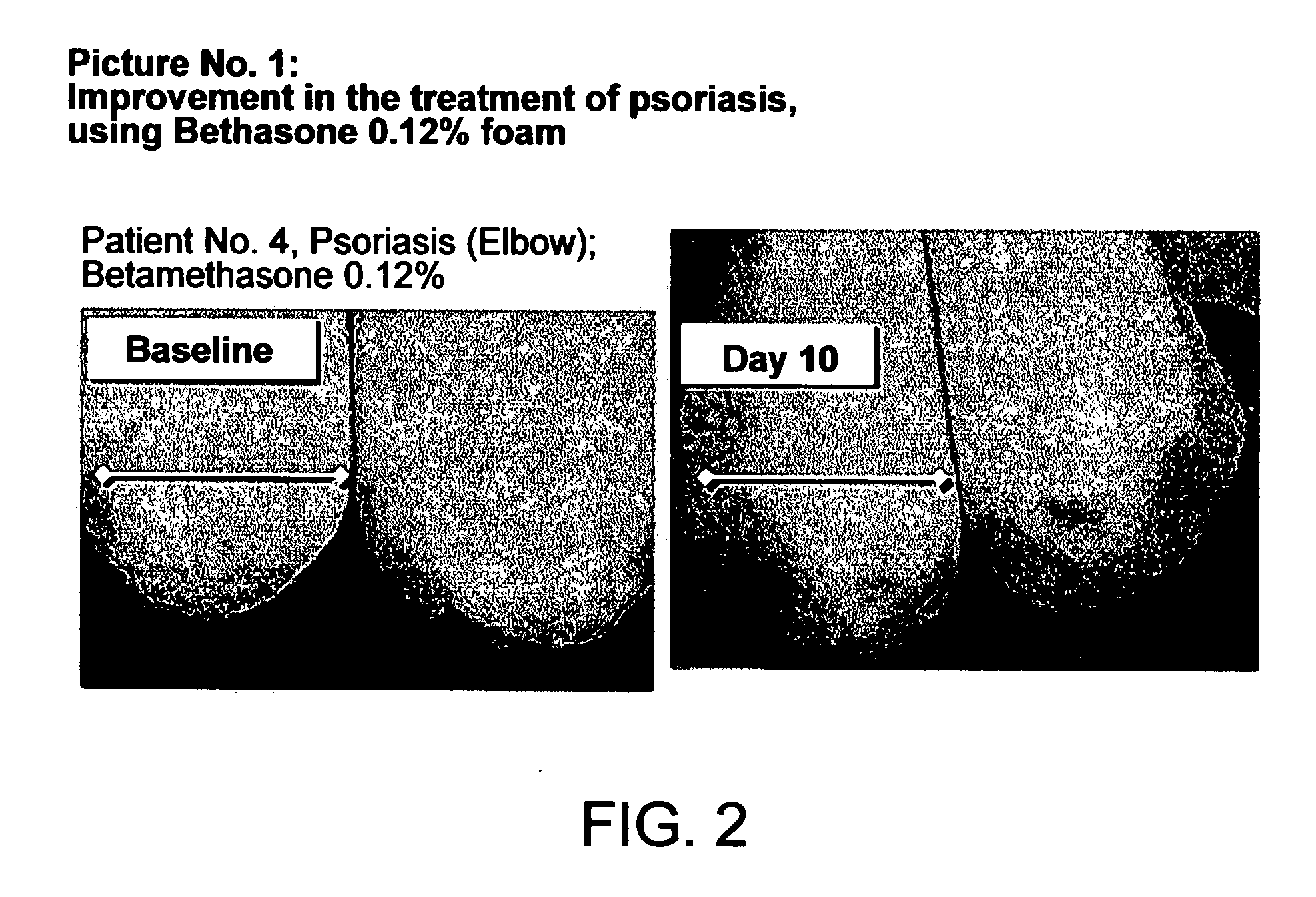

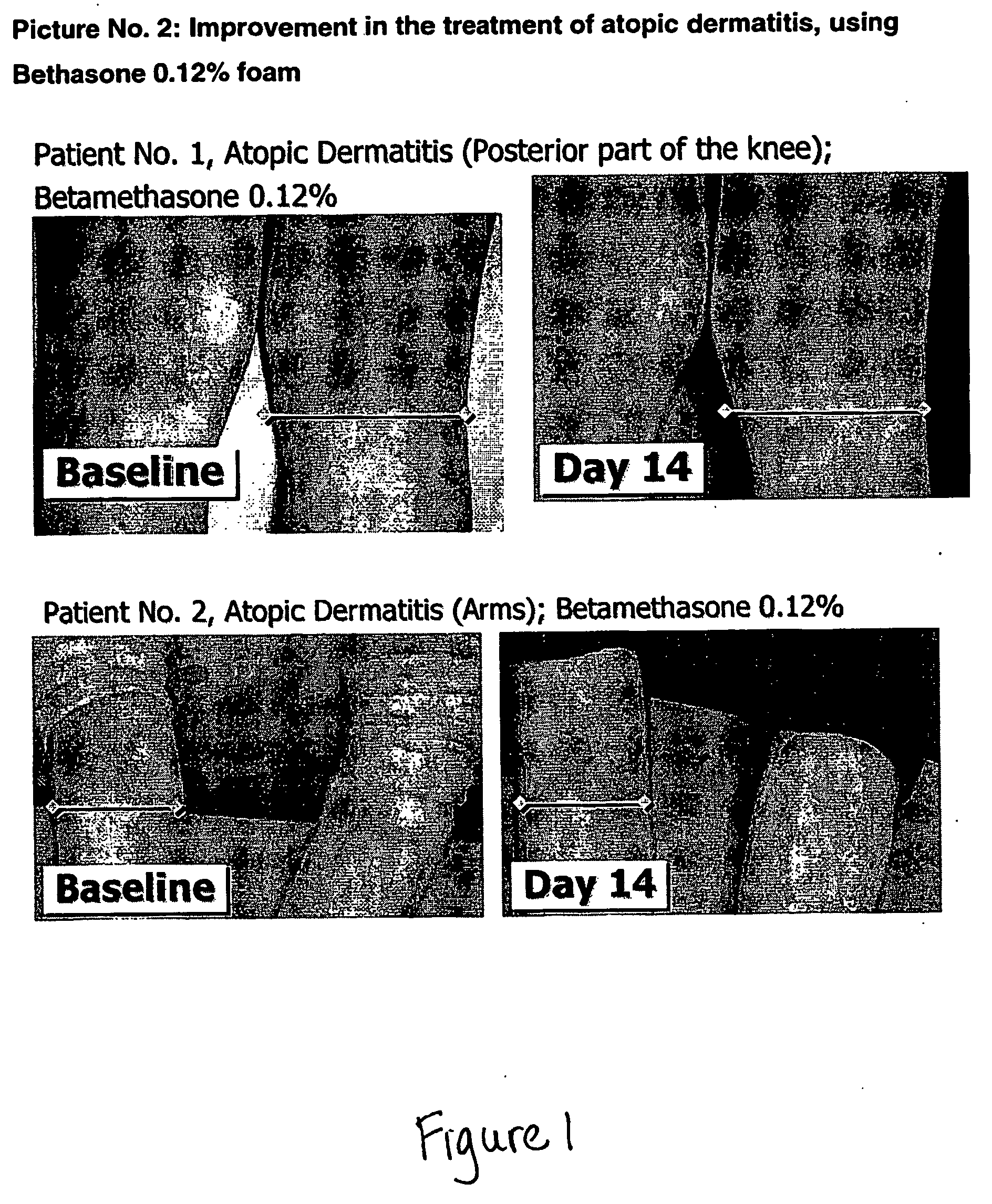

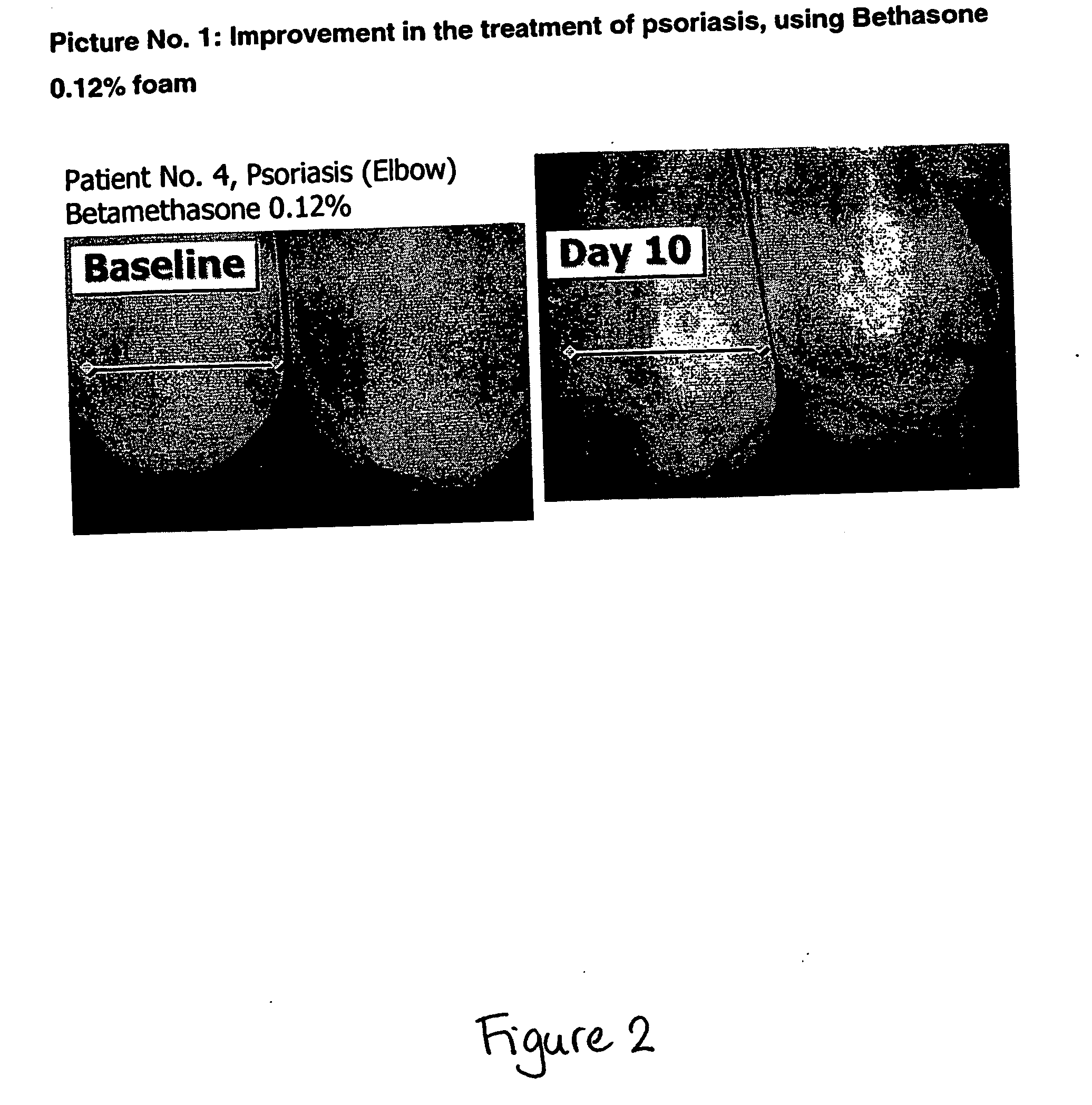

Cosmetic and pharmaceutical foam

InactiveUS20080031907A1Efficient ConcentrationReduce sensitivityAntibacterial agentsBiocideAlcohol freeVegetable oil

The invention relates to uses of an alcohol-free cosmetic or pharmaceutical foam carrier comprising water, a hydrophobic solvent, a foam adjuvant agent, a surface-active agent and a water gelling agent as a flame retardant or flame resistant foam. The hydrophobic solvent is preferably mineral oil; medium chain triglycerides; isopropyl myristearate or octyl dodecanol, silicone oil or vegetable oil or mixtures thereof. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, also making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil-soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Cosmetic and pharmaceutical foam

InactiveUS20060140984A1Lower yield strengthRubbing easy and efficientCosmetic preparationsBiocideAlcohol freeAdjuvant

The invention relates to an alcohol-free cosmetic or pharmaceutical foam carrier comprising water, a hydrophobic solvent, a foam adjuvant agent, a surface-active agent and a water gelling agent. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

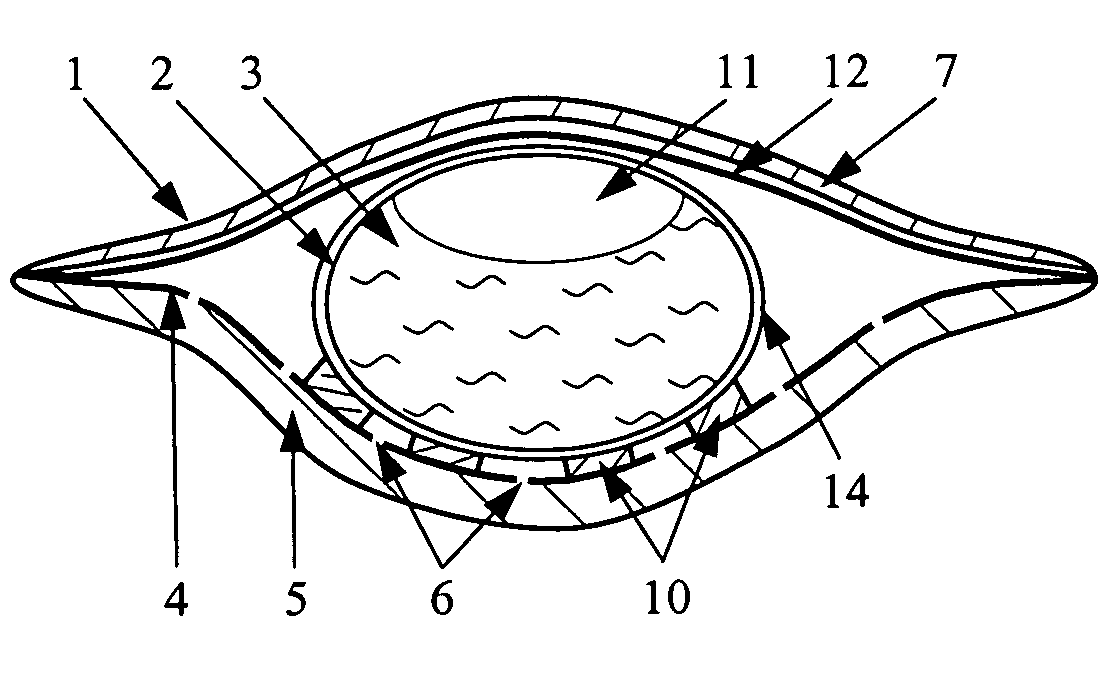

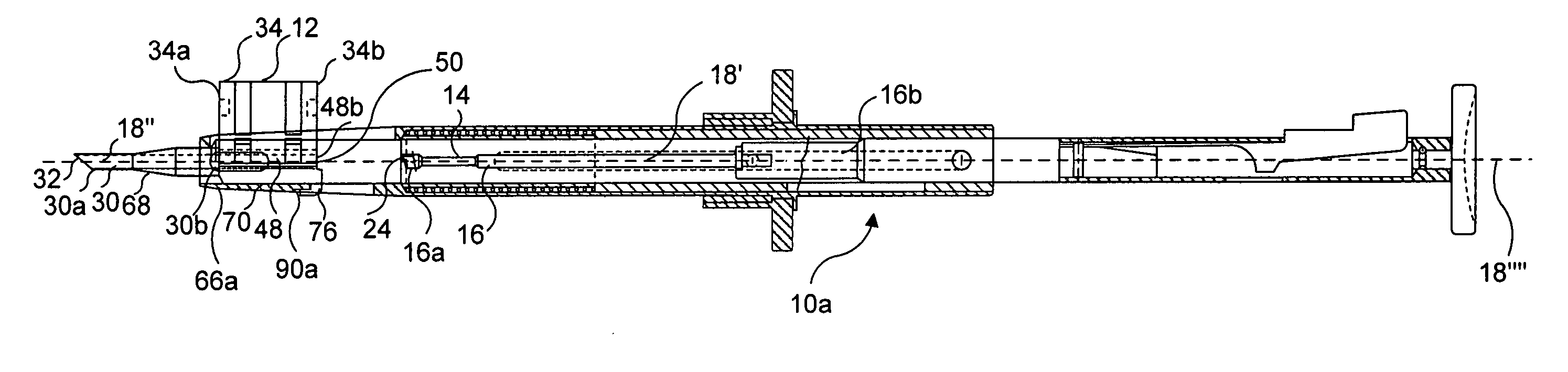

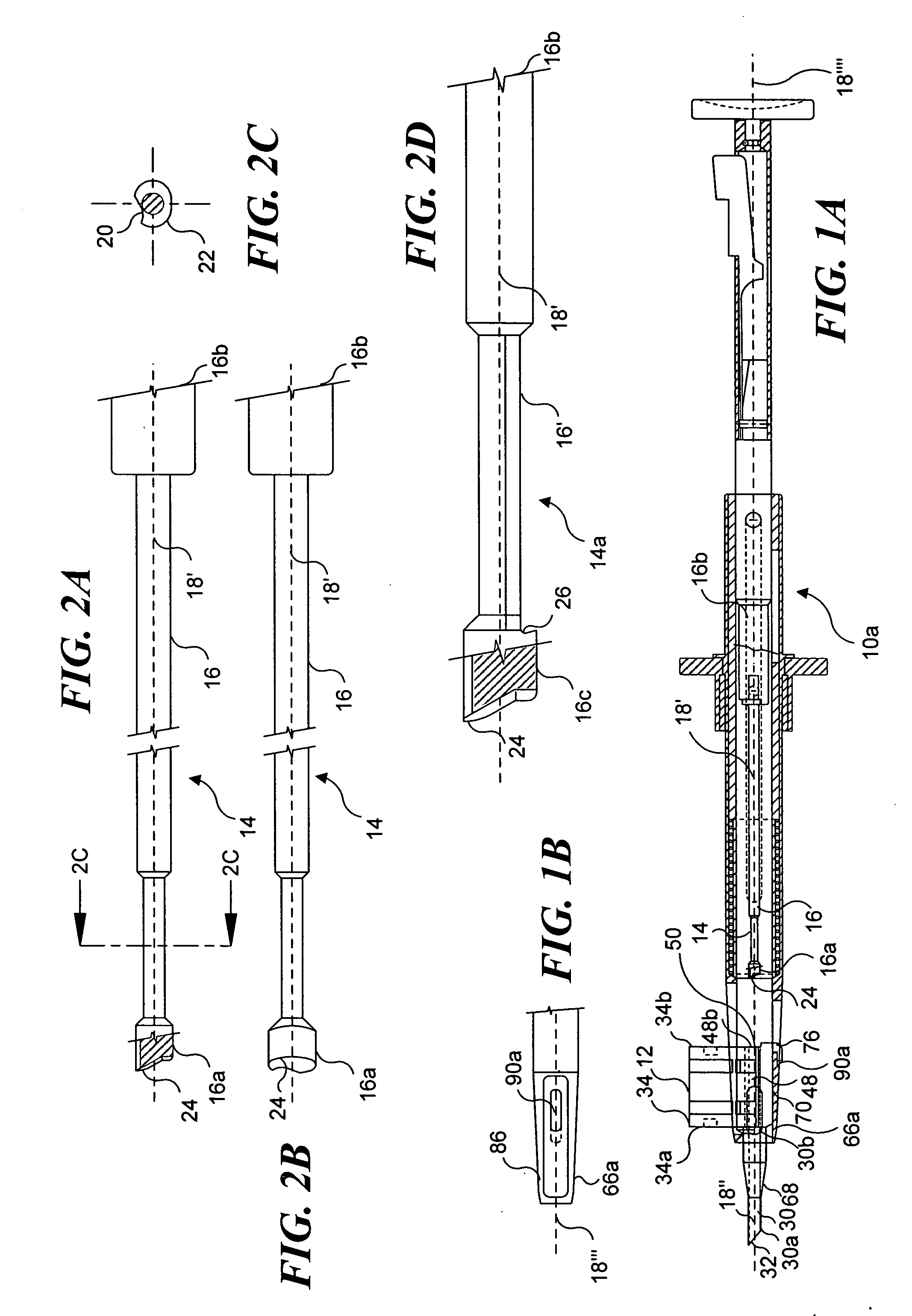

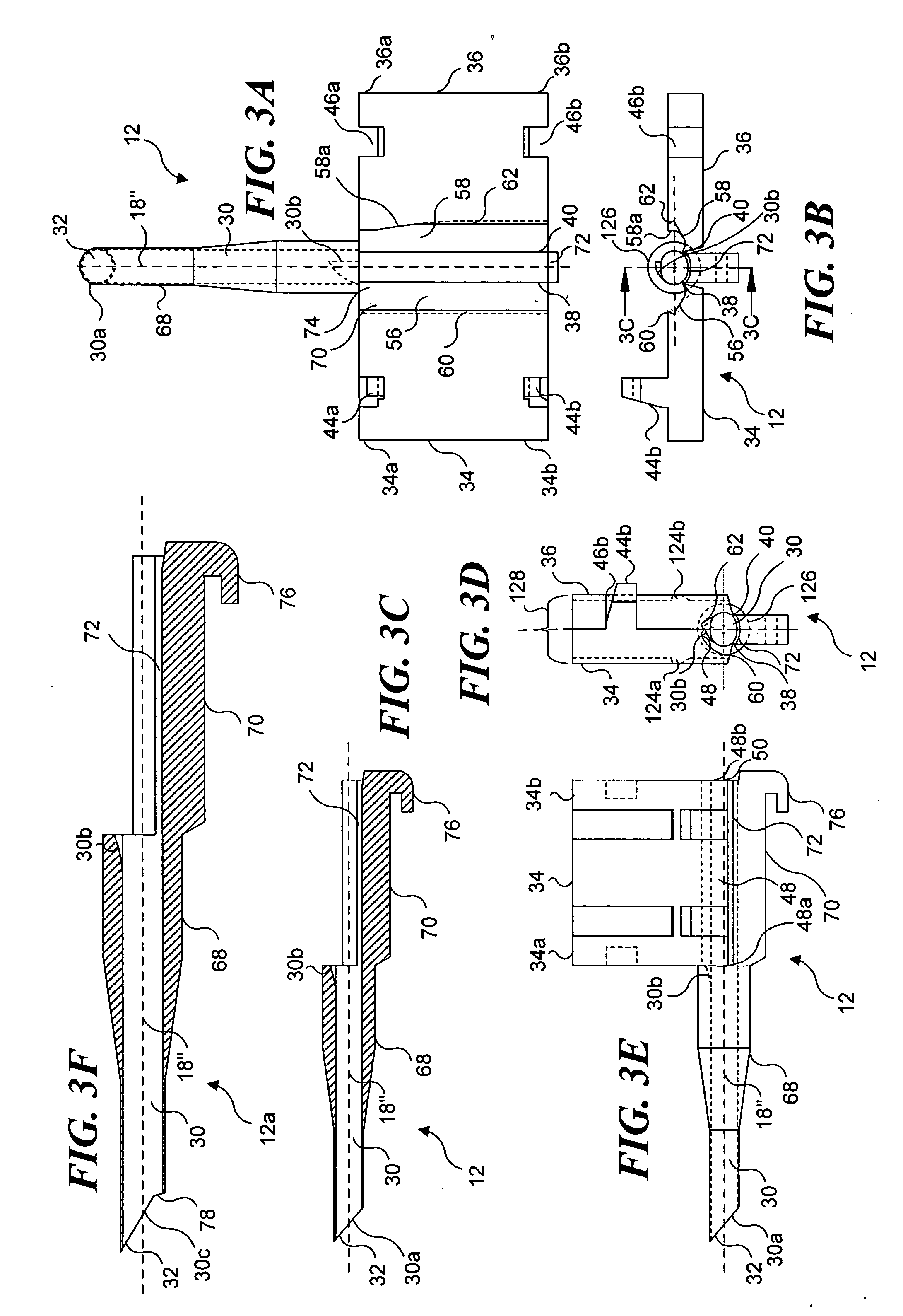

Intraocular lens inserter system components

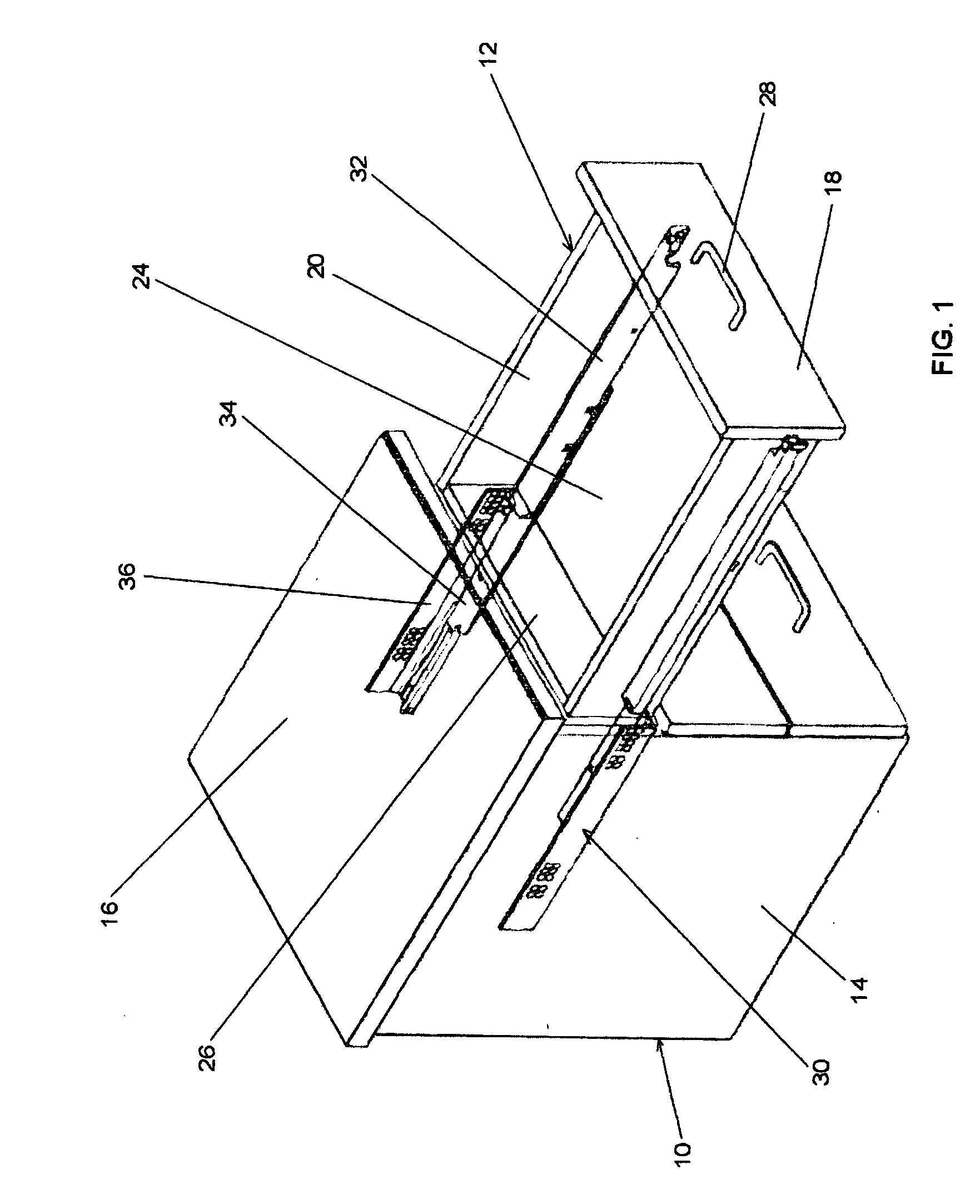

InactiveUS20060167466A1Avoid damageApply evenlyEye surgeryIntraocular lensIntraocular lens insertionEngineering

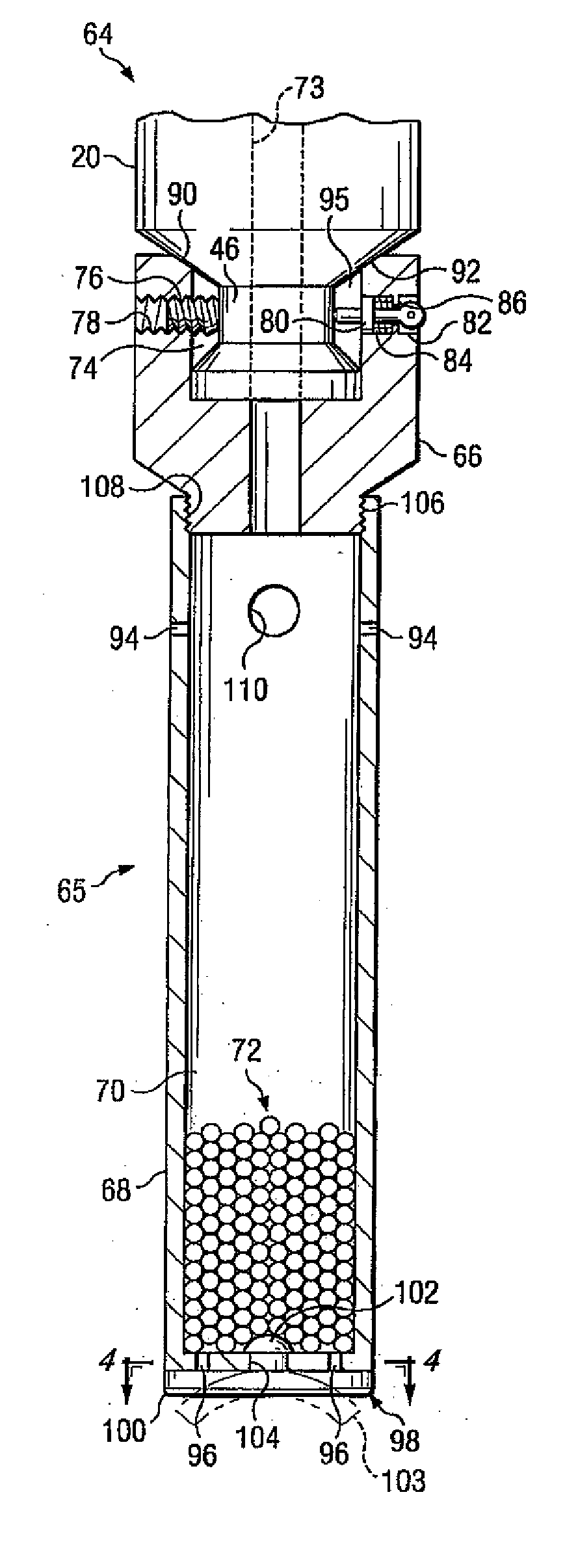

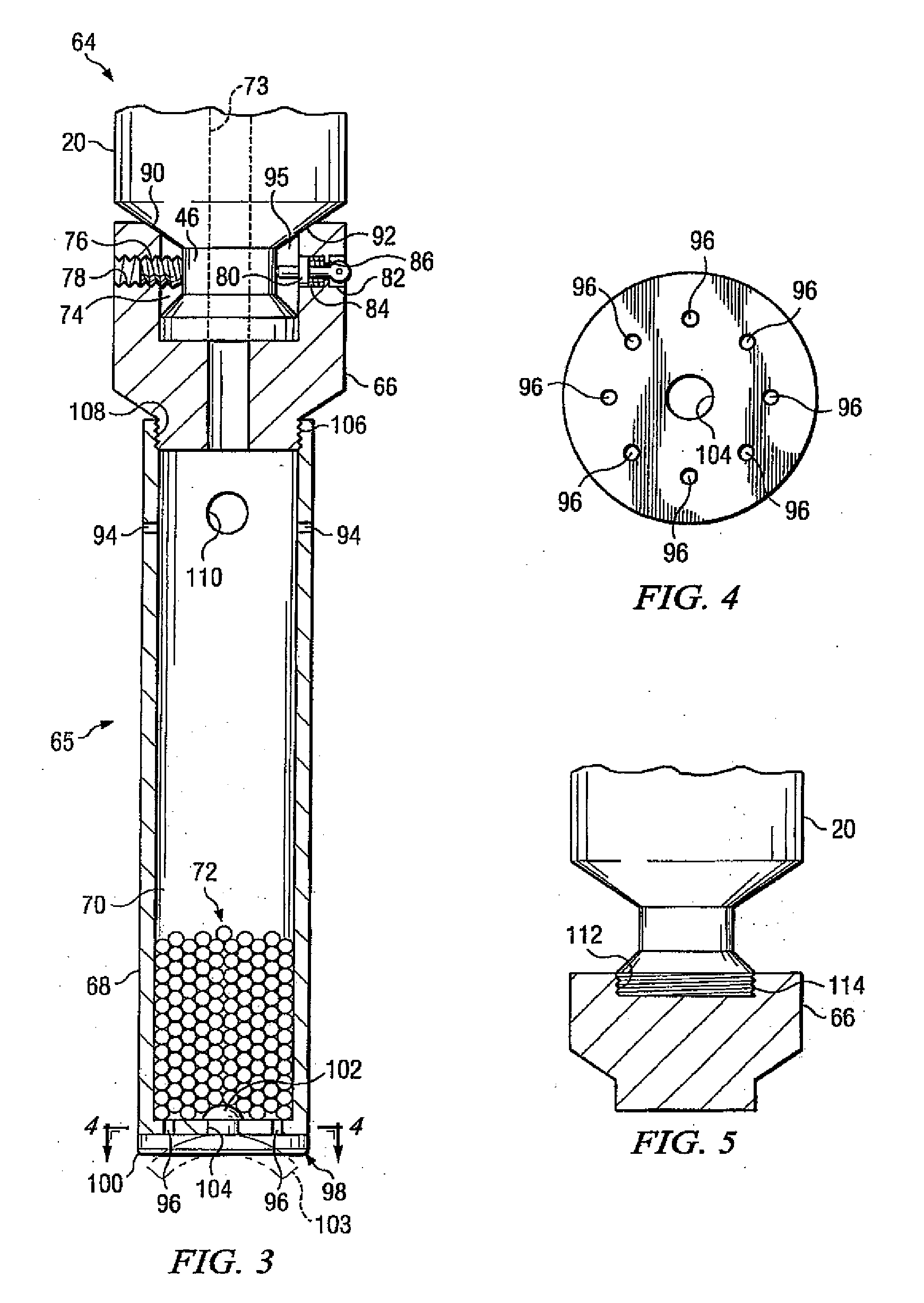

Disclosed are an intraocular lens (IOL) push rod, an IOL cartridge, multiple embodiments of an IOL cartridge housing, and a method for folding an IOL for insertion into an eye during ocular surgery. The distal end of the push rod is contoured to apply force to a substantial portion of the perimeter of an IOL to advance the IOL through a bore of the cartridge. Two hinges couple flanges on the IOL cartridge to a central portion that supports an IOL when protected by a cover for an extended storage time. The IOL cartridge has a locking element that engages a cartridge housing or IOL inserter. Each cartridge housing accepts the IOL cartridge with the IOL in an unfolded state. The cartridge bore is unobstructed and is tapered to fold one side of the IOL over the other as the IOL is advanced through the bore and into an eye.

