Patents

Literature

330 results about "Calcium Sulfate Dihydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Siloxane polymerization in wallboard

ActiveUS20070022913A1Small expansionDimensional stabilitySolid waste managementWoven fabricsDihydrate Calcium SulfateSlurry

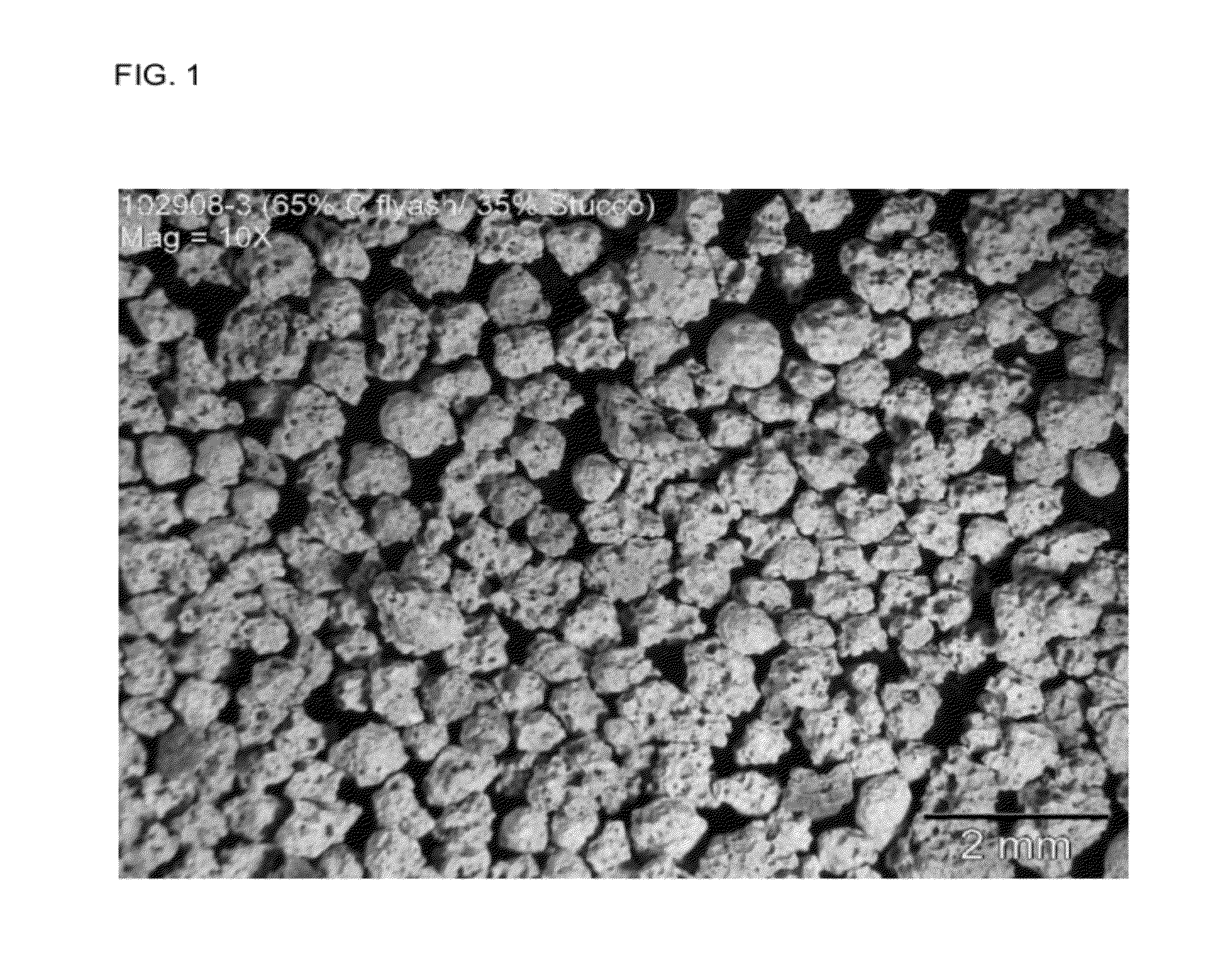

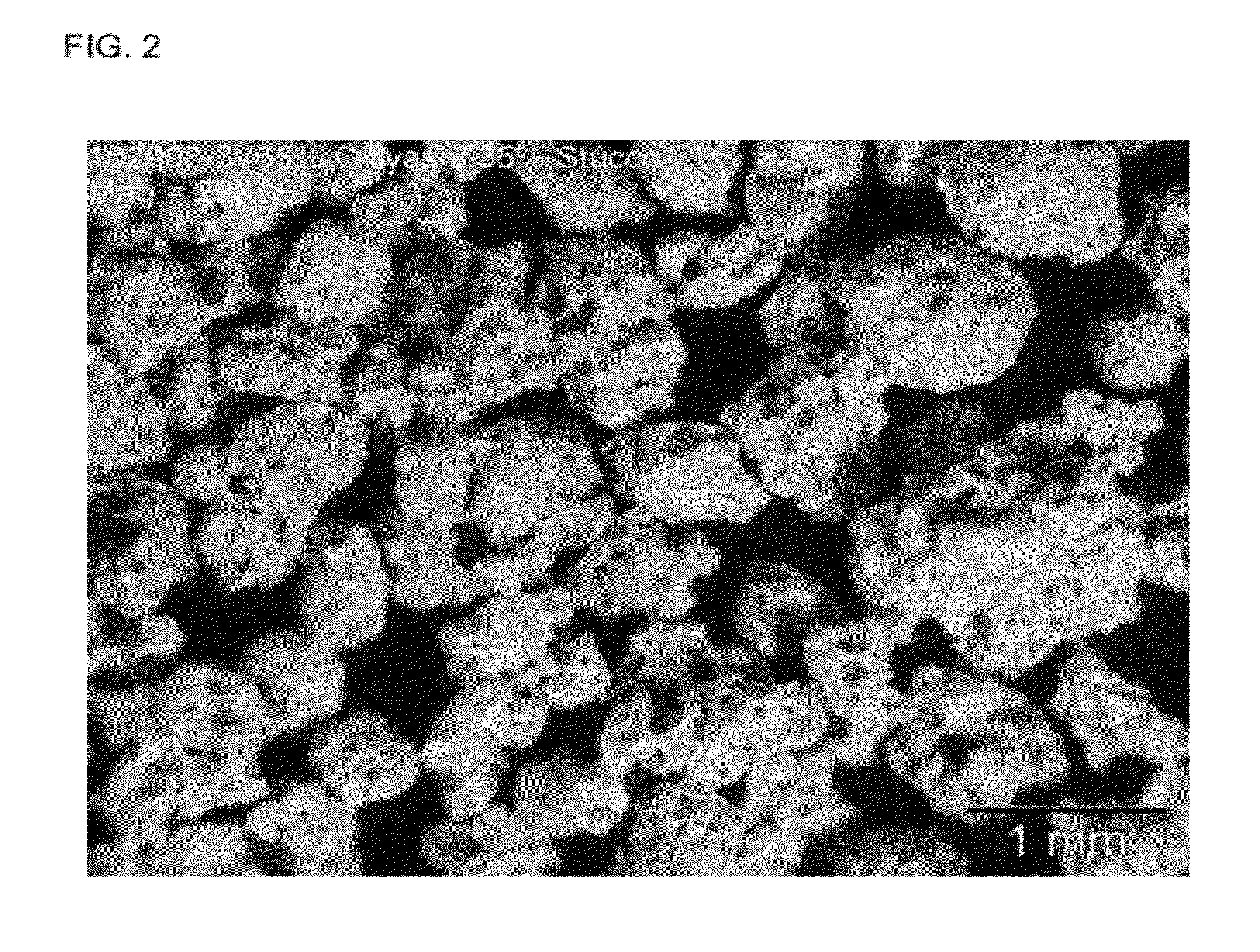

Polymerization of siloxane is improved using a gypsum-based slurry that includes stucco, Class C fly ash, magnesium oxide and an emulsion of siloxane and water. This slurry is used in a method of making water-resistant gypsum articles that includes making an emulsion of siloxane and water, then combining the slurry with a dry mixture of stucco, magnesium oxide and Class C fly ash. The slurry is then shaped as desired and the stucco is allowed to set and the siloxane polymerizes. The resulting product is useful for making a water-resistant gypsum panel having a core that includes interwoven matrices of calcium sulfate dihydrate crystals and a silicone resin, where the interwoven matrices have dispersed throughout them a catalyst comprising magnesium oxide and components from a Class C fly ash.

Owner:UNITED STATES GYPSUM CO

Fire-resistant gypsum

InactiveUS20050263925A1Point becomes highImprove fire resistanceConstruction materialWood working apparatusGlass fiberFiber

An improved, fire-resistant, set gypsum composition contains set calcium sulfate dihydrate as the major ingredient and a reinforcing ingredient of resilient, flexible, boron-free glass fibers. Continuous filament forming glass compositions with a softening point preferably greater than about 1580° F. (about 860° C.) and more preferably greater than about 1681° F. (about 916° C.) may be used. The fibers typically are distributed as their separate constituent individual glass filaments uniformly throughout the set calcium sulfate dihydrate.

Owner:OWENS CORNING FIBERGLAS TECH INC

Mold-resistant gypsum panel and method of making same

InactiveUS6893752B2Reduce the growth of moldImprove anti-mold performancePretreated surfacesRecord information storageSodium PyrithioneEvaporation

A mold-resistant gypsum panel includes a core of an interlocking matrix of calcium sulfate dihydrate crystals, a facing material on at least one side of the panel and a salt of pyrithione dispersed through both the core and the facing materials. A method of making a mold-resistant gypsum product is also provided. A slurry of calcined gypsum, water and a water-soluble pyrithione salt is formed, then deposited on a sheet of facing material. The slurry on the facing material is shaped into a panel and maintained under conditions sufficient for the calcined gypsum to react with the water to form a core comprising an interlocking matrix of set gypsum crystals. Heating of the panel causes evaporation of the water that did not react with the calcined gypsum.