Owner:DUSEK VACLAV

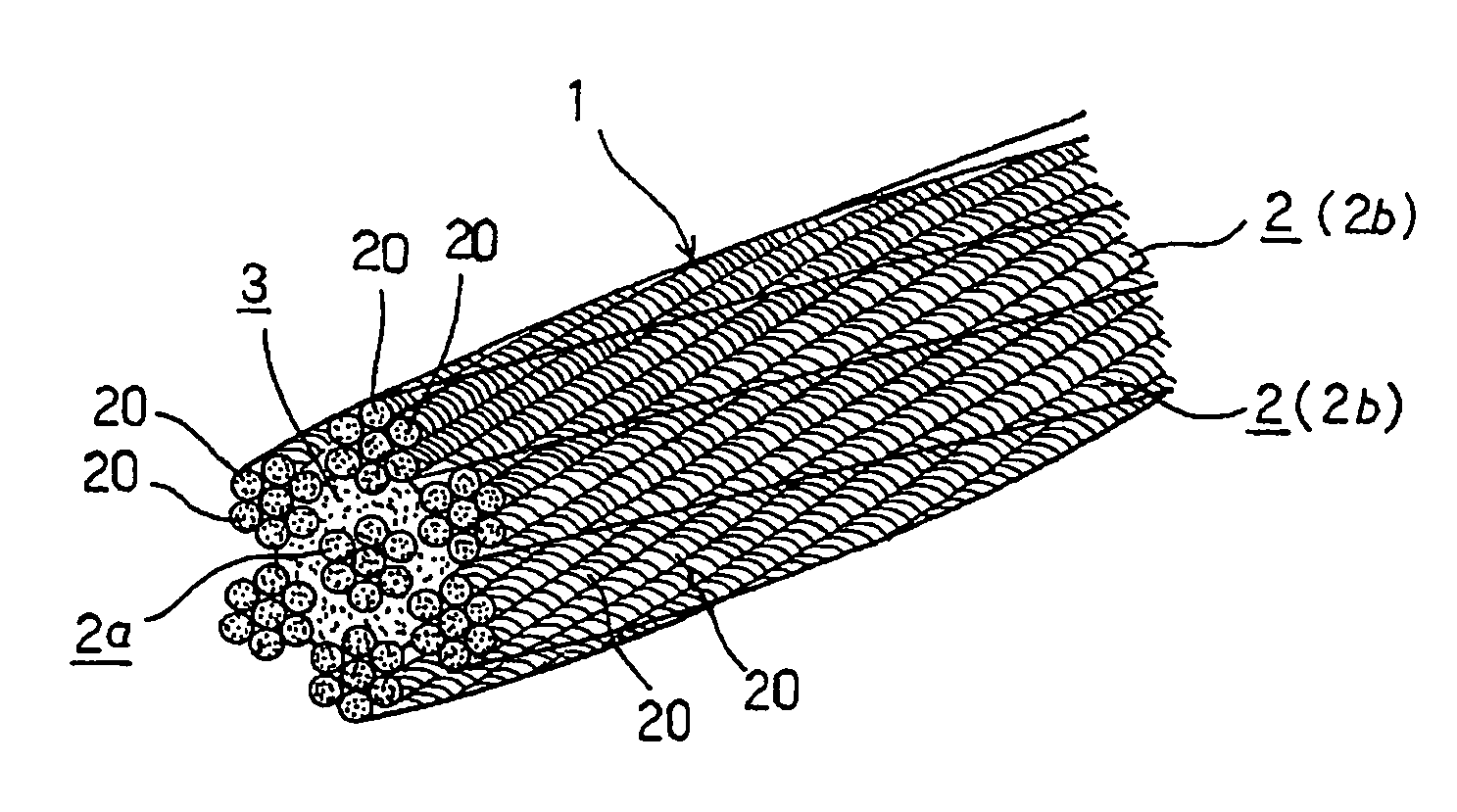

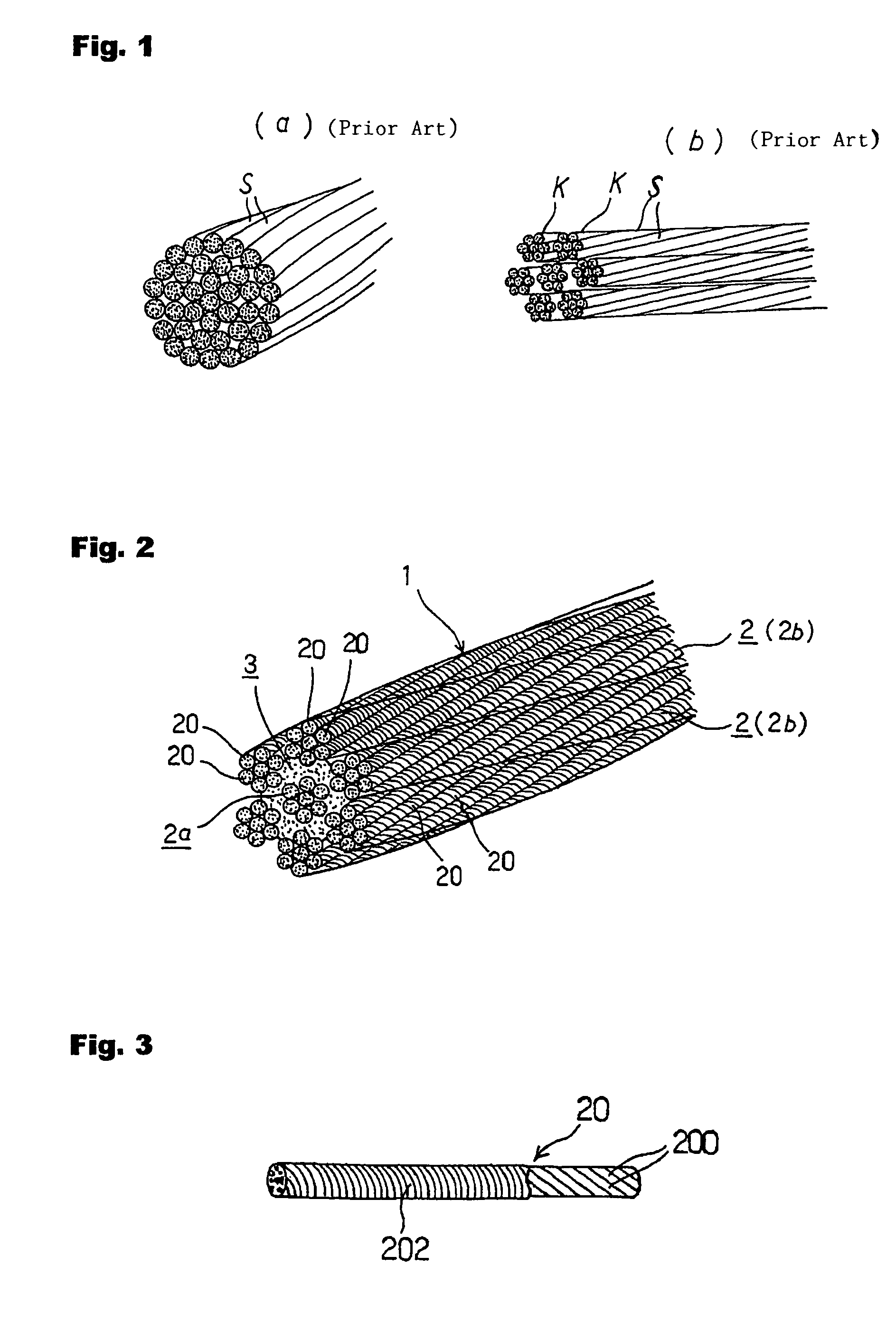

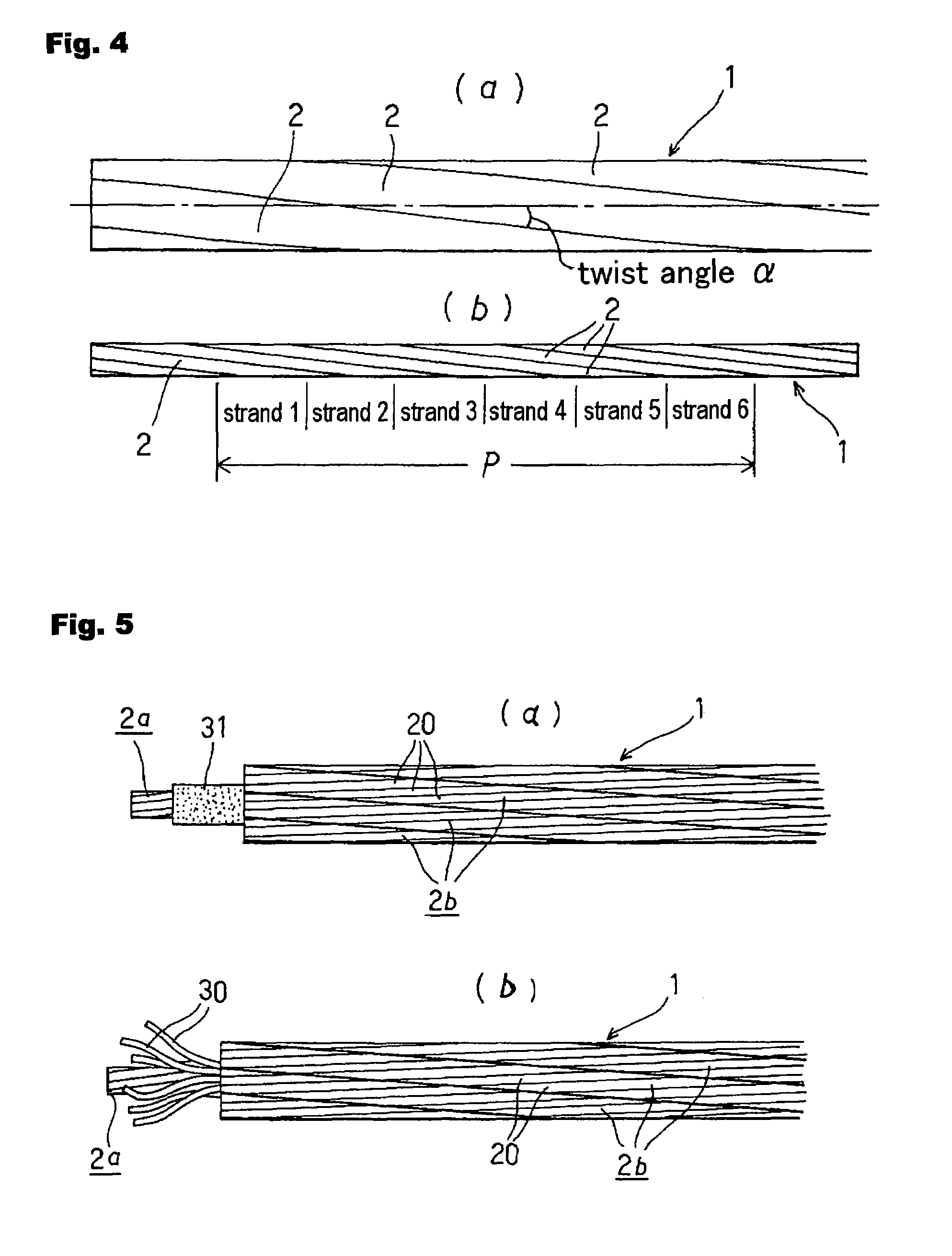

Cable made of high strength fiber composite material

A practical cable made of a high strength fiber composite material is provided, which has high and stable strength, in addition, has even axial tension against bending and thus has a stable shape, and can be wound on a reel without shape deformation, and is hardly buckled when it is inserted into a hole or cylinder. The cable is formed by singly twisting a plurality of high strength fiber composite materials is used as a strand, and a plurality of the strands are twisted together at a twist angle of 2 to 12 degrees in a direction opposite to a twist direction of the strands, so that a double twist structure is made.

Owner:TOKYO ROPE MFG

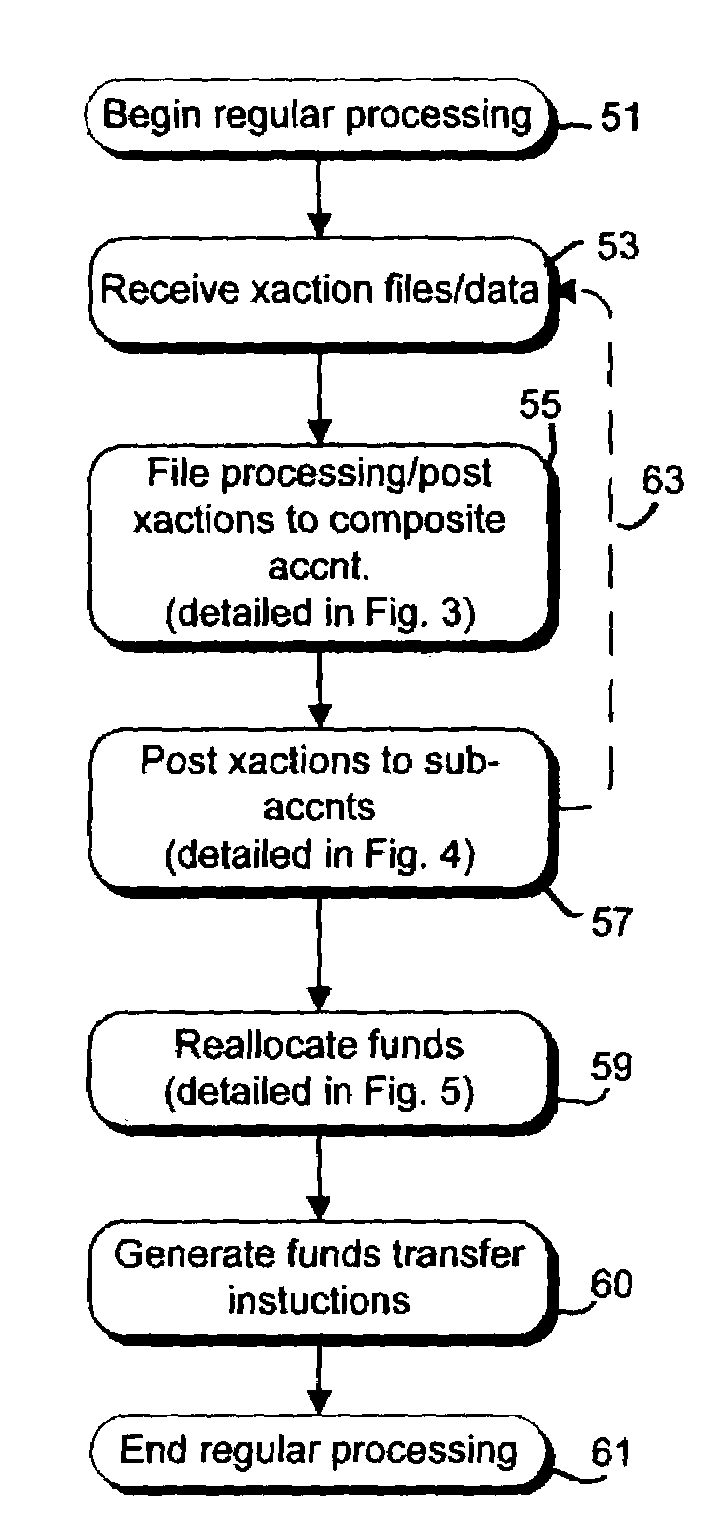

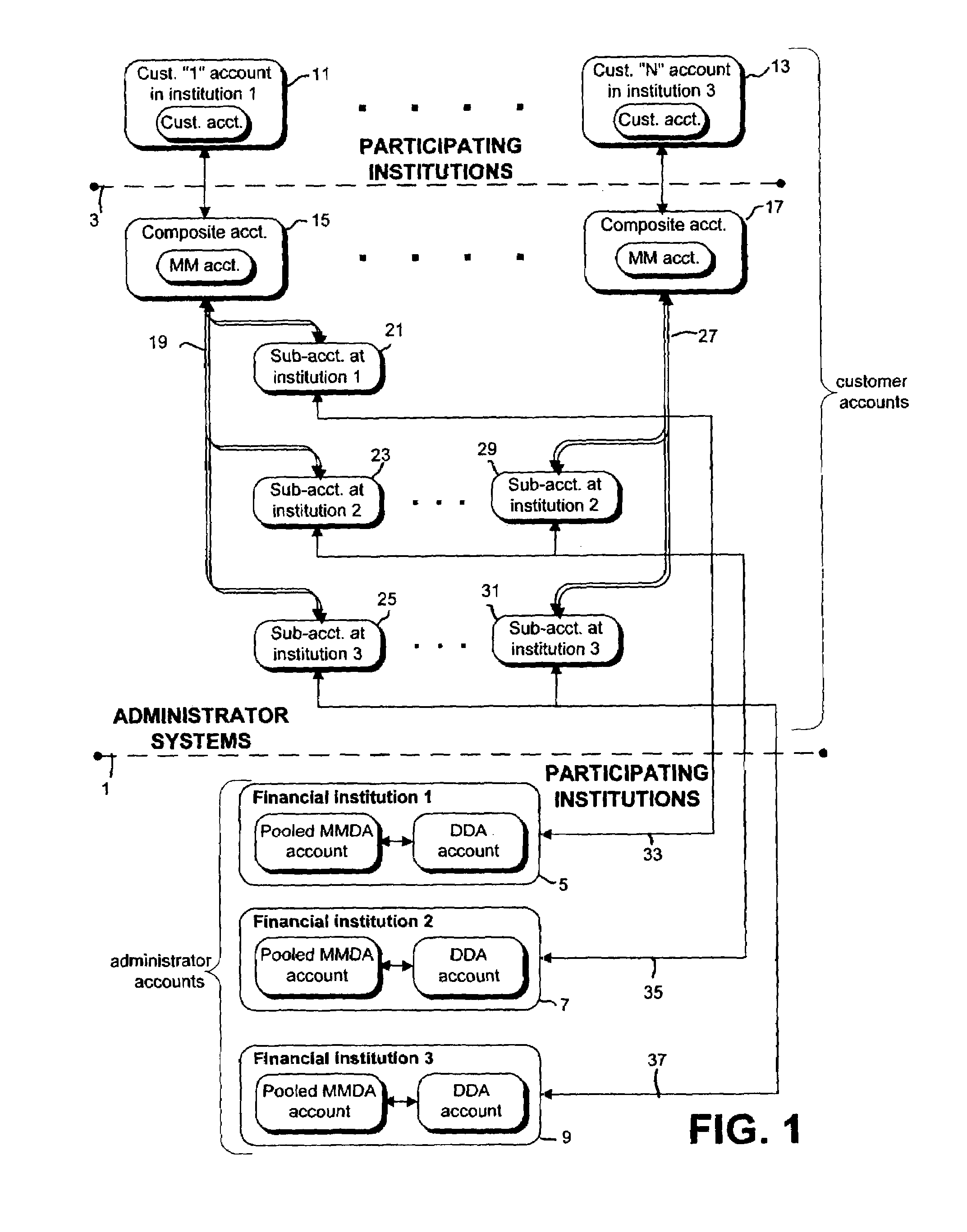

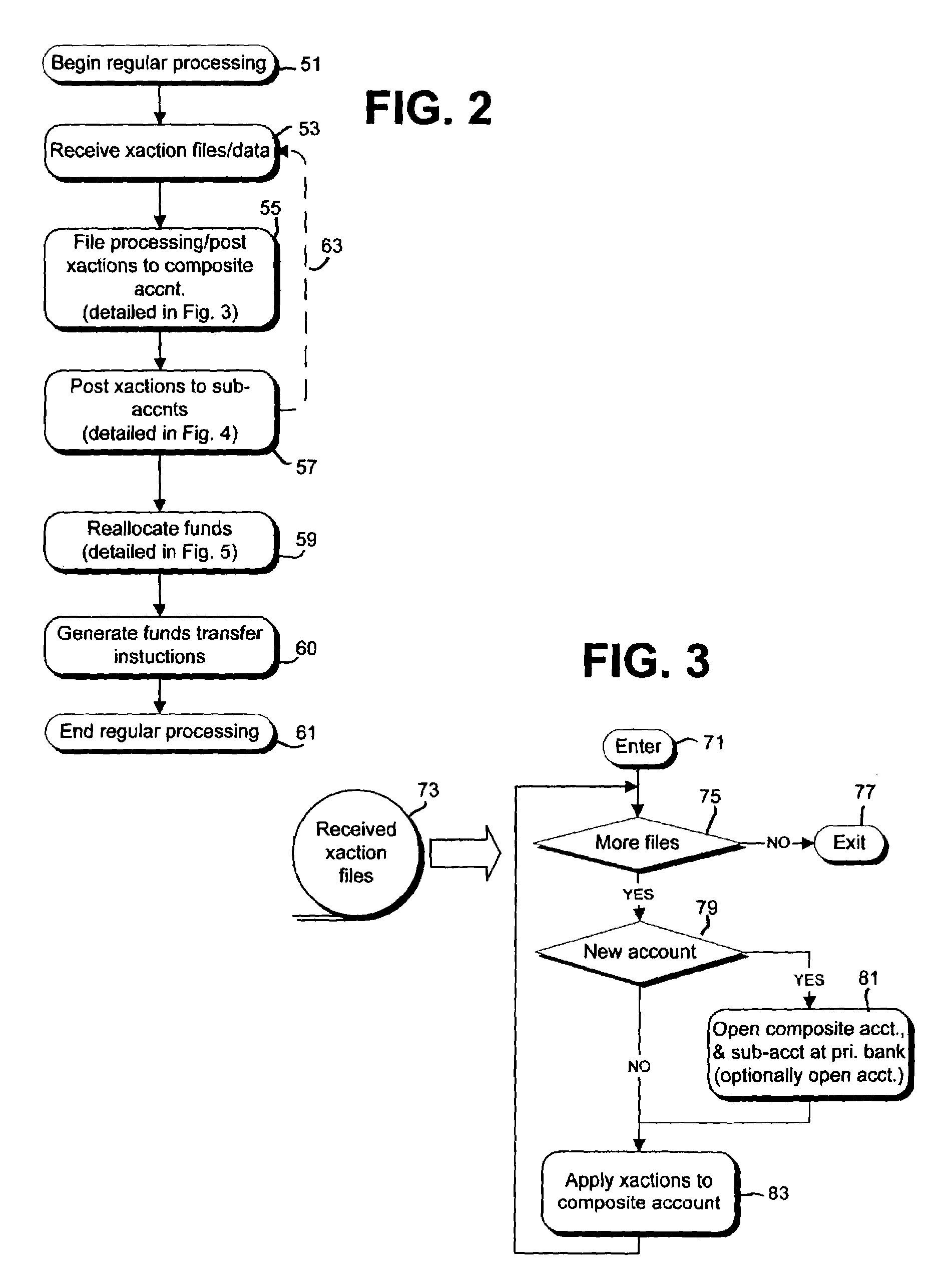

Systems and methods for providing enhanced account management services for multiple banks

This invention includes methods for delivering account management services to multiple financial institutions that provide for customer deposit accounts without transaction but than nevertheless offer interest and receive enhanced deposit insurance. The methods apply at least one customer transaction to that customer's deposit account, and then re-allocate customer-deposited funds among the plurality of financial institutions in order that, for each customer, the risk of loss is not substantially increased, and that, for each financial institution, the amount of customer-deposited funds is not substantially decreased. Preferably, risk of loss is reduced by increasing the fraction of each customer's deposited funds covered by FDIC deposit insurance, and interest and enhanced insurance are available by innovative management of customer transactions and accounts. This invention also includes computer systems for practicing the methods and program products for accordingly configuring such computer systems.

Owner:ISLAND INTPROP

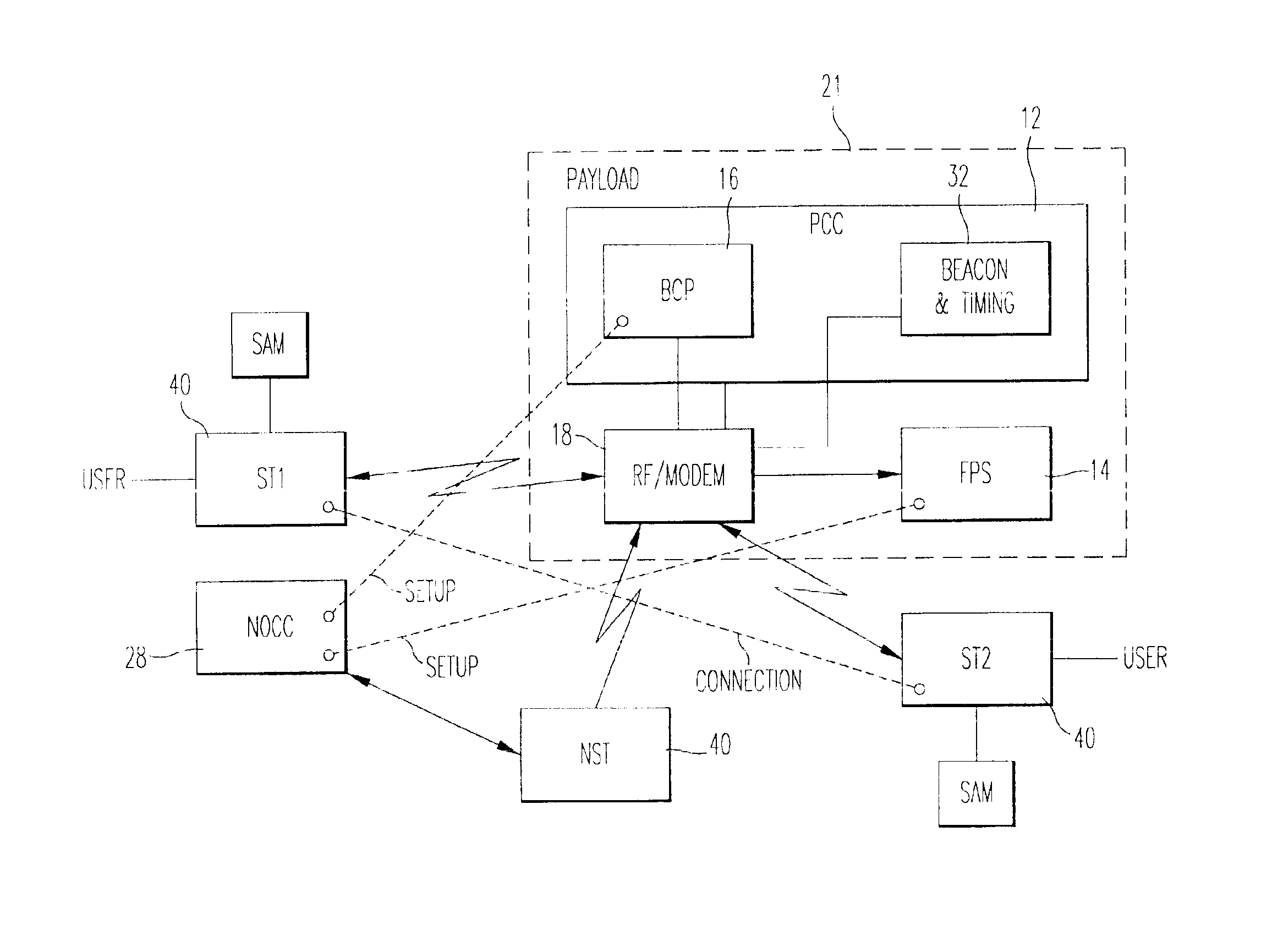

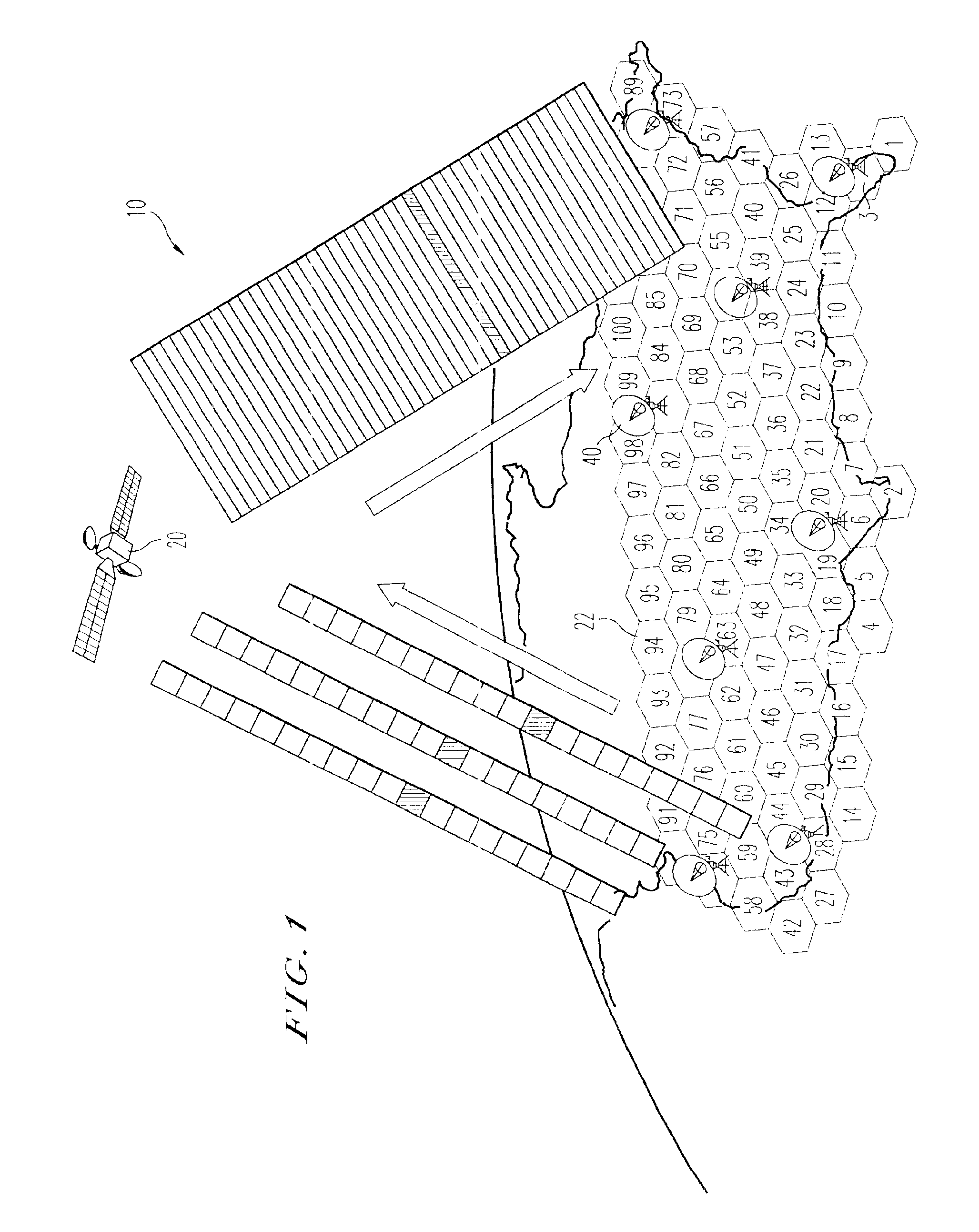

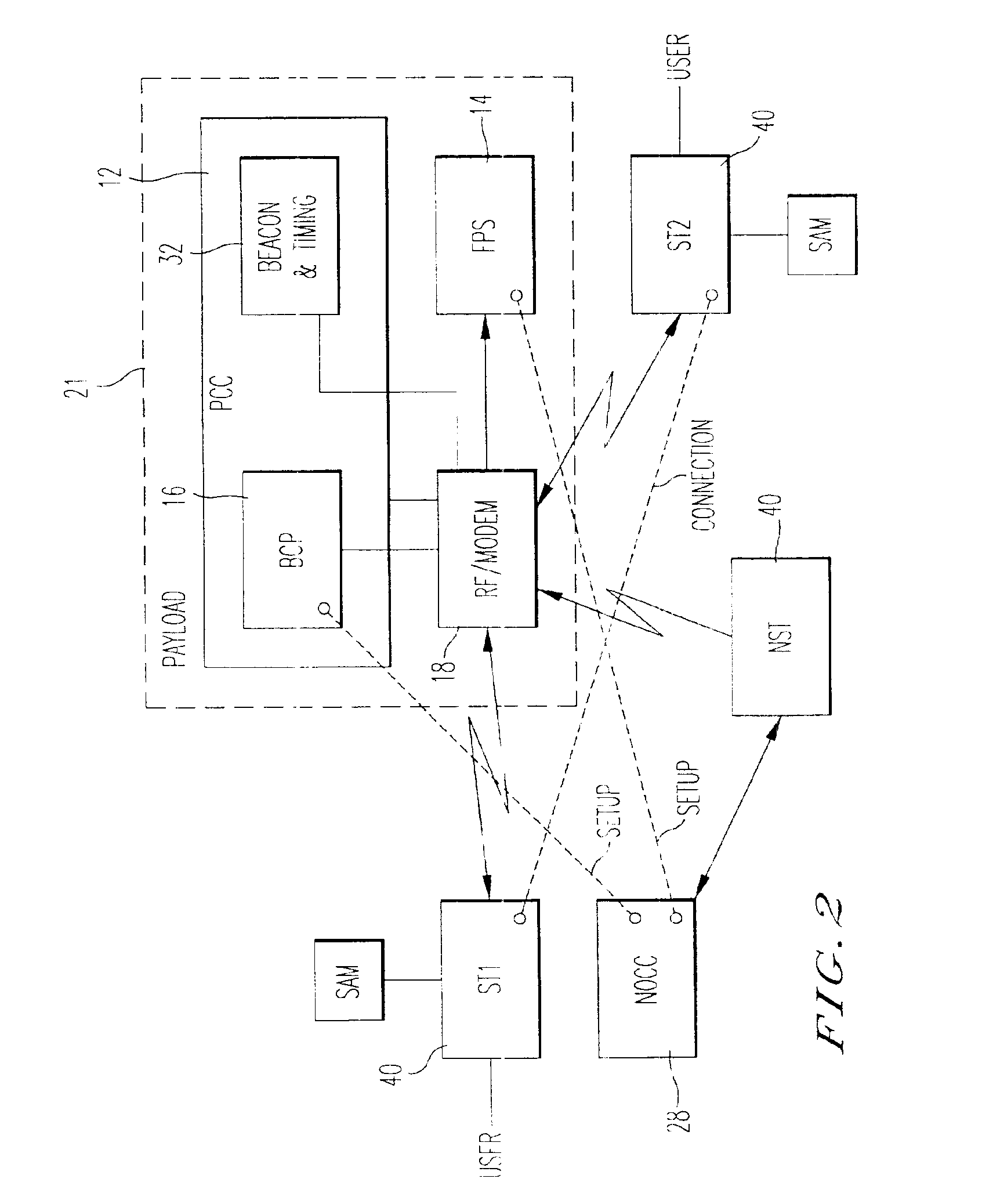

System for providing satellite bandwidth on demand employing uplink frame formatting for smoothing and mitigating jitter and dynamically changing numbers of contention and data channels

InactiveUS6842437B1Limit jitterReduce fragmentationTime-division multiplexRadio transmissionSatelliteOn demand

A method of transmitting time division multiplexed data from a satellite terminal to a satellite wherein the satellite terminal receives a command indicating to transmit data during a frame comprising a plurality of timeslots in accordance with a timeslot reordering scheme. The timeslot reordering scheme is selected to spread data from respective satellite terminals to different timeslots throughout the frames. A processor monitors the use of channels by the satellite terminals, stores bandwidth requests using queues, allocates channels in accordance with bandwidth requests and a bandwidth allocation algorithm, and transmits the channel allocations in a frame. Timeslots not allocated to any of the satellite terminals are contention channels. The number of contention channels changes dynamically, depending on demand for the plurality of channels by the satellite terminals. Queues are provided for each channel for storing high and low priority rate requests and high and low priority volume requests. The bandwidth allocation algorithm determines the preemption of the queues, and allocation priorities.

Owner:HUGHES NETWORK SYST

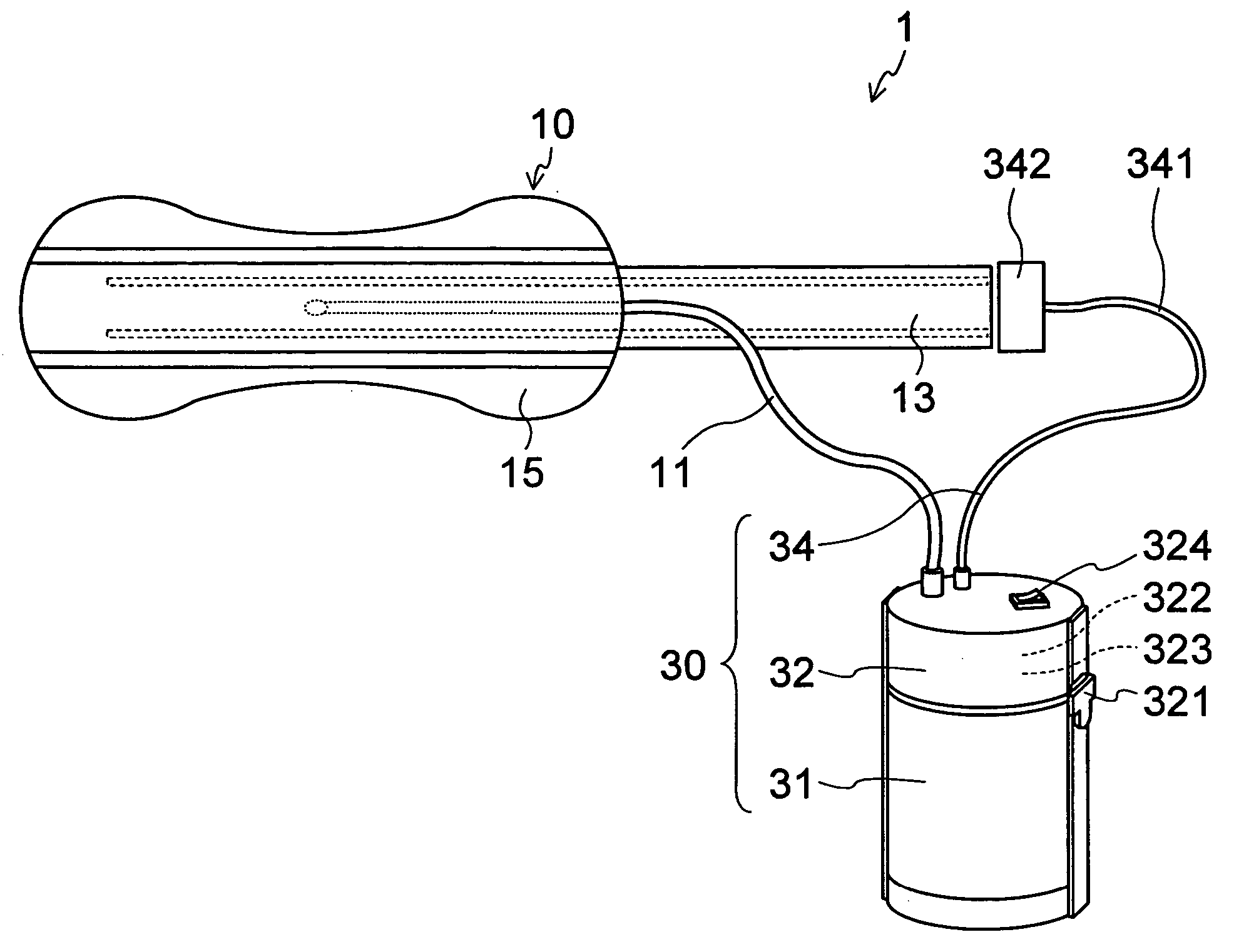

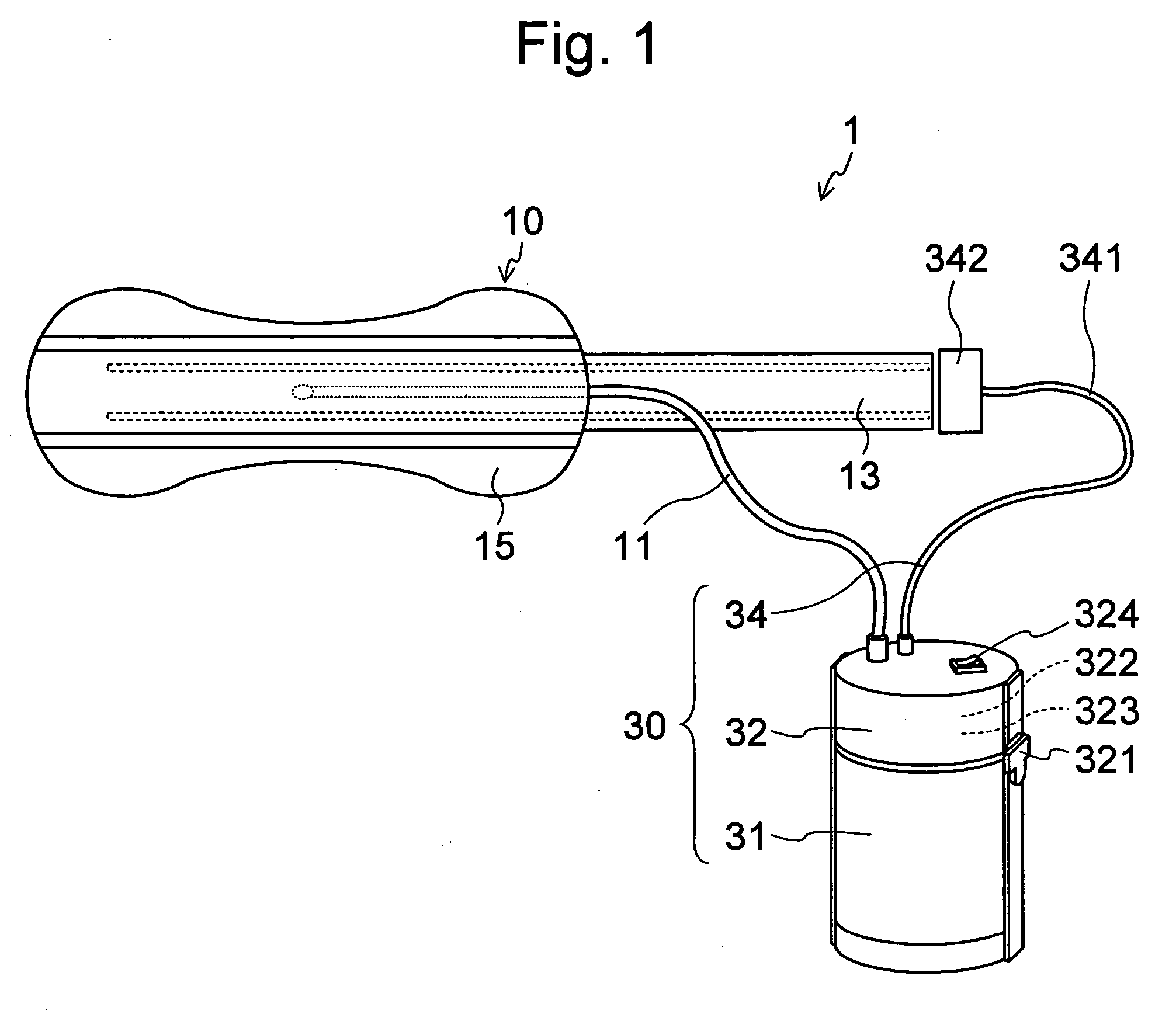

Wound treatment device employing negative pressure

Owner:APPLIED TISSUE TECH

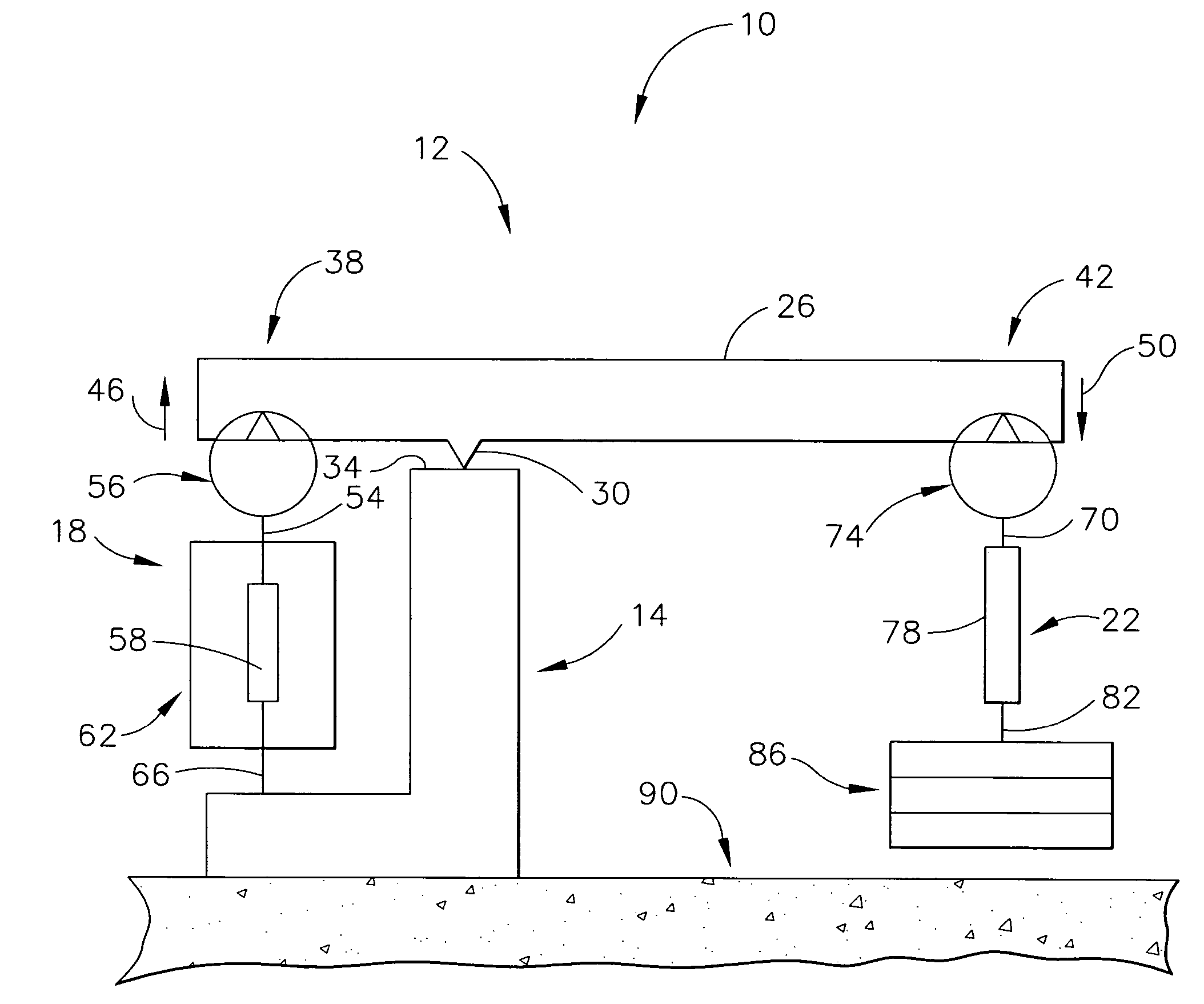

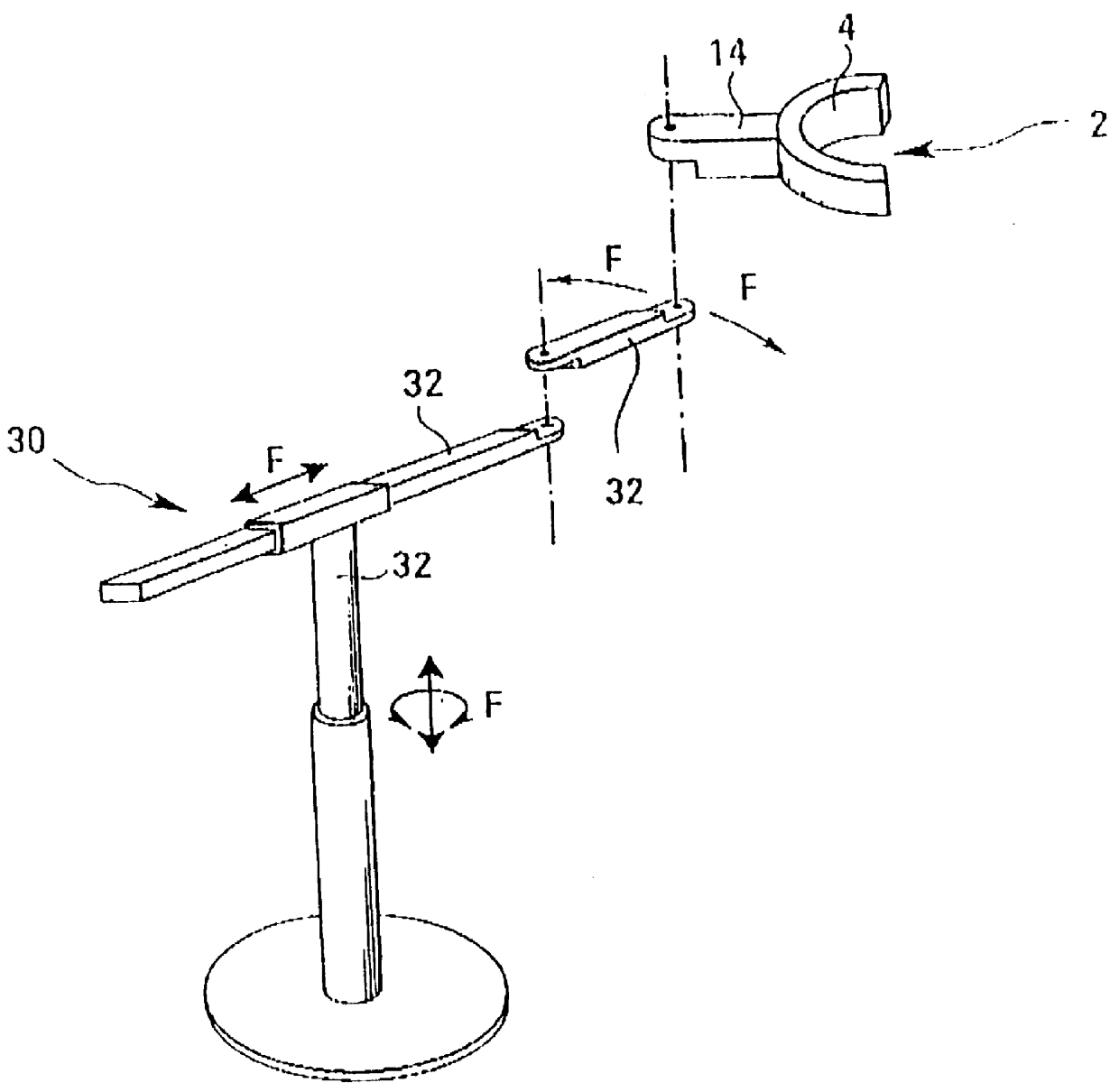

System, apparatus and method for testing under applied and reduced loads

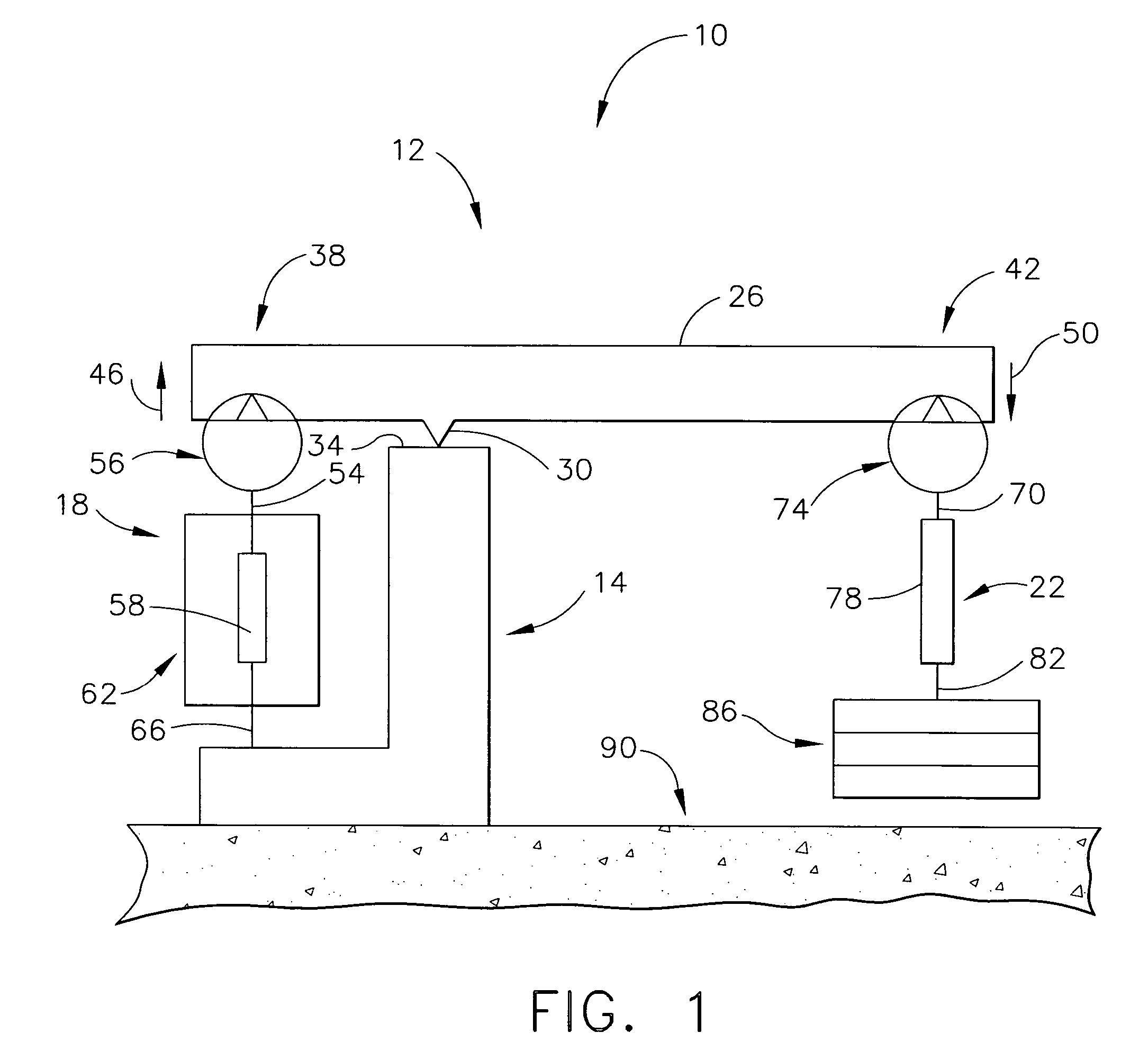

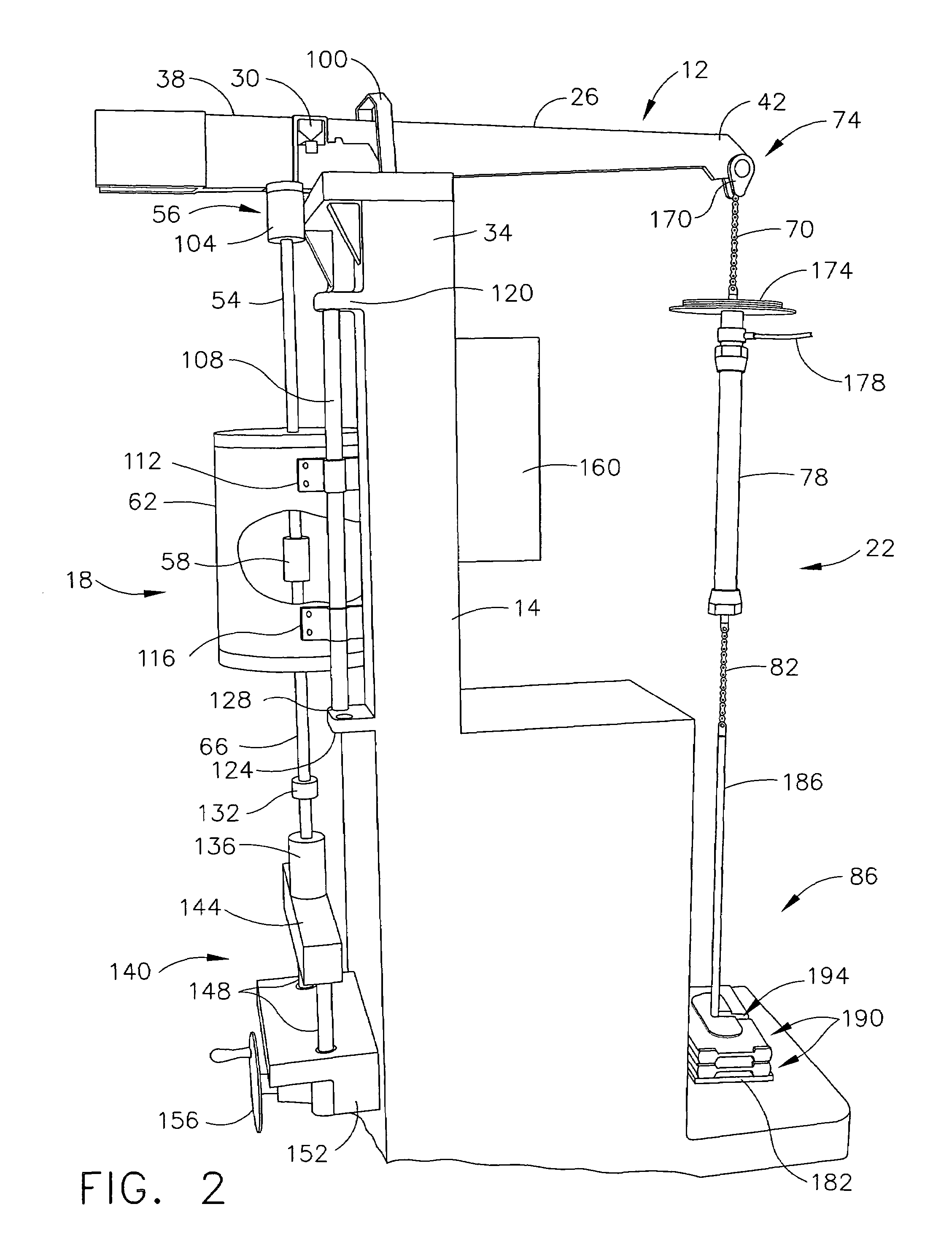

InactiveUS7353715B2Easy maintenanceApply evenlyMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringLoad regulation

A system which cyclically applies and reduces a load on a test specimen and which can use an apparatus comprising: (a) a frame; (b) a load adjusting section having a fluidic mechanical muscle that contracts and extends in length to cyclically apply and reduce a load; (c) a load train section frame for subjecting a test specimen to the load; and (d) a lever arm configured to apply and reduce the load from the loading adjusting section to the load train section. The system and apparatus can be used in a method for cyclically applying and reducing a load on a test specimen to thereby subject the test specimen to tensile testing and can also comprise a mechanism for decoupling at least a portion of the load from the test specimen when the load is reduced.

Owner:GENERAL ELECTRIC CO

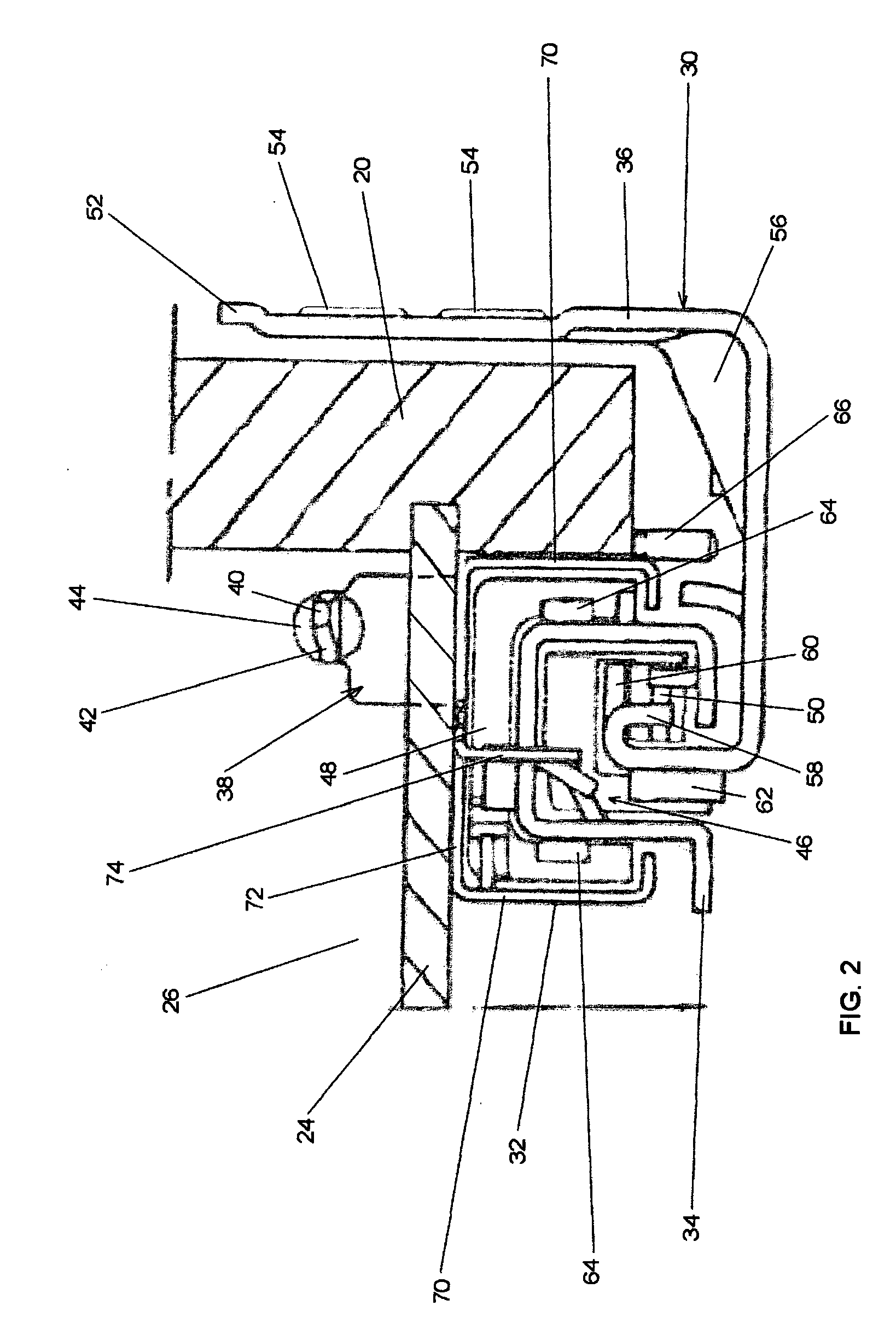

Undermount drawer slide

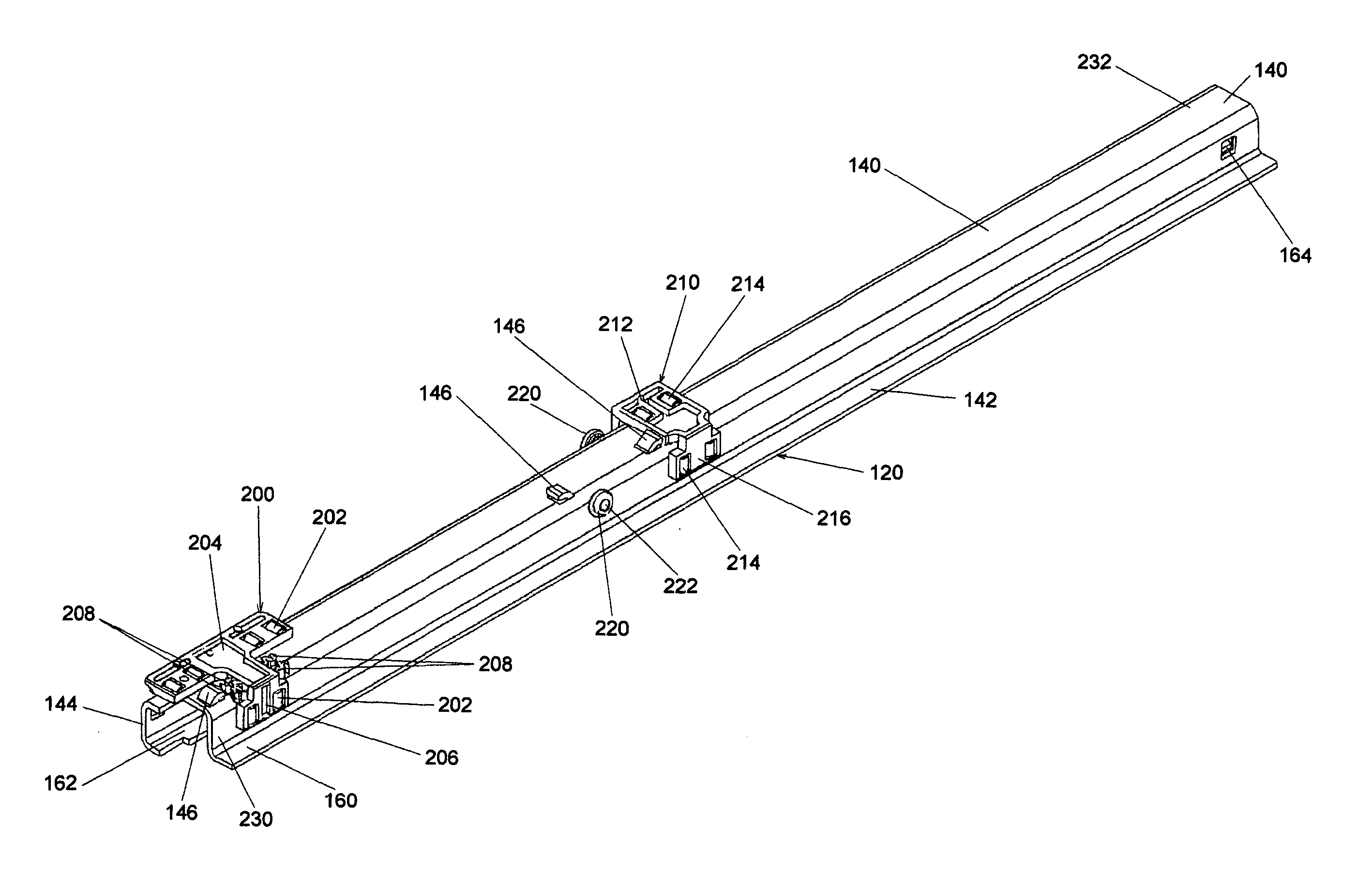

InactiveUS20050231083A1Easy to manufactureReduce forceDrawersFittingEngineeringMechanical engineering

An undermount drawer slide with a carriage for retaining rollers and for placement in between members of said drawer slide, wherein the carriage has shock absorbing stops. Also an undermount drawer slide with a one-piece self closer that is capable of being self-contained when fully assembled and which biasedly urges the undermount drawer slide assembly into a closed position when the drawer or drawer member engages the self closer. Lastly, an undermount drawer slide that has a quick connect device attached to a drawer for reversibly mounting the drawer onto an undermount drawer slide assembly, where the quick connect device includes a vertical adjustment mechanism that relies upon a toggle that is infinitely and affirmatively positionable by a threaded screw adjuster.

Owner:GARCIE KENT CLIFTON JR

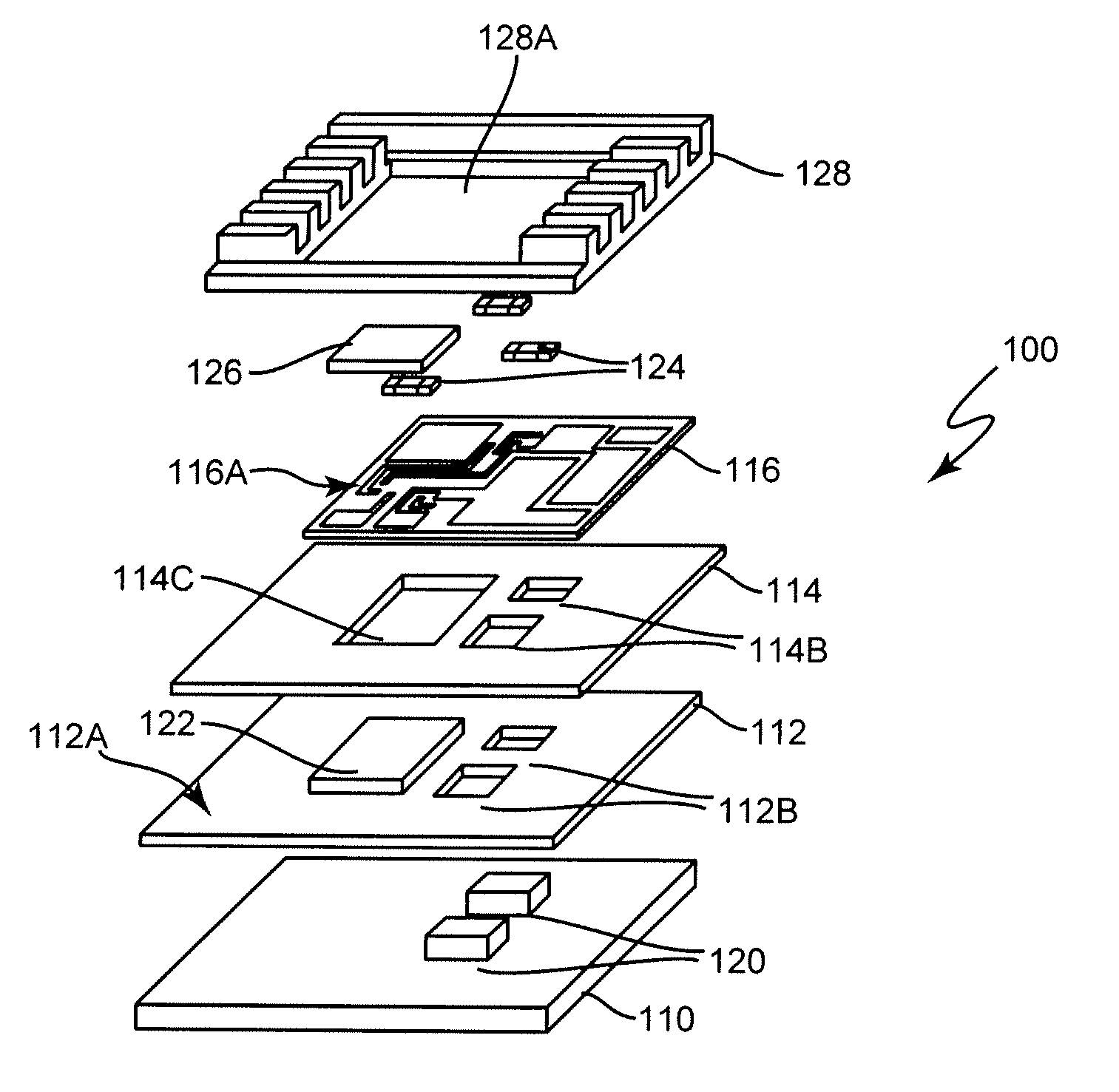

Method and Apparatus for Three-Dimensional Integration of Embedded Power Module

InactiveUS20070230221A1Reduces packaging overheadPackaging overhead is reducedTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCo-fired ceramicInductor

A modified planar Low Temperature Co-Fired Ceramic (LTCC) high conductance inductor, embedding a large cross section conductor, supports a stacked arrangement of heat spreader, inductor and active device layers. Interlayer electrical connections connect the layers. Optionally, a DC-DC converter includes the modified planar LTCC high conductance inductor, embedding a large cross section conductor, supporting a stacked arrangement of heat spreader, capacitor and active device layers, the active devices layer including the switching transistors. The active devices layer may include semiconductor dies embedded in a substrate.