Owner:UNITED STATES GYPSUM CO

Acoustical gypsum board panel and method of making it

ActiveUS20080299413A1Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

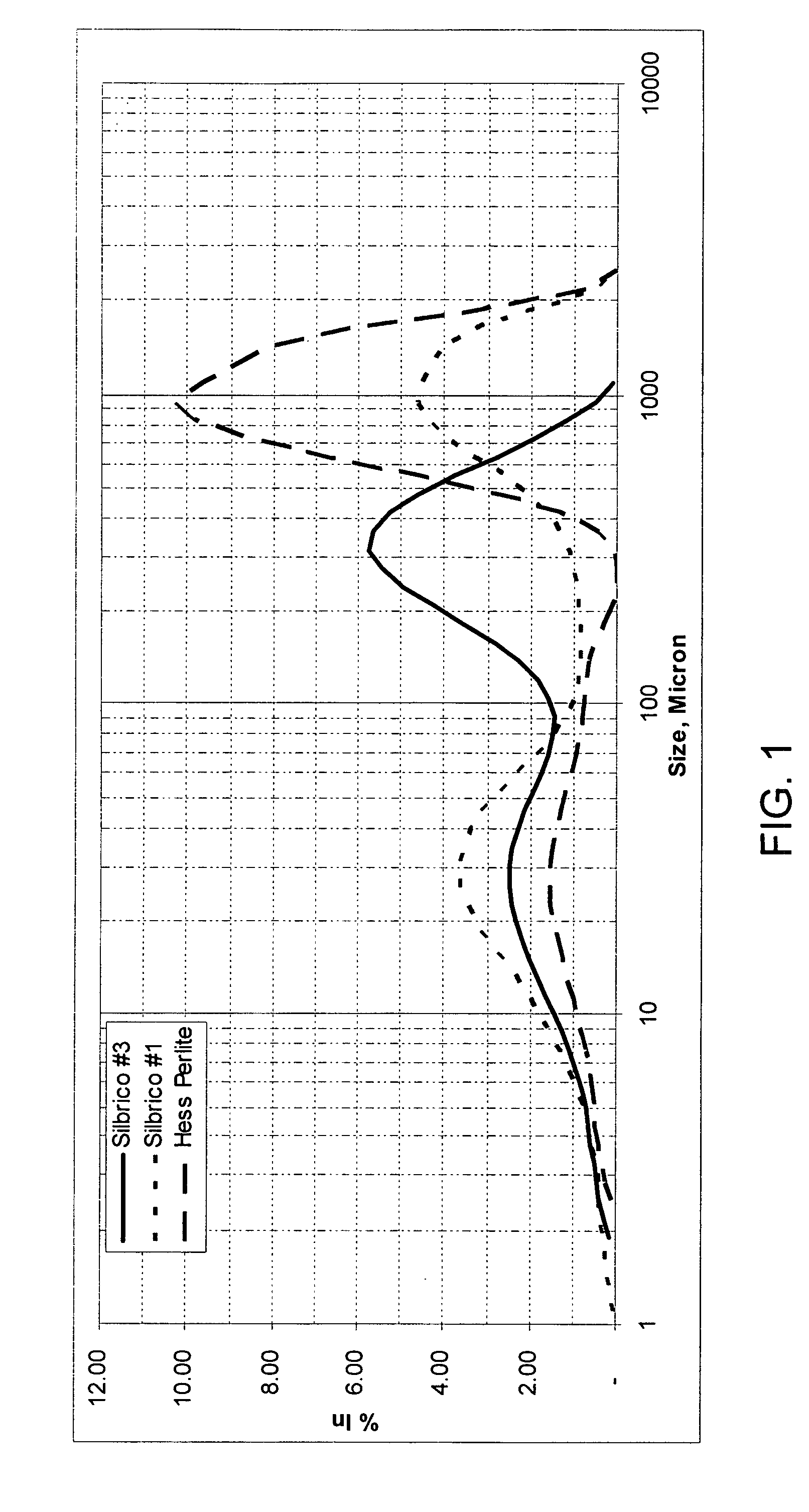

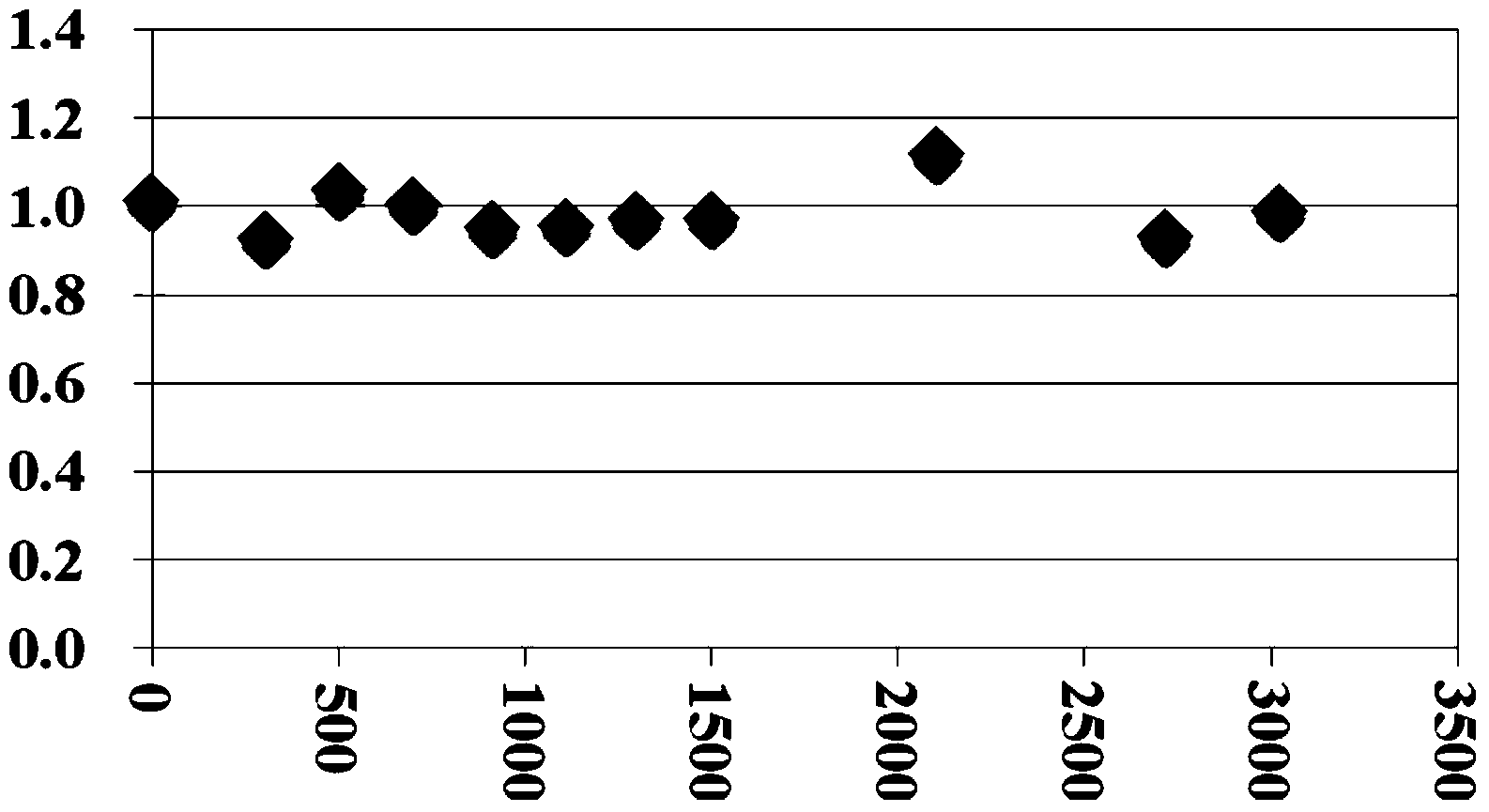

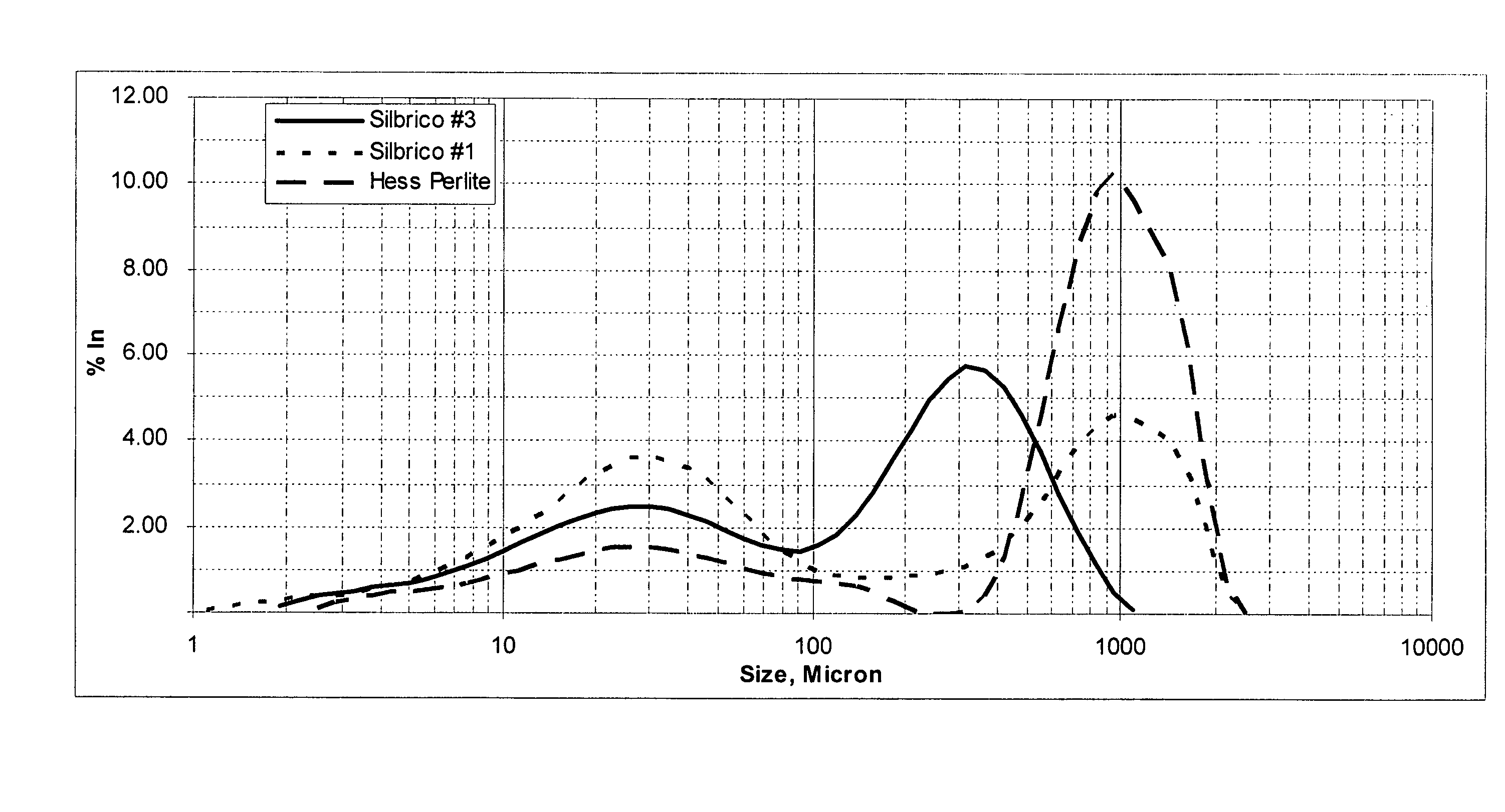

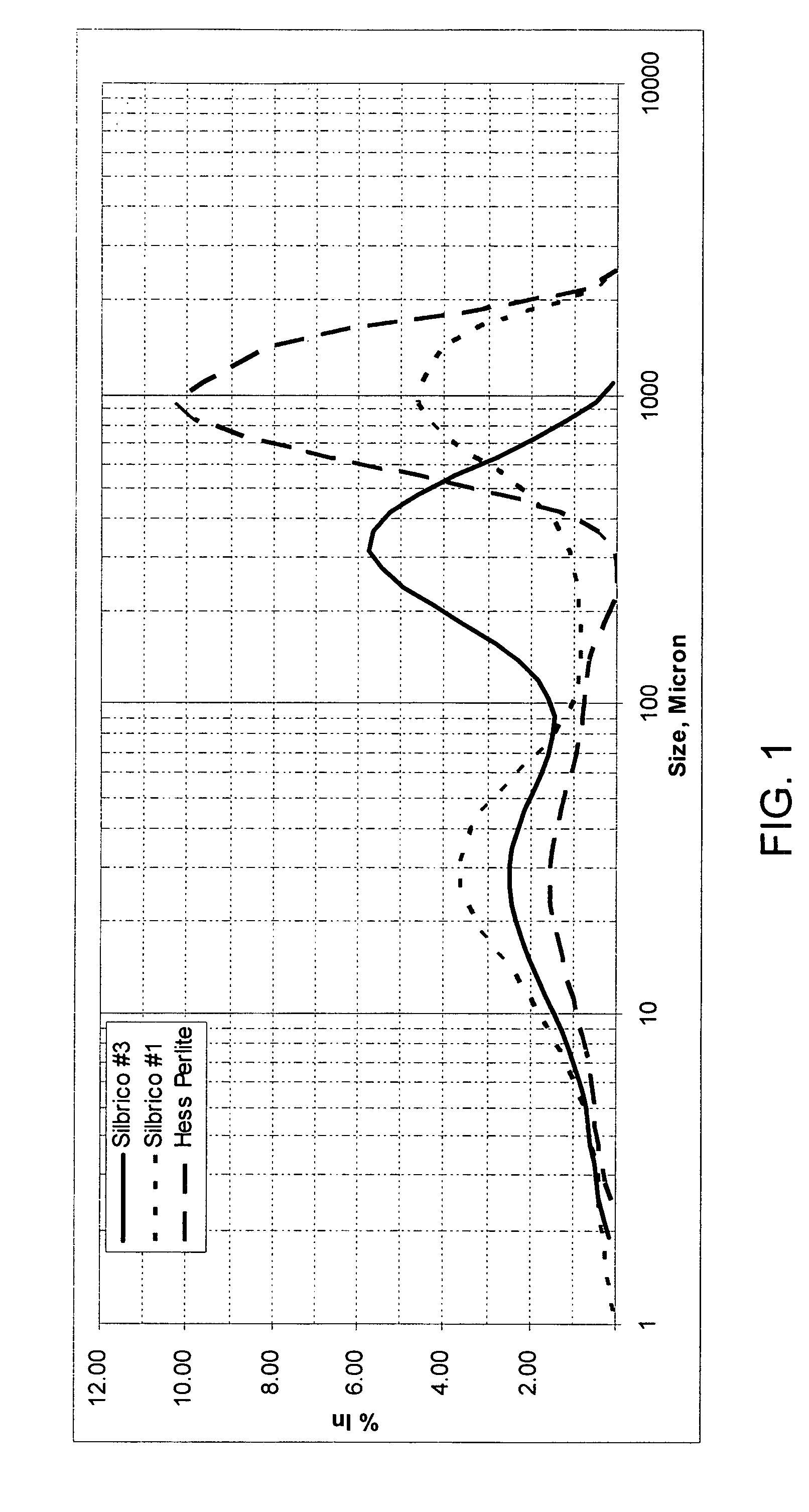

The acoustical product of the present invention comprises an acoustical product including a matrix of calcium sulfate dihydrate crystals and expanded perlite distributed throughout the matrix. The expanded perlite has a particle size distribution with at least 10% of the perlite having a particle diameter of 700 microns or more, and the amount of expanded perlite to calcium sulfate dihydrate is about 35% to about 75% by weight, based upon the dry weight of the calcium sulfate dihydrate. A dispersing agent and glass fibers having a particle length of about ¼ inch to about 1 inch are dispersed throughout the gypsum matrix.

Owner:UNITED STATES GYPSUM CO

Fiberboard with improved water resistance

ActiveUS7413603B2High strengthImprove waterproof performanceSolid waste managementWood working apparatusSlurryWater resistant

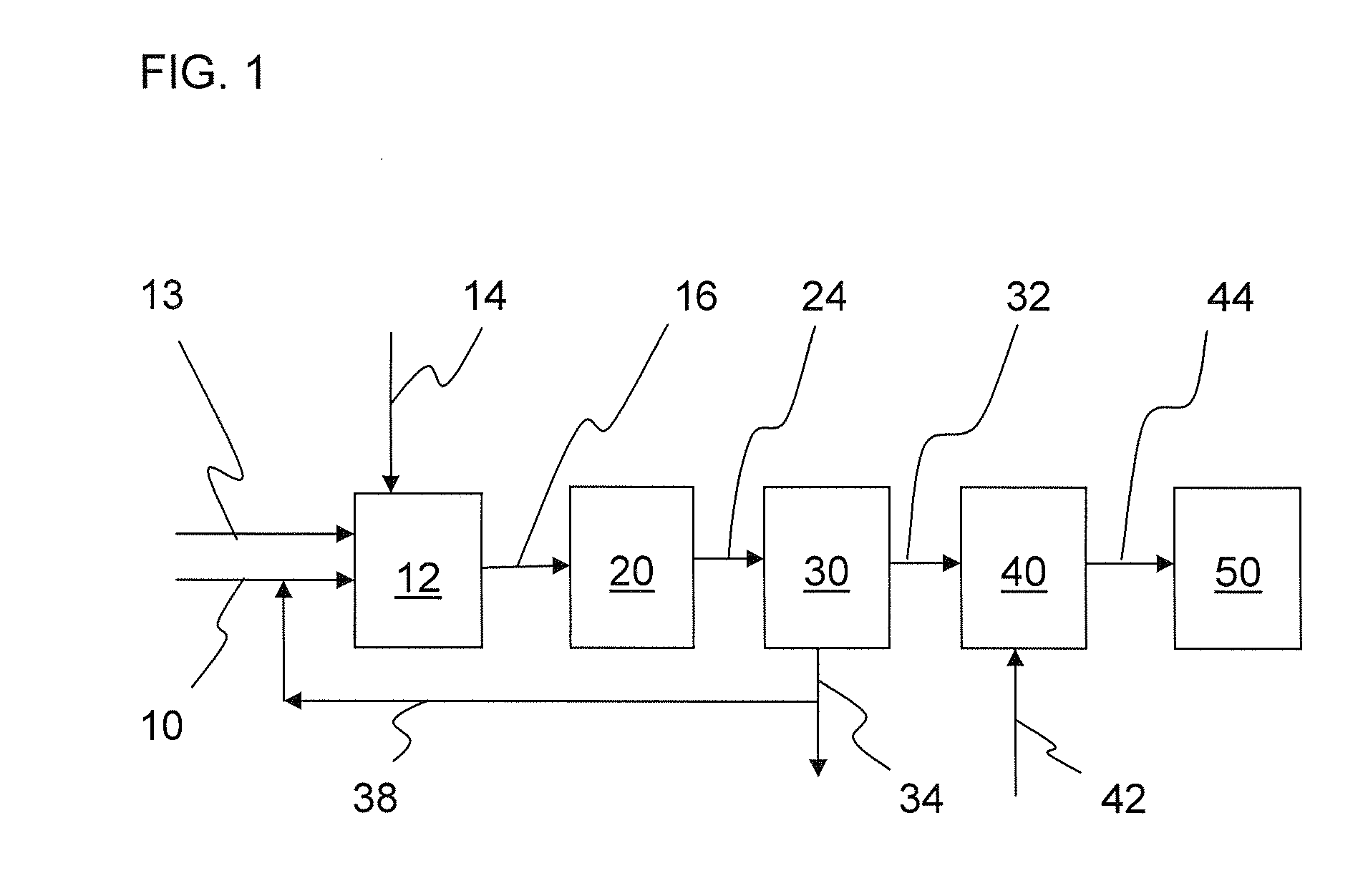

Articles, including fiberboard, are made from a pumpable, flowable slurry including alpha-calcined calcium sulfate hemihydrate anchored in pores of host particles, alpha-calcined calcium sulfate hemihydrate, a silicone compound, magnesium oxide, and water. The magnesium oxide catalyzes the reaction of the silicone compound into a silicone resin. In a preferred method of making a water resistant fiberboard calcium sulfate dihydrate is combined with the host particles and water to form a slurry which is heated under pressure to calcine the calcium sulfate dihydrate to form alpha-calcined calcium sulfate hemihydrate. After relieving the pressure, a silicone compound and magnesium oxide are added to the slurry. The slurry is dewatered to form a filter cake, which is then formed into a desired shape and allowed to set.

Owner:UNITED STATES GYPSUM CO

Phase-change energy-storage material

InactiveCN103666381AImprove cycle stabilityRaise the ratioHeat-exchange elementsFiberSodium phosphates

The invention relates to a phase-change energy-storage material which comprises the following components in percentage by mass: 75%-99% of an energy storage main body material, 0.1%-10% of a thickening agent, 0.2%-15% of a nucleating agent and 0.01%-8% of a reinforcing material, wherein the energy storage main body material comprises crystal water and salt; the thickening agent comprises one or more of an inorganic thickening agent, fibers, polyacrylates, polyurethanes and a natural polymer thickening agent; the nucleating agent comprises one or more of sodium pyrophosphate, sodium phosphate decahydrate, calcium sulfate dihydrate, potassium sulfate, potassium borate, barium hydroxide octahydrate, sodium phosphate dibasic dodecahydrate and sodium sulfate; the reinforcing material comprises one or more of metal and metal oxide powder, carbon materials, nanoparticles and foam materials. By selecting proper materials and ratio, the supercooling degree and the phase separation phenomenon are reduced and good circulating stability is achieved; especially the reinforcing material is added into a system to form a heat-conducting network so as to improve the heat conductivity of the material by more than two times.

Owner:PIONEER ENERGY JIANGSU

Acoustical gypsum board panel and method of making it

ActiveUS8057915B2Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

Owner:UNITED STATES GYPSUM CO

Method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum

The invention provides a method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum, comprising the technological steps of purification, crystal transforming reaction, oriented crystallization, washing and separation, and drying and pulverization. The method concretely comprises the following steps of: enhancing the taste of calcium sulfate dlhy in the desulfurized gypsum to be greater than 95% through a purification treatment; dissolving and recrystallizing the desulfurized gypsum at 70 to 98 DEG C under the normal pressure through adding prepared habit modifiers, transforming into the alpha semi-hydrated gypsum and then carrying out oriented crystallization on the alpha semi-hydrated gypsum to form a short column-shaped alpha semi-hydrated gypsum crystal under the function of an oriented crystal type stabilizer, wherein the length-diameter ratio of the short column-shaped alpha semi-hydrated gypsum crystal is less than 1:3, the 2h breaking strength is greater than 6.5 MPa, the compression strength is greater than 23 MPa, the dry breaking strength is greater than 25 MPa, and the dry compression strength is greater than 53 MPa. The method can be widely used in the fields of ceramics, automobiles, precise casting, heterogenic casting and the like.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Process for manufacturing ultra low consistency alpha- and beta- blend stucco

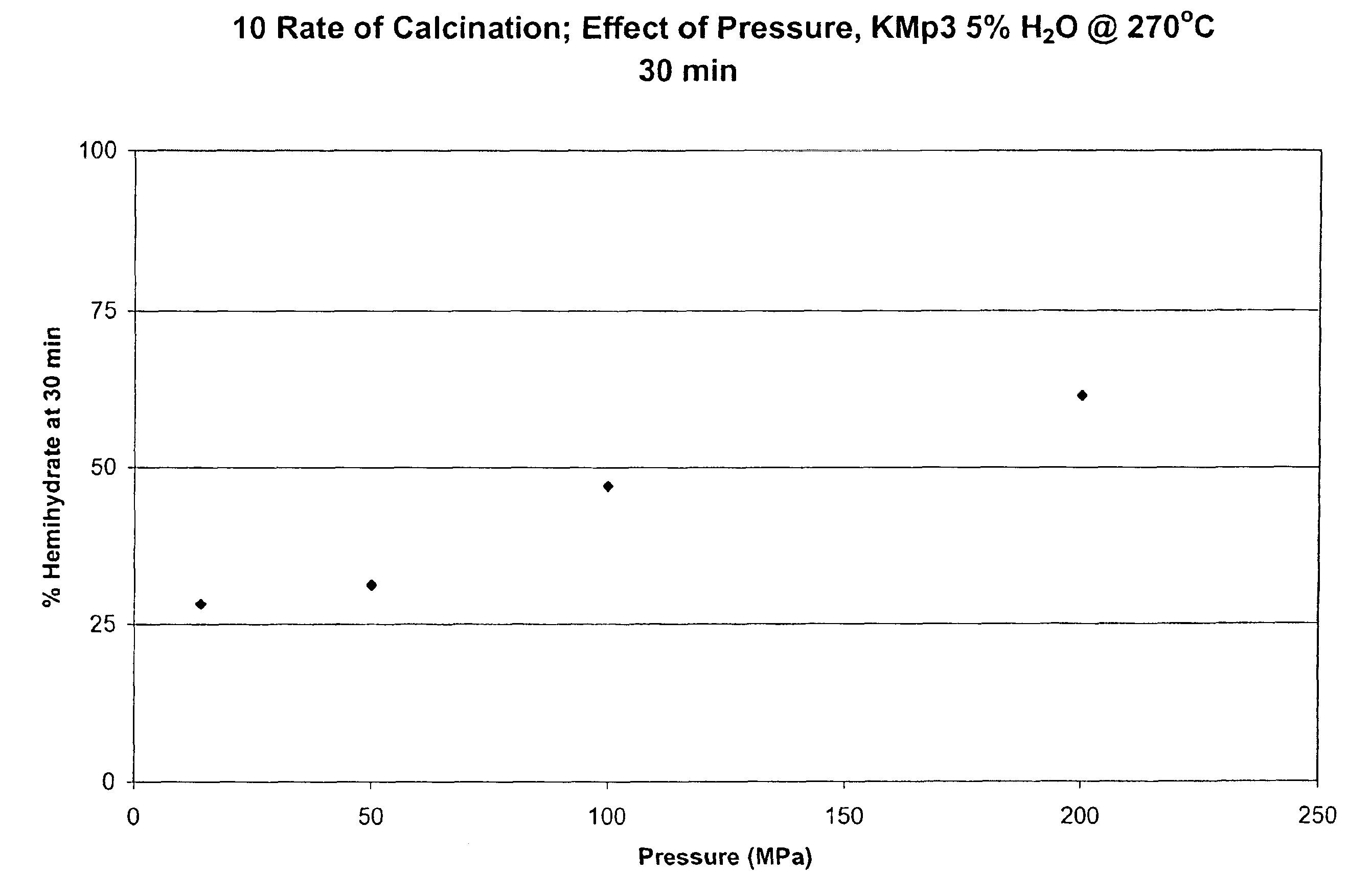

InactiveUS20080069762A1Cheap methodAid in reactivityCalcium/strontium/barium sulfatesFluidized bedSlurry

A process is disclosed for making a blend of alpha- and beta-stucco including a slurry calcination step to produce alpha calcium sulfate hemihydrate followed by a fluidized bed calcination step to produce beta calcium sulfate hemihydrate. The process starts with 50-75% gypsum-containing solids slurry, and then steam calcines the slurry in a first reactor to form partially calcined gypsum slurry which contains calcium sulfate dihydrate and alpha calcium sulfate hemihydrate. The partially calcined slurry is then dewatered. Then the filter cake is fed into a kettle to complete the calcination process by converting the calcium sulfate dihydrate of the filter cake material into beta calcium sulfate hemihydrate.

Owner:UNITED STATES GYPSUM CO

Calcium sulphate-based composition and methods of making same

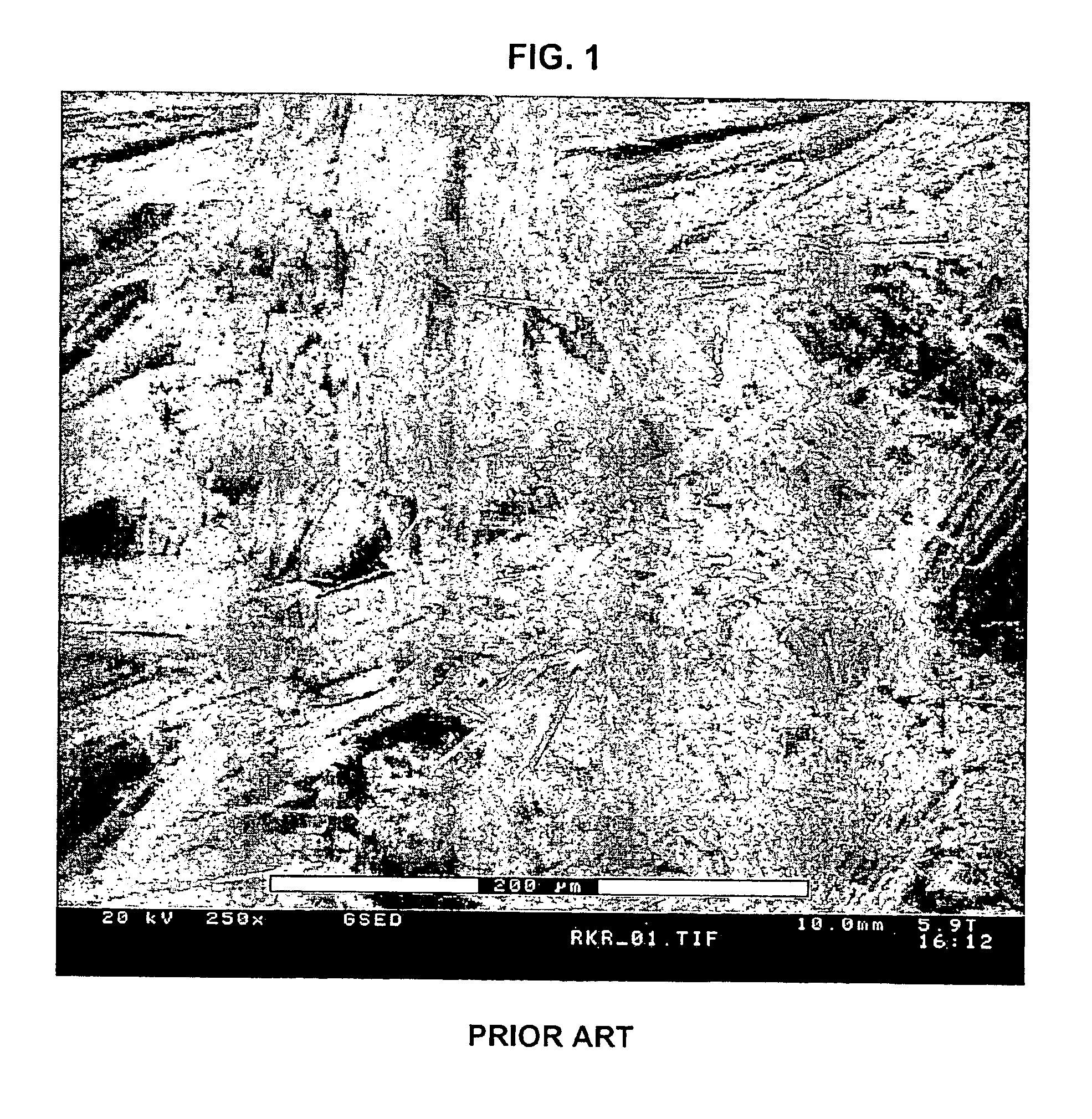

InactiveUS6964704B2Good crystal shapeSolid waste managementCalcium/strontium/barium sulfatesHigh pressureBriquette

Owner:G B TECH LLC

Compositions suitable for use as joint compounds and related methods

ActiveUS20080305252A1Formaldehyde freeAntifouling/underwater paintsLayered product treatmentJoint compoundCalcium Sulfate Dihydrate

The invention provides a composition useful as a joint compound comprising water, a filler comprising one or more of calcium carbonate, calcium sulfate dihydrate or calcium sulfate hemihydrate, a binder and / or a biocide, wherein the composition after curing is formaldehyde-free.