Owner:VIRGINIA TECH INTPROP INC

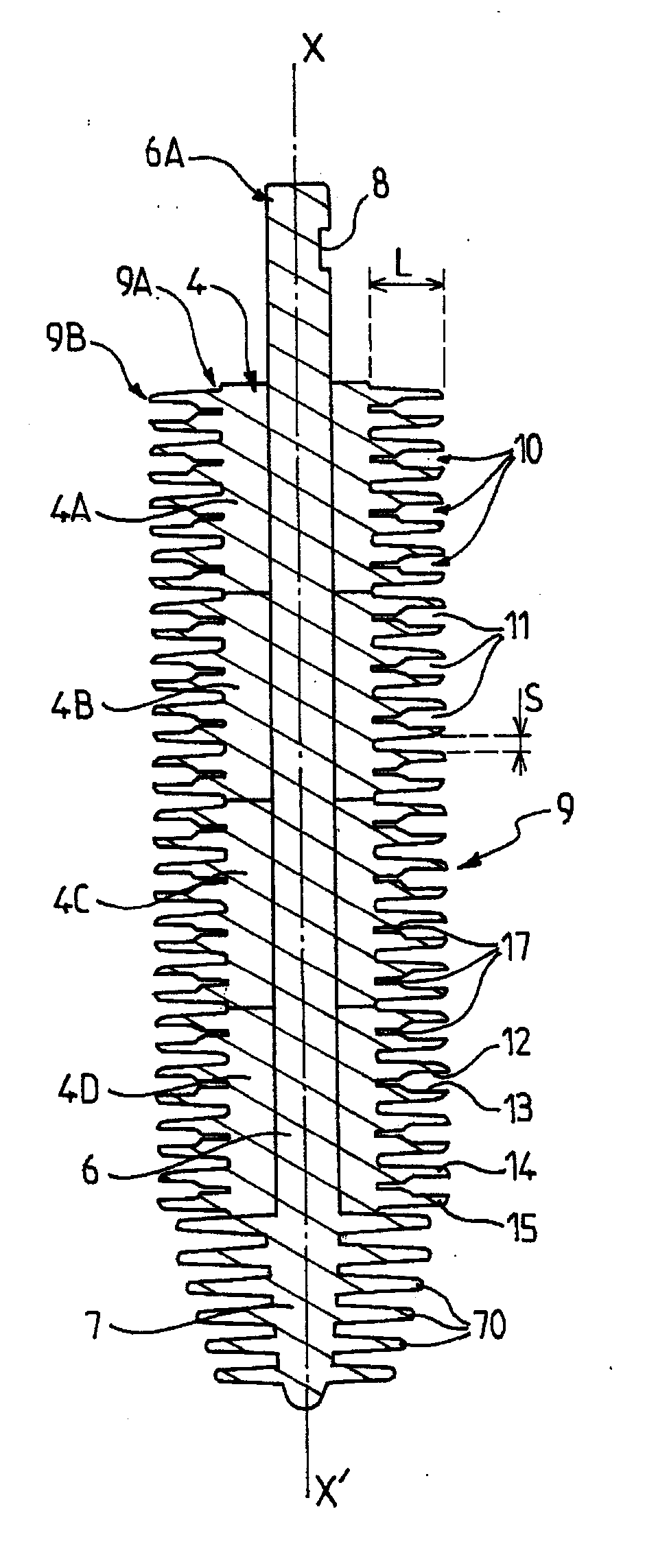

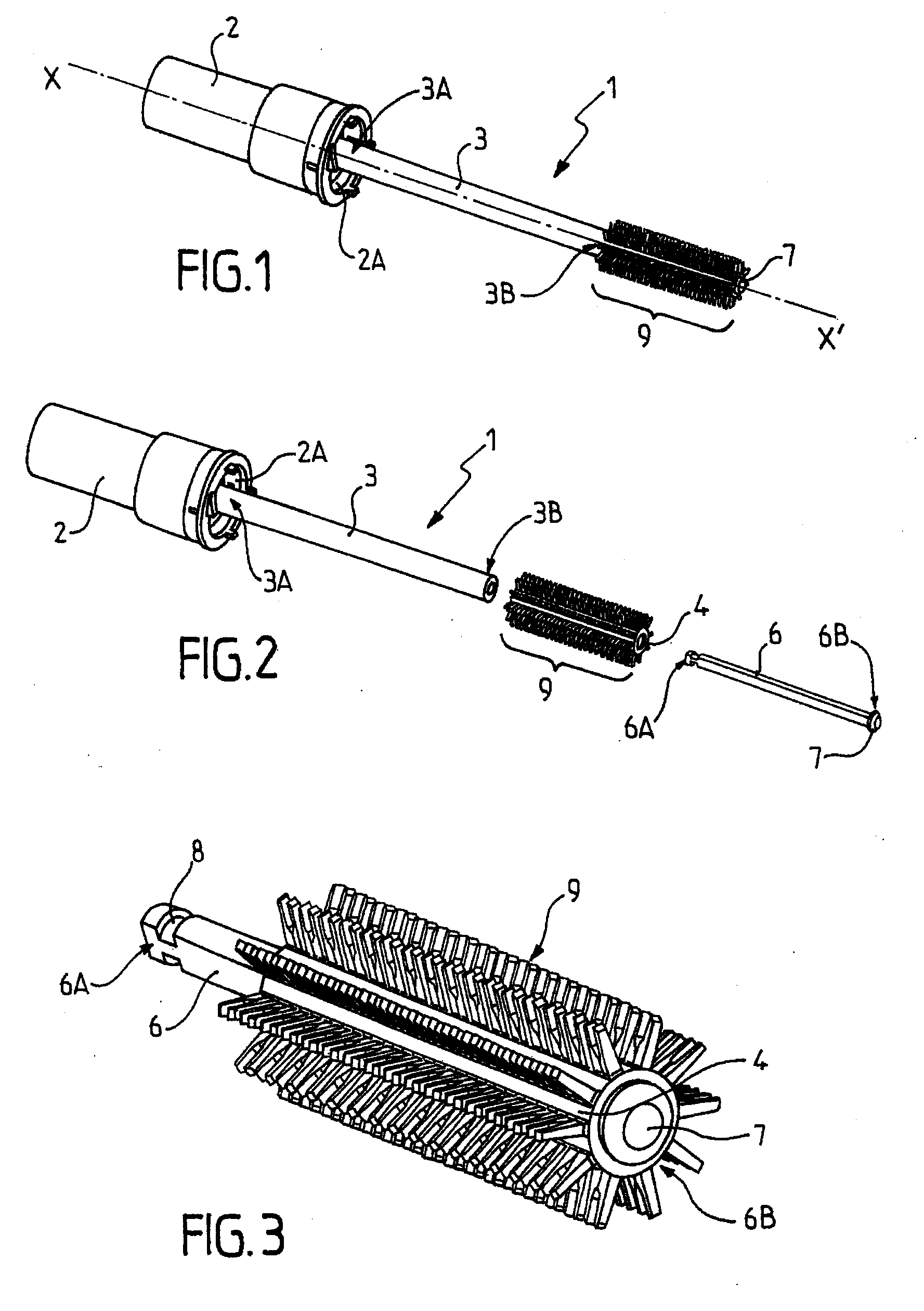

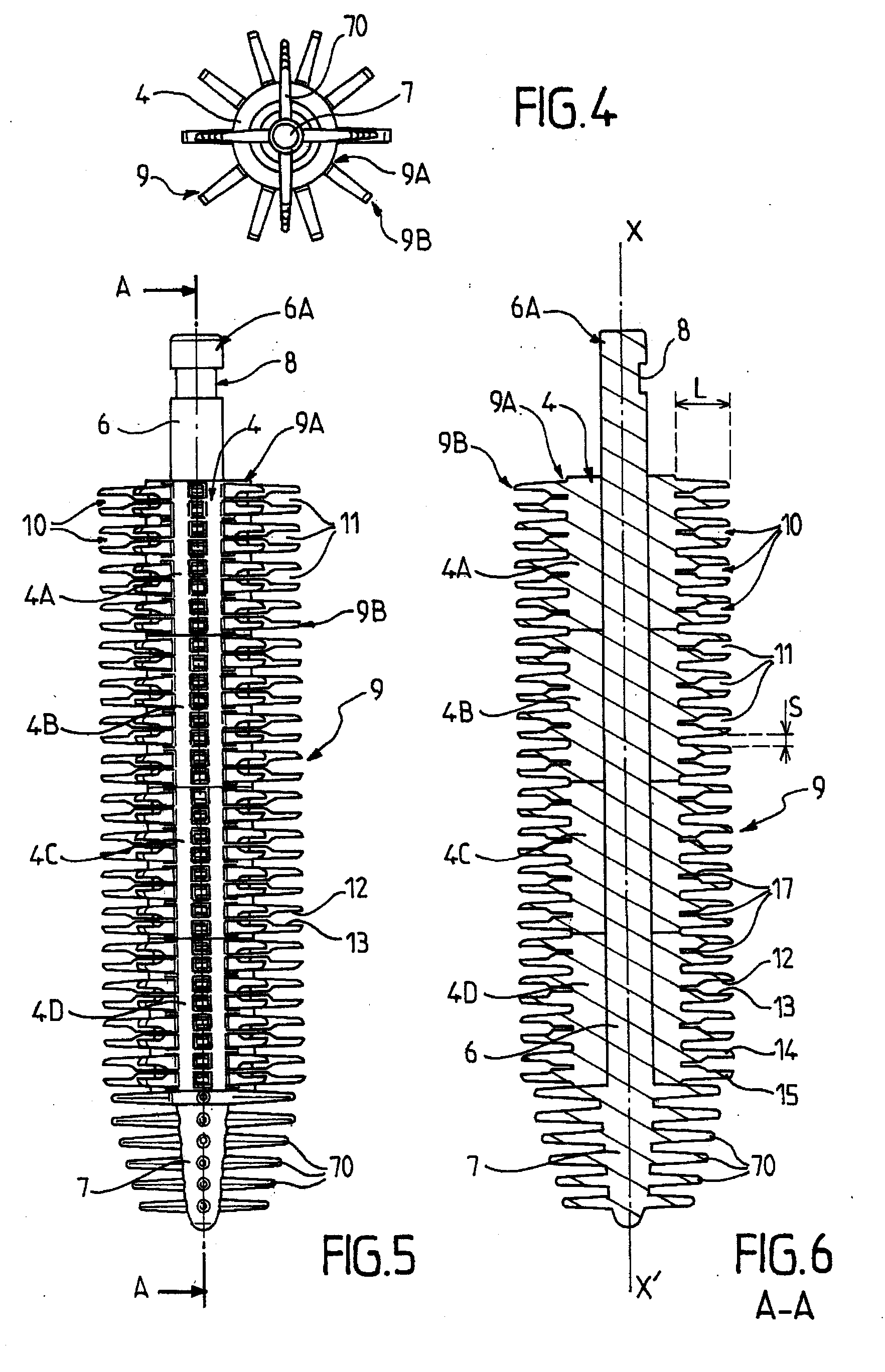

Instrument having walls for applying a composition on eyelashes or eyebrows

ActiveUS20070062551A1Accurate collectionApply evenlyBrushesPackaging toiletriesLiquid compositionEngineering

An instrument for applying a liquid or semi-liquid composition on the eyelashes or the eyebrows, comprising a core together with applicator means designed to collect the composition and to apply it on the eyelashes or the eyebrows, the applicator means projecting from the core between respective bases and tips, wherein the applicator means are arranged to form at least one hollow itself defining at least one applicator volume shaped firstly to contain the composition and secondly to enable at least one eyelash or eyebrow hair to pass therethrough in order to be coated in composition, the applicator volume extending from the tip towards the core along a fraction only of the length of the applicator means, the applicator volume being defined by at least first and second substantially solid walls disposed facing each other, each of the first and second walls presenting a nature that is substantially two-dimensional.

Owner:YVES SAINT LAURENT PARFUMS SOCIETE ANONYME

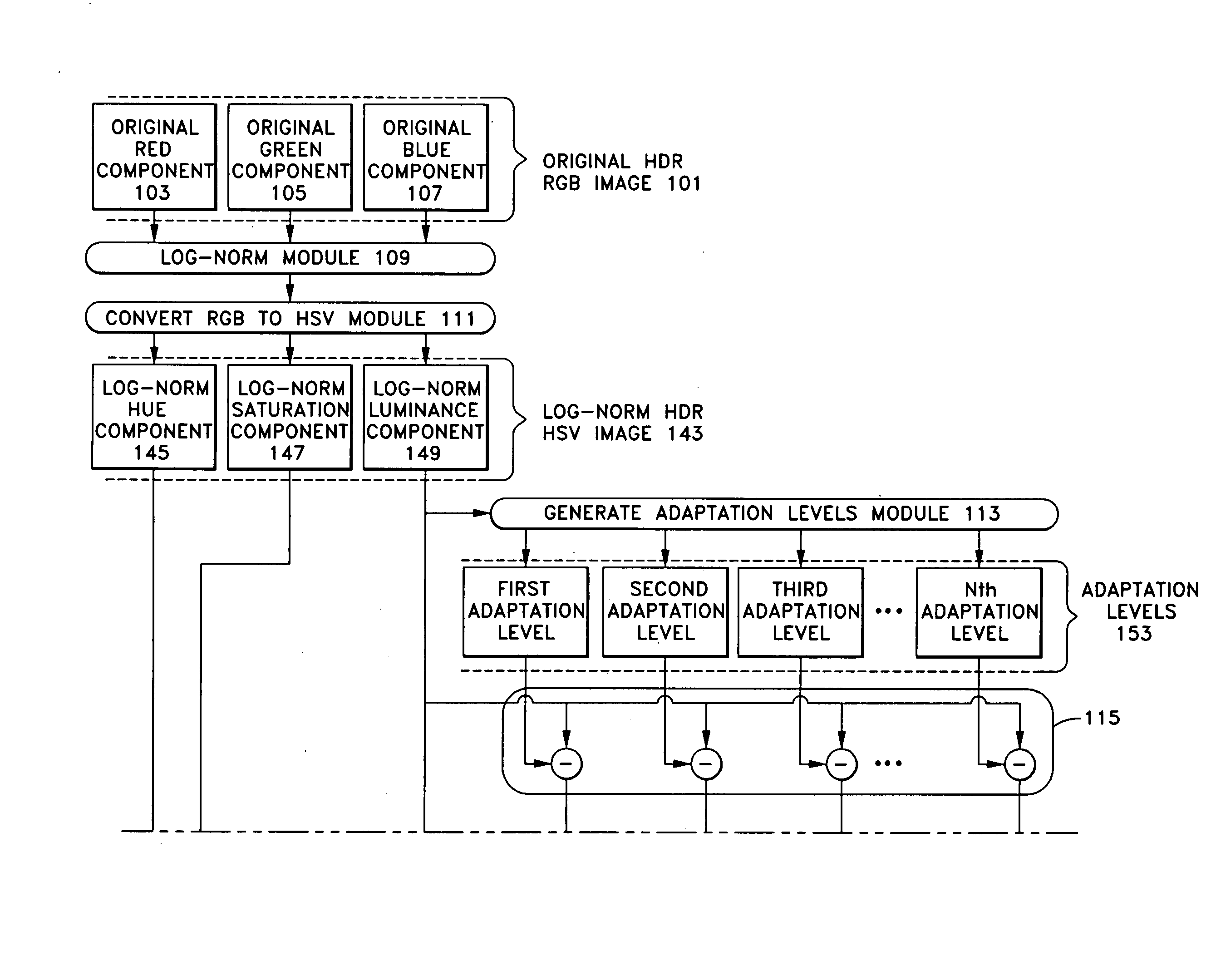

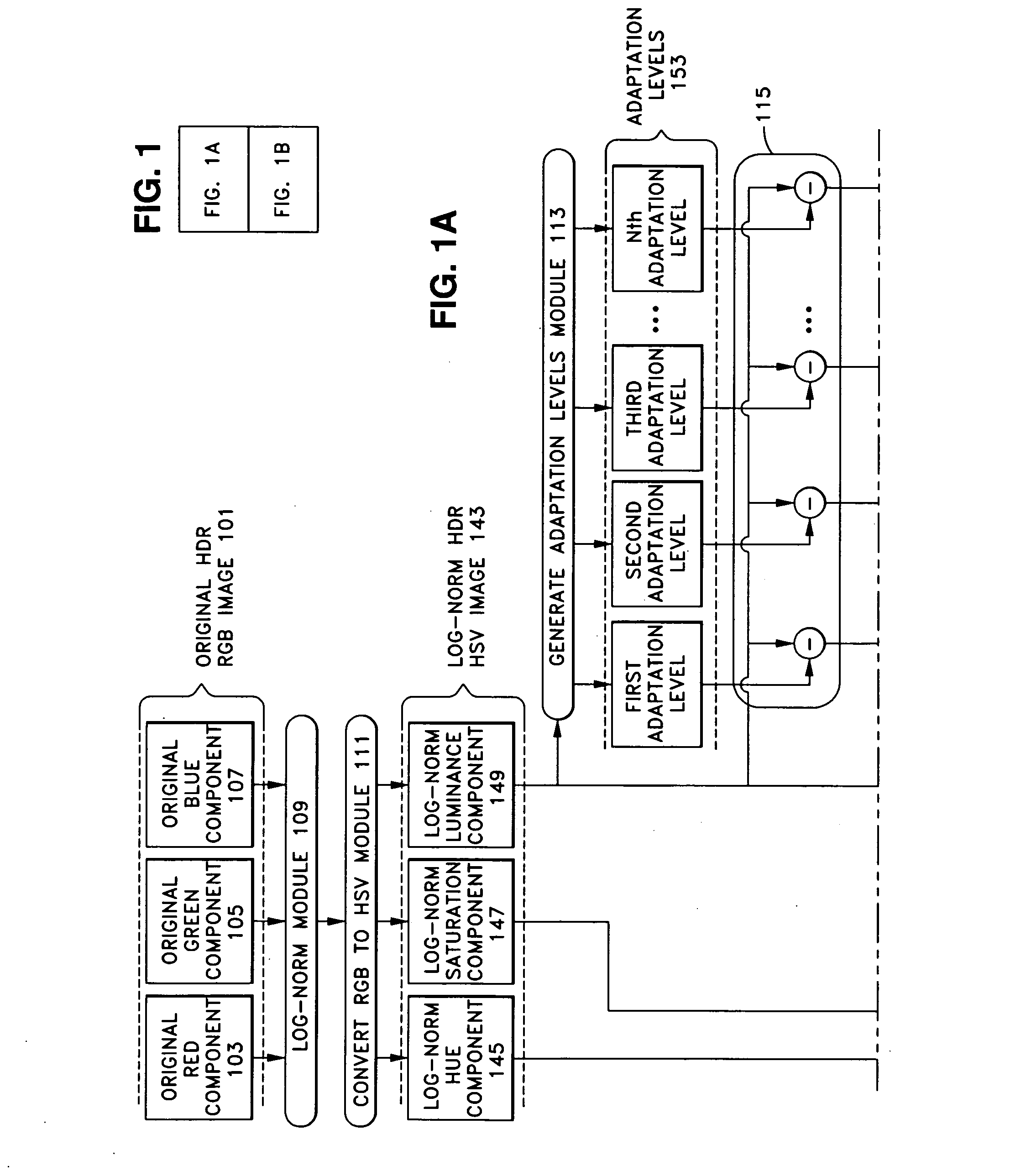

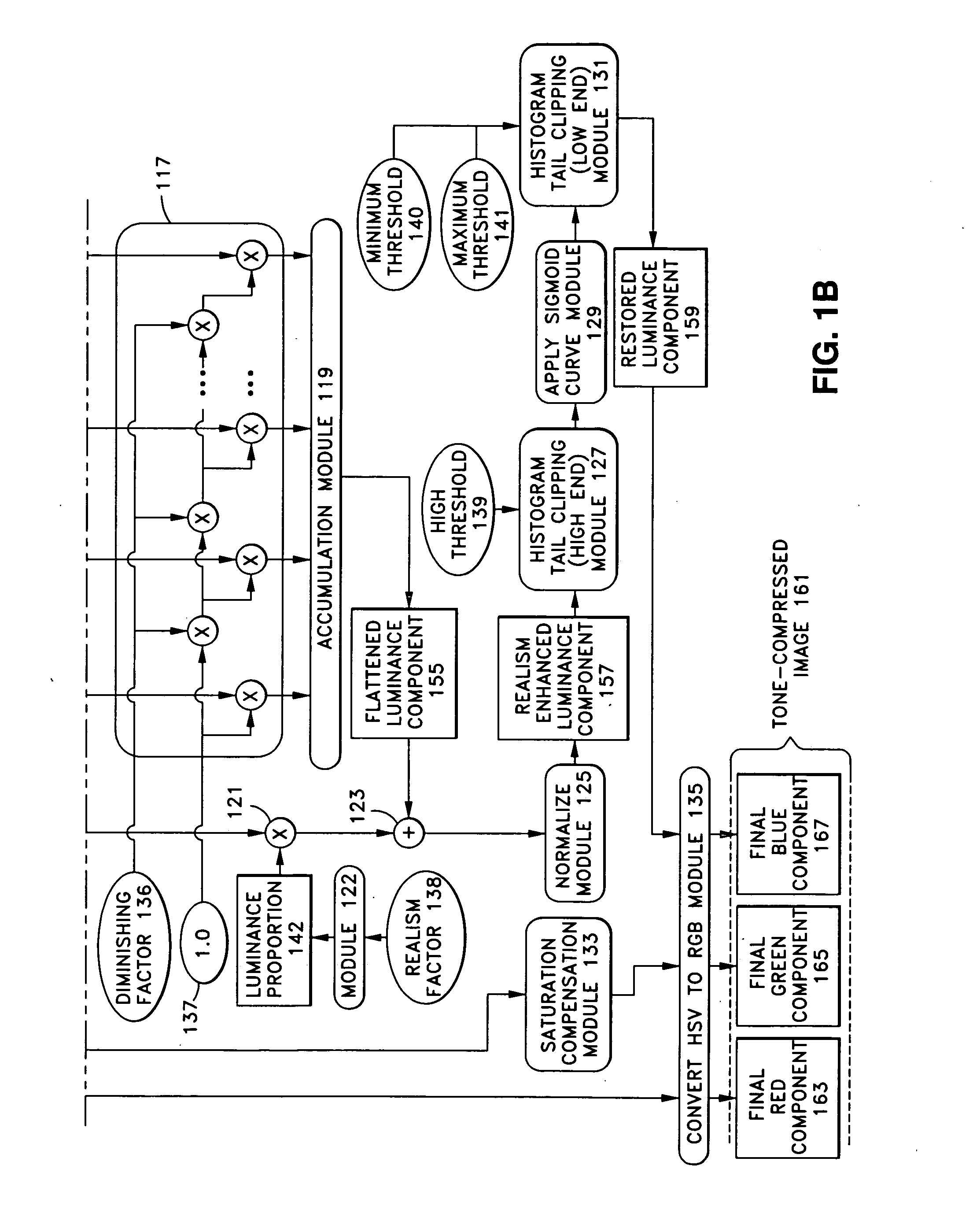

Tone mapping of high dynamic range images

InactiveUS20070014470A1Enhanced visual cuesReduce artifactsImage enhancementImage analysisTone mappingHue

Tone mapping a high dynamic range (HDR) image is performed by obtaining a log-norm luminance component based on a normalized logarithm of the HDR image. The log-norm luminance component is flattened (tone-compressed) using incrementally-spaced adaptation levels, which are increasingly blurrier representations of the log-norm luminance component, weighted by a diminishing factor. Visual cues are restored by injecting a proportion of values of the log-norm luminance component, applying histogram tail clipping, and applying a sigmoid curve mapping, to create a restored luminance component. A tone-compressed image is obtained by mapping luminance of the HDR image using the restored luminance component and adjusting saturation of the mapped HDR image.

Owner:CANON KK

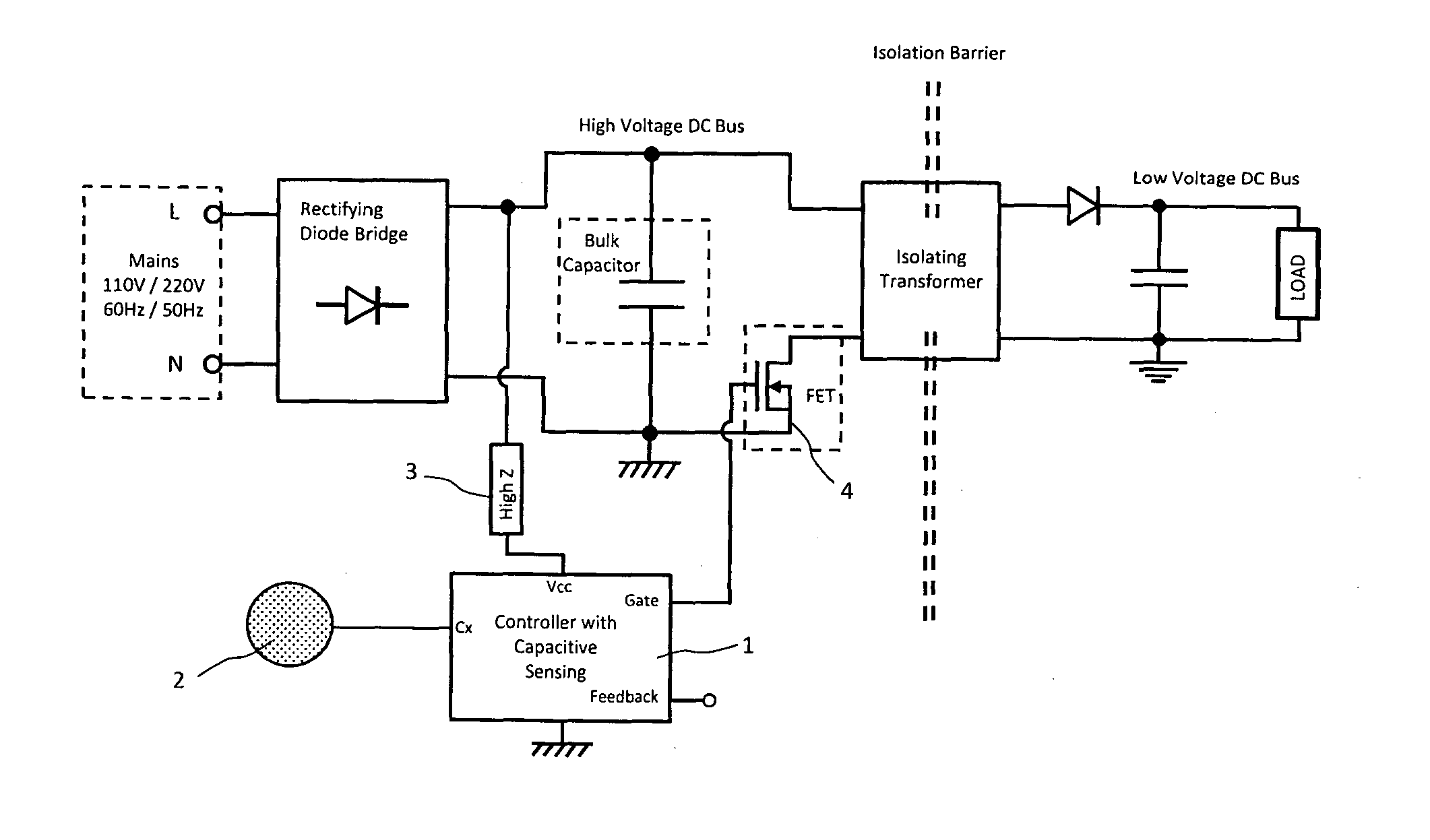

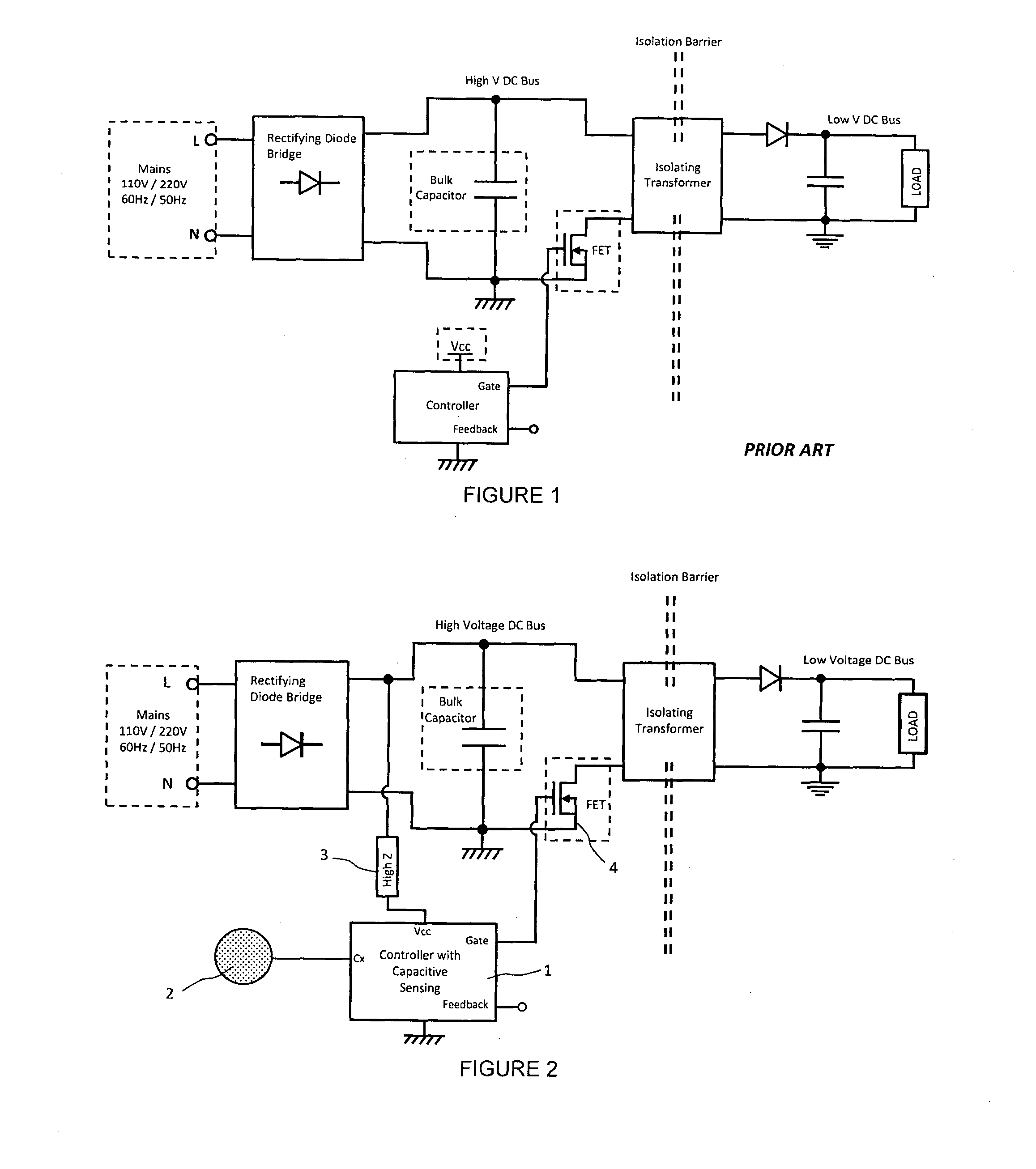

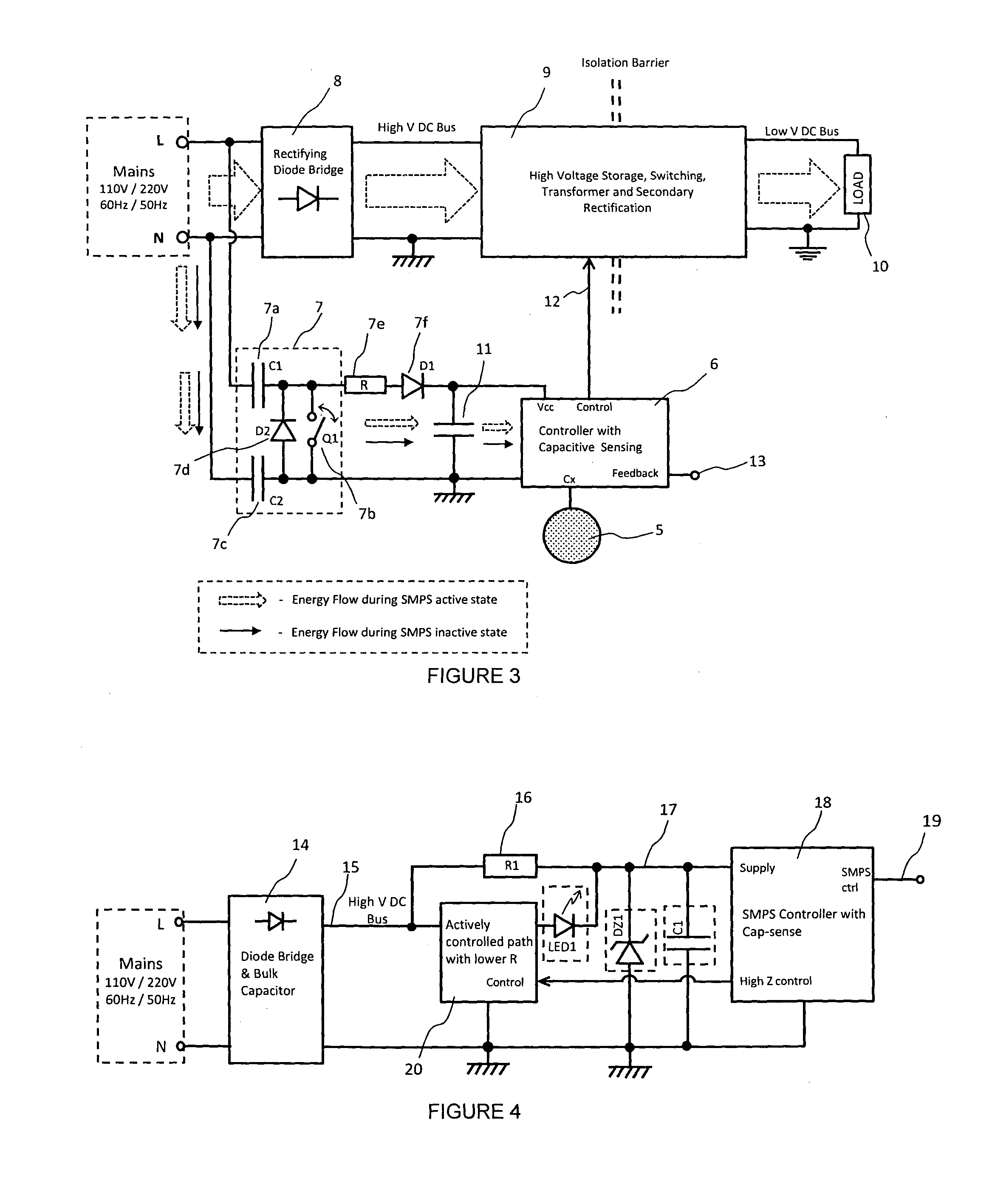

Capacitive sensing enabled switch mode power supply and data transfer

InactiveUS20140253032A1Improve immunityReduce lossesBatteries circuit arrangementsCapacitance measurementsCapacitanceCapacitive sensing

A microchip for control of a switch mode power supply (SMPS), with said microchip also having the ability to measure capacitance of an electrode or sense plate structure or structures, and use of a low power, power supply structure to supply said microchip, said power supply structure distinct from the main energy path via said SMPS to a load. The microchip may control said SMPS to transition between an active state and an inactive state, with the measured capacitance used to determine a condition for state transition. In said SMPS inactive state, only the microchip draws power to operate its capacitive sensing circuitry, leading to a significant SMPS standby losses decrease compared to prior art. Further teachings by the present invention include capacitive sensing based data transfer, universal charging platforms for mobile devices, noise immunity enhancements, various lighting embodiments as well as SMPS operation improvements.

Owner:AZOTEQ PTY LTD

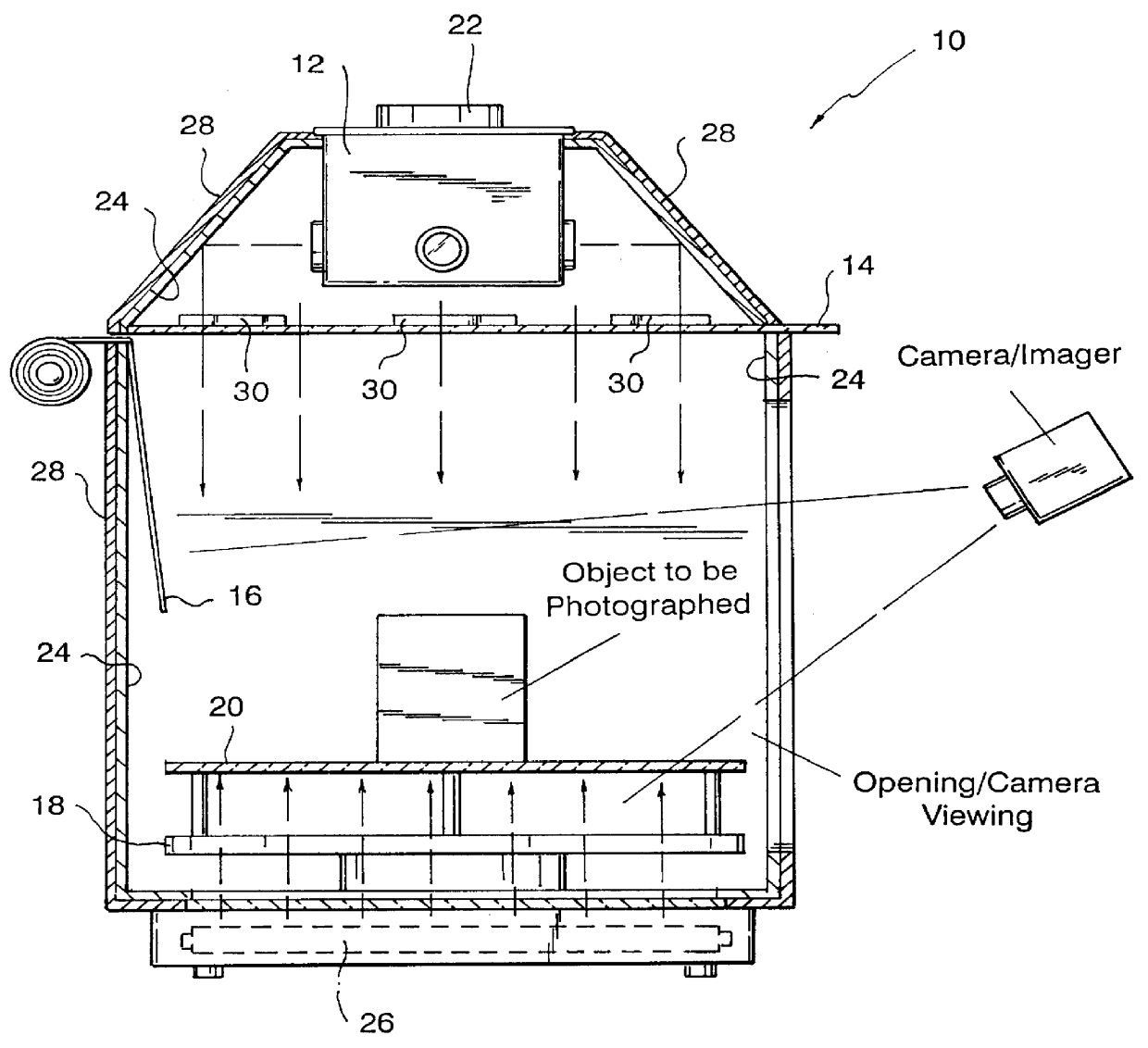

Self-contained photo studio lighting apparatus

InactiveUS6106124ARemove shadowsUniform lightFurnace componentsLighting heating/cooling arrangementsLight equipmentEffect light

A self-contained photography studio apparatus for photographing at least one subject comprising means to support and spatially orient the subject to be photographed, means for illuminating said subject so as to provide uniform illumination and substantially eliminate shadows, and means for controlling the temperature on and in the vicinity of said subject, wherein each of the recited means is integral, and a method for using the apparatus.