Owner:UNITED STATES GYPSUM CO

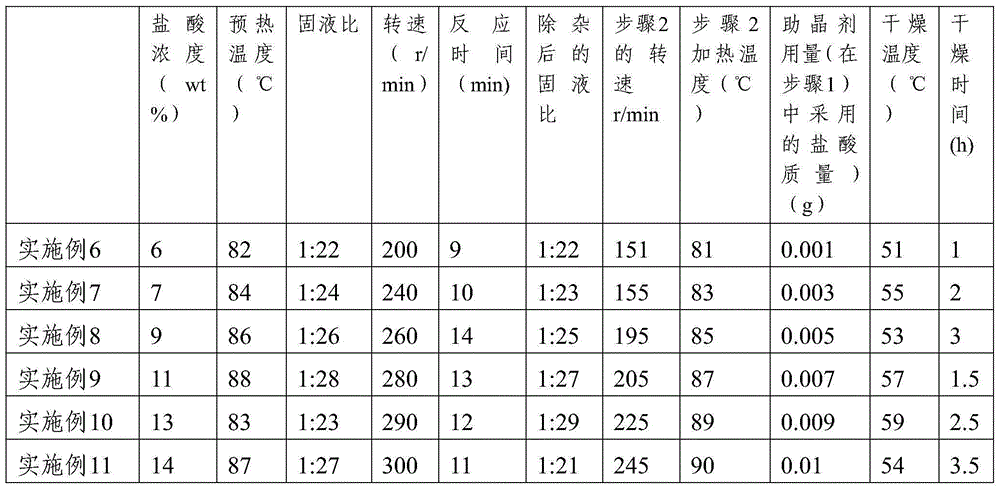

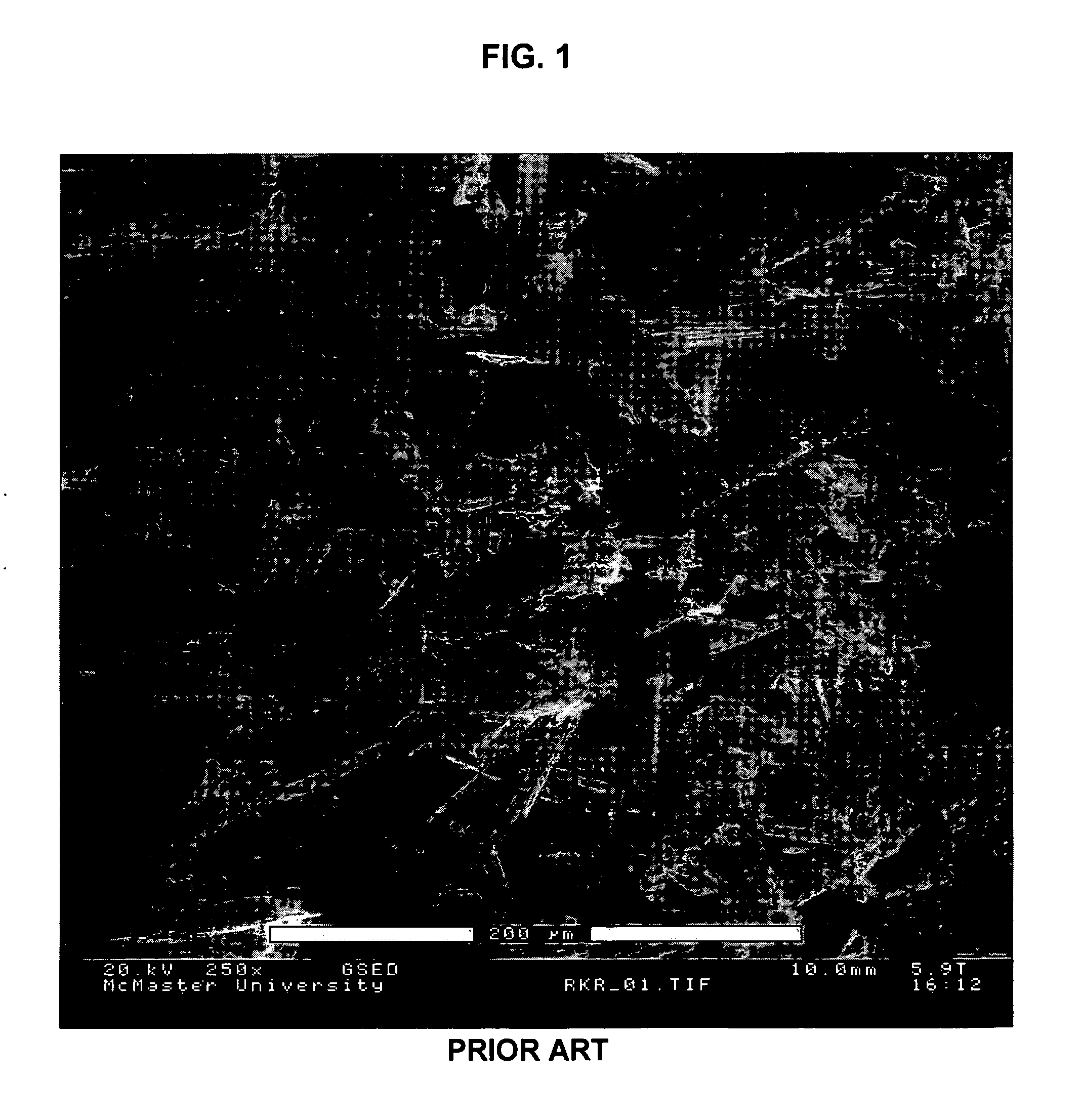

Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

InactiveCN104005086ANot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

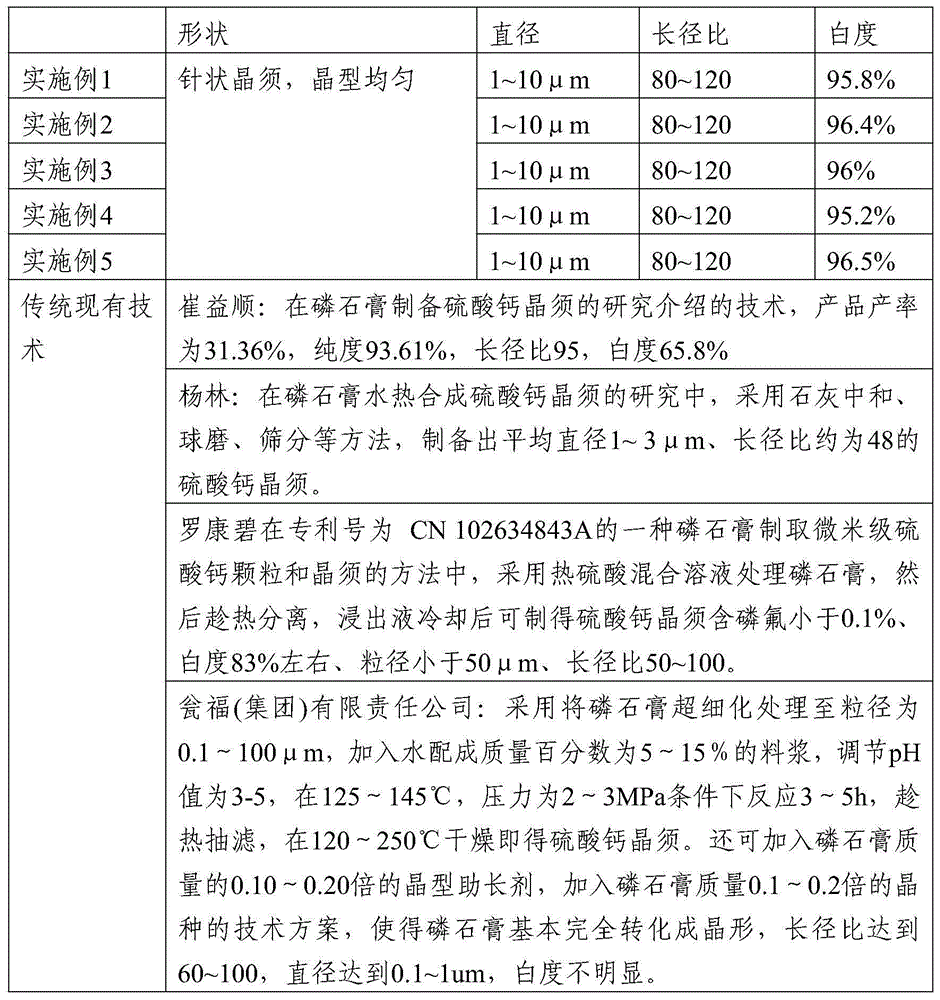

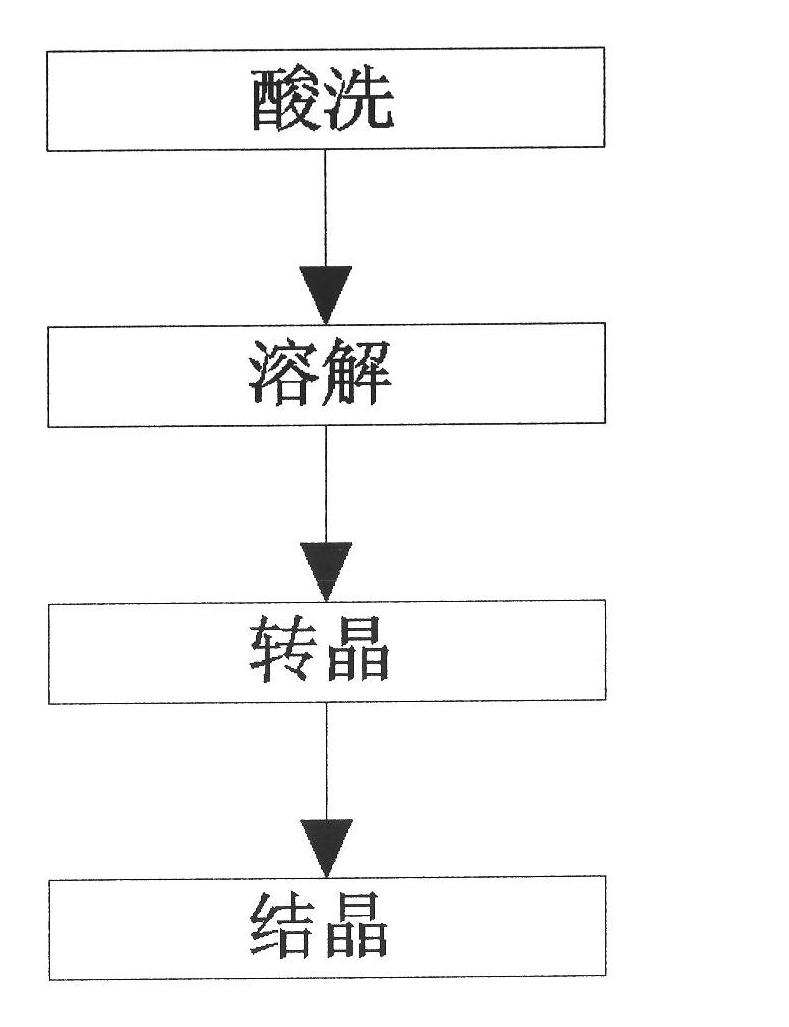

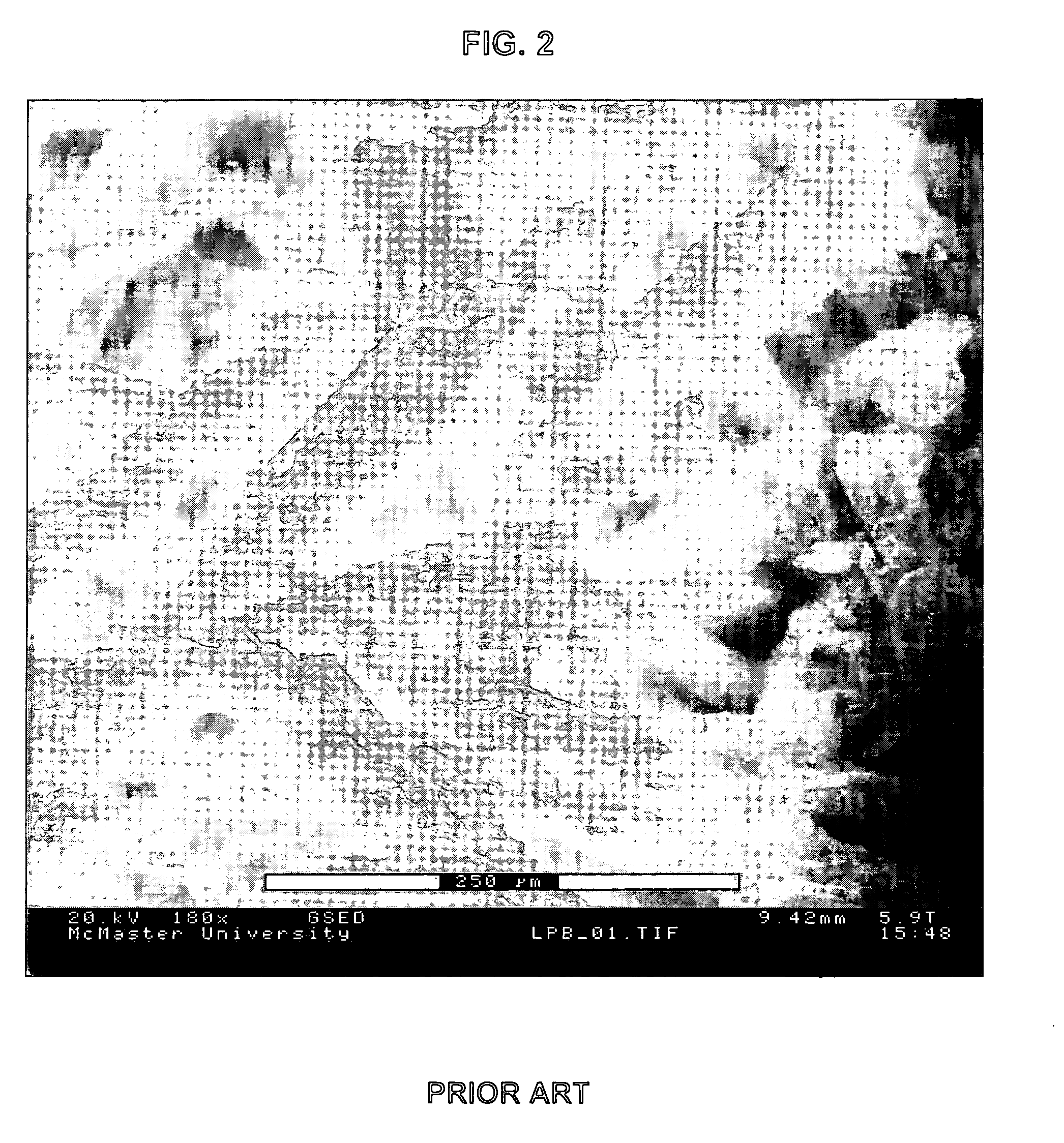

Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

ActiveCN102352535ASimple manufacturing processEasy to implementPolycrystalline material growthFrom normal temperature solutionsDispersityCalcium sulfate crystals