Owner:TARSIA JOSEPH

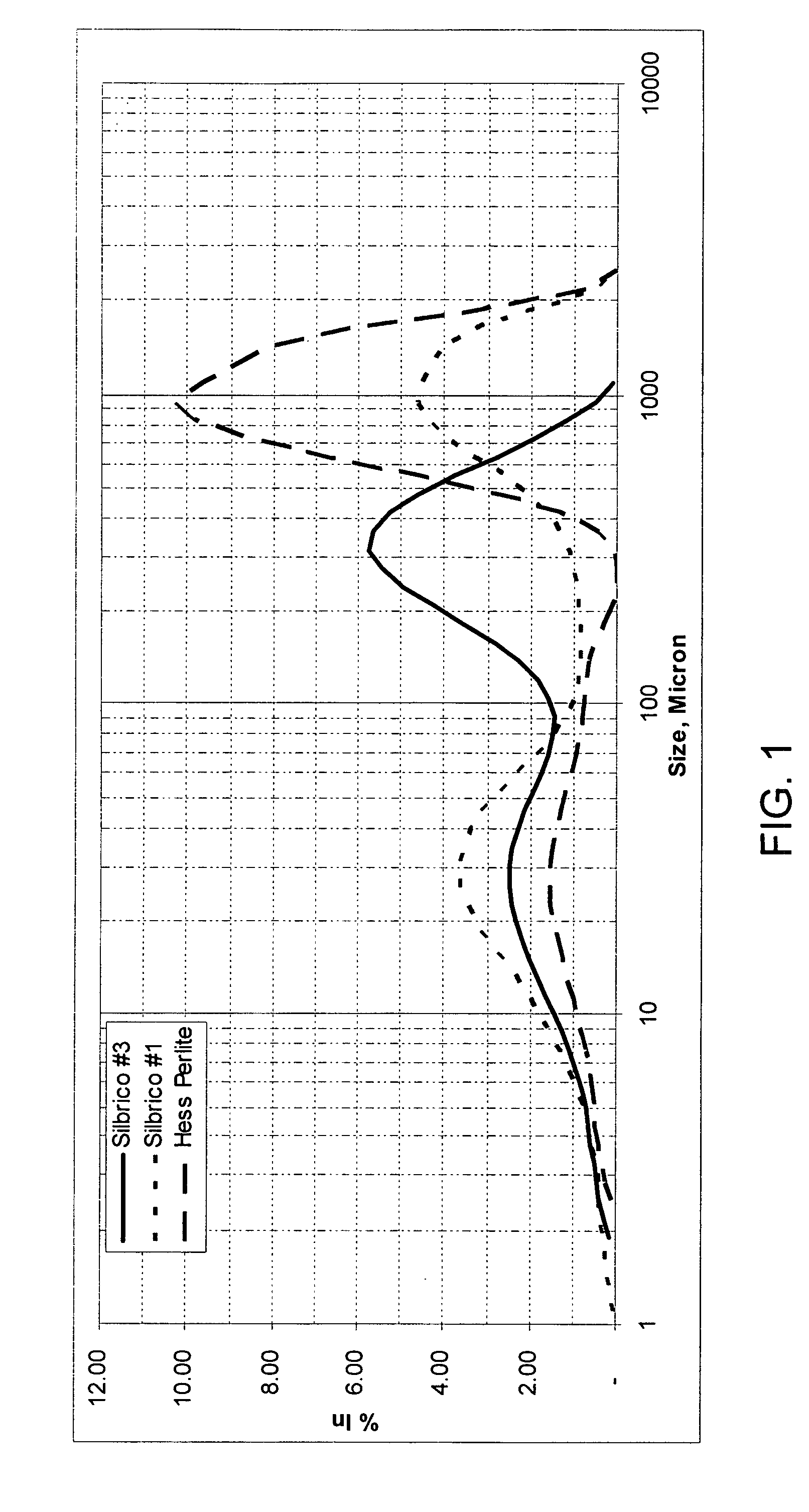

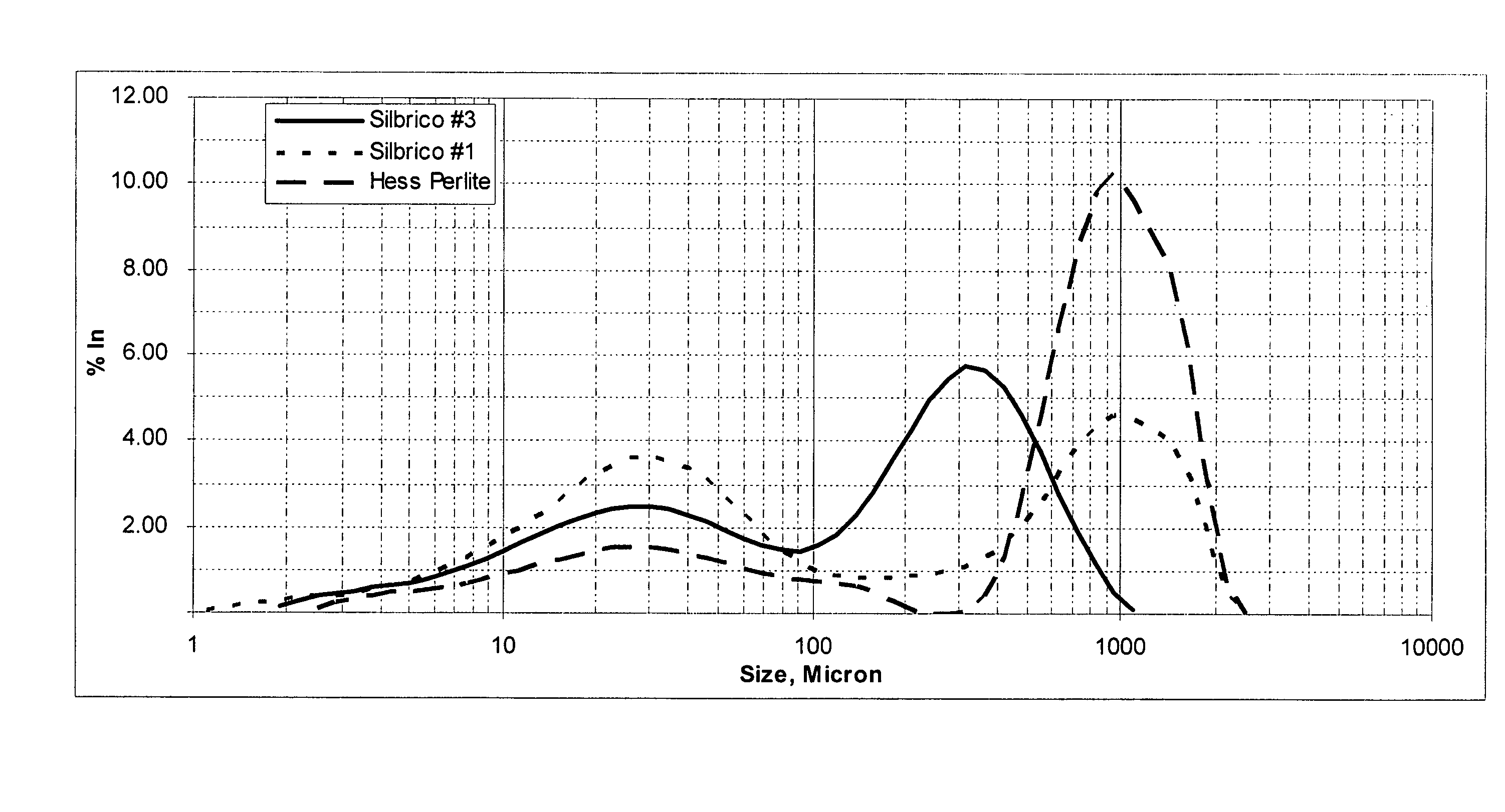

Acoustical gypsum board panel and method of making it

ActiveUS20080299413A1Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

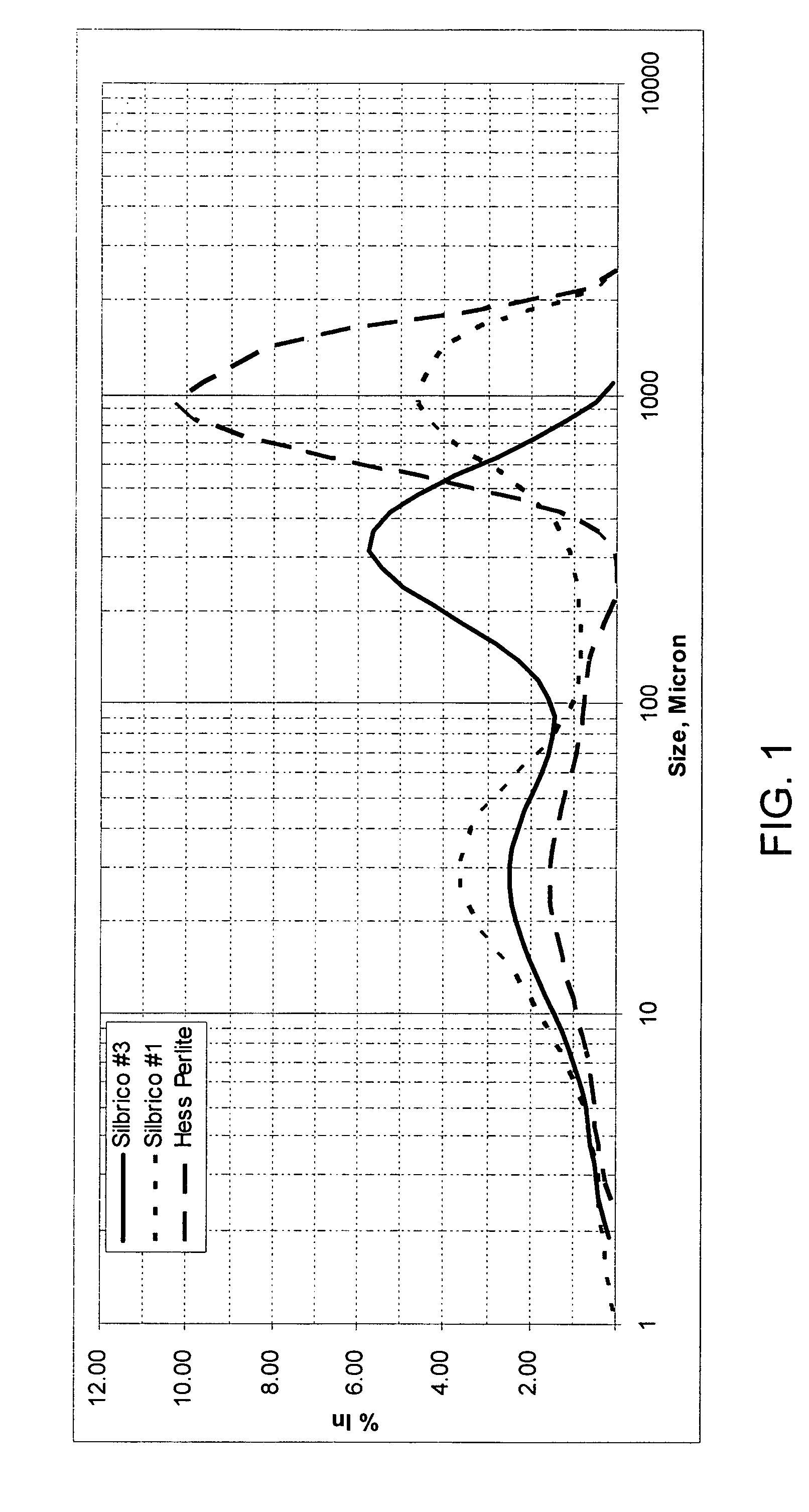

The acoustical product of the present invention comprises an acoustical product including a matrix of calcium sulfate dihydrate crystals and expanded perlite distributed throughout the matrix. The expanded perlite has a particle size distribution with at least 10% of the perlite having a particle diameter of 700 microns or more, and the amount of expanded perlite to calcium sulfate dihydrate is about 35% to about 75% by weight, based upon the dry weight of the calcium sulfate dihydrate. A dispersing agent and glass fibers having a particle length of about ¼ inch to about 1 inch are dispersed throughout the gypsum matrix.

Owner:UNITED STATES GYPSUM CO

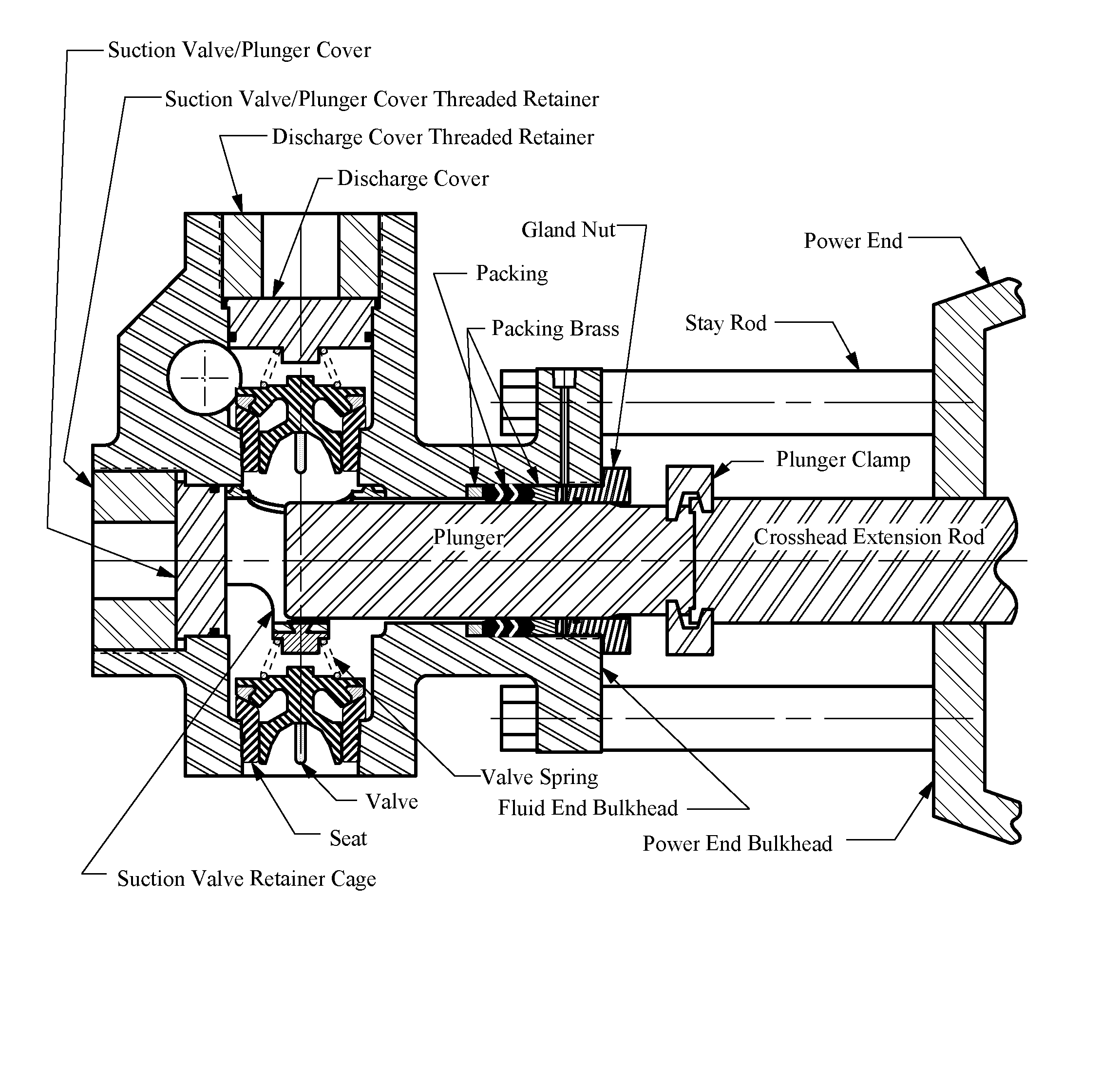

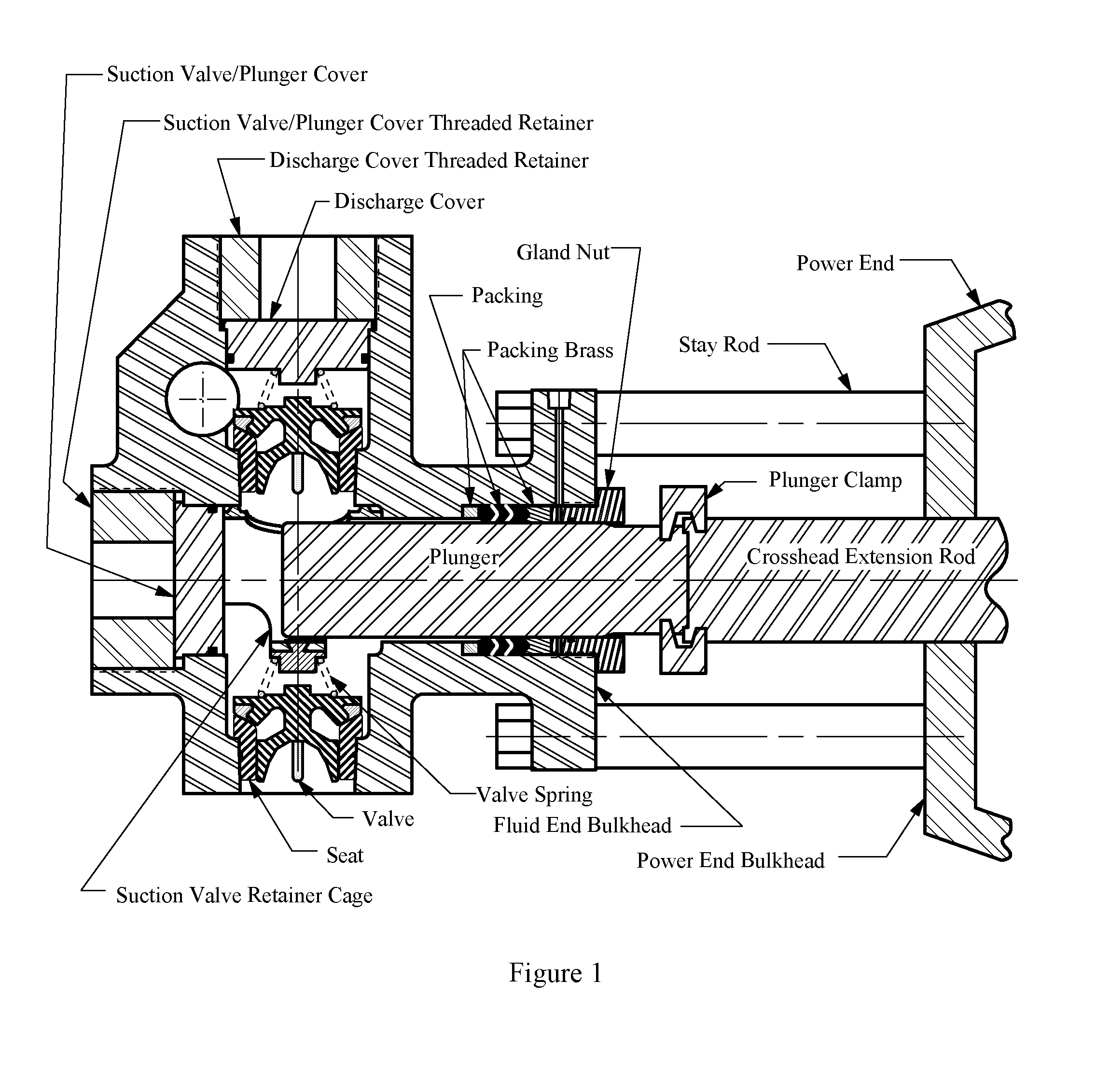

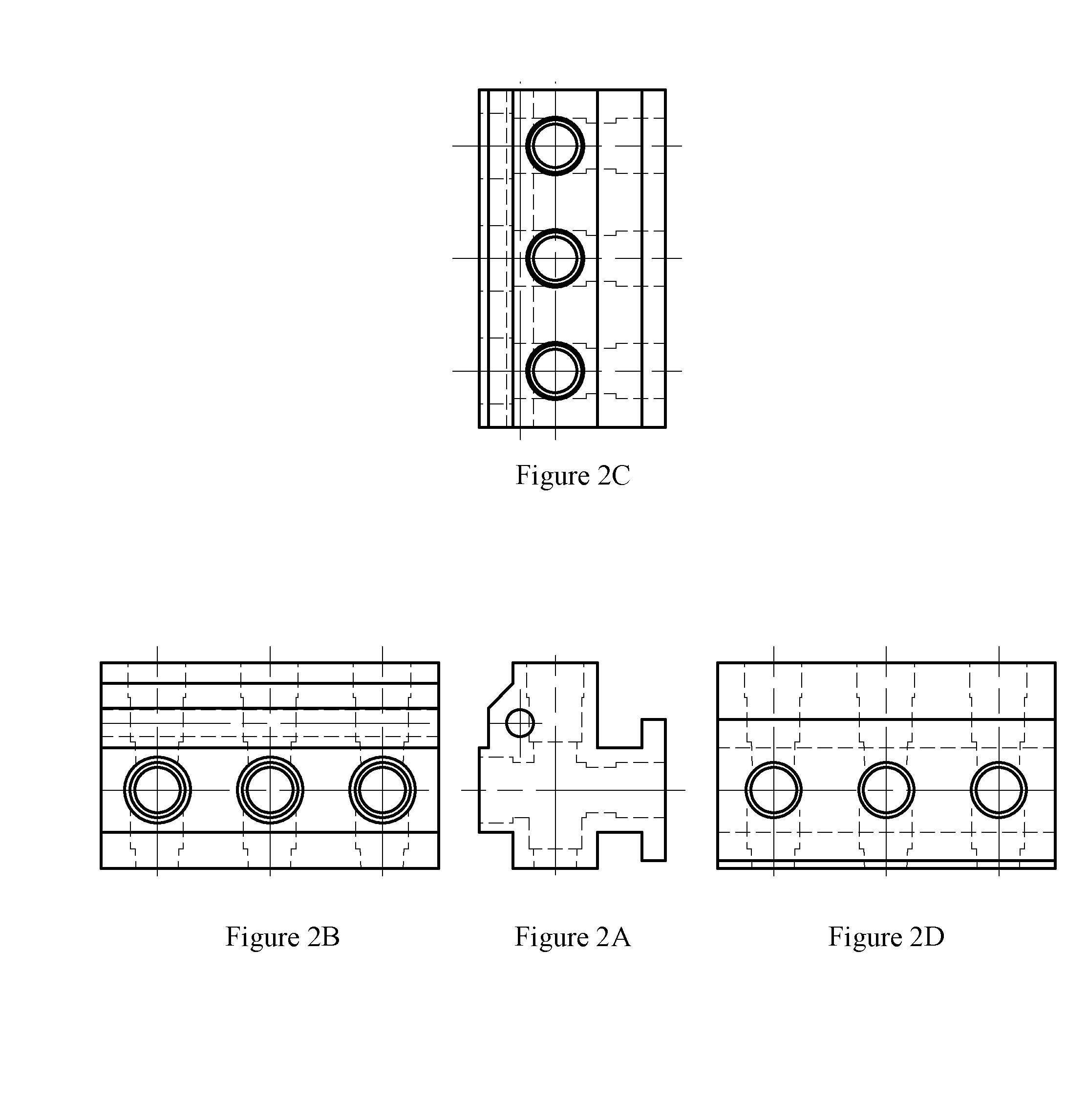

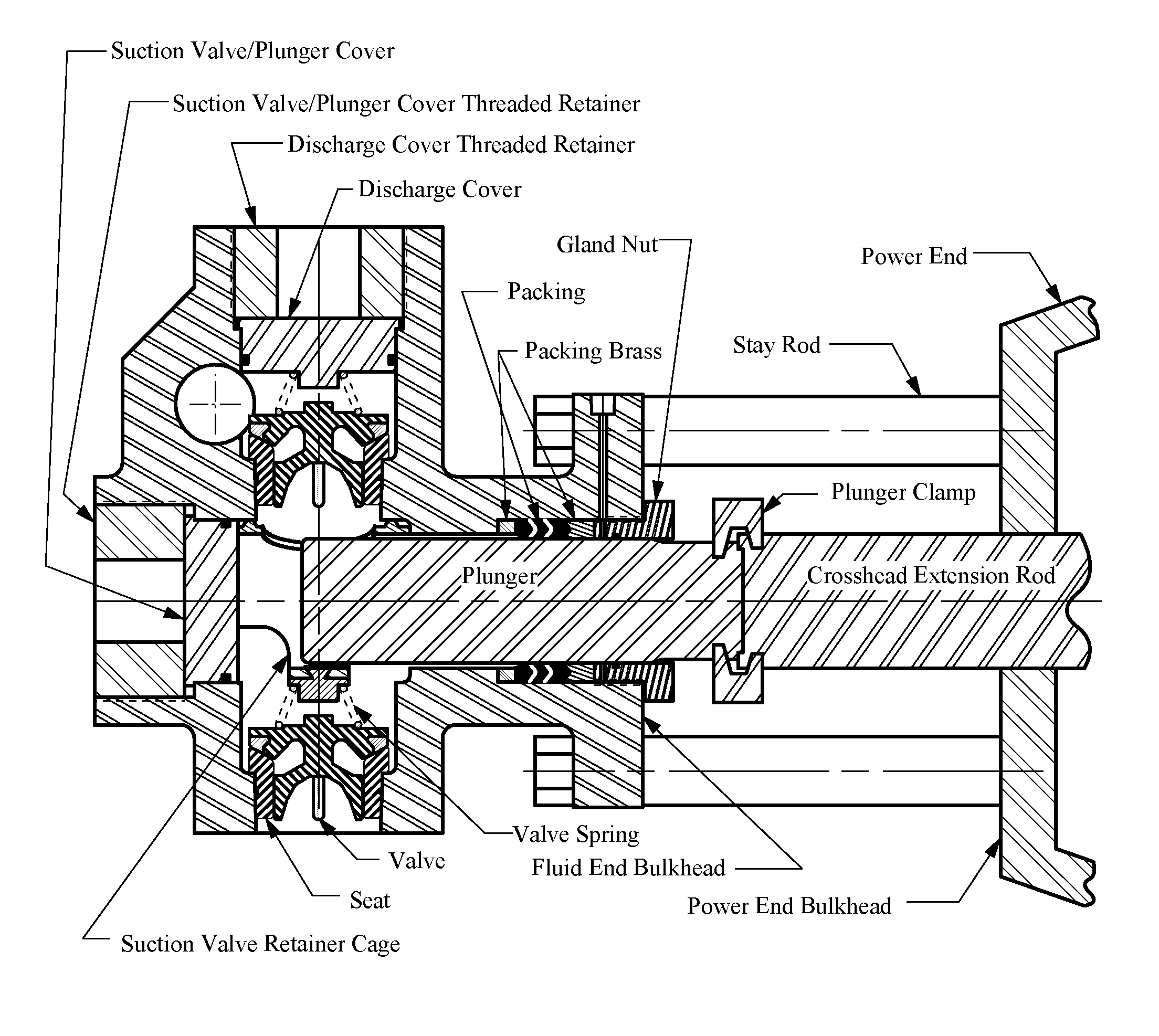

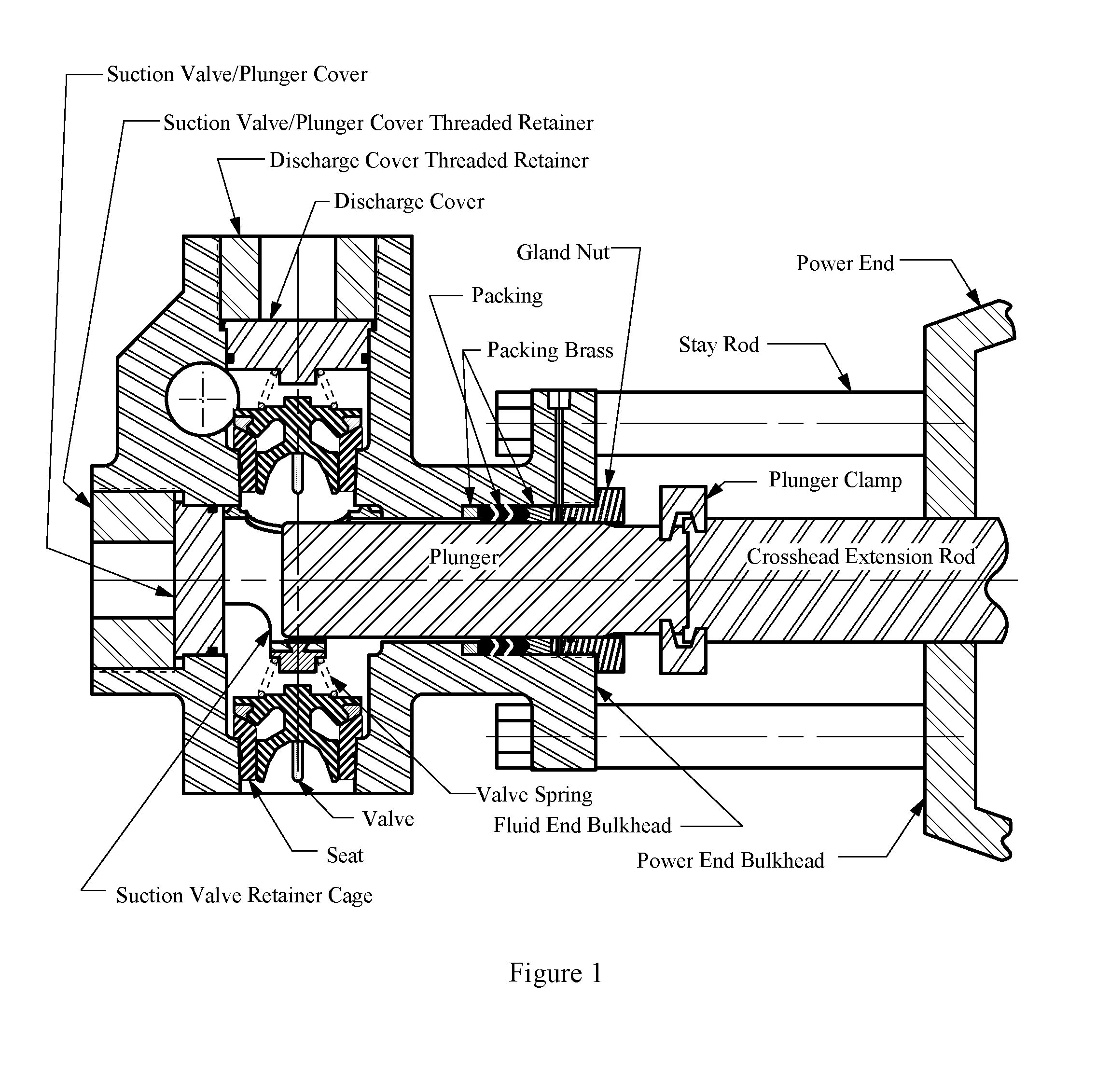

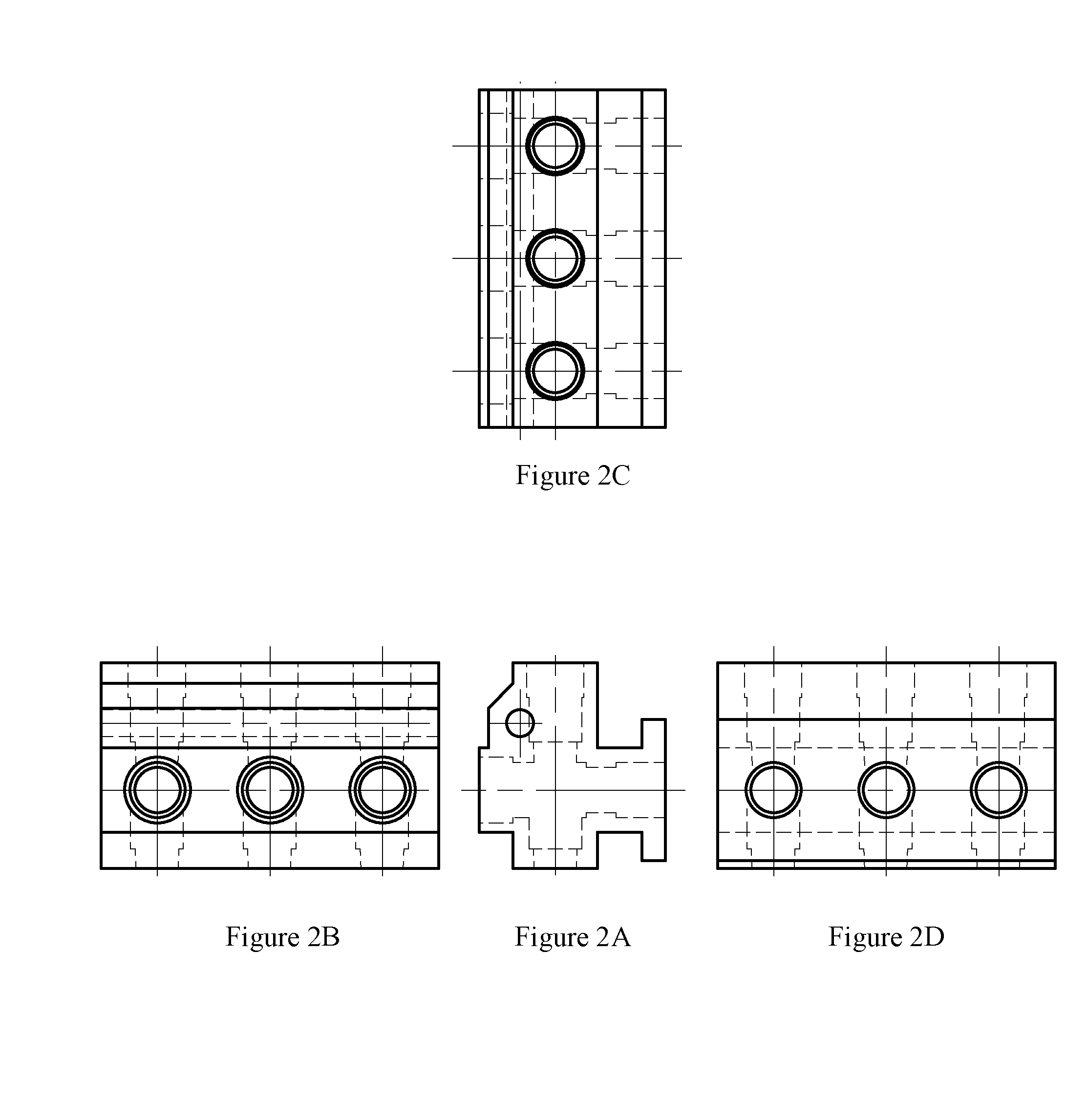

Fluid end with carbide valve seat and adhesive dampening interface

ActiveUS9435454B2Avoid fracturesApply evenlyPositive displacement pump componentsCheck valvesInterference fitCarbide

Owner:ALTIS INVESTMENTS LLC

Polymer composite diaphragm and its preparing method

InactiveCN1851957AReduce the probability of short circuitImprove electrical performanceCell component detailsTextiles and paperPolymer compositesOrganic solvent

This invention discloses a polymer compound membrane and its preparation method, in which, the method includes: mixing strengthening bodies of a matrix film and inorganic nm materials in an organic solvent to get a uniform slurry to be coated on both sides of a non-woven cloth to get a polymer compound membrane, in which, said strengthening bodies are selected from the following three: 1, an organic monomer and its related initiator, 2, two or more than two polymers, 3, organic monomers and their related initiators and two or more than two polymers, 4, organic monomers and two or more than two polymers.

Owner:PEKING UNIV

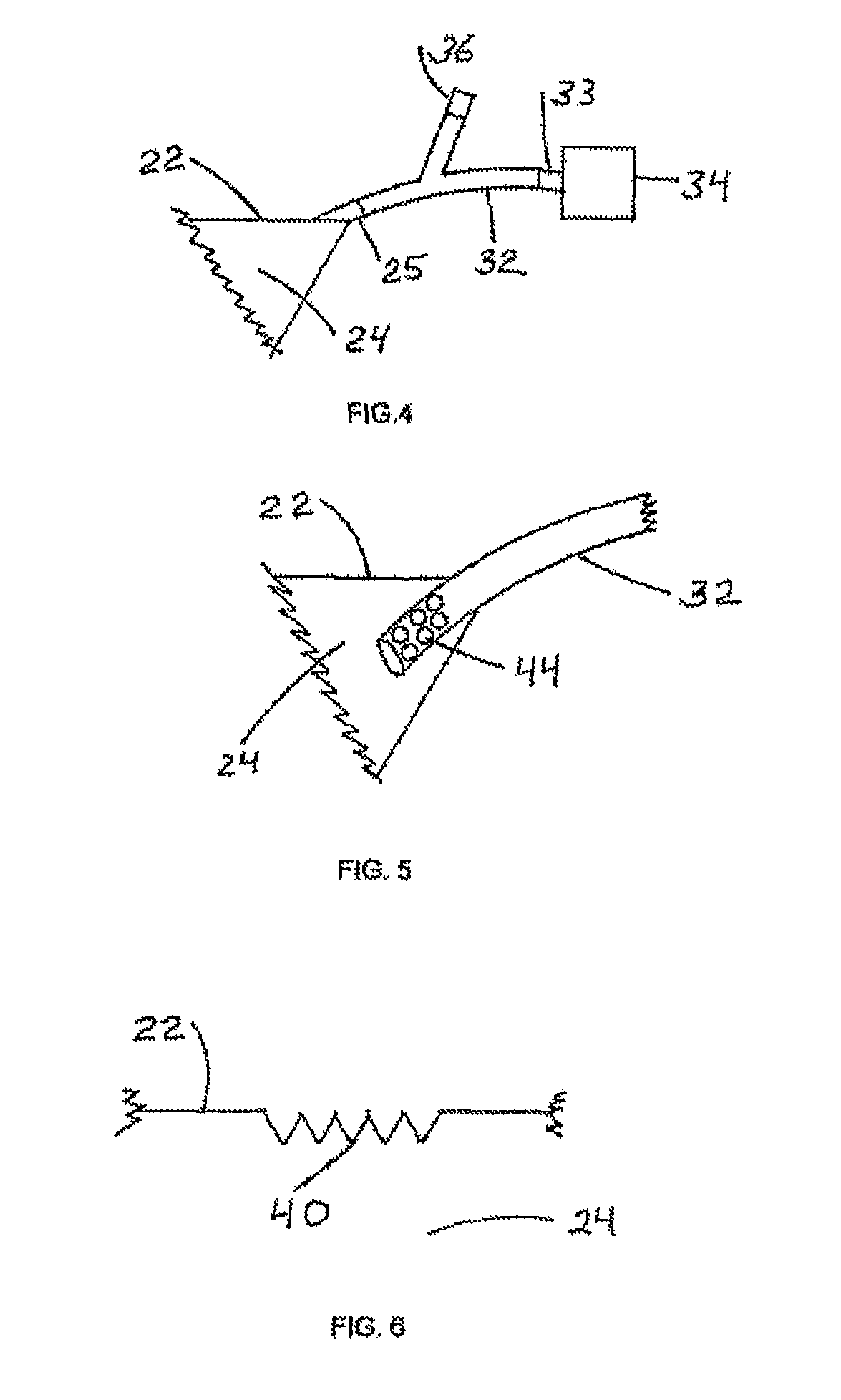

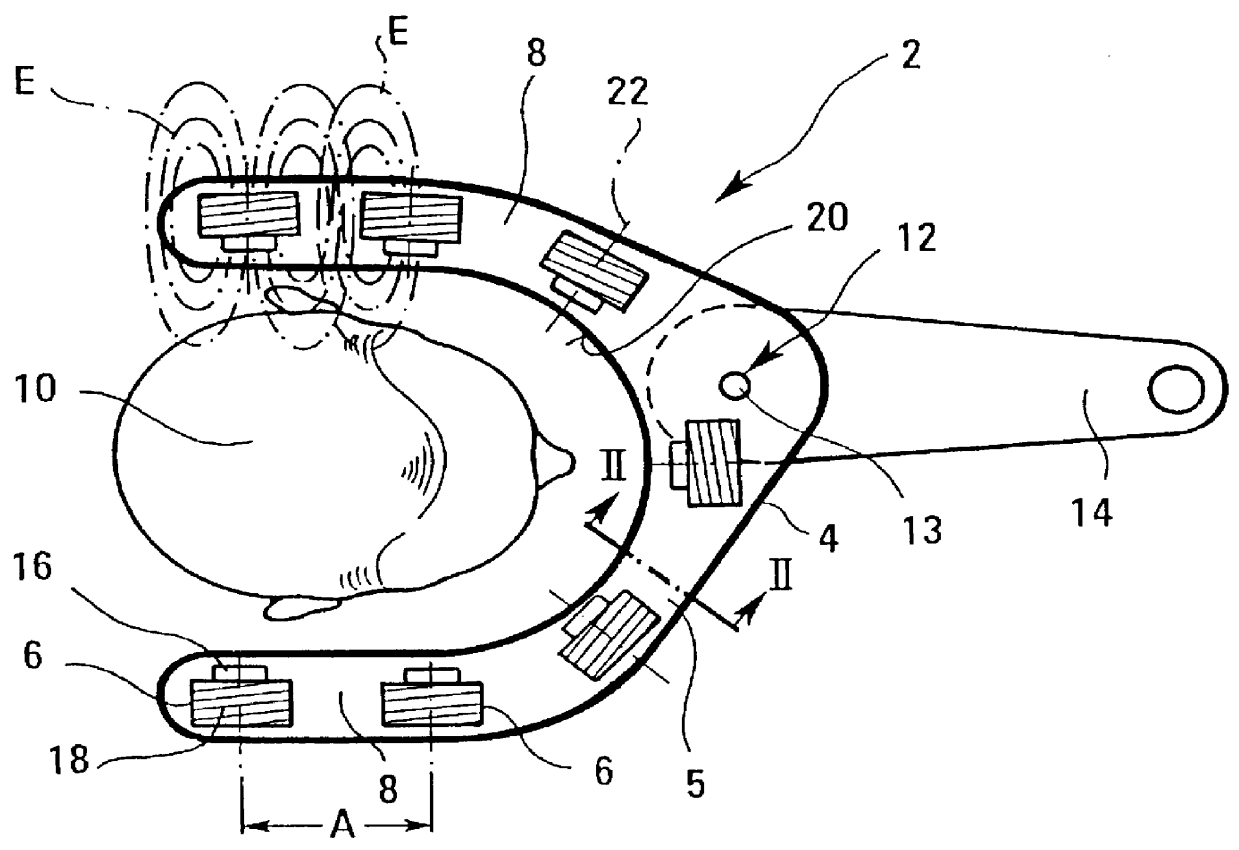

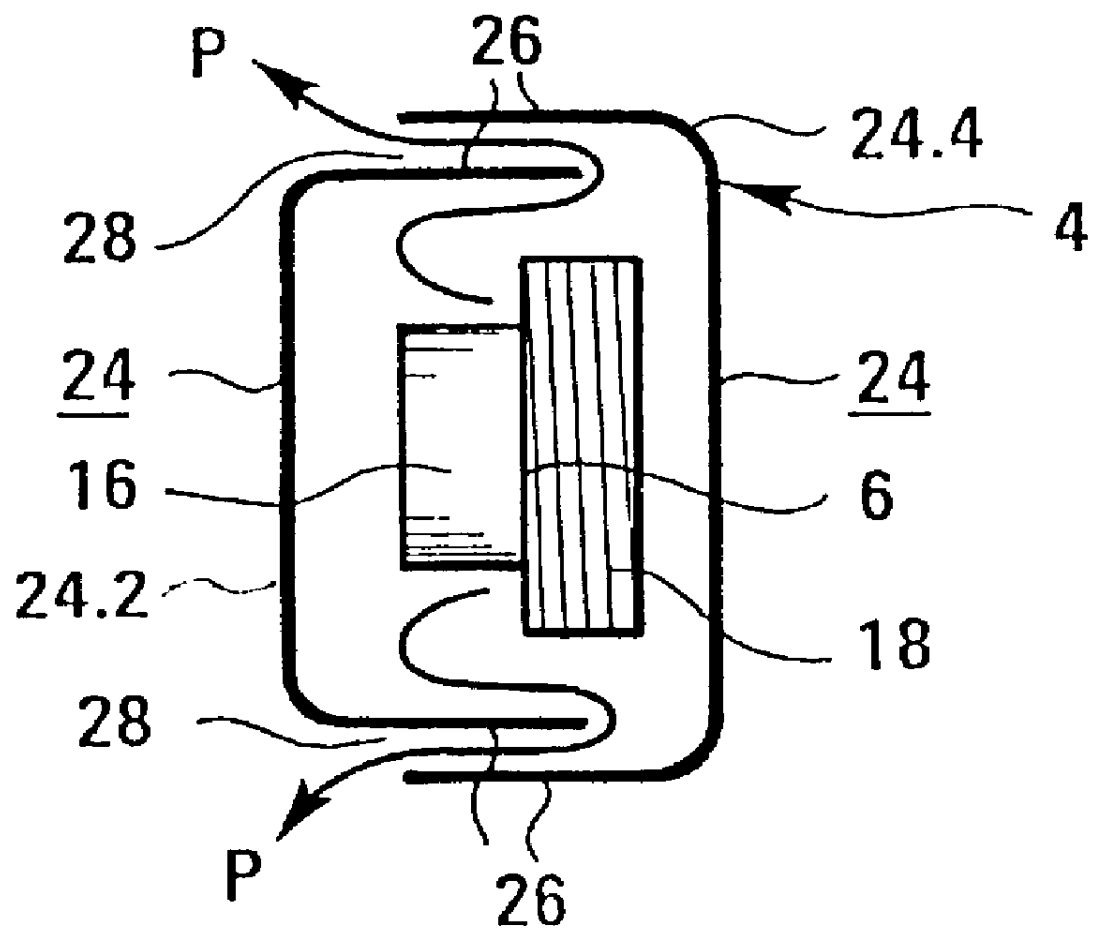

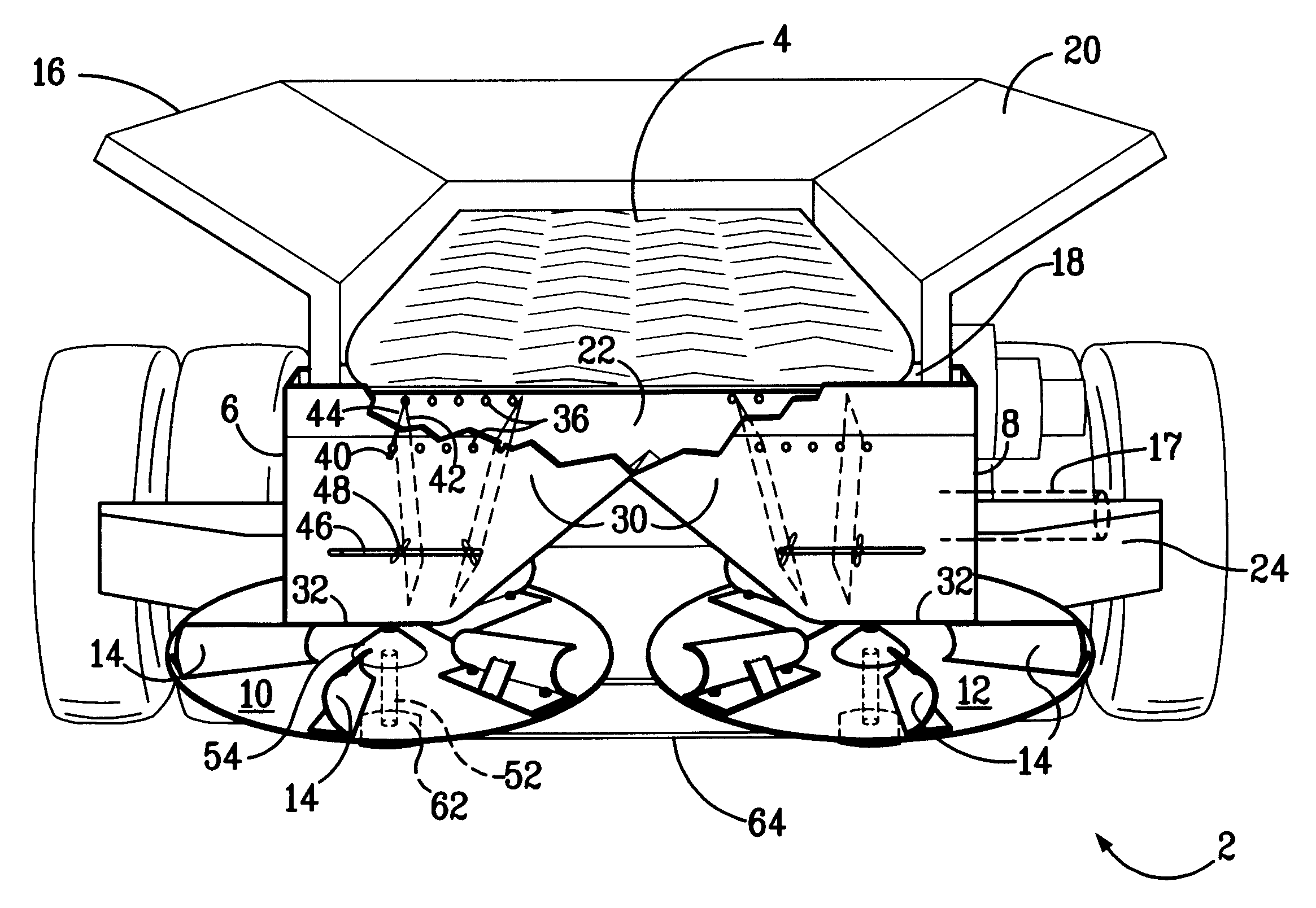

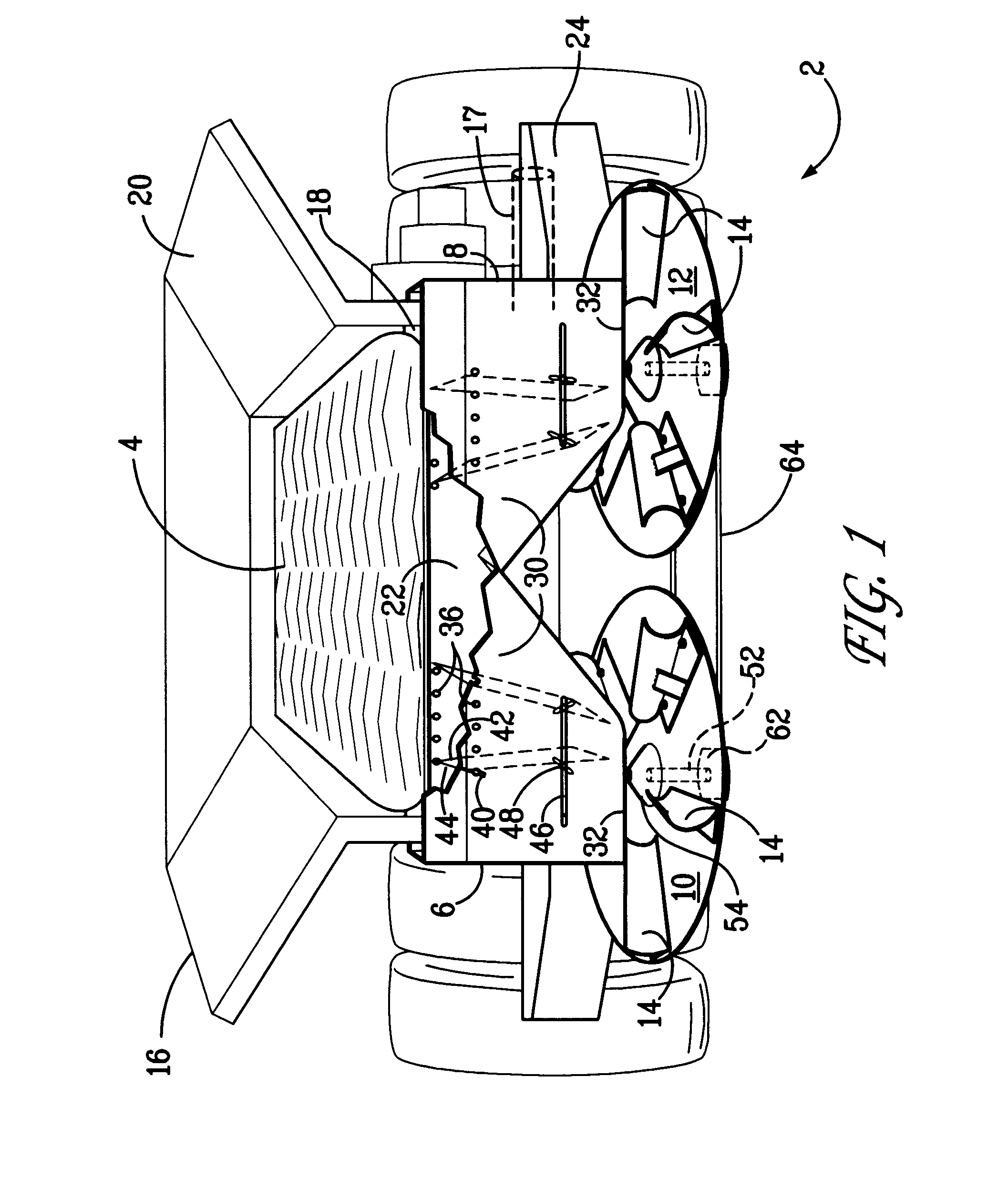

Apparatus for the treatment of disorders of tissue and/or the joints

InactiveUS6048302APromote healingSecure supportElectrotherapySurgeryElectromagnetic fieldBiomedical engineering

An apparatus for the treatment of disorders of tissue and / or the joints in the area of the jaw or neck of a patient (10), particularly for the treatment of periodontosis, is depicted, wherein the apparatus comprises a housing (4) that surrounds at least the area of the jaw or neck to be treated. A number of coils (6) is also provided for generating at least one electromagnetic field (E) which can be applied to the area to be treated. The coils (6) are arranged in the interior (5) of the housing (4).

Owner:BIO MAGNETIC THERAPY SYST

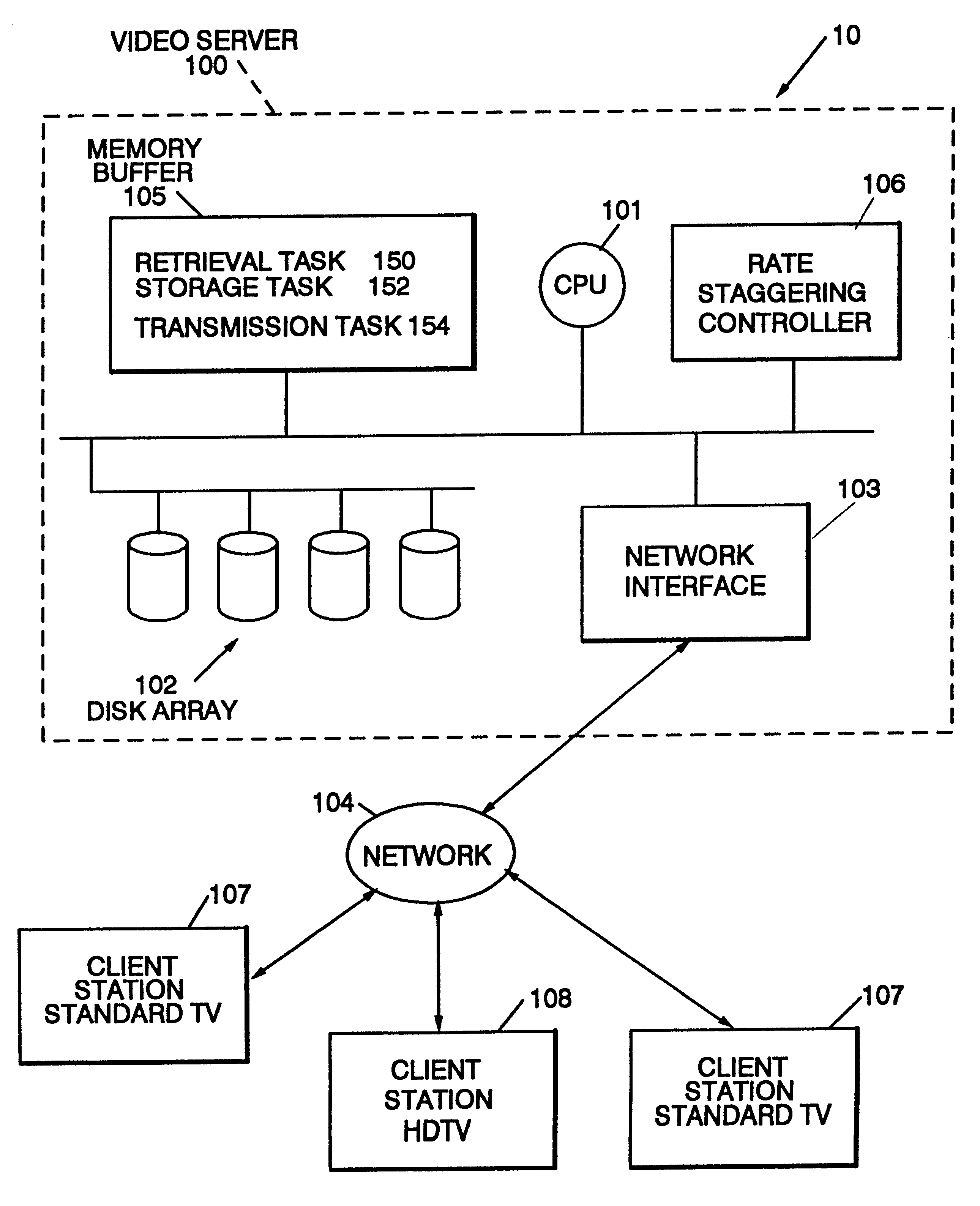

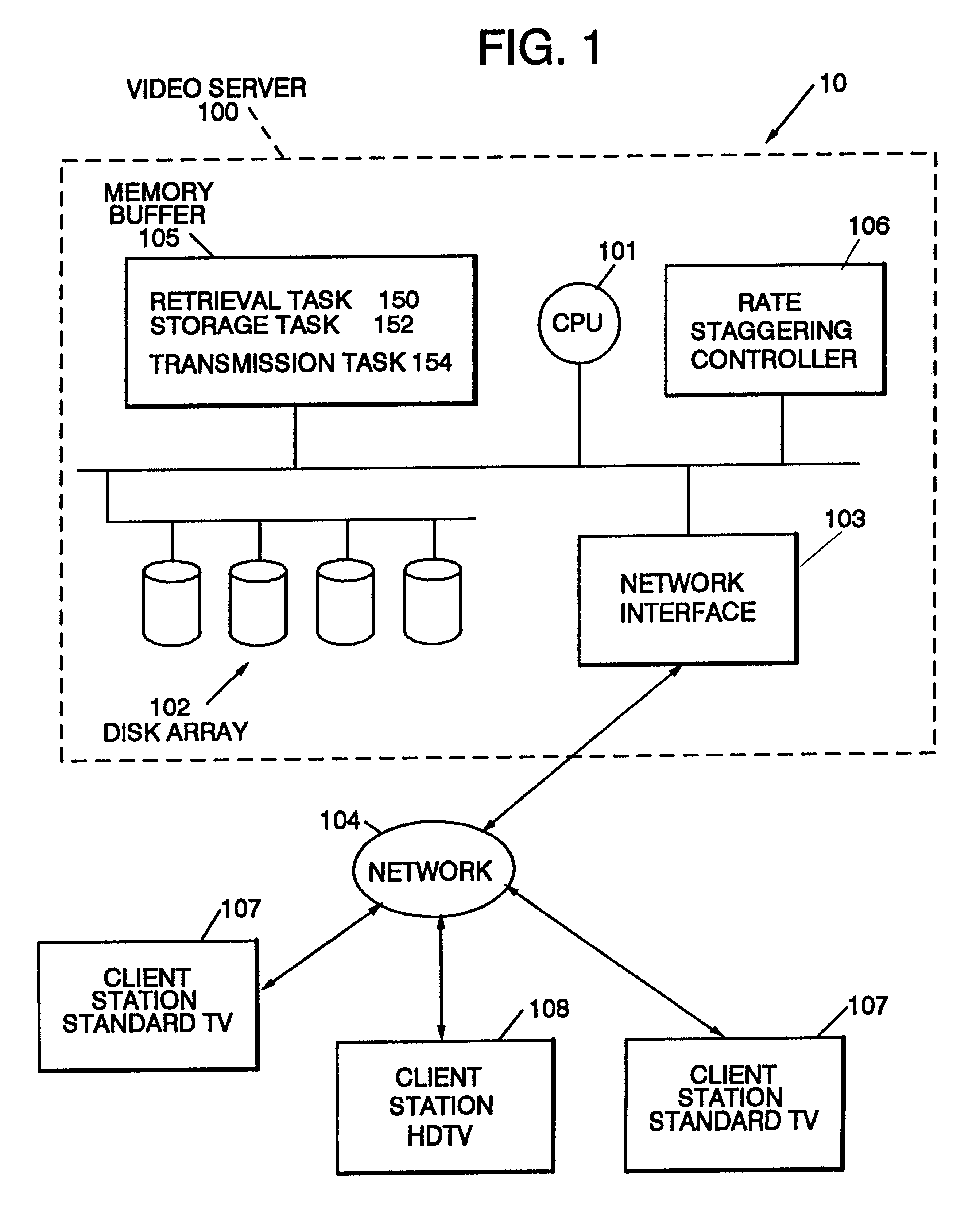

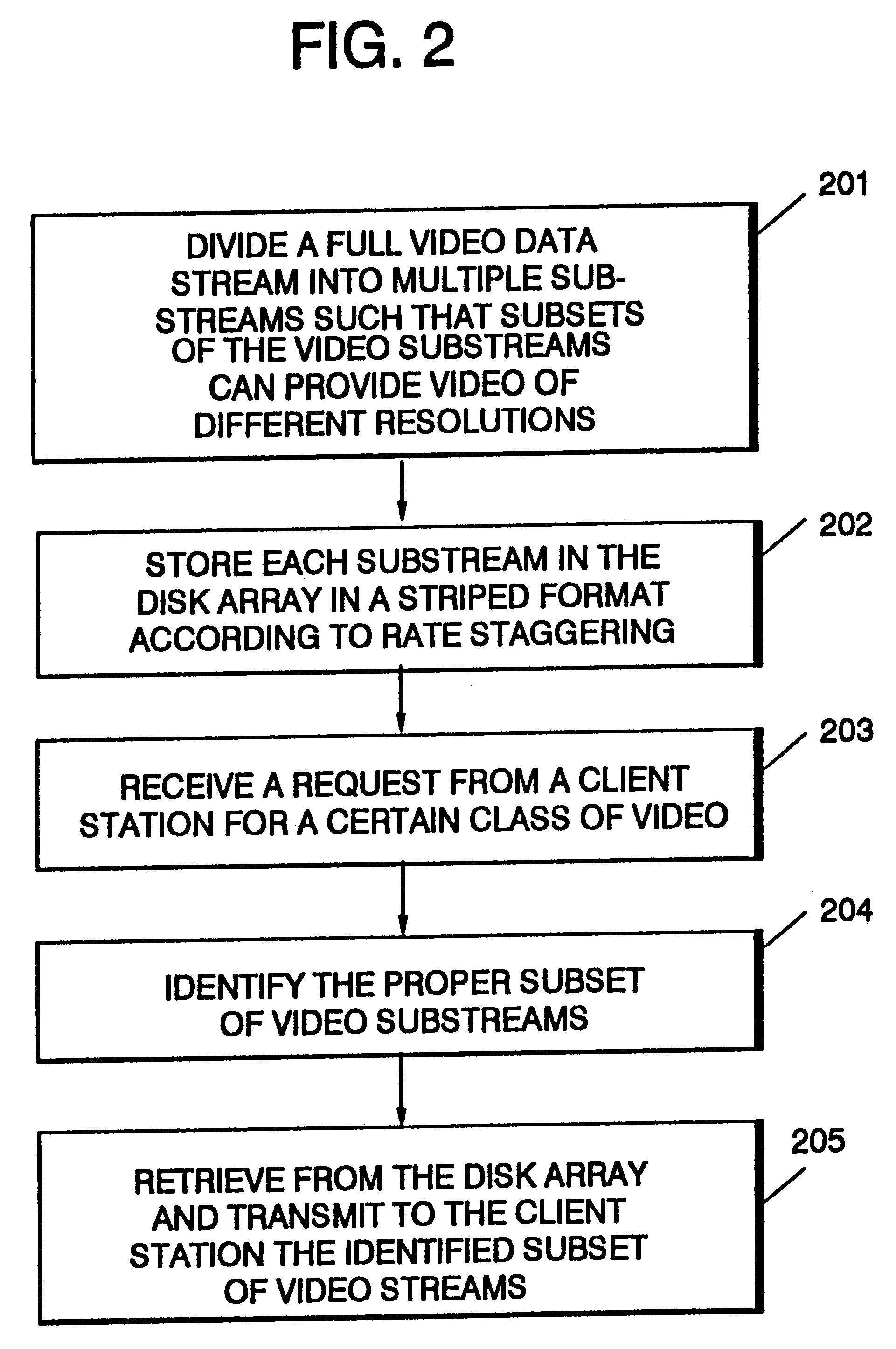

Method and apparatus for storing and retrieving scalable video data in a disk-array-based video server

InactiveUS6240243B1Apply evenlyTelevision system detailsColor television detailsData processing systemVideo transmission

The rate staggering technique for efficient storage and retrieval of video data is embodied in a data processing system including a disk array based video server, which includes a disk array for storing video data, a processor for processing data, a memory buffer for storing video data and a rate staggering controller. Data is transferred to a network from video server through a network interface and from the network to client stations employing devices having differing resolution capabilities. The processor executes tasks under control of the rate staggering controller. These tasks include a retrieval task which retrieves scalable video from the array of disks, a storage task which stores videos temporarily in the memory buffer, and a transmission task which transmits video to client stations through the network.