The invention discloses a method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure. The method comprises the following steps: 1) pickling; 2) dissolving; 3) rotating crystal; and 4) crystallizing, after crystallizing, carrying out solid-liquid separation, washing filter cake with water, and drying to obtain calcium sulfate crystal whiskers. The method disclosed by the invention has the advantages that: the preparation process is simple and is easy to achieve, and the production efficiency is high; higher-purity and higher-whiteness calcium sulfate crystal whiskers are prepared by adopting a normal-pressure recrystallization method, controlling related process conditions and utilizing the characteristic that the dissolubility of main component calcium sulfate dihydrate of desulfurized gypsum in specific solution changes obviously along with the temperature; obtained calcium sulfate crystal whisker product has regular morphology, low agglomeration and good dispersity; and in addition, inorganic acid solution used for recrystallization can be recycled, and inorganic acid solution is not consumed in the reaction process, thereby creating better economic benefit, environmental benefit and social benefit, reducing the burden of coal-fired power plant and increasing enterprise benefits.

Owner:上海大学浙江嘉兴新兴产业研究院

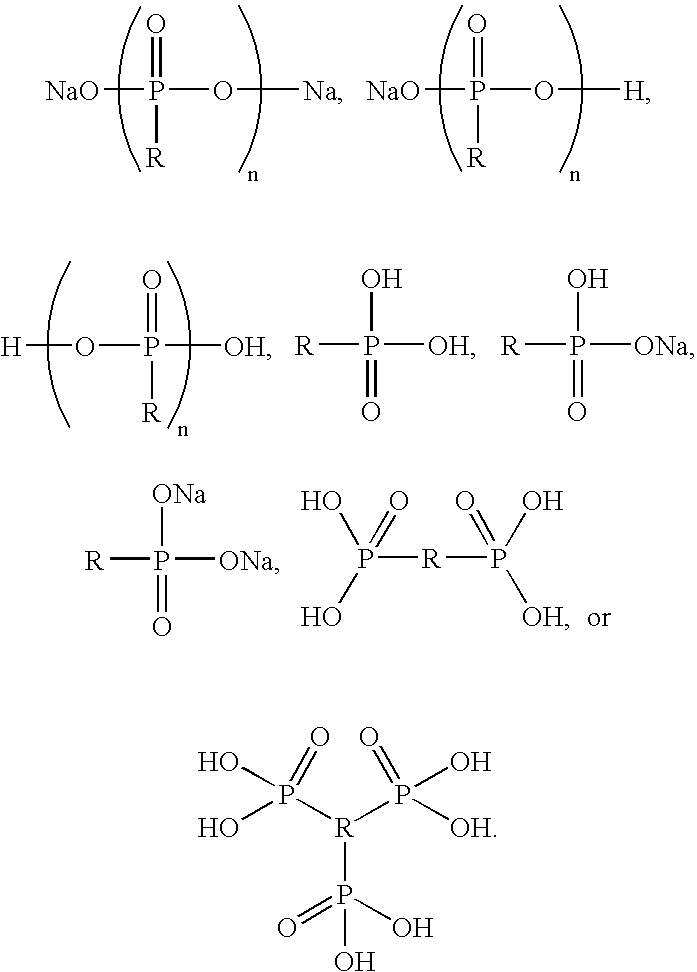

Wet gypsum accelerator and methods, composition, and product relating thereto

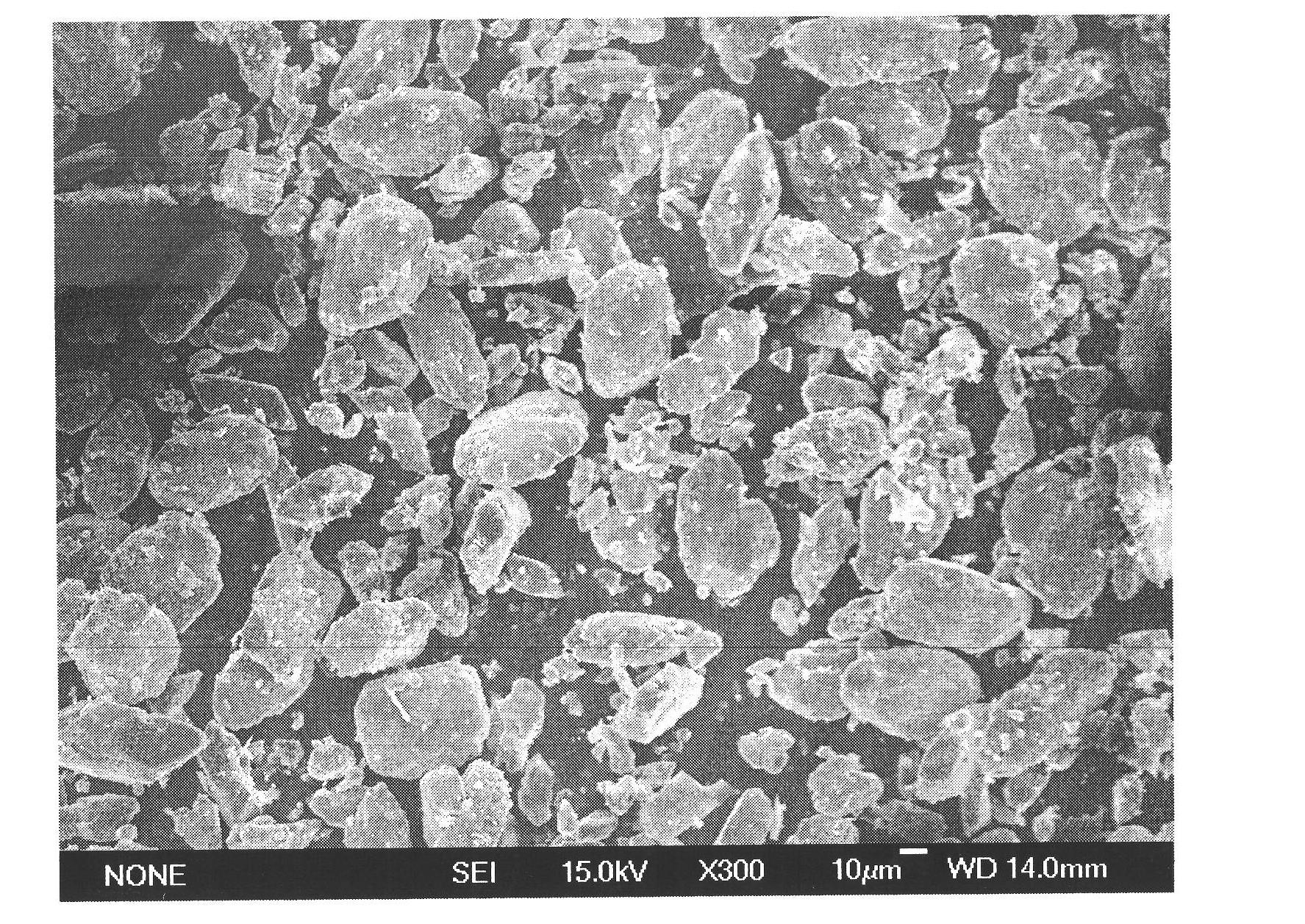

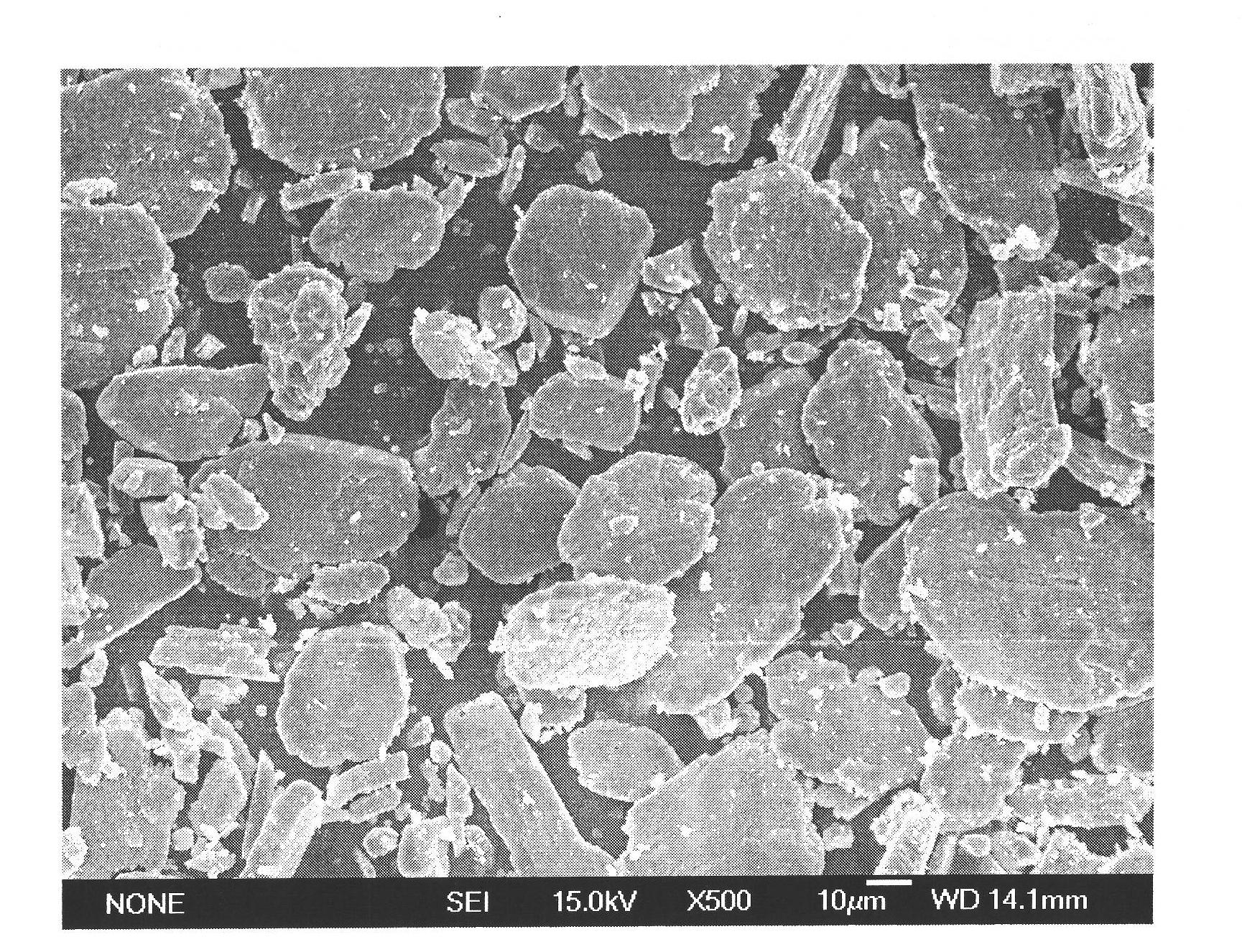

InactiveUS20060243171A1Improve efficiencyIncreased hydration rateGrain treatmentsPhosphatePhysical chemistry

A wet gypsum accelerator comprising ground product having a median particle size of from about 0.5 micron to about 2 microns and calcium sulfate dihydrate, water, and at least one additive selected from the group consisting of (i) an organic phosphonic compound, (ii) a phosphate-containing compound, or (iii) a mixture of (i) and (ii), is disclosed. Also disclosed are a method of preparing a wet gypsum accelerator, a method of hydrating calcined gypsum to form an interlocking matrix of set gypsum, a set gypsum-containing composition, and a set gypsum-containing product.

Owner:UNITED STATES GYPSUM CO

Gypsum products and method for their manufacture

ActiveUS20060283356A1Improve waterproof performanceReduced strengthSolid waste managementLaminationWaxEmulsion

A method is provided which uses an improved emulsion to imparting water-resistance to gypsum products. In one embodiment, gypsum products comprise calcium sulfate dihydrate and an emulsion which comprises a saponified wax, a nonsaponifiable wax, an alkyl phenol, a surfactant / dispersant salt of polynaphthalenesulfonic acid, and carboxymethylcellulose. Optionally, the emulsions may contain a preservative, e.g., a biocide (mildewcide, fungicide, etc.). These gypsum products resist the uptake of water and therefore resist biological infestation without addition of a preservative.

Owner:HEXION INC

Fiberboard with improved water resistance

ActiveUS20070056478A1High strengthImprove waterproof performanceSolid waste managementWood working apparatusSlurryWater resistant

Articles, including fiberboard, are made from a pumpable, flowable slurry including alpha-calcined calcium sulfate hemihydrate anchored in pores of host particles, alpha-calcined calcium sulfate hemihydrate, a silicone compound, magnesium oxide, and water. The magnesium oxide catalyzes the reaction of the silicone compound into a silicone resin. In a preferred method of making a water resistant fiberboard calcium sulfate dihydrate is combined with the host particles and water to form a slurry which is heated under pressure to calcine the calcium sulfate dihydrate to form alpha-calcined calcium sulfate hemihydrate. After relieving the pressure, a silicone compound and magnesium oxide are added to the slurry. The slurry is dewatered to form a filter cake, which is then formed into a desired shape and allowed to set.

Owner:UNITED STATES GYPSUM CO

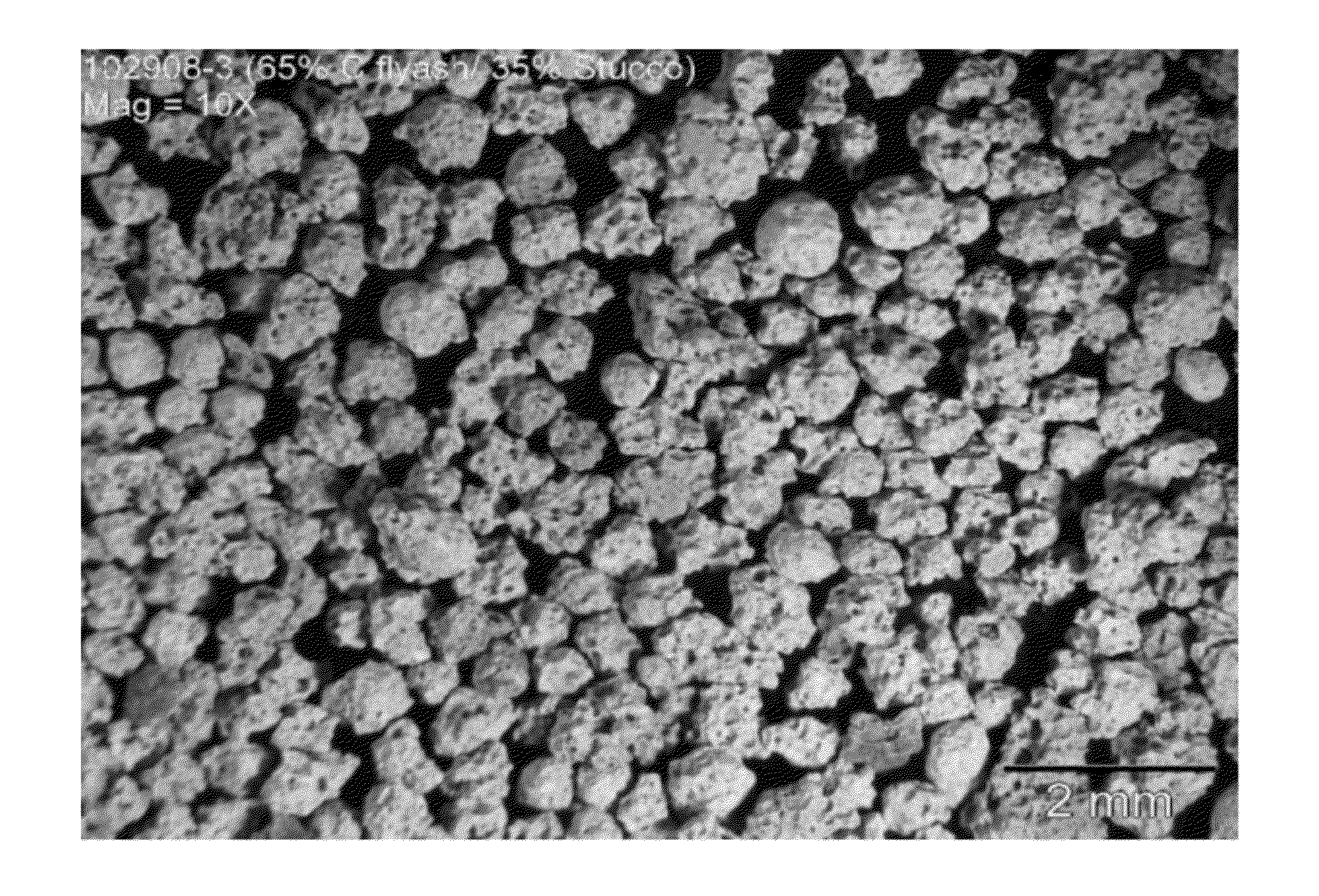

Method for In-Situ Manufacture of a Lightweight Fly Ash Based Aggregate

InactiveUS20120167804A1Short setting timeHigh compressive strengthSolid waste managementCeramicwarePolymer scienceAir entrainment

A method of making a rapid setting lightweight homogeneous foamed fly ash based cementitious aggregate composition with improved compressive strength for products such as panels is disclosed. The method mixes fly ash, alkali metal salt of citric acid, foaming agent for entraining air, optional foam stabilizing agent, a calcium sulfate such as stucco or gypsum, and water. Compositions are also disclosed which include mixtures of fly ash, particularly Class C fly ash alone or in mixtures with Class F fly ash, alkali metal salts of citric acid, foaming agents, a calcium sulfate such as calcium sulfate dihydrate or hemihydrate and an optional portland cement.

Owner:UNITED STATES GYPSUM CO

Bone repair material

The bone repair material comprises the following components:A) a first granular component with a diameter larger than 20 μm chosen from the group of: calcium phosphate, calcium pyrophosphate, or calcium sulfate dihydrate;B) a second component chosen from the group of apatite powder with a particle diameter smaller than 1 μm, (preferably smaller than 100 nm); andB) a third component comprising water or an aqueous solution, wherebyC) the volume fraction of the second and third component represents at least 35 volume-% of the total bone repair material.

Owner:DR H C ROBERT MATHYS STIFTUNG +1

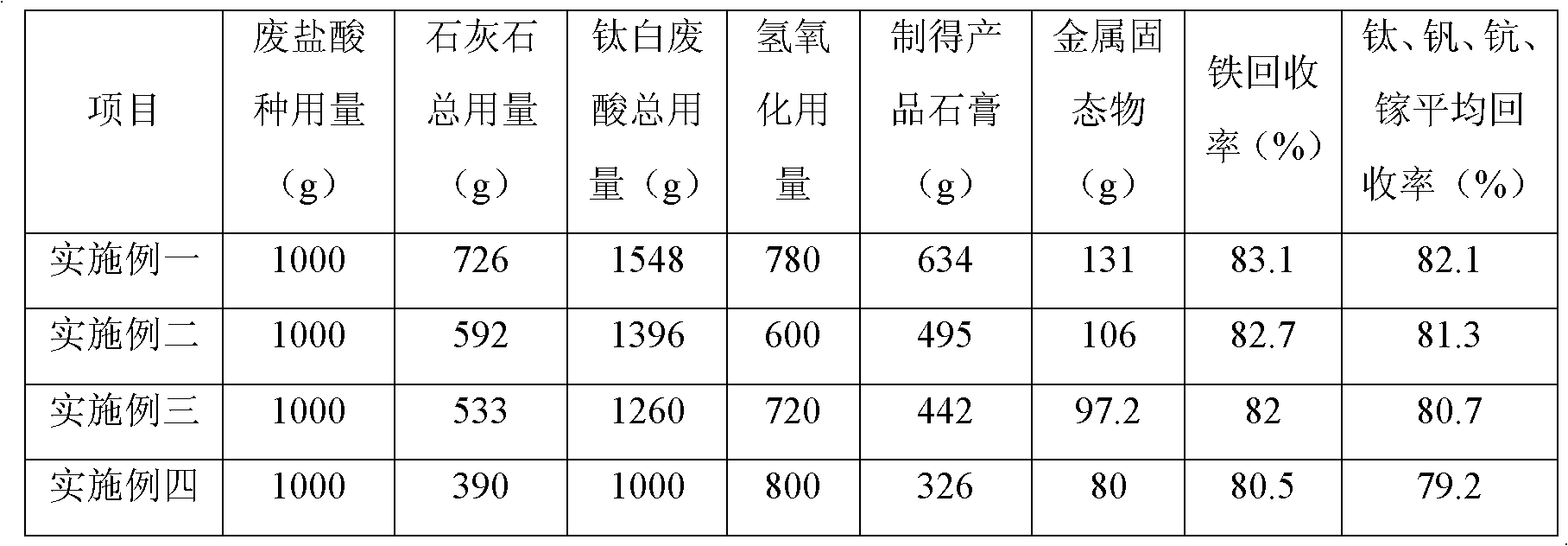

Comprehensive Utilization Method of Titanium White Waste Acid Wastewater

InactiveCN102275970ASolve pollutionNew vitalityElectrolysis componentsIron oxides/hydroxidesState of artWastewater

The invention discloses a comprehensive utilization method of titanium white waste acid wastewater, which belongs to the field of metallurgy. The method of the invention aims to solve the technical problem in the prior art that the titanium white waste acid wastewater cannot be fully utilized at low cost. The method for comprehensive utilization of titanium white waste acid waste water comprises the following steps: a. adding limestone to the hydrochloric acid solution, fully reacting to obtain a calcium chloride solution; b. adding titanium white waste acid or waste water to the calcium chloride solution, filtering after fully reacting Obtain calcium sulfate dihydrate and filtrate, described calcium sulfate dihydrate obtains product gypsum through drying process; c, the filtrate obtained in step b is used as the raw material for preparing calcium chloride solution and reacts with limestone, after repeating steps a and b more than once , adding sodium hydroxide solution to the filtrate obtained in step b, and filtering to obtain a sodium chloride solution and a precipitate rich in iron, titanium, vanadium, scandium and gallium after sufficient reaction. The method of the invention has low cost, can well solve the problem of environmental pollution caused by titanium dioxide waste acid and waste water, and has good promotion prospects.

Owner:攀枝花市尚亿科技有限责任公司

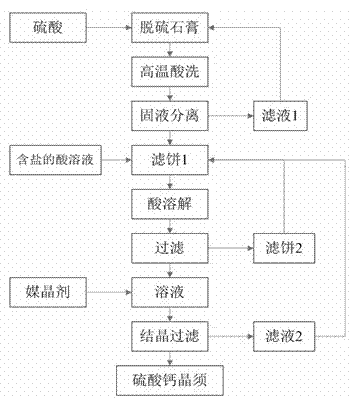

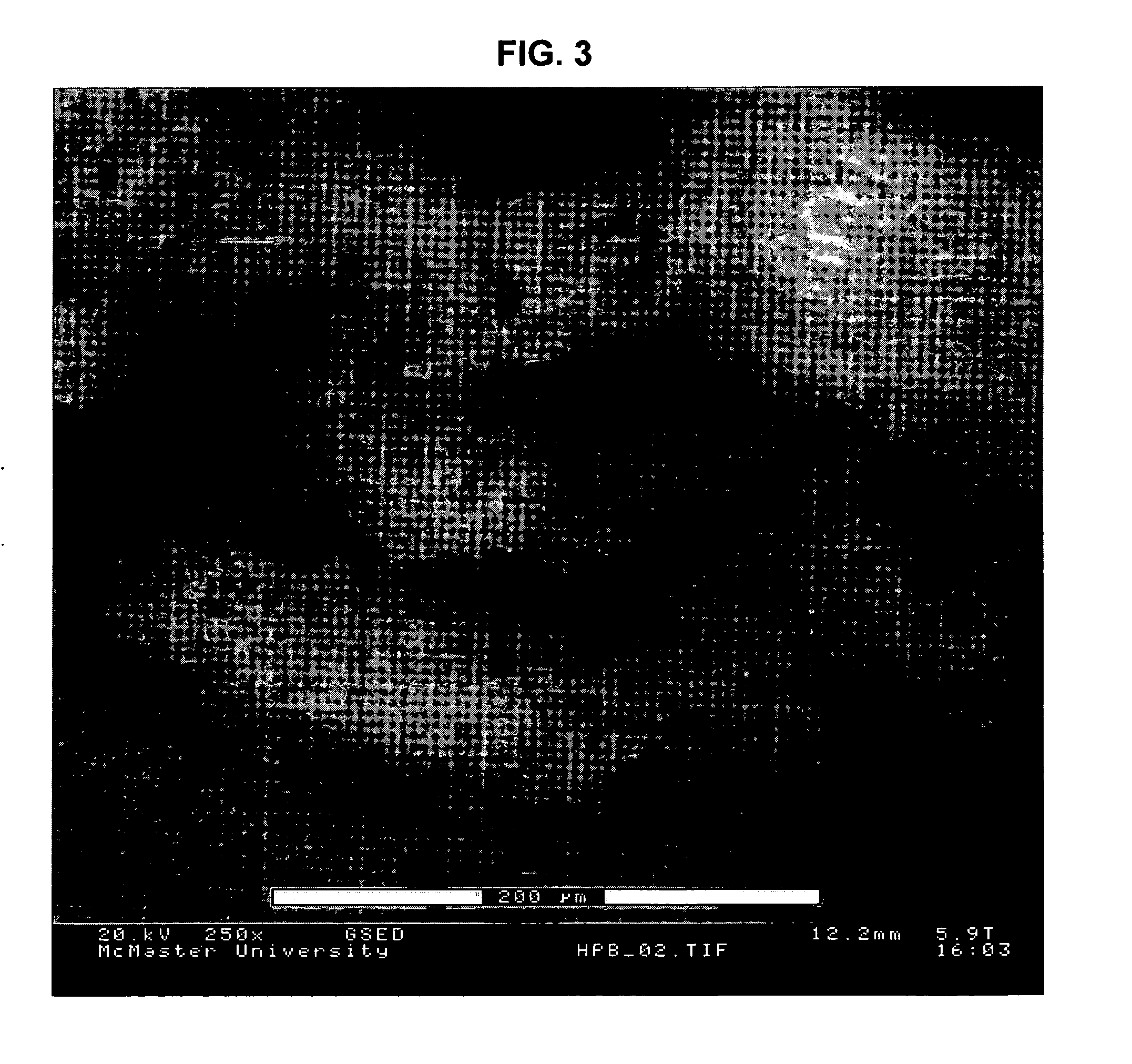

Method for preparing high-purity calcium sulfate dihydrate crystal whisker by using metallurgic flue gas desulfurization gypsum recrystallization process

ActiveCN104846440APromote conversionImprove Calcium UtilizationPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryCalcium Sulfate Dihydrate

The invention discloses a method for preparing a high-purity calcium sulfate dihydrate crystal whisker by using a metallurgic flue gas desulfurization gypsum recrystallization process. The method comprises the steps of pickling metallurgic flue gas desulfurization gypsum to remove a small deal of calcium carbonate or calcium oxide and soluble impurities; dissolving the gypsum by using a salt-containing acid solution to obtain a product used as a raw material for preparing the high-purity calcium sulfate dihydrate crystal whisker; adding a medium crystal agent to control the controllable growth of a calcium sulfate crystal whisker to form a calcium sulfate crystal whisker with controllable length-to-diameter ratio and complete crystal appearance, filtering and drying to obtain the calcium sulfate dehydrate crystal whisker. The recycling of the high-added-value calcium sulfate crystal whisker prepared from the metallurgic flue gas desulfurization gypsum is realized under normal-pressure and mild conditions according to the recrystallization principle. The raw material adopted in the method is available, the production process condition is simple, the added value of the high-purity crystal whisker is high, and the produced calcium sulfate dihydrate crystal whisker has the characteristics of small diameter, high length-to-diameter ratio, complete and uniform appearance and stable performance, can be used as a reinforcing material to be applied to an additive for industries such as plastics, rubber, papermaking, ceramics and the like and has a wide application prospect.