Owner:IBM CORP

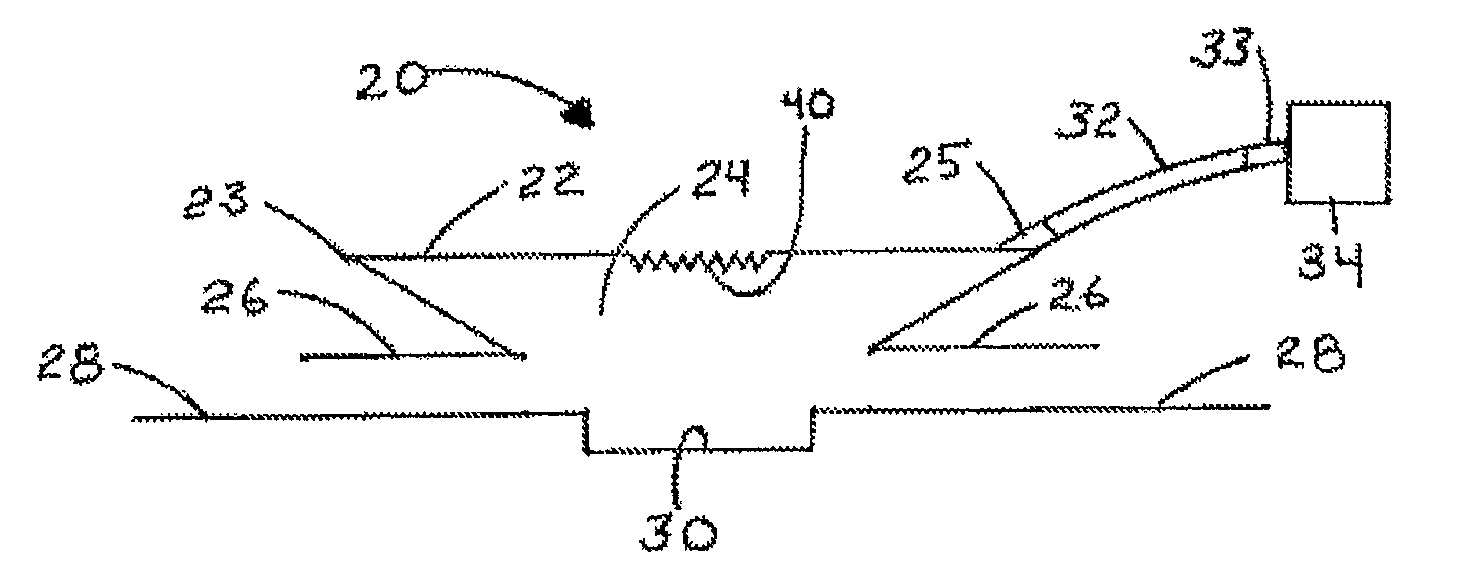

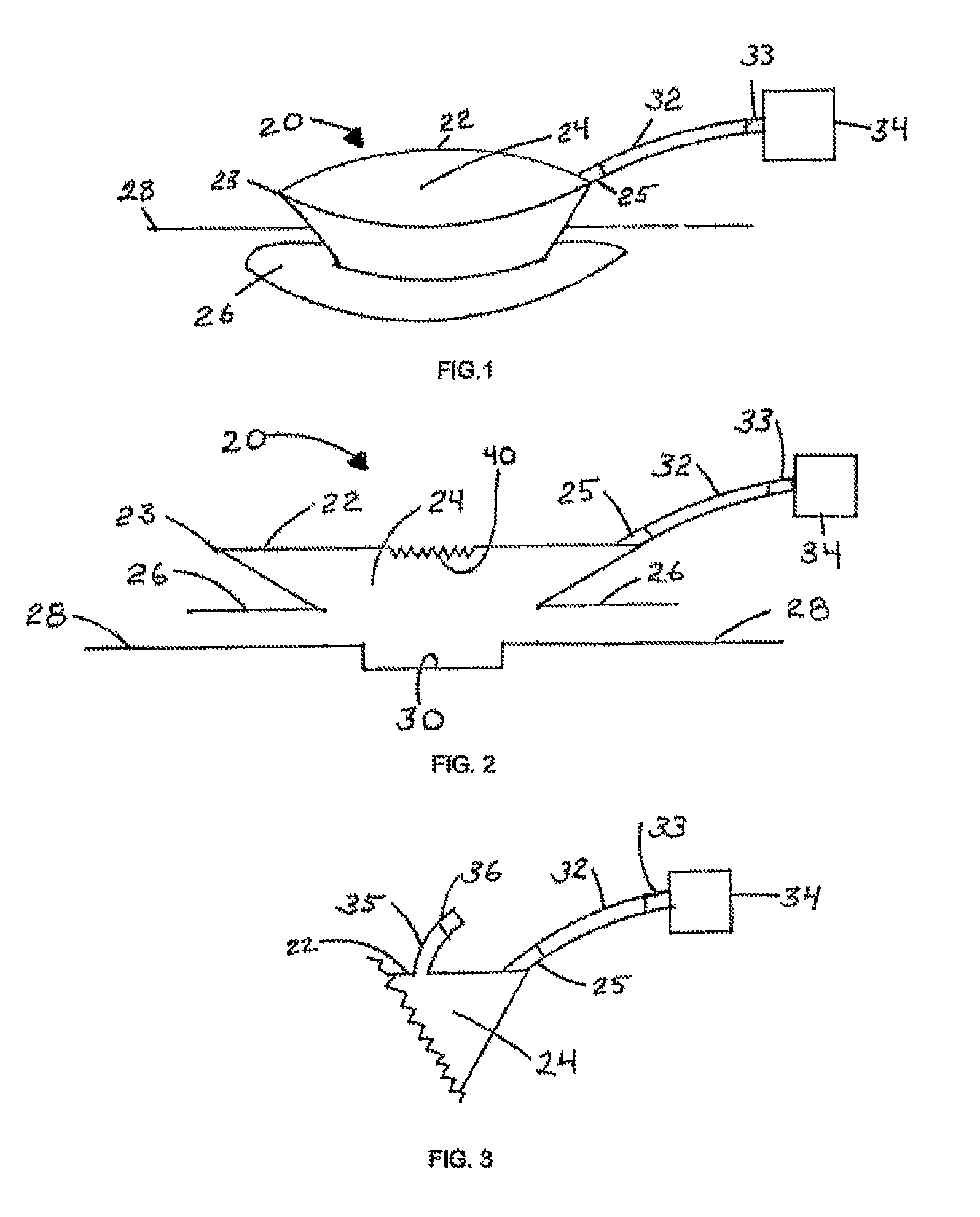

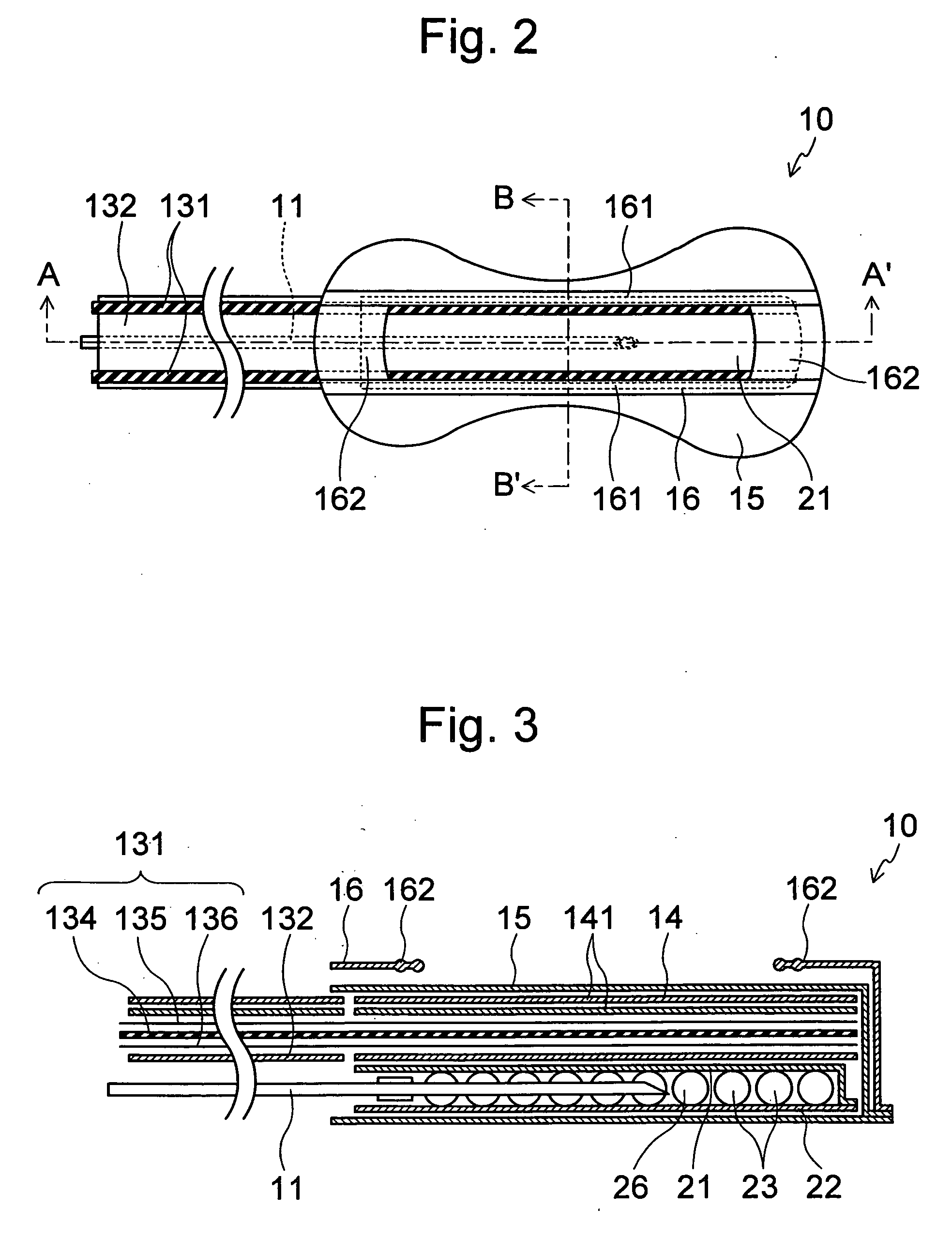

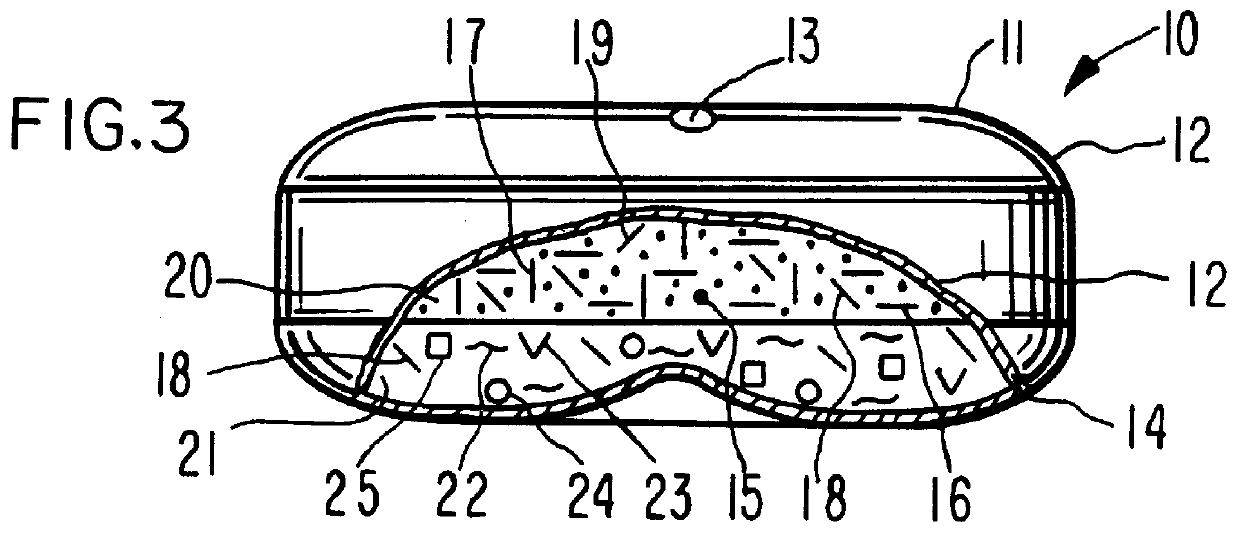

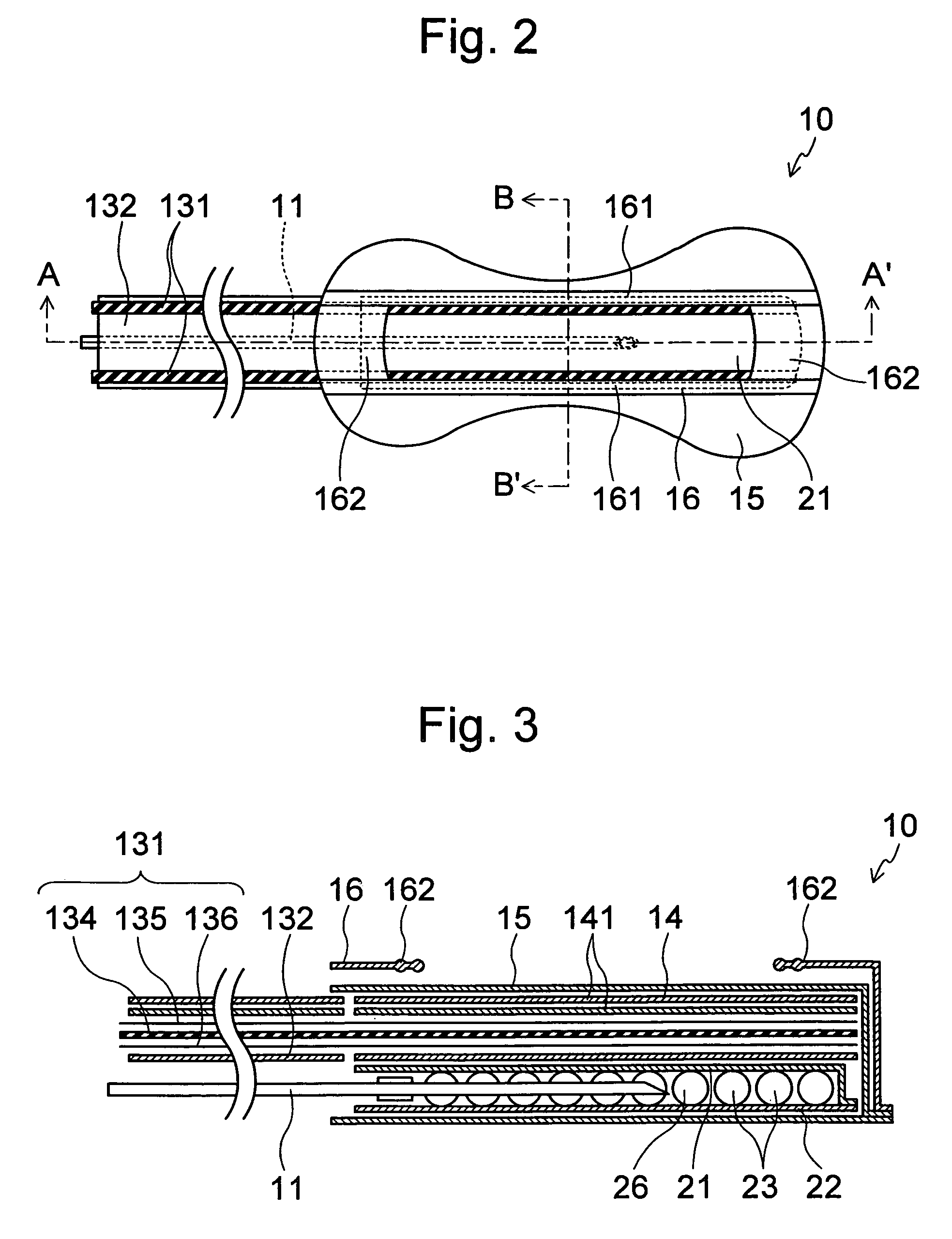

Urine receiver and urine collection processing system implementing urine receiver

InactiveUS20060015081A1Good adhesionPrevent leakageNon-surgical orthopedic devicesSuction devicesUrine leakageSkin surface

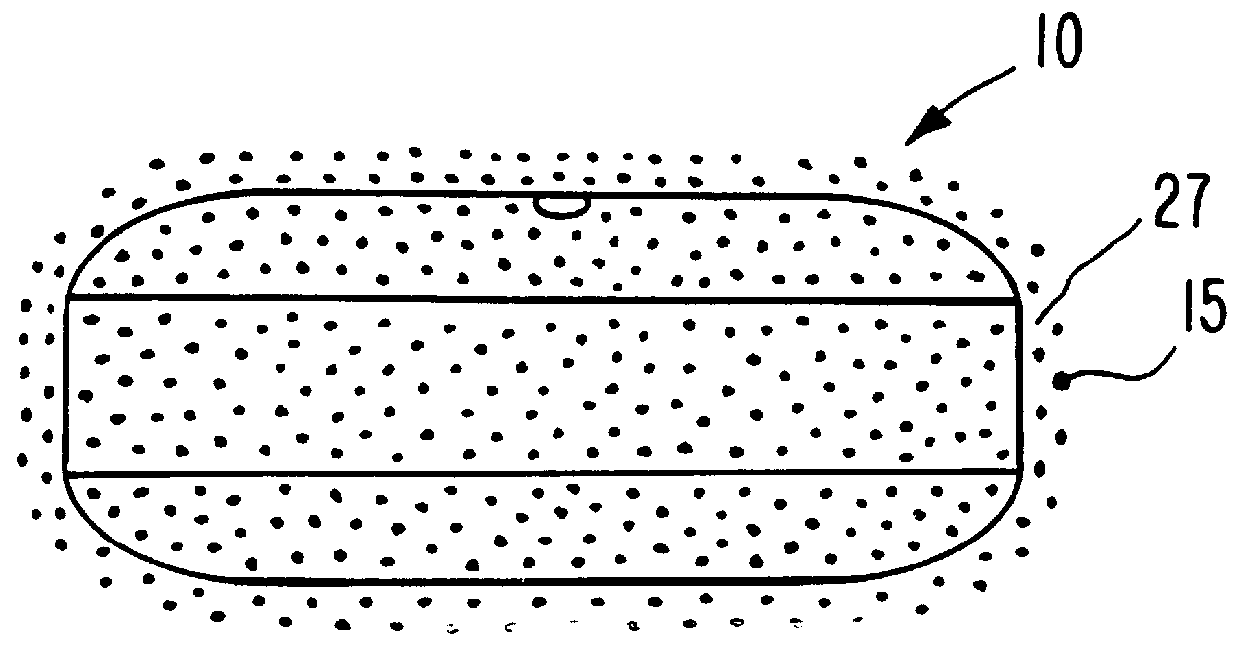

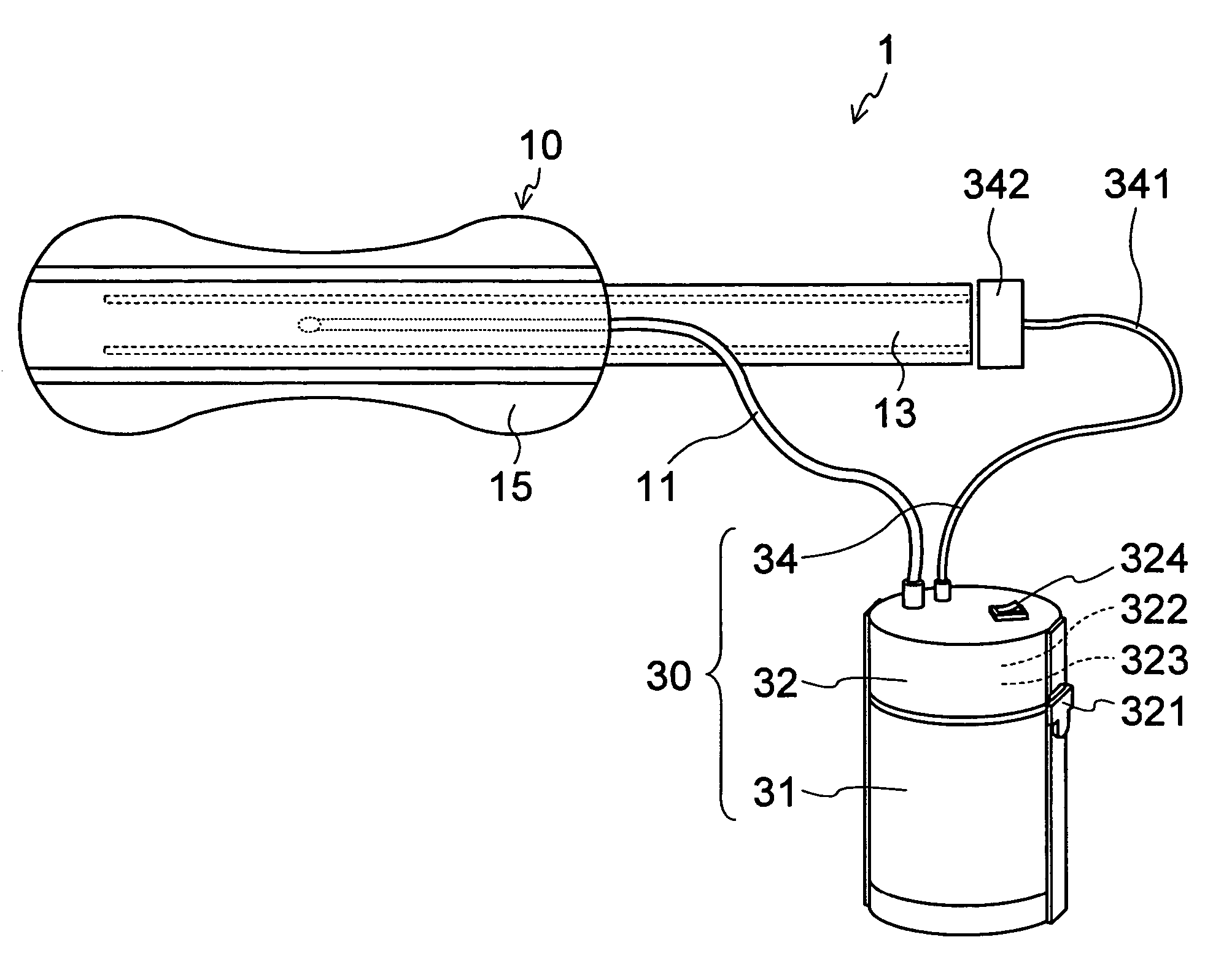

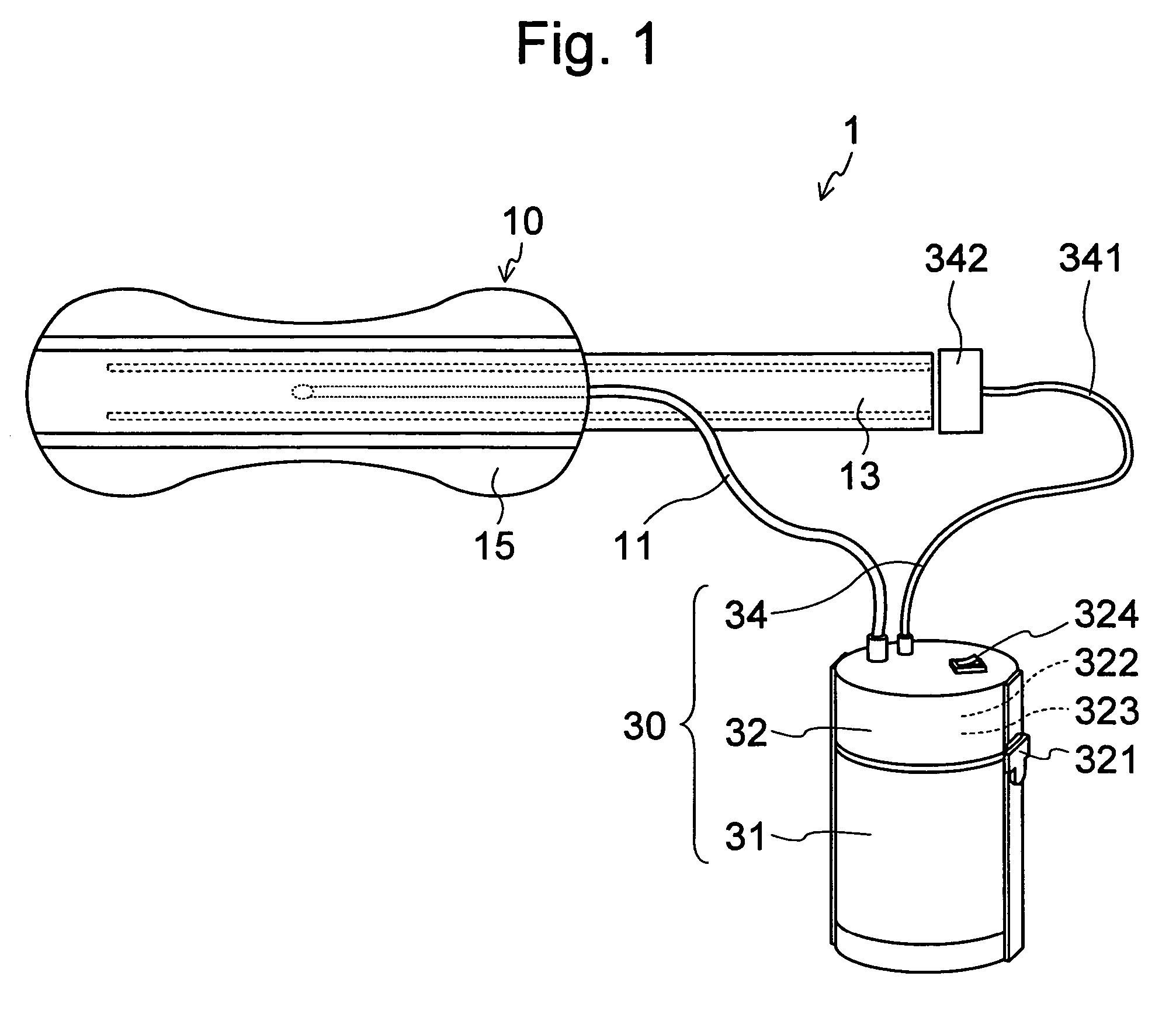

A urine receiver which is sanitary, easy to attach, and furthermore, prevents urine leakage even when a wearer repeatedly changes positions is provided. A urine receiver 10 is implemented in a urine collection processing system wherein urine discharged from the wearer is suctioned into a urine tank via a urethral tube. The urine receiver 10 comprises, at the least: a liquid permeable, air-impermeable sheet 21 which is placed opposite of and covering the urethral meatus of the wearer; a leak-proof sheet 22 which is placed on the surface of the air-impermeable sheet 21 opposite to the urethral meatus and bonds to the outer border of the air-impermeable sheet 21; a suction part 26 which is provided between the air-impermeable sheet 21 and the leak-proof sheet 22 and to which the urethral tube 11 is connected; and a gathers part 16 for sealing the space between the air-impermeable sheet 21 and the wearer's skin surface which is provided on the outer border part of the air-impermeable sheet 21 on the urethral meatus side.

Owner:UNI CHARM CORP

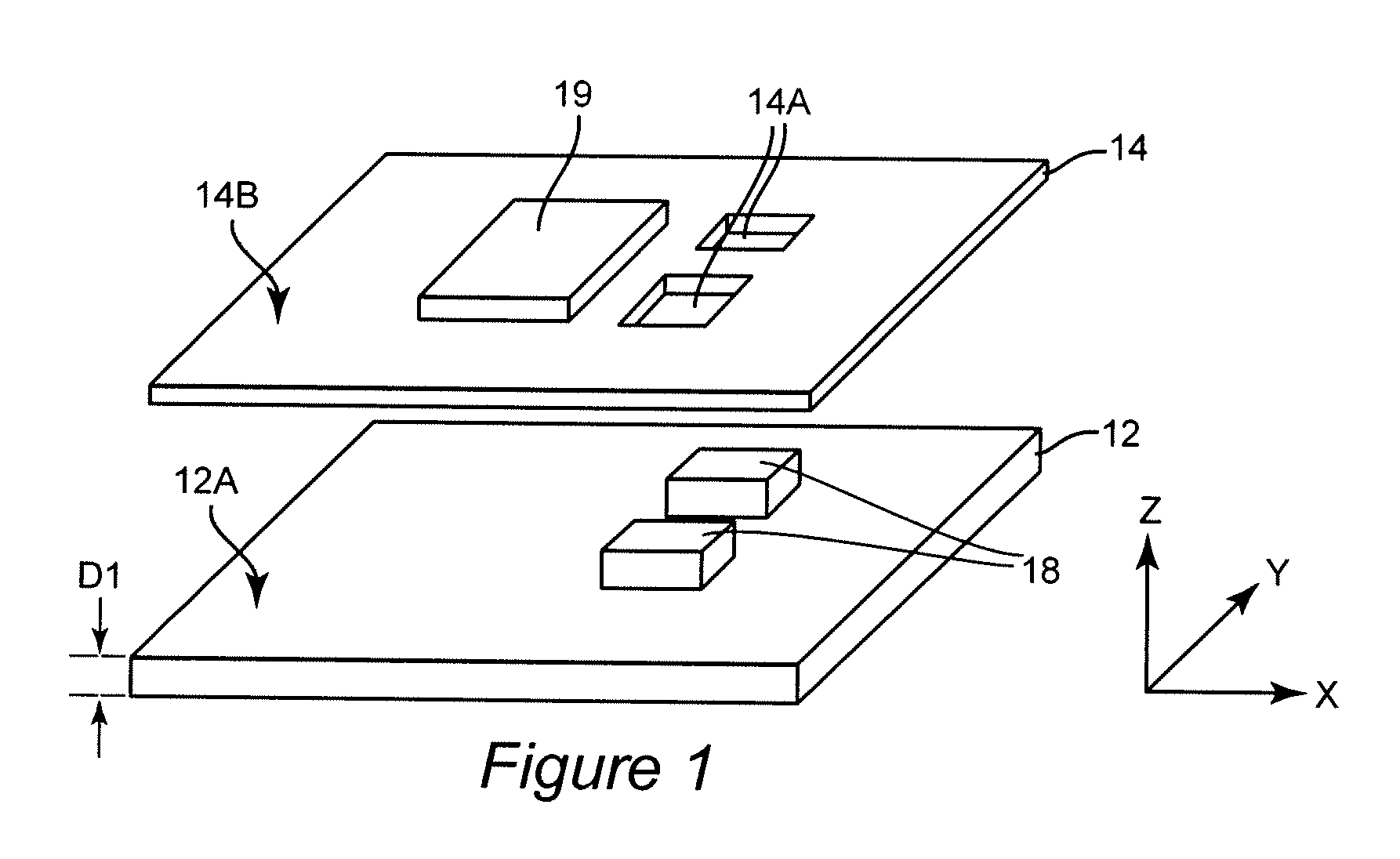

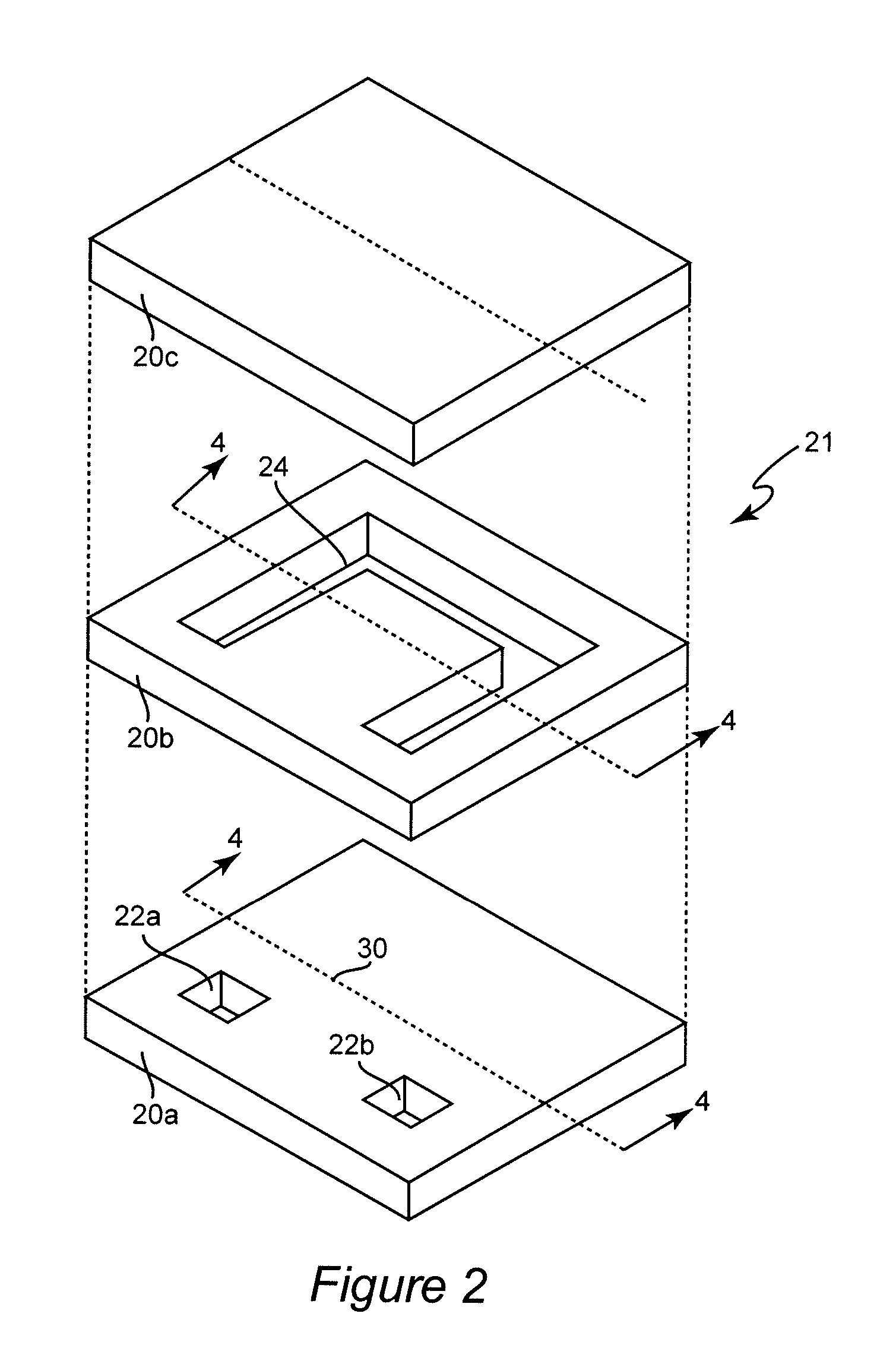

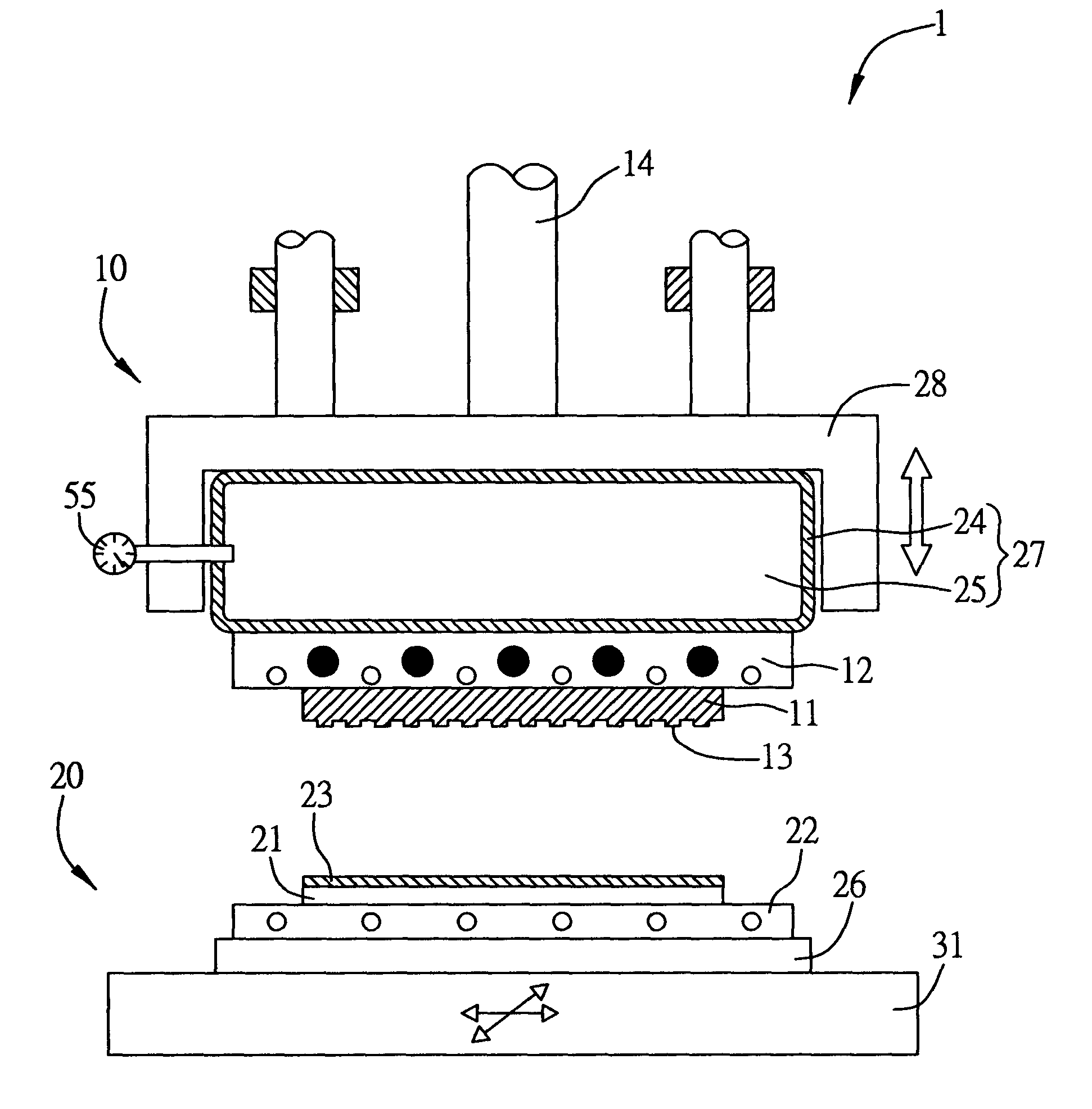

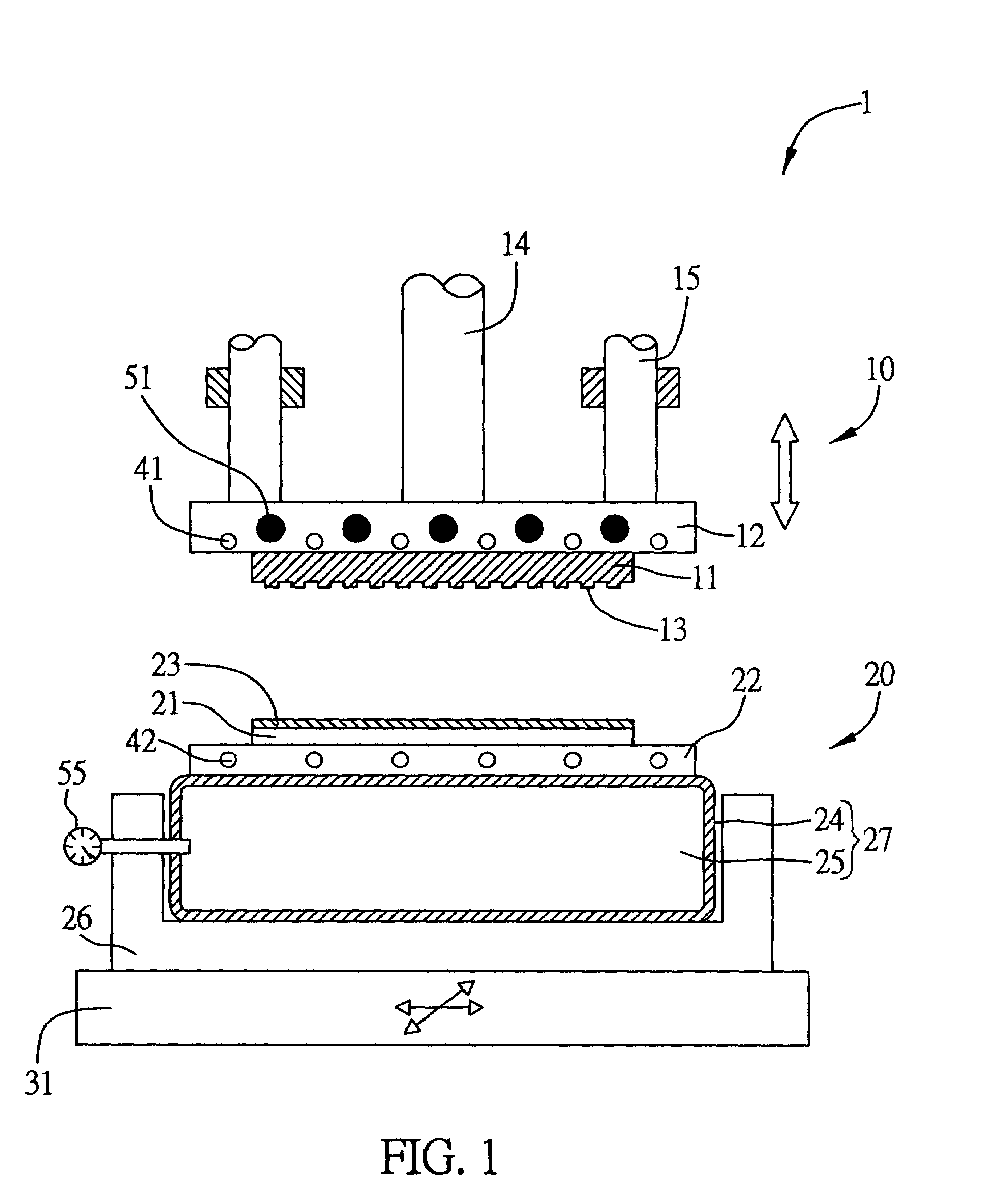

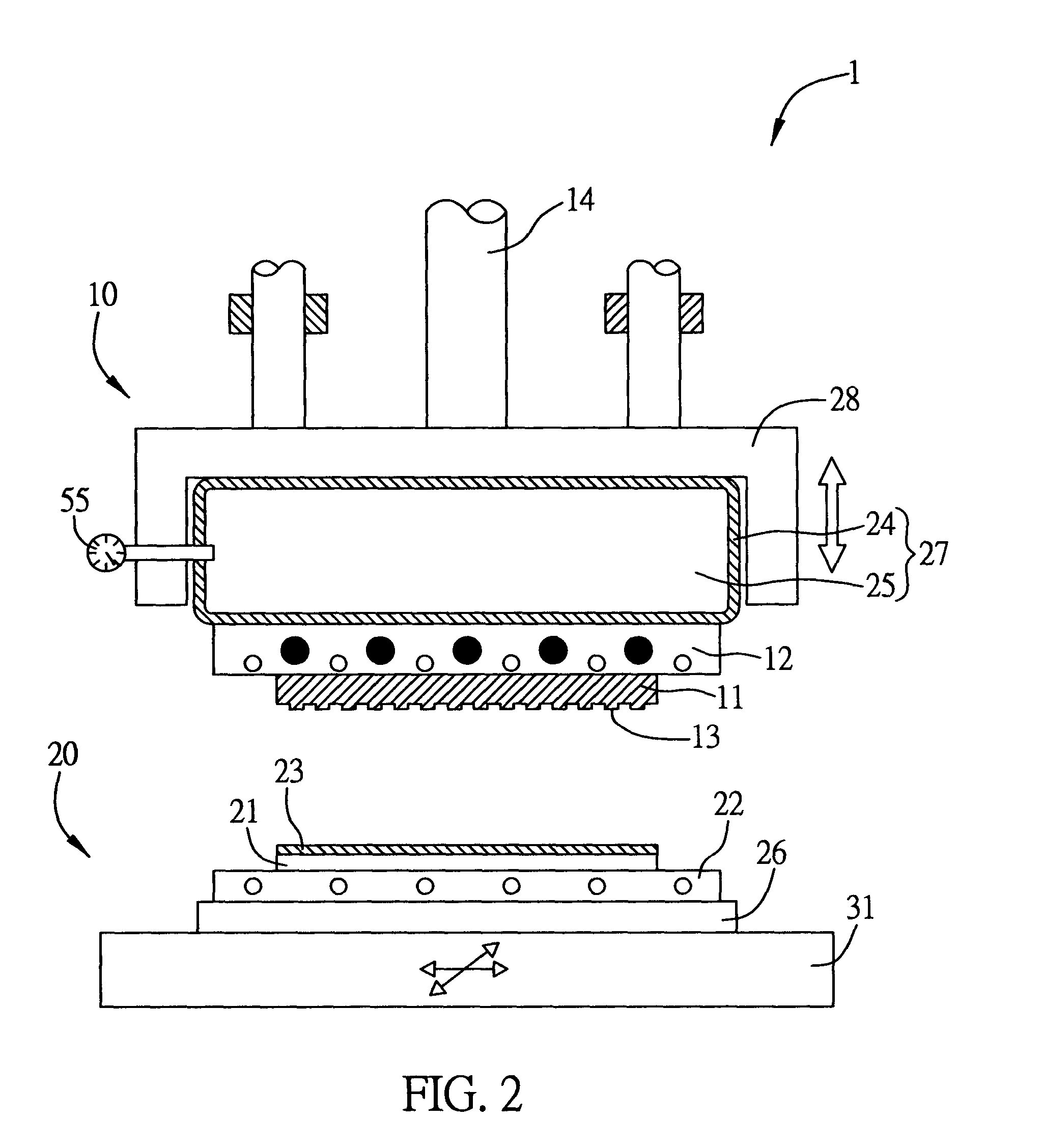

Parallelism adjustment device

InactiveUS7204686B2Enhance horizontal alignmentHigh level of freedomNanoinformaticsConfectioneryNanoimprint lithographyElectrical and Electronics engineering

A parallelism adjustment device applicable to nano-imprint lithography has an imprint unit, a carrier unit, a parallelism adjustment mechanism, and a driving source. The imprint unit has a first molding plate and an imprinting mold mounted on the first molding plate. The carrier unit has a second molding plate and a substrate mounted on the second molding plate. The parallelism adjustment mechanism has an enclosed resilient film and a fluid filled therein, and is coupled to at least one of the first and second molding plates. The driving source drives at least one of the imprint unit and the carrier unit to form contact between the mold and the moldable layer. The parallelism adjustment device is pressed via the contact to adjust parallelism for the imprint mold and the substrate and uniformly distributes the pressure between the mold and the substrate, making the molding quality of nano-imprint lithography significantly improved.