Owner:KUNMING METALLURGY INST

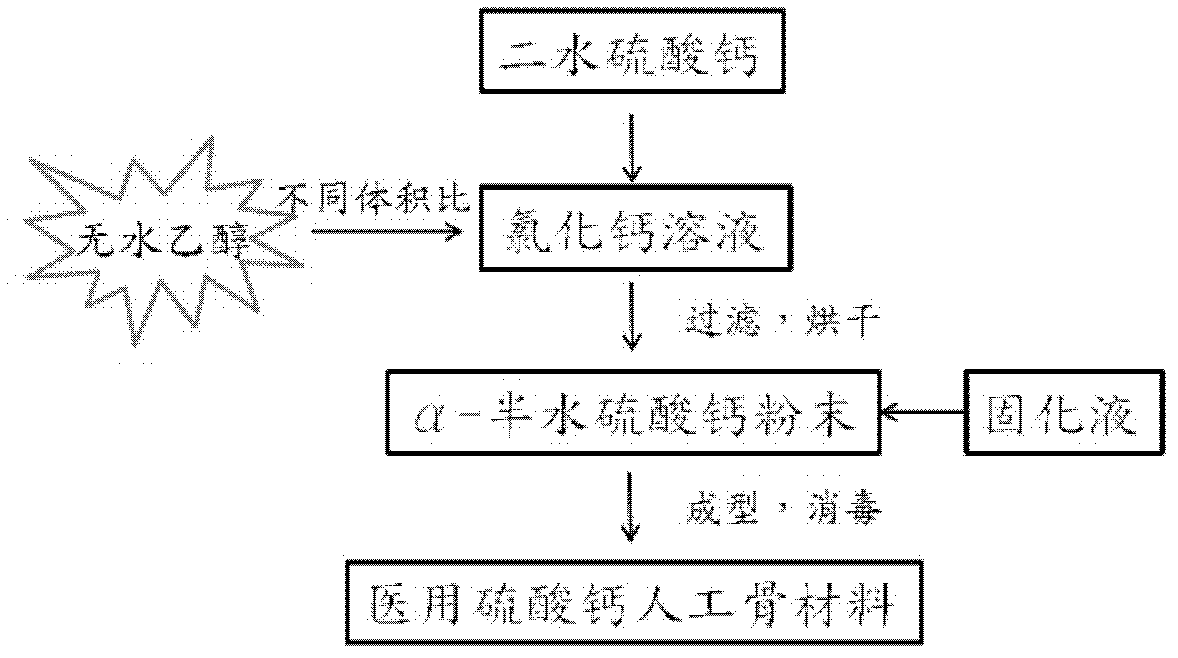

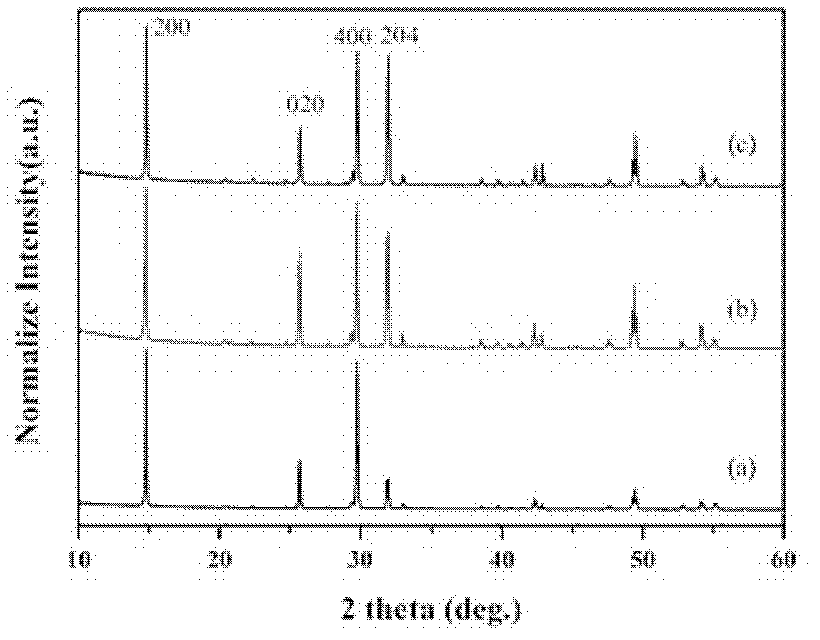

Preparation methods of medical alpha-calcium sulfate hemihydrate powder and calcium sulfate artificial bone material

ActiveCN102633287AImprove grain morphologySmall sizeCalcium/strontium/barium sulfatesProsthesisArtificial boneParticle-size distribution

The invention discloses preparation methods of medical alpha-calcium sulfate hemihydrate powder and a calcium sulfate artificial bone material, belonging to the field of medical biomaterials. According to the invention, alpha-calcium sulfate hemihydrate is prepared by adding anhydrous alcohol to a reactant liquid containing calcium chloride, a crystal modifier and distilled water, wherein the volume ratio of the anhydrous alcohol to the distilled water is 0.01-2, so that the crystal water of calcium sulfate dihydrate is partially removed in the reactant liquid. Due to the modification effect of the anhydrous alcohol, the grain morphology and size of the alpha-calcium sulfate hemihydrate powder are effectively improved, and isometric or approximately isometric alpha-calcium sulfate hemihydrate powder with high purity and uniform crystal structure and particle size distribution is obtained. A medical calcium sulfate artificial bone material prepared by mixing and curing the alpha-calcium sulfate hemihydrate powder with a curing liquid can effectively improve the compressive strength, prolong the degradation time and improve the biological performance, so that the medical calcium sulfate artificial bone material has high performance and good application prospects in the technical fields of medical bone transplantation and bone repair.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Freeze-thaw durable geopolymer compositions and methods for making same