Owner:IND TECH RES INST

Spreader attachment

InactiveUS6209808B1Easy to controlIncrease widthCentrifugal wheel fertilisersRoads maintainenceEngineeringKnife blades

A dual disc spreader attachment utilizing a specific direction of disc rotation, pinpoint control of the impact point of material onto the disc and blade design to provide an optimal scatter pattern.

Owner:GVM

Well chemical treatment utilizing plunger lift delivery system with chemically improved plunger seal

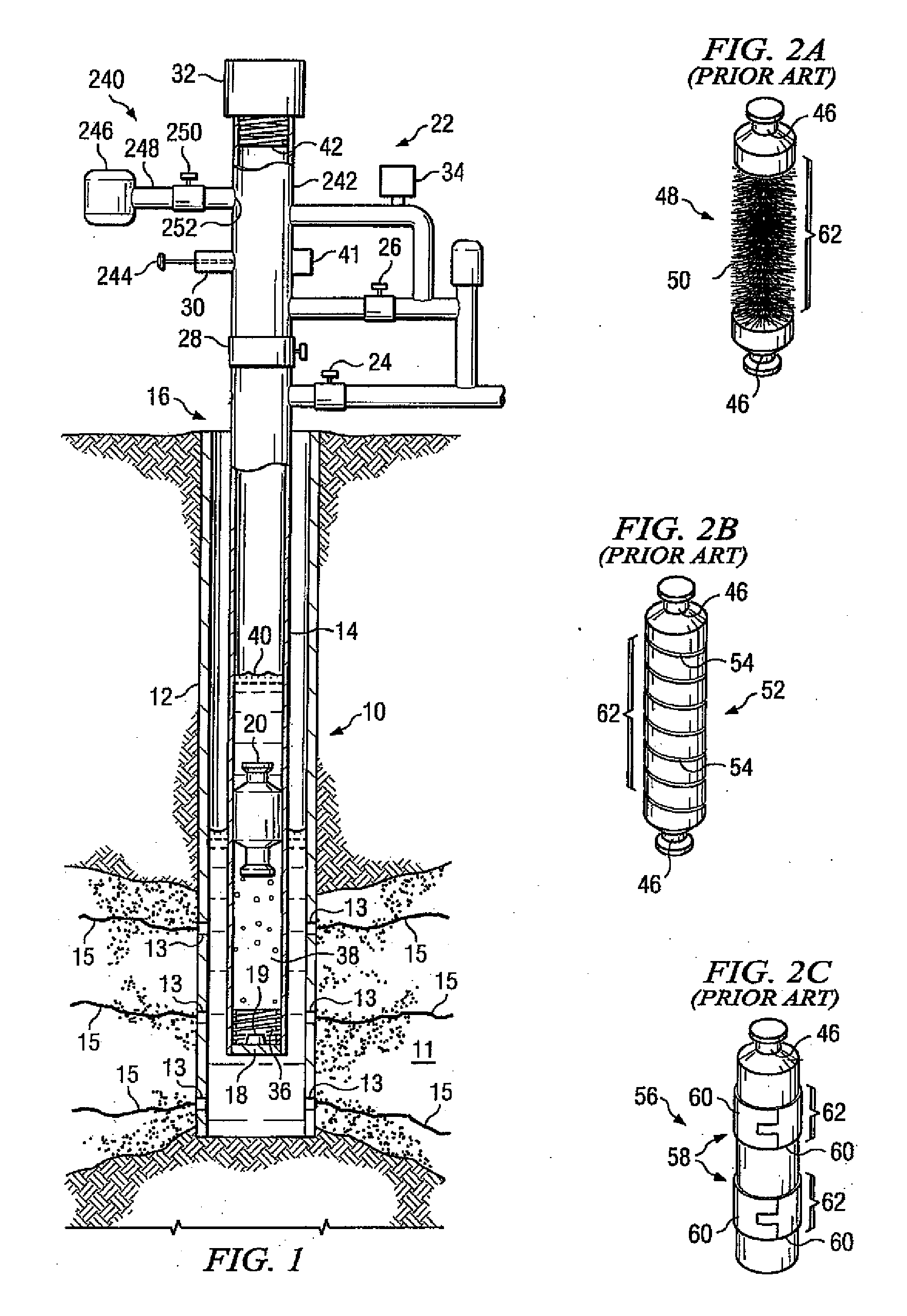

InactiveUS20070039739A1Improve efficiencyOptimize volumeCleaning apparatusFluid removalChemical treatmentFoaming agent

An apparatus incorporating a chemical seal and method for removing fluids from a well is disclosed. The chemical seal is created by a foaming agent which, when in the presence of gas and fluids present in the well, and when agitated by the apparatus, creates foam between the apparatus and the walls of the well in which it operates. The foam improves the seal between the apparatus and the inner wall of the well, improving the efficiency of the apparatus in lifting fluids from the well. Furthermore, the chemical seal improves the distribution of treatment chemicals within the well as it reduces liquid flowback. Automatic recharging or reapplication of the foaming agent and / or treatment chemicals to the apparatus can be accomplished with a chemical application assembly associated with the well.

Owner:CONOCOPHILLIPS CO

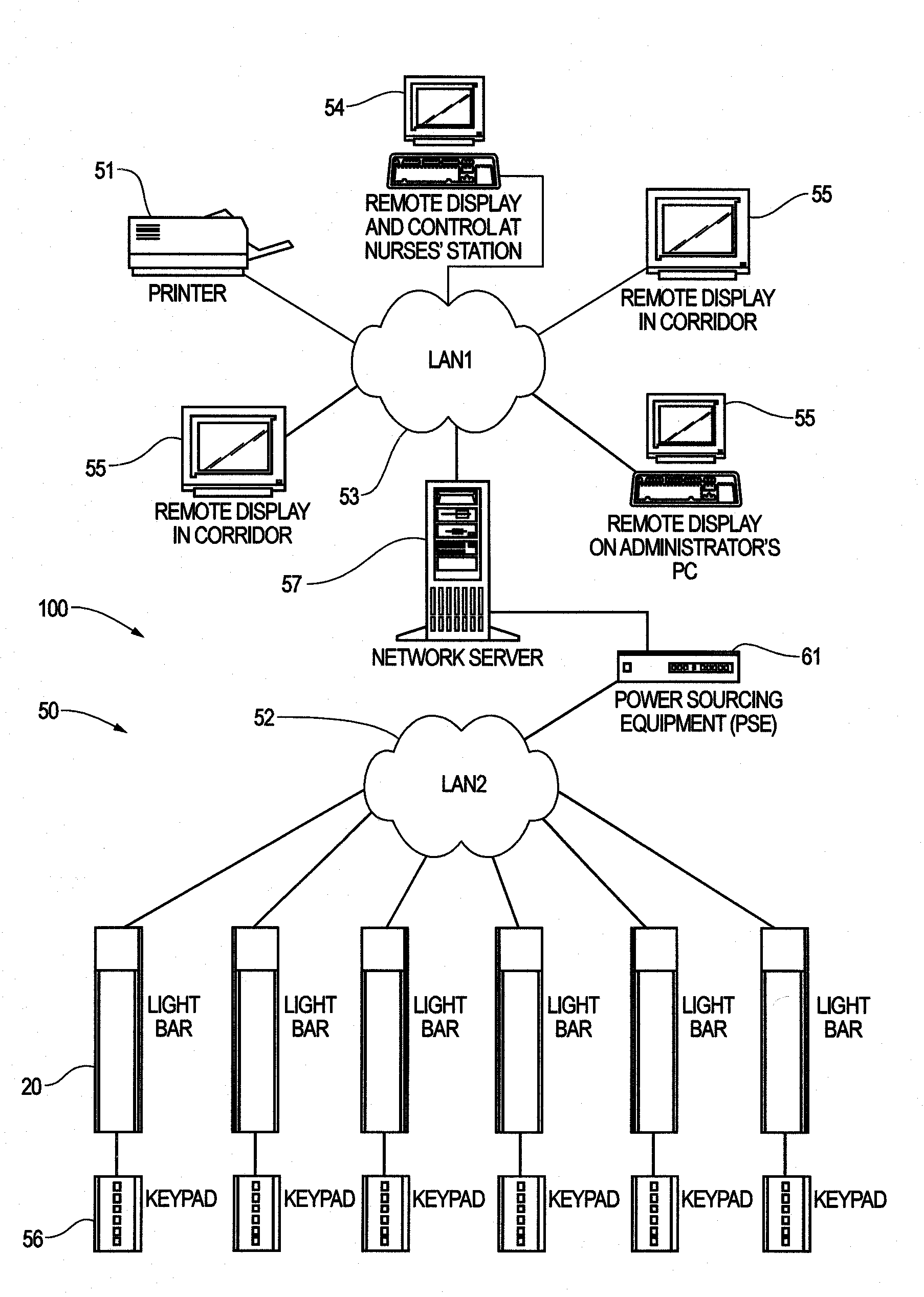

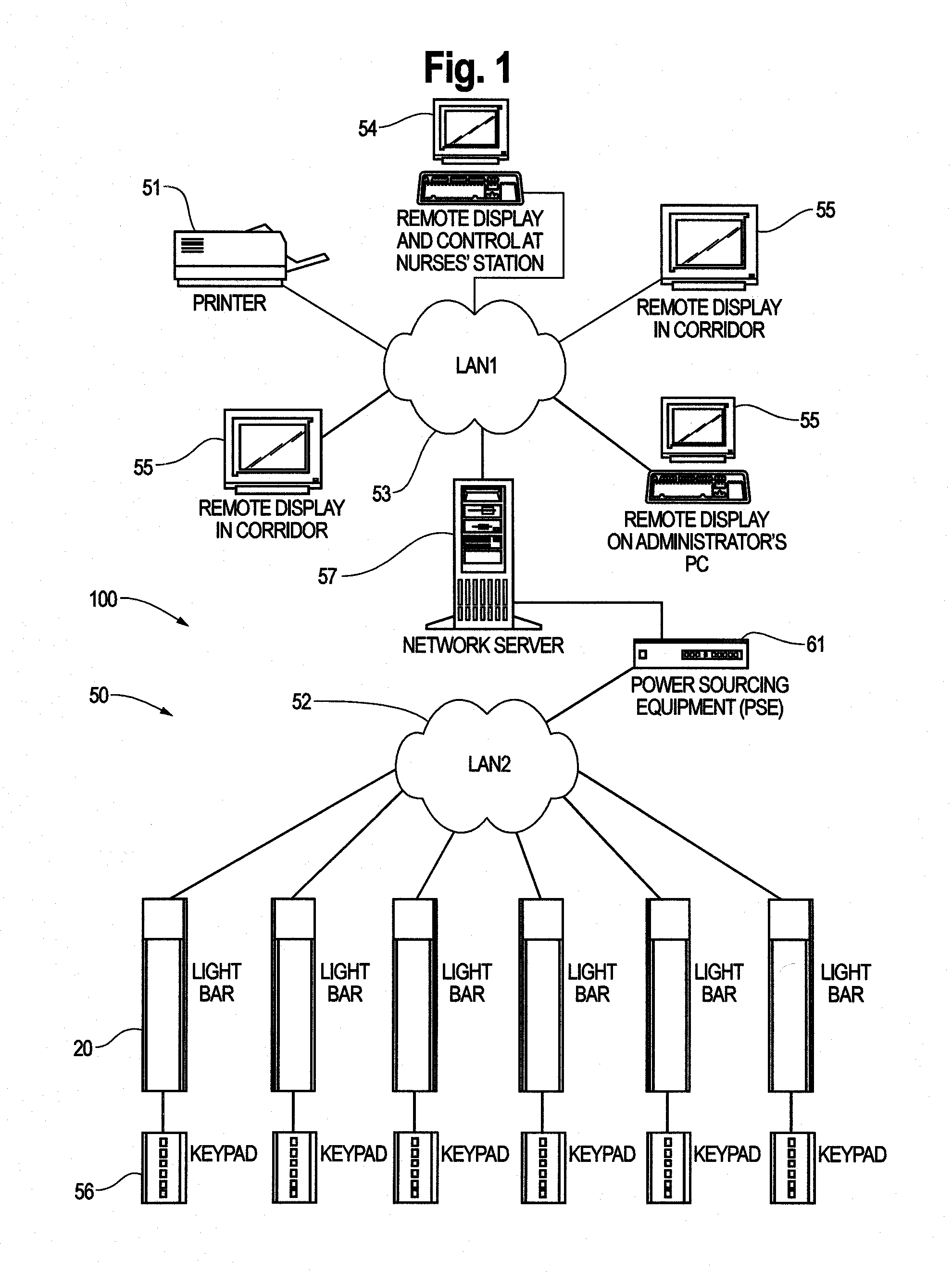

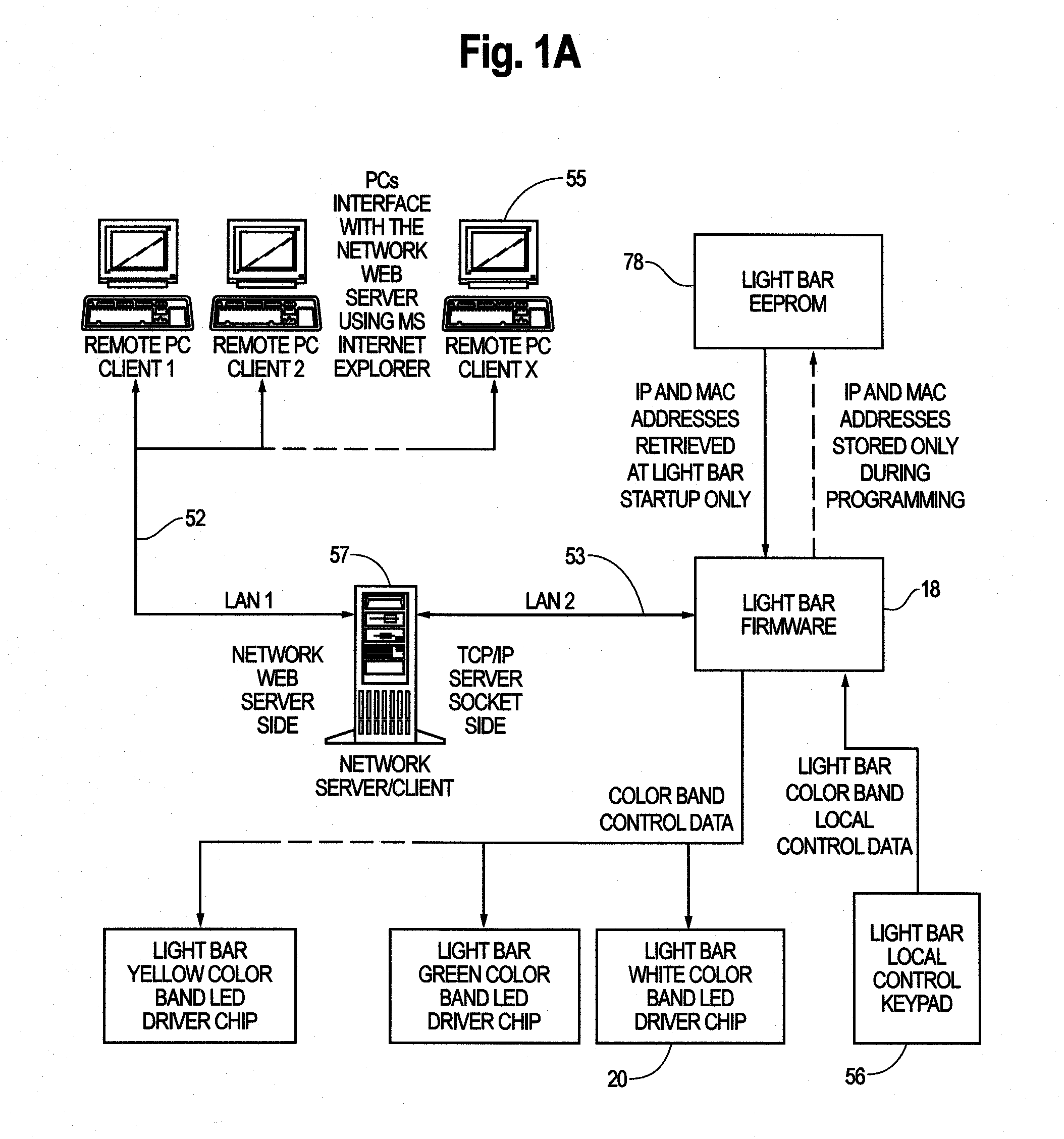

Modular signal device for a room occupancy management system and a method for using same

InactiveUS20090066486A1Avoid bleedingUniform brightnessElectric/electromagnetic visible signallingOrder telegraph apparatusModularityEngineering

A method and a system for using a modular signal device for a room occupancy management system are disclosed here. The method includes the steps of determining the occupancy status of a room associated with the device and generating a signal in the device in response to the determination of the status of the room. The device may be a light bar displaying different color patterns in response to the occupancy status of the room. A room occupancy management system is also disclosed. The system includes a signal device for generating a signal displaying the occupancy status of an associated room and a control unit for controlling the device.

Owner:OMNI CONTROL SYST

Acoustical gypsum board panel and method of making it

ActiveUS8057915B2Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

Owner:UNITED STATES GYPSUM CO

Fluid End with Carbide Valve Seat and Adhesive Dampening Interface

ActiveUS20140070127A1Avoid fracturesApply evenlyPositive displacement pump componentsCheck valvesEngineeringHigh pressure

A tungsten carbide seat for high-pressure oilfield well service pumps is disclosed. A bonding agent, in conjunction with an interference tapered fit between the valve seat and fluid end housing eliminates stresses created in prior art interference fits. Three interface embodiments are disclosed: a shallow taper combined with a shoulder, a steep taper without a shoulder, and a compound surface in which the seat has an external concave surface and the housing surface that mates with the seat has a convex surface.

Owner:ALTIS INVESTMENTS LLC

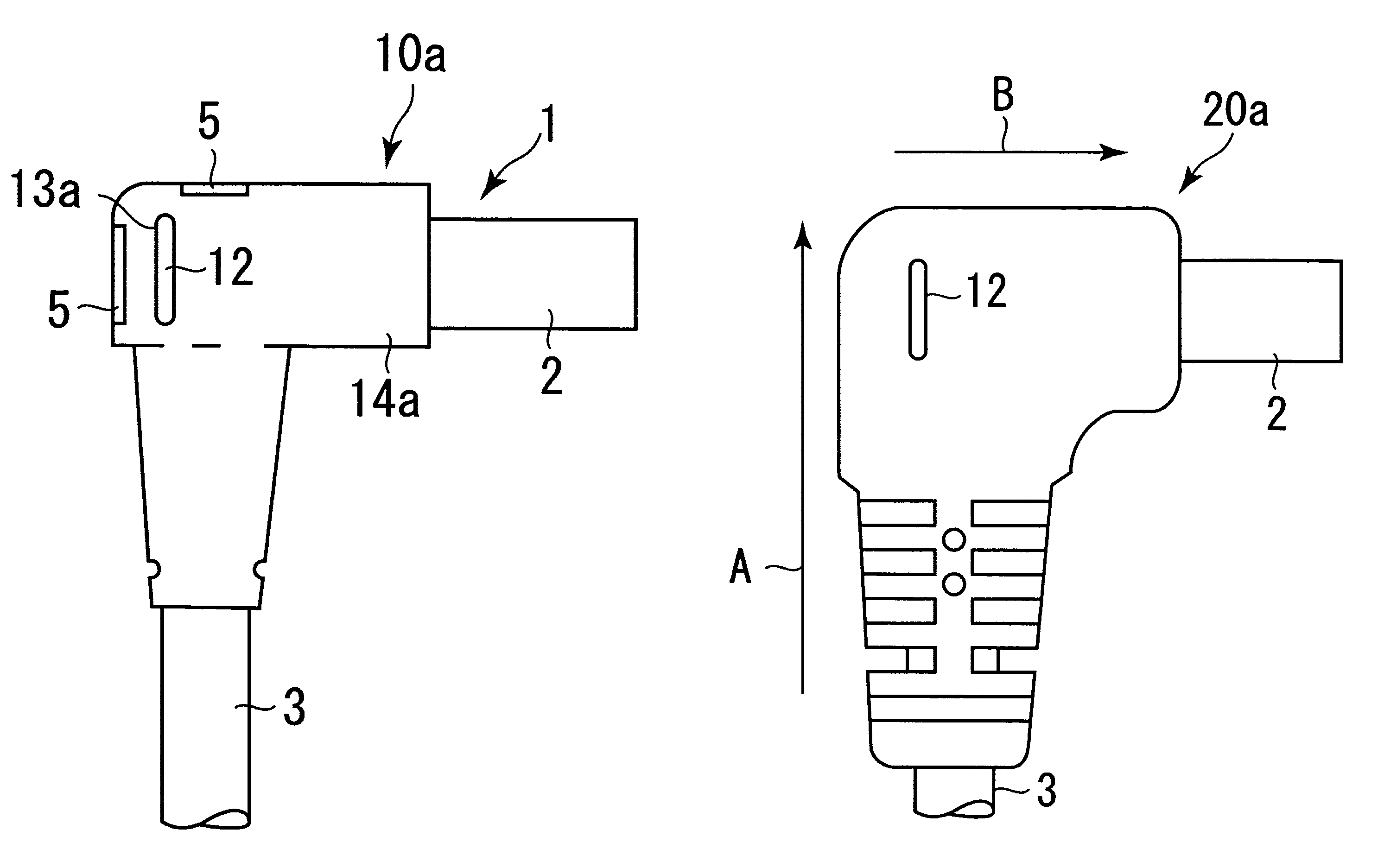

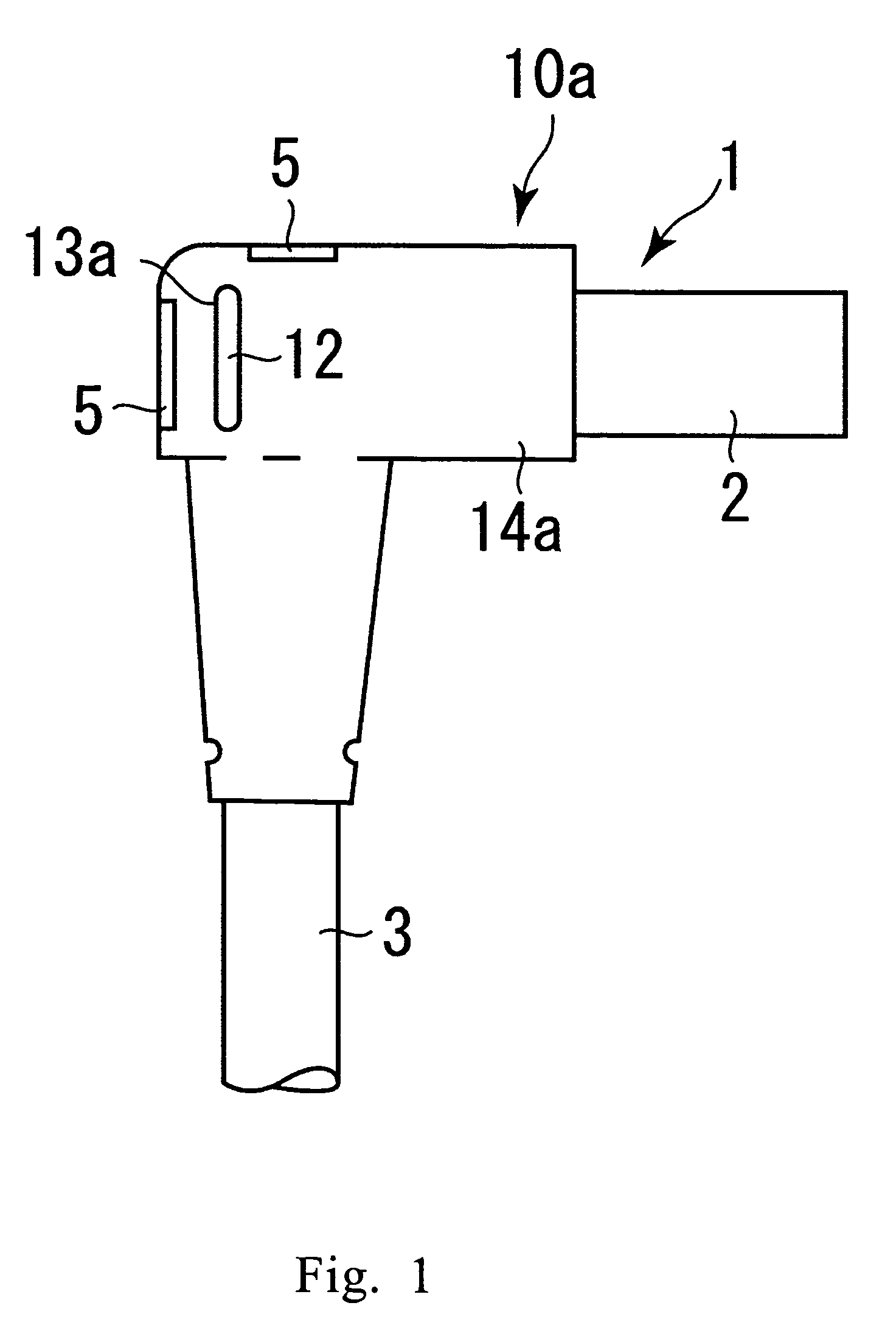

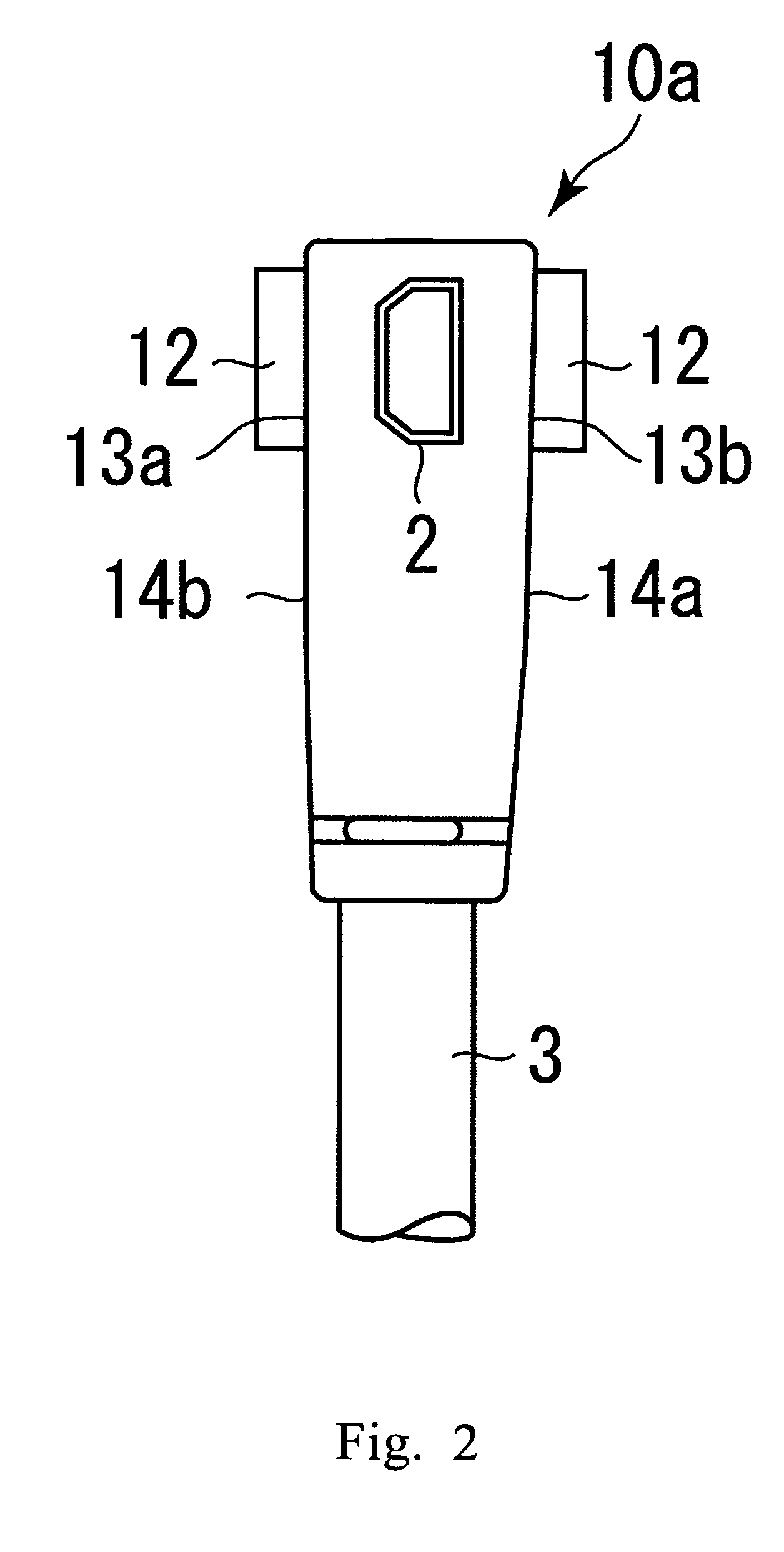

Connector with resin molded portion

InactiveUS7018236B2Avoid misalignmentAvoid problemsRelieving strain on wire connectionContact member assembly/disassemblyShell moldingEngineering

A connector includes a connector main body 1 having a metallic electrical connecting portion 2, an inner molded portion 10a provided outside the connector main body and having a pair of protrusions 12 which are integrally formed on the opposite surfaces of the inner molded portion 10a, and an outer molded portion 20a provided outside the inner molded portion so that the protrusions 12 are partially exposed on the outer surface of the outer molded portion 20a. The pair of protrusions 12 protrude toward a pair of metal molds for molding the outer molding portion, respectively.

Owner:MITSUMI ELECTRIC CO LTD

Therapy for neurological diseases

InactiveUS6036973AAvoiding toxic rangeShorten the progressPowder deliveryPill deliveryDiseaseNervous system

A dosage form is disclosed for administering 10 ng to 1200 mg tacrine to a patient in need of tacrine therapy.

Owner:ENCINAL PHARMA INVESTMENTS

Urine receiver and urine collection processing system implementing urine receiver

InactiveUS7220250B2Good adhesionPrevent leakageNon-surgical orthopedic devicesSuction devicesUrine leakageSkin surface

A urine receiver which is sanitary, easy to attach, and furthermore, prevents urine leakage even when a wearer repeatedly changes positions is provided. A urine receiver 10 is implemented in a urine collection processing system wherein urine discharged from the wearer is suctioned into a urine tank via a urethral tube. The urine receiver 10 comprises, at the least: a liquid permeable, air-impermeable sheet 21 which is placed opposite of and covering the urethral meatus of the wearer; a leak-proof sheet 22 which is placed on the surface of the air-impermeable sheet 21 opposite to the urethral meatus and bonds to the outer border of the air-impermeable sheet 21; a suction part 26 which is provided between the air-impermeable sheet 21 and the leak-proof sheet 22 and to which the urethral tube 11 is connected; and a gathers part 16 for sealing the space between the air-impermeable sheet 21 and the wearer's skin surface which is provided on the outer border part of the air-impermeable sheet 21 on the urethral meatus side.

Owner:UNI CHARM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com