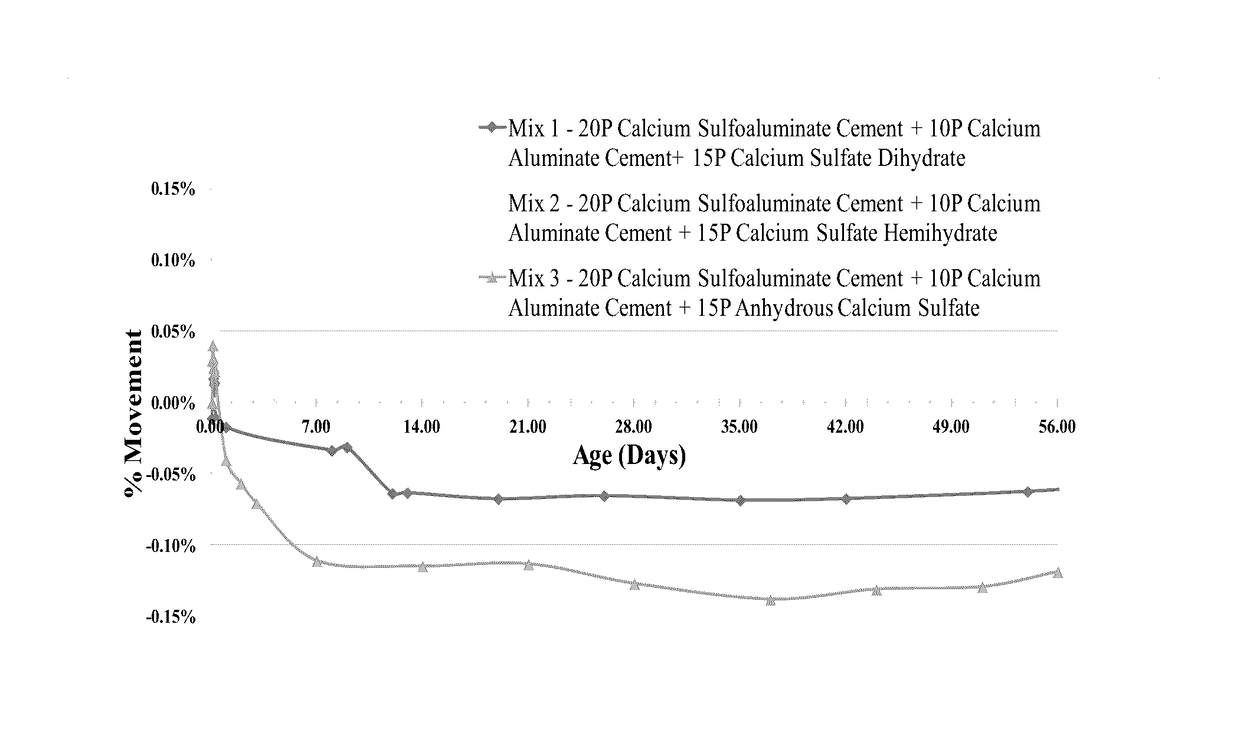

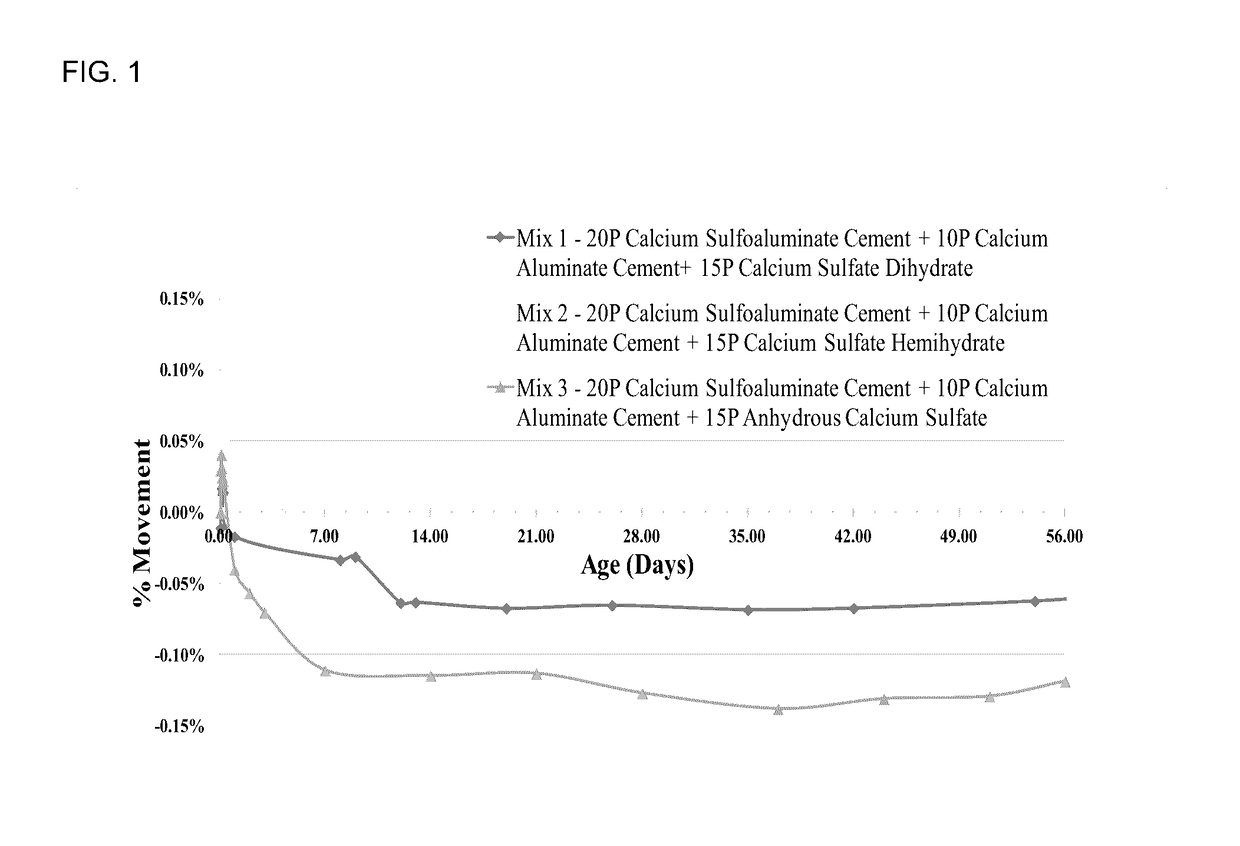

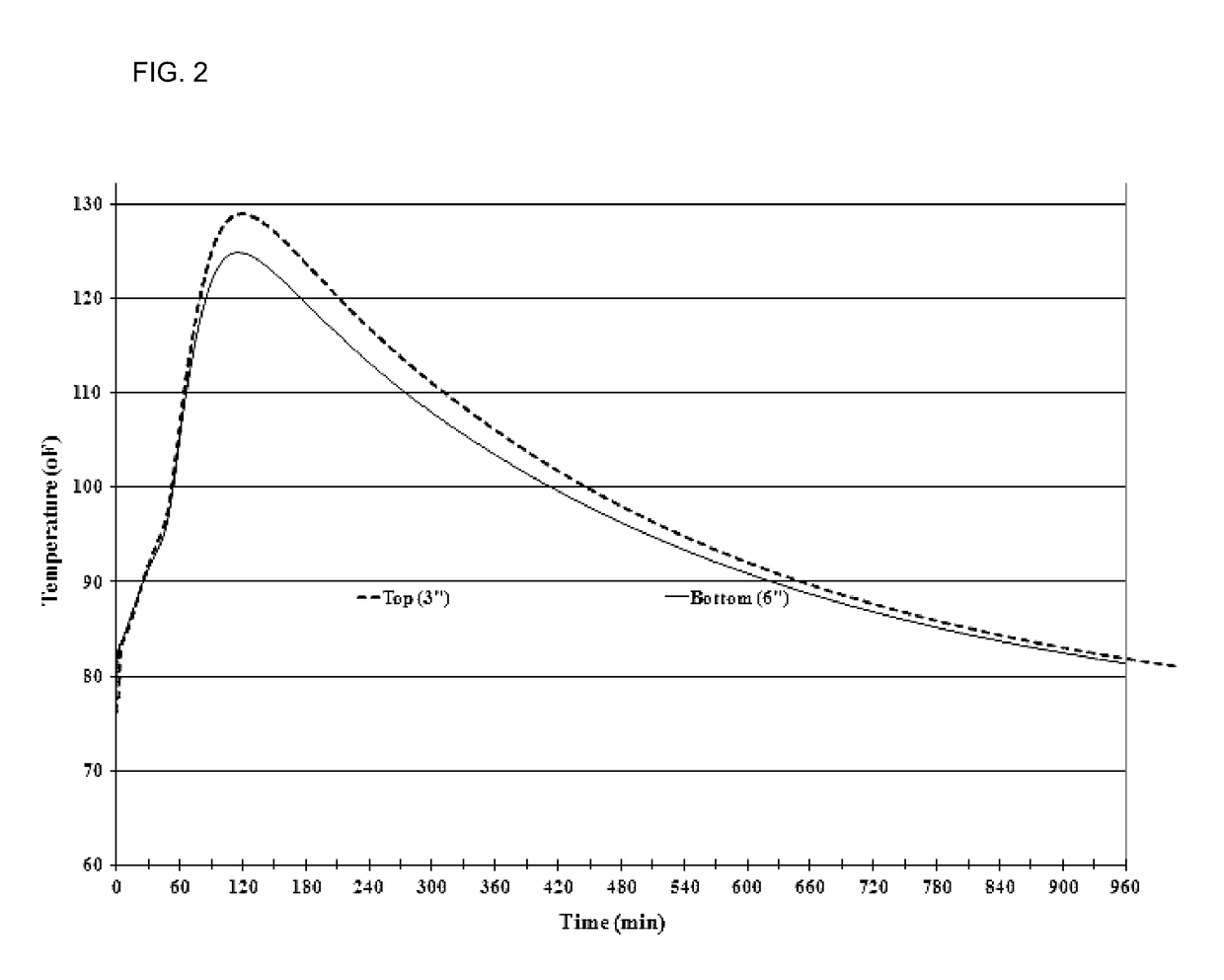

ActiveUS9624131B1Excellent freeze-thaw durability behaviorGood dimensional stabilityIn situ pavingsSolid waste managementFreeze thawingAnhydrous Calcium Sulfate

A freeze-thaw durable, dimensionally stable, geopolymer composition including: cementitious reactive powder including thermally activated aluminosilicate mineral, aluminate cement preferably selected from at least one of calcium sulfoaluminate cement and calcium aluminate cement, and calcium sulfate selected from at least one of calcium sulfate dihydrate, calcium sulfate hemihydrate, and anhydrous calcium sulfate; alkali metal chemical activator; and a freeze-thaw durability component selected from at least one of air-entraining agent, defoaming agent, and surface active organic polymer; wherein the composition has an air content of about 4% to 20% by volume, more preferably about 4% to 12% by volume, and most preferably about 4% to 8% by volume. The compositions are made from a slurry wherein the water / cementitious reactive powder weight ratio is 0.14 to 0.45:1, preferably 0.16 to 0.35:1, and more preferably 0.18 to 0.25:1. Methods for making the compositions are also disclosed.

Owner:UNITED STATES GYPSUM CO

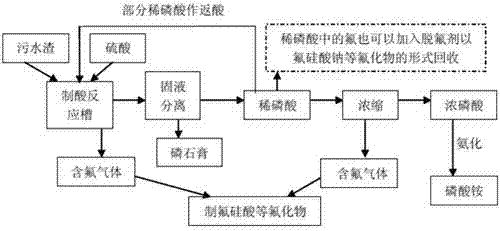

Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

InactiveCN102502552AImprove use valueEffective way to usePhosphatesAlkali orthophosphate fertiliserO-Phosphoric AcidAgricultural engineering

The invention discloses a method for recycling phosphorus and fluoride in the sewage residue of a phosphorus fertilizer plant. According to the method, the sewage residue is decomposed by using sulfuric acid, the phosphorus and the fluoride in the sewage residue are extracted, calcium sulfate dihydrate crystal or calcium sulfate hemihydrate crystal and diluted phosphoric acid solution are generated, diluted phosphoric acid and phosphogypsum which is the by-product are obtained through solid-liquid separation, the diluted phosphoric acid is concentrated into concentrated phosphoric acid, the escaped fluorine containing gas is recycled in the process of concentrating the phosphoric acid and making acid and produced into the fluoride such as the fluosilicic acid and the like, or defluorination agent is added into the diluted phosphoric acid to recycle fluoride resources in the form of the fluoride such as the sodium fluosilicate and the like, and the obtained concentrated phosphoric acid can be used to prepare other phosphate products such as the ammonium phosphate and the like by using the traditional method. The method can be used to effectively recycle the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant so that the waste materials can be changed into the valuable materials and the recycling value of the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant can be improved. The method has good economic benefit and environment protection significance.

Owner:WENGFU (GRP) CO LTD

Process for manufacturing ultra low consistency alpha- and beta- blend stucco

InactiveUS7588634B2Cheap methodEnergy efficiencyCalcium/strontium/barium sulfatesFluidized bedSlurry

A process is disclosed for making a blend of alpha- and beta-stucco including a slurry calcination step to produce alpha calcium sulfate hemihydrate followed by a fluidized bed calcination step to produce beta calcium sulfate hemihydrate. The process starts with 50-75% gypsum-containing solids slurry, and then steam calcines the slurry in a first reactor to form partially calcined gypsum slurry which contains calcium sulfate dihydrate and alpha calcium sulfate hemihydrate. The partially calcined slurry is then dewatered. Then the filter cake is fed into a kettle to complete the calcination process by converting the calcium sulfate dihydrate of the filter cake material into beta calcium sulfate hemihydrate.

Owner:UNITED STATES GYPSUM CO

Method and material to form a cast from gypsum

InactiveUS20080081317A1High dimensional accuracyEasy to separateImpression capsDental articulatorsArtificial EyesProsthesis

A method is disclosed for forming an accurate stone cast from an impression of a body region, used for the purpose of prosthetic fabrication, such as dental crowns and artificial eyes and hearing aids. The initial step with this unique method is to first acquire a suitable amount of dental stone catalyst. One type of a suitable stone catalyst is calcium sulfate dihydrate. The dental stone catalyst is engaged onto the internal surface of the impression. This catalyst, placed in the area between impression material and stone, will act to hasten the initial setting of wet, mixed dental stone that is in closest proximity to the impression. The result is a stratified set of the stone. Setting of the wet, mixed dental stone occurs first at the impression / stone interface. The mixed stone better resists distortion upon setting and the resultant set stone cast is more accurate.

Owner:WHITE DENNIS JOSEPH

Dental prosthesis fabrication

A method is disclosed for forming an accurate stone cast from a dental hydrocolloid impression, used for the purpose of prosthetic fabrication, such as dental prostheses. The dental stone catalyst, calcium sulfate dihydrate, is engaged onto the internal surface of set hydrocolloid impression. This catalyst, placed in the area between impression material and wet, mixed stone, will act to hasten the initial setting of dental stone that is in closest proximity to the impression. The result is a stratified set of the stone. Setting of the wet, mixed dental stone occurs first at the impression / stone interface. The setting radiates outwardly, away from the impression / stone interface. The mixed stone better resists distortion upon setting and the resultant set stone cast is more accurate.

Owner:WHITE DENNIS JOSEPH

Alpha-type calcium sulfate hemihydrate compositions and methods of making same

InactiveUS20050188898A1Good crystal shapeSolid waste managementCeramic shaping apparatusHemihydrate Calcium SulfateBriquette

Owner:G B TECH LLC

Complex acetaminophen vitamin C dispersion tablet and preparing method thereof

InactiveCN1507862AQuick effectDefinite curative effectOrganic active ingredientsAntipyreticSorbyl alcoholCross-link

The present invention relates to compound paracetamol vitamin C disperser tablet and its preparation method. It is formed from paracetamol, vitamin C, disintegrant, filling agent, correctives, adhesive and lubricating agent according to the ratio of 200-400:200-400:1-60:1-100:1-60:2-50:1-10. The disintegrant is carboxy methyl starch sodium, hydroxypropyl starch, low-substituted hydroxypropyl cellulose, calcium cellulose glycollate, cross-linked sodium cellulose glycollate, sodium lauryl sulfate, and the filling agent is lactose, mannitol, sorbyl alcohol, starch, modified starch, beta-dextrin, calcium sulfate dihydrate, microcrystal cellulose, and the corrective is wintergreen oil, peperitol, aspatan, citric acid, cane sugar, sterioside, the adhesive is polyvidone, hydroxypropyl cellulose, gelling starch and ethyl cellulose, and the lubricating agent is magnesium stearate, calcium stearate, polyglycol 6000 and talcum powder.

Owner:严洁

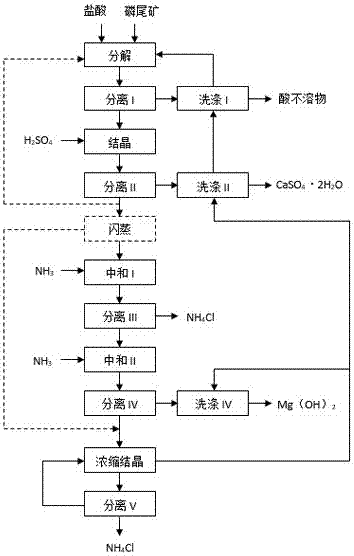

Method for preparing calcium sulfate whiskers and magnesium hydroxide by decomposing phosphate tailings through hydrochloric acid

InactiveCN107098372ASolve unhandled problemsMitigating the security concerns of stockpilingMagnesium chloridesCalcium/strontium/barium sulfatesSlurryToxic industrial waste

The invention relates to a method for preparing calcium sulfate whiskers and magnesium hydroxide by decomposing phosphate tailings through hydrochloric acid. The method comprises the following steps: adding phosphate tailings and hydrochloric acid into a decomposing tank to adequately react in the decomposing tank, and carrying out solid-liquid separation I on reacted slurry, so as to separate first mother solution and solid waste residues, wherein the solid waste residues are acid-insoluble substances; adding sulfuric acid into the first mother solution to react for crystallization, so as to generate the calcium sulfate whiskers; carrying out solid-liquid separation on crystallized slurry, so as to separate calcium sulfate dihydrate whiskers, wherein the mother solution is a mixed mother solution containing magnesium chloride and hydrochloric acid; after magnesium chloride in the mixed mother solution reaches a certain concentration, starting to take out a part of mixed mother solution, carrying out flash evaporation to evaporate HCl in the mother solution so as to obtain the mother solution mainly containing magnesium chloride, and returning the rest part of the mixed mother solution to the decomposing tank; introducing ammonia gas into the magnesium chloride mother solution, and carrying out solid-liquid separation, so as to obtain a relatively pure magnesium chloride mother solution and magnesium ammonium chloride solids containing a small amount of impurities; and absorbing HCl gas in the front stage by a magnesium ammonium chloride solution to enable the pH value of the magnesium ammonium chloride solution to be close to neutrality, and carrying out concentration and crystallization, so as to obtain magnesium ammonium chloride crystals. The method has the advantage that magnesium hydroxide and the calcium sulfate whiskers which have relatively high quality can be produced from industrial waste and the cheap raw materials.

Owner:HUBEI SANNING CHEM

Slurry and acoustical panel with reduced bound water

ActiveUS20090011251A1Reduce amountReduce the temperatureLamination ancillary operationsSolid waste managementBound waterSlurry

A composition for a slurry for manufacture of a building panel includes one or more fillers, one or more binders and water. One or more fillers is an expanded perlite at least partially covered with a film-forming, thermoplastic polymer coating Some embodiments use calcined or uncalcined gypsum as a binder or filler. One embodiment is a building panel that includes a solid matrix of calcium sulfate dihydrate crystals bound to expanded perlite.A method of making the panel includes acquiring expanded perlite and coating it with film-forming, thermoplastic polymer coating. After the expanded perlite is prepared, it is combined with water other optional fillers and one or more binders to form a slurry. The slurry is shaped into a panel and allowed to dry.

Owner:UNITED STATES GYPSUM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